Patents

Literature

405 results about "Glycol methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Functionalized vinyl polymer nanoparticles

Owner:MICHELIN RECH & TECH SA

Elastomeric composition reinforced with a funtionalized non-aromatic vinyl polymer filler

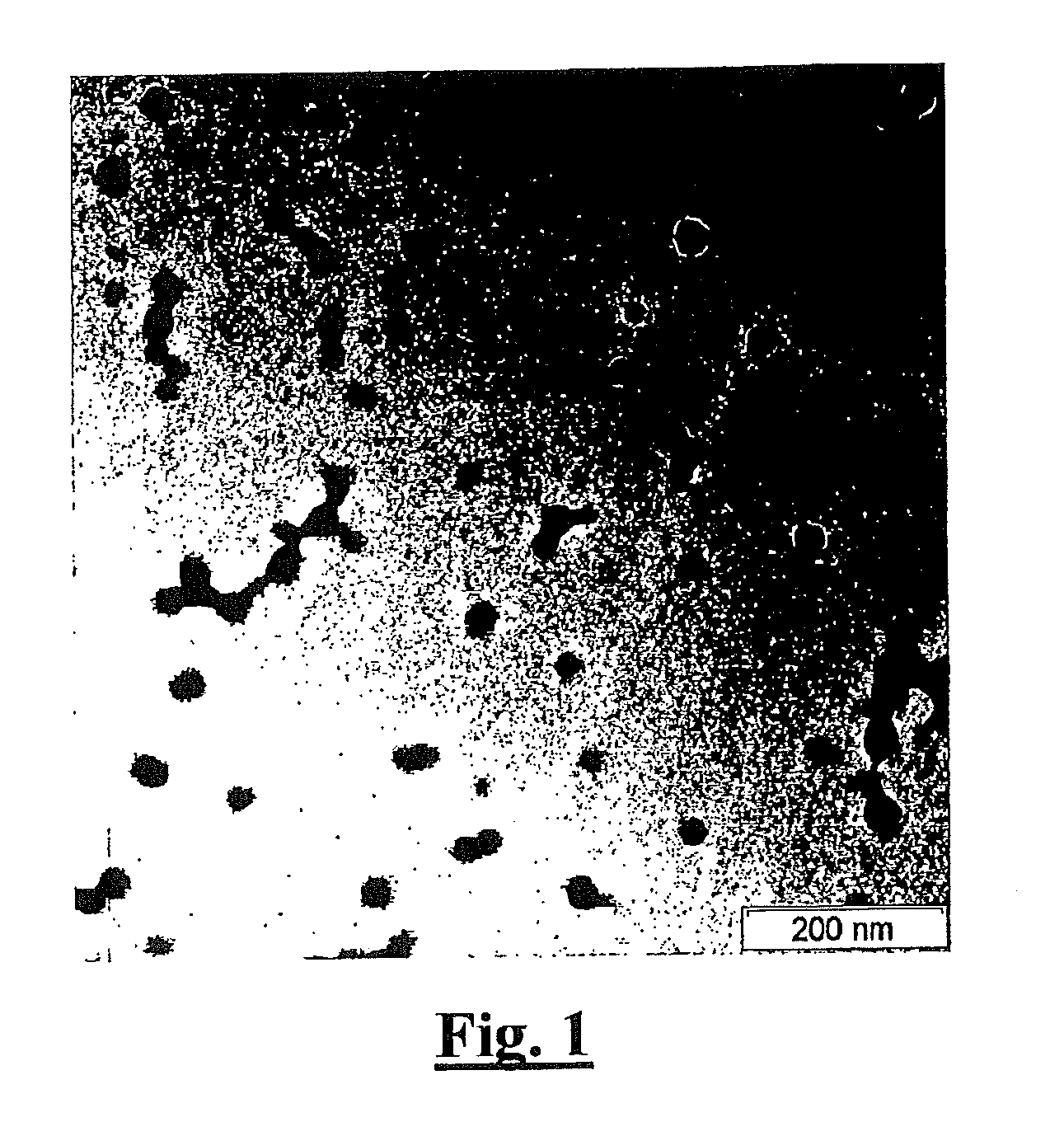

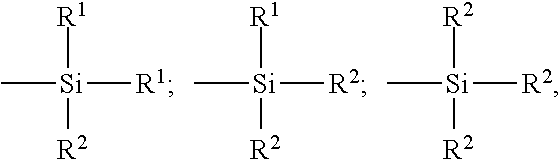

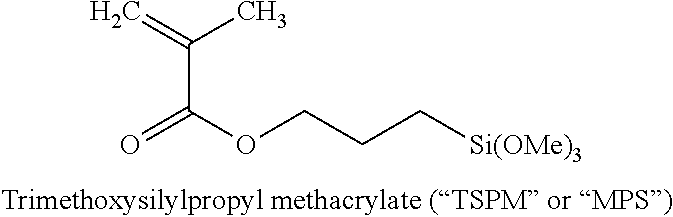

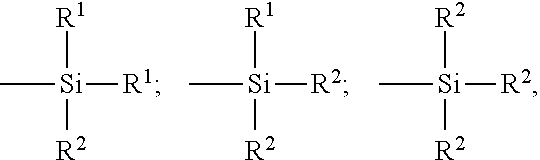

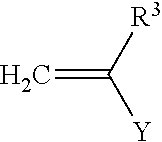

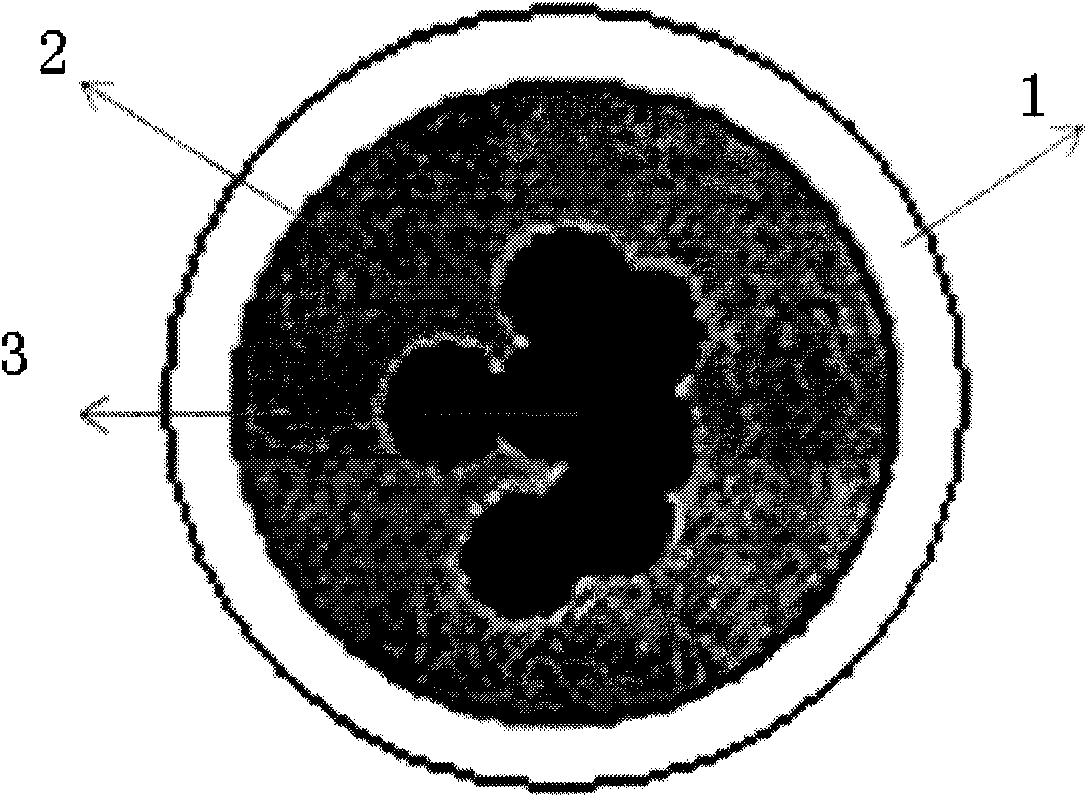

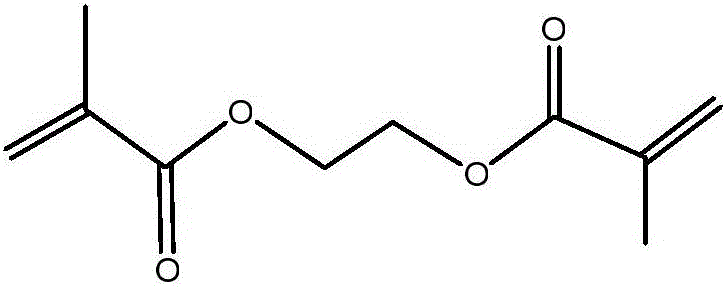

Rubber composition based on at least one diene elastomer, a polymer filler as reinforcing filler, a coupling agent providing the bond between the polymer filler and the elastomer. The polymer filler comprises nanoparticles of non-aromatic vinnyl polymer (“NAVP”) bearing a function Z of formula ≡Si—X, X representing a hydroxyl or hydrolysable group. The NAVP is in particular a copolymer of methyl methacrylate, trimethoxysilylpropyl methacrylate and ethylene glycol dimethacrylate, in the form of nanobeads the diameter of which is between 10 and 100 nm.

Owner:MICHELIN RECH & TECH SA

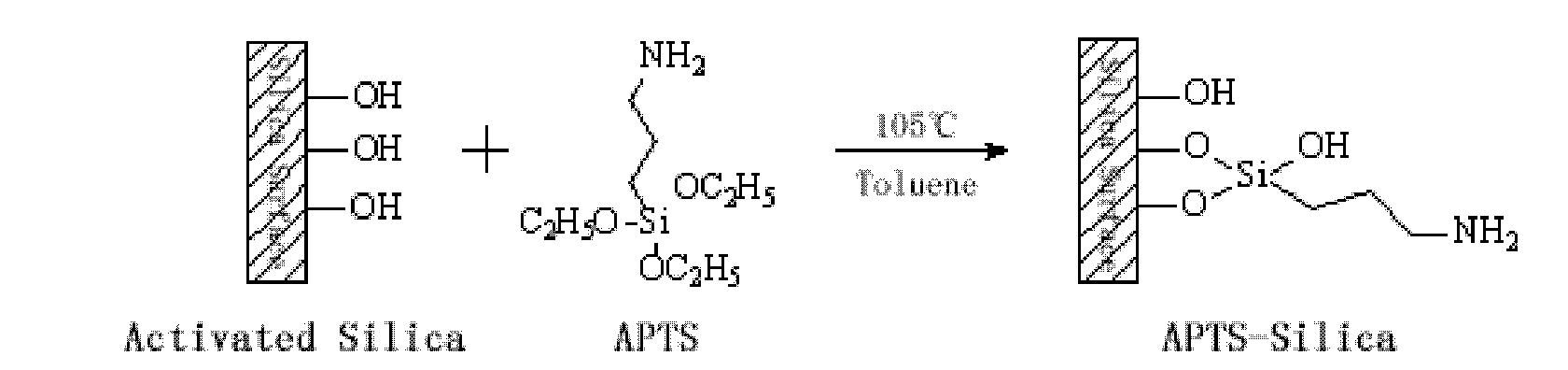

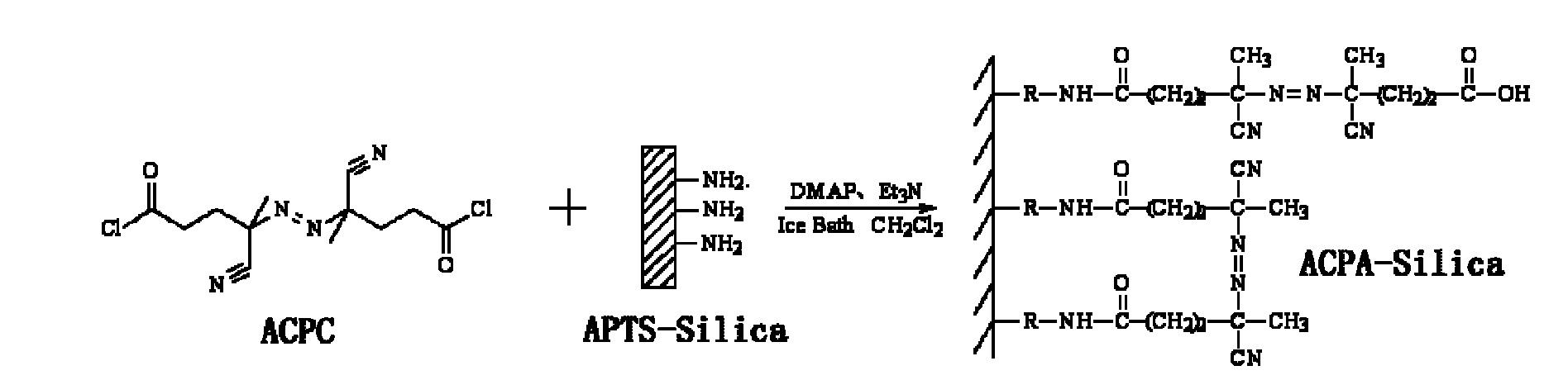

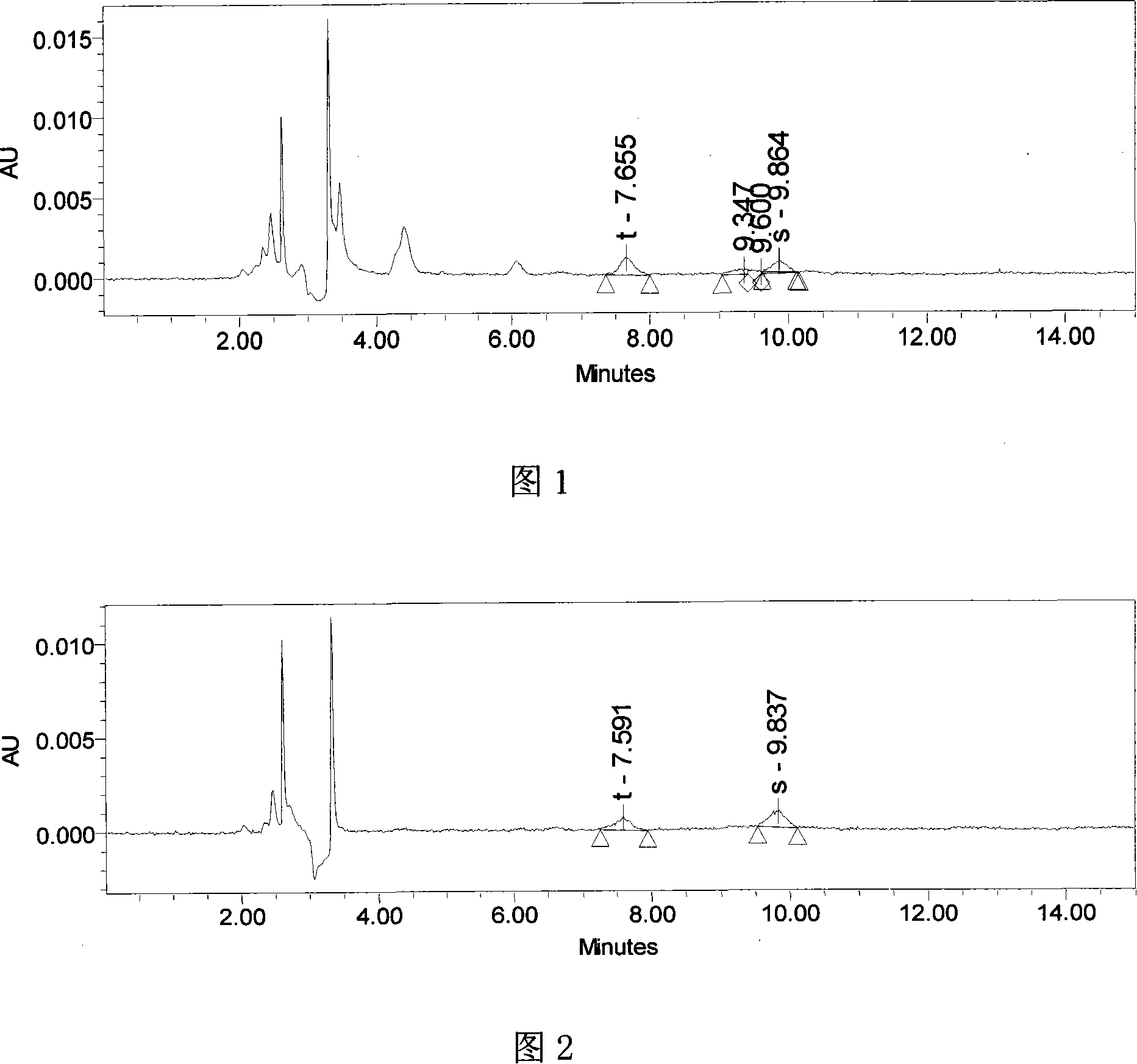

Preparation method and application of molecular imprinted polymer on silica surface for specifically adsorbing patulin

A preparation method and application of a molecular imprinted polymer on the silica surface for specifically adsorbing patulin belong to the technical field of bioassay. The method comprises the following steps: firstly pretreating the silica surface; siliconizing the silica surface to prepare APTS-silica and introducing amino groups; preparing ACPA-silica by dewatering and esterifying or an acyl chloride intermediate method and grafting an azo initiator on the silica surface; and finally taking the patulin analog 2-hydroxynicotinic acid as a template to replace molecules, taking acrylamide, methylacrylic acid, 4-vinyl pyridine and trifluoromethyl acrylic acid as the functional monomers and taking ethylene glycol dimethacrylate (EDMA) as a cross-linking agent to obtain the molecular imprinted polymer on the silica surface in acetonitrile and pyridine solvents by thermal initiation. The invention has the following advantages: as the pretreatment method for liquid chromatography of trace patulin in apple juice and related products, the polymer prepared by the invention can specifically adsorb the enriched patulin, the sample is simply and quickly treated and can be reused multiple times, and the polymer is resistant to acid and alkali treatment and is preserved under normal temperature, at the same time, the invention avoids the recovery loss caused by the traditional steps of removing impurities by alkaline washing by liquid-liquid extraction and removing organic solvents by rotary evaporation and reduces the usage amount of the organic solvents.

Owner:SHANGHAI JIAO TONG UNIV

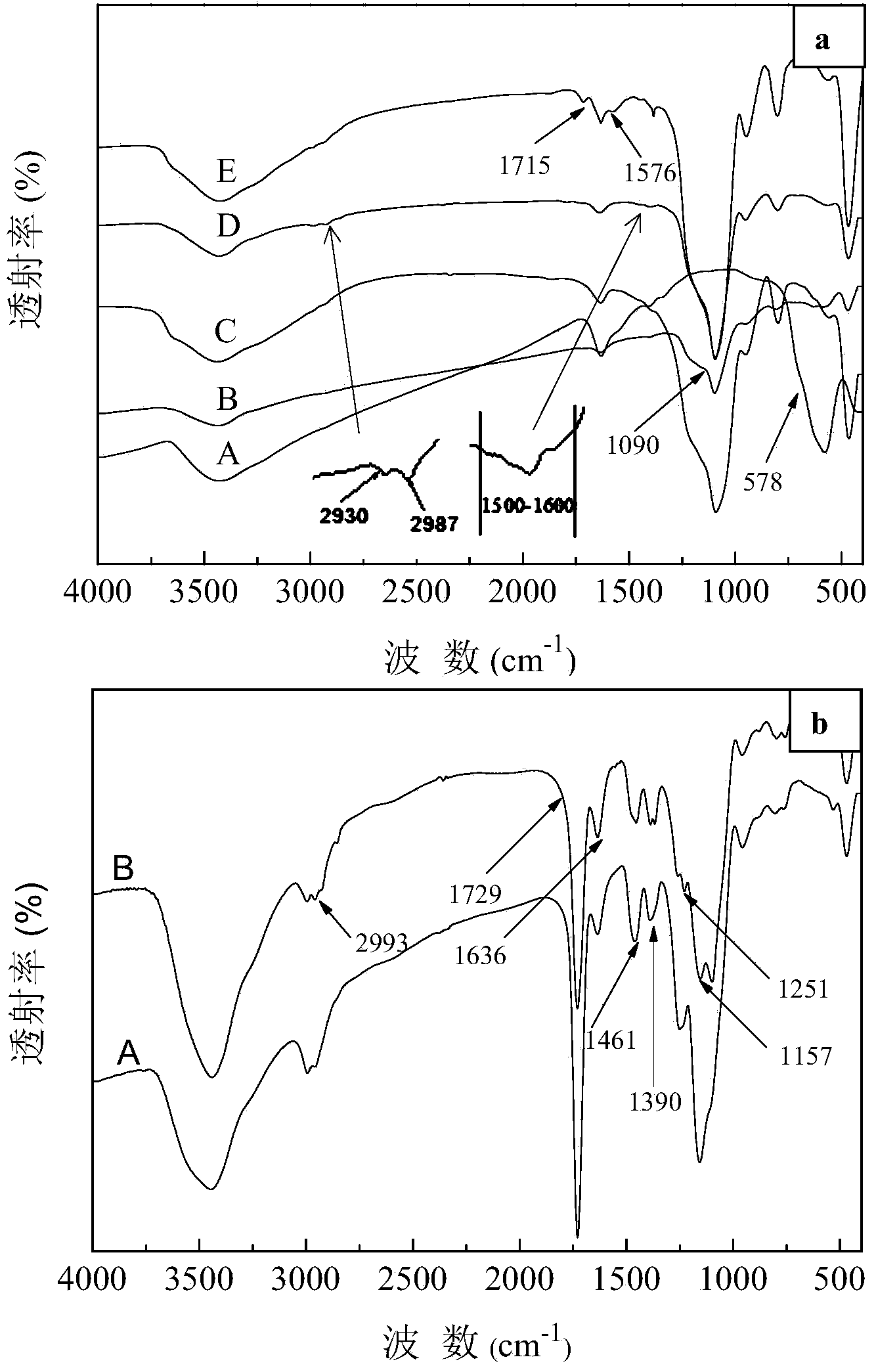

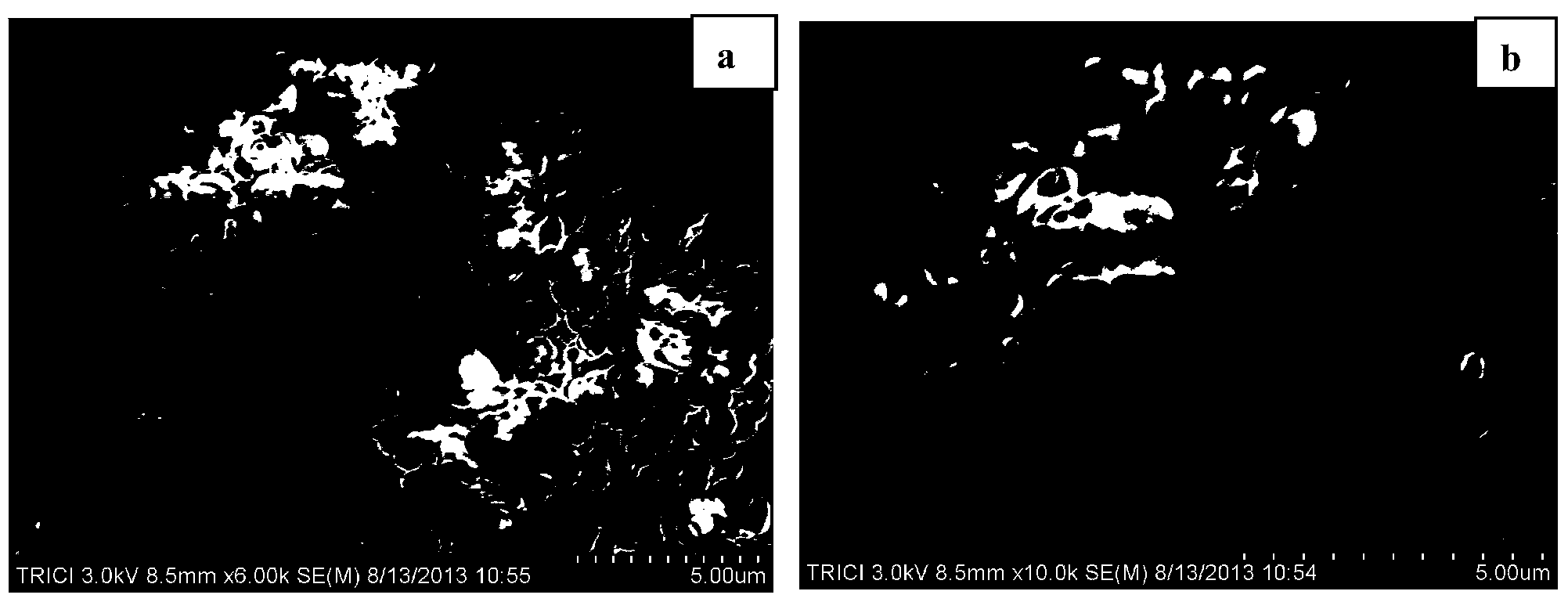

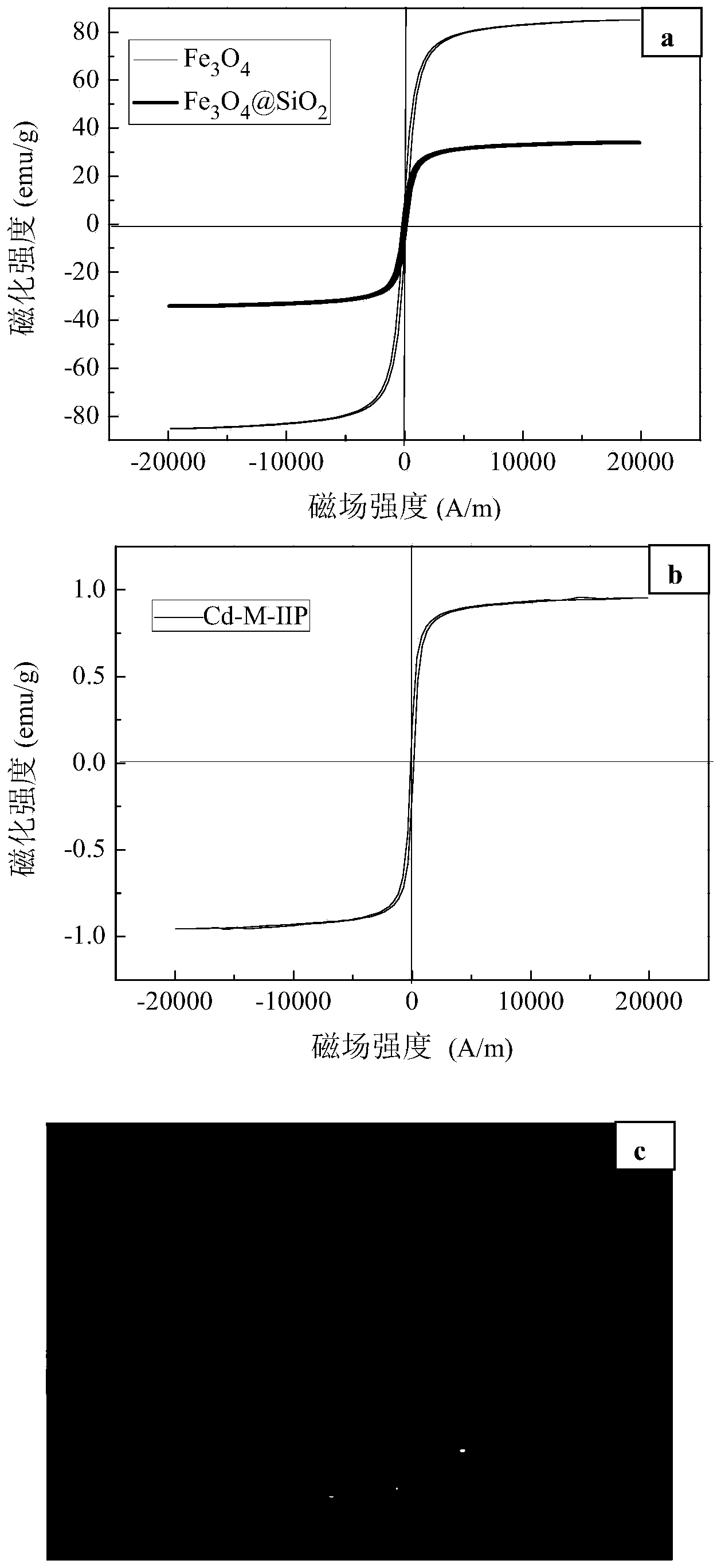

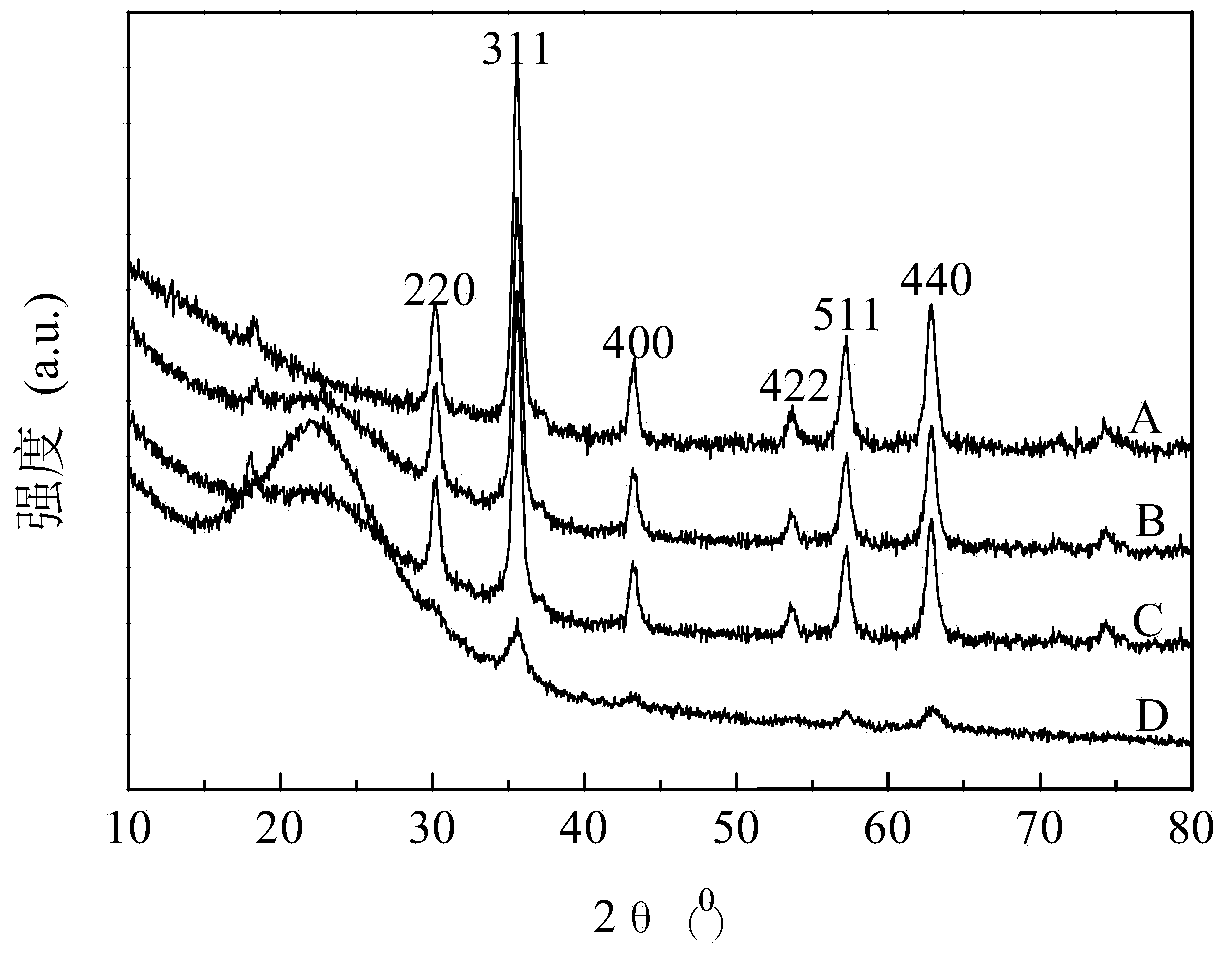

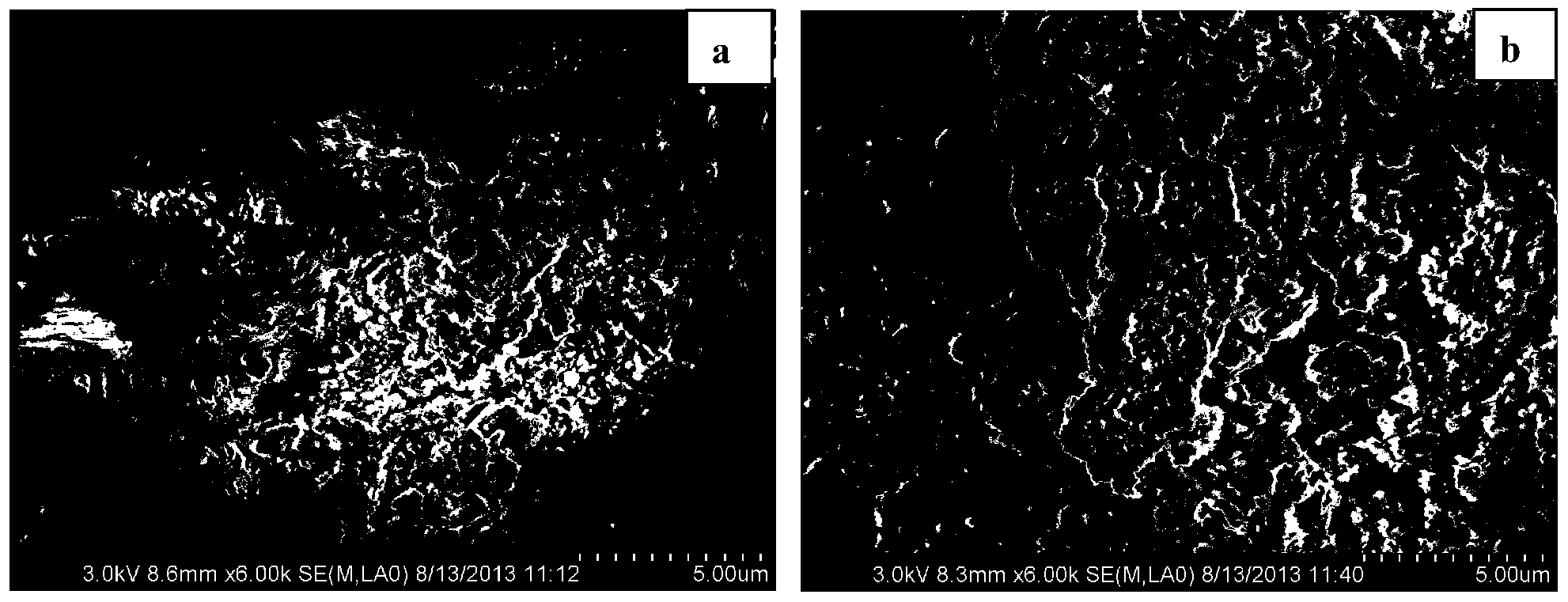

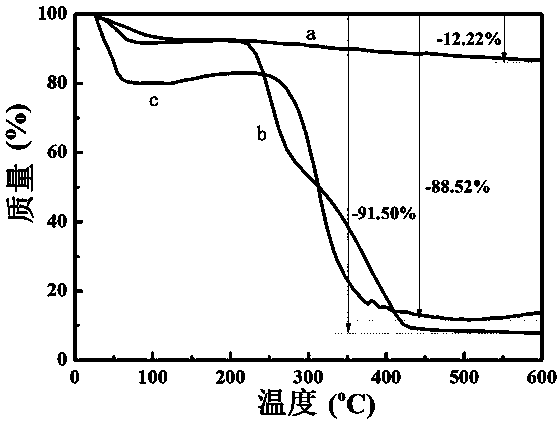

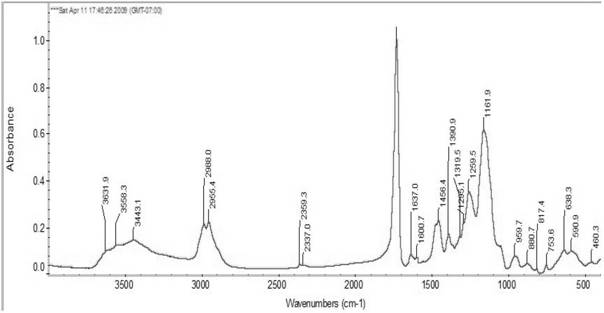

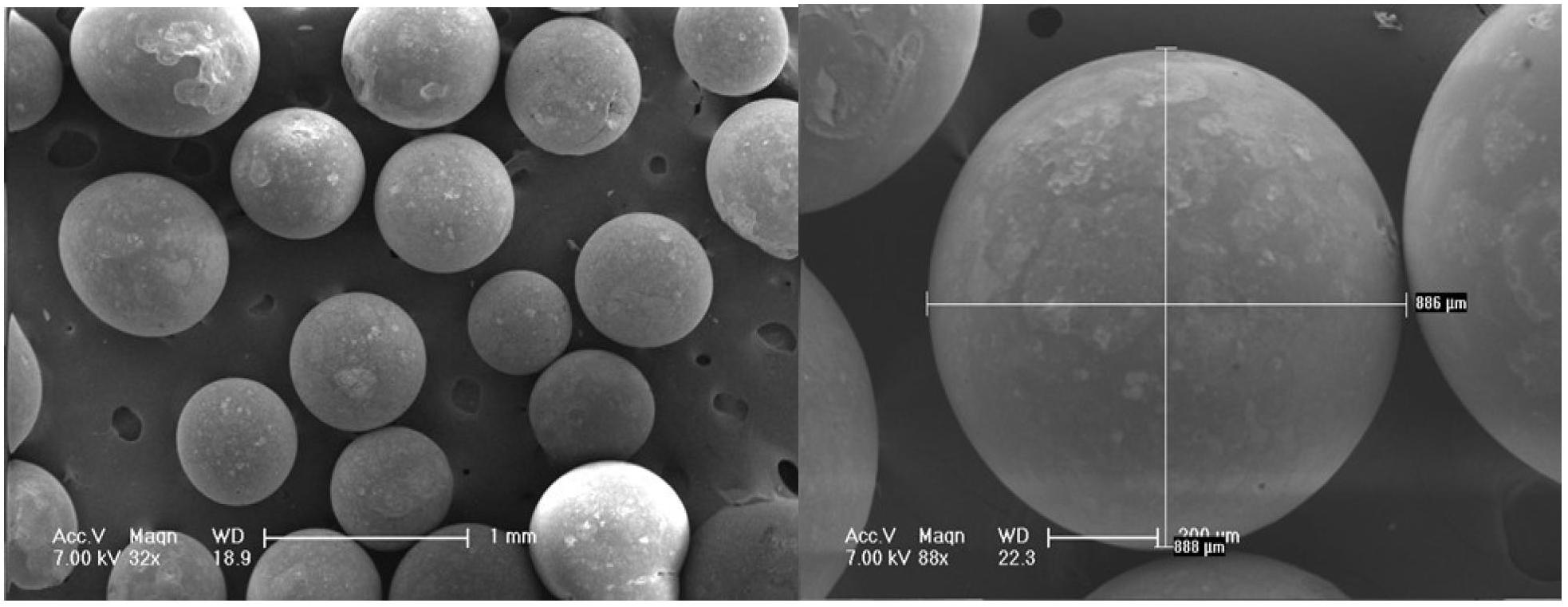

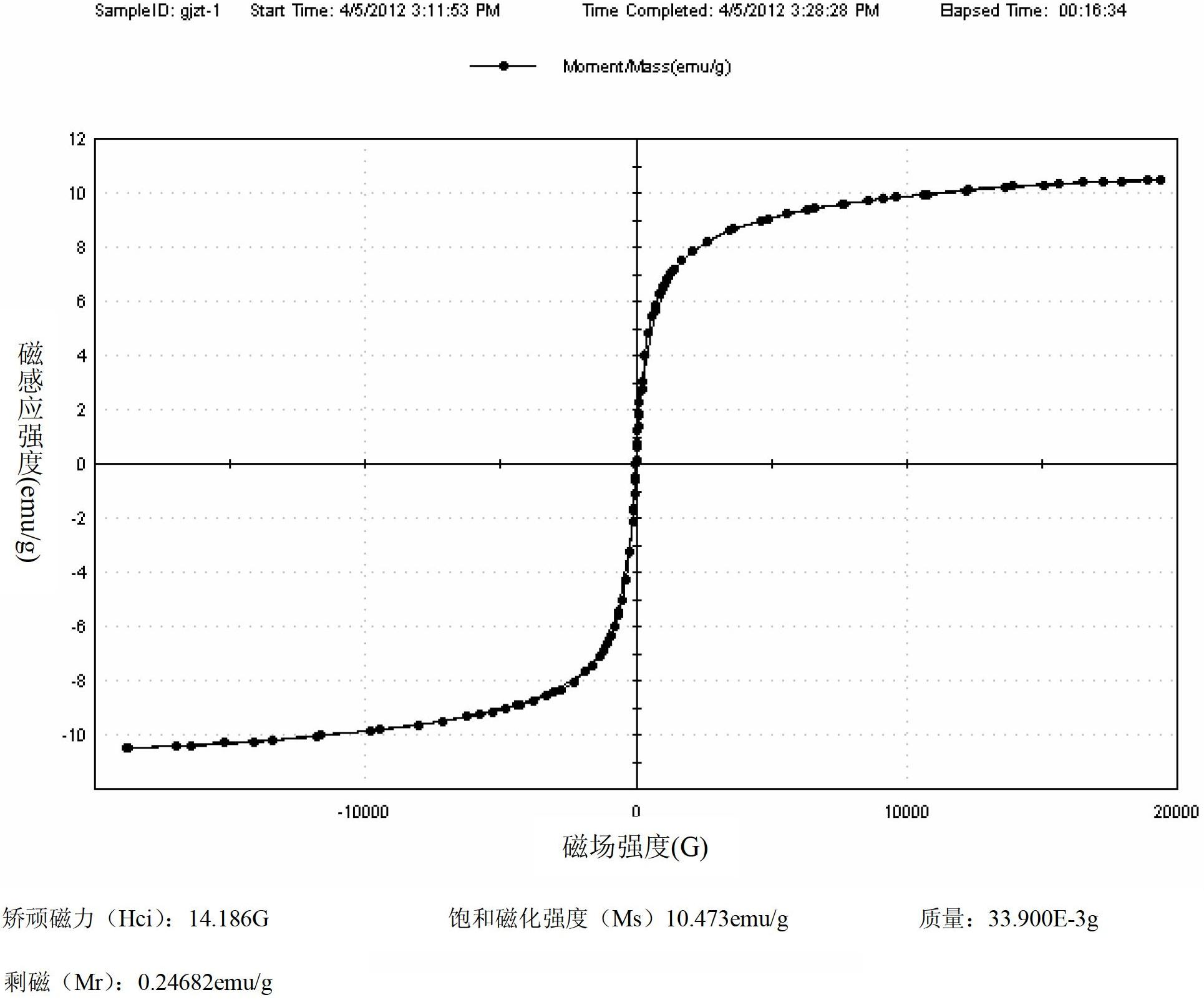

Preparation method of magnetic cadmium ion surface imprinted polymer

InactiveCN103709342AImprove introduction efficiencyHigh adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesMicrosphereDouble bond

The invention relates to a preparation method of a magnetic cadmium ion surface imprinted polymer, which comprises the following steps: synthesizing magnetic Fe3O4@SiO2 microspheres through a coprecipitation method and a sol-gel method, and treating with acid to increase the surface hydroxyl content; introducing polymerizable double bonds onto the surfaces of the Fe3O4@SiO2 microspheres through a two-step method, namely grafting amino groups onto the surfaces of the microspheres by using aminosilane coupling agent, and generating the double bonds through reaction between acid anhydride and the amino groups; and finally, performing polymerization reaction by taking the Fe3O4@SiO2 microspheres as carriers, taking Cd(II) as a template, taking ethylene glycol dimethacrylate as crosslinking agent and taking methacrylic acid and salicylaldoxime as monomers, and washing off the template Cd(II) after the reaction, thus obtaining a polymer layer with a large number of Cd(II) imprinted holes distributed on the surfaces of the Fe3O4@SiO2 microspheres. The magnetic cadmium ion surface imprinted polymer provided by the invention can be used for separation and removal of cadmium ions.

Owner:HEBEI UNIV OF TECH

Tsiklomitsin molecular engram polyalcohol and uses of the same

InactiveCN101130580AImprove purification efficiencyHighly selective separation and enrichmentComponent separationFunctional monomerSpatial structure

The invention discloses an abricycline molecule stamp polymer, which is characterized by the following: mixing mold fermentmycin molecule, functional monomer methacrylic acid, cross linker dimethyl acroleic acid glycol ester and trigger azobisisobutyronitrile with mass ratio at 1-5 : 2-10 : 80 : 0. 1-0. 5; polymerizing at original position; possessing 'memory' function for the spatial structure of the abricycline mold molecule; possessing high selective separating enriched property for abricycline and oxytetracycline in residue analysis sample solution; filling the product into small column of polypropene shell; getting abricycline molecule stamp solid phase extraction column.

Owner:ZHEJIANG CENT FOR DISEASE CONTROL & PREVENTION

A method to prepare the phase-change material wrapped by microcapsule

InactiveCN101550328AMeet the needs of full-band camouflageInorganic material magnetismHeat-exchange elementsPotassium persulfateParaffin wax

A method to prepare the phase-change material wrapped by microcapsule, wherein, 1. Weigh paraffin and methyl methacrylate (MMA) at a mass ratio of 1:3; 2. Weigh 0.5% glycol dimethacrylate (GDMA), 1% methacrylic acid (MAA) and 1% sodium dodecyl sulfate (SDS), 1.5% potassium persulfate, 1%-15% ferrite and 400% deionized water (to the total mass of Item 1); 4. Add ferrite and molten paraffin into the solution of Item 3; 5. Emulsify the solution under ultrasonic sound and add MMA, GDMA and MAA; 6. Re-emulsify and transfer the obtained solution into a device with mechanical agitation, condenser tube, gas inlet and feed inlet; 7. Aerate and remove oxygen 0.5h, heat it in water bath to 70 DEG C, add potassium persulfate and cool the solution to room temperature to obtain the phase-change material wrapped by microcapsule. The material is used in such fields as building, heat-storing temperature-adaptable textile, and electronic equipment.

Owner:BEIJING JIAOTONG UNIV

Self-reinforced hybrid hydrogel used for artificial muscles and preparation method thereof

InactiveCN103224633AHigh strengthAvoid breakingProsthesisMetal ions in aqueous solutionControllability

The invention relates to a self-reinforced hybrid hydrogel used for artificial muscles and a preparation method thereof. According to the invention, sodium alginate is used as a high-molecular skeleton, acrylamide and derivative thereof are used as polymerizable monomers, divinyl benzene, N,N'-methylene bis acrylamide or ethylene glycol dimethacrylate is used as a chemical cross-linking agent, an aqueous metal salt solution is used as an ion cross-linking agent, and then the hydrogel with high elasticity and high toughness is prepared. During a process of preparing the hydrogel, an organic matter emulsion containing metal ion aqueous solution is added. When the prepared hydrogel is stretched by external forces to a certain extent, the gel deforms to extrude the organic matter emulsion, and metal ions are released and then crosslinked with the sodium alginate in the hybrid gel, thereby substantially improving gel intensity and preventing gel fracture. The preparation method has advantages of good controllability, simple technology and low cost, the obtained hydrogel material can be self-reinforced, and is expected to be applied in fields of artificial cartilage, artificial muscle, flexible robot manufacture, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of magnetic zinc ion surface-imprinted polymer

InactiveCN103709341AImprove introduction efficiencyHigh adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesMicrosphereDouble bond

The invention relates to a preparation method of a magnetic zinc ion surface-imprinted polymer, which comprises the following steps: synthesizing magnetic Fe3O4@SiO2 microspheres by a coprecipitation process and a sol-gel process, and treating with acid to enhance the surface hydroxy content; introducing a polymerizable double bond onto the surface of the Fe3O4@SiO2 microspheres by a two-step process, i.e. grafting amino group onto the microsphere surface by using an aminosilane coupling agent, and reacting acid anhydride with the amino group to generate the double bond; and finally, carrying out polymerization reaction by using the Fe3O4@SiO2 microspheres as a carrier, Zn (II) as a template, ethylene glycol dimethacrylate as a crosslinking agent and methacrylic acid and salicylaldoxime as monomers, and after the reaction finishes, washing out the template Zn (II) to obtain the polymer layer in which abundant Zn (II) imprinted holes are distributed on the Fe3O4@SiO2 microsphere surface. The magnetic zinc ion surface-imprinted polymer can be used for separating and removing zinc ions.

Owner:HEBEI UNIV OF TECH

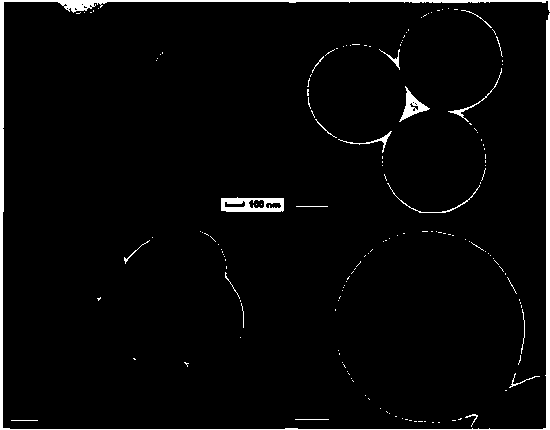

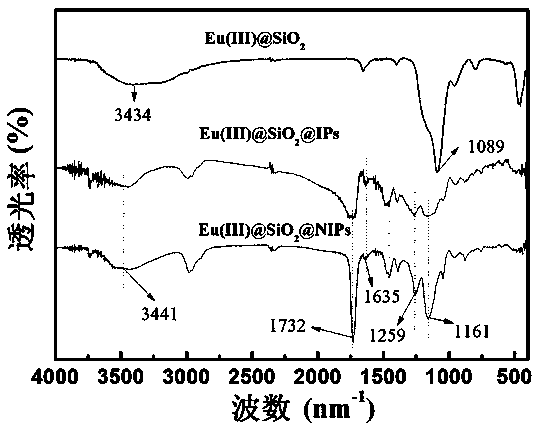

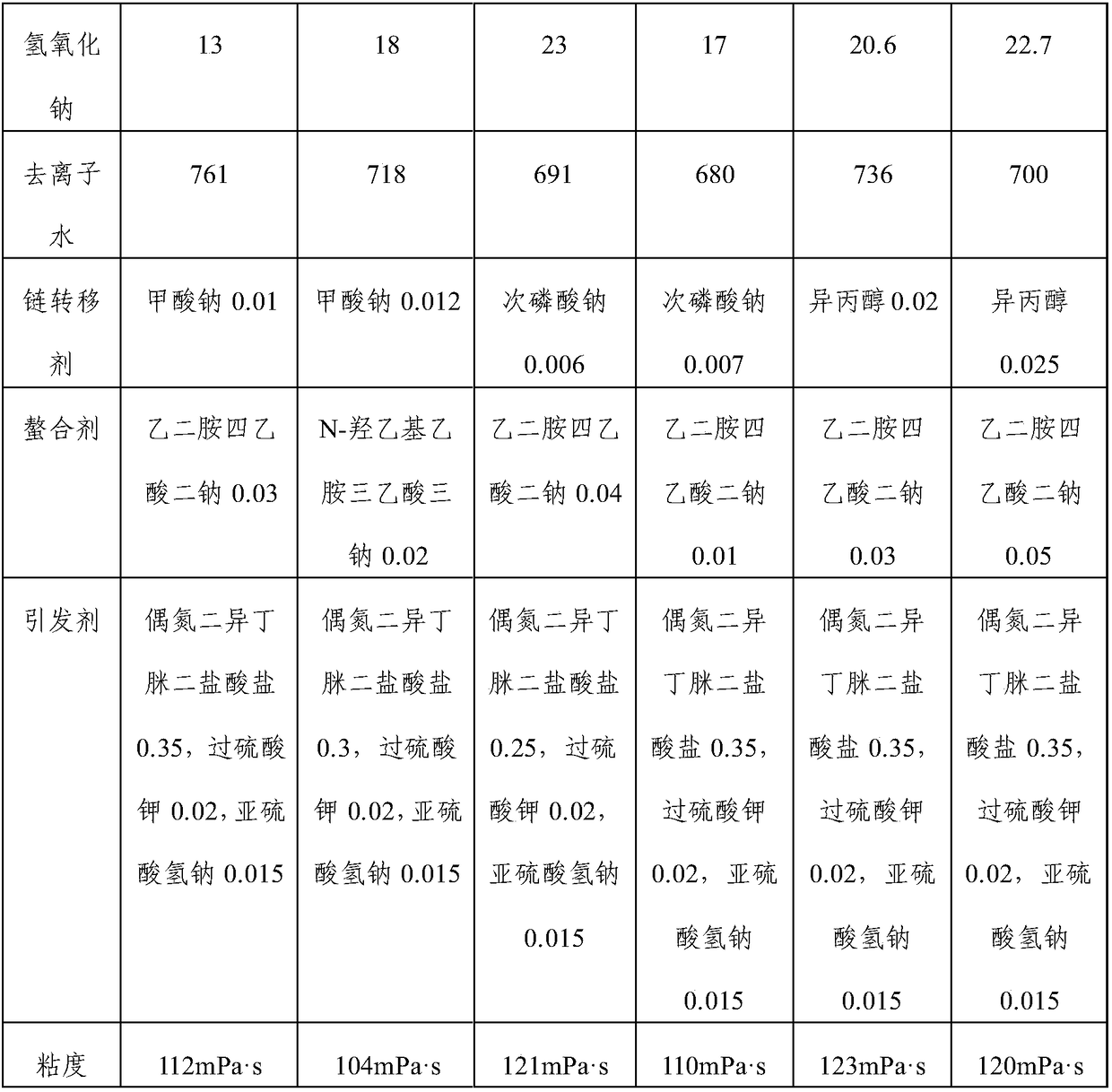

Preparation and application of fluorescence ion imprinting probe

InactiveCN104292381AHigh sensitivityExcellent ion recognition performanceFluorescence/phosphorescenceLuminescent compositionsFluoProbesFunctional monomer

The invention relates to a preparation method and application of a fluorescence ion imprinting probe and in particular relates to a method for preparing a fluorescence ion imprinting probe for detecting Cu<2+> as well as application of the fluorescence ion imprinting probe to detecting trace Cu<2+> in water, belonging to the technical fields of material preparation and detection. The invention particularly discloses a method for preparing an imprinting fluorescence probe by taking a metal europium ion complex as a luminous group, a bivalent Cu ion as a template molecule, methacrylic acid (MAA) as a functional monomer, ethylene glycol dimethacrylate (EGDMA) as a cross-linking agent and azodiisobutyronitrile (AIBN) as an initiator. The trace analysis detection experiment and selective experiment are used for researching the selective analysis performance of the prepared fluorescence probe. The result proves that the obtained fluorescence imprinting probe has excellent Cu ion identification performance.

Owner:JIANGSU UNIV

Flavone magnetic molecularly imprinted polymer, preparation of flavone magnetic molecularly imprinted polymer, and application of flavone magnetic molecularly imprinted polymer to bamboo-leaf flavone separation

InactiveCN102659982AWith dynamic memory functionOther chemical processesAlkali metal oxides/hydroxidesCross-linkFunctional monomer

Flavone magnetic molecularly imprinted polymer, preparation of the flavone magnetic molecularly imprinted polymer, and application of the flavone magnetic molecularly imprinted polymer to bamboo-leafflavone separation belong to the technical field of drug separation. Preparation of flavone magnetic molecularly imprinted polymer microspheres include subjecting nano Fe3O4 subjected to surface modification by oleic oil, template molecule luteolin, functional monomer 4-ethylpyridine and cross linking agent ethylene glycol dimethacrylate to suspension polymerization according to a template molecule, functional monomer and crosslinking agent ratio of 1:5-8:80. The flavone magnetic molecularly imprinted polymer microspheres are applicable to selective enrichment and purification of bamboo-leaf flavones in bamboo-leaf extract, and the preparation is simple, quick, high in recovery rate and the like and is widely applicable to the field of separation of natural flavone compounds.

Owner:INT CENT FOR BAMBOO & RATTAN

Anti-algae anti-aging fishing net

InactiveCN105442086ASimple processing technologyImprove toughnessStain/soil resistant fibresConjugated synthetic polymer artificial filamentsEpoxyPolystyrene

The invention discloses an anti-algae anti-aging fishing net prepared from the following components: polystyrene, polyethylene fibers, nylon fibers, MBS resin, an epoxy resin adhesive film, ethylene glycol dimethacrylate, a calcium carbonate powder, an attapulgite powder, dibutyl phthalate and calcium stearate. The prepared fishing net has simple processing technology; ultraviolet intermittent irradiation treatment is carried out in a process of polyethylene fiber treatment, and the prepared fishing net can be allowed to have extremely strong performance of preventing algae attachment; the nylon fibers have the defects that the nylon fibers have poor optical rotation resistance, are prone to yellowing and have the strength decreased when illuminated for a long time by the sun outdoor, so a hexamethylene diamine and maleic anhydride mixture is adopted for treating the nylon fibers, the problems are solved, and the anti-aging ability of the prepared fishing net is greatly improved; and through addition of the treated attapulgite powder, mechanical properties of the fishing net are improved, and the toughness is enhanced.

Owner:CHAOHU TIANYU FISHING TACKLE CO LTD

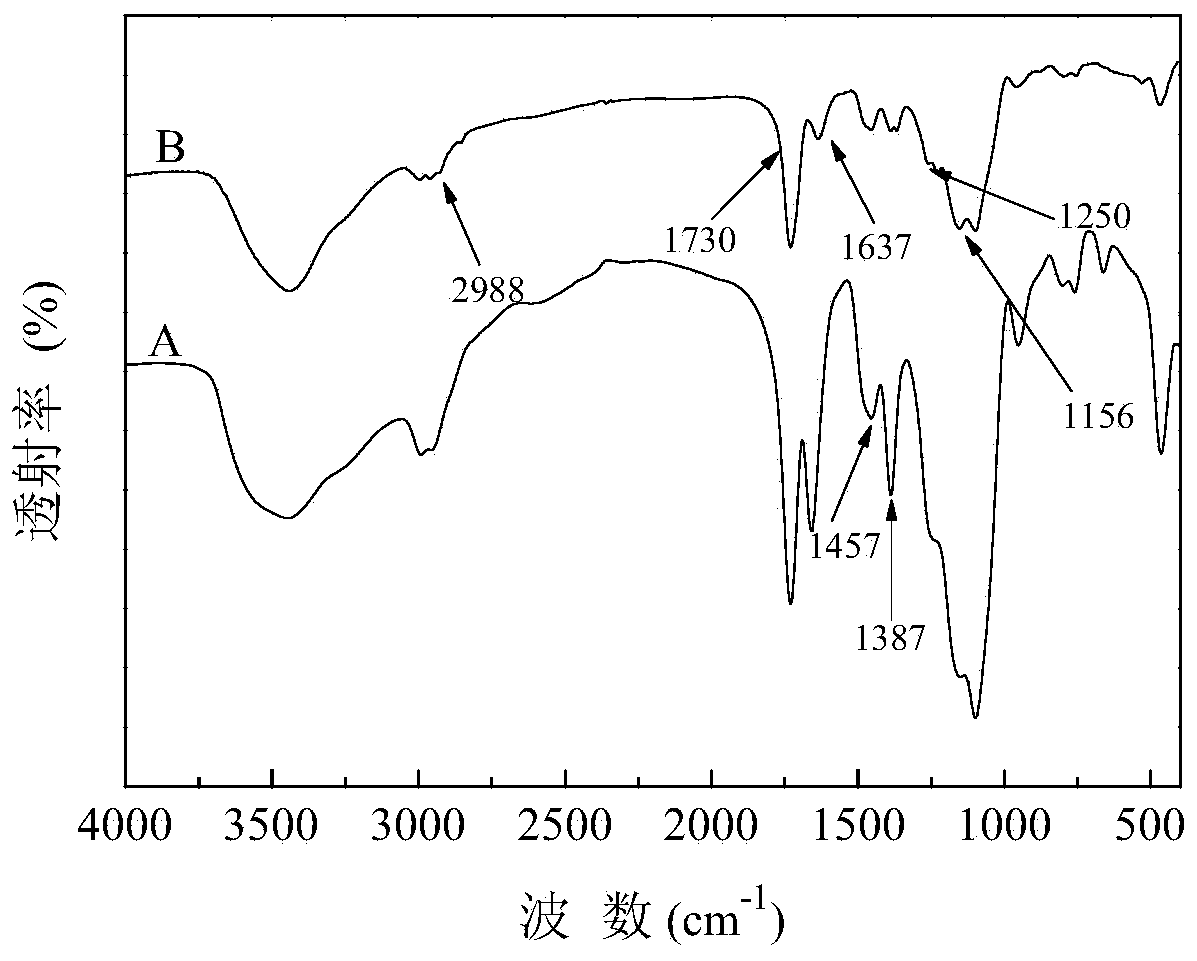

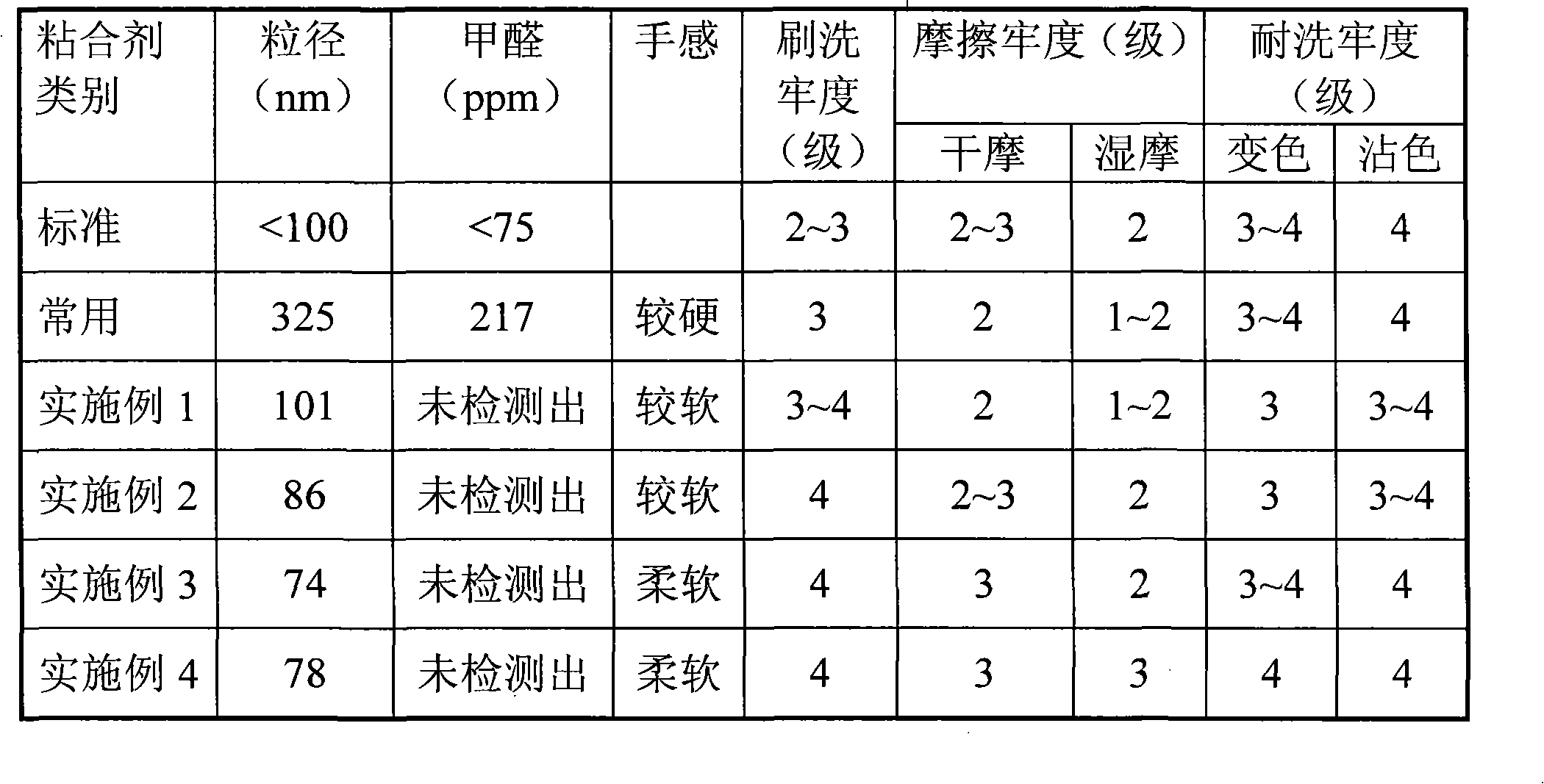

Formaldehyde-free self-crosslinked nanometer emulsion coating dye printing cementing substance and method for making same

InactiveCN101265670AImprove printing fastnessExcellent environmental protection productDyeing processHydrophilic monomer(Hydroxyethyl)methacrylate

A formaldehyde-free self-crosslinking nanometer emulsion coating printing and dyeing adhesive and a preparation method thereof. According to the technical proposal provided by the invention, the formaldehyde-free self-crosslinking nanometer emulsion coating printing and dyeing adhesive contains: crosslinking monomer 1-20, hard monomer 1-20, hydrophilic monomer 0-5, initiator 0.01-0.5, and surfactant 2-5; the mass part is taken as the unit. The crosslinking monomer can be one of or a combination of hydroxyethyl acrylate, hydroxypropyl acrylate, hydroxybutyl acrylate, hydroxyhexyl acrylate, methyl methacrylate, glycol methacrylate, and propylene glycol monomethacrylate. When the formaldehyde-free self-crosslinking nanometer emulsion coating printing and dyeing adhesive is used in fabric coating printing or dyeing, no mesh blocking or roll coating happens; the printing and dyeing pattern has bright color, and clear figure and pattern; the fabric feels soft; and the color fastness is excellent.

Owner:JIANGNAN UNIV

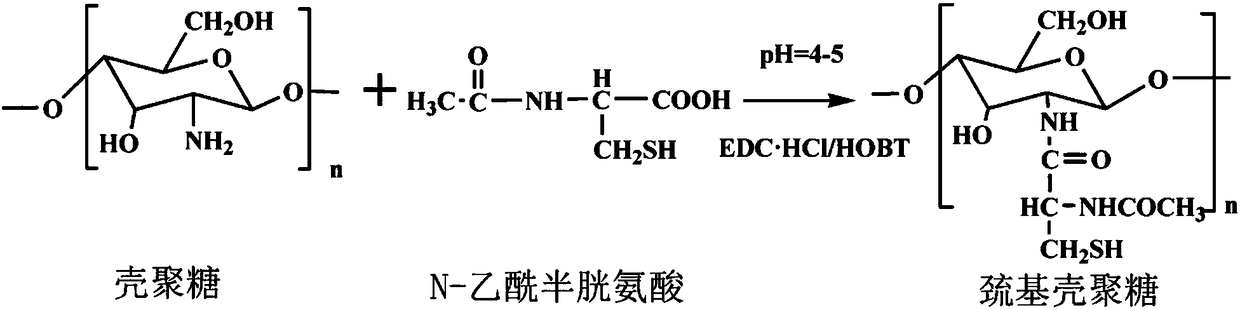

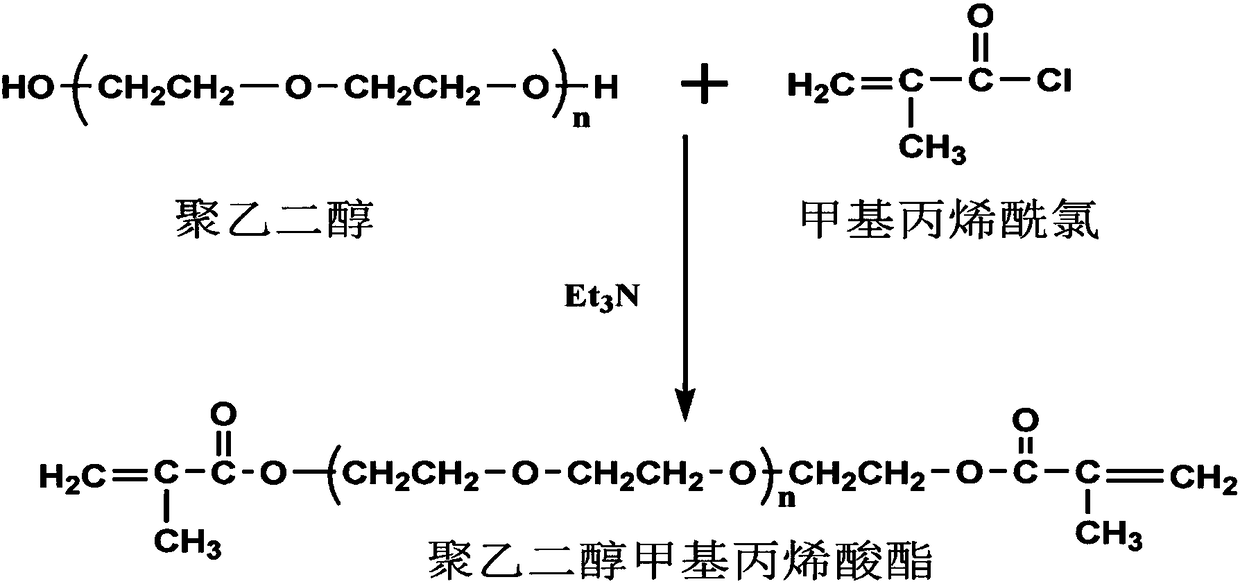

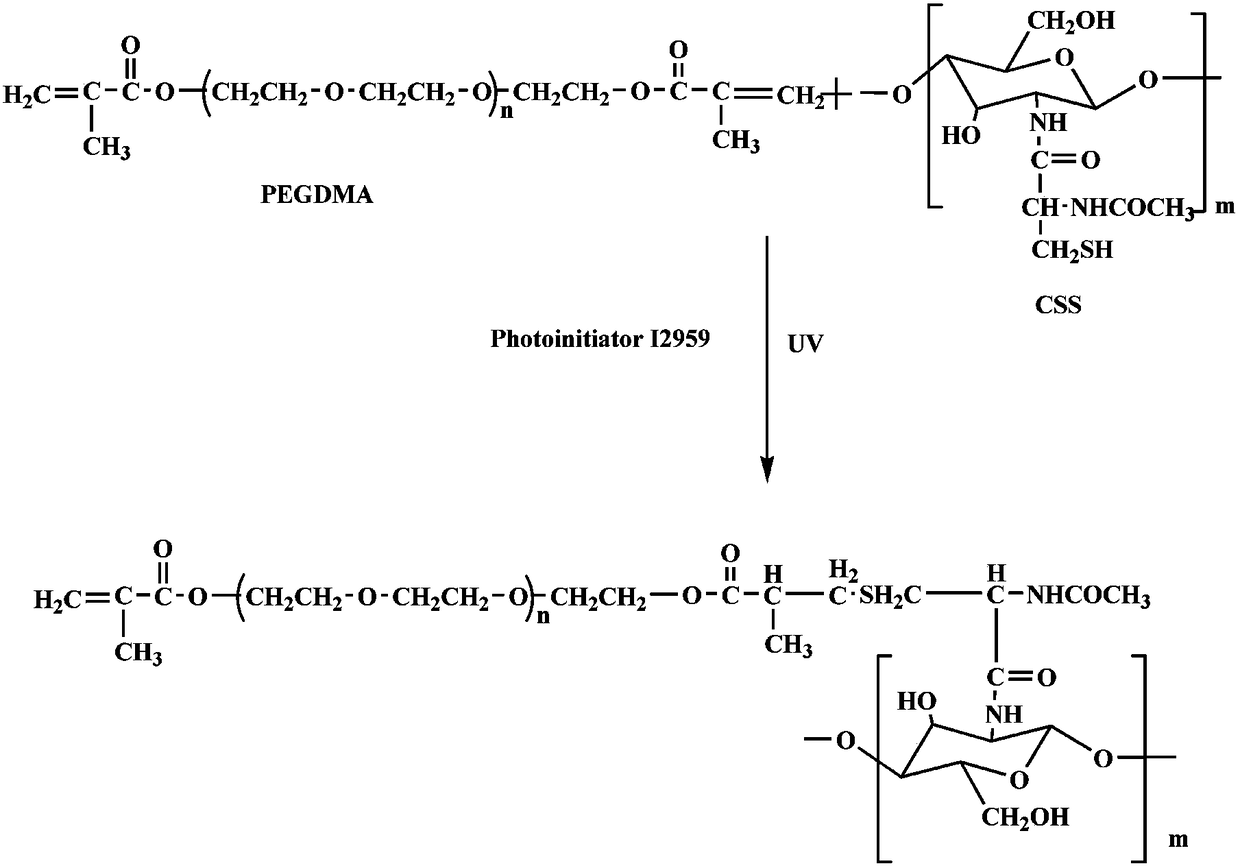

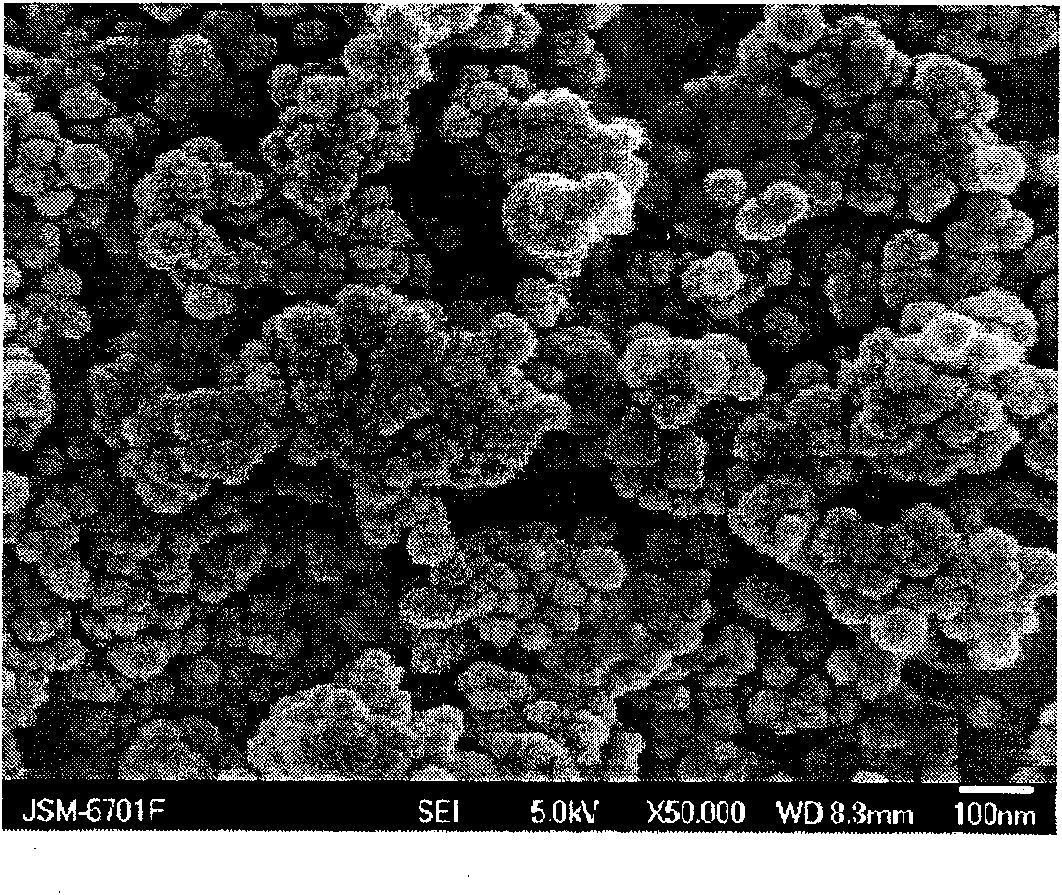

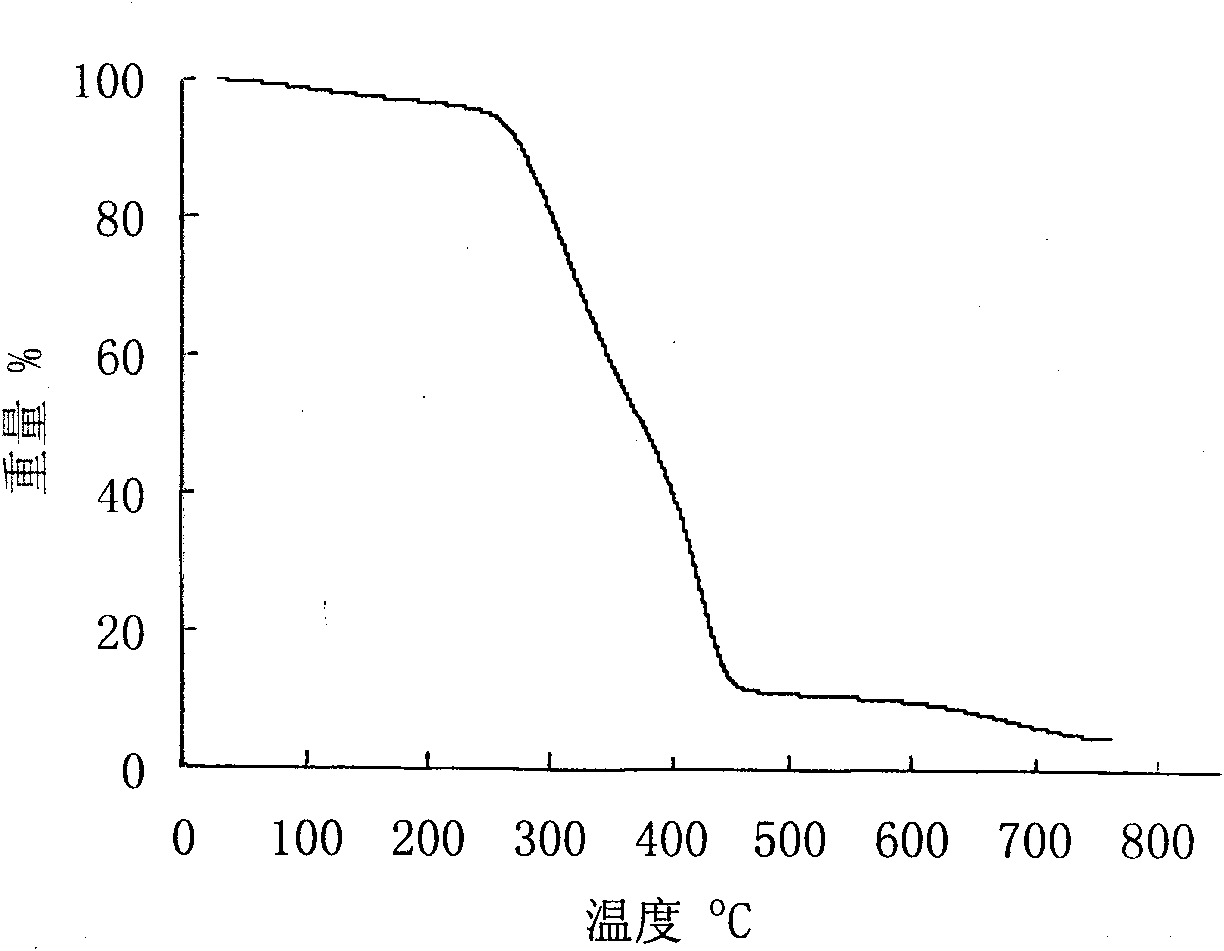

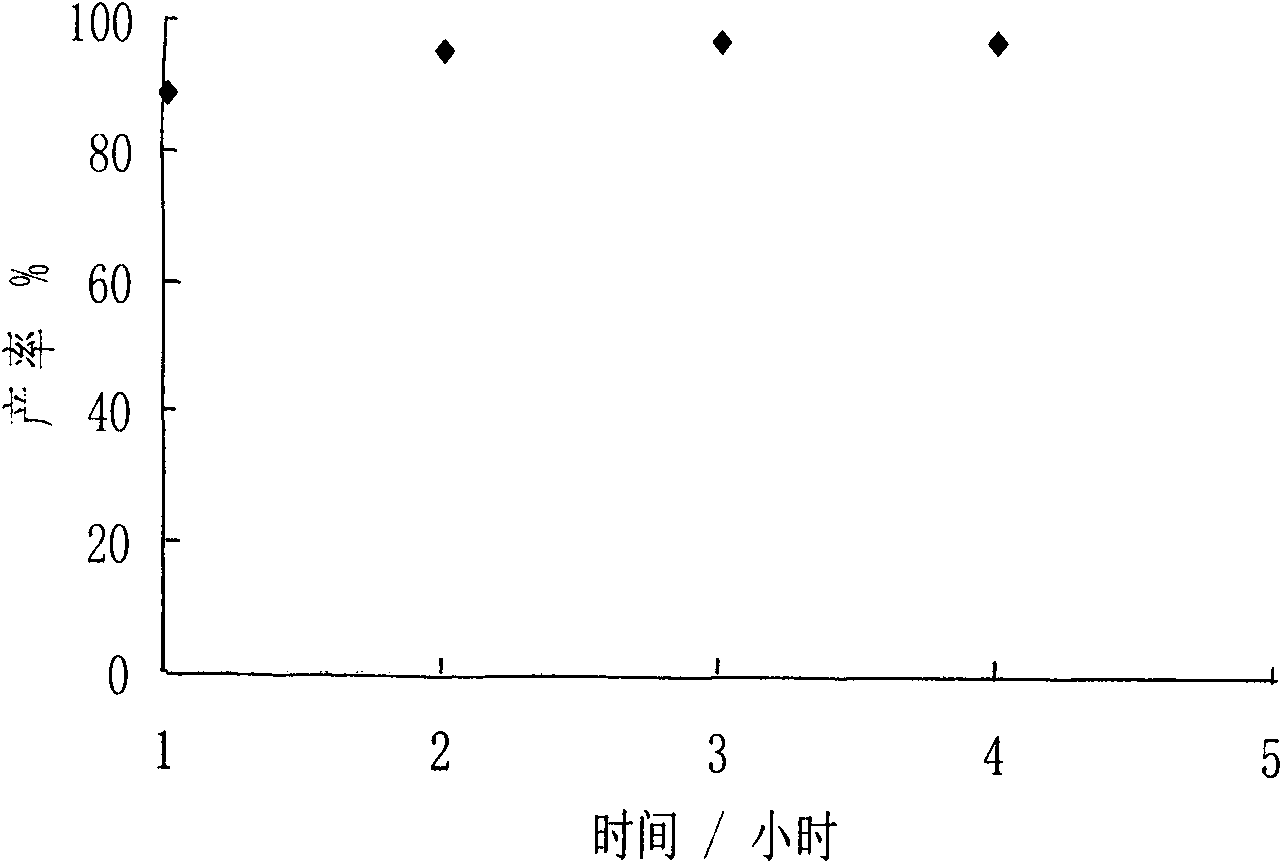

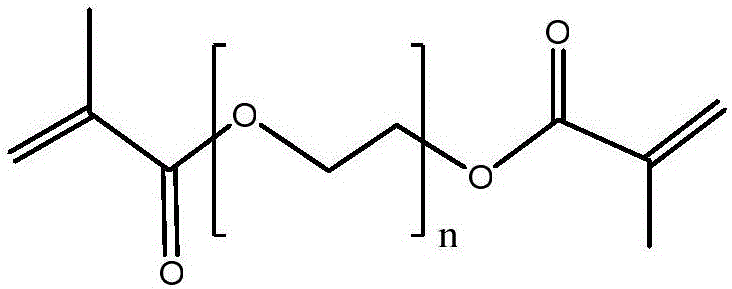

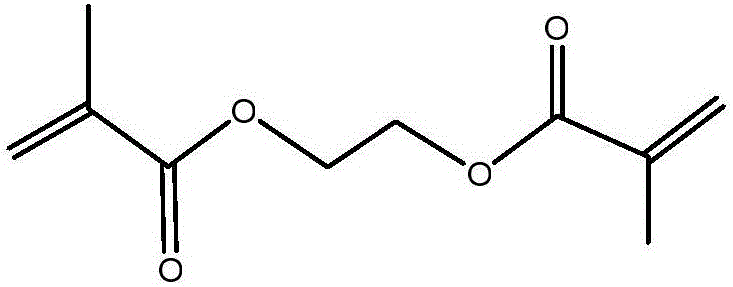

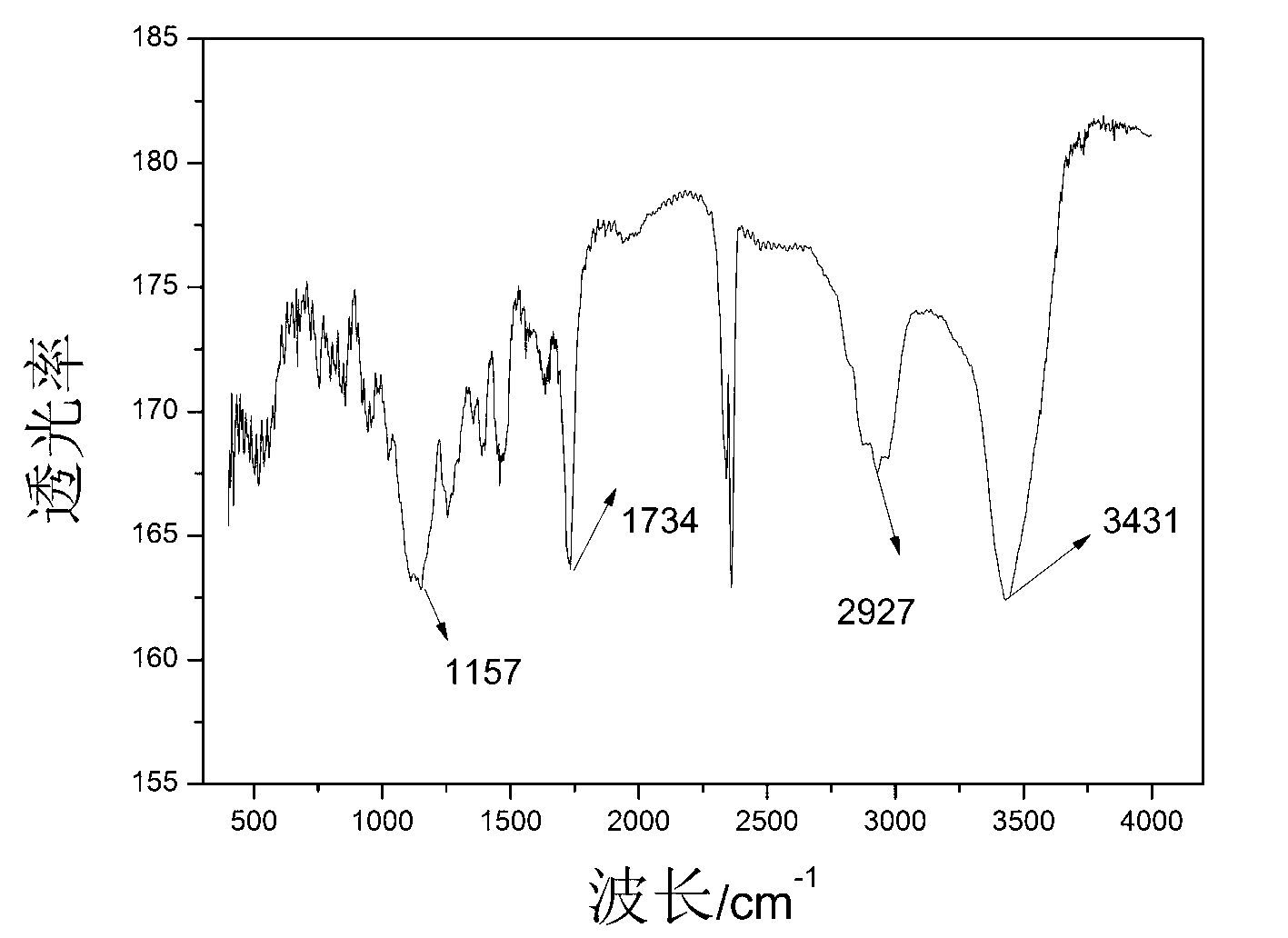

Photocrosslinked thiolated chitosan-polyethylene glycol methacrylate hydrogel used for tissue adhesive, and preparation method thereof

InactiveCN108314790AHigh mechanical strengthGood biocompatibilitySurgical adhesivesBiocompatibility TestingGlycol methacrylate

The invention relates to a photocrosslinked thiolated chitosan-polyethylene glycol methacrylate hydrogel used for a tissue adhesive, and a preparation method thereof. The hydrogel is obtained throughphotocrosslinking a thiolated chitosan solution and a polyethylene glycol methacrylate solution. The preparation method comprises the following steps: preparation of thiolated chitosan, preparation ofpolyethylene glycol methacrylate, and preparation of the photocrosslinked thiolated chitosan-polyethylene glycol methacrylate hydrogel. The thiolated chitosan and polyethylene glycol methacrylate arerespectively prepared, and the proportions of the two components are adjusted to well control the crosslinking speed, the mechanical strength and the bonding strength of the hydrogel; and the prepared hydrogel has excellent biocompatibility and biodegradability, has excellent cohesiveness to tissues, and is a hydrogel used for the tissue adhesive.

Owner:DONGHUA UNIV

Cross-linked quaternary phosphonium ionic liquid and preparation thereof and application in CO2 cycloaddition reaction

InactiveCN101613372AImprove thermal stabilityHigh selectivityGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsCross-linkPhosphonium

The invention provides a cross-linked quaternary phosphonium ionic liquid. The preparation method comprises the following steps: mixing 4-ethenyl benzyl chloride with triphenyl phosphonium at mol ratio of 1:1-1:1.5, heating to the room temperature to 60 DEG C, and reacting for 20-48h to obtain the quaternary phosphonium ionic liquid; mixing ethylene glycol dimethacrylate with the quaternary phosphonium ionic liquid at mol ratio of 1:1-5:1, adding azo diisobutyronitrile which is 1-5% of the total molar weight of the ethylene glycol dimethacrylate and the quaternary phosphonium ionic liquid, heating to the temperature of 60-90 DEG C, and reacting for 20-48h; and washing reaction products by acetone and tetrahydrofuran in turn to obtain the cross-linked quaternary phosphonium ionic liquid. Experiment proves that the cross-linked quaternary phosphonium ionic liquid catalyst provides high catalytic activity to a reaction of CO2 epoxy compound for generating five-membered cycle compound, and has very high selectivity and high conversion rate. Reaction conditions are optimized, yield is up to 99.2%, and the selectivity is 100%.

Owner:NORTHWEST NORMAL UNIVERSITY

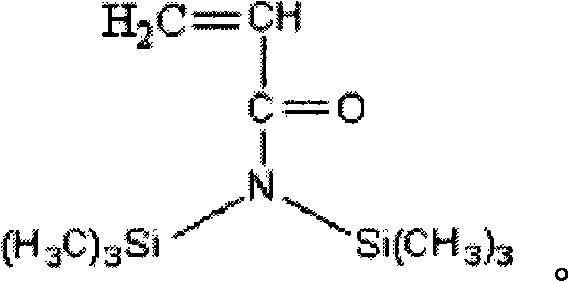

Silicone-hydrogel compound for soft contact lens and soft contact lens produced using the compound

ActiveCN101688042AHydrophilicIncrease moisture contentIntraocular lensOptical elementsCross-linkHigh water content

The present invention relates to a silicone hydrogel composition for a soft contact lens and a soft contact lens using the same which comprises silicone N,O-bis(trimethylsilyl)acrylamide monomer and 2-hydroxyethyl methacrylate added with water soluble N-vinyl-2-pyrrolidone or N,N-dimethylacrylamide monoer to improve hydrophilic property and a cross-linking agent such as ethylene glyx>l dimethacrylate or divinyl benzene to provide a hydrophilic property, high water content rate, high oxygen permeability, good elongation and optical transmission.

Owner:BESKON KO +1

Cetirizine molecularly imprinted polymer monolithic column and preparation method thereof

InactiveCN104209104AEasy to makeSimple experimentOther chemical processesSolid sorbent liquid separationTetrafluoroborateGlycol synthesis

The invention relates to a cetirizine molecularly imprinted polymer monolithic column and a preparation method thereof. The cetirizine molecularly imprinted polymer monolithic column is composed of raw materials of, by mass, 1-3% of cetirizine, 3-4% of 4-vinyl pyridine, 20-25% of ethylene gylcol dimethacrylate, 42-45% of mixed solution (eutectic solvent) of ethylene glycol and choline chloride, 4-5% of dimethylformamide, 13-22% of 1-butyl-3-methylimidazolium tetrafluoro borate and 0.5-1% of azobisisobutyronitrile. The method includes the steps of adding ionic liquid and the eutectic solvent of ethylene glycol and choline chloride to a polymerization system, using cobalt ions as a metal ion hub to enhance the effect of imprinting recognition, and preparing molecularly imprinted polymer (MIP) of a successive rod shape in a stainless steel column. The cetirizine molecularly imprinted polymer (MIP) monolithic column obtained through the preparation method has the advantages of good permeability and obvious imprinting effects and can have the model cetirizine imprinting factors up to 31.54, and meanwhile, the method is simple in preparation process and avoids the use of volatile liquid, thereby reducing harmful gas emission to the environment.

Owner:TIANJIN MEDICAL UNIV

Artemisinin molecule imprinting polymer on surface of porous microsphere silica gel as well as preparation and application methods thereof

InactiveCN101845126AAdsorptiveSelectiveOrganic chemistryBulk chemical productionCross-linkPolymer science

The invention relates to an artemisinin molecule imprinting polymer on the surface of porous microsphere silica gel. The artemisinin molecule imprinting polymer is prepared by adopting the steps of: selecting the porous microsphere silica gel as a basal material, taking vinyl triethoxysilane as a coupling agent, artemisinin as a template molecule, methacrylate and acrylamide as functional monomers, ethylene glycol dimethacrylate as a cross-linking agent and azodiisobutyronitrile as an initiating agent, preparing a polymer and removing the artemisinin in the polymer. The invention also provides a preparation method and an application method of the artemisinin molecule imprinting polymer on the surface of the porous microsphere silica gel. The artemisinin molecule imprinting polymer on the surface of the porous microsphere silica gel can separate the artemisinin from other structural analogues, such as artemether, and the like under normal pressure and temperature and supercritical conditions, is especially suitable for supercritical conditions and has specific adsorption property, selectivity and favorable mechanical stability; and the preparation method is simple, convenient and suitable for large-scale popularization and application.

Owner:EAST CHINA UNIV OF SCI & TECH

Anticorrosion antiageing fishing net

InactiveCN105463622ASimple processing technologyImprove performanceFishing netsConjugated cellulose/protein artificial filamentsHexamethylenediaminePolystyrene

The invention discloses an anticorrosion antiageing fishing net, made from the following components: polystyrene, 2-methylimidazole, polyethylene fiber, nylon fiber, bamboo powder, waste PCB powder, ethylene glycol dimethacrylate, calcium carbonate powder, attapulgite powder, dibutyl phthalate and calcium stearate. The fishing net is simple in machining process, by pre-modifying processing on the polyethylene fiber, the performance of the made fishing net is greatly improved, due to the defect of poor optical activity resistance, the nylon fiber is easily yellowed in the sunlight for a long term and reduced in strength, the nylon fiber is processed by a mixture of hexamethylenediamine and maleic anhydride, these problems are solved, and the antiageing capacity of the made fishing net is greatly improved; by matching the processed waste PCB powder with the bamboo powder, the anticorrosion and antibacterial capacities of the fishing net are greatly improved, thus prolonging the service life of the fishing net.

Owner:巢湖市瑞强渔具有限责任公司

Method for preparing ultra macropore type rigid macromolecule medium by using suspension liquid of fine particles of calcium carbonate

InactiveCN1695795AControl quantityReduce sizeIon-exchange process apparatusOther chemical processesChromatographic separationPolyvinyl alcohol

A process for preparing the rigid high-molecular medium with ultra-large pores from calcium carbonate microparticles suspension includes preparing suspension of calcium carbonate, mixing glicide methylacrylate, benzoin ether, span-80 and ethanediol dimethylacrylate, dispersing said suspension in the mixed solution to become emulsion, emulsifying in the aqueous solution of polyvinyl alcohol, rotating while polymerizing reaction under ultraviolet irradiation, and washing with water and absolute alcohol. It can be used for chromatography.

Owner:TIANJIN UNIV

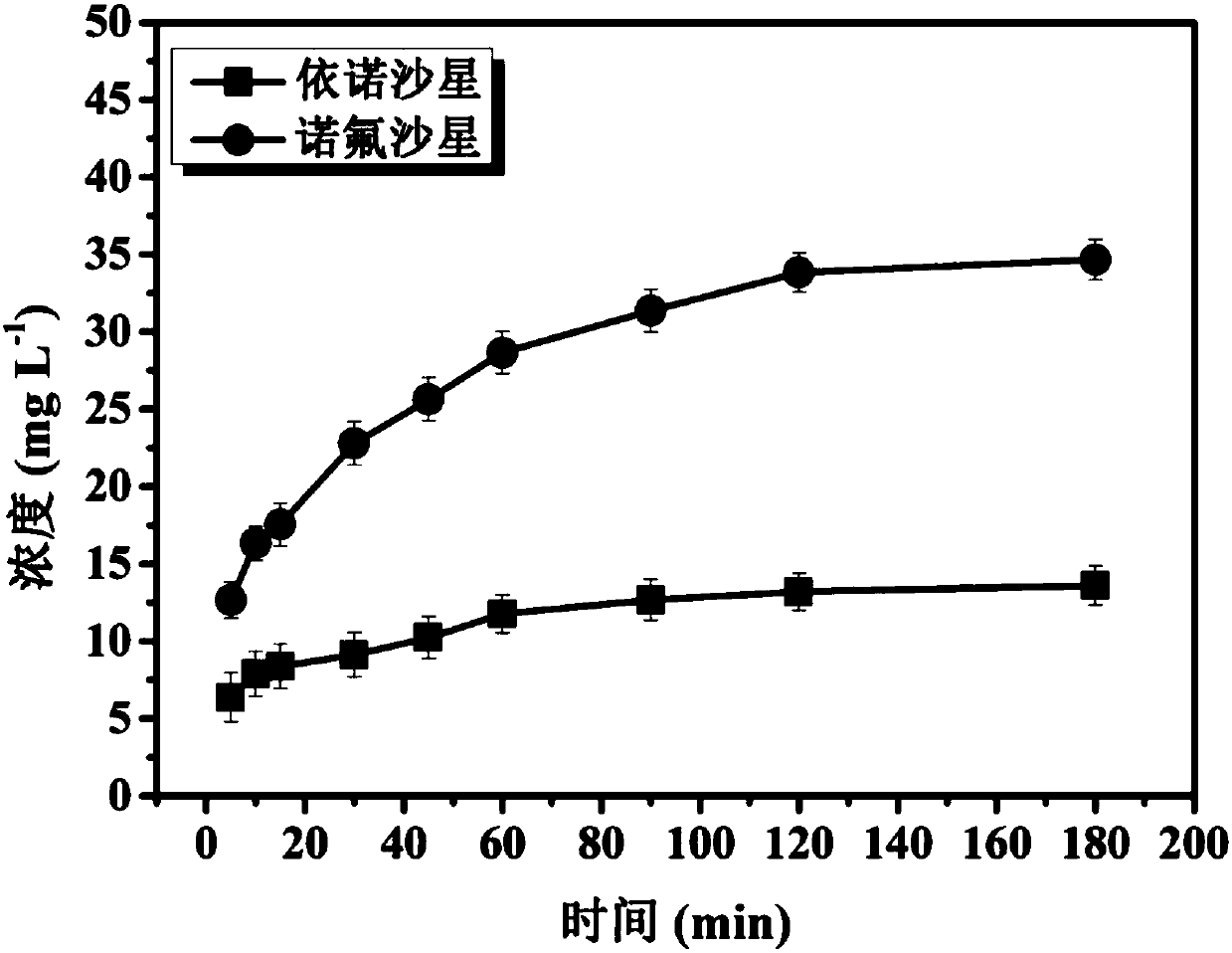

Preparation method of molecularly imprinted composite membrane material for selective separation of enoxacin

InactiveCN108201795AMultiple recognition sitesImprove mechanical propertiesMembranesSemi-permeable membranesCross-linkFunctional monomer

The invention relates to a preparation method of a molecularly imprinted composite membrane material, and belongs to the technical field of new materials. The specific steps are as follows: firstly, preparing carbon nanosphere gels with different concentrations as a coagulation bath, putting a preparation desired polyvinylidene fluoride membrane into the carbon nanosphere coagulation bath, and preparing a CNS@PVDF membrane through a phase inversion process; secondly, synthesizing a layer of polydopamine on the surface of the CNS@PVDF membrane to obtain a dCNS@PVDF membrane, and grafting doublebonds on the surface of the membrane through a silane coupling agent to facilitate imprinting polymerization reaction; and finally, performing imprinting polymerization reaction by using ethylene glycol dimethacrylate as a cross-linking agent, acrylamide as a functional monomer and azobisisobutyronitrile as an initiator, so that a high-performance imprinted composite membrane for separating enoxacin molecules is prepared based on molecular imprinting technology. The preparation method has the advantages of simple operation, easy implementation and higher yield, and is expected to be applied to industrial production.

Owner:JIANGSU UNIV

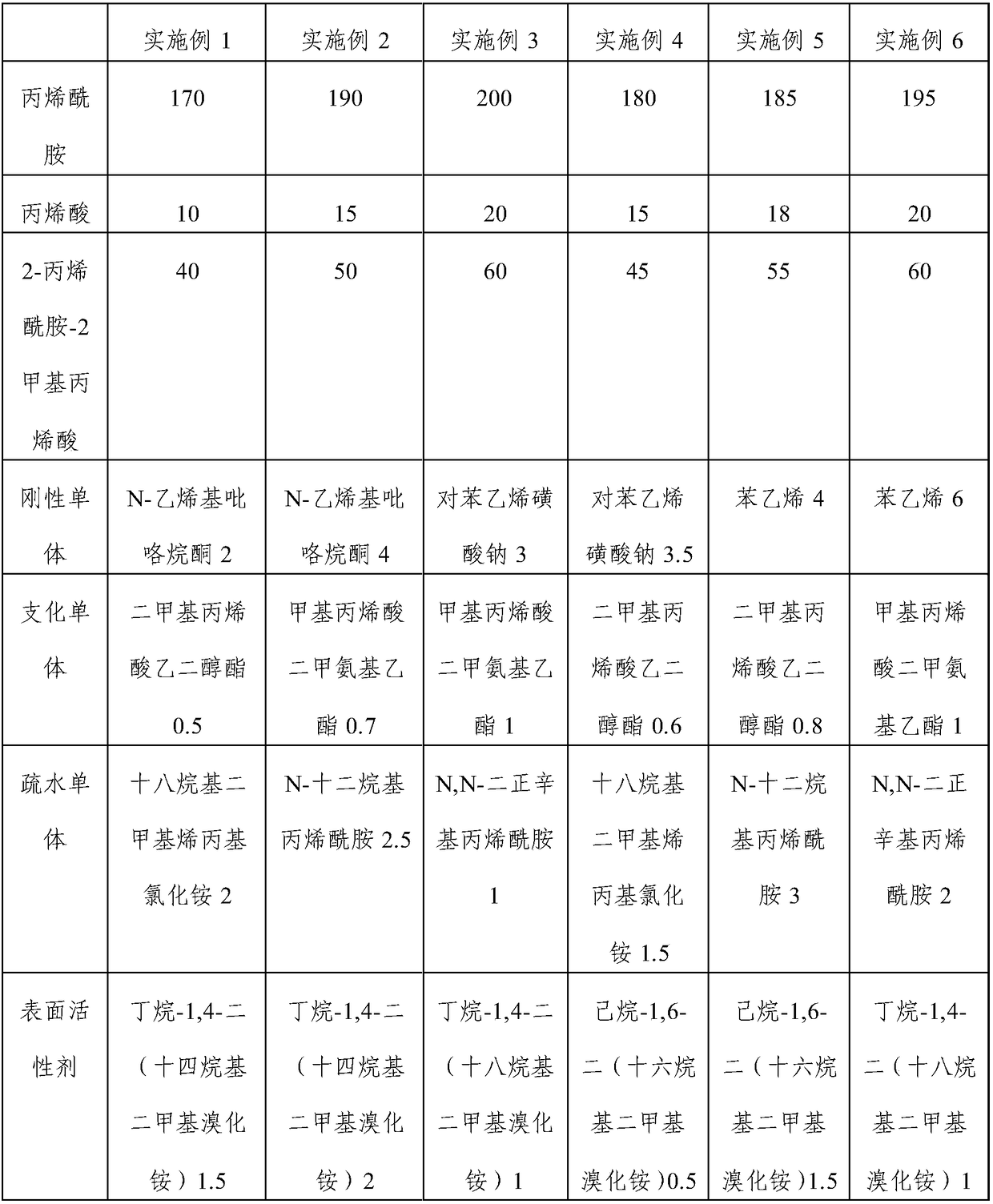

Micro-branched micro-cross-linked association polymer, preparation method and applications thereof

ActiveCN108264607AGood temperature and salt resistanceEnhance molecular chain rigidityGeneral water supply conservationSolventTemperature resistance

The invention relates to a micro-branched micro-cross-linked association polymer, a preparation method and applications thereof. The preparation method comprises: (1) carrying out initial mixing: mixing acrylamide, acrylic acid, 2-acrylamide-2-methyl propanesulfonic acid, a rigid monomer, a branched monomer, a hydrophobic monomer, a surfactant and a solvent, wherein the rigid monomer is any one ora variety of materials selected from N-vinylpyrrolidone, styrene and sodium p-styrenesulfonate, the branched monomer is ethylene dimethacrylate and / or 2-(dimethylamino)ethyl methacrylate, and the hydrophobic monomer is any one or a variety of materials selected from N,N-di-n-octyl acrylamide, N-dodecyl acrylamide and octadecyl dimethylallyl ammonium chloride; (2) adjusting the pH value by addingan alkali; (3) adding an auxiliary agent; and (4) polymerizing: adding an initiator to the mixed solution treated in the step (3), and initiating a polymerization reaction so as to obtain the micro-branched micro-cross-linked association polymer, wherein the obtained micro-branched micro-cross-linked association polymer has excellent temperature resistance and excellent salt resistance.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Copper ion imprinted polymer and application thereof

InactiveCN102659971AIncrease varietyExpand the scope ofOther chemical processesAlkali metal oxides/hydroxidesFunctional monomerPolymer science

The invention belongs to the field of analysis and detection of metal ions in water environment, and discloses a copper ion imprinted polymer, which comprises a polymer carrier and a functional monomer 1,4 - dihydroxy anthraquinone embedded in the polymer carrier, wherein the polymer carrier uses ethylene glycol dimethacrylate as a monomer. The preparation method comprises the following steps of: (1) mixing the 1,4 - dihydroxy anthraquinone with an organic solvent and a soluble copper salt, adding a crosslinking agent and an initiator agent, and reacting for 18 to 20hr at a temperature of 50 to 65 DEG C in the absence of oxygen; and (2) after washing, adding nitric acid to remove the copper ions. By a way that the functional monomer is embedded in a polymer network and a precipitation polymerization method, the imprinted polymer with selective adsorption for the copper ions is synthesized. The ion imprinted polymer has a specific recognition capability for the copper ions, and has better selectivity. Without connecting a double bond capable of being reacted with the crosslinking agent with the 1,4-dihydroxy anthraquinone in advance, the selection type and scope of the functional monomer is expanded, and the reaction steps are simplified.

Owner:SHANGHAI OCEAN UNIV

Polyhedral oligomeric silsesquioxane-containing amphiphilic block copolymer anti-fog/anti-frost coating and preparation method

The invention discloses a polyhedral oligomeric silsesquioxane-containing amphiphilic block copolymer anti-fog / anti-frost coating and a preparation method. The coating is realized by carrying out an acyl bromide reaction on amino POSS to obtain an initiating agent POSS-Br with atom transfer radical polymerization, triggering monomer dimethylaminoethyl methacrylate and monomer sulfobetaine methacrylate to form a block polymer, and carrying out ultraviolet light curing cross-linked film-formation with poly ethyleneglycol dimethacrylate to form a semi-interpenetrating network. POSS with low surface energy is enriched on the surface of the coating to take a hydrophobic effect, acrylic ester polymers PDMAEMA and PSBMA take a hydrophilic effect and also enable the coating to have high stability and durability, and SBMA (sulfobetaine methacrylate) can also improve the transparency of the coating. According to the coating, the materials are easily obtained, the method is simple and convenient, the condition is controllable, and the prepared amphiphilic coating has good anti-fog and anti-frost performance.

Owner:TIANJIN UNIV

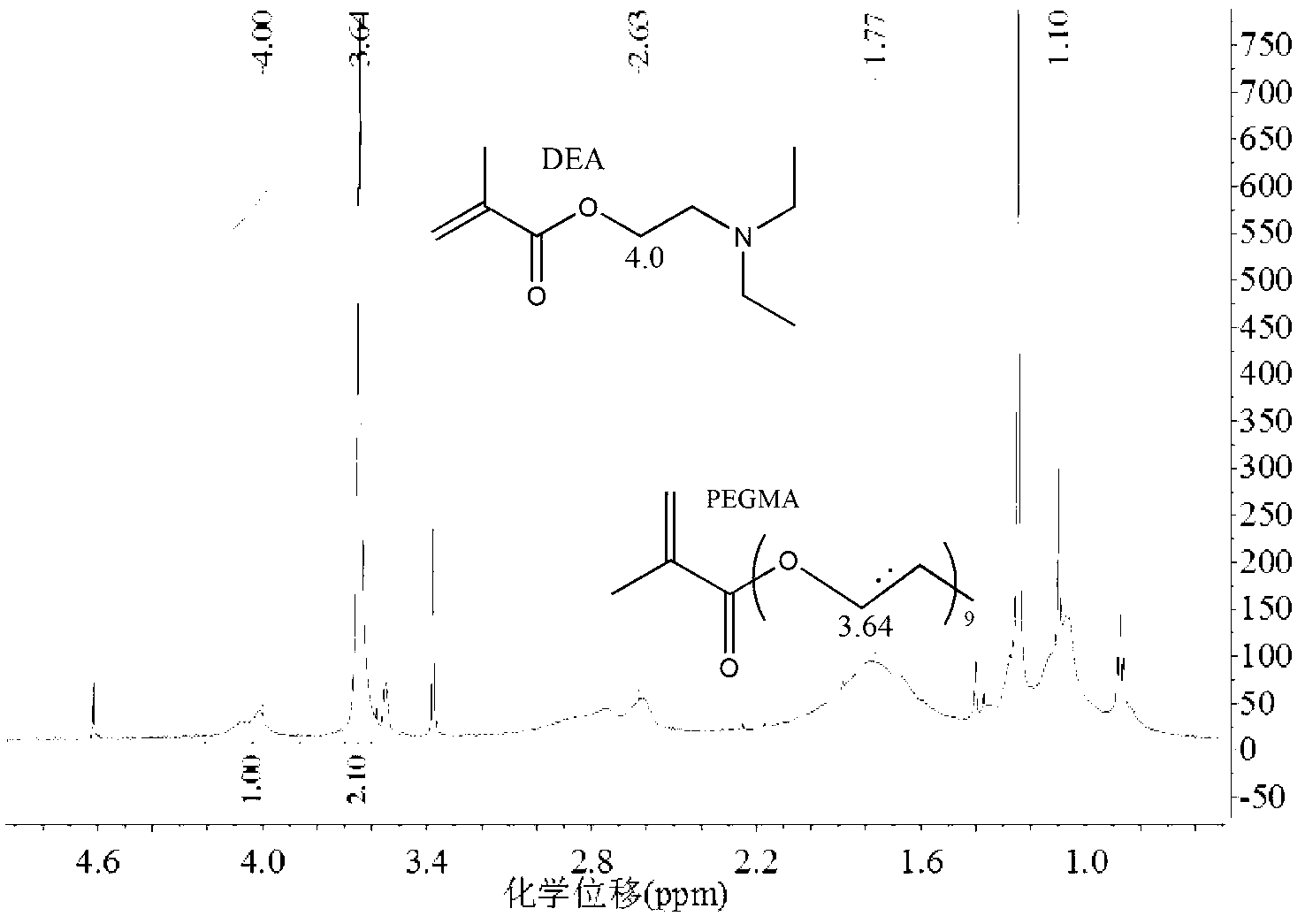

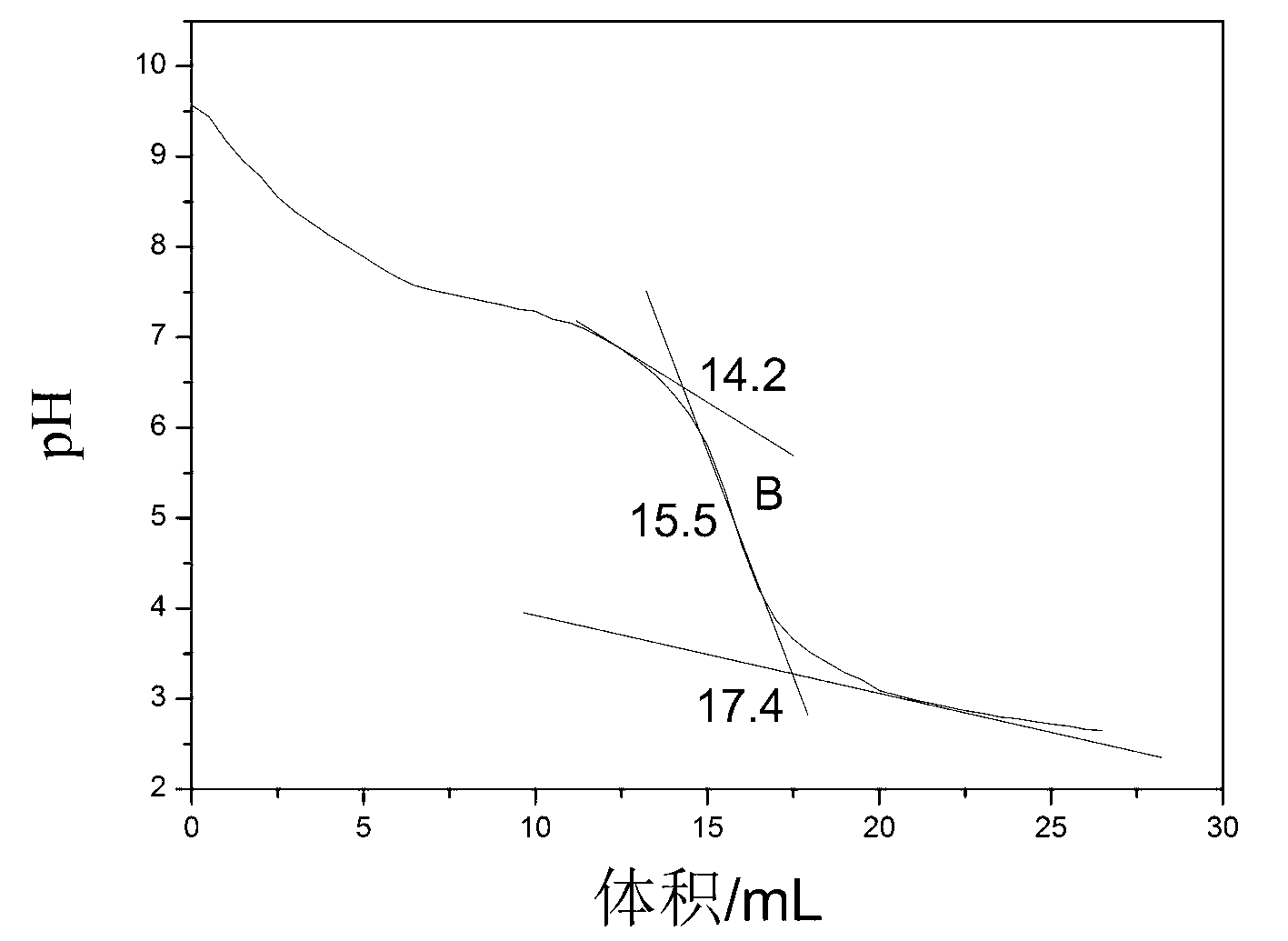

Preparation method of pH responsive cation nanogel

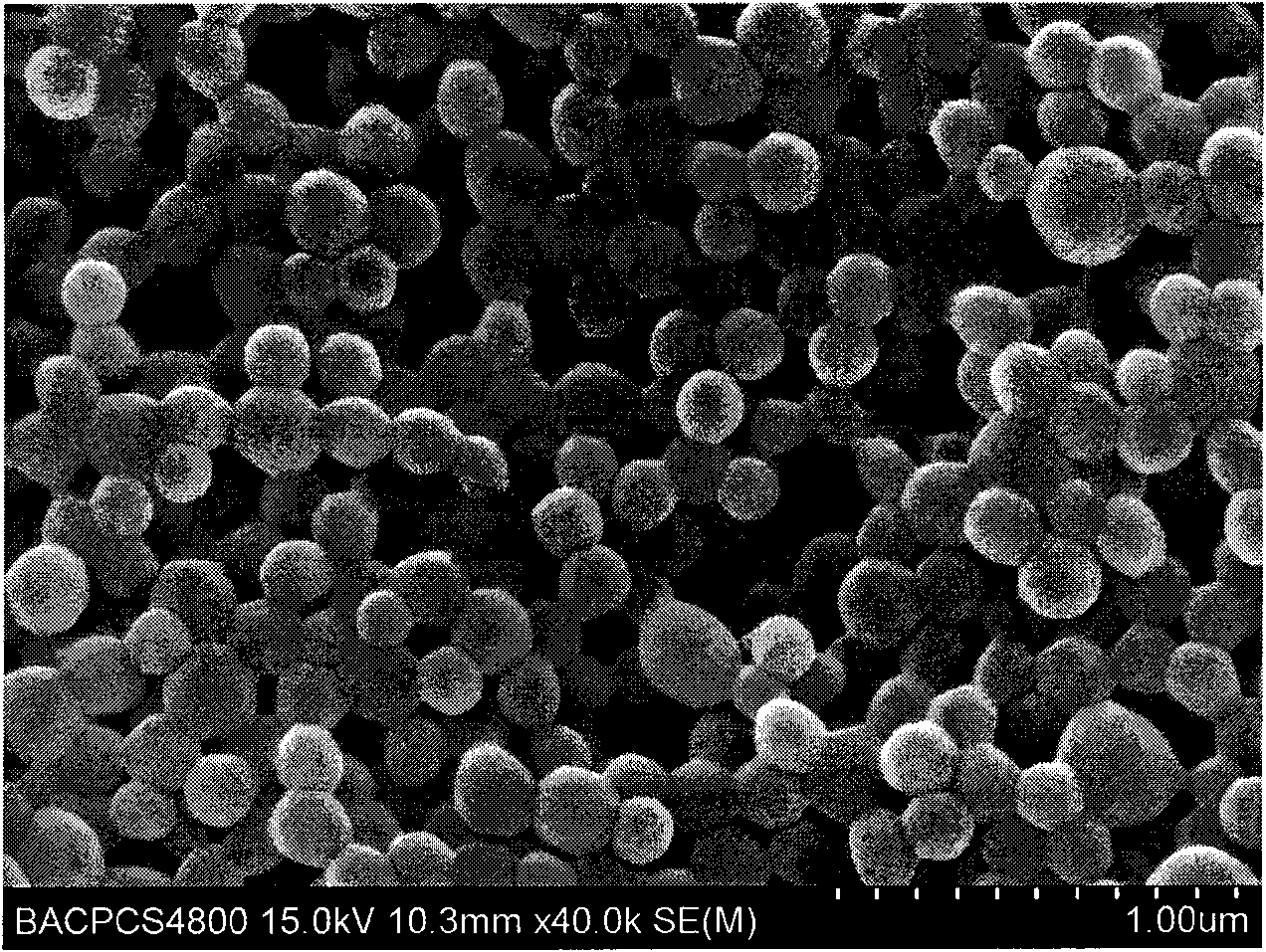

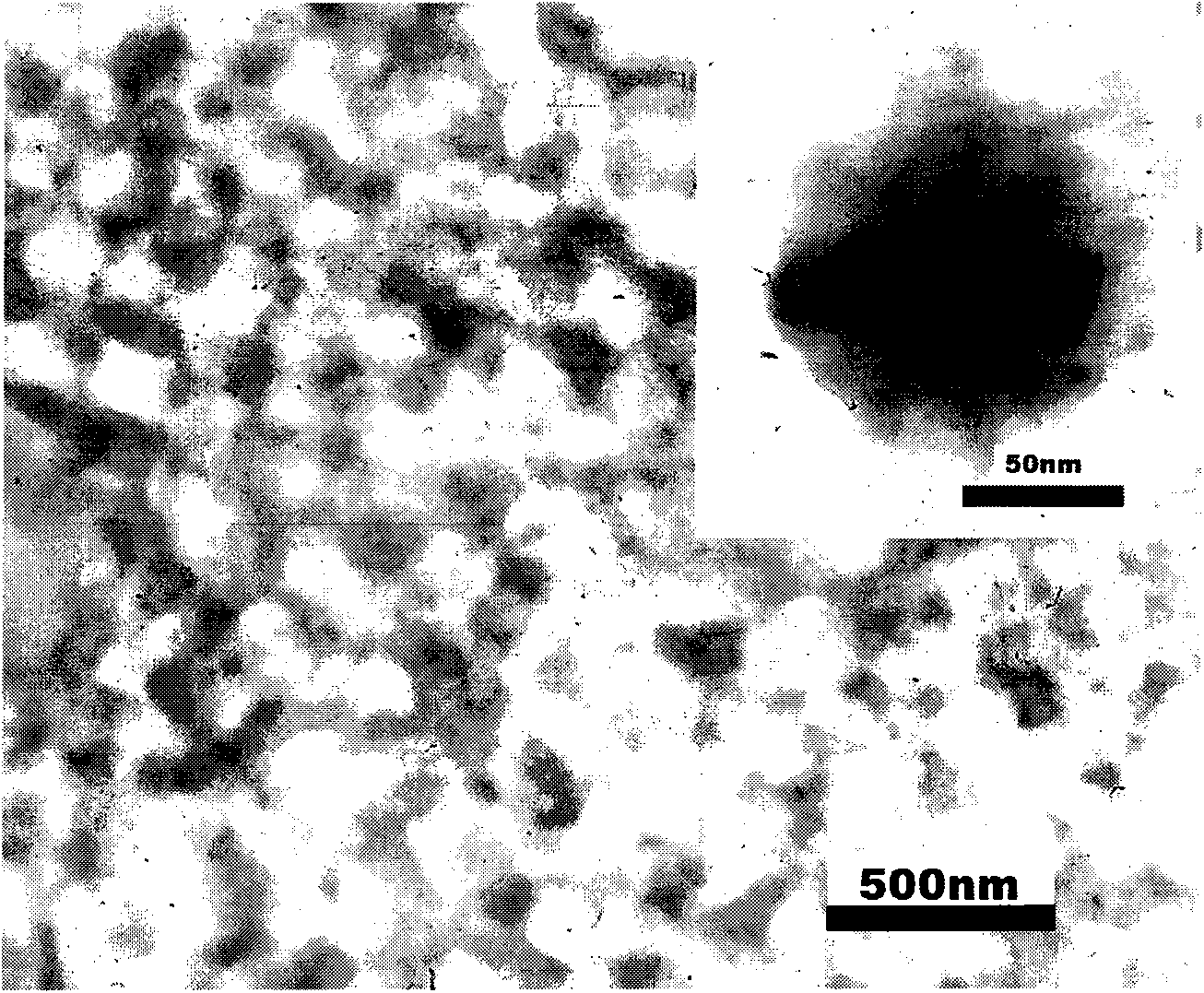

InactiveCN103275268AGood pH responsivenessImprove dispersion stabilityDispersion stabilityMethacrylate

The invention discloses a preparation method of pH responsive cation nanogel. The preparation method comprises the following steps: lauryl sodium sulfate and polyethylene glycol dimethyl acrylic ester are sufficiently dissolved in water to prepare a water-phase solution, ethylene glycol dimethacrylate and cationic monomer methylacrylic acid-(N, N-diethyl amine) ethyl ester or 2-(diisopropyl amino) ethyl methacrylate are uniformly mixed to obtain a mixture, and then the mixture is added into the water-phase solution to prepare microemulsion, and a water solution with an initiator is added in the microemulsion to react for 20-24 h to obtain the pH responsive cation nanogel dispersion liquid. The nanogel prepared has good pH responsiveness and dispersion stability, can be placed stably for more than 3 months, and the number-average grain size of the nanogel is smaller than 100 nm.

Owner:TAIYUAN UNIV OF TECH

Four-layer-color synthetic resin block and preparation method thereof

ActiveCN103273713AEasy to processGood dimensional stabilitySynthetic resin layered productsArtificial teethPolymer scienceIron oxide black

The invention discloses a four-layer-color synthetic resin block and a preparation method thereof. The four-layer-color synthetic resin block is formed by four layers of structures sequentially, each layer of the structures comprise components as follows: polymethyl methacrylate, iron oxide red, iron oxide black, iron oxide yellow, titanium white, methyl methacrylate and ethylene glycol dimethacrylate. The preparation method comprises the steps as follows: polymethyl methacrylate powder is dried at a temperature of 80-90 degrees; four layers of materials are prepared in proportion respectively, and each layer of the materials are required to be mixed uniformly and kneaded until doughing time, so that a plastic dough material is formed; four layers of the plastic dough material are subjected to hot-pressing and bounded together in order in a die, the hot-pressing temperature is 110-130 DEG C, and the hot-pressing time is 10-20 min; and the four-layer-color synthetic resin block after hot-pressing is subjected to heat treatment at a temperature of 80-90 DEG C for 10-12 h, so that a four-layer-color synthetic resin block product is obtained. A dental model or temporary crown bridge, which is processed through the four-layer-color synthetic resin block, is natural and vivid in developing, and the preparation method is simple.

Owner:SHANDONG HUGE DENTAL MATERIAL CO LTD

Macroporous strong alkaline carbon nanotube composite ion exchange resin and preparation method thereof

ActiveCN102372812ASolve compound problemsIn situ functionalizationAnion exchangersHydration reactionCarbon nanotube

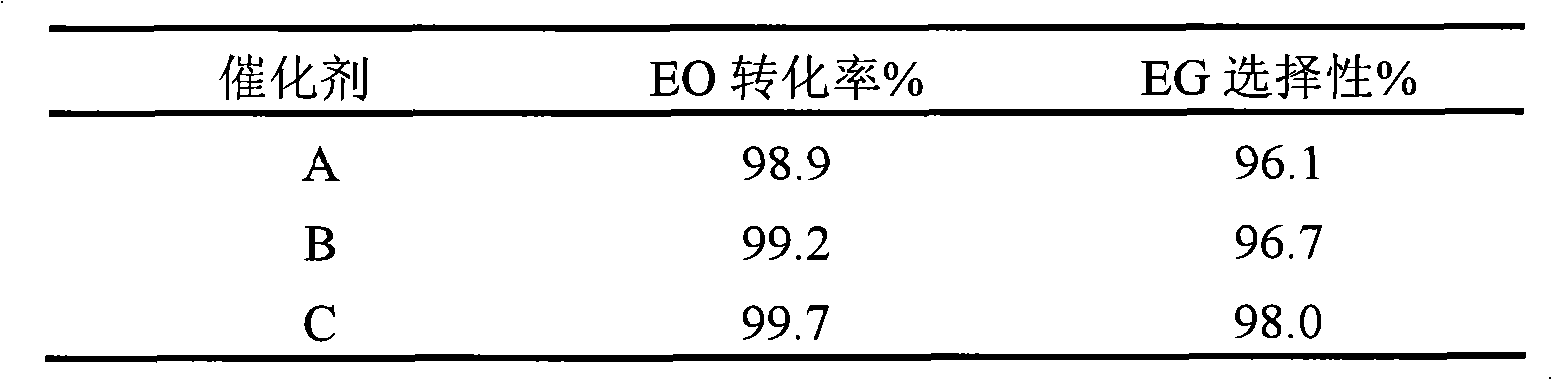

The invention relates to a macroporous strong alkaline carbon nanotube composite ion exchange resin and a preparation method thereof, and aims to solve problems of weak heat resistance and weak swelling resistance of an ion exchange resin in a prior art. The macroporous strong alkaline carbon nanotube composite ion exchange resin comprises the following components: (1) 40-65% of monomer; (2) 3-10% of copolymerization monomer; (3) 0.1-10% of nano material; and (4) 0.1-2% of initiator. The monomer is at least one selected from p-chloromethyl styrene, 4-(3-chloropropyl) styrene, 4-(3-bromopropyl) styrene, 4-(4-chlorobutyl) styrene, 4-(4-brombutyl) styrene, 4-(5-chloroamyl) styrene and 4-(5-bromoamyl) styrene; the copolymerization monomer is at least one selected from EGDMA, dipropenyl benzene, divinyl phenyl methane and divinyl benzene; the nano material is at least one selected from multi-wall carbon nanotube, single arm carbon nanotube and fullerene of C60 or C70; the initiator is at least one selected from benzoyl peroxide, azodiisobutyronitrile, lauroyl peroxide and cumyl hydroperoxide. The invention also provides a preparation method of the macroporous strong alkaline carbon nanotube composite ion exchange resin. The above technical scheme well solves the problems and can be applied to industrial production of ethylene oxide catalytic hydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature-resistant adhesive tape as well as high-temperature-resistant release film and high-temperature-resistant adhesive used by high-temperature-resistant adhesive tape

ActiveCN104789167AImprove high temperature resistanceImprove heat resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolytetramethylene terephthalatePolyvinyl alcohol

The invention relates to a high-temperature-resistant adhesive tape as well as a high-temperature-resistant release film and a high-temperature-resistant adhesive used by the high-temperature-resistant adhesive tape. A raw material formula of the high-temperature-resistant adhesive comprises the following components: 40-80 parts of ethylene glycol dimethacrylate, 20-30 parts of octadecyl acrylate, 5-10 parts of phenyltrimethoxysilane, 5-10 parts of vinyltriisopropenyloxysilane, 2-10 parts of nano-silica, 1-5 parts of aluminium hexafluoroacetylacetonate, 2-6 parts of polyvinyl alcohol, 2-5 parts of an emulsifier, 1-3 parts of an initiator and 200-350 parts of deionized water. A raw material formula of a film spraying material of the high-temperature-resistant release film comprises the following components: 60-80 parts of polyimide, 10-30 parts of 1,3,5-tris(3,3,3-trifluoropropyl)methylcyclotrisiloxane, 5-25 parts of polybutylene terephthalate, 2-10 parts of an ethylene vinyl acetate copolymer, 2-8 parts of vinyl phenyl silicon oil, 1-3 parts of dioctyl sebacate and 1-4 parts of dibutyltin dilaurate. The heat-resistant pressure sensitive adhesive tape prepared by the invention can work at 70-160 DEG C and can resist the high temperature of 600 DEG C or above in a short time.

Owner:苏州市伽俐电子有限公司

Fur-imitating static flocking binder and preparation method thereof

ActiveCN102220099AGood flexibilityImprove cold resistanceEster polymer adhesivesIsooctyl acrylateAcrylonitrile

The invention relates to a fur-imitating static flocking binder and a preparation method thereof; and the fur-imitating static flocking binder is prepared by the following raw materials: lauryl alcohol polyoxyethylene (40) ether, lauryl sodium sulfate, butyl acrylate, ethylene glycol dimethacrylate, N-hydroxymethyl acrylamide, ethyl hexyl acrylate, acrylonitrile, acrylic acid, ammonium persulfate and deionized water, which are made into polymer emulsion through seed emulsion polymerization. The fur-imitating static flocking binder has remarkable advantages of cold resistance, wear resistance, drapability and wrinkle resistance and other indexes, thus greatly improving the quality of the fur-imitating static flocking product.

Owner:LIAONING FIXED STAR FINE CHEM

Preparation method of magnetic lead ion surface imprinting polymer

InactiveCN103709325AImprove introduction efficiencyImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesMicrosphereDouble bond

The invention discloses a preparation method of a magnetic lead ion surface imprinting polymer. The method comprises the following steps: firstly, synthesizing magnetic Fe3O4@SiO2 microspheres by using a 'coprecipitation method' and a 'sol-gel method', processing by using an acid, so as to improve the hydroxy content of the surface; then leading polymerizable double bonds to the surfaces of the Fe3O4@SiO2 microspheres by using a 'two-step process', firstly, grafting amino on the surfaces of the microspheres by using an amino silane coupling agent; generating double bonds by using reaction of anhydride and amino; finally taking the Fe3O4@SiO2 microspheres as a carrier, the Pb(II) as a template, ethylene glycol dimethacrylate as a crosslinking agent and methacrylic acid and salicylaldoxime as monomers to carry out polymerization reaction; and washing off the template Pb(II) after reaction is ended, so as to obtain a polymer layer with a lot of Pb(II) imprinting cavities distributed at the surfaces of the Fe3O4@SiO2 microspheres. The magnetic lead ion surface imprinting polymer disclosed by the invention can be applied to separation and removal of lead ions.

Owner:HEBEI UNIV OF TECH

Bionic dental adhesive composition and preparation method thereof

InactiveCN103610598ASimple preparation processGood adhesionImpression capsDentistry preparationsBionicsProtein structure

The invention discloses a bionic dental adhesive composition and a preparation method thereof. The composition is composed of 20-75% of dopamine derivative, 20-70% of ethylene glycol dimethacrylate, 1.5-10% of 4-methacryloxyethyl trimellitic anhydride, 0.1-1% of camphorquinone and 0.1-1% of N,N-ethyl dimethylaminomethacrylate. The dental adhesive composition containing dopamine derivative is prepared by simulating the natural mussel protein structure; and the composition has the advantages of simple preparation technique and favorable bonding effect, and has wide application prospects.

Owner:广州市易轩生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com