Polyhedral oligomeric silsesquioxane-containing amphiphilic block copolymer anti-fog/anti-frost coating and preparation method

A technology of polysilsesquioxane and amphiphilic block, which is applied in coating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Preparation of polydimethylaminoethyl methacrylate containing POSS:

[0057] Dissolve 0.1024g POSS-Br, 27.2μL 1,1,4,7,10,10-hexamethyltriethylenetetramine, 1.887g dimethylaminoethyl methacrylate, 2ml tetrahydrofuran in 10ml of magnetic stirring In the Schlenk bottle, the freeze-thaw cycle was performed three times under the protection of nitrogen, then 0.0144 g of cuprous bromide was added to the bottle, the stopper was quickly covered, the air was exchanged three times, and the reaction was stirred at 50 ° C for 1.5 h. After the reaction, it was quenched with a small amount of tetrahydrofuran, then passed through the column with neutral alumina, then rotary evaporated and precipitated with refrigerated n-hexane three times, and the obtained polymer was dried in a vacuum oven for 24 hours to obtain the product POSS-(PDMAEMA) 43 -Br.

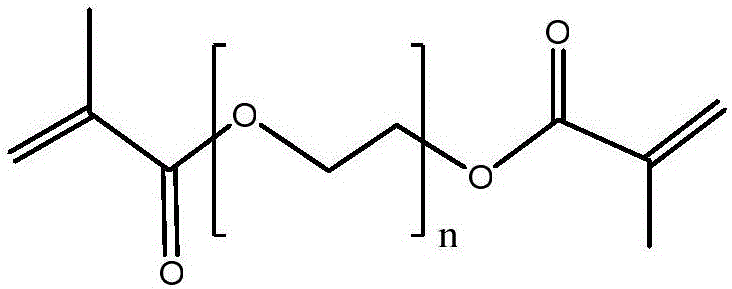

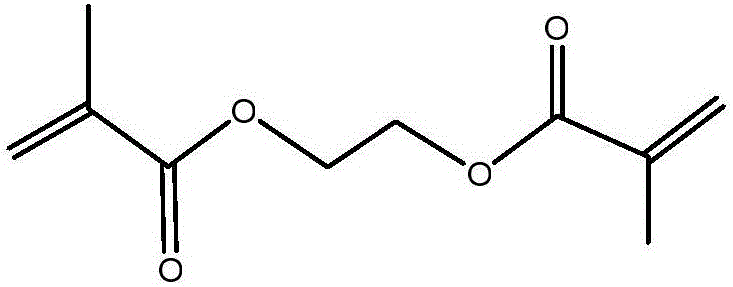

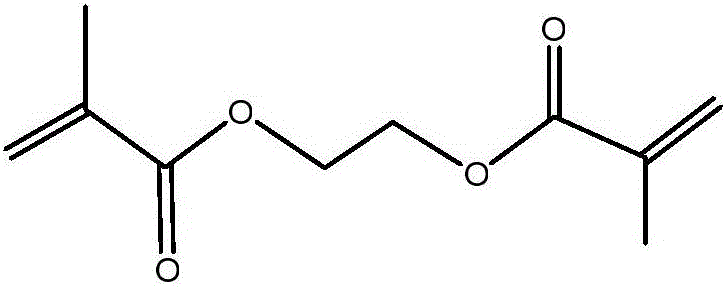

[0058] The structural formula of polydimethylaminoethyl methacrylate containing POSS is

[0059] in

[0060] (2) POSS-containi...

Embodiment 2

[0074] (1) Preparation of polydimethylaminoethyl methacrylate containing POSS:

[0075] Dissolve 0.1024g POSS-Br, 27.2μL 1,1,4,7,10,10-hexamethyltriethylenetetramine, 1.887g dimethylaminoethyl methacrylate, 2ml tetrahydrofuran in 10ml of magnetic stirring In the Schlenk bottle, the freeze-thaw cycle was performed three times under the protection of nitrogen, then 0.0144 g of cuprous bromide was added to the bottle, the stopper was quickly covered, the gas was changed three times, and the reaction was stirred at 50°C for 2 hours. After the reaction, it was quenched with a small amount of tetrahydrofuran, then passed through the column with neutral alumina, then rotary evaporated and precipitated with refrigerated n-hexane three times, and the obtained polymer was dried in a vacuum oven for 24 hours to obtain the product POSS-(PDMAEMA) 65 -Br.

[0076] The structural formula of polydimethylaminoethyl methacrylate containing POSS is

[0077] in

[0078] (2) POSS-containing...

Embodiment 3

[0092] (1) Preparation of polydimethylaminoethyl methacrylate containing POSS:

[0093] Dissolve 0.1024g POSS-Br, 27.2μL 1,1,4,7,10,10-hexamethyltriethylenetetramine, 1.887g dimethylaminoethyl methacrylate, 2ml tetrahydrofuran in 10ml of magnetic stirring In the Schlenk bottle, the freeze-thaw cycle was performed three times under the protection of nitrogen, then 0.0144 g of cuprous bromide was added to the bottle, the stopper was quickly covered, the air was exchanged three times, and the reaction was stirred at 50°C for 2.5 hours. After the reaction, it was quenched with a small amount of tetrahydrofuran, then passed through the column with neutral alumina, then rotary evaporated and precipitated with refrigerated n-hexane three times, and the obtained polymer was dried in a vacuum oven for 24 hours to obtain the product POSS-(PDMAEMA) 95 -Br.

[0094] The structural formula of polydimethylaminoethyl methacrylate containing POSS is

[0095] in

[0096] (2) POSS-contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com