Patents

Literature

3145results about How to "Improve durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

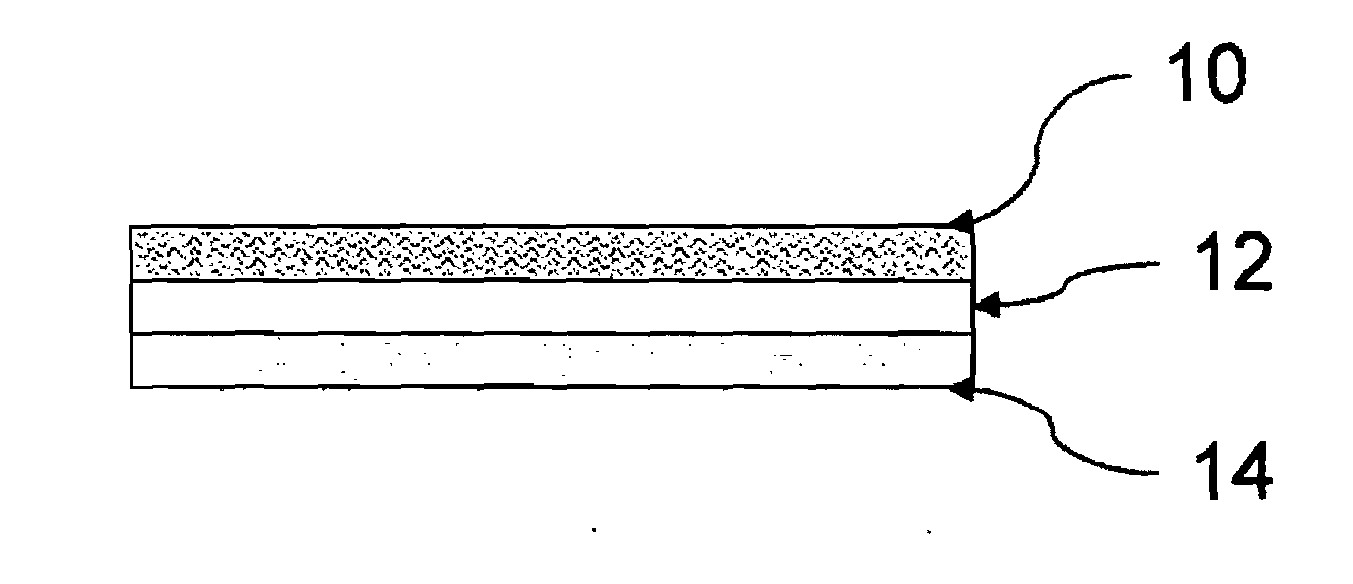

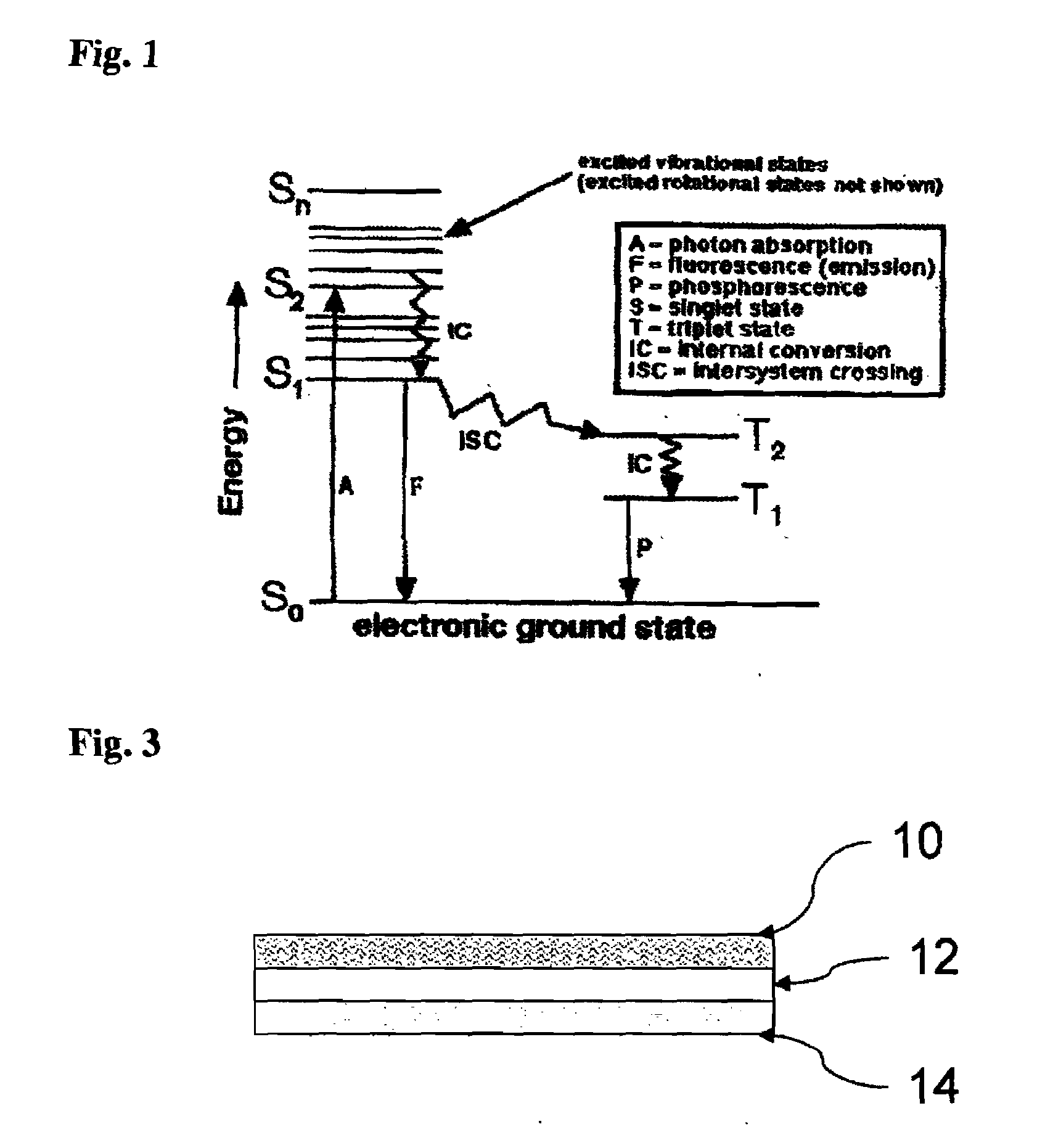

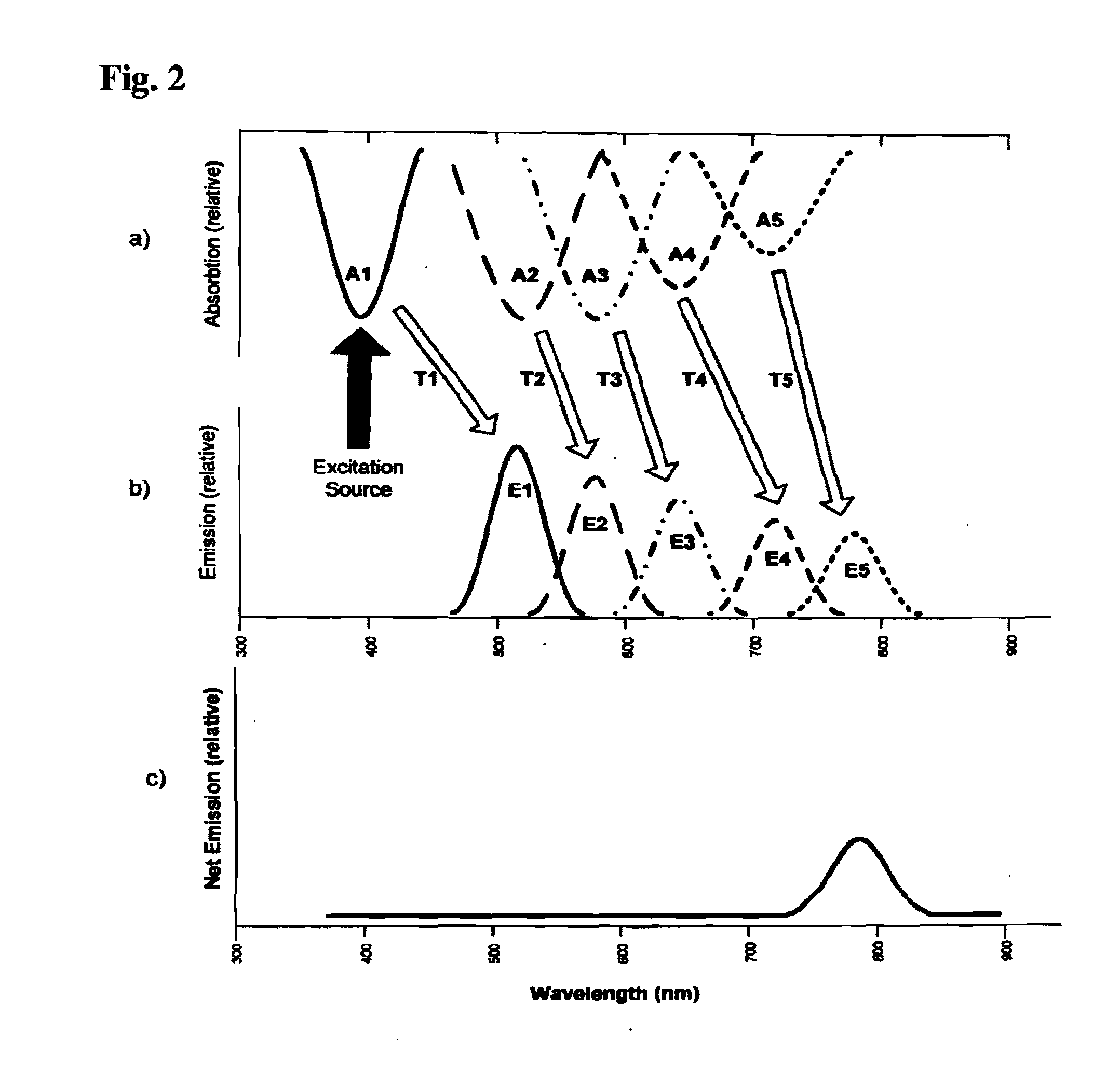

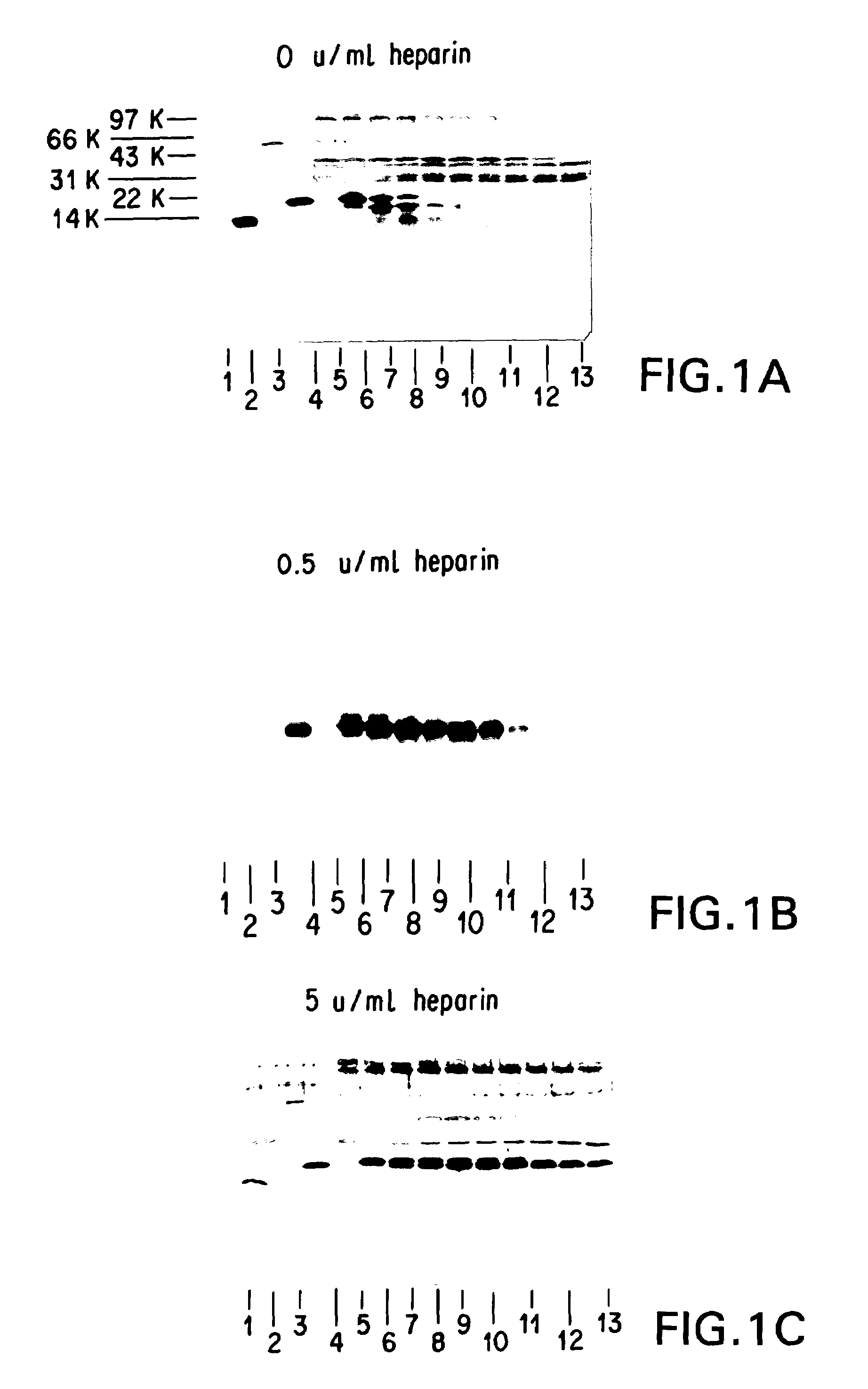

Photoluminescent Compositions, Methods of Manufacture and Novel Uses

InactiveUS20120183677A1High strengthImprove durabilityPhotometryBleaching apparatusPhotoluminescenceElectromagnetic radiation

Owner:PERFORMANCE INDICATOR LLC

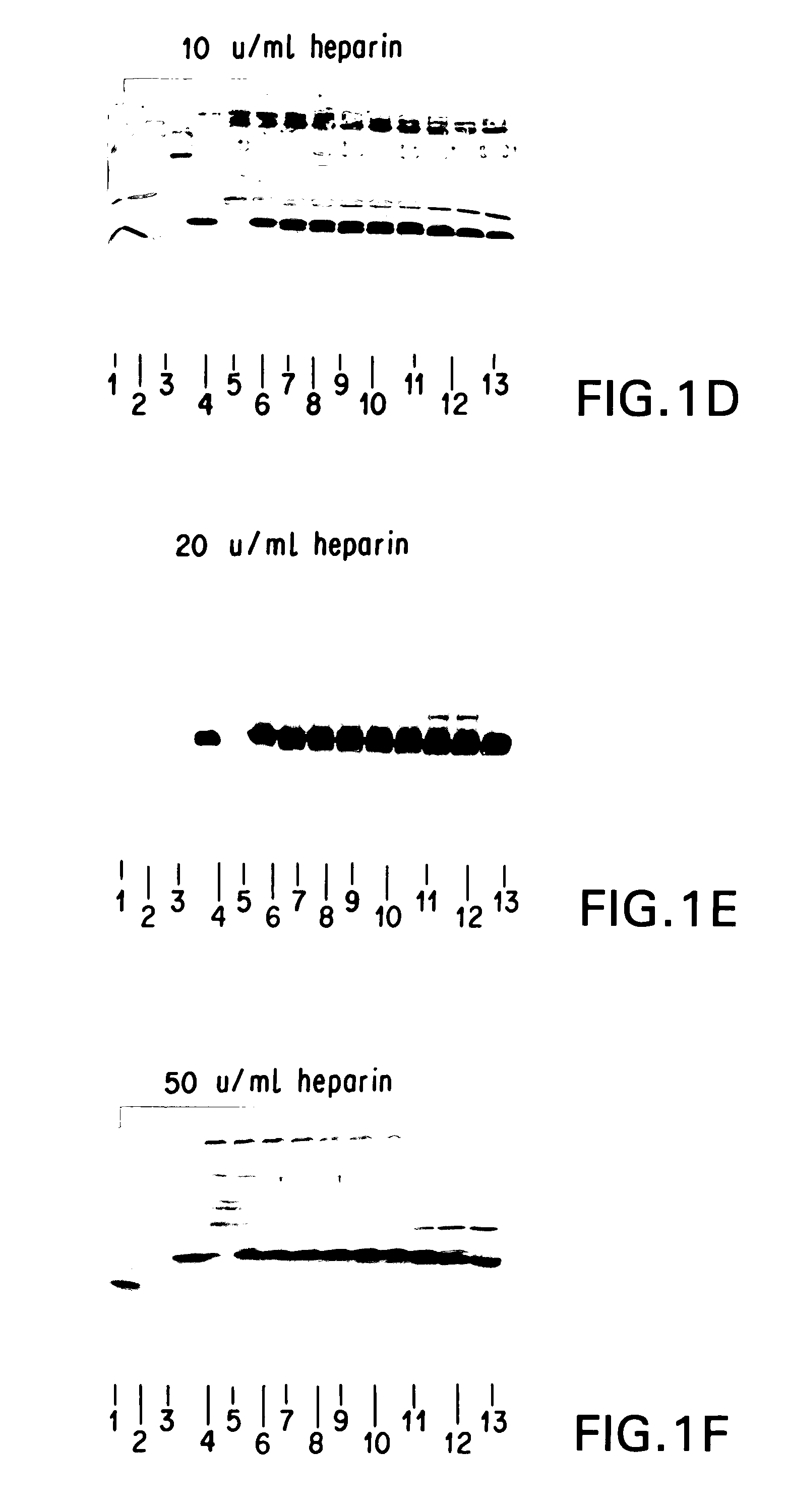

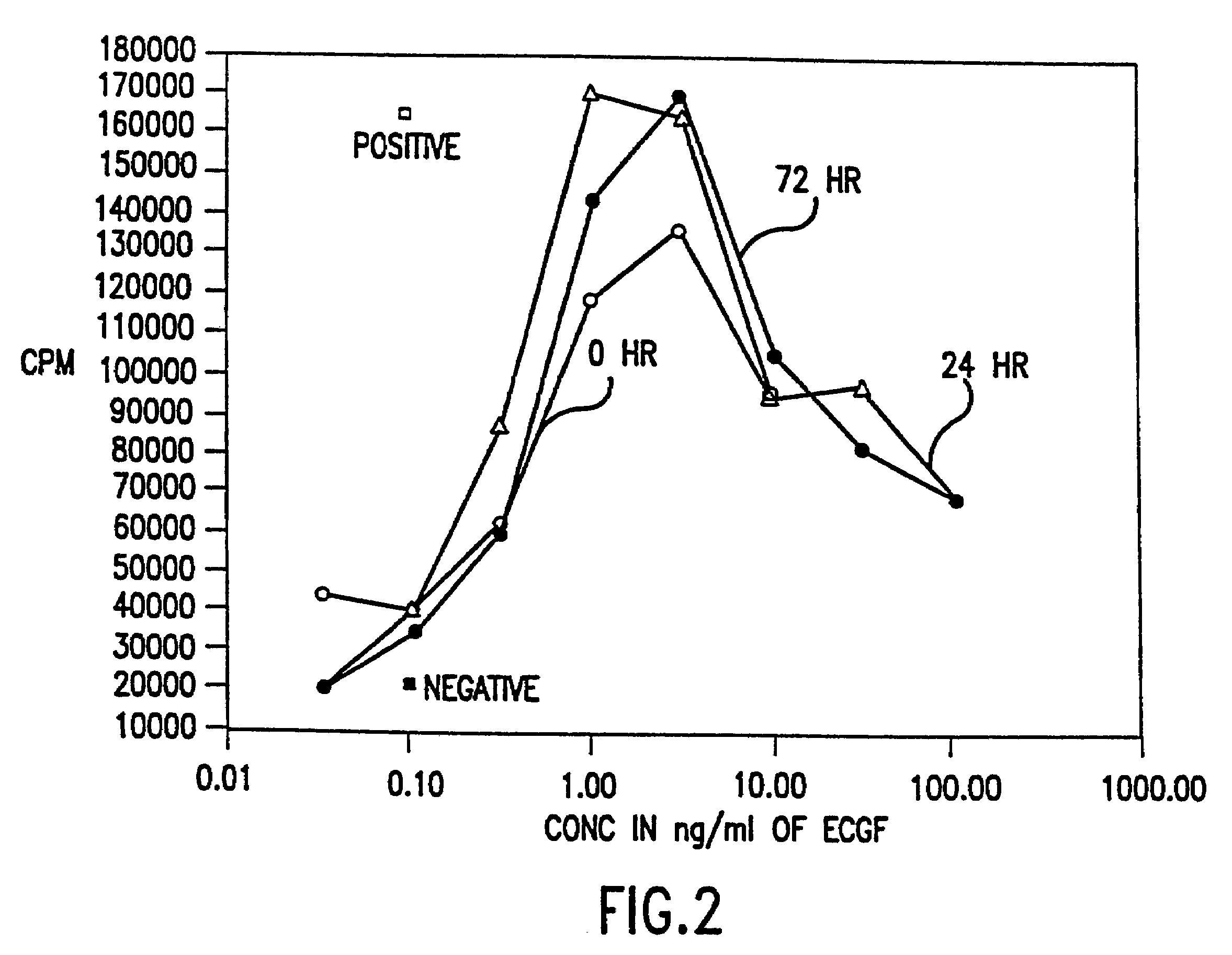

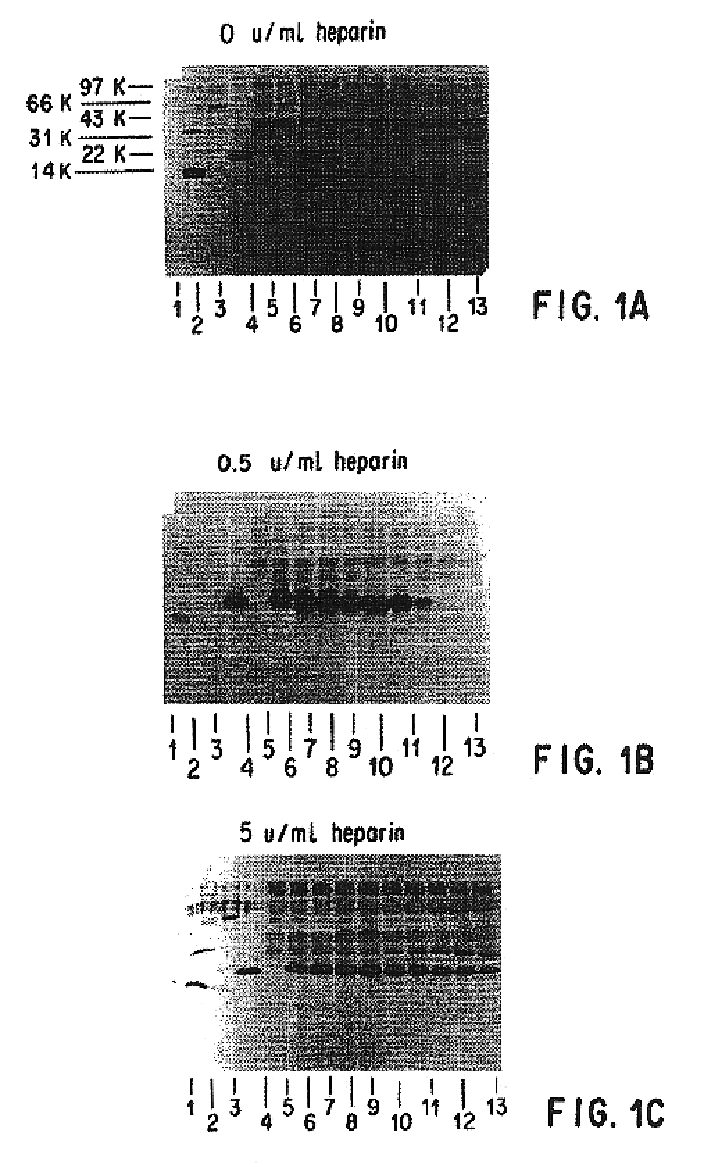

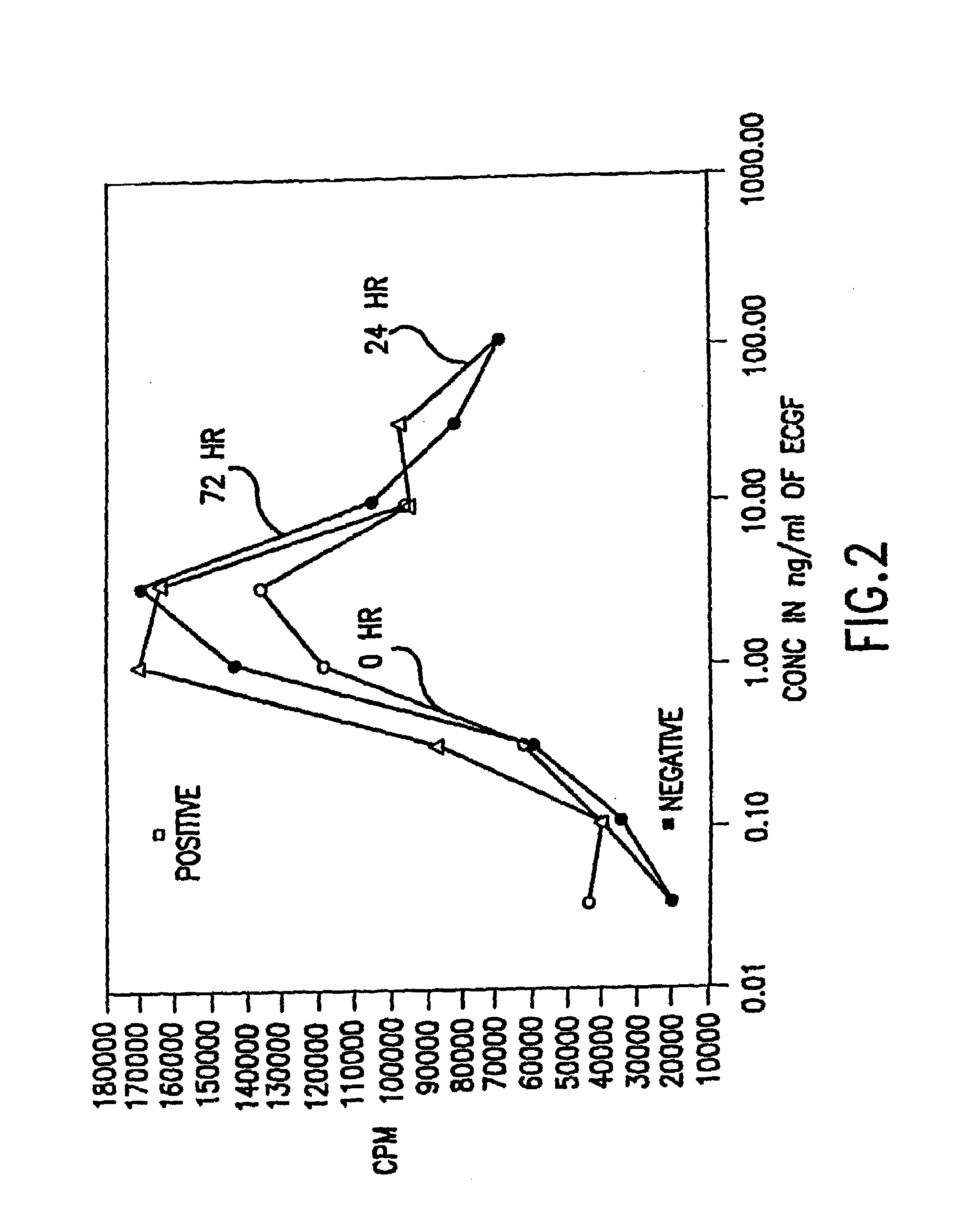

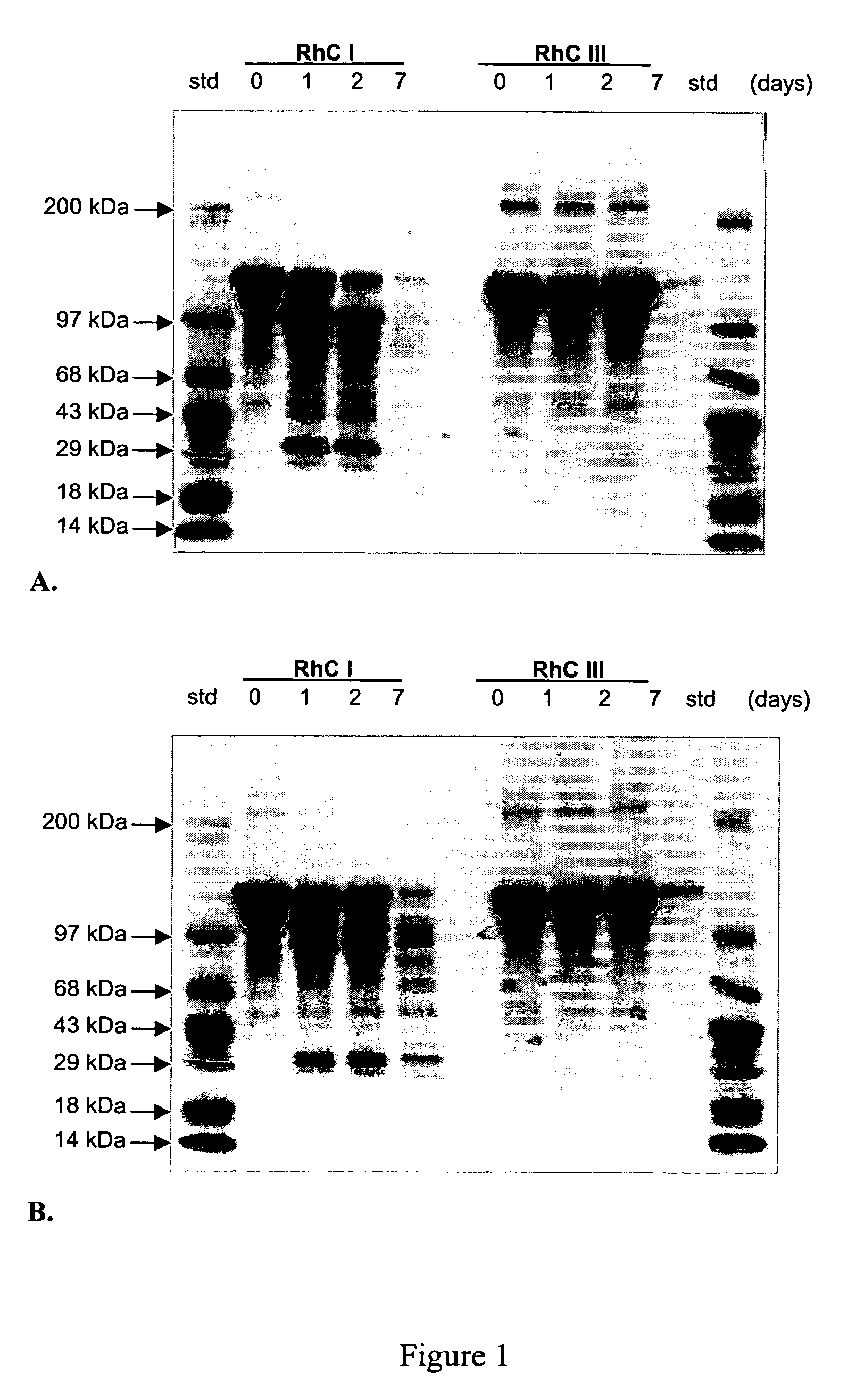

Supplemented and unsupplemented tissue sealants, methods of their production and use

ActiveUS7189410B1Low antigenicityDecreasing thrombogenicityAntibacterial agentsOrganic active ingredientsTissue sealantVascular dilatation

This invention provides a fibrin sealant bandage, wherein said fibrin sealant may be supplemented with at least one composition selected from, for example, one or more regulatory compounds, antibody, antimicrobial compositions, analgesics, anticoagulants, antiproliferatives, anti-inflammatory compounds, cytokines, cytotoxins, drugs, growth factors, interferons, hormones, lipids, demineralized bone or bone morphogenetic proteins, cartilage inducing factors, oligonucleotides polymers, polysaccharides, polypeptides, protease inhibitors, vasoconstrictors or vasodilators, vitamins, minerals, stabilizers and the like. Also disclosed are methods of preparing and / or using the unsupplemented or supplemented fibrin sealant bandage.

Owner:AMERICAN NAT RED CROSS

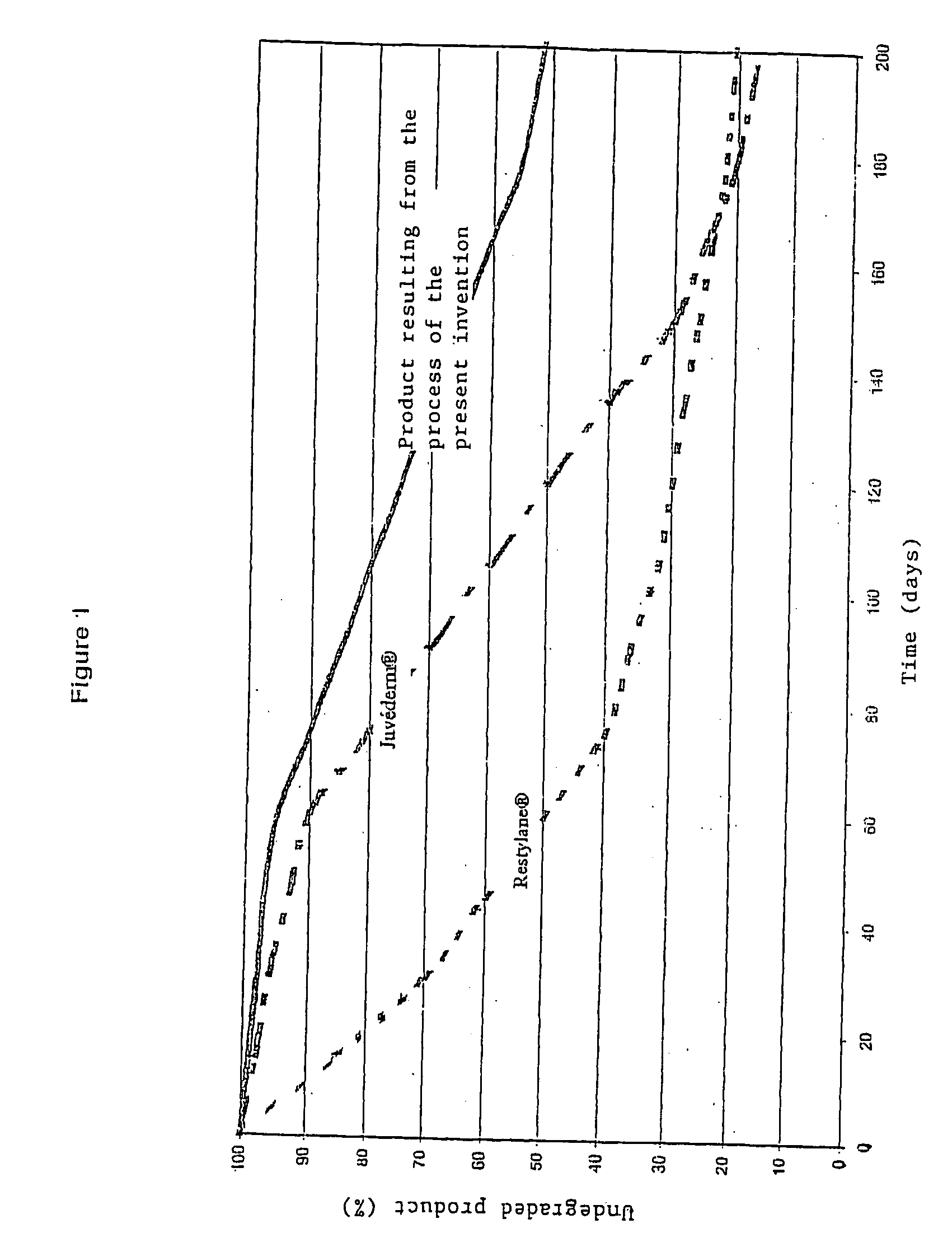

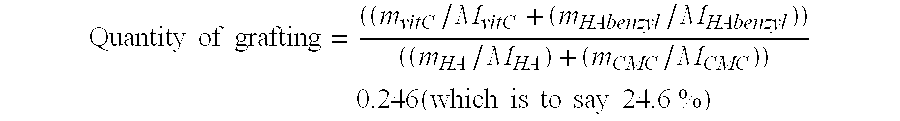

Complex matrix for biomedical use

InactiveUS20060246137A1Easy to useEnhance lipPowder deliveryOrganic active ingredientsCross-linkComplex matrix

A complex matrix is constituted by at least one biocompatible polymer of natural origin, cross linked and to which are grafted small chains of a molecular weight less than 50,000 Da with an amount of grafting of 10 to 40%, as well as a process for preparation of a biocompatible matrix that is partly degradable, constituted by at least one polymer of natural origin, consisting: on the one hand, grafting small chains of molecular weight less than 10,000 Da, with a grafting amount of 10 to 40%, on the other hand, cross linking the principal polymer chains to create a homogeneous matrix.

Owner:ANTEIS SA

Plaster for promoting muscles and bones, and preparation and application thereof

InactiveCN102188673AImprove disease resistanceGood effectHeavy metal active ingredientsAnthropod material medical ingredientsPhellodendron amurenseLigusticum chuanxiong

The invention relates to a Chinese medicine plaster for treating diseases in muscles and bones, in particular to a plaster for promoting muscles and bones, and preparation and application thereof. The plaster is prepared by mixing pastes and powders; wherein the raw materials of the pastes by weight comprise: 25-60g of clematis root, 25-60g of heracleum, 25-60g of incised notopterygium rhizome, 25-60g of erycibe obtusifolia, 25-60g of garden balsam stem, 25-60g of gentiana macrophylla, 25-60g of prepared common monkshood daughter root, 25-60g of dried ginger, 25-60g of cinnamon, 25-60g of harlequin glorybower leaf and twig, 25-60g of rhizoma corydalis, 25-60g of ligusticum wallichii, 25-60g of frankincense, 25-60g of cowherb seed, 25-60g of lingzhi mushroom, 25-60g of gastrodia elata and 25-60g of astragalus, 25-60g of one or more of honeycomb, radix aconiti brachypodi and nux vomica, 0.1-3kg of minium and 0.5-5kg of vegetable oil; and the raw materials of the powders by weight comprise: 15-45g of clematis root, 15-45g of heracleum, 15-45g of incised notopterygium rhizome, 15-45g of phellodendron amurense, 15-45g of dragon's blood, 15-45g of gastrodia elata, 15-45g of nux vomica, 15-45g of rhizoma corydalis, 15-45g of borneol, 15-45g of harlequin glorybower leaf and twig and 15-45g of common monkshood mother root. The plaster for promoting muscles and bones has balanced effect, high medicine utilization ratio and good treatment effect.

Owner:赵贵凤

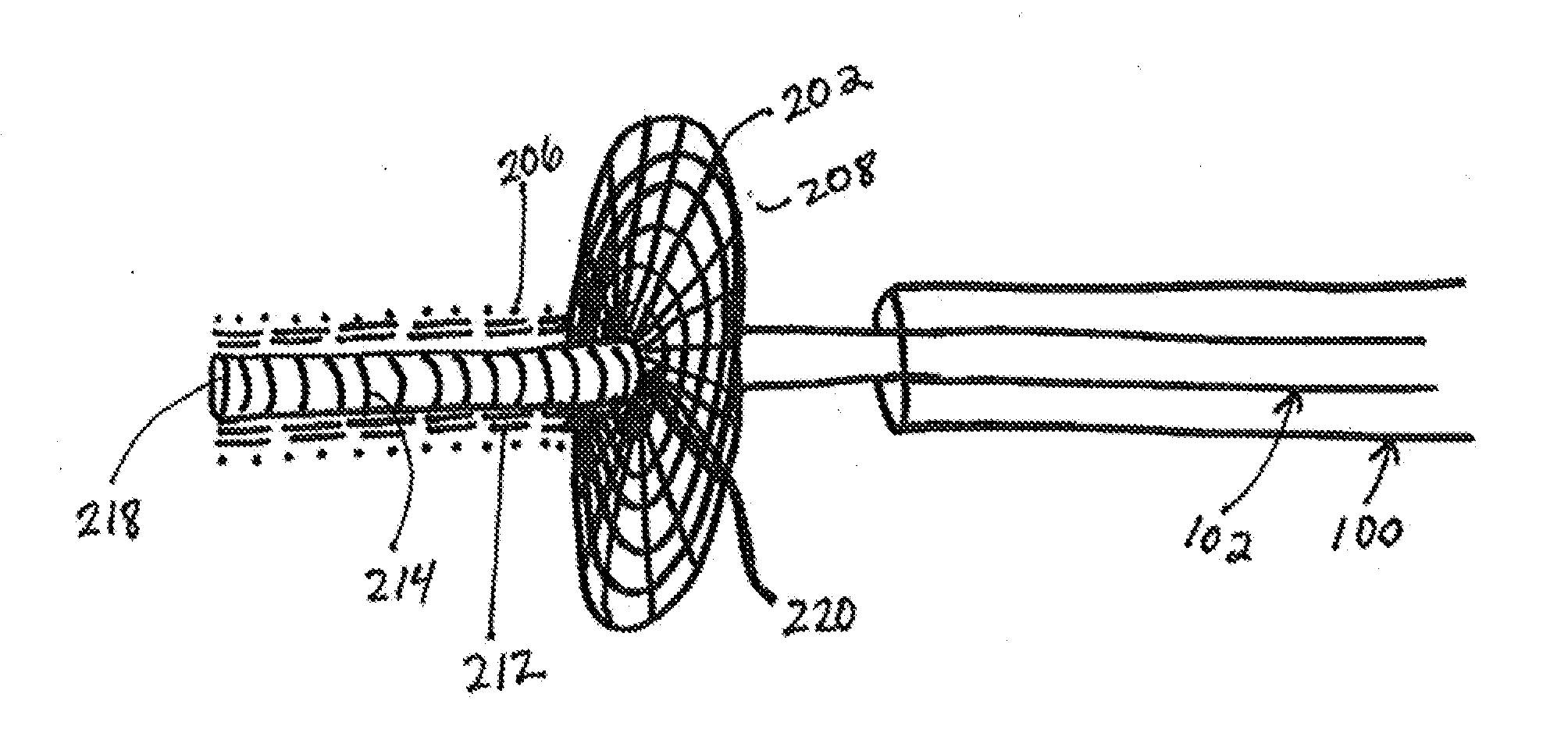

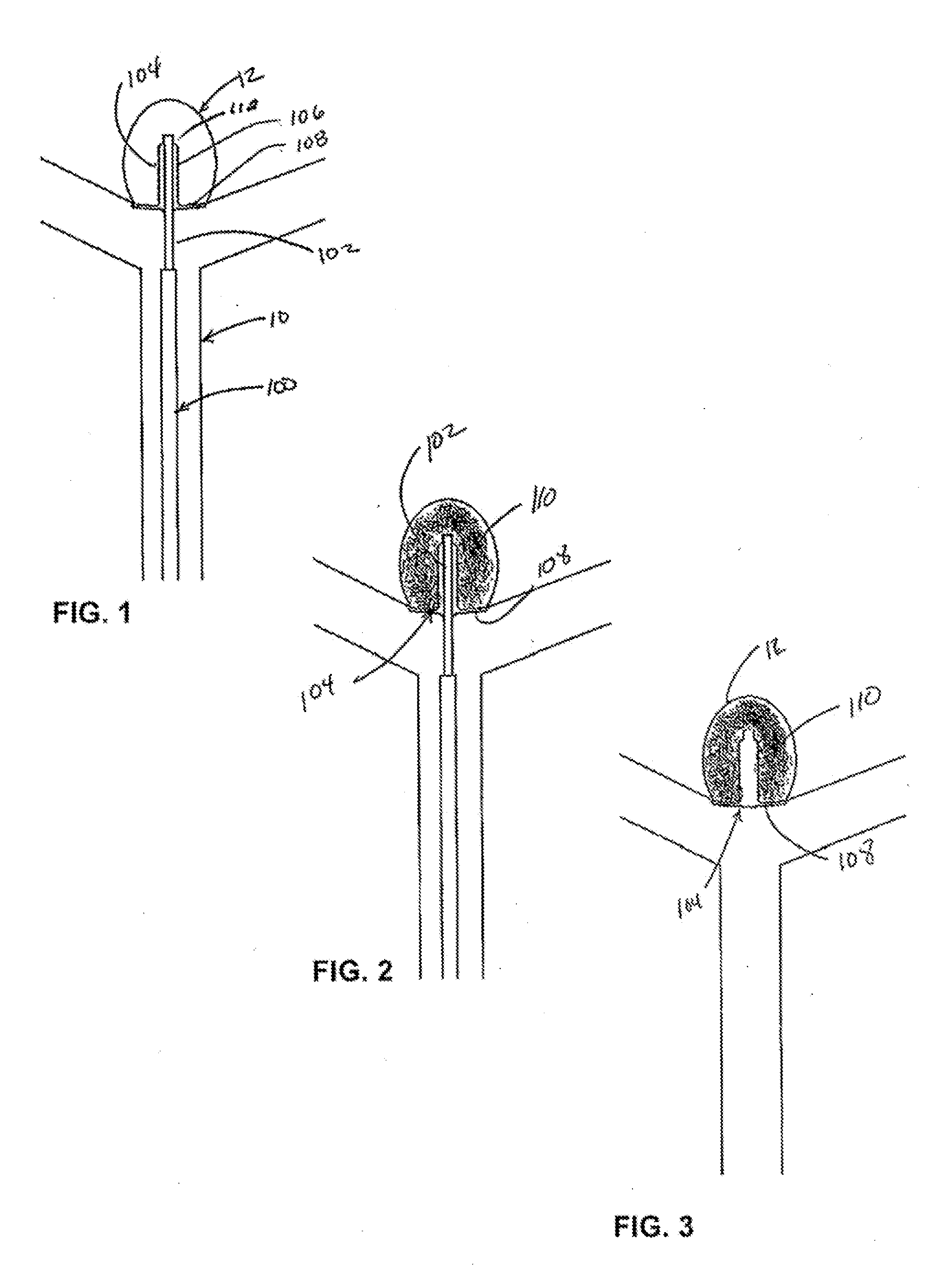

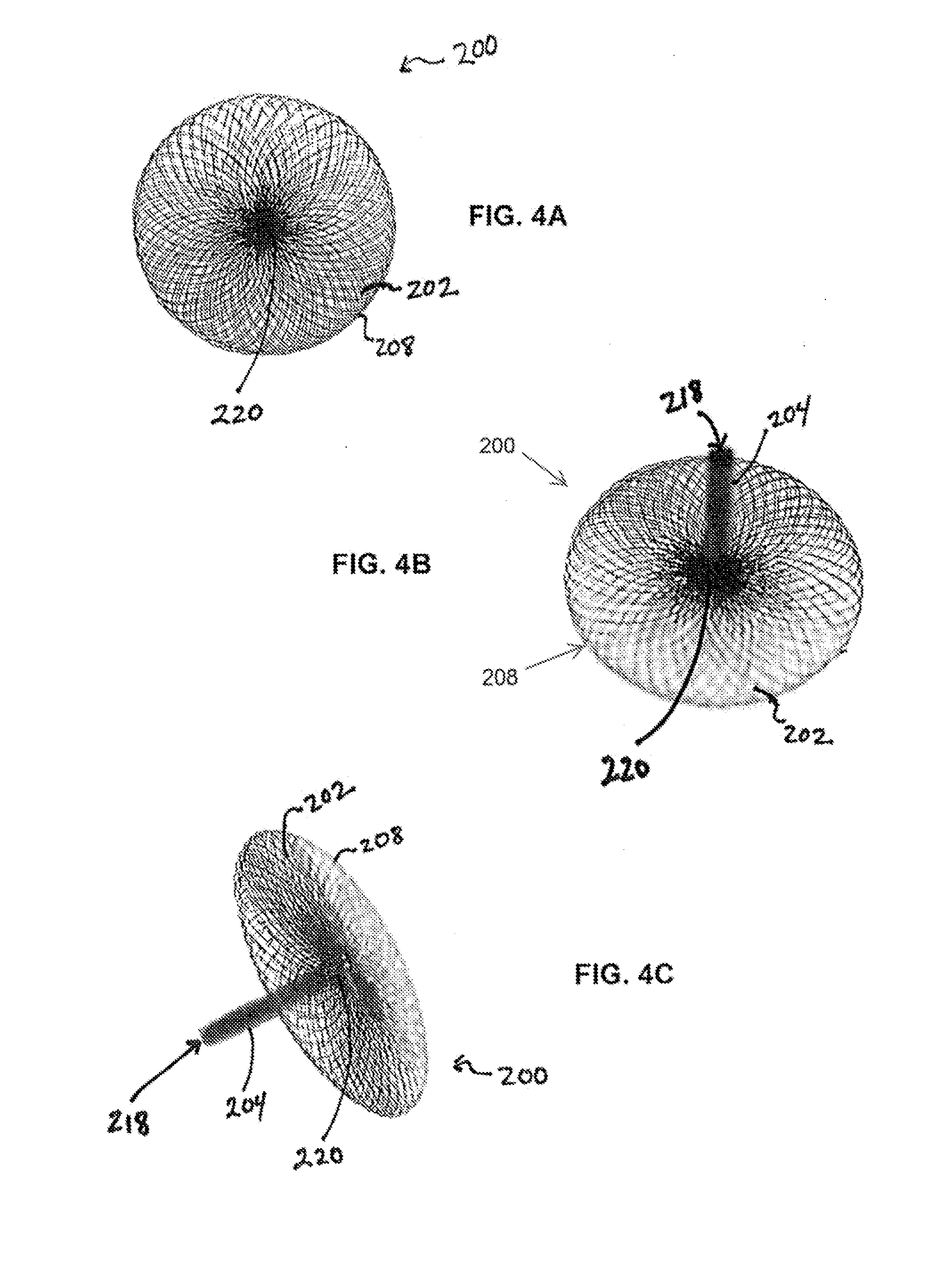

Aneurysm cover device for embolic delivery and retention

InactiveUS20110144669A1Improve durabilityImprove abilitiesOcculdersWound clampsAneurysm neckBrain aneurysm

An implant for treating brain aneurysms, especially terminal aneurysms, comprises a neck cover and elongate shaft removably secured to an embolic delivery catheter. As such, the shaft aids in directing and placing the cover at the aneurysm neck, protecting the delivery catheter from adhesion with the embolic material, and securing the cover in place with connection or adhesion of the shaft to the embolic material delivered through the catheter. The implant can be anchored at the aneurysm either by interface and / or adhesion of the shaft or shaft and cover with the resident embolic materials.

Owner:TYCO HEALTHCARE GRP LP

Supplemented and unsupplemented tissue sealants, methods of their production and use

InactiveUSRE39321E1Decreasing thrombogenicityLow antigenicityAntibacterial agentsOrganic active ingredientsTissue sealantVascular dilatation

This invention provides a fibrin sealant dressing, wherein said fibrin sealant may be supplemented with at least one composition selected from, for example, one or more regulatory compounds, antibody, antimicrobial compositions, analgesics, anticoagulants, antiproliferatives, antiinflammatory compounds, cytokines, cytotoxins, drugs, growth factors, interferons, hormones, lipids, demineralized bone or bone morphogenetic proteins, cartilage inducing factors, oligonucleotides polymers, polysaccharides, polypeptides, protease inhibitors, vasoconstrictors or vasodilators, vitamins, minerals, stabilizers and the like. Also disclosed are methods of preparing and / or using the unsupplemented or supplemented fibrin sealant dressing.

Owner:AMERICAN NAT RED CROSS

Methods for treating wound tissue and forming a supplemented fibrin matrix

InactiveUS7196054B1Low antigenicityDecreasing thrombogenicityOrganic active ingredientsSurgical adhesivesTissue sealantVascular dilatation

Owner:AMERICAN NAT RED CROSS

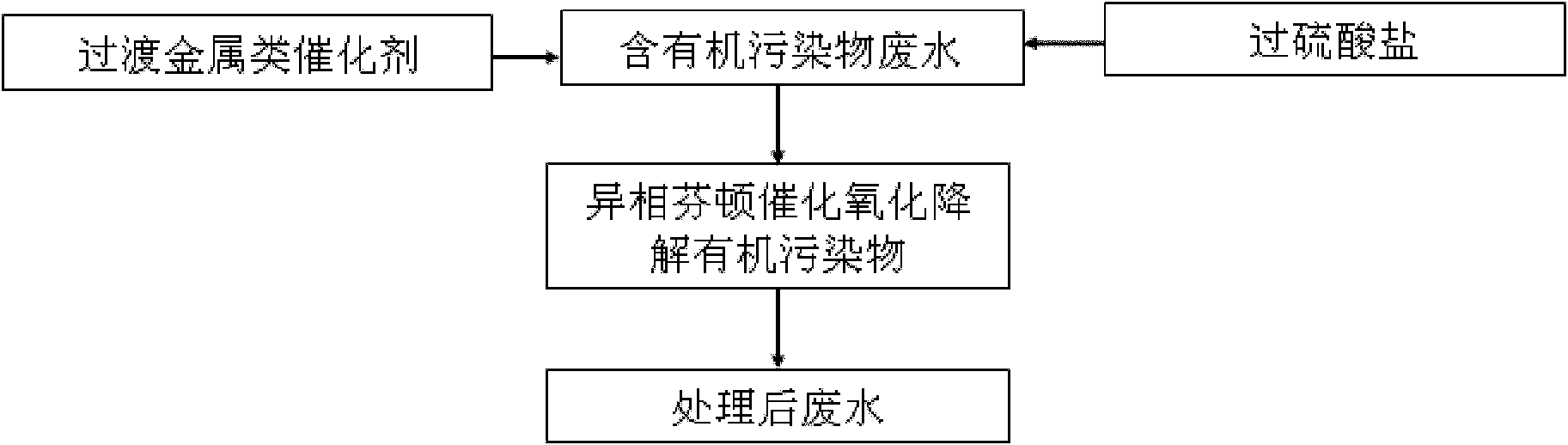

Processing method of heterocatalysis persulfate Fenton oxidation water

InactiveCN102020350ALong-lasting and efficient purificationImprove durabilityWater/sewage treatment by oxidationPersulfateFenton reagent

The invention proposes a processing technology of heterocatalysis persulfate Fenton oxidation water. In the method, transitional metal, transitional metallic oxide and a transitional metal / transitional metallic oxide composite material are used as out-phase Fenton reagents; and persulfate is catalyzed and decomposed to generate hydroxyl radical free radical, thus oxidizing to remove the organic matters in the waste water. Compared with the water treatment technique of homogeneous phase persulfate, the out-phase transitional metal and the transition metal oxide catalyst can slowly release transitional metal icons, thus ensuring that the organic matters in the water are purified lastingly and efficiently by the processing method of the heterocatalysis persulfate Fenton oxidation water. The processing technology of heterocatalysis persulfate Fenton catalyzed oxidation water built by the invention is suitable for processing various organic wastewater, has the advantages of good durability, high efficiency, environmentally friendliness, and no secondary pollution, is easy to operate, conforms to the requirements of actual water treatment units, and has great application potential in the field of environmental pollution regulation.

Owner:HUAZHONG NORMAL UNIV

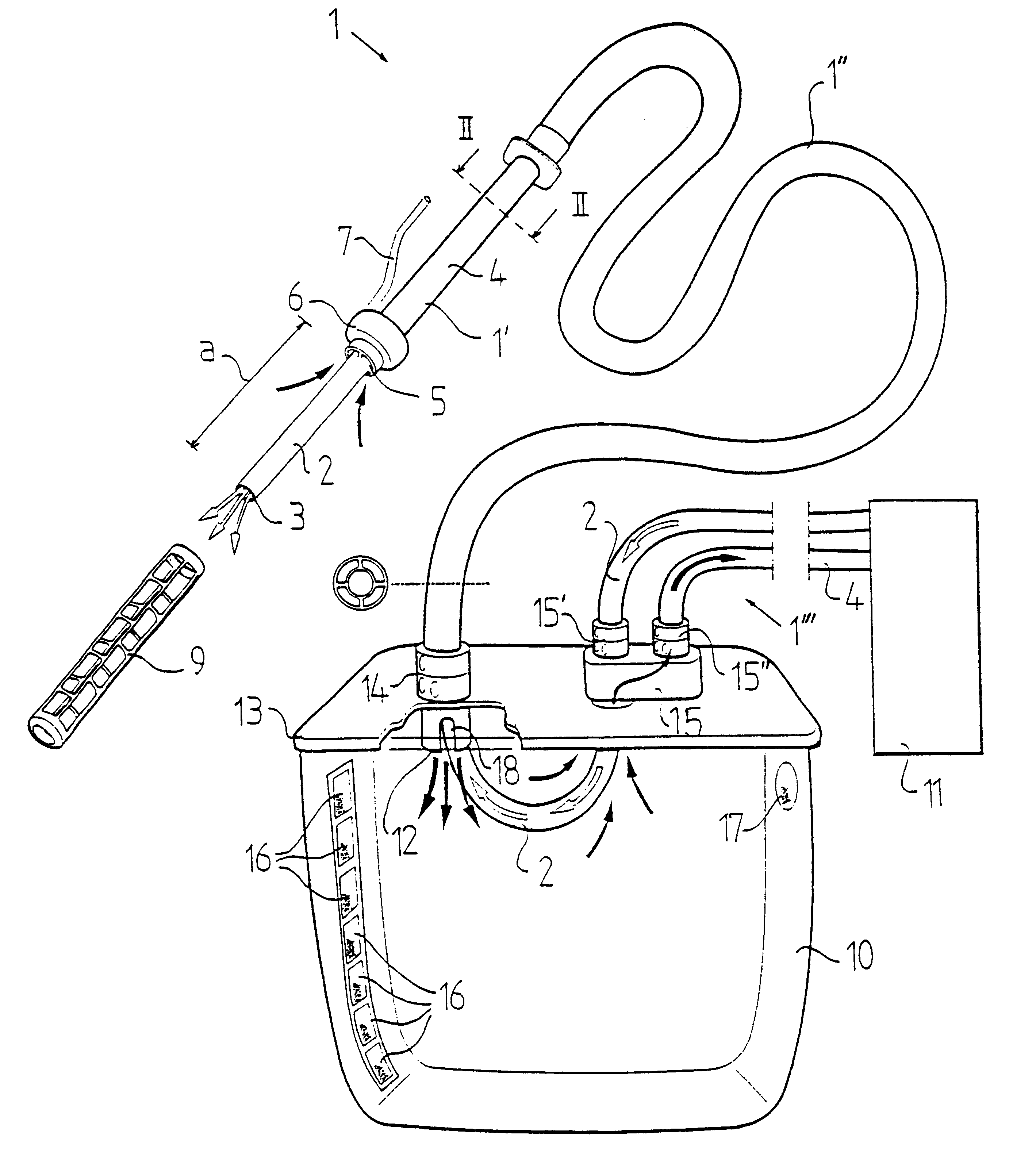

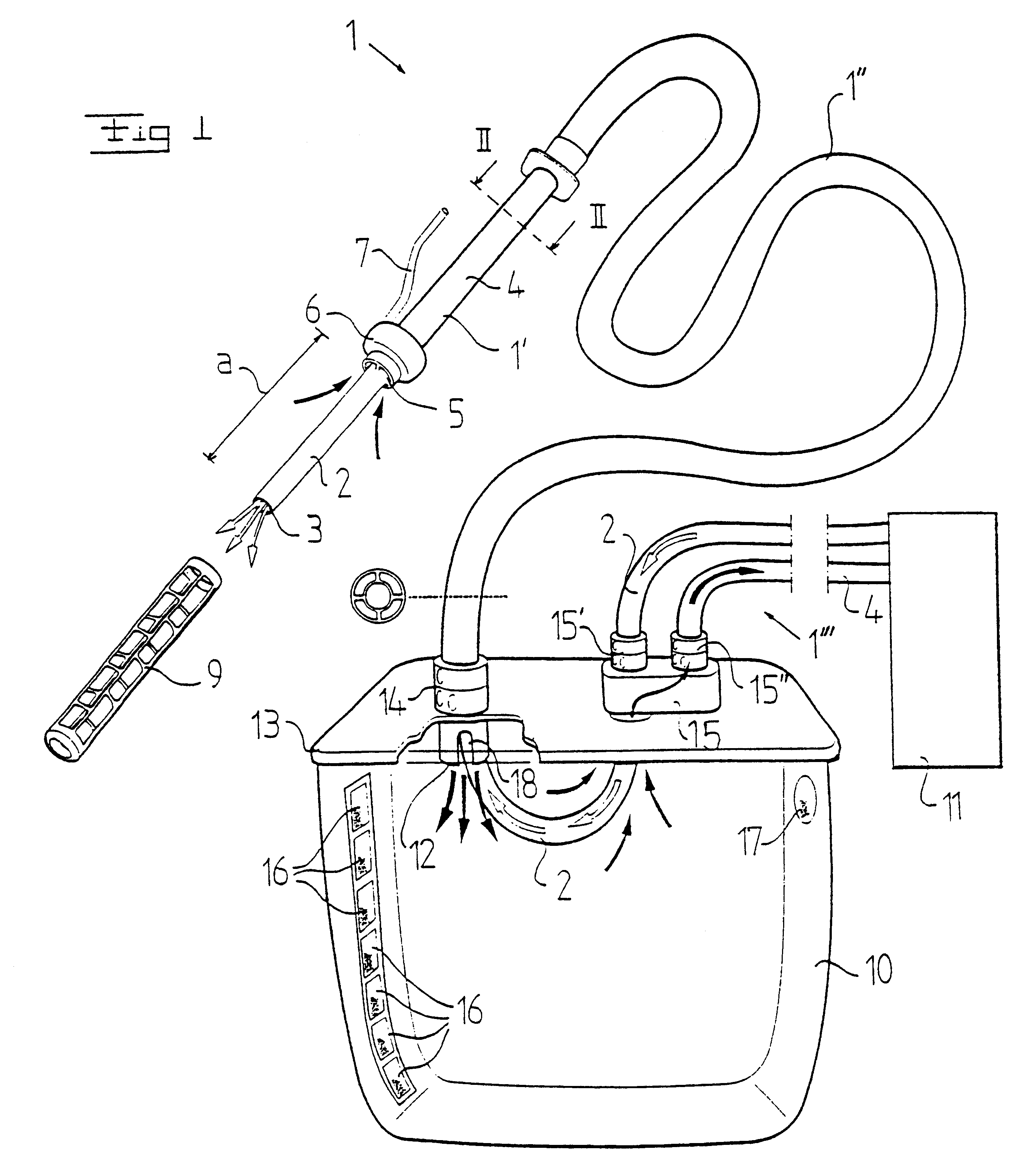

Device for supplying inhalation gas to and removing exhalation gas from a patient

InactiveUS6634360B1Easy to transportThe equipment is easy to operateTracheal tubesSurgeryTracheal tubeLarynx

An integrated tracheal tube / suction ventilation and co-committal secretion removal device having first and second coaxially arranged conduits where the first interior conduit forms a lumen to deliver gas, and a circumferentially arranged second conduit lumen is structurally adapted to serve as an integral suction lumen for removal of both expiratory gases and secretions. The distal end outlets of both lumens terminate between the device's fixing member and its distal end. The two lumen outlets are arranged such that relative to each other and the device the first interior pipe conduit forming lumen's outlet is located at the distal end and the second pipe conduit lumen's outlet is located at or near the distal side of the fixing member. This selection of relative positioning facilitates optimal deliver of breathing gas to a user in conjunction with removal of expiratory gases and secretions. The device is sized for location of the fixing member to its distal end from a patient's carina to a patient's larynx.

Owner:ALORO MEDICAL

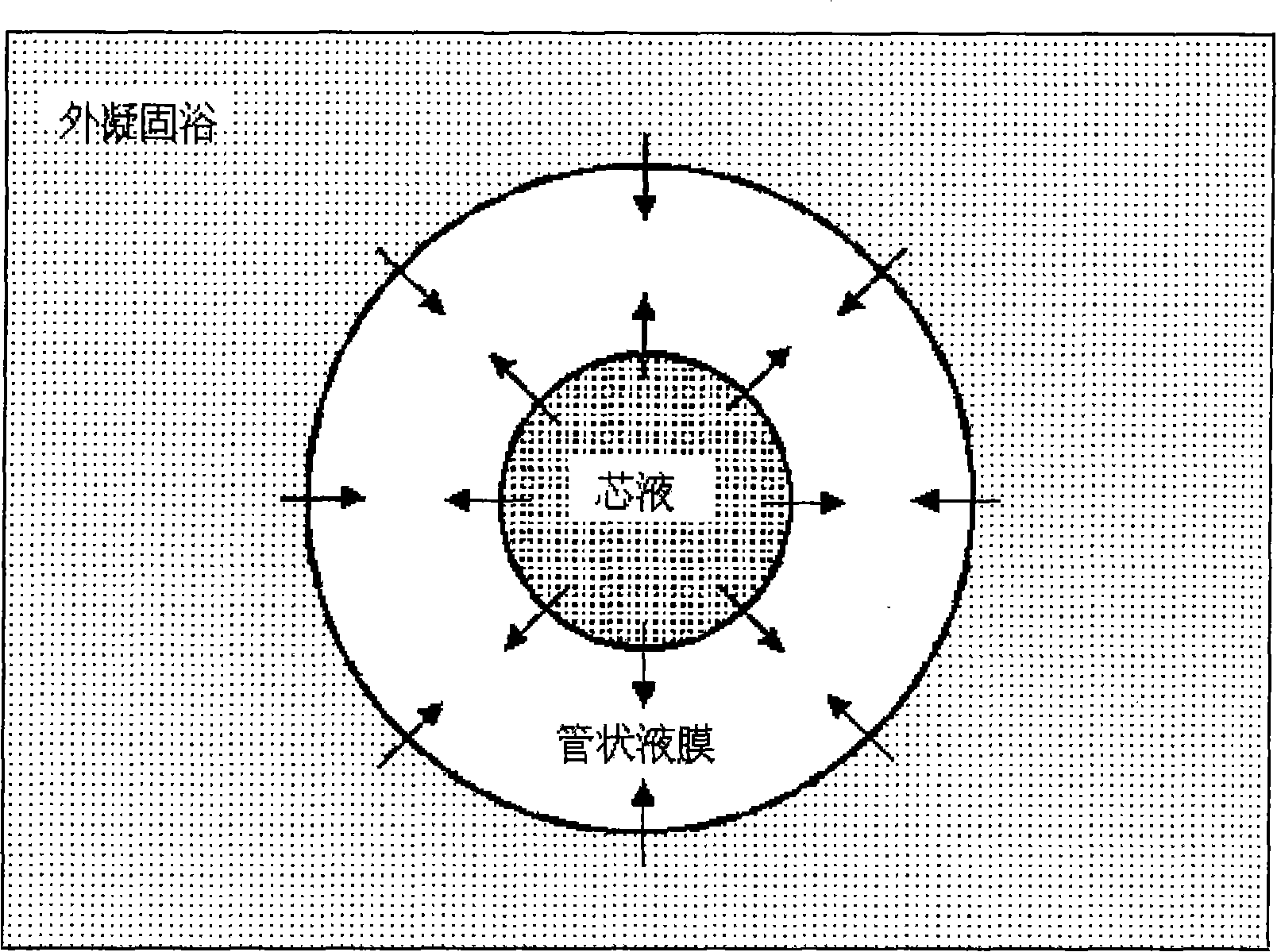

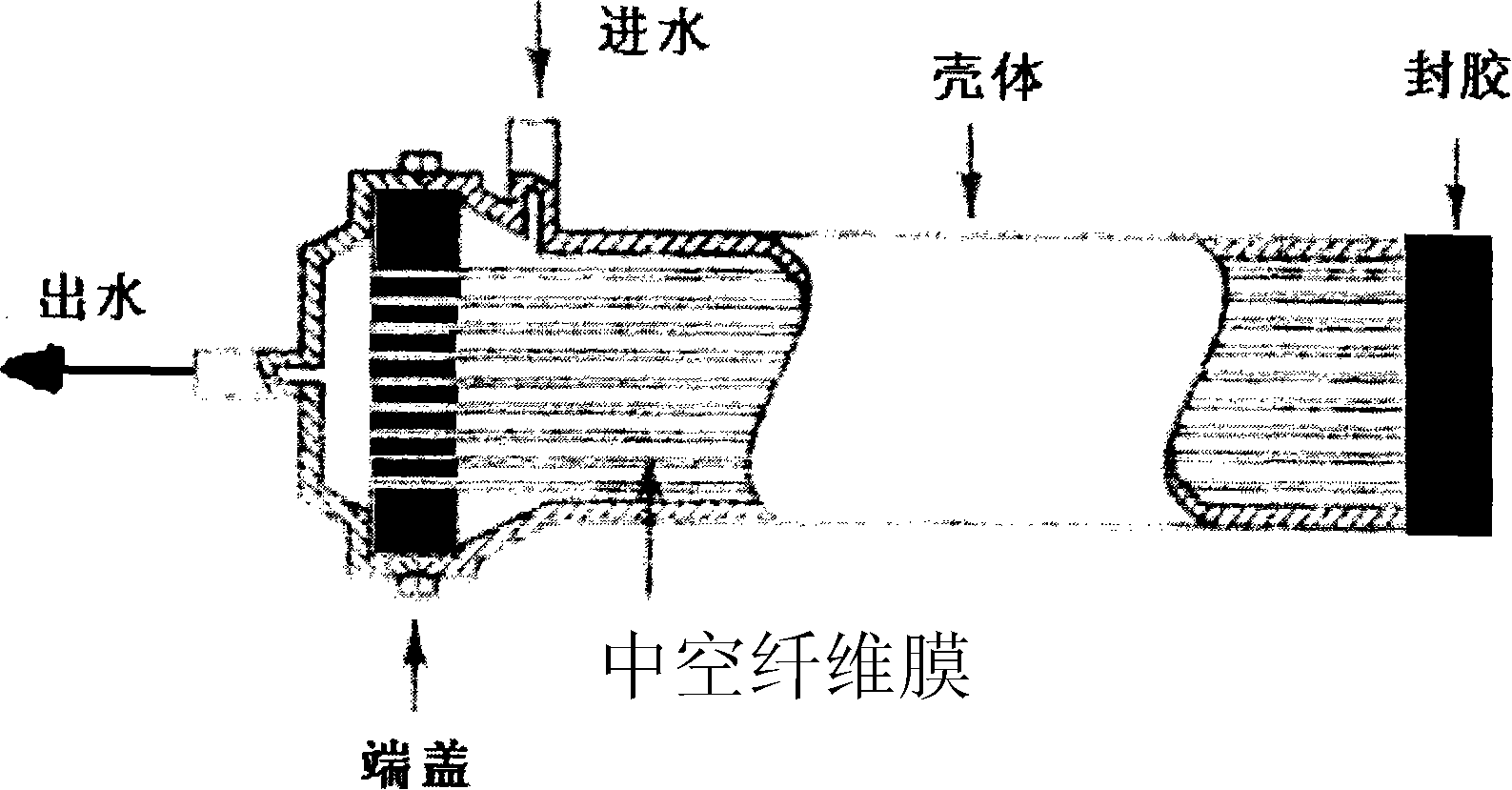

Hydrophilicity kynoar hollow fiber microporous membrane and preparation method thereof

ActiveCN101190401AImprove anti-pollution performanceAvoid adsorptionSemi-permeable membranesHollow fibrePorosity

The invention discloses a hydrophilic polyvinylidene fluoride hollow fiber microporous membrane and the preparation method thereof. The main composition and the mass content of the membrane are 70% to 90% of polyvinylidene fluoride, amphiphilic poly-(propylene oxide-oxirane), 5% to 29% of poly-(methacrylic acid- acrylic acid) or poly-(methacrylic acid methyl ester-vinyl alcohol) copolymer and 1% to 5% of nano-silicon dioxide. The membrane preparation method is that all the components are mixed and dissolved with aperture regulator, thickener and solvent to obtain the membrane preparation liquid; after that, the hollow fiber forming is carried out through a dry-wet spinning technique, and finally cleaning and drying are implemented. The obtained membrane has adjustable internal diameter and external diameter, 60% to 80% of porosity and the aperture ranging from 0.01micron to 0.2micron. As a water disposal separating membrane material with excellent performance, the invention has the advantages of being able to be fully humid, organic adsorption resistance and great water flux, etc.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

Polysaccharide alcohol antiseptic gel

InactiveUS20050182021A1Reduce contactPrevent microbial growthBiocideCosmetic preparationsSodium PyrithioneOrganic acid

An alcohol-based composition for sanitizing surfaces has persistent sanitizing properties after evaporation of the alcohol. The composition includes a cationic polysaccharide, an organic acid, alcohol, and water. The cationic polysaccharide can be chitosan, cationic guar or cationic starch. The cationic polysaccharide can be complexed with a transition metal, such as zinc or copper, or with a chelating agent, such as pyrithione.

Owner:HALOSOURCE INC

Implantable collagen compositions

InactiveUS20060100138A1Improve durabilityImproved ease of handlingConnective tissue peptidesSurgical adhesivesTissue augmentation

The present invention relates to collagen compositions suitable for use in various tissue augmentation procedures.

Owner:FIBROGEN INC

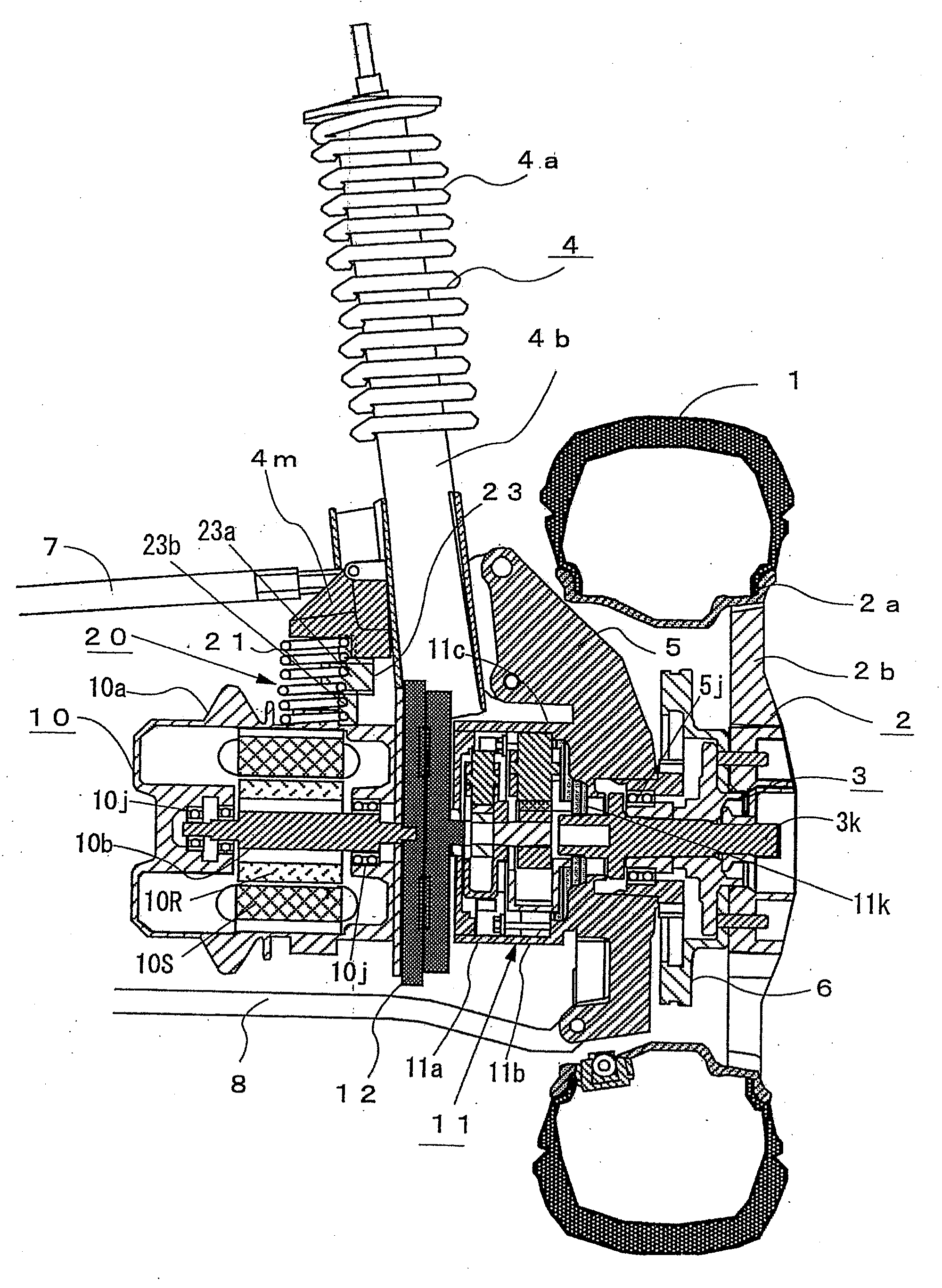

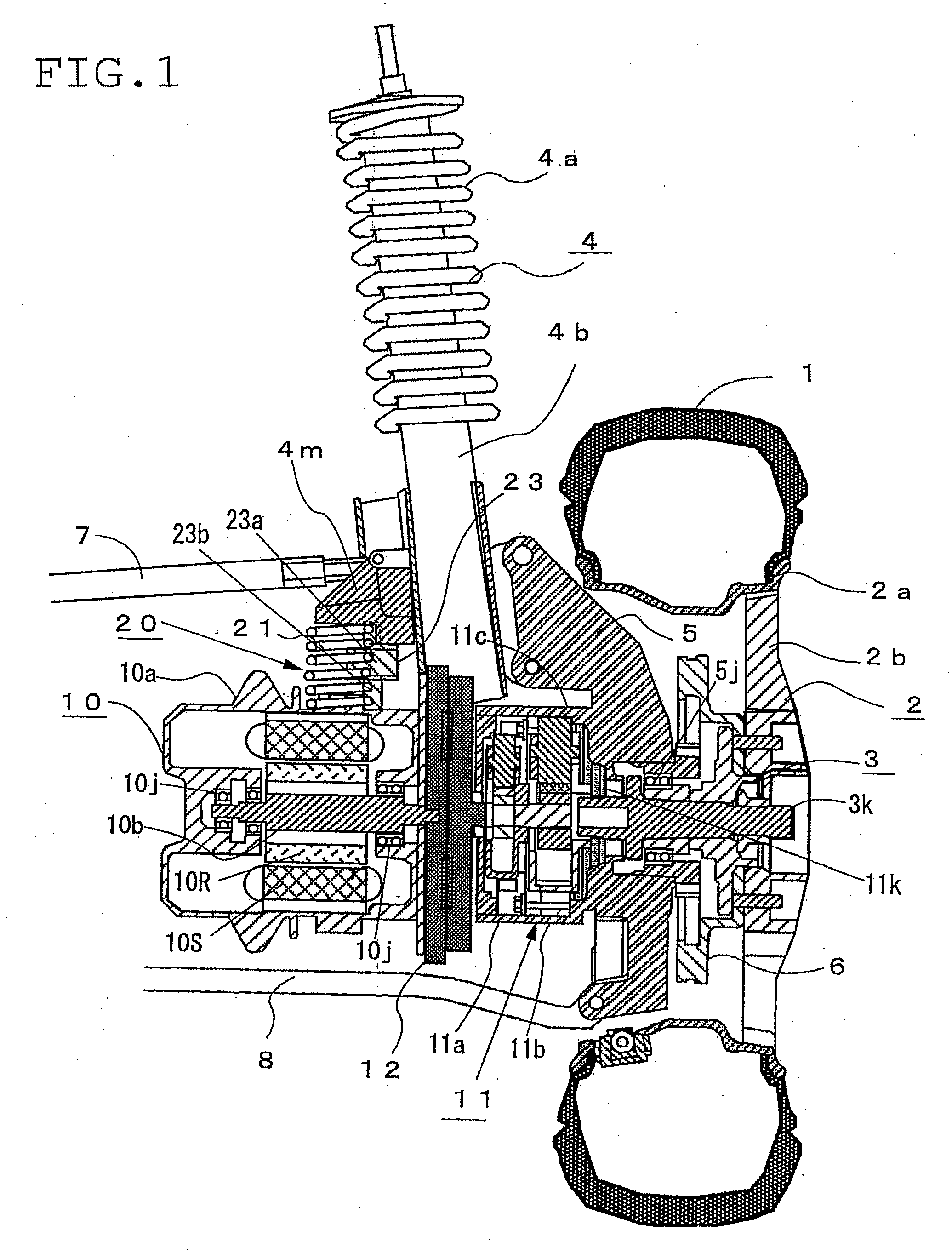

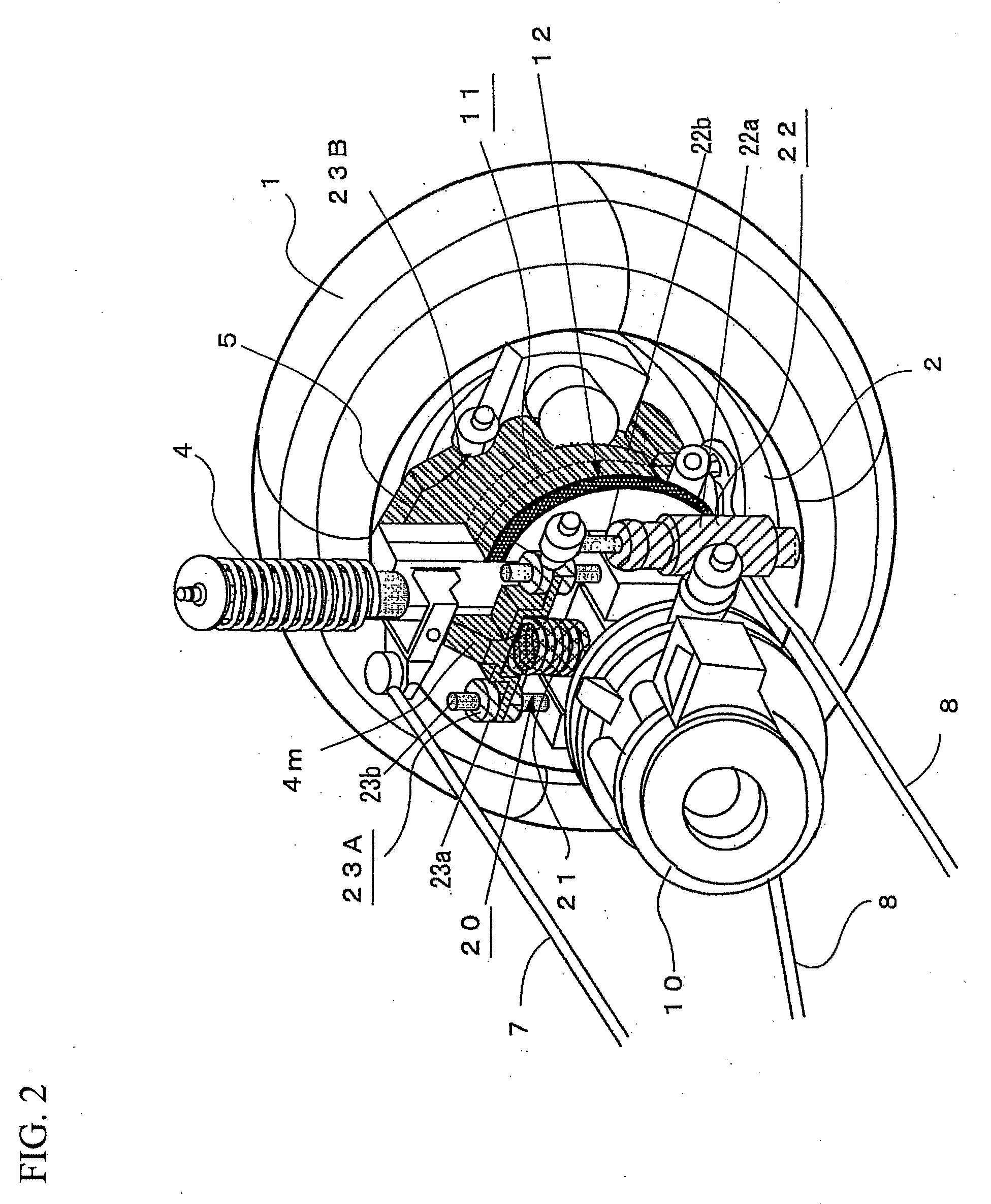

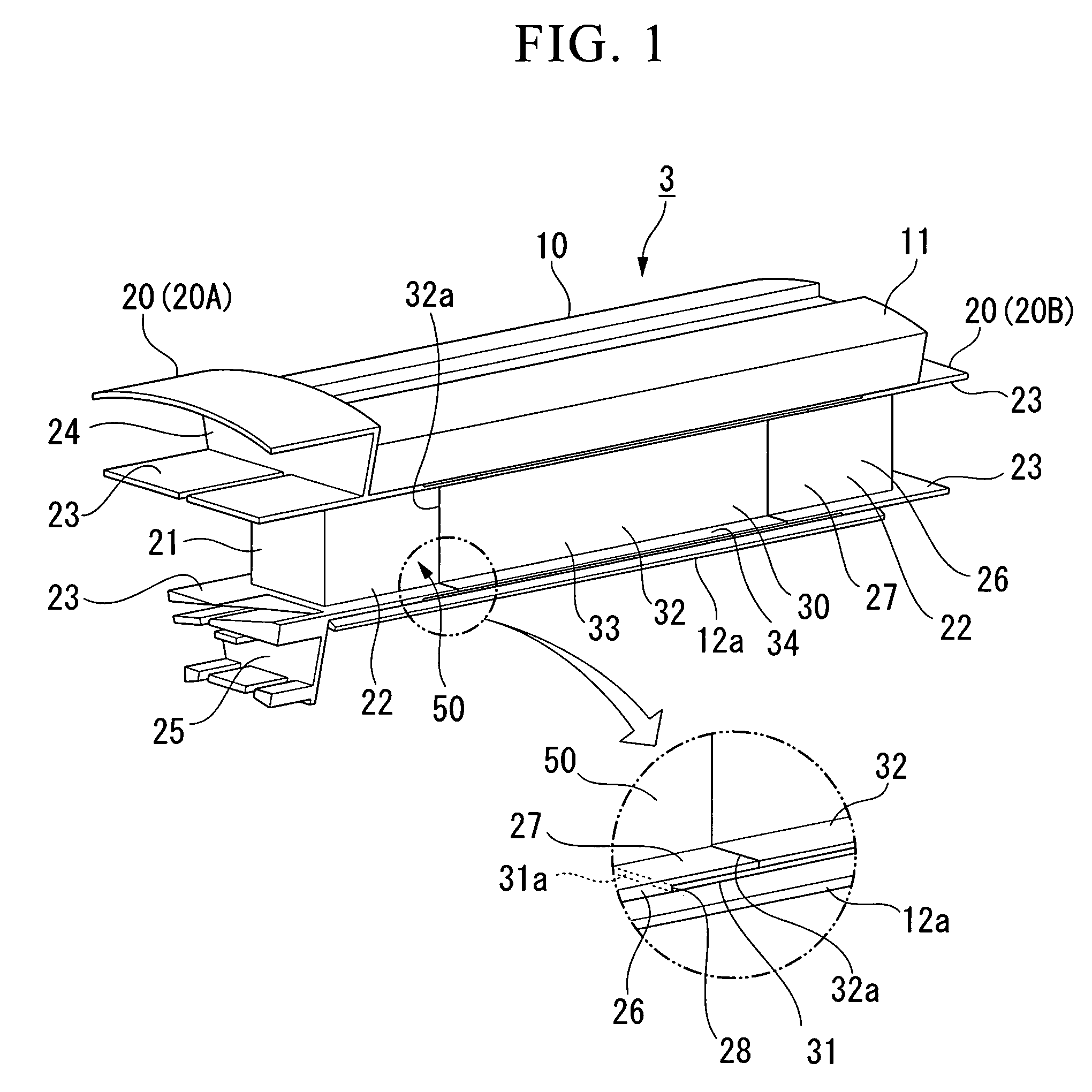

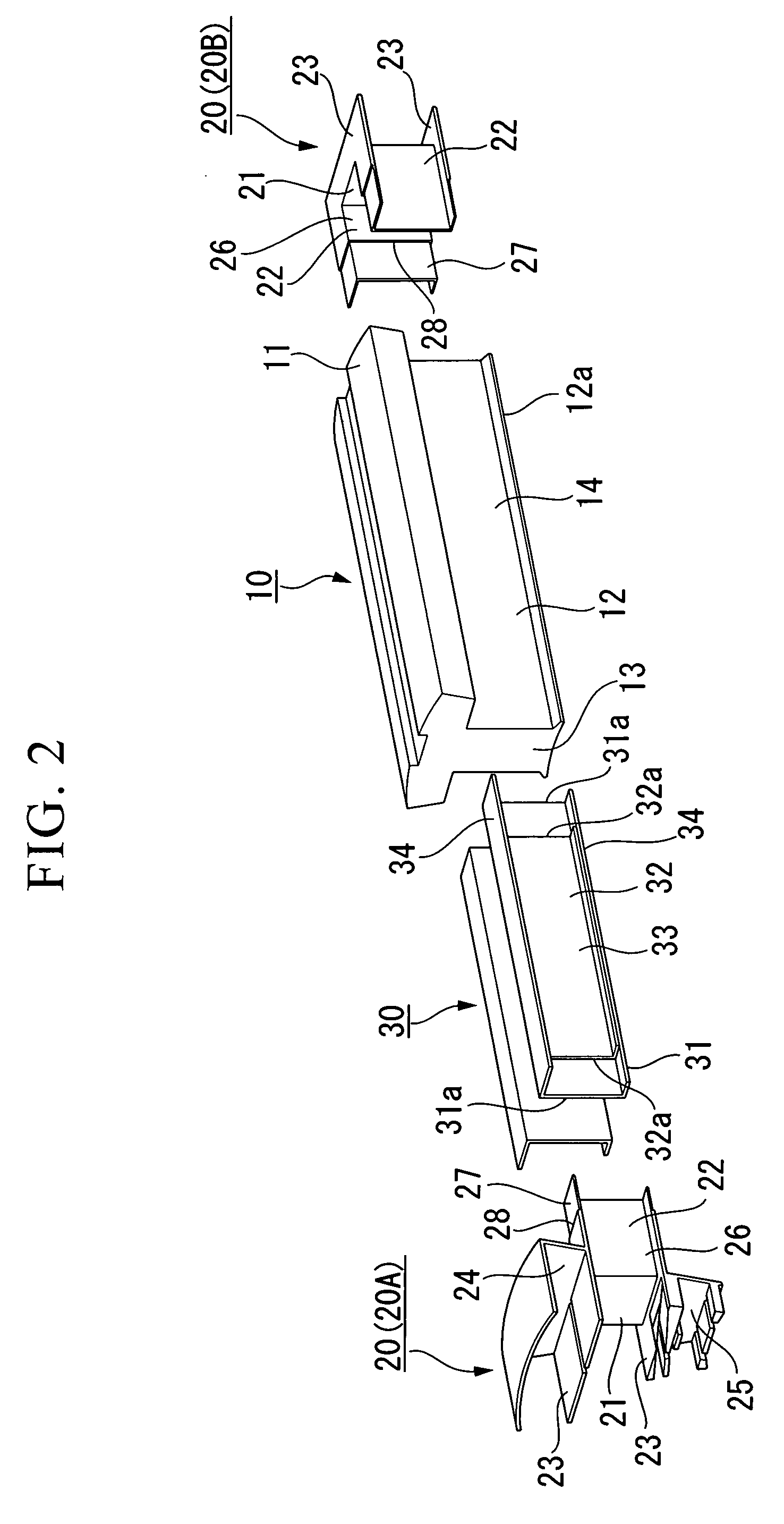

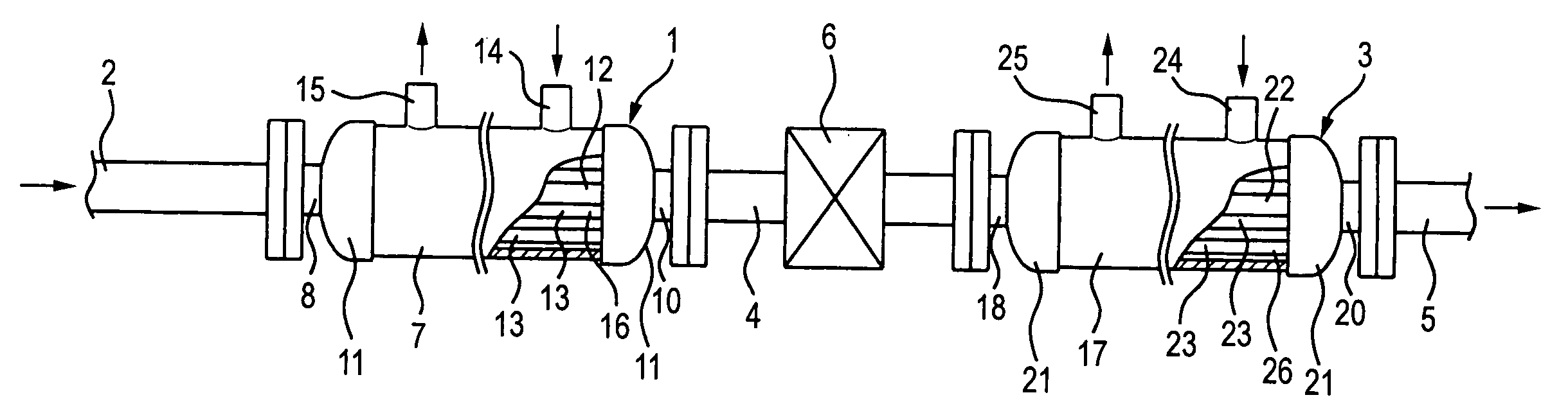

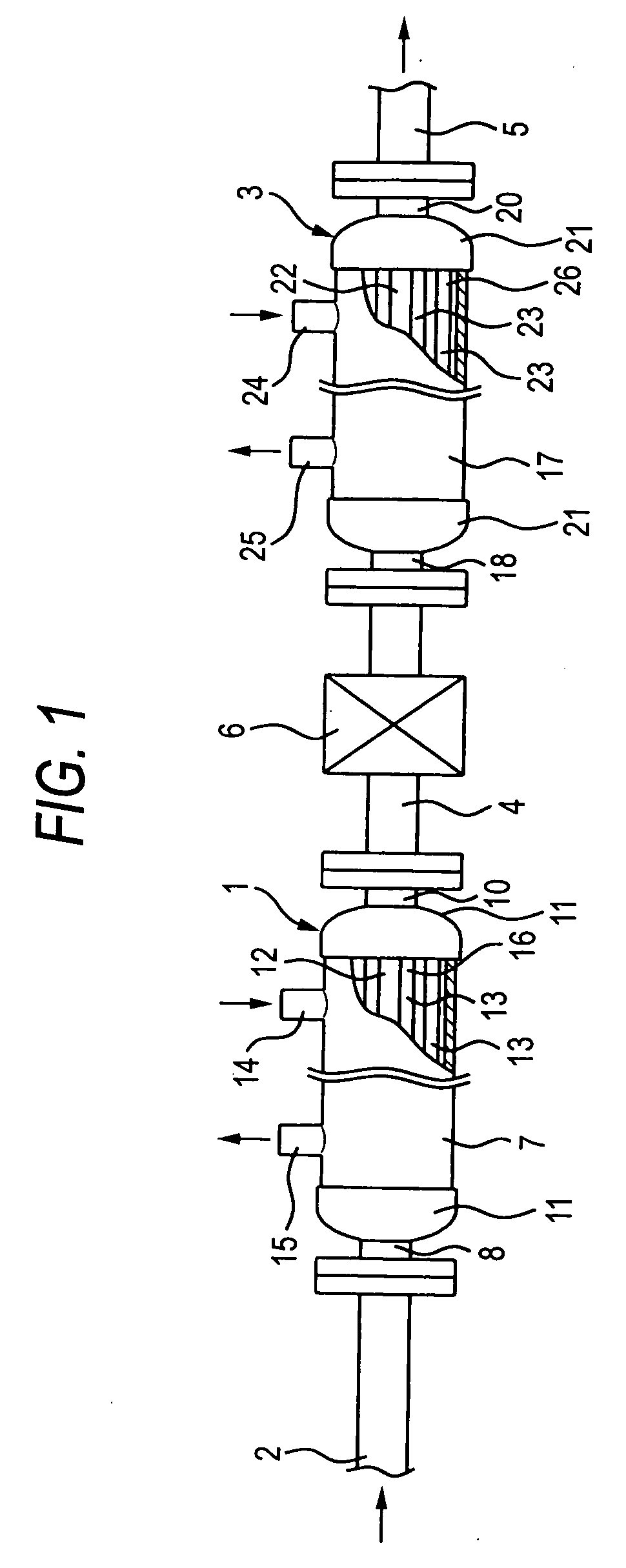

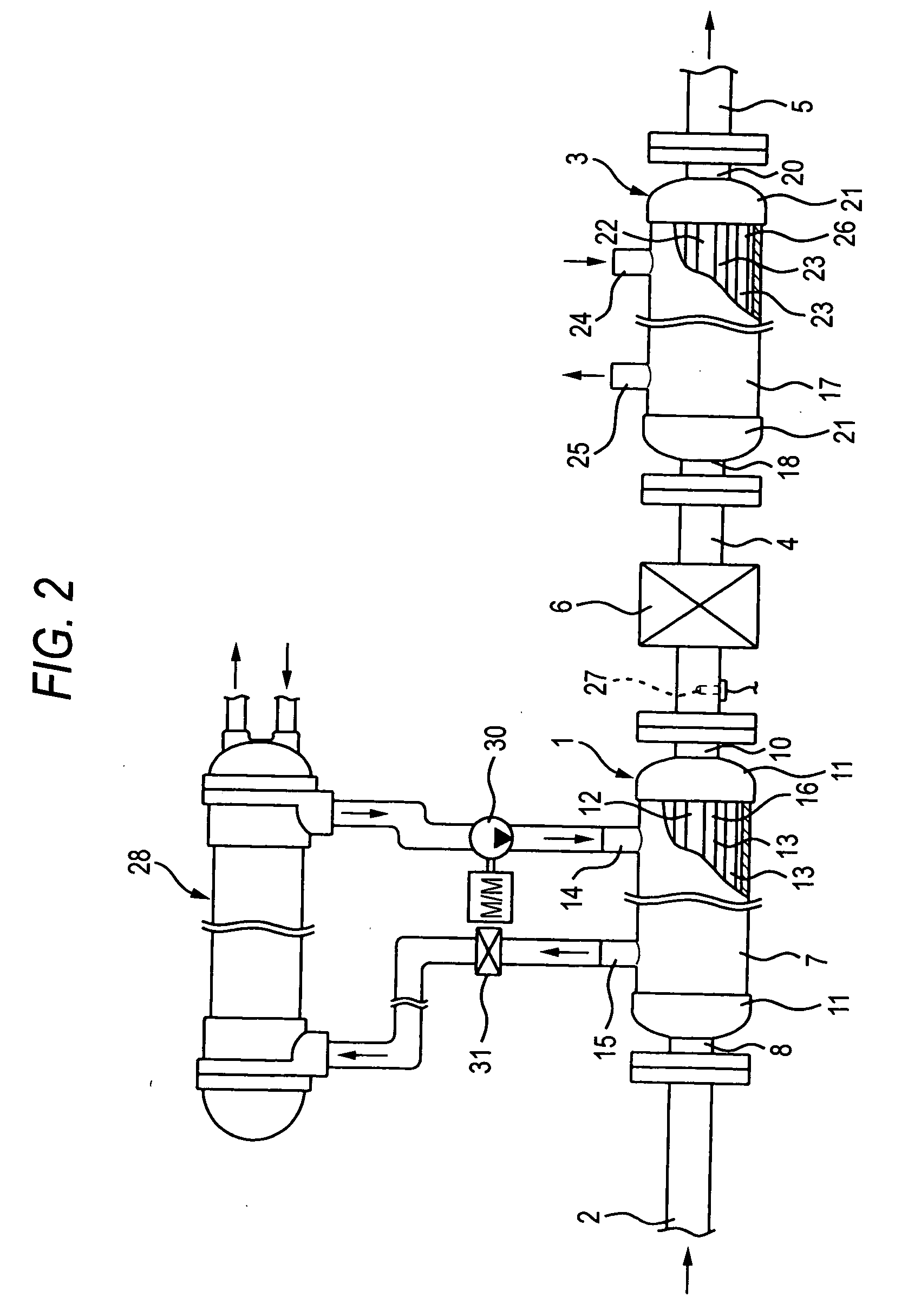

In-wheel motor system

InactiveUS20090133944A1Improve durabilityLarge drive forceElectric devicesElectric propulsion mountingKnuckleEngineering

An electric motor 10 and a reduction gear mechanism 11 are connected to each other by a flexible coupling 12, such as an Oldham's coupling, which is a power transmission mechanism. Also, a casing 11c of the reduction gear mechanism 11 is integrally structured together with a knuckle 5, which is an unsprung part of a vehicle, or mounted to the knuckle 5. Further, a motor case 10a of the electric motor 10 is mounted to a motor mounting member 4m provided on the lower part of a strut 4 for suspending the knuckle 5 through the medium of a shock absorbing mechanism 20 equipped with a spring member 21, a damper, and two guide members 23 for guiding the operating direction of the spring member 21 and the damper. An in-wheel motor system thus structured allows the mass of the motor 10 to act as the mass of a dynamic damper and thus features not only improved ground contact performance and riding comfort of a vehicle running on a rough road but also superior space efficiency.

Owner:BRIDGESTONE CORP

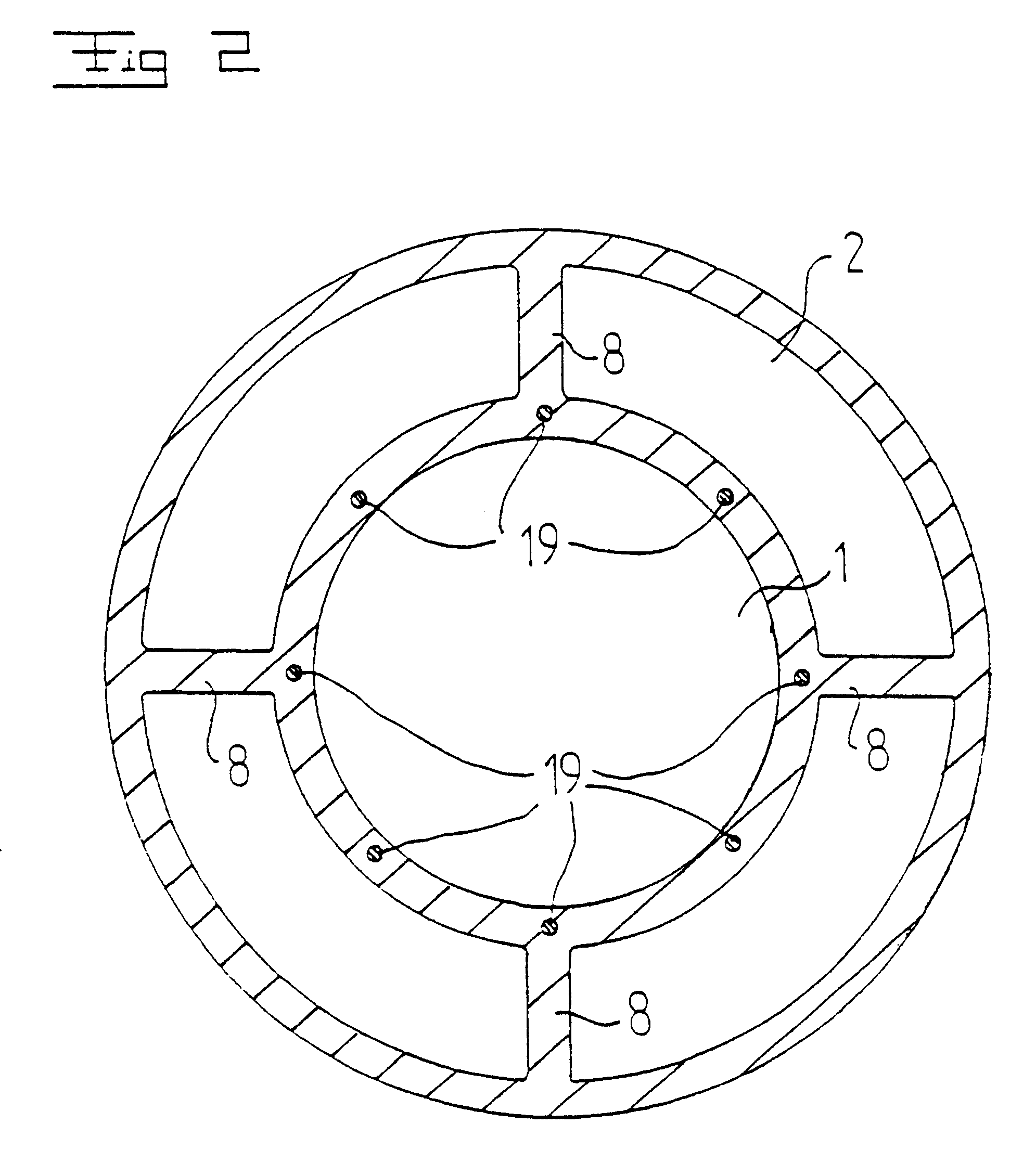

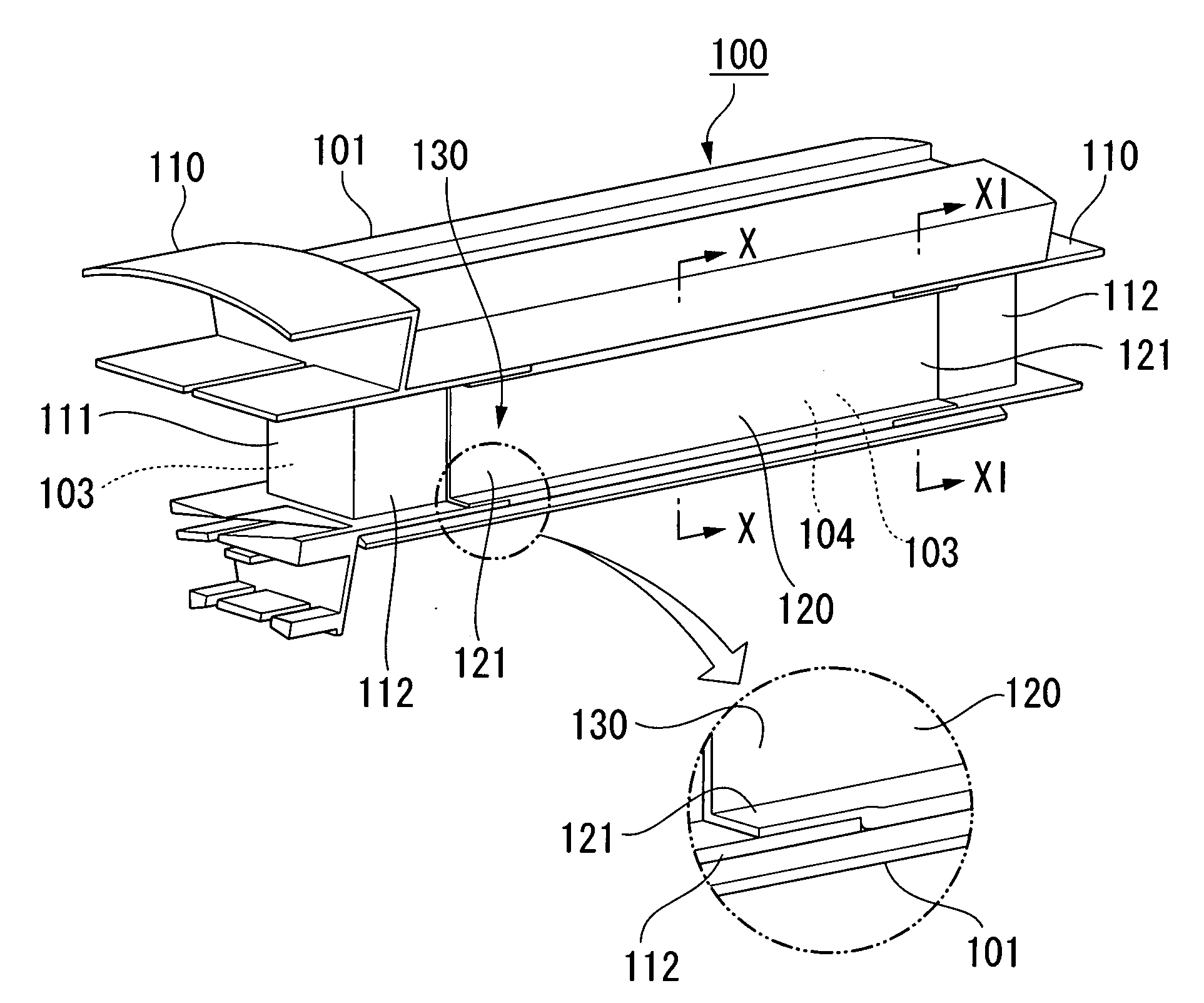

Insulation structure of rotary electrical machinery

InactiveUS20070222324A1Heat generated can be radiatedImprove cooling effectWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machineryConductor Coil

An insulation structure of rotary electrical machinery which electrically insulates teeth of a stator from a winding wound on the teeth includes: an insulator made from hard insulation material, disposed on both axial ends of the teeth, and having a side wall disposed along a side surface of the teeth crossing to a circumferential direction thereof, and a high-heat-conductive electrical-insulation resin sheet disposed along the side surface of the teeth and insulating the teeth from the winding, wherein an axial end portion of the high-heat-conductive electrical-insulation resin sheet is disposed between the side wall of the insulator and the side surface of the teeth and is stacked on the side wall in a prescribed axial extent.

Owner:HONDA MOTOR CO LTD

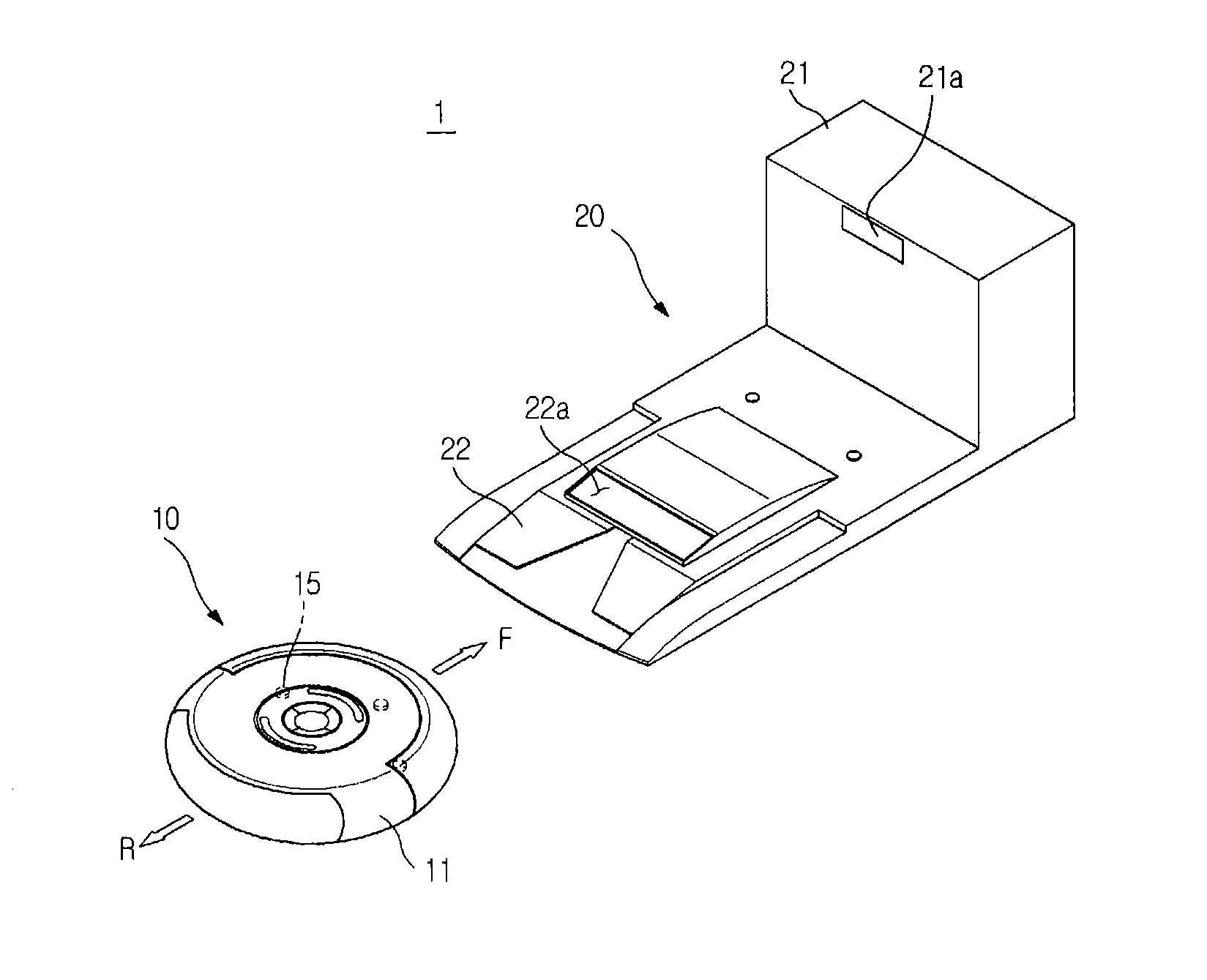

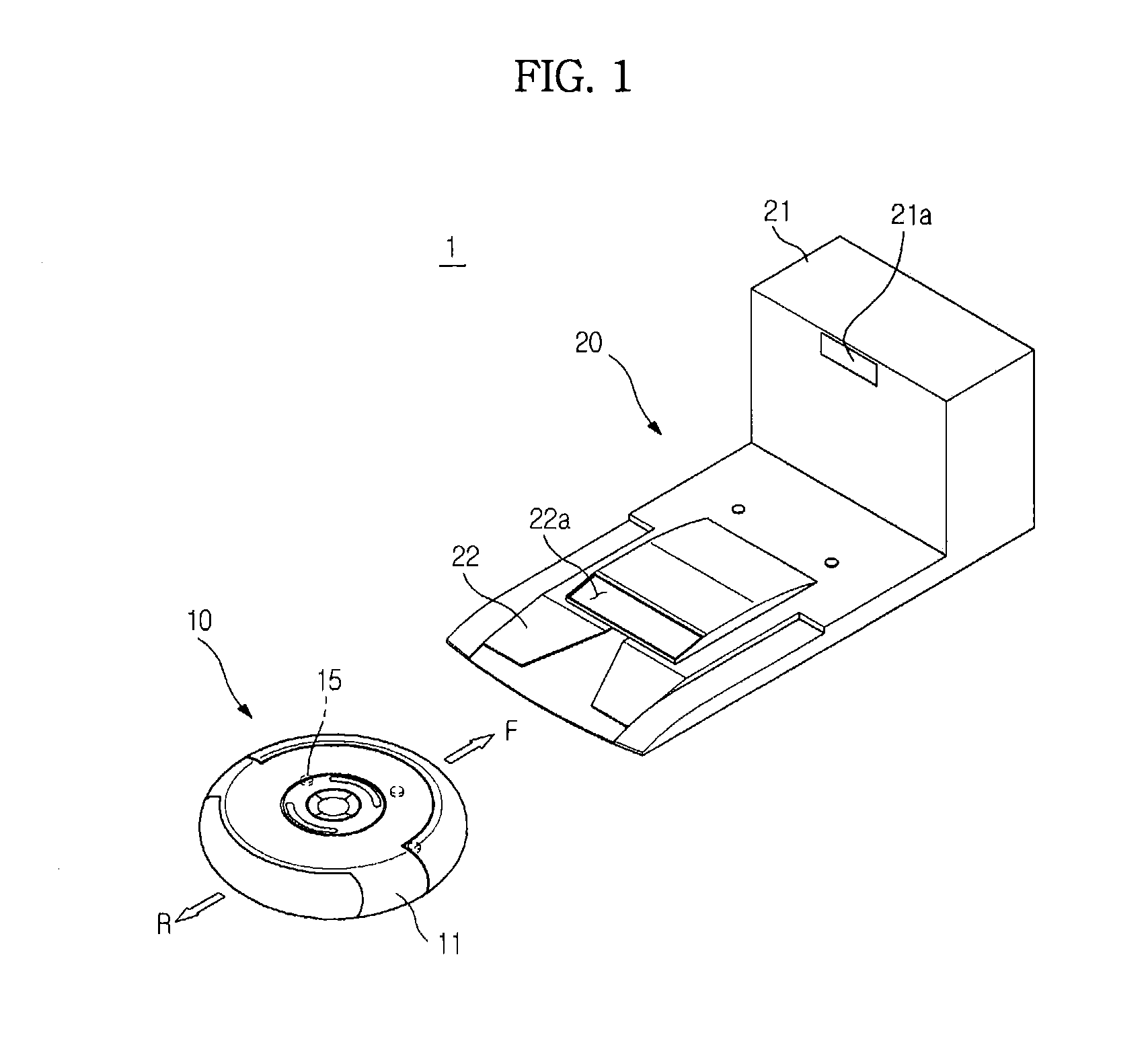

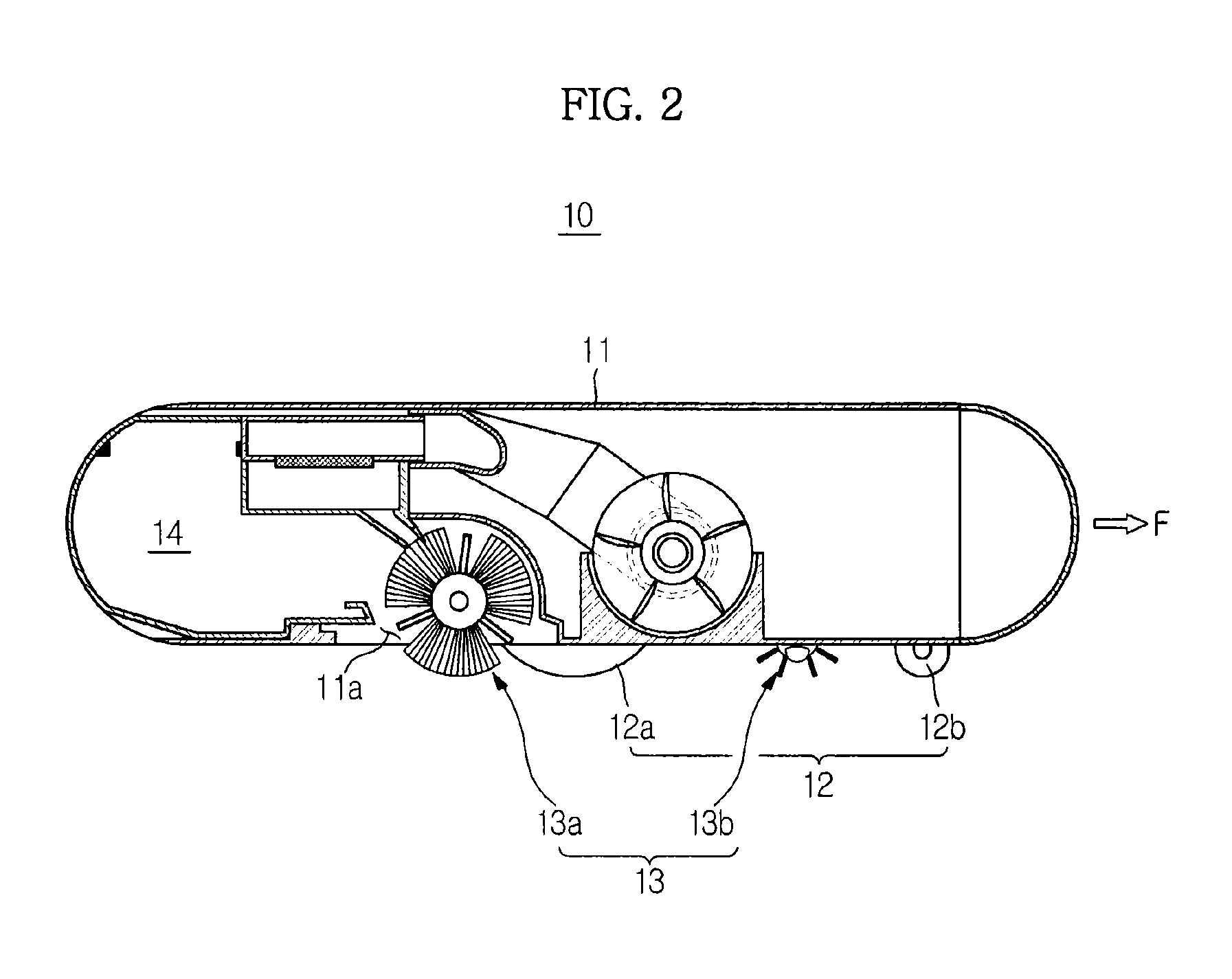

Cleaning system and maintenance system thereof

ActiveUS20130055521A1Improve durabilityIncrease performanceCarpet cleanersFloor cleanersEngineeringMaintenance system

A cleaning system includes a robot cleaner having an opening unit and a first dirt container funneled to the opening unit, and a maintenance station to which robot cleaner is docked to discharge dirt stored in the first dirt container The maintenance station includes a first inlet hole configured to intake dirt from the first dirt container through the opening unit, a first outlet hole configured to blow air into the first dirt container, a circulating passage provided between the first inlet hole and the first outlet hole, a second dirt container disposed on the circulation passage to store dirt taken in from the robot cleaner, a draft apparatus having a draft fan and a fan motor to drive the draft fan to circulate air through the circulating passage, and a second outlet hole configured to discharge air inside the circulating passage of the maintenance station to an outside.

Owner:SAMSUNG ELECTRONICS CO LTD

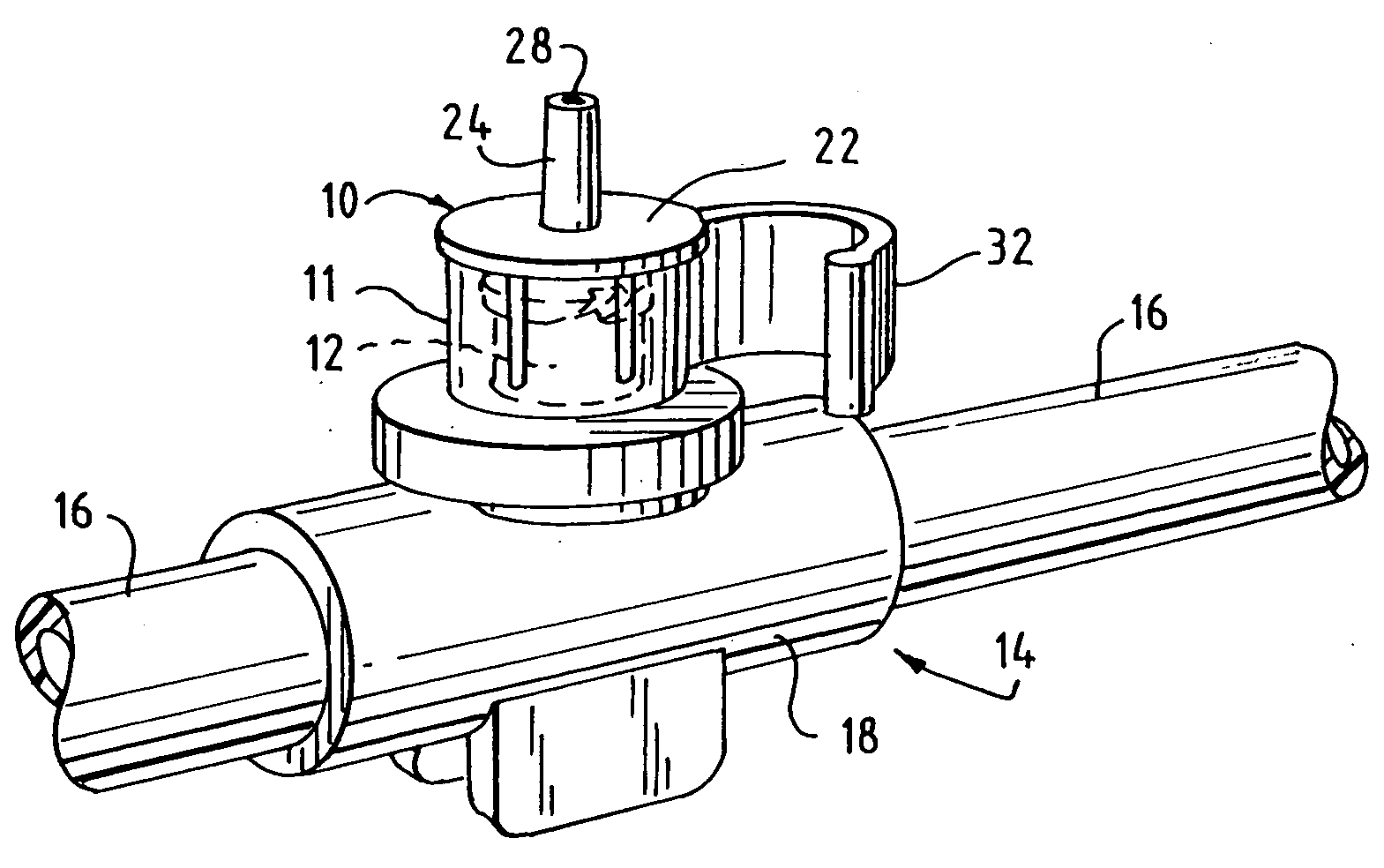

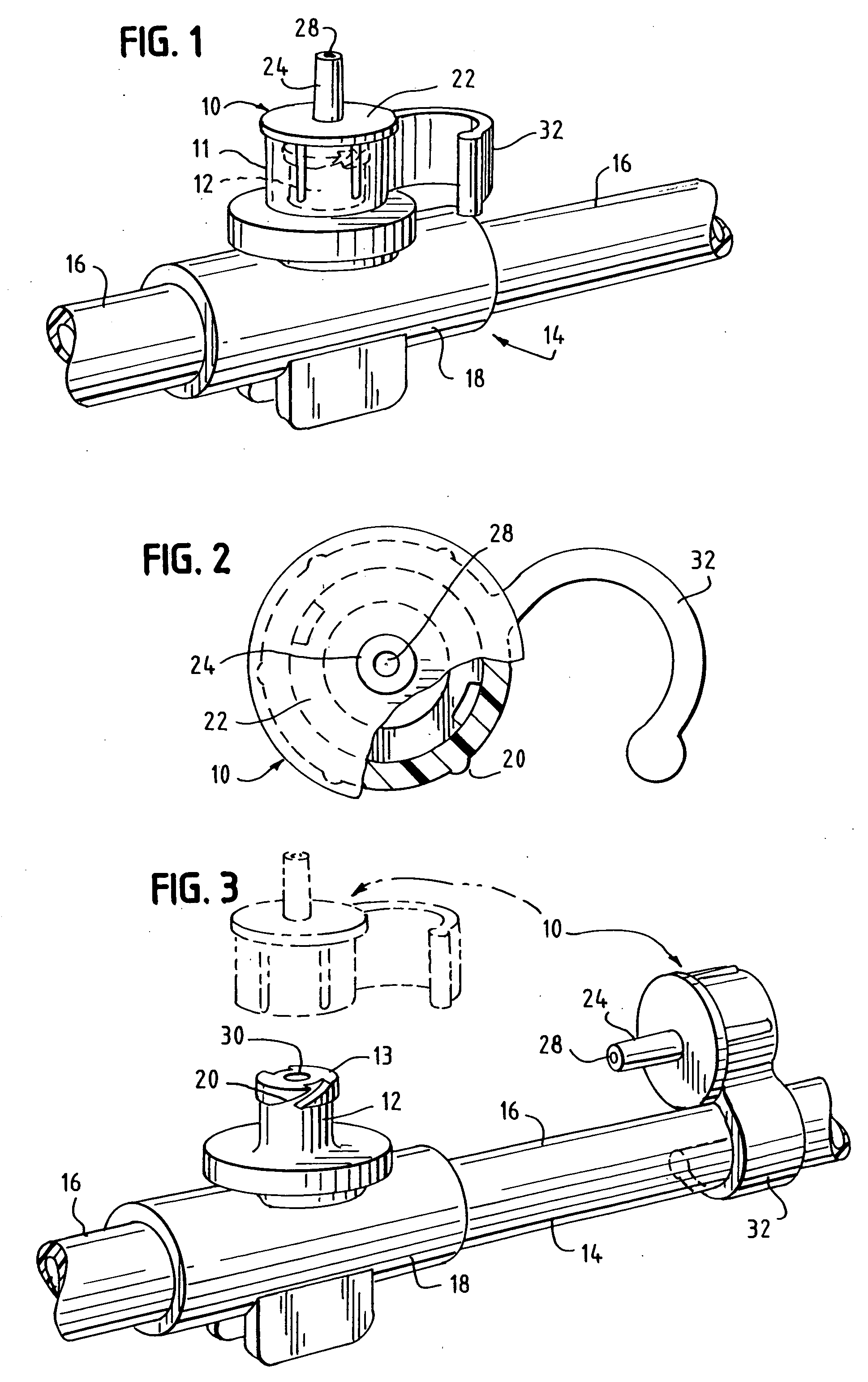

Closure for tubular access port

ActiveUS20070093762A1Provides adequateImprove durabilityInfusion devicesTube connectorsLine tubingEngineering

A closure for a tubular access port in a medical fluid flow line or other container comprises a removable cap for enclosing and sealing the tubular access port. The cap has a closed end wall. The end wall carries an extending poker to facilitate the pushing of an antiseptic-carrying material into a lumen of the access port. The poker has an outer diameter that is less than the inner diameter of the access port. A method of using the poker is also described.

Owner:B BRAUN MEDICAL

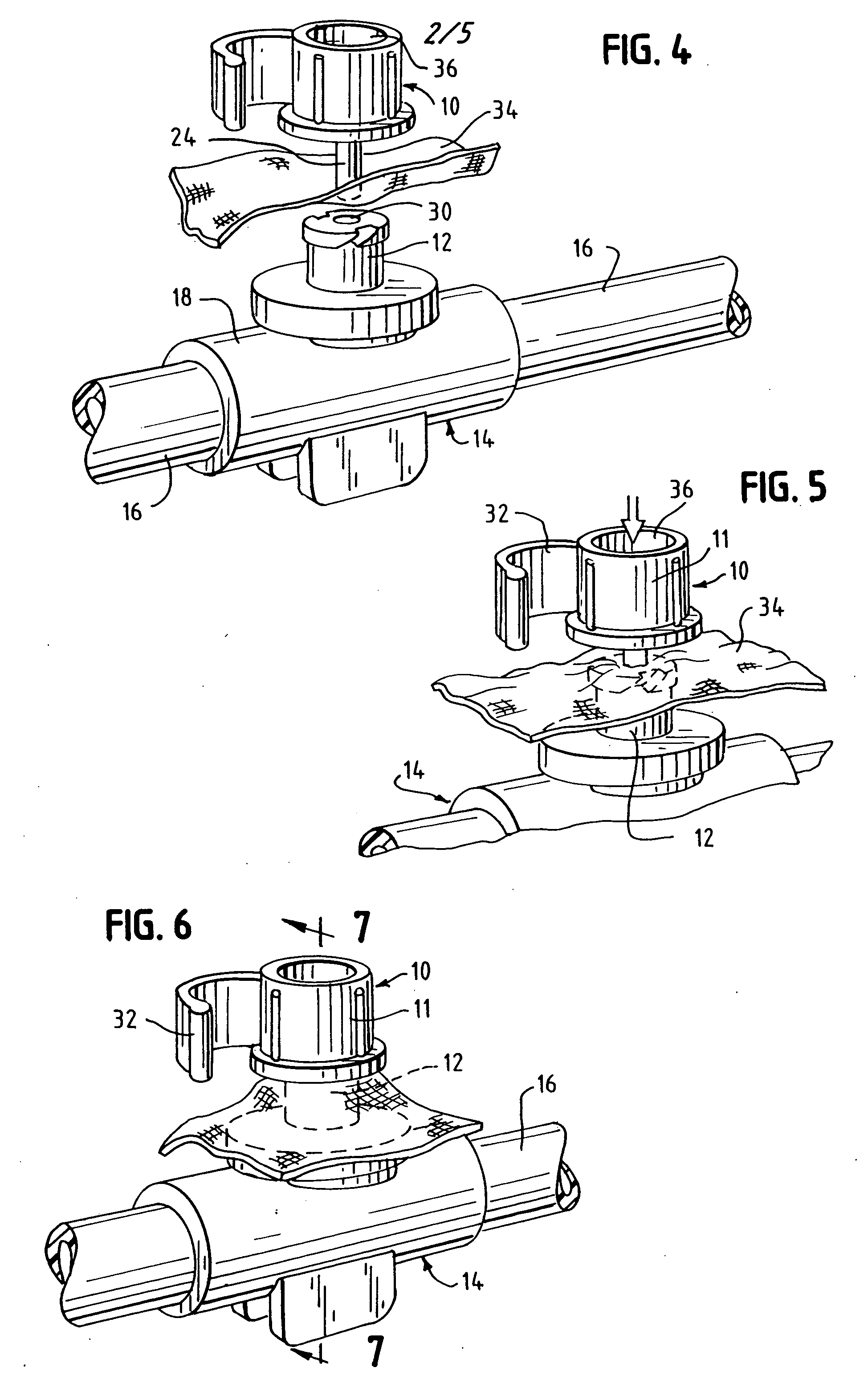

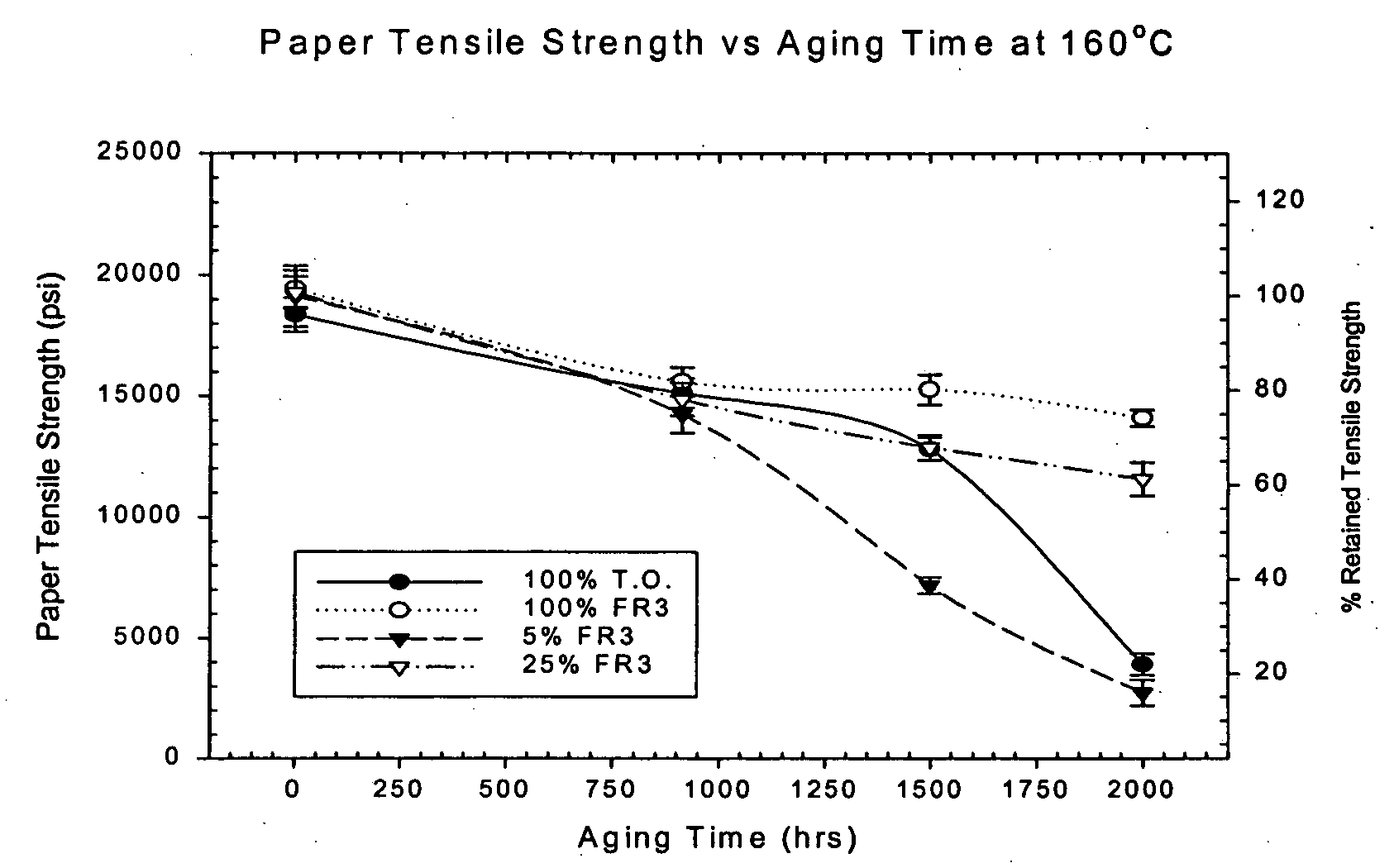

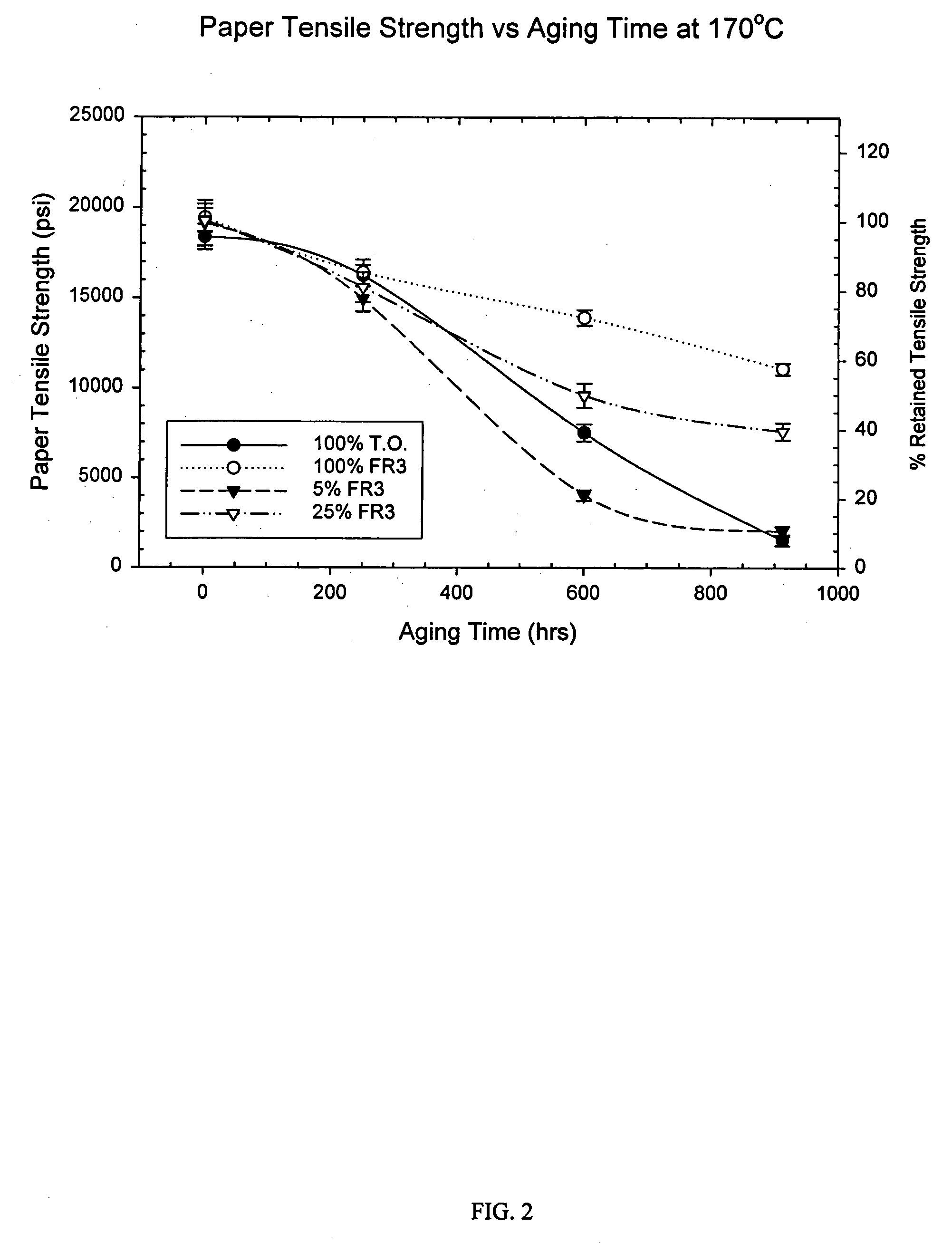

Additive for dielectric fluid

ActiveUS20050072964A1Improve durabilityImprove lifeTransformers/inductances coolingTransformers/inductances casingsCompound (substance)Dielectric

A dielectric fluid comprising hydrocarbon liquid admixed with an ester-based compound, wherein the ester-based compound is present in an effective amount to impart breakdown inhibiting properties to a paper insulation material when the dielectric fluid is in contact with the paper material.

Owner:COOPER IND INC

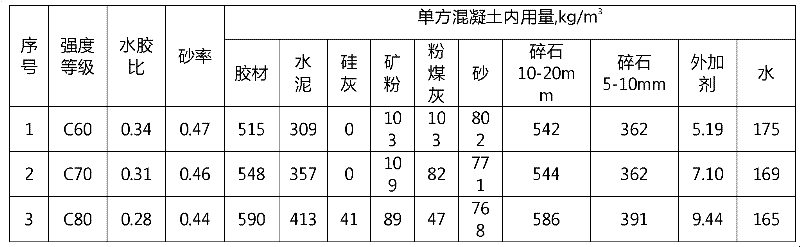

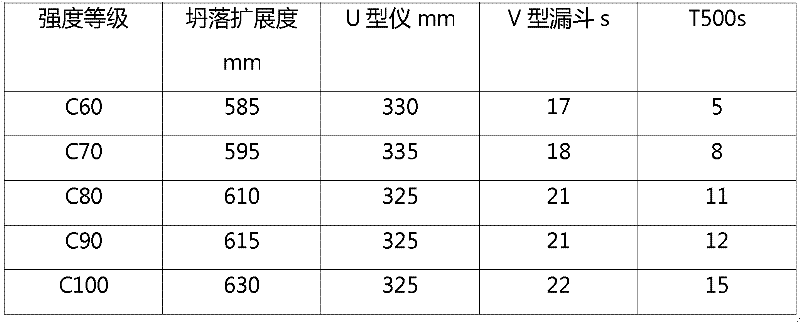

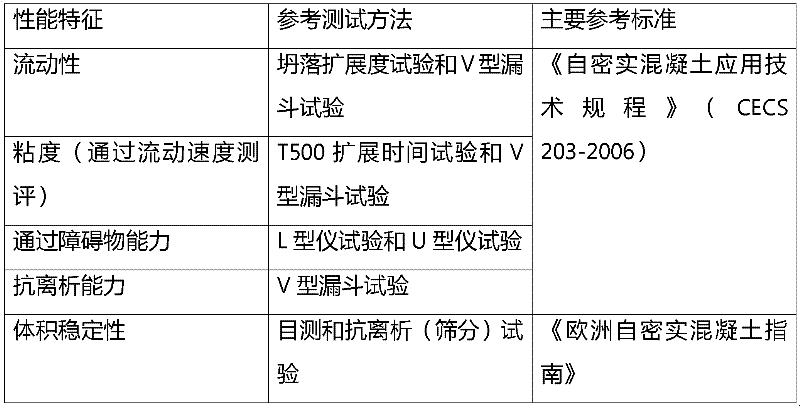

Self-compacting concrete and design method of mixing proportion thereof

The invention relates to the technical field of concrete for building casting, specifically to self-compacting concrete and a design method of the mixing proportion of the concrete. The invention is characterized in that the self-compacting concrete is prepared by uniformly stirring the following raw materials in mixing proportion: 300-400kg / m<3> of cement, 70-150kg / m<3> of fly ash, 70-150kg / m<3> of mineral powder, 0-50kg / m<3> of silicon powder, 750-850kg / m<3> of sand, 850-1050kg / m<3> of stone, 4.4-28kg / m<3> of additive and 150-175kg / m<3> of water. Compared with the prior art, the self-compacting concrete disclosed by the invention has obviously improved flowing property, self-compacting property and durability of the concrete mixture, and is particularly applicable to the engineering structures limited by the construction operation space such as the structures with high casting quantity, large casting depth and height, complex shape, densely arranged reinforcing bars, thin walls, concrete-filled steel tubes and the like.

Owner:HEFEI TIANZHU BAOHE SPECIAL CONCRETE

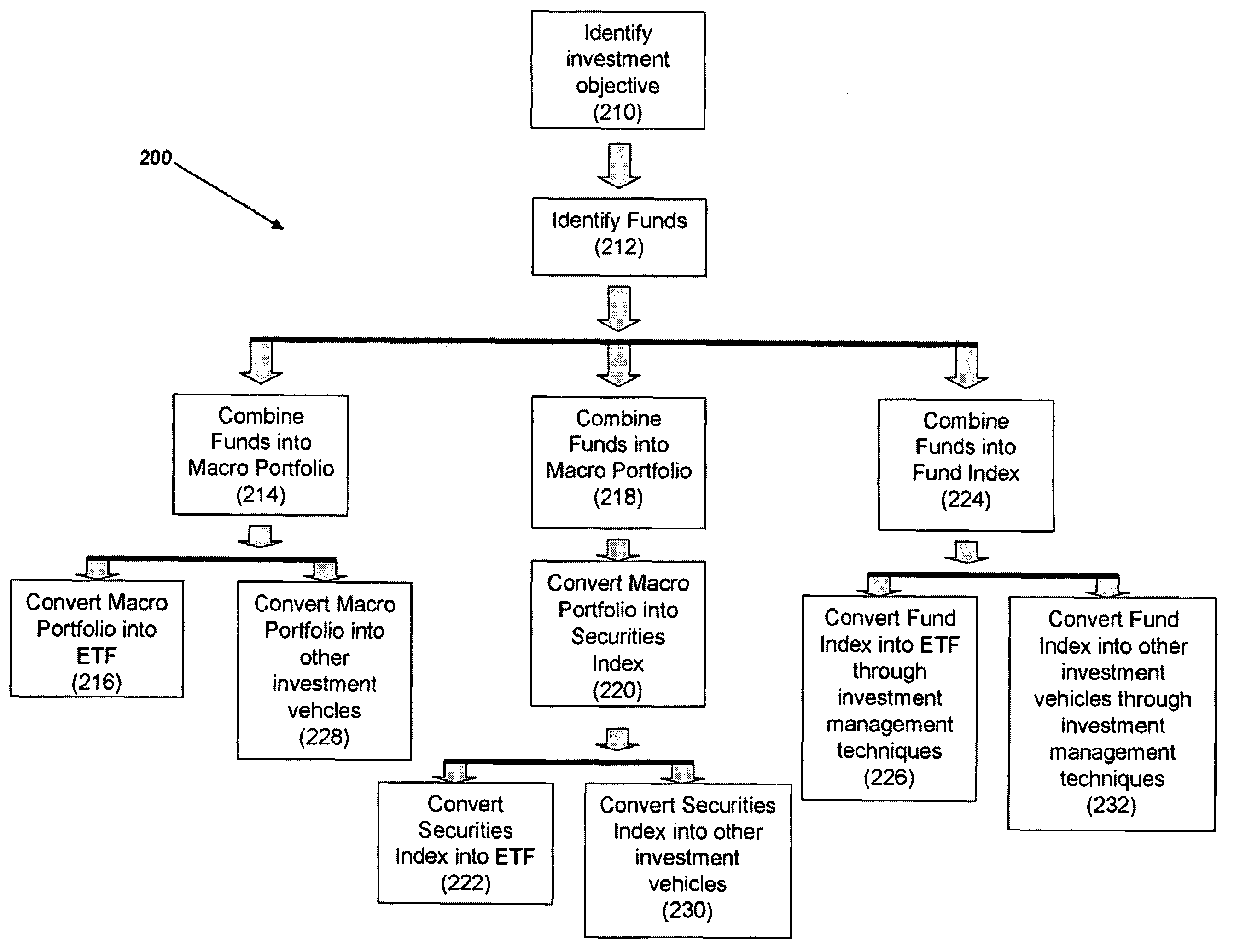

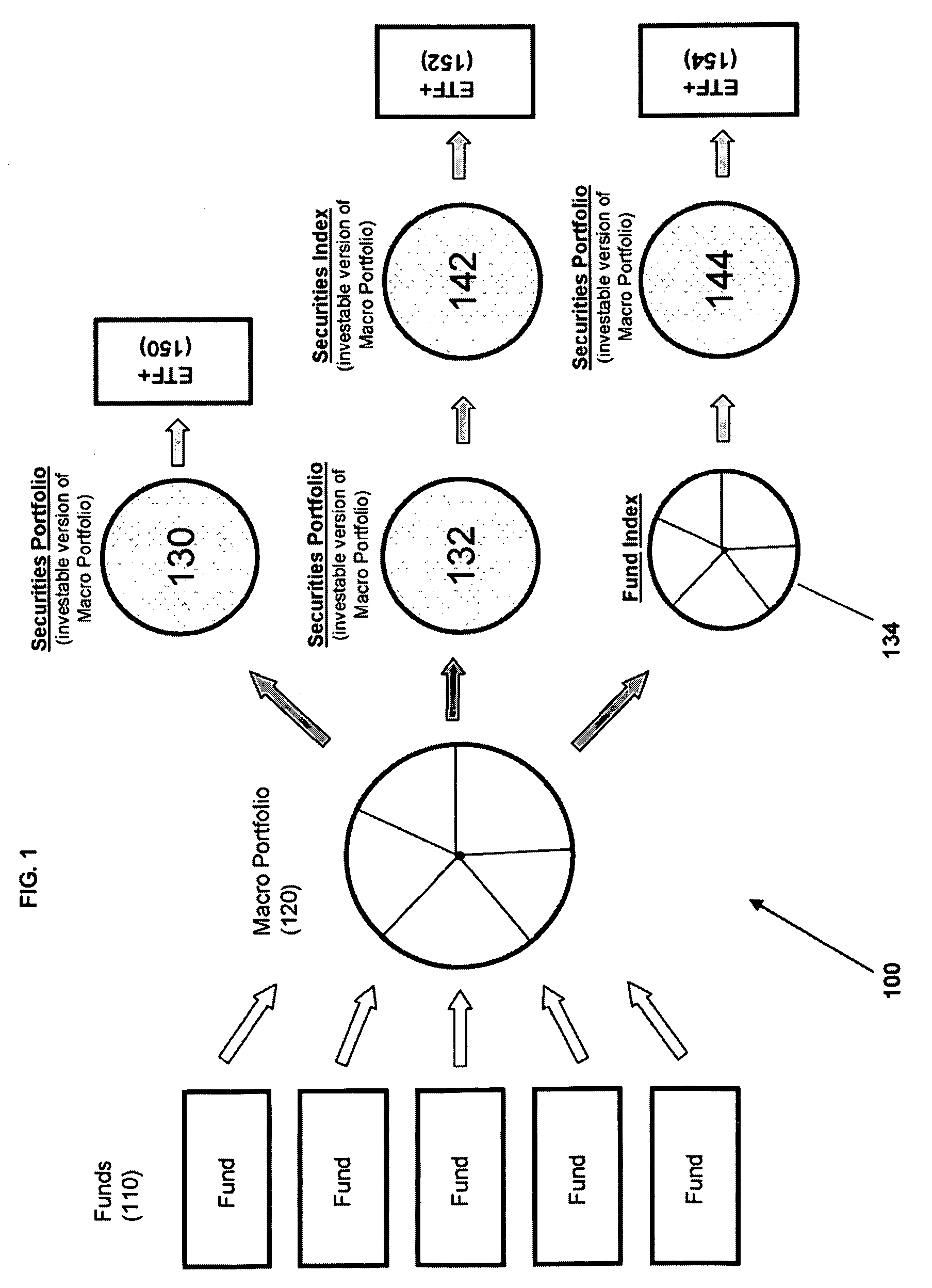

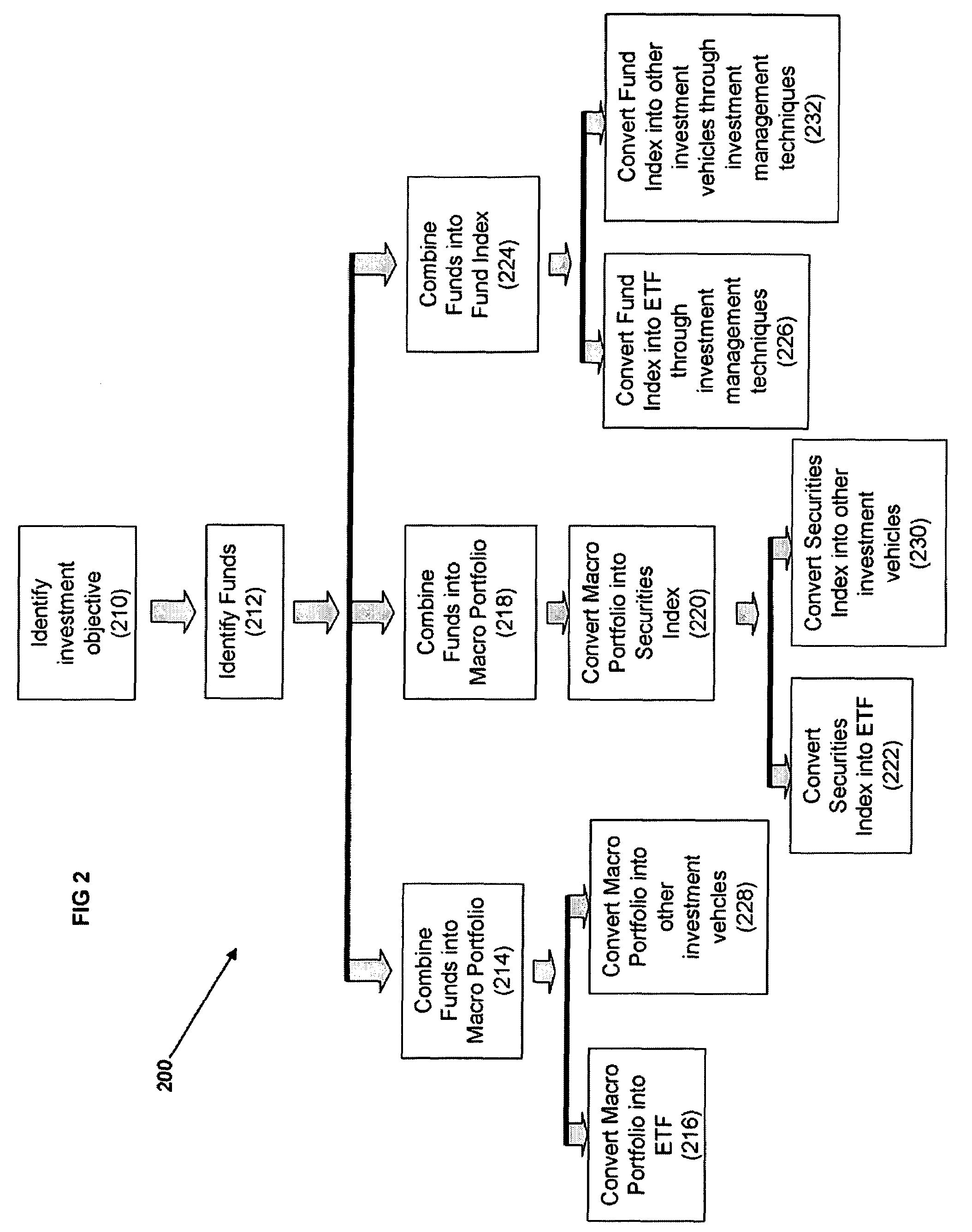

Systems and methods for constructing exchange traded funds and other investment vehicles

A method of forming an exchange traded fund (ETF) can include the steps of identifying an investor investment need, identifying funds that can be combined together to meet the investment goal, combining the identified funds to form a macro portfolio and converting the macro portfolio into an ETF. The step of converting the macro portfolio into an ETF can include one or more of generating a set of securities that, when combined, create a portfolio that tracks the performance of the macro portfolio, and constricting an index that is designed to track the performance of the macro portfolio. Other investment vehicles can be formed.

Owner:F SQUARED INVESTMENTS

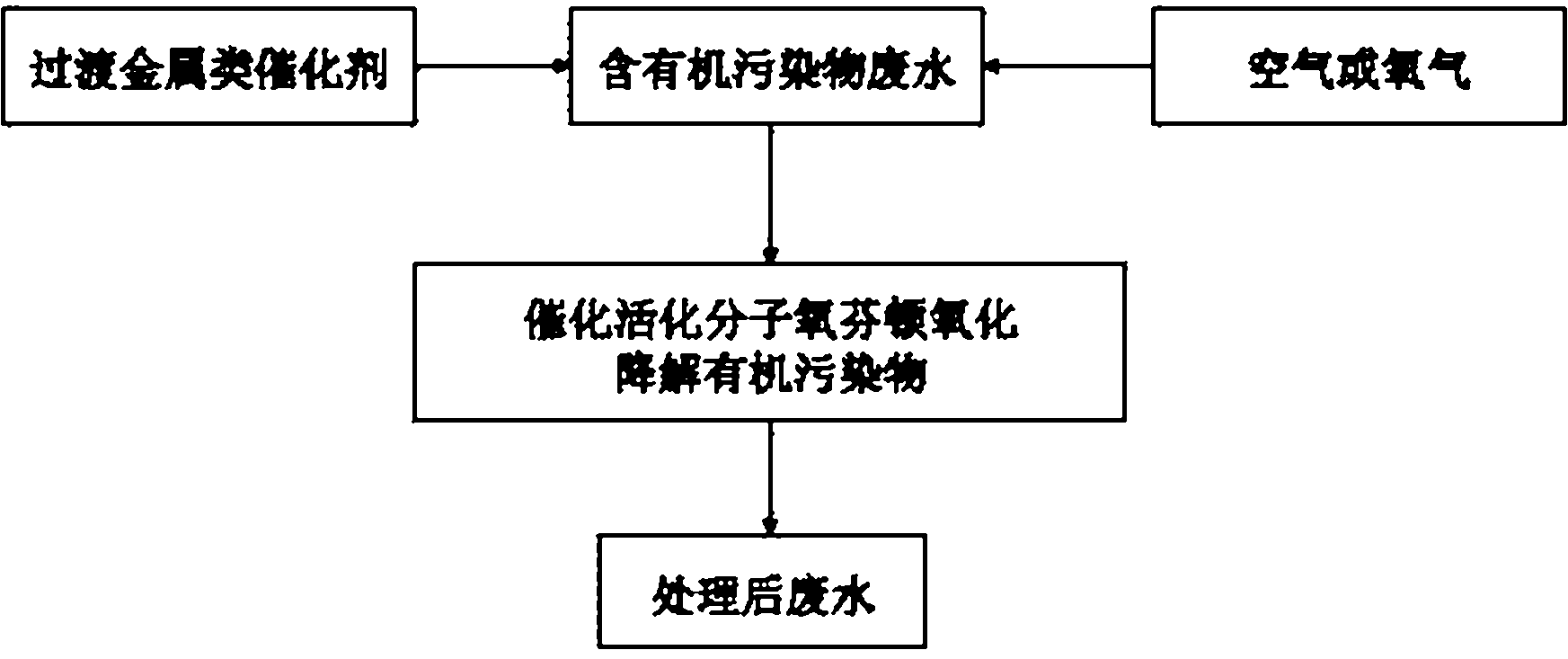

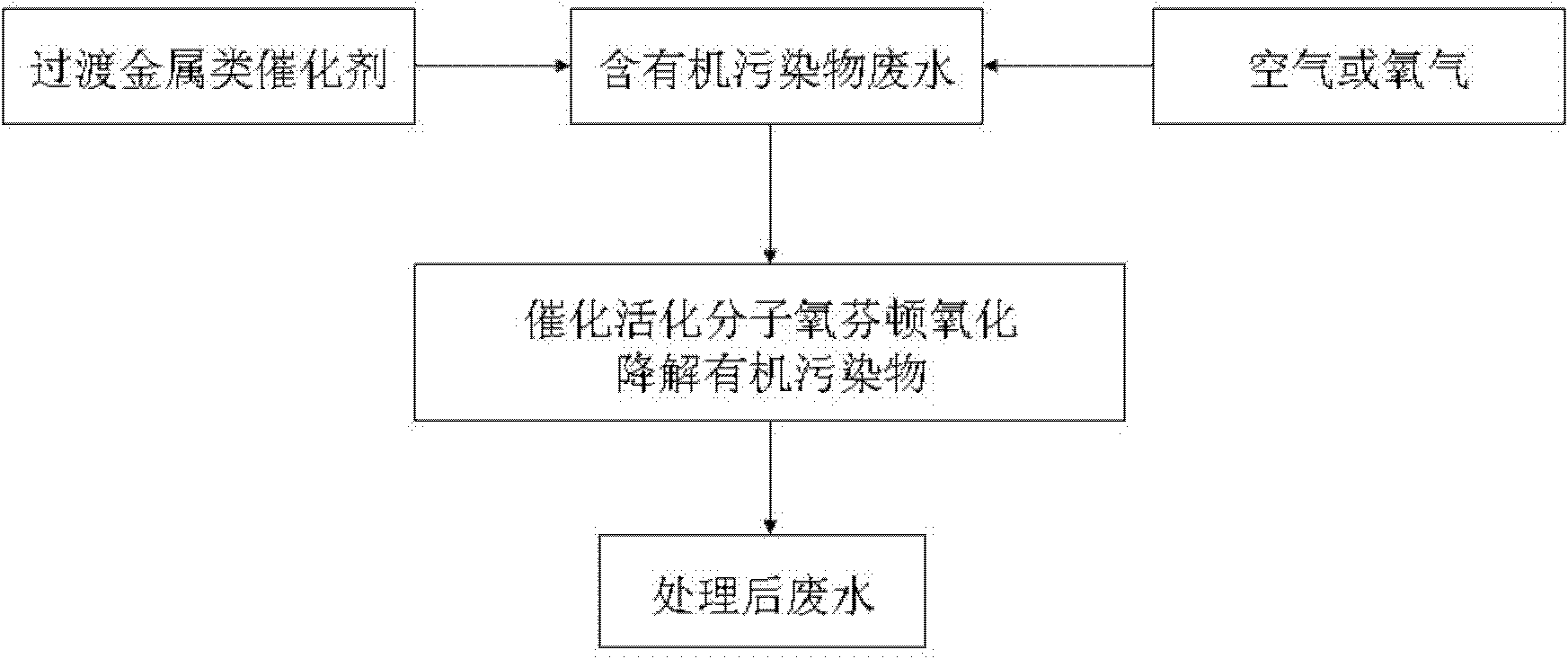

Method for treating water by Fenton oxidization of activated molecular oxygen

InactiveCN102173500AWide variety of sourcesLow costWater/sewage treatment by oxidationCatalytic oxidationPollution

The invention provides a method for treating water by the Fenton oxidization of activated molecular oxygen. In the method, transition metal ions, transition metal and transition metal oxides are used as activated molecular oxygen catalysts to generate hydroxyl radicals, so that organic matters in wastewater are removed by oxidization. Compared with a Fenton water treatment technology in which hydrogen peroxide is used as an oxygen source, the method has the advantages that: in a Fenton reaction of the activated molecular oxygen, molecular oxygen in air and oxygen are used as the oxygen sourcedirectly, so the oxygen source is wide, convenient and low in cost, and the water treatment cost is reduced greatly. The method for treating the water by the Fenton oxidization of the activated molecular oxygen is suitable for the treatment of various kinds of organic wastewater, high in durability and efficiency, is environment-friendly and easy to operate, does not have secondary pollution, meets the requirement of actual water treatment units, and has large application potential in the field of environmental pollution regulation.

Owner:HUAZHONG NORMAL UNIV

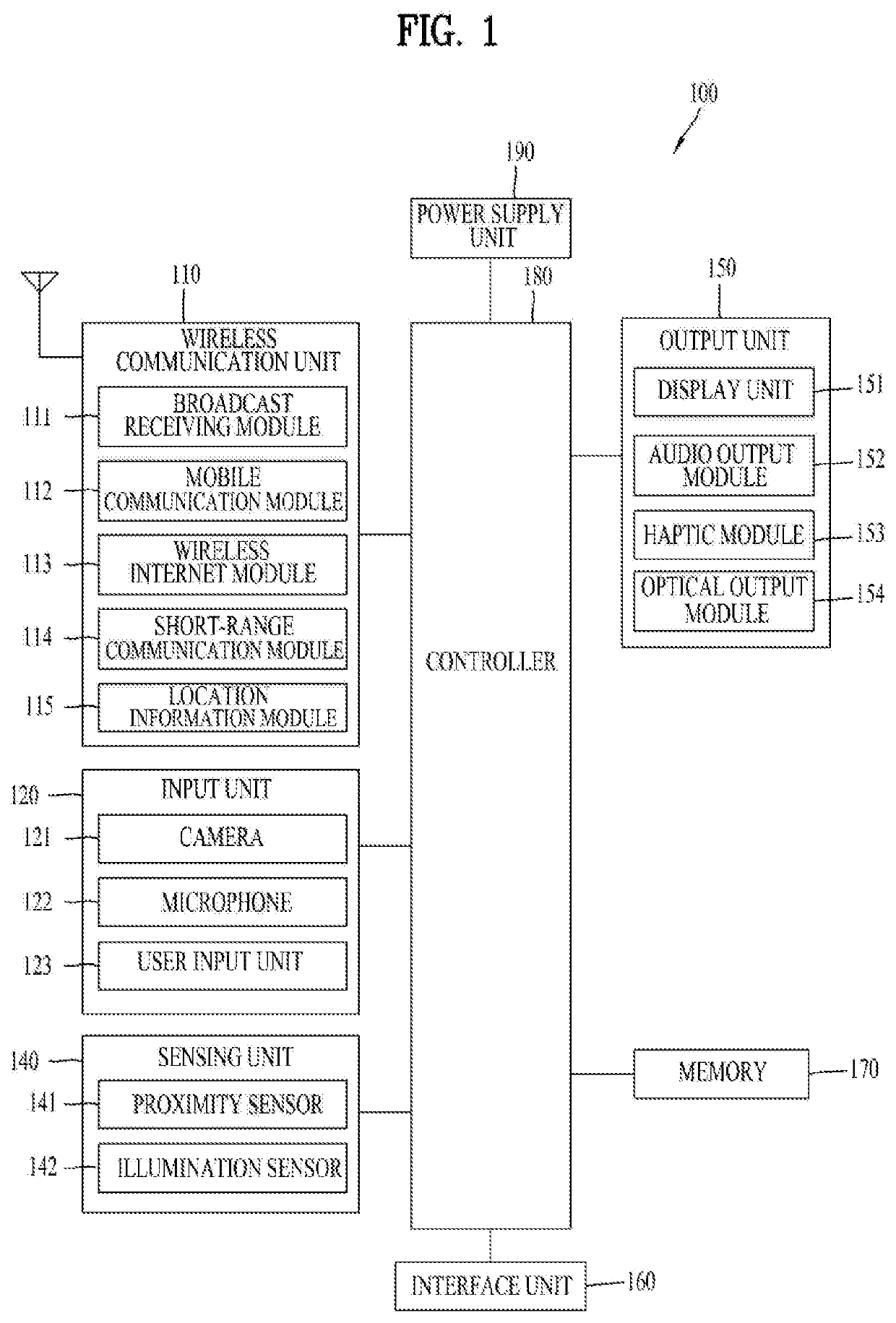

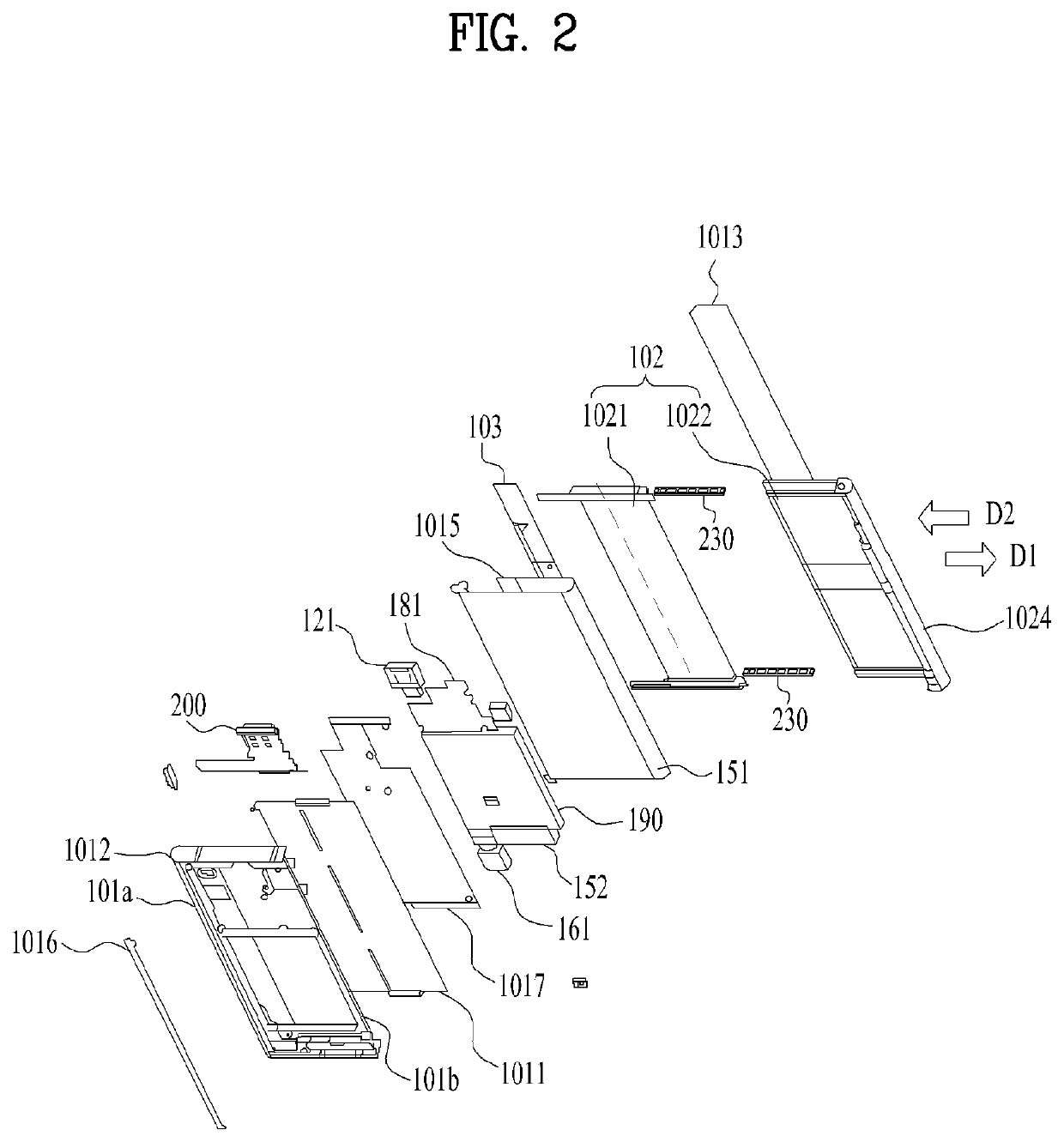

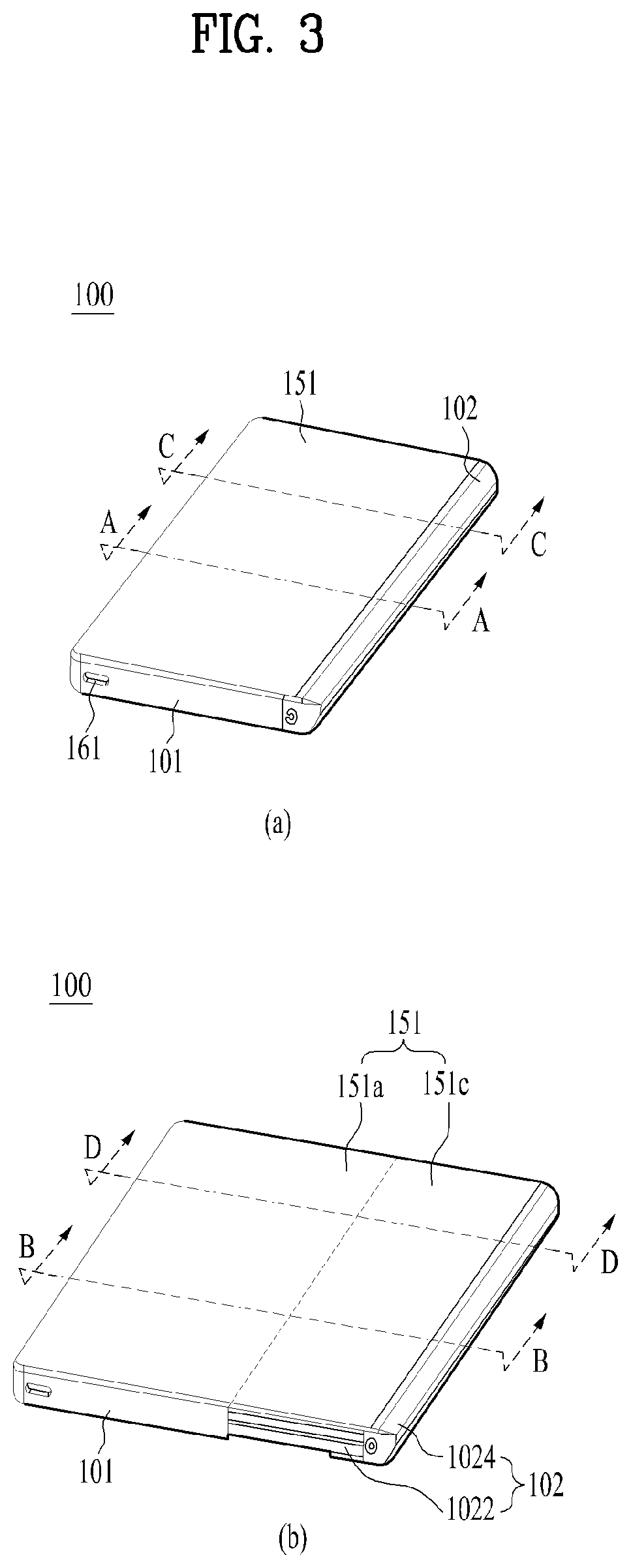

Mobile terminal

PendingUS20200264660A1Improve durabilityIncreased durabilityDigital data processing detailsTelephone set constructionsMobile endEngineering

A mobile terminal includes a first frame, a second frame slidably-movable in a first direction or in a second direction opposite to the first direction from the first frame, a slide frame movable in the first direction or in the second direction with respect to the second frame, a flexible display unit including a first region coupled to the first frame, a second region coupled to the slide frame, and a third region positioned between the first region and the second region and bent while surrounding the second frame, a driving unit disposed to be positionally biased in a third direction perpendicular to the first direction, wherein the driving unit provides a force to the second frame to move, and a linear guide positioned between the first frame and the second frame and guiding the movement of the second frame in the first direction or in the second direction. The mobile terminal may improve durability of the flexible display unit by not restricting a point where the flexible display unit is bent to a specific position.

Owner:LG ELECTRONICS INC

Ceramal material for manufacturing hydrogen-enriched water and preparing method and application thereof

The invention belongs to the technical field of new environment-friendly materials, and particularly relates to a ceramal material for manufacturing hydrogen-enriched water and the preparing method and application thereof. The ceramal material is prepared from, by weight, 30-85 parts of base material component, 20-60 parts of hydrogen-enriched component, 2-25 parts of anti-microbial component, and 3-30 parts of binder. The base material component is prepared from tourmaline, serpeggiante, silicon oxide, calcium oxide and zeolite. The hydrogen-enriched component is prepared from magnesium metal powder, magnesia powder and KDF alloy powder. The anti-microbial component is prepared from zinc oxide, titanium oxide and cerium oxide. The binder is prepared from one or more of high-purity distilled water, carboxypropyl cellulose and bentonite. The ceramal material can be used for manufacturing alkalescent water, negative-potential water and hydrogen-enriched water and also has an anti-microbial function and a water activating function. The invention further provides the preparing method and application of the ceramal material. The technology is simple and easy to realize. The ceramal material can be applied to products including water purifiers, water purifying kettles and cups.

Owner:山东木齐健康科技有限公司

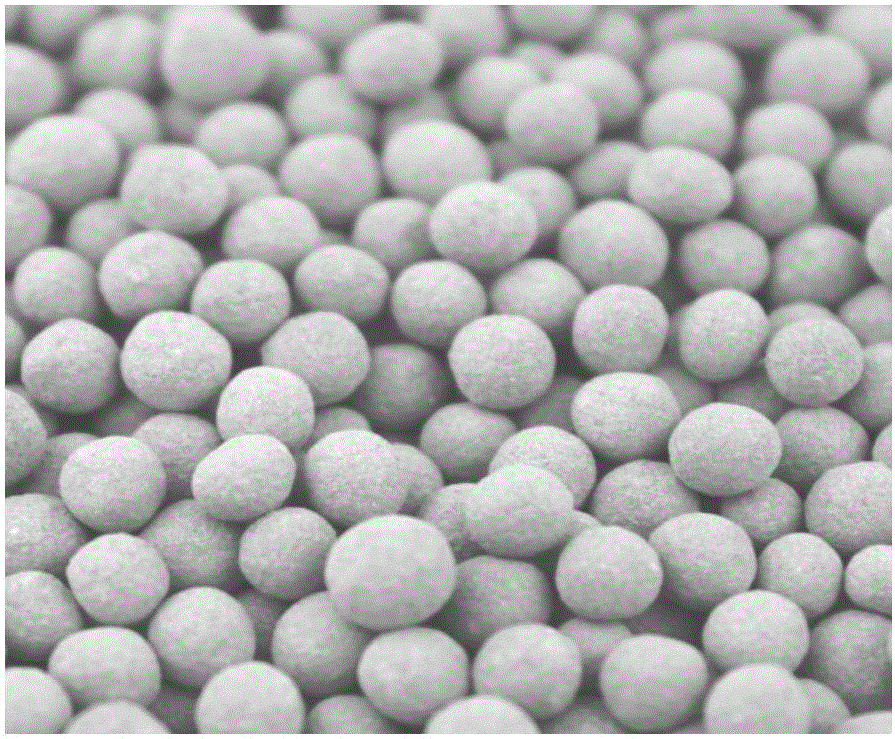

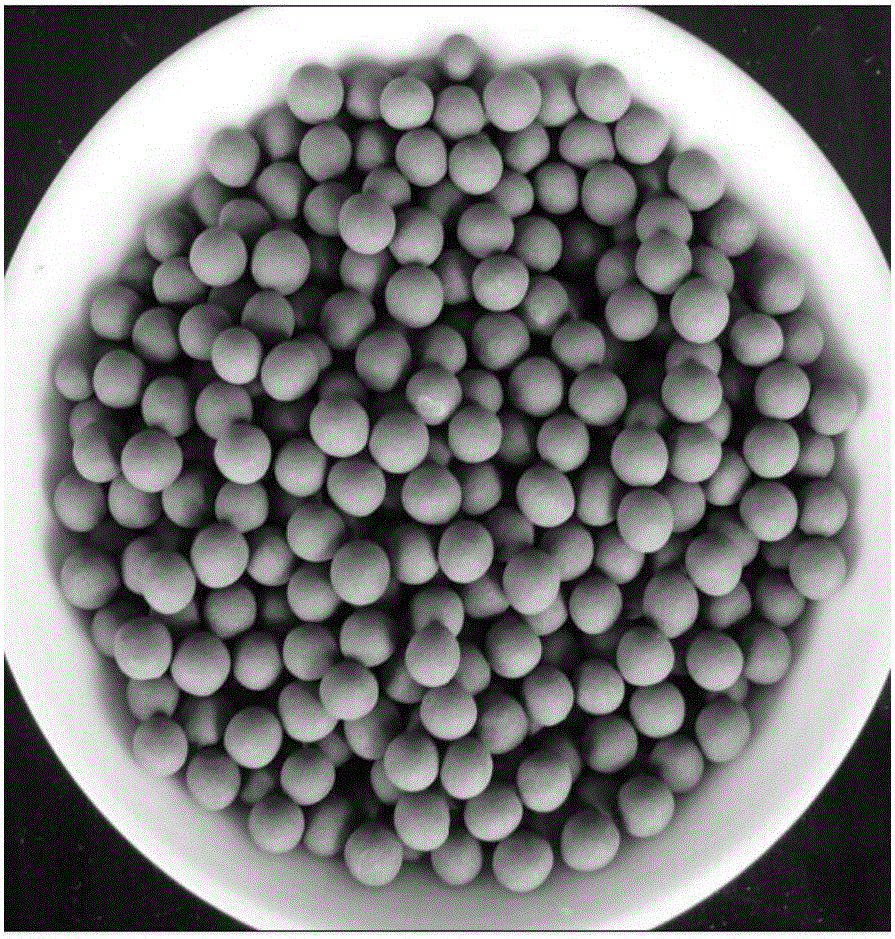

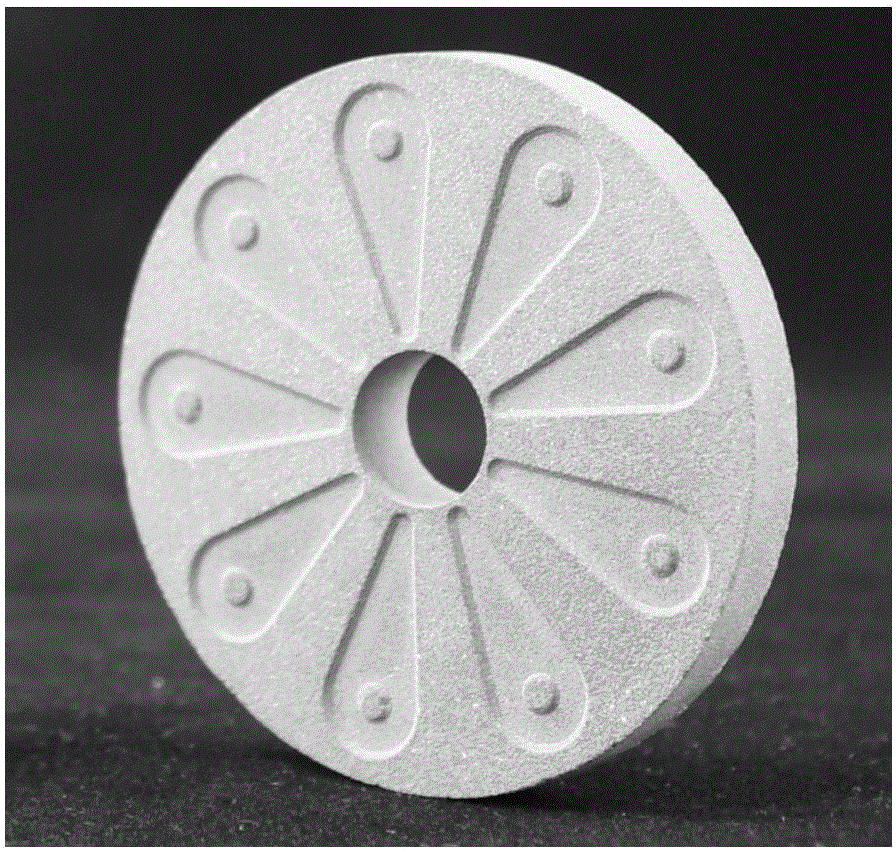

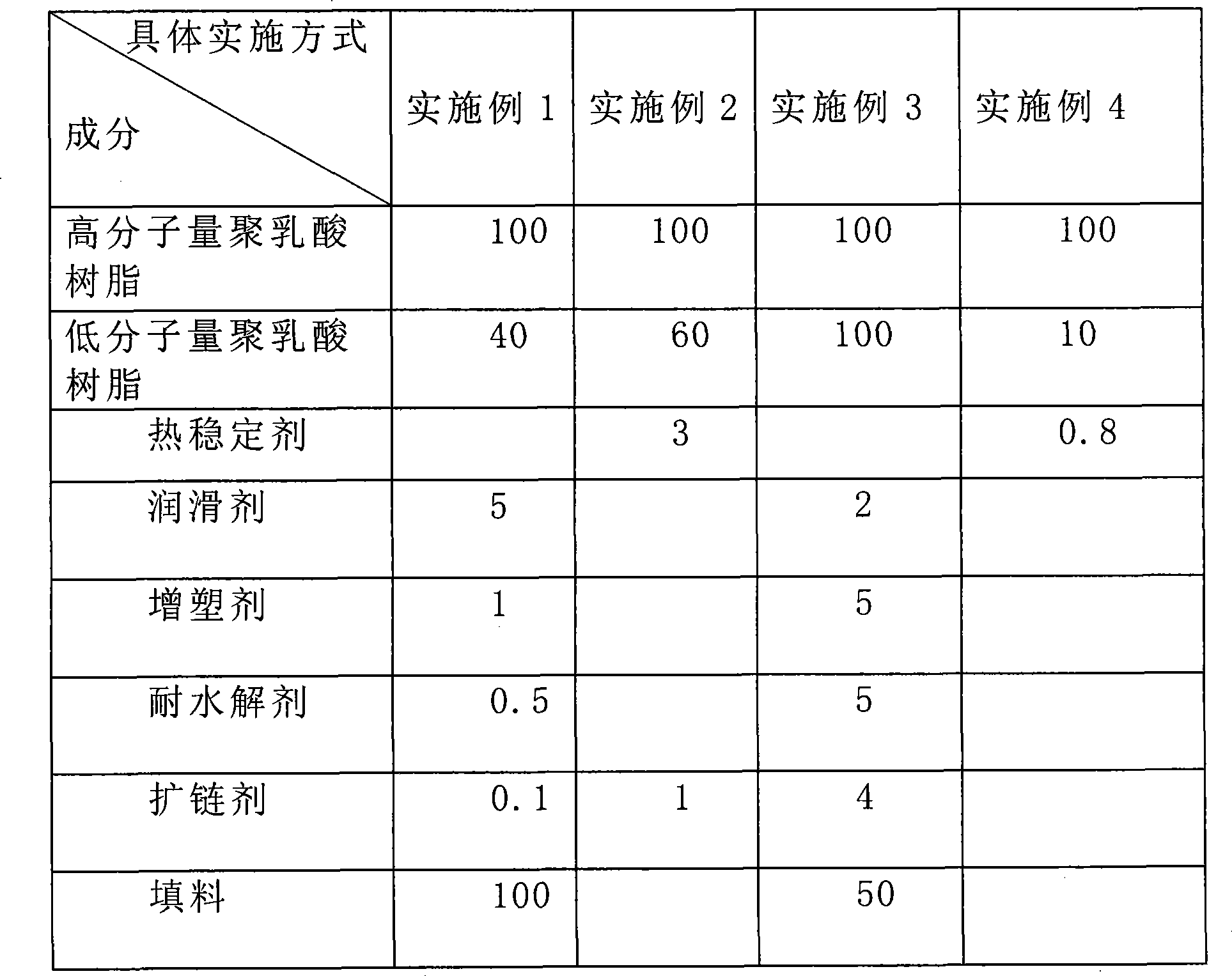

Low cost full-biodegradable polylactic acid sheet material and preparation method thereof

The invention provides a low-cost full-biodegradation polylactic acid sheet and a preparation method thereof, which belong to the technical field of biomaterial. The invention solves the problems that molecular weight attenuation is larger, about 35 percent of the materials with one grade are incapable of directly being recycled to participate in the use, the cost is high as well as popularization and use range are limited during the melt processing of the polylactic acid sheet. The low-cost full-biodegradation polylactic acid sheet is extruded and shaped by the components as the following weight portions: 100 portions of high molecular weigh polylactic resin; 10 to 100 portions of low molecular weigh polylactic resin and 0.2 to 30 portions of processing materials; the number average molecular weight of the high molecular weigh polylactic resin is 90,000 to 150,000 Daltons; the number average molecular weight of the low molecular weigh polylactic resin is 50,000 to 90,000 Daltons. The low-cost full-biodegradation polylactic acid sheet has the advantages of low cost, good mechanical property, good durability, excellent secondary shaping property, simple method and technique flow as well as high maneuverability.

Owner:ZHEJIANG HISUN BIOMATERIALS

Silver alloy wire and preparation method thereof

The invention relates to a silver alloy wire and a preparation method thereof. The silver alloy wire is prepared from the following components of 0.5-10 percent of Au, 0-1 percent of Pt, 1-6 percent of Pd, 0-1 percent of Rh, 0-1 percent of Cu, 0-500ppm of Ln, 0-200ppm of Ce, 0-0.5 percent of Al, 0.7-3 percent of Ti, 0-0.2 percent of Si, 0-0.3 percent of Zn, 0-1 percent of Sn, 0-10 percent of Be and the balance of Ag. A directional continuous casting process is adopted. The prepared silver alloy wire overcomes the problem that the bonded silver wire is easily subjected to sulfur corrosion in the prior art, and has a series of other excellent characteristics.

Owner:YANTAI YINUO SEMICON MATERIAL CO LTD

Preparation of permanent color inks from water-soluble colorants using specific phosphonium salts

Water-fastness in aqueous ink-jet inks containing water-soluble dyes is achieved by using a specific ionic species having a charge opposite to that on the dye molecule. Anionic dyes typically contain sulfonate (or carboxylate) anionic groups. Using at least one specific ionic species of opposite charge, specifically, phosphonium salts, causes the colorant components to "crash" or precipitate out of the water-based ink onto the print medium due to the formation of a suitable charge complex between the ionic parts of the dye and the opposite charge of the counter-ion species. Other positively charged salts, such as quaternary ammonium salts, carbonium salts, iodonium salts, sulfonium salts, and pyrillium salts may be used to improve aqueous dispersion stability and thus printability. Such additional cationic salt partially replaces the phosphonium salt(s). Alternatively, certain surfactants, such as aromatic ethoxylates, polyethylene oxide ethers, or polypropylene oxide ethers may be used to improve print quality.

Owner:HEWLETT PACKARD DEV CO LP

Antibacterial viscose containing artemisia argyi oil component and production method of antibacterial viscose

ActiveCN103556250AHigh antibacterial rateImprove durabilityArtificial filaments from viscosePolymer scienceAnti bacterial

The invention relates to antibacterial viscose containing an artemisia argyi oil component and a production method of the antibacterial viscose. The antibacterial viscose takes an artemisia argyi oil microcapsule as an antibacterial agent and a spinning solution is composed of the artemisia argyi oil microcapsule and mucilage glue, wherein the adding ratio of the artemisia argyi oil microcapsule is 10%-30% of alpha cellulose in the mucilage glue and the antibacterial property index are as follows: the antibacterial value is more than 4.0 and the sterilization value is 2.7. The production method of the antibacterial viscose containing the artemisia argyi oil component comprises the following steps: preparing artemisia argyi emulsion, preparing the artemisia argyi oil microcapsule, preparing the mucilage glue, preparing the spinning solution, and spinning and molding. The antibacterial viscose not only has the advantages of maintaining water absorption and air permeability of common viscose and being comfort to wear, but also has high antibacterial rate and good endurance; meanwhile, the antibacterial viscose has a good skin-caring effect and can be widely applied to home textile articles, underwear, sports shirts and the like.

Owner:潍坊欣龙生物材料有限公司

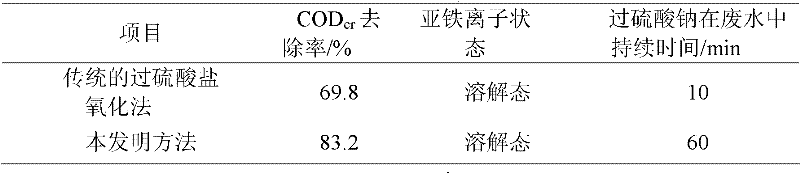

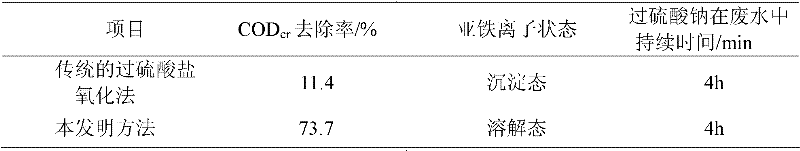

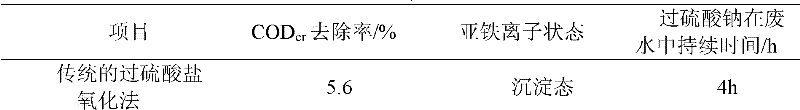

A kind of complexed ferrous activated persulfate oxidation water treatment method

InactiveCN102259993APrevent precipitationReduce acid costMultistage water/sewage treatmentChemical oxygen demandSulfate

The invention discloses a water treatment method utilizing complex-ferrous-activated persulfate oxidation. The treatment method comprises the following steps: (1) firstly determining the pH value and CODcr (chemical oxygen demand) value of wastewater to be treated; (2) adding a complexing agent which is selected according to the pH value to the wastewater, and then adding ferrous ion to the wastewater for sufficiently mixing; and (3) adding a persulfate to the wastewater treated in the step (2) according to the CODcr value for full reaction to obtain purified wastewater. The method is applicable to the wastewater with various pH values; by using the method, the acid feeding cost is greatly reduced and the treatment cost of per ton of wastewater is lowered by approximate 20%; in addition, complex ferrous can slowly release free ferrous ion, thus ensuring that organic pollutants in the wastewater are durably and efficiently purified by a persulfate oxidation method and increasing the pollutant removal efficiency by 20-30%; and the method has the advantages of good durability and high efficiency, is environmentally-friendly, is easy to operate, and has great application potential in the field of environmental pollution treatment.

Owner:SOUTH CHINA UNIV OF TECH

EGR gas cooling apparatus

InactiveUS20050188965A1Improve durabilityReduce thermal stressInternal combustion piston enginesNon-fuel substance addition to fuelCooling temperatureProcess engineering

The pre-EGR gas cooler 1 for cooling the EGR gas introduced from the EGR pipe, and an post-EGR gas cooler for introducing the pre-EGR gas cooled in the EGR gas cooler 1 to cool it to a target cooling temperature are coupled in series, and an EGR valve is mounted for controlling the flow rate of the EGR gas between the pre-EGR gas cooler 1 and the post-EGR gas cooler 3. According to the invention, EGR gas cooling apparatus with improved durability can be obtained, and EGR valves with low product cost and high storage efficiency can be provided.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

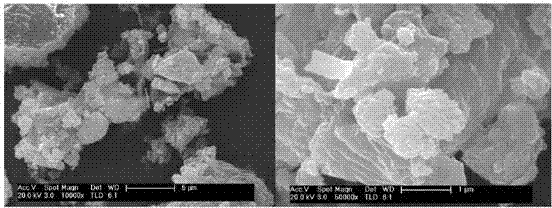

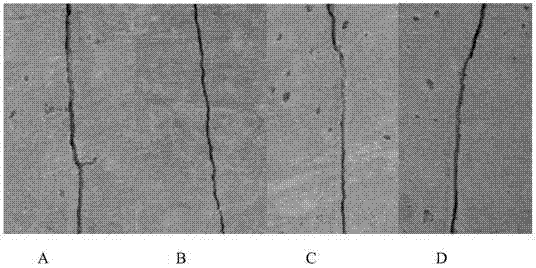

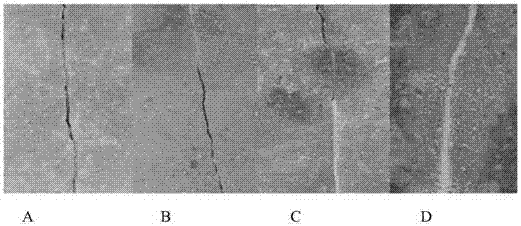

Preparation method of cement-based material having deep self-repairing function

ActiveCN104261736AGood repairing effectAccelerated carbonate mineralization depositionC constantNondestructive testing

The invention provides a preparation method of a cement-based material having a deep self-repairing function. The preparation method disclosed by the invention comprises the following steps of: mixing concentrated solution of carbonic anhydrase generating bacteria with saccharomycete powder according to the mass ratio of (50-60) to 1, and immobilizing on a same carrier; mixing a substrate with a nutritional substance according to the mass ratio of (30-40) to 1, and fixing on another carrier; adding cement, sand and water by taking the carriers as lightweight aggregates, wherein the mass of the carriers is 17-23% of the total mass of mortar; uniformly stirring, and forming a test piece; and manufacturing a crack of the test piece after standard curing, and introducing air to maintain and repair under 25-30 DEG C constant-temperature water bath conditions. The repairing process of the test piece is monitored by utilizing a concrete nondestructive detection technology (ultrasonic sound); the repairing result is detected through a water permeability test; the result shows that the crack is completely repaired after repairing for 21 d; in addition, compared with other microbiological methods for repairing cracks of the cement-based material, the crack repairing speed and repairing depth are greatly improved.

Owner:SOUTHEAST UNIV

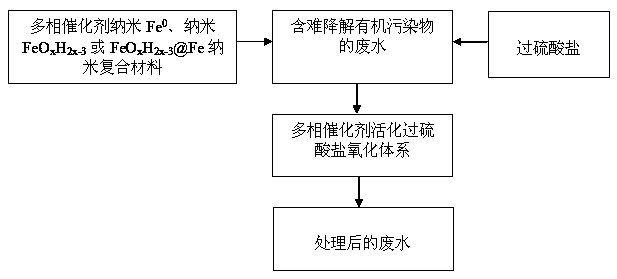

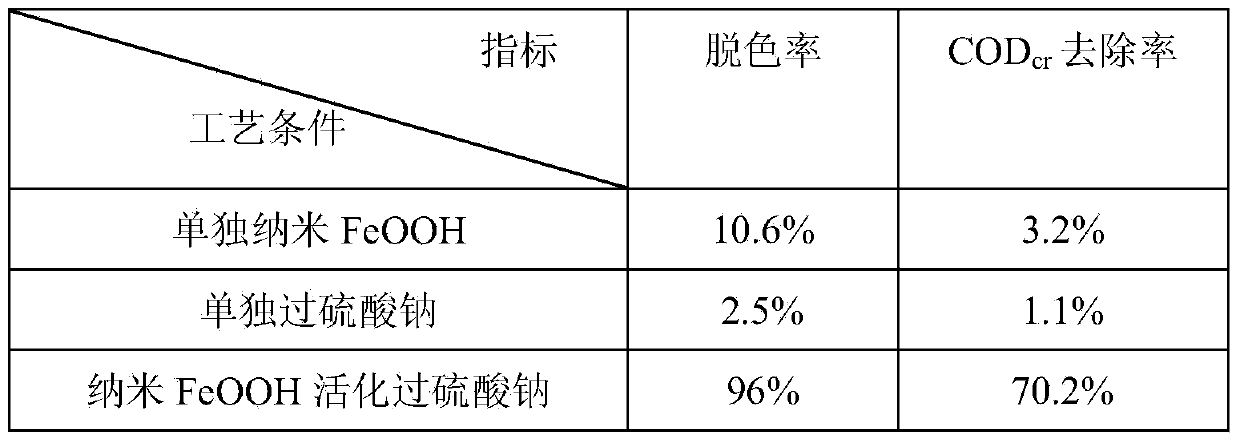

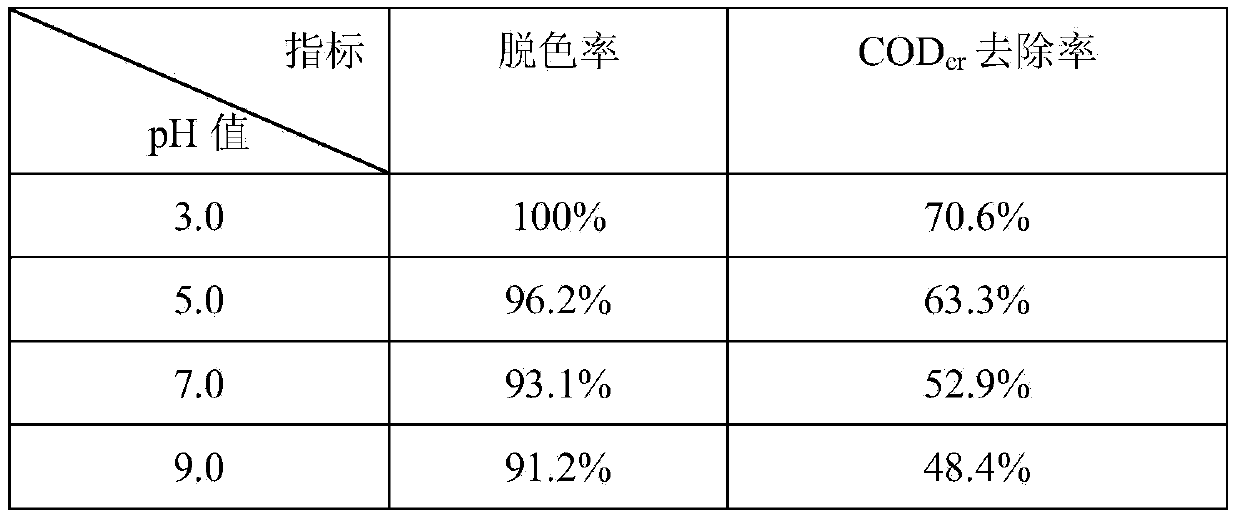

Method for utilizing heterogeneous catalyst to efficiently activate persulfate so as to treat organic wastewater

ActiveCN103435144AIncrease profitShort reaction timeWater/sewage treatment by oxidationSolid phasesNano catalyst

The invention discloses a method for utilizing a heterogeneous catalyst to efficiently activate persulfate so as to treat organic wastewater, belonging to the technical field of water pollution control. According to the method, nano Fe0, nano FeOxHy (y=2x-3 or 3y=6x-8) and FeOxHy@Fe0 (FeOxHy@Fe0, y=2x-3 or 3y=6x-8) nano composite materials are used as a heterogeneous catalyst, so that persulfate is activated to produce sulfate free radicals having strong oxidizing property, thereby removing nondegradable organic substances in wastewater. Besides, due to the characteristics of high specific area, high catalytic activity and the like, the solid-phase nano catalyst can efficiently and persistently activate the persulfate to be subjected to heterogeneous activation. The method is applicable to treatment of various organic wastewater, has the advantages of high efficiency, favorable persistence, convenient operation process and environment friendliness, and can efficiently remove toxic and harmful pollutants in the wastewater in a wider pH value range, thus providing broad prospects for treatment of toxic, harmful and nonbiodegradable organic wastewater.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com