Self-compacting concrete and design method of mixing proportion thereof

A technology of self-compacting concrete and mixing ratio design, applied in the field of concrete for building pouring, can solve problems such as many uncertain factors and difficult control, and achieve the effect of improving flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

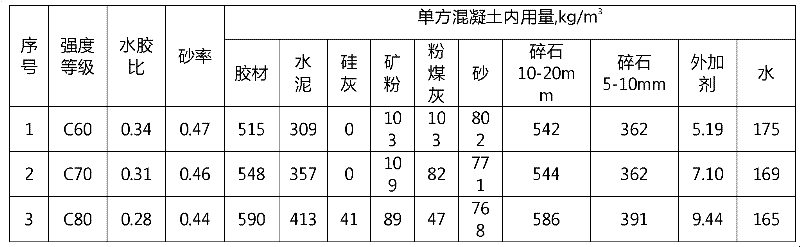

[0041] The present invention is aimed at the self-compacting concrete of different strength grades and adopts the raw material mixing of different proportions to form, as shown in Table 1, in the table are the proportions of self-compacting concrete of C60, C70 and C80 three kinds of intensities:

[0042] Table 1

[0043]

[0044] A kind of mix ratio design method of self-compacting concrete among the present invention, adopts following steps:

[0045] a) According to the statistical standard deviation σ of the concrete strength of the same label, use the following formula to calculate the preparation strength of self-compacting concrete:

[0046] f cu,0 ≥f cu,k +1.645σ,

[0047] When the design strength grade is greater than or equal to C60, the preparation strength shall be calculated according to the following formula:

[0048] f cu,0 ≥1.15f cu,k ;

[0049] where f cu,0 - concrete preparation strength, f cu,k - concrete cube compressive strength, σ - standard de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com