Patents

Literature

242results about "Fibre diaphragms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

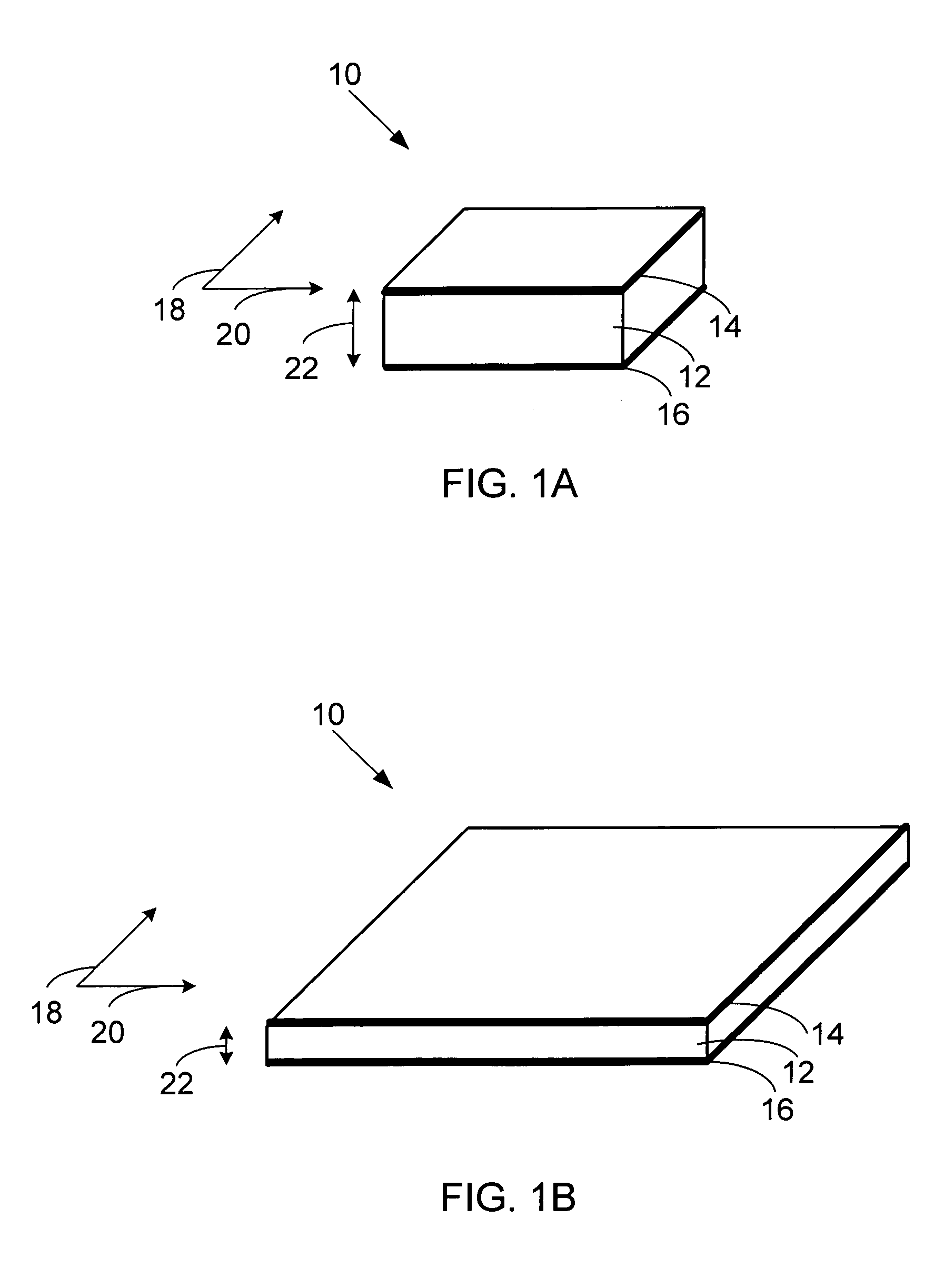

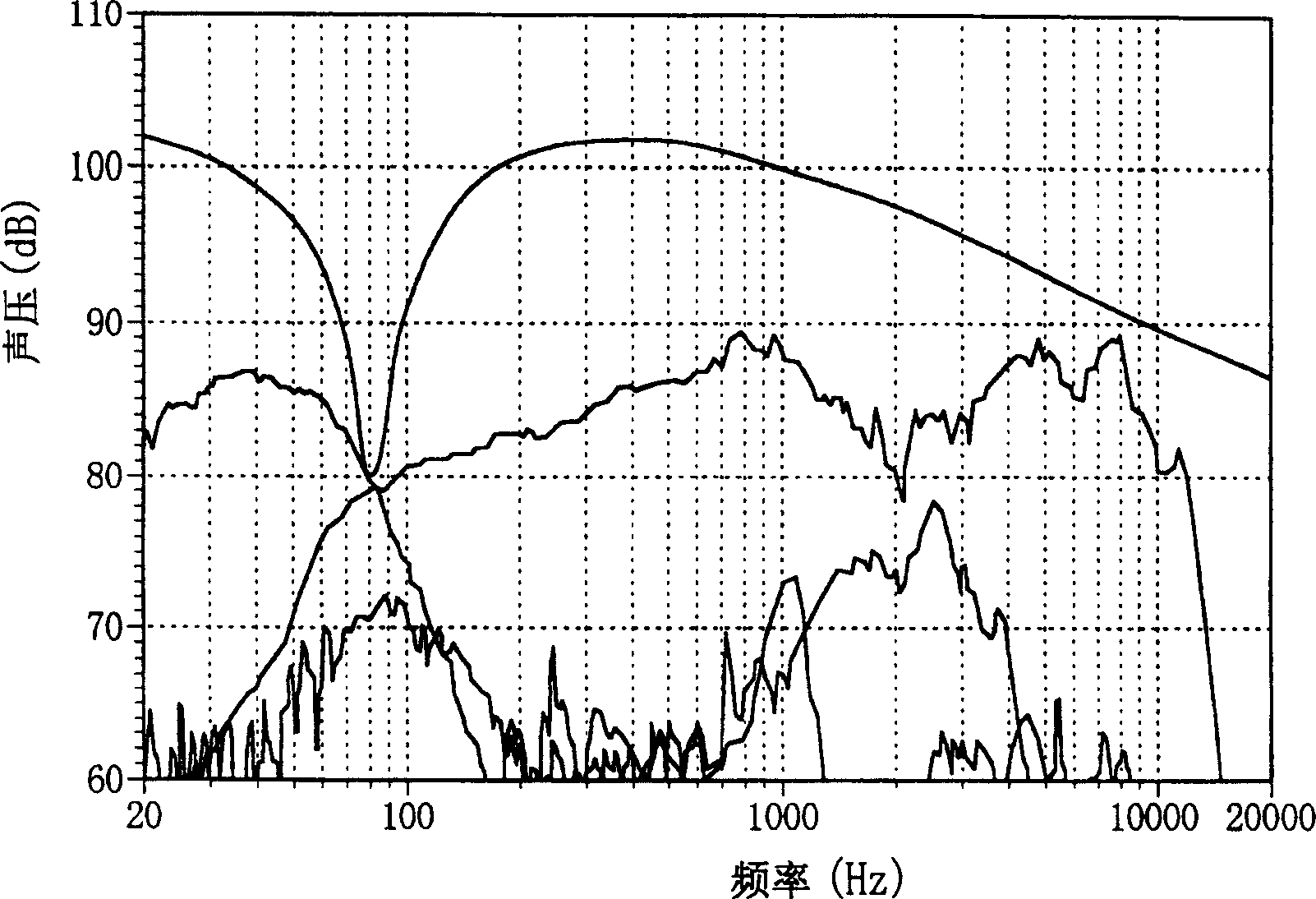

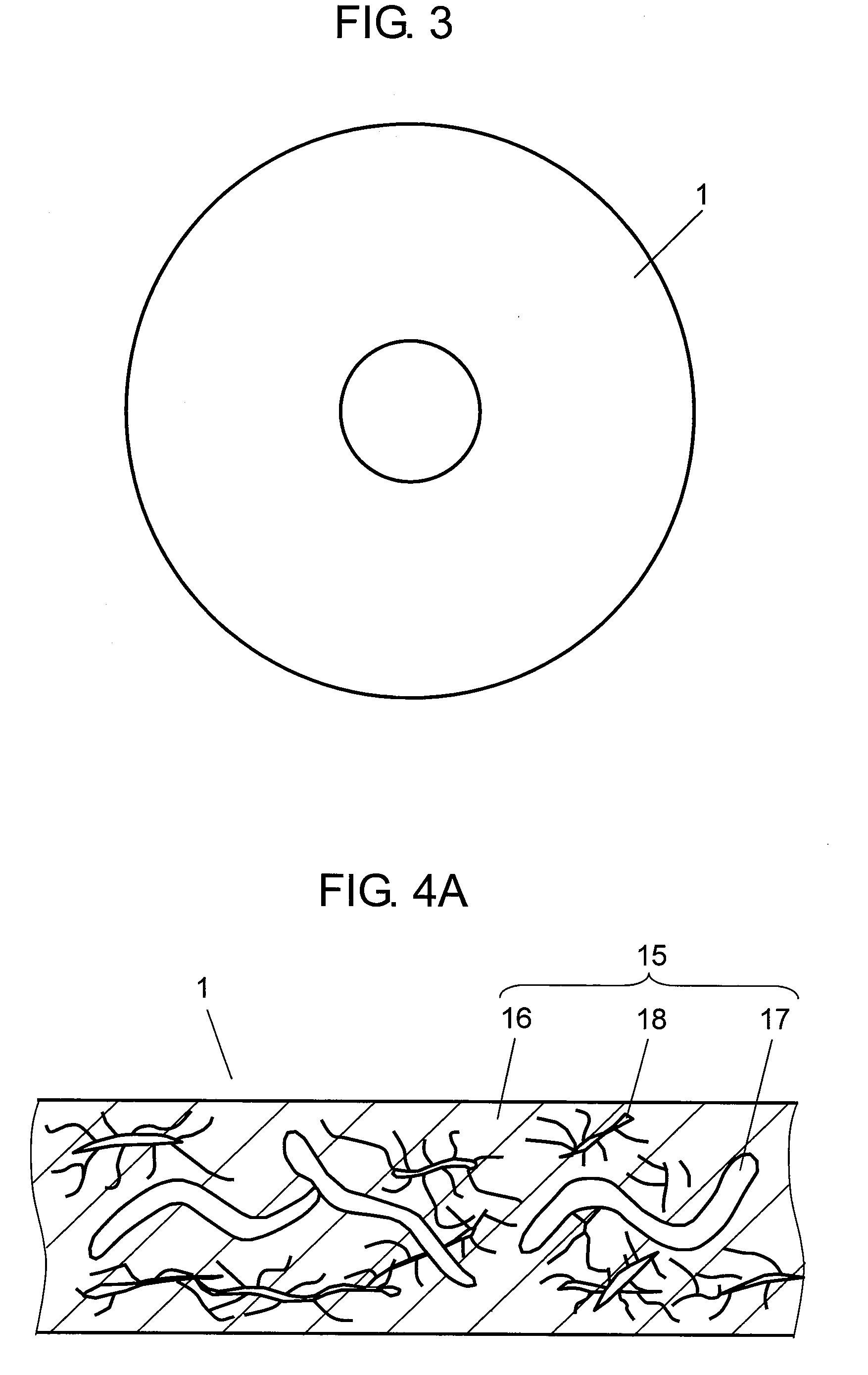

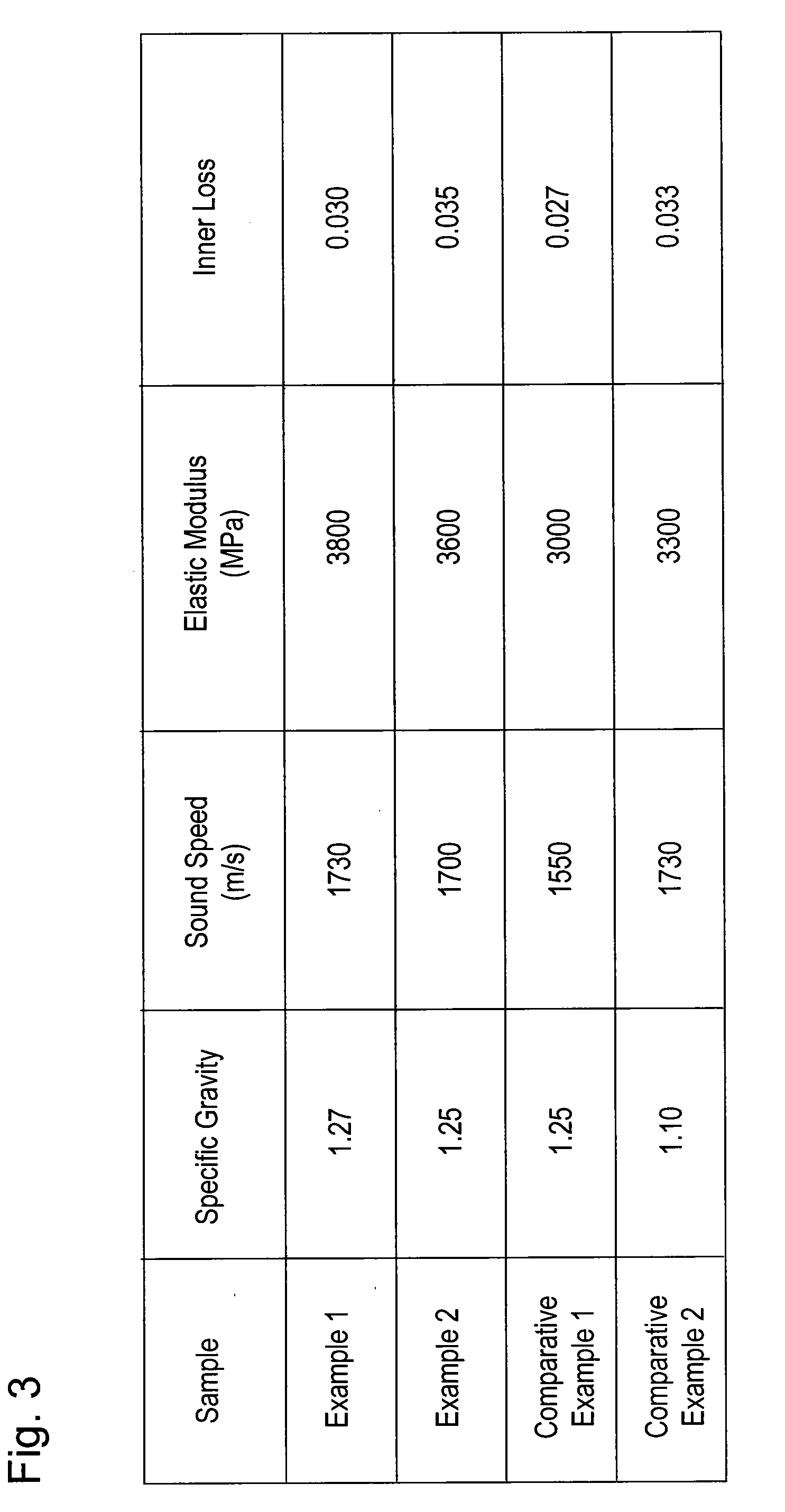

Acoustic Diaphragm and Speaker Having the Same

InactiveUS20080260188A1Good physical propertiesImprove sound qualityFibre diaphragmsPolymeric diaphragmsFiberNanofiber

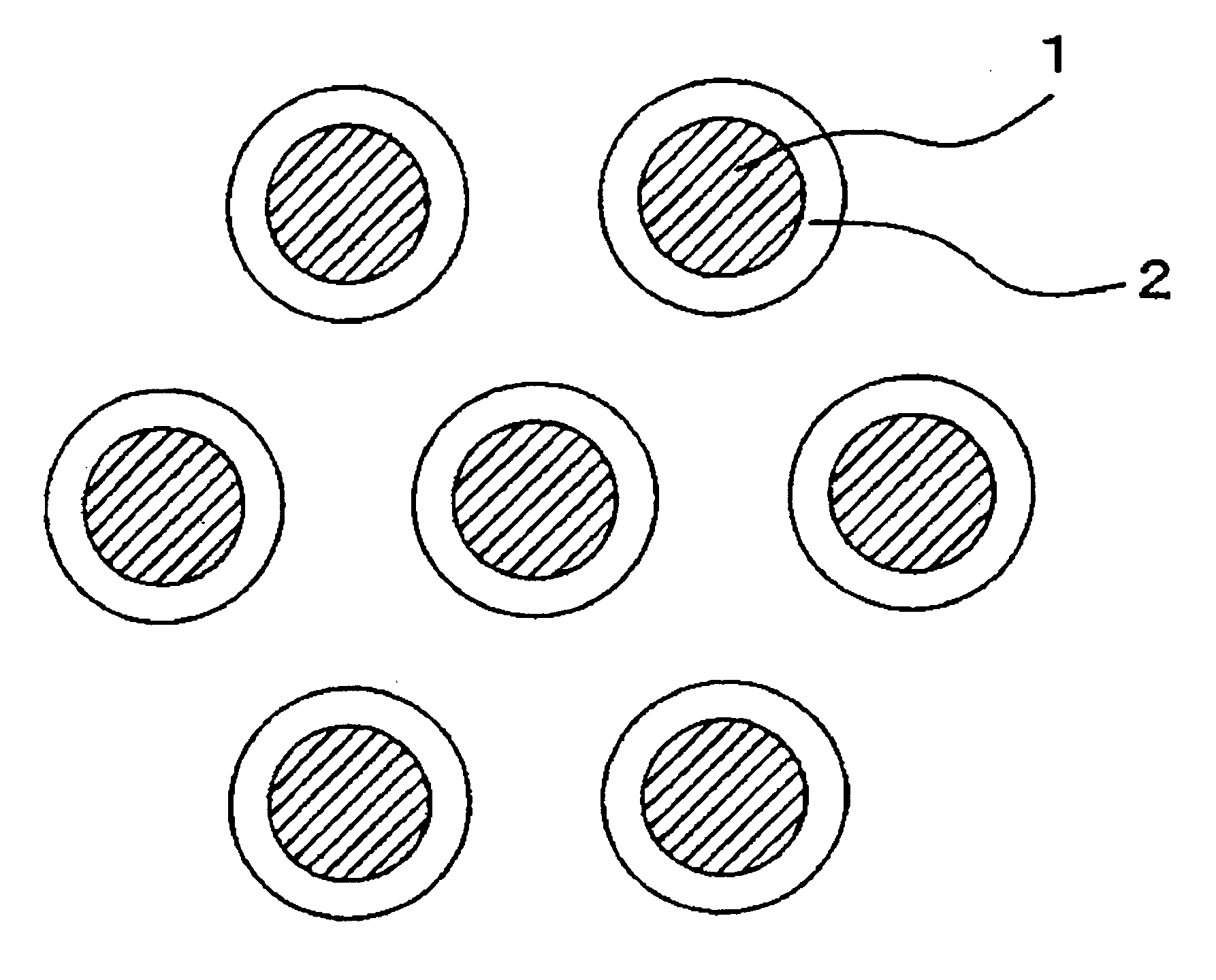

Disclosed herein is an acoustic diaphragm for converting electrical signals into mechanical signals to produce sounds. The acoustic diaphragm comprises carbon nanotubes or graphite nanofibers as major materials. Preferably, the carbon nanotubes or graphite nanofibers are included or dispersed in the acoustic diaphragm. Since the acoustic diaphragm has excellent physical properties in terms of elastic modulus, internal loss and strength, it can effectively achieve superior sound quality and high output in a particular frequency band as well as in a broad frequency band.

Owner:KH CHEM CO LTD

Loudspeaker plastic cone body

ActiveUS20060147081A1Easy to adjustImprove flow characteristicsFibre diaphragmsPolymeric diaphragmsFilling materialsEngineering

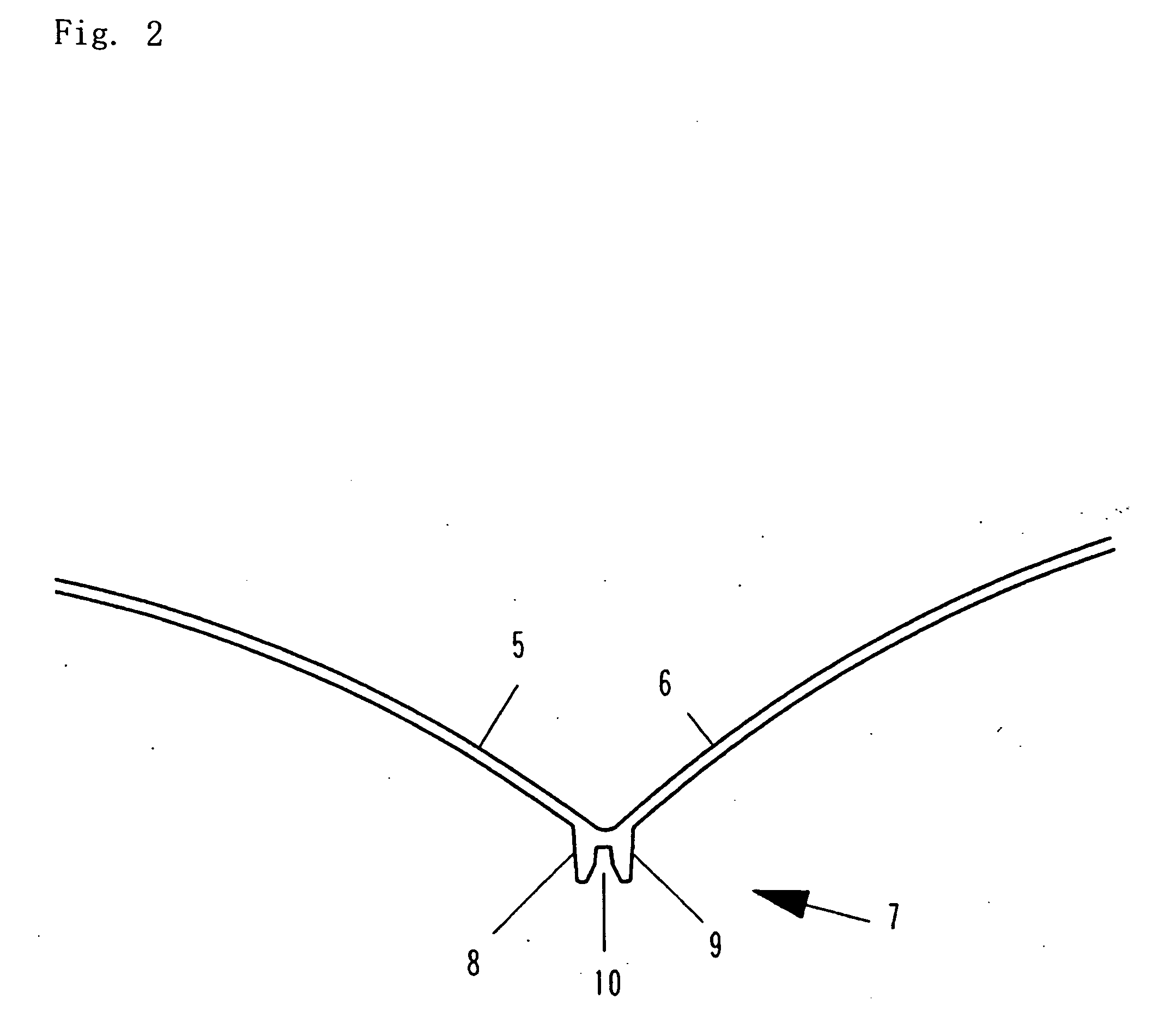

A loudspeaker cone body made of plastic includes a base carrier material and a filler material. The base carrier material is selected to optimize overall flow, weight and stiffness. The filler material may be a nanomaterial that provides for adjustment of process and acoustic related characteristics in the loudspeaker cone body that become relevant when the loudspeaker cone body is operated in a loudspeaker. Acoustic related characteristics that may be adjusted include a stiffness to weight ratio and an acoustic damping of the loudspeaker cone body. A predetermined weight percent of the filler material may be combined with the base carrier material to obtain repeatable desired acoustic related characteristics. The acoustic related characteristics may be adjusted by changing the predetermined weight percent of the filler material.

Owner:HARMAN INT IND INC

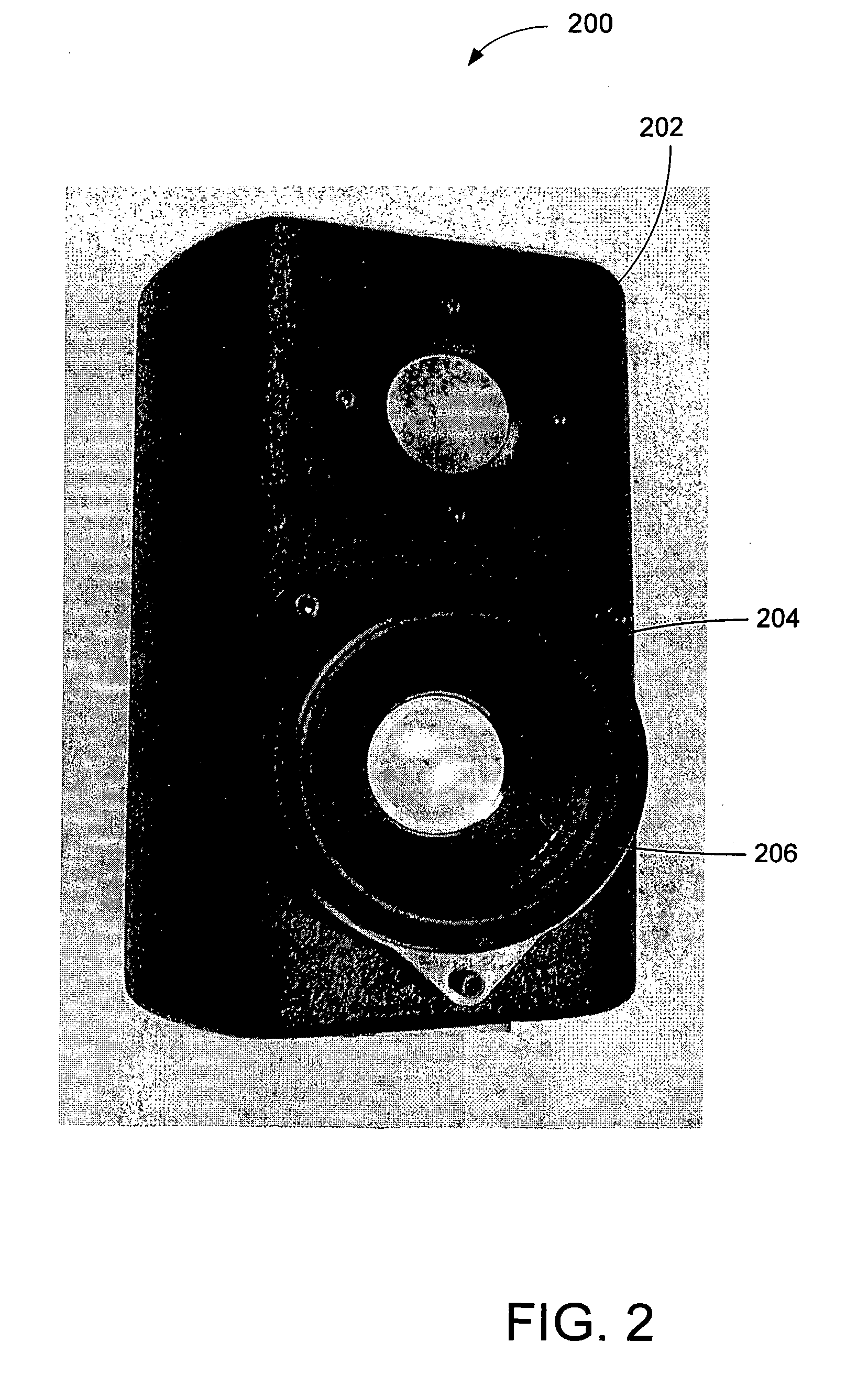

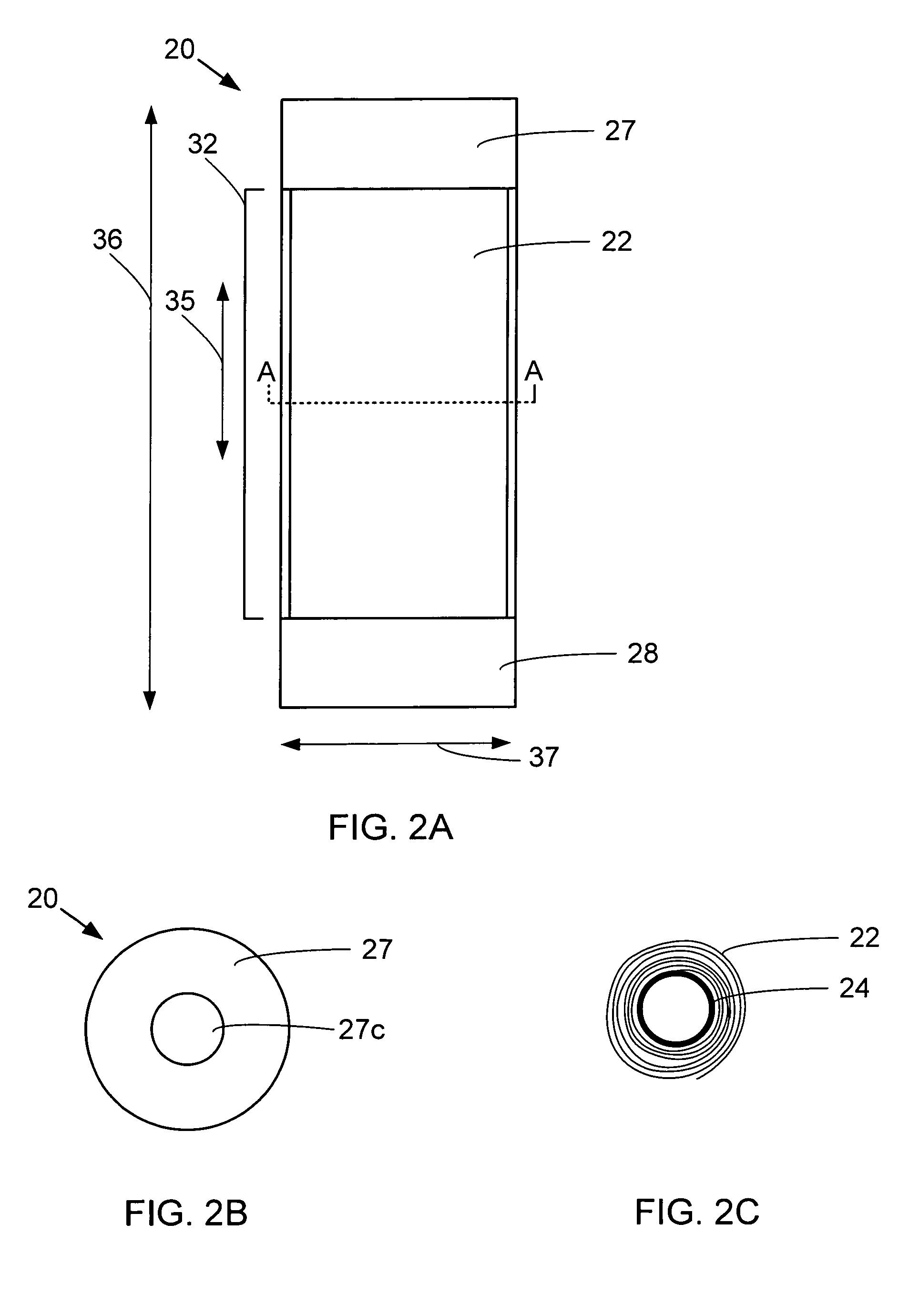

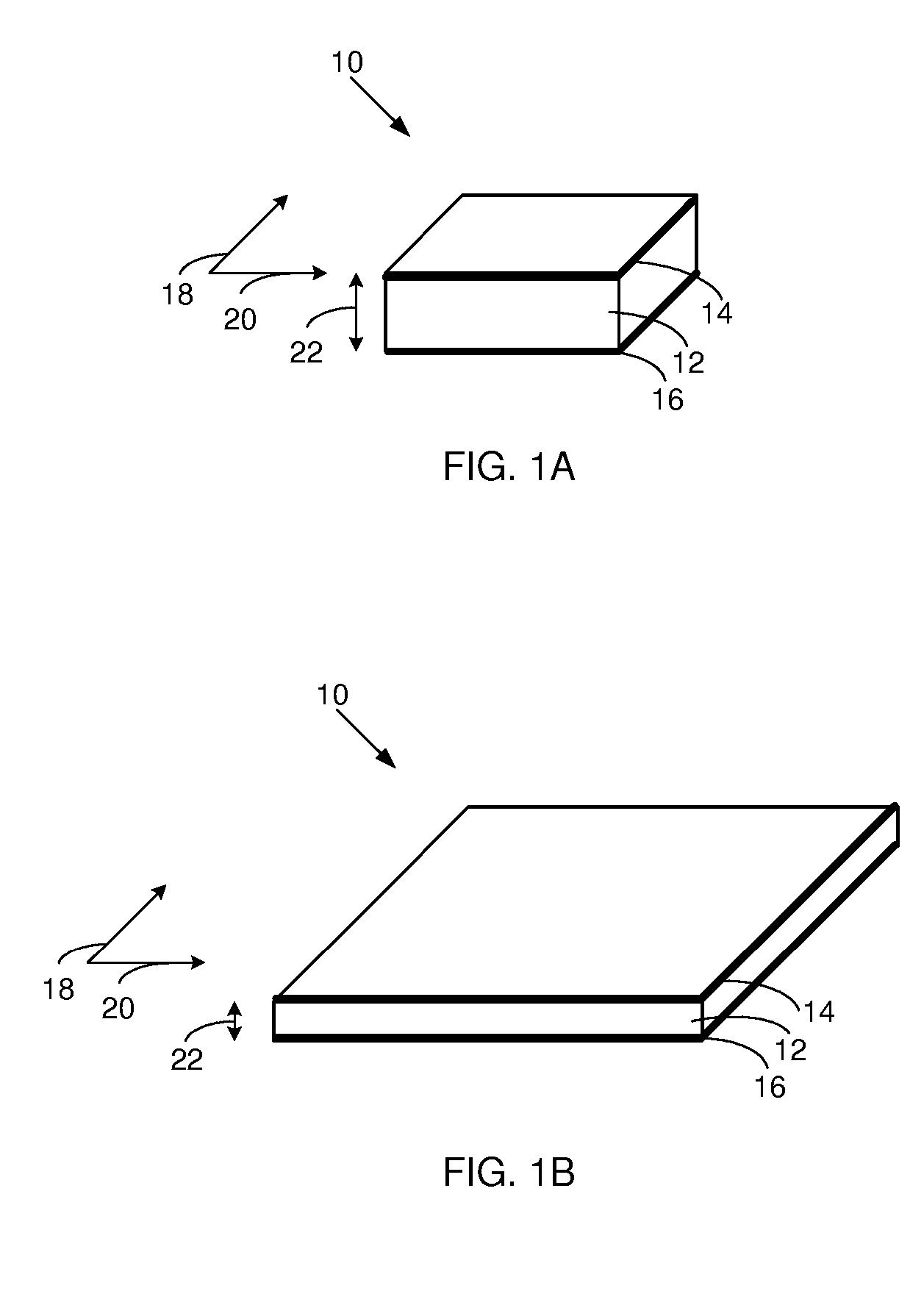

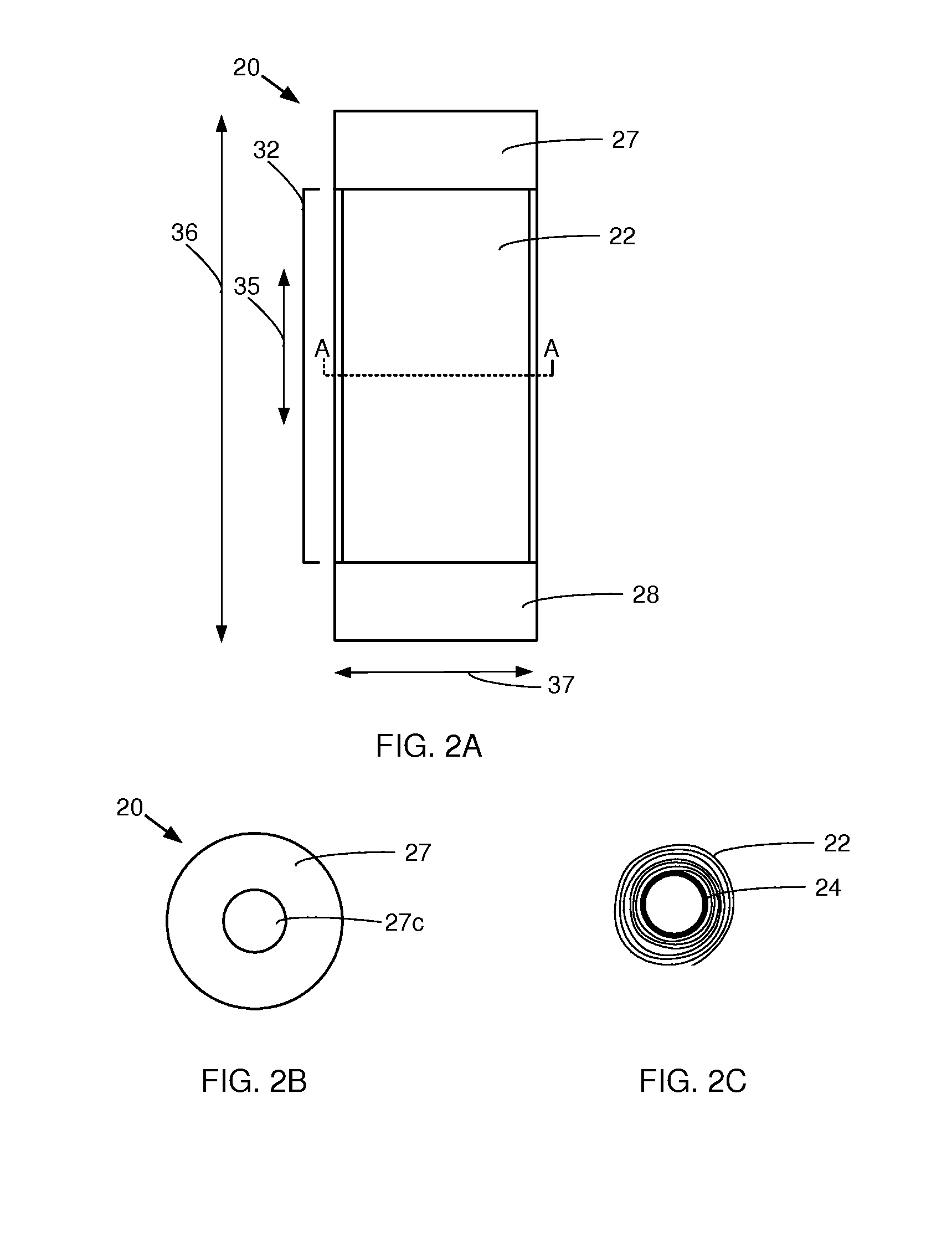

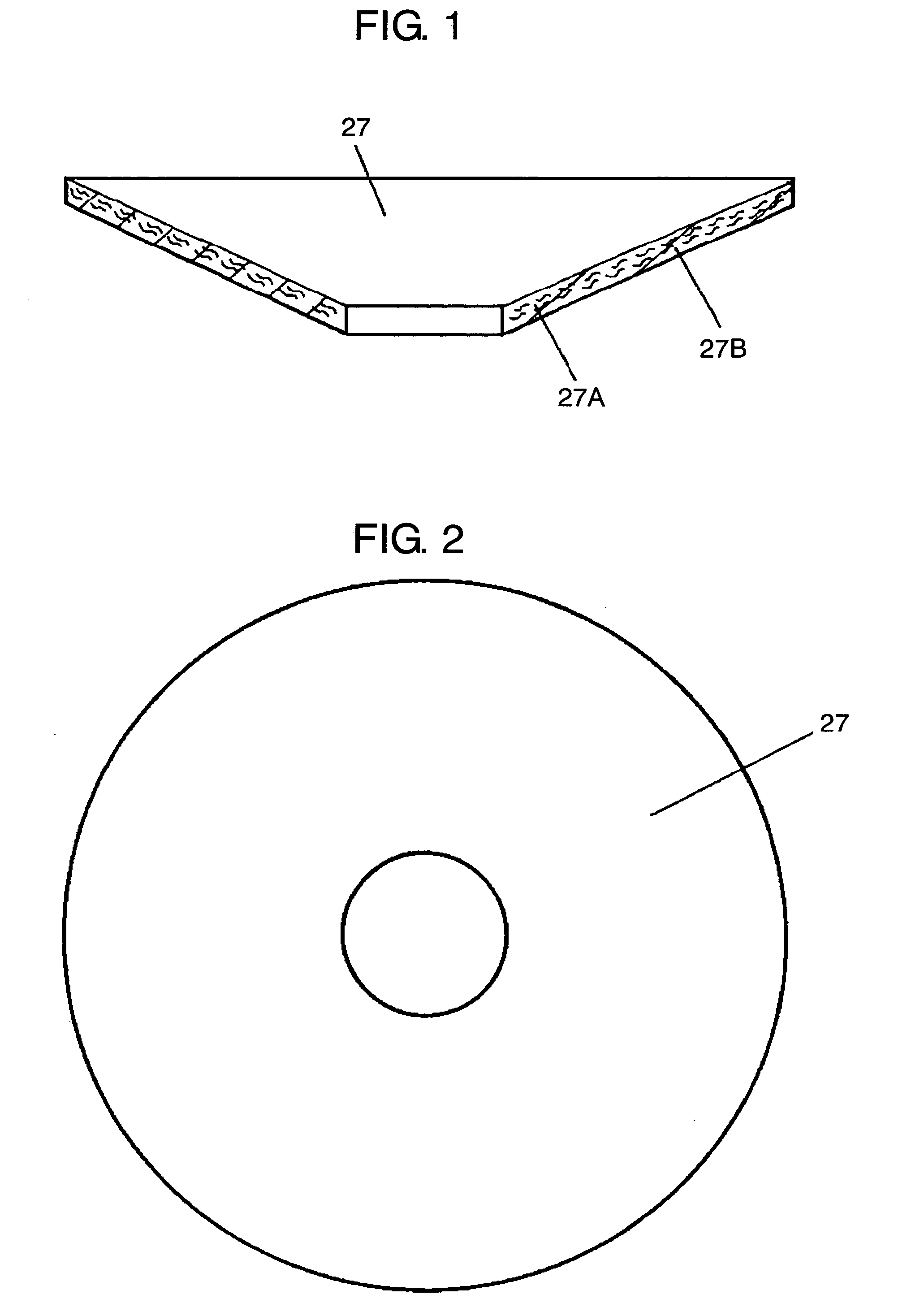

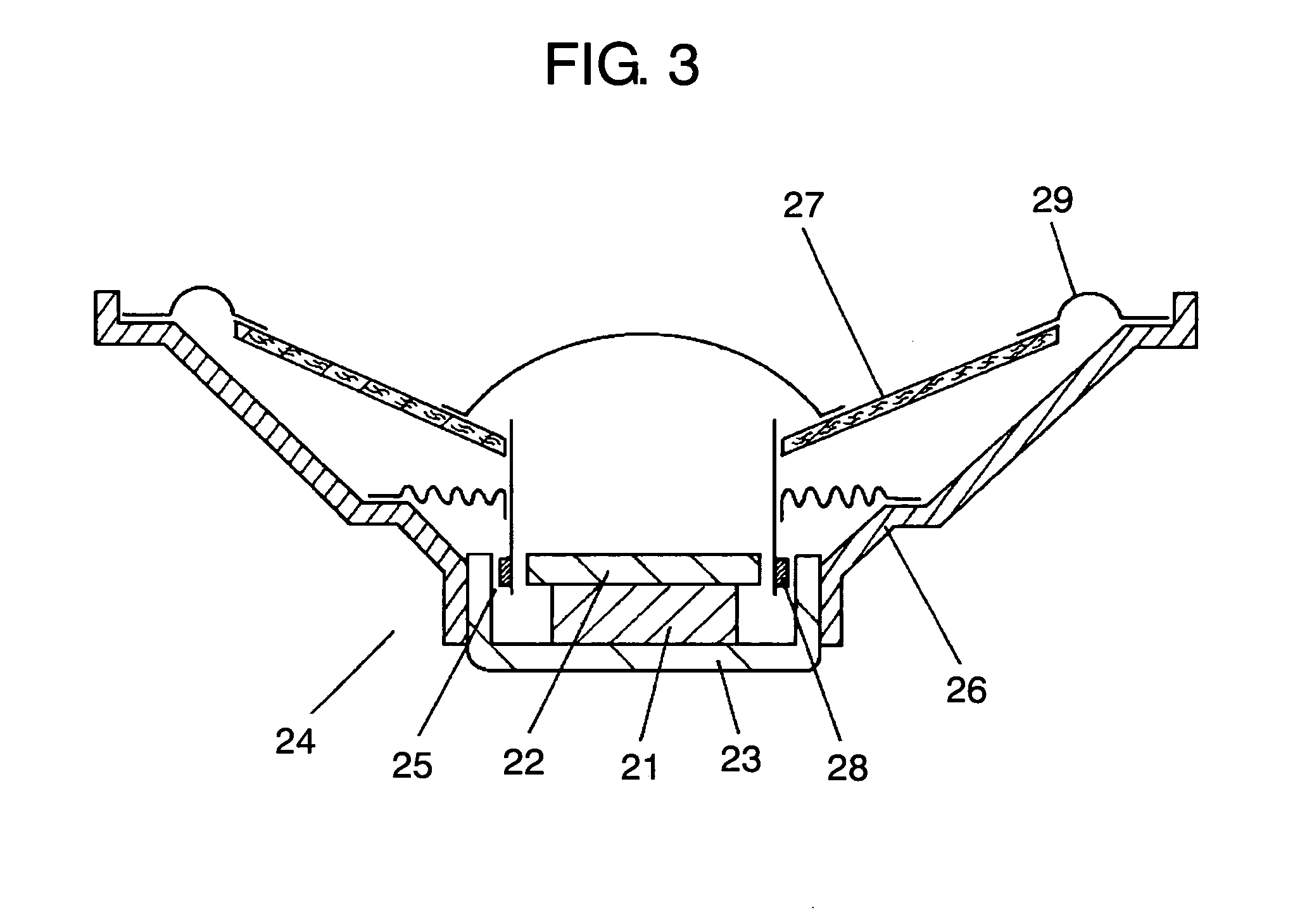

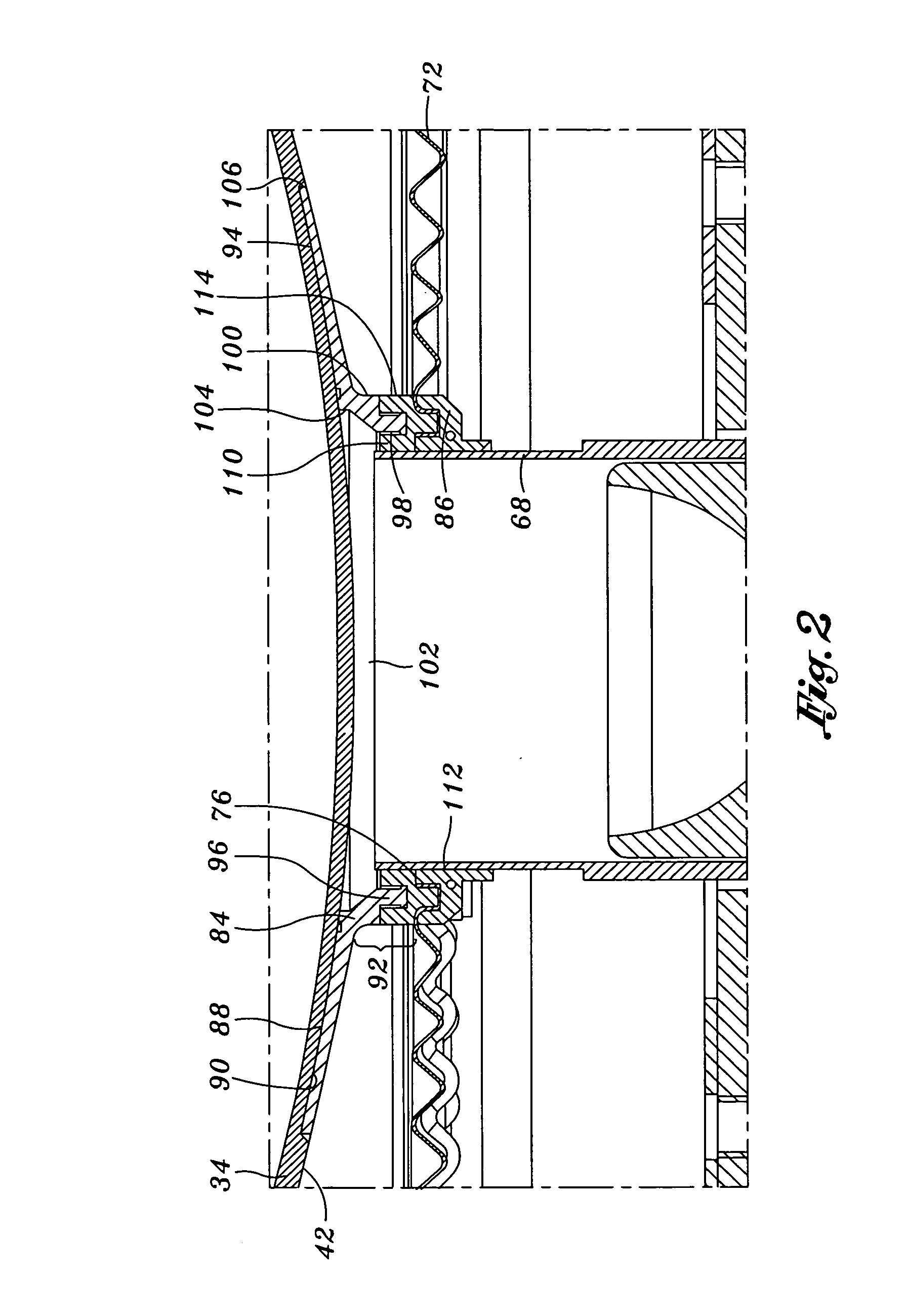

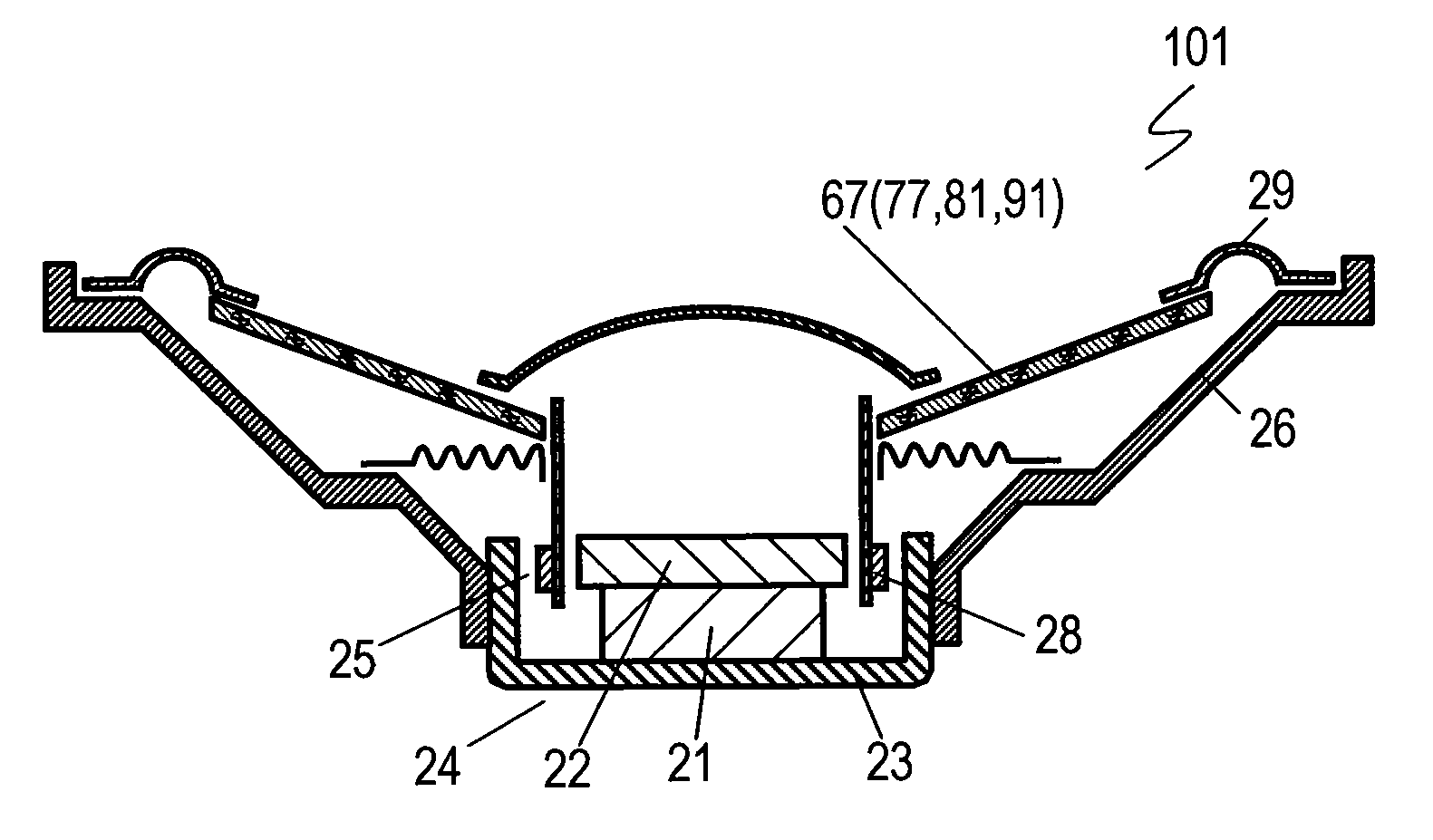

Rolled electroactive polymers

InactiveUS7233097B2Improves mechanical/electrical energy conversionImprove performancePiezoelectric/electrostriction/magnetostriction machinesFlexible member pumpsPolymer scienceMechanical energy

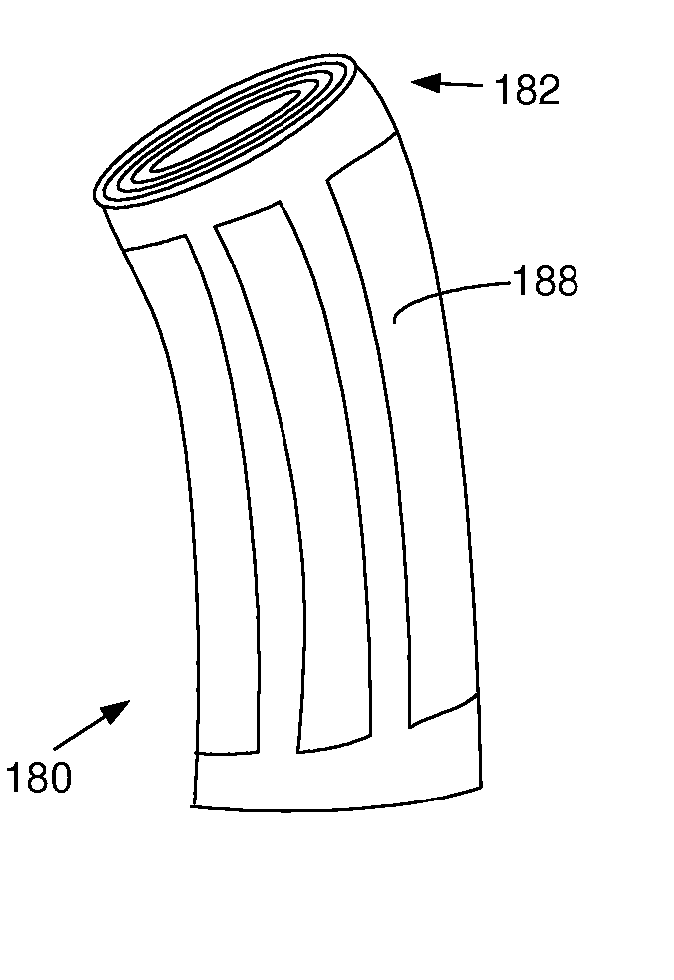

The invention describes rolled electroactive polymer devices. The invention also describes employment of these devices in a wide array of applications and methods for their fabrication. A rolled electroactive polymer device converts between electrical and mechanical energy; and includes a rolled electroactive polymer and at least two electrodes to provide the mechanical / electrical energy conversion. Prestrain is typically applied to the polymer. In one embodiment, a rolled electroactive polymer device employs a mechanism, such as a spring, that provides a force to prestrain the polymer. Since prestrain improves mechanical / electrical energy conversion for many electroactive polymers, the mechanism thus improves performance of the rolled electroactive polymer device.

Owner:SRI INTERNATIONAL

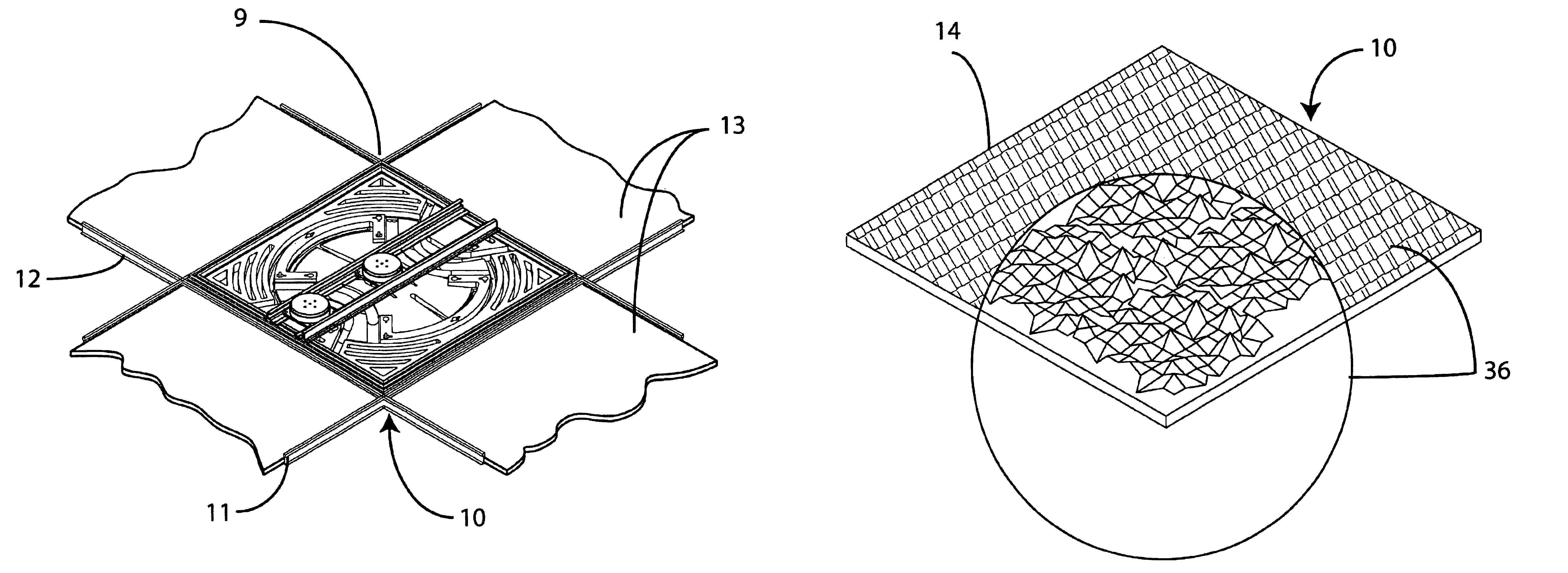

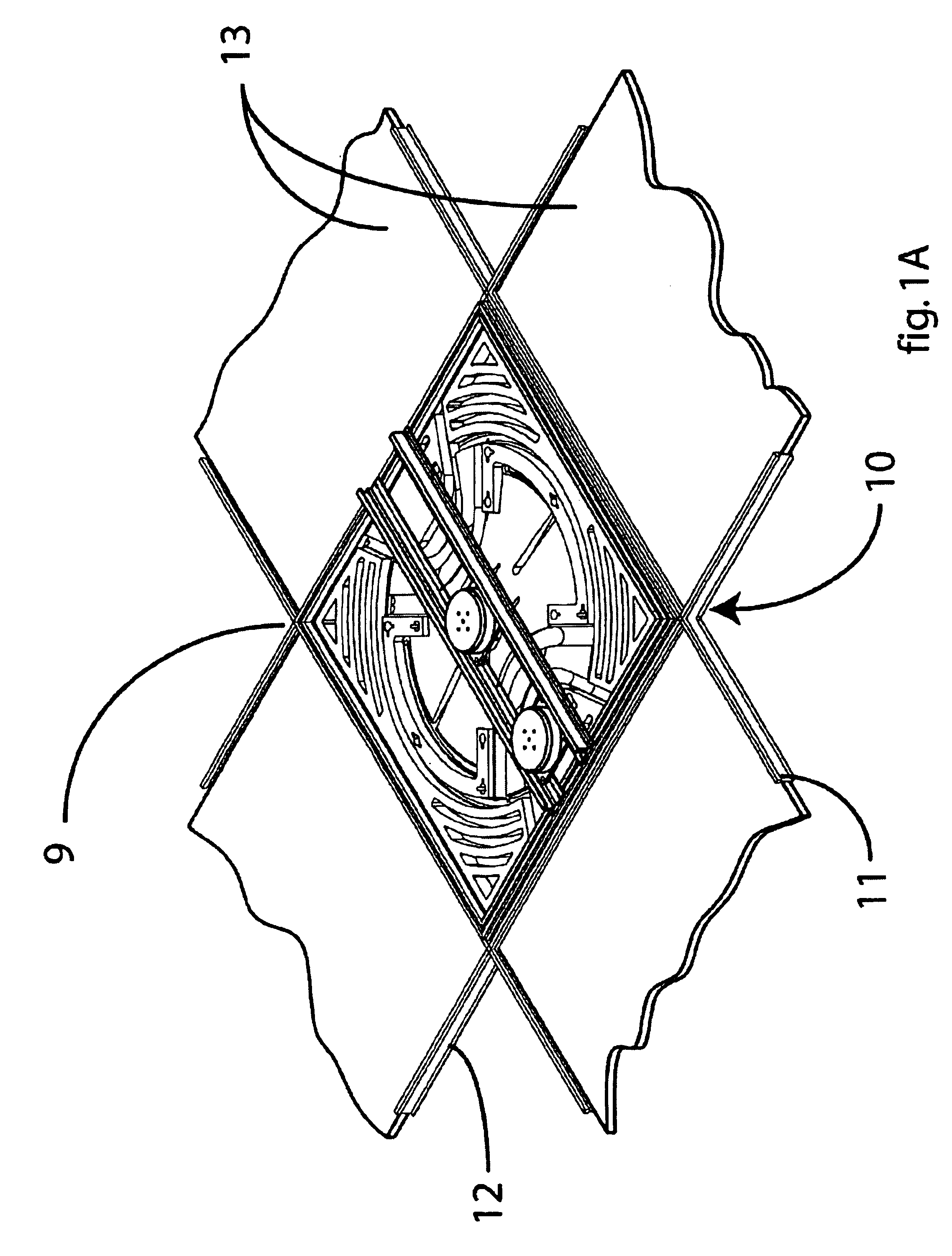

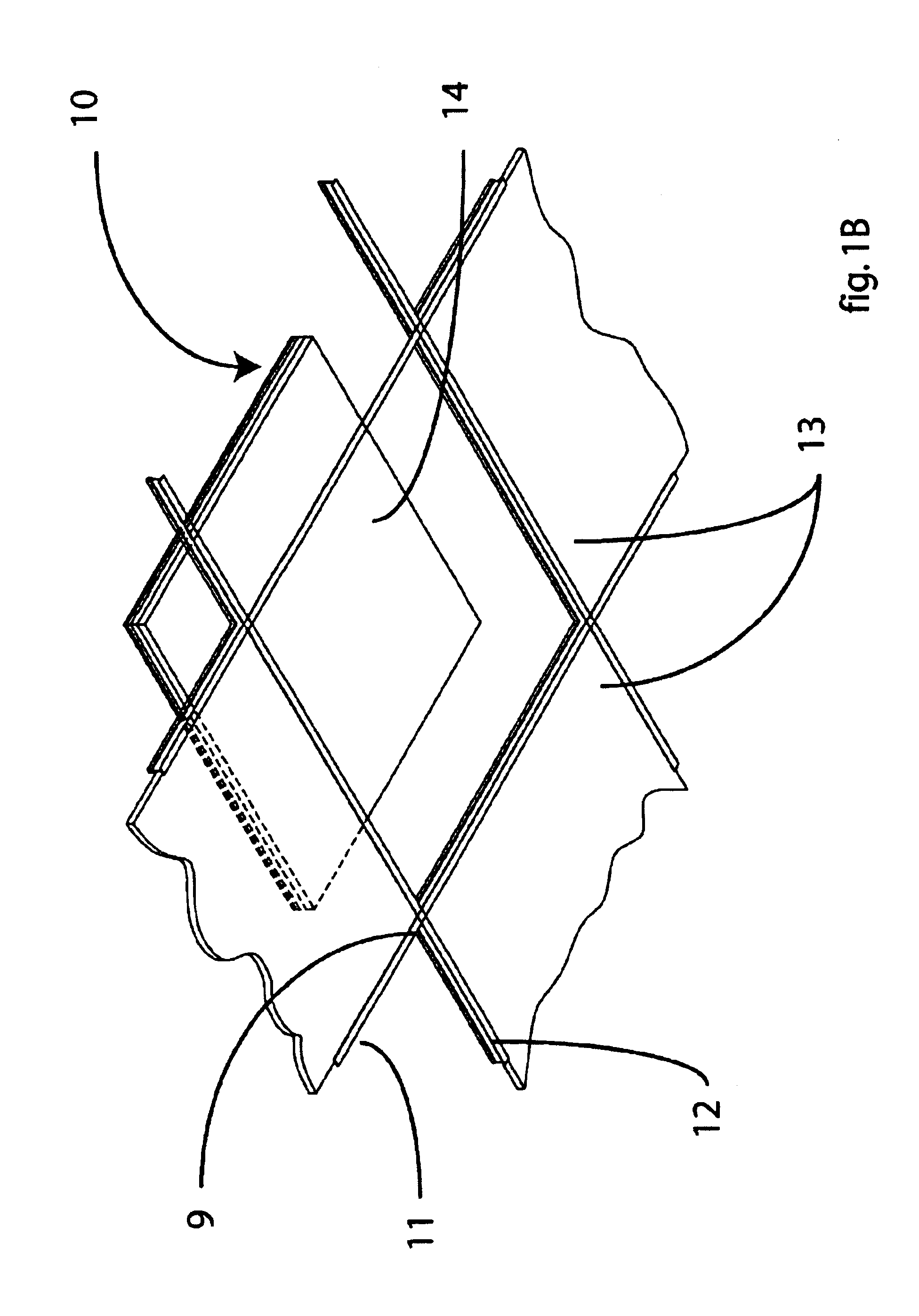

Ceiling tile loudspeaker

InactiveUS6215881B1Sustain and propagateCeilingsProgram control using wired connectionsBrickTransducer

A ceiling tile adapted to be supported in an overhead opening and function as a loudspeaker. The tile is in the form of a distributed mode acoustic radiator with a transducer mounted wholly and exclusively on the radiator at a location for coupling to resonant bending wave modes so as to vibrate the radiator and cause it to resonate.

Owner:NEW TRANSDUCERS LTD

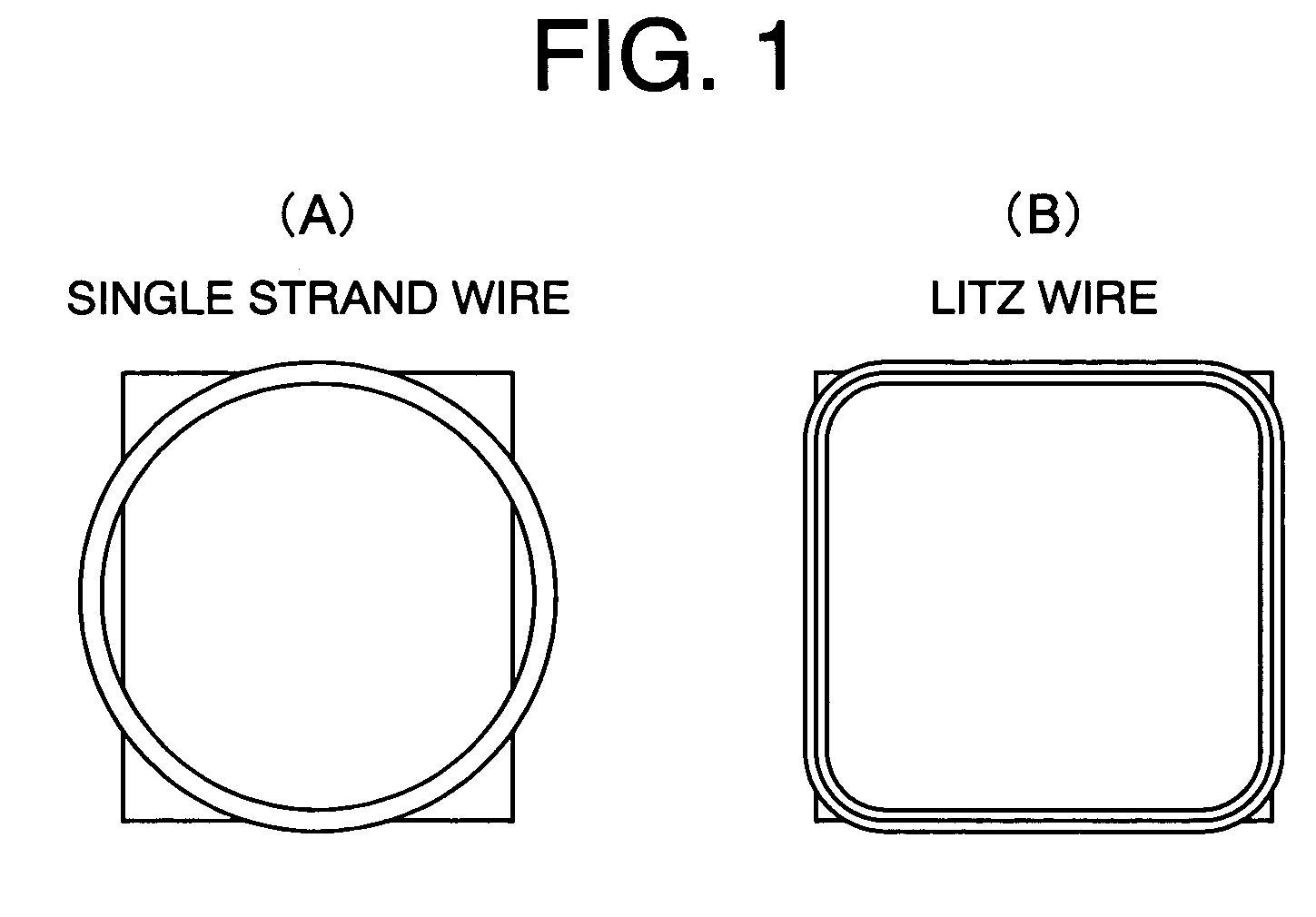

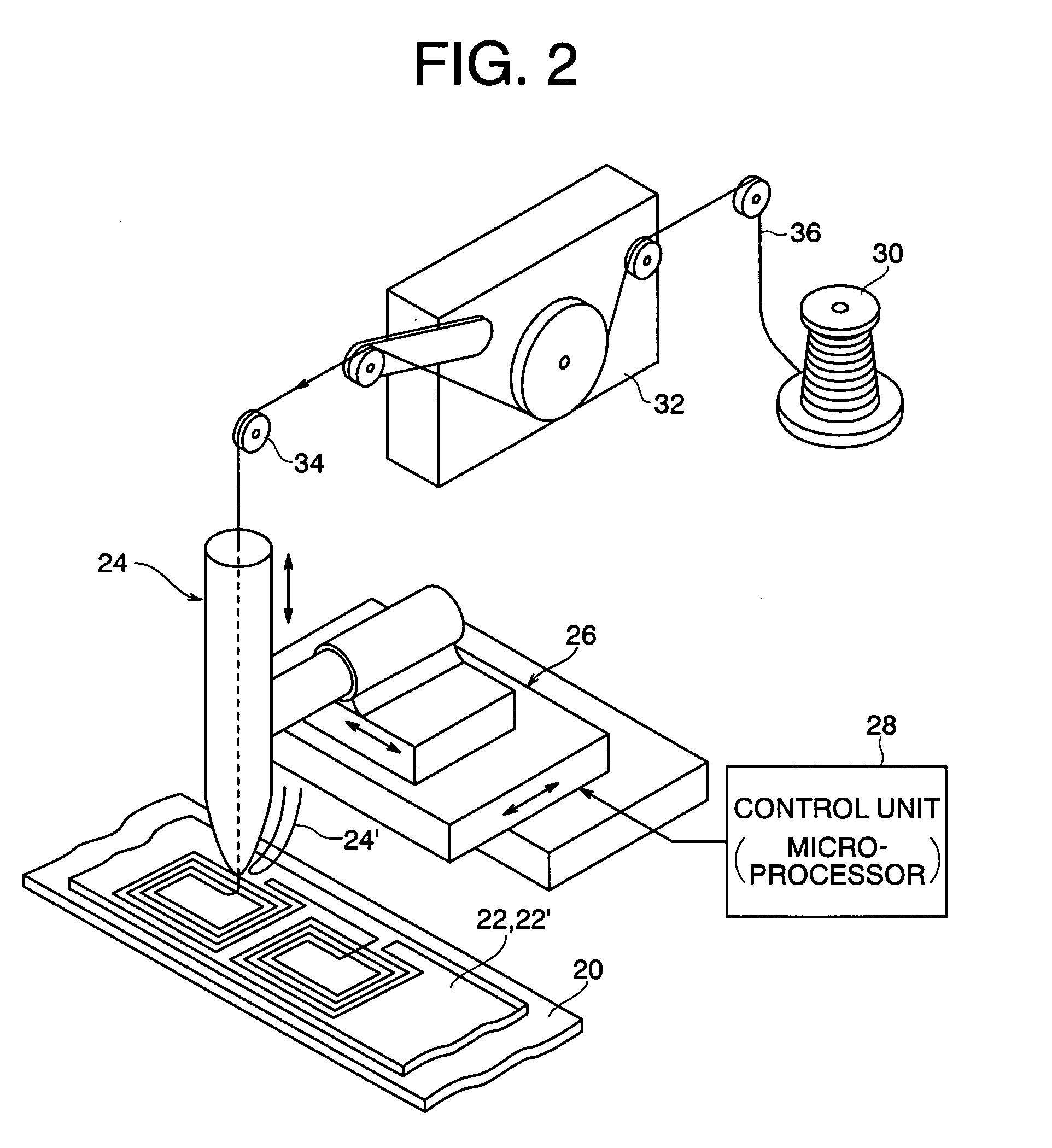

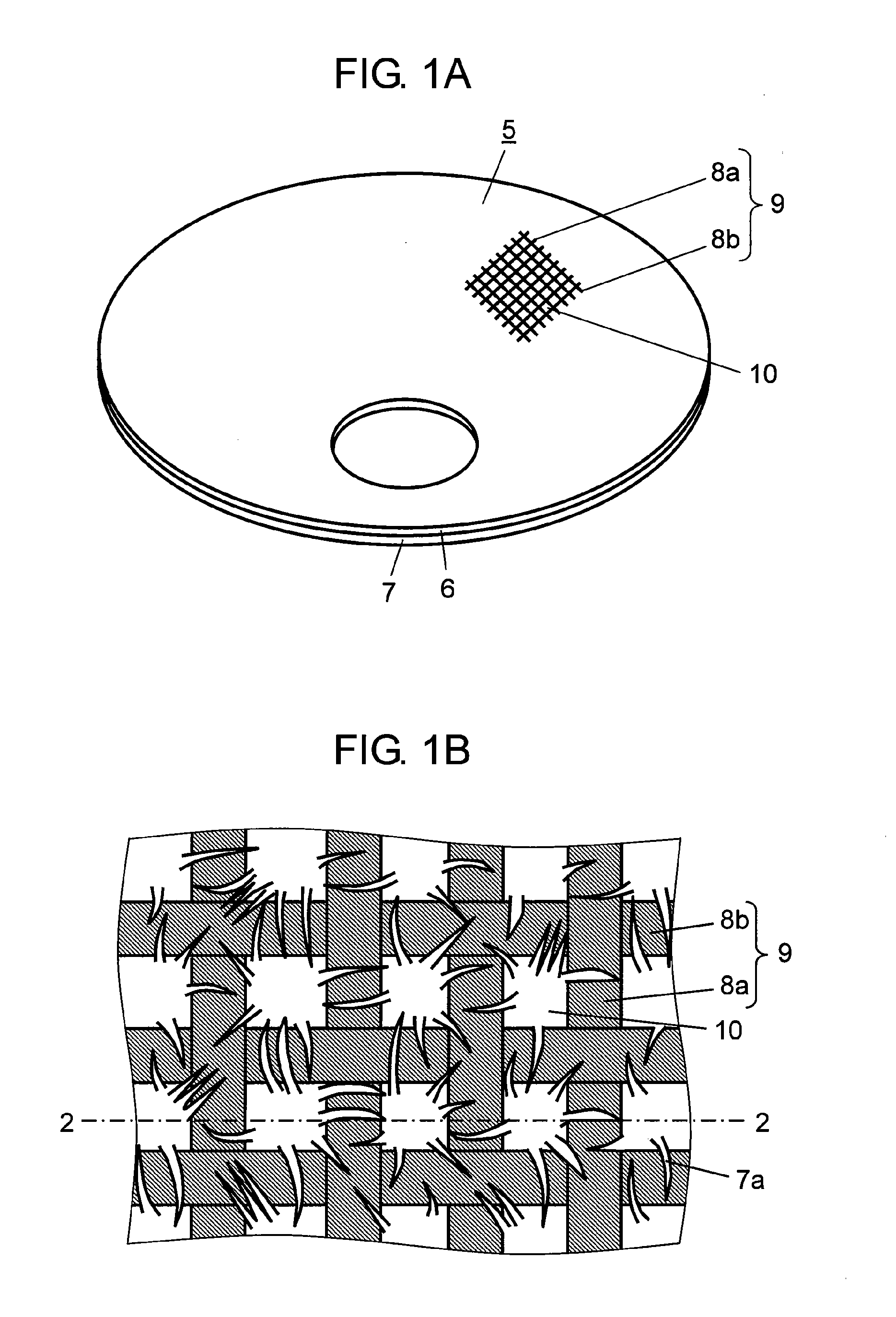

Woven or knitted fabric, diaphragm for speaker, and speaker

InactiveUS20070190881A1Low production costIncrease flexibilityFibre diaphragmsWeft knittingFiberEngineering

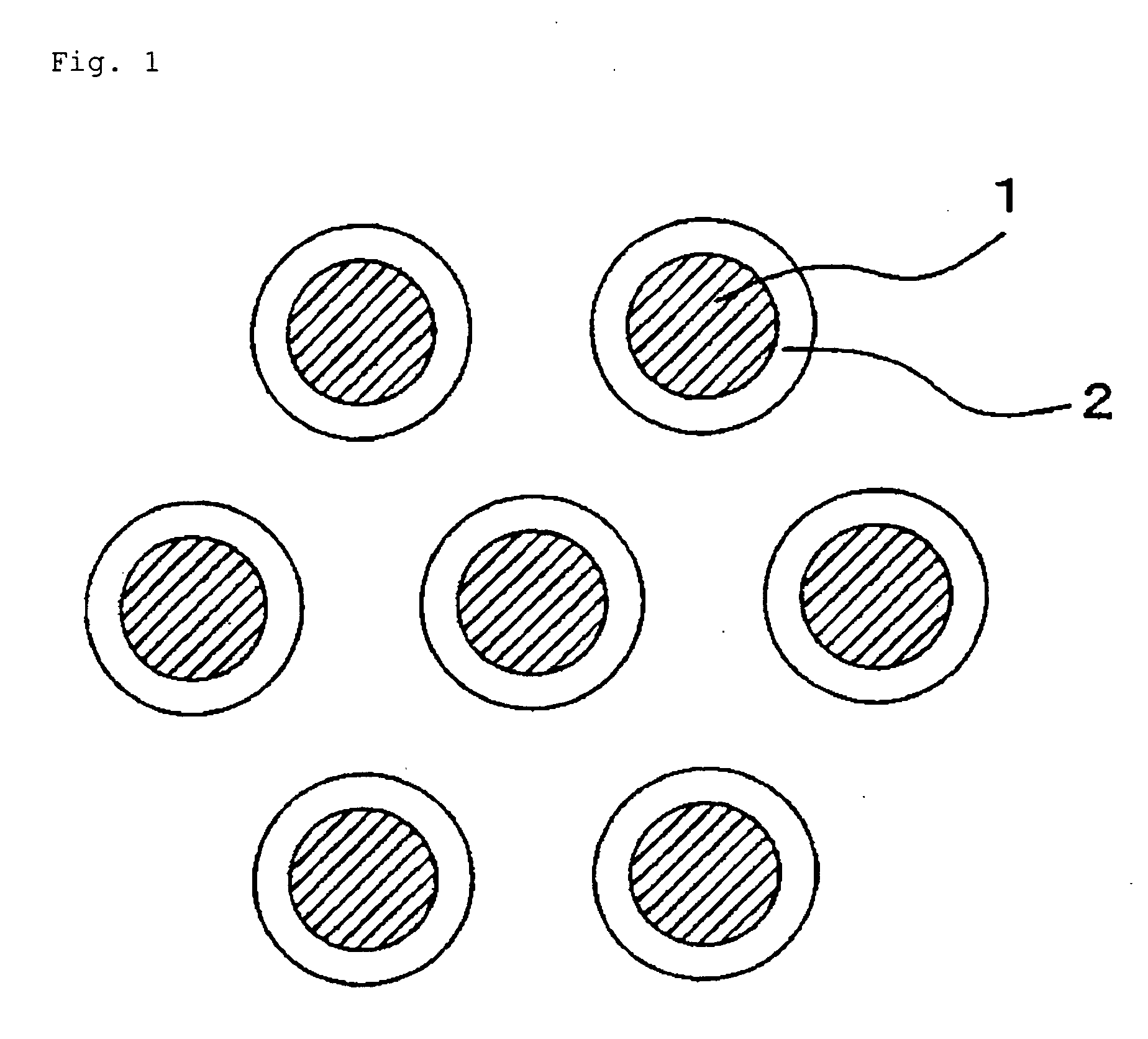

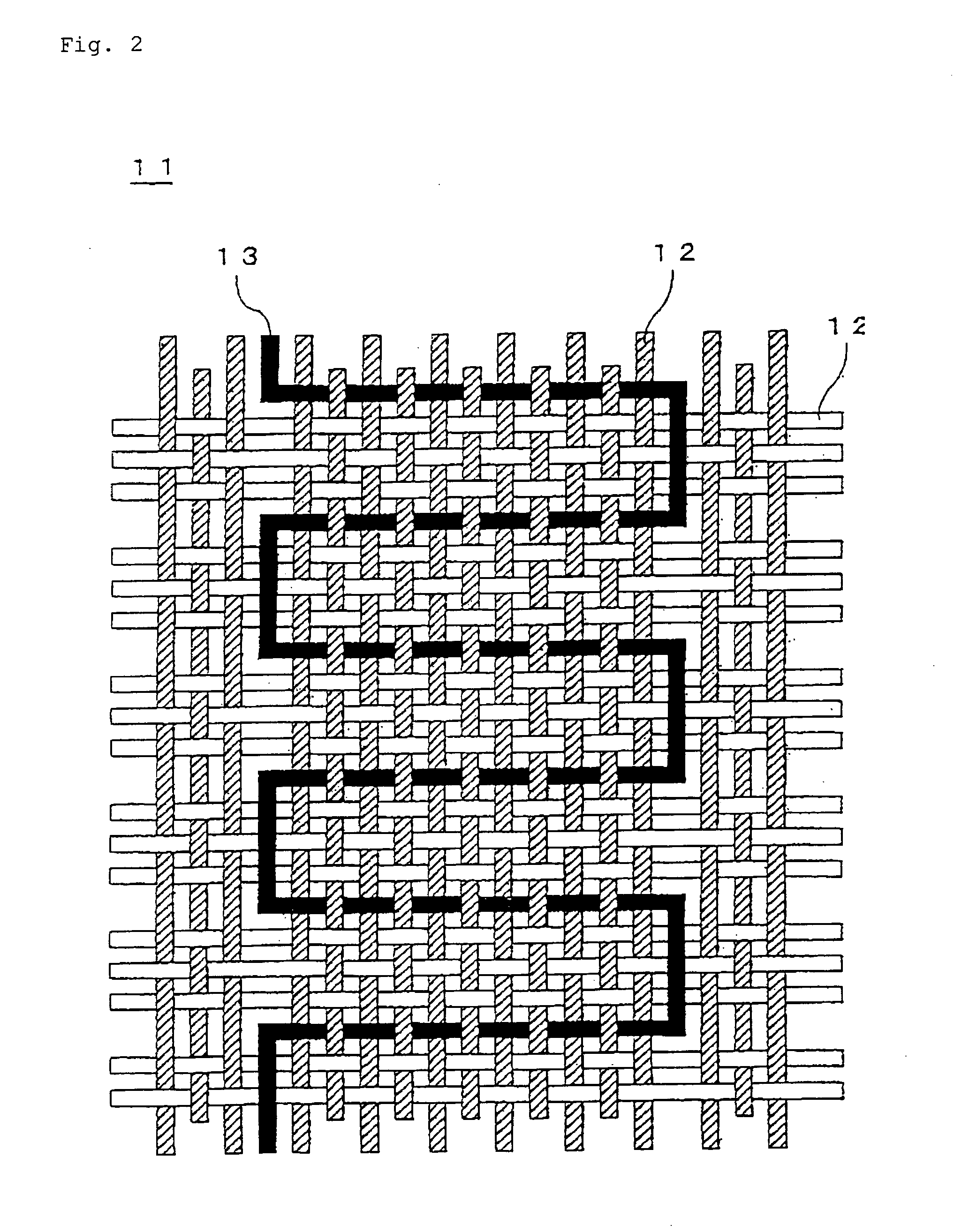

The invention aims to provide a woven / knitted fabric containing a conductive fiber preferably usable especially for a diagram for a speaker, and a diaphragm for a speaker and a speaker using the woven / knitted fabric. A woven / knitted fabric comprising a conductive fiber and a non-conductive fiber, wherein the woven / knitted fabric has a woven structure or a knitted structure of said non-conductive fiber and a continuous wiring forming a coil of the conductive fiber.

Owner:KB SEIREN LTD

Rolled electroactive polymers

InactiveUS20080022517A1Increase conversionsImprove performanceFlexible member pumpsMedical devicesPolymer scienceMechanical energy

The invention describes rolled electroactive polymer devices. The invention also describes employment of these devices in a wide array of applications and methods for their fabrication. A rolled electroactive polymer device converts between electrical and mechanical energy; and includes a rolled electroactive polymer and at least two electrodes to provide the mechanical / electrical energy conversion. Prestrain is typically applied to the polymer. In one embodiment, a rolled electroactive polymer device employs a mechanism, such as a spring, that provides a force to prestrain the polymer. Since prestrain improves mechanical / electrical energy conversion for many electroactive polymers, the mechanism thus improves performance of the rolled electroactive polymer device.

Owner:SRI INTERNATIONAL

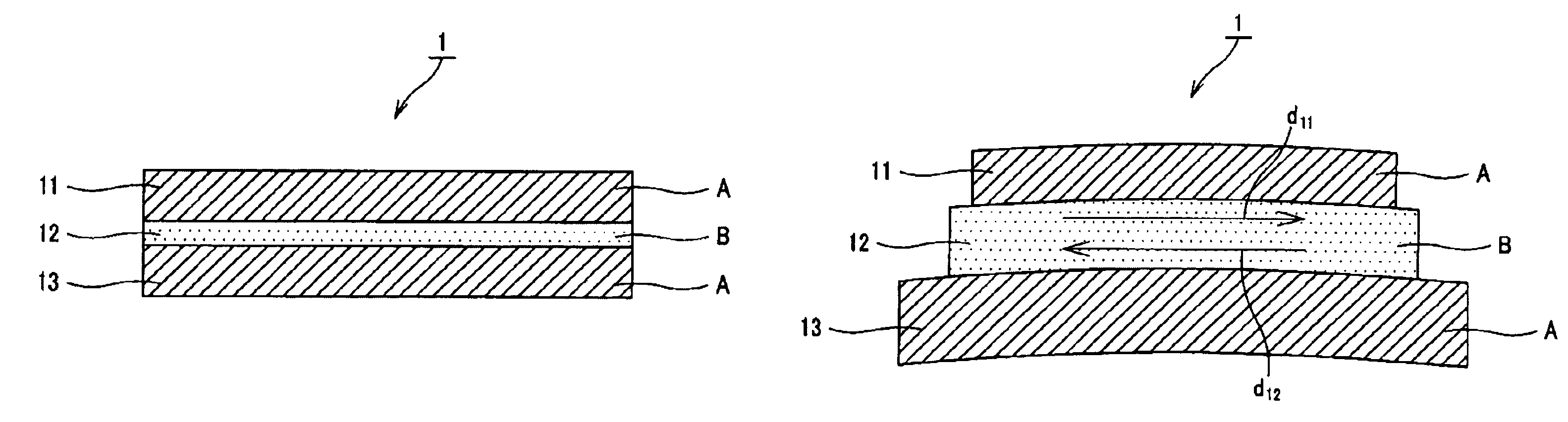

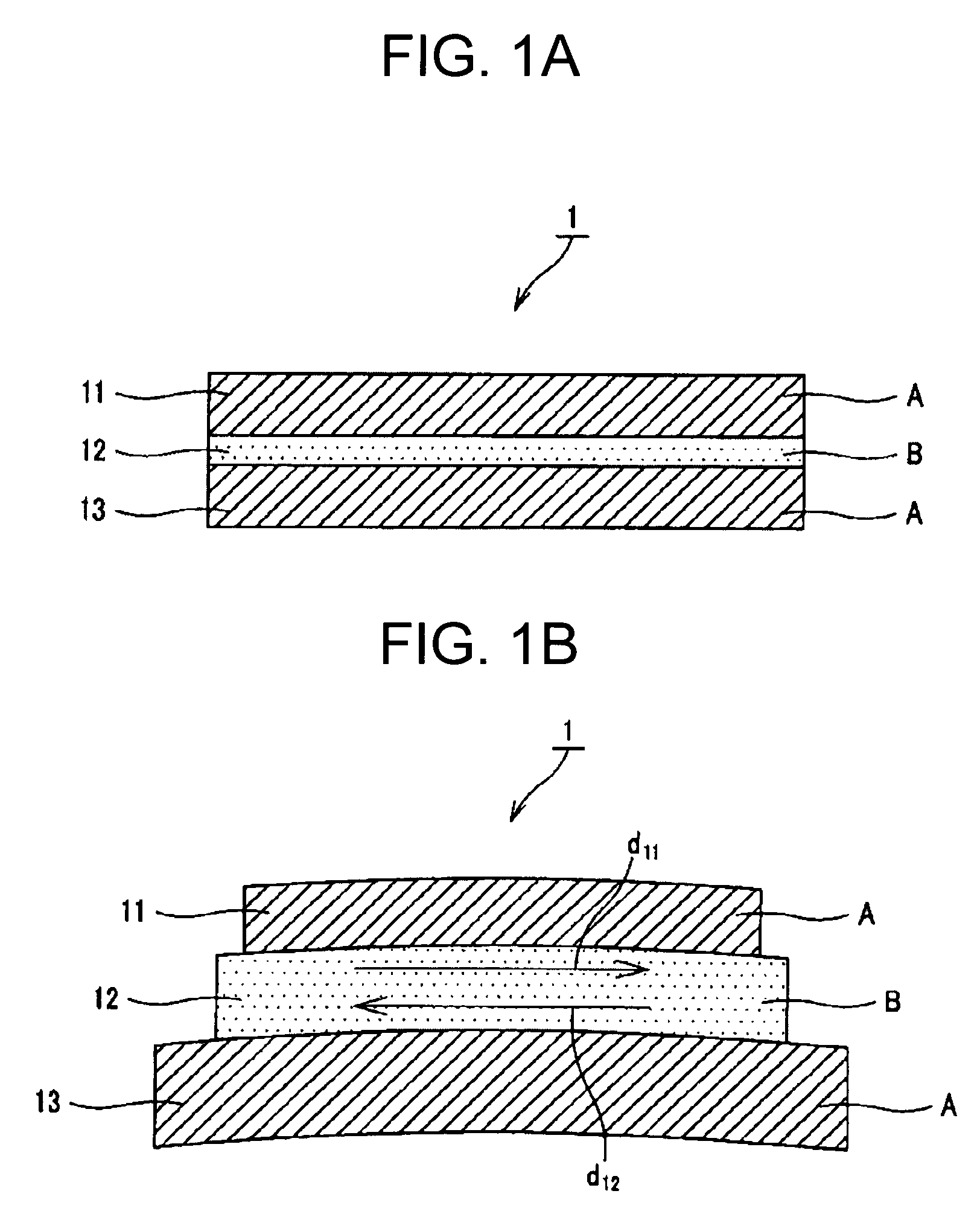

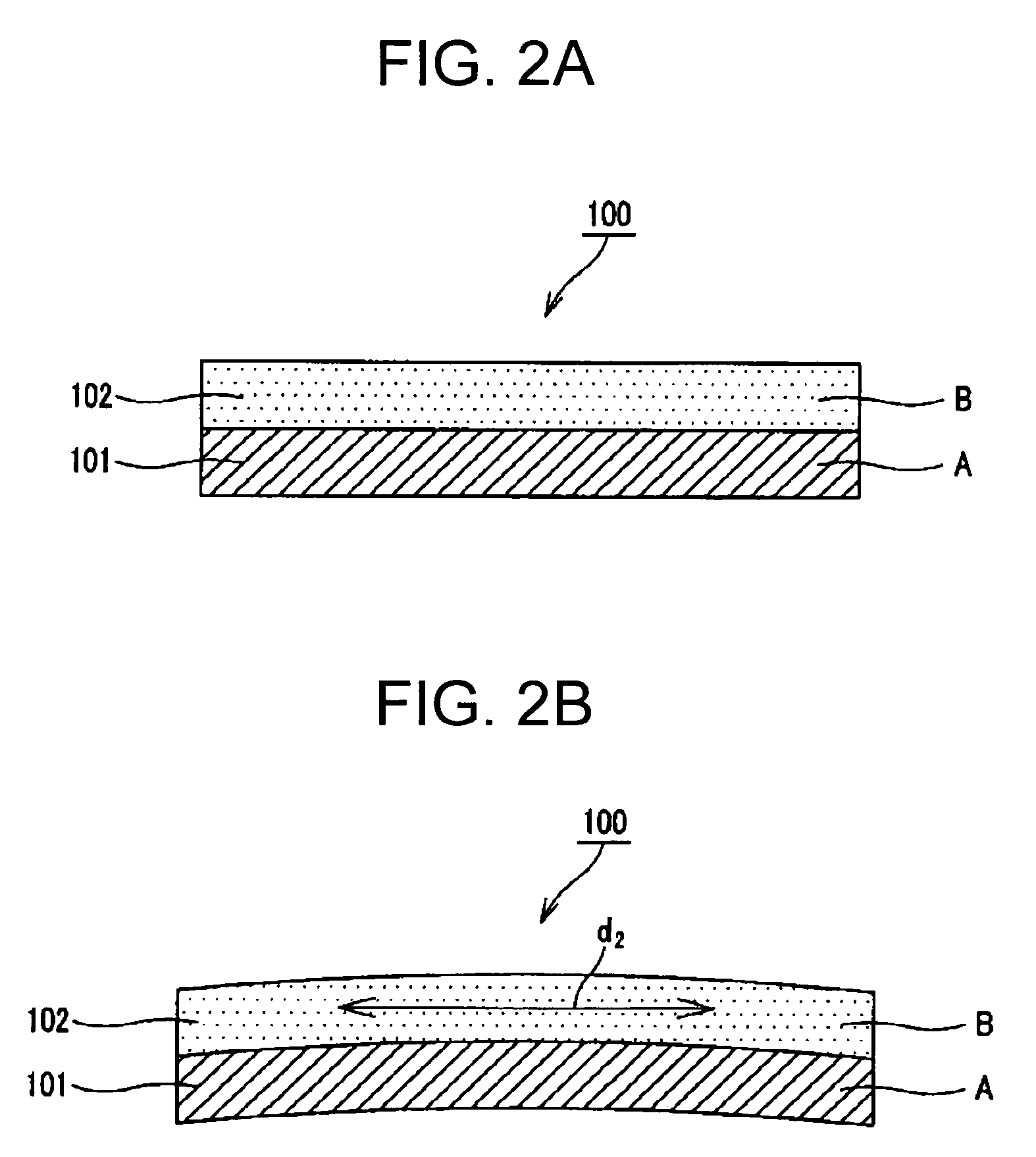

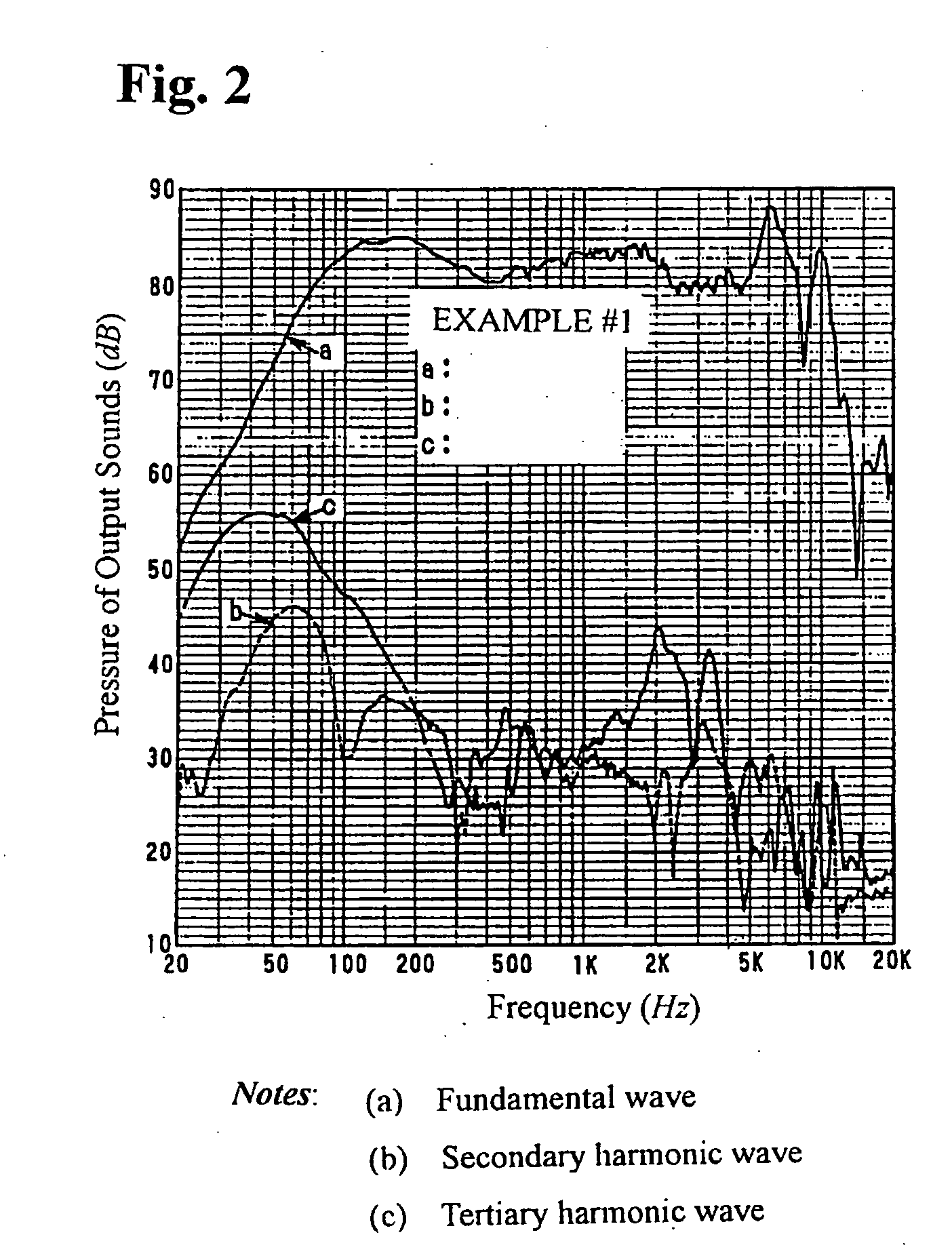

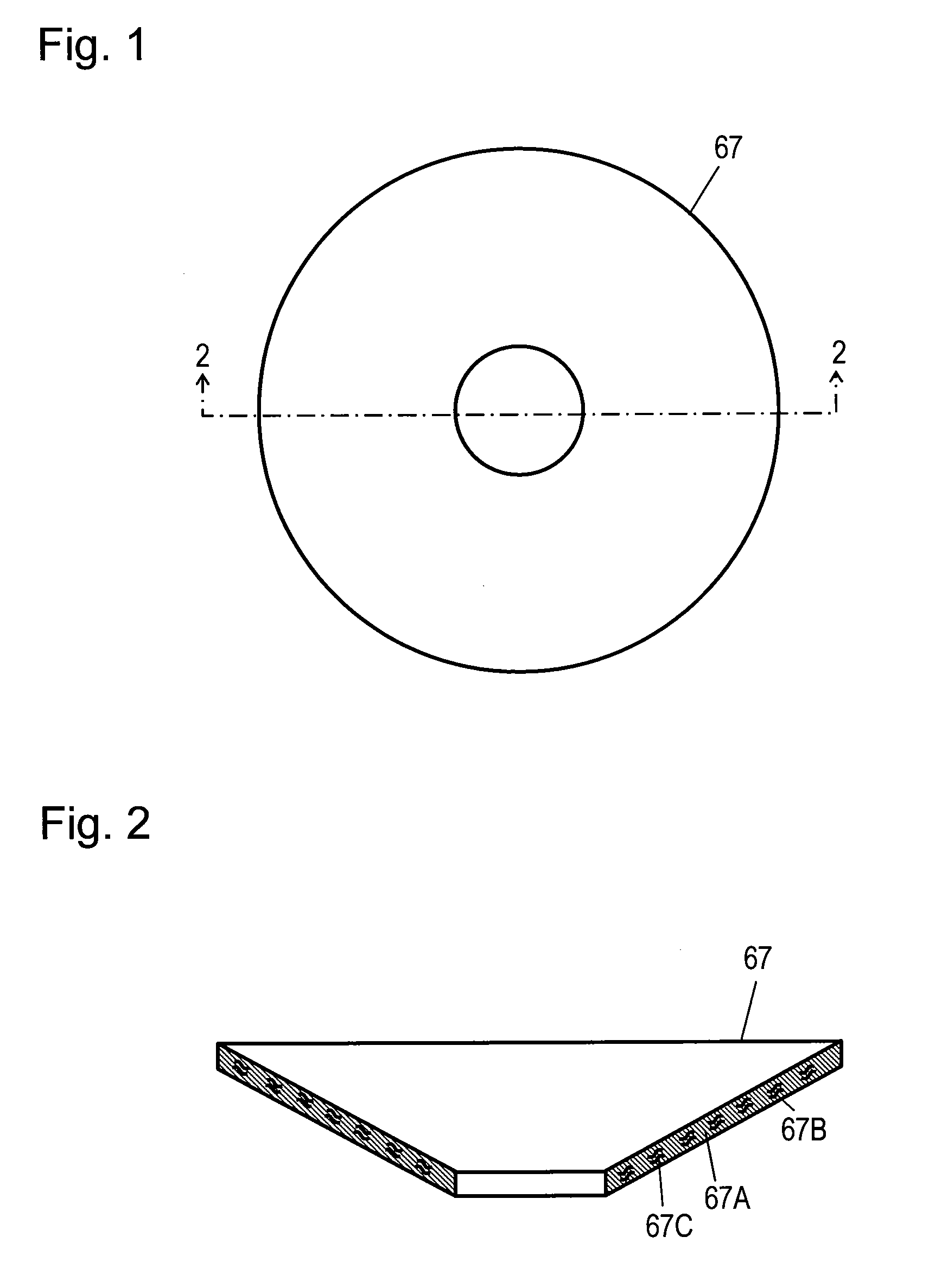

Acoustic vibratory plate

InactiveUS7726441B2Effectively increases an internal lossFlattening of peak-dipFibre diaphragmsTransducer detailsPolymer sciencePolymer

There is provided an acoustic vibratory plate having at least first to third laminated bodies layered. In the acoustic vibratory plate, the first and third laminated bodies are formed of a polymer material, and the second laminated body is formed of a polymer material different from the polymer material forming the first and third laminated bodies in dynamic internal loss.

Owner:SONY CORP

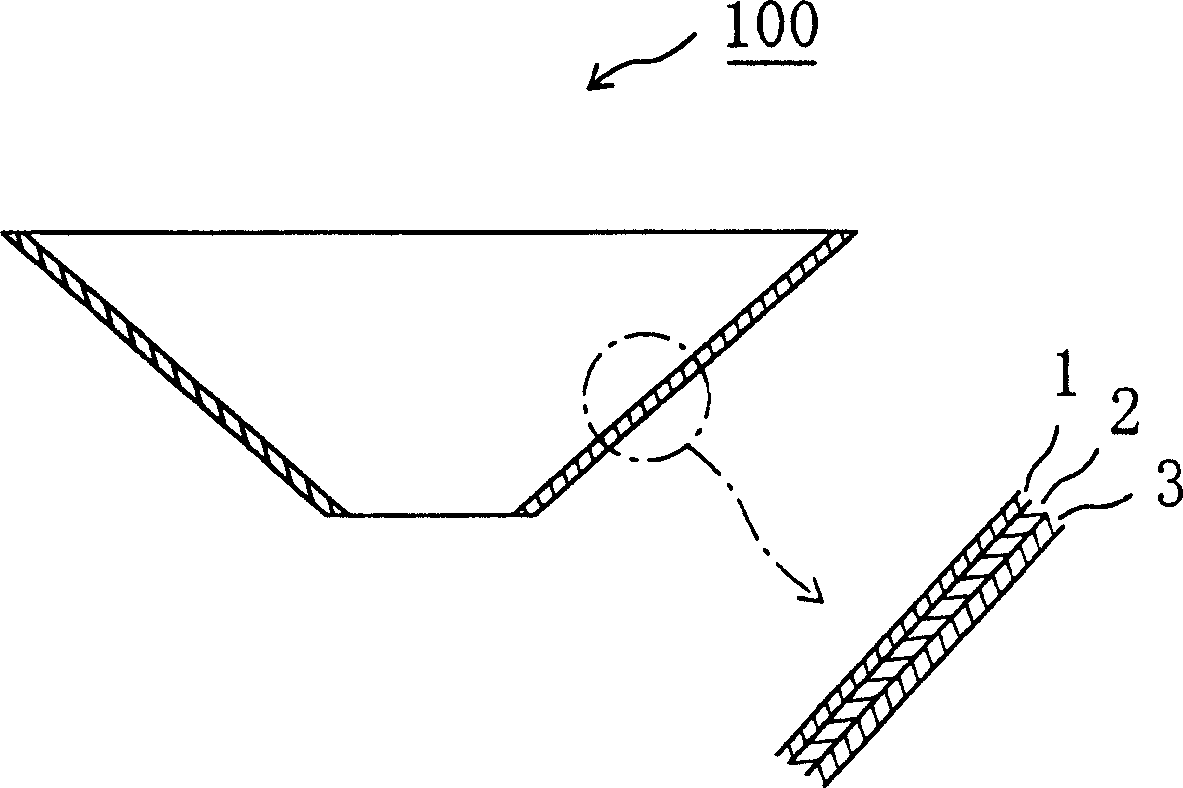

Loudspeaker diaphragm and its mfg. method

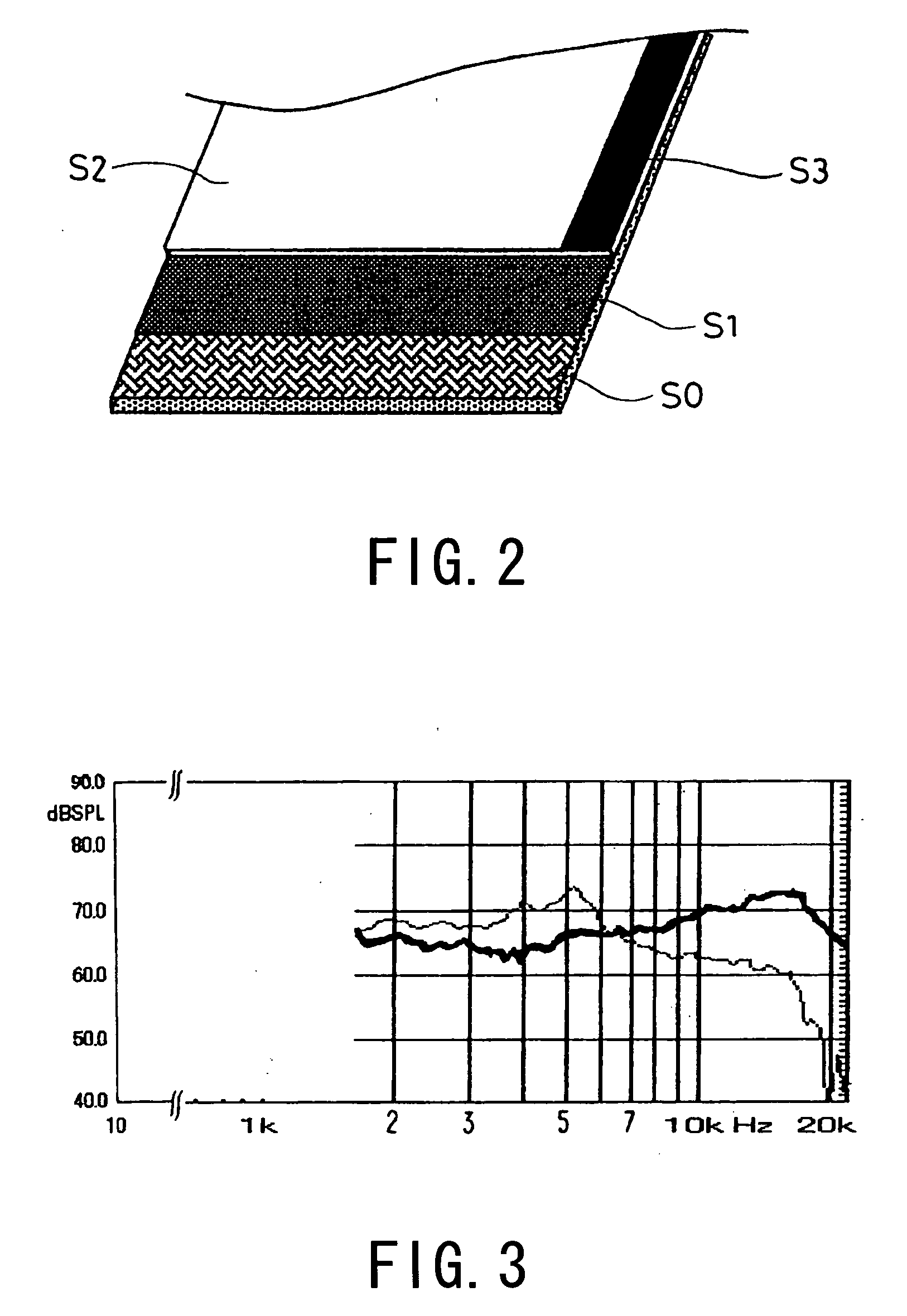

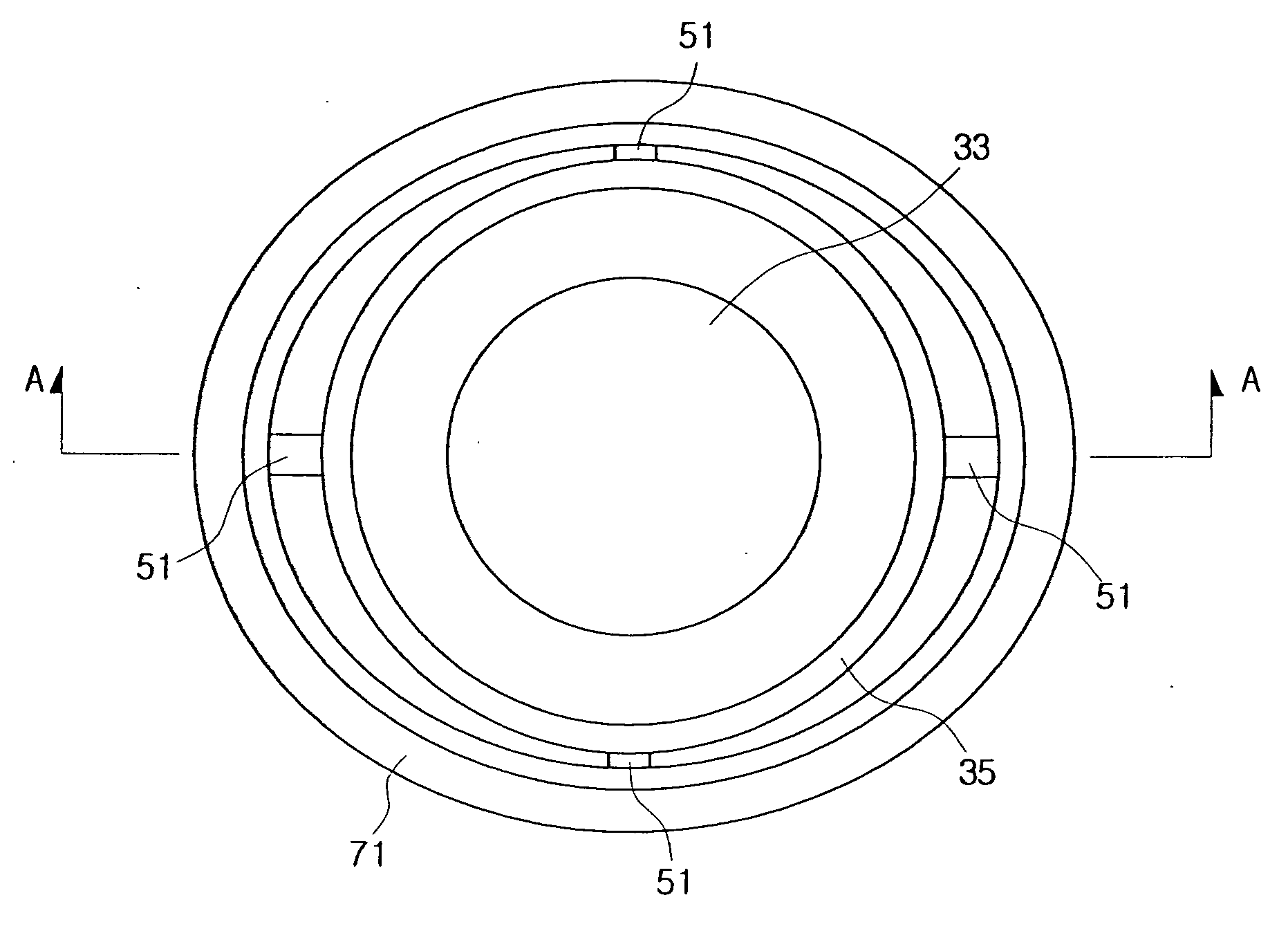

A loudspeaker diaphragm having light weight and an excellent balance between a rigidity and an internal loss, and a simple and inexpensive method for manufacturing such a diaphragm are provided. A loudspeaker diaphragm according to the present invention includes a base layer having a woven fabric of a polyethylene naphthalate fiber impregnated with a thermosetting resin, and optionally a thermoplastic resin layer and / or a thermoplastic elastomer layer. The polyethylene naphthalate fiber is preferably an untwisted fiber. A fiber / resin ratio in the base layer is preferably in the range of 60 / 40 to 80 / 20. Preferably, the thermoplastic resin layer has a finely foamed structure and an average diameter of a cell in the finely foamed structure is 10 to 60 mum.

Owner:ONKYO KK

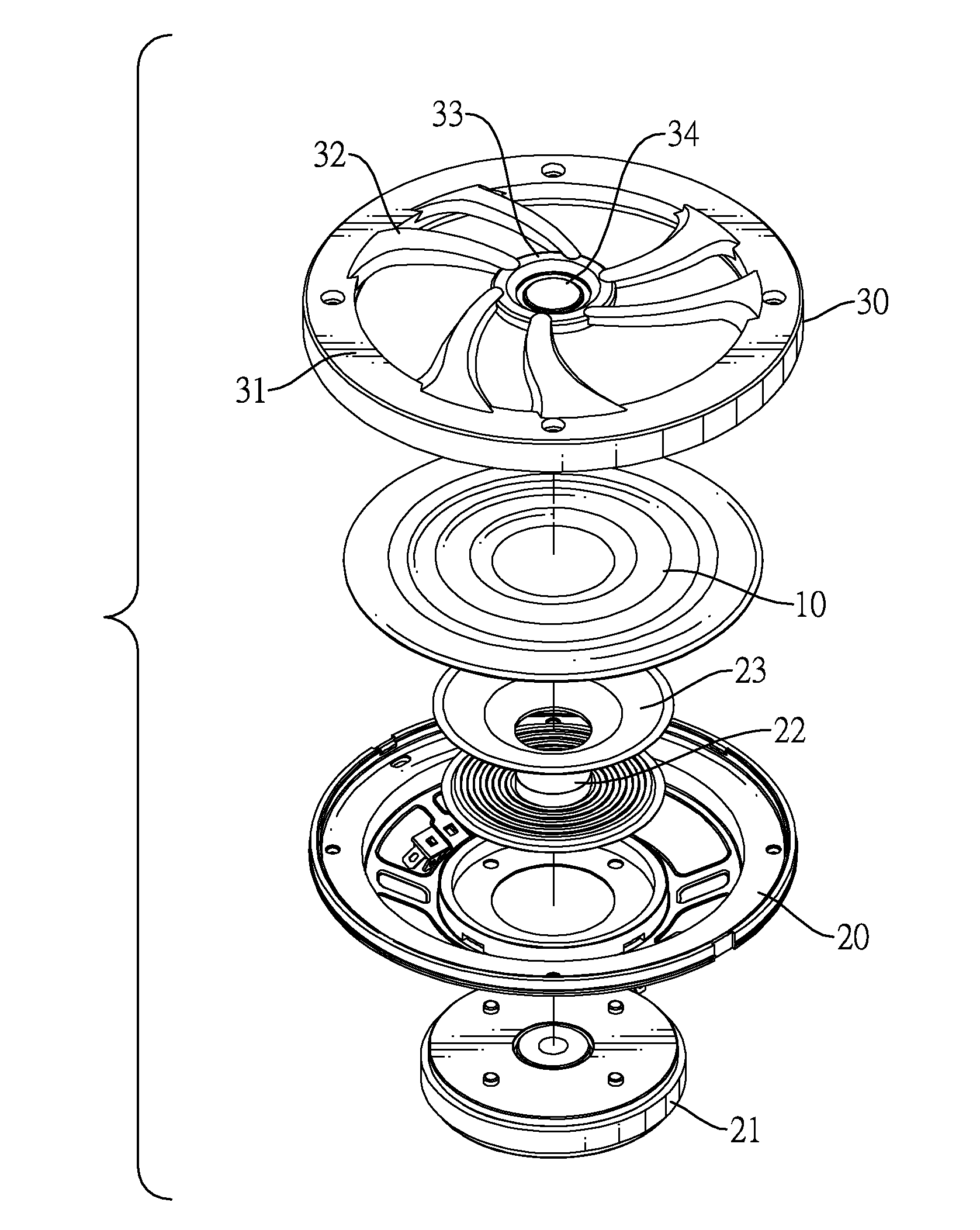

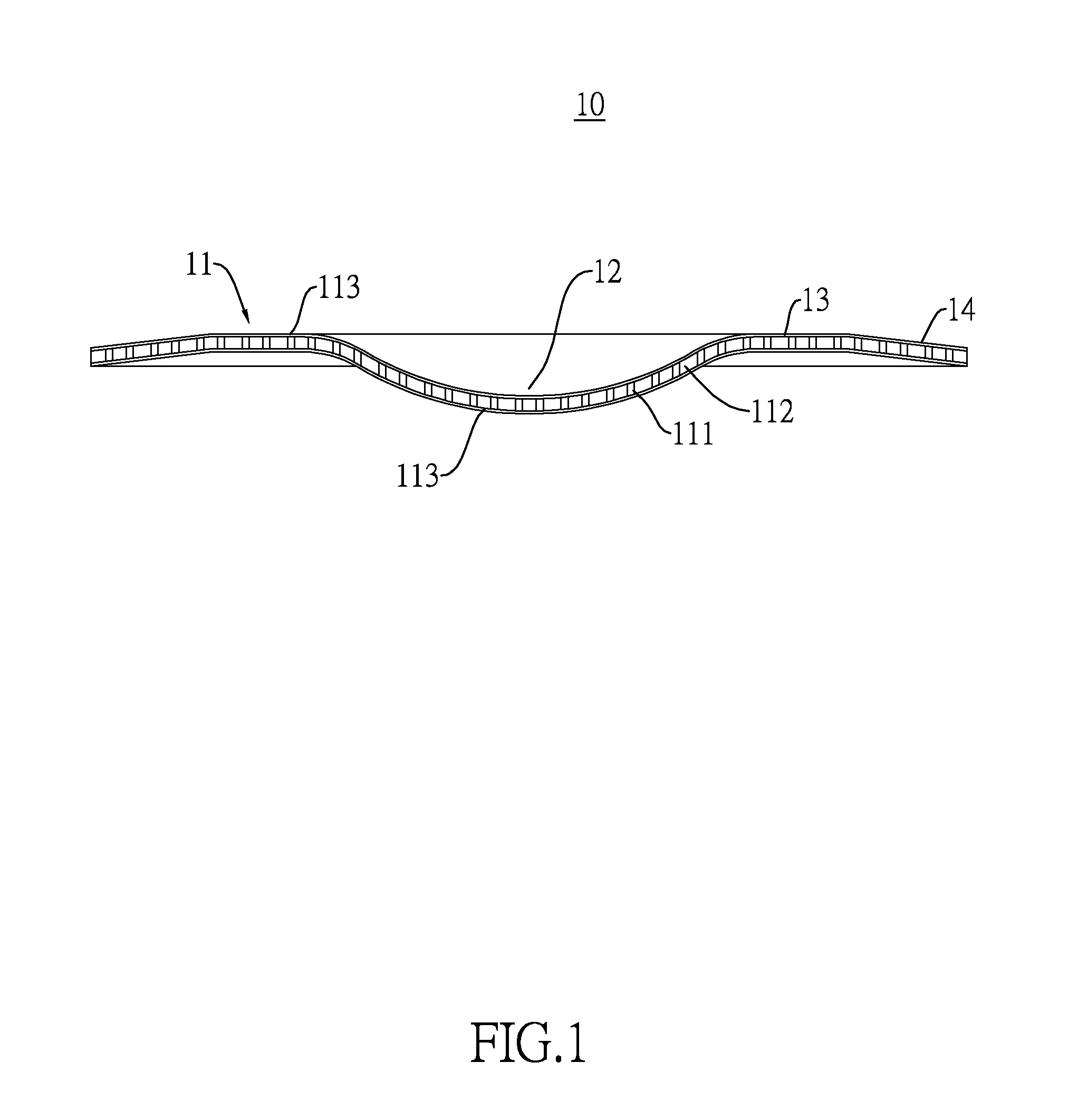

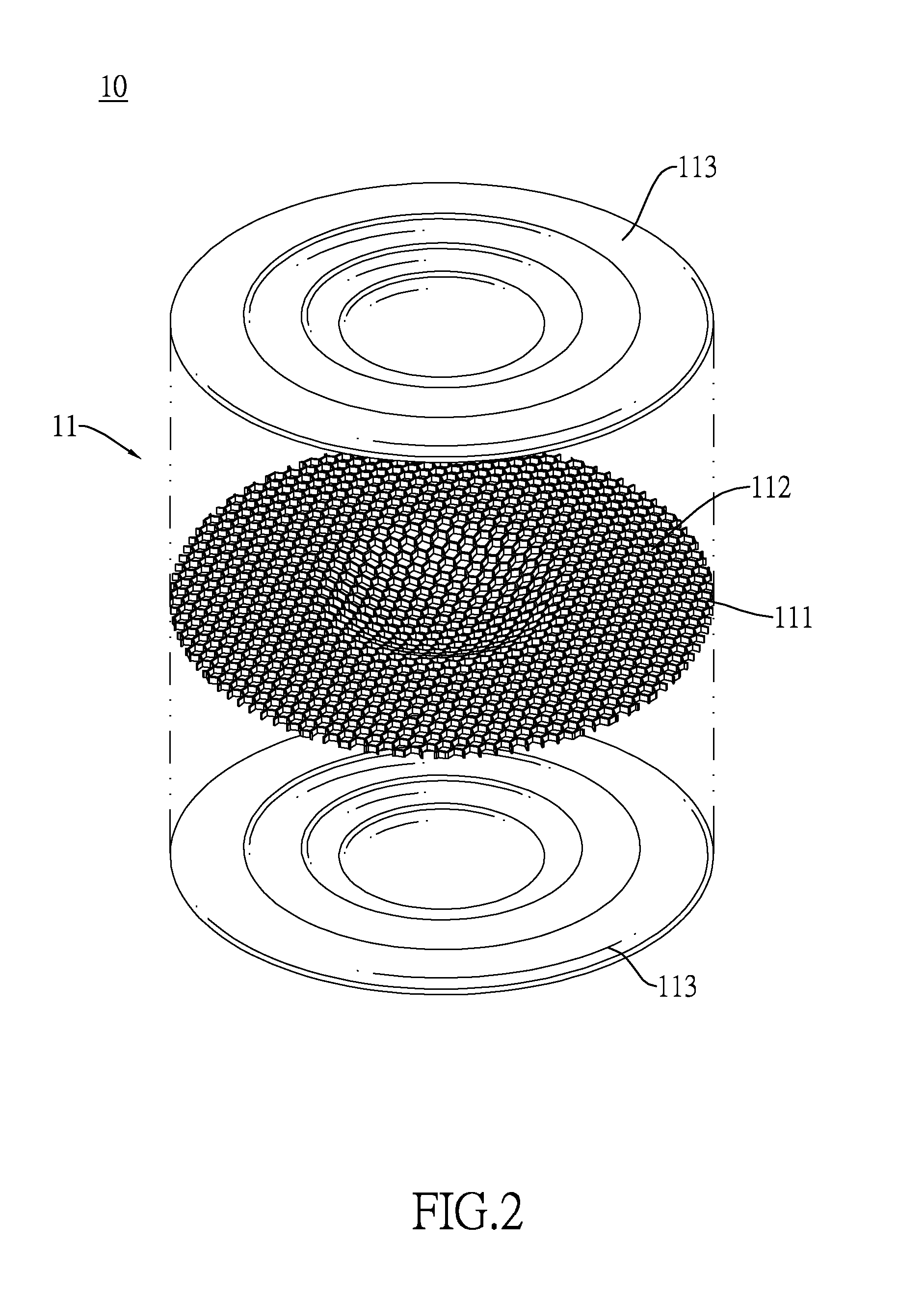

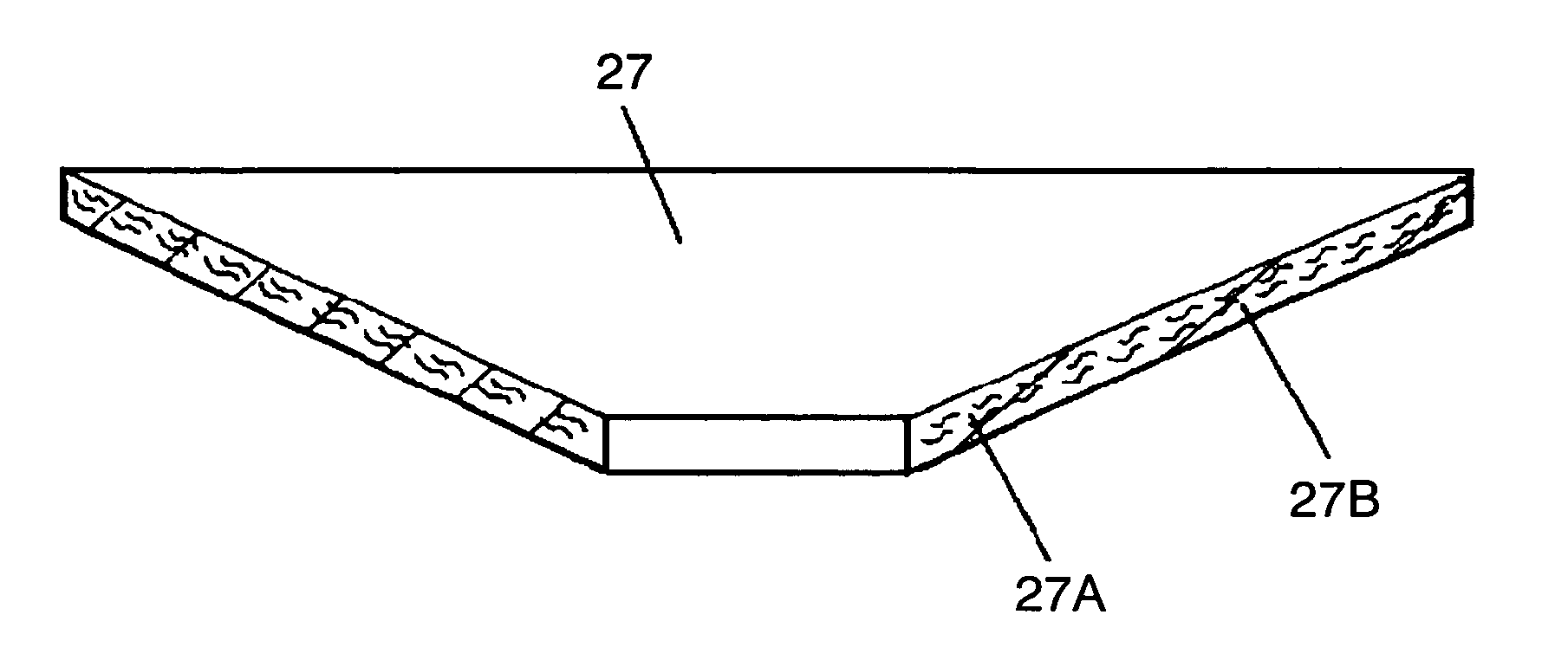

Vibration diaphragm and speaker with a vibration diaphragm

InactiveUS20120281861A1Improve rigidityFibre diaphragmsTransducer detailsEngineeringMechanical engineering

Owner:HI TECH SOUND SYST

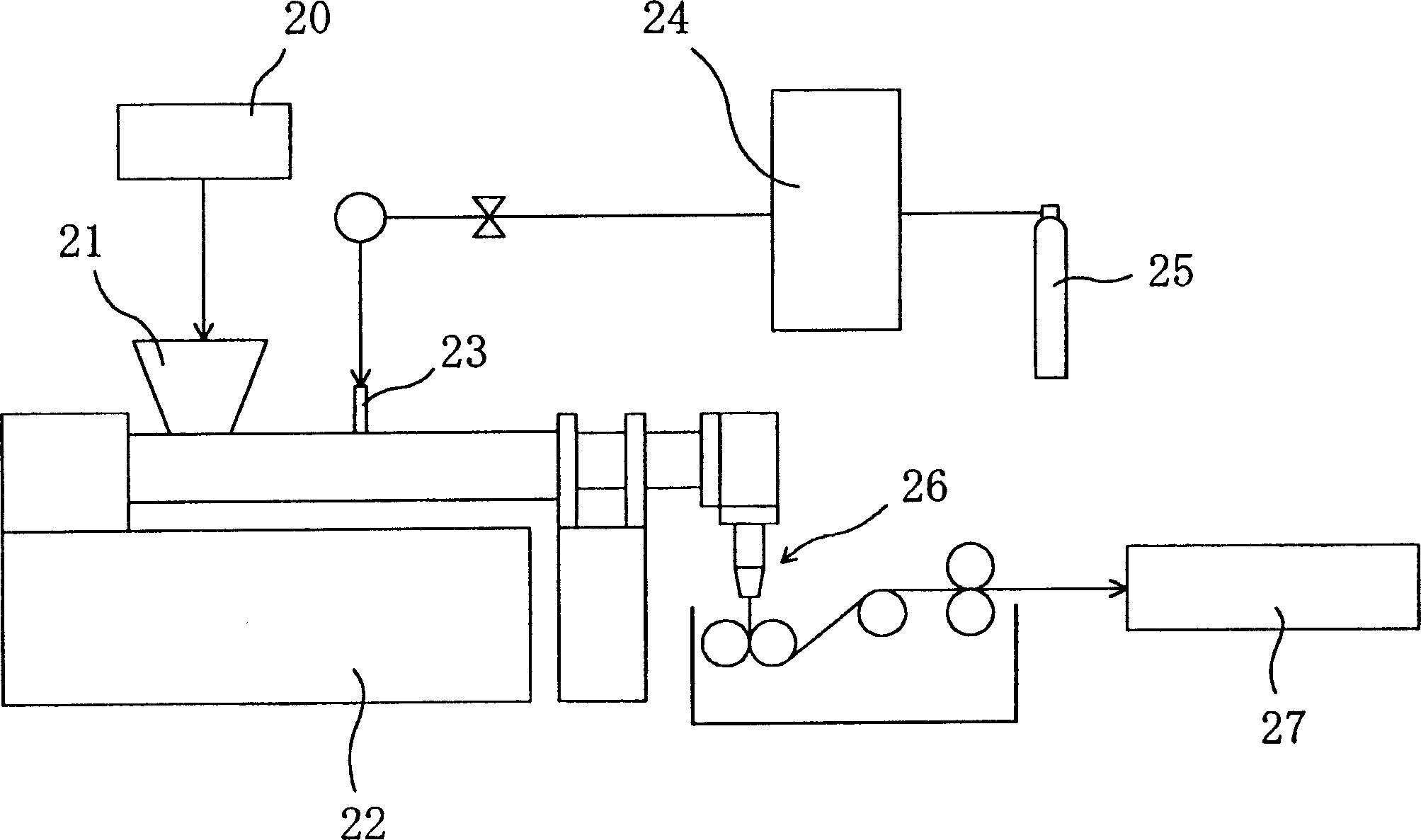

Speaker, speaker-use diaphragm, dust cap, production methods and production devices for them

InactiveUS20070131478A1The degree of freedom becomes largerNice appearanceFibre diaphragmsPolymeric diaphragmsFiberProduction rate

A speaker diaphragm or a dust cap formed by injection molding a mixture at least containing a resin material and a fiber material. The speaker diaphragm or the dust cap combines the advantages of both a paper diaphragm and a resin diaphragm. The advantage of a paper diaphragm is a large degree of freedom in setting physical properties. The advantages of a resin diaphragm are being excellent in moisture resistance reliability, strength, external appearance, productivity and dimension stability.

Owner:PANASONIC CORP

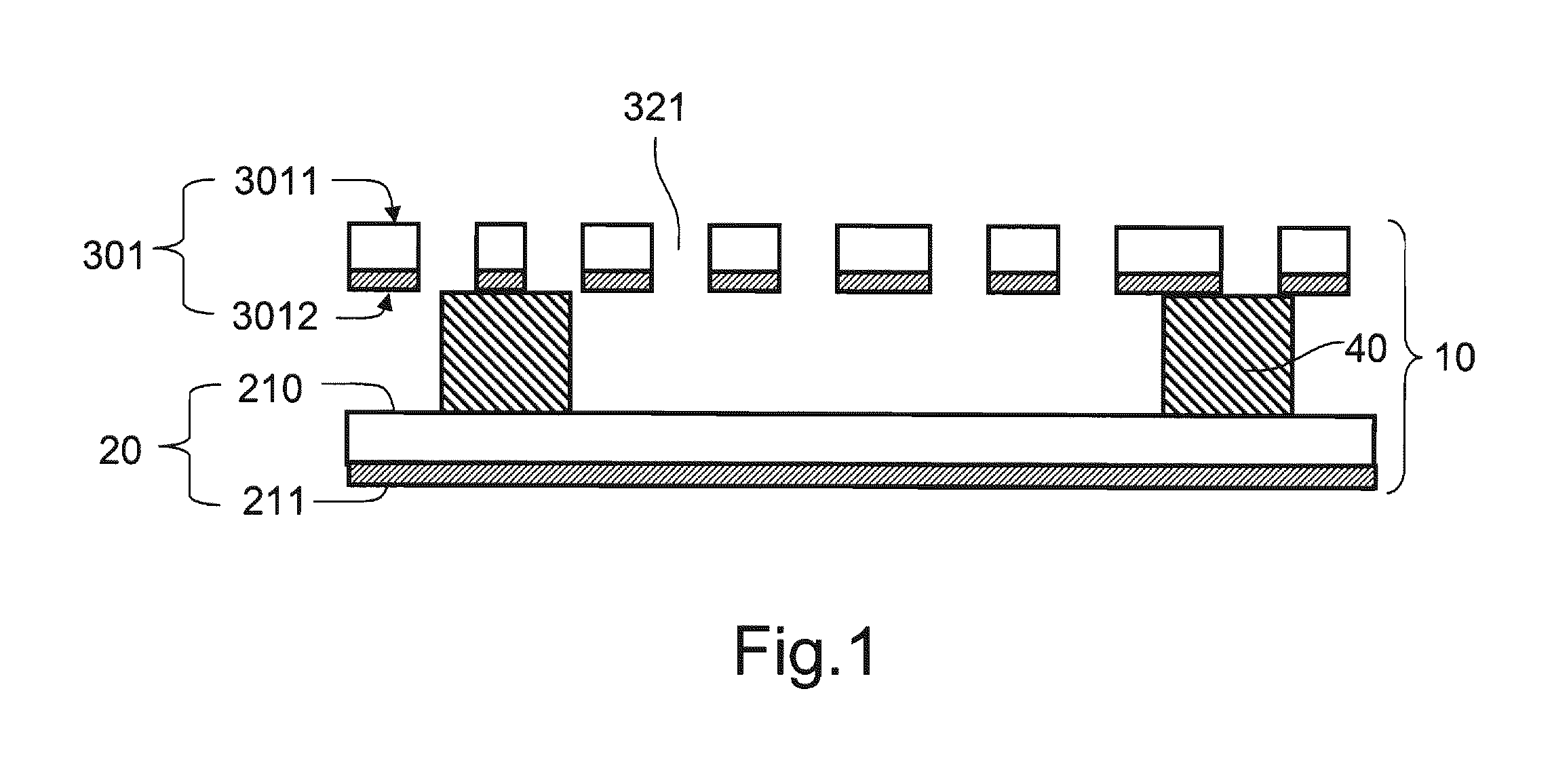

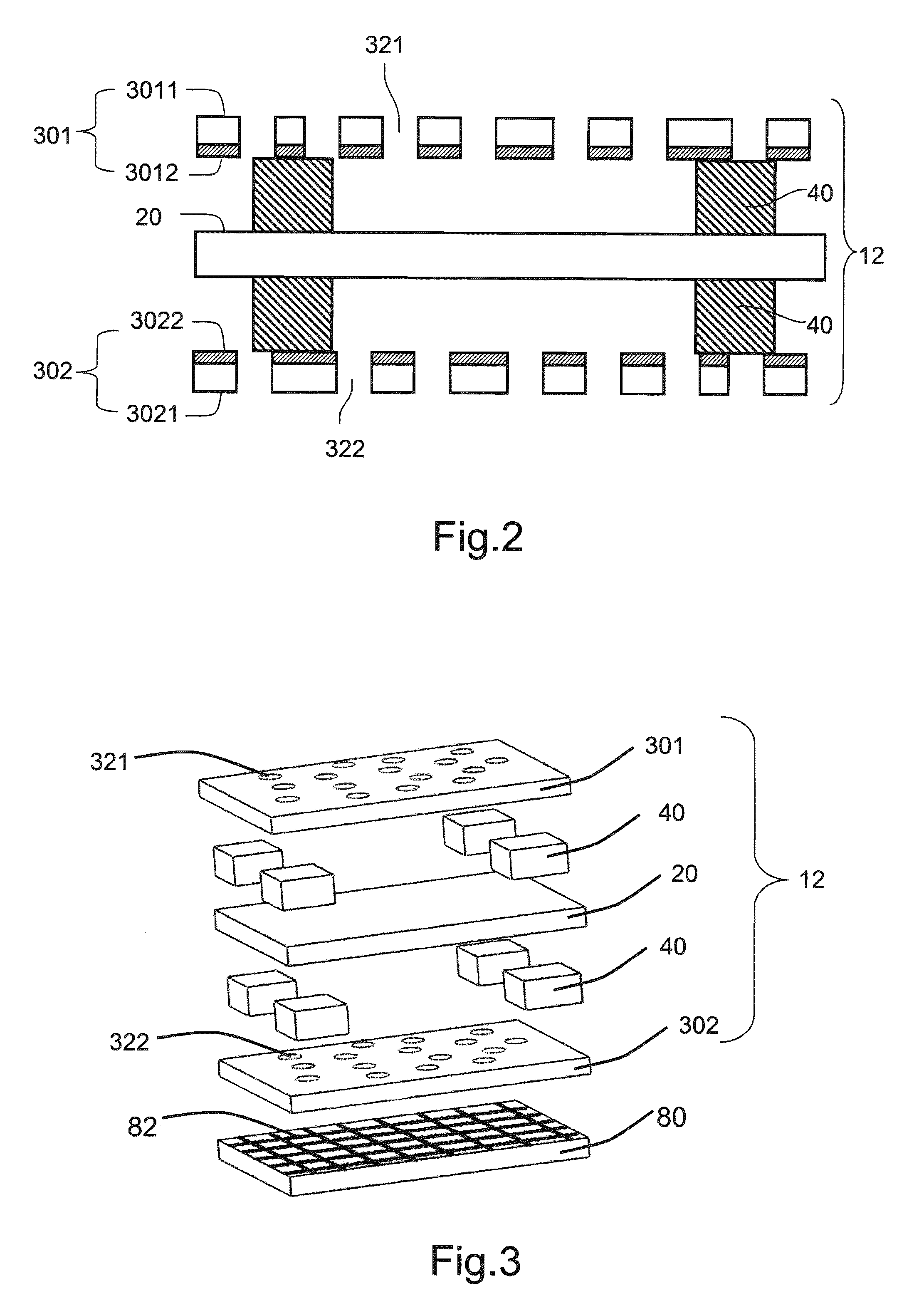

Transparent speaker and display module integrating the same

ActiveUS20110033074A1Improve visual effectsImprove the display effectFibre diaphragmsTransducer casings/cabinets/supportsLoudspeakerComputer science

A transparent speaker is suitable for being disposed on a display panel. The transparent speaker includes a transparent membrane, a transparent electrode plate, and spacers. Each transparent electrode plate has a plurality of openings. The display panel includes a plurality of pixels. The pixels emit optical signals. A Moire spatial period of the optical signals is less than 600 μm after the optical signals pass through the transparent speaker. When the transparent speaker is disposed on the display panel, a user is able to watch an image on the display panel through the transparent speaker without being interfered by a Moire.

Owner:IND TECH RES INST

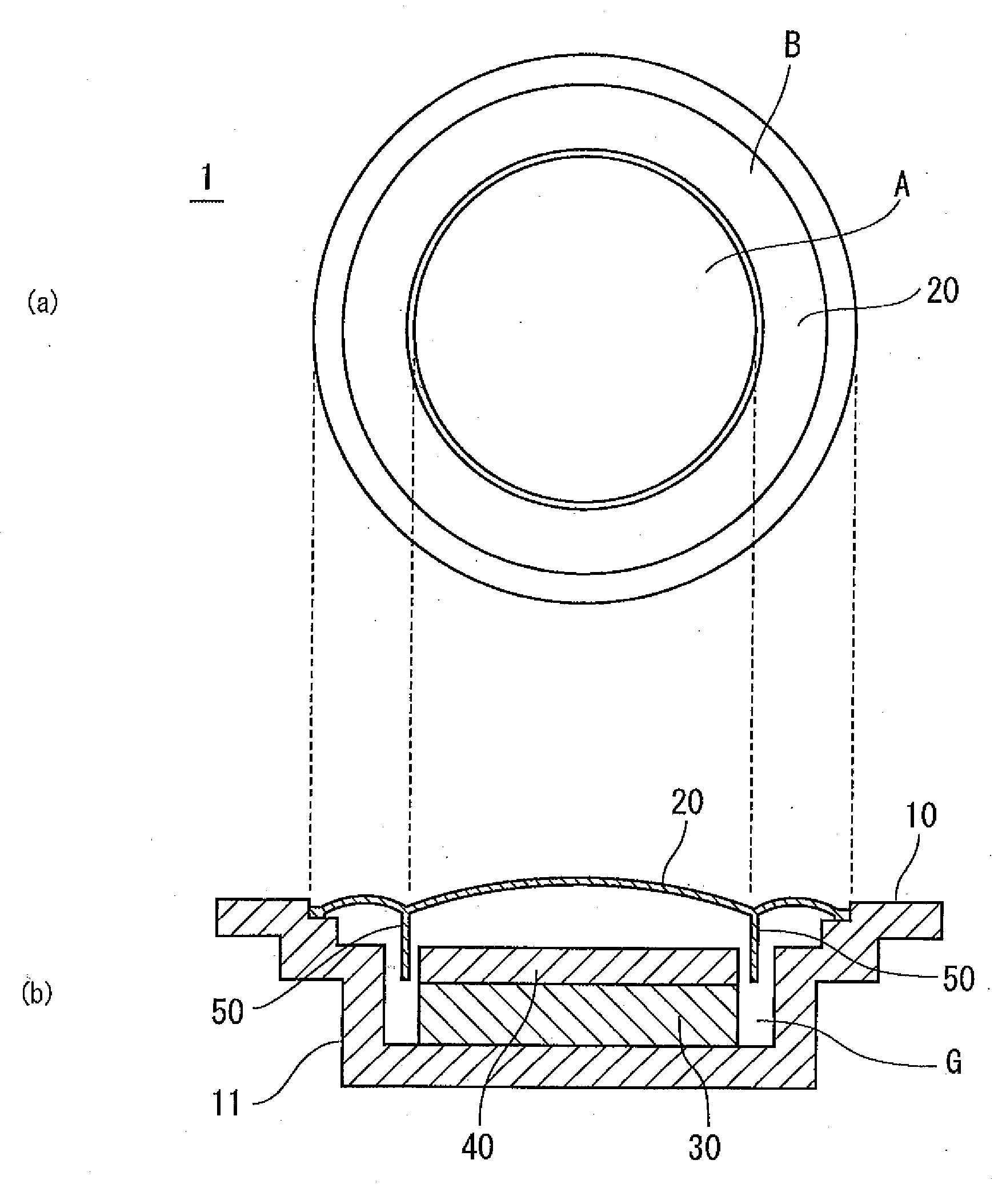

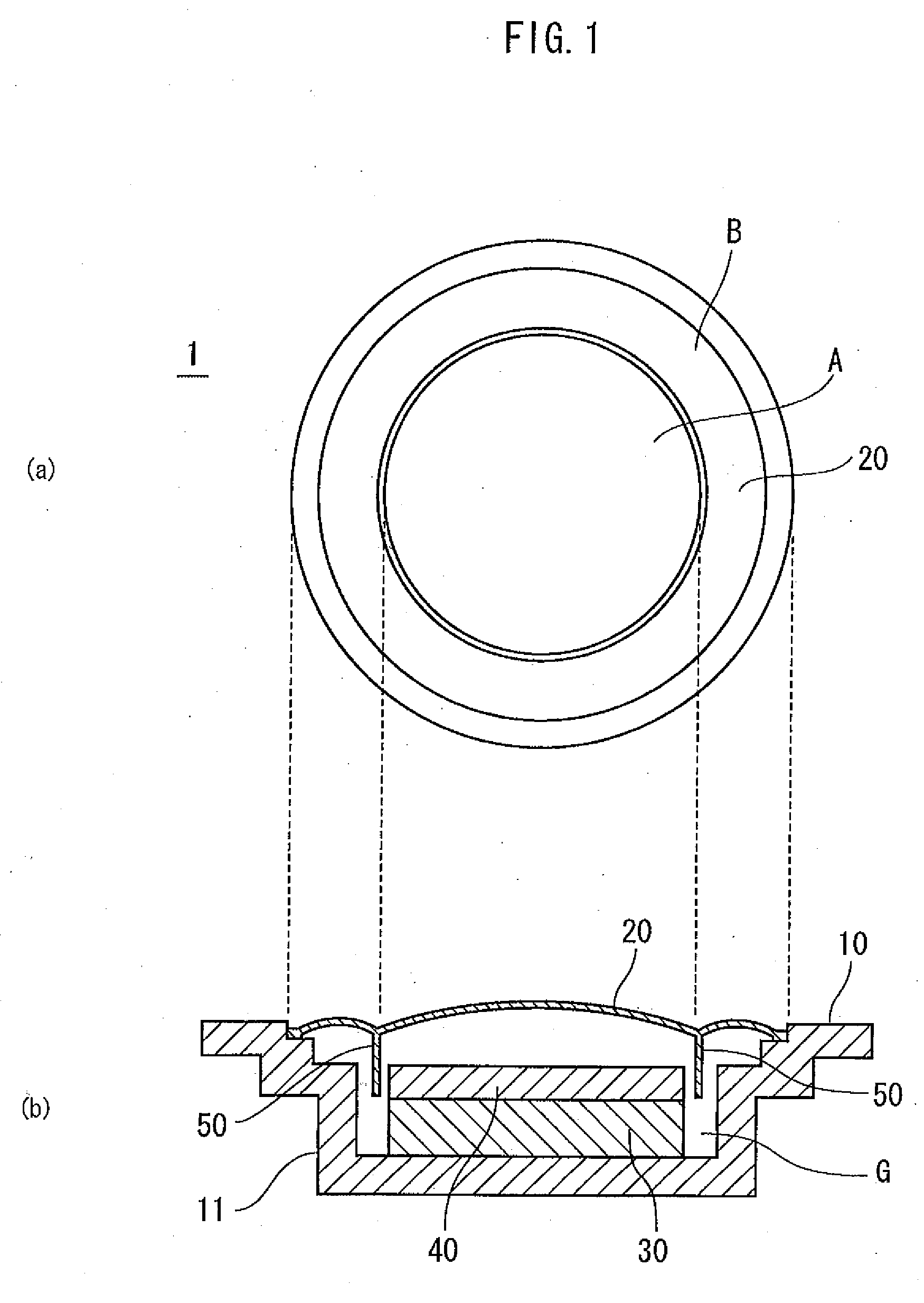

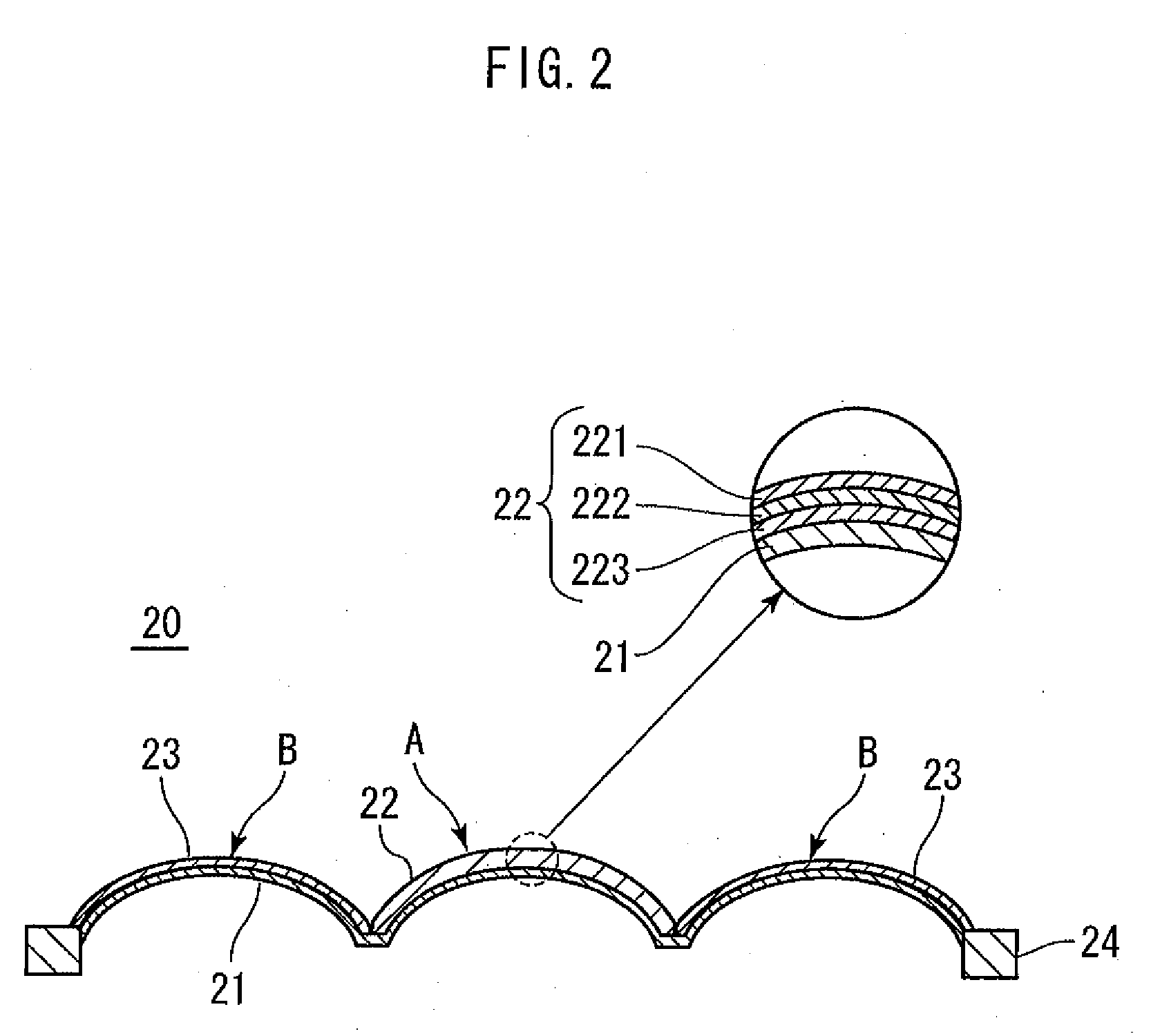

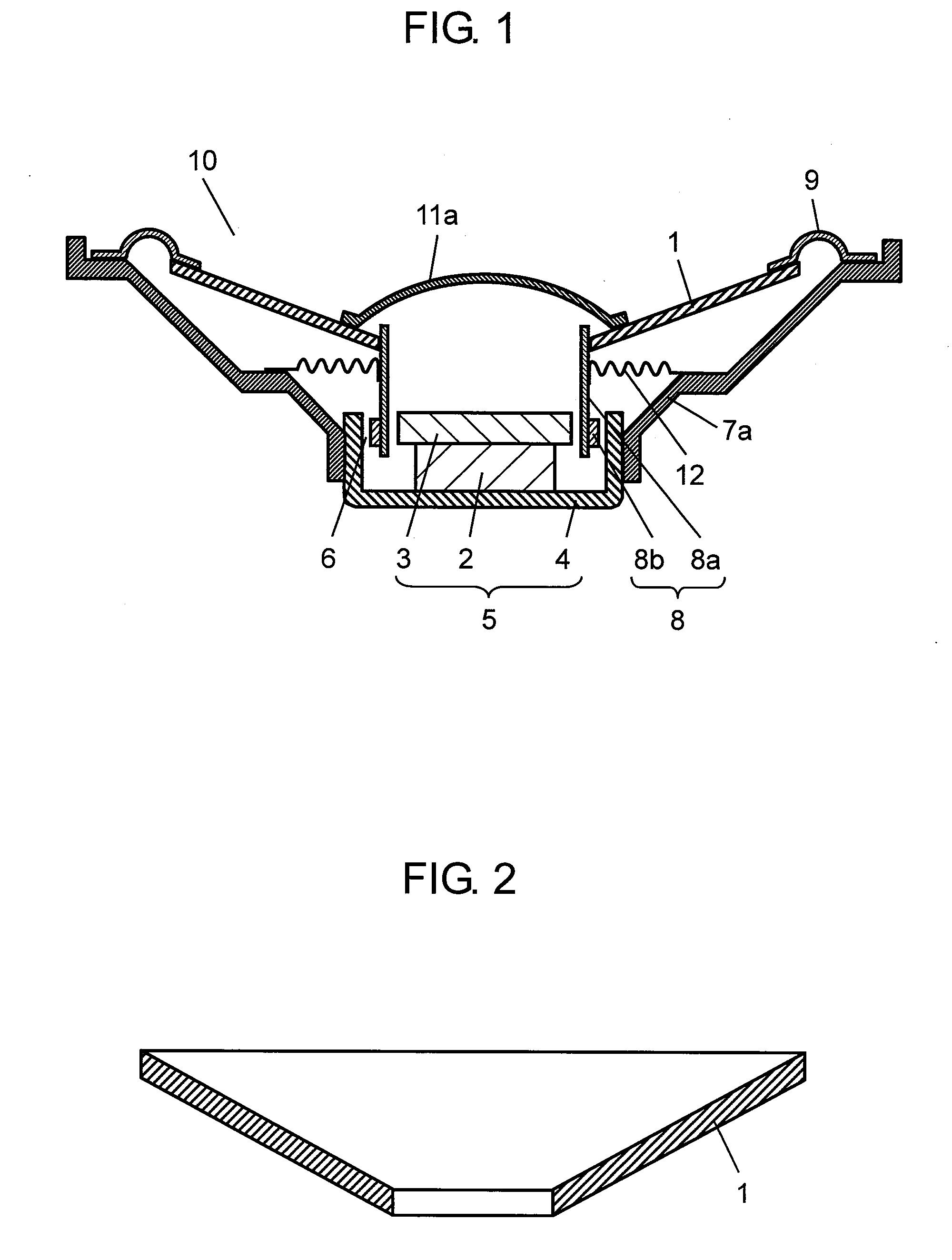

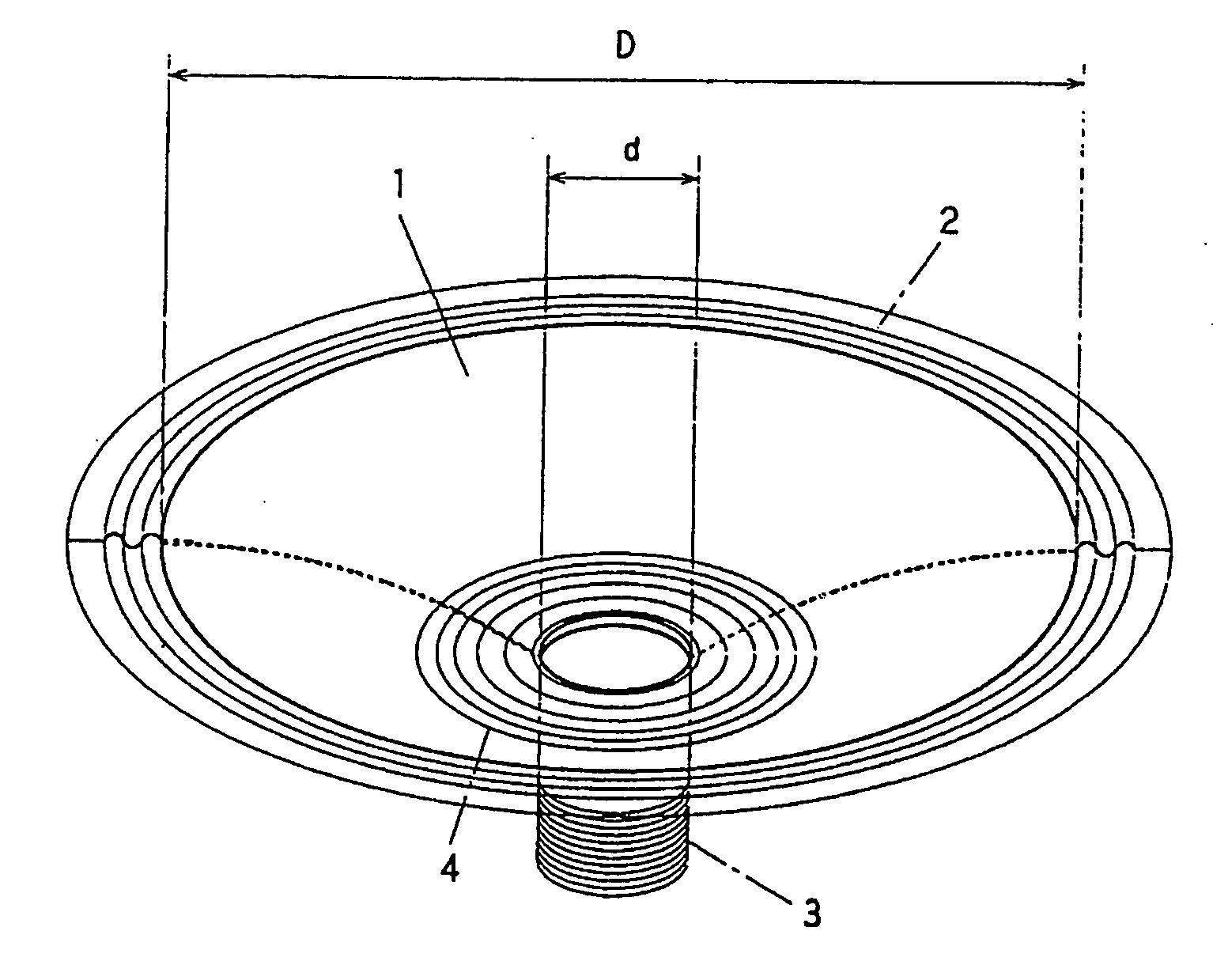

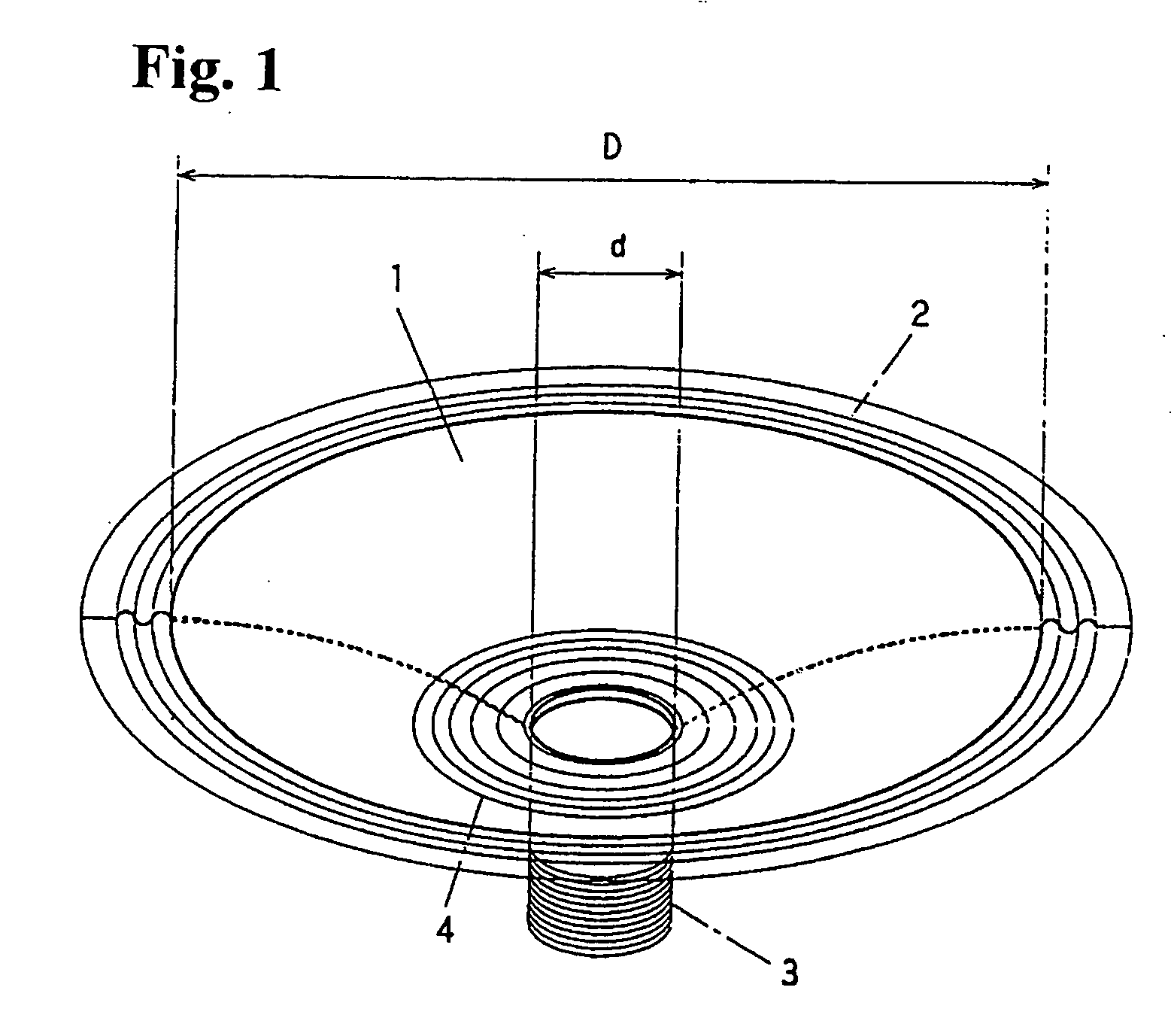

Dome-shaped diaphragm and loudspeaker using the same

InactiveUS20090304225A1High frequency responseLow costFibre diaphragmsTransducer detailsPolyethylene terephthalateCarbon fibers

The present invention provides a dome-shaped diaphragm fabricated based on a film base of polyethylene terephthalate resin film. The diaphragm includes a first vibrating part of a dome shape or a flat shape, and a second vibrating part of an annular shape. The second vibrating part includes a peripheral portion of the film base provided around a central portion of the film base. The first vibrating part includes the central portion of the film base, a thermosensitive adhesive resin film, provided on the central portion, and a fiber sheet made of a woven fabric using carbon fiber or an embossed nonwoven fabric. The fiber sheet is layered over the central portion with the thermosensitive adhesive resin film interposed therebetween.

Owner:HOSIDEN CORP

Planar speaker

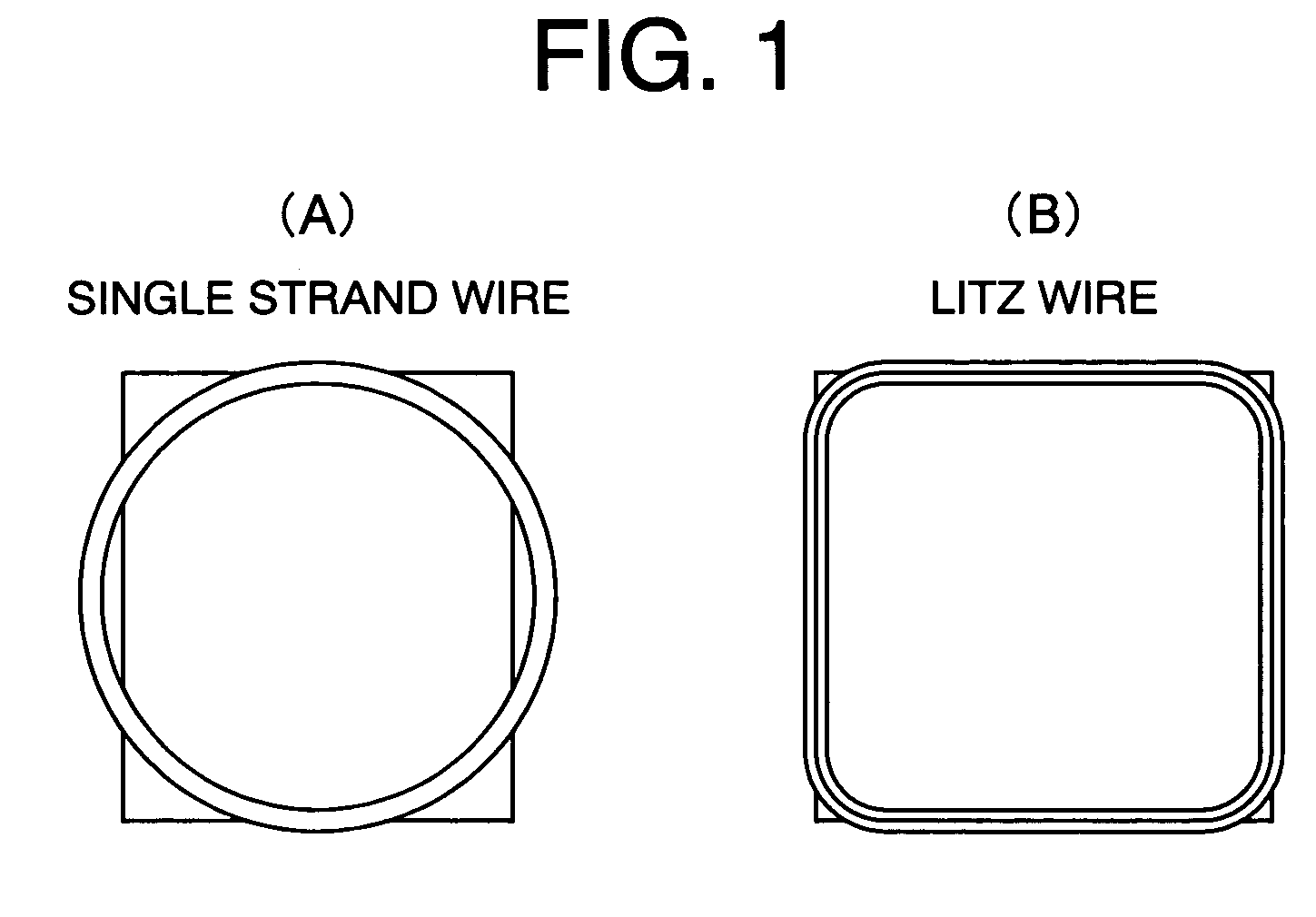

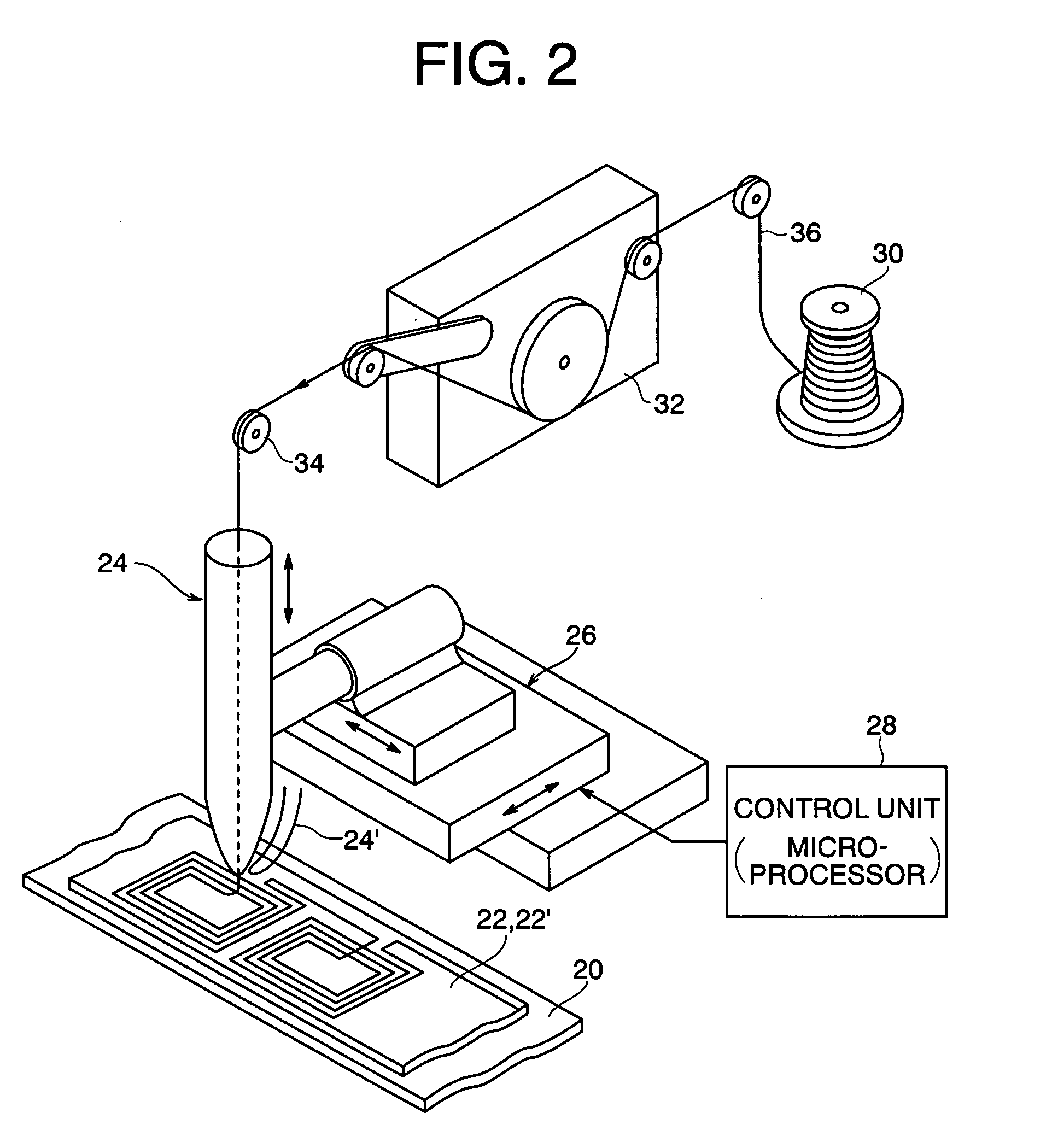

InactiveUS20050152577A1Less variation in impedanceIncrease freedomFibre diaphragmsPlane diaphragmsElectrical conductorTransducer

Owner:FURUKAWA ELECTRIC CO LTD

Speaker motor and speaker

ActiveUS8175321B2Promote reproductionHeat dissipationFibre diaphragmsMetallic diaphragmsMetallic materialsEngineering

A diaphragm for a speaker includes two portions. The first portion is made of metallic material for producing a high frequency tone. The second portion is made of a non-metallic material for producing a low frequency tone. The first portion is joined at a first peripheral edge to a voice coil while a second peripheral edge is joined at a first peripheral edge of the second portion to form the diaphragm.

Owner:SAMSON TECHNOLOGIES

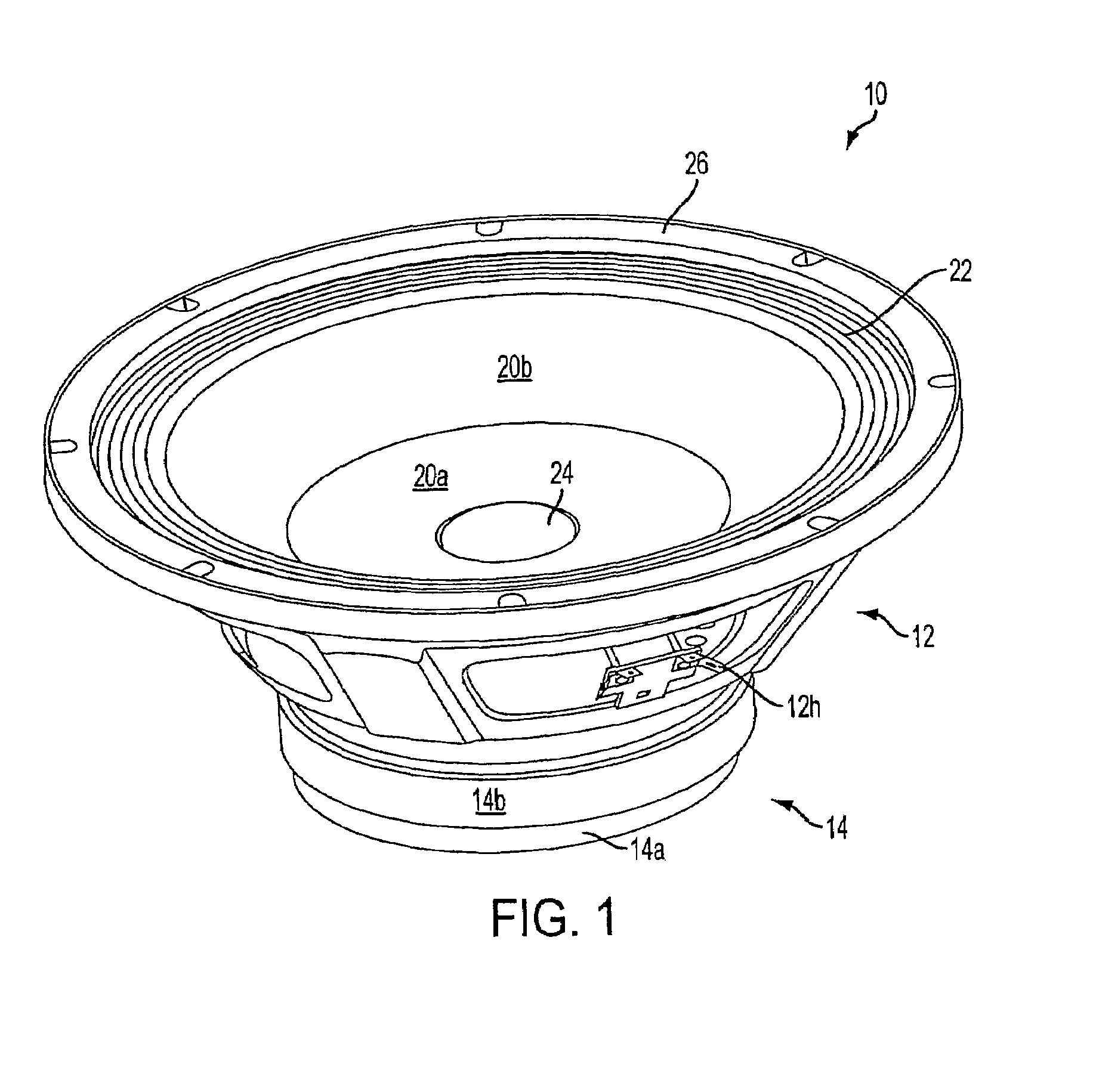

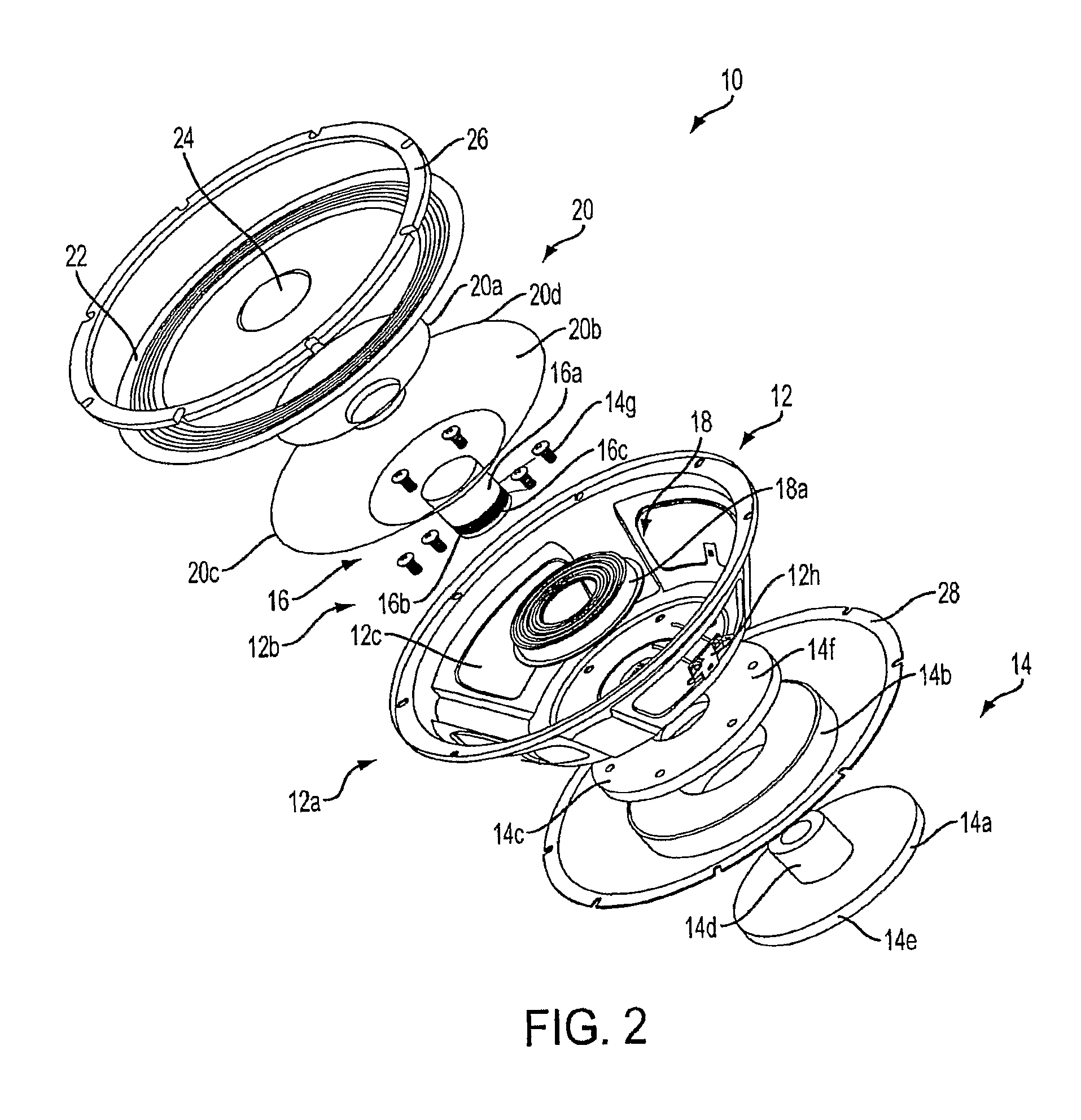

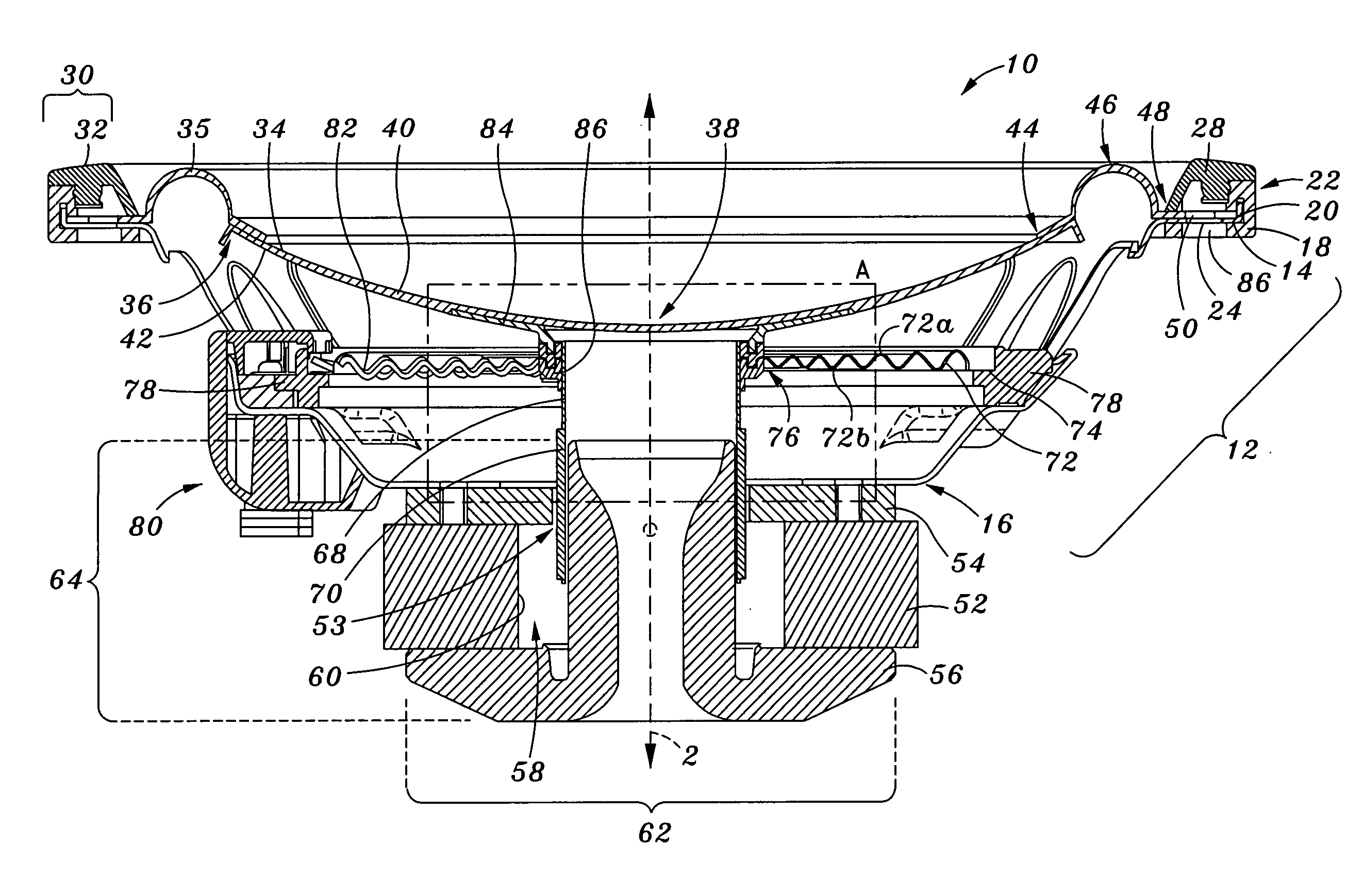

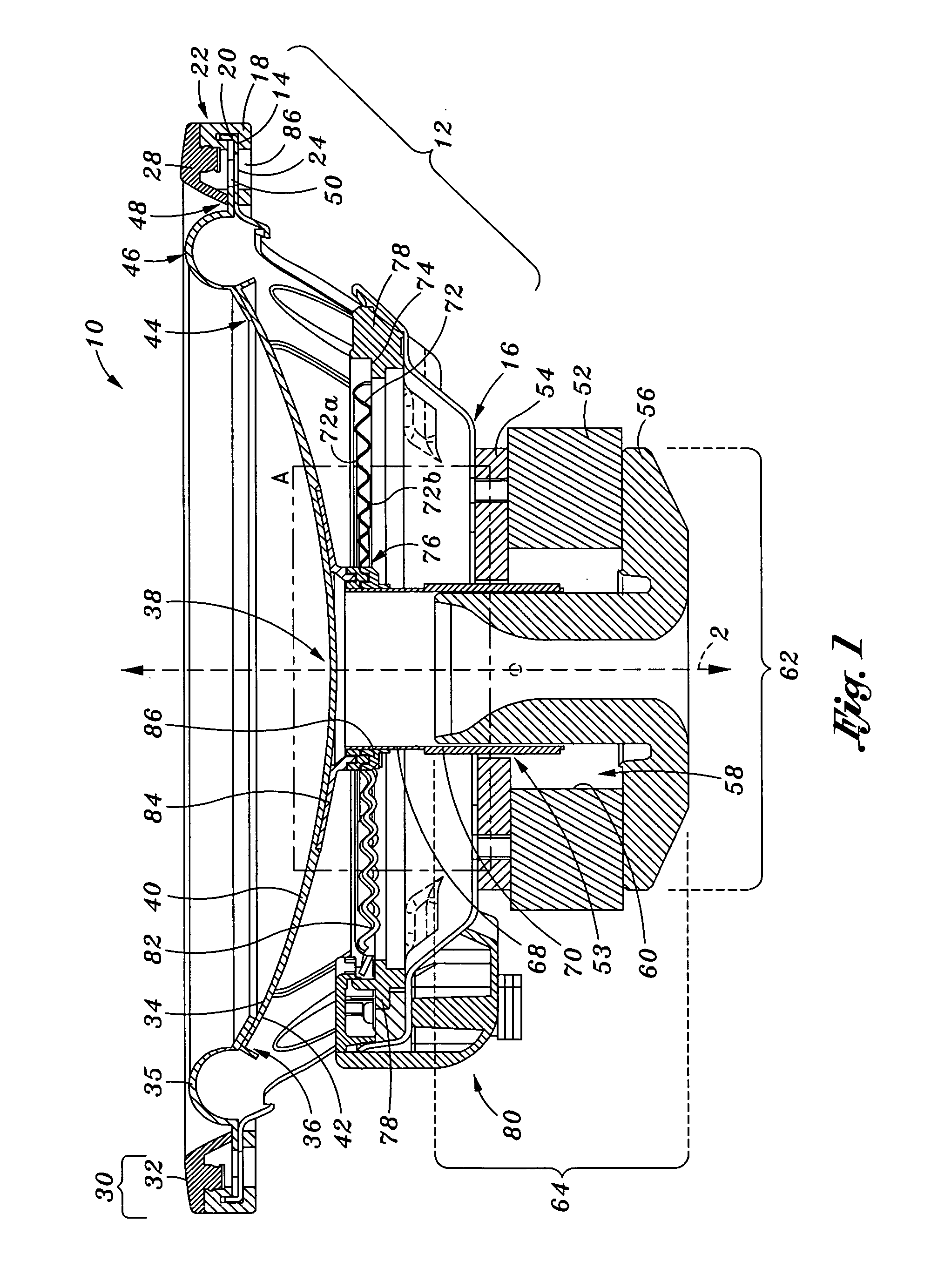

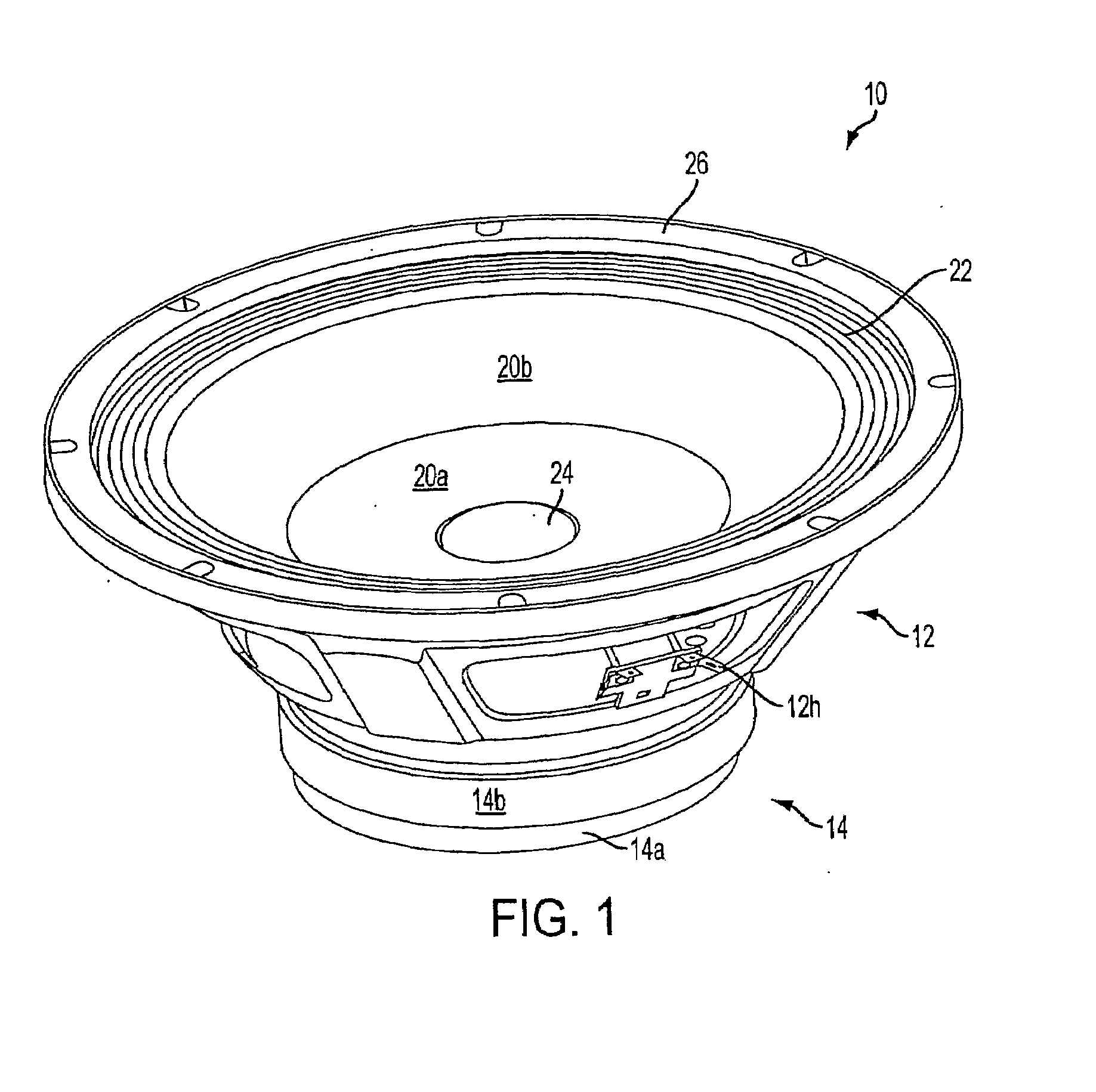

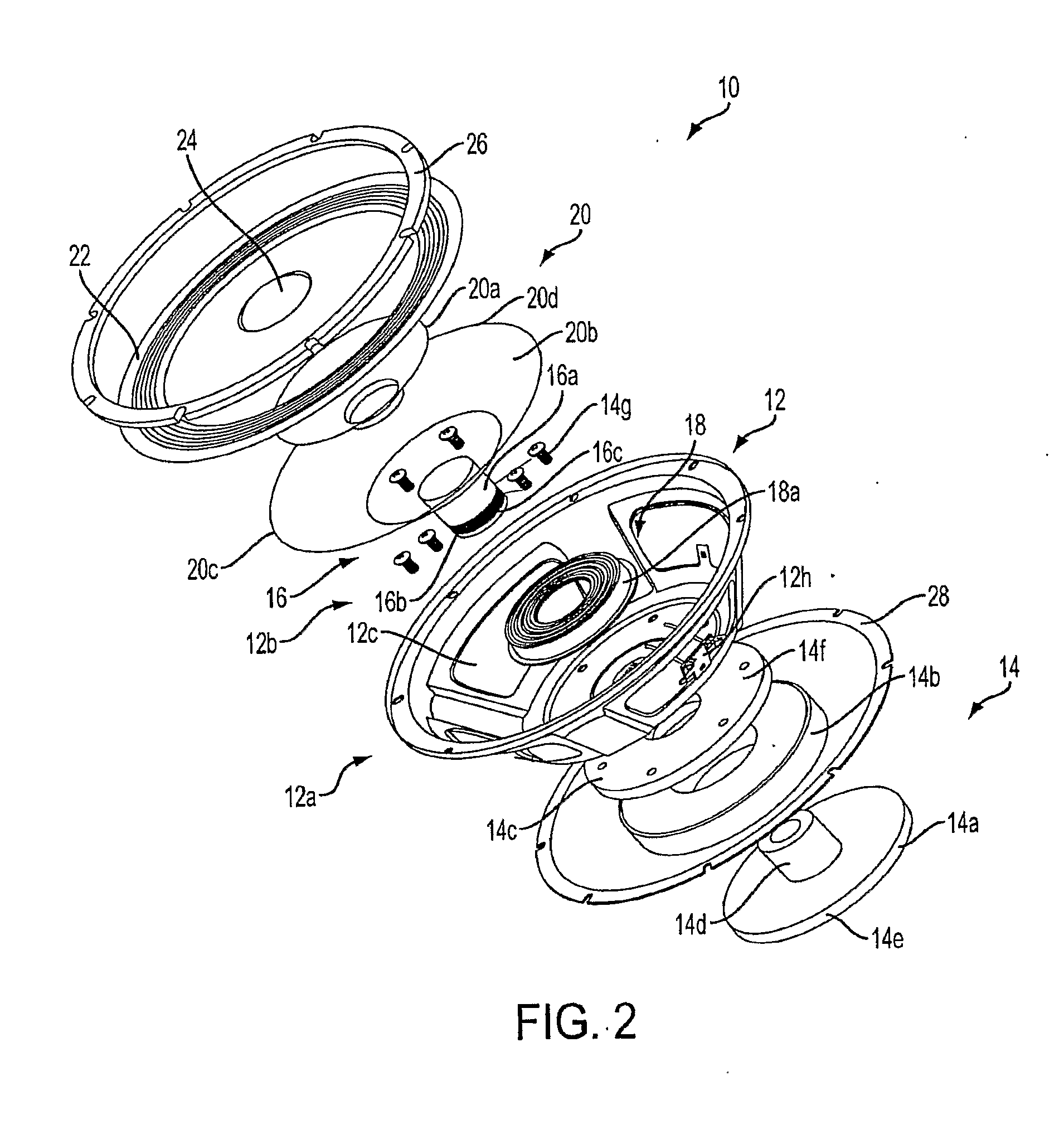

Loudspeaker bobbin interconnection assembly

A bobbin interconnection assembly in a moving coil loudspeaker is disclosed. The assembly includes a first coupling member fixed to a central region of a diaphragm of the loudspeaker. The assembly also includes a second coupling member that may be removably engaged to the first coupling member. The second coupling member is fixed to an inner rim of an annular damper, and to a voice coil bobbin.

Owner:SOUND SOURCES TECH

Diaphragm for speaker, frame for speaker, dust cap for speaker, speaker and apparatus using them, and method for manufacturing component for speaker

ActiveUS20100059309A1Improve productivityHigh strengthFibre diaphragmsTransducer detailsFiberProduction rate

A speaker diaphragm is configured by a compound mixed with resin and bamboo fiber. The diaphragm satisfying the advantage of the bamboo fiber of high sound quality and a large degree of freedom in the setting of the characteristic value of the diaphragm and the advantage of the diaphragm made of a resin with improved humidity resistance reliability and strength, excellent external appearance, and enhanced productivity and dimension stability is obtained.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

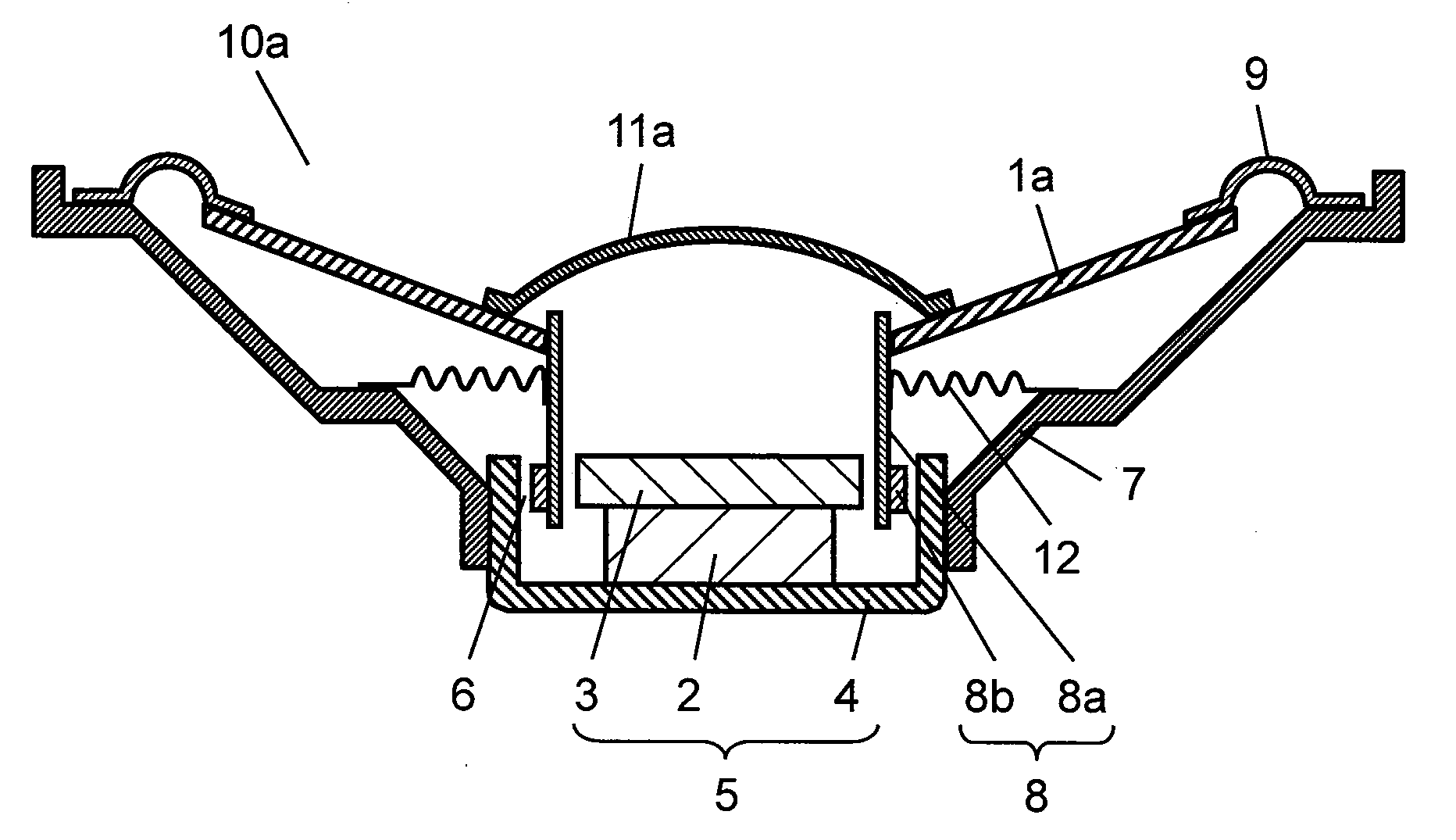

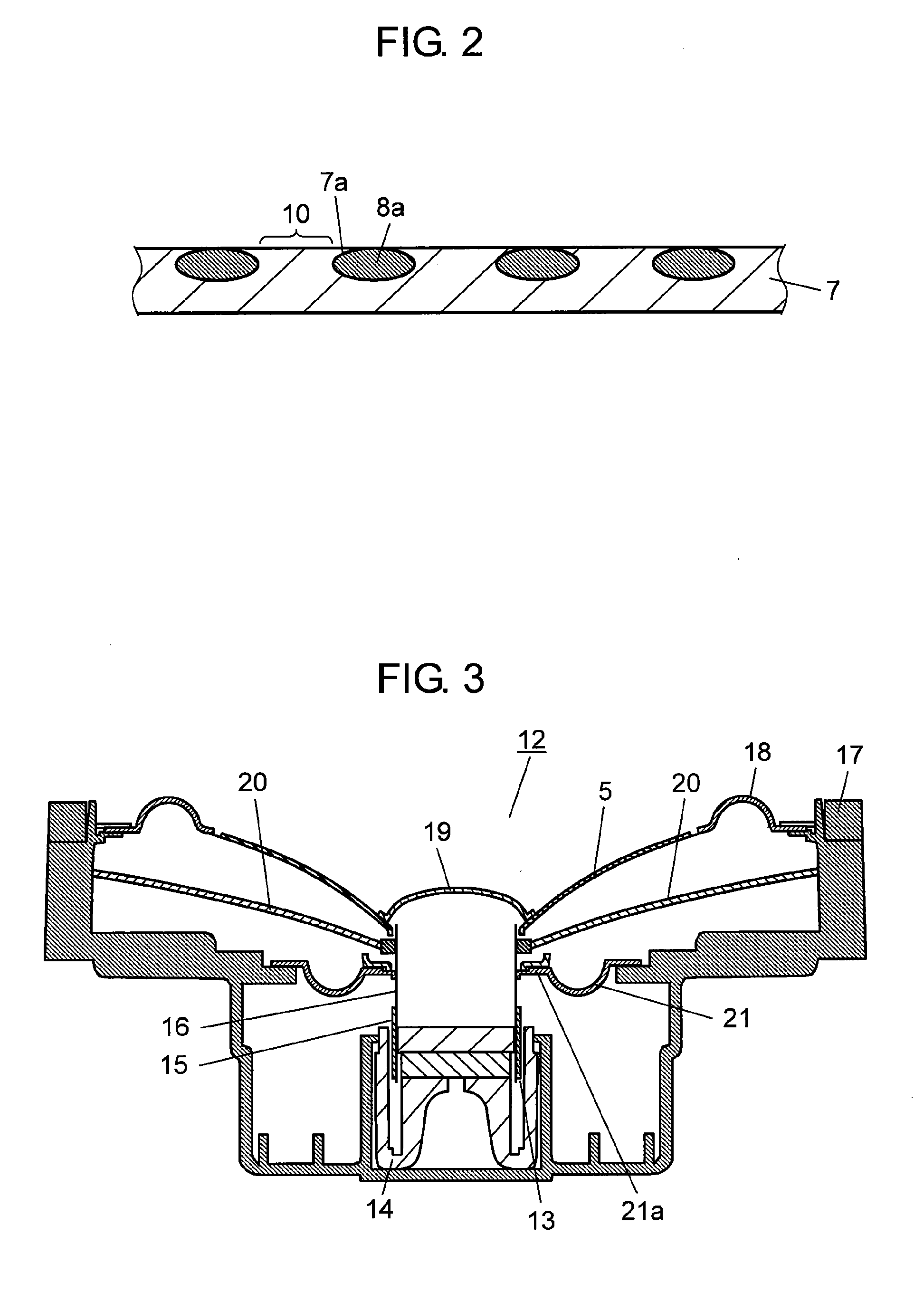

Speaker diaphragm and speaker using the same

InactiveUS20060062422A1Simple processHigh bonding strengthFibre diaphragmsTransducer detailsBobbinEngineering

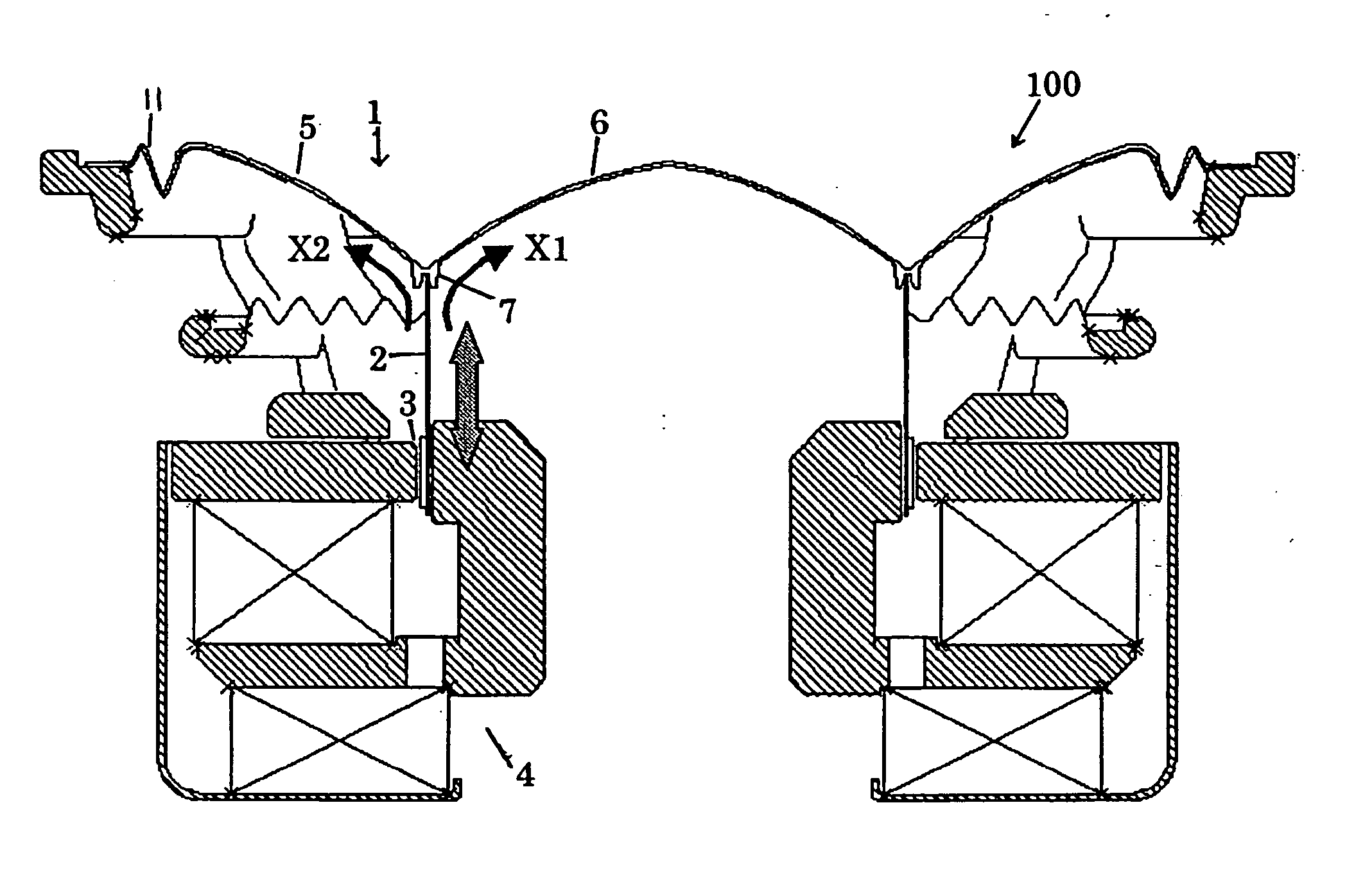

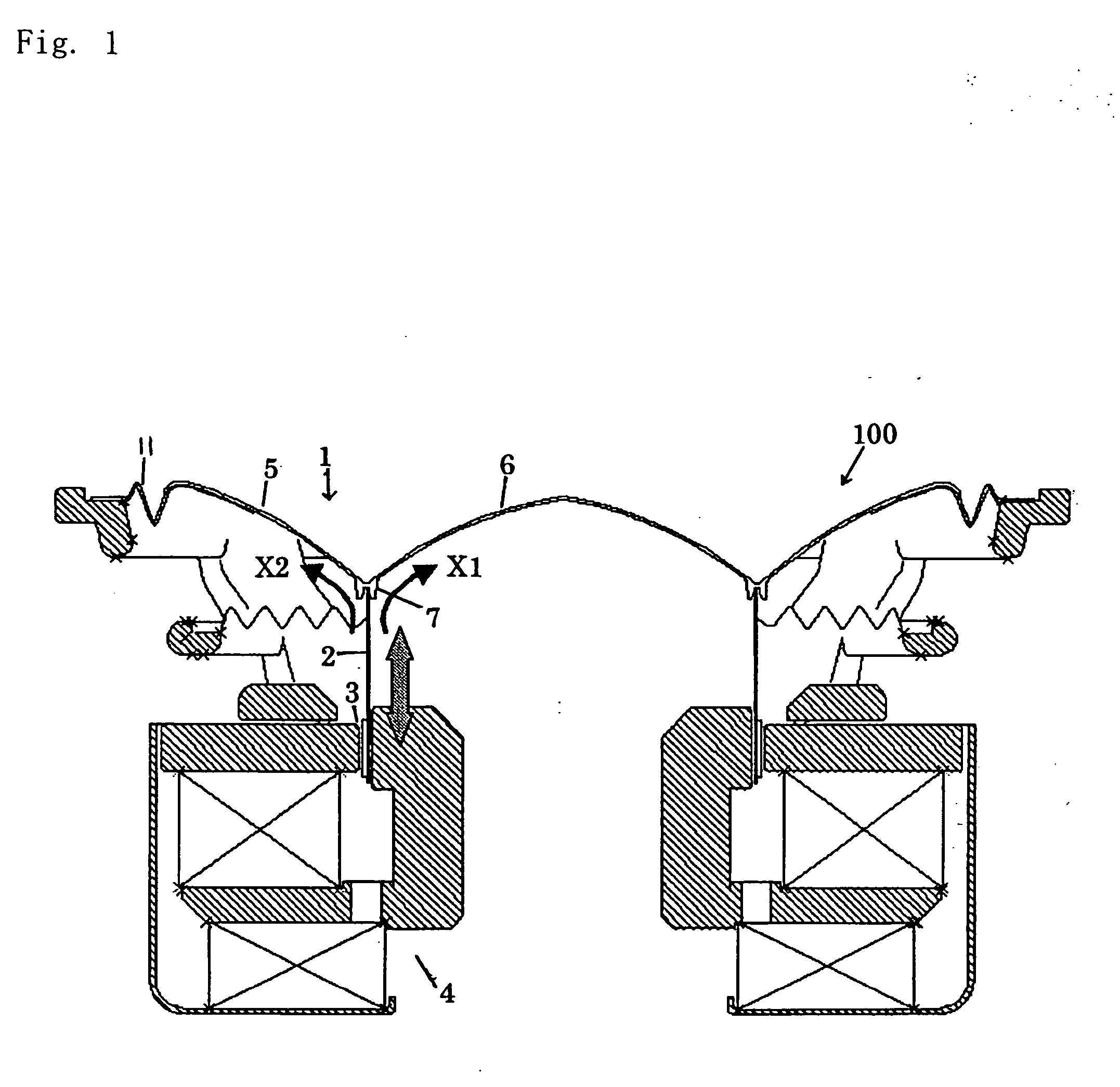

A speaker diaphragm 1 includes a first diaphragm portion 5, a second diaphragm portion 6 integrally molded with the first diaphragm portion 5, and a bobbin-receiving portion 7 protruding from a back side of a connecting portion between the first diaphragm portion 5 and the second diaphragm portion 6, with one end of a voice coil bobbin 2 being bonded to the bobbin-receiving portion 7. The bobbin-receiving portion 7 includes a first extension 8 extending backwards from the first diaphragm portion 5 and a second extension 9 extending backwards from the second diaphragm portion 6. A bobbin-receiving groove 10 is defined between the first extension 8 and the second extension 9. The voice coil bobbin 2 is inserted in and bonded to the bobbin-receiving groove 10.

Owner:ONKYO KK

Speaker motor and speaker

ActiveUS20100092023A1Improve acoustic reproductionProviding heat dissipationFibre diaphragmsMetallic diaphragmsMetallic materialsEngineering

A diaphragm for a speaker includes two portions. The first portion is made of metallic material for producing a high frequency tone. The second portion is made of a non-metallic material for producing a low frequency tone. The first portion is joined at a first peripheral edge to a voice coil while a second peripheral edge is joined at a first peripheral edge of the second portion to form the diaphragm.

Owner:SAMSON TECHNOLOGIES

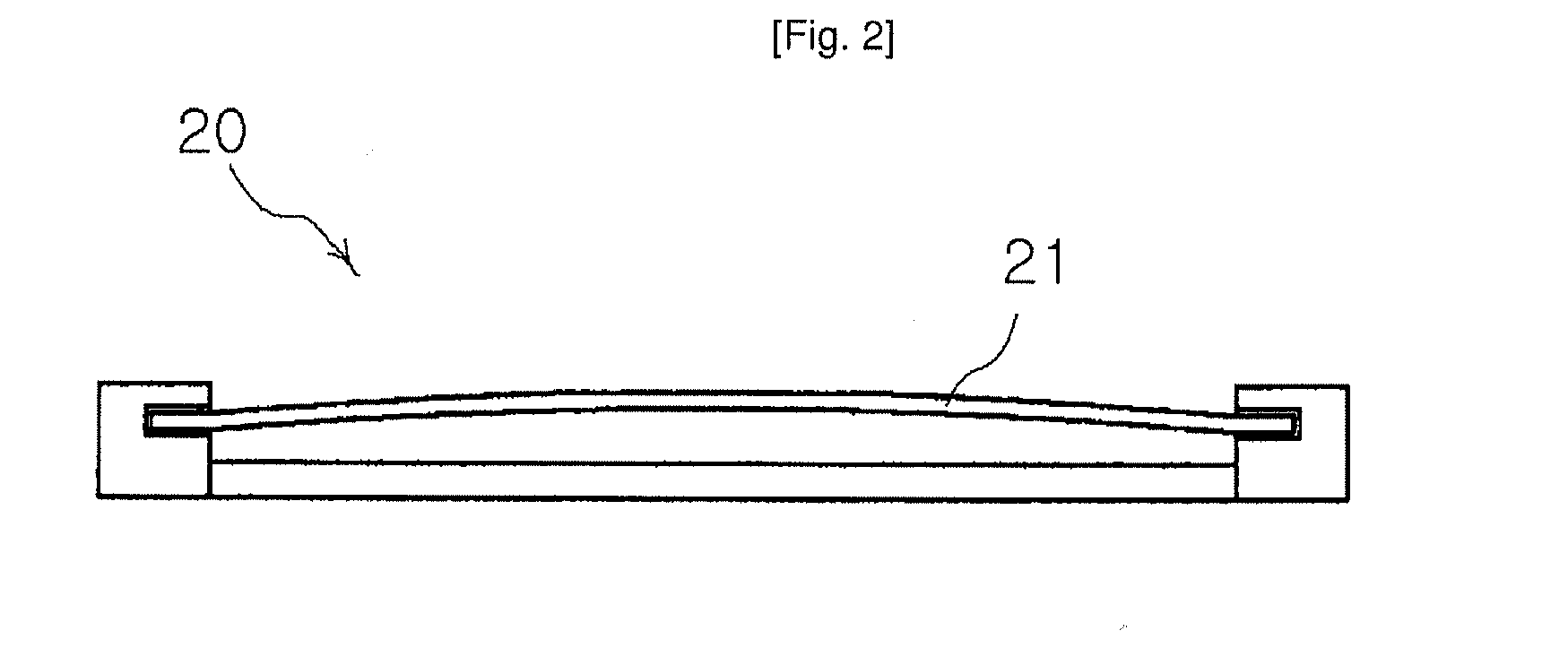

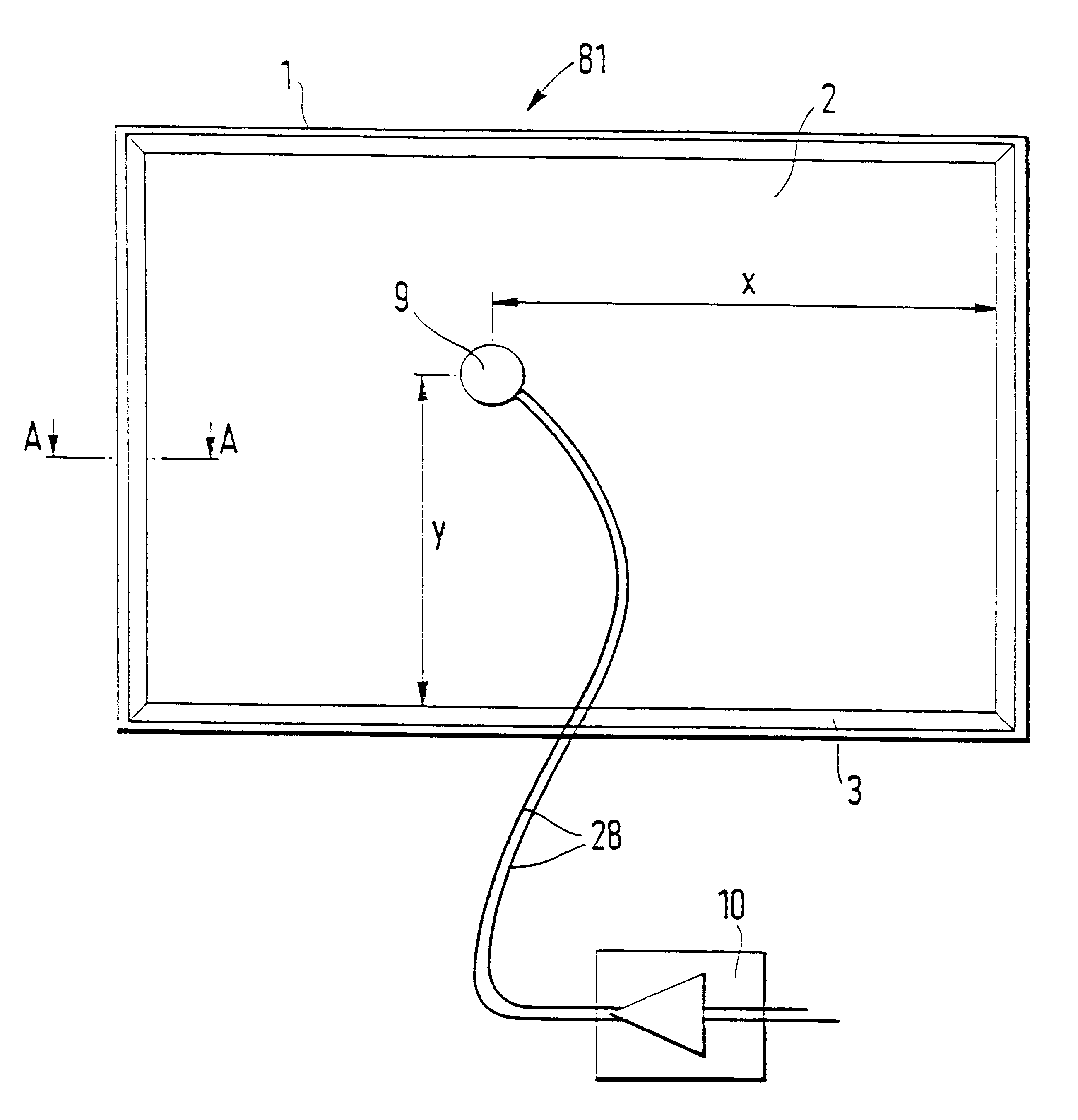

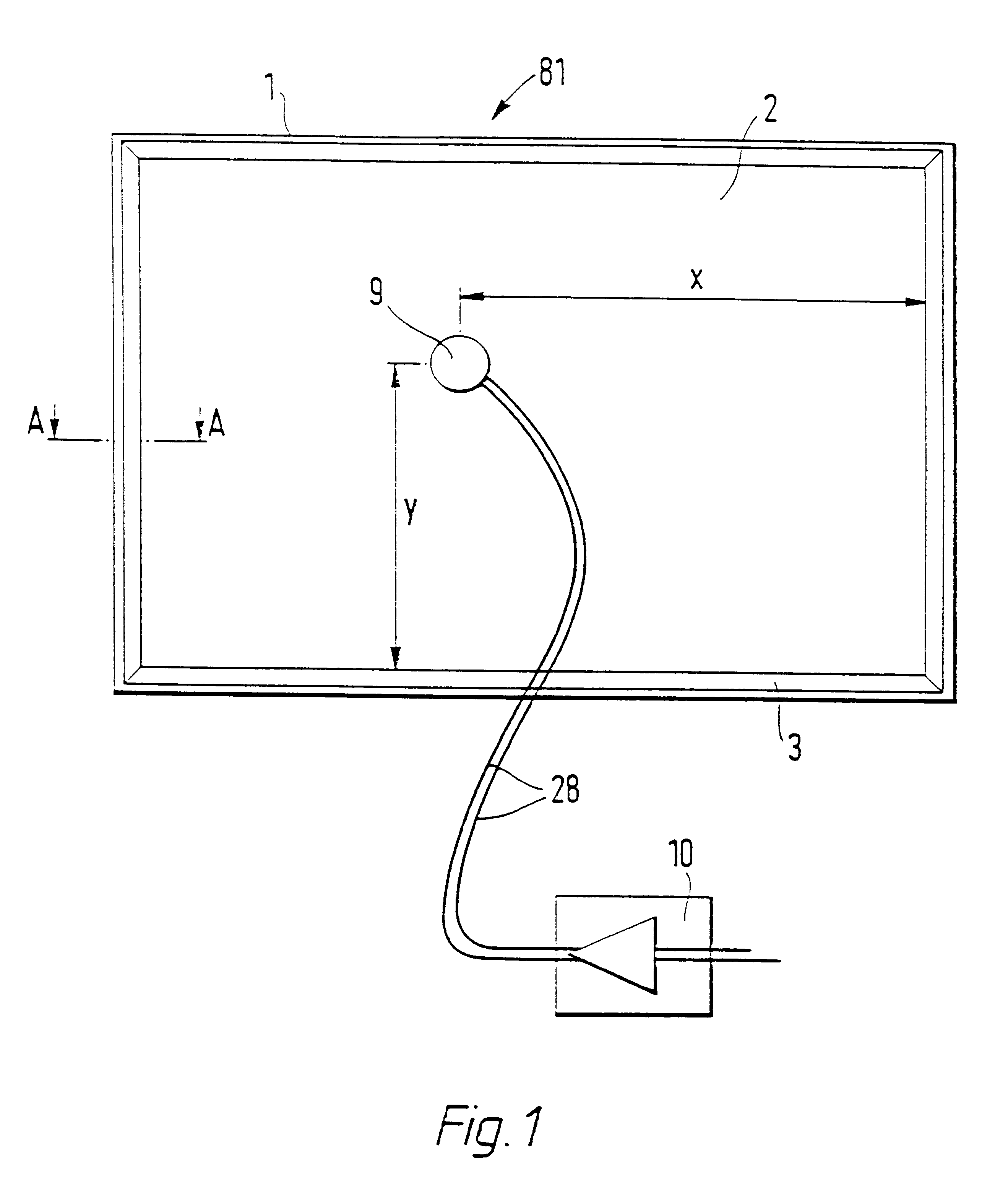

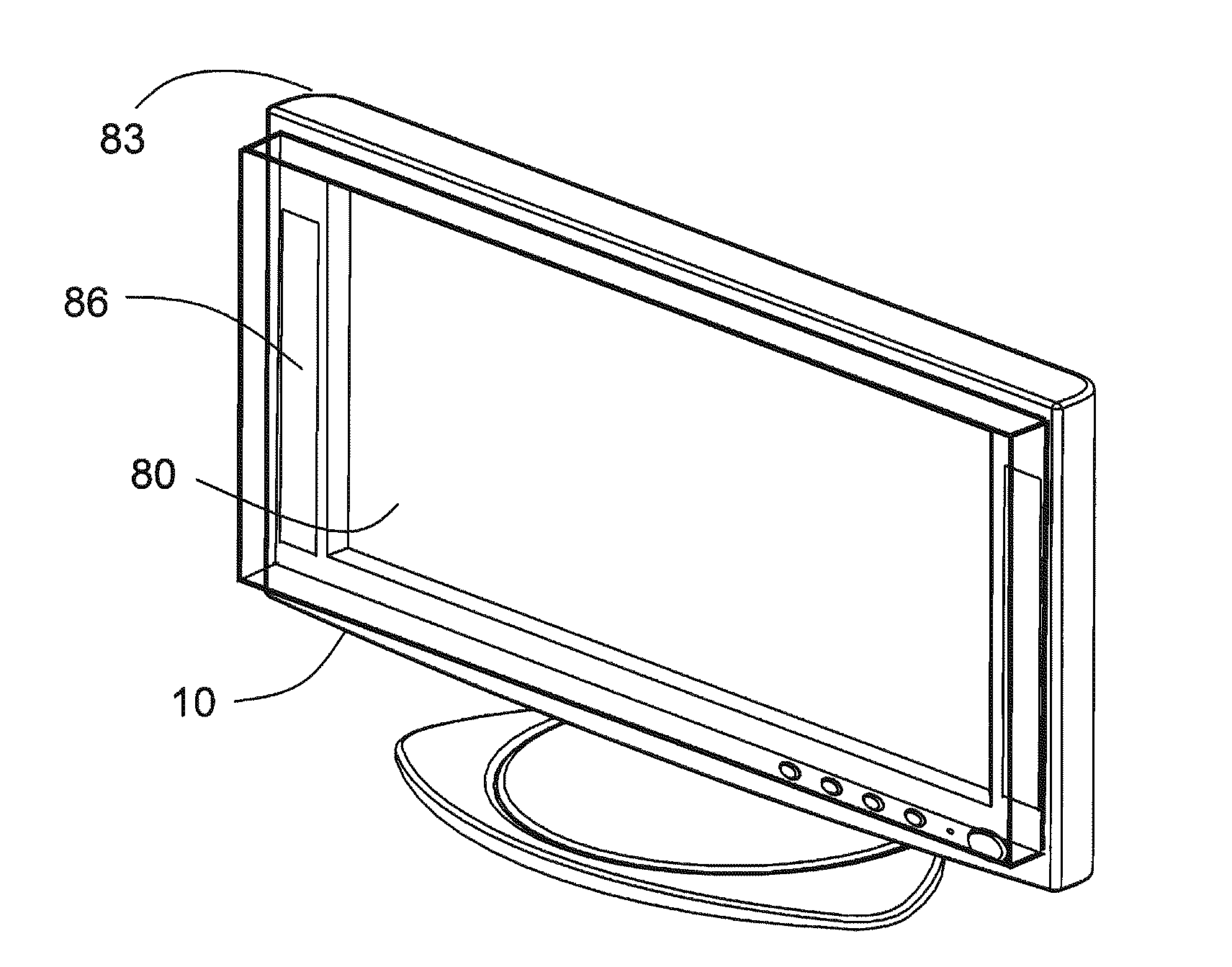

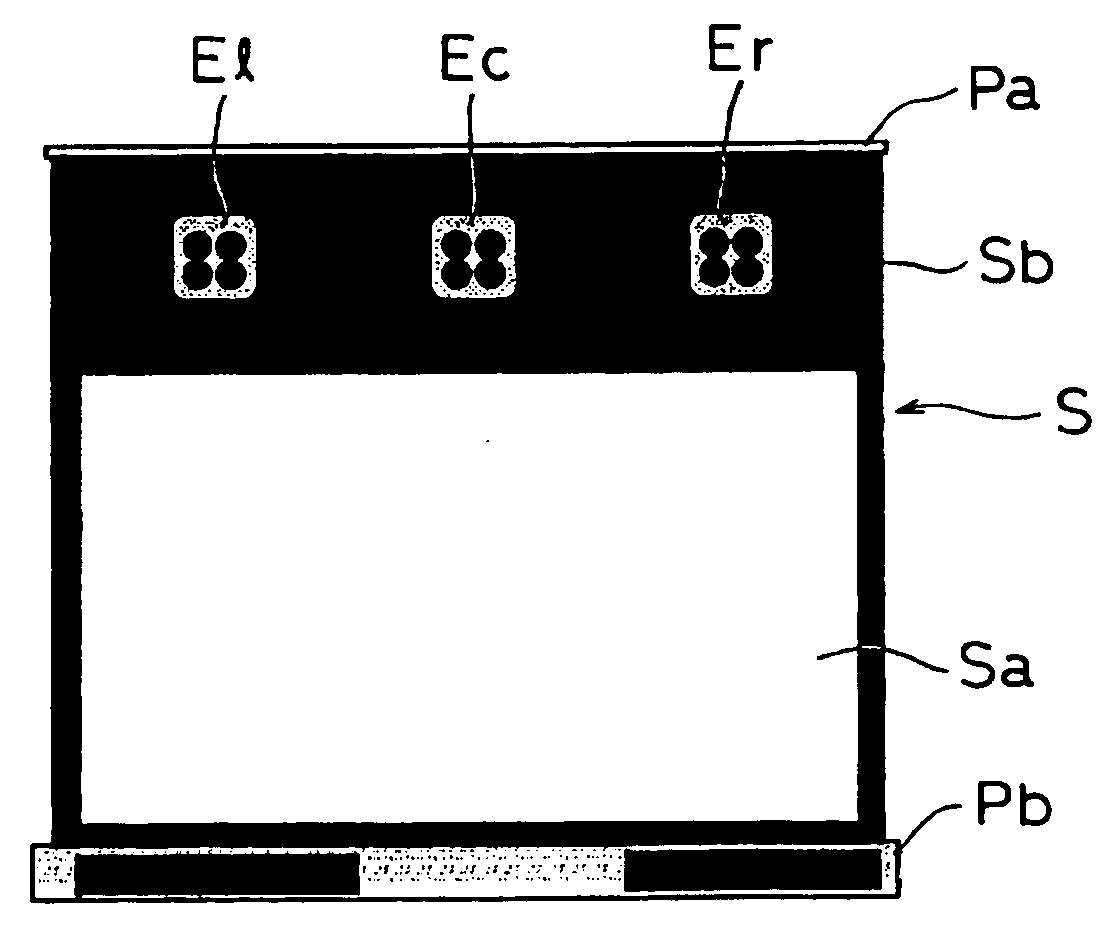

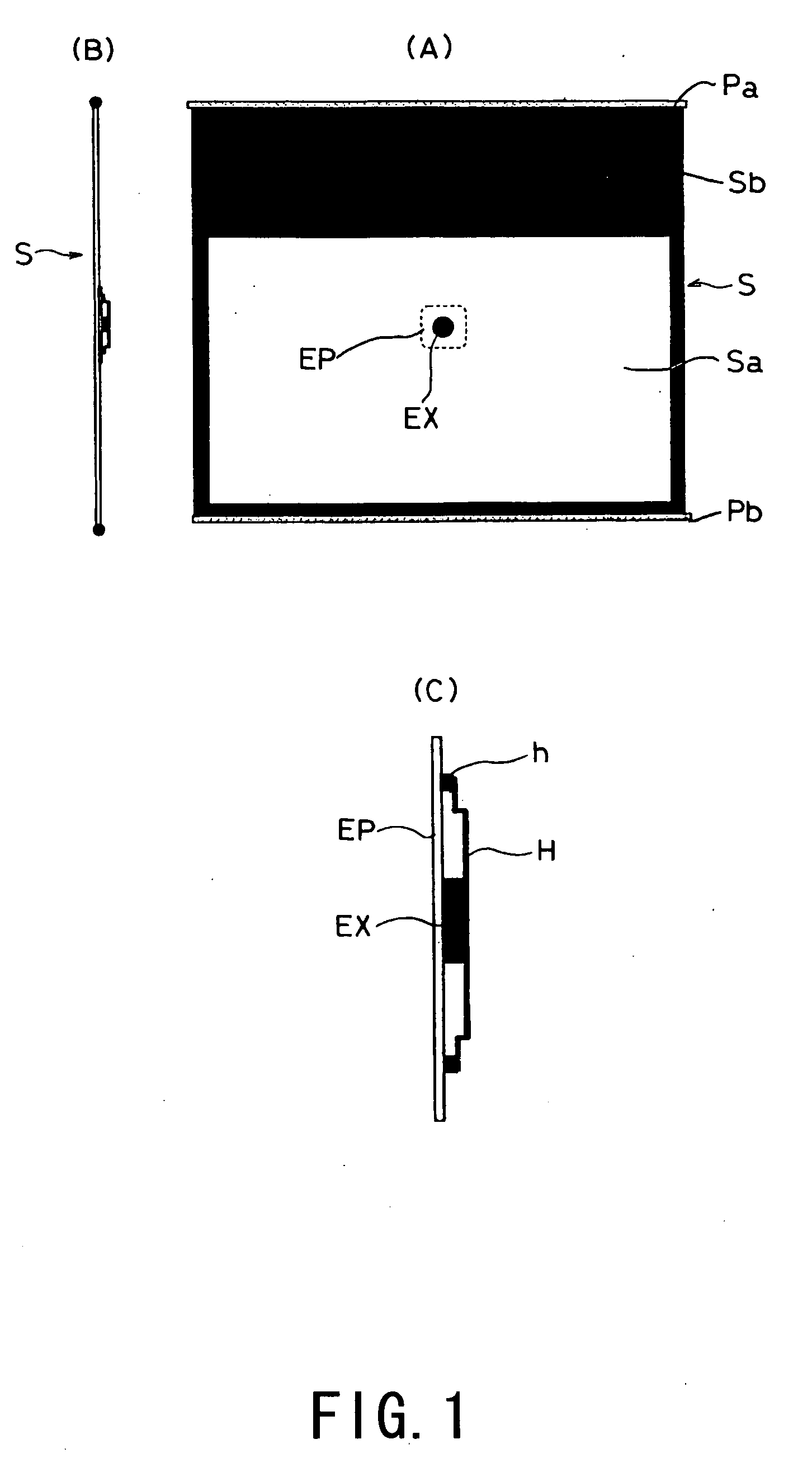

Screen-Integrated Speaker

InactiveUS20080285778A1Configuring a high-quality sound multi-channel speakerEasy to deploy and rollFibre diaphragmsTransducers for sound channels pluralityFiberEngineering

A screen-integrated speaker in which mutual interference among channels does not occur easily, a high quality sound and a wide range of frequency are ensured, flexible and light, and downsizing for storage and transport are easy owing to its easiness of rolling up and deployment under a multi-channel structure is provided. The screen-integrated speaker according to an aspect of the invention includes a screen mainly composed of a fibrous structure and an exciter mounted to the back surface of the screen. Preferably, a exciting panel is interposed between the exciter and the screen.

Owner:TEJIN FIBERS LTD +1

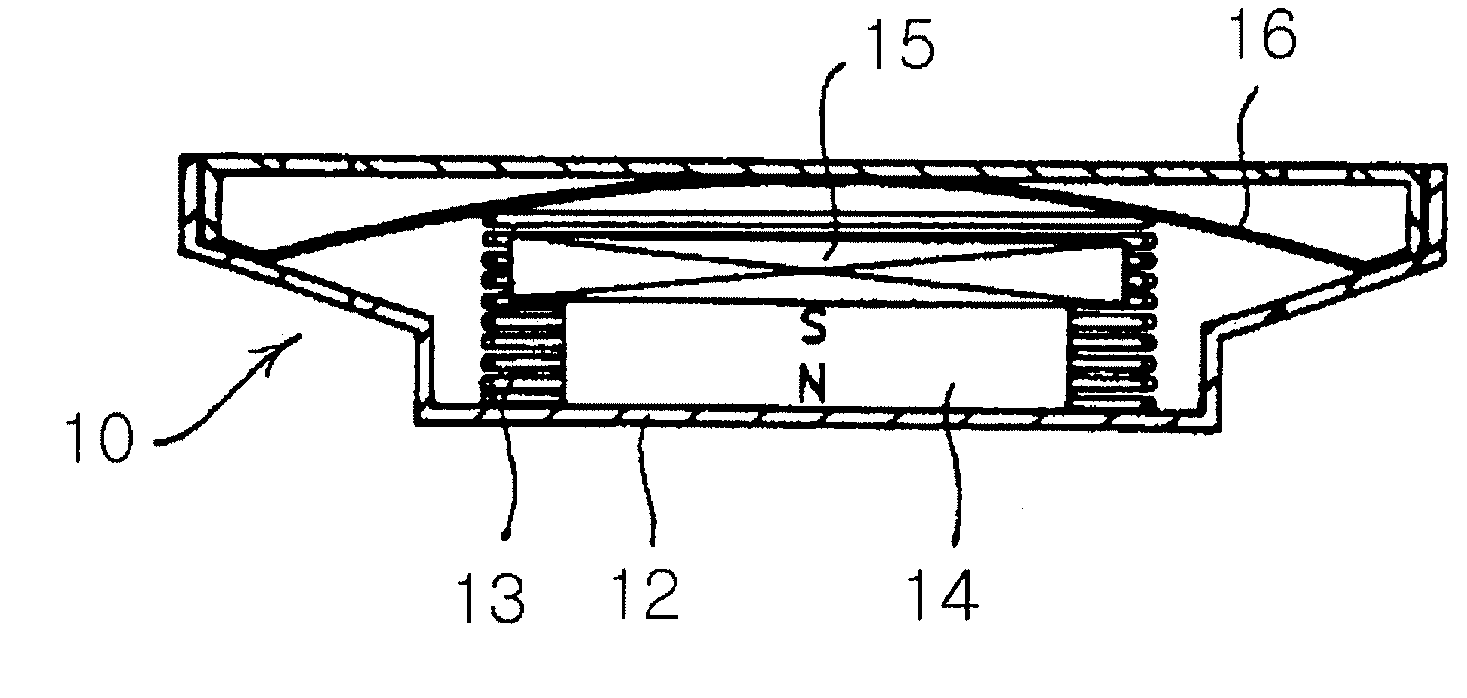

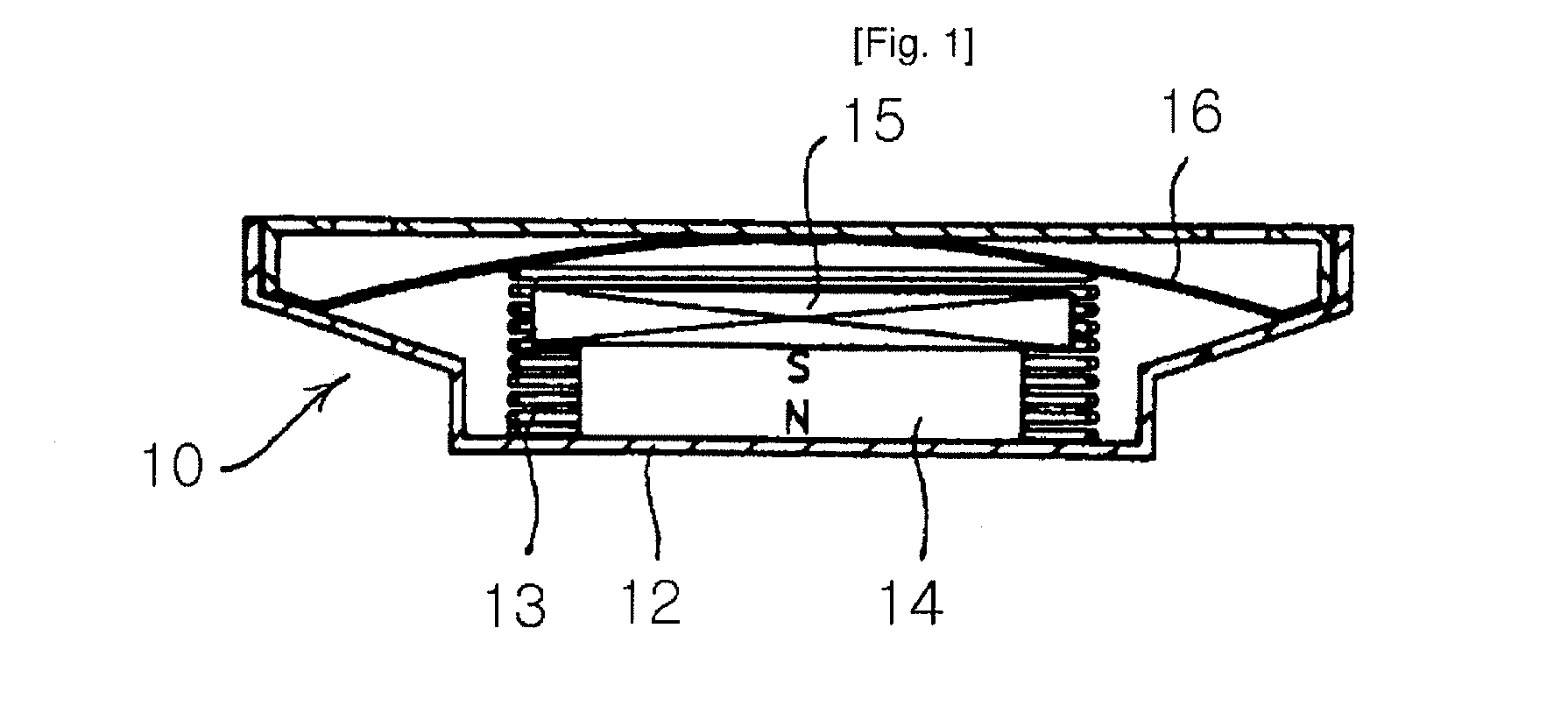

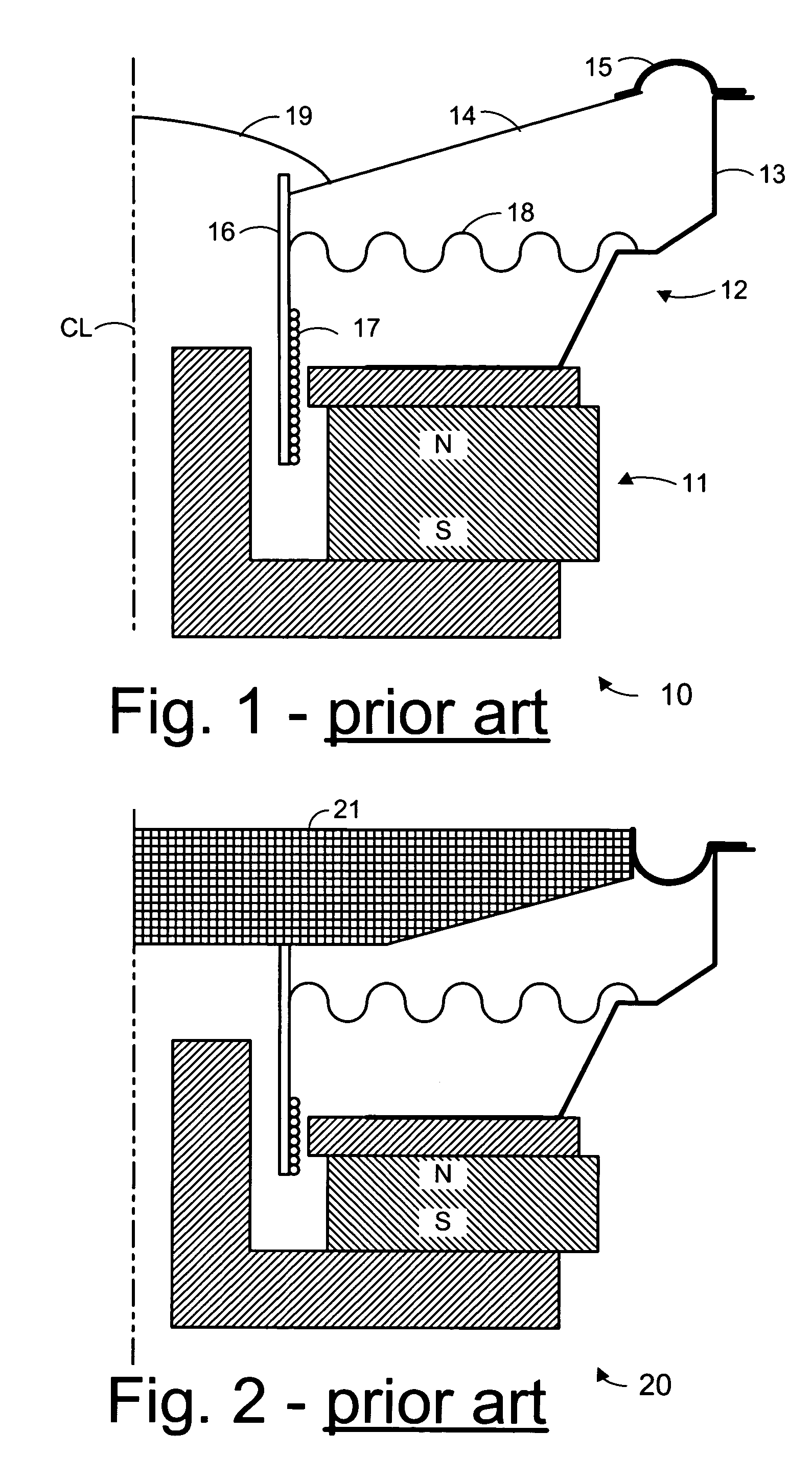

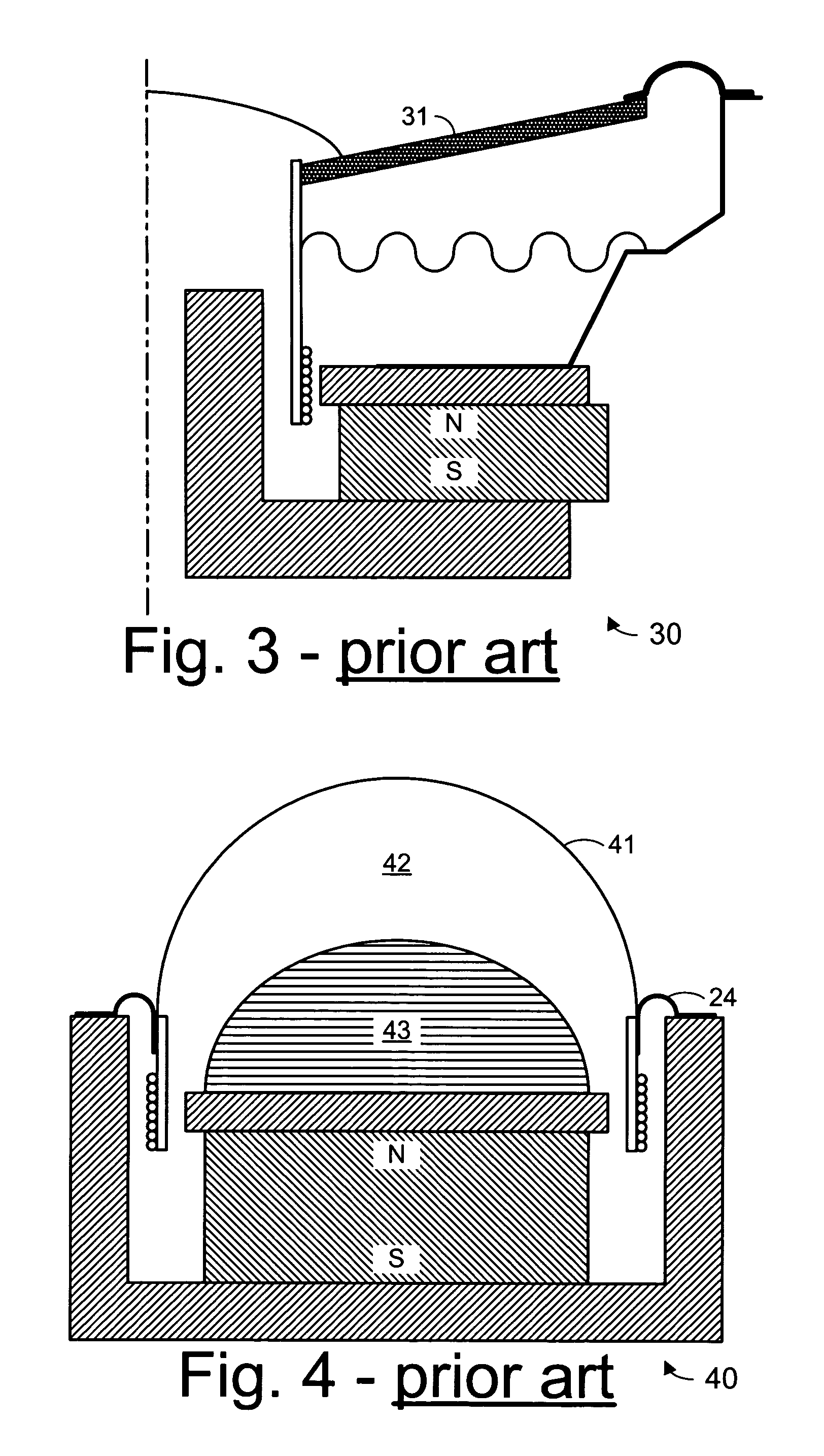

Vibration-sound generating device and yoke thereof

InactiveUS20060233415A1Improved performance of speakerImprove vibration performanceFibre diaphragmsTransducer detailsEngineeringSound production

A vibration-sound generating device and yoke thereof are described. The vibration-sound generating device comprises a diaphragm, a vibration part comprising a magnet and a yoke, which is positioned apart from the diaphragm by a desired distance, a suspension elastically supporting the vibration part, a supporting part supporting the diaphragm and the suspension, and a voice coil electromagnetically driving the diaphragm and the vibration part. The yoke of the invention has higher specific gravity and magnetic permeability than iron. So that it can improve performance of vibration and sound device.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Speaker Diaphragm

InactiveUS20080027158A1High affinityIncrease valueFibre diaphragmsNon-planar diaphragms/conesCelluloseLoudspeaker

A smaller-sized and acoustically excellent speaker diaphragm is inexpensively provided using the mixture of a specially surface-coated woody material and a mass-producible synthetic resin.The mixture is composed of a non-chlorinated synthetic resin and a powdery cellulose material whose particle size falls within a range of from 5 μm to 500 μm. The cellulose material has been subjected to a surface treatment to enhance its affinity to the non-chlorinated synthetic resin, and 30% to 70% by weight of the cellulose material is contained in the mixture.

Owner:PANASONIC CORP +1

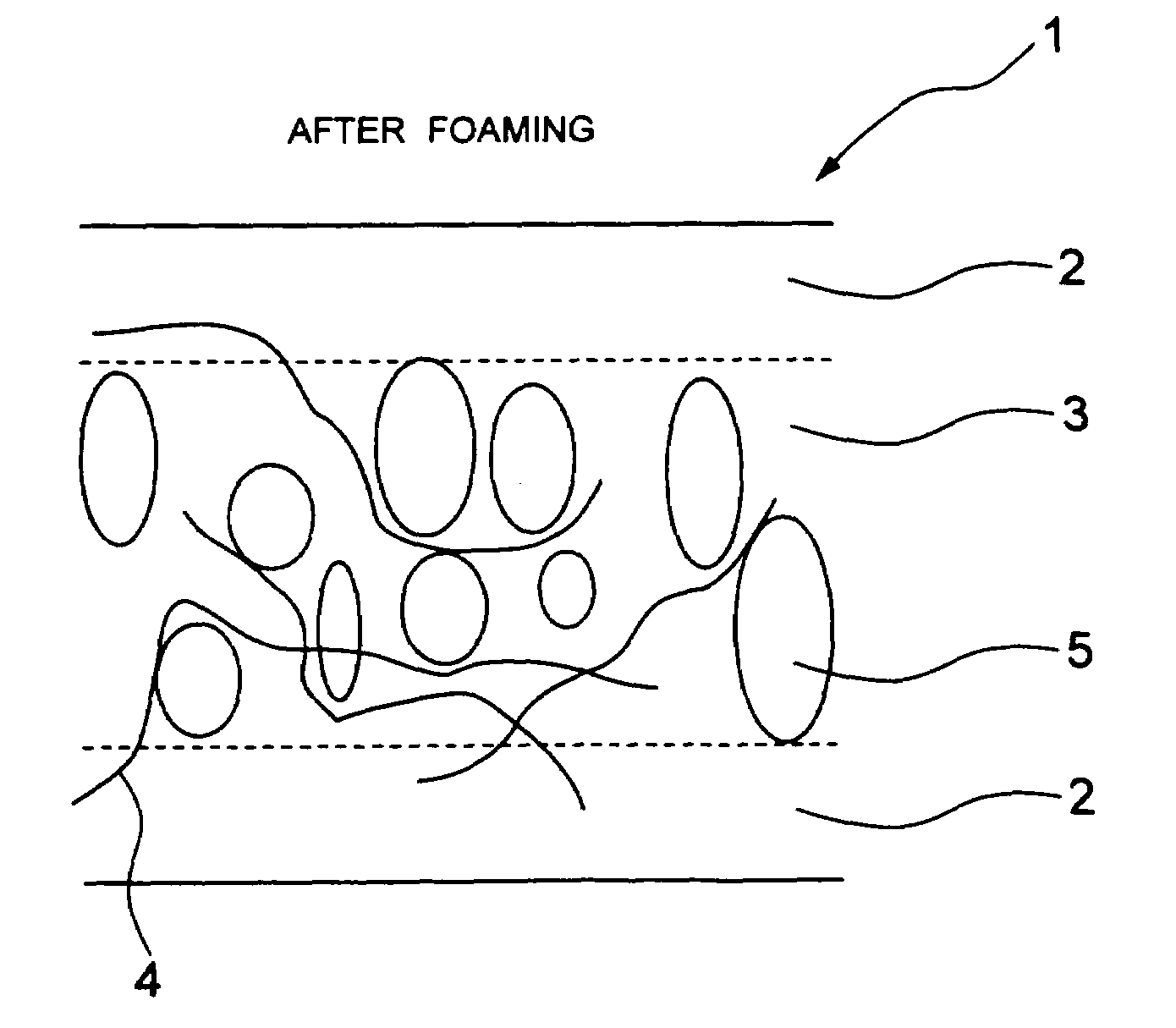

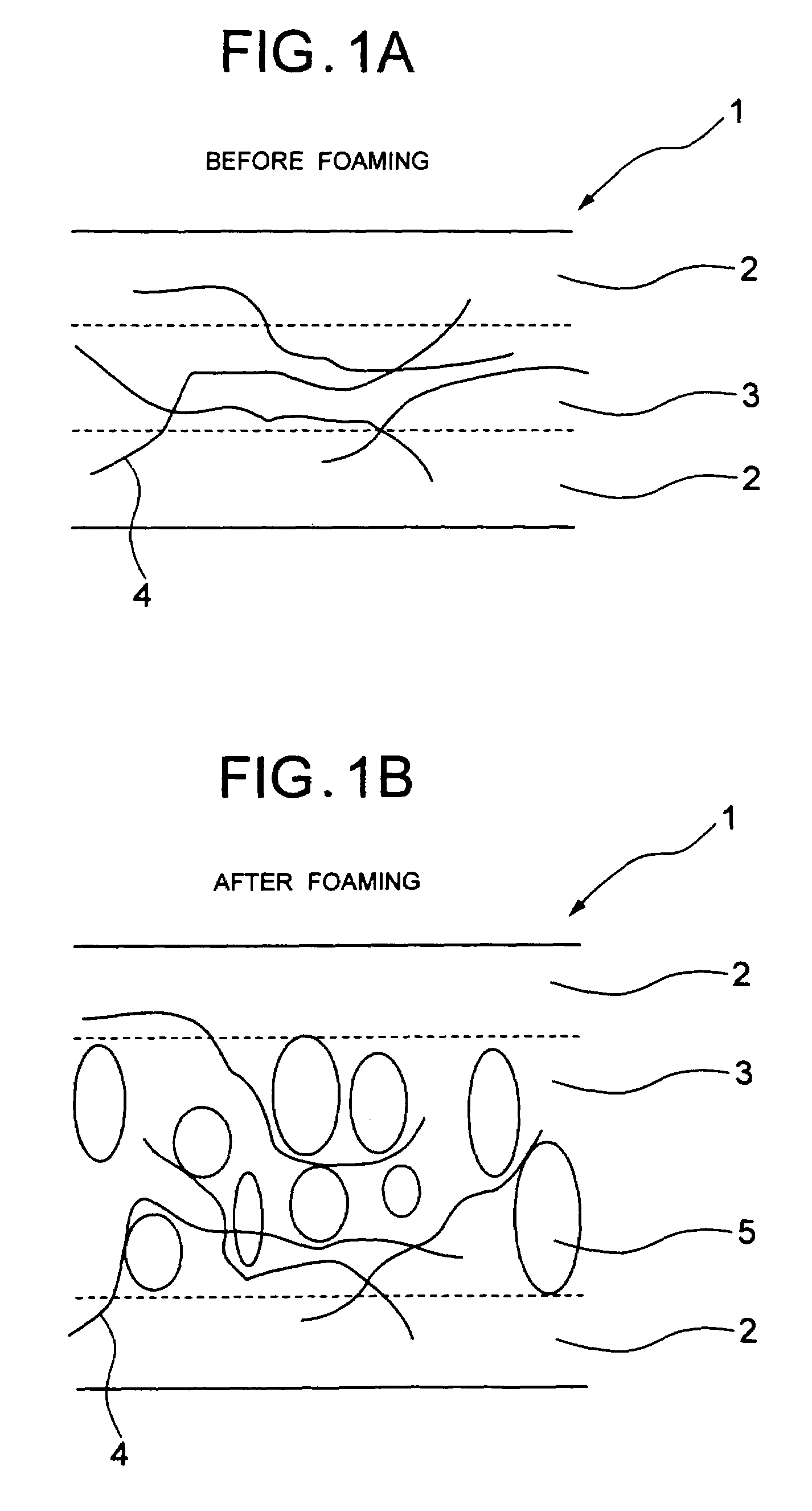

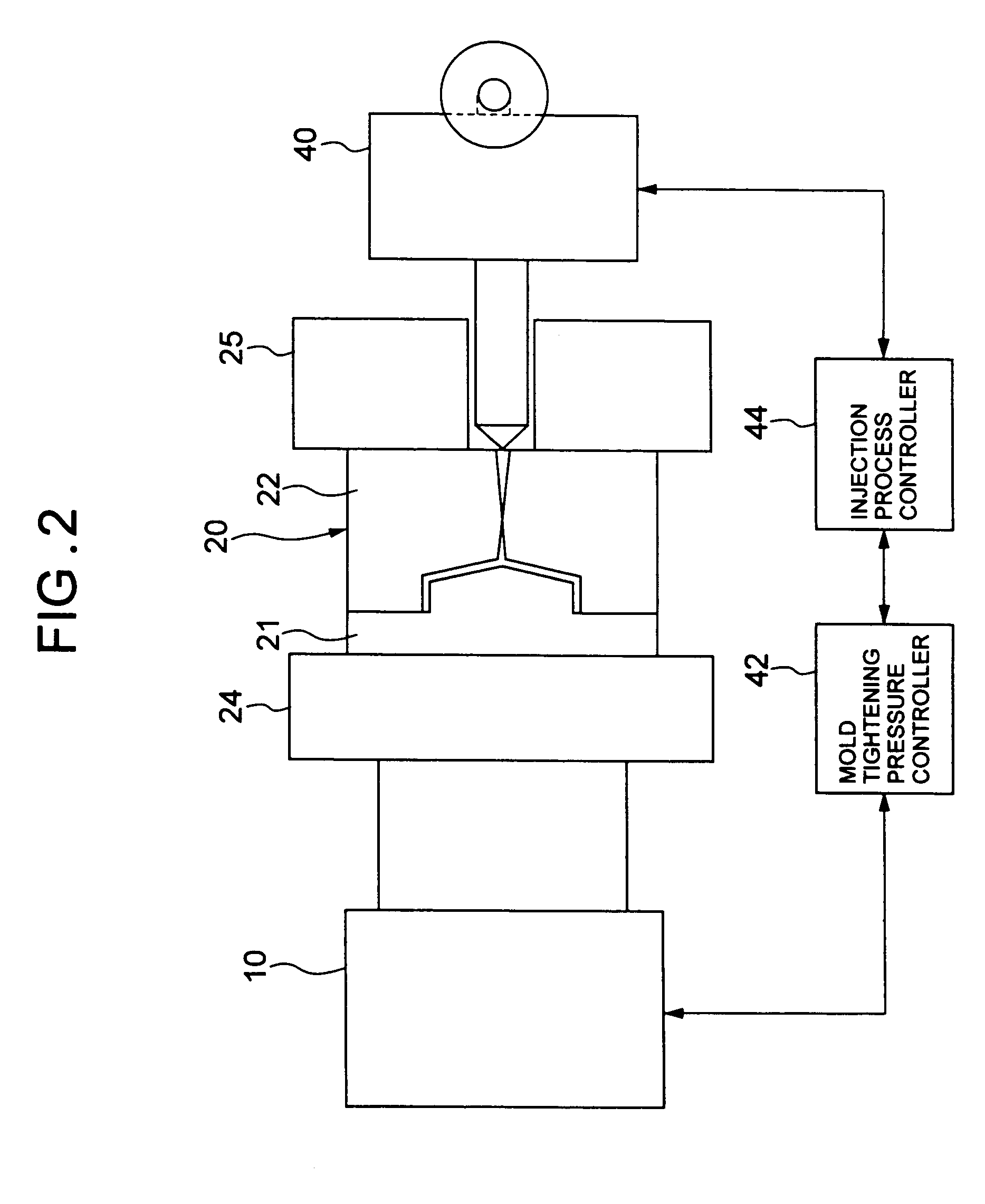

Diaphragm for electroacoustic transducer and method of making the same

InactiveUS7092544B2Improve rigidityImprove environmental resistanceFibre diaphragmsPolycrystalline material growthFiberSurface layer

A molten resin is injected into a cavity together with long fibers. Opposite surfaces of the resin are solidified as a fiber-resin mixture temperature drops. These surface layers become non-foam layers. A foam layer is created between the non-foam layers. A pressure reduction process is applied to cause a spring back effect when the foam layer is created. A diaphragm having these three layers can be manufactured in an inexpensive process, but physical characteristics and appearances of the diaphragm are not sacrificed.

Owner:PIONEER CORP +1

Nanoporous diaphragm for electromagentic transducer

An electromagnetic transducer such as a tweeter audio speaker, having a very low density diaphragm constructed of a nanoporous material such as aerogel or the like. The solid aerogel diaphragm has improved rigidity and reduced susceptibility to breakup modes. The aerogel may be provided with a skin of e.g. metal, plastic, or oxide to protect it, and it may be built by filling a conventional cone. The skin may encapsulate part or all of the aerogel body's surface, and it may further encapsulate the bobbin, or even the entire voice coil assembly. The nanoporous material comprises a very large percentage of the diaphragm's overall volume, giving the diaphragm a very low overall mass density with respect to conventional diaphragms. This allows diaphragm configurations, such as solid filled spheres, which have excellent stiffness without suffering from the large mass that such shapes would mandate if constructed from conventional materials.

Owner:TURNMIRE PATRICK M +2

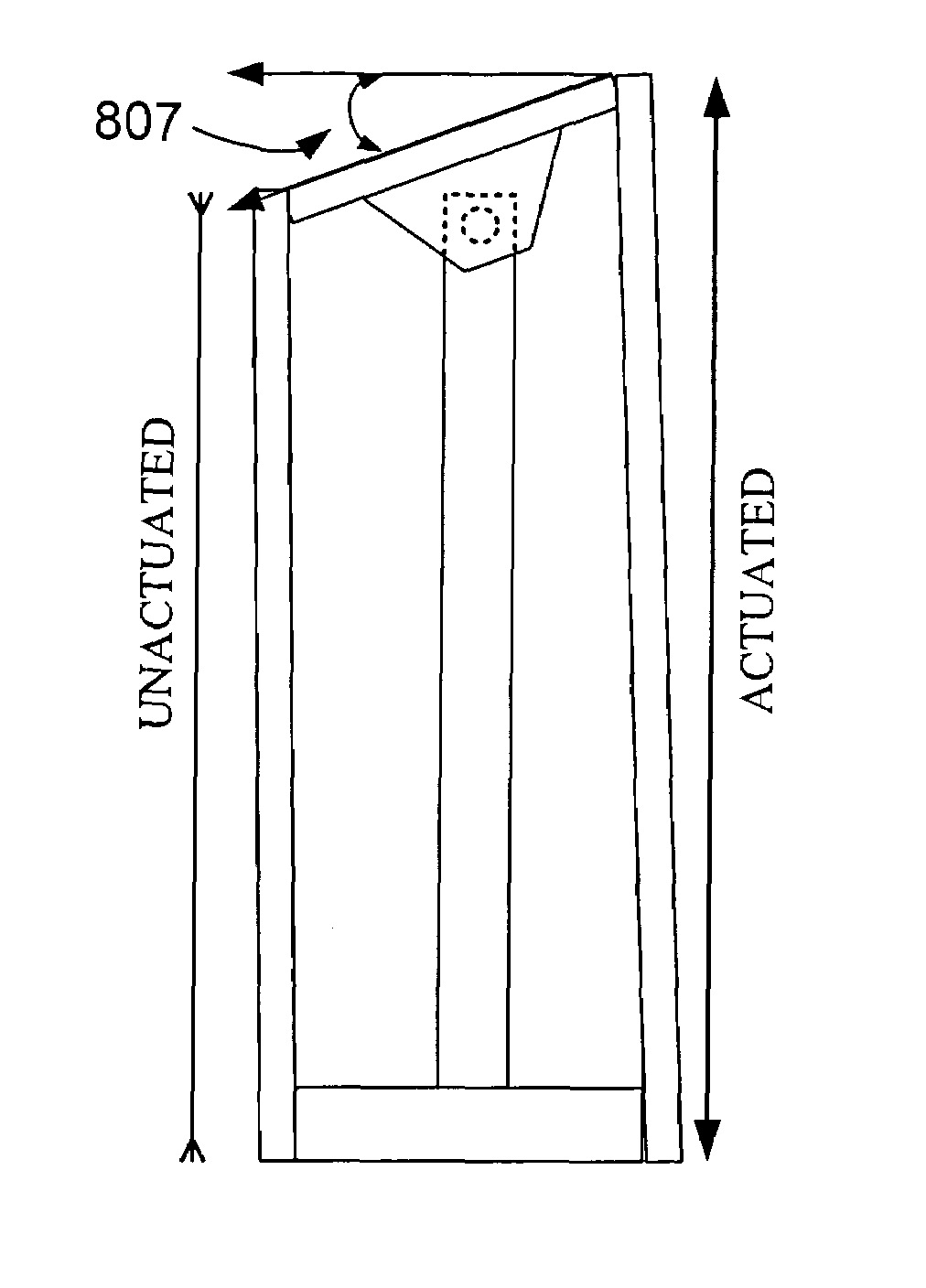

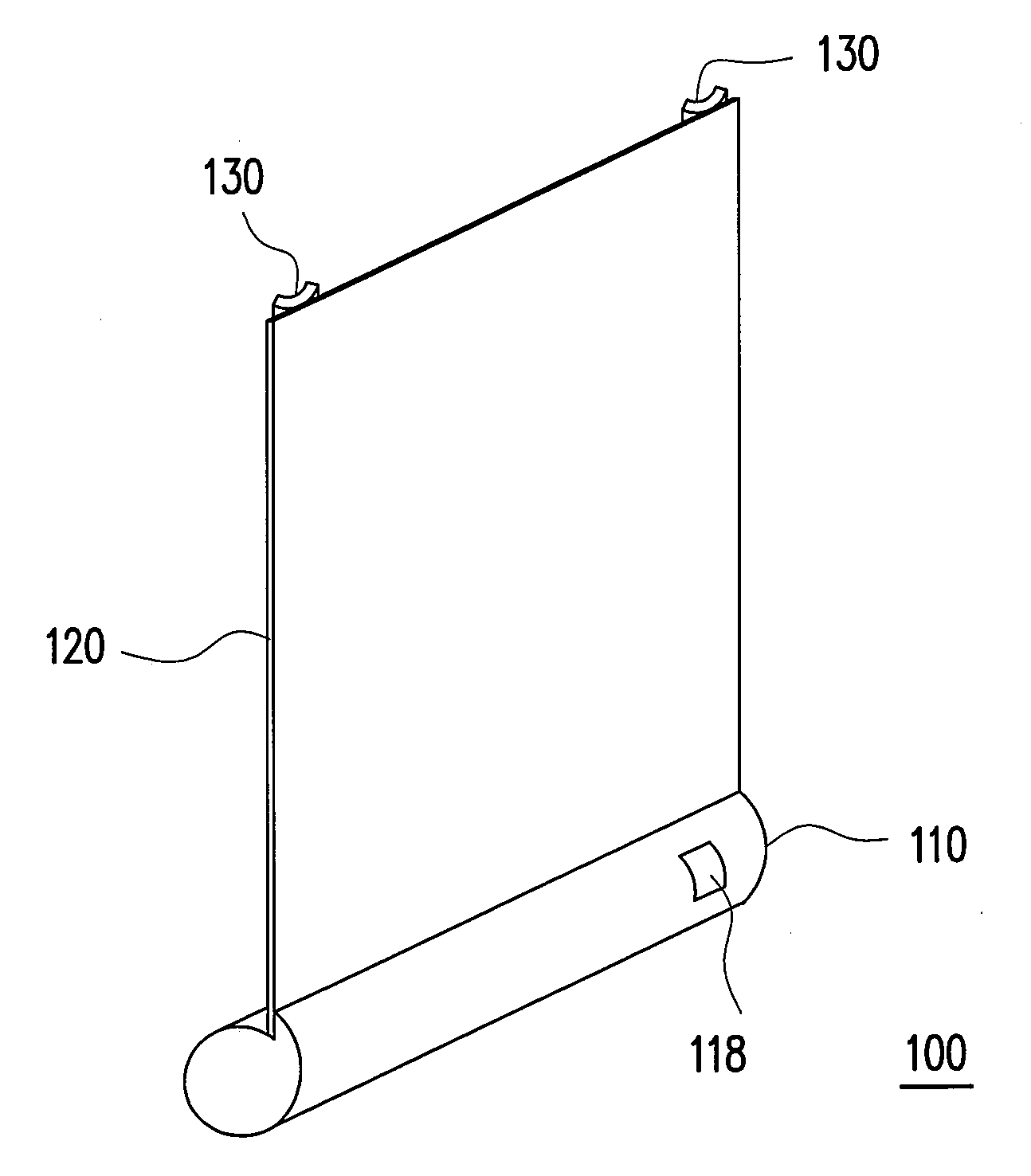

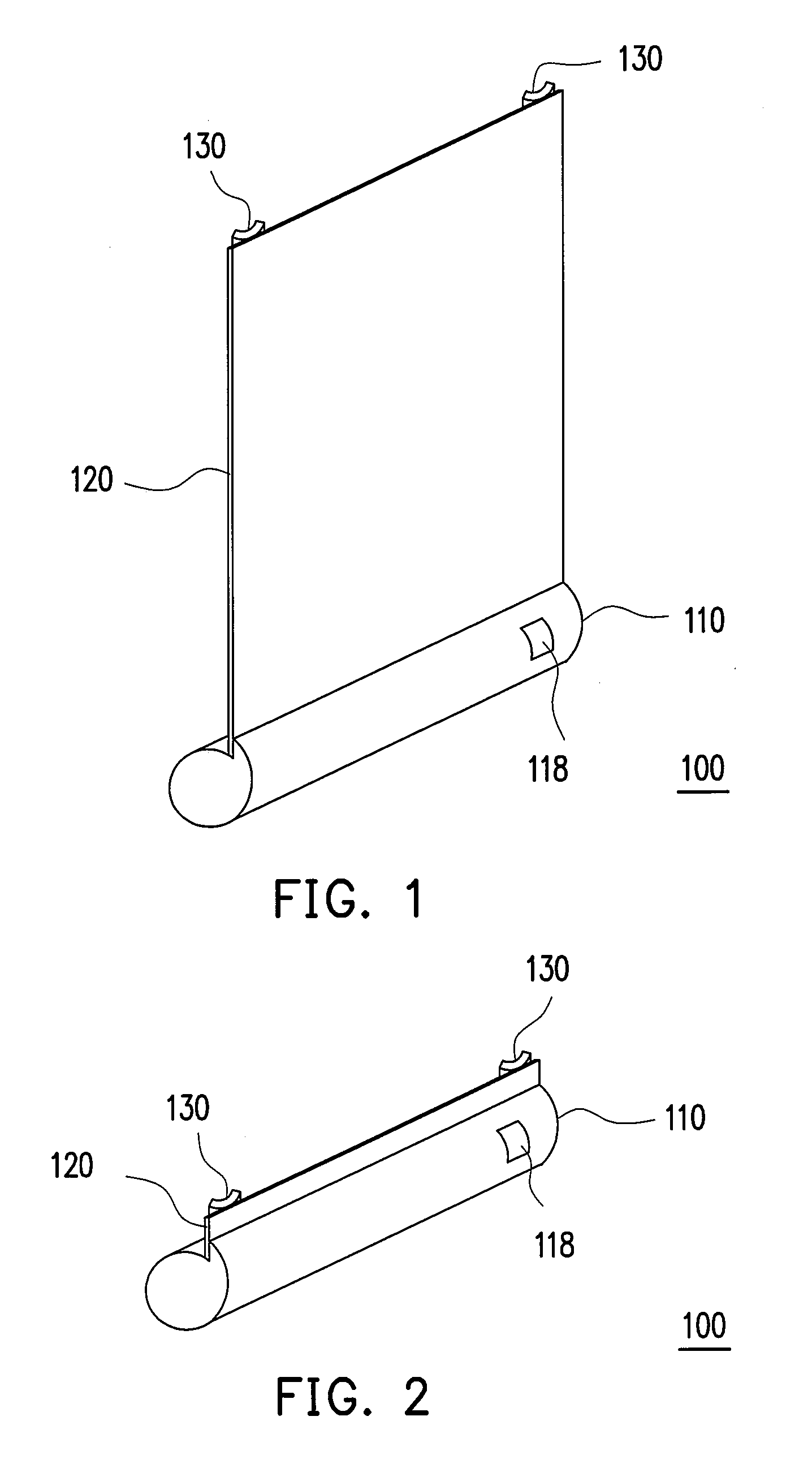

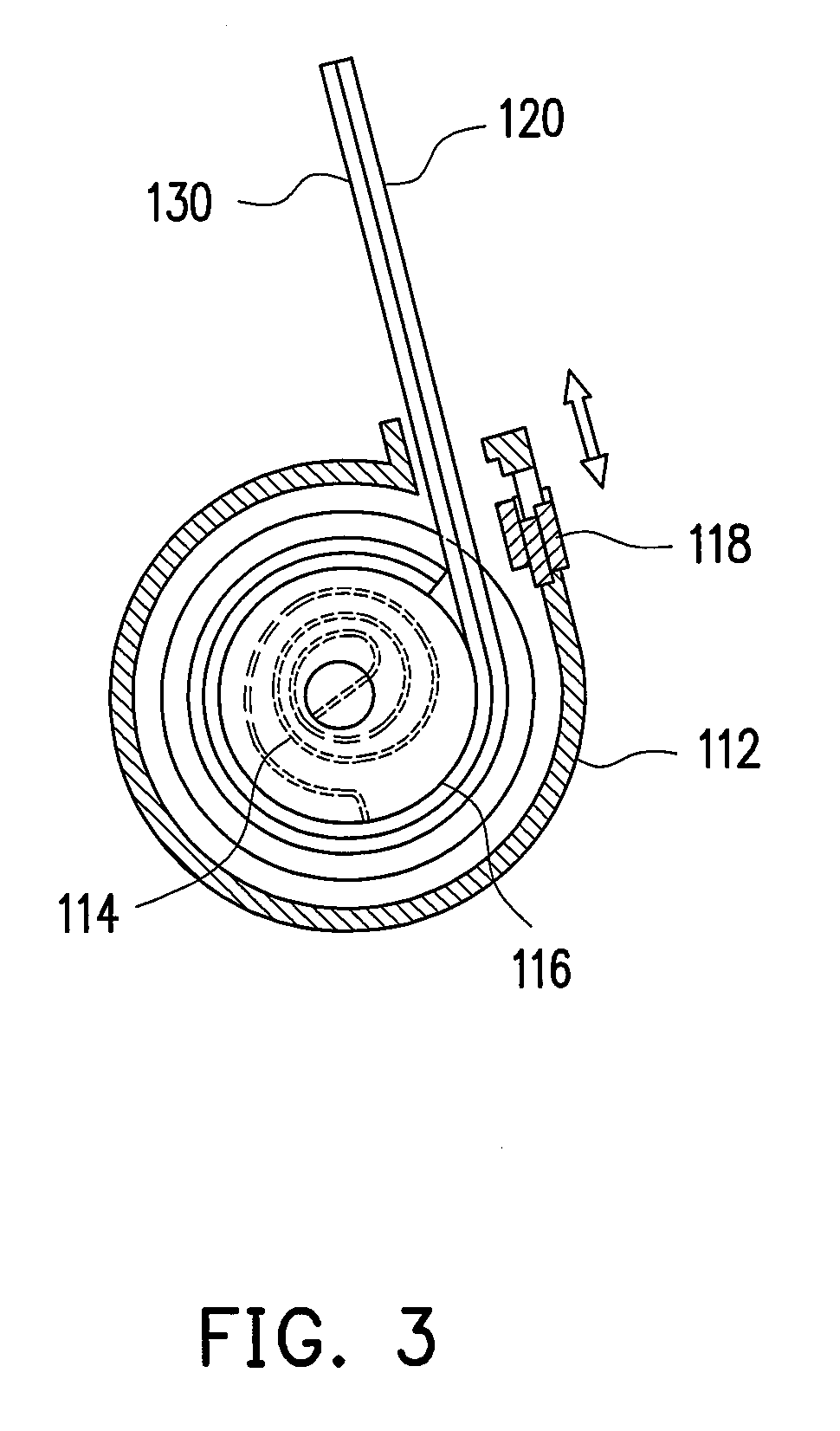

Flexible speaker

A flexible speaker including a retractor, a flexible speaker panel, and at least one support element is provided. The flexible speaker panel is connected to the retractor, and is capable of being rolled up and received in the retractor. The support element, capable of memorizing shape, is disposed on the flexible speaker. The support element is used for being rolled up and received in the retractor, together with the flexible speaker. When the flexible speaker panel is spread from the retractor, the support element supports the flexible speaker and keeps the flexible speaker panel being steady in a spread state, and the size of the spread region is determined by the user.

Owner:IND TECH RES INST

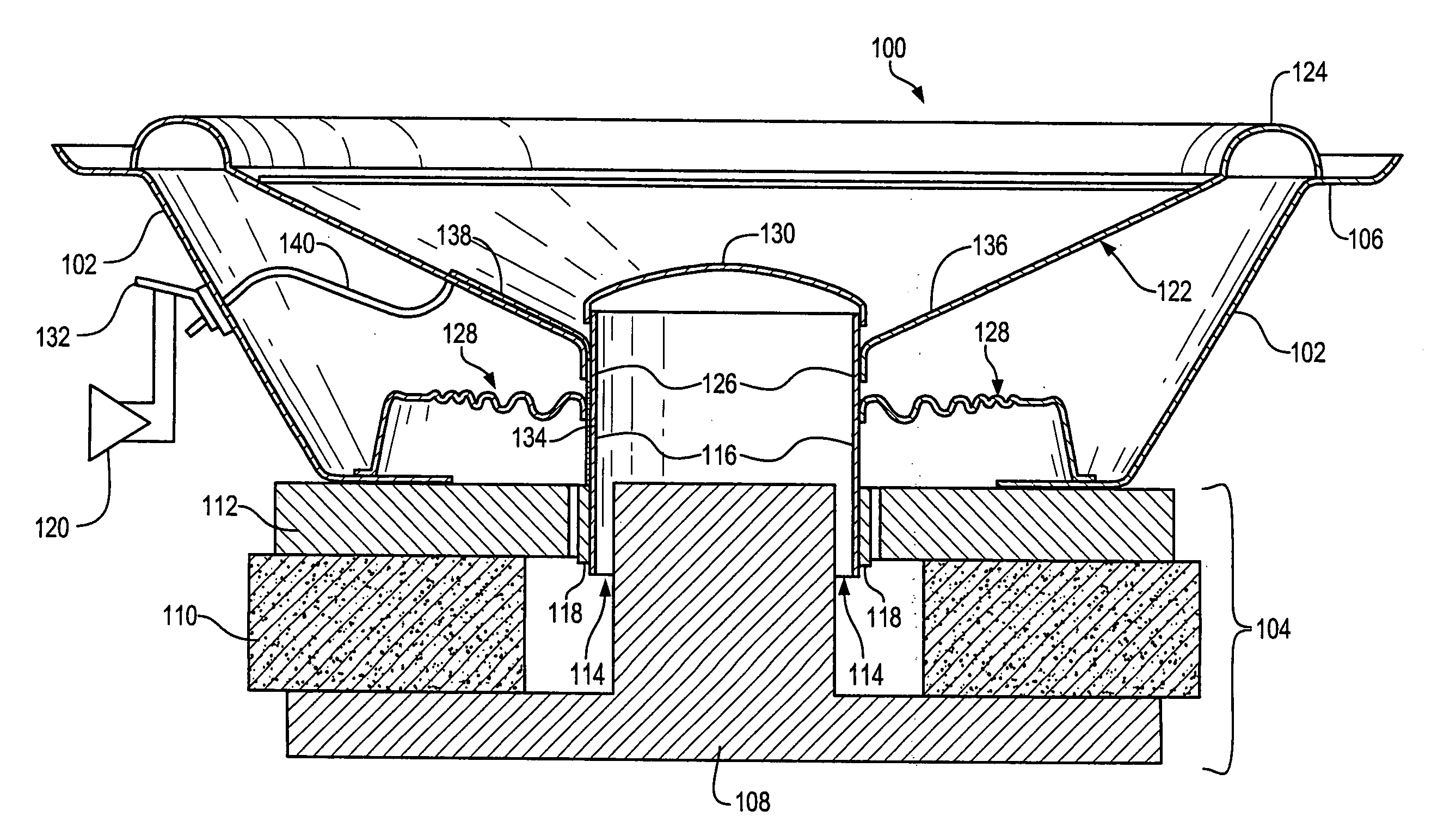

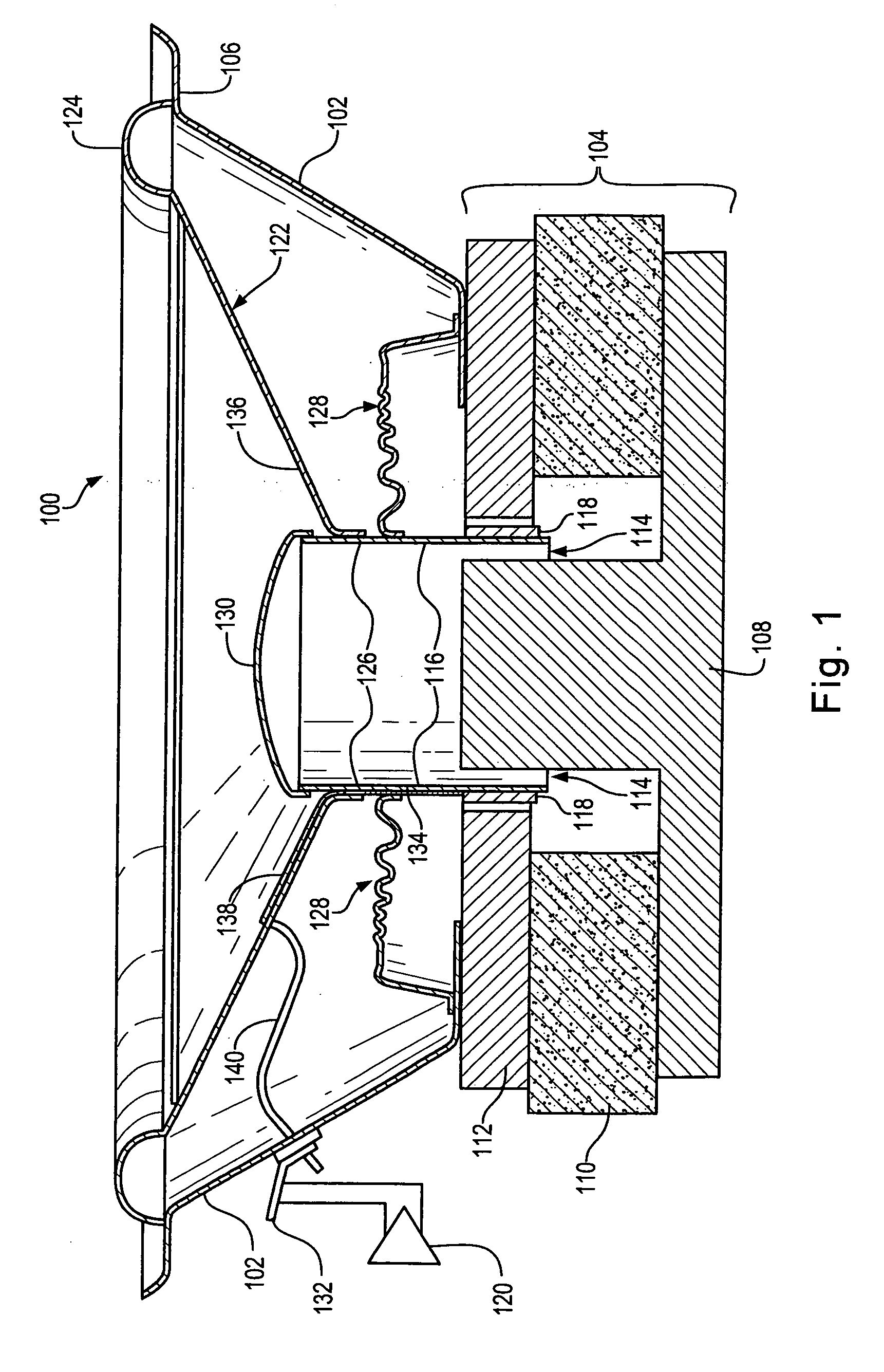

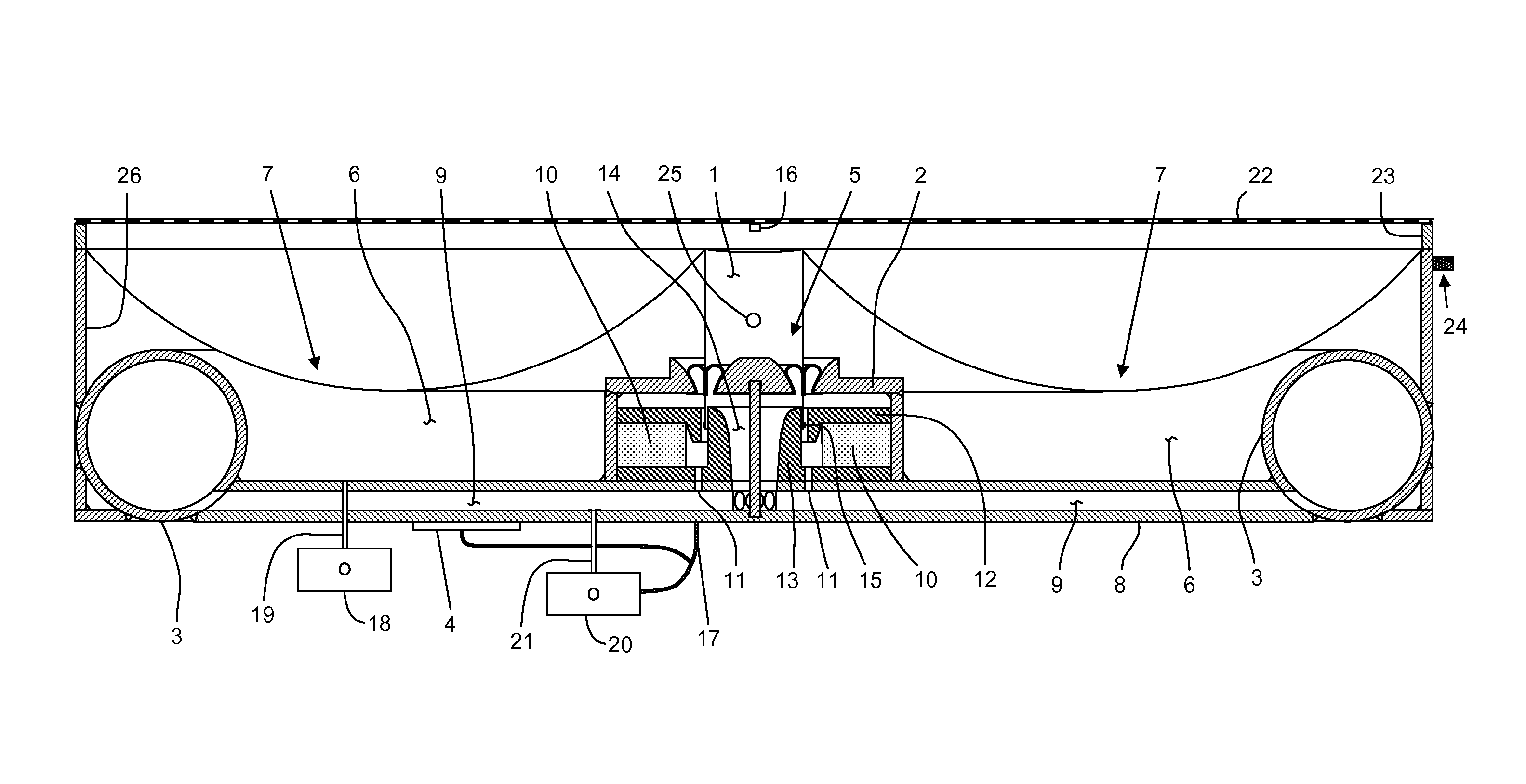

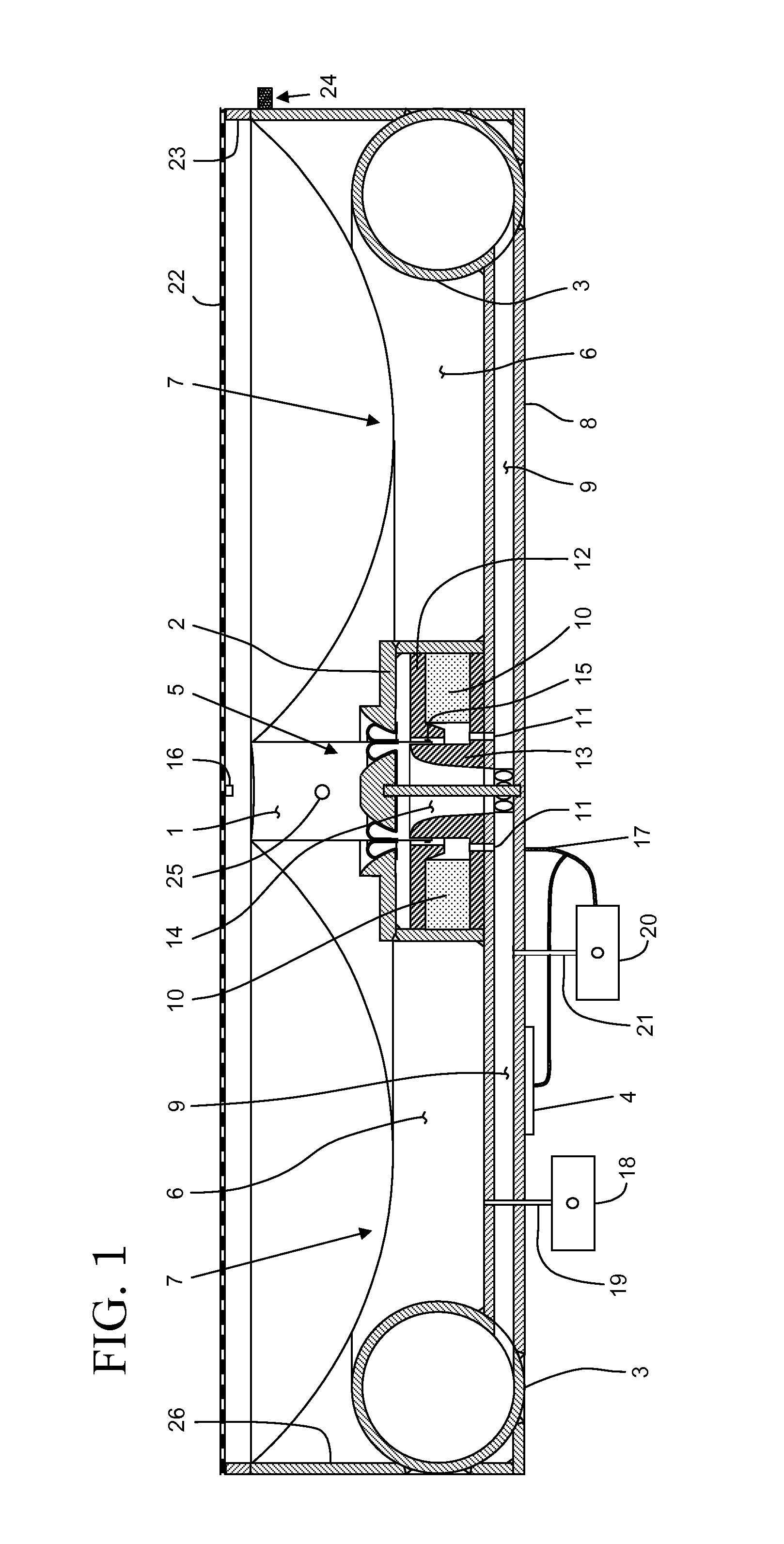

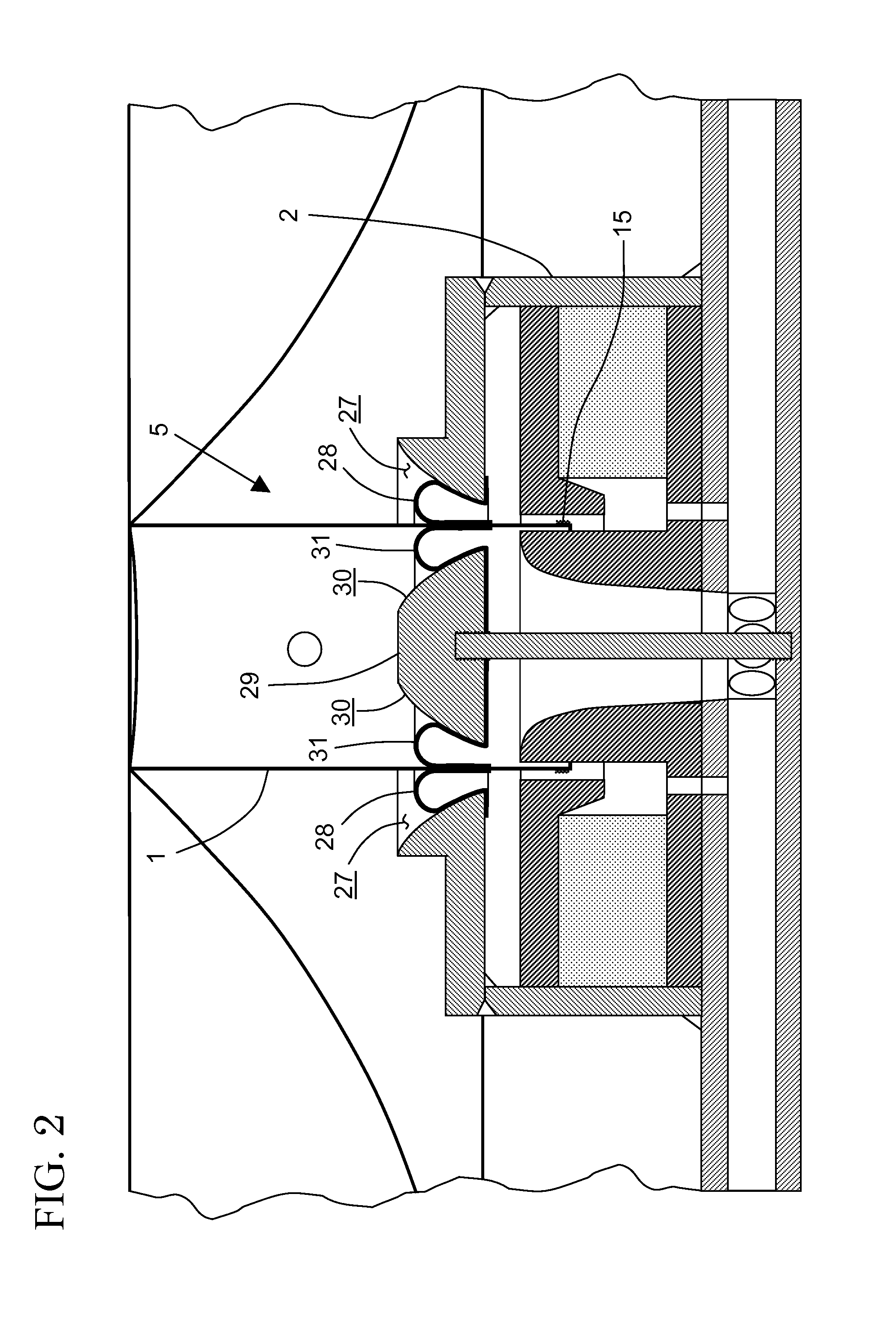

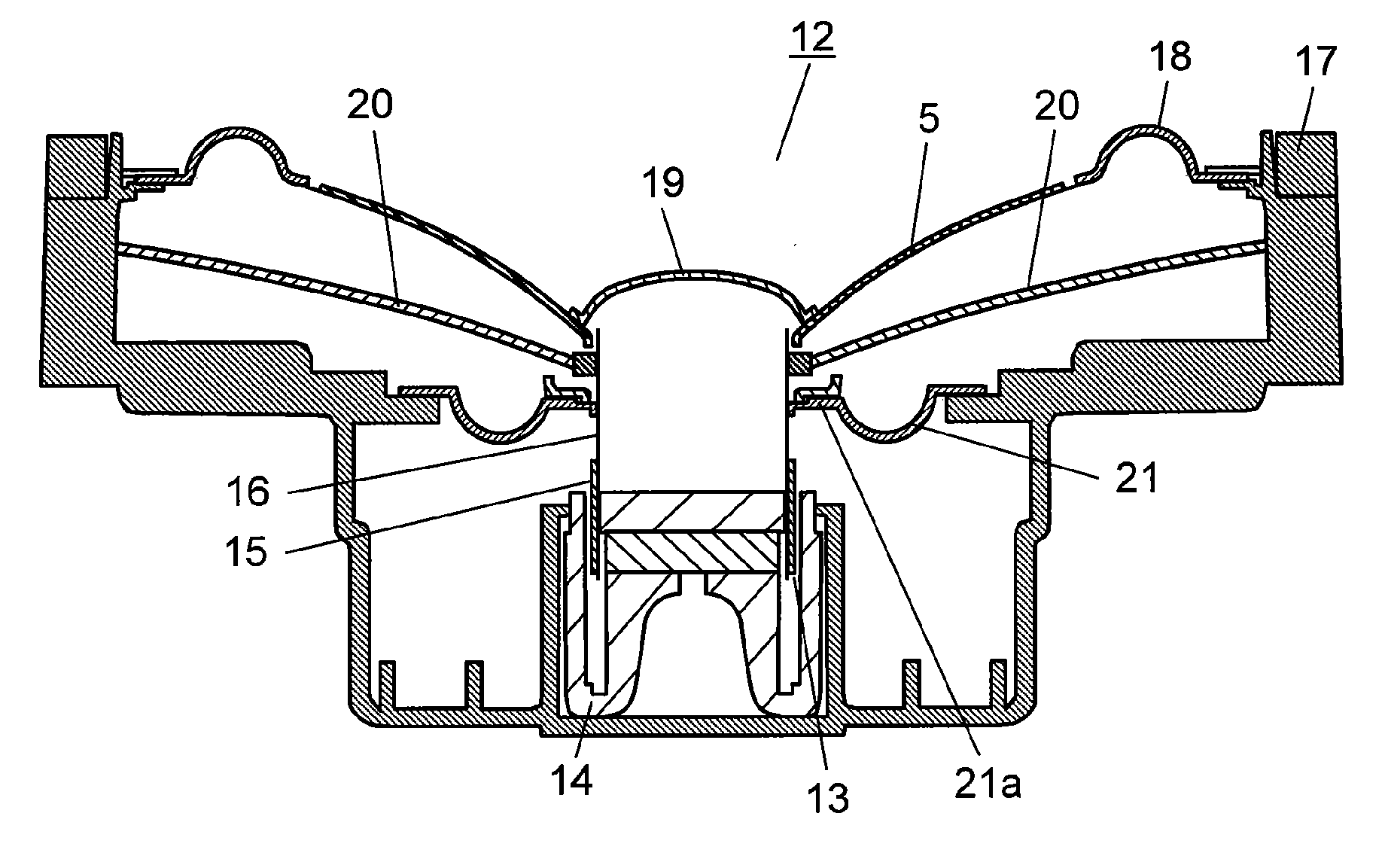

Acoustic actuator and passive attenuator incorporating a lightweight acoustic diaphragm with an ultra low resonant frequency coupled with a shallow enclosure of small volume

InactiveUS7885418B1High operational stiffnessSuppress spurious noiseFibre diaphragmsEar treatmentFrequency couplingOperation mode

Disclosed is a loudspeaker assembly incorporating innovations resulting in an enclosure of very small volume to which is integrated a large area, shallow and lightweight acoustic diaphragm assembly capable of a natural resonant frequency of a few Hertz. This is achieved by incorporating a vacuum chamber in conjunction with a chamber containing compressed gas or vapor that acts against a movable pressure boundary of changeable area being mechanically coupled with the acoustic radiating diaphragm. In an alternative operating mode, the apparatus also serves as a passive low frequency acoustic attenuator.

Owner:HALLMAN WILLIAM BRIAN

Speaker diaphragm, speaker using said diaphragm, and speaker diaphragm manufacturing method

ActiveUS20100296688A1Improves speaker sound qualityHigh modulusFibre diaphragmsTransducer detailsEngineeringYoung's modulus

A speaker diaphragm includes a fabric layer in which impregnated thermosetting resin is thermally cured, and a paper layer integrated on a rear face of this fabric layer. Fluffs of the paper layer filling stitches of the fabric layer are entangled with threads of the fabric layer from a surface of the fabric layer, and are firmly fixed by thermosetting resin. This integrates the layers in the state that the paper layer is filled in the stitches of the fabric layer. Accordingly, internal loss and Young's modulus of the speaker diaphragm can be increased. As a result, the speaker sound quality can be improved.

Owner:PANASONIC CORP

Diaphragm for speaker, speaker using the diaphragm, and system using the speaker

InactiveUS20100172533A1Improve sound qualityFibre diaphragmsTransducer detailsSound qualityEngineering

A loudspeaker diaphragm contains polylactic acid, and bamboo charcoal mixed in the polylactic acid. The diaphragm does not affect environment and provides a loudspeaker with high sound quality.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

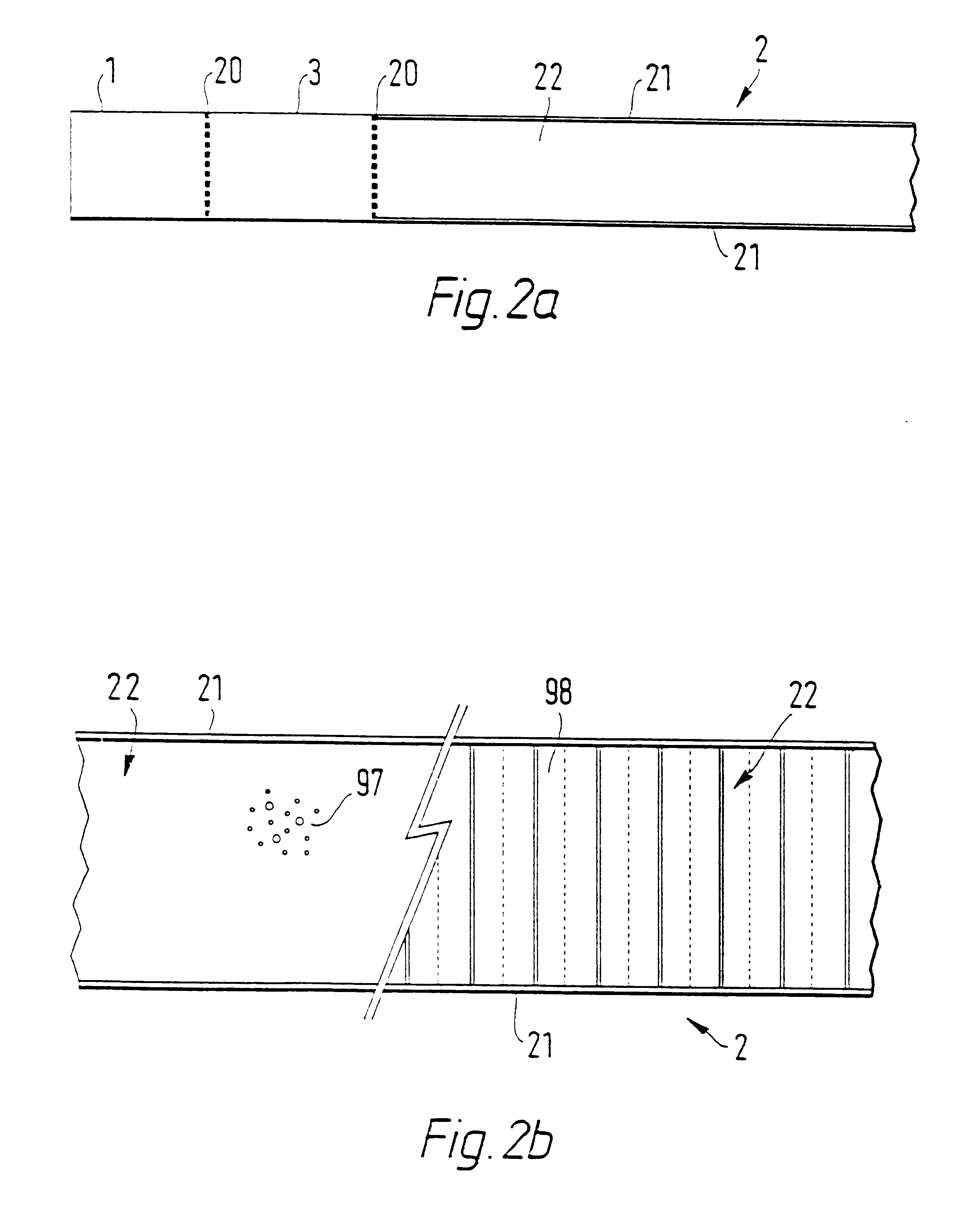

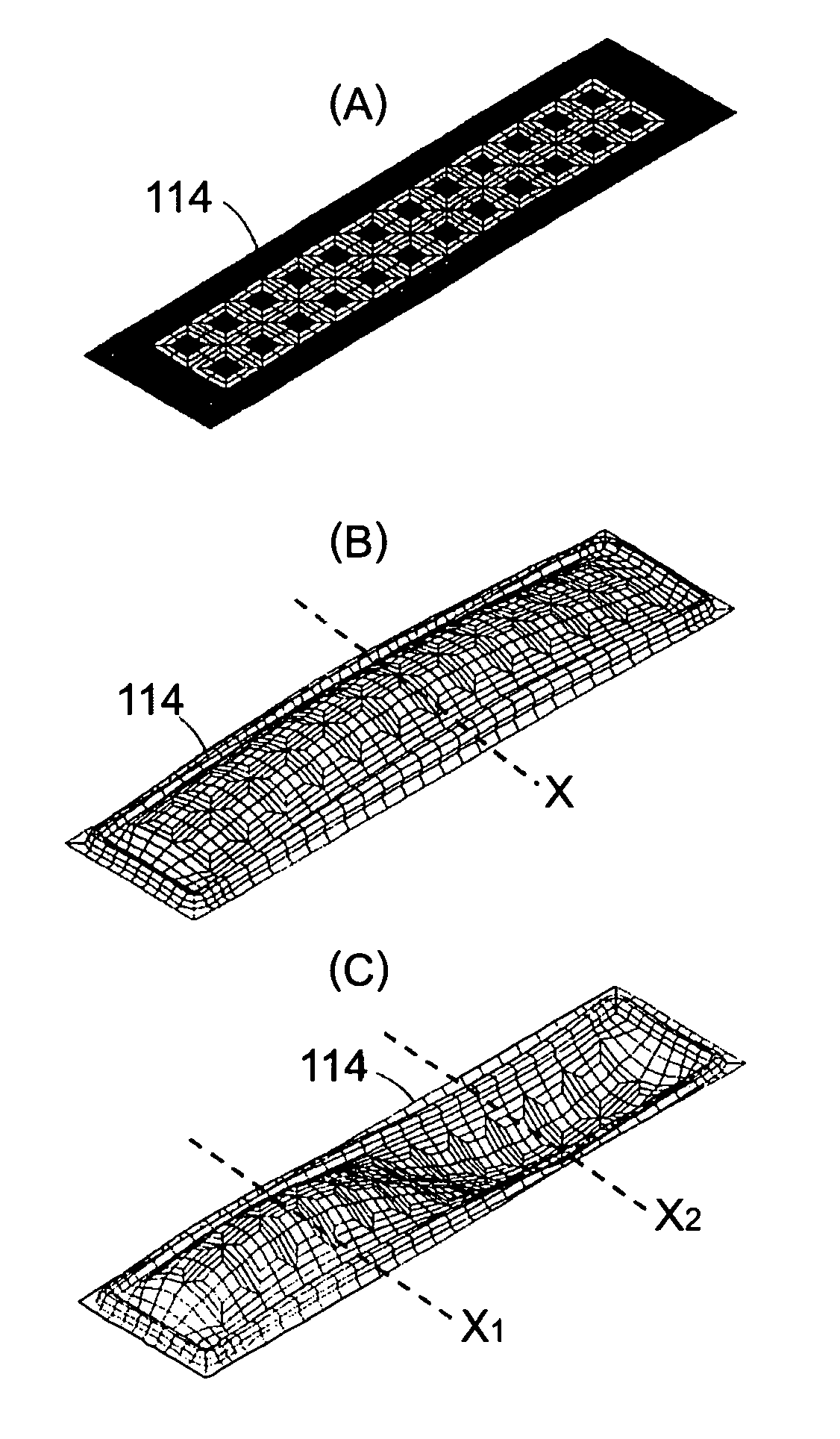

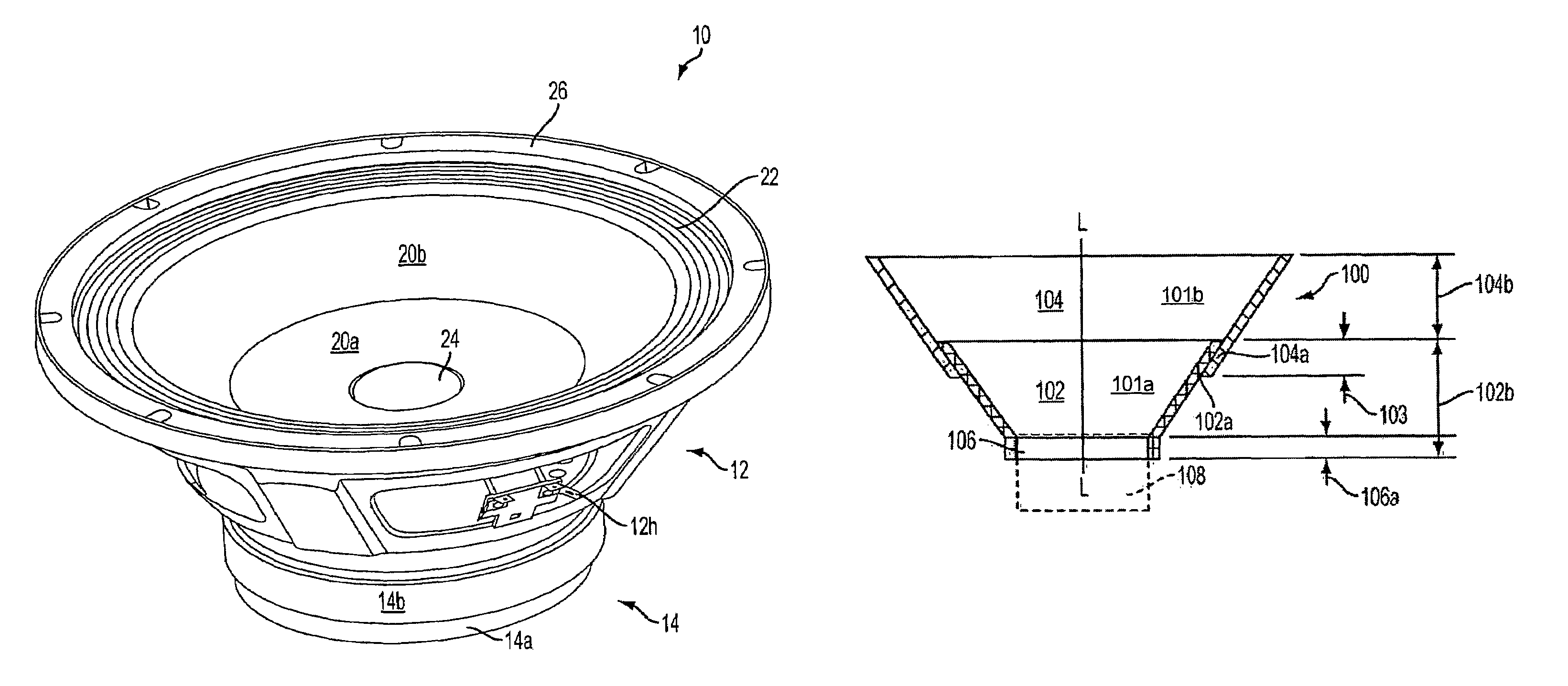

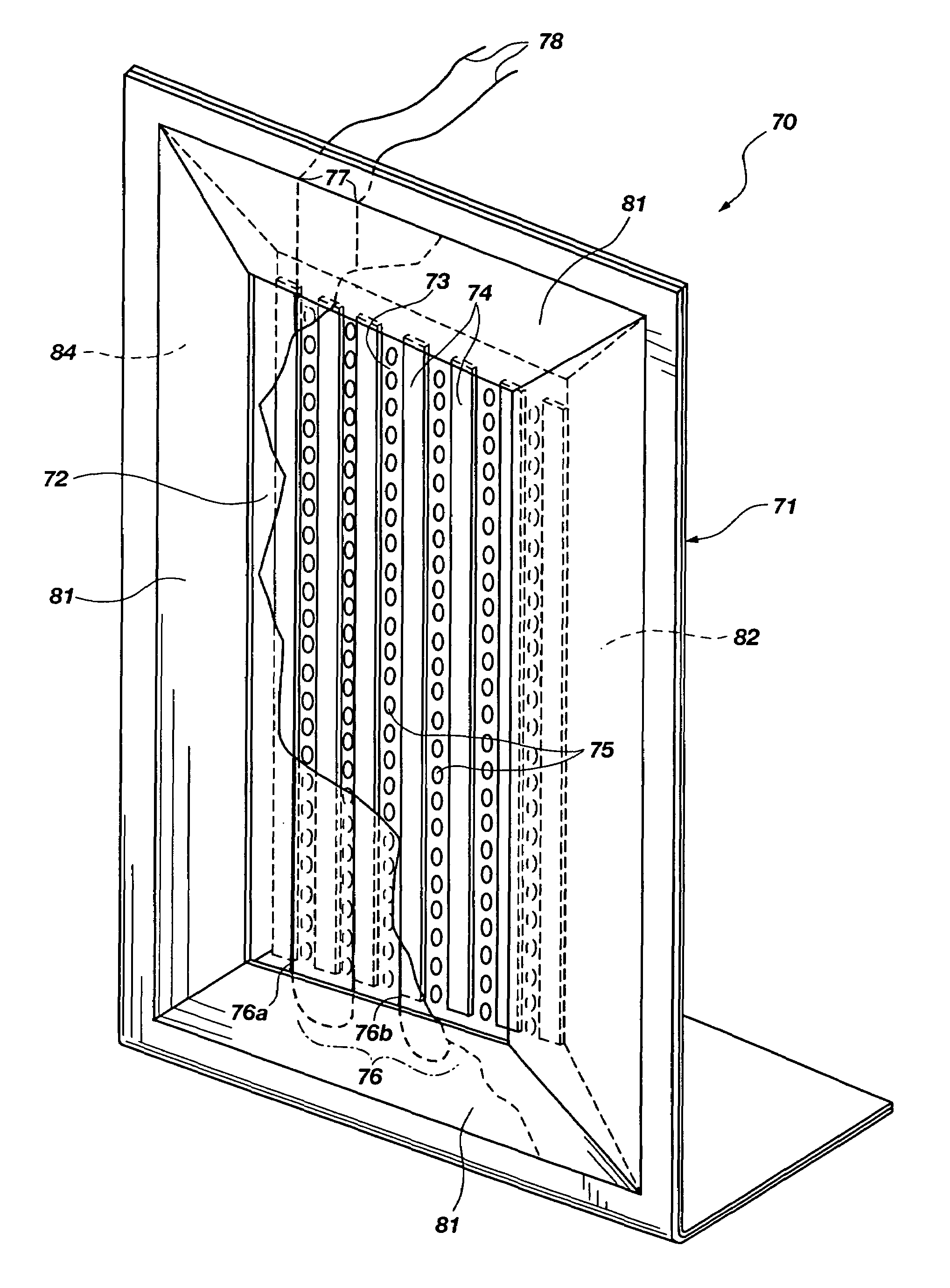

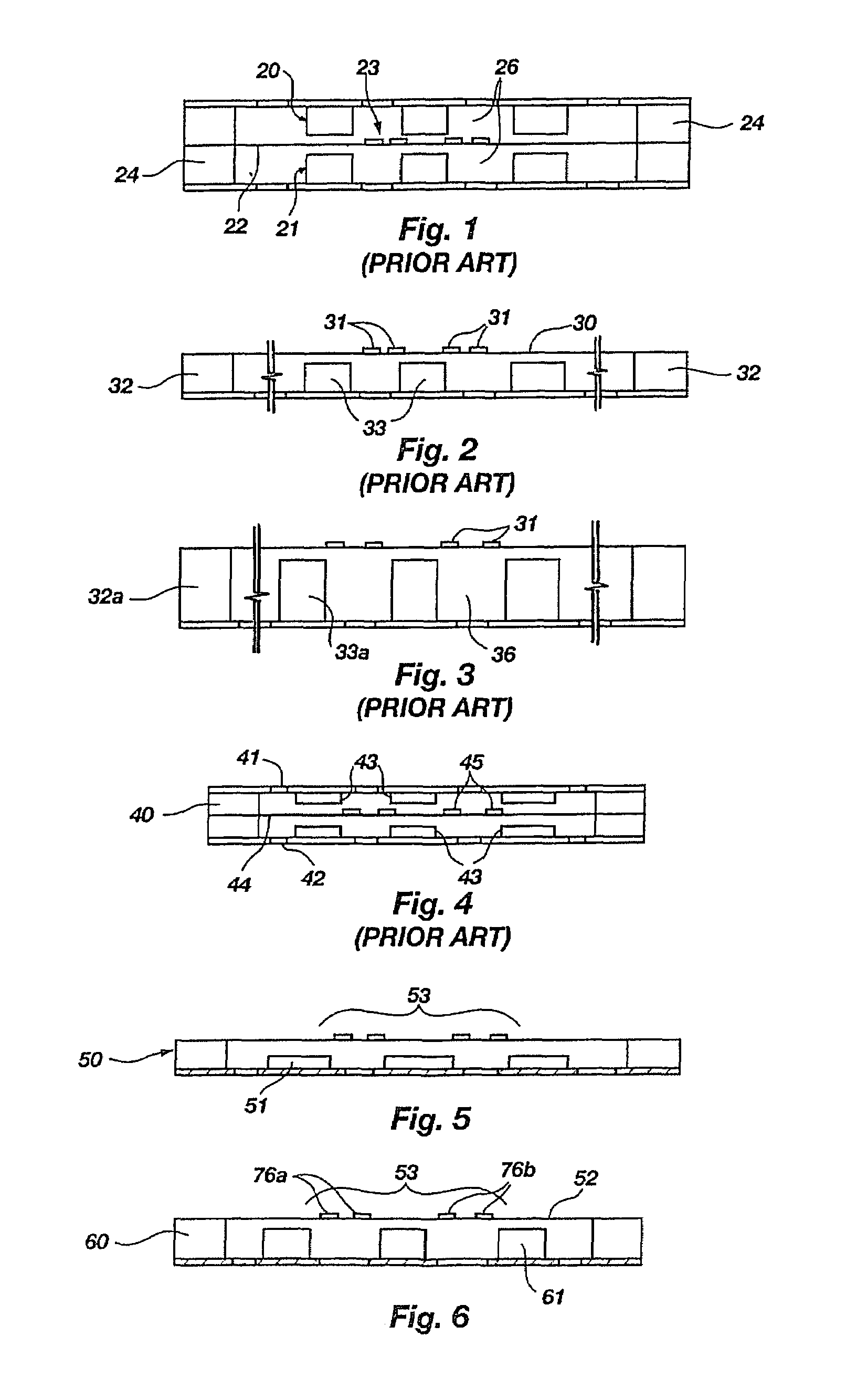

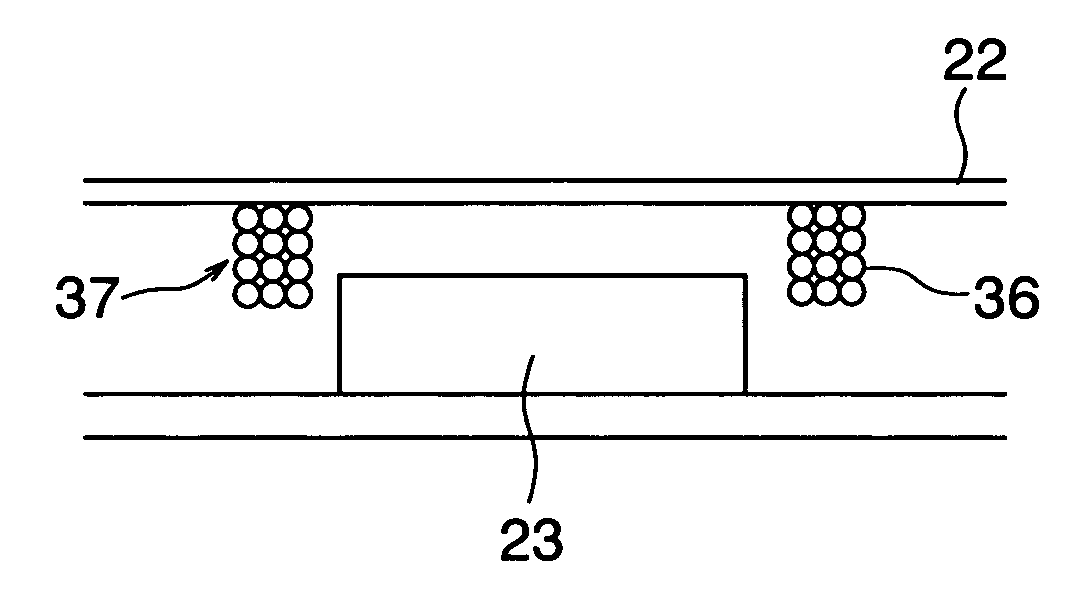

Planar diaphragm loudspeaker and related methods

ActiveUS6929091B2High-quality sound reproductionEasy and cost-effective to manufactureFibre diaphragmsMicrophonesFiberEngineering

A planar diaphragm loudspeaker for use in a suspended ceiling grid and related methods of manufacturing are provided. The loudspeaker includes a rectangular, planar diaphragm of polymer material sized to fill an opening of the ceiling grid. The front surface of the diaphragm defines a three-dimensional, textured pattern formed by a secondary operation, such as, etching, perforating, and adhesion of granular or fiber material. The diaphragm may include an outer region about the periphery of the diaphragm having a density of at least 5 pcf and an inner region circumscribed by the outer region, thereby providing sufficient structural stiffness to the outside perimeter of the diaphragm and eliminating the need of an outer frame. The density of the inner region is at or below about 3 pcf throughout the inner region. Also, a shroud may secured to the diaphragm, in which the shroud and the diaphragm are securable in a first orientation for flush mounting or in a second orientation for tegular-drop mounting. The loudspeaker may also include a bracket rigidly attached to the diaphragm at two spaced locations in the outer region and extending across the inner region between the spaced locations.

Owner:AUDIO TECH ASSOC

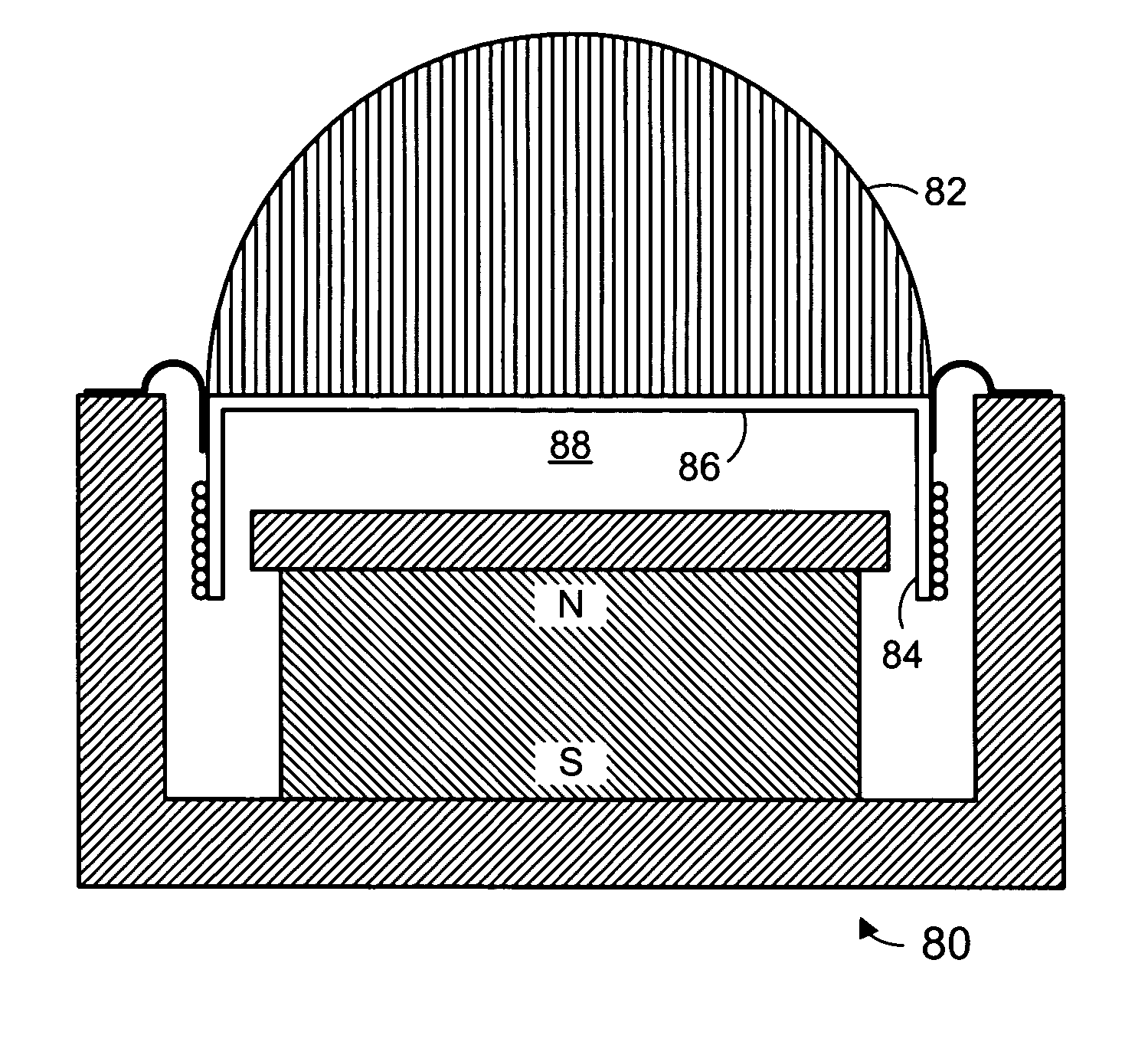

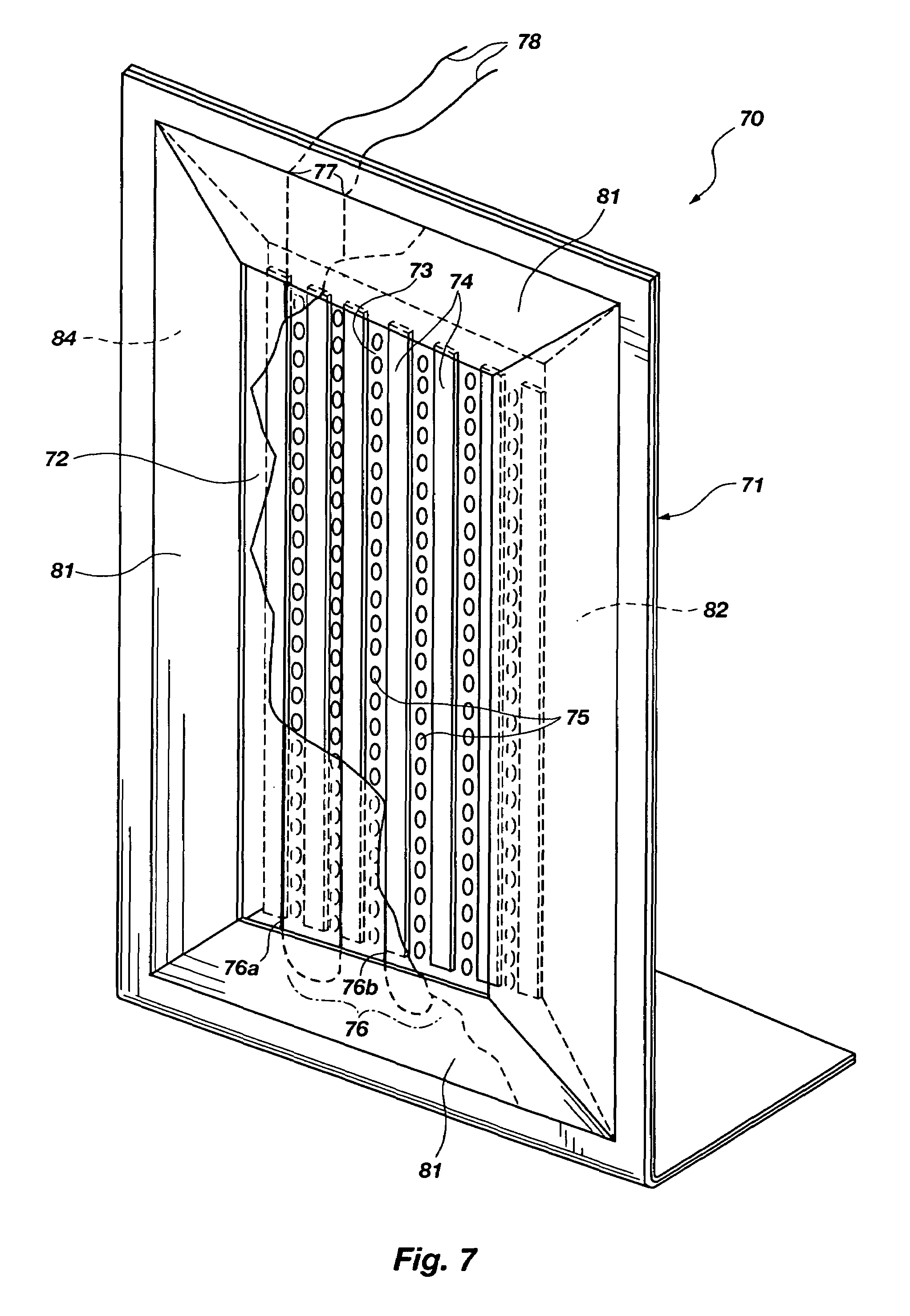

Single end planar magnetic speaker

InactiveUS7251342B2Favorable in cost of constructionSmall sizeFibre diaphragmsTransducer detailsHigh energyEngineering

A single end planar magnetic speaker system having at least one thin film, flexible diaphragm (72, 90) having a front side and a rear side for converting an input electrical signal into a corresponding acoustic output, the at least one diaphragm including a predetermined conductive region (76) and a predetermined non-conductive region; a magnetic structure (92) utilizing nonferite high energy magnets of a predetermined thickness wherein the magnets are each at least as wide as they are deep; the magnets having a magnetic strength wherein when compared to magnets of a ferrite type of same width as the nonferite high energy magnets but which have increased depth to yield at least nearly the same magnetic strength as the high energy magnets in the magnetic structure, doubling the depth of the high energy magnets in the magnetic structure, doubling the depth of the high energy magnets in the magnetic structure yields an increase in speaker sensitivity of at least 3 dB while the doubling the depth of the ferrite type magnet will yield a gain of less than 3 dB, and the system further includes a mounting structure coupled to the diaphragm to capture the diaphragm, to hold it in a predetermined state of tension and space it at a predetermined distance from the magnetic structure.

Owner:LRAD CORPORATION

Planar speaker

InactiveUS7283636B2Less variation in impedanceIncrease freedomFibre diaphragmsPlane diaphragmsElectrical conductorTransducer

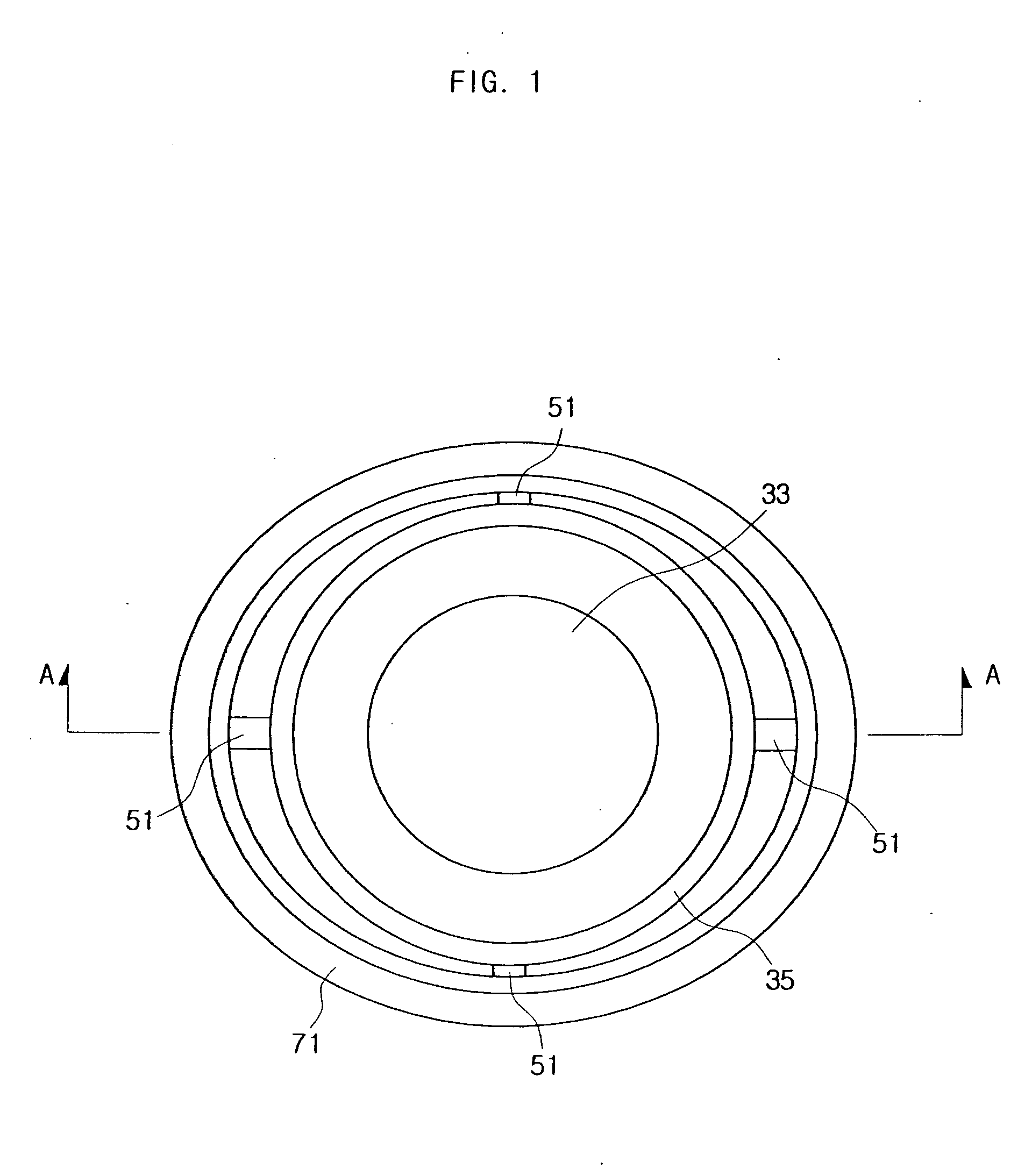

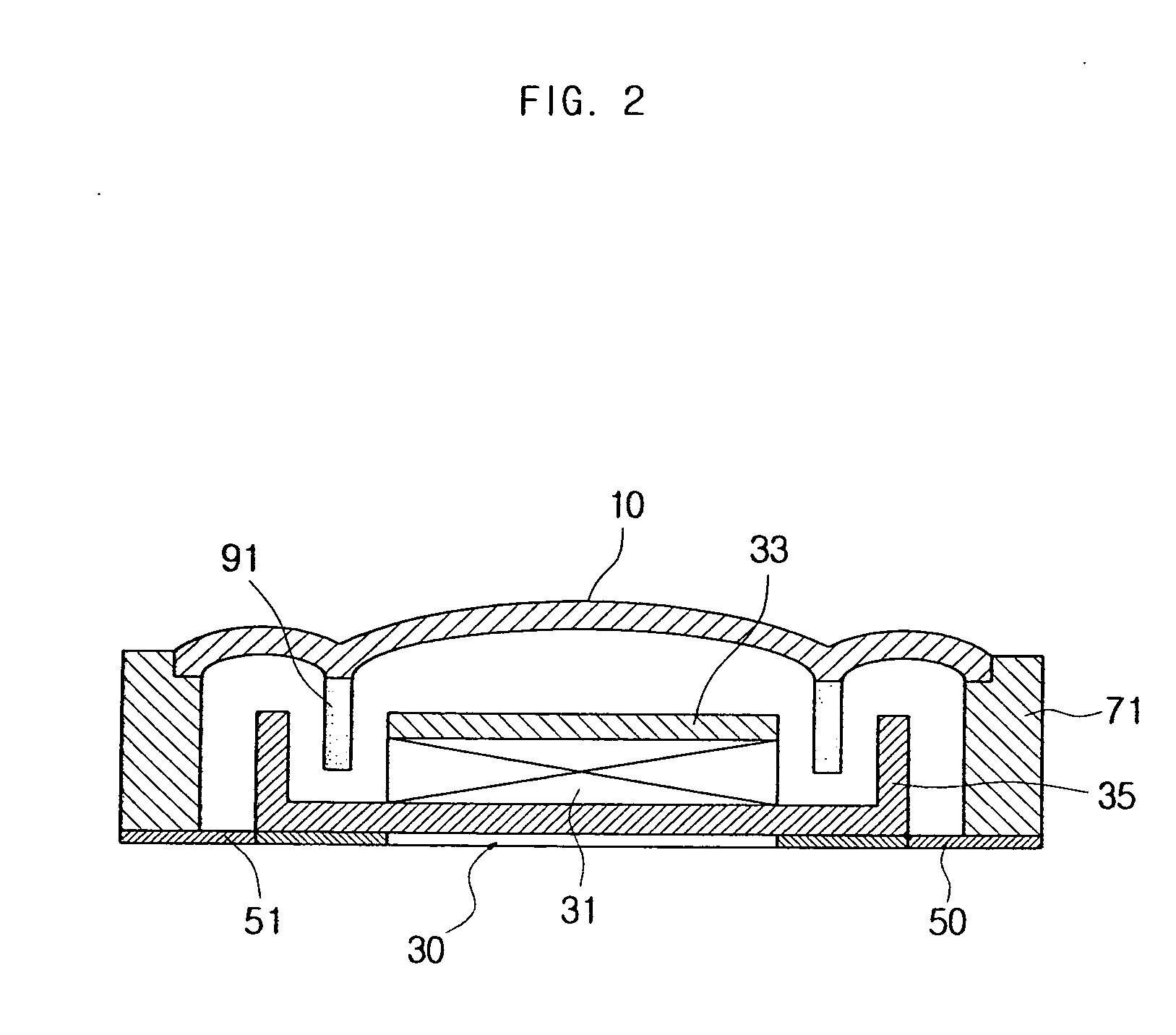

The present invention provides a planer acoustic transducer including a vibrating diaphragm including a spiral voice coil provided on both surfaces or on one surface of an insulating base film; and a permanent magnet corresponding to the voice coil, wherein, in the vibrating diaphragm, the spiral voice coil is formed by applying a wire conductor, in a coil pattern, onto a sheet-like substrate having an adhesive layer on at least one surface thereof. Alternatively, at least a portion of the vibrating diaphragm, which portion corresponds to the loop of a first or second vibration mode, is reinforced with a rigidity-imparting member; the substrate of the vibrating diaphragm is formed of a resin foam; or the voice coil is formed three-dimensionally.

Owner:FURUKAWA ELECTRIC CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com