Patents

Literature

5803 results about "Pressure reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pressure reducing valve, often referred to as a pressure regulator, is an apparatus that controls the flow of a liquid or gas and automatically discontinues the flow once a certain pressure level is attained.

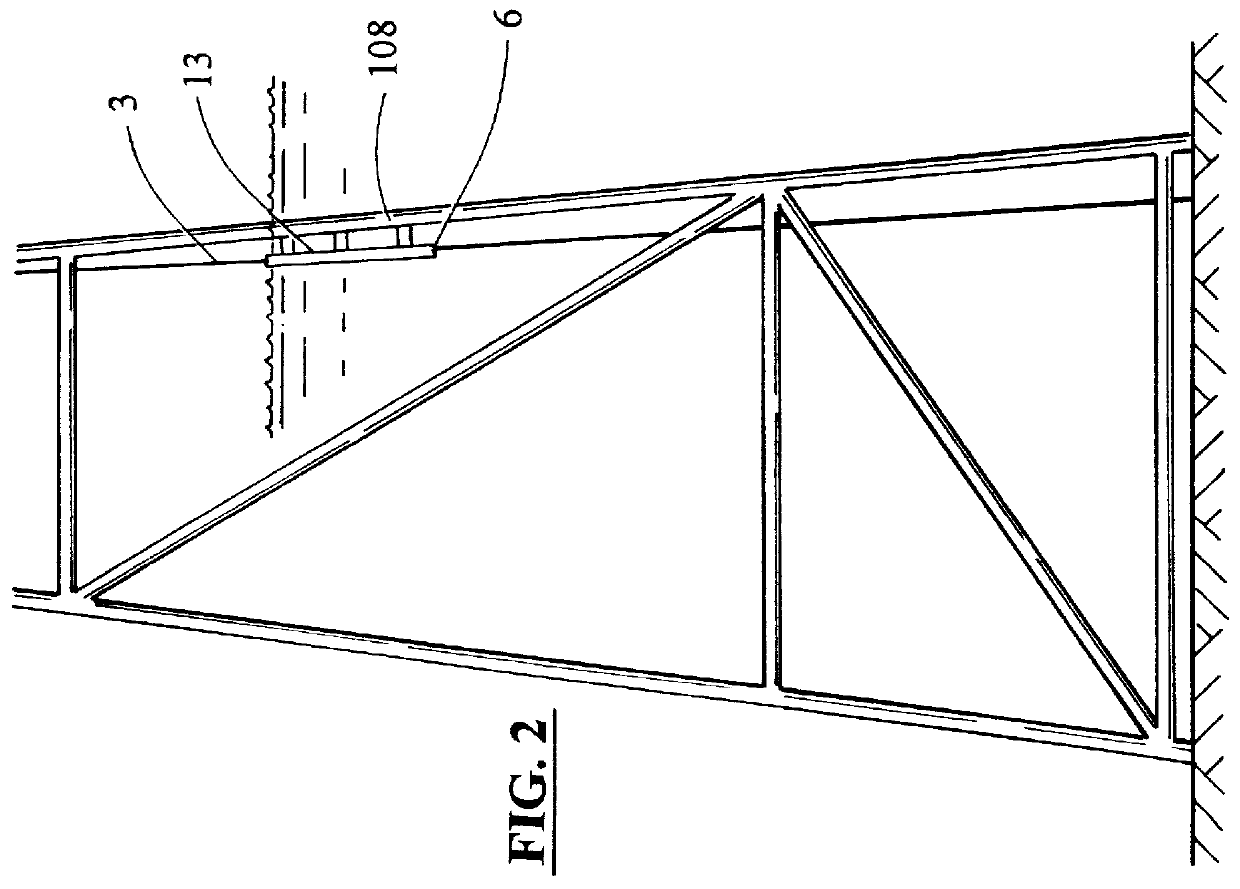

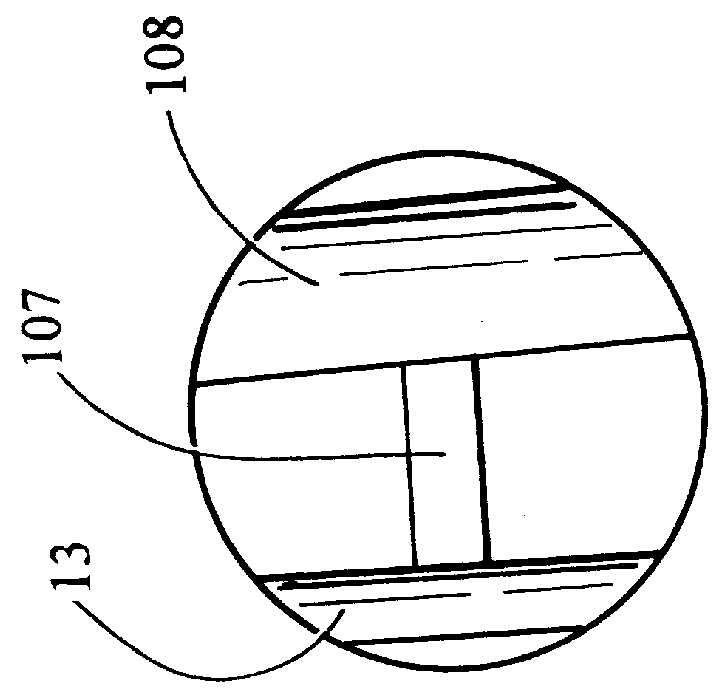

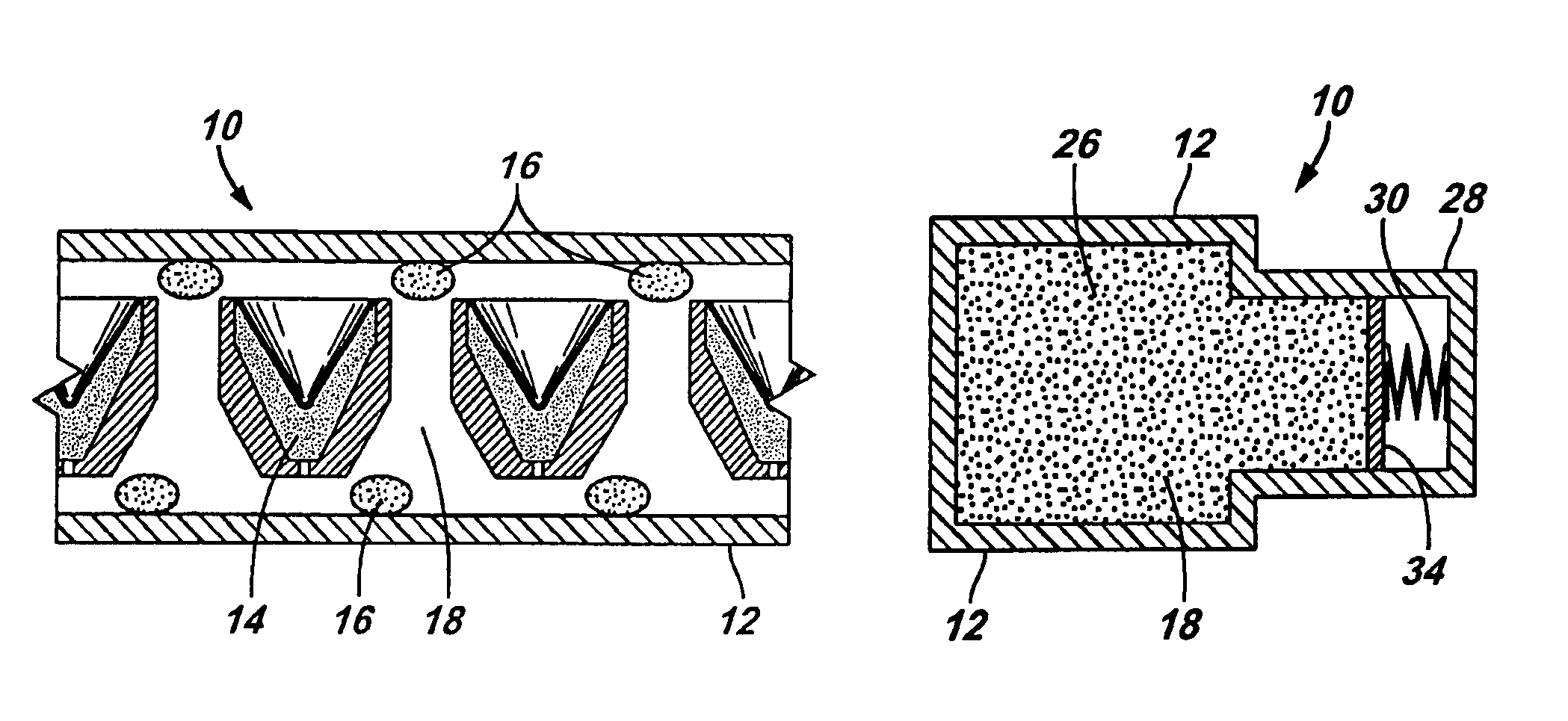

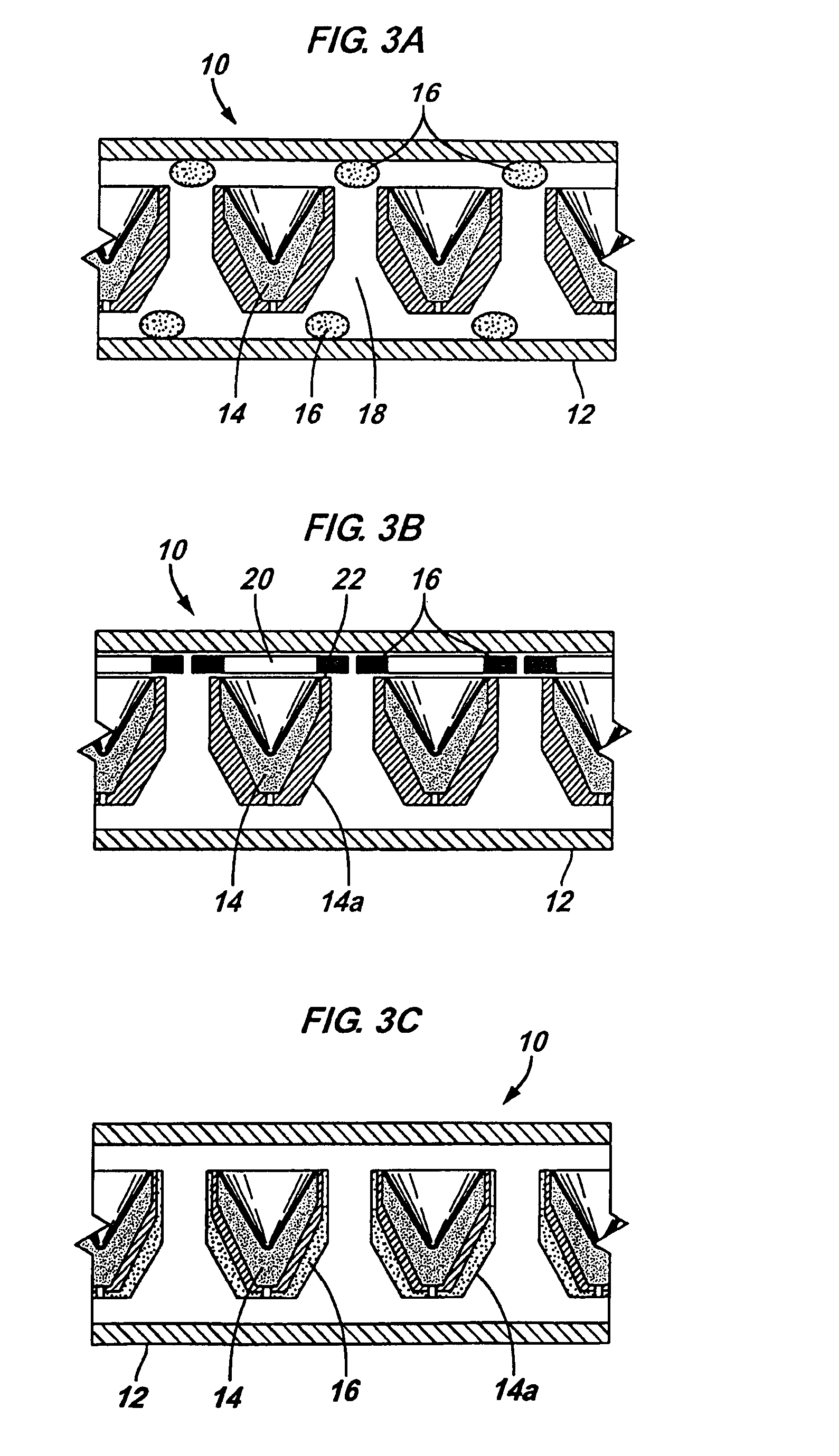

Method for manufacture of minimum porosity, wrinkle free composite parts

A process and associated apparatus used to prepare a thermoplastic composite from a plurality of plies of thermoplastic resin prepregs. The prepregs are formed into a composite structure under two chambers; a rigid outer chamber (of any convenient size or shape) and a second flexible inner chamber containing a prepreg lay-up. The absolute pressures are reduced concurrently in a stepwise method in both chambers. This concurrent, stepped pressure reduction is accomplished at a rate which prevents the vacuum bag from moving far from the prepregs, and prevents wrinkles from forming in the prepregs. Pinching off the diffusion paths required for the removal of unwanted gases is eliminated. The lay-up is then heated and the absolute pressure in the outer rigid chamber is increased. This pressure constrains the flexible inner chamber during out-gassing of the thermoplastic resin, preventing wrinkles from forming in the prepregs. The absolute pressure in the outer rigid chamber is increased to atmospheric pressure or greater causing the prepregs to consolidate. A low absolute pressure is maintained in the flexible inner chamber. The temperature is then increased to the cure temperature of the resin and held for a time sufficient for the resin to cure. The resulting consolidated thermoplastic resin is substantially void free and detectable wrinkles are absent.

Owner:HALE HAROLD P

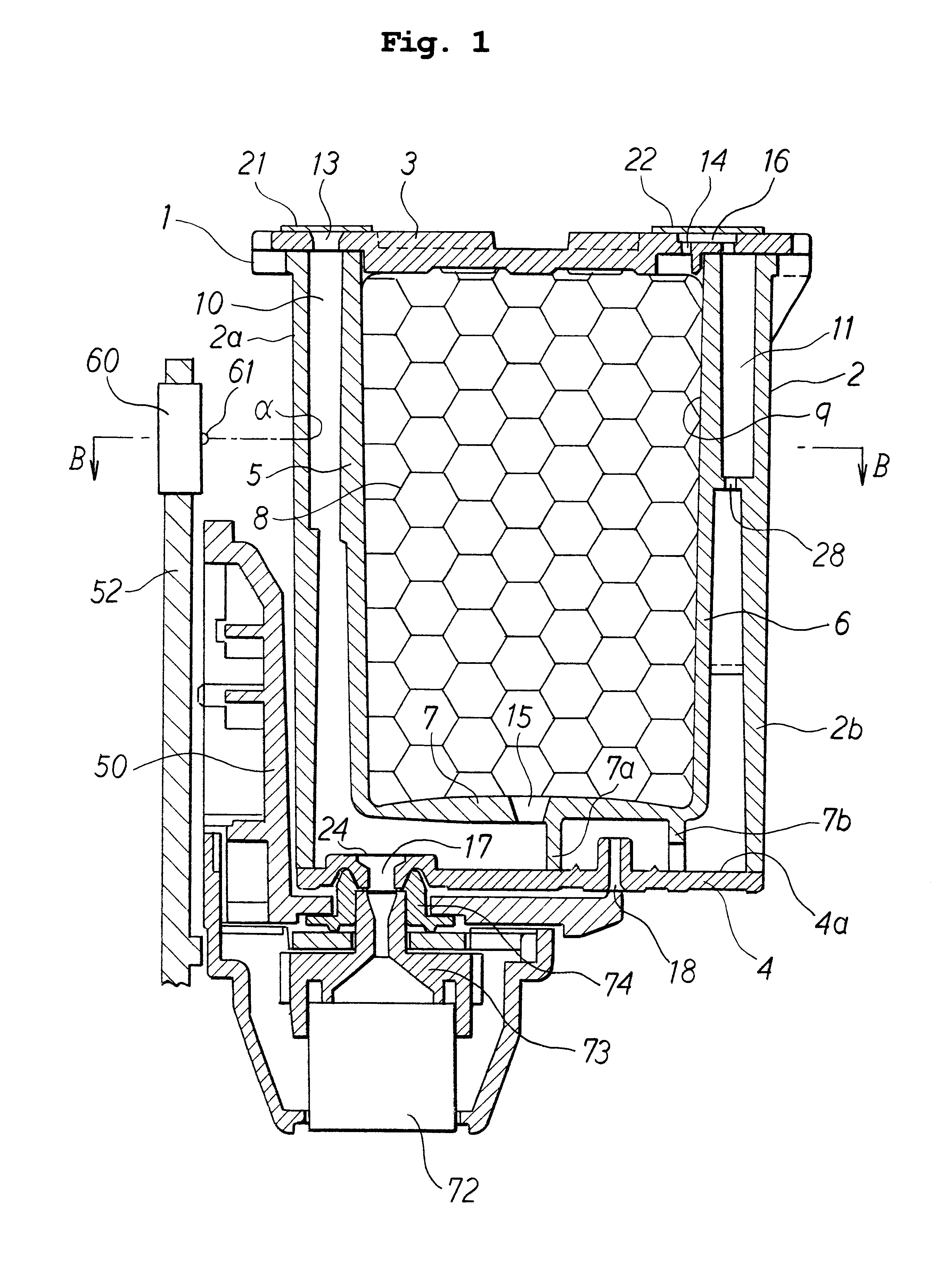

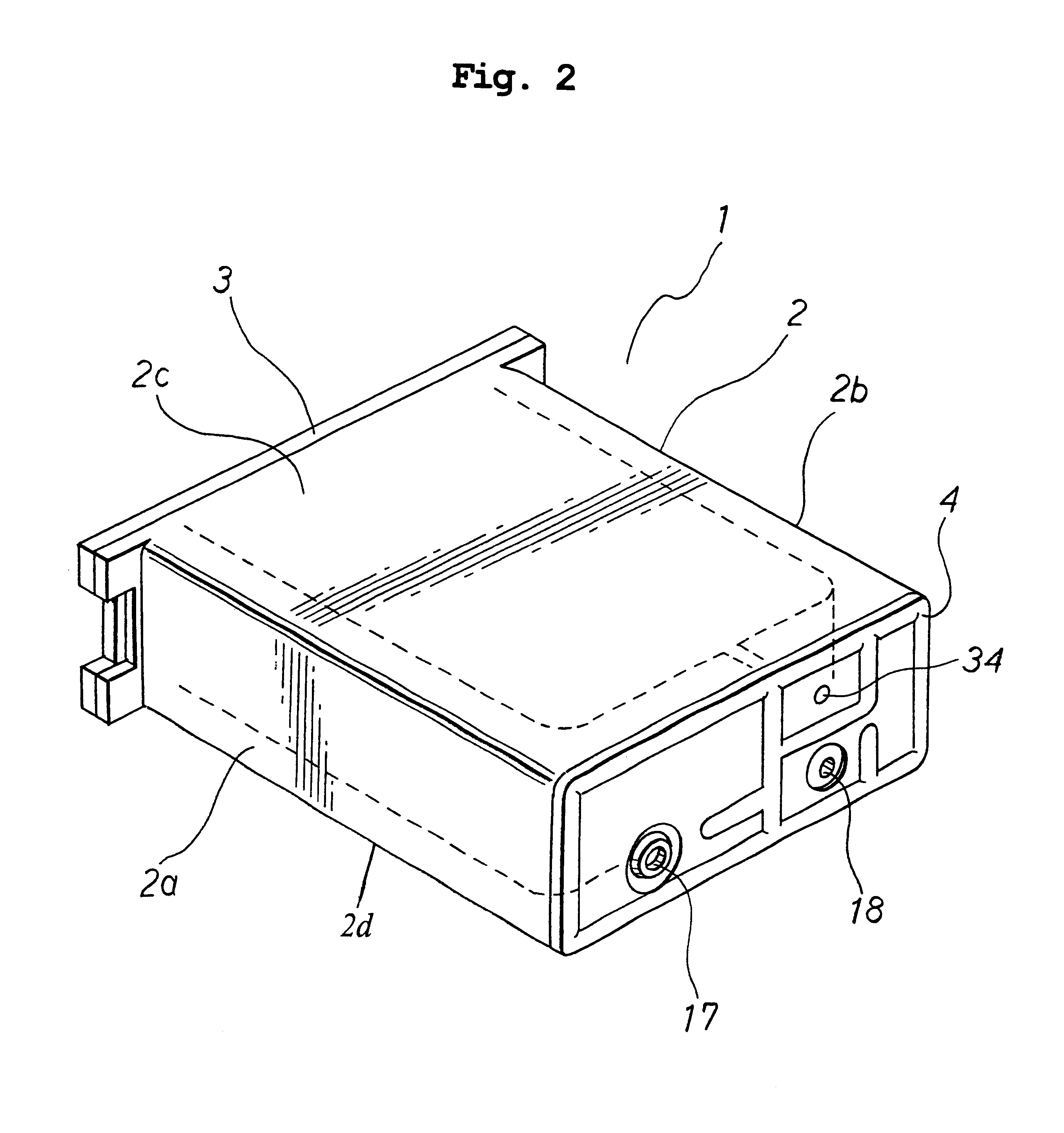

Ink cartridge and remaining ink volume detection method

An ink cartridge has a first partitioning wall 5 and a third partitioning wall 7 for dividing the inside of a case 2 into a first ink chamber 9 and a second ink chamber 10, and a second partitioning wall 6 for demarcating an atmosphere connection chamber 11. In an upper case cover 3 are formed an ink filling hole 13 communicating with the second ink chamber 10 and a pressure reduction hole 14 communicating with the atmosphere connection chamber 11. Therefore, when ink filling is being done, the filling apparatus and the pressure reduction apparatus need only be brought to bear from one side of the upper case cover, resulting in improved work efficiency. Ink filling can be performed efficiently because the ink successively passes to the second ink chamber 10 and the first ink chamber 9. After ink filling, the ink filling hole 13 and the pressure reduction hole 14 can easily be sealed off with sealing material. An ink cartridge is thus provided that can be easily assembled at low cost.

Owner:BROTHER KOGYO KK

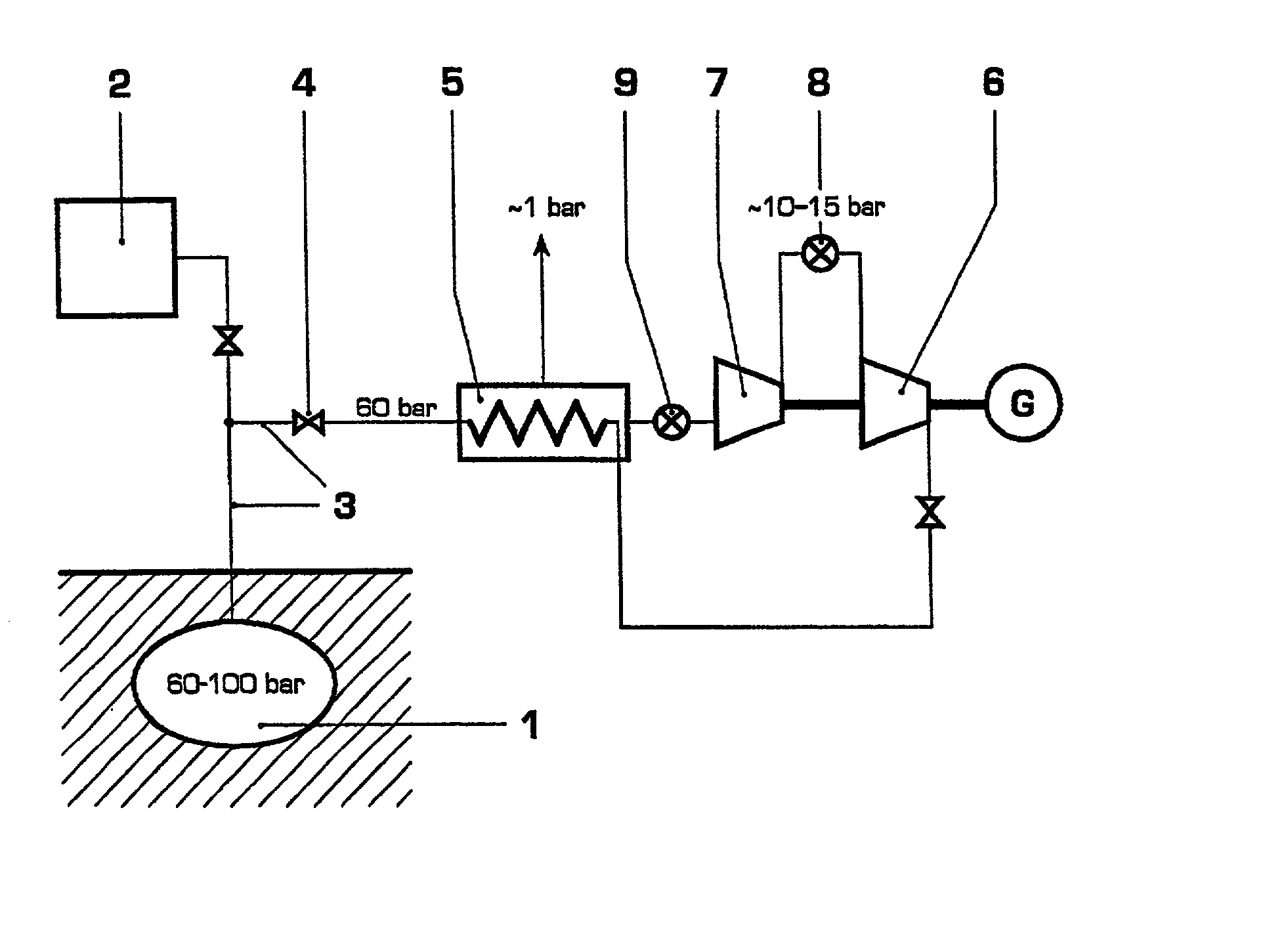

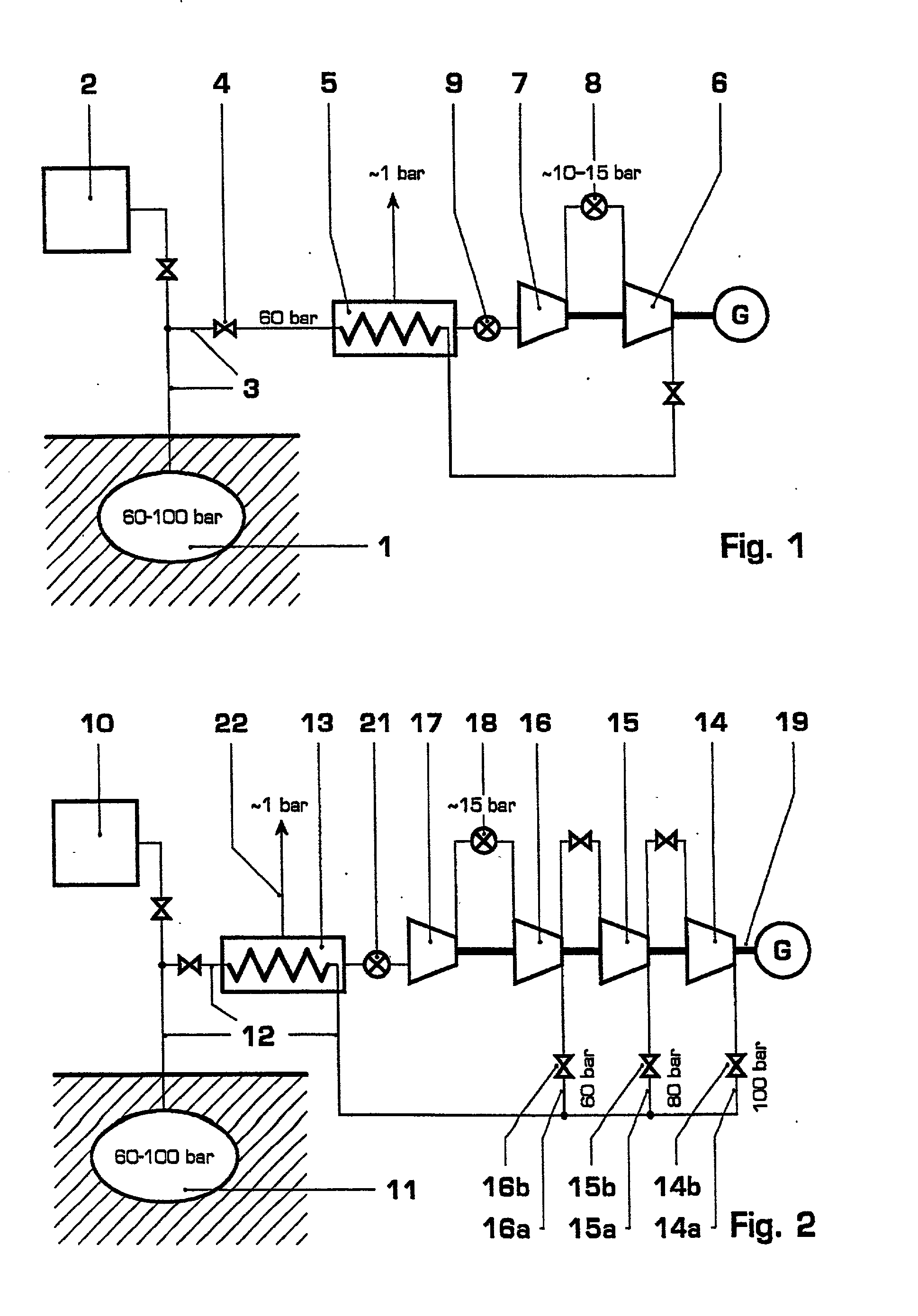

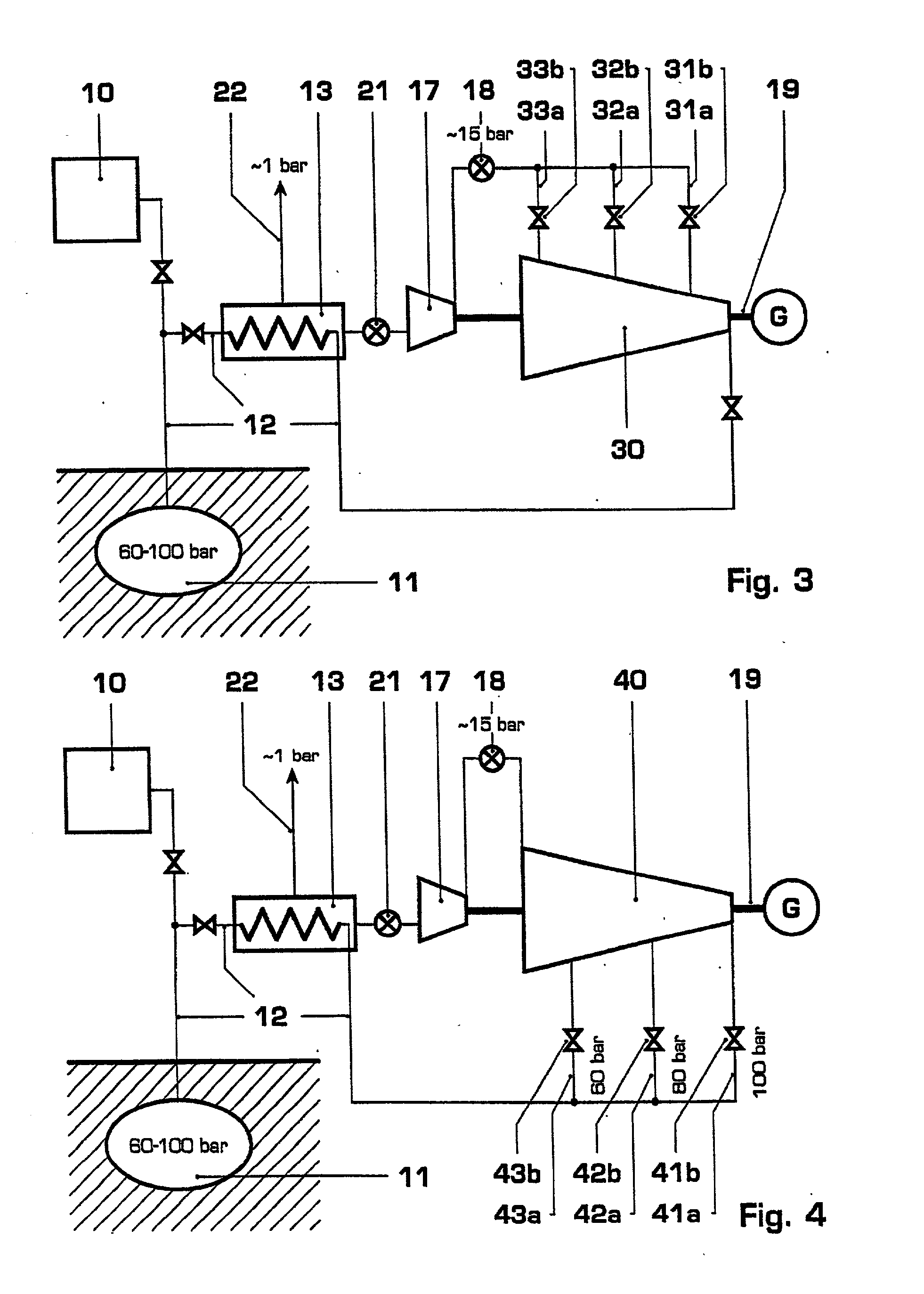

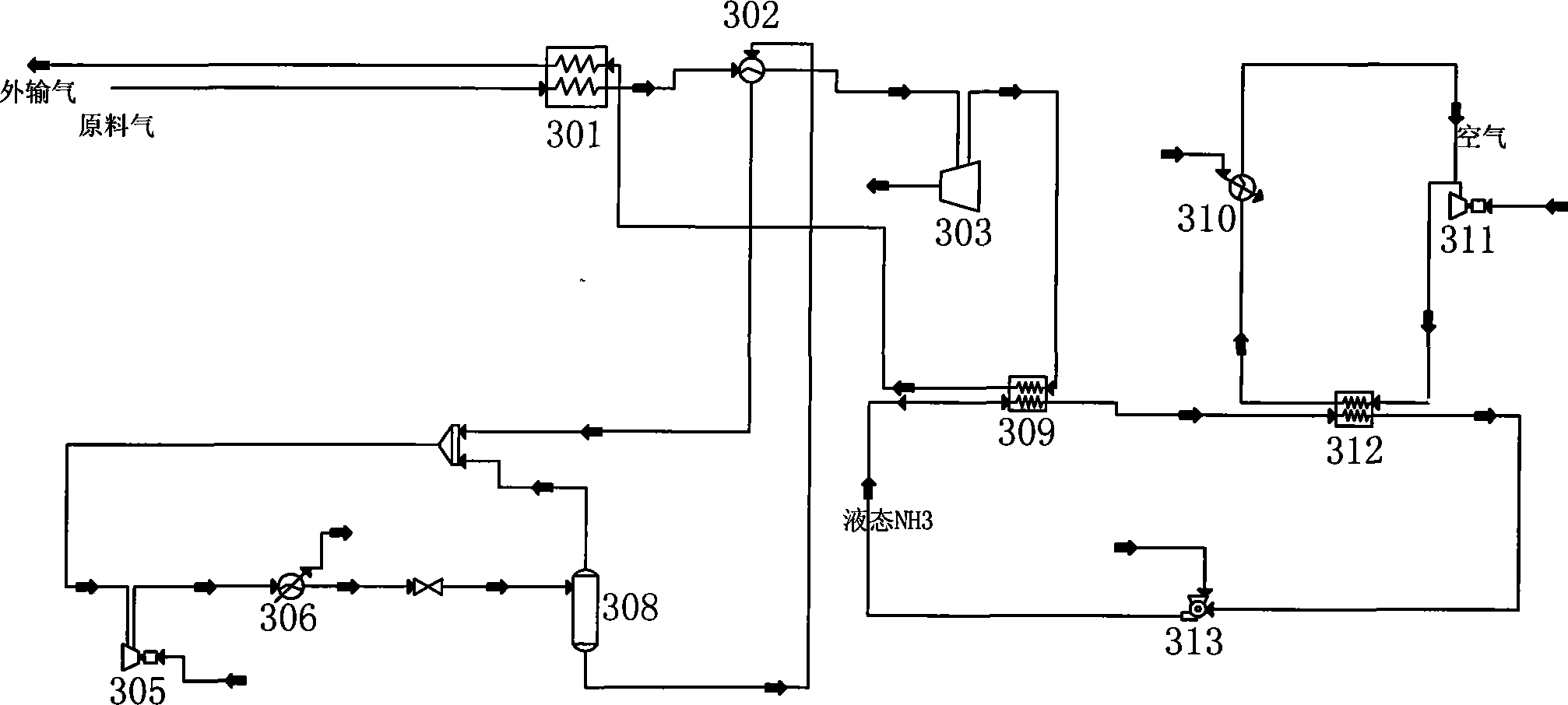

Power generation plant with compressed air energy system

InactiveUS20030131599A1Avoid power outagesImprove efficiencyGas turbine plantsJet propulsion plantsThermal energy storageEngineering

A power generation plant with a compressed air energy storage system comprises a means to reduce the pressure of air extracted from a compressed air storage cavern for the use in a combustion turbine. The means to reduce the air pressure comprises at least one expansion turbine and means to control the size of pressure reduction. Furthermore, the expansion turbine is arranged on a rotor shaft that drives a generator. The means for pressure redact, according to the invention, avoid power losses and provide an increased overall efficiency of the power generation plant.

Owner:GENERAL ELECTRIC TECH GMBH

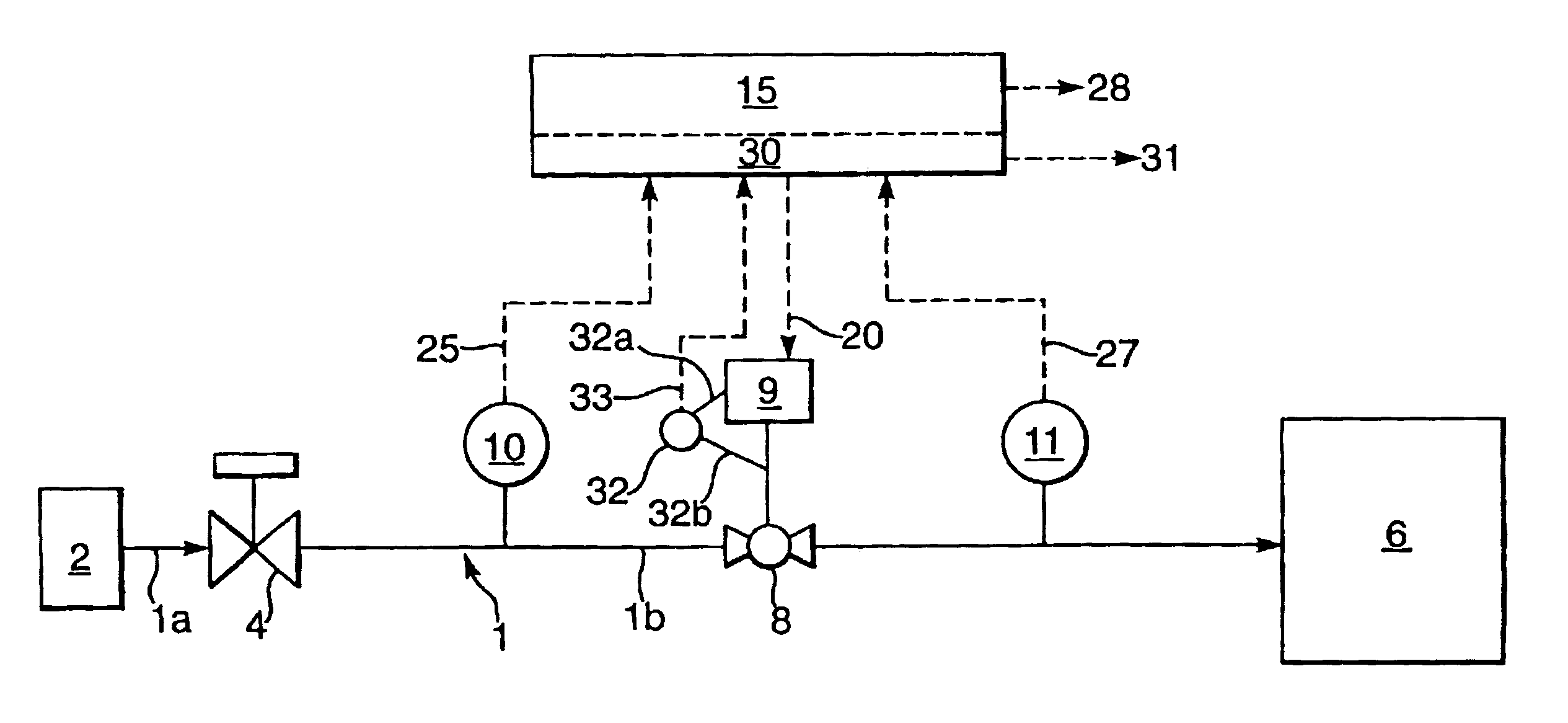

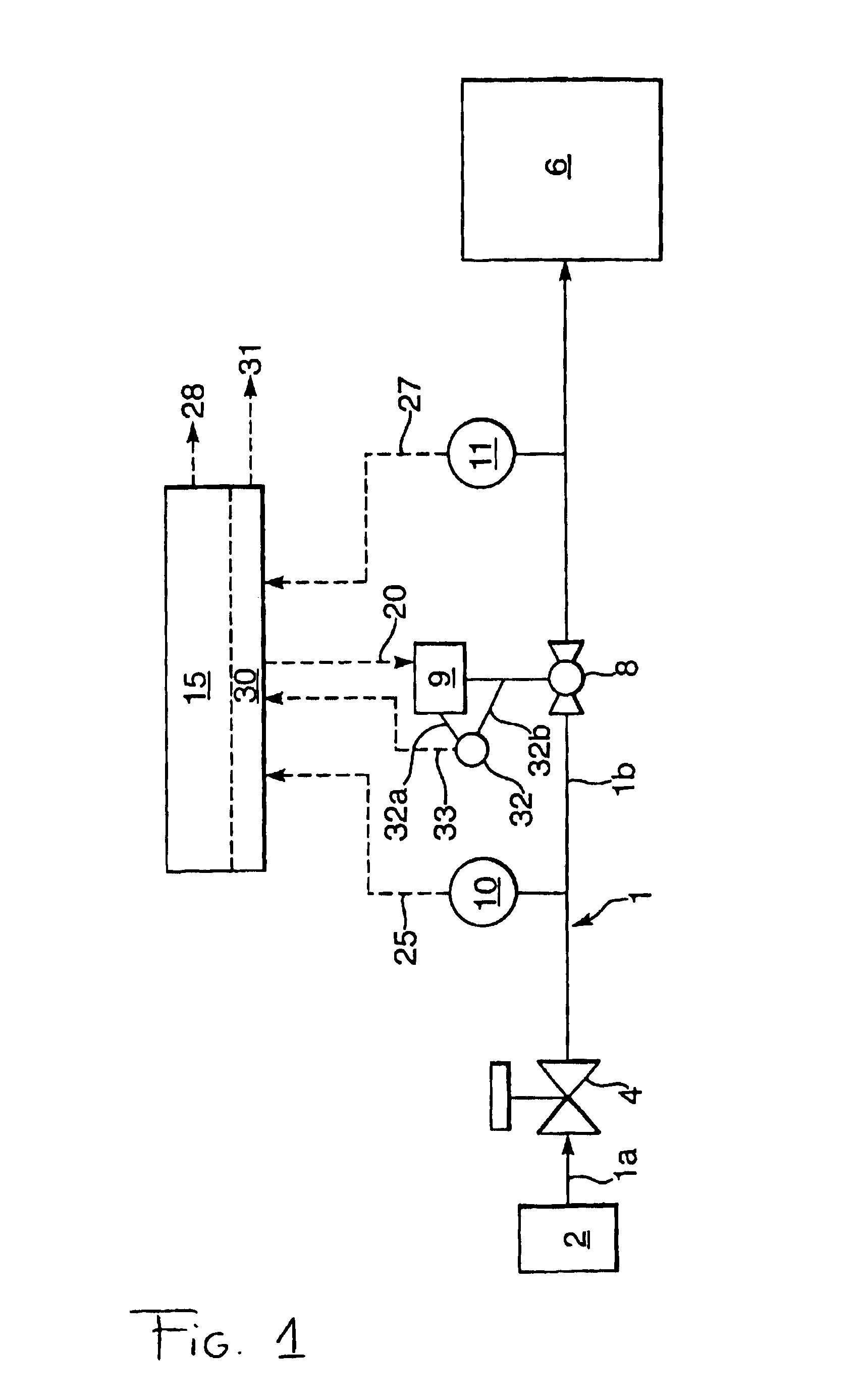

Over-pressure protection system

InactiveUS6880567B2Operating means/releasing devices for valvesEqualizing valvesSafety controlEngineering

An over-pressure protection system having a conduit section extending between a pressure reduction valve and a low-pressure fluid handling system, a shut-off valve provided with an actuator arranged in the conduit section, pressure sensors arranged one on either side of the shut-off valve in the conduit section, a safety control system that communicates with the actuator and the pressure sensors which produces a signal when it detects a high pressure in the conduit section, and a self-diagnostic system for checking the shut-off valve and the pressure sensors that communicates with the actuator, the pressure sensors and the safety control system, which self-diagnostic system produces a signal when it detects a failure in either the shut-off valve or the pressure sensors or both.

Owner:SHELL OIL CO

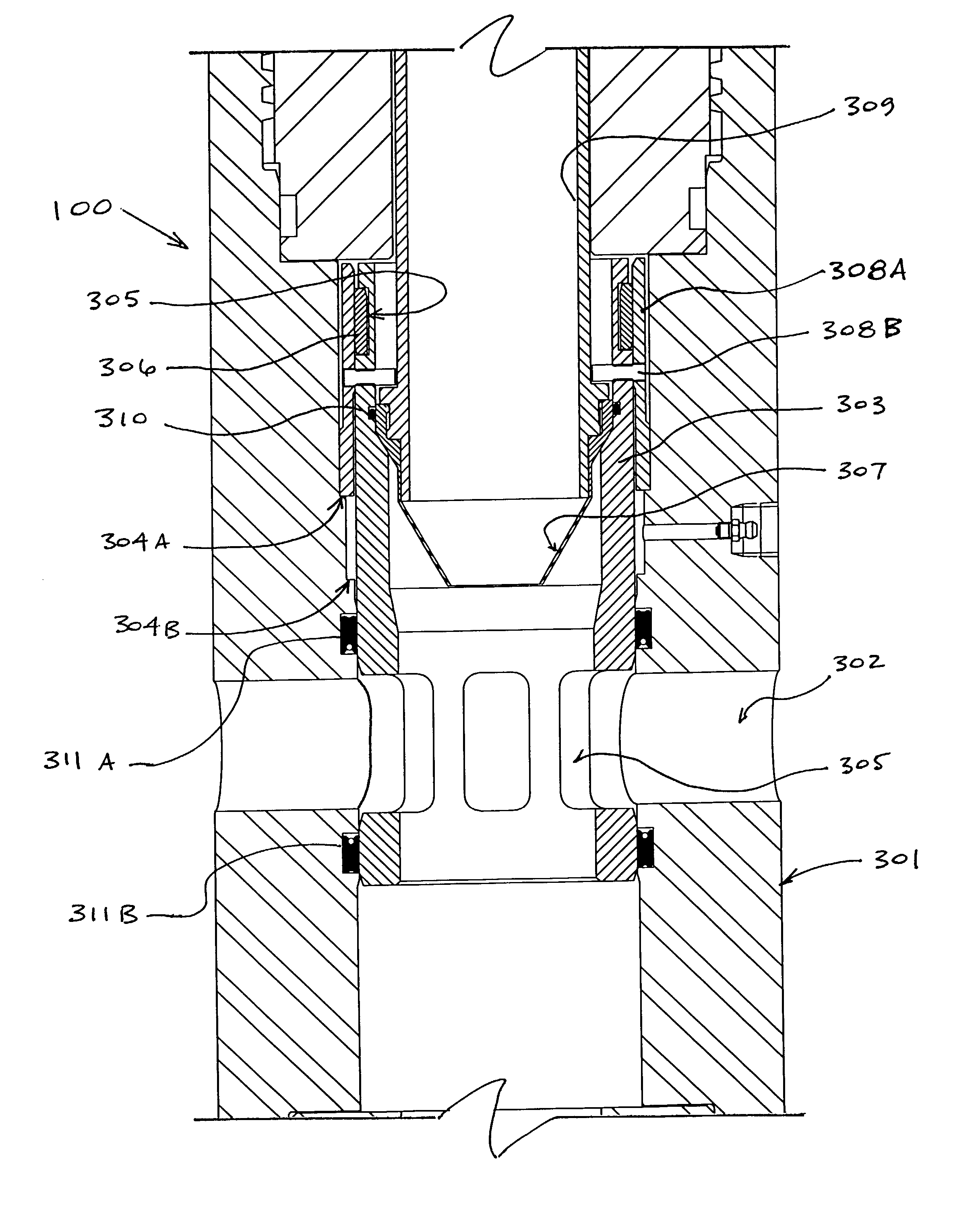

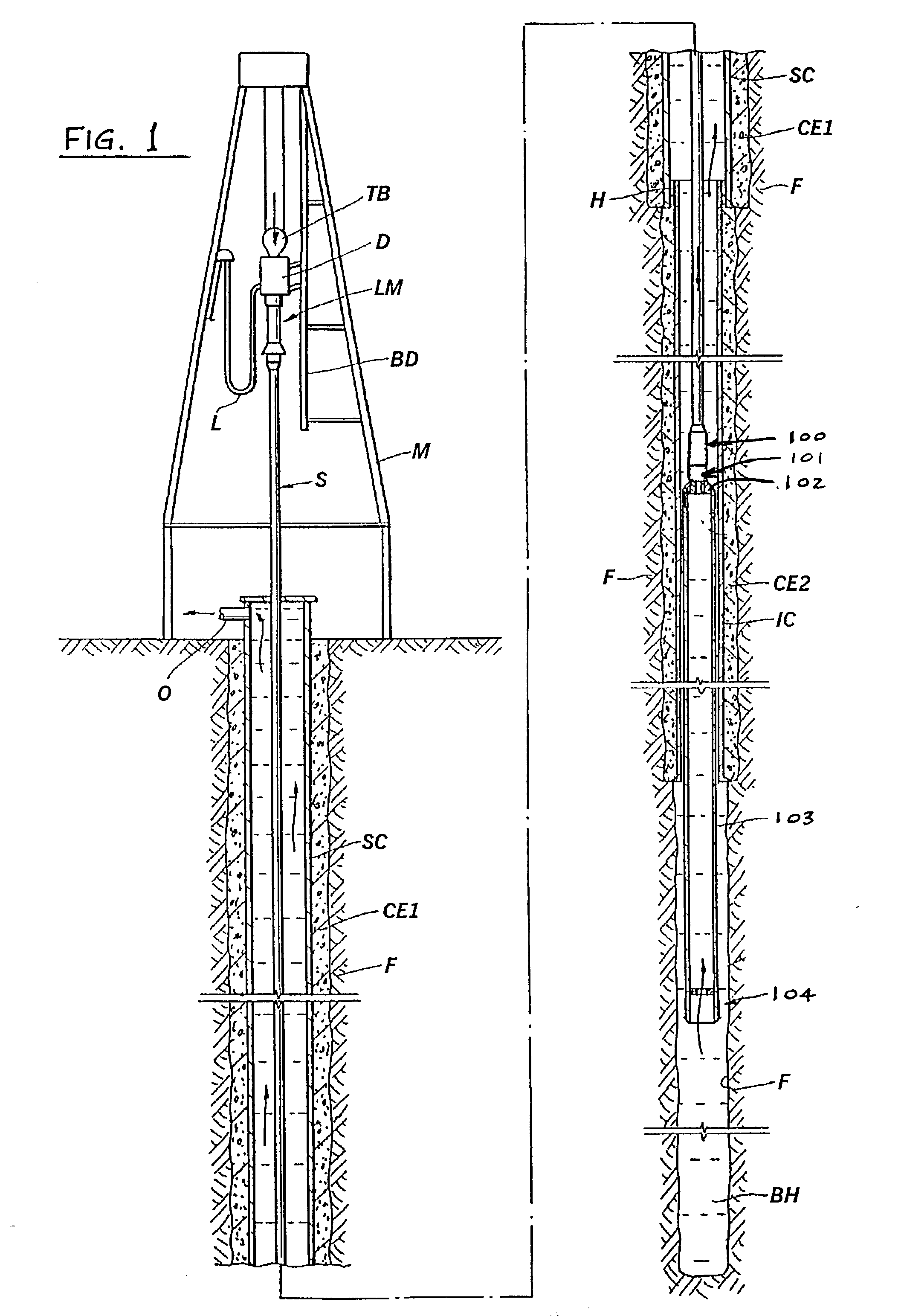

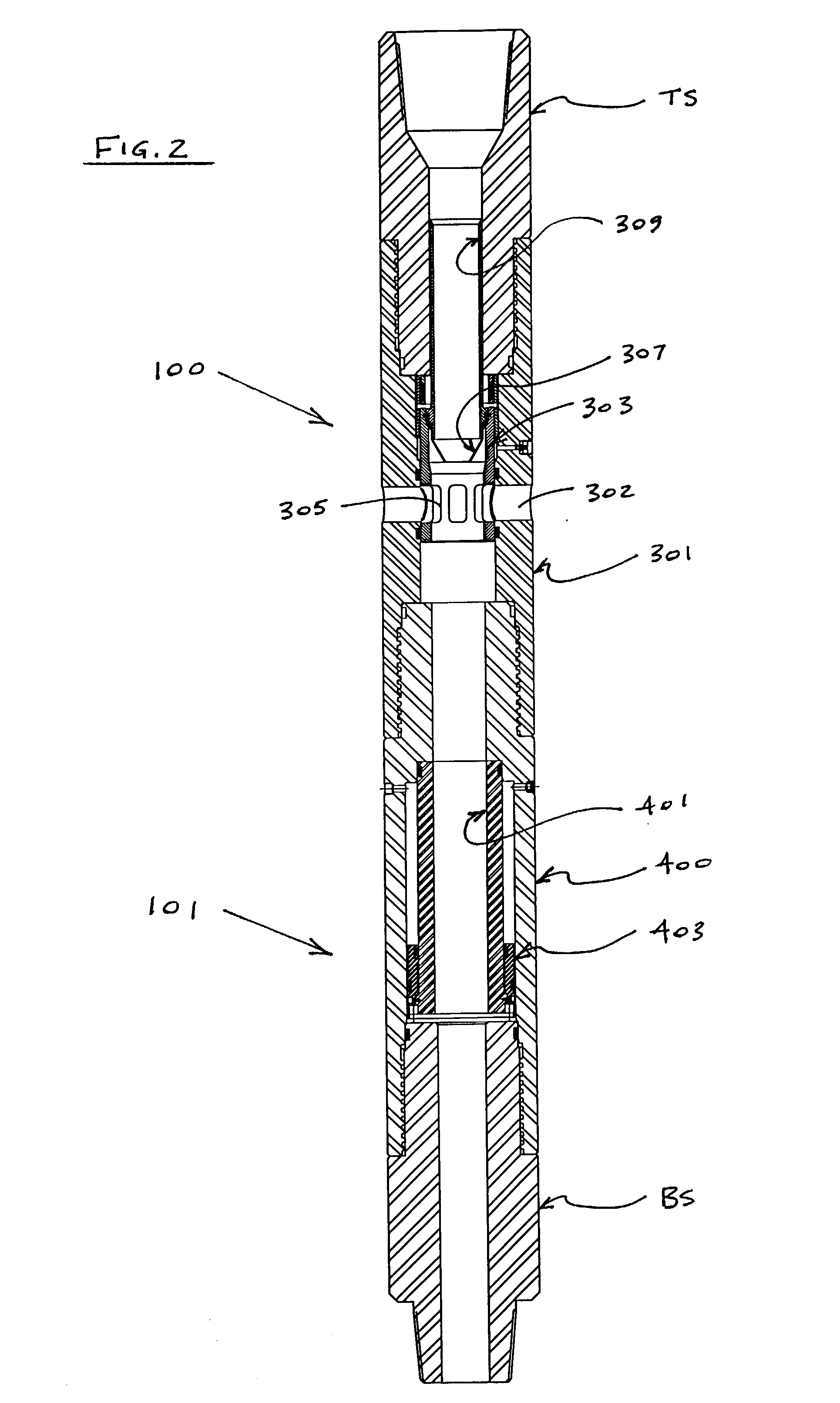

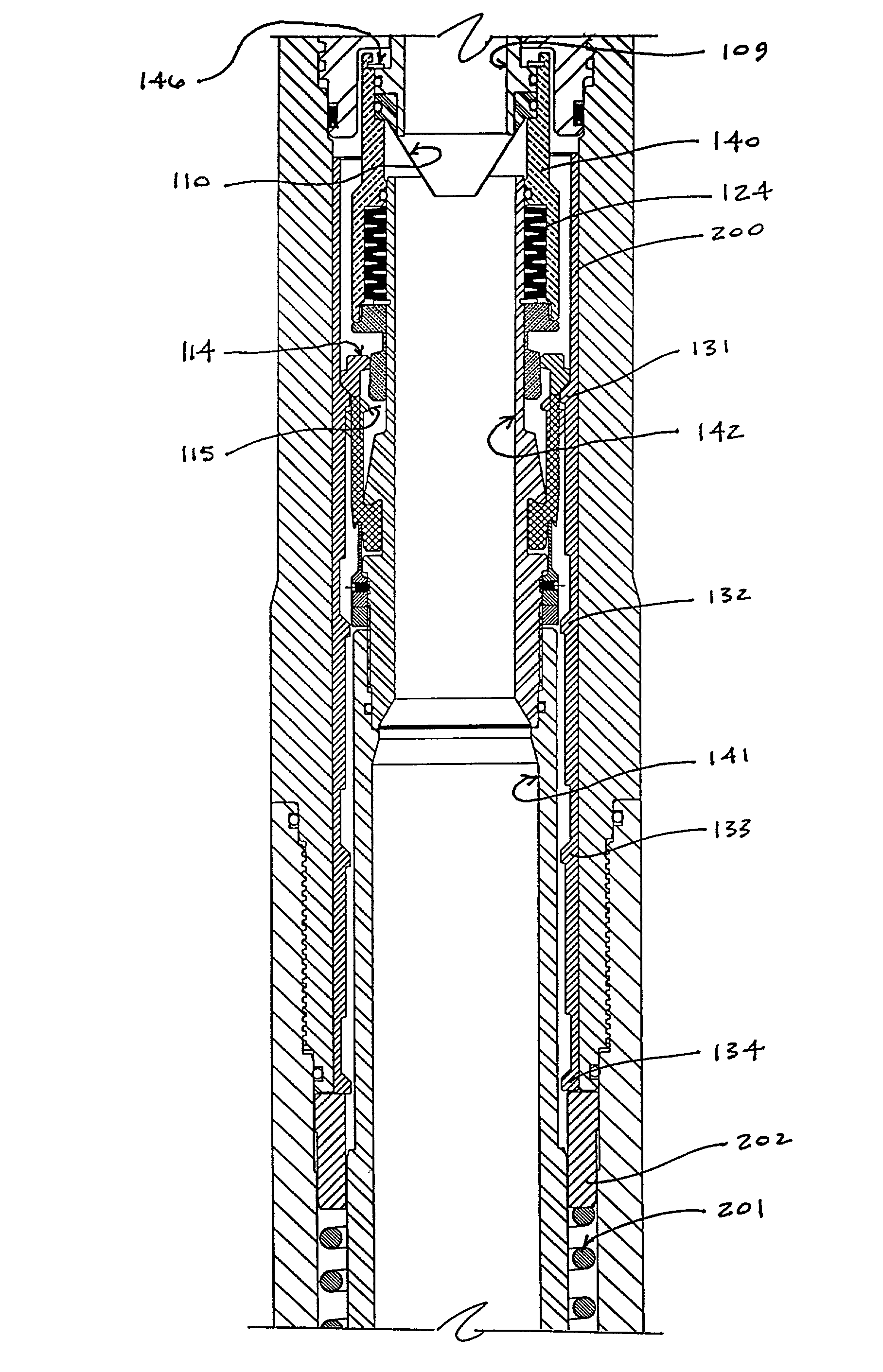

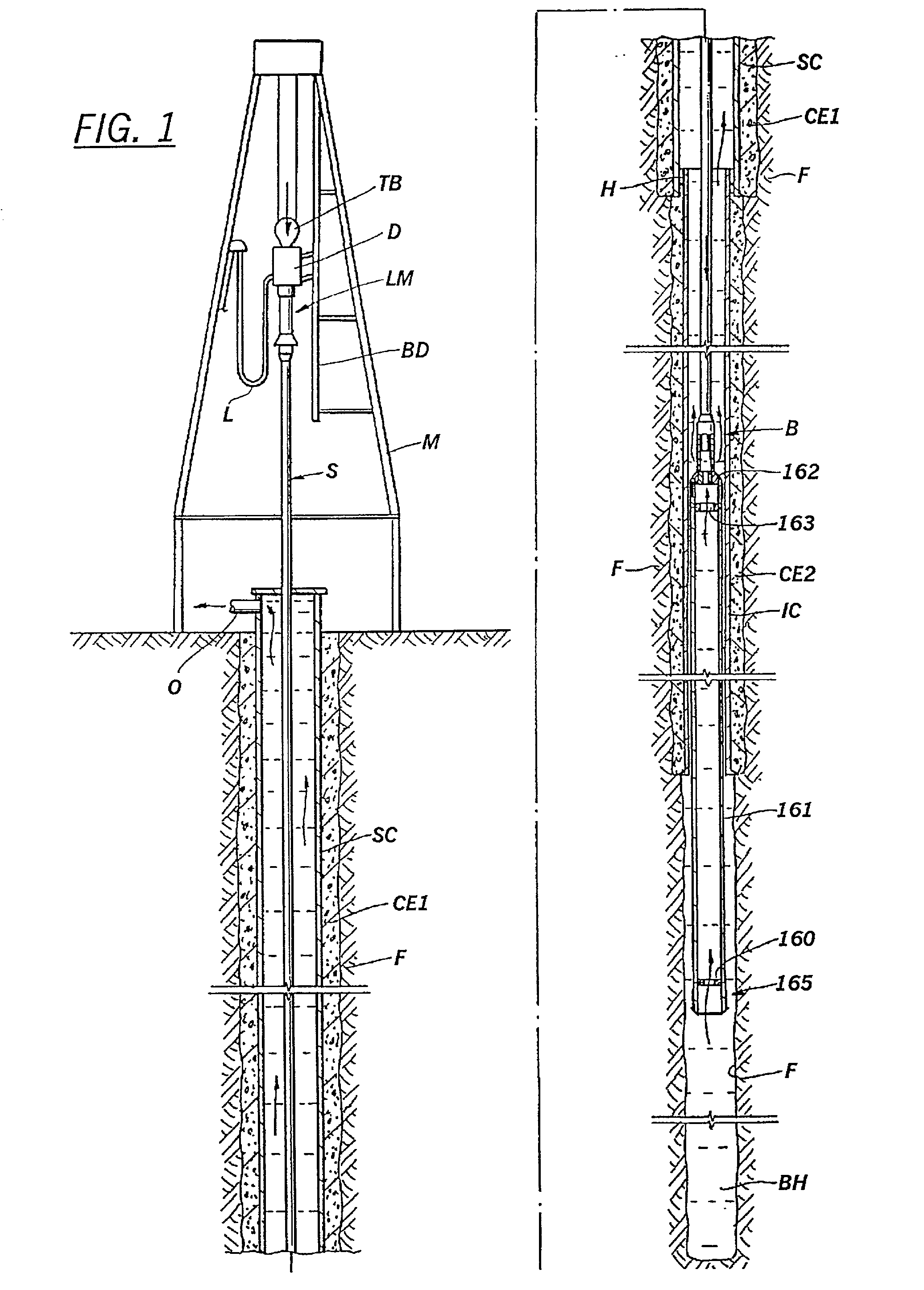

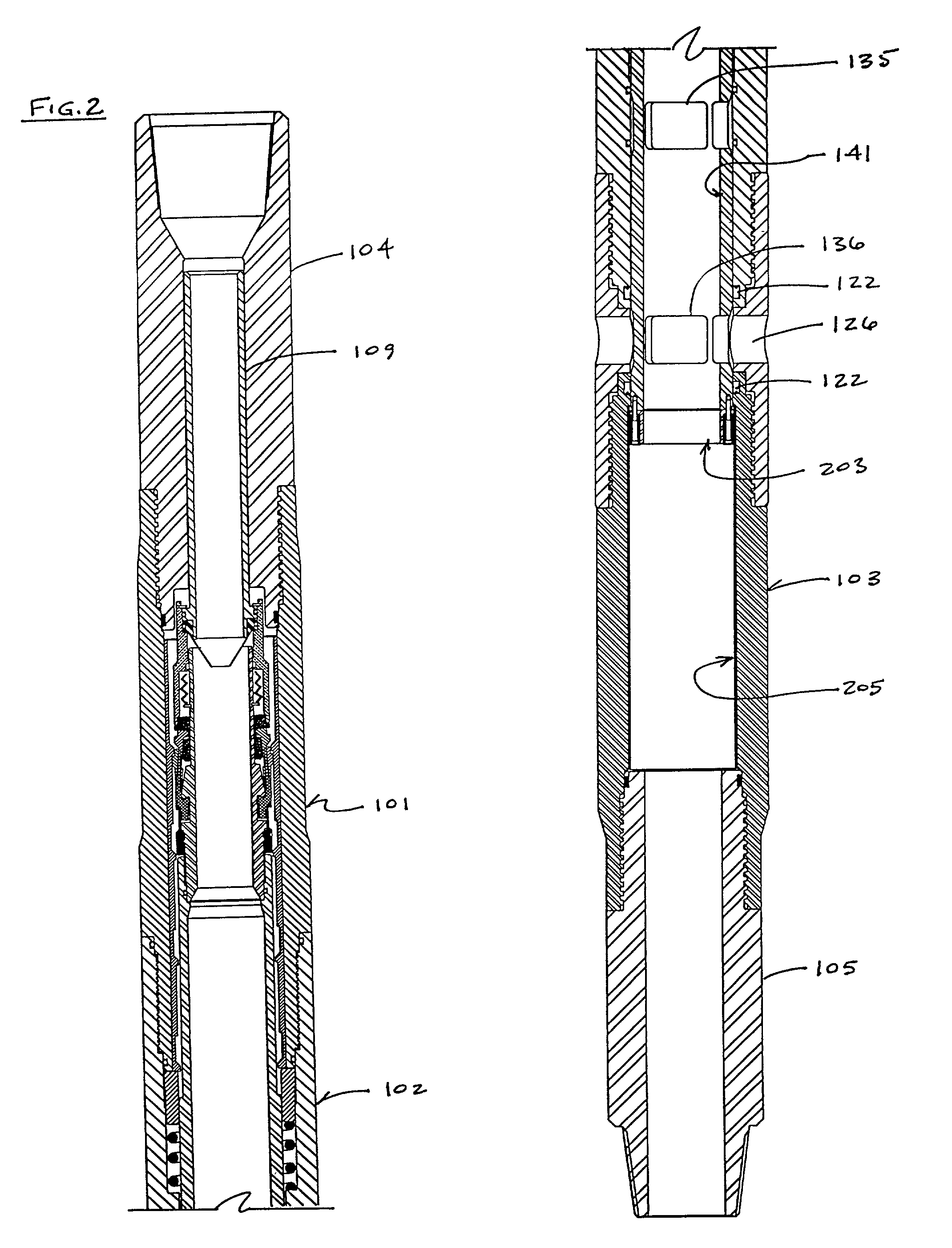

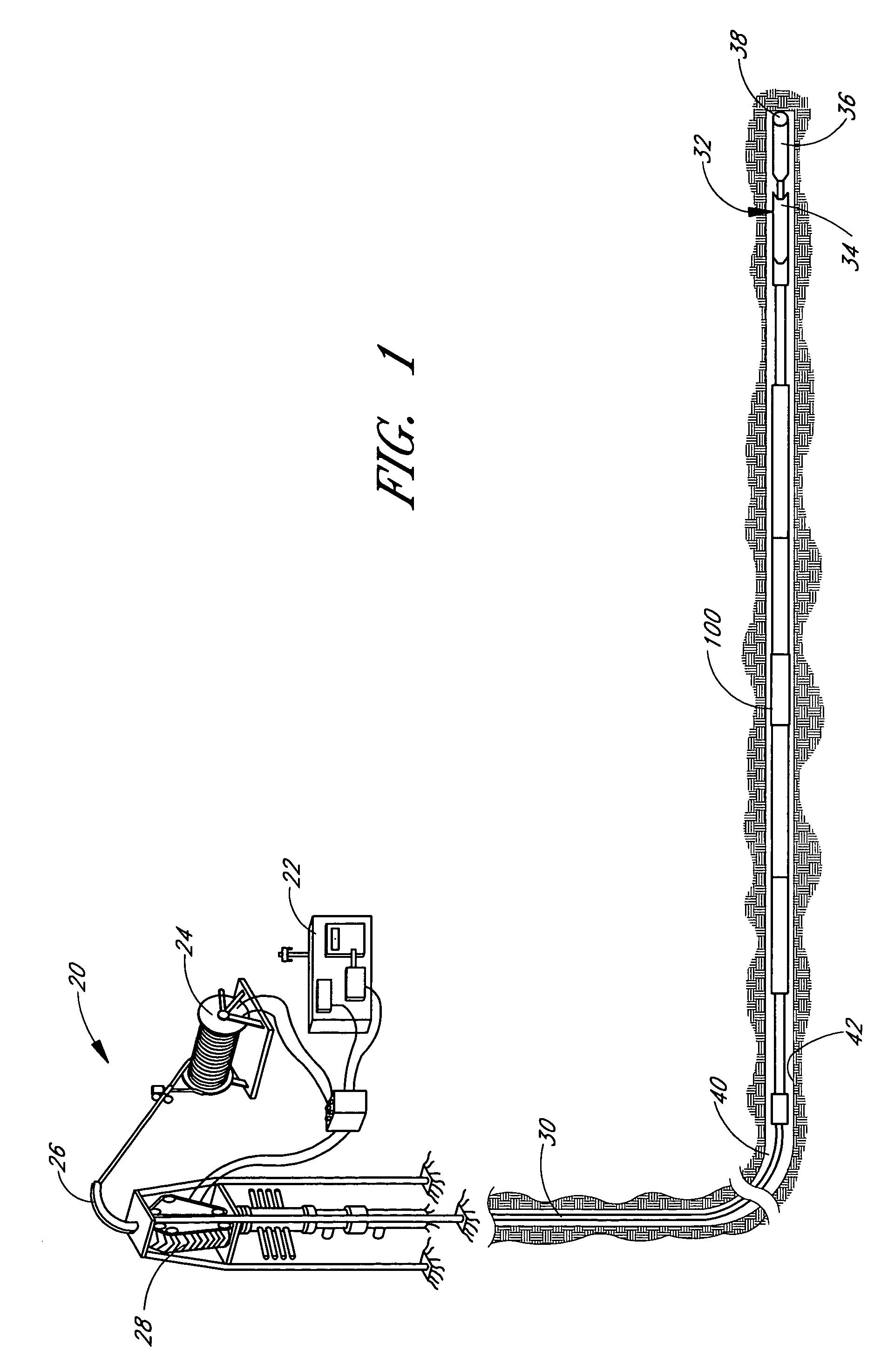

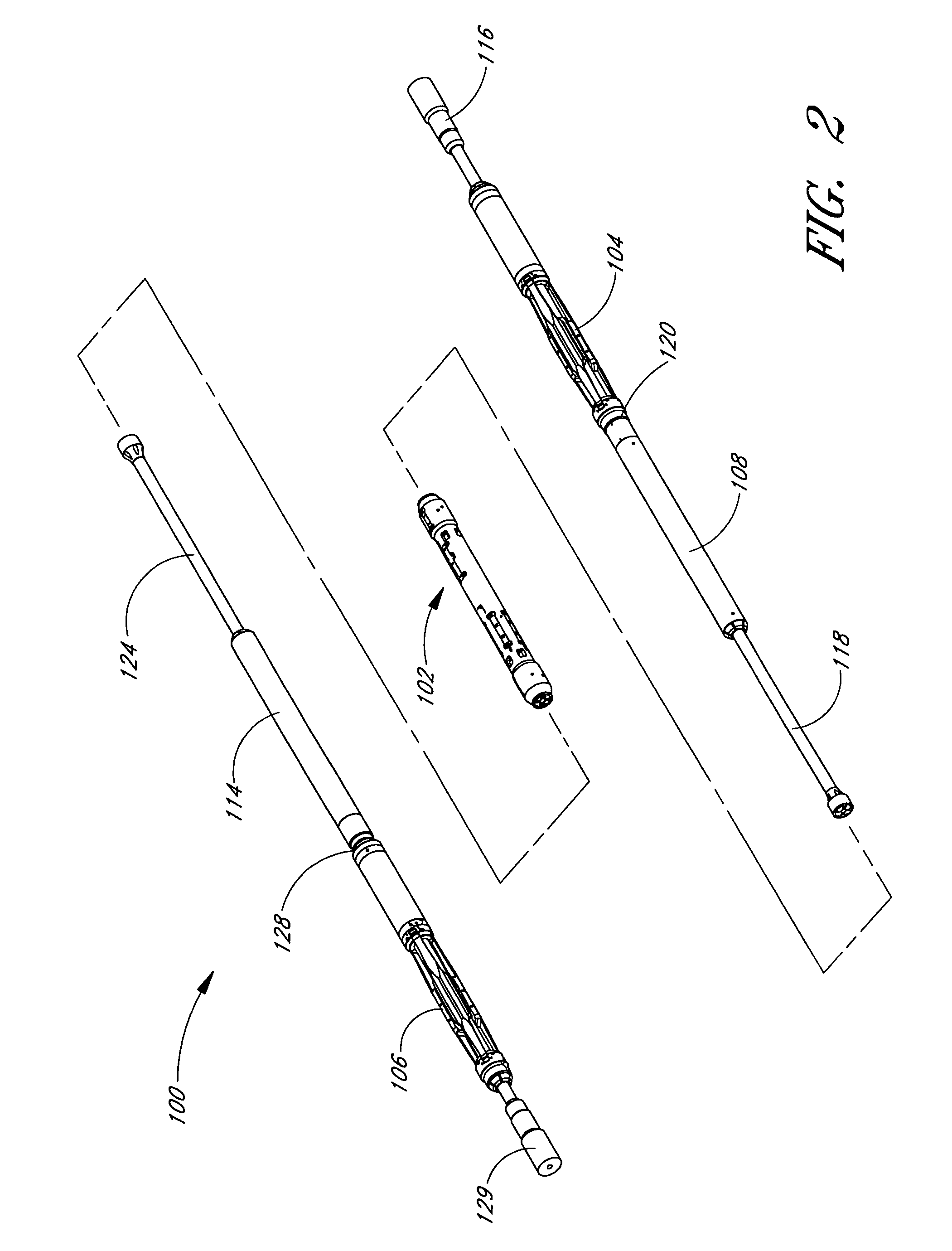

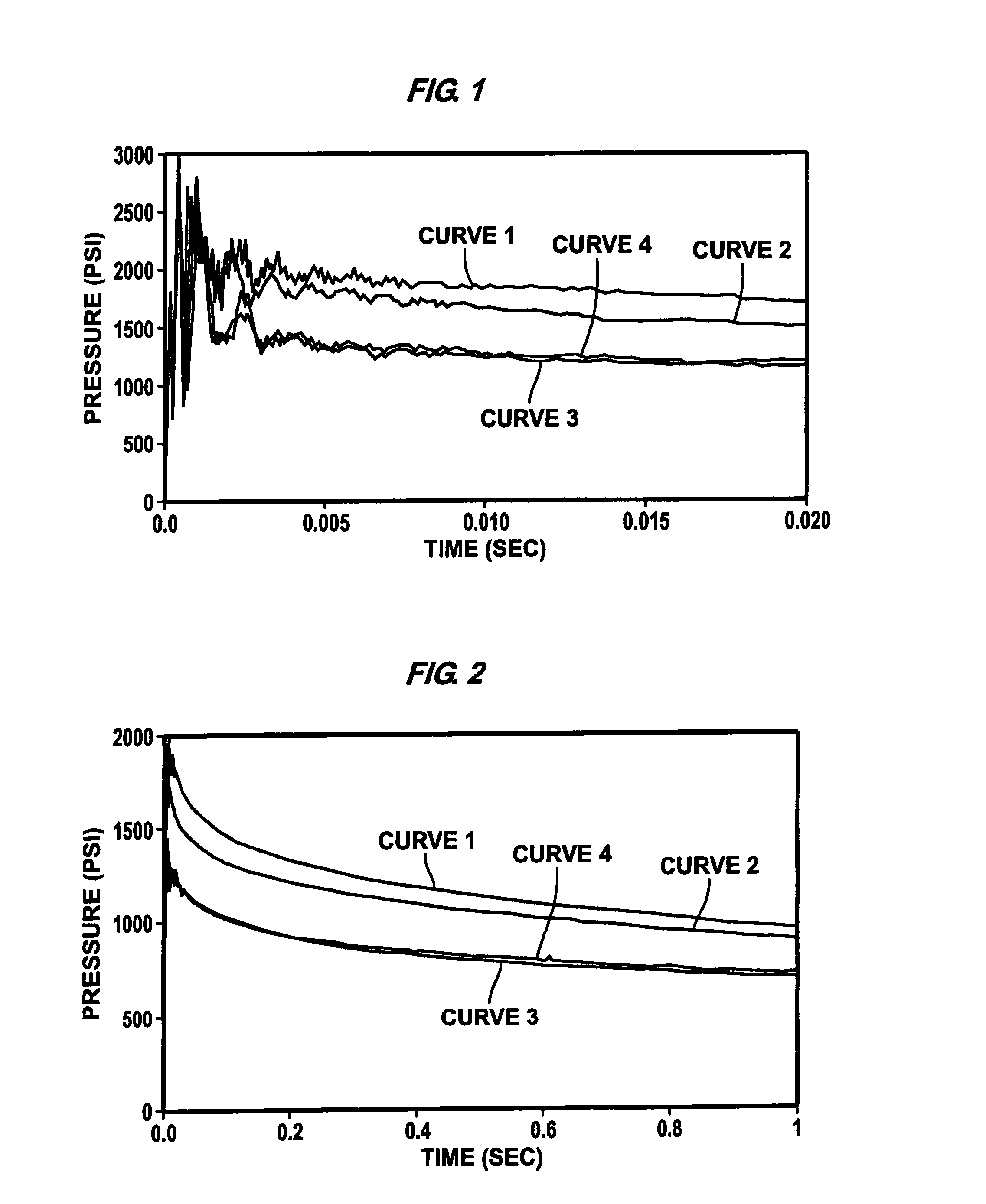

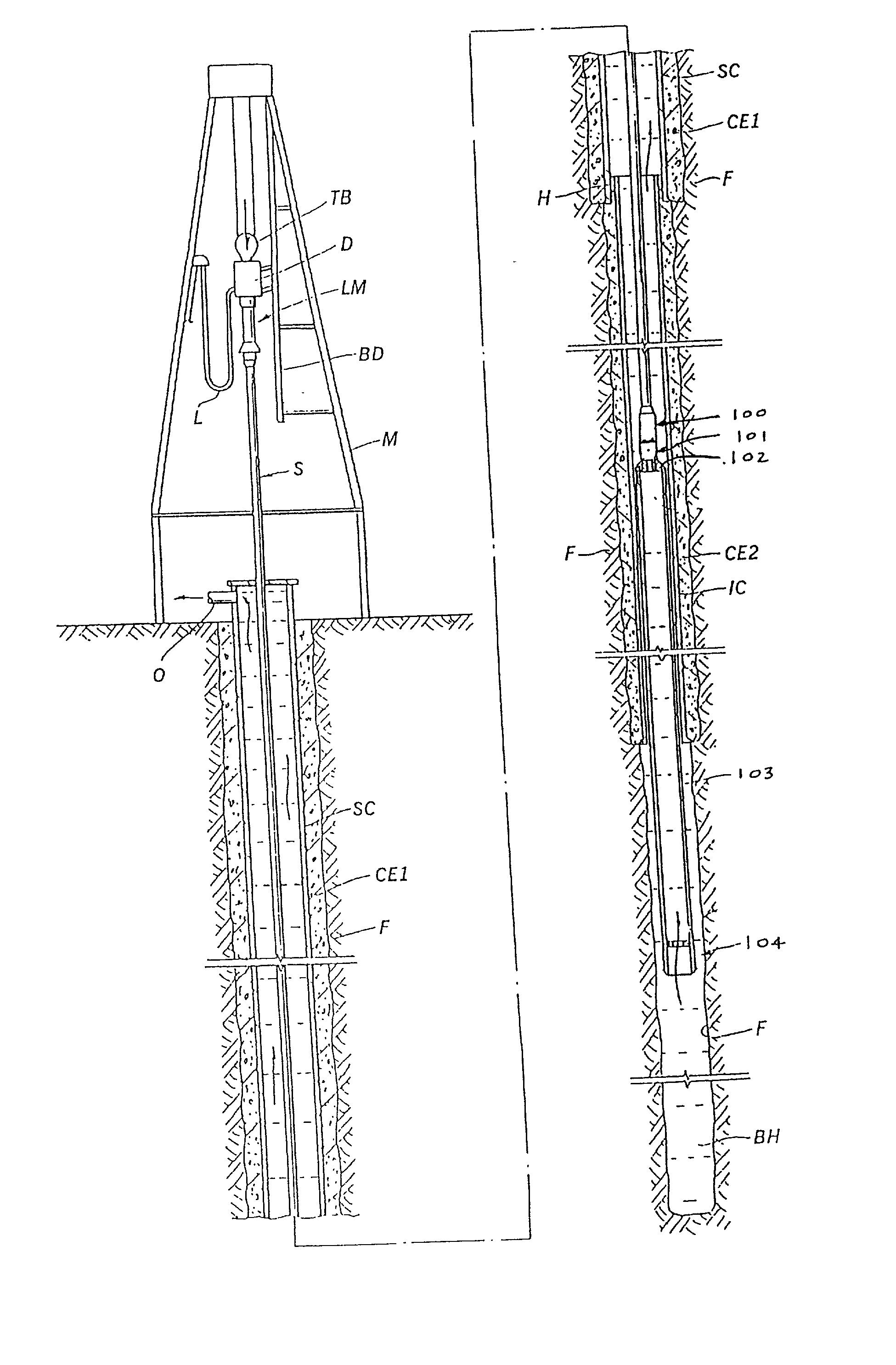

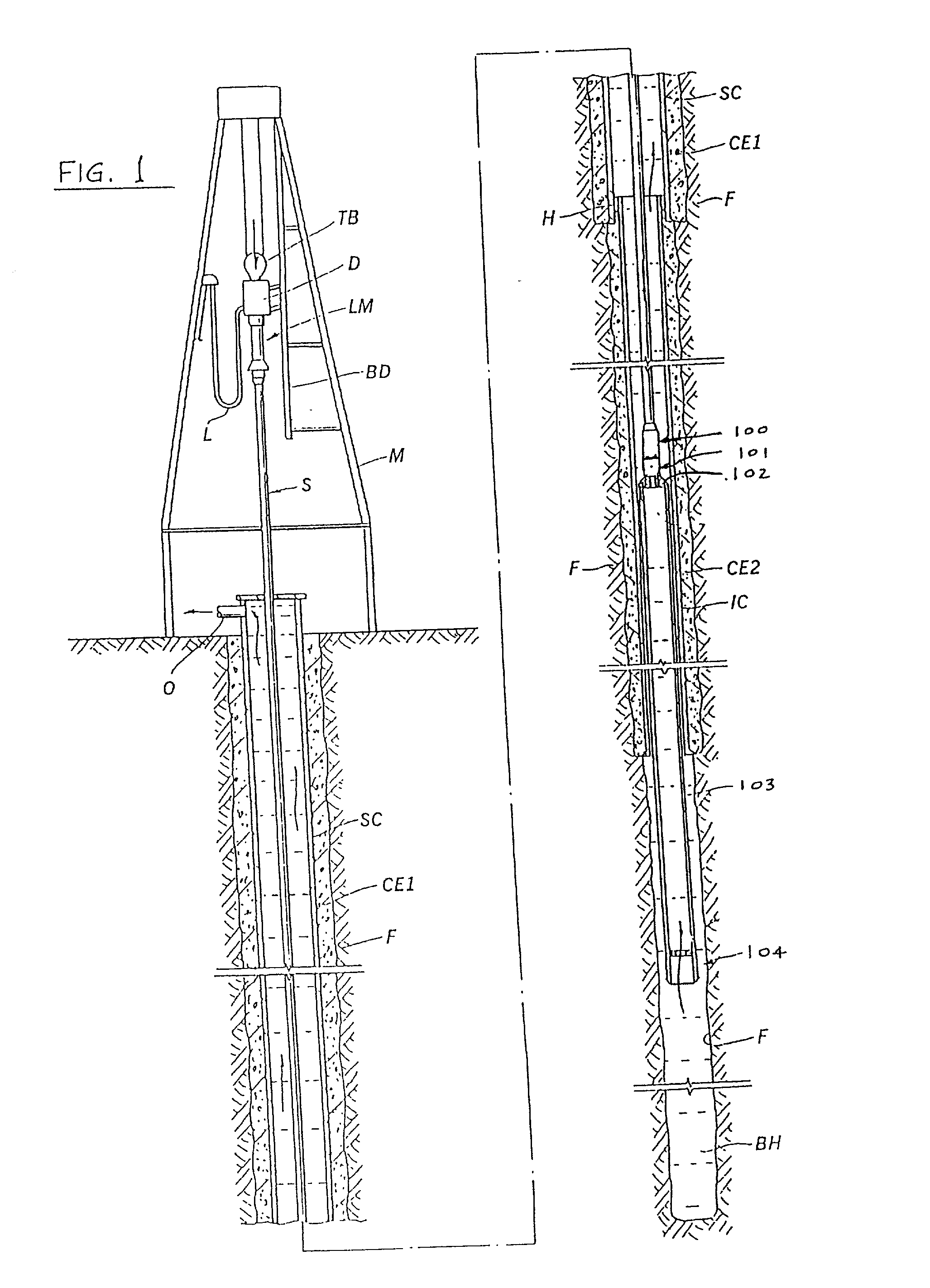

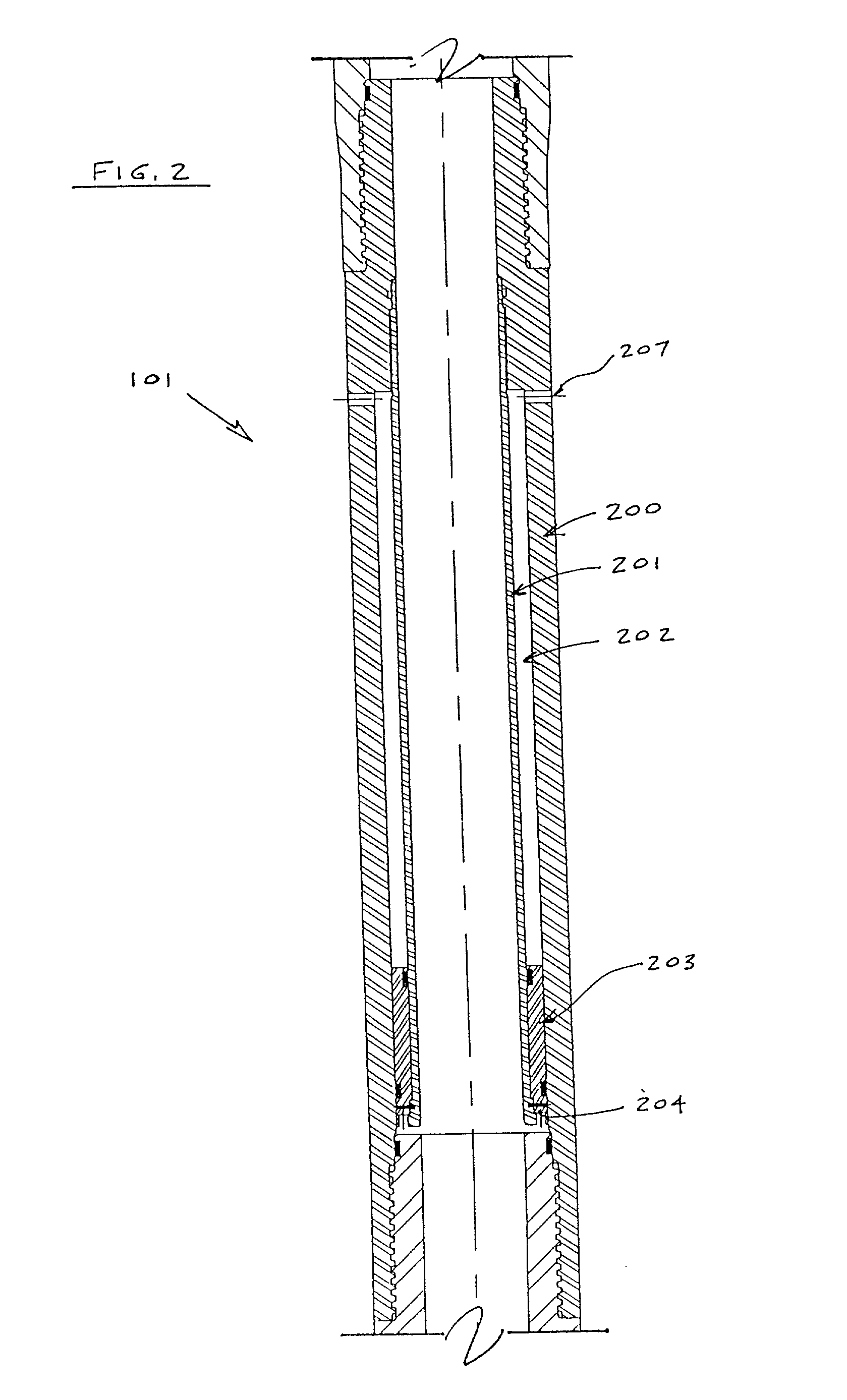

Downhole surge reduction method and apparatus

InactiveUS20040000406A1Facilitate surge pressureEasy to operateDrilling rodsFluid removalPressure reductionMechanical engineering

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole through drilling fluid on a drill pipe using a running tool with the benefits of surge pressure reduction are disclosed. In accordance with the present invention, a surge pressure reduction tool includes a diverter device having a housing with a set of flow holes formed therein and a sliding sleeve residing within the housing having a set of flow ports formed therein. By aligning the set of flow holes of the housing with the set of flow ports of the sleeve, the tool is set in a "surge pressure reduction" mode. By shifting, or axially indexing, the sleeve downward, the set of flow holes is blocked by the sleeve thus setting the tool in a "cementing" or "circulation" mode. This shifting or indexing is accomplished using an indexing mechanism. The indexing mechanism of the present invention includes a spring ring which is initially compressed and set in a circumferential groove formed around the top of the sleeve. As the sleeve is shifted downward from surge reduction mode to cementing / circulation mode, the spring ring decompresses radially outward to engage a circumferential groove formed in the housing. This effectively locks the sliding sleeve in the cementing / circulation mode. In accordance with the present invention, a surge pressure reduction tool further includes a volume compensation device which enables the diverter device to be shifted axially downward into the cementing / circulation mode even where the drilling / production liner or sub-sea casing is plugged with drill cuttings or downhole debris. In the cementing / circulation mode, a flow path is established for cement or drilling fluid to flow downward from the drill pipe, through the diverter device, volume compensation device, and running tool, and out into the borehole via the drilling / production liner or sub-sea casing. In the surge pressure reduction mode, an alternative flow path is established for drilling fluid to flow upward from the borehole into the drilling / production liner or sub-sea casing, through the running tool and volume compensation device, and into an annular space between the drill pipe and the borehole via the set of flow holes of the diverter device.

Owner:ALLAMON INTEREST +1

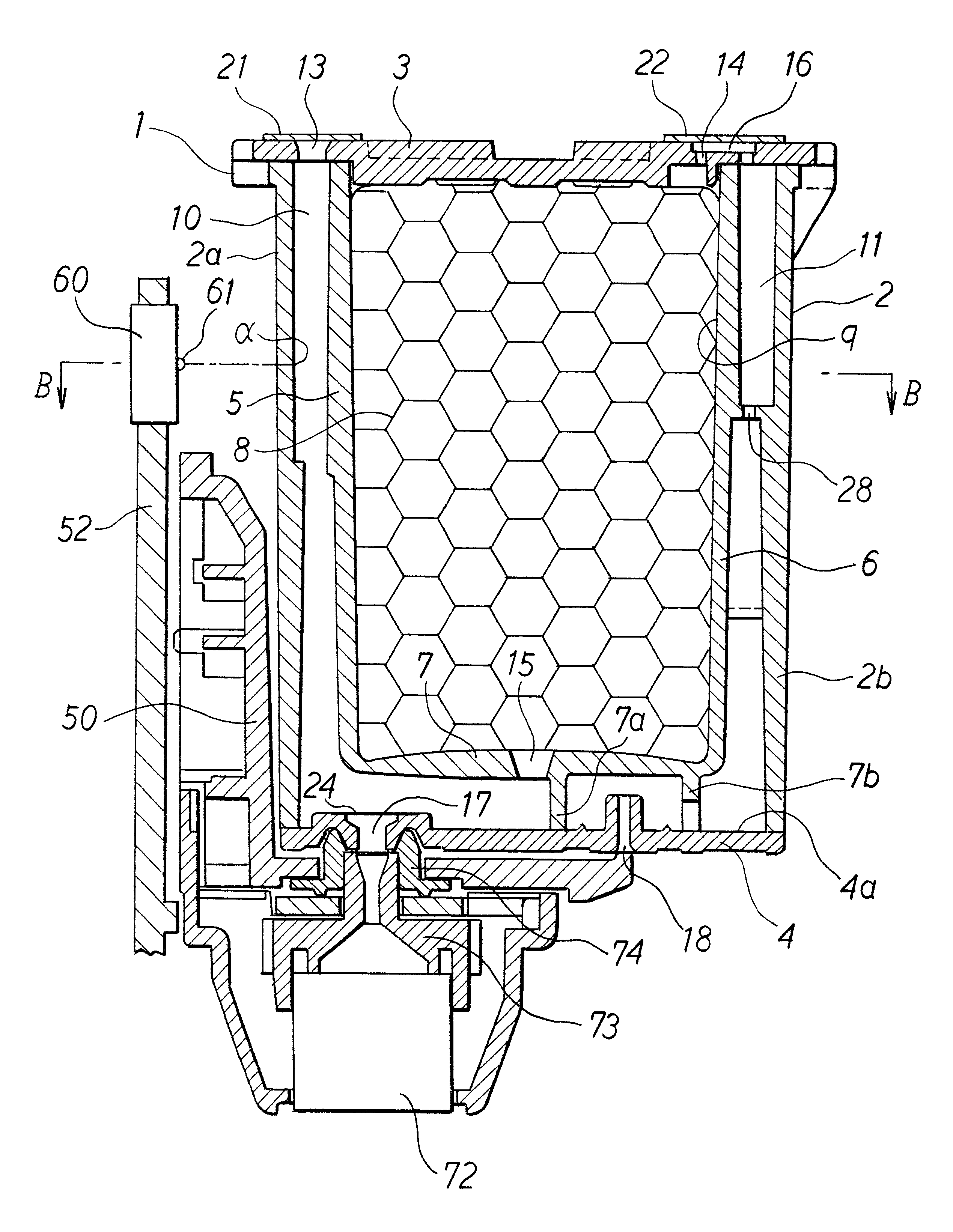

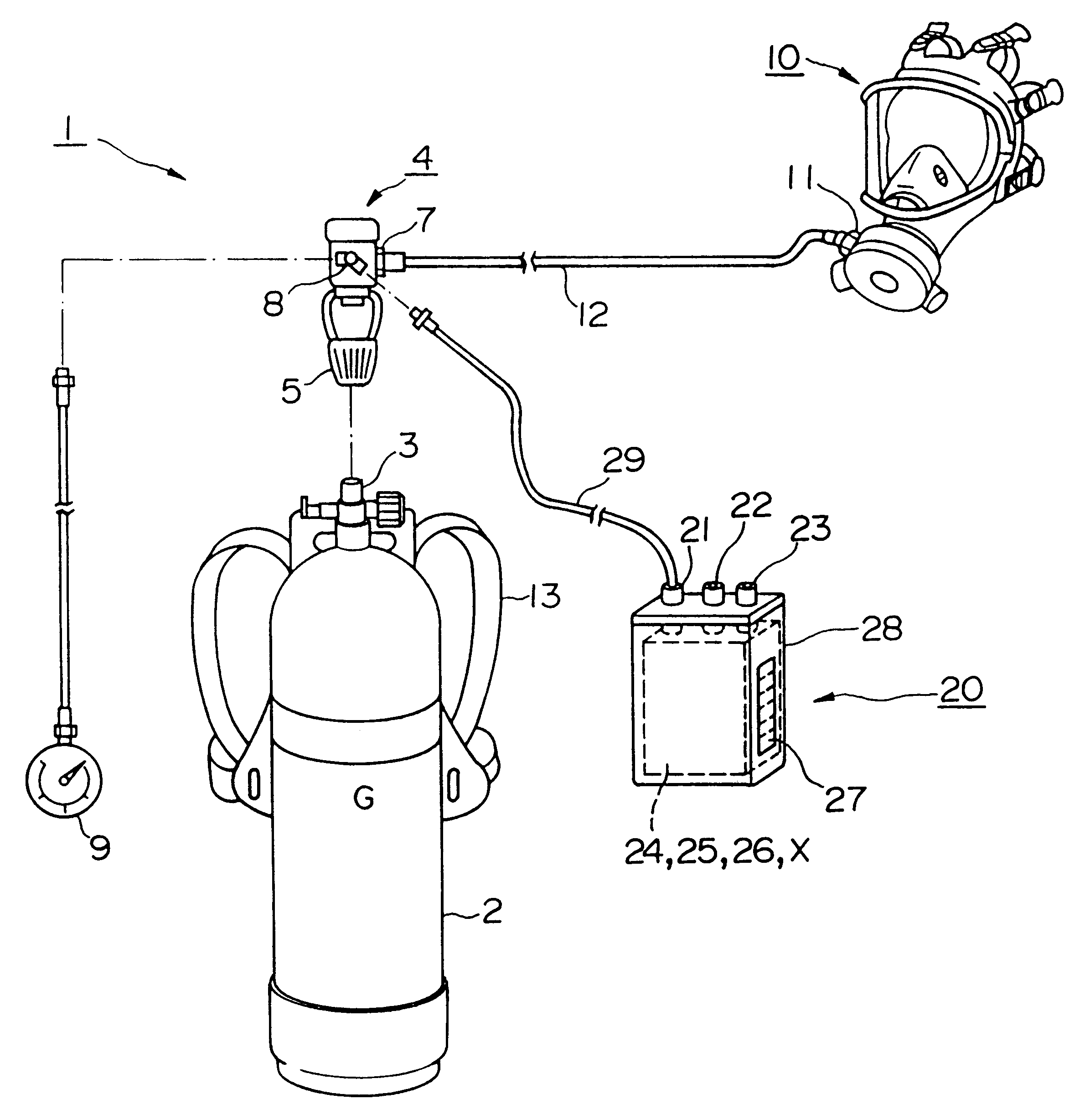

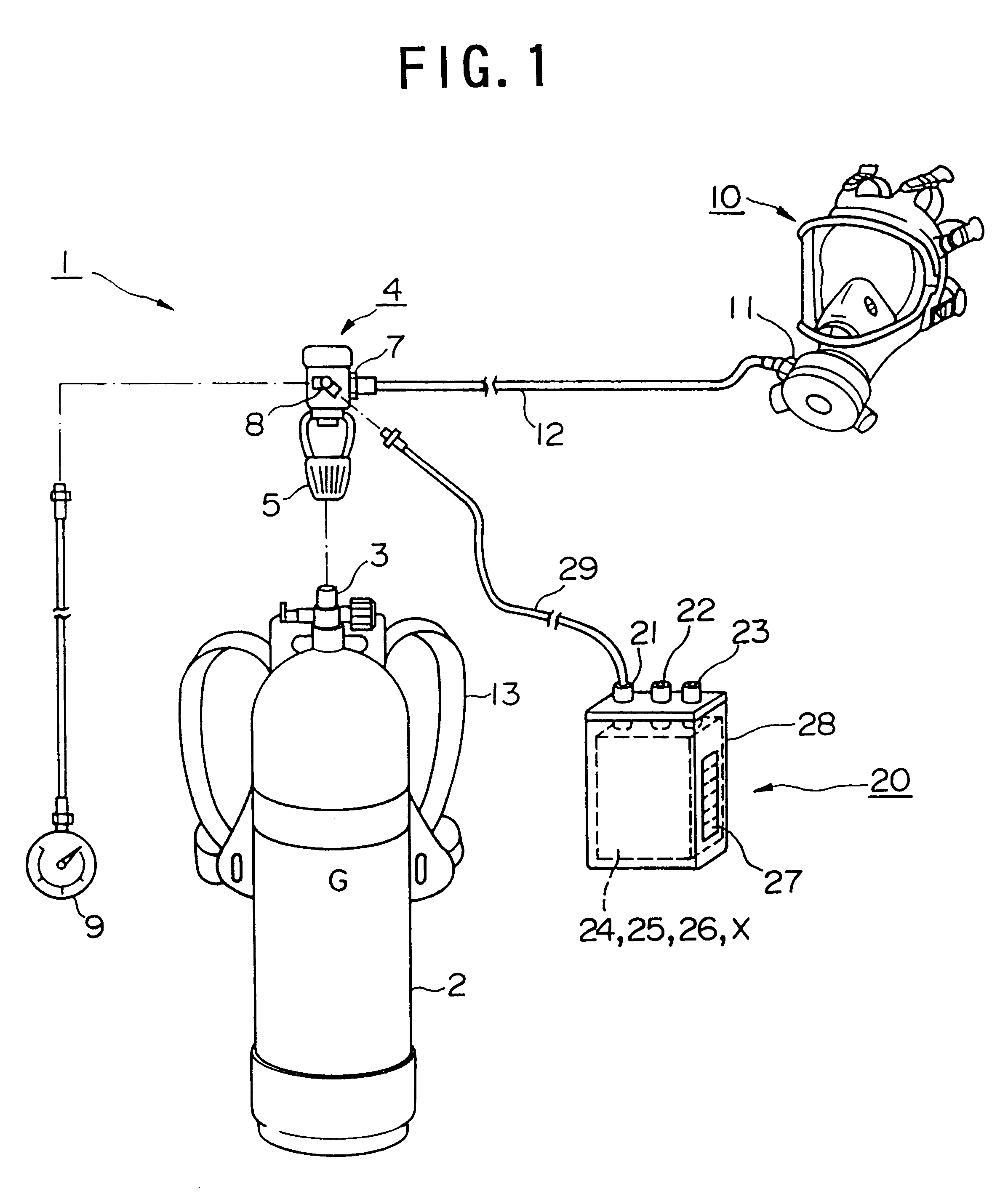

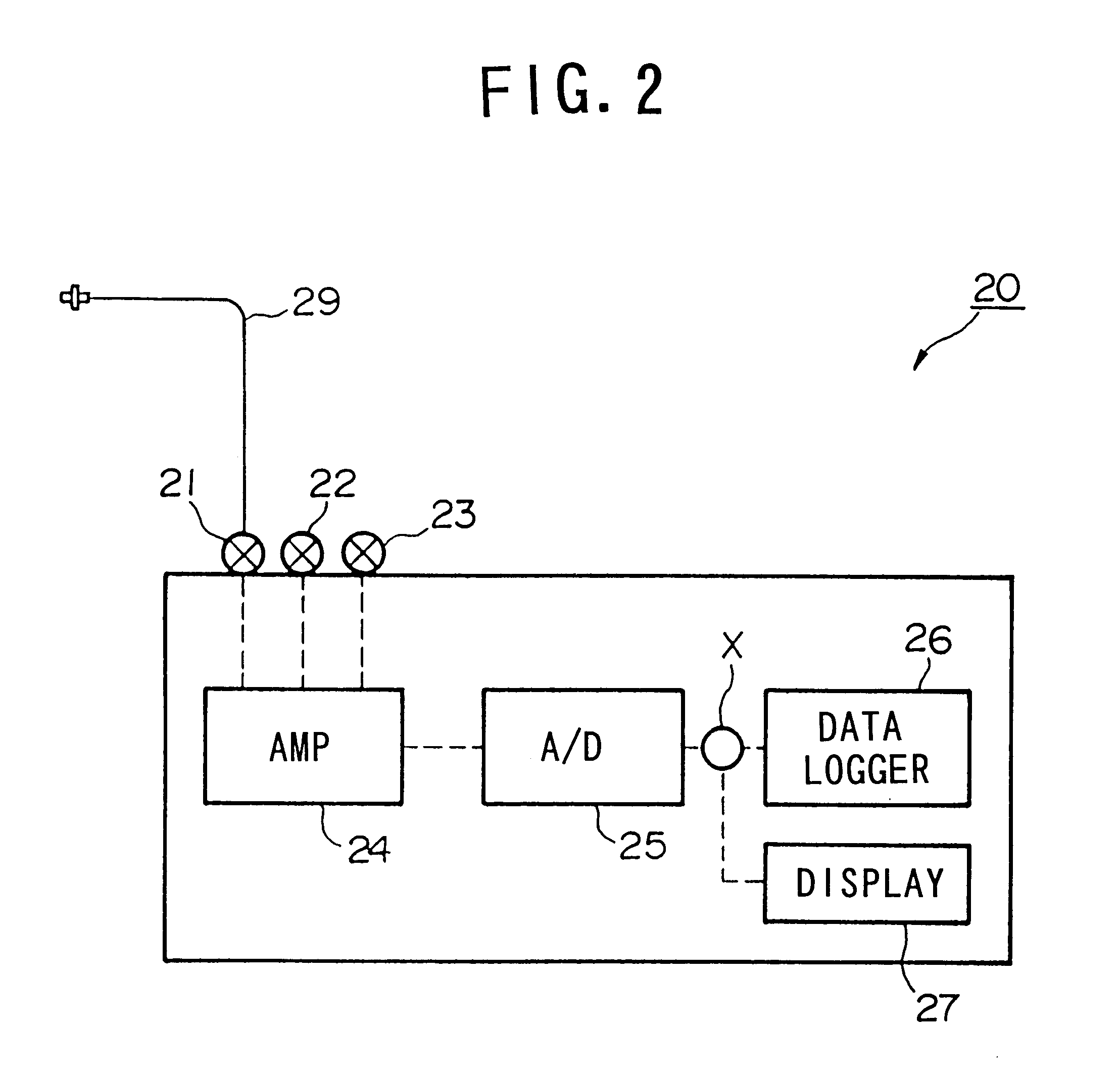

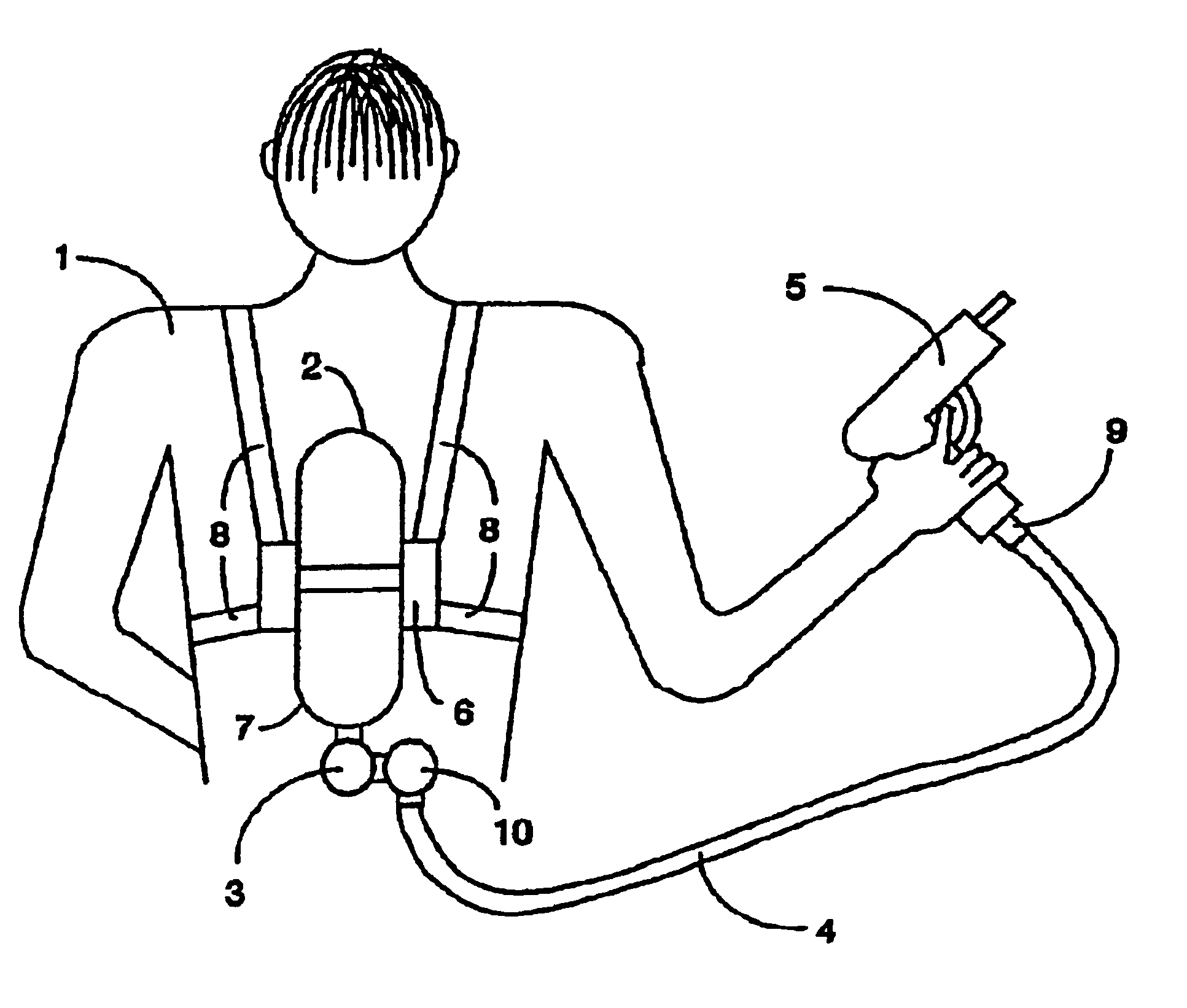

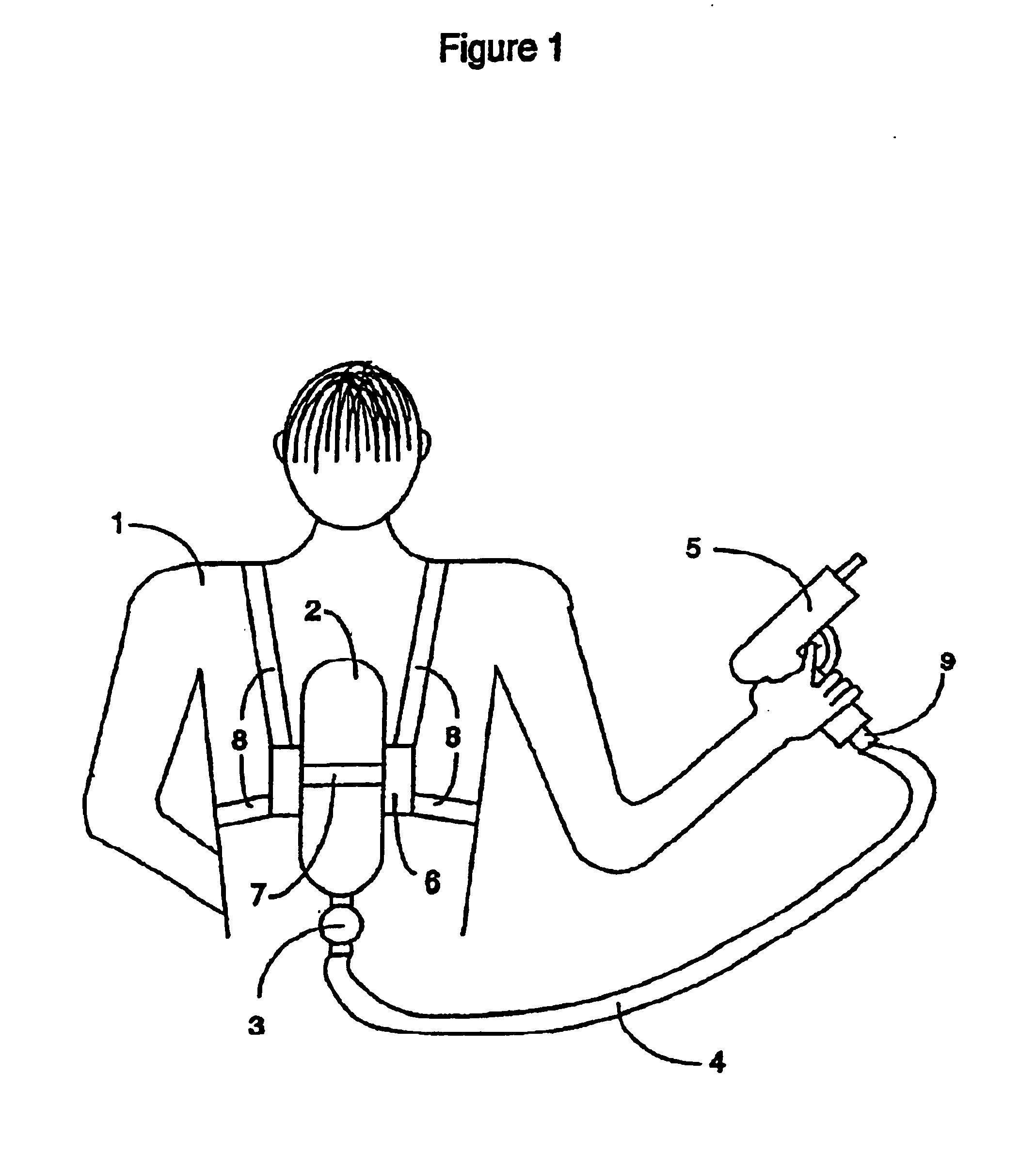

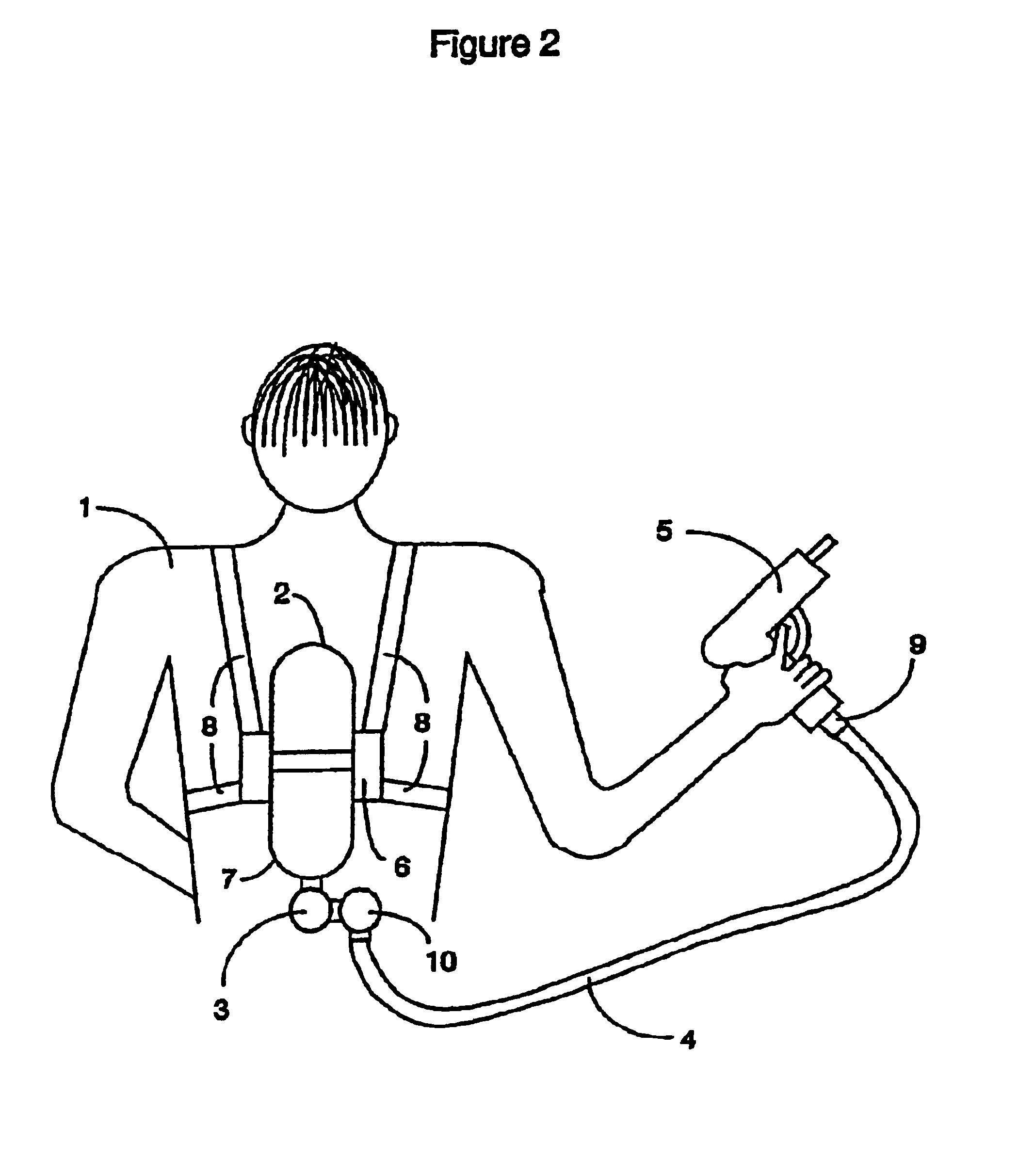

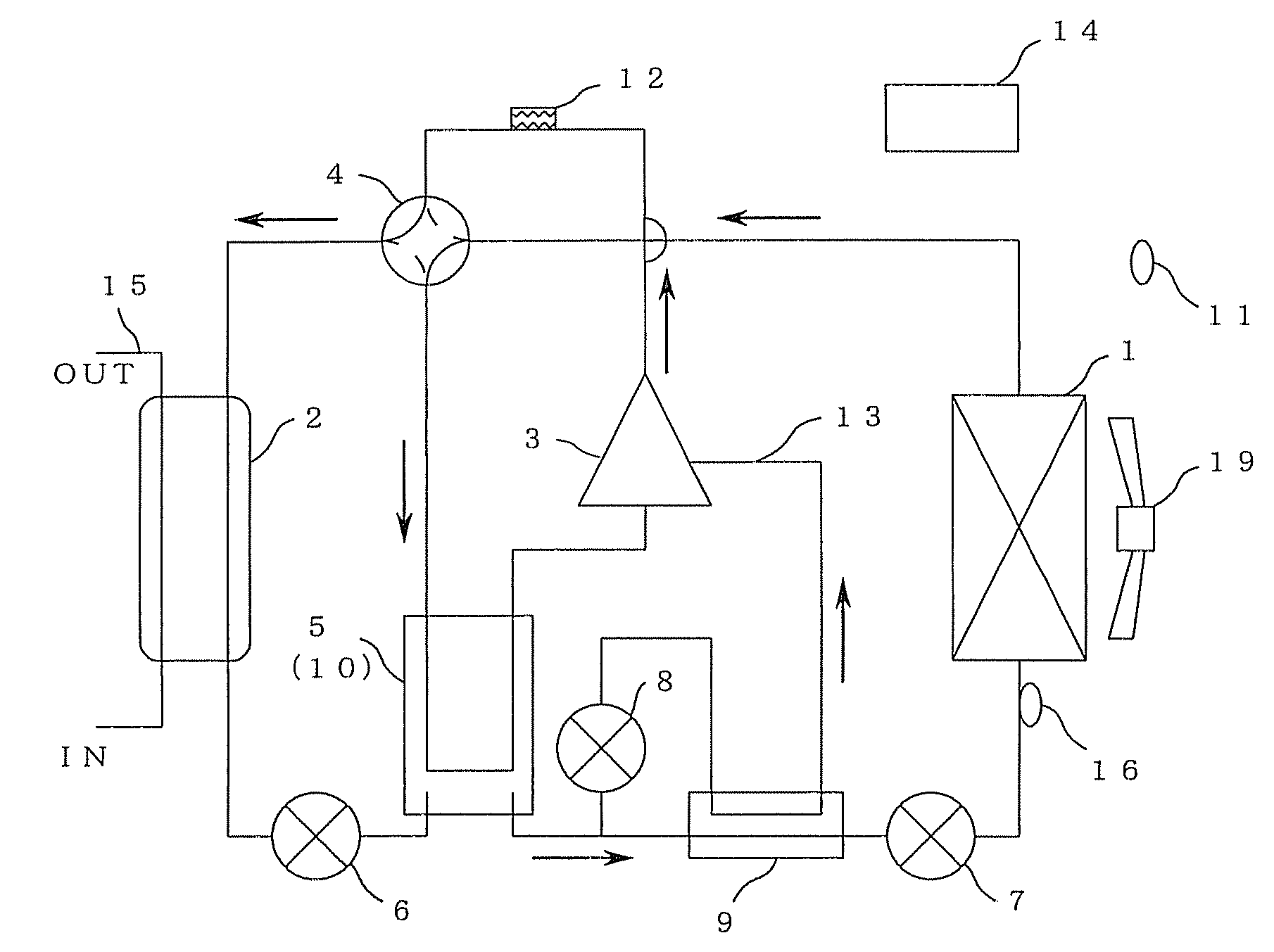

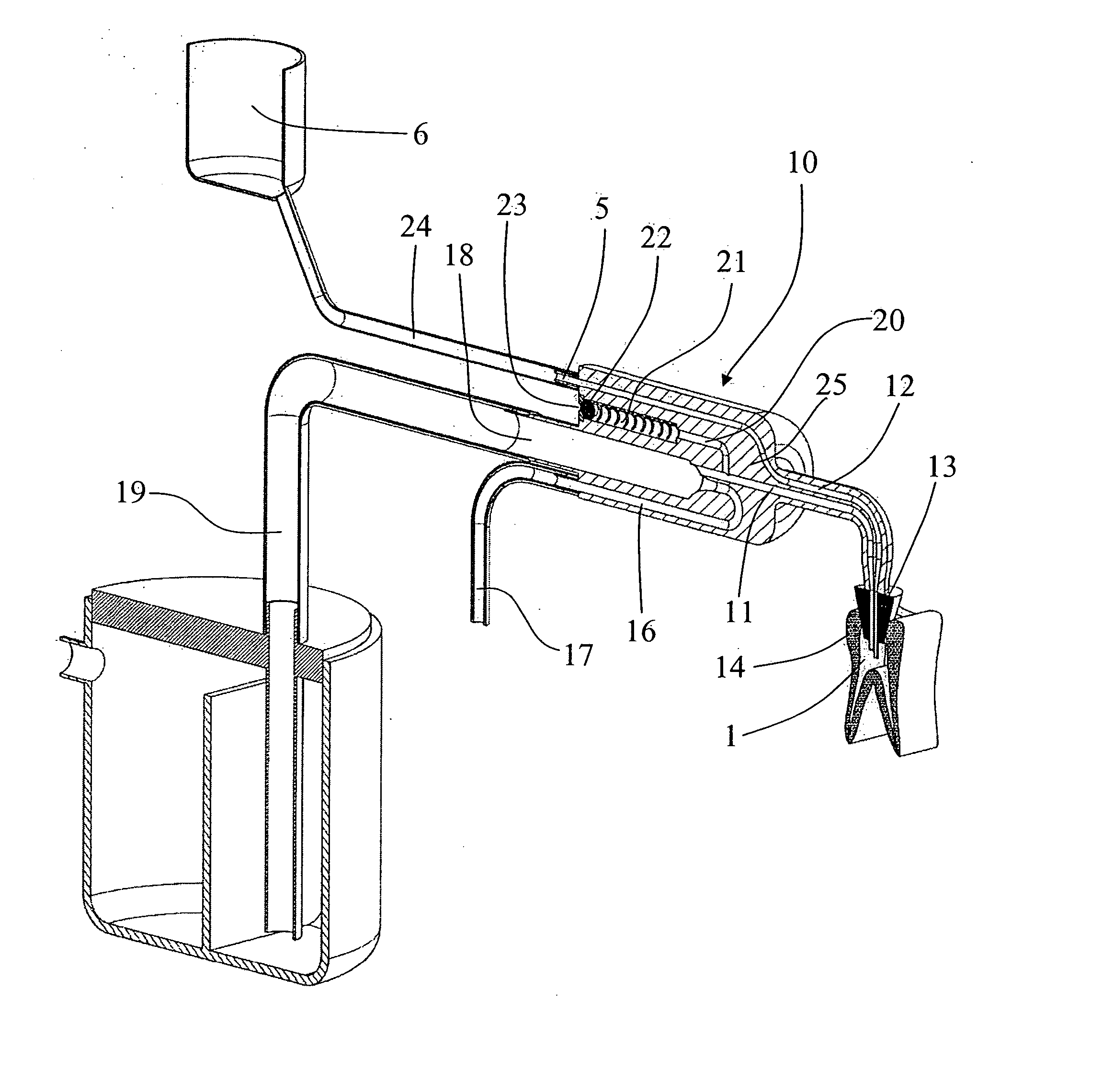

Respiratory gas consumption monitoring device and monitoring method

InactiveUS6258039B1Accurate measurementEasy to useRespiratorsRespiratory organ evaluationDisplay deviceEngineering

The present invention relates to a respiratory gas consumption monitoring method and monitoring device that is portable and has high measurement accuracy, for enabling the analysis and prediction of the respiratory behavior of subjects employing a variety of different types of breathing apparatuses in water, etc. Respiratory gas consumption monitoring device (20), for monitoring the respiratory gas consumption of the user of a breathing apparatus (1) in which a respiratory gas (G) inside a high pressure gas container (2) is reduced in pressure at pressure regulator (4) and supplied to a breathing mask (10), is provided with:a primary pressure sensor (21) for detecting the pressure prior to pressure reduction at pressure regulator (4);a temperature sensor (22) for correction;an environmental pressure sensor (23) for detecting the environmental pressure;an amplifier (24) for amplifying the signals from the aforementioned sensors;an A / D converter (25) for performing analog / digital conversion of the amplified signal;a data logger (26) for recording and storing the analog / digital converted signals; anda display (27) for display.In addition, as needed, a computer (X) for calculating, analyzing, and predicting data may be housed in housing (28), and connected to breathing apparatus (1) by connecting primary pressure sensor (21) to a high pressure opening (8) of pressure regulator (4) using a high pressure hose (29).

Owner:NIPPON SANSO CORP +1

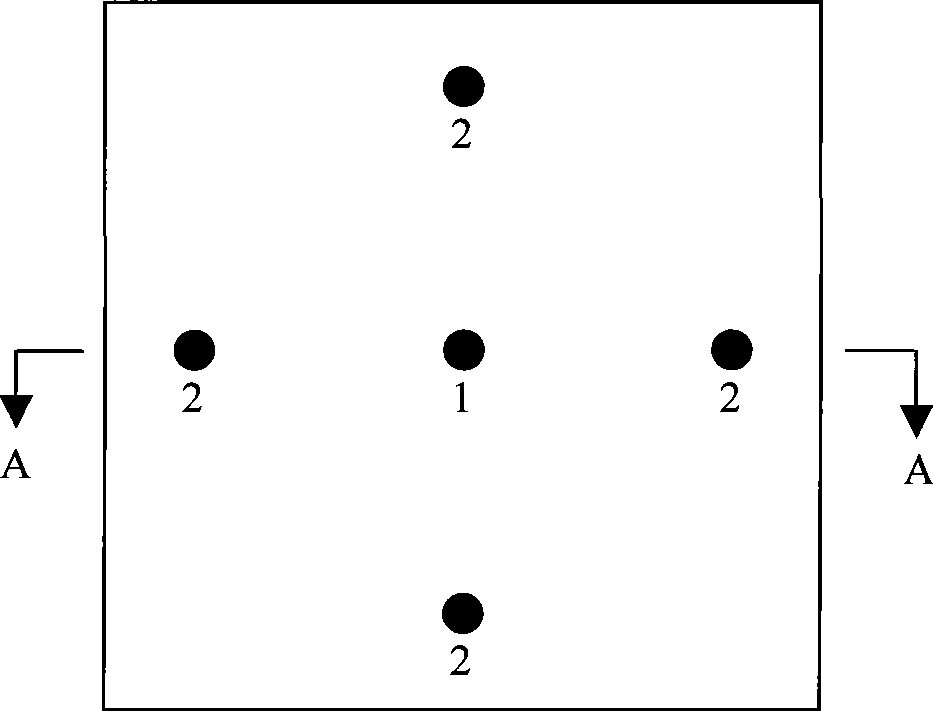

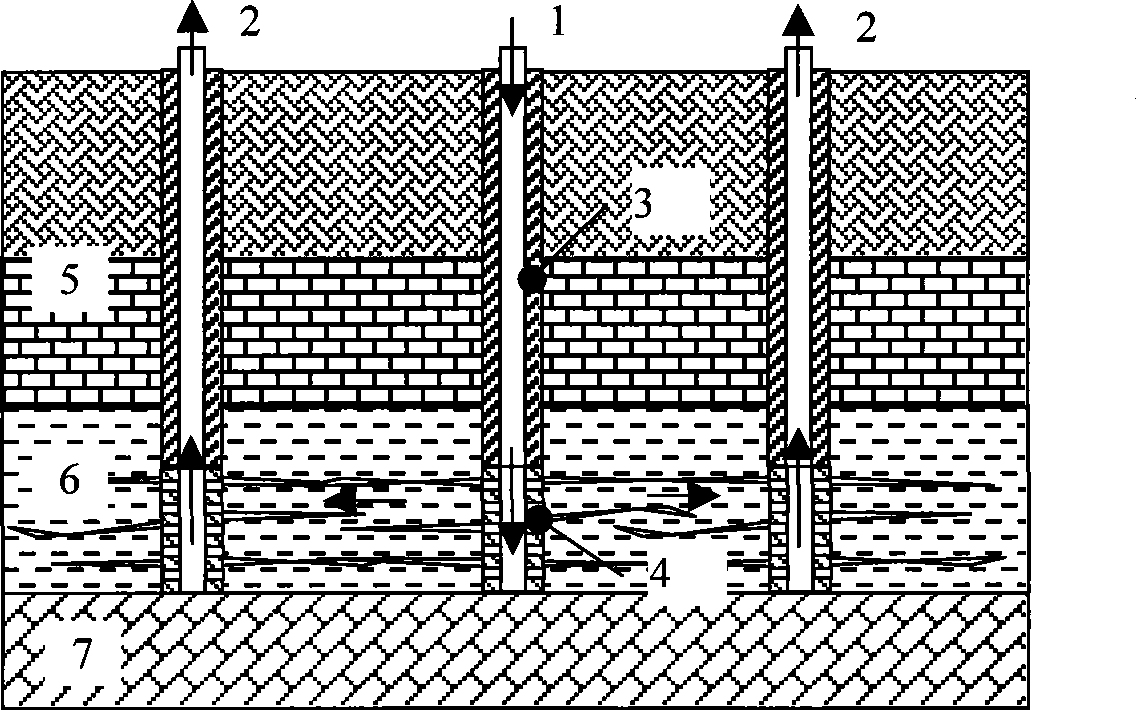

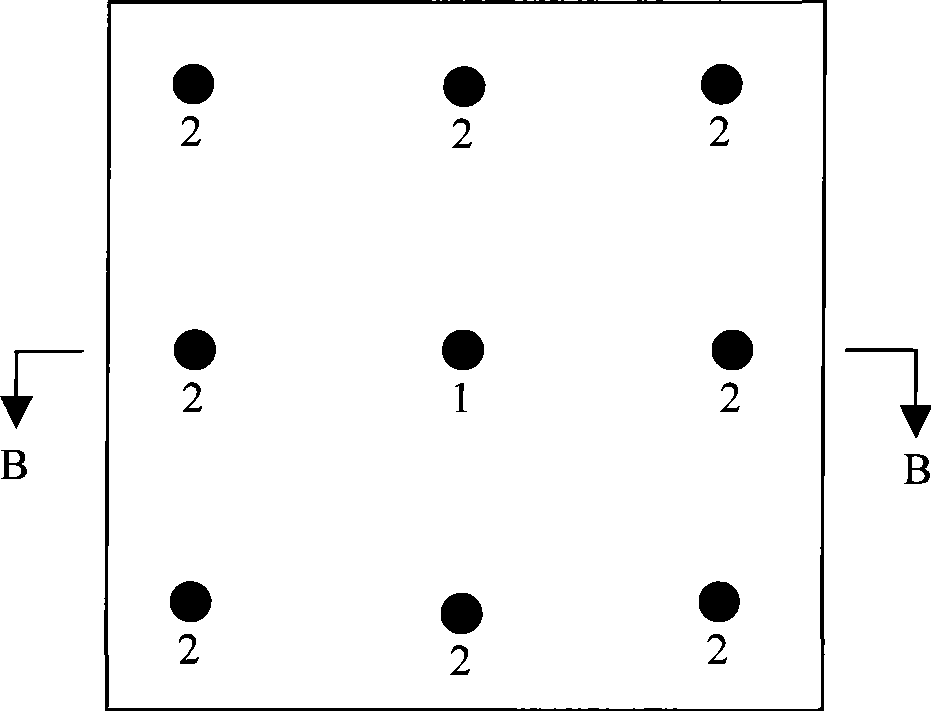

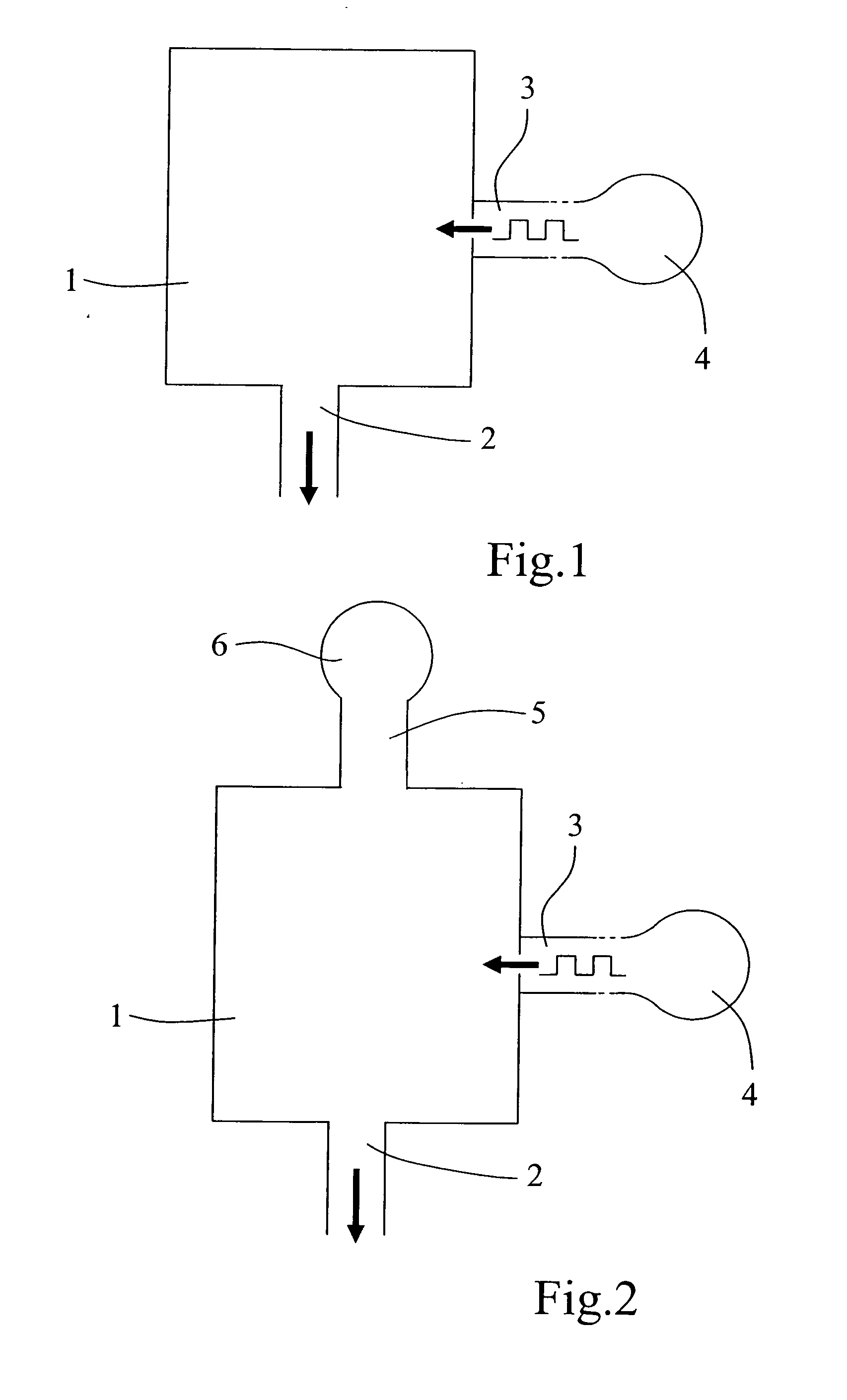

Method for pumping coalbed gas by heating coal bed

ActiveCN101418679AAchieve separationEfficient extractionFluid removalGas removalWater vaporDistilled water

Provided is a method for heating coal seam and extracting coal seam gas. Firstly, a plurality of vertical wells are drilled from the ground to the coal seam, after the drilled well reached to the coal seam, the coal seam is inserted with a screen tube casing (4), the section above the coal seam is inserted with a heat insulation casing (31) and the well is correspondingly fixed. At least one well of the wells is selected to be a heat source injection well (1) and other wells are gas production wells (2), steam with high temperature and high pressure is injected into the heat source injection well (1) to perform fracturing to communicate all the wells in the network. Drainage and pressure reduction are performed to the gas production wells (2) to extract the mixed gas of the coal seam gas and steam. The mixed gas of the coal seam gas and steam is cooled by known cooling method so as to obtain gaseous coal seam gas and liquid distilled water to realize the separation of the mixed gas. According to the change of the coal seam temperature, the heat source injection well (1) and the gas production wells (2) are allocated to control the heated coal seam and extract coal seam gas. The method of he invention can effectively perform the extraction of the coal seam gas, accelerate the coal seam extraction speed, and improve the extraction rate.

Owner:TAIYUAN UNIV OF TECH

Method for extracting and refining rutin

ActiveCN102718820AReduce pollutionGuaranteed withdrawal rateSugar derivativesSugar derivatives preparationAlkaline waterOrganic solvent

A method for extracting and refining rutin comprises the following steps of (1) extraction: smashing raw materials, adding organic solvent into the smashed raw materials, performing extraction for 2-4 times, mixing extracting solution and concentrating the mixed extracting solution to thick extract with organic solvent content smaller than or equal to 5wt%; (2) alkali dissolution-acid sediment: adding alkaline water into the thick extract, then heating the mixture and stirring, filtering the heated mixture, regulating pH of alkaline filtrate to be 3-4, standing, filtering, drying to obtain a rutin pure product; and (3) mother liquor treatment: enabling obtained acid mother liquor to penetrate through a chromatographic column filled with resin, after the acid mother liquor penetrates through the chromatographic column, firstly using deionized water to wash a column bed until outflow liquid is neutral and colorless, introducing eluent into the chromatographic column and collecting eluate until outflow liquid is colorless, concentrating the eluate to the volume which is 5-10% of the original volume in a pressure reduction mode, cooling the concentrated eluate to achieve crystallization, filtering, using the deionized water to elute a filter cake, and drying the eluted filter cake to obtain a mother liquor rutin product. The prepared rutin is high in yield and purity, and the quality of the rutin reaches the international standard.

Owner:湖南莱崔尔生物科技有限公司

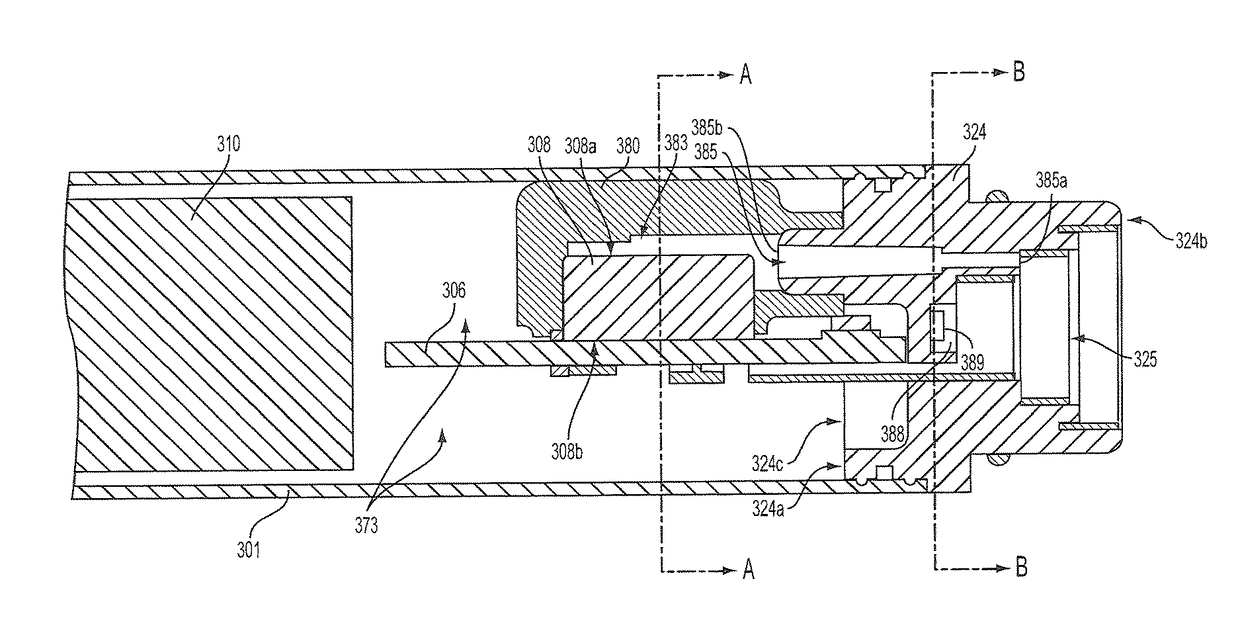

Downhole surge reduction method and apparatus

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole through drilling fluid on a drill pipe using a multifunction diverter tool with the benefits of surge pressure reduction are disclosed. In accordance with the present invention, a multi-function diverter tool includes a housing assembly with a set of flow holes formed therein and a sliding sleeve arranged within the housing assembly having two sets of flow ports formed therein at different axial locations along the sleeve. By aligning either set of flow ports of the sleeve with the flow holes of the housing, the tool is set in a "surge pressure reduction" mode. By shifting, or axially indexing, the sleeve downward, the set of flow holes becomes blocked by the sleeve thus setting the tool in a "circulation" or "cementing" mode. This shifting or indexing is accomplished using an indexing mechanism. The multi-function diverter tool of the present invention can be shifted from a first "surge pressure reduction" mode to a "circulation mode," from the "circulation mode" to a second "surge pressure reduction" mode, and finally from the second "surge pressure reduction" mode to a "cementing" mode. The indexing mechanism of the present invention includes a return spring and brake system which provides the tool with more reliable shifting functionality.

Owner:ALLAMON INTEREST

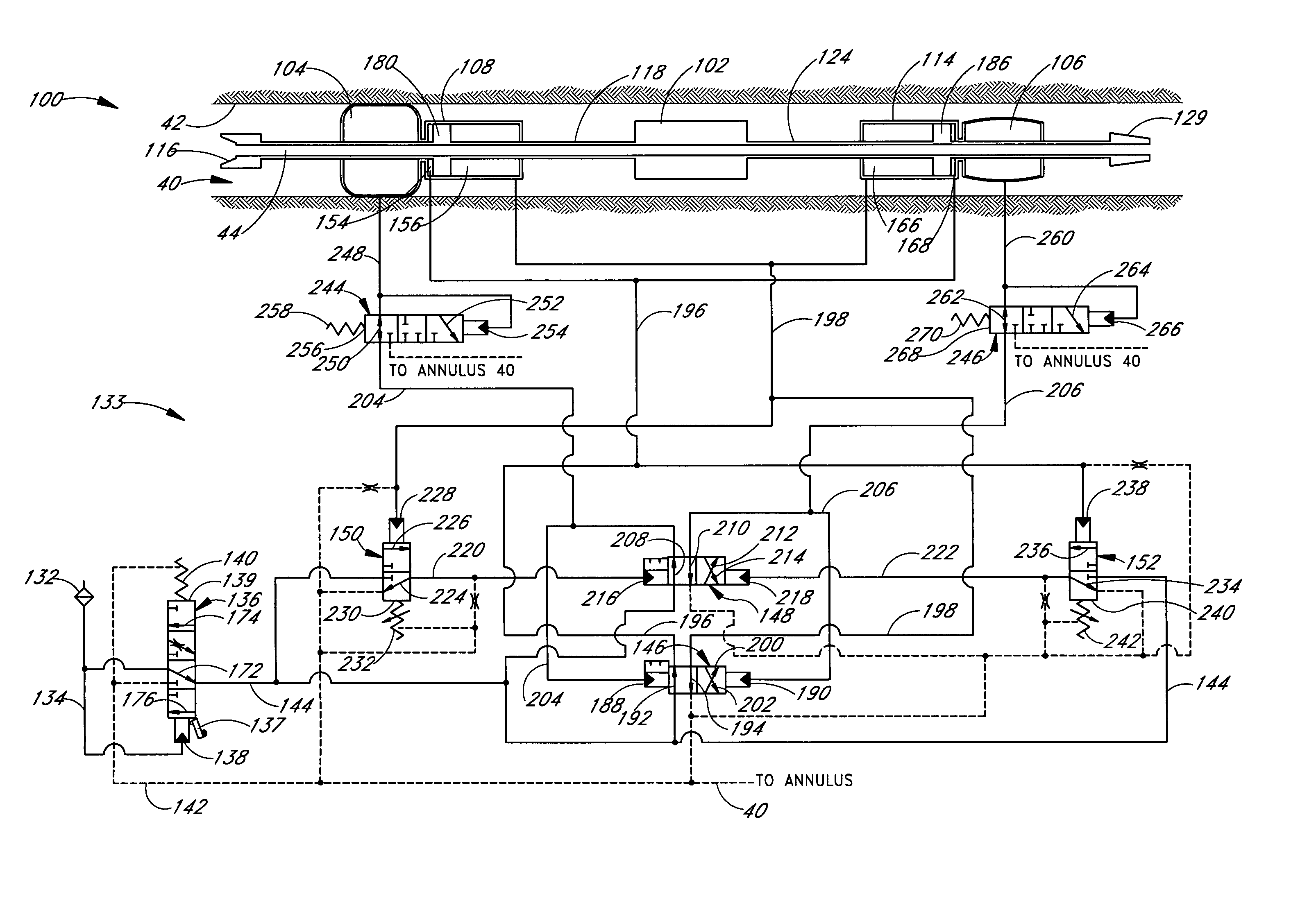

Tractor with improved valve system

InactiveUS7080700B2Long time lagBetter shiftingDrilling rodsReciprocating drilling machinesWorking fluidDetent

A hydraulically powered tractor includes an elongated body, two gripper assemblies, at least one pair of aft and forward propulsion cylinders and pistons, and a valve system. The valve system comprises an inlet control valve, a two-position propulsion control valve, a two-position gripper control valve, two cycle valves, and two pressure reduction valves. The inlet control valve spool includes a hydraulically controlled deactivation cam that locks the valve in a closed position, rendering the tractor non-operational. The propulsion control valve is piloted on both ends by fluid pressure in the gripper assemblies. The propulsion control valve controls the distribution of operating fluid to and from the propulsion cylinders, such that one cylinder performs a power stroke while the other cylinder performs a reset stroke. Each end of the gripper control valve is piloted by a source of high-pressure fluid selectively admitted by one of the cycle valves. The gripper control valve controls the distribution of operating fluid to and from the gripper assemblies. The cycle valves are spring-biased and piloted by fluid pressure in the propulsion cylinders, so that the gripper control valve shifts only after the cylinders complete their strokes. The pressure reduction valves limit the pressure within the gripper assemblies. These valves are spring-biased and piloted by the pressure of fluid flowing into the gripper assemblies. Some or all of the valves include centering grooves on the landings of the spools, which reduce leakage and produce more efficient operation. The propulsion control and gripper control valves include spring-assisted detents to prevent inadvertent shifting.

Owner:WWT NORTH AMERICA HLDG

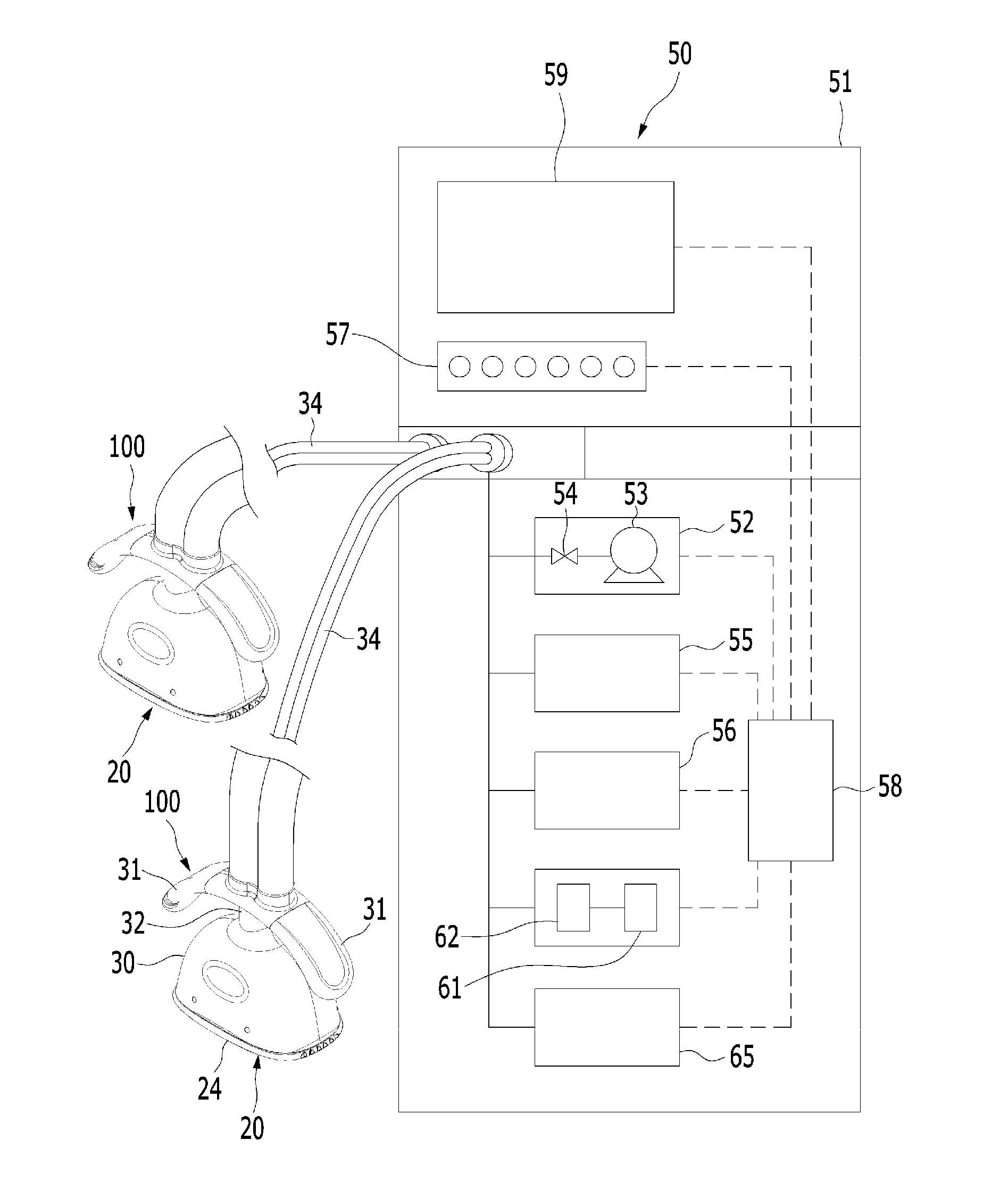

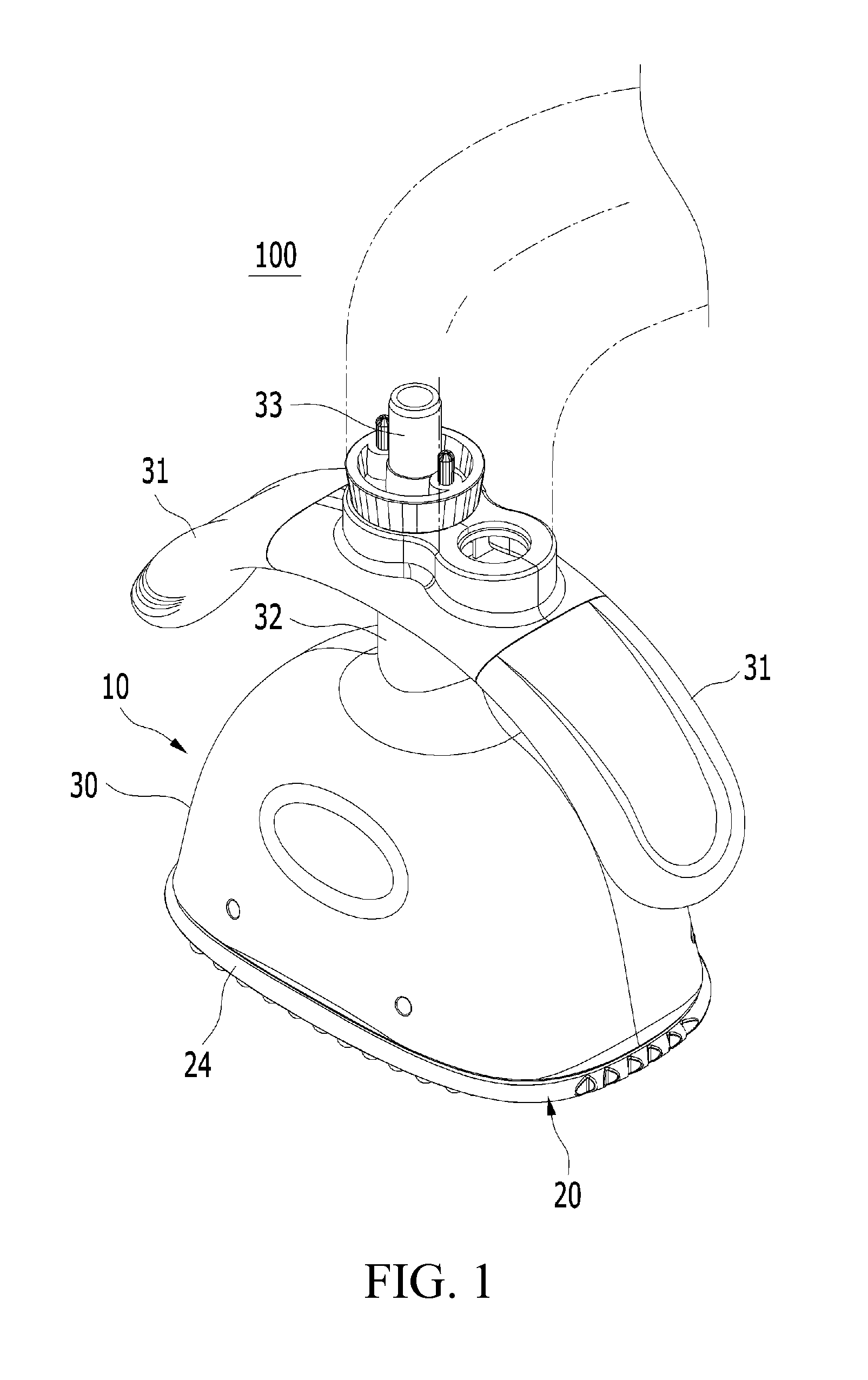

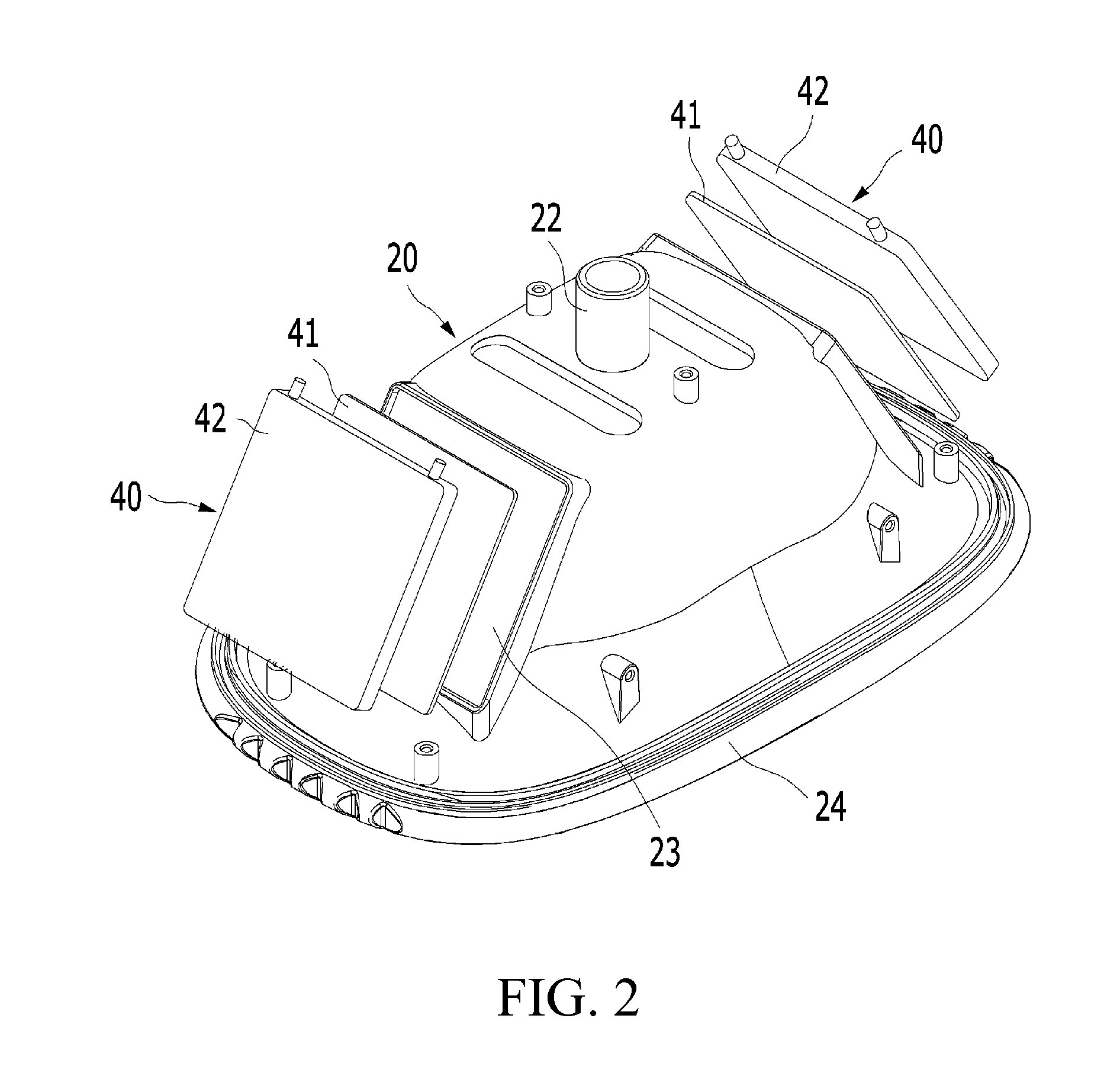

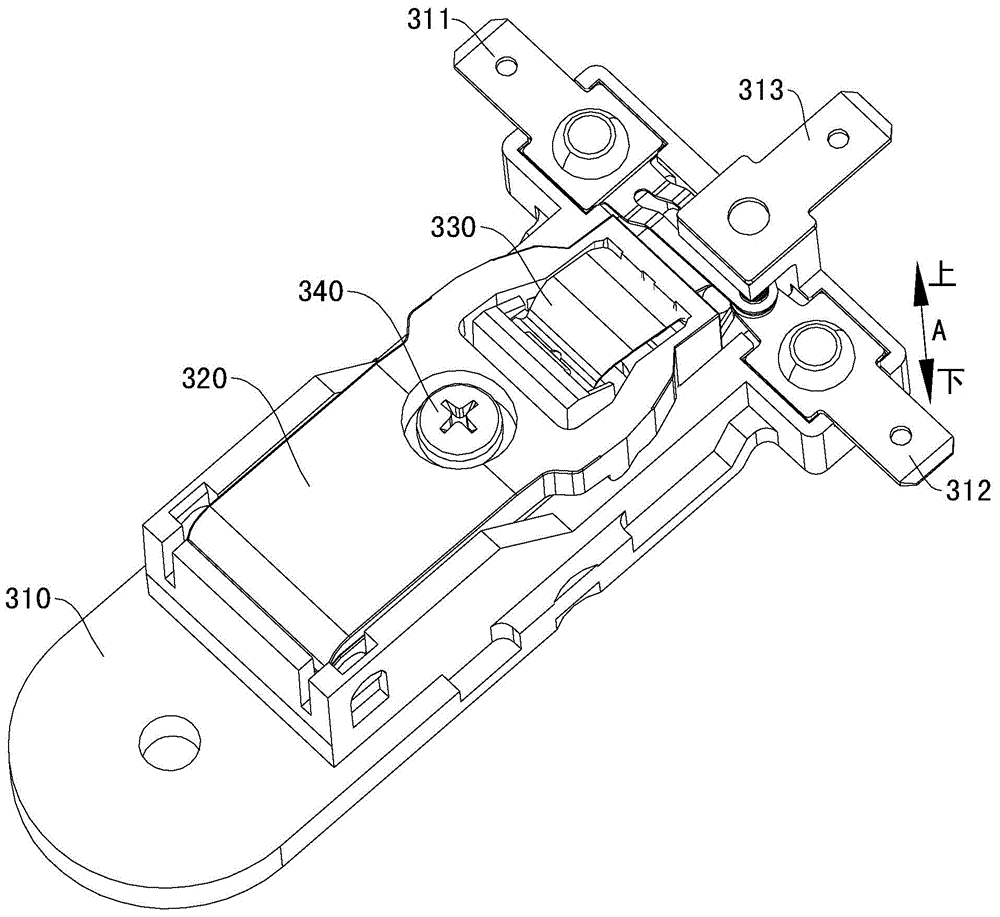

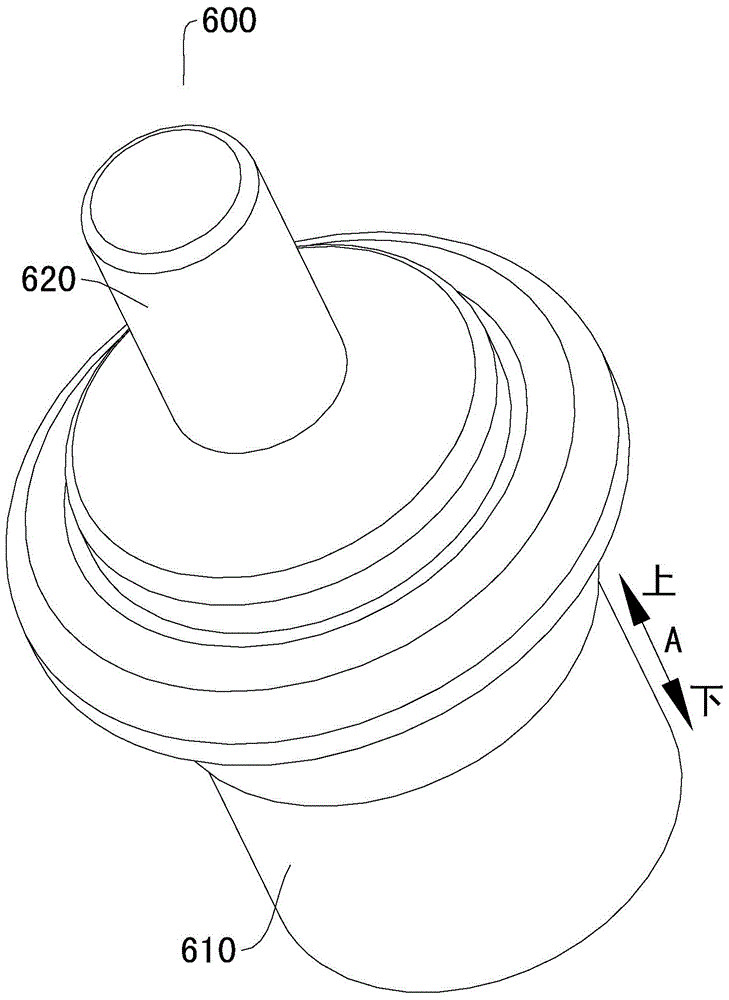

Metallic heating/cooling pressure-reduction skin management device

InactiveUS20150283022A1Adequate decompressionEfficient deliveryDevices for heating/cooling reflex pointsUltrasound therapyPressure reductionSkin exposure

Provided is a pressure-reduction skin management device, which includes: a suction unit for sucking the skin by applying a pressure reduction force to the skin so as to more effectively transfer a stimulus for skin management to the skin while sufficiently securing the pressure reduction force; and a skin stimulation unit provided on the suction unit, for applying energy to the expanded skin. The suction unit includes: a suction cup having a space formed therein and an open lower end to transfer the energy to the skin when coming into contact with the skin; and a housing surrounding the upperportion and the side surface of the suction cup while being spaced apart outward from the suction cup, the housing forming the outer shape of the suction unit. The skin stimulation unit includes a heating / cooling unit provided on the suction cup, for heating or cooling the suction cup.

Owner:UNISPATECH

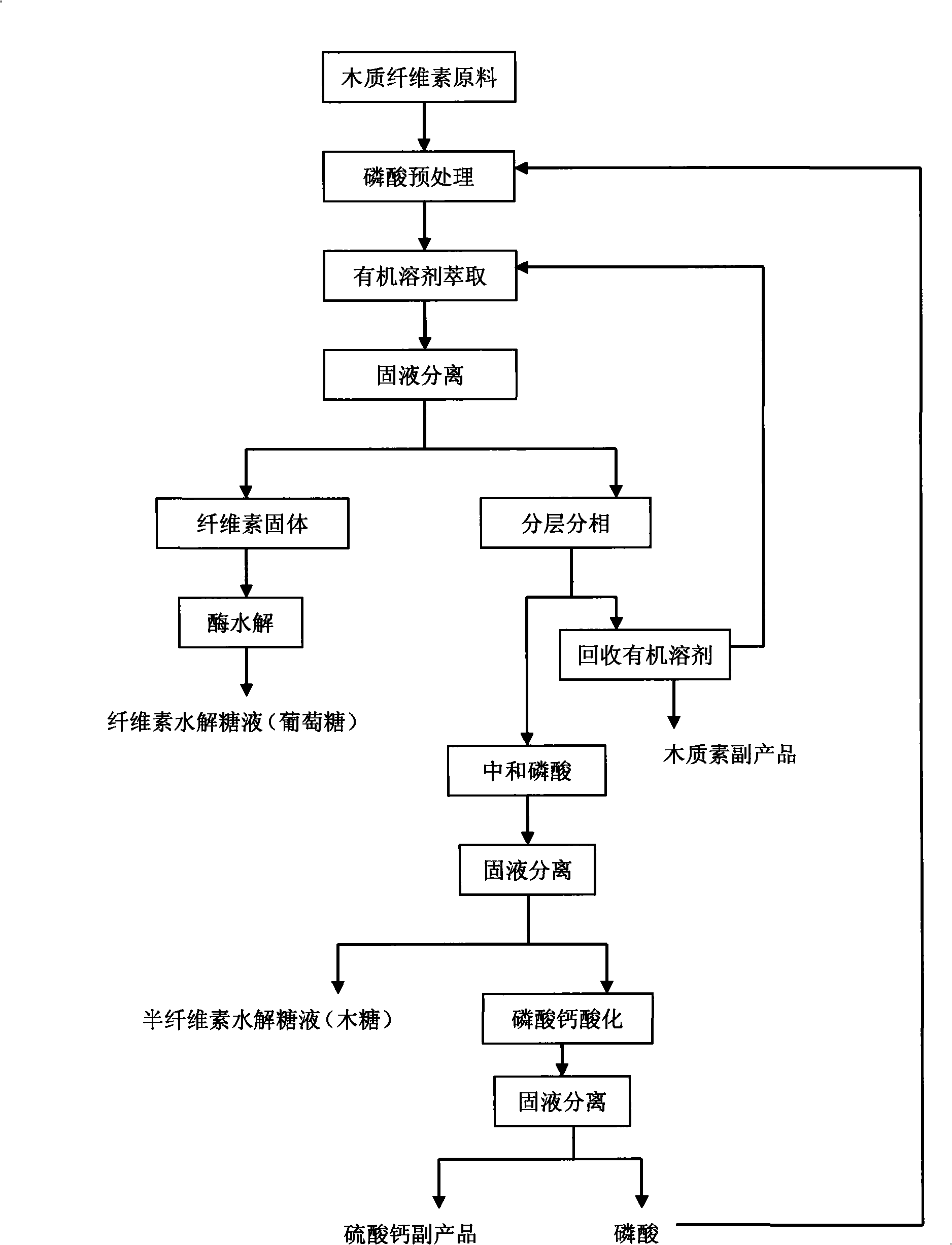

Process for preparing multicomponent liquid glucose and lignose while effectively hydrolyzing lignocellulosic biomass

InactiveCN101285106ASimple recycling processNot volatileSulfate preparationLignin derivativesLiquid glucoseFiltration

The invention discloses a method for efficiently hydrolyzing lignocellulosic biomass and synchronously preparing multi-component liquid glucose and lignin. The method comprises the steps that: the lignocellulosic biomass through physical crushing is added with phosphoric acid to perform acid hydrolysis; then organic solvent is added to extract the lignin, the layering and the phase separation are performed, then the lignin is extracted out while the organic solvent is reclaimed under the condition of pressure reduction and distillation; phosphoric acid can be reclaimed through steps such as neutralization, filtration, acidification and so on, hemicellulose hydrolyzed liquid glucose is obtained at the same time; and the remained cellulose undergoes the zymohydrolysis to prepare cellulosic hydrolyzed liquid glucose. The method can separate lignin, hemicellulose and cellulose, remarkably decreases the degree of crystallinity of the cellulose hydrolyzed by phosphoric acid, and remarkably improves the zymohydrolysis efficiency; and the prepared hydrolyzed liquid glucose does not contain fermentation inhibitors. The method has mild treatment conditions, simple process and less side reactions; the phosphoric acid and the organic solvent can both be reclaimed and circularly used; and the method is environment-friendly, and has broad social and economic benefits.

Owner:NANJING UNIV OF TECH

Method for preparing large-scale graphene through supercritical carbon dioxide exfoliation

ActiveCN102515155AReduce forceReduce the number of layersGrapheneBulk chemical productionMicrometerGraphite

The invention relates to a method for preparing large-scale graphene through supercritical carbon dioxide exfoliation. Supercritical carbon dioxide is adopted as an exfoliant, a surfactant is adopted as a dispersant, graphite powder and the dispersant are put in an autoclave, the carbon dioxide is pumped in the autoclave and circularly flows in a supercritical state, and then the pressure is reduced quickly to be normal pressure; the process is repeated so that the materials undergo pressure increment and pressure reduction several times; and the layers of the graphene is controlled by controlling the times of pressure increment and pressure reduction, so as to prepare the large scale graphene. Compared with the prior art, the invention has the advantages as follows: large-scale (hundreds of micrometers) high-quality graphene can be prepared; the method belongs to physical exfoliation, the treatment conditions are mild, and the quality of the graphene cannot be damaged; besides, the carbon dioxide used in the method is nontoxic, cheap and easy to obtain, and the technology is simple.

Owner:上海利物盛纳米科技有限公司

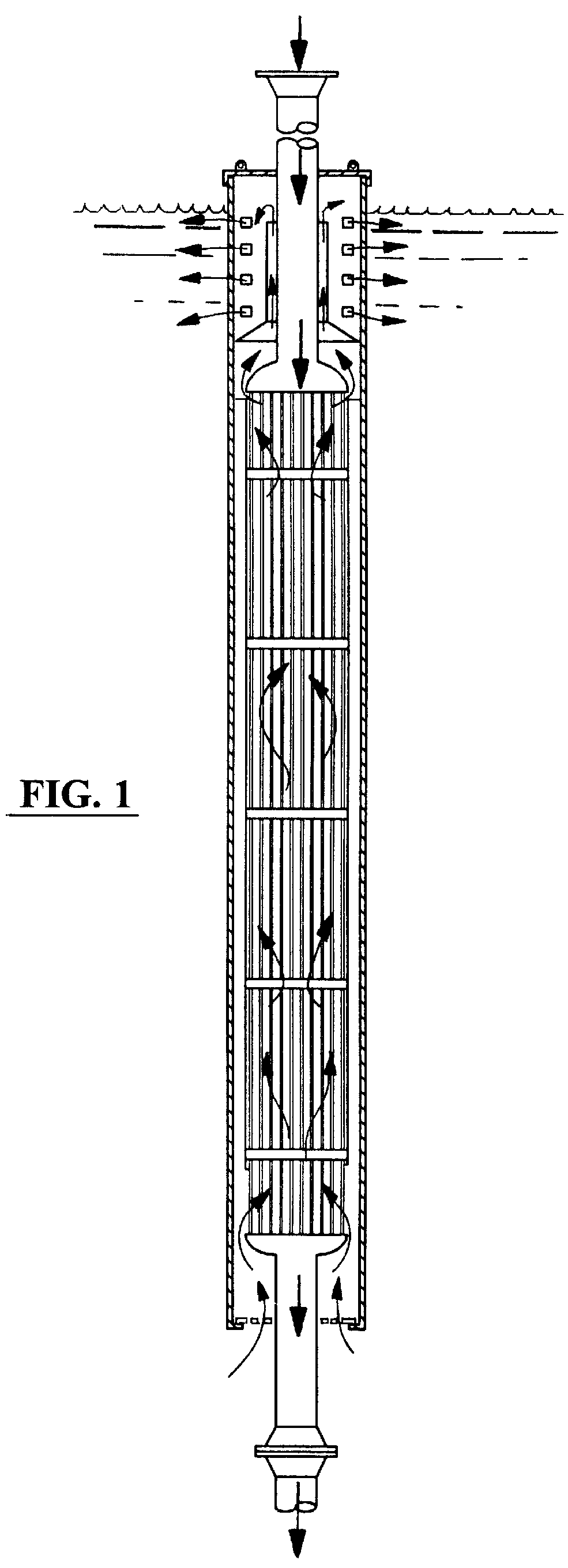

Passive, thermocycling column heat-exchanger system

InactiveUS6142215AImprove permeabilityEasy maintenanceOther heat production devicesAir heatersActive coolingTitanium

A heat exchanger system suitable for facilitating the economical cooling of hot fluids in the vicinity of a body of water. The preferred embodiment of the present invention contemplates a vertical, or combination vertical and horizontal thermosyphonic, passive, heat exchanger column situated in a body of water and enveloped by a caisson or the like, and configured to facilitate, through percolation, enhanced circulation of seawater therethrough and effecting significant cooling of a hot, hydrocarbon well stream, or other hot fluid in the vicinity of a body of water. A vertically situated bundle of tubes forms the heat exchanger, which may include a system of staggered baffles to direct the flow of cooling seawater to effect even temperature distribution throughout the tube bundle. The present system further teaches a system for cooling high pressure, hot fluids as may be found in a deep hydrocarbon reserve offshore, utilizing a the vertical heat exchange column of the present invention. Upon passing through the system, a gaseous fluid stream, significantly cooled, should experience a commensurate pressure reduction and allow the use of conventional pipeline materials. The present system dispenses with the necessity of providing expensive, pro-active cooling, generally expending significant fuel, or the necessity of constructing an expensive, high pressure, non-corrosive pipeline of, for example, titanium or the like.

Owner:EDG

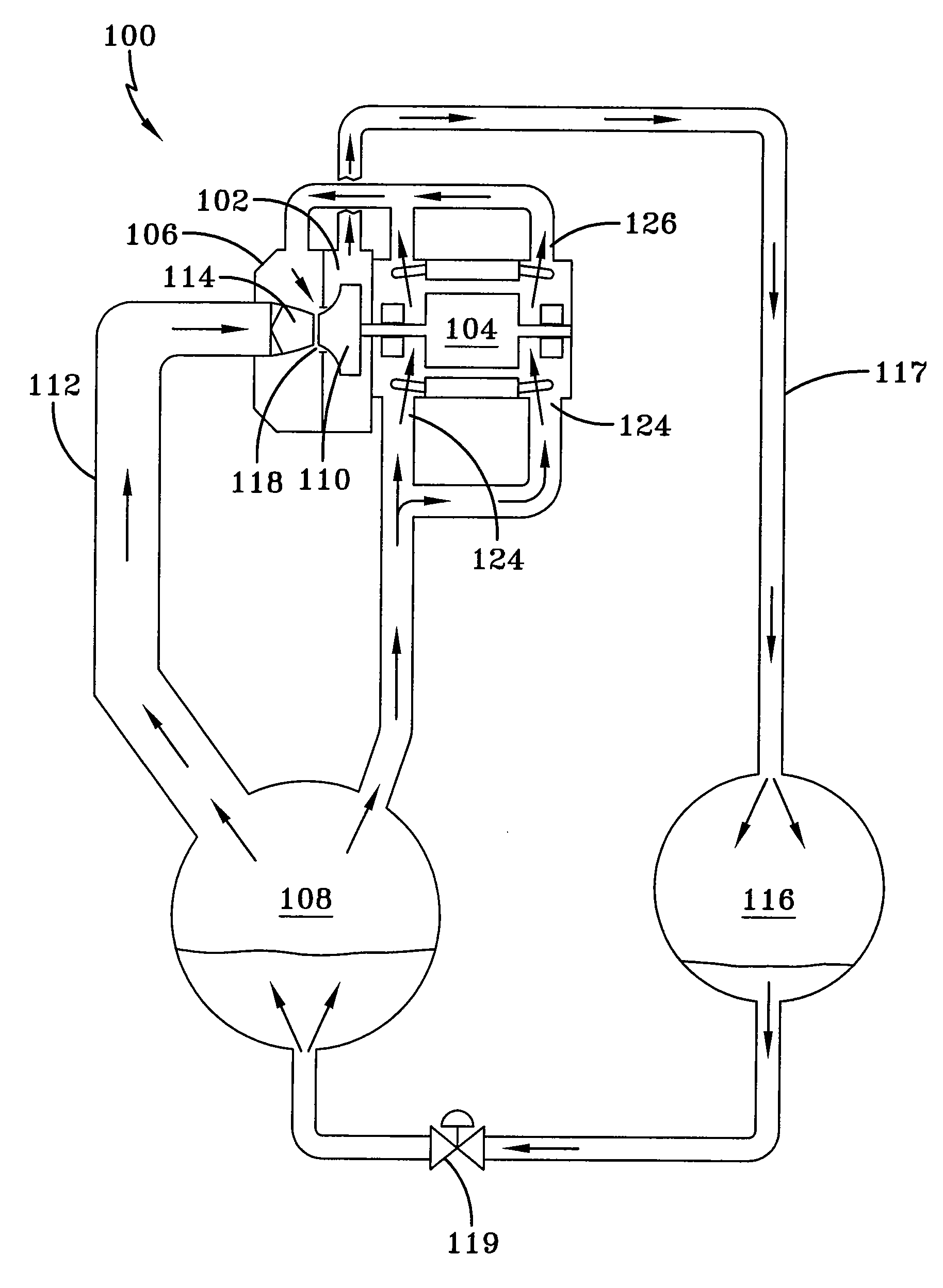

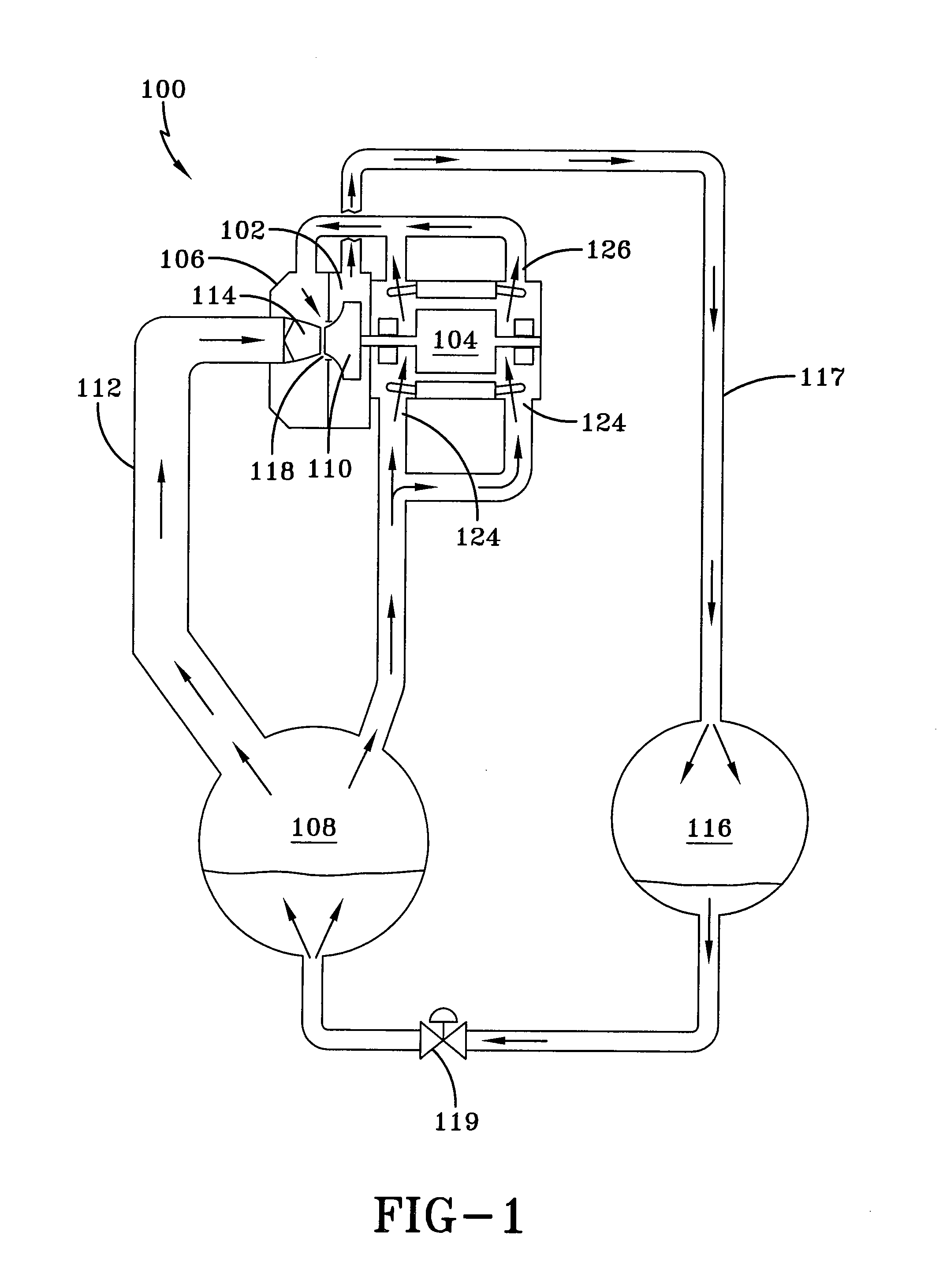

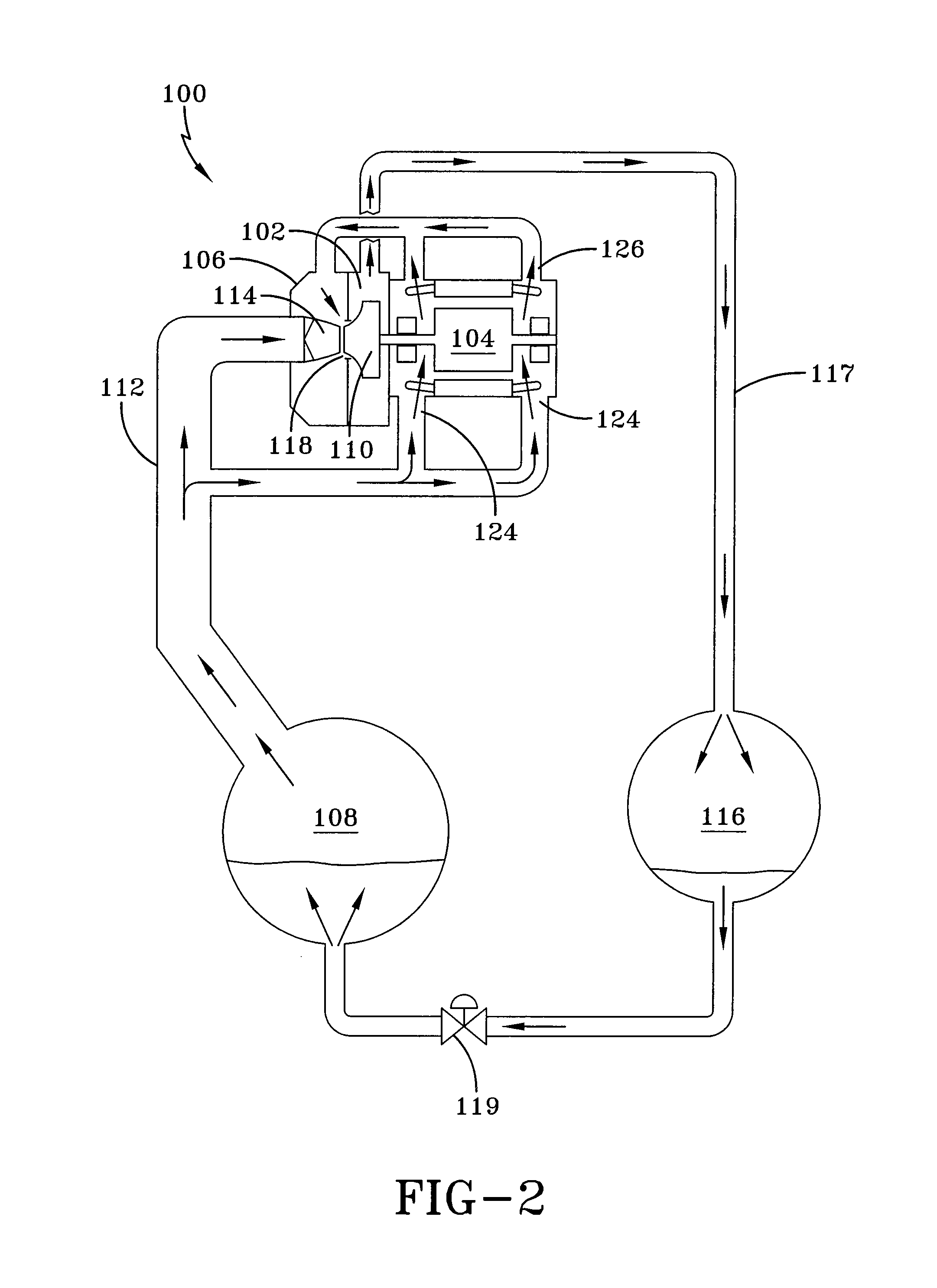

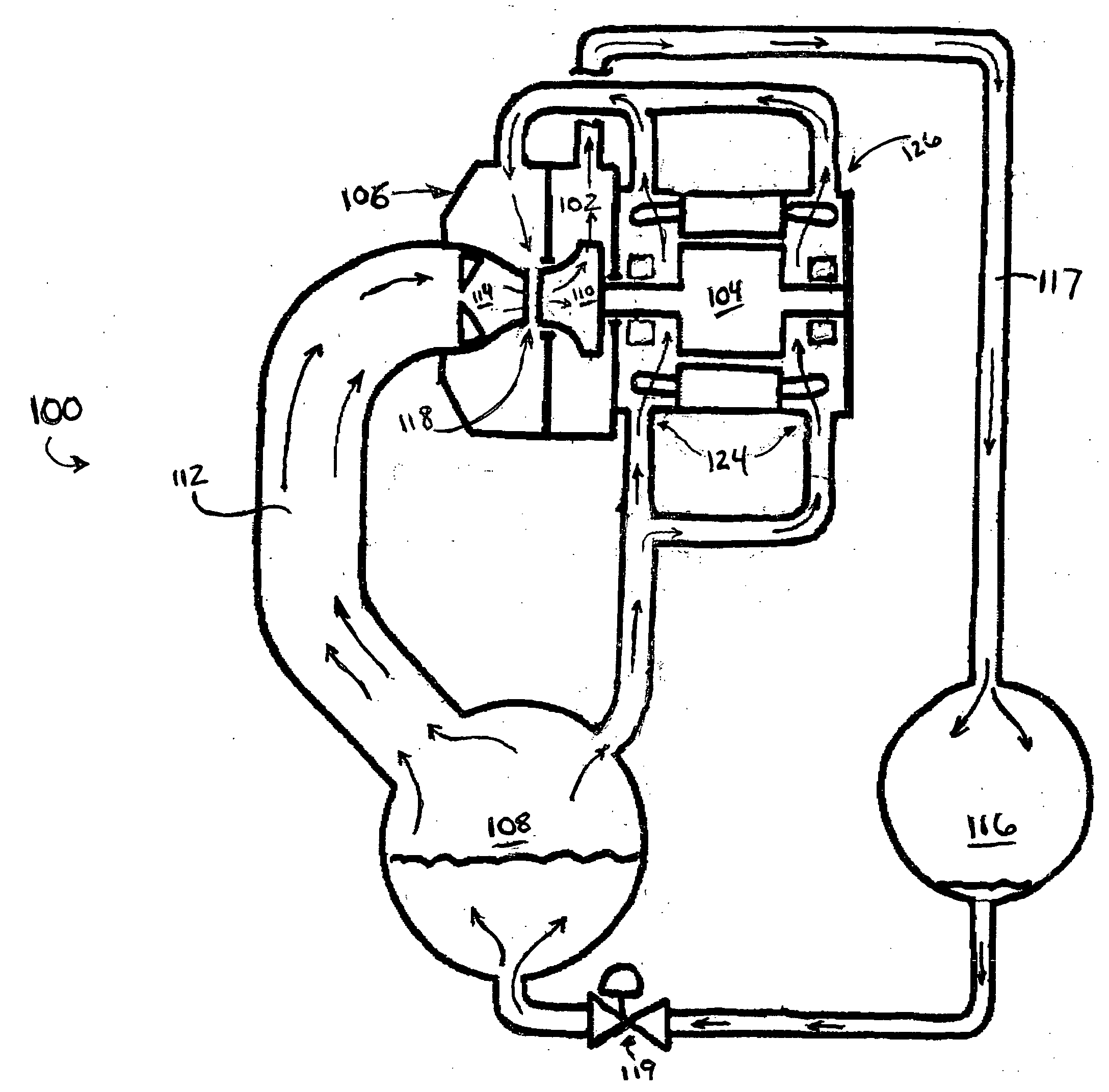

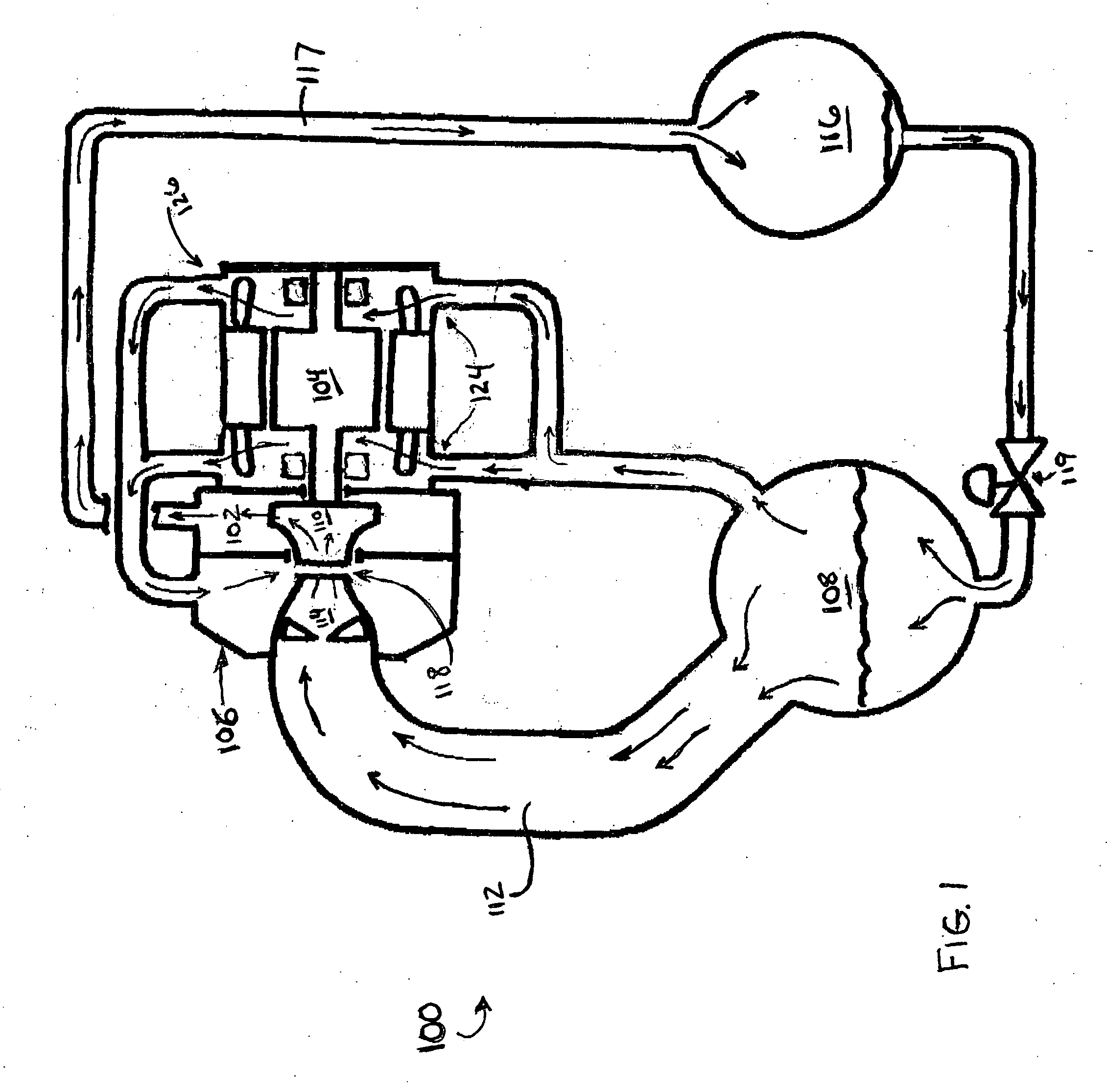

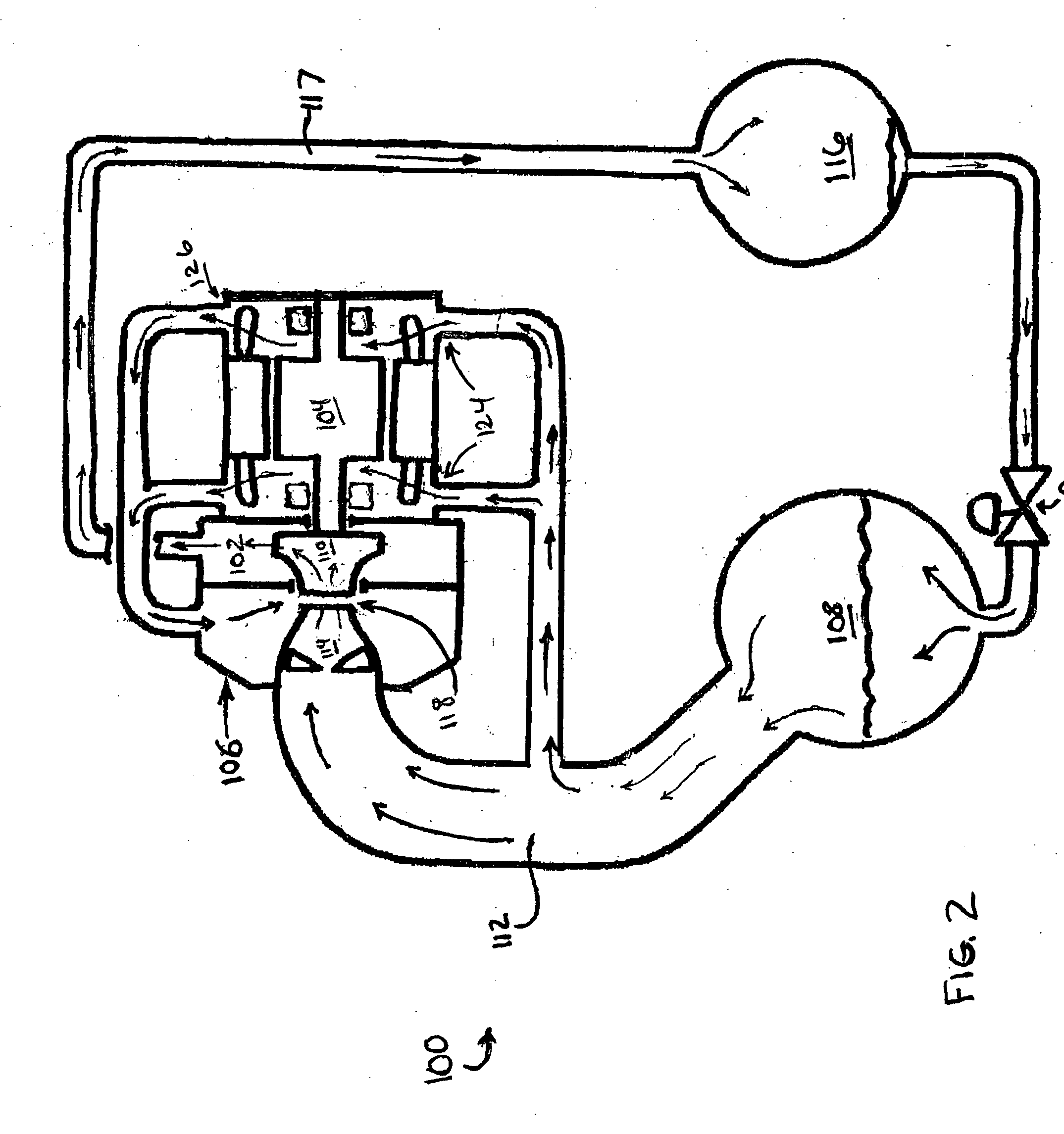

System and method for cooling a compressor motor

ActiveUS7181928B2Unacceptable compromises to system efficiencyImprovement in motor coolingCompressorPump componentsEngineeringAir compressor

Apparatus and methods are provided for cooling motors used to drive gas and air compressors. In particular, the cooling of hermetic and semi-hermetic motors is accomplished by a gas sweep using a gas source located in the low-pressure side of a gas compression circuit. The gas sweep is provided by the creation of a pressure reduction at the compressor inlet sufficient to draw uncompressed gas through a motor housing, across the motor, and out of the housing for return to the suction assembly. The pressure reduction is created by means provided in the suction assembly, such as a nozzle and gap assembly, or alternatively a venturi, located upstream of the compressor inlet. Additional motor cooling can be provided by circulating liquid or another cooling fluid through a cooling jacket in the motor housing portion adjacent the motor.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Pressure cooker

The invention discloses a pressure cooker. The pressure cooker comprises a cooker body, a cooker cover, an on-off switch, a controller, a pressure reduction device and a pressure detection device, wherein the cooker cover is arranged on the cooker body; the on-off switch is arranged on the cooker body or the cooker cover and provided with an input terminal, a first output terminal and a second output terminal, and the input terminal is connected with a power supply and also connected with the first output terminal; the controller is connected with the first output terminal and the power supply respectively; one end of the pressure reduction device is connected with the second output terminal and the controller, and the other end of the pressure reduction device is connected with the power supply; and the pressure detection device is arranged on the cooker body or the cooker cover and connected with the on-off switch, and the pressure detection device controls the input terminal to be disconnected with the first output terminal and connected with the second output terminal when pressure in the cooker body is higher than the predetermined value. The pressure cooker according to the embodiment of the invention can realize overflow-free steam pressure reduction in case of excess pressure, and therefore, has the advantages of high security, good cleanliness and sanitariness and the like.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

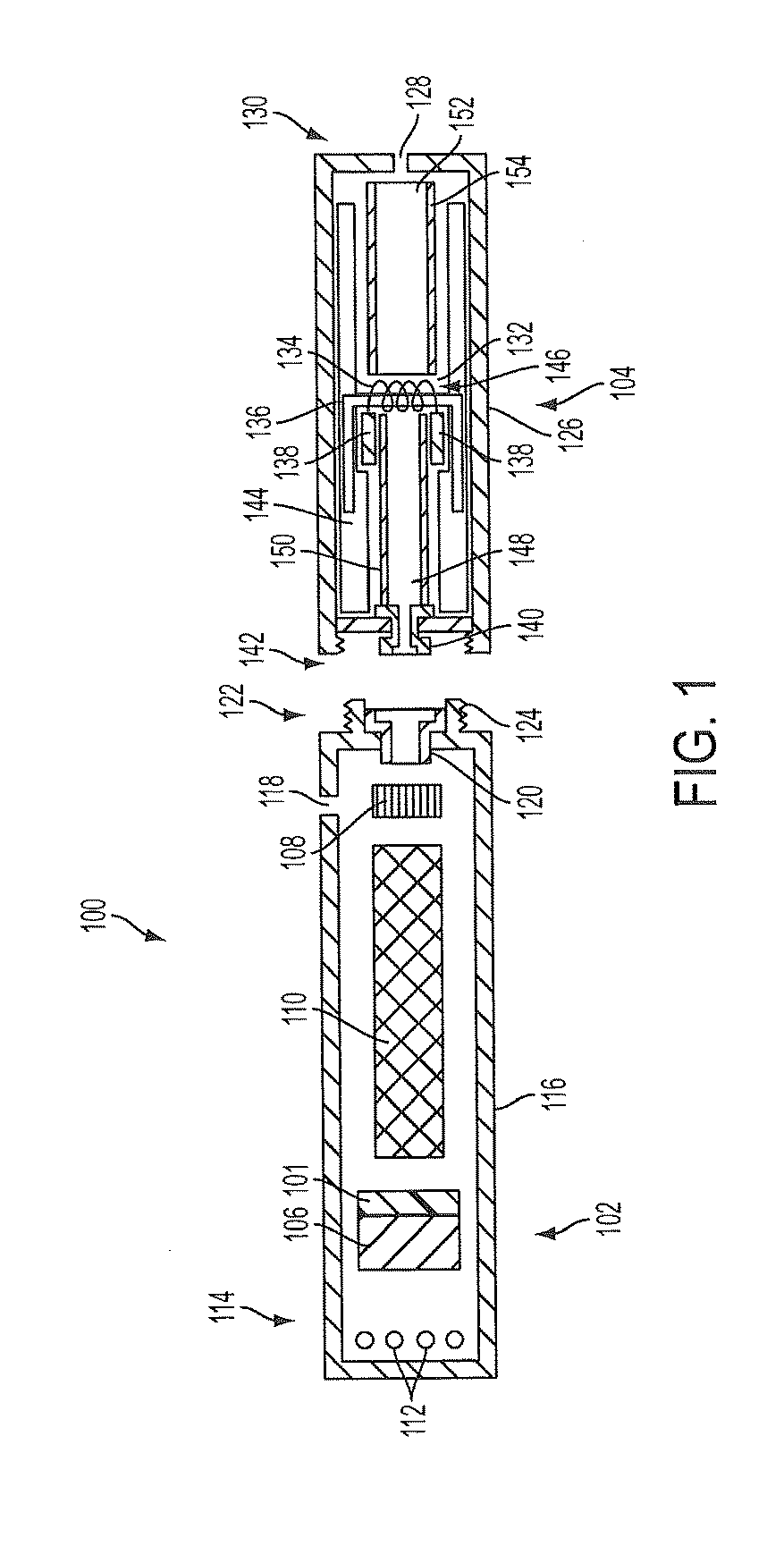

Apparatus and method for using a lightweight portable air/gas power supply

ActiveUS6932128B2Easily and quickly refilledHigh pressure levelTravelling sacksLiquid fillingFiberMulti-valve

A lightweight carbon fiber air / gas supply vessel storing high pressure air / gas. The air / gas supply vessel output is controlled by an adjustable pressure reduction valve which varies output pressure from very high to low pressure levels. An alternative multi-valve system uses a first pressure reduction valve to reduce output pressure from the very high levels in the air / gas supply vessel to an intermediate pressure level, and a second pressure reduction valve that reduces the air / gas pressure from the intermediate level to a fine tunable low pressure level. In both embodiments, the output of the last pressure reduction valve used is connected to a high pressure cable which in turn uses a standard universal fitting which can be coupled to most pneumatically powered equipment. Additional high pressure reservoir vessels can be used to replenish the lightweight air / gas supply vessel when its supply of air / gas is depleted.

Owner:SPEED AIR SYST

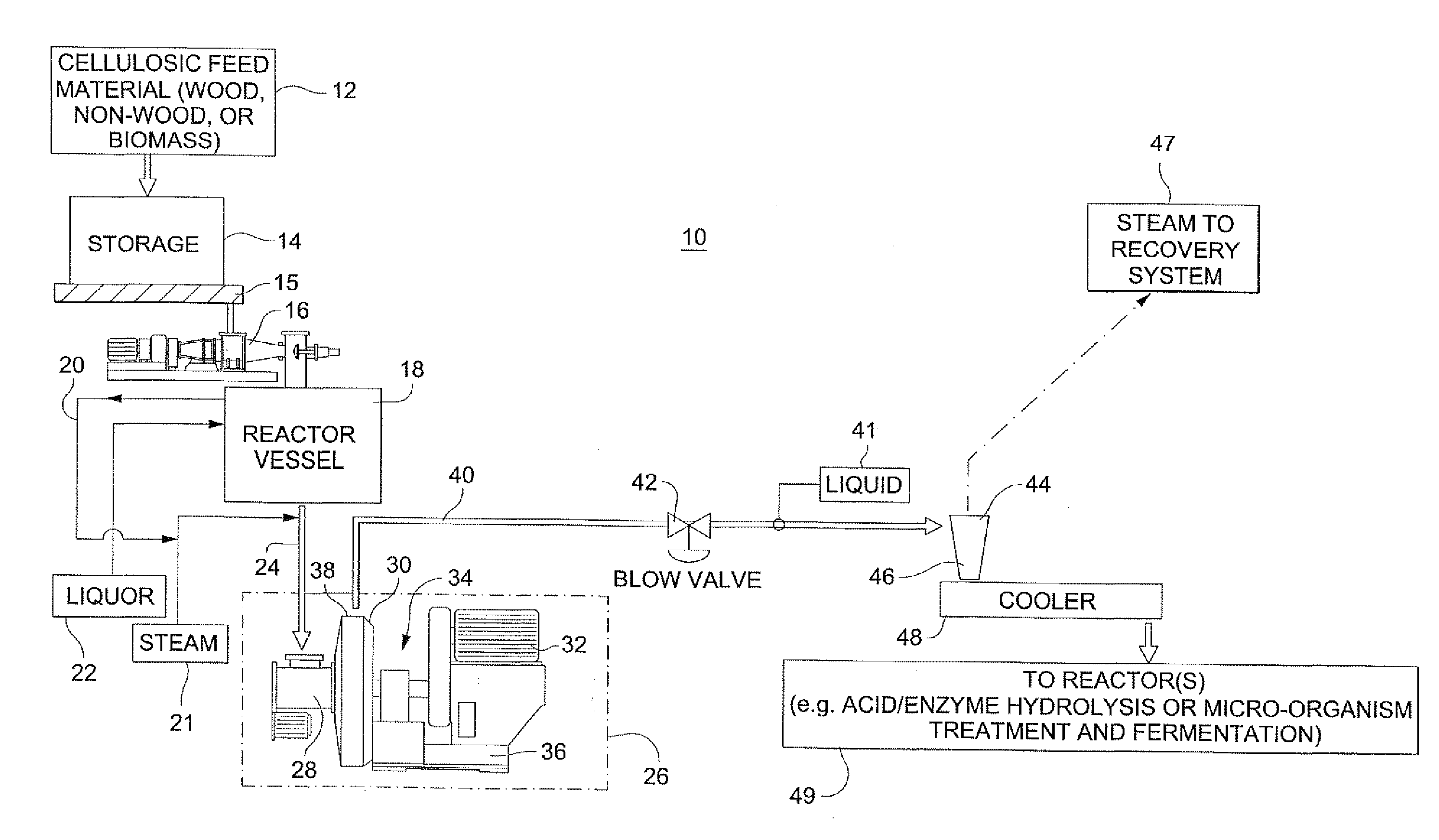

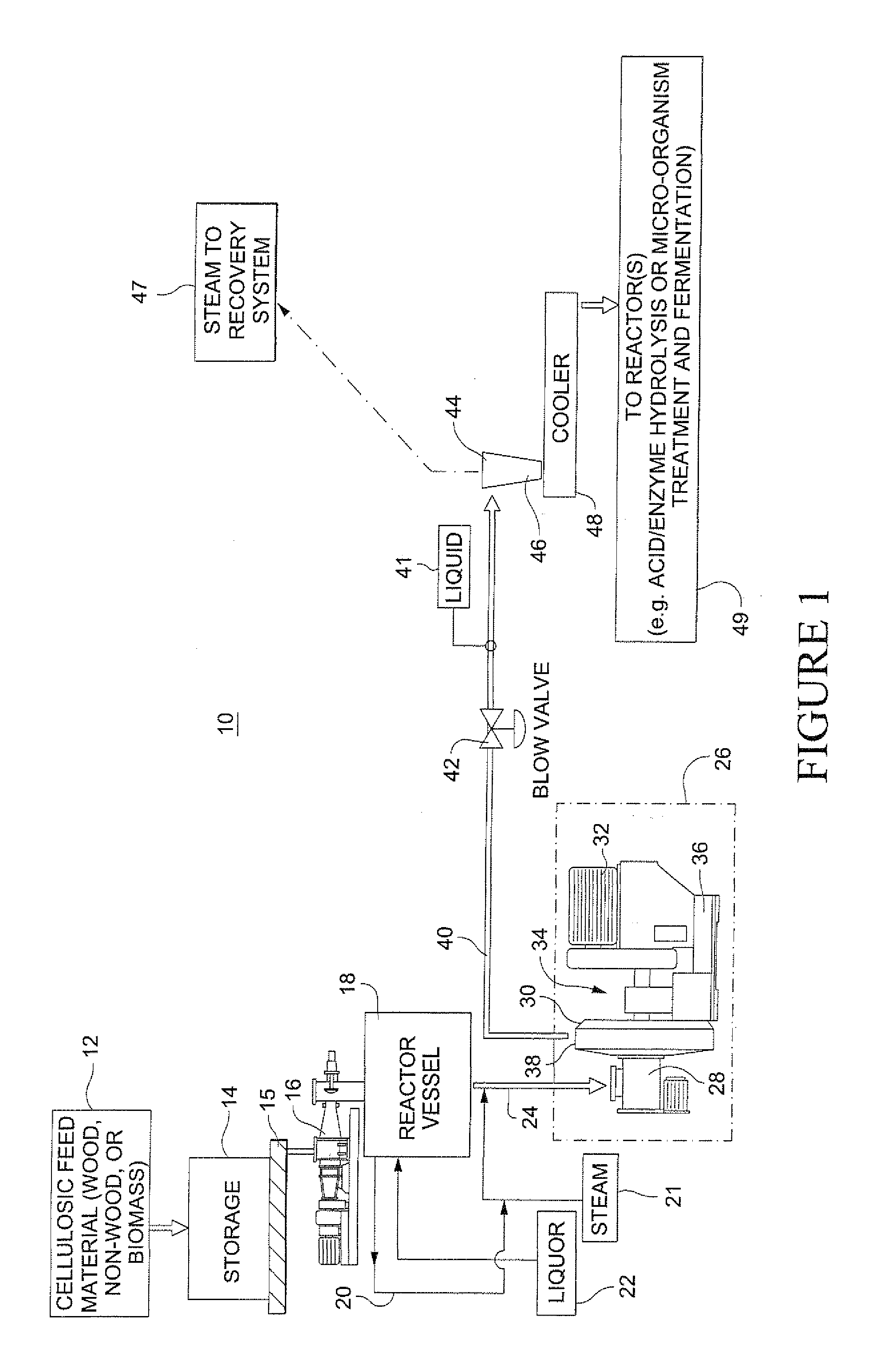

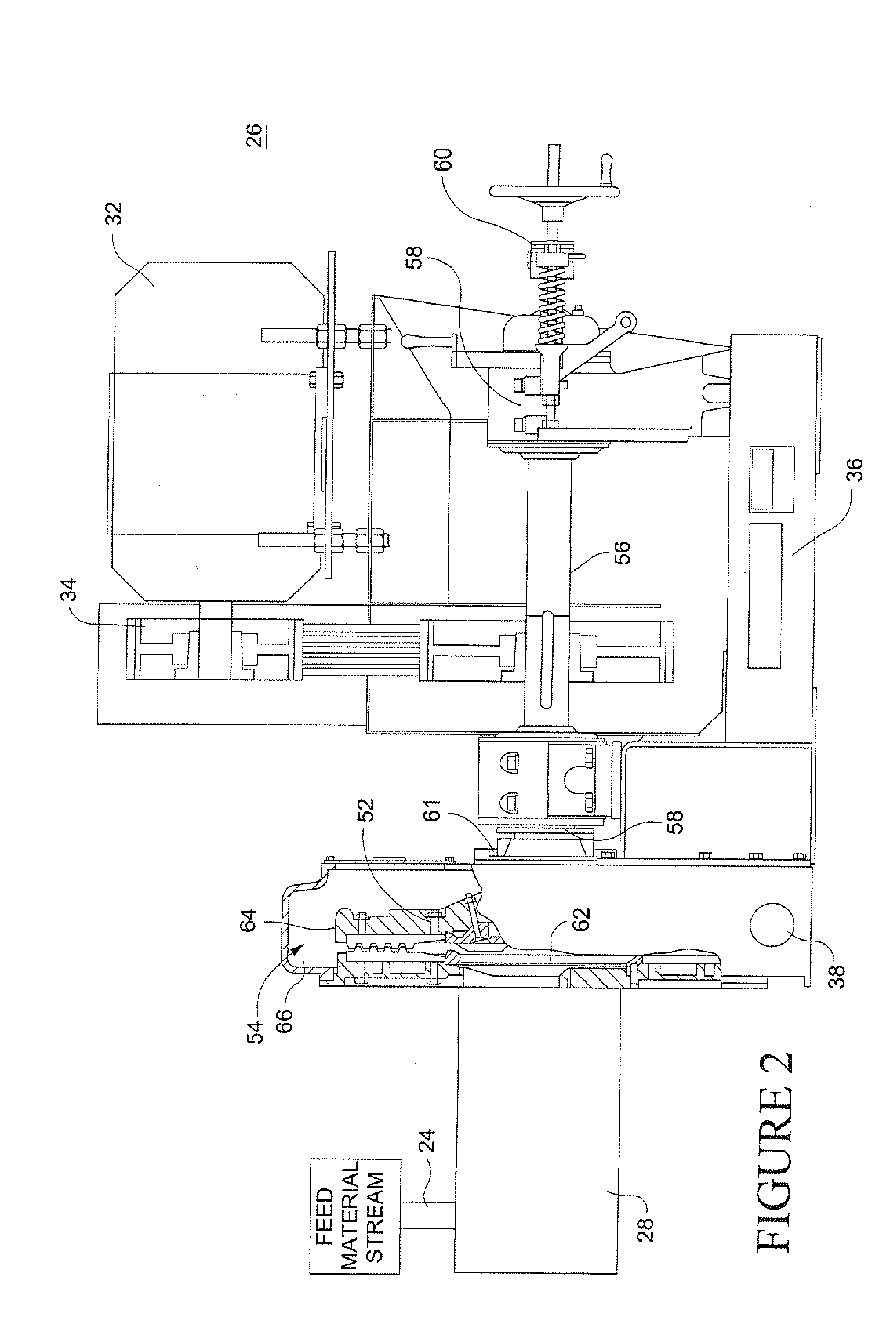

High pressure compressor and steam explosion pulping method

InactiveUS20080277082A1Reduce pressureRapid pressurePretreatment with water/steamPulp beating/refining methodsProcess engineeringHigh pressure

A steam explosion pulping method including: impregnating a cellulosic biomass feed material in a pressurized reactor vessel; discharging the impregnated feed material from the vessel to a high pressure compressor; elevating a pressure of the feed material in the compressor; discharging the pressurized feed material from the compressor to a conduit coupled to a blow valve; rapidly reducing pressure of the pressurized feed material as the feed material passes through the blow valve, and pulping the feed material by expansion of fluid in the feed material during the rapid pressure reduction.

Owner:ANDRITZ INC

Method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas

InactiveCN101816886APromote regenerationSolve pollutionDispersed particle separationAir quality improvementMass ratioSorbent

The invention provides a method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas. The method comprises the following steps: dedusting and cooling the coal-fired flue gas containing SO2, NOx and CO2; leading the gas into an adsorbent for saturated adsorption at the adsorption temperature of 50-100 DEG C and the adsorption pressure of 50-10000Pa; evacuating the coal-fired flue gas, desorbing the adsorbent by means of pressure reduction or temperature rise, and then repeatedly using; leading the desorbed gas into ammonia water for absorption treatment, wherein, the mass ratio of the ammonia water to the mixed gas containing SO2, NOx and CO2 is 2-6:1, the absorption temperature is 30-50 DEG C, and the absorption pressure is 5000-12000Pa; and recycling the gas to generate ammonium sulfate, ammonium nitrate and ammonium carbonate. The method can achieve simultaneouse desulfuration, denitration and decarbonization, and has small investment, low cost and low energy consumption; and the method can be widely applied to purification treatment of SO2, NOx and CO2 in the waste gas discharged from fixed fire coal sources such as thermal power plants, smelting plants, oil refinery, chemical plants and the like.

Owner:KUNMING UNIV OF SCI & TECH

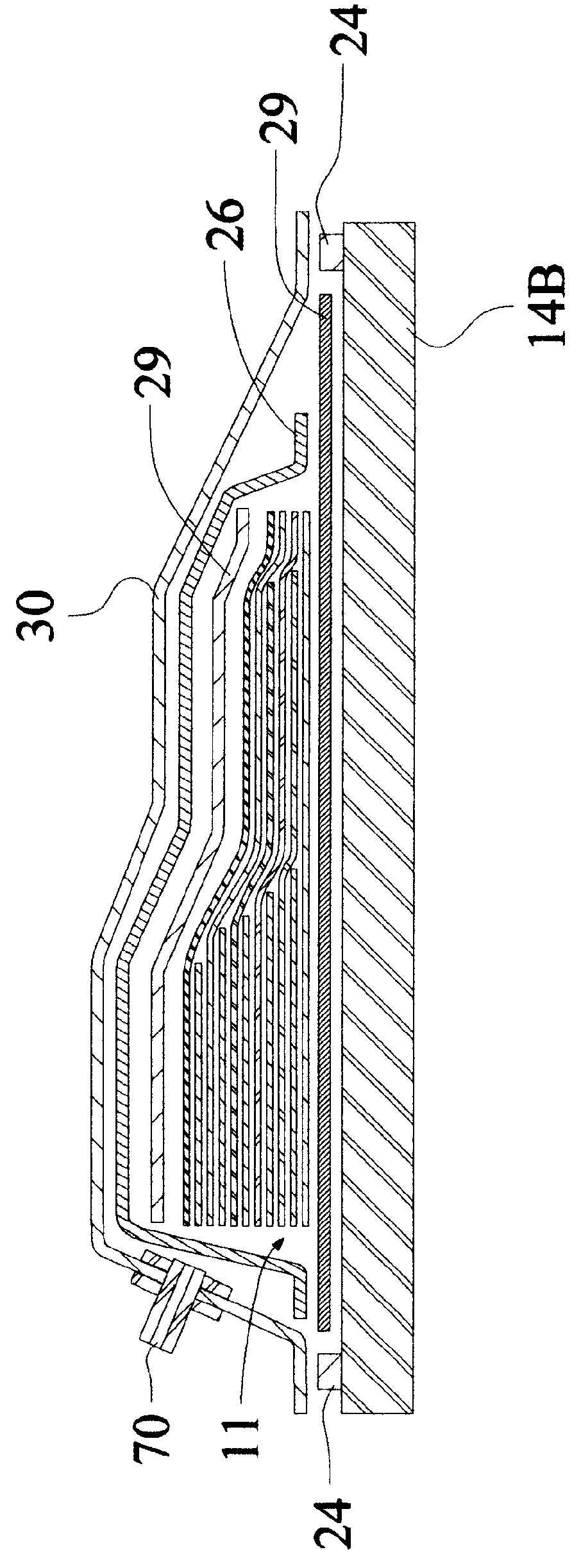

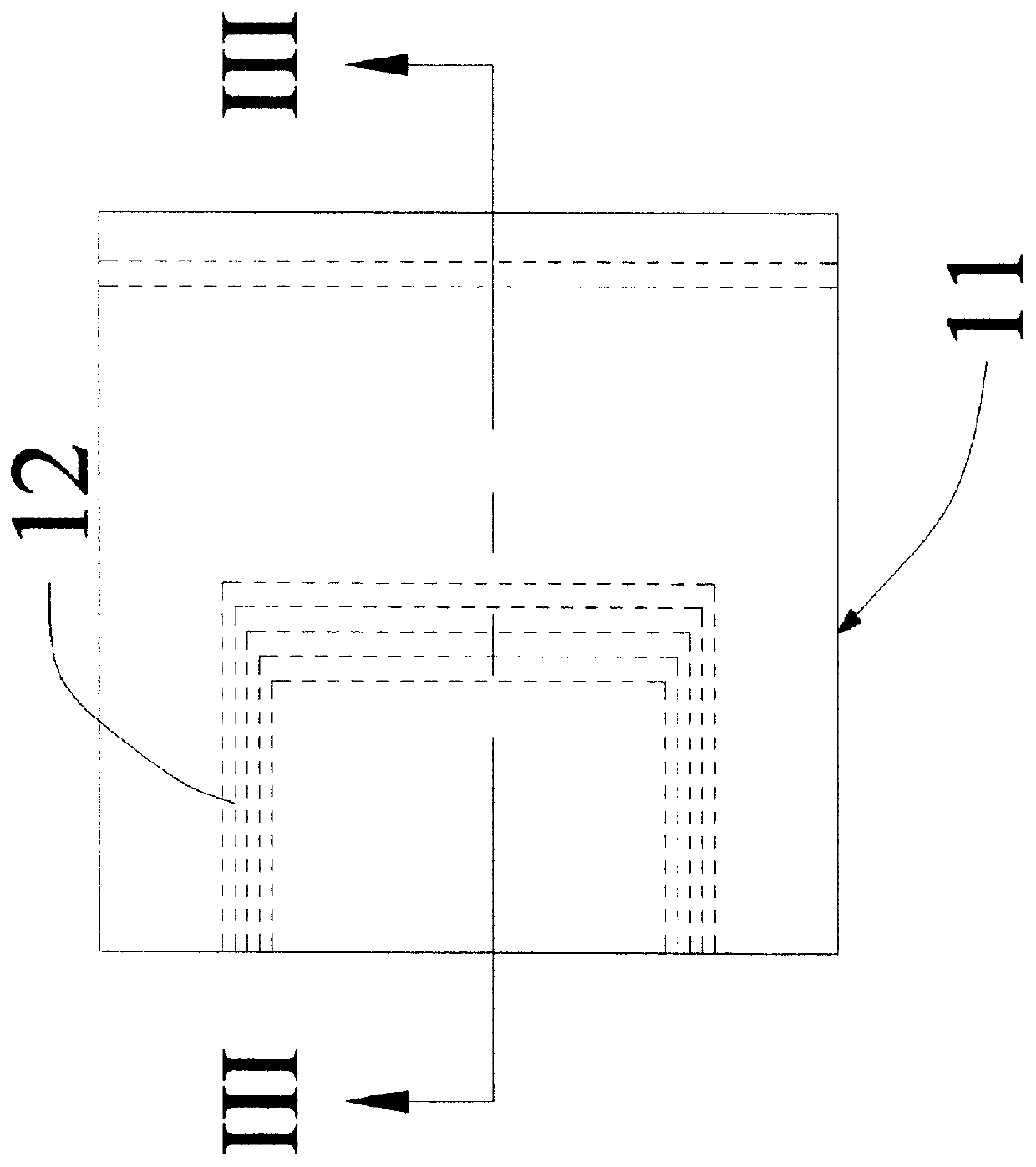

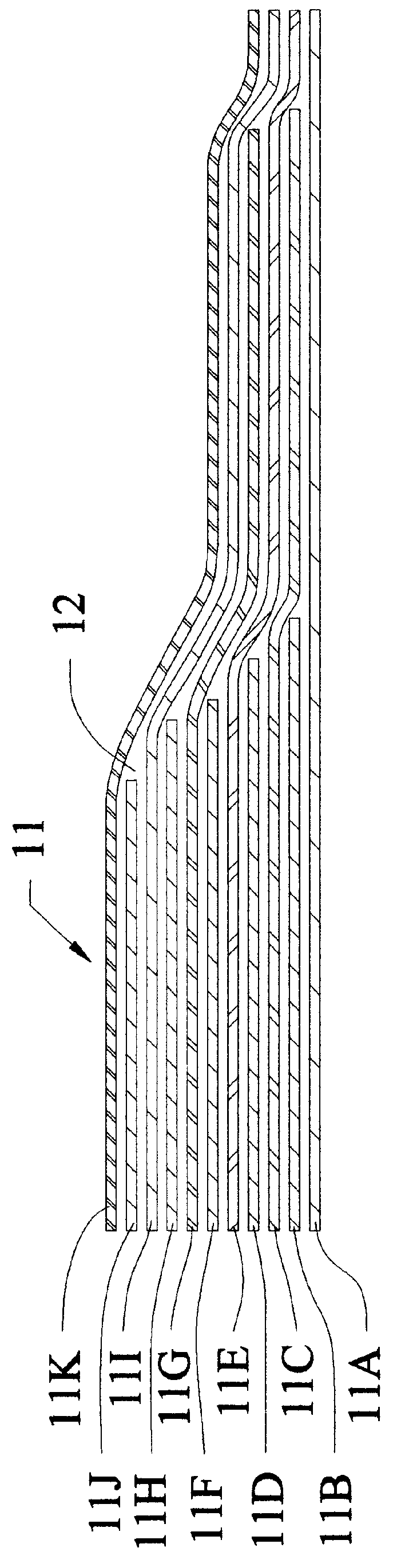

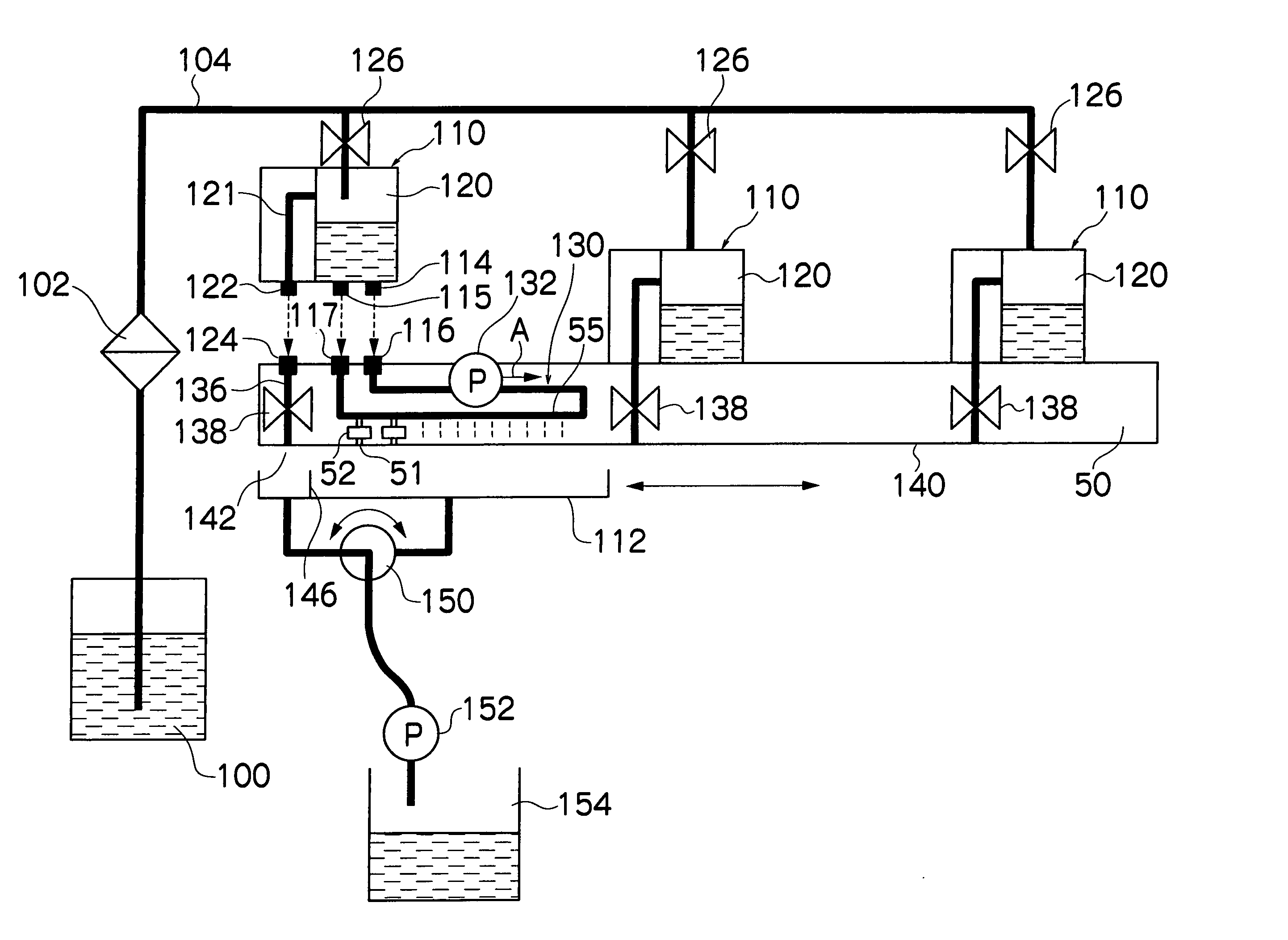

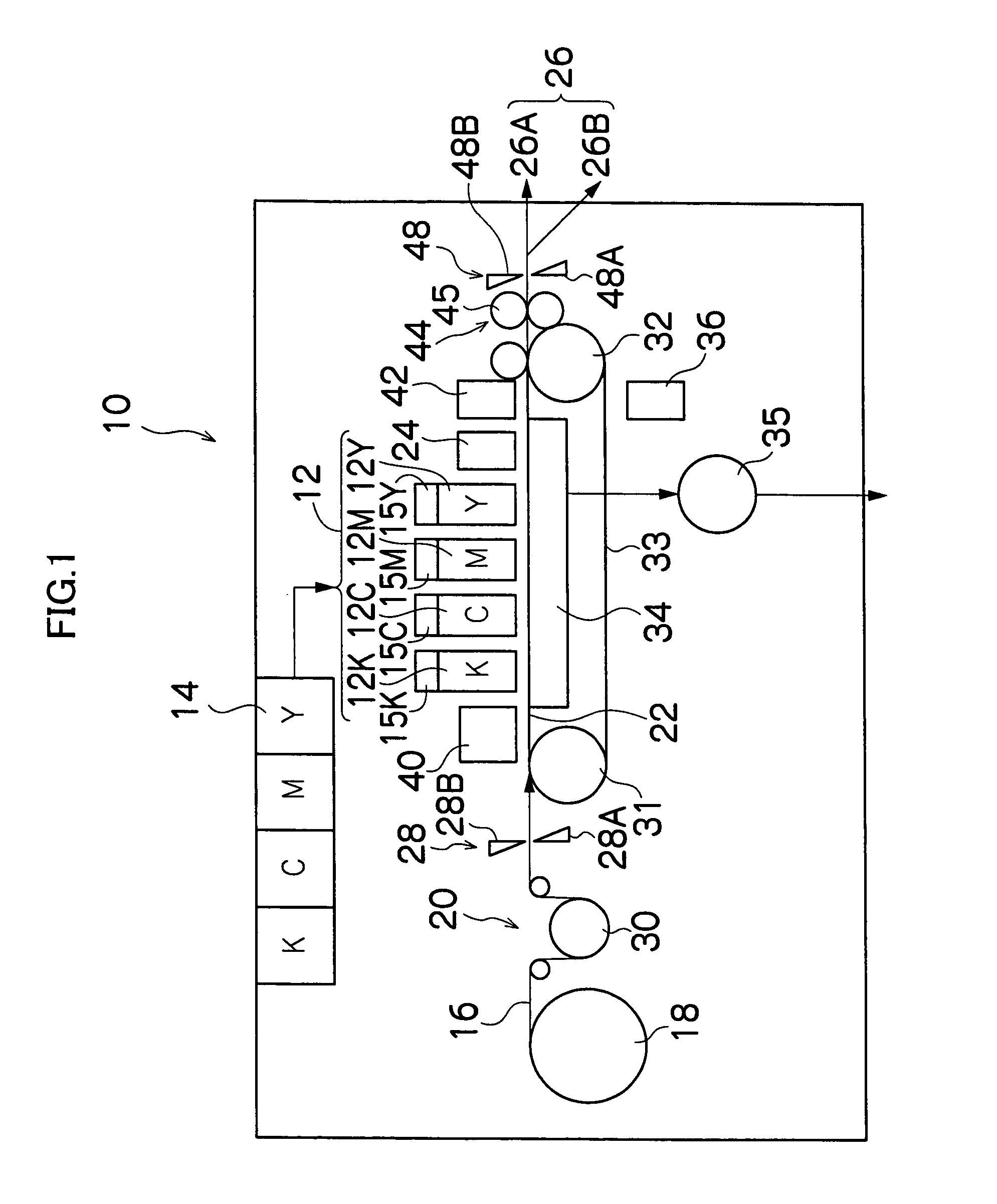

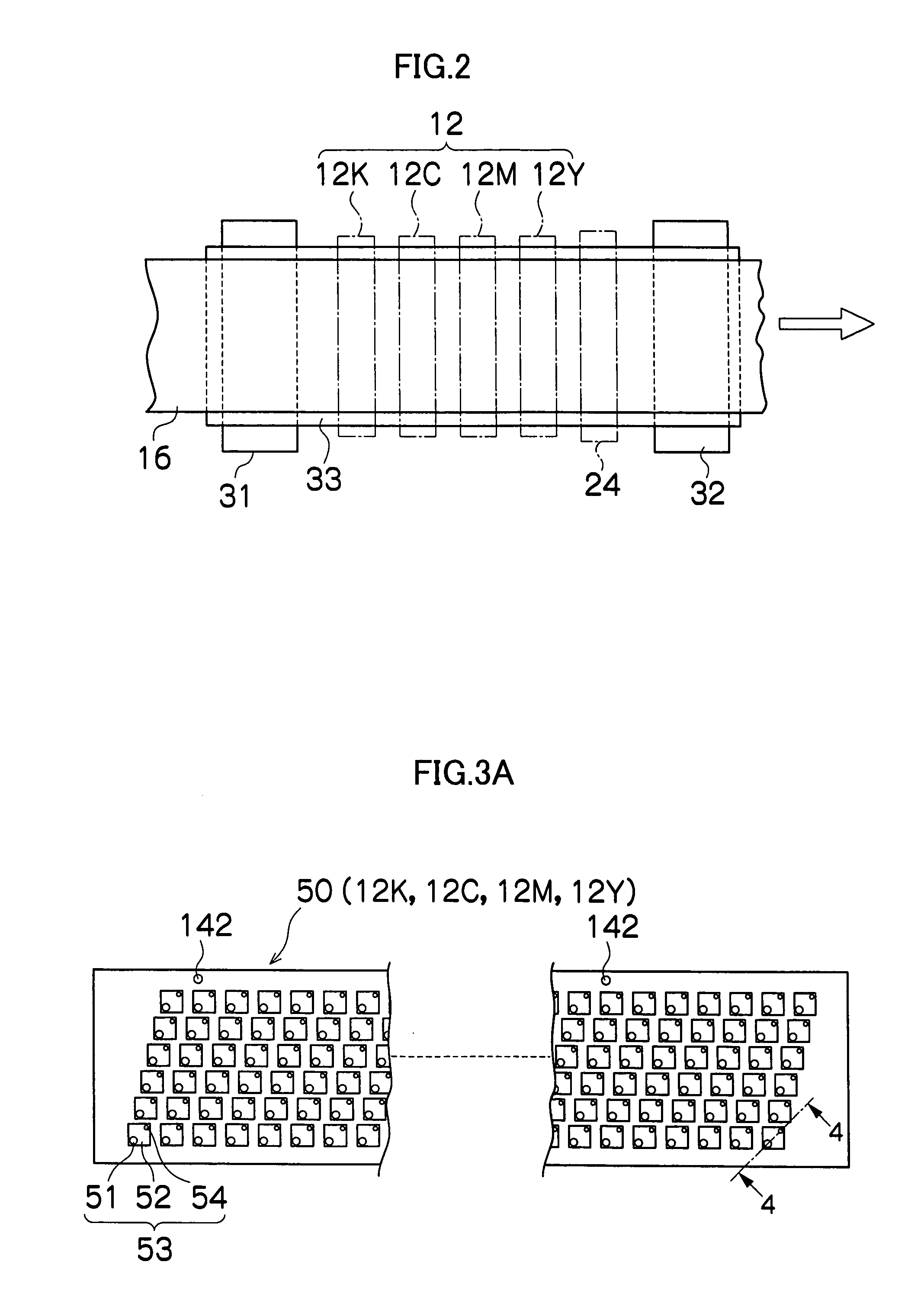

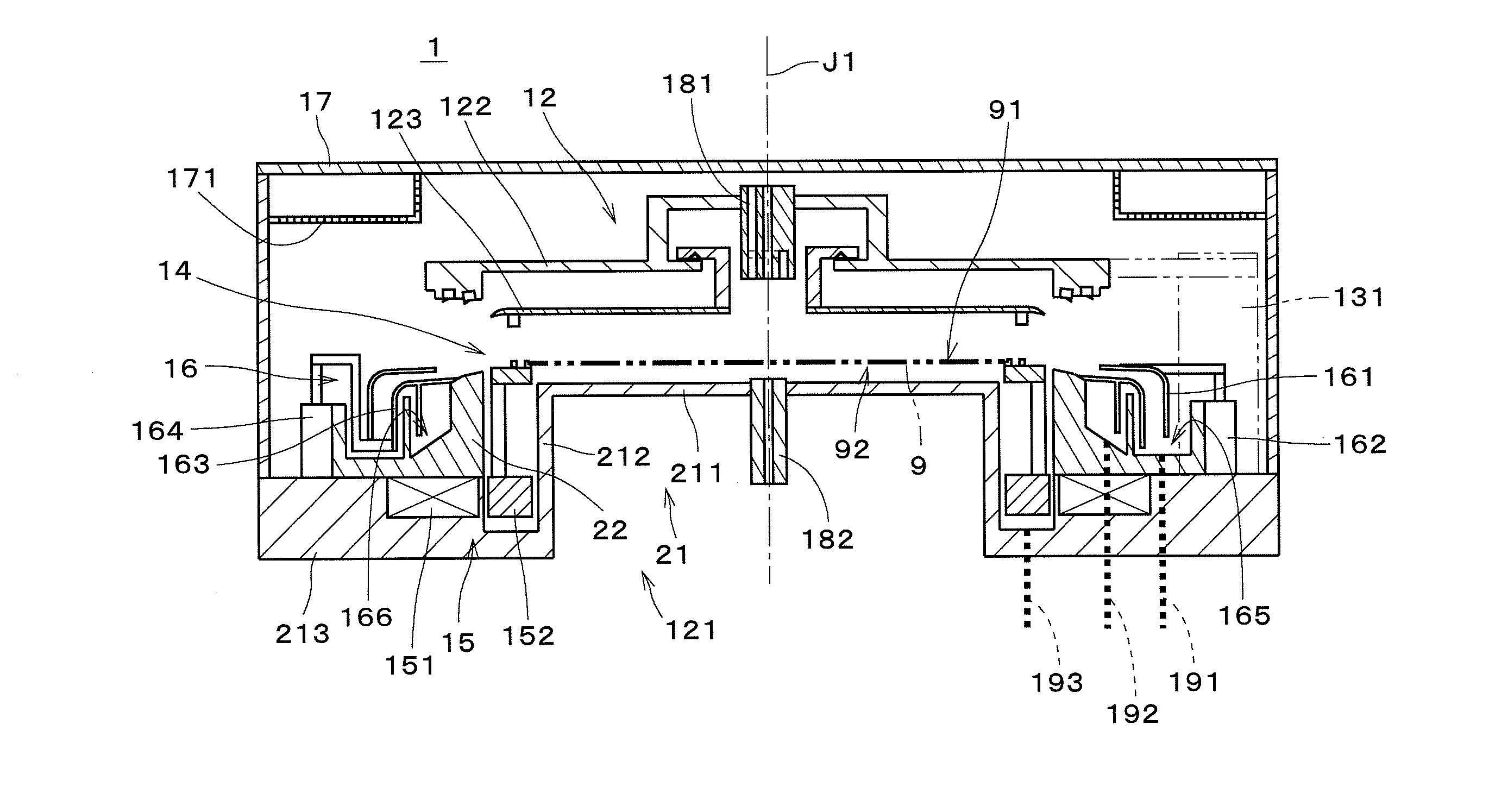

Inkjet recording head assembly and inkjet recording apparatus

The inkjet recording head assembly comprises: a recording head which has nozzles discharging ink; a main tank which is a supply source of the ink; and an auxiliary tank which communicates with the main tank, the auxiliary tank being in direct connection to the recording head without interposing tubes, a circulation channel being formed by the auxiliary tank and an ink flow channel in the recording head, the auxiliary tank having an exhaust channel connected to a pressure reduction device which reduces inner pressure of the auxiliary tank.

Owner:FUJIFILM HLDG CORP

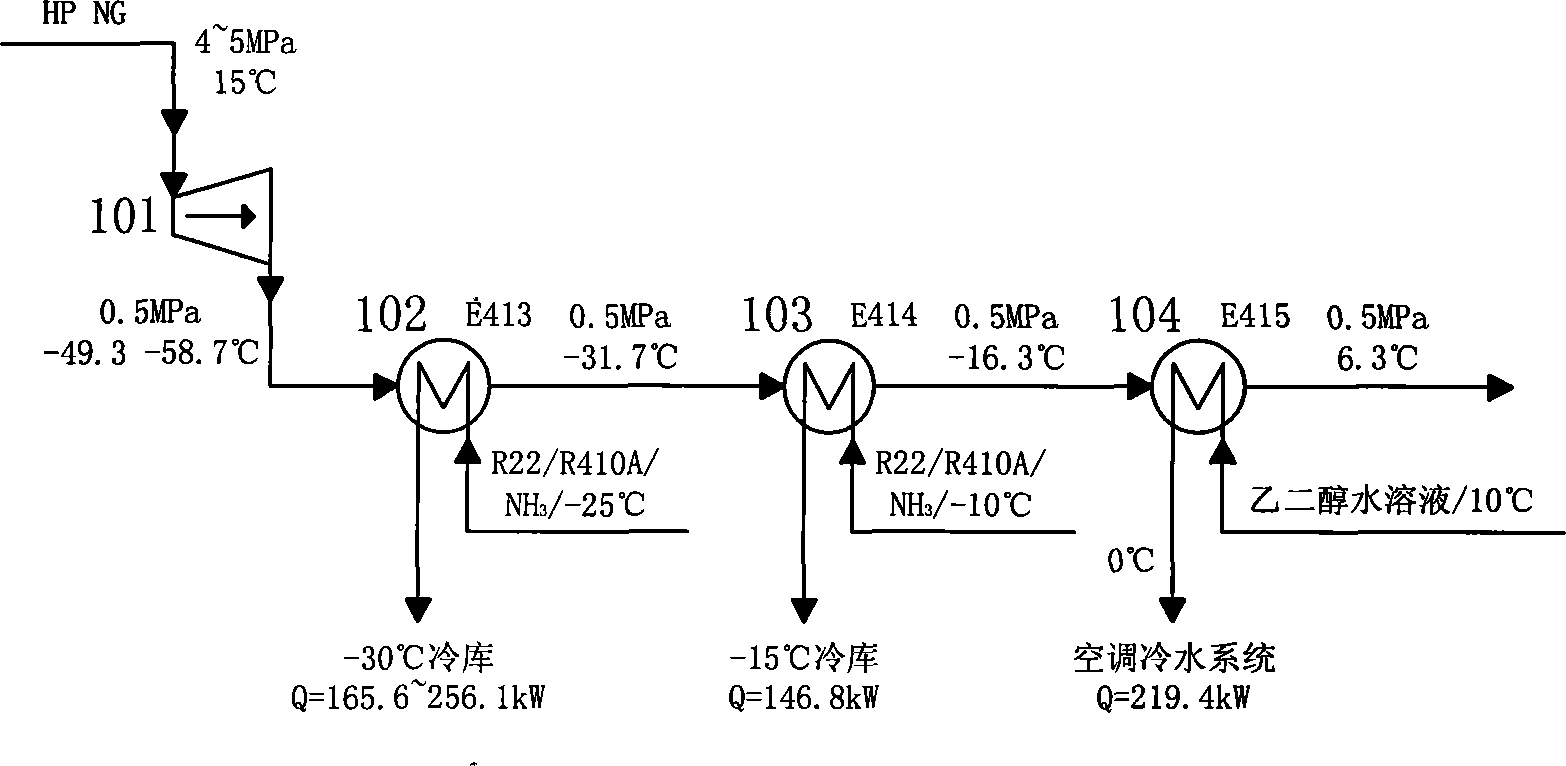

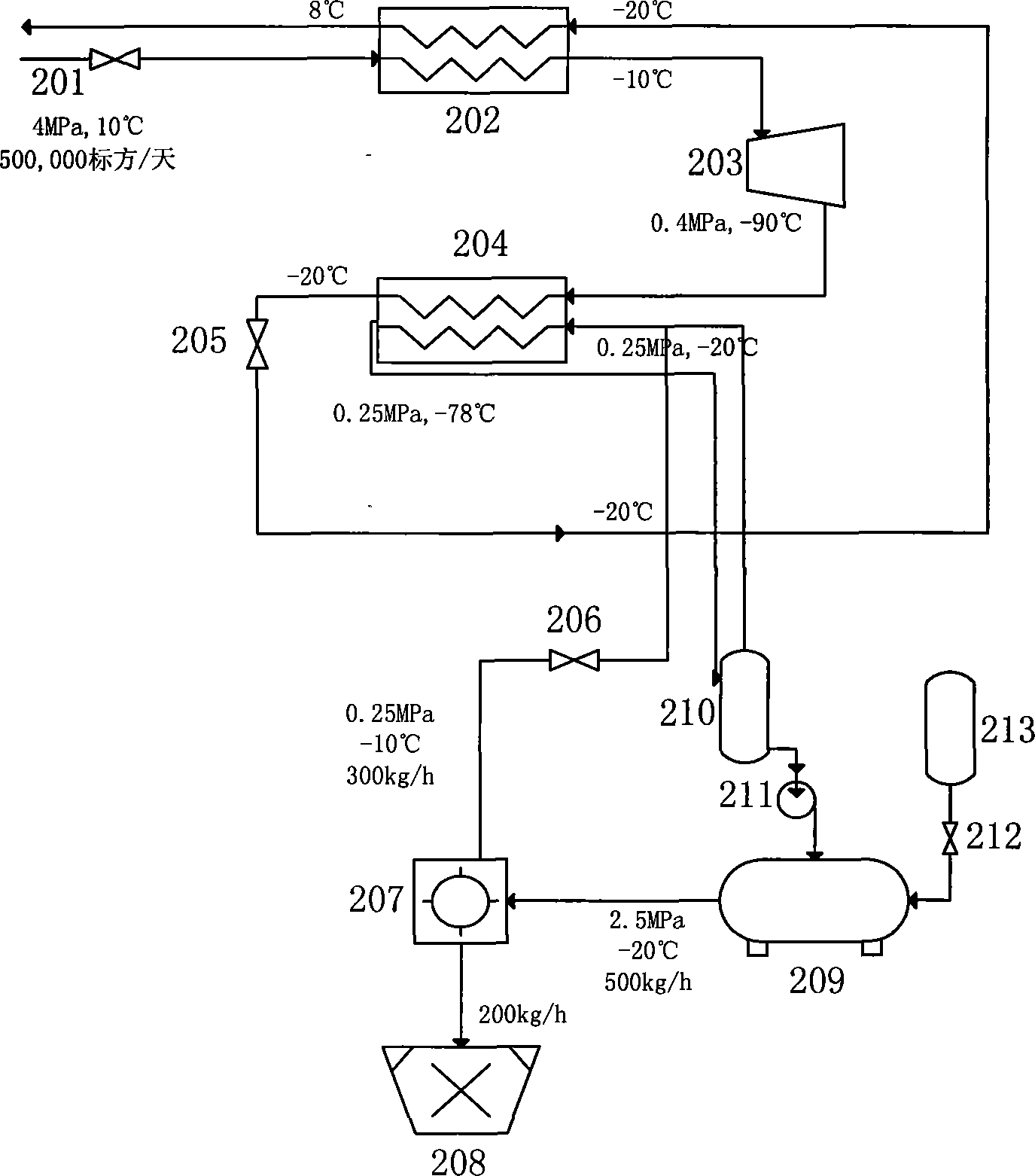

Method for utilizing pressure energy of natural gas

InactiveCN101245956AImprove utilization efficiencySimple processing technologyCompression machinesStationary plate conduit assembliesWaste rubberEngineering

The invention discloses a method which utilizes natural gas pressure energy; namely, the pressure and the temperature of the natural gas in a high pressure pipeline are reduced by a no-power refrigerator so as to gain low temperature natural gas which then exchanges the heat with a normal-temperature refrigerant which is sent by a normal-temperature tank; the low temperature refrigerant with temperature reduced enters a refrigerant storage tank for standby and is finally delivered to a cold energy user; the normal-temperature natural gas with temperature increased enters the pipeline. The method which utilizes natural gas pressure energy has convenient and practical whole process technique and high efficiency, spends little investment on the self-pressure energy in the pressure reduction process of the high pressure natural gas which is recovered by a pressure modulating station, converts the pressure energy into the cold energy with low operation cost, leads the cold energy to be used by cold quantity users of cold storages, cold water air conditioners, wasted rubber deep-cold crushing round the pressure modulating station by means of the refrigerant, etc., or to be made into ice blocks and dry ice products for abroad sale, etc., thus gaining huge economic benefits, improving the utilization ratio of the energy resource and eliminating the safe hidden trouble which is generated by sudden coolness of the equipment in the normal pressure modulating process.

Owner:GUANGZHOU GAS

Amido-containing ionic liquid used for absorbing acidic gases and preparation method and application thereof

ActiveCN101993378ASynthetic raw materials are cheap and easy to obtainLow costDispersed particle separationSulfonic acids salts preparationPressure reductionIonic liquid

The invention provides an amido-containing ionic liquid used for absorbing acidic gases and a preparation method and application thereof and in particular relates to a method for absorbing acidic gases of CO2, H2S, SO2 and the like by using an amido-containing ionic liquid. The amido-containing ionic liquid comprises one or more of primary amine, secondary amine and tertiary amine, wherein positive ions of the ionic liquid are derived from organic polyamines, negative ions of the ionic liquid are derived from inorganic acid or organic acid, and the ionic liquid is prepared by mixing the organic polyamines with the inorganic acid or organic acid and then carrying out neutralization reaction through acid and alkali. The ionic liquid has the advantages of low cost, simple preparation method,strong absorbing capability and short balance time, can be used for the enriching of acidic gases, the deacidification refining of acid-containing gases of natural gas, refinery gas, methane, coal gas, synthesis gas, coke-oven gas, pyrolysis gas, smoke, motor vehicle tail gas and the like and the purification of gases under a proper space and an operating environment; meanwhile, the ionic liquid absorbing the acidic gases can release the acidic gases through pressure reduction and temperature raise, thus the absorbing capability of the ionic liquid is restored and the multiple absorption property of the ionic liquid is better.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

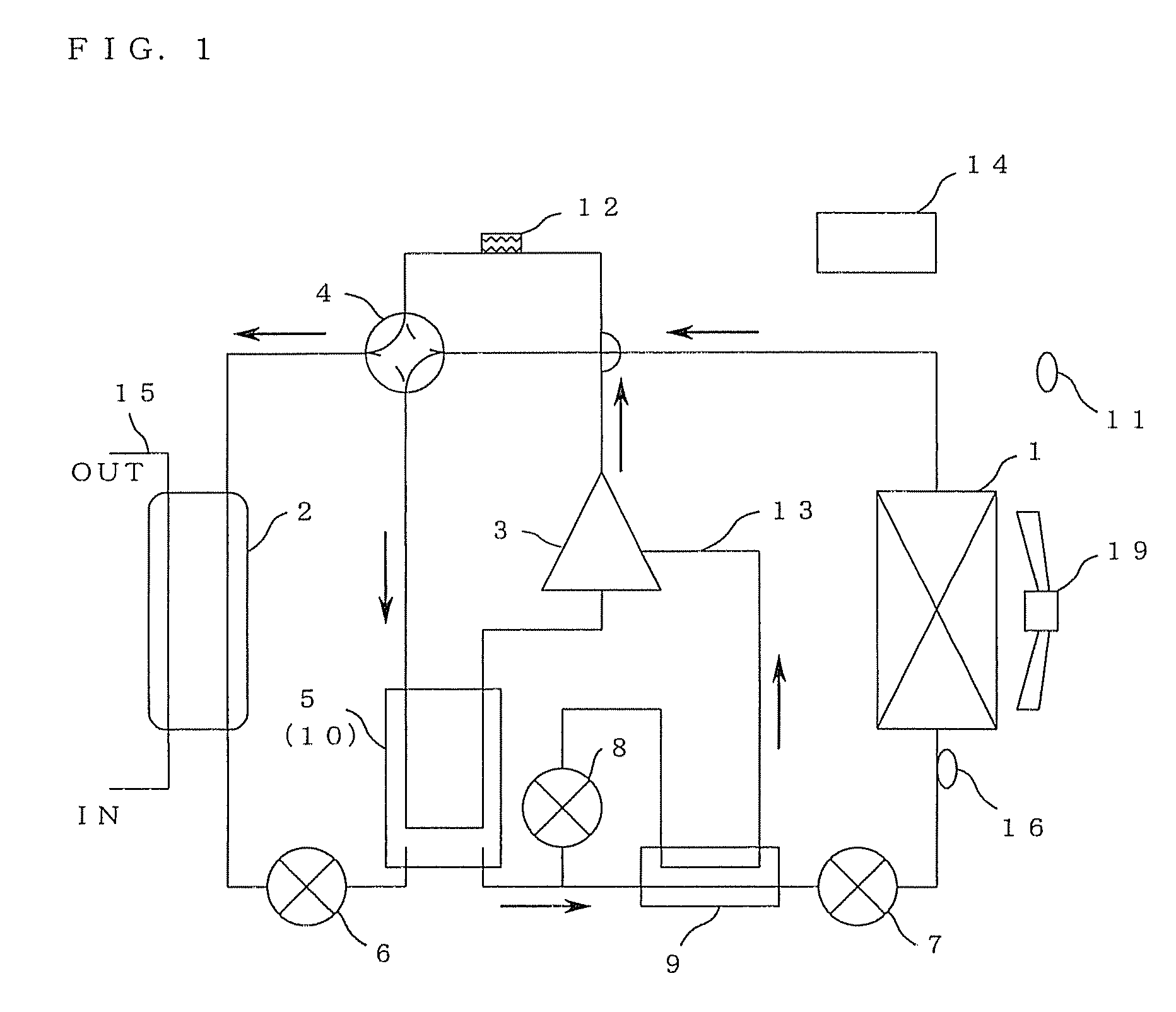

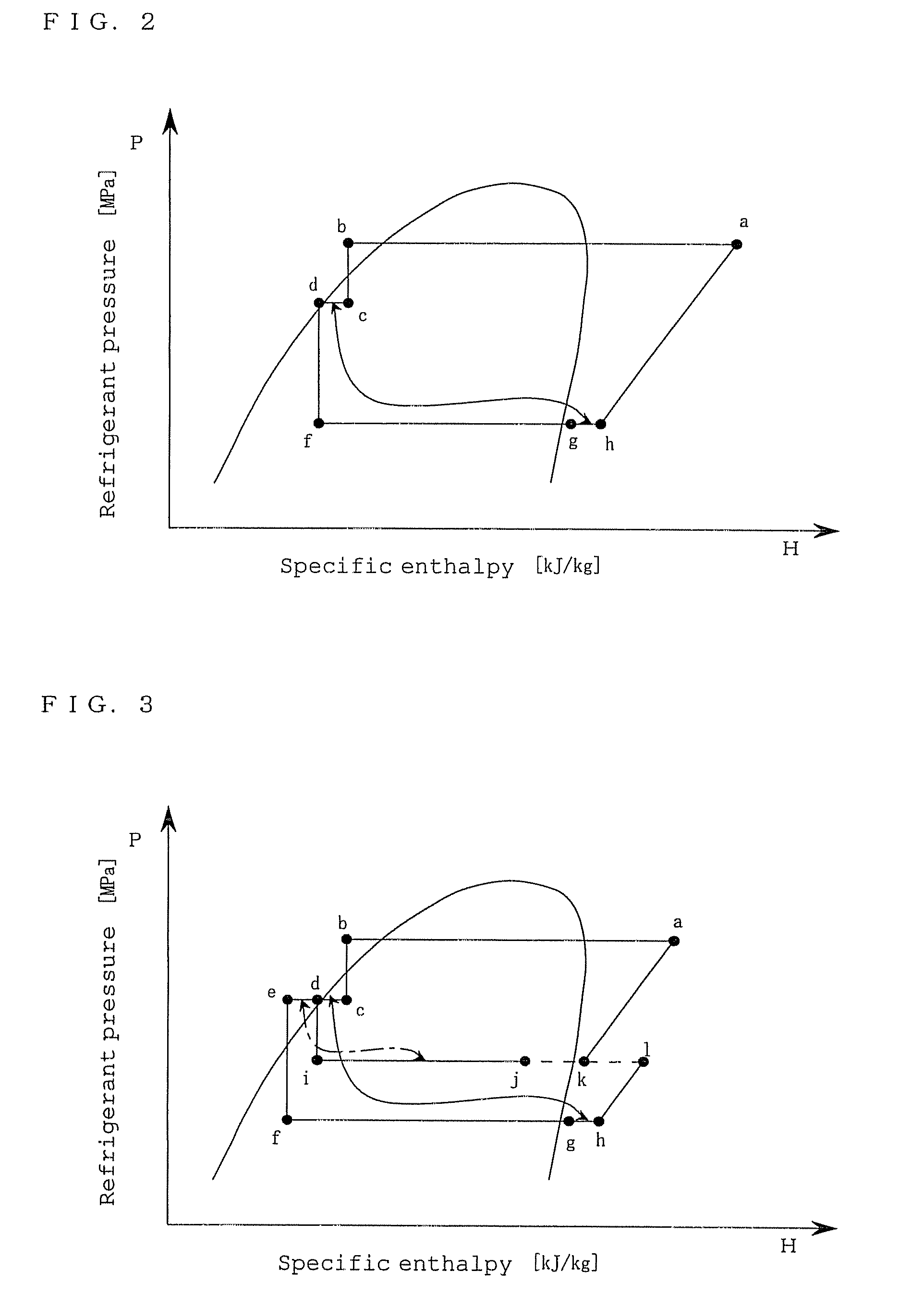

Heat pump type hot water supply outdoor apparatus

ActiveUS20090241569A1High hot water supply/heating capabilityHighly effective hot water supply/heating operationMechanical apparatusCompression machines with non-reversible cyclePlate heat exchangerCondensation temperature

A heat pump type hot water supply outdoor apparatus, in a compressor, a water heat exchanger, a first expansion valve, a medium pressure receiver, a second expansion valve, and an air heat exchanger are connected circularly, has an injection circuit, which is a bypass for a part of the refrigerant between the medium pressure receiver and the second pressure reduction unit, to inject the part of refrigerant into a compression chamber of the compressor, and has a third expansion valve and an internal heat exchanger for carrying out heat exchange between the refrigerant whose pressure is reduced by the third expansion valve and the refrigerant between the medium pressure receiver and the second expansion valve, a pressure detection sensor for detecting a condensing pressure, and a controller for starting an injection control by the third expansion valve at the time when the condensing pressure detected by the pressure sensor or the condensing temperature calculated from the condensing pressure becomes a first predetermined value or more and stopping the injection control at the time when the condensing pressure or the condensing temperature becomes a second predetermined value which is smaller than the first predetermined value, or less. With this arrangement, an appropriate injection control can be realized and a high hot water supply / heating capability operation can be carried out.

Owner:MITSUBISHI ELECTRIC CORP

Method and apparatus for reducing pressure in a perforating gun

InactiveUS7121340B2Stress minimizationReduce gas pressureConstructionsAmmunitionDetonationEngineering

Owner:SCHLUMBERGER TECH CORP

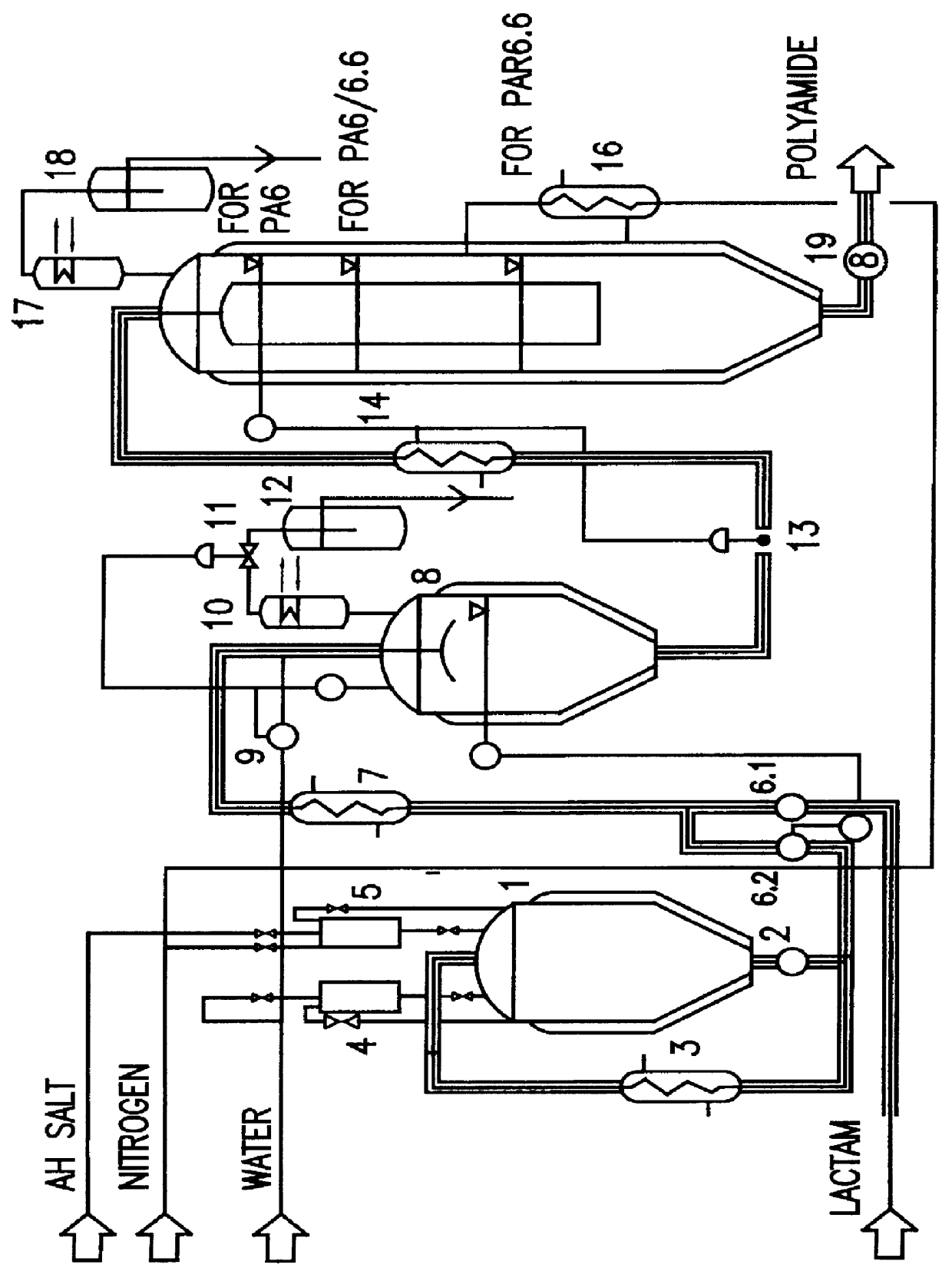

Process and device for the standardized continuous production of polyamides

InactiveUS6136947AHigh viscosityOvercome disadvantagesChemical recyclingHexamethyldiamineHexamethylenediamine

PCT No. PCT / EP96 / 05514 Sec. 371 Date Nov. 13, 1998 Sec. 102(e) Date Nov. 13, 1998 PCT Filed Dec. 10, 1996 PCT Pub. No. WO90 / 21758 PCT Pub. Date Jun. 19, 1997A process and device for the standardised continuous production of polyamide 6, polyamide 6.6 and / or copolyamides from e-caprolactam and / or adipic acidic hexamethylenediamine or adipic acid and hexamethylenediamine uses a combination of known specific processes to design a polymerisation reactor in which product with sufficiently high quality can be produced with the most efficient possible use of the energy applied and in such a way that the initial substances can be used alternately in the individual processing stages: pre-heating of the initial products using a common heat exchanger to 190-300 DEG C.; polymerisation of the initial products in a pressure stage with or without elimination of water and product recycling at 150-280 DEG C. and a pressure of <20 bar, dewatering of the polymer melt in a one to five turn coil under slow pressure reduction; and final condensation of the melt in at least one common vertical reactor at temperatures of between 210 and 285 DEG C.

Owner:POLYMER ENG

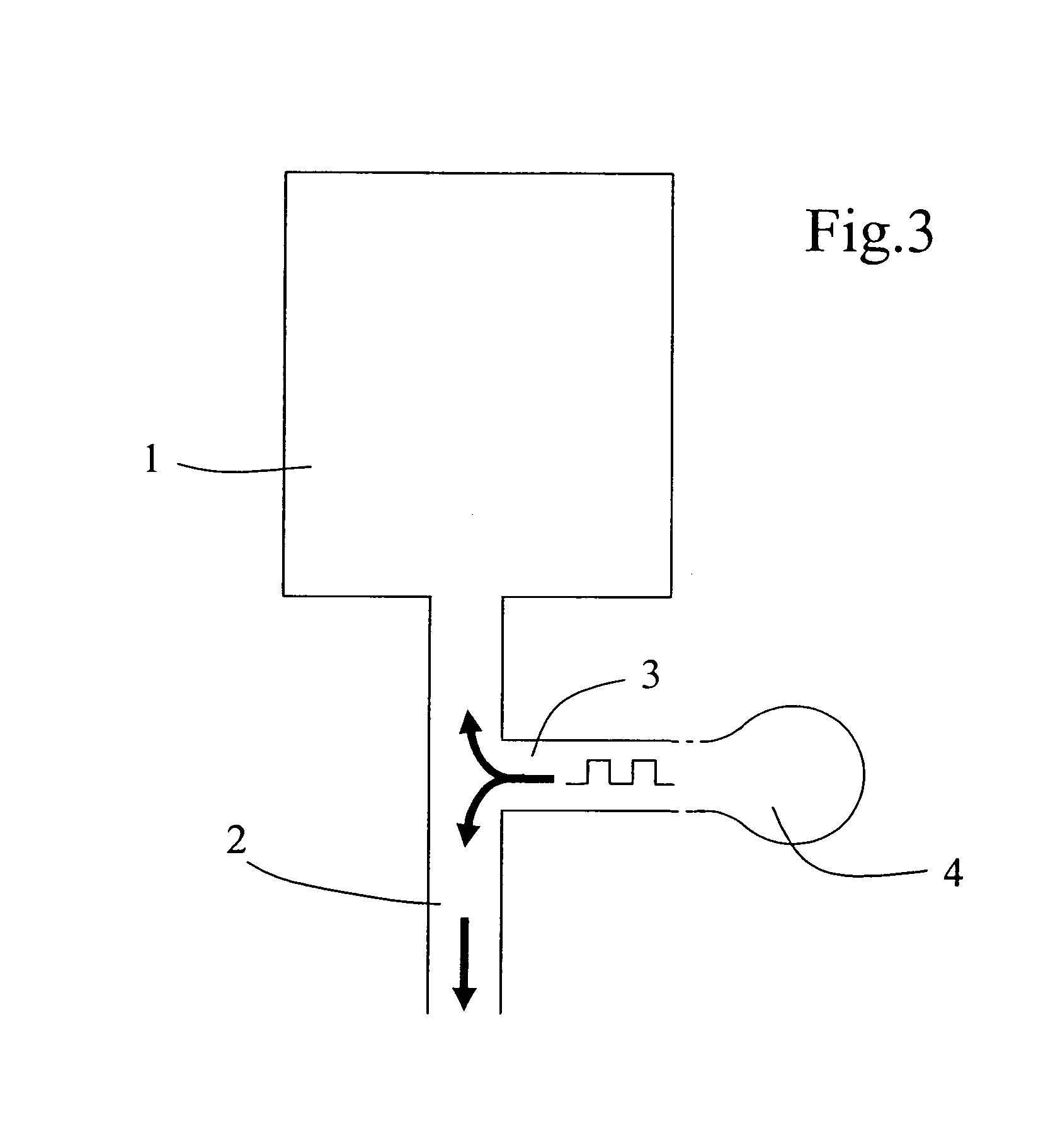

Surge pressure reduction apparatus with volume compensation sub

InactiveUS20030136563A1Promote circulationEasy to operateFluid removalFlushingOcean bottomWell drilling

A method and apparatus for use in the oil well industry for running in drilling / production liners and sub-sea casings down a borehole on a drill pipe using a running tool with the benefits of surge pressure reduction are disclosed. A surge pressure reduction tool in accordance with the present invention includes a diverter device having a set of flow holes which diverter device can be shifted between a "surge pressure reduction" mode and a "cementing" or "circulation" mode. A tool in accordance with the present invention further includes a volume compensation device which enables the diverter device to shift axially downward into the cementing or circulation mode even where the drilling / production liner or sub-sea casing is plugged with drill cuttings or downhole debris. In the cementing / circulation mode, a flow path is established for cement / drilling fluid to flow downward from the drill pipe, through the diverter device, volume compensation device, and running tool, and out into the borehole via the drilling / production liner or sub-sea casing. In the surge pressure reduction mode, an alternative flow path is established for drilling fluid to flow upward from the borehole into the drilling / production liner or sub-sea casing, through the running tool and volume compensation device, and into an annulus between the drill pipe and the borehole via the set of flow holes of the diverter device.

Owner:FRANKS INT +1

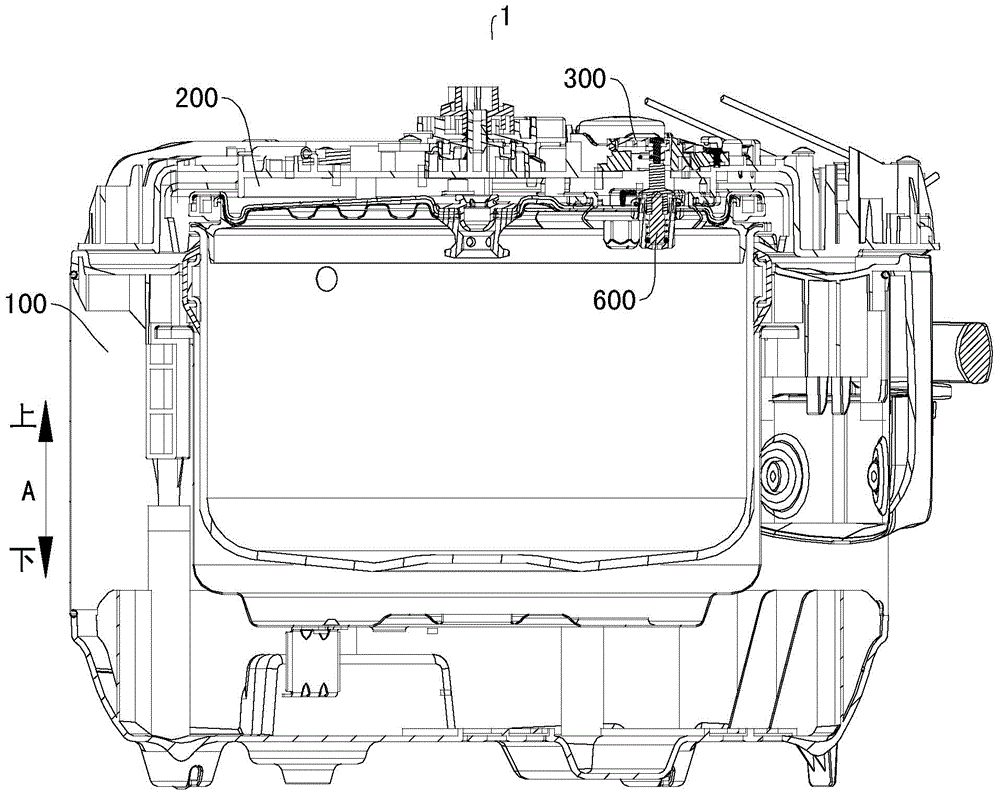

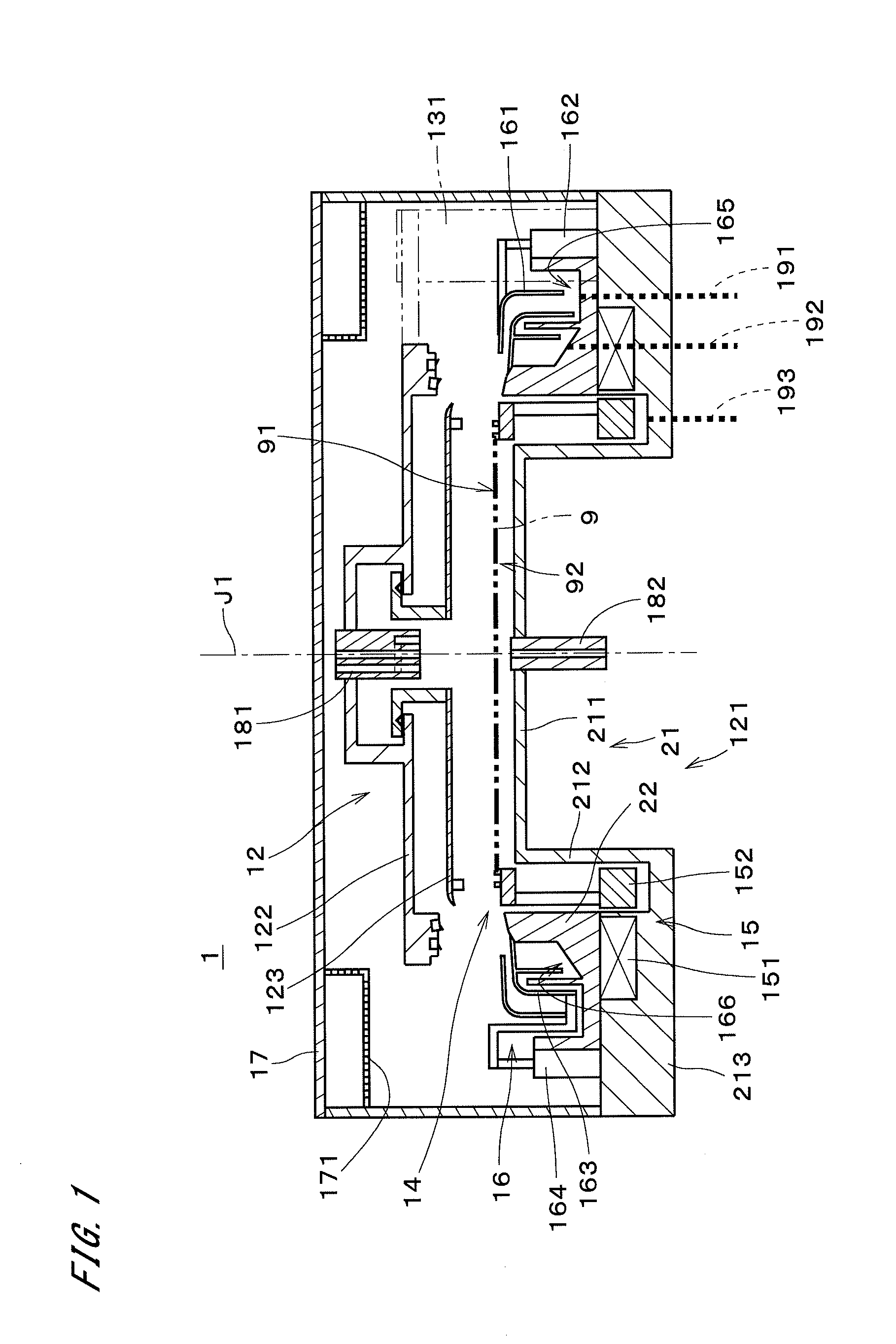

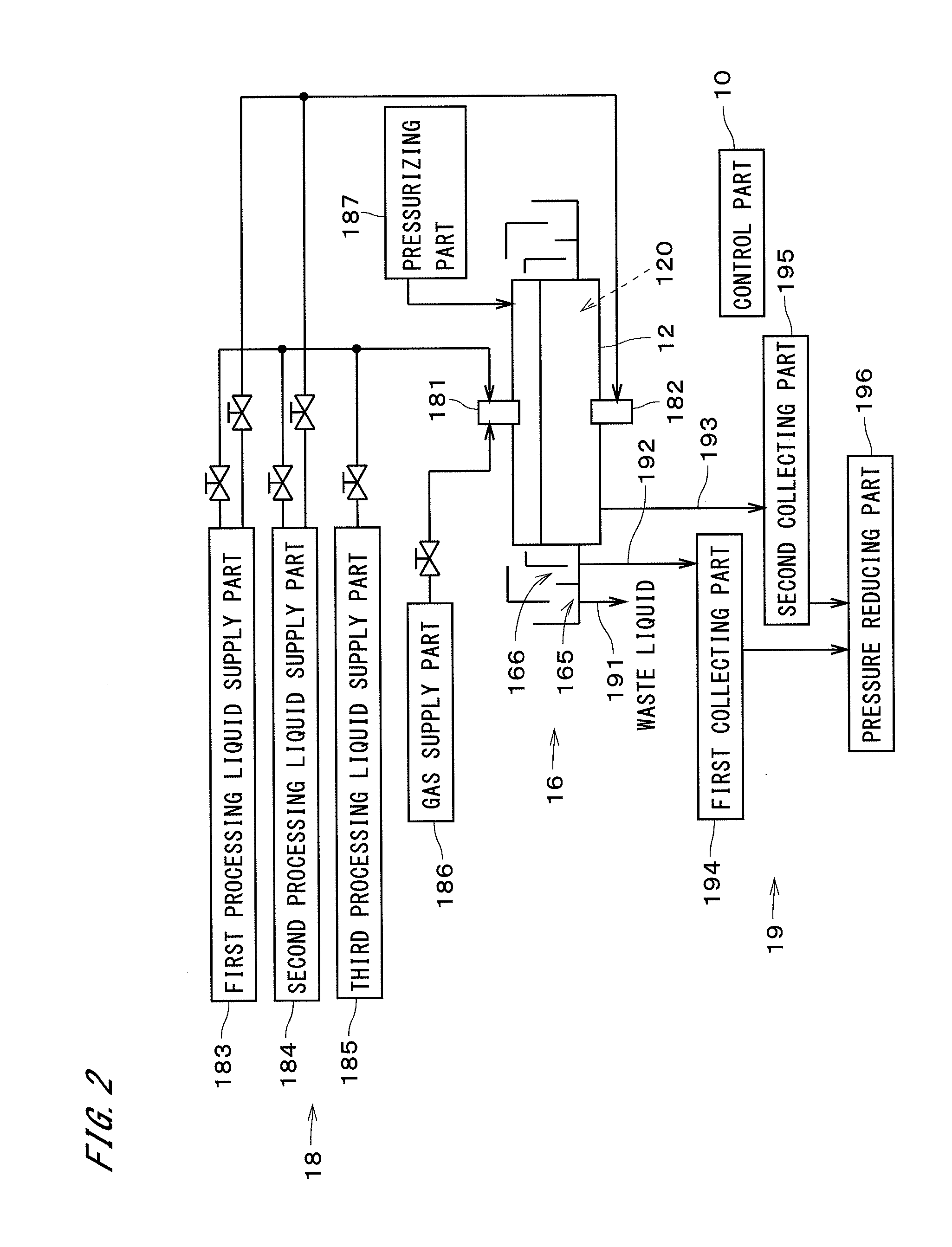

Substrate processing apparatus

ActiveUS20140060423A1Improve efficiencyProcess is performedLiquid surface applicatorsSpraying apparatusEngineeringPressure reduction

A substrate processing apparatus includes a chamber, a substrate holding part, a substrate rotating mechanism, a liquid receiving part, and an upper nozzle. The chamber includes a chamber body and a chamber cover, and the chamber cover is moved up and down. While the chamber cover is in contact with the chamber body, a small sealed space is formed and some processings involving pressure reduction or pressurization are performed. When the chamber cover is moved up, an annular opening is formed between the chamber cover and the chamber body. On an outer side relative to the annular opening, positioned are a first cup part and a second cup part. A processing liquid spattering from a substrate is received by the first cup part or the second cup part. In the substrate processing apparatus, it is possible to perform various processings in the small chamber.

Owner:DAINIPPON SCREEN MTG CO LTD

Simplified Cleaning And Filling Device

ActiveUS20070287125A1Simple processSmall batchHollow article cleaningWheelchairs/patient conveyanceEngineeringPressure reduction

Device for difficult intervention in a closed enclosure, comprising a duct, a first end of which is intended to penetrate within the chamber, the duct being furthermore connected: to a pressure reduction means, the function of which is to lower the pressure within the enclosure; to an outlet duct for extracting the sucked-up material; and to a duct connected to a device for suddenly relieving the pressure and to an opening in the device for bringing the end of the duct into contact with the external air when the pressure within the enclosure reaches a value below a certain threshold.

Owner:WEILL DAVID

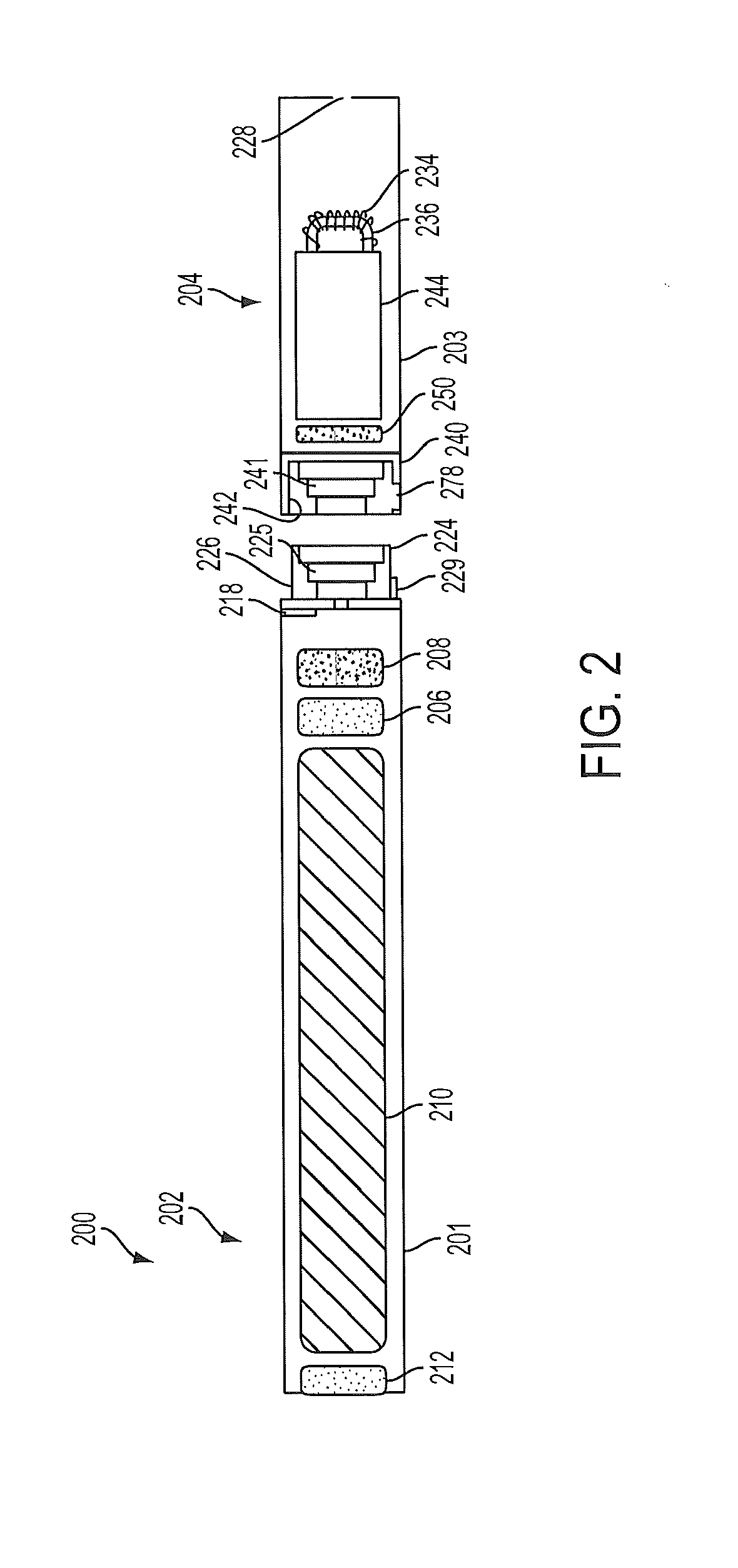

Control body for an electronic smoking article

ActiveUS9839238B2Function increaseReduce and prevent passageTobacco devicesEngineeringPressure reduction

The present disclosure provides a control body adapted for use in an electronic smoking article. The control body includes a shell and a coupler that is adapted to connect the control body to a cartridge of an electronic smoking article. The coupler further is adapted to communicate a pressure reduction within the coupler to a pressure reduction space in the shell. Also positioned within the shell is an electronic circuit board having a pressure sensor attached thereto. The electronic circuit board can be positioned to be parallel to a central axis of the shell. A first end of the pressure sensor can be isolated within the pressure reduction space, and a second end of the pressure sensor can be in communication with a normal pressure space within the shell. One or more light emitting diodes can be attached to the electronic circuit board. At least a portion of the coupler can be light transmissive so that light from the LED is visible through the coupler.

Owner:RAI STRATEGIC HLDG INC

System and method for cooling a compressor motor

ActiveUS20050284173A1Improvement in motor coolingExcellent motor coolingCompressorPump componentsDecreased pressureAir compressor

Apparatus and methods are provided for cooling motors used to drive gas and air compressors. In particular, the cooling of hermetic and semi-hermetic motors is accomplished by a gas sweep using a gas source located in the low-pressure side of a gas compression circuit. The gas sweep is provided by the creation of a pressure reduction at the compressor inlet sufficient to draw uncompressed gas through a motor housing, across the motor, and out of the housing for return to the suction assembly. The pressure reduction is created by means provided in the suction assembly, such as a nozzle and gap assembly, or alternatively a venturi, located upstream of the compressor inlet. Additional motor cooling can be provided by circulating liquid or another cooling fluid through a cooling jacket in the motor housing portion adjacent the motor.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com