Patents

Literature

20343results about "Spraying apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible conduit with locking element

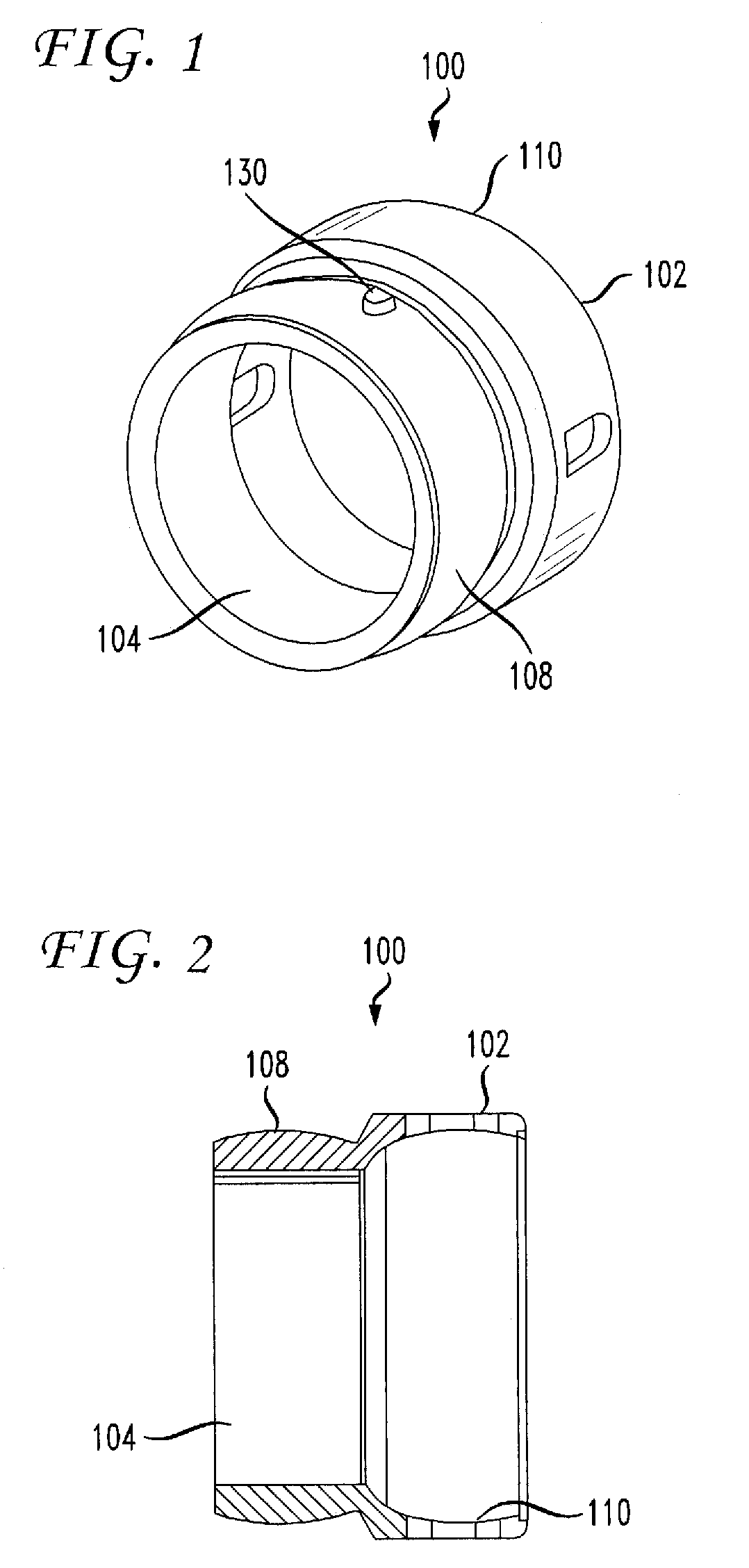

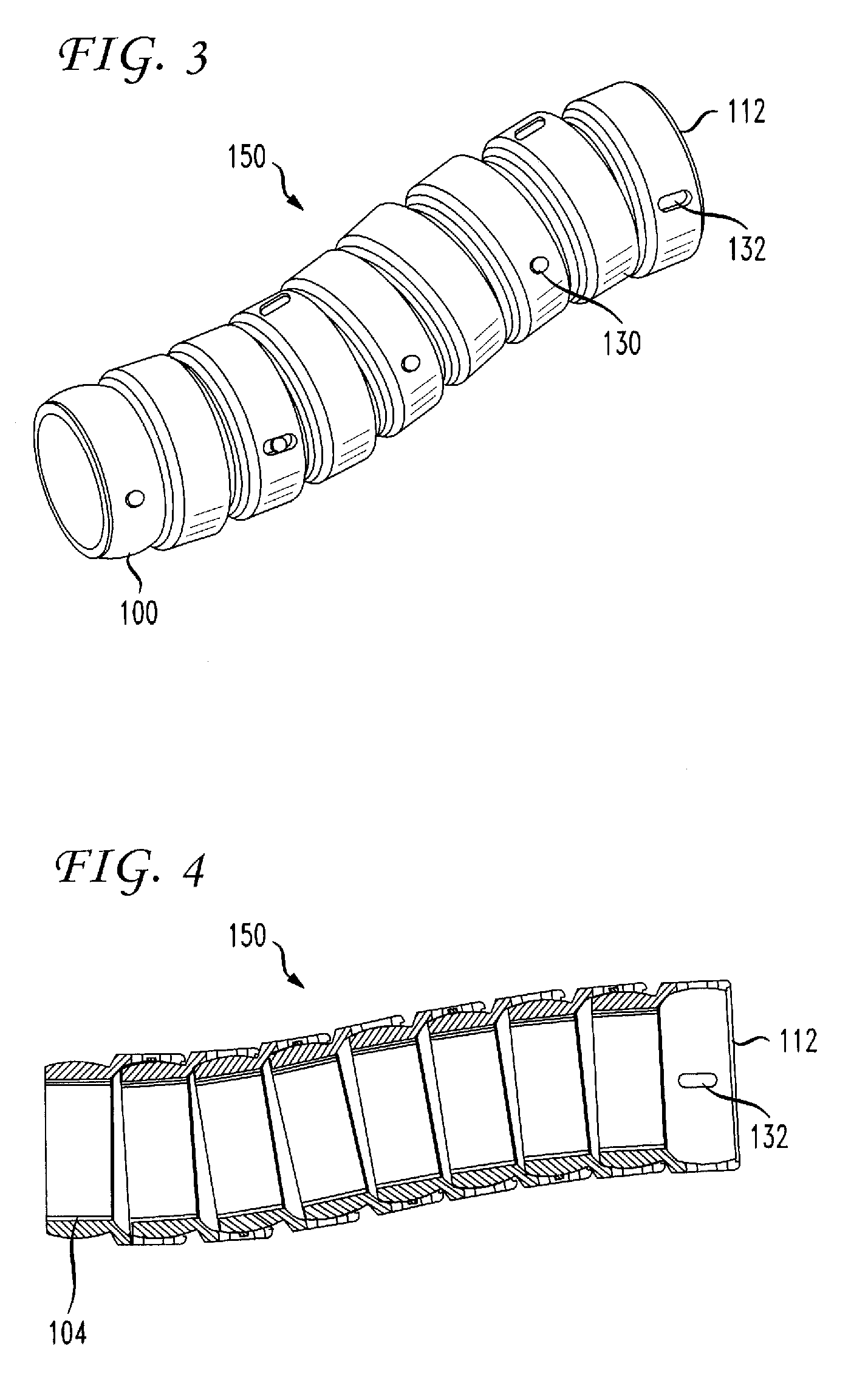

A flexible conduit for insertion into a body lumen comprises a plurality of elements coupled end to end to define a conduit lumen. A first one of the elements includes a male portion and a female portion. A second element includes a female portion having an inner surface configured to engage a male portion of an outer surface of the first element to form a first ball joint. A third element includes a male portion, an outer surface of the male portion of the third element configured to engage an inner surface of the female portion of the first element to form a second ball joint. The male and female portions of the first element are adapted to frictionally engage the female portion of the second element and the male portion of the third element to establish a rigid connection therebetween.

Owner:BOSTON SCI SCIMED INC

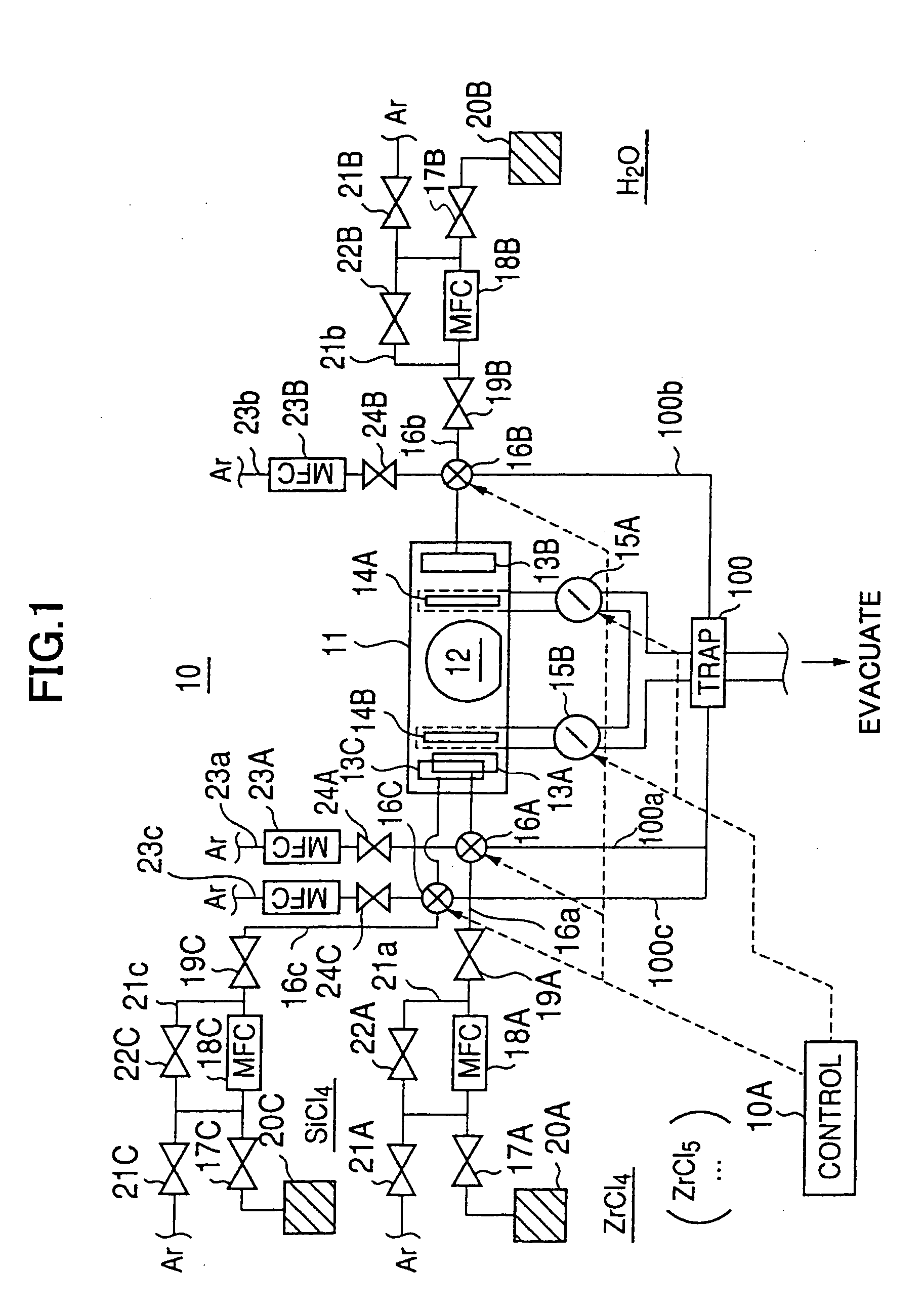

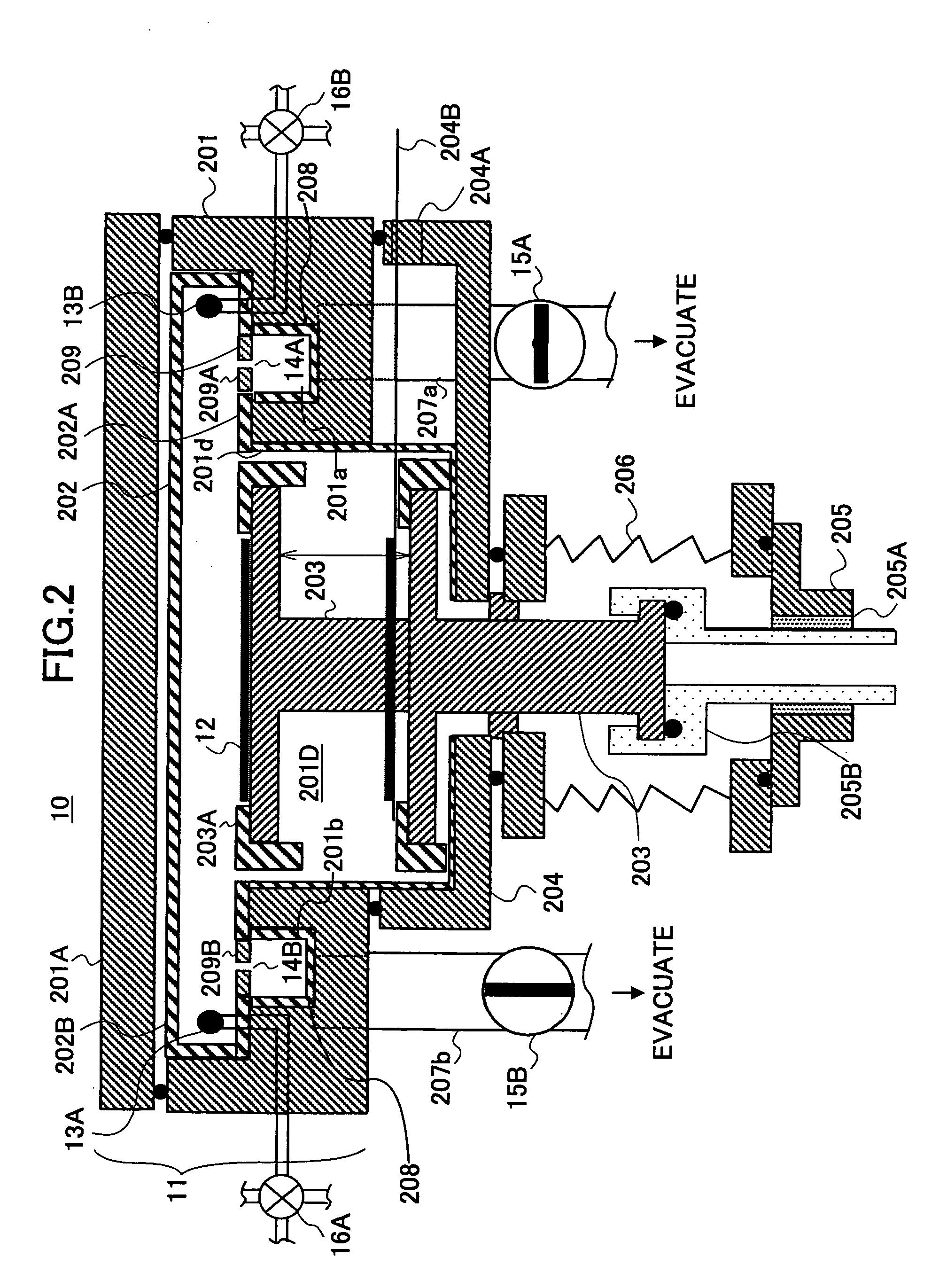

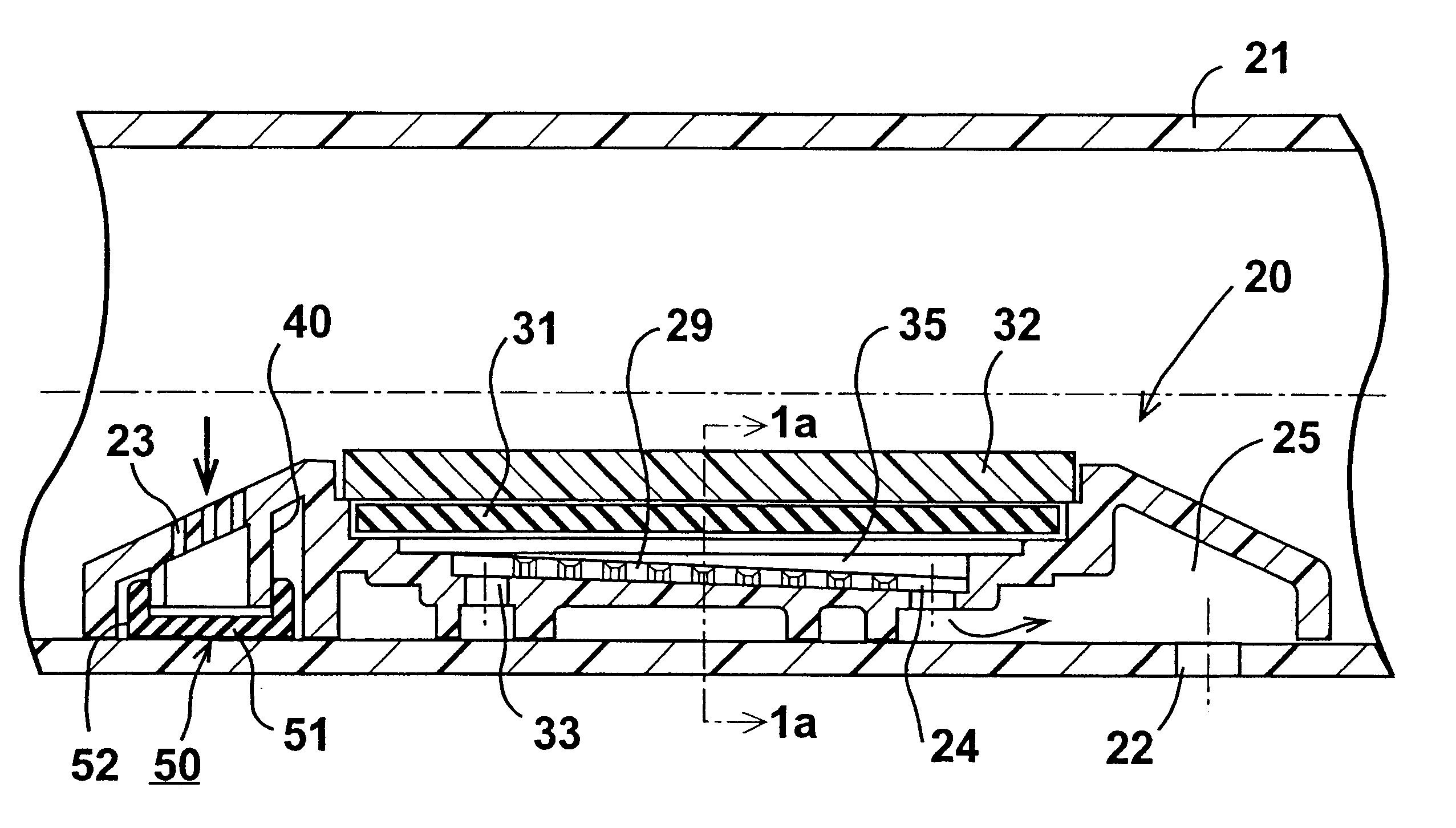

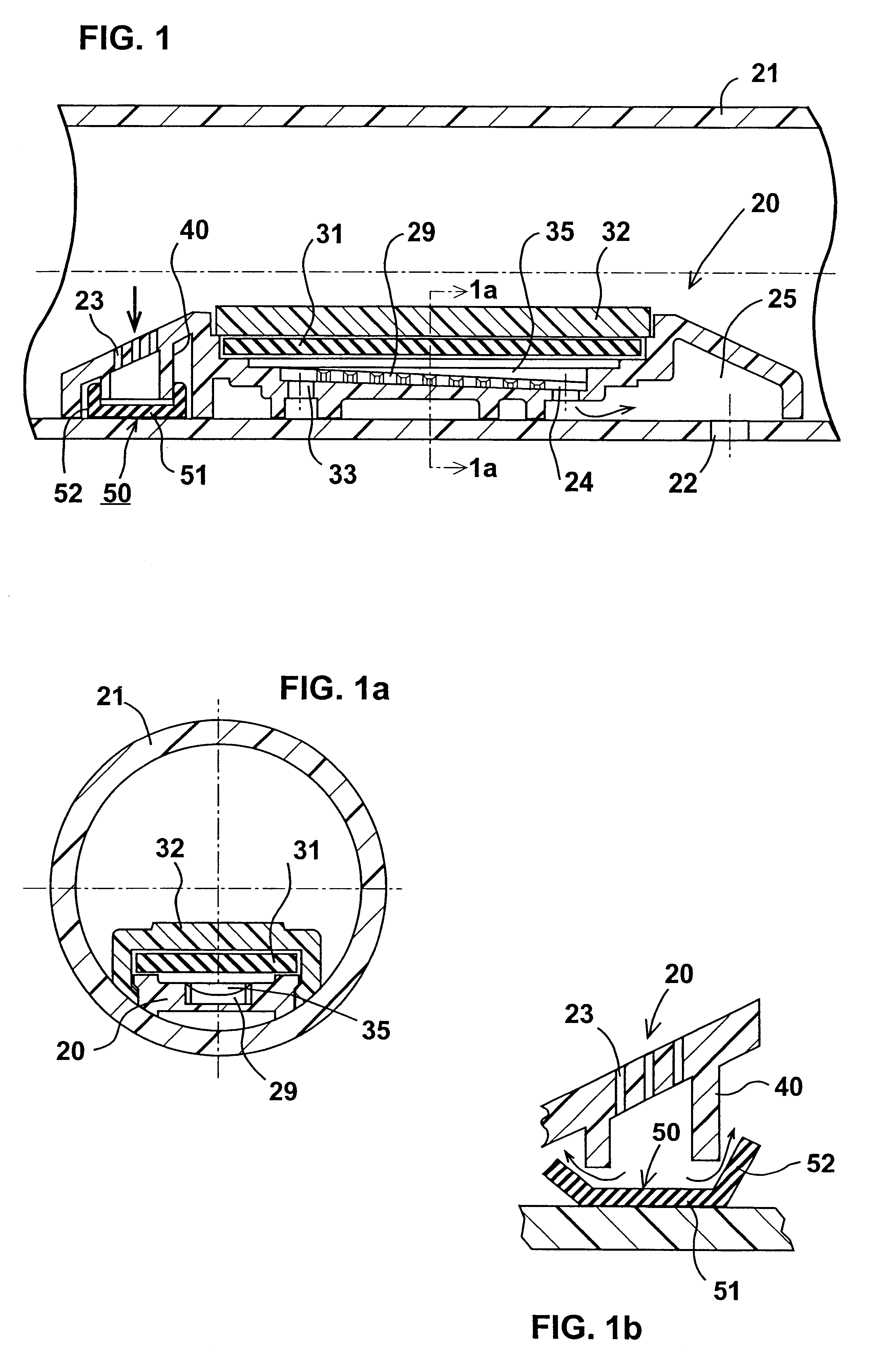

Substrate processing apparatus and substrate processing method, high speed rotary valve, and cleaning method

InactiveUS20050074983A1Increase speedFilm growth efficientlyPlug valvesLiquid surface applicatorsRotary valveEngineering

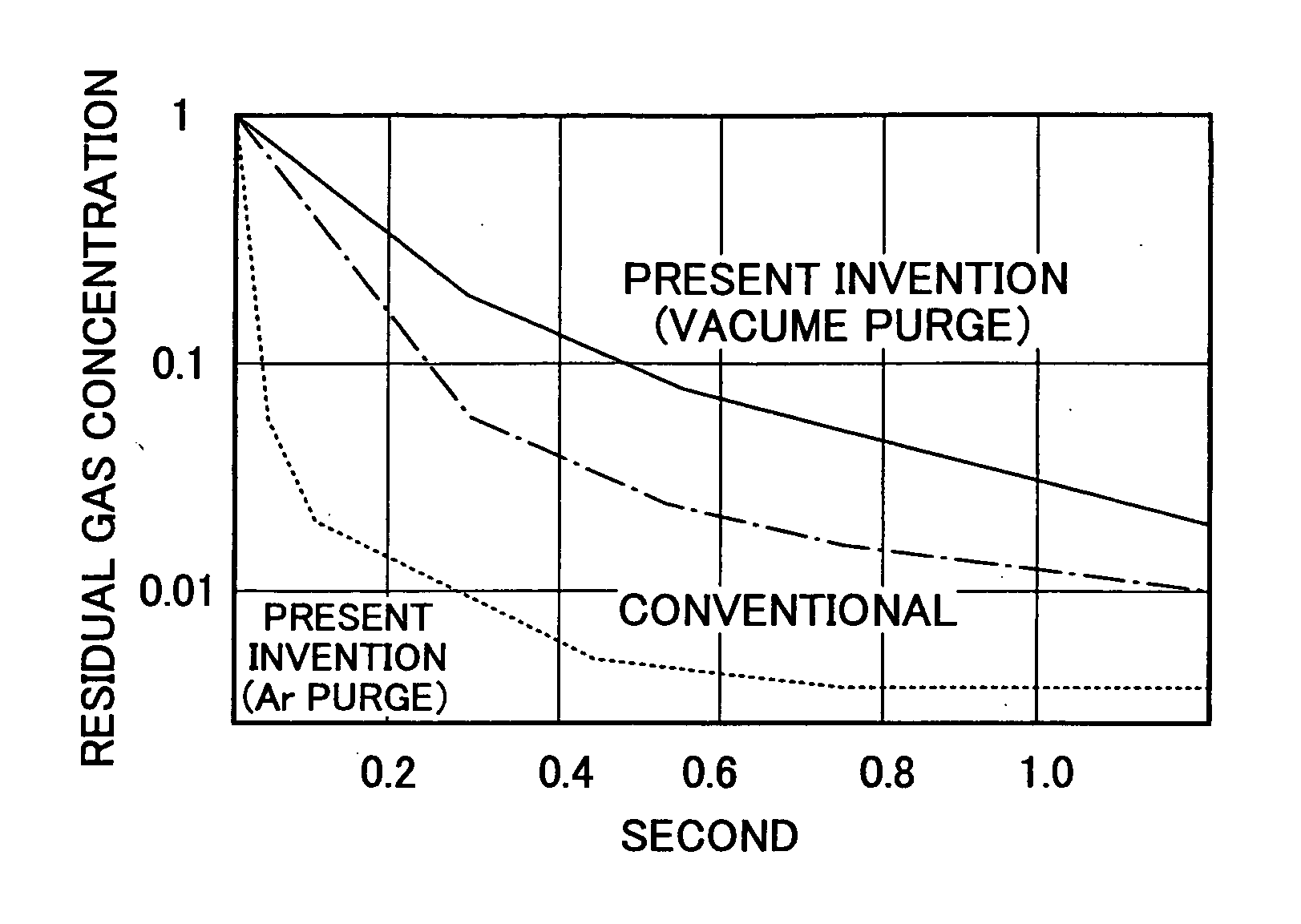

A substrate processing apparatus includes a processing vessel provided with a stage holding thereon a substrate to be processed and evacuated at an evacuation port, and a source gas supplying system that supplies plural source gases to the processing vessel separately in the form of a laminar flow, wherein the evacuation port has a slit-form shape extending in a direction generally intersecting perpendicularly to a direction of the laminar flow, the evacuation port is engaged with a valve having a valve body formed with a slit-form opening corresponding to the slit-form shape of the evacuation port, the slit-form opening being provided so as to cause a displacement with respect to the evacuation port in a direction generally intersecting perpendicularly to an extending direction of the evacuation port, the valve changing a degree of valve opening thereof via displacement of said slit-form opening.

Owner:TOKYO ELECTRON LTD

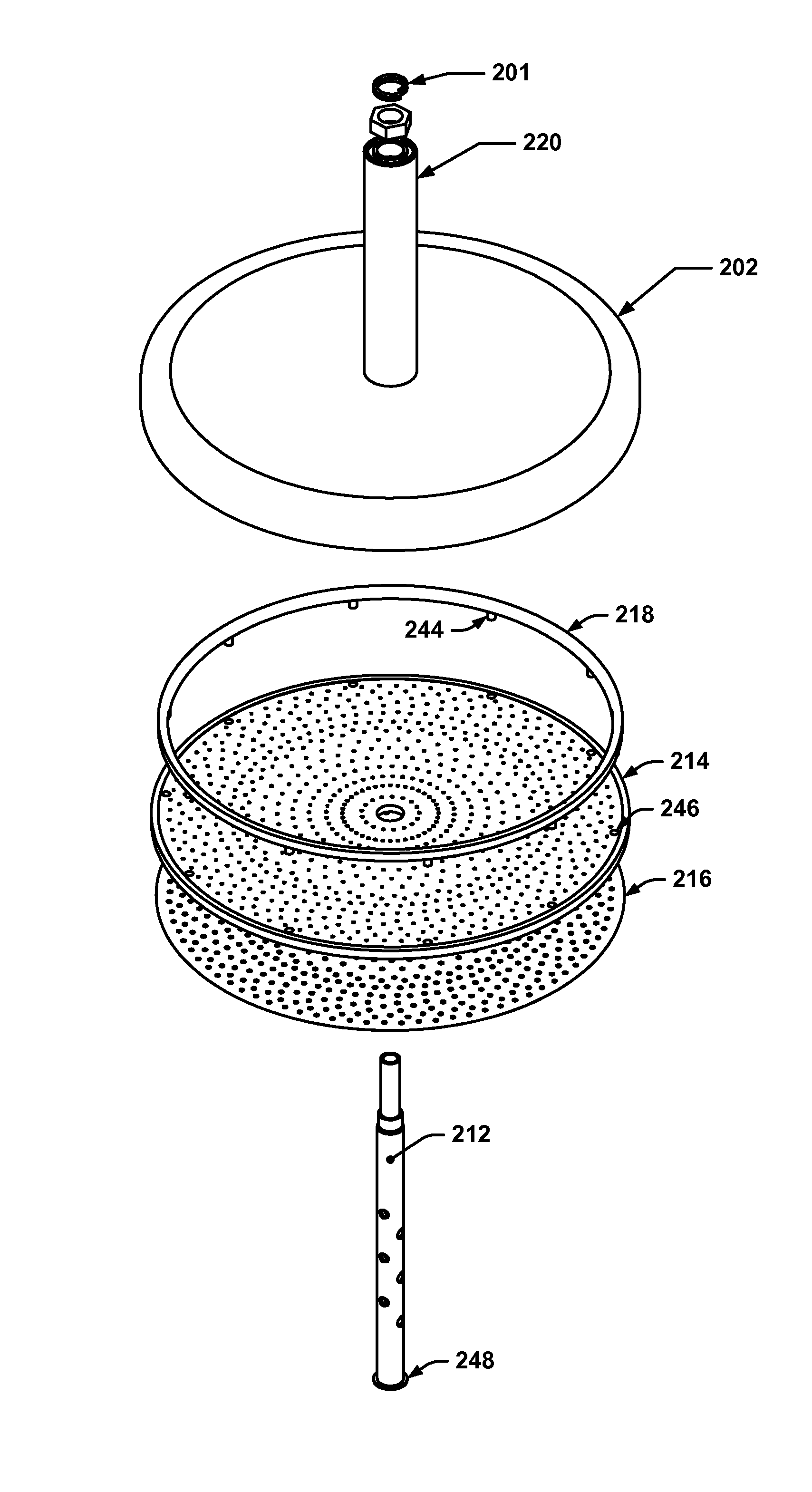

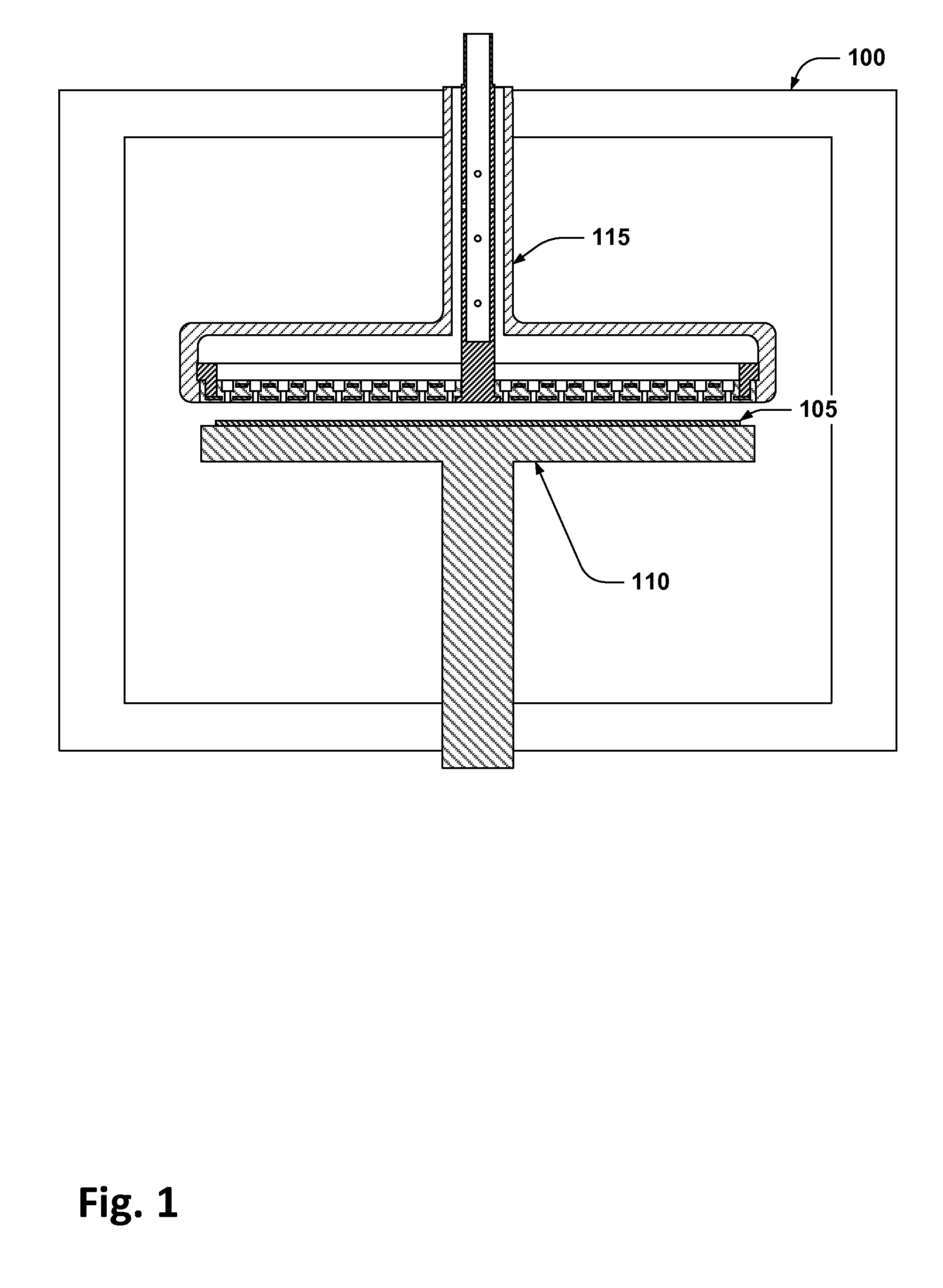

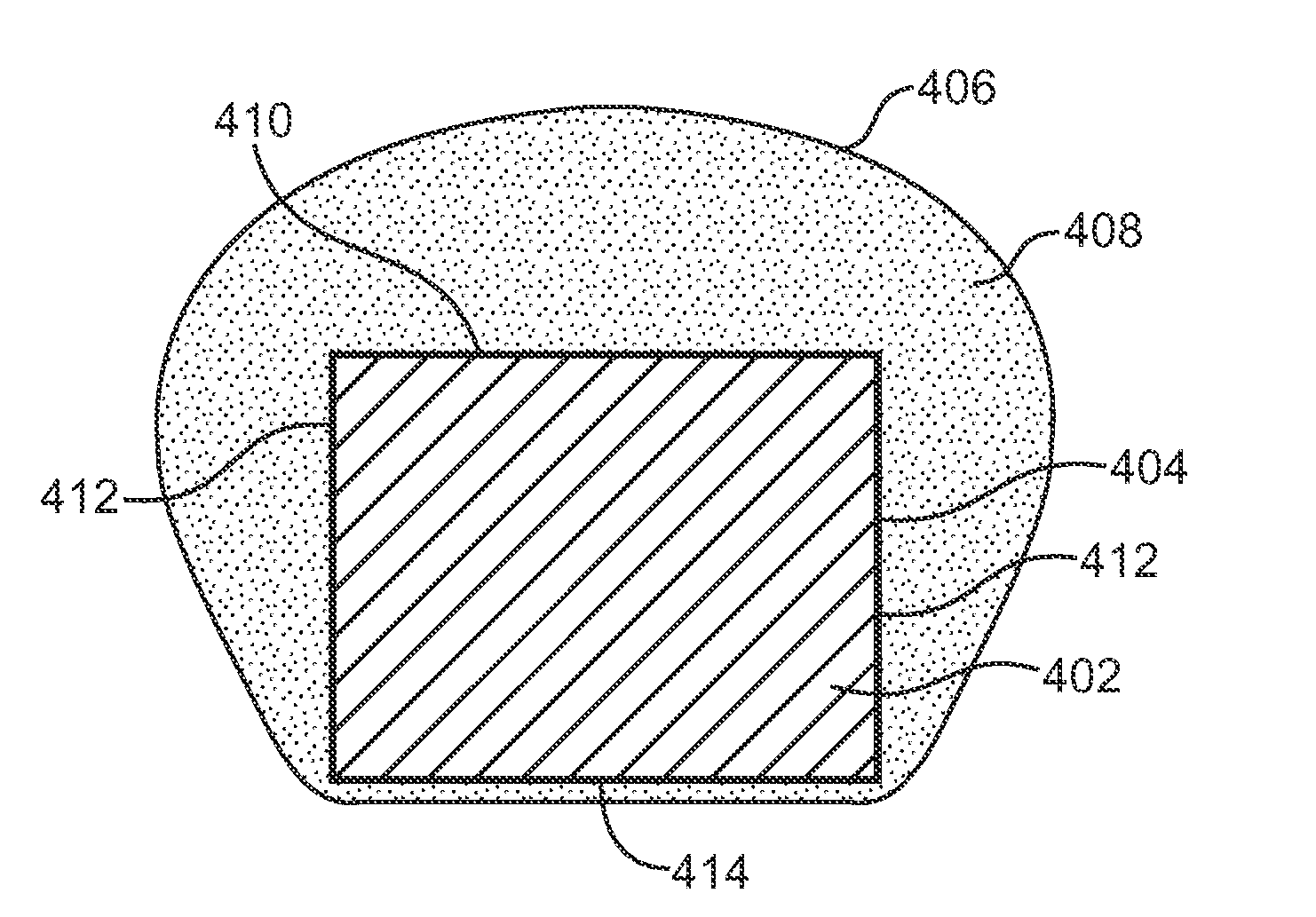

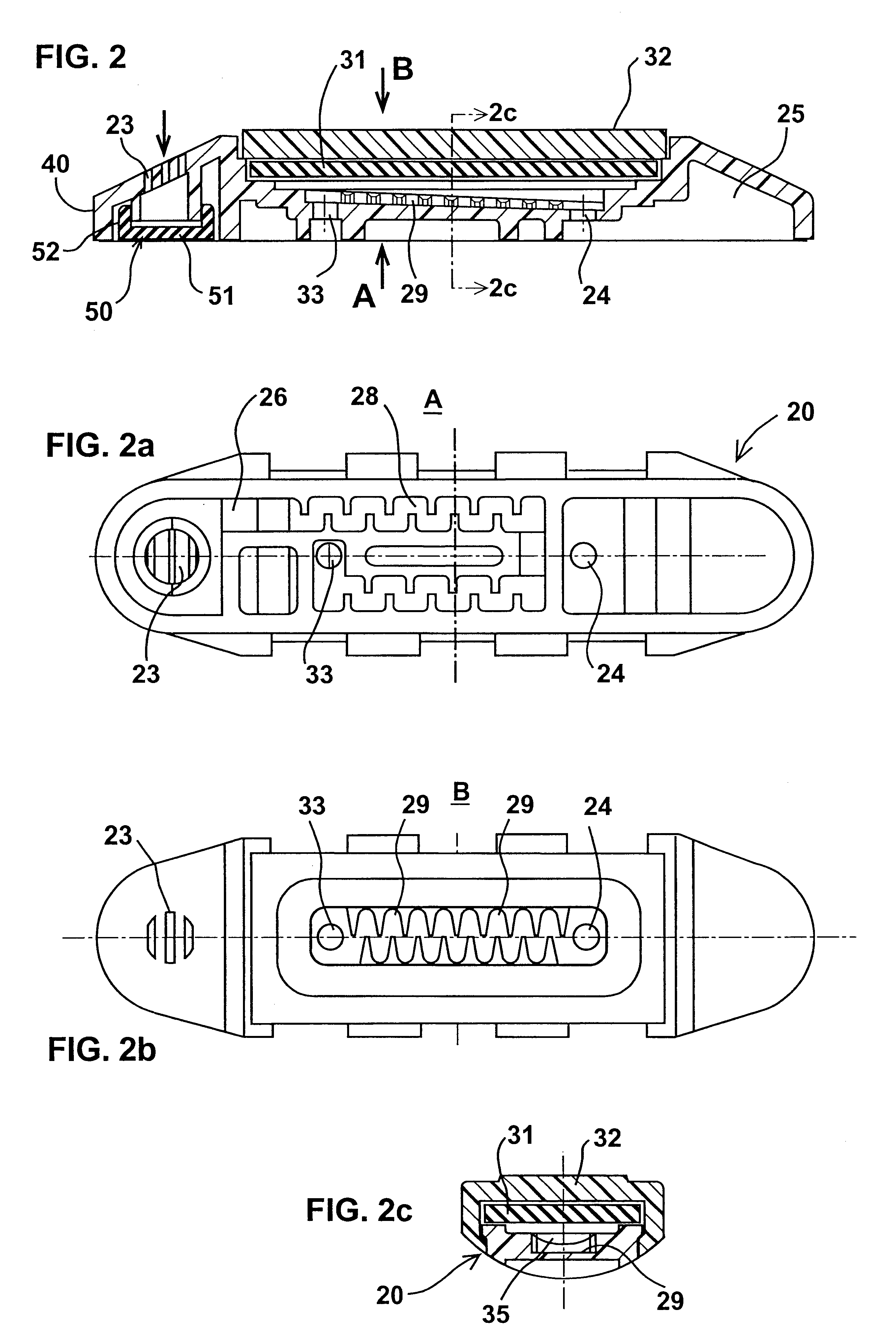

Hybrid ceramic showerhead

ActiveUS20120222815A1Large caliberSmall diameterSpraying apparatusSemiconductor/solid-state device manufacturingMetallurgyDc voltage

Various implementations of hybrid ceramic faceplates for substrate processing showerheads are provided. The hybrid ceramic showerhead faceplates may include an electrode embedded within the ceramic material of the faceplate, as well as a pattern of through-holes. The electrode may be fully encapsulated within the ceramic material with respect to the through-holes. In some implementations, a heater element may also be embedded within the hybrid ceramic showerhead faceplate. A DC voltage source may be electrically connected with the hybrid ceramic showerhead faceplate during use. The hybrid ceramic faceplates may be easily removable from the substrate processing showerheads for easy cleaning and faceplate replacement.

Owner:NOVELLUS SYSTEMS

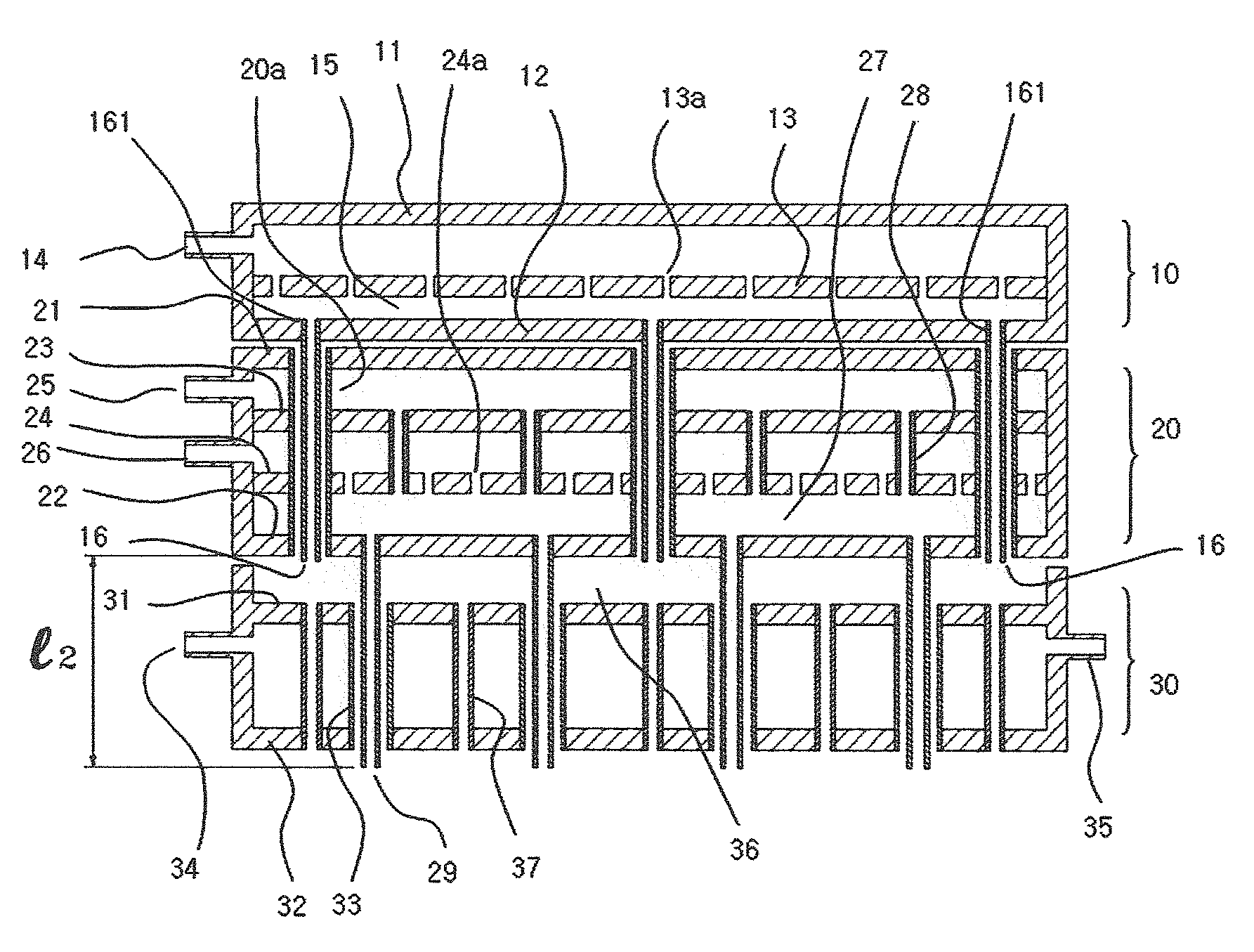

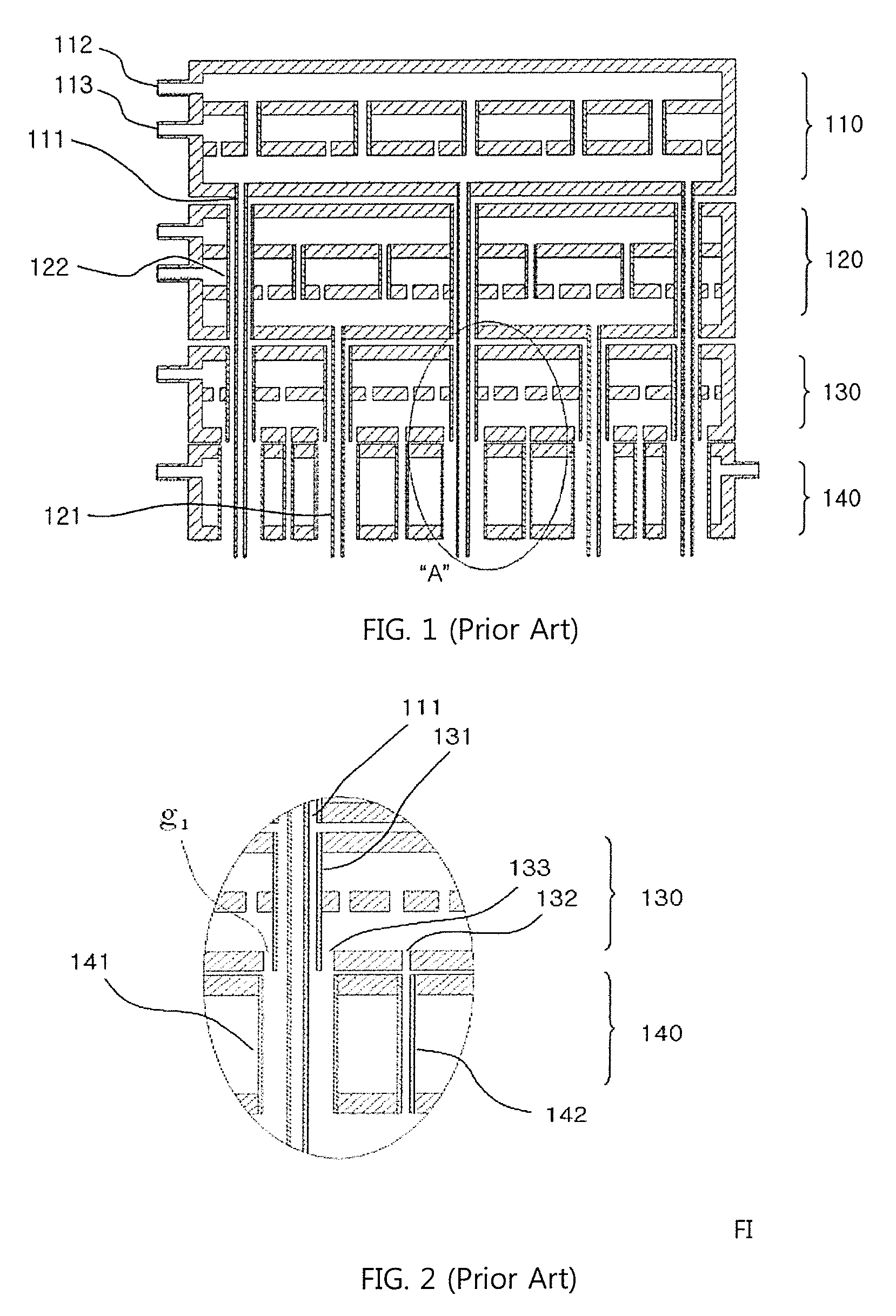

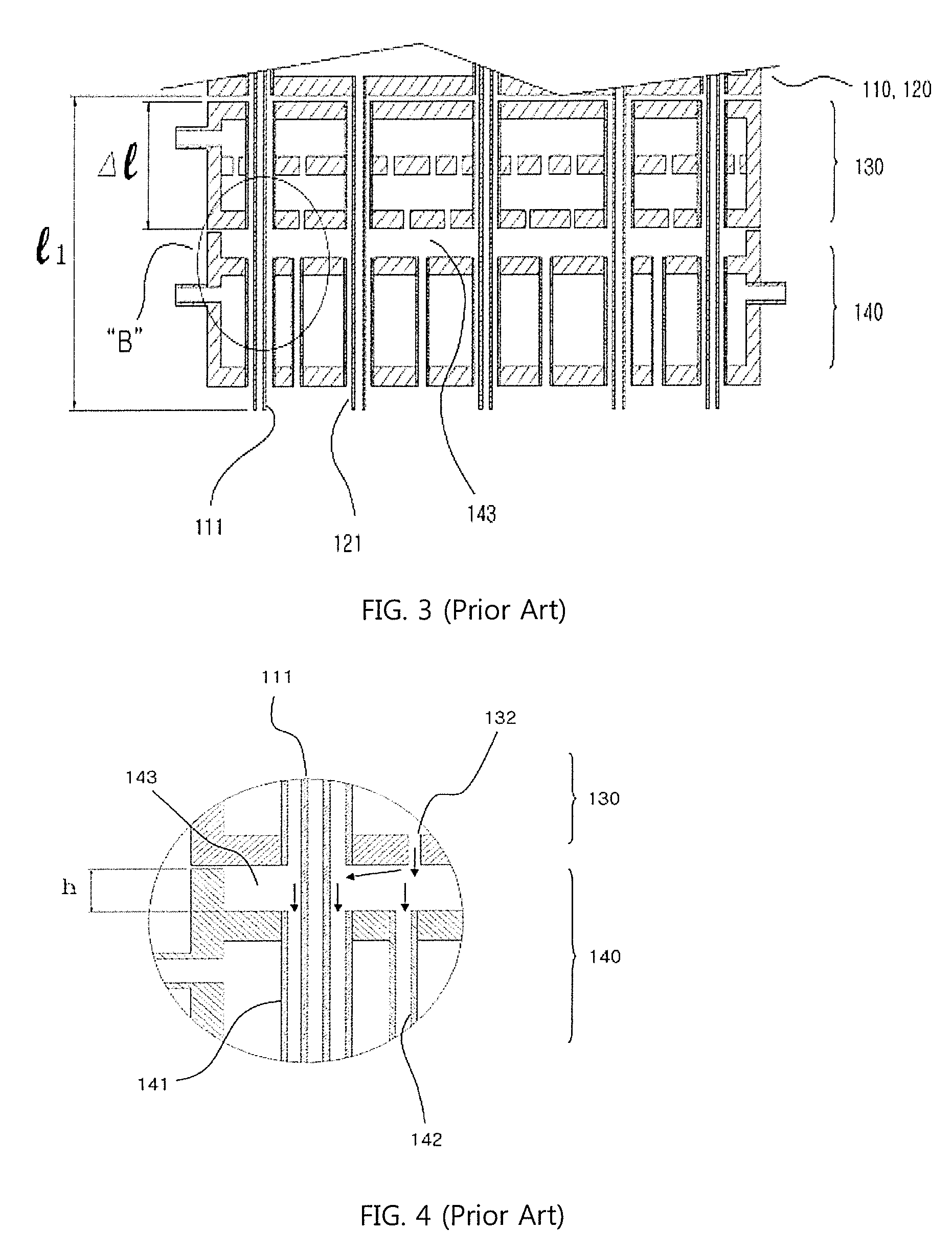

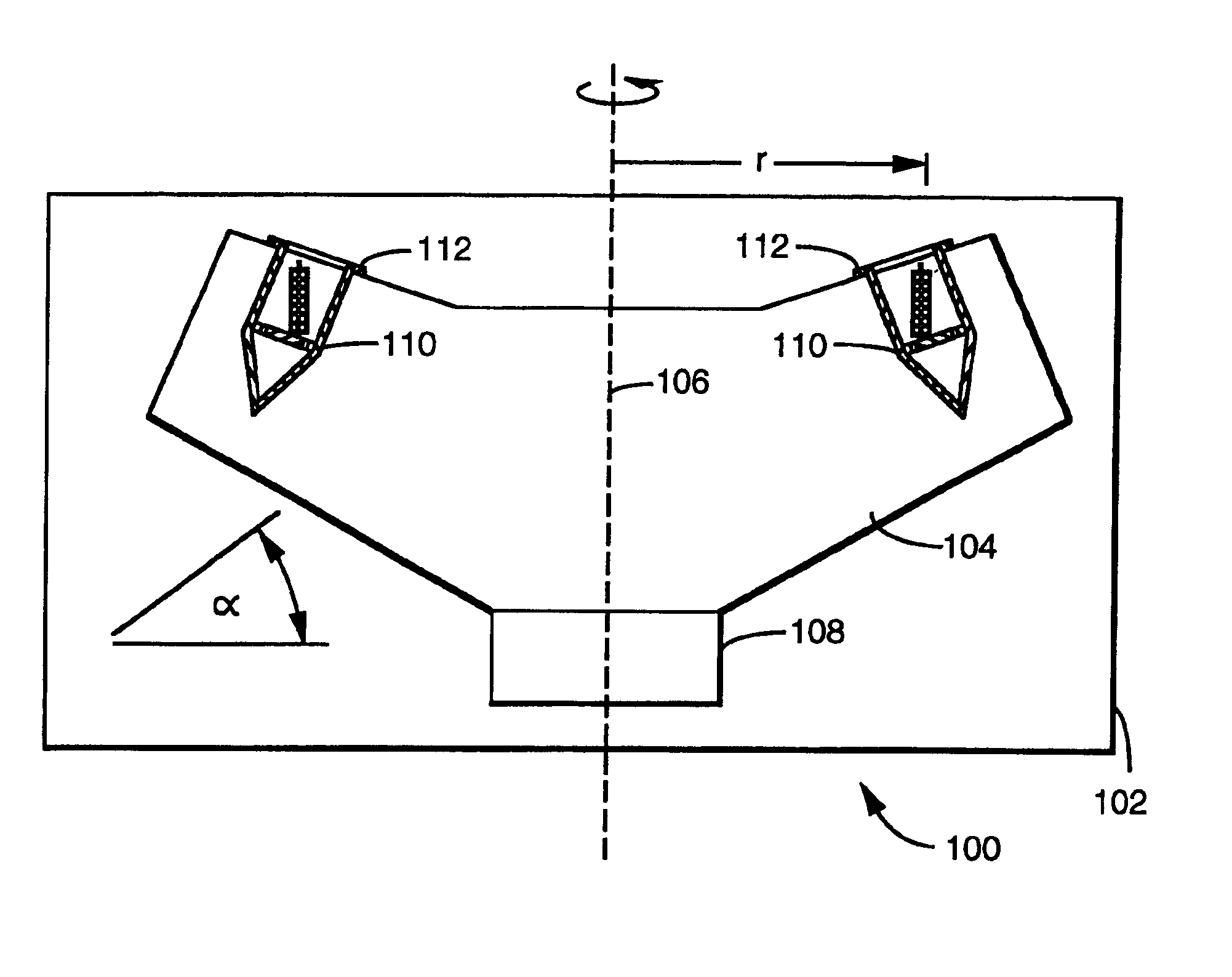

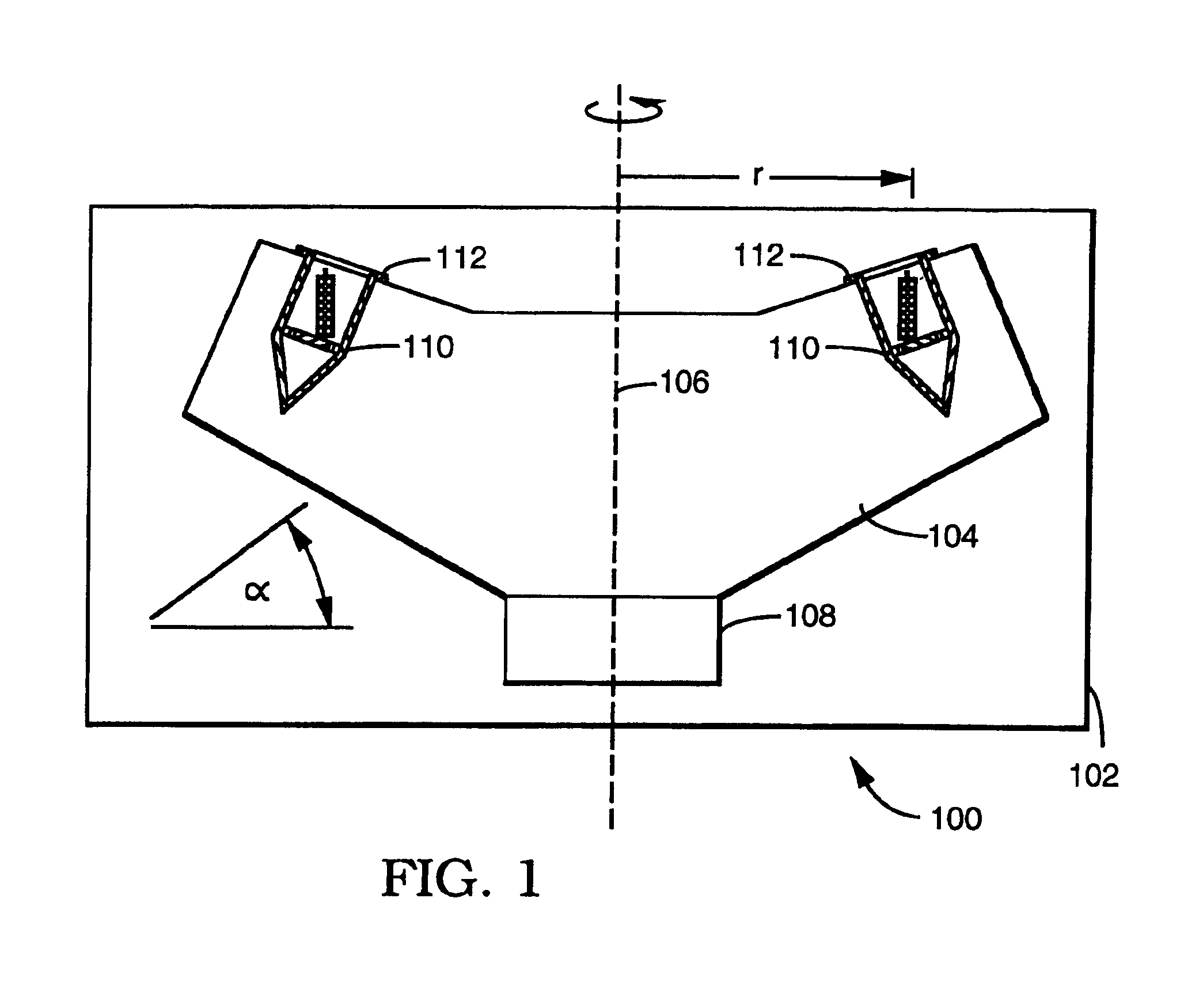

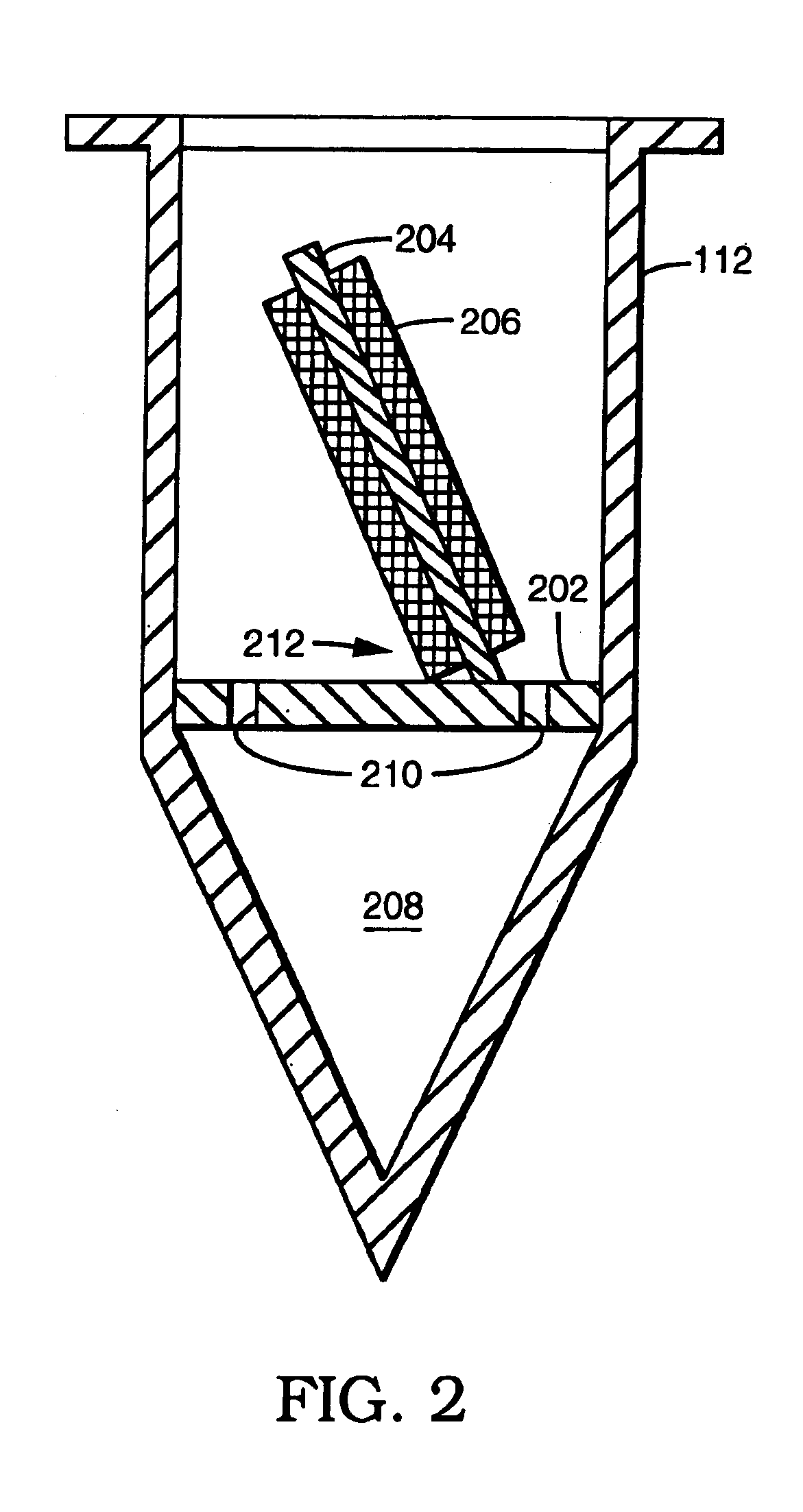

Showerhead for film depositing vacuum equipment

ActiveUS9315897B2Shorten the lengthAccurate supplySpraying apparatusSemiconductor/solid-state device manufacturingReactive gasMixed gas

A showerhead for film-depositing vacuum equipment having an effect shortening the length of injection tubes for a reactive gas is presented. The injection tubes extend from the bottom of a reactive gas showerhead module, and two different kinds of reactive gases are mixed with an injection support gas within a reactive showerhead module so as to inject the mixed gas. The showerhead for film-depositing vacuum equipment includes the reactive gas showerhead module above a cooling jacket and a purge gas showerhead module above the reactive gas showerhead module. The injection tubes of the reactive gas showerhead module pass through the cooling jacket disposed below the reactive gas showerhead module, and the injection tubes of the purge gas showerhead module pass through the reactive gas showerhead module disposed below the purge gas showerhead module, thereby enabling the purge gas to flow into a purge gas redistribution space defined above the cooling jacket.

Owner:KOREA INST OF IND TECH

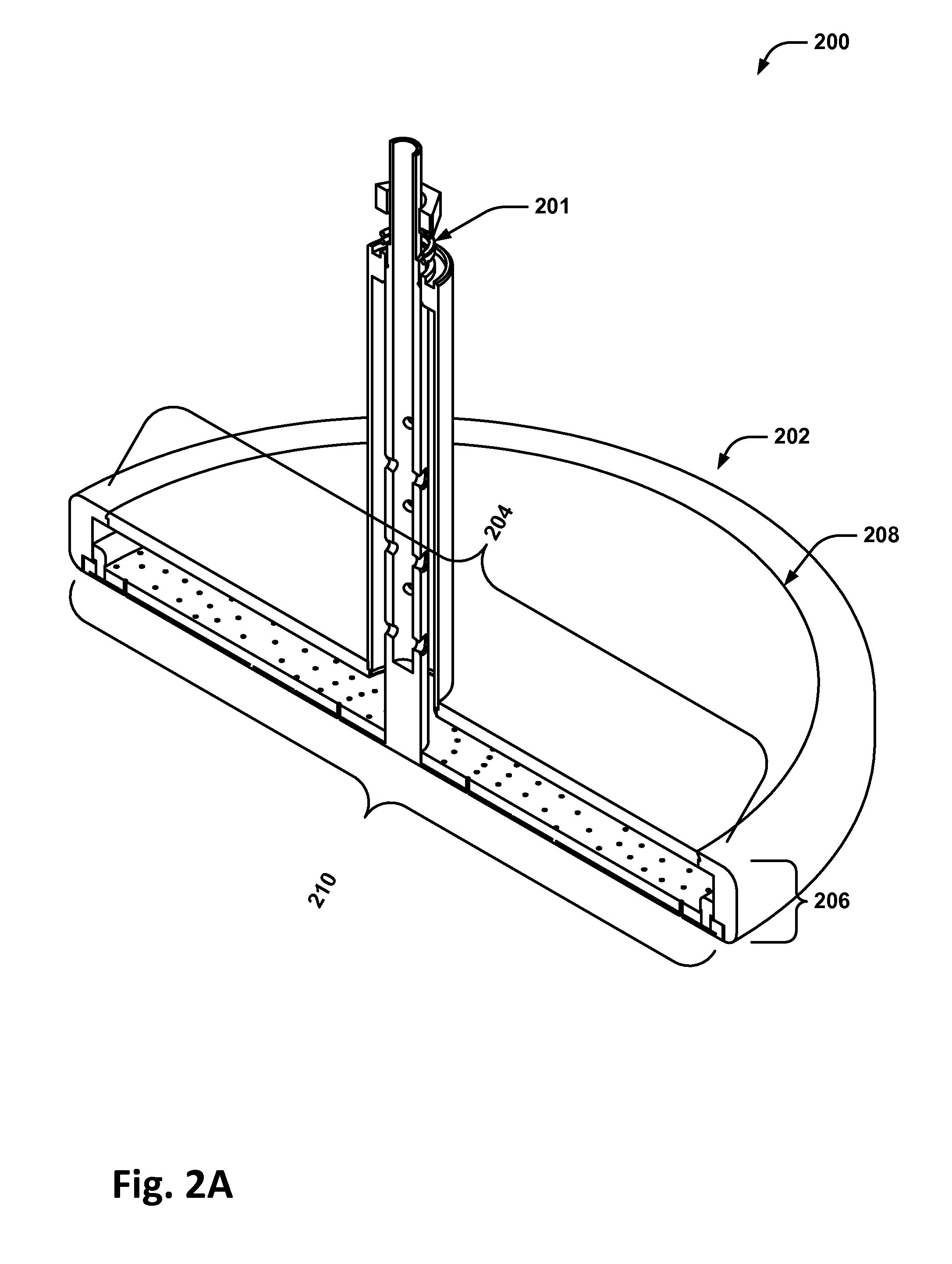

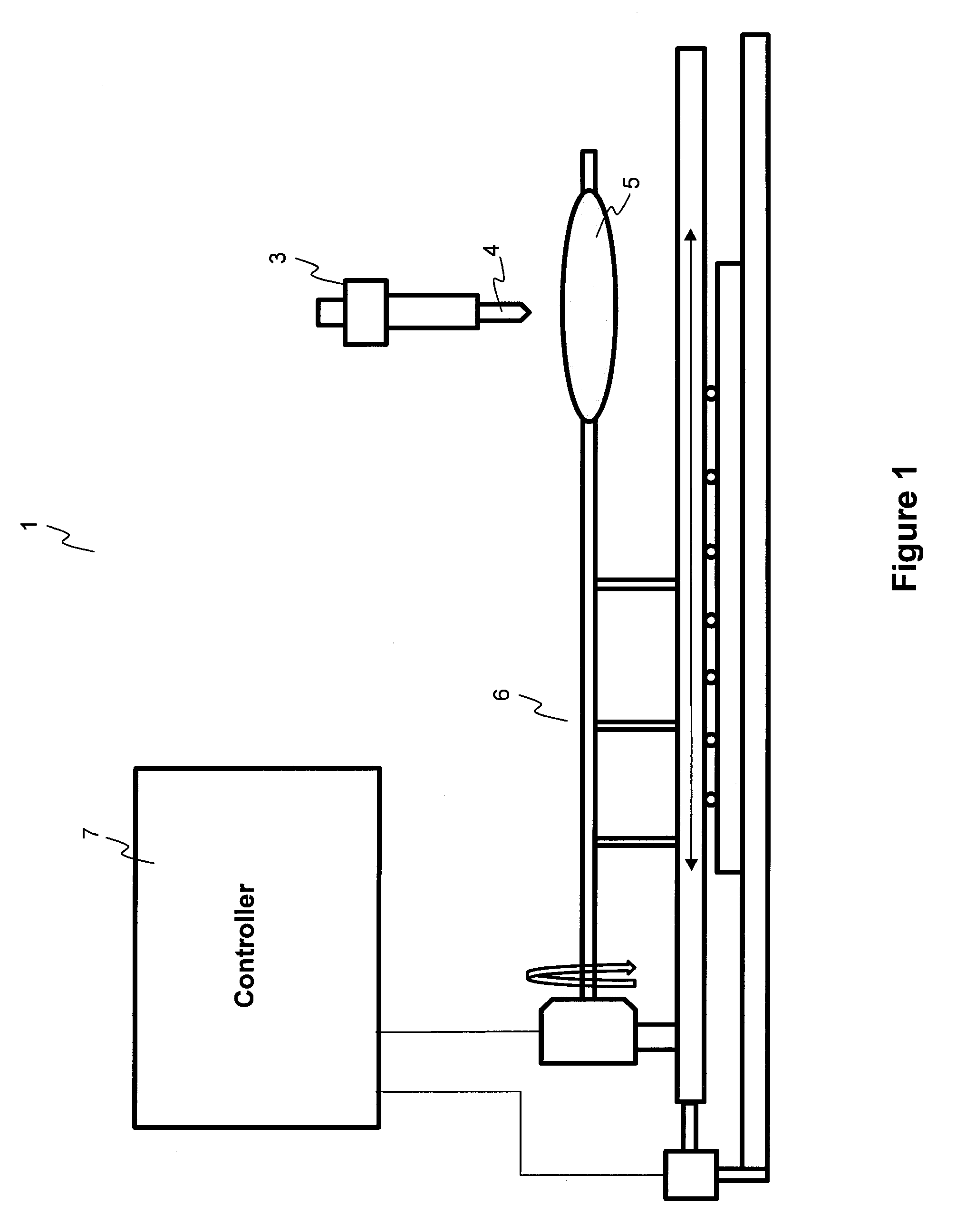

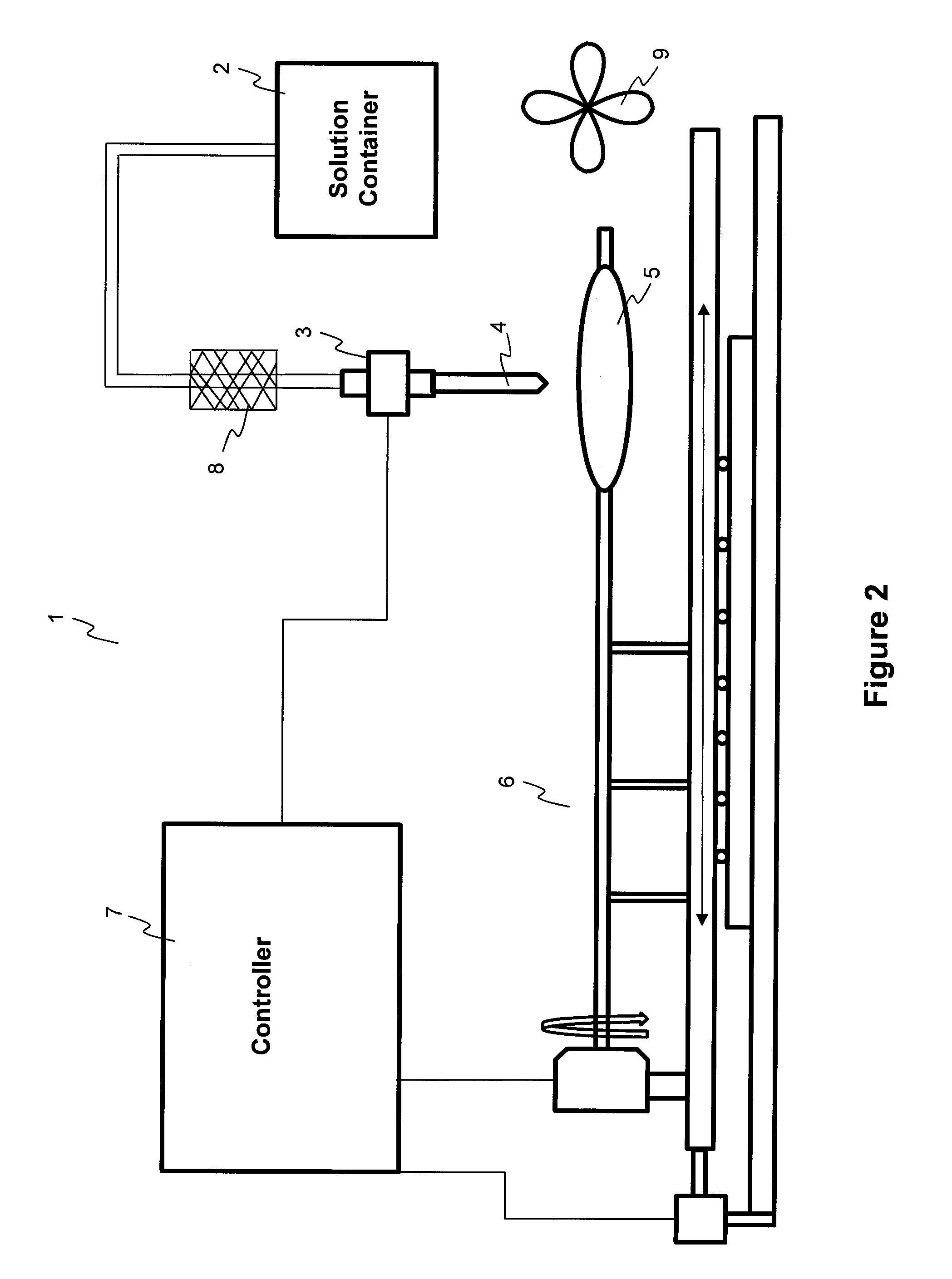

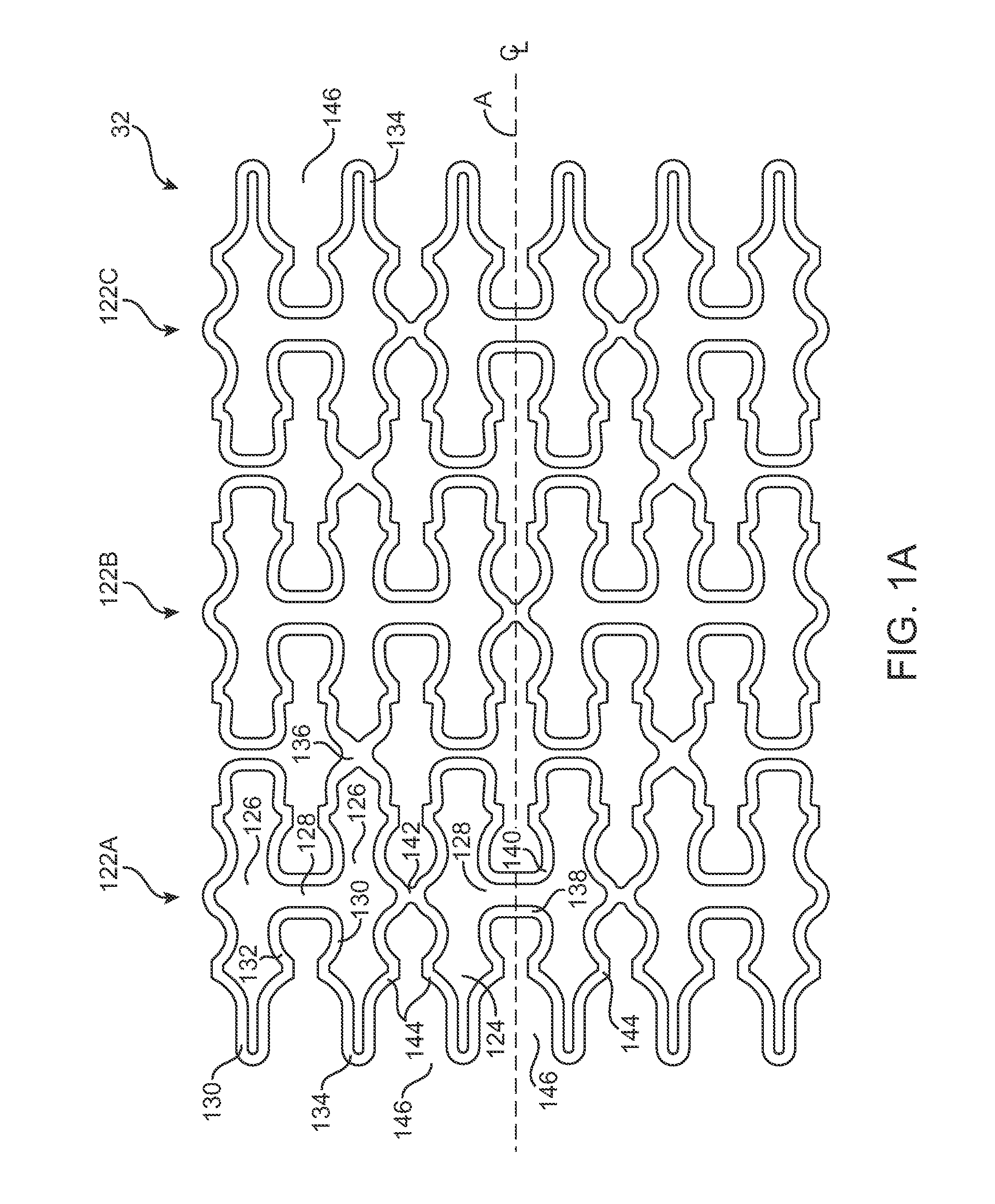

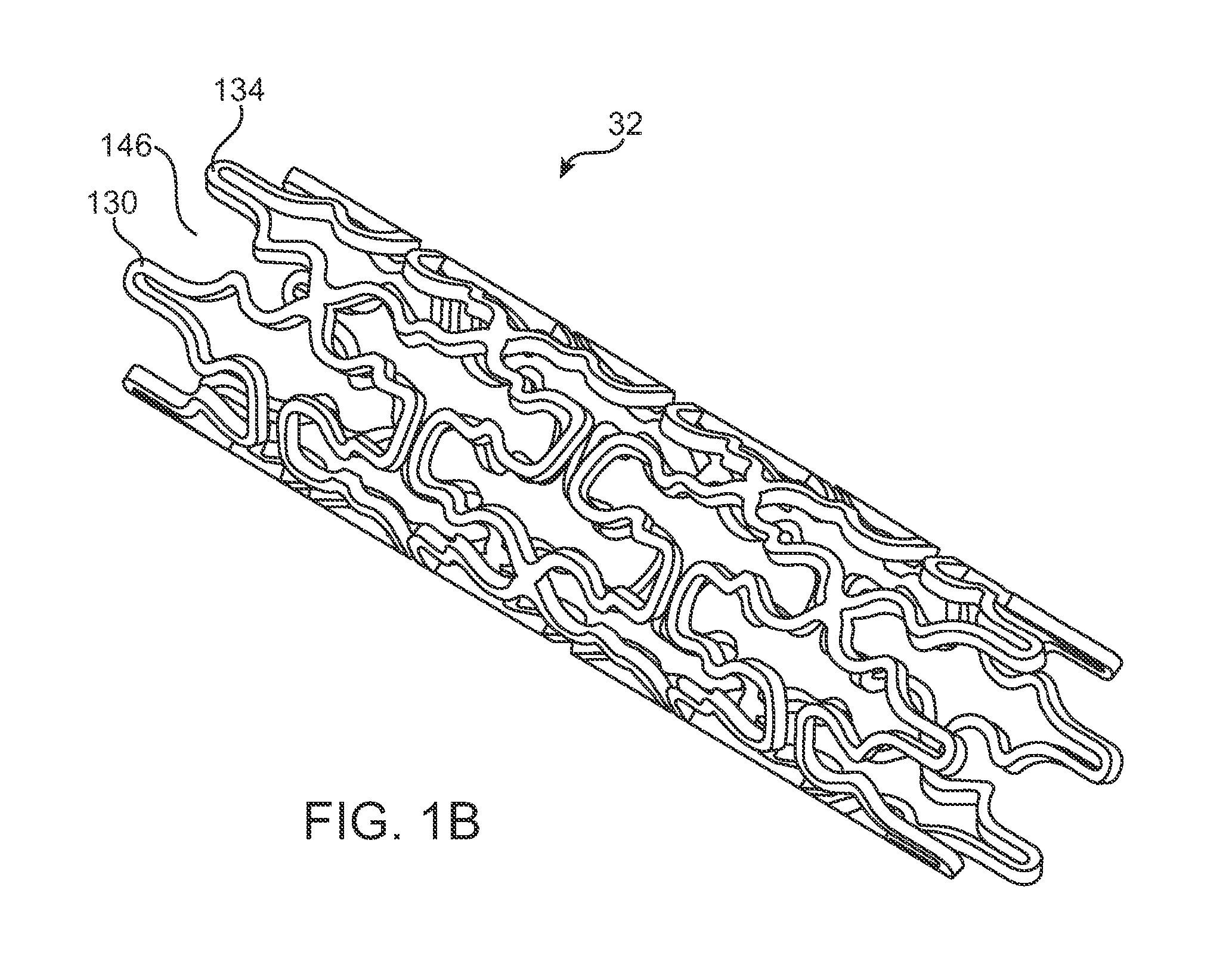

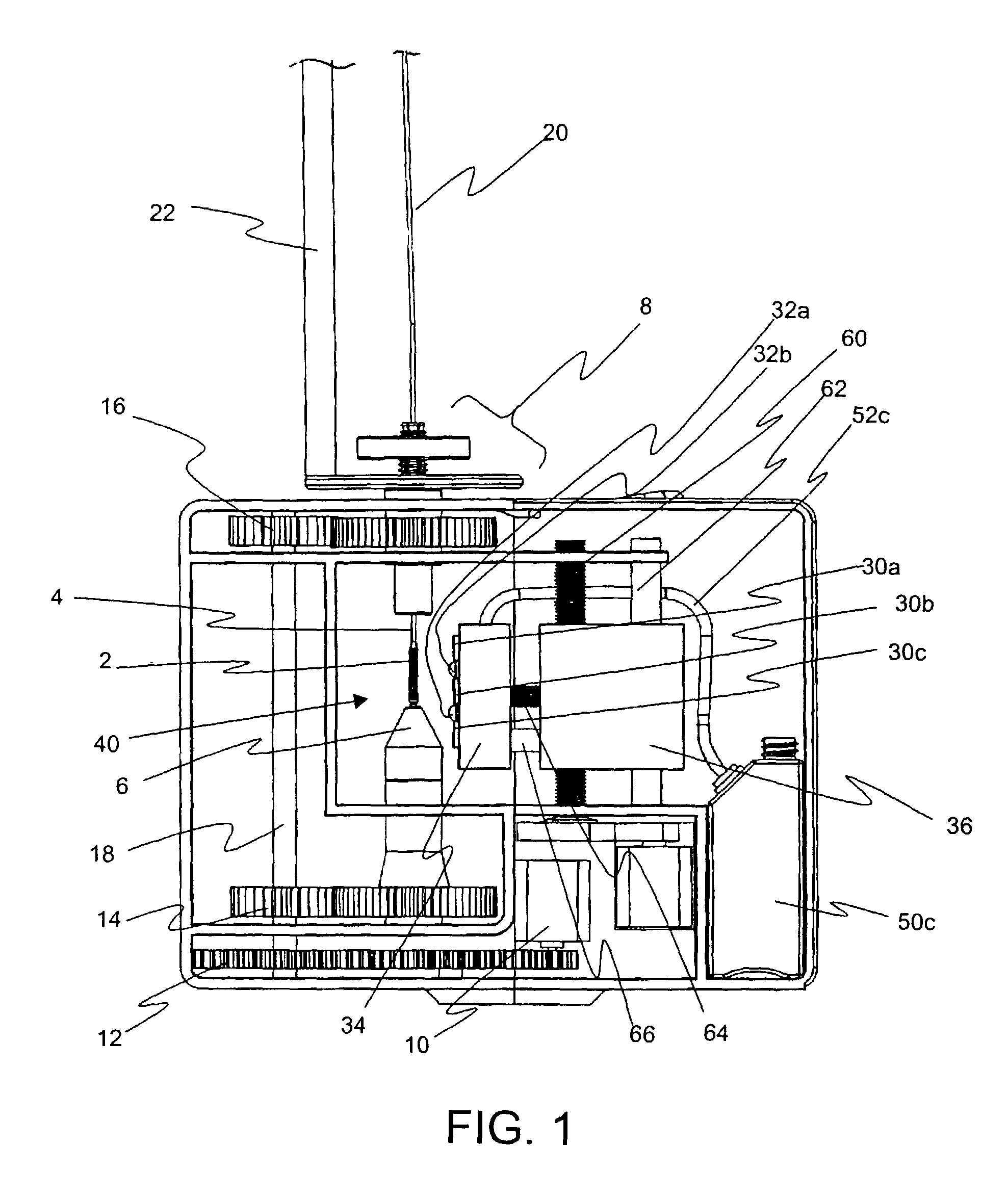

Apparatus and method for depositing a coating onto a surface of a prosthesis

A patterned coating on a prosthesis, for example a stent, and a method for forming the coating are disclosed. Additionally, an apparatus for forming the patterned coating is disclosed.

Owner:ABBOTT CARDIOVASCULAR

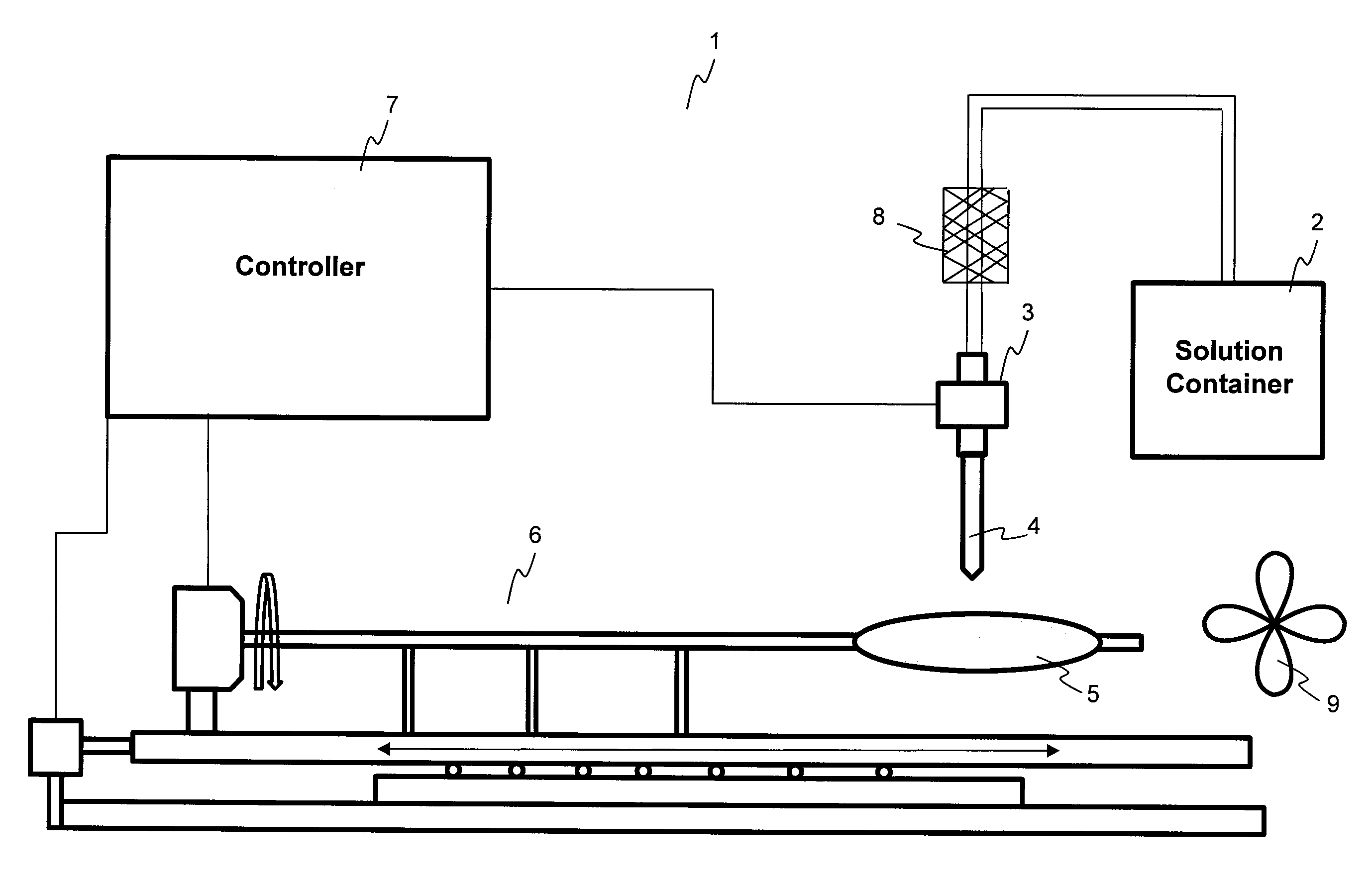

Methods and apparatuses for coating balloon catheters

ActiveUS20100055294A1Destroy surface tensionUniform coatingBalloon catheterGlovesTransverse axisSolvent

Embodiments of the invention relate to a method and apparatus for coating a medical device. In one embodiment, the method for preparing a substantially uniform coated medical device includes (1) preparing a coating solution comprising a solvent, a therapeutic agent, and an additive; (2) loading a metering dispenser with the coating solution; (3) rotating the medical device about the longitudinal axis of the device and / or moving the medical device along the longitudinal or transverse axis of the device; (4) dispensing the coating solution from the metering dispenser onto a surface of the medical device and flowing the coating solution on the surface of the medical device while the medical device is rotating and / or linearly moving; and (5) evaporating the solvent, forming a substantially uniform coating layer on the medical device.

Owner:LUTONIX INC

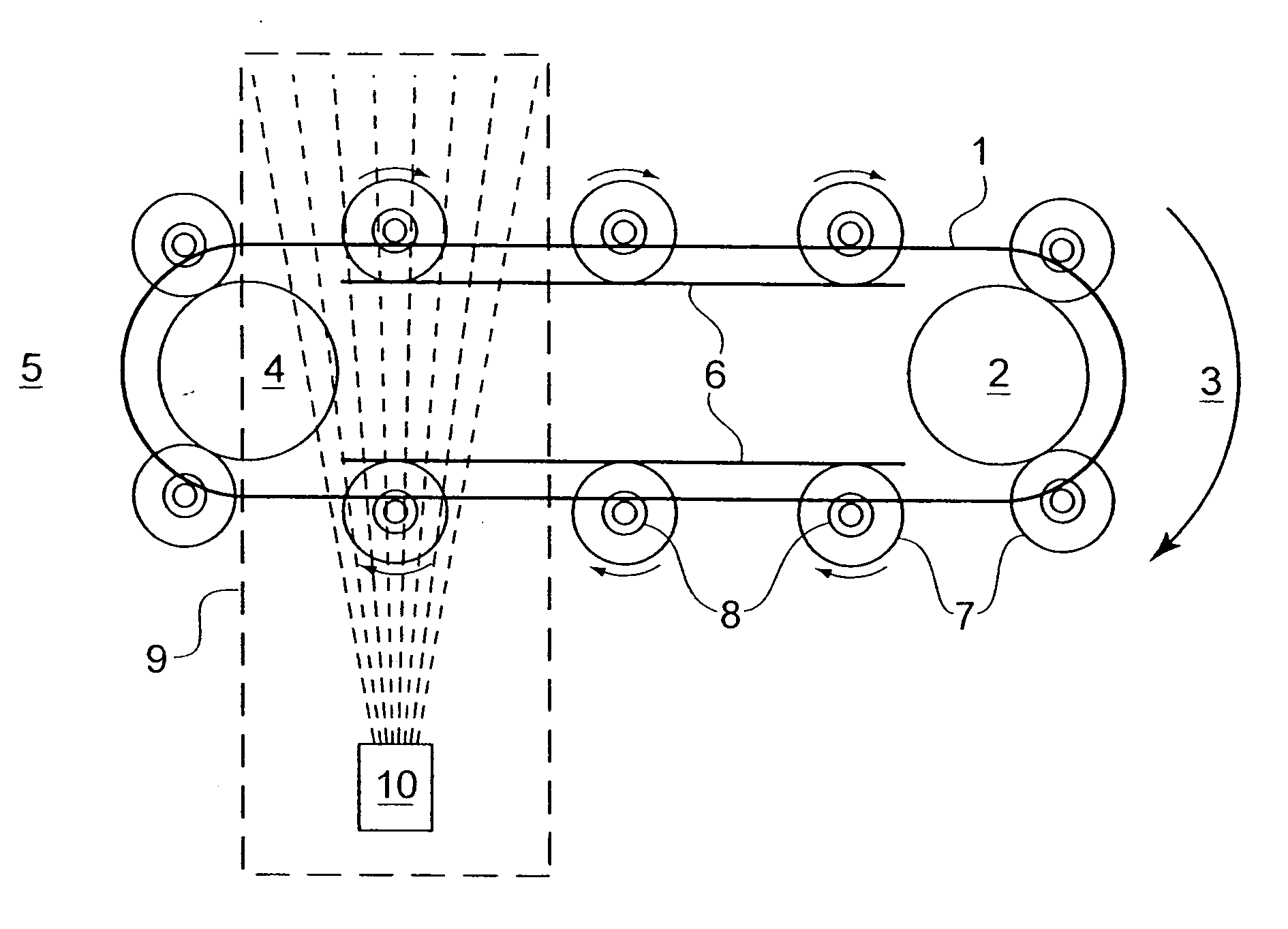

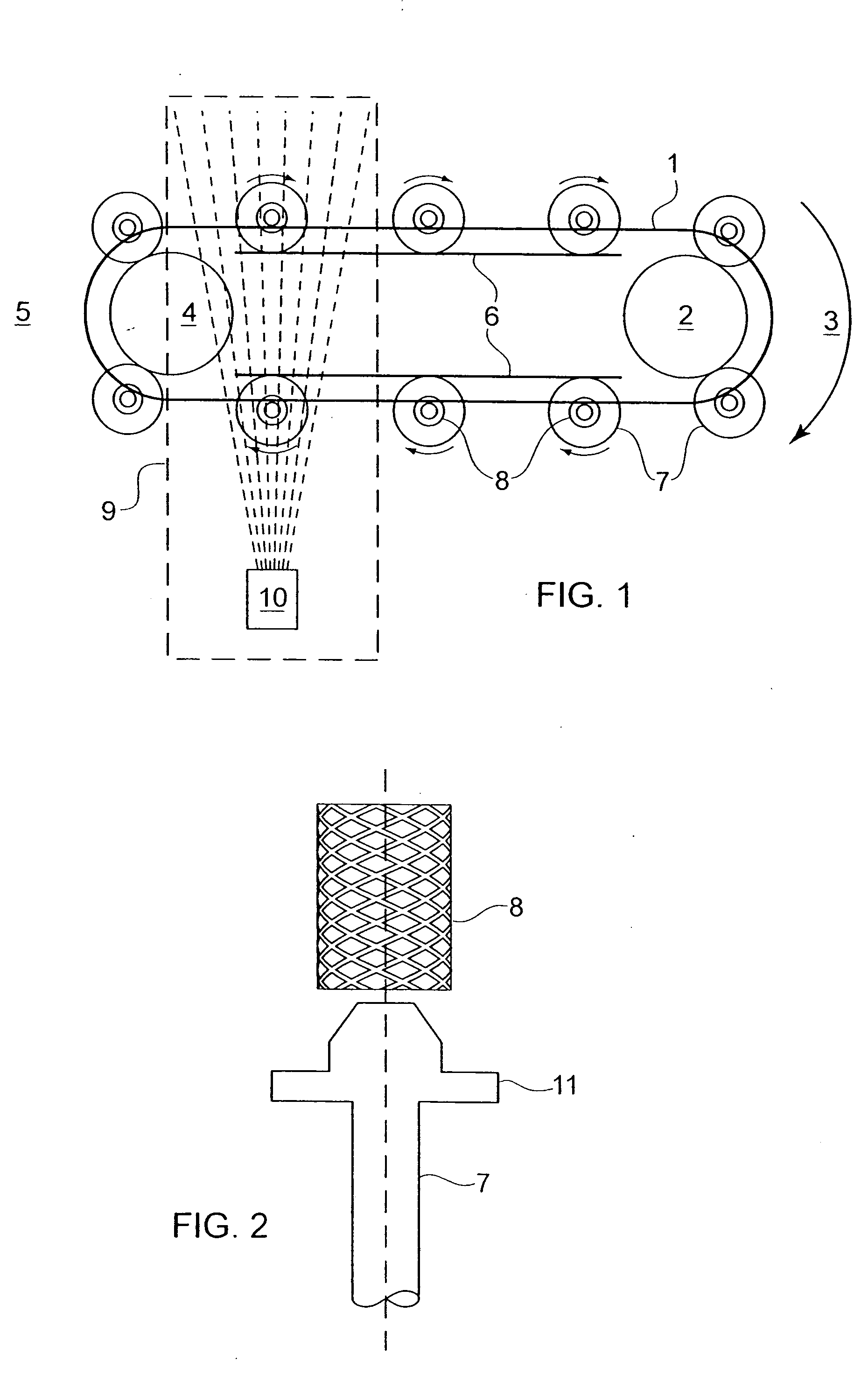

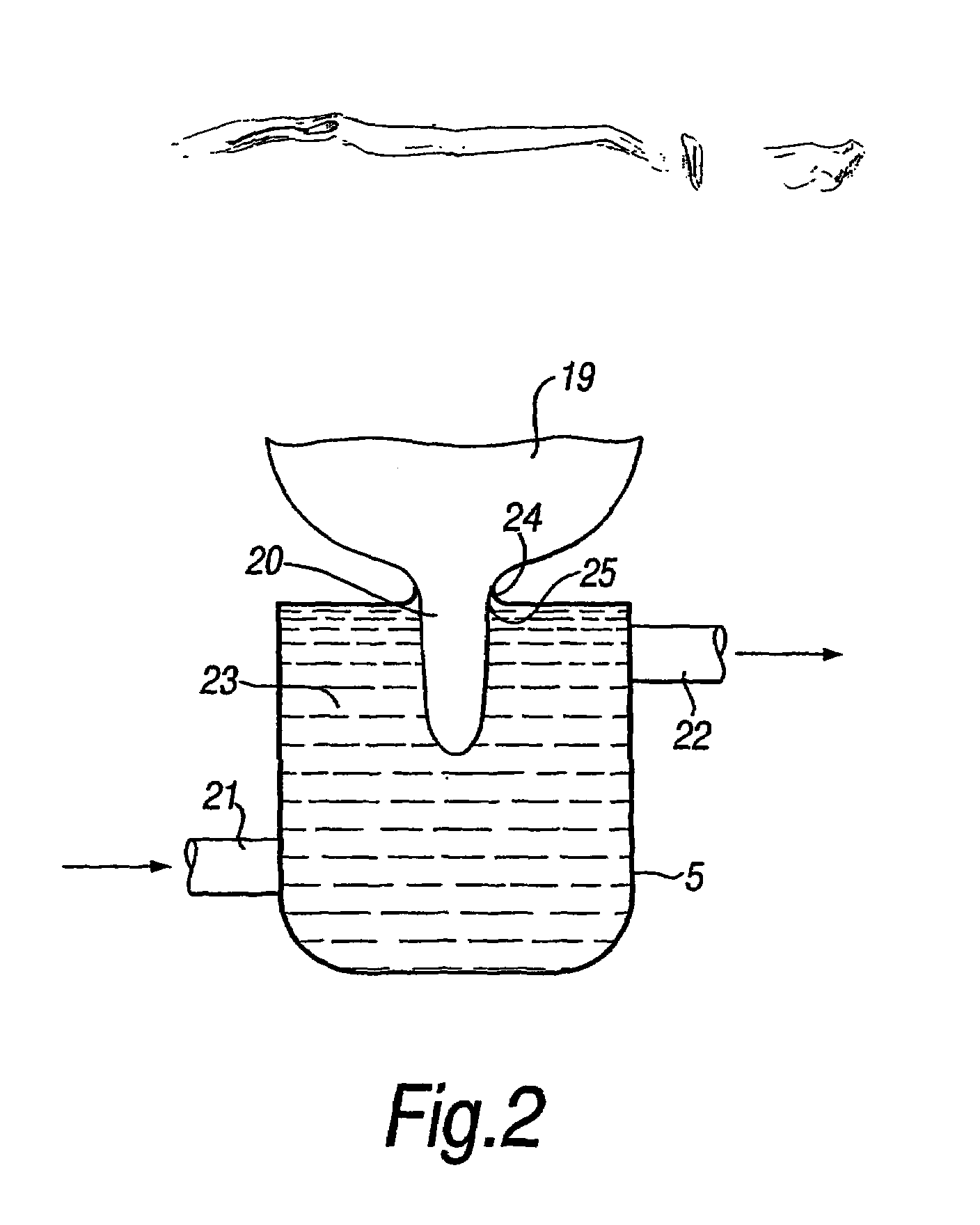

Method for coating multiple stents

ActiveUS20050079274A1Facilitate stent handlingLong exposureSpraying apparatusPretreated surfacesMedicineInsertion stent

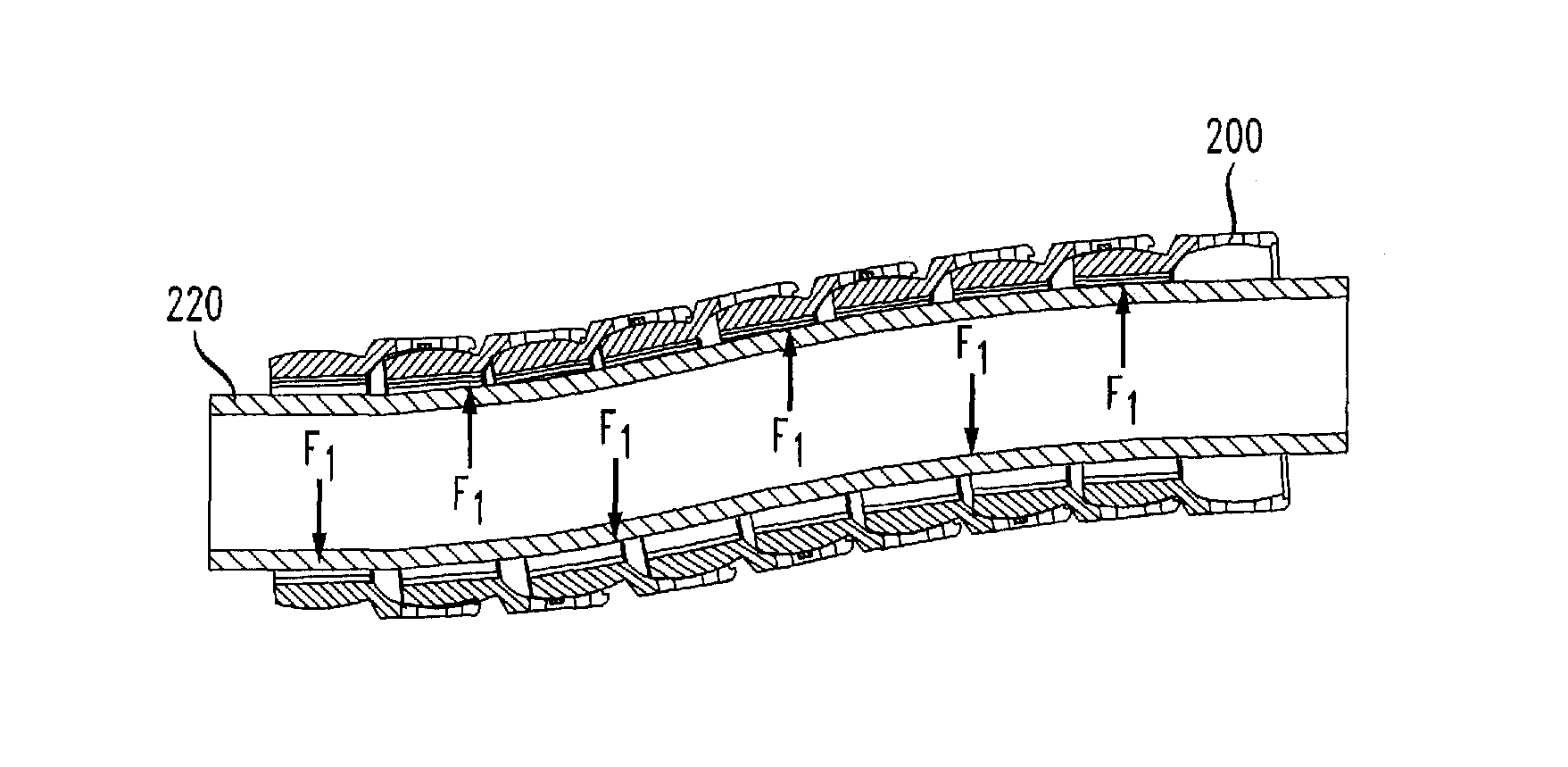

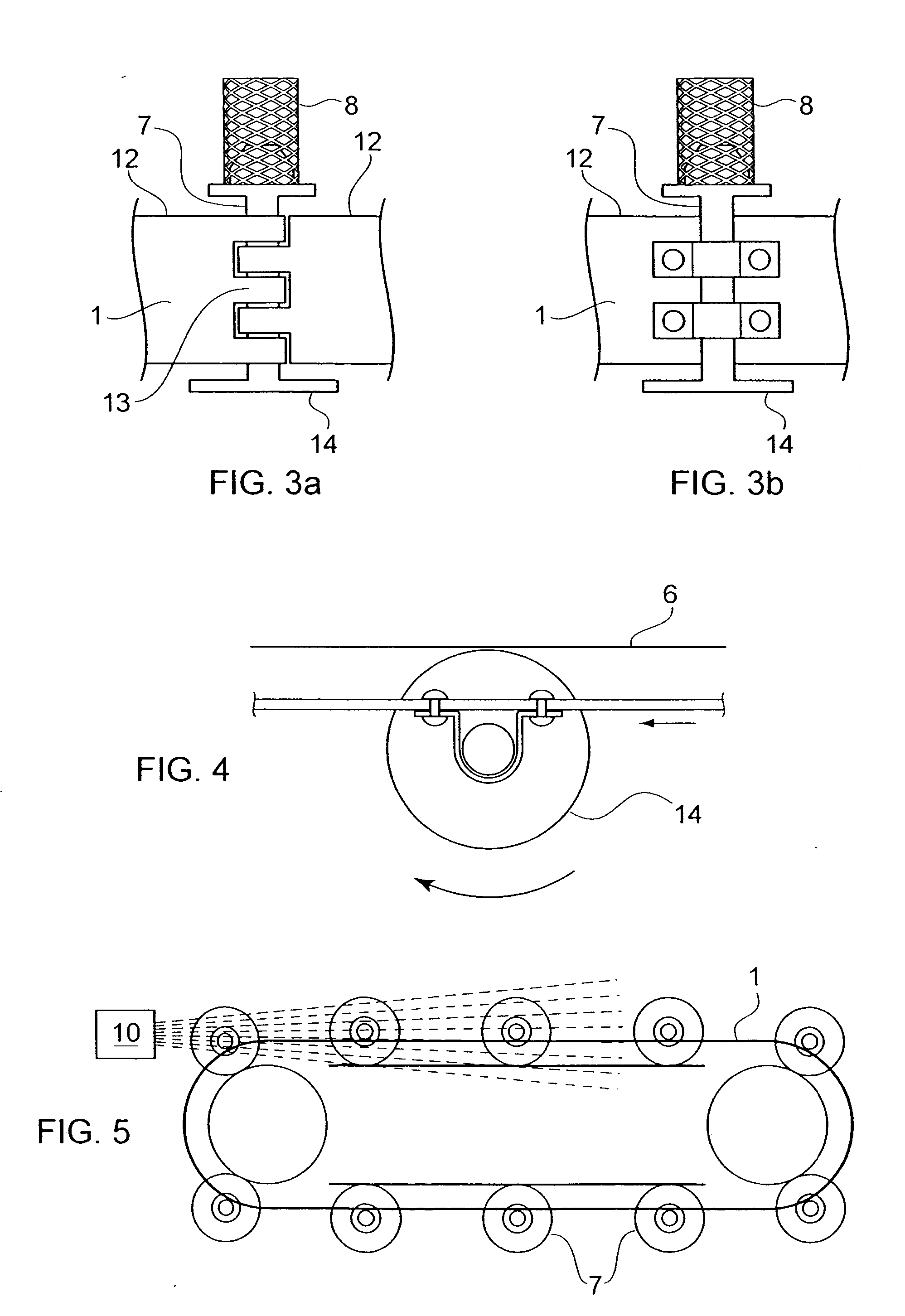

An improved method for high-volume production of coated stents with highly uniform stent coatings using a roll coating technique is provided. In a first embodiment, uncoated stents are placed onto rotating stent holders with automated stent handling equipment. The holders are mounted on an endless conveyer belt which advances the stents toward a stent coater. As the stents advance through the coater, the holders rotate, thereby rolling the stents about their longitudinal axes as coating material is sprayed toward them, ensuring the stents are uniformly coated on their exterior and interior surfaces. After the conveyer turns to carry the coated stents back toward the loading area, the rotating stents pass again through the coating spray, downstream of the initial coating location, thereby increasing the efficient utilization of the coating material. The conveyer then advances the coated stents to an unloading area for removal before the holders return to the stent loading area to receive new stents.

Owner:BOSTON SCI SCIMED INC

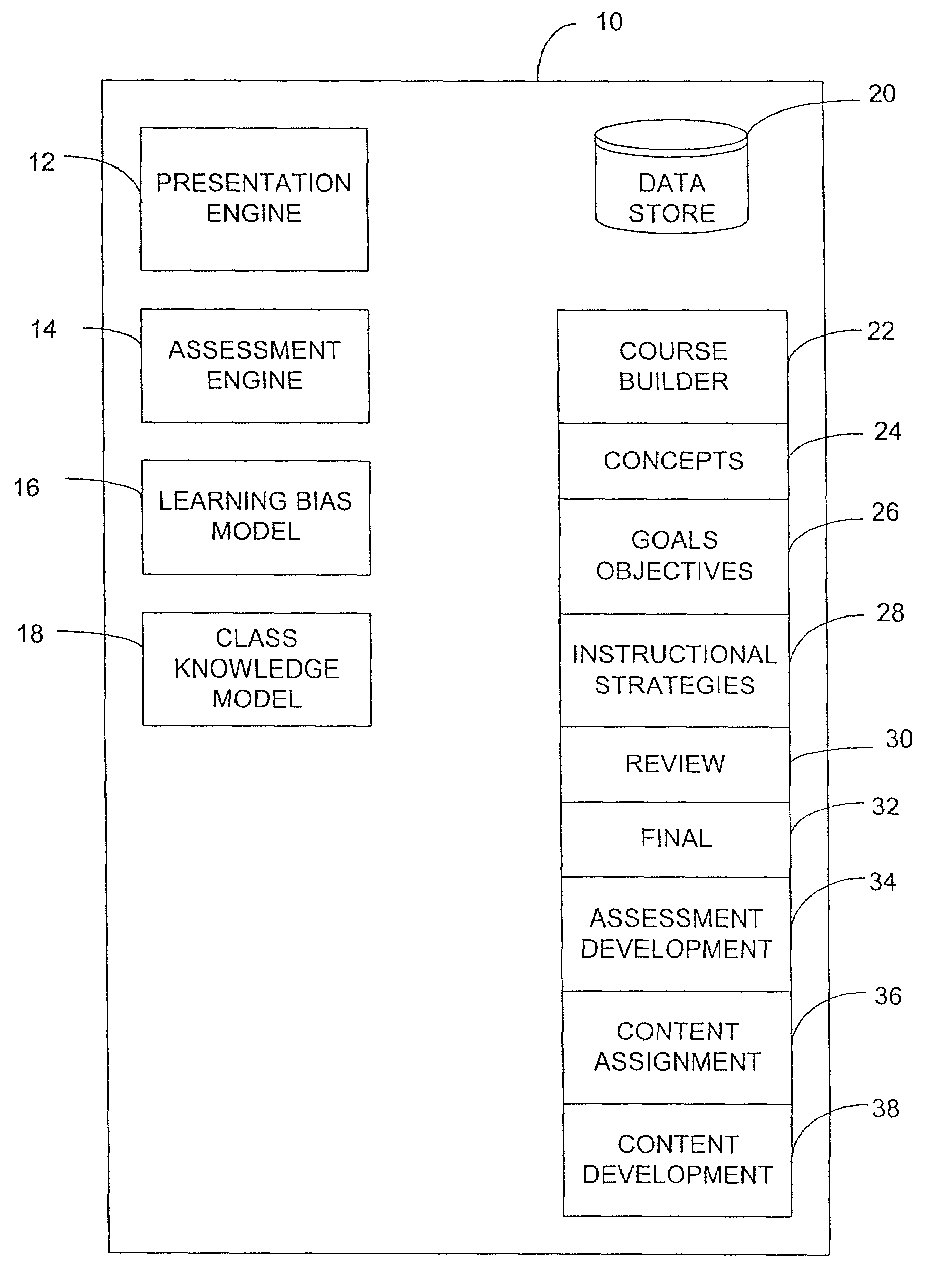

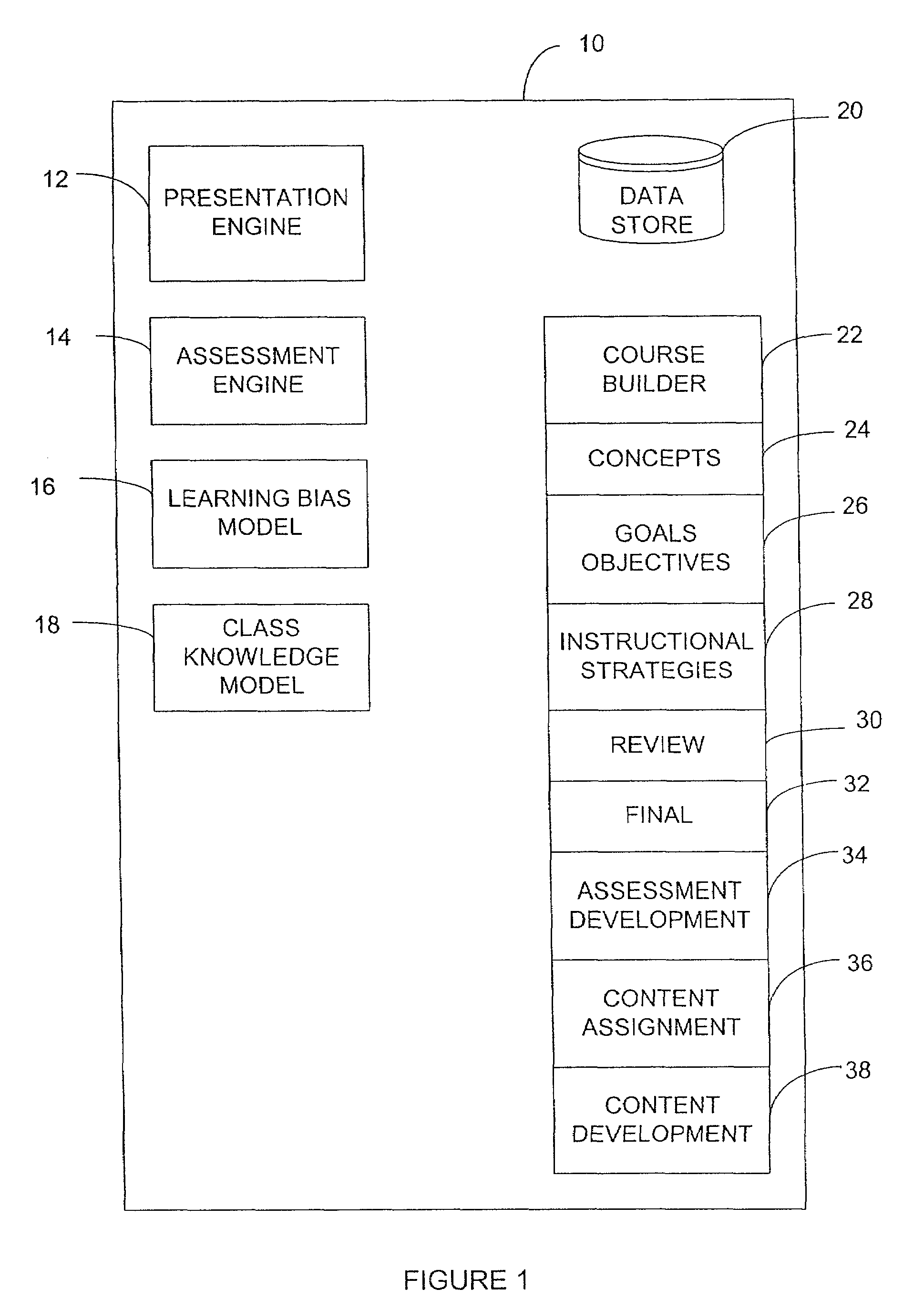

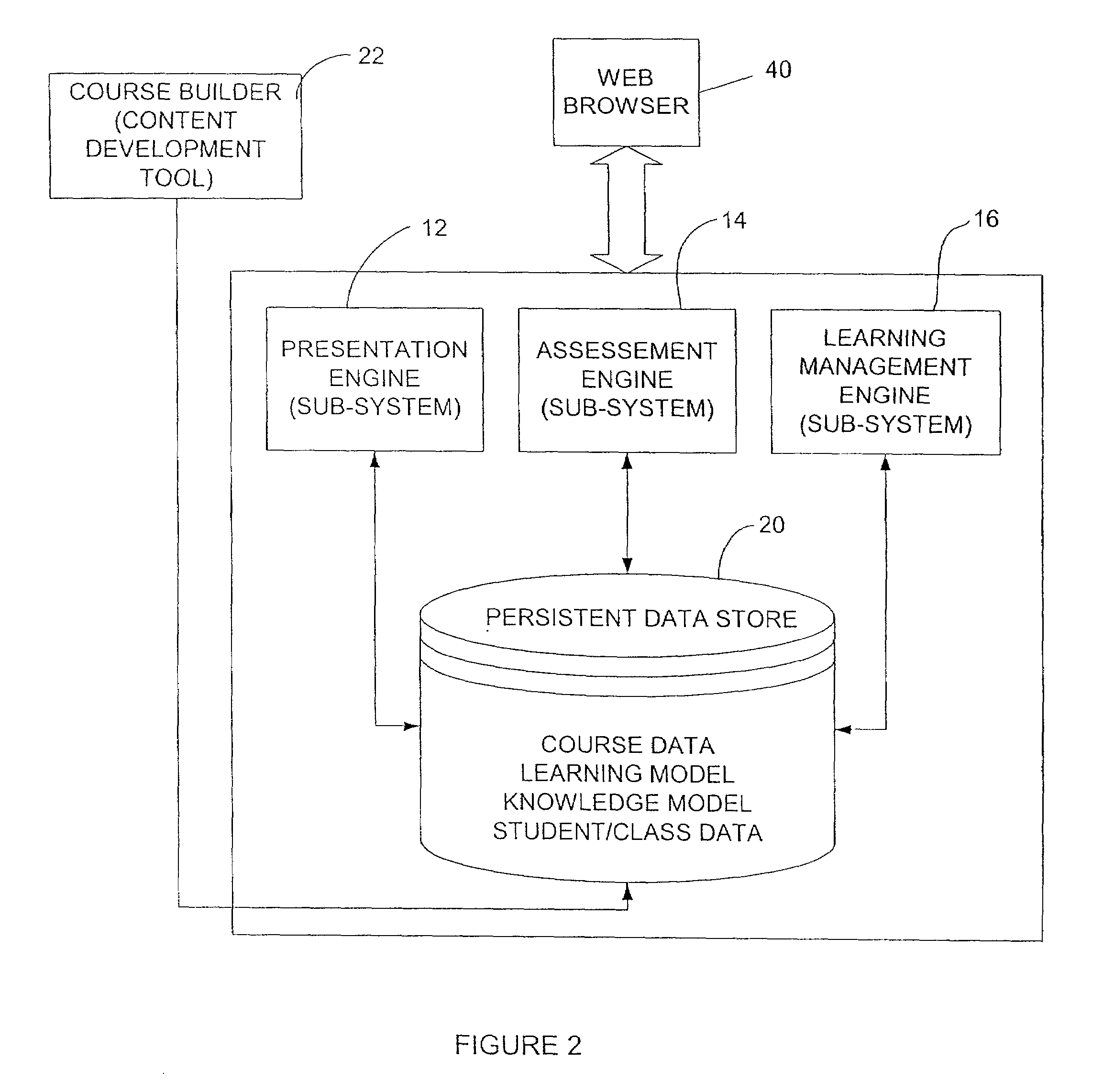

Method and system for training in an adaptive manner

InactiveUS6978115B2Good comprehensionReduce in quantityLiquid surface applicatorsSpraying apparatusSubject matterStudy methods

A learning method and system are disclosed that assess a learner's understanding of the subject matter and the learner's preferred learning style by presenting and reviewing the information in various types of teaching strategies and then selecting the teaching strategies in which the student learns best. As the student responds to questions presented during the course, a learning bias model is developed for the learner based on which teaching styles provide the best level of comprehension for the learner and then presents concepts from the course within those learning strategies most suitable to the student.

Owner:POINTECAST CORP

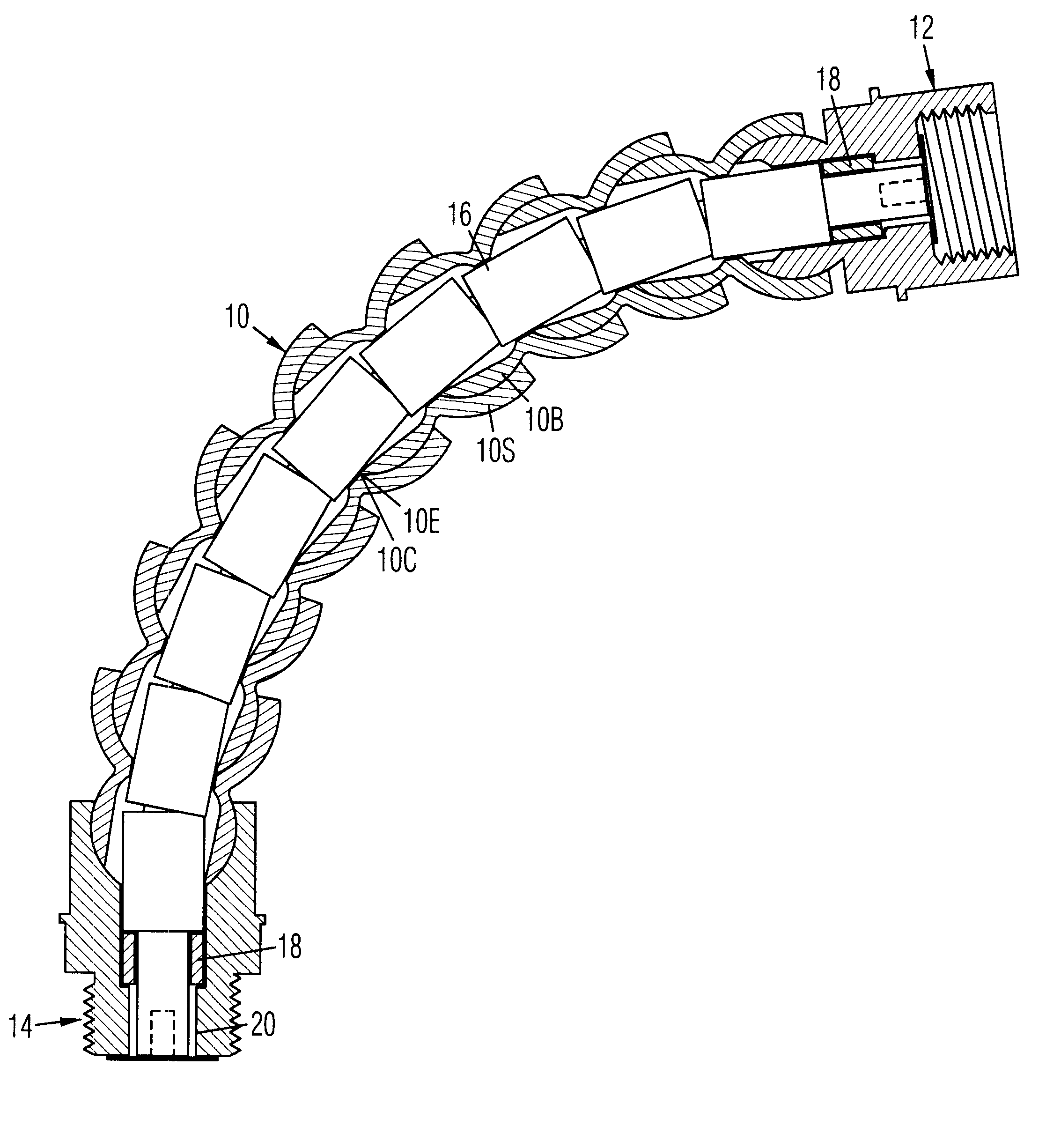

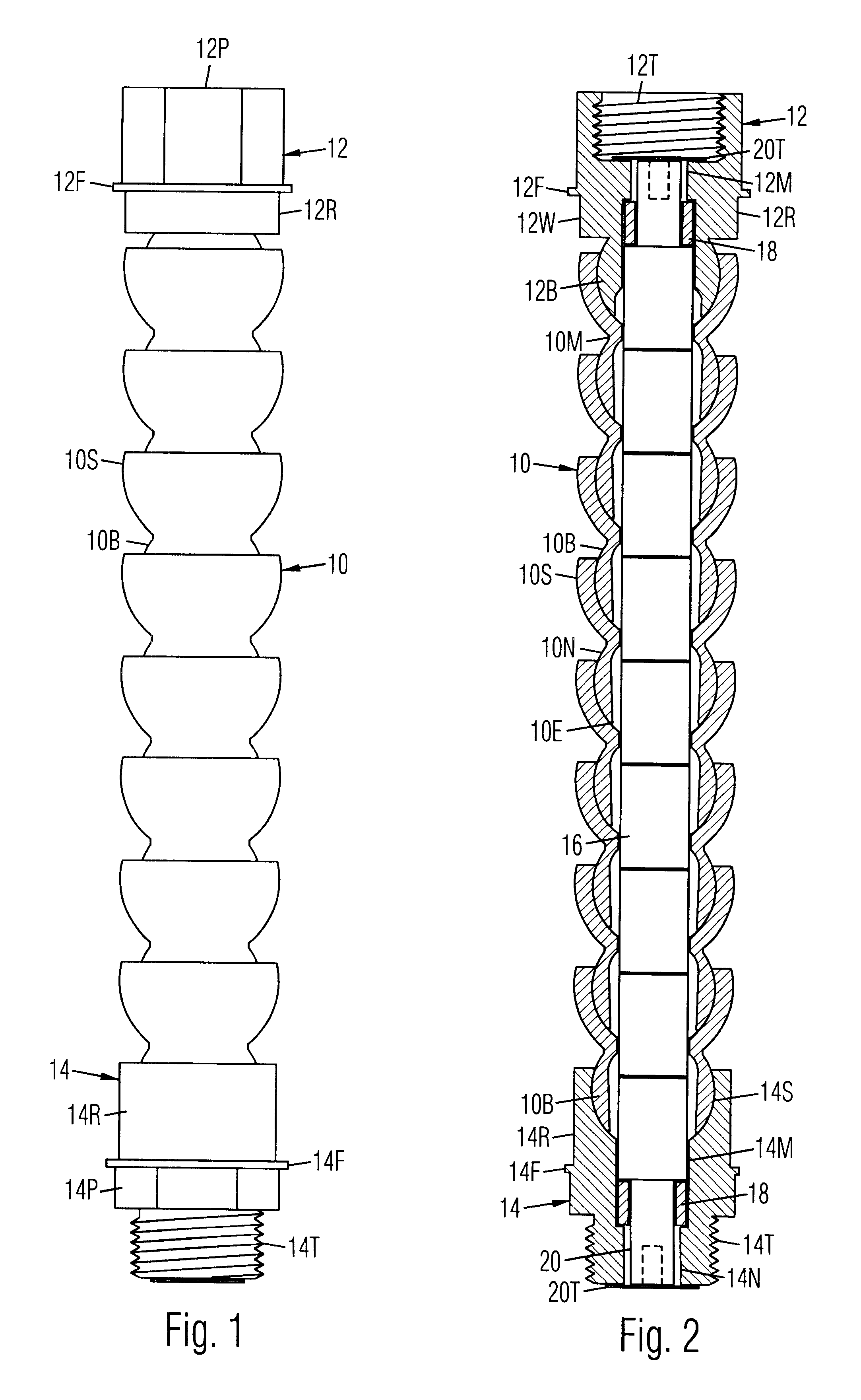

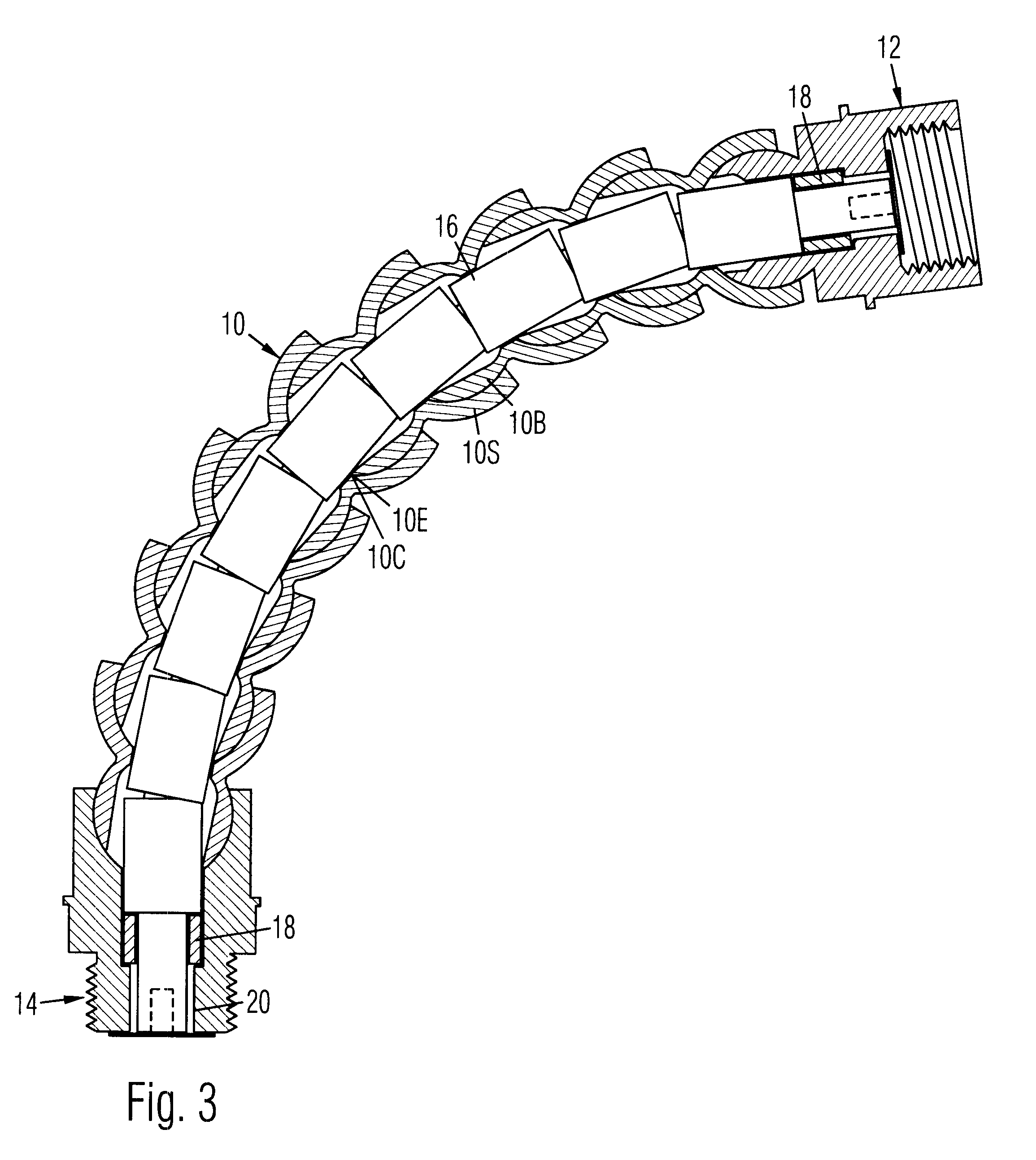

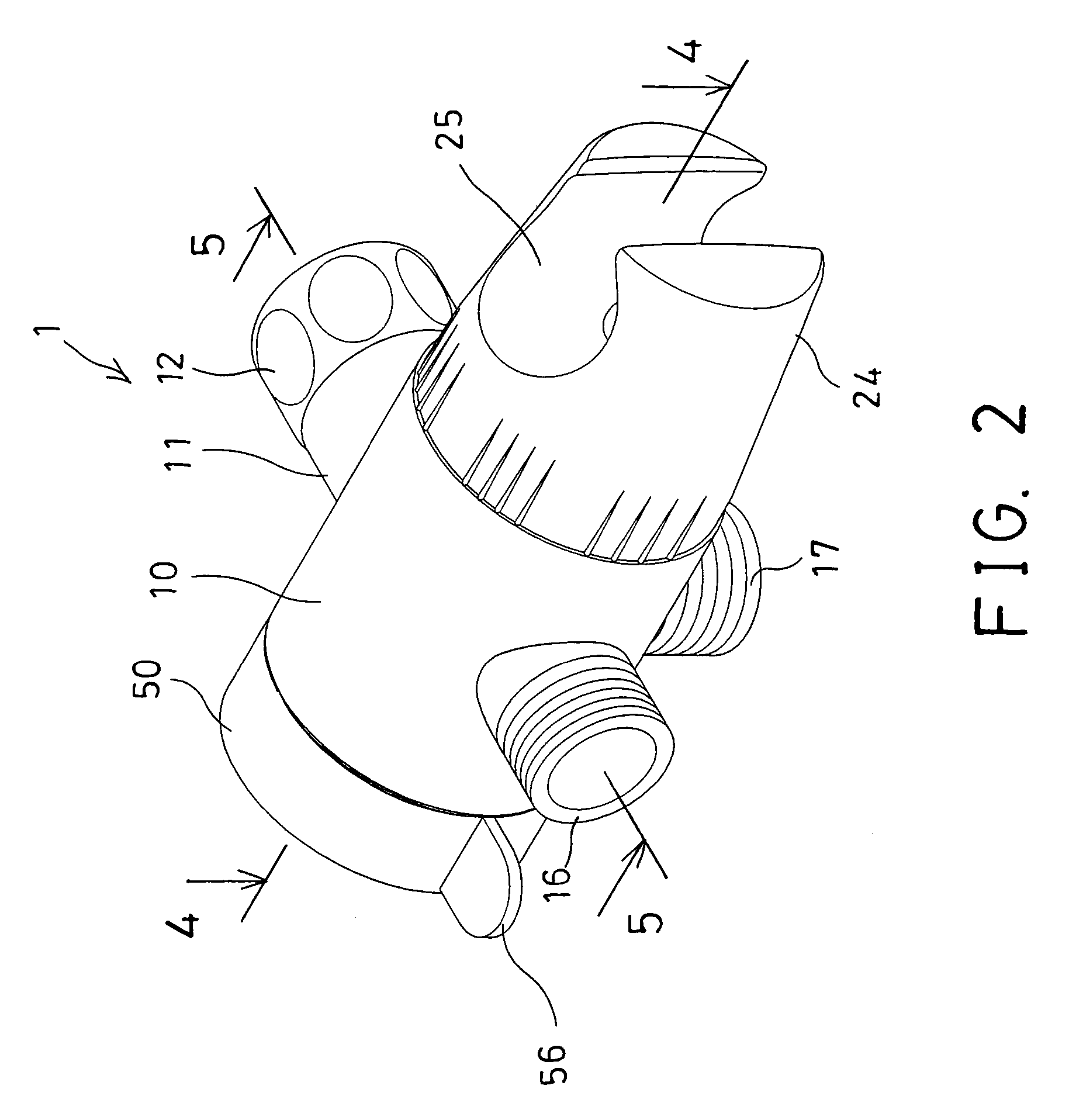

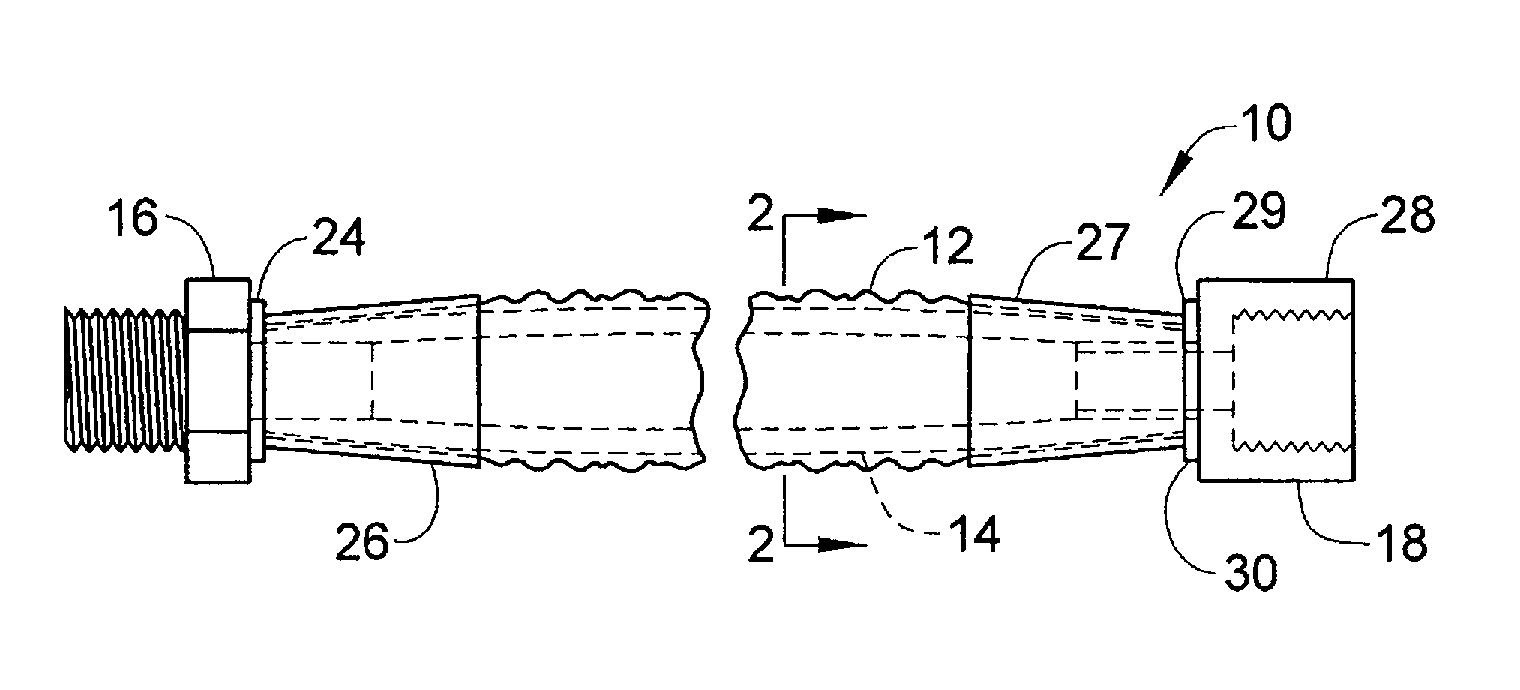

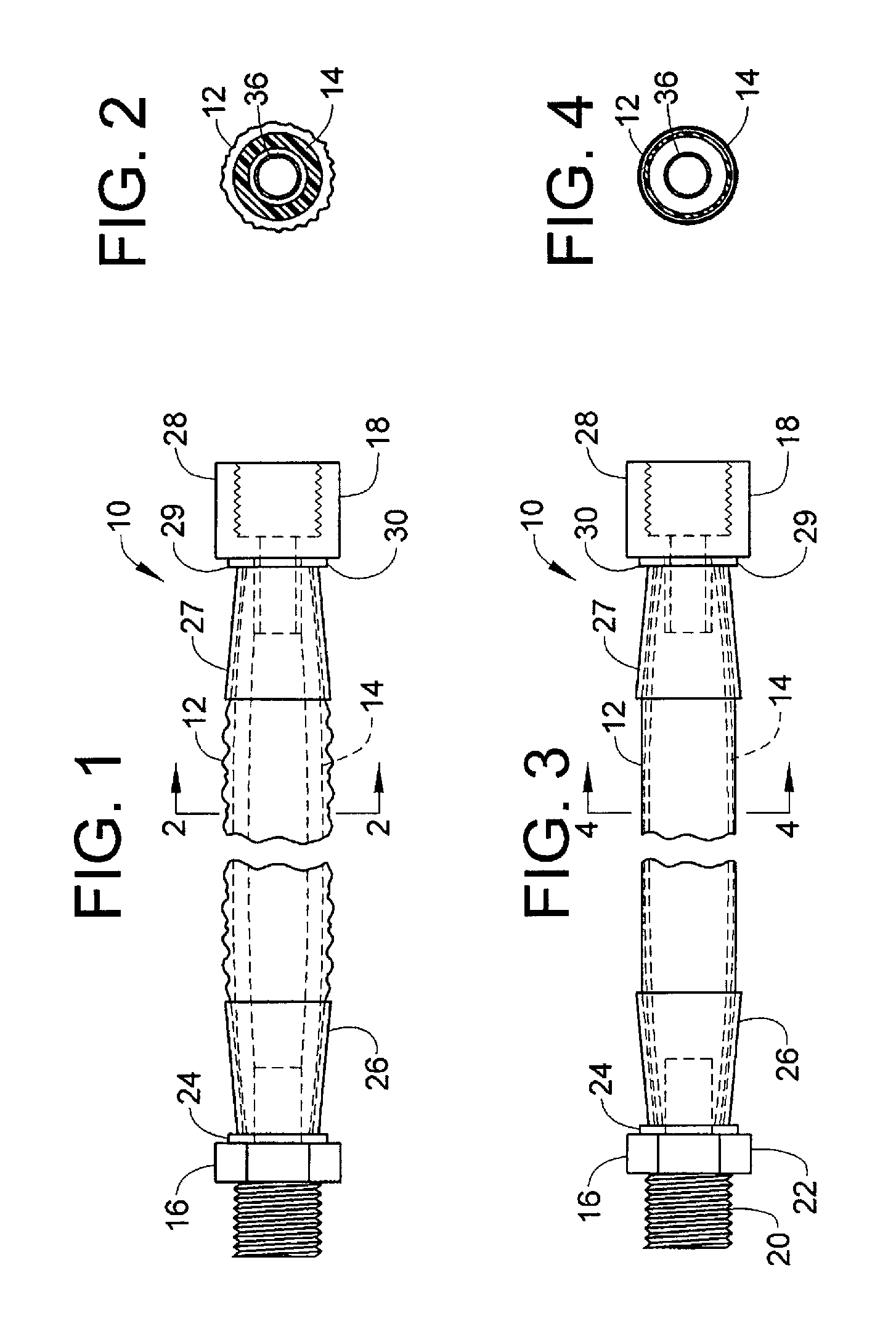

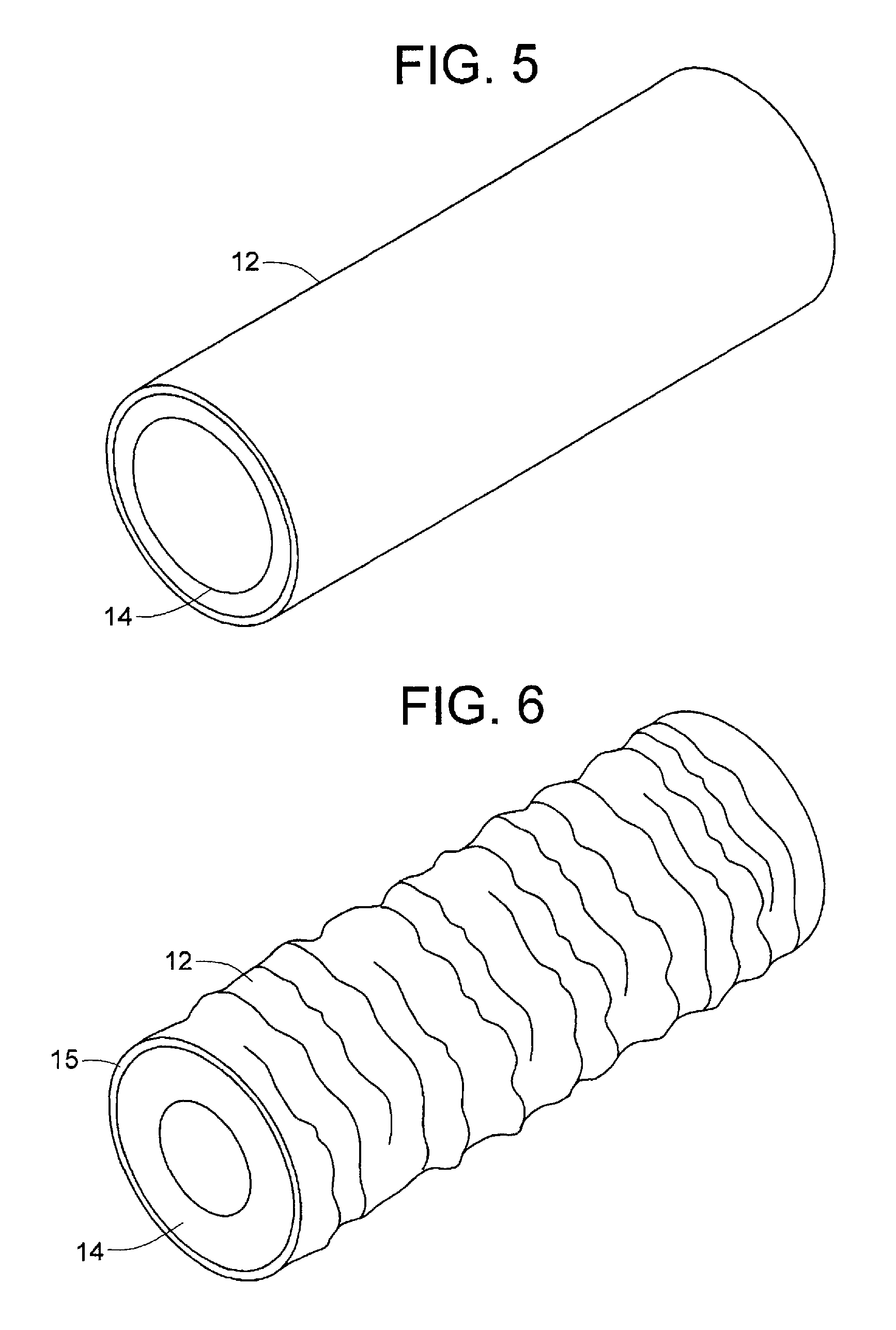

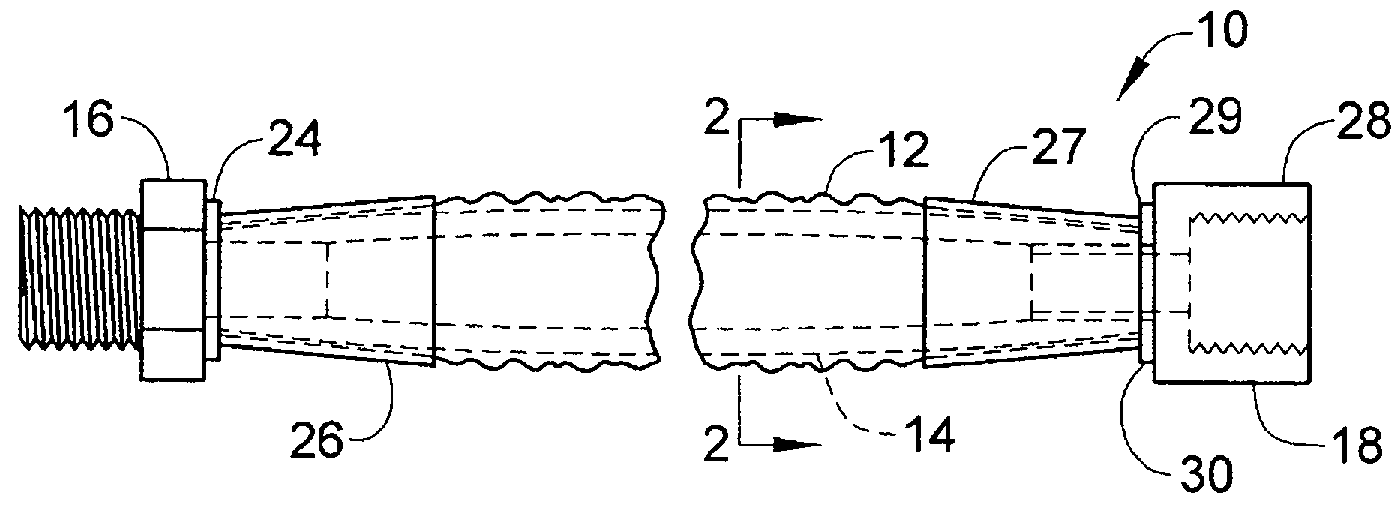

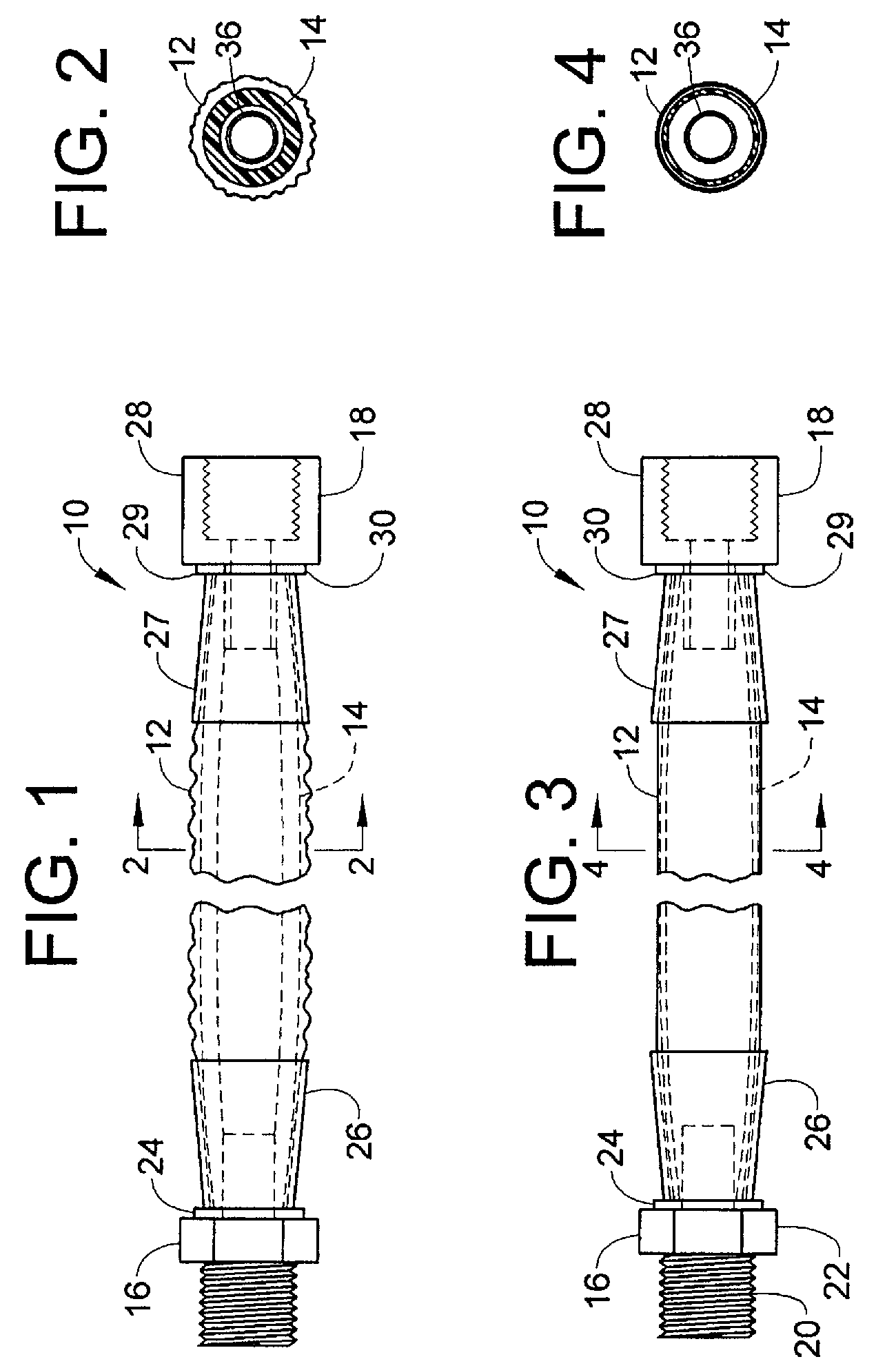

Flexible sectioned arm with internal overbending-prevention sleeves

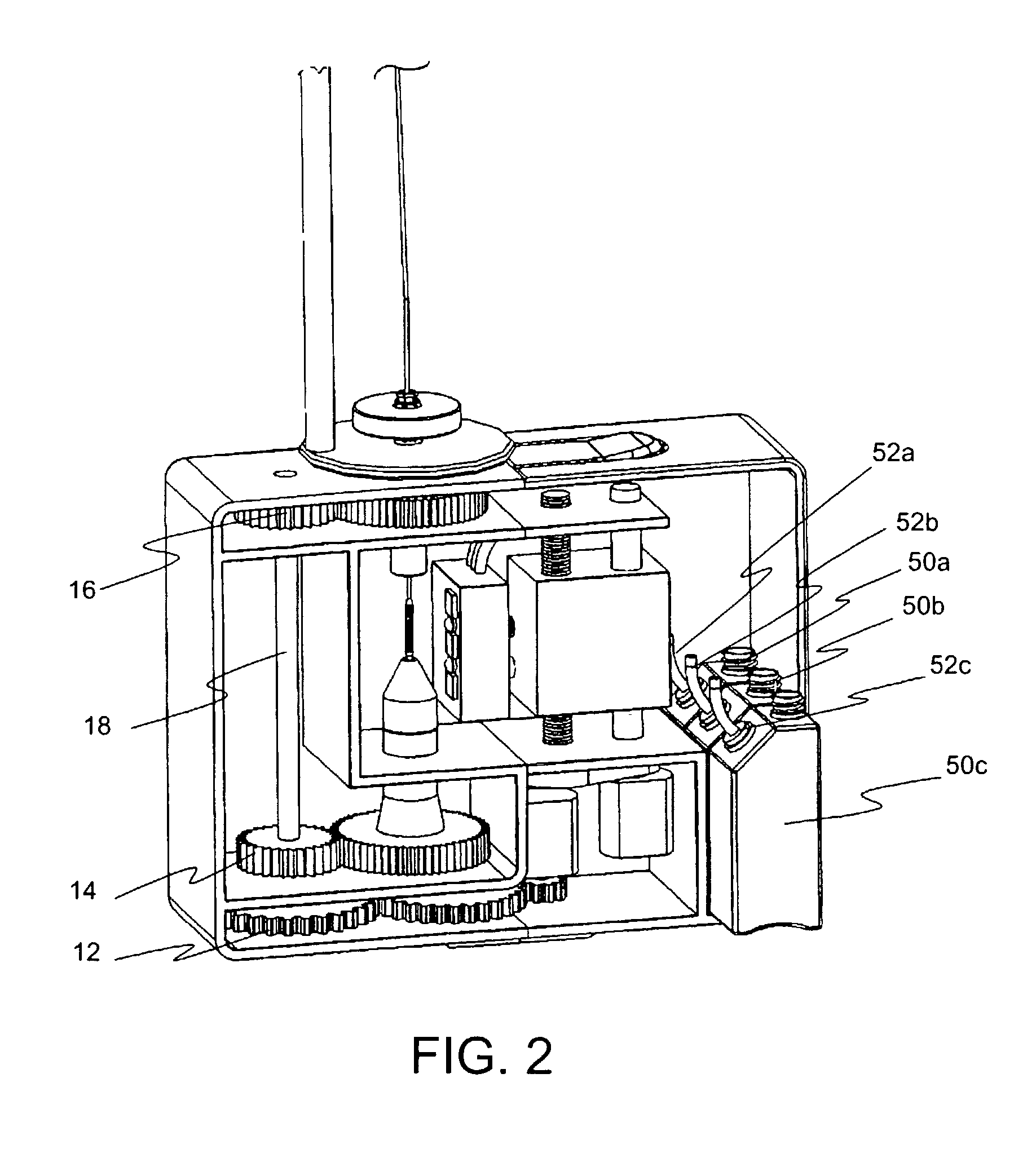

A flexible, sectioned plastic arm for a showerhead comprises a series of interconnected ball-and-socket (B&S) sections (10) with a proximal (shower pipe) end piece (12) and a distal (showerhead) end piece (14). Each B&S section has a proximal (cup or socket) end (10S) and a distal (ball) end (10B). The proximal end piece has a proximal end with female threads which can be screwed onto a shower pipe and a ball-shaped distal end for snapping into the socket of the most proximal section of the shower arm. The distal end piece has a proximal end with a socket for snapping onto the most distal end section of the shower arm and a distal end with male threads (12T) which can be screwed onto the showerhead. The arm has a through hole containing a series or chain of cylindrical brass or other metal sections, tubes, or sleeves (16). These prevent the arm from being bent too far, thereby to keep the B&S from separating. The two end tubes abut a pair of respective resilient spacers (18) or springs (18S), which in turn abut shoulders in the end pieces to keep the series of tubes in place. Inside the series of tubes is a flexible plastic tube (20) for carrying the water without leakage. A T-shaped end fitting (20T) is attached to each end of the plastic tube. These end fittings hold the tube in the arm. The top arm of the T of the distal end fitting sits in the bottom of the female threaded end of the proximal end piece. The top arm of the T of the distal end fitting sits on the very end of the male threaded end of the distal end piece.

Owner:SHOWERTEK

Use of plasma in formation of biodegradable stent coating

Metallic stents are treated with a gaseous species in a plasma state under conditions causing the species to polymerize and to be deposited in polymerized form on the metallic stent surface prior to the application of a drug-polymer mixture, which is done by conventional non-plasma deposition methods. The drug-polymer mixture once applied forms a coating on the stent surface that releases the drug in a time-release manner and gradually erodes, leaving only the underlying plasma-deposited polymer. In certain cases, the plasma-deposited polymer itself erodes or dissolves into the physiological medium over an extended period of time, leaving only the metallic stent. While the various polymers and drug remain on the stent, the plasma-deposited polymer enhances the adhesion of the drug-polymer anchor coating and maintains the coating intact upon exposure to the mechanical stresses encountered during stent deployment.

Owner:XTENT INC

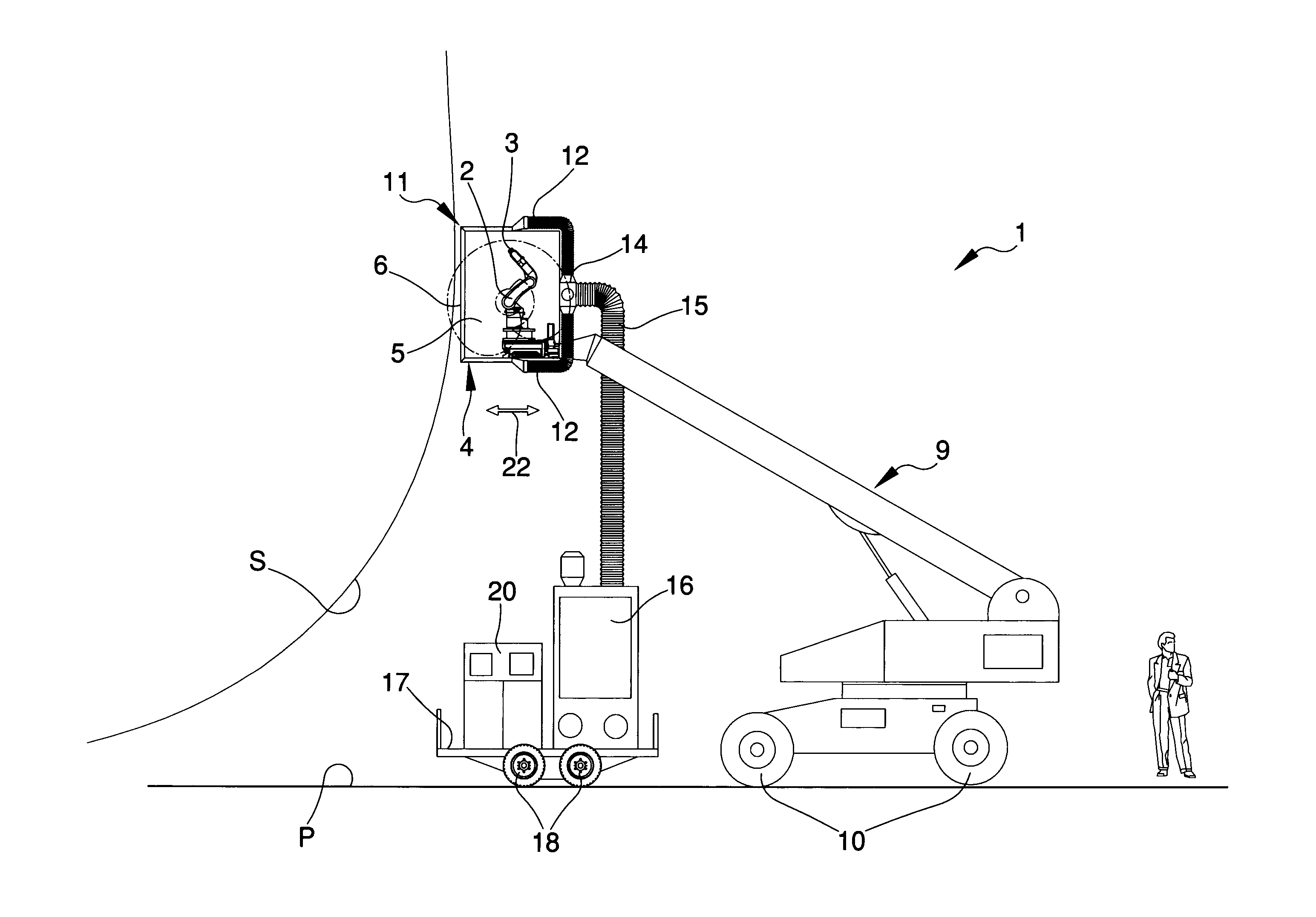

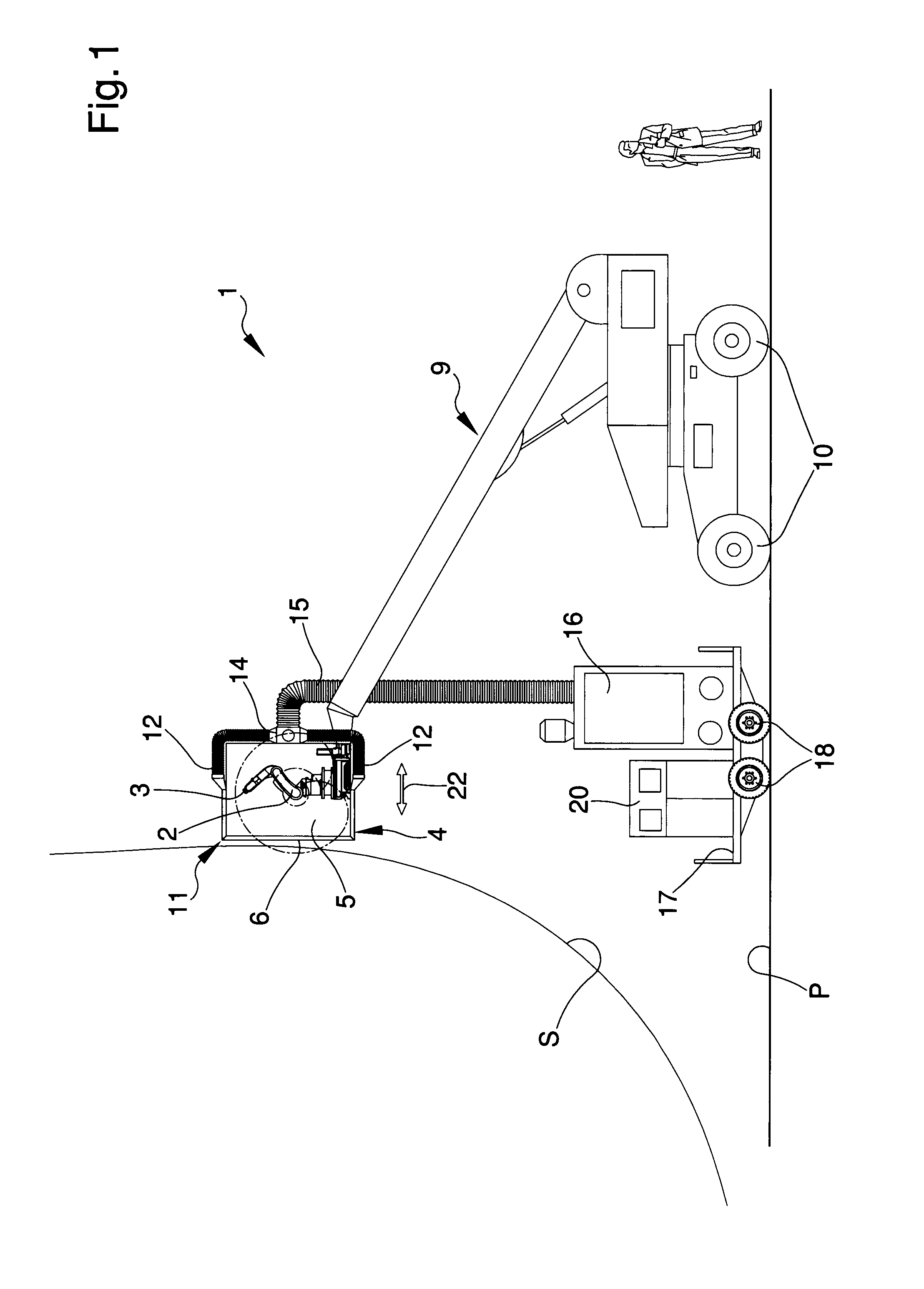

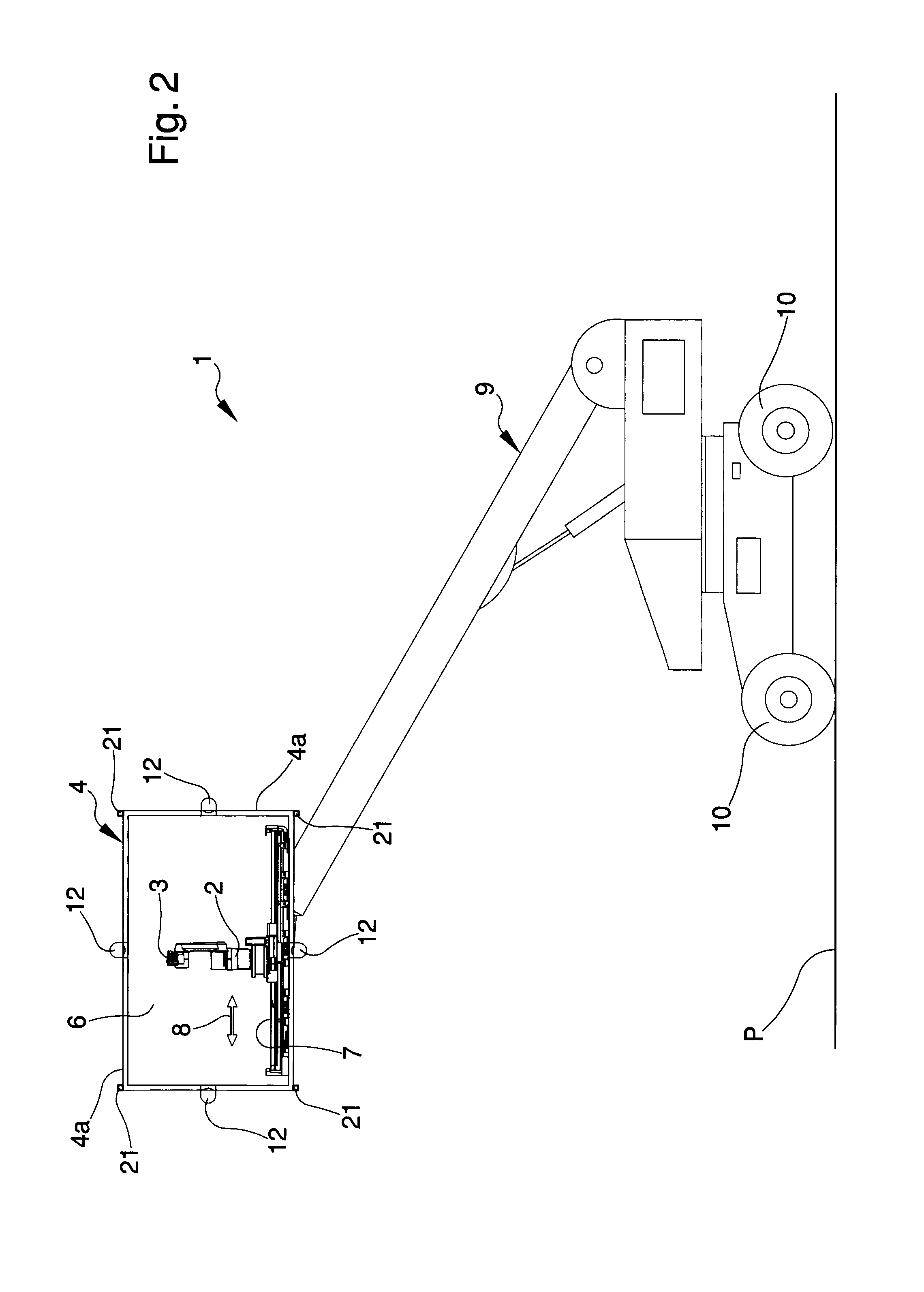

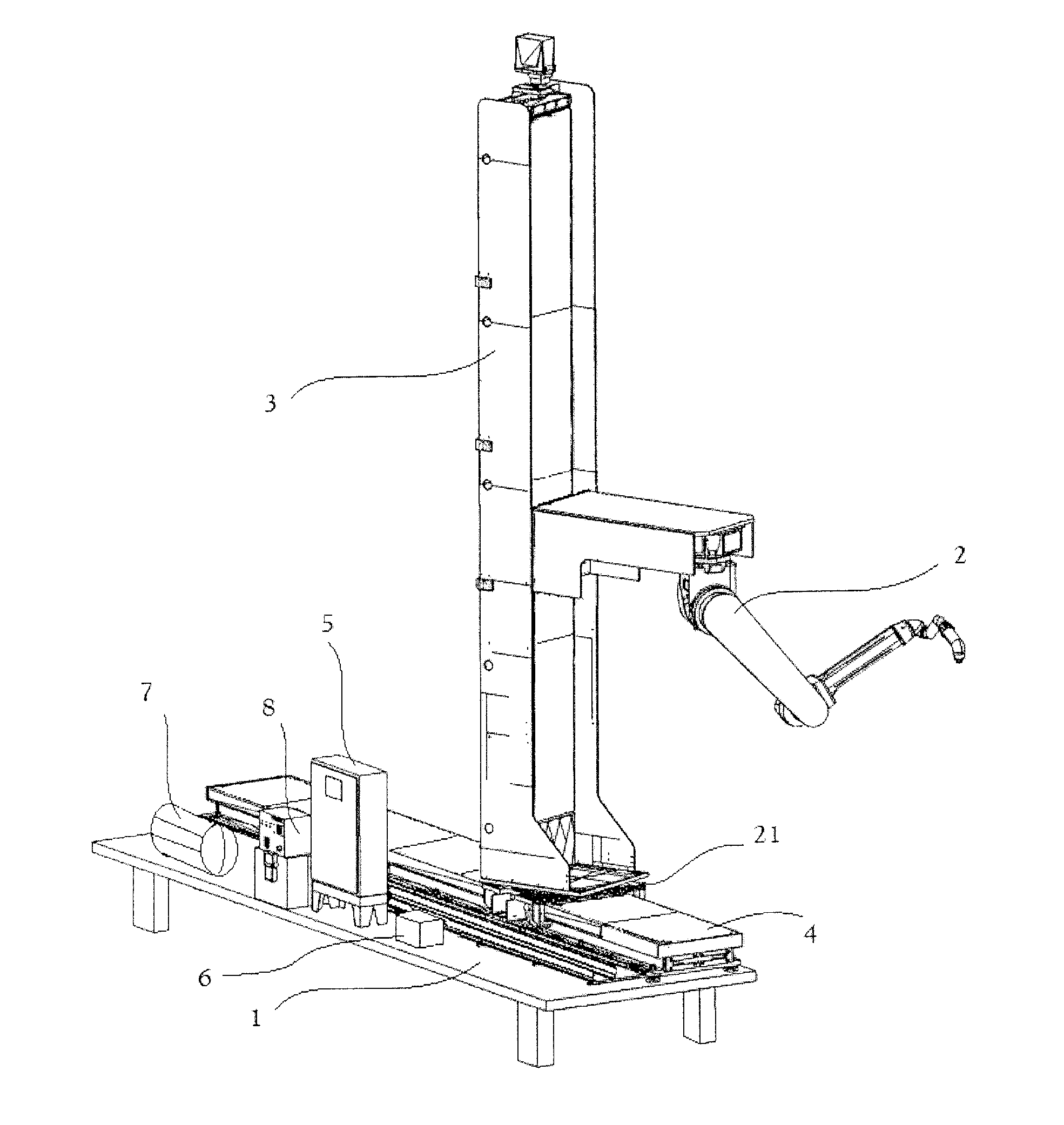

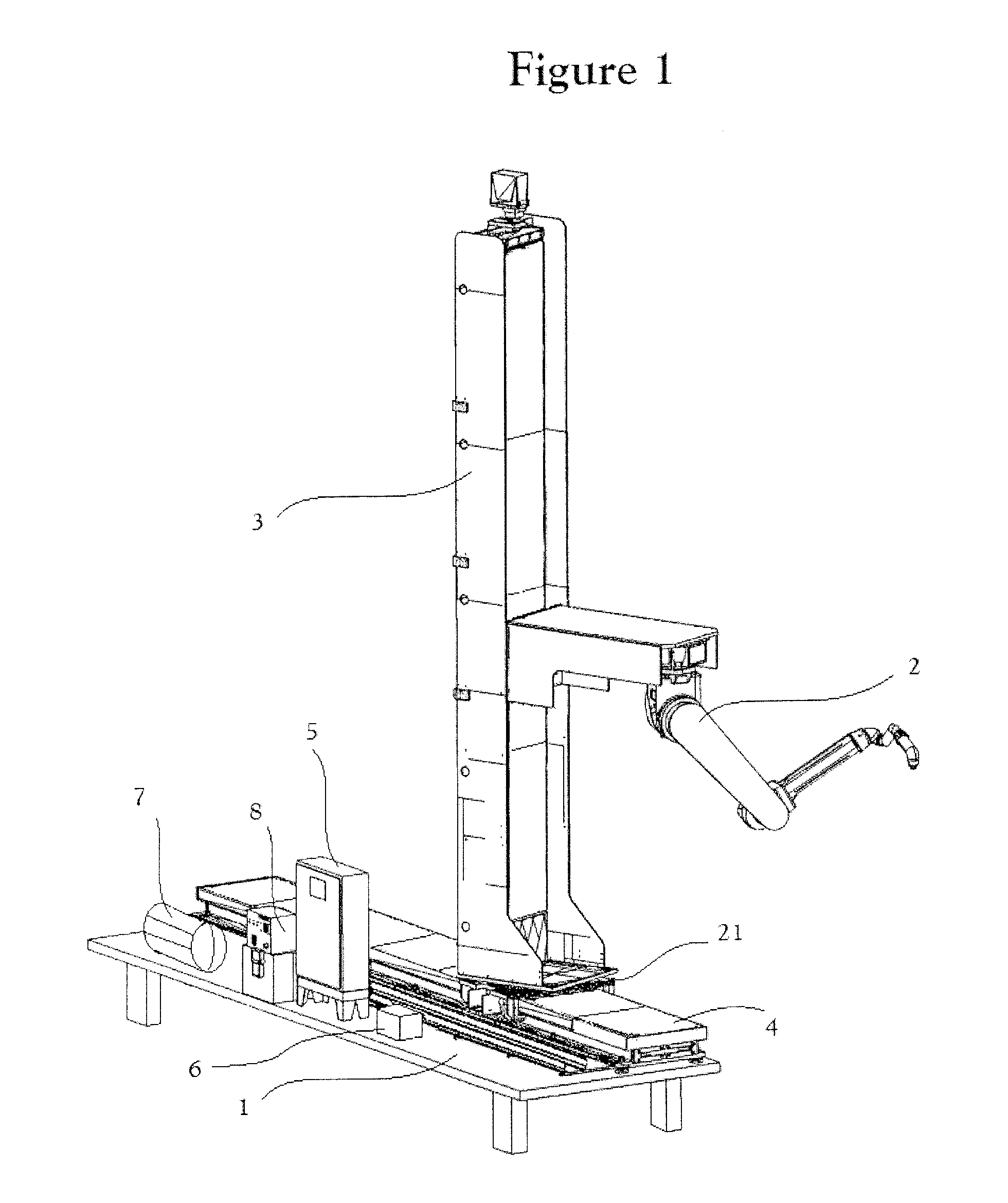

Apparatus and method for the painting of hulls of boats or the like

ActiveUS20130243963A1Reduce in quantityGuaranteed to workDry-dockingSlipwaysCommand and controlControl engineering

Apparatus for painting hulls of boats includes at least an anthropomorphic robot having paint dispensing elements, at least a supporting body which defines a chamber for containing the robot and which includes at least an opening for applying paint on a reference surface, handling elements of the body along at least a direction of moving close to / away from the surface, air suction elements to form a suction stream substantially along the entire surrounding edge of the opening, according to a preset suctionable air flow, command and control elements operatively connected to the handling elements to control movement of the body along the moving direction, sensor elements associated with the body to detect the distance of the surrounding edge from the reference surface and operatively connected to the command and control elements, the latter being programmed to adjust the distance of the surrounding edge of the opening from the reference surface.

Owner:RINA VINCENZO

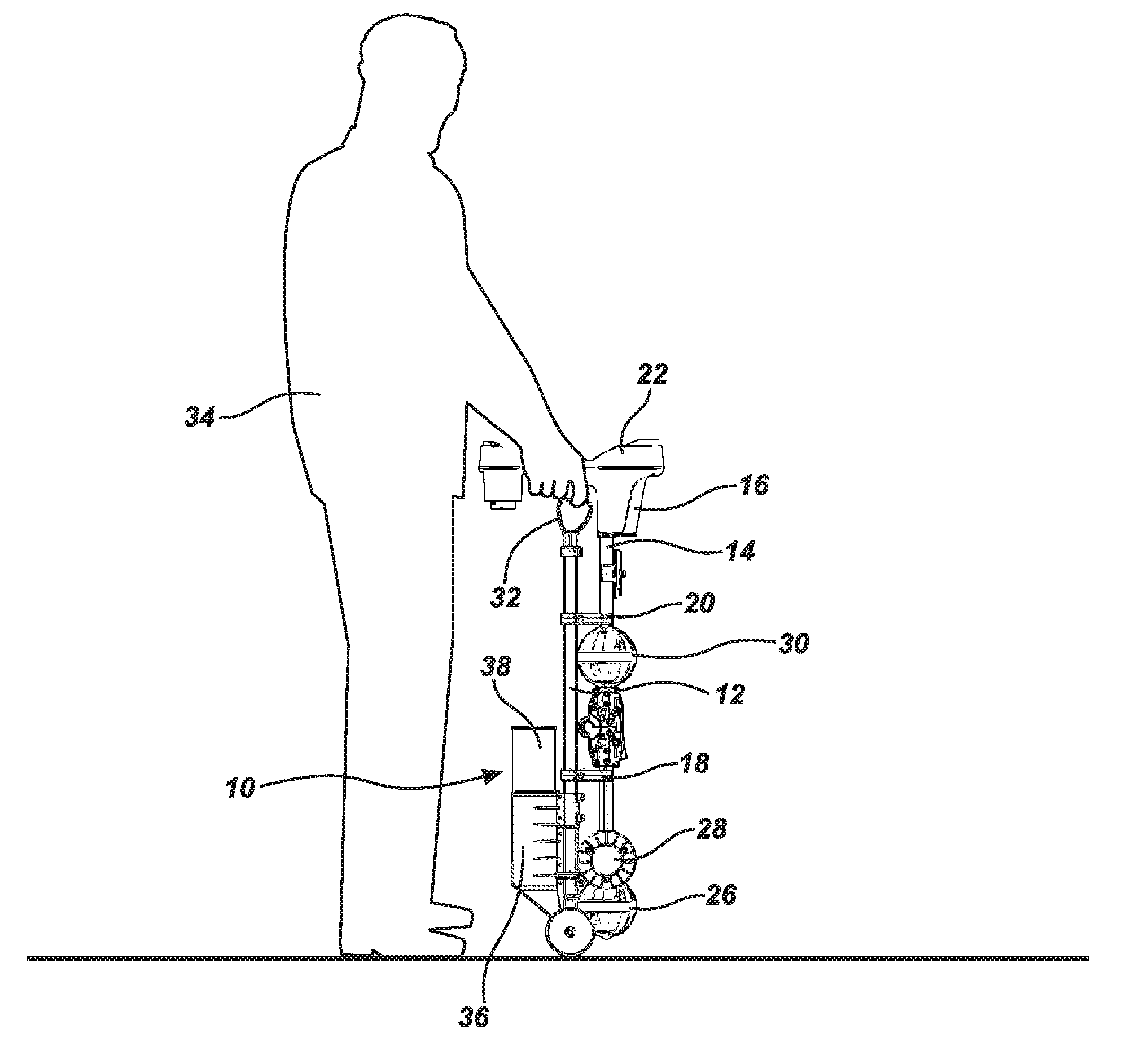

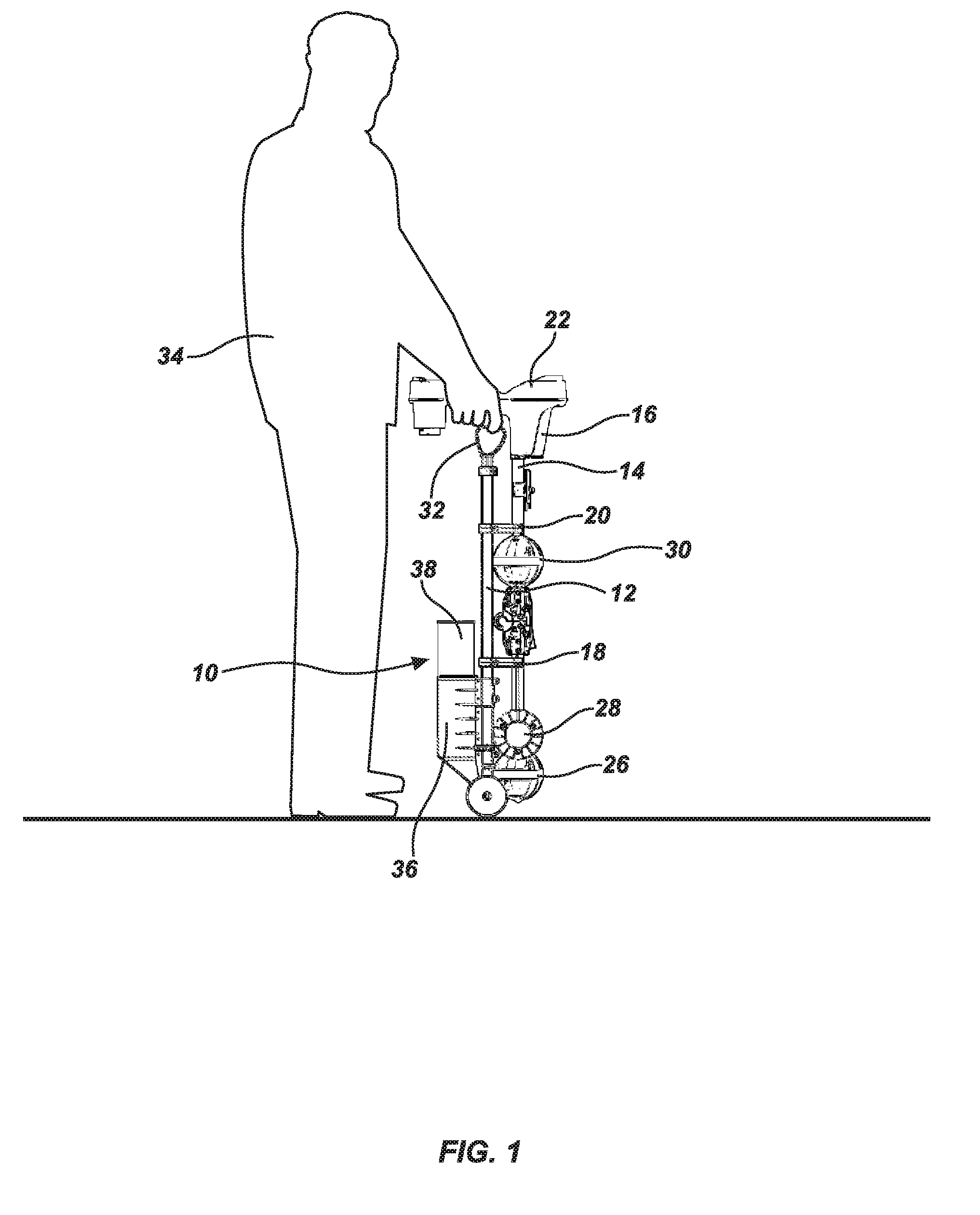

Marking Paint Applicator for Portable Locator

A marking paint applicator for a portable electronic locator that locates buried cables and pipes via electromagnetic emissions includes an elongated support structure and a manually moveable trigger mechanism mounted adjacent an upper end of the support structure. At least one bracket assembly is provided for removably connecting the support structure to an antenna mast of the portable locator so that the trigger mechanism will be adjacent a handle of the locator and the trigger mechanism can be squeezed by a finger of an operator's hand while grasping the handle. A receptacle is mounted to the support structure for carrying an inverted aerosol paint can and positioning a valve stem of the aerosol paint can for spraying paint onto the ground to mark the location of a buried cable or pipe. An actuating mechanism is capable of selectively deflecting the valve stem to cause the aerosol paint can to spray paint onto the ground to mark the location of a buried cable or pipe. A linkage connects the trigger mechanism to the actuating mechanism for deflecting the valve stem when the trigger mechanism is squeezed.

Owner:SEEKTECH A CALIFORNIA CORP

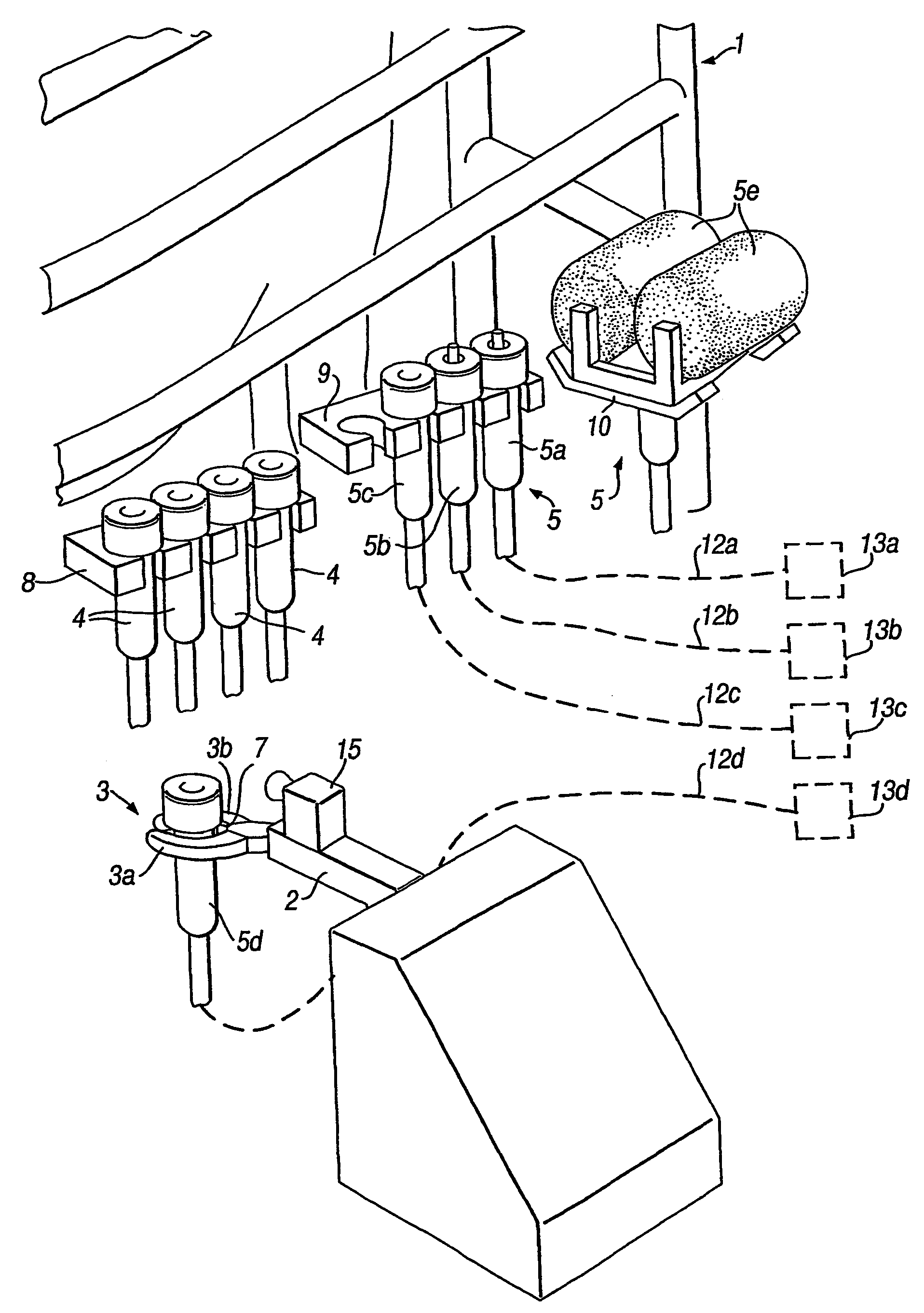

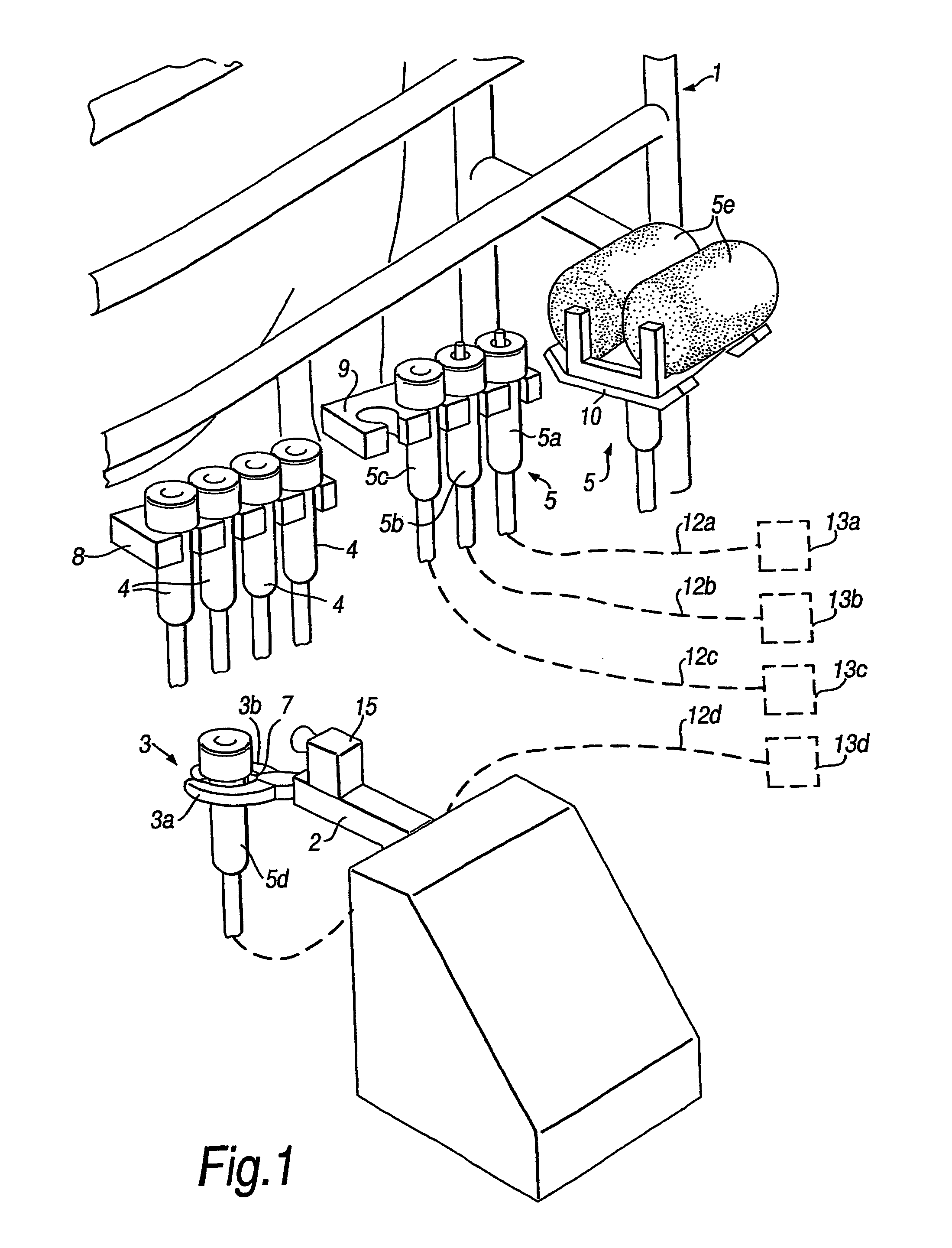

Method and apparatus for treating the teats of an animal

InactiveUS7377232B2Good choiceImprove versatilityLiquid surface applicatorsCathetersAnimal scienceMedicine

In an automatic milking installation including a robot arm (2) with a gripper (3) for attaching teat cups (4) to the teats of an animal, e.g. a cow, to be milked, for applying a teat dip to the teats after milking different members, such as spray nozzles (5a, 5b), dipping cups (5c, 5d) and sponge or cloth rollers (5e), are provided for applying different teat dip compositions. Under the control of a computer, the robot arm collects the member (5) appropriate for supplying the selected composition and takes it to a position appropriate for application of that composition. The selection can e effected in dependence upon the teat skin condition, e.g. detected by a camera (15) and / or environmental conditions.

Owner:DELAVAL HLDG AB

Drip irrigation lines

InactiveUS6302338B1Reduce sensitivityAbility to saveClimate change adaptationWatering devicesWater dischargePore water pressure

A drip irrigation line includes a plurality of emitter units secured within a water supply tube such that each emitter unit defines with the tube a flow-control passageway having an inlet port communicating with the interior of the water supply tube and an outlet port communicating with a water discharge opening in the water supply tube. Each emitter unit includes a one-way valve at one of the ports. Such port has an opening circumscribed by a cylindrical boss, and the one-way valve thereat includes a cap having a skirt of elastomeric material normally engaging the outer surface of the cylindrical boss to block reverse water flow into the flow-control passageway, but is deformable under water pressure to permit forward flow from the tube interior into the flow-control passageway.

Owner:COHEN

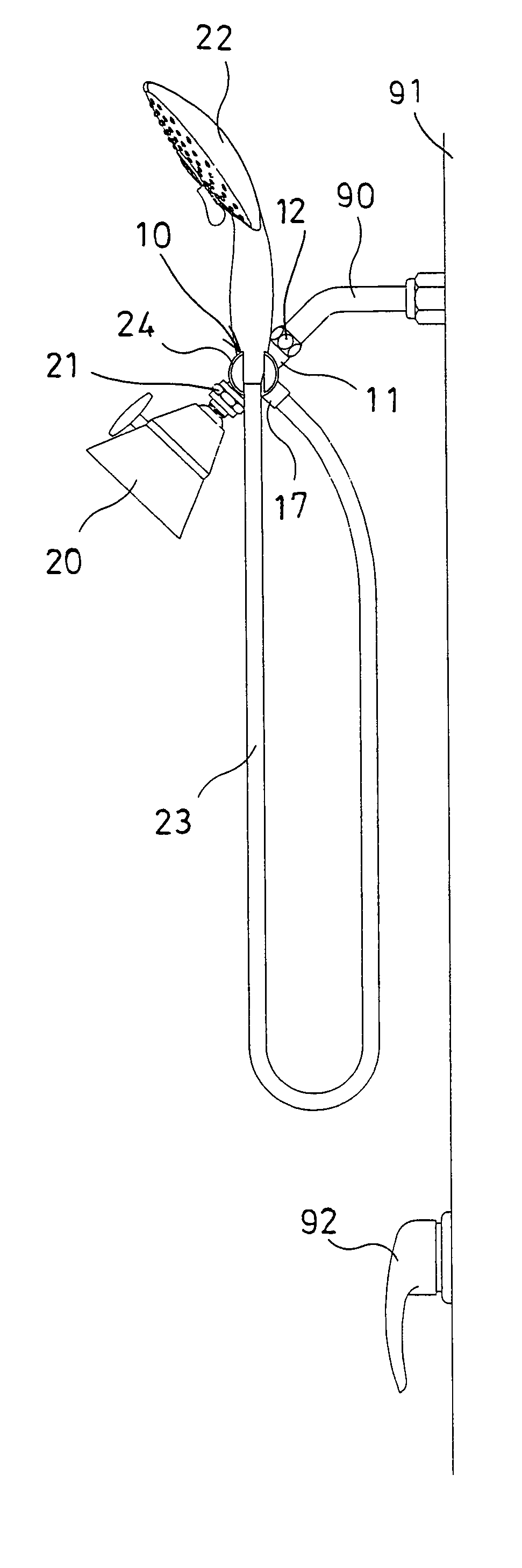

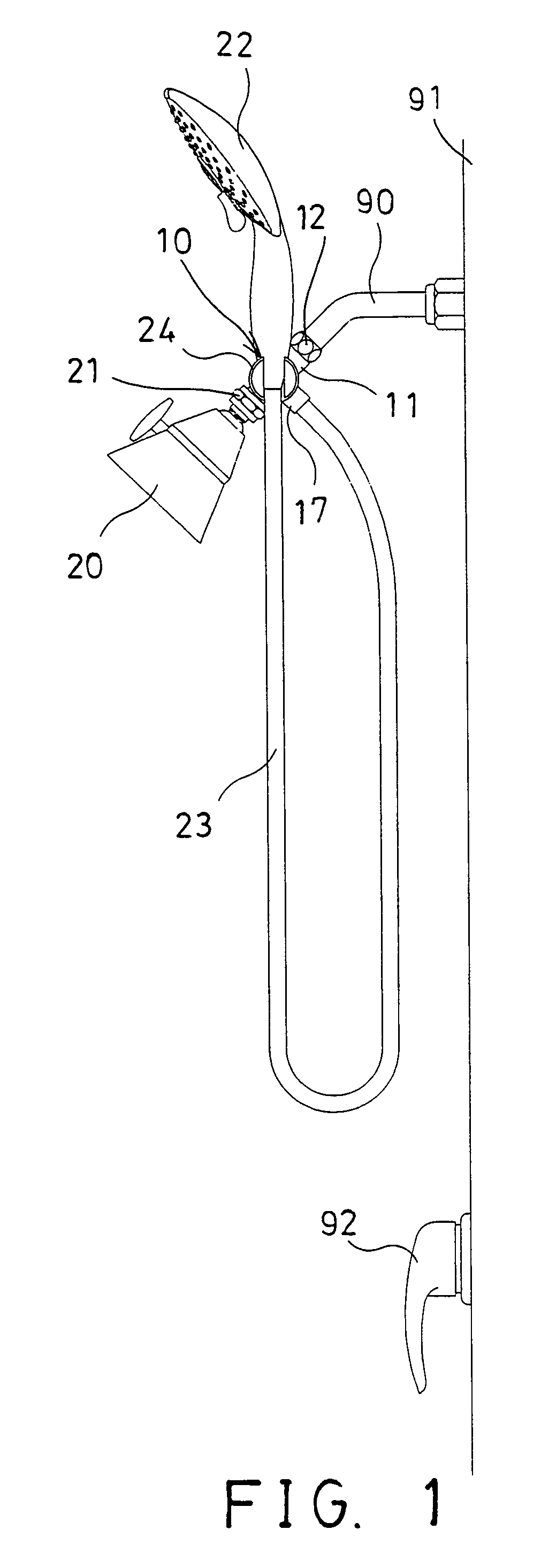

Holder device for shower head and nozzle

Owner:INTERLINK PROD INT INC

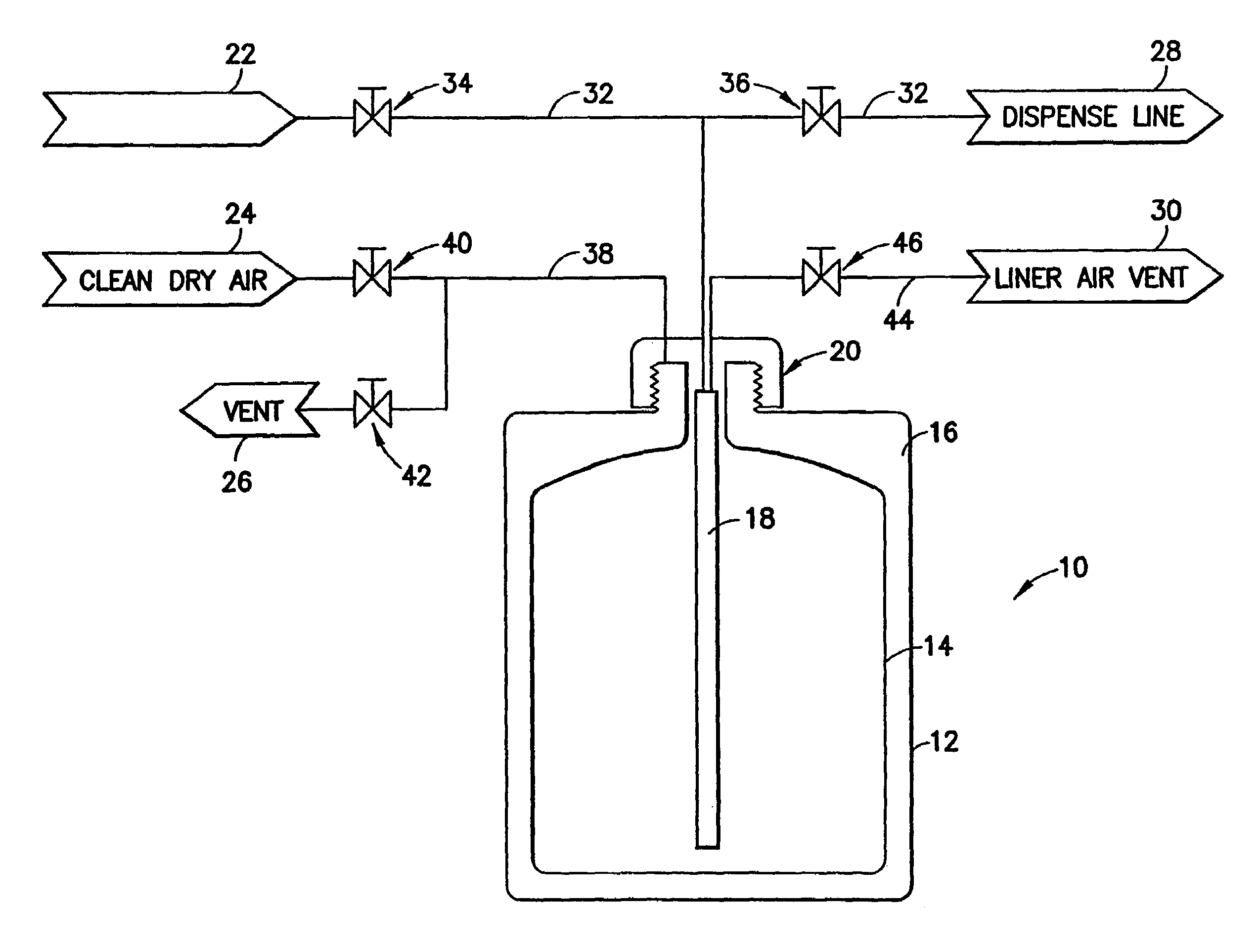

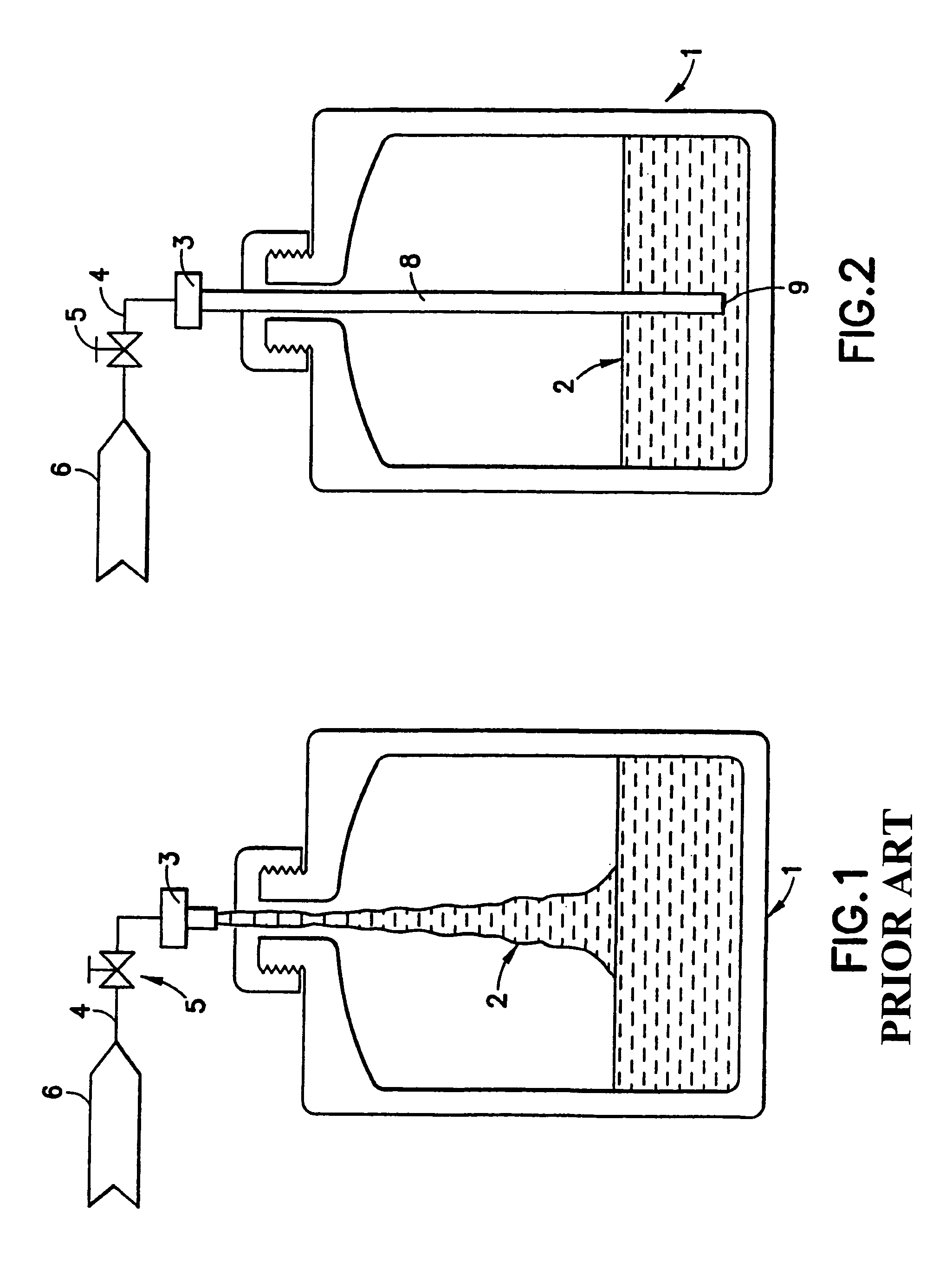

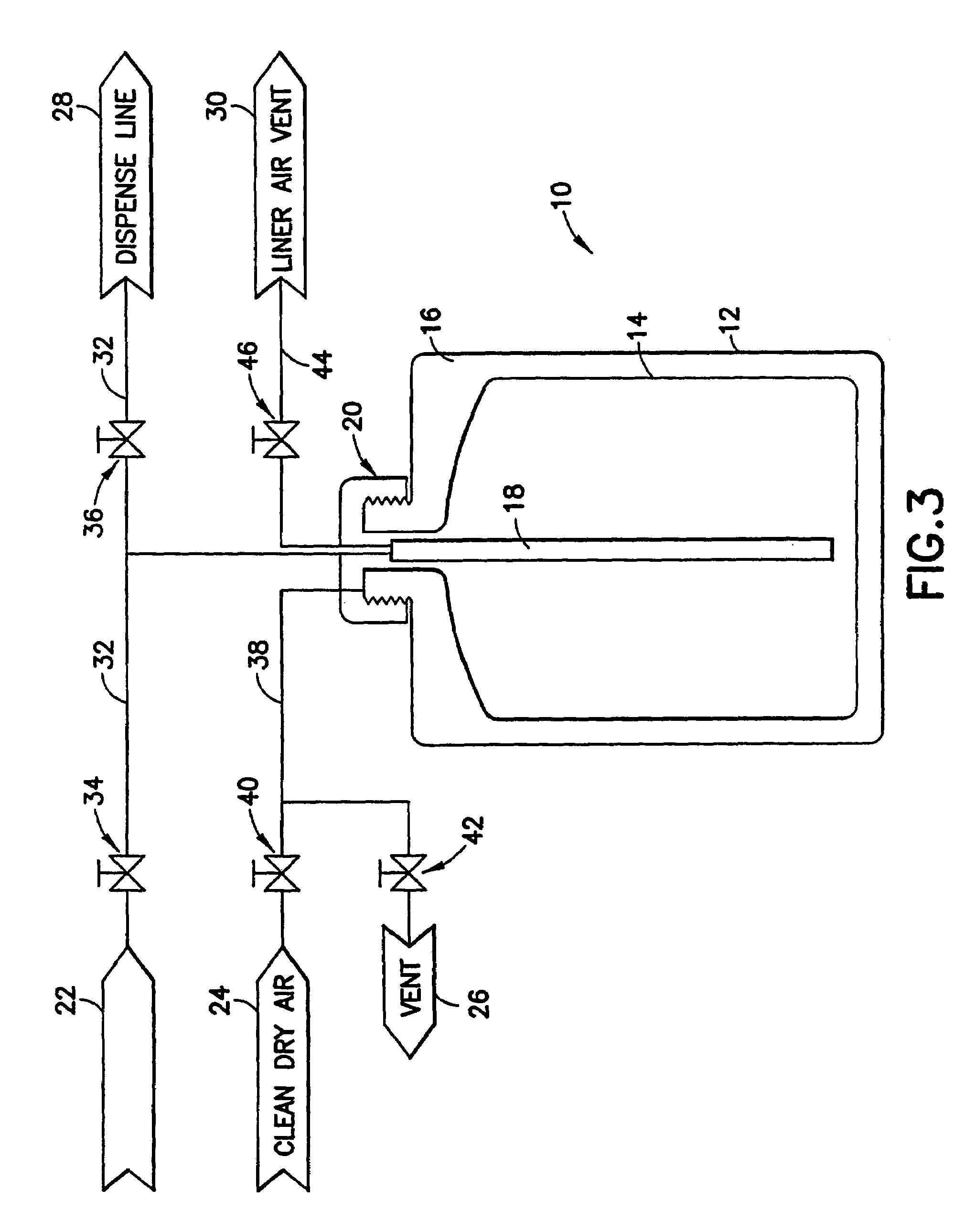

Apparatus and method for minimizing the generation of particles in ultrapure liquids

ActiveUS7188644B2Reduce Particle GenerationLess particle generationSpraying apparatusLiquid transferring devicesAir liquid interfaceEngineering

A system and method of reducing particle generation in packaging containers used to transport ultra pure liquids. Particle generation in the containers is reduced by reducing the air-liquid interface present during filling, transport, and dispensing of the liquid.

Owner:ADVANCED TECH MATERIALS INC

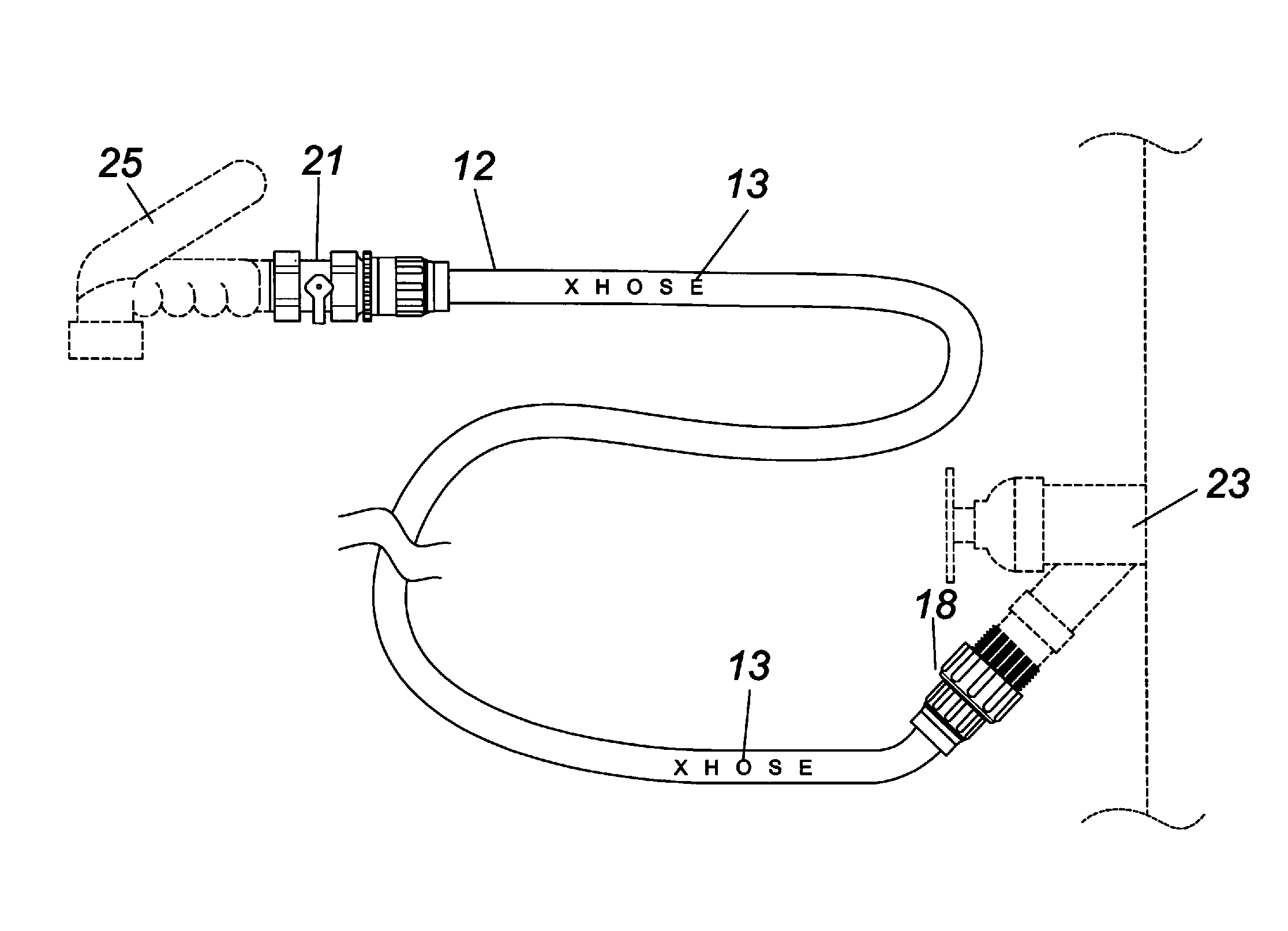

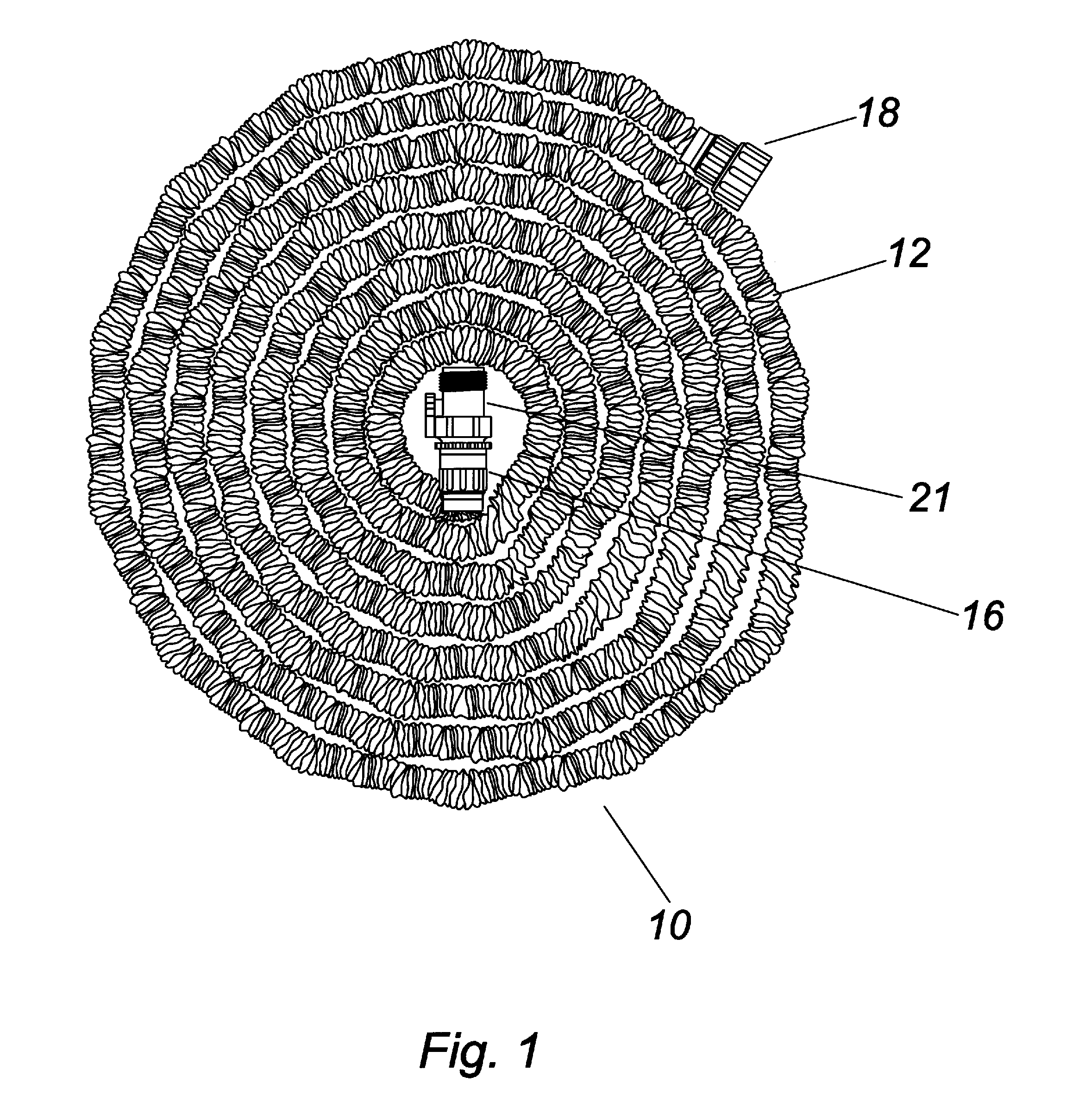

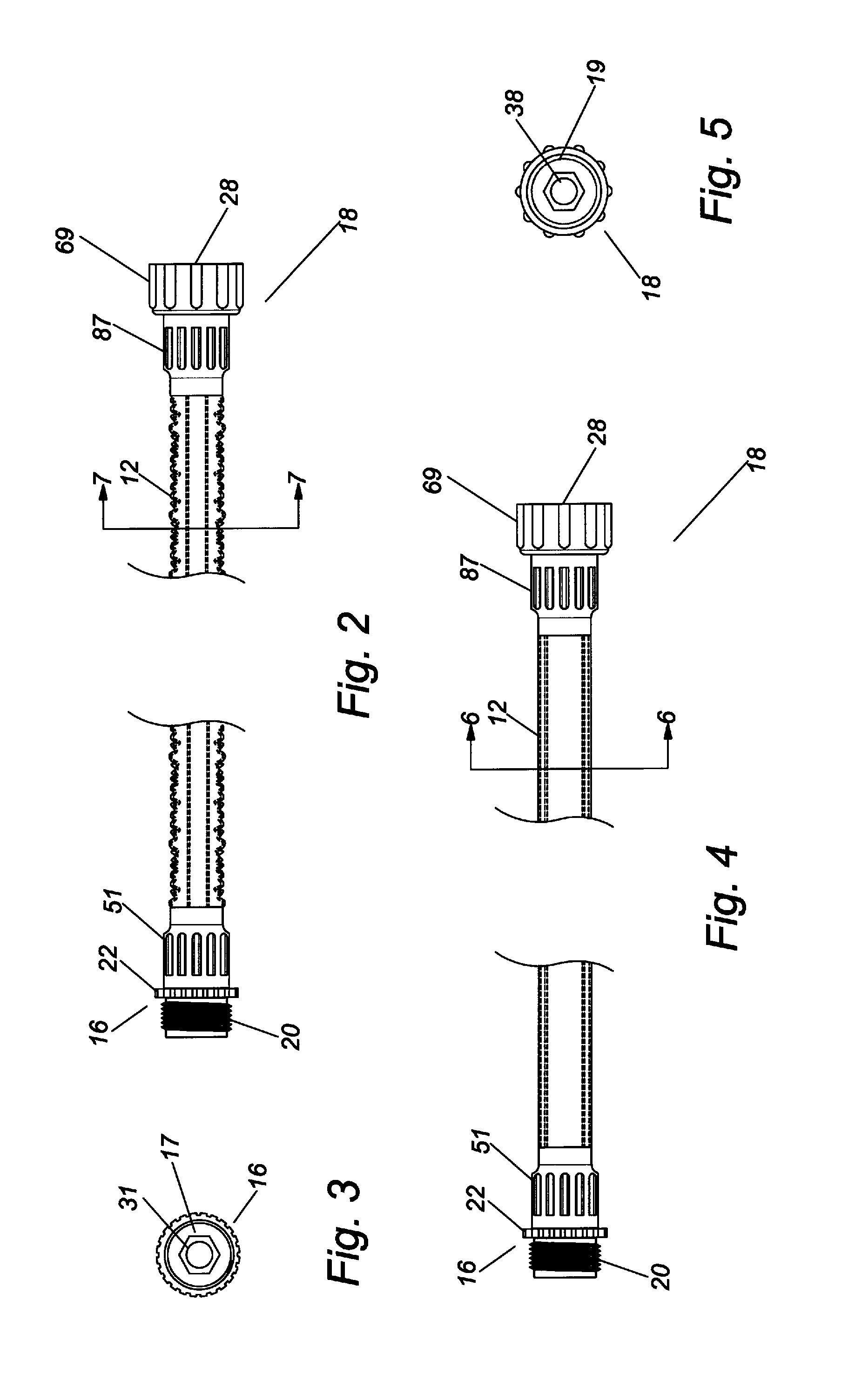

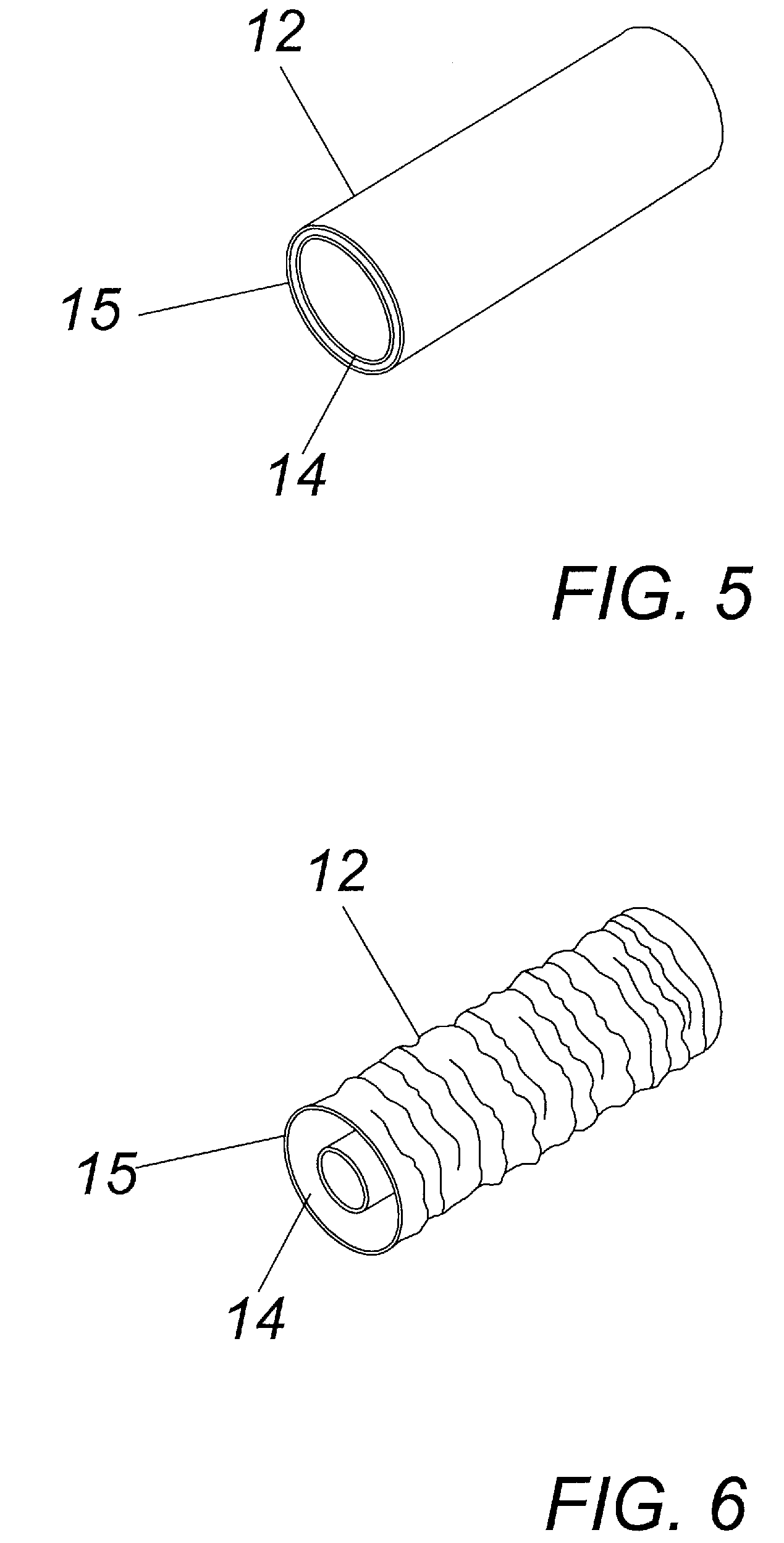

Expandable and contractible hose

A hose which automatically expands longitudinally and automatically expands laterally upon the application of a fluid pressure is disclosed. The hose can automatically expand longitudinally up to six times its unexpanded or contracted length. Upon release of the fluid pressure within the hose, the hose will automatically contract to a contracted condition. The hose includes an inner tube made from an elastic material and an outer tube made from a non-elastic material. The inner tube is positioned concentrically within the outer tube in both a contracted condition and an expanded condition. The outer tube is secured to the inner tube only at a first end of the inner and outer tubes and at a second end of the inner and outer tubes. The outer tube moves laterally and longitudinally with respect to the inner tube when the tubes are transitioning between a contracted condition and an expanded condition.

Owner:TELEBRANDS CORP

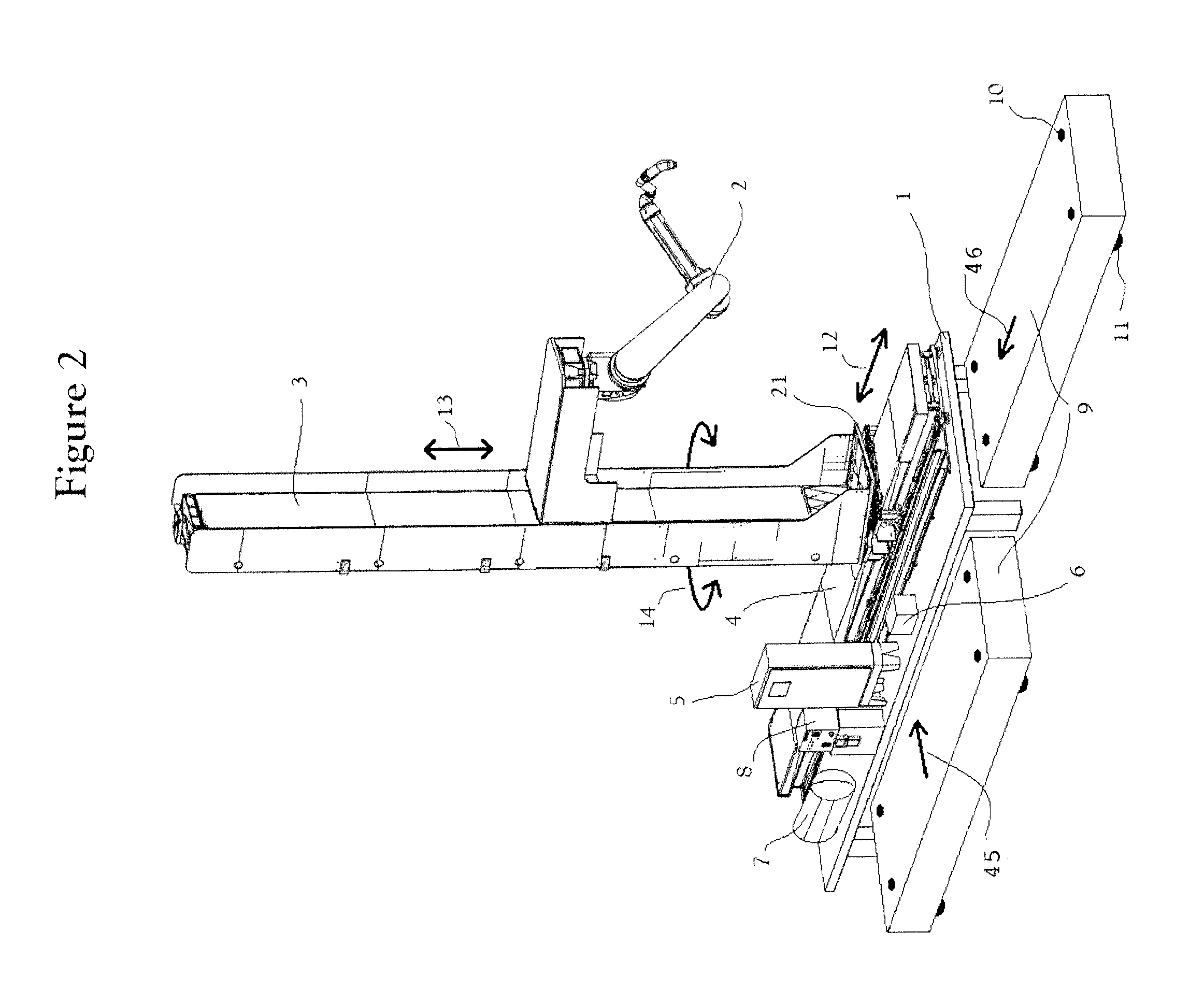

Robotic system for applying surface finishes to large objects

InactiveUS20150375390A1Economically efficientProgramme-controlled manipulatorSpraying apparatusRobotic systemsSurface finishing

A robotic system for performing surface finishing processes on a large object, is provided, the system includes at least one platform having a connected robot, the robot performing a surface finishing process on the large object. Also included is an automatic guided vehicle (AGV) separable of the platform movable independent of the platform for moving under the platform, lifting up the platform and moving the platform multiple locations along or around the large object to extend a useful working envelope of the robot.

Owner:ENCORE AUTOMATION

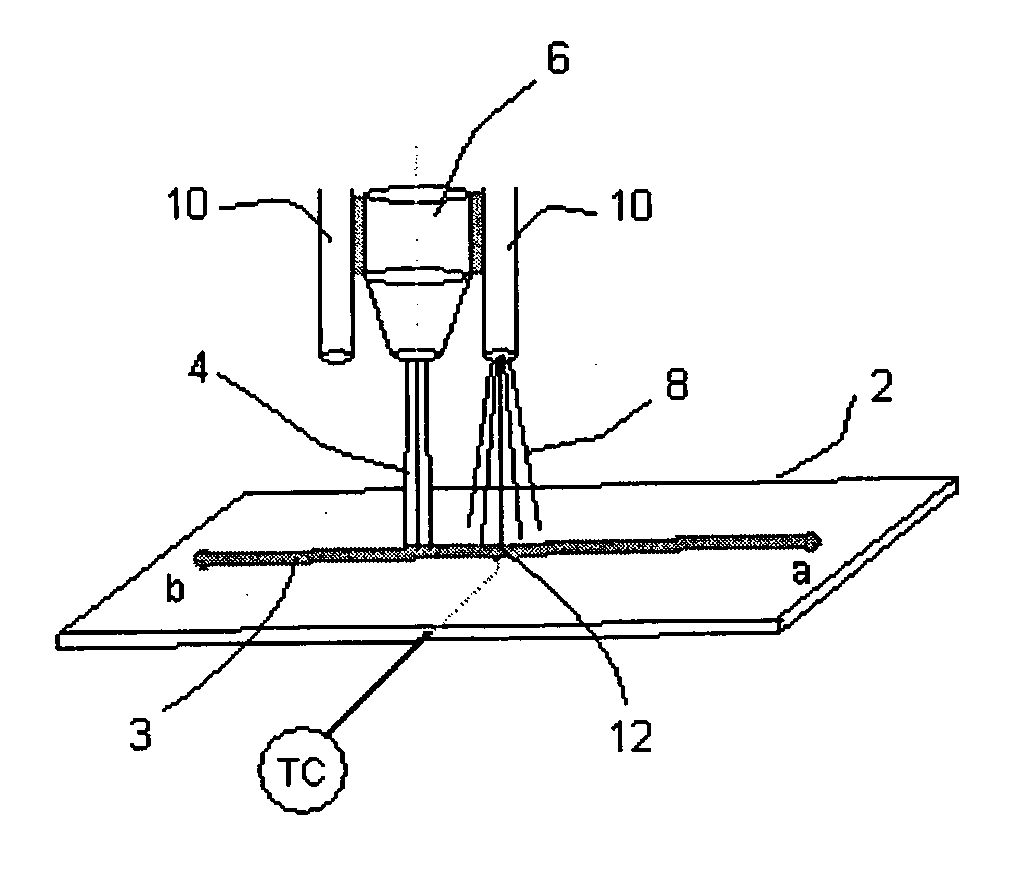

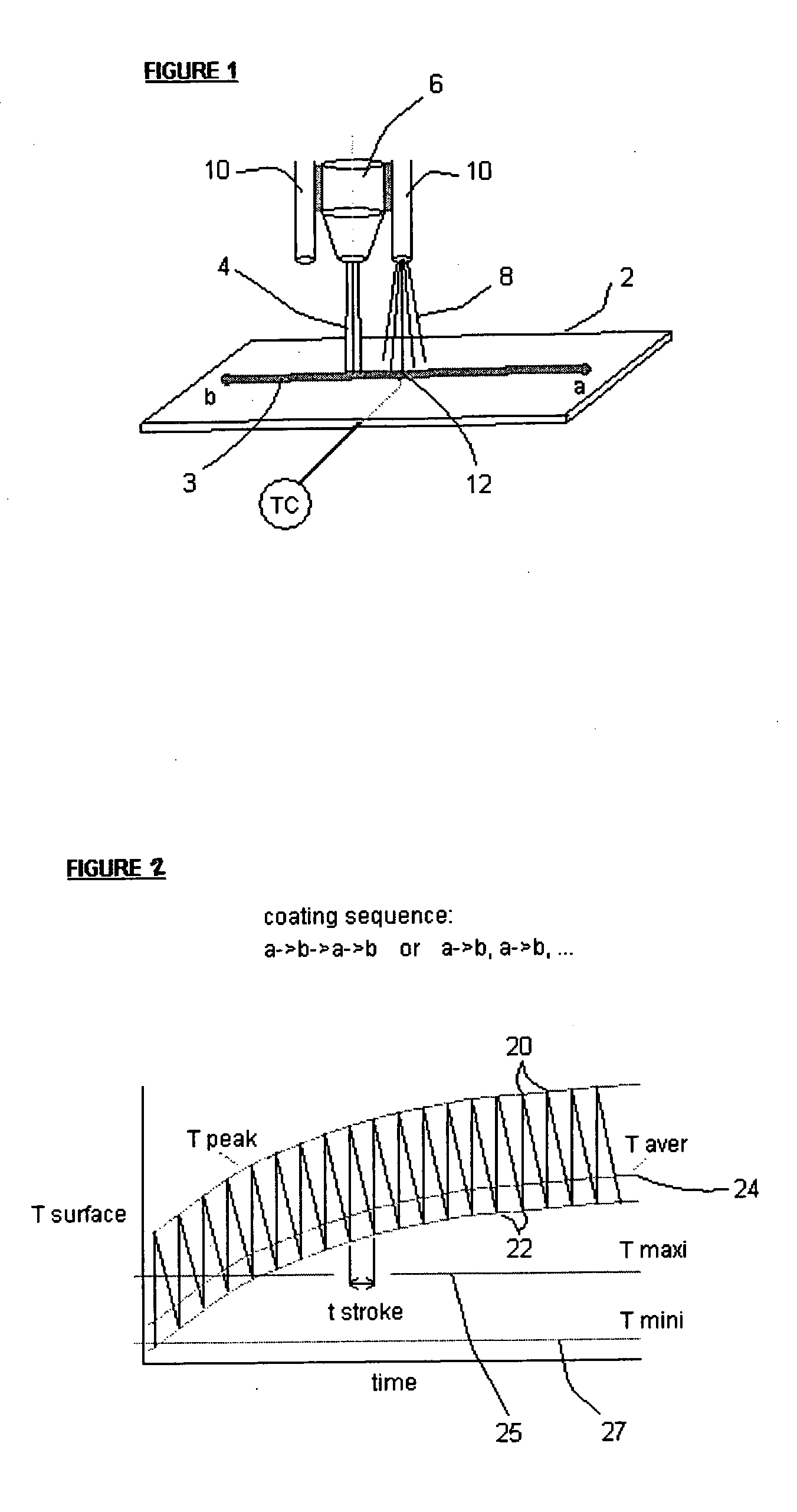

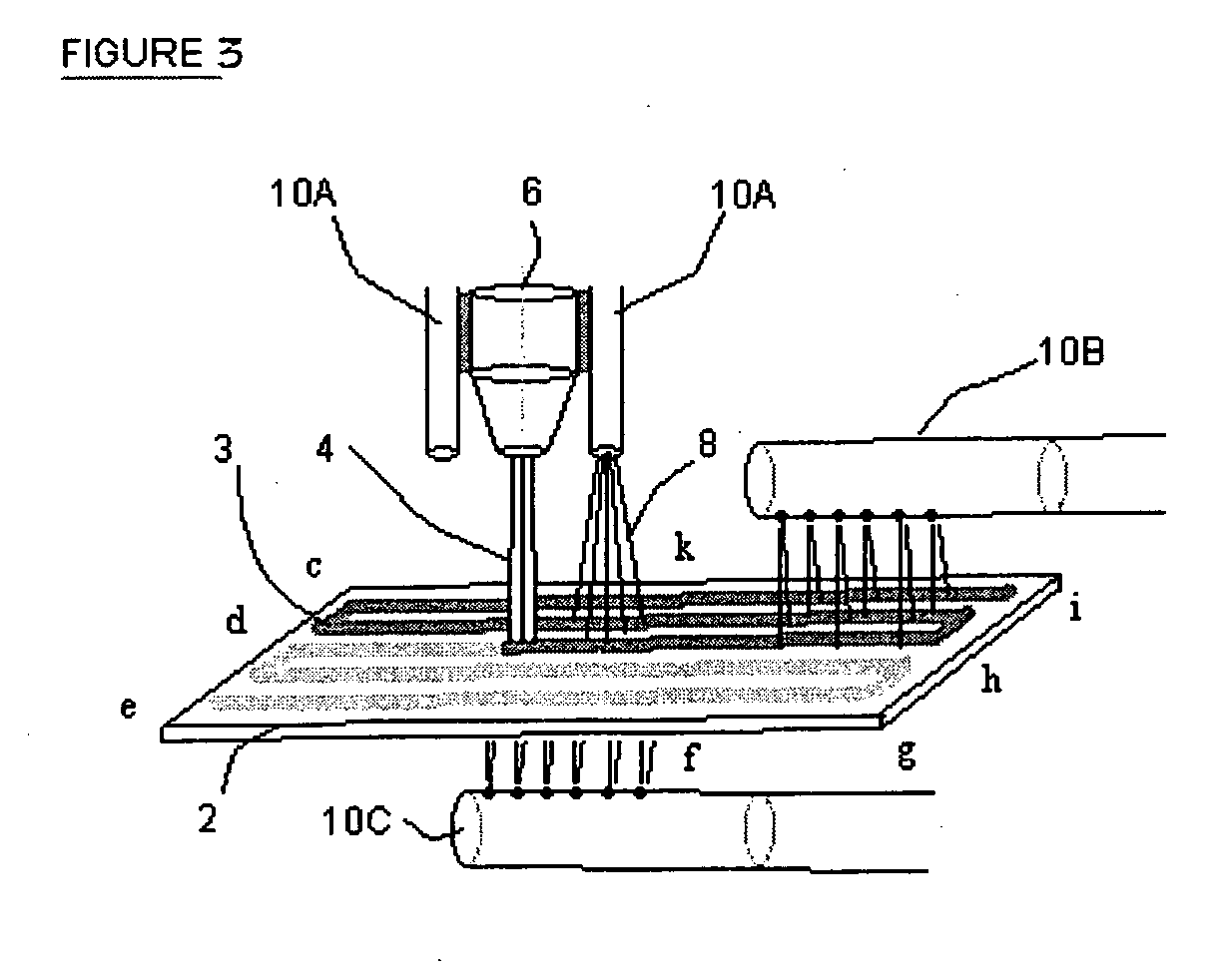

Thermal deposition coating method

ActiveUS20060228465A1Excellent coating production rateDamaging internal stressLiquid surface applicatorsMolten spray coatingThermal depositionRelative motion

A process for the thermal deposition coating of a workpiece, said process comprising the steps of: (c) thermally depositing a coating on a metallic surface of a workpiece from a deposition head wherein at least one condition selected from the group of: coating deposition rate onto said surface, relative motion between the surface and said deposition head, and cryogenic coolant application rate onto said workpiece is controllable; (d) substantially simultaneously measuring temperatures at a plurality of locations over the metallic surface of the workpiece; (c) determining an average temperature of the temperatures measured in step (b); (d) comparing the average temperature to a preselected minimum temperature and a preselected maximum temperature for the workpiece; and (e) adjusting at least one of the controllable conditions if said average temperature is not between the preselected minimum temperature and the preselected maximum temperature for the workpiece. Standard deviations of all temperature readings and controlling the relative motion speed between the thermal coating deposition head and the workpiece provide another improvement for obtaining temperature uniformity over the workpiece surface.

Owner:AIR PROD & CHEM INC

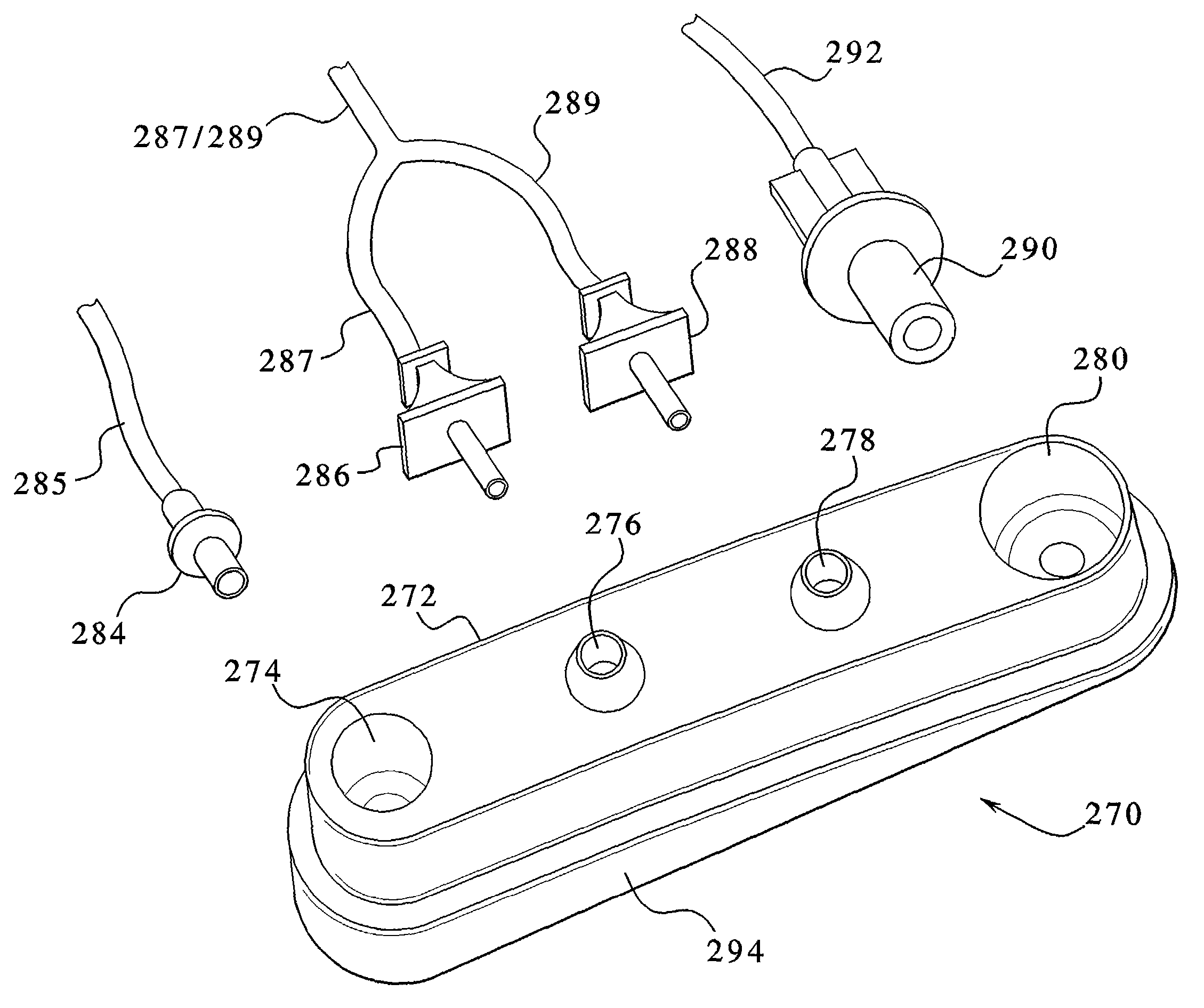

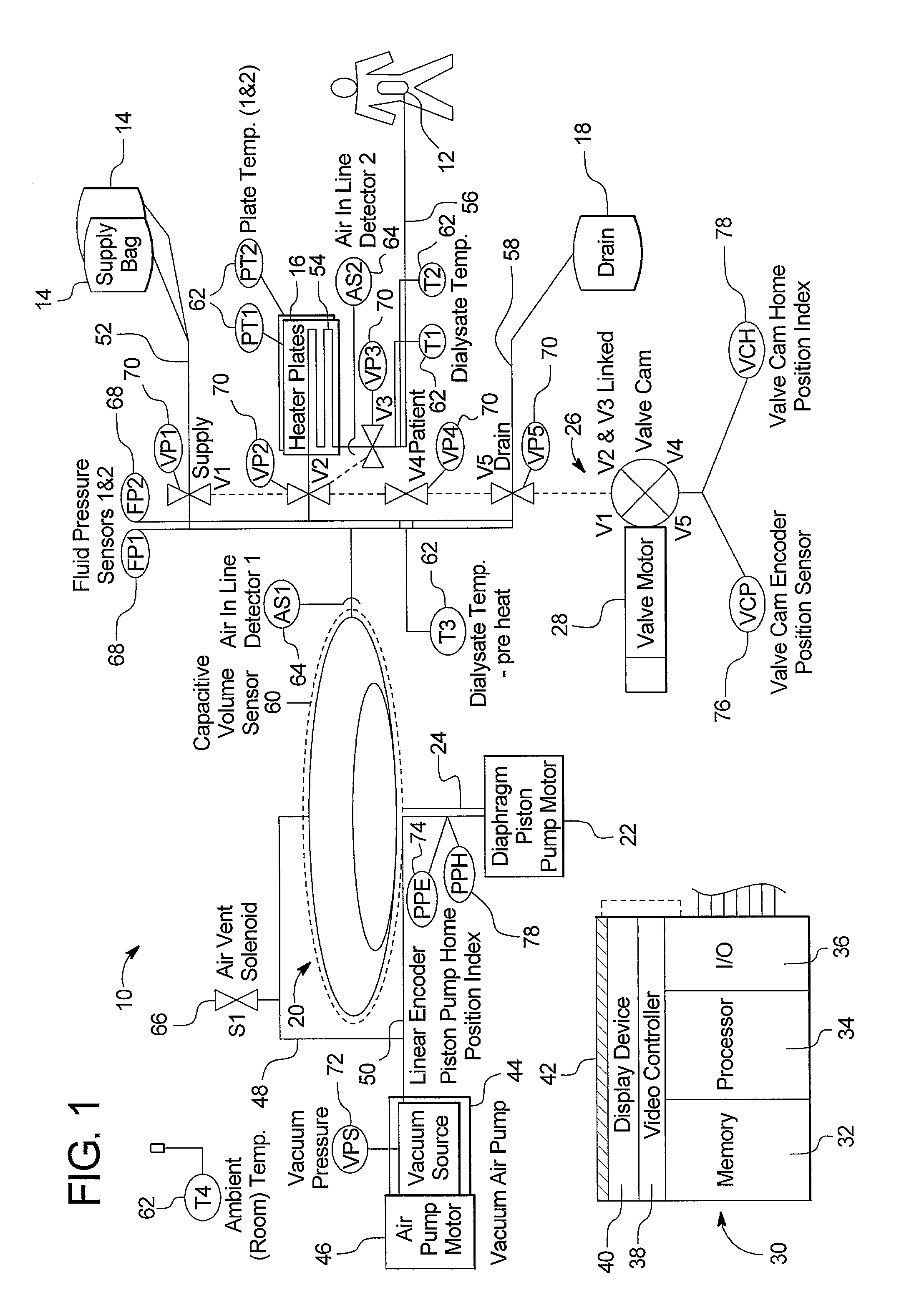

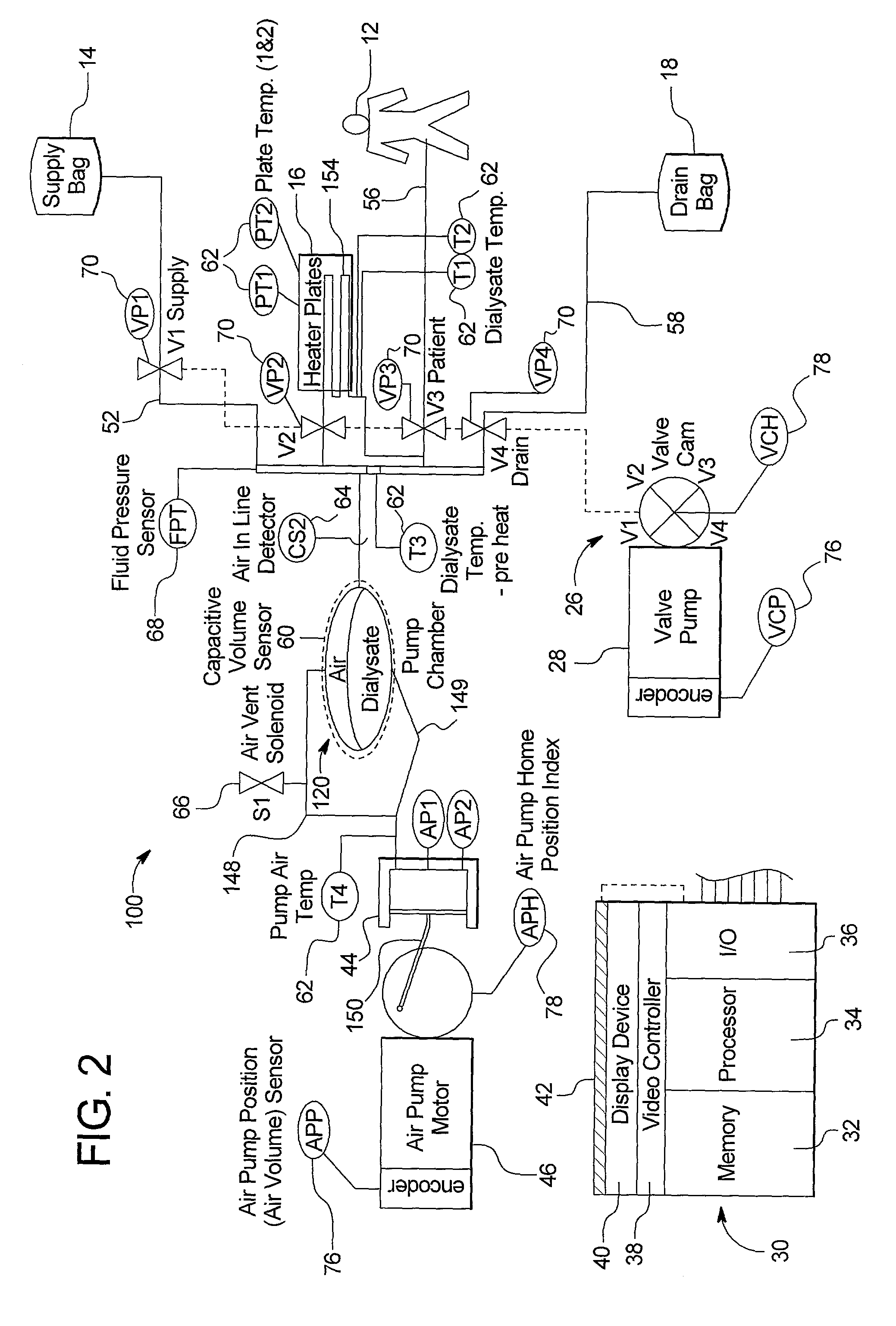

One-piece tip protector and organizer

A method, system and apparatus for performing peritoneal dialysis are provided. To this end, in part, a device for organizing a number of tubes extending from a unit of a medical fluid system is provided. The organizing device includes a body having a number of openings that each can removably receive an end of one of the number of tubes.

Owner:BAXTER HEALTHCARE SA +1

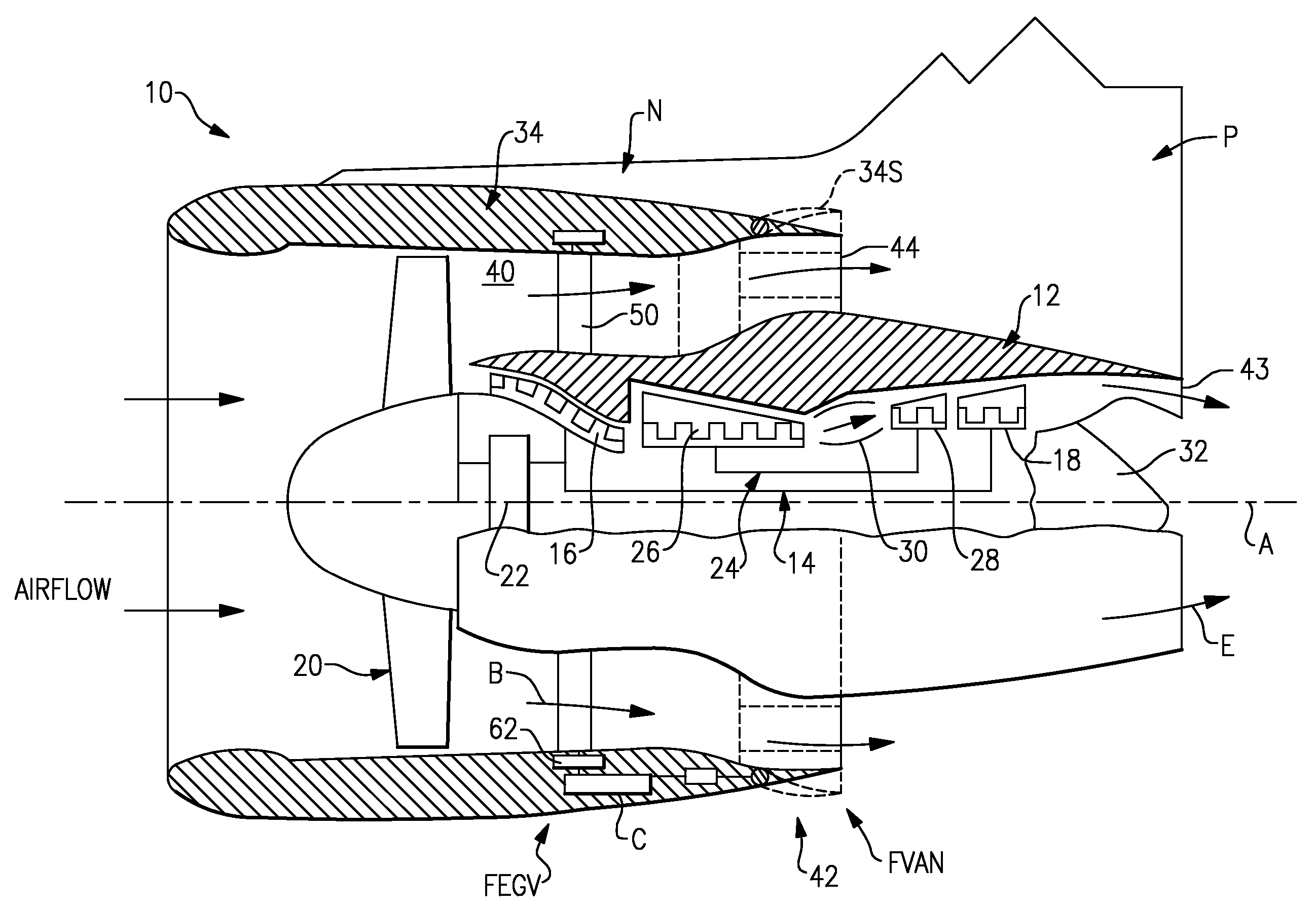

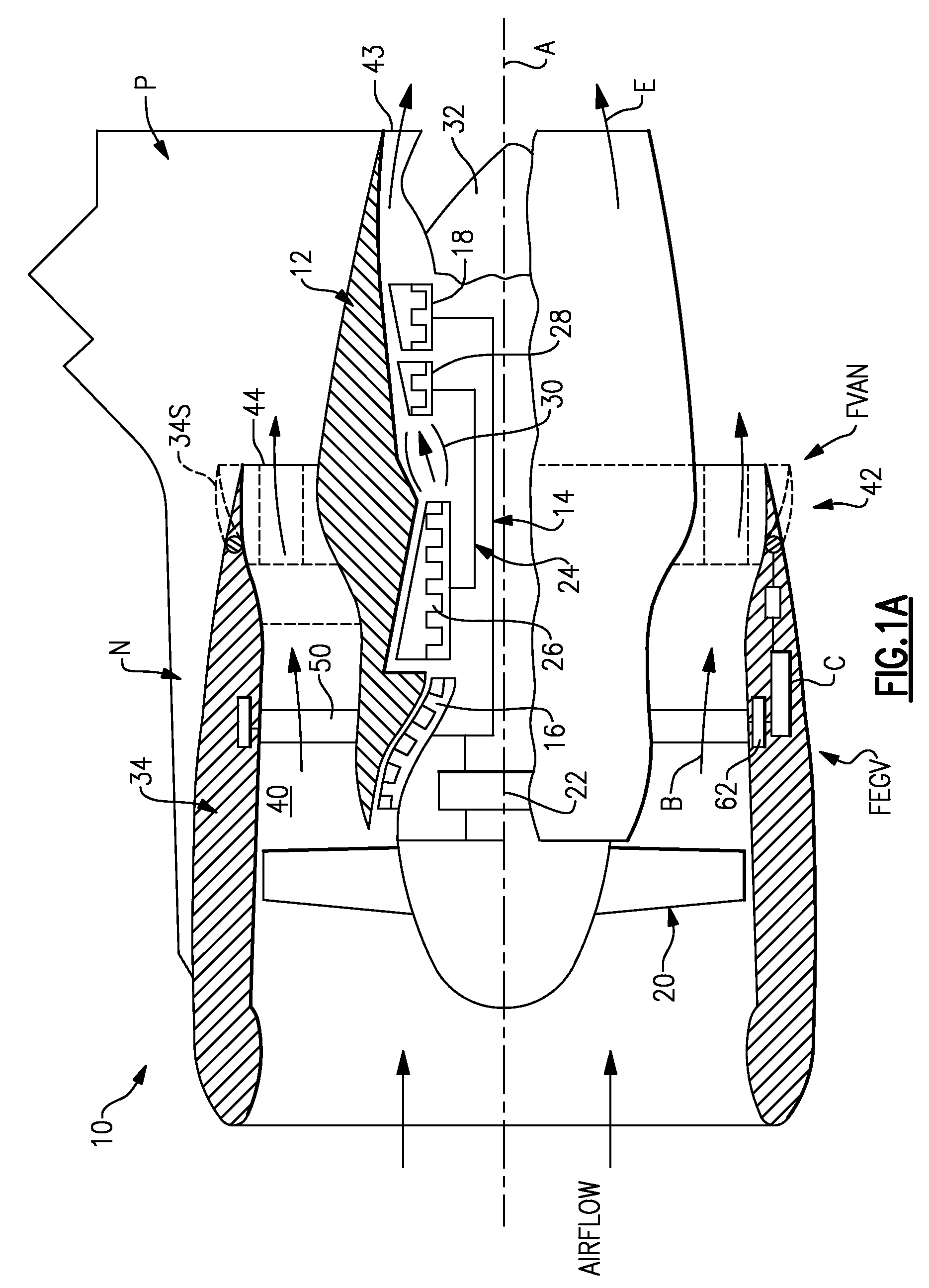

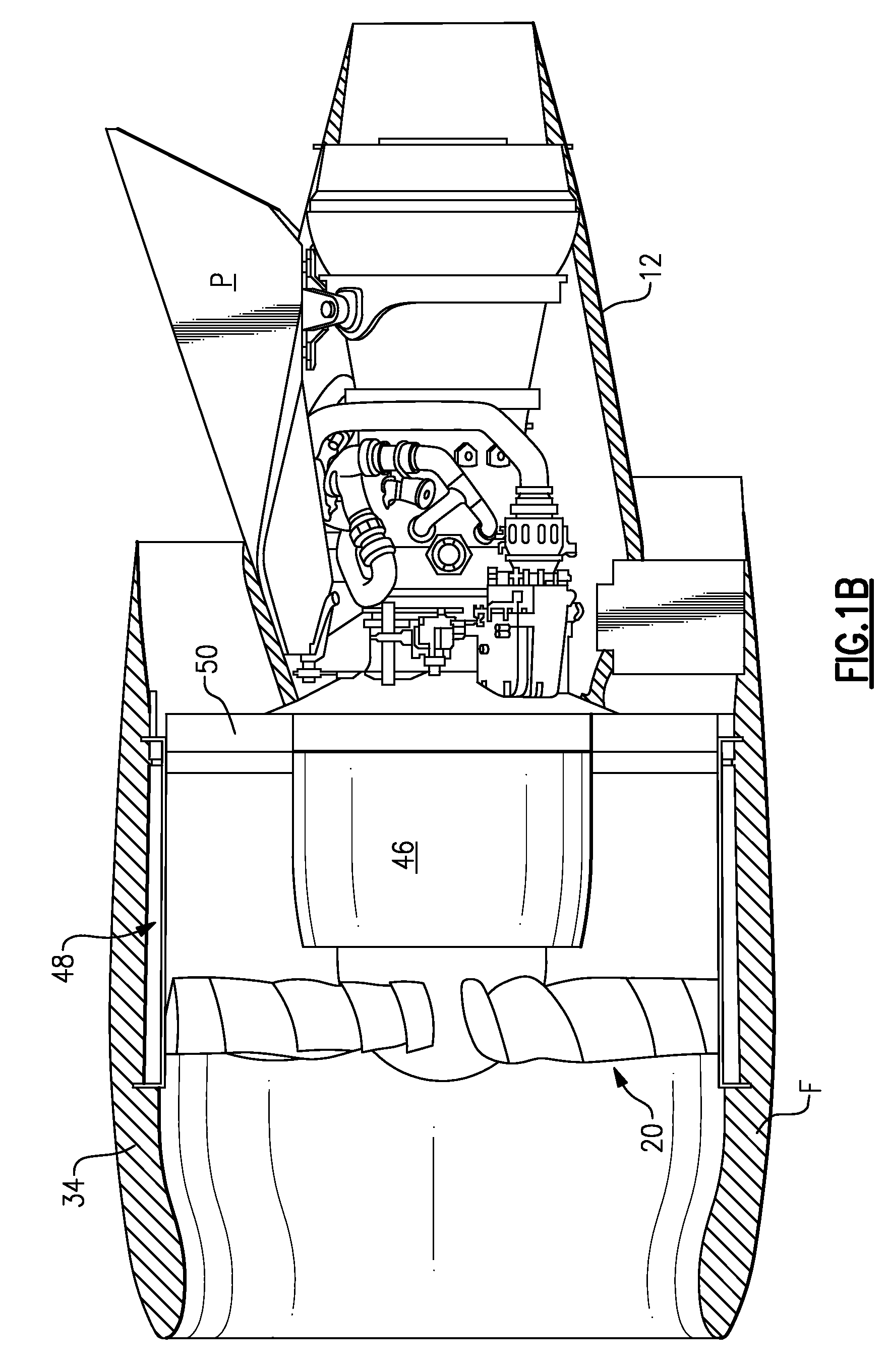

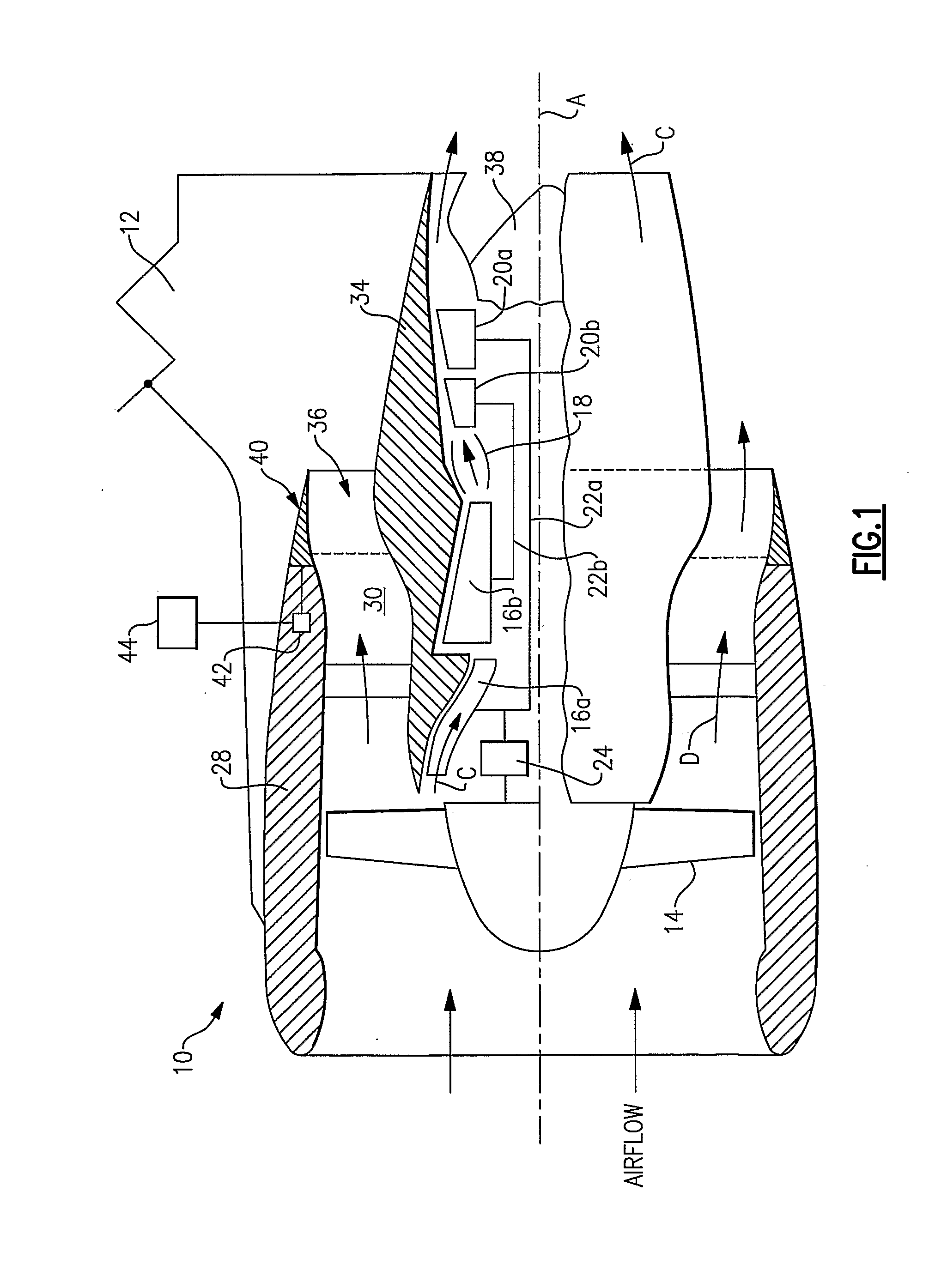

Gas turbine engine with variable geometry fan exit guide vane system

ActiveUS20090097967A1Reduce bypass flowMinimize thrust reverser requirementWind motor controlPump componentsTurbofanVariable geometry

A turbofan engine includes a variable geometry fan exit guide vane (FEGV) system having a multiple of circumferentially spaced radially extending fan exit guide vanes. Rotation of the fan exit guide vanes between a nominal position and a rotated position selectively changes a fan bypass flow path to permit efficient operation at various flight conditions.

Owner:RAYTHEON TECH CORP

Stent coating device

The present invention is a method and device, which is suitable for use in an operating theater just prior to implantation, for selectively applying a medical coating to an implantable medical device, for example a stent. Disclosed is a device for use with a stent deployed on a catheter balloon. The device is configured to apply a medical coating of a desired thickness to the surface of a stent only. This is done by use of a drop-on-demand inkjet printing system in association with an optical scanning device. The device is further configured so as to, if necessary, apply a plurality of layered coats, each layered coat being of a different coating material, and if appropriate, different thickness. The section of the housing in which the stent is held during the coating procedure is detachable from the housing base. The detachable housing section may be easily cleaned and re-sterilized or simply disposed or simply disposed of.

Owner:BOSTON SCI SCIMED INC +1

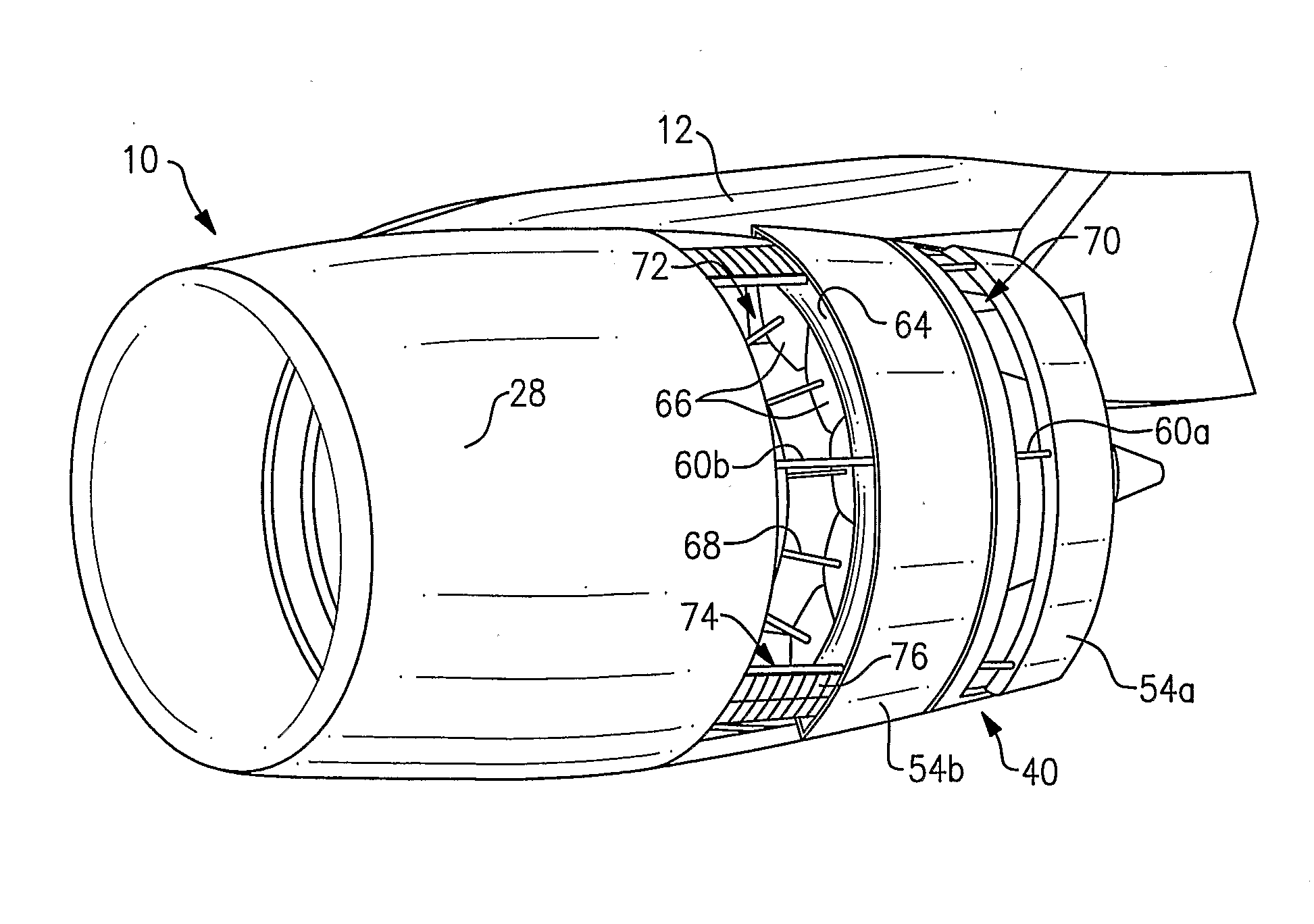

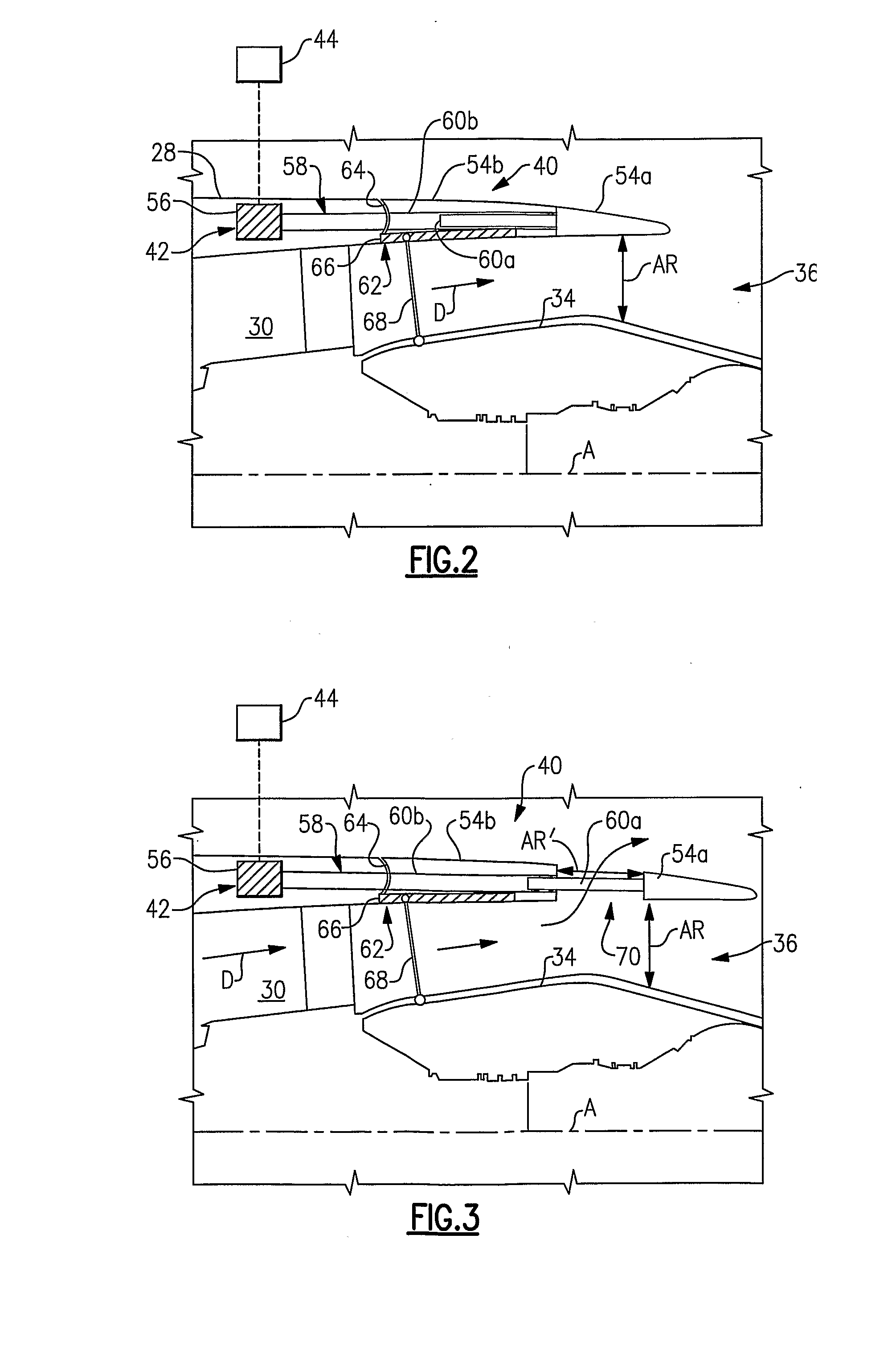

Tri-body variable area fan nozzle and thrust reverser

A gas turbine engine system includes a fan (14), a housing (28) arranged about the fan, a gas turbine engine core having a compressor (16) at least partially within the housing, and a fan bypass passage (30) downstream of the fan for conveying a bypass airflow (D) between the housing and the gas turbine engine core. A nozzle (40) associated with the fan bypass passage includes a first nozzle section (54a) that is operative to move in a generally axial direction to influence the bypass airflow, and a second nozzle section that is operative to also move in a generally axial direction between a stowed position and a thrust reverse position that diverts the bypass airflow in a thrust reversing direction. An actuator (42) selectively moves the first nozzle section and the second nozzle section to influence the bypass airflow and provide thrust reversal.

Owner:RTX CORP

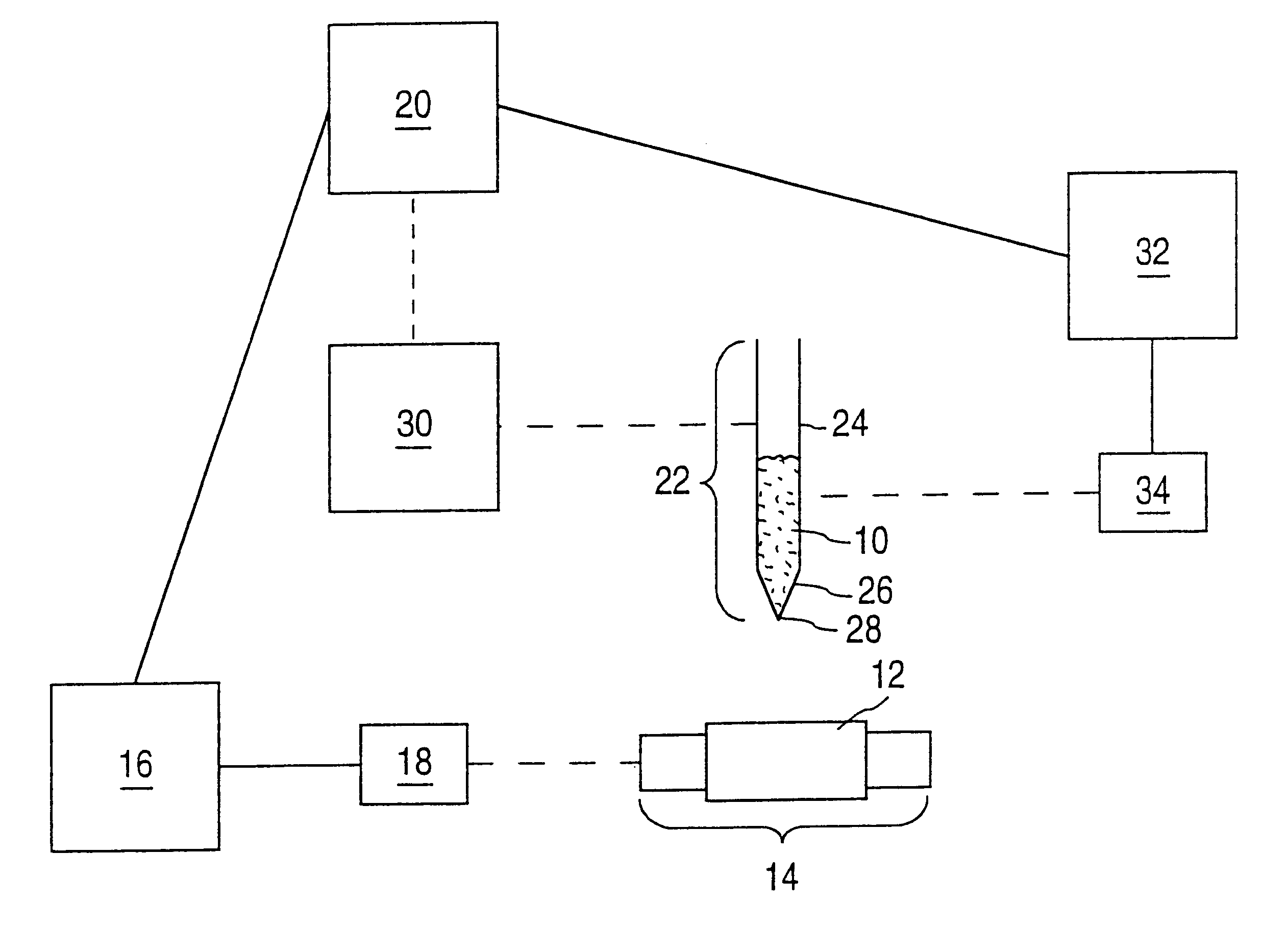

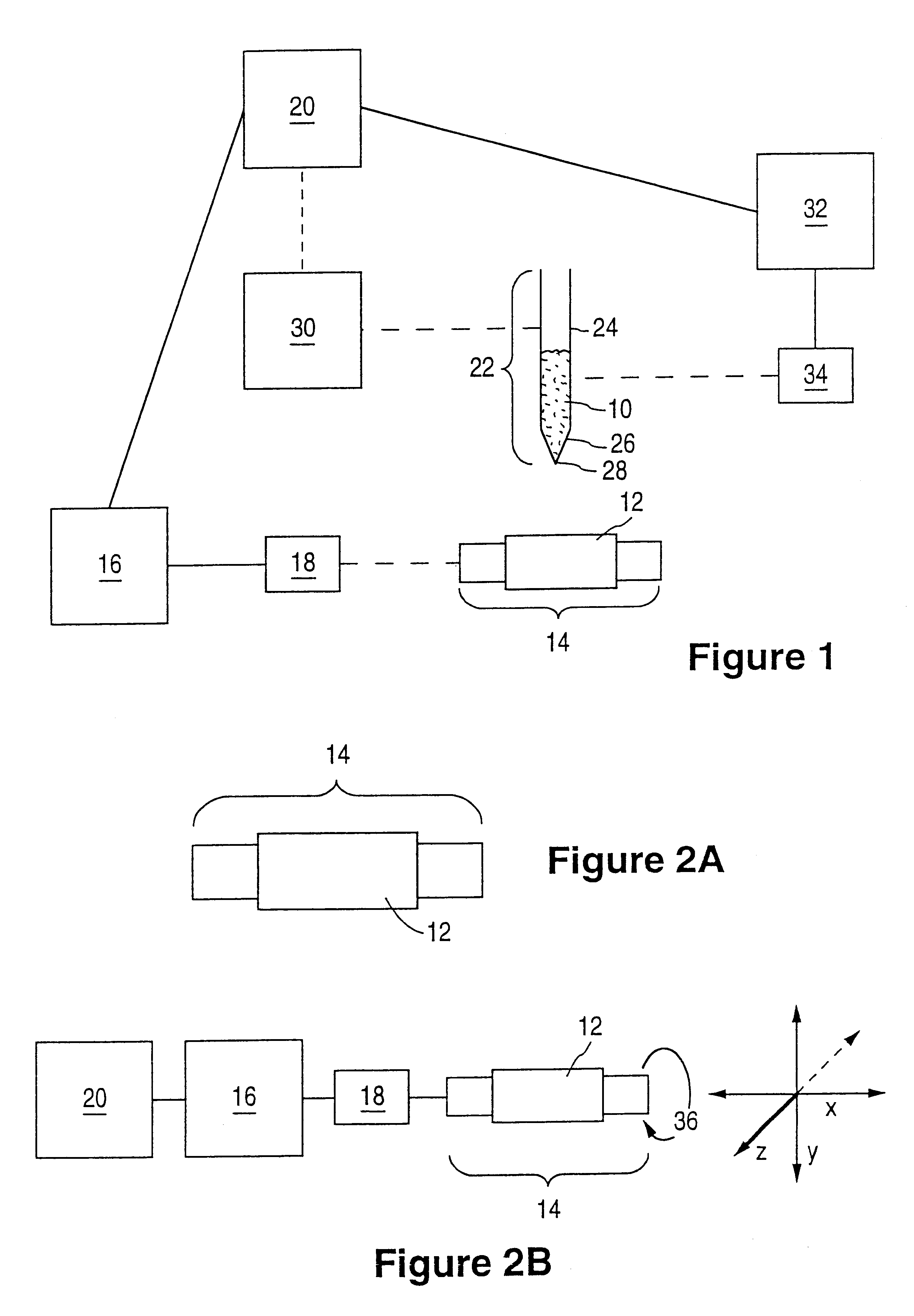

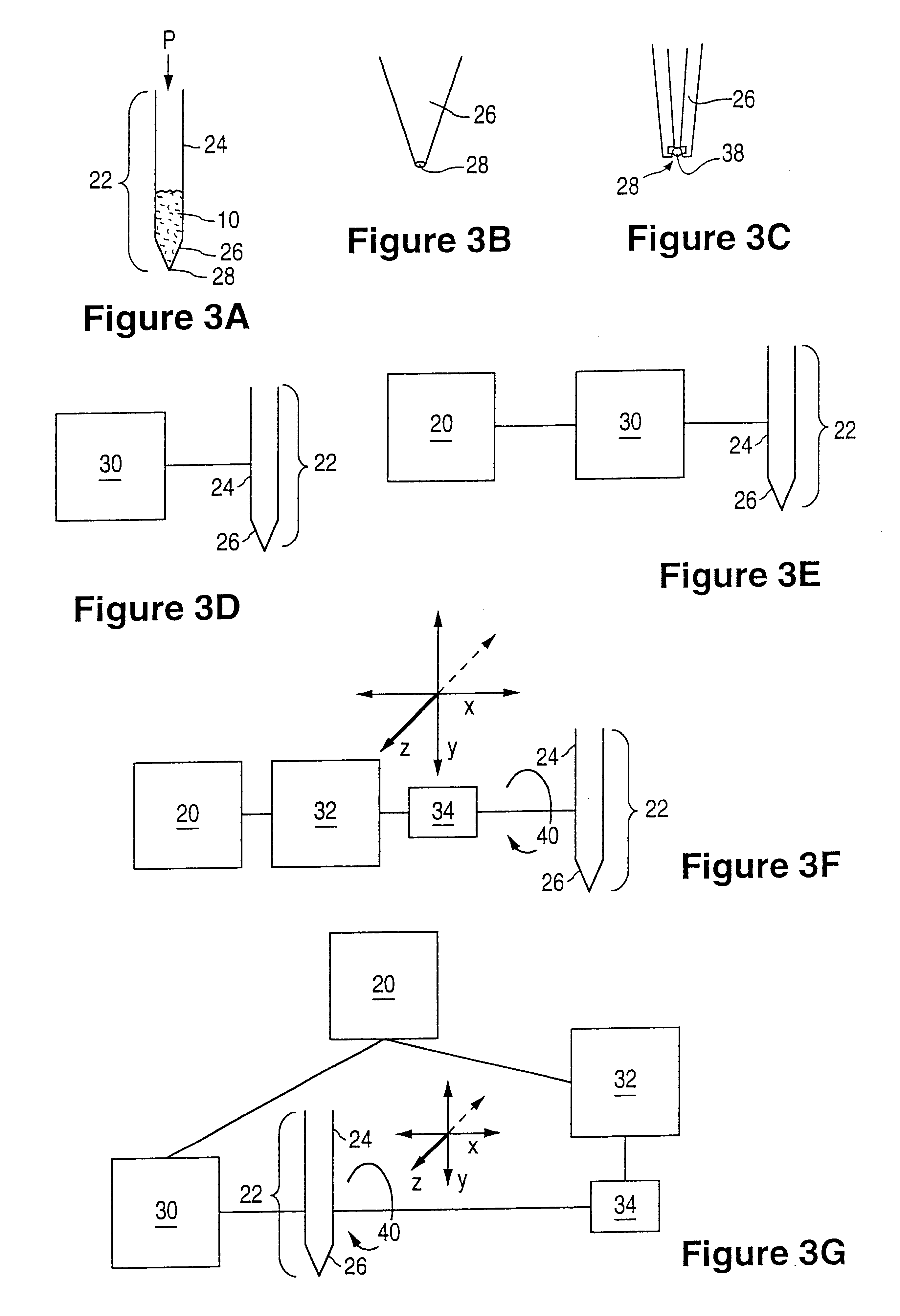

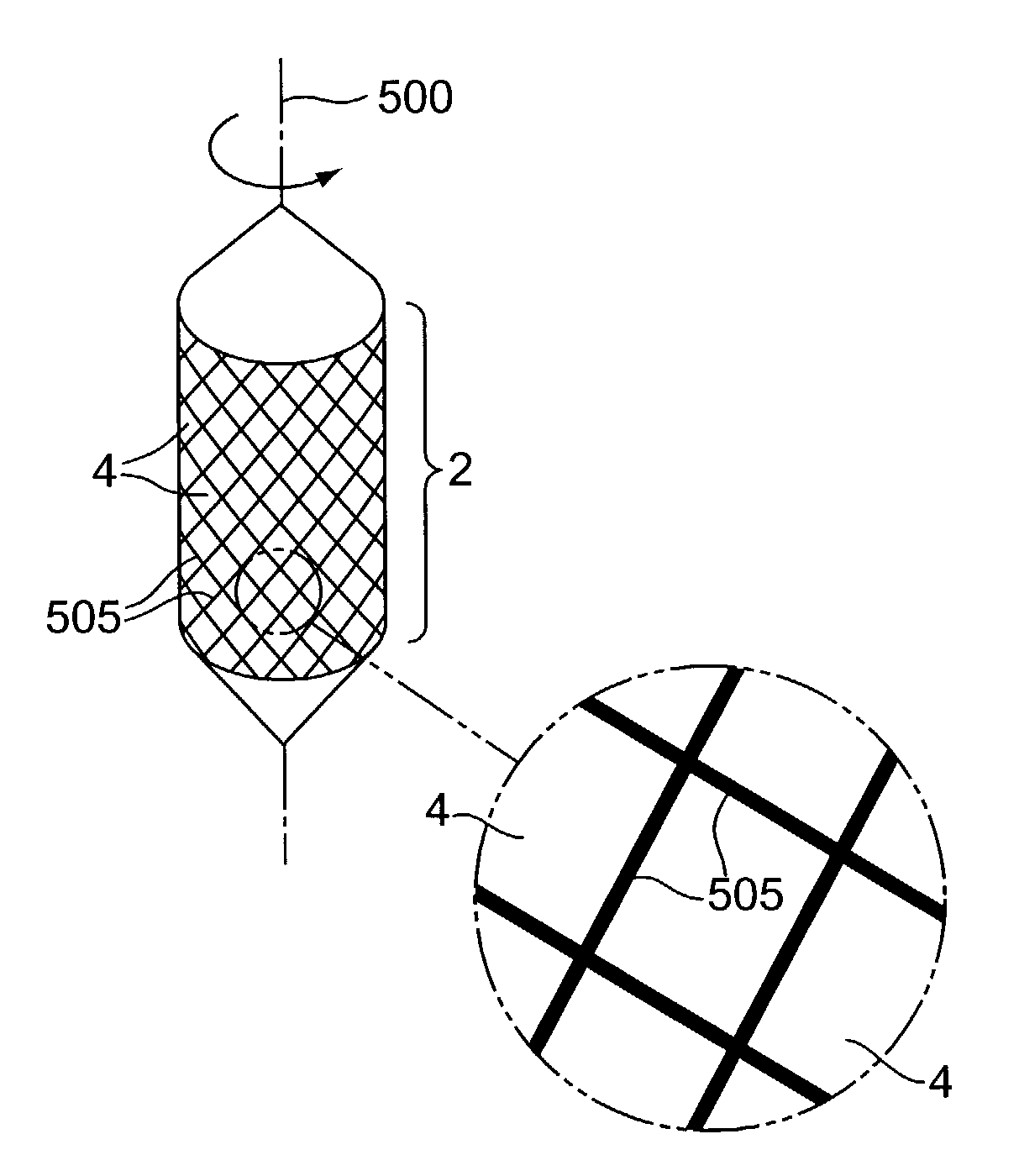

System for the process of coating implantable medical devices

Methods of coating an implantable device and a system for performing such methods are disclosed. An embodiment of the method includes applying a coating substance to the surface of an implantable device, and rotating the implantable device in a centrifuge. The method can uniformly coat the implantable device with the coating substance and to remove unwanted accumulations of coating substance entrained between struts or crevices in the implantable device body. This system is applicable to methods for coating intraluminal stents, synthetic grafts, and stent coverings with therapeutic compositions comprising therapeutic agents mixed with a polymeric matrix and a solvent.

Owner:ABBOTT CARDIOVASCULAR

Expandable garden hose

A flexible garden hose having an inner tube member made from elastic material and an outer tube member made from a non-elastic material. The inner tube member is secured to the outer tube member only at an inlet coupler and an outlet coupler. The inlet coupler is constructed to secure to a water supply provided from a conventional household water spigot. The outlet coupler is coupled to a flow restrictor allowing the inner tube member to equalize in pressure with pressurized water received from the water supply. Pressurized water expands the elongated inner tube member longitudinally along a length of the inner tube member and laterally across a width of the inner tube member thereby substantially increasing the length of the hose to an expanded condition wherein the hose contracts to a substantially decreased length when there is a decrease in pressurized water.

Owner:TELEBRANDS CORP

Expandable hose assembly

ActiveUS8291942B2Reduce and eliminate formingPipe couplingsSuction cleanersEngineeringFluid pressure

A hose which automatically expands longitudinally and automatically expands laterally upon the application of a fluid pressure is disclosed. The hose can automatically expand longitudinally up to six times its unexpanded or contracted length. Upon release of the fluid pressure within the hose, the hose will automatically contract to a contracted condition. The hose includes an inner tube made from an elastic material and an outer tube made from a non-elastic material. The inner tube is positioned concentrically within the outer tube in both a contracted condition and an expanded condition. The outer tube is secured to the inner tube only at a first end of the inner and outer tubes and at a second end of the inner and outer tubes. The outer tube moves laterally and longitudinally with respect to the inner tube when the tubes are transitioning between a contracted condition and an expanded condition.

Owner:TELEBRANDS CORP

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

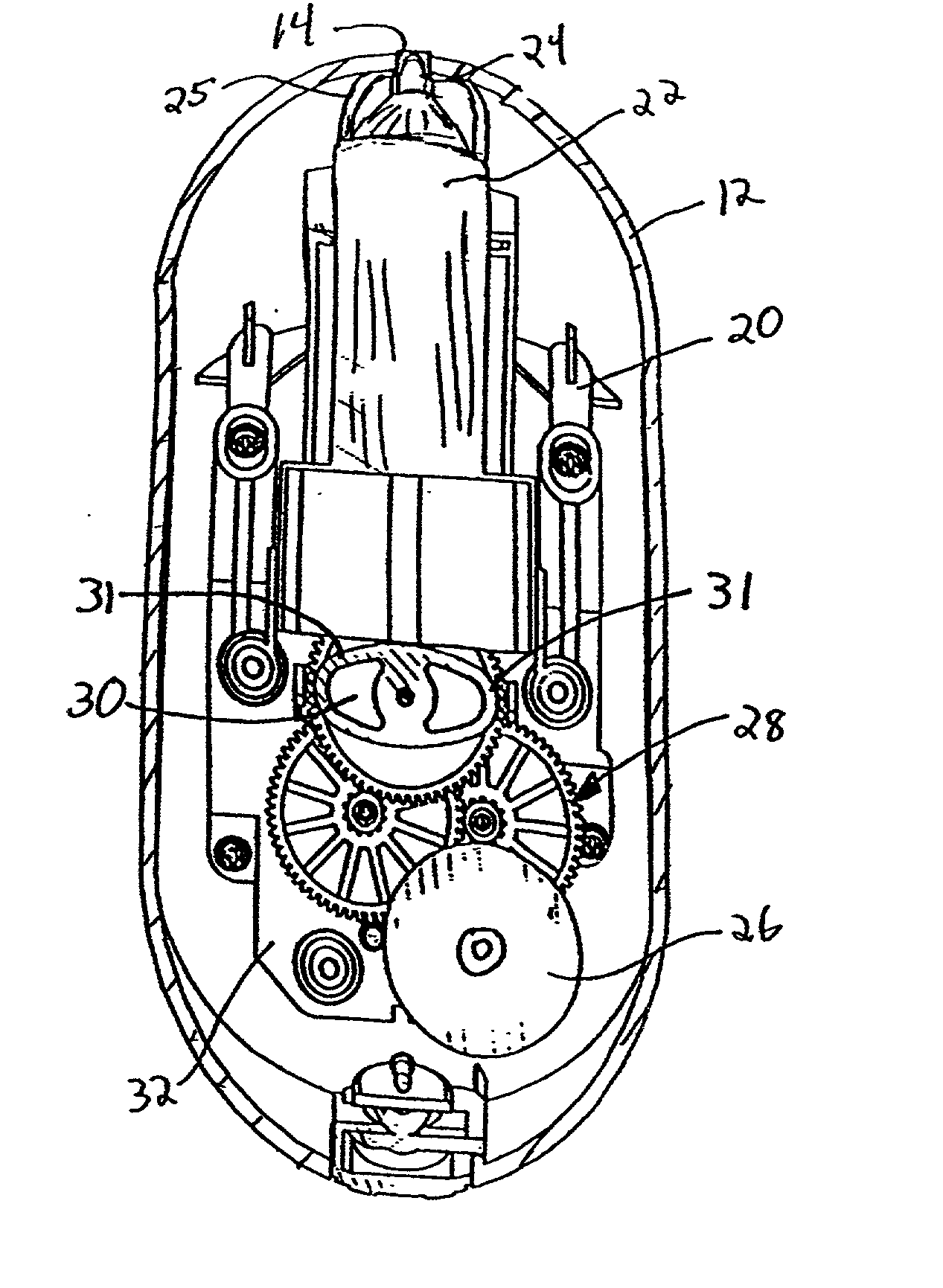

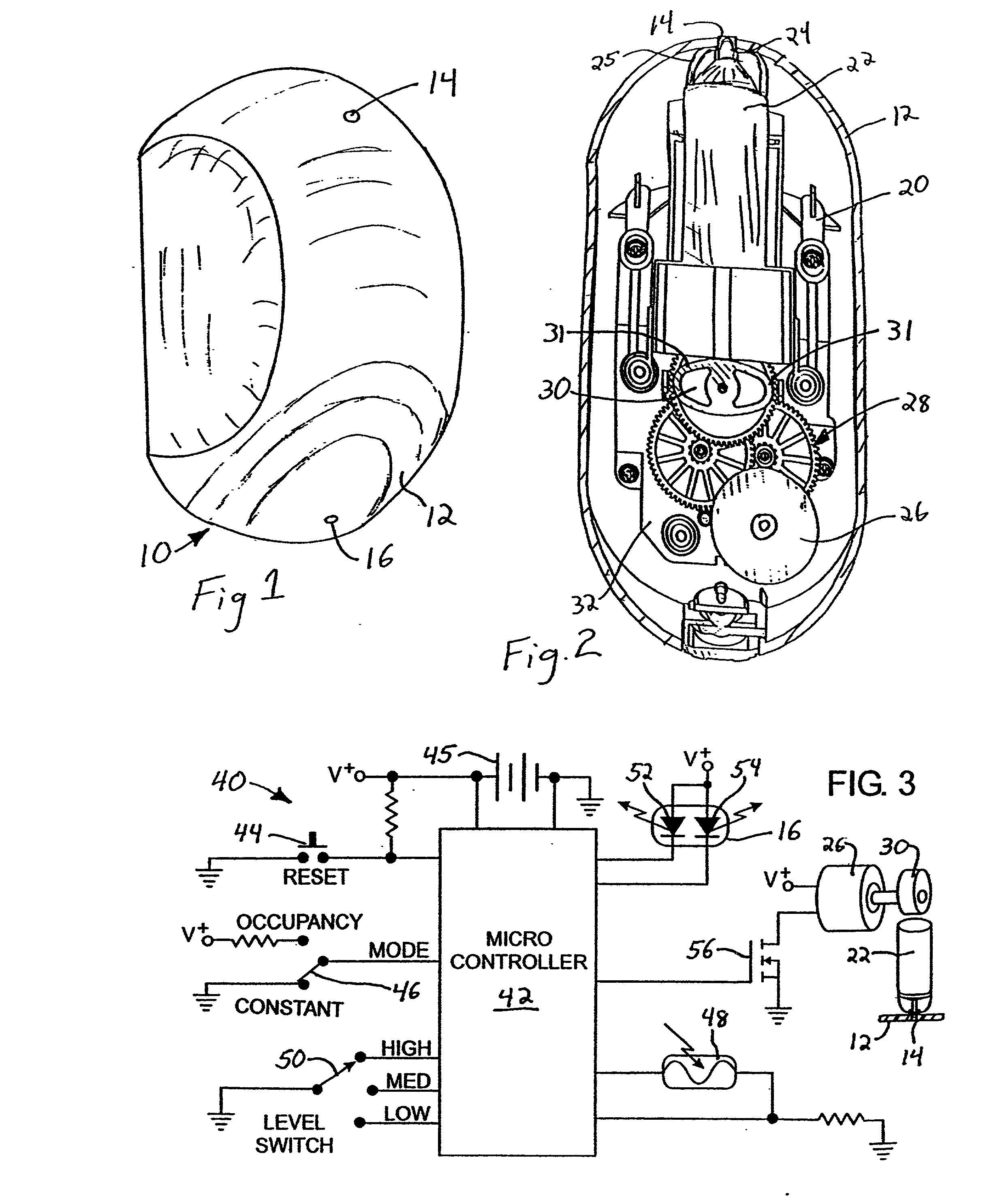

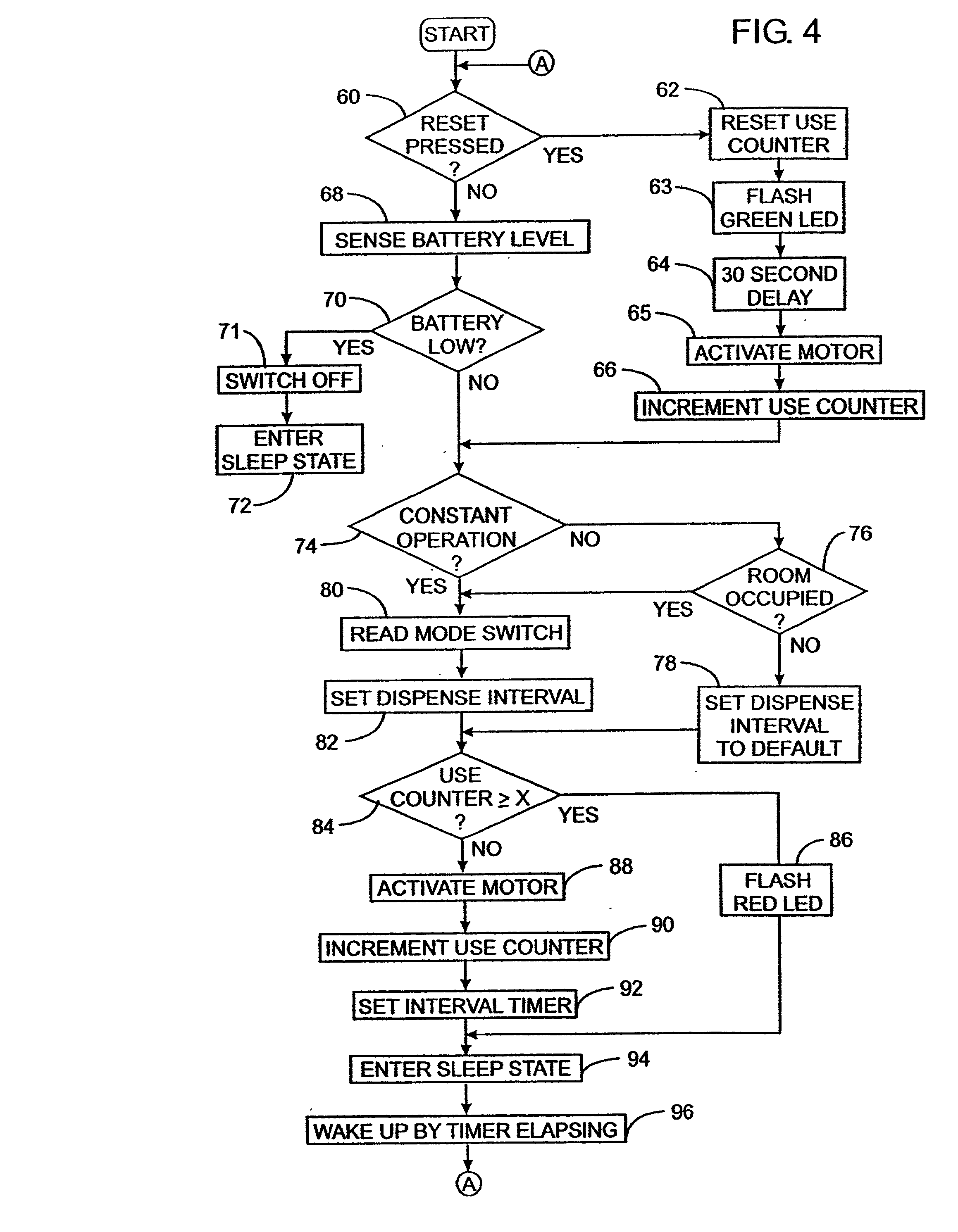

Automatic air freshener with dynamically variable dispensing interval

InactiveUS20020130146A1Time indicationSpraying apparatusAir purifierElectrical and Electronics engineering

An apparatus periodically dispenses an air freshening substance from a pressurized container into a room. A device is provided to sense when the room is occupied, such as by detecting the light level in the room. The air freshening substance is dispensed more frequently when the room is being used than at other times. However, the dispensing continues even when the room is unoccupied to treat odors arising from objects permanently located in the room.

Owner:JOHNSONDIVERSEY INC

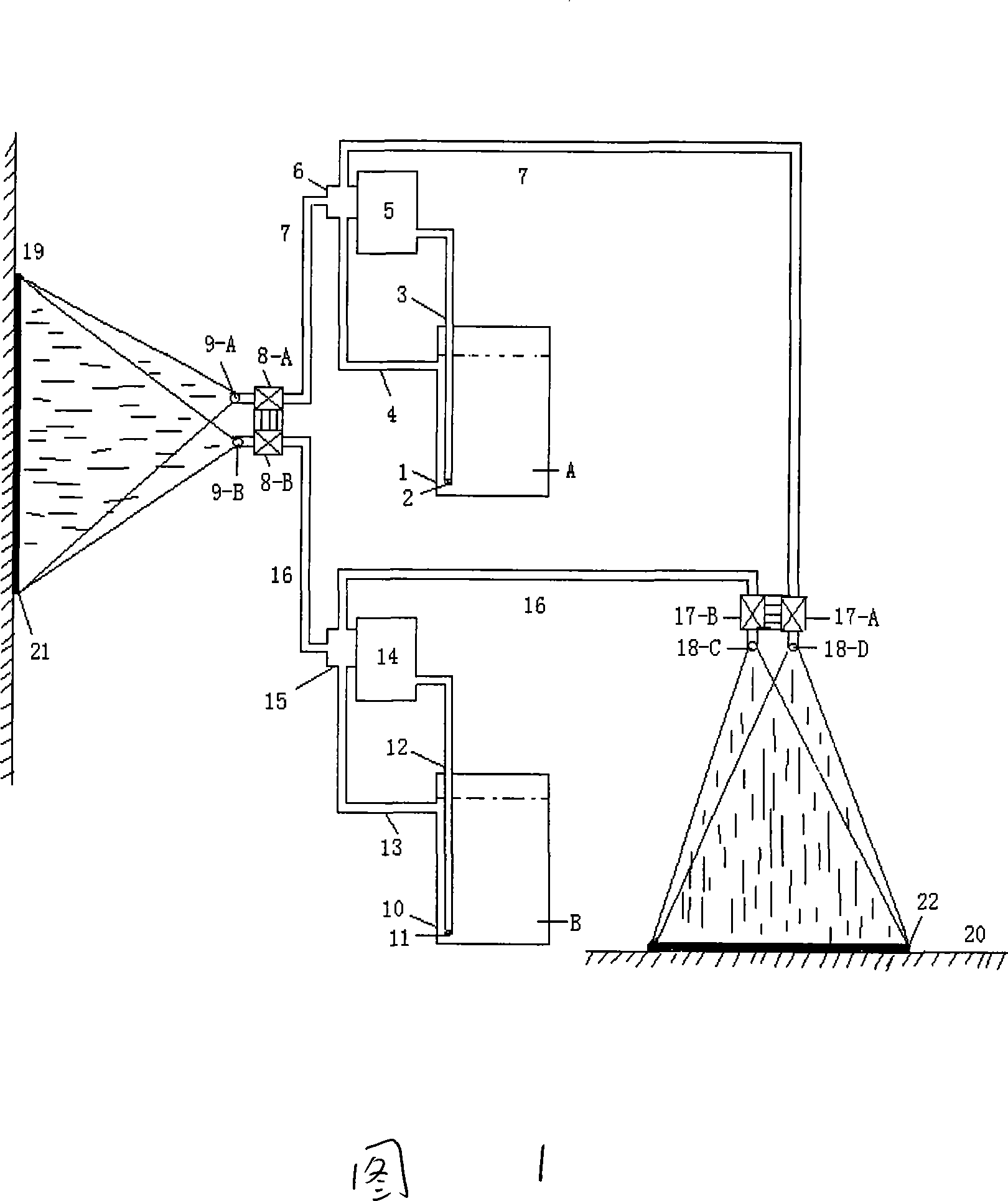

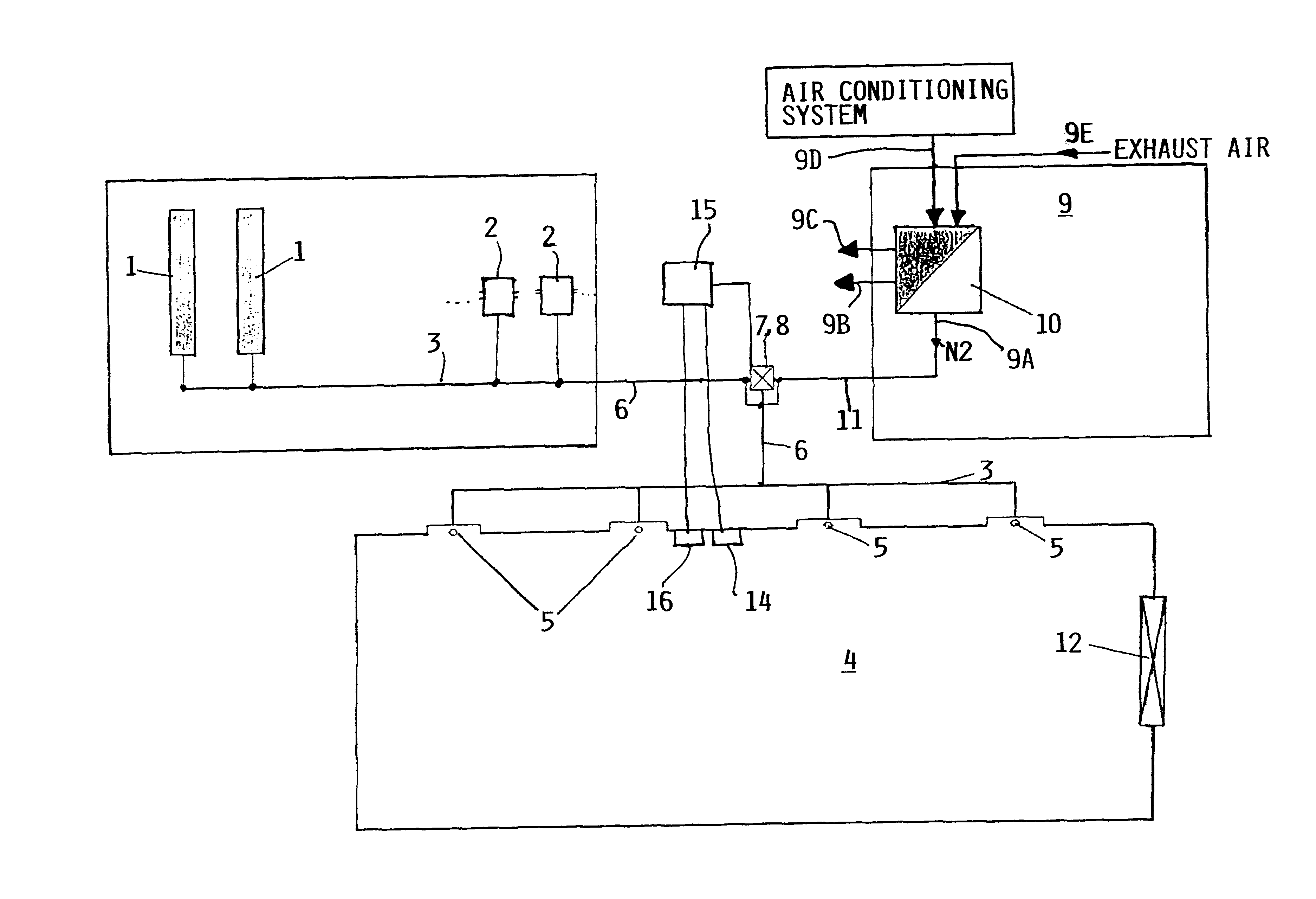

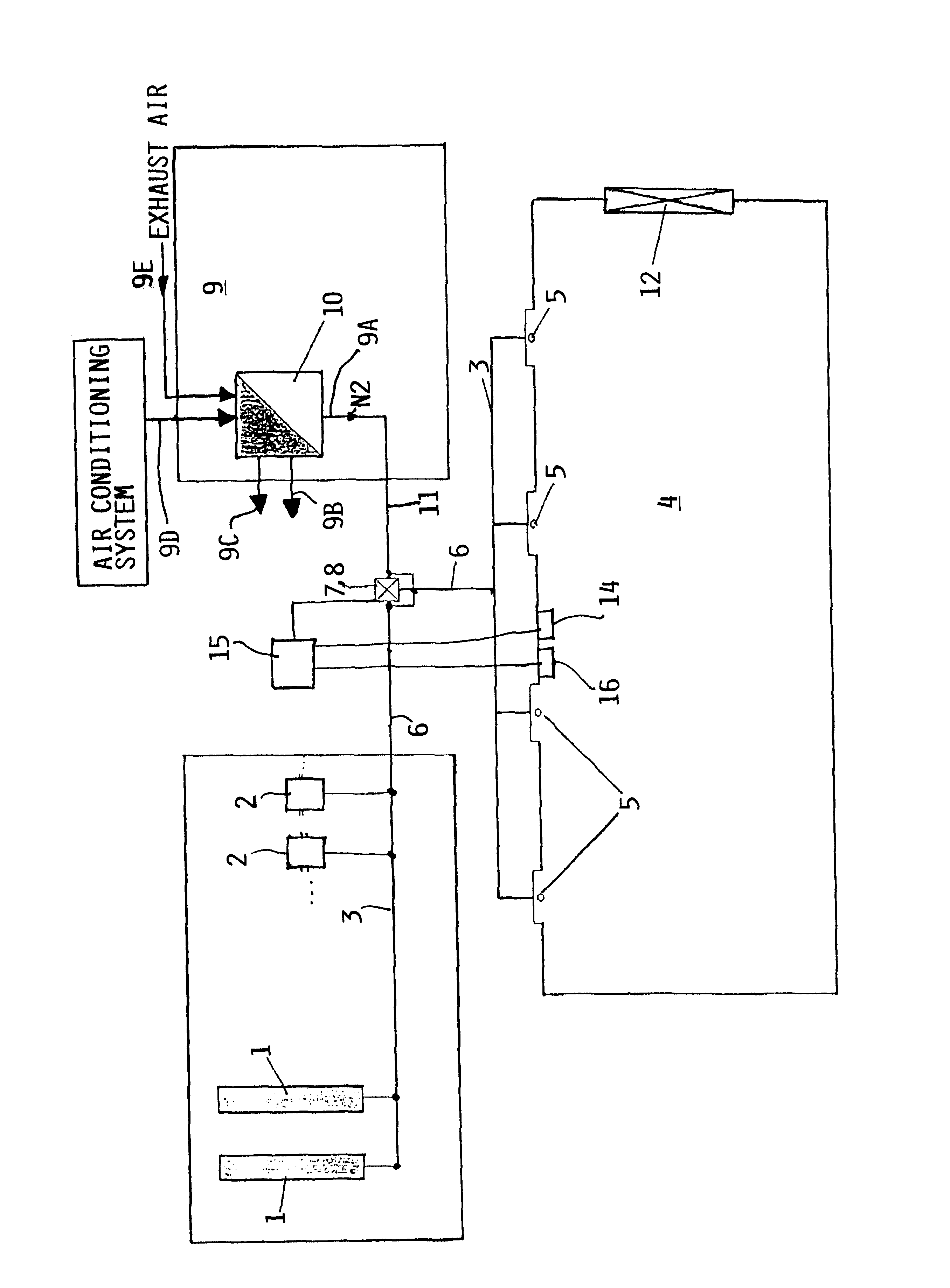

Method and system for extinguishing fire in an enclosed space

InactiveUS6601653B2Reduce oxygen concentrationImprove concentrationAir-treatment apparatus arrangementsSpraying apparatusHigh rateNitrogen

A system for suppressing fire in an enclosed space, e.g. an aircraft cabin or freight compartment, includes nitrogen tanks and / or generators to rapidly supply a limited quantity of nitrogen with-a high flow rate, and a membrane system to supply an essentially unlimited quantity of nitrogen at a lower supply rate for a long duration. The membrane system includes a selectively permeable membrane that separates nitrogen gas from ambient environmental air that is supplied into the membrane system. Once a fire is detected, nitrogen is supplied from the nitrogen gas tanks and / or generators at a high rate to rapidly increase the nitrogen concentration and establish a reduced oxygen concentration (e.g. 12 vol. %) in the enclosed space. Then, nitrogen is supplied from the membrane system at a reduced rate for a long duration to maintain the reduced oxygen concentration in the enclosed space until the fire is extinguished by oxygen starvation.

Owner:AIRBUS OPERATIONS GMBH

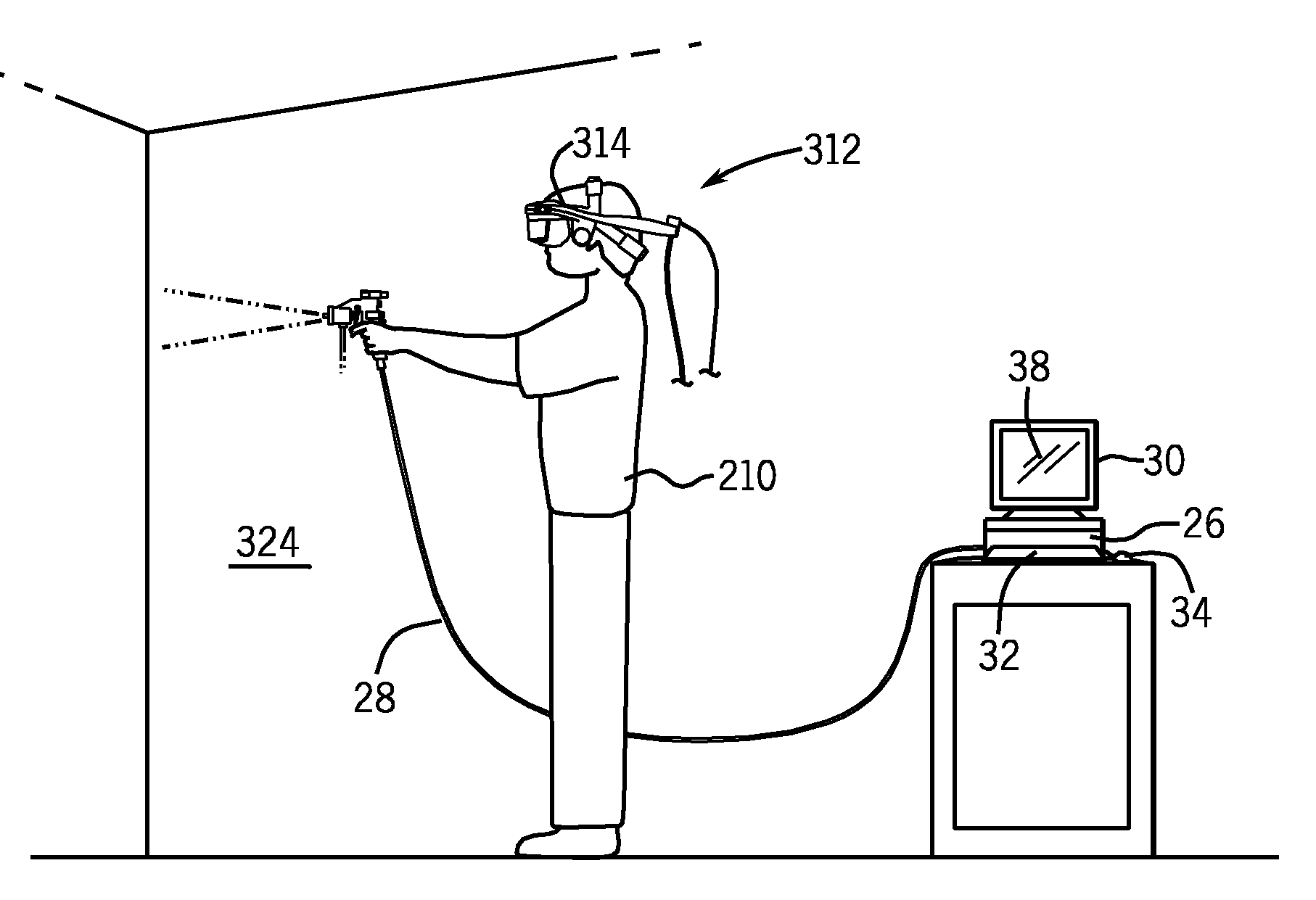

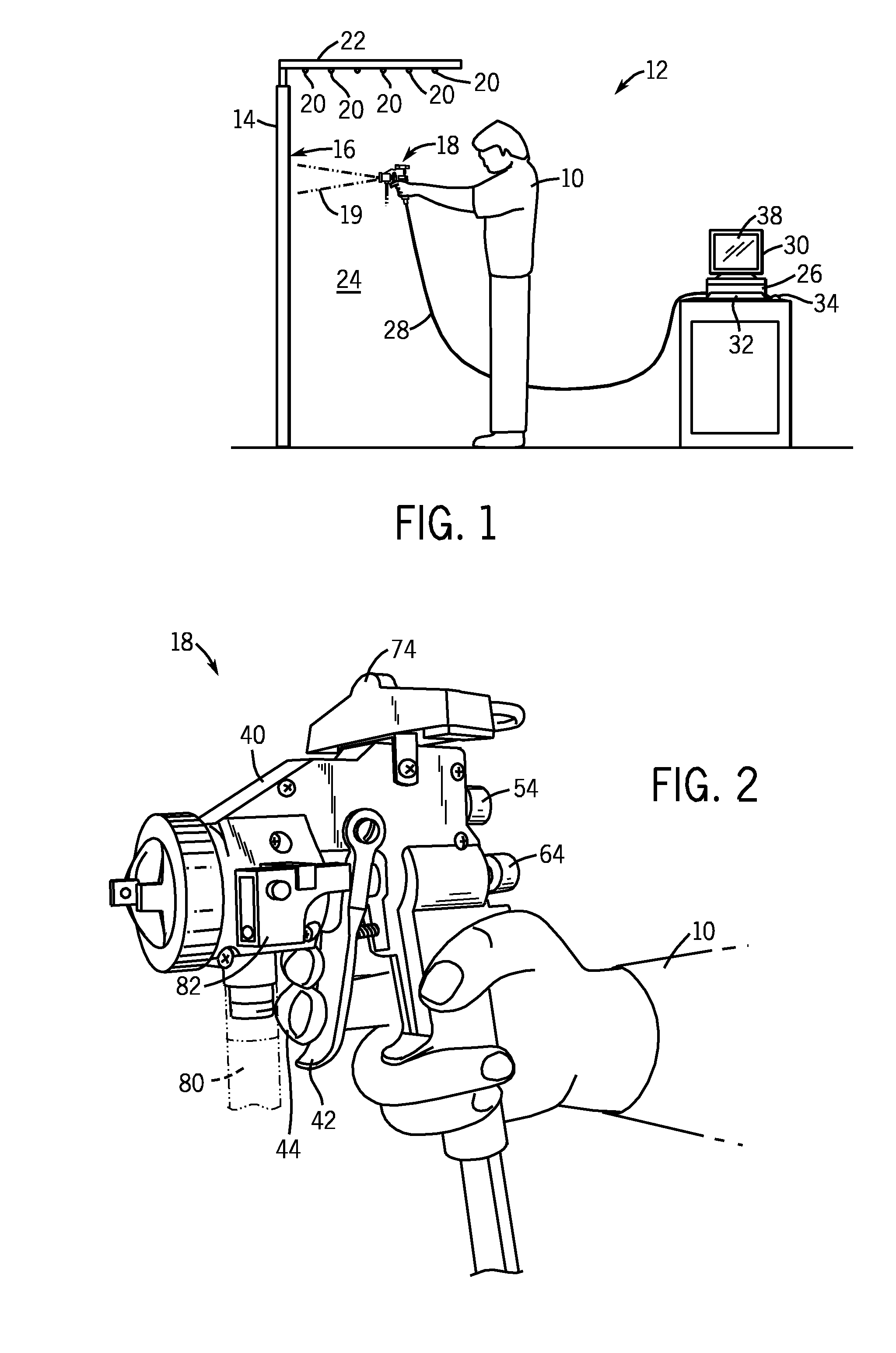

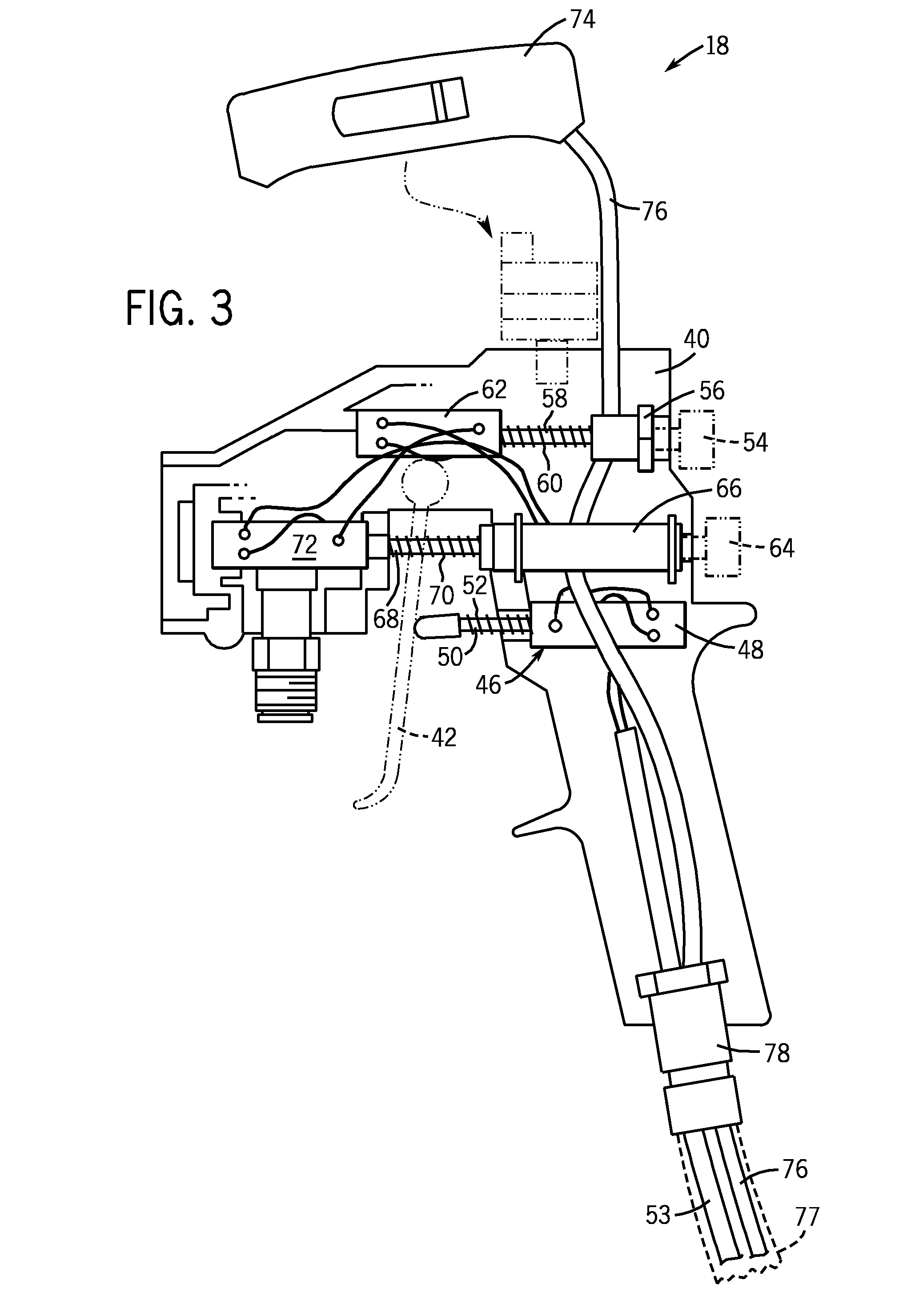

Virtual coatings application system

InactiveUS20070209586A1Accurate dataAvoid interferenceProgramme controlLiquid surface applicatorsSimulationMotion tracking system

A virtual coatings application system has several features to enhance the realism of simulated spray painting. The system generally includes a display screen on which is defined a virtual surface (such as a truck door) that is intended to be virtually painted or coated by the user. Alternatively, the system includes a head-mounted display unit that displays a virtual spray painting environment in which the virtual surface is defined. The user operates an instrumented spray gun controller that outputs one or more signals representing data as to the status of the controls on the spray gun controller. The system also has a motion tracking system that tracks the position and orientation of the spray gun controller with respect to the virtual surface. Simulation software generates virtual spray pattern data in response to at least the data from the spray gun controller and the position and orientation data received from the tracking system. Virtual spray pattern images are displayed in real time on the virtual surface in accordance with the accumulation of virtual spray pattern data at each location on the virtual surface.

Owner:UNIV OF NORTHERN IOWA RES FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com