Patents

Literature

1633results about "Pipe couplings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

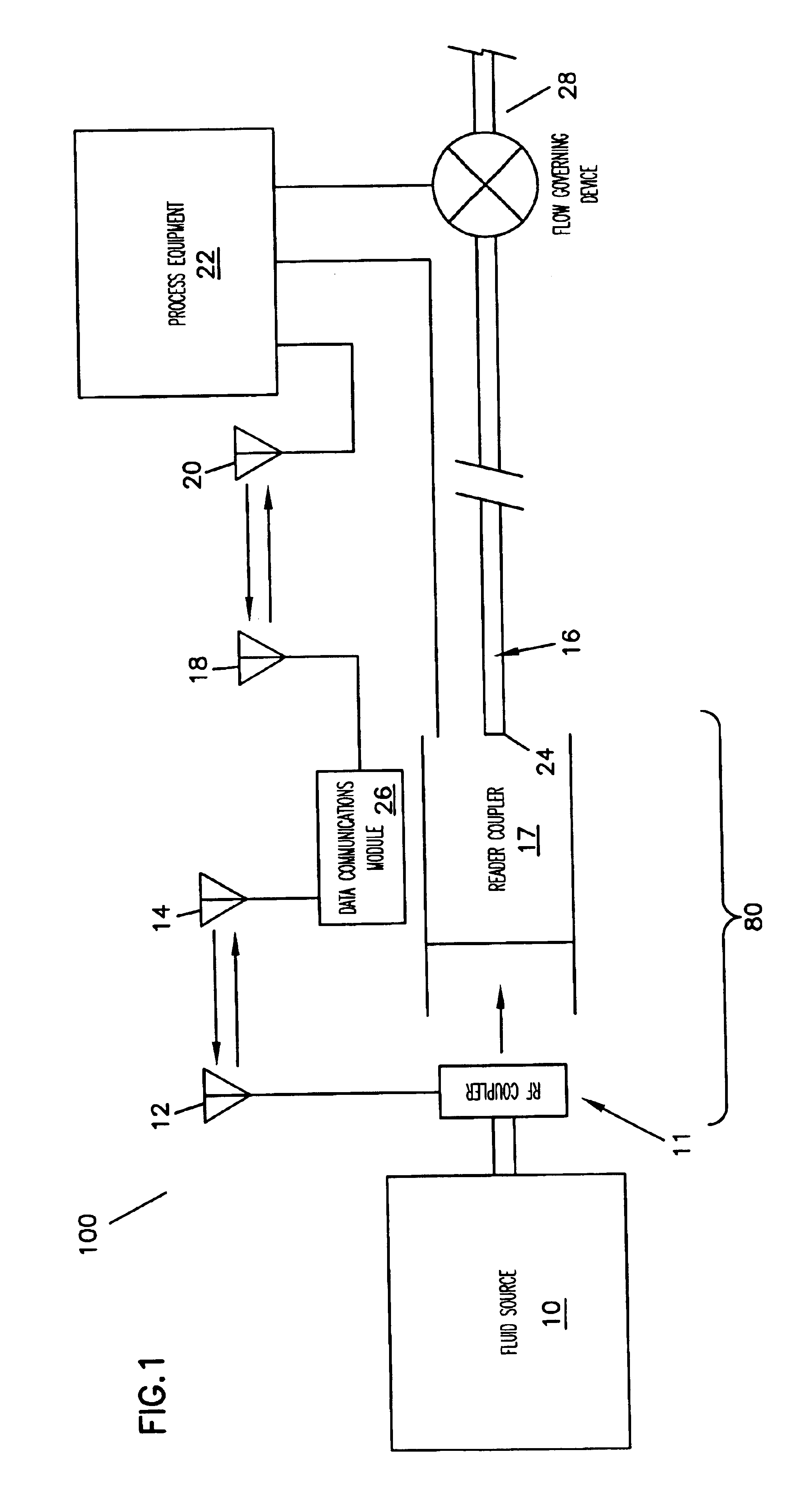

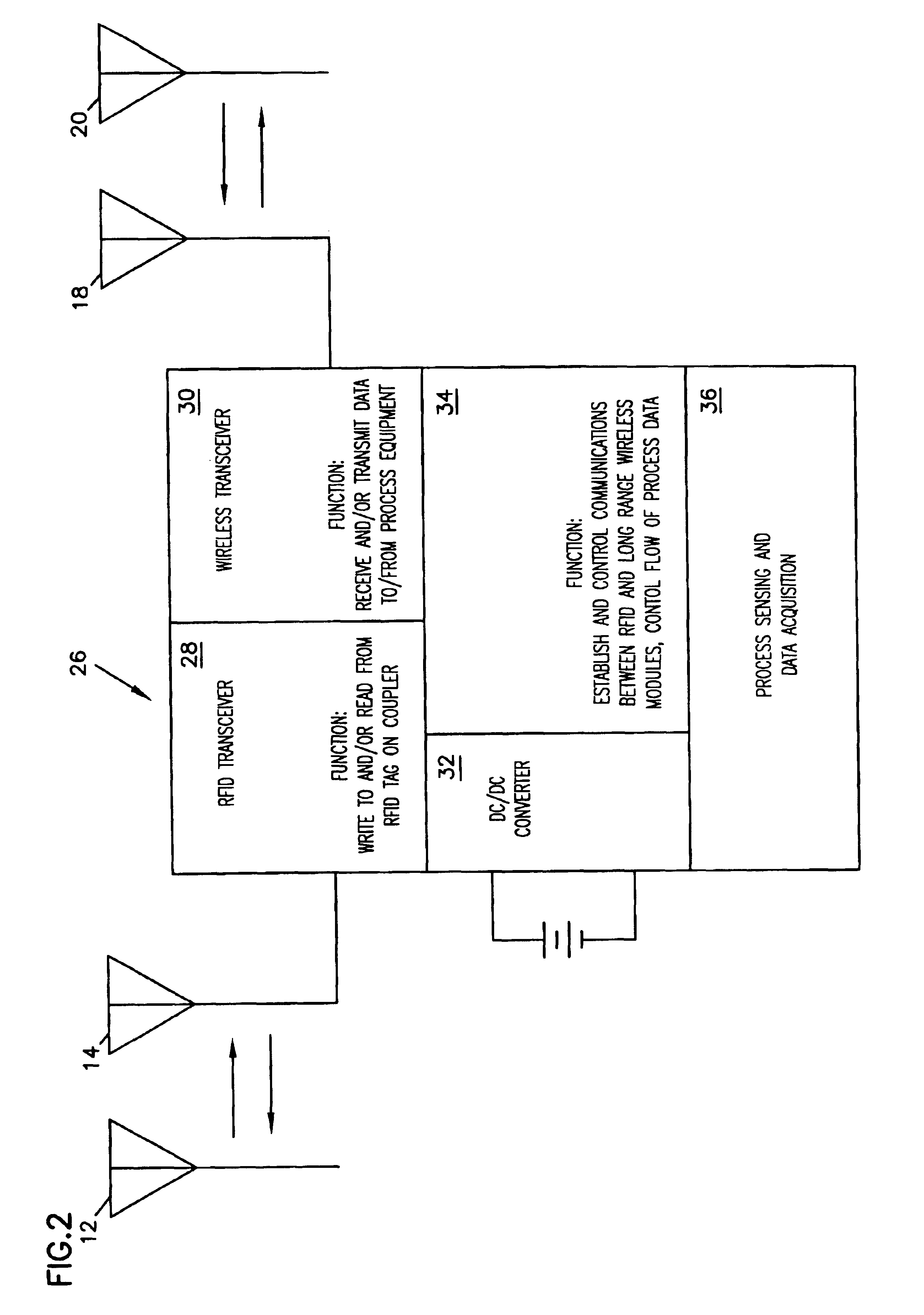

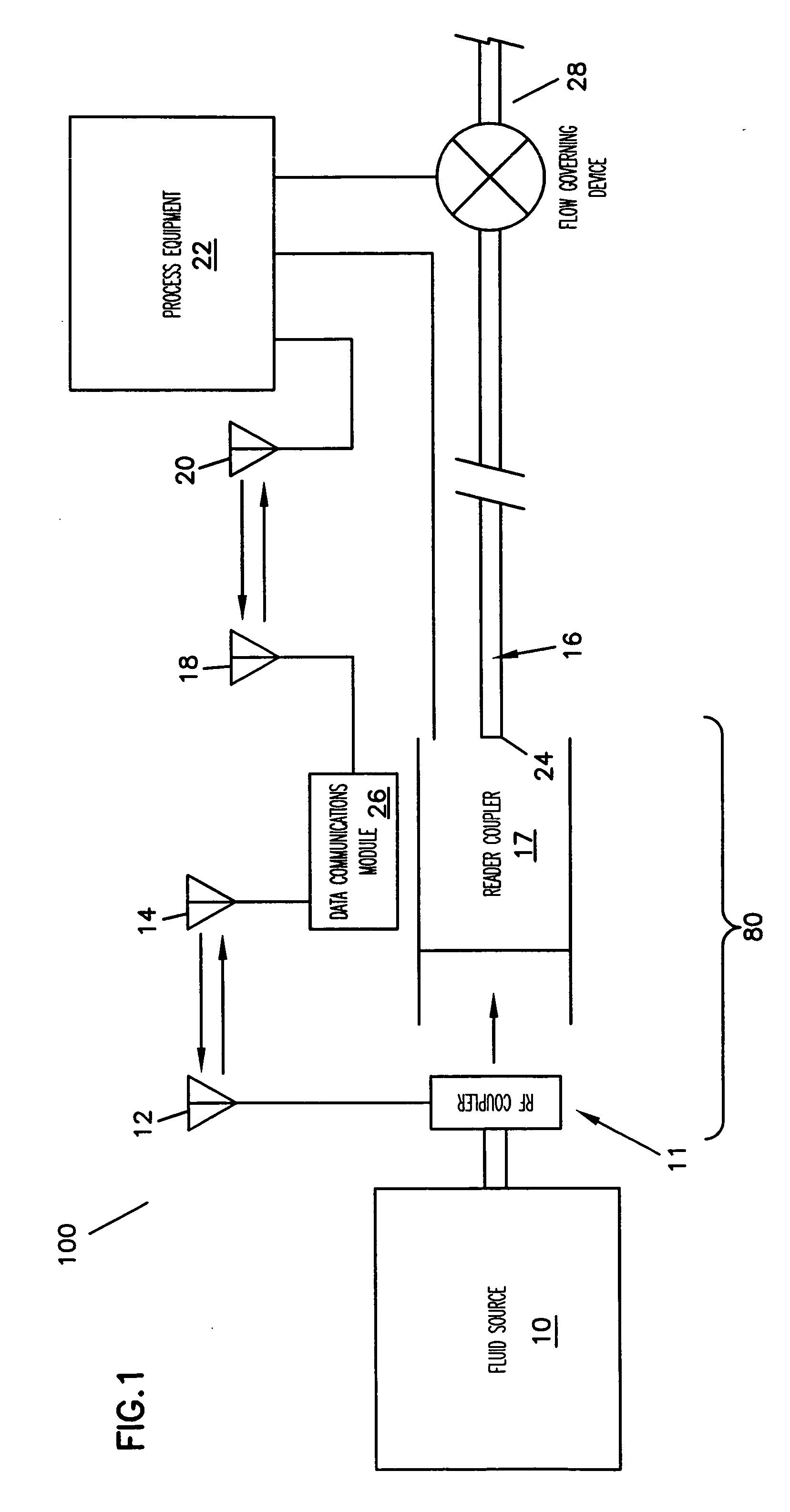

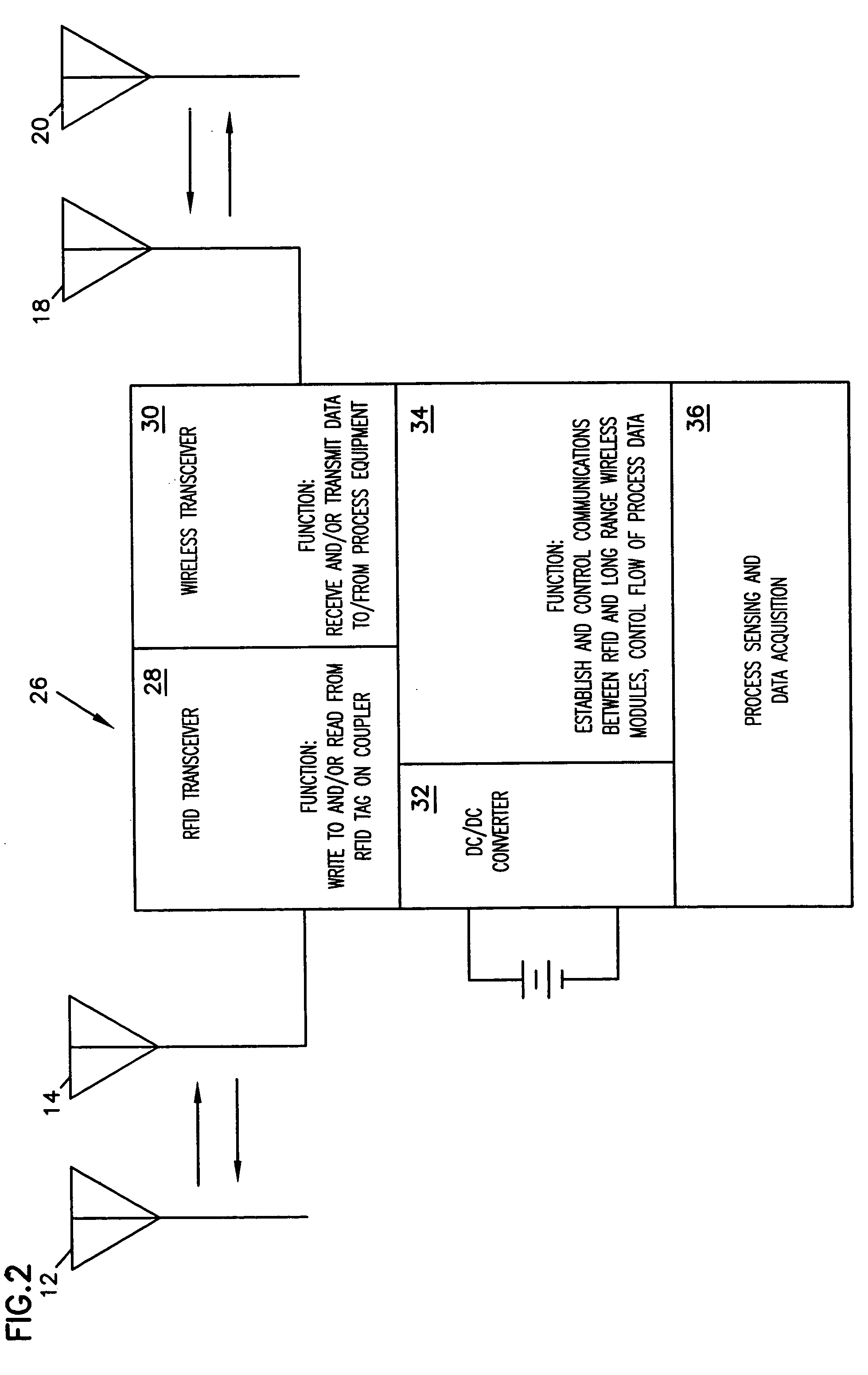

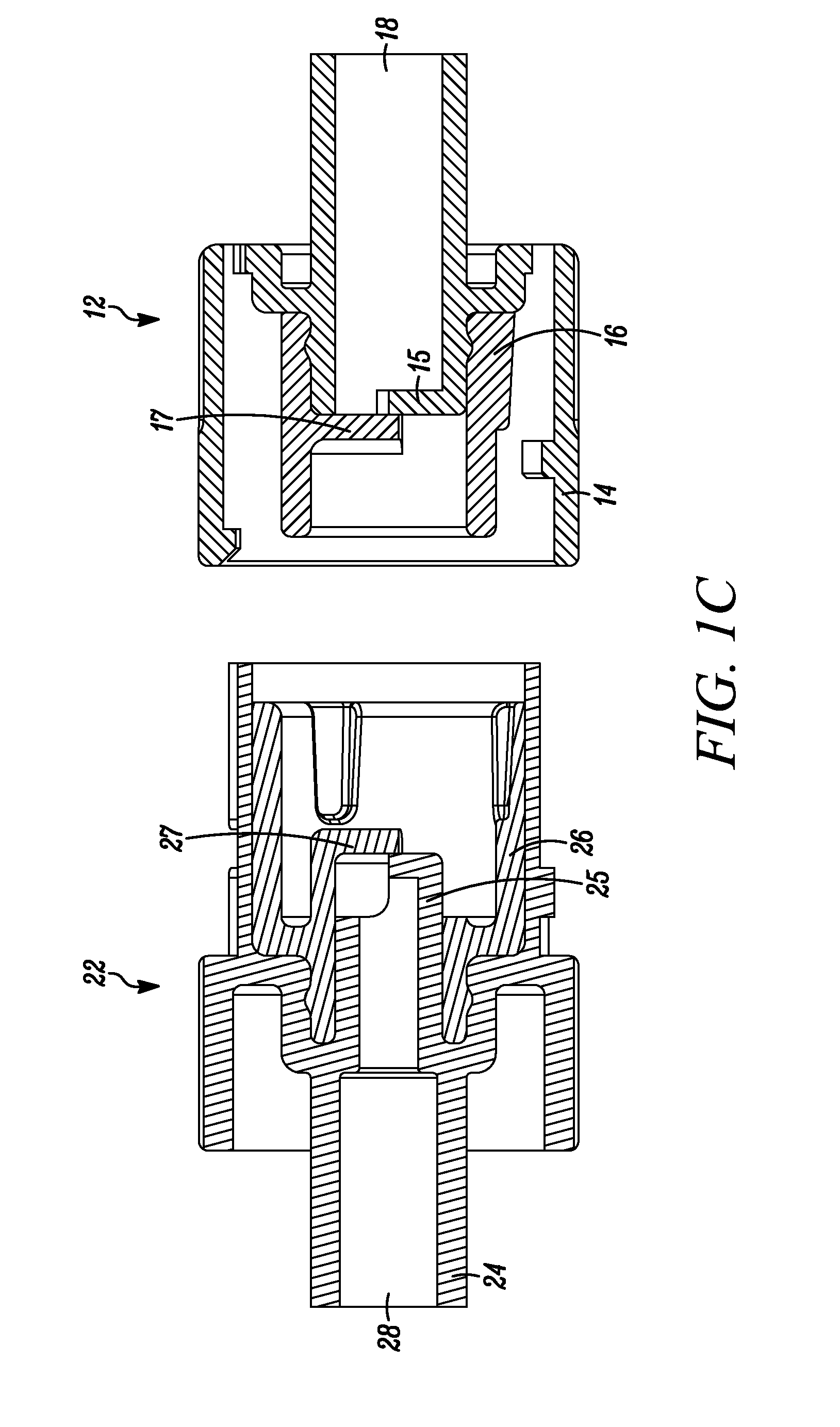

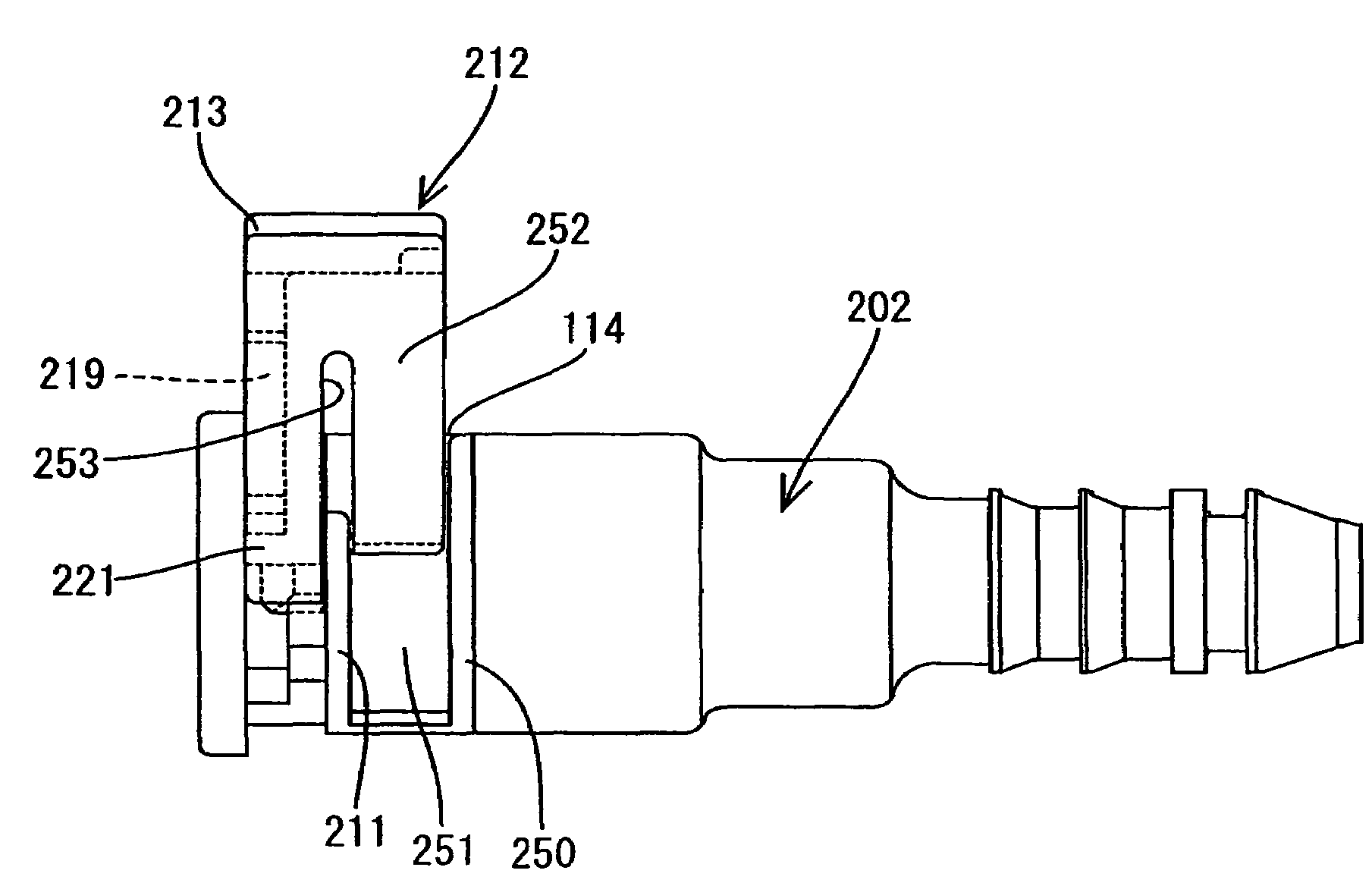

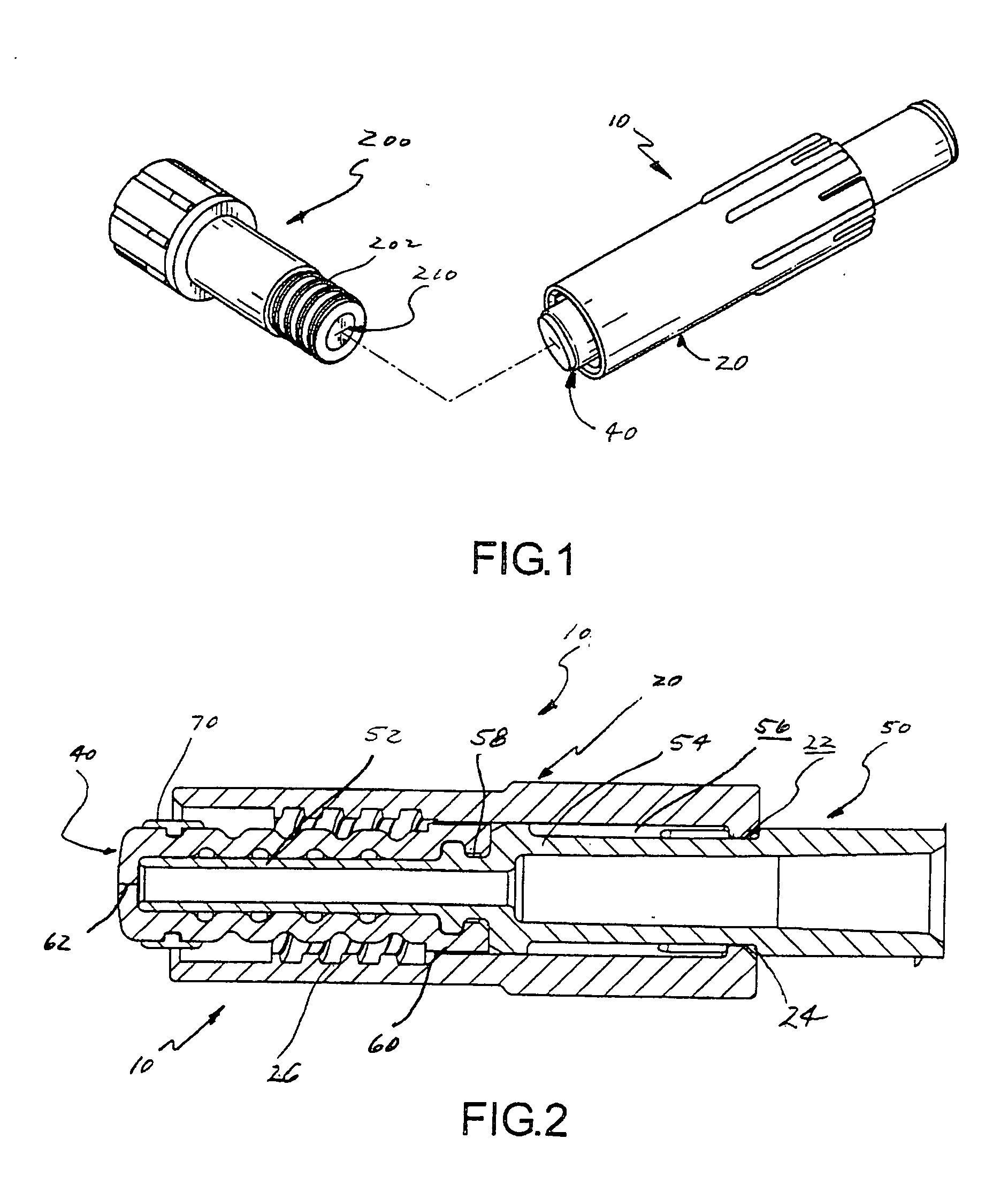

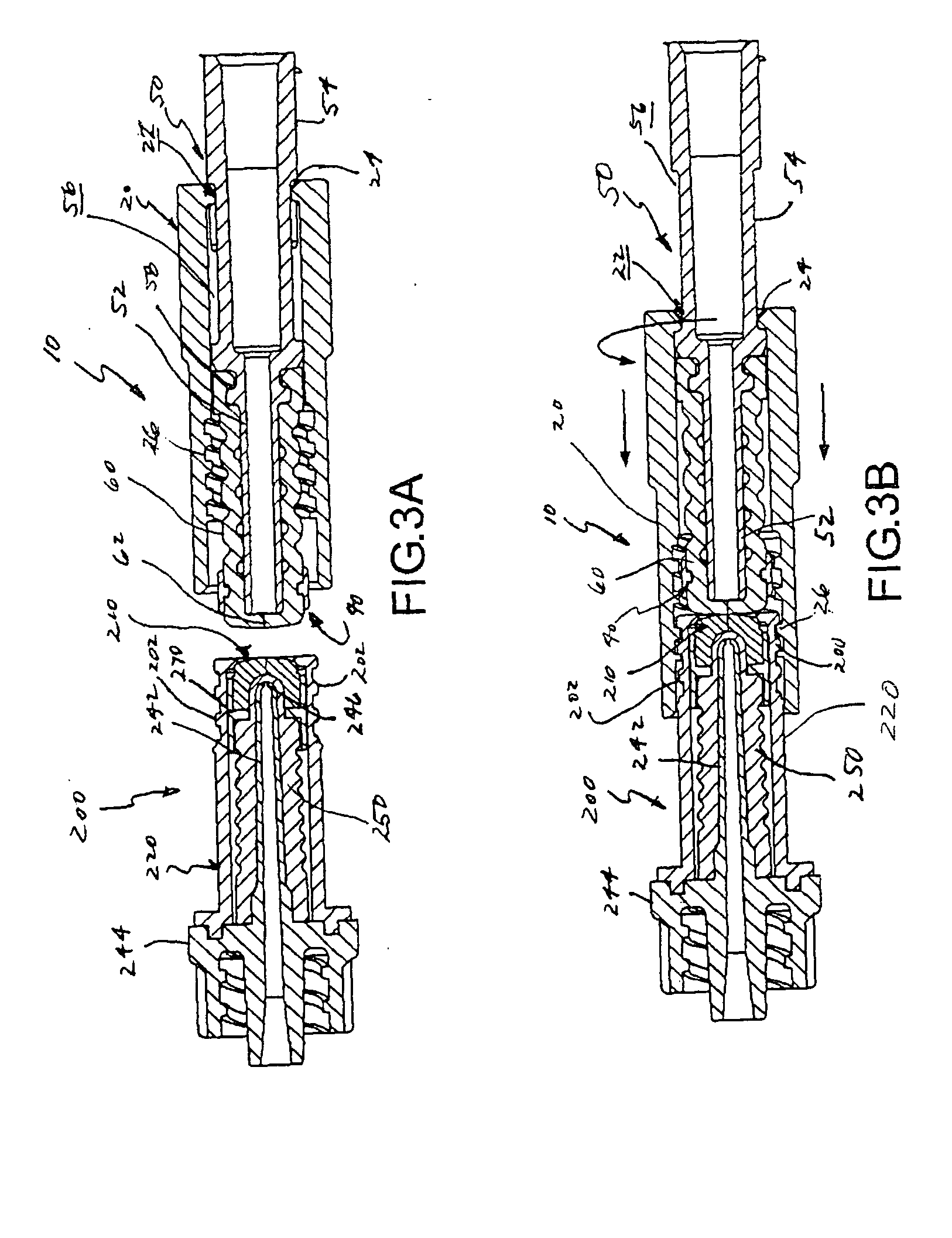

Connector apparatus and method for connecting the same

InactiveUS6897374B2Less powerAvoid misconnectionPipe couplingsInsulated cablesFluid controlEngineering

A connector apparatus for controlling fluid dispensing / transmission that includes a control component for communication between couplers thereof. A first coupler has a transmitter, and is releasably connected with a mating reader coupler that has a transmitter and fluid control device to exchange information with the transmitter of the first coupler. The transmitters communicate and are operated by wireless means such as by RF devices. Upon confirming that the first coupler is properly coupled to the mating coupler and that the first coupler has a proper identification, the fluid control device controls fluid flow, using the transmitters of the first coupler and the mating reader coupler, under predetermined parameters, e.g., pressure, temperature, duration, and flow rate, as indicated in the first coupler.

Owner:COLDER PRODS

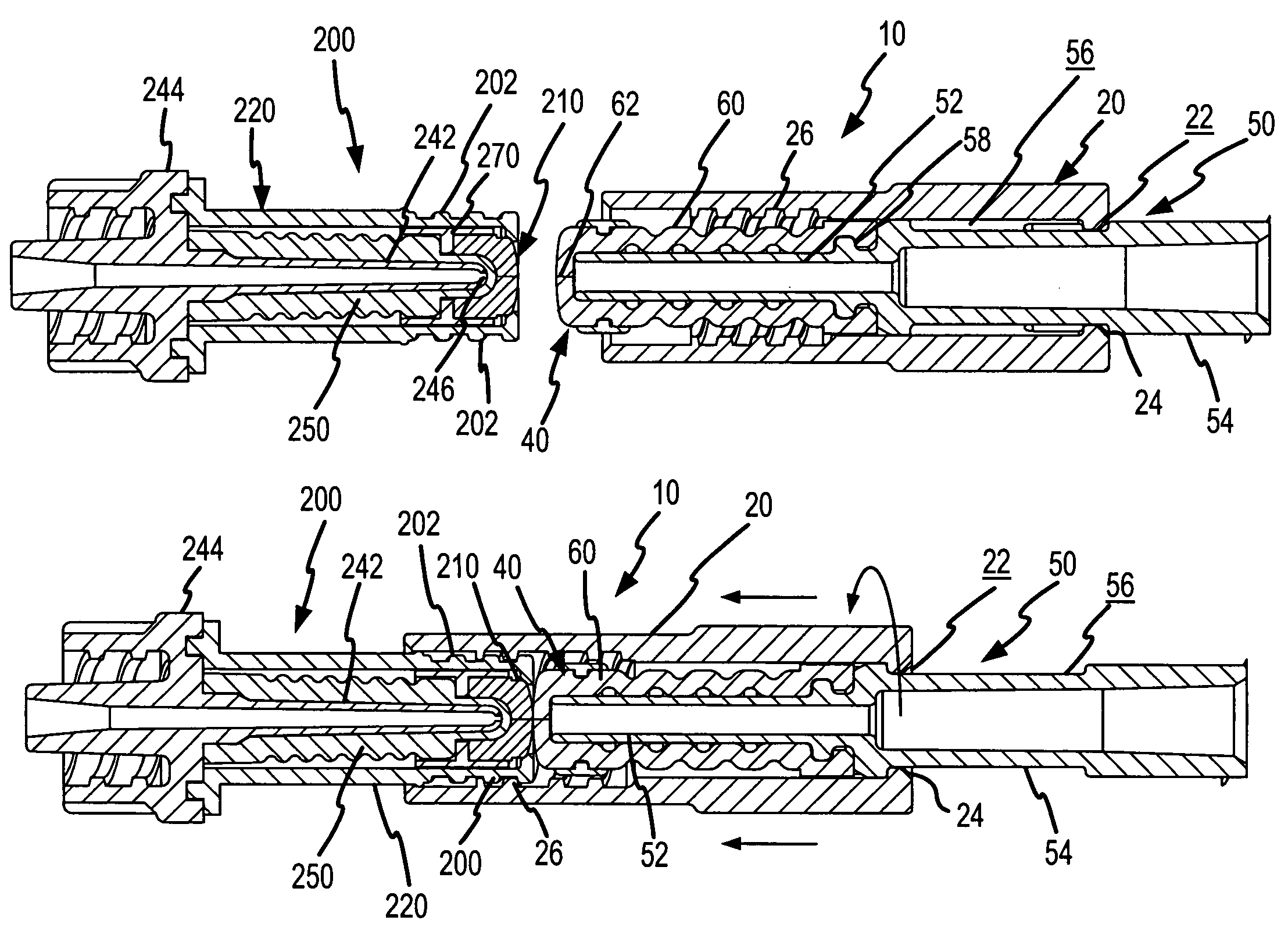

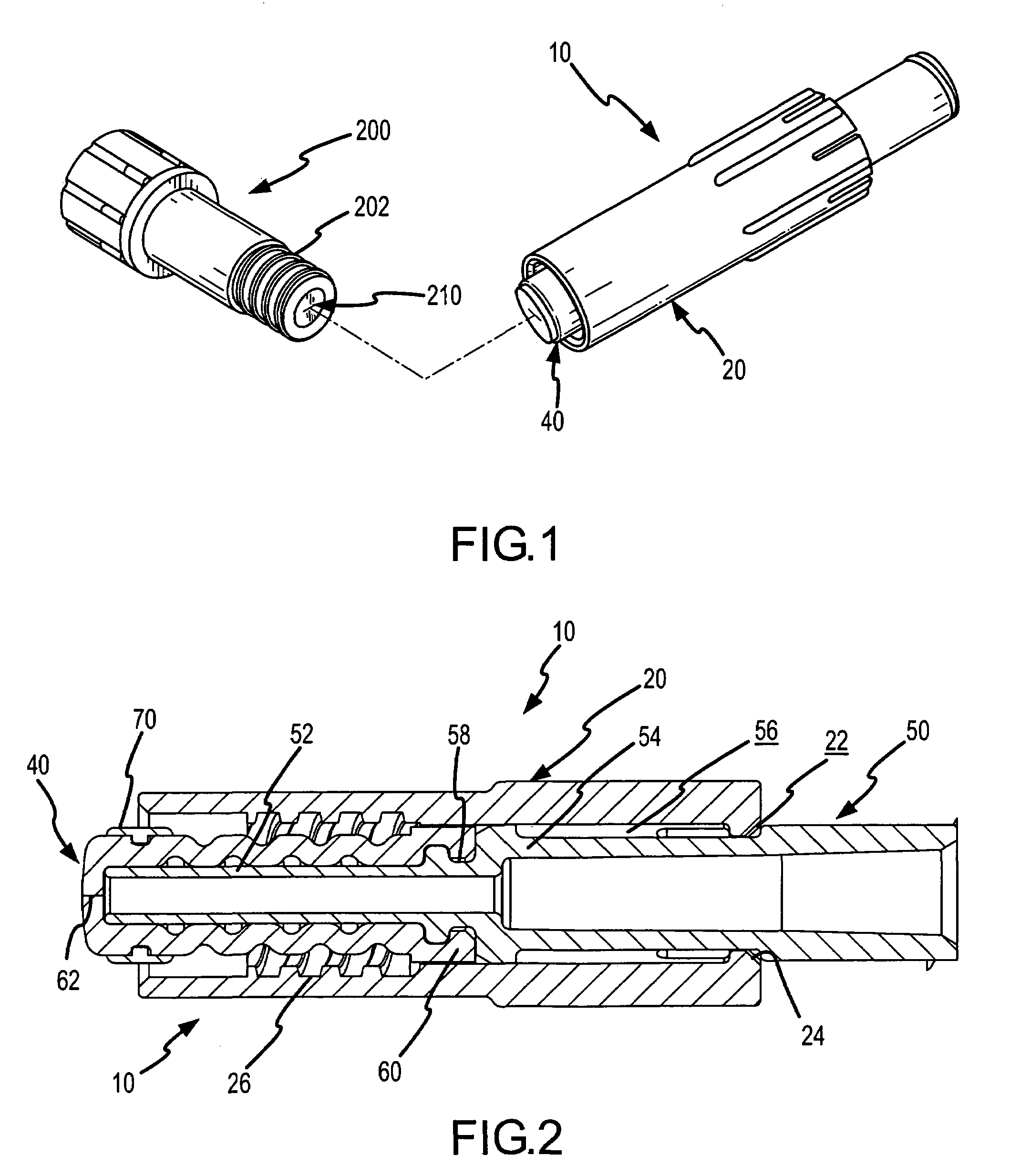

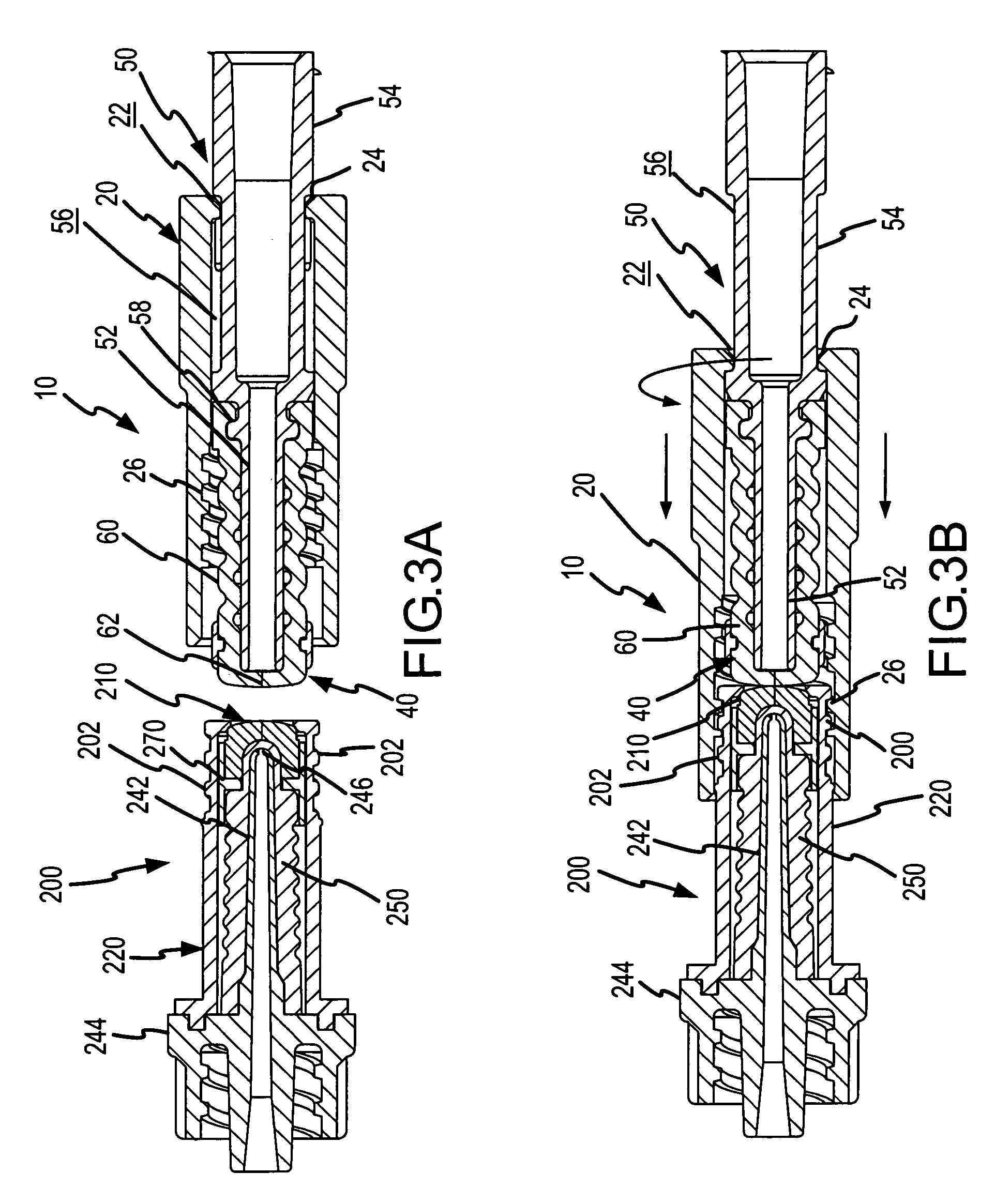

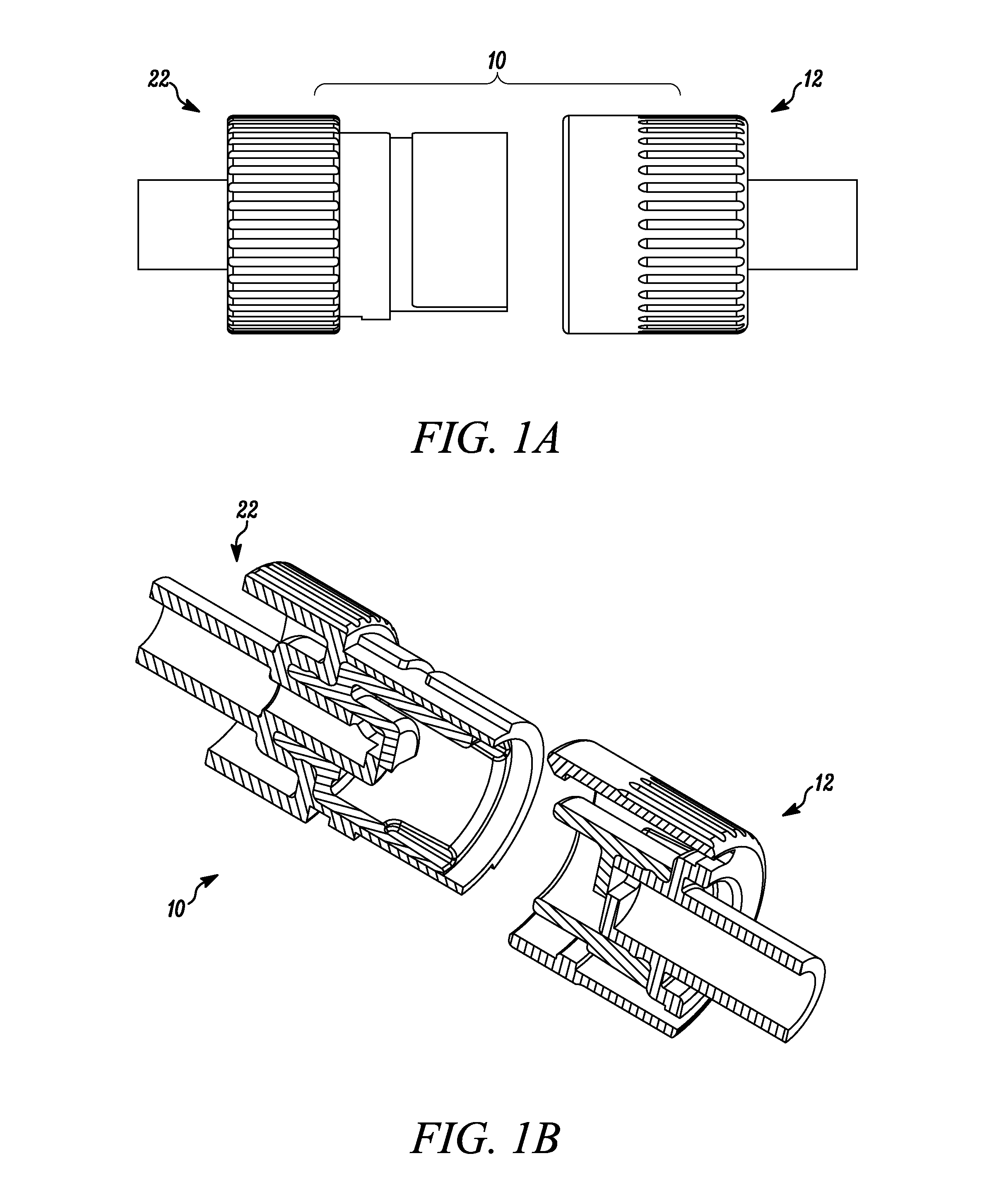

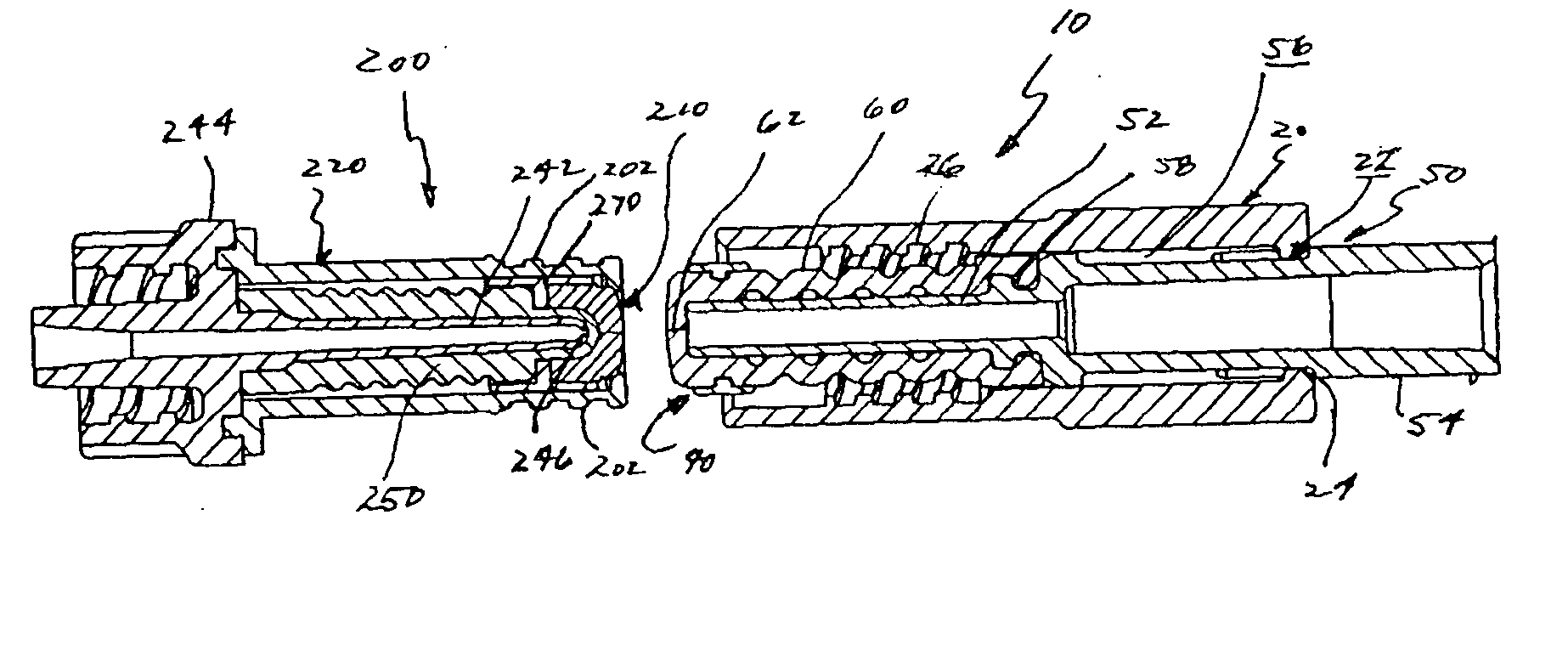

Swabable fluid connectors and fluid connector pairs

InactiveUS7396051B2Easy to cleanReduce the possibilityFluid pressure sealed jointsJoints with sealing surfacesDistal portionInterconnection

A first fluid connector is provided for selective interconnection to and fluid transfer with a second fluid connector. The first connector comprises a fluid passageway, an internal member and an outer collar supportably disposed about the internal member for selective advancement and retraction relative thereto. At least a portion of the fluid passageway may extend through the internal member. The outer collar may be selectively retracted to facilitate cleaning of the internal member. In some embodiments, the outer collar and internal member may be disposed so that a distal portion of the internal member is substantially flush with or a distal portion of internal member projects beyond a distal end of the outer collar when the outer collar is in a retracted position relative thereto. To facilitate cleaning, a distal end or distal portion of the internal member may be substantially closed when the first and second connectors are disconnected. The second connector may be adapted to facilitate fluid interconnection with the first connector, and may also present a cleanable distal end when disconnected.

Owner:BAXTER ENGLEWOOD

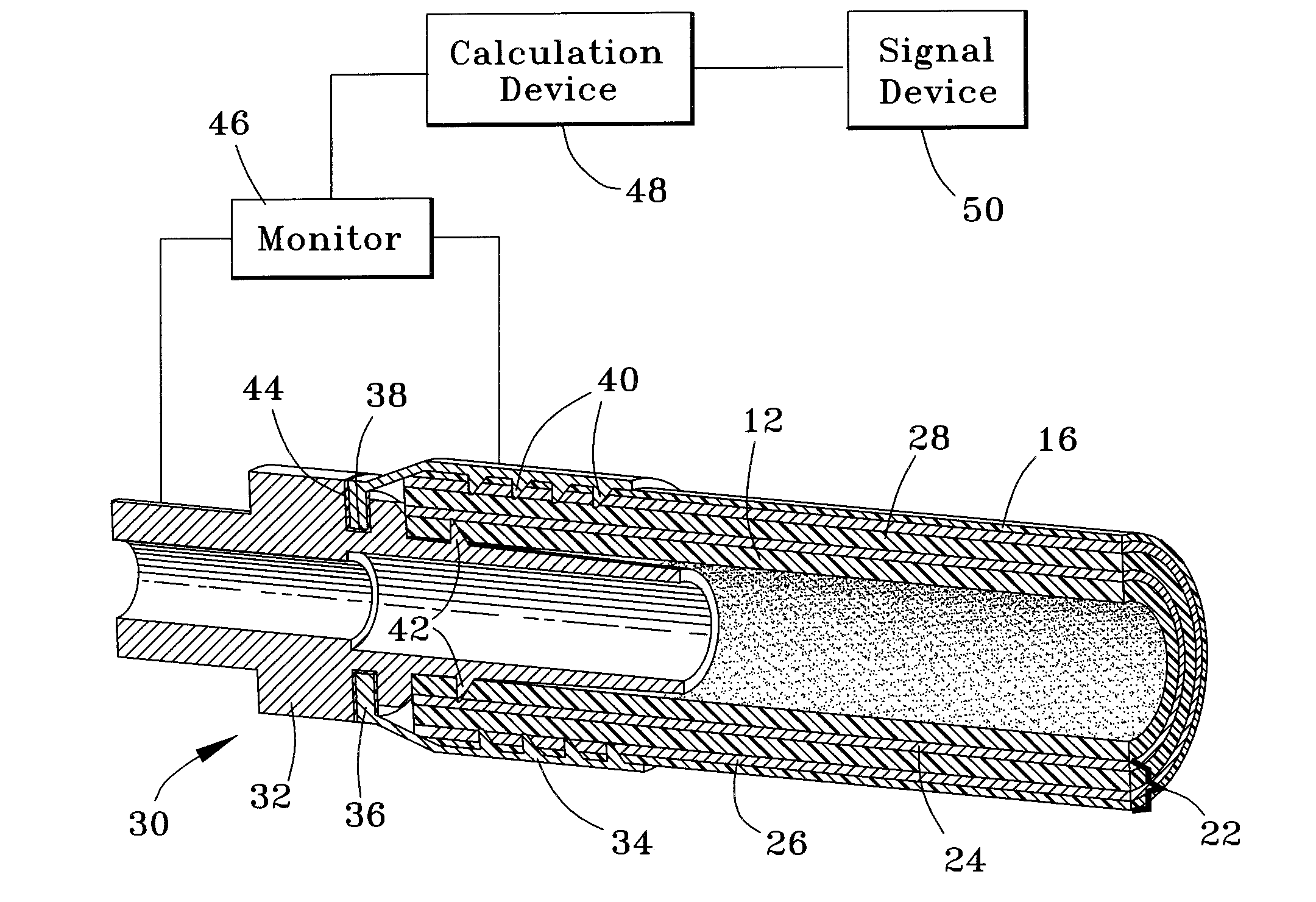

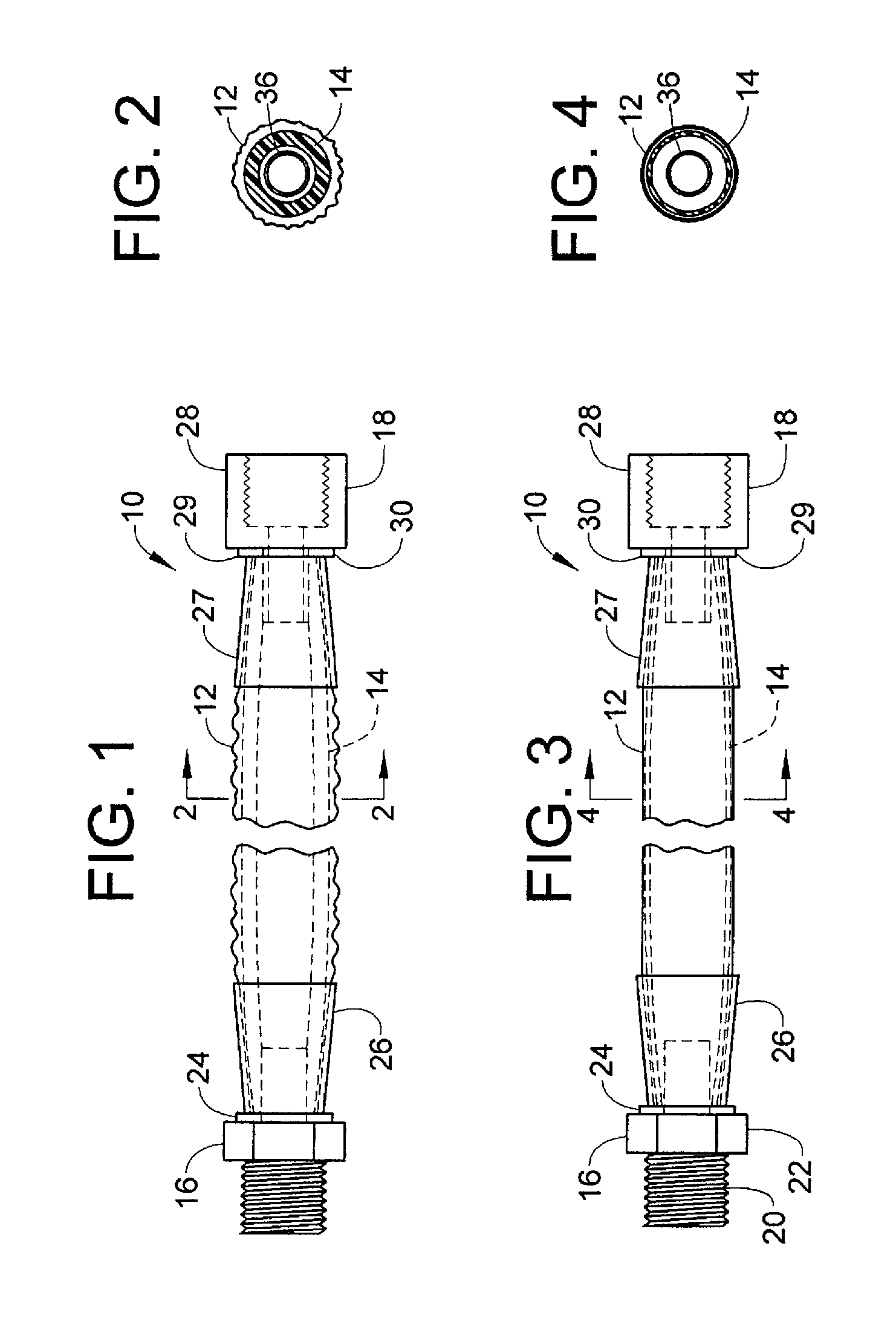

Degradation detection system for a hose assembly

A hose fault detection system includes a hose assembly including a hose having first and second conductive layers. The hose assembly has an electrical characteristic. A fault detector is in electrical communication with the first and second conductive layers. The fault detector includes an indicator operatively connected to the hose assembly. A method for monitoring the structural integrity of a hose assembly includes providing a fault detection system having a hose assembly including a hose having a first conductive layer and a second conductive layer. The hose assembly has an electrical characteristic. The electrical characteristic of the hose assembly is compared to a threshold value. A visual indicator in operative communication with the hose assembly is illuminated when the electrical characteristic goes beyond the threshold value.

Owner:DANFOSS POWER SOLUTIONS II TECH AS

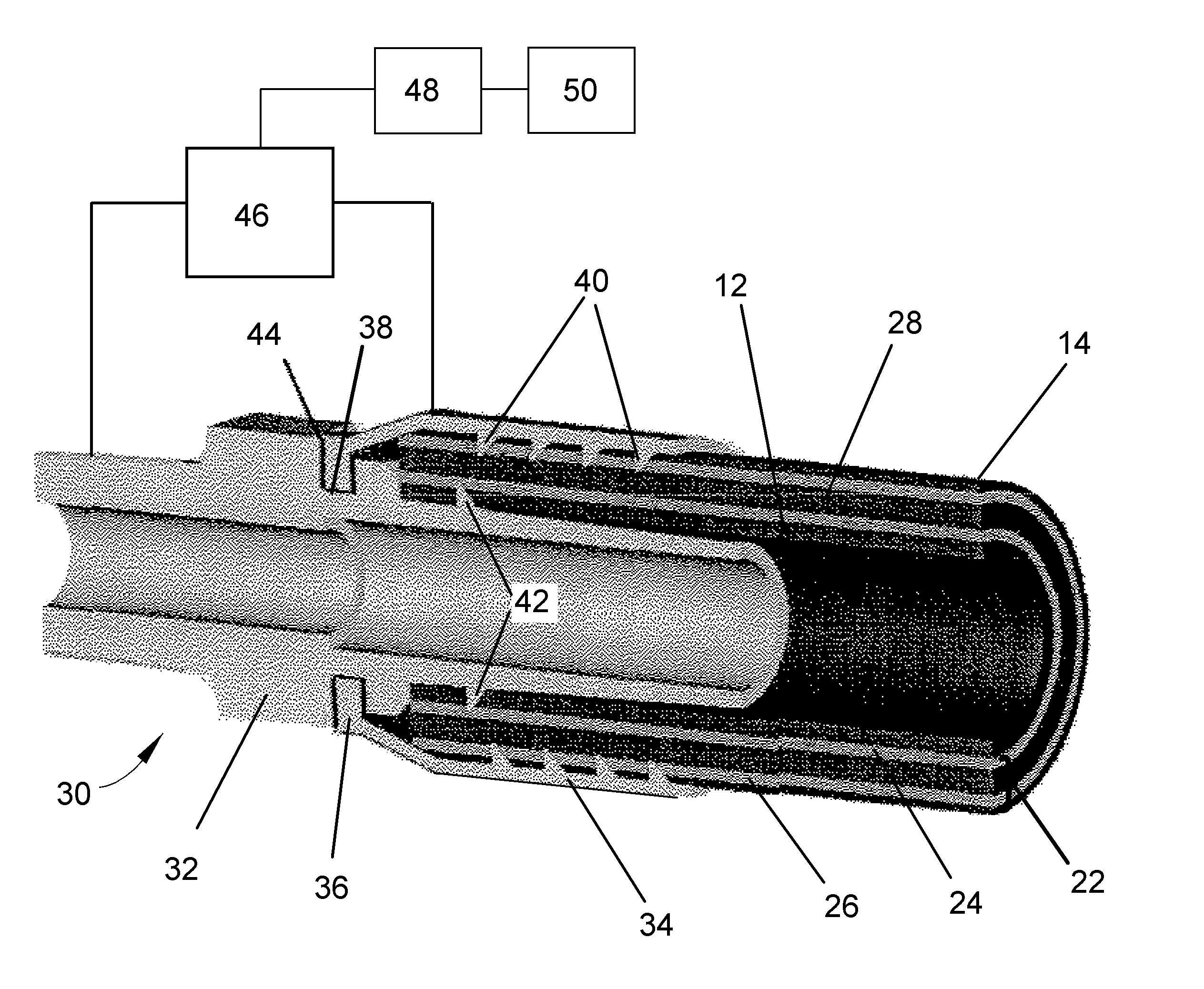

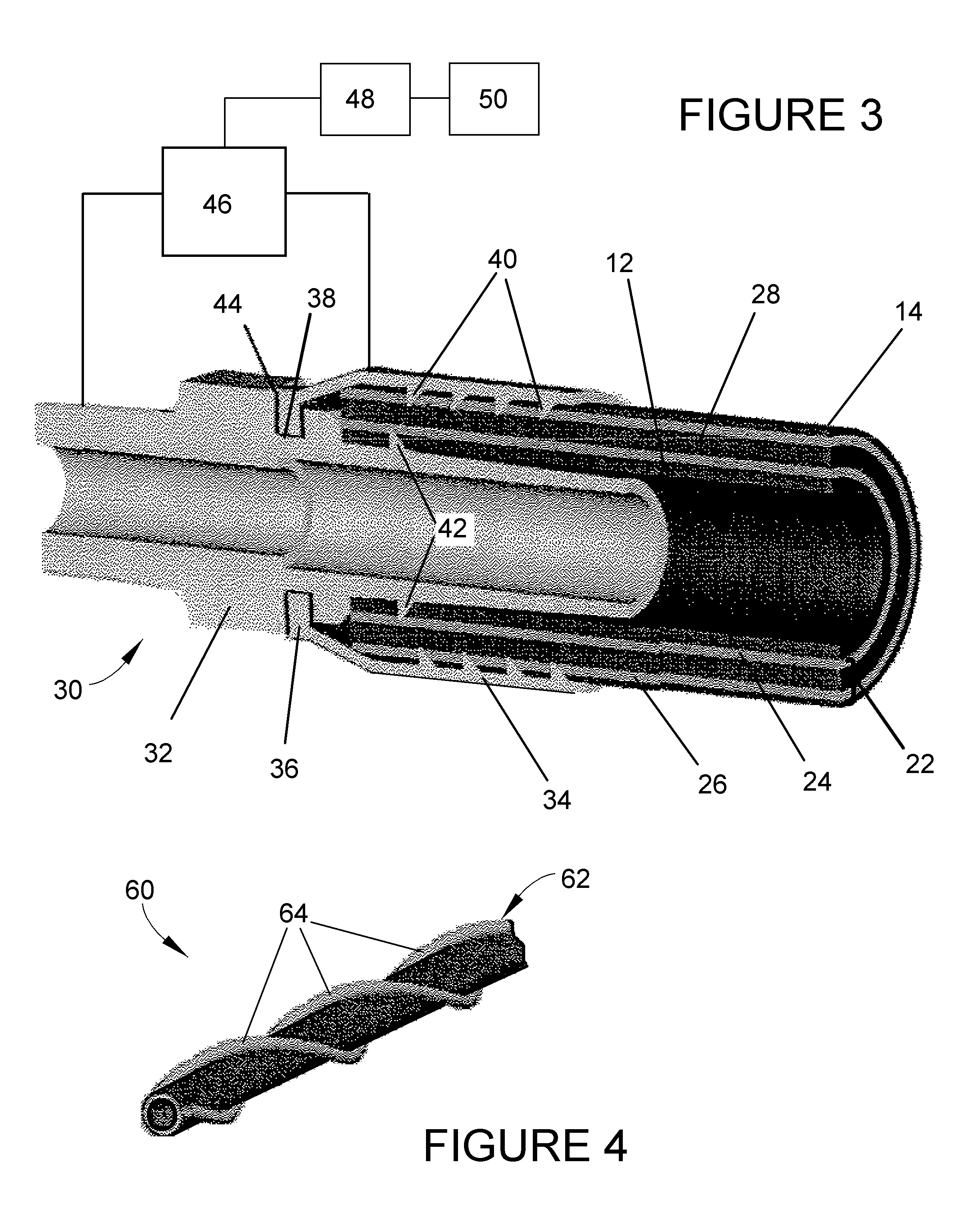

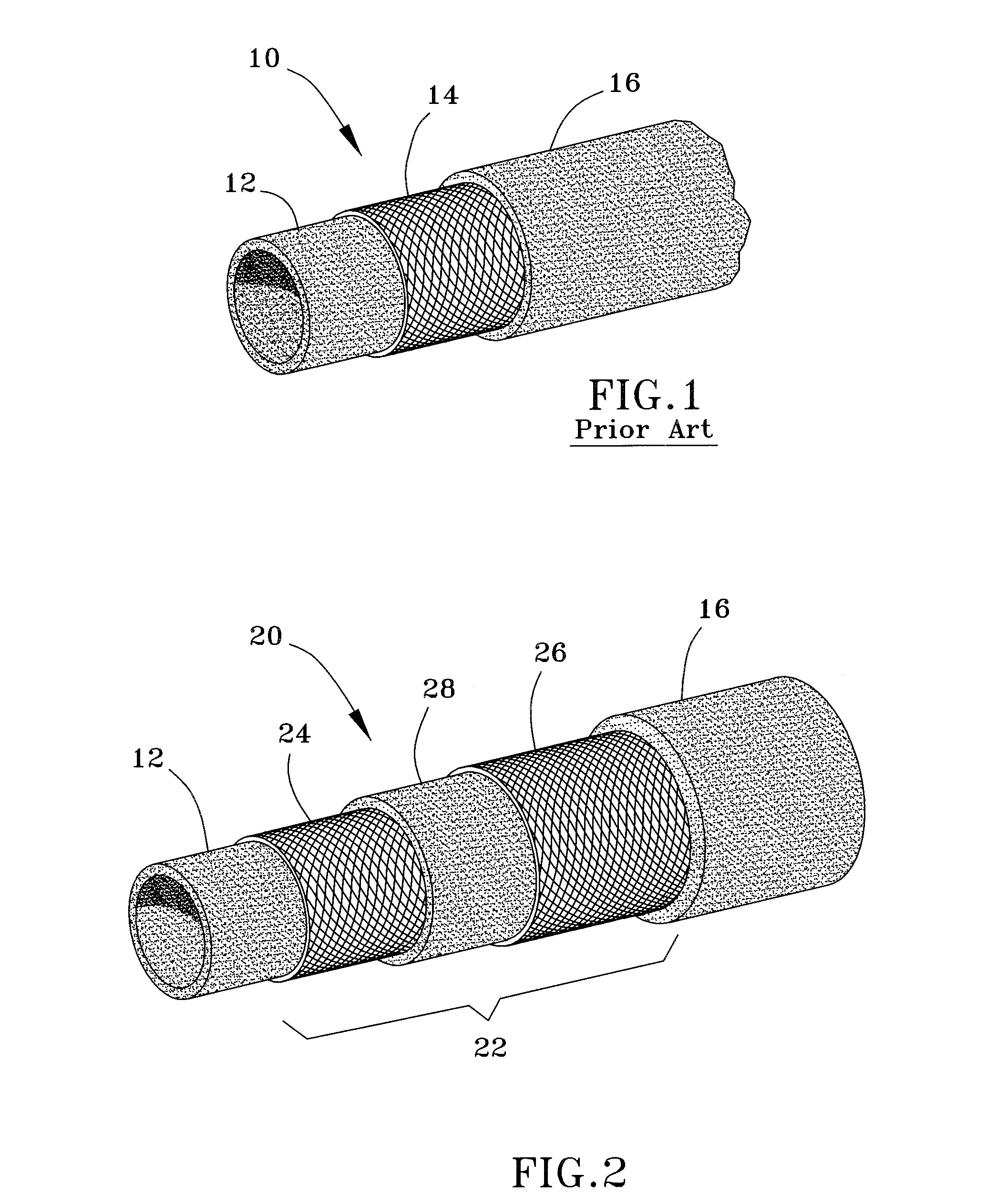

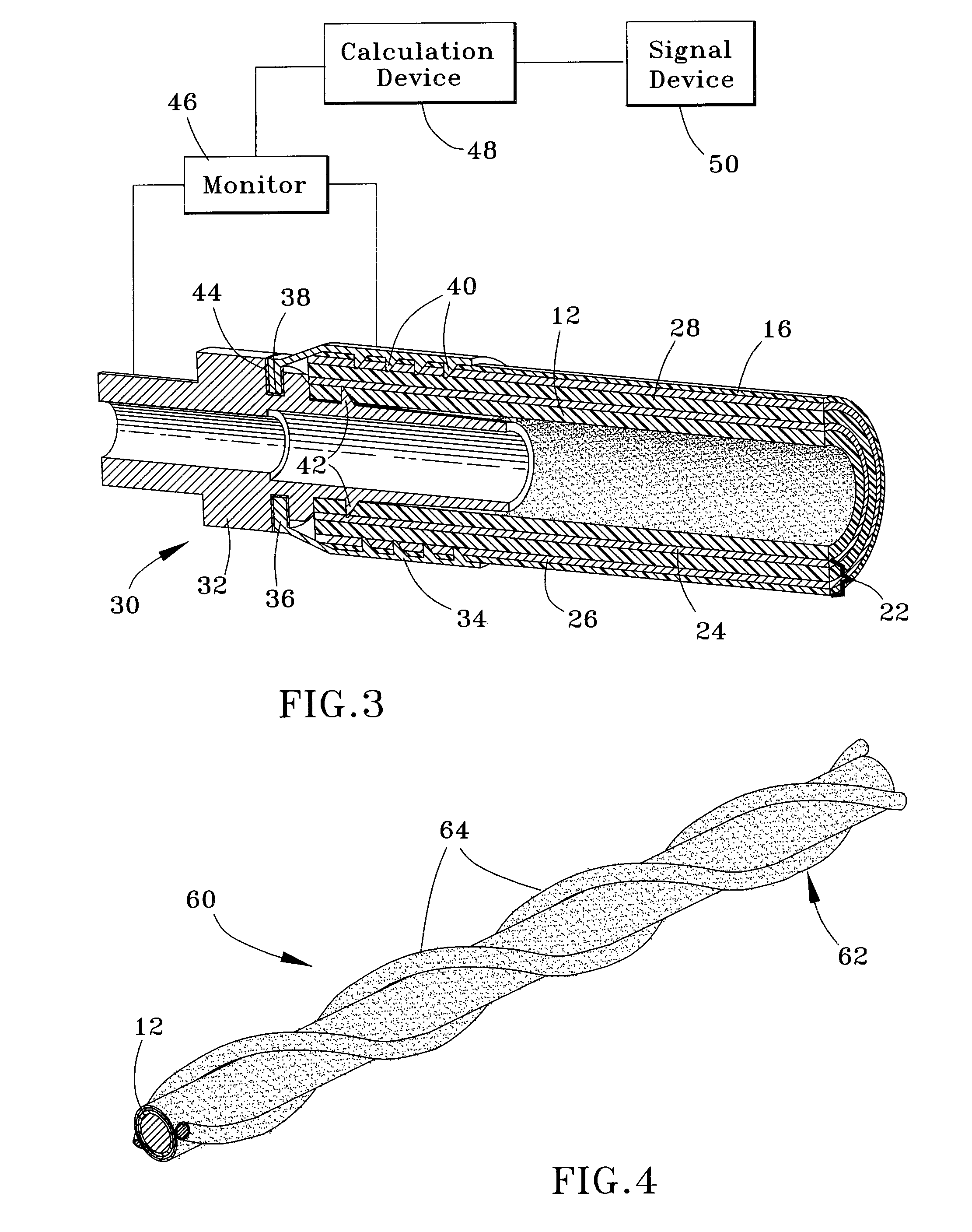

Hydraulic hose with integral life-sensing capability and method therefor

ActiveUS20060196252A1Detection of fluid at leakage pointTesting/calibration apparatusElectrical conductorProcess equipment

A system and method for predicting structural failure of a wall of a fluid containment vessel, such as a hydraulic hose or other type of pressurized conduit of types used in mobile machinery, automotive, aerospace, manufacturing, and process equipment. The wall of the vessel has an innermost layer for contact with the fluid contained by the vessel, and an outermost layer parallel with the innermost layer. The system includes strain-sensing means between the innermost and outermost layers and comprising at least one conductor parallel to the innermost layer of the wall. The system and method entail sensing changes in an electrical property associated with the at least one conductor resulting from distortion of the wall of the vessel causing distortion of the at least one conductor.

Owner:PURDUE RES FOUND INC

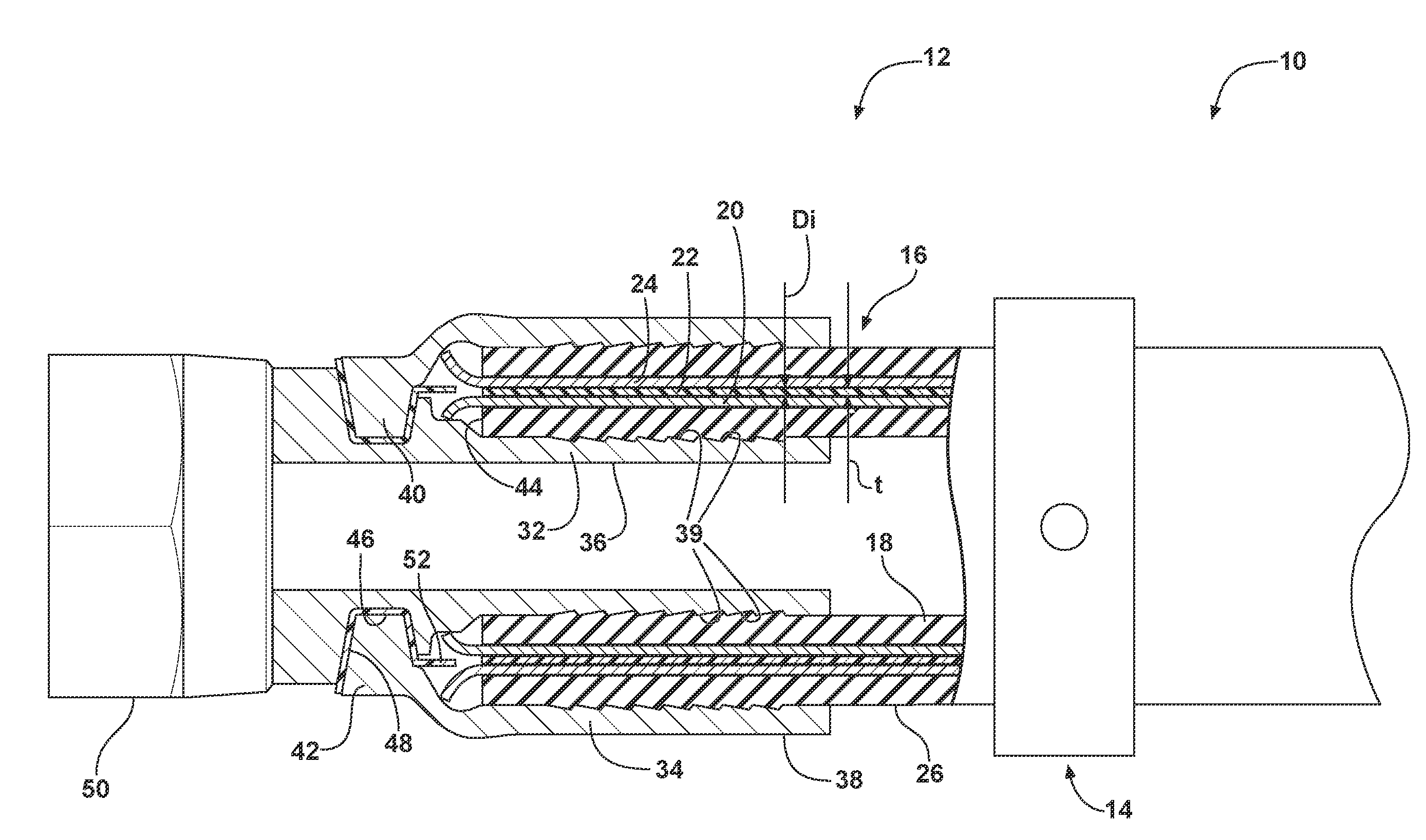

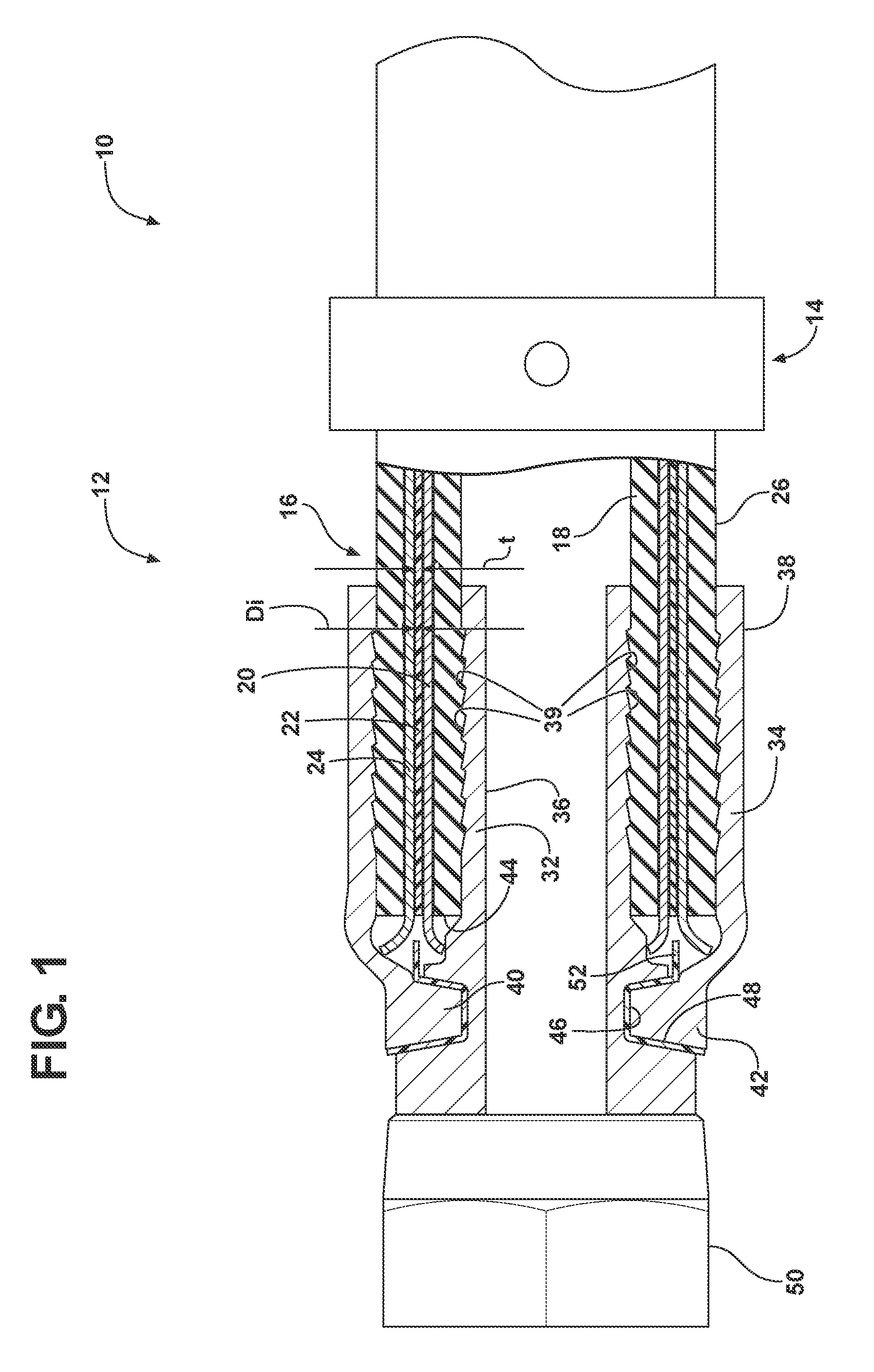

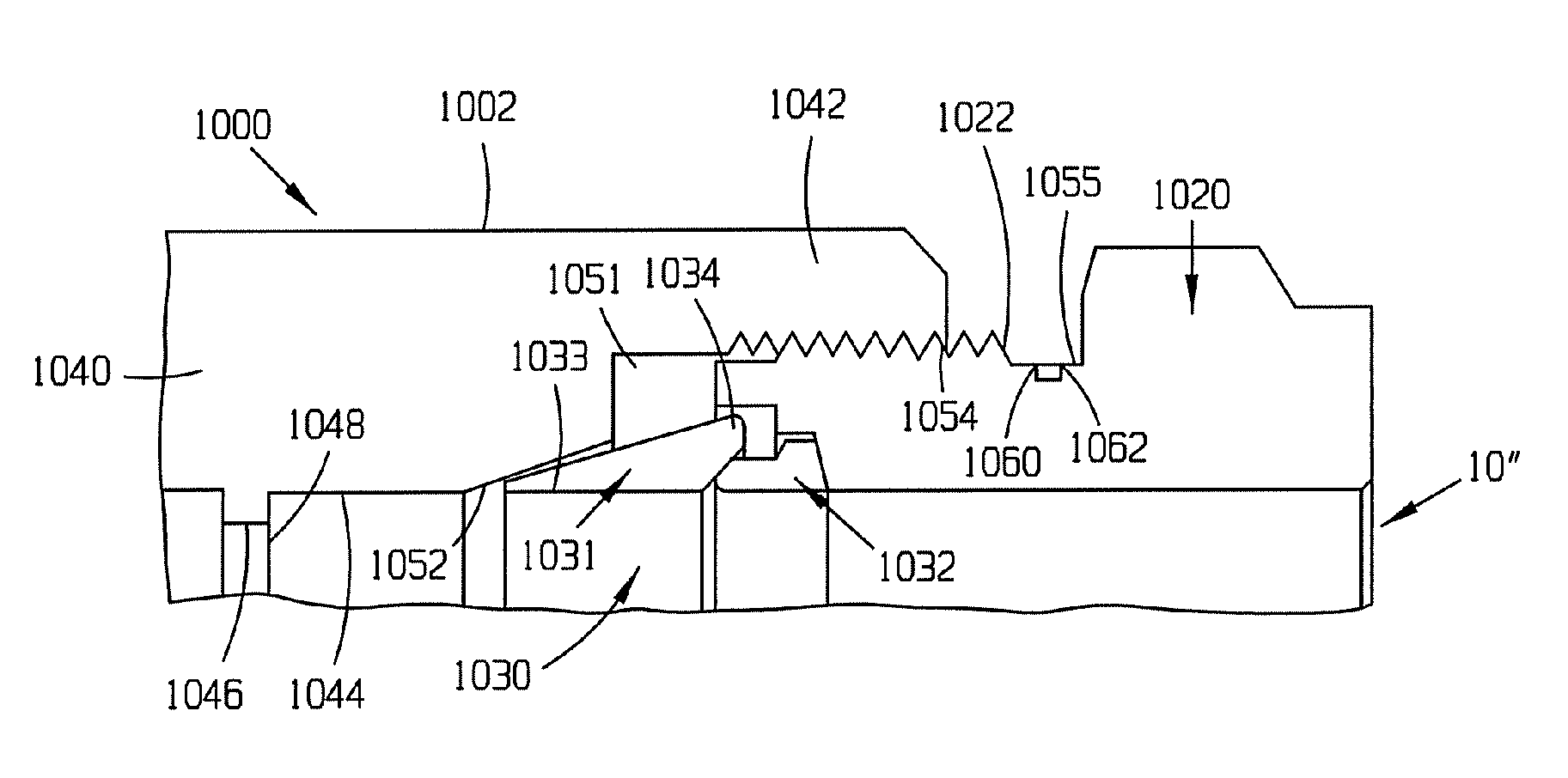

Safety connector apparatus

ActiveUS8257286B2Preventing inadvertent sealing connectionScaffold connectionsPneumatic massageMating connectionCompression therapy

A connector apparatus includes first and second mating connectors that can be joined to make a fluid connection. The connectors are constructed to discriminate improper connectors so that no fluid tight connection can be formed with improper connectors. The connector apparatus can be used with a system for compression therapy to prevent deep vein thrombosis.

Owner:KPR U S LLC

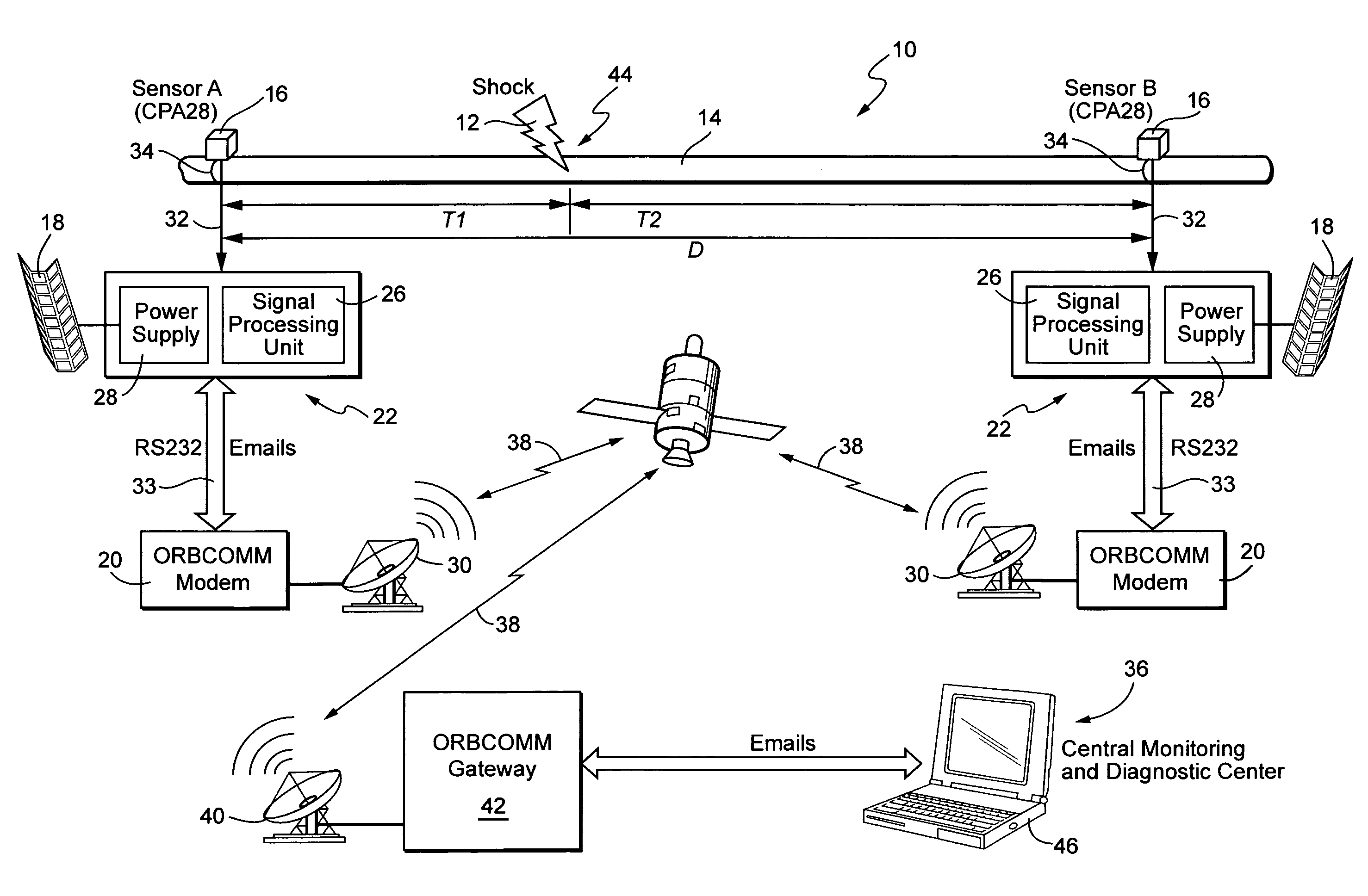

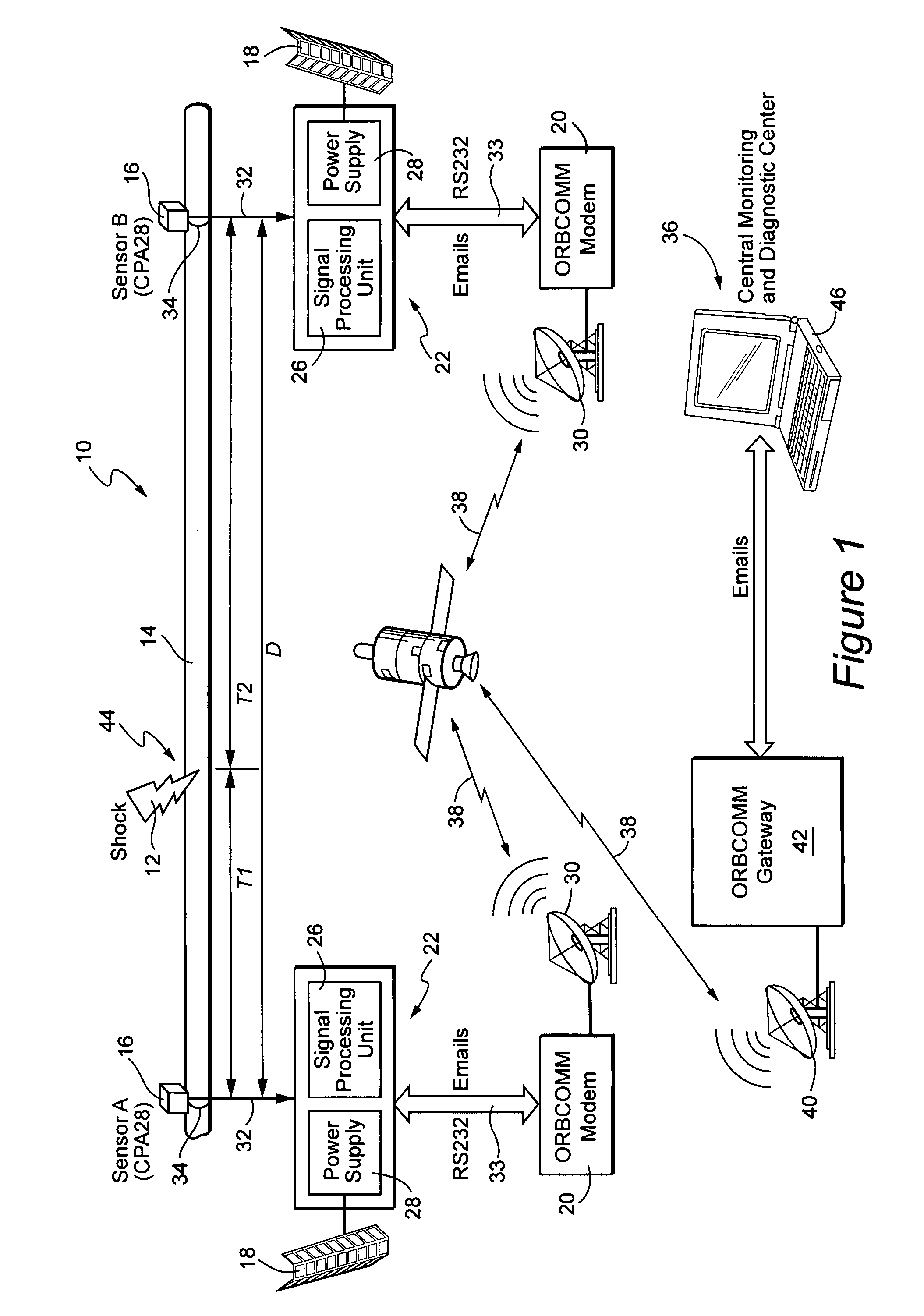

Acoustic impact detection and monitoring system

ActiveUS7607351B2Cost effectiveQuick checkMultiple-port networksVibration measurement in fluidHydrophoneTelecommunications link

A system is disclosed for detecting and locating harmful impacts to pipelines using sensors placed along the pipeline. The exact spacing of sensors is site specific and is set with the goal of maximizing sensor spacing without reducing system performance and reliability. At each sensor location, preferably there are four basic components, i.e., a hydrophone, solar power components, and data processing and communications equipment. Each hydrophone directly measures the acoustic noise fluctuation in a pipe section, which propagates at long distances in the pipeline at the specific speed of sound for the particular type of pipe. If specific signal parameters exceed a programmed threshold, a detection message is generated and transmitted via a communications link to a central monitoring and diagnostic center.

Owner:GENERAL ELECTRIC CO

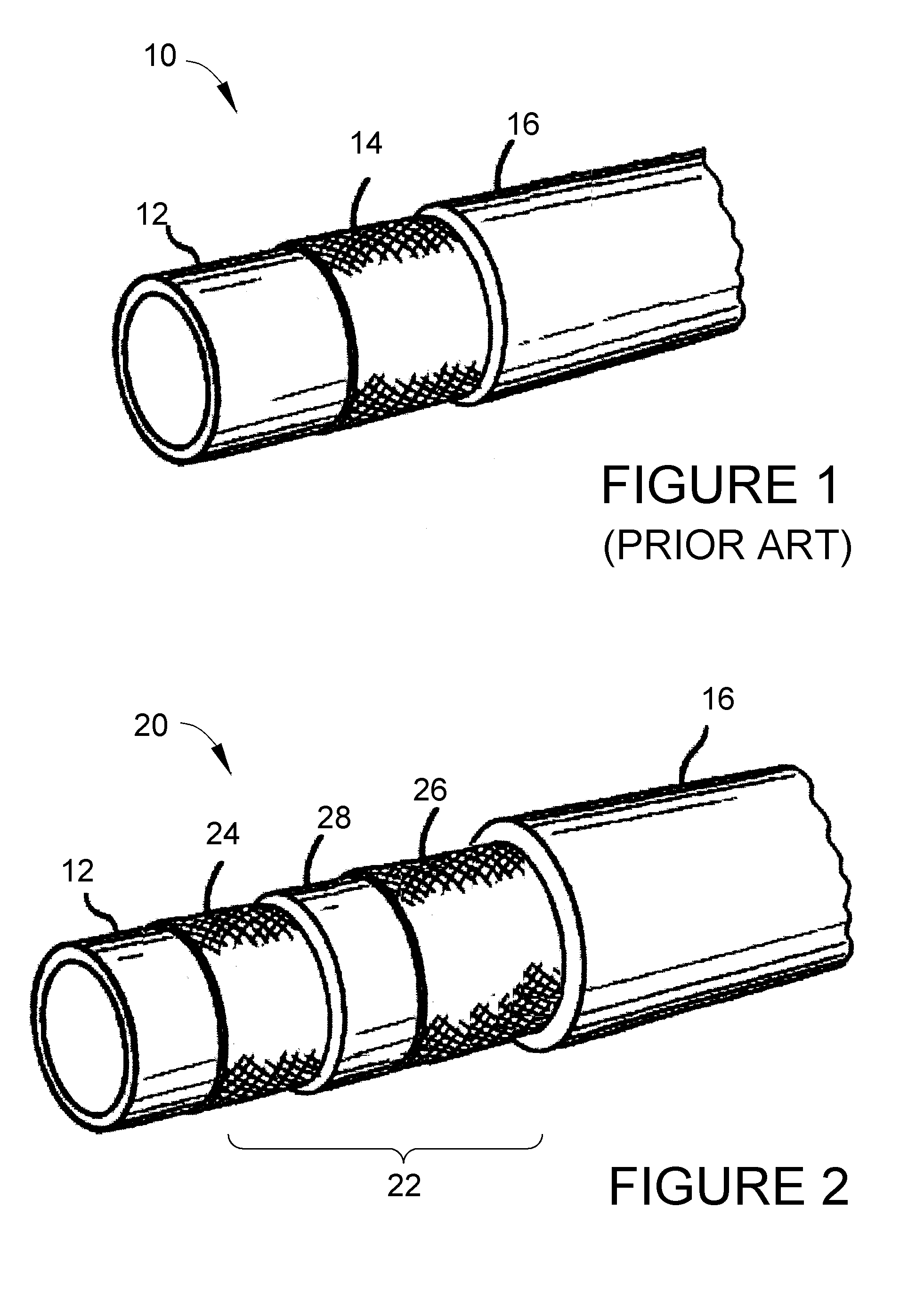

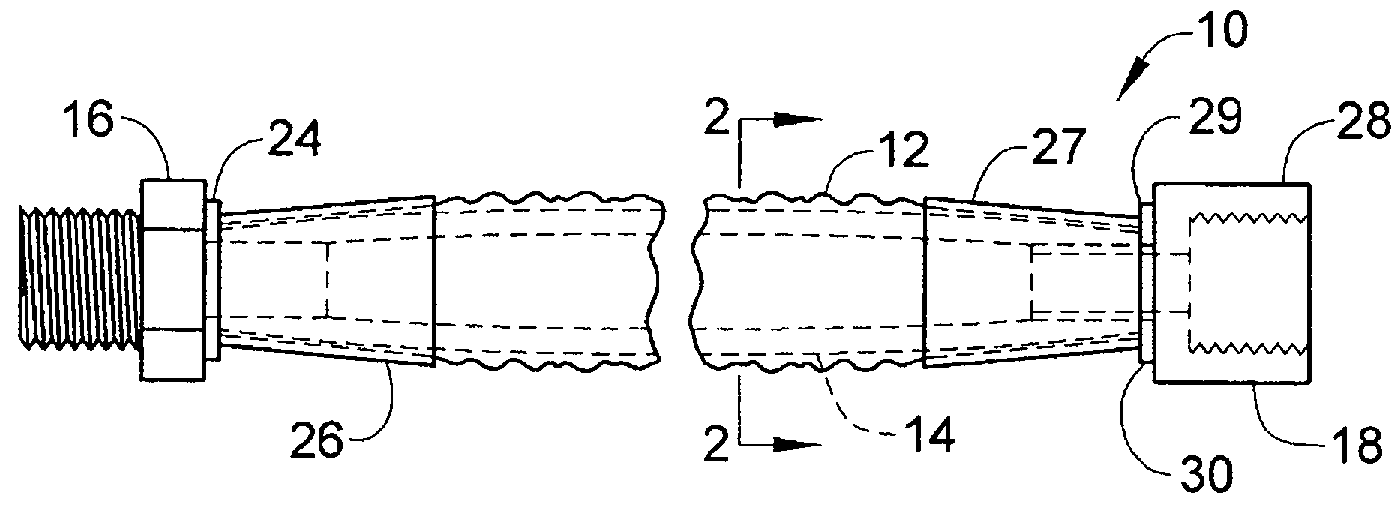

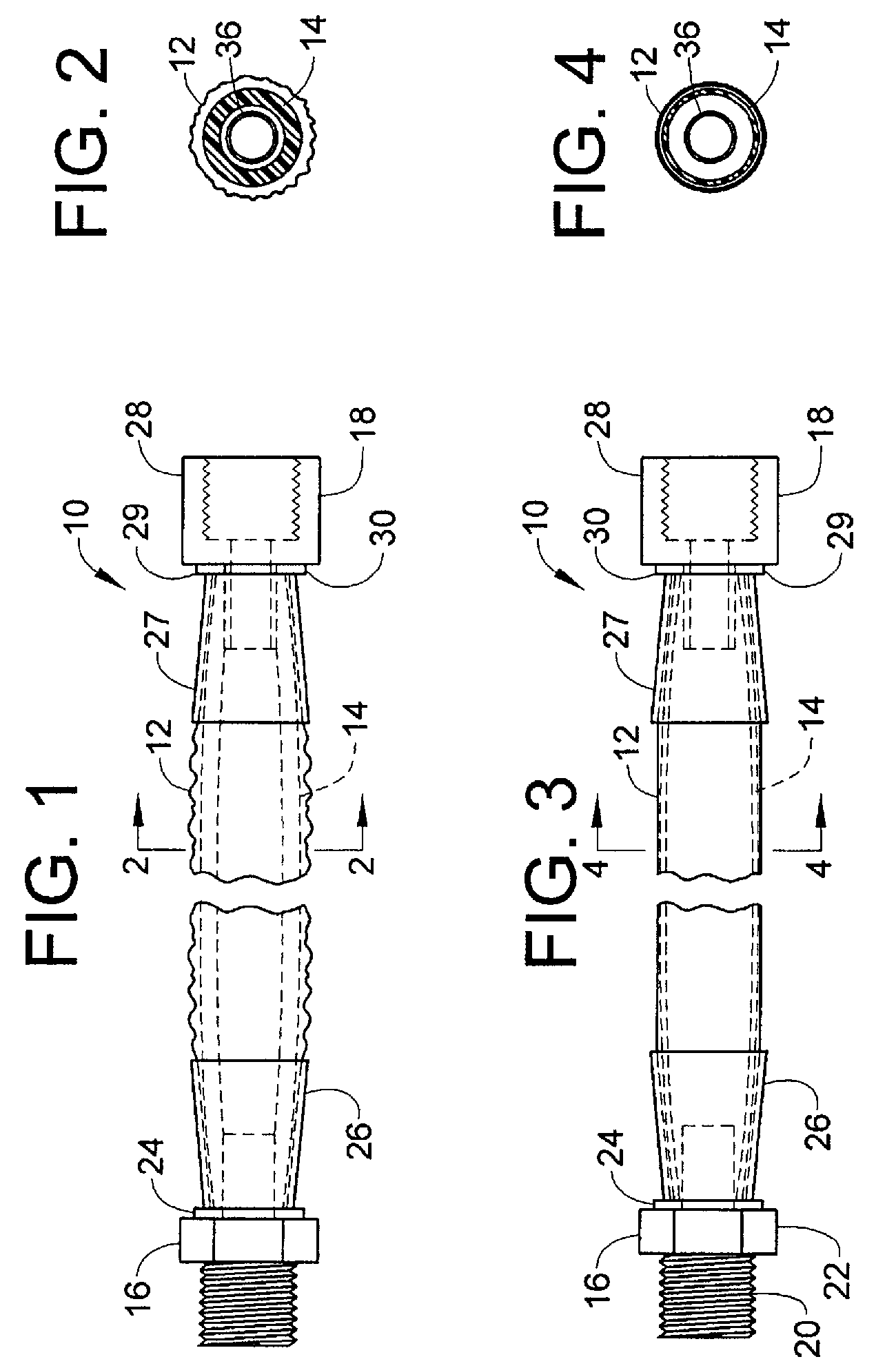

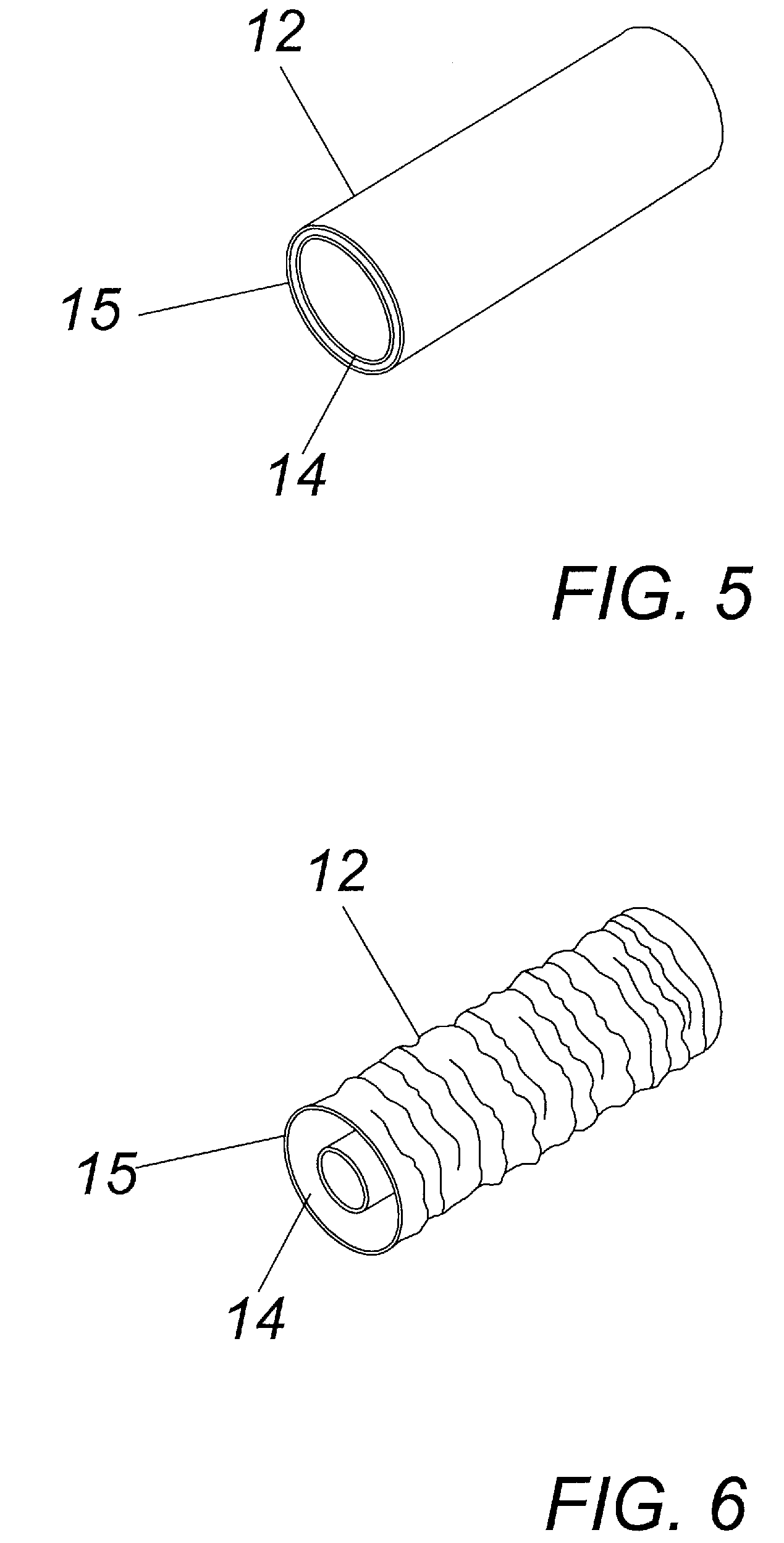

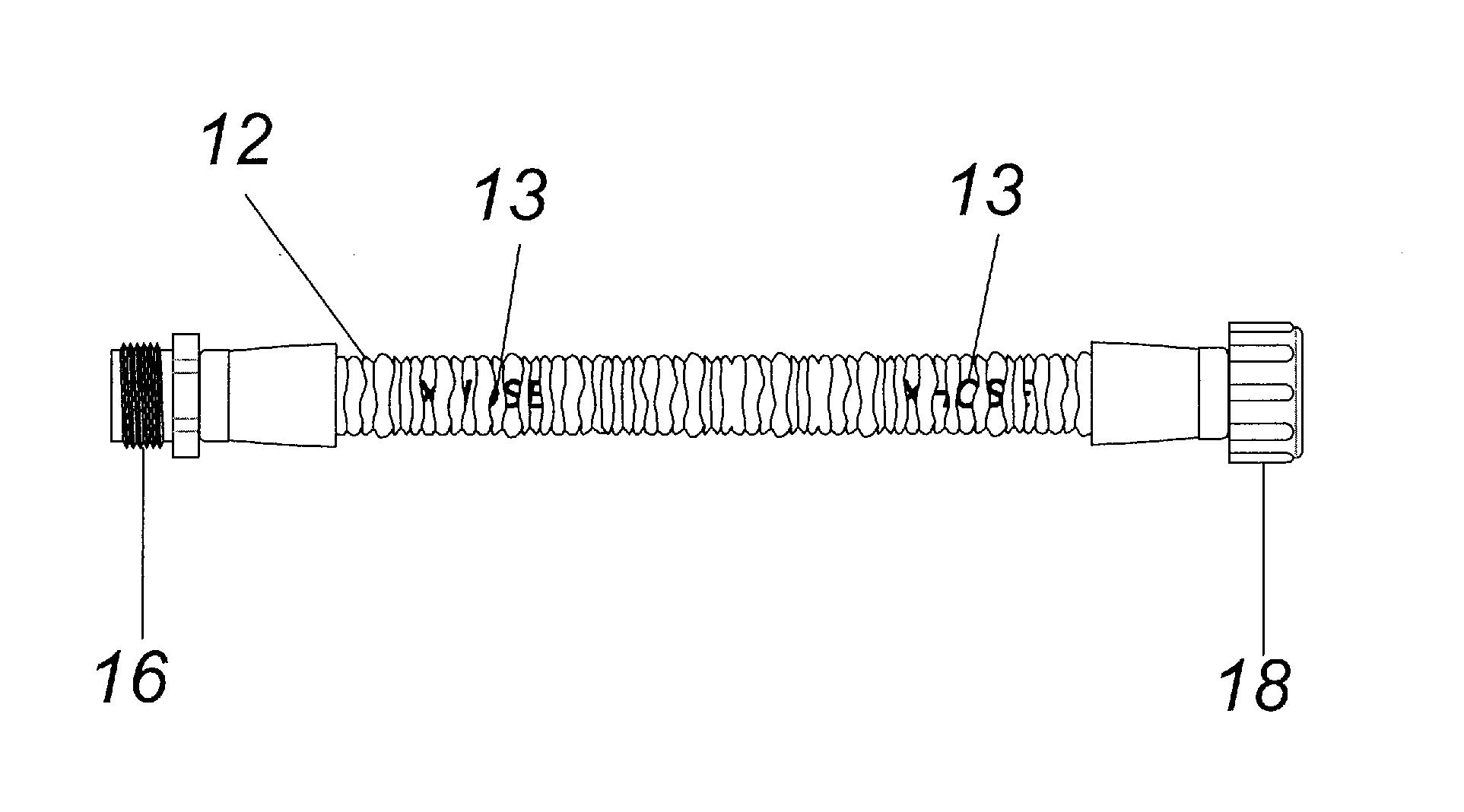

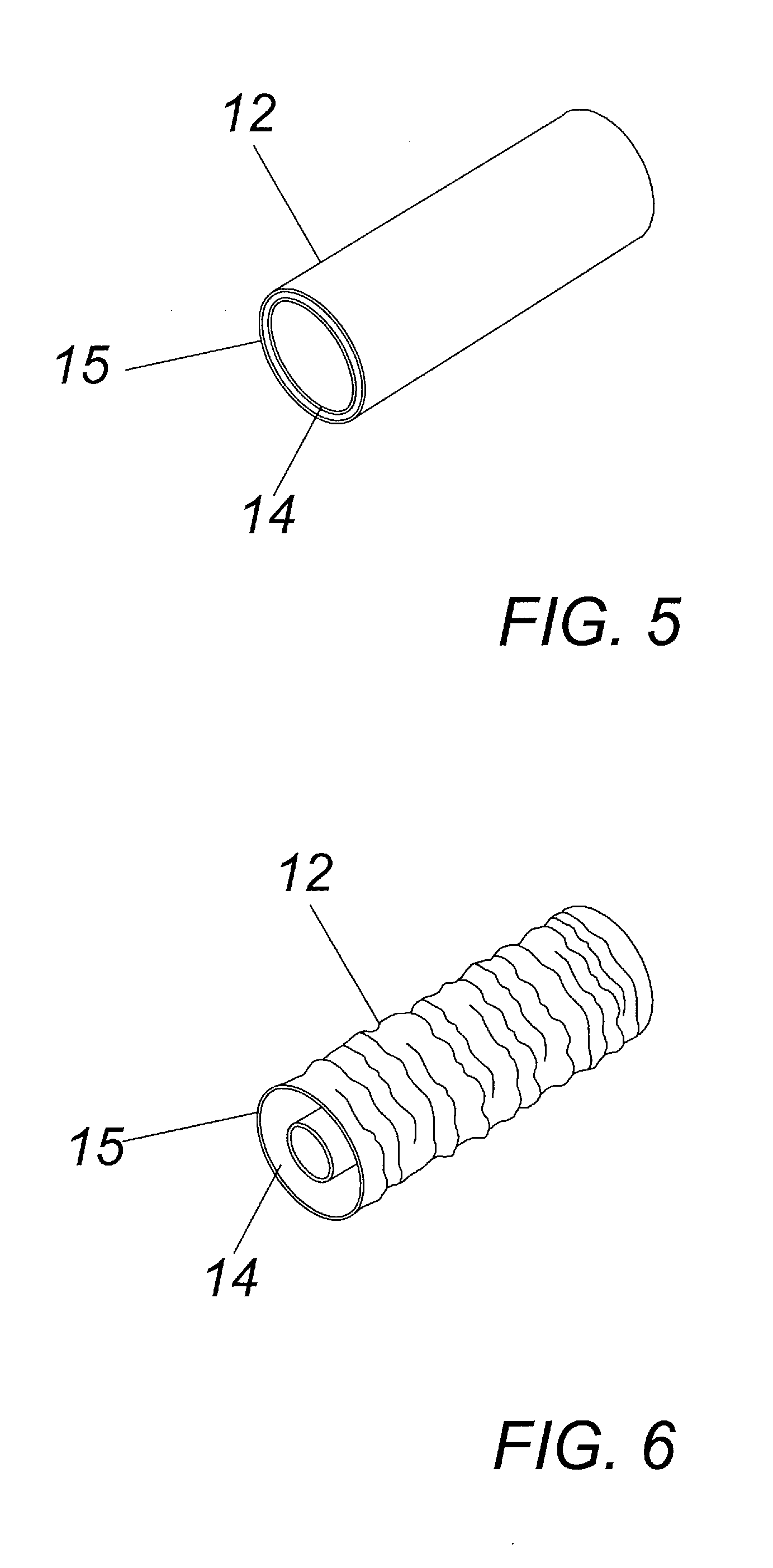

Expandable hose assembly

ActiveUS8291942B2Reduce and eliminate formingPipe couplingsSuction cleanersEngineeringFluid pressure

A hose which automatically expands longitudinally and automatically expands laterally upon the application of a fluid pressure is disclosed. The hose can automatically expand longitudinally up to six times its unexpanded or contracted length. Upon release of the fluid pressure within the hose, the hose will automatically contract to a contracted condition. The hose includes an inner tube made from an elastic material and an outer tube made from a non-elastic material. The inner tube is positioned concentrically within the outer tube in both a contracted condition and an expanded condition. The outer tube is secured to the inner tube only at a first end of the inner and outer tubes and at a second end of the inner and outer tubes. The outer tube moves laterally and longitudinally with respect to the inner tube when the tubes are transitioning between a contracted condition and an expanded condition.

Owner:TELEBRANDS CORP

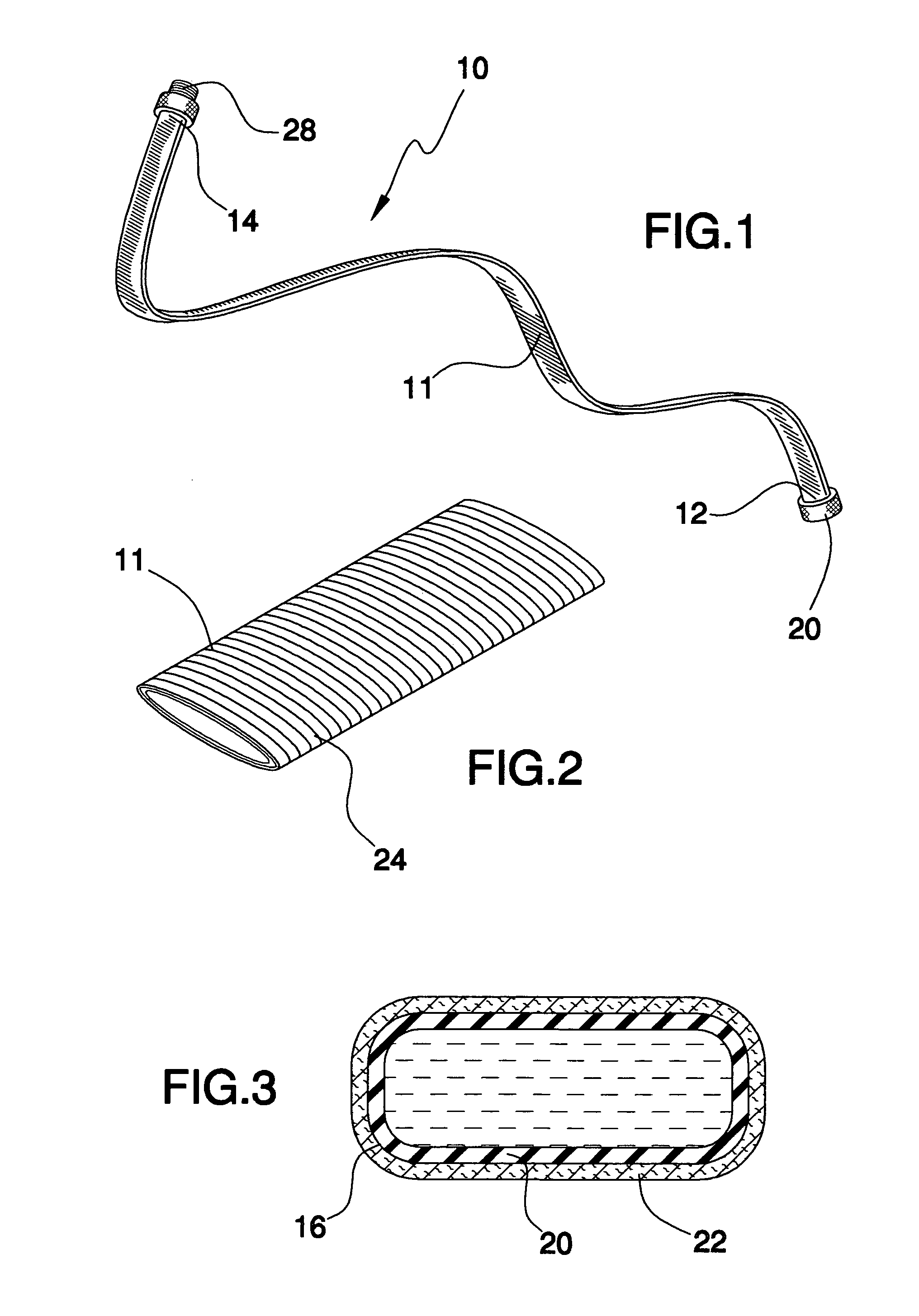

Garden hose assembly

InactiveUS6955189B1Prevent trippingImprove visibilityPipe couplingsFlexible pipesEngineeringScrew thread

A garden hose assembly includes an elongated and flexible tubular member that includes an open first end, an open second end and a peripheral wall extending between the first and second open ends. A cross-section taken traversely to a longitudinal axis of the tubular member has a generally oblong shape when the tubular member is filled with a fluid and a substantially flattened shape when the tubular member is not filled with a fluid. The tubular member has an outer surface colored a fluorescent color. A threaded female coupler is fluidly coupled to the first end and a threaded male coupler is fluidly coupled to the second end.

Owner:WEYKER RICH J

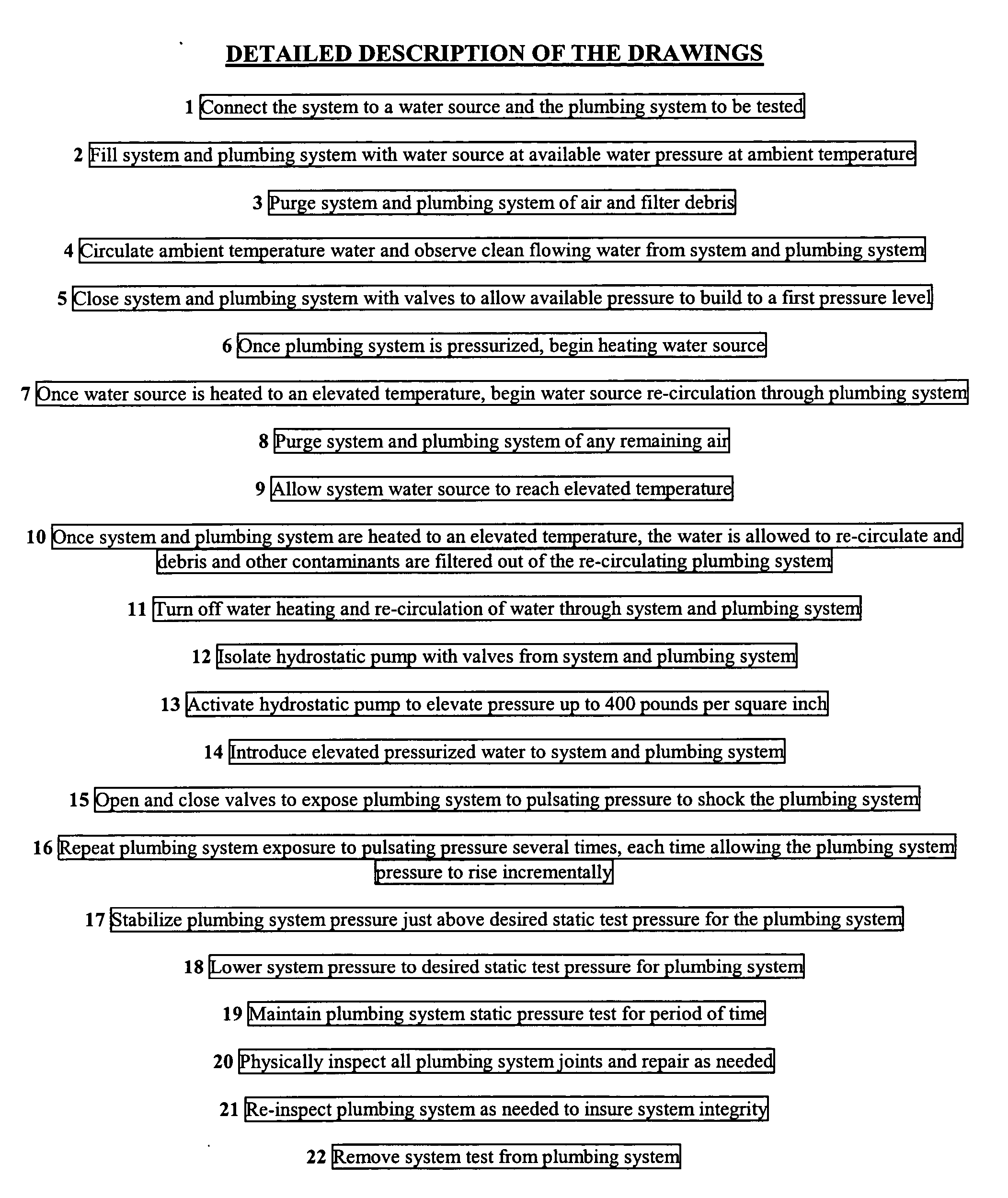

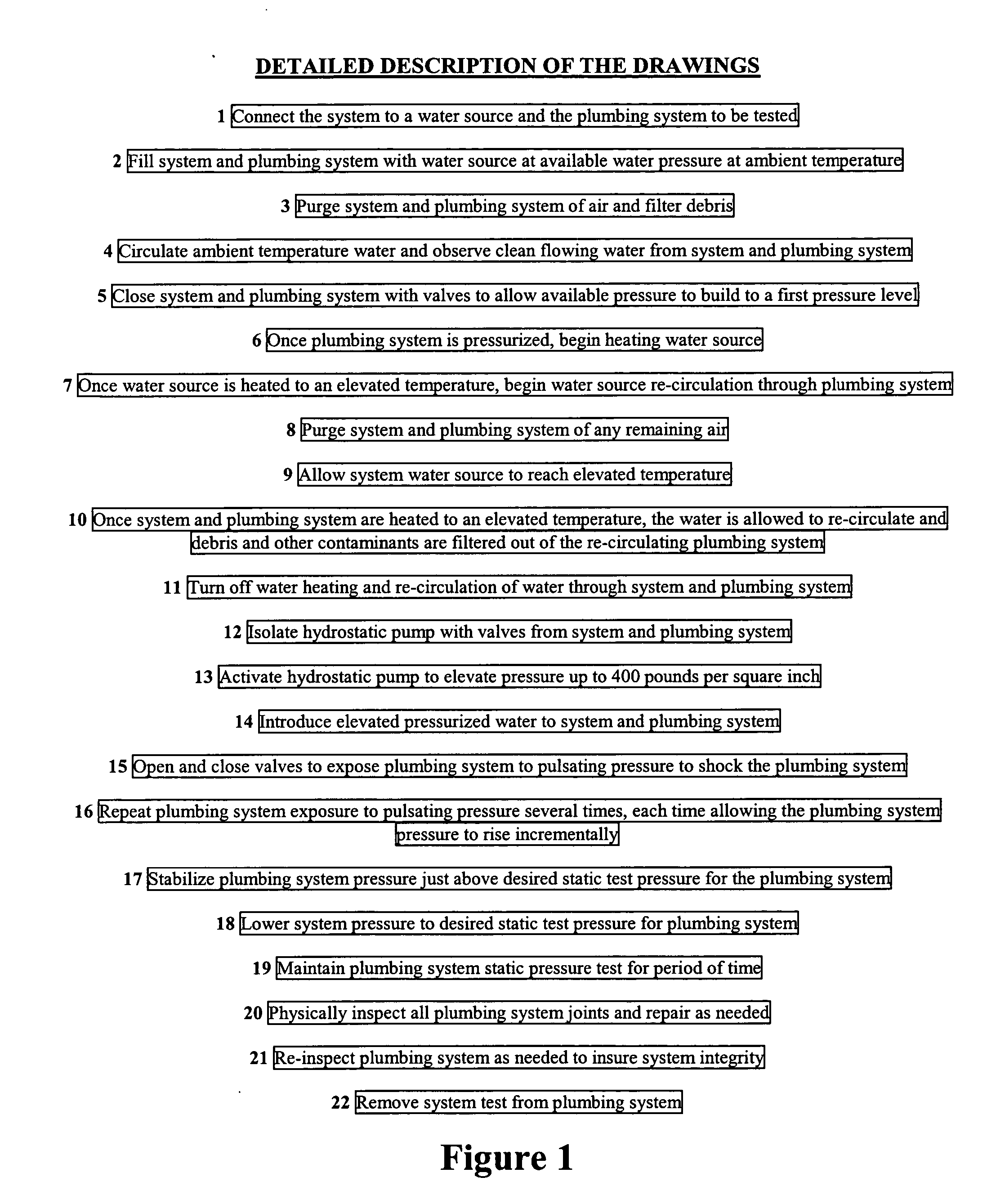

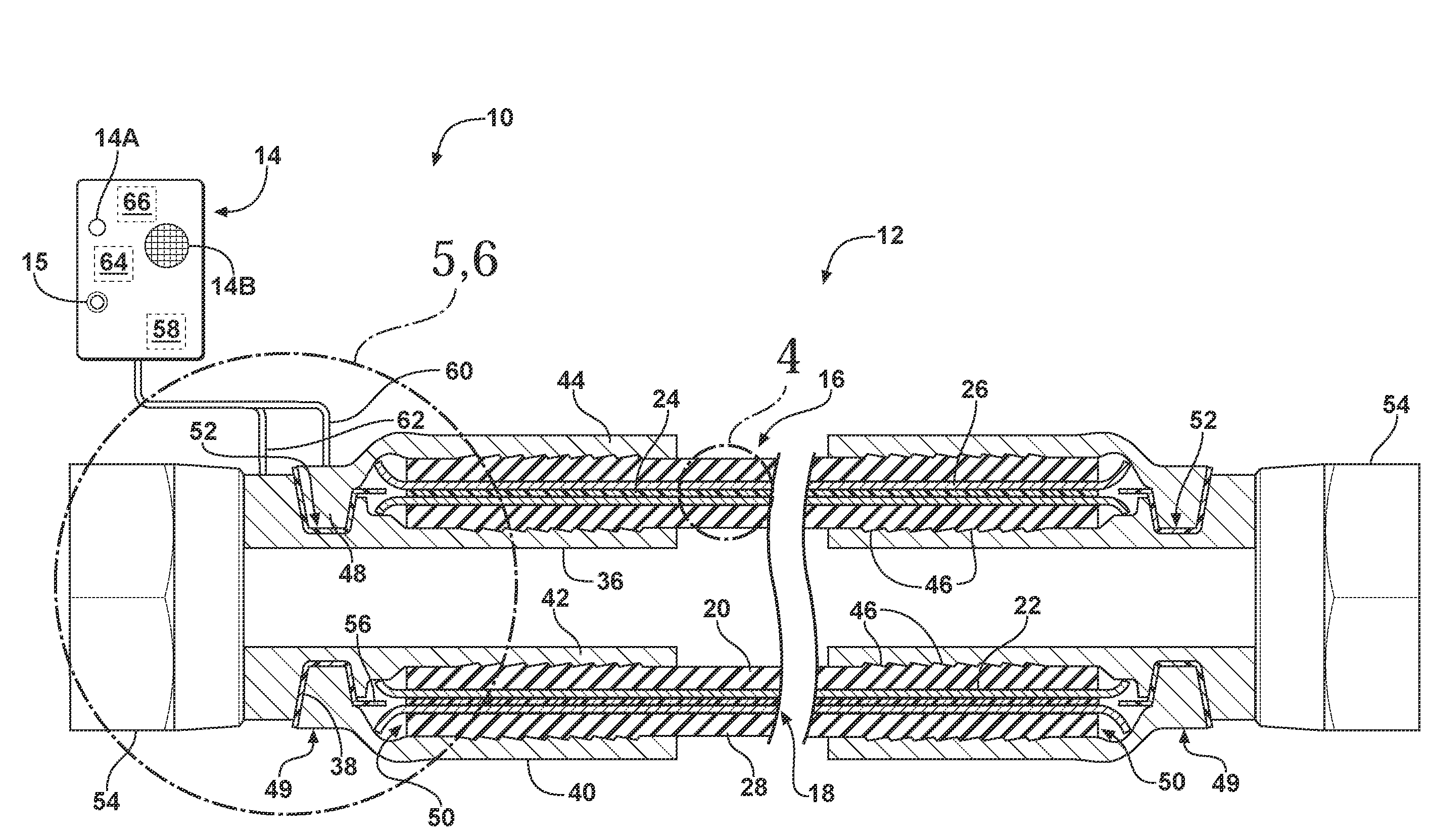

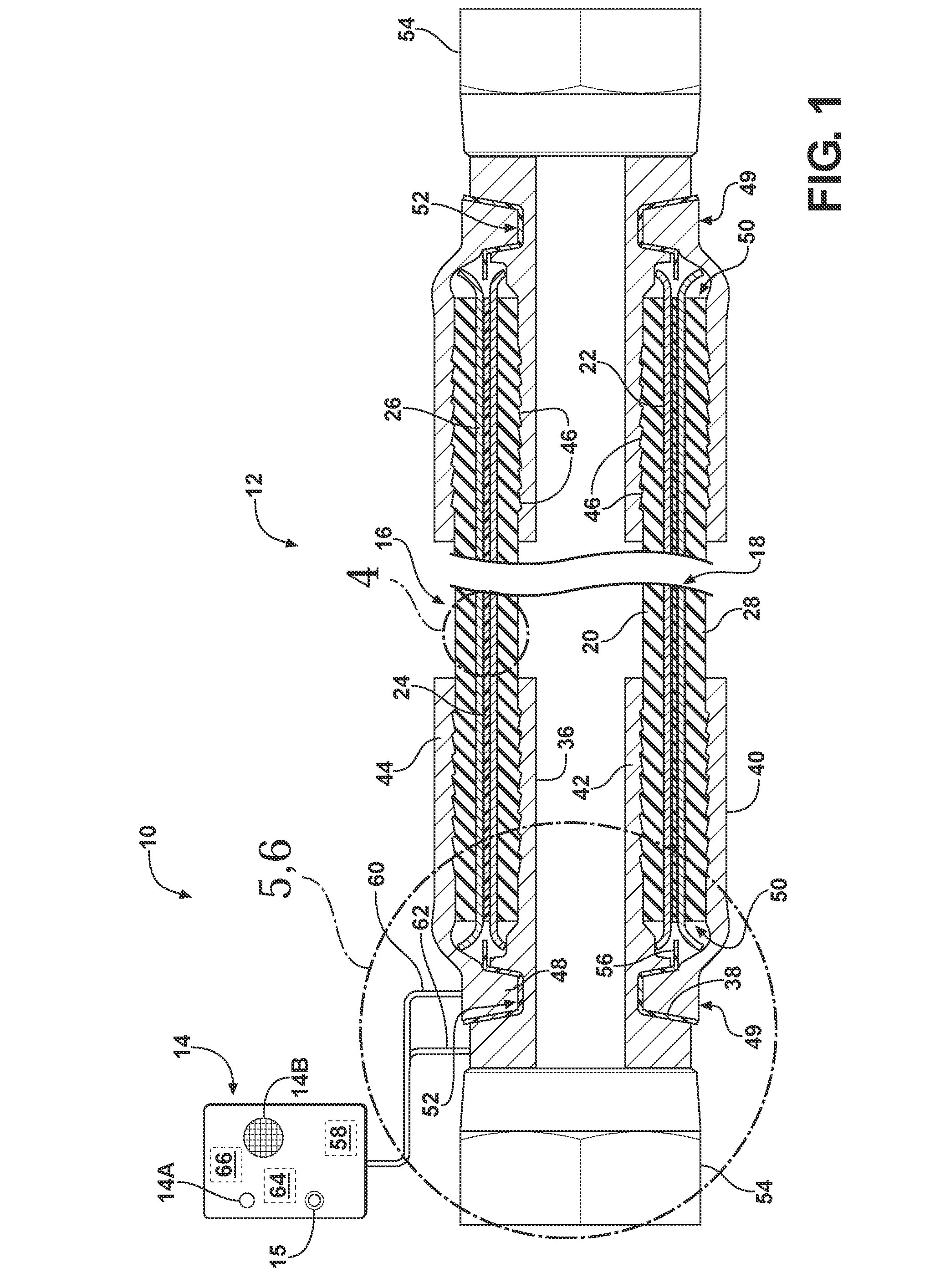

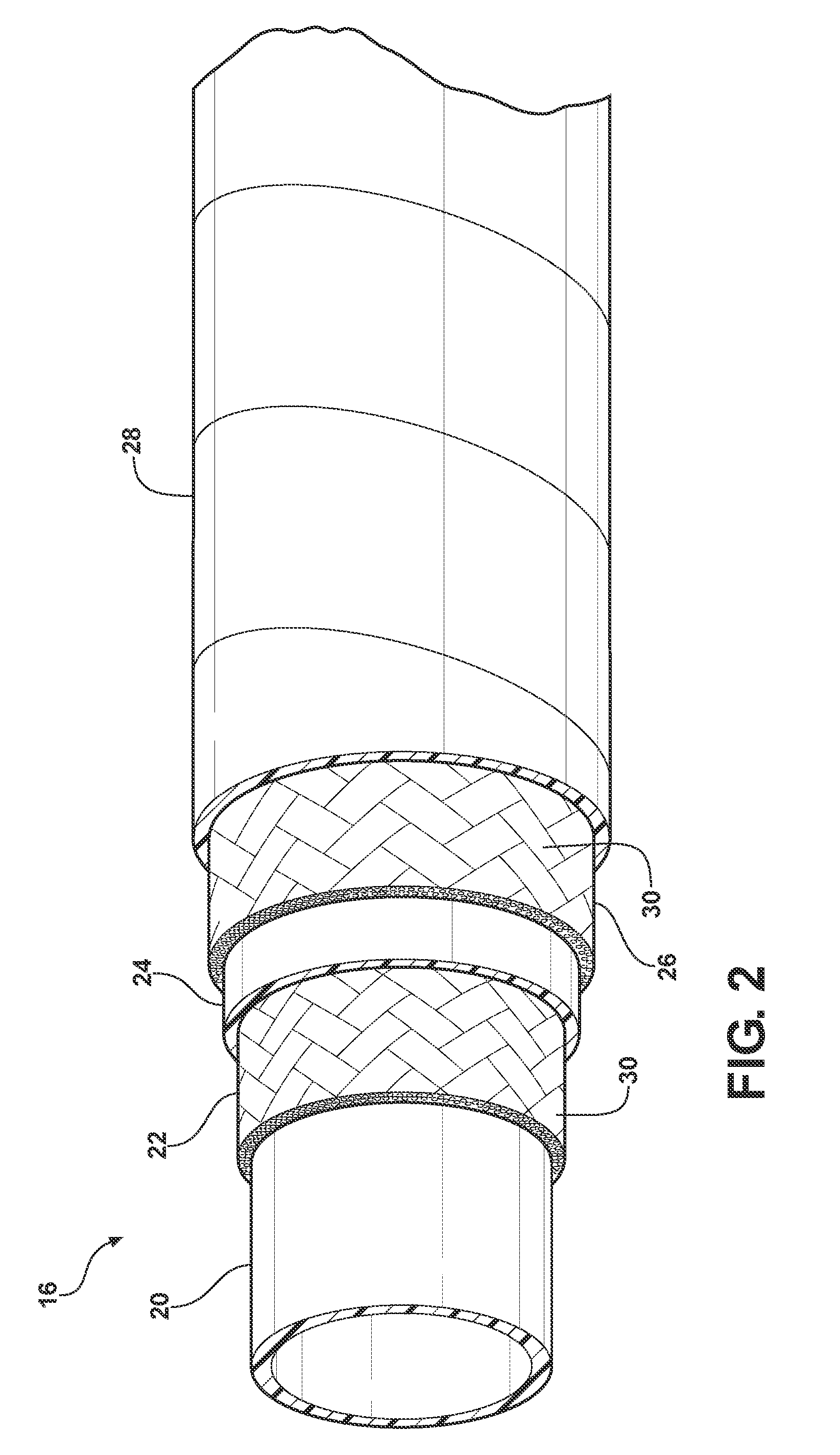

System and method for detecting and preventing leaks in pressurized piping systems

InactiveUS20060196251A1Easy and inexpensive to operateEasy and inexpensive to and maintainDetection of fluid at leakage pointPipe couplingsHydrostatic pressureEngineering

A system and method for testing plumbing systems for leaks by which the original plumbing system is cleaned and flushed using ambient temperature water followed by cleaning and flushing with pressurized recirculating elevated temperature water to filter debris and contaminants, shocking the plumbing system with elevated temperature and high pressure surges followed by a hydrostatic pressure test designed to expose the existence of any leaks in the plumbing system in the rough plumbing stage of construction prior to enclosing the plumbing system in a structure.

Owner:ROBERT C RICHEY TRUSTEE OF THE ROBERT C RICHEY FAMILY TRUST

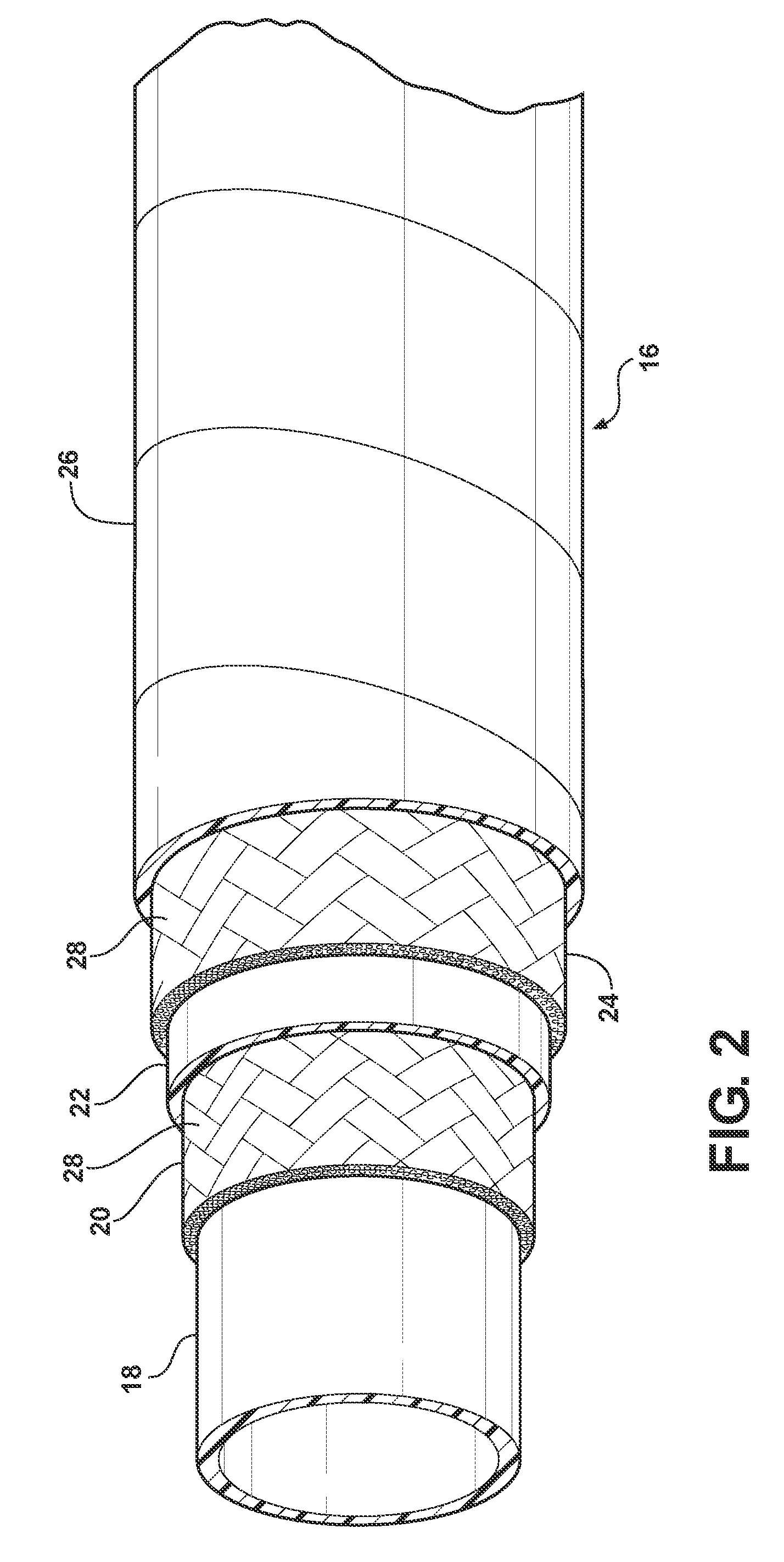

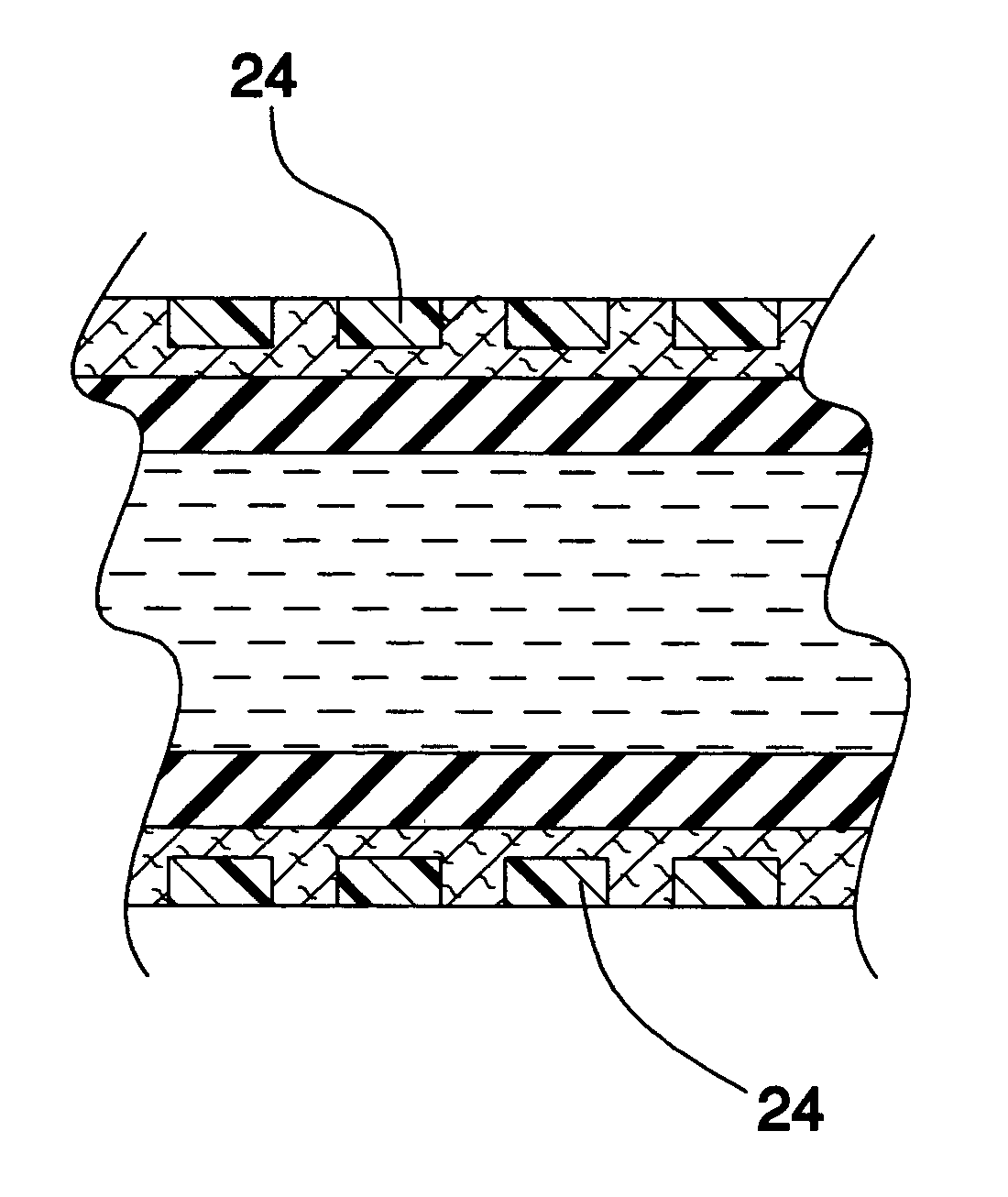

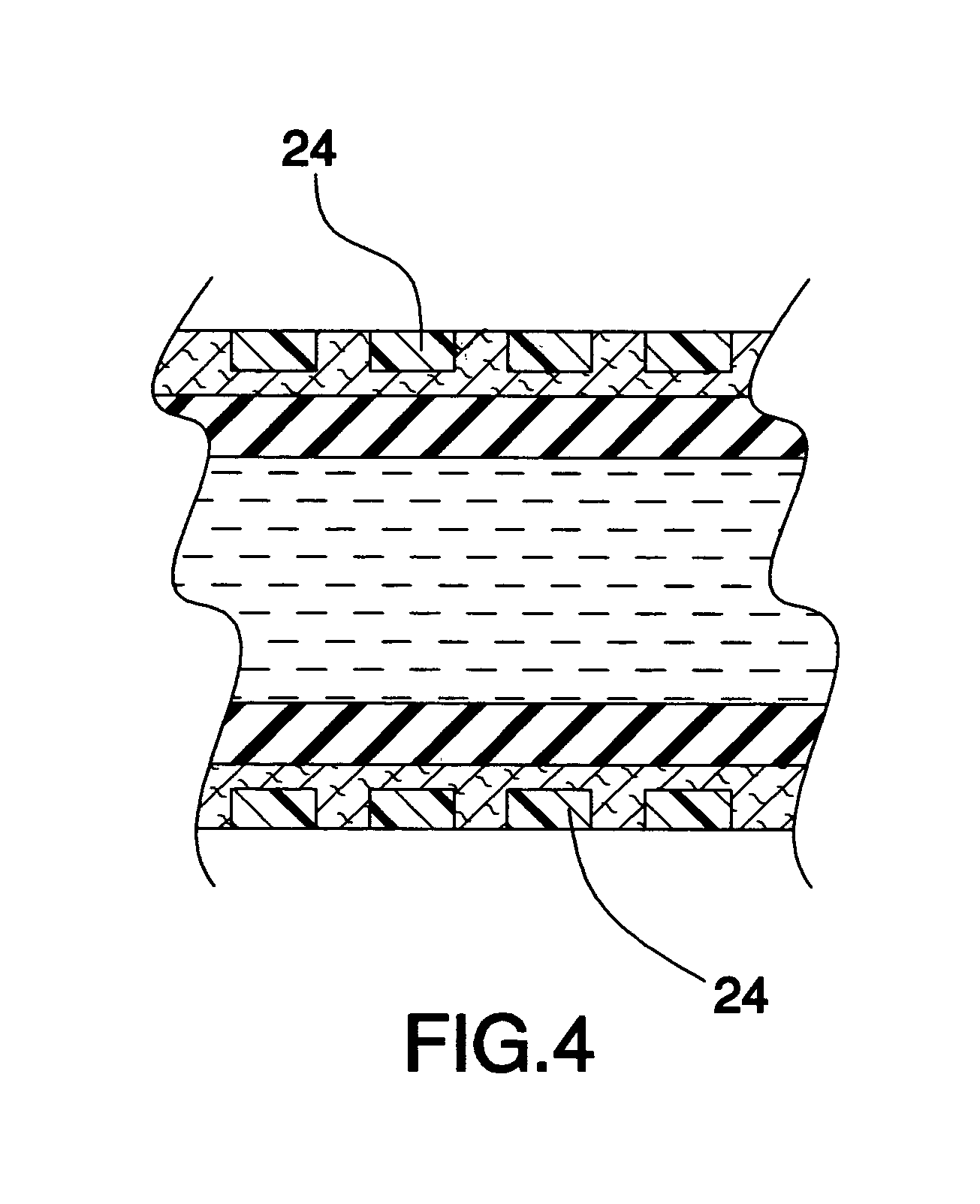

Hose with fault detection capability

A hose fault detection system includes a hose assembly and a fault detector. The hose assembly includes a first conductive layer, second conductive layer, and an intermediate layer that is disposed between the first and second conductive layers. Each of the first and second conductive layers has an electrical characteristic. The fault detector is configured for detecting an electrical change based on the electrical characteristic to signify a potential impending failure of at least one of the first and second conductive layers of the hose. The fault detector includes a sensing device, a recording device and a digital processor. The sensing device is in electrical communication with the first and second conductive layers to measure the electrical characteristic. The recording device is configured for storing the measured electrical characteristic.

Owner:DANFOSS POWER SOLUTIONS II TECH AS

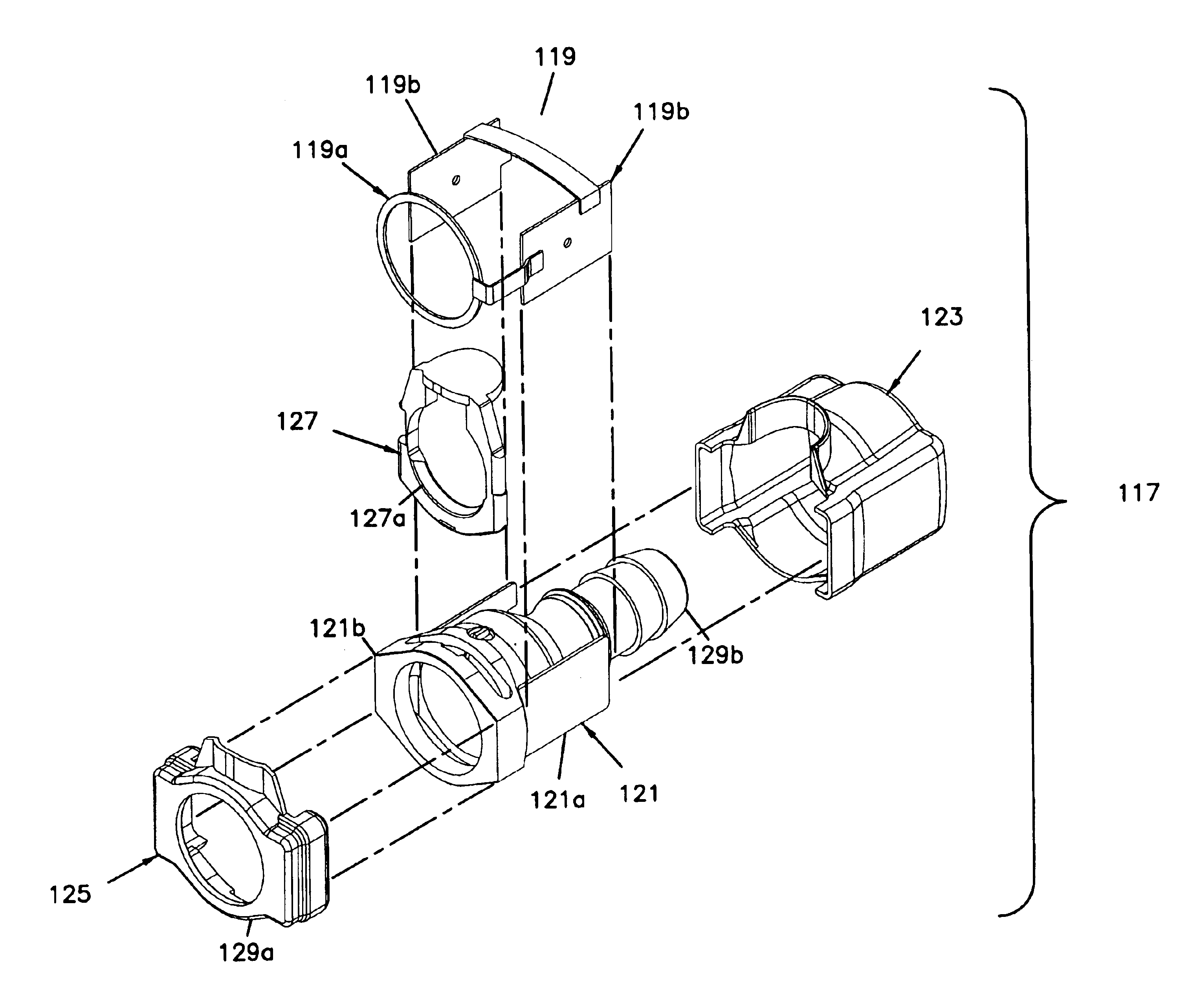

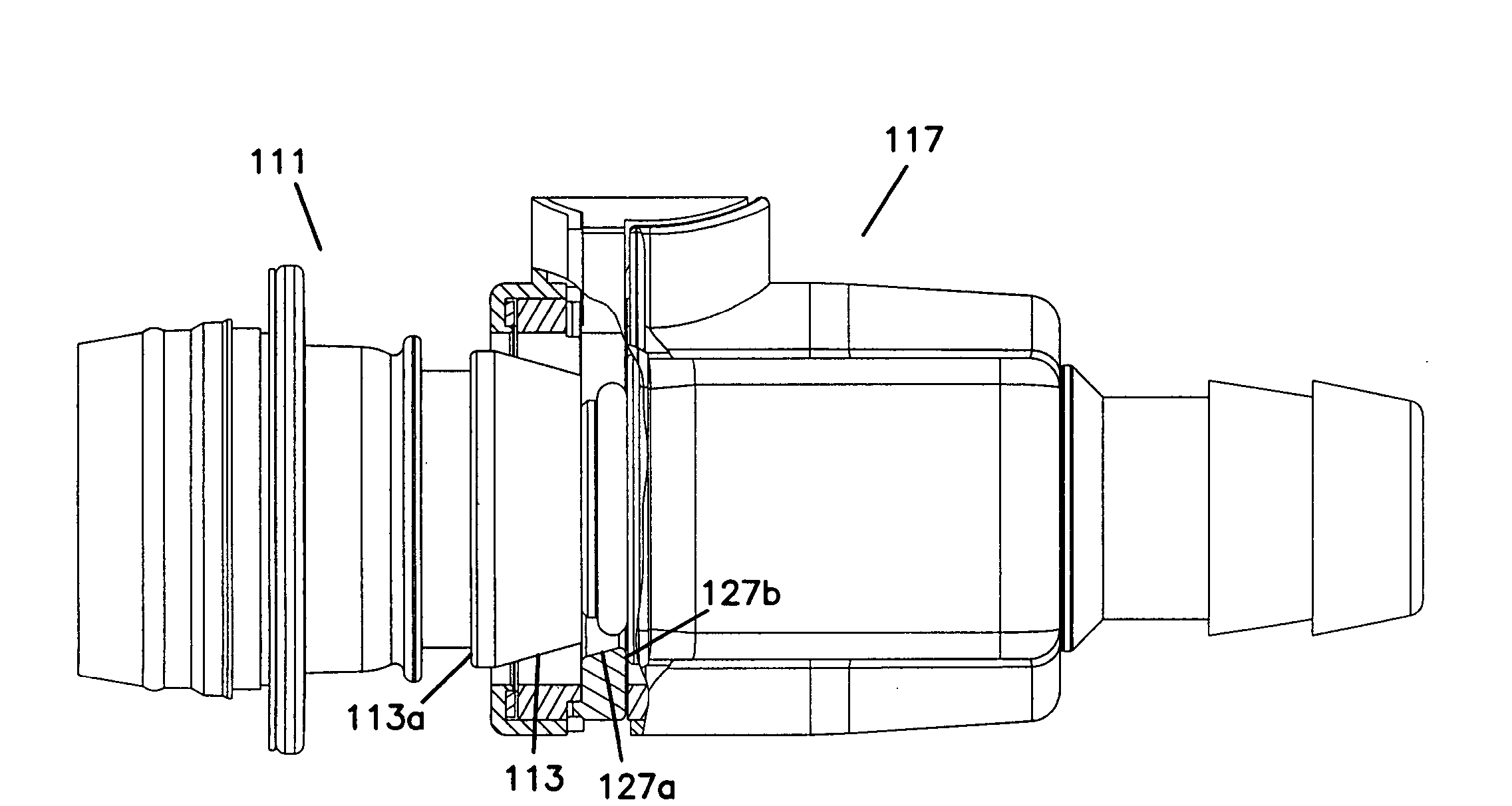

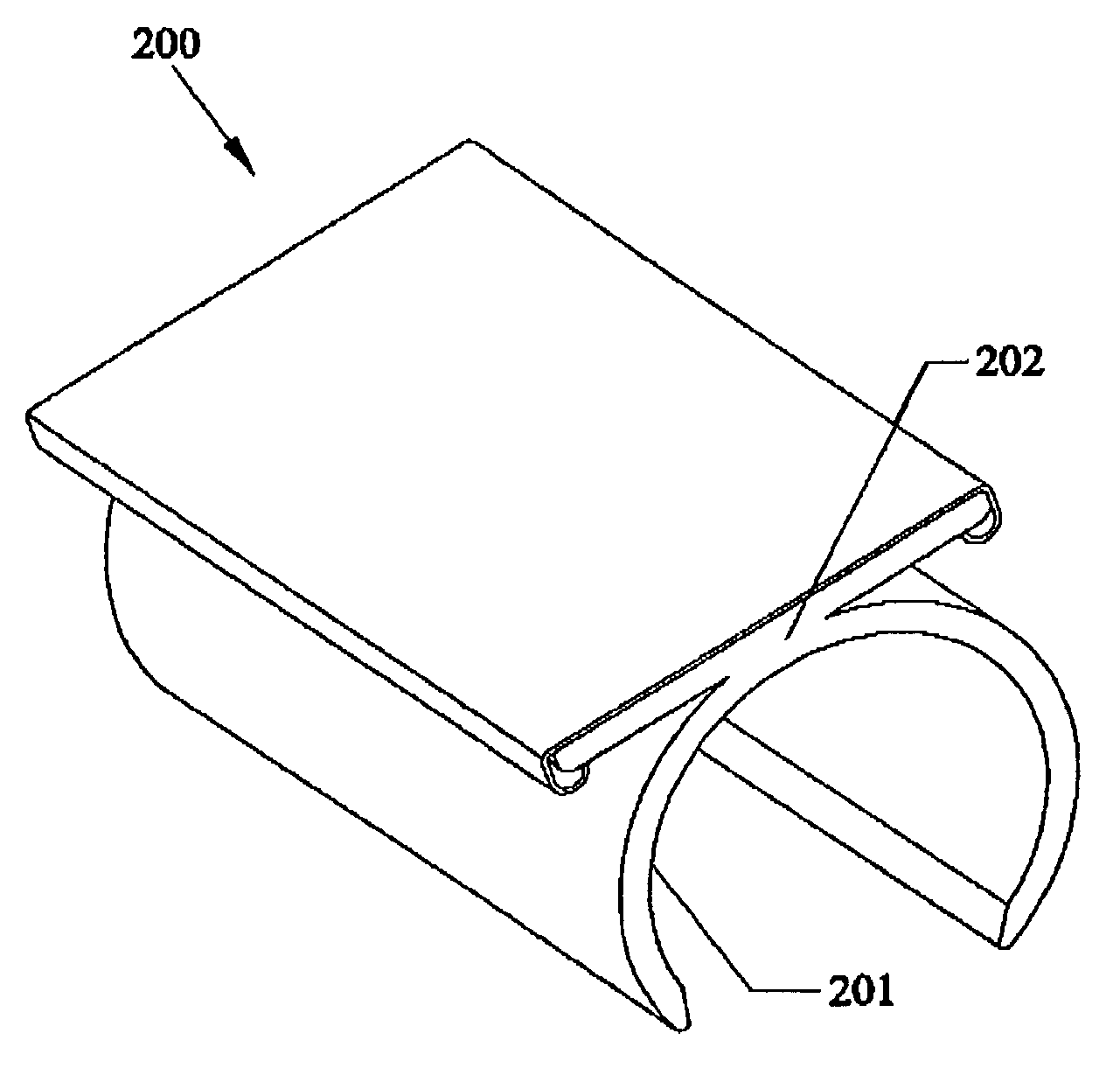

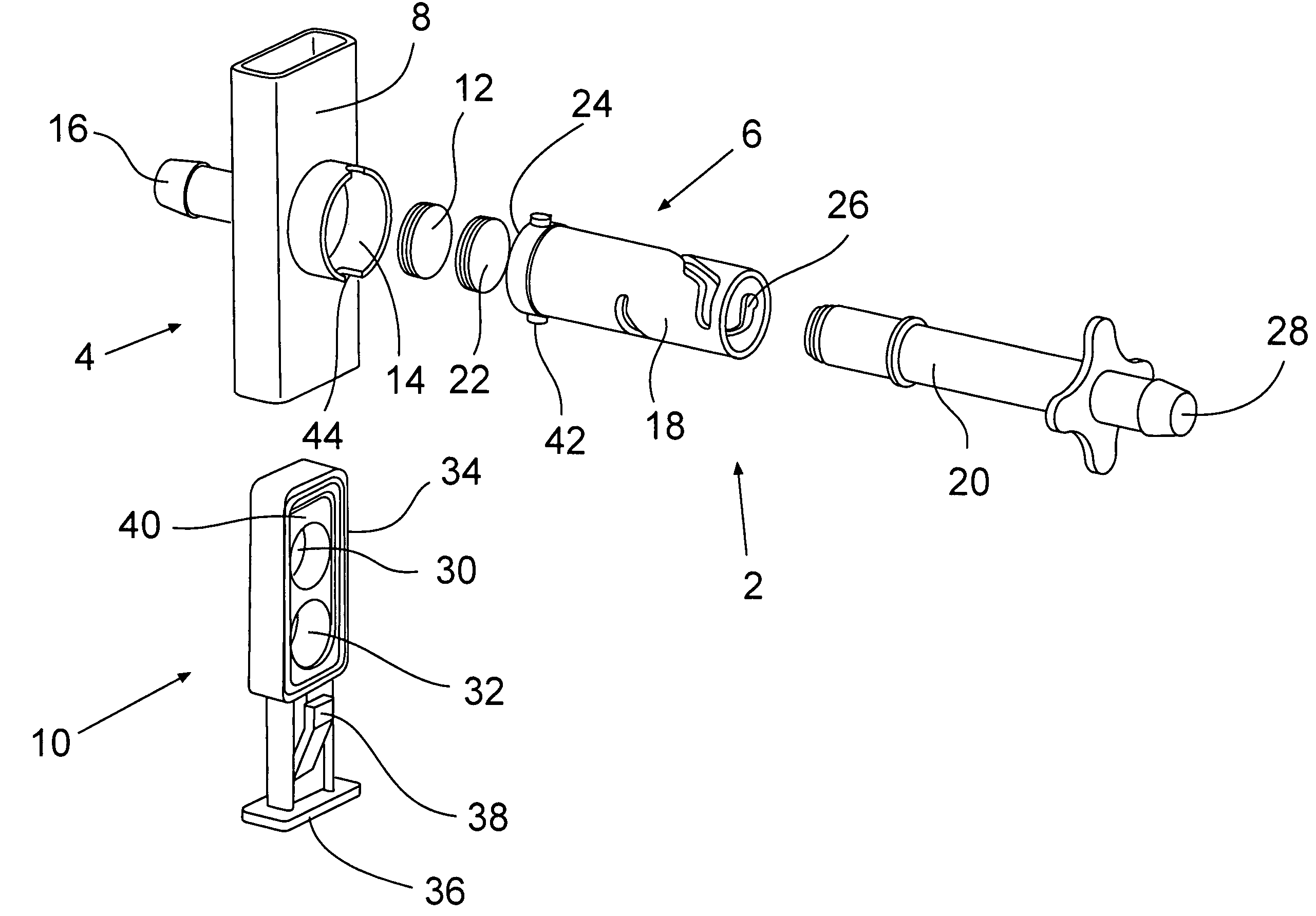

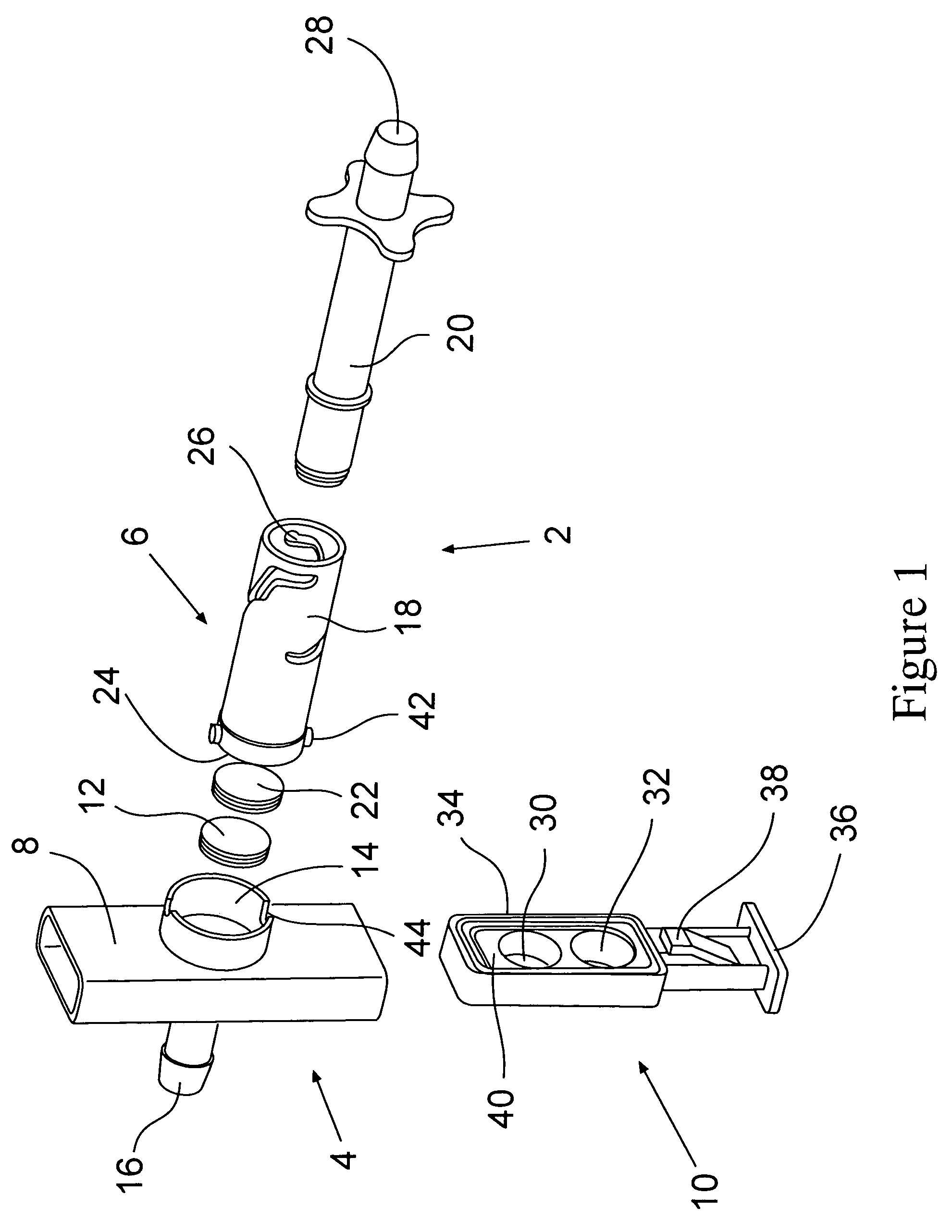

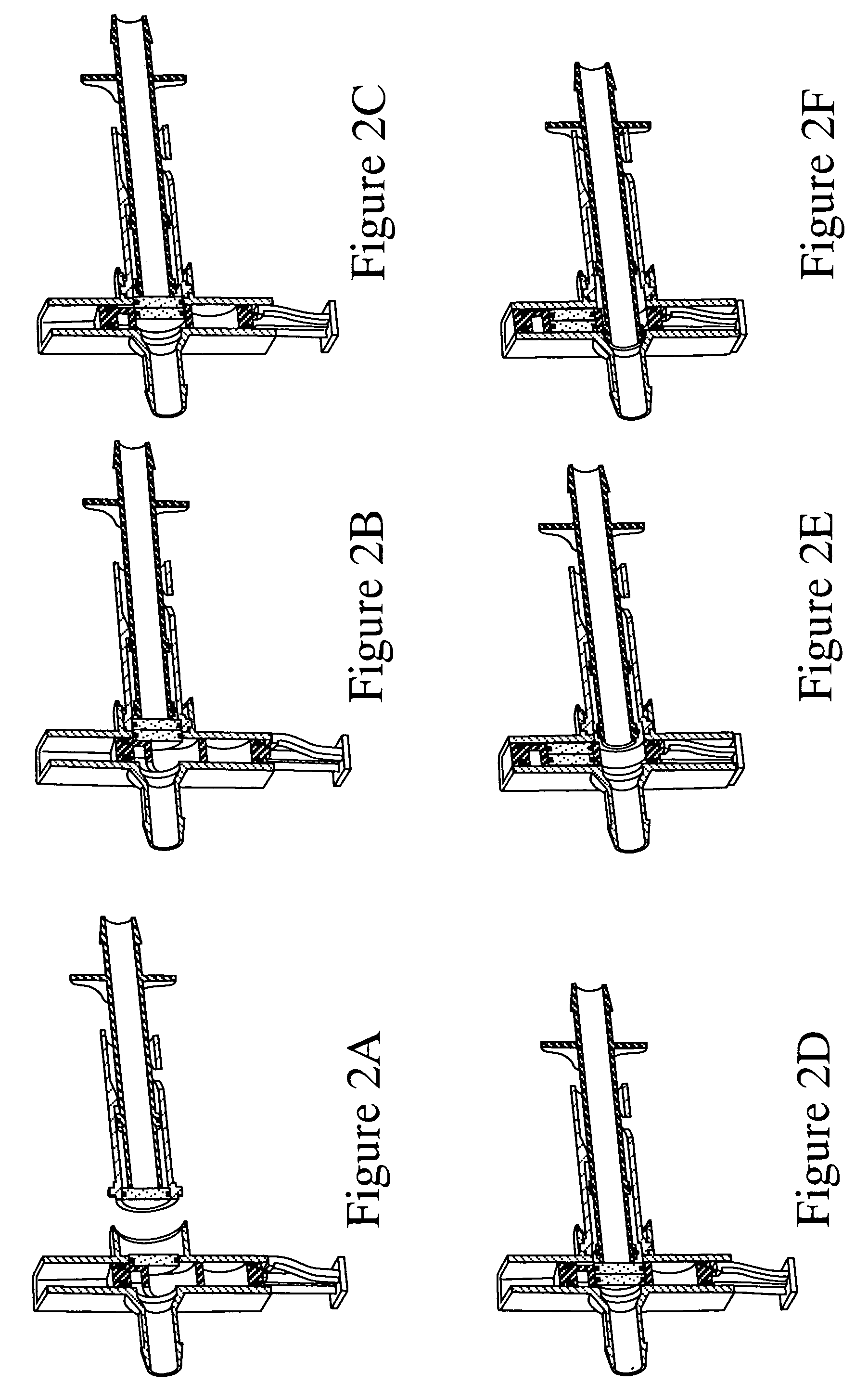

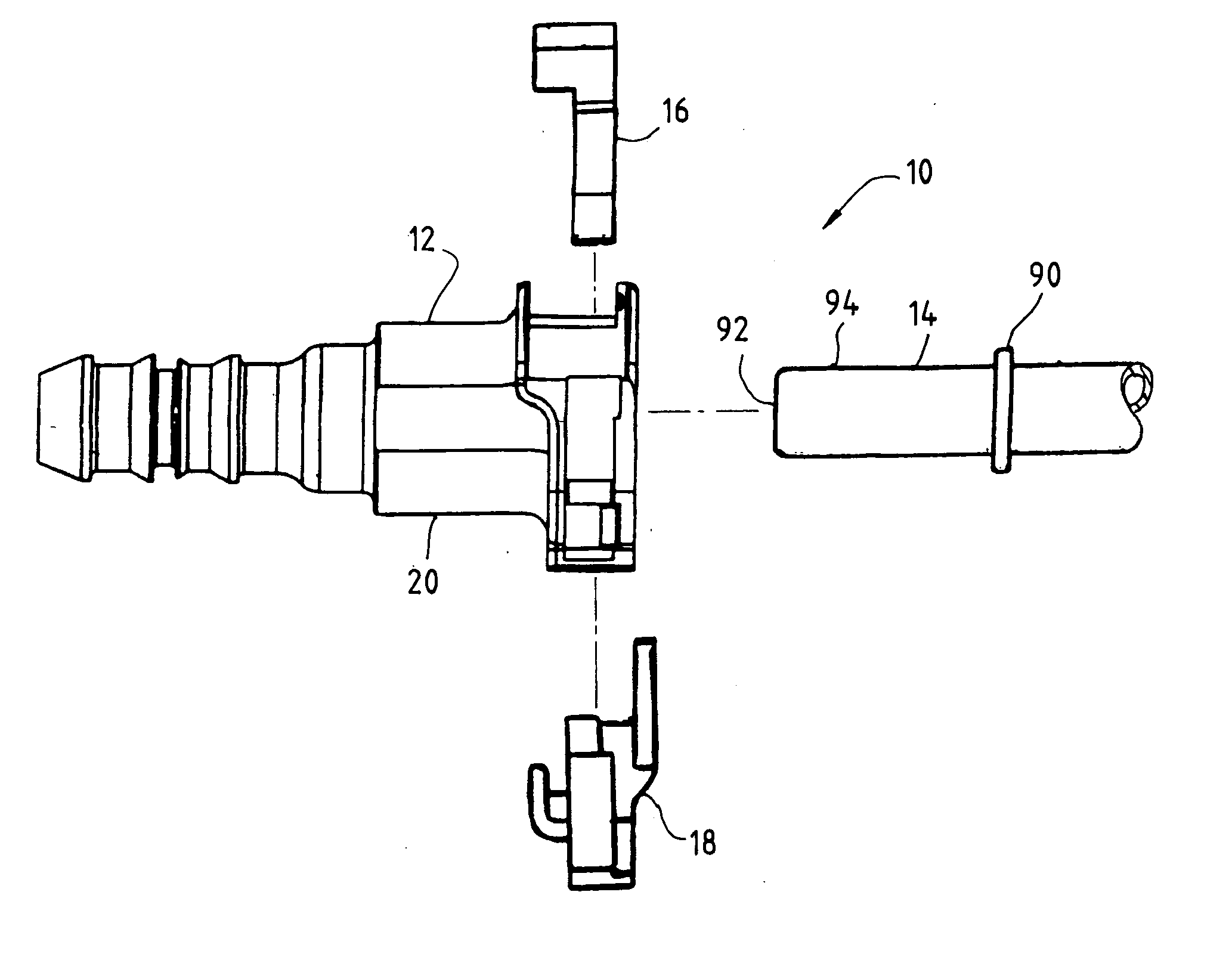

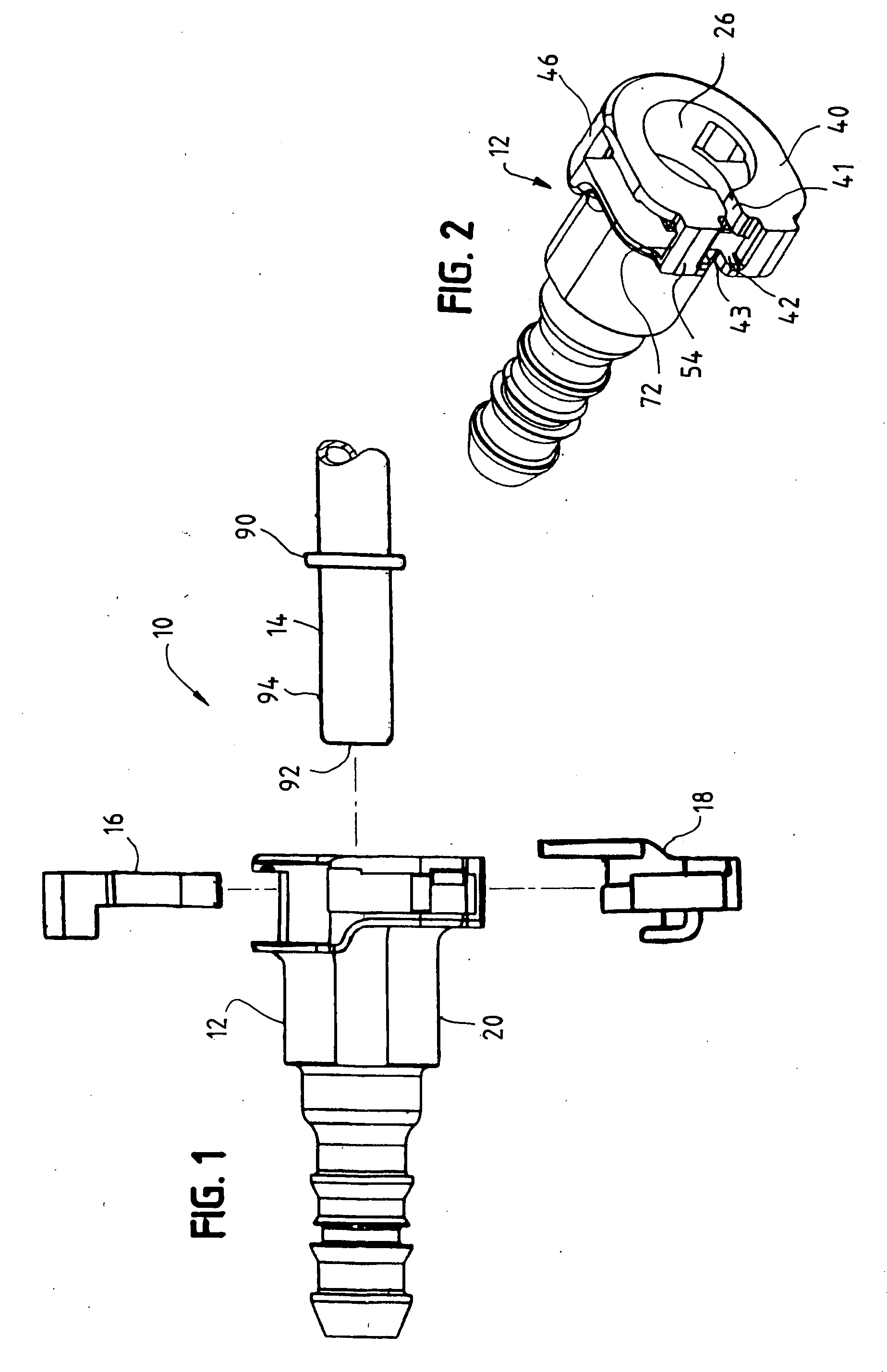

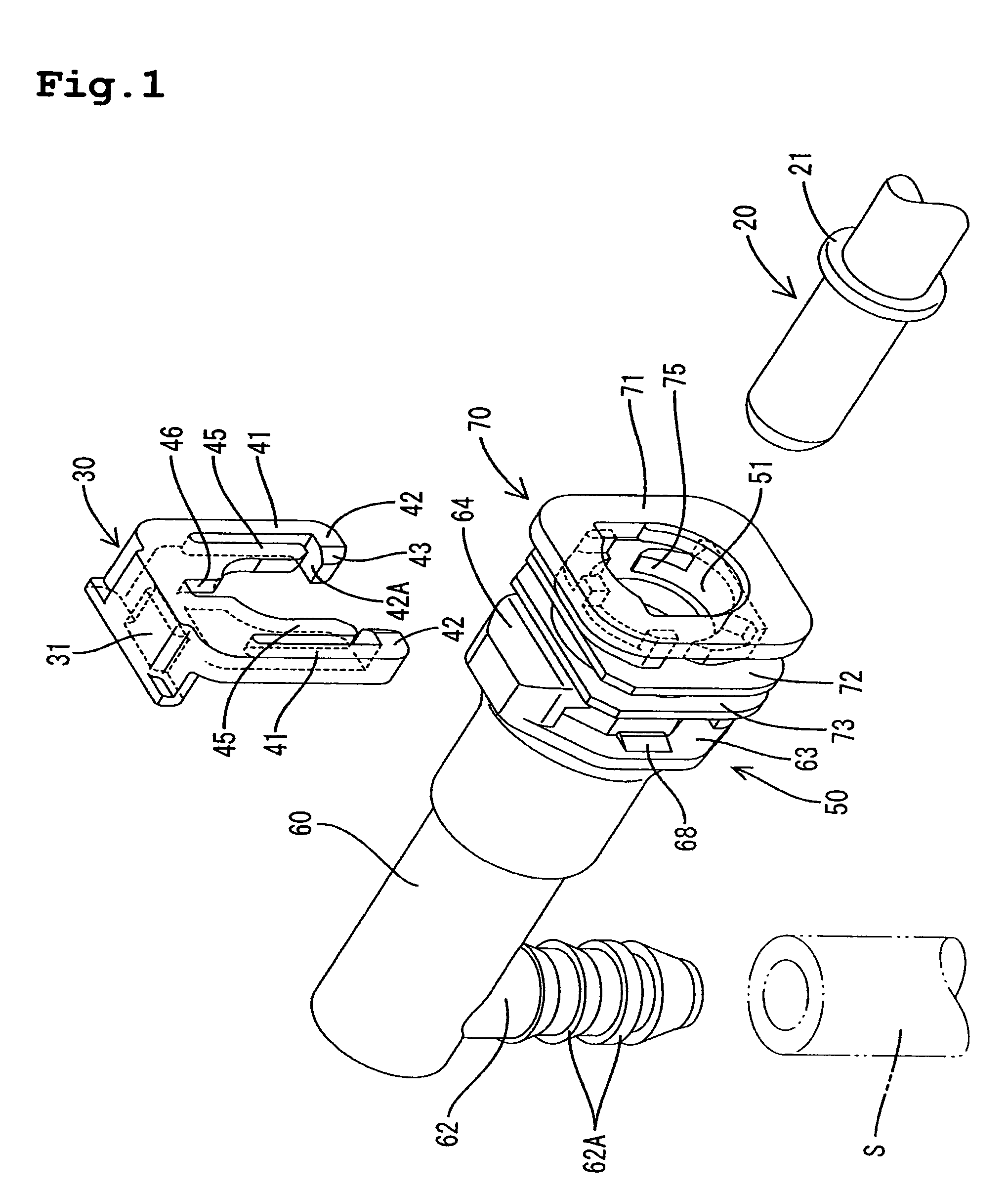

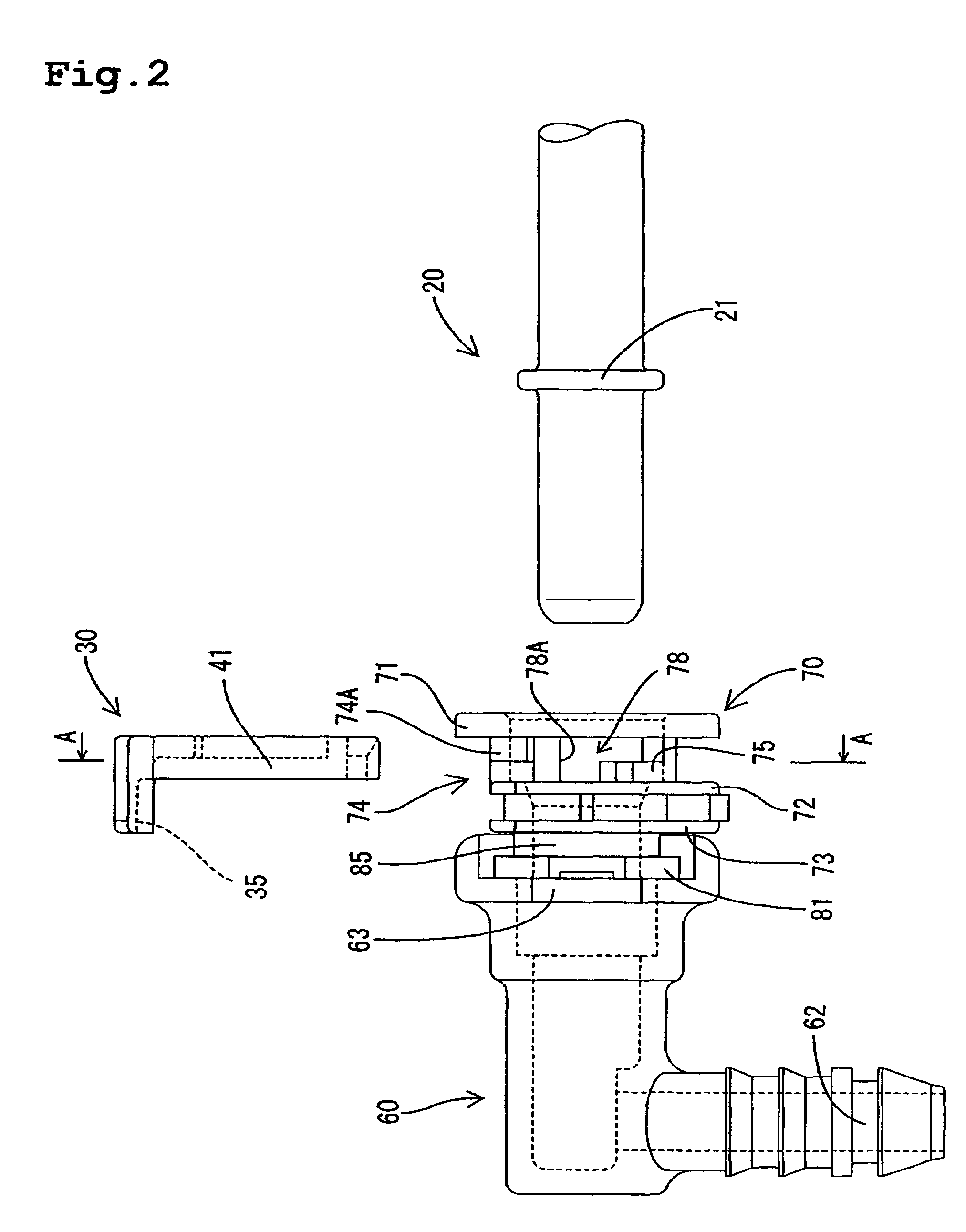

Connector apparatus and method for connecting the same for controlling fluid dispensing

InactiveUS20050211934A1Efficient communicationEnabling useOperating means/releasing devices for valvesPipe couplingsFluid controlEngineering

A connector apparatus for controlling fluid dispensing / transmission that includes a control component for communication between couplers thereof. A first coupler has a transmitter, and is releasably connected with a mating reader coupler that has a transmitter and fluid control device to exchange information with the transmitter of the first coupler. The transmitters communicate and are operated by wireless means such as by RF devices. Upon confirming that the first coupler is properly coupled to the mating coupler and that the first coupler has a proper identification, the fluid control device controls fluid flow, using the transmitters of the first coupler and the mating reader coupler, under predetermined parameters, e.g., pressure, temperature, duration, and flow rate, as indicated in the first coupler.

Owner:COLDER PRODS

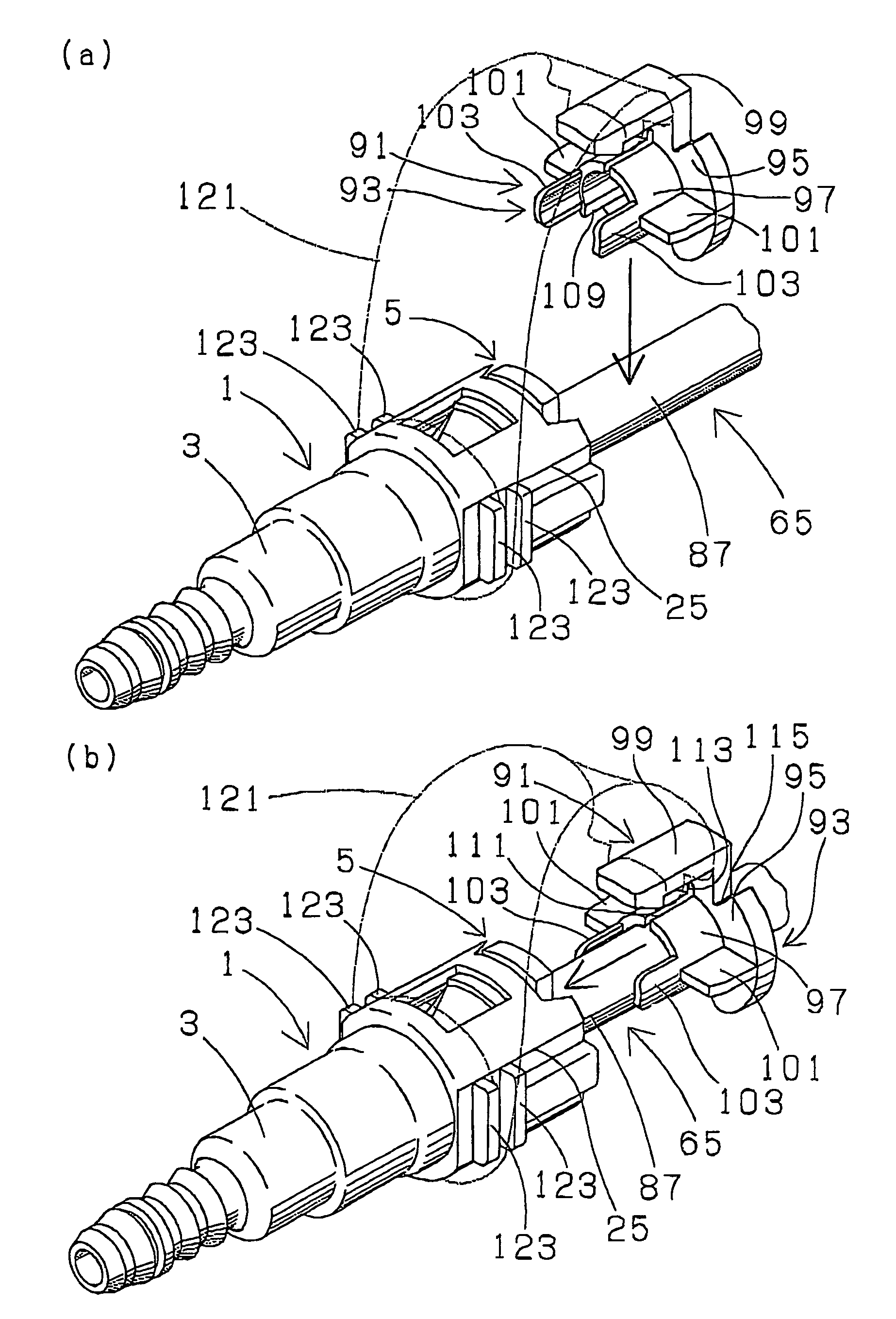

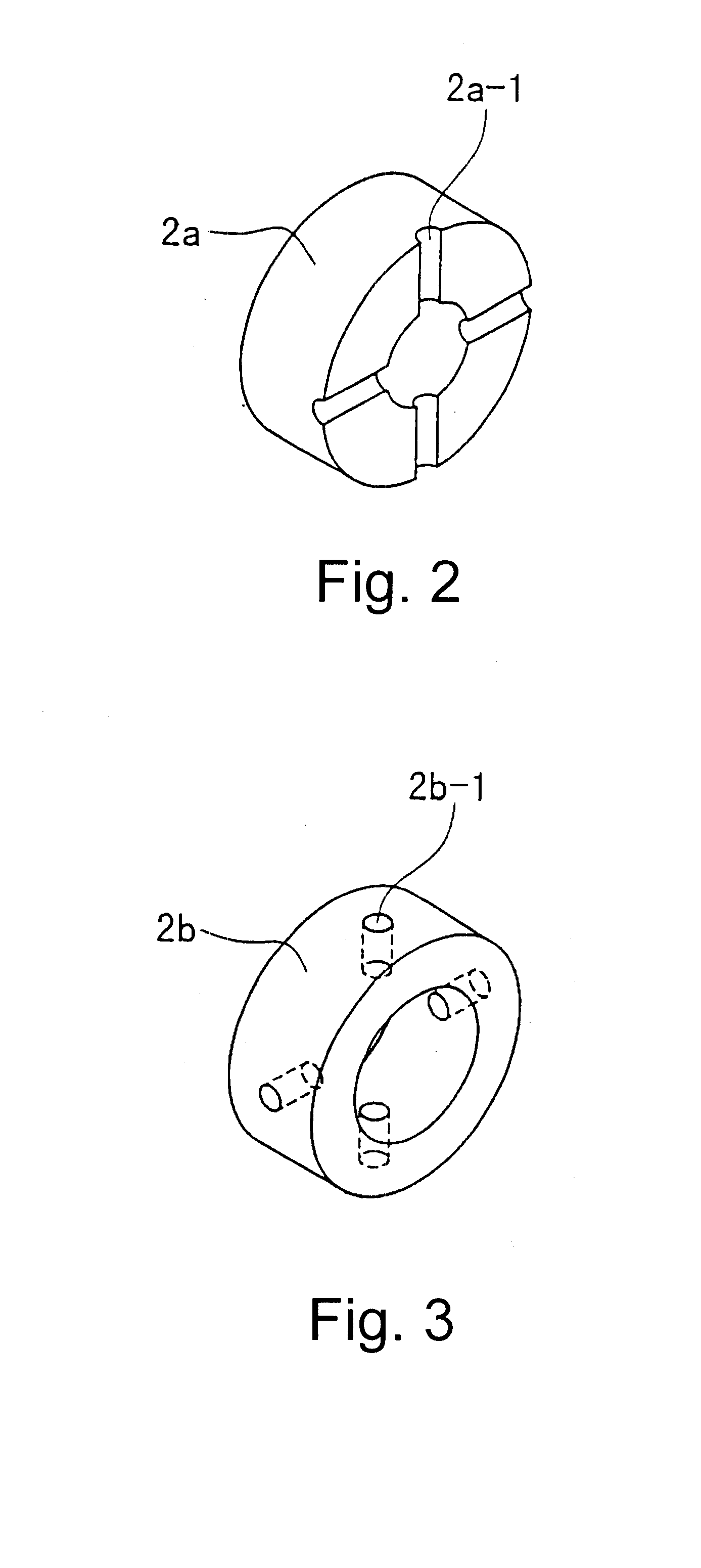

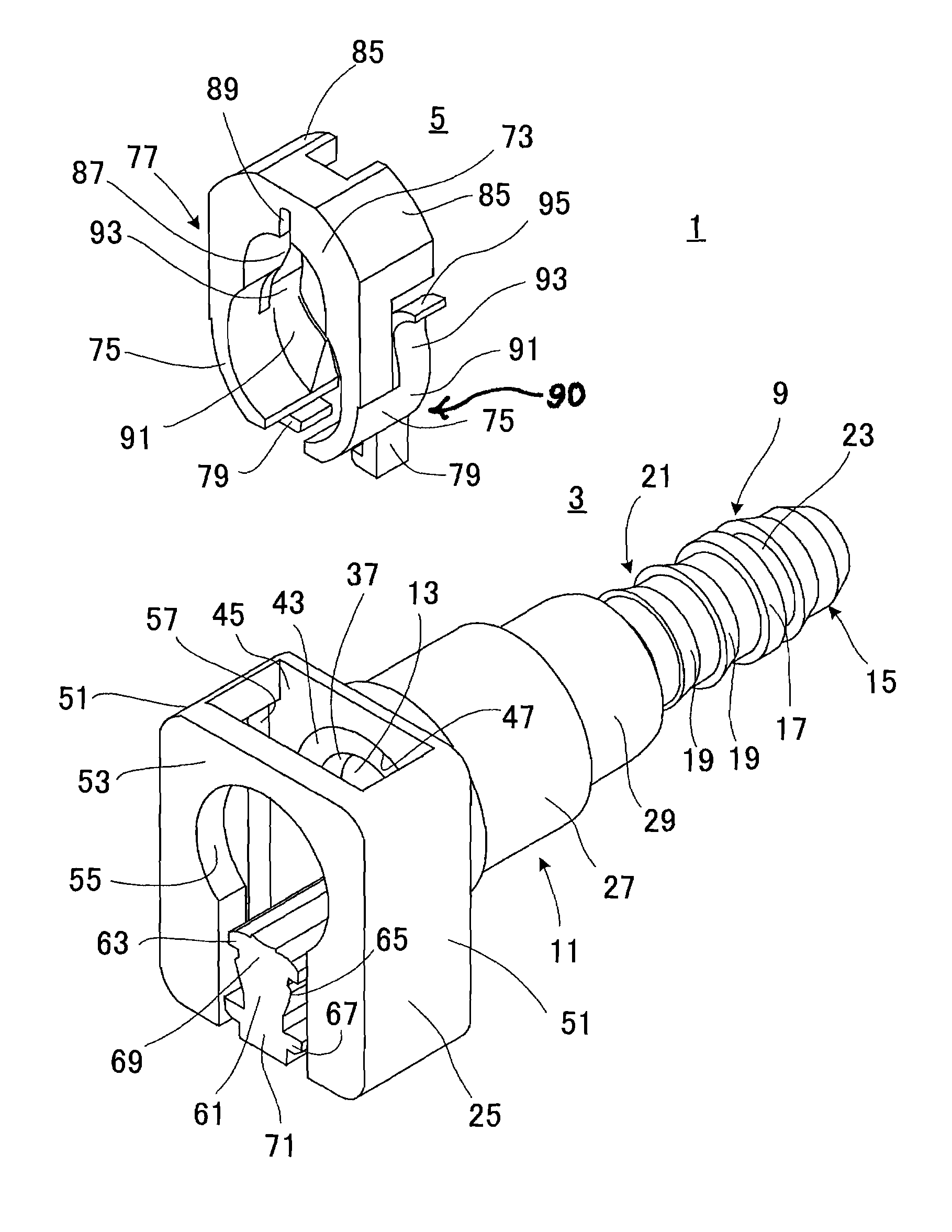

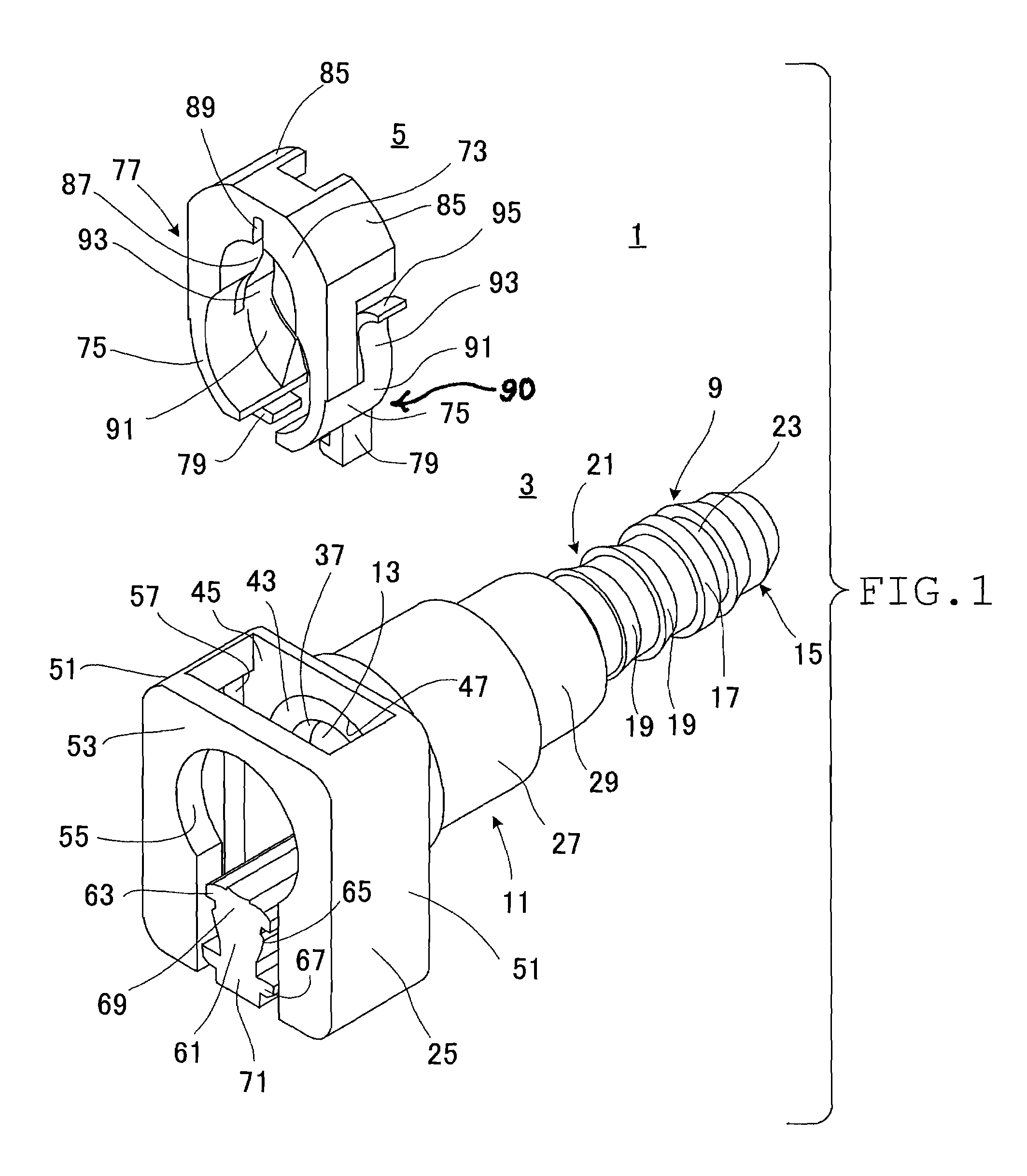

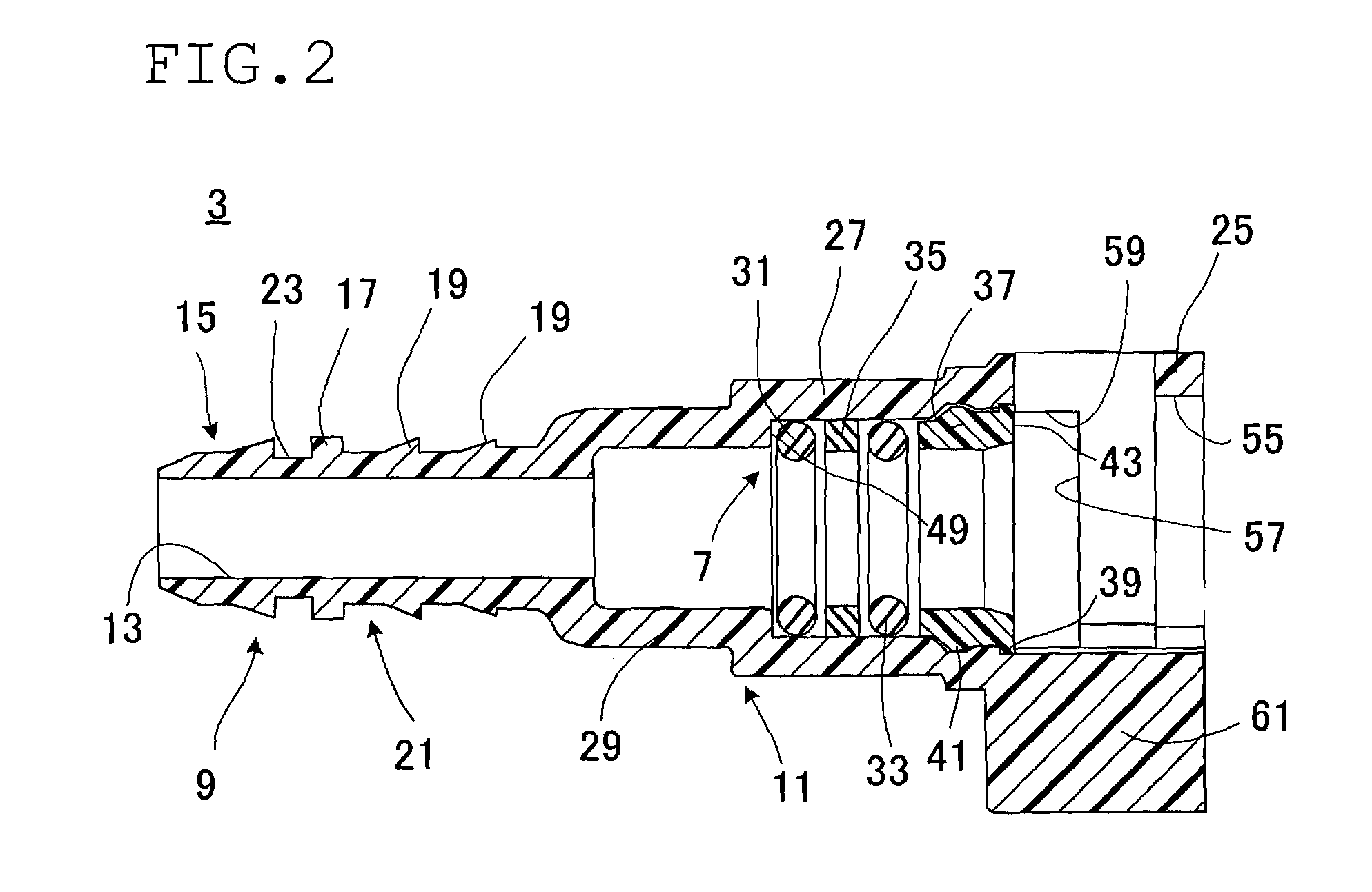

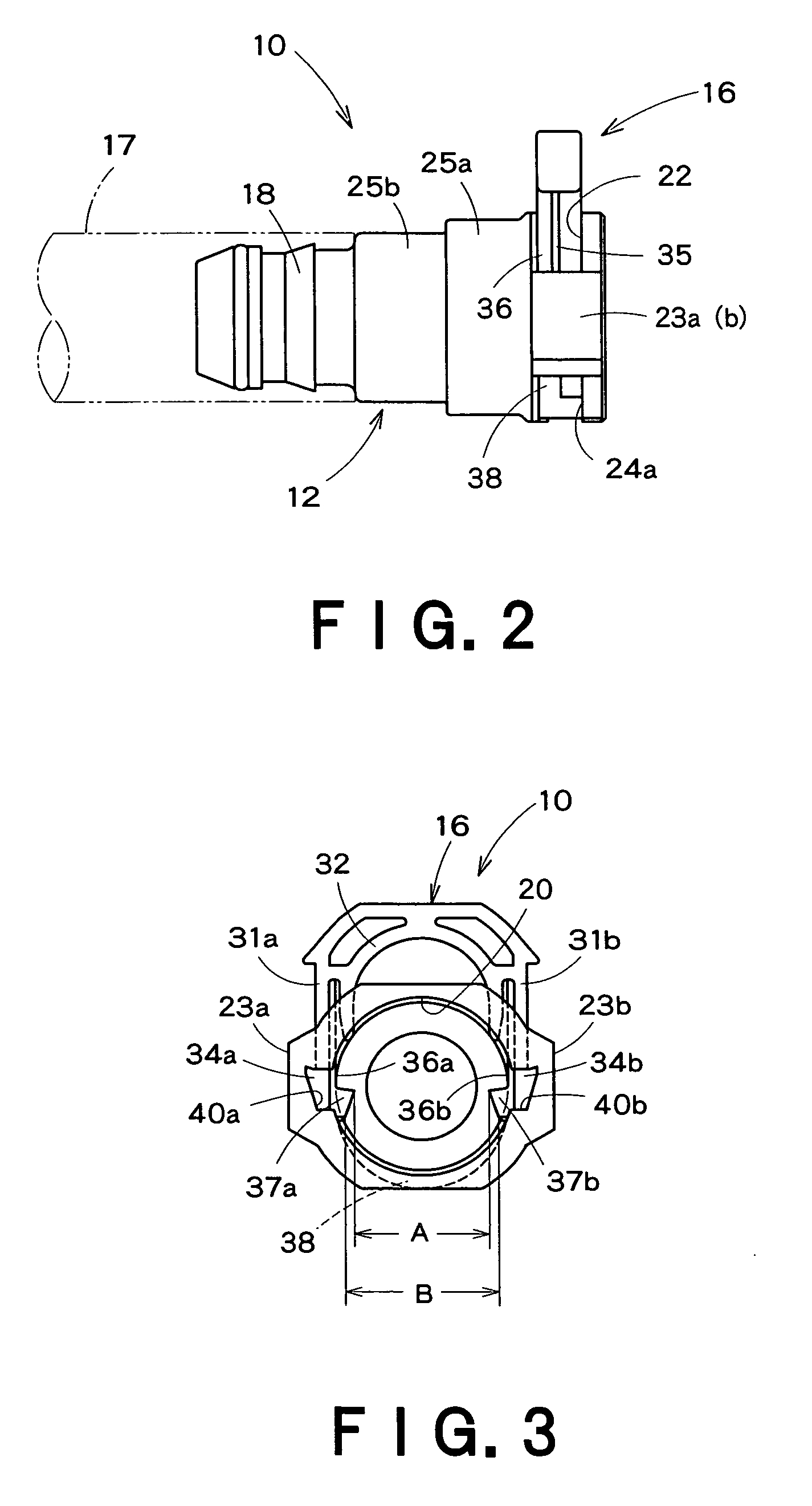

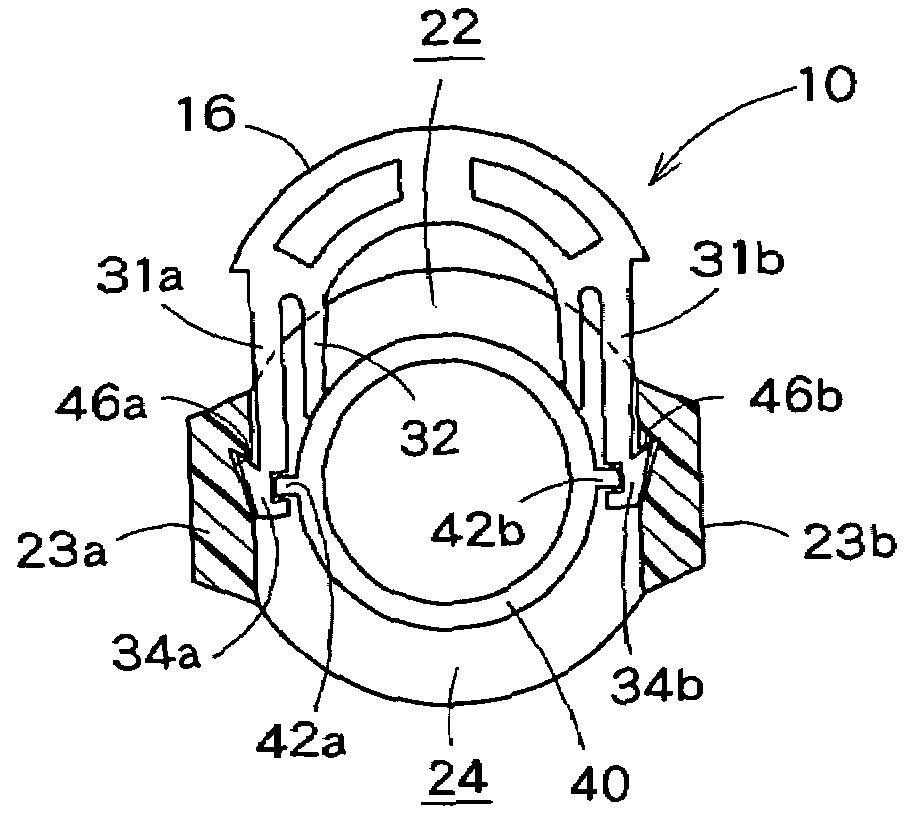

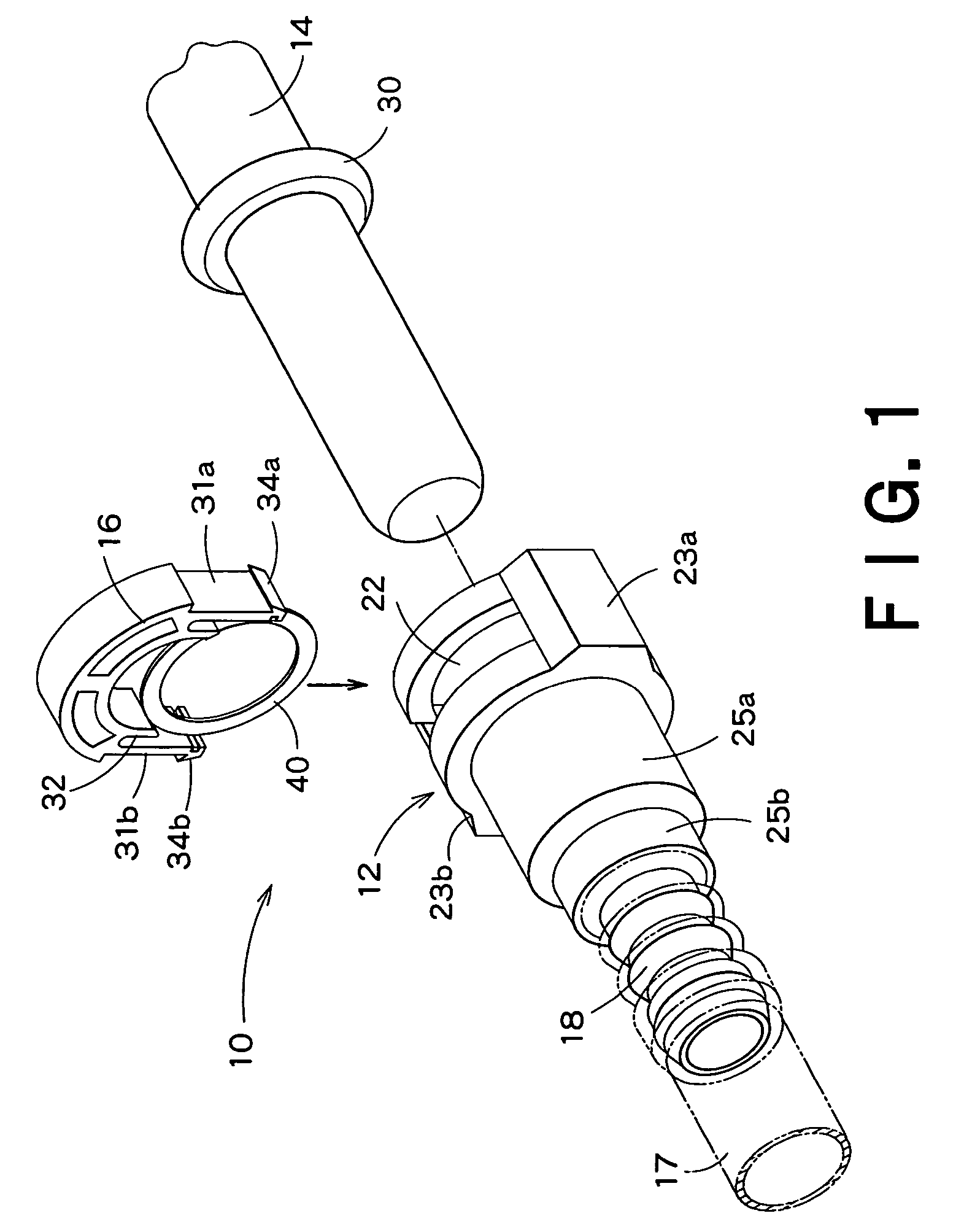

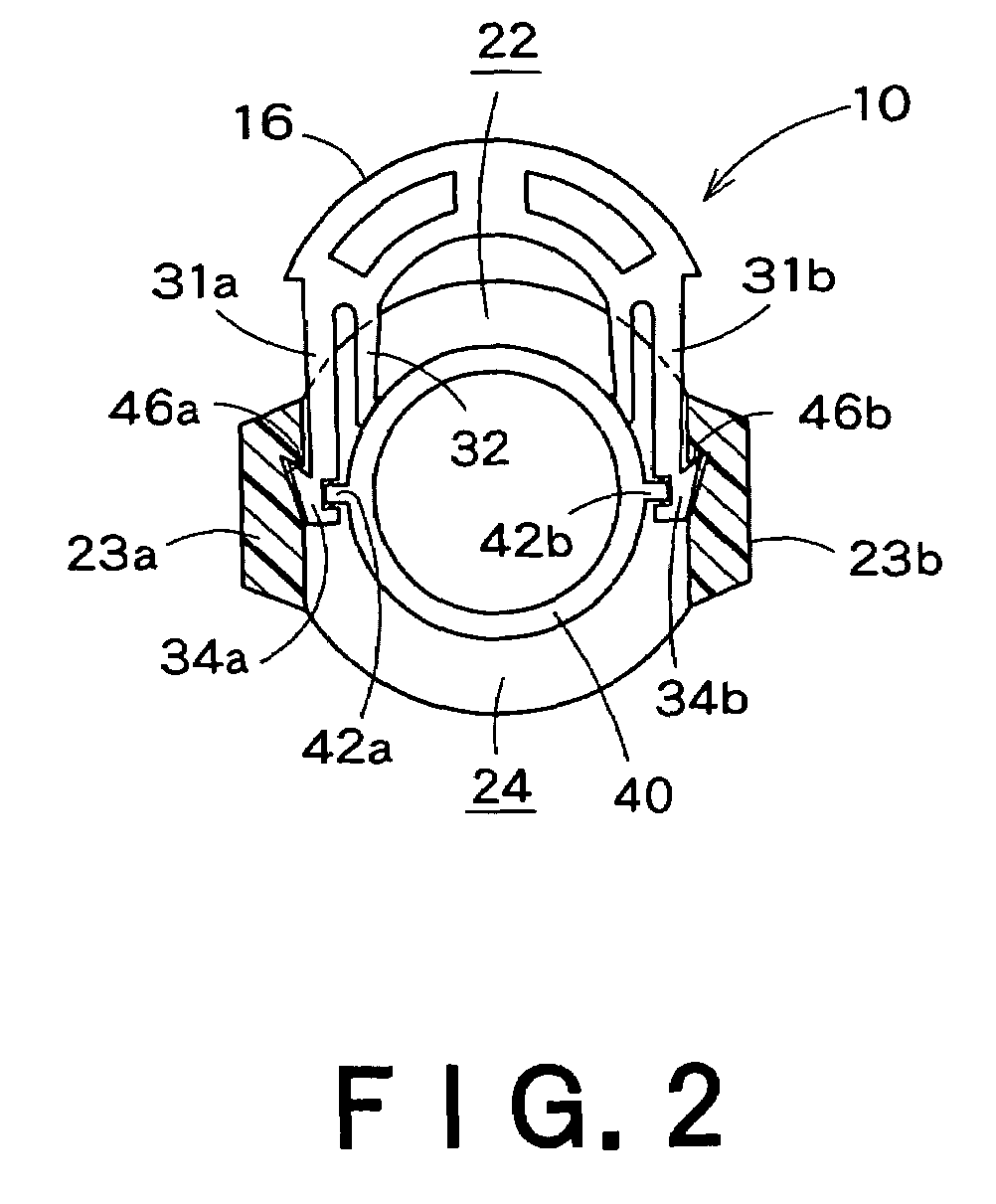

Connection verifying device and connection verifying structure for a pipe and a connector

ActiveUS7316428B2Stable and uniform escape-resistant forceStop function is enhancedSleeve/socket jointsPipe supportsEngineeringMechanical engineering

Connection verifying device for a pipe and a connector has a body portion, a stop and verification arm and an abutment finger. The body portion includes an abutment plate and a fit-on portion. The stop and verification arm extends from an outer periphery of the abutment plate in one axial direction, while the abutment finger protrudes from one axial end of the fit-on portion in one axial direction. The abutment finger is arranged so as to abut and urge an annular projection of a pipe into an engagement slit of a retainer when the pipe and the connector are in half-fitting relation.

Owner:SUMITOMO RIKO CO LTD

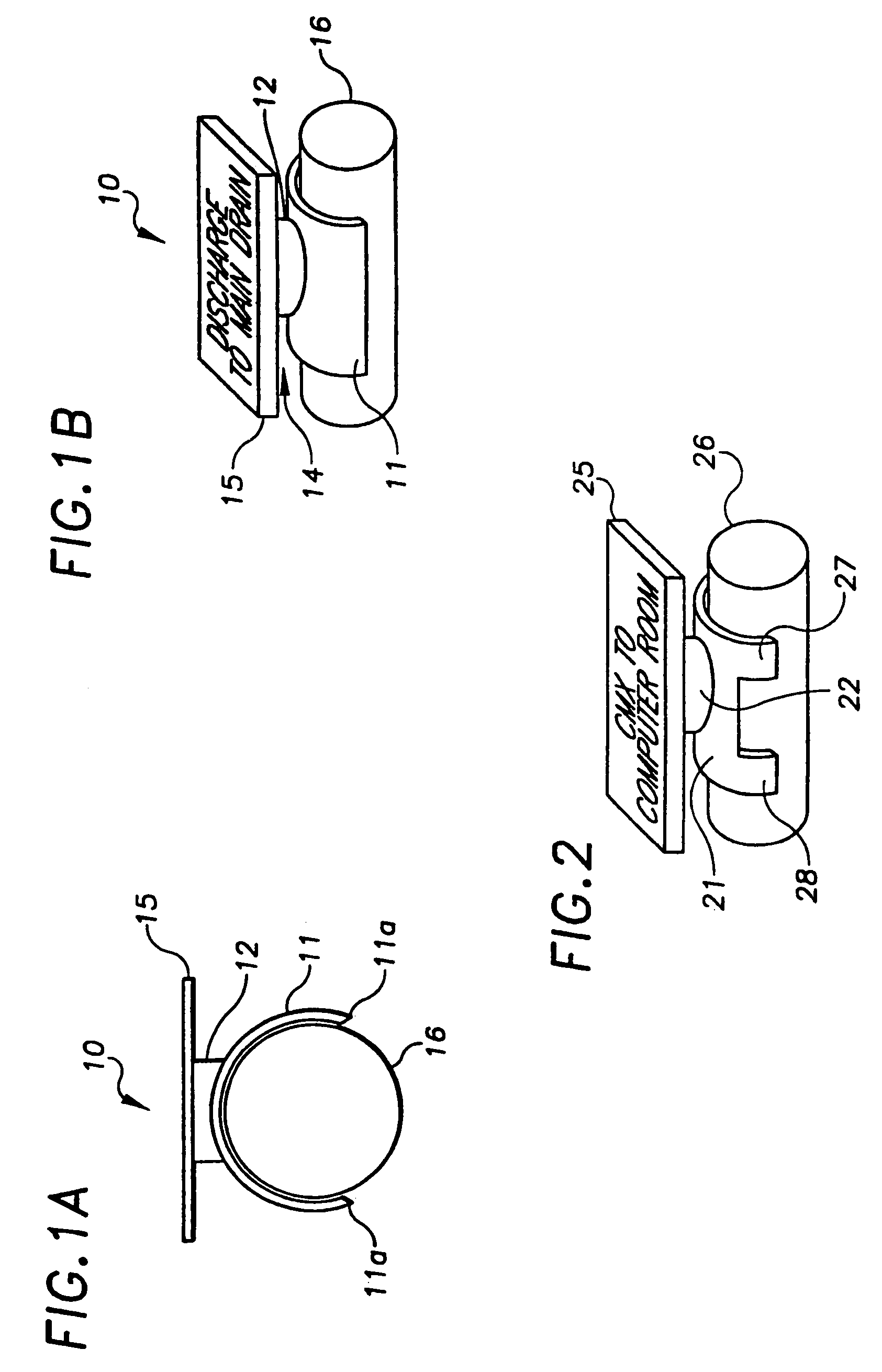

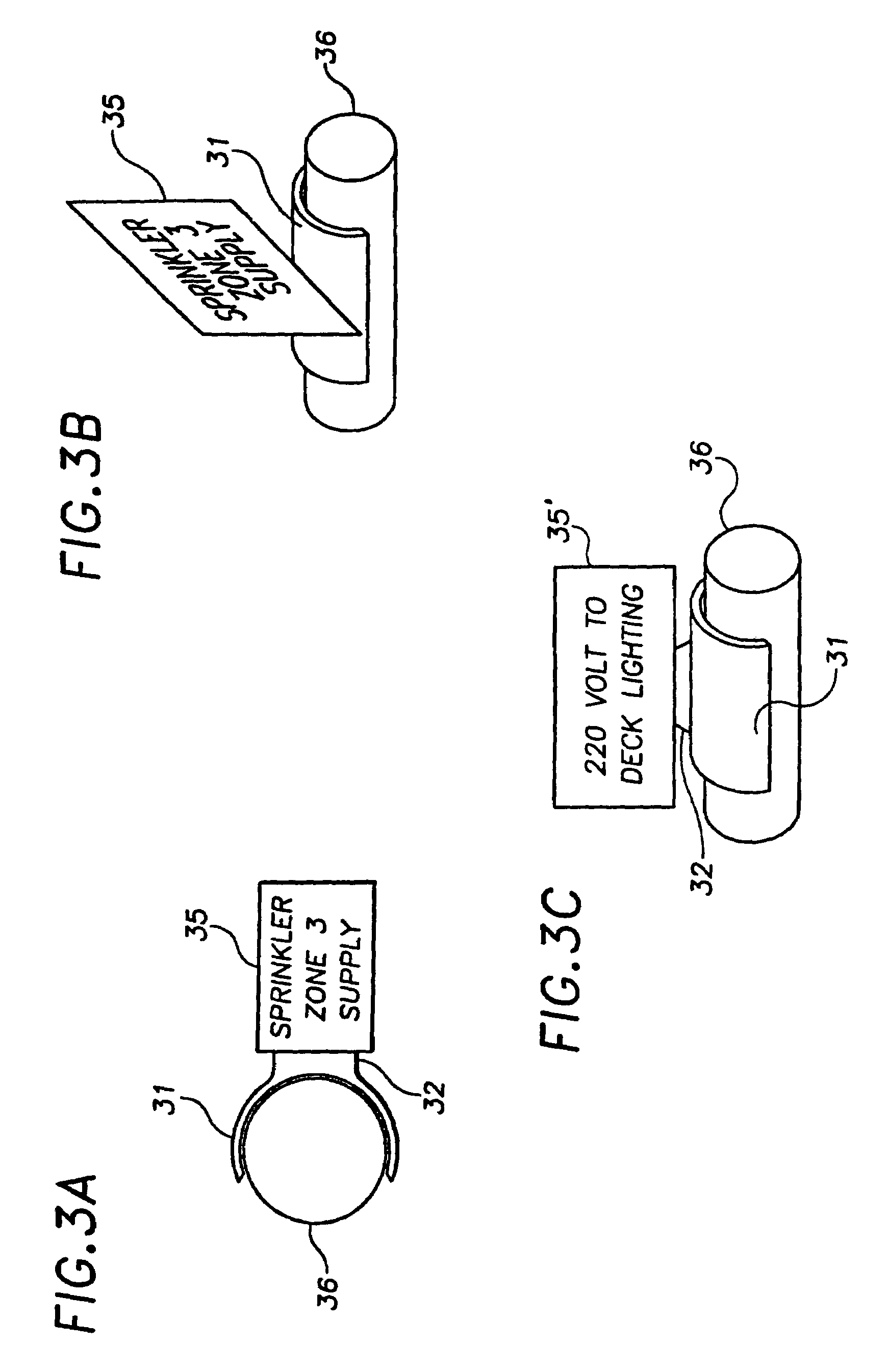

Labeler for pipes, conduits, tubes, and rods

Owner:THE VOLUSIA HLDG CORP

Hydraulic hose with integral life-sensing capability and method therefor

ActiveUS7555936B2Detection of fluid at leakage pointTesting/calibration apparatusElectrical conductorProcess equipment

Owner:PURDUE RES FOUND INC

Sterile connector

A sterile to sterile connection device comprising a connector and one or more coupling devices. The connector has body portion which has two openings sealed from the environment so as to form a sterile environment within the connector. At least one of the openings being sealed from the environment by a sterile barrier plug. The connector also has a port capable movement within the body of the connector to at least an open and a closed position. The coupling device is formed of a body having two openings and a stem having a bore through at least a portion of the stem. The stem is contained within the body and capable of moving at least linearly through the body between a first and second stem position. One of the openings of the stem is sealed from the environment by a sterile barrier plug and the other is sealed to a presterilized component. The coupling device opening containing the sterile barrier plug is attached to either the inlet or outlet of the connector.

Owner:MILLIPORE CORP

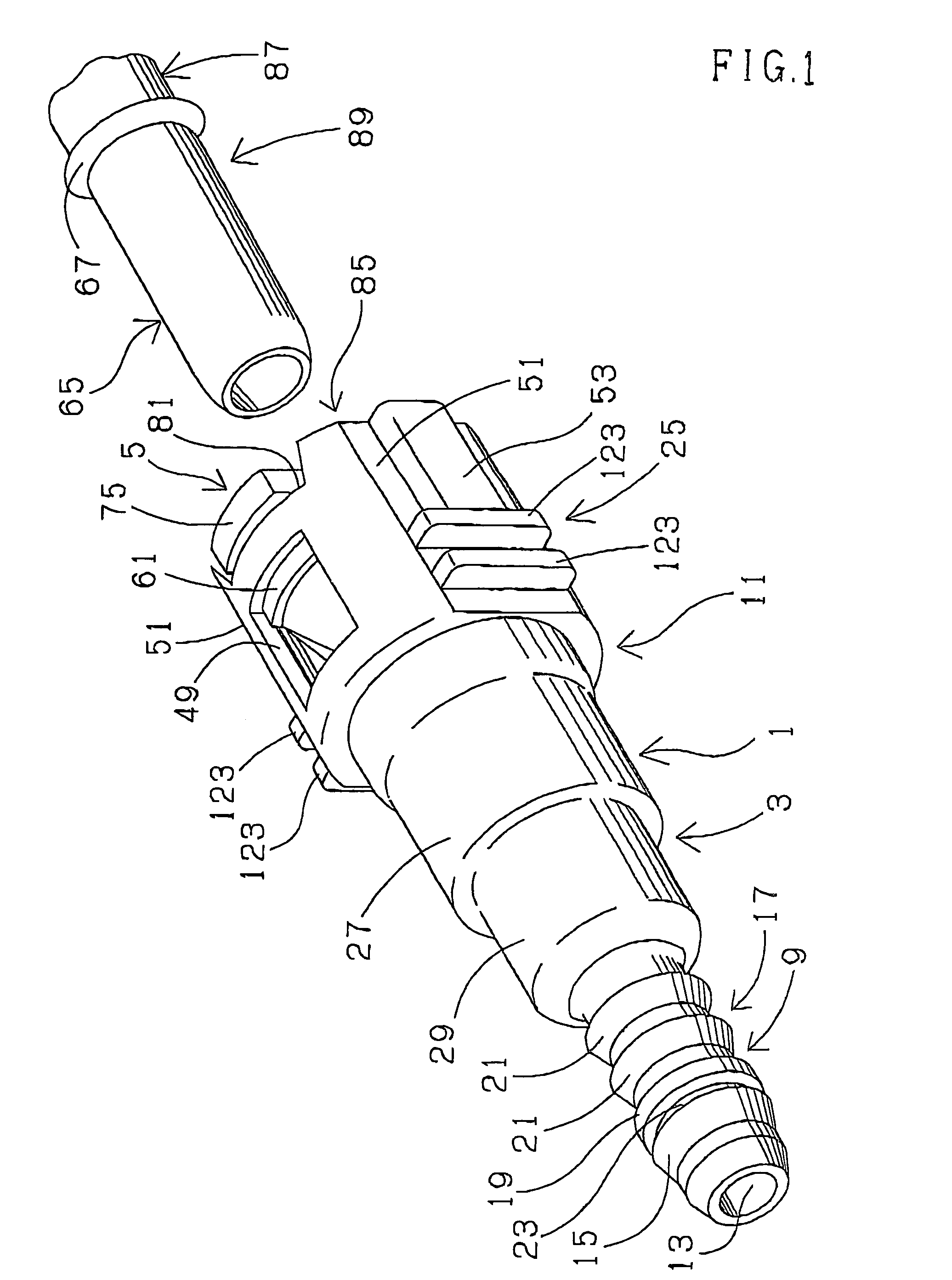

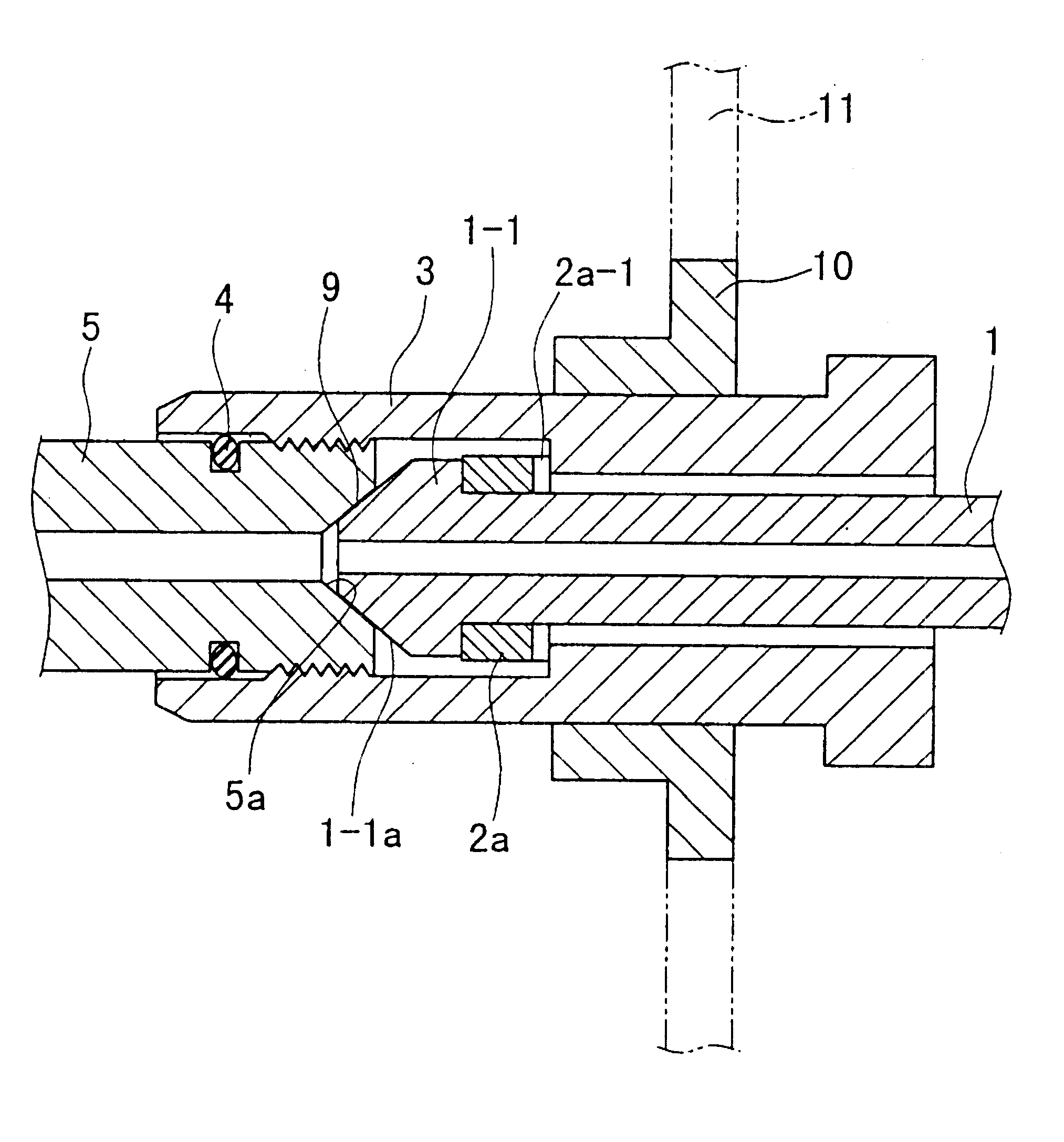

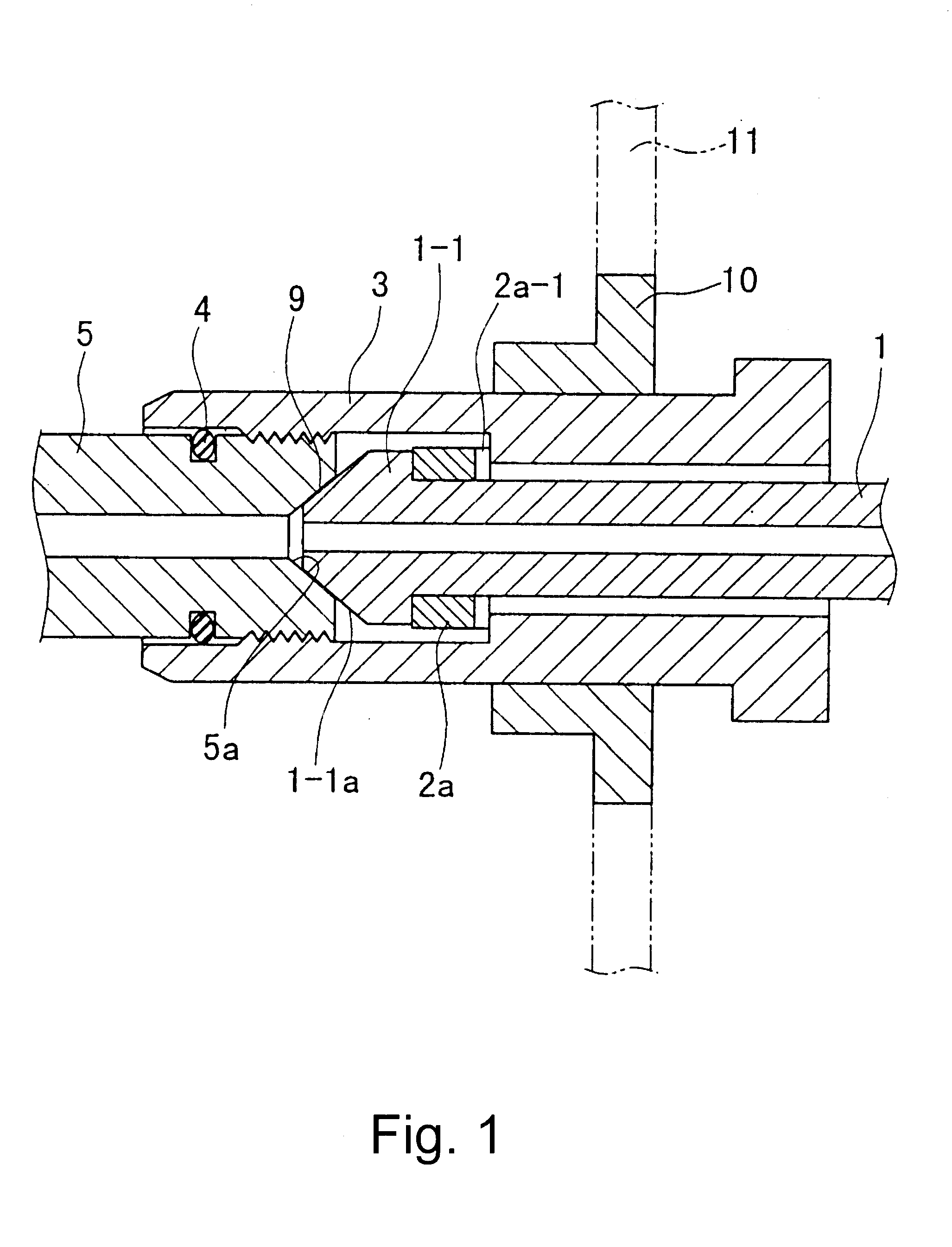

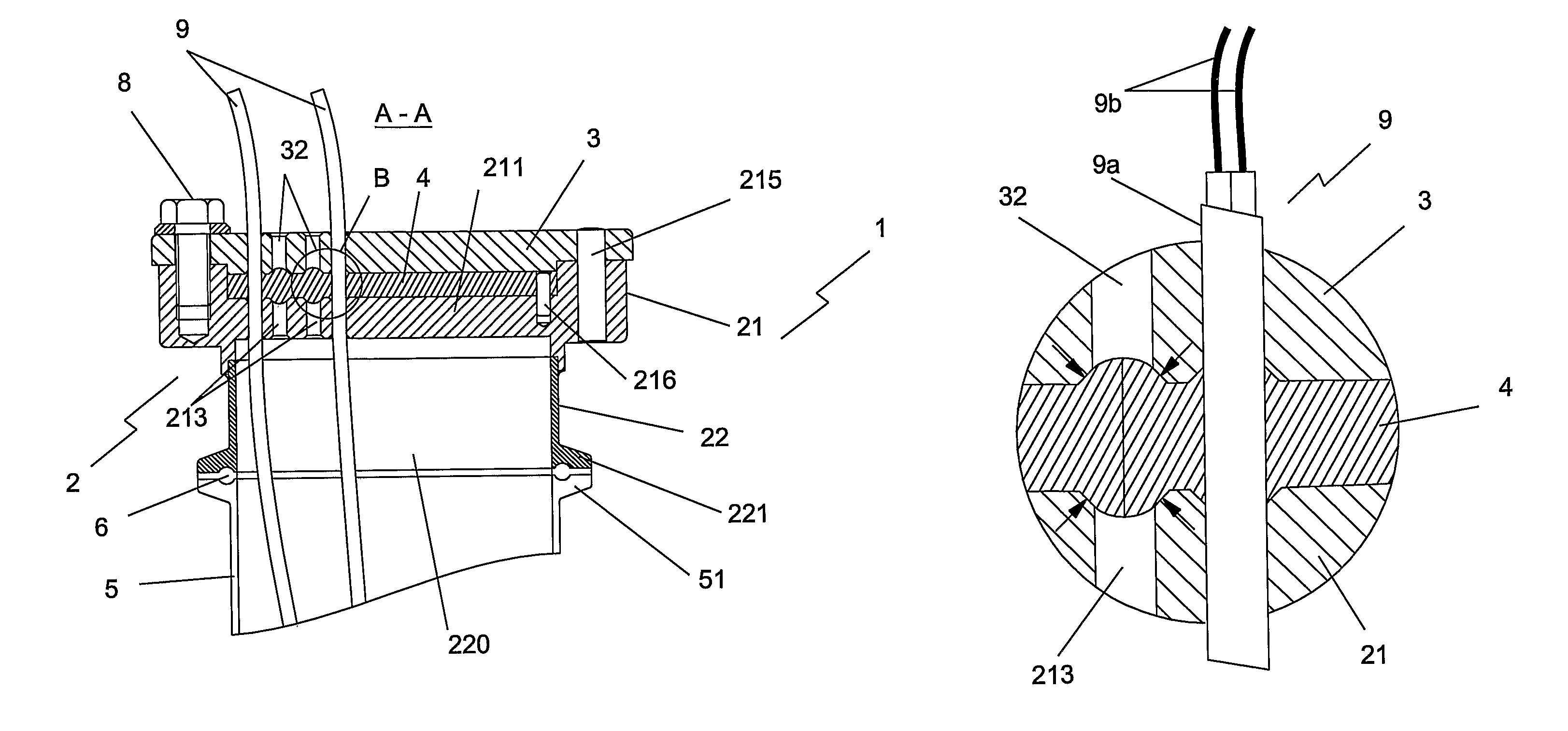

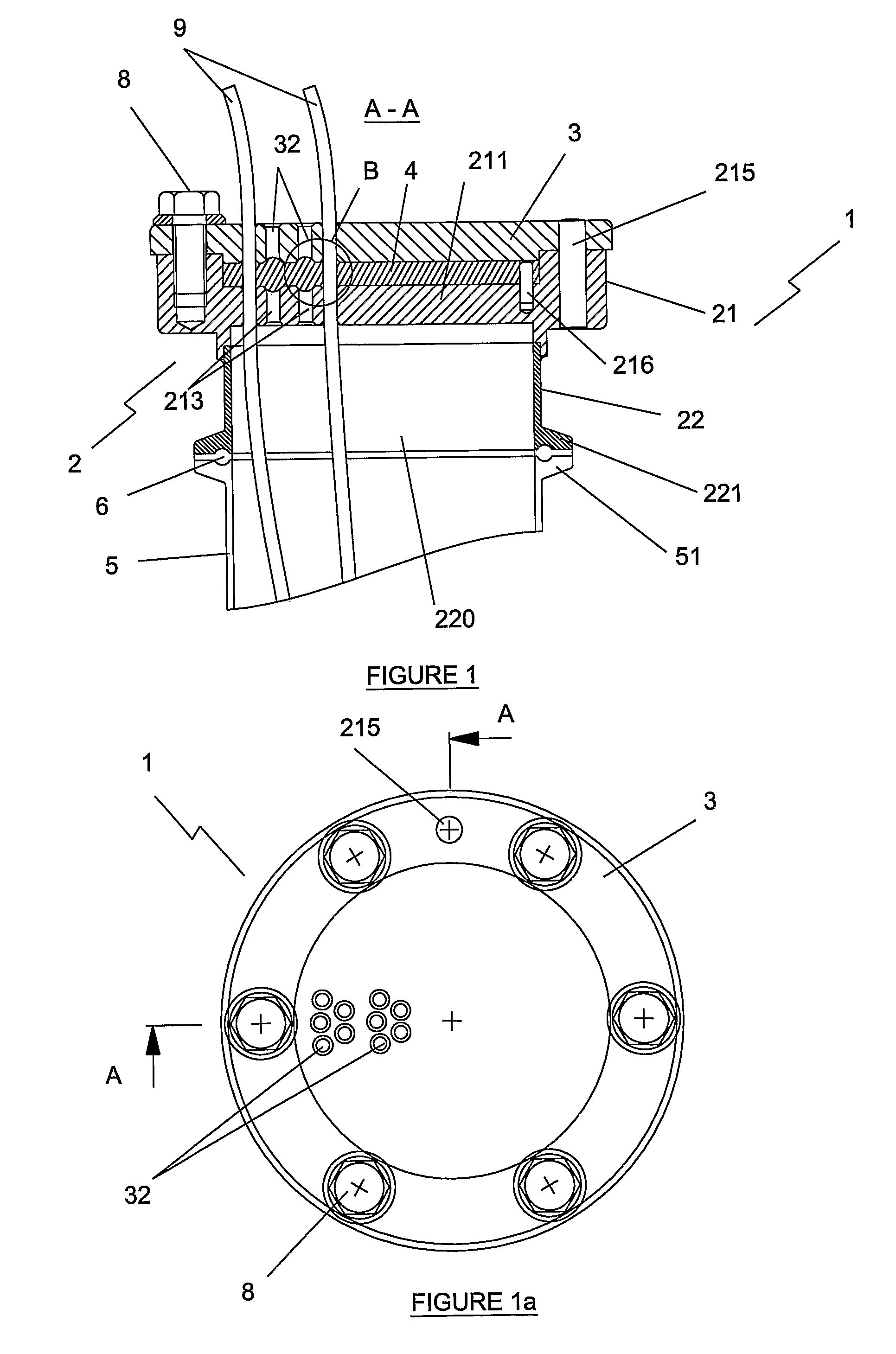

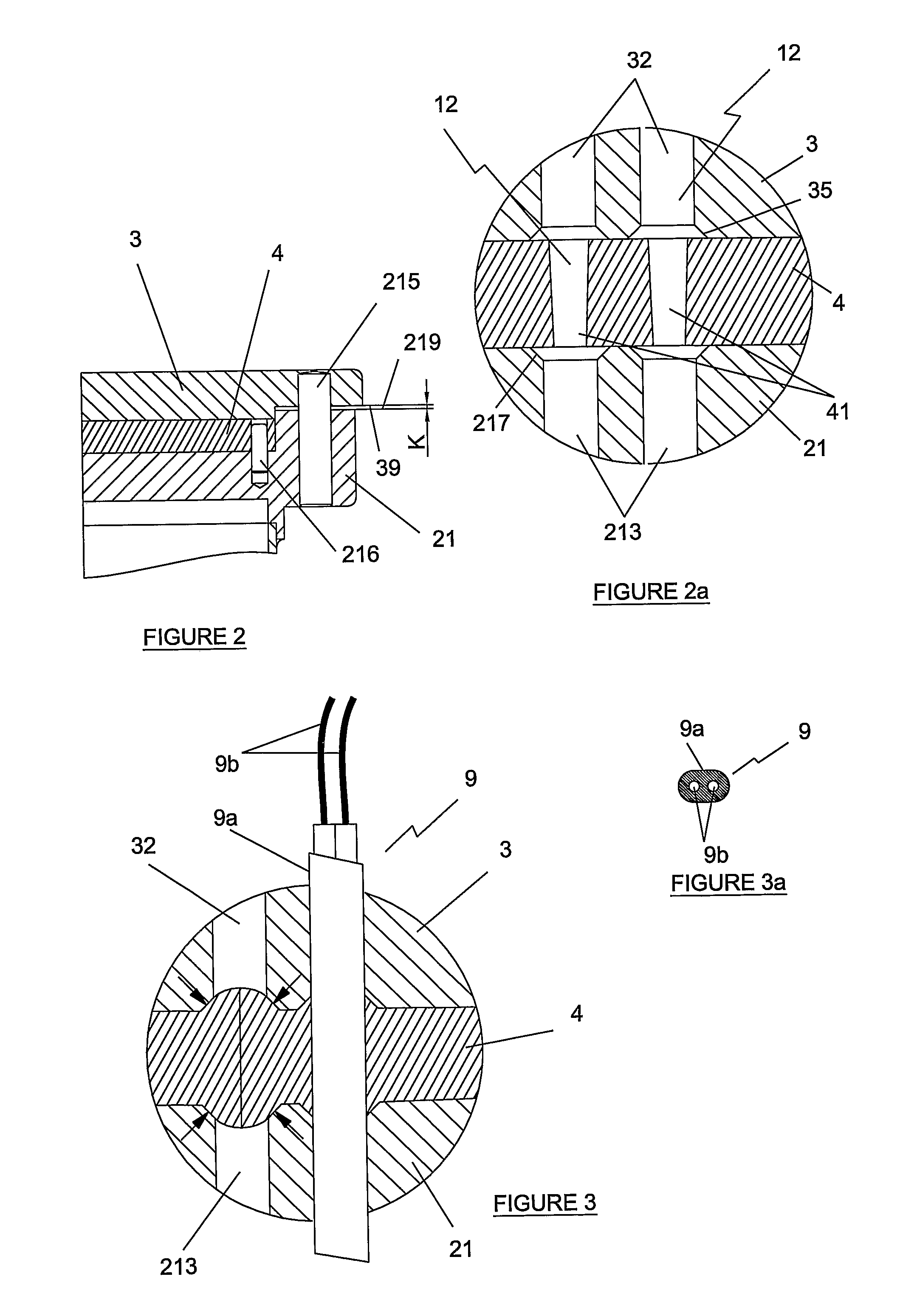

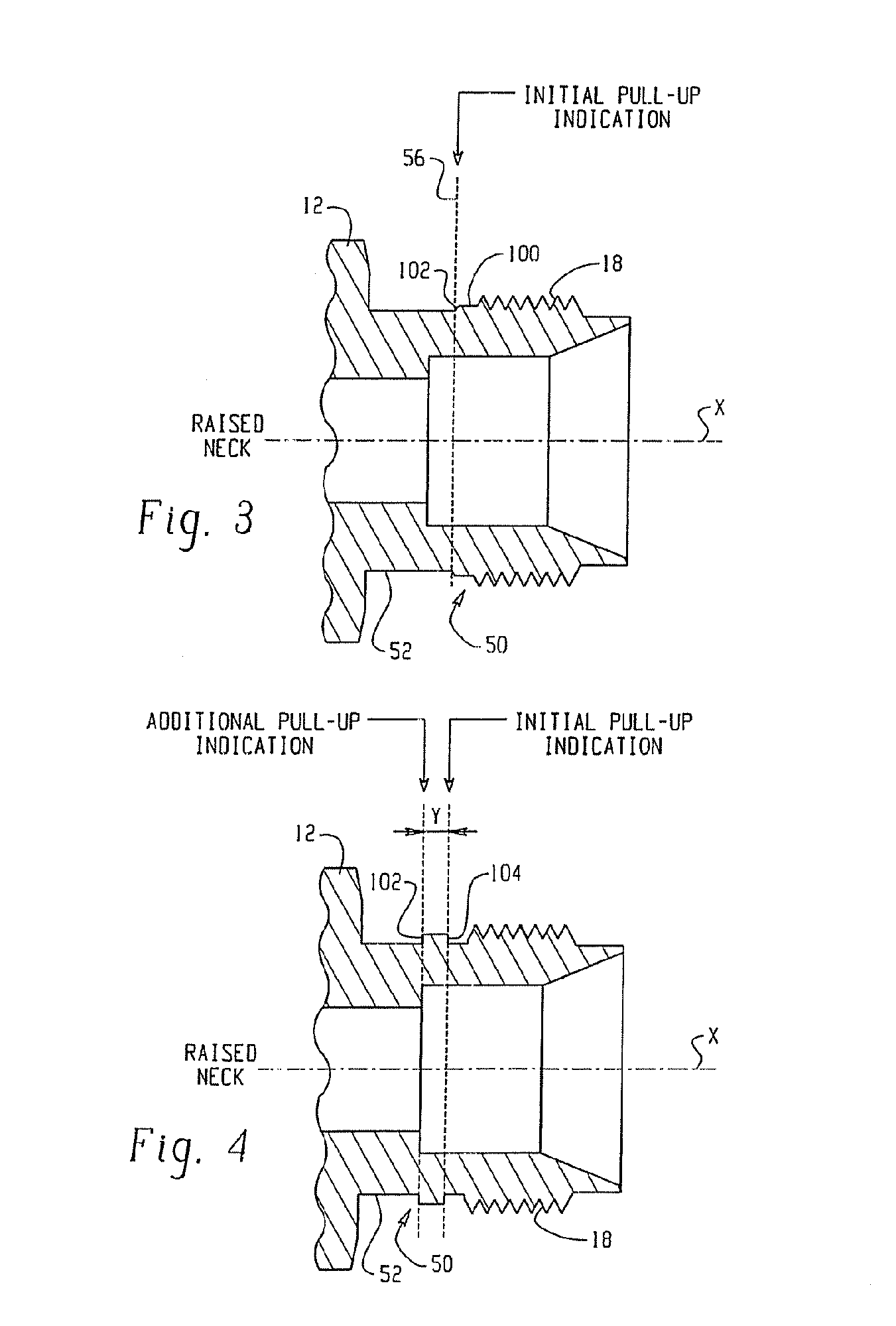

High pressure fuel injection pipe for diesel engine

The invention is to provide a high pressure fuel injection pipe for a diesel engine wherein a fuel, leaked from a seat port is discharged to the outside of a head cover without leaking into the head cover so that a leakage of fuel can be promptly detected and is directed to the high pressure fuel injection pipe formed by abutting and engaging a pressure portion formed on a connecting head of a fuel injection pipe body to a pressure receiving seat portion of a counterpart member so as to provide a firm connection of the fuel injection pipe body to the counterpart member by screwing a fastening nut to press the connecting head to the counterpart member, wherein an annular washer having at least one groove or through hole formed in a radial direction on the circumference of the washer and a seal member is disposed in the vicinity of an outer end portion of a threaded engagement potion defined between the fastening nut and the counterpart member so that a fuel leaked into the inside of the fastening nut from a seat portion defined between the pressure seat portion formed on the connecting head and the pressure receiving seat of the counterpart member may be discharged to the outside through the groove or through hole. Alternatively, the leaked fuel may be discharged to the outside through a through hole which is formed on the fastening nut.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

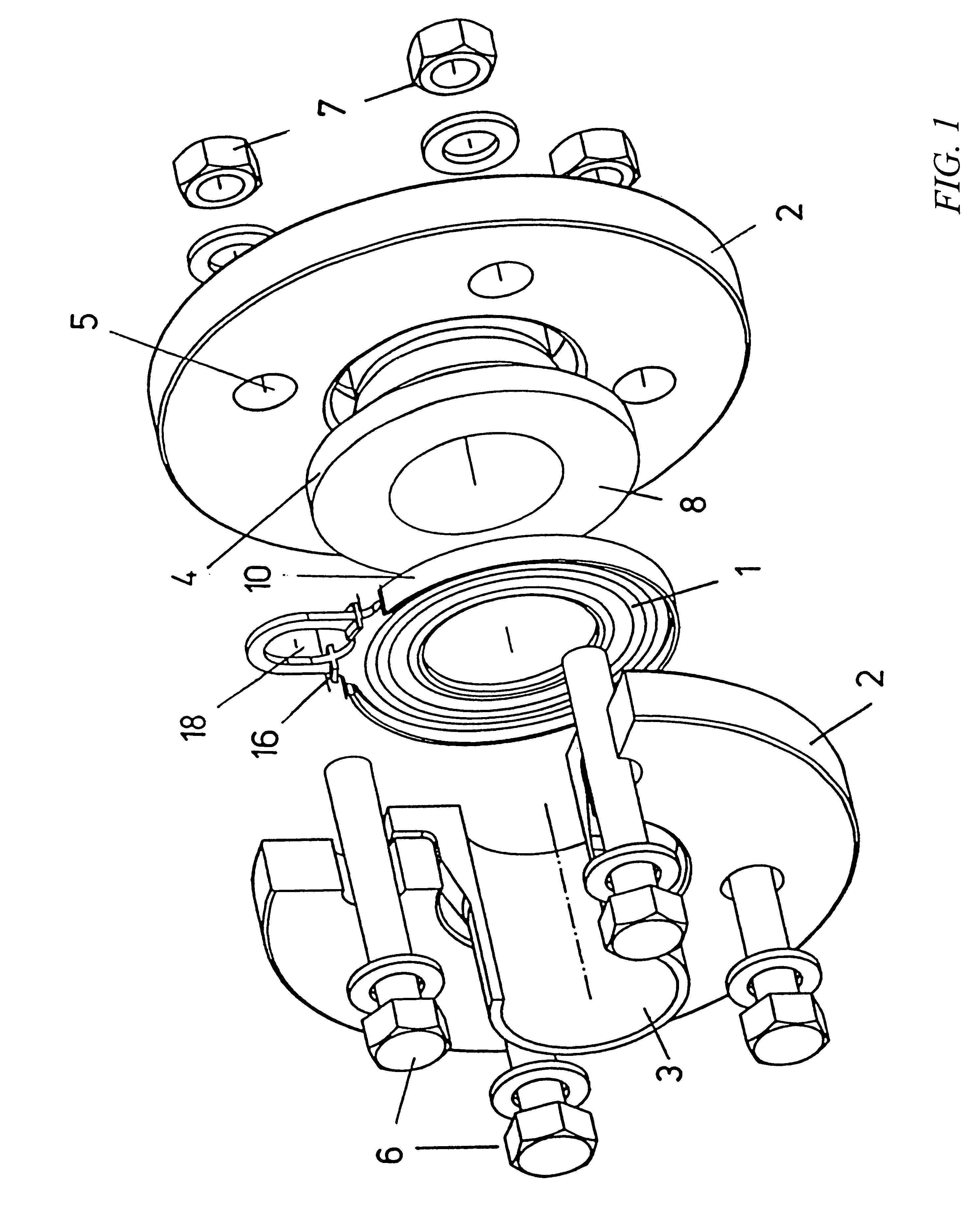

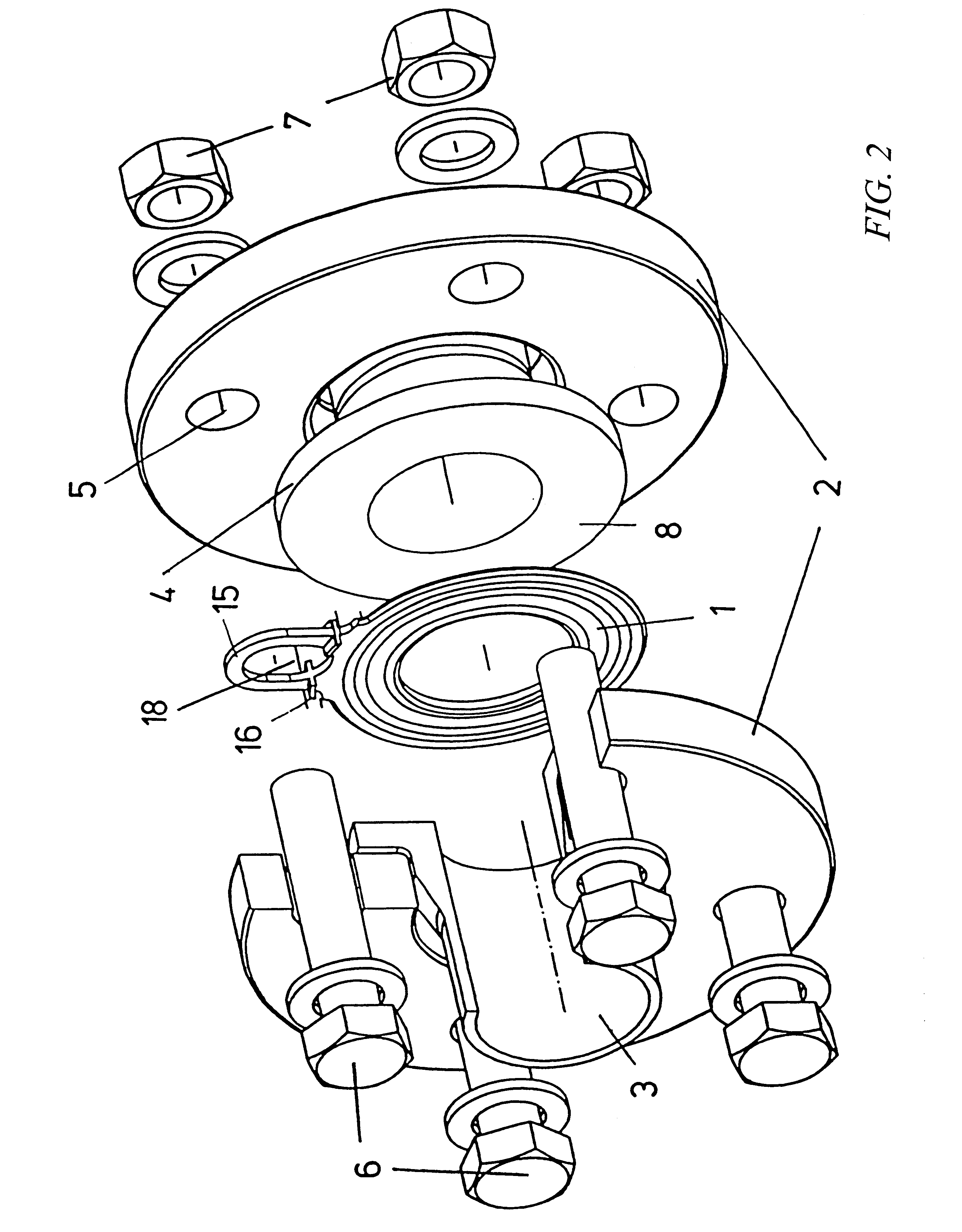

Bulkhead connector

The present invention relates to a bulkhead connector assembly providing a sealing arrangement for sealingly feeding a conduit between two environments. The assembly provides a first and second coupling components having a first and second surface respectively. A gap is formed between the first and second surfaces. The first coupling component has an aperture which extends between the first surface and a first environment and the second coupling component has an aperture which extends between the second surface and a second environment. Each aperture is adapted for receiving a conduit therethrough. A resiliently deformable gasket is provided to be placed into the gap and the gasket also is provided with a bore for a conduit to pass through the gasket. Means for compressing the gasket in the gap are provided to deform the gasket on compression so as to collapse the gasket bore against itself or against any conduit occupying the bore, so as to form a leak-proof seal between the apertures of the coupling components and the gasket.

Owner:GL TOOL & MFG

Quick connector

Owner:SUMITOMO RIKO CO LTD

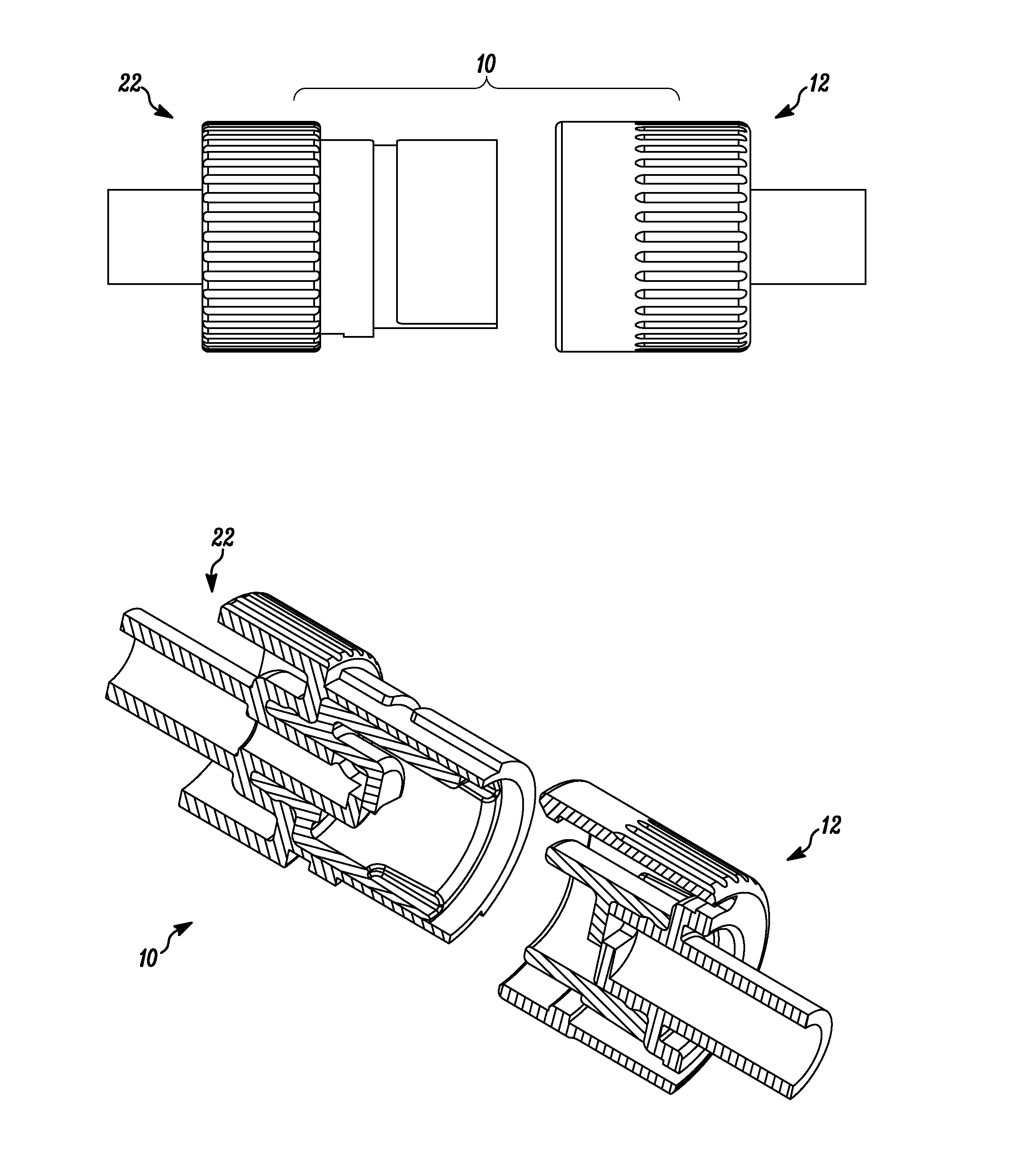

Connector and related method

InactiveUS20120042971A1Reduce the possibilityBlock fluid flowPipe couplingsCouplingsEngineeringNozzle

A connector for transferring a fluid includes a first connector and a second connector. Each connector includes a first outer portion including a first obstructive portion and defining a first fluid passageway for receiving a fluid therein. Each connector further includes a first central nozzle coupled to the first outer portion. The central nozzle includes a first engagement member. The first central nozzle is movable between a first position and a second position with rotation of the first outer portion. In the first position, the first obstructive portion and the first engagement portion substantially overlap to impede fluid flow through the first fluid passageway. In the second position, at least one of the first engagement member and the first obstructive member is displaced to allow fluid flow through the first fluid passageway.

Owner:PY DANIEL

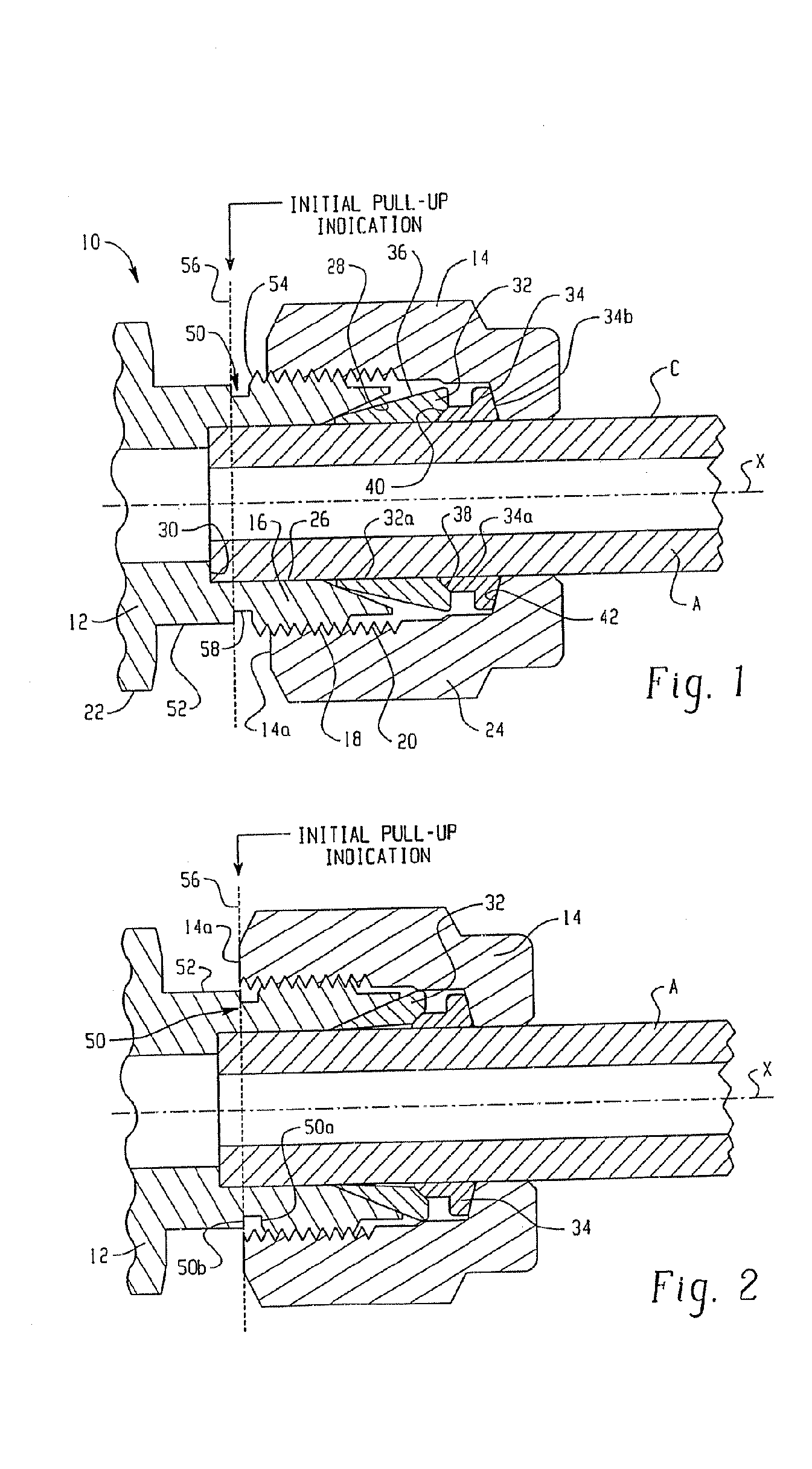

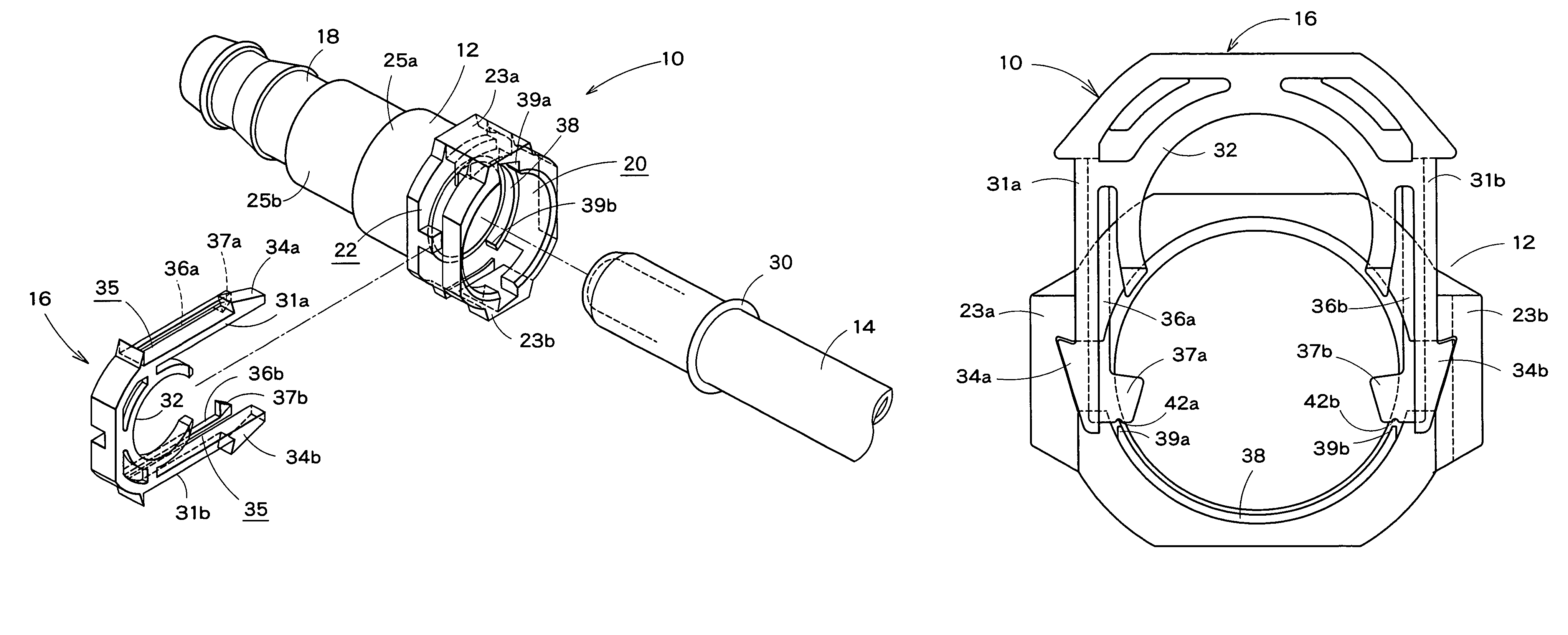

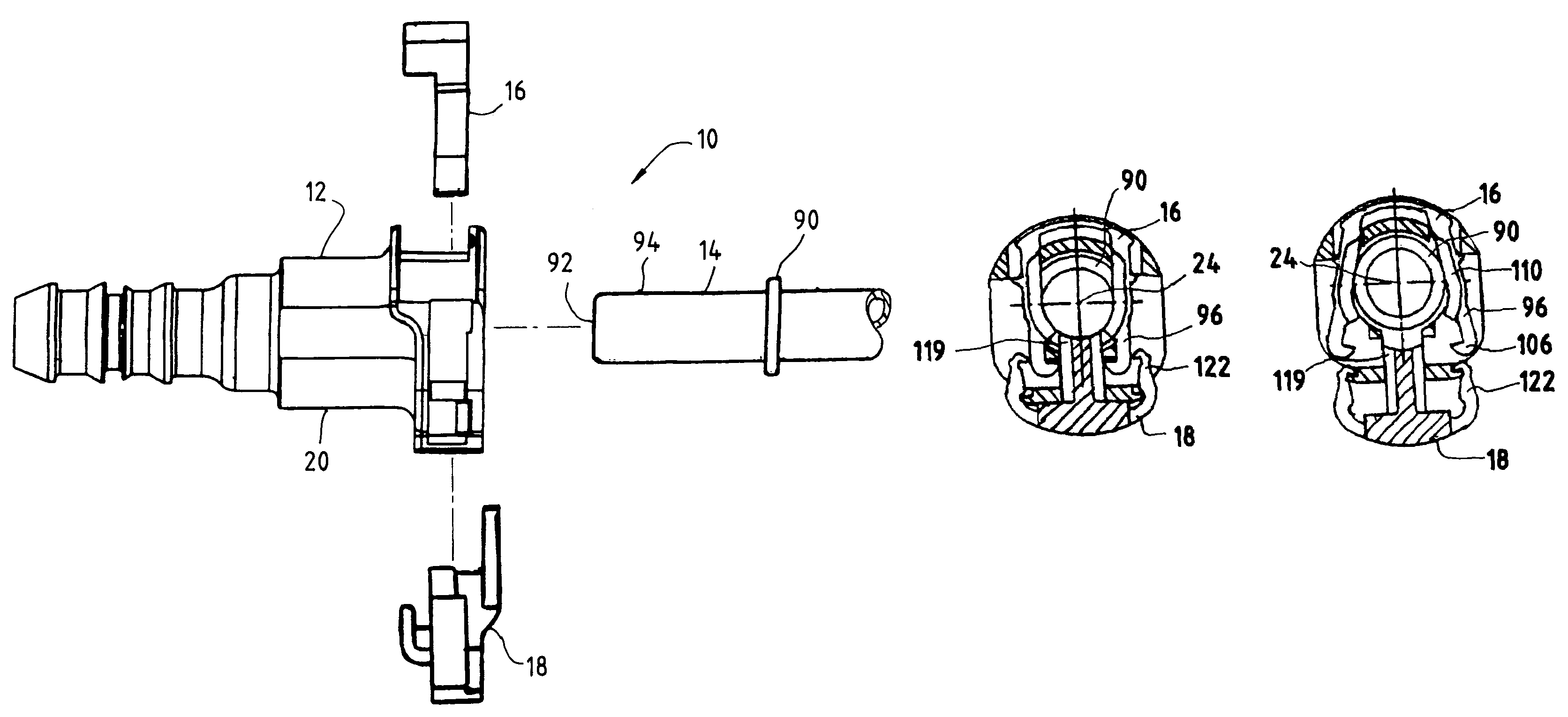

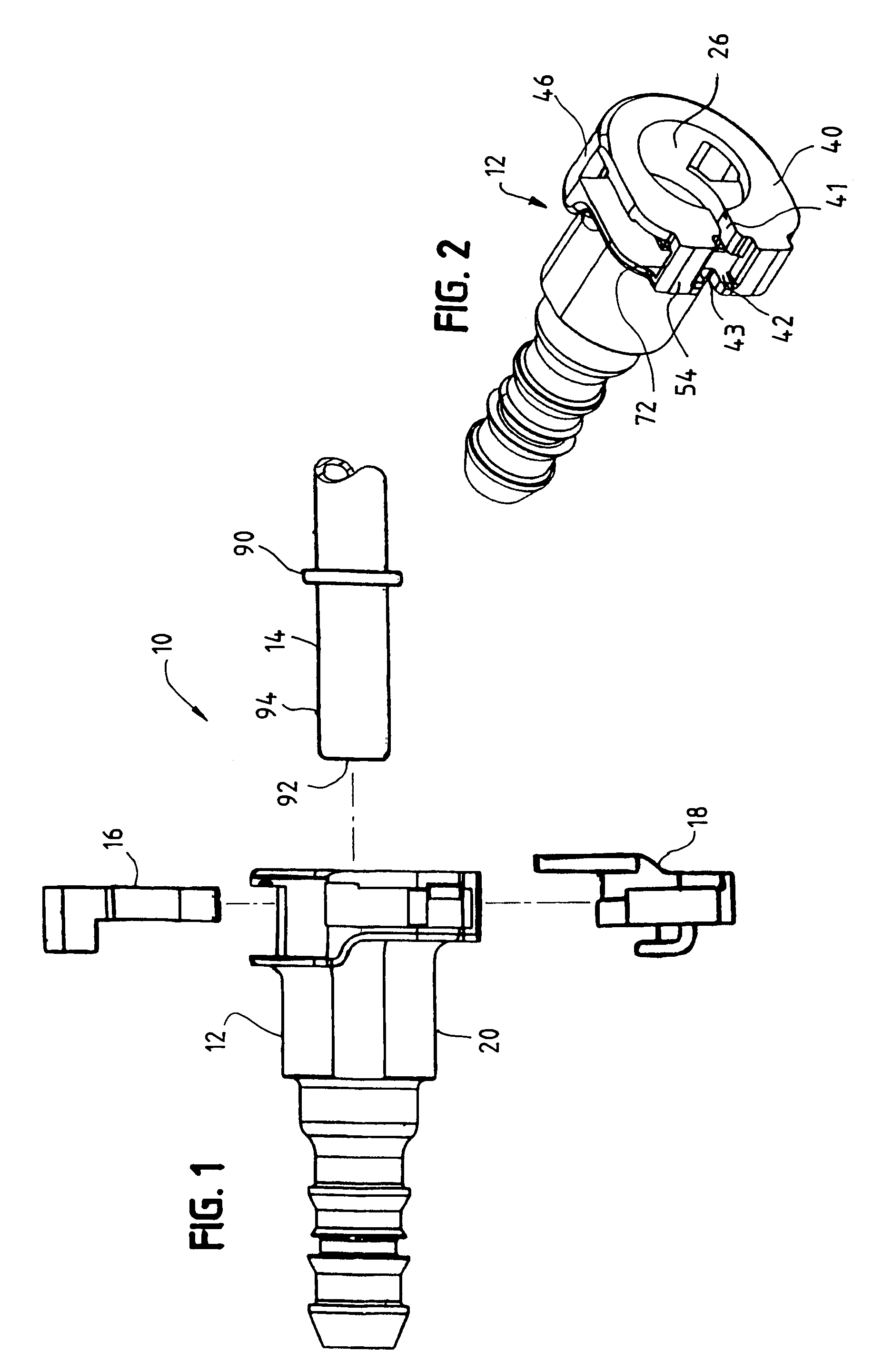

Secondary latch/verifier for a quick connector

A quick connector coupling comprising a female connector body, a tubular male member, a primary retainer and a secondary latch / verifier. The female connector body has a through bore and transverse slots open to the bore. The male tubular member with an annular upset extends into the through bore. The primary retainer is disposed within the slots and releasably connects the male member to the connector body. The secondary latch / verifier is disposed in the slots and is releasably coupled to the connector body and moveable between latched position in which it precludes release of the primary retainer and an unlatched position. In one form, the secondary latch includes a retainer beam arranged to move the secondary latch to its unlatched position on insertion of the male member. In another form the secondary latch / verifier includes externally positioned verifier and additional latch to releasably retain the male member.

Owner:TI GRP AUTOMOTIVE SYST LLC

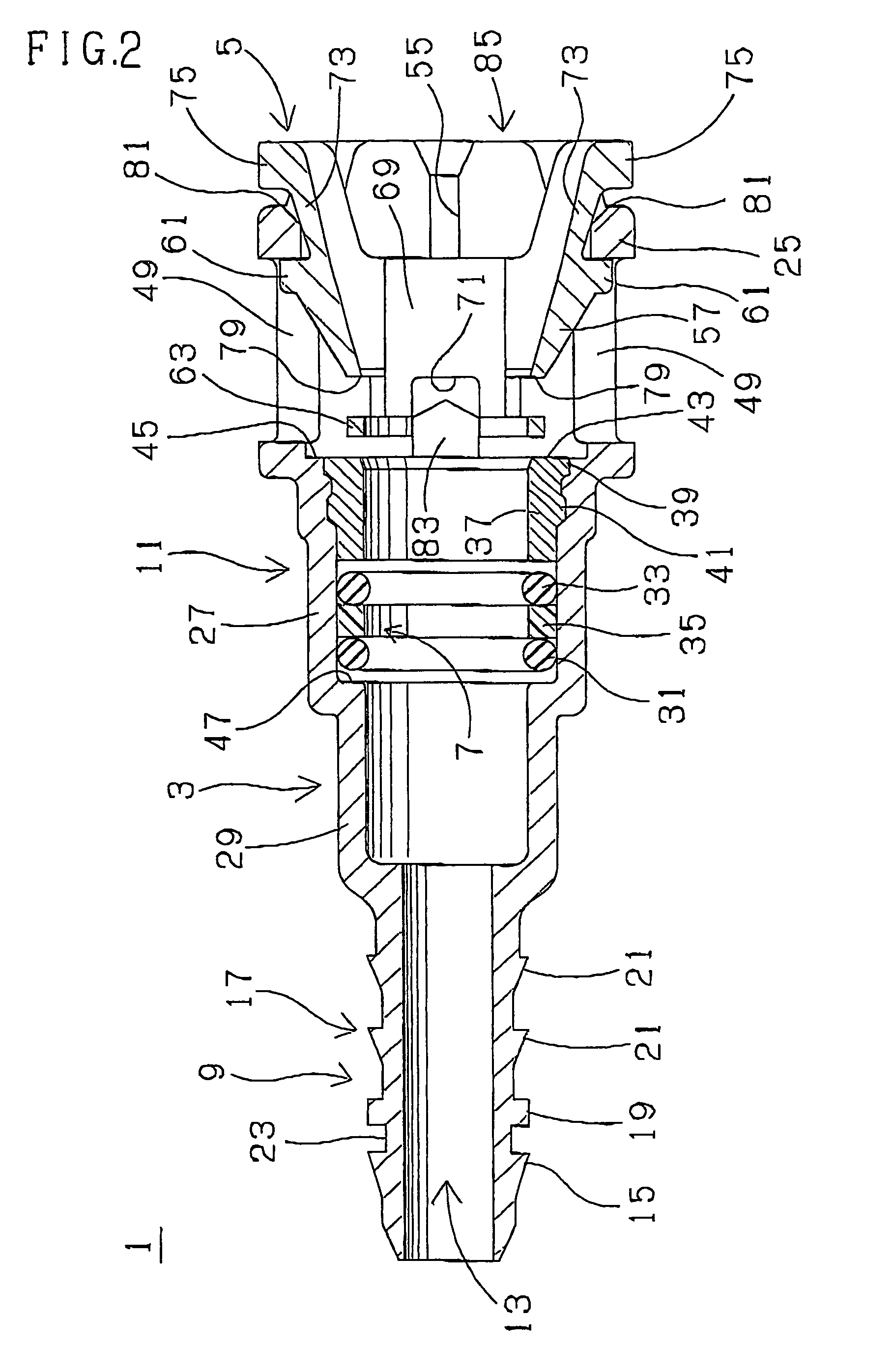

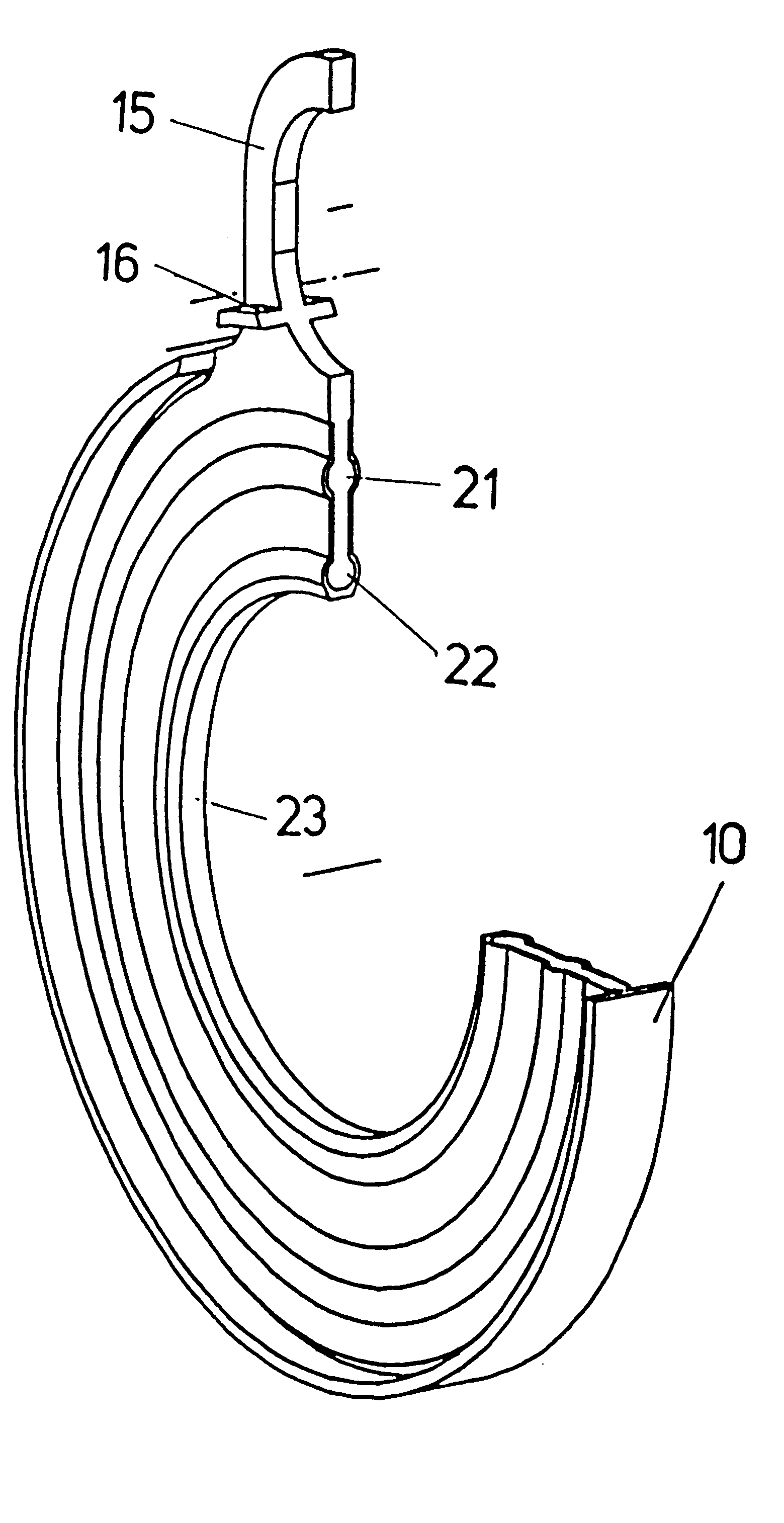

Expandable hose assembly

ActiveUS20120234425A1Reduce and eliminate kinkReadily uncoupledPipe couplingsSuction cleanersEngineeringFluid pressure

A hose which automatically expands longitudinally and automatically expands laterally upon the application of a fluid pressure is disclosed. The hose can automatically expand longitudinally up to six times its unexpanded or contracted length. Upon release of the fluid pressure within the hose, the hose will automatically contract to a contracted condition. The hose includes an inner tube made from an elastic material and an outer tube made from a non-elastic material. The inner tube is positioned concentrically within the outer tube in both a contracted condition and an expanded condition. The outer tube is secured to the inner tube only at a first end of the inner and outer tubes and at a second end of the inner and outer tubes. The outer tube moves laterally and longitudinally with respect to the inner tube when the tubes are transitioning between a contracted condition and an expanded condition.

Owner:TELEBRANDS CORP

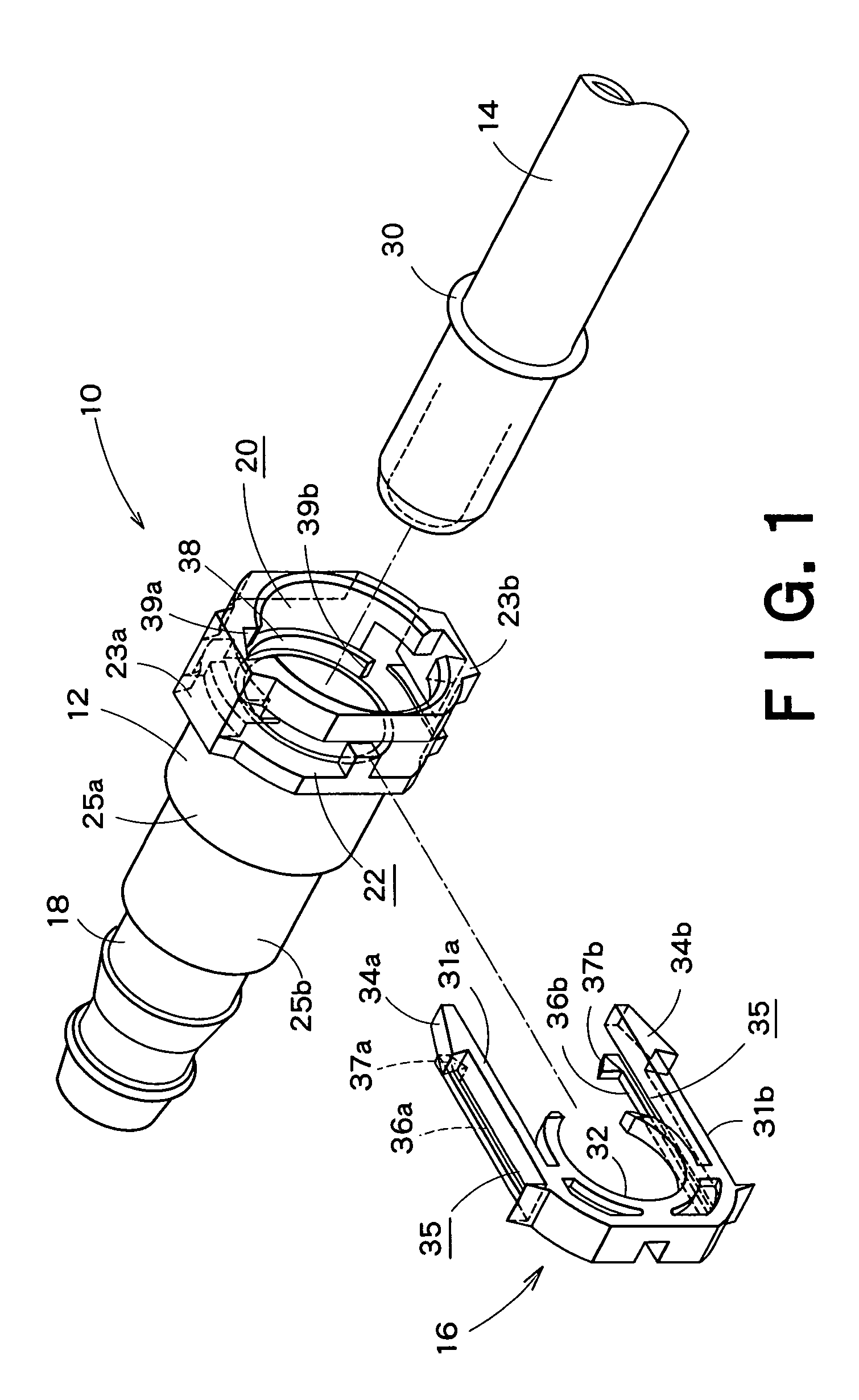

Pipe joint

ActiveUS7464970B2Improve assembly efficiencyPossible to selectPipe couplingsCouplingsEngineeringFlange

A pipe joint for connecting a rigid pipe with a retaining flange to a tube includes a pipe joint body formed with a through bore and a window in communication with the bore. A tube connector portion may be connected at an angle to a rigid pipe connector portion. A pipe retainer provided with locking pieces can be located in two positions relative to the pipe joint body. The first position allows the retaining flange to pass through the locking pieces. The second position retains the rear of the retaining flange and prevents inadvertent removal of the rigid pipe. The retaining pieces engage the rear of the flange through the window communicating with the bore. The locking direction of the retainer can be altered relative to the tube connector portion to suit different applications and ease assembly.

Owner:TOGO SEISAKUSYO CORP

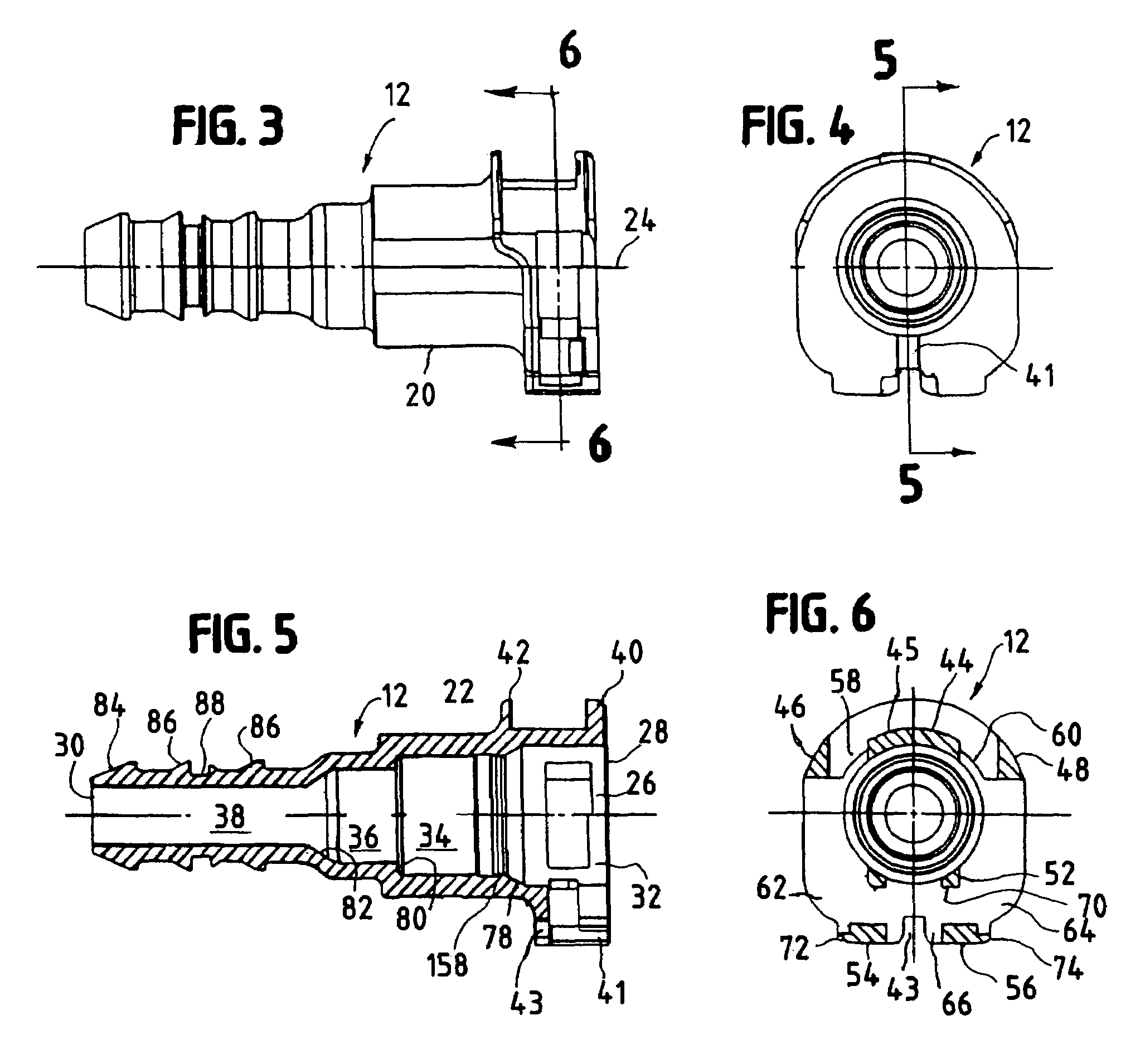

Quick-connect coupling

A quick-connect coupling has a retainer for retaining a tube in a coupling body. The retainer is pressed in the coupling body so as to lock the tube in place in the coupling body. The retainer cannot be fully pressed in the coupling body and projects from the coupling body to indicate that the tube is not properly connected to the coupling body unless the tube is inserted completely in the coupling body. The retainer is combined with complete connection verifying legs that enables the retainer to be able to be pressed in the coupling body when an annular ridge formed in an end part of a tube inserted in the coupling body is advanced beyond a position where the retainer is able to engage with the annular ridge.

Owner:SANOH KOGYO KK

Secondary latch/verifier for a quick connector

A quick connector coupling comprising a female connector body, a tubular male member, a primary retainer and a secondary latch / verifier. The female connector body has a through bore and transverse slots open to the bore. The male tubular member with an annular upset extends into the through bore. The primary retainer is disposed within the slots and releasably connects the male member to the connector body. The secondary latch / verifier is disposed in the slots and is releasably coupled to the connector body and moveable between latched position in which it precludes release of the primary retainer and an unlatched position. In one form, the secondary latch includes a retainer beam arranged to move the secondary latch to its unlatched position on insertion of the male member. In another form the secondary latch / verifier includes externally positioned verifier and additional latch to releasably retain the male member.

Owner:TI GRP AUTOMOTIVE SYST LLC

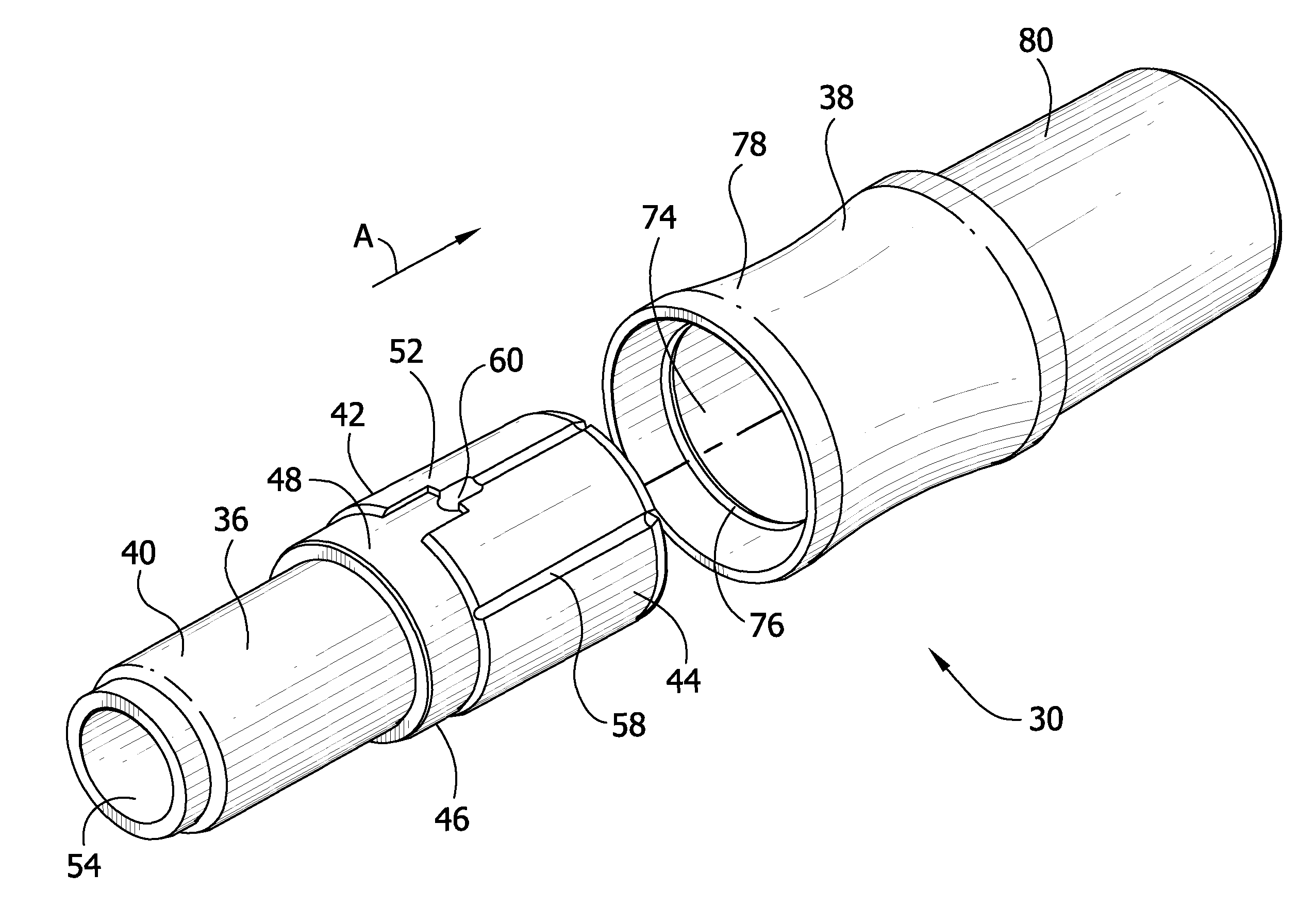

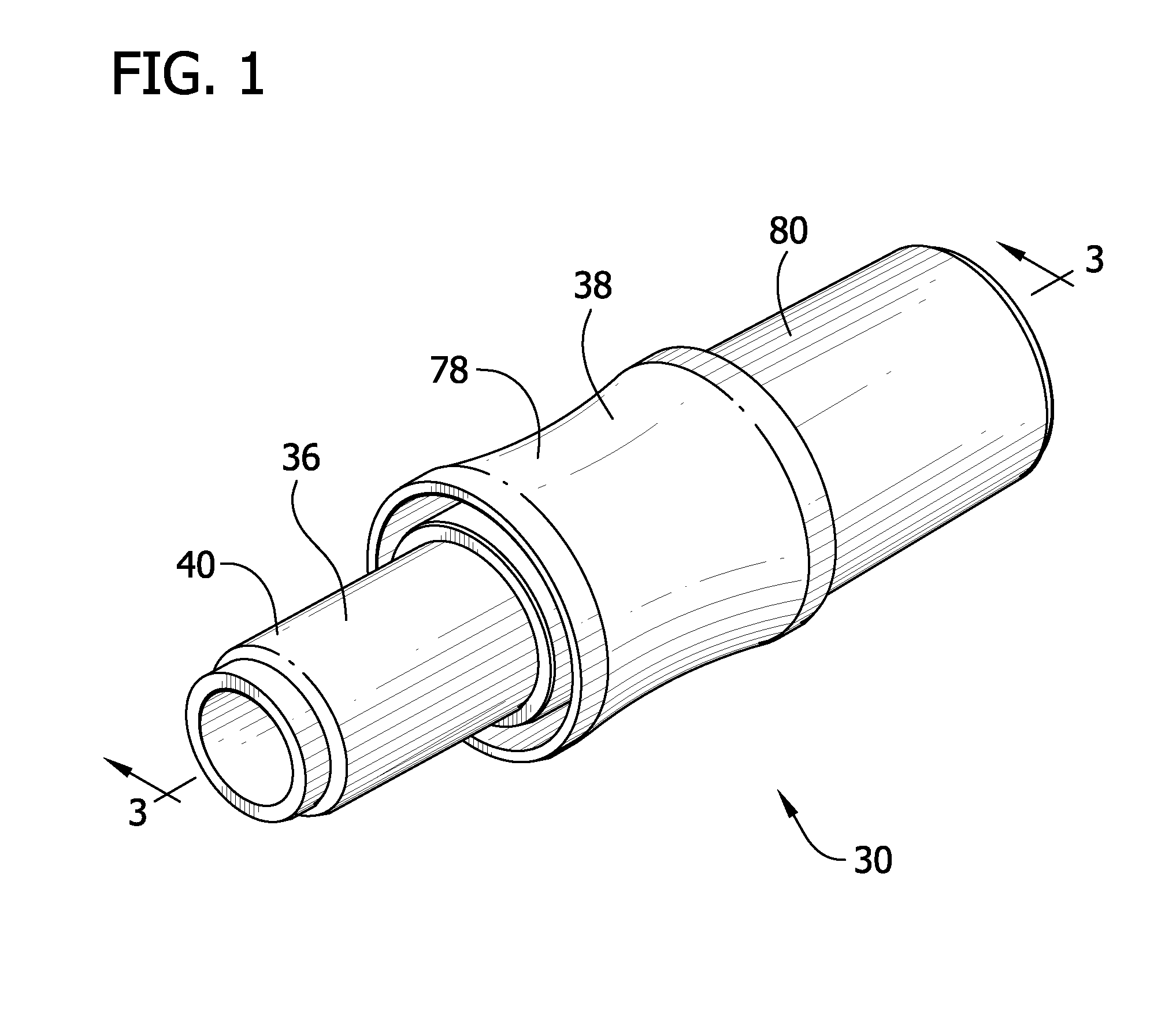

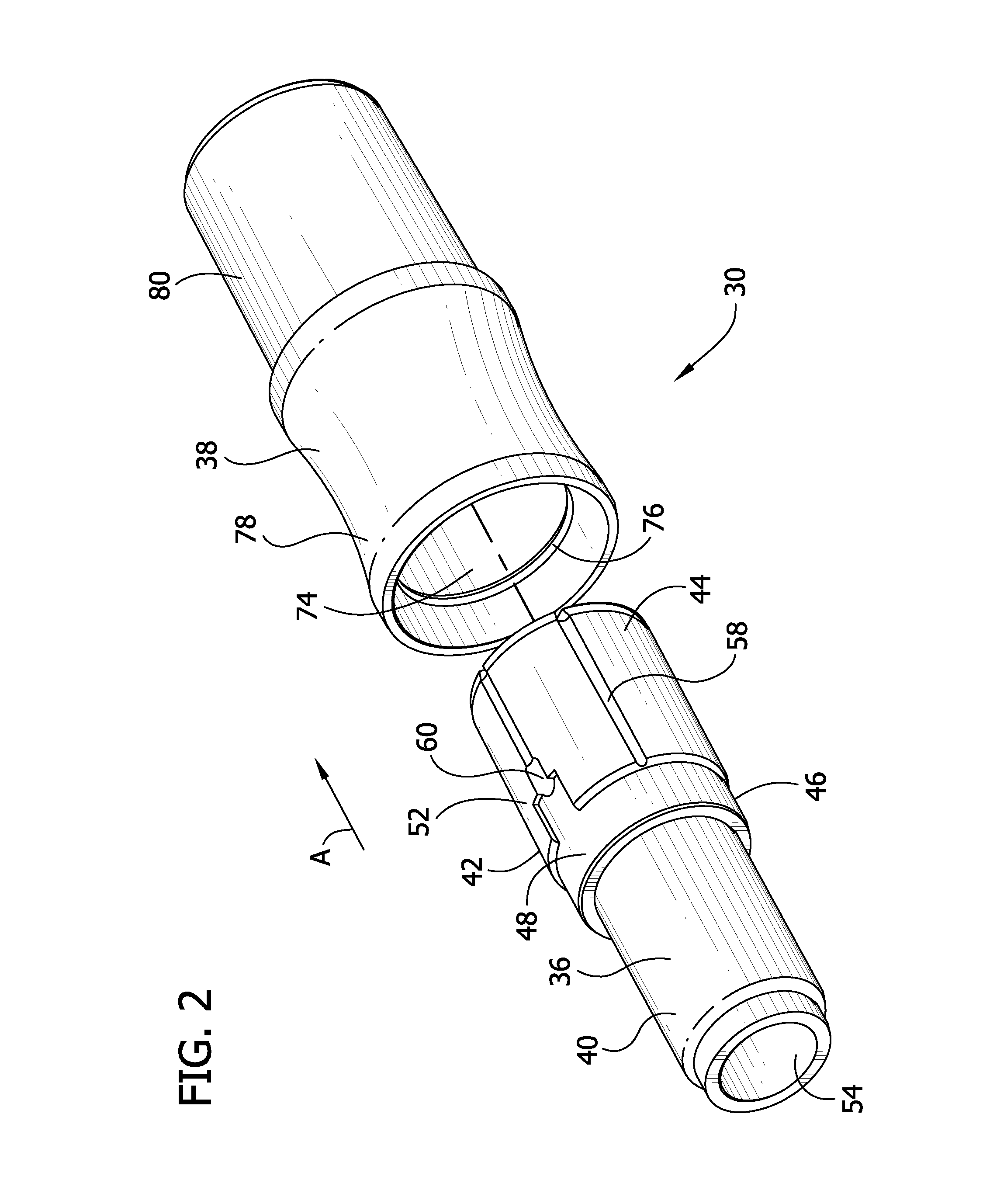

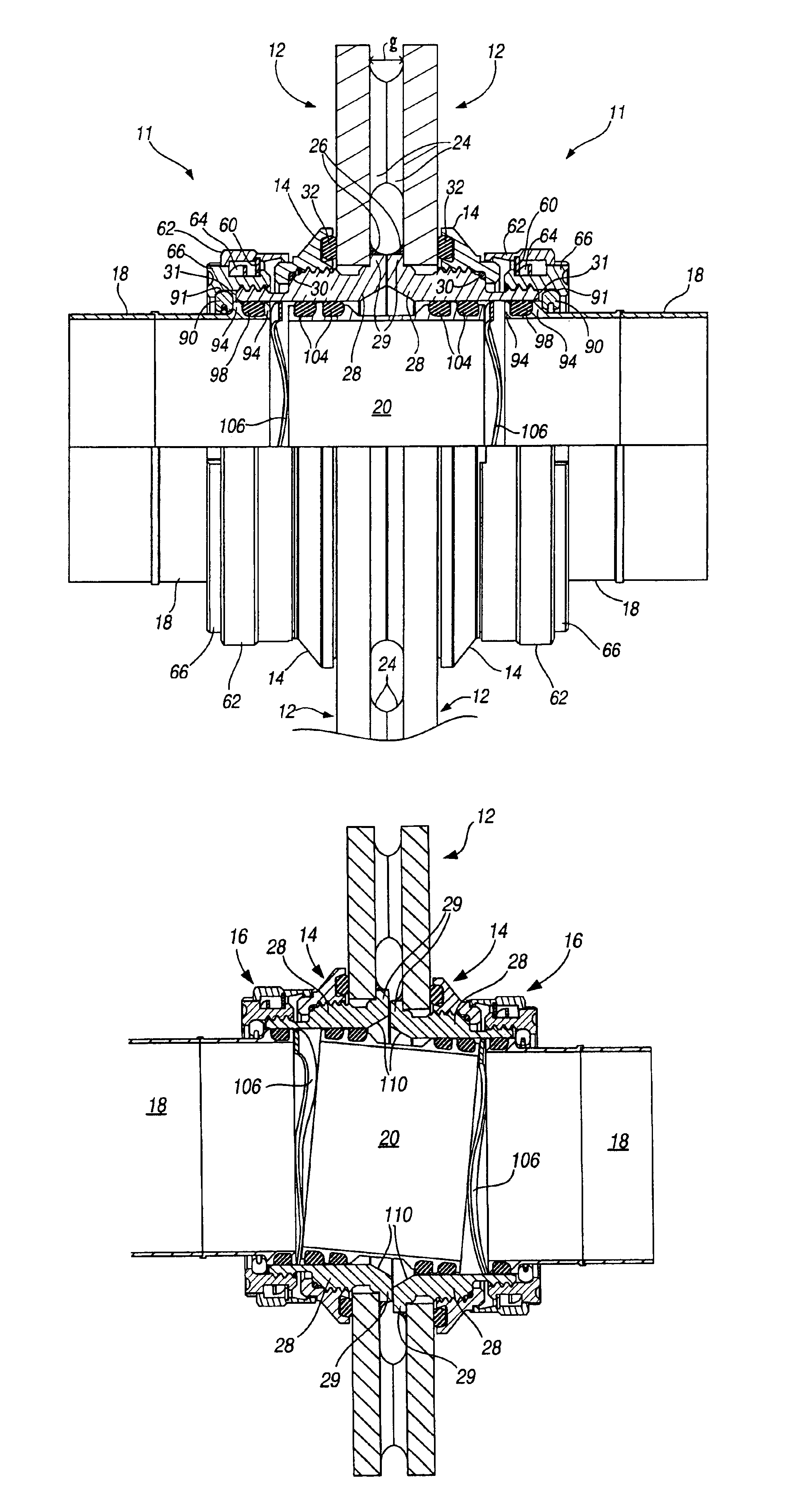

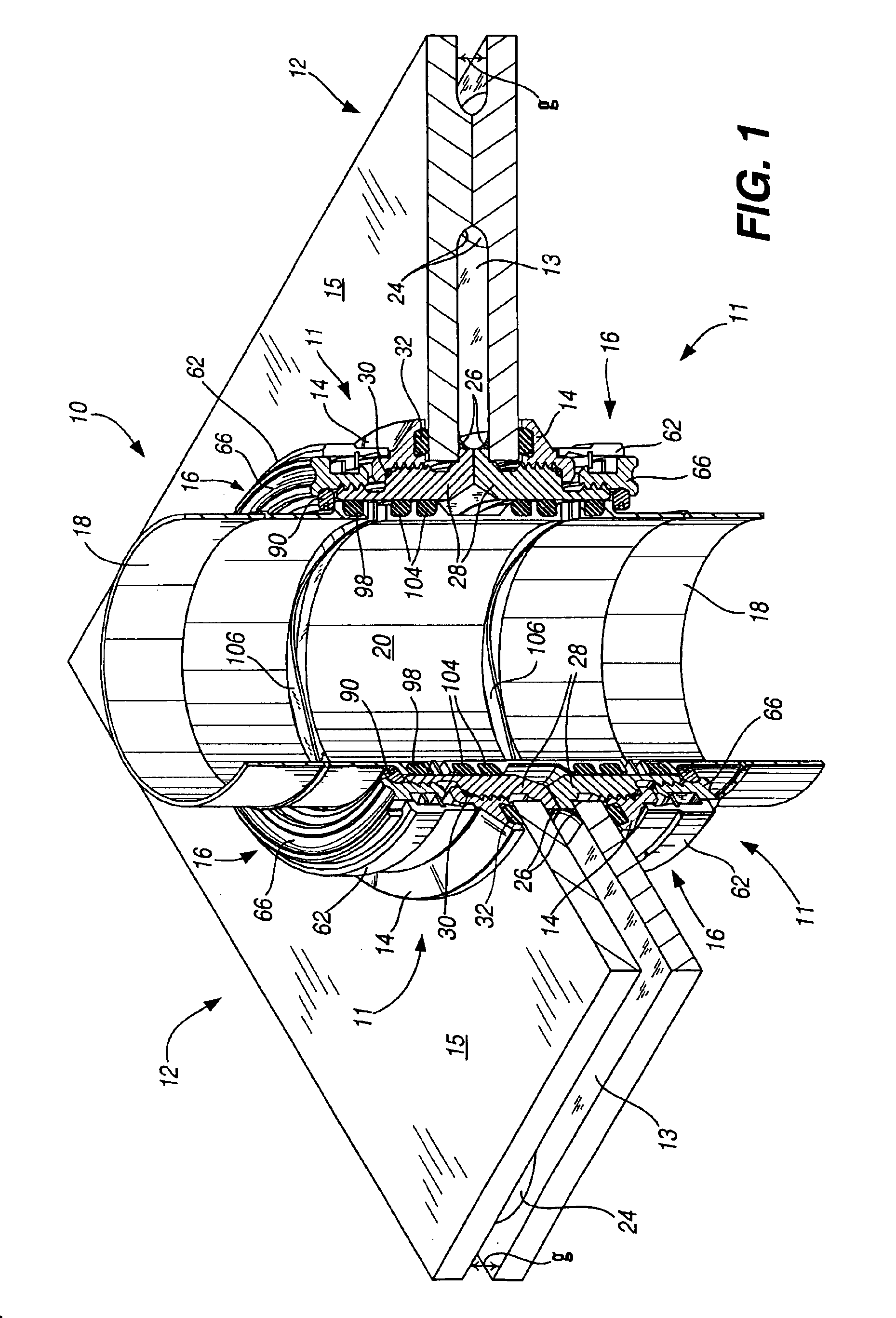

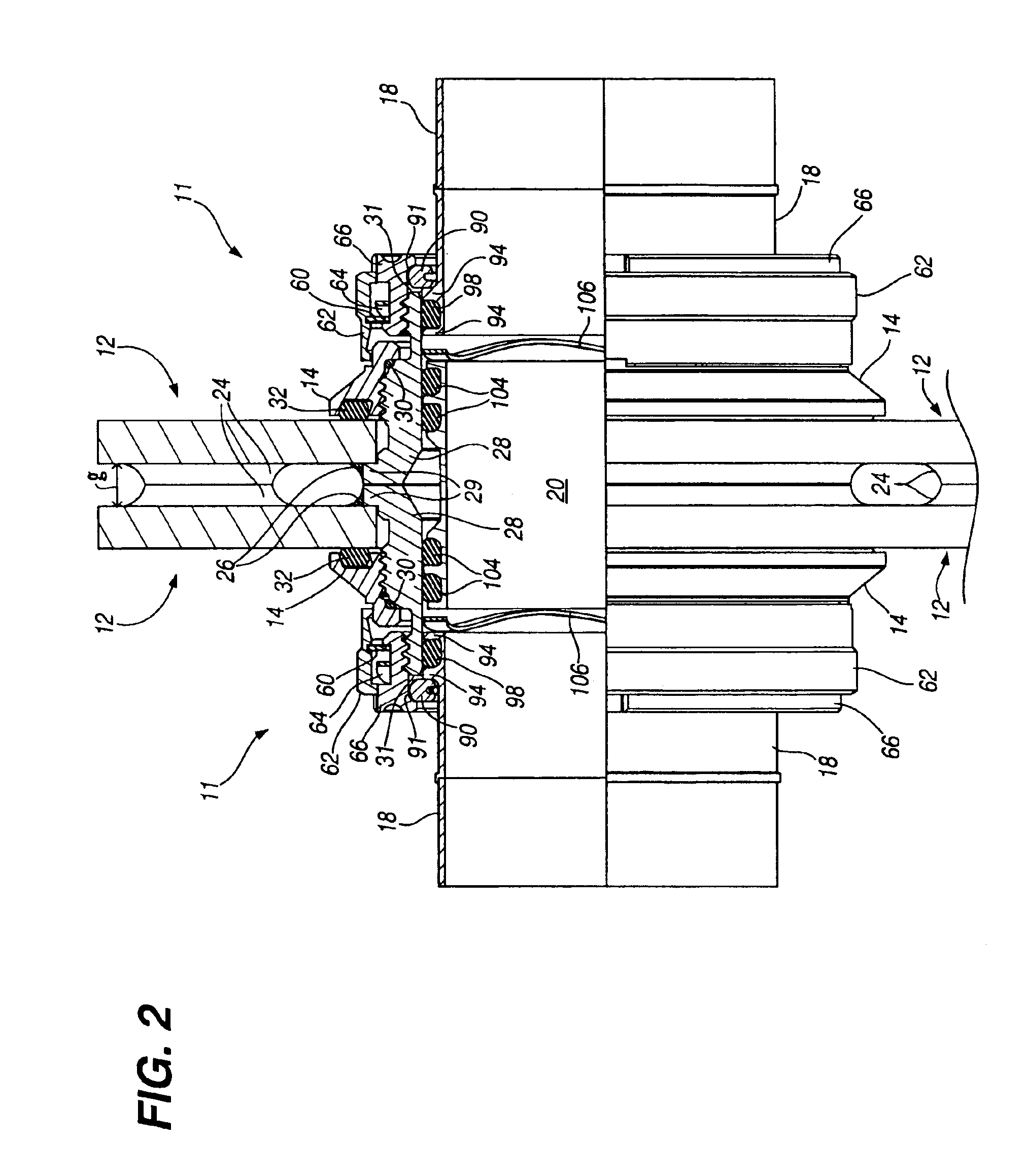

Positive locking fitting assembly

A positive locking fitting assembly is provided for interconnecting two adjacent structures, such as two modular components of an aircraft. The fitting assembly includes a pair of couplers which attach to the respective modular components, and a transfer tube which interconnects the couplers. Each coupler has a positive locking feature which prevents inadvertent uncoupling during operation. A plurality of redundant seals are incorporated throughout the construction of the fitting assembly which ensures a leak proof relationship not only between the joined pair of modular components, but also through the structure of the elements of the fitting assembly itself.

Owner:EATON INTELLIGENT POWER LIMITED

Swabable fluid connectors and fluid connector pairs

InactiveUS20060157971A1Easy to cleanReduce the possibilityFluid pressure sealed jointsJoints with sealing surfacesDistal portionEngineering

A first fluid connector is provided for selective interconnection to and fluid transfer with a second fluid connector. The first connector comprises a fluid passageway, an internal member and an outer collar supportably disposed about the internal member for selective advancement and retraction relative thereto. At least a portion of the fluid passageway may extend through the internal member. The outer collar may be selectively retracted to facilitate cleaning of the internal member. In some embodiments, the outer collar and internal member may be disposed so that a distal portion of the internal member is substantially flush with or a distal portion of internal member projects beyond a distal end of the outer collar when the outer collar is in a retracted position relative thereto. To facilitate cleaning, a distal end or distal portion of the internal member may be substantially closed when the first and second connectors are disconnected. The second connector may be adapted to facilitate fluid interconnection with the first connector, and may also present a cleanable distal end when disconnected.

Owner:BAXTER ENGLEWOOD

Quick connector

ActiveUS7390029B2Avoids false locking effectivelyCompact structureClosuresPipe couplingsEngineeringMechanical engineering

A quick connector has a housing, a retainer for locking a tube at a correct position for complete connection in the housing and a restraining ring for restraining the retainer from being pressed into the housing to its locking position unless the tube is inserted in the housing and placed at the correct position for complete connection to avoid connecting the tube to the quick connector in a falsely locked state. The restraining ring is provided with locking bars that engage with the legs of the retainer to restrain the retainer from being pressed into the housing. The locking bars permit releasing the restraining ring to its releasing position to enable the retainer to be pressed into the housing to the locking position.

Owner:SANOH KOGYO KK

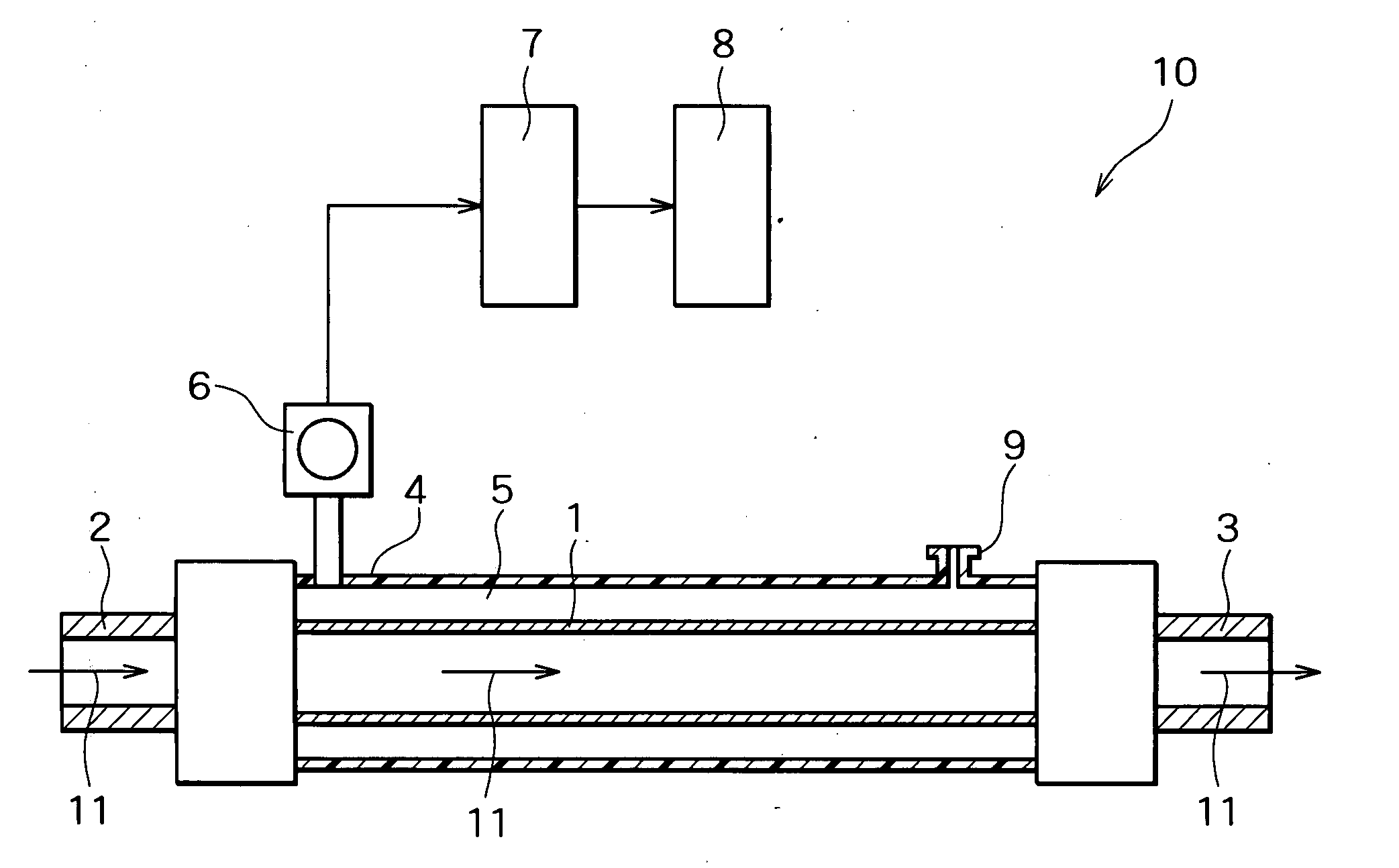

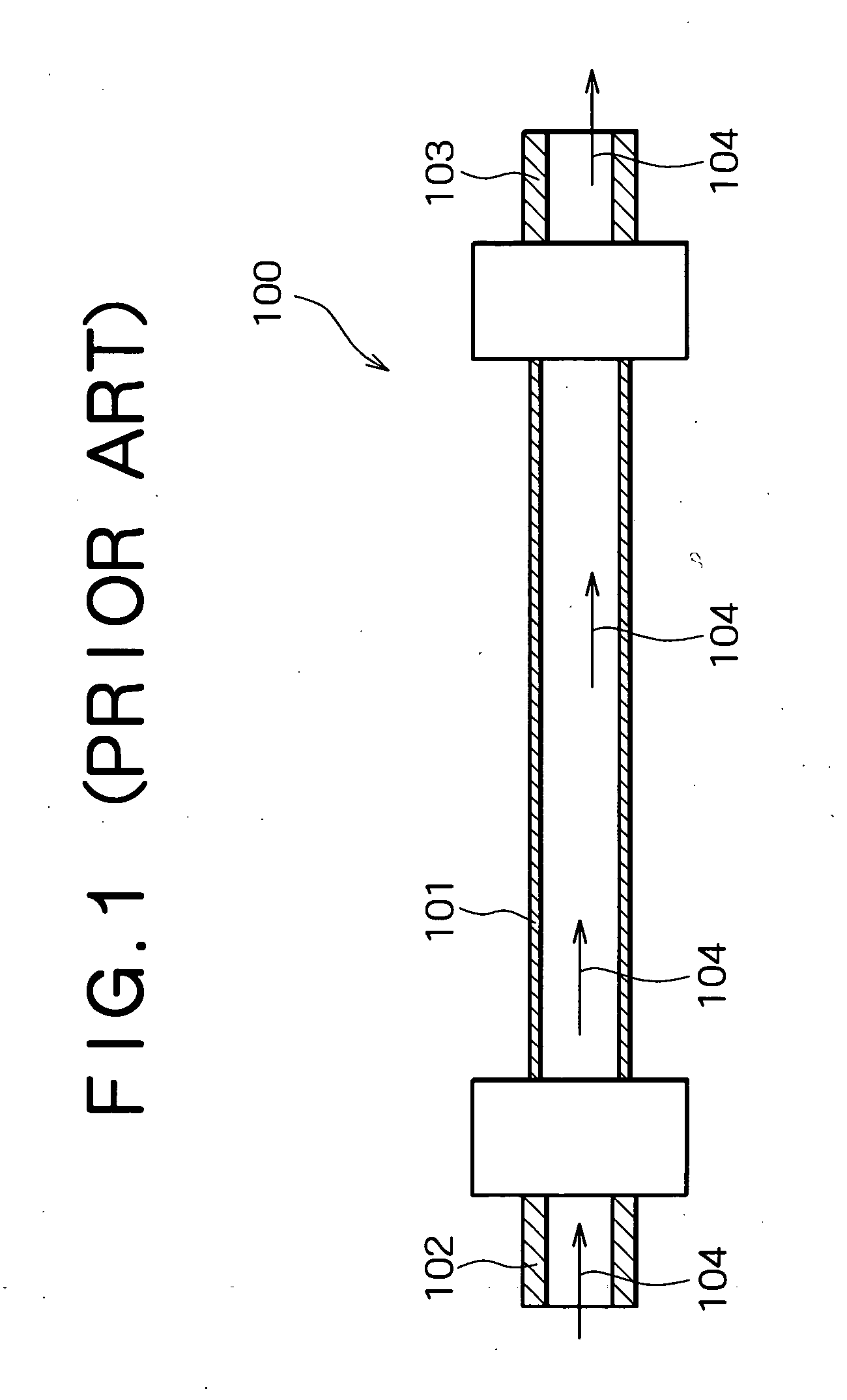

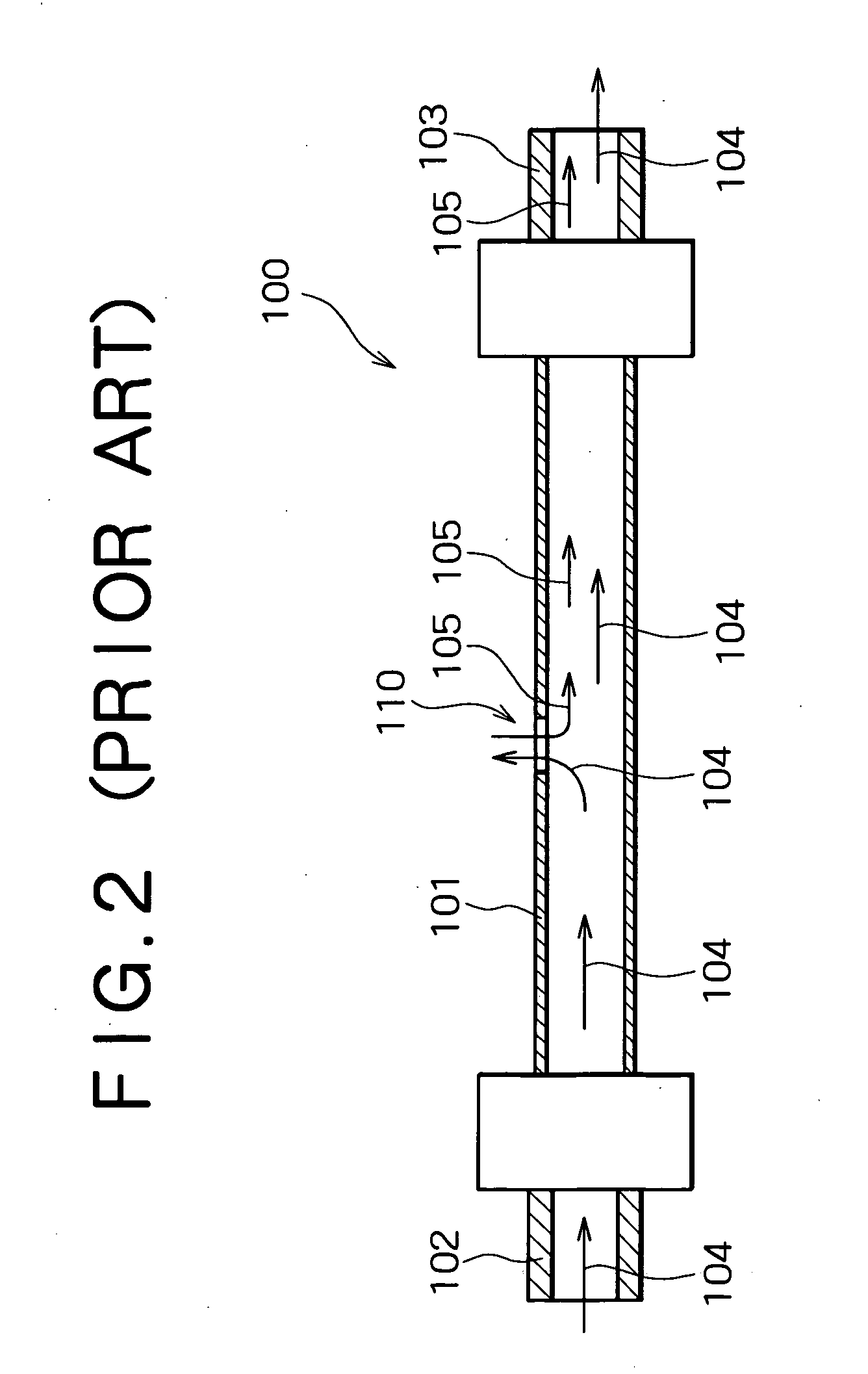

Piping structure having leak detection function and leak detector

InactiveUS20050166666A1Minimize impactIncrease pressureDetection of fluid at leakage pointMeasurement of fluid loss/gain rateDouble tubePipe fitting

A covering member having a valve encloses a flexible hose to form a double pipe. Gas supply pipe fittings are attached to respective ends of the double pipe to form a hermetic space between the flexible hose and covering member. The covering member also has a pressure-measuring device to which a decision unit equipped with an alarm device is connected. The same gas or liquid as the one flowing through the flexible hose is introduced to the hermetic space from the valve provided in the covering member, and sealed in the hermetic space by closing the valve. The pressure in the hermetic space is set so as to be higher than the pressure produced in the flexible hose when the gas or liquid is flowing. The pressure-measuring device measures the pressure in the hermetic space while the gas or liquid flows in the flexible hose, and the decision unit compares the measured value with a reference value. As a result, if the value measured by the pressure-measuring device is lower than the reference value, the decision unit decides that a breakage has occurred and then the alarm device activates an alarm.

Owner:LASERFRONT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com