Patents

Literature

167 results about "Structural failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It has been suggested that portions of this article be split out into articles titled List of bridge failures, Dam failure, List of catastrophic collapses of radio masts and towers and List of aircraft structural failures.() (February 2018

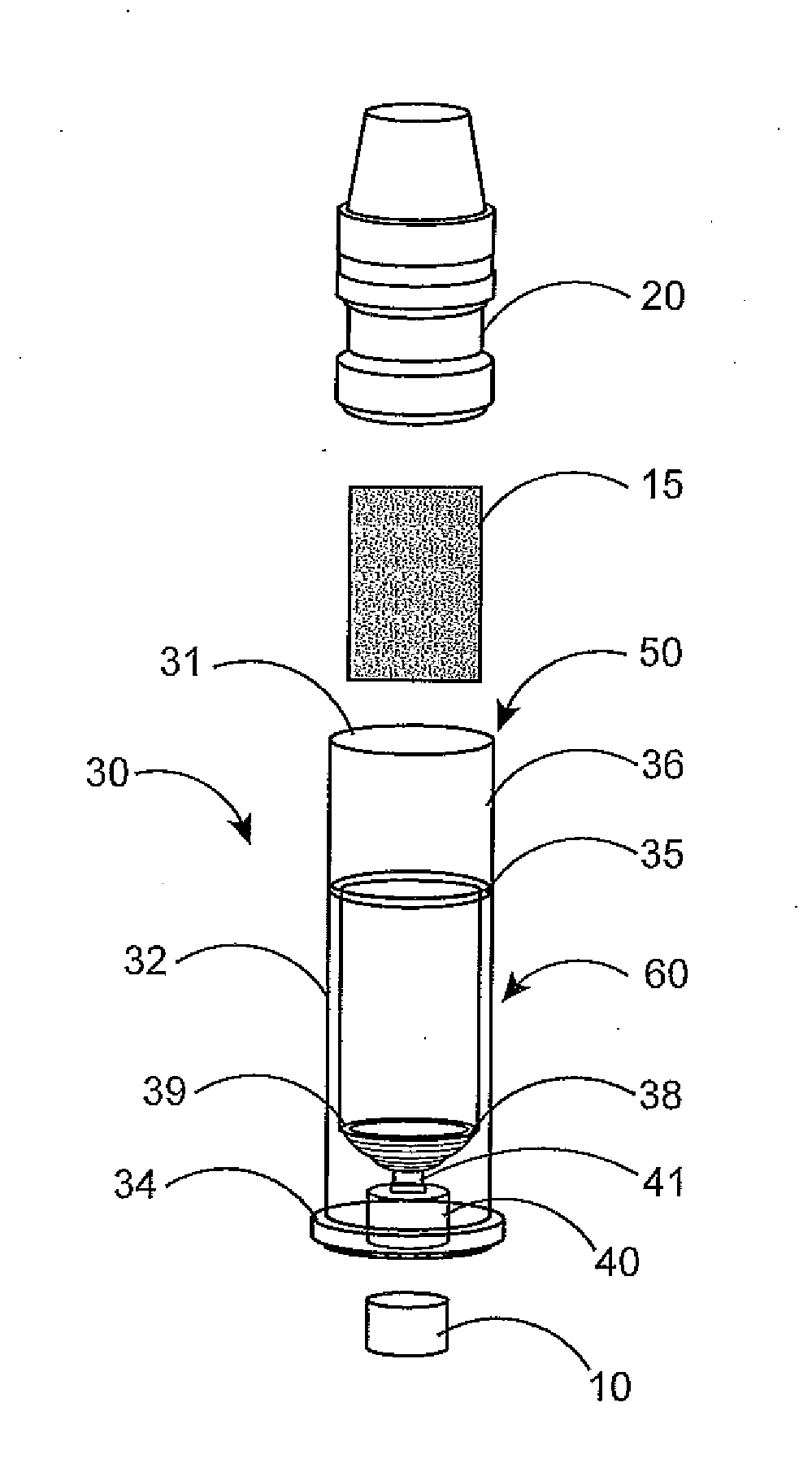

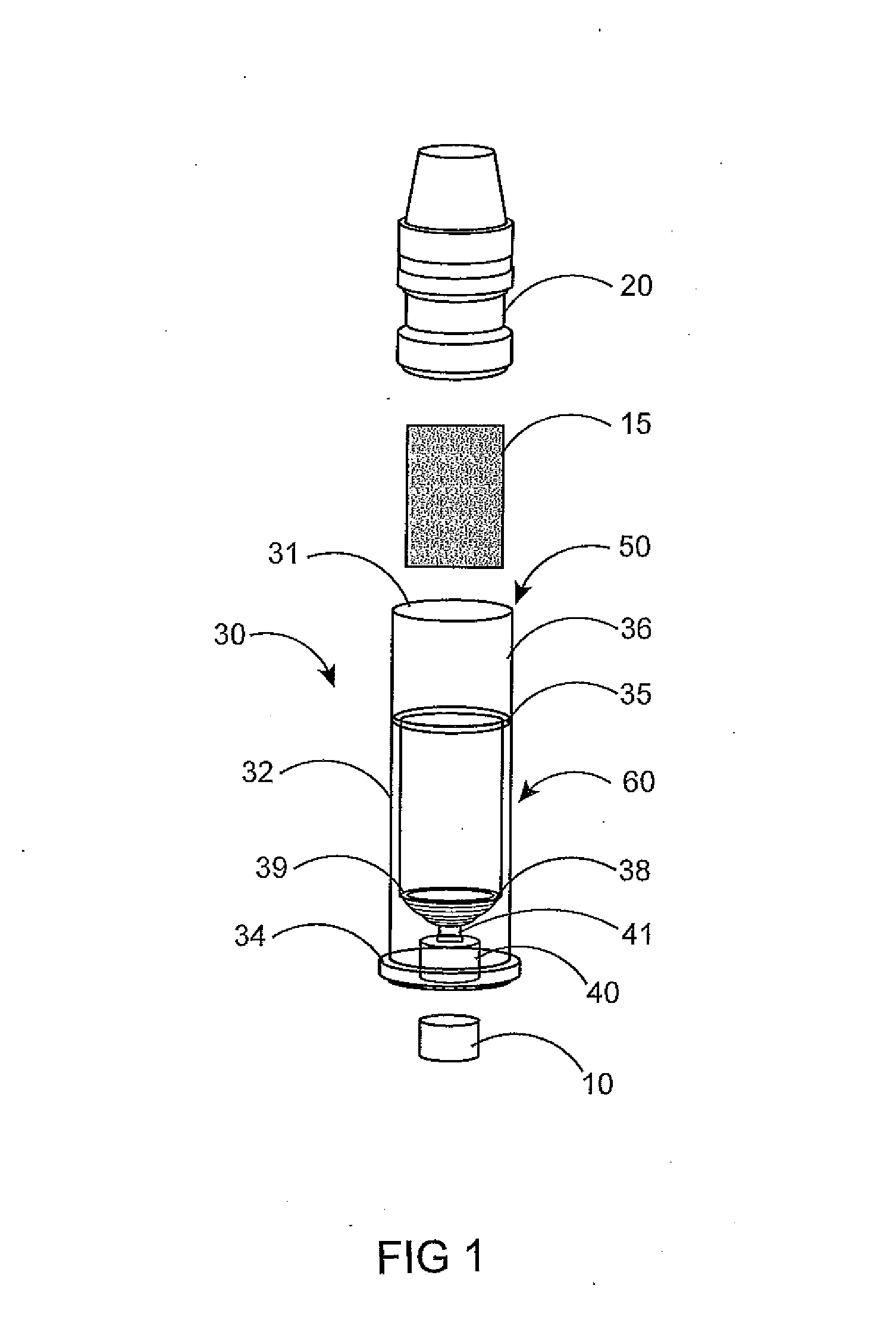

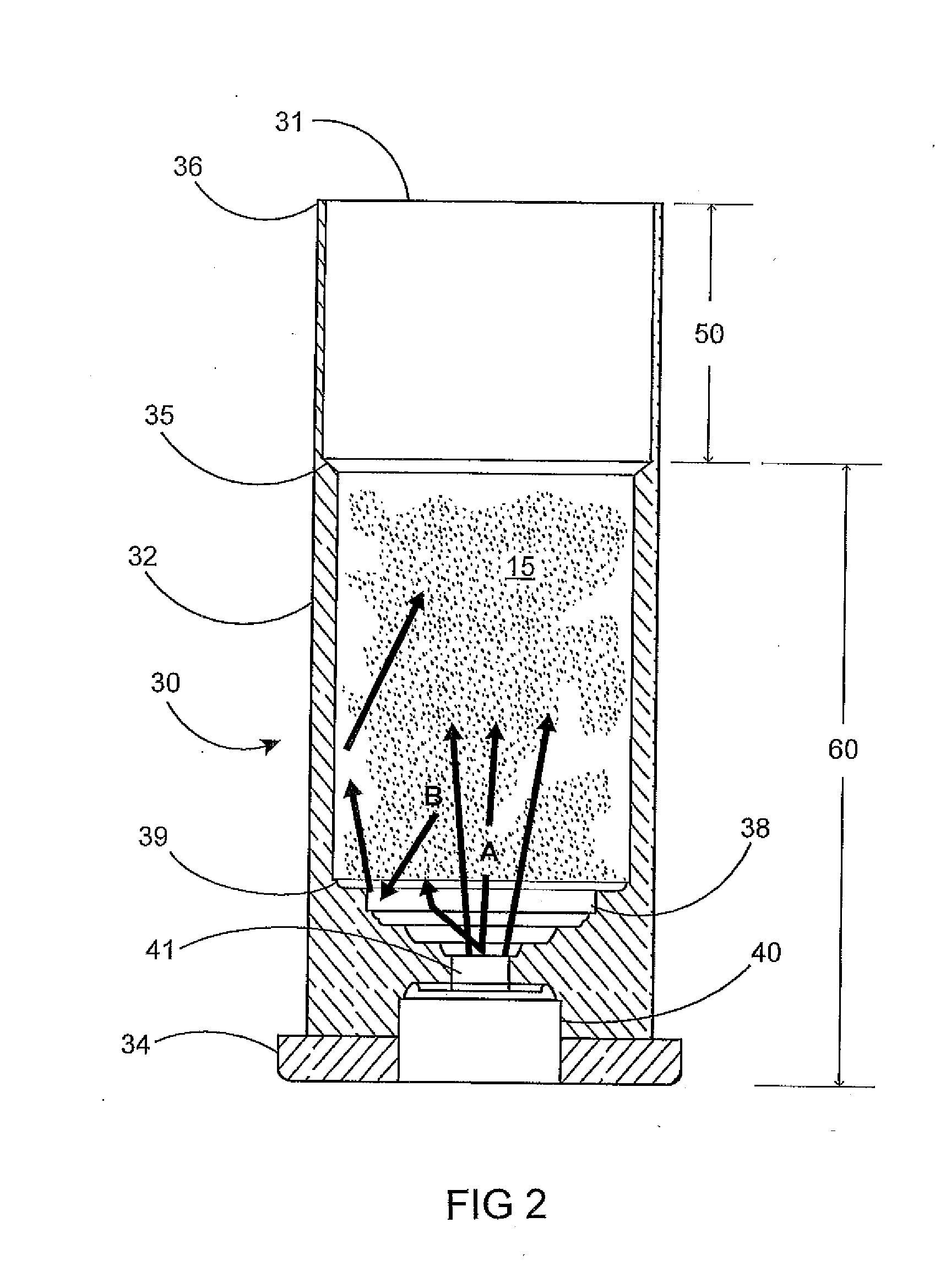

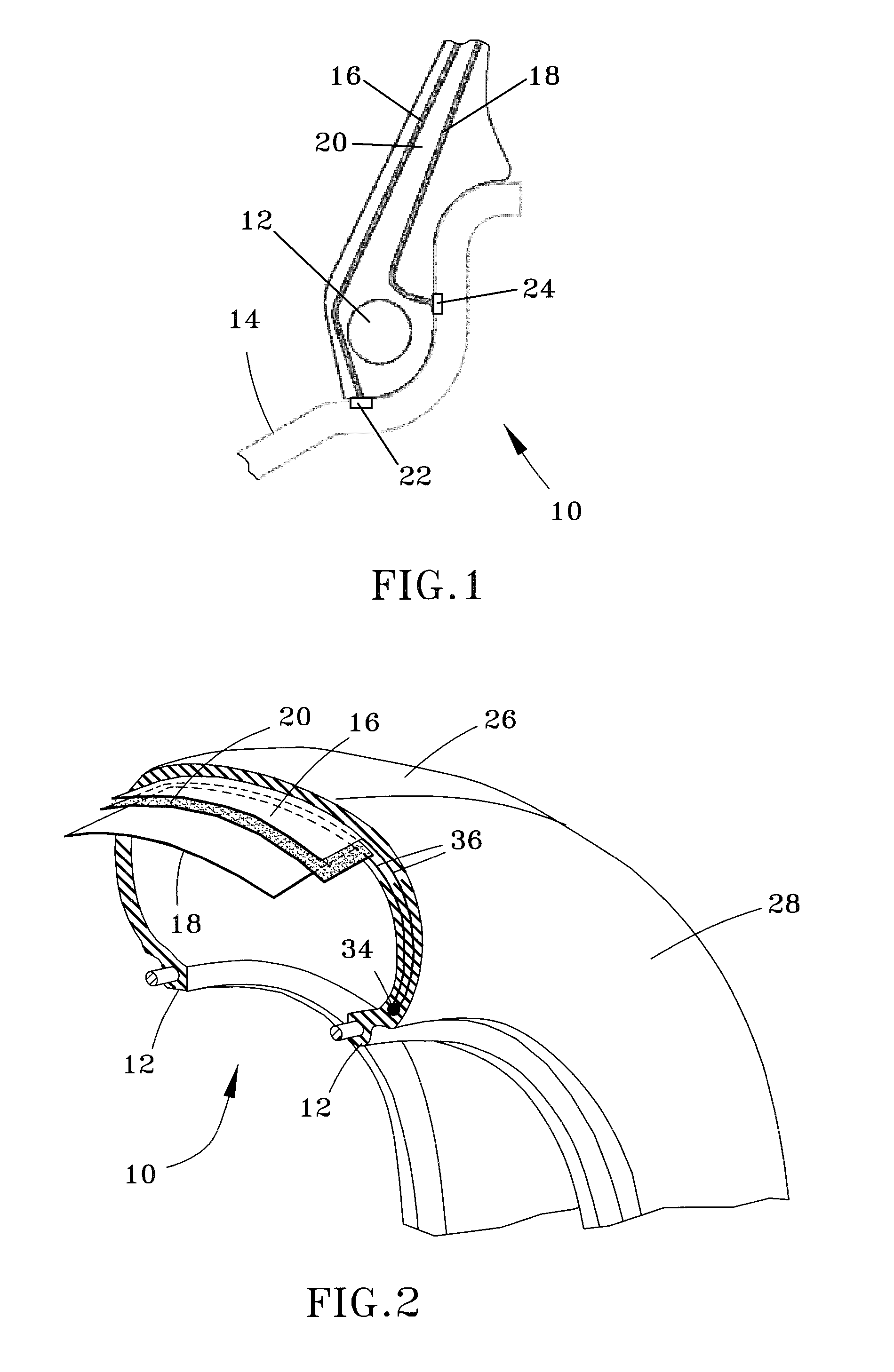

Reusable Plastic Ammunition Casing

InactiveUS20160265886A1Evenly dispersedCartridge ammunitionPlastic injection moldingStructural failure

A reloadable plastic ammunition casing is provided for firearm use. The plastic casing is preferably constructed from currently available polymeric materials using plastic injection molding techniques. In the preferred embodiment the casing includes a cylindrical body having a top portion and a bottom portion. The top portion having an open end for receiving a propellant and a top lip for retaining a projectile. The bottom portion has an internal casing floor that includes at least one concentric step down towards a centrally located primer pocket such that an installed primer is located in blast communication with the concentric steps on the casing floor. The concentric steps uniformly disburse, distribute, and deflect the heat and gas pressures within the casing when fired, thereby avoiding structural failure, allowing for multiple reloads of a casing constructed entirely out of plastic.

Owner:ALDRICH LONNIE +2

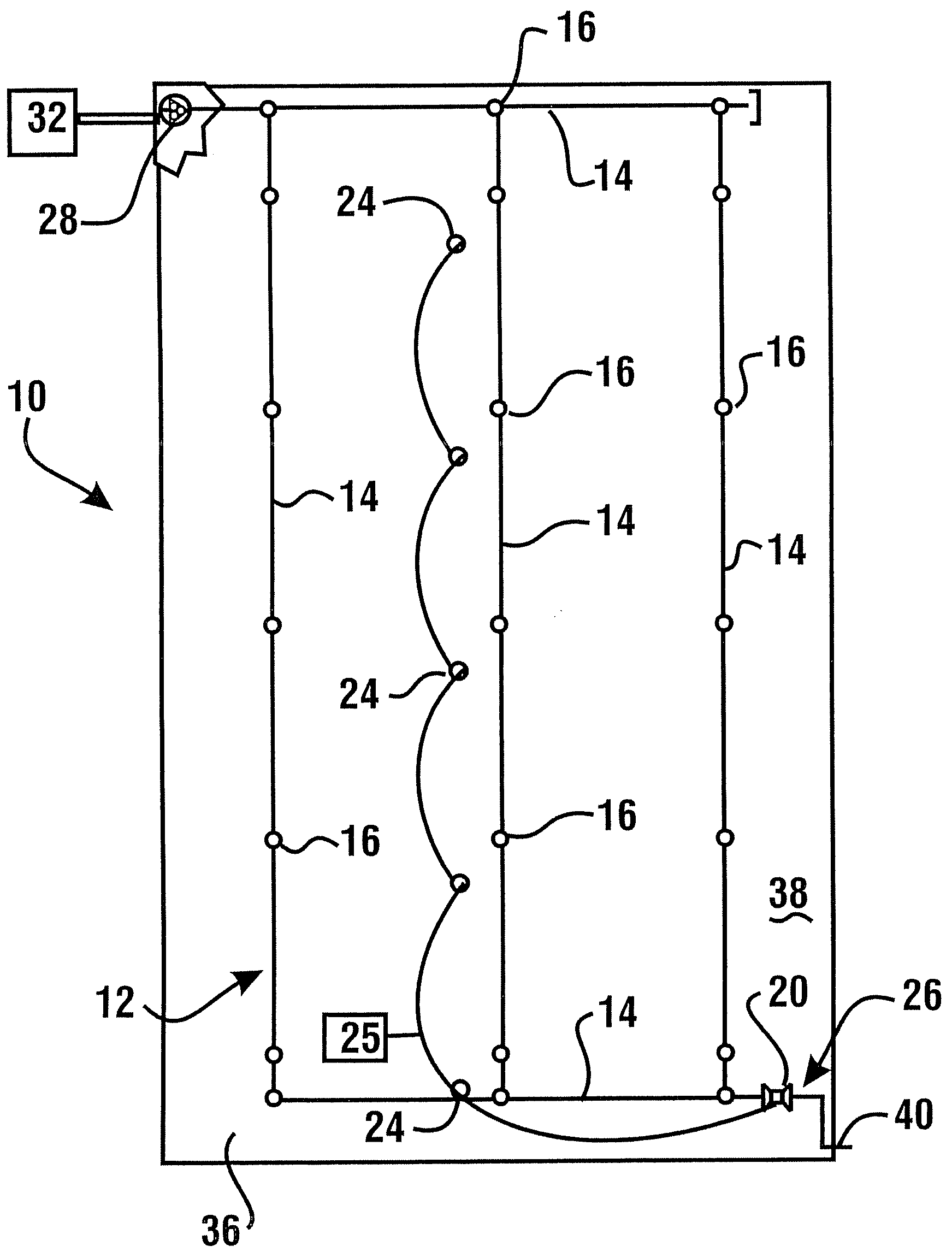

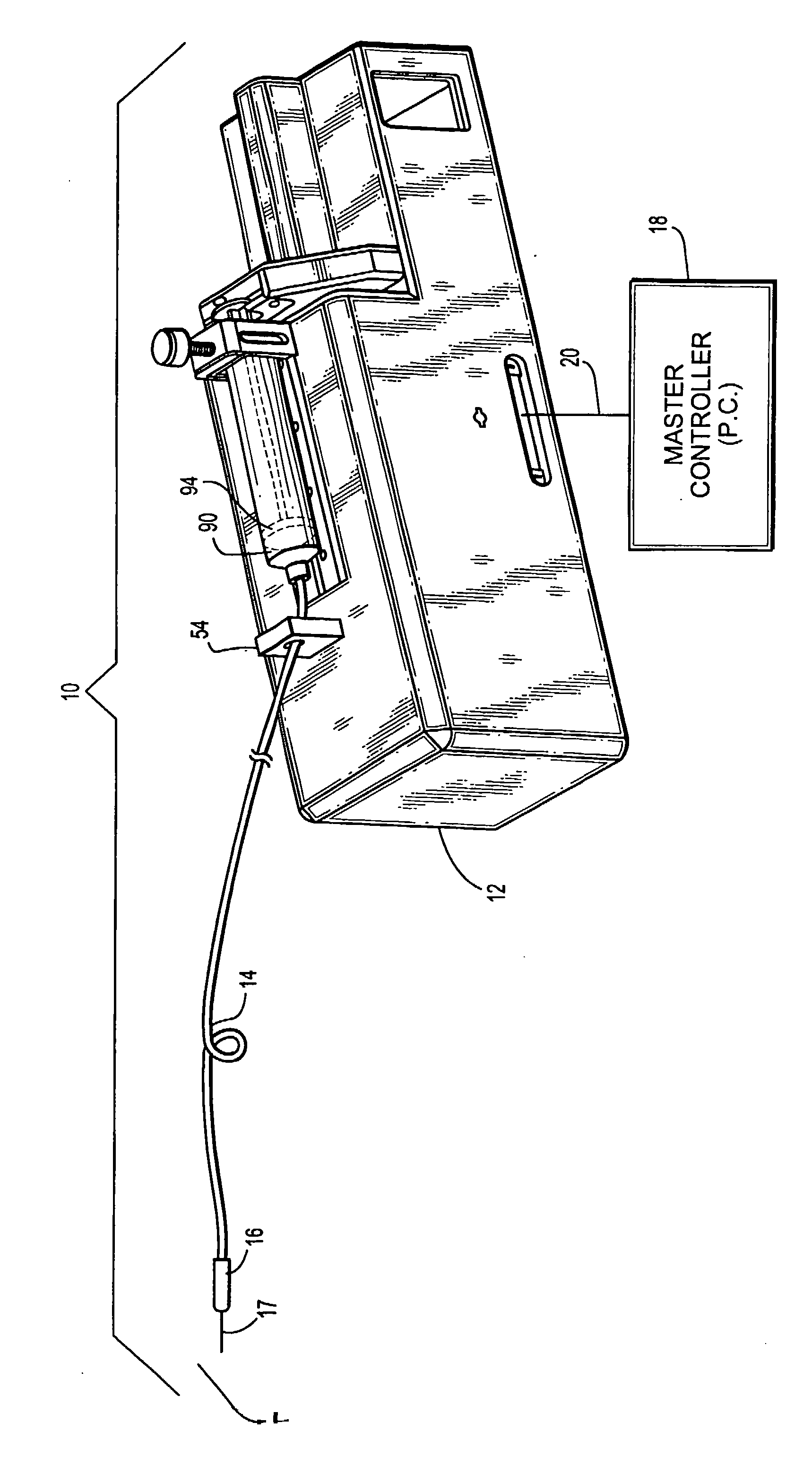

Fire Suppression System

InactiveUS20070221388A1Satisfied with the resultMore cost-effectivelyFire rescueBoring toolsElectricityFire detector

Owner:LUBRIZOL ADVANCED MATERIALS INC

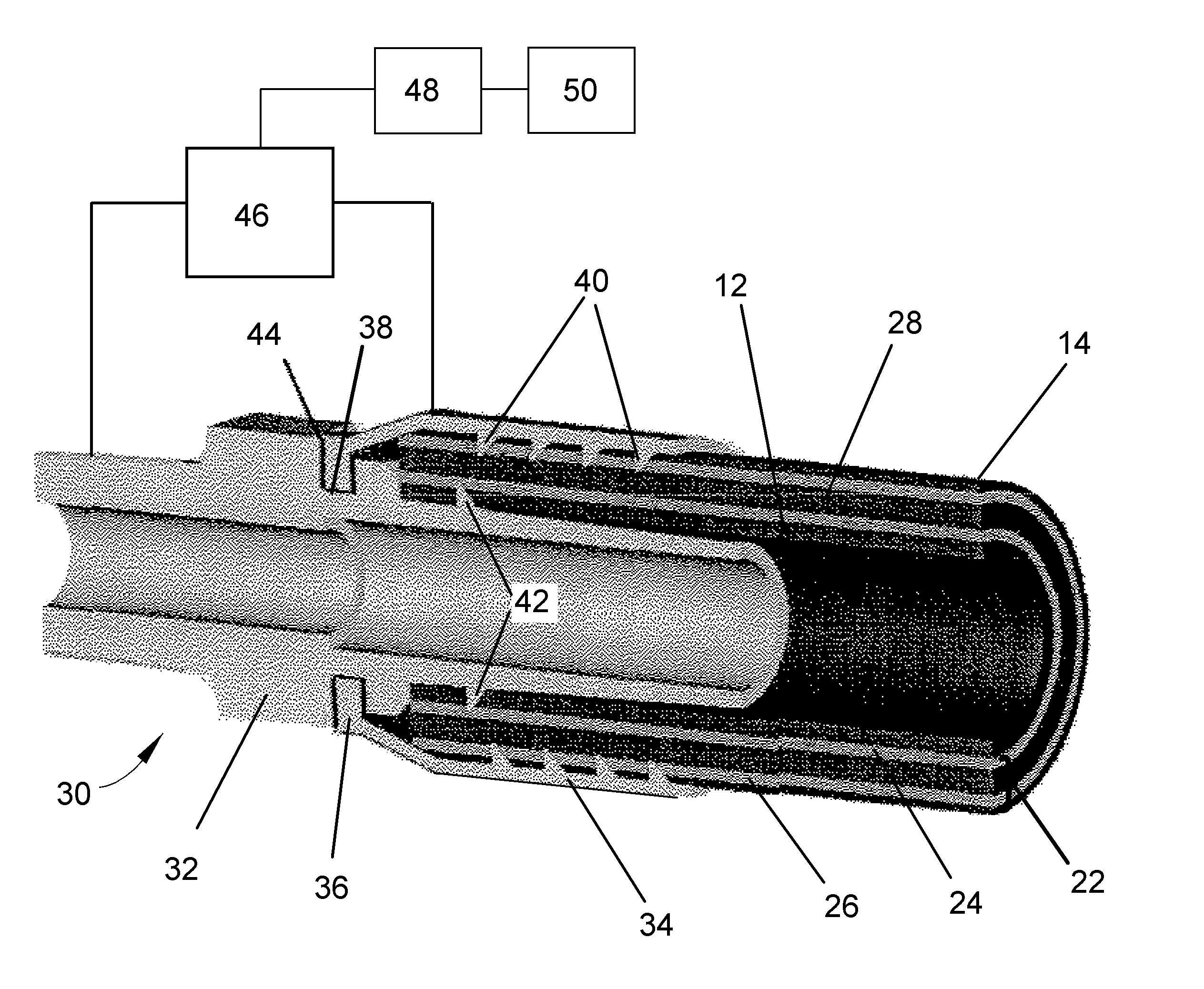

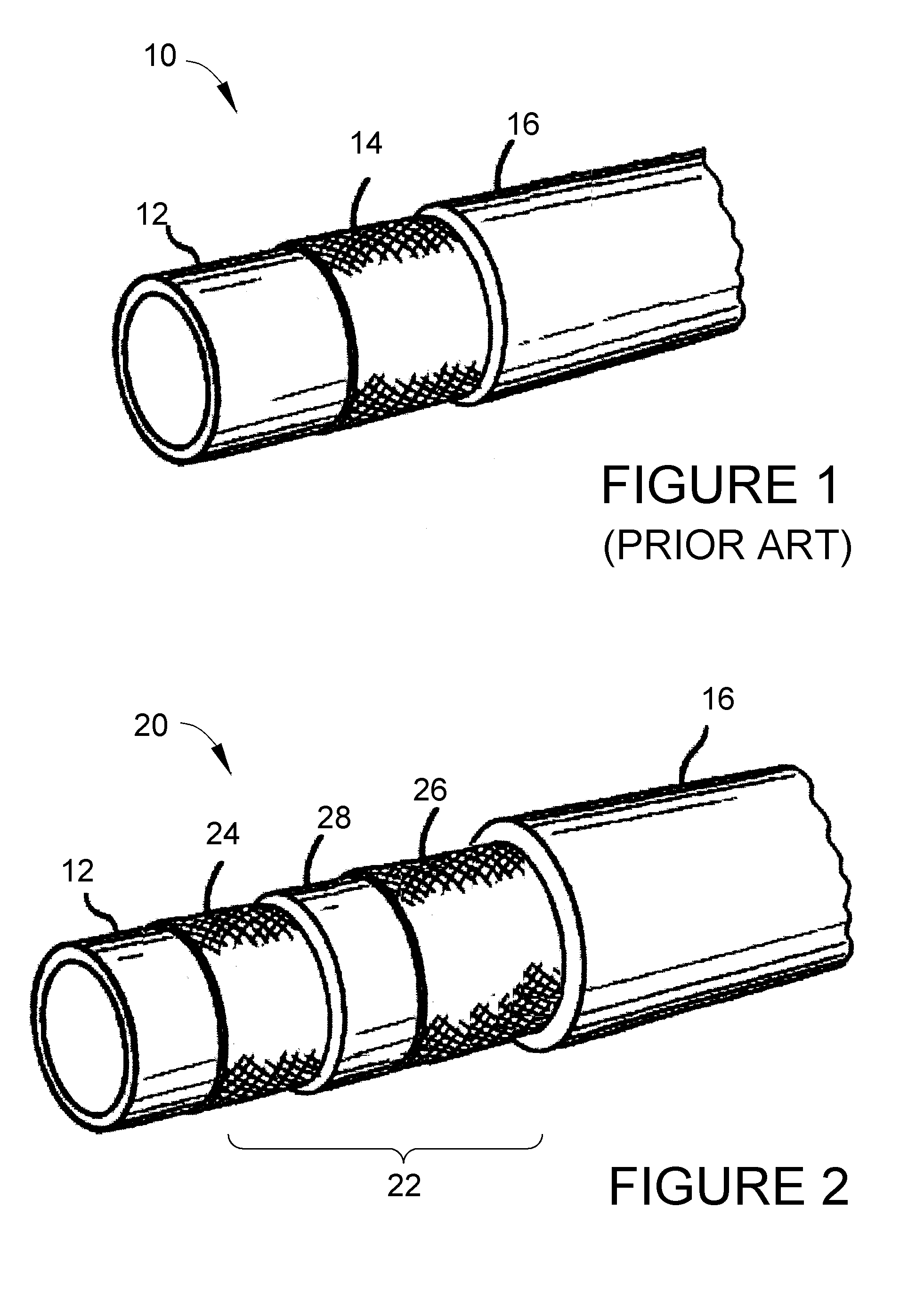

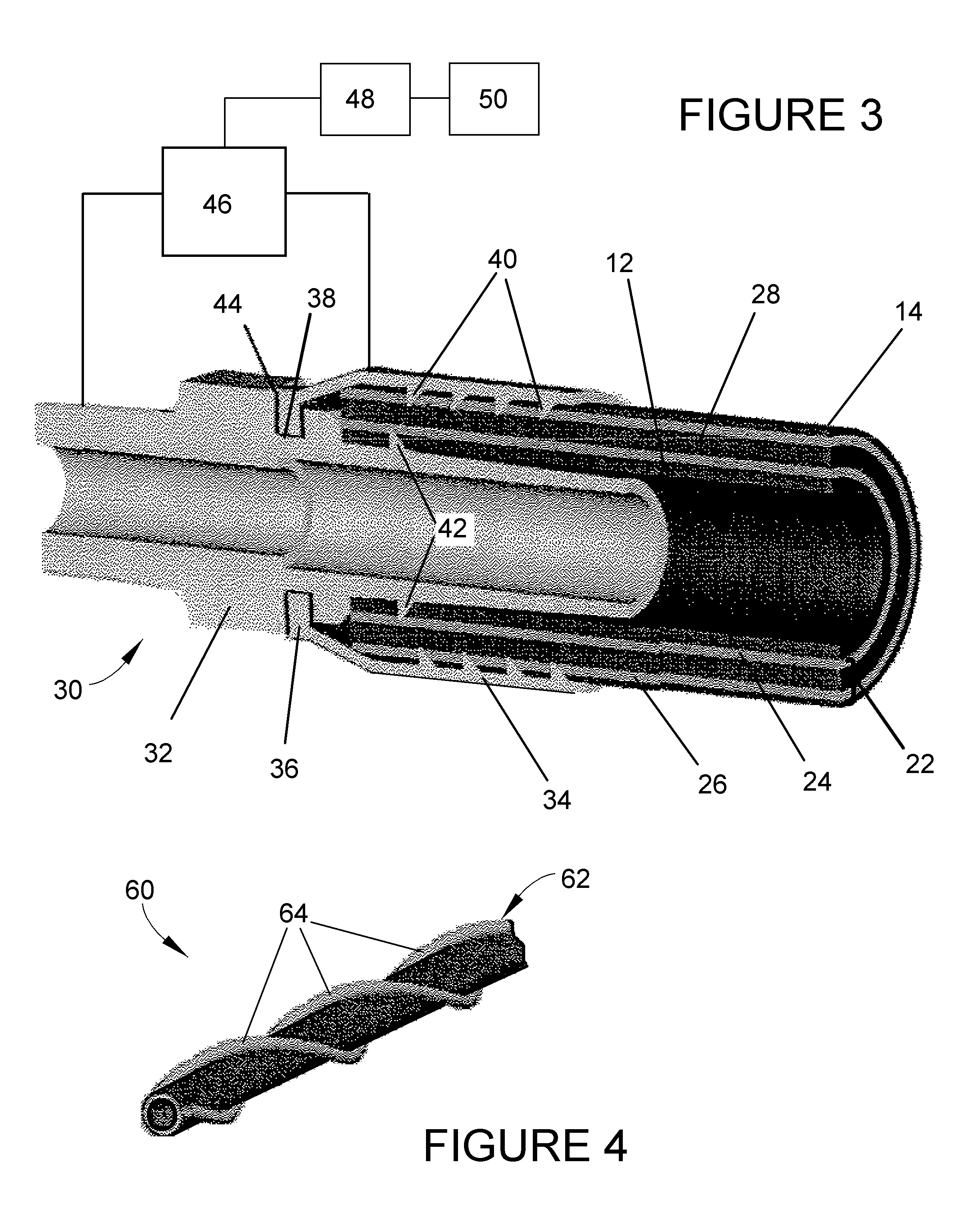

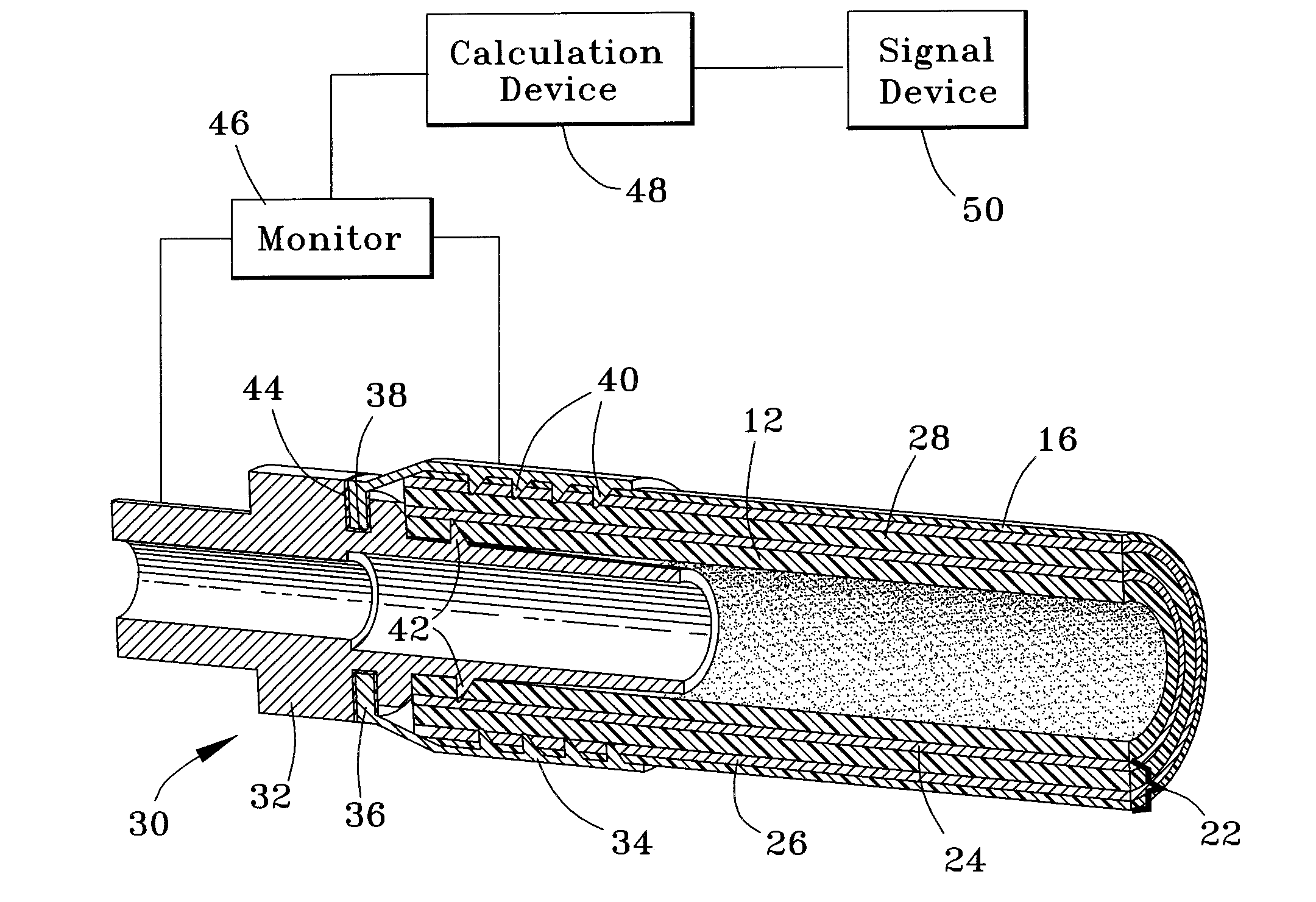

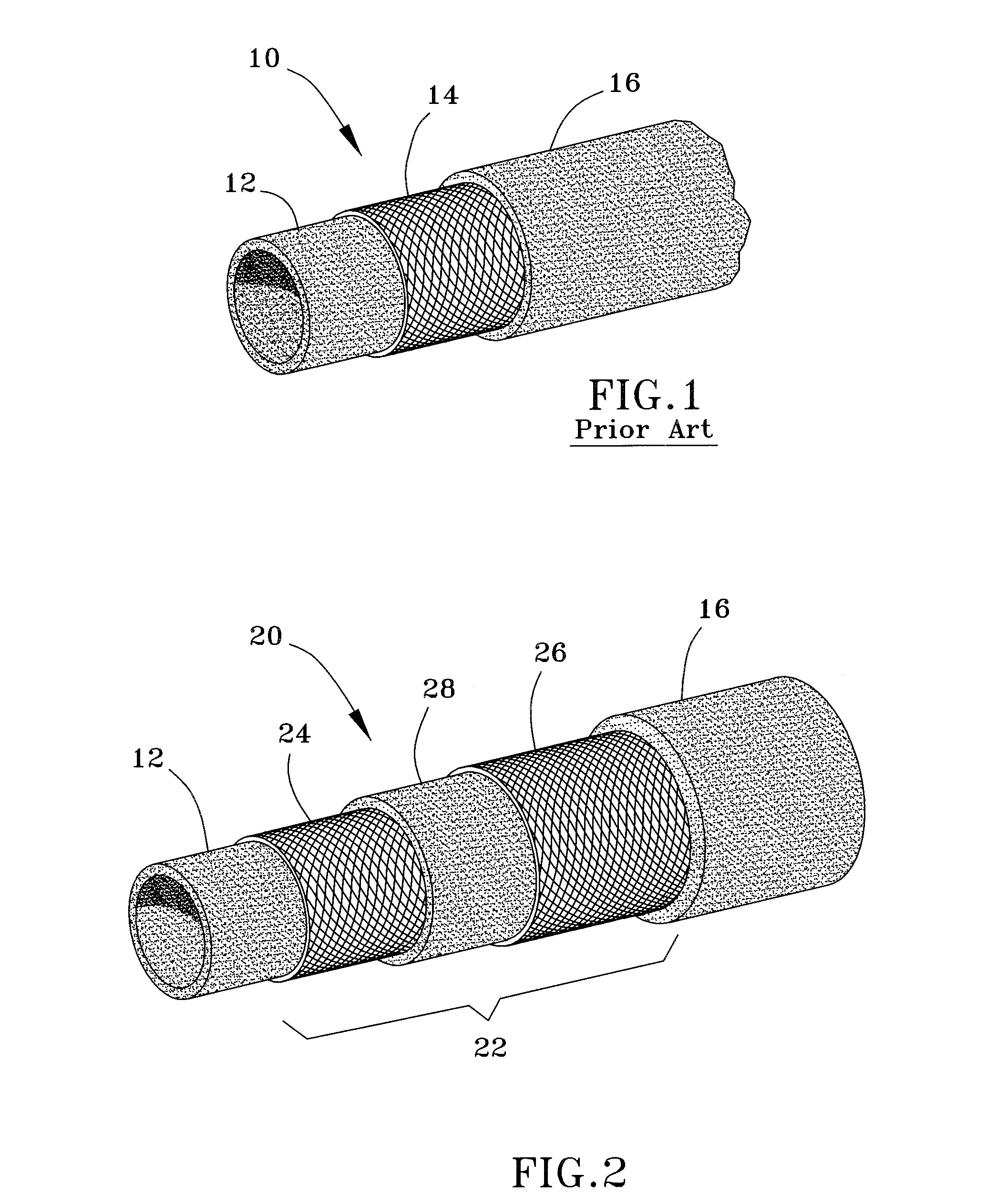

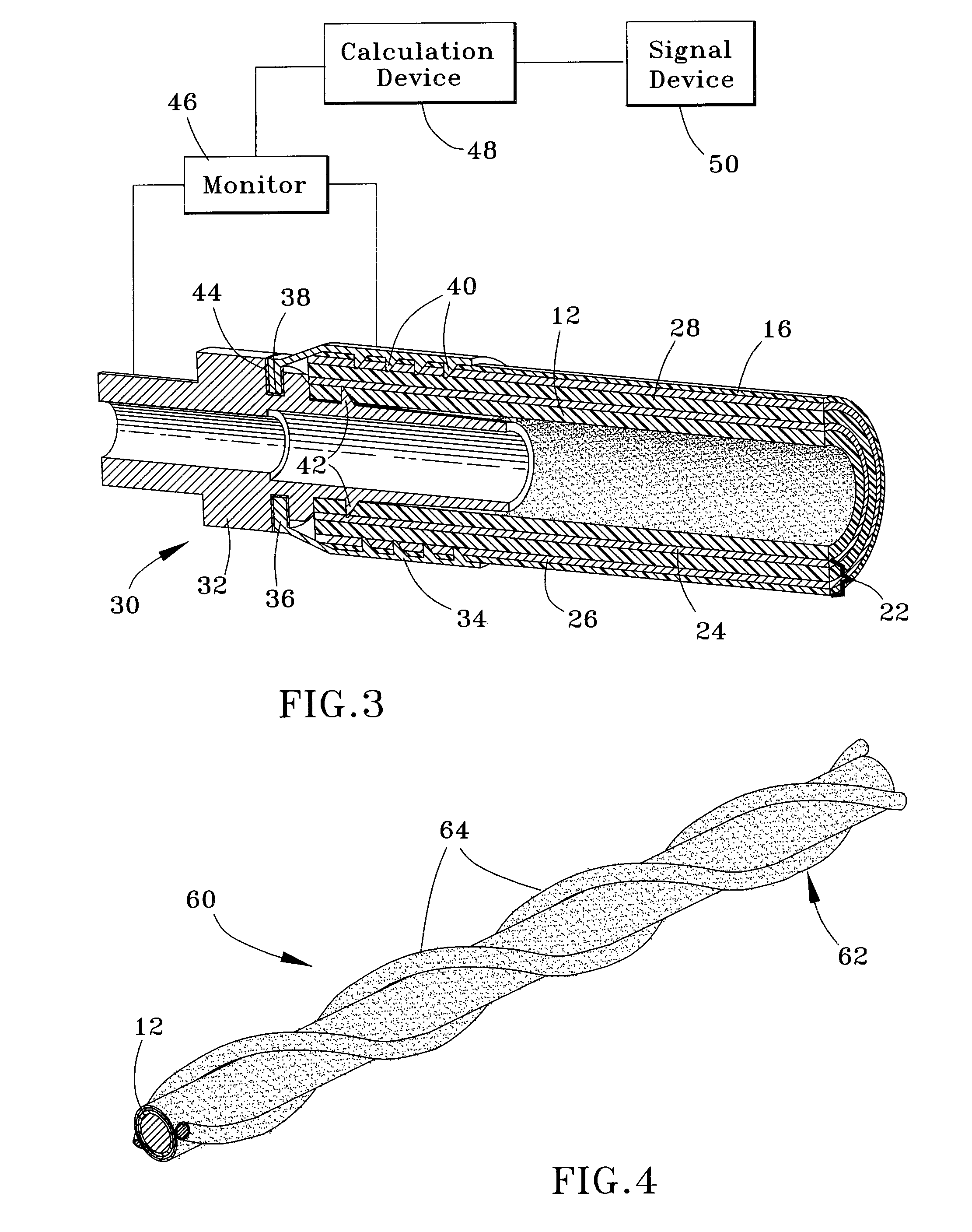

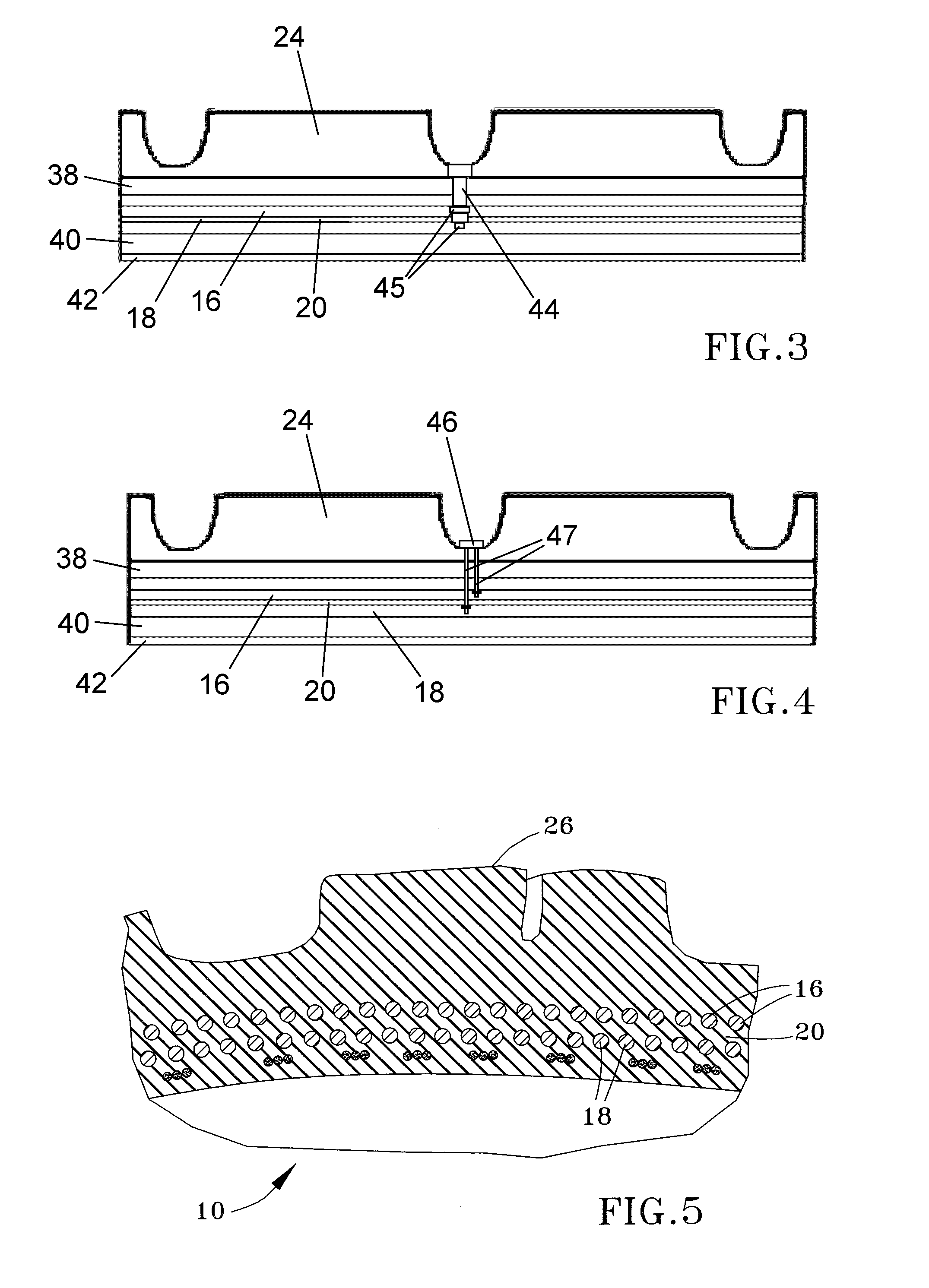

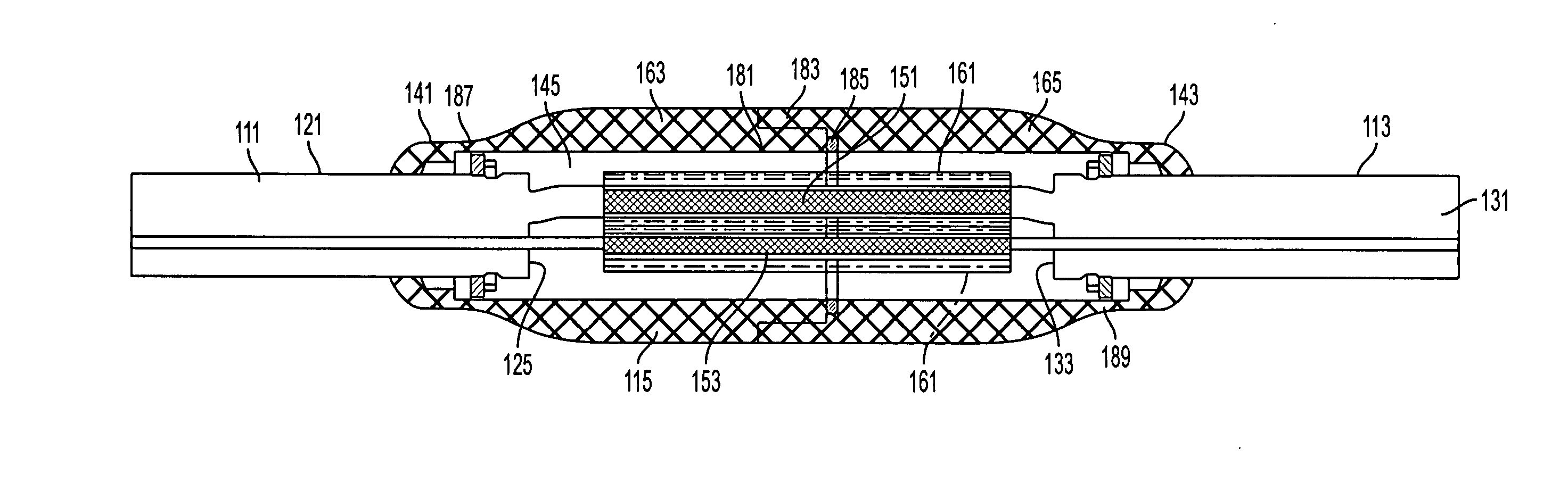

Hydraulic hose with integral life-sensing capability and method therefor

ActiveUS20060196252A1Detection of fluid at leakage pointTesting/calibration apparatusElectrical conductorProcess equipment

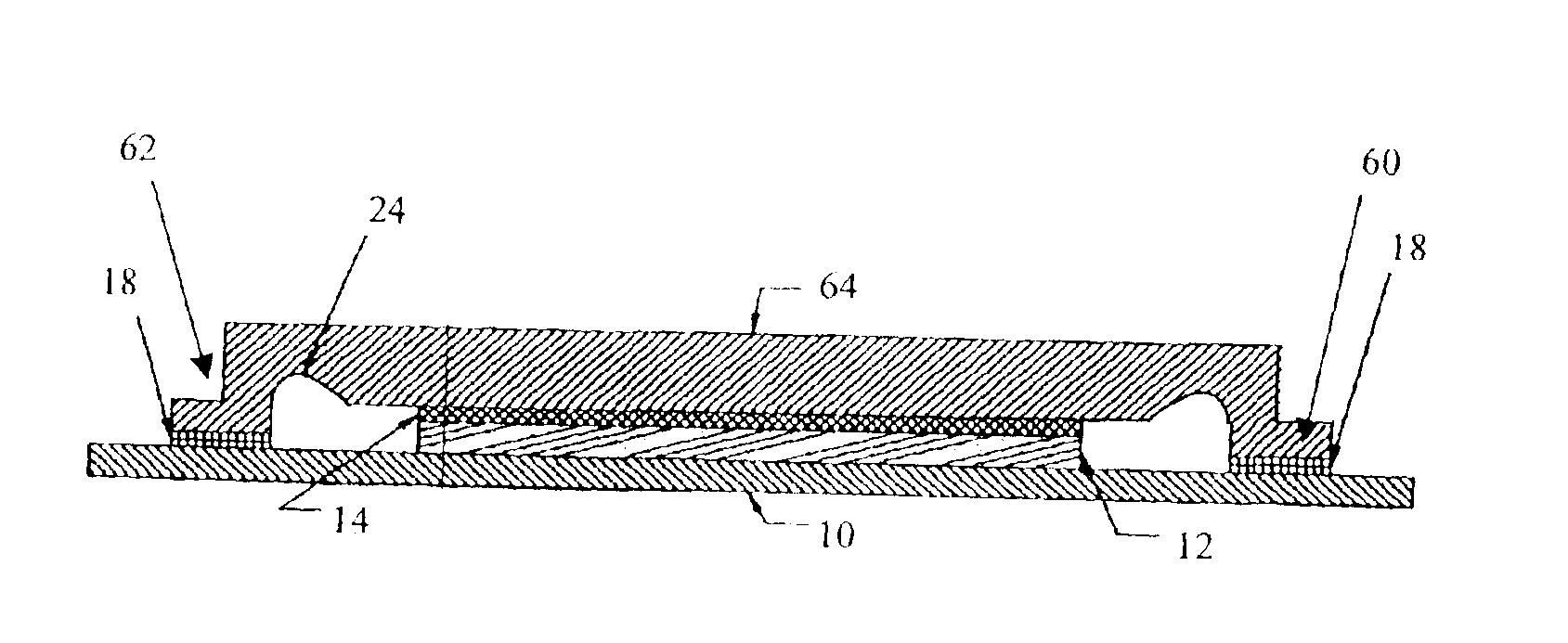

A system and method for predicting structural failure of a wall of a fluid containment vessel, such as a hydraulic hose or other type of pressurized conduit of types used in mobile machinery, automotive, aerospace, manufacturing, and process equipment. The wall of the vessel has an innermost layer for contact with the fluid contained by the vessel, and an outermost layer parallel with the innermost layer. The system includes strain-sensing means between the innermost and outermost layers and comprising at least one conductor parallel to the innermost layer of the wall. The system and method entail sensing changes in an electrical property associated with the at least one conductor resulting from distortion of the wall of the vessel causing distortion of the at least one conductor.

Owner:PURDUE RES FOUND INC

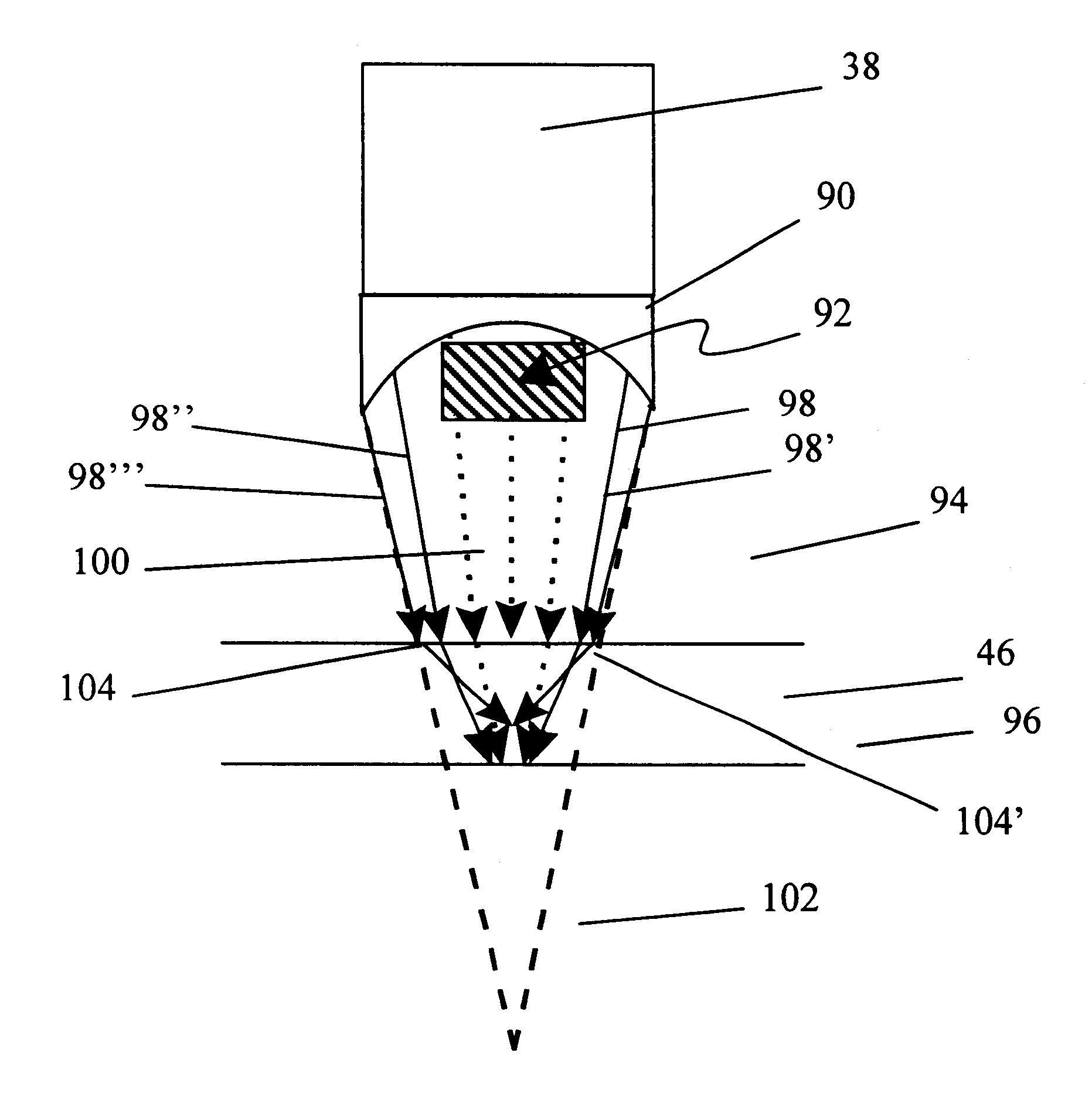

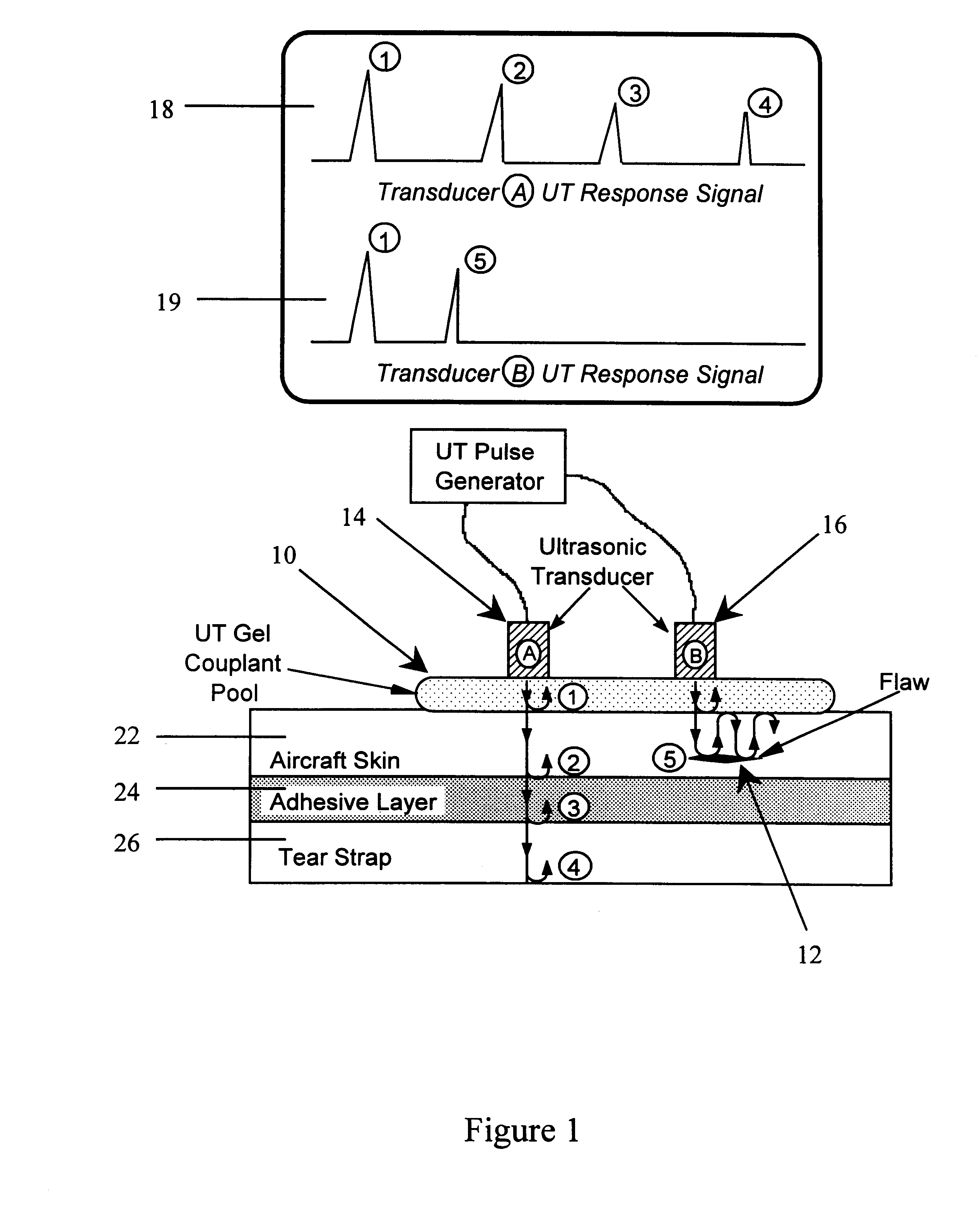

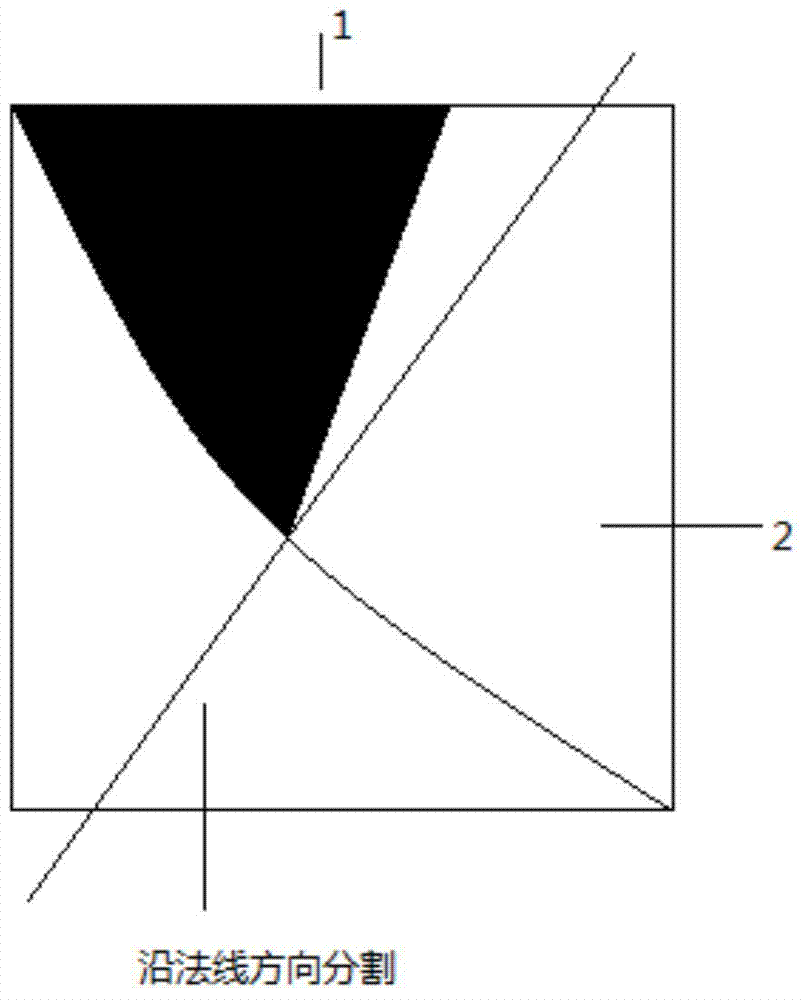

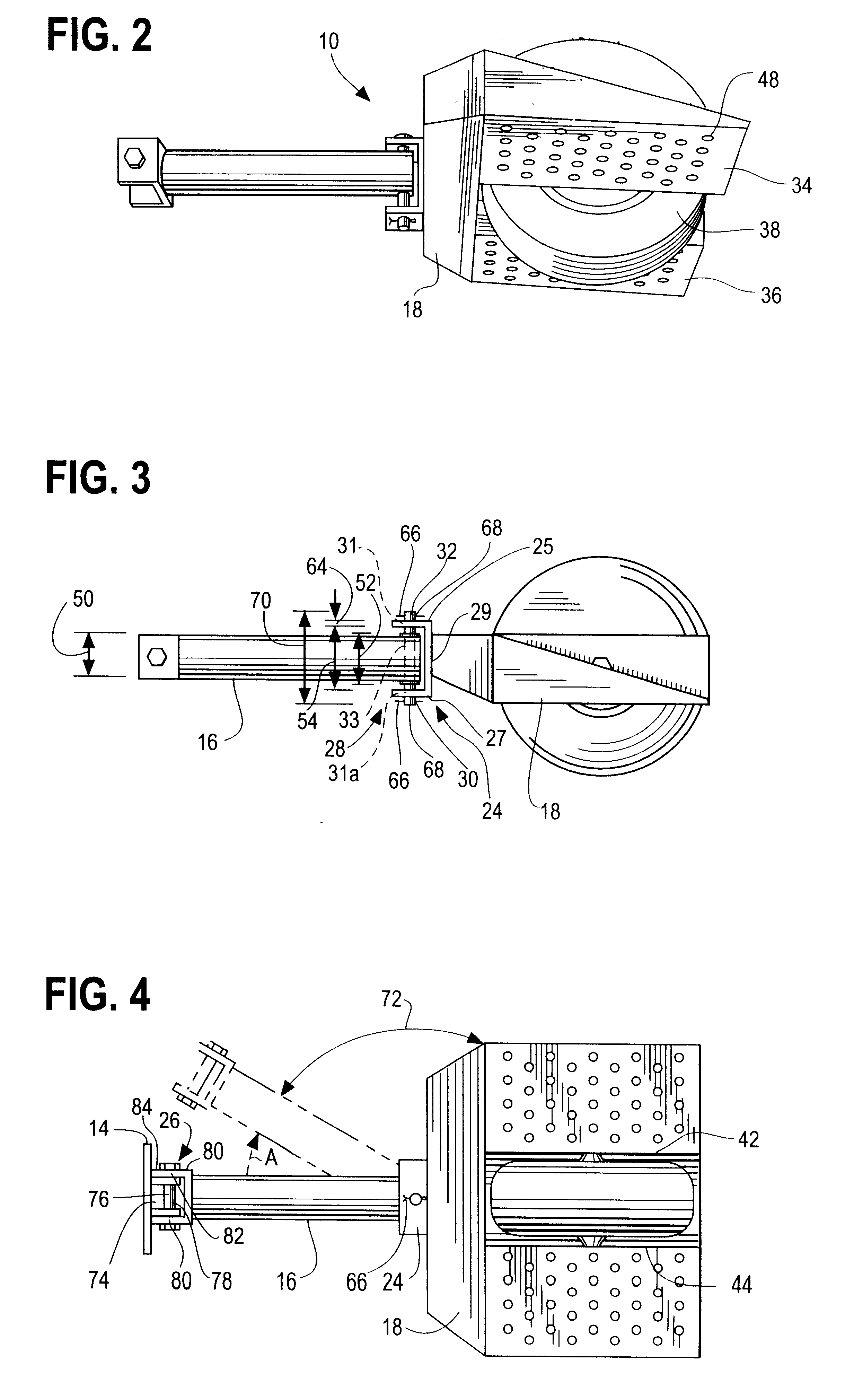

Ultrasonic inspection apparatus and method using a focused wave device

InactiveUS6234025B1Improving conventional ultrasonic inspectionIncrease total distance traveledAnalysing solids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceSonificationSignal on

An ultrasonic pulse echo inspection apparatus and method for detecting structural failures. A focus lens is coupled to the transducer to focus the ultrasonic signal on an area to be inspected and a stop is placed in the focus lens to block selected ultrasonic waves. Other waves are not blocked and are transmitted through the structure to arrive at interfaces therein concurrently to produce an echo response with significantly less distortion.

Owner:SANDIA NAT LAB

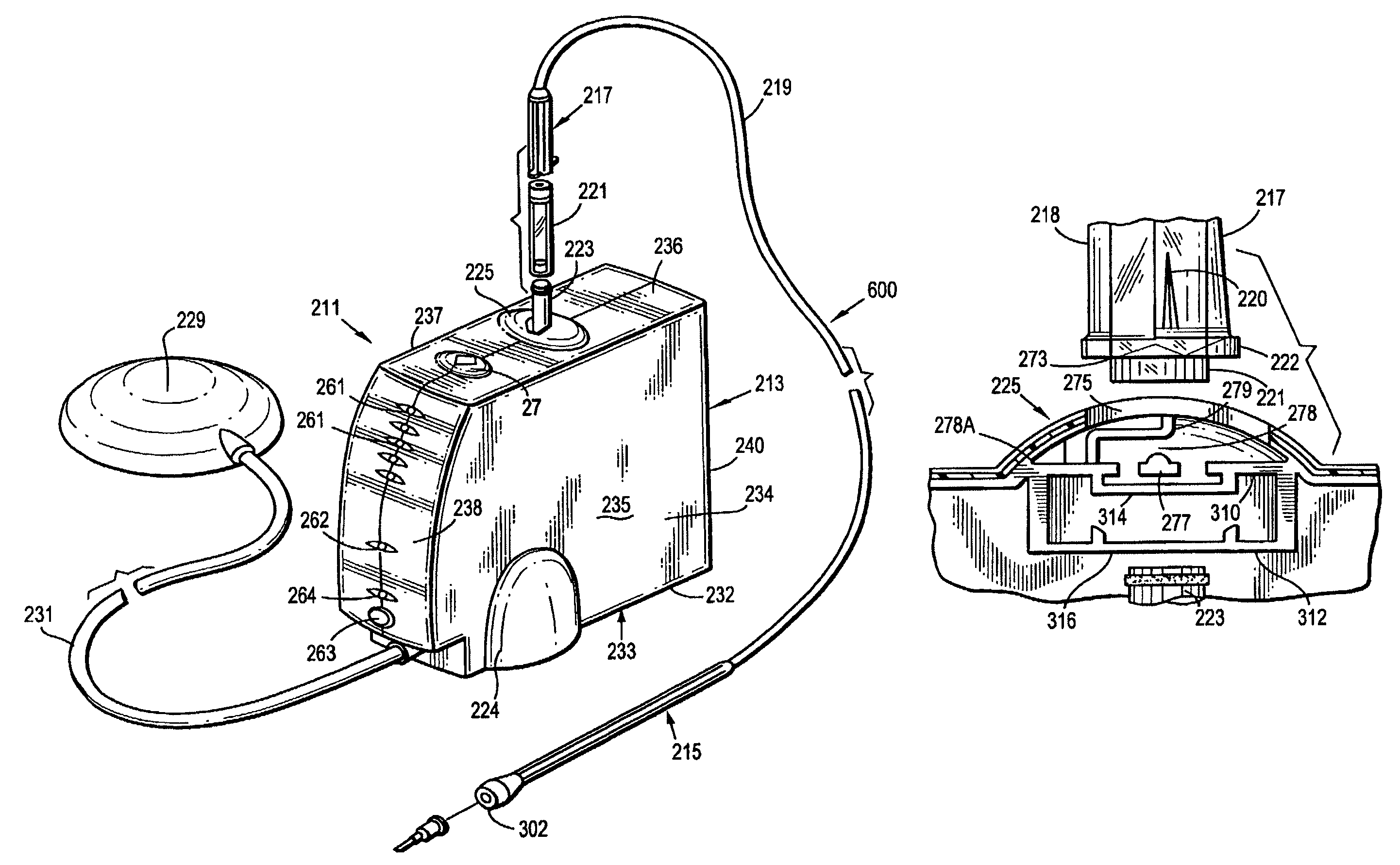

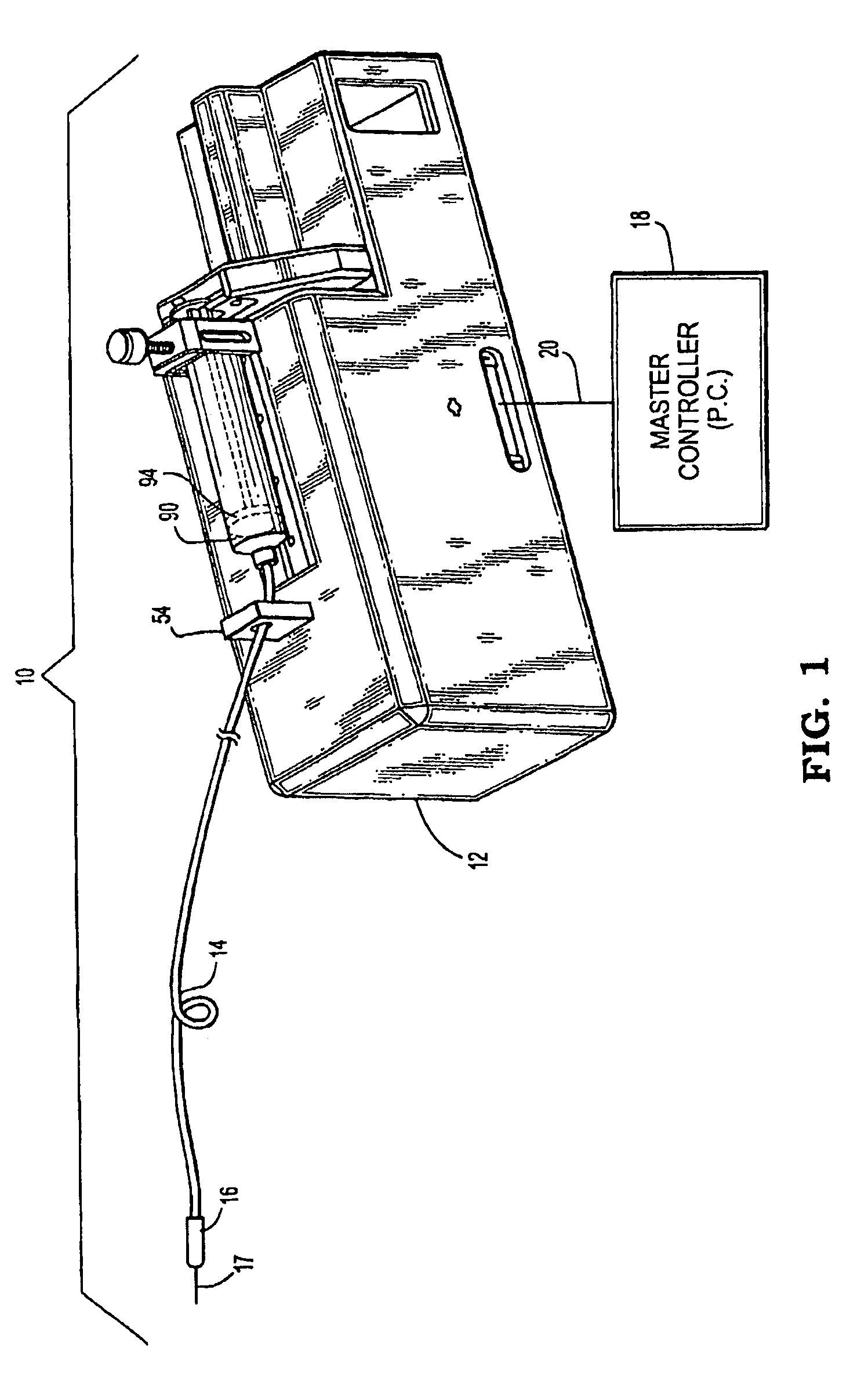

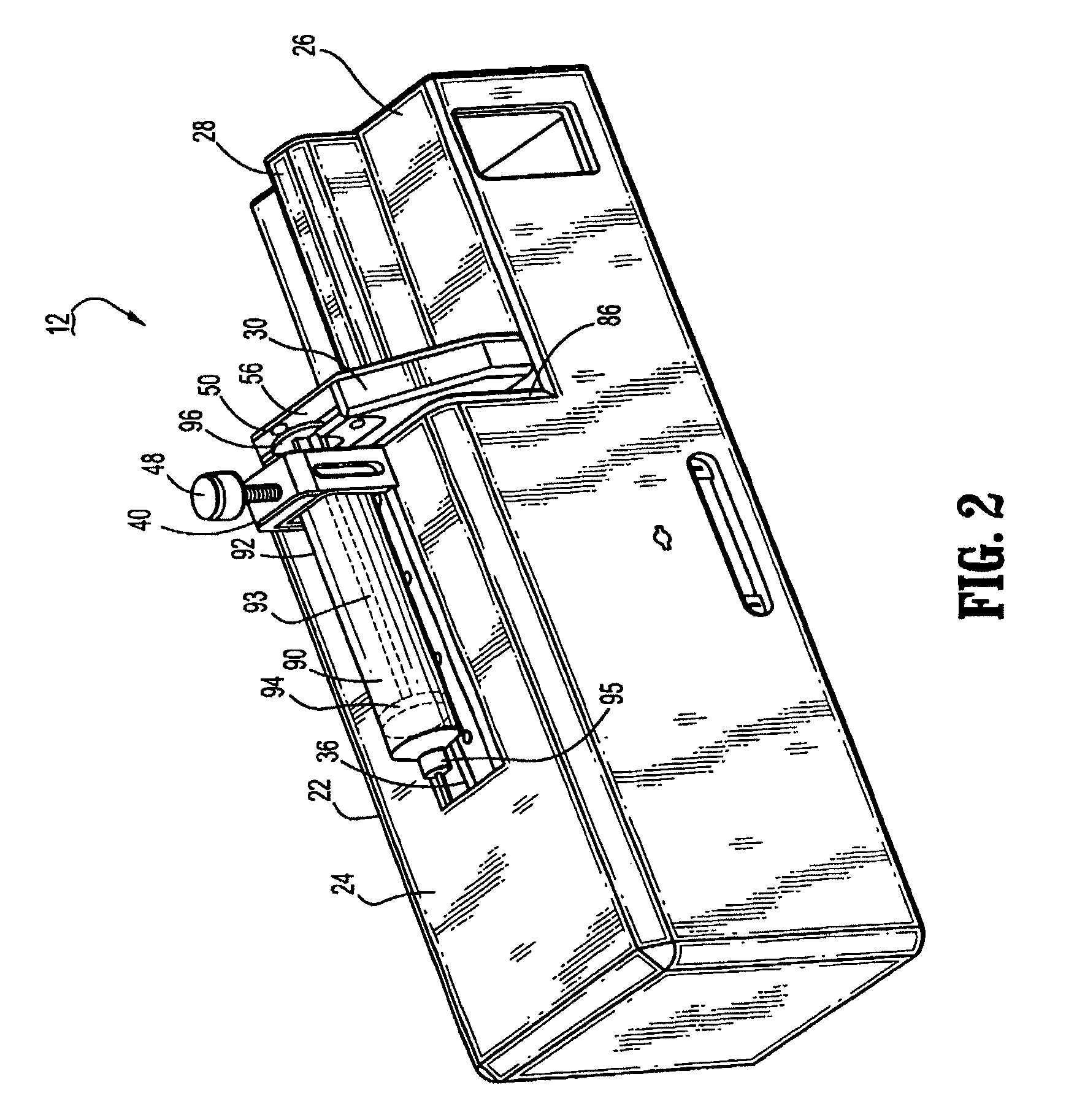

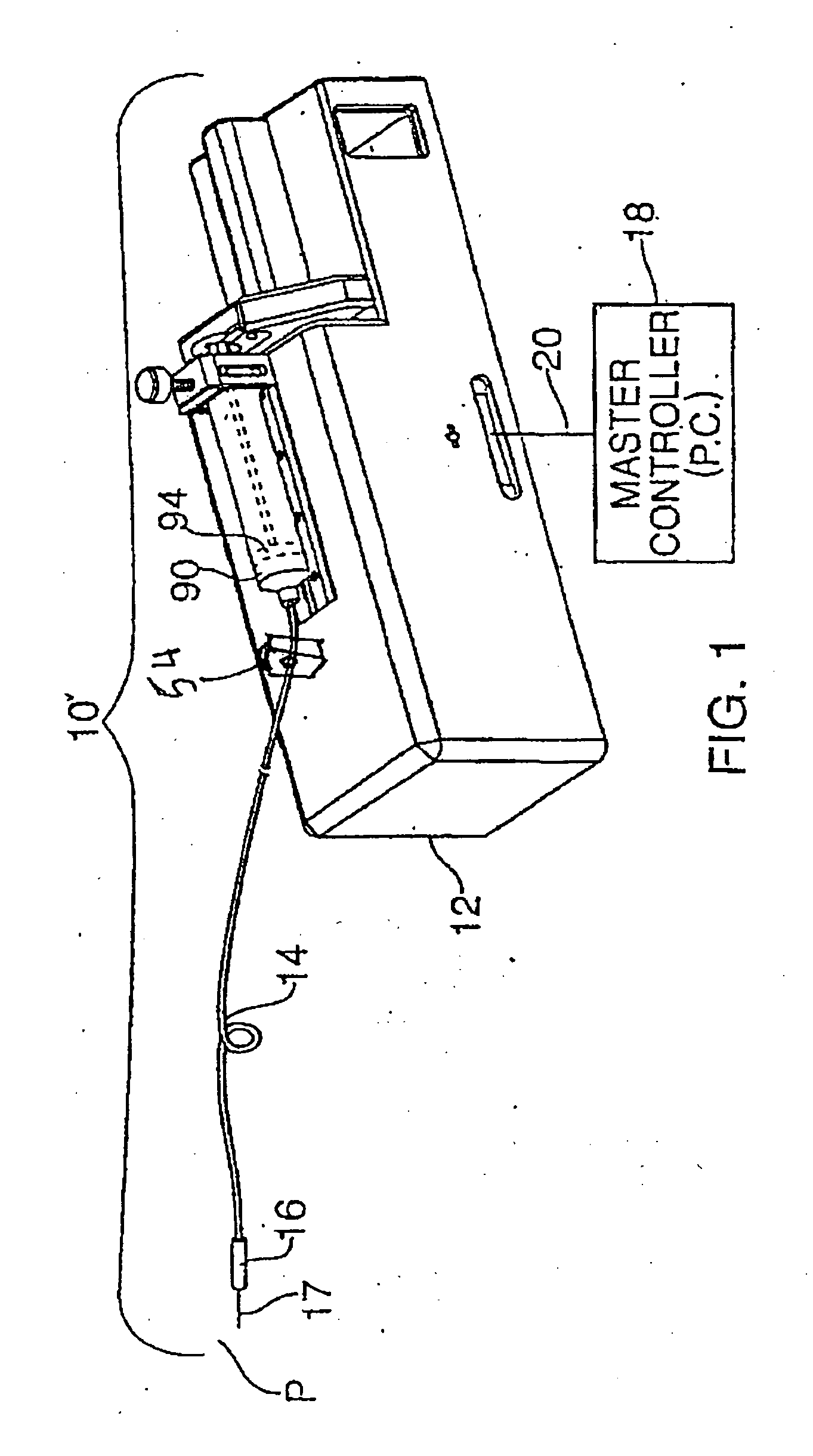

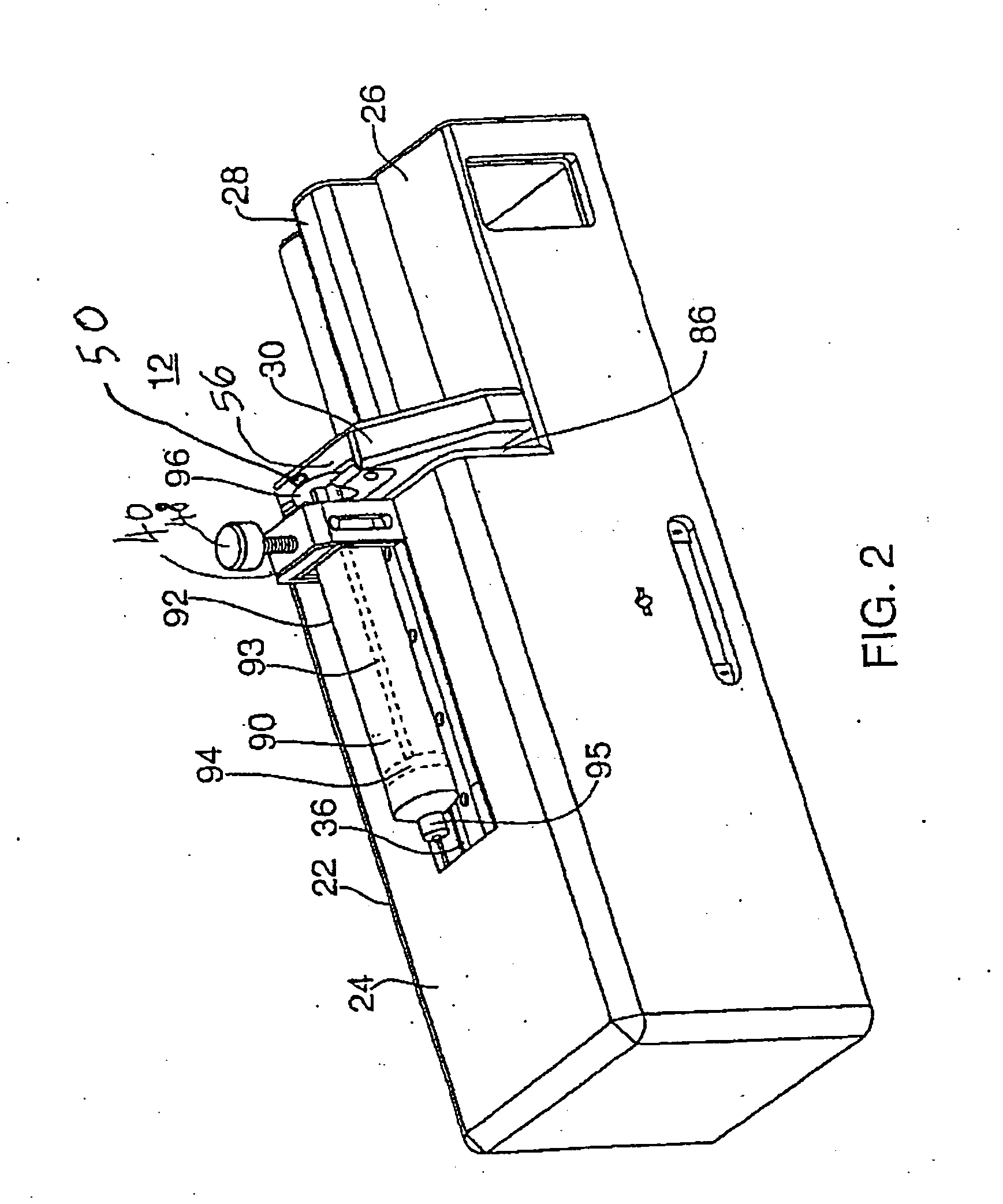

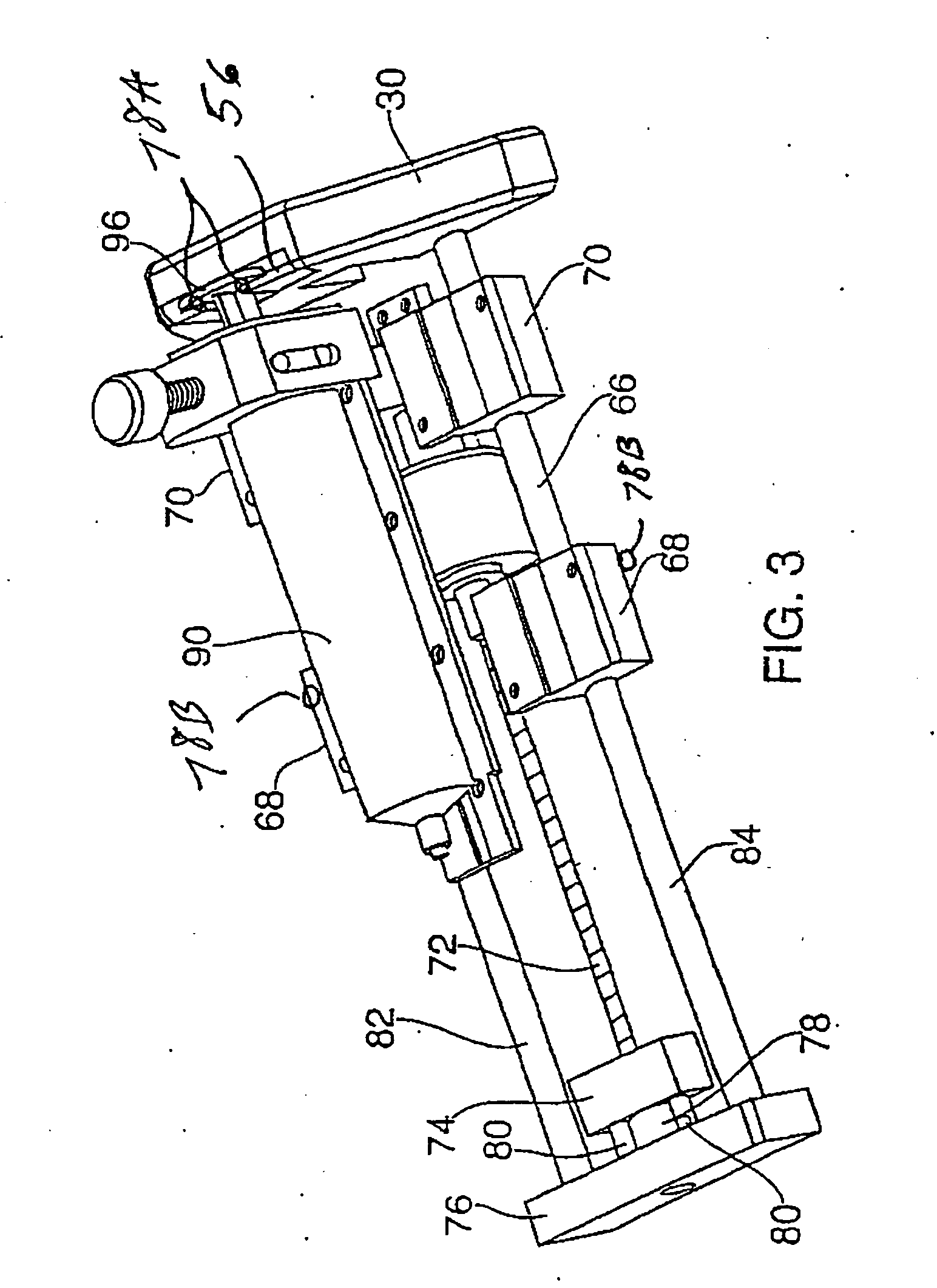

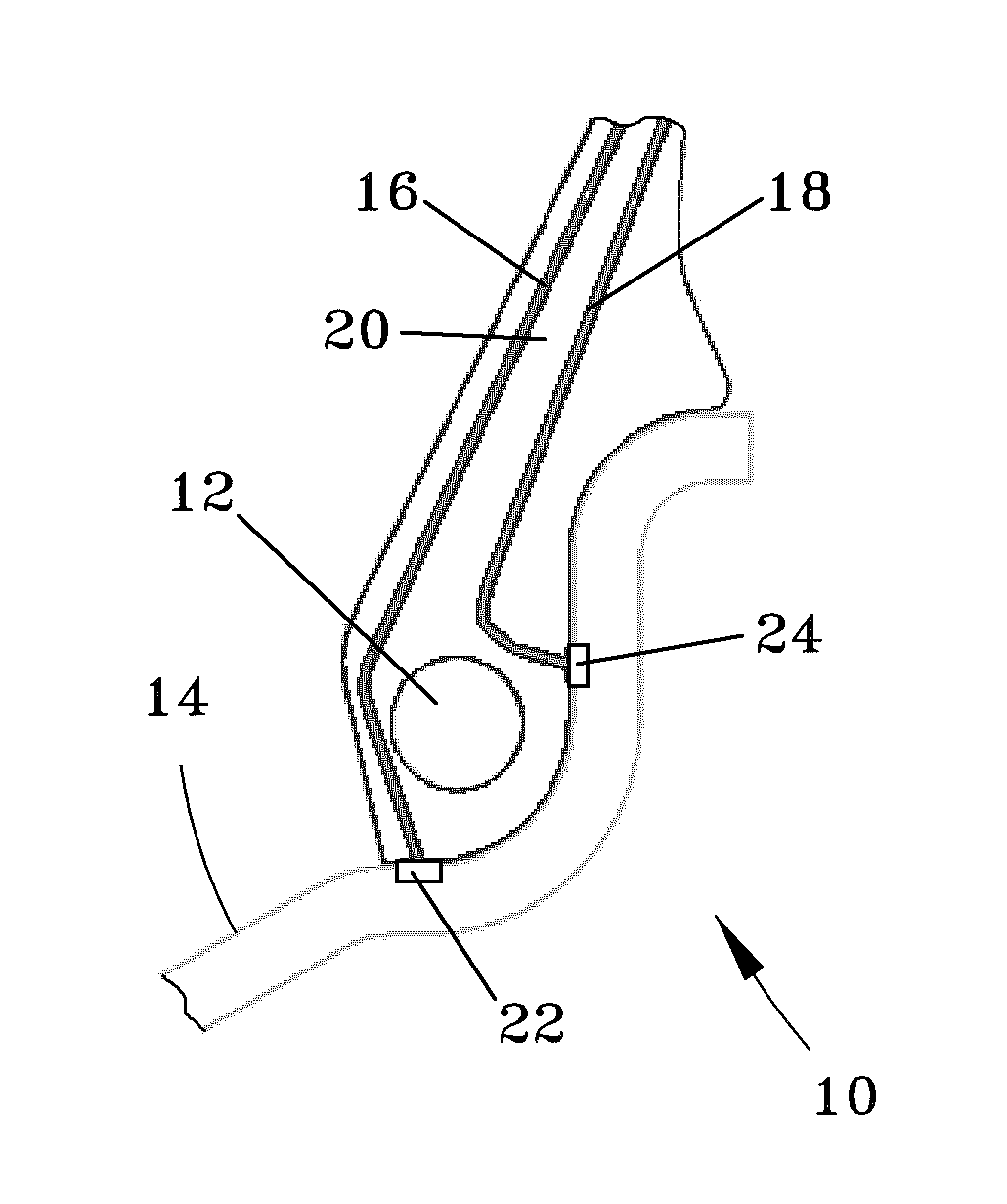

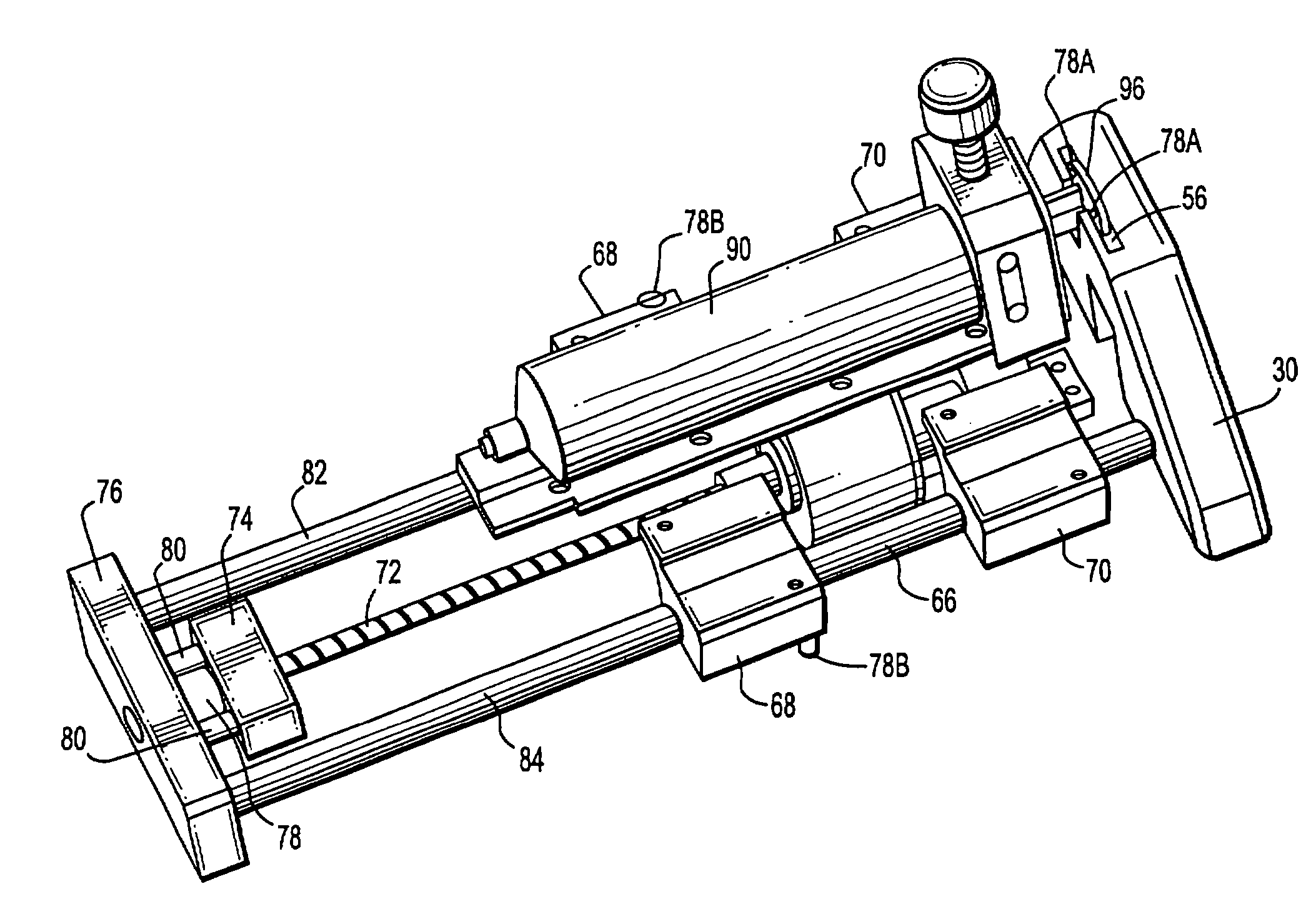

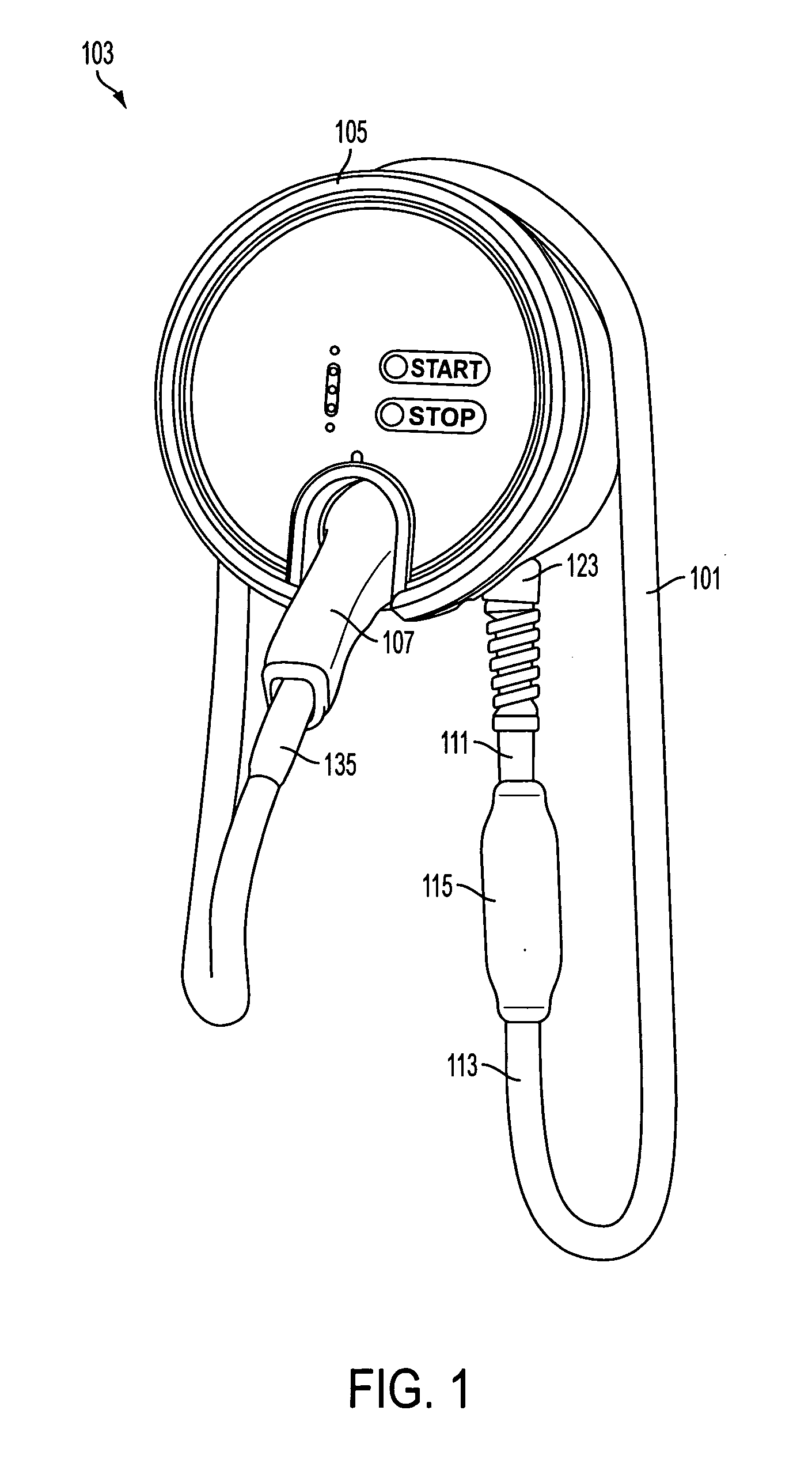

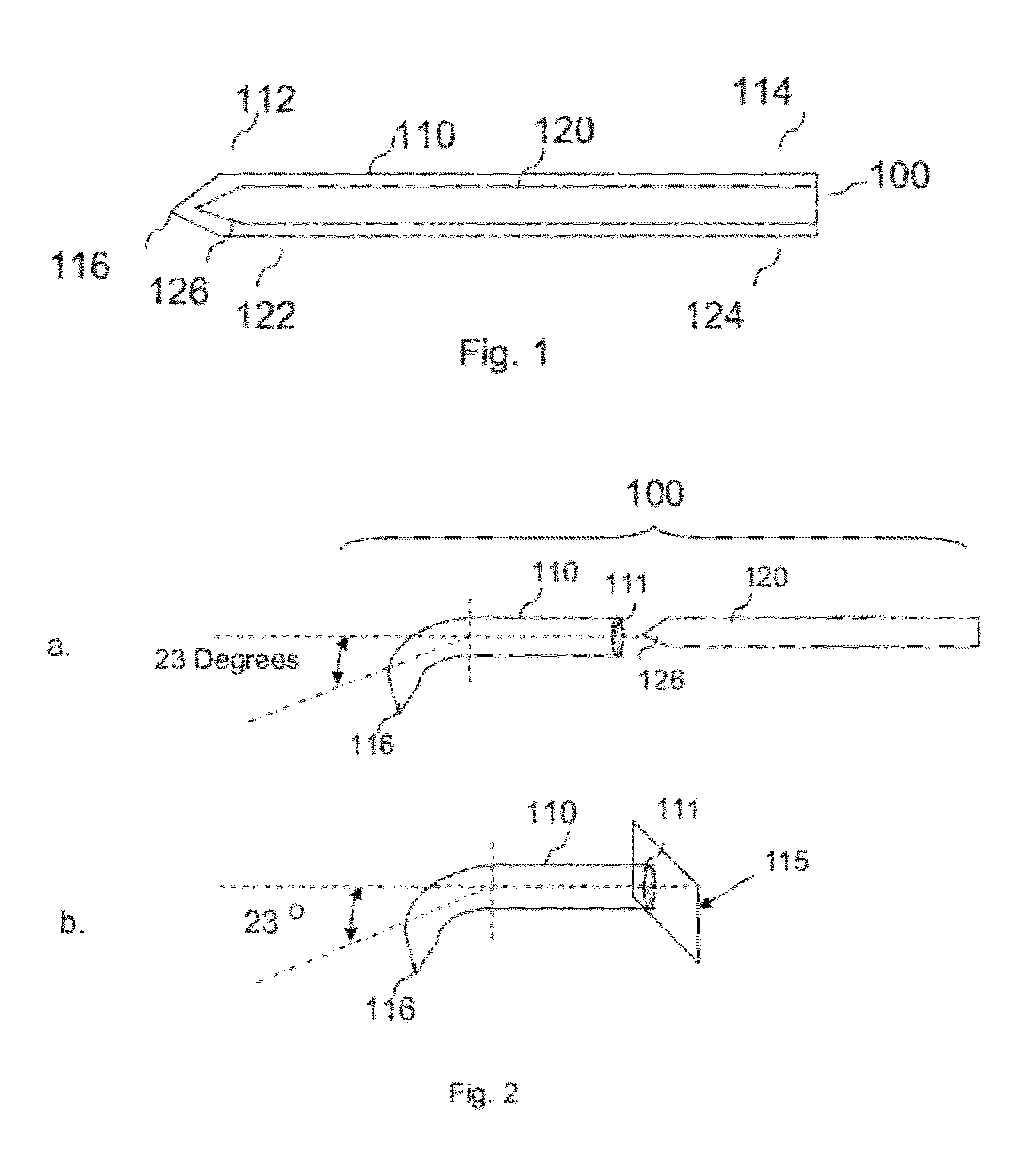

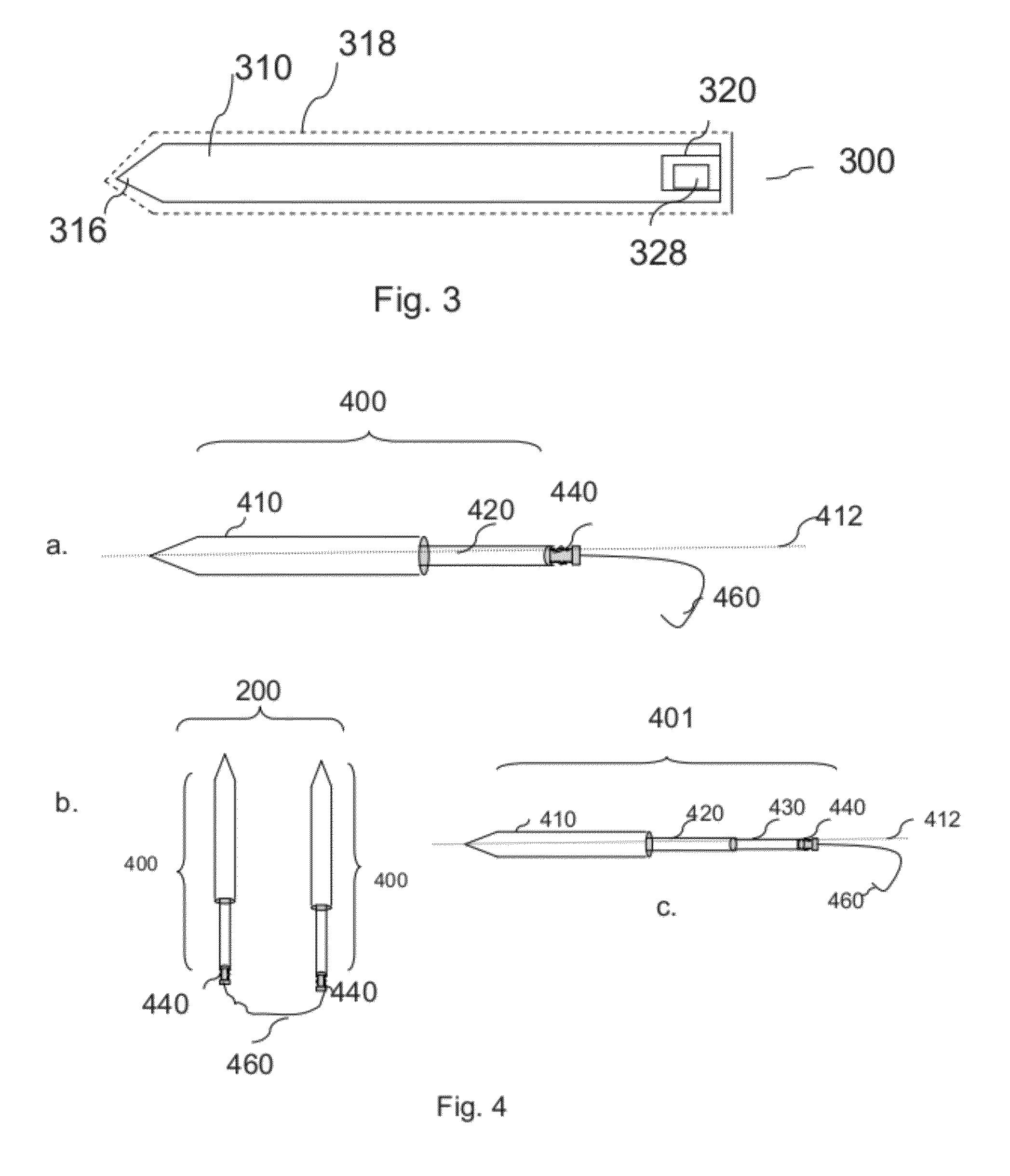

Handpiece for fluid administration apparatus

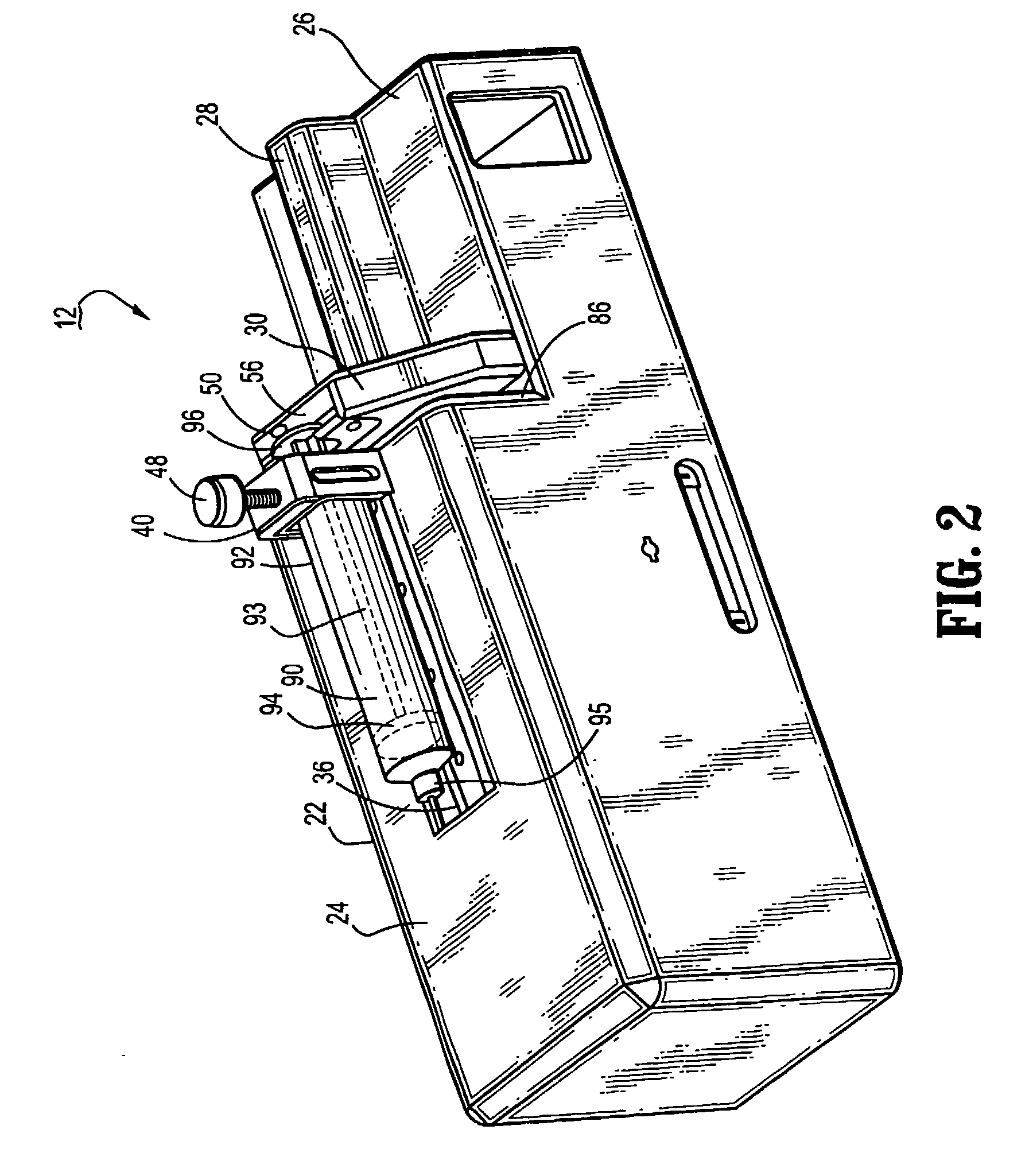

InactiveUS7625354B2Easy to operateEasy and efficient assemblyPharmaceutical delivery mechanismMedical devicesMedication infusionPressure threshold

A handpiece assembly is provided that is adapted for use with a medication infusion system that applies pressure to the handpiece assembly for delivering medication to a body. The handpiece assembly includes a cartridge holder that is configured for disposal of a medication cartridge. A tubing is provided having a first end, which is sealed with the cartridge holder such that the cartridge holder facilitates communication between the tubing and the medication cartridge. A handpiece is sealed with a needle and the second end of the tubing so that the tubing and the needle are in communication. One of the cartridge holder, the tubing, the needle or the handpiece is configured for a selective structural failure at a predetermined pressure threshold applied to the handpiece assembly from the medication infusion system. The cartridge holder may be designed to facilitate aspiration.

Owner:MILESTONE SCIENTIFIC INC

Hydraulic hose with integral life-sensing capability and method therefor

ActiveUS7555936B2Detection of fluid at leakage pointTesting/calibration apparatusElectrical conductorProcess equipment

Owner:PURDUE RES FOUND INC

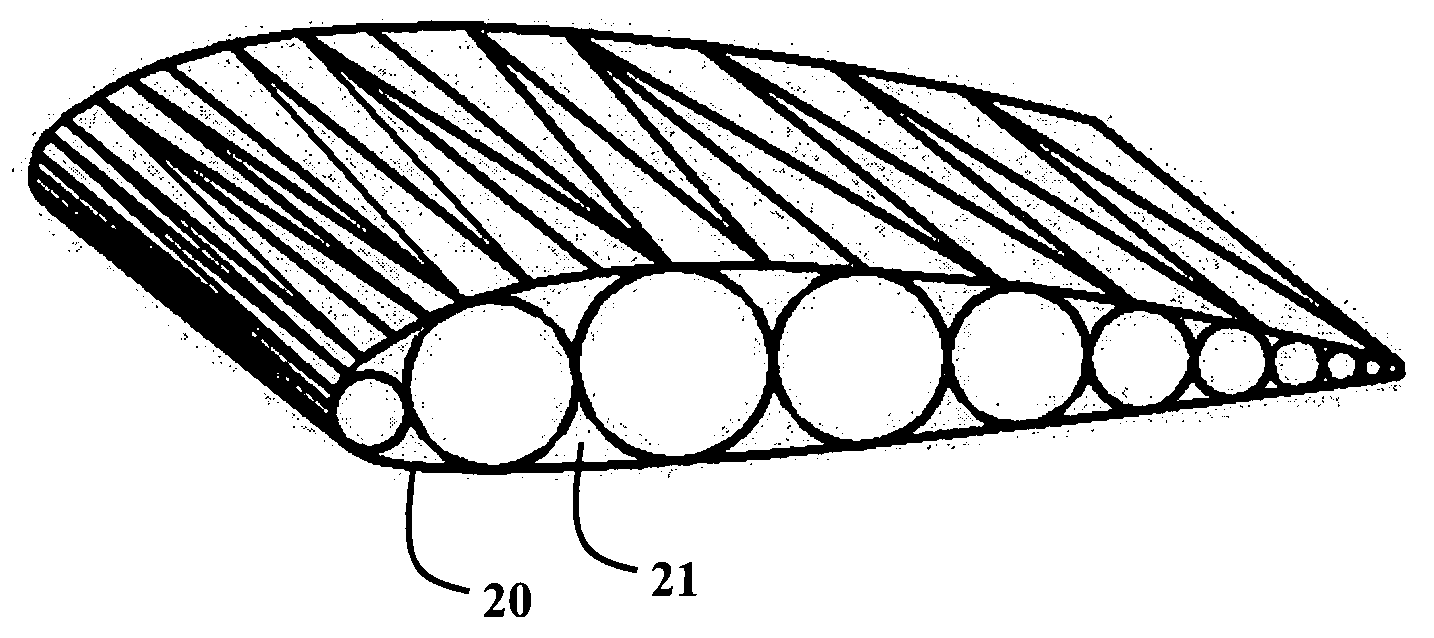

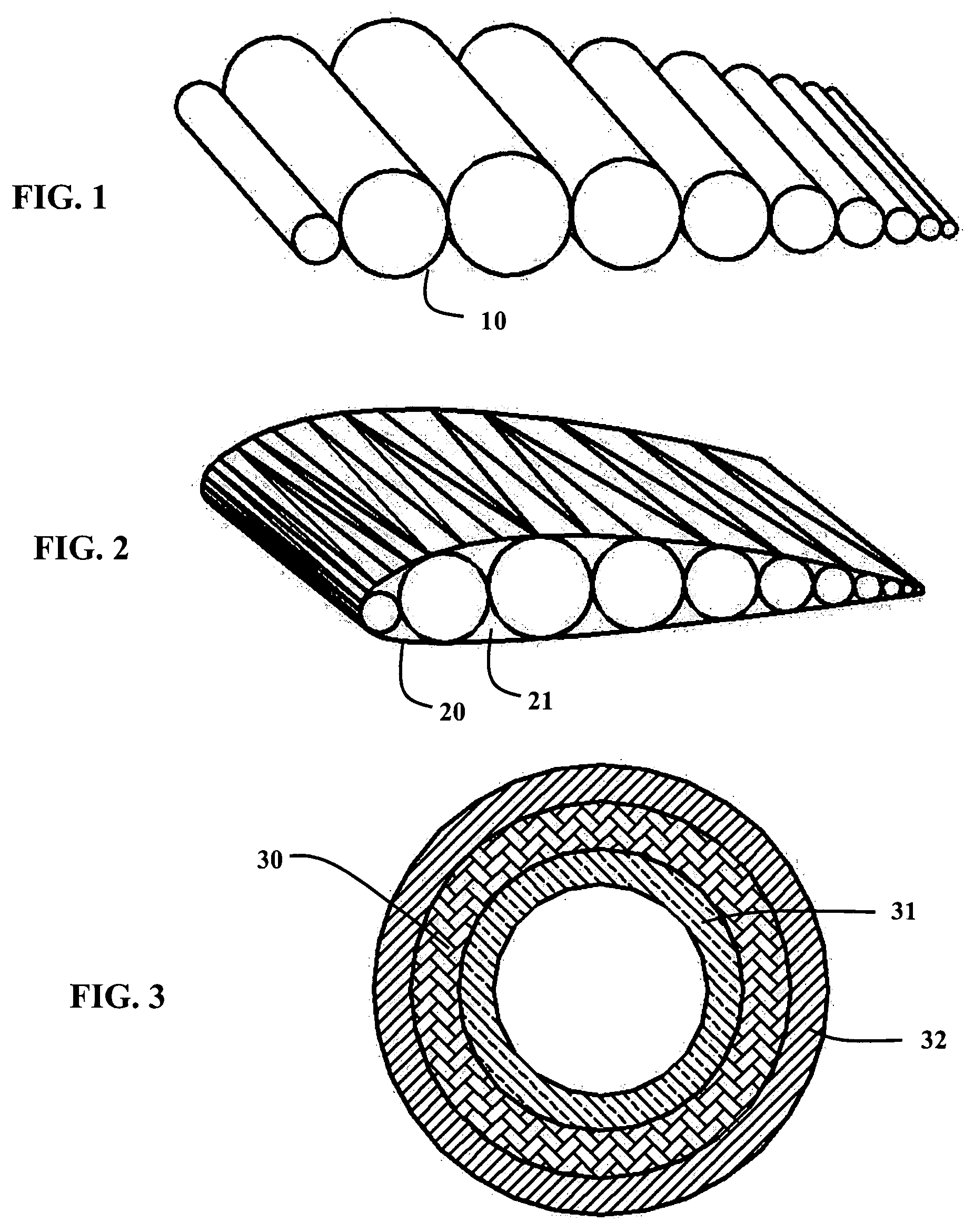

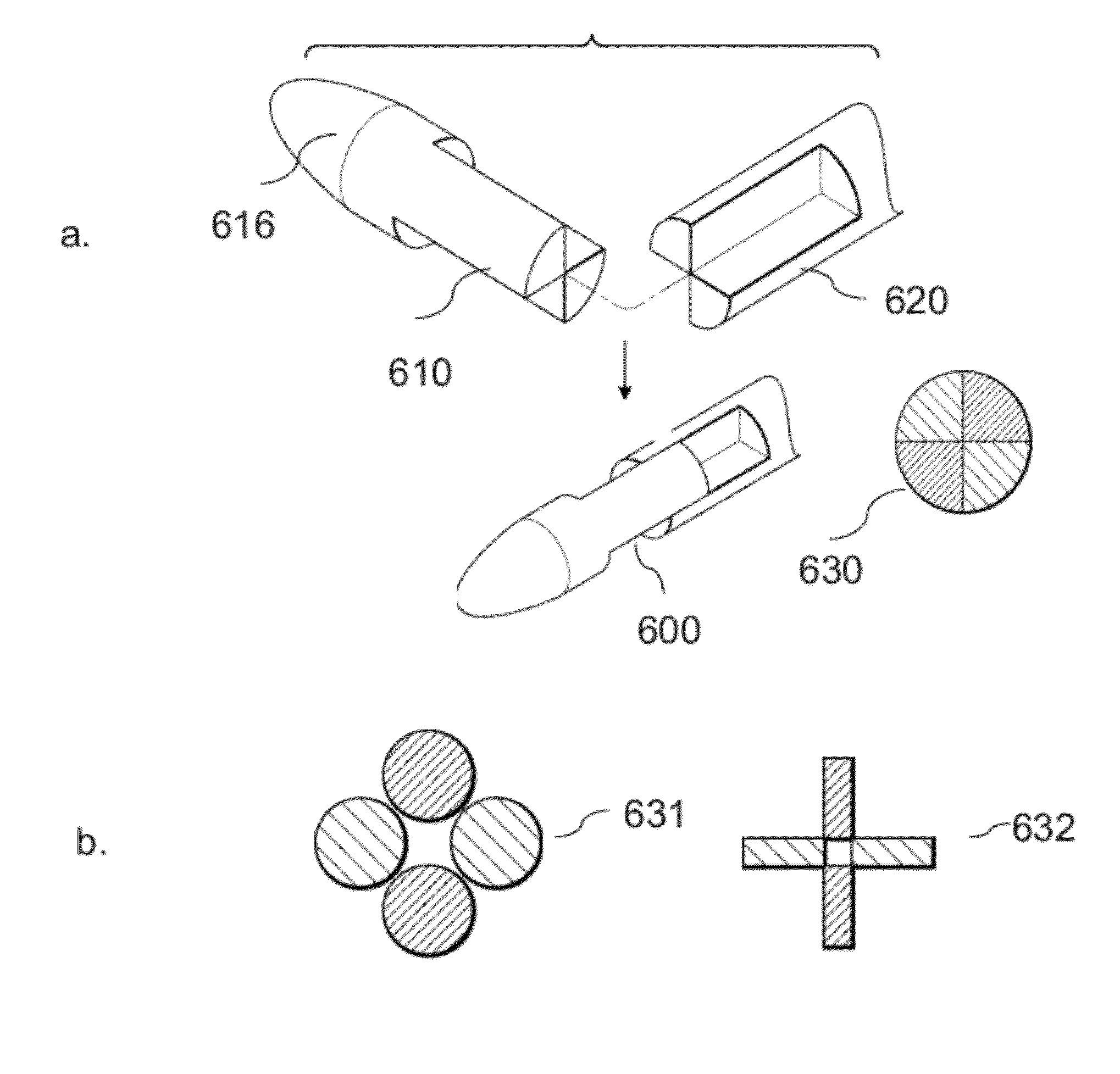

Deployable, rigidizable wing

InactiveUS20050151007A1Increase stiffnessImprove aerodynamic characteristicsUnmanned aerial vehiclesWing shapesChemical compositionPolymer resin

A novel design and construction method for an inflatable, rigidizable wing for a terrestrial or planetary flying vehicle. The wing is caused to deploy from an initially packed condition and to assume its functional shape by means of an inflation gas. After inflation, the wing is rigidized by any of several means, such that the inflation gas is no longer required. The composite wing is fabricated from a base reinforcement material, often a fabric, which is coated with a polymer resin that hardens when exposed to a curing mechanism. Several activation mechanisms exist by which to initiate rigidization of such a structure, including elevated temperature, ultraviolet light, and chemical constituents of the inflation gas. The resultant wing has fundamental advantages compared to existing inflatable wings, including improved stiffness, and reduced susceptibility to structural failure in response to puncture.

Owner:ILC DOVER LP

Handpiece for fluid administration apparatus

InactiveUS20060102174A1Prevent leakageEliminate operator errorsPharmaceutical delivery mechanismMedical devicesMedication infusionPressure threshold

A handpiece assembly is provided that is adapted for use with a medication infusion system that applies pressure to the handpiece assembly for delivering medication to a body. The handpiece assembly includes a cartridge holder that is configured for disposal of a medication cartridge. A tubing is provided having a first end, which is sealed with the cartridge holder such that the cartridge holder facilitates communication between the tubing and the medication cartridge. A handpiece is sealed with a needle and the second end of the tubing so that the tubing and the needle are in communication. One of the cartridge holder, the tubing, the needle or the handpiece is configured for a selective structural failure at a predetermined pressure threshold applied to the handpiece assembly from the medication infusion system. The cartridge holder may be designed to facilitate aspiration.

Owner:MILESTONE SCIENTIFIC INC

Structures with integral life-sensing capability

InactiveUS20070131035A1Continuous monitoringRemoval from serviceVehicle testingTesting/calibration apparatusElectricityElectrical resistance and conductance

A structure subjected to stresses that can lead to structural failure. The structure includes first and second conductive layers and an intermediate layer therebetween formed of a dielectric, semiconductive, or resistive material, such that the first, second, and intermediate layers form in combination an electrical element, namely, a capacitive or resistive element. The electrical element is located within the structure so as to be physically responsive to transitory and permanent distortions of the structure resulting from extrinsic and intrinsic sources. The structure further includes applying an electrical potential to at least one of the first and second conductive layers so as to generate an electrical signal from the electrical element, sensing changes in the electrical signal generated by the electrical element in response to the electrical element physically responding to the transitory and permanent distortions, and transmitting the changes in the electrical signal to a location remote from the structure.

Owner:PURDUE RES FOUND INC

Handpiece For Fluid Administration Apparatus

InactiveUS20080281265A1Easy to operateEasy and efficient assemblyInfusion needlesMedication infusionPressure threshold

A handpiece assembly is provided that is adapted for use with a medication infusion system that applies pressure to the handpiece assembly for delivering medication to a body. The handpiece assembly includes a cartridge holder that is configured for disposal of a medication cartridge. A tubing is provided having a first end, which is sealed with the cartridge holder such that the cartridge holder facilitates communication between the tubing and the medication cartridge. A handpiece is sealed with a needle and the second end of the tubing so that the tubing and the needle are in communication. One of the cartridge holder, the tubing, the needle or the handpiece is configured for a selective structural failure at a predetermined pressure threshold applied to the handpiece assembly from the medication infusion system. The cartridge holder may be designed to facilitate aspiration.

Owner:MILESTONE SCIENTIFIC INC

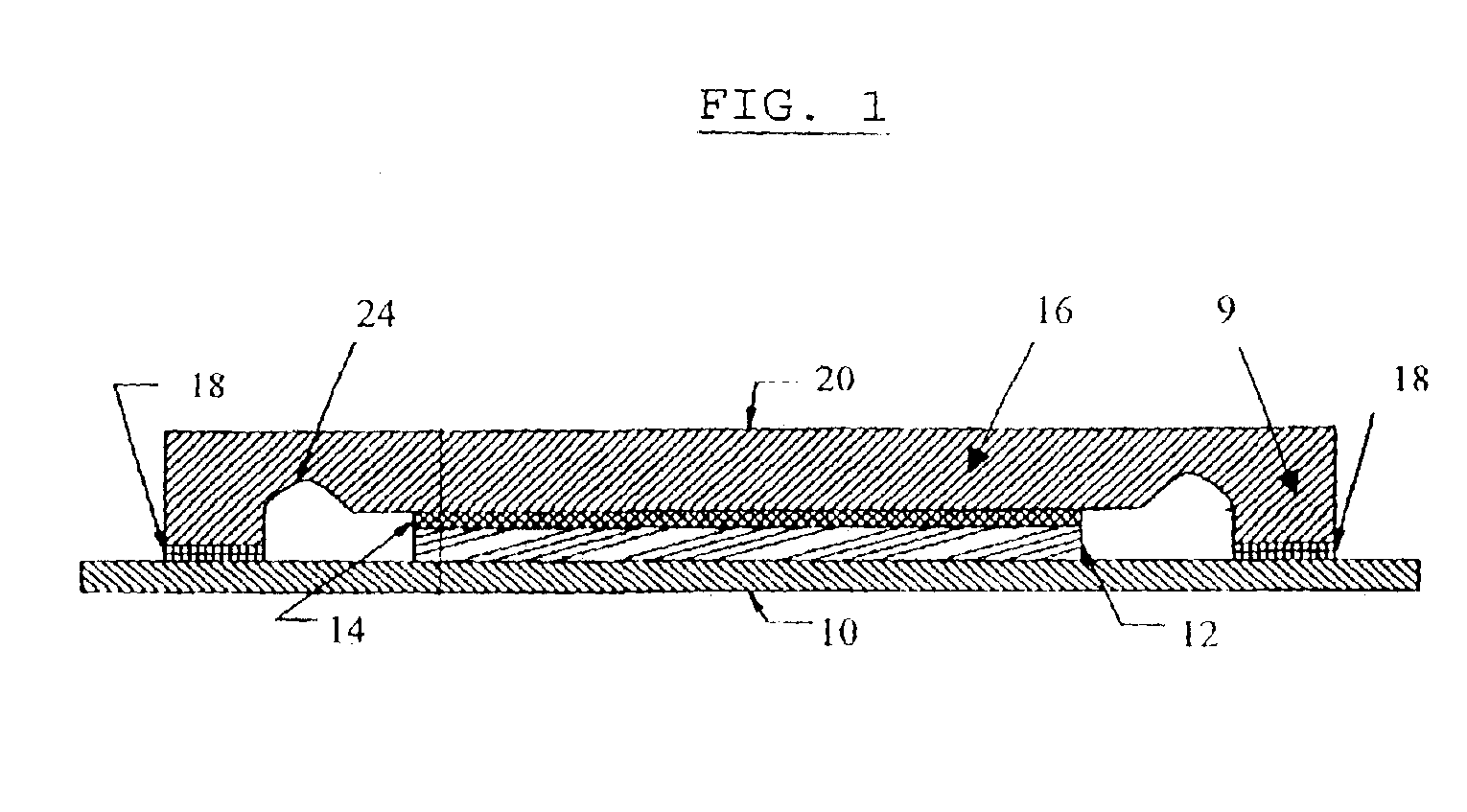

Integrated heat spreader lid

InactiveUS6906413B2Semiconductor/solid-state device detailsCasings/cabinets/drawers detailsEngineeringThermal expansion

A heat spreader lid includes an outer periphery region having a lip for bonding to an underlying substrate board, a center region, and one or more strain isolation regions. The strain isolation regions are located between the center region and the outer periphery region and may comprise a number of slots cut partially or completely through the lid in a pattern surrounding or partially surrounding the center region. The strain isolation regions provide isolation of strain and relief of stress due to thermal expansion of the lid despite constraint at its periphery by the bonded lip, resulting in less thermally-induced warping of the center region, less thermally-induced stress on the bond between the lip and the substrate board, and / or less thermally-induced deflection of the substrate board. The reduced warping, stress, and / or deflection increases the reliability of the system by reducing the propensity for delamination or separation in the interface between the lid and the die, and / or by reducing the chance of structural failure in the bond between the lid and the substrate board.

Owner:HONEYWELL INT INC

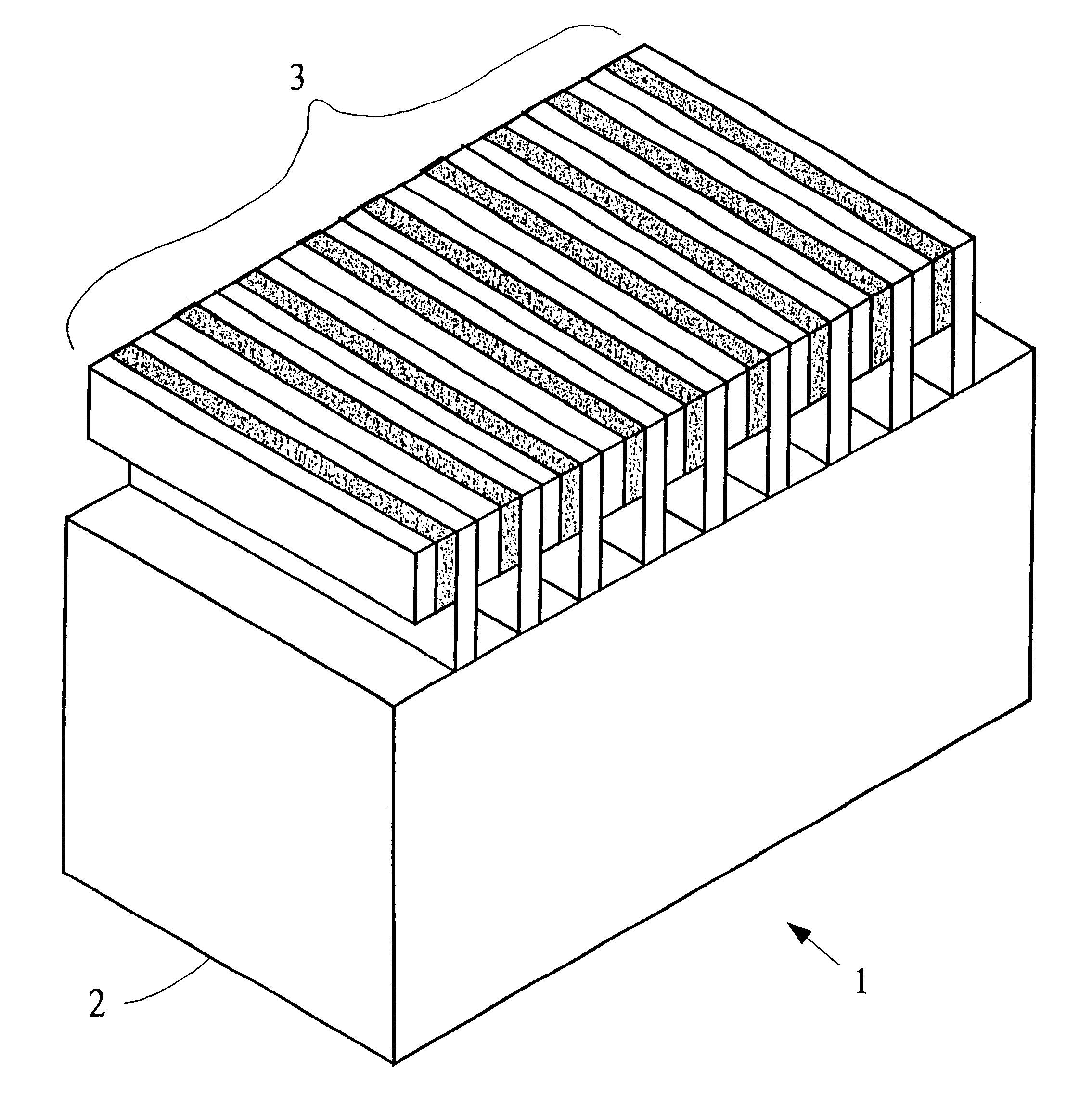

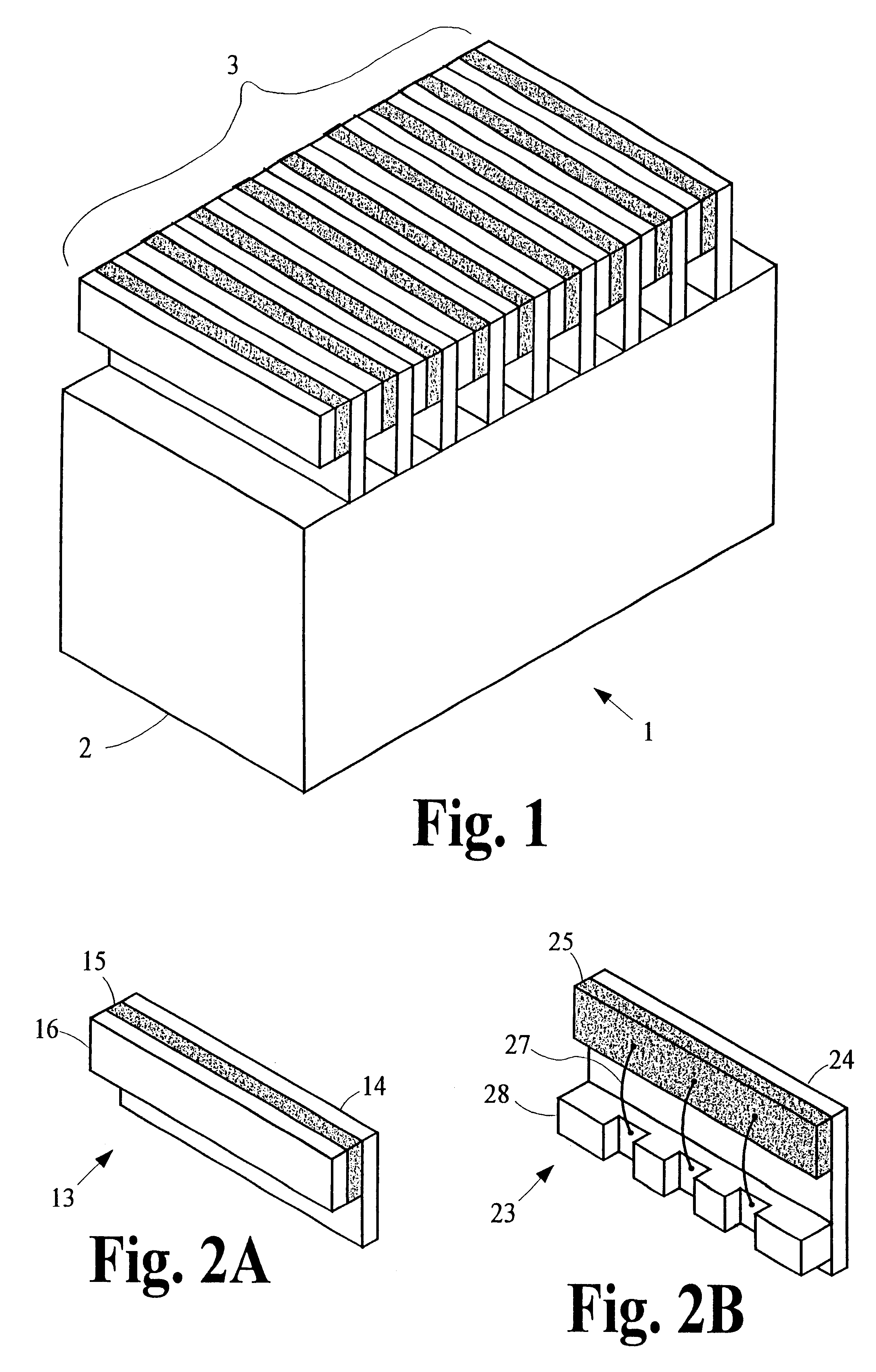

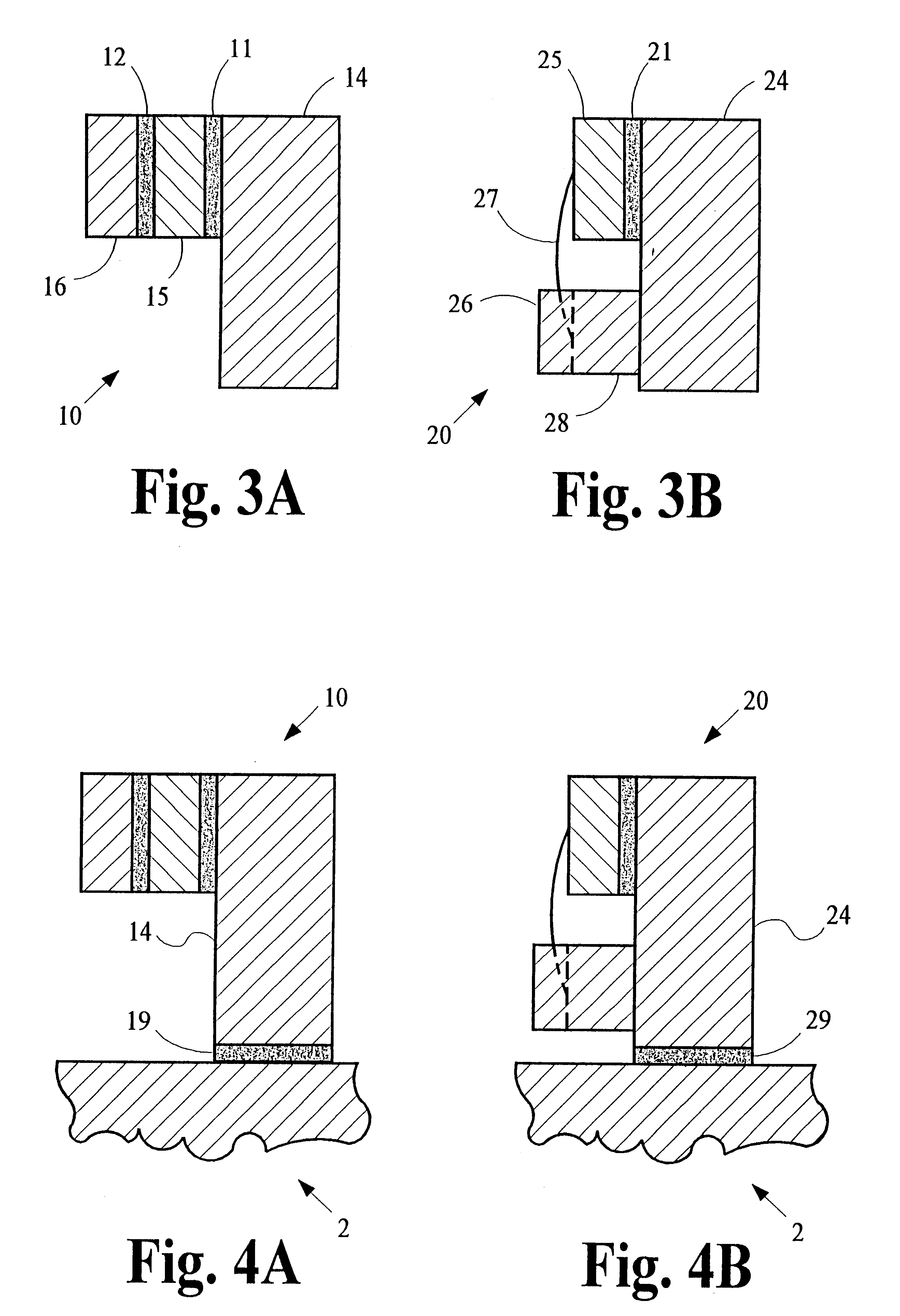

Solder and material designs to improve resistance to cycling fatigue in laser diode stacks

InactiveUS6424667B1Improve resistance to cycling fatigueReduce mechanical strainOptical wave guidanceSemiconductor laser arrangementsMaterial DesignThermal expansion

Laser modules that are operated intermittently are prone to stop operating after only a few thousand cycles or less. The laser modules sometimes experience a significant increase in operating temperature before they stop operating and, in some cases, manifest an opening of the electrical circuit that connects the laser diodes in the stack of laser subassemblies. In extreme cases, the laser module disintegrates into component subassemblies. These problems arise from structural failures in affixing agents like solder that are used to affix component parts to each other. The structural failures are caused by cyclical thermal expansion and contraction of component parts that exceed the elastic limit of the solder. Resistance to global plastic deformation (creep) and to local plastic deformation (fatigue) is improved by selecting materials to reduce mechanical strain and increase resistance to creep and fatigue, by altering the structural design of the laser module to reduce mechanical strain induced into the affixing agents, and by altering operational practices to reduce the range of temperatures imposed on laser module components. One design method improves resistance to creep and fatigue by controlling the thickness of the affixing agents used to affix component parts to each other.

Owner:JDS UNIPHASE CORP

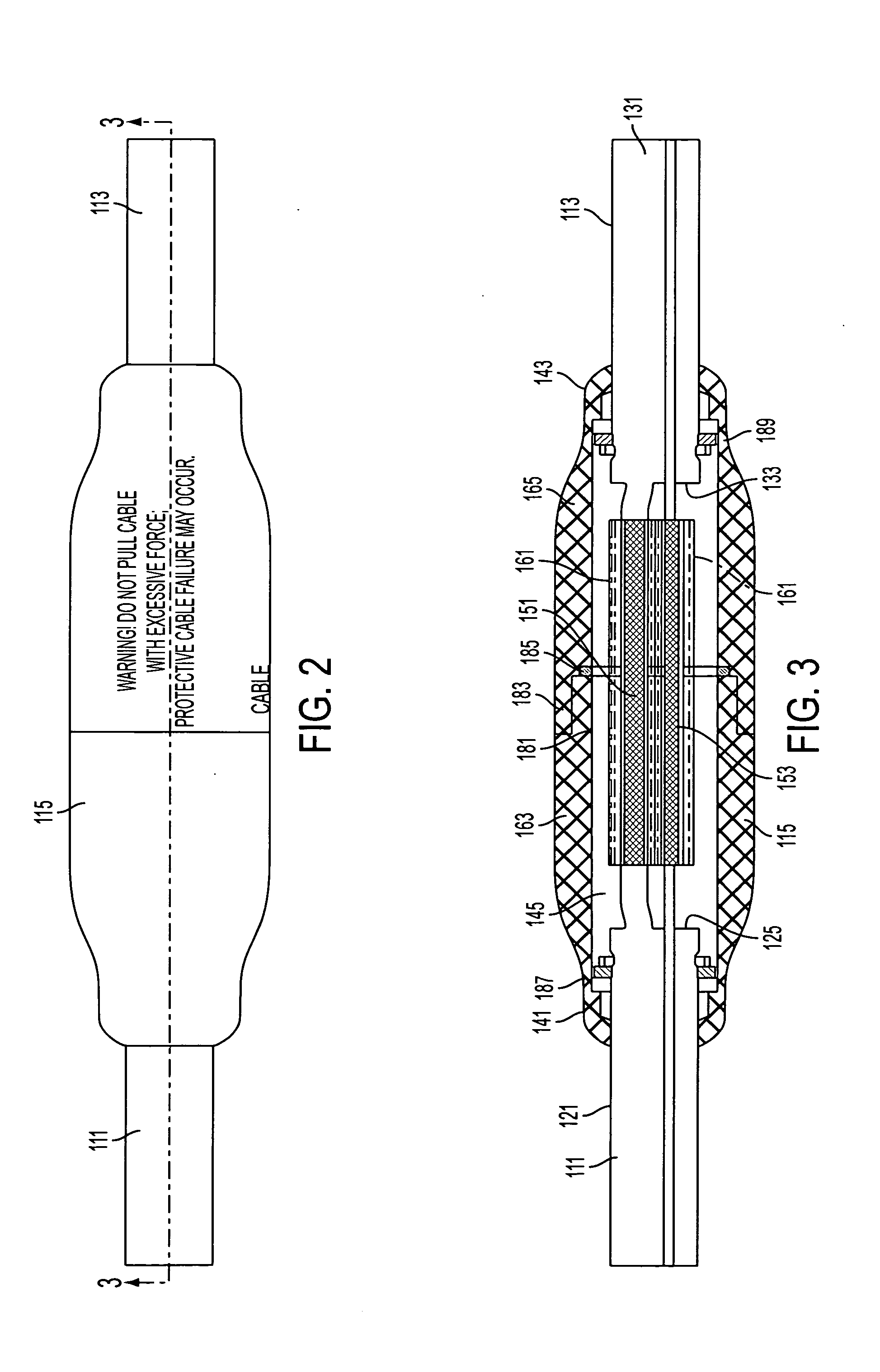

Break-away cable connector

InactiveUS20130187601A1Minimize the possibilityBatteries circuit arrangementsRelieving strain on wire connectionCritical levelBody positions

An electric vehicle charging station having a console, a cable and a vehicle connector. The cable is connected with a break-away system that allows for a controlled structural failure of one of the cable connections when the vehicle connector is pulled away from the console with a critical level of force. The break-away system could be a body positioned along the length of the cable, and could be a connection between the cable and either the console or the vehicle connector.

Owner:WEBASTO CHARGING SYST INC

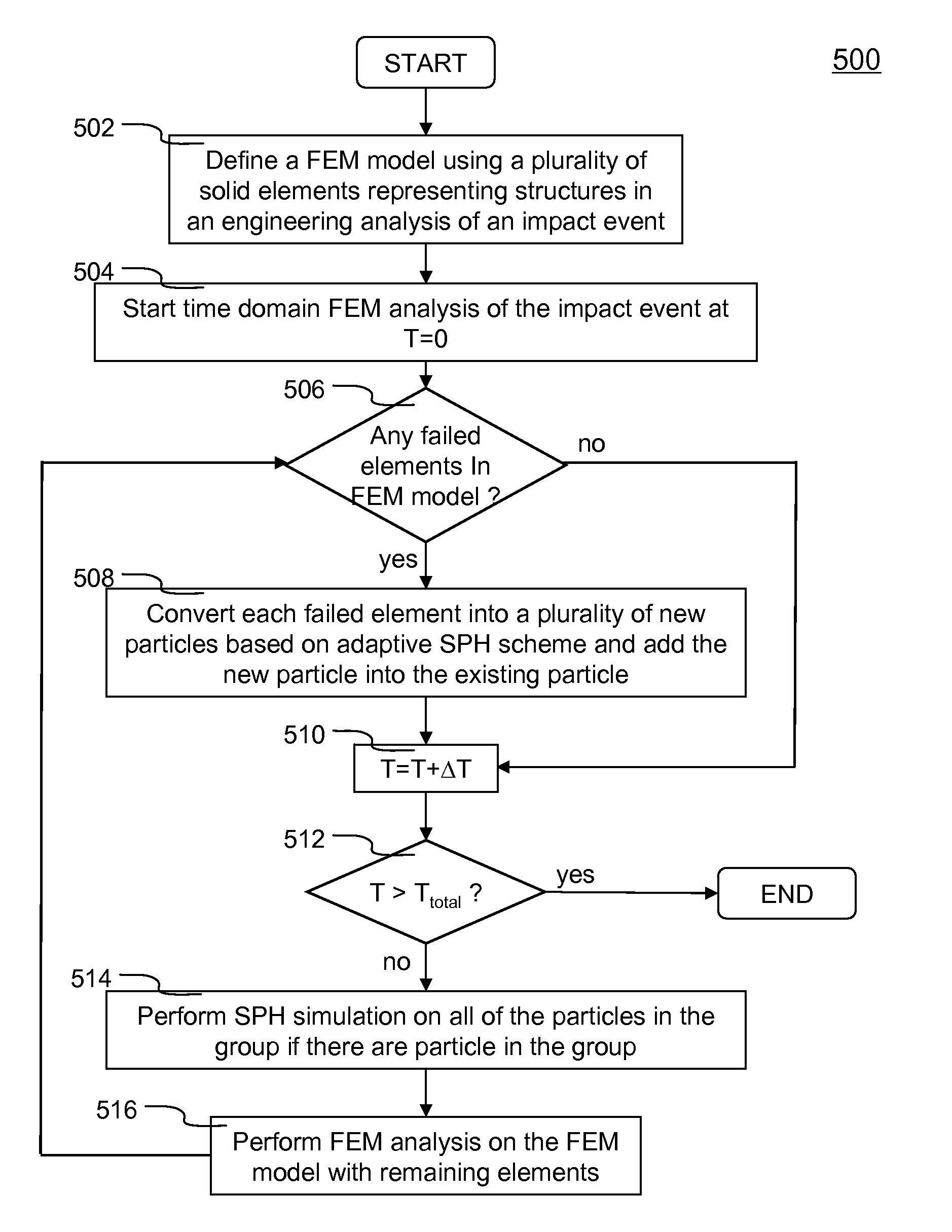

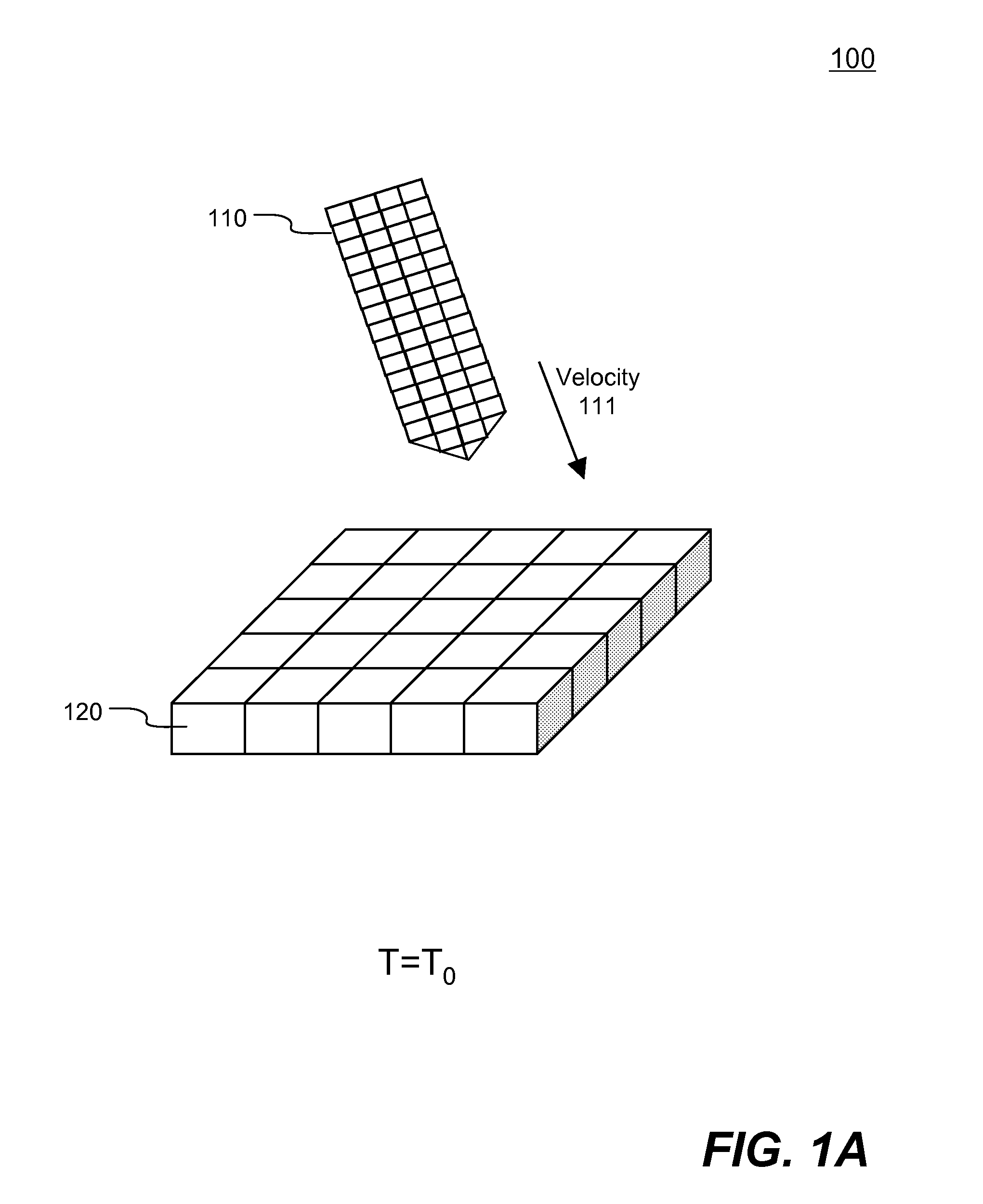

Methods and systems of engineering analysis using a hybrid approach with FEM and adaptive SPH

ActiveUS20090228246A1Real timeComputation using non-denominational number representationInvestigating material hardnessSmoothed-particle hydrodynamicsMomentum

Systems and methods of computer aided engineering analysis using hybrid approach of finite element method (FEM) and adaptive smoothed particle hydrodynamics (SPH) are described. According to one aspect, a computer-aided engineering analysis is performed to simulate an impact event between structures. A FEM grid model is created to represent the structures using a plurality of solid elements which represents geometry and material properties. Once a contact between two structures resulted into a material or structural failure according to predefined material constitutive equation, solid elements representing the failed portion of the structure are removed. Each failed solid element is then replaced by a plurality of particles to be analyzed using the SPH analysis. The particles replacing the failed element inherit all of the states and properties of the failed element, such as location, mass, velocity, acceleration, etc. The replacement is conducted according to the principles of mass, momentum and energy conservation.

Owner:ANSYS

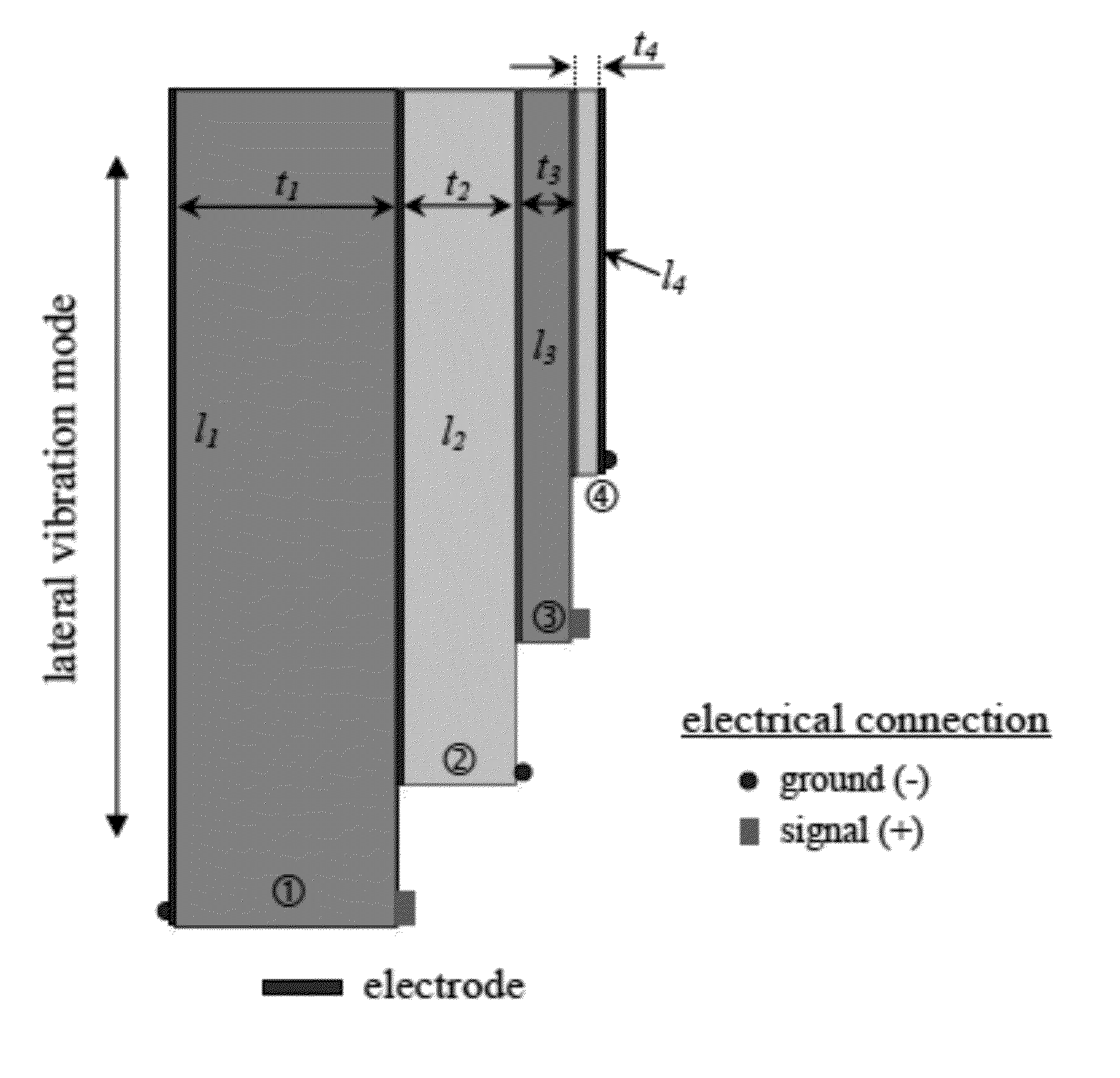

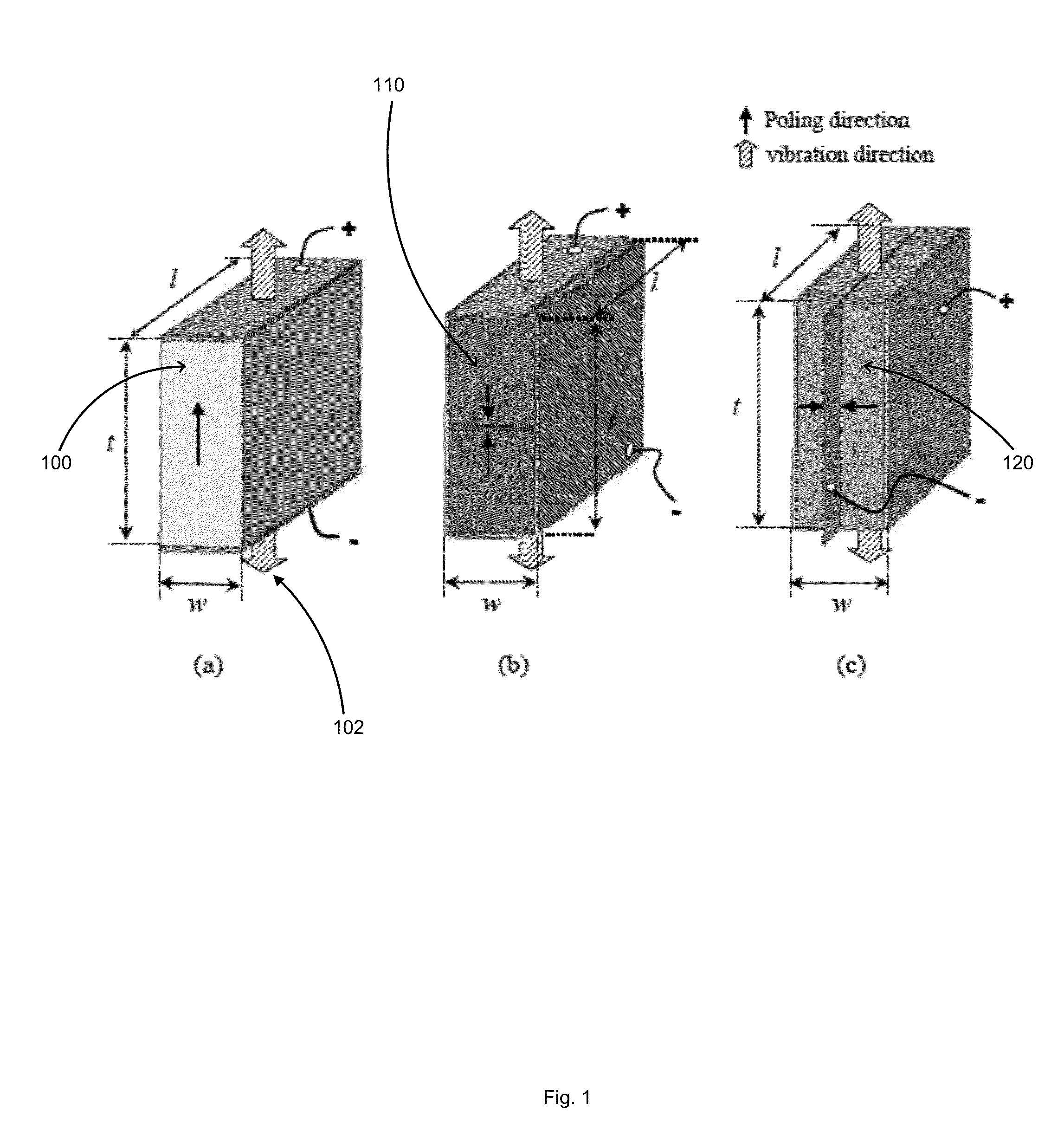

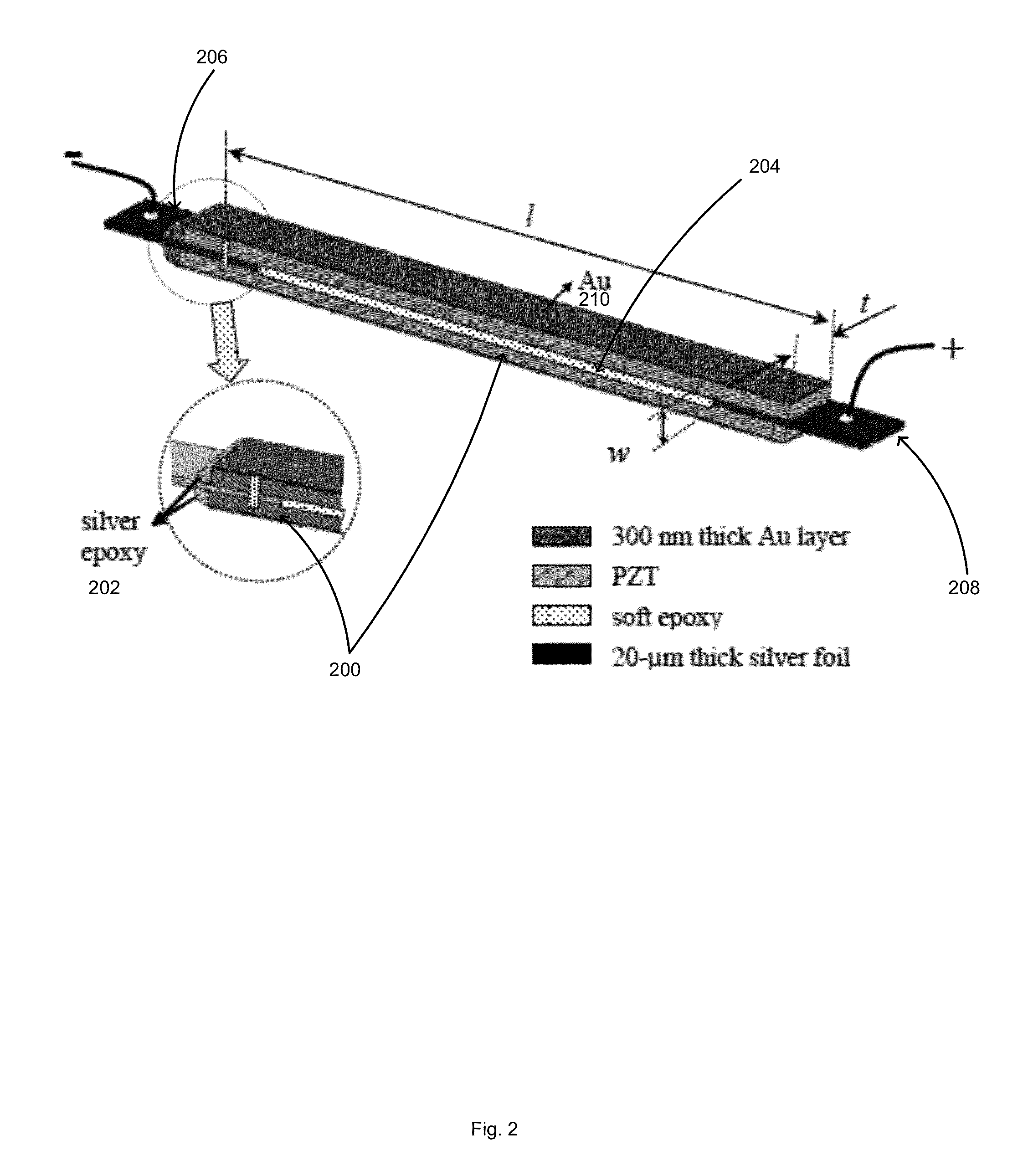

Ultrasound Transducer and Method for Making the Same

ActiveUS20130069484A1High power outputSimple and inexpensive processUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonic sensorTransducer

The present application provides a multilayer lateral mode coupling method for phased array construction and transducer devices built accordingly. This disclosure describes and demonstrates that the electrical impedance of a phased array can be substantially reduced and readily controlled to be close to the source impedance. The fabrication process is relatively simple and inexpensive. In addition, the elements are robust for use in 1.5, 2, 3 or other dimensional configurations, over an extended period of operation, without structural failure, and providing a high power output required for imaging and / or medical therapy applications.

Owner:SUNNYBROOK HEALTH SCI CENT +1

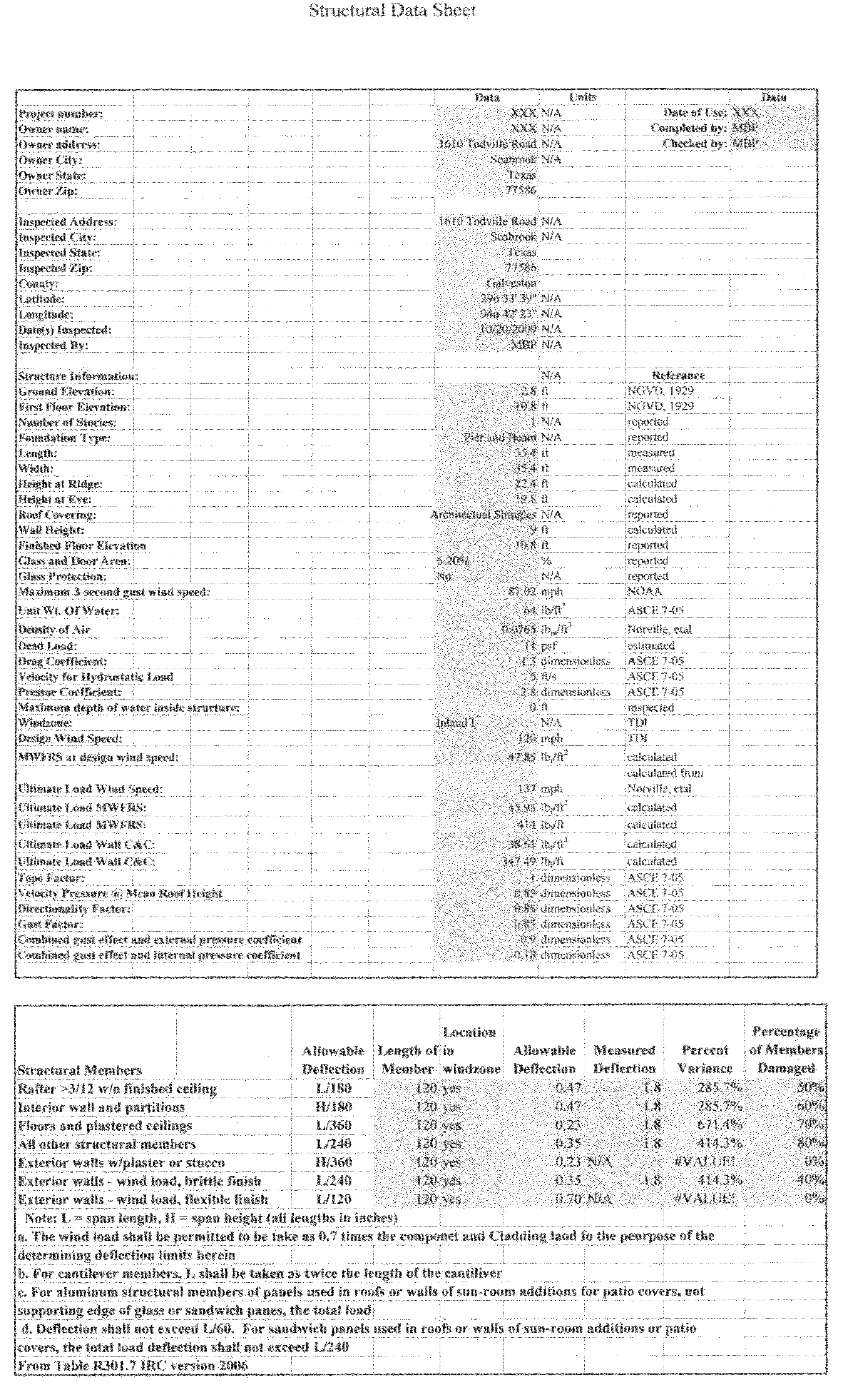

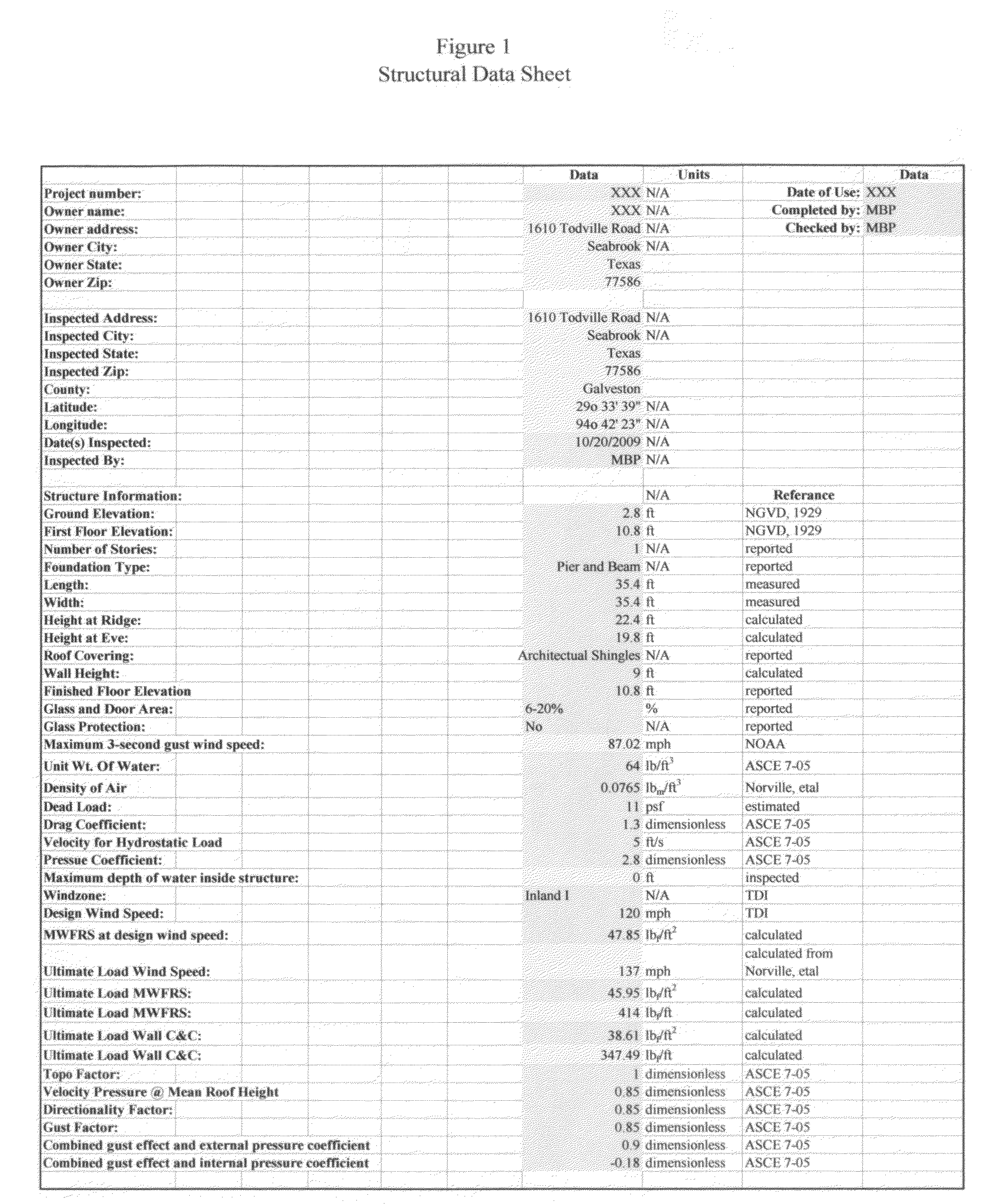

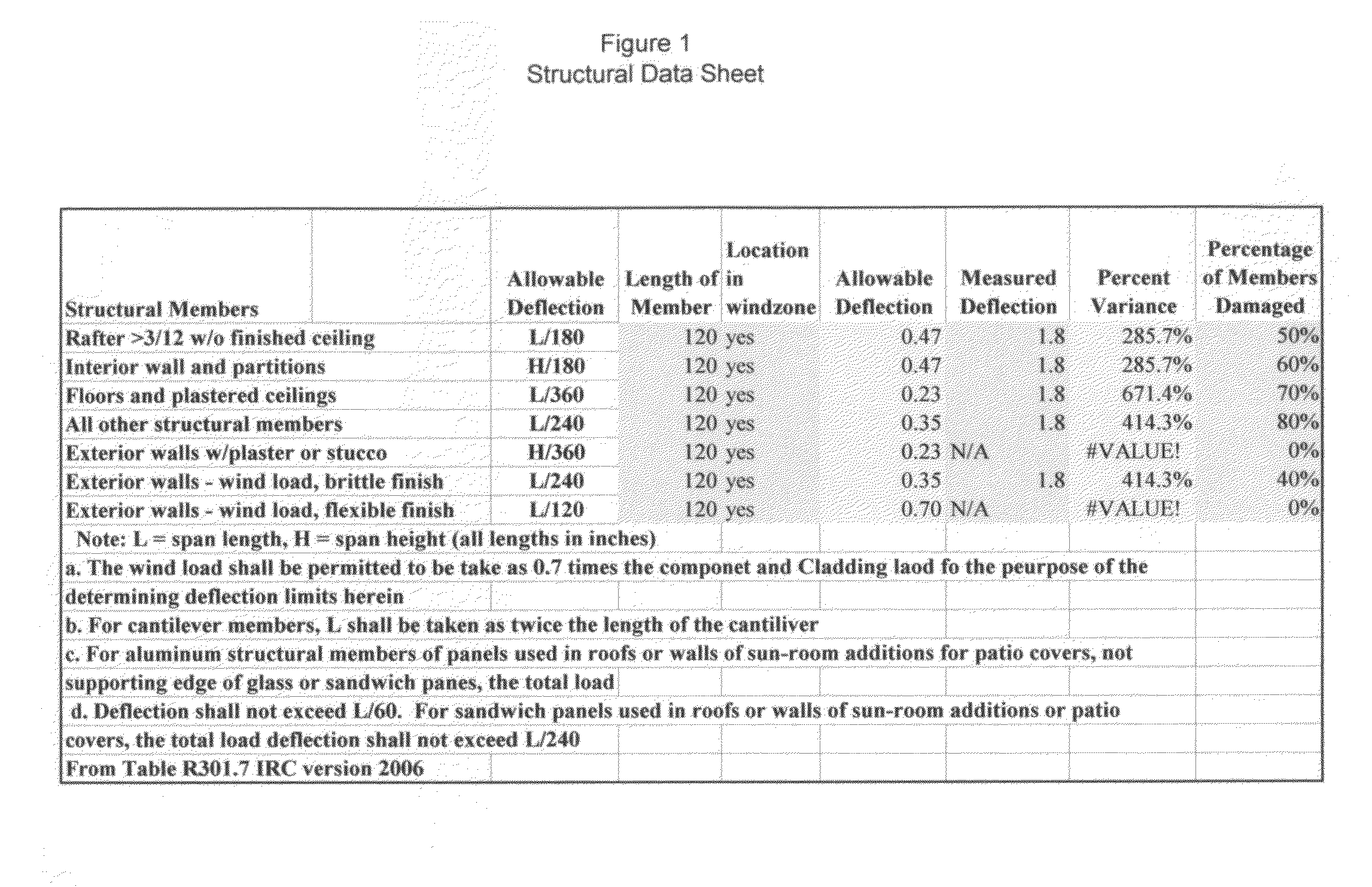

Method to determine percentage of damage to structure from single or multiple forces

The present invention is directed at providing a numerical analysis method to determine the damage sustained on a structure based upon the physical dimensions of a the structure, the structure's design wind speed and the forces applied during an event such as a hurricane or man made event. The method includes the steps of creating a timeline by which event forces can be plotted and compared to an ultimate load of the structure, individual loads placed upon the structure as well as a sum of the individual loads placed upon the structure. By using this method, the user is able to identify the time at which the ultimate load of the structure was exceeded and the maximum individual and total loads occurred. The method further identifies the time when the structural failure likely initiated and the time by which the structural failure was likely complete. The method further provides a determination of the percentage individual load at the time the ultimate load is breeched as well as a time step of forces applied to the structure throughout the course of the event.

Owner:PHELPS MATTHEW B

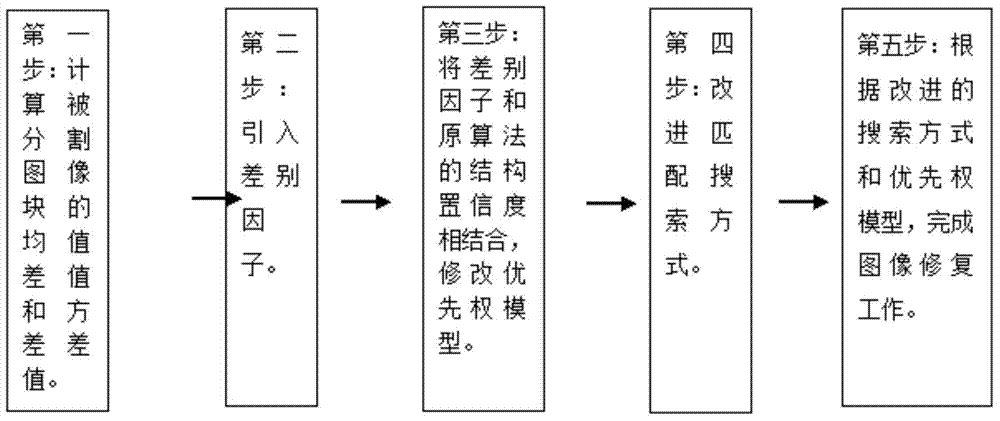

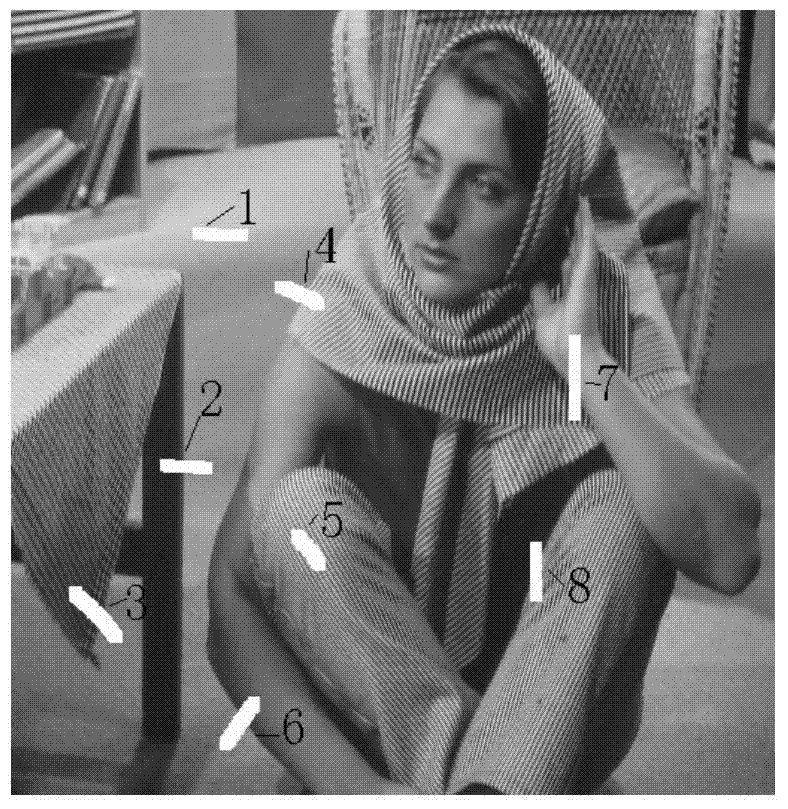

Criminisi image restoration method based on textures and edge features

InactiveCN103700093ASuppress Priority RepairAvoid destructionImage enhancementImage analysisPattern recognitionEdge structure

The invention discloses a criminisi image restoration method based on textures and edge features. A difference factor which enhances the discrimination capability for a structural part is introduced in a priority model to optimize priority calculation through analyzing texture structure features and edge structure features. The Criminisi image restoration method disclosed by the invention can effectively restrain priority repair of texture parts, and prevent the texture part from extending excessively to an edge part to result in image linear structural failure.

Owner:HANGZHOU DIANZI UNIV

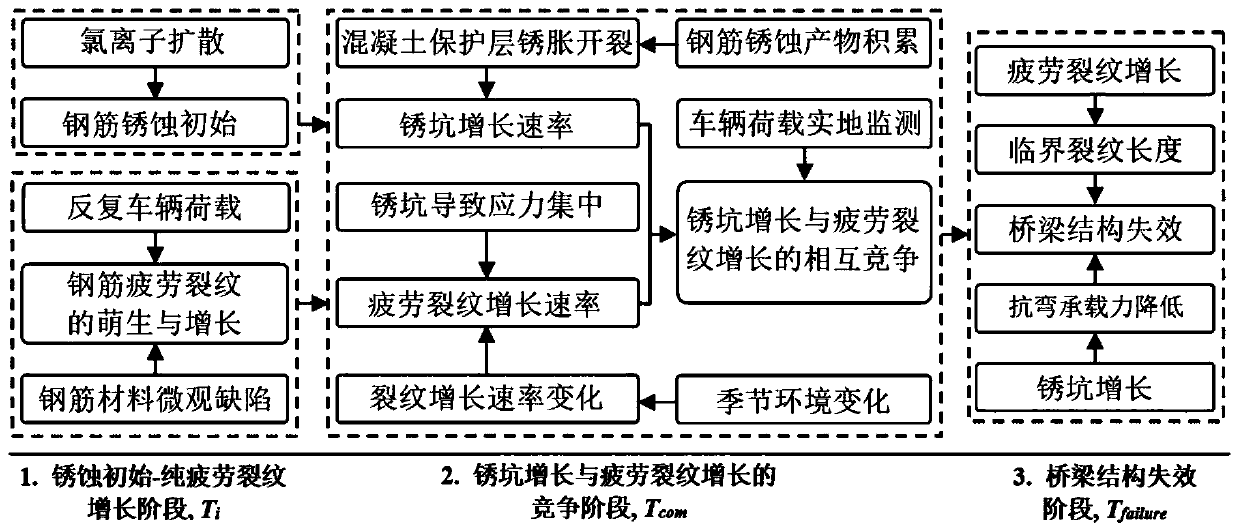

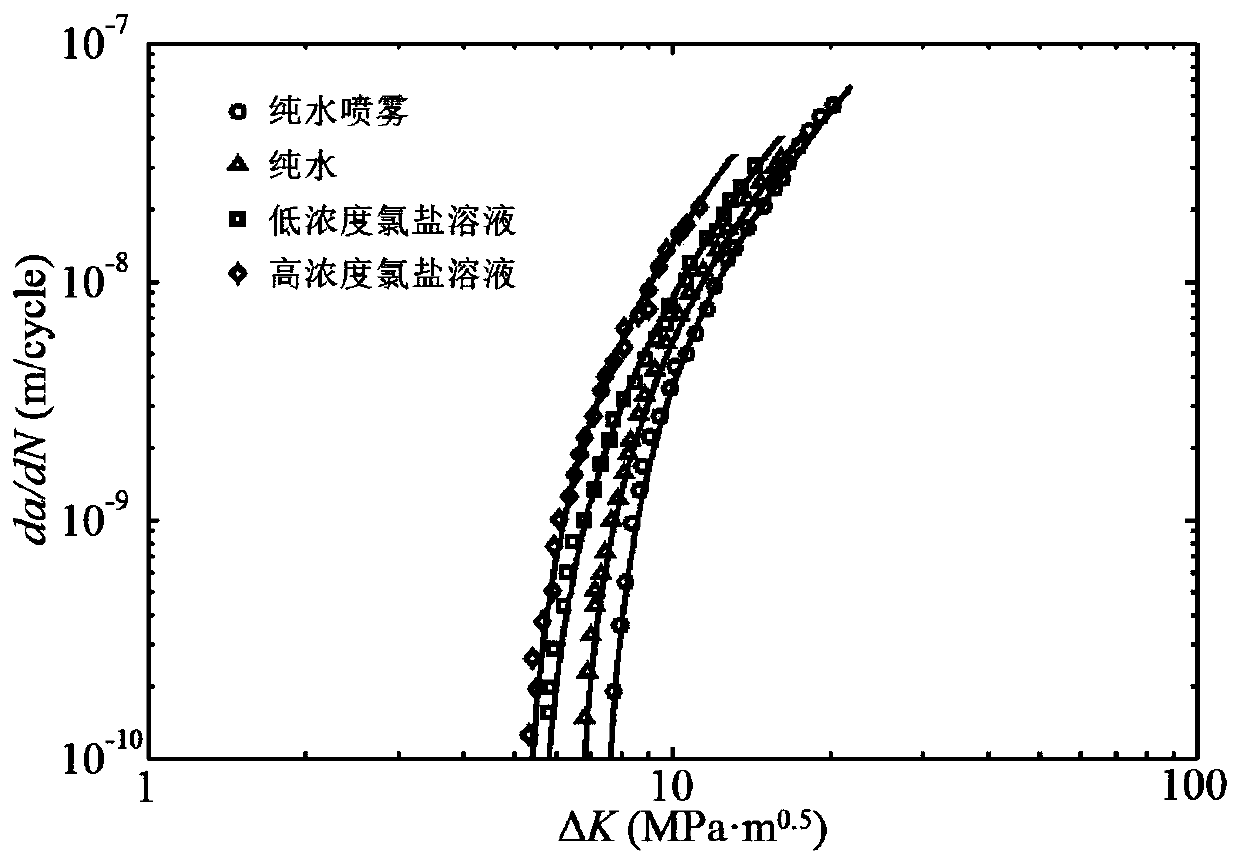

Method for predicting service life of reinforced concrete bridge under conditions of seasonal corrosion and fatigue coupling

ActiveCN109827855AEnables corrosion fatigue life assessmentNovel forecasting methodWeather/light/corrosion resistanceMaterial testing goodsStress concentrationRebar

The invention discloses a method for predicting the service life of a reinforced concrete bridge under the conditions of seasonal corrosion and fatigue coupling. The method comprises the steps: dividing the service life of the reinforced concrete bridge into three stages: corrosion initiation-pure fatigue crack development stage, a rust pit and fatigue crack competing development stage and a structure failure stage; establishing an initial reinforcing steel bar corrosion model and a rust pit growth model based on the Fick second diffusion law and the consideration of the influence of concreterust expansion cracking damage; testing and simulating a reinforcing steel bar crack propagation rule under the influence of a four-season environment, and determining fatigue crack growth characterization parameters; constructing a stress intensity factor model considering the influence of stress concentration, and proposing a steel bar corrosion fatigue crack growth analysis method correspondingto a four-season environment; enabling the structural failure criterion to be clear, combining with the vehicle load observation information, performing the systematic consideration of the competitive coupling relation between rust pit growth and fatigue crack growth, judging a failure mode in real time, and achieving the prediction of the service life of the bridge. The method is novel and reasonable, and can provide technical support for safety assessment of the concrete bridge.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

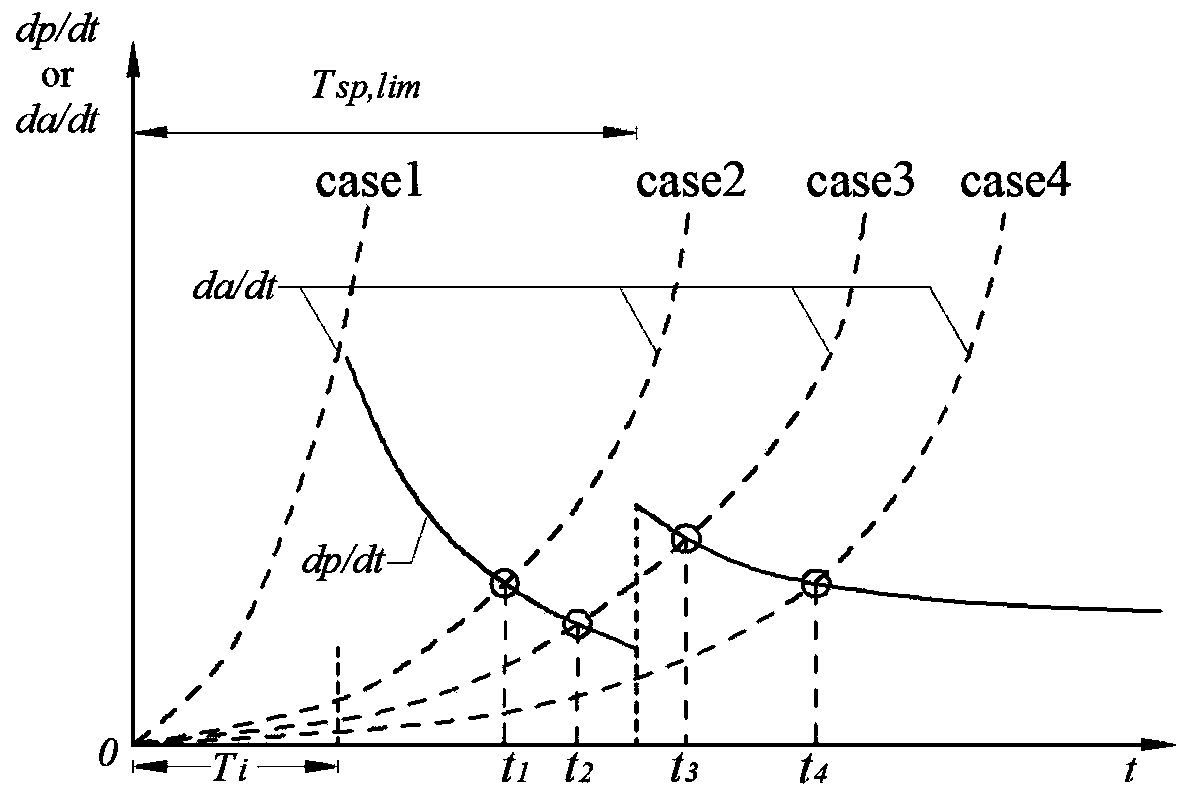

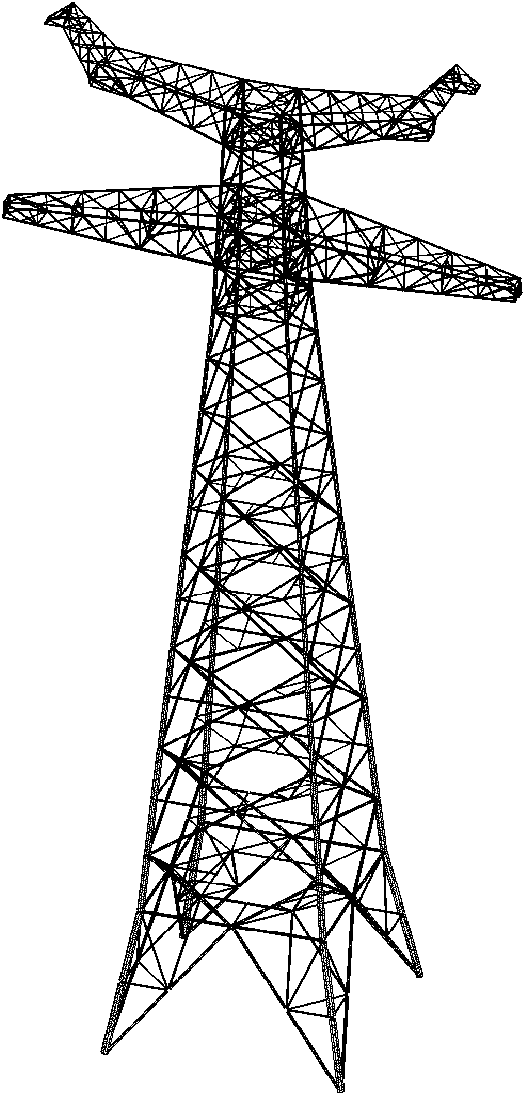

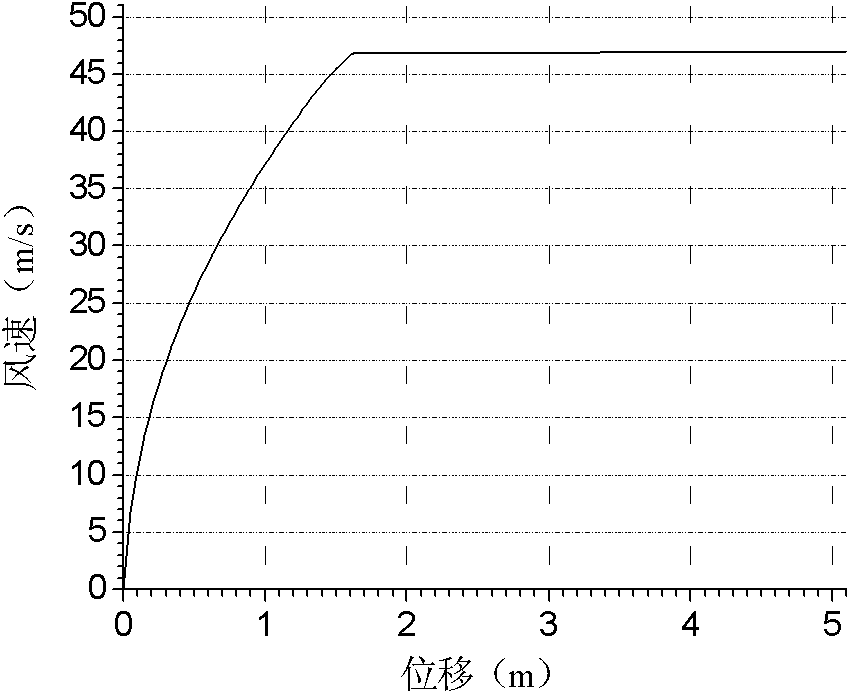

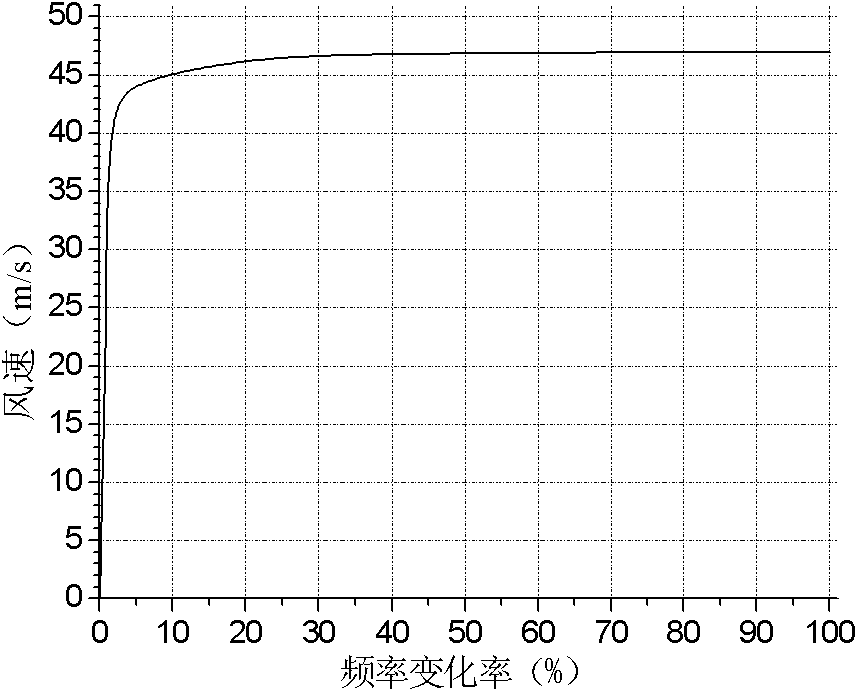

Power characteristic-based power transmission tower structural failure early warning method

InactiveCN101956476AEarly warning is accurateAvoid major accidentsTowersTransmission towerElement model

The invention discloses a power characteristic-based power transmission tower structural failure early warning method, which comprises the following steps of: (1) establishing a power transmission tower high-fidelity dynamic finite element model; (2) establishing a functional relation between a power transmission tower power characteristic change rate and load; (3) acquiring the power characteristic of the power transmission tower in the working state by utilizing a vibration sensor; and (4) early warning the power transmission tower structural failure according to the actually measured power characteristic change rate and the functional relation. By combining the actually measured power characteristic and the structural transcendental analysis, the structural failure problem of the power transmission tower in the working state can be early warned; and by applying the high-fidelity modeling technology and operating state mode identification technology, the method can accurately perform early warning before the structural failure to avoid major accidents.

Owner:SOUTHEAST UNIV

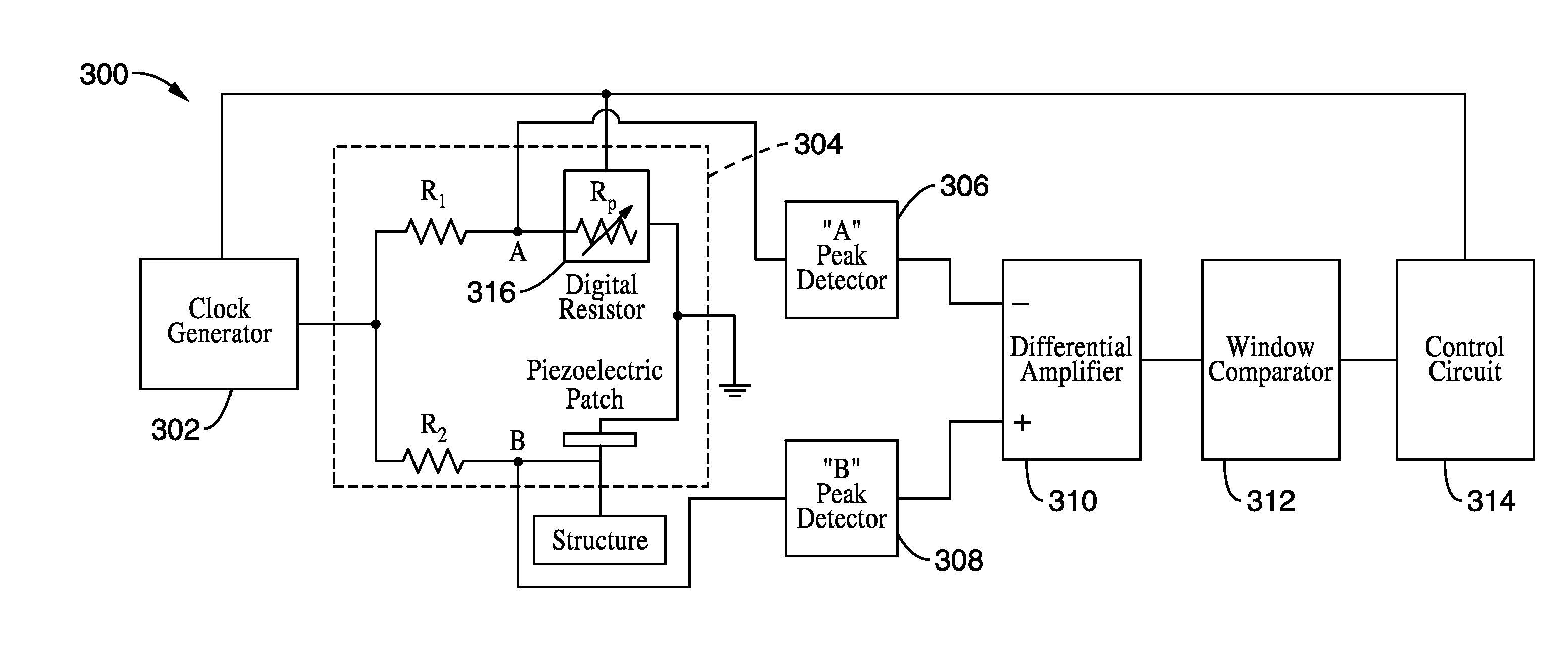

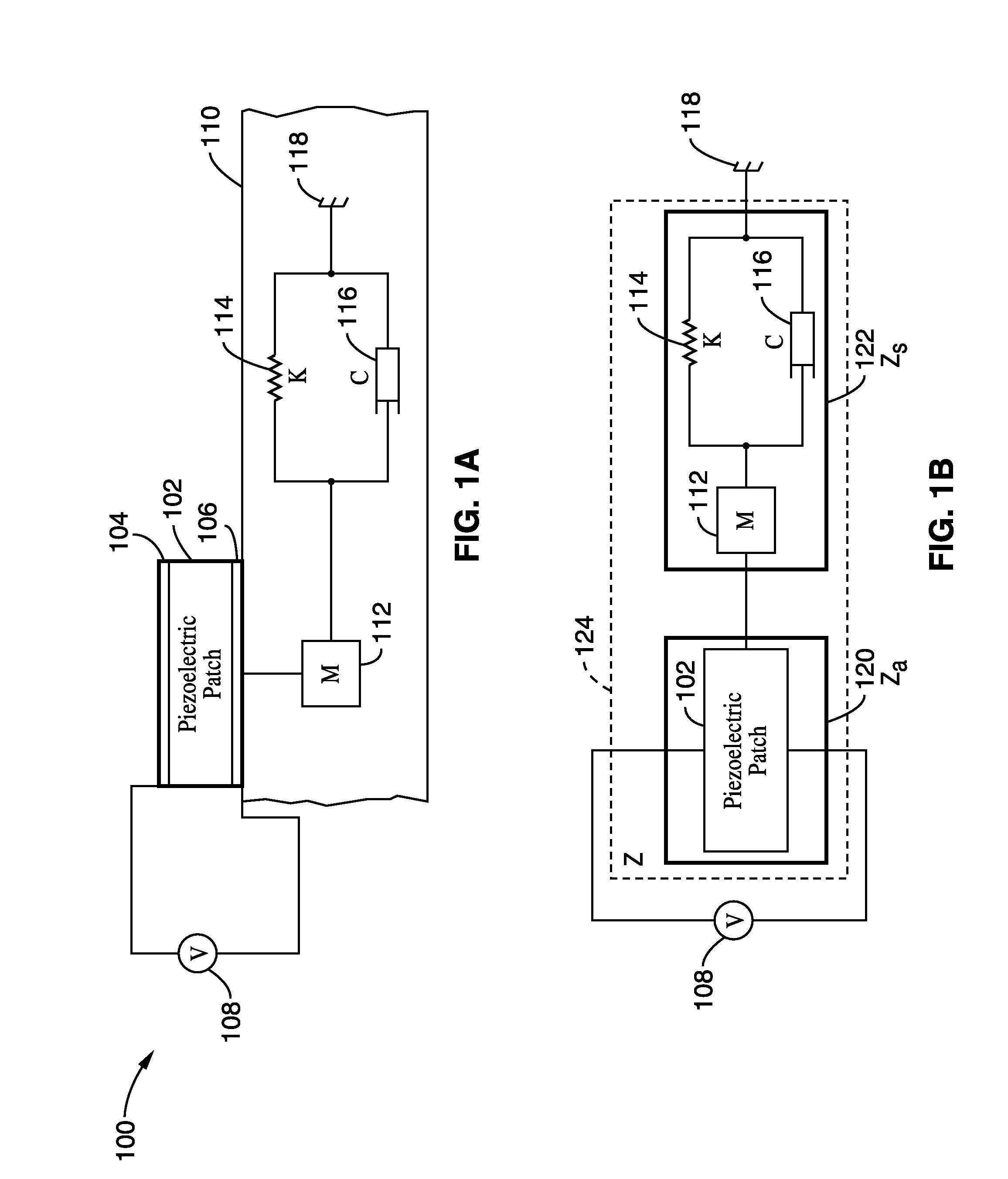

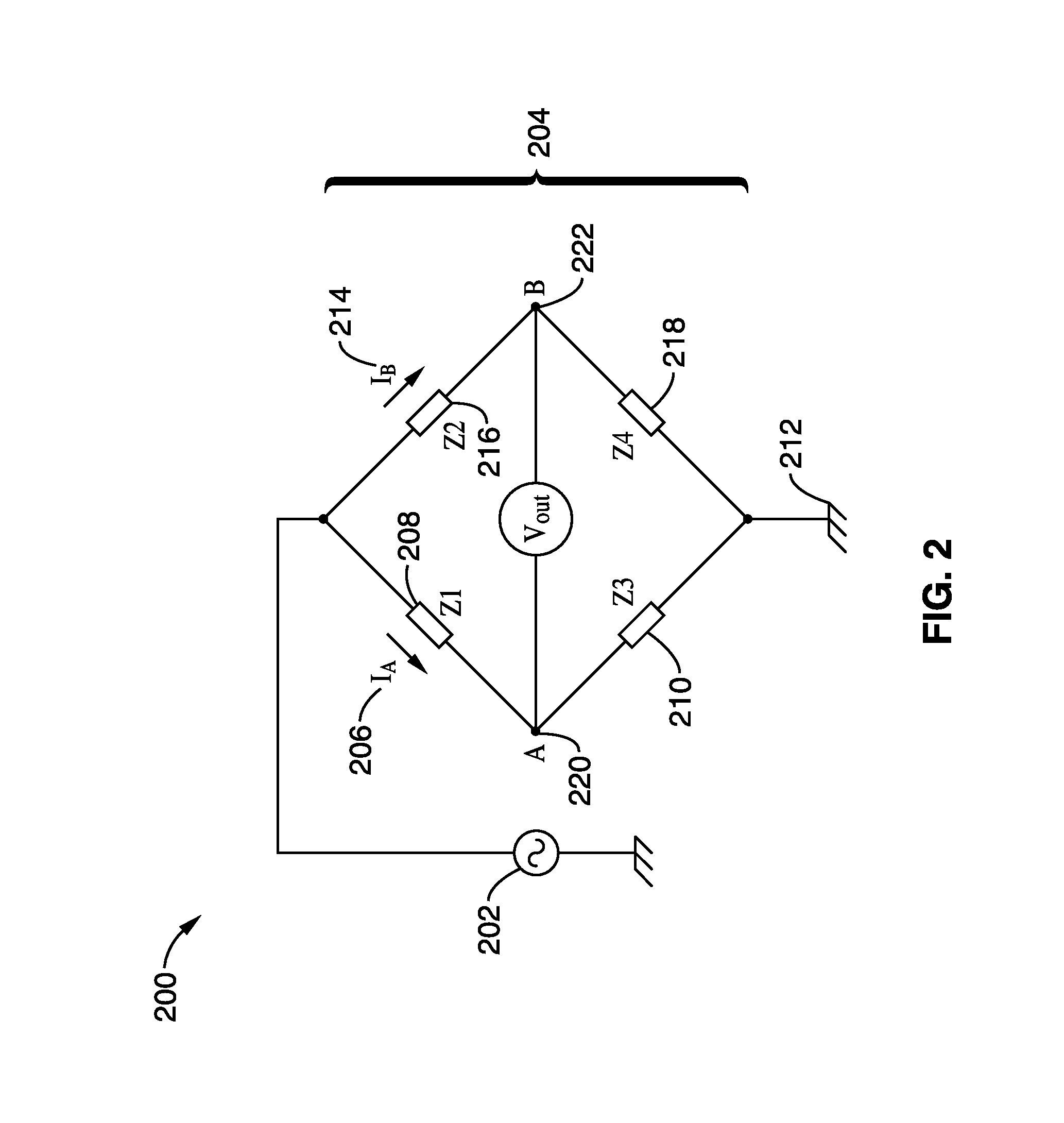

Structural health monitoring circuit

InactiveUS20080231294A1Increase the sensing areaImpedance variation can be readilyMaterial impedanceAc/dc measuring bridgesElectrical resistance and conductanceElectricity

A structural health monitoring circuit apparatus and method are based on electrical impedance variations of a piezoelectric patch, which is attached to a structure to be monitored. The circuit compares a known good sweep of frequency-impedance pairs with a contemporaneous sweep to generate an alarm when an error bound is exceeded. The impedance of the piezoelectric patch is determined though adjustment of a variable reactance in a bridge configuration. By suitable design of the bridge elements, the electrical impedance of the piezoelectric patch may be directly measured. A microprocessor controlled version of this device consumes less than 2 W of power, which may be further reduced by further large scale integration or reduction to a state machine on a programmable gate array. Ultimately, this device may give personnel warnings to aircraft, automobiles, bridges, elevated roads, buildings, or home structural failures.

Owner:NORTH DAKOTA STATE UNIV RES FOUND

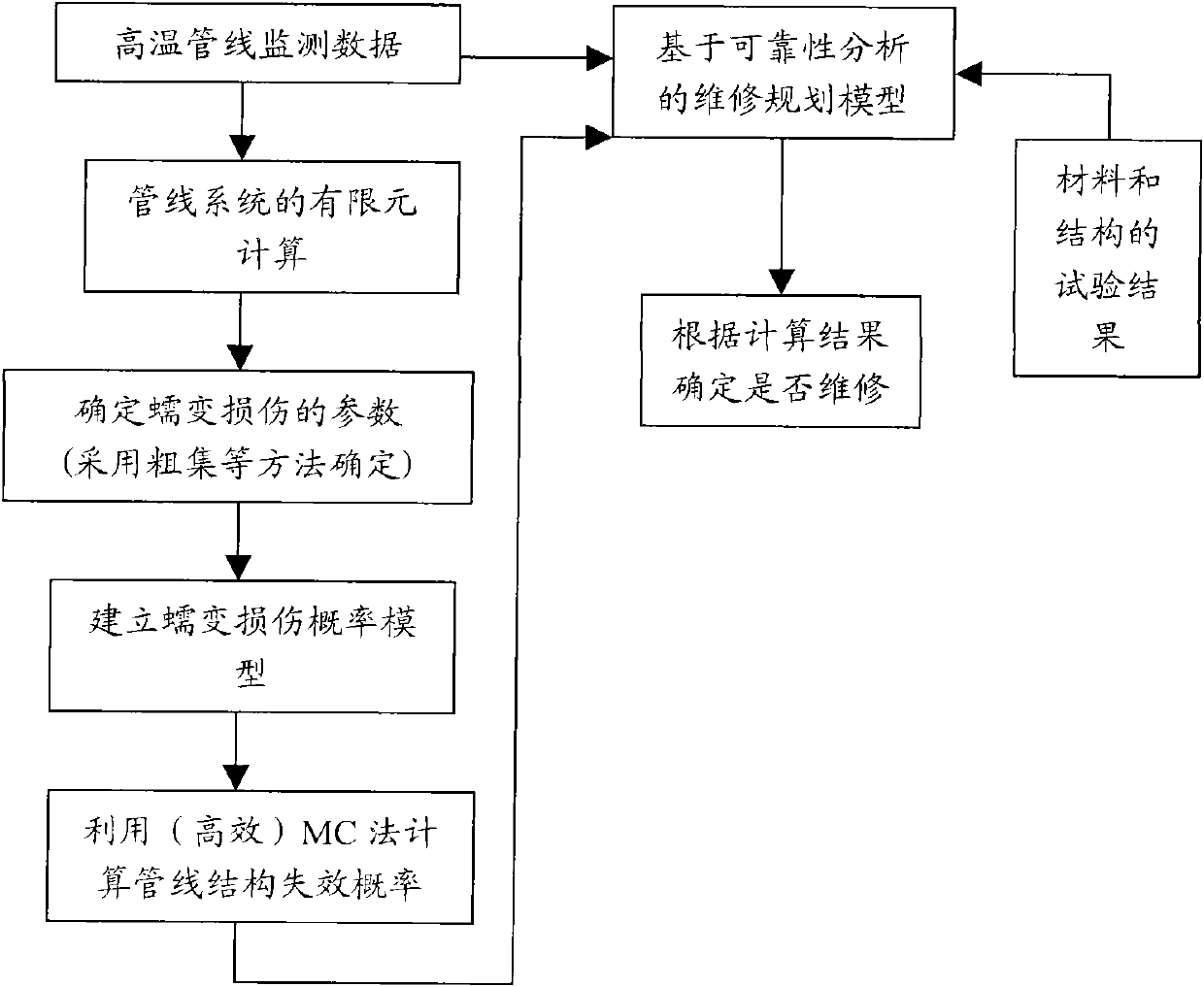

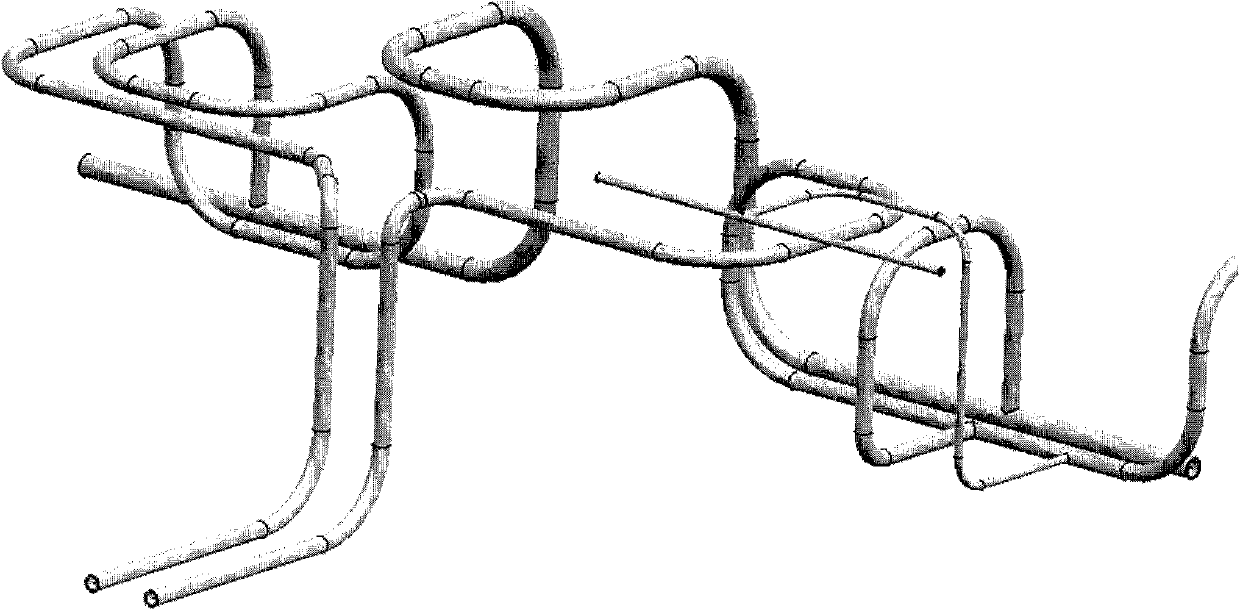

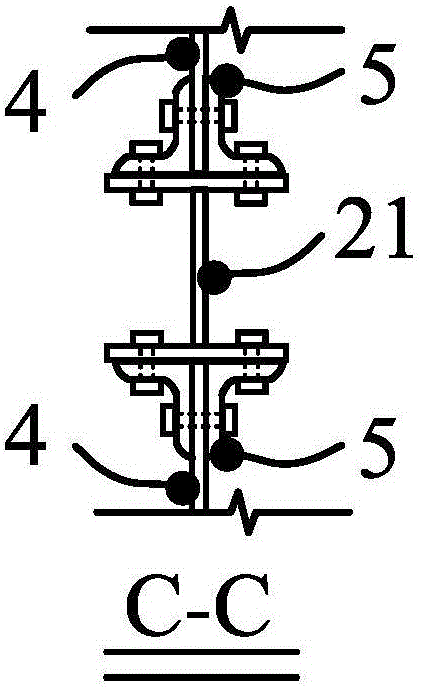

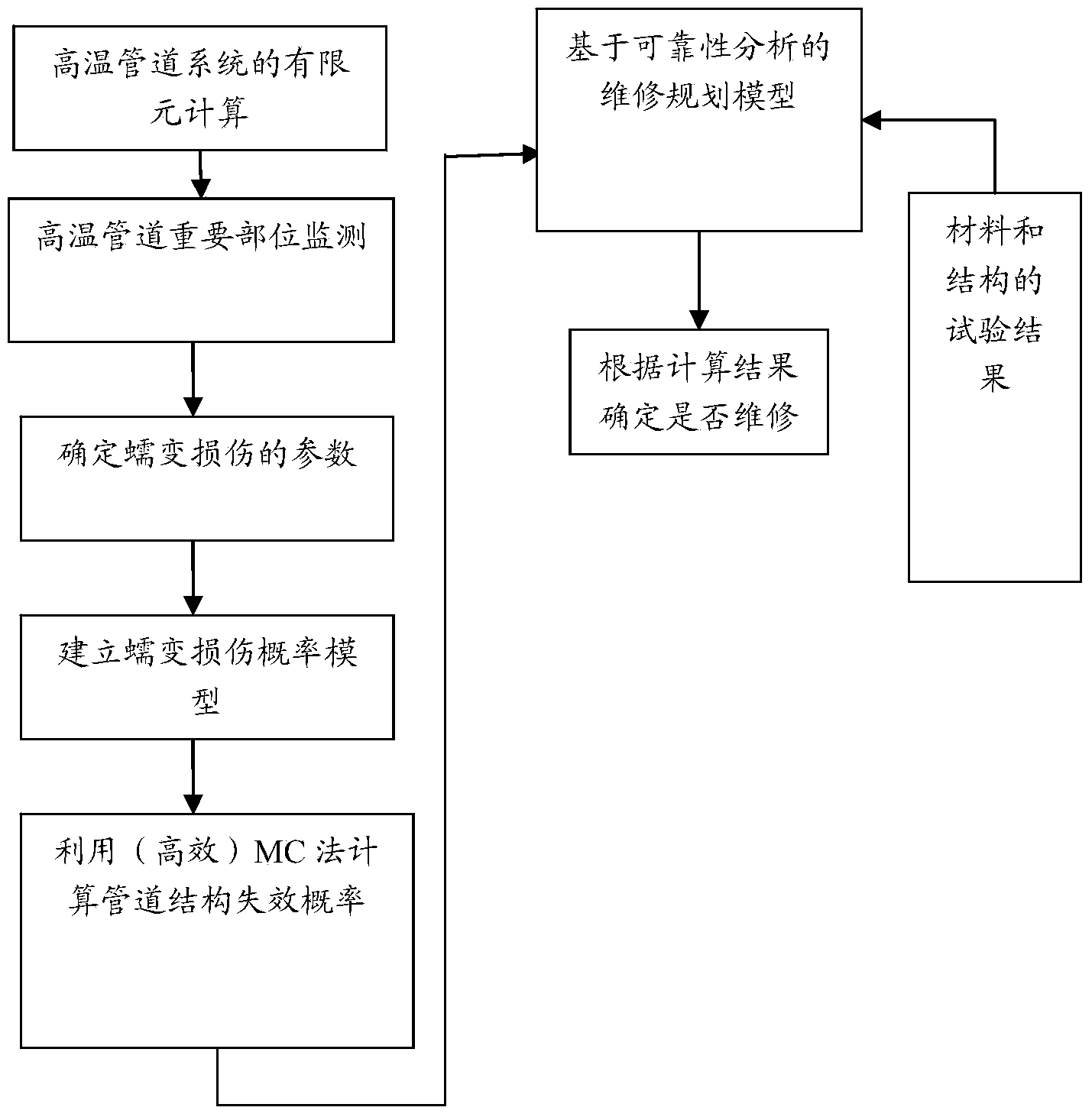

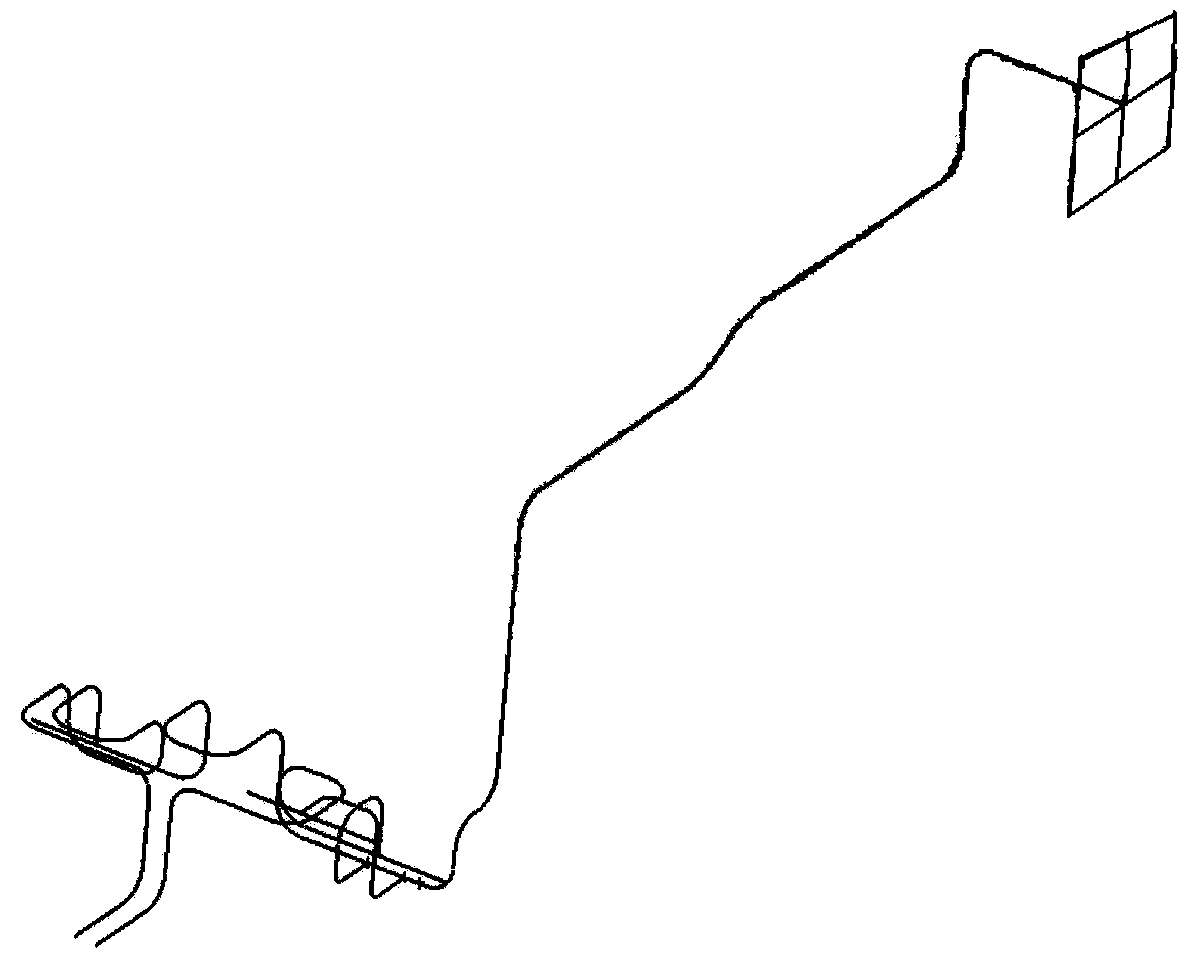

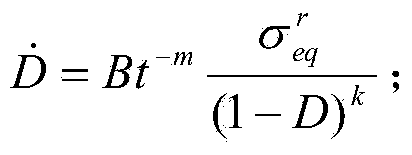

Method for realizing reliability maintenance planning of high temperature pipeline system

InactiveCN101994908AAccurately determineEfficient and accurate determinationStructural/machines measurementPipeline systemsStructural reliabilityMaintenance planning

The invention relates to a method for realizing reliability maintenance planning of a high temperature pipeline system, which comprises the following steps of: collecting and acquiring detection data of a high temperature pipeline system; calculating a finite element of the high temperature pipeline system; determining creep damage parameters according to the influence degree of all factors on the life of the high temperature pipeline; creating a creep damage probability model through determining the probability distribution of the creep damage parameters; calculating a structural failure probability according to the creep damage probability model; creating a maintenance planning model based on reliability analysis according to the detection data, test results of materials and structures of the high temperature pipeline system and the structural failure probability; and carrying out calculation processing according to the maintenance planning model to obtain the optimal maintenance time of the high temperature pipeline system. By adopting the method for realizing the reliability maintenance planning of the high temperature pipeline system, the structural reliability is determined efficiently and accurately, a maintenance scheme can be accurately determined, the similar problem of the maintenance planning of the high temperature pipelines in other fields can be solved, and the method has wider application range.

Owner:EAST CHINA UNIV OF SCI & TECH

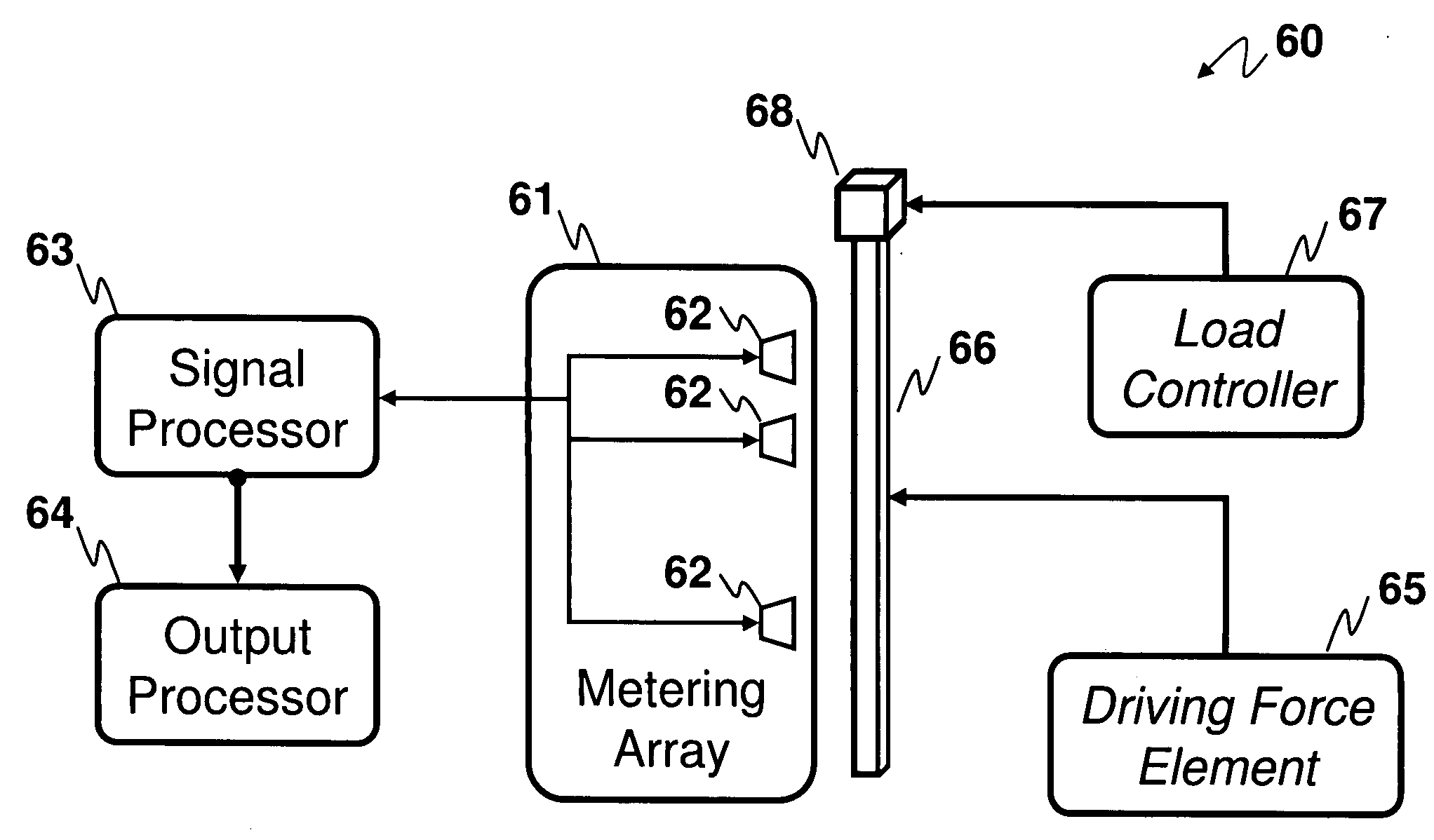

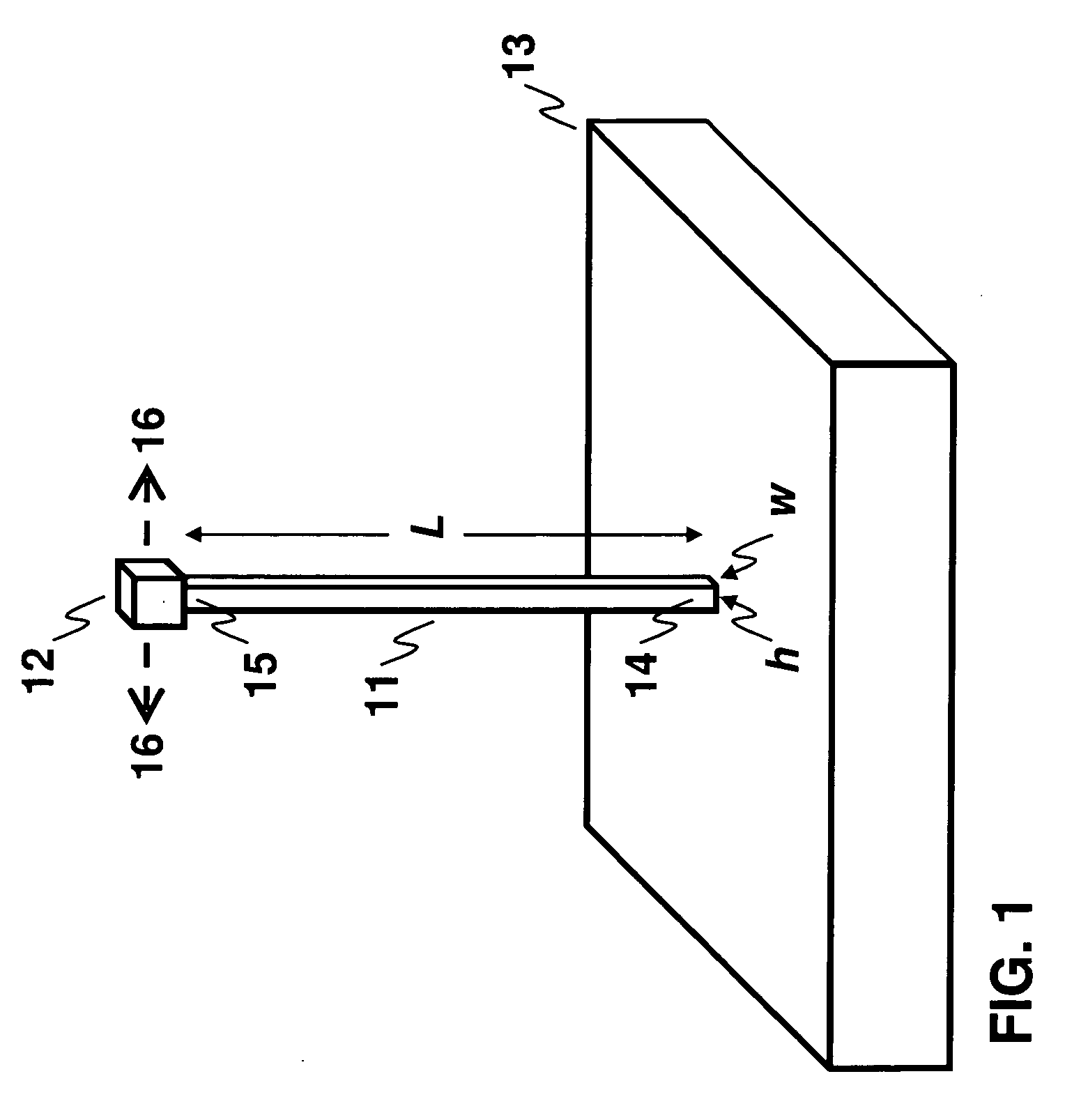

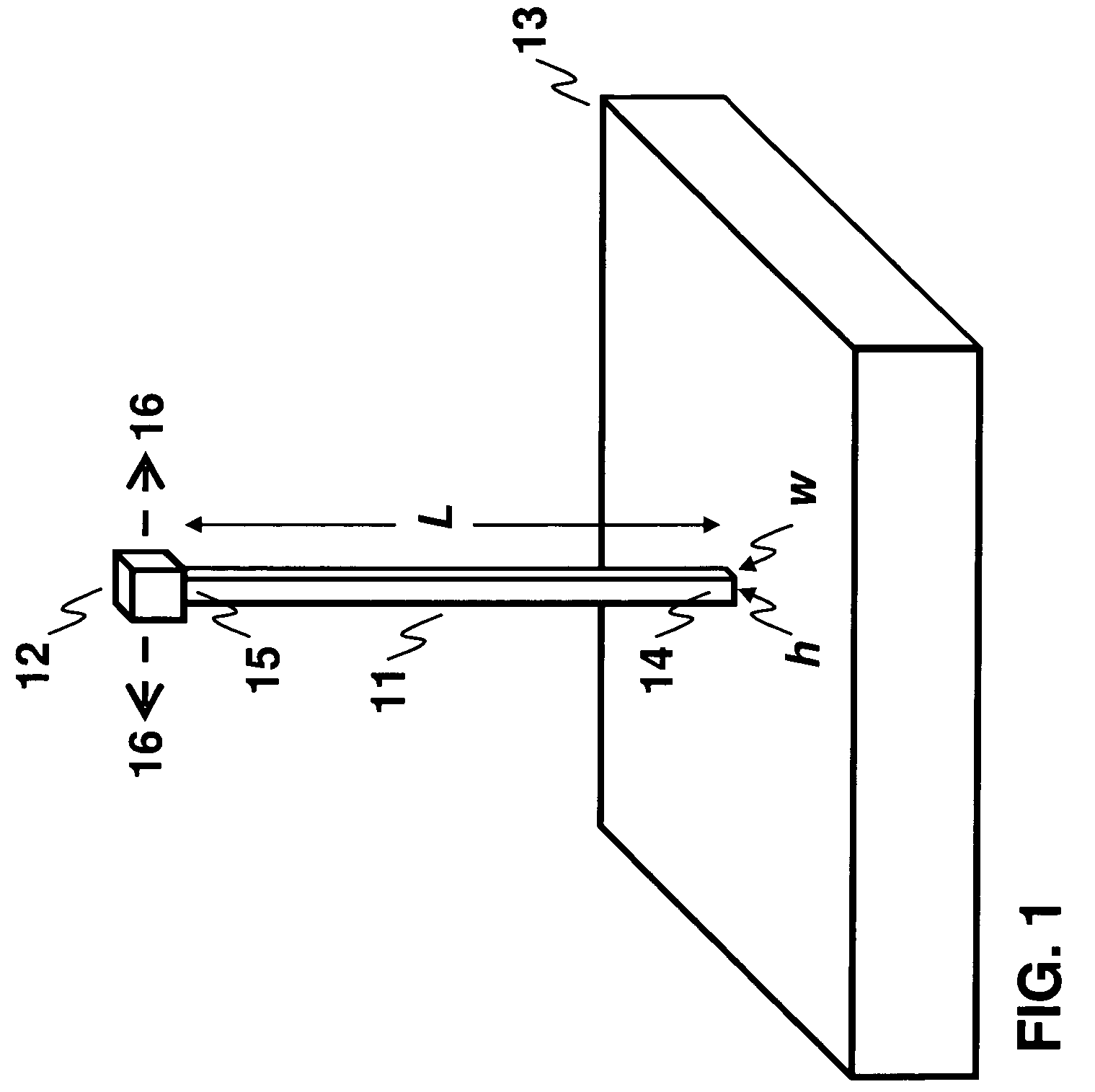

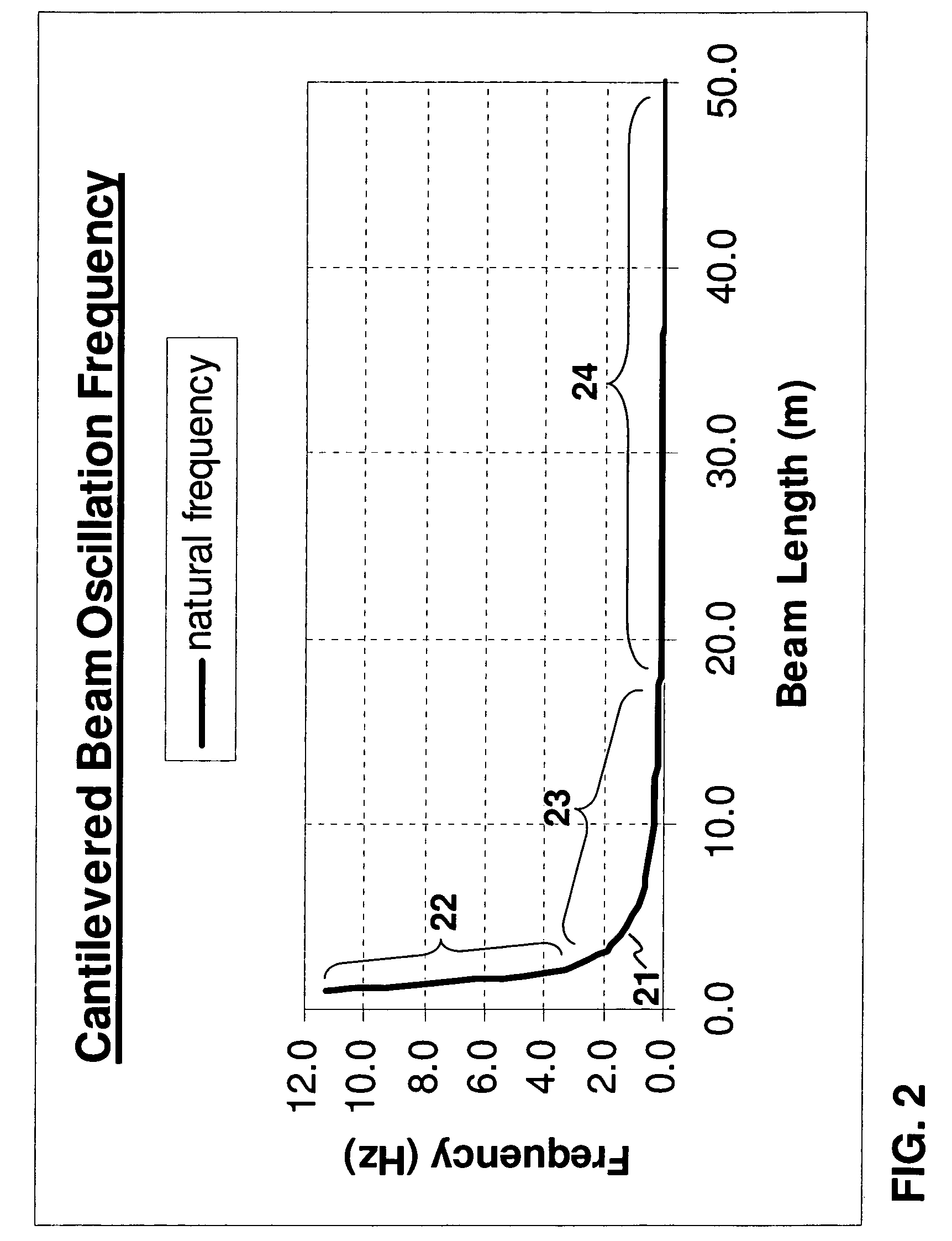

System and method for detecting onset of structural failure

A system for detecting the onset of structural failure in a structural element subject to a mechanical load comprises a metering array, a signal processor, and an output processor. The metering array measures physical quantities associated with the structural element. The signal processor transforms the measured physical quantities into a series of sample mode spectra, and the output processor generates output as a function of the series of sample mode spectra. Methods are also disclosed for detecting the onset of failure in a structural element subject to a mechanical load, for structural testing, and for structural health monitoring.

Owner:AEROJET ROCKETDYNE OF DE

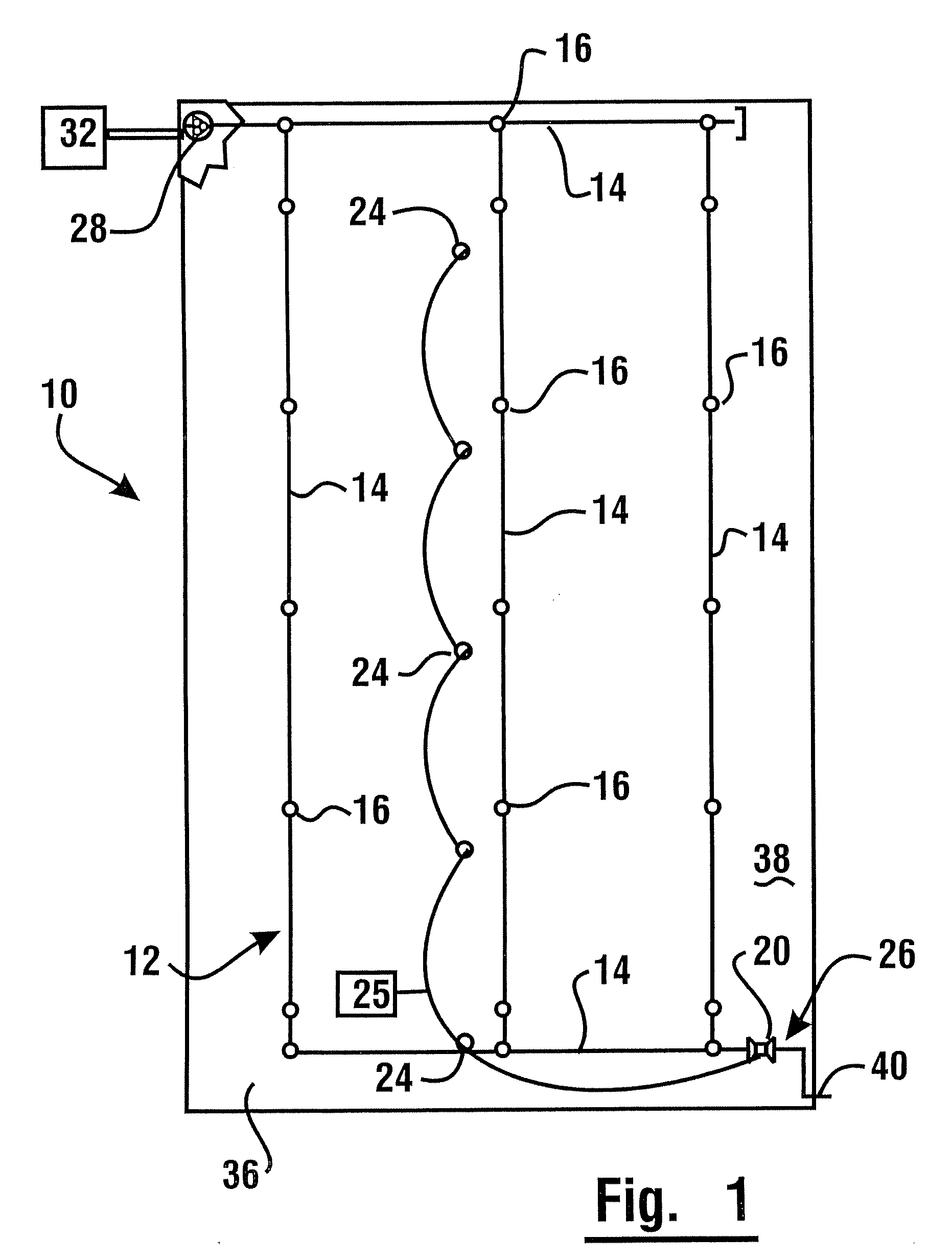

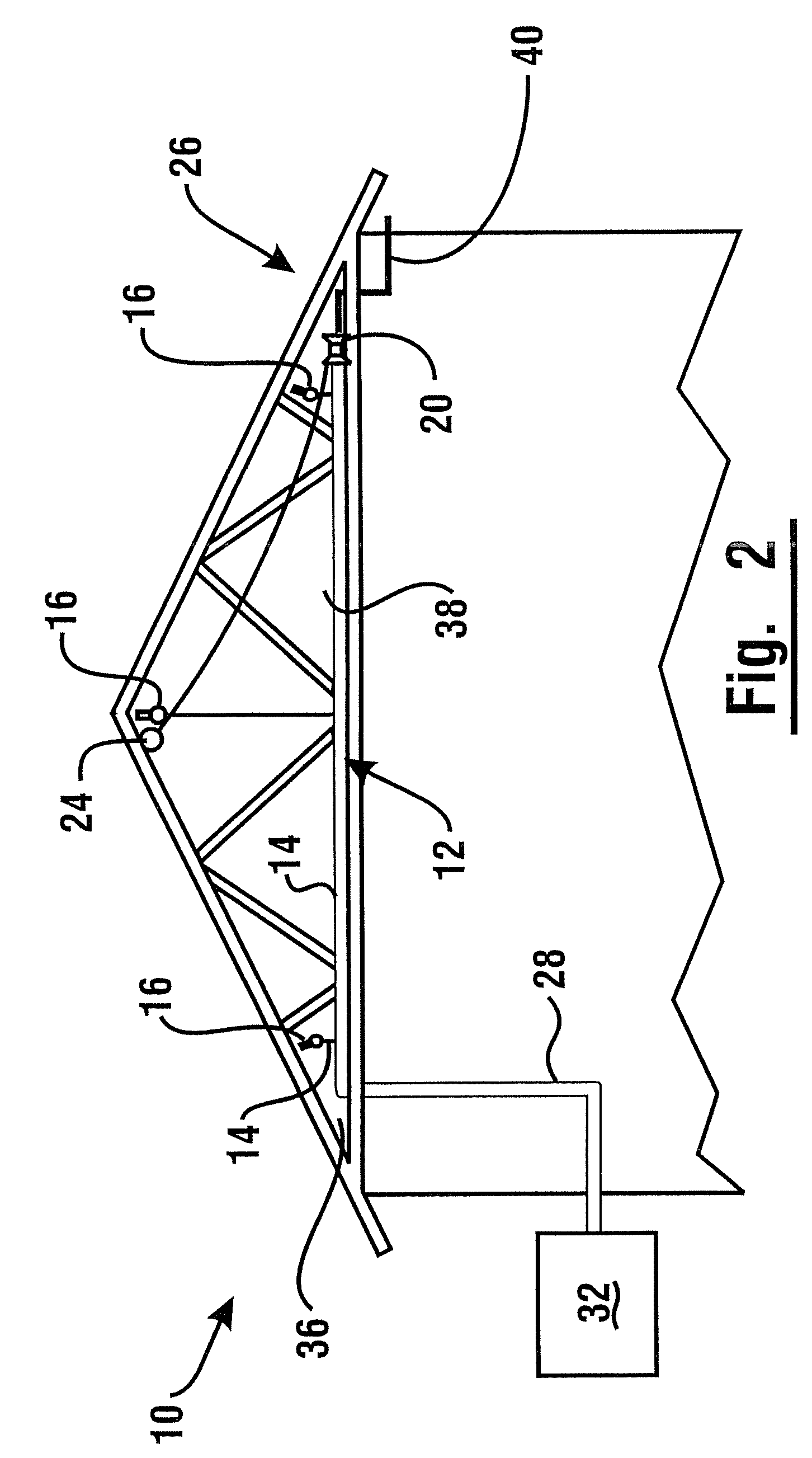

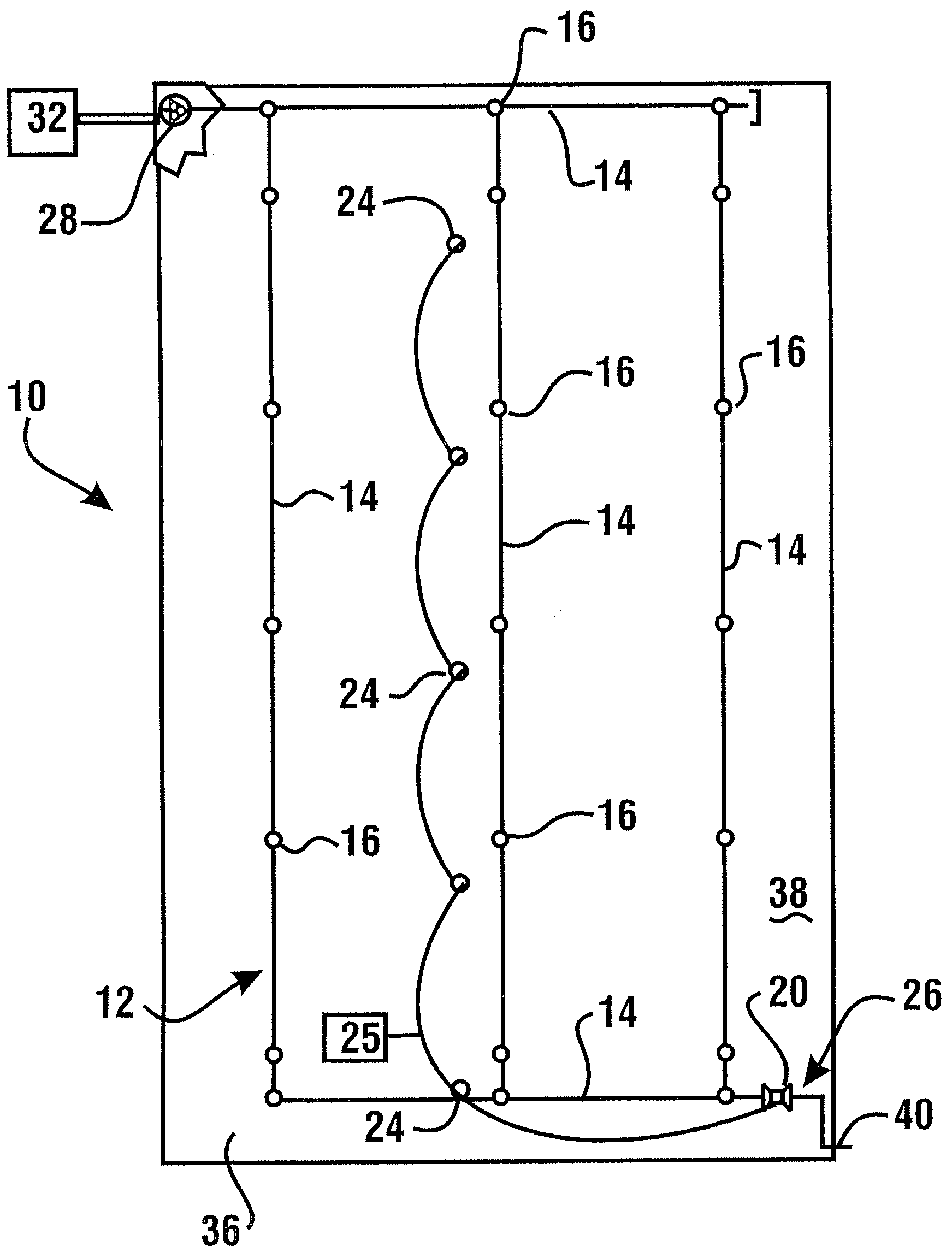

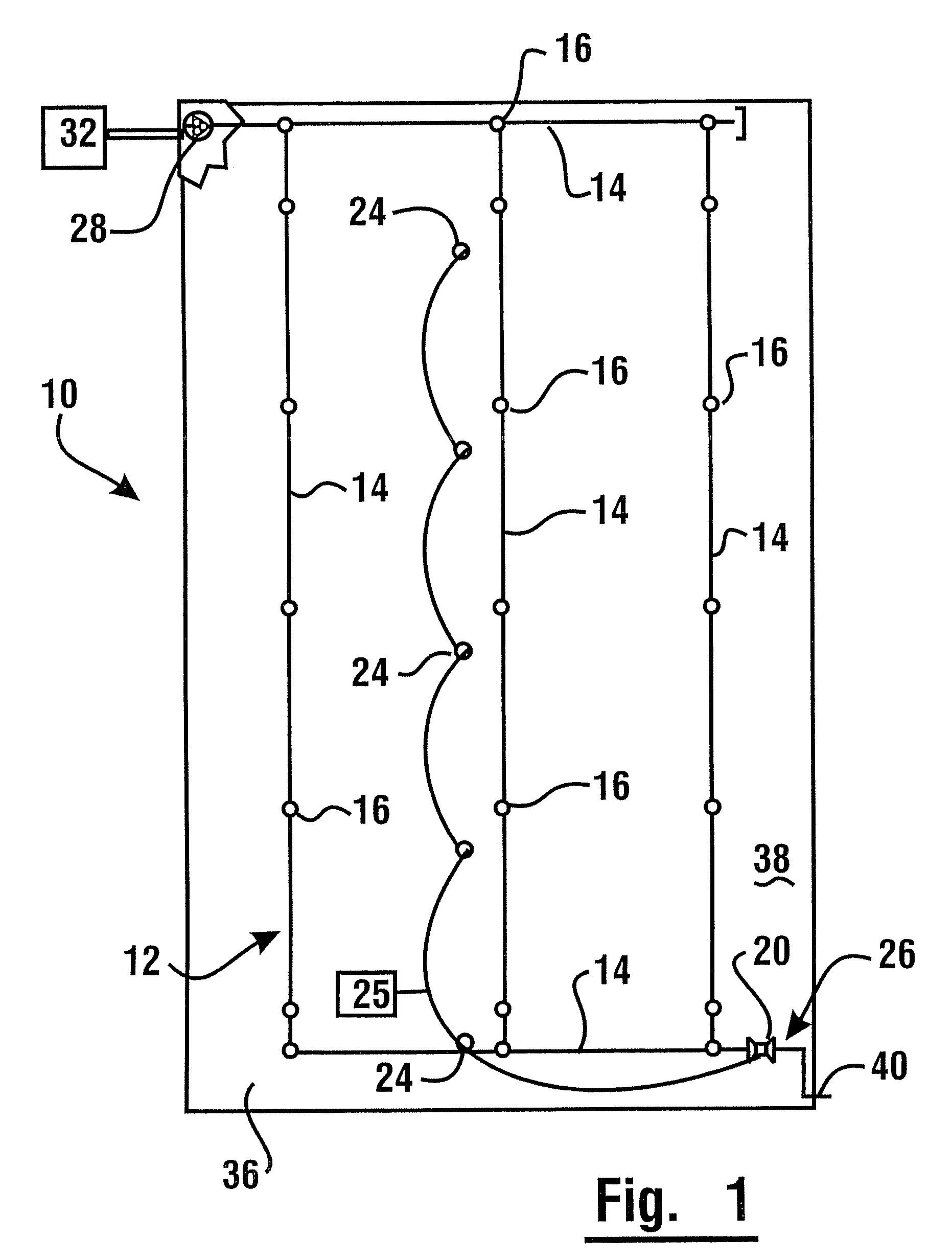

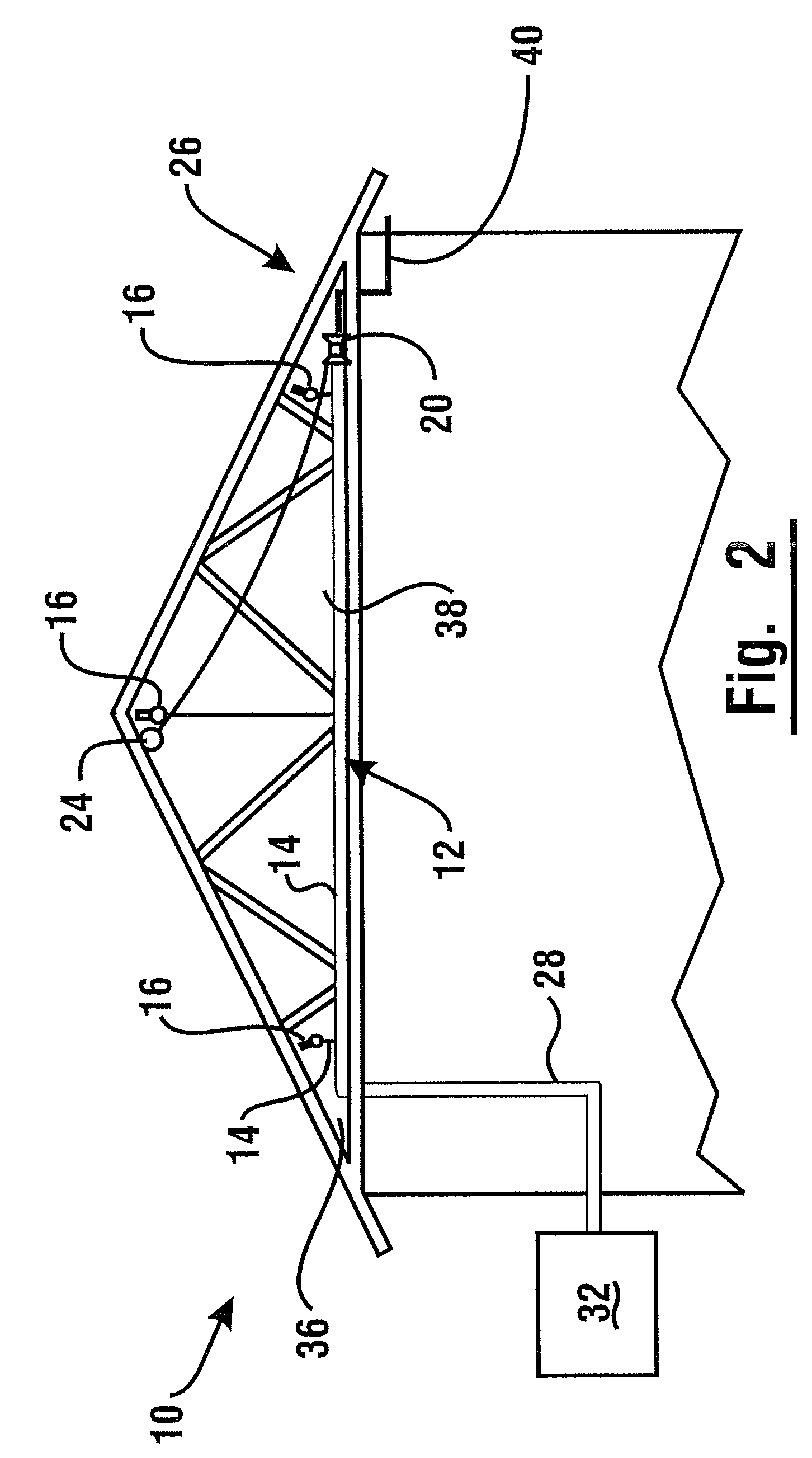

Fire suppression system

A sprinkler system comprises a network of CPVC conduits and a plurality of sprinklers. The system includes an electrically activated solenoid control valve to allow fluid to flow in the pipe network. One or more fire detectors operate independently of the condition of the sprinklers. Upon detection of an incipient fire situation, a fire detector sends an electrical signal to cause activation of the control valve. Upon activation of the control valve, fire suppression fluid is caused to flow through the conduits before the incipient fire situation matures into a sprinkler-triggering event. The cooling effect of fluid flowing through the conduit enables the conduit to resist structural failure prior to sprinkler deployment. The control valve may be disposed at a remote location in the sprinkler line and be operable as part of an inspector's test connection.

Owner:LUBRIZOL ADVANCED MATERIALS INC

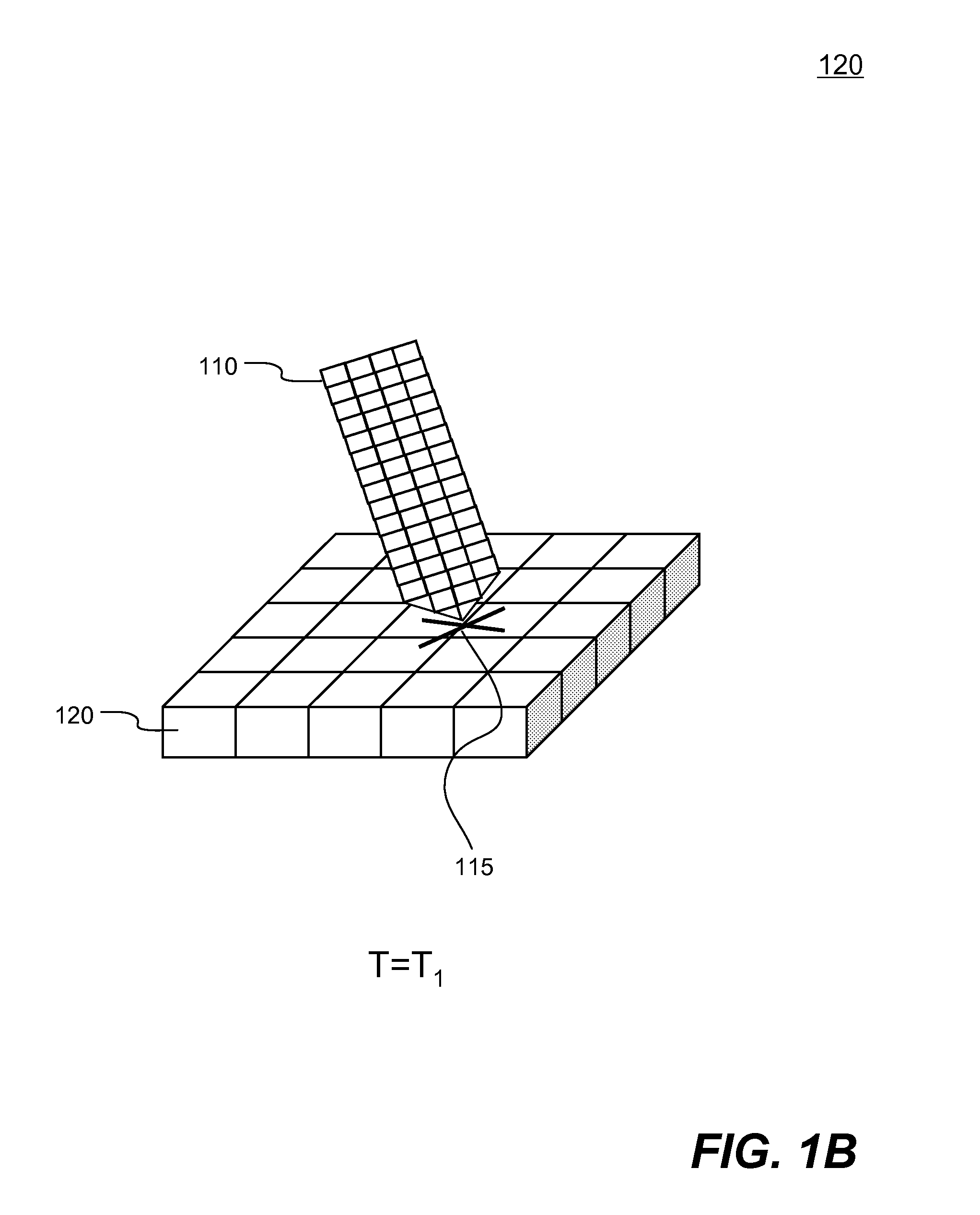

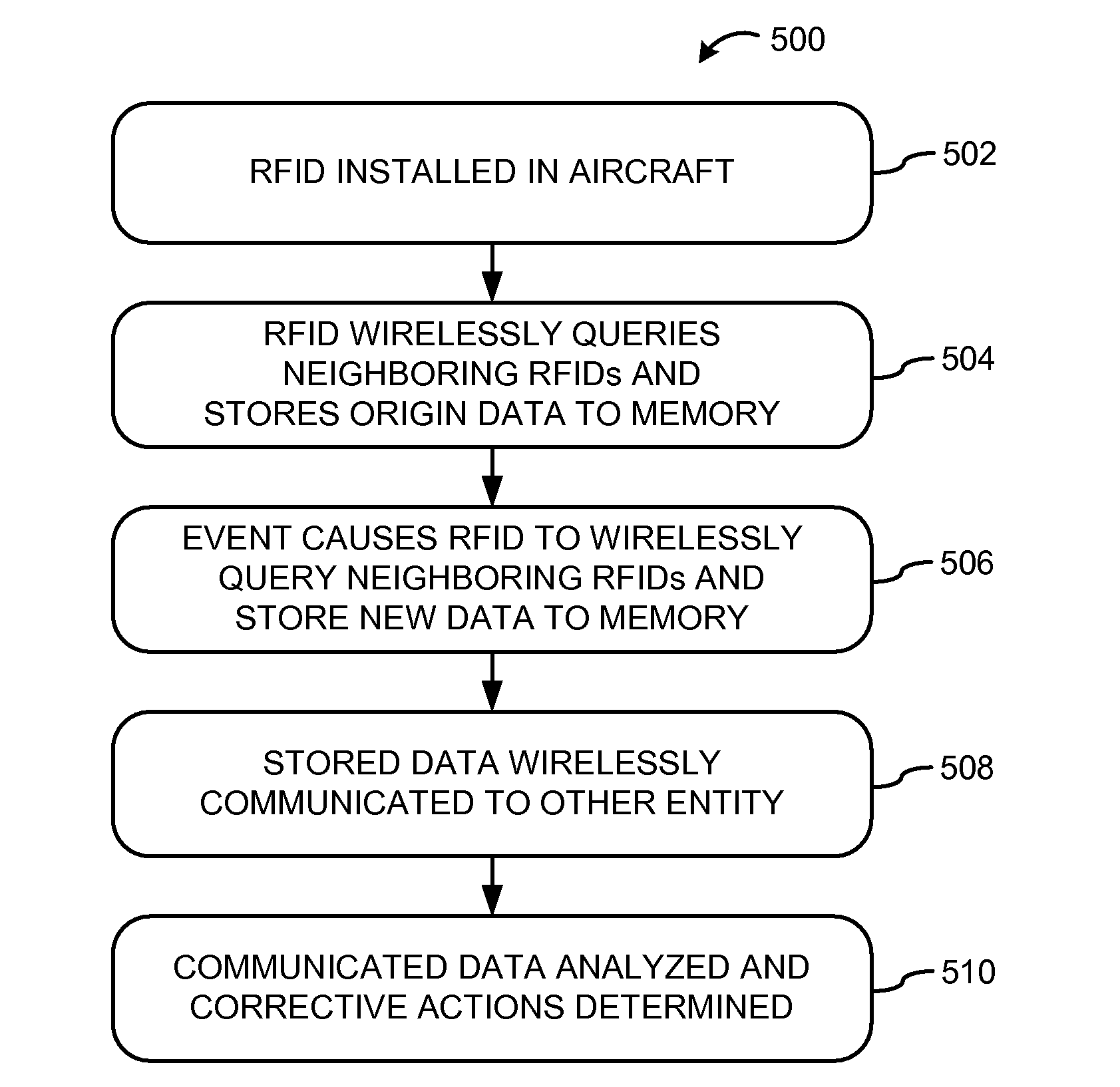

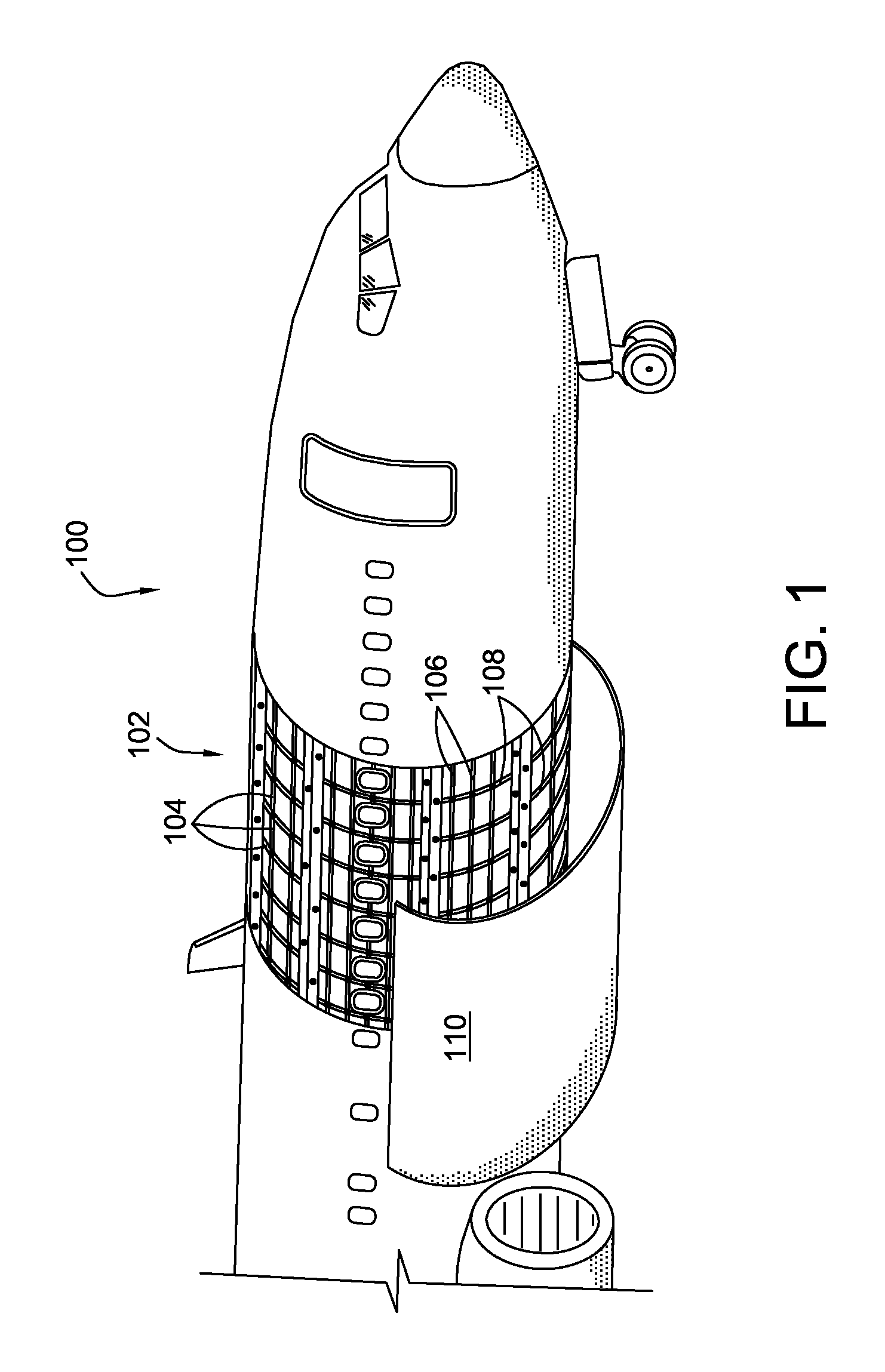

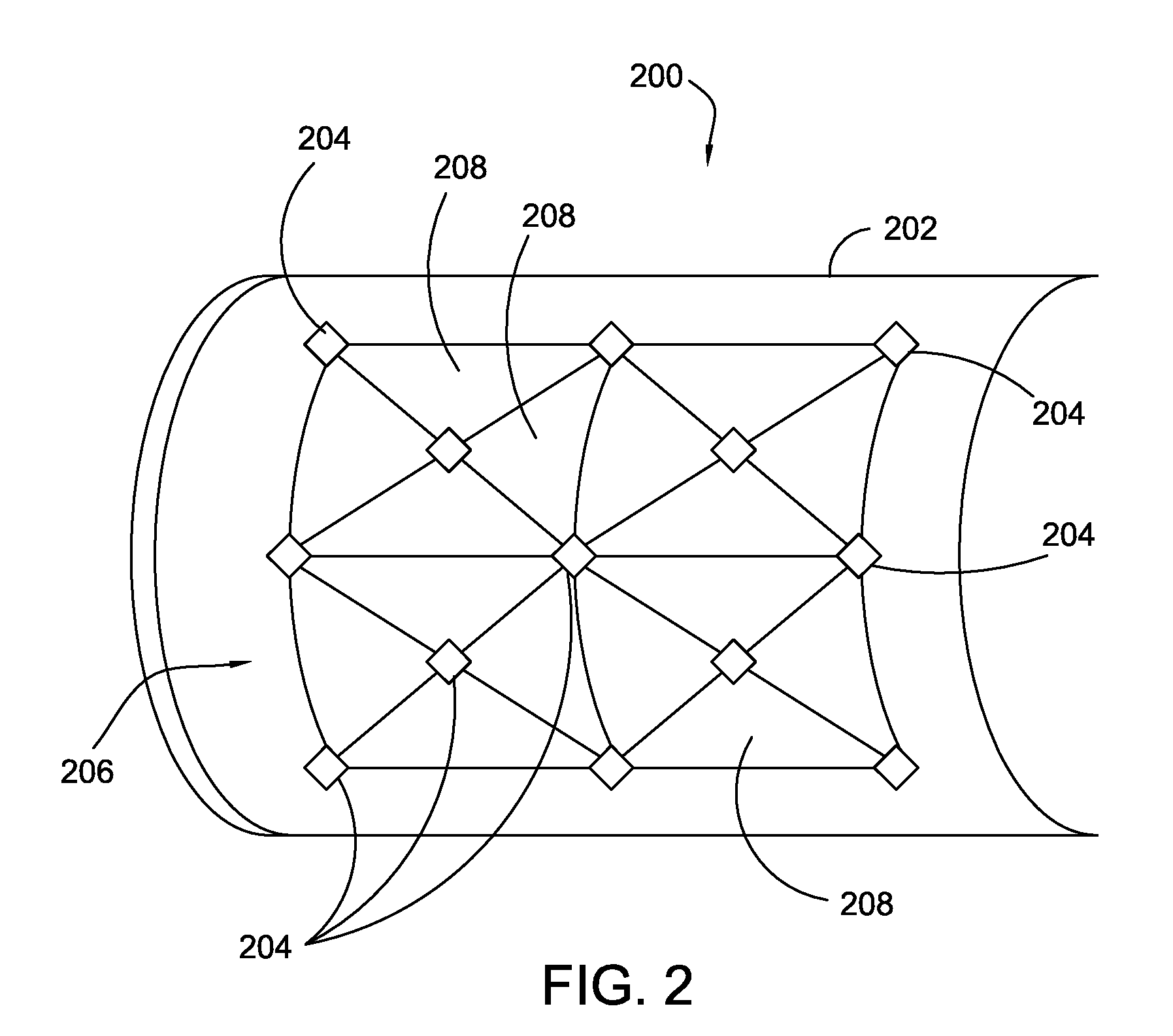

Physical Finite Element Model

ActiveUS20090189784A1Vehicle testingElectric/magnetic position measurementsElement modelComputer science

a plurality of RFIDs is installed on aircraft or other structure. The RFIDs can query one another upon original installation and in response to predetermined event detection, and determine their relative locations within a mesh. The determined location data and other information are stored within the respect memories of the RFIDs. The stored data can be later accessed and used in analyzing damage or structural failure of the aircraft. Corrective measures are thus expedited because before-and-after structural comparisons can be readily made, with or without reference to original engineering data for the aircraft.

Owner:THE BOEING CO

System and method for detecting onset of structural failure

A system for detecting the onset of structural failure in a structural element subject to a mechanical load comprises a metering array, a signal processor, and an output processor. The metering array measures physical quantities associated with the structural element. The signal processor transforms the measured physical quantities into a series of sample mode spectra, and the output processor generates output as a function of the series of sample mode spectra. Methods are also disclosed for detecting the onset of failure in a structural element subject to a mechanical load, for structural testing, and for structural health monitoring.

Owner:AEROJET ROCKETDYNE OF DE

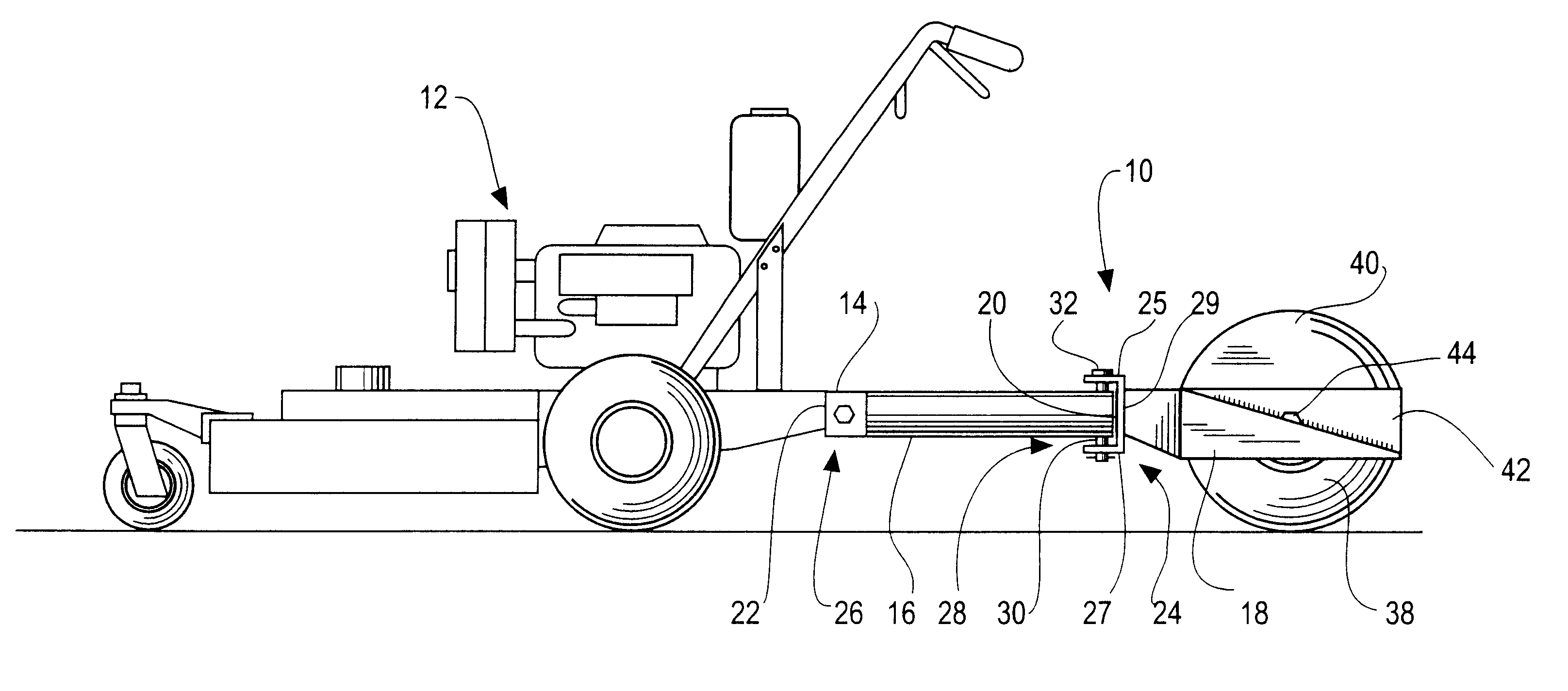

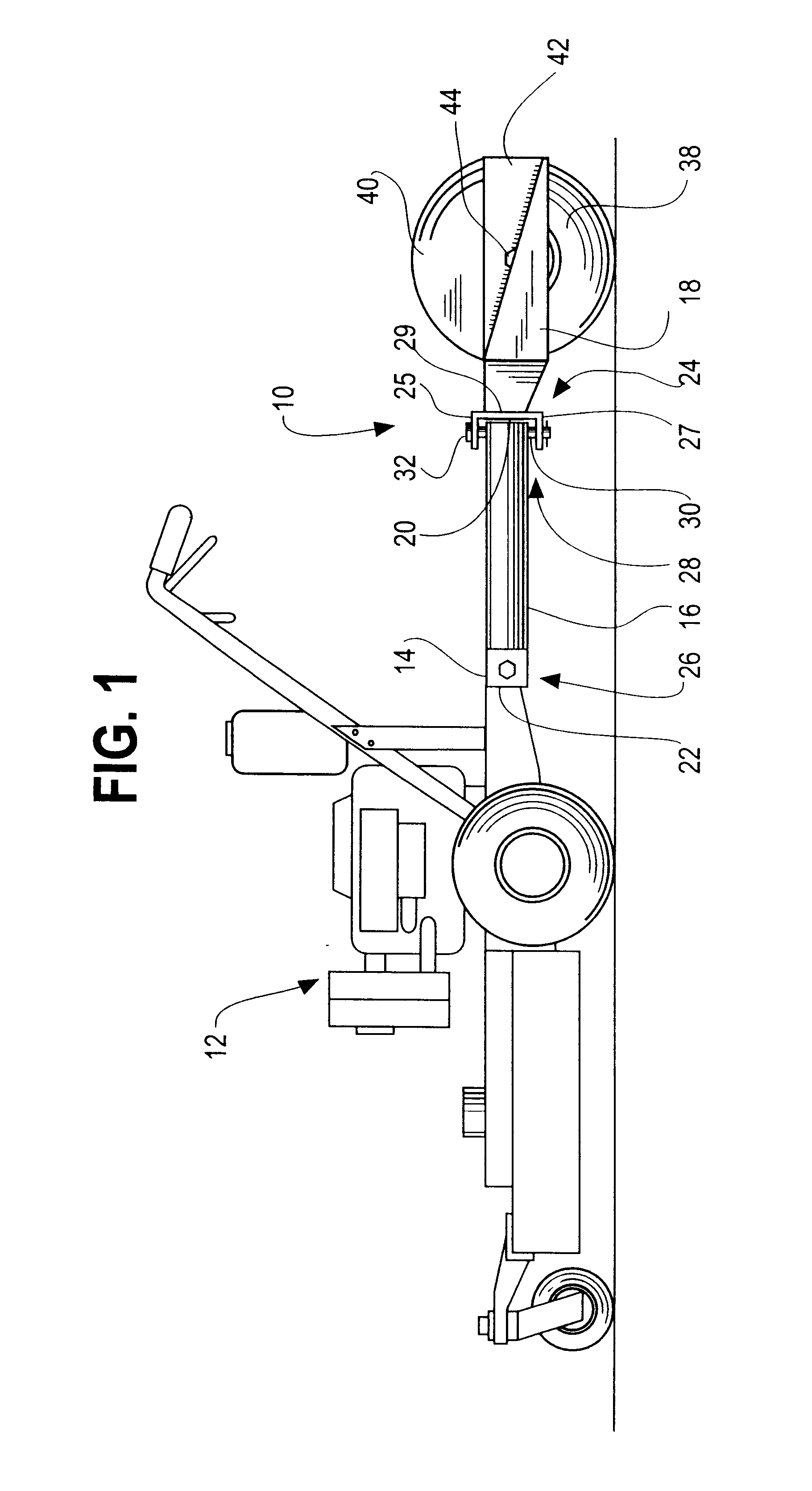

Walk behind mower sulky apparatus with improved operator platform attachment means

Owner:HAVENER ENTERPRISES

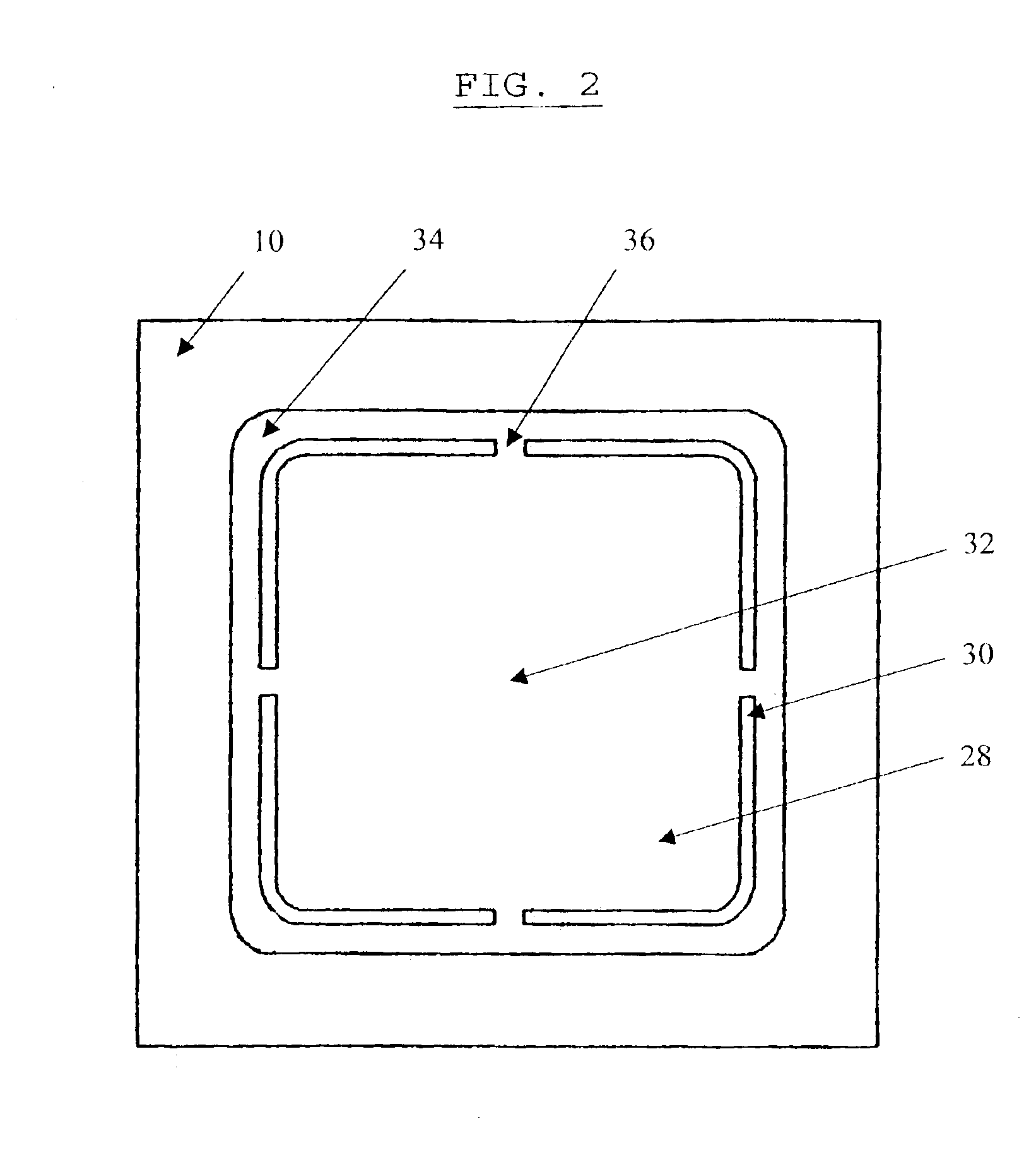

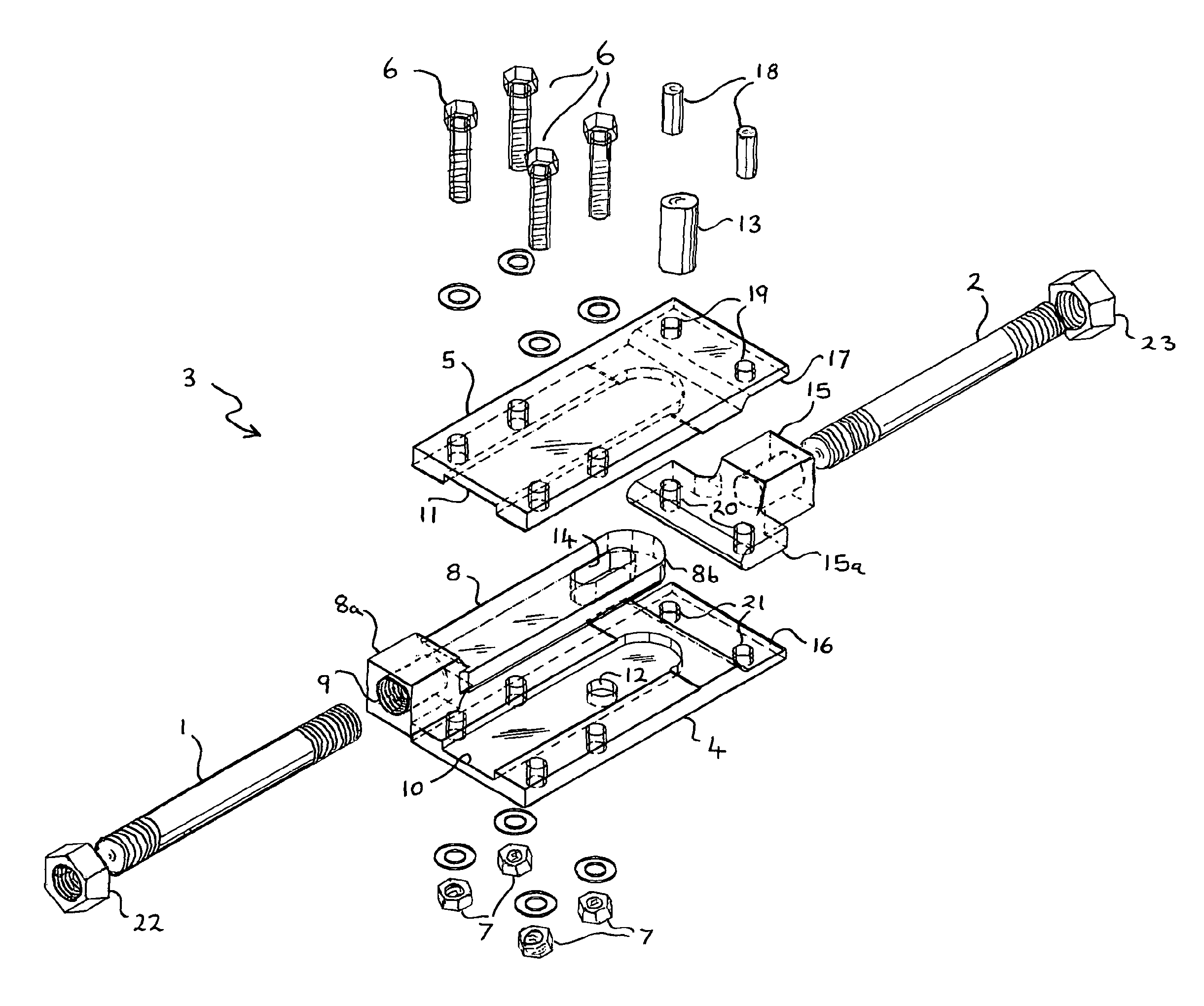

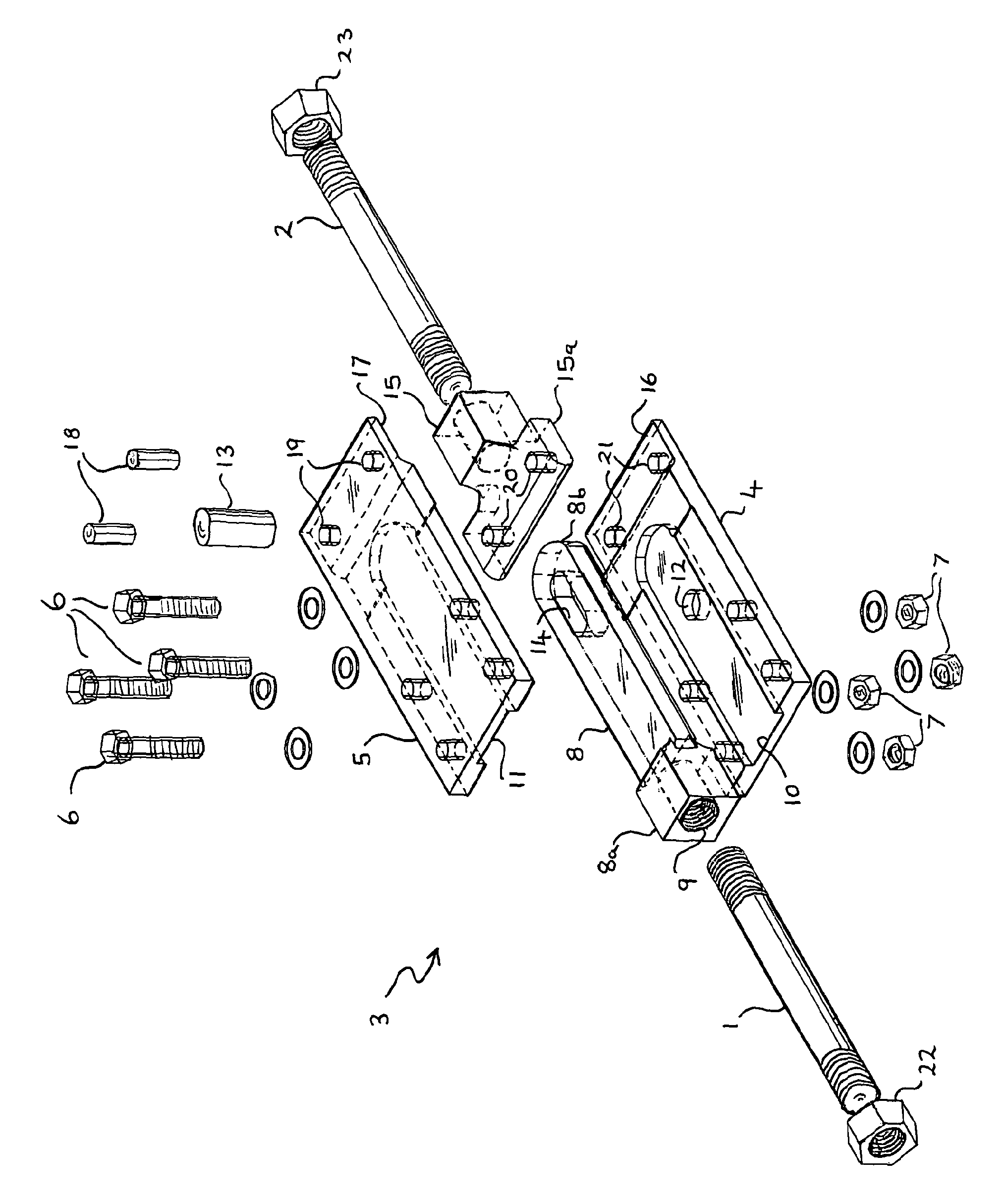

Building anchor systems

ActiveUS8806836B2Prevent and inhibit catastrophic structural failure of structurePreventing and inhibiting structural failureGirdersLocking fastenersEngineeringStructural failure

A building anchor system includes a pair of elongate anchor rods (1,2), an anchor rod coupling joint (3) for joining the anchor rods end-on-end, the anchor rod coupling joint comprising or including a sleeve (4, 5, 6&7) for connection to an end of one of the anchor rods (1) a slideable arm (8) receivable in the sleeve for connection to an end of the other anchor rod (2) a closed slot within the arm or sleeve for slideably receiving the free end of a stop member (13) by which movement of the anchor rods along their major axis is possible to the extent allowed by the length of the slot, and frictional adjustment means (6,7) acting between the arm and the sleeve by which they may be joined and by which the force required to move them with respect to each other can be selectively varied. The invention also extends of a method of preventing or inhibiting catastrophic structural failure of a building by installing one or more anchor systems of the type described.

Owner:CINTEC INT

Flight acceptable knitting needles

A knitting needle has multiple segments, at least one of which is relatively non-rigid, wherein the segments can be combined to produce a needle that is sufficiently rigid to be used for knitting, while also having diminished usefulness as a weapon. In three major classes of embodiments, one of the segments fits inside the other in a telescoping manner, one of the segments wraps around the other, or the two segments can fit together in some sort of slotted fashion. There may be one or more engineered points of structural failure. Segments can be held together frictionally, magnetically, threadably, using a snap or twist and lock fitting, or in any other suitable manner. Contemplated segments can have any suitable composition, including especially a bendable plastic or a foam rubber.

Owner:EG POP

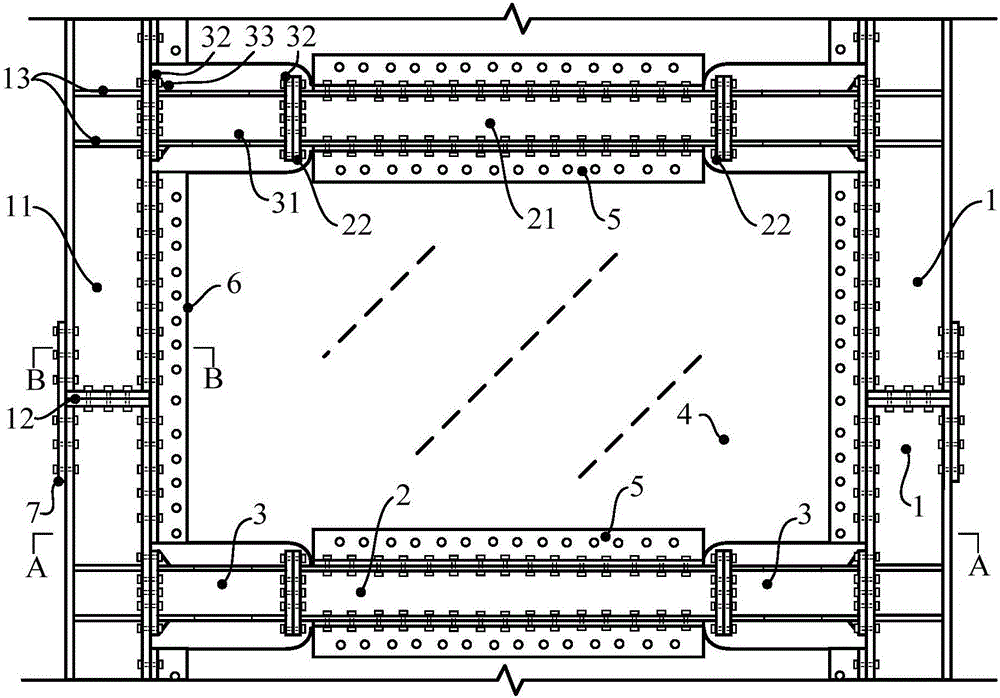

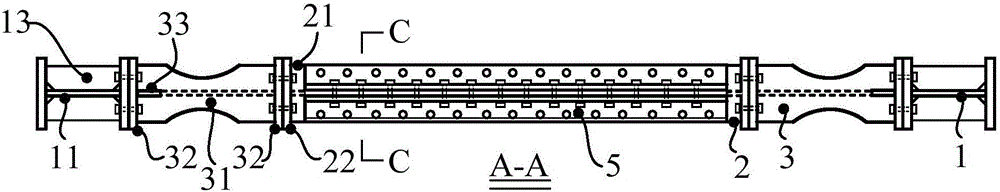

Fabricated steel frame and steel plate shear wall structure replaceable after earthquake

InactiveCN106049671AGuarantee the construction qualityGuaranteed economic lossWallsSteel frameSteel columns

The invention discloses a fabricated steel frame and steel plate shear wall structure replaceable after an earthquake. The fabricated steel frame and steel plate shear wall structure comprises frame steel columns, main steel beams, post-earthquake replaceable energy dissipating joints and post-earthquake replaceable embedded steel plates. Webs of column bodies of the frame steel columns are connected through first end plates. Second end plates of each main steel beam are fixedly arranged at the two ends of a corresponding beam body. Third end plates of each post-earthquake replaceable energy dissipating joint are fixedly arranged at the two ends of a corresponding beam section, and connected with the corresponding second end plate of the corresponding beam body and an inner flange of the corresponding column body through bolts correspondingly. The post-earthquake replaceable embedded steel plates are connected with the inner flanges of the corresponding column bodies and the corresponding beam bodies through bolts, and long grooves are formed in the portions, making contact with the corresponding post-earthquake replaceable energy dissipating joints, of the four corners of each post-earthquake replaceable embedded steel plate. Internal force can be effectively transmitted, and it is guaranteed that the structural integrity and stress performance are given to full play; and structural failure and a failure mechanism are actively controlled, it is guaranteed that a main body structure is kept in an elastic state, plastic energy dissipation and damage occur in designated local positions, post-earthquake replacement and repairing are facilitated, and economic loss is reduced.

Owner:BEIJING JIAOTONG UNIV

Power station high-temperature pipe system maintenance method based on non-probability reliability theory

ActiveCN103646166AAccurate predictionEfficient and accurate determinationSpecial data processing applicationsRepair timeLine tubing

The invention relates to a power station high-temperature pipe system maintenance method based on the non-probability reliability theory. The power station high-temperature pipe system maintenance method includes the steps of conducting finite element calculation on the strength of a power station high-temperature pipe system, determining key detection parts of the power station high-temperature pipe system, determining creep damage parameters with the non-probability reliability theory, building a creep damage probability model by determining the creep damage parameters, calculating structural failures according to the creep damage probability model, building a maintenance method model based on reliability analysis according to detected data, materials of the power station high-temperature pipe system and structure test results, and determining the optimum maintenance time of the high-temperature pipe system according to the maintenance method model and the actual engineering maintenance cost. The non-probability reliability maintenance method is achieved through the power station high-temperature pipe system, the structural probability reliability is efficiently and accurately determined, maintenance plans can be accurately determined, the maintenance method can solve similar problems of high-temperature pipes in other fields, and therefore the application range is wide.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com