Patents

Literature

128 results about "Critical level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

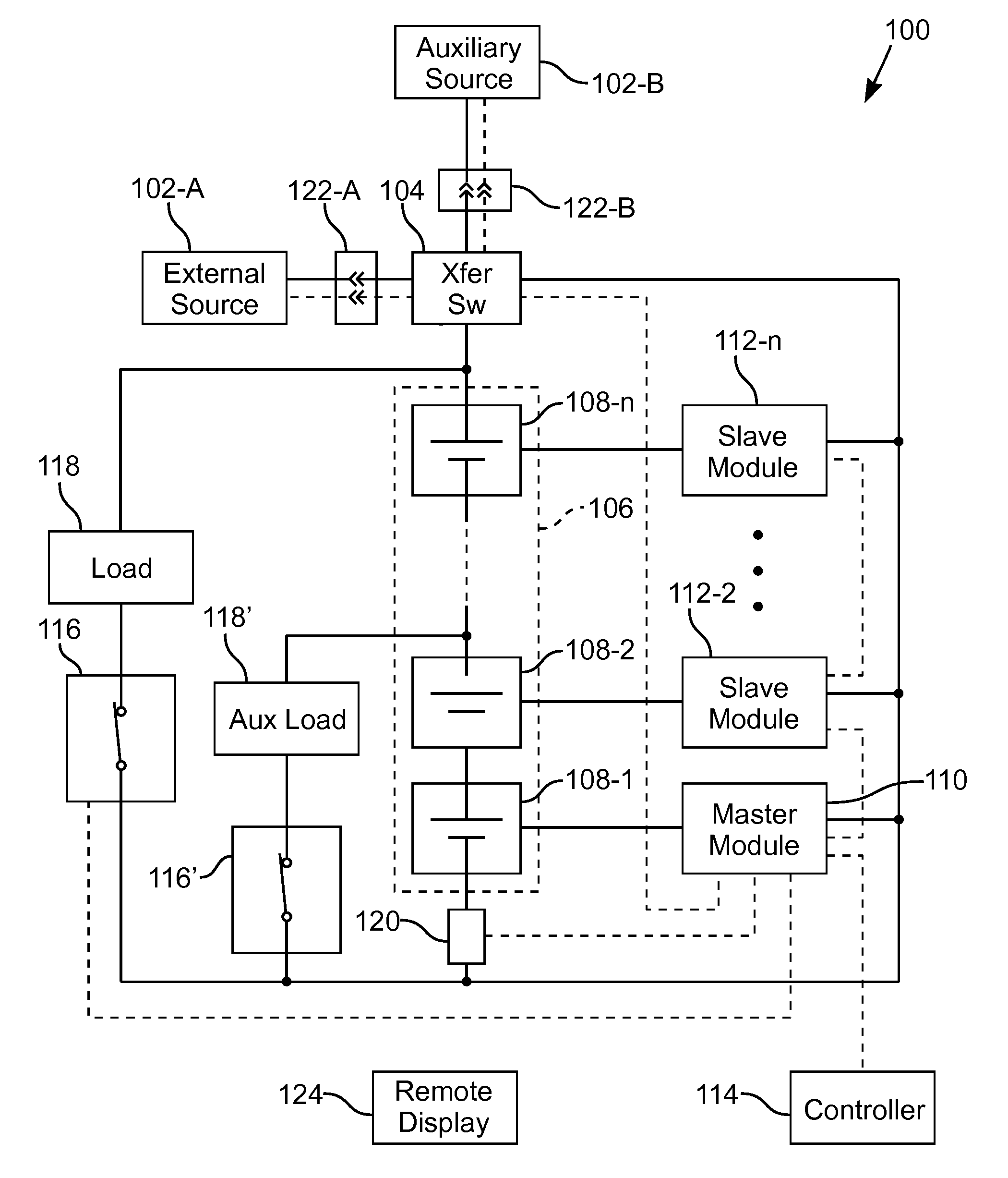

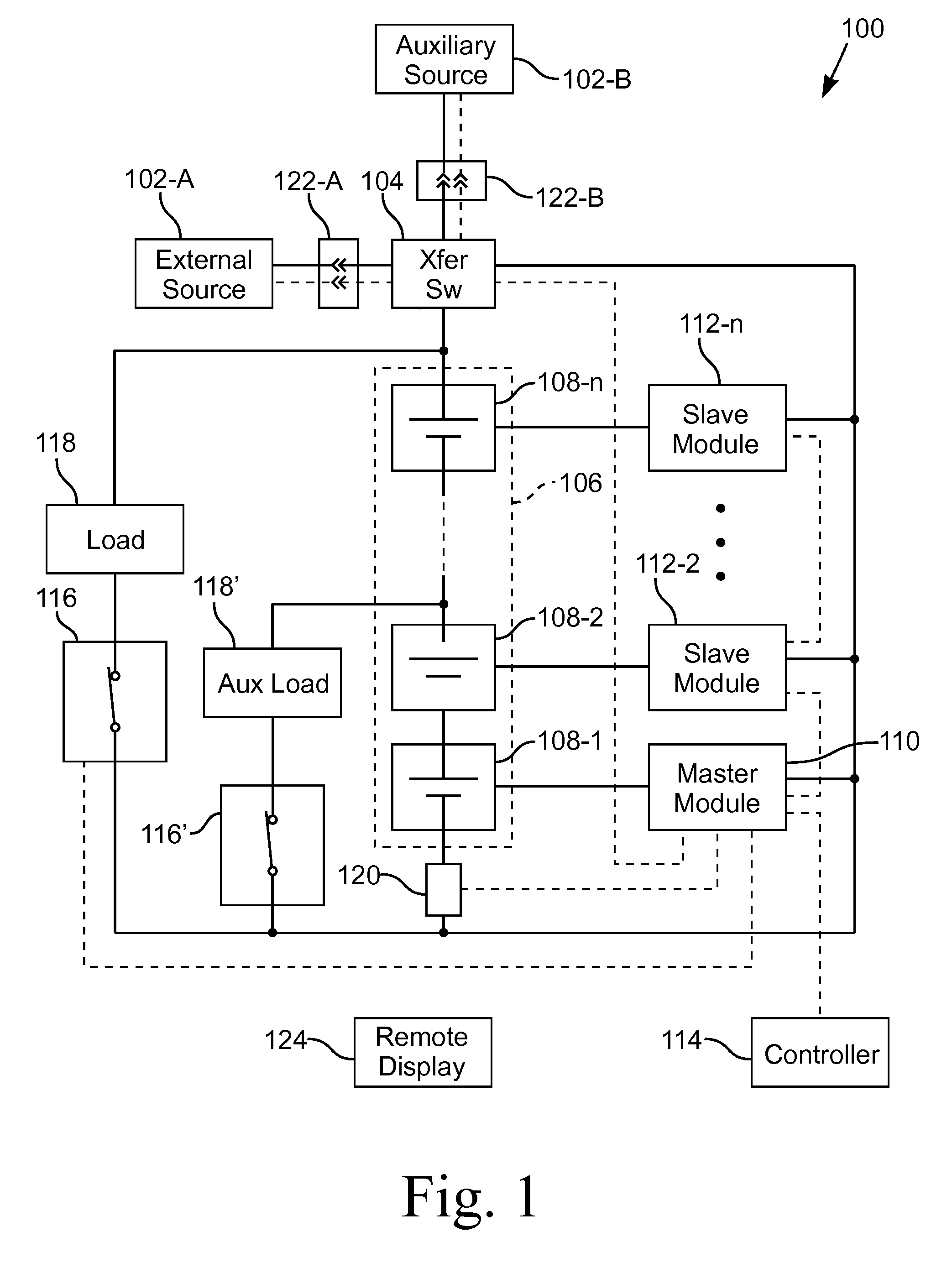

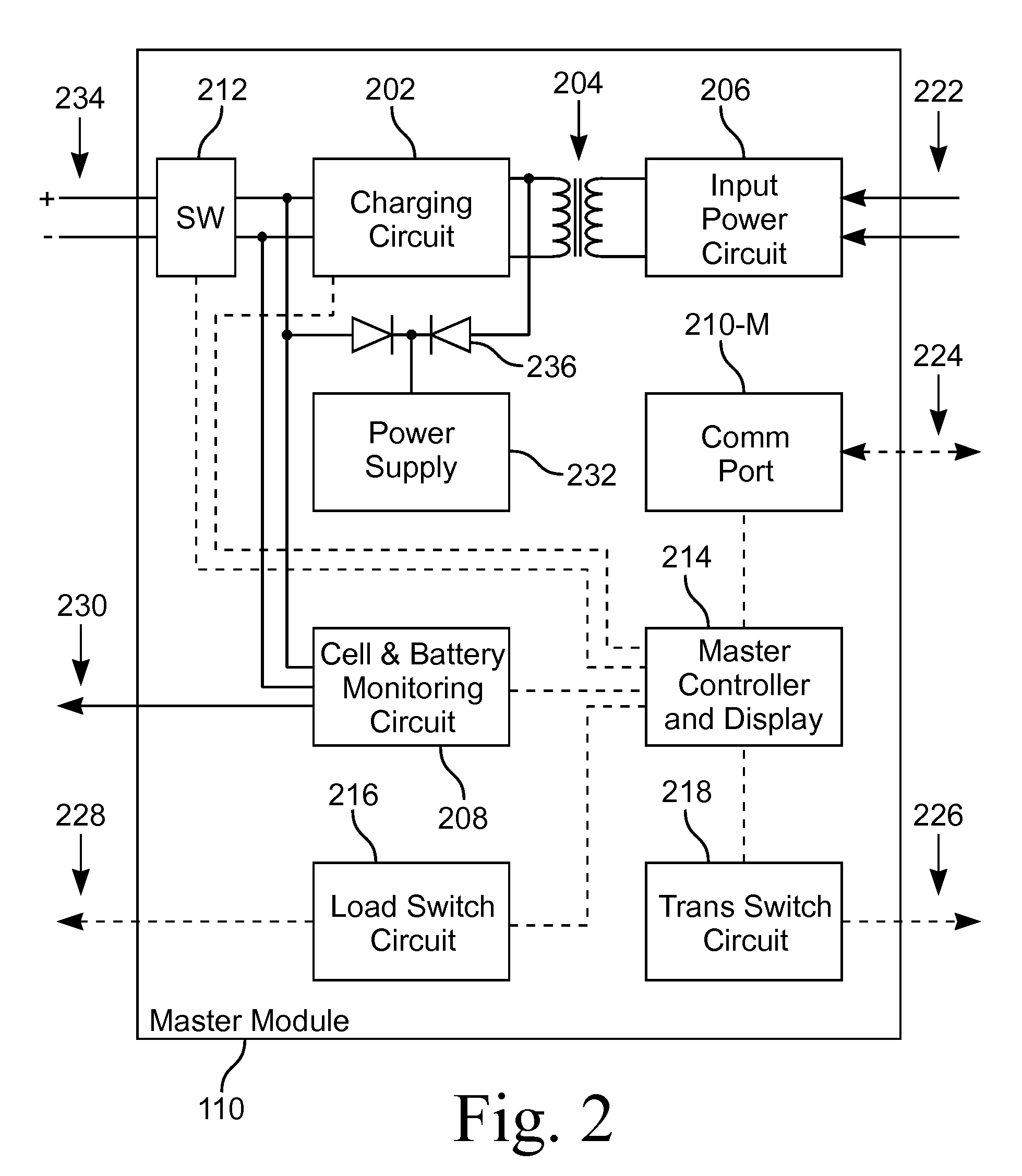

Battery management system

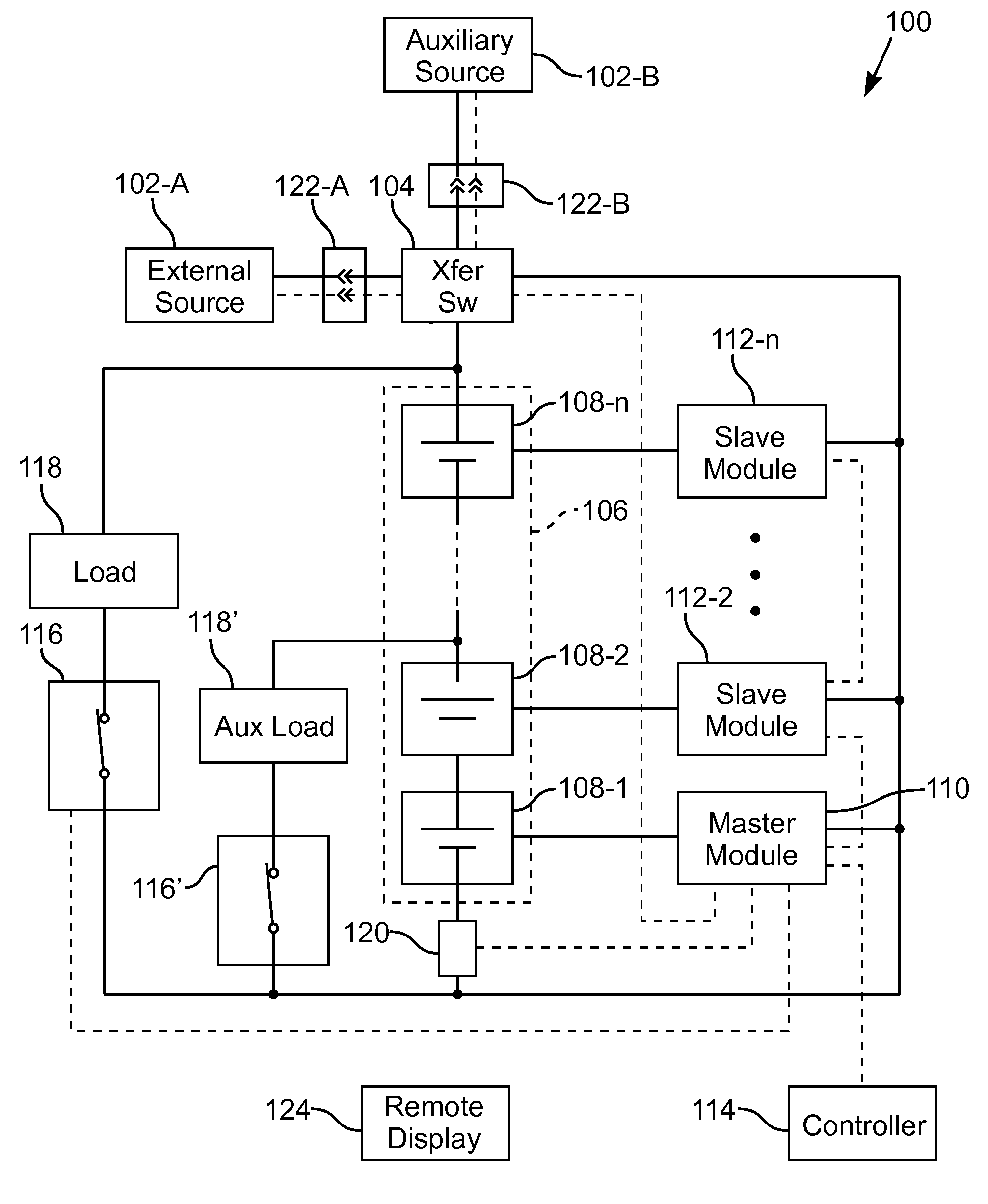

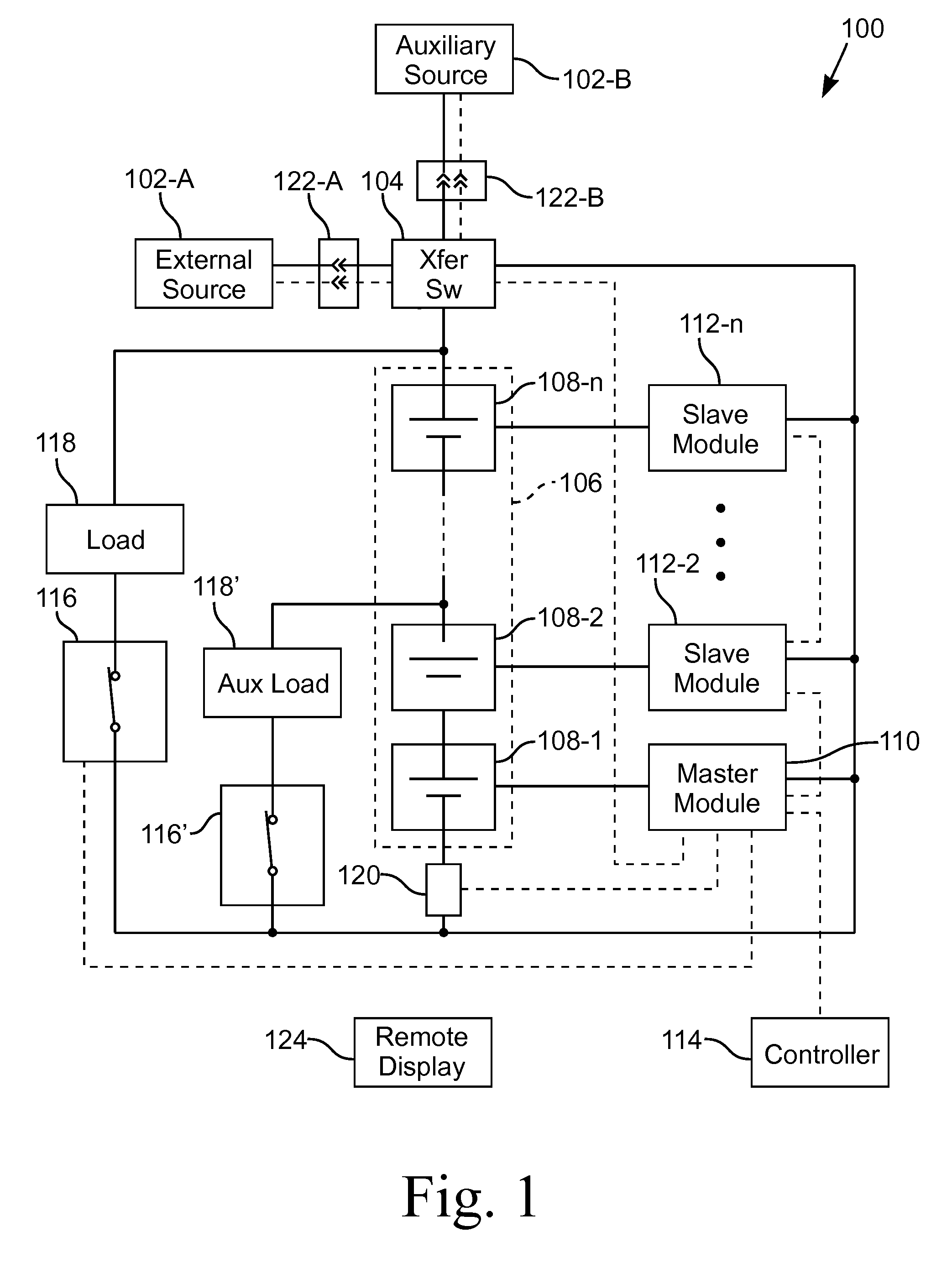

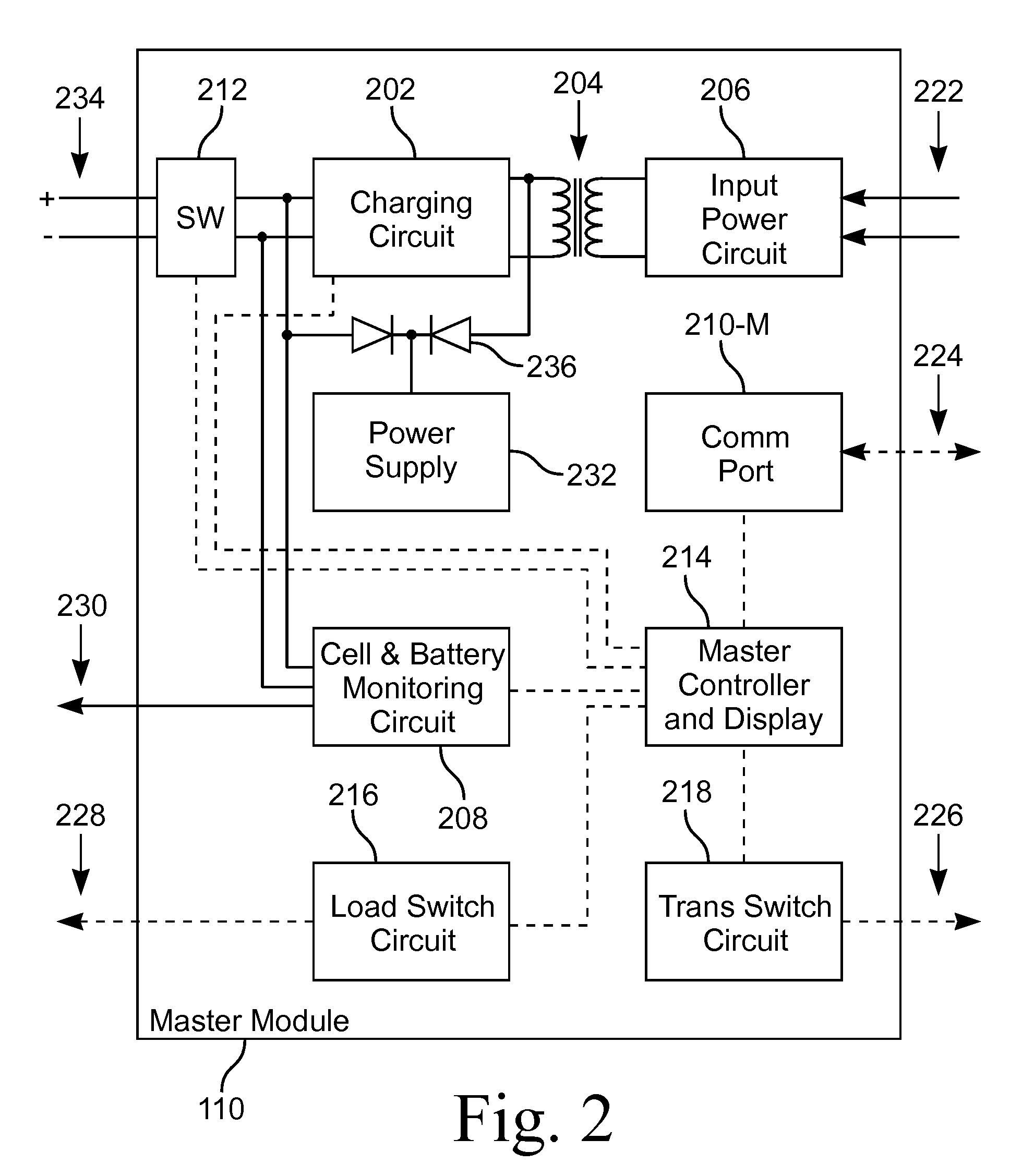

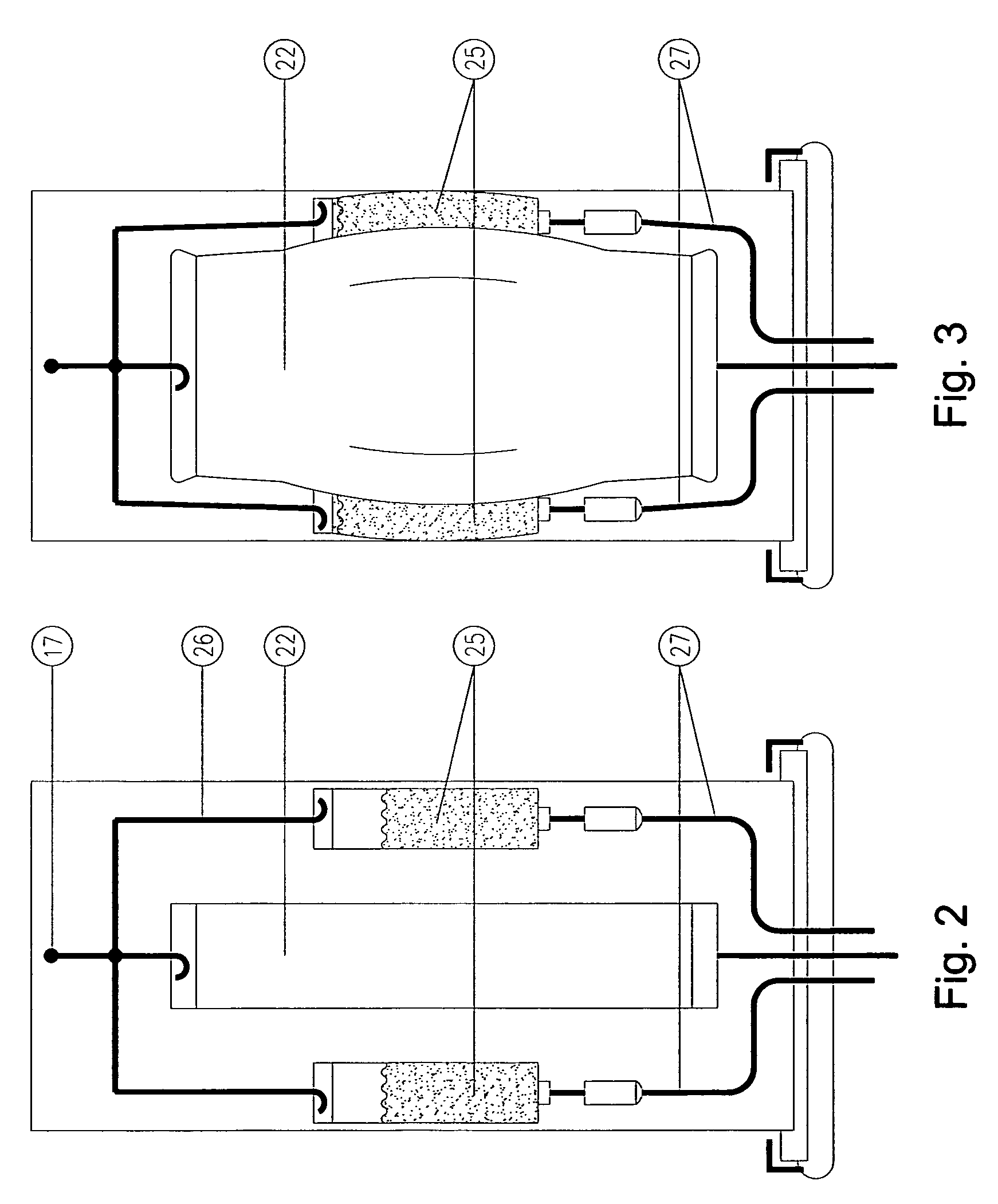

ActiveUS20090146610A1Easy maintenanceEasy to replaceCharge equalisation circuitSecondary cells charging/dischargingCritical levelTransfer switch

Apparatus for a modular battery management system with interchangeable slave modules connected to each cell and including a master module controlling and managing the battery system. All the modules receive power through a transfer switch that selectively switches between an external source, an auxiliary source, and the battery. The modules are configured to connect to a cell of the battery for charging and monitoring the cell individually. Each module is electrically isolated from the other modules. The modules are autonomous and shut down the battery and disconnect the module when a critical parameter of the cell is reached. When the battery is in service and a cell parameter approaches the critical level, the master controller instructs the corresponding slave module to charge the cell using battery power. The master module initializes the slave modules to uniquely identify the modules.

Owner:TRIGIANI ANTONIO

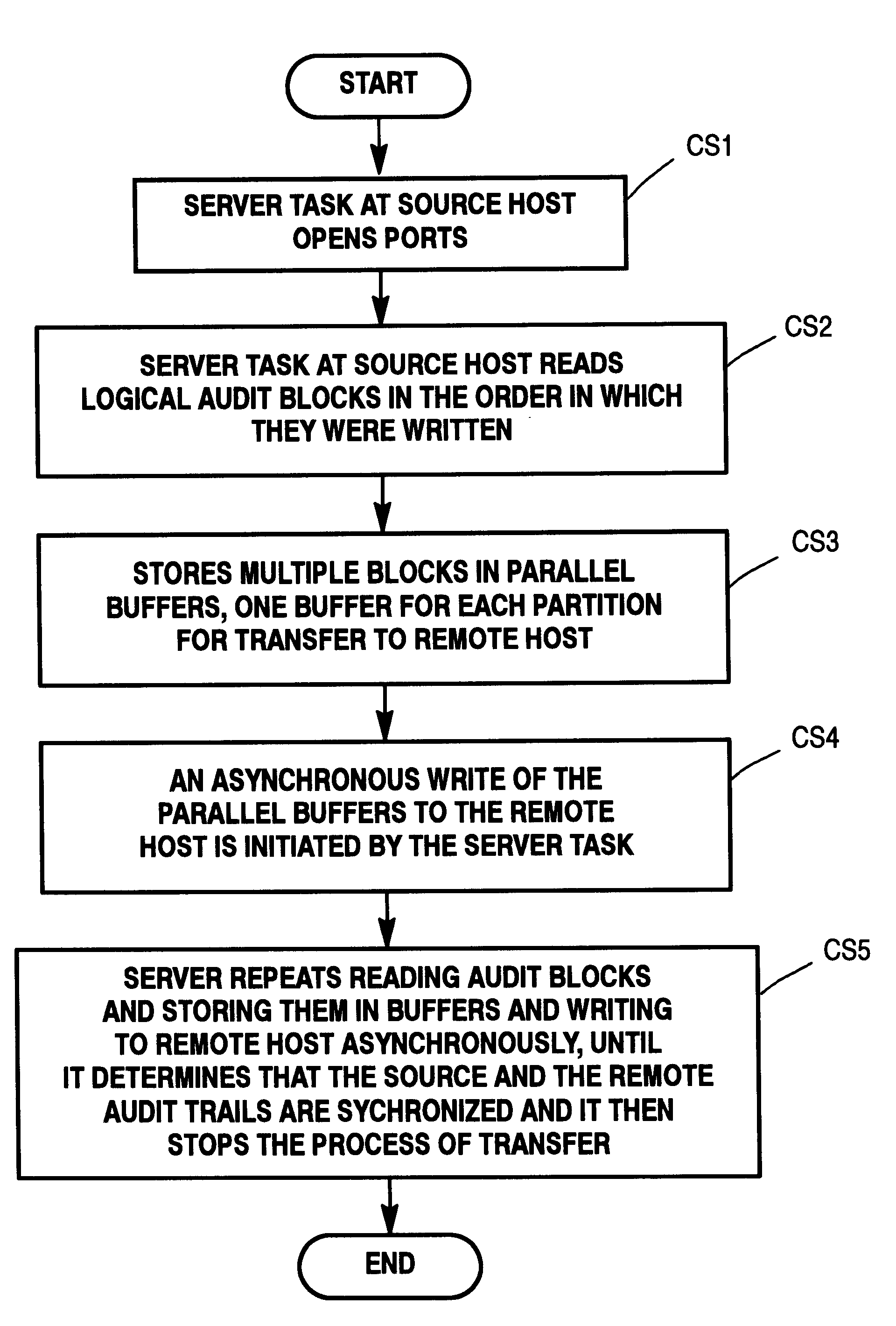

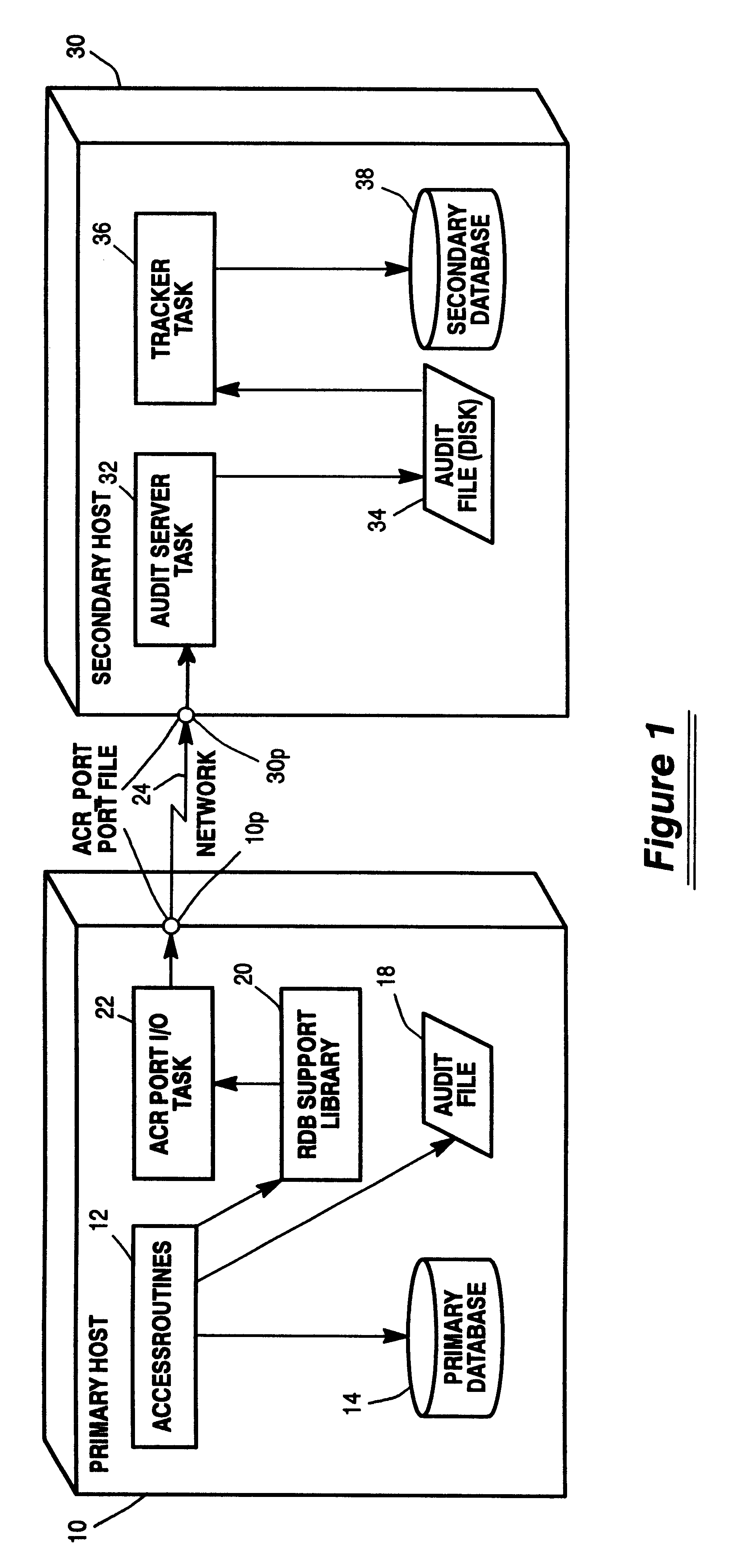

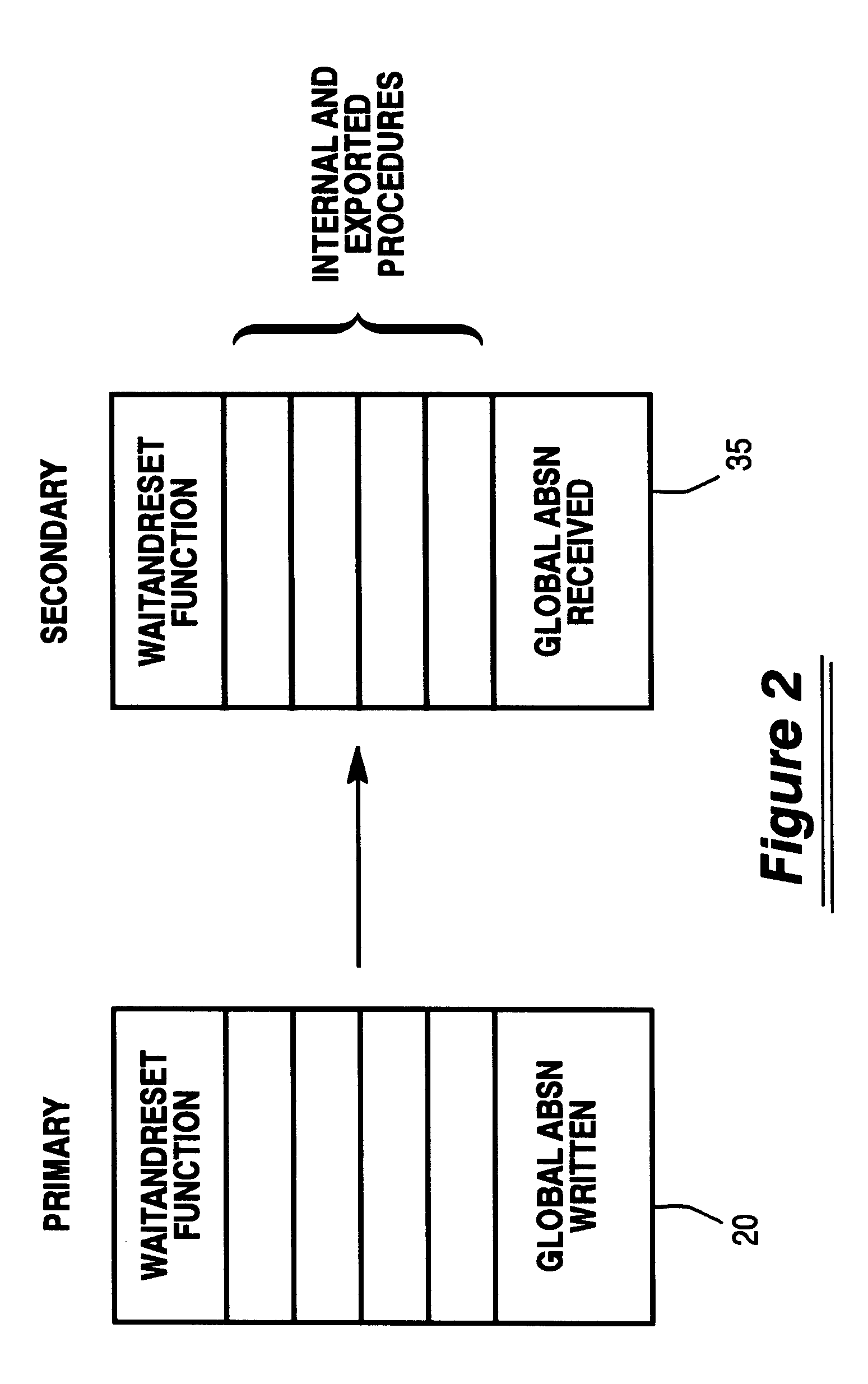

Tracker sensing method for regulating synchronization of audit files between primary and secondary hosts

InactiveUS6446090B1Easy accessPromote recoveryData processing applicationsError detection/correctionFile synchronizationCritical level

Owner:UNISYS CORP

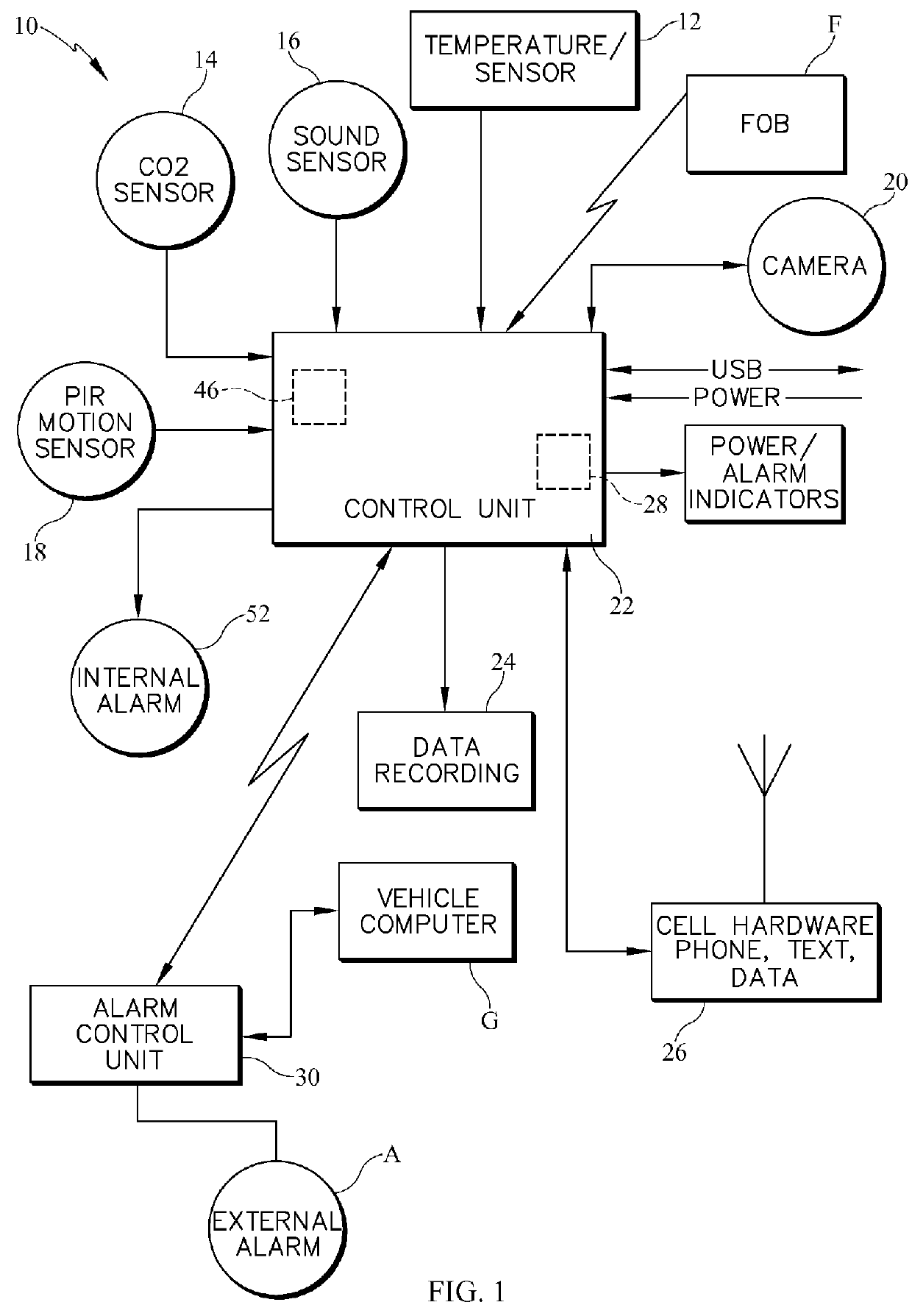

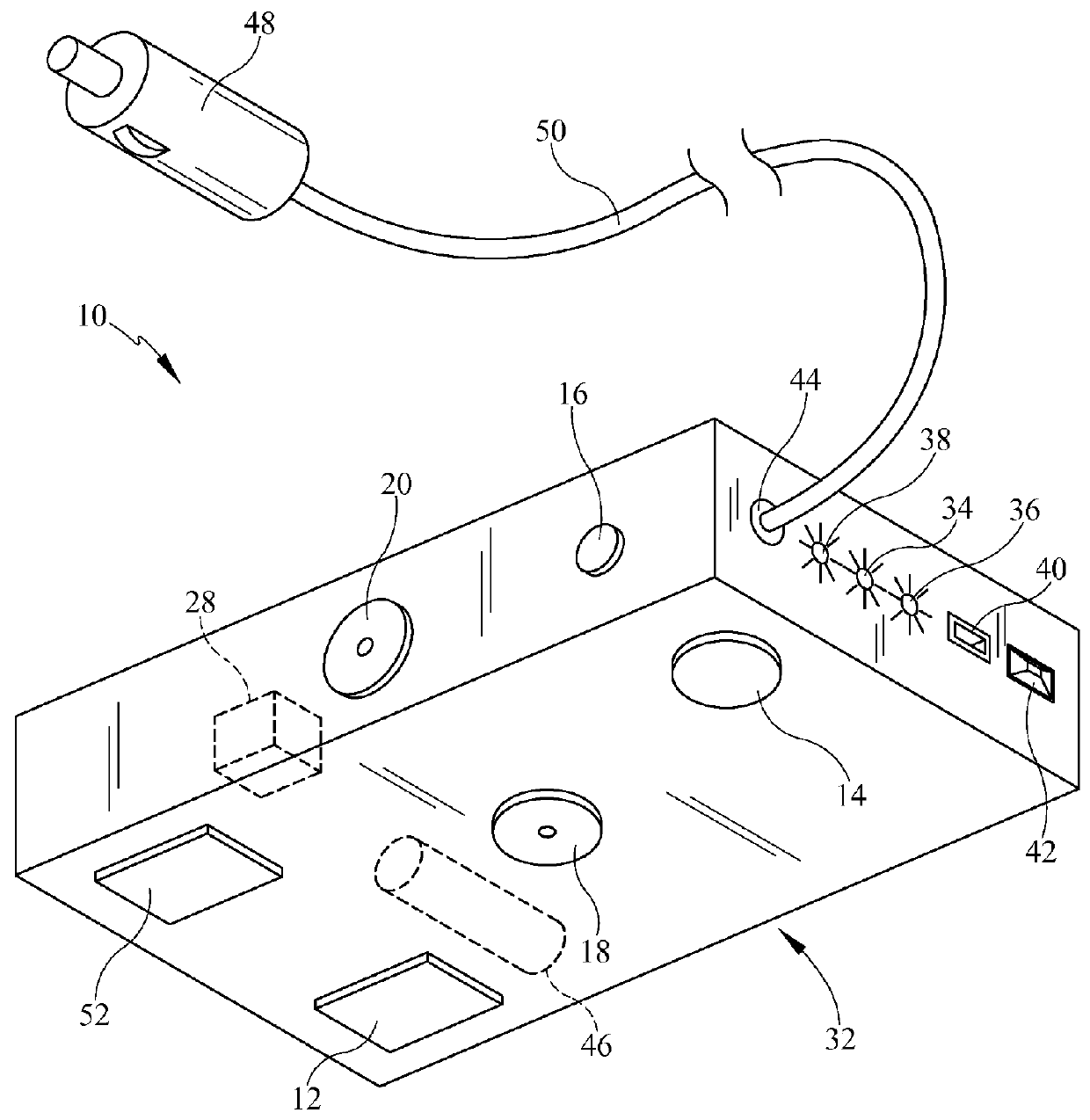

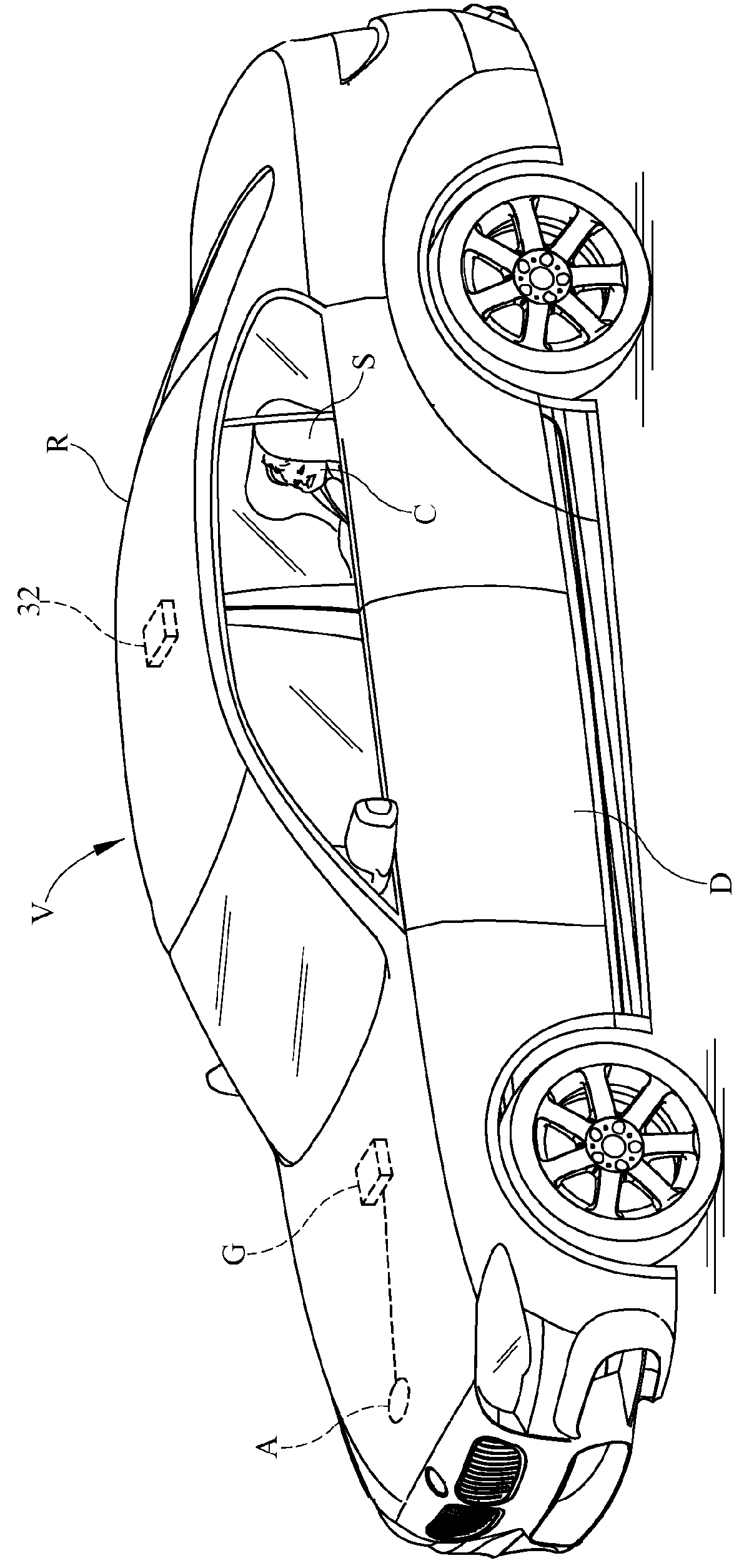

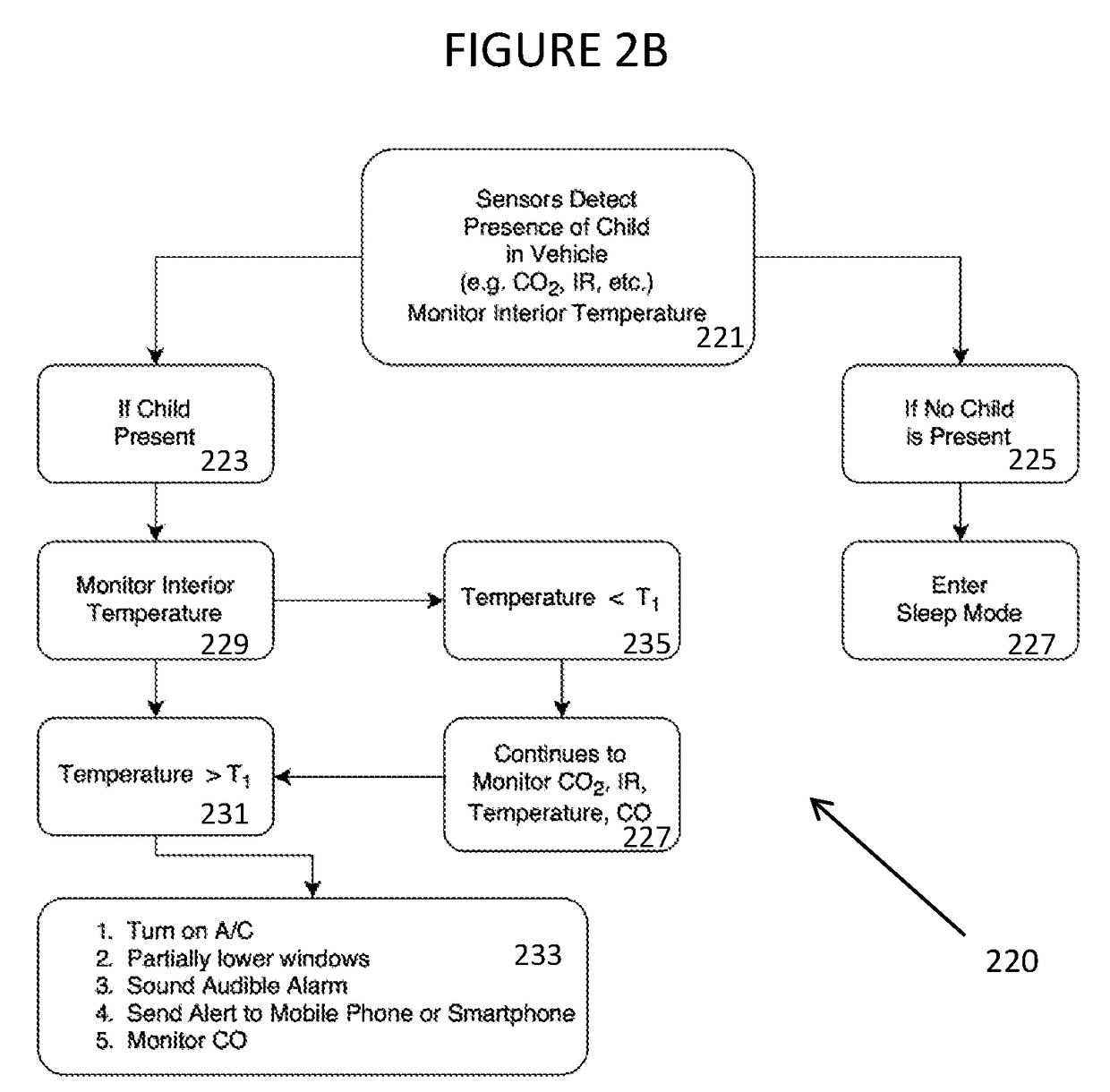

Unattended vehicle passenger detection system

ActiveUS9227484B1Reducing false alarmAvoid harmAir-treating devicesVehicle heating/cooling devicesCritical levelFacial recognition system

A system detects the presence of a living being within a vehicle and triggers an alarm should the temperature rise above or fall below a predetermined threshold limit. The system uses a carbon dioxide monitor to determine for the living being's presence, which is backed up by one or more subsystems that include a motion sensor that senses motion, a sound sensor that senses sounds, especially those made by distressed living beings, and a camera that uses facial recognition software to detect a face within the vehicle. The alarm can be staged so that a lower level of alarm is triggered when the hazardous temperature is approaching, but has not yet reached critical levels, and one of the subsystems has detected a living being within the vehicle, but the others have not yet activated, and a higher level alarm once critical temperatures have been reached.

Owner:JUSTICE WAYNE P +2

Battery management system

ActiveUS8547065B2Easy maintenanceEasy to replaceCharge equalisation circuitSecondary cells charging/dischargingCritical levelTransfer switch

Apparatus for a modular battery management system with interchangeable slave modules connected to each cell and including a master module controlling and managing the battery system. All the modules receive power through a transfer switch that selectively switches between an external source, an auxiliary source, and the battery. The modules are configured to connect to a cell of the battery for charging and monitoring the cell individually. Each module is electrically isolated from the other modules. The modules are autonomous and shut down the battery and disconnect the module when a critical parameter of the cell is reached. When the battery is in service and a cell parameter approaches the critical level, the master controller instructs the corresponding slave module to charge the cell using battery power. The master module initializes the slave modules to uniquely identify the modules.

Owner:TRIGIANI ANTONIO

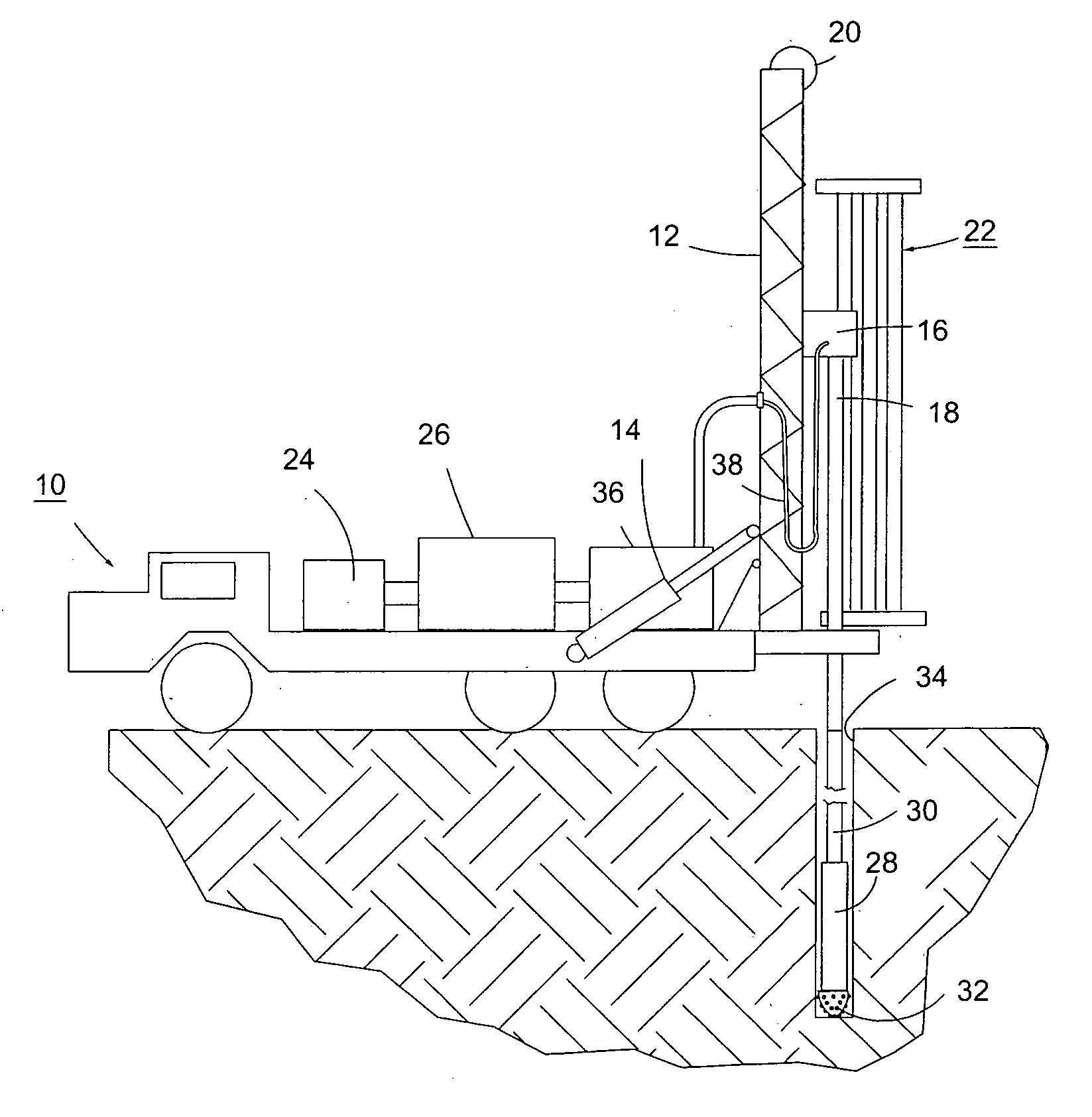

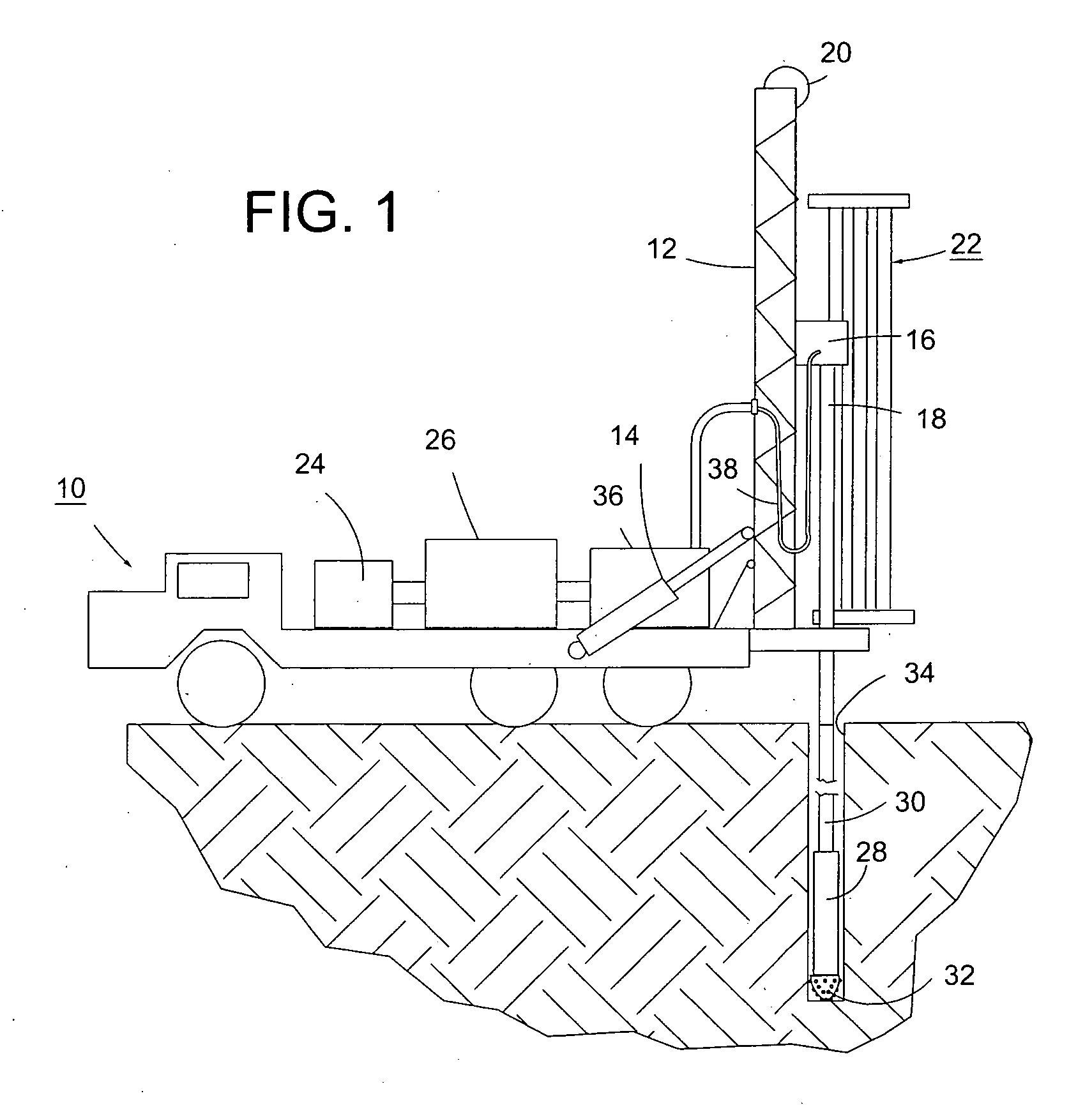

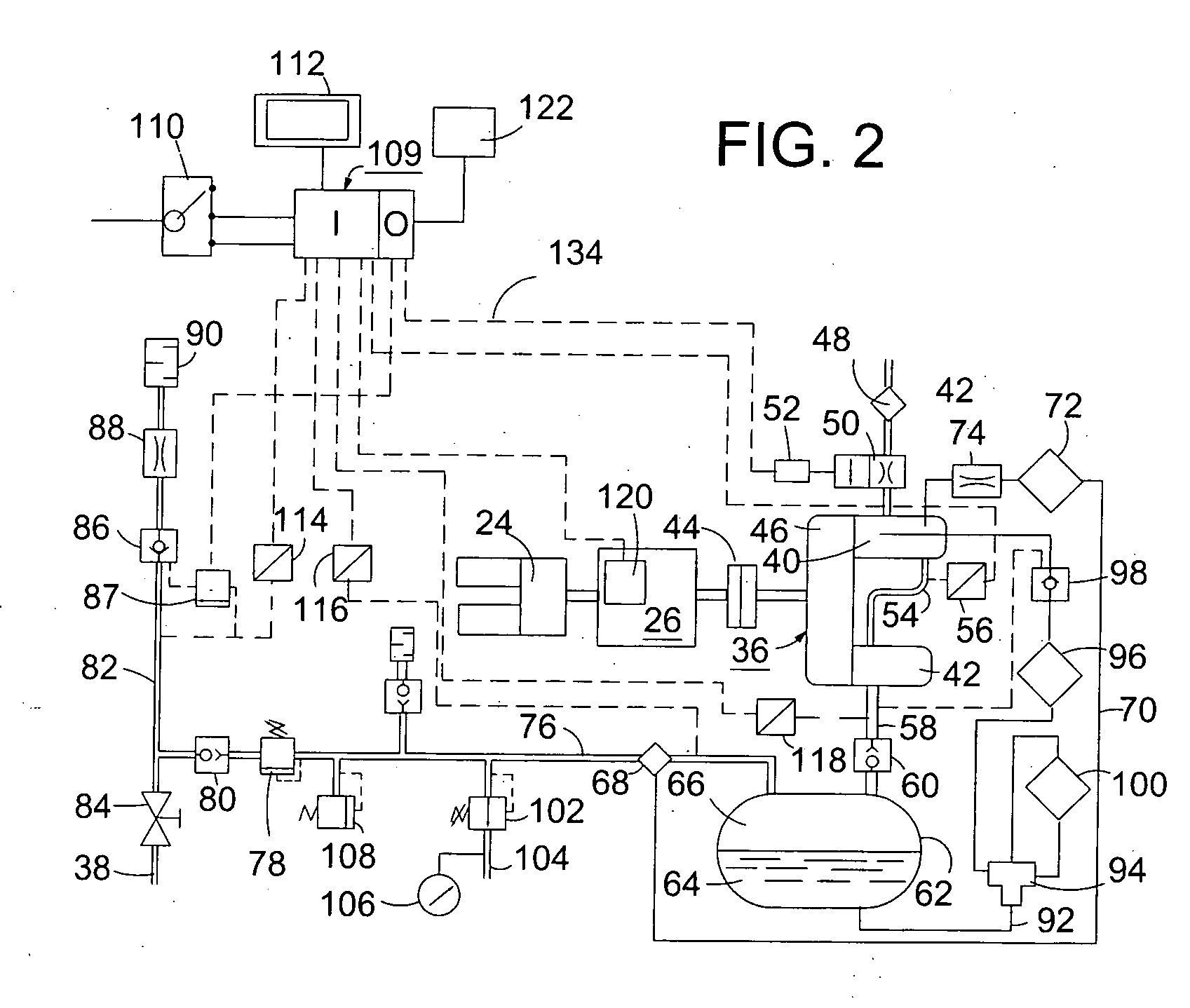

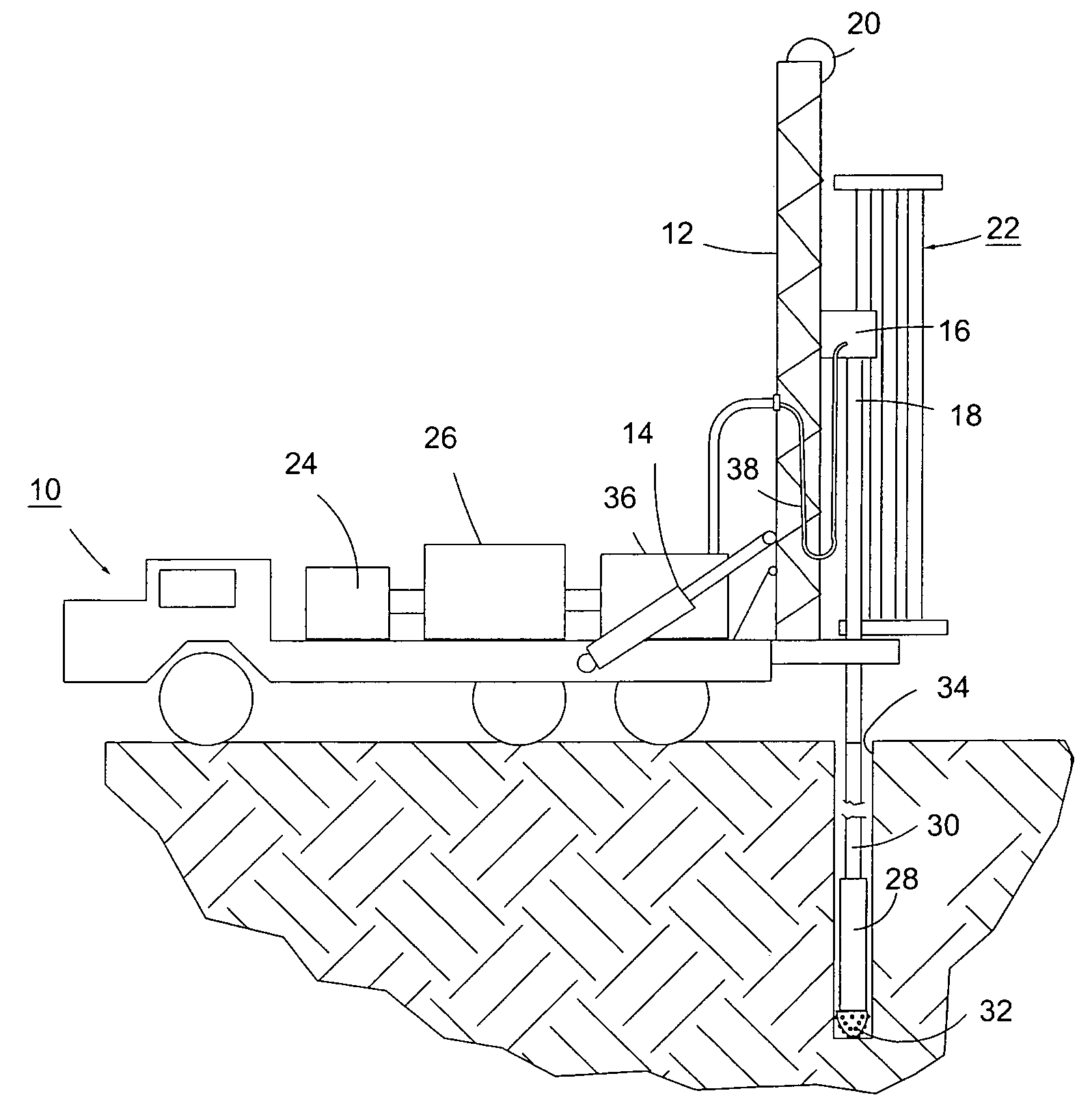

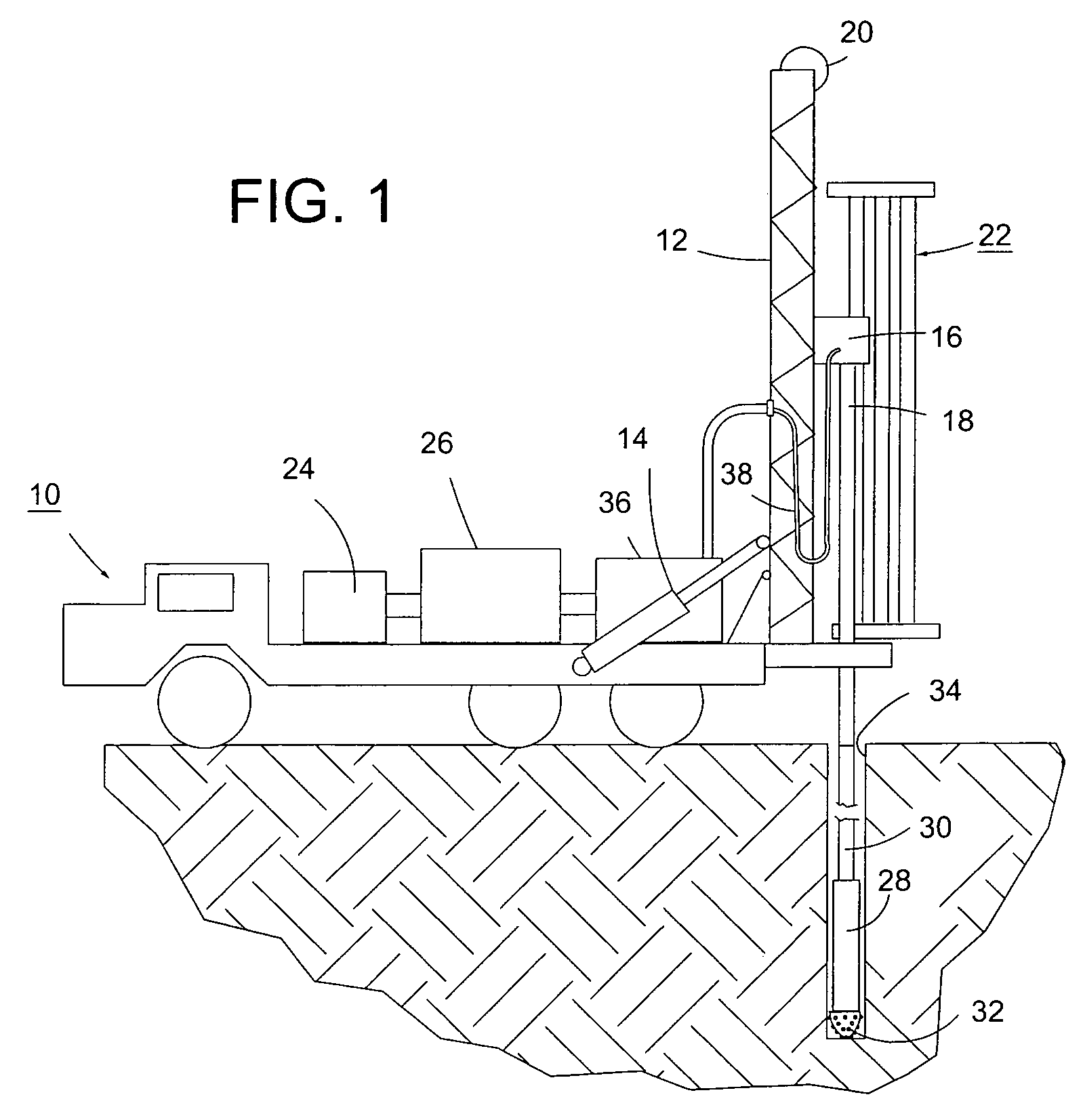

Earth drilling rig having electronically controlled air compressor

InactiveUS20070246262A1Reduce generationImprove drilling qualityDrilling rodsConstructionsCritical levelElectronic controller

In an earth drilling rig in which an air compressor and one or more hydraulic pumps are driven by the same engine, the intake throttle of the compressor is controlled by an electronic controller having a proportional integral derivative control. The controller minimizes unloading of the compressor, allowing the engine to operate more efficiently, the hydraulic system to provide more consistent power to drilling functions and the volume and pressure of compressed air to be optimized for the drilling conditions encountered. The electronic controller also operates a blowdown valve at the discharge side of an air receiver, and effects various overrides of the control system, for example when air discharge temperature approaches a critical level, or when an overpressure condition is detected.

Owner:SCHRAMM INC

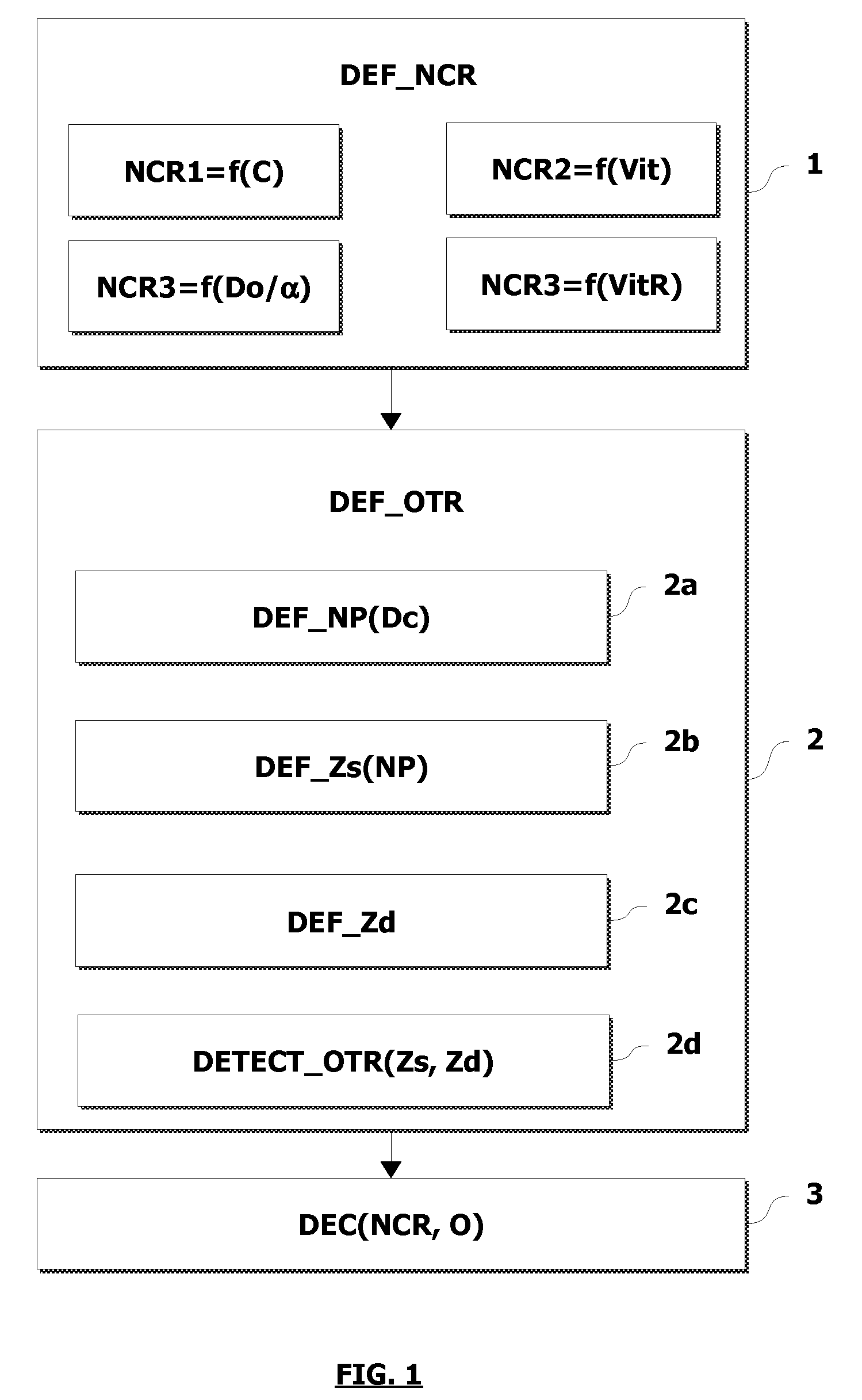

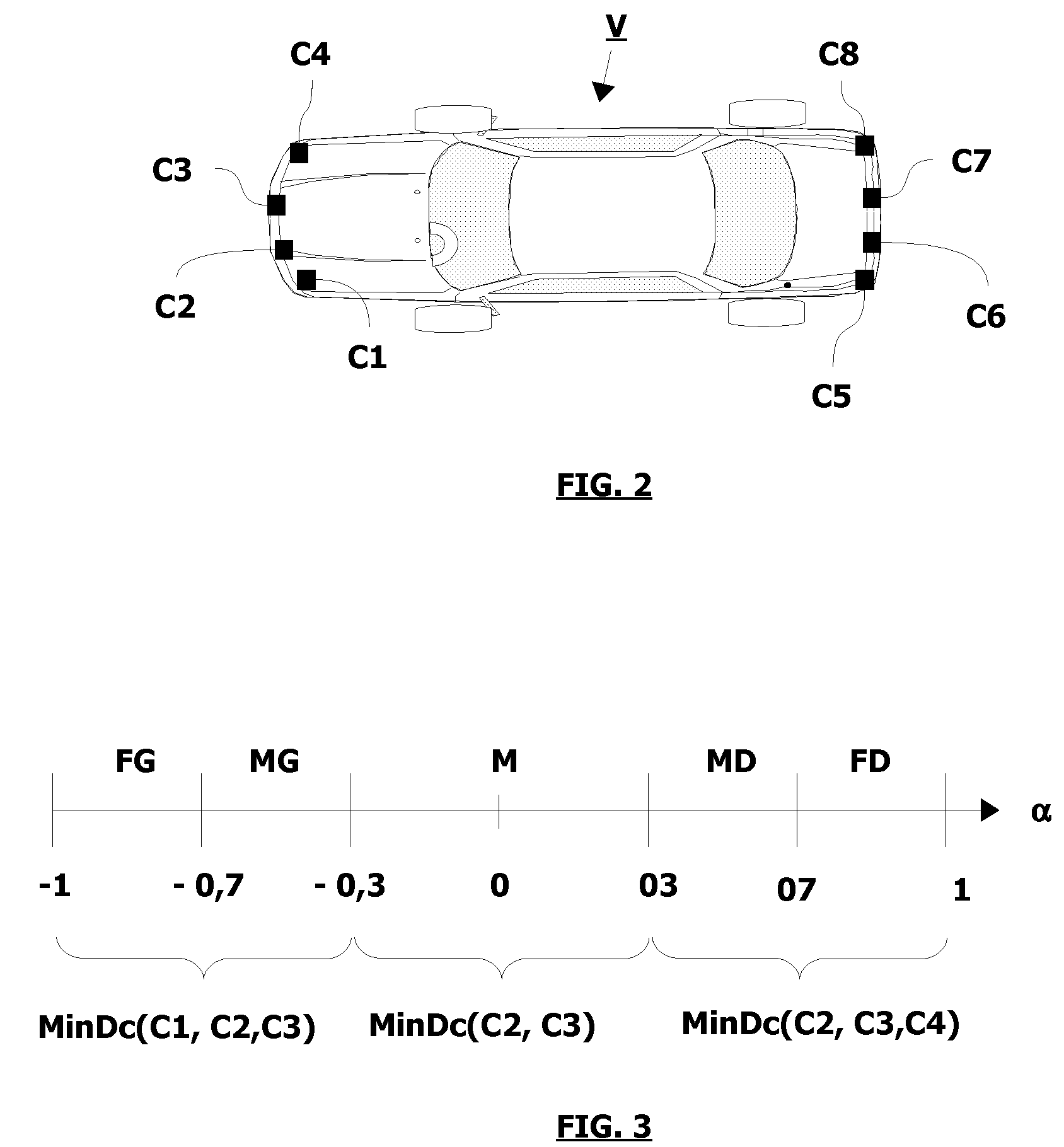

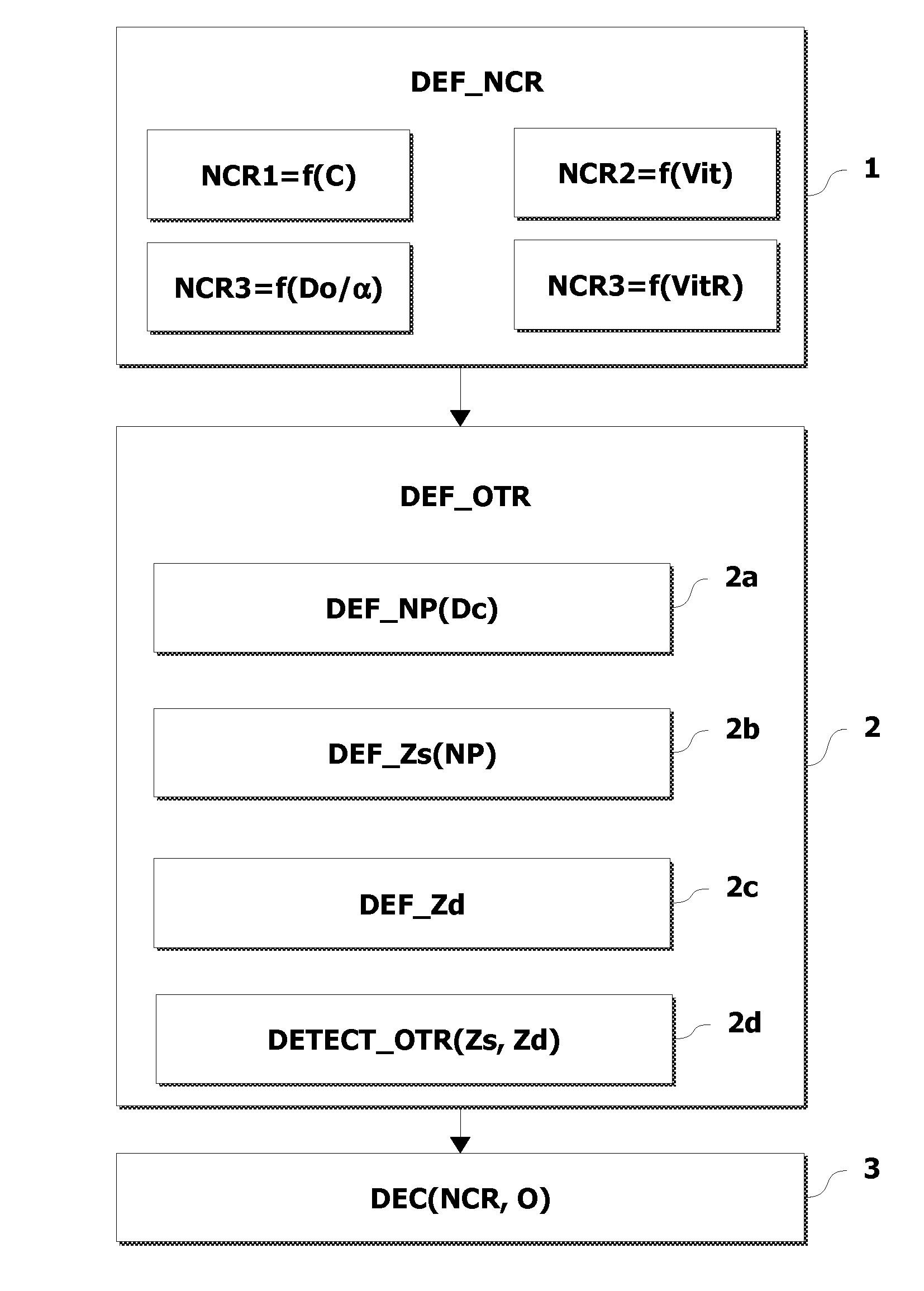

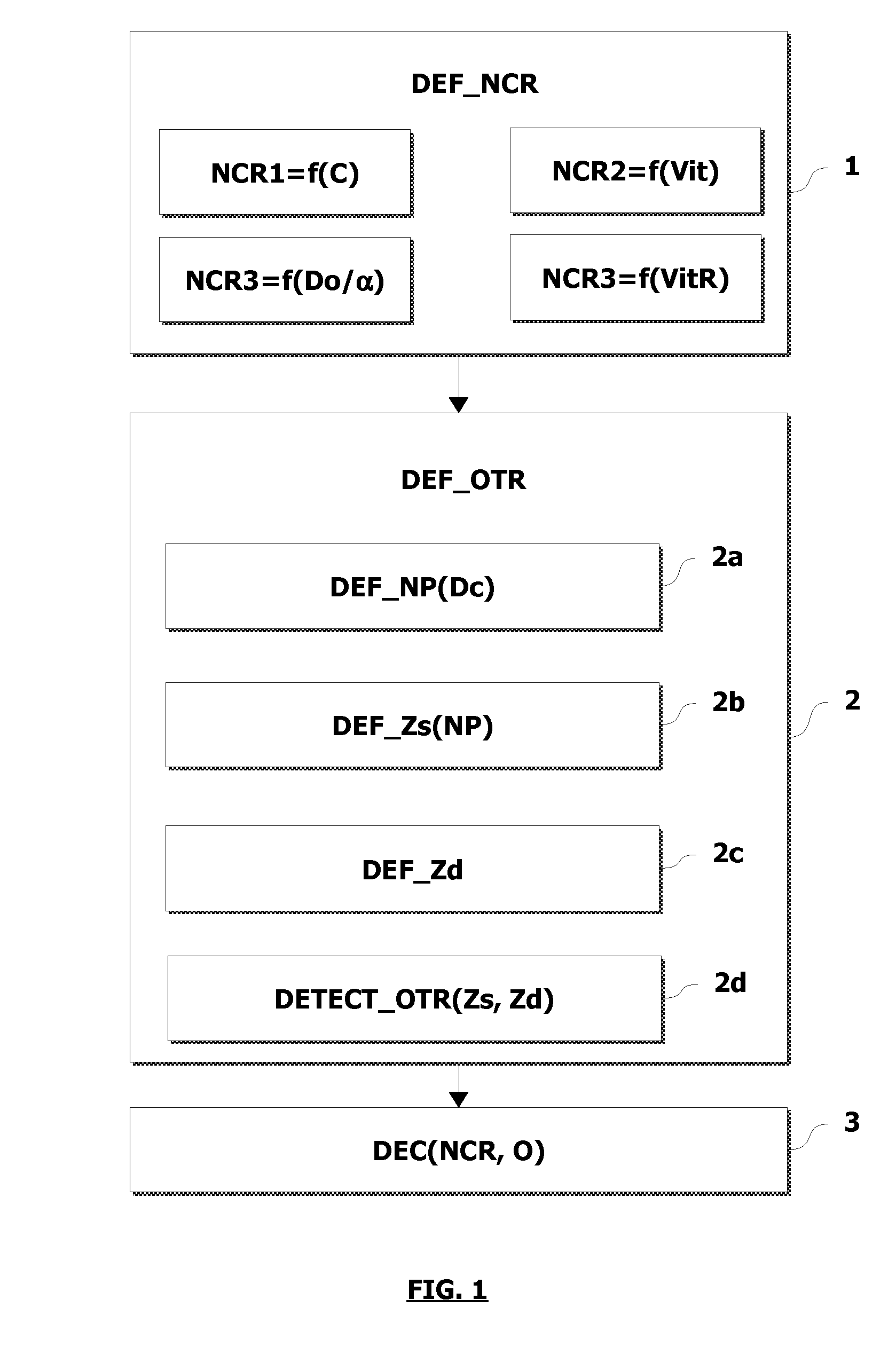

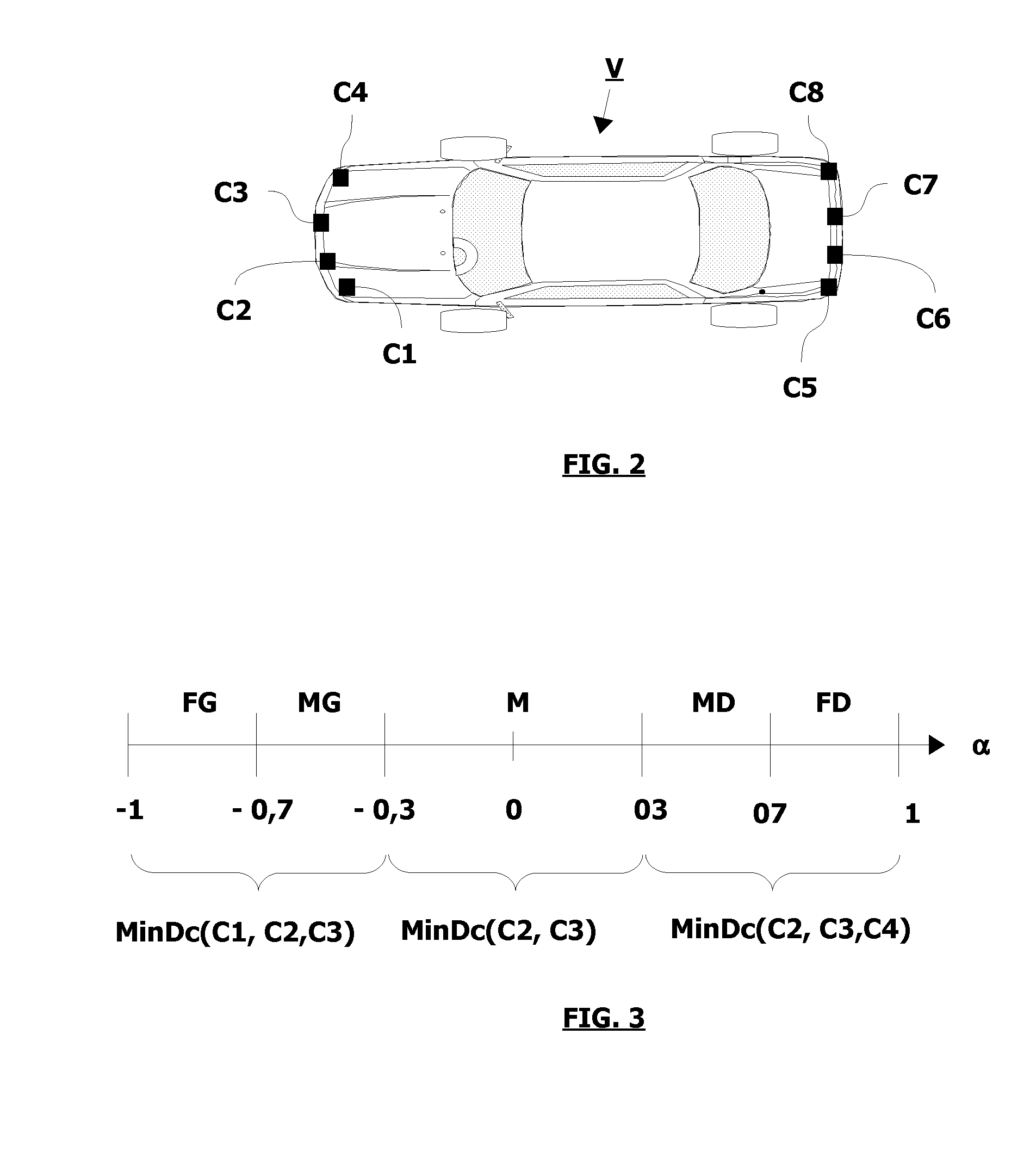

Method for monitoring the environment of an automatic vehicle

Owner:VALEO VISION SA

Method for monitoring the environment of an automatic vehicle

ActiveUS20100191433A1Resolution problemAnalogue computers for trafficAutomatic initiationsCritical levelEngineering

Owner:VALEO VISION SA

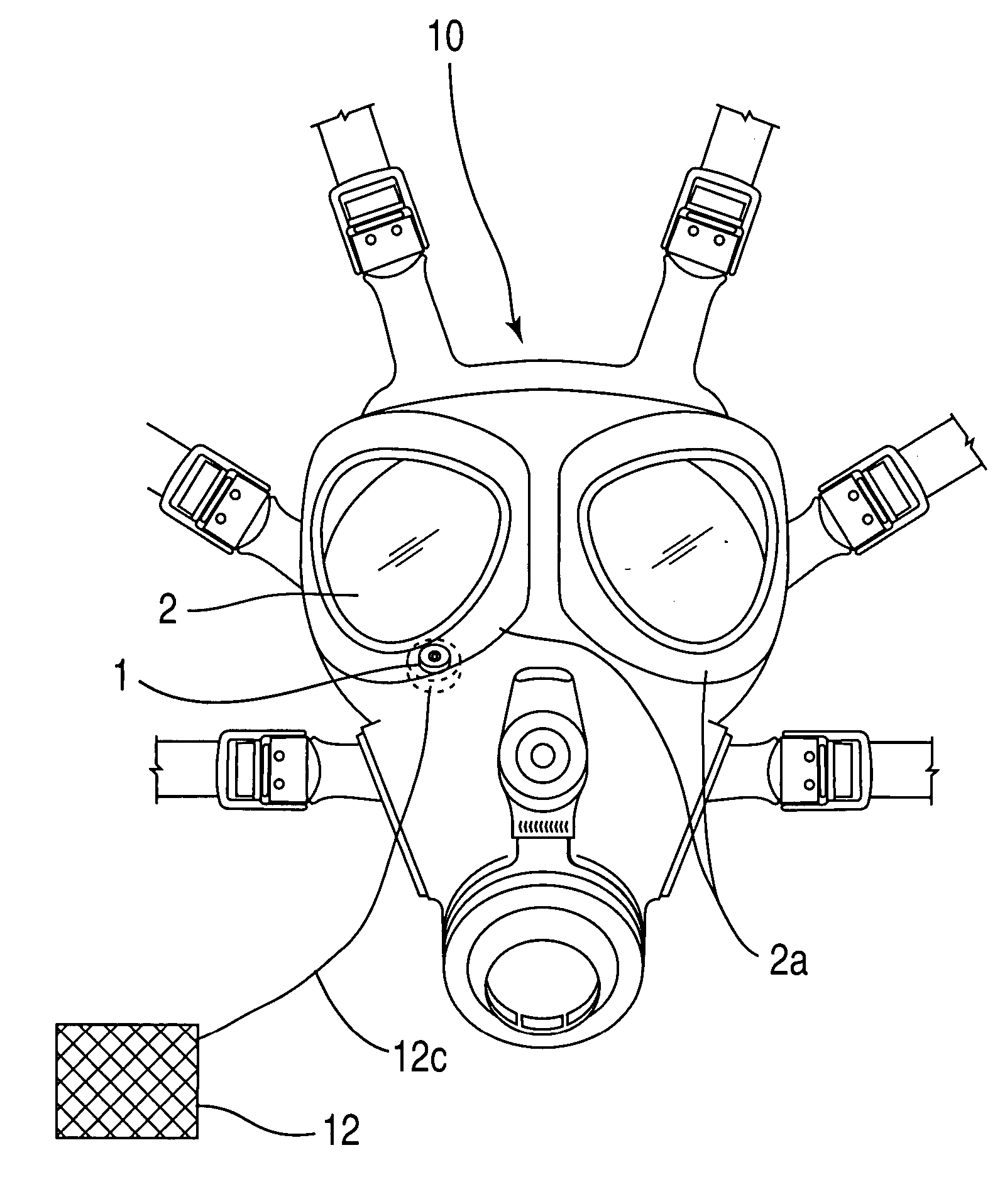

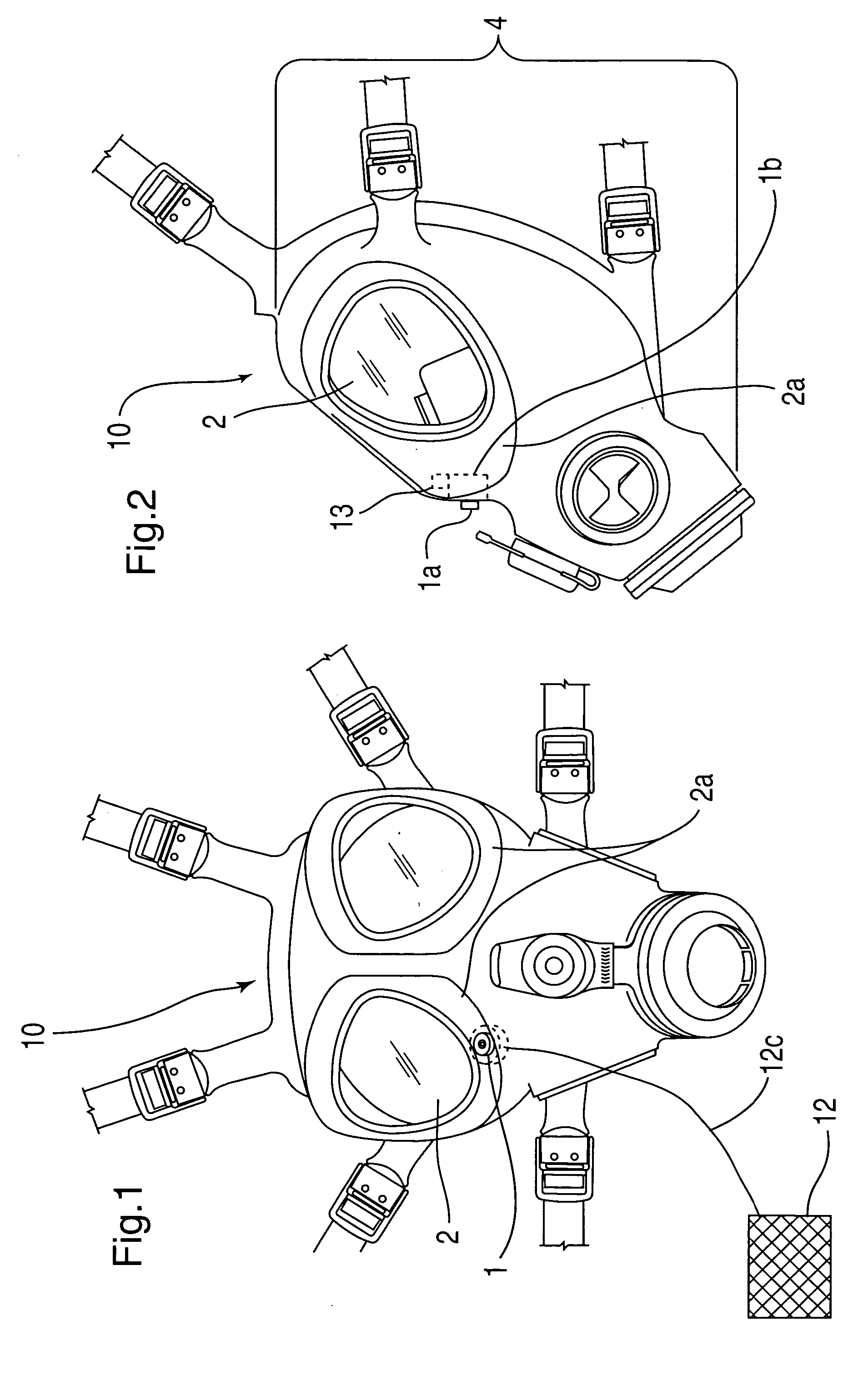

Pressure indicator for positive pressure protection masks

InactiveUS20050263155A1Easy to detectOperational securityChemical protectionHeat protectionHead-up displayInterior space

A pressure indicator for positive pressure protection masks, including powered air purifying respirators (PAPRs) that monitors and determines relative air pressure between the internal space of a protection mask and the ambient environment to alert users of negative or threshold level air pressure, and in turn, to ensure safe operation of the protection masks. The pressure indicator, which is incorporated in the mask, alerts users when the air pressure in the mask reaches a critical level by transmitting optical signals, auditory signals, vibrational signals or a combination thereof that are detectable by the user. The optical signals are projected into the user's line of vision either directly or through a head-up display. The pressure indicator may cause the signal to indicate a safe and danger mode, or may cause the signal to indicate only during a danger mode.

Owner:IMMEDIATE RESPONSE TECH +1

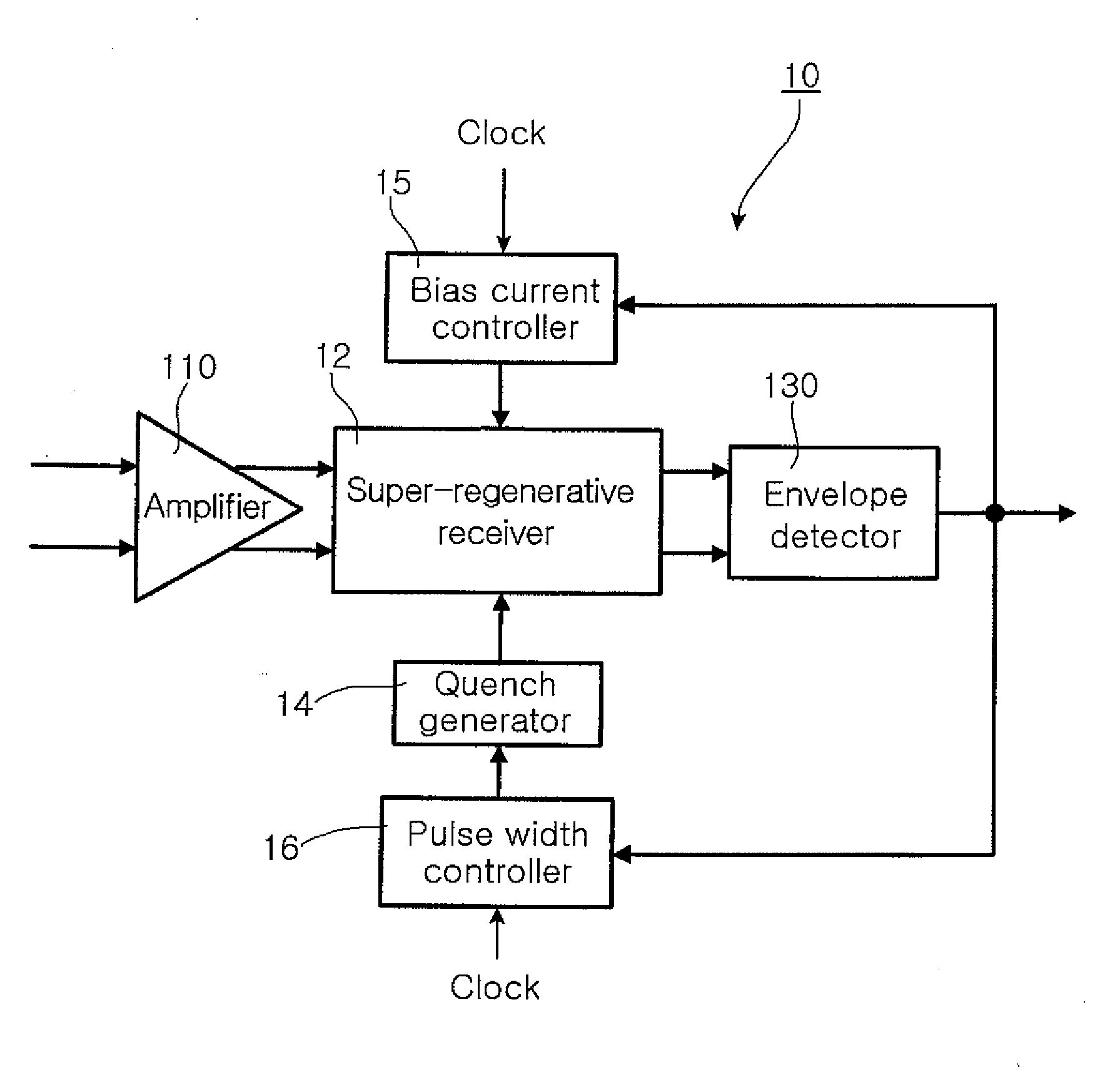

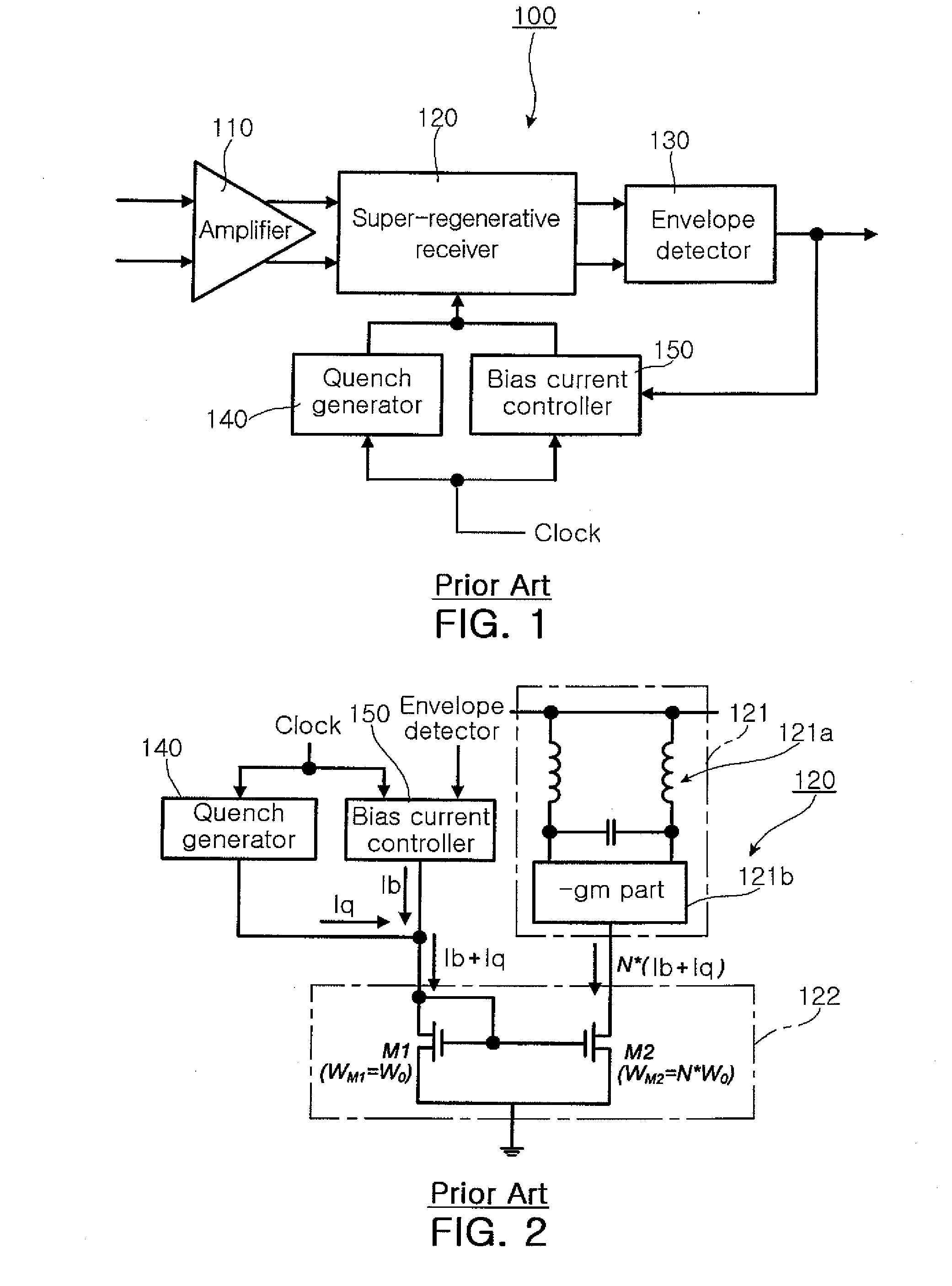

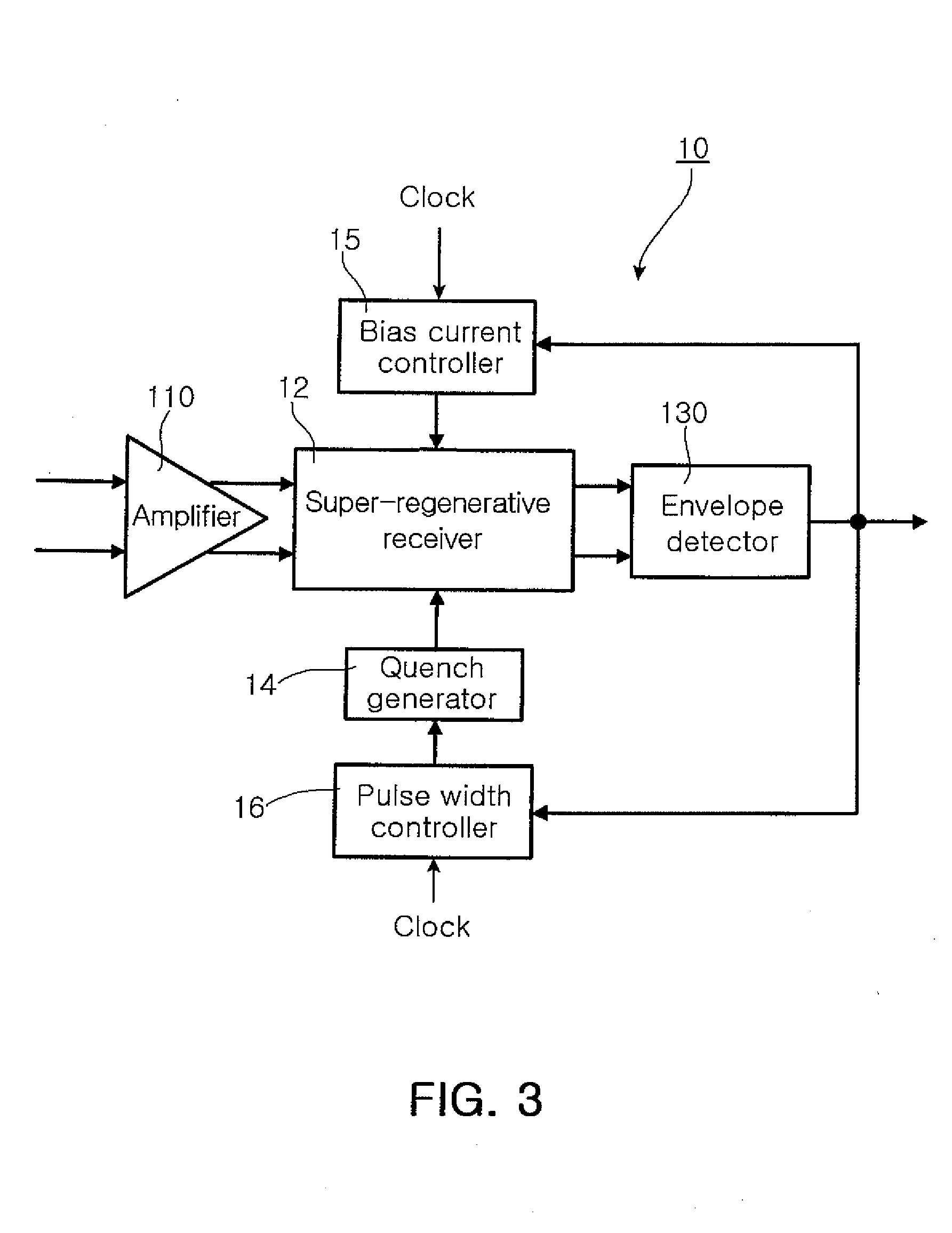

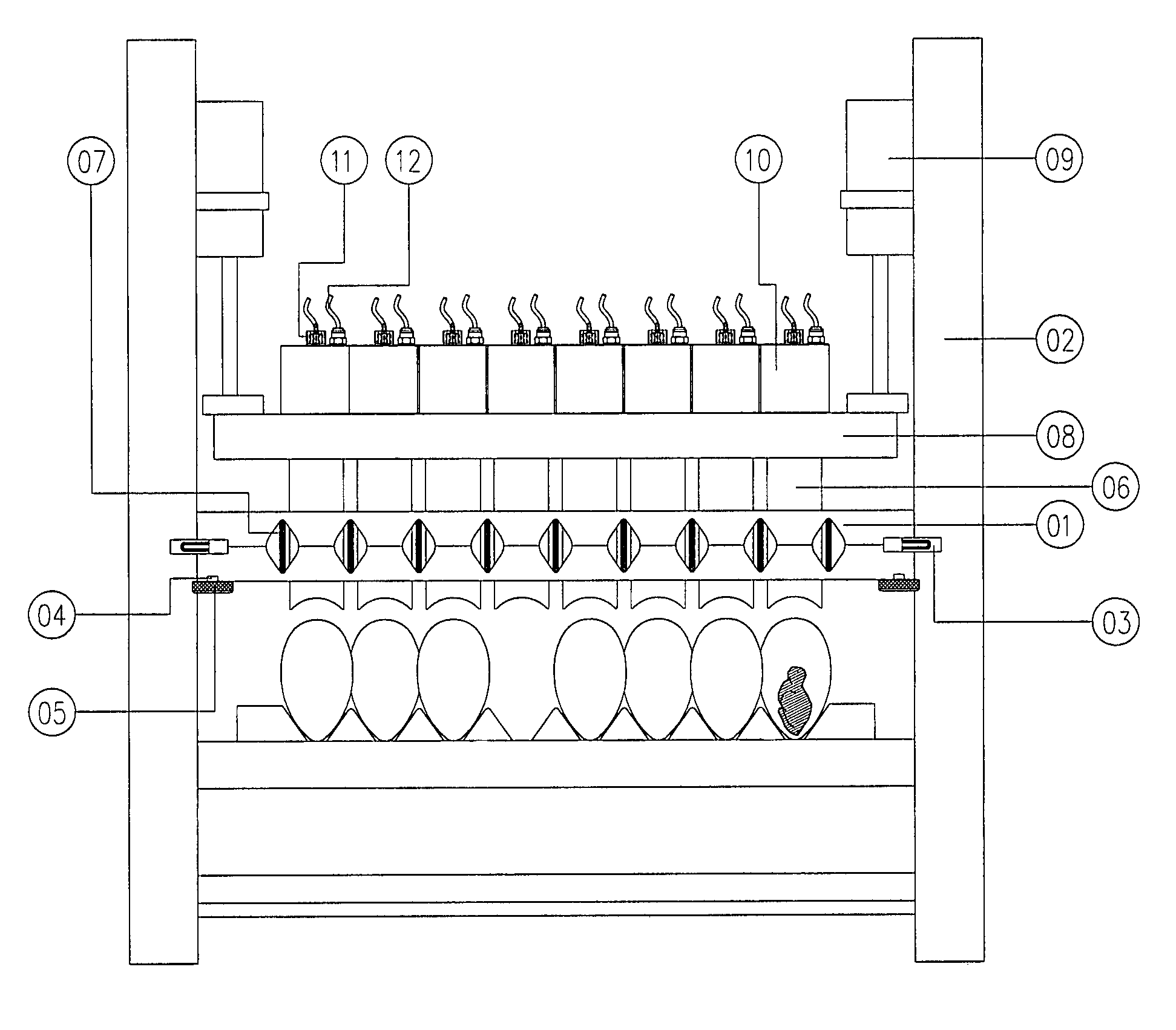

Super-regenerative receiver

InactiveUS20070139130A1Improve featuresResonant long antennasPulse automatic controlDriving currentCritical level

A super-regenerative receiver including a super-regenerative oscillator is disclosed. The super-regenerative receiver includes a super-regenerative oscillator for generating an oscillation signal when receiving driving current exceeding a predetermined critical level. The receiver also includes a bias current controller for generating bias current according to an output of the super-regenerative oscillator, and a pulse width controller for receiving a predetermined clock and controlling a width of the clock according to the output of the super-regenerative oscillator. The super-regenerative receiver further includes a quench generator receiving the width-controlled clock from the pulse width controller and generating quench current that varies according to the pulse width of the clock. The driving current for oscillation equals to a sum of the bias current N-times multiplied and the quench current.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

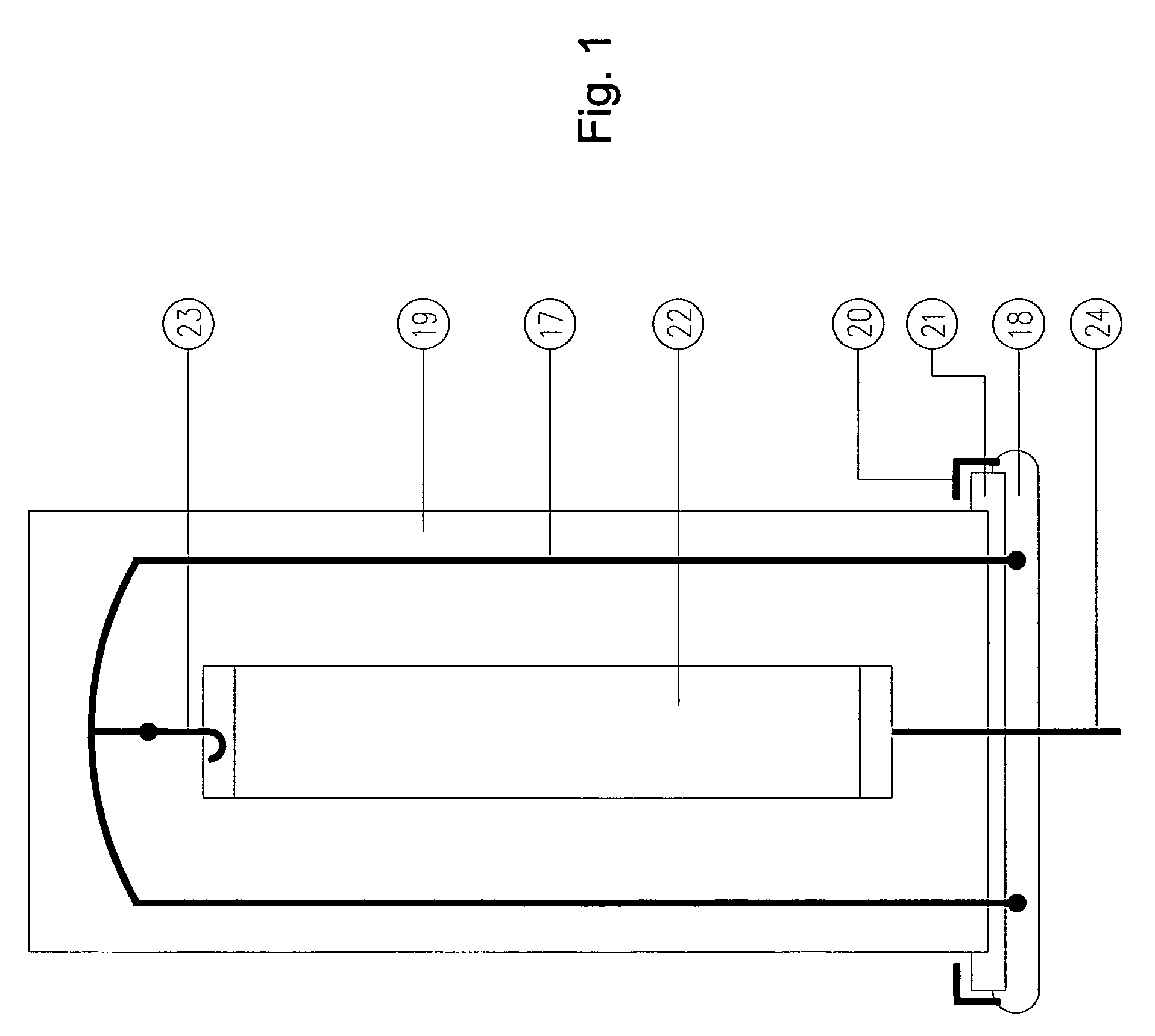

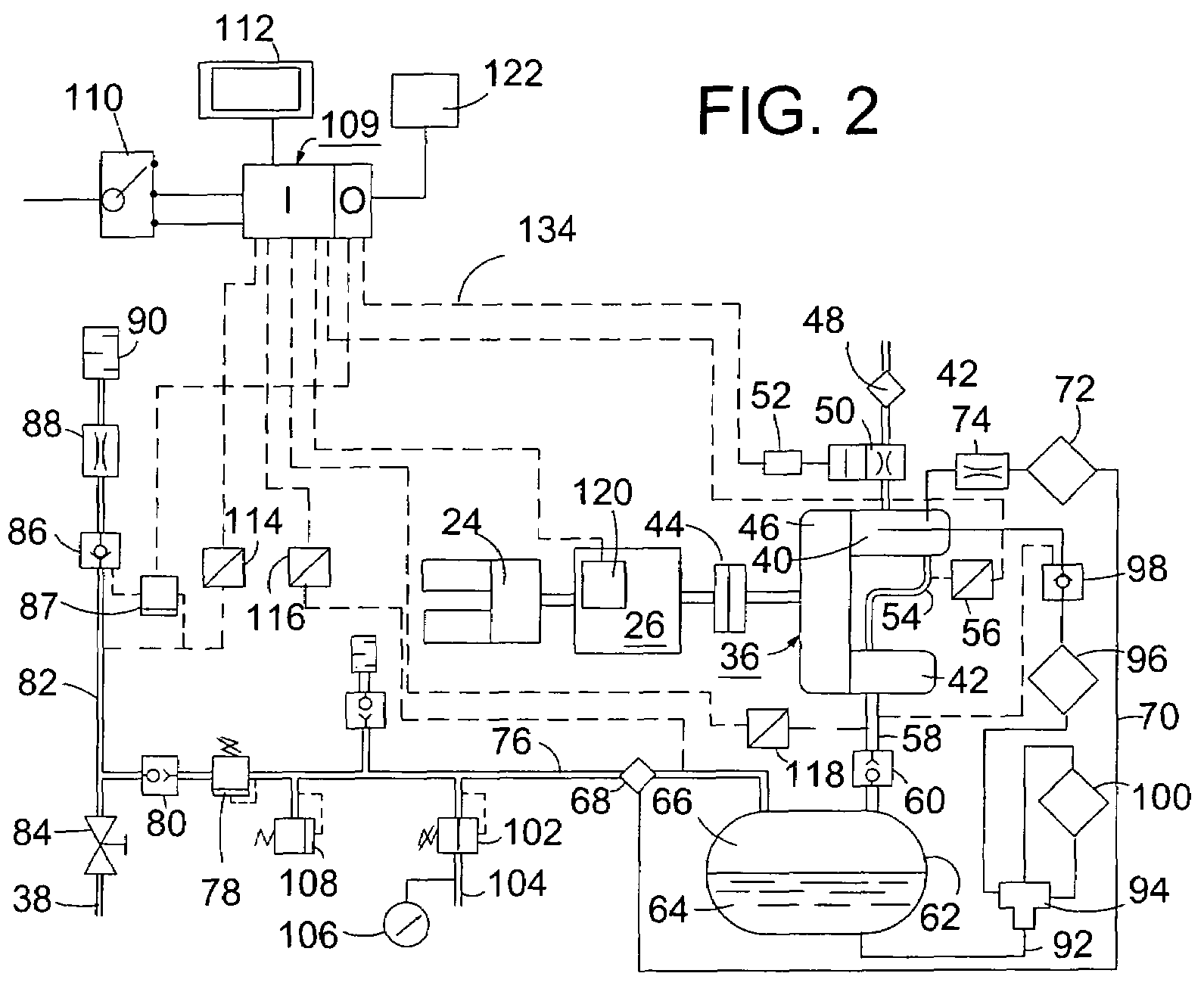

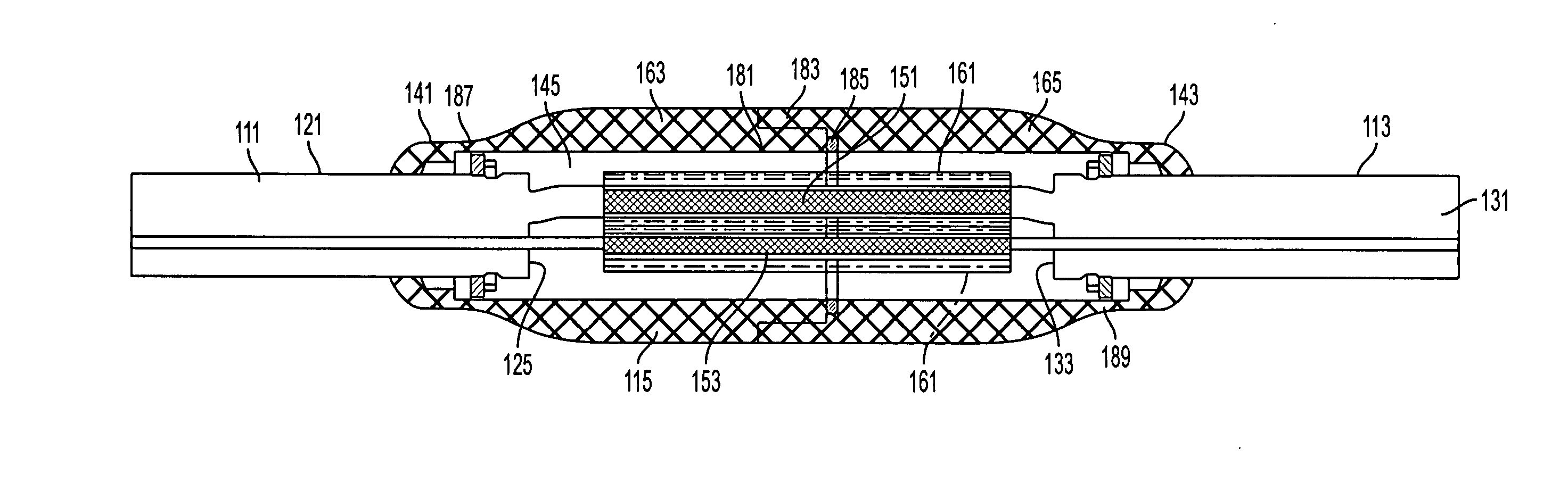

Egg vaccination apparatus

ActiveUS7721674B2Minimizing of movementMinimize the possibilityEar treatmentCannulasVaccinationCritical level

An automatic vaccinator of eggs, consisting of a system for applying vaccine with a vaccine chamber in which vaccine bags are hung and with an air bag that, when expanded, forces the vaccine from the bags and through tubing to a distribution manifold and the injectors, so that the vaccine is delivered to the eggs, is disclosed. A pressure sensor is installed in the distribution manifold and connected to a regulator, measuring the pressure in the distribution manifold at the point farthest from the vaccine chamber and controlling the pressure in the air bag to maintain a uniform quantity of vaccine being injected into the eggs and turning off the vaccinator if the pressure falls below a critical level, signaling that the vaccine bags are empty. The mechanical unit includes a system to support, align and secure the injectors over the egg tray, composed of two plates that work independently, a support plate and an alignment plate.

Owner:MERIAL INC

Earth drilling rig having electronically controlled air compressor

InactiveUS7503409B2Minimize switchingAvoid problemsSurveyReciprocating drilling machinesElectronic controllerCritical level

In an earth drilling rig in which an air compressor and one or more hydraulic pumps are driven by the same engine, the intake throttle of the compressor is controlled by an electronic controller having a proportional integral derivative control. The controller minimizes unloading of the compressor, allowing the engine to operate more efficiently, the hydraulic system to provide more consistent power to drilling functions and the volume and pressure of compressed air to be optimized for the drilling conditions encountered. The electronic controller also operates a blowdown valve at the discharge side of an air receiver, and effects various overrides of the control system, for example when air discharge temperature approaches a critical level, or when an overpressure condition is detected.

Owner:SCHRAMM INC

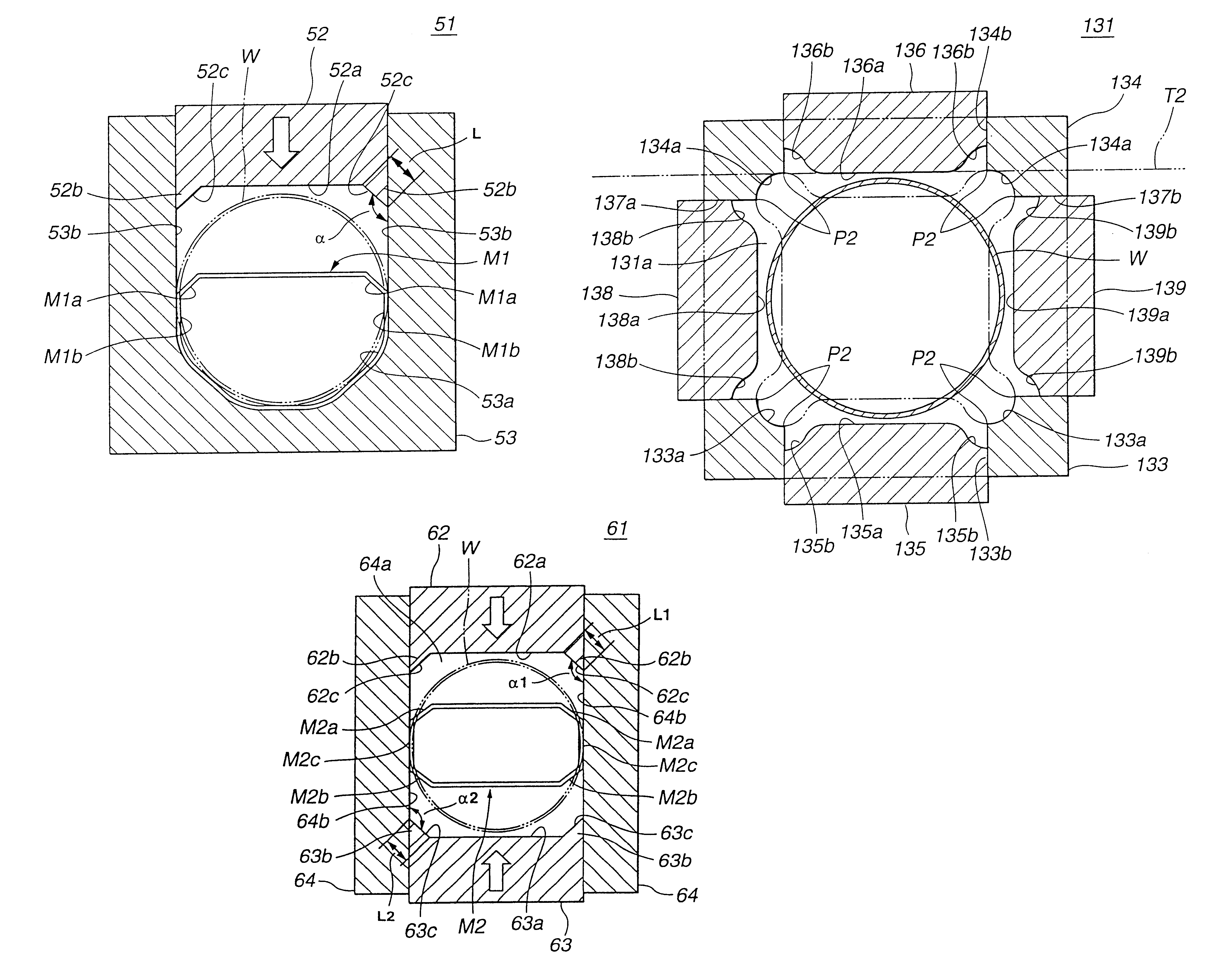

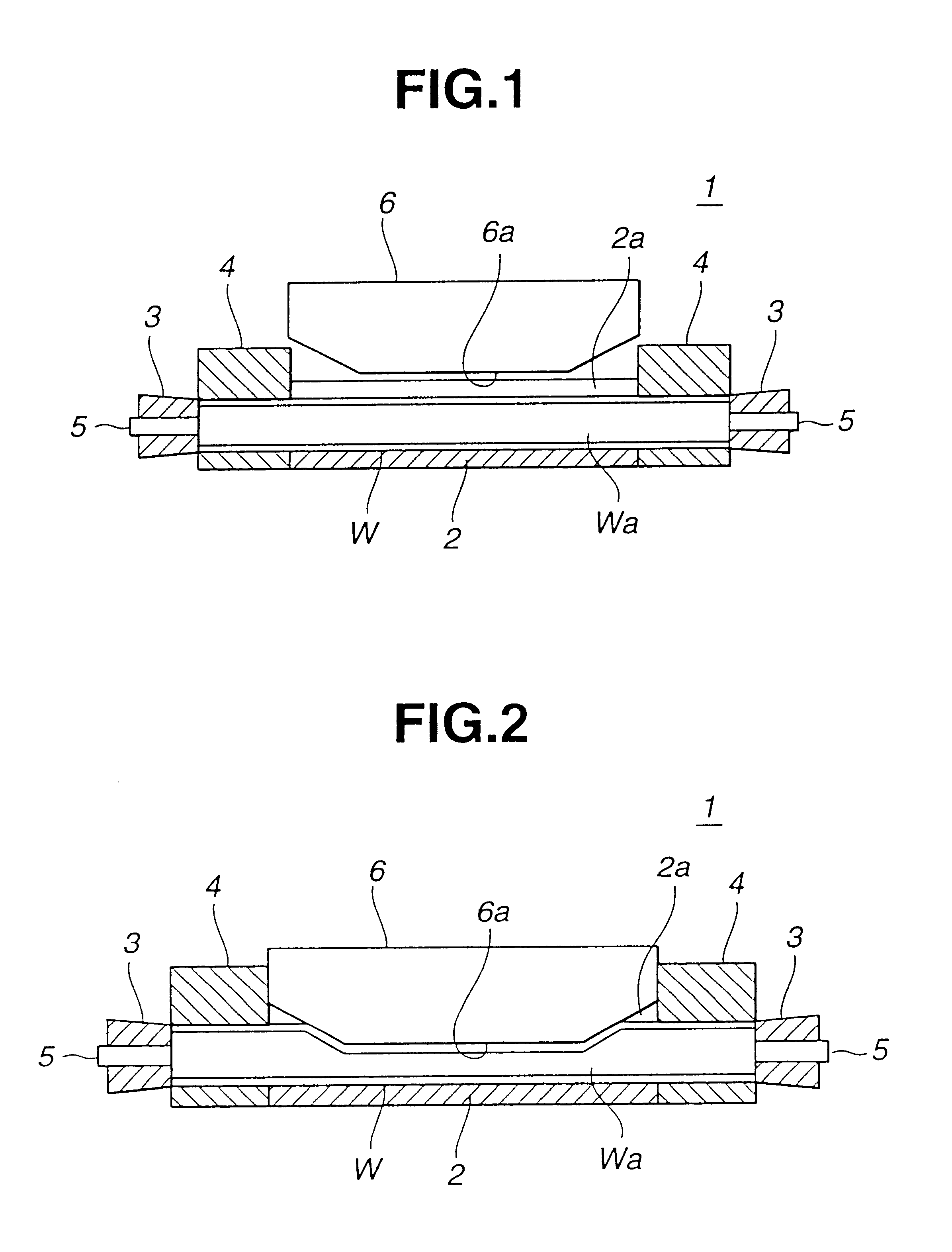

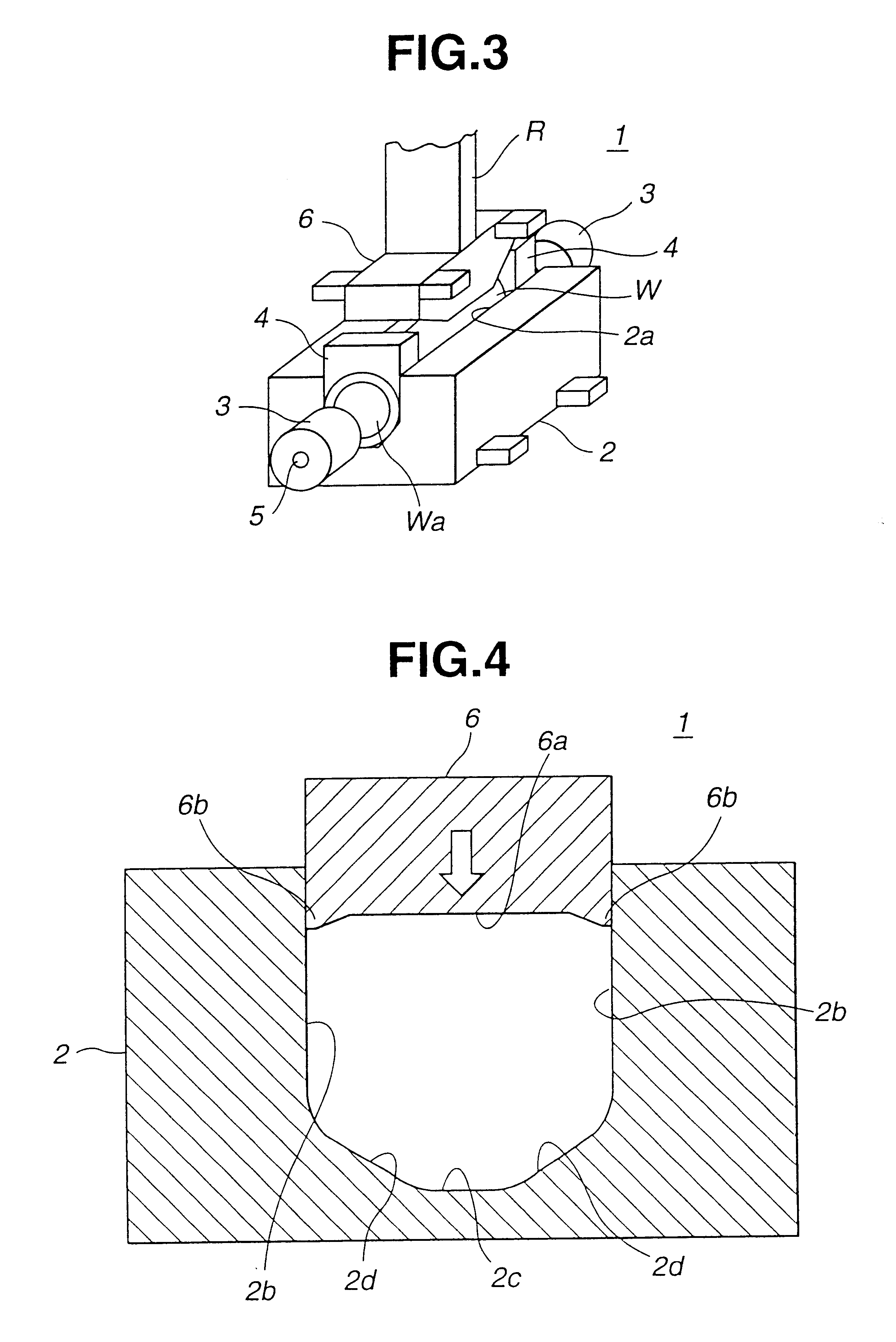

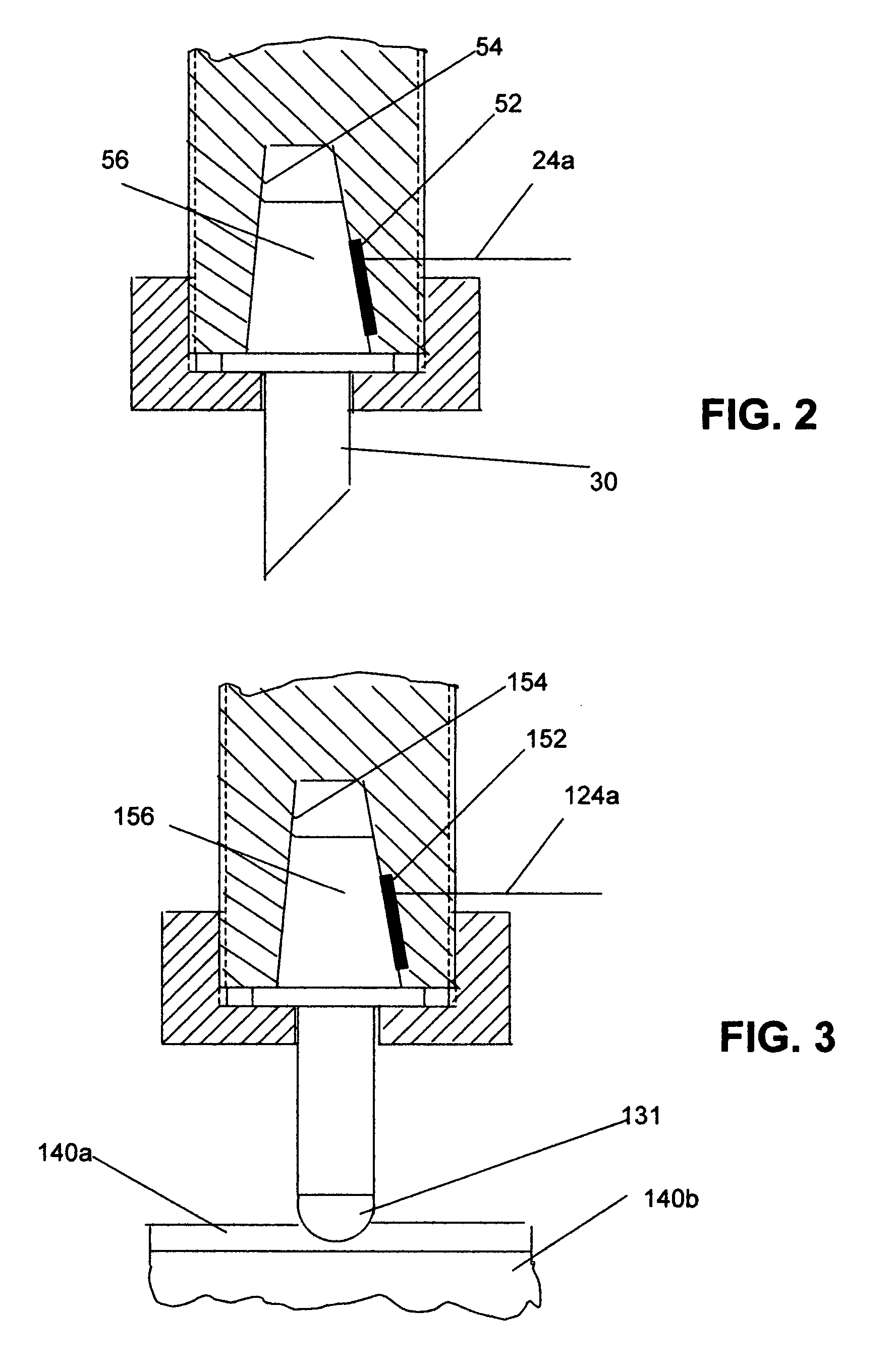

Method and device for forming tubular work into shaped hollow product by using tubular hydroforming

For forming a tubular work into a shaped hollow product by using hydroforming process, a method and a device are described. In the method, female and male dies are prepared. The female die has a longitudinally extending cavity which has a polygonal cross section when receiving the male die. The tubular work is placed into the cavity of the female die. The interior of the tubular work is then fed with a hydraulic fluid, and the pressure of the fluid is increased to a given level. The given level is smaller than a critical level that causes a bulging of the tubular work. The male die is then pressed against the tubular work to deform the same while keeping the hydraulic fluid at the given level, thereby forming a shaped hollow product that has a polygonal cross section that conforms to that of the cavity. The pressing work is continued until a circumferential length of the shaped hollow product becomes shorter than that of the tubular work.

Owner:NISSAN MOTOR CO LTD

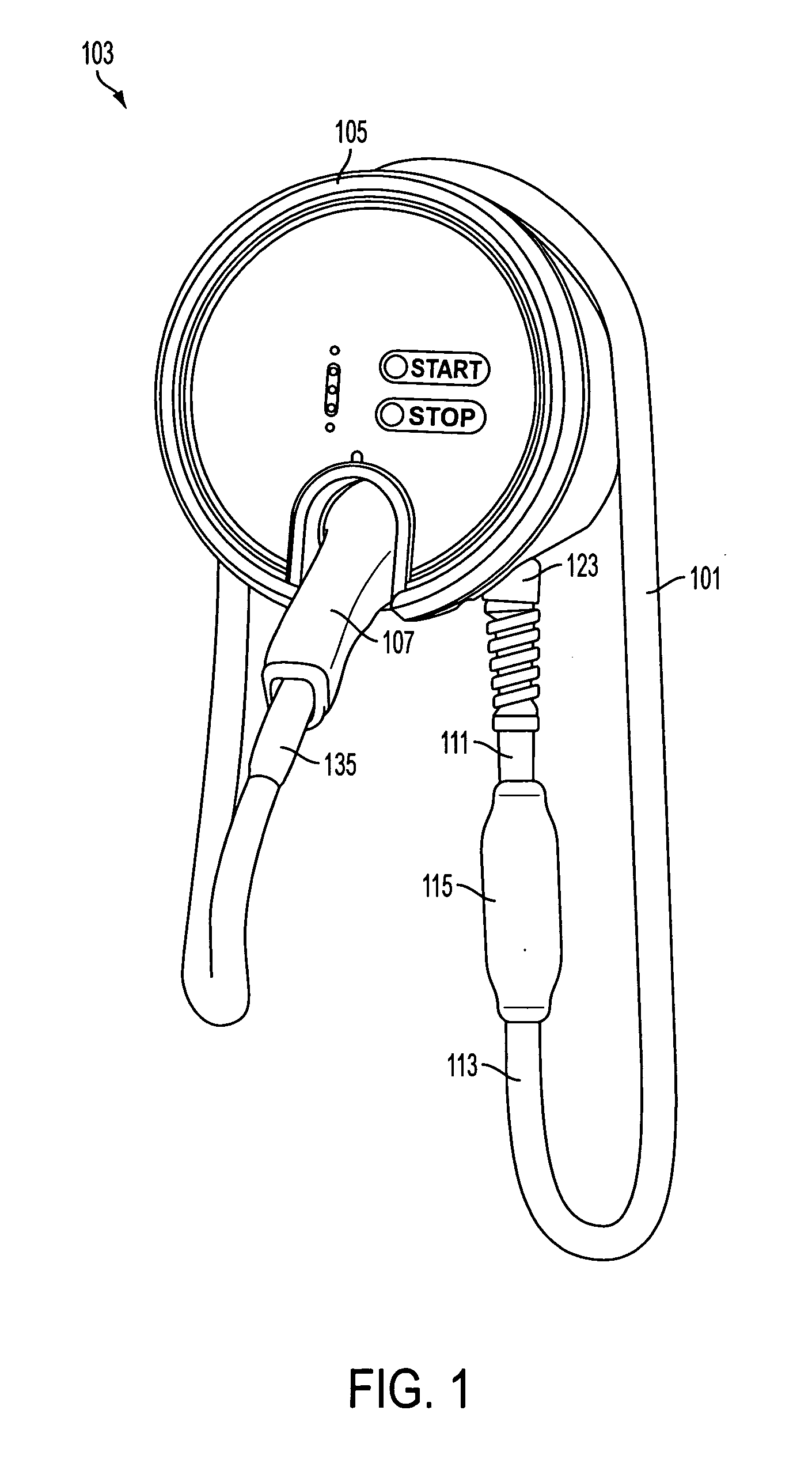

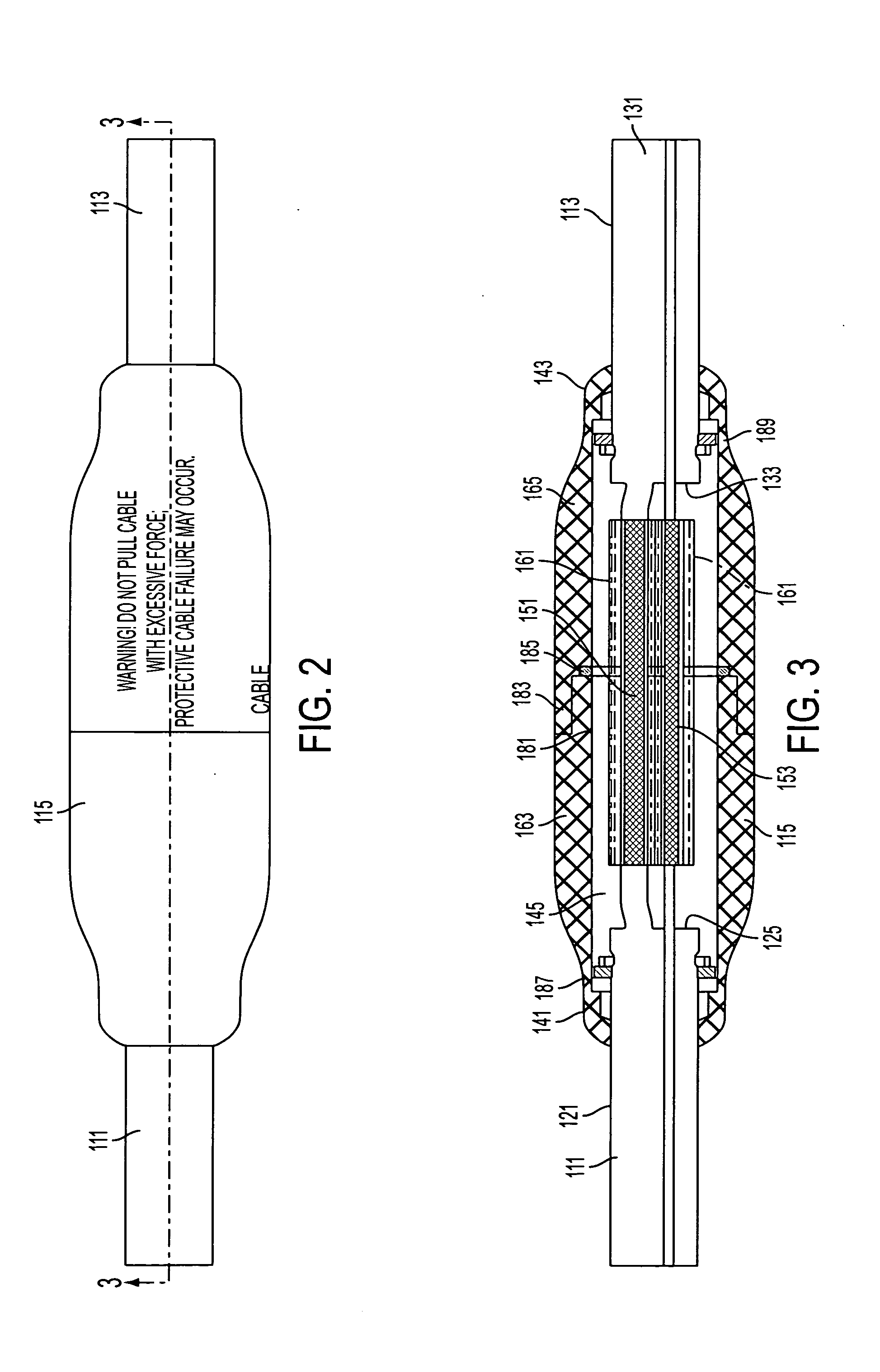

Break-away cable connector

InactiveUS20130187601A1Minimize the possibilityBatteries circuit arrangementsRelieving strain on wire connectionCritical levelBody positions

An electric vehicle charging station having a console, a cable and a vehicle connector. The cable is connected with a break-away system that allows for a controlled structural failure of one of the cable connections when the vehicle connector is pulled away from the console with a critical level of force. The break-away system could be a body positioned along the length of the cable, and could be a connection between the cable and either the console or the vehicle connector.

Owner:WEBASTO CHARGING SYST INC

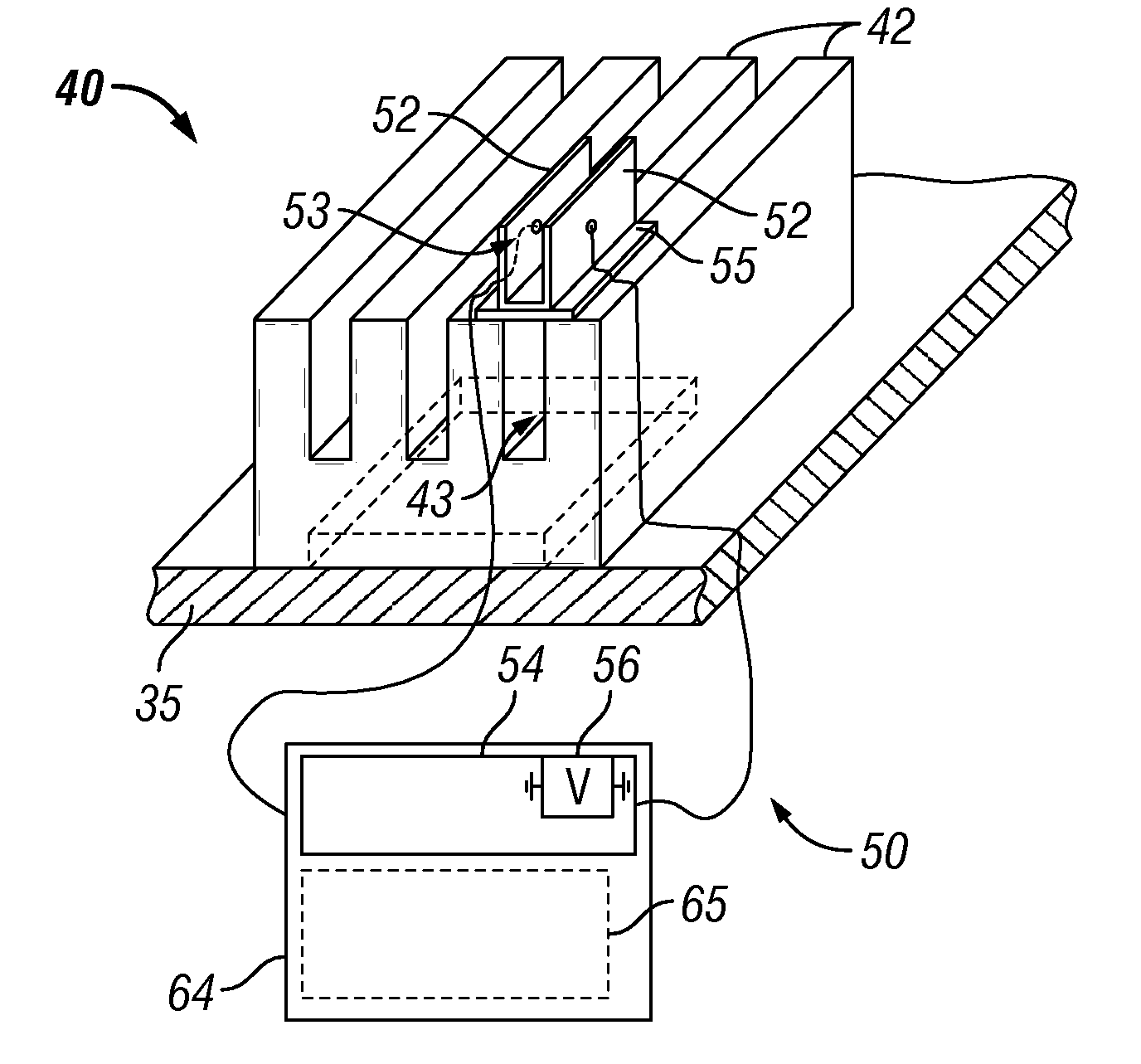

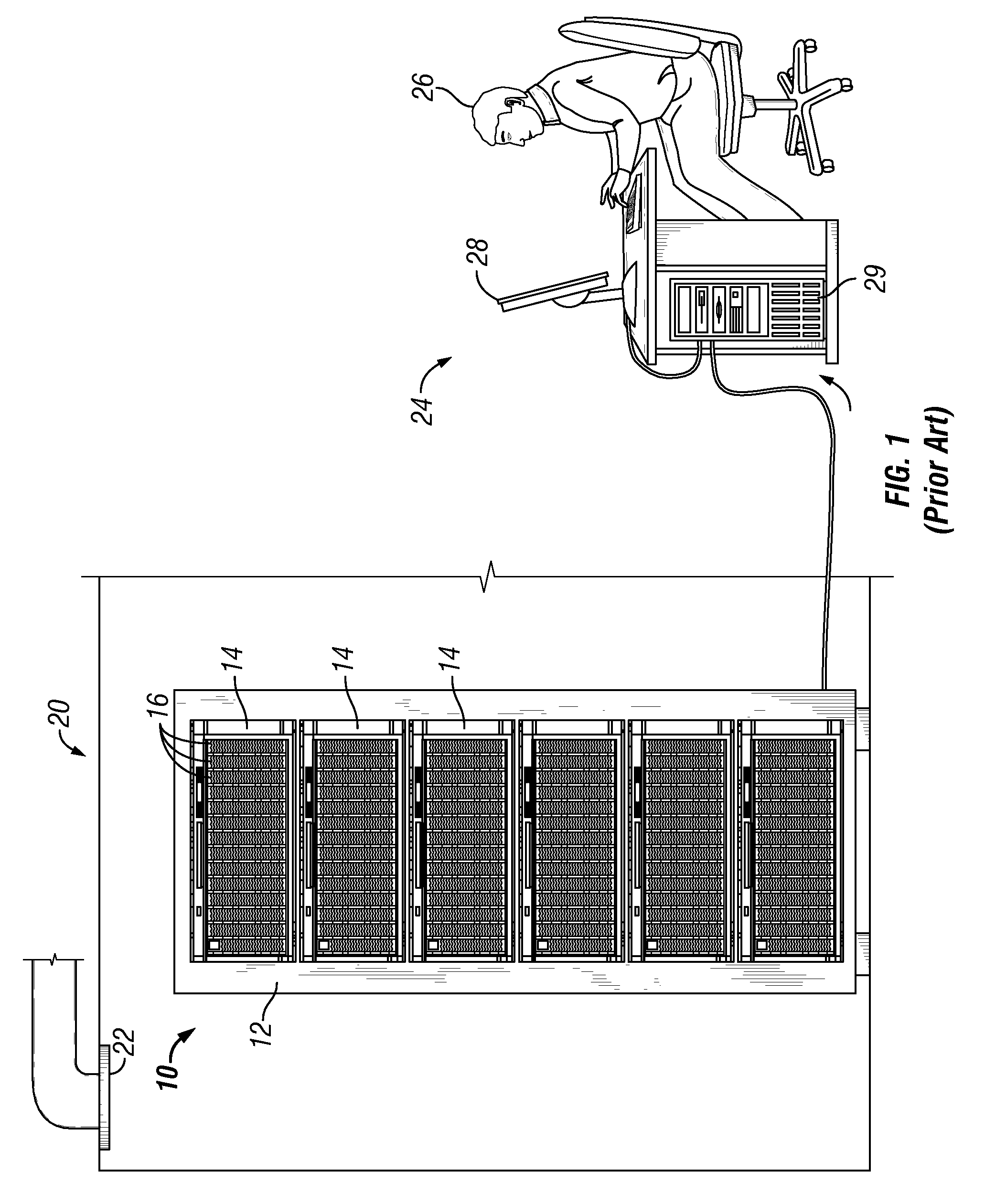

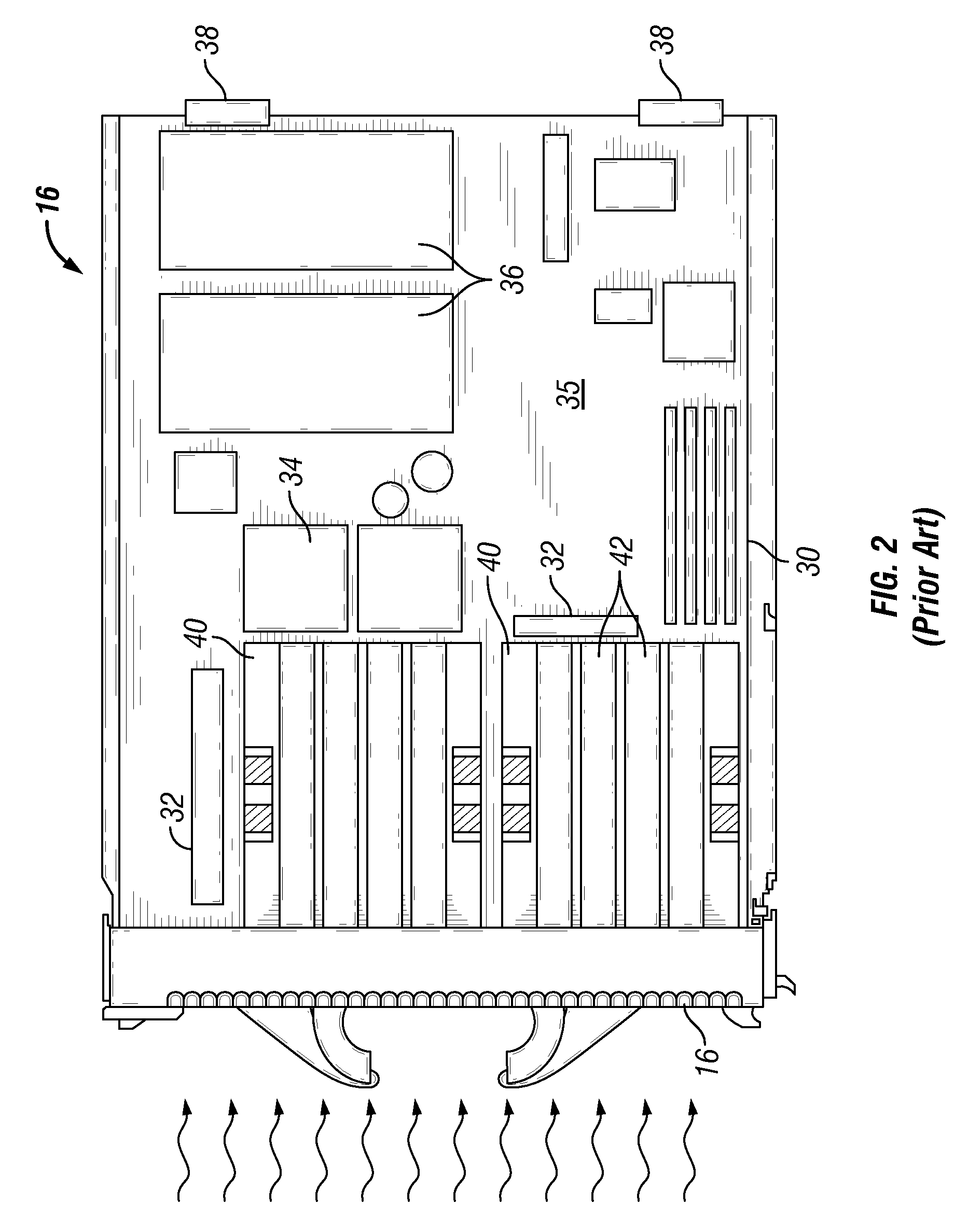

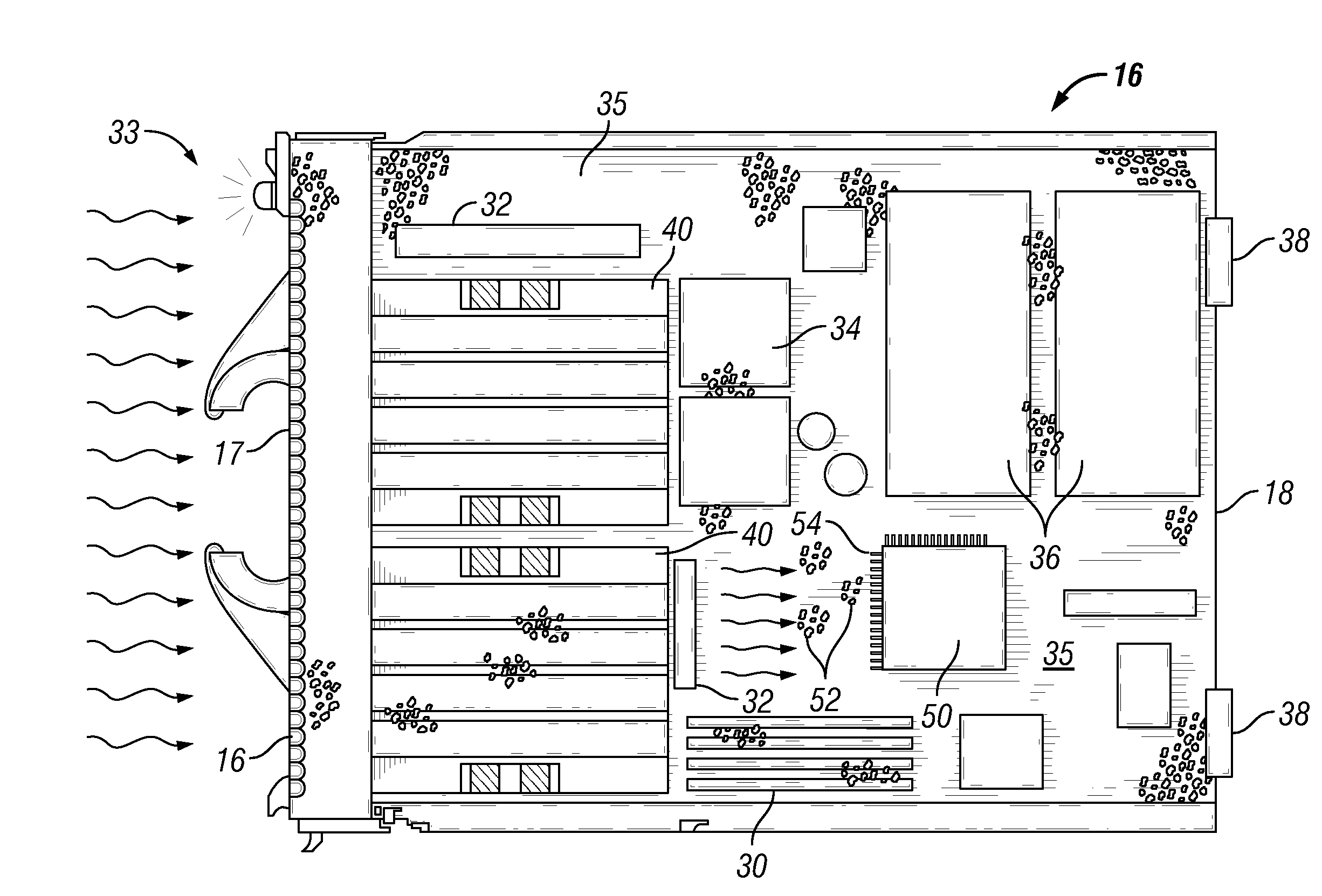

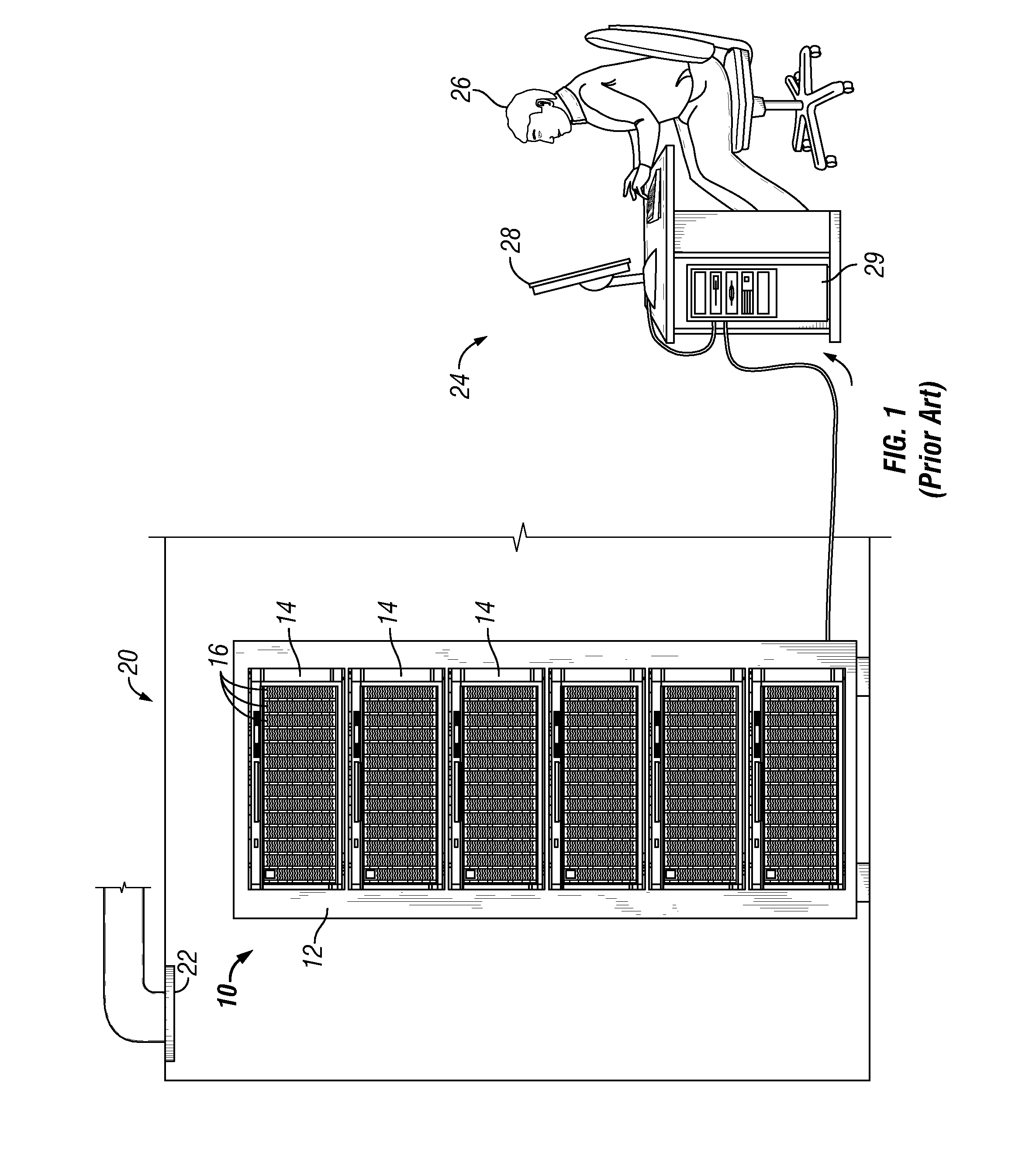

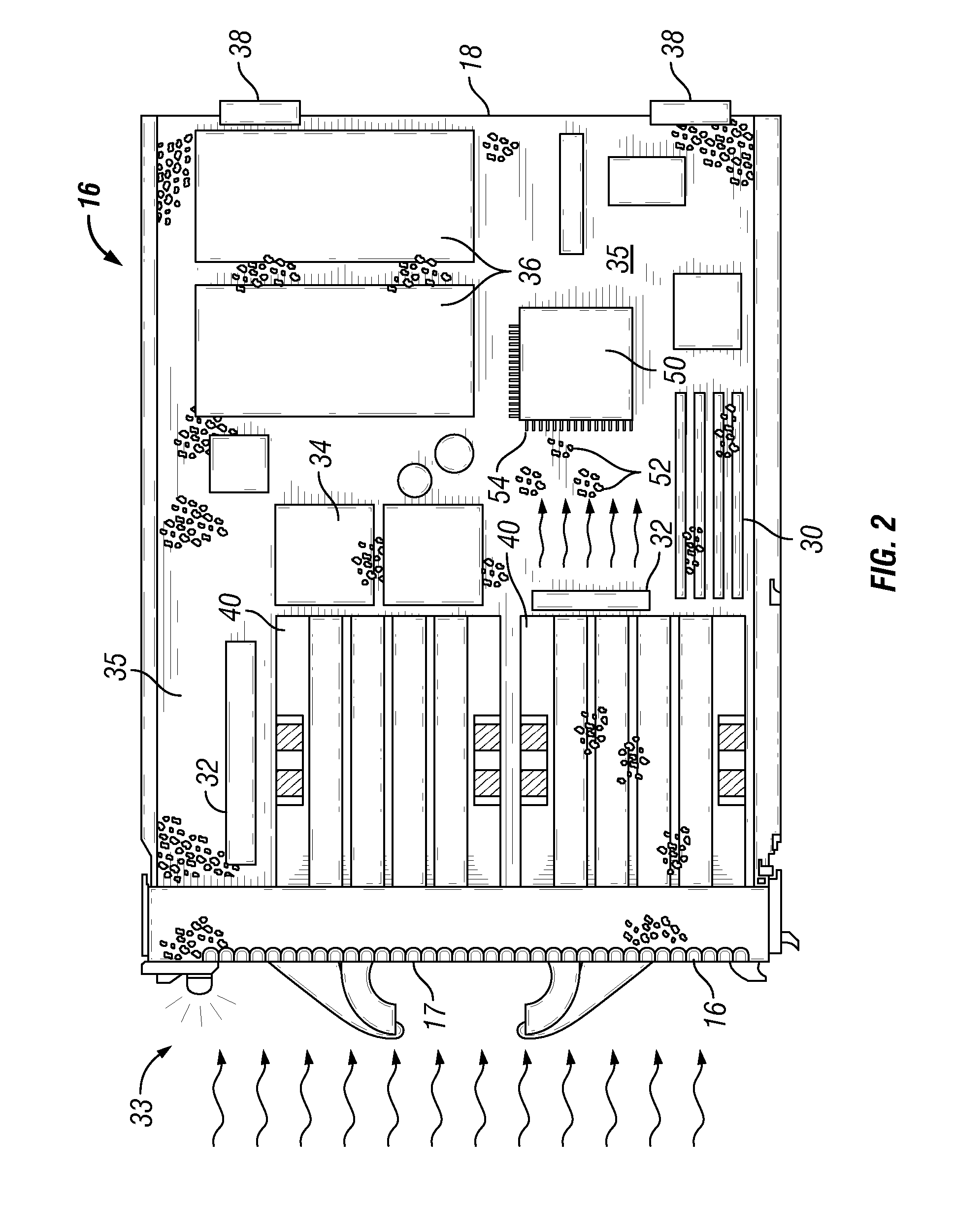

Capacitive detection of dust accumulation in a heat sink

InactiveUS20090021270A1Resistance/reactance/impedenceSemiconductor/solid-state device detailsCritical levelDust detection

A system and method for electronically detecting the accumulation of dust within a computer system using a capacitive dust sensor. The dust detection system may be implemented on a smaller computer, such as an individual PC, or in a more expansive system, such as a rack-based server system (“rack system”) having multiple servers and other hardware devices. In one embodiment, each server in a rack system includes a capacitive sensor responsive to the accumulation of dust. The capacitive sensor may include one or more capacitive plates integral with a heatsink. As dust collects on the capacitive plates, the capacitance increases. When a capacitance setpoint is reached, indicating the dust has reached a critical level, an alert is generated. The alerts may be received by a management console for the attention of a system administrator. Each alert may contain the identity of the server generating the alert, so that the system administrator knows which server(s) are to be removed for cleaning.

Owner:IBM CORP

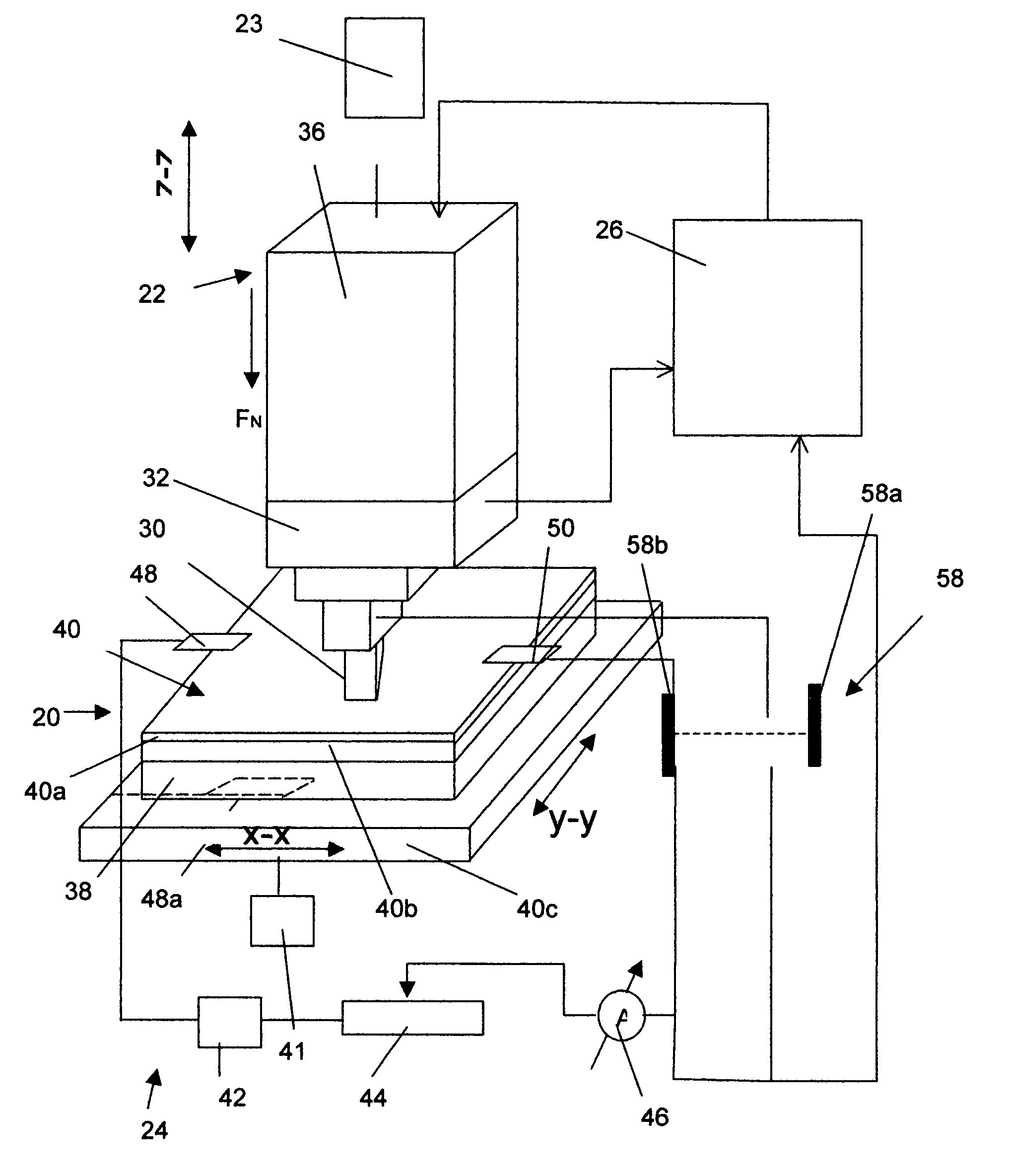

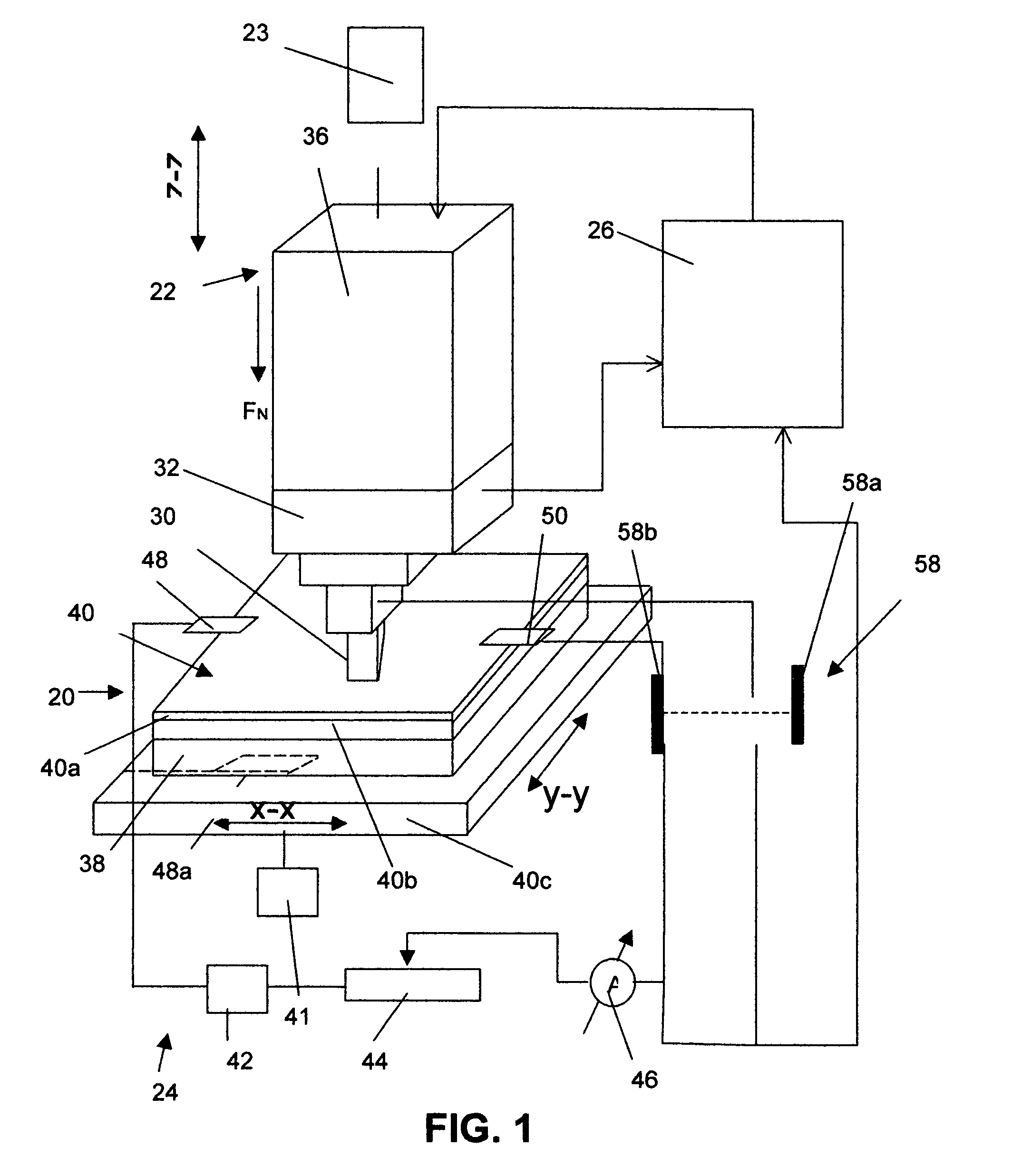

Method and apparatus for determining characteristics of thin films and coatings on substrates

InactiveUS20050172702A1Reliability in interpretationSuitable apparatusWeather/light/corrosion resistanceInvestigating material hardnessCritical levelCritical load

A method and apparatus of the invention are intended for determining characteristics of thin films, layers and coatings on under-layers and substrates when the films, layers and coatings have electrical characteristics measurably different from those of the under-layers and substrates. The method consists of selecting an object with an appropriate combination of a coating and substrate having different electrical characteristics, connecting one electrical contact to either the coating when the coating is more conductive than its substrate or to the substrate when the coating is less conductive than its substrate, connecting a second electrical contact to either the coating when the coating is conductive or to a conductive indenter when the coating is non-conductive, causing a relative movement between the indenter and the coating with application of an either constant or increasing force with simultaneous monitoring of electrical characteristics of the aforementioned circuit, until these characteristics change substantially and reach a critical level. The substantial changes in the electrical characteristics correspond to film or coating removal and exposure of the under-layer or substrate to the indenter. The characteristics of the thin films, layers and coatings are evaluated based on either critical load or distance or number of cycles corresponding to the substantial change in the electrical characteristics. The invention also relates to an apparatus for realization of the method.

Owner:NEVMET CORP

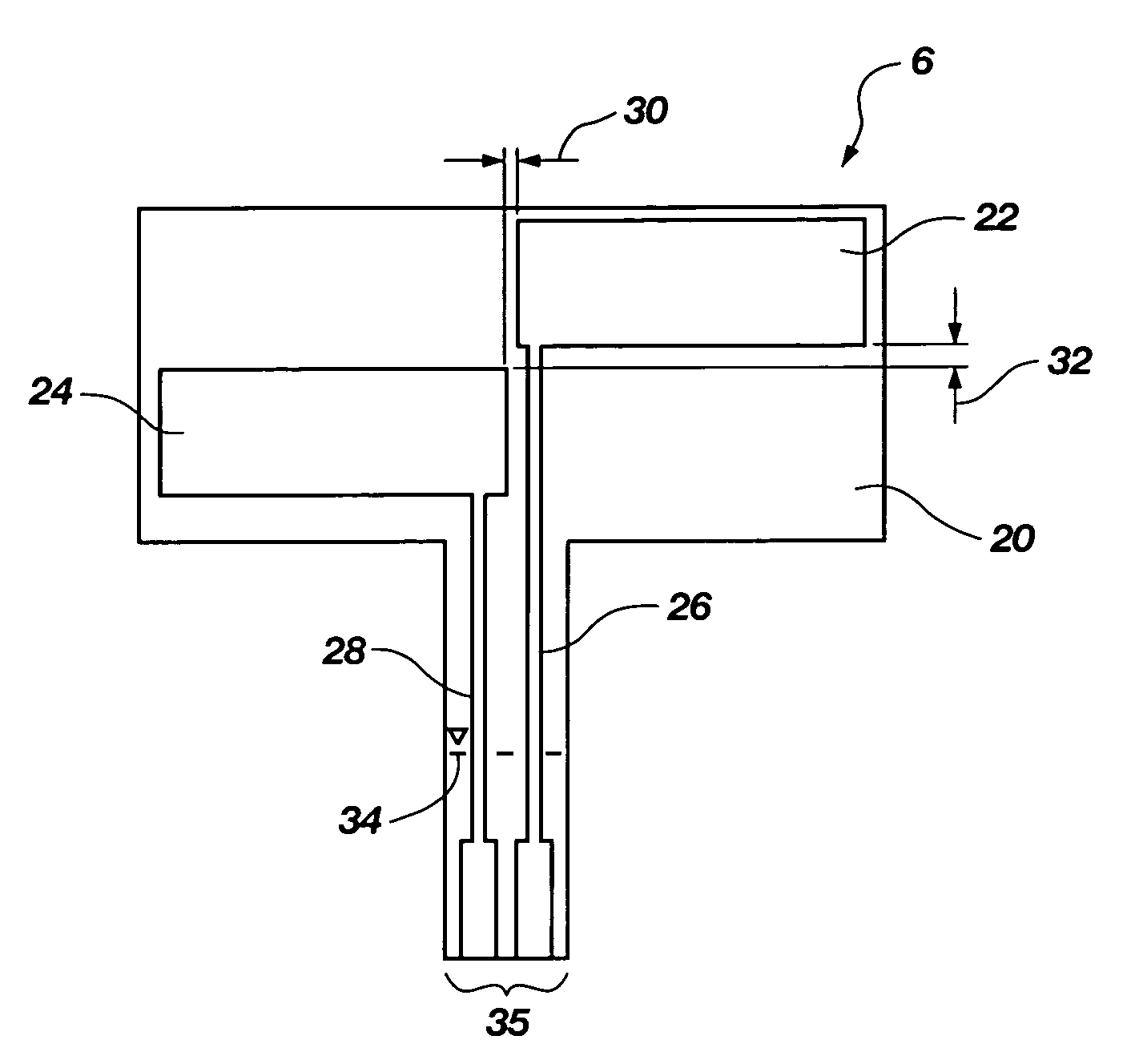

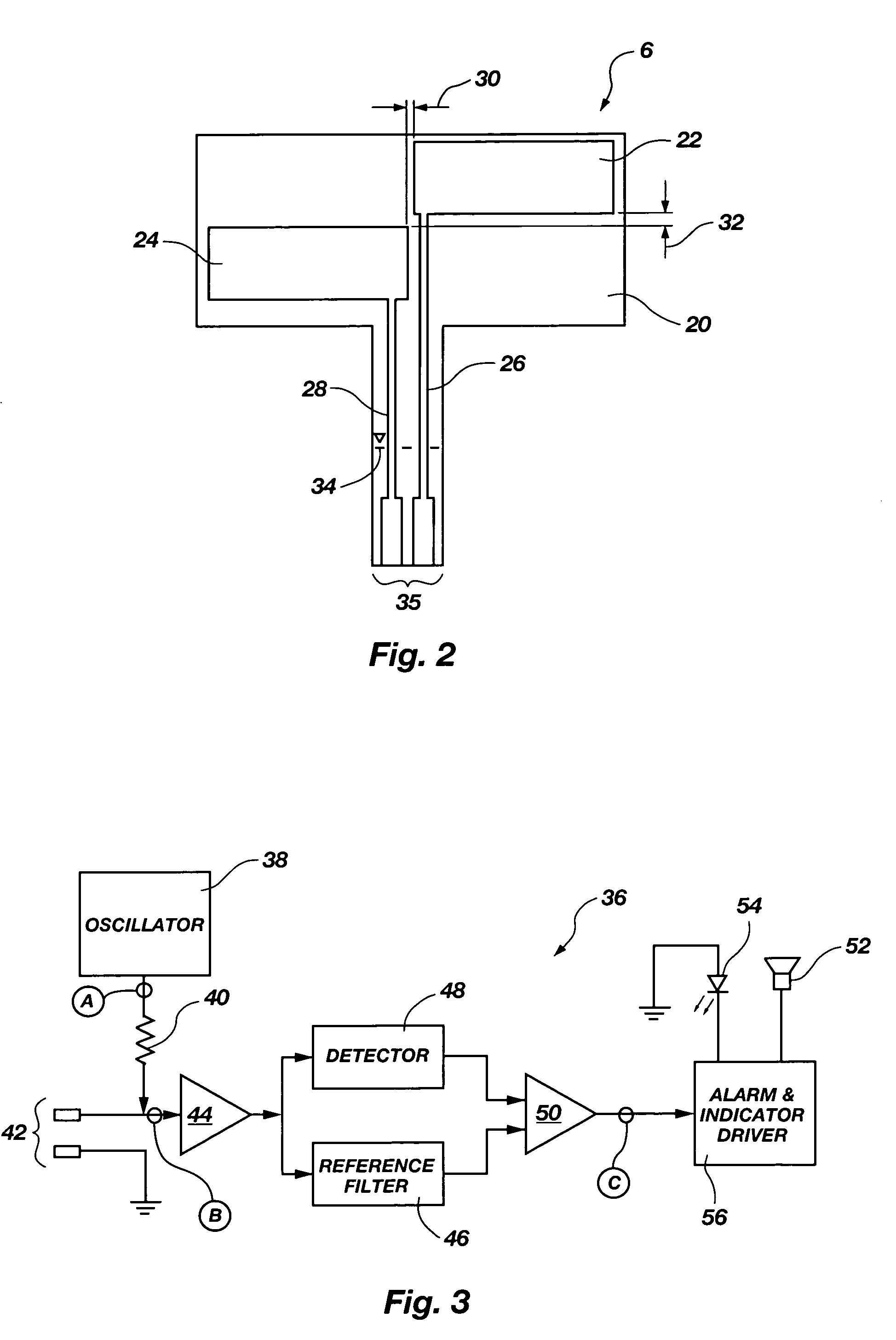

Method and apparatus for detection of fluid level in a container

InactiveUS7127943B1Accurately detect rapidly changing fluid levelReduce the effect of capacitanceMachines/enginesLubrication indication devicesCritical levelLiquid level sensor

A fluid level sensor is disclosed having first and second vertically and horizontally nonoverlapping electrode plates for placing on a wall of a fluid container. Most preferably, the plates are also vertically spaced from each other. The capacitor plates are driven by a high frequency square wave. By forming nonoverlapping plates and driving them using a high frequency, the level of a fluid within the container, particularly viscous fluid, is more accurately detected. Control and detection circuitry is also disclosed to trigger an alarm if the fluid level drops below a critical level within the container.

Owner:ROCKY MOUNTAIN COMPOSITES

Process for the preparation of high activity carbon monoxide hydrogenation catalysts; the catalyst compositions, use of the catalysts for conducting such reactions, and the products of such reactions

InactiveUS20020028745A1High viscosity indexReduce pointsHydrocarbon from carbon oxidesOrganic compound preparationMagnesium saltHigh activity

A process for the preparation of a catalyst useful for conducting carbon monoxide hydrogenation reactions, particularly Fischer-Tropsch reactions; the catalyst compositions, use of the catalyst compositions for conducting such reactions, and the products of these reactions. The steps of the process for producing the catalyst comprise mixing together in solution (a) a compound, or salt of a Group VIII metal, e.g., Co(NO3)2; (b) a compound, or salt of magnesium, e.g., Mg(NO3)2; (c) a compound, salt, or powdered oxide of a Group IVB metal, e.g., zirconia; (d) a refractory inorganic oxide, e.g., kieselguhr; and (e) an ammonium or alkali metal salt precipitating agent, e.g., Na2CO3, to produce a precipitated solids mass, or catalyst precursor, and then reducing the precipitated solids mass, or catalyst precursor, to form a catalyst, e.g., (100 Co:6 MgO:10 ZrO2:200 kieselguhr). The precipitated solids mass, or catalyst precursor, is shaped and brought to a critical level of moisture, and reduced. A catalyst formed from the precursor in this manner has greater activity, and selectivity in the production of high melting waxes in conducting Fischer-Tropsch reactions, and gas make is lower, than in the use of catalysts made conventionally, i.e., from precursors of similar composition at differing moisture levels.

Owner:EXXON RES & ENG CO

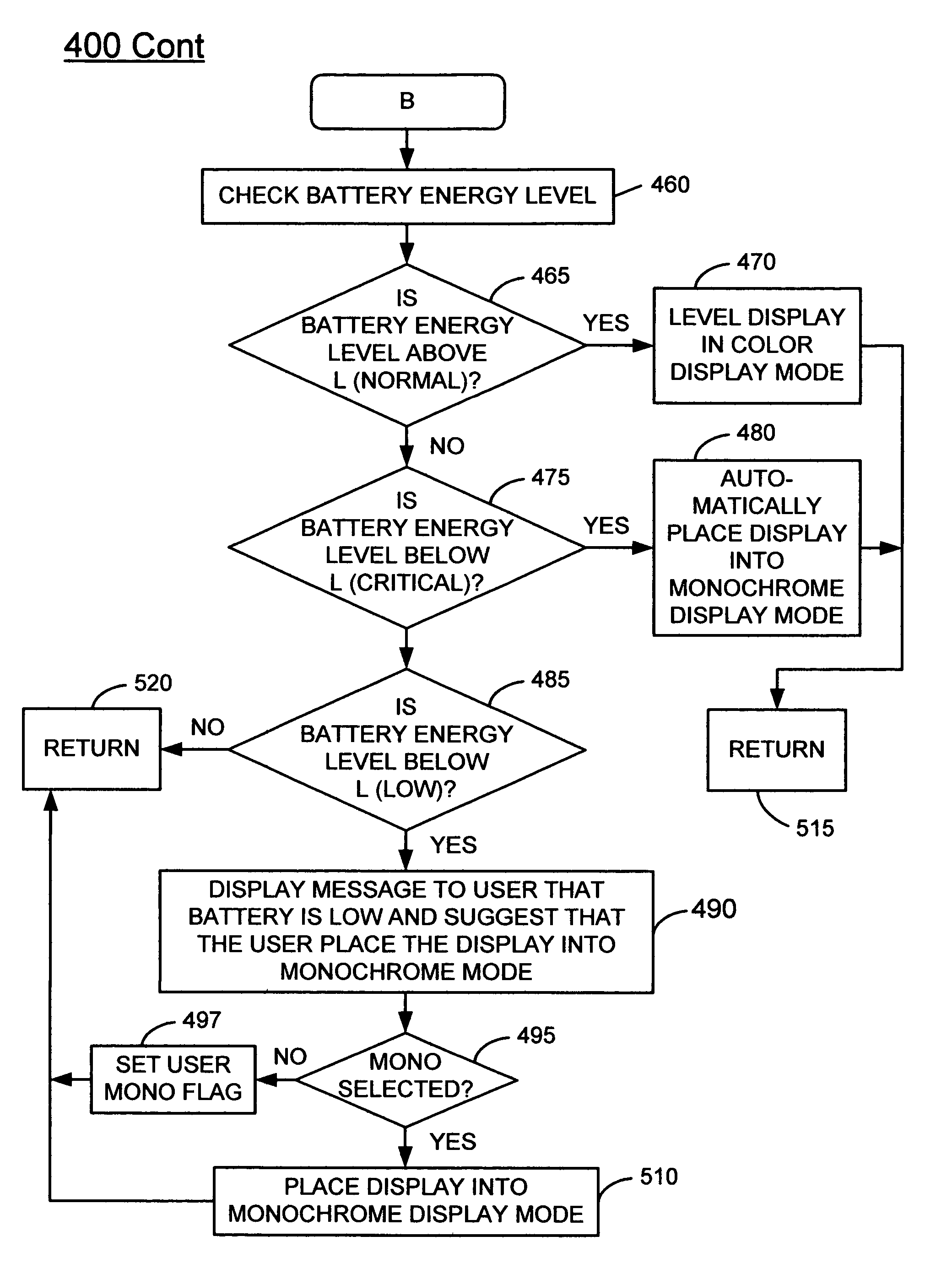

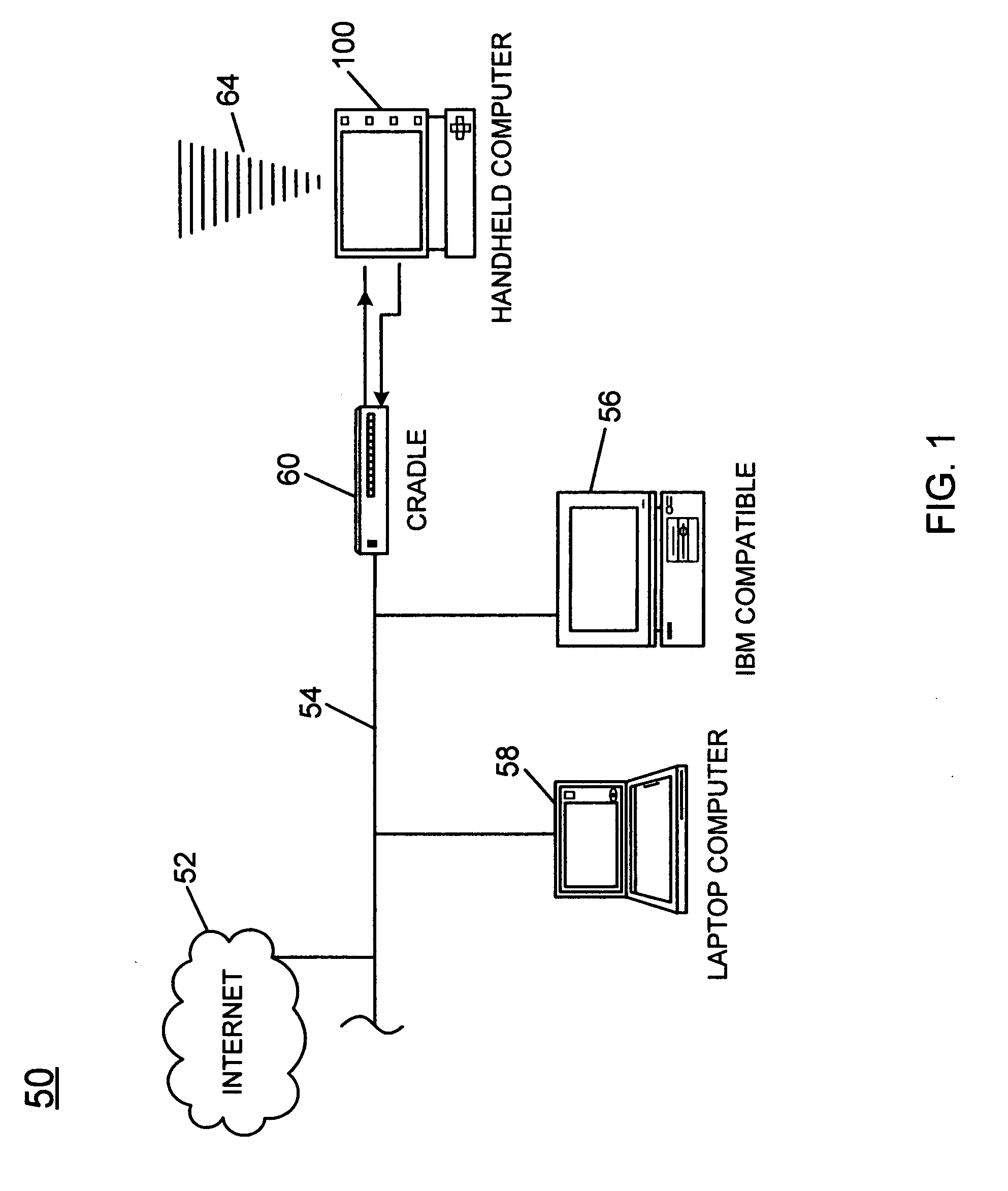

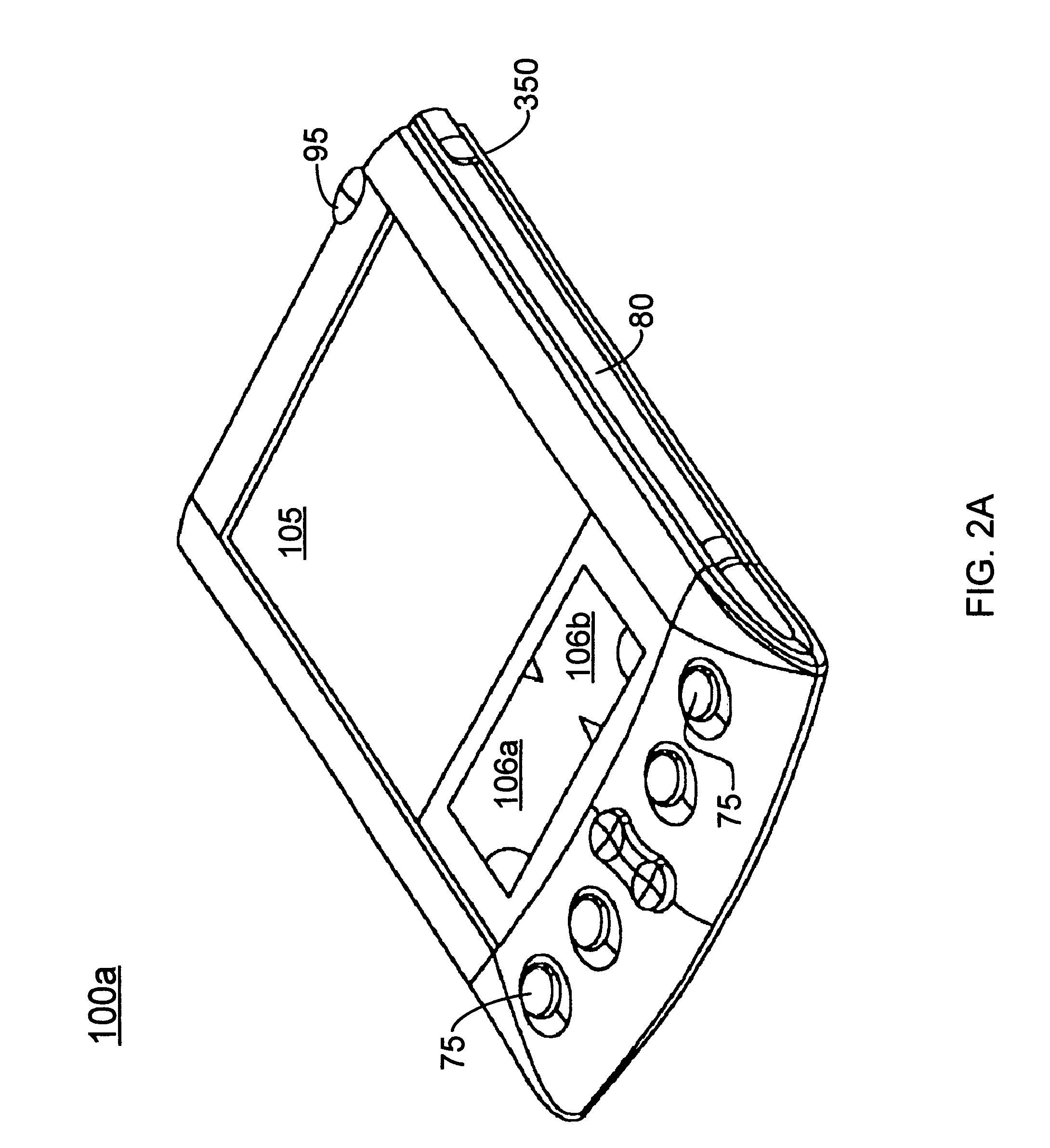

Method and apparatus for user selectable display mode for intelligently enhancing battery life

InactiveUS7002569B1Extend battery lifeProlong lifeEnergy efficient ICTCathode-ray tube indicatorsElectrical batteryDisplay device

A method and system for enhancing the life of a battery within a portable or otherwise battery operated electronic device. The method and system provide user selectable display modes, e.g., from color to monochrome, that can be changed in order to enhance the life of the device's battery. The monochrome display mode can be selected by the user when the battery level is detected below a predefined threshold. In one embodiment, the electronic device is a hand held computer system with a display device. When the battery level is detected as below a preselected level, a message is generated on the computer display screen. The message informs the user that the display mode of the screen can be changed to enhance the battery life. If selected, the display mode can change from color to monochrome thereby saving power because the monochrome display does not utilize a back-lighting element. In one embodiment, color sequential techniques are used to provide a flat panel color display. Within the display, a transreflective layer provides reflective light for monochrome applications. When the battery energy returns to normal levels, the color display mode can be re-entered automatically. It is appreciated that the display mode changes can also be performed automatically if the battery level falls below certain critical levels.

Owner:QUALCOMM INC

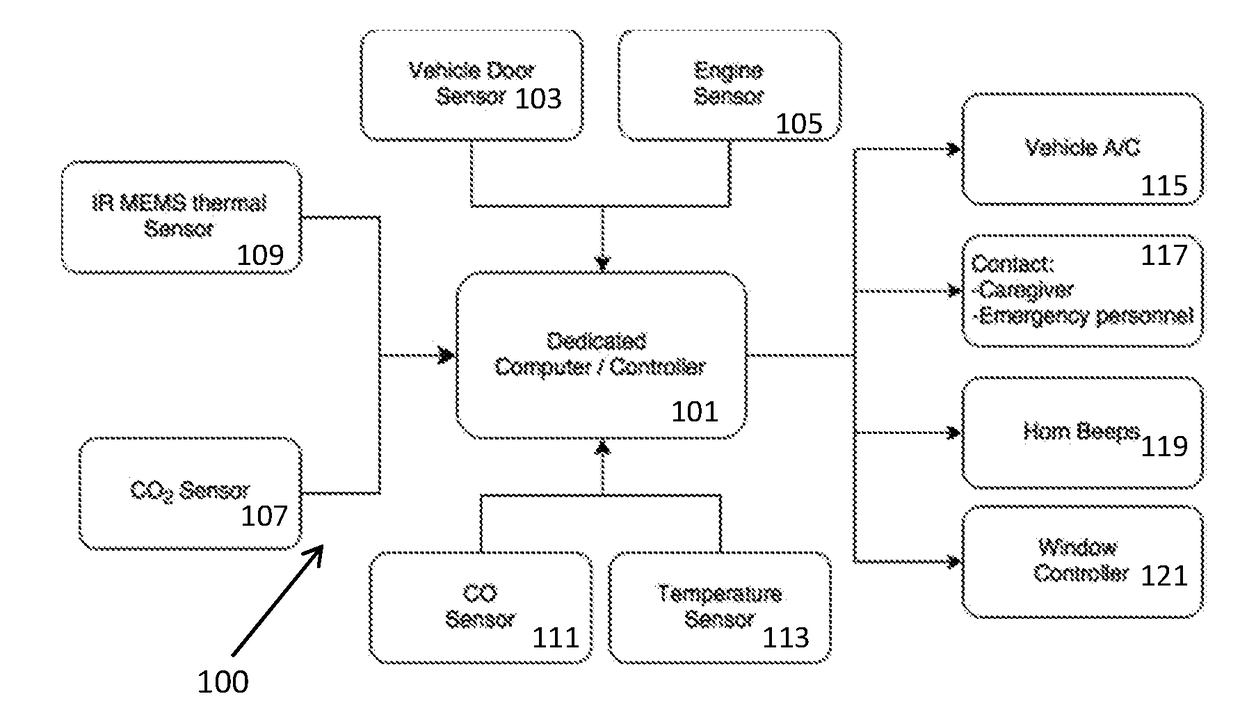

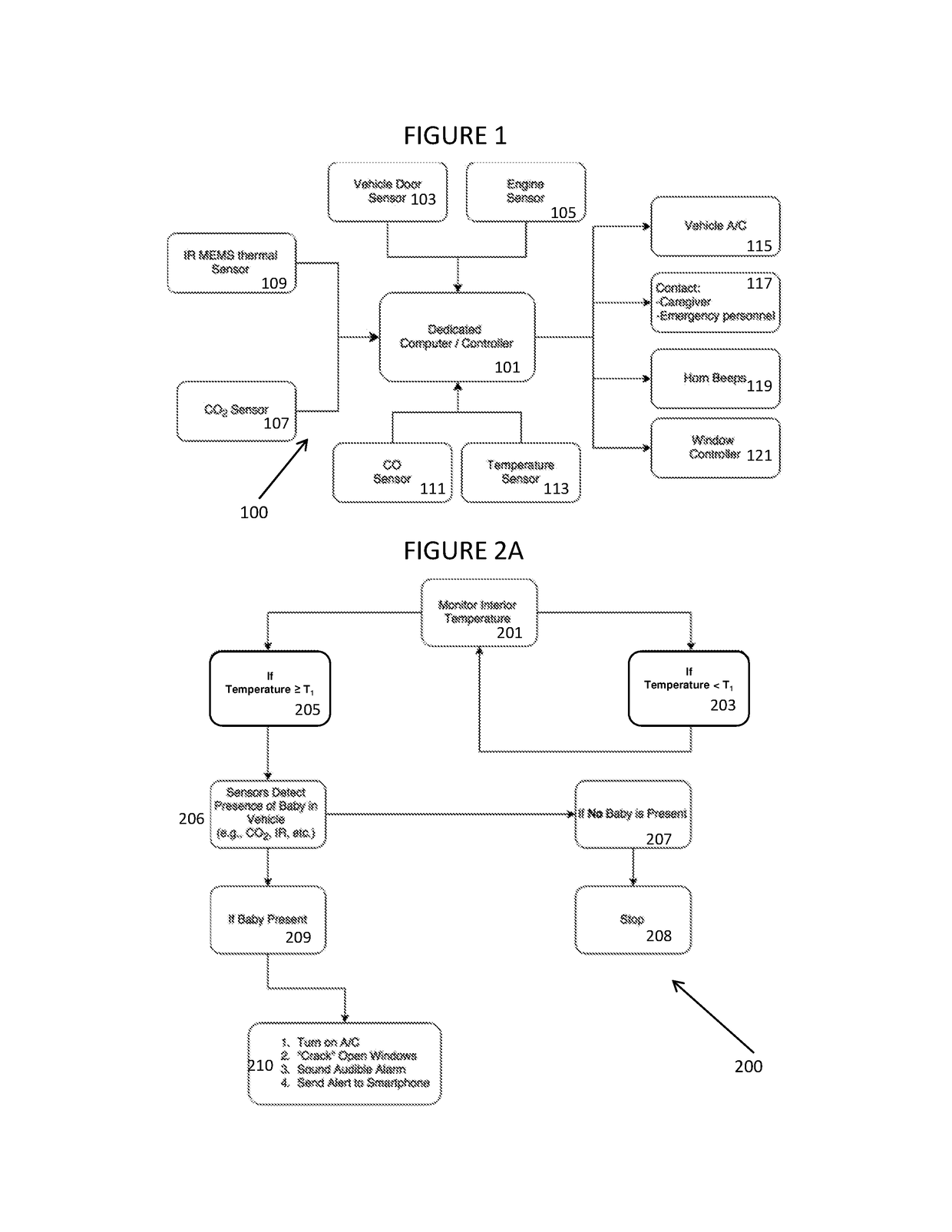

Vehicular heatstroke prevention device

ActiveUS20170158186A1Eliminate needAvoid temperatureVehicle heating/cooling devicesCaregiver personCritical level

A passive vehicular heatstroke prevention system monitors carbon dioxide (CO2) and infrared (IR) energy levels to determine whether a child is present inside a closed vehicle, and, if so, monitors the temperature in the vehicle and, if the temperature in the vehicle exceeds at least one preset critical value, automatically lowers the temperature in the vehicle and contacts the driver / caregiver and / or emergency personnel. The system detects the presence of a child in the closed vehicle by detecting a critical level of carbon dioxide in the air within the vehicle, while monitoring the interior vehicle temperature and takes corrective action to prevent the temperature from exceeding a preset value, such as by activating the vehicle's air conditioning unit and lowering the vehicle's windows, as well as contacting the driver / caregiver and / or emergency personnel.

Owner:SOIFER SCOTT ANDREW

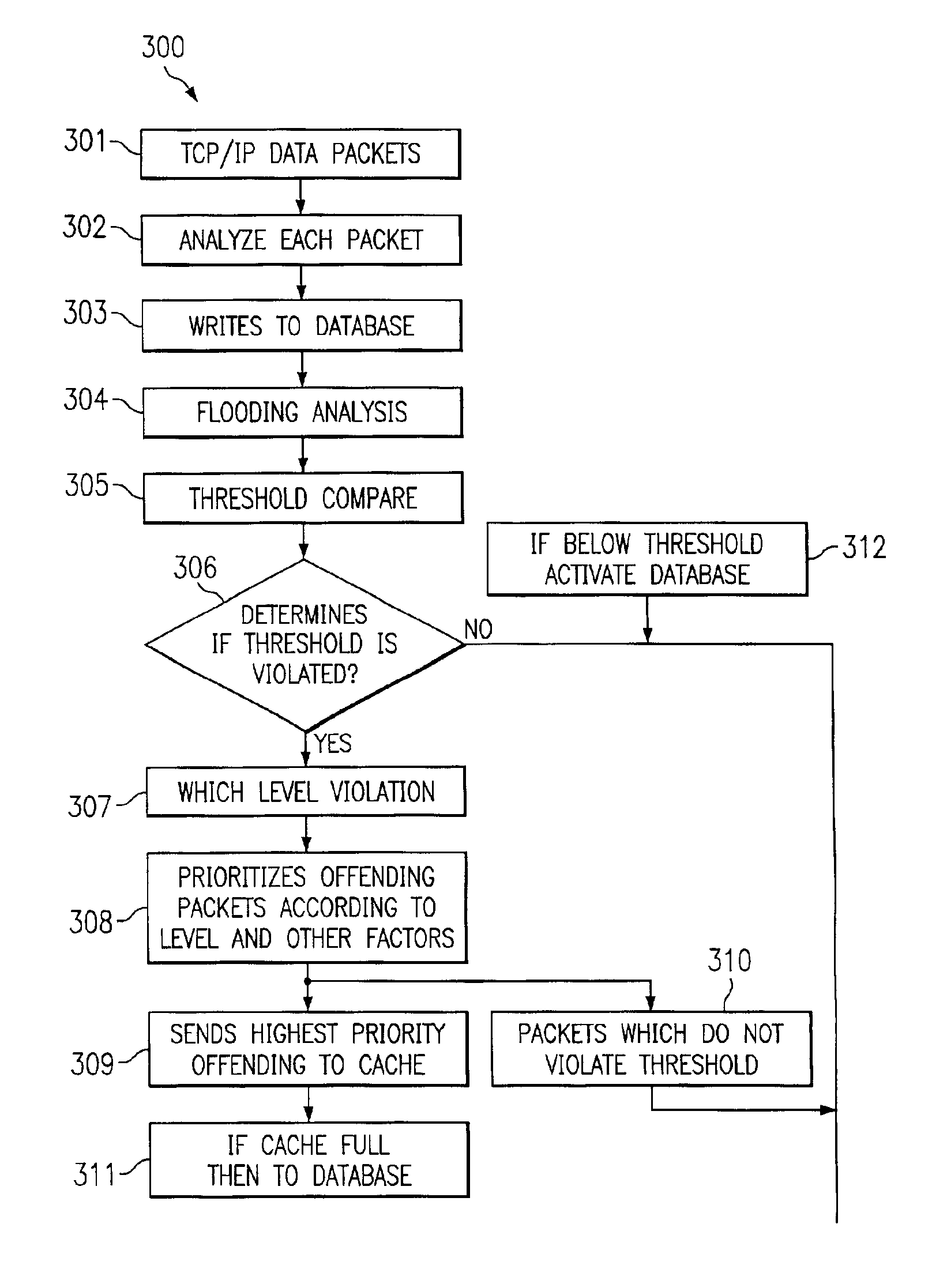

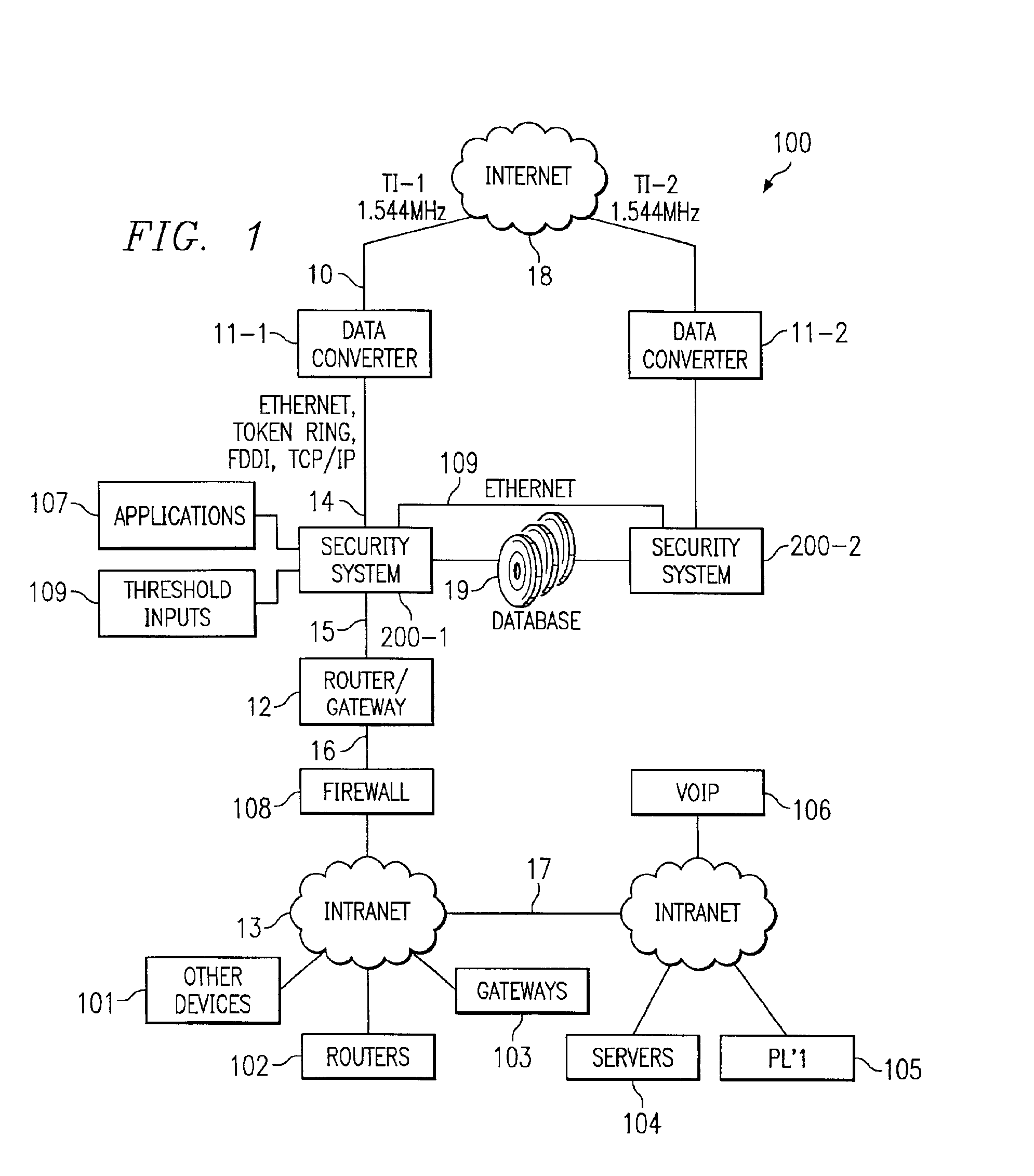

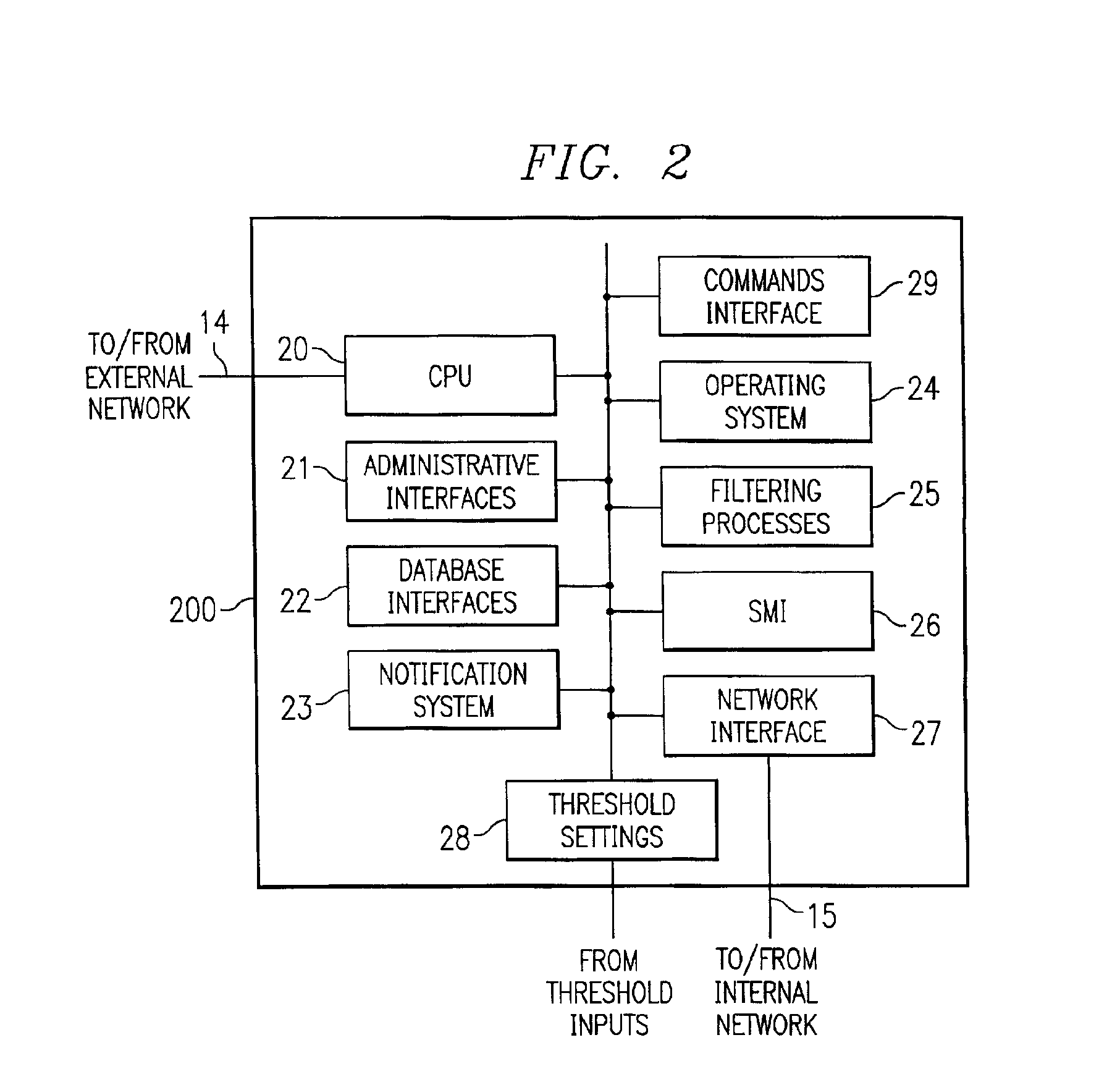

System and method for traffic management control in a data transmission network

InactiveUS6930978B2Prevent floodingAvoid flowError preventionFrequency-division multiplex detailsTraffic capacityCritical level

A traffic management system sniffs data arriving at any point in a system. The sniffer operates to remember certain parameters pertaining to the data. When the amount of data arriving at the point begins to reach a critical level (usually dependent upon data processing capability associated with that point), the system begins to remove (and share) subsequent arriving data based, in part, upon the remembered parameters of recently received data. Data that is stored is returned to the system when the critical threshold recedes.

Owner:TREND MICRO INC

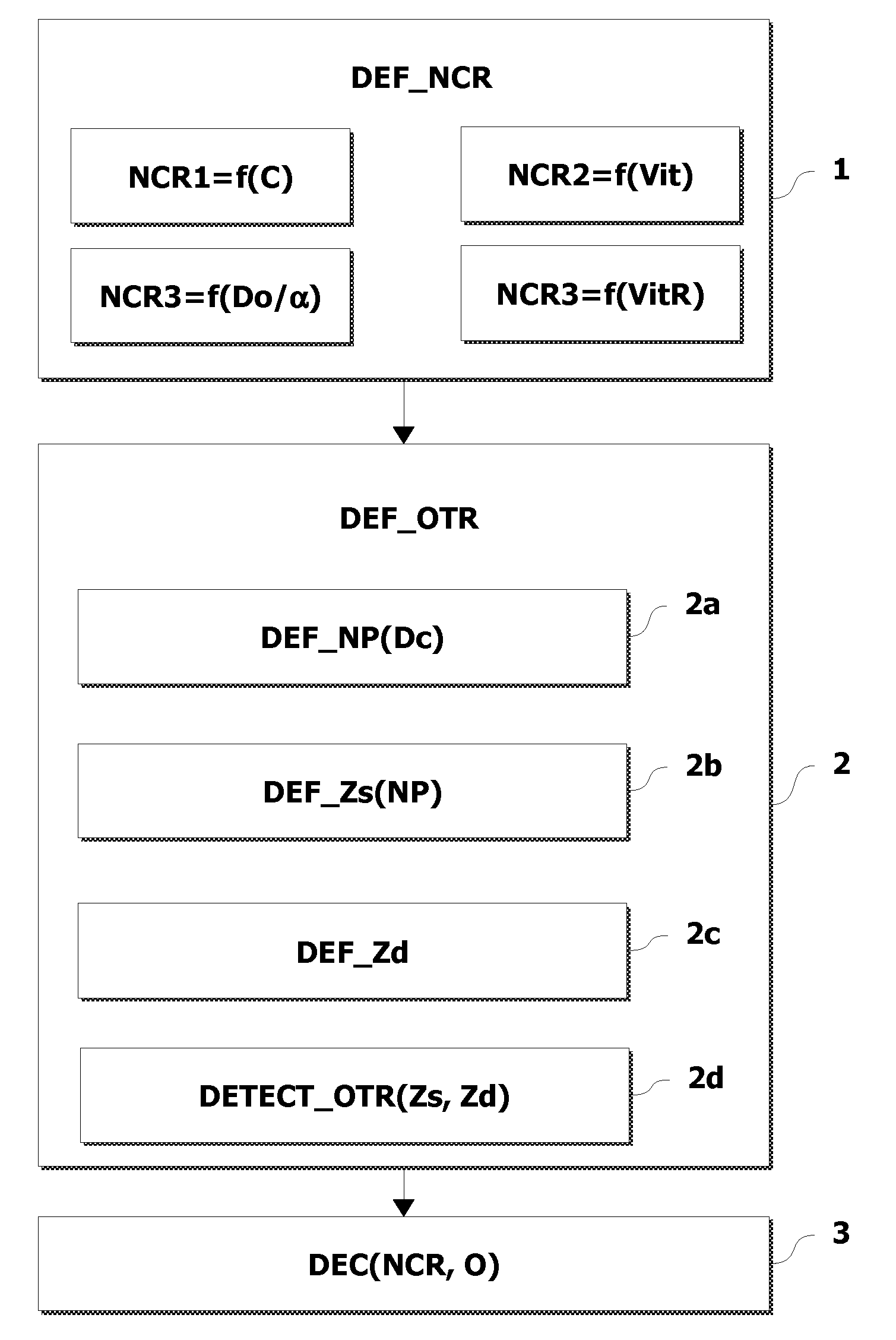

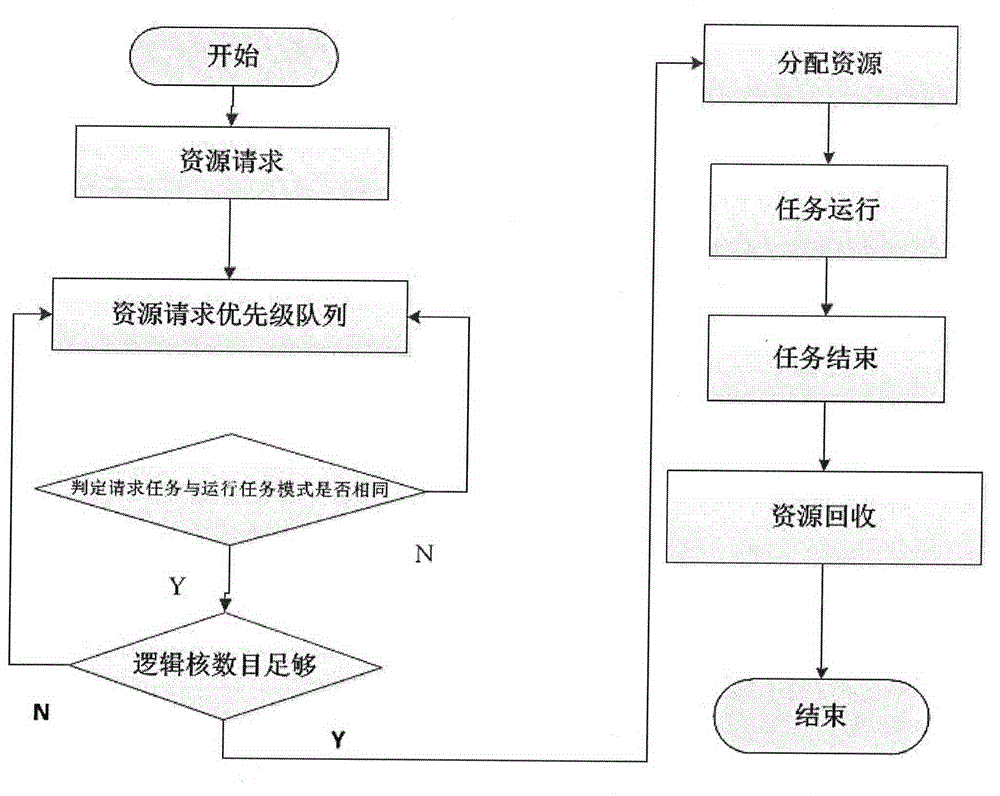

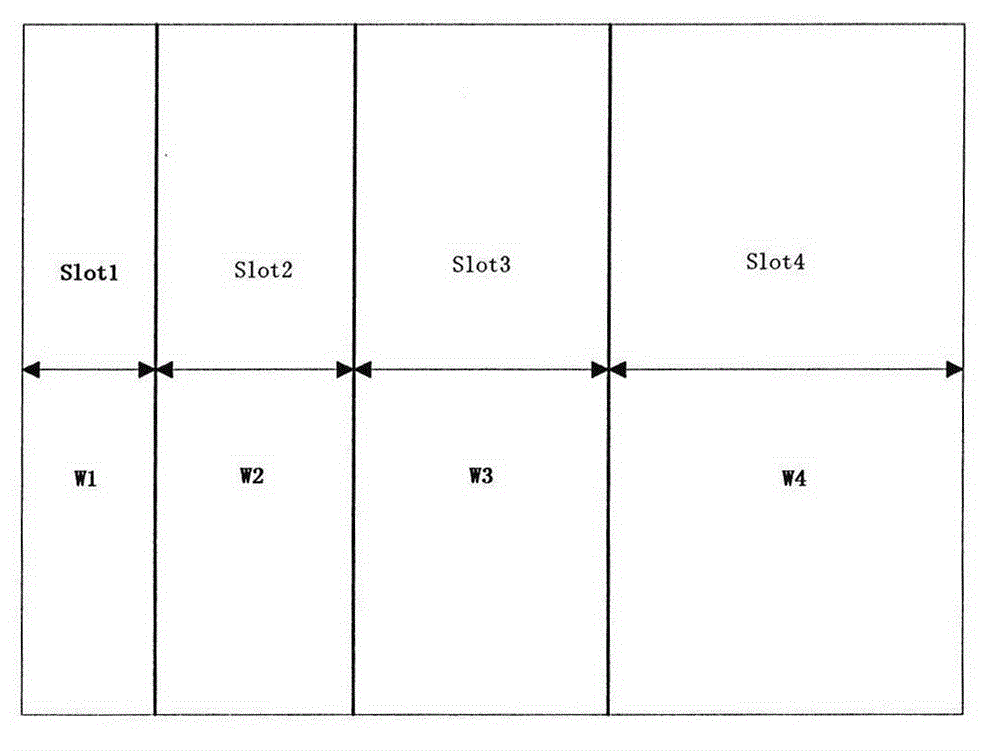

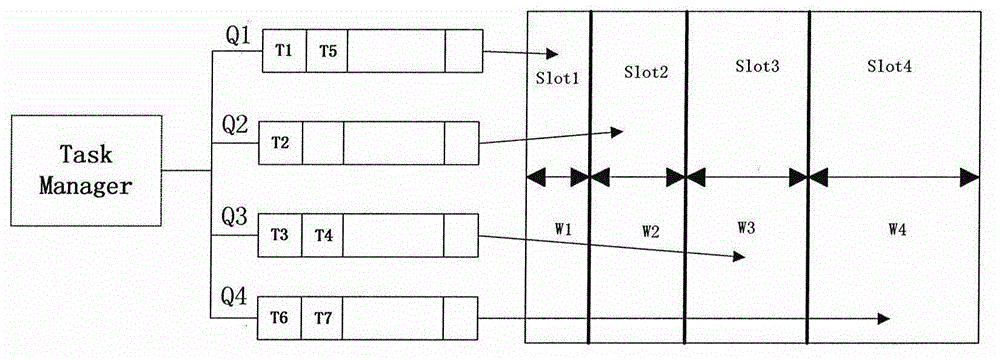

Mapping method for multimode real-time tasks and multimode computing resources

InactiveCN104834556ADynamic and Efficient MappingImprove computing powerMultiprogramming arrangementsCritical levelResource utilization

The invention discloses a mapping method for multimode real-time tasks and multimode computing resources. The mapping method comprises the steps of judging modes of upper mode management and task attribute decision services according to respectively periodic operation; updating a global task queue; updating task attributes which are changed in the global task queue; determining task priorities according to deadlines of tasks and task critical levels and performing uniquifying on the task priorities; searching a computing resource carrier set available for the tasks according to a task computing pattern; trying to allocate the tasks to the computing resources with the best task processing performance one by one according to priorities of elements in the computing resource carrier set from high to low, and determining the computing resource carrier attributes of the tasks; adding the tasks in a PPC task queue through a PPC processor according to an EDF scheduling method; inserting the tasks to proper positions of a many-core task queue through a many-core processor according to a scheduling algorithm. The mapping method for multimode real-time tasks and multimode computing resources can be used for effectively improving the operating performance of the system, the success rate of multimode task scheduling and the utilization rate of resources.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

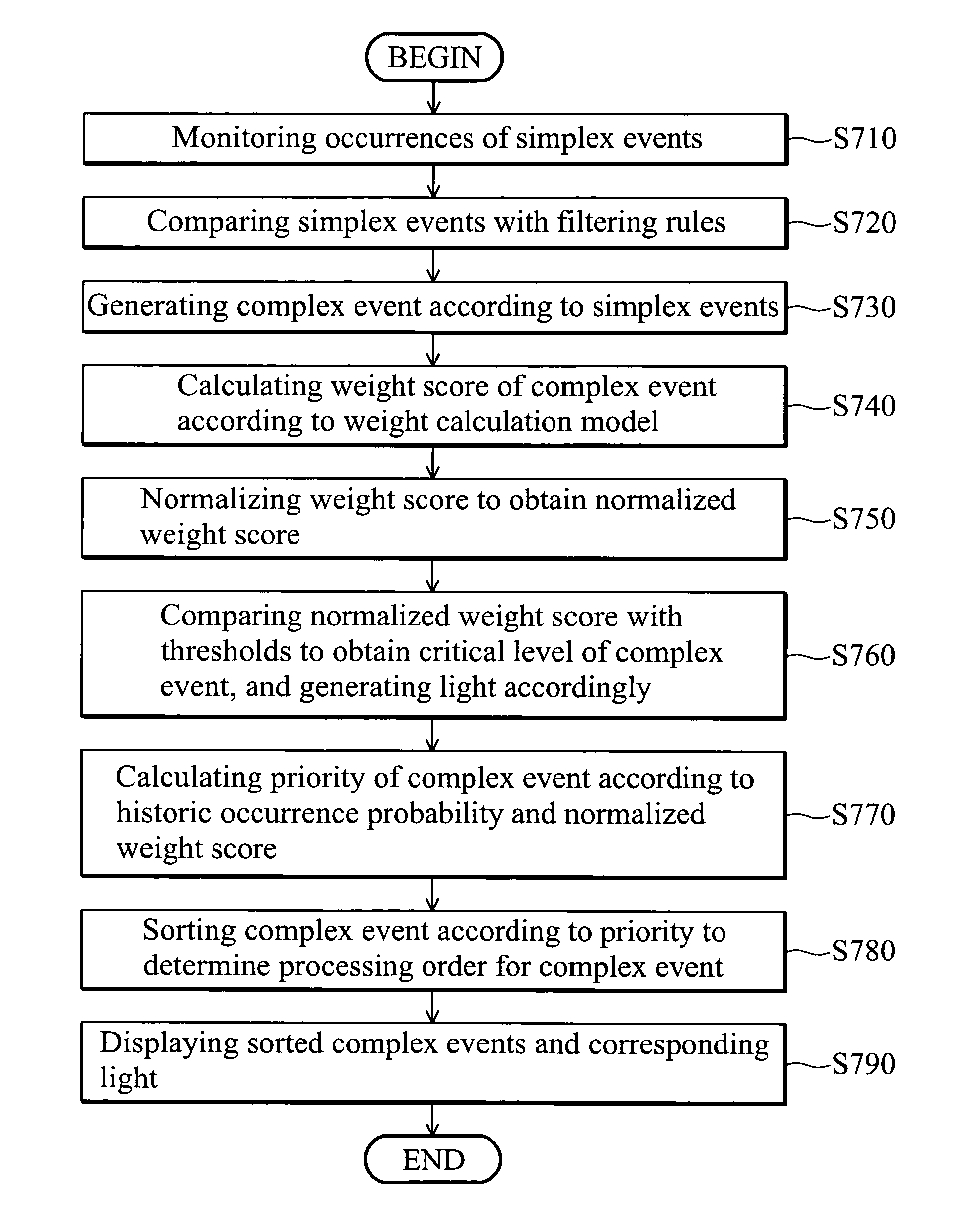

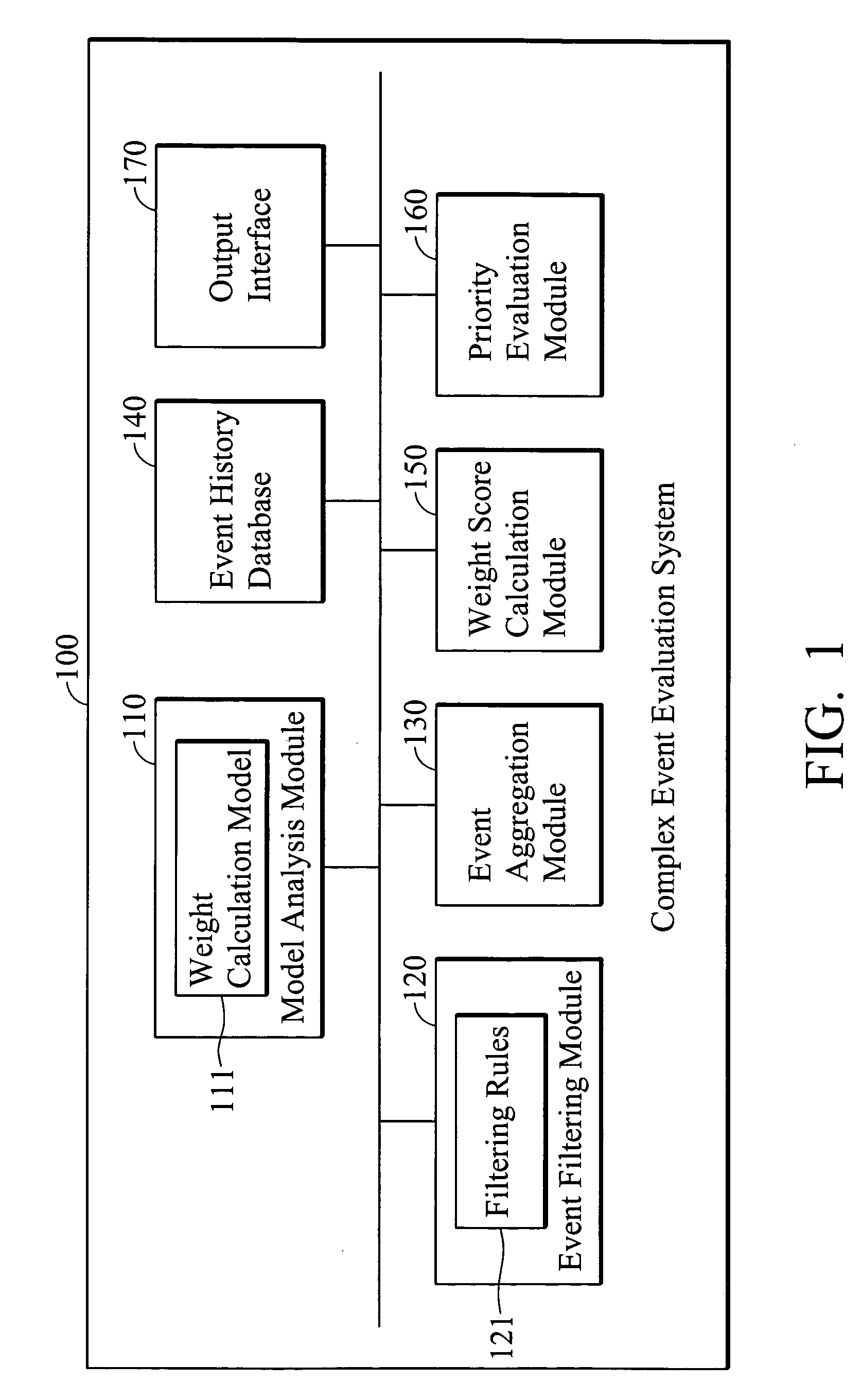

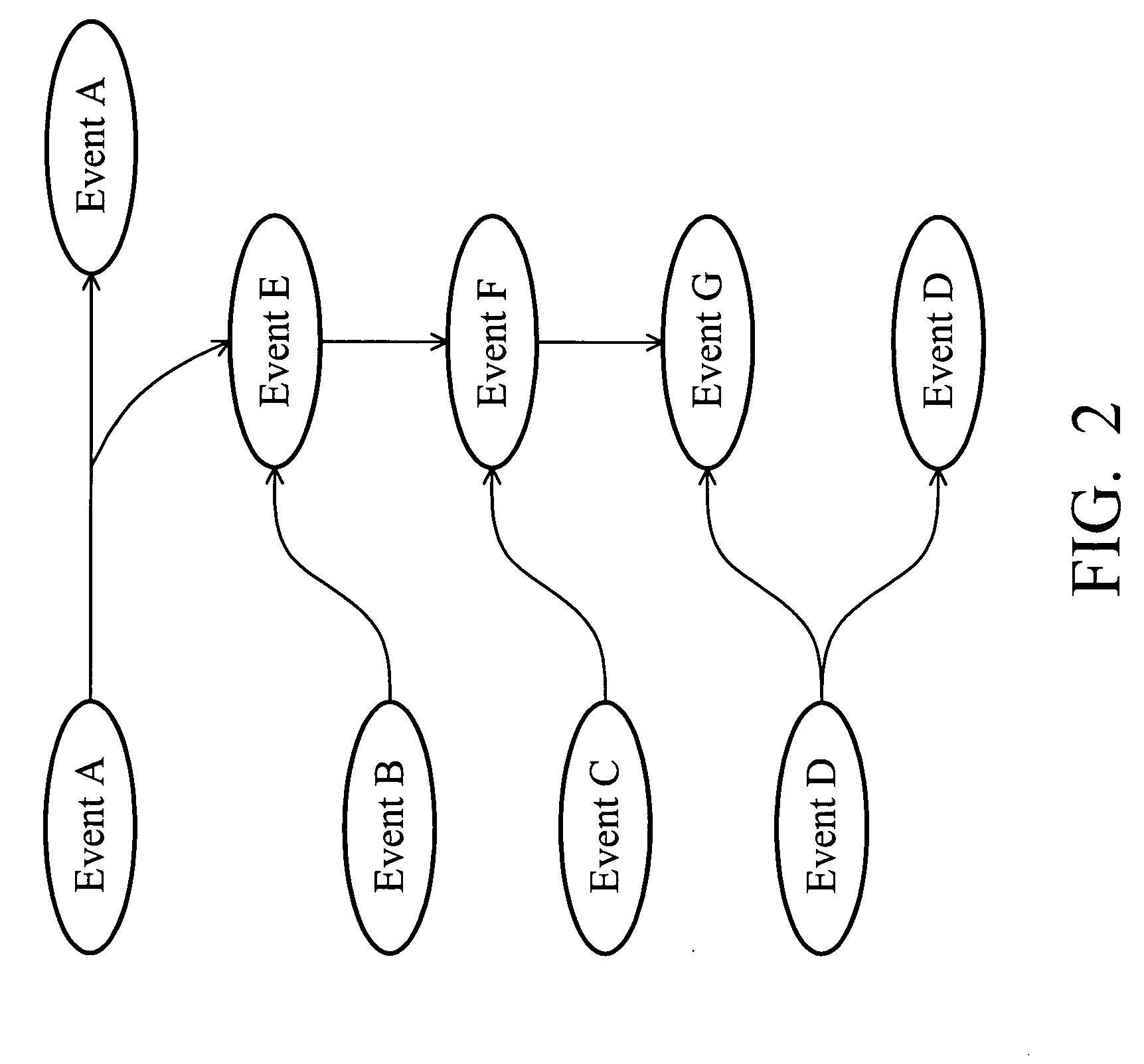

Complex event evaluation systems and methods

InactiveUS20080114574A1Medical simulationAmplifier modifications to reduce noise influenceCritical levelEvaluation system

Complex event evaluation systems and methods are disclosed. A mathematics model for complex events and corresponding factors, and calculates a critical level of respective complex events according to weightings of respective factors in the mathematics model are provided. If several complex events occur simultaneously, a priority of respective complex events is calculated according to the historic occurrence of respective complex events. The critical level and priority of respective complex events are provided to users for decision making. Additionally, the mathematics model is established and adjusted according to the feedback scores for complex events.

Owner:INSTITUTE FOR INFORMATION INDUSTRY

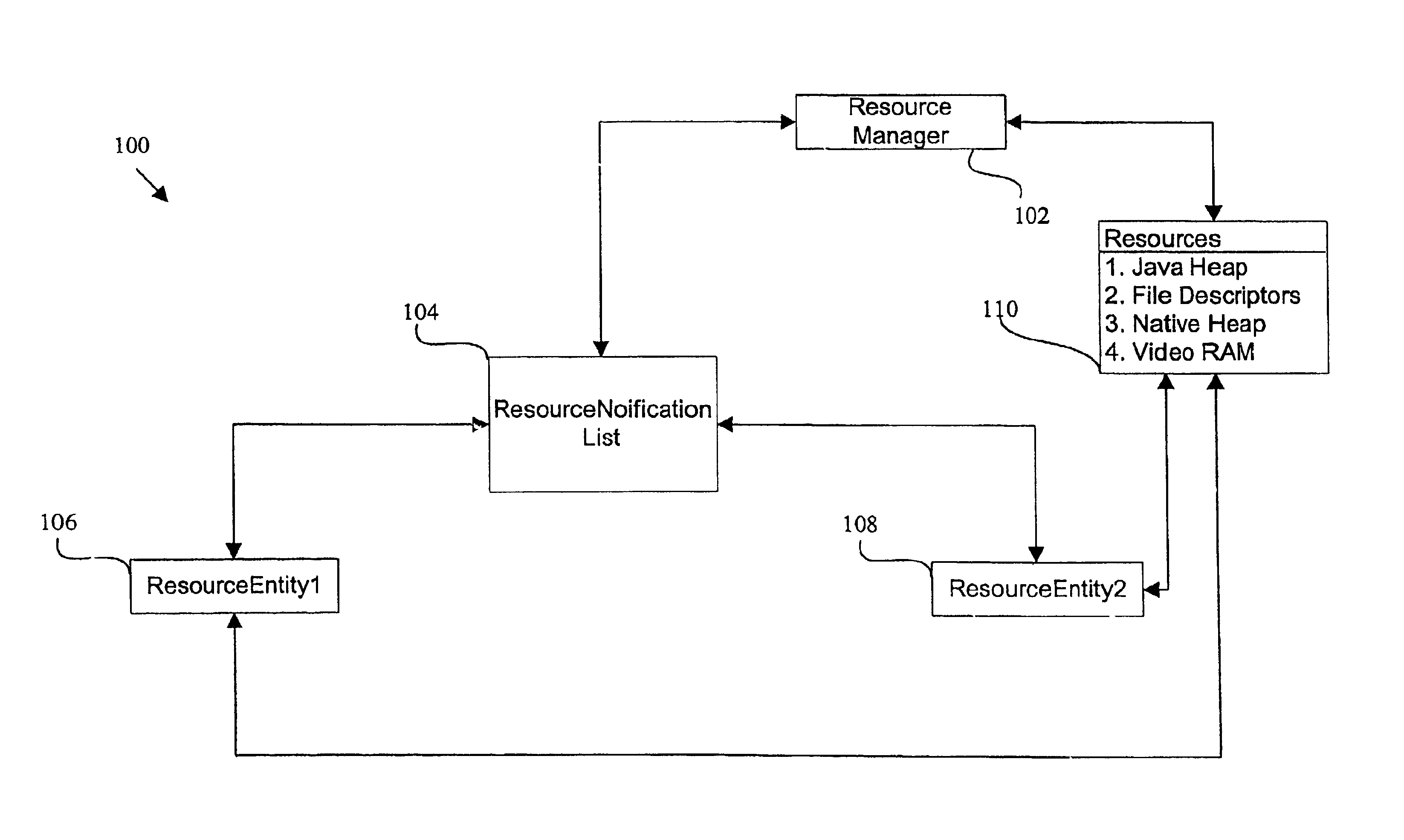

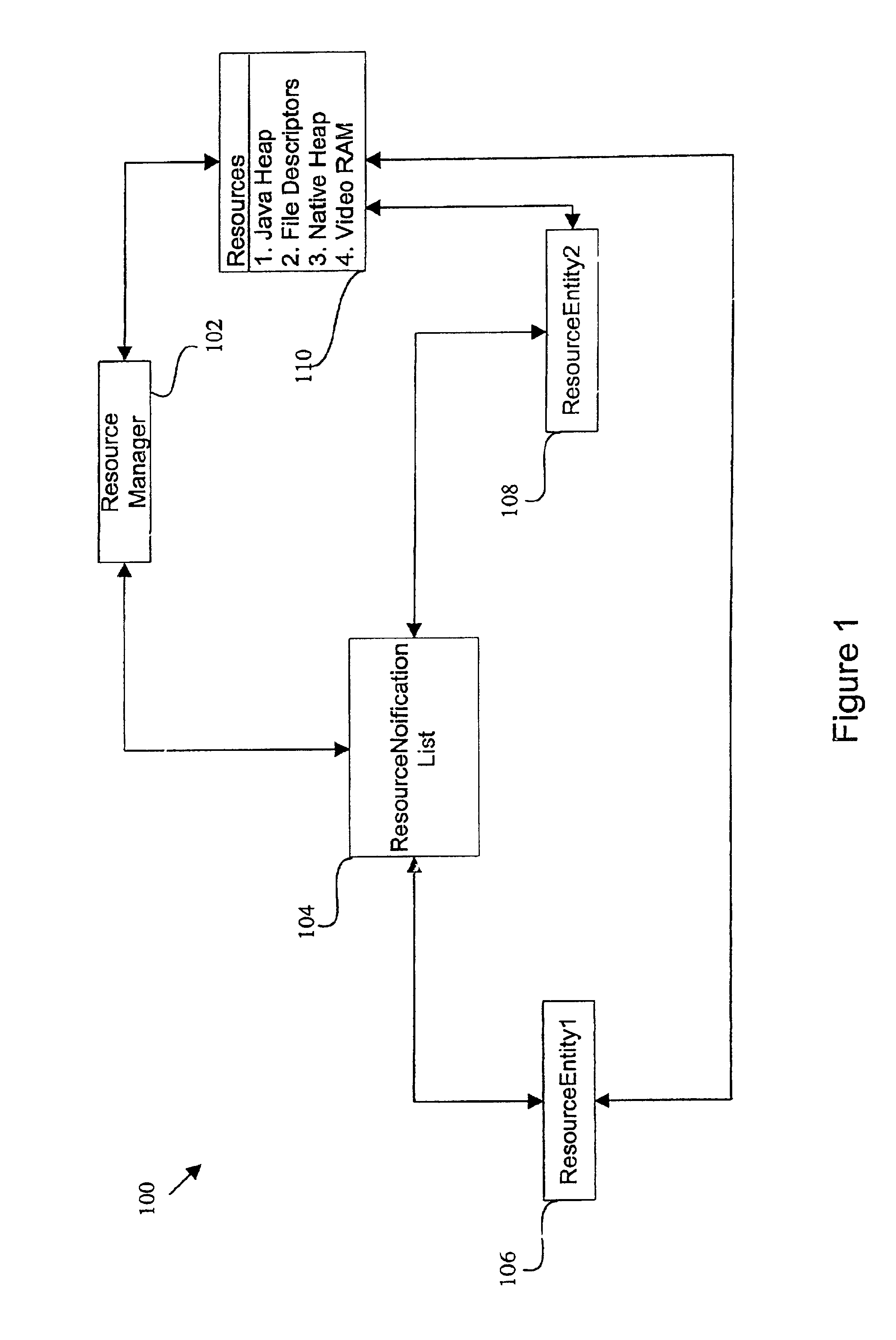

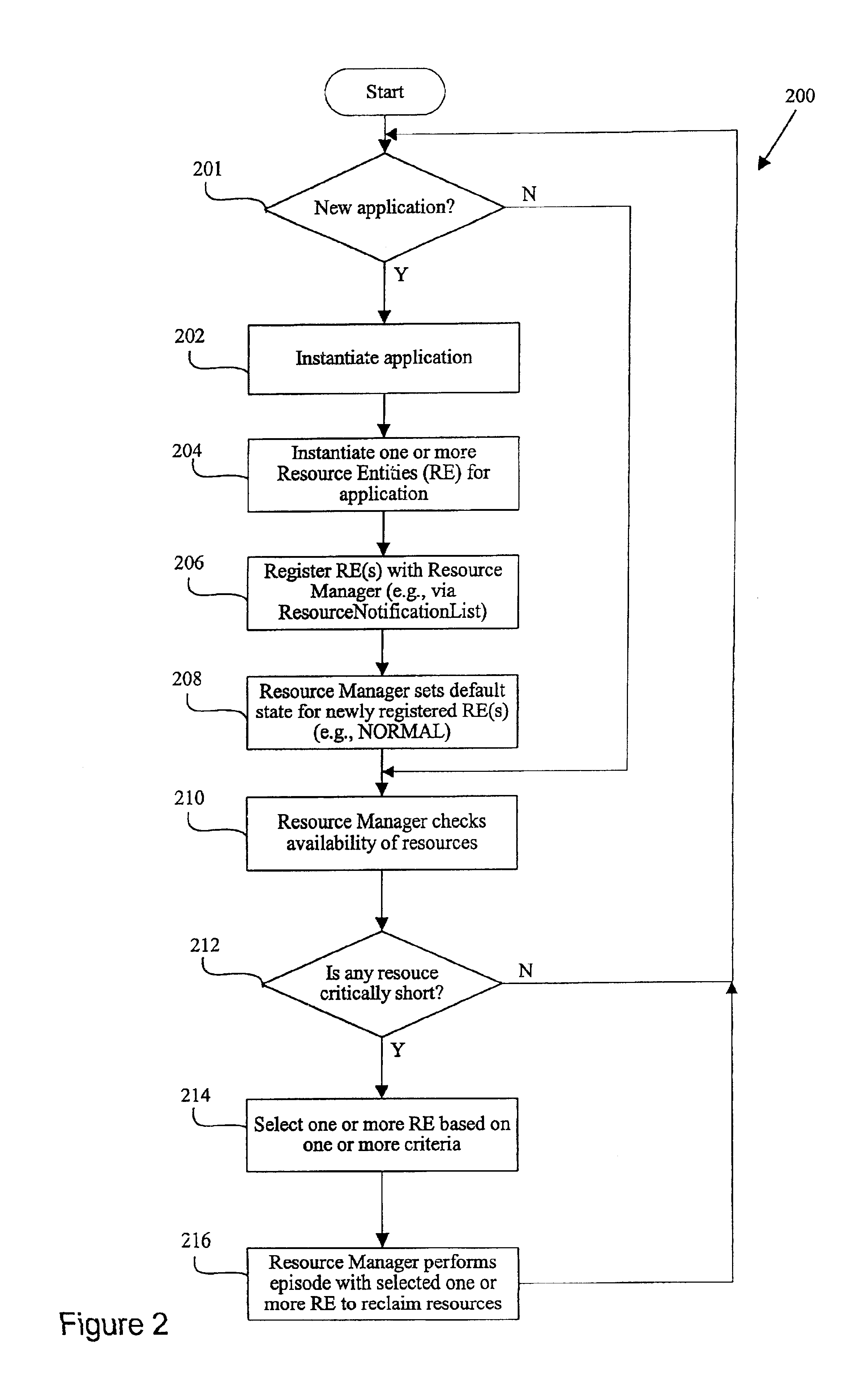

Resource managing system for changing resource consumption state of the lower priority resource entity to more restrictive state when resource reached critical level

Disclosed are methods and apparatus for managing resources. In general terms, a resource manager manages resource consumption of several resource entities which are each capable of consuming resources. The resource manager tracks the availability of such resources and determines whether a resource is critically short or reaches a particular usage level. When a resource becomes critically short or reaches a particular usage level, the resource manager selects one or more resource entities based on one or more criteria. For example, a resource entity which has the least restrictive resource usage policy or state is selected. The resource manager then requests that the selected resource entity changes its resource usage state to a more restrictive state. Of course, when resource usage reaches an acceptable level, the resource manager may also inform each resource entity (or previously selected resource entities) that they may set their resource consumption state to a less restrictive state.

Owner:ORACLE INT CORP

Capacitive detection of dust accumulation using microcontroller component leads

A system and method are used for electronically detecting the accumulation of dust within a computer system using a capacitive dust sensor. The dust detection system may be implemented on a smaller computer, such as an individual PC, or in a more expansive system, such as a rack-based server system (“rack system”) having multiple servers and other hardware devices. In one embodiment, each server in a rack system includes a capacitive sensor responsive to the accumulation of dust. The capacitive sensor may include one or more capacitive plates integral with a heatsink. As dust collects on the capacitive plates, the capacitance increases. When a capacitance setpoint is reached, indicating the dust has reached a critical level, an alert is generated. The alerts may be received by a management console for the attention of a system administrator. Each alert may contain the identity of the server generating the alert, so that the system administrator knows which server(s) are to be removed for cleaning.

Owner:LENOVO GLOBAL TECH INT LTD

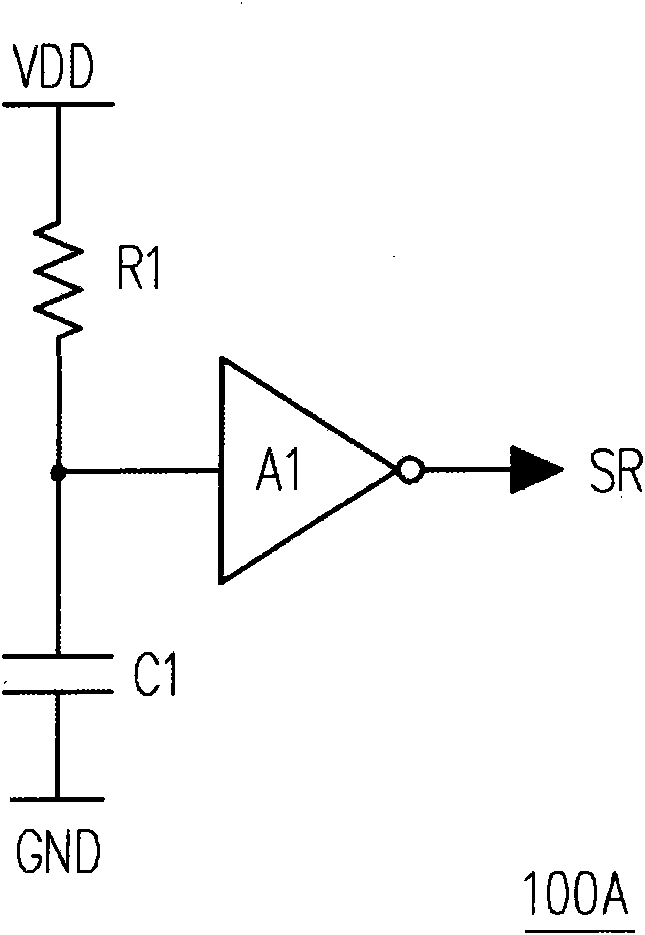

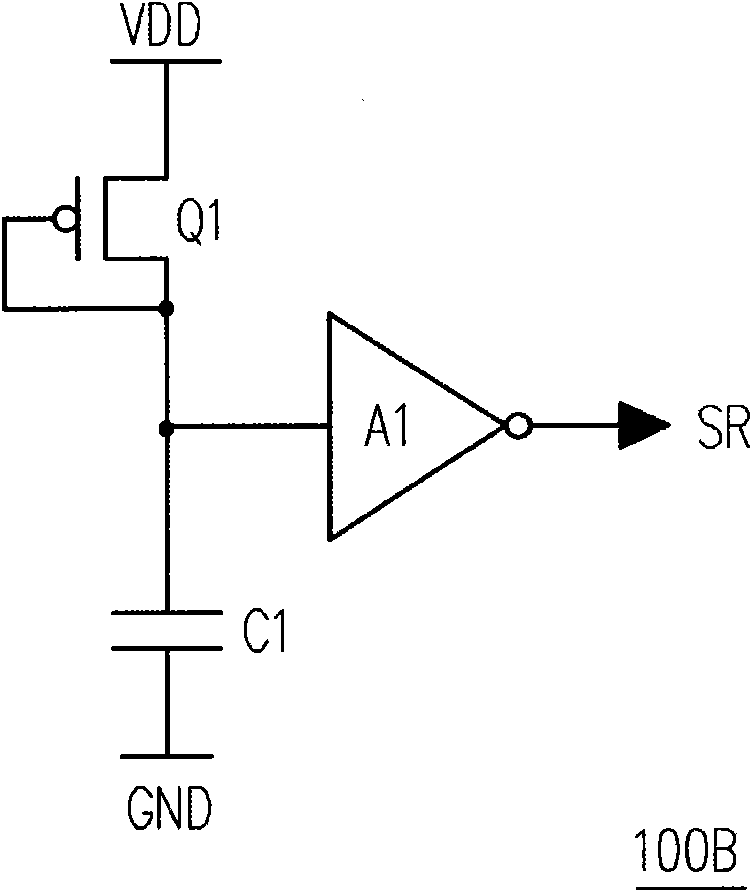

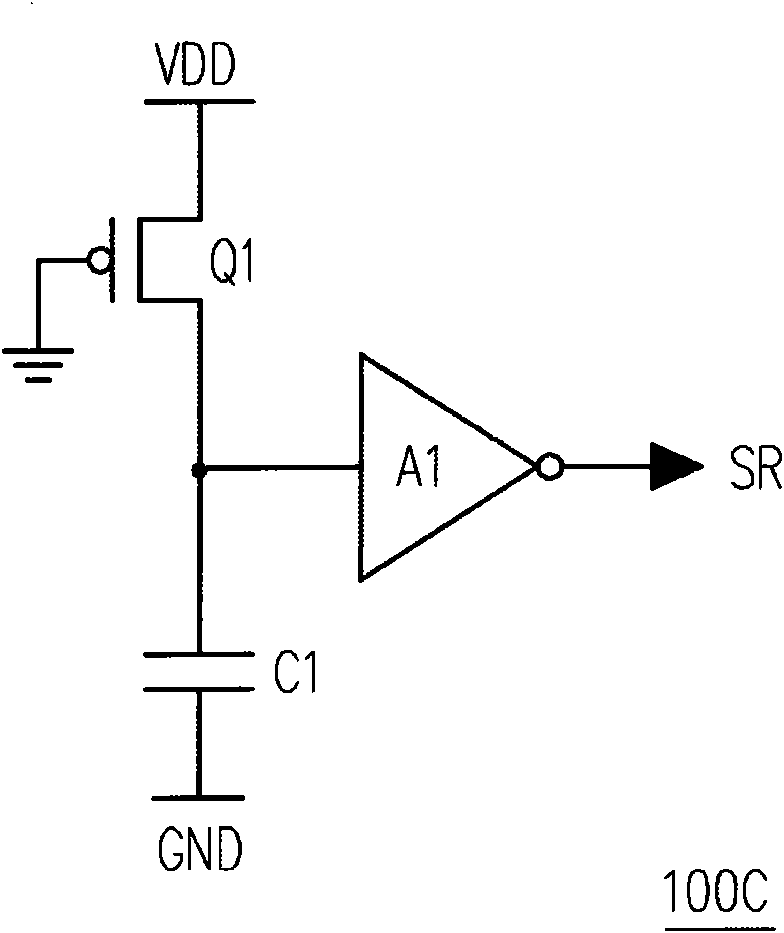

Power supply resetting circuit

InactiveCN102377416AFast dischargeMake sure to reset the signalCurrent/voltage measurementElectronic switchingCapacitanceCritical level

The invention relates to a power supply resetting circuit, which comprises a power supply resetting unit, a voltage detection unit and a switch unit, wherein the power supply resetting unit is provided with a resistor and capacitor circuit coupled to the input end of the power supply resetting unit, in addition, a delay input voltage is generated, the power supply resetting unit outputs a resetting signal at the output end according to the delay input voltage and the first critical level, the voltage detection unit detects a power supply voltage and generates a switch signal according to the reduction of the deflection voltage by the level of the power supply voltage. In addition, the switch unit is coupled between the input ends of the voltage detection unit and the power supply resetting unit, and the input end of the power supply resetting unit is conducted to a reference voltage according to the conduction of the switch signal.

Owner:HOLTEK SEMICON

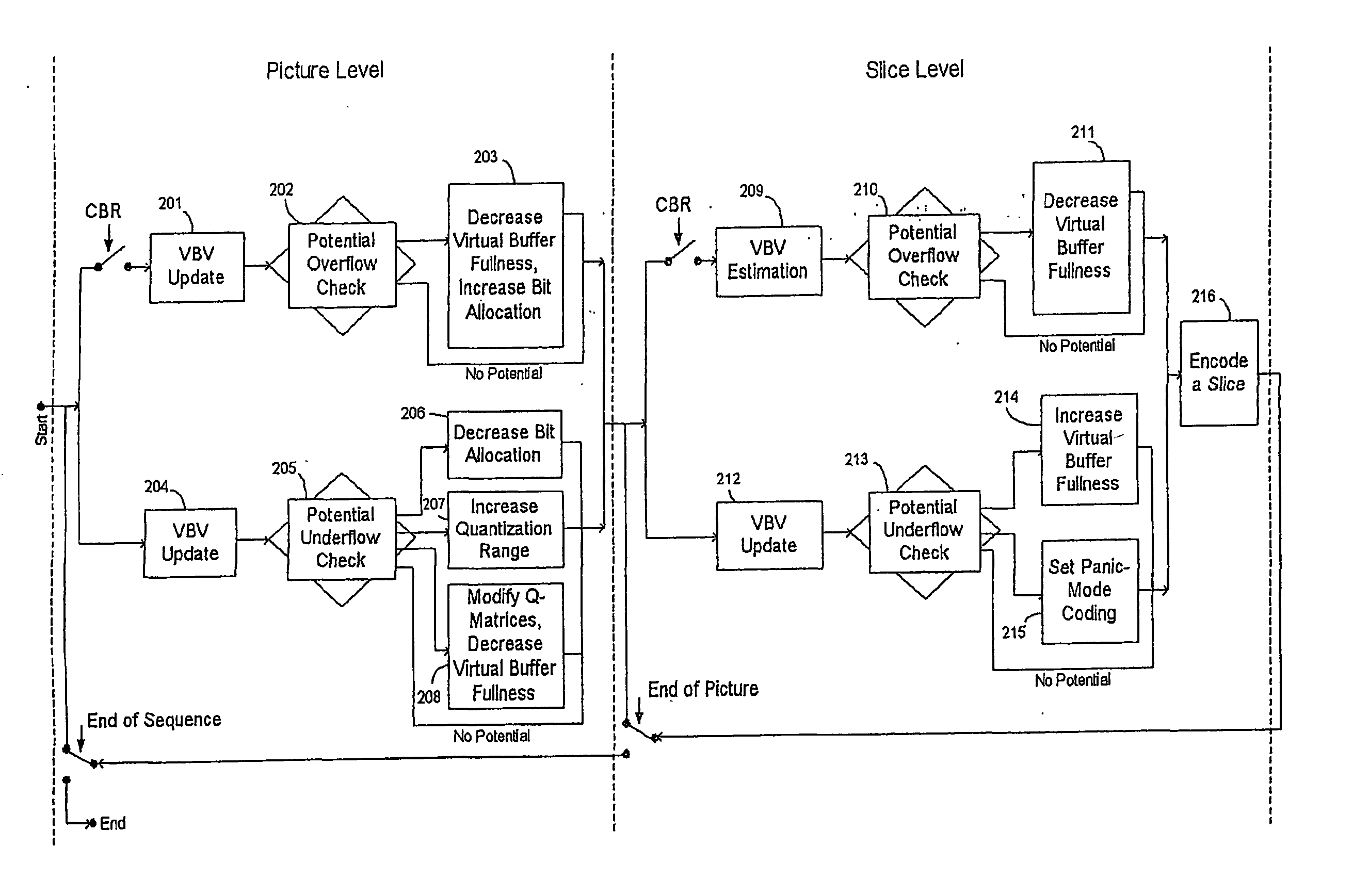

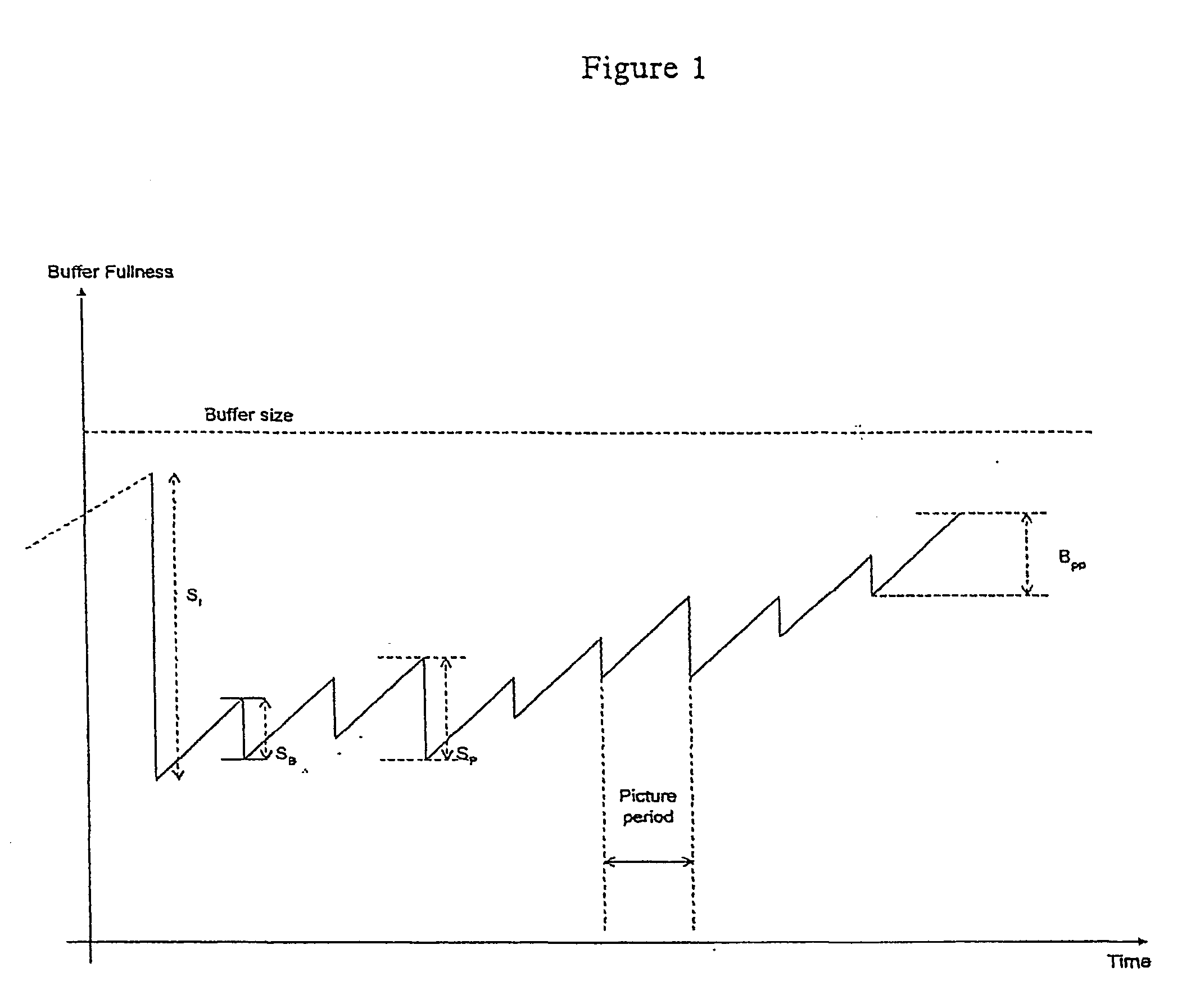

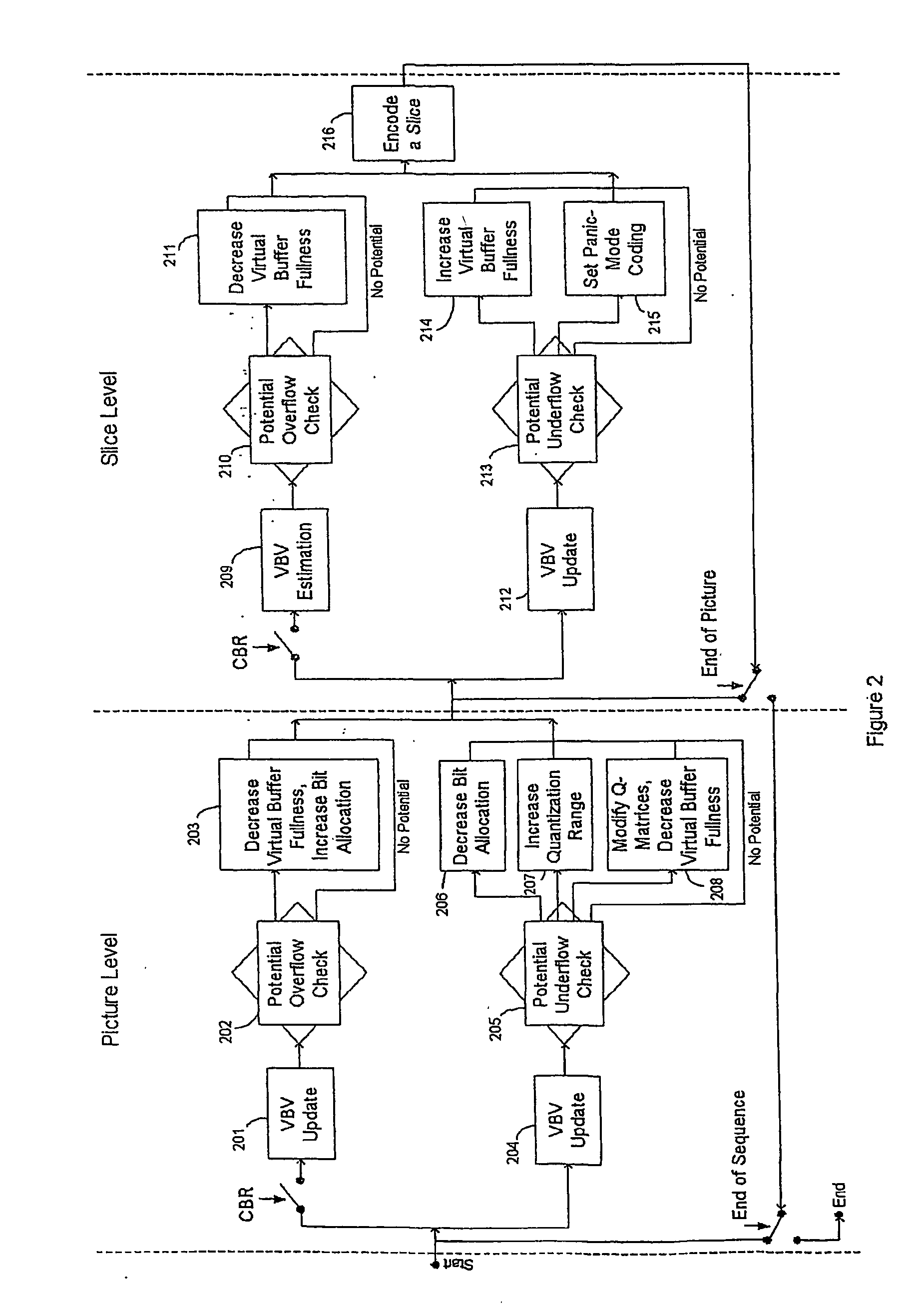

Method and apparatus for video buffer verifier underflow and overflow control

InactiveUS20040105492A1Easy to solveImprove video qualityColor television with pulse code modulationColor television with bandwidth reductionComputation complexityCritical level

Owner:STMICROELECTRONICS ASIA PACIFIC PTE

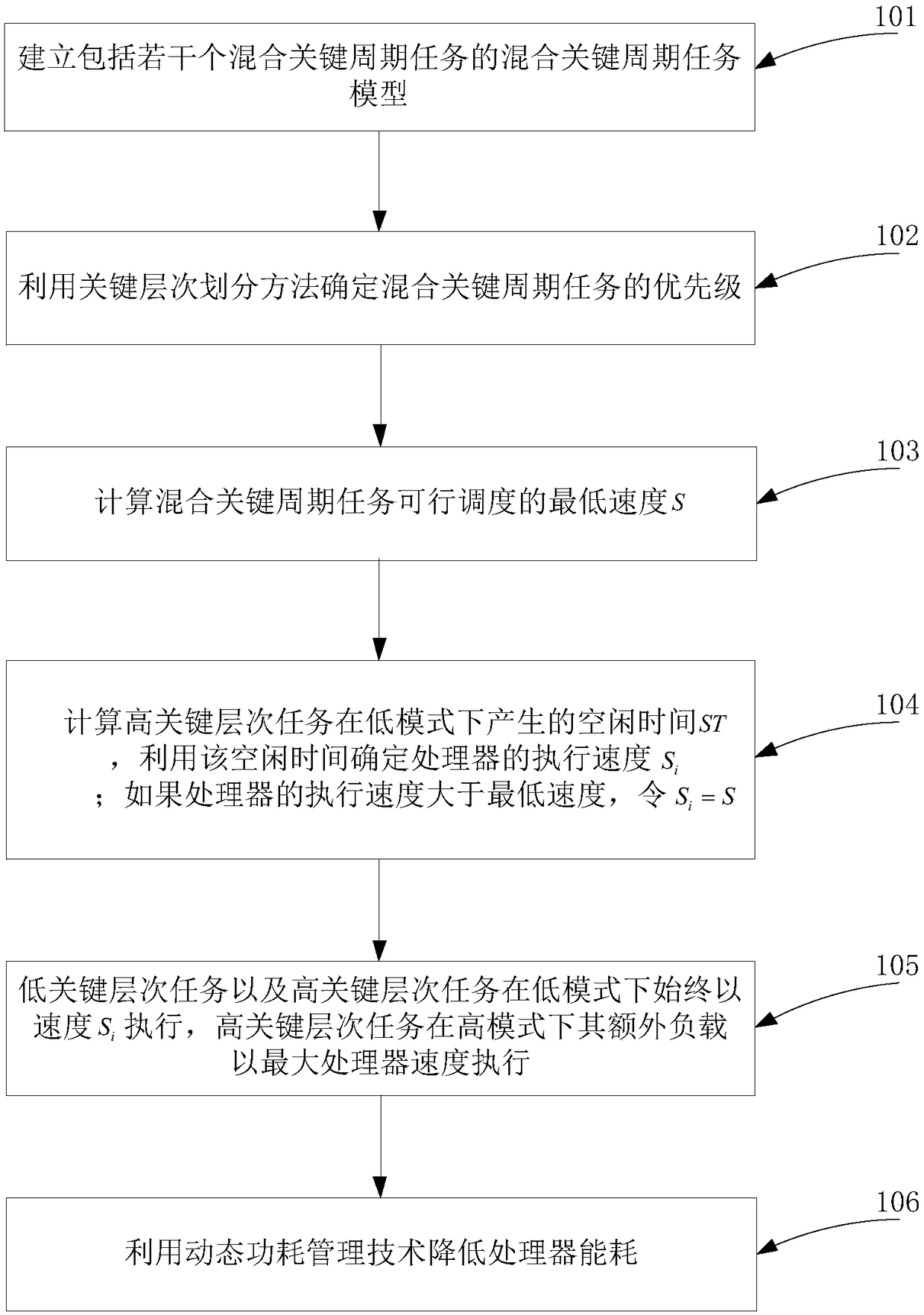

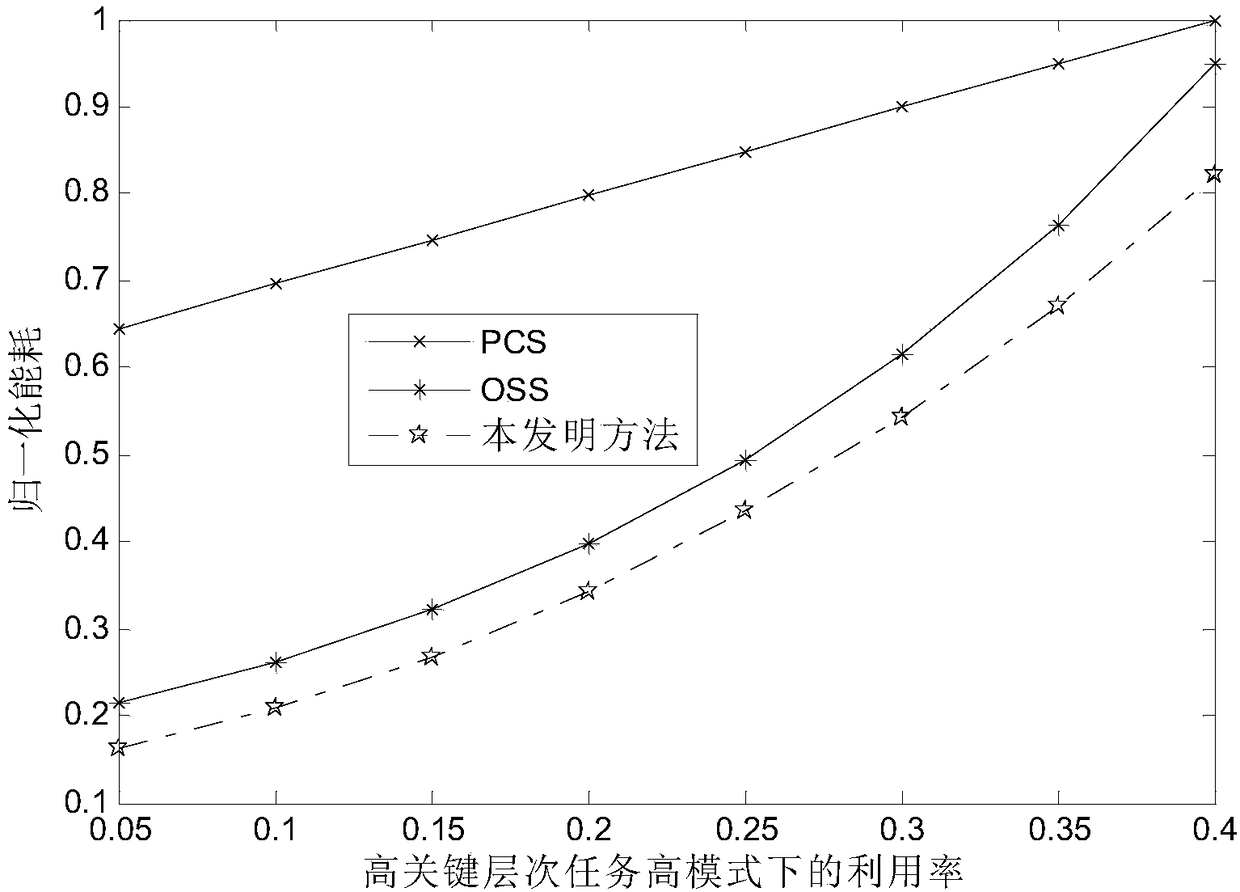

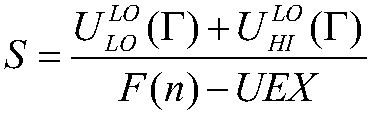

Energy consumption optimization method for fixed priority periodic task in hybrid critical system

ActiveCN108984292AReduce energy consumptionEnsure full implementationProgram initiation/switchingResource allocationCritical levelIdle time

The invention relates to an energy consumption optimization method for a fixed priority periodic task of a hybrid critical system, the method comprising the following steps: establishing a hybrid critical periodic task model comprising a plurality of hybrid critical periodic tasks; determining priority of hybrid critical periodic tasks by using the critical hierarchy partitioning method; calculating the lowest feasible speed S of hybrid critical period task scheduling; calculating an idle time ST generated by a task of a high critical level in a low mode, and determining an execution speed Siof the processor by using the idle time, wherein the low level critical tasks and high level critical tasks are always executed at speed Si in low mode, and the high critical level tasks are executedat maximum processor speed with extra load in high mode; using dynamic power management technology to reduce processor power consumption. The method of the invention effectively reduces the system energy consumption by utilizing the idle time generated by the high-critical-level tasks and the dynamic power consumption management technology.

Owner:HUAQIAO UNIVERSITY

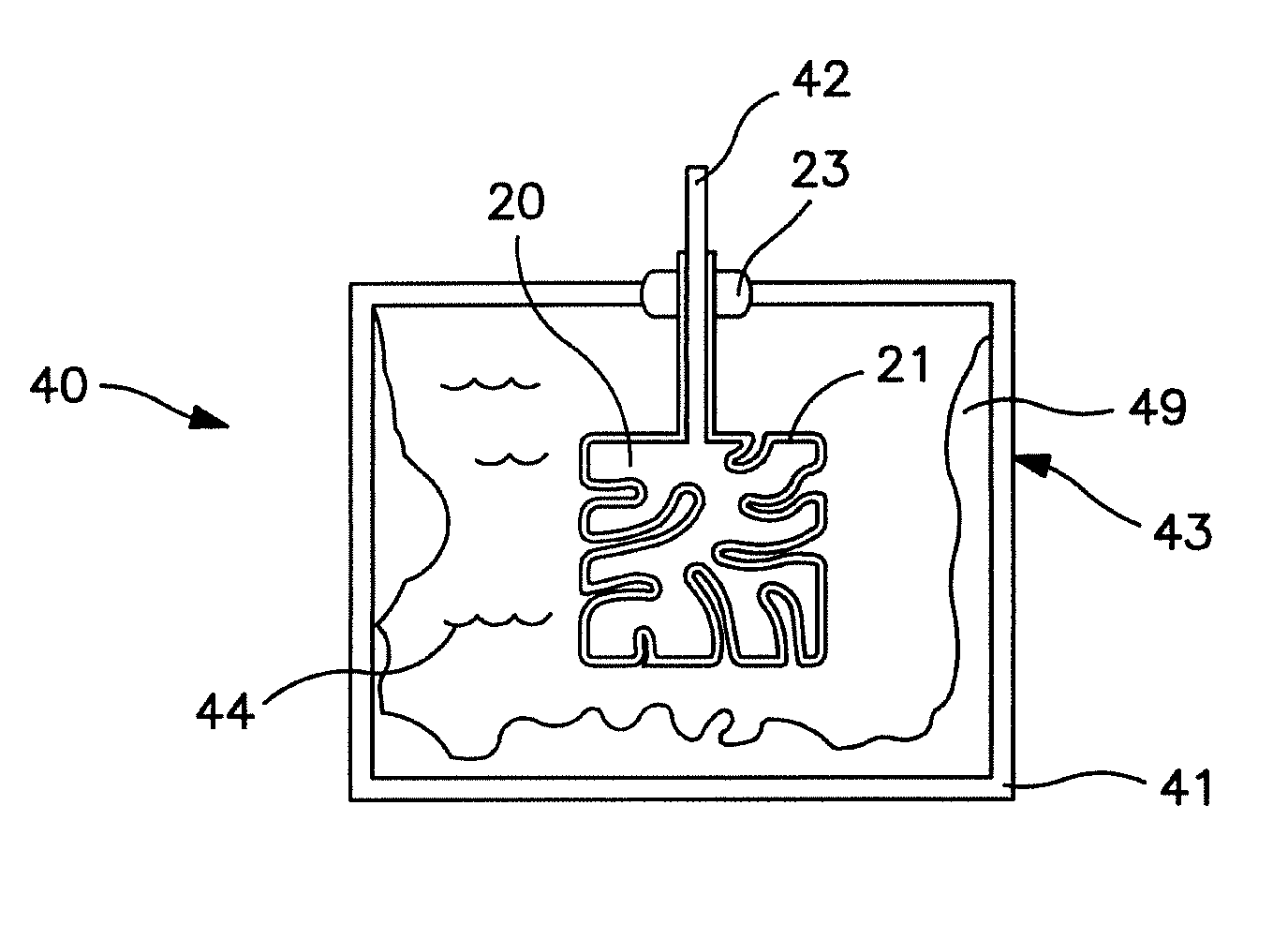

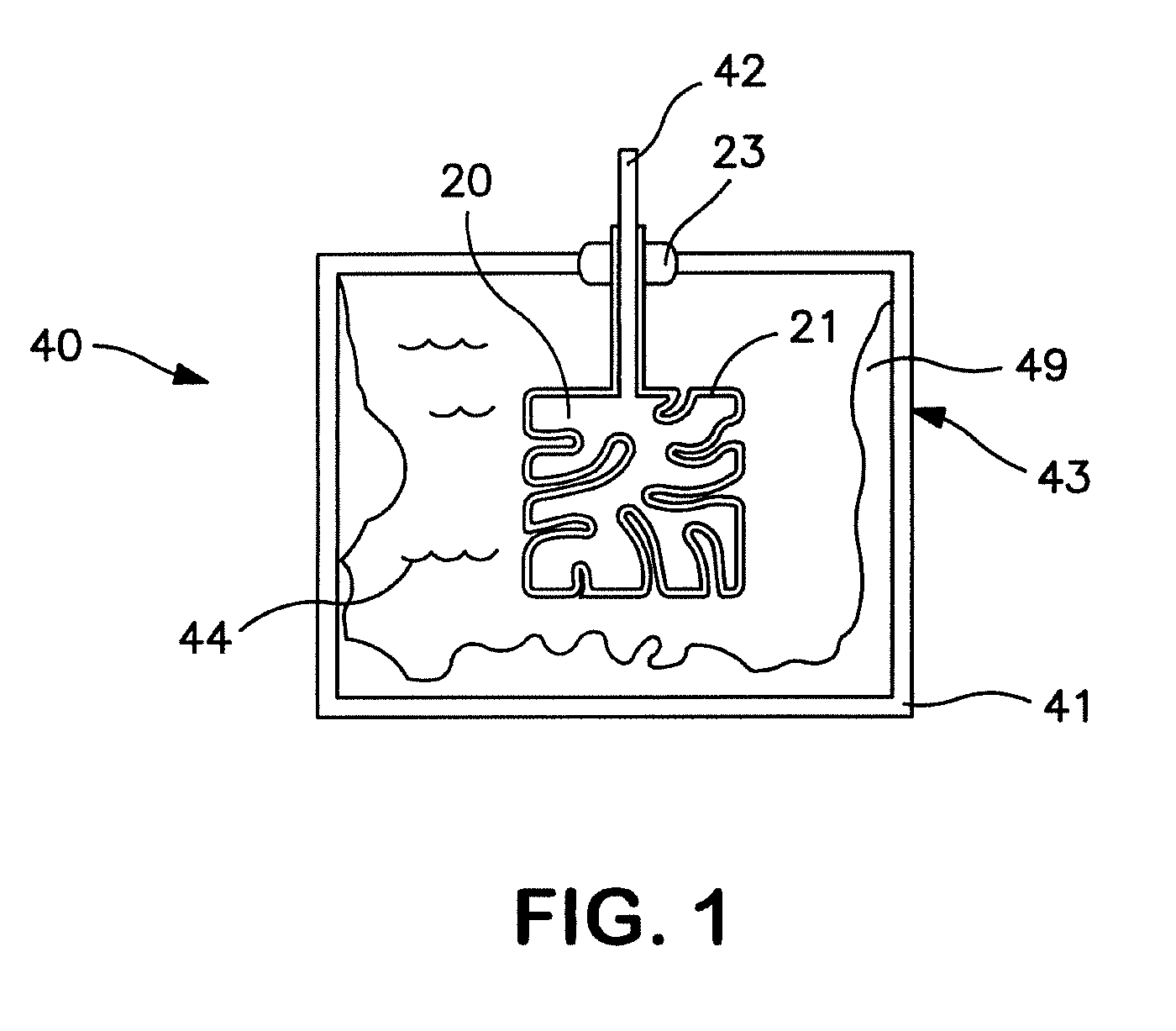

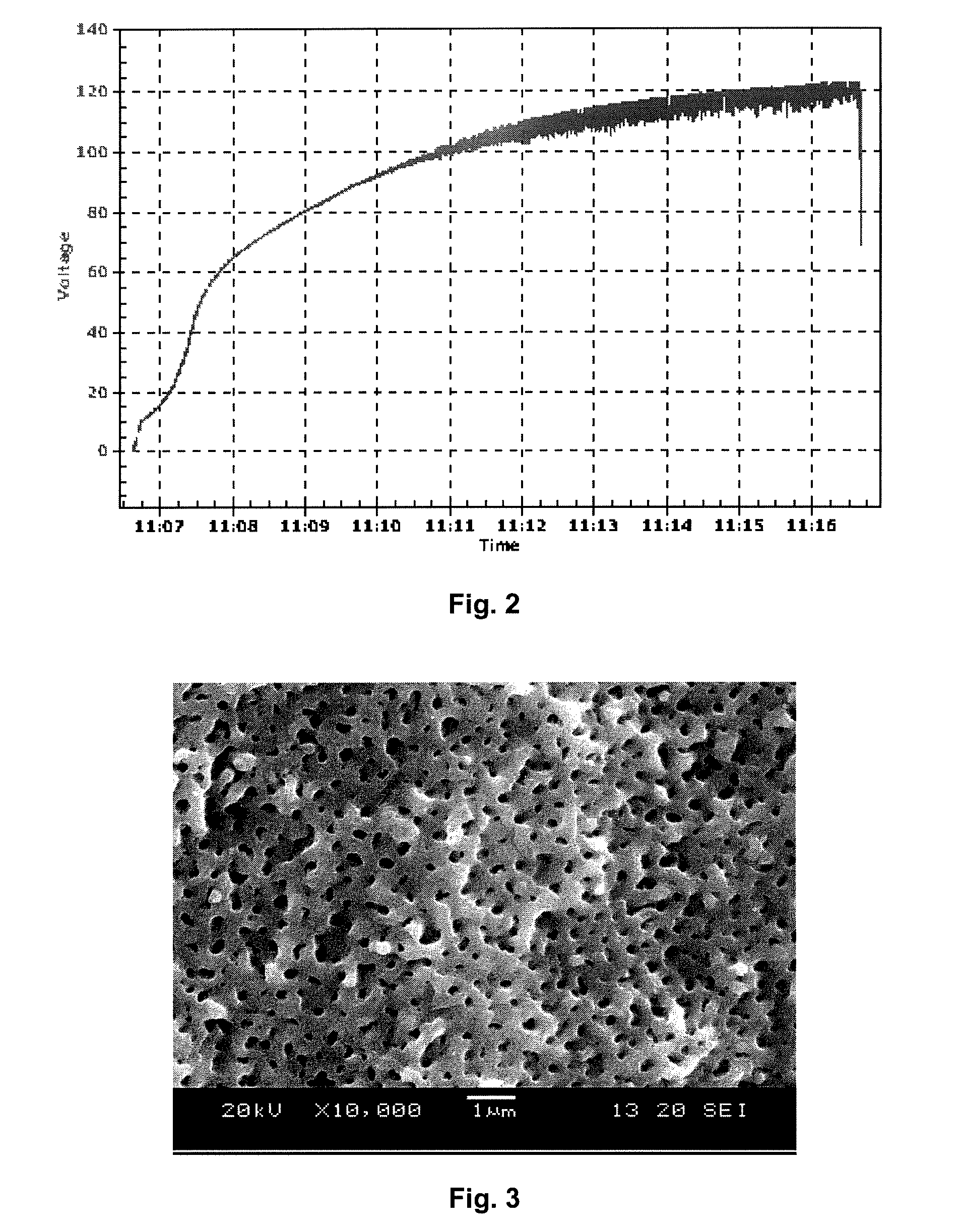

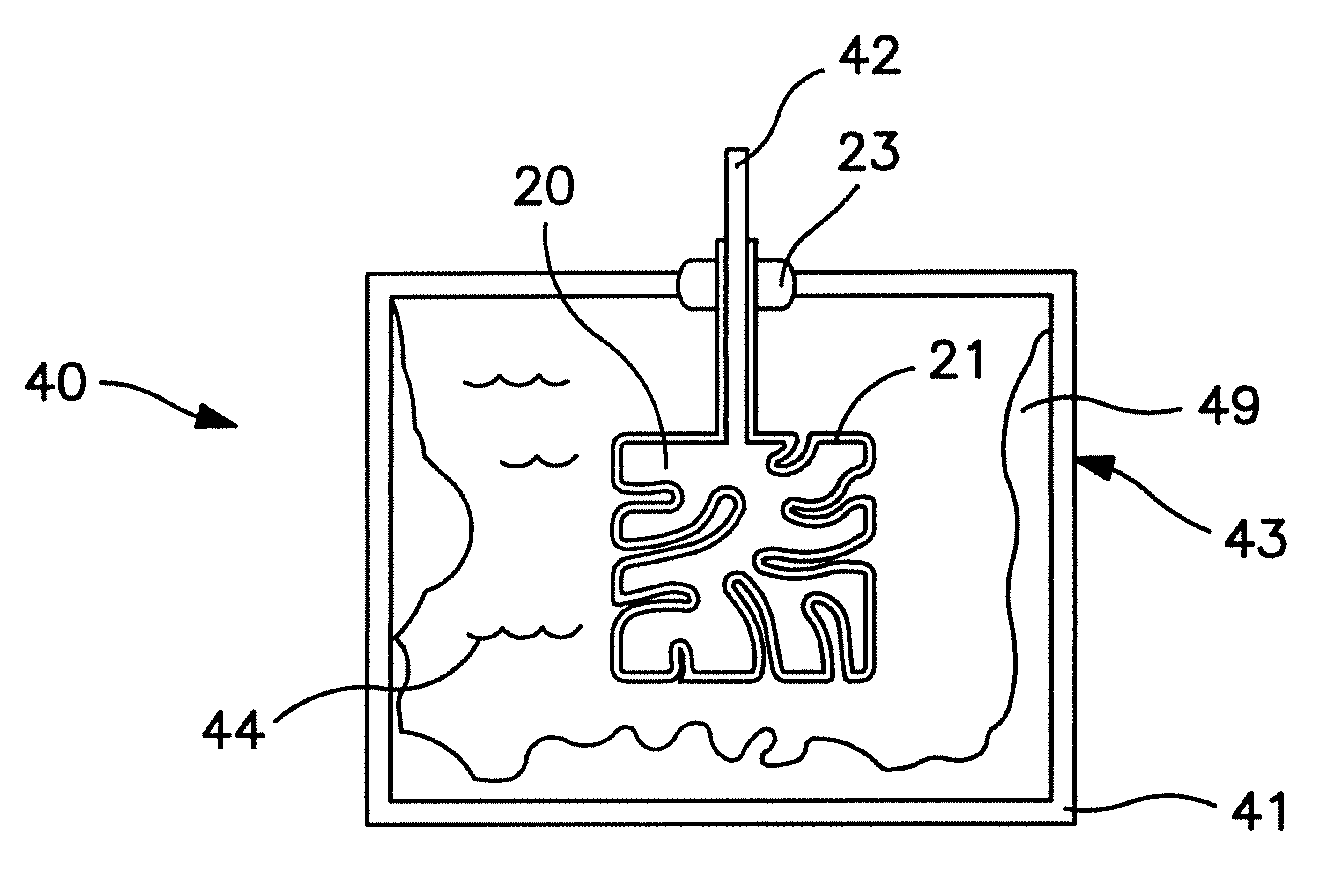

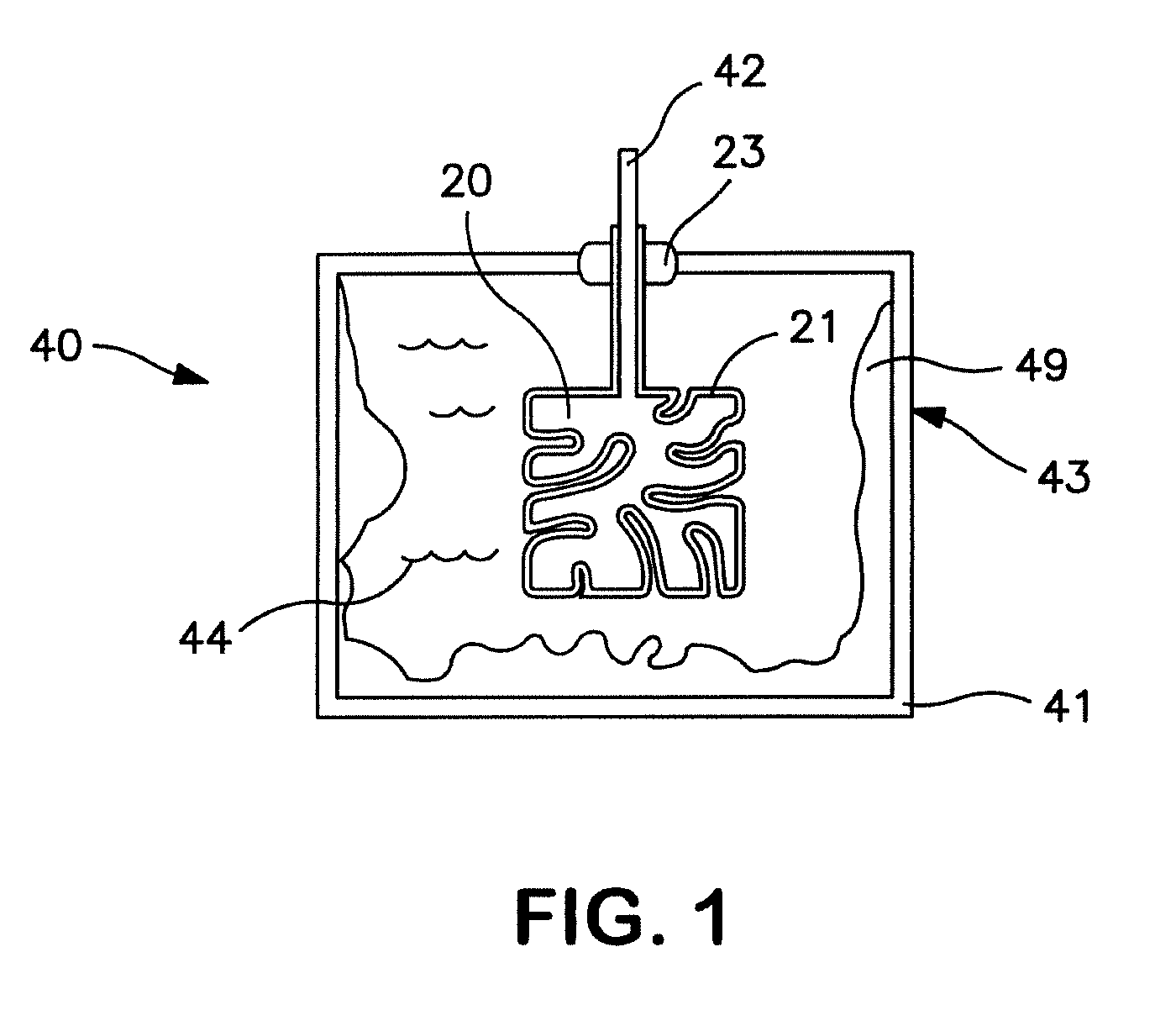

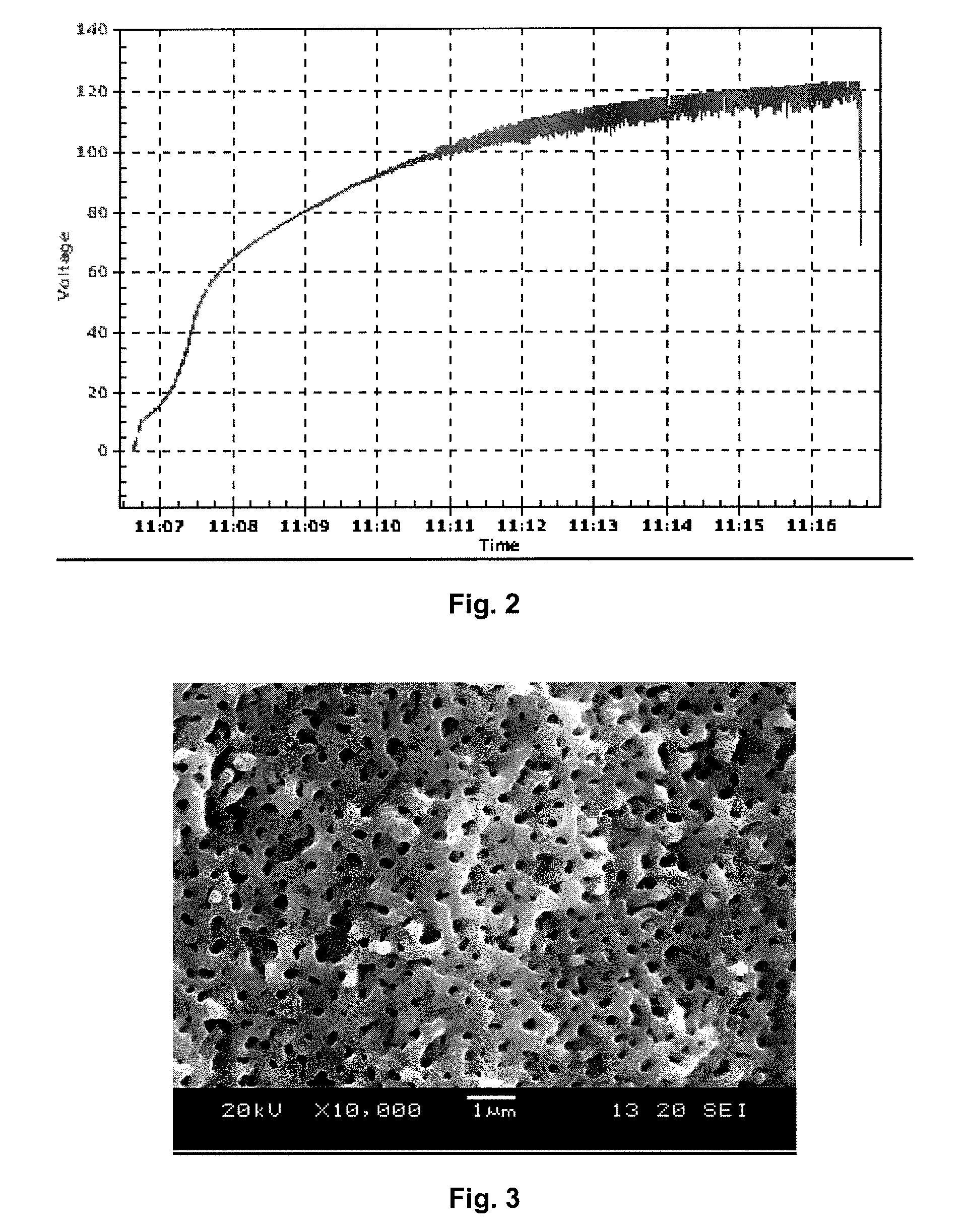

Substrate for use in wet capacitors

A porous substrate for use in a wide variety of applications, such as wet capacitors, is provided. The substrate is formed by subjecting a metal substrate to a voltage while in solution to initiate anodic formation of an oxide film. Contrary to conventional anodization processes, however, the newly created oxide quickly breaks down to once again expose the metal surface to the electrolytic solution. This may be accomplished in a variety of ways, such as by raising the voltage of the solution above a critical level known as the “breakdown voltage”, employing a corrosive acid in the solution that dissolves the oxide, etc. Regardless of the mechanism employed, the nearly simultaneous process of oxide growth / breakdown results in the formation of a structure having pores arranged at substantially regular intervals. The resulting structure is highly porous and can exhibit excellent adhesion to electrochemically-active materials and stability in aqueous electrolytes.

Owner:KYOCERA AVX COMPONENTS CORP

Substrate for Use in Wet Capacitors

ActiveUS20100067174A1Machining electrodesLiquid electrolytic capacitorsPorous substrateCritical level

A porous substrate for use in a wide variety of applications, such as wet capacitors, is provided. The substrate is formed by subjecting a metal substrate to a voltage while in solution to initiate anodic formation of an oxide film. Contrary to conventional anodization processes, however, the newly created oxide quickly breaks down to once again expose the metal surface to the electrolytic solution. This may be accomplished in a variety of ways, such as by raising the voltage of the solution above a critical level known as the “breakdown voltage”, employing a corrosive acid in the solution that dissolves the oxide, etc. Regardless of the mechanism employed, the nearly simultaneous process of oxide growth / breakdown results in the formation of a structure having pores arranged at substantially regular intervals. The resulting structure is highly porous and can exhibit excellent adhesion to electrochemically-active materials and stability in aqueous electrolytes.

Owner:KYOCERA AVX COMPONENTS CORP

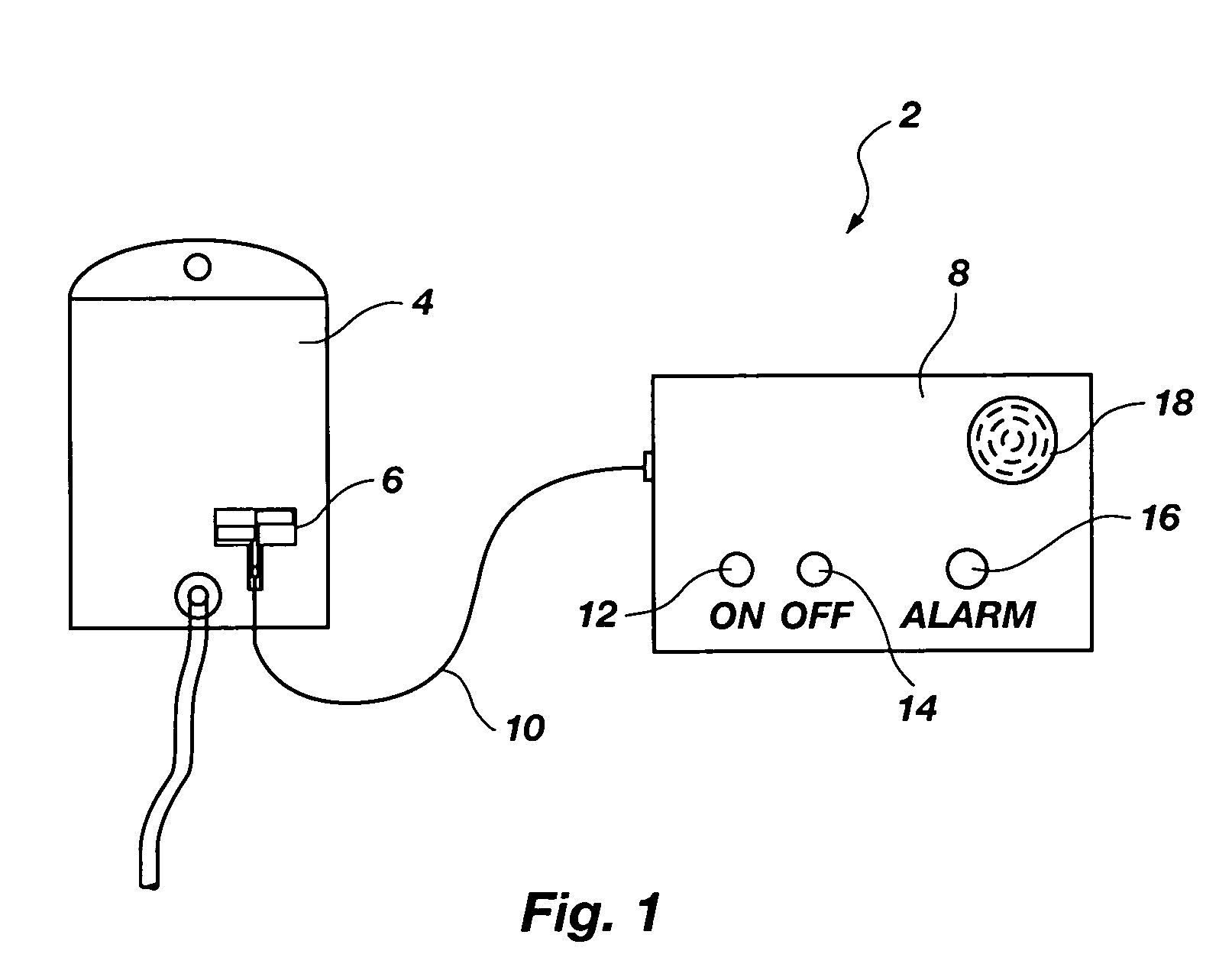

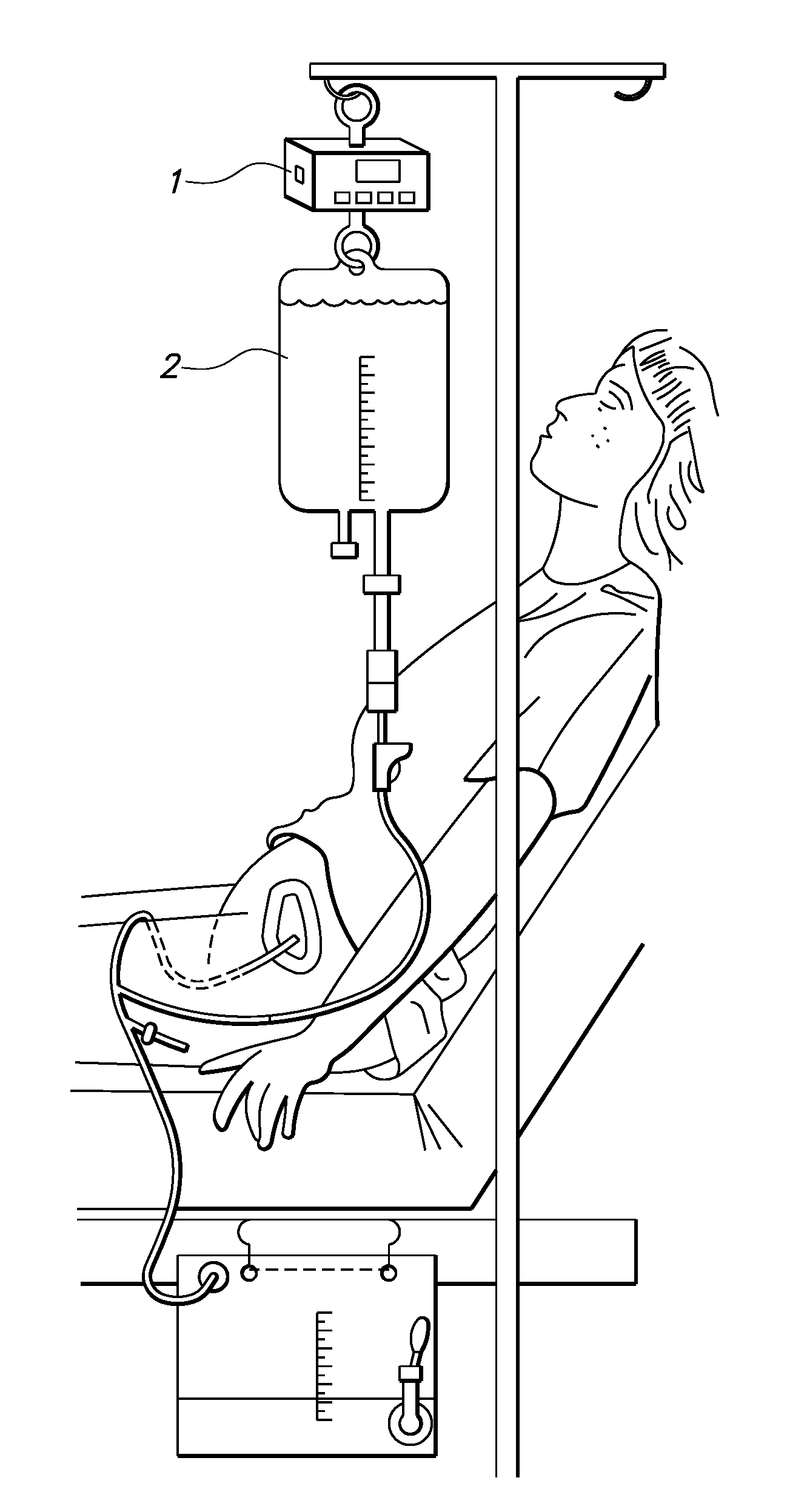

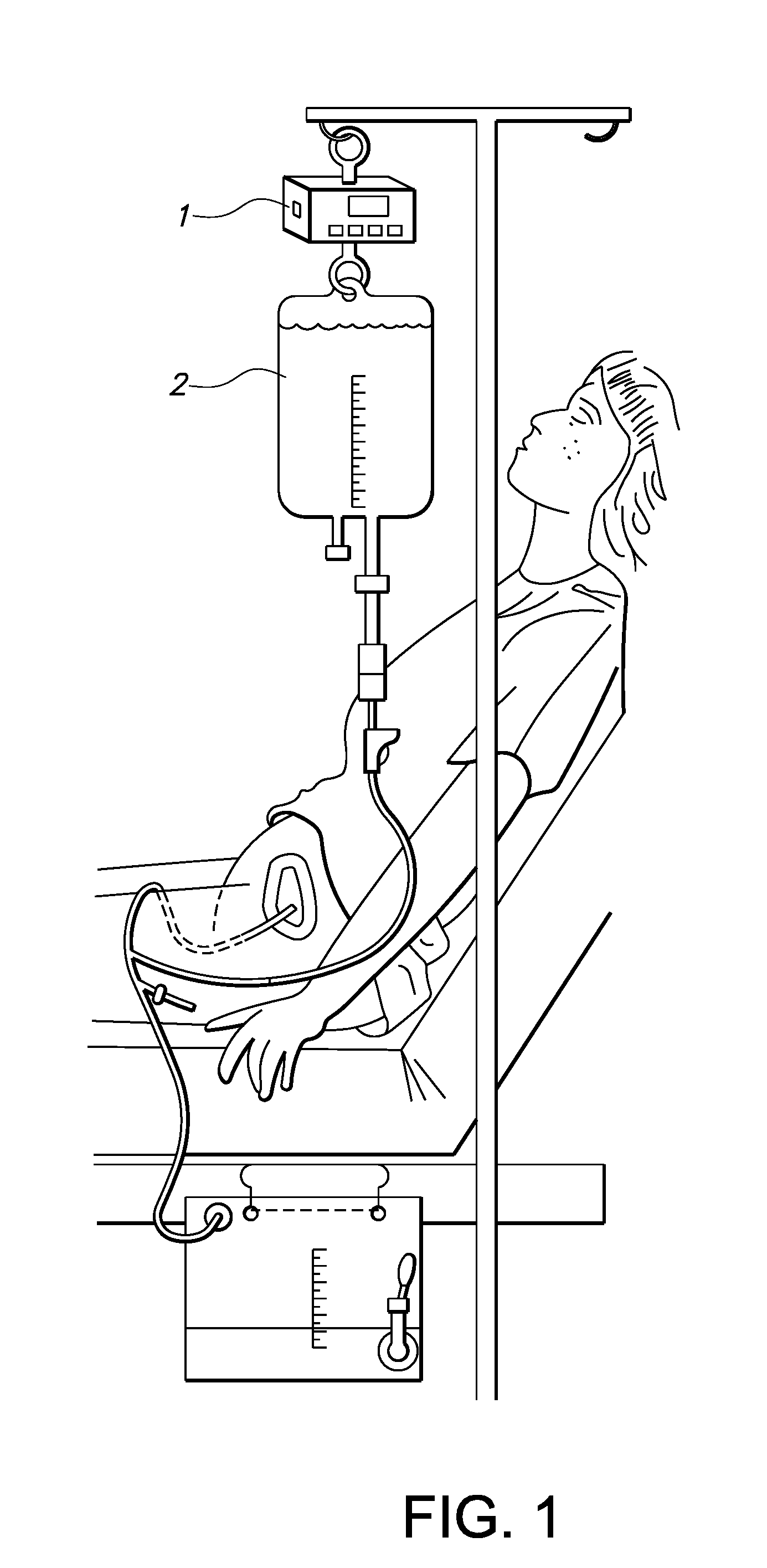

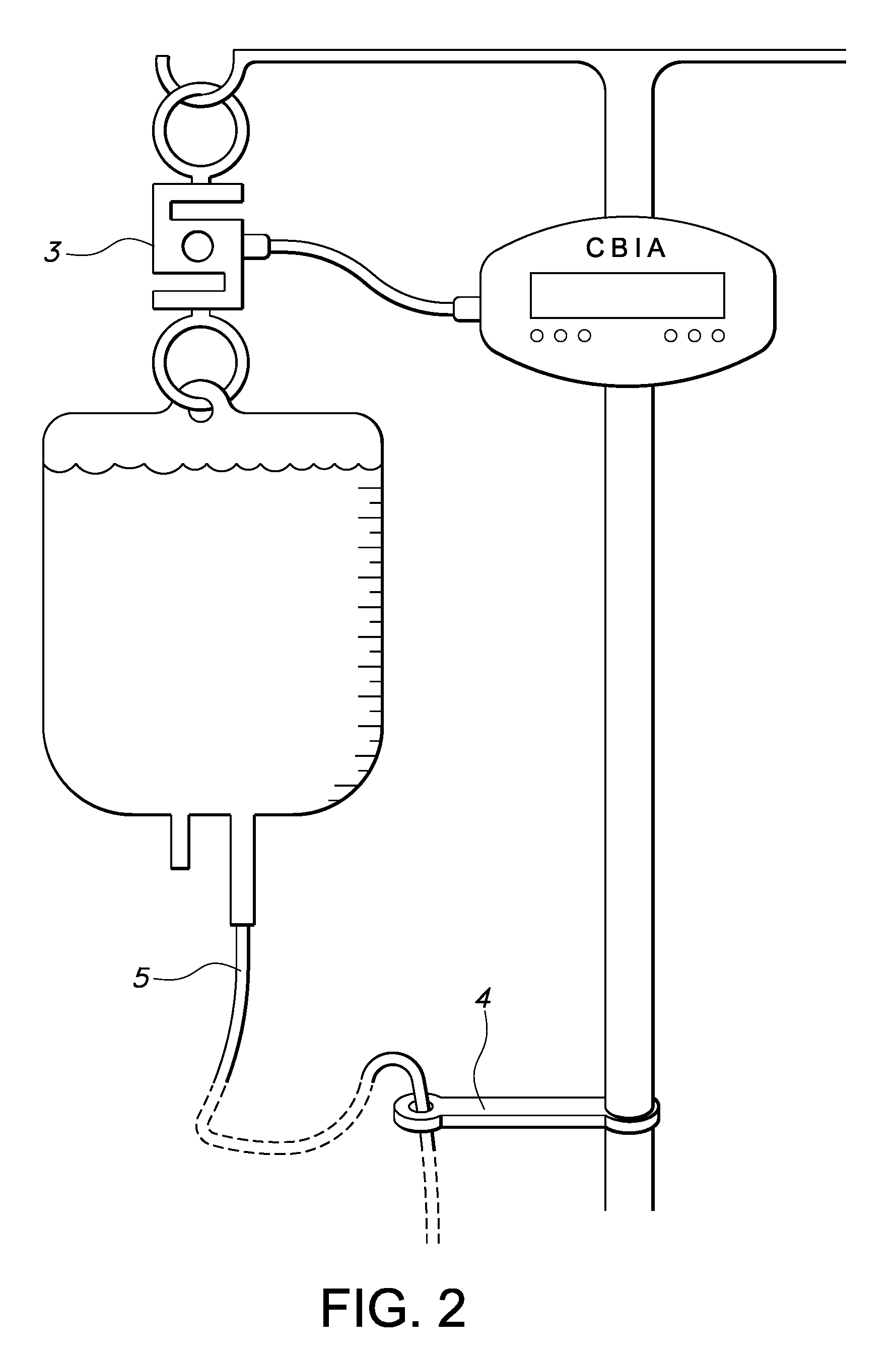

Continuous bladder irrigation alarm

InactiveUS20130060211A1Improve morbidityIncreased mortalityCannulasMedical devicesCritical levelTotal occlusion

An alarm capable of determining the flow time remaining of irrigation fluid is disclosed. It is also contemplated that the device can detect a partial or complete blockage in the system or empty fluid bag and alert medical personnel locally or remotely as required. The device is capable of calculating the time remaining before the CBI irrigation fluid in the irrigation fluid bag reaches a pre-set level that necessitates changing the bag or the actual time of day or night when the irrigation will be approaching the critical level. Additionally, the user can be alerted to the CBI irrigation fluid in the irrigation fluid bag reaching a pre-set level that necessitates changing the bag before the fluid level becomes critical.

Owner:ADAMS JR JOHN D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com