Patents

Literature

33results about How to "Ensure full implementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

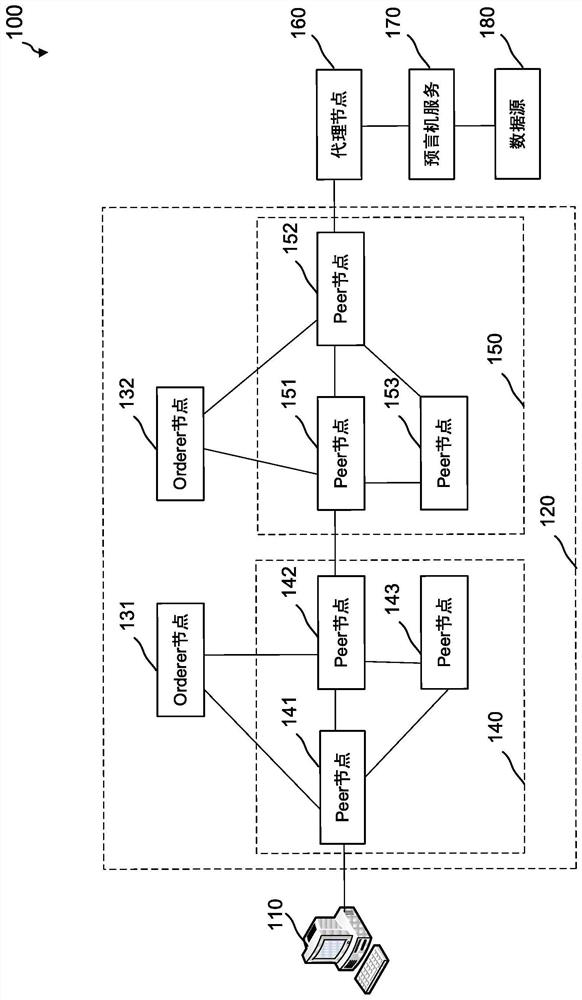

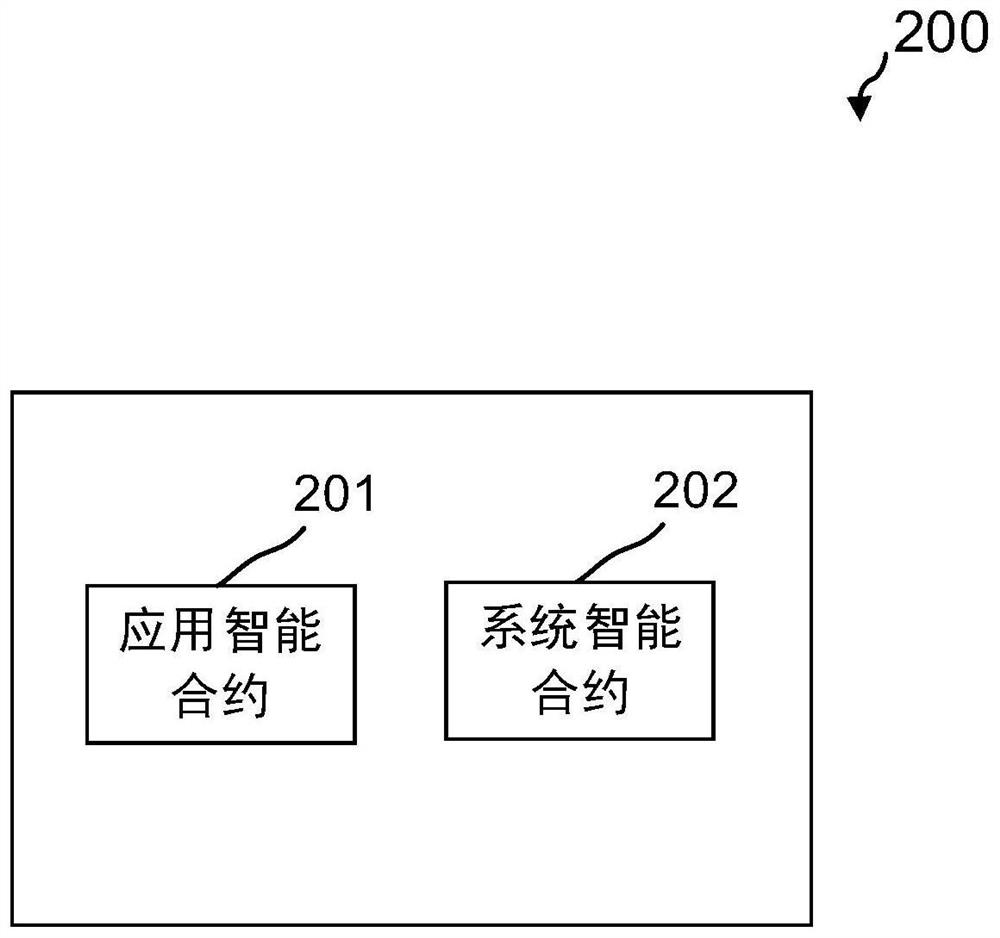

A method and apparatus for executing transactions in block chain network

ActiveCN109981679AEnsure full implementationUser identity/authority verificationClient-sideChain network

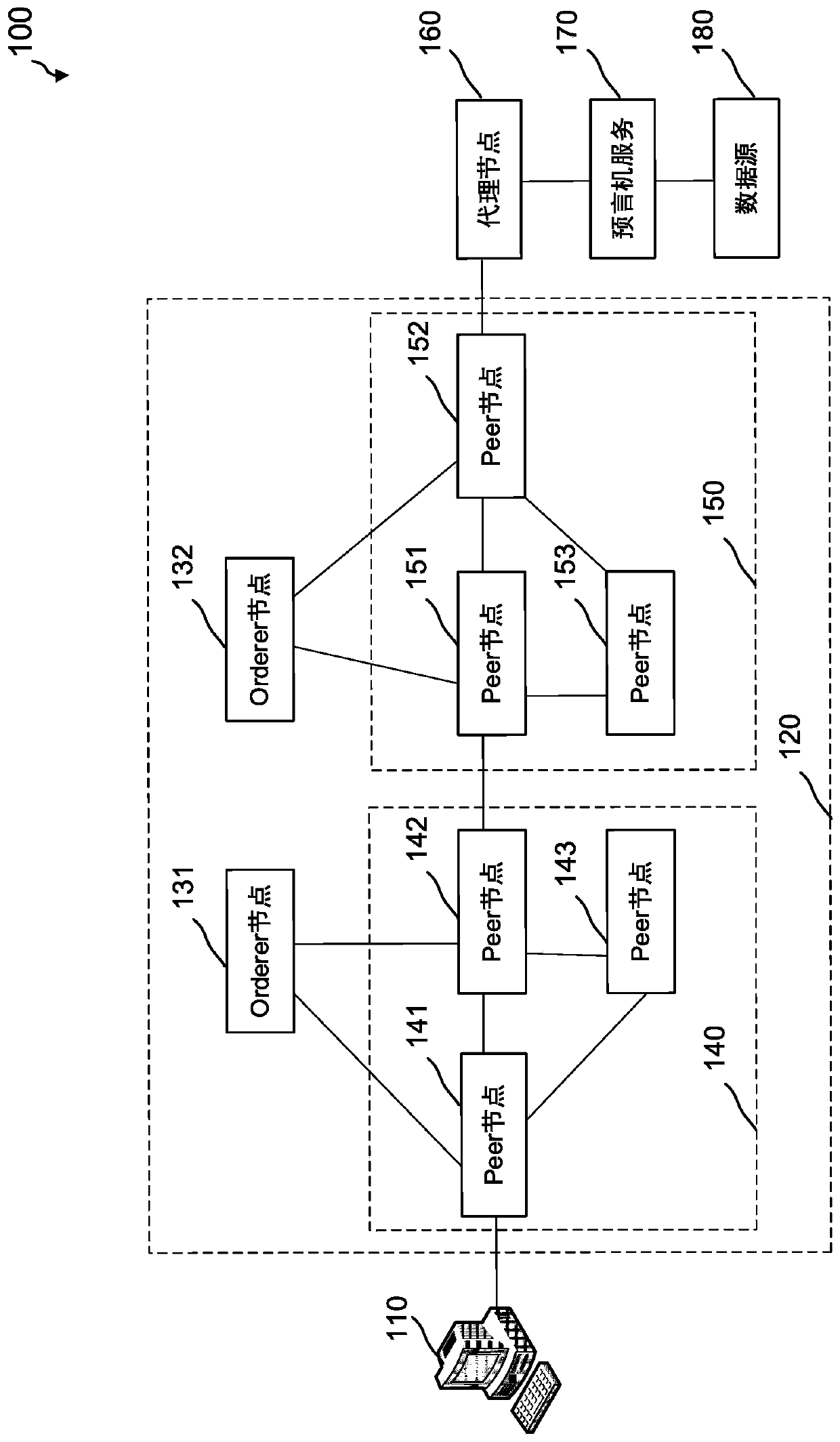

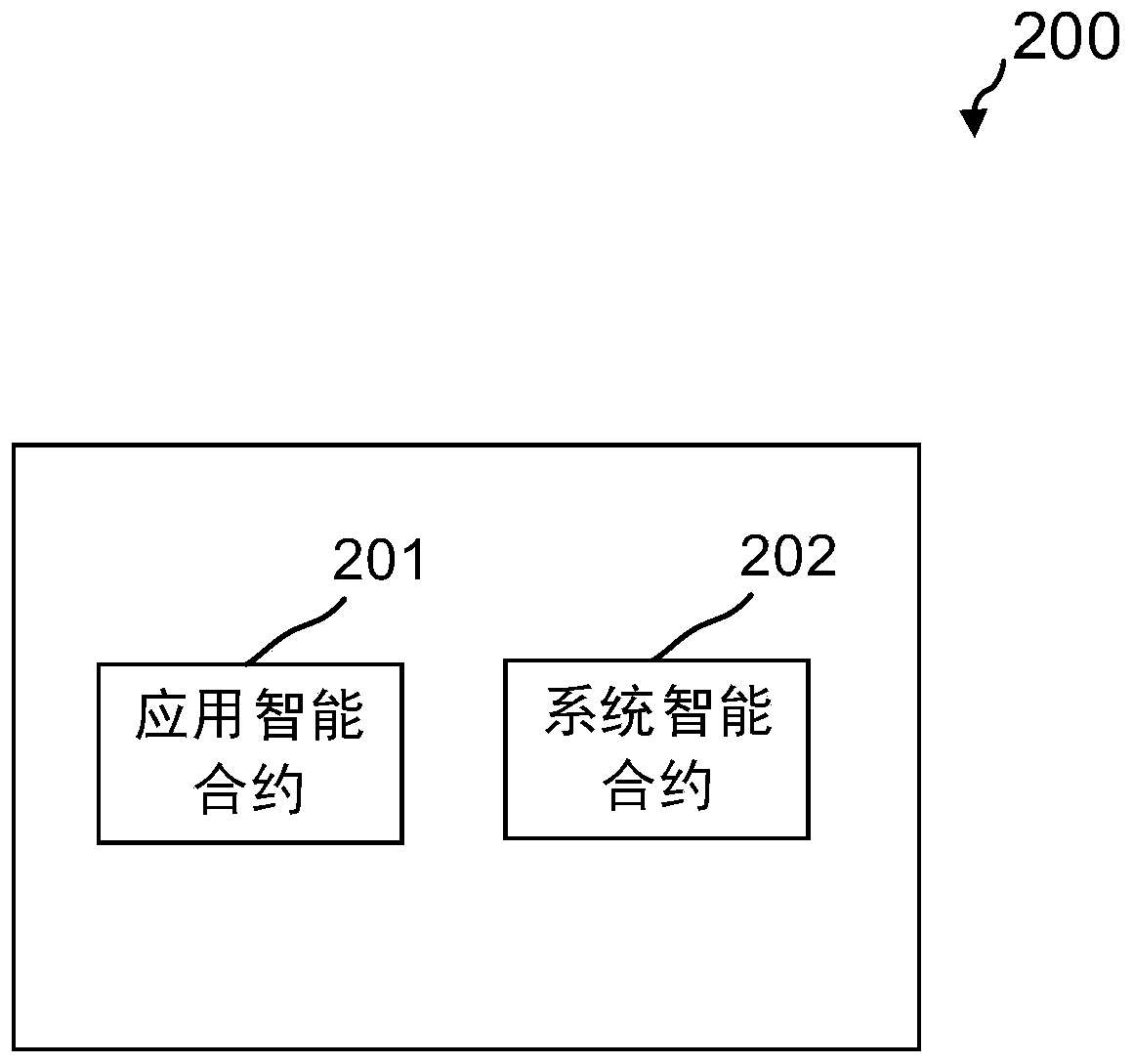

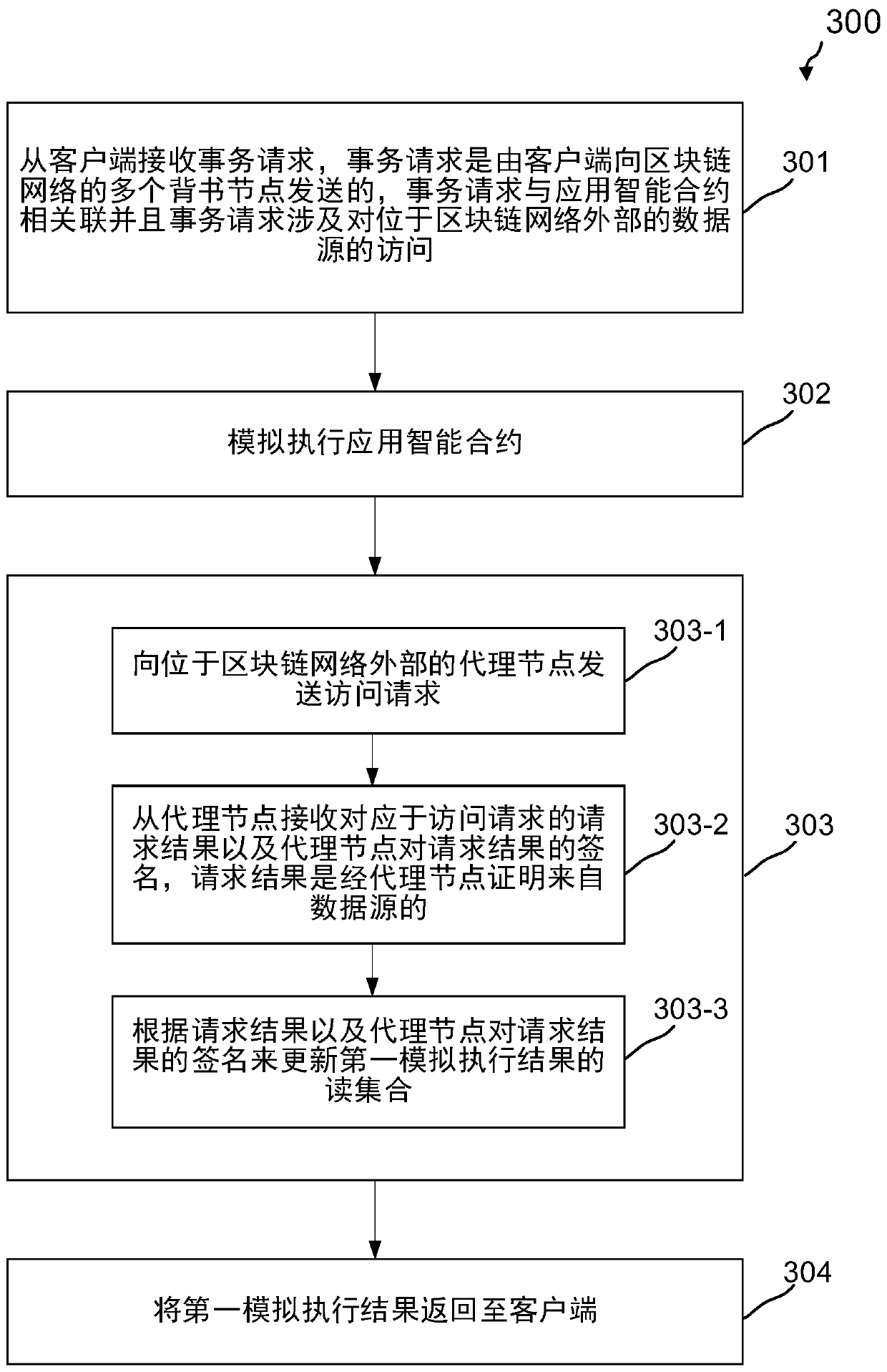

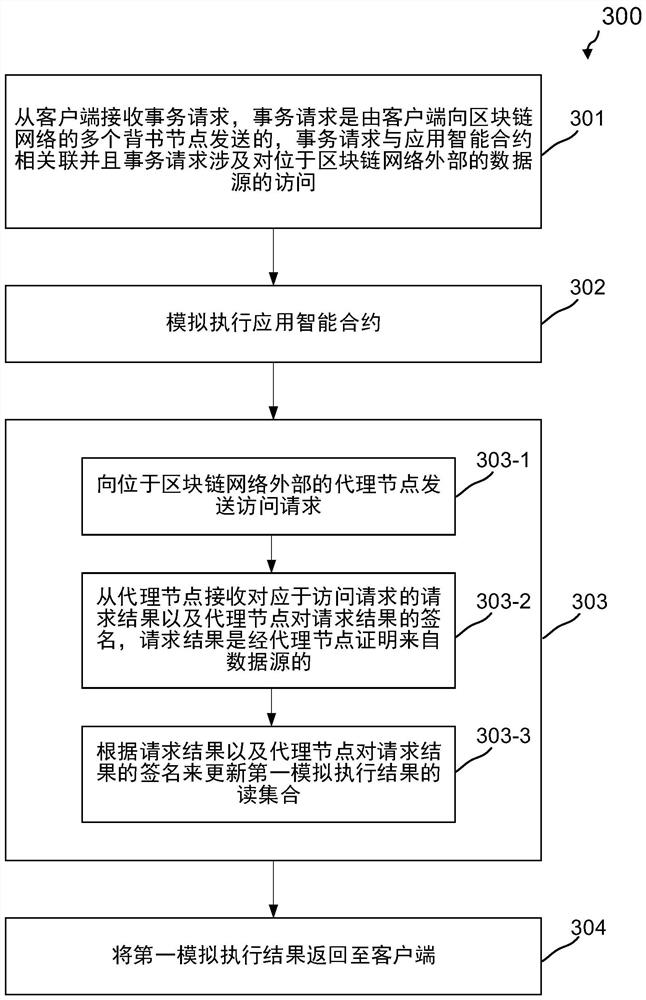

The embodiment of the invention relates to a method and a device for executing transactions in a block chain network. The method comprises: receiving a transaction request from a client, the transaction request being sent to a plurality of endorsement nodes, associated with an application smart contract, and involving access to an external data source; simulating execution of the application smartcontract; executing the system intelligent contract in the process of executing the application intelligent contract in a simulation manner to generate a first simulation execution result of the affair: sending an access request to an agent node outside a block chain network, receiving a request result and a signature for the request result from the agent node, and updating a read set of the first simulation execution result according to the request result and the signature; and returning the first simulation execution result to the client. The embodiment of the invention provides a scheme for supporting a plurality of endorsement nodes to access the same external data source in a block chain, so that the execution of a transaction can be ensured through the consistency of the reading sets generated at the plurality of endorsement nodes and related to the external data source.

Owner:SHANGHAI DIANRONG INFORMATION TECH CO LTD

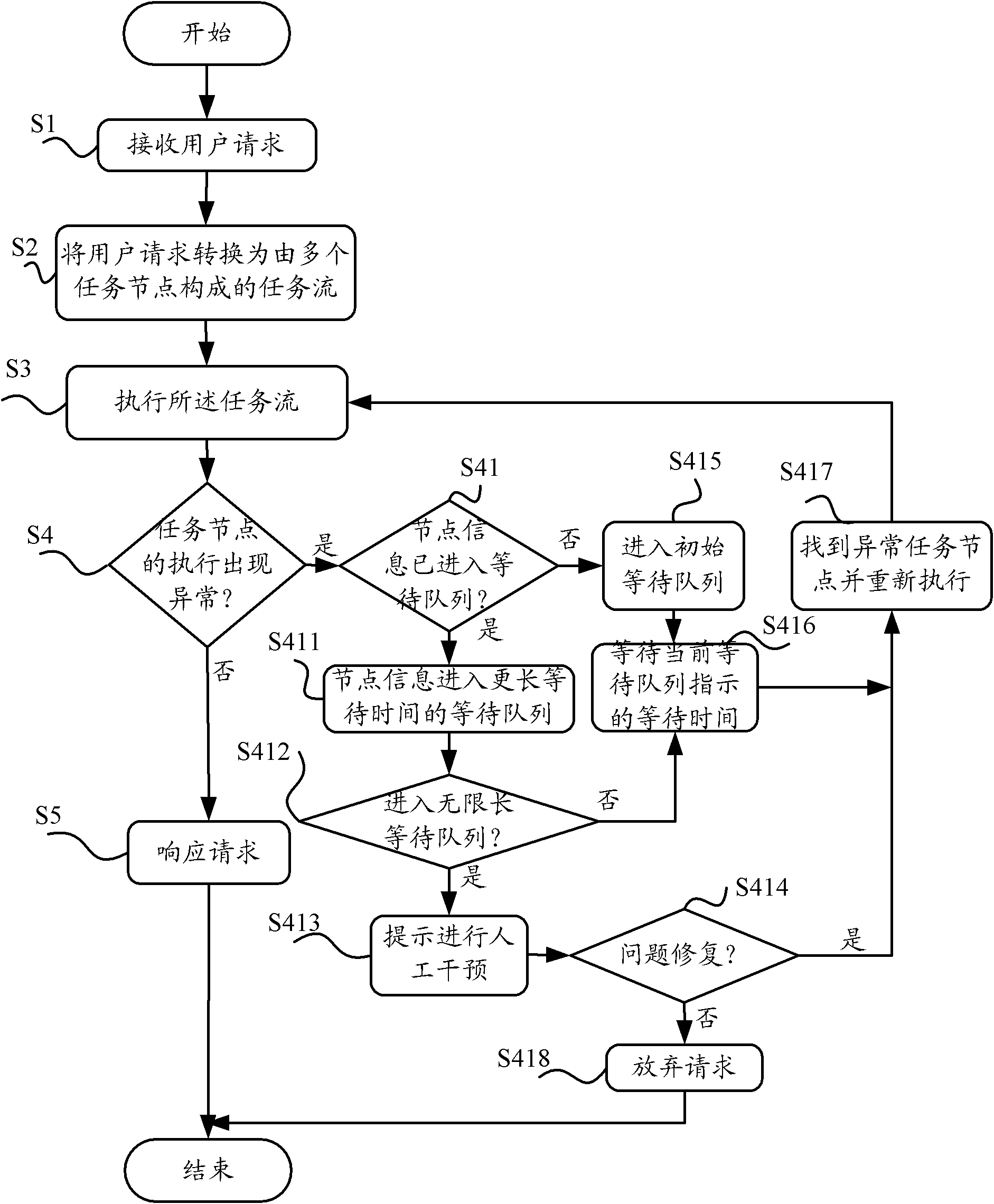

Method and device for treating abnormality of task flows

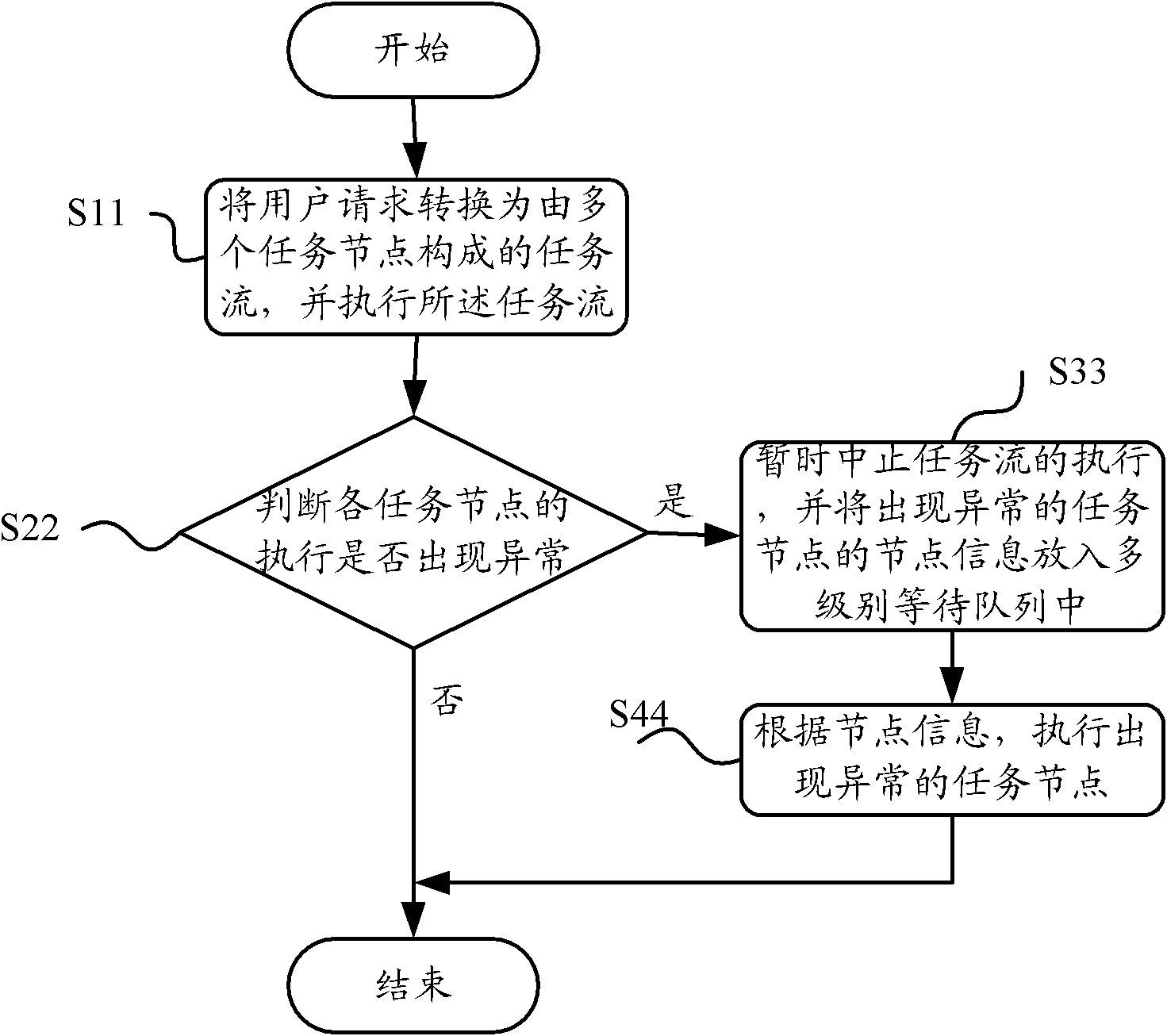

InactiveCN102929709AReduce data volumeImprove efficiencyProgram initiation/switchingOperating systemWaiting time

The invention relates to a method and a device for treating abnormality of task flows. The method comprises the following steps of: (1) converting a user request into a task flow consisting of a plurality of task nodes, and performing the task flow; (2) judging whether the task nodes are performed abnormally or not; (3) temporarily stopping performing the task flow if a certain task node is performed abnormally, and placing the information of the abnormal task node into multi-level waiting queues which respectively indicate a plurality of different waiting time; and (4) performing the abnormal task node according to the information of the node. By the method and the device, the request can be performed completely, the final integrity and the consistency of the data and the state of the request are guaranteed, manual recovery efficiency is improved, and a uniform and stable interface is formed.

Owner:ALIBABA GRP HLDG LTD

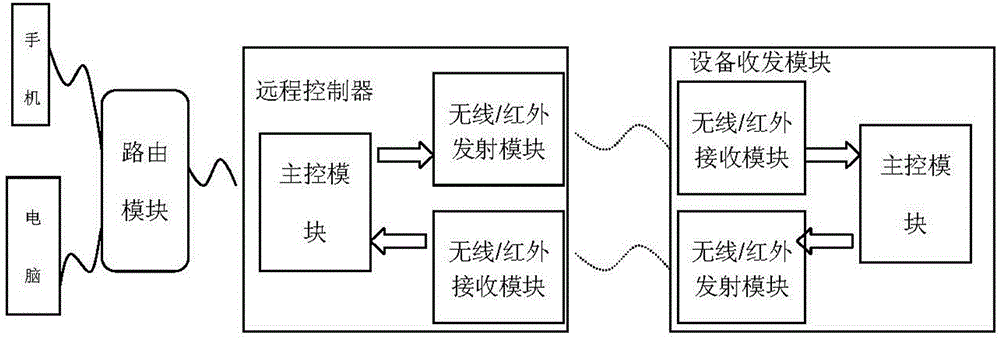

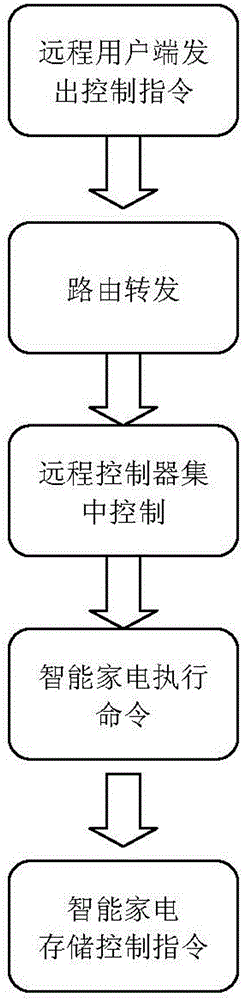

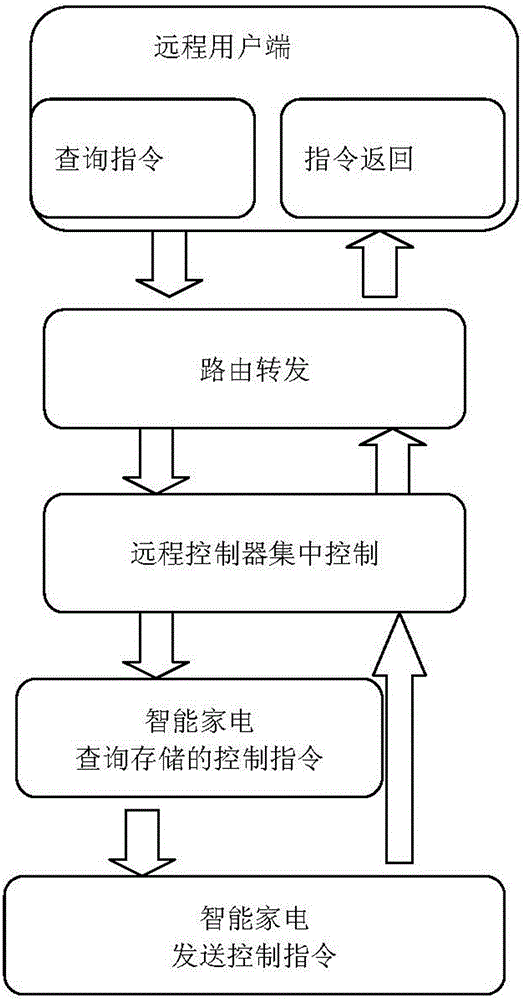

Bidirectional control system and method of intelligent household electrical appliances

InactiveCN105116739AEnsure full implementationImplement many-to-many controlComputer controlProgramme total factory controlTablet computerRemote control

The present invention discloses a bidirectional control system and method of intelligent household electrical appliances. The system can utilize a plurality of remote user terminals to control various intelligent household electrical appliances needing to be operated. A user operates the devices, such as a mobile phone, a tablet computer, a computer, etc., to input a control instruction, the control instruction reaches a remote controller (a remote control module) via a network, and the remote controller forwards the data to the intelligent household electrical appliances to execute, at the same time, the execution states returned by the intelligent household electrical appliances are obtained in different manners. The remote controller comprises a transferring sending module, a transferring receiving module and a main control module, and the main control module analyzes the communication data between the remote user terminals and the intelligent household electrical appliances, and forwards to the corresponding remote user terminals or the intelligent household electrical appliances via the transferring sending module. According to the present invention, the intelligent household electrical appliances can be controlled completely, the current states of all intelligent household electrical appliances can be grasped and controlled timely and at any time, thereby improving the controllability, accuracy and convenience of an intelligent home.

Owner:周良

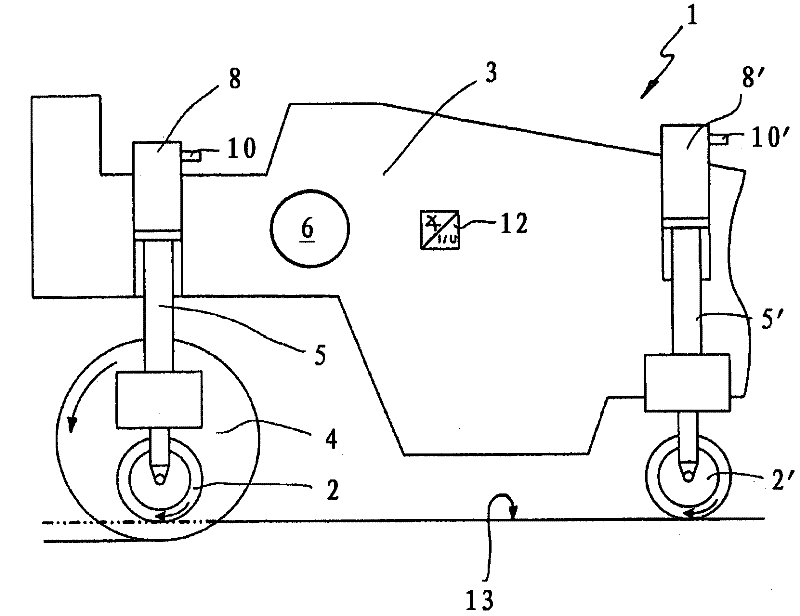

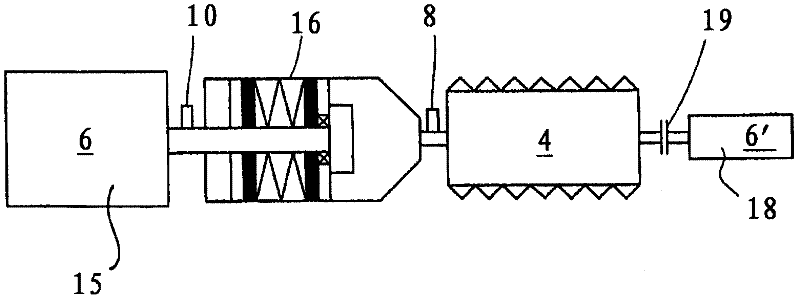

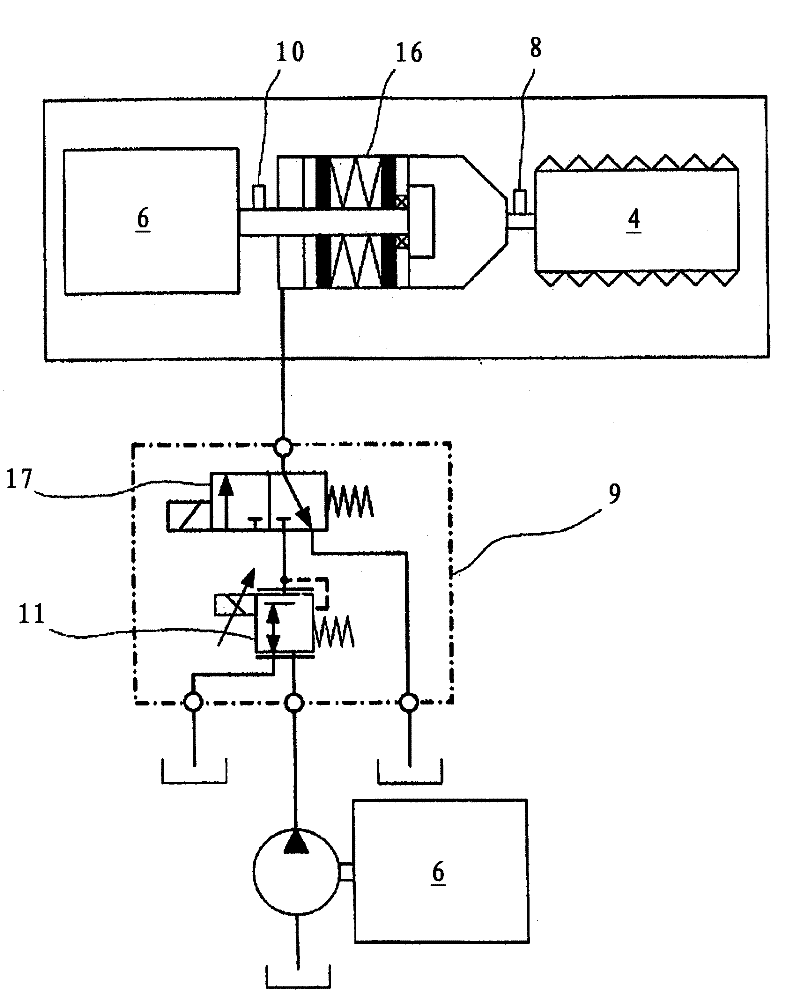

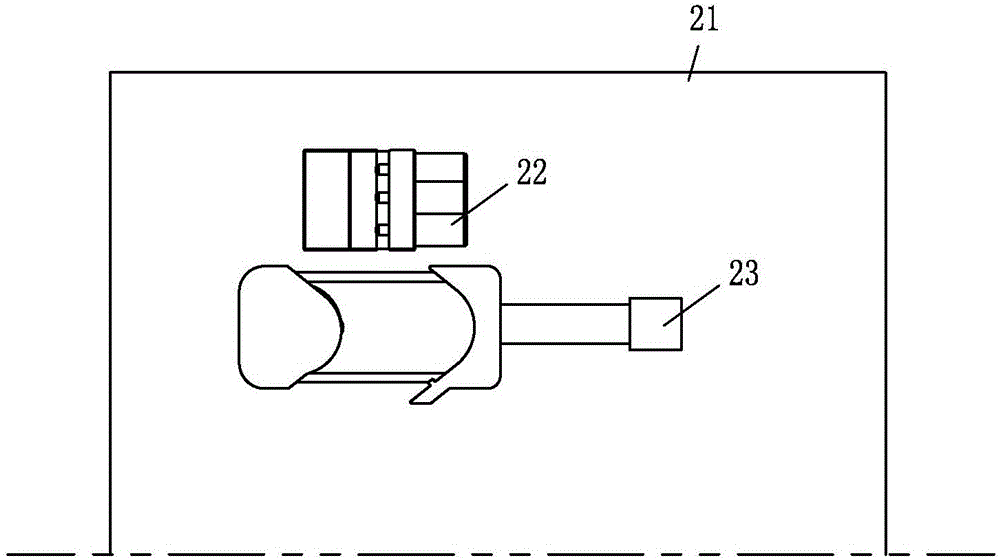

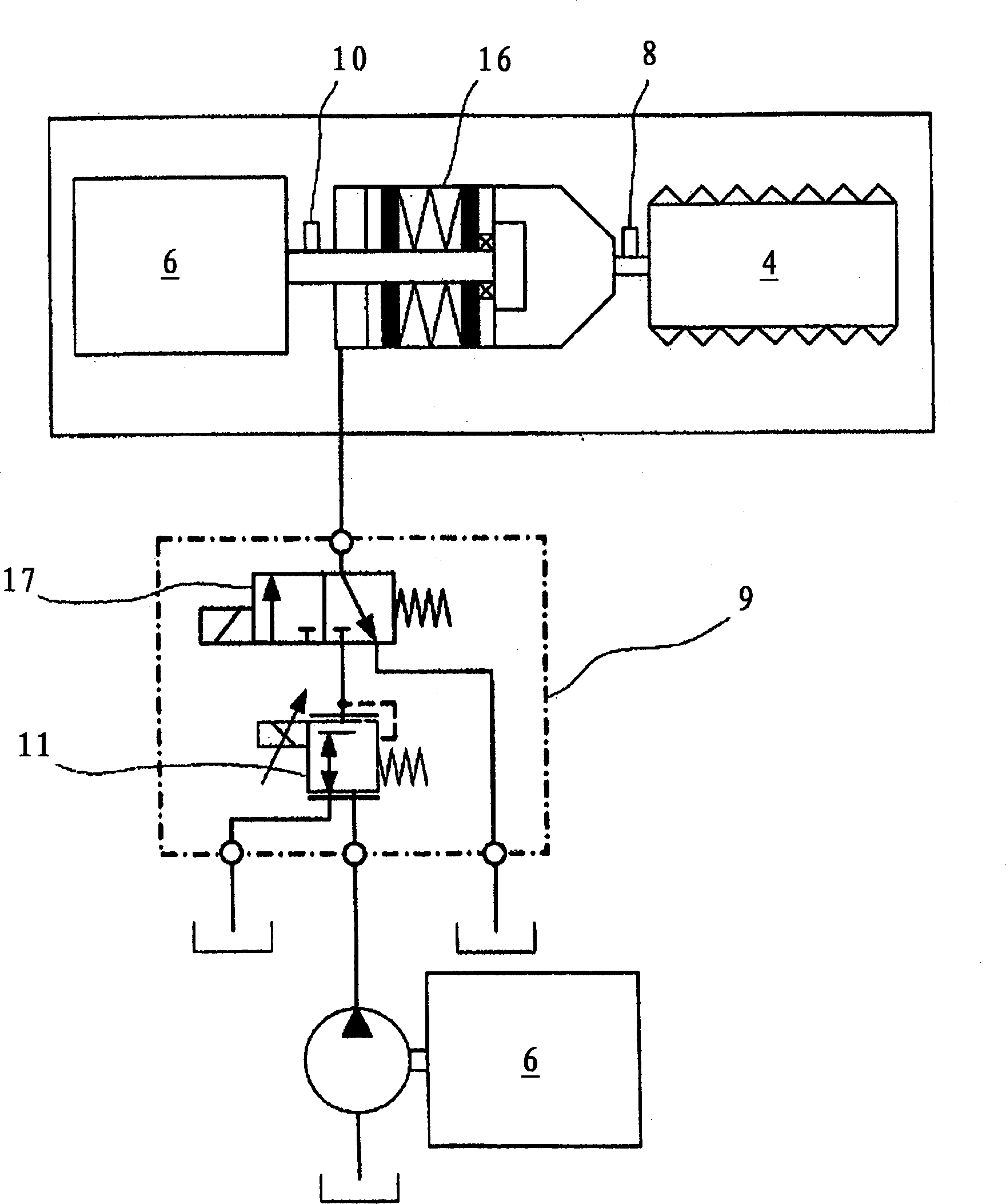

Apparatus for processing ground surfaces

InactiveCN102304891AEnsure full implementationTilling equipmentsWorking accessoriesEngineeringControl theory

Owner:BOMAG

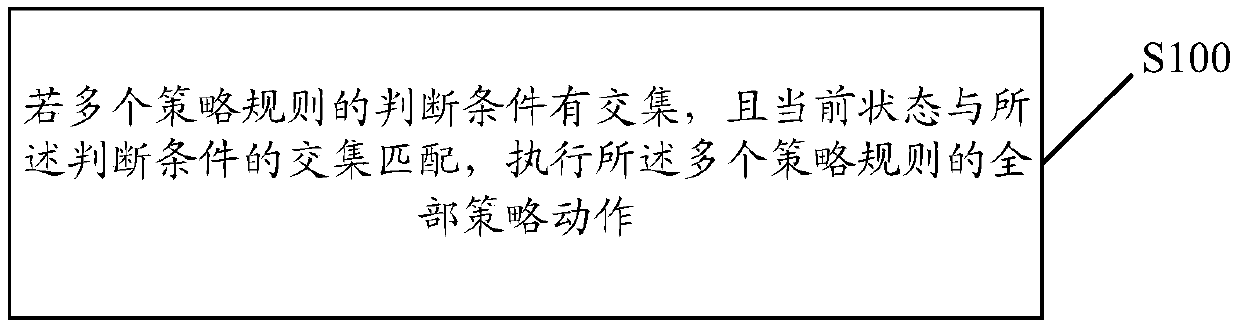

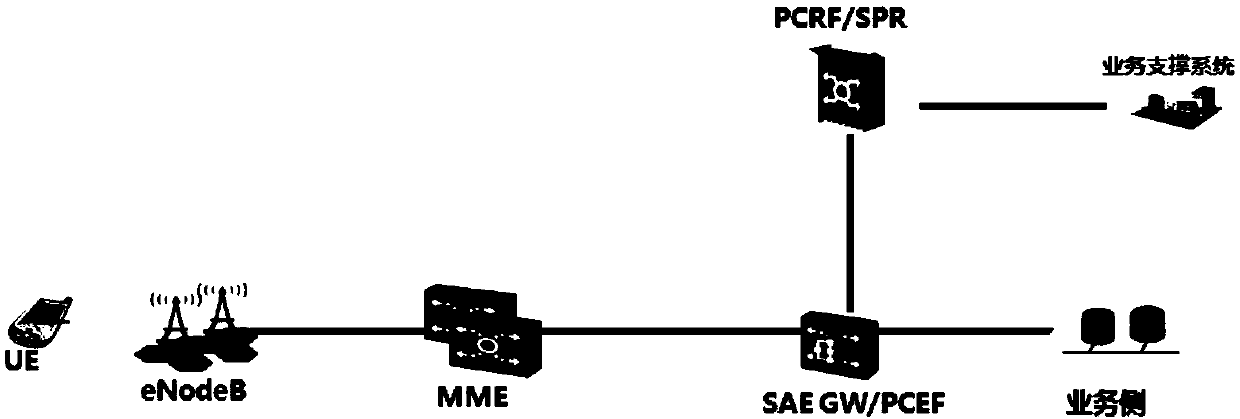

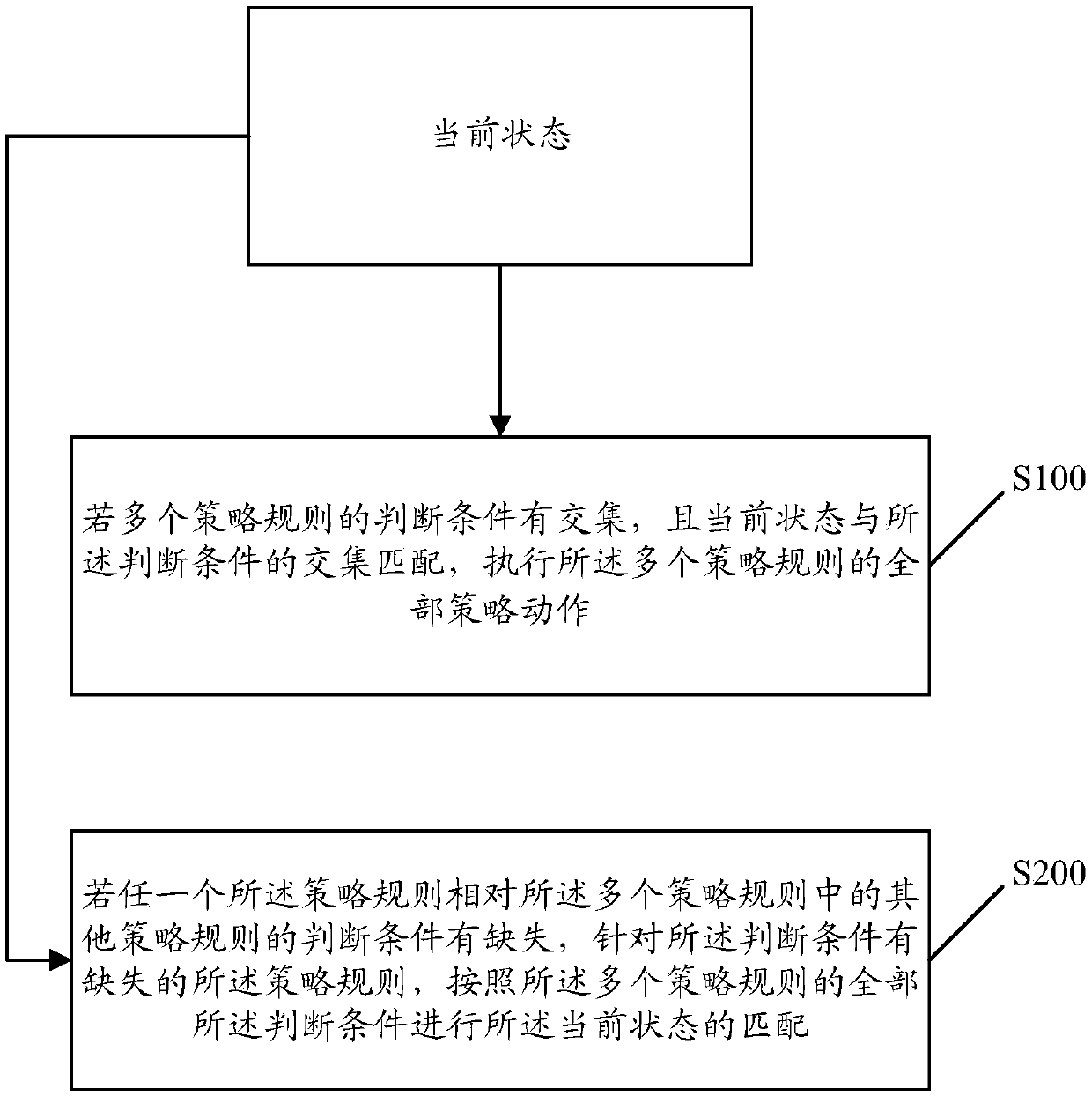

Policy rule processing method and device, functional network element and storage medium

InactiveCN110650023AReduce omissionsEnsure full implementationMetering/charging/biilling arrangementsData miningComputer science

The embodiment of the invention provides a policy rule processing method and device, a functional network element and a storage medium. The policy rule processing method is applied to a strategy ruleexecution function, and comprises the step of executing all strategy actions of a plurality of strategy rules if judgment conditions of the plurality of strategy rules have intersection and a currentstate is matched with the intersection of the judgment conditions.

Owner:CHINA MOBILE COMM LTD RES INST +1

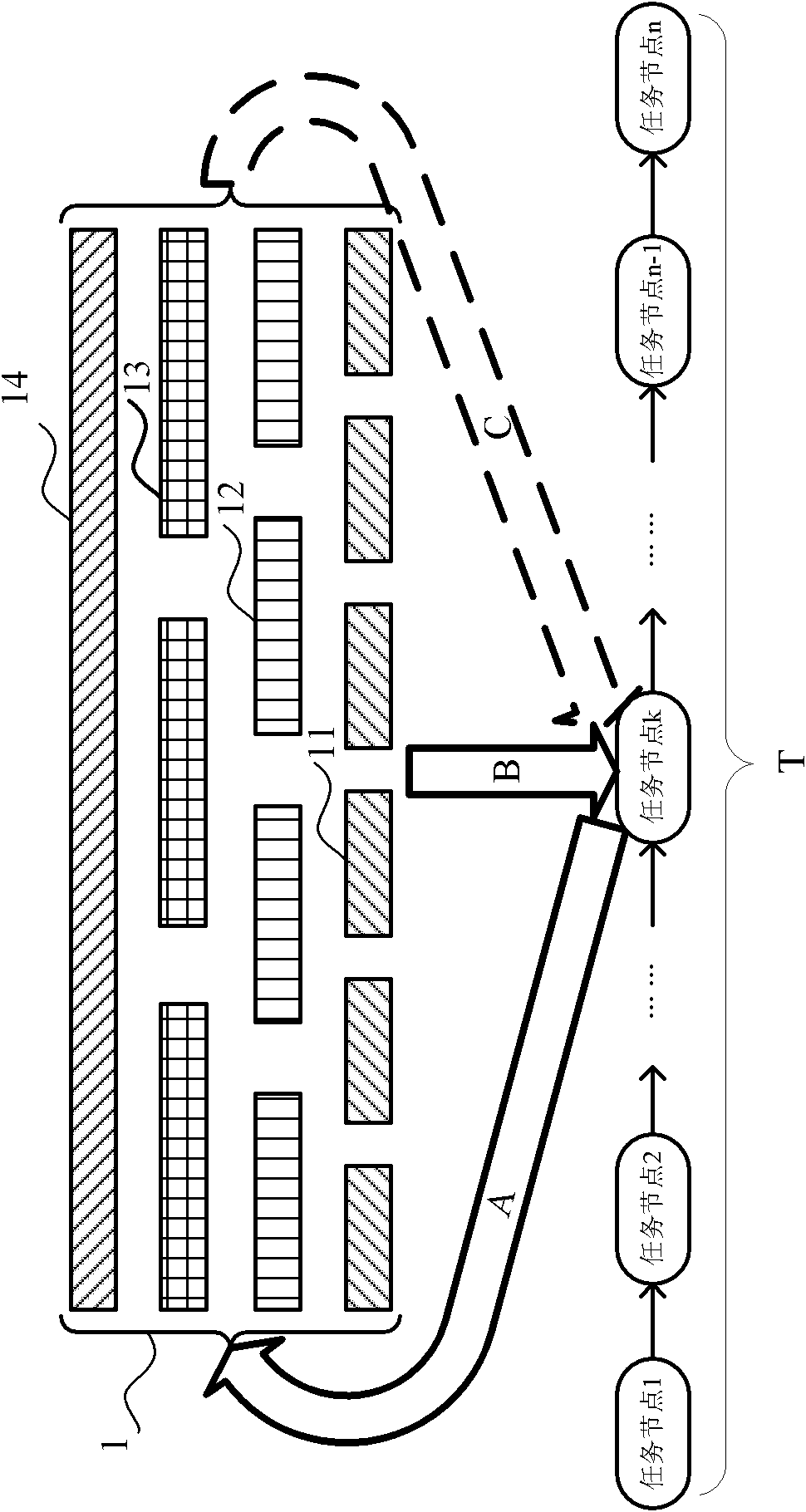

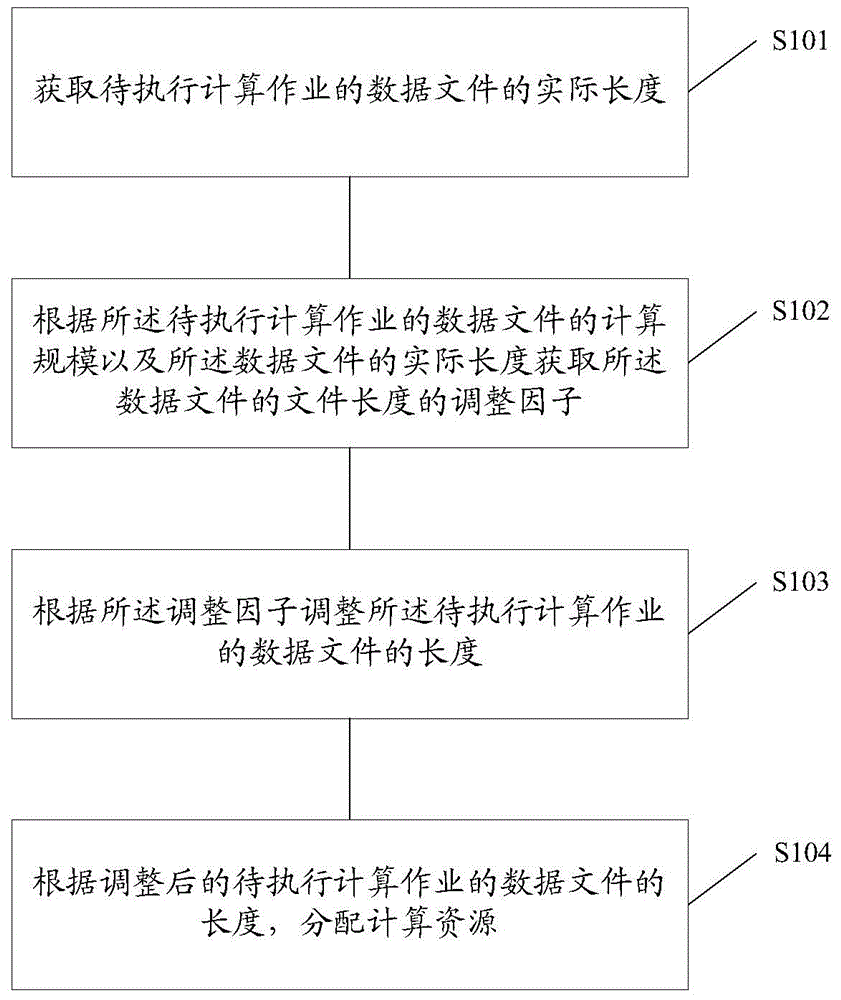

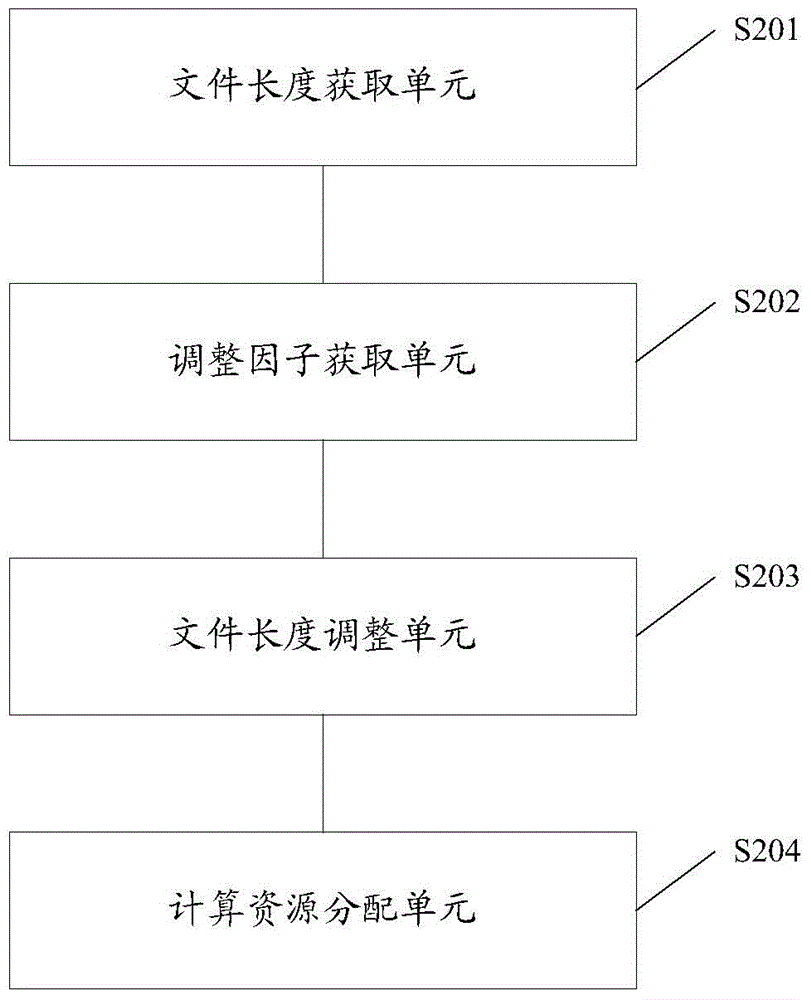

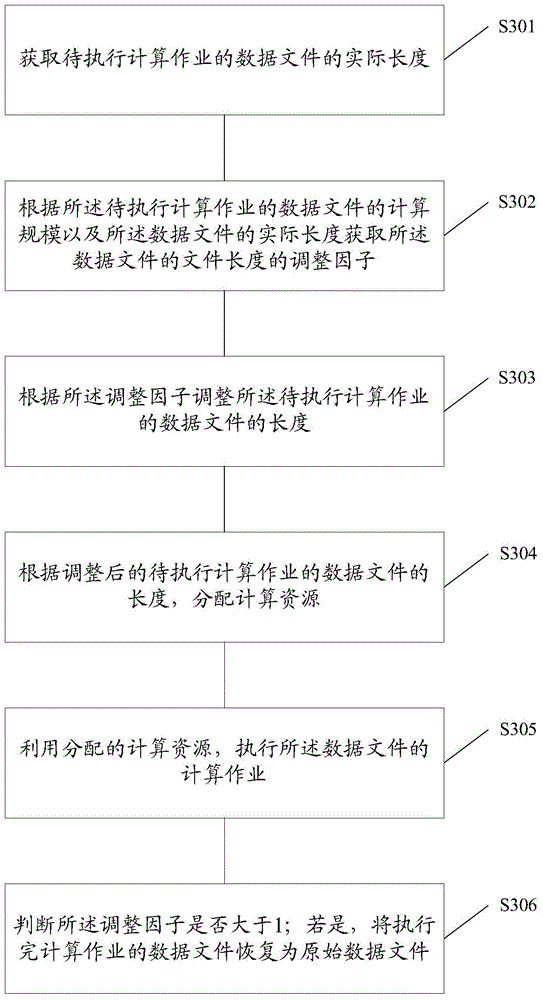

Resource allocation method, computation speedup method and device for distributed computation

ActiveCN104636397AEnsure full implementationWeb data indexingSpecial data processing applicationsData fileResource based

The invention provides a resource allocation method and device for distributed computation, and a computation speedup method and device for distributed computation. The resource allocation method for distributed computation comprises the steps that obtaining a physical length of a data file to be executed a calculating operation; obtaining a tuning factor of a file length of the data file based on a calculating scale of the data file to be executed the calculating operation and the physical length of the data file; adjusting the length of the data file to be executed the calculating operation based on the tuning factor; allocating the computing resources based on the adjusted length of the data file to be executed the calculating operation. According to the resource allocation method and the computation speedup method, the allocated computing resources can not only meet the requirement on the aspect of the data file length, but also meet the requirement on the aspect of the calculating scale, and more effective processing on the data file is guaranteed at the same time of the full and rational utilization of the calculating resources.

Owner:ADVANCED NEW TECH CO LTD

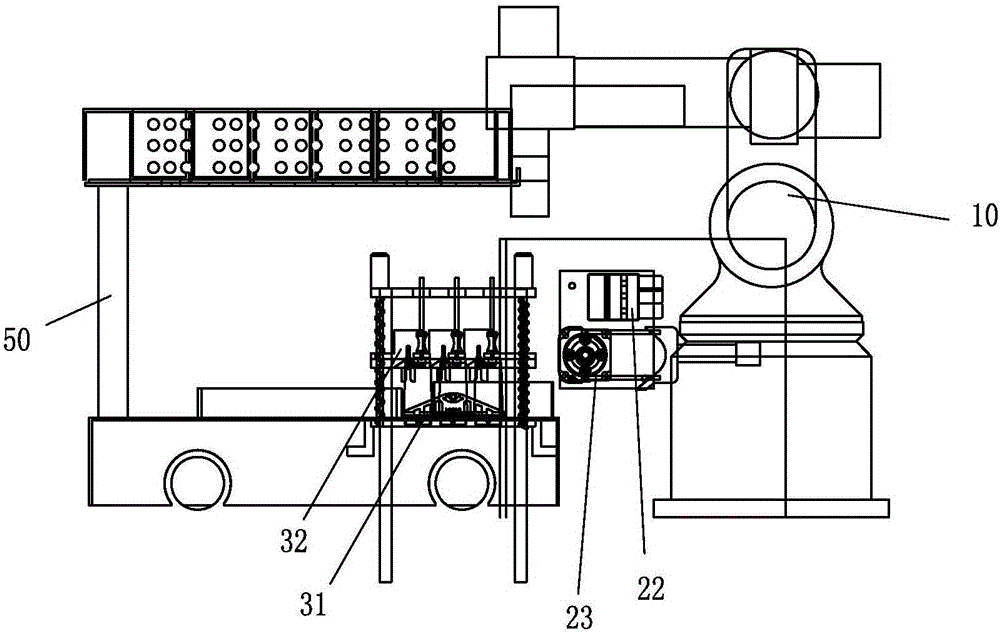

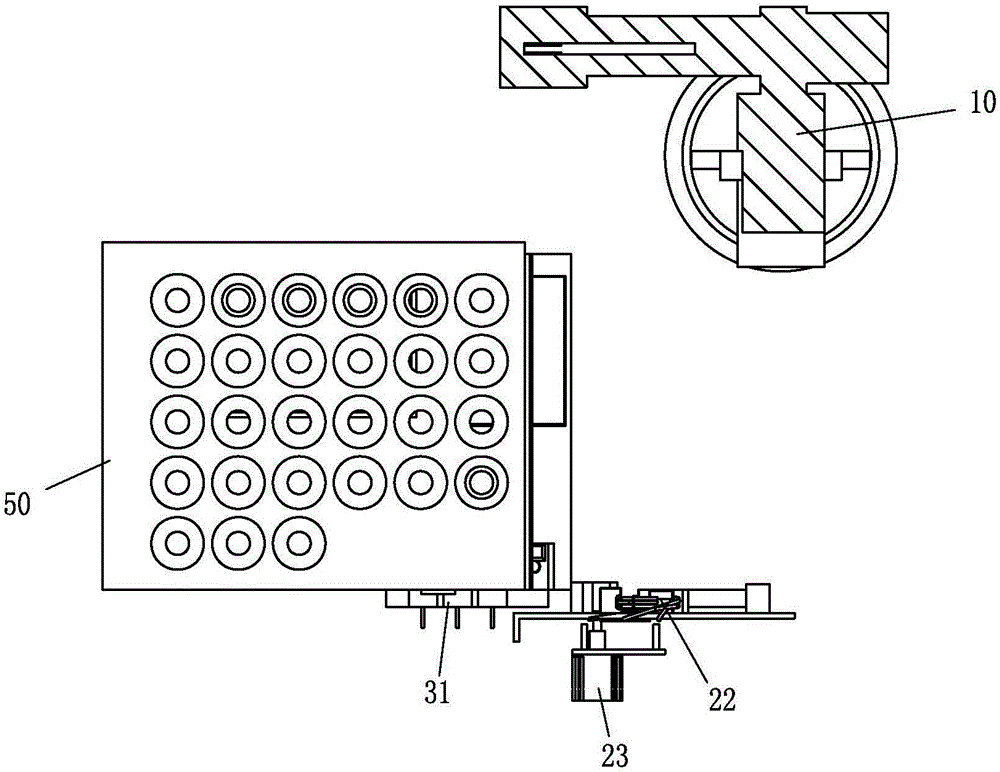

Full-automatic drug sterility inspection enrichment system of sterile bin and operation method of system

ActiveCN106226151AImprove operational sensitivityImprove work efficiencyPreparing sample for investigationPeristaltic pumpSterile environment

The invention discloses a full-automatic drug sterility inspection enrichment system of a sterile bin and an operation method of the system. The enrichment system comprises a sterile operation car, an automatic operation manipulator and an operation table; the sterile operation car comprises a car base, a wastewater box, a filter containing box and a garbage box are arranged on the car base, filter hole sites are arranged over a water inlet of the wastewater box, a container frame is installed on a support frame arranged on one side of the car base and provided with container containing hole sites used for containing containers of at least one type and at least one operation hole site used for containing a container to be operated, and needle clamping devices are arranged at the corresponding operation hole sites; a clamping mechanism, a peristaltic pump, a pressure detection mechanism and a sealed cutting mechanism are installed on the operation table. Accordingly, the high-efficiency full-automatic drug sterility inspection enrichment process can be achieved in a sterile environment of the sterile bin, artificial participation is not needed, the hidden danger that the sterile environment is manually destroyed does not exist, and the system can be suitable for conducting enrichment operation on bacterium inspection of various kinds of drugs packaged in various kinds of drug bottles or bags.

Owner:牛刚 +1

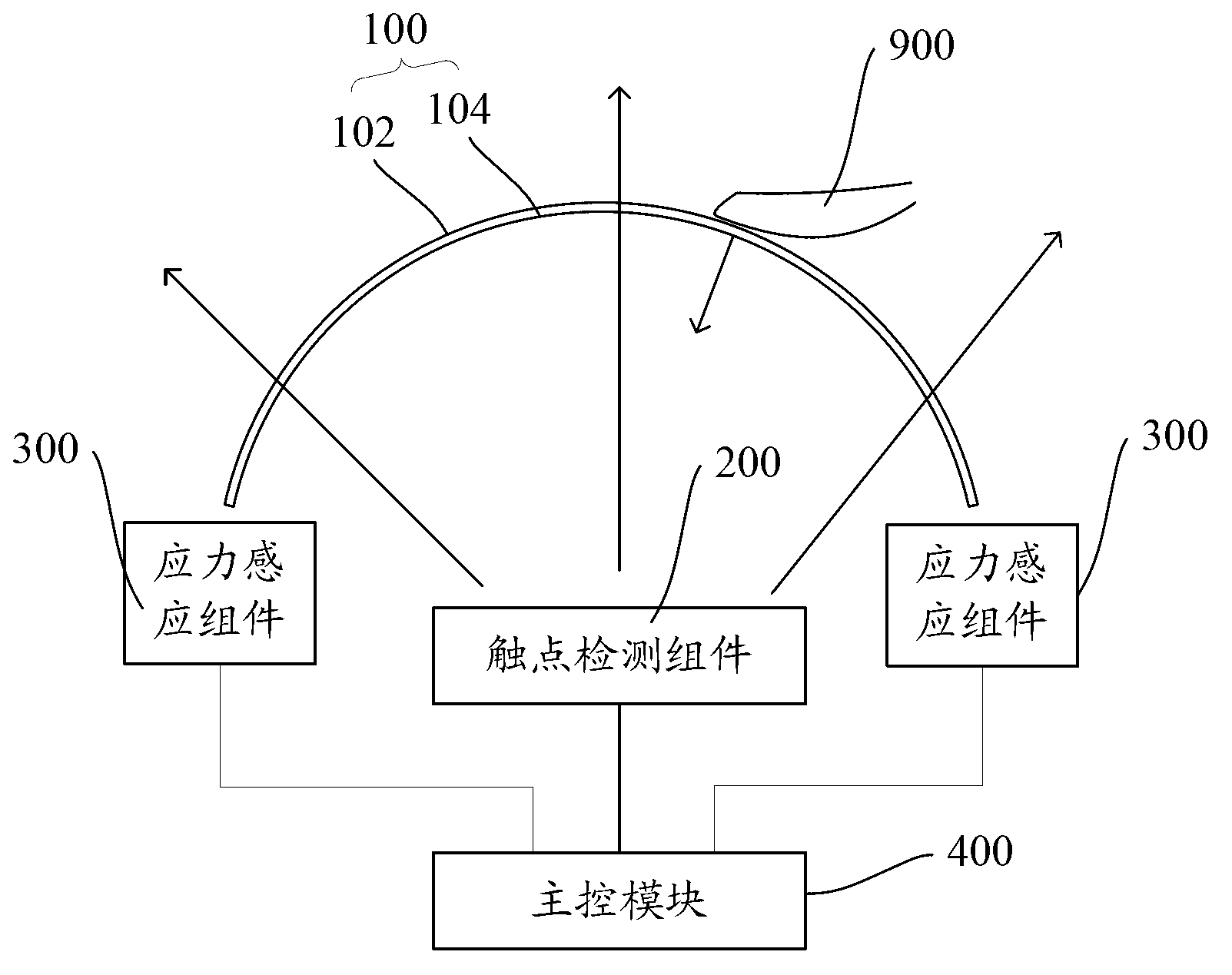

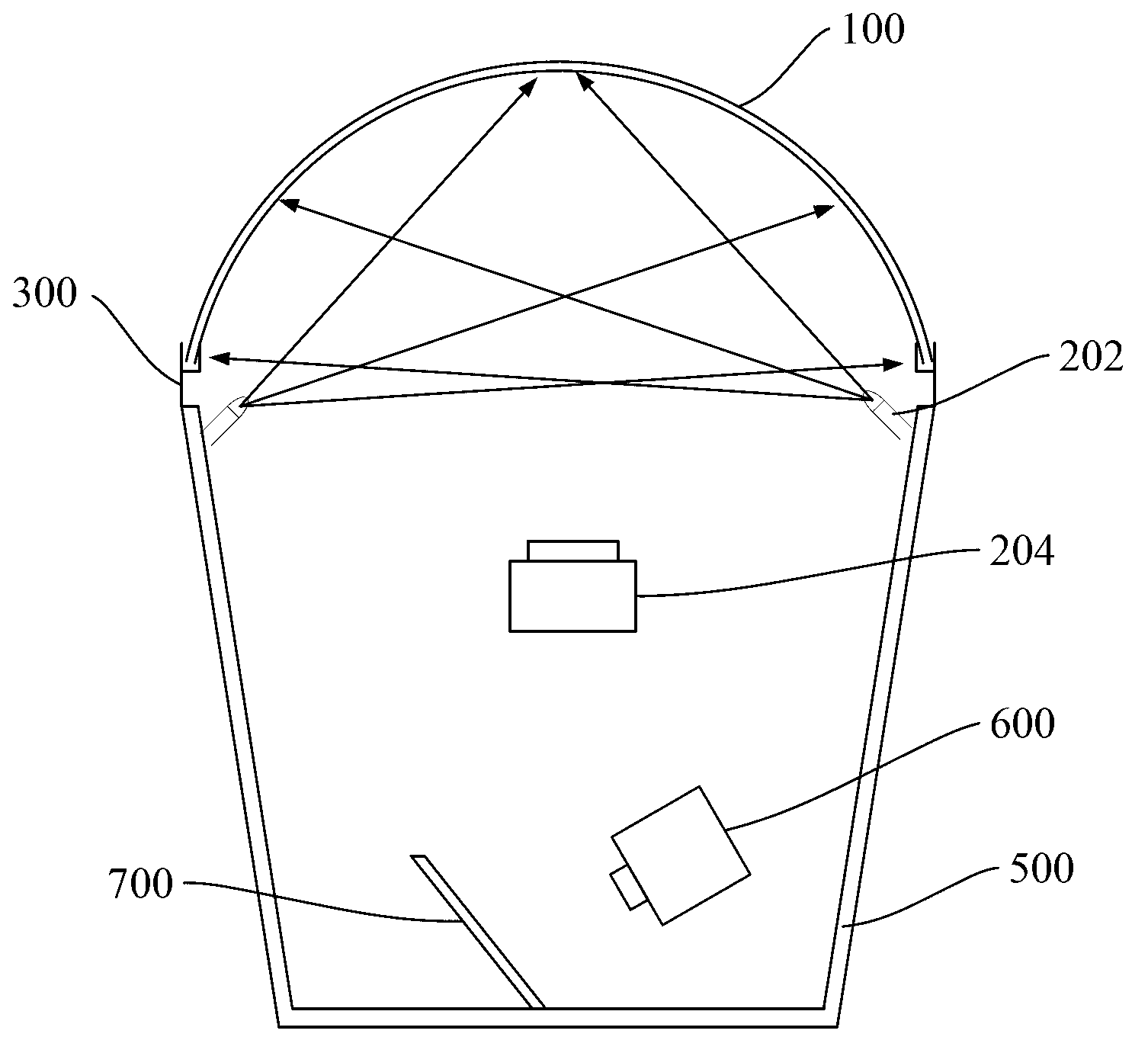

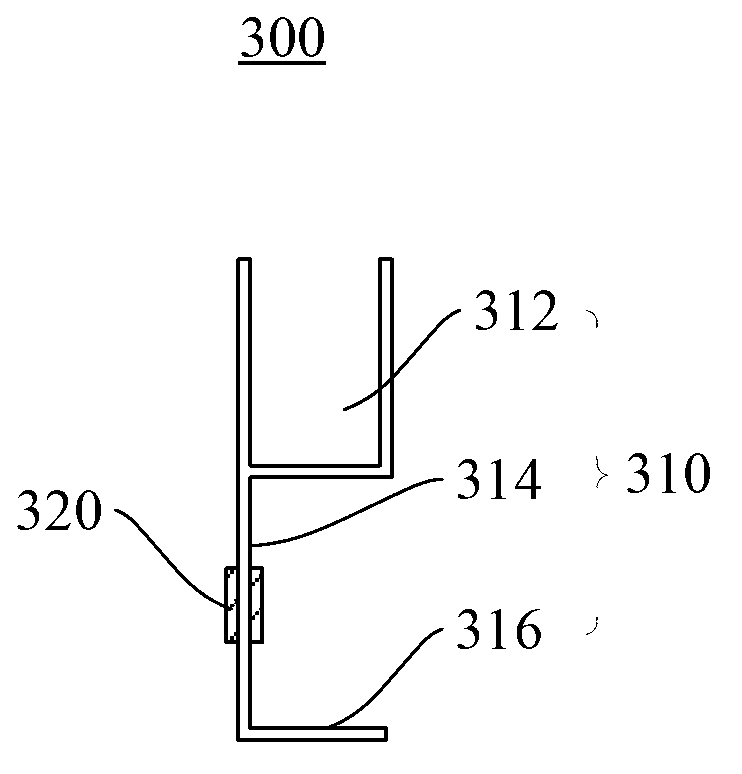

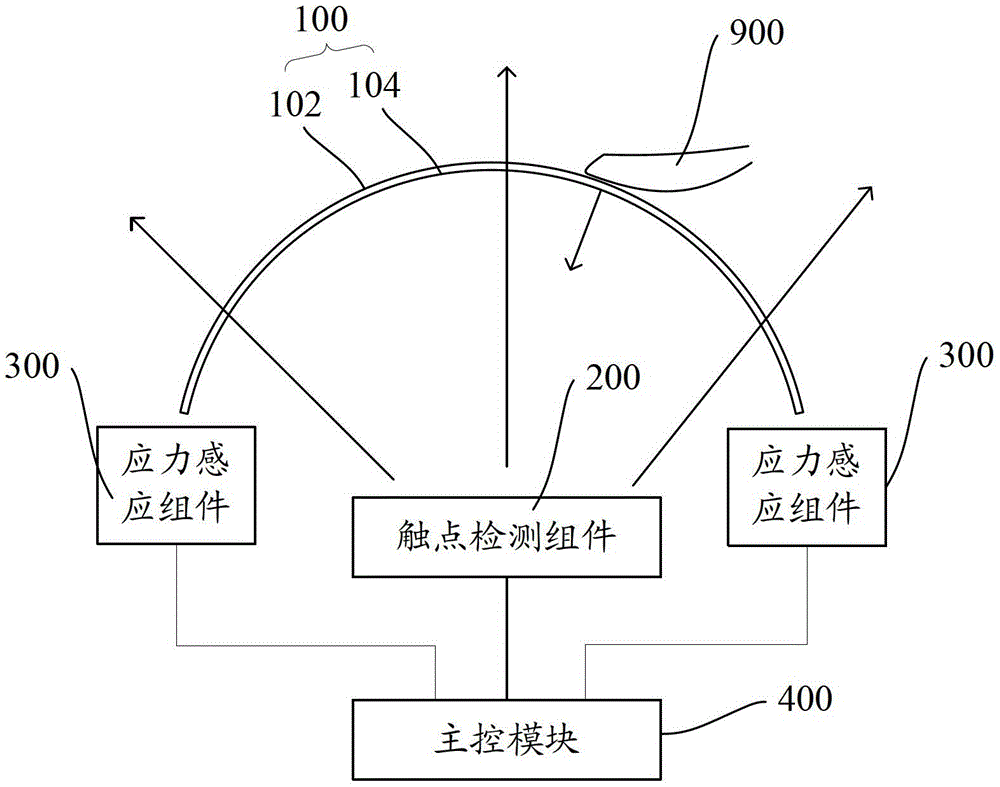

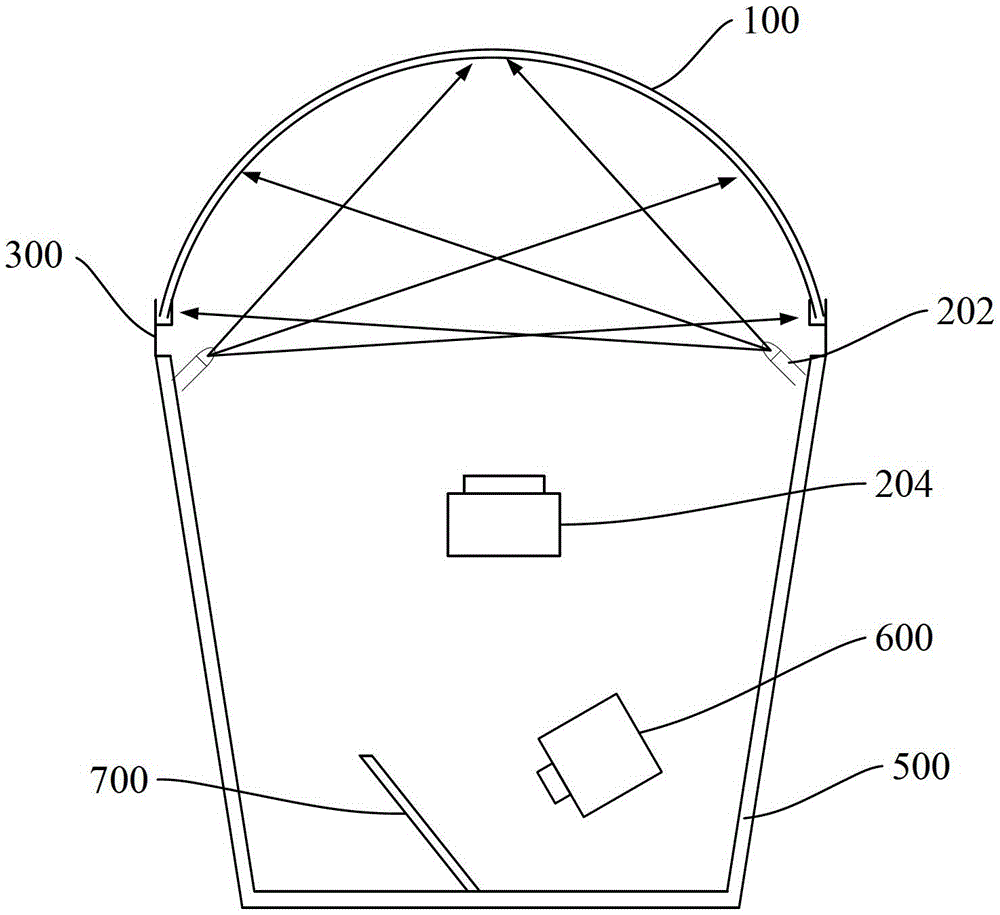

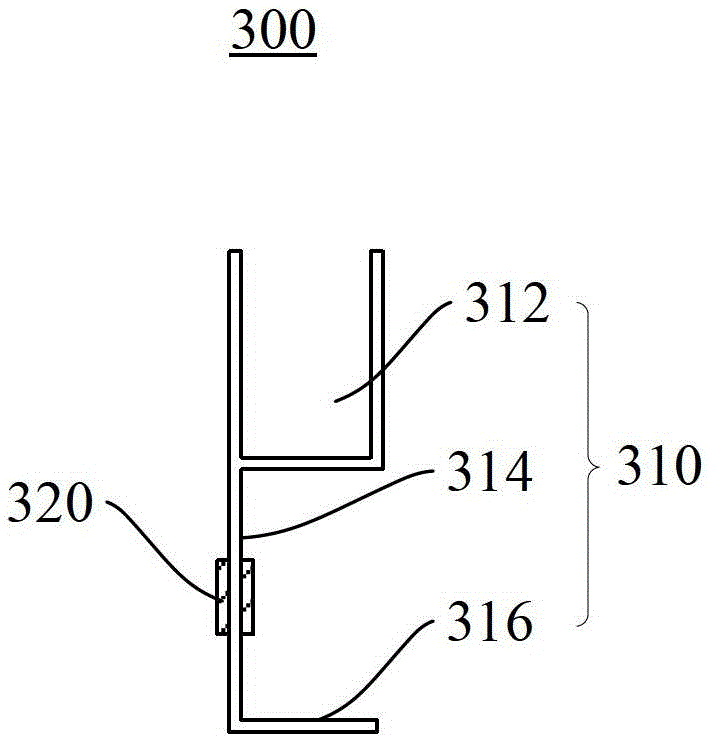

Touch control device and touch control detection method based on curved face display

ActiveCN103019478AEnsure full implementationAvoid misuseInput/output processes for data processingProjection screenStress induction

The invention discloses a touch control device based on curved face display. The touch control device based on the curved face display comprises a curved face type projection screen, a touch spot detection component, stress induction components and a main control module, wherein the curved face type projection screen is provided with an outward bulgy touch control face and a projection face opposite to the touch control face; the touch spot detection component is located on one side of the projection face and detects touch spot position data by emitting infrared light to the curved face type projection screen and further receiving the infrared light reflected by a touch object on one side of the touch control face; each stress induction component is used for generating stress data by the time the curved face type projection screen is touched; and the main control module obtains the touch spot position data and the stress data and judges whether the touch control occurs or not. The invention also discloses a touch control detection method applied to the device. With the adoption of the device and the method, the execution of a touch control instruction in the actual occurrence of touch control is guaranteed, so that a contactless type misoperation is prevented.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

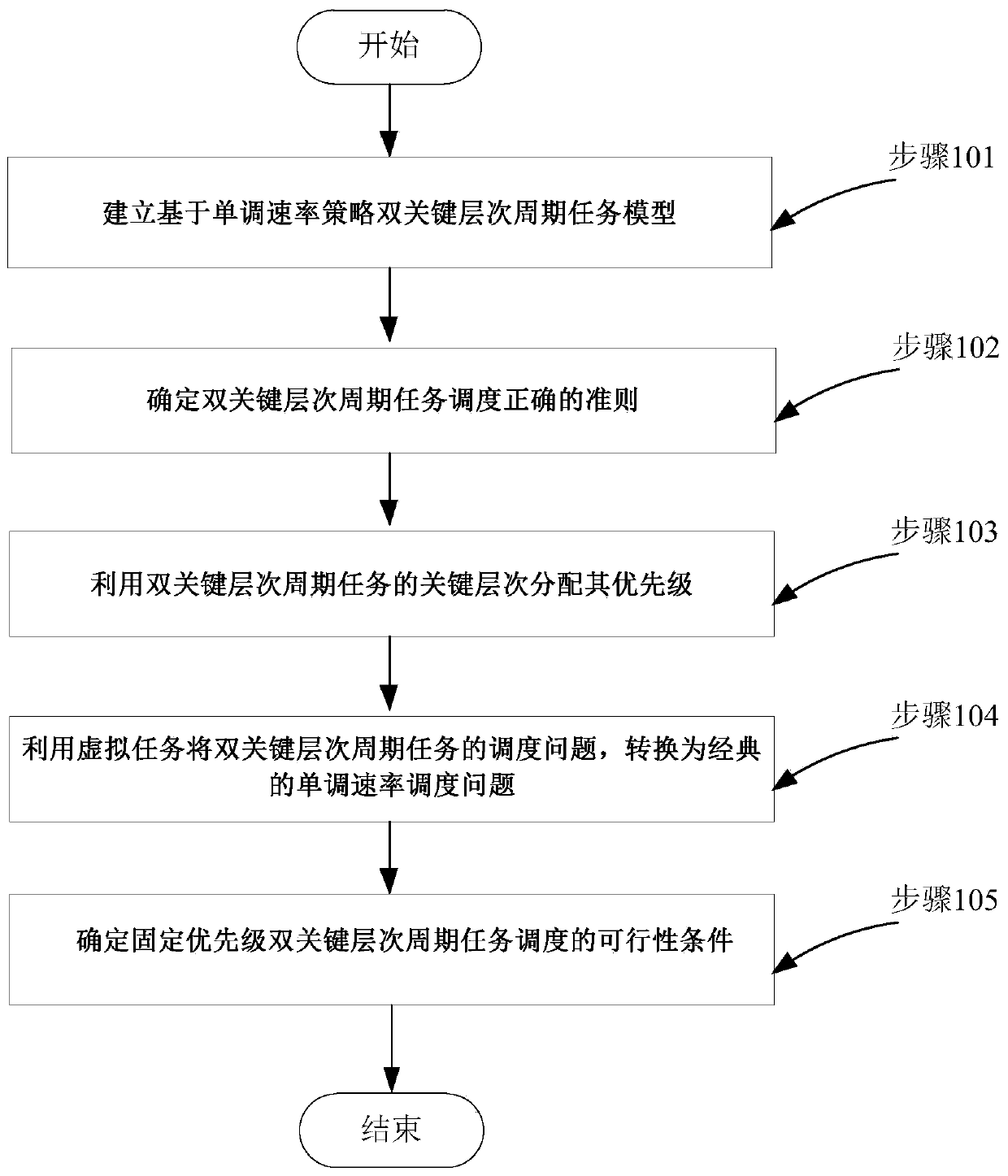

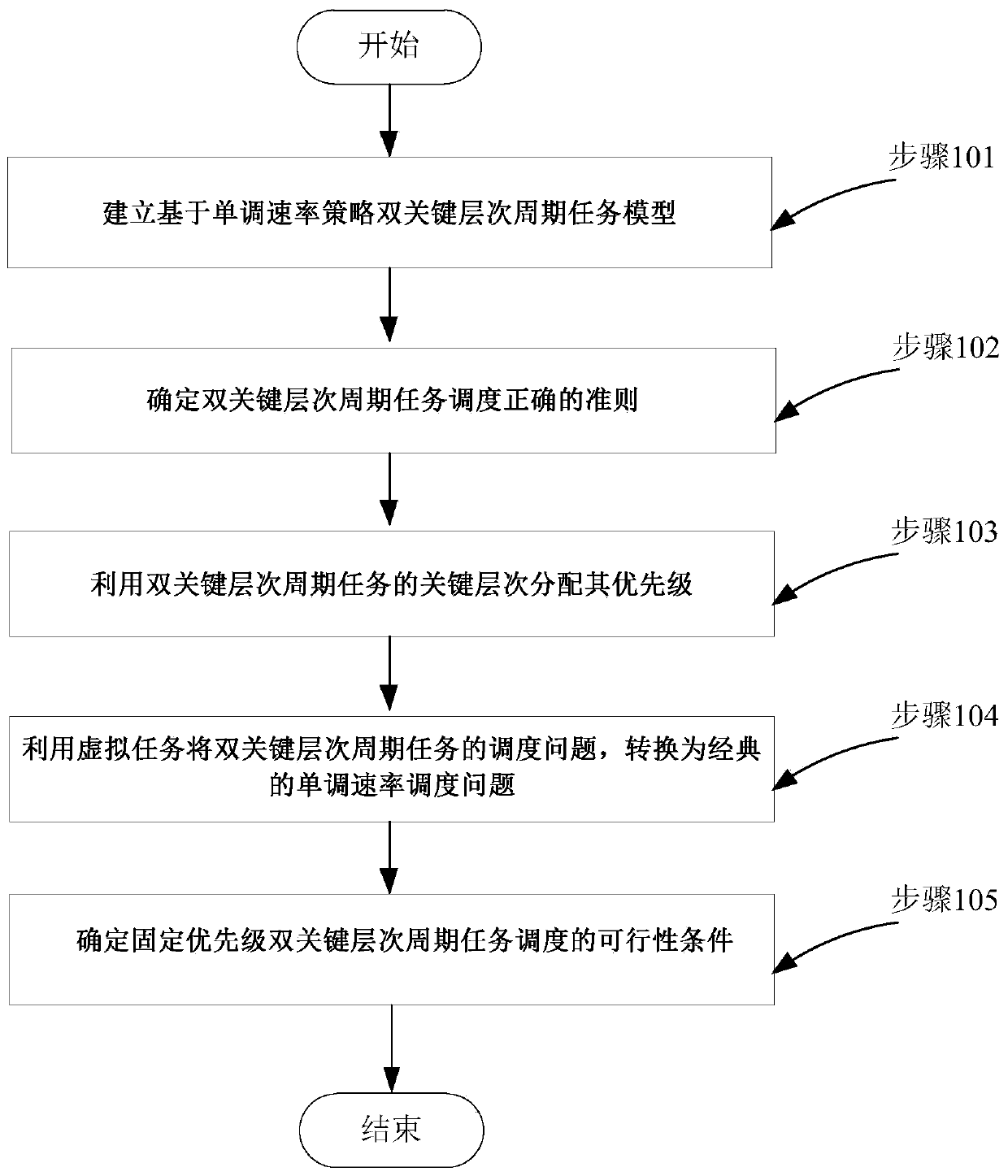

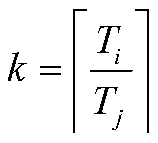

Fixed priority hybrid key system scheduling method based on virtual tasks

ActiveCN109918185AReduce operating overheadReduce time complexityProgram initiation/switchingTime complexityDistributed computing

The invention discloses a fixed priority hybrid key system scheduling method based on virtual tasks. The method comprises the following steps: establishing a double-key-level periodic task model basedon a monotonous rate strategy; determining a criterion that the dual-key hierarchical periodic task scheduling is correct; distributing the priority of the dual-key-level periodic task by utilizing the key levels of the dual-key-level periodic task; converting the scheduling problem of the double-key-level periodic task into a classical monotonous rate scheduling problem by using the virtual task; and determining feasibility conditions of the fixed-priority double-key-level periodic task scheduling. According to the method, the scheduling problem of the fixed-priority double-key-level periodic task is converted into the classical monotonous rate scheduling problem through the method for constructing the virtual task, the time complexity of double-key-level periodic task scheduling is effectively reduced, and a simple and efficient solution is provided.

Owner:HUAQIAO UNIVERSITY

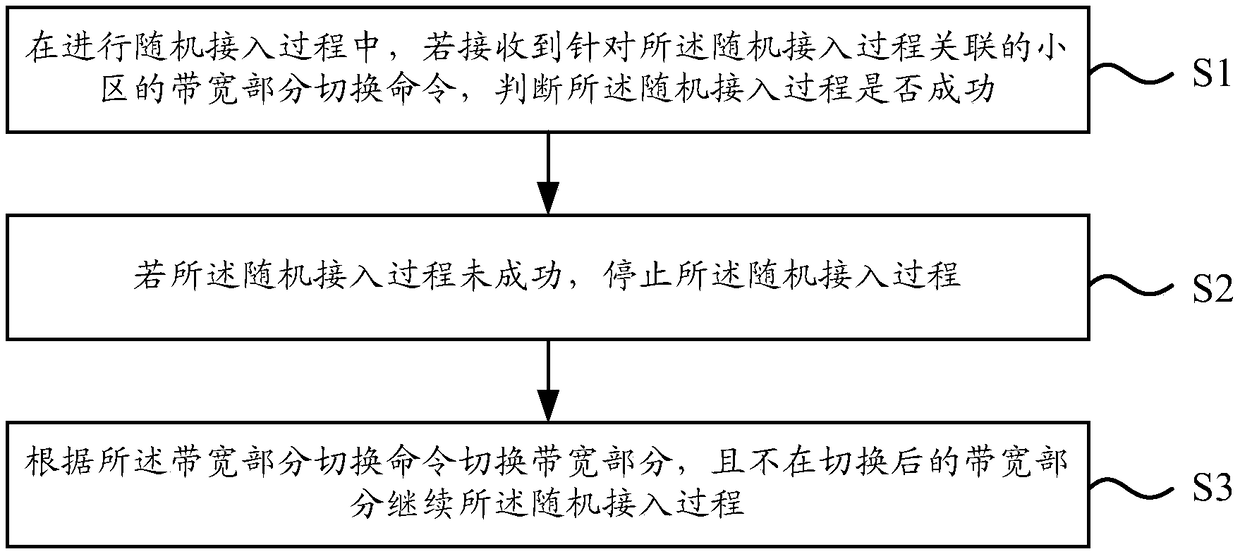

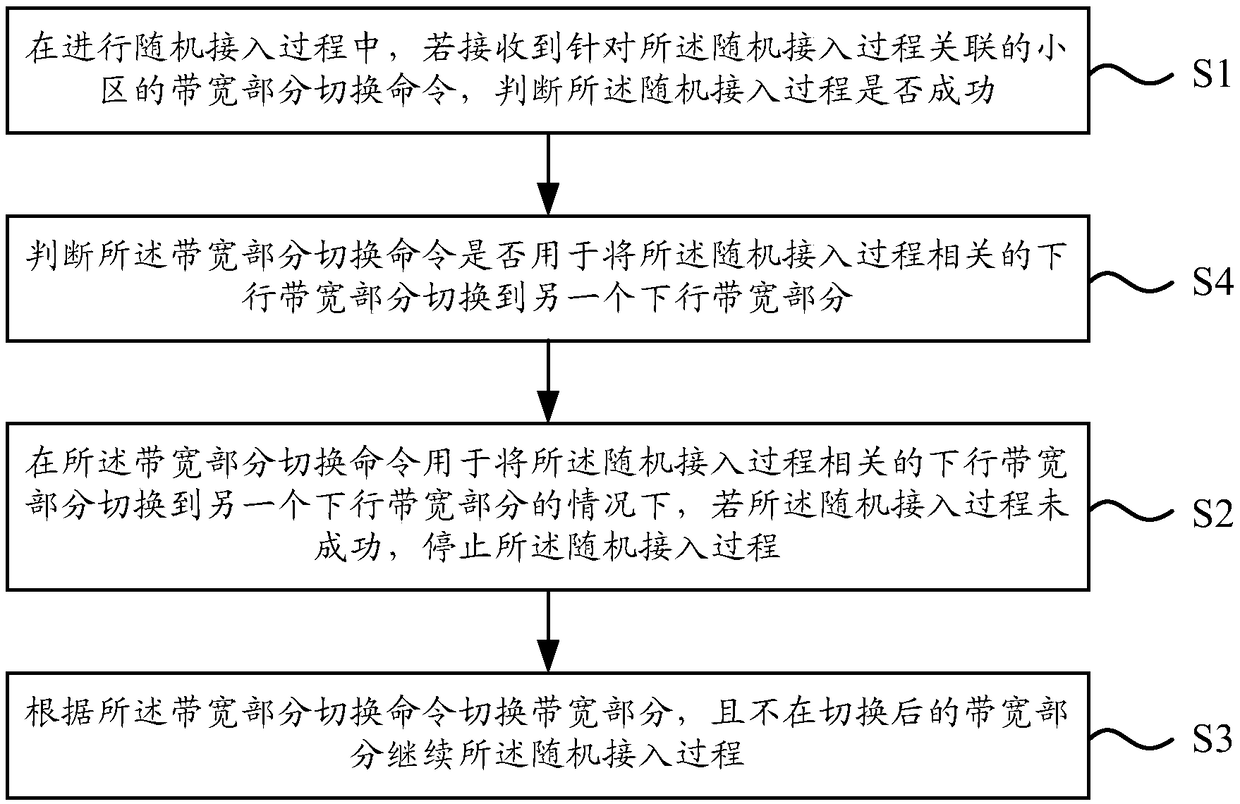

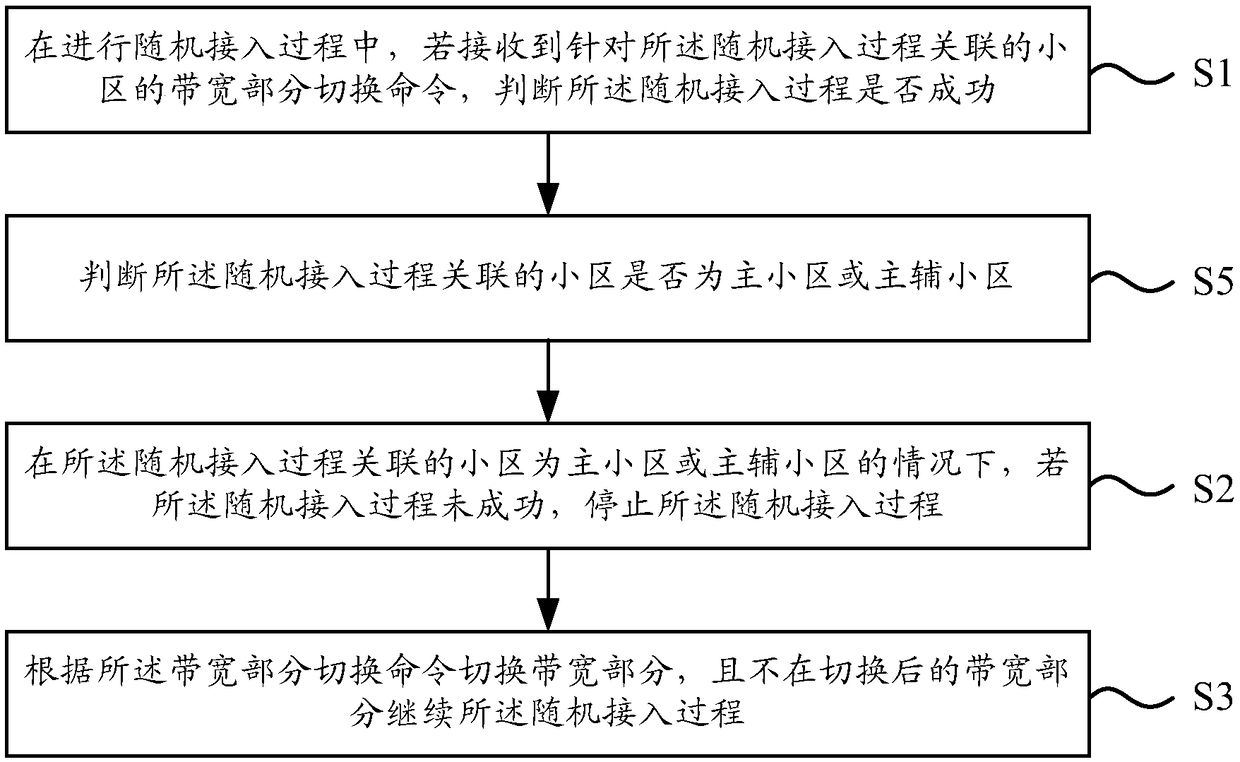

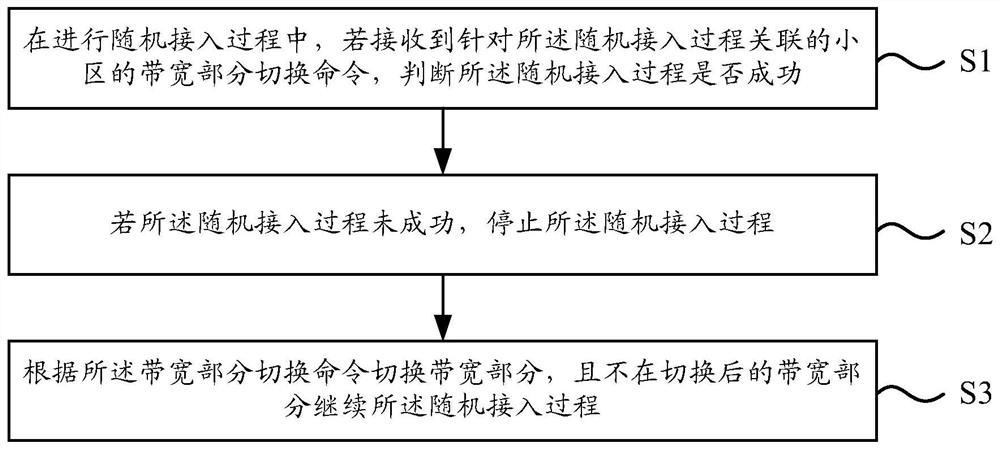

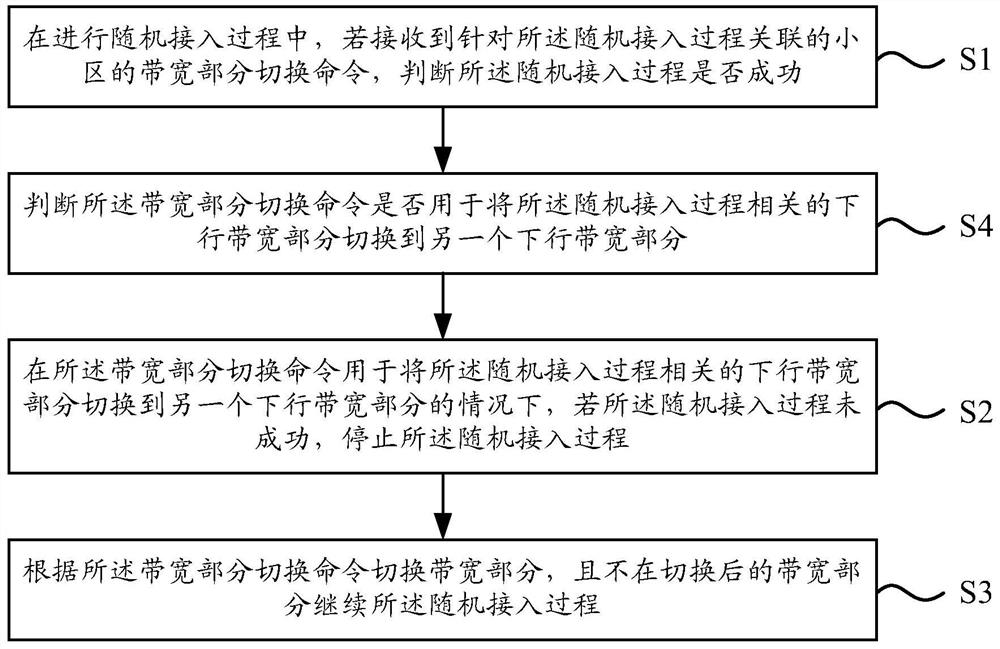

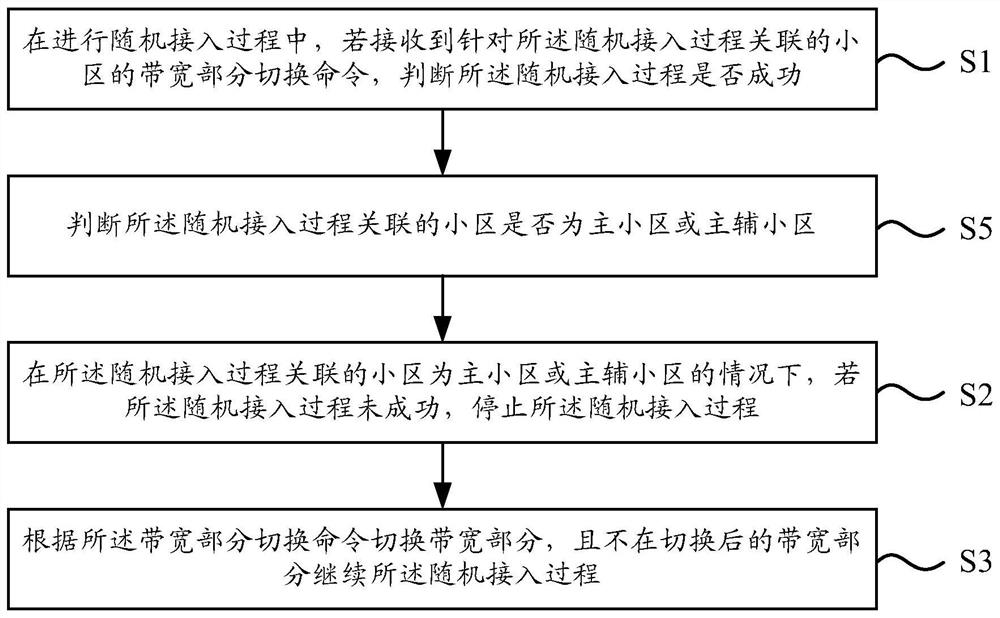

Random access control method and random access control device

ActiveCN109076620AAvoid wastingEnsure full implementationWireless communicationUser equipmentEmbedded system

The embodiment of the present invention relates to a random access control method. The random access control method includes the steps: during a process of performing random access, if receiving a bandwidth partial switchover command for a cell associated with the random access process, determining whether the random access process is successful; if the random access process is unsuccessful, stopping the random access process; and according to the bandwidth partial switchover command,switching the bandwidth portion without continuing the random access process for the switched bandwidth portion. The random access control method can avoid the situation in the related art, for continuing the previously stopped random access process, the switching operation according to the bandwidth switchingcommand is equivalent to not being executed, thus wasting resources of user equipment, so as to guarantee that the bandwidth switching command is actually executed, and the user equipment can continue communication through the switched bandwidth portion.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

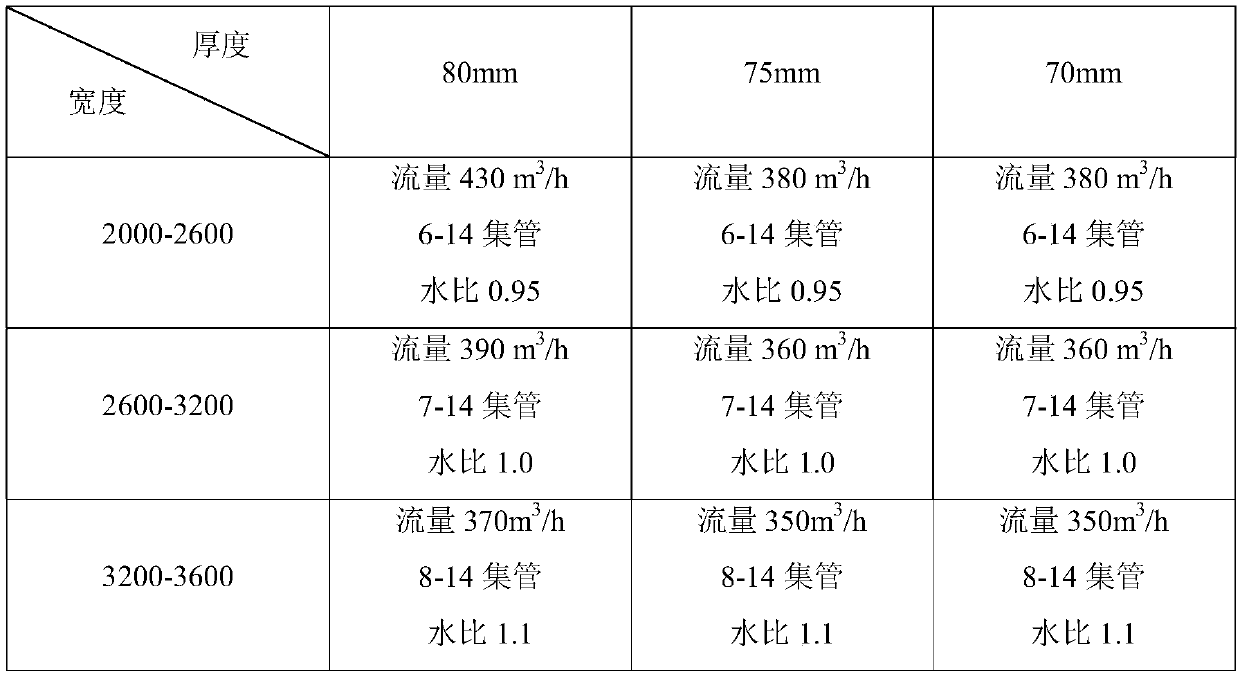

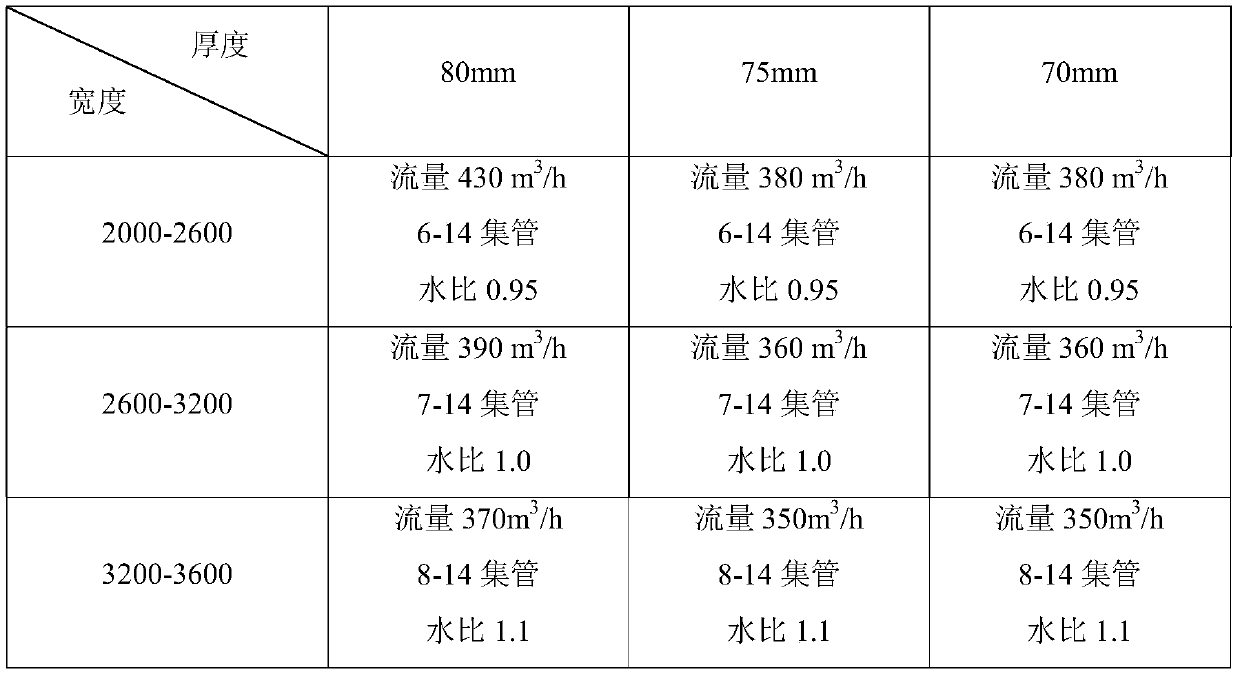

Production method of crack arresting steel for container ship

ActiveCN110076196ALarge amount of depressionAccurate and effective production processTemperature control deviceWork cooling devicesSheet steelUltra fast

The invention discloses a production method of crack arresting steel for a container ship. Billets having different cross sections are selected for rolling according to different finished product widths, the rolling pass is reduced, and the reduction in pass is increased; as for planning arrangement, according to the characteristics that the rolling mode is special and the rolling frequency is slow, the time in a furnace is shortened through blank positions in a heating furnace, execution of a heating technology is ensured, and the surface quality is ensured; the heating process ensures the uniformity of a plate slab in the thickness direction; a rolling technology uses a full longitudinal rolling or full horizontal rolling manner as many as possible, and the effective compression ratio isincreased; and in order to refine grains, the intermediate billet is subjected to ultra-fast cooling, different cooling technologies are set according to specifications, and a finished steel sheet cooling technology is determined. A stable production technology for accurately and effectively producing the crack arresting steel can be realized, the stability of the production technology of the crack arresting steel meets the batch industrial production, the mechanical properties, the product quality stability and various indexes meet the standard requirement, and the production process is easyto control.

Owner:NANJING IRON & STEEL CO LTD

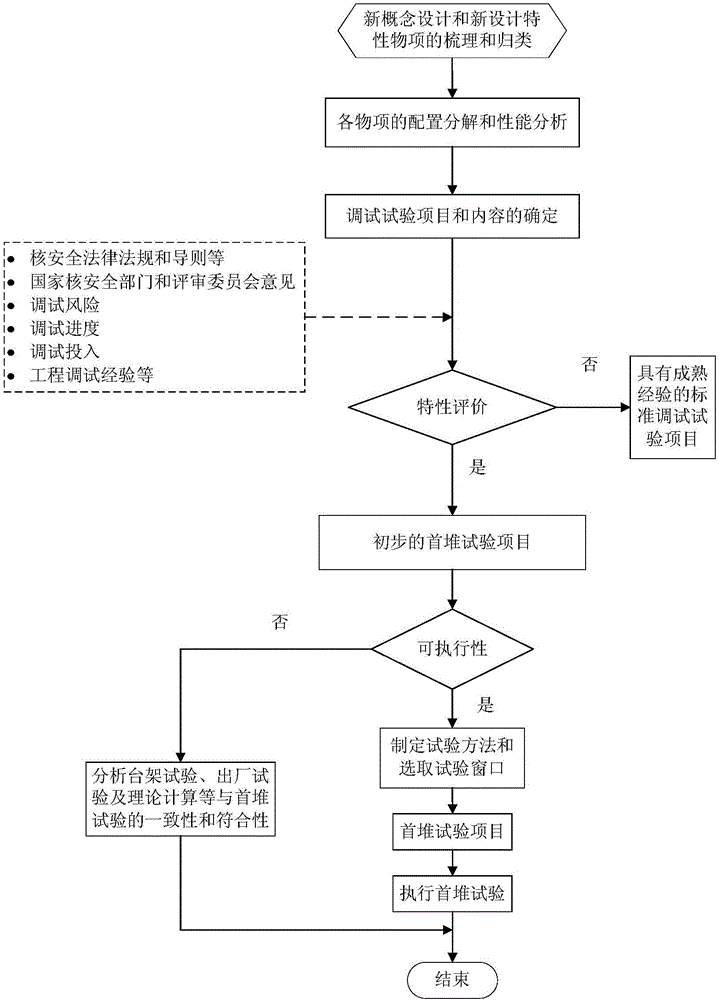

Method for establishing initial reactor test items of advanced pressurized water reactor nuclear power station debugging stage

PendingCN106093616AEnsure safetyIntegrity guaranteedPower supply testingDecompositionPressurized water reactor

The invention belongs to the technology of nuclear power station design and specifically relates to a method for establishing initial reactor test items of an advanced pressurized water reactor nuclear power station debugging stage. The method comprises steps of arrangement and classification of items using new concept design and having new designed characteristics; item configuration decomposition and performance analysis; determination of debugging testing items and content; characteristic evaluation of debugging testing items and content, enforceability prediction and alternative solution analysis, and test method establishment and test window selection. The method may guarantee accurate establishment of a series nuclear power reactor type initial set debugging plan and smooth and effective development of debugging operation, fully and completely verifies the items using new concept design and having new designed characteristics so as to guarantee later safe and stable operation of the reactor type nuclear power station.

Owner:CHINA NUCLEAR POWER ENG CO LTD

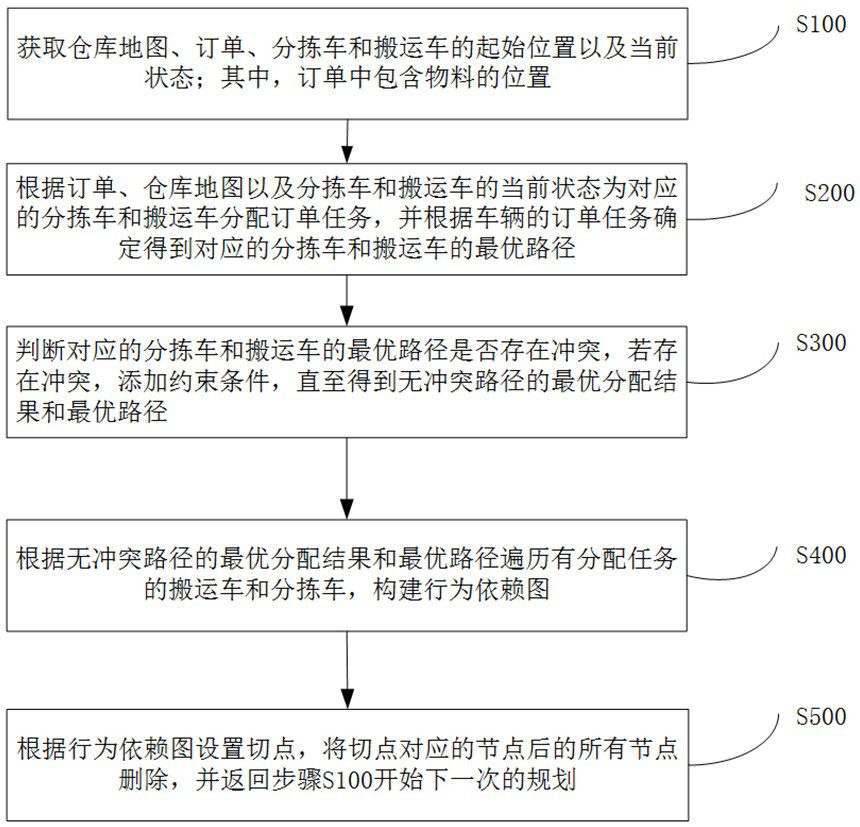

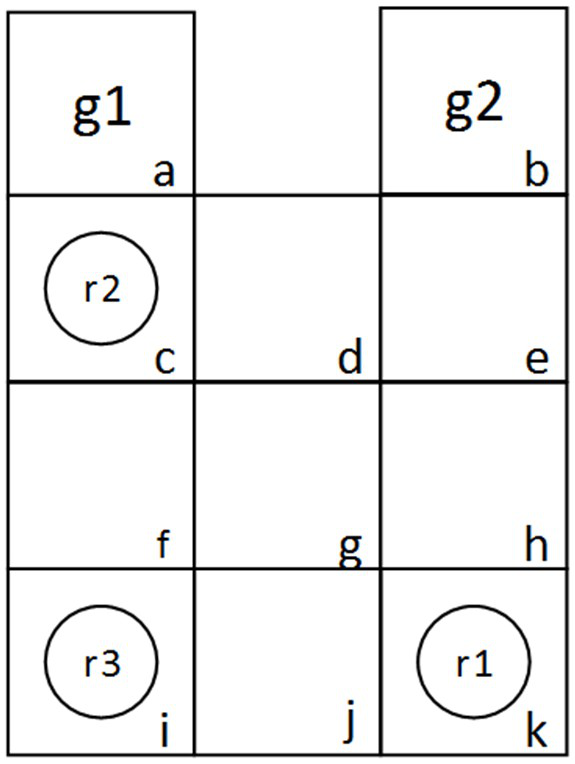

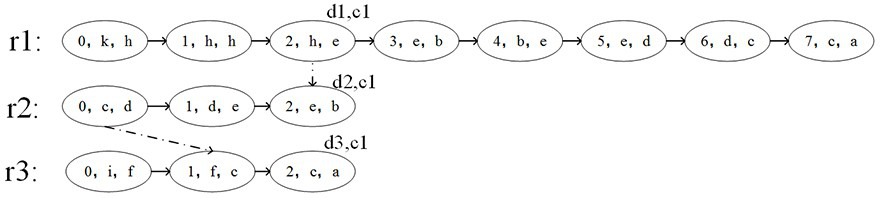

Multi-vehicle-type collaborative sorting and scheduling method based on behavior dependency graph

ActiveCN114757591AEnsure full implementationGuaranteed continuous executionResourcesLogisticsSimulationOperations research

The invention discloses a multi-vehicle-type collaborative sorting and scheduling method based on a behavior dependency graph. The method comprises the following steps: acquiring a warehouse map, orders, starting positions and current states of sorting vehicles and carrying vehicles; according to the orders, the warehouse map and the current states of the sorting vehicles and the carrying vehicles, order tasks are allocated for the corresponding sorting vehicles and the carrying vehicles, and according to the order tasks of the vehicles, the optimal paths of the corresponding sorting vehicles and the carrying vehicles are determined and obtained; judging whether the optimal paths of the corresponding sorting vehicles and carrying vehicles have conflicts or not, and if yes, adding constraint conditions until an optimal allocation result and an optimal path of a conflict-free path are obtained; according to the optimal allocation result of the conflict-free path and the optimal path, carrying vehicles and sorting vehicles with allocation tasks are traversed, and a behavior dependence graph is constructed; and setting tangency points according to the behavior dependency graph, deleting all nodes behind the nodes corresponding to the tangency points, and starting next planning. And the sorting scheduling efficiency is effectively improved.

Owner:HUNAN UNIV

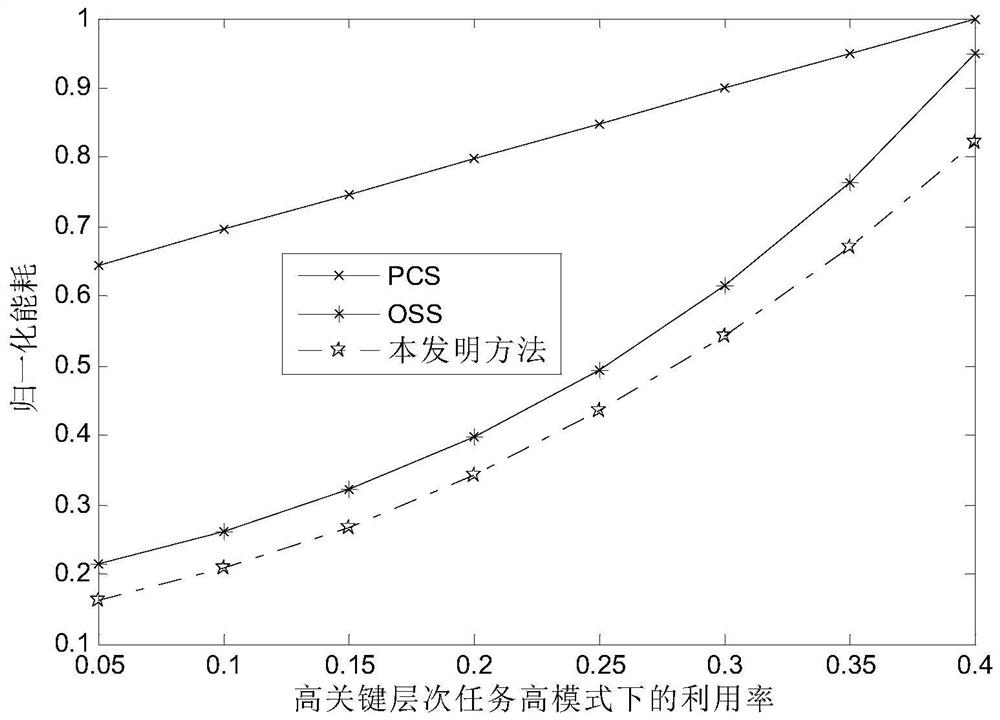

Energy consumption optimization method based on dynamic idle time mixed key periodic tasks

ActiveCN110806795AAvoid wastingExtended service lifeProgram initiation/switchingResource allocationReal-time computingDistributed computing

The invention discloses an energy consumption optimization method based on a dynamic idle time mixed key period task, which comprises the following steps of: A, scheduling a mixed key period task setby using a dynamic priority strategy; b, calculating a unified static speed SU of the periodic task; c, recycling idle time IHI generated by the executed high-key-level periodic tasks and dynamic idletime IC generated when all the periodic tasks are completed in advance in the low mode; d, calculating the speed SL of the periodic task in the low mode according to the available idle time I = IHI +IC of the system, and when the execution time of the high-key-level periodic tasks in the low mode exceeds the worst execution time of the periodic tasks in the low mode, entering the high mode, executing the high-key-level periodic tasks in the high mode at the fastest processor speed all the time, and discarding all the low-key-level periodic tasks. The method has the advantages of reducing energy consumption and the like.

Owner:HUAQIAO UNIVERSITY

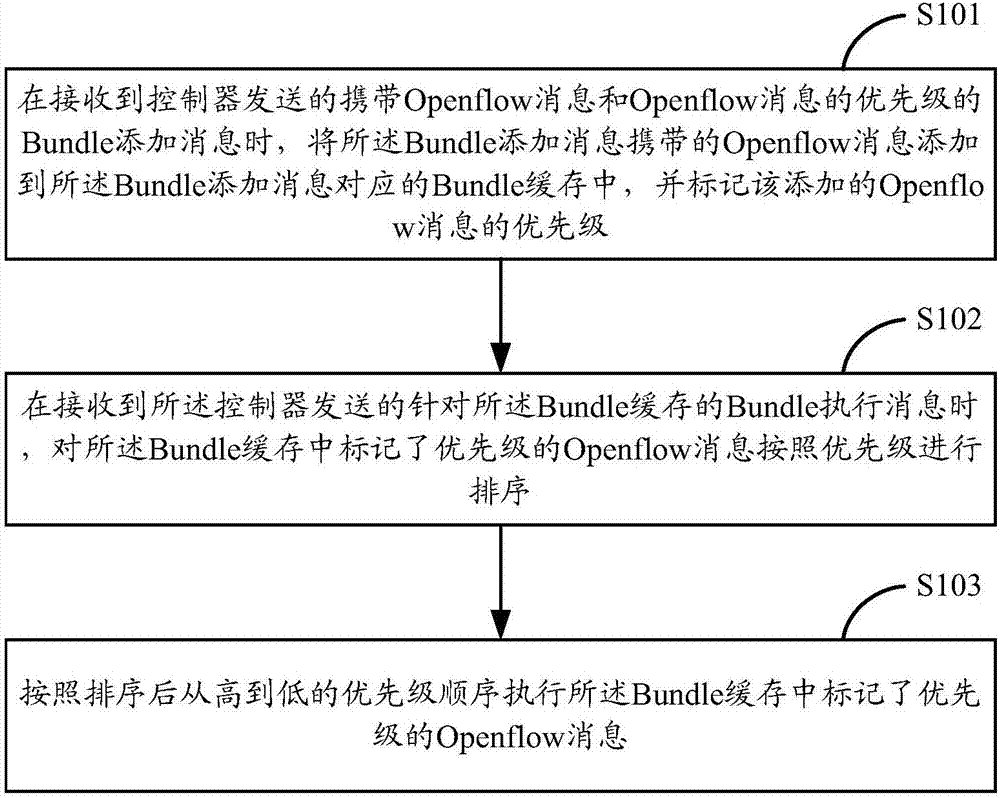

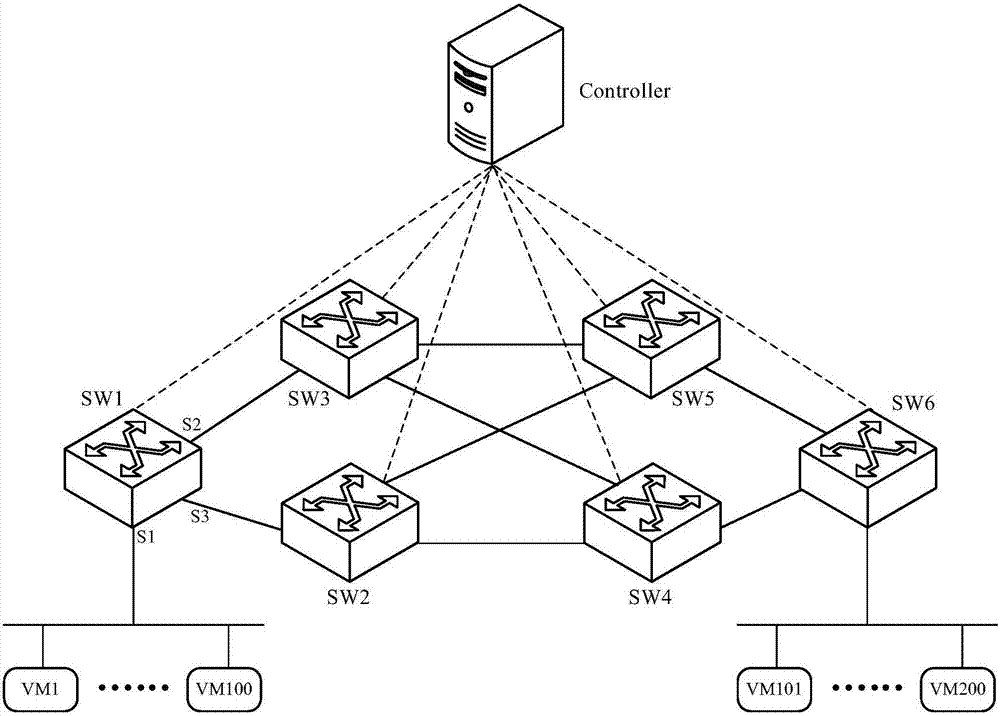

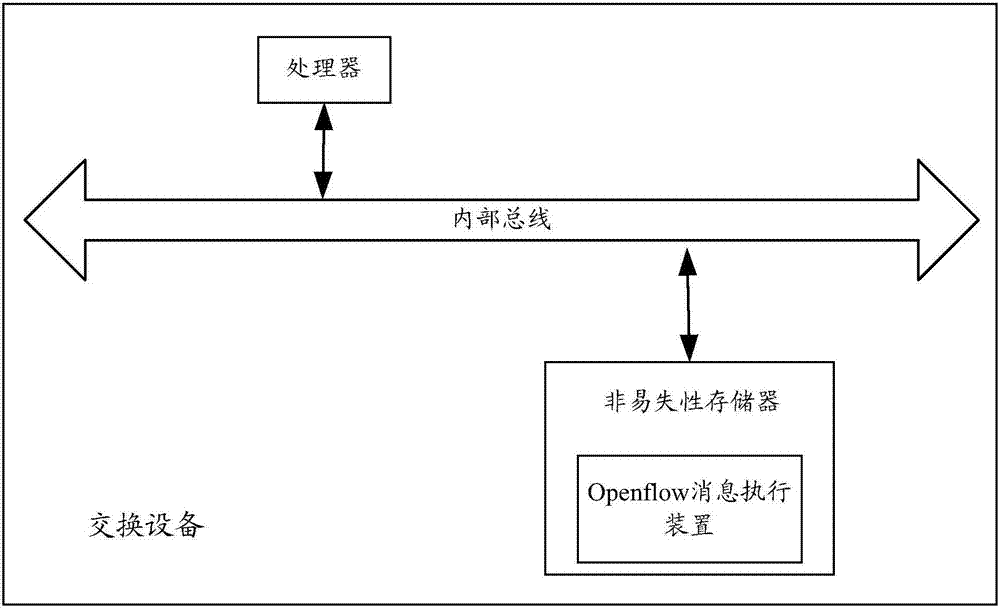

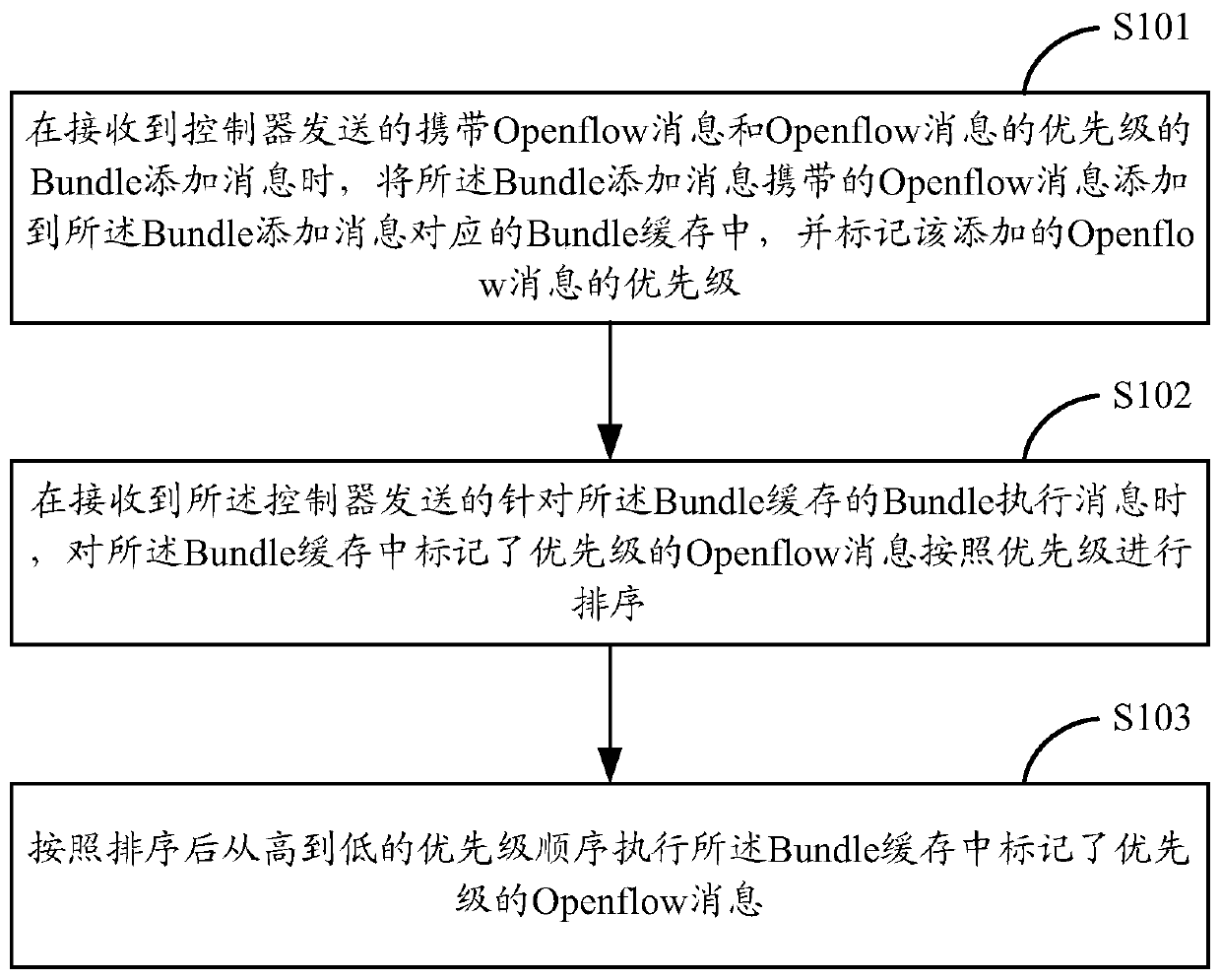

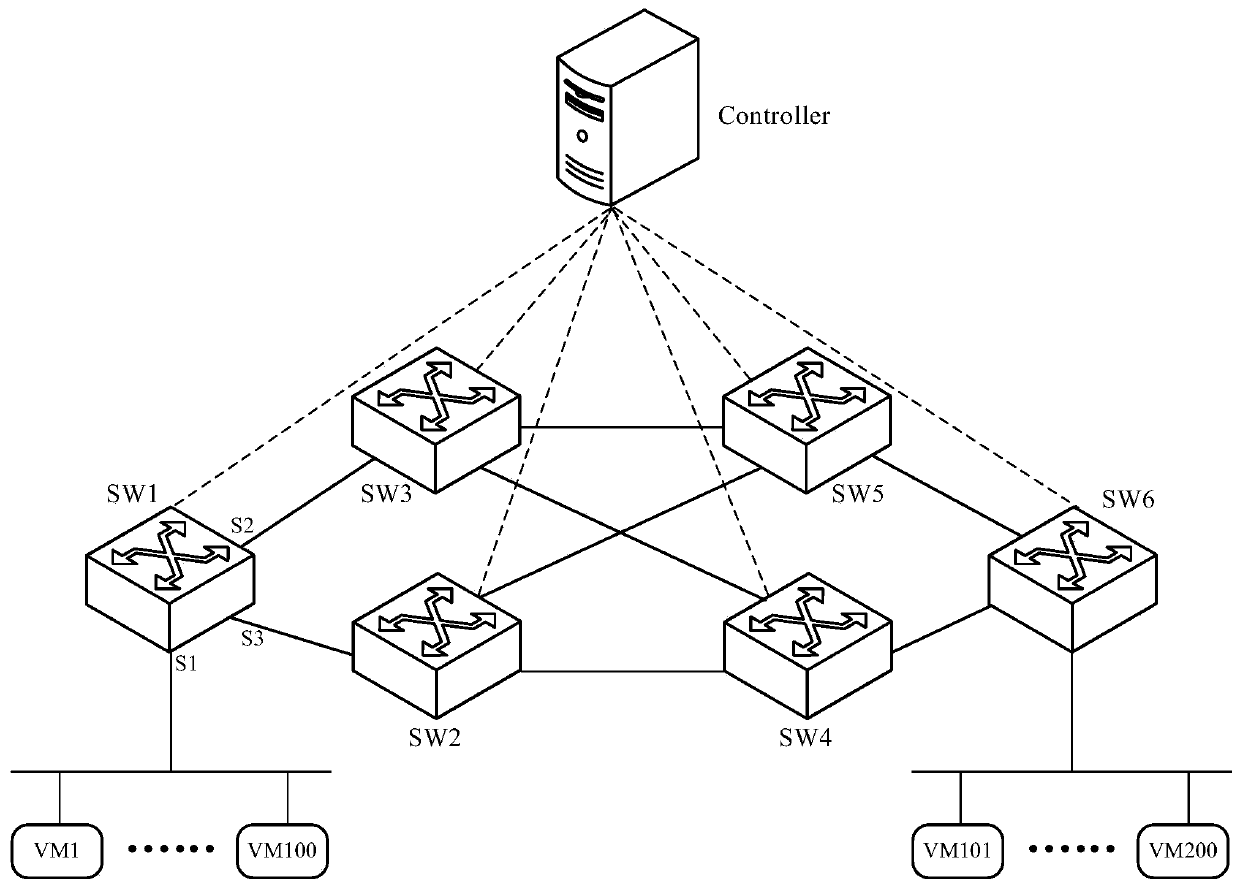

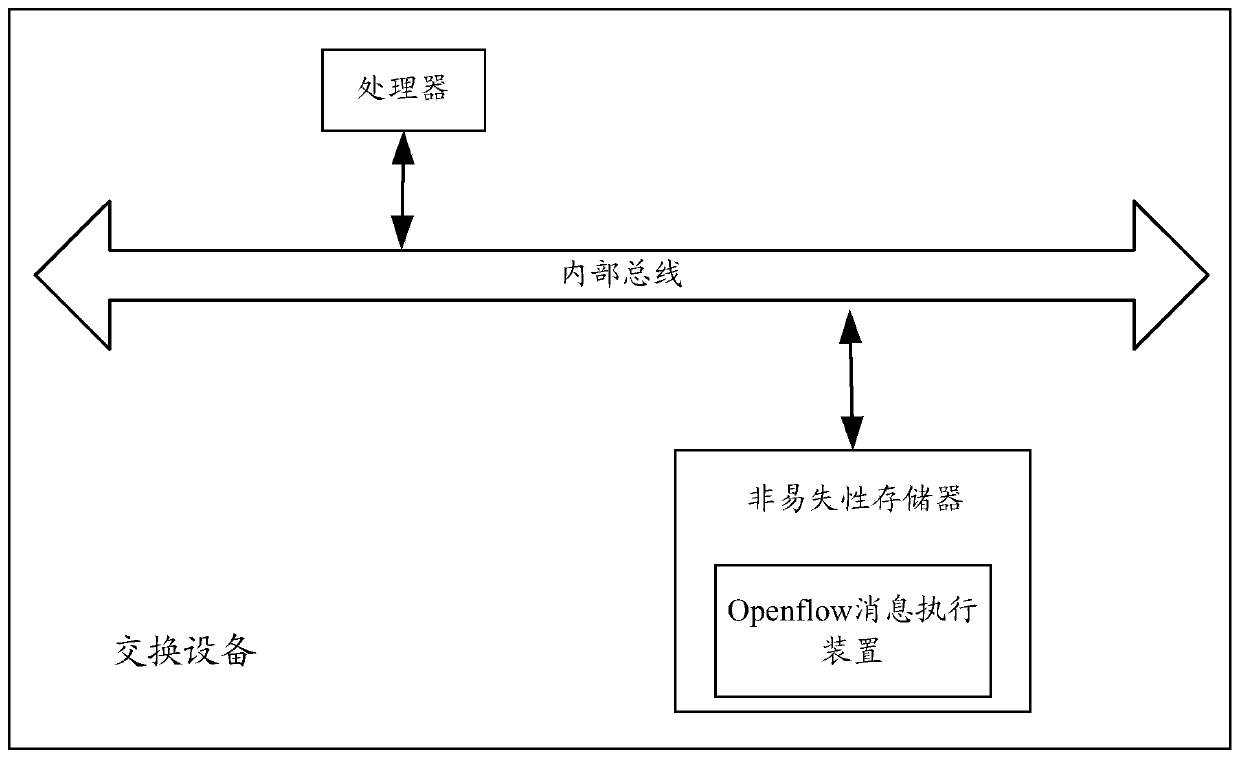

Openflow message execution method and device

ActiveCN106911595AEnsure full implementationAchieve optimizationData switching networksOpenFlowOperating system

The invention provides an Openflow message execution method which is applied to a switching device. The method comprises the steps that when a Bundle add message which is sent by a controller and carries Openflow messages and the priority of the Openflow messages is received, the Openflow messages carried by the Bundle add message are added to Bundle cache corresponding to the Bundle add message, and the priority of the added Openflow messages is marked; when a Bundle execution message sent by the controller for the Bundle cache is received, the Openflow messages with marked priority in the Bundle cache are sorted by priority; and the Openflow messages with marked priority in the Bundle cache are executed in sorted descending priority order.

Owner:NEW H3C TECH CO LTD

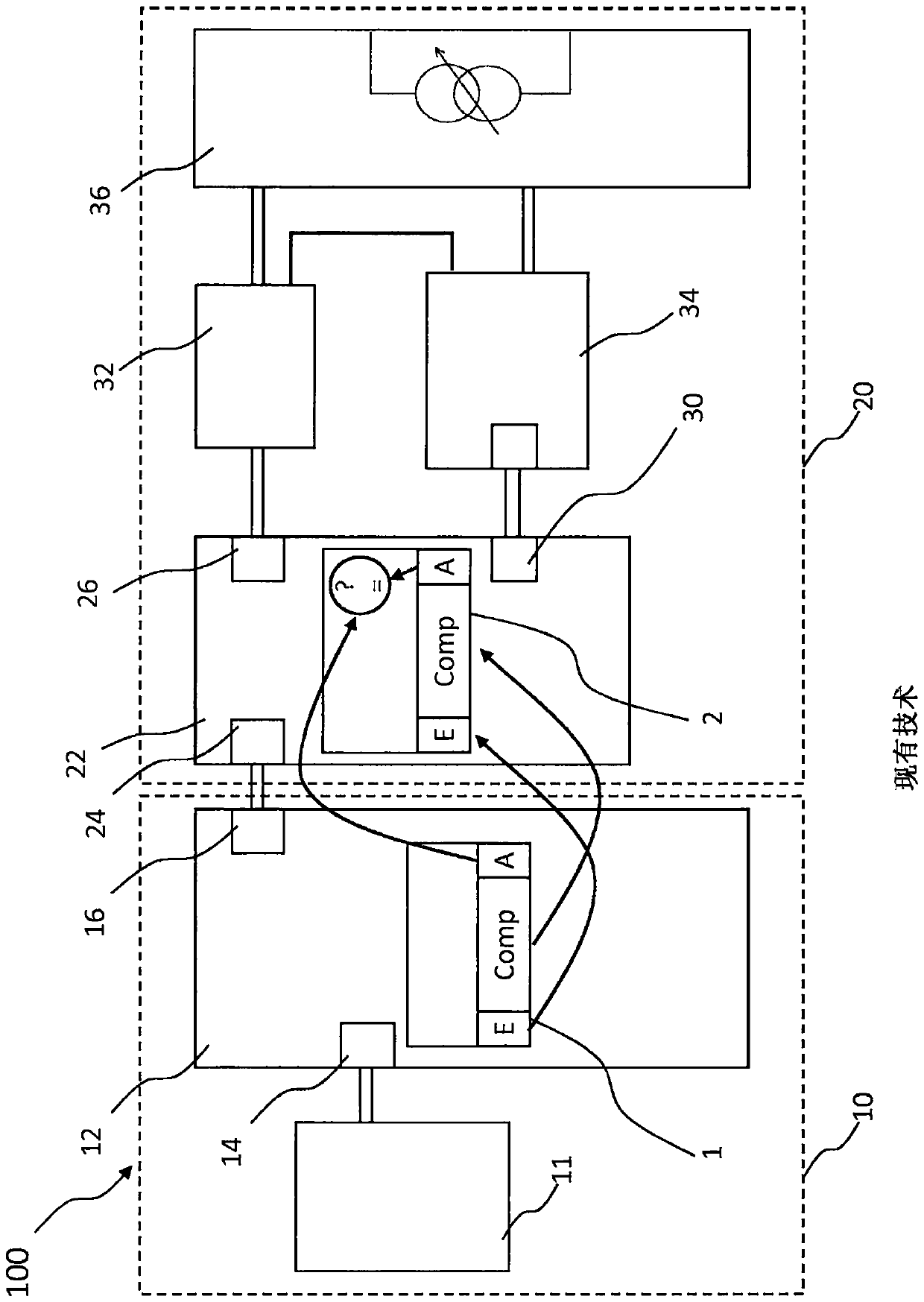

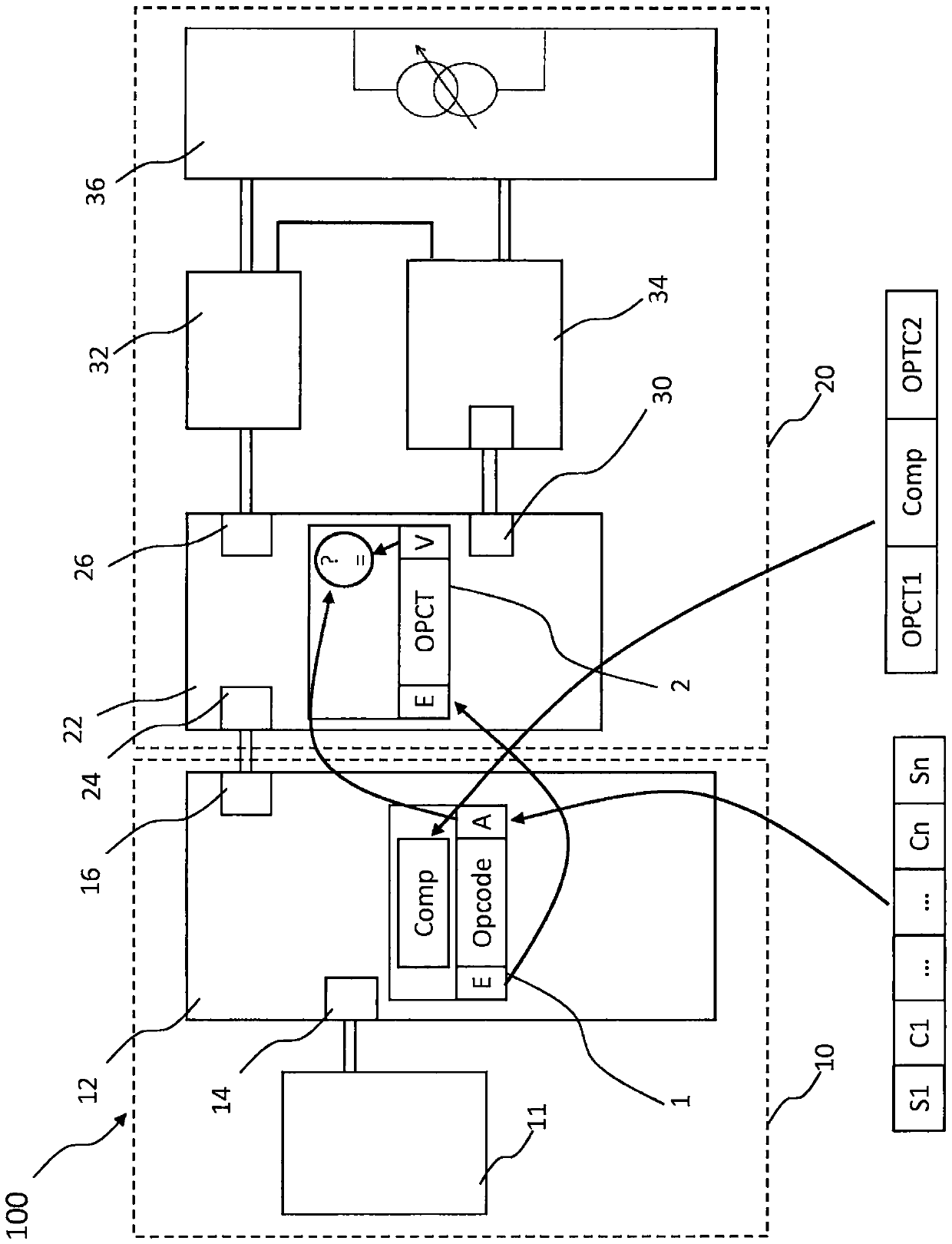

Electronic circuit for a field device used in automation technology

InactiveCN110268342AEnsure full implementationReduced execution stepsProgramme controlComputer controlParallel computingTest algorithm

Electronic circuit for a field device used in automation technology, having: - a first digital processor (1) with a first set of machine instructions for executing an algorithm (Comp) running on the processor (1), wherein the first processor (1) is set up to execute a test algorithm (Opcode) in order to calculate output data (A), wherein the test algorithm (Opcode) uses at least some, preferably all, machine instructions of the part of the first set of machine instructions used to execute the algorithm (Comp) to calculate the output data (A), - a second digital processor (2) with a second set of machine instructions for executing at least one verification algorithm (OPCT), wherein the second processor (2) is set up to execute the verification algorithm (OPCT) in order to calculate verification data (V), and wherein the electronic circuit, in particular the second processor (2), is set up to check the first processor (1) on the basis of the output data (A) calculated by the first processor (1) and the verification data (V) calculated by the second processor (2).

Owner:EHNDRESS KHAUZER GMBKH KO KG

Touch device and touch detection method based on curved display

ActiveCN103019478BEnsure full implementationAvoid misuseInput/output processes for data processingSurface displayProjection screen

The invention discloses a touch control device based on curved face display. The touch control device based on the curved face display comprises a curved face type projection screen, a touch spot detection component, stress induction components and a main control module, wherein the curved face type projection screen is provided with an outward bulgy touch control face and a projection face opposite to the touch control face; the touch spot detection component is located on one side of the projection face and detects touch spot position data by emitting infrared light to the curved face type projection screen and further receiving the infrared light reflected by a touch object on one side of the touch control face; each stress induction component is used for generating stress data by the time the curved face type projection screen is touched; and the main control module obtains the touch spot position data and the stress data and judges whether the touch control occurs or not. The invention also discloses a touch control detection method applied to the device. With the adoption of the device and the method, the execution of a touch control instruction in the actual occurrence of touch control is guaranteed, so that a contactless type misoperation is prevented.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

An openflow message execution method and device

ActiveCN106911595BEnsure full implementationAchieve optimizationData switching networksOpenFlowDistributed computing

The present invention provides a method for executing an Openflow message, which is applied to a switching device. The method includes: when receiving a binding Bundle adding message carrying an Openflow message and the priority of the Openflow message sent by a controller, carrying the Bundle adding message The Openflow message is added to the Bundle cache corresponding to the Bundle addition message, and the priority of the added Openflow message is marked; when the Bundle execution message for the Bundle cache sent by the controller is received, the The Openflow messages marked with priority in the Bundle cache are sorted according to the priority; and the Openflow messages marked with priority in the Bundle cache are executed according to the sorted order of priority from high to low.

Owner:NEW H3C TECH CO LTD

Method and apparatus for executing transactions in a blockchain network

ActiveCN109981679BEnsure full implementationUser identity/authority verificationExternal dataData source

Embodiments of the present disclosure relate to methods and apparatus for performing transactions in a blockchain network. The method includes: receiving a transaction request from a client, the transaction request is sent to multiple endorsement nodes, is associated with an application smart contract and involves access to an external data source; simulates the execution of the application smart contract; Execute the system smart contract in the process to generate the first simulation execution result of the transaction, which includes: sending an access request to the proxy node outside the blockchain network, receiving the request result from the proxy node and signing the request result, according to the request result and Sign to update the read set of the first simulation execution result; return the first simulation execution result to the client. Embodiments of the present disclosure provide a scheme that supports multiple endorsement nodes to access the same external data source in the blockchain, so that transactions can be ensured through the consistency of read sets related to external data sources generated at multiple endorsement nodes execution.

Owner:SHANGHAI DIANRONG INFORMATION TECH CO LTD

Machine tool

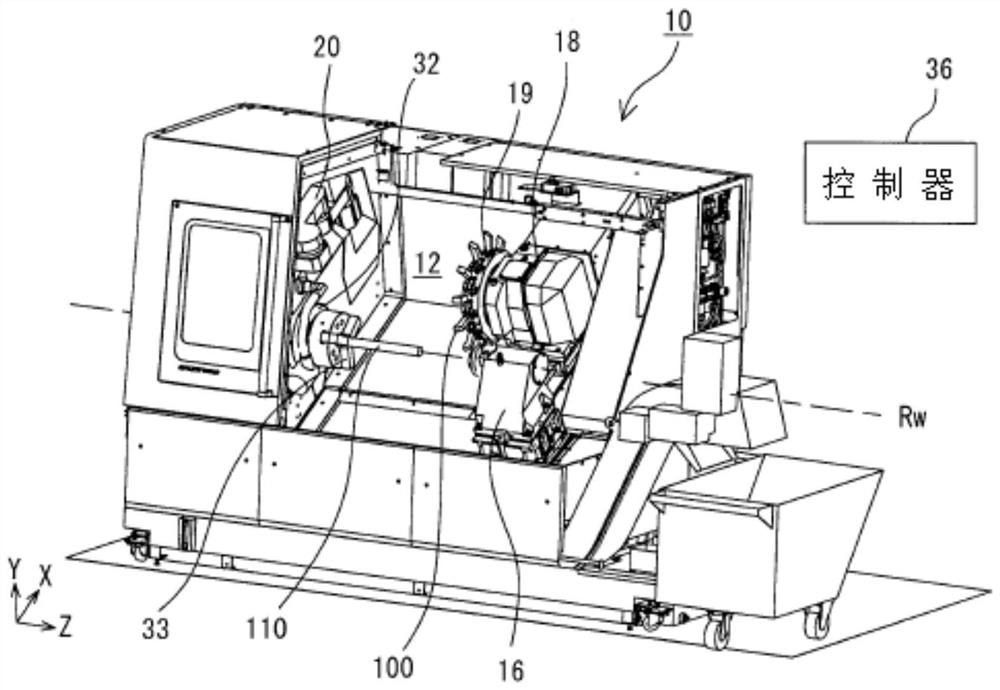

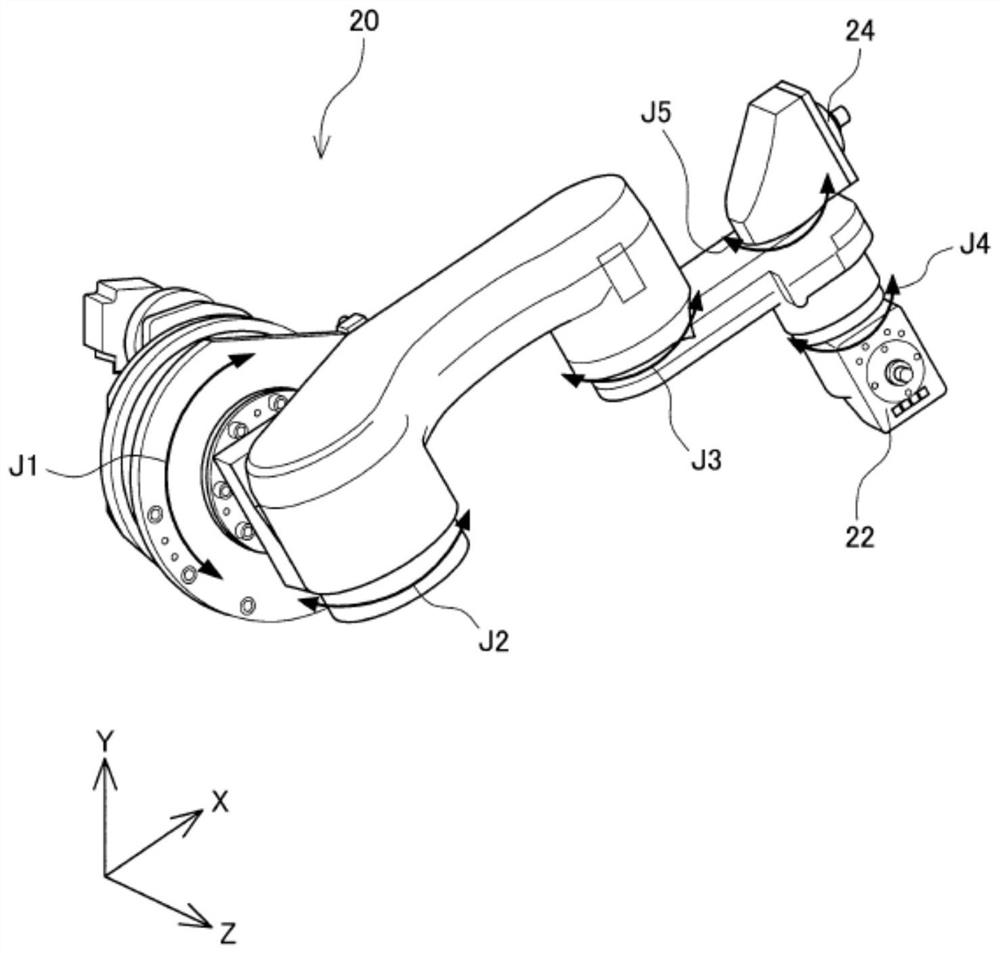

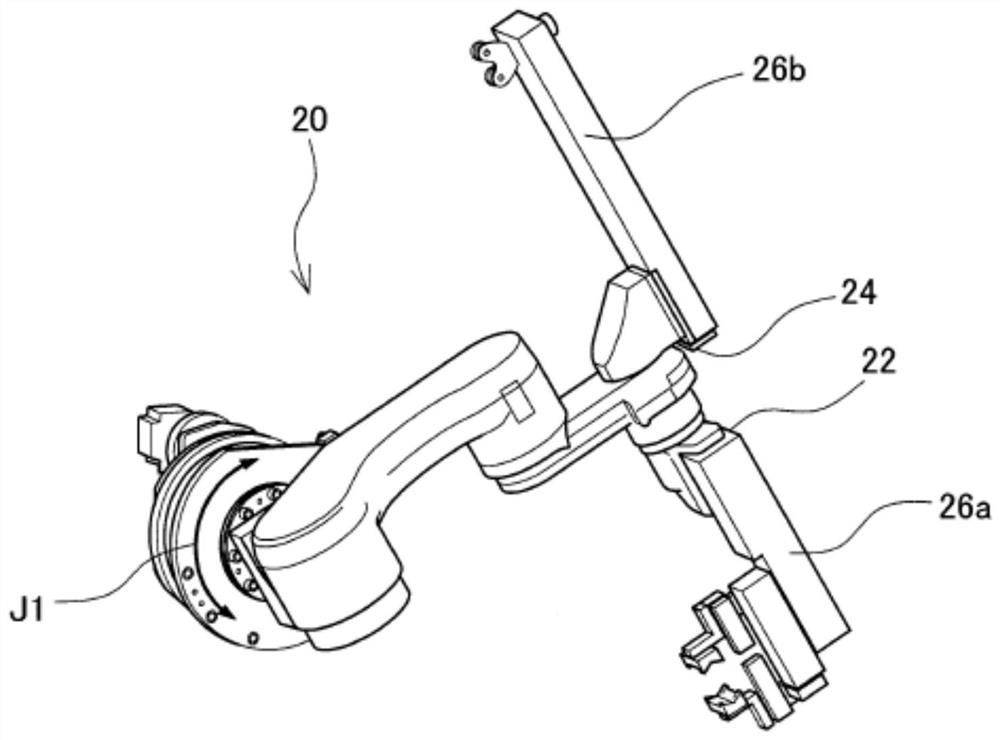

PendingCN112338616AEnsure full implementationReduce replacement frequencyJointsGripping headsControl engineeringComputer science

A machine tool is disclosed. The machine tool includes a robot which is compact and which enables easy use of different end effectors for respective purposes. An internal robot includes a plurality ofjoints that are composed of a base joint and parallel joints, and a plurality of links. The distal end is split into two or more branches, each having a tool changer. An end effector is detachably attachable to each of the tool changers. Rotation of the base joint causes a change between a first tool-following position and a second tool-following position, so that different end effectors are usedfor respective purposes by using an end effector attached to a tool changer in the first tool-following position and using an end effector attached to another tool changer in the second tool-following position.

Owner:OKUMA CORP

Random access control method and random access control device

ActiveCN109076620BAvoid wastingEnsure full implementationWireless communicationEngineeringUser equipment

The embodiments of the present disclosure relate to a random access control method, including: during the random access process, if a bandwidth part switching command for a cell associated with the random access process is received, judging whether the random access process is successful ; If the random access process is unsuccessful, stop the random access process; switch bandwidth parts according to the bandwidth part switching command, and do not continue the random access process in the switched bandwidth part. According to the embodiments of the present disclosure, it is possible to avoid the situation in the related art that in order to continue the previously stopped random access process, the switching operation made according to the bandwidth switching instruction is equivalent to not being executed, which wastes resources of the user equipment, thereby ensuring The bandwidth switching instruction is actually executed, and the user equipment can continue communication through the switched bandwidth part.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

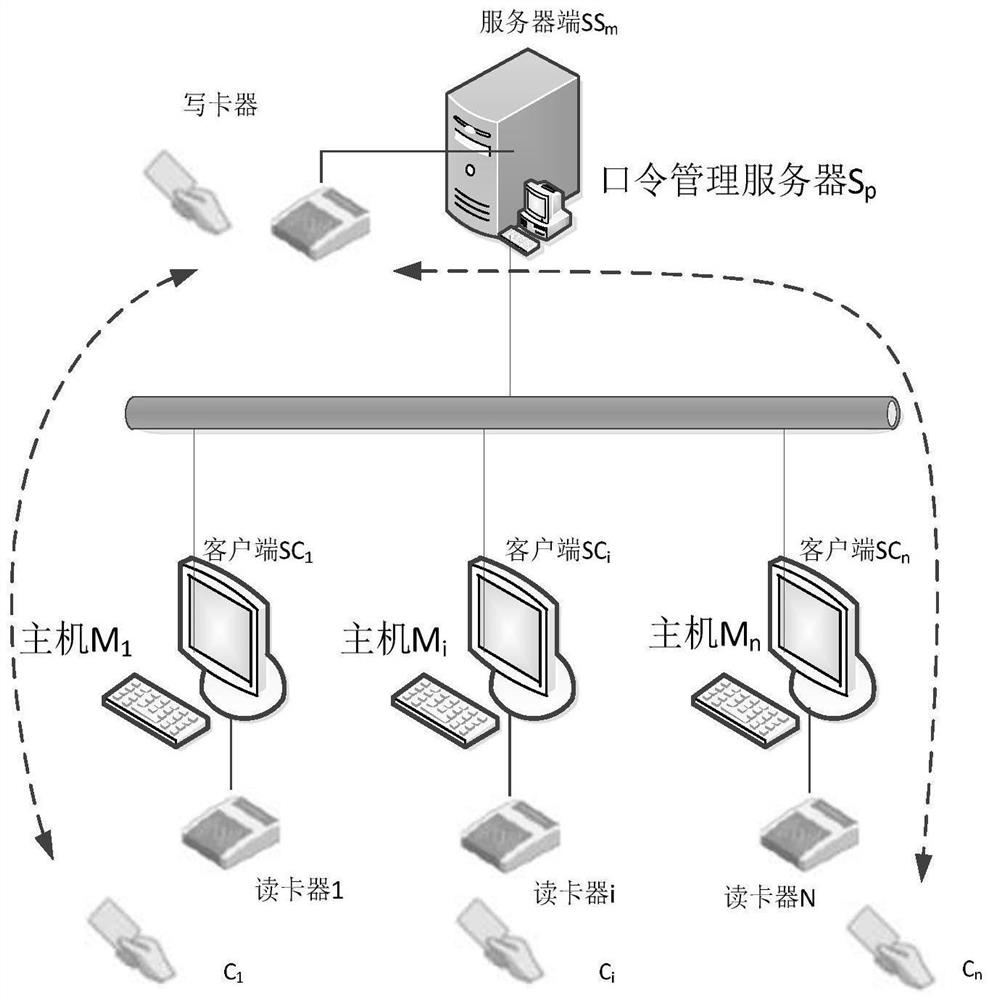

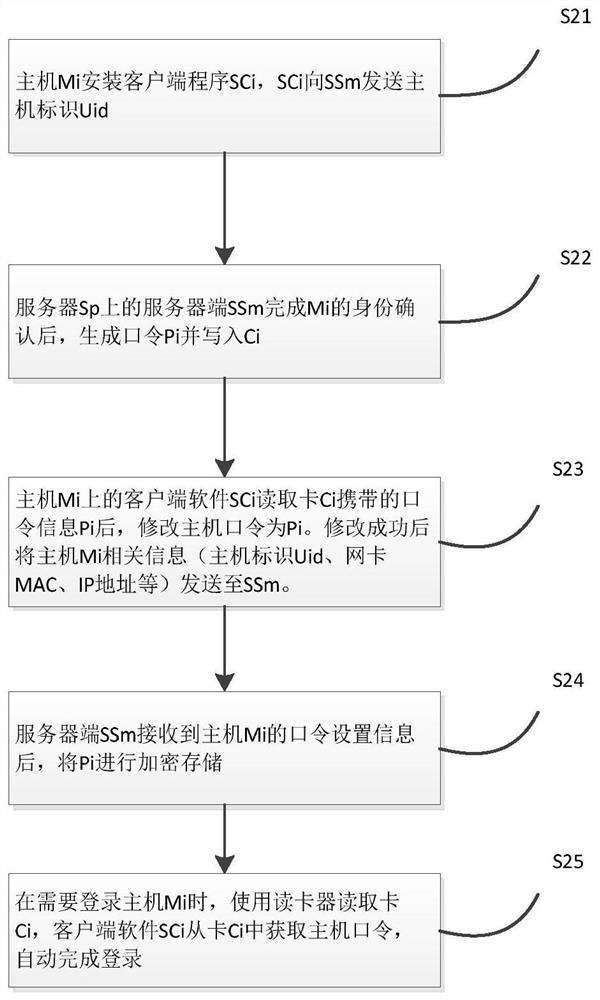

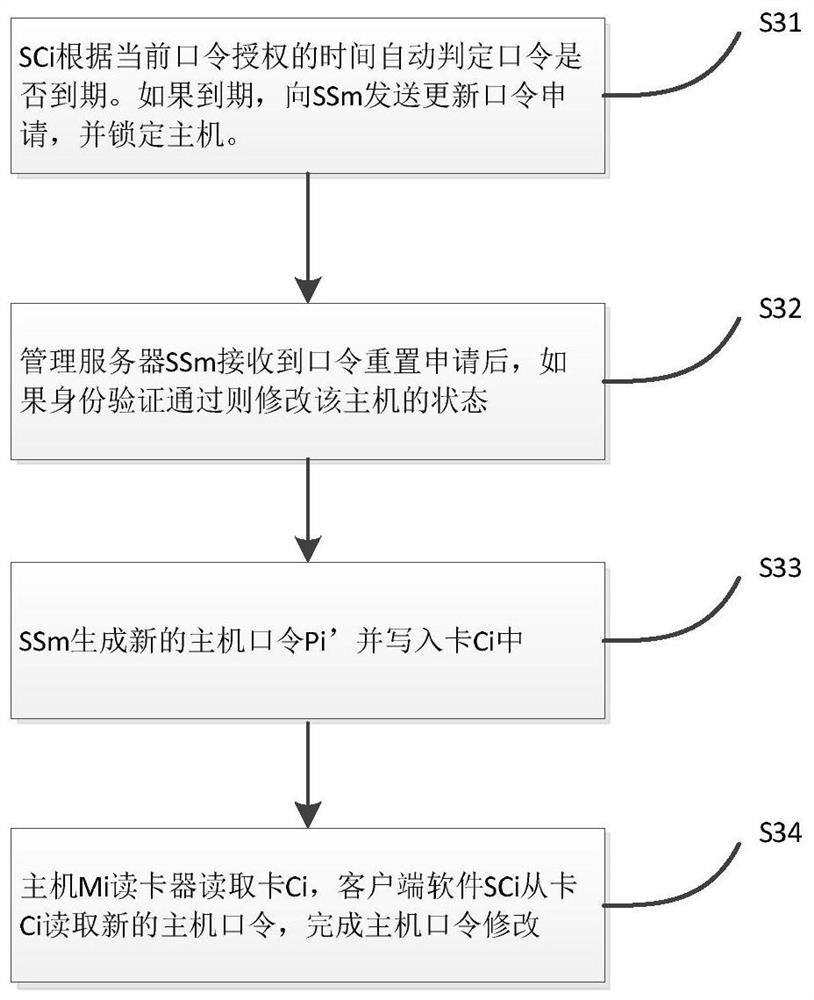

A zero-trust based host password control method

ActiveCN113055382BReduce the risk of weak passwordsRealize unified managementUser identity/authority verificationInternet privacyIdentity recognition

The invention discloses a method for managing and controlling host passwords based on zero trust, including a method for bringing hosts into management and control, a method for forcibly resetting host passwords after the expiration date, and a method for processing abnormal login passwords; the invention generates passwords through password construction strategies The password can meet the password strength requirements of the host, significantly reducing the risk of weak passwords of the host, and realizes the management and audit of the host password through unified management and control, ensures the implementation of the regular forced replacement policy of the host password, and saves the host password to the entity's identification card , which significantly increases the difficulty of password cracking and identity forgery. At the same time, users do not need to record complex host passwords, and can complete password-free login with an ID card, realizing the full lifecycle management of host passwords.

Owner:HUANENG POWER INT INC +1

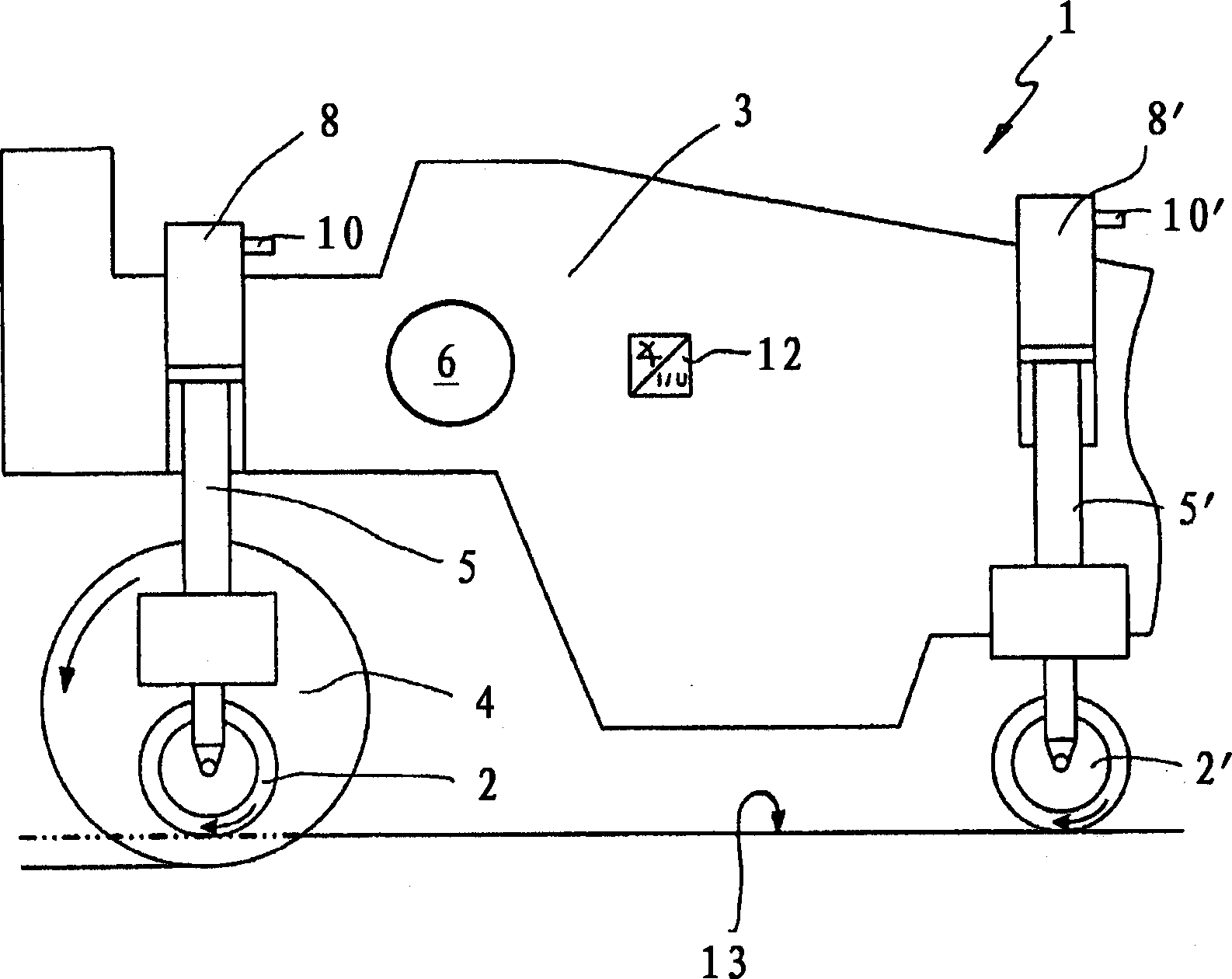

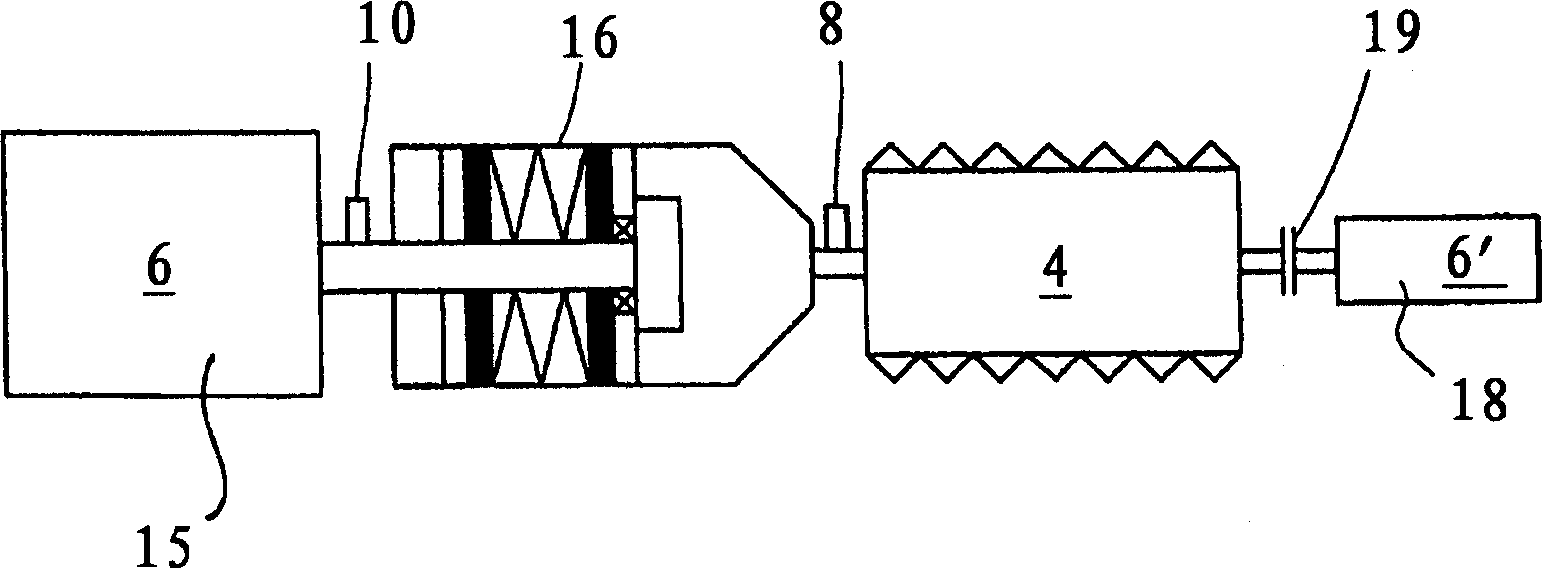

Apparatus for processing ground surfaces

InactiveCN102304891BEnsure full implementationTilling equipmentsWorking accessoriesEngineeringEarth surface

An apparatus for processing ground surfaces comprises a moving device, a working device, especially a milling device for milling the ground surface, and a drive device for driving the moving device and the working device, wherein the working device is movable between a working position, in which it is in operative engagement with the ground surface, and a maneuvering position, in which it is not in operative engagement with the ground surface, wherein a sensor device is provided which detects the maneuvering position and / or at least one working parameter of the working device, namely its power consumption, working speed, rotational speed or its inclination, and / or at least one load parameter of the moving device, and a control device which reduces the frictional connection between the drive device and the working device and / or the drive power transmitted by the drive device to the working device in the maneuvering position and / or in case of the detection of a deviation of the at least one detected working parameter or load parameter from a set parameter value.

Owner:BOMAG

Sterile cabin fully automatic drug sterility inspection and enrichment system and its operation method

ActiveCN106226151BImprove operational sensitivityImprove work efficiencyPreparing sample for investigationSterile environmentPeristaltic pump

The invention discloses a full-automatic drug sterility inspection enrichment system of a sterile bin and an operation method of the system. The enrichment system comprises a sterile operation car, an automatic operation manipulator and an operation table; the sterile operation car comprises a car base, a wastewater box, a filter containing box and a garbage box are arranged on the car base, filter hole sites are arranged over a water inlet of the wastewater box, a container frame is installed on a support frame arranged on one side of the car base and provided with container containing hole sites used for containing containers of at least one type and at least one operation hole site used for containing a container to be operated, and needle clamping devices are arranged at the corresponding operation hole sites; a clamping mechanism, a peristaltic pump, a pressure detection mechanism and a sealed cutting mechanism are installed on the operation table. Accordingly, the high-efficiency full-automatic drug sterility inspection enrichment process can be achieved in a sterile environment of the sterile bin, artificial participation is not needed, the hidden danger that the sterile environment is manually destroyed does not exist, and the system can be suitable for conducting enrichment operation on bacterium inspection of various kinds of drugs packaged in various kinds of drug bottles or bags.

Owner:牛刚 +1

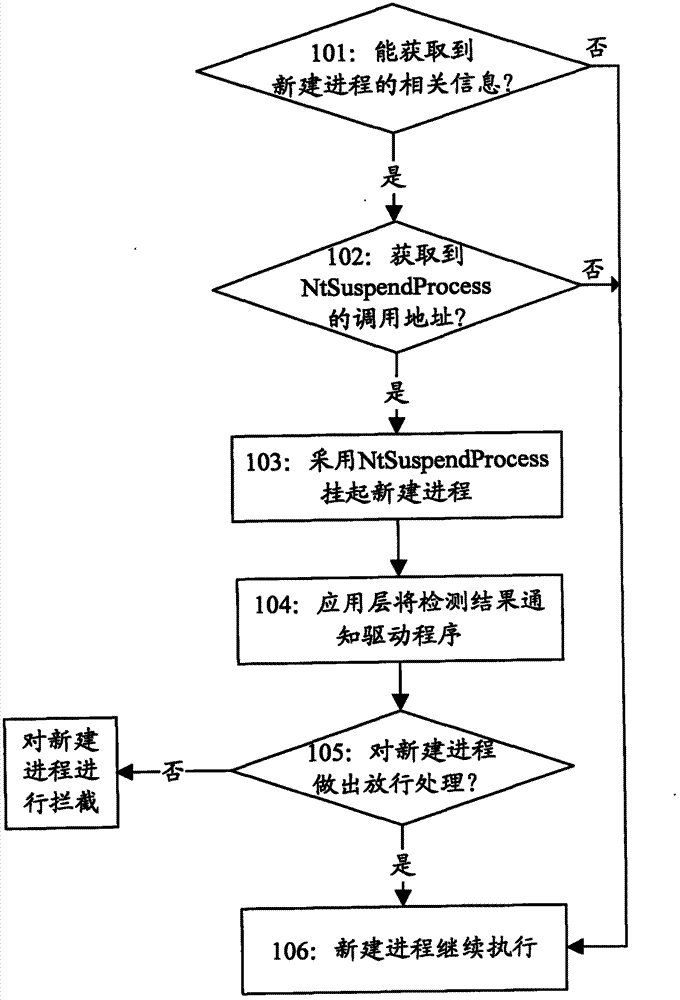

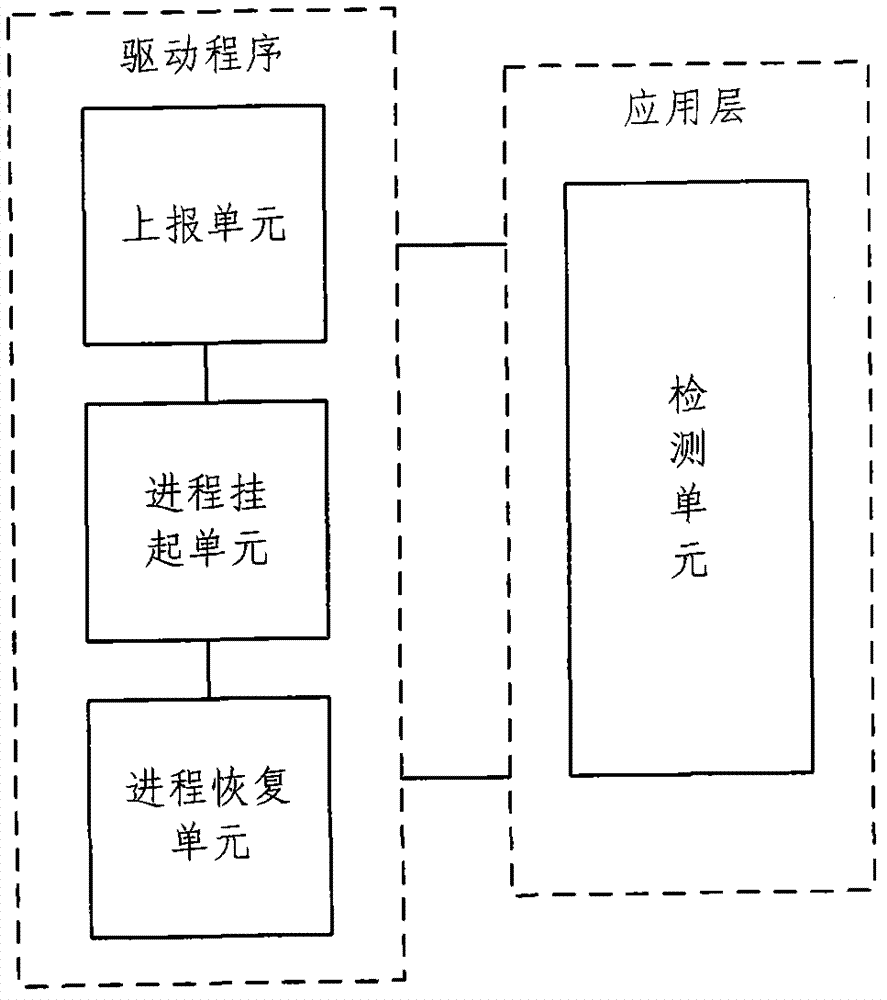

Method and system for detecting process creation during real-time protection

ActiveCN102081720BRealize detectionEnsure full implementationMultiprogramming arrangementsComputer security arrangementsSoftware engineeringProtocol Application

The invention discloses a method for detecting process creation during real-time protection. The method comprises the following steps that: a driving program reports related information of a new process required during detection of an application layer to the application layer to notice the application layer to perform scanning detection after the process is created; and the driving program suspends the new process when the application layer performs the scanning detection according to the related information of the new process. The invention also discloses a system for detecting the process creation during the real-time protection. A process suspending unit in the system is used for suspending the new process through the driving program when the application layer performs the scanning detection. By the method and the system, the new process can be detected without the interruption of the process of a creator.

Owner:TENCENT TECH (SHENZHEN) CO LTD

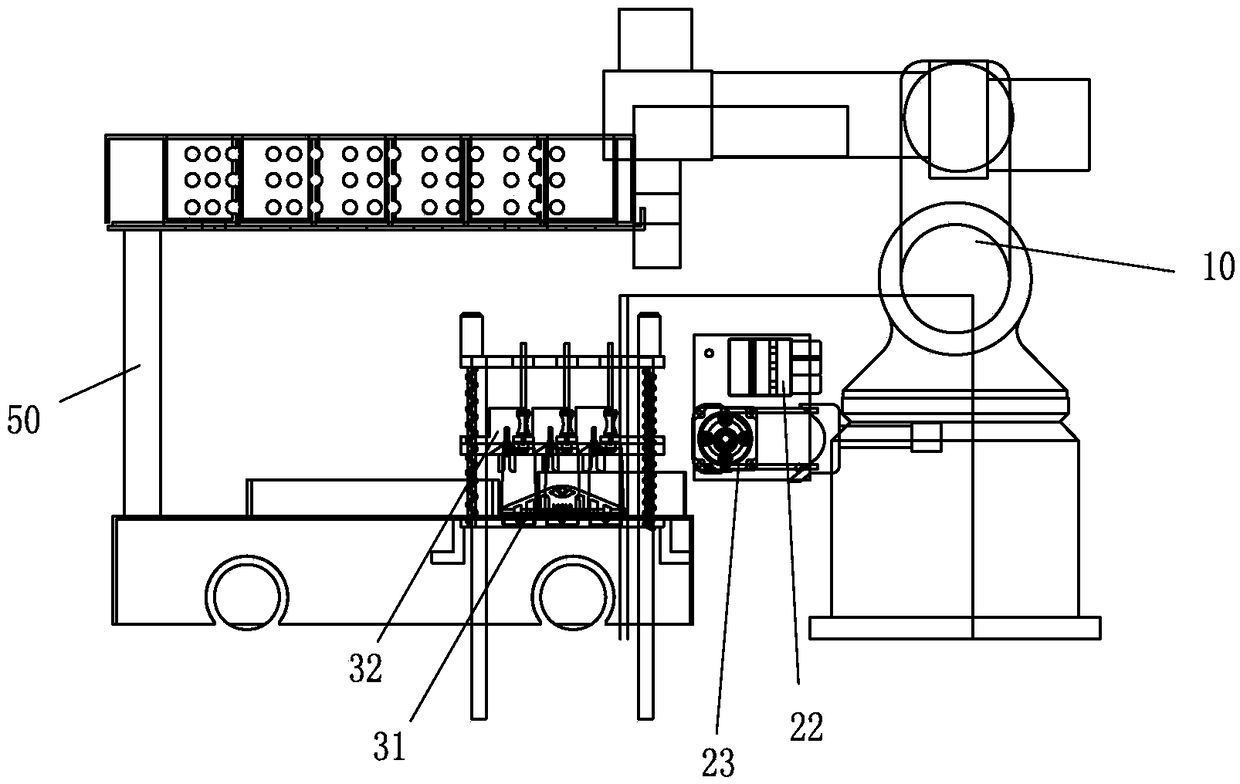

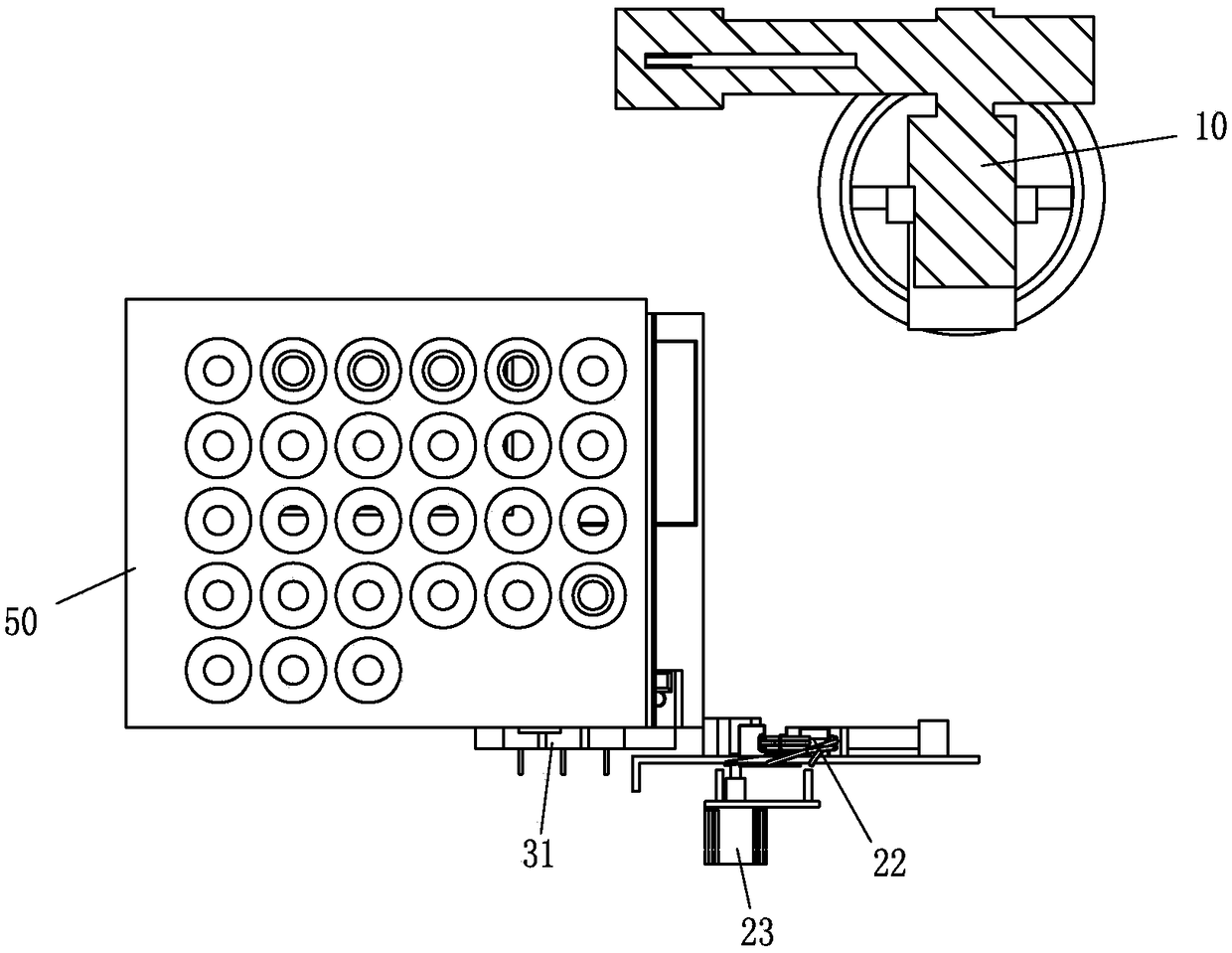

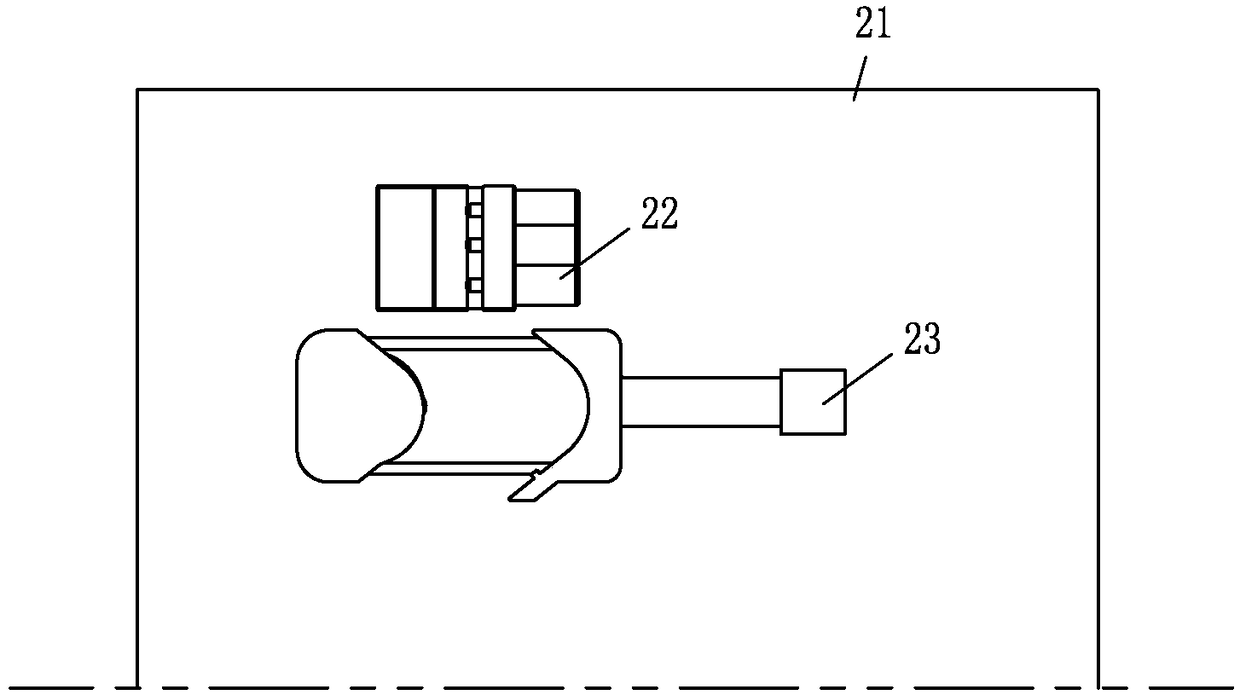

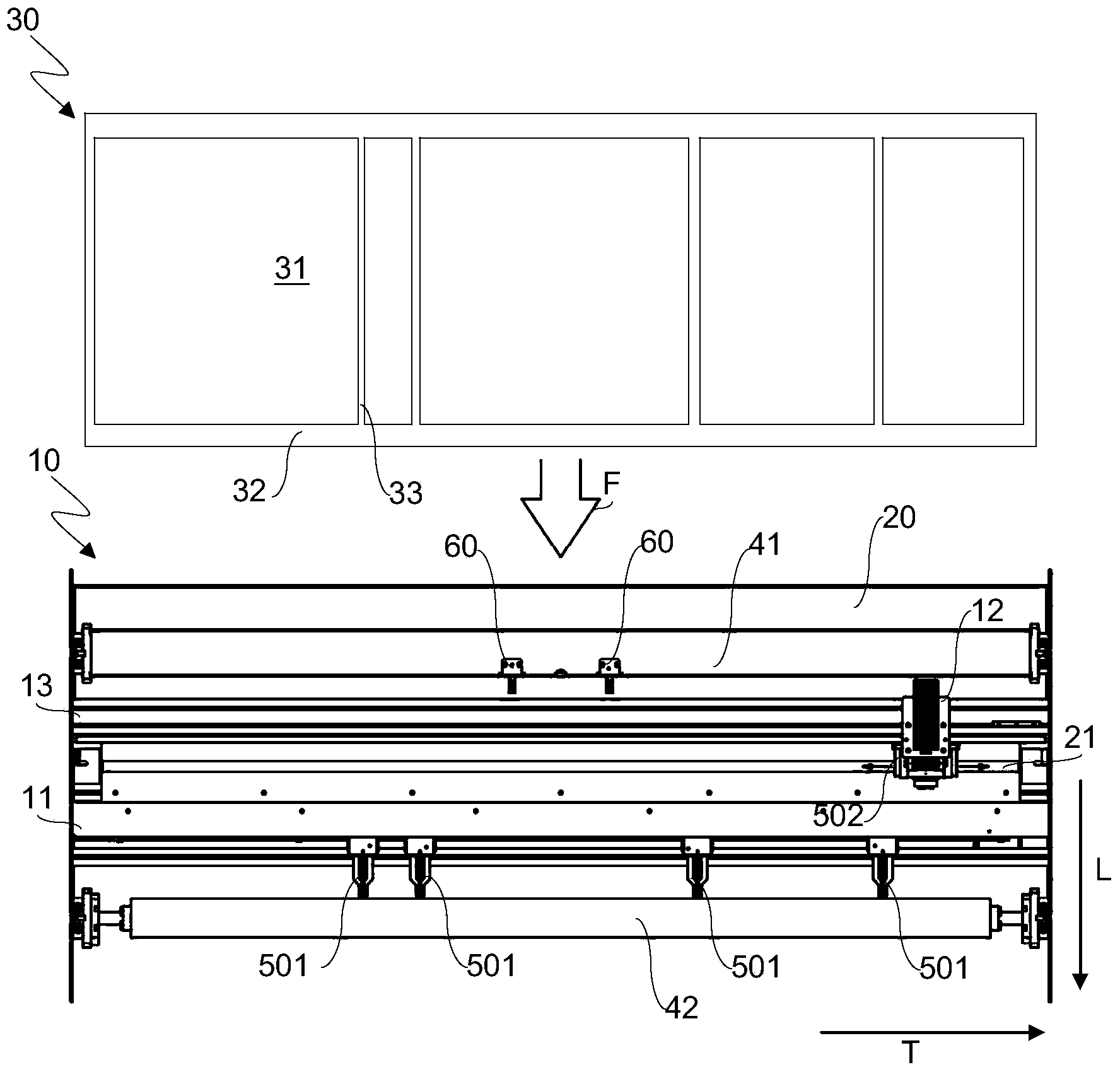

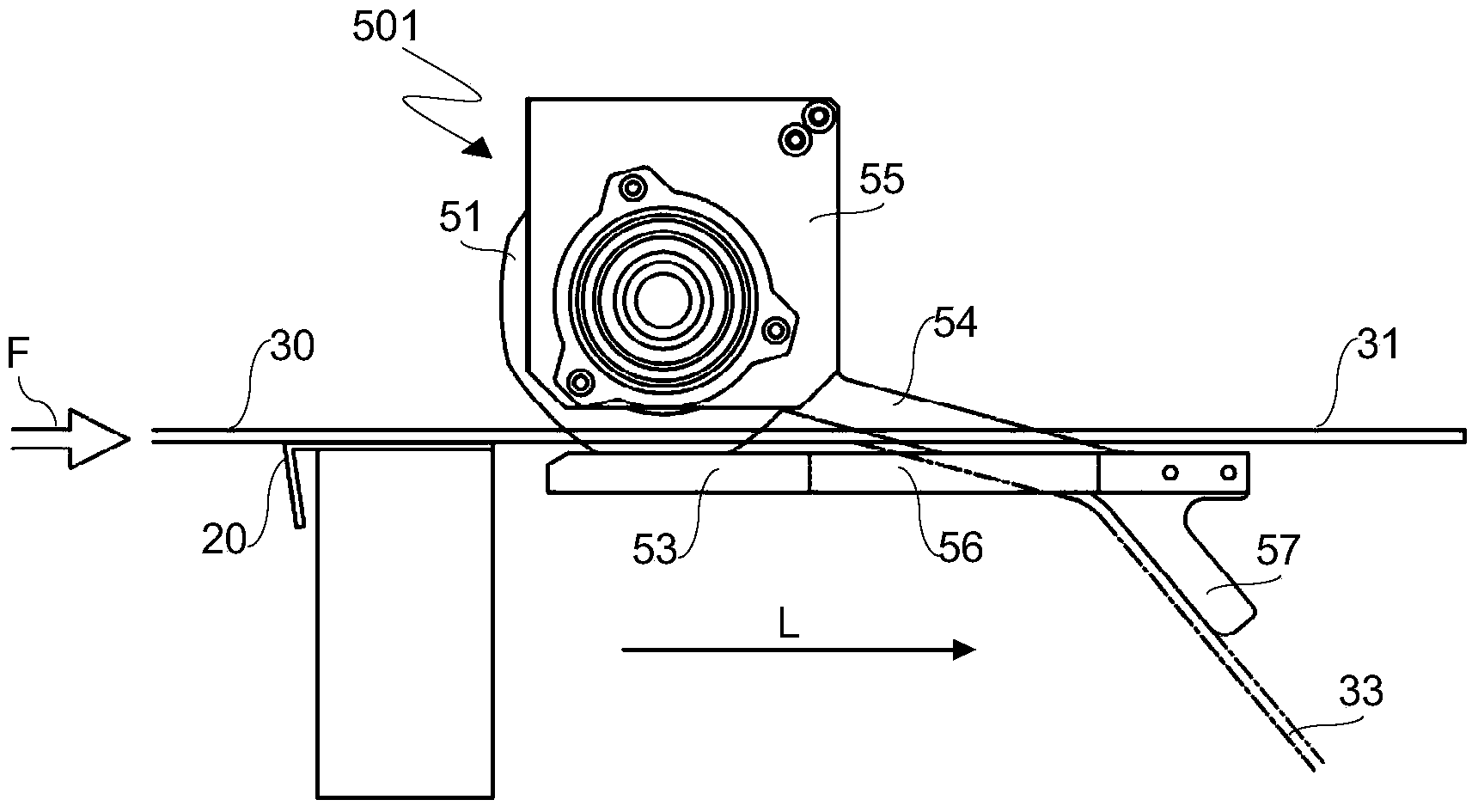

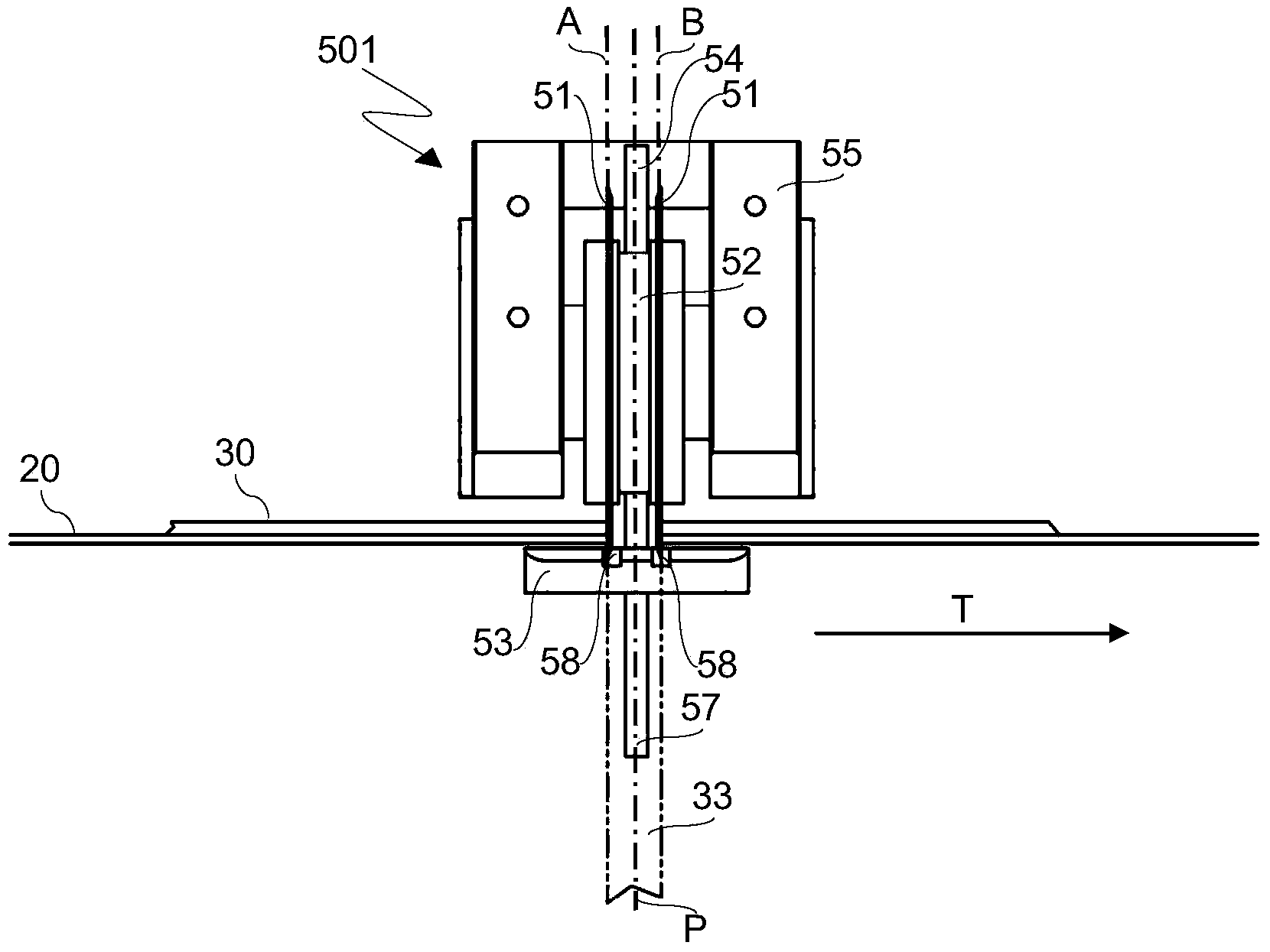

Cutter for printed substrates

The invention relates to a cutter (10) for cutting printed substrates, said cutter (10) comprising a supporting plane(20) adapted to receive a printed substrate (30) comprising a plurality of images (31) separated by a plurality of edges (32, 33) perpendicular to each other in a feeding direction (F), and a plurality of cutting units (50) suitable for cutting said printed substrate (30) along said edges (32, 33) in a longitudinal direction (L), parallel to said feed direction (F), and in a transverse (T), perpendicular to said feeding direction (F). Each cutting unit (50) comprises a pair of parallel blades (51), spaced apart at a distance corresponding to the width of the edges (32, 33), a backing plane (53) arranged underneath the supporting plane (20) of the cutter (10) and suitable to provide a backing surface to said blades (51) during cutting, and a connecting arm (54) which extends from a frame (55) of the cutting unit (50) on which the blades (51) are mounted to said backing plane (53) in a direction opposite to the cutting direction. The connecting arm (54) is parallel to the blades (51) and is arranged between the blades (51) on a plane (P) parallel to the planes (A, B) on which the blades (51) lie, and the portion of the backing plane (53) comprised between the area arranged underneath the blades (51) and the area wherein the connecting arm (54) is fixed comprises a through opening (56). Thanks to this configuration, the edges (32, 33) between the images printed on the substrate (30) may be cut in a single step by the cutting units and substrate scraps may be separated directly during cutting operations without the need for manual intervention of an operator.

Owner:FOTOBA INT SRL

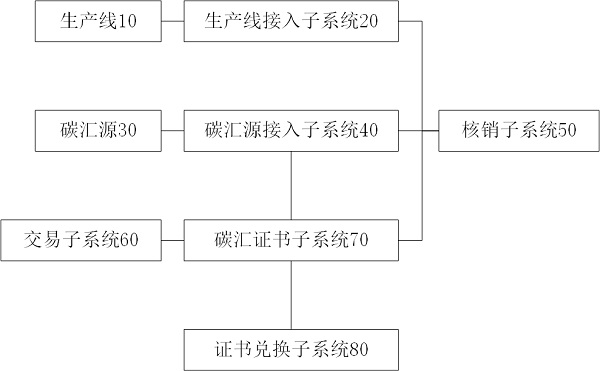

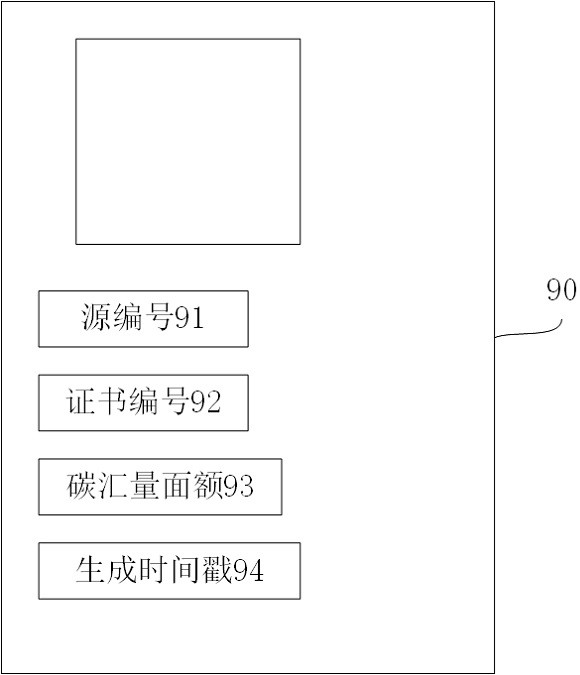

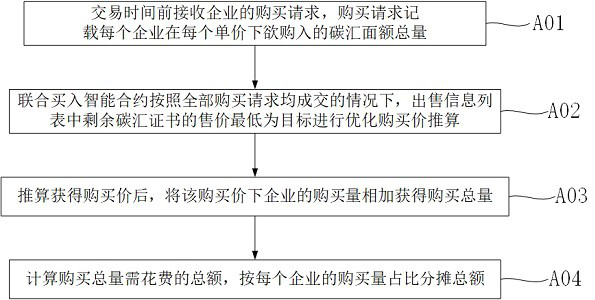

Carbon neutralization verification system based on block chain

PendingCN114266571AEnsure full implementationProcess stabilityDatabase distribution/replicationPayment protocolsSoftware engineeringCarbon sink

The invention relates to the technical field of information, in particular to a block chain-based carbon neutralization verification system, which comprises a production line access subsystem, a carbon confluence access subsystem, a carbon sink certificate subsystem, a transaction subsystem and a cancel-after-verification subsystem, the carbon confluence access subsystem determines the carbon confluence amount per unit time of a carbon confluence, the carbon confluence certificate subsystem periodically generates carbon confluence certificates, a token is generated on a block chain, the token and the certificate number are the same, the transaction subsystem uploads transaction information to the block chain, and the verification subsystem receives carbon confluence certificate verification request information of an enterprise and sends the verification request information to the carbon confluence access subsystem. And if the sum of the denominations of the carbon sink quantity of the carbon sink certificates cancelled after verification of the associated production line number in the period is not lower than the determined carbon emission, the carbon neutralization verification of the production line is determined to be passed. The method has the substantive effects that automatic periodic cancel-after-verification can be realized, and the execution of carbon neutralization is ensured; the reduction of carbon emission is facilitated.

Owner:浙江数秦科技有限公司

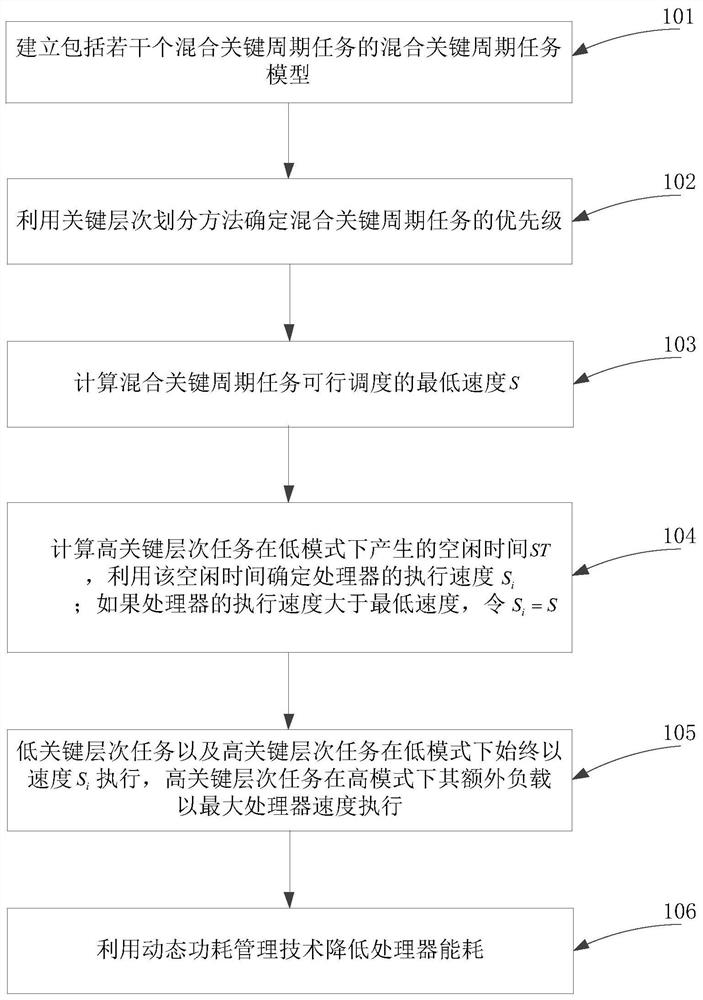

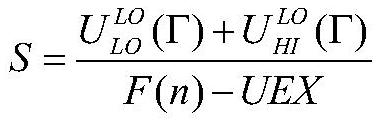

Energy consumption optimization method for fixed-priority periodic tasks in mixed-critical systems

ActiveCN108984292BReduce energy consumptionEnsure full implementationProgram initiation/switchingResource allocationIdle timeDynamic power management

The invention relates to a method for optimizing energy consumption of fixed-priority periodic tasks in a mixed critical system, comprising the following steps: establishing a mixed critical periodic task model including several mixed critical periodic tasks; using a key hierarchy division method to determine the priority of the mixed critical periodic tasks ;Calculate the minimum speed S of the feasible scheduling of mixed critical period tasks; calculate the idle time ST generated by high critical level tasks in low mode, and use this idle time to determine the execution speed S of the processor i ;Low critical level tasks and high critical level tasks are always at speed S in low mode i Execution; high-level critical tasks are executed at maximum processor speed with their additional load in high mode; use dynamic power management technology to reduce processor power consumption. The method of the invention effectively reduces system energy consumption by utilizing the idle time generated by the high-level critical level task and the dynamic power consumption management technology.

Owner:HUAQIAO UNIVERSITY

A kind of production method of anti-crack steel for container ship

ActiveCN110076196BLarge amount of depressionAccurate and effective production processTemperature control deviceWork cooling devicesProcess engineeringHeating furnace

The invention discloses a method for producing crack arresting steel for container ships. By selecting billets with different sections according to different widths of finished products and rolling them, the number of rolling passes is reduced and the reduction in passes is increased. Due to the characteristics of slow production rhythm, use the space left in the heating furnace to reduce the time in the furnace to ensure the execution of the heating process and ensure the surface quality; the heating process ensures the uniformity of the thickness direction of the slab; the rolling process adopts full longitudinal rolling or full transverse rolling as much as possible The rolling method increases the effective compression ratio; in order to refine the grain, the intermediate billet is cooled ultra-fast, and different cooling processes are set according to the specifications and the cooling process of the finished steel plate is determined. In this way, an accurate and effective stable production process for the production of crack arrest steel is realized, so that the stability of the production process of crack arrest steel meets the requirements of batch industrial production and various indicators such as mechanical properties and product quality stability meet the standard requirements, and the production process is easy to control.

Owner:NANJING IRON & STEEL CO LTD

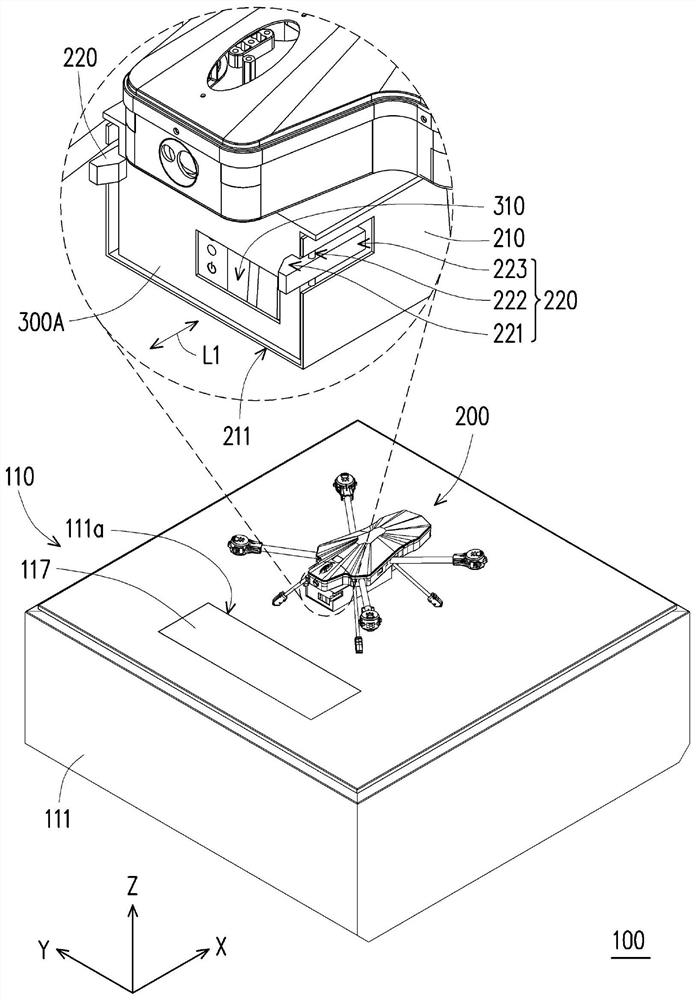

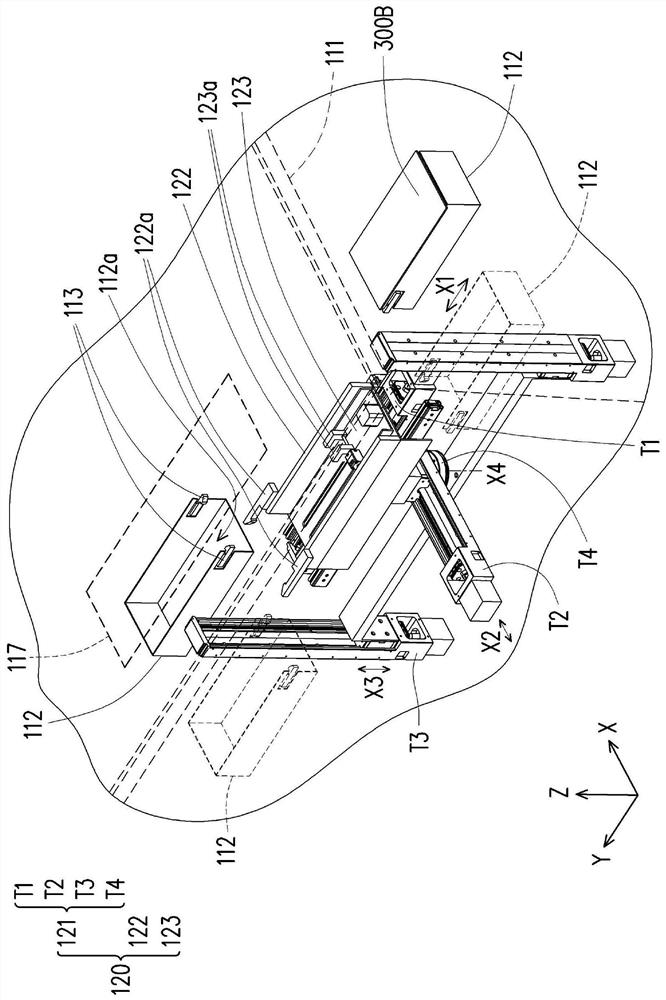

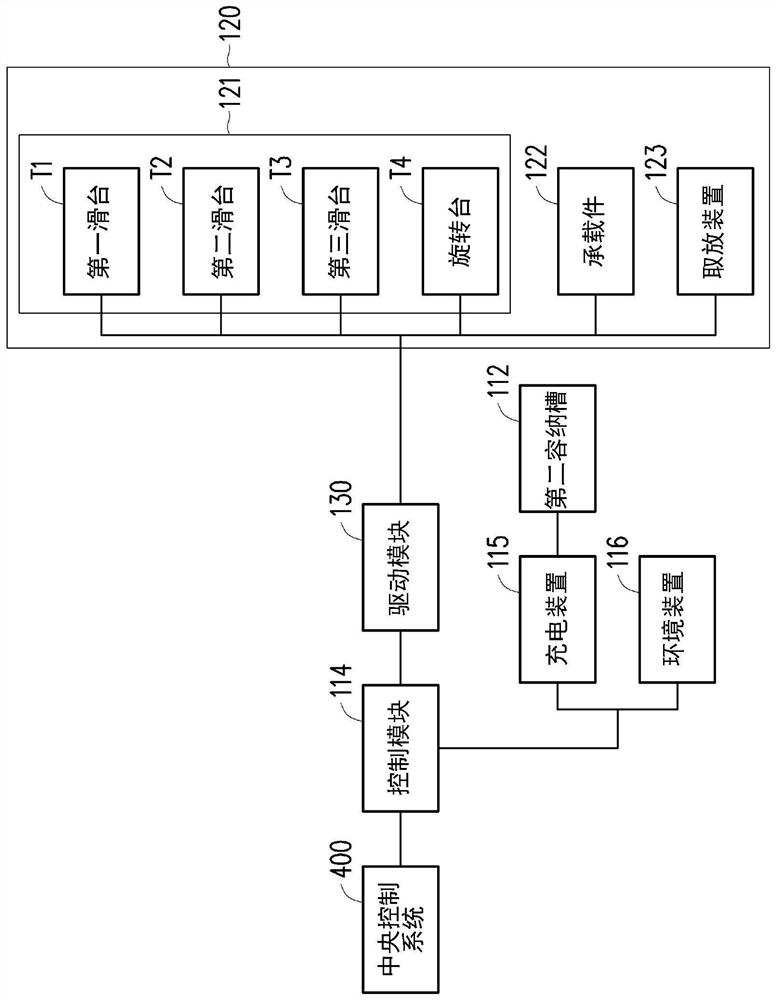

Battery replacement mechanism, battery replacement system and battery replacement method

PendingCN113928164AImprove battery lifeSustainabilityCharging stationsElectric propulsion mountingElectrical batteryStructural engineering

The invention provides a battery replacement mechanism which is used for taking and placing a battery into a first accommodating groove, the first accommodating groove is provided with a first clamping hook for buckling the battery in the first accommodating groove; the battery replacement mechanism comprises a multi-axial sliding table assembly, a bearing piece and a taking and placing device; the bearing piece is movably arranged on the multi-axial sliding table assembly, and the taking and placing device is movably arranged on the bearing piece; the bearing piece comprises a second clamping hook, and the taking and placing device comprises a lock catch; the second clamping hook is used for loosening the first clamping hook of the first containing groove so that the battery can enter and exit from the first containing groove, and the lock catch is used for being connected with the battery and dragging the electrically-driven back-and-forth bearing piece. The invention also provides a battery replacement system and a battery replacement method for the unmanned aerial vehicle. According to the battery replacement mechanism, the battery replacement system and the battery replacement method, the structure is simple, and battery replacement or maintenance can be efficiently carried out without damaging the battery.

Owner:CORETRONIC INTELLIGENT ROBOTICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com