Apparatus for processing ground surfaces

A technology of equipment and ground surface, which is applied in the field of equipment for dealing with the ground surface, can solve problems such as acceleration of construction machinery, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

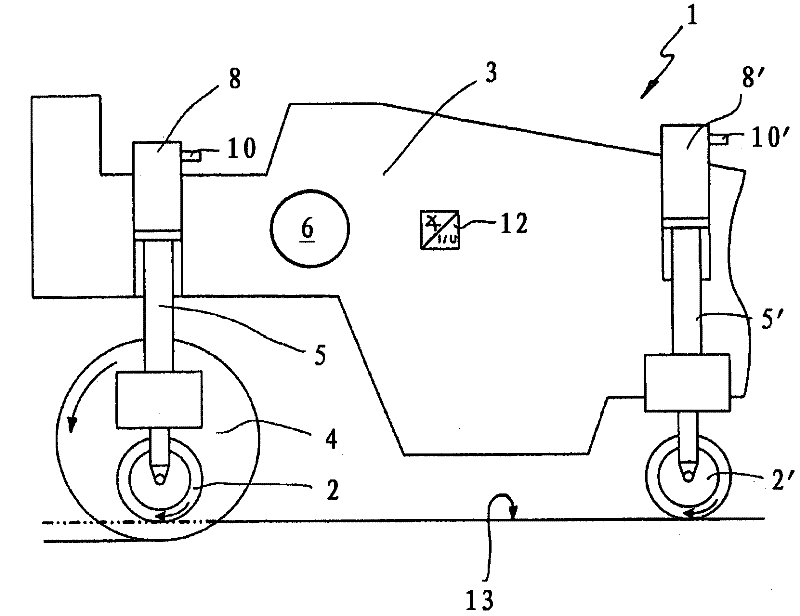

[0041] Such as figure 1 The plant or construction machine 1 shown in FIG. 1 includes a frame 3 and a drive 6 . The drive device 6 serves to drive the movement device 2 and the working device 4 , which in this example is a milling device. In the present embodiment the movement device 2 is formed by wheels. The milling device 4 can be decoupled from the drive device 6 by means of a coupling device (not shown) and can be brought into a raised position (not shown) by means of a lifting device 5 on the frame 3 .

[0042] The lowered position shown here corresponds to the working position or working stroke for milling the ground surface 13 shown. As shown in the figure, the working device 4 rotates in the opposite direction to the machine 1 or the wheel 2 during the working stroke. In the raised or maneuvered position (not shown), the work implement 4 is no longer engaged with the ground surface 13 to be milled. In this position, the device moves "backwards" to the start of a ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com