A kind of production method of anti-crack steel for container ship

A technology for container ships and production methods, applied in workpiece cooling devices, manufacturing tools, metal rolling, etc., can solve the problems of temperature fluctuations in the rolling process, rolling waste in the rolling head, low yield at one time, etc. The effect of large reduction, reduction of rolling passes, and increase of effective compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

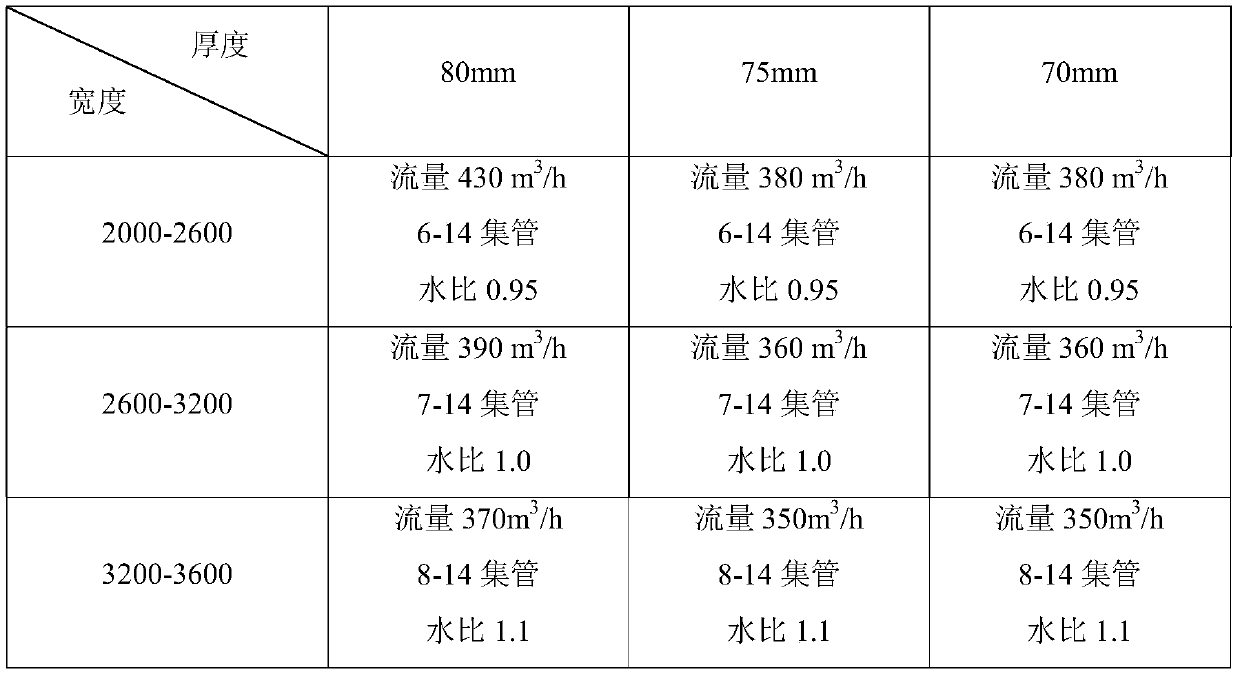

[0024] Embodiment 1 is to produce order crack arrest steel with a thickness of 70mm and a width of 2060mm. Before production, a detailed production plan must be formulated, preparations for production should be made, and production should be optimized according to the following steps after confirming the production conditions:

[0025] 1. Material type design: choose the thickness of the thickest continuous casting billet section 320mm, according to the principle of reducing rolling passes, select the billet design of the full longitudinal rolling method, the product target width design is 2130mm, and the billet size is 320*2130*L. The billet design can be directly cross-rolled, reducing the number of forming passes and increasing the effective pass reduction.

[0026] 2. Billet heating: Due to the full longitudinal rolling of the billet, the heating temperature limit of the slab is 1145-1155°C. In order to ensure the uniformity of the thickness direction of the steel plate, th...

Embodiment 2

[0031] Embodiment 2 is to produce order crack arrest steel with a thickness of 80mm and a width of 2880mm. Before production, a detailed production plan must be formulated, preparations for production should be made, and production should be optimized according to the following steps after confirming the production conditions:

[0032] 1. Material type design: choose the thickness of the thickest continuous casting billet section 320mm, according to the principle of reducing rolling passes, choose the billet design of the full cross rolling method, the product target width design is 2955mm, and the billet size is 320*2955*L. Billet design, in order to directly transfer steel to cross rolling in the rolling process, reduce forming passes and increase effective pass reduction.

[0033] 2. Billet heating: Due to the full cross-rolling of the billet, the upper limit of the slab heating temperature is 1150-1160°C. In order to ensure the uniformity of the thickness direction of the s...

Embodiment 3

[0038] Embodiment 3 is to produce order crack arrest steel with a thickness of 75mm and a width of 3250mm. Before production, a detailed production plan must be formulated, preparations for production should be done, and production should be optimized according to the following steps after confirming the production conditions:

[0039] 1. Material type design: choose the thickness of the thickest continuous casting slab section 320mm, according to the principle of reducing the rolling pass, choose the blank design of the full cross rolling method, the product target width design is 3475mm, and the blank size is 320*3475*L. For billet design, only vertical and horizontal rolling can be selected.

[0040] 2. Billet heating: due to the full cross-rolling of the billet, the lower limit of the slab heating temperature is 1140-1150°C. In order to ensure the uniformity of the thickness direction of the steel plate, the heating time of the heating furnace is controlled at 320-370min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com