A current-assisted composite spinning forming device and method for deep cup-shaped thin-walled parts

A thin-walled part, composite spinning technology, used in forming tools, manufacturing tools, other household appliances, etc., can solve problems such as re-adjustment of production cycle, discontinuous operation process, material rupture, etc., to reduce discontinuity, Improve production efficiency and increase the effect of pass reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

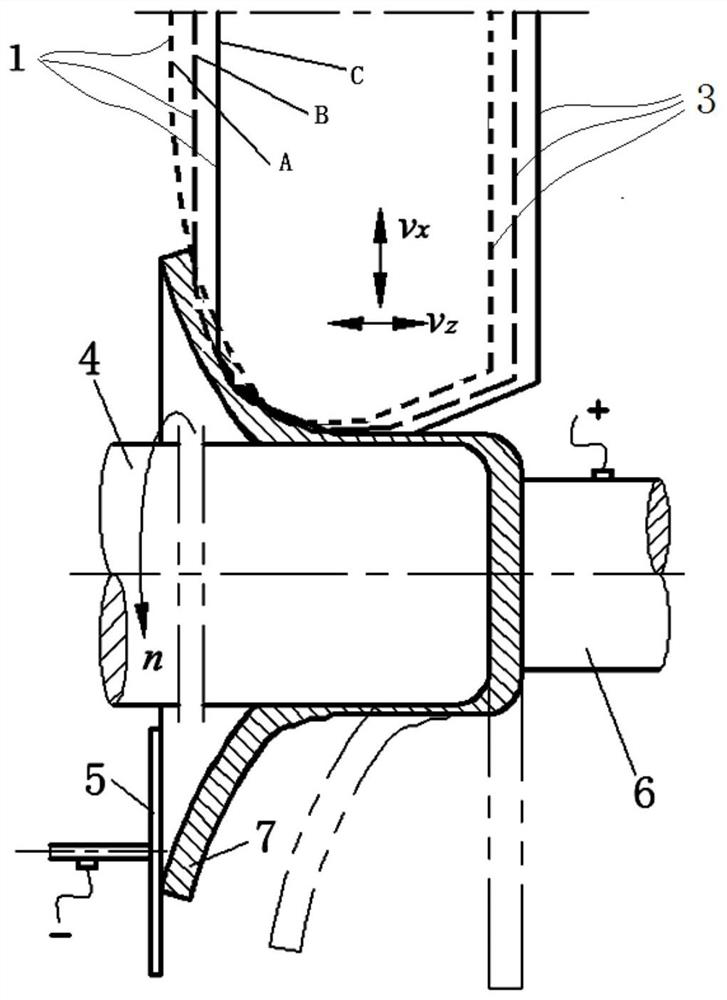

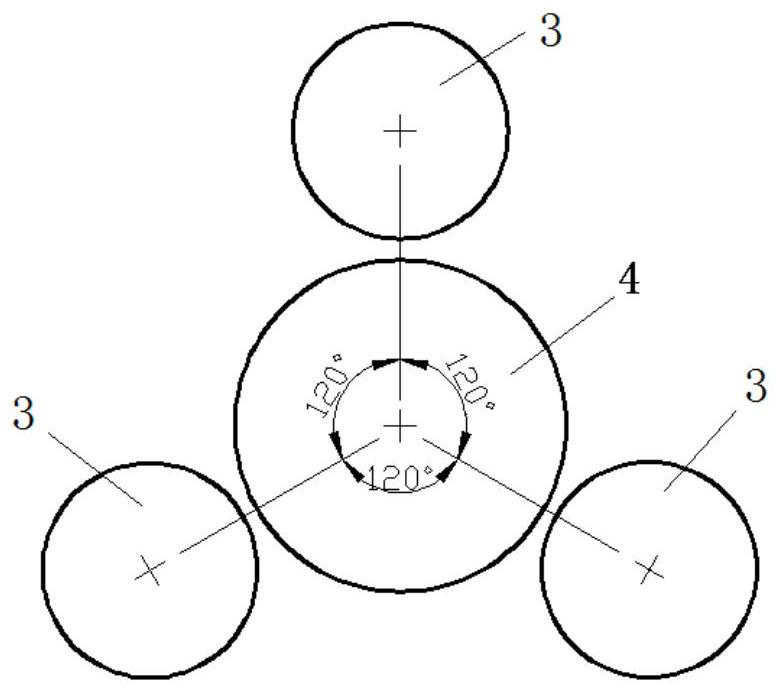

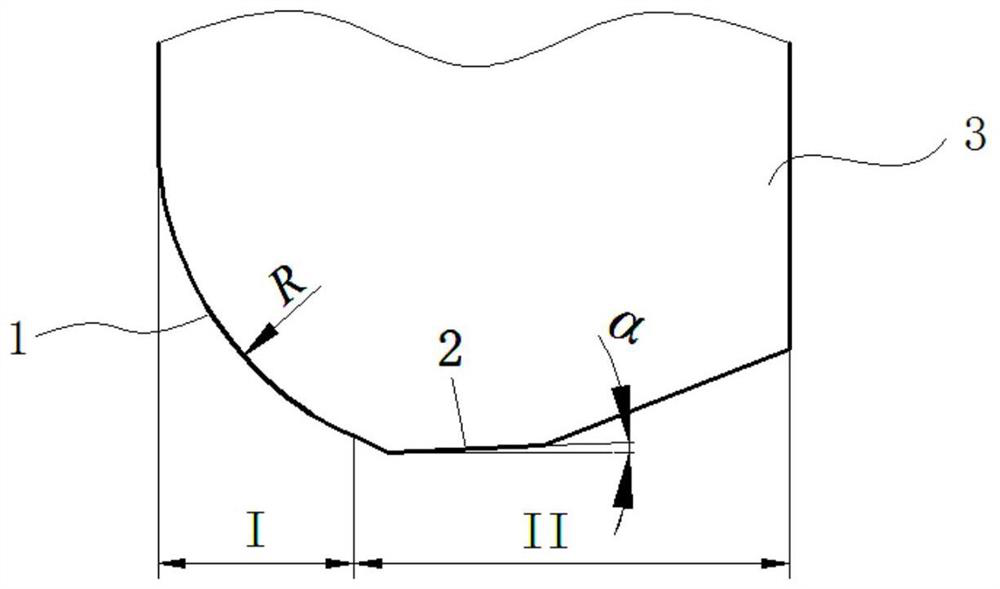

[0038] like Figure 1-4 mentioned. The invention discloses a current-assisted composite spinning forming device for deep cup-shaped thin-walled parts, which includes a spinning mandrel 4, a tail top 6, and a plurality of spinning wheels 3 equally distributed on the circumference of the spinning mandrel 4; each The rotary wheels 3 are arranged at staggered distances in the axial and radial directions of the spinning mandrel 4; the spinning surface of each rotary wheel 3 includes a drawing spinning surface 1, a flow spinning section, and a shaping spinning surface 2; The staggered arrangement is that the deep-drawing spinning surface 1 , the flow spinning section and the shaping spinning surface 2 of each roller 3 are evenly staggered in the axial and radial directions of the spinning mandrel 4 .

[0039] figure 1 It is that the present invention places the three rotary wheels at the same position in the circumferential direction in order to compare the relative positions of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com