Conduit single arm sliding/guiding support assembly

A technology for supporting components and pipe sheets, which is applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of distance limitation, large space occupation, tearing and damage of pipe insulation layer, etc., to reduce friction , the effect of taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The sliding / guiding support assembly of the present invention will be further described below with reference to the drawings and embodiments.

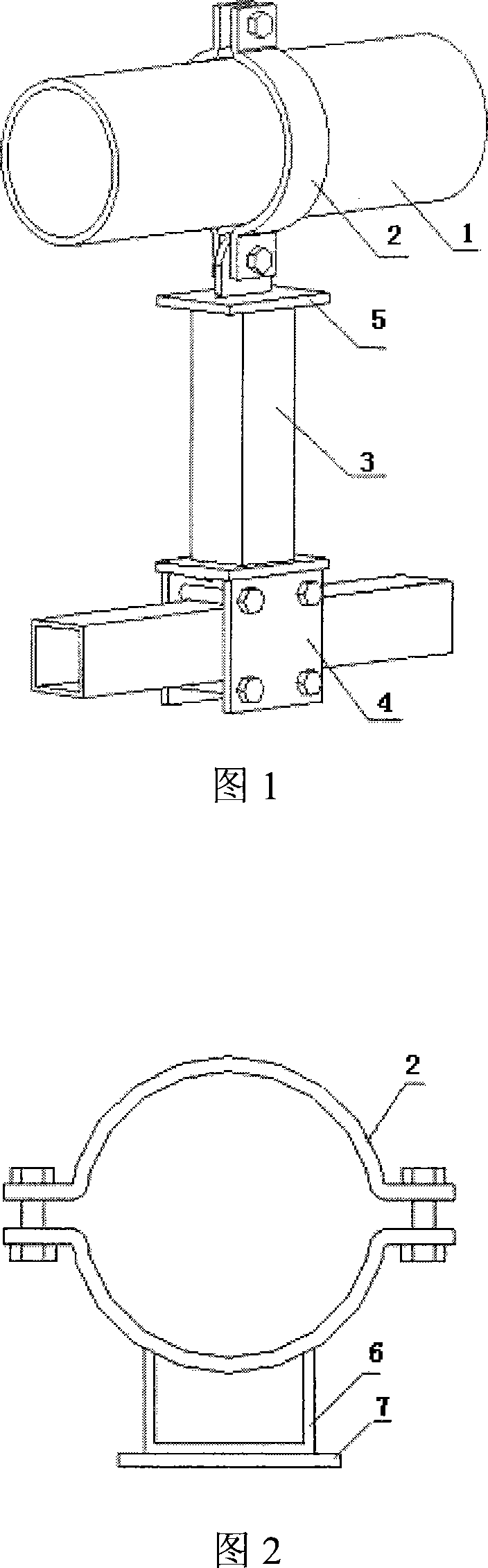

[0030] As shown in Figure 1, a pipeline single-arm sliding / guiding support assembly includes a pipe clamp 2 for clamping the supported pipeline, wherein it also includes a single-arm structural beam 3, and the root of one end of the single-arm structural beam 3 It is fixedly connected with the monorail sliding constraint assembly 4 so as to fix the single-arm structural beam 3 on structures such as columns, walls or floors, and the pipe clamp 2 is connected with the other end of the single-arm structural beam 3 through the pipe connection assembly 5 to realize the pipeline Required sliding / guiding constraints.

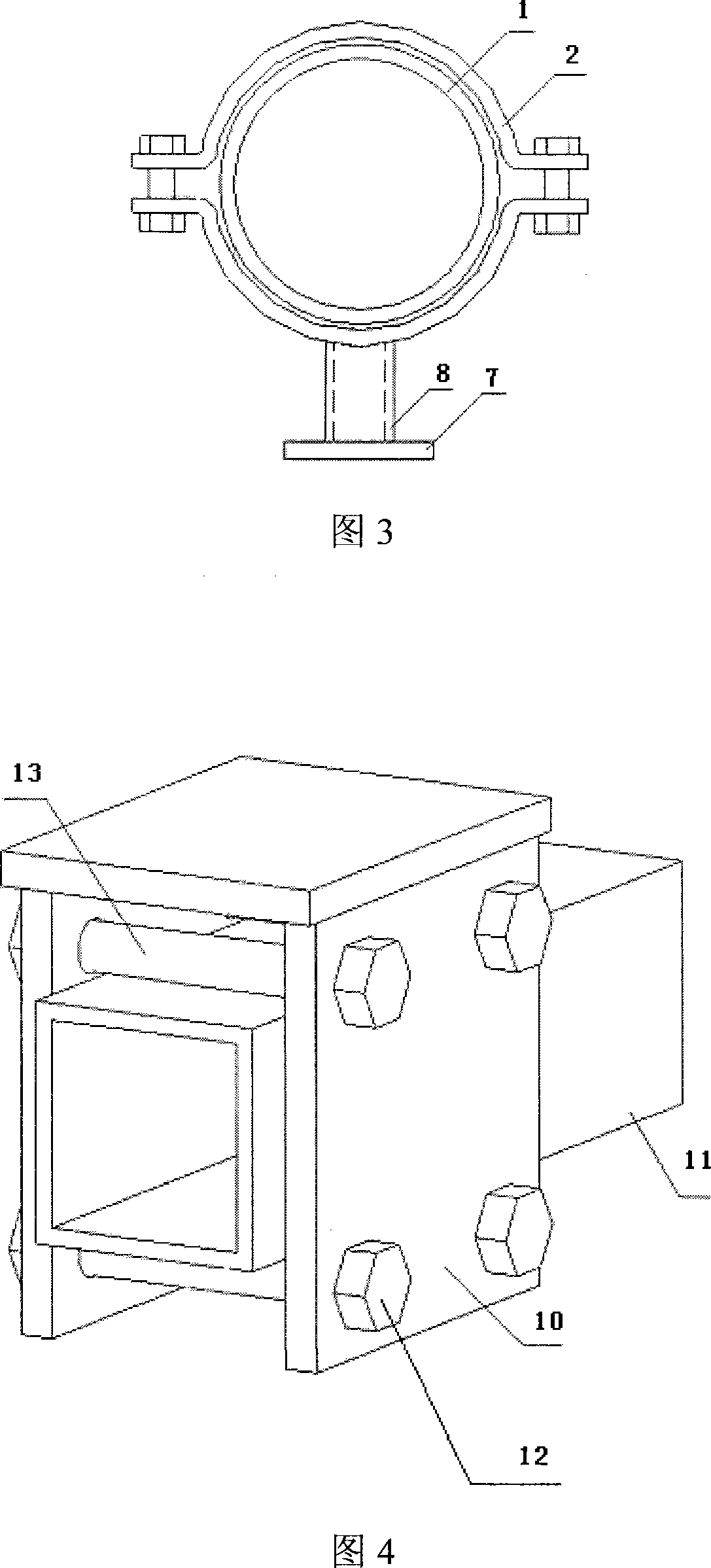

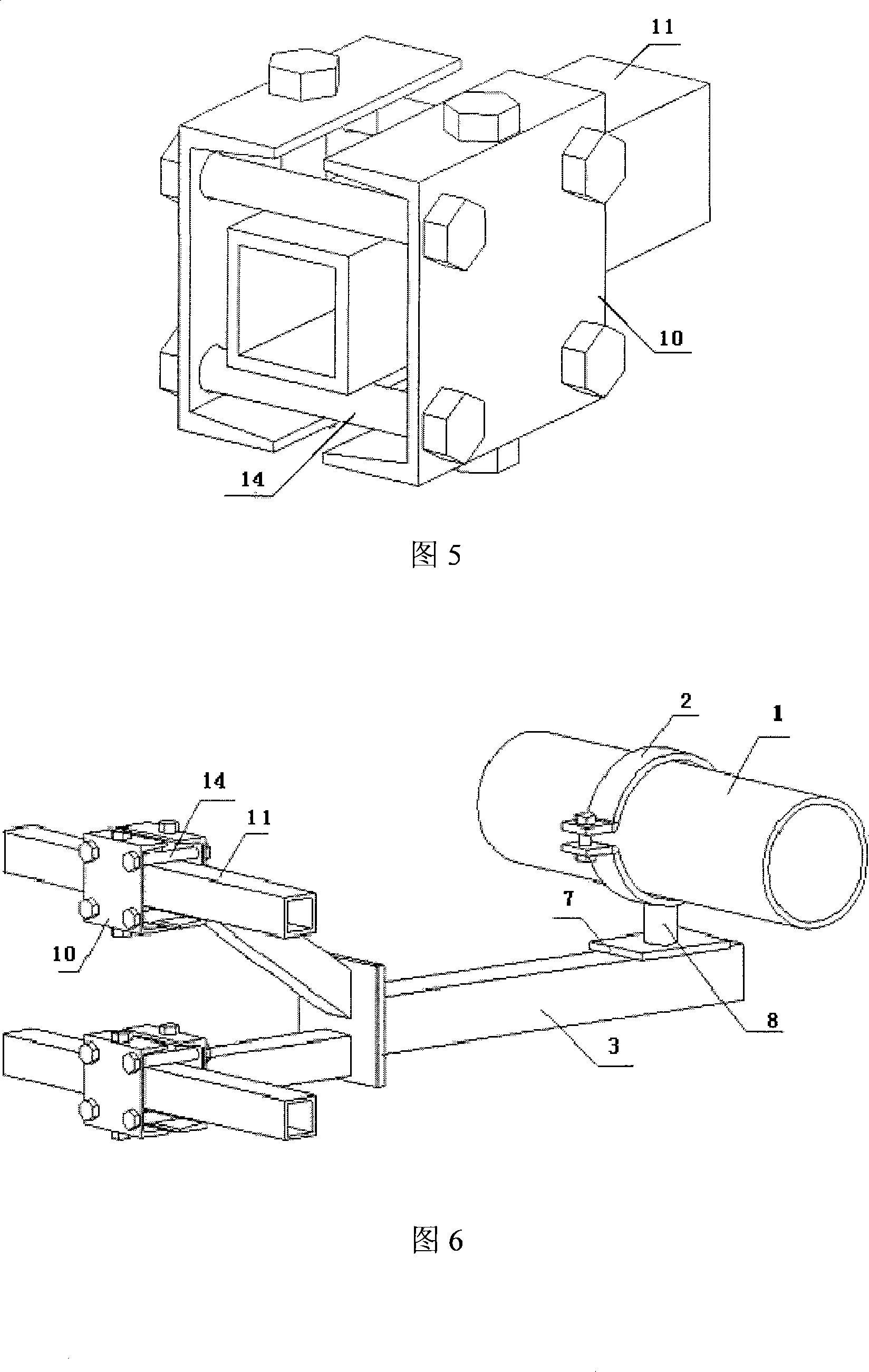

[0031] As shown in Figures 2, 3, 4, 6, 7 and 8, the pipe connection assembly 5 is composed of a U-shaped plate 6 or a support pipe 8 and a bottom plate 7; the pipe connection assembly 5 can also be made of a U-shaped pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com