Vibration cable

A cable and integrated technology, applied in the field of sensor cables, can solve the problems of unsatisfactory anti-interference, durability and diversity of signal transmission, reduce the vibration space of the wire, reduce reliability and other problems, achieve difficult bending and displacement, and ensure stability. The effect of stability and cross-sectional shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

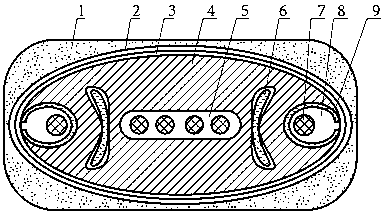

[0015] Such as figure 1 A vibrating cable shown includes a sheath layer 1, a shielding layer 2, a polyester film layer 3, an insulator 4, a signal line 5 and a bare wire 7, and the sheath layer 1 is coaxially shielded from the outside to the inside. Layer 2, polyester film layer 3 and insulator 4, the center of the insulator 4 is provided with four-core parallel integrated signal lines 5, and a groove 8 is respectively formed on the outer edge of the insulator at both ends of the parallel integrated signal line, and a groove 8 is provided in the groove. The rigid inner liner 9 that is attached to the wall, the bare wire 7 is set inside the rigid inner liner 9, the cross-sectional area of the rigid inner liner is greater than the cross-sectional area of the bare wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com