Patents

Literature

1695results about "Permanent-magnet clutches/brakes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

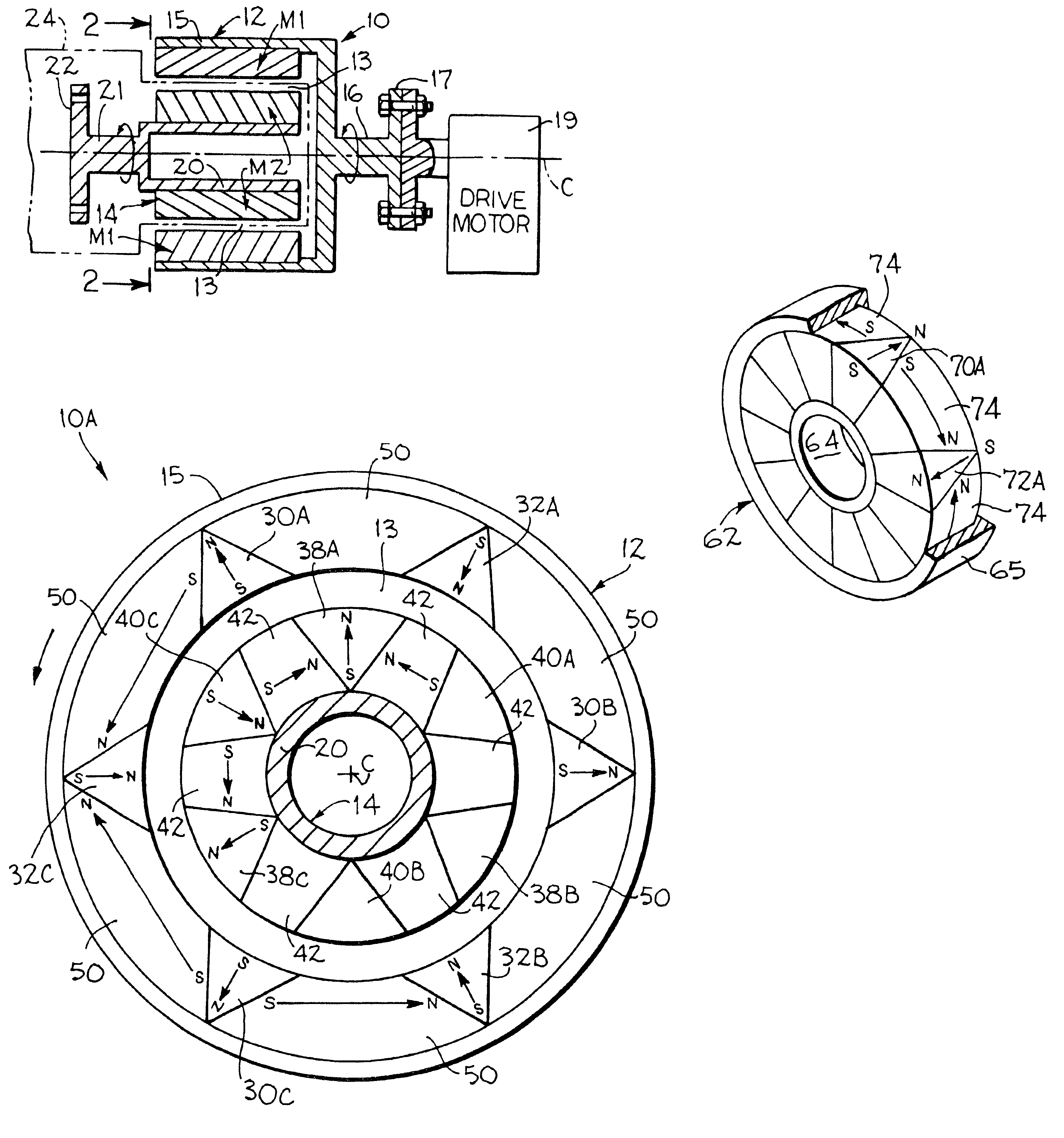

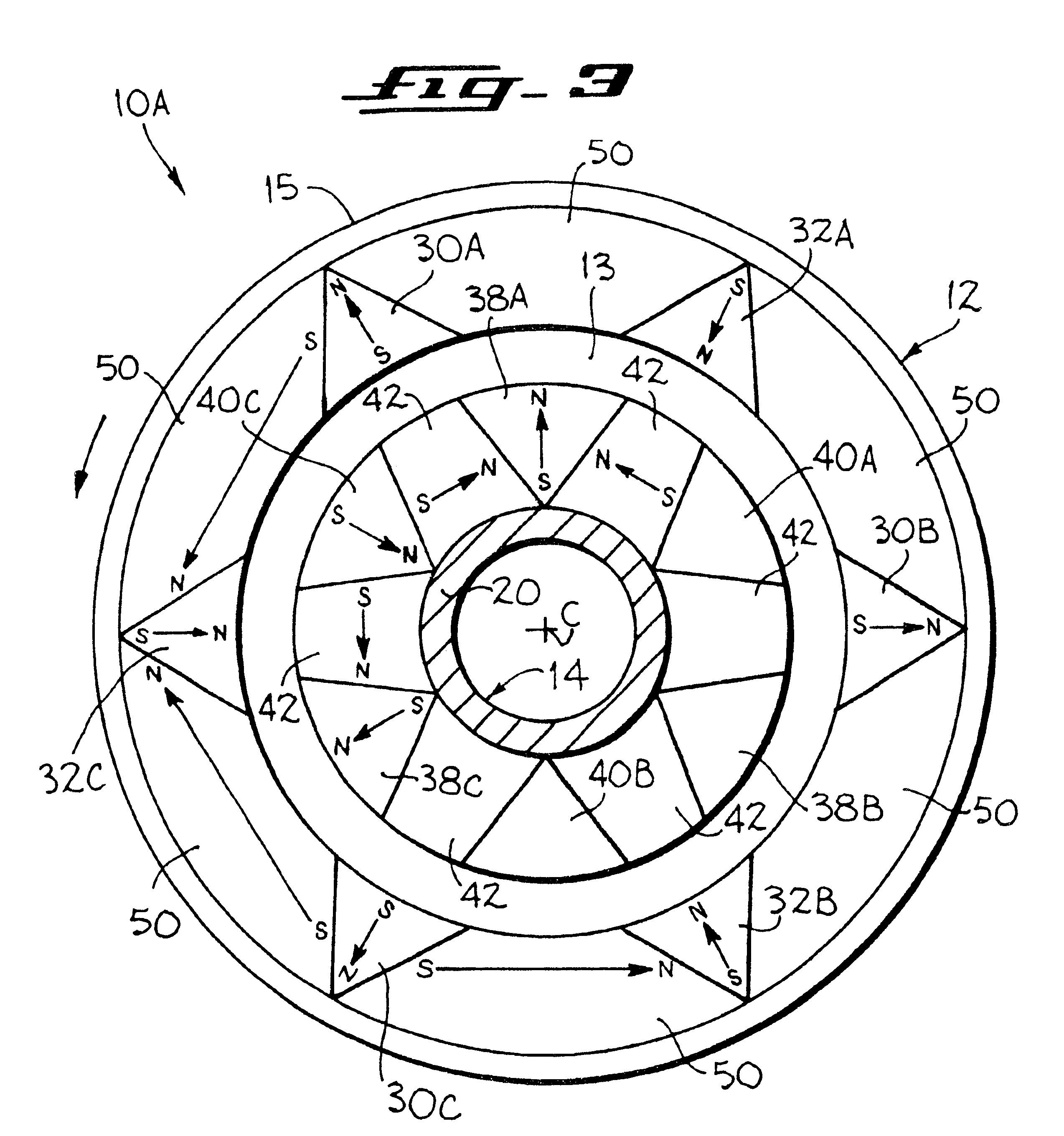

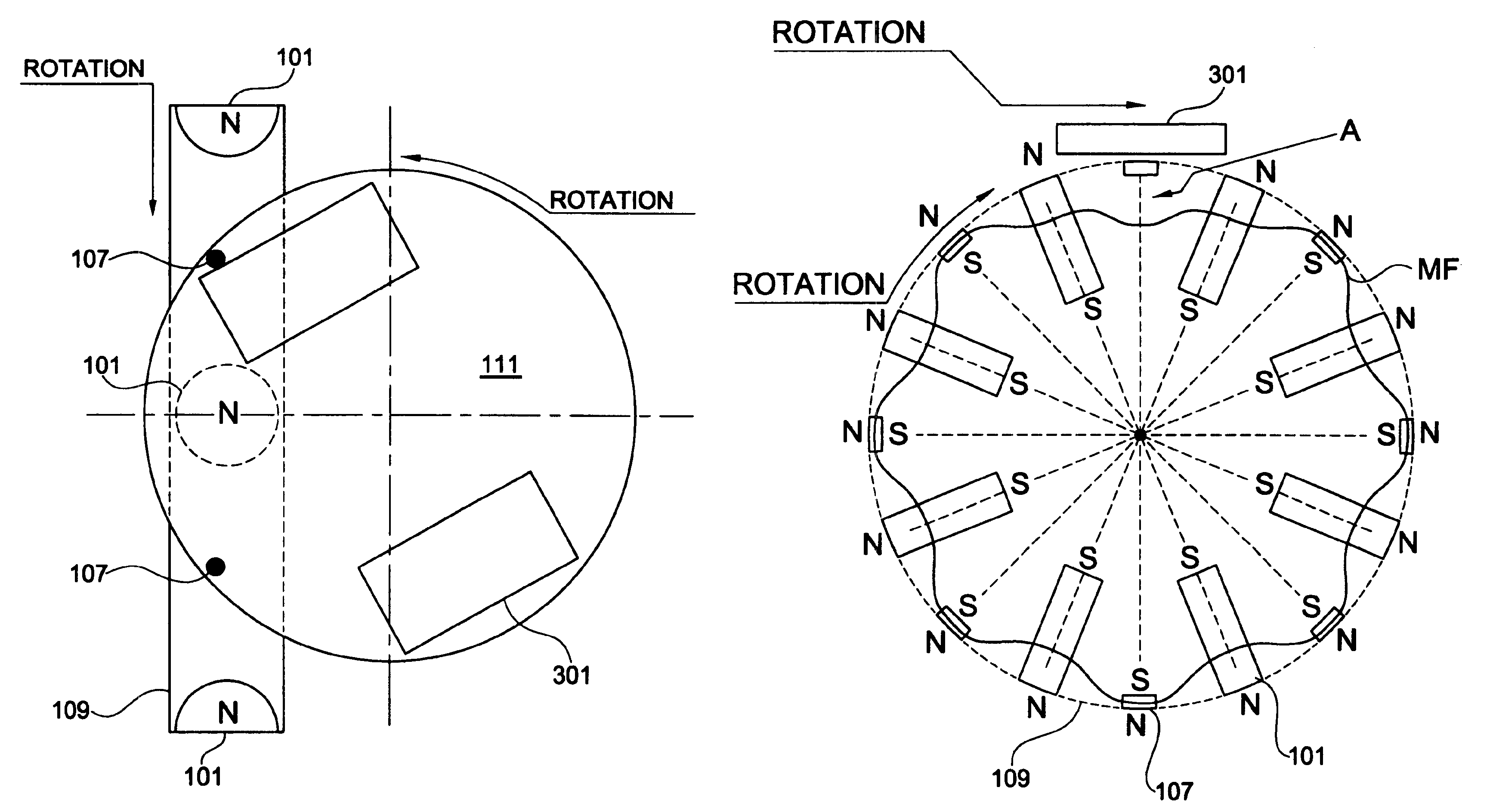

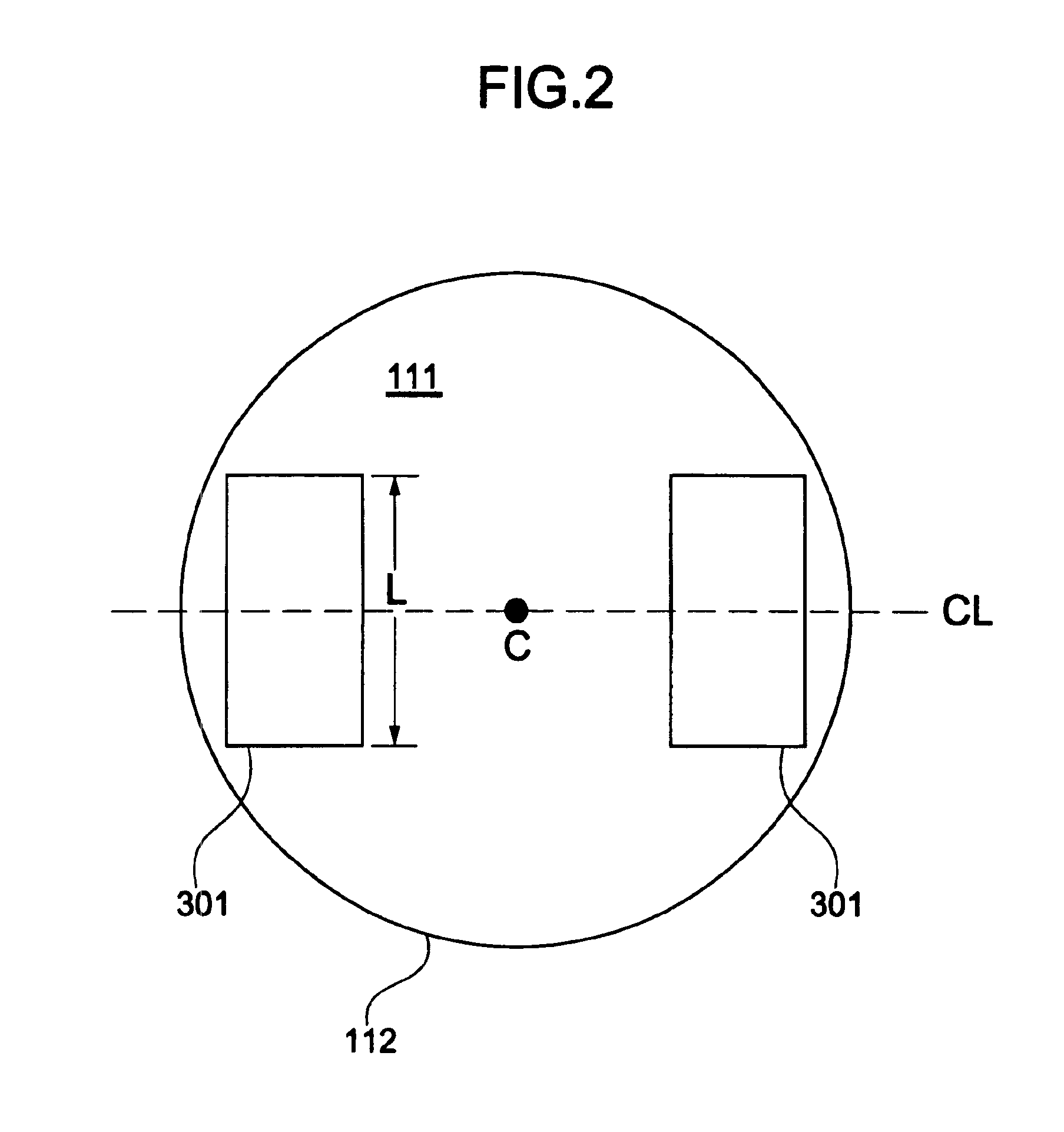

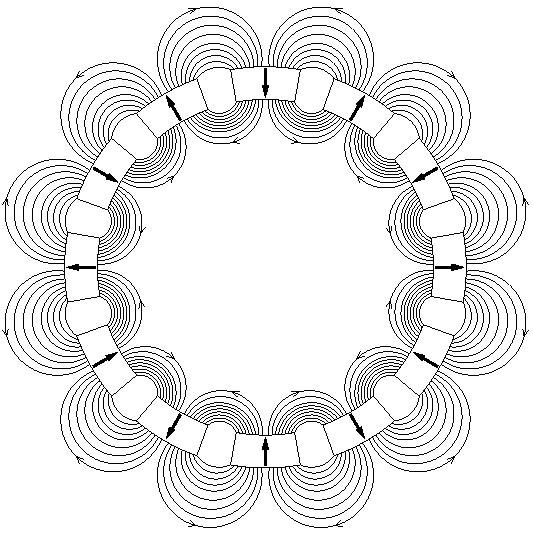

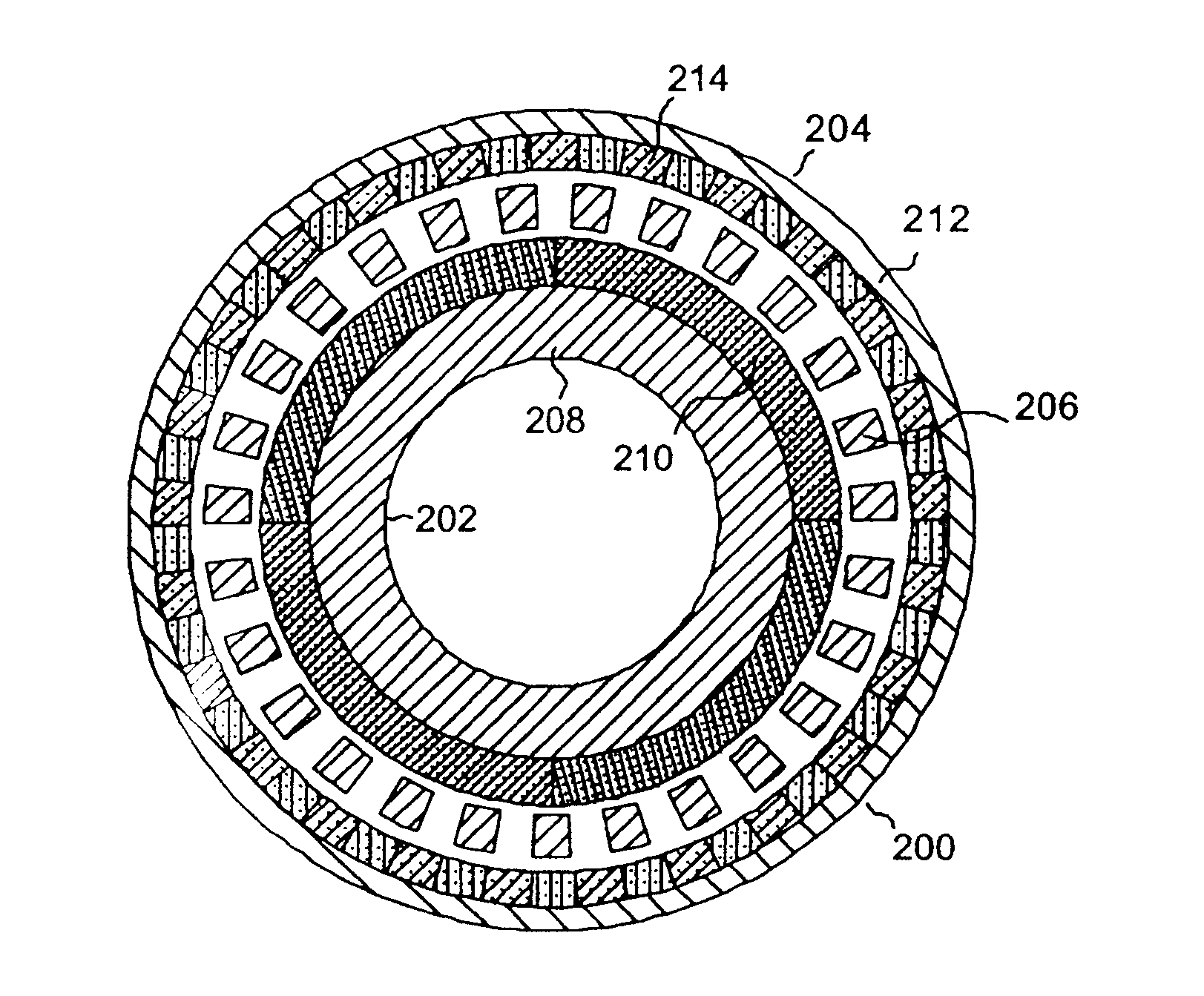

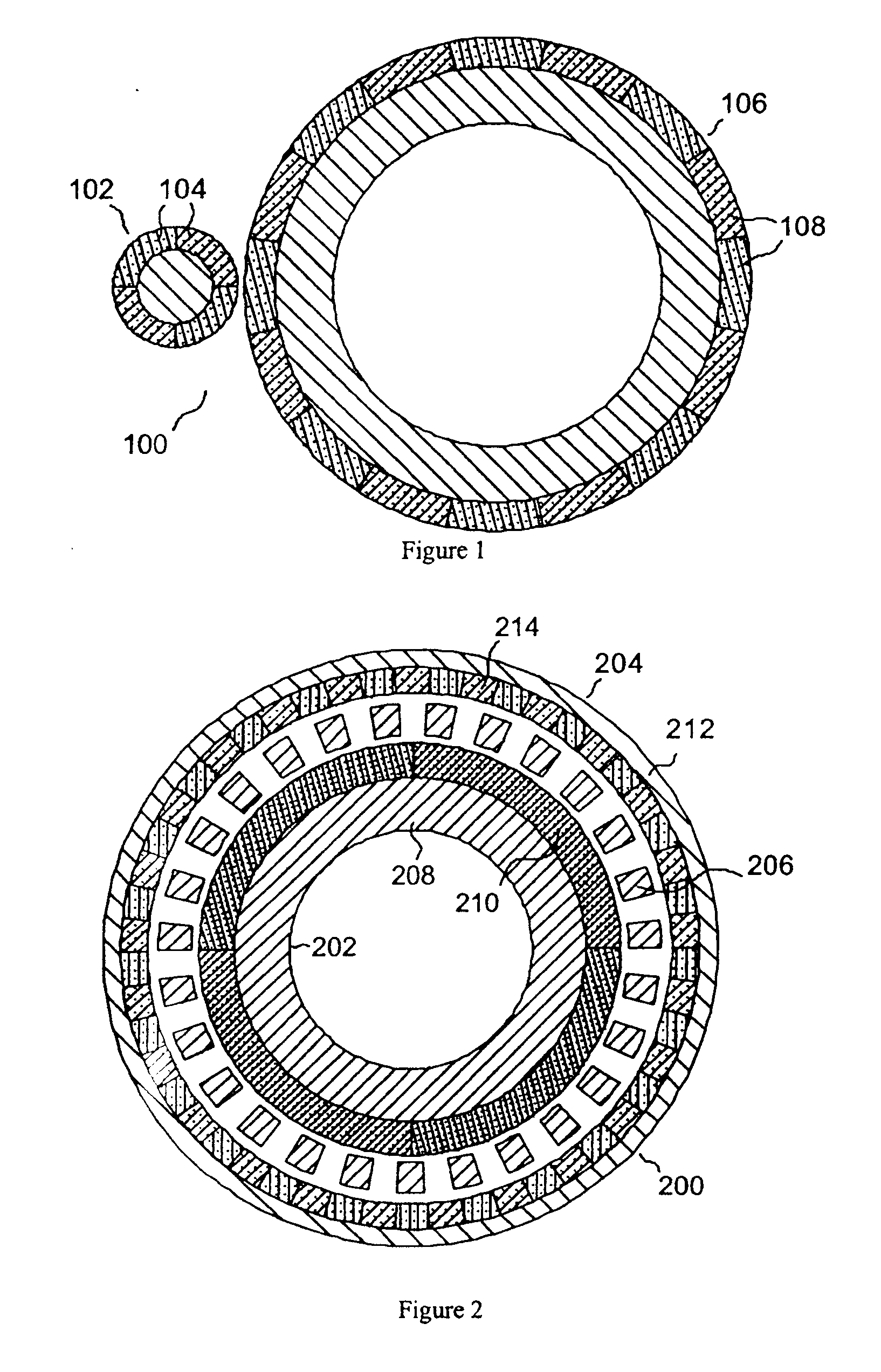

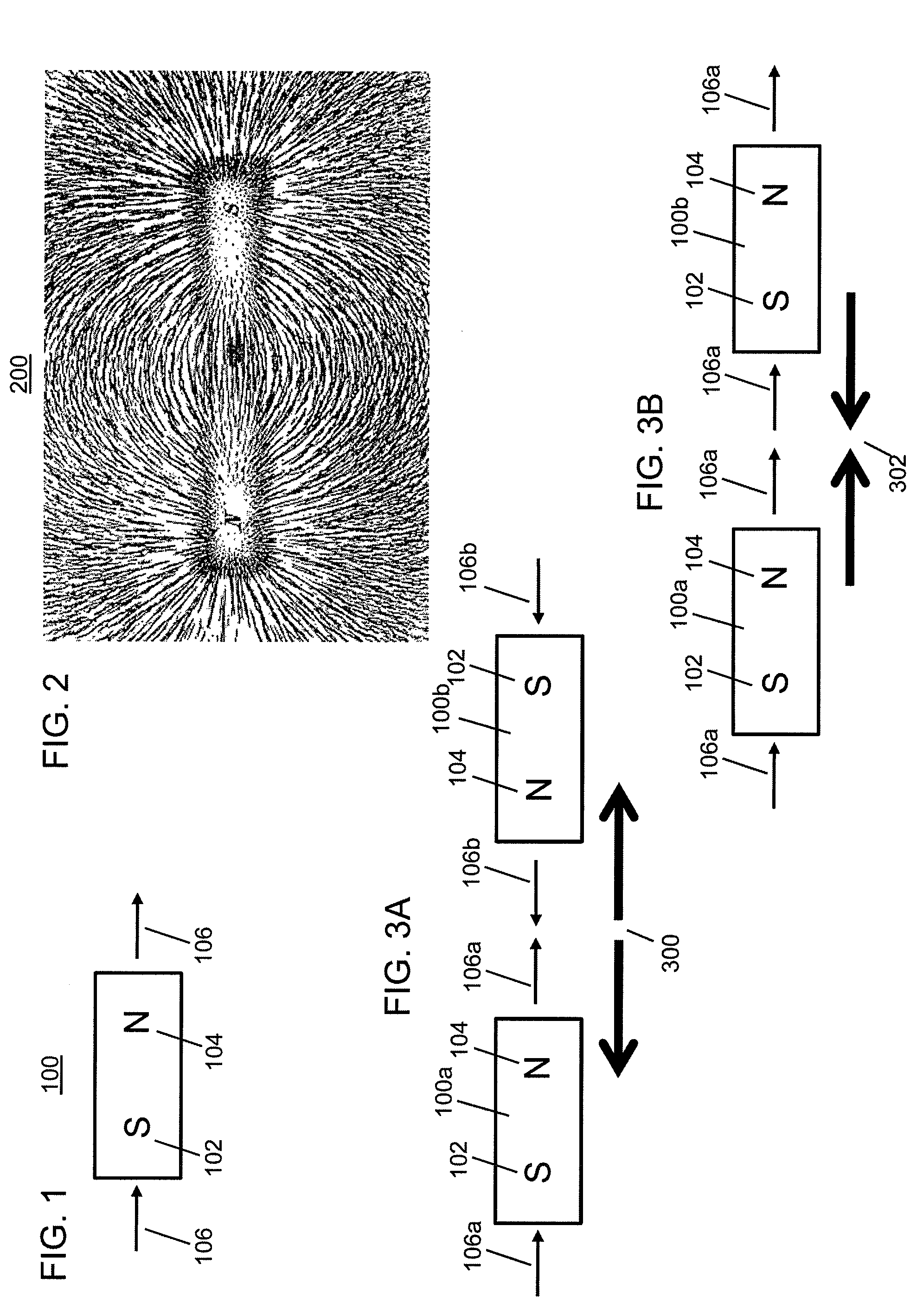

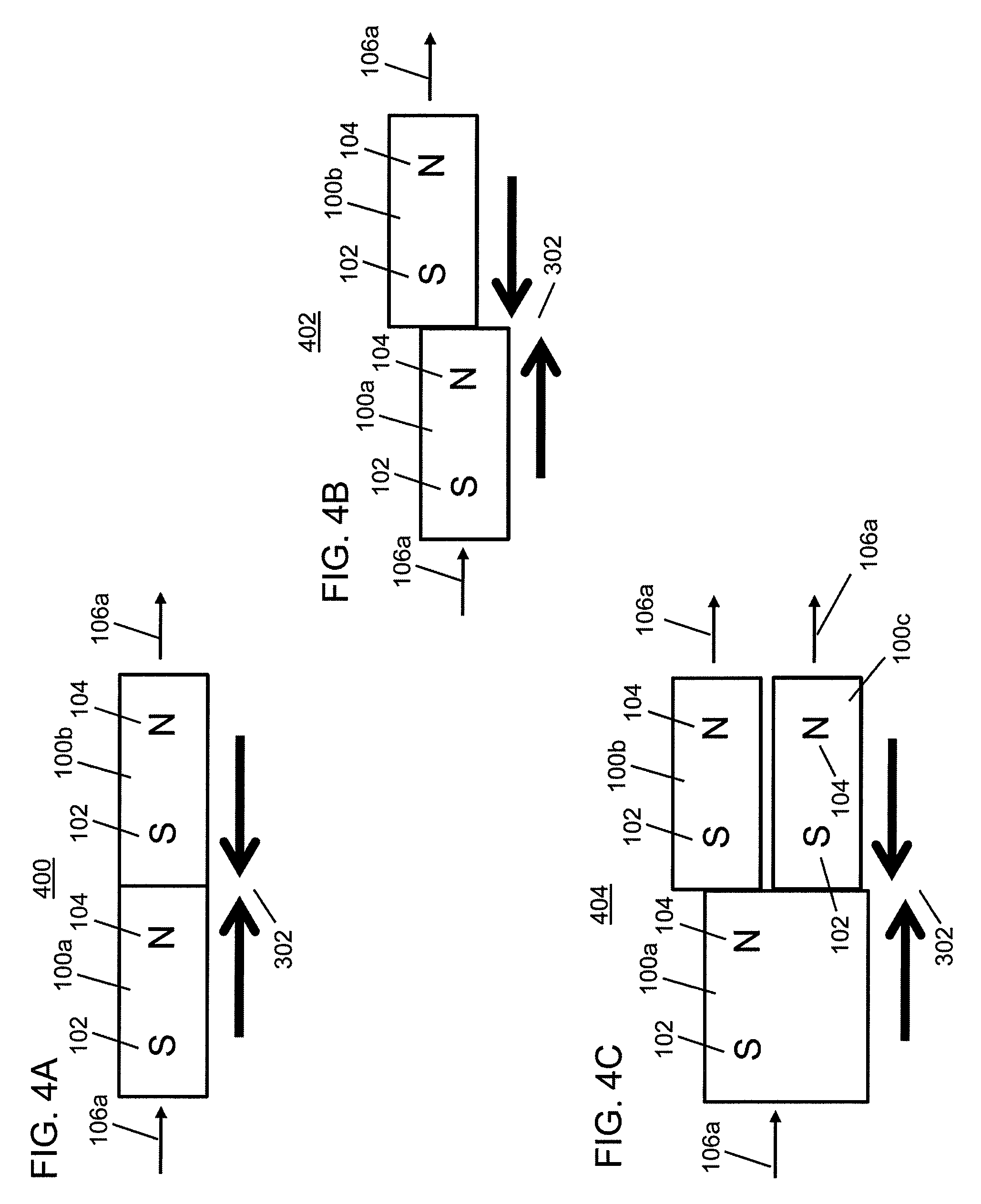

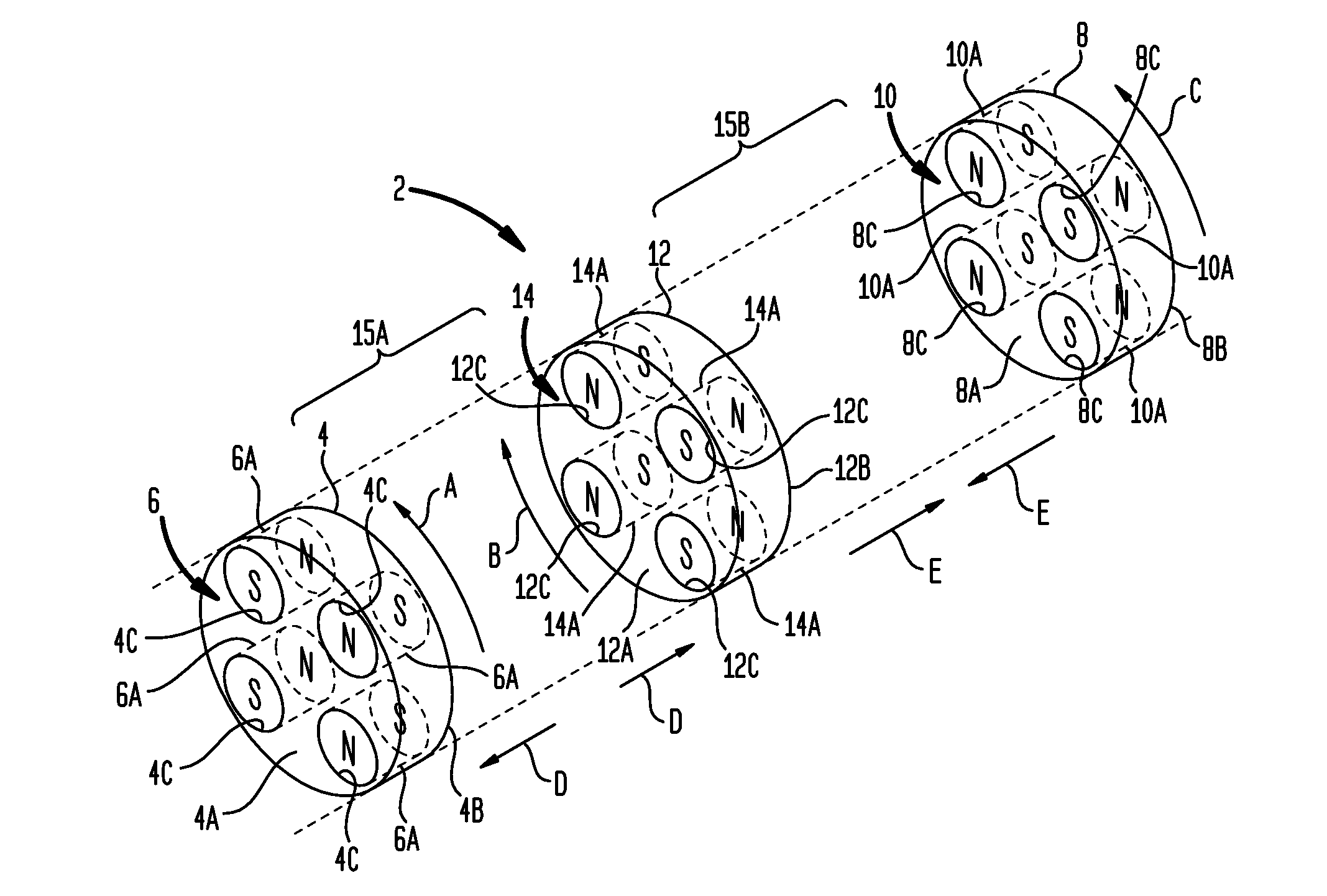

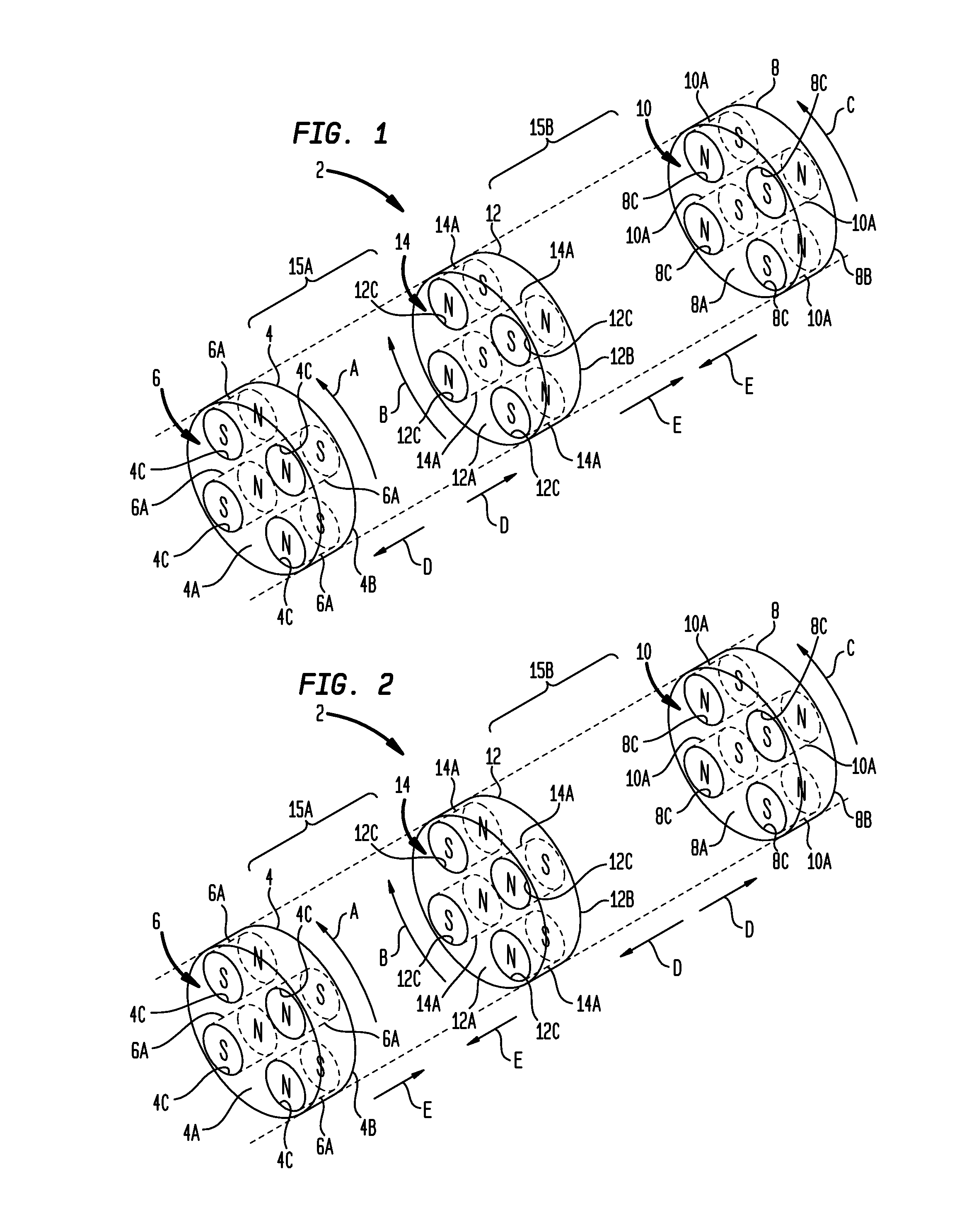

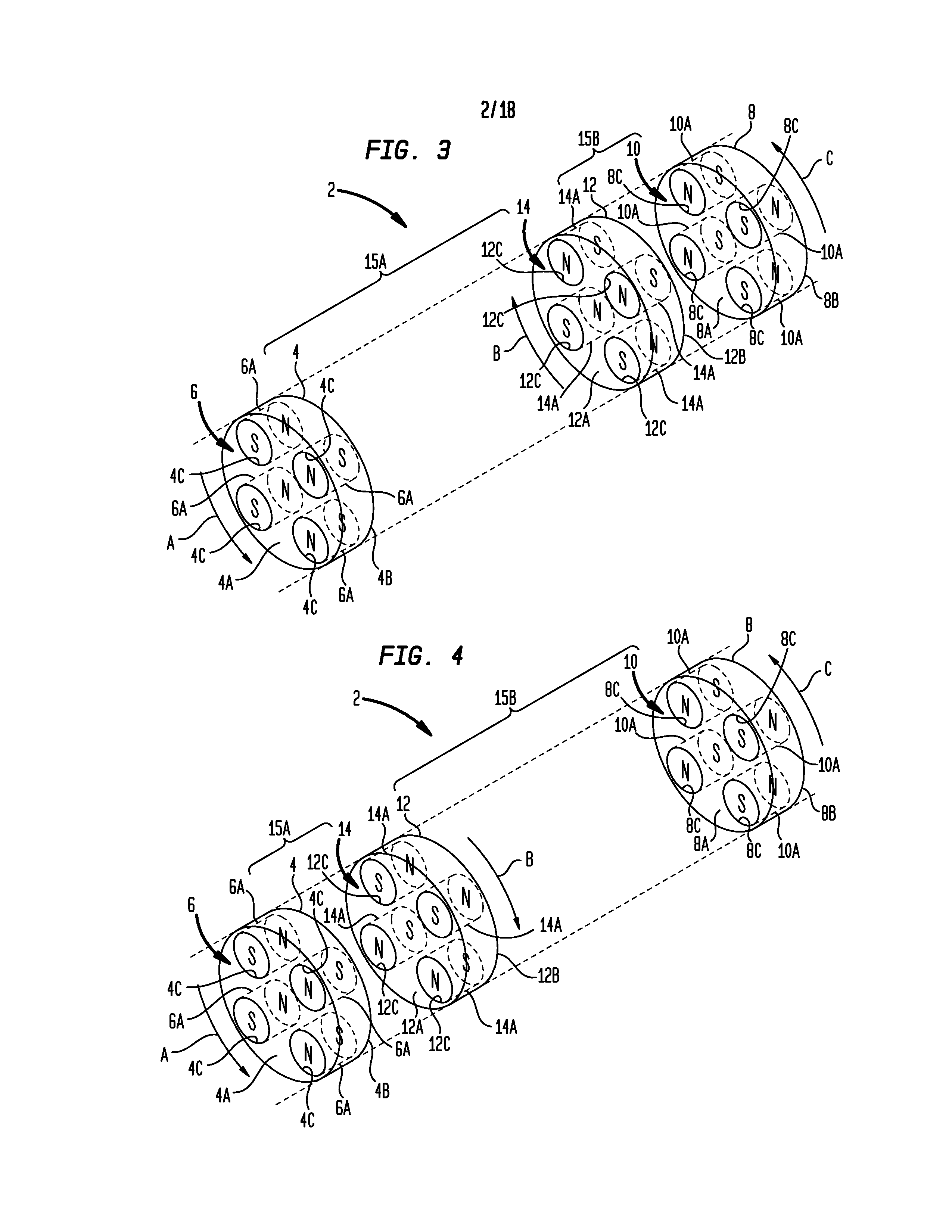

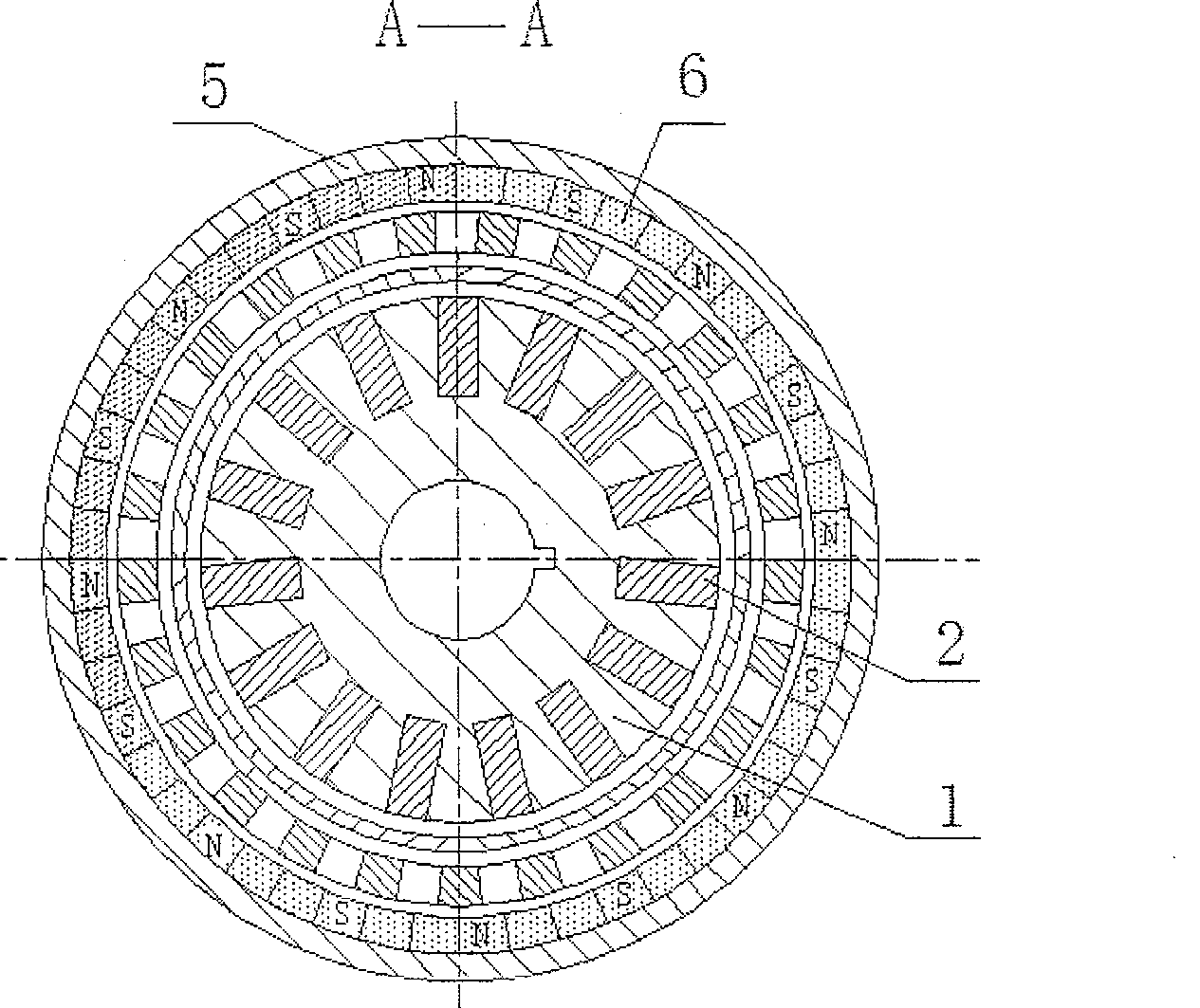

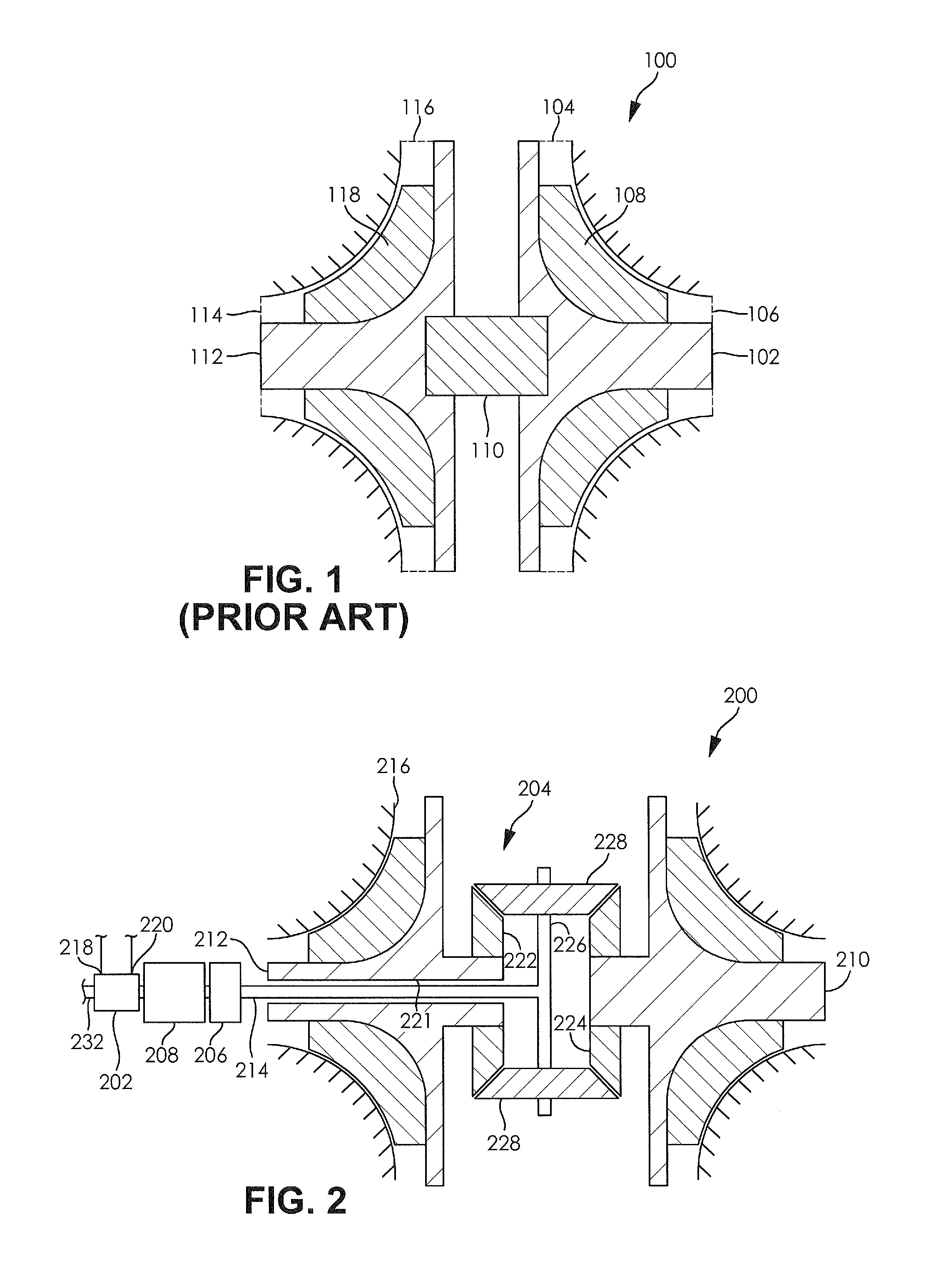

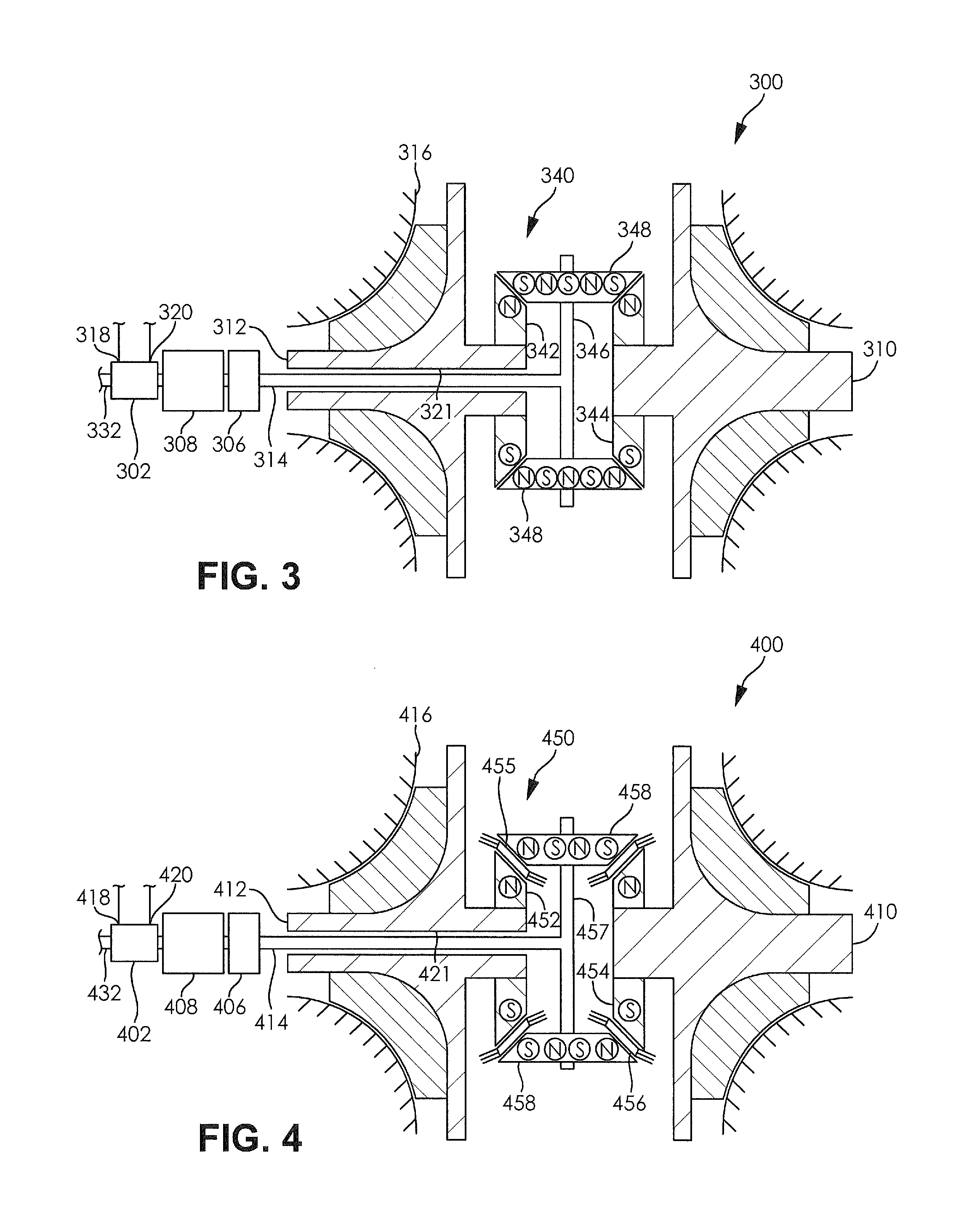

Magnetic coupling using halbach type magnet array

InactiveUS6841910B2Reduce leakageIncrease the magnetic field strengthMagnetic circuit rotating partsPermanent-magnet clutches/brakesCouplingMagnetization

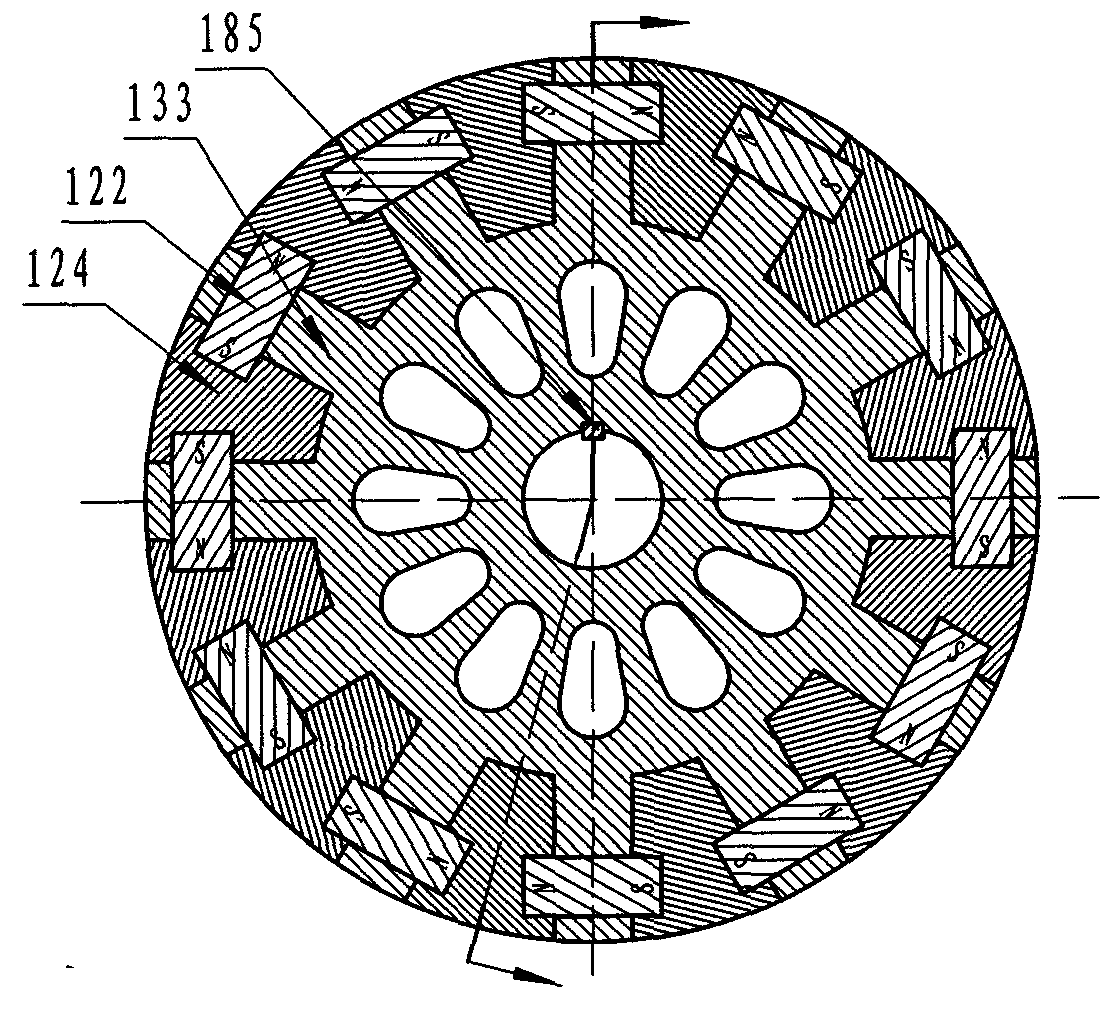

A magnetic coupling having two opposed annular arrays of angularly spaced permanent magnets magnetized to create magnetic north poles and magnetic south poles alternately spaced about each array. The north-pole and south-pole magnets of each array are tapered in cross-section from their surfaces at the gap to an annular surface of the array spaced from the gap, and permanent magnet spacer magnets completely fill in the space between the north-pole and south-pole magnets from the annular surface of the array at the gap to the spaced annular surface with the spacer magnets being magnetized generally transversely to the direction of magnetization of the adjacent north-pole, south-pole magnets so that the magnetic field created by the permanent magnets extends across the gap and annularly through each array to cause one of the arrays to rotate in synchronism with the other array.

Owner:QUADRANT TECH CORP

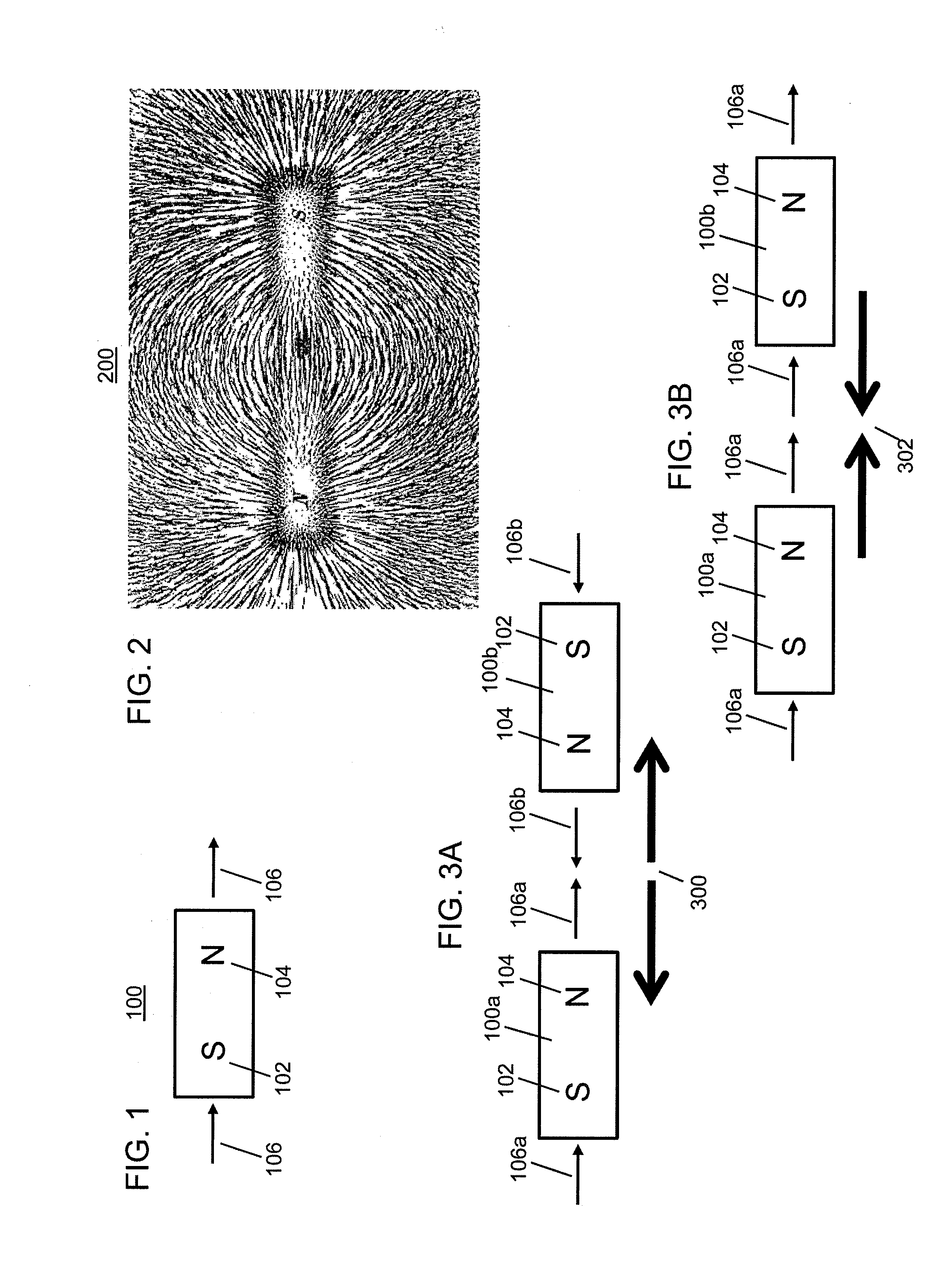

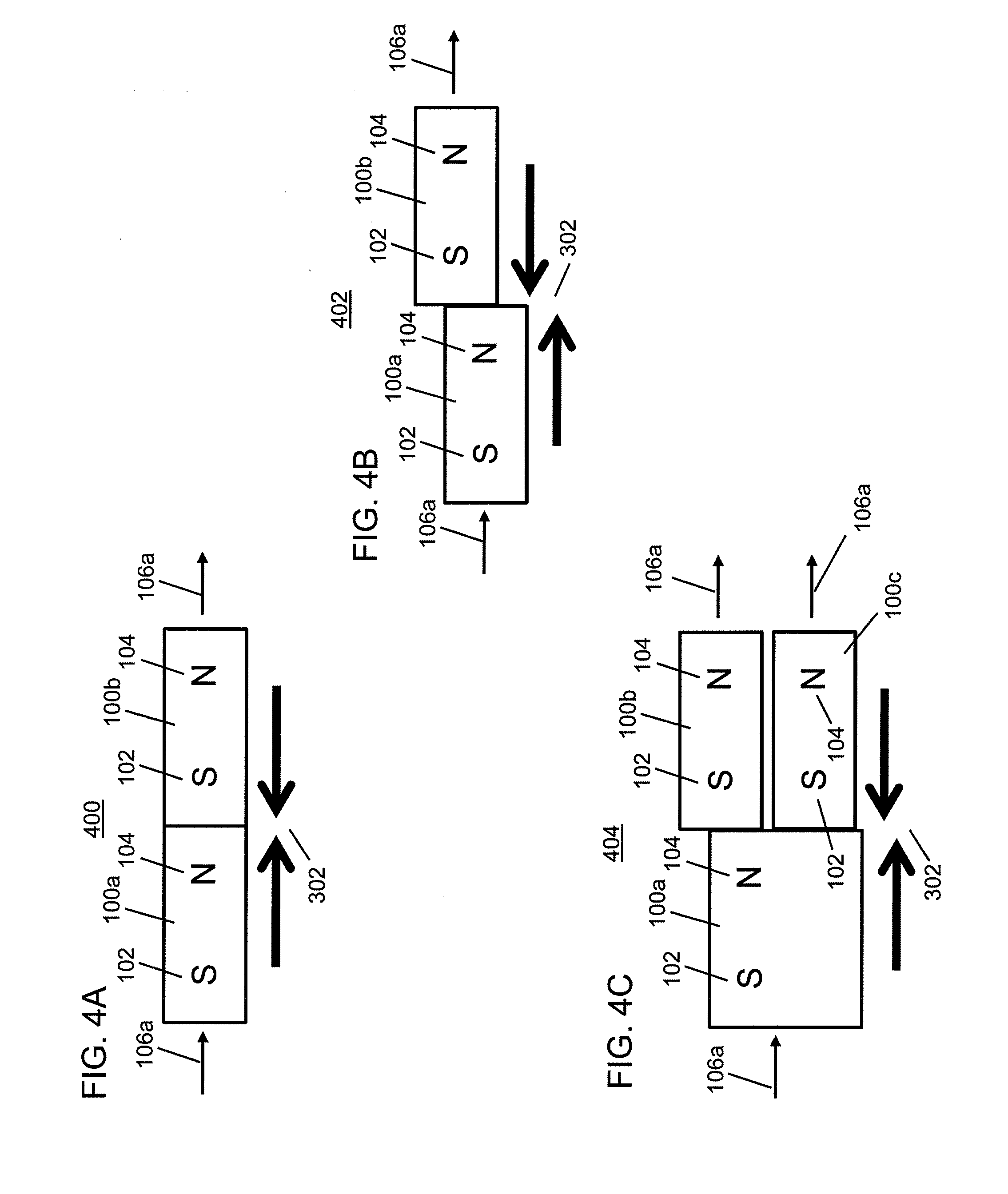

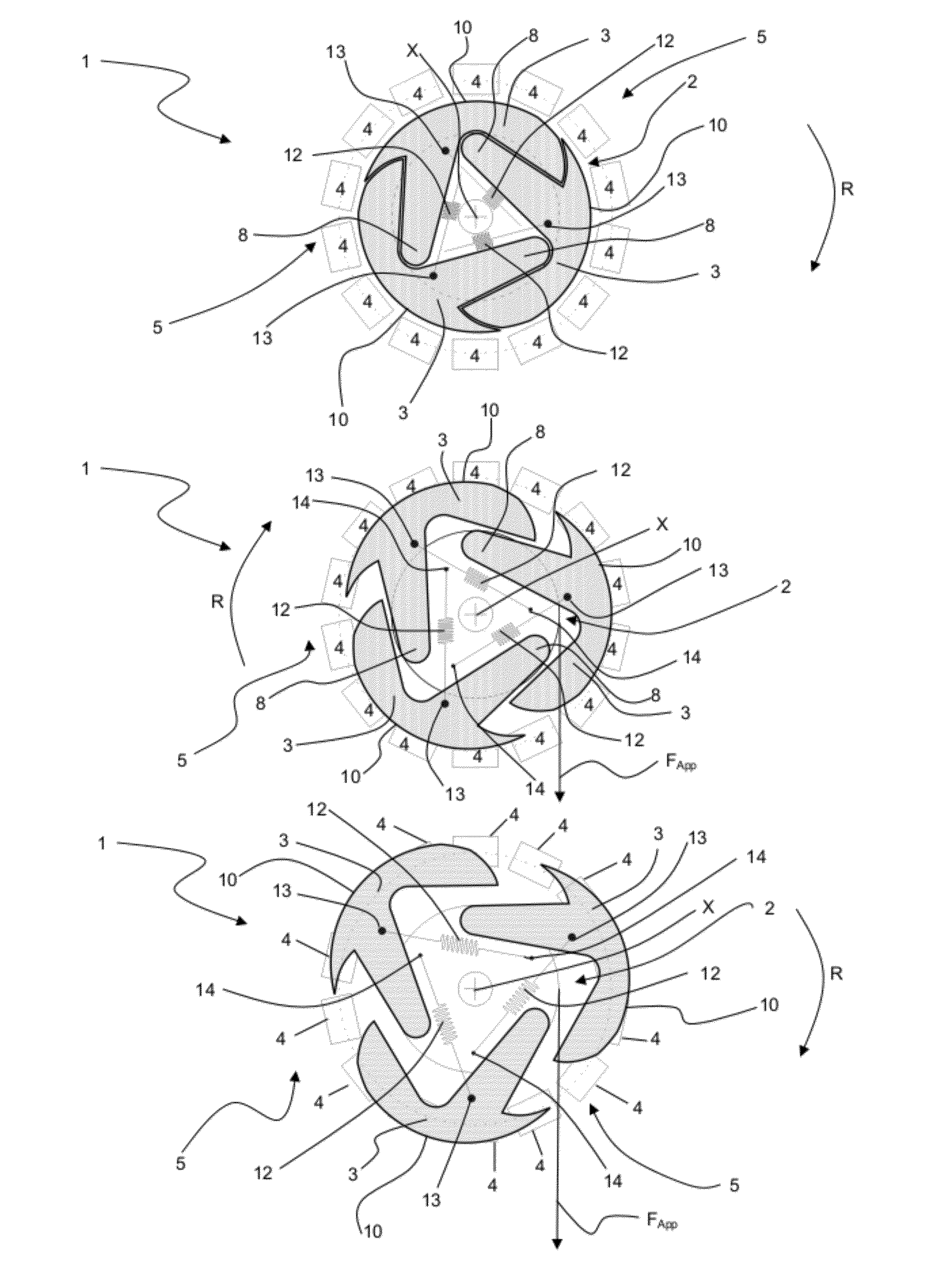

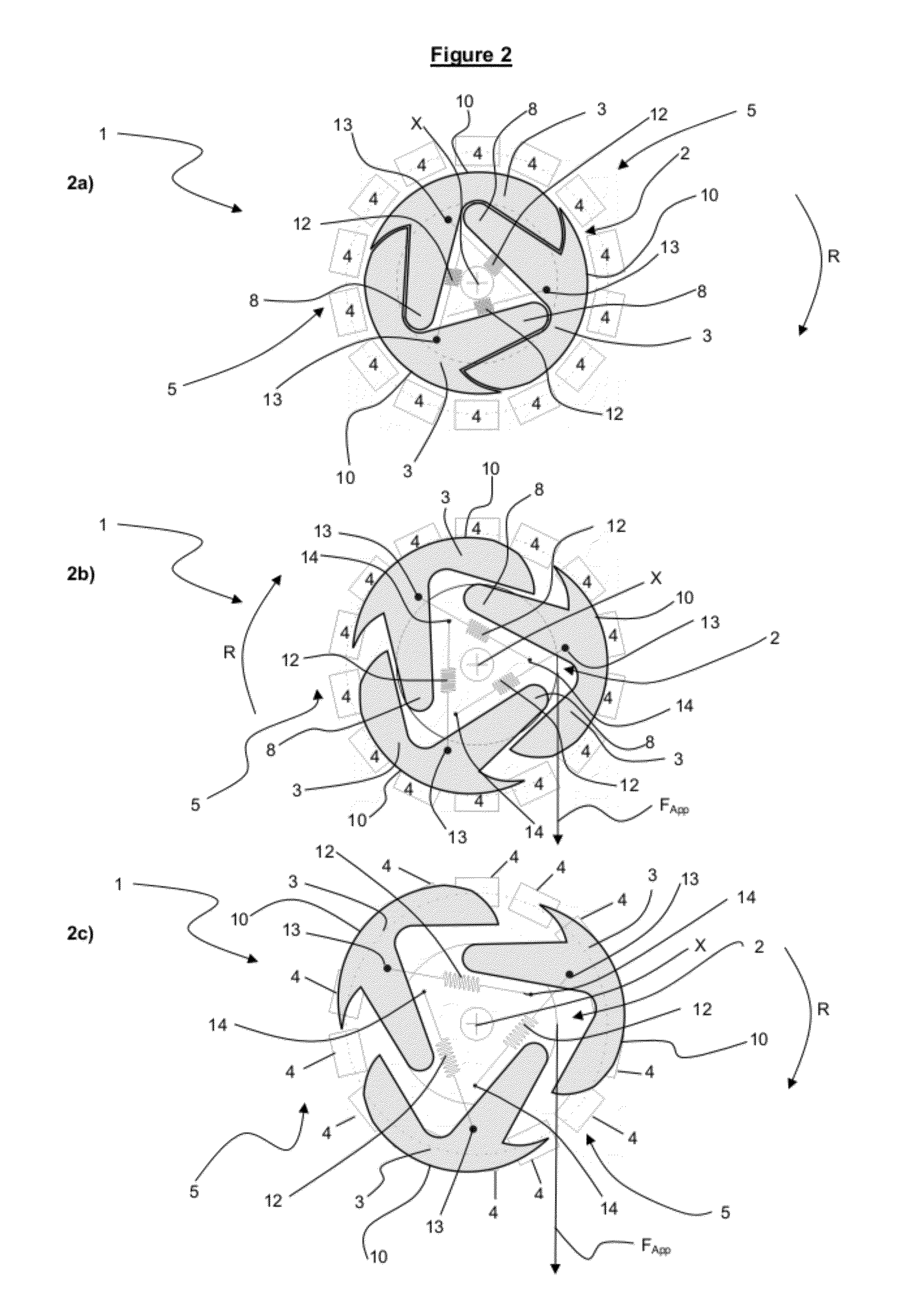

Field emission system and method

InactiveUS20090278642A1Electromagnets without armaturesPermanent magnetsElectric fieldAtomic physics

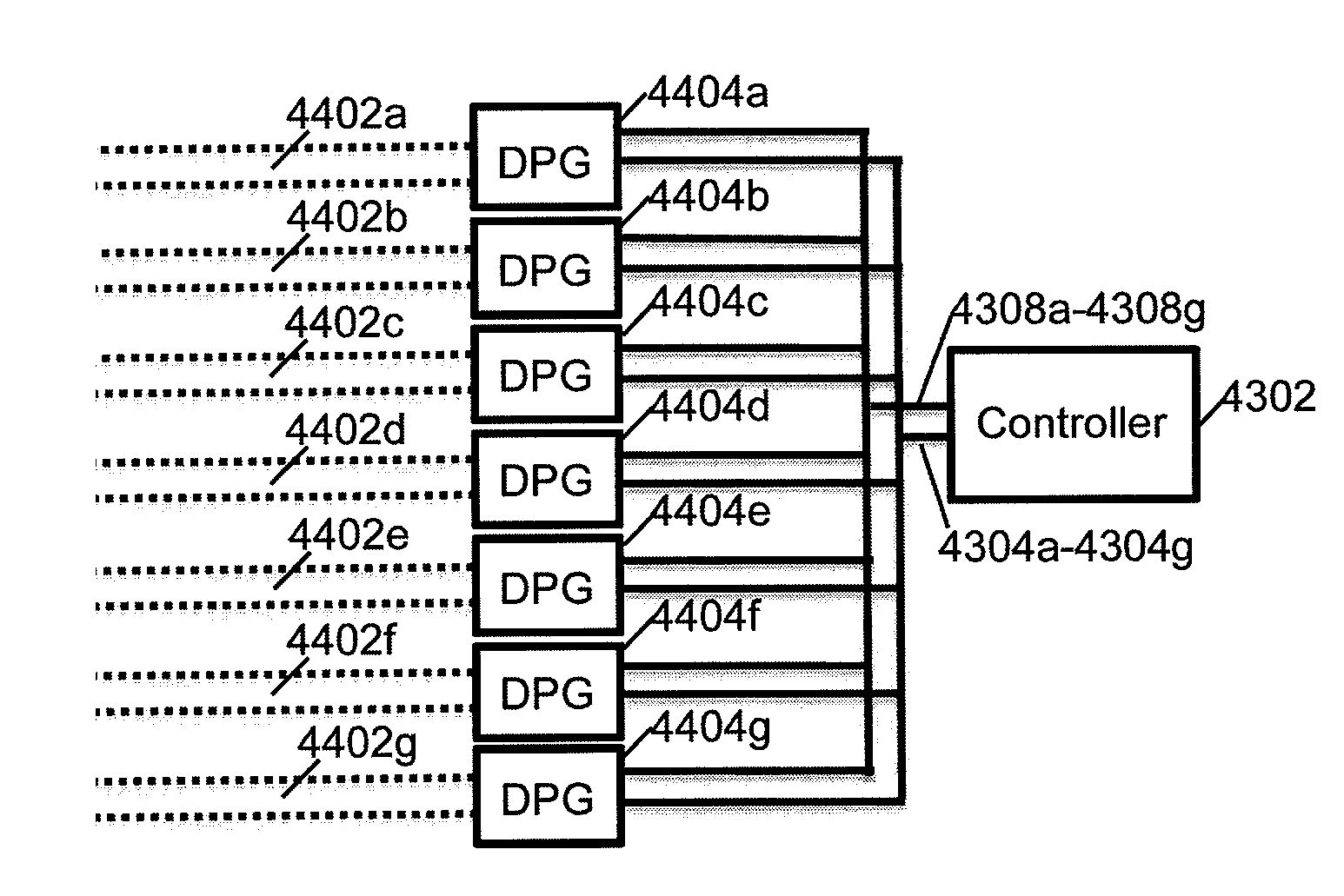

An improved field emission system and method is provided that involves field emission structures having electric or magnetic field sources. The magnitudes, polarities, and positions of the magnetic or electric field sources are configured to have desirable correlation properties, which may be in accordance with a code. The correlation properties correspond to a desired spatial force function where spatial forces between field emission structures correspond to relative alignment, separation distance, and the spatial force function.

Owner:CORRELATED MAGNETICS RES LLC

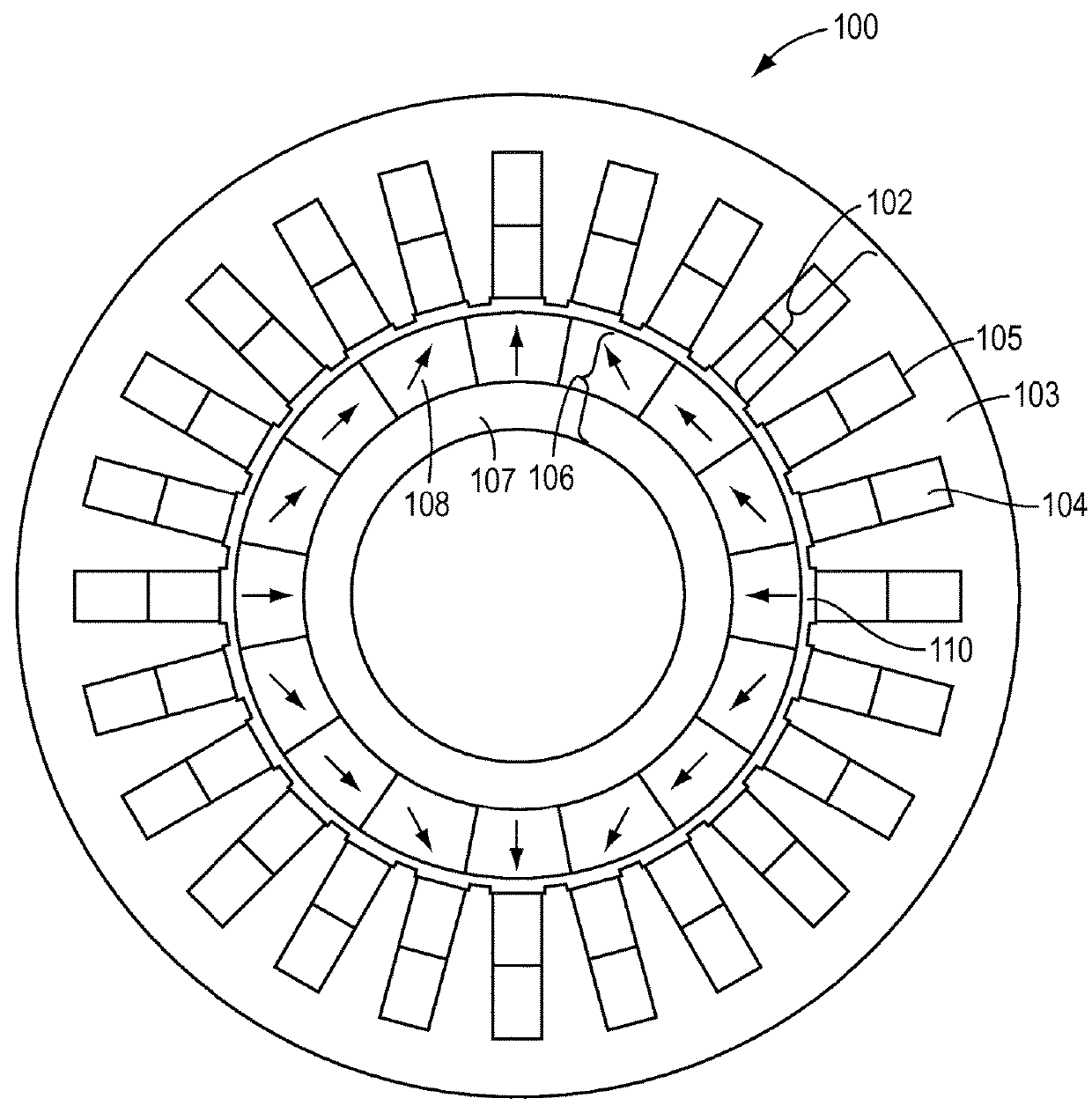

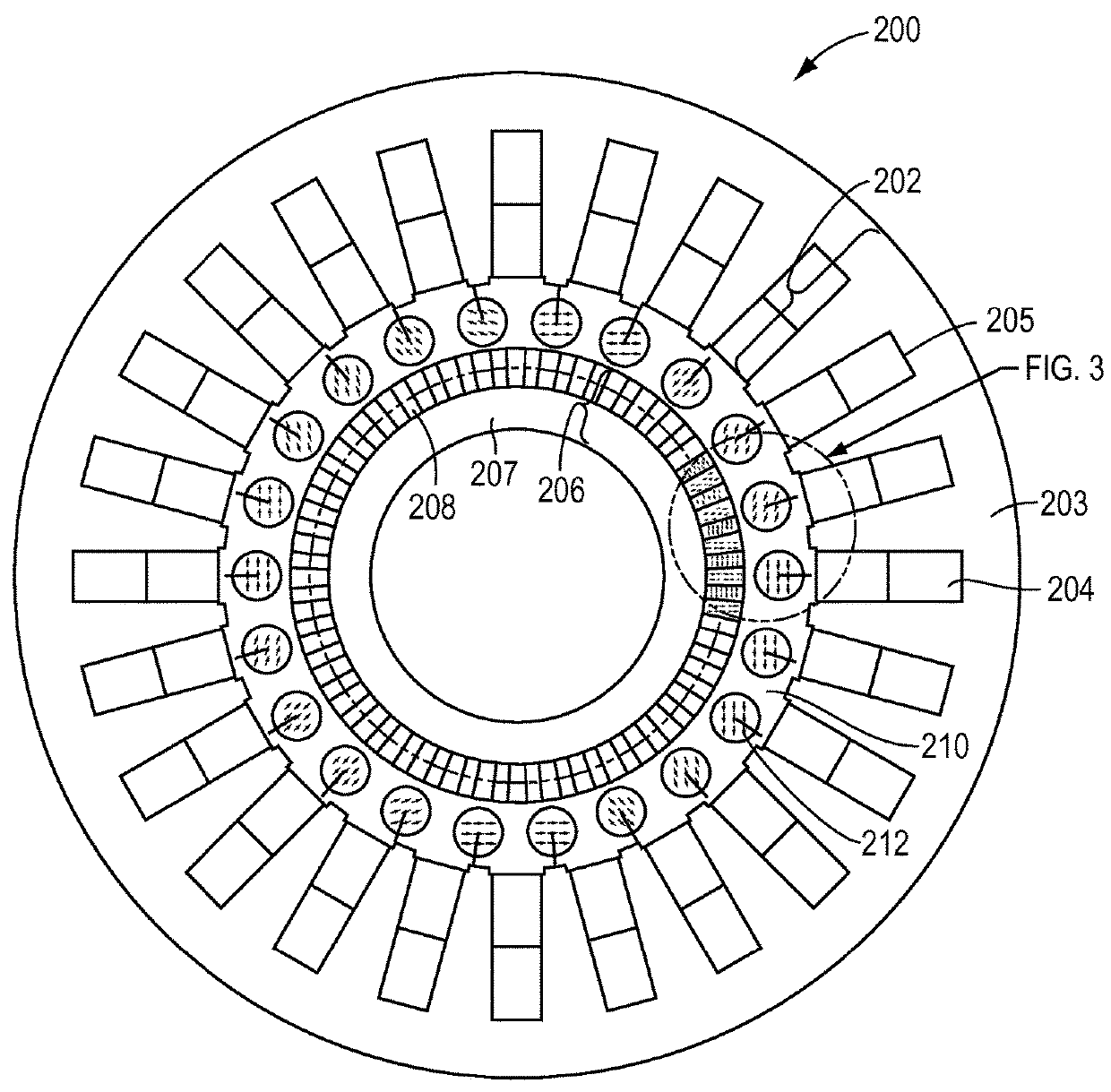

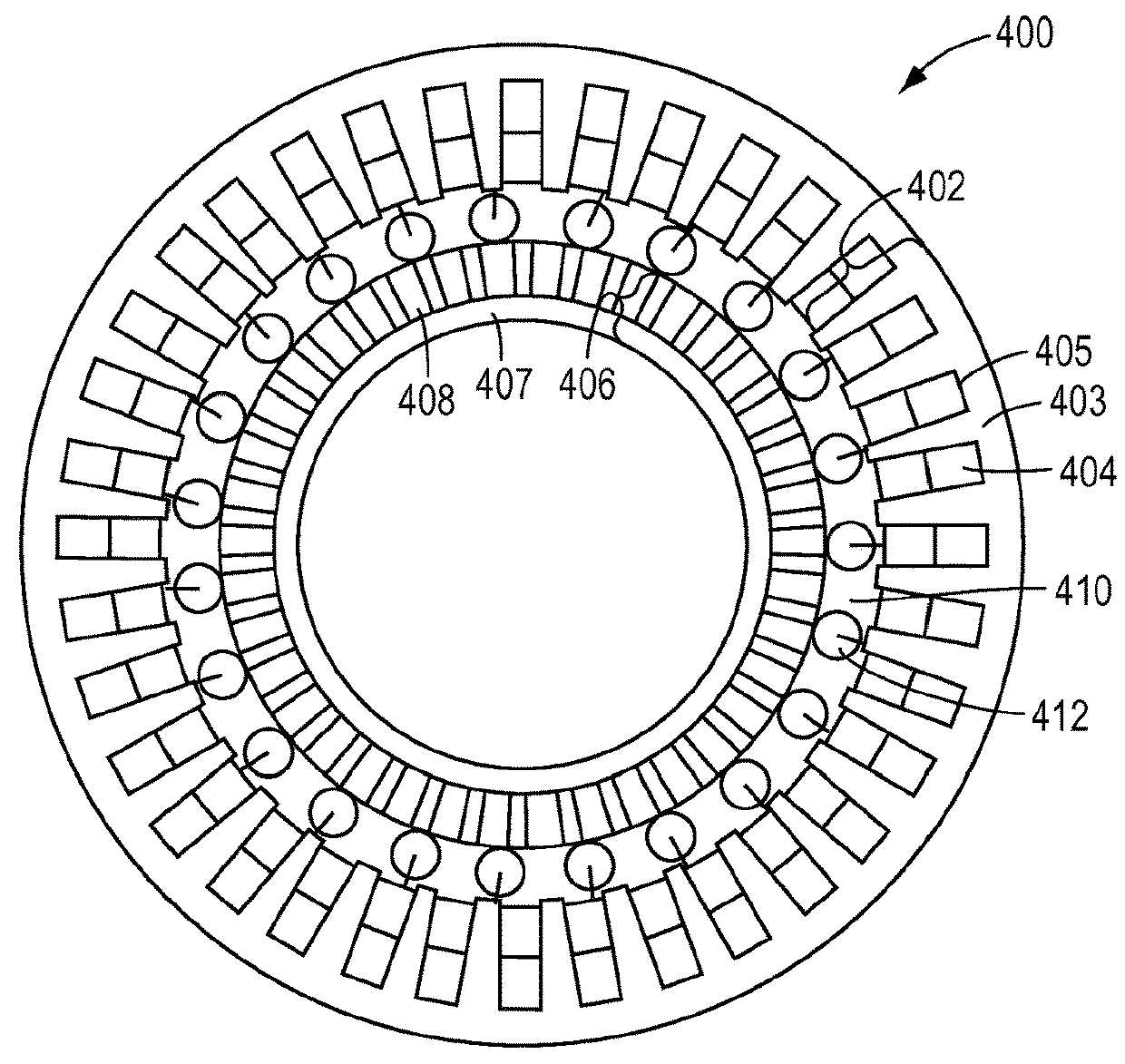

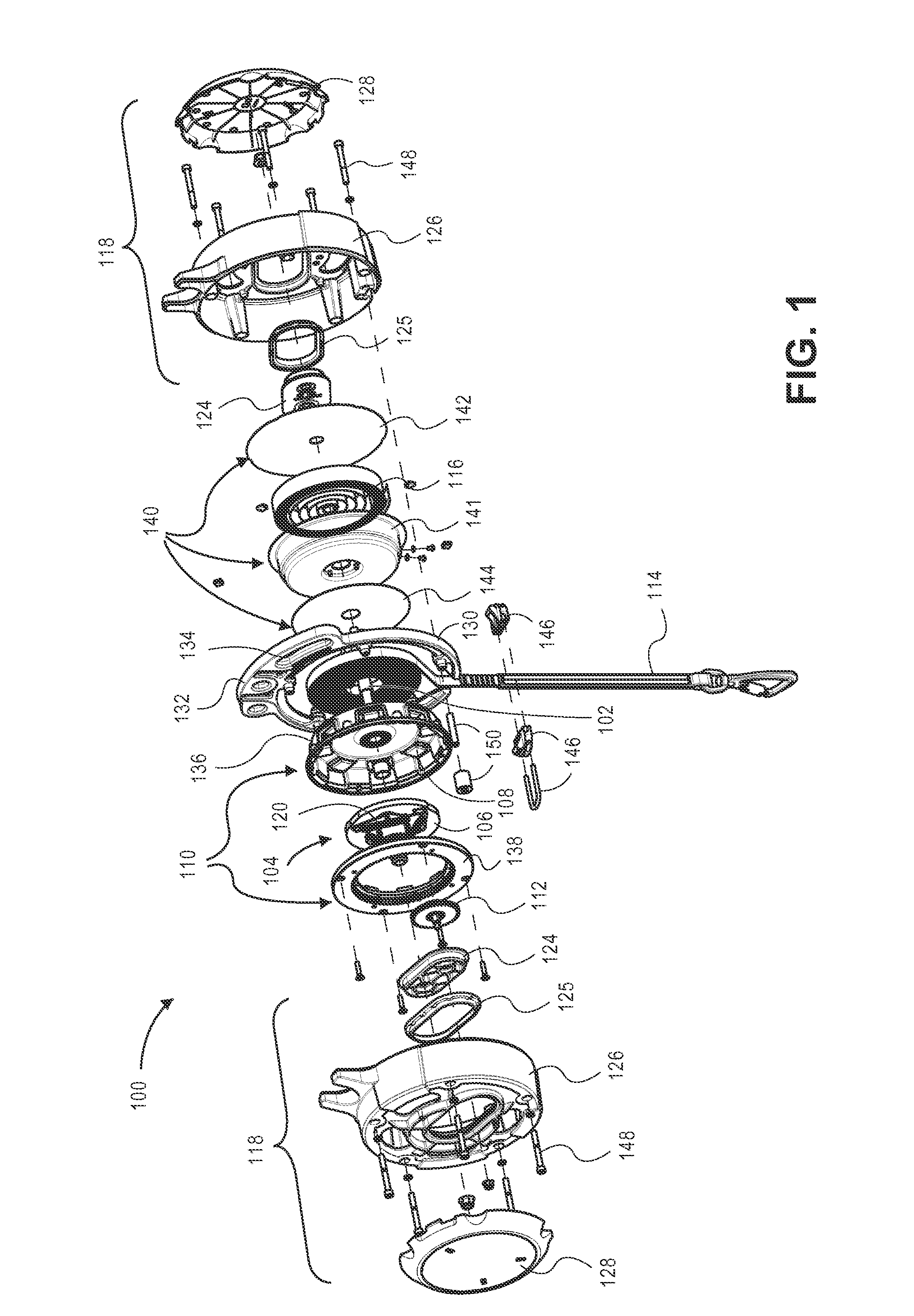

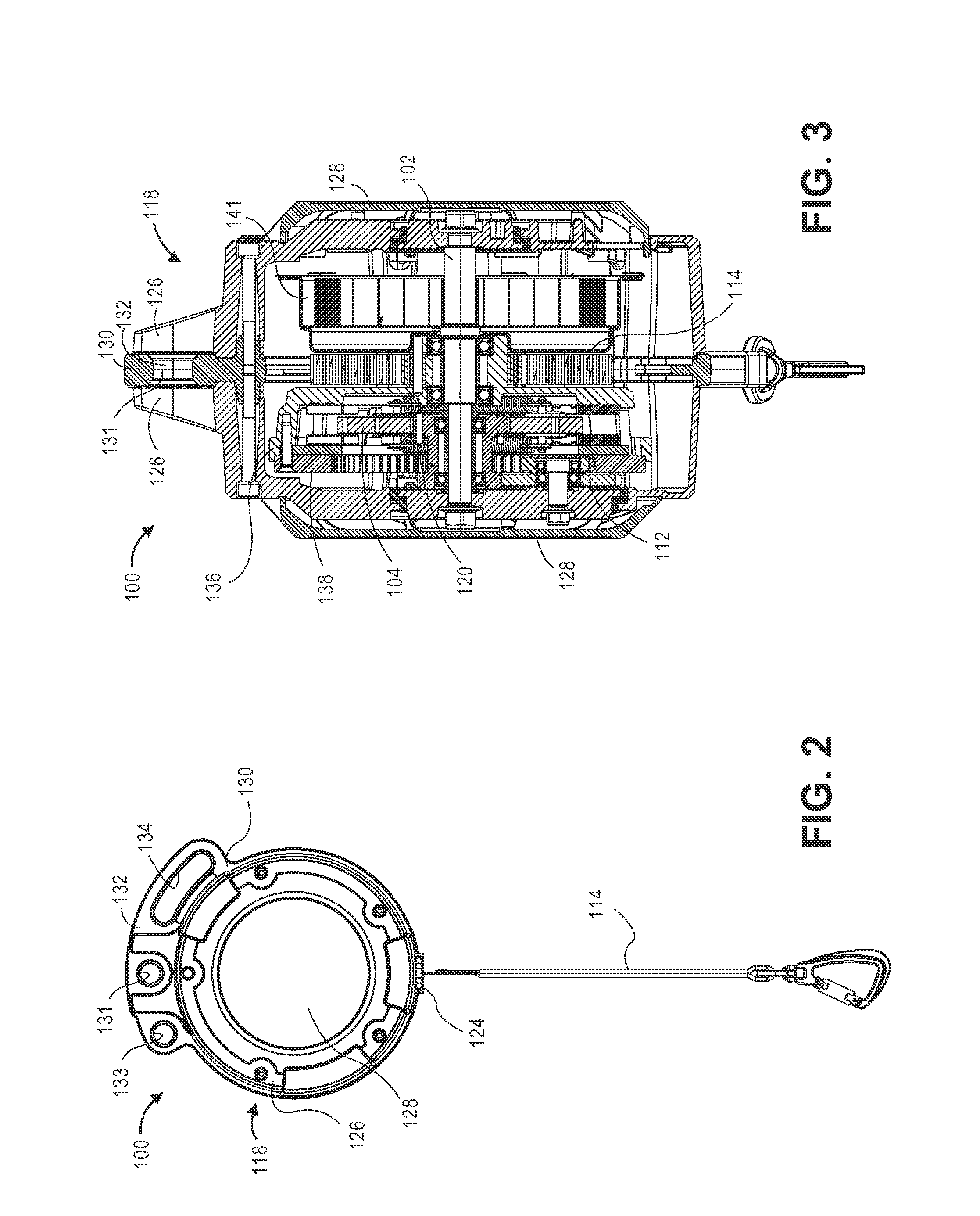

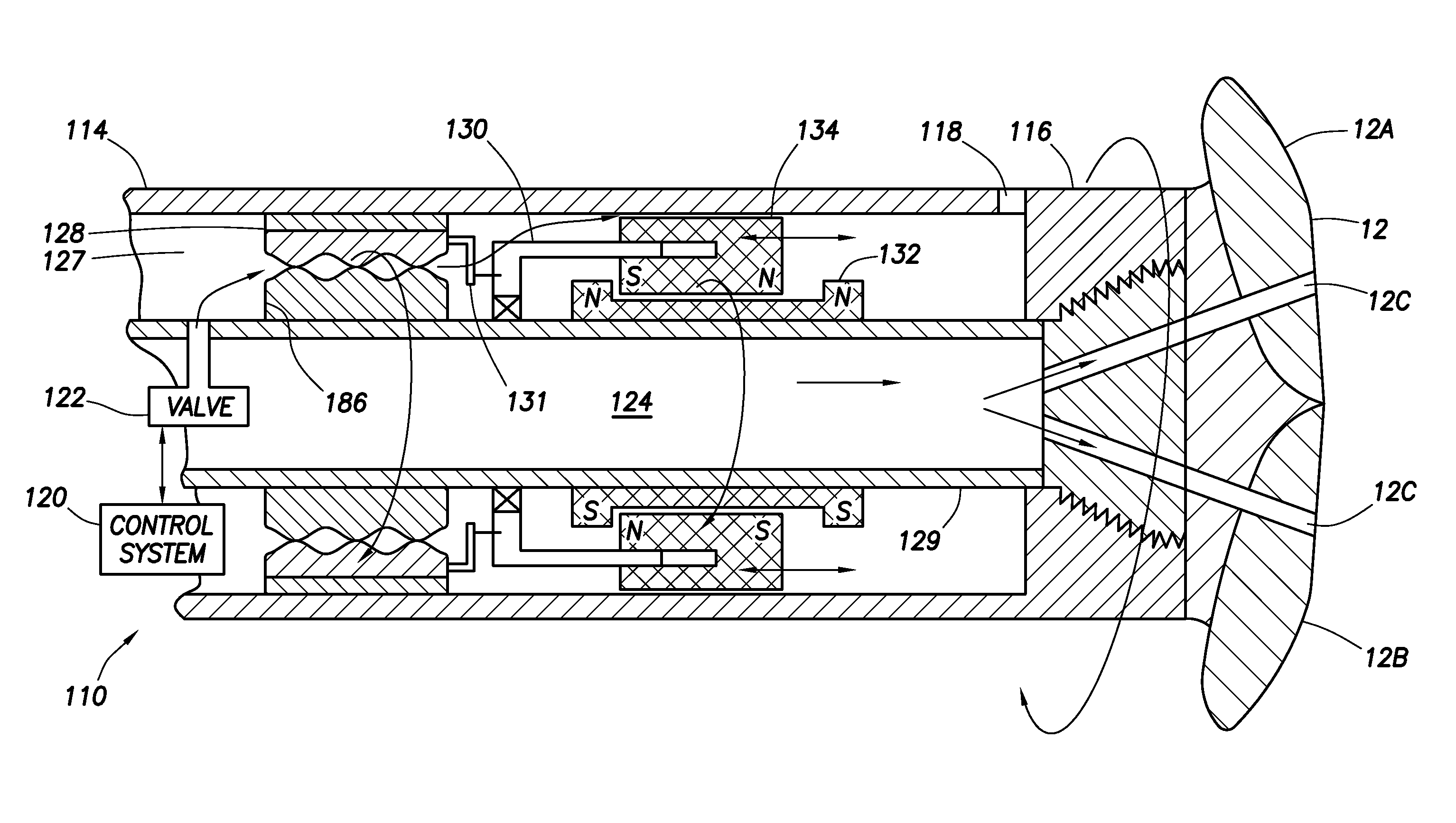

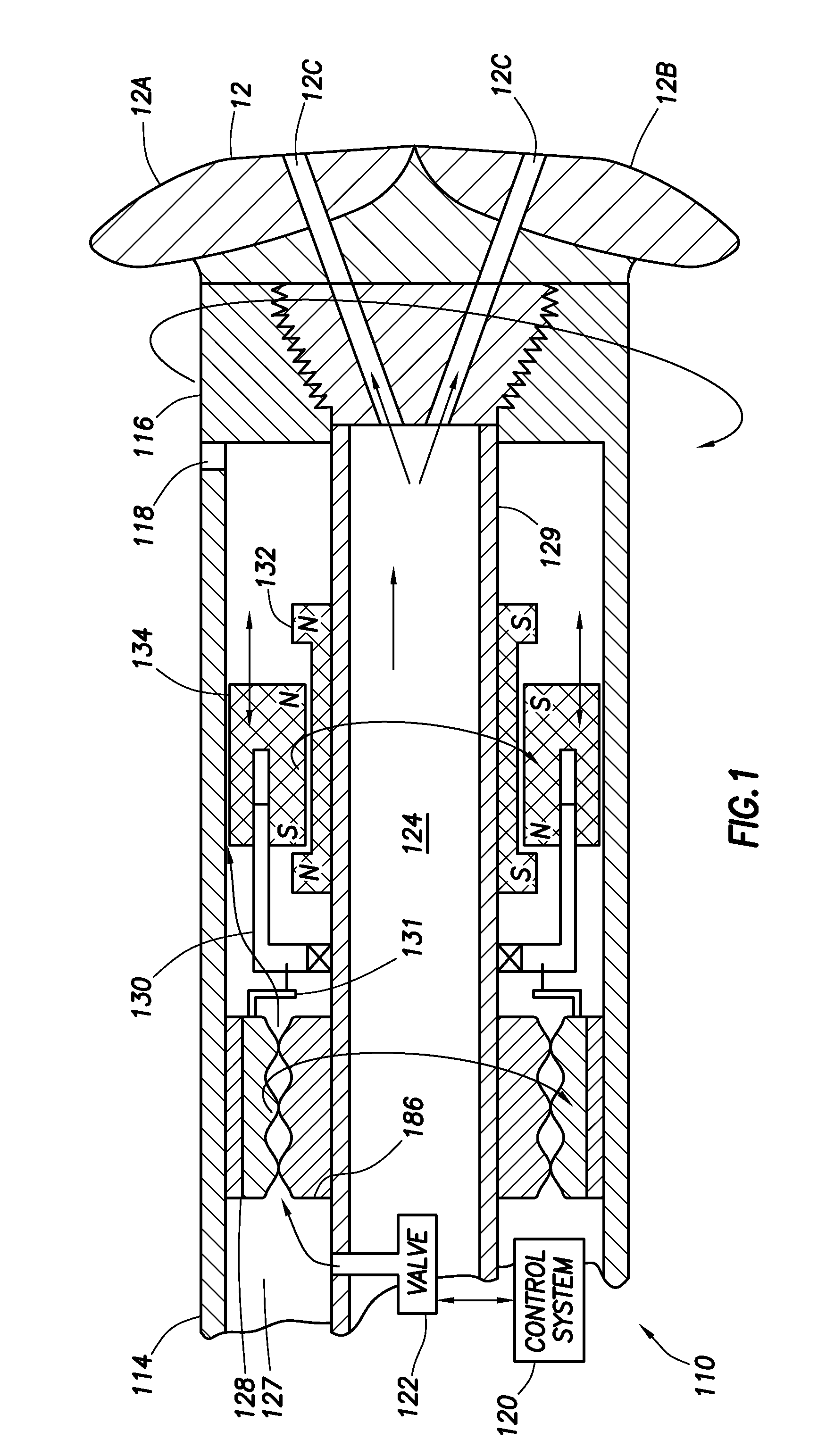

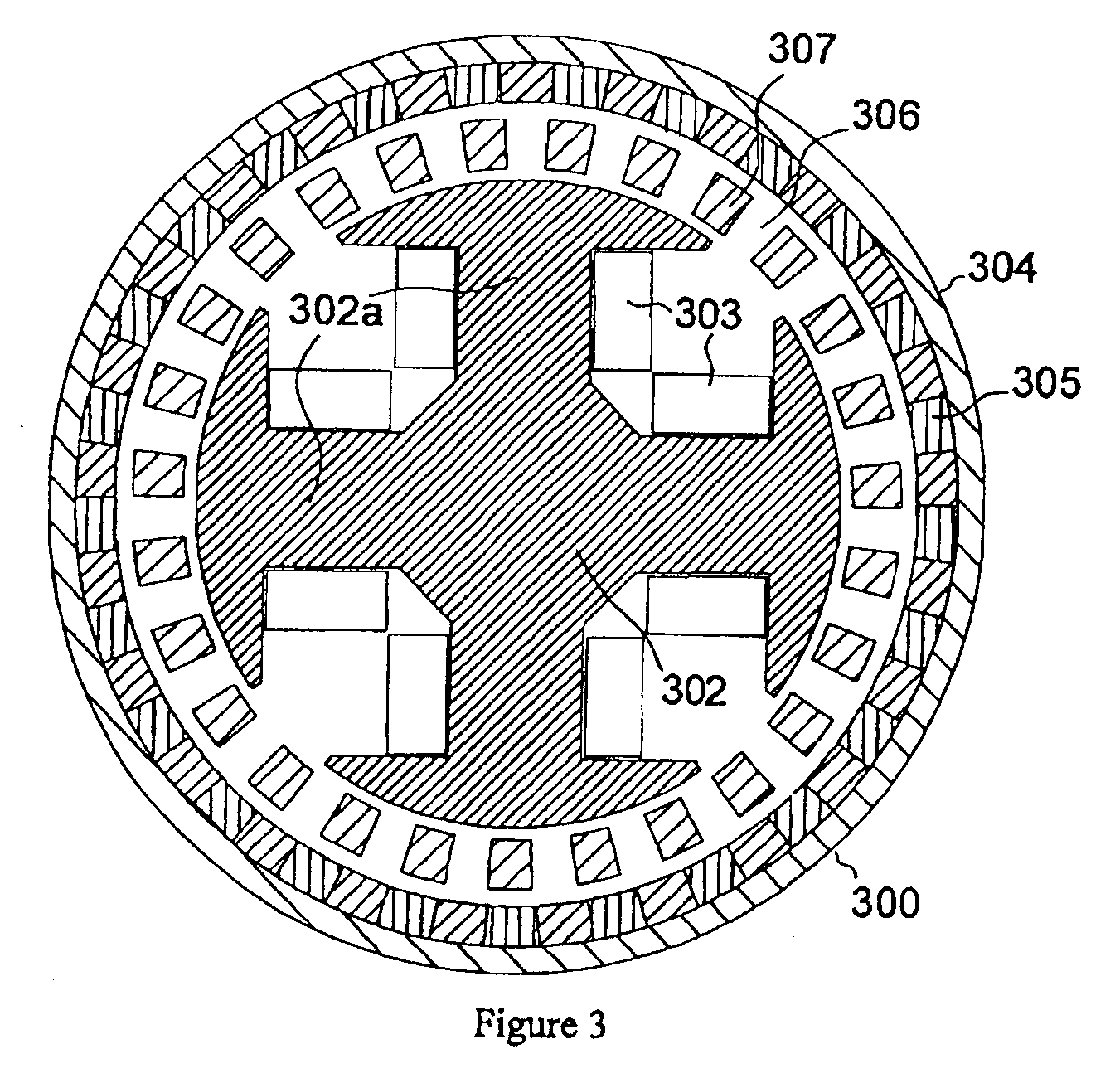

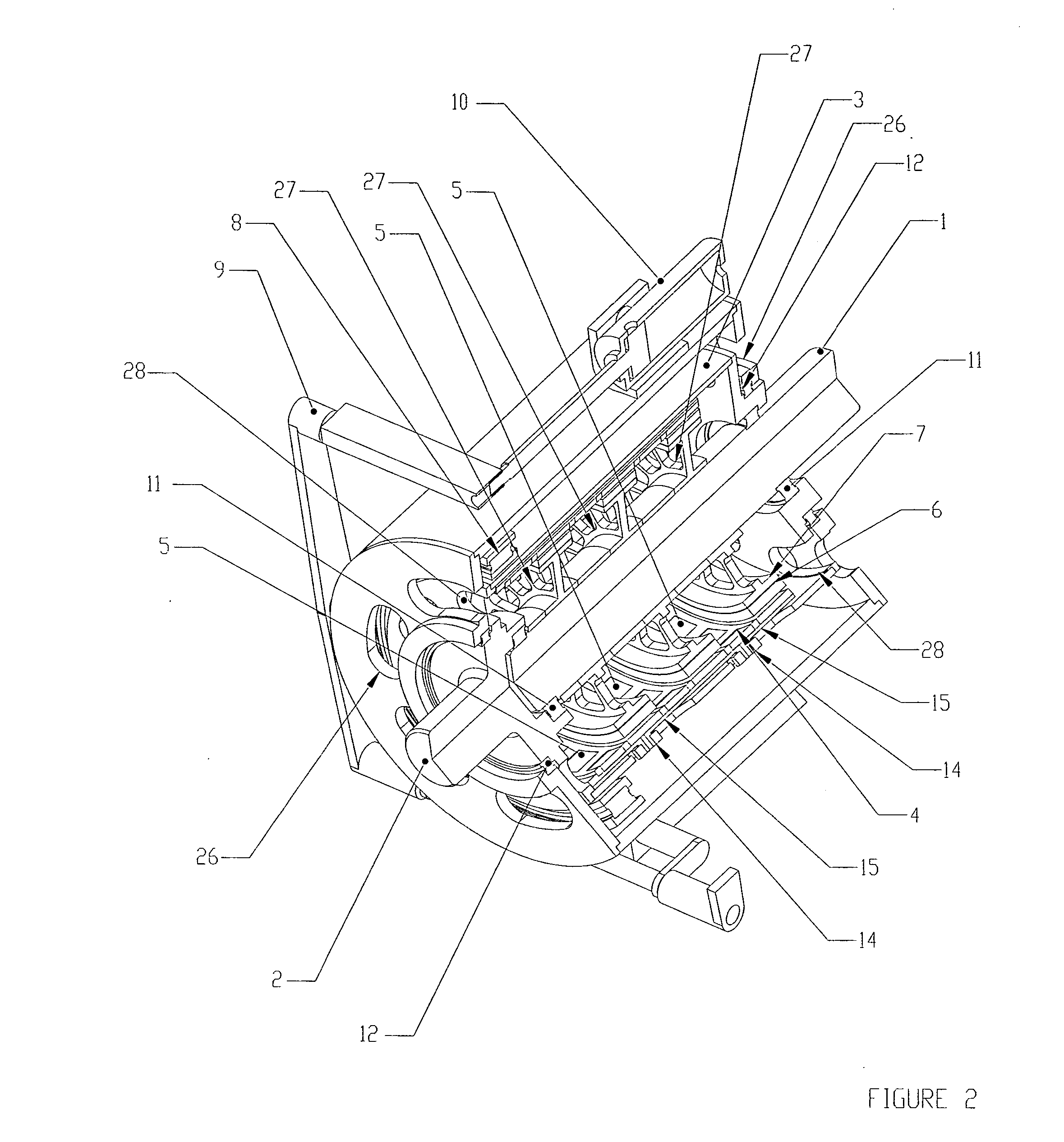

Magnetic drive devices, and related systems and methods

A magnetic drive device may comprise a stator comprising a plurality of windings for generating a first number of magnetic pole pairs and a rotor comprising a plurality of permanent magnets for generating a second number of magnetic pole pairs that differs from the first number of magnetic pole pairs. The magnetic drive device may further comprise a plurality of free-spinning interpole elements disposed within an air gap between the stator and the rotor. The interpole elements may produce a magnetomotive force and harmonically couple the magnetic pole pairs of the stator with the magnet pole pairs of the rotor.

Owner:NAT OILWELL VARCO LP

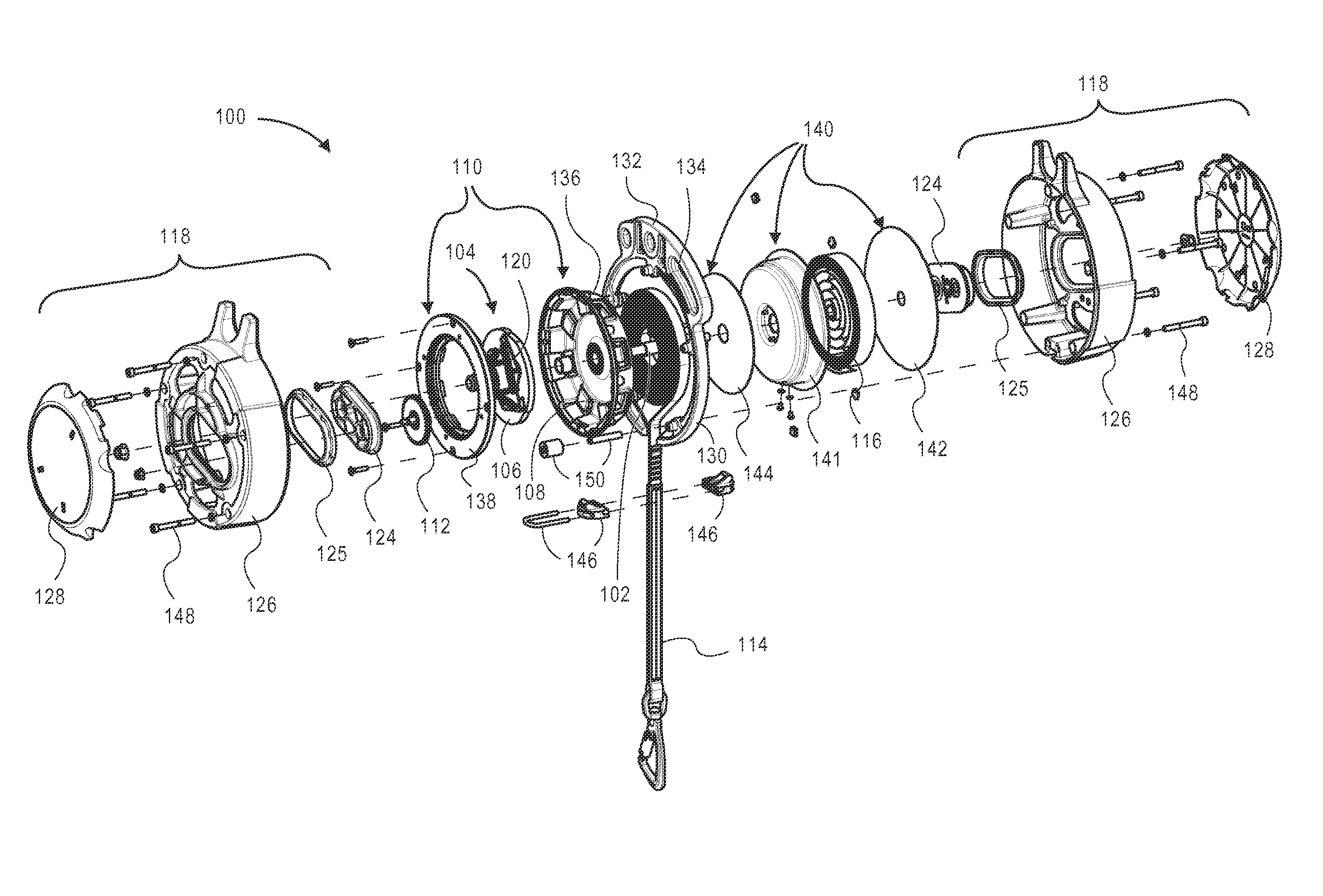

Braking mechanisms

ActiveUS20120055740A1Improve braking effectEffective meanSafety beltsSelf acting brakesEngineeringEddy current

An eddy-current braking mechanism including a rotor, rotatable about a rotor axis; at least one electrically conductive member coupled to the rotor for rotation therewith; at least one magnet configured to apply a magnetic field extending at least partially orthogonal to the plane of rotation of the conductive member, and characterised in that upon rotation of the rotor, the conductive member is configured to move at least partially radially from the rotor axis into the applied magnetic field.

Owner:EDDY CURRENT PARTNERSHIP

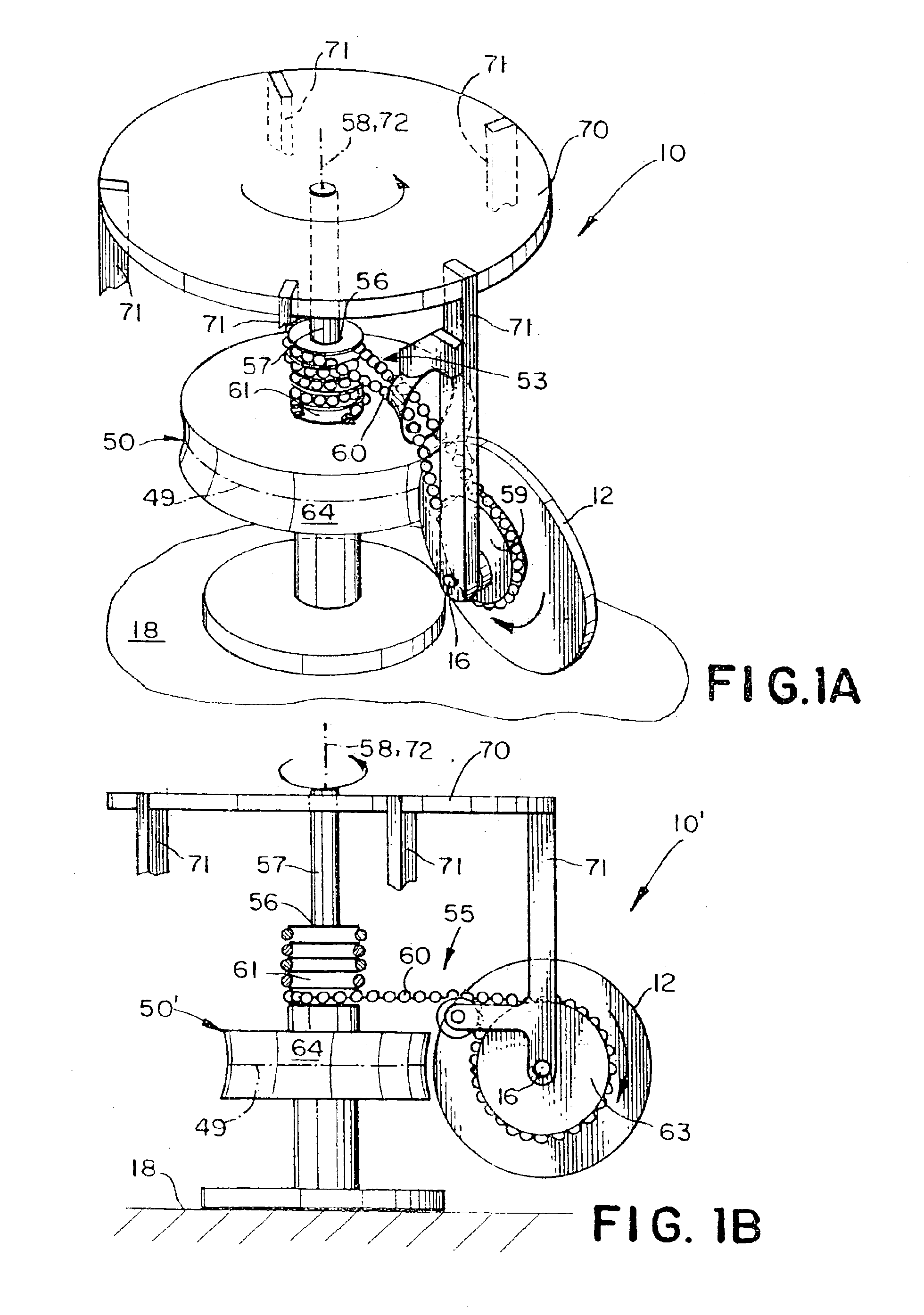

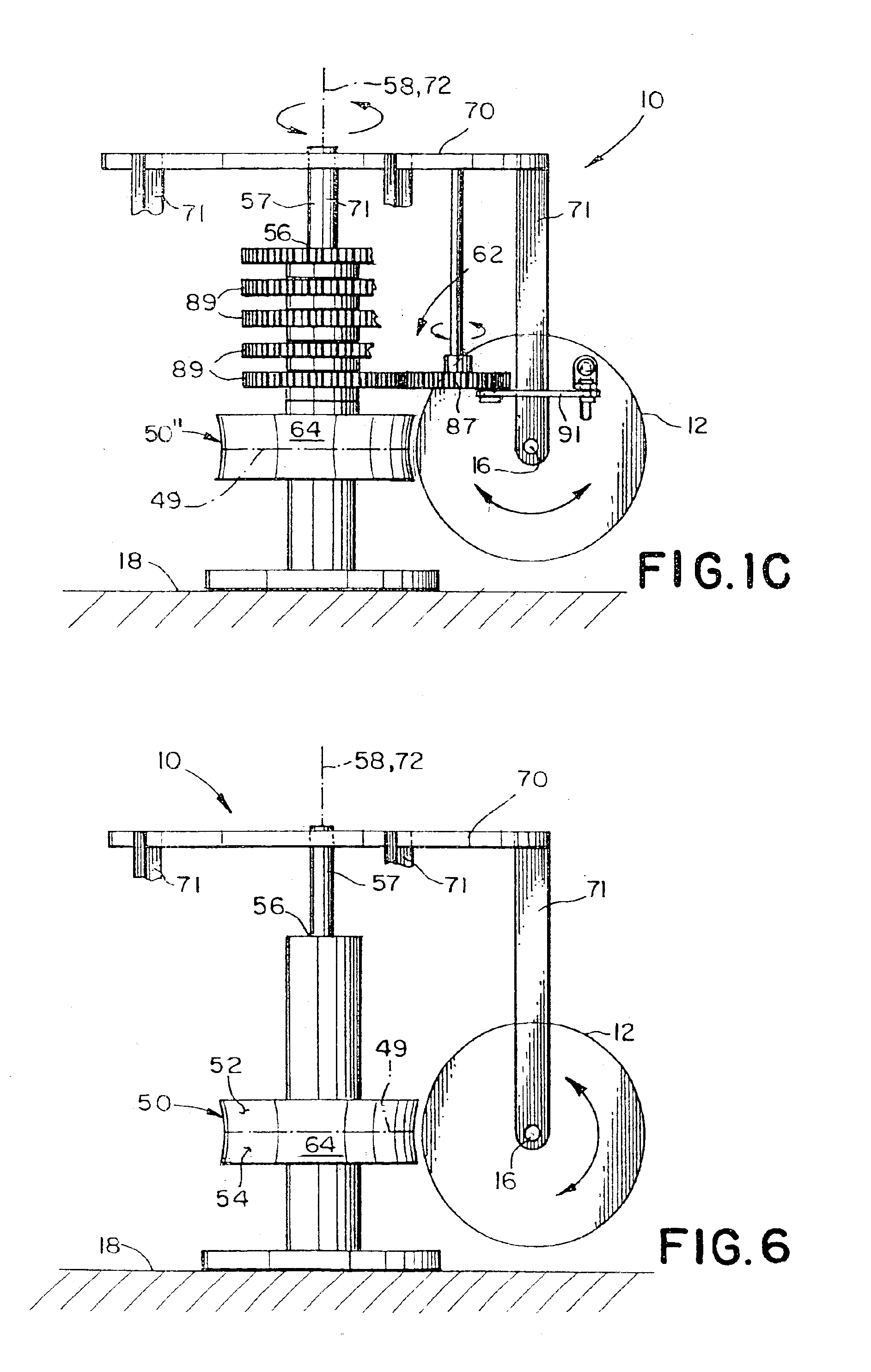

Permanent magnet motor

A motor providing unidirectional rotational motive power is provided. The motor has a generally circular stator with a stator axis, an outer surface, and a circumferential line of demarcation at about a midpoint of the outer surface. The motor also includes one or more stator magnets attached to the outer surface of the stator. The stator magnets are arranged in a generally circular arrangement about the stator axis and generate a first magnetic field. An armature is attached to the stator for rotation therewith, the armature having an axis parallel to the stator axis. One or more rotors, are spaced from the armature and coupled thereto by an axle for rotation about an axis of each rotor, each rotor rotating in a plane generally aligned with the armature axis. Each rotor includes one or more rotor magnets, with each rotor magnet generating a second magnetic field. The second magnetic field generated by each rotor magnet interacts with the first magnetic field to cause each rotor to rotate about the rotor axis. A linkage assembly drivingly connects each rotor to the stator to cause the armature to rotate about the armature axis thereby providing the unidirectional rotational motive power of the motor.

Owner:FECERA FR J

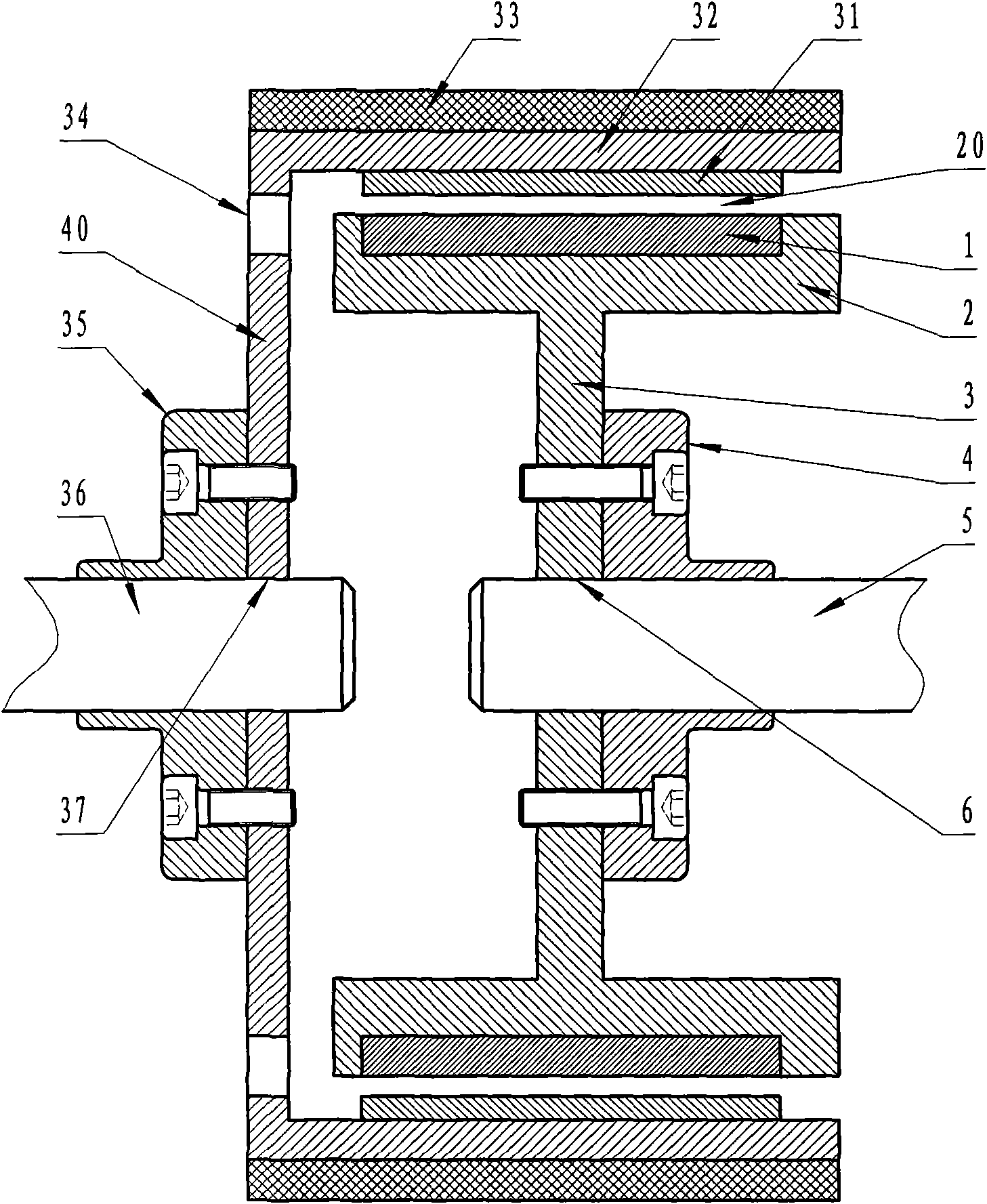

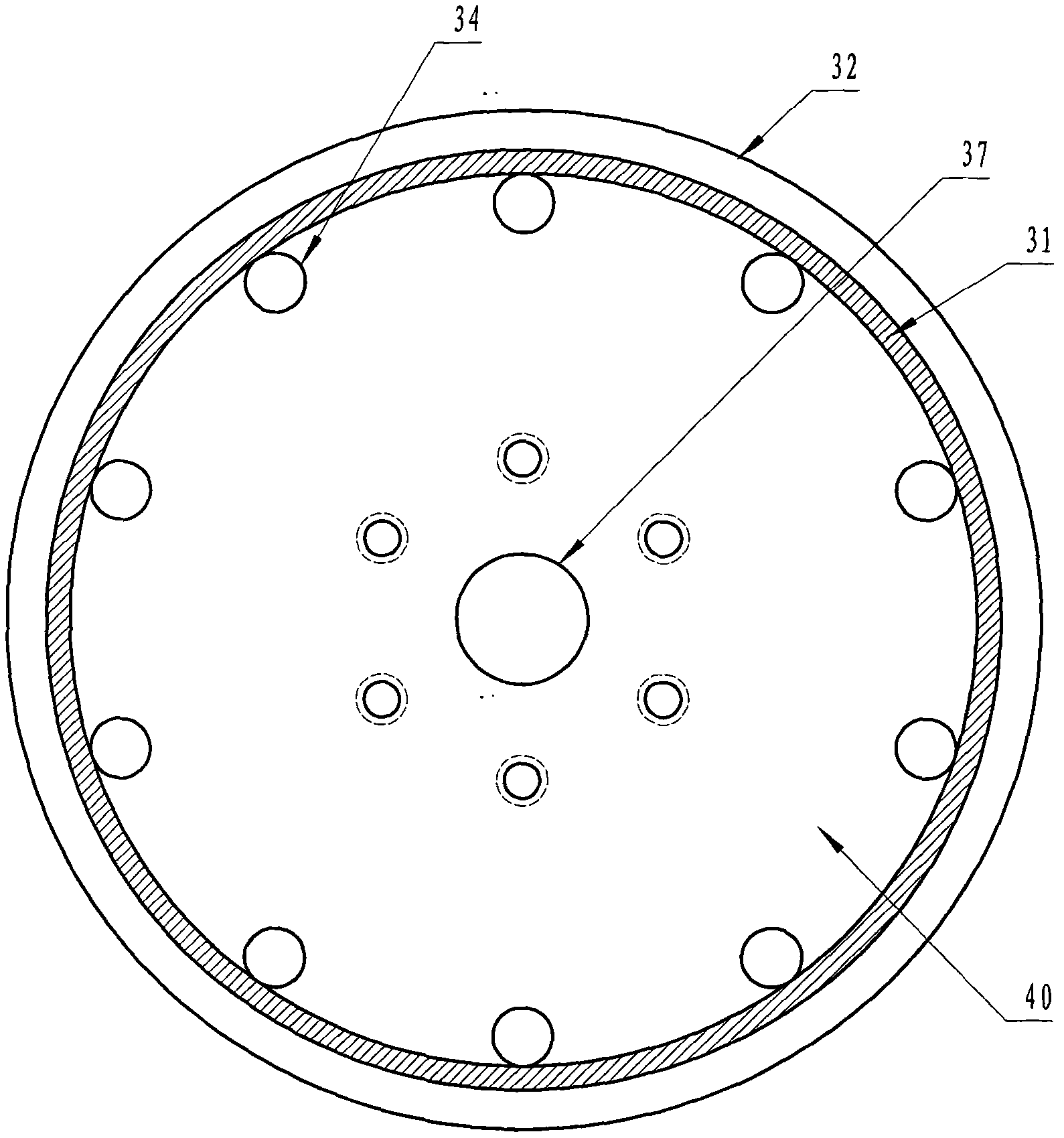

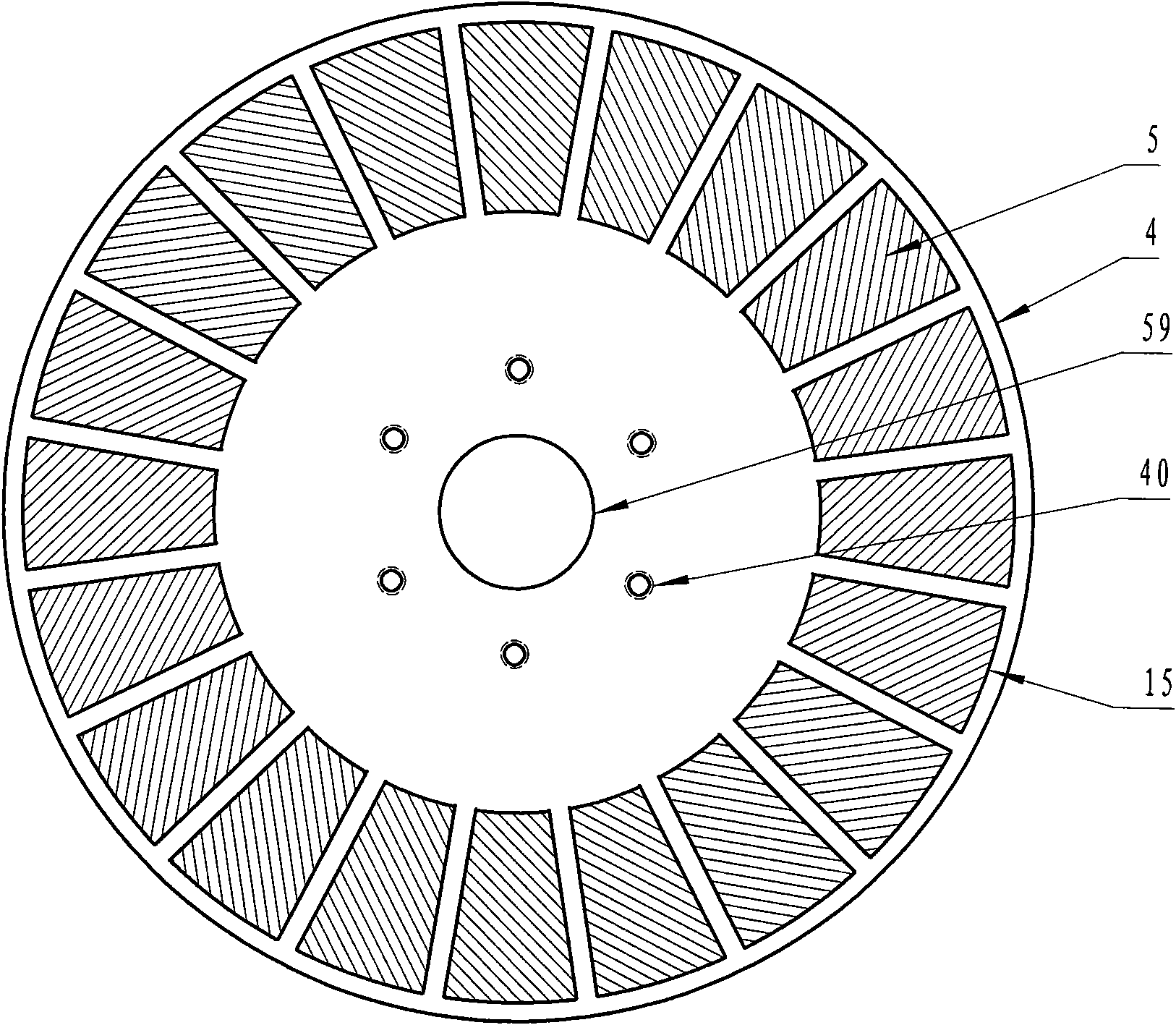

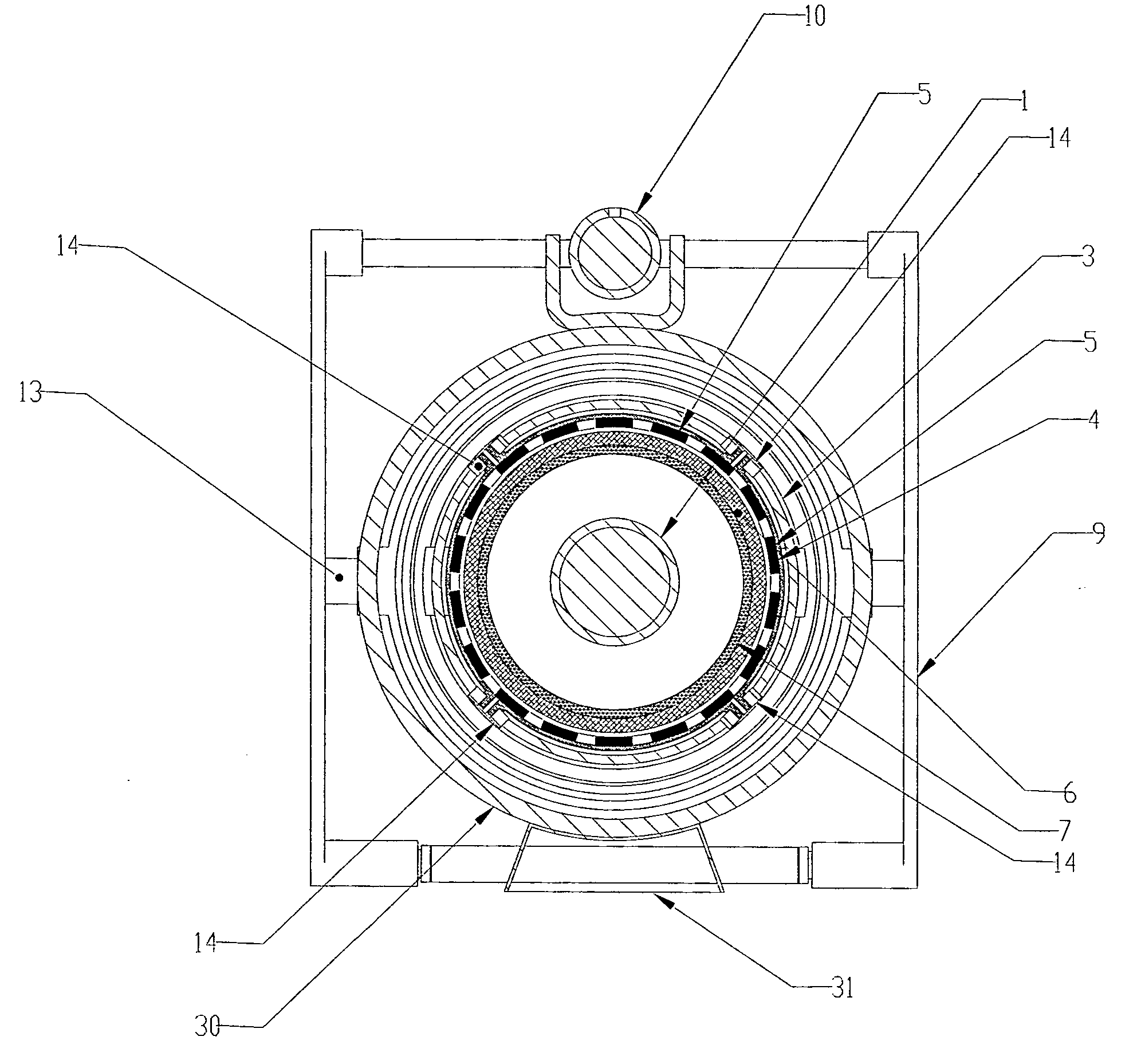

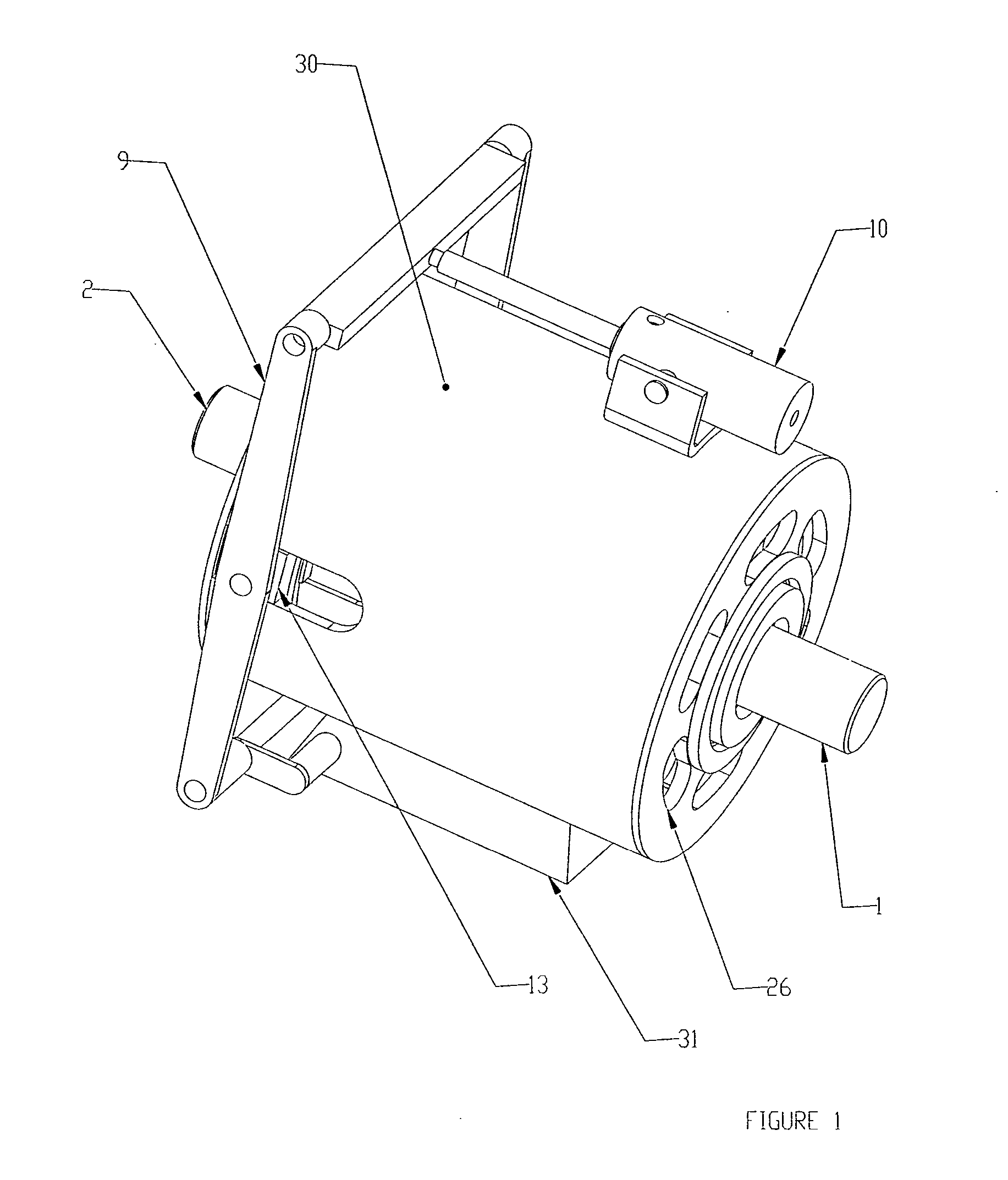

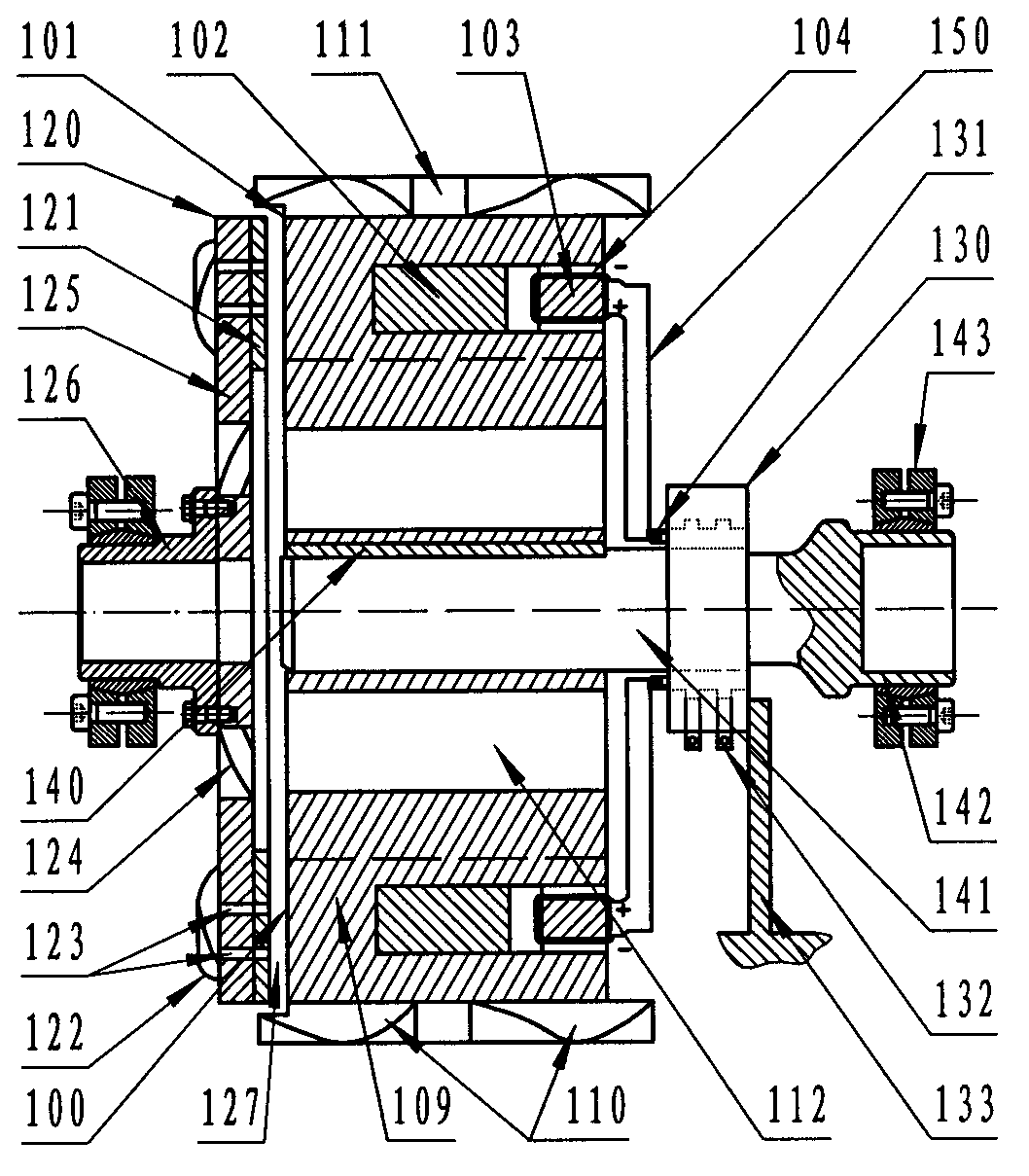

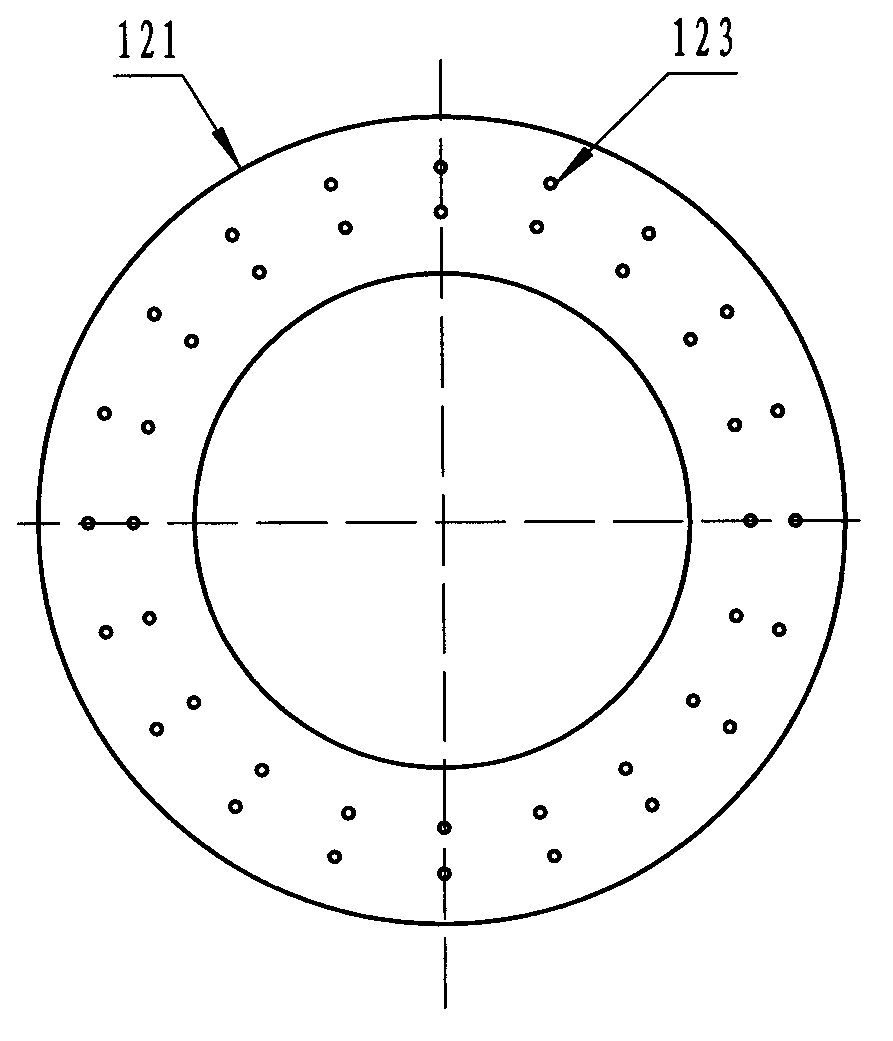

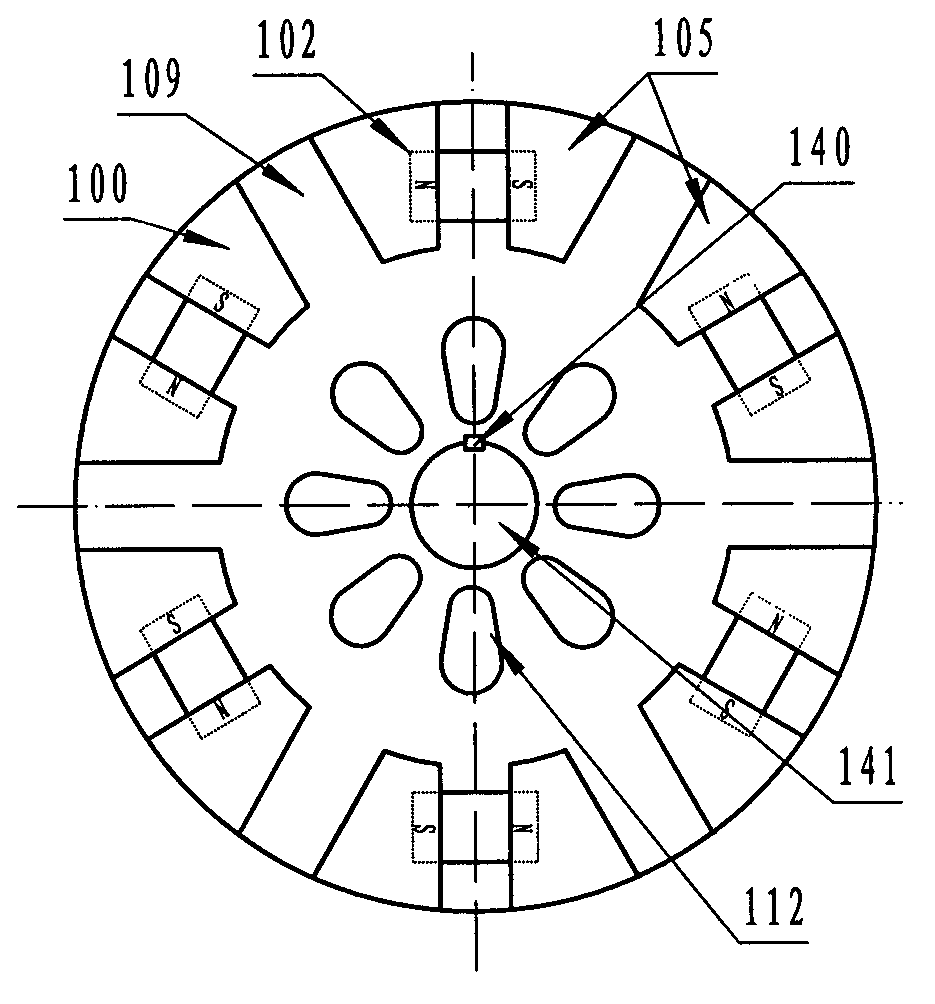

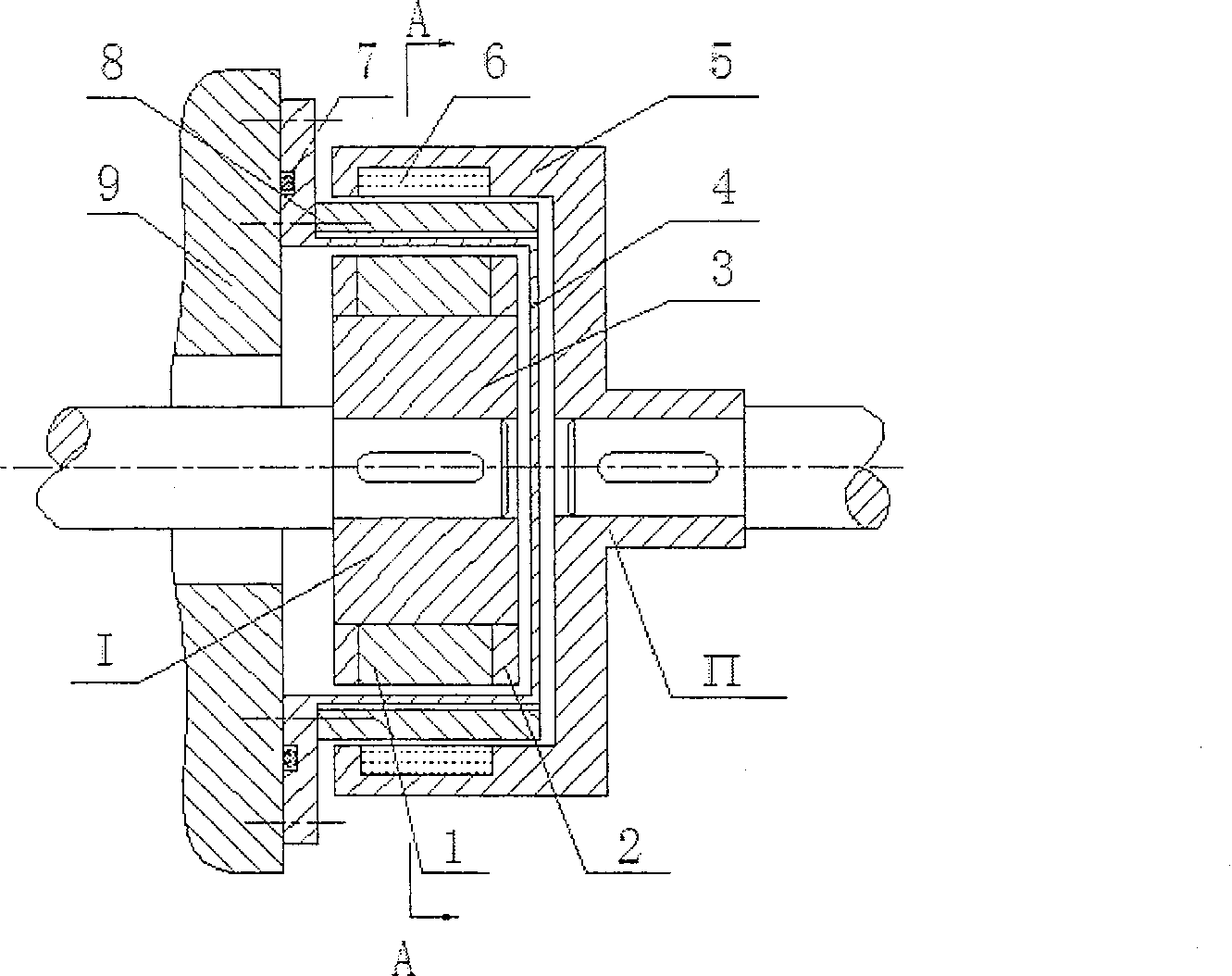

Permanent magnet coupling device for cylindrical transmission shaft

InactiveCN101931308ASignificant technological progressPermanent-magnet clutches/brakesDrive shaftCoupling

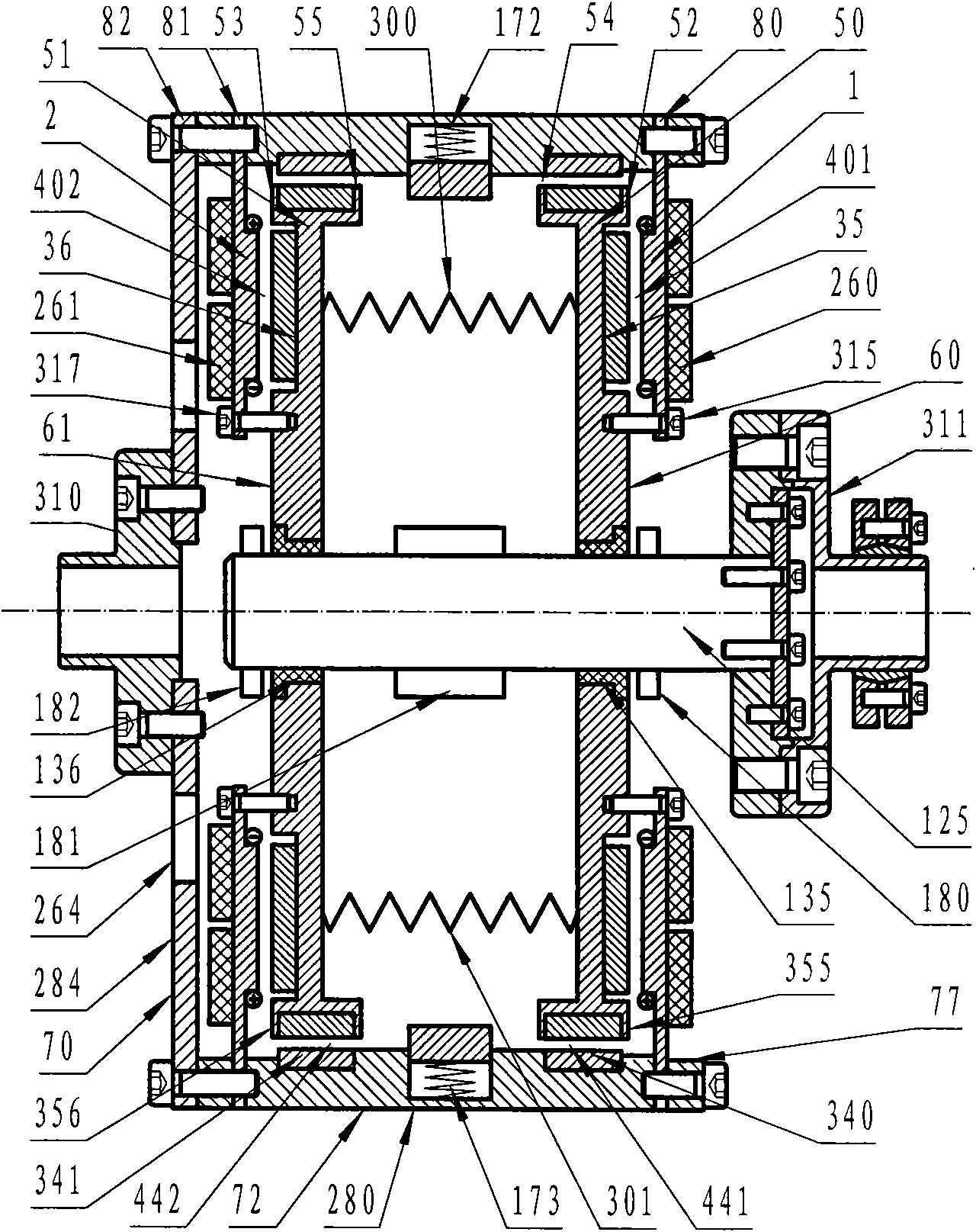

A permanent magnet coupling device for a cylindrical transmission shaft comprises at least a group of outer rotor drum assemblies and a group of inner rotor drum assemblies, at least a pair of outer rotor drum shaft coupling mechanisms adaptive to the outer rotor drums, at least a pair of inner rotor drum shaft coupling mechanisms adaptive to the inner rotor drums and corresponding input shaft couplings and output shaft couplings, wherein each group of outer rotor drum assemblies and each group of inner rotor drum assemblies are nested with each other and coupled by permanent magnet air gap magnetic fields; at least radial air gap magnetic field permanent magnet coupling assemblies or axial air gap magnetic field permanent magnet coupling assemblies are arranged and assembled on the adjacent corresponding positions of the outer rotor drums and the inner rotor drums; and the outer rotor drums and the inner rotor drums are coupled with the corresponding input shaft couplings or output shaft couplings by the corresponding adaptive rotor drum coupling mechanisms. The device has the characteristics of higher transmission efficiency, simple and reliable structure, convenient installation, resistance to severe environment, tolerance for shaft eccentricity, load isolation, reduction of vibration and noises, prolonging of equipment life, etc, and has the advantages of not damaging the motors and not affecting the safety of power grids.

Owner:北京麦格纳传动科技有限公司

Permanent magnetic speed regulation, brake or load apparatus capable of stepless adjustment of magnetic field intensity

InactiveCN104065236AAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesAutomatic transmissionCentrifugation

The invention discloses a permanent magnetic speed regulation, brake or load apparatus capable of stepless adjustment of magnetic field intensity. The apparatus is characterized in that the apparatus is a of single-rotating disk / multi-rotating disk type structure , a single-rotating cylinder / multi-rotating cylinder type structure, a rotating disk and rotating cylinder combination type structure or a rotating disk and rotating cylinder compound structure, and is mainly composed of a driving rotor, a driven rotor, a work magnetic coupling air gap / medium, a magnetic leakage magnetic circuit / air gap, a magnetic leakage magnetic circuit air gap adjusting disc and an adjusting mechanism. The apparatus provided by the invention is applied to such technical fields as coupling transmission, load speed regulation, automatic transmission, brake and braking, load rotation, power cut-off / combination, motor energy conservation, a household electrical appliance (including an air conditioner, an electric fan and a washing machine) and the like. The technical scheme is used for designing and manufacturing a permanent magnetic speed regulator, a speed regulation shaft coupling, an automatic transmission, a braking device, a load / loading device, a centrifugation load speed regulator or a clutch or a novel energy-saving household electrical appliance.

Owner:林英楠

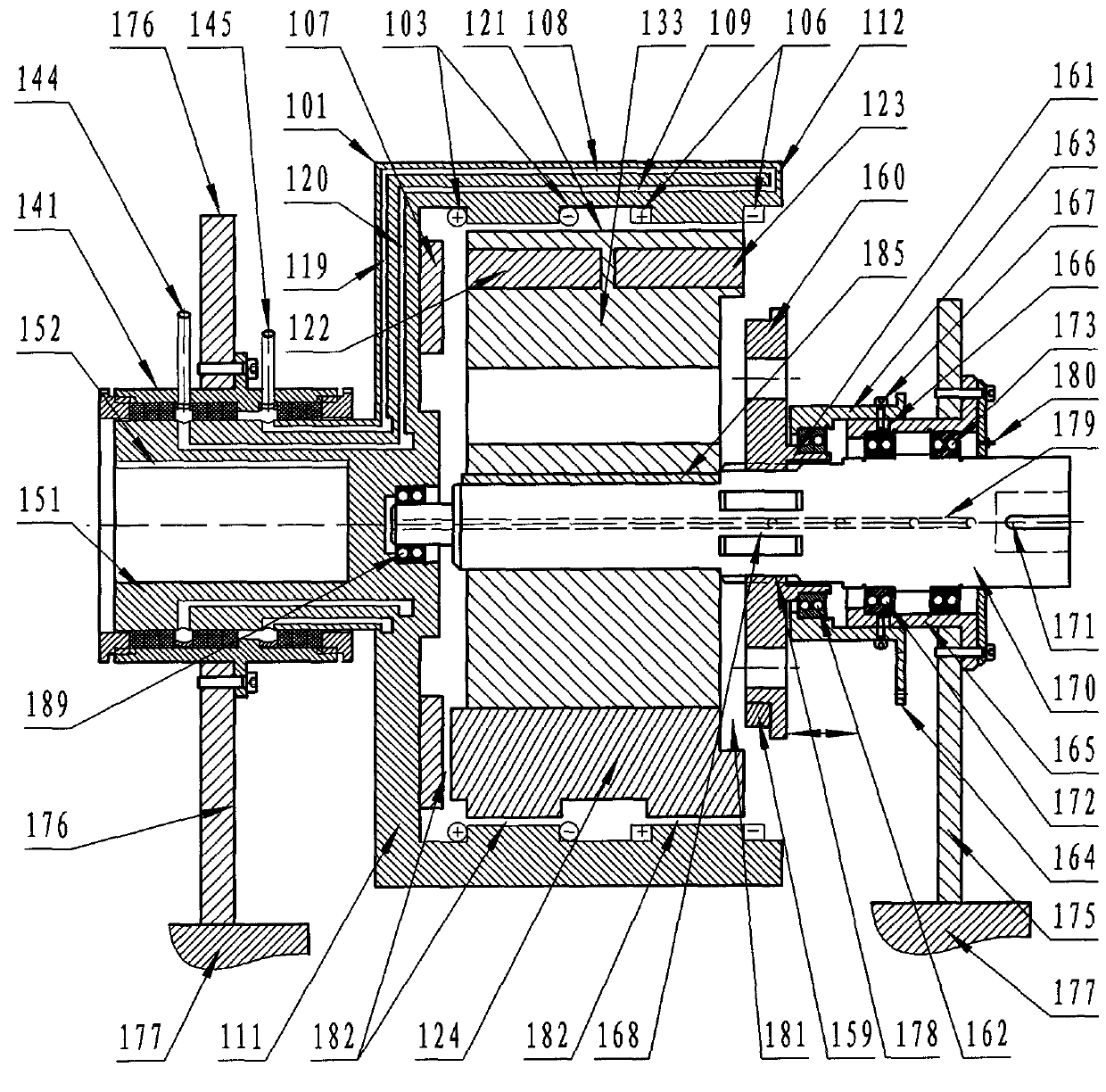

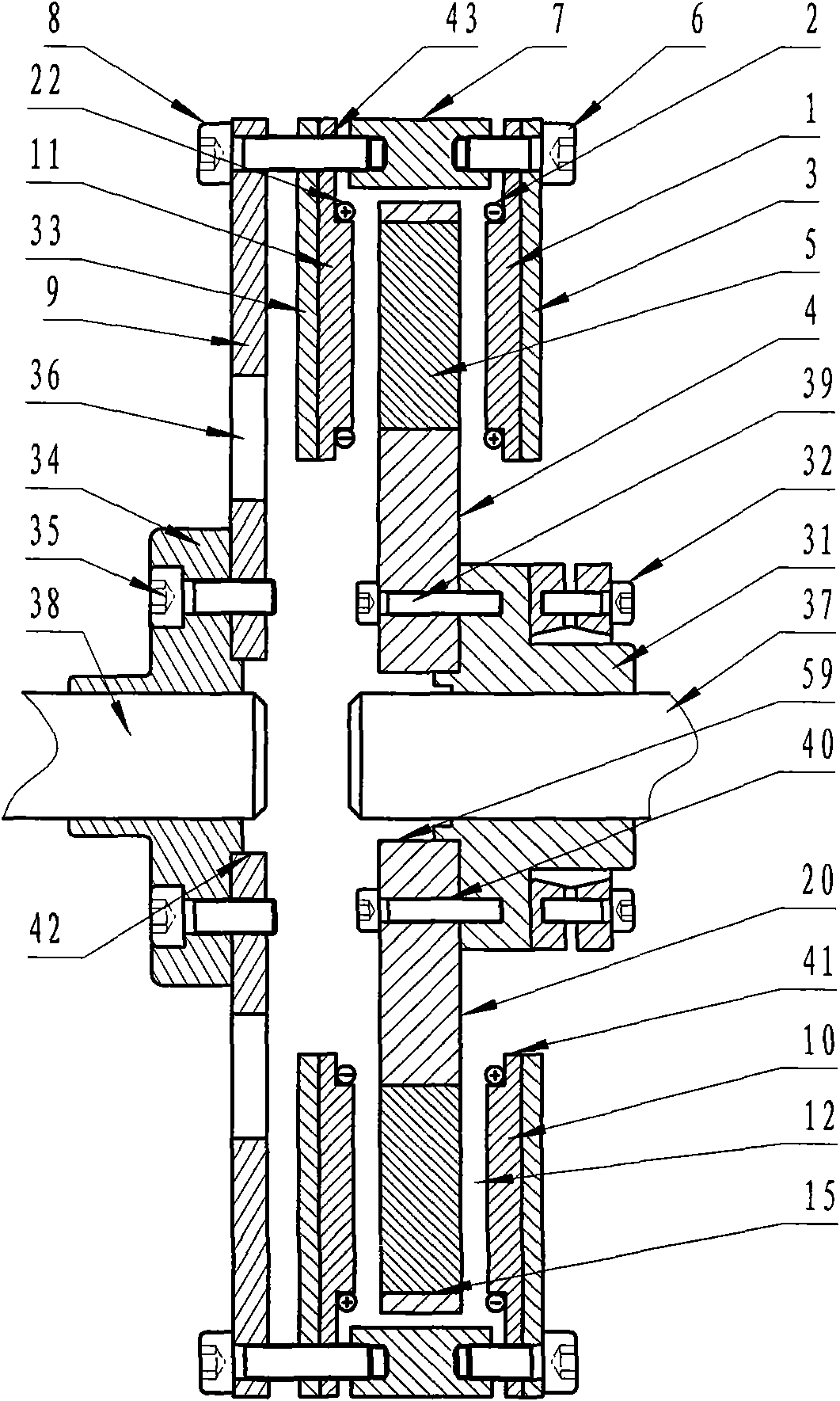

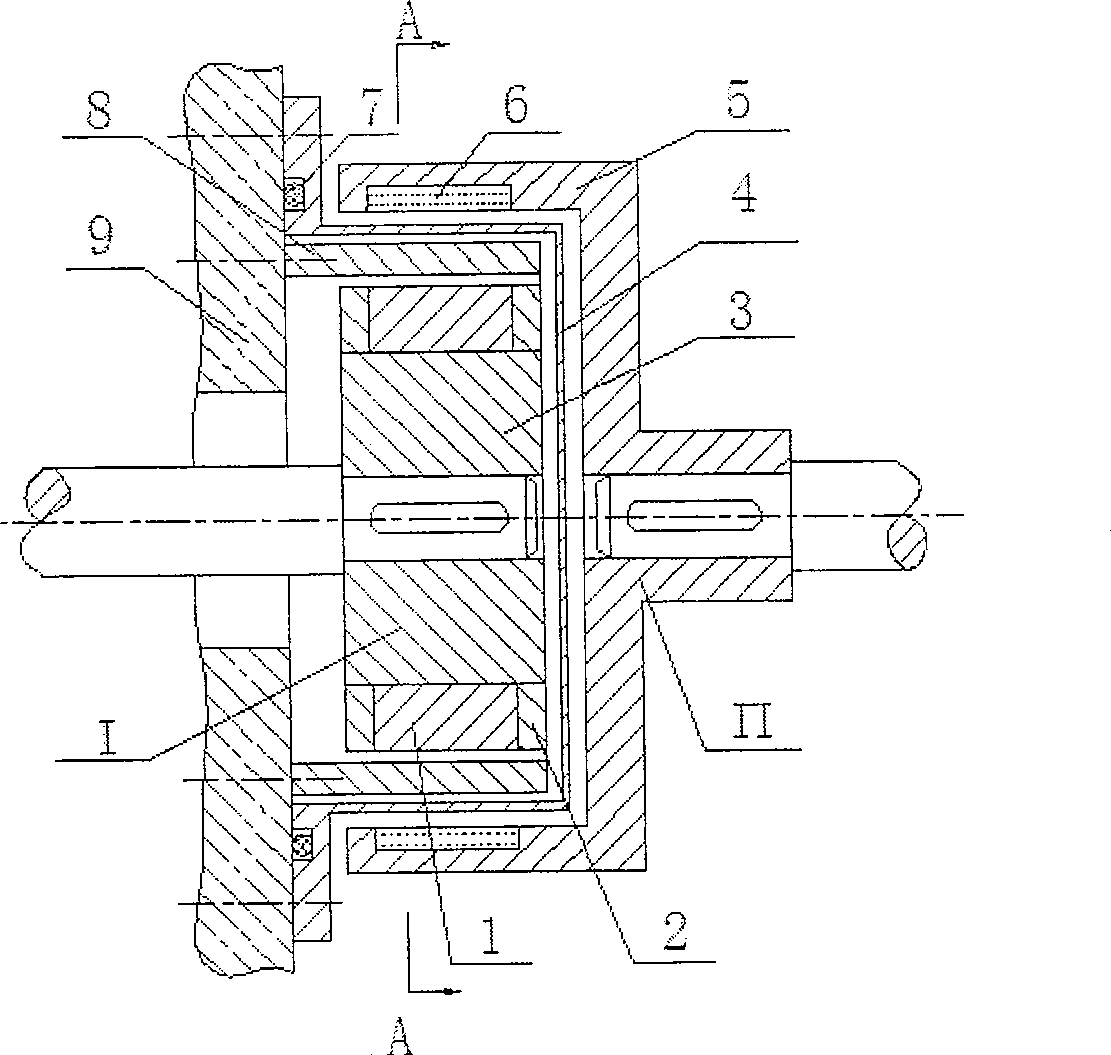

Transmission shaft permanent magnet coupling drive and speed regulation device capable of adjusting magnetic torque

InactiveCN101997391ASignificant technological progressLeaps of technological progressSynchronous machinesAsynchronous induction clutches/brakesDrive shaftCoupling

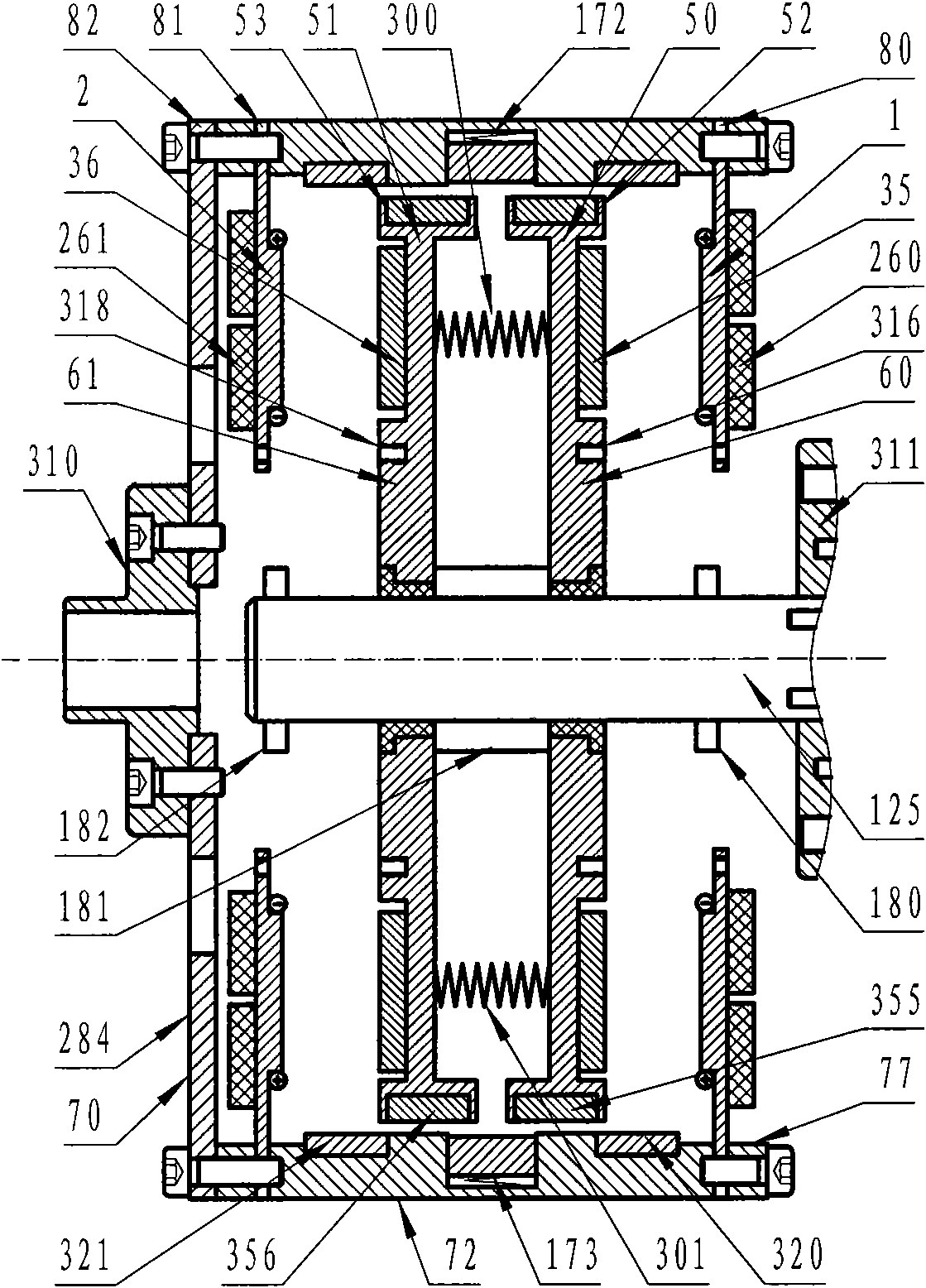

The invention discloses a transmission shaft permanent magnet coupling drive and speed regulation device capable of adjusting magnetic torque, which has a turntable type, barrel type or turntable and barrel combined structure. The device consists of at least one set of axial magnetic field permanent magnet coupling component or / and radial magnetic field permanent magnet coupling component, at least one pair of diving permanent magnet coupling turntable coupling shaft mechanisms which are fit with a driving turntable in the permanent magnet coupling component, a corresponding driving shaft coupling, at least one pair of driven permanent magnet coupling turntable coupling shaft mechanisms which are fit with a driven permanent magnet coupling turntable in the permanent magnet coupling component, a corresponding driven shaft coupling, a pair of permanent magnet coupling turntable air gap and coupling area adjusting mechanisms and a pair of integrated assembling mechanisms which ensures that the system is an integrated structure and is convenient to package, transport and install. The device is applicable in the technical field of transmission shaft coupling drive, the technical field of load speed regulation and the field of power dragging.

Owner:北京麦格纳传动科技有限公司

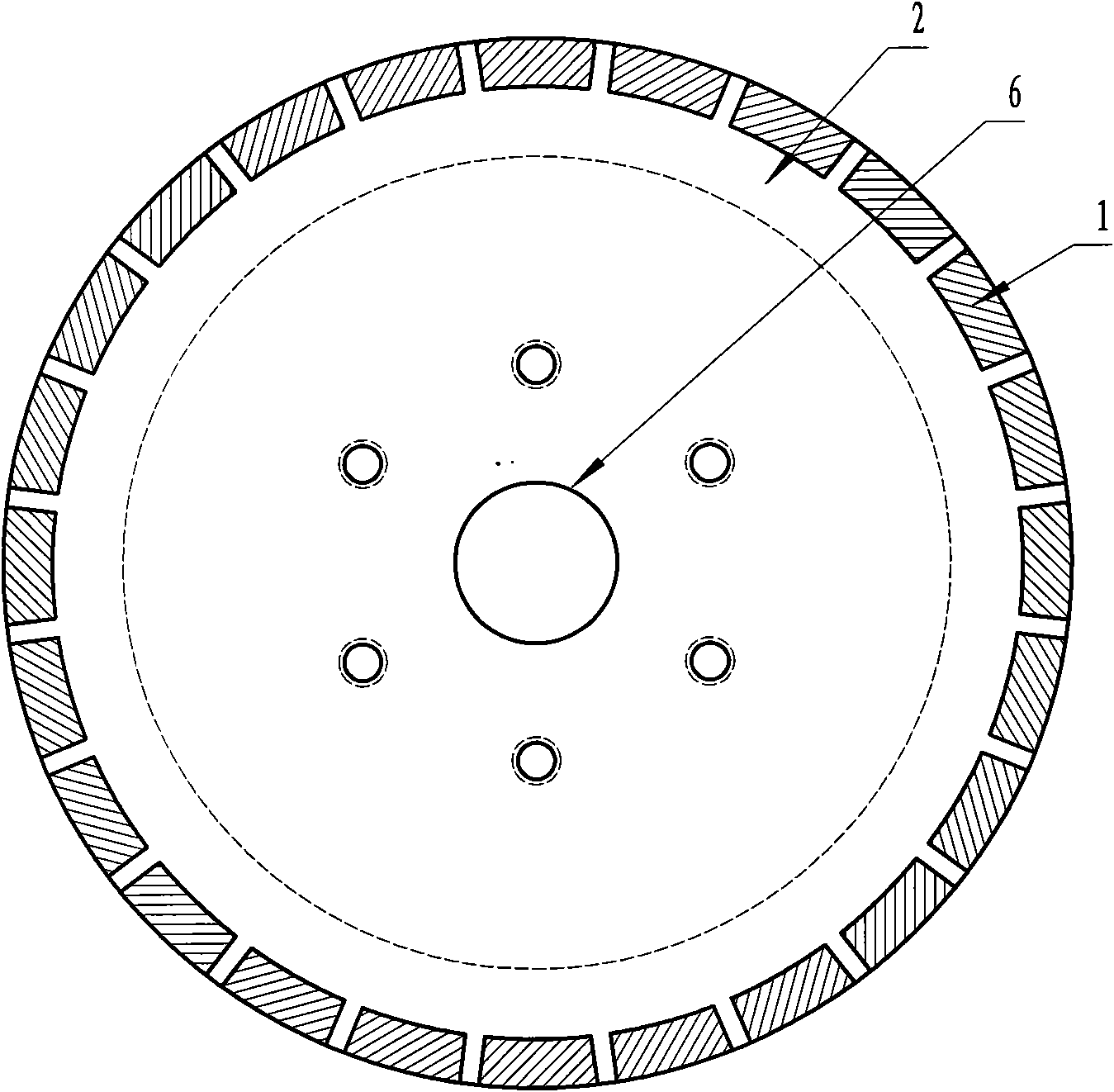

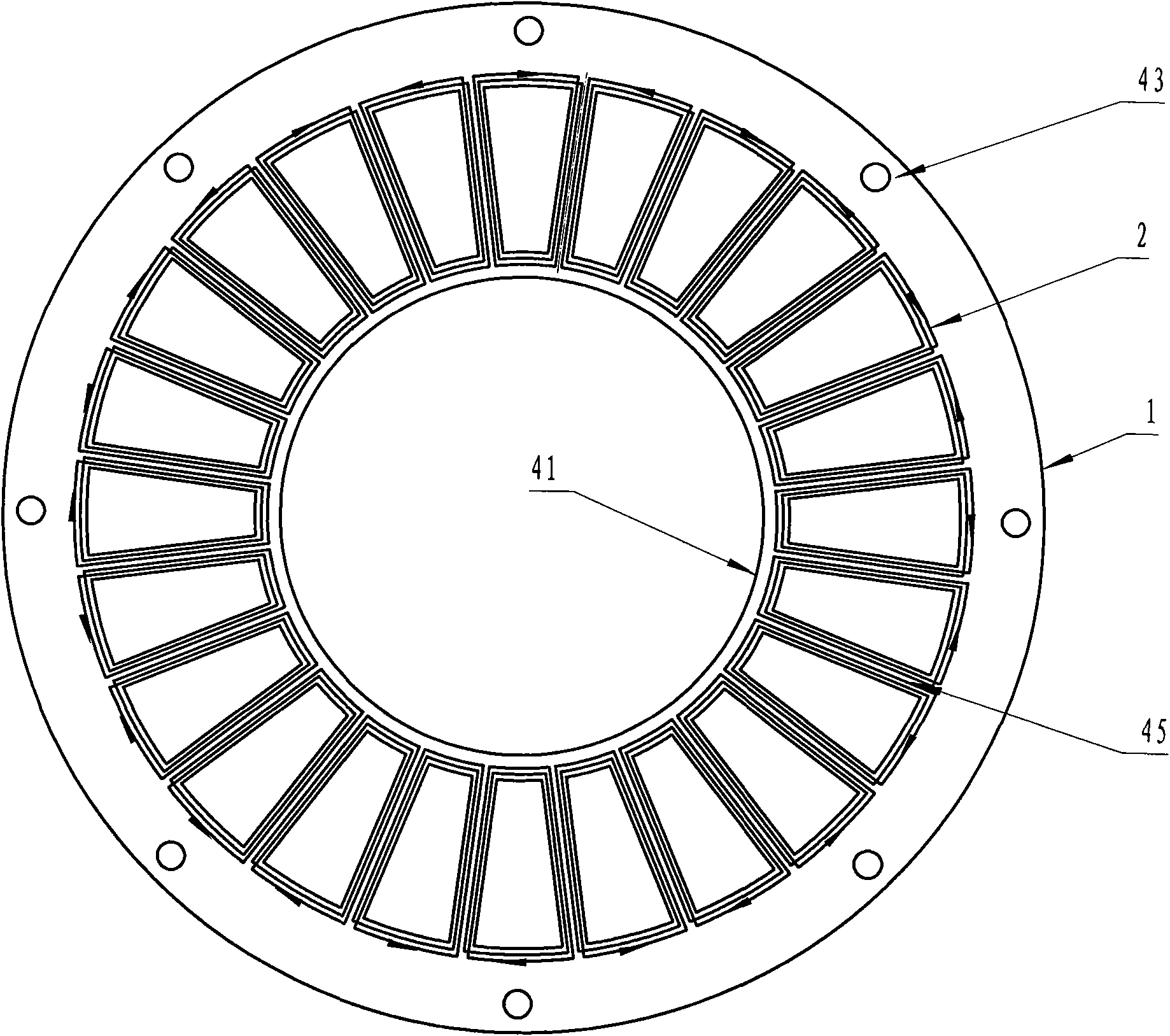

Efficient permanent magnet coupling device for transmission shaft

InactiveCN101931309ASignificant technological progressPermanent-magnet clutches/brakesPermanent magnet rotorDrive shaft

An efficient permanent magnet coupling device for a transmission shaft comprises armature winding rotor disks and adaptive armature winding disk shaft coupling mechanisms, permanent magnet rotor disks and adaptive permanent magnet disk shaft coupling mechanisms and input and output shaft couplings, wherein the armature winding rotor disks comprise armature windings and armature winding installing disks; the permanent magnet rotor disks comprise a group of permanent magnets and a permanent magnet installing disk; the permanent magnets are respectively assembled on the circumference of the permanent magnet installing disk, with N and S poles staggered; the armature winding rotor disks and the permanent magnet rotor disks are, face to face, coaxially installed and are coupled with the corresponding input and output shaft couplings by the adaptive disk shaft coupling mechanisms; and air gaps exist between the armature winding rotor disks and the permanent magnet rotor disks. The device has the characteristics of higher transmission efficiency, simple and reliable structure, convenient installation, resistance to severe environment, tolerance for shaft eccentricity, load isolation, reduction of vibration and noises, prolonging of equipment life, etc, and has the advantages of not damaging the motors and not affecting the safety of power grids.

Owner:林贵生

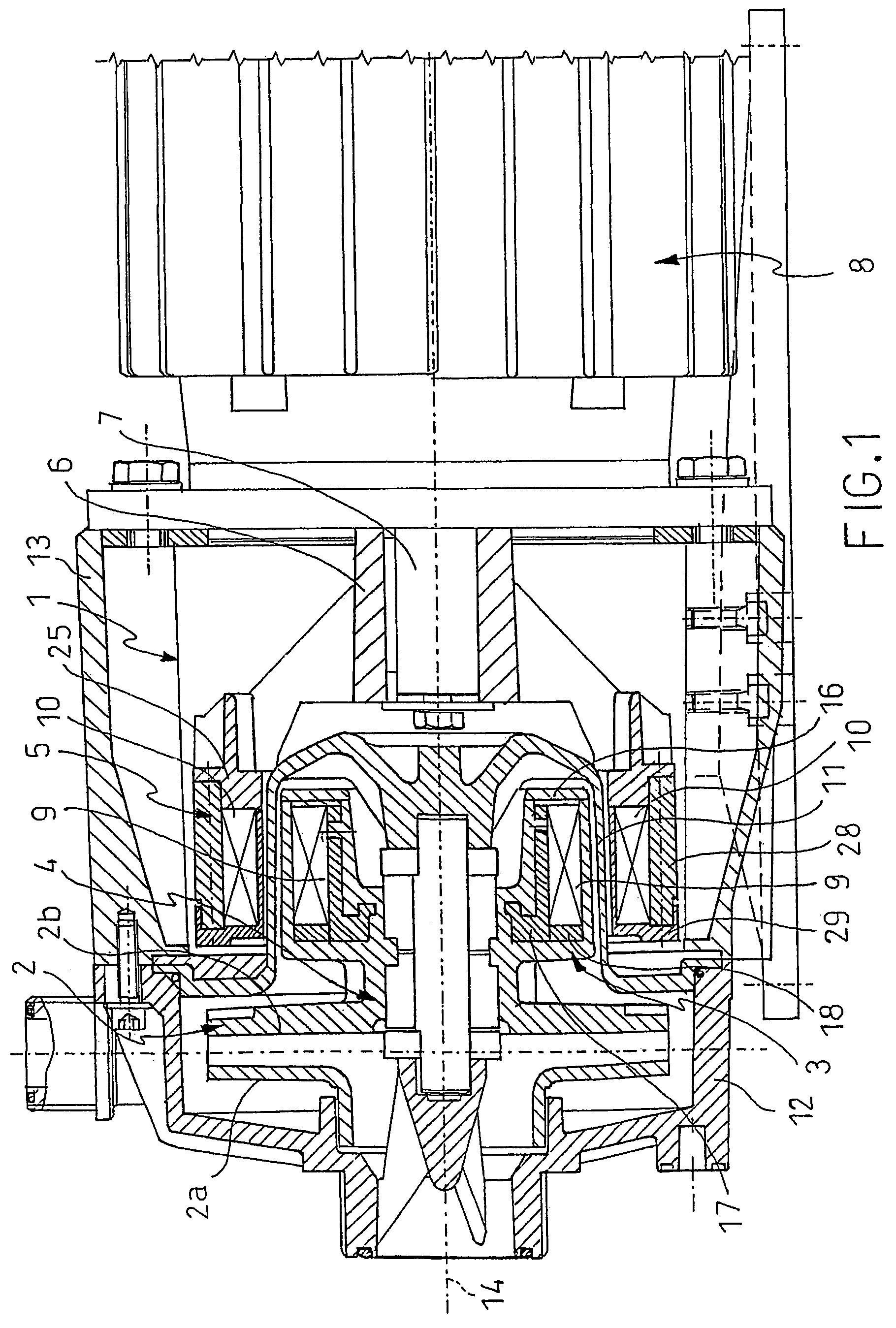

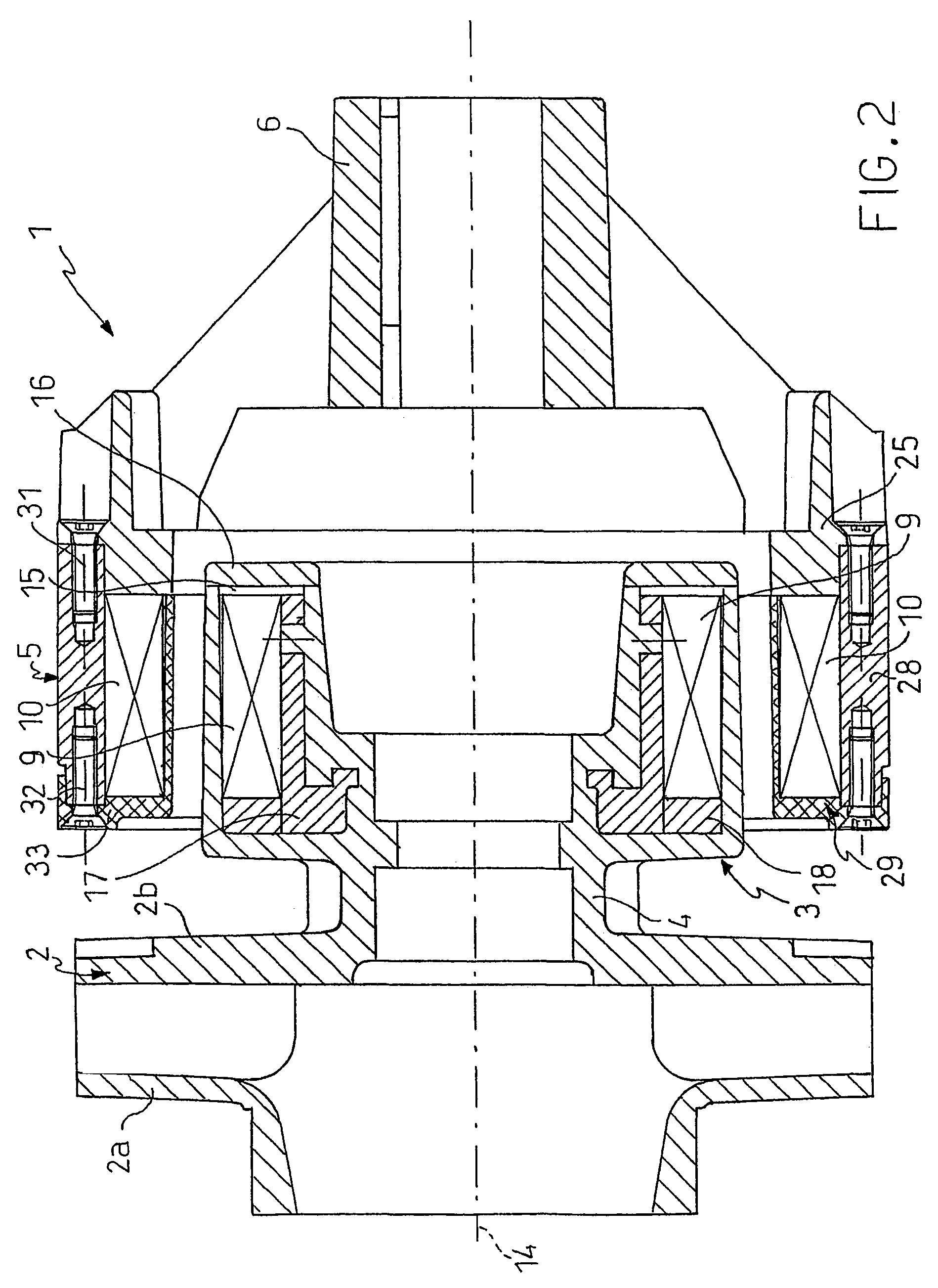

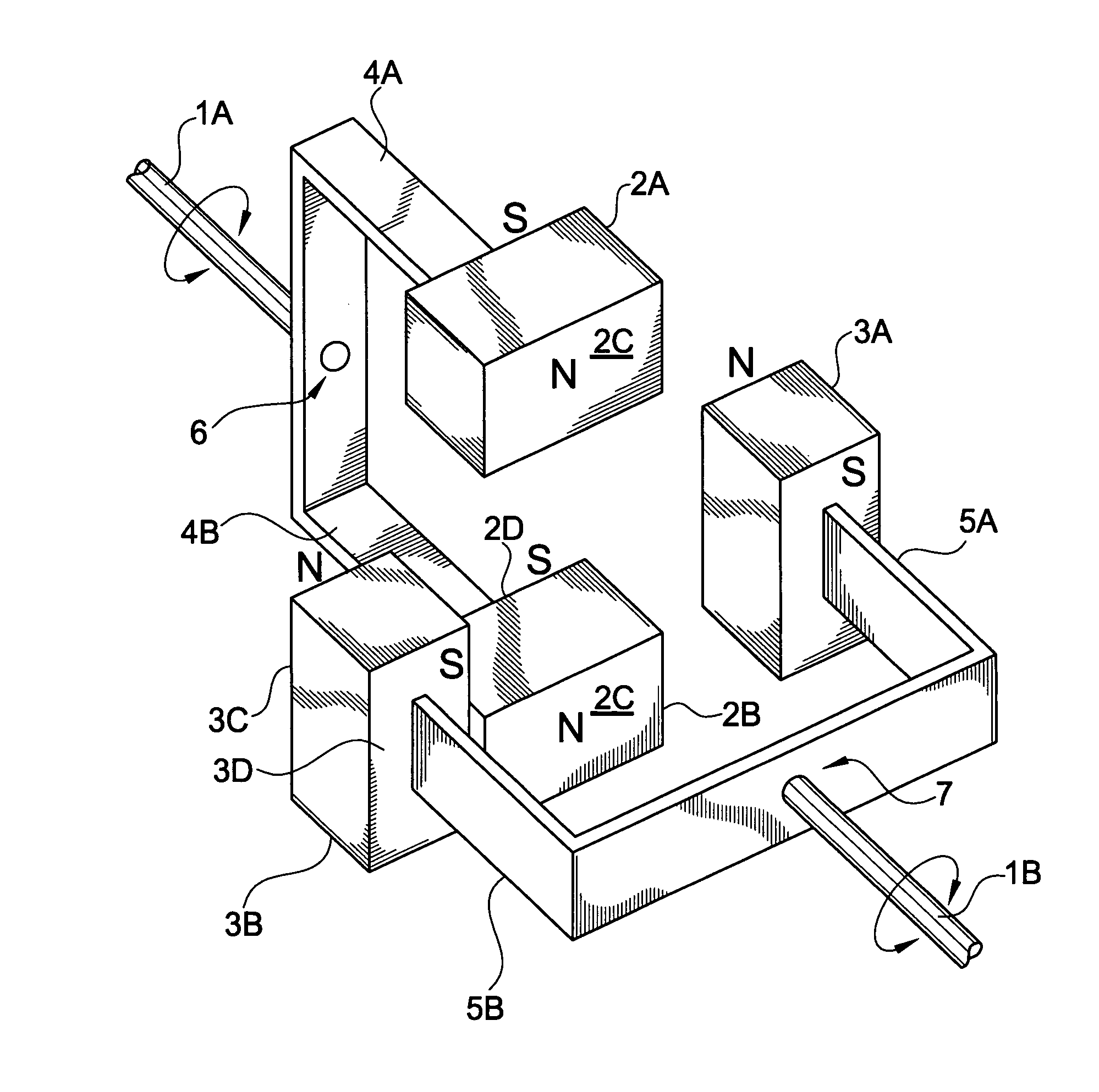

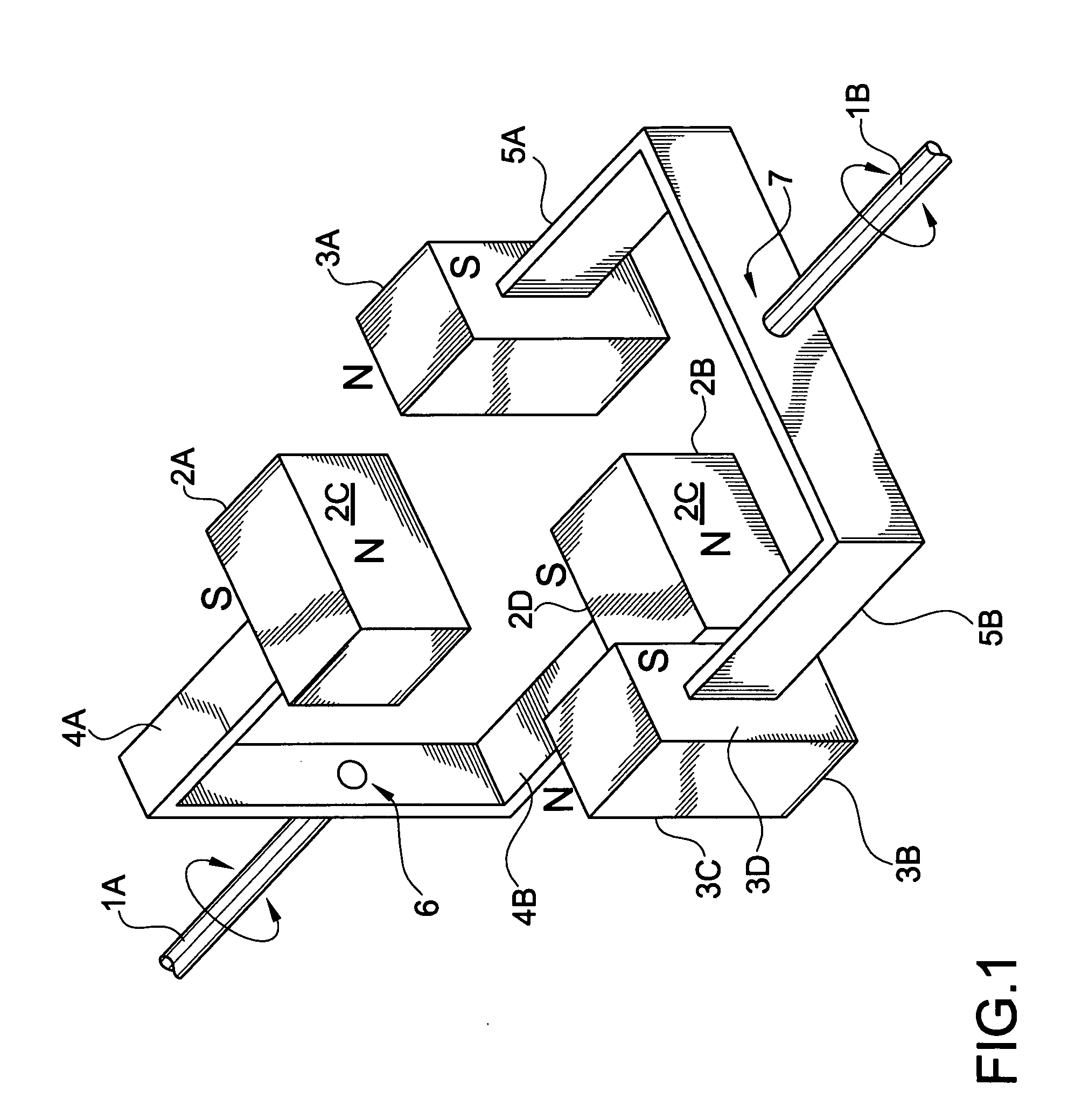

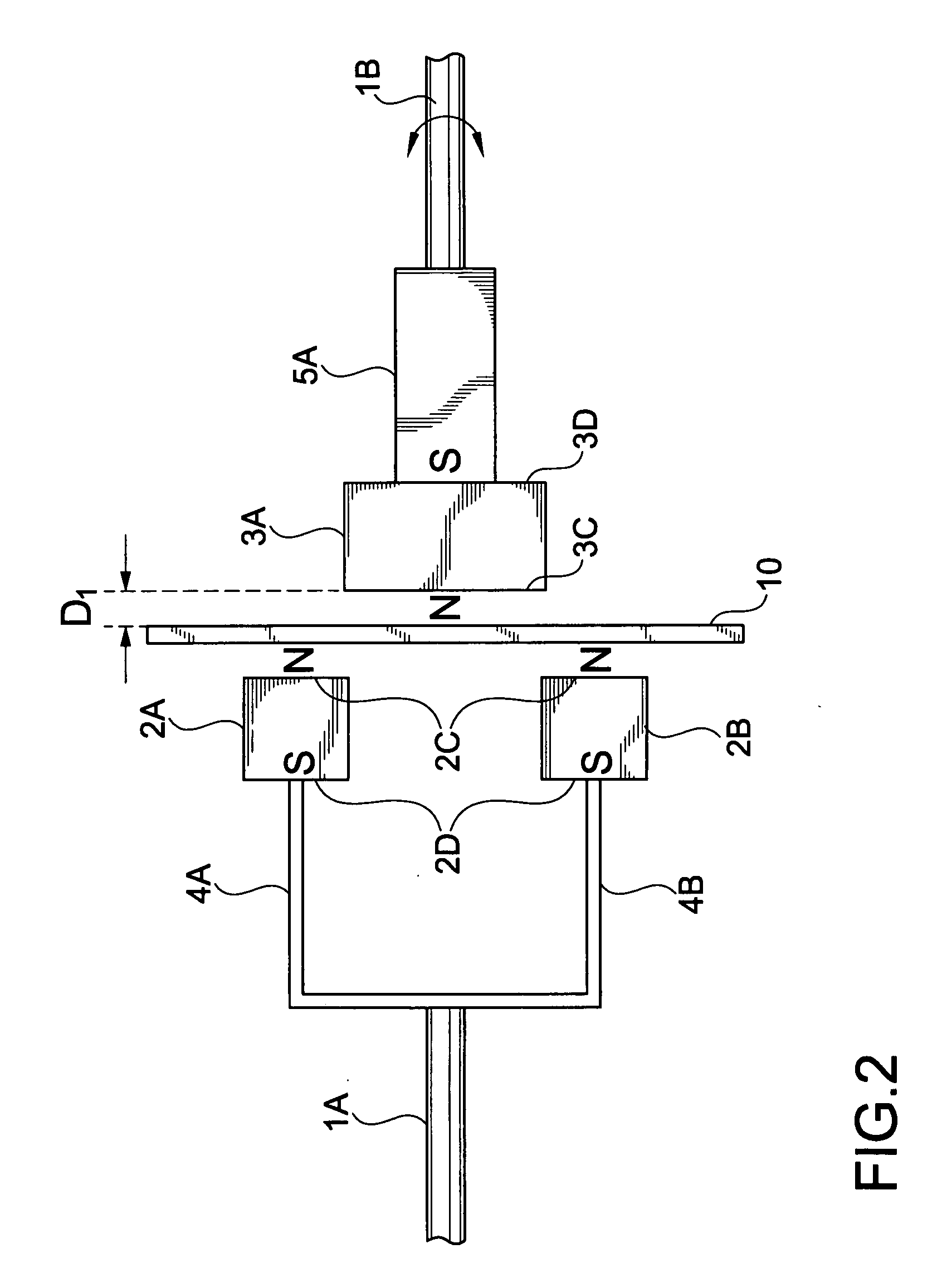

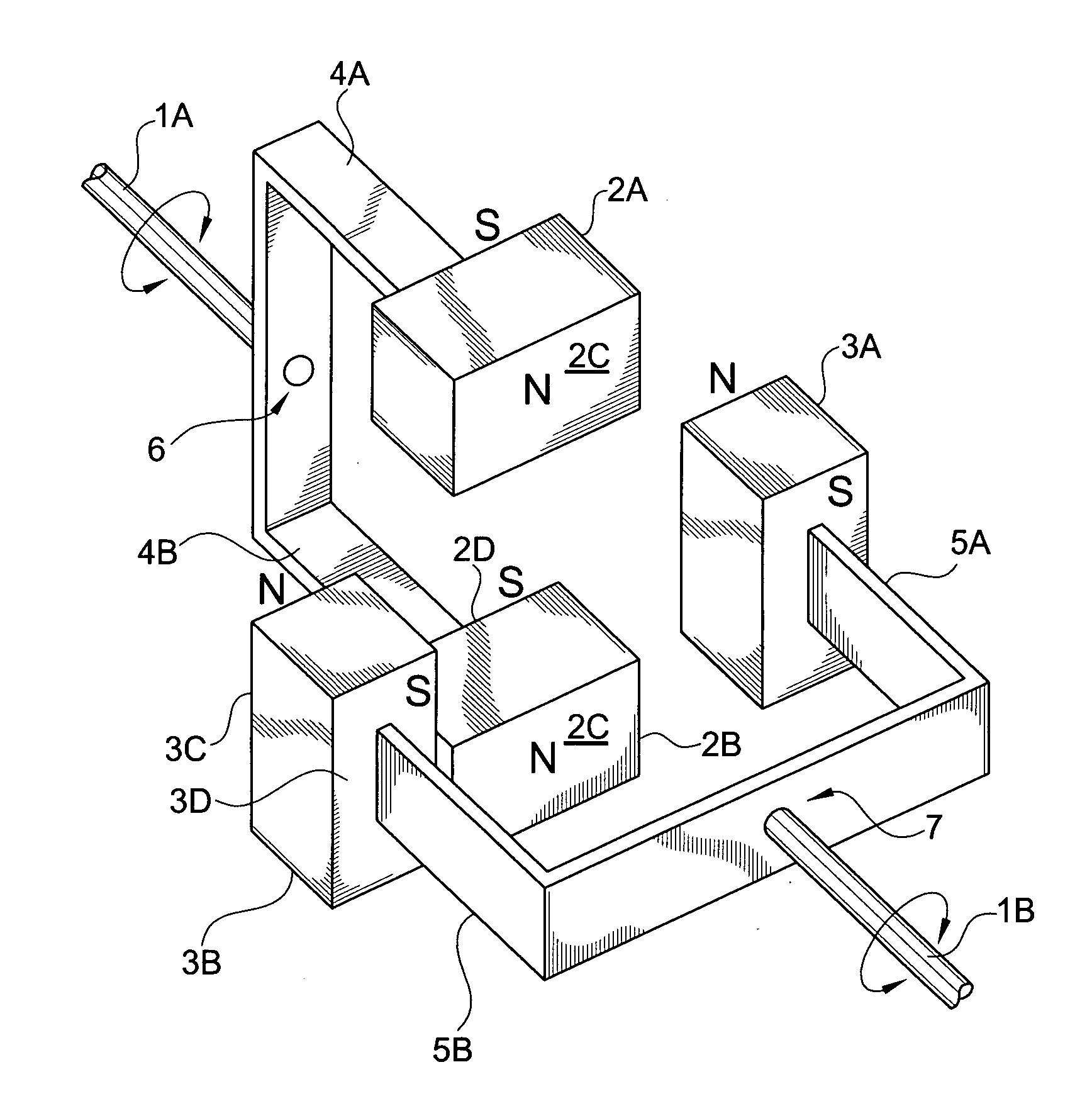

Mechanical drive system operating by magnetic force

InactiveUS7057320B2Magnetic circuit rotating partsMagnetically actuated clutchesMagnetic tension forceDrive shaft

A mechanical drive system operating by magnetic force, to be fitted on a pump, comprises a basic structure on which a drive shaft, which extends along a longitudinal axis, is supported rotatably. A driving element operatively connected to the drive shaft is provided with driving magnets arranged in a ring. A driven element provided with driven magnets arranged in a ring is also mounted on the basic structure. A bell is inserted between the driving element and the driven element and isolates the environment containing the driven element. The driving element and the driven element comprise respective cages each having seats for housing the respective driving magnets or driven magnets.

Owner:C D R POMPE

Torque converter and system using the same

InactiveUS6930421B2Increase productionReduce friction and wearMagnetic circuitPermanent-magnet clutches/brakesEngineeringFlywheel

A torque converter includes a flywheel rotating about a first axis, the flywheel including a first body portion, a first plurality of permanent magnets mounted in the first body portion, each of the first plurality of permanent magnets extending along a corresponding radial axis direction with respect to the first axis, and a second plurality of permanent magnets mounted in the first body portion, each of the second plurality of permanent magnets being located between a corresponding adjacent pair of the first plurality of permanent magnets, and a generator disk rotatable about a second axis perpendicular to the first axis, the generator disk including a second body portion, and a third plurality of permanent magnets within the second body portion magnetically coupled to the first and second pluralities of permanent magnets.

Owner:CAMEL CLUB

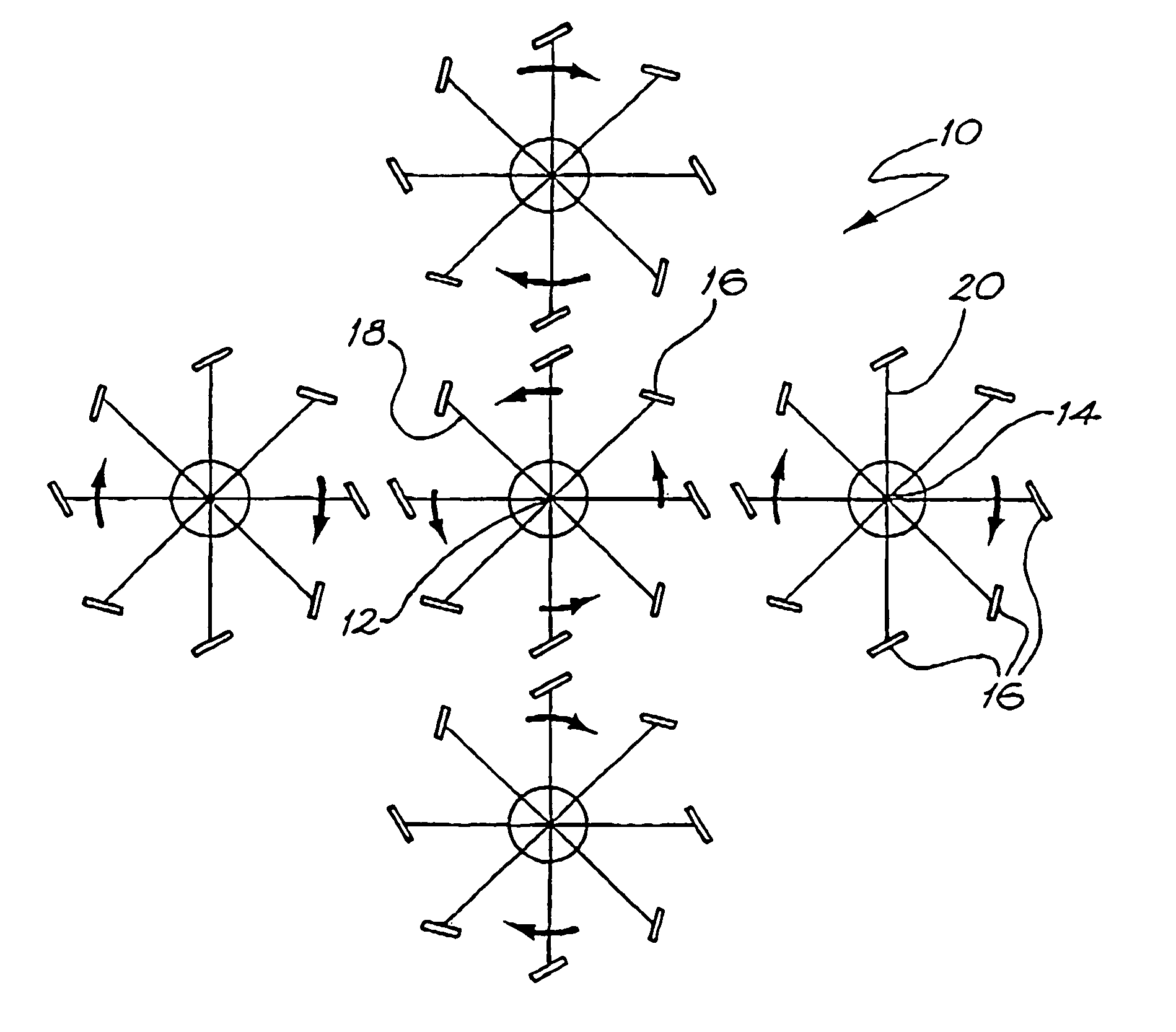

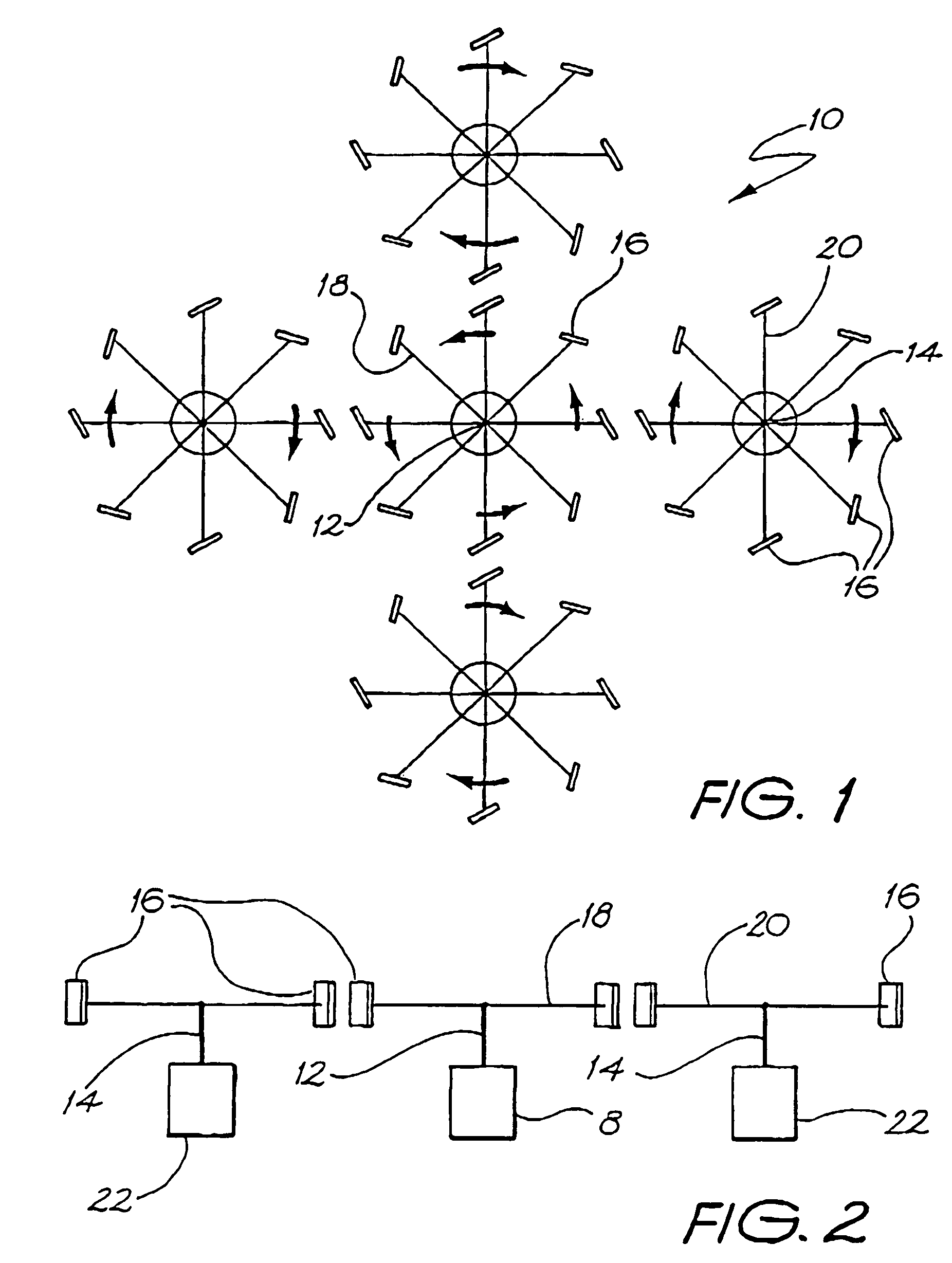

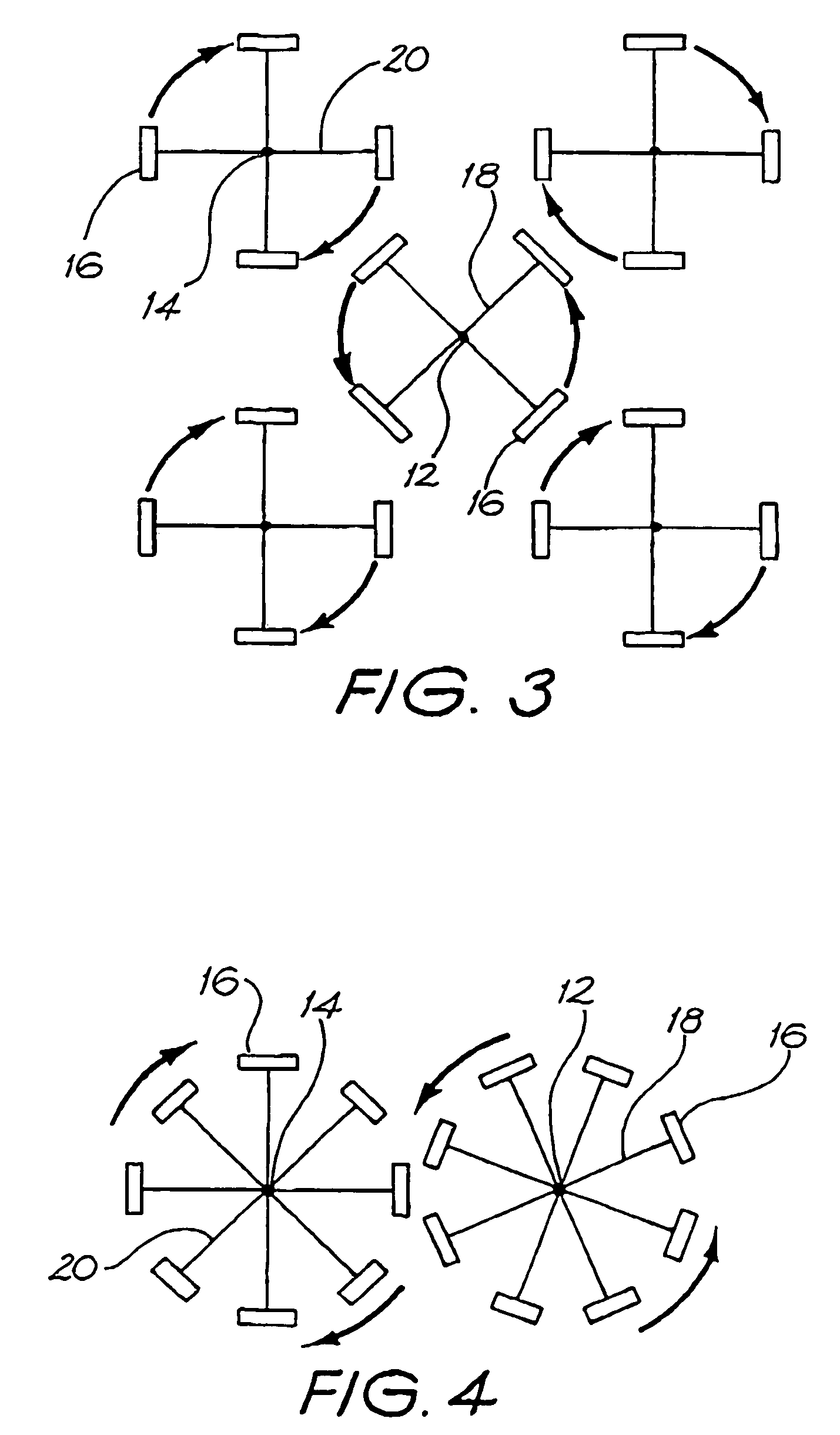

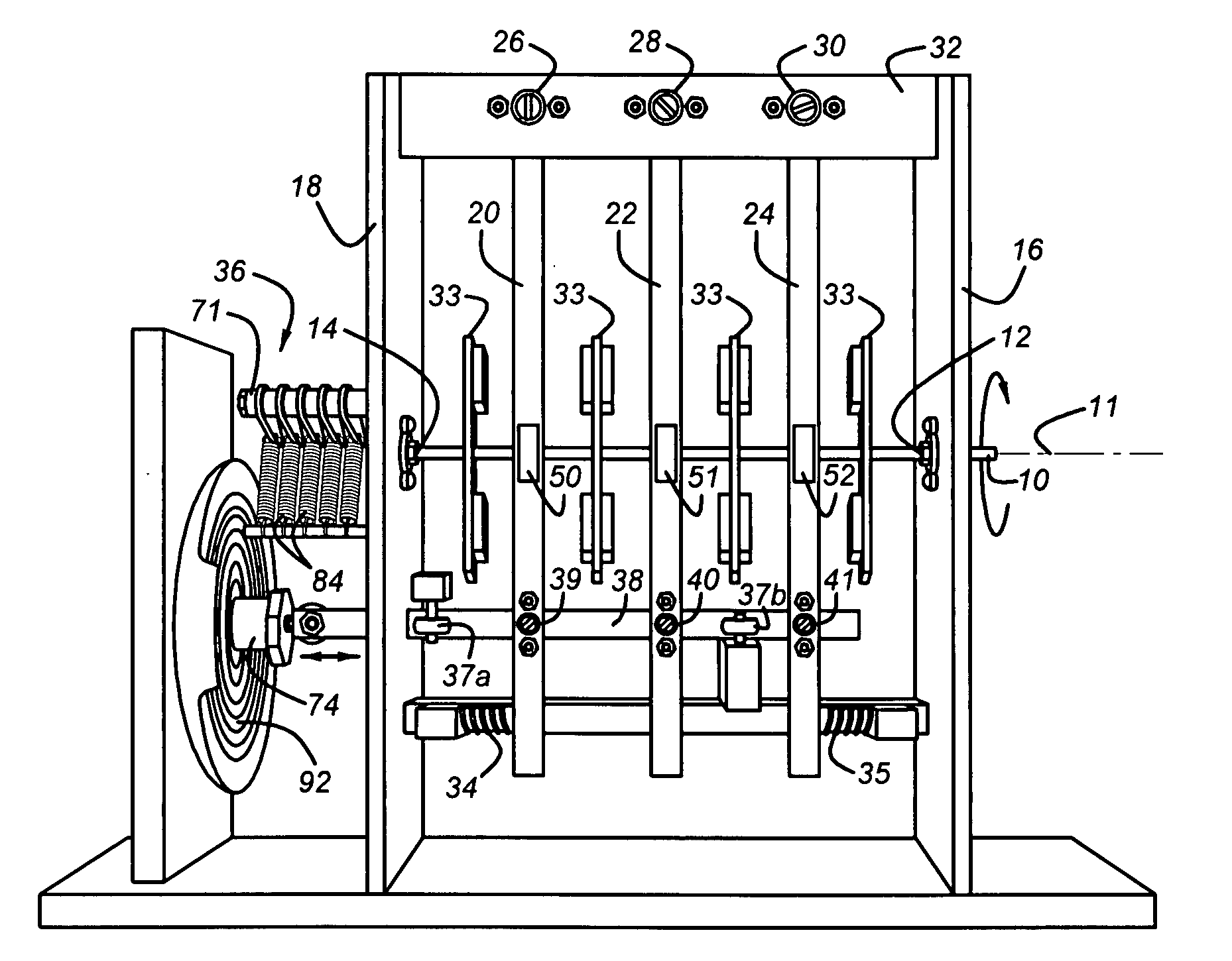

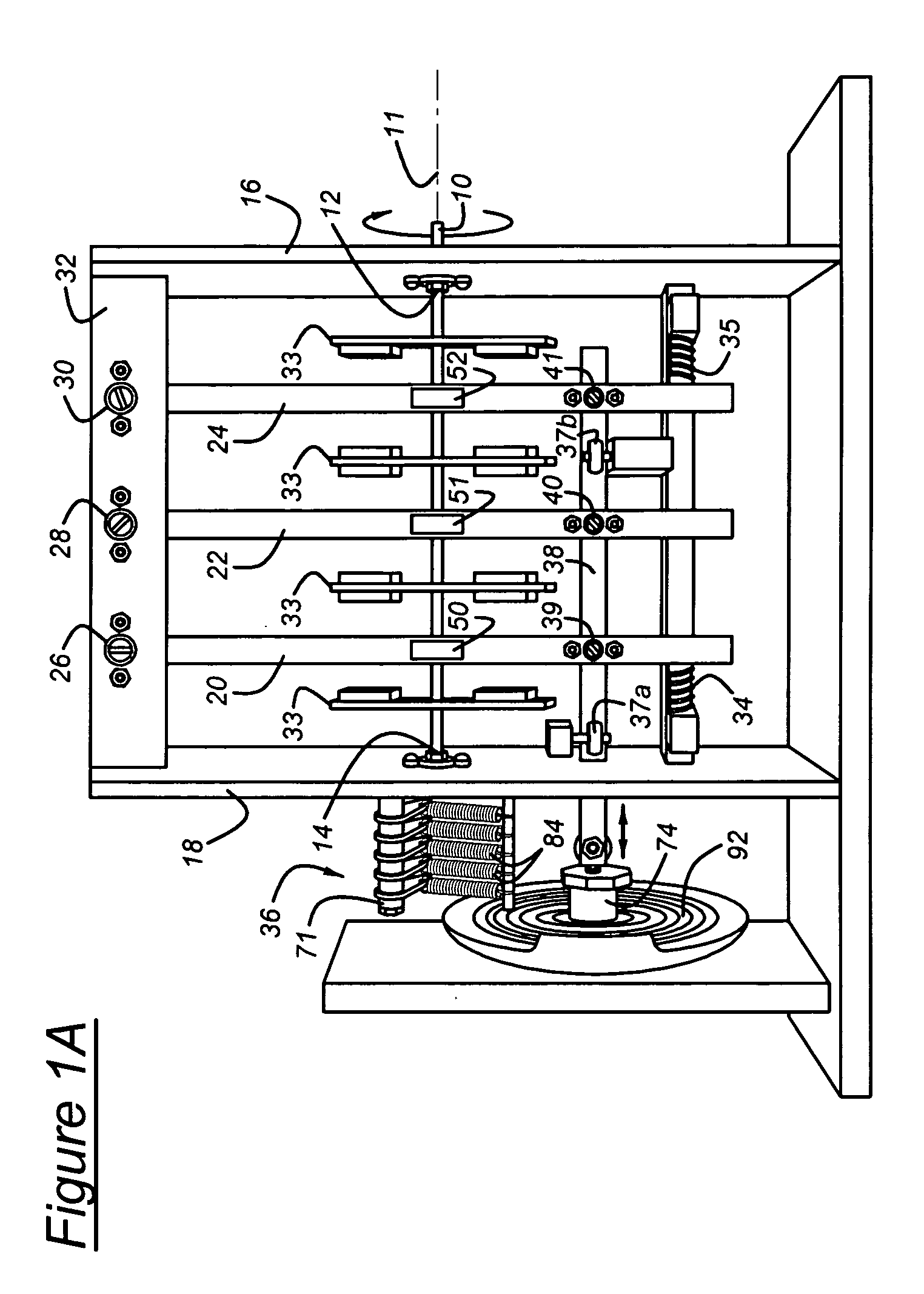

Drive apparatus

InactiveUS7024963B2Minimal heat lossIncrease its rotational inertiaMagnetic circuitGearingElectricityDrive shaft

An apparatus for inducing drive is shown that includes a primary drive shaft and four secondary drive shafts. The primary shaft and secondary shafts are fitted with magnets that are oriented such that when the primary shaft is rotated the secondary shafts are caused to rotate due to attractive or repulsive forces. The primary shaft is connected to and rotated by a rotational energy source such as a motor powered by electricity or a battery, although any source of energy to cause rotation of the primary shaft may be used. Each secondary shaft is fitted with two annular magnetic discs that are oriented to vertically support the weight of the shaft (and any attachments / fittings thereto) above the alternating or generating device. The discs can be arranged to provide either an attractive or repulsive magnetic force between them.

Owner:THE GABRIELLE BAKEY FAMILY TRUST

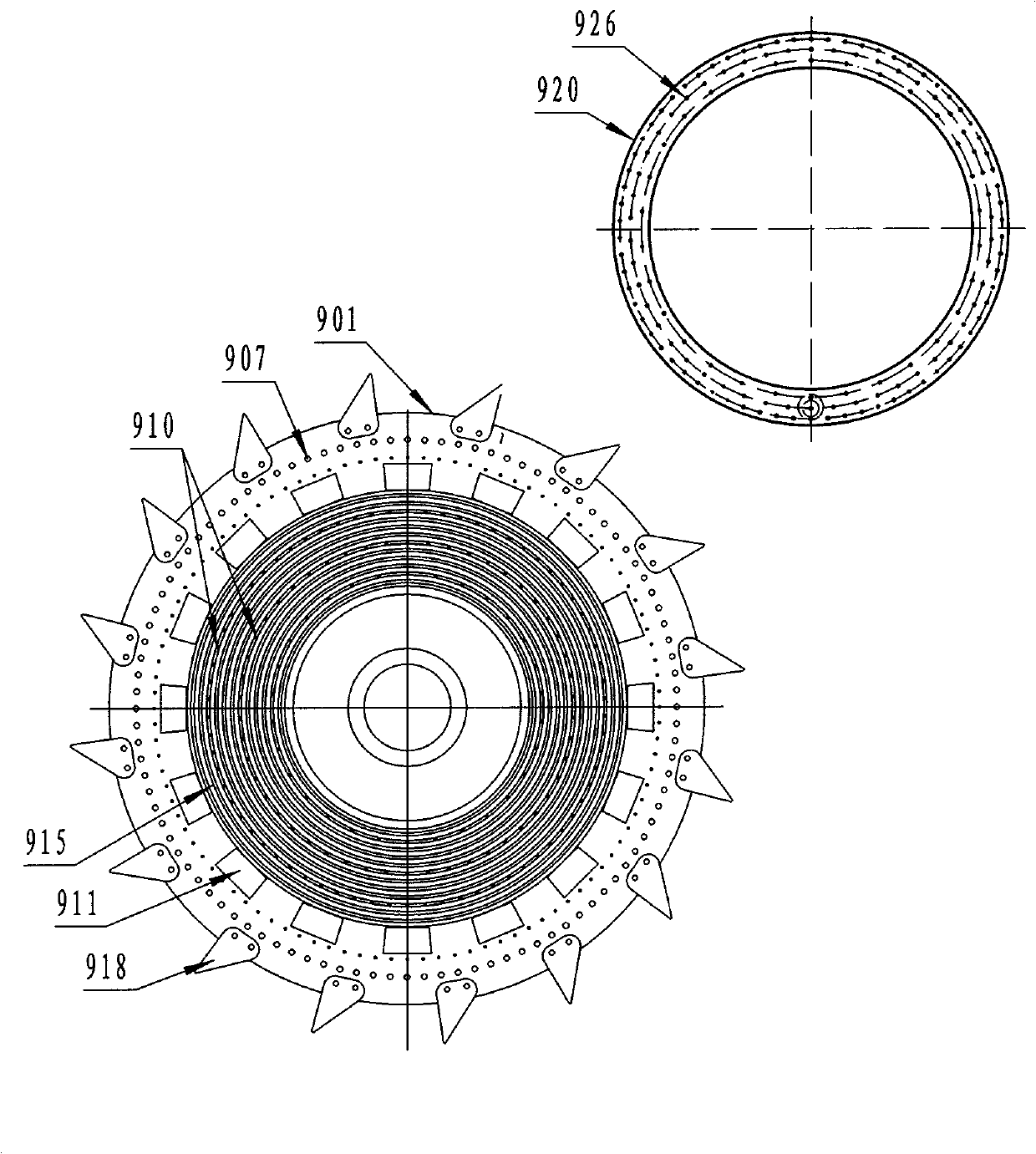

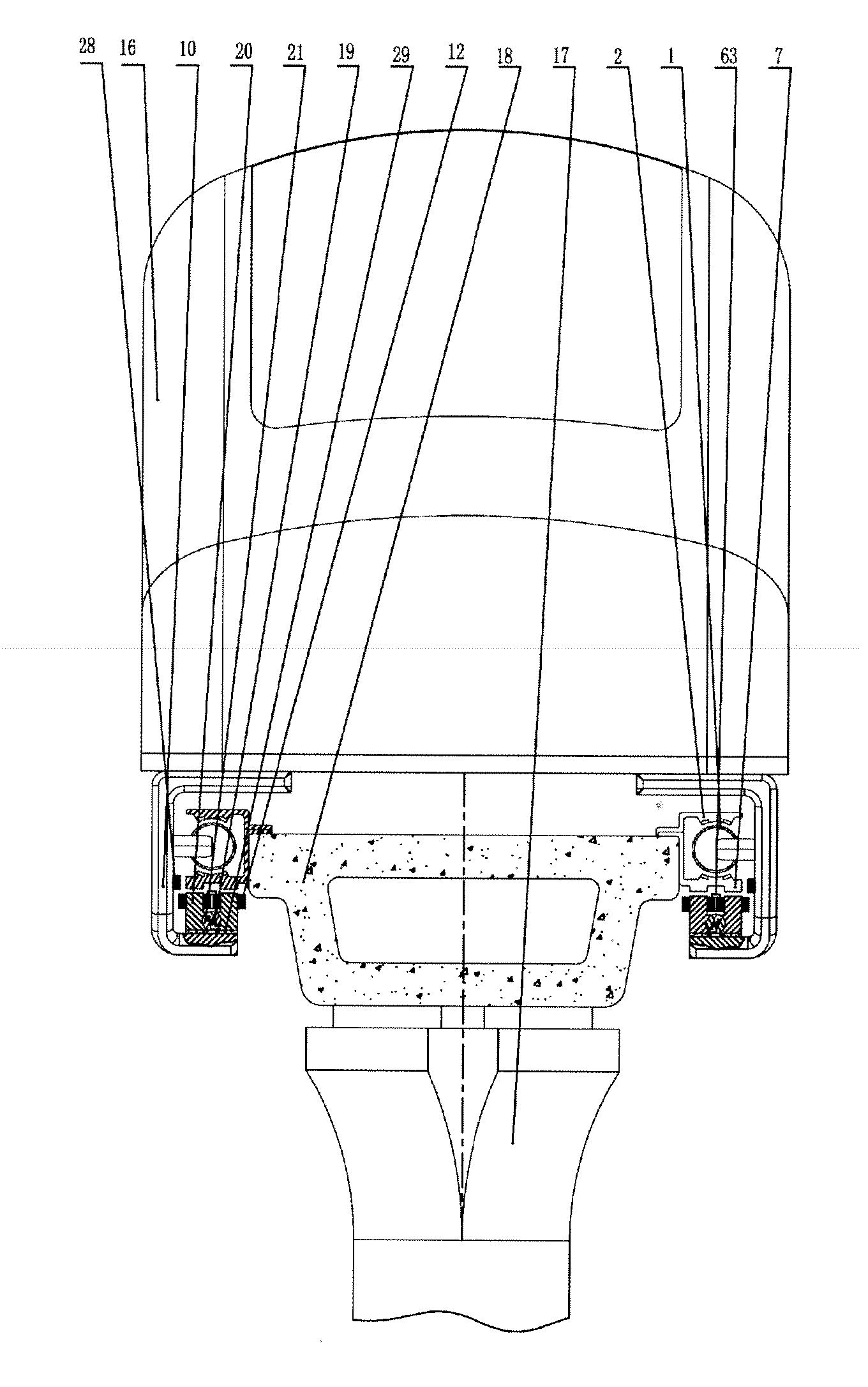

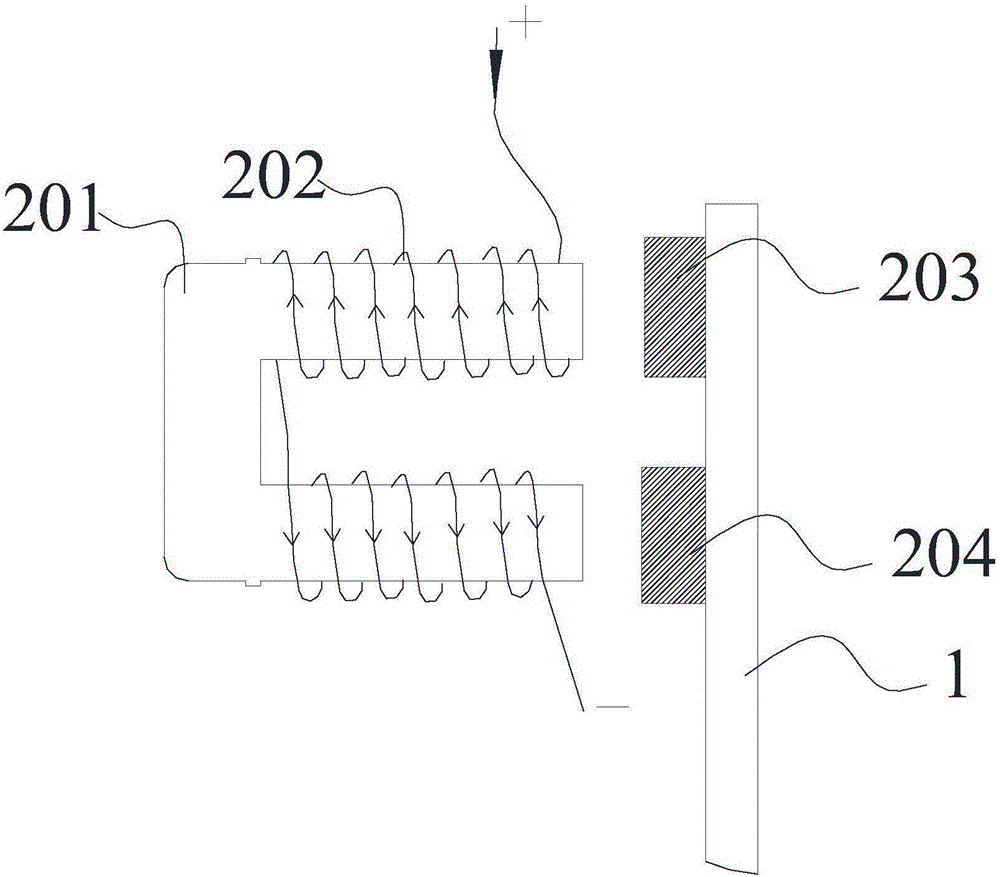

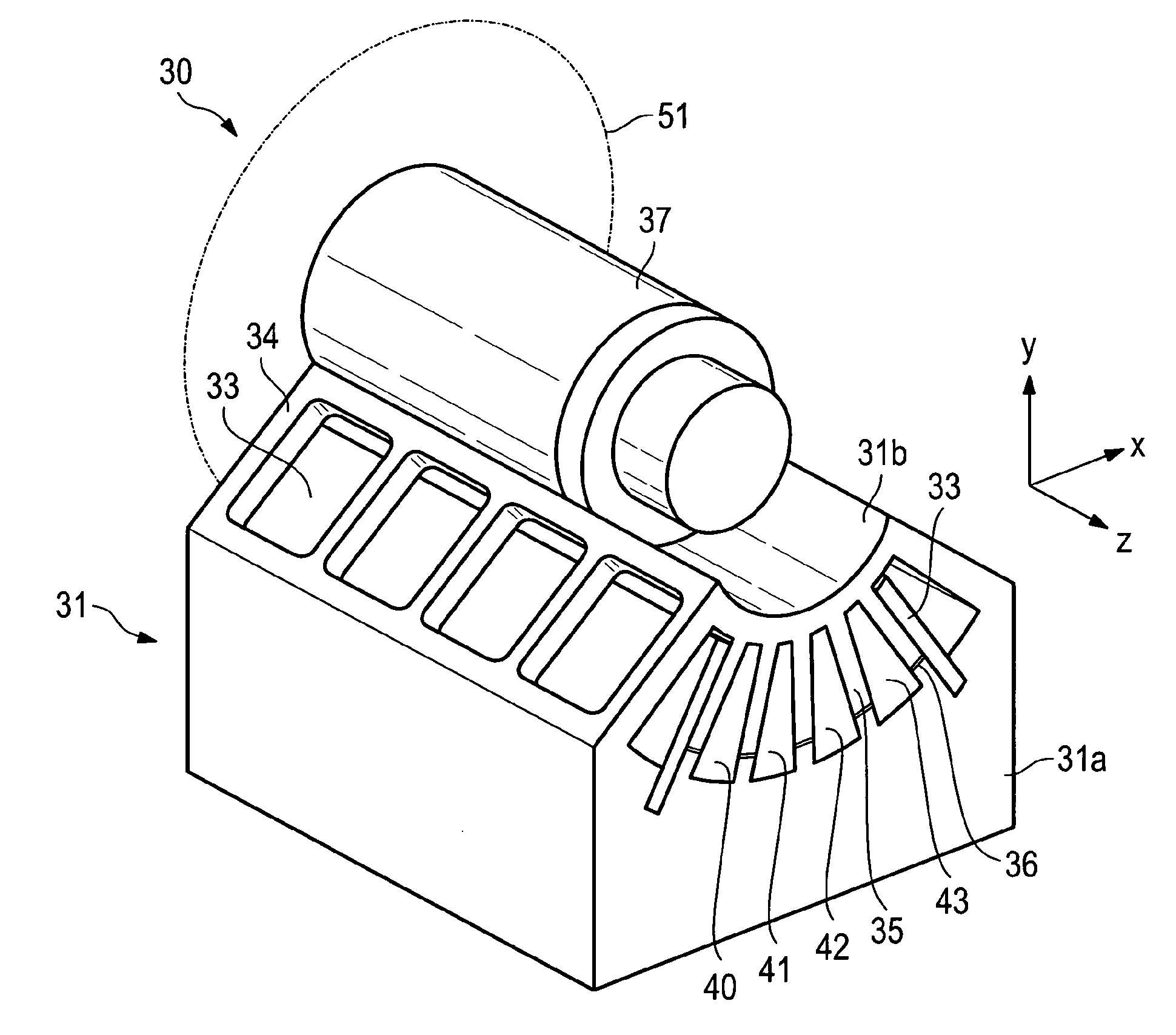

Permanent-magnet eddy current retarder based on Halbach array

InactiveCN102497085AImprove utilization efficiencyIncrease the magnetic field strength of the working air gapPermanent-magnet clutches/brakesOptical axisCoupling

Rotors are installed on a transmission shaft; the transmission shaft is installed in a central hole of a fixing plate; two ends of a bidirectional screw shaft are installed inside holes above the central hole of the fixing plate; two ends of each of three linear optical shafts are fixed into holes in front of, behind and below the central hole of the fixing plate; each of the two rotors consists of a Halbach-array permanent-magnet ring and a retaining rack; an outer cylindrical surface of the permanent-magnet ring is fixed inside a center hole of the retaining rack; a radial clearance is formed between an inner cylindrical surface of the permanent-magnet ring and an outer cylindrical surface of each rotor; four installing holes are uniformly distributed on the retaining rack; an upper installing hole is matched with the bidirectional screw shaft through a screw nut; the other three installing holes are matched with the linear optical shafts through linear bearings; and a servo motor is connected whit the bidirectional screw shaft through a shaft coupler. In the radial-array permanent-magnet eddy current retarder, the utilization ratio of a magnet is high, the brake moment is large, the response is quick, the heat dissipating conditions are good and the stepless regulation of the brake moment is realized.

Owner:ZHEJIANG UNIV

Line dispensing device with eddy current breaking for use with climbing and evacuation

Owner:EDDY CURRENT PARTNERSHIP

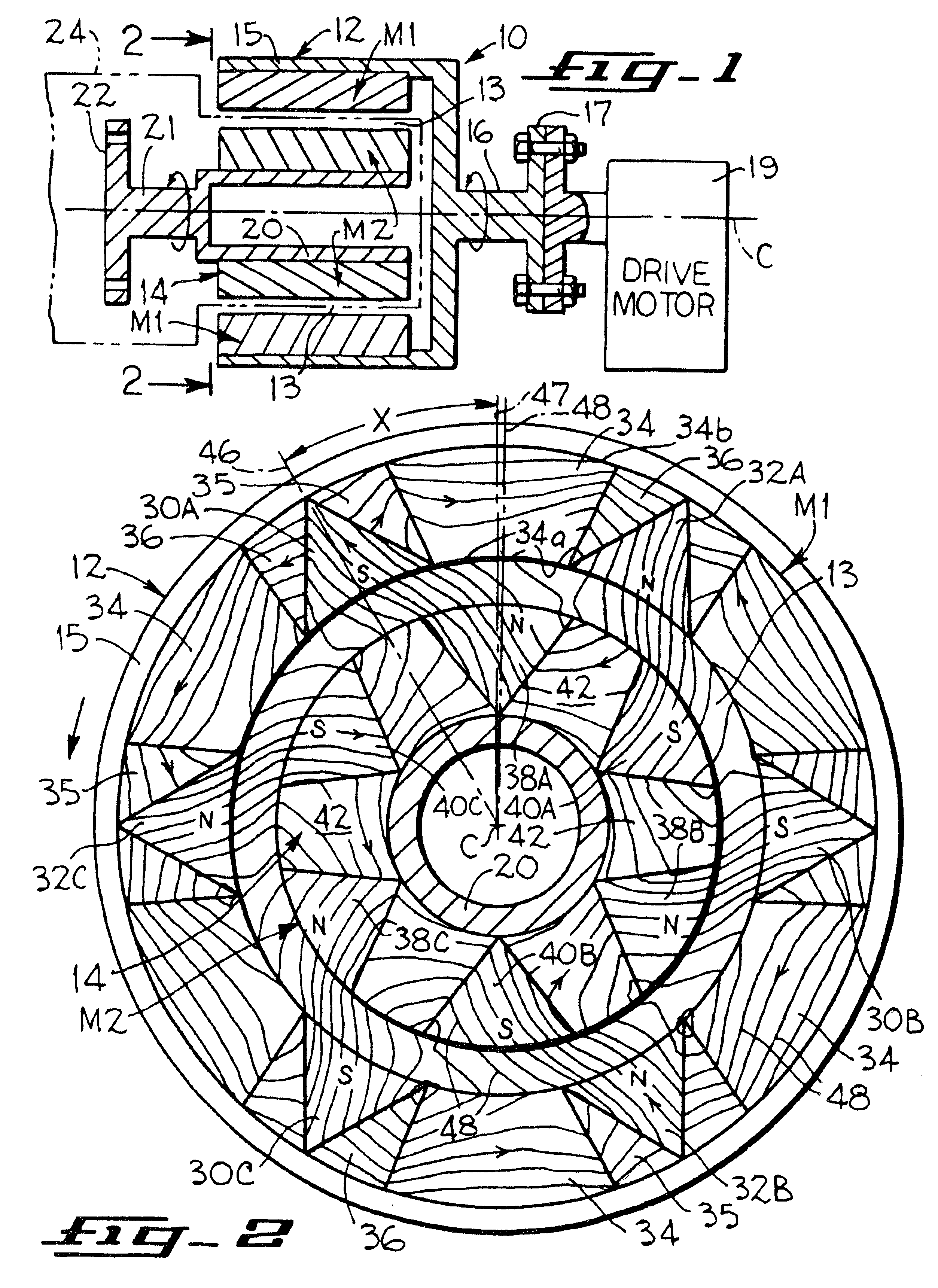

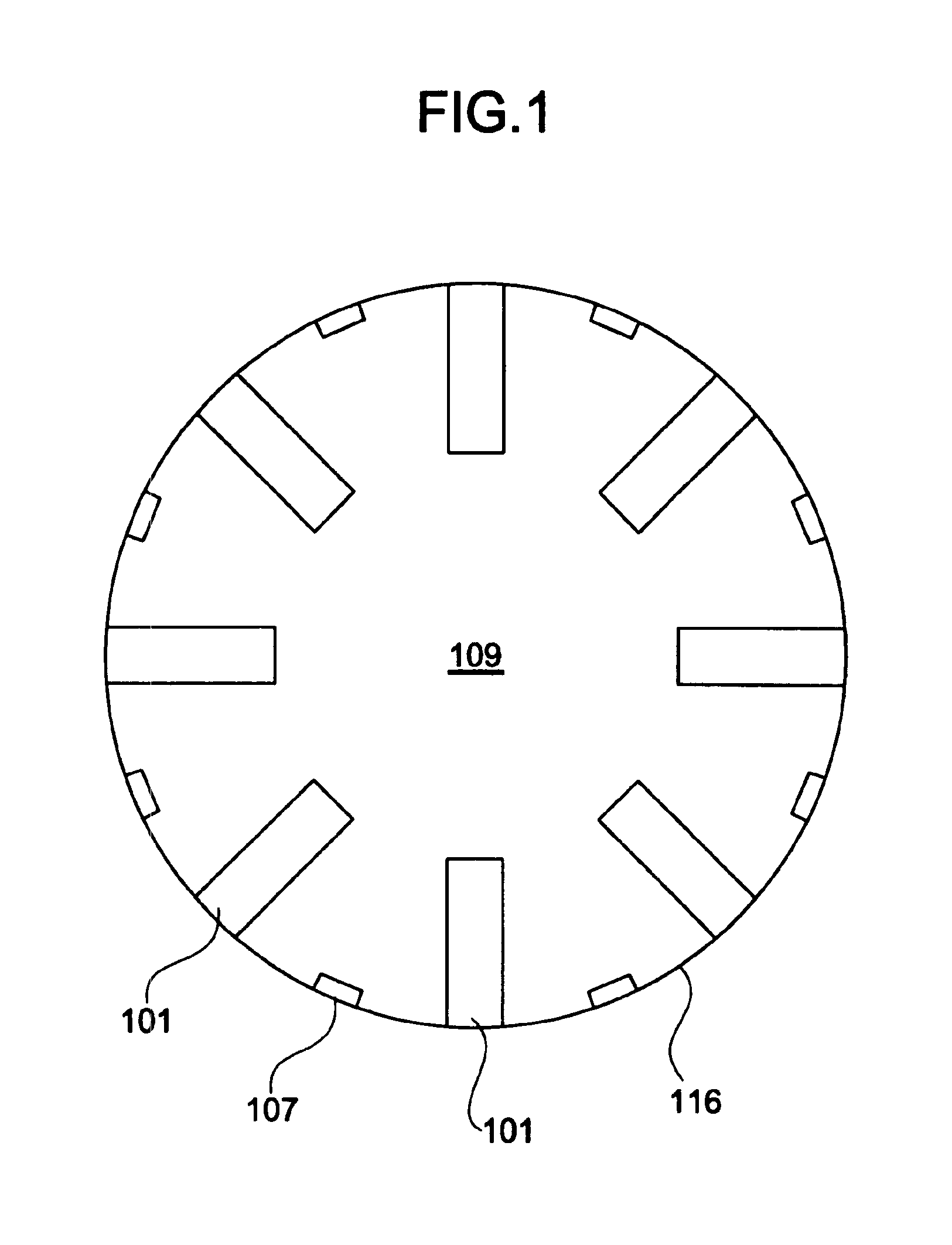

Permanent magnet generator

ActiveUS20060244327A1Easy to startMagnetic circuit rotating partsPermanent-magnet clutches/brakesElectrical conductorRotor magnets

A generator for producing electric power includes a drive mechanism, such as a drive motor, having a rotor supported for rotation about an axis. A first generator magnet driveable by the rotor includes a reference pole facing in a first direction. A second generator magnet driveable by the rotor includes a pole of opposite polarity from the reference pole located near the reference pole and facing in the first direction. The first and second generator magnets produce a magnetic field whose flux extends between the reference pole of the first generator magnet and opposite pole of the second generator magnet. A stator includes an electrical conductor winding located adjacent the first and second magnets such that the magnetic field repetitively intersects the winding as the rotor driveably rotates. The drive motor for operating the generator includes a pair of first and second rotor magnets spaced angularly about the axis and supported on the rotor, a reciprocating magnet, and an actuator for moving the first reciprocating magnet cyclically toward and away from the first pair of the rotor magnets, for cyclically rotating the first pair of rotor magnets relative to the reciprocating magnet.

Owner:KUNDEL STEPHEN

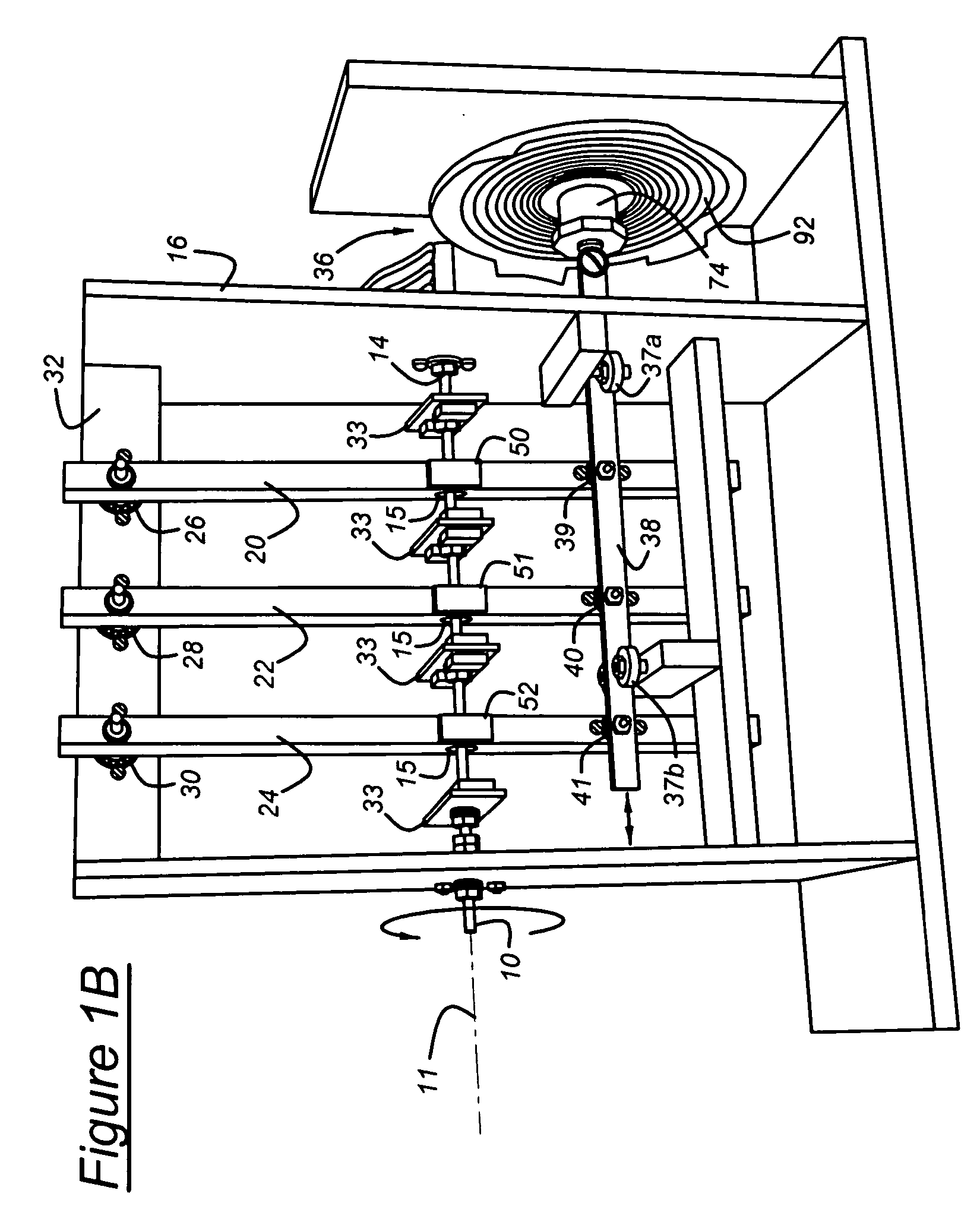

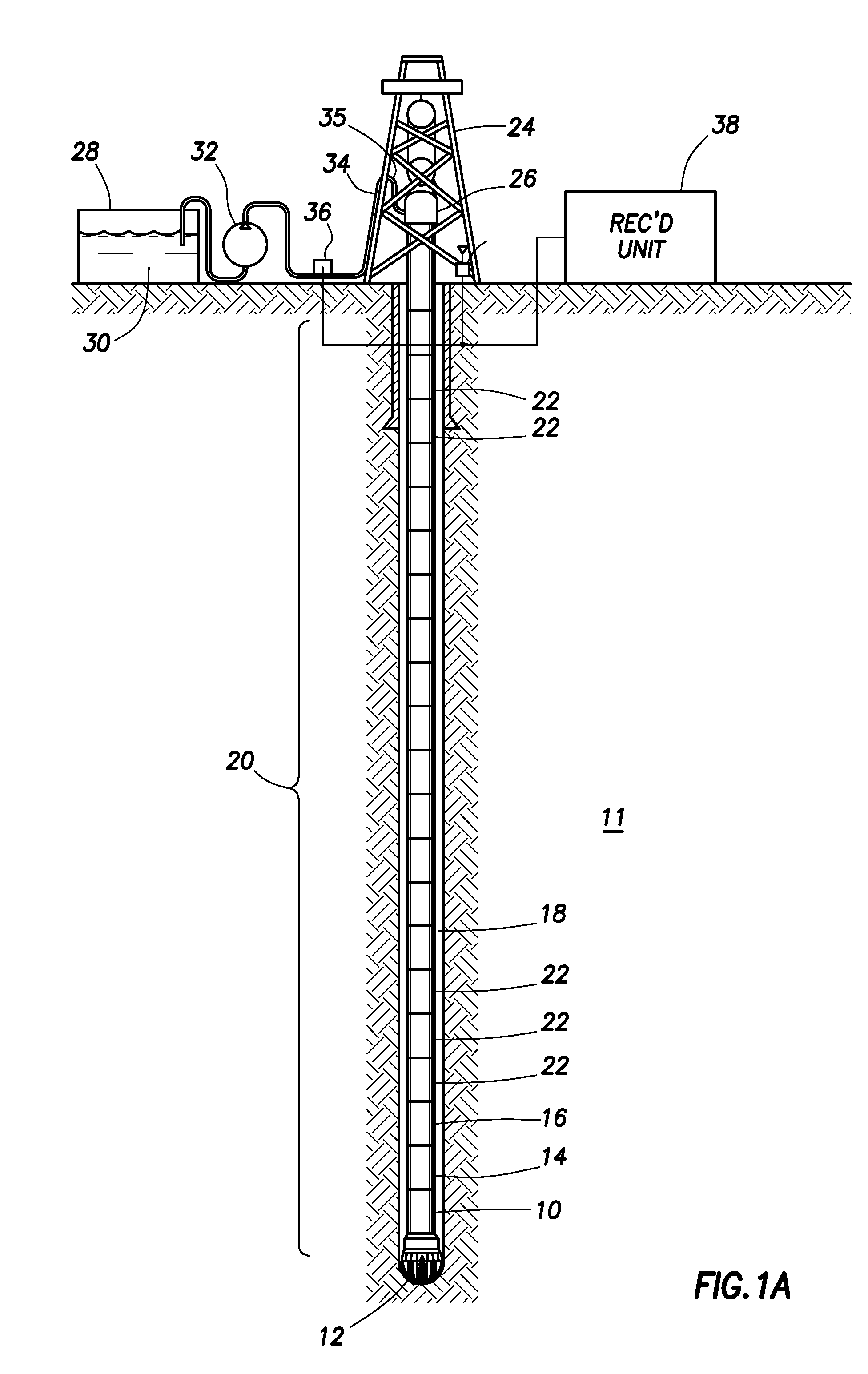

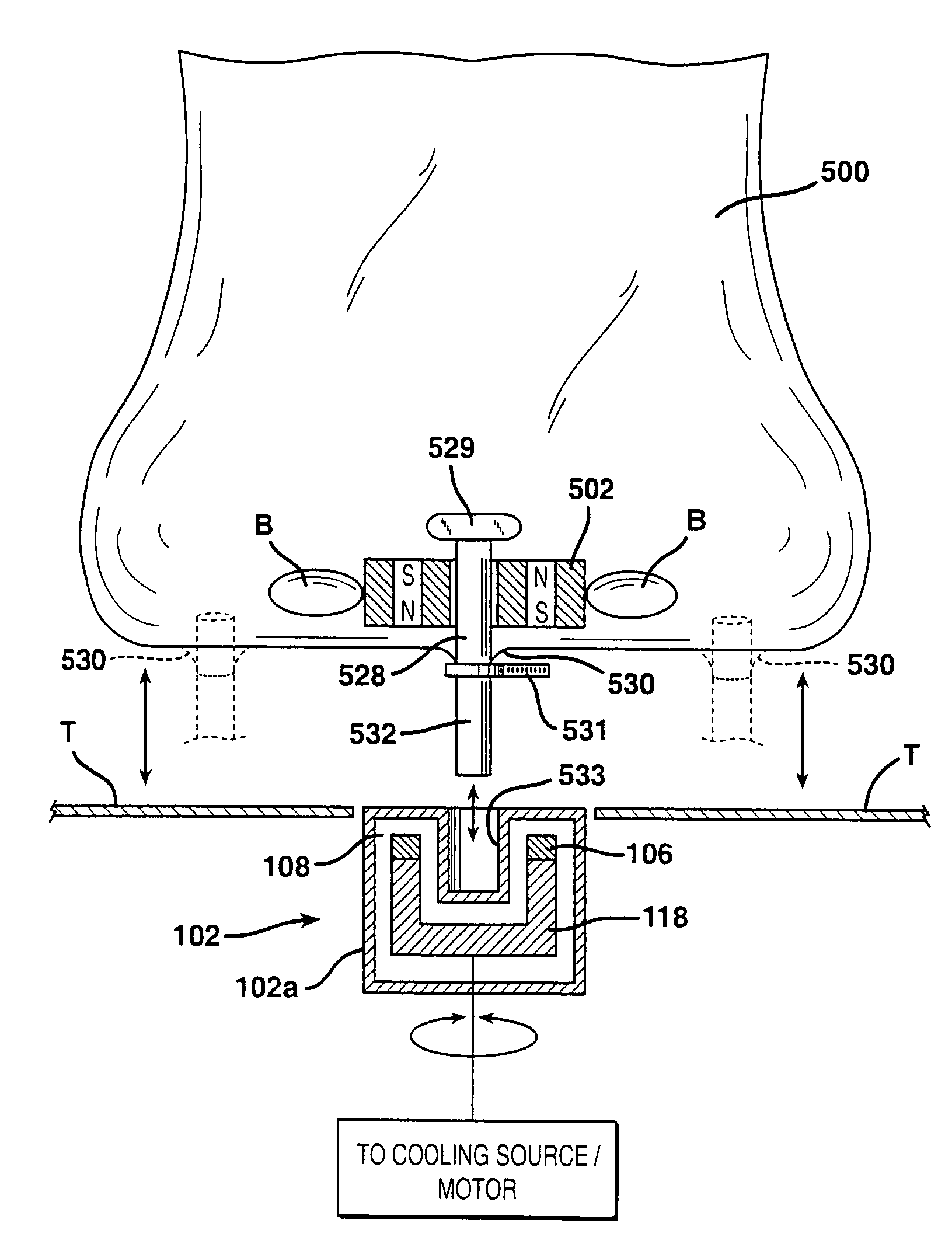

Wellbore instruments using magnetic motion converters

A directional drilling system, a drilling hammer and a fluid flow telemetry modulator use a plurality of magnets arranged to convert rotational motion into reciprocating linear motion. Various types of motor can provide rotational motion to a part of the magnets and various linkages and other devices can cause steering or operation of a modulator valve. A torsional drilling hammer uses a plurality of magnets arranged to convert reciprocating linear motion into reciprocating rotational motion. A motor and linkage drives the linearly moving part of the magnets, and the rotating part provides torsional impact be striking the linearly moving part of the magnets.

Owner:SCHLUMBERGER TECH CORP

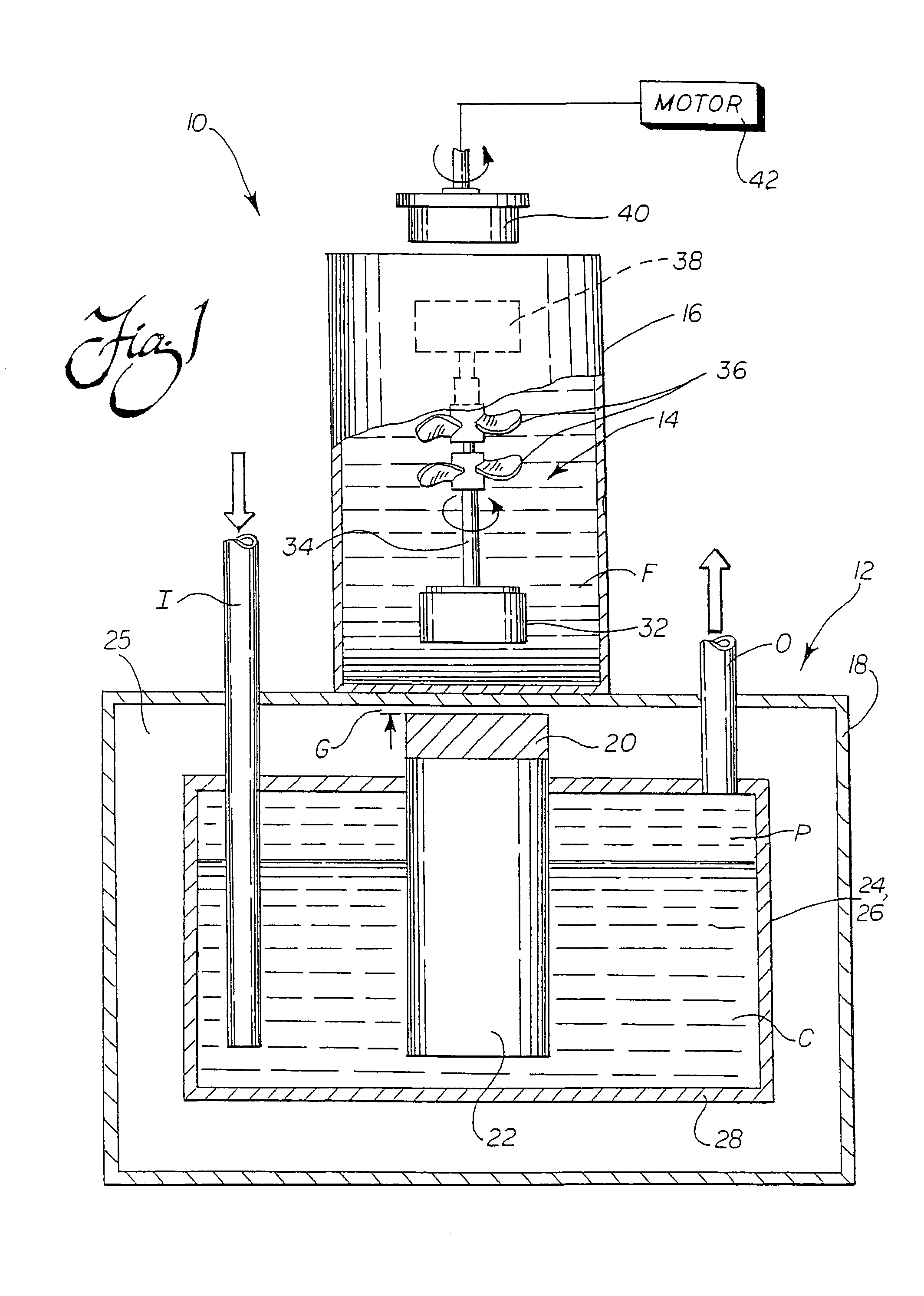

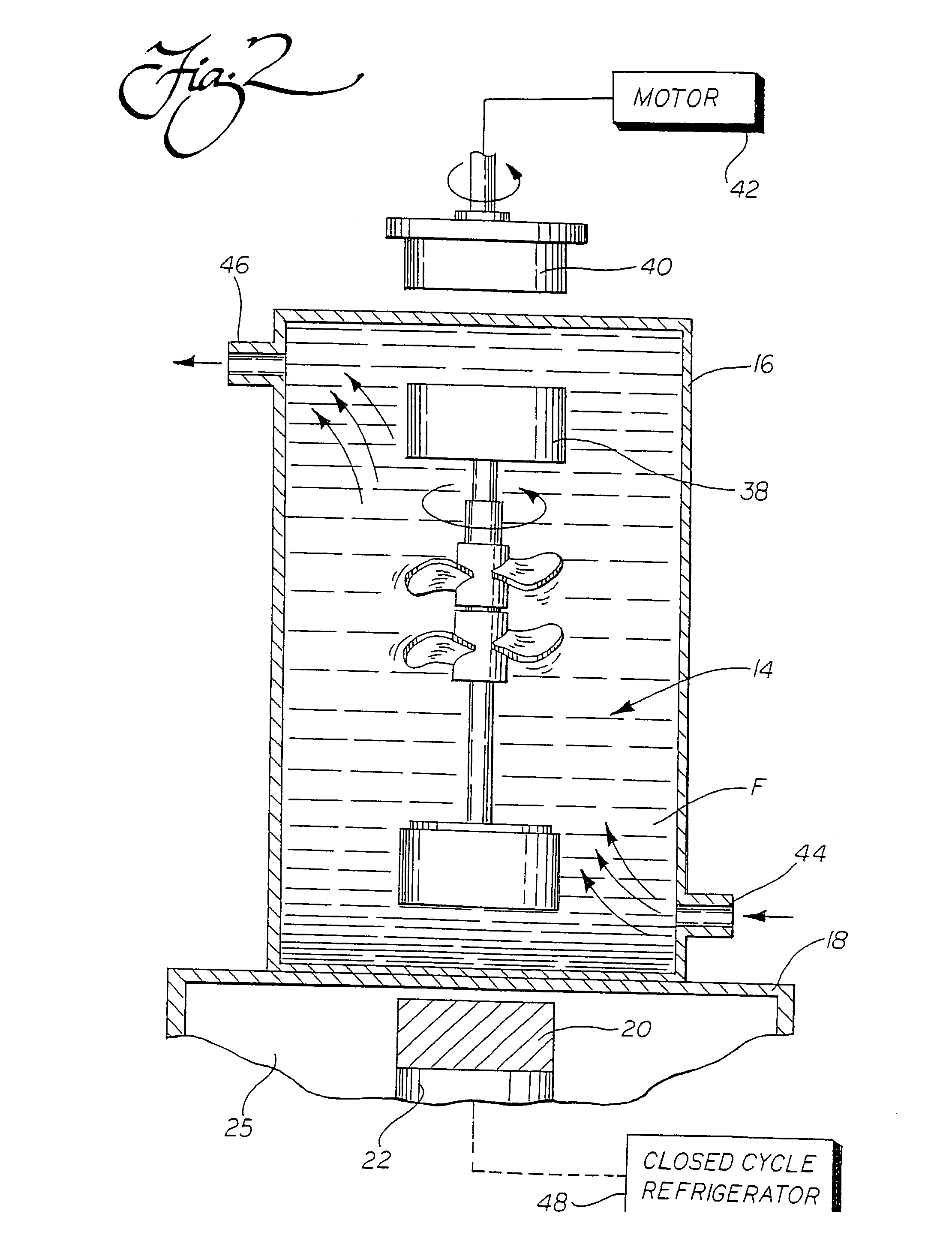

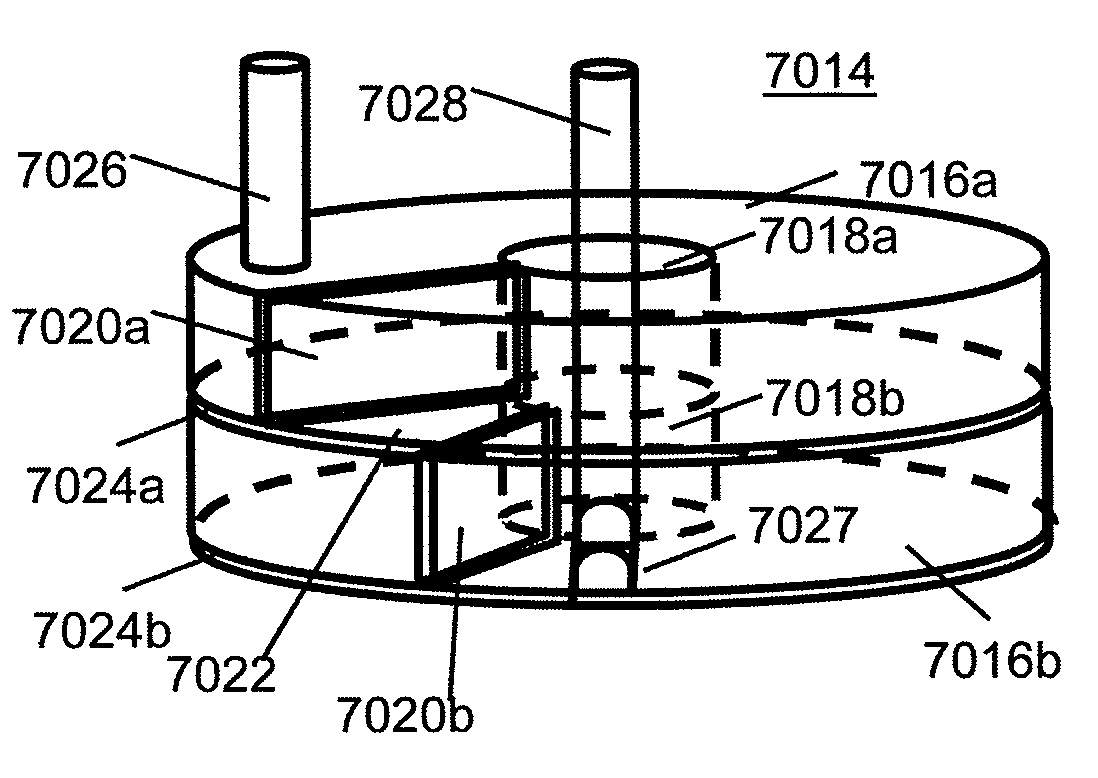

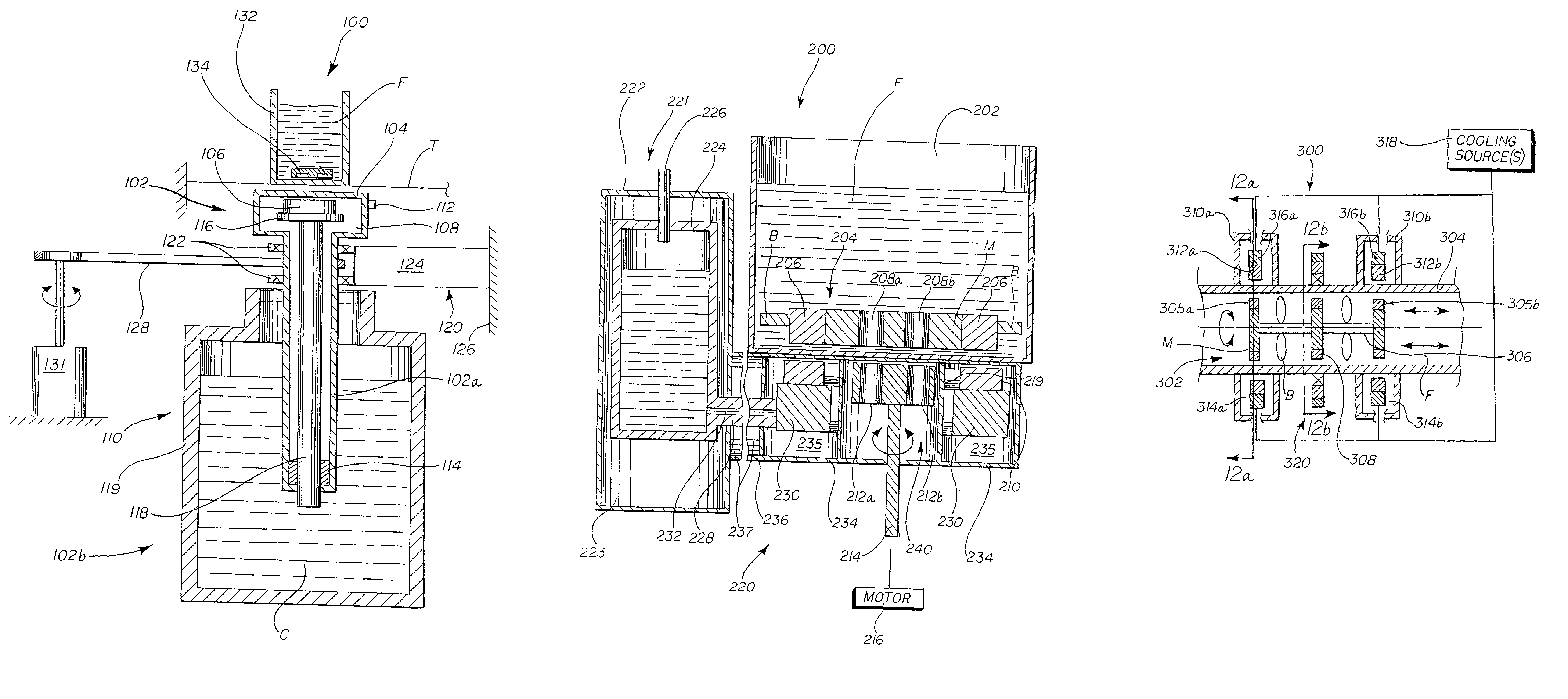

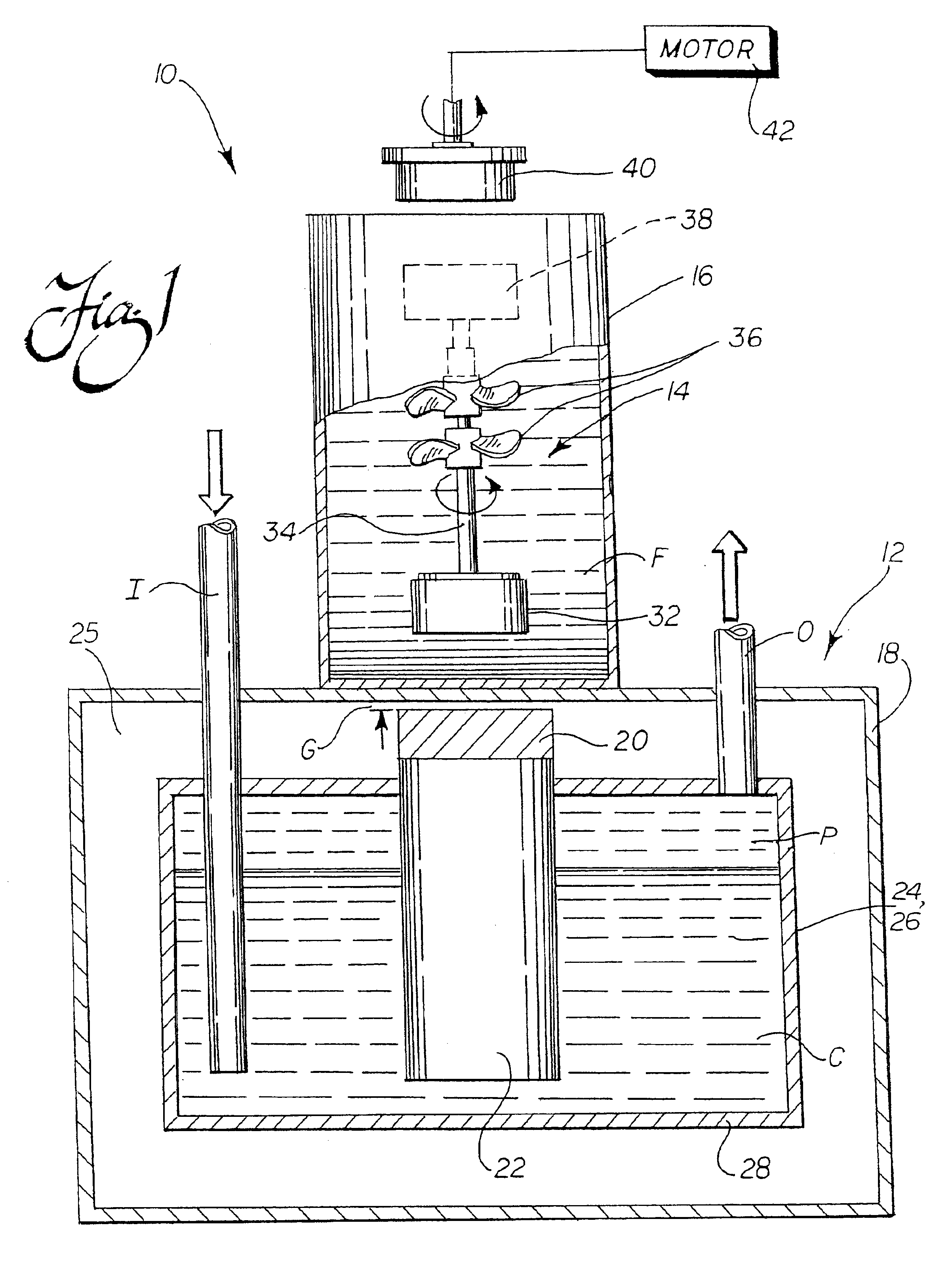

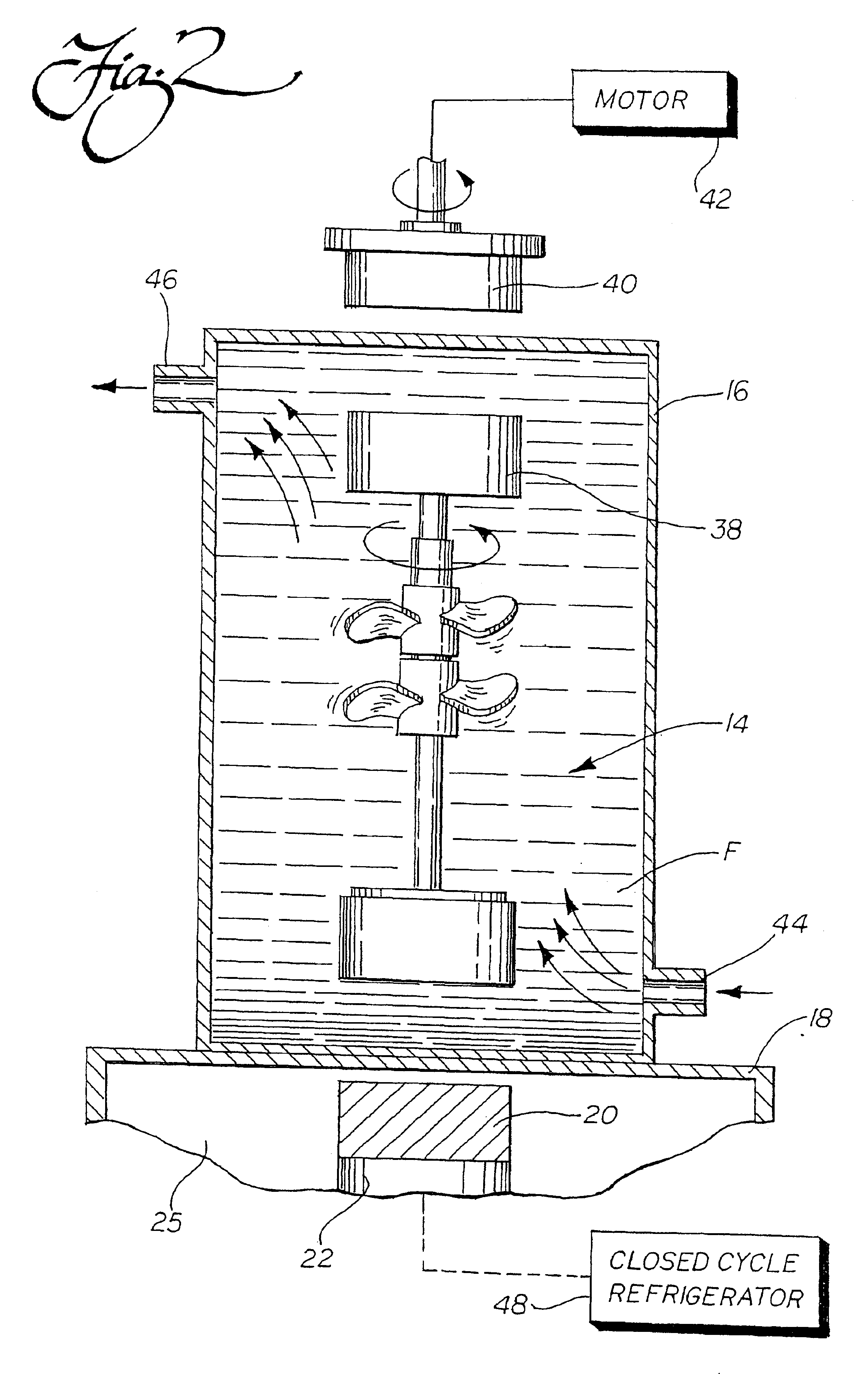

Sterile fluid pumping or mixing system and related method

InactiveUS7357567B2Transportation and packagingRotary stirring mixersMixed systemsBiomedical engineering

A system for pumping or mixing a fluid using a levitating, rotating magnetic element and various other components for use in a pumping or mixing system are disclosed. The magnetic element is placed in a vessel or container that can be positioned in close proximity to a superconducting element. The vessel or container may be sealed with the magnetic element and a product therein, with the fluid being introduced after sealing. Preferably, the vessel or container is capable of holding fluid volumes greater than 10 liters.

Owner:PALL TECH UK

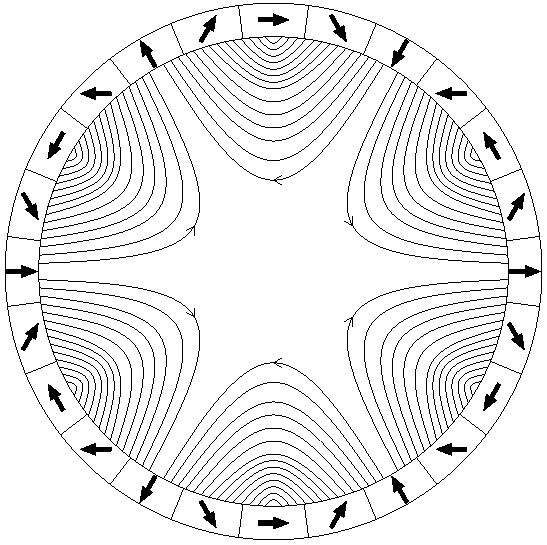

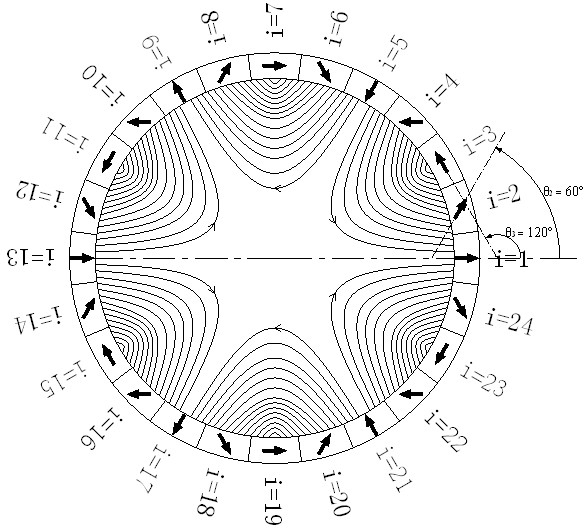

Magnetic gear

InactiveUS20110127869A1Total current dropDynamo-electric gearsSynchonous clutches/brakesPole pieceConductor Coil

Owner:MAGNOMATICS LTD

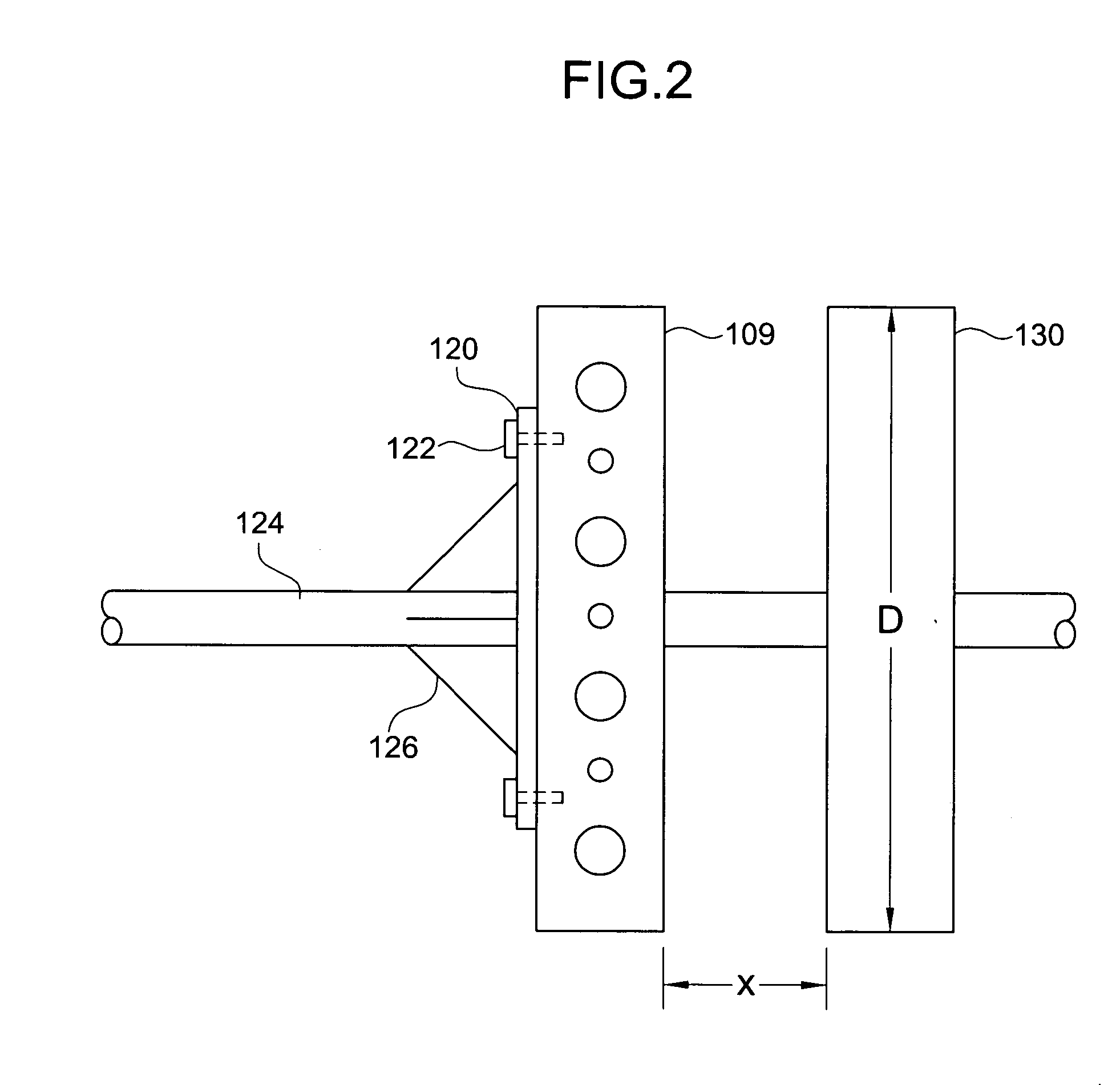

Apparatus for transferring torque magnetically

ActiveUS20050189830A1Overcome limitationsMagnetically actuated clutchesDynamo-electric gearsEngineeringCylindrical geometry

An apparatus for transferring torque magnetically with a primary rotary member and a secondary rotary member. The primary rotary member has permanent magnets mounted circumferentially on a cylinder, the secondary rotary member having a cylindrical geometry with electroconductive material arranged on its outer periphery and parallel to the axes of the rotary members. The secondary rotary member also having magnetically permeable material. The secondary rotary member is placed partially or totally inside the primary rotating member. The secondary rotary member's axial position relative to the primary rotating member can be varied by a suitable mechanical structure. This causes the two rotary members to axially overlap one another more or less as desired. Rotation of the primary rotary member causes rotation of the secondary rotary member, since magnetic flux lines emanating from the permanent magnets mounted on the primary rotating member, cut through all, or part of, the electroconductive material placed on the periphery of the secondary rotary member. This can vary the torque transmitted between the two rotary members, thereby enabling the varying of the rotational speed of the secondary rotary member relative to the primary rotary member.

Owner:OSERAN WILLIAM A +1

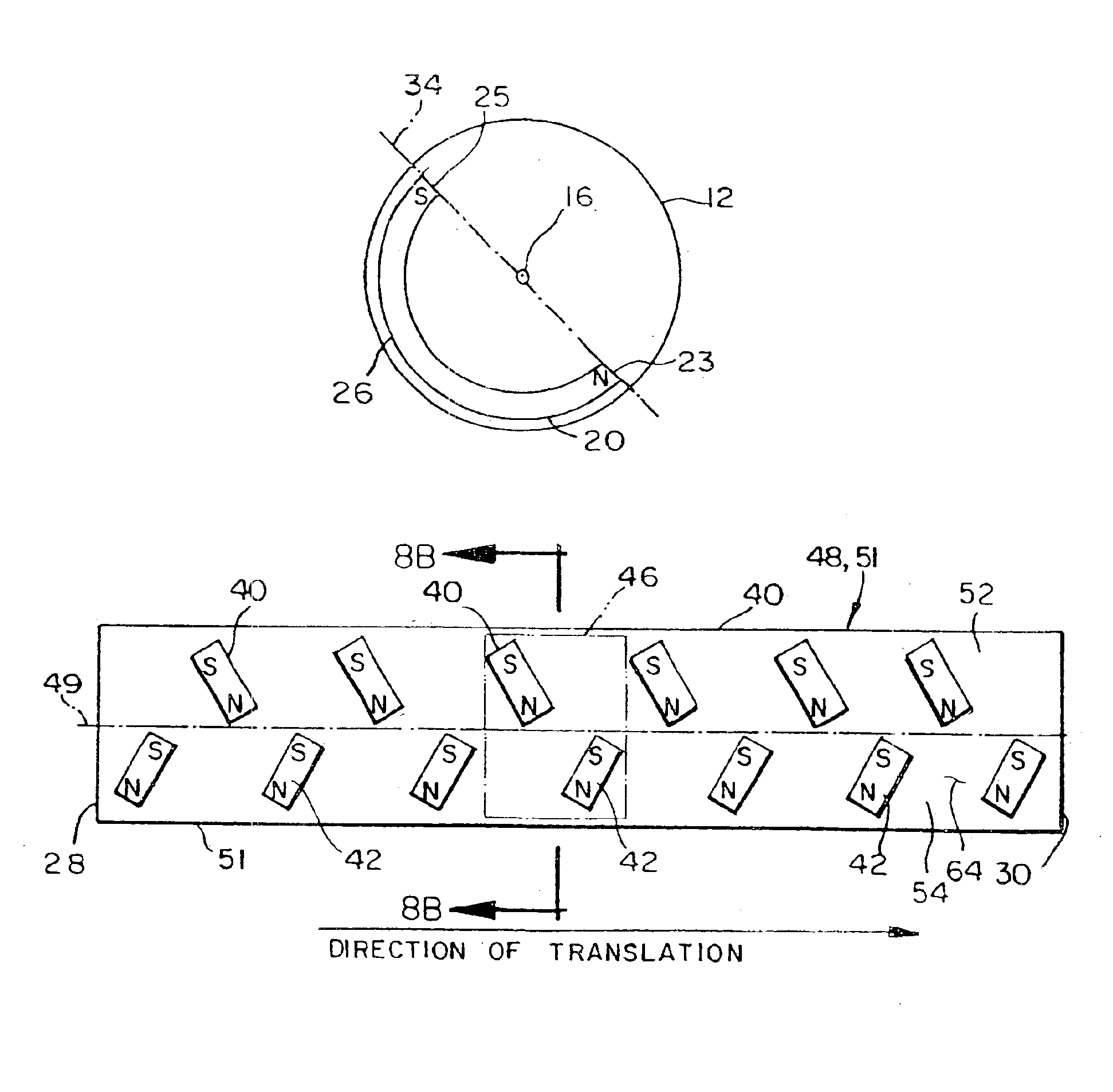

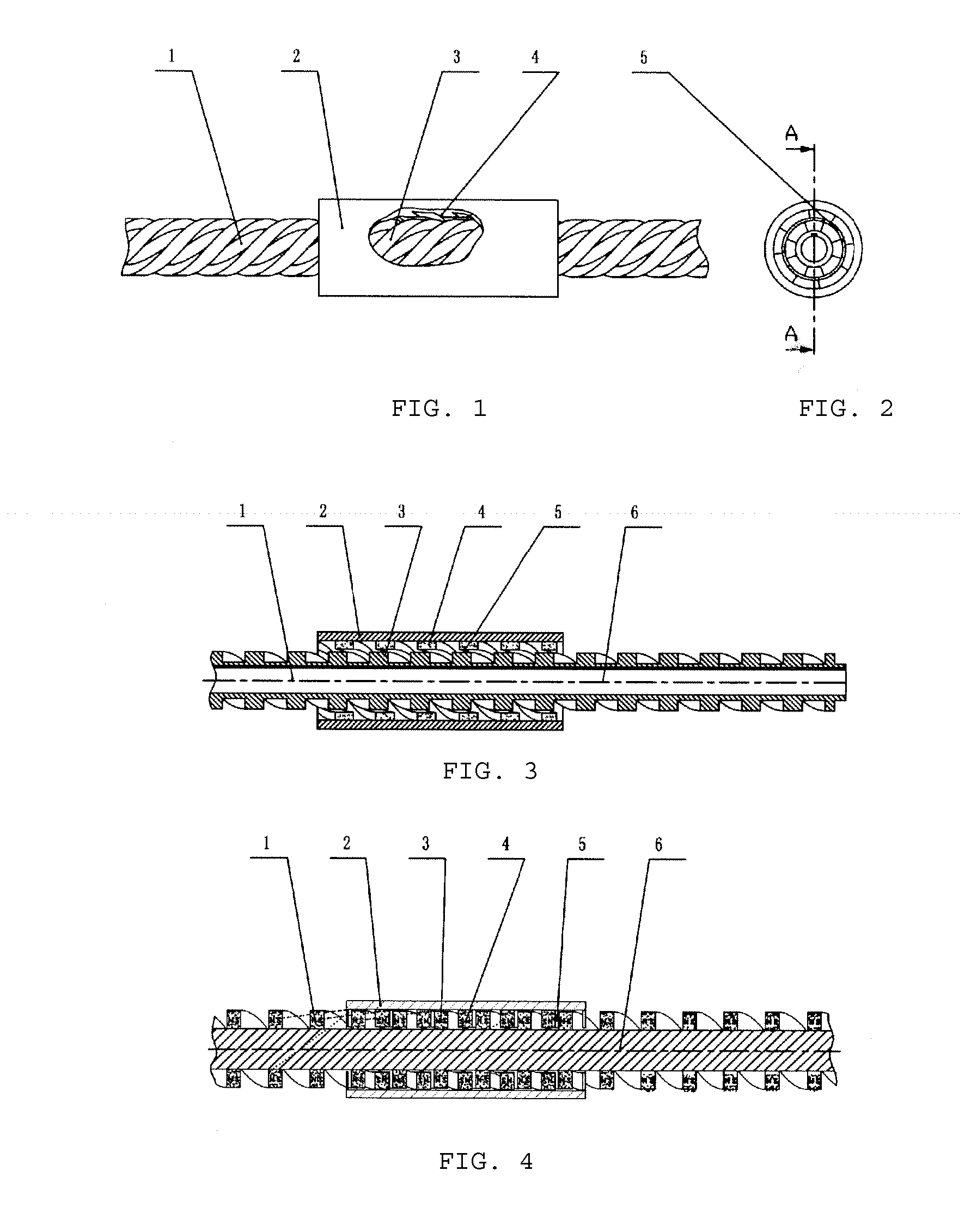

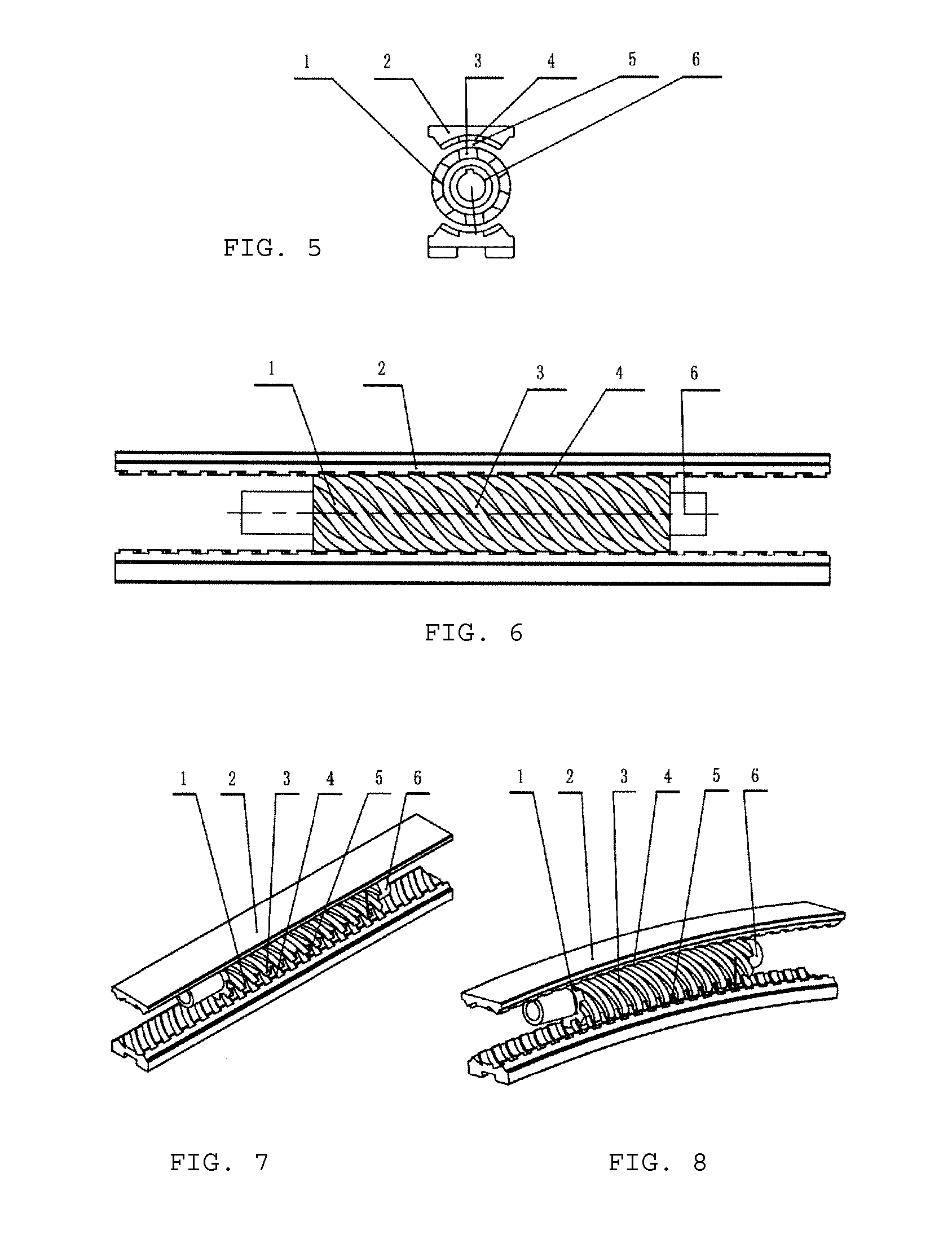

Linear permanent magnet drving system and permanent magnet driving and magnetic suspension roadway system

InactiveUS20110271867A1Improve transmission efficiencyMaximum effectivenessRail devicesRailway componentsLinear motionLow speed

The invention relates to a linear permanent magnet driving system and a permanent magnet driving maglev train rail system, the linear permanent magnet driving system comprises spiral rotors and stators, wherein at least one of the spiral rotor and the stator adopts the structure having a permanent magnet while the other one adopts the structure having the permanent magnet or a magnetizer; when the spiral rotors are driven by an engine to rotate, linear motion of the spiral rotors is achieved by means of the magnetic force between both, and speed of the linear motion of the spiral rotors can reach supersonic speed at most. By applying the linear permanent magnet driving system to the permanent magnet driving maglev train rail system, the entire rail can avoid the use of both permanent magnet and driving coil, and the construction cost of maglev train rail is equivalent to that of the current high-speed wheel / rail. The permanent magnet driving maglev train can save energy by 60 to 90% compared with wheel / rail train when traveling at low speed below 80 kilometers per hour and save energy by about 50% compared with high-speed wheel / rail train when traveling at high speed above 200 kilometers per hour. The invention can realize the interchangeability of maglev rail and common rail, leading the maglev rail to universality, networkability and compatibility in modern transportation.

Owner:LIU ZHONGCHEN

Torque transfer system and method of using the same

InactiveUS20060111191A1Reduce frictionAvoid generatingMagnetically actuated clutchesPermanent-magnet clutches/brakesTransfer systemTorque transmission

A system for transferring rotational motion includes a first rotational shaft extending along a first axial direction, and a second rotational shaft disposed along a second axial direction and spaced apart from the first rotational shaft, wherein the first rotational shaft is magnetically coupled to the second rotational shaft.

Owner:MAGNETIC TORQUE INT

Field emission system and method

Owner:CORRELATED MAGNETICS RES LLC

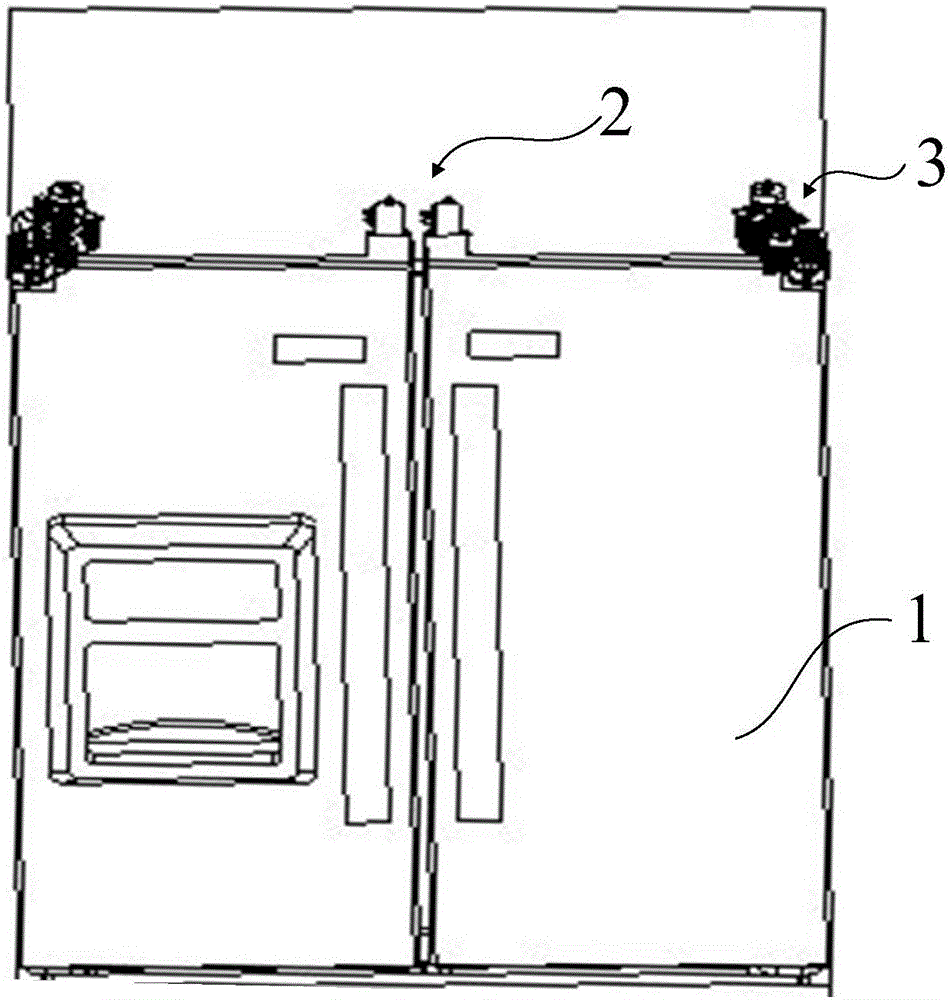

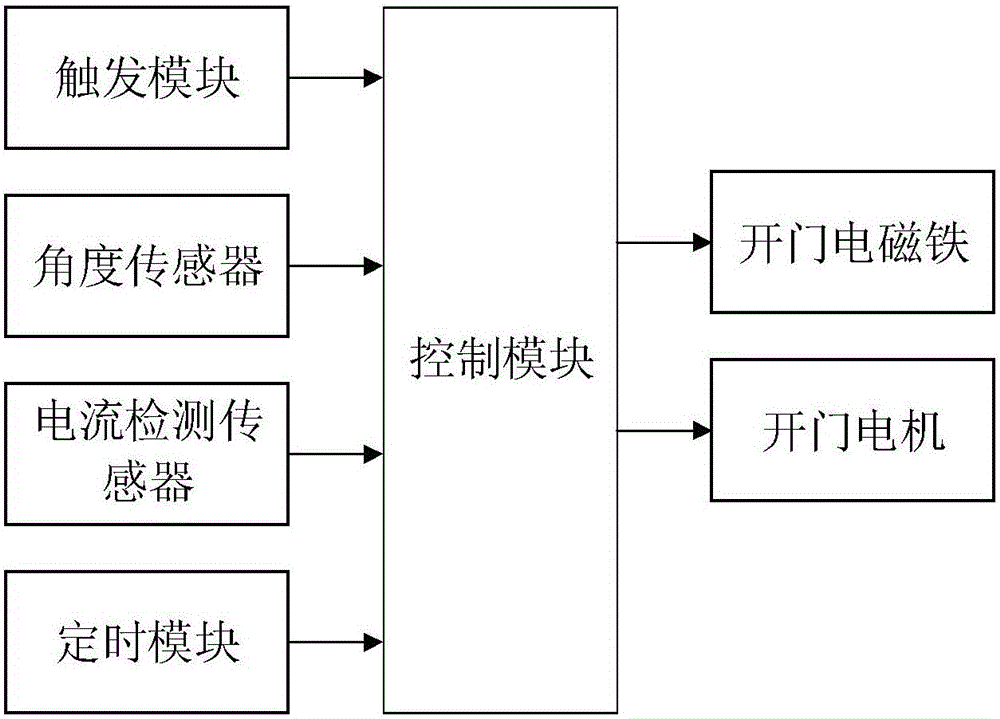

Door opening motor assembly, automatic door opening system, work method and refrigerator

ActiveCN105971439AReach the automaticTo close the doorPower-operated mechanismPermanent-magnet clutches/brakesTransmitted powerElectromagnetic clutch

The invention belongs to the field of household appliances and particularly relates to a door opening motor assembly, an automatic door opening system, a work method and a refrigerator. The door opening motor assembly comprises a door opening motor, a front stage gear set, an output shaft, a rear stage gear set and an electromagnetic clutch, wherein the front stage gear set is located at the door opening motor end; the output shaft is used for controlling a door to rotate; and the rear stage gear set is located at the output shaft end. The electromagnetic clutch is used for enabling the front stage gear set to be in transmission fit with the rear stage gear set after being electrified, i.e., after the electromagnetic clutch is electrified, the front stage gear set and the rear stage gear set are engaged with a clutch gear in the electromagnetic clutch, so that the torque of the door opening motor is transmitted to the output shaft. The door opening motor assembly pushes the clutch gear to the transmission position of the front stage gear set and the rear stage gear set after being electrified through the electromagnetic clutch, and the door opening motor transmits power to the output shaft so as to achieve the purpose of automatic door opening and closing; if the power is cut off, the electromagnetic clutch enables the clutch gear to be disconnected from the transmission position; and therefore, the purpose of manual door opening and closing is achieved.

Owner:HEFEI HUALING CO LTD +1

Sterile fluid pumping or mixing system and related method

InactiveUS6837613B2Keep sterileTransportation and packagingRotary stirring mixersMixed systemsBiomedical engineering

A system for pumping or mixing a fluid using a levitating, rotating magnetic element and various other components for use in a pumping or mixing system are disclosed. The magnetic element is placed in a vessel or container that can be positioned in close proximity to a superconducting element. The vessel or container may be sealed with the magnetic element and a product therein, with the fluid being introduced after sealing. Preferably, the vessel or container is capable of holding fluid volumes greater than 10 liters.

Owner:PALL TECH UK

Power generating systems

InactiveUS20070007835A1Reduce friction and wearPermanent-magnet clutches/brakesMechanical energy handlingTransfer systemEngineering

A power generating system includes a torque converter system receiving a rotational motion having a first torque from a source and producing a rotational output having a second torque different from the first torque, a transfer system having a first portion coupled to the rotational output of the torque converter system and a second portion magnetically coupled to the first portion, and a generator system coupled to the transfer system to produce and electrical output.

Owner:CAMEL CLUB

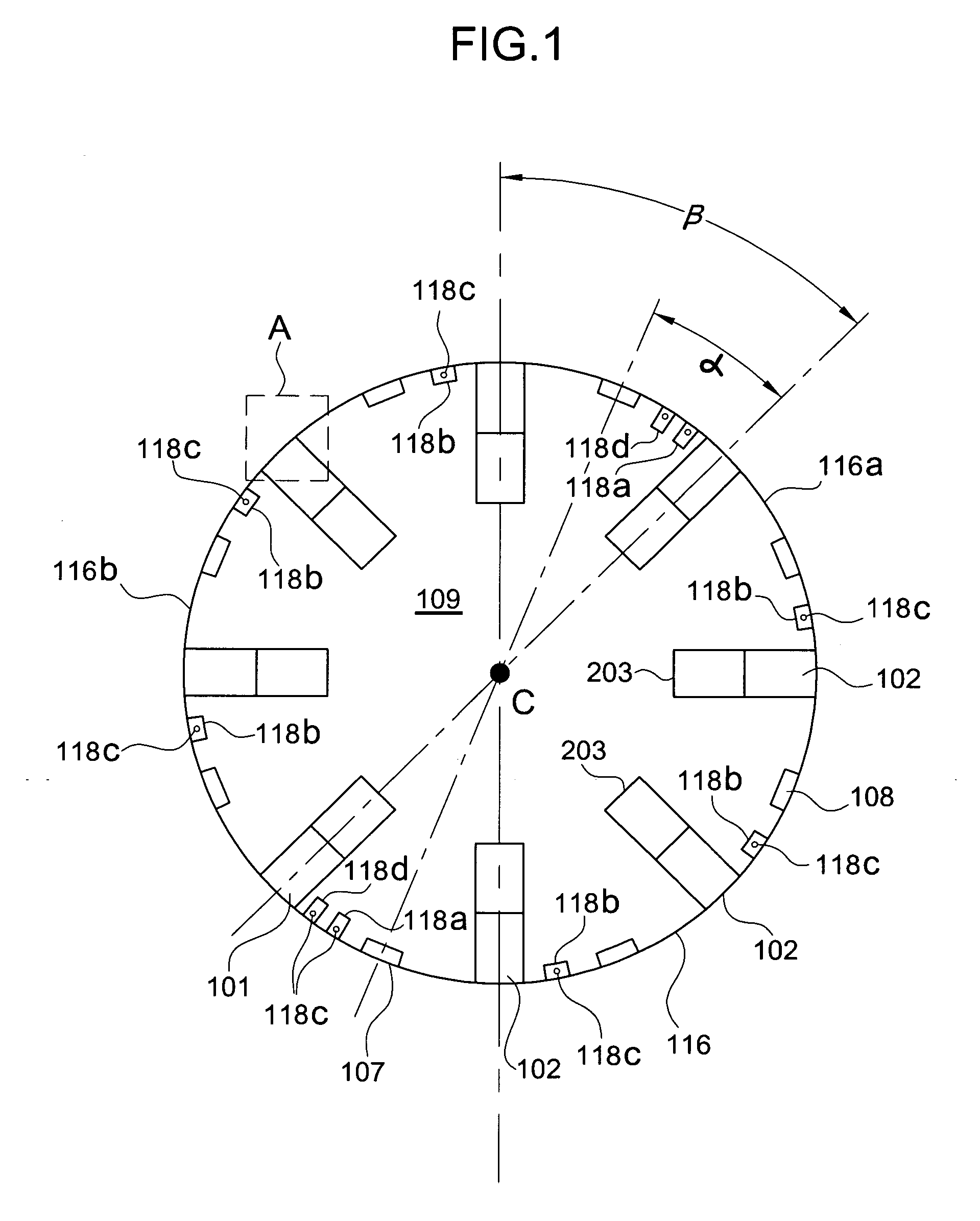

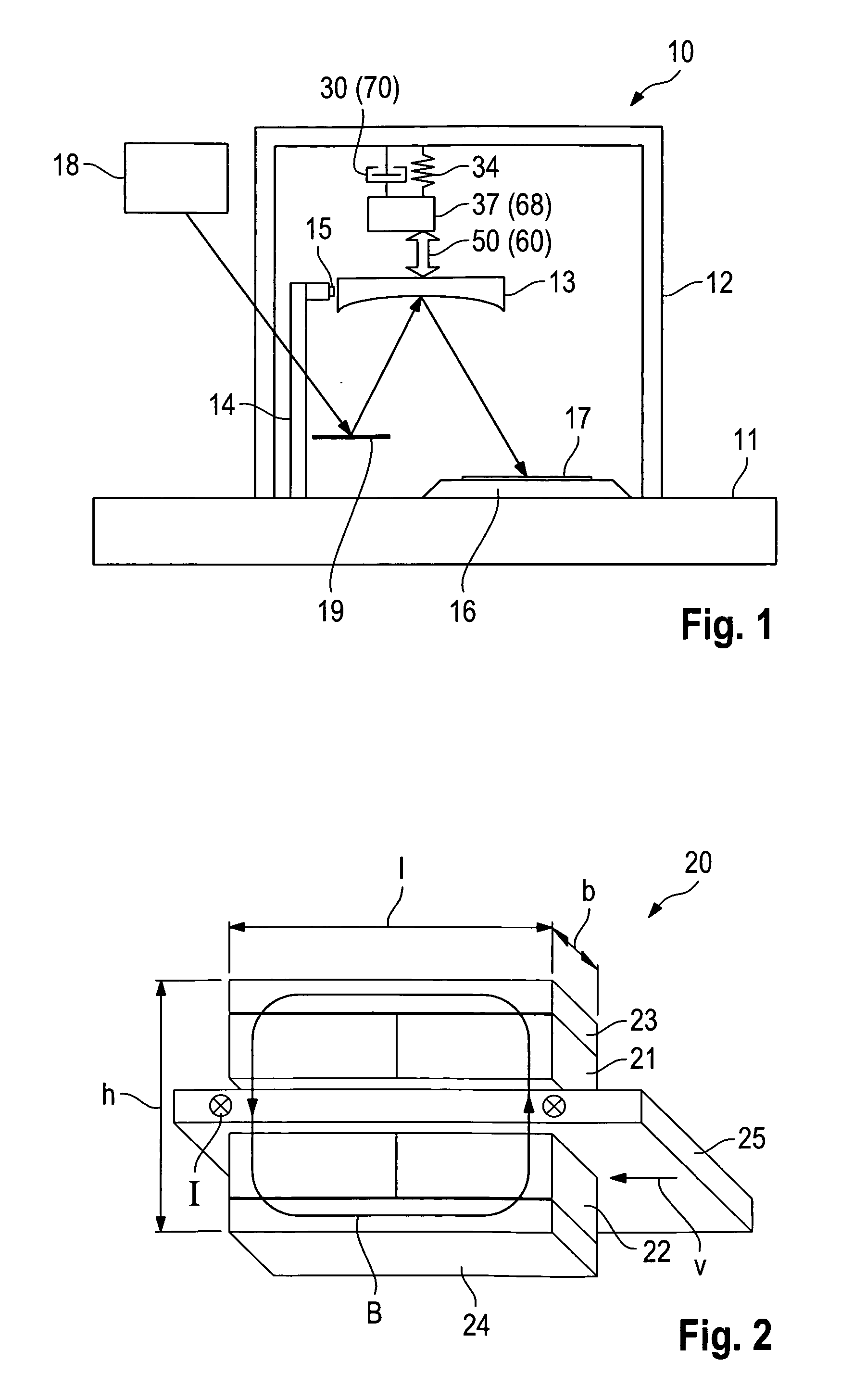

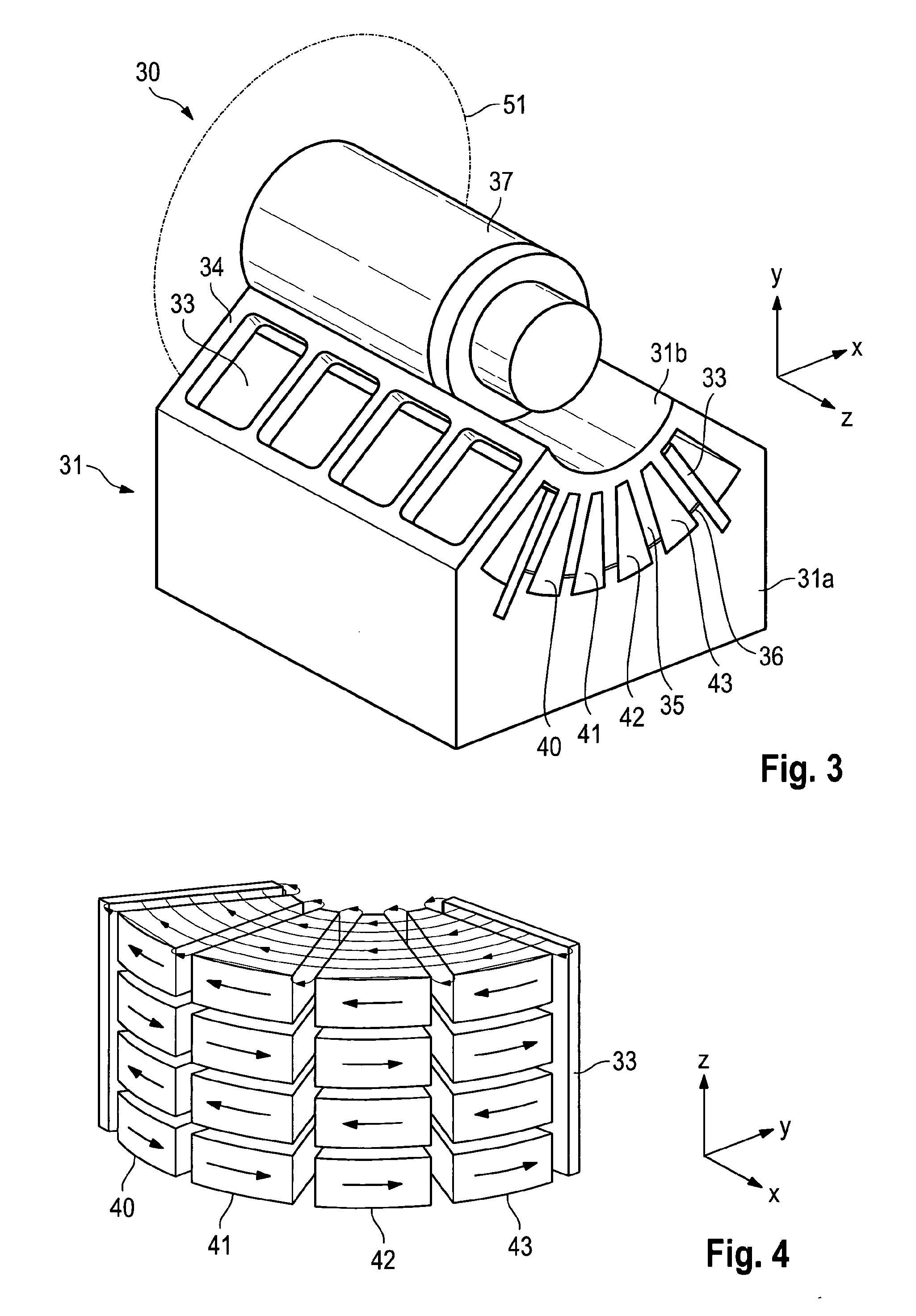

Lithography device with eddy-current brake

ActiveUS20140346909A1Reduce maintenanceEasy to useAsynchronous induction clutches/brakesPhotomechanical exposure apparatusLithographic artistRelative motion

A lithography device includes an eddy-current brake for damping the movement of a structural element of the lithography device. The eddy-current brake includes a plurality of magnets disposed in an arc-shaped arrangement, and a plurality of electrically conductive sheets arranged respectively between adjacent ones of the magnets. A relative movement between the magnets and the electrically conductive sheets in a direction to be damped inducing eddy currents in the electrically conductive sheets.

Owner:CARL ZEISS SMT GMBH

Permanent magnet drive apparatus and operational method

InactiveUS8487484B1Magnetic circuitPermanent-magnet clutches/brakesMagnetic tension forcePush and pull

A magnetic drive apparatus includes first and second magnet carriers carrying first and second permanent magnet arrangements. An intermediate magnet carrier disposed between the first and second magnet carriers carries a third permanent magnet arrangement. The magnet carriers are arranged for rotation relative to each other such that the magnet arrangements produce magnetic interactions that result in power stroke forces causing the magnet carriers to undergo relative reciprocation in first and second stroke directions during power zone portions of the relative rotation. The magnetic interactions impart substantially no power stroke forces during dead zone portions of the relative rotation. The dead zones include magnet carrier relative rotation positions wherein opposing magnetic poles are mutually coaxially aligned but produce a substantially equal balance of push and pull magnetic forces. The apparatus may be synchronized so that the dead zones coincide with top dead center and bottom dead center relative reciprocation positions.

Owner:COLSON ANDREW E JR MR

Permanent-magnet speed regulation, braking or loading apparatus with adjustable coupled flux

InactiveCN104242598ASolving Cantilever Axis ProblemsFor the purpose of online lubricationChemical industryPermanent-magnet clutches/brakesAutomatic transmissionMagnetic field coupling

The invention relates to a permanent-magnet speed regulation, braking or loading apparatus with an adjustable coupled flux. The apparatus is characterized in that a driving plate is a permanent-magnet coupling plate and a driven plate or braking plate is a flux switch type permanent-magnet plate; or the flux switch type permanent-magnet plate is used as a driving plate and the permanent-magnet coupling plate is used as driven plate / braking plate. The permanent-magnet coupling plate and the flux switch type permanent-magnet plate are in an air gap and magnetic field coupling structure mode; the installing sequences of the permanent-magnet coupling plate and the flux switch type permanent-magnet plate can be interchanged; and both the permanent-magnet coupling plate and the flux switch type permanent-magnet plate can serve as the driving plate and driven plate respectively and the internal and external nesting positions of the two plates also can be interchanged. The provided apparatus can be applied to technical fields like coupling transmission and load speed regulation, an automatic transmission unit, braking, rotary loading, power cutting off / combination, electromotor energy saving, household appliances, a sealed pump, petrochemical engineering, and wind power generation and the like; and the technical scheme employed by the apparatus can be used for designing and manufacturing a permanent-magnet speed controller, a speed-regulation coupler, an automatic transmission unit, a brake device, a loading / unloading device, a centrifugal load speed regulator or clutch, or a novel energy-saving household appliance.

Owner:林英楠

Asynchronous magnetic couplings for high temperature resistant high performance oblique slot type rotor

InactiveCN101483378AReduce the temperatureOvercome temperaturePermanent-magnet clutches/brakesMagnetic tension forceReliable transmission

The present invention relates to technical field of magnetic transmission in mechanical engineering, particularly a high temperature resistant high performance tapered slot type rotor asynchronous magnetic coupling, which comprises an outer rotor with magnetism, a inner rotor without magnetism, separation sleeve, and adjustable magnetic pole piece with teeth; the outer rotor comprises an outer rotor basal body and magnetic pole; the magnetic pole forms a certain helix angle with axial cord; the inner rotor comprises a inner rotor basal body, a magnetic induction prime conductor and end rings; the magnetic induction prime conductor embeds in angular deep groove of the inner rotor basal body in helical shape; the separation sleeve covers the inner rotor and is set between the inner rotor and the outer rotor; the adjustable magnetic pole piece with teeth is fixed on the machine body and can be disposed inside or outside of the separation sleeve; the outer magnetic rotor forms an outer layer air gap with the adjustable magnetic pole piece; the inner rotor forms an inner layer air gap with the adjustable magnetic pole piece. The above structure is disposed on the inside and outside circular conical surface to form circular cone asynchronous magnetic transmission. The advantages of the invention are as following: high temperature resistant, smooth, steady and reliable transmission, high usage of permanent magnet and big transmitting torque of unit volume.

Owner:JIANGSU UNIV

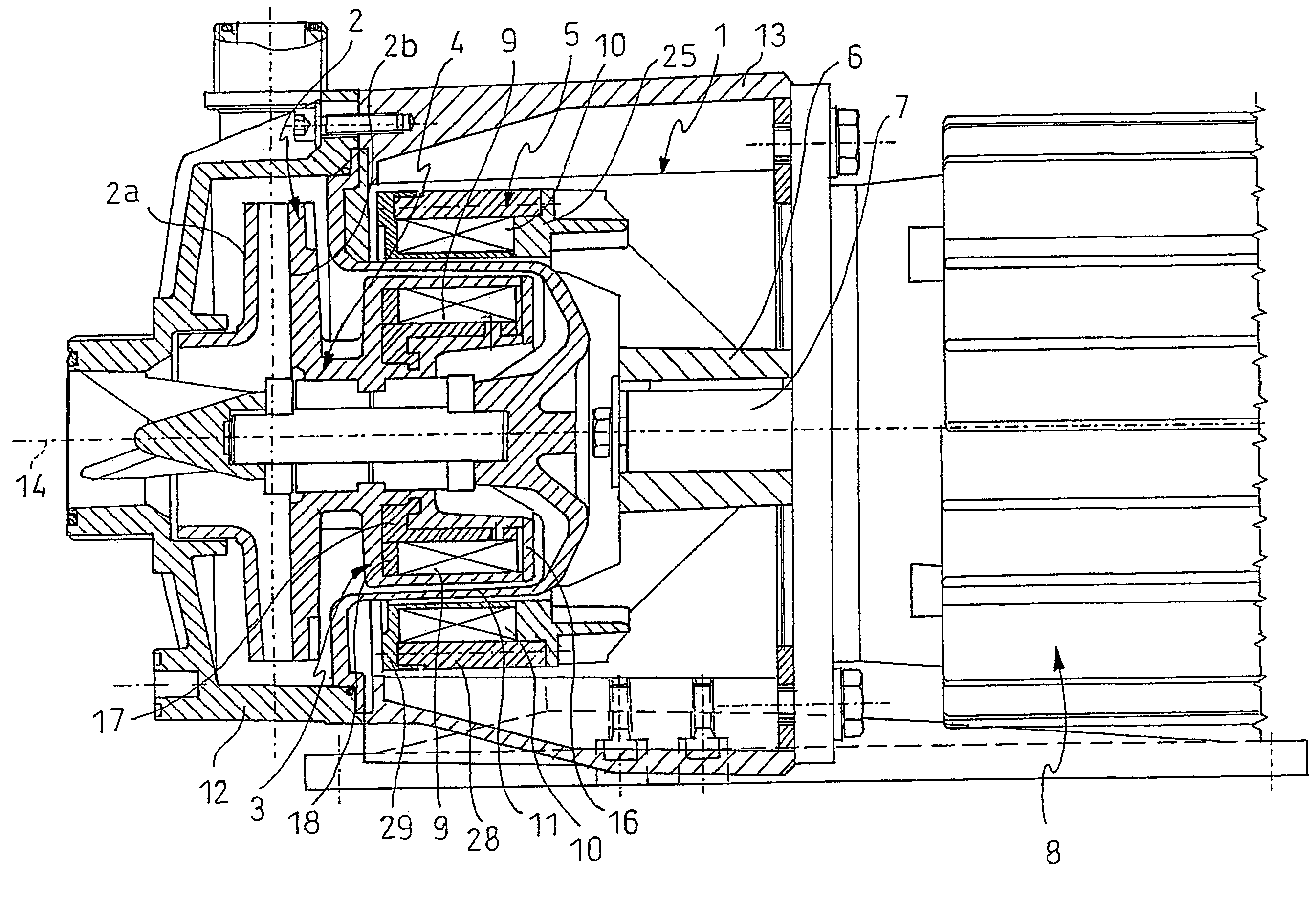

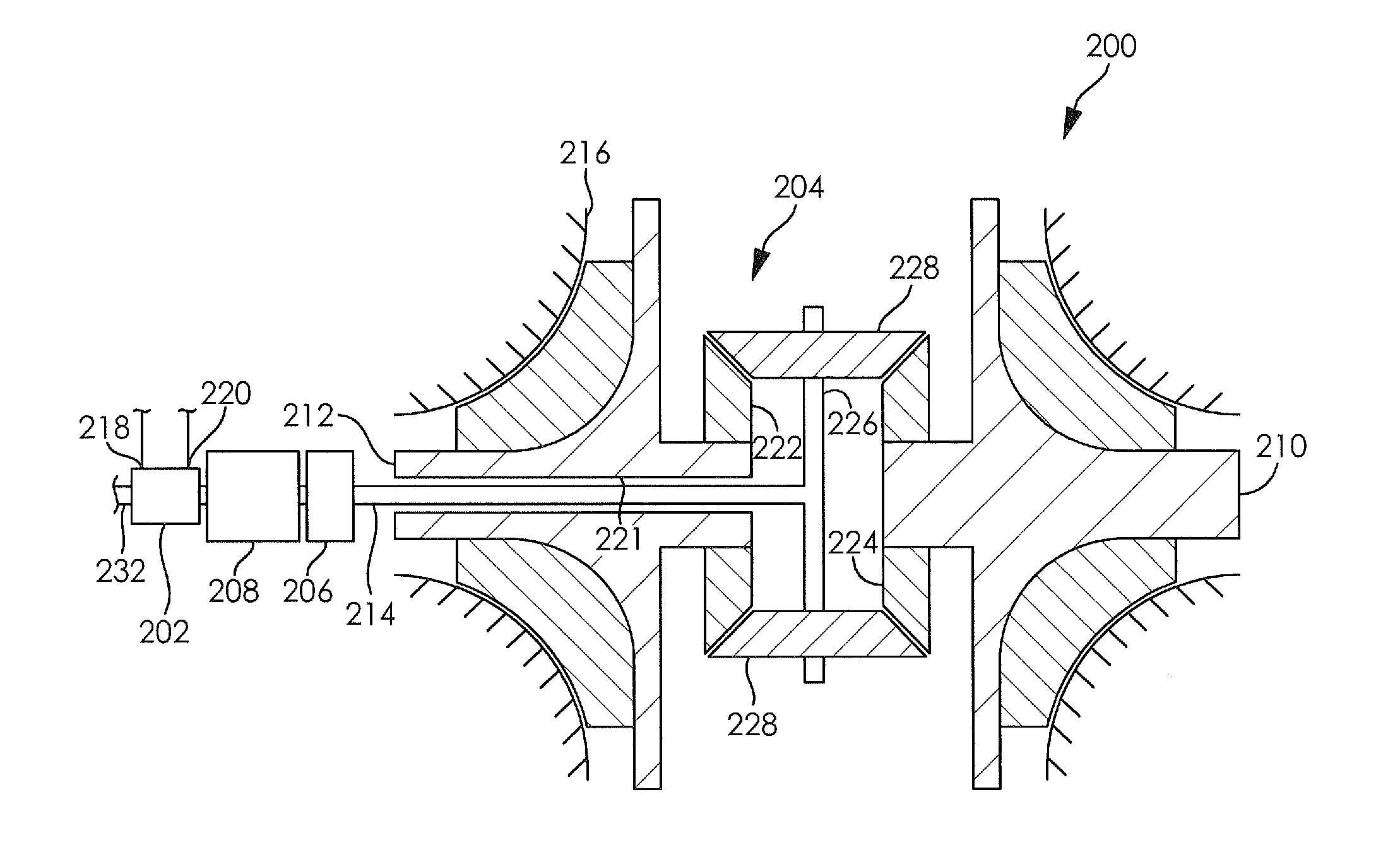

Internal combustion engine coupled turbocharger with an infinitely variable transmission

InactiveUS20140223901A1Reduces turbo lagImprove internal efficiencyInternal combustion piston enginesGas turbine plantsTurbochargerInternal combustion engine

A turbocharger for use with an internal combustion engine is provided. The turbocharger comprises a differential device having a carrier portion, a compressor portion, and a turbine portion. The compressor portion is in driving engagement with a first portion of the differential device. The turbine portion is in driving engagement with a second portion of the differential device. The carrier portion of the differential device is in driving engagement with an infinitely variable transmission. The infinitely variable transmission is in driving engagement with the internal combustion engine. The turbocharger is simply controlled, reduces turbo lag, decreases a boost threshold of the turbocharger, and increases an efficiency of the internal combustion engine.

Owner:DANA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com