Efficient permanent magnet coupling device for transmission shaft

A technology of permanent magnetic coupling and drive shaft, applied in permanent magnetic clutches/brakes, electromechanical devices, electric brakes/clutches, etc., can solve problems such as disorder, inconsistency, and increased conductor resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

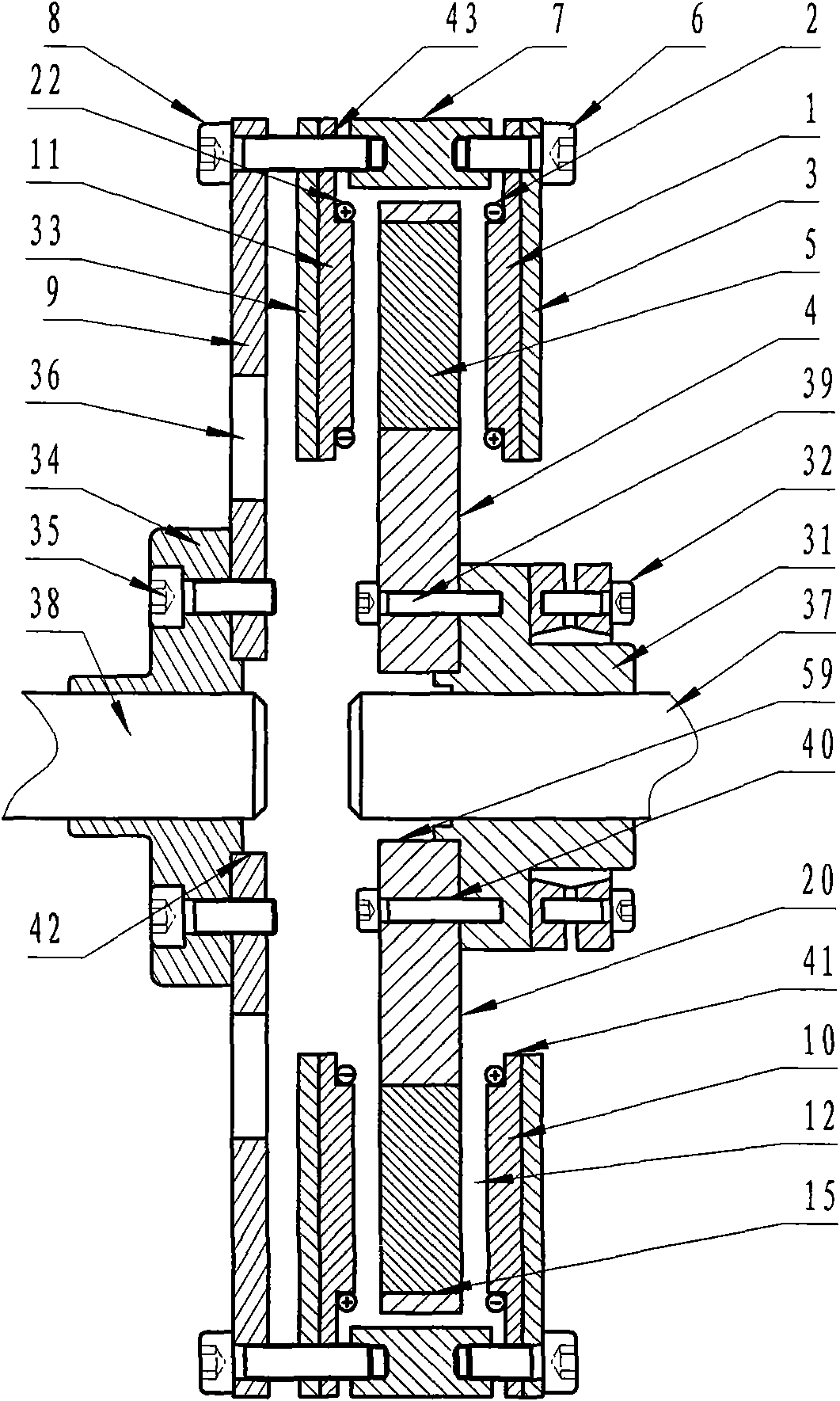

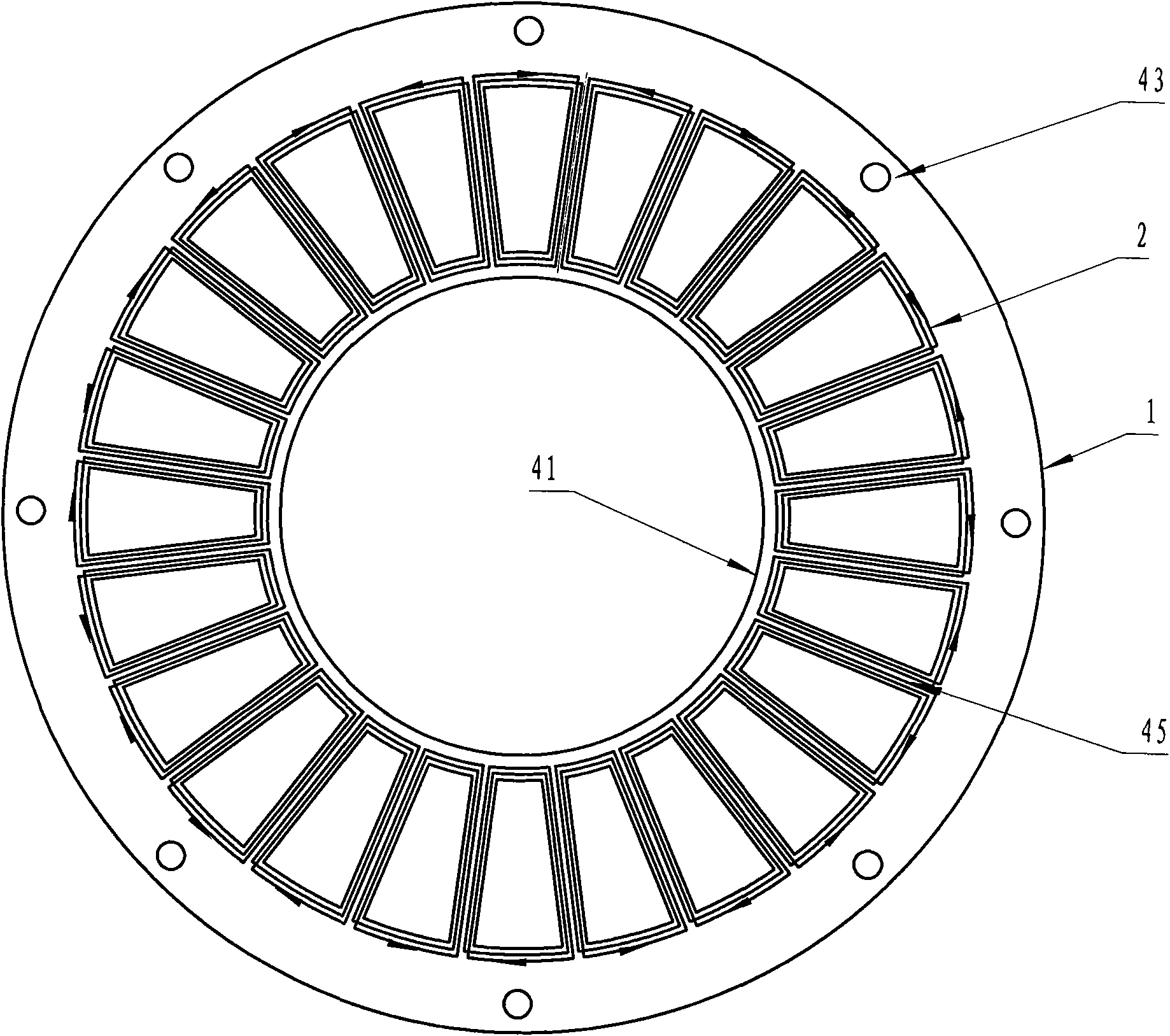

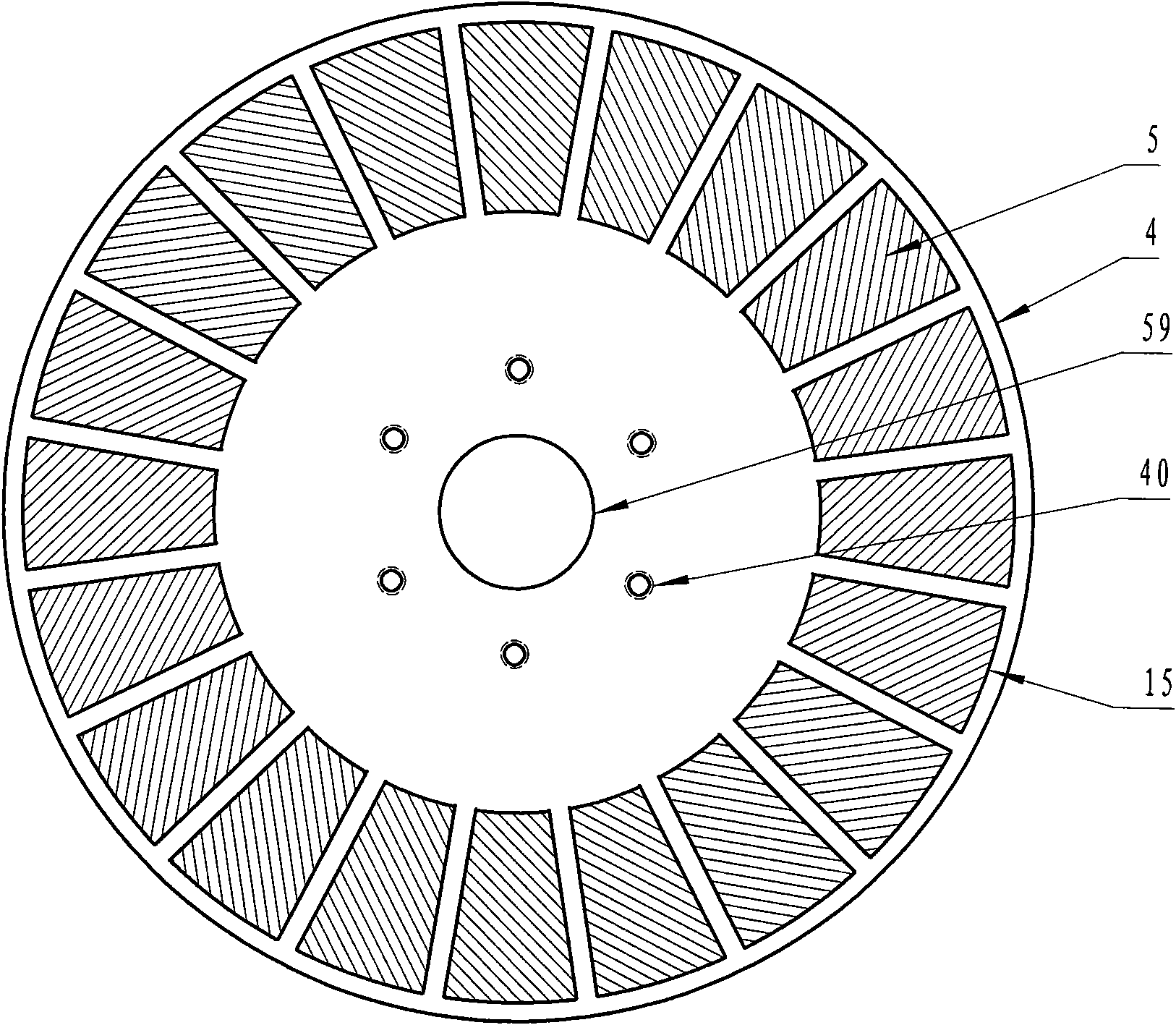

[0056] like figure 1 , figure 2 and image 3 One embodiment of the invention is shown, with two sets of permanent magnetic coupling assemblies arranged "back to back", which consist of two secondary armature winding rotor discs (1 and 2, 11 and 22) and corresponding armature Winding disk coupling mechanism (6, 7, 43, 8 and 9), two adjacent permanent magnet rotor disks are arranged "back to back" and merged into permanent magnet rotor disks (4 and 5) coupled on both sides and matched with them The permanent disk coupling mechanism (39, 40) and the corresponding input coupling (34, 35) and output coupling (31, 32) are composed of the armature winding rotor disk consisting of 24 armature windings (2) and It is composed of an armature winding mounting plate (1) for assembling the armature winding, and the armature winding is a fan-shaped multi-turn armature winding, figure 2 Each armature winding (2) has three turns, the head end and the end short circuit are closed, and the ...

Embodiment 2

[0060] like Figure 4 , Figure 5 and Image 6 As shown, this example is provided with two sets of permanent magnetic coupling components, which are arranged back to back according to "armature winding rotor disc-permanent magnet rotor disc, permanent magnet rotor disc---armature winding rotor disc", using the central short axis and Torque transmission sliding bar structure, which consists of two armature winding rotor disks (101 and 102, 111 and 122) and the corresponding armature winding disk coupling mechanism (106, 107, 143, 108 and 109), two Auxiliary permanent magnet rotor disks (104 and 105) and their matching permanent disk coupling mechanisms (149, 147, 148, 150, 151 and 152) and corresponding input couplings (134, 135) and output couplings (153, 132), the armature winding rotor disc is composed of 24 armature windings (102) and the armature winding mounting plate (101) for assembling the armature winding, and the armature winding is a fan-shaped turn and the turns ...

Embodiment 3

[0063] like Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, there are four sets of permanent magnetic coupling components in this example, according to "armature winding rotor disk---permanent magnet rotor disk, permanent magnet rotor disk---armature winding rotor disk, armature winding rotor disk--- The permanent magnet rotor disk, the permanent magnet rotor disk --- the armature winding rotor disk" are arranged back to back, and adopt the central short axis and the torque transmission slider structure. There are four differences from Embodiment 2: one is the device Doubled permanent magnetic coupling assembly is added in the middle; the second central turntable (218) is added, and the second center turntable (218) is fixed to the appropriate position on the central short shaft with a keyway, a spline or a tight fit, In order to support the torque transmission slide bar (247) and transmit torque; the third is that the two armature winding mounting plates (260) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com