Patents

Literature

425results about "Boiler indication operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

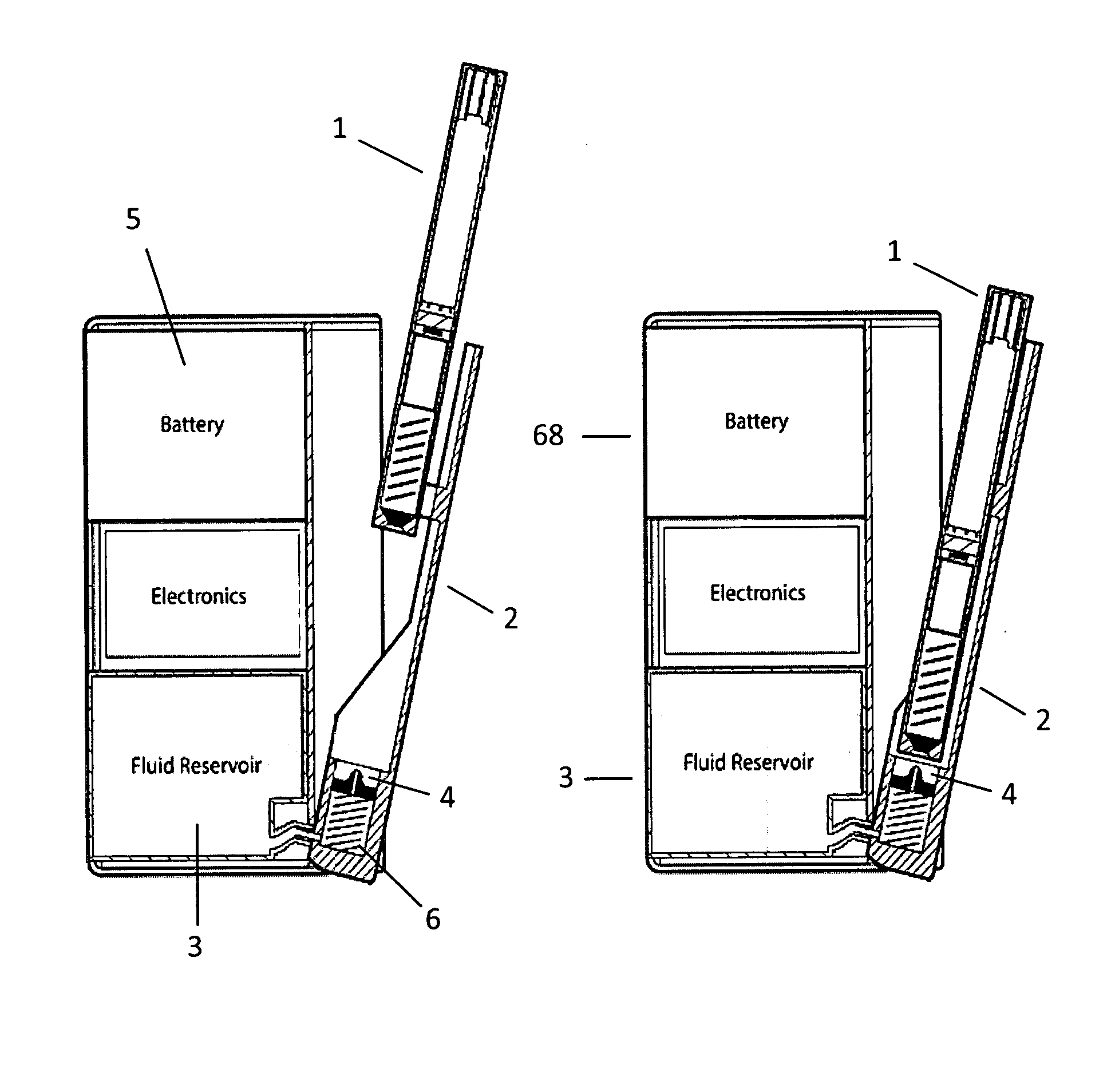

Electronic vaporiser system

An electronic cigarette vaporiser system includes a piezo-electric pump (6) with multiple piezo-actuators, in which a microcontroller independently adjusts the phase or timing or power of each voltage pulse that triggers a piezo-actuator. The microcontroller continuously or regularly monitors the efficiency or performance of the entire pump (6) and adjusts the phase, timing, or power delivered to each piezo-actuator relationship until or so that the optimum pumping performance is achieved.

Owner:AYR LTD

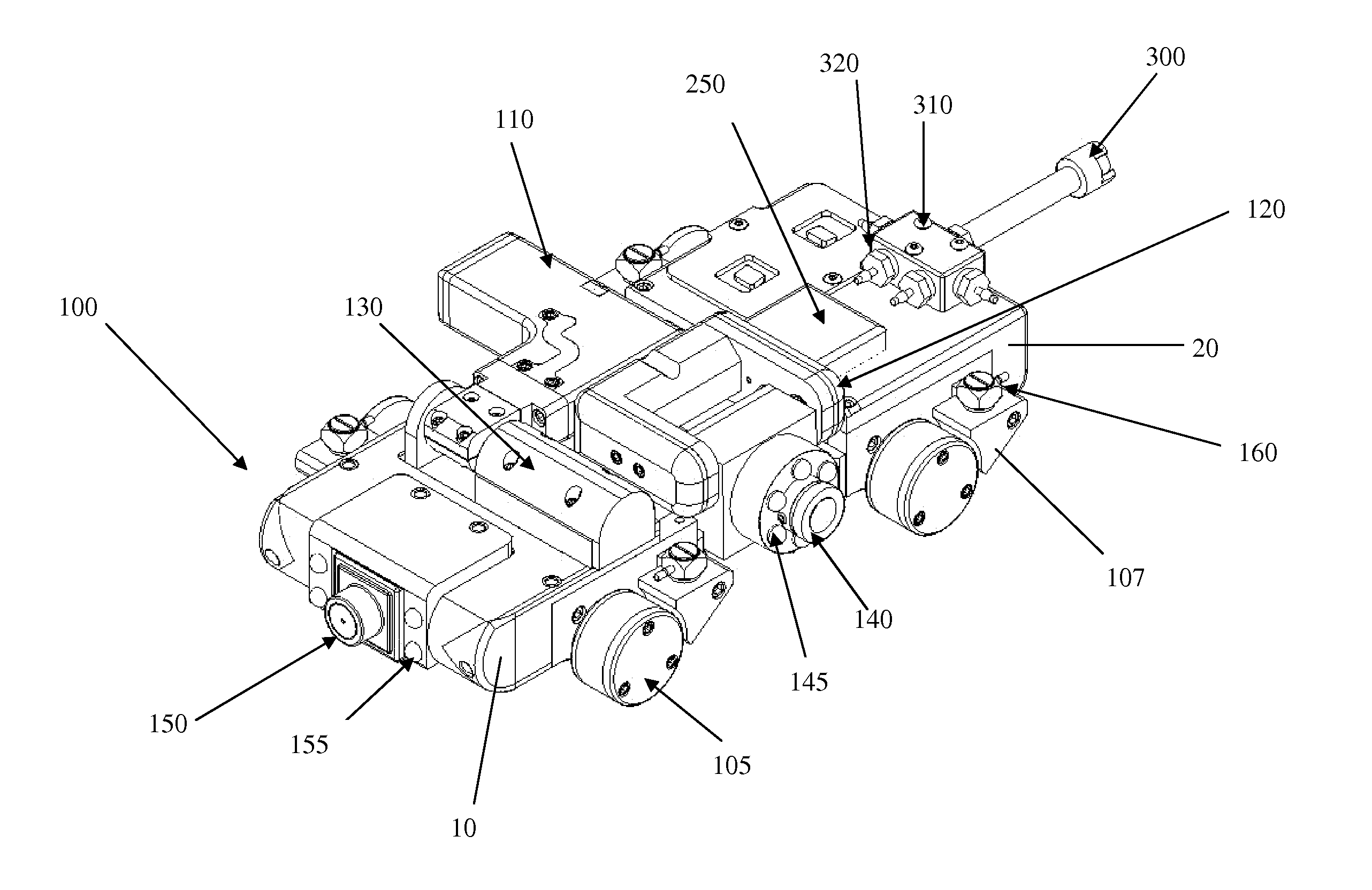

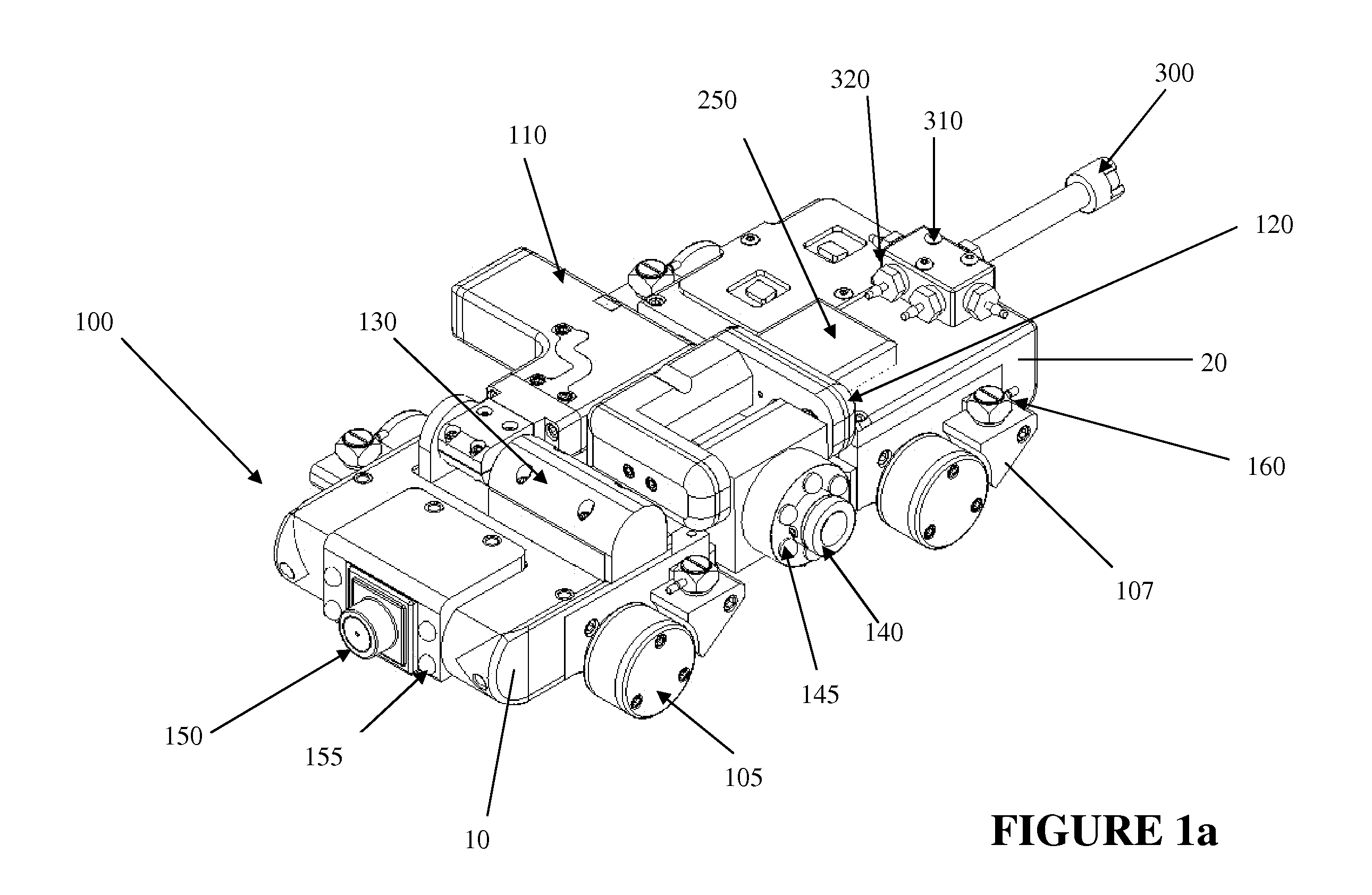

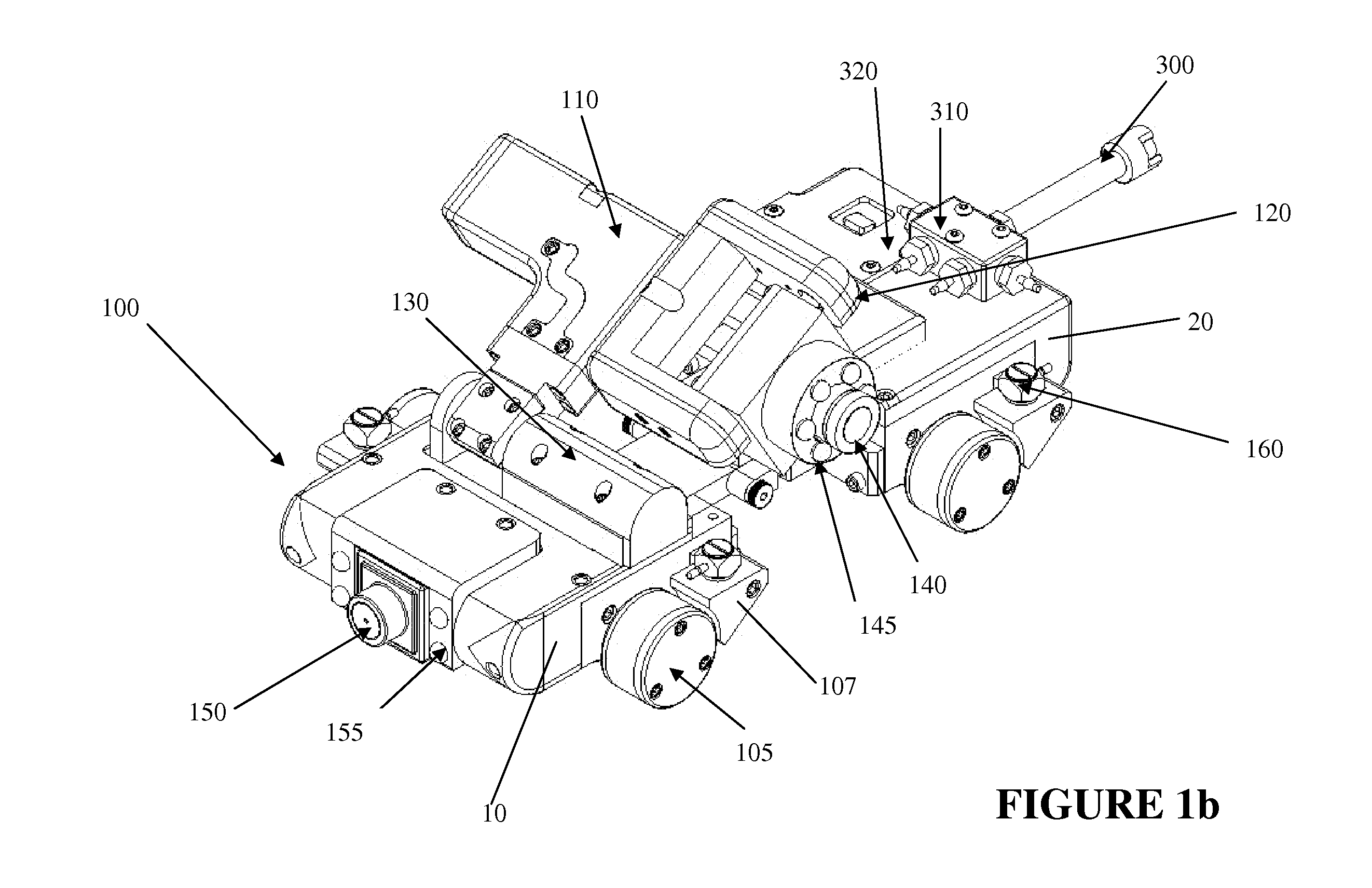

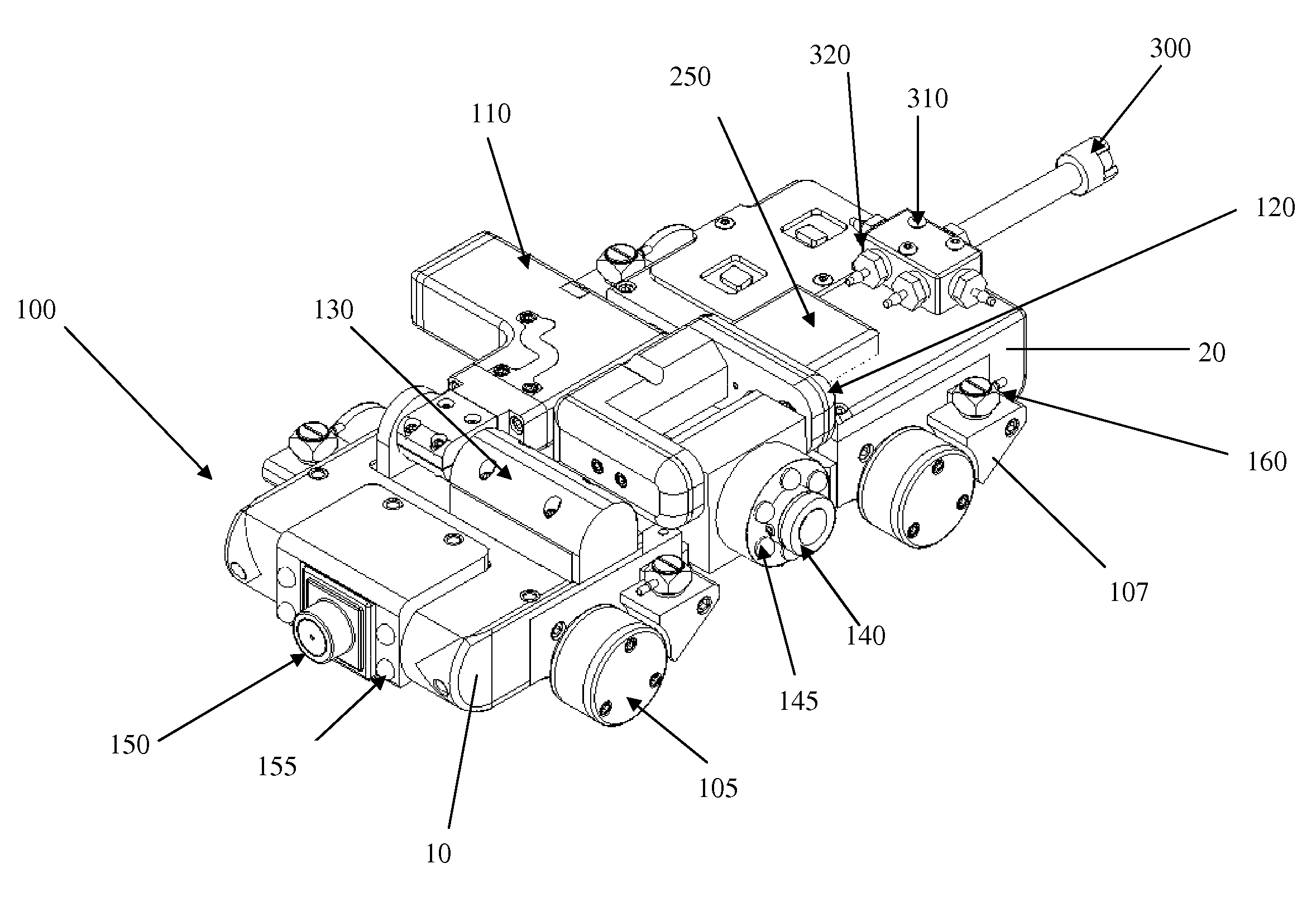

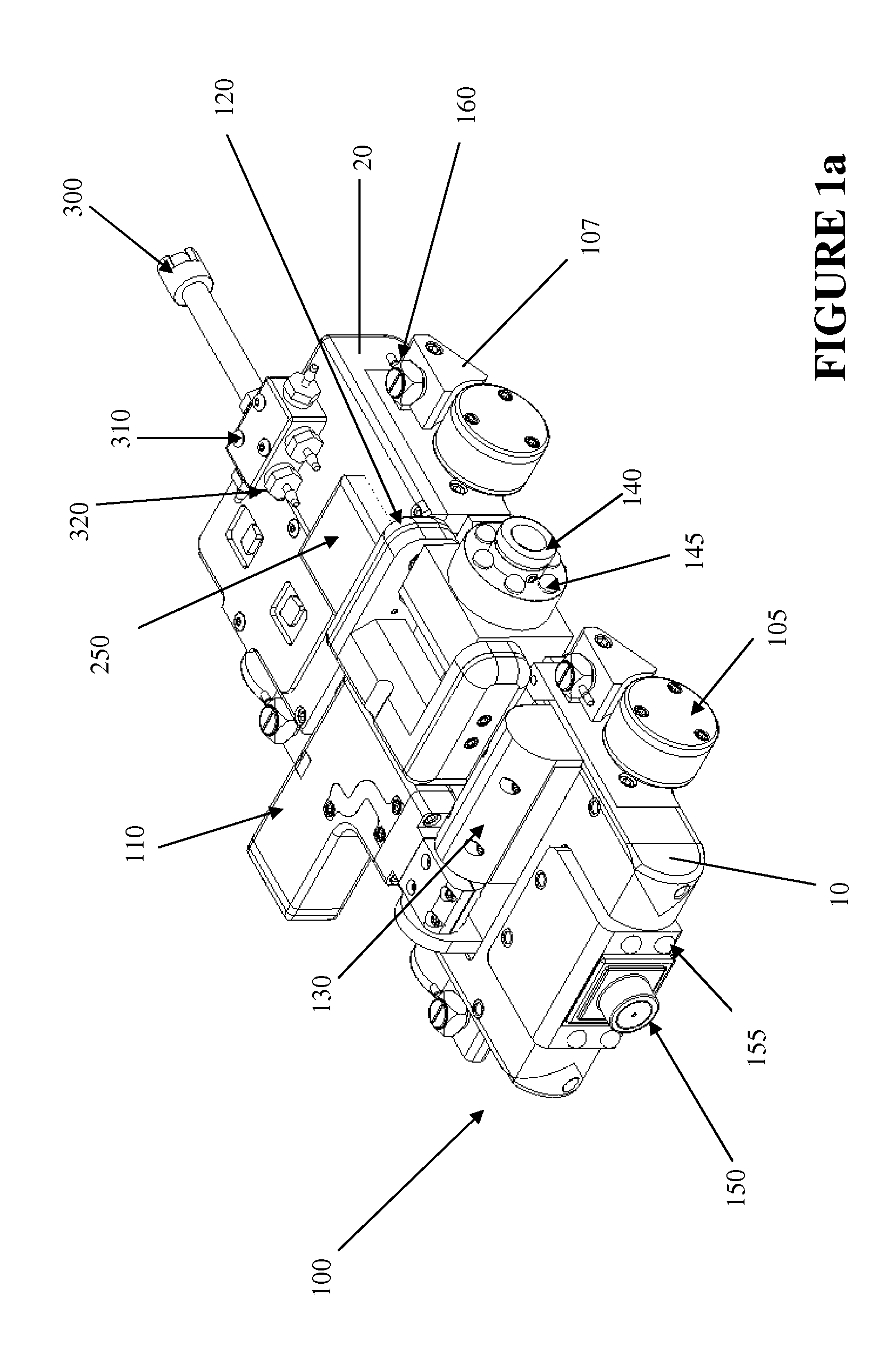

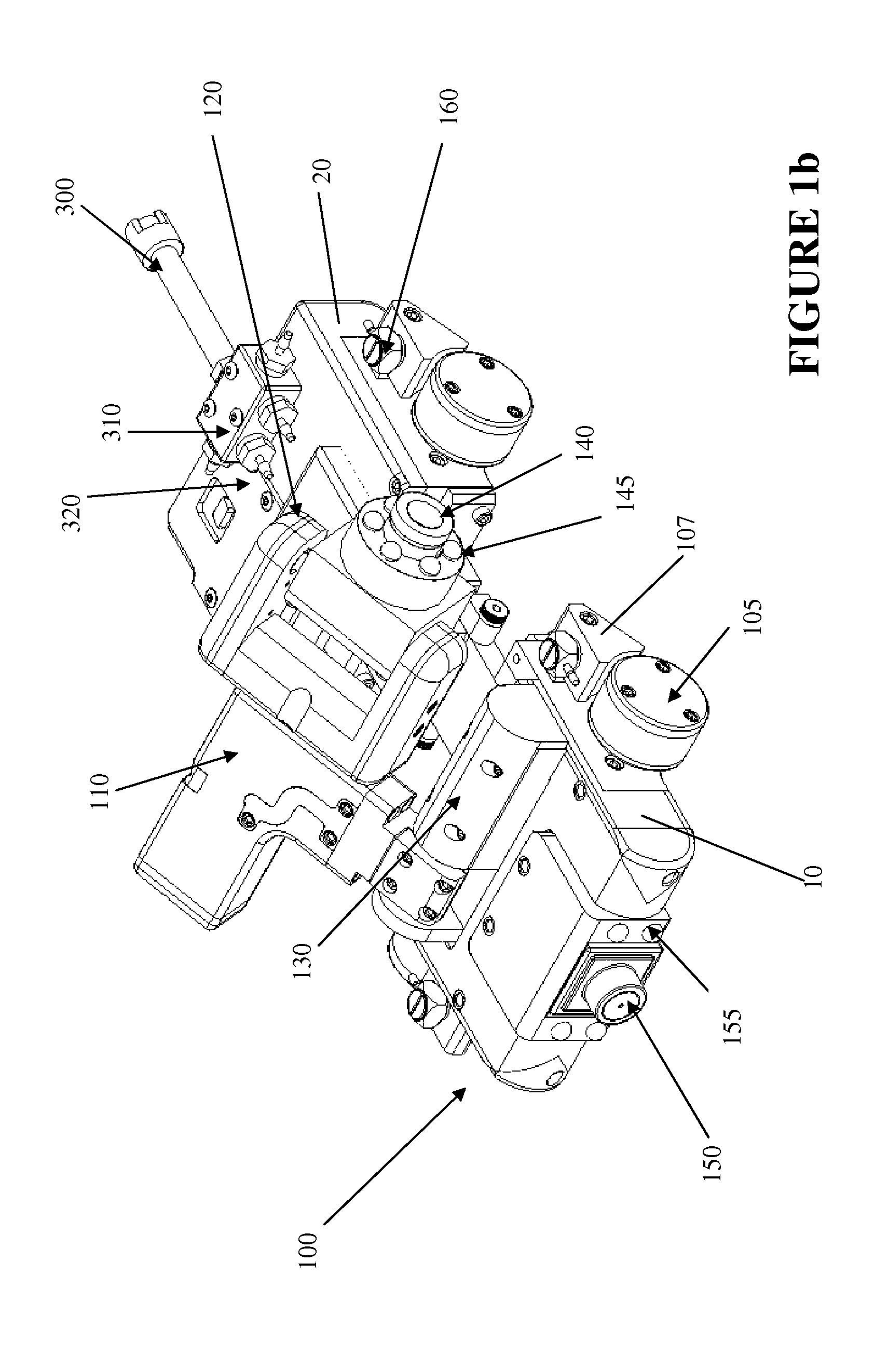

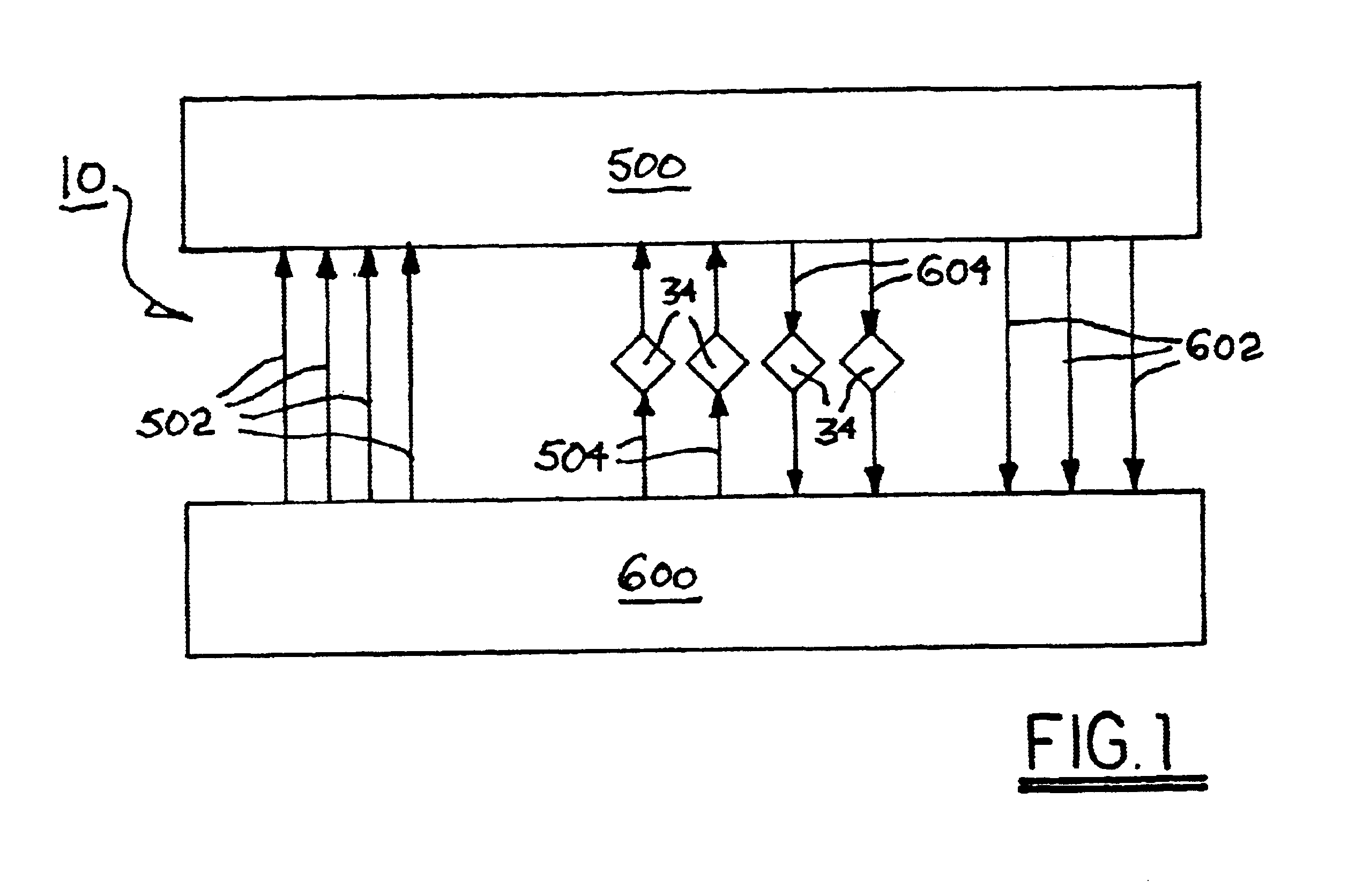

Inspection system and inspection process utilizing magnetic inspection vehicle

An inspection vehicle configured to inspect steam generators includes a front chassis having two independently driven magnetic wheels, a rear chassis having two independently driven magnetic wheels, and a connecting member flexibly connecting the front chassis to the rear chassis to permit relative motion between the front chassis and the rear chassis along at least one axis. The connecting member, front chassis, and rear chassis collectively define a receiving area. The inspection vehicle also includes a navigation camera disposed on the front chassis and a pan and tilt inspection camera assembly including a first rotatable arm driven by a first motor, a second rotatable arm disposed on a distal portion of the first rotatable arm, the second rotatable arm being driven by a second motor, and an inspection camera rotatably disposed on a distal portion of the second arm, the inspection camera being driven by a third motor, the camera assembly being dimensioned to be received within the receiving area in a stowed position.

Owner:ROLLS ROYCE CONTROL SYST HLDG CO

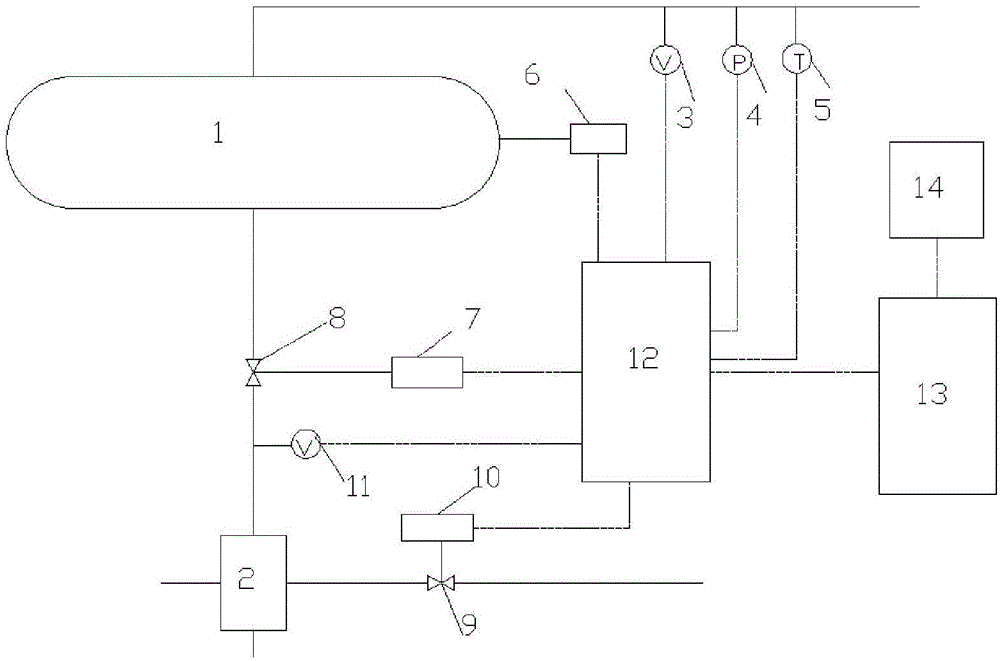

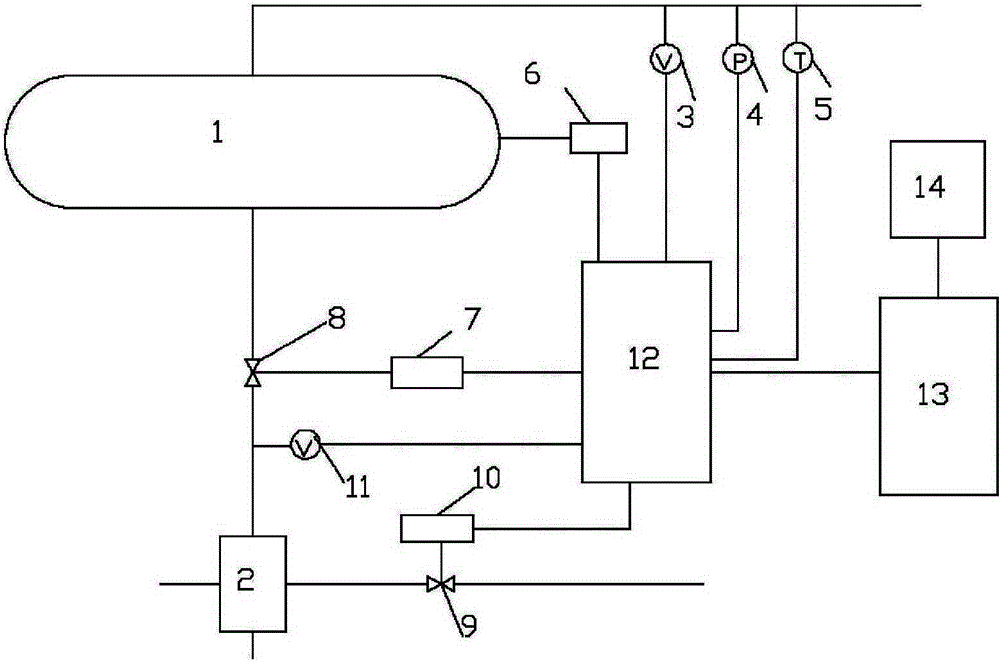

Intelligent measurement and control boiler system dynamically calculating water loss according to drum water level

InactiveCN105135406AKeep abreast of the operation status in timeAvoid wastingBoiler indication operationsBoiler cleaning apparatusData connectionEngineering

The invention provides a boiler system. A monitoring diagnosis controller calculates water loss of a boiler by calculating the ratio of the sum of the steam mass, the change mass of drum water and the sewage discharge mass to the mass of water input into the boiler. The monitoring diagnosis controller is in data connection with a cloud server, so that monitored data are transmitted to a cloud server; the cloud server is connected with a client side, and the client side can obtain the monitored data by means of the cloud server. By means of the client side, the operation condition of water loss of the boiler can be mastered in time, and by means of the client side, the situation that due to water loss of the boiler, a large amount of heat is wasted can be avoided in time.

Owner:SHANDONG UNIV OF TECH

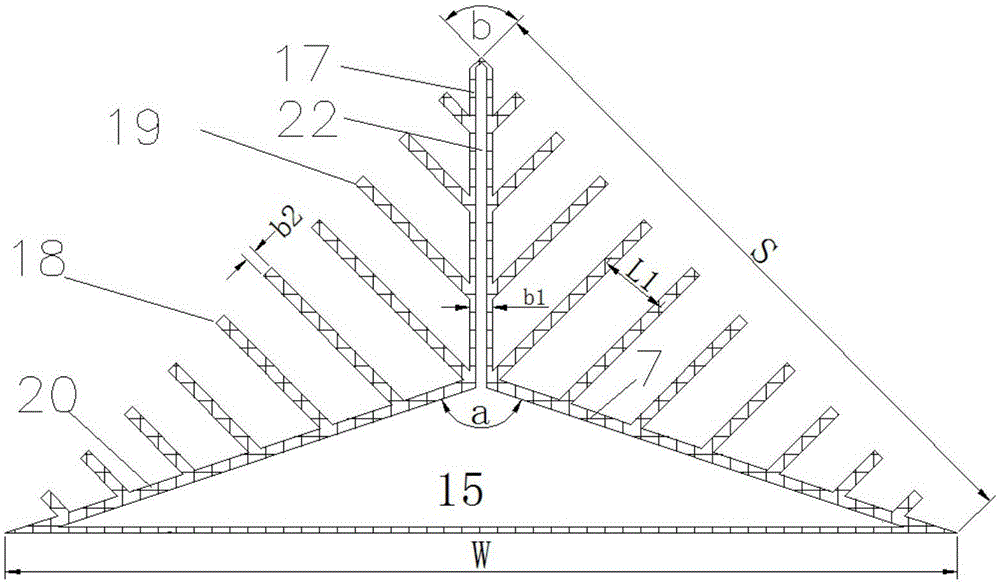

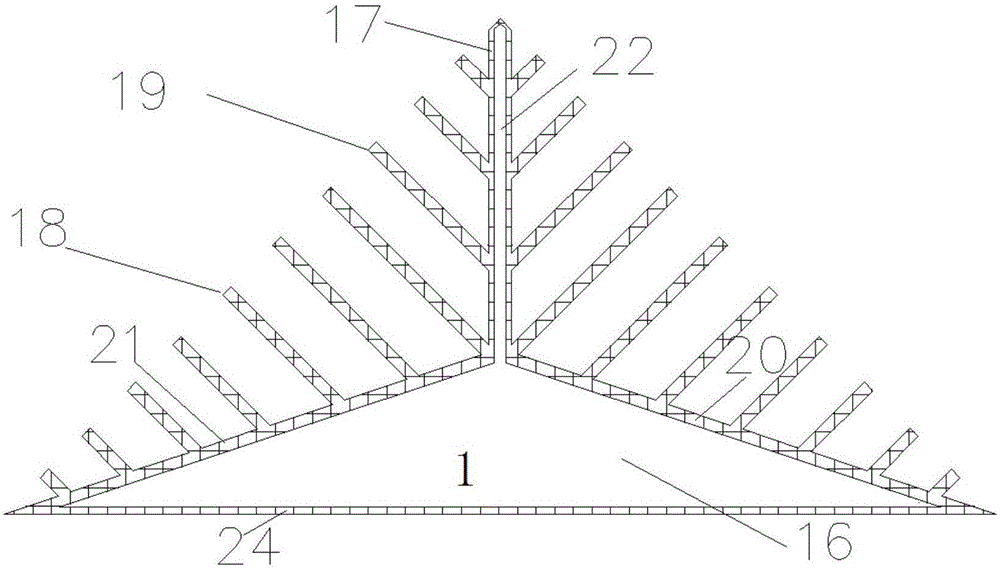

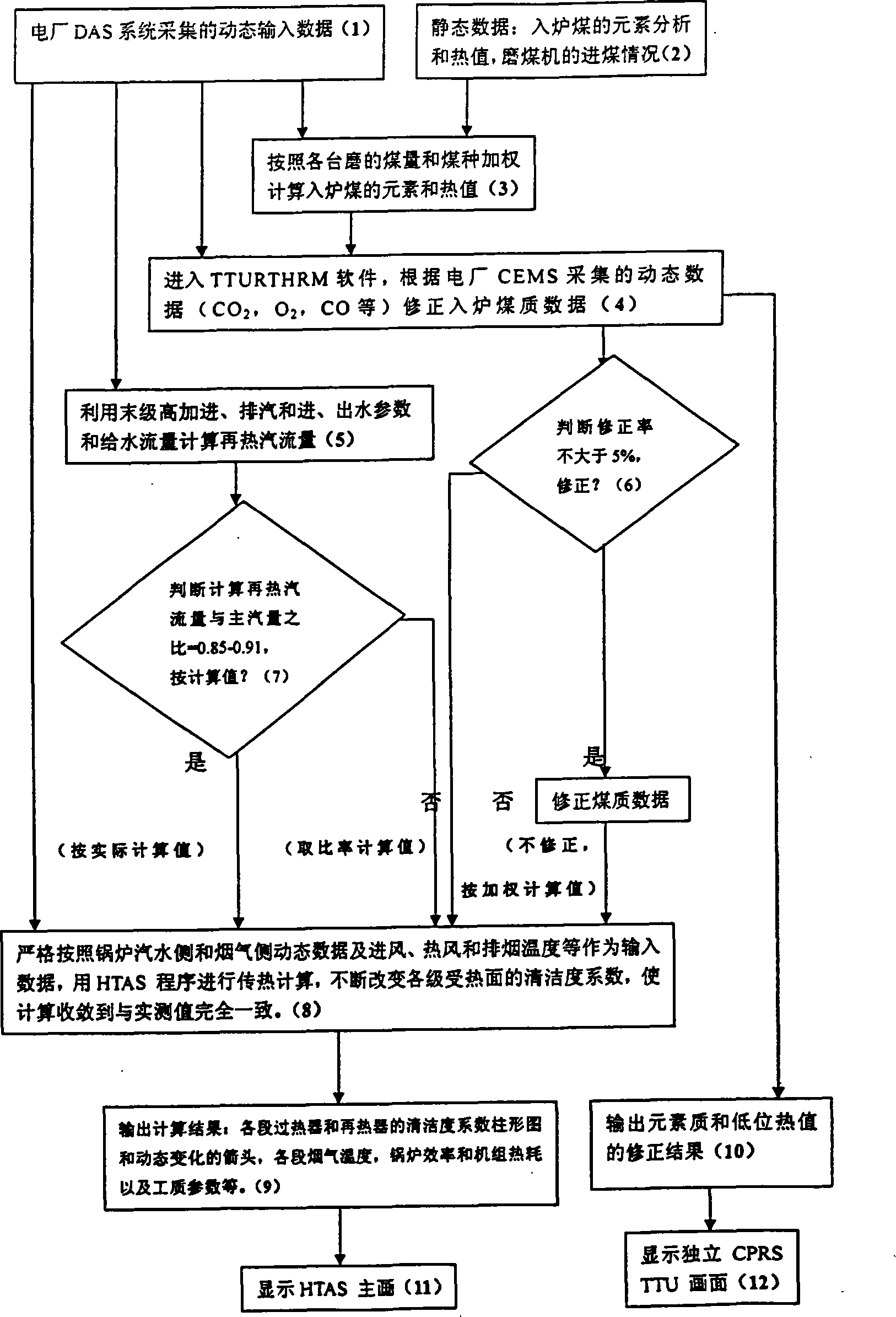

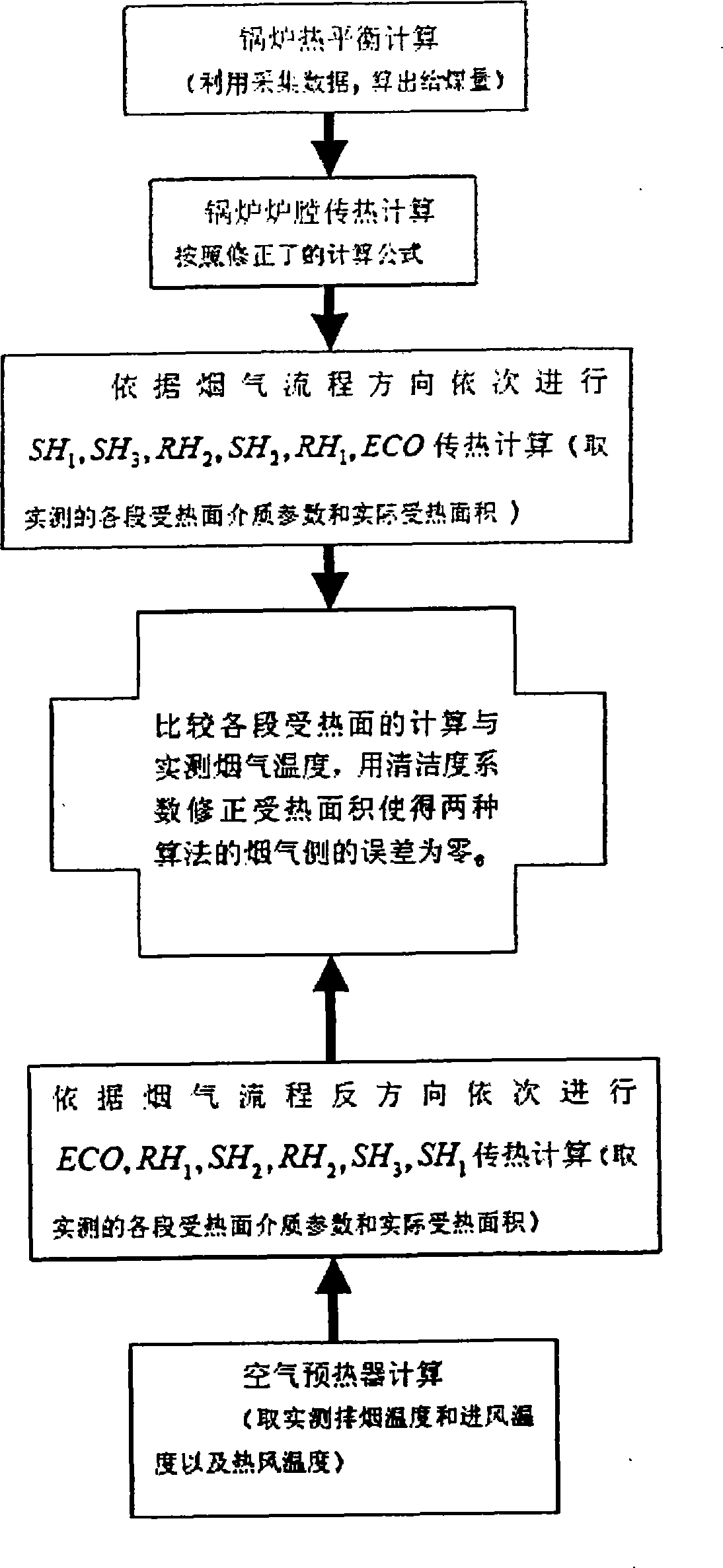

Online detecting, soot blowing and optimal energy-saving method for large coal-fired boiler

InactiveCN101034009AAccurate calculationSave fuelRadiation pyrometryBoiler indication operationsEngineeringSoot

This invention relates to a energy-saving method of large coal burning boiler's on-line measuring and soot blowing optimizing. The feature lays: the invention takes new developed HTAS procedure as main, combine with TTURTHERM procedure and infrared fume pyroscope, to form a integrated system that is able to accuracy and significance monitor and count large boiler heating surface cleanness degree, so to realize soot blowing-optimizing and energy-saving.

Owner:SHANGHAI POWER EQUIP RES INST

Use of disulfonated anthracenes as inert fluorescent tracers

InactiveUS20050025659A1Quantity minimizationDetection of fluid at leakage pointSamplingAnthraceneSteam line

The use of an isomer of anthracene disulfonic acid as an inert fluorescent tracer is described and claimed. The utility of this type of inert fluorescent tracer in boiler systems to trace unwanted carryover of boiler water into a steam line is also described and claimed.

Owner:ECOLAB USA INC

Cloud-computing-based boiler blow-off system conducting control according to blow-off water quality

InactiveCN105222119AKeep abreast of the operation status in timeAvoid wastingBoiler indication operationsBoiler cleaning apparatusData connectionThermal energy

The invention provides a boiler system. A water quality analyzer is arranged on a blow-off pipeline and used for measuring the quality of water in the blow-off pipeline. The water quality analyzer is in data connection with a monitoring and diagnosis controller so as to receive measured data and control the opening degree of a blow-off valve according to the measured data. If some measured index exceeds the upper limit of the data, the monitoring and diagnosis controller automatically increases the opening degree of the blow-off valve through a valve adjusting device. If some measured index is lower than the upper limit of the data, the monitoring and diagnosis controller automatically decreases the opening degree of the blow-off valve through the valve adjusting device. The monitoring and diagnosis controller is in data connection with a cloud server so as to transmit monitoring data to the cloud server. The cloud server is connected with a client-side. The client-side can acquire the monitoring data through the cloud server. The client-side can know the blow-off operation condition of a boiler through the client-side in time. Blow-off parameters can be adjusted through the client-side in time, and therefore a large amount of thermal energy waste caused by failures of a boiler blow-off system can be prevented.

Owner:SHANDONG UNIV OF TECH

Use of disulfonated anthracenes as inert fluorescent tracers

InactiveUS7220382B2Quantity minimizationDetection of fluid at leakage pointSamplingAnthraceneSteam line

The use of an isomer of anthracene disulfonic acid as an inert fluorescent tracer is described and claimed. The utility of this type of inert fluorescent tracer in boiler systems to trace unwanted carryover of boiler water into a steam line is also described and claimed.

Owner:ECOLAB USA INC

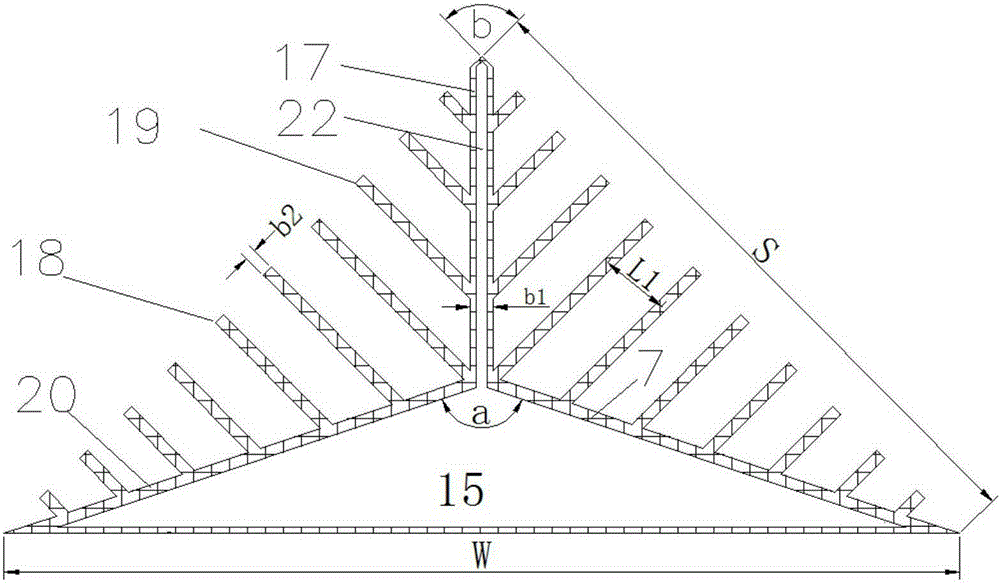

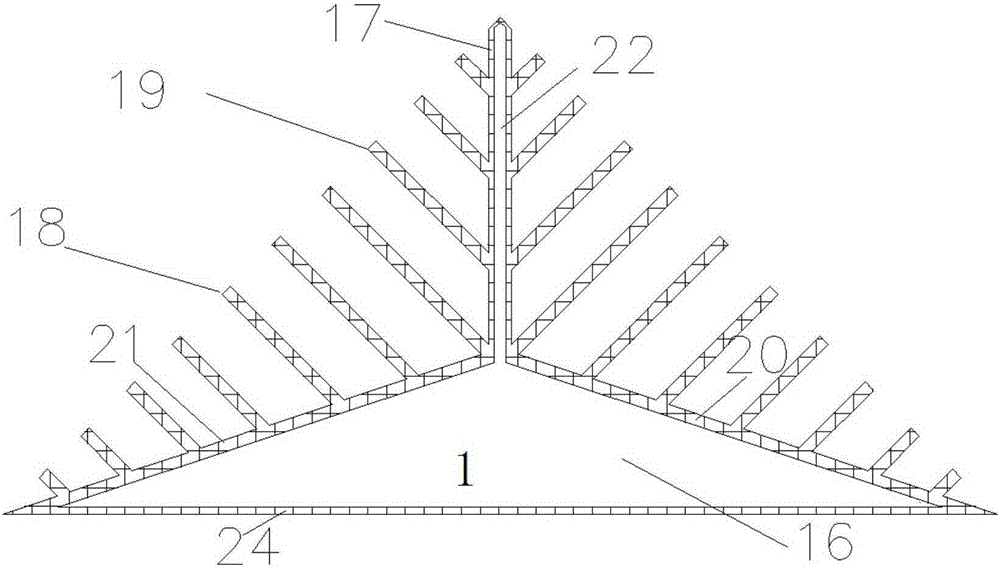

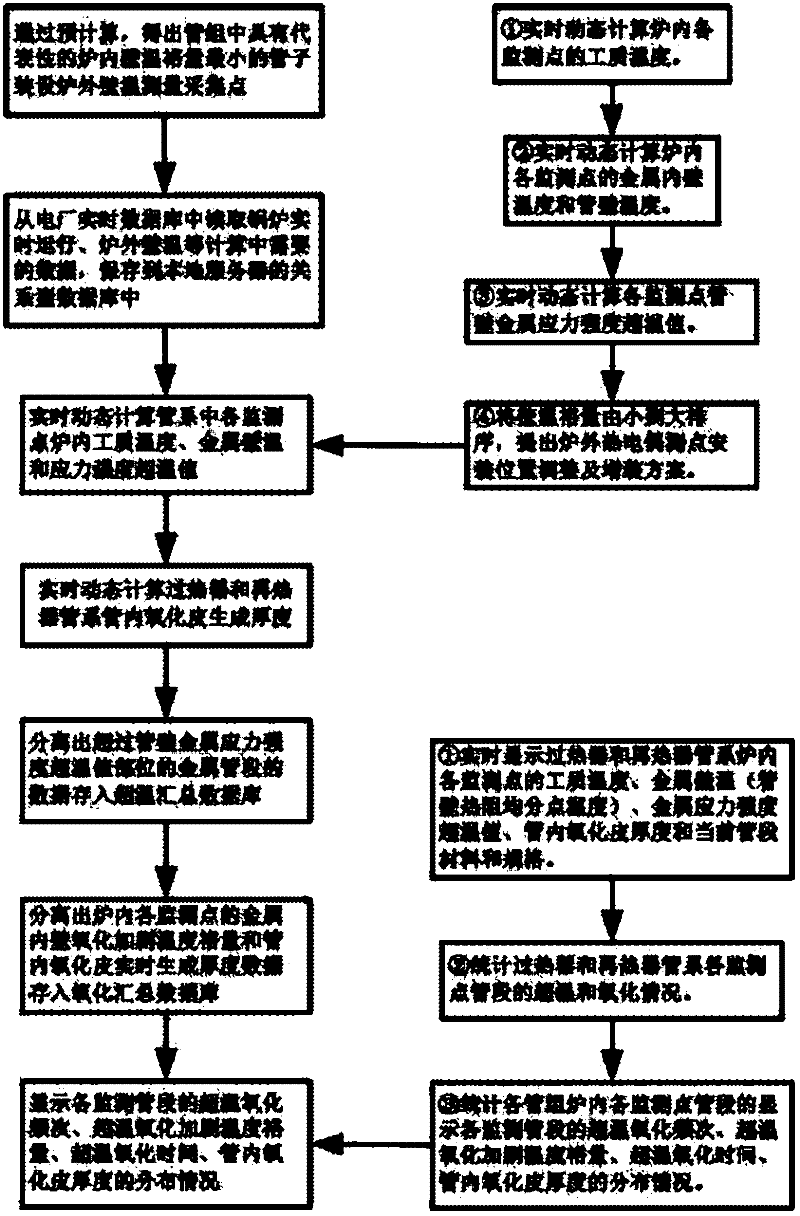

Method for avoiding overheat tube burst in tubular boiler of power station boiler

ActiveCN102444885AExtended service lifeEliminate squibBoiler indication operationsBoiler controlPower stationRelational database

The invention relates to a method for avoiding overheat tube burst in a tubular boiler of a power station boiler, belonging to the technical field of power station boilers. The method comprises the following steps: selecting representative tubes from a nest of tubes to install measurement acquisition points of temperature of an outer wall of the boiler; reading data from a power plant real-time database, and storing the data in a relational database of a local server; dynamically calculating the generation thicknesses of scale cinder in tubes of overheater and reheater in real time; separating out data of metal tube sections of parts exceeding metal stress strength overtemperature values of tube walls from calculated results and storing the data in an overtemperature summarizing database; and according to calculated inner wall working medium boundary layer temperature, metal inner wall oxidation aggravation temperature margin and real-time generation thickness of scale cinder in the tubes, automatically generating a visual distribution graph according to sequence. The method provided by the invention can accurately give out a tube burst early warning of the power station boiler, and preset measurements can be taken to avoid great direct financial losses to enterprises and nation caused by tube burst of the power station boiler.

Owner:SHANGHAI WANGTE ENERGY RESOURCE SICENCE & TECH

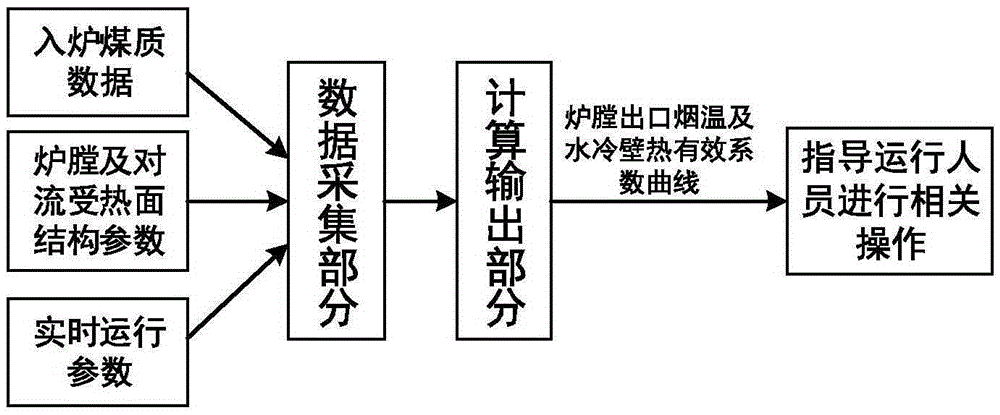

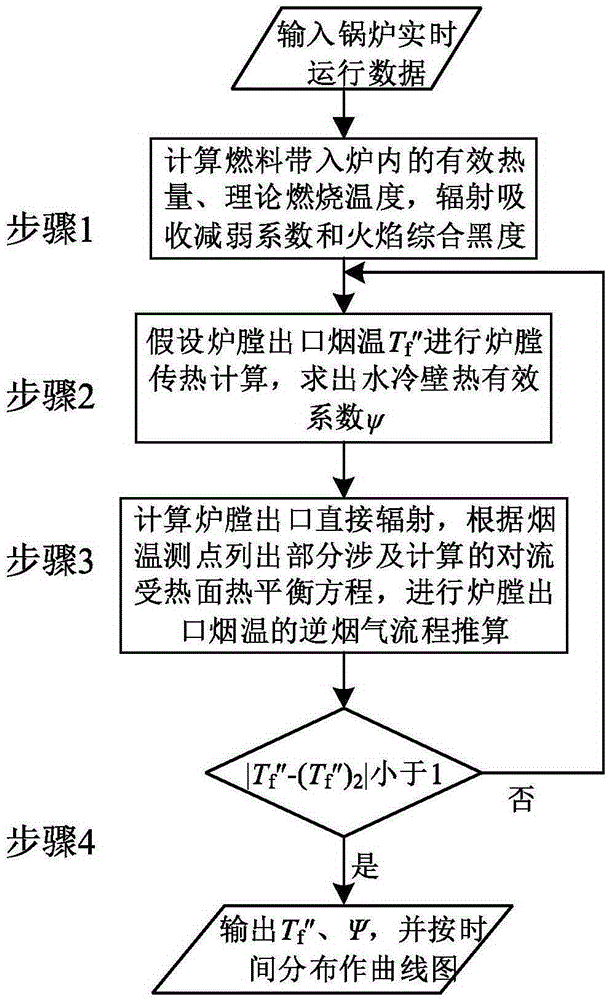

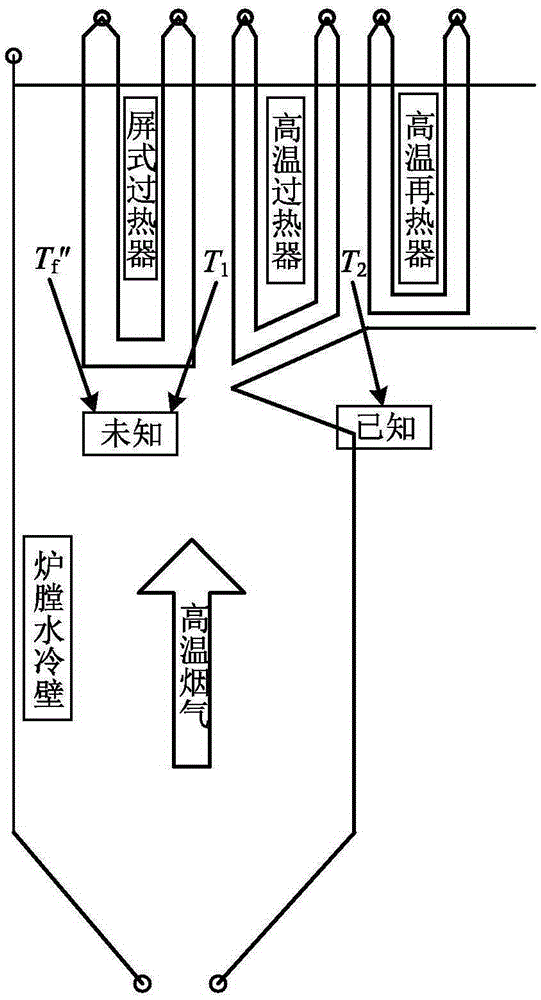

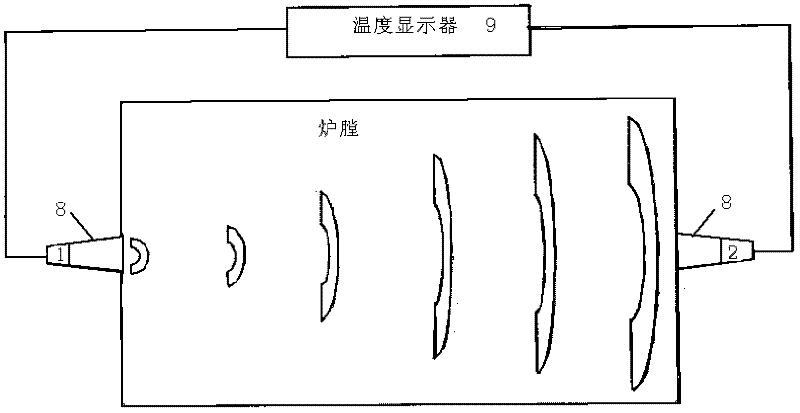

Method for soft measurement of smoke temperature of outlet of hearth based on real-time slagging condition of hearth

The invention discloses a method for soft measurement of the smoke temperature of an outlet of a hearth based on the real-time slagging condition of the hearth to overcome the defects of an existing method for soft measurement of the smoke temperature of the outlet of the hearth. According to the method, the real-time slagging condition of the hearth is reflected through the heat effective coefficient of the water-cooled furnace wall during soft measurement of the smoke temperature, and the real-time changeability of the real-time slagging condition of the hearth is calculated and considered; a calculation output part mainly includes calculation of comprehensive heat transfer of the hearth and part of a convection heating surface and output of the heat effective coefficient of the water-cooled furnace wall and the smoke temperature of the outlet of the hearth; on the basis that the number of measurement points of a boiler is not increased, the quality parameter and the structure parameter of coal placed into the boiler and the real-time operation parameter of the boiler are collected, a model for real-time calculation and soft measurement of the smoke temperature of the outlet of the hearth is established by combining the heat transfer balance calculation of the hearth with the heat transfer balance calculation of the convection heating surface and considering the real-time slagging condition in the hearth; a real-time value of the smoke temperature of the outlet of the hearth can be output, the real-time slagging condition in the hearth can be provided, and the real time value of the smoke temperature of the outlet of the hearth and the real-time slagging condition in the hearth can serve as visual data references for conducting hearth ash blowing and water desuperheating of the high-temperature heating surface by operating personnel.

Owner:SOUTHEAST UNIV

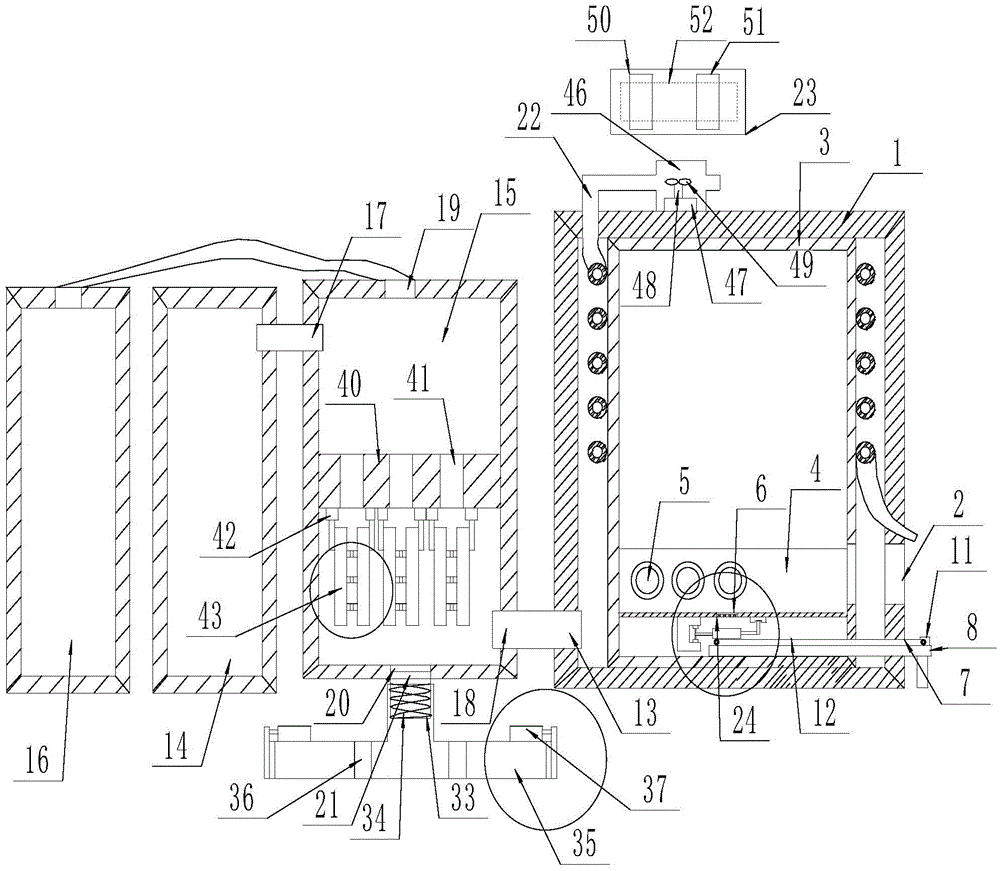

Novel circulation environment-friendly boiler for power plant

InactiveCN105650617ARealize the function of multi-channel flue gas samplingBoiler indication operationsBoiler controlEngineeringAir blower

The invention discloses a novel circulation environment-friendly boiler for a power plant. The novel circulation environment-friendly boiler comprises a boiler body which is fixedly installed on the ground; a pulverized coal feeding opening is formed in the side surface of the bottom of the boiler body, and a heat transferring barrel is sleeved with the boiler body; a pulverized coal feeding opening is formed in the side surface of the bottom of the heat transferring barrel, and a burning groove corresponding to the pulverized coal feeding opening is formed in the bottom inside the heat transferring barrel; and a controller is arranged outside the boiler body and is electrically connected with an air blower, a speed-changing turbo charger air outlet mechanism, an electric control door opening mechanism, a firing-resisting conveying belt mechanism and a waste gas recovering and purifying mechanism. The novel circulation environment-friendly boiler has the beneficial effects of being simple in structure and high in practicability.

Owner:HENAN UNIV OF URBAN CONSTR

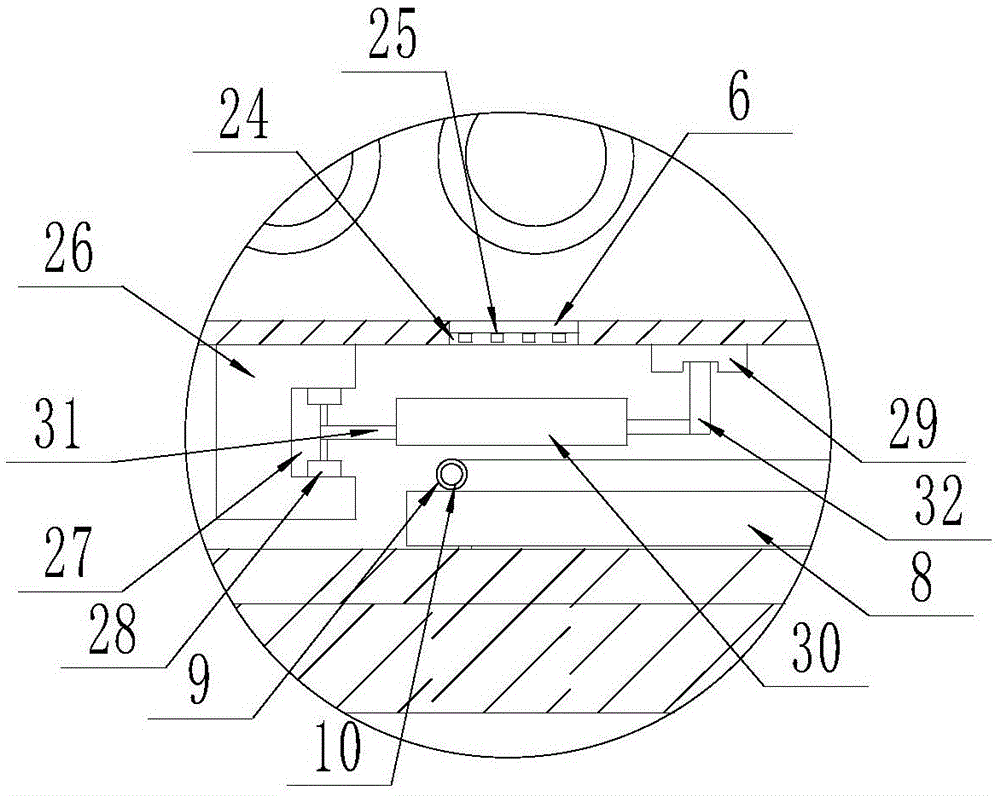

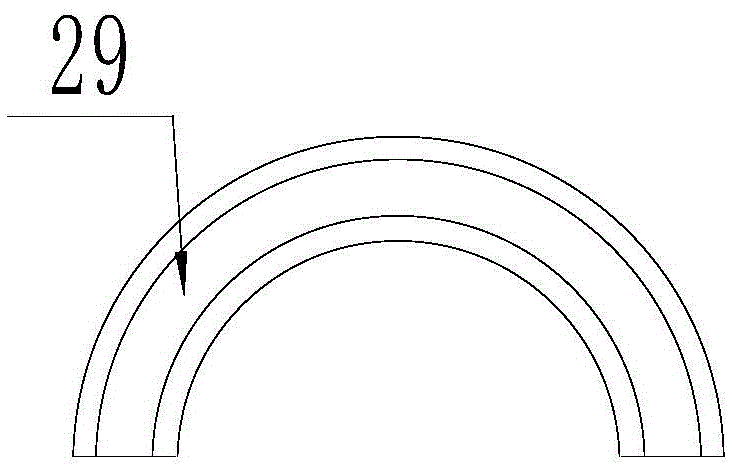

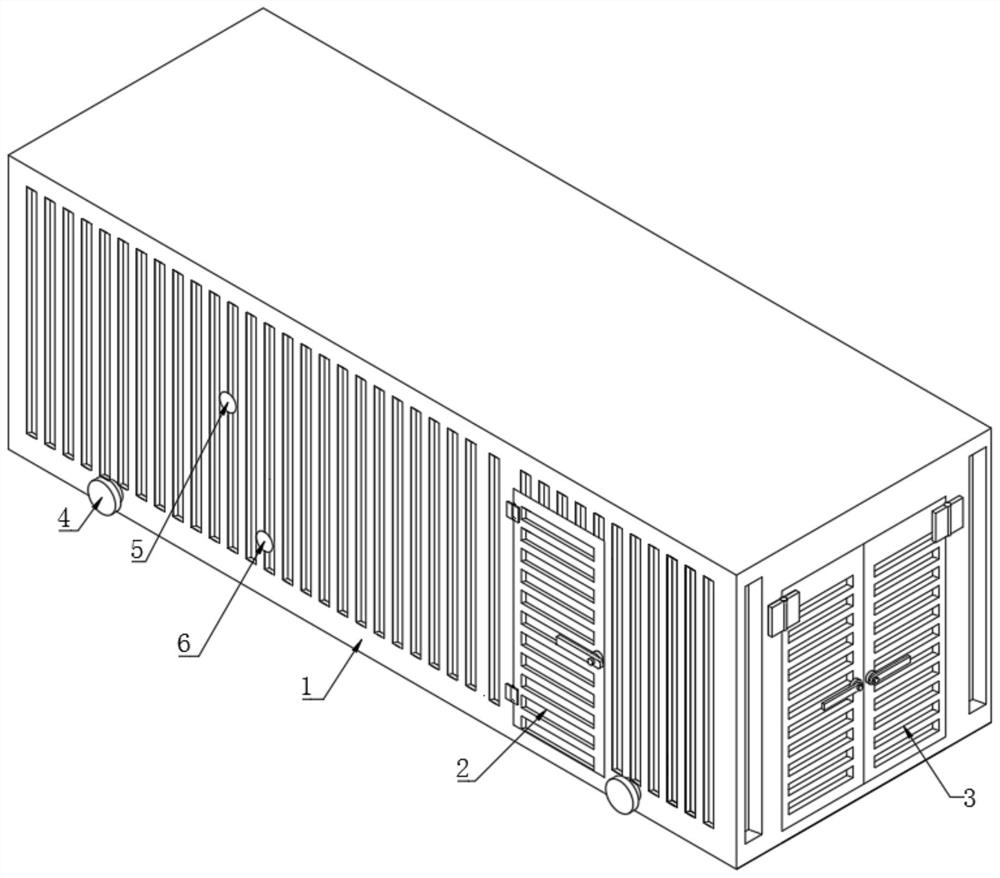

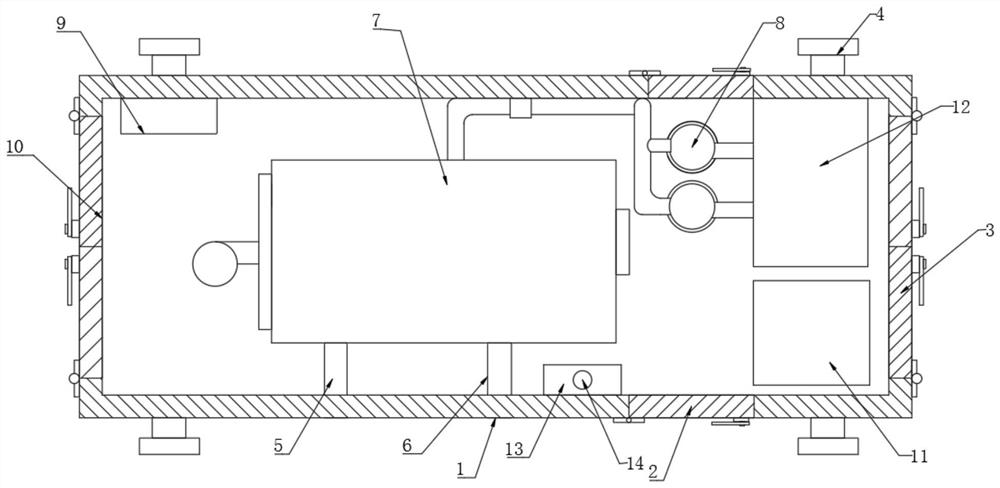

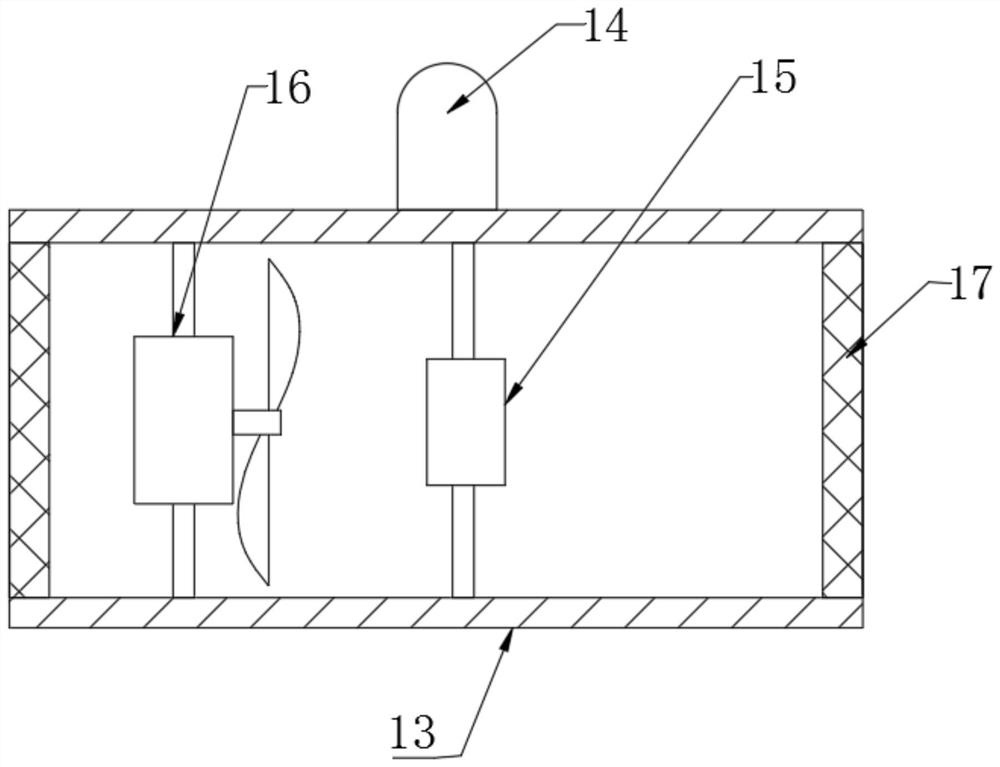

Skid-mounted movable boiler room

InactiveCN113266815ASpeed up the flowEasy to moveFluid heatersBoiler supporting/setting arrangementsToxic gasWater storage

A skid-mounted movable boiler room comprises a container, wherein production doors are hinged to two ends of the left side of the container, a distribution box is fixedly connected to the inner wall of the left side of the container, a boiler is fixedly connected to the lower end of the middle in the container, a water storage tank is fixedly connected to the front end of the right side in the container, and a daily oil tank is fixedly connected to the rear end of the right side in the container. The device is simple in structure, an exhaust fan rotates to introduce air in the container into the container, and when a toxic gas sensor detects harmful gas, an alarm box gives an alarm to timely remind a worker to open a rear access door and a side access door to accelerate air flow, so that the boiler can work stably in the container. When the boiler needs to be moved, a rope is sleeved with a reinforcing lifting lug, a crane is used for pulling the rope, the container is driven to move to a truck, the truck moves to a proper place to work, and therefore, the boiler can be conveniently moved.

Owner:宋占友

Method for monitoring wall temperature of heating surface and thickness of scale cinder of boiler superheater or reheater

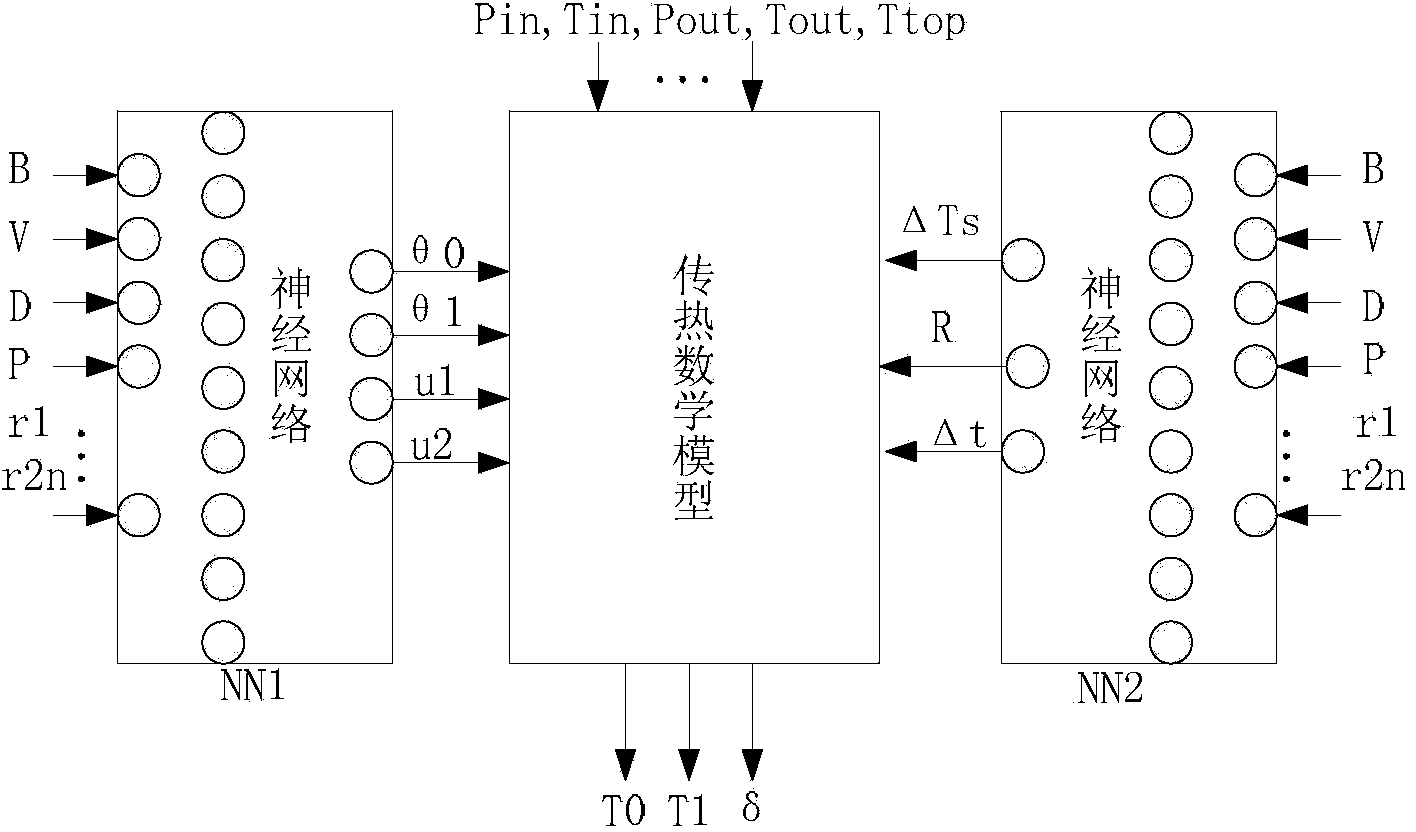

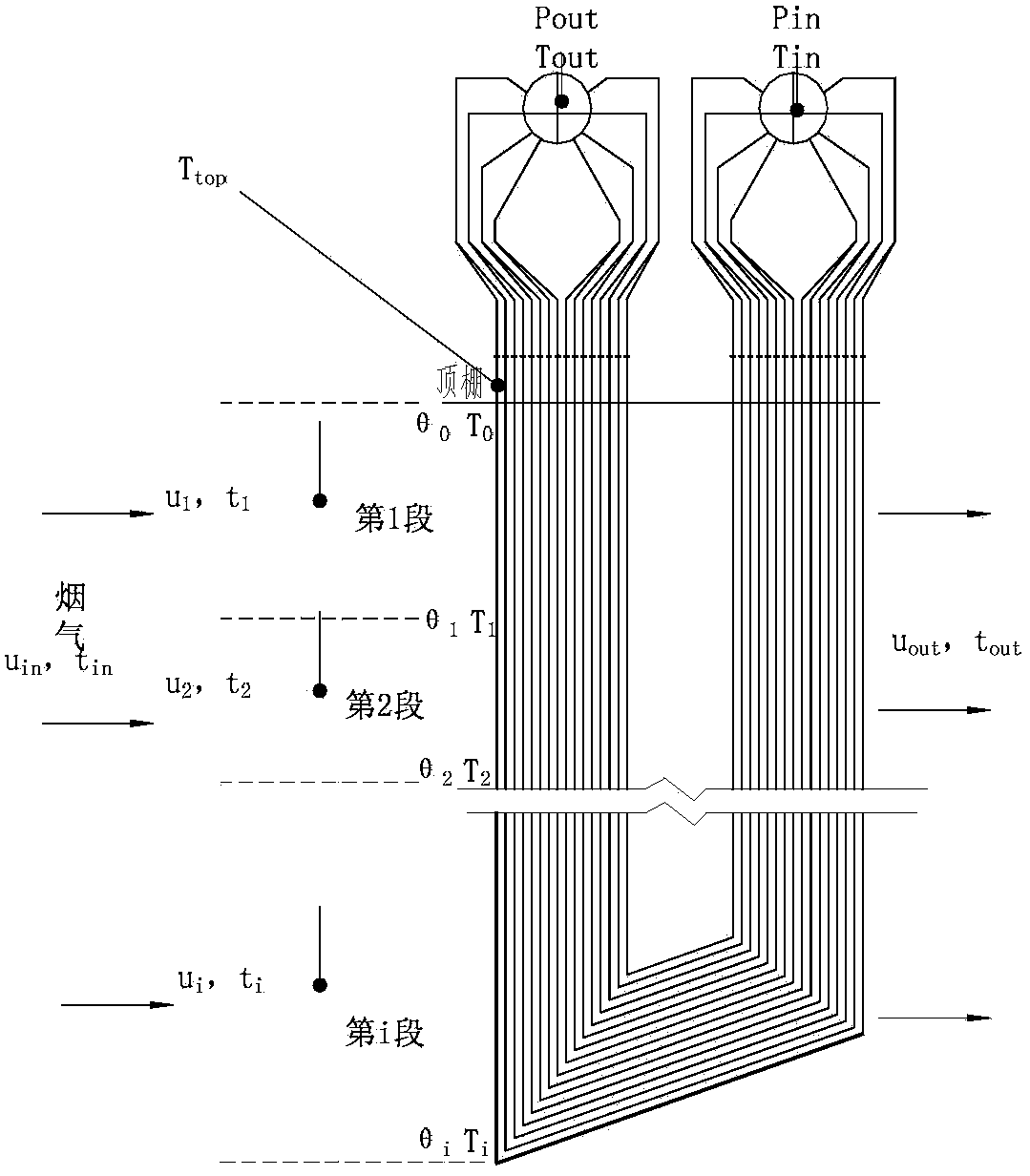

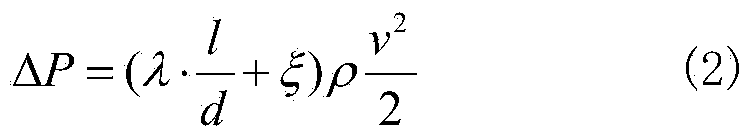

The invention discloses a method for quantitatively and online monitoring the metal wall temperature of a heating surface and the thickness of a scale cinder (scale layer) of a boiler superheater or a reheater. The method includes the steps that according to operating parameters of a boiler, flue-gas temperature and speed of partition sections in the front of a pipe are predicted and monitored through a neutral network, and based on the flue-gas temperature and the speed, the distribution of the wall temperature of the heating surface and the thickness of the scale cinder (scale layer) of the superheater or the reheater are acquired according to a heat transfer mathematical model of the heating surface. The method has the advantages that the method is simple, rapid and capable of being continuously conducted, regular automatic learning can be achieved, the method can be used for quantitatively monitoring the wall temperature of the heating surface and the thickness of the scale cinder in the actual operating process of the pulverized coal boiler, and a quantitative basis is provided for preventing pipe explosion through optimizing, adjusting and controlling thermal deviation and for managing the service life of the heating surface of the boiler.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

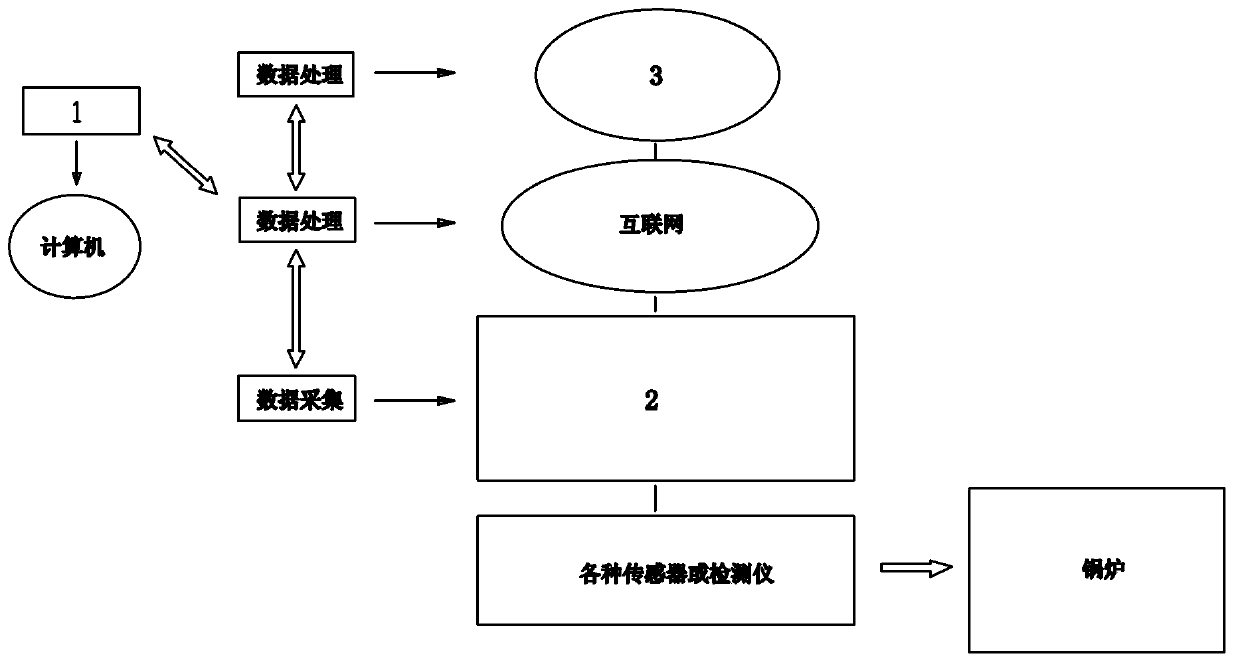

Coal-fired boiler interactive online monitoring method

InactiveCN103900071ARealize real-time online monitoring functionRealize the man-machine dialogue functionBoiler indication operationsBoiler controlMathematical modelData acquisition

The invention relates to a coal-fired boiler interactive online monitoring method. The coal-fired boiler interactive online monitoring method includes the steps that various sensors, a feed water flow meter and a coal-fired metering device are installed on a boiler body on the site; acquired signals are divided into variable signals of the sensors needing installing and status signals; acquired signal data are connected to a data acquisition unit in an interactive control cabinet through a cable, digital-analog signal conversion is conducted through the data acquisition unit, the data are transmitted to the internet through a wireless network transmission terminal, remote data transmission is achieved, and the signal data are remotely transmitted to a computer for monitoring through a network; a mathematical model is built through the computer for monitoring to process the signal data, and online computing information is acquired. The coal-fired boiler interactive online monitoring method has the advantages that information and an operating boiler can be online monitored in real time, the man-machine conversation function can be achieved through a touch screen additionally arranged on the on-site control cabinet, a fireman can know the actual operating status of the boiler on the site, operation is optimized, and operating parameters of the boiler are optimal.

Owner:杭州齐曼节能环保技术有限公司

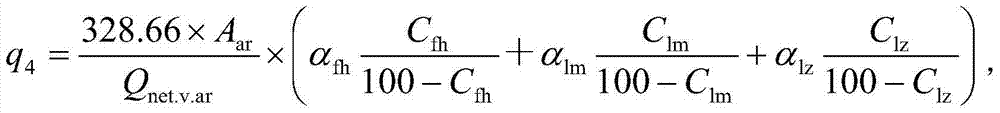

Method for monitoring intra-furnace dynamic wall temperature in high-temperature tube system of power station boiler

ActiveCN102494325AExtended service lifeReduce generationThermometer detailsBoiler indication operationsPower stationReal-time data

The invention discloses a method for monitoring intra-furnace dynamic wall temperature in a high-temperature tube system of a power station boiler in the technical field of the power station boilers. The method disclosed by the invention comprises the steps of: precomputing to obtain a representative tube with the minimal allowance of intra-furnace inner wall temperature in a tube group for installation of a furnace outer wall temperature measurement and collection point; reading data required for calculation of real-time operation of the boiler, the extra-furnace wall temperature and the like from a real-time database of a power plant, and storing the data in a relational database of a local server; generating real-time dynamic calculation of intra-furnace working medium temperature and intra-furnace metal wall temperature of a superheater and reheater tube system of the power station boiler according to real-time data of the real-time operation and the extra-furnace metal wall temperature; and separating the data of a metal tube section exceeding a tube wall metal stress intensity over-temperature value part and storing the data in an over-temperature summary database. The method disclosed by the invention effectively combines dynamic online calculation with dynamic online monitoring of practical working conditions so that the technical effect of prolonging the service life of the tube system is achieved and the technical problem on preventing over-temperature tube explosion of the tube system of the power station boiler is solved.

Owner:SHANGHAI WANGTE ENERGY RESOURCE SICENCE & TECH

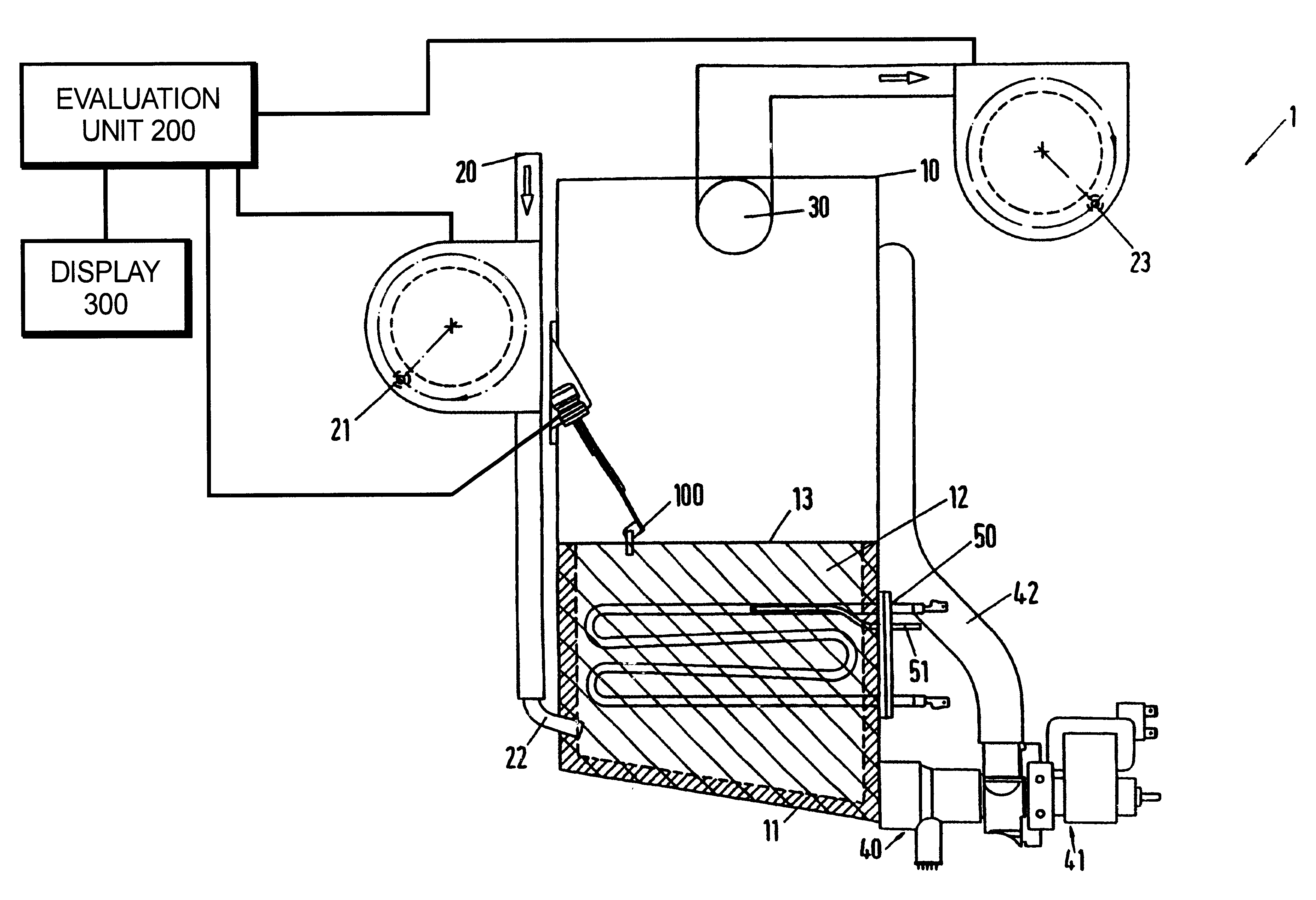

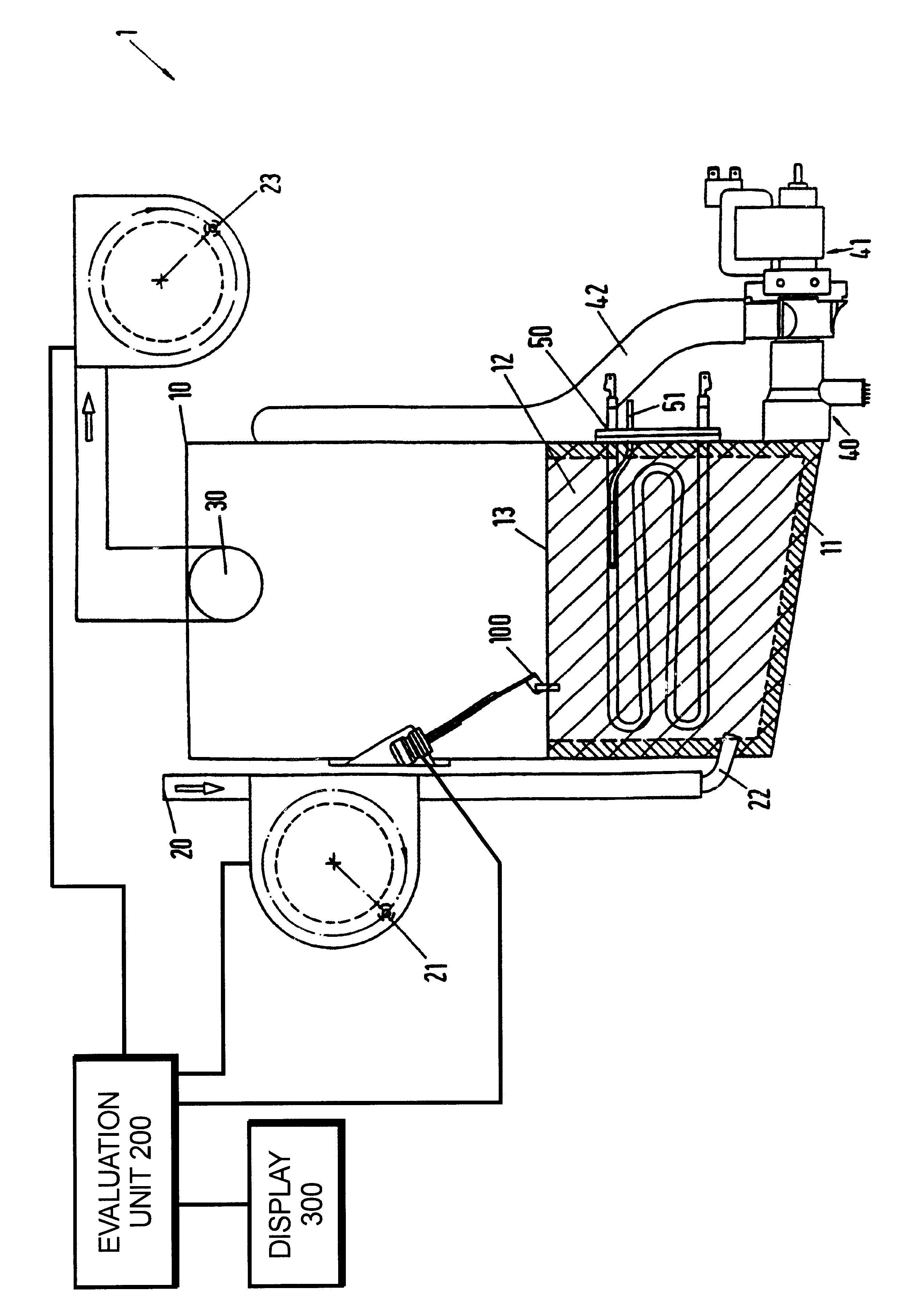

System for electronically monitoring scaling in an apparatus for heating and/or evaporating a liquid

InactiveUS6510782B1Easy to monitorSteam generation heating methodsBoiler indication operationsLevel sensorEngineering

A system for electronically monitoring scaling in an apparatus for heating and / or evaporating a liquid, comprising a container for at least temporarily receiving the liquid. The container comprises a liquid inlet, a liquid outlet and / or a vapor outlet and a heating element for evaporating liquid from the container. An evaluation unit is connected to at least one liquid level indicator and at least one flowmeter. A value relating to a desired filling volume of the container can be inputted into the evaluation unit and / or can be stored therein. The desired filling volume can be compared to a nominal liquid level in the evaluation system when water is constantly added by the flow meter, whereby the nominal liquid level is detected by the liquid level indicator, or to a nominal filled-in quantity detected by the flowmeter when the liquid flow indicator regulates the level of the filled-in liquid. A signal can be sent by the evaluation unit, wherein the signal is a measure of the absolute nominal liquid level, the absolute nominal filled-in quantity, the nominal liquid level relative to the desired liquid level, and / or the nominal filled-in quantity relative to the desired filled-in quantity.

Owner:RATIONAL AG

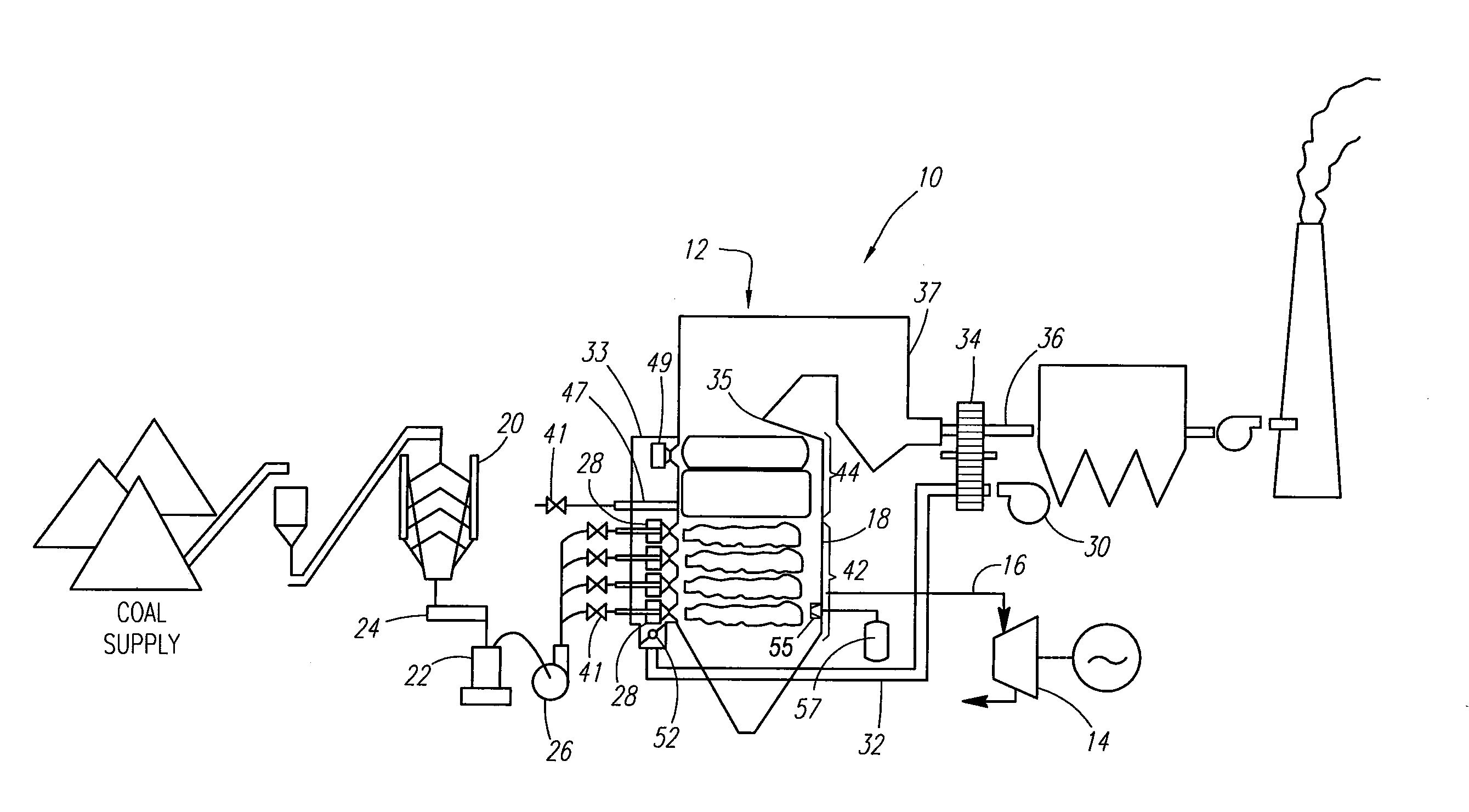

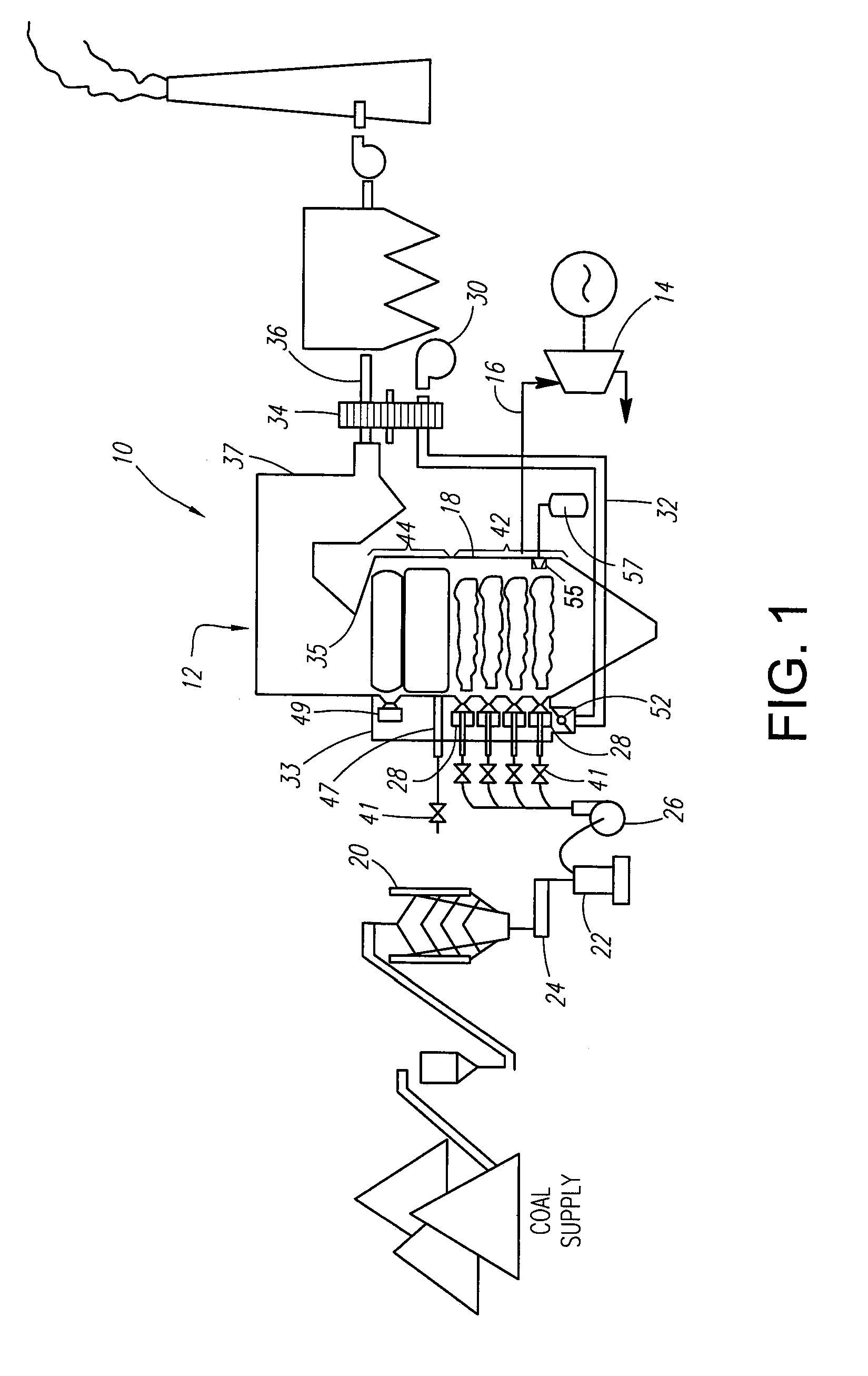

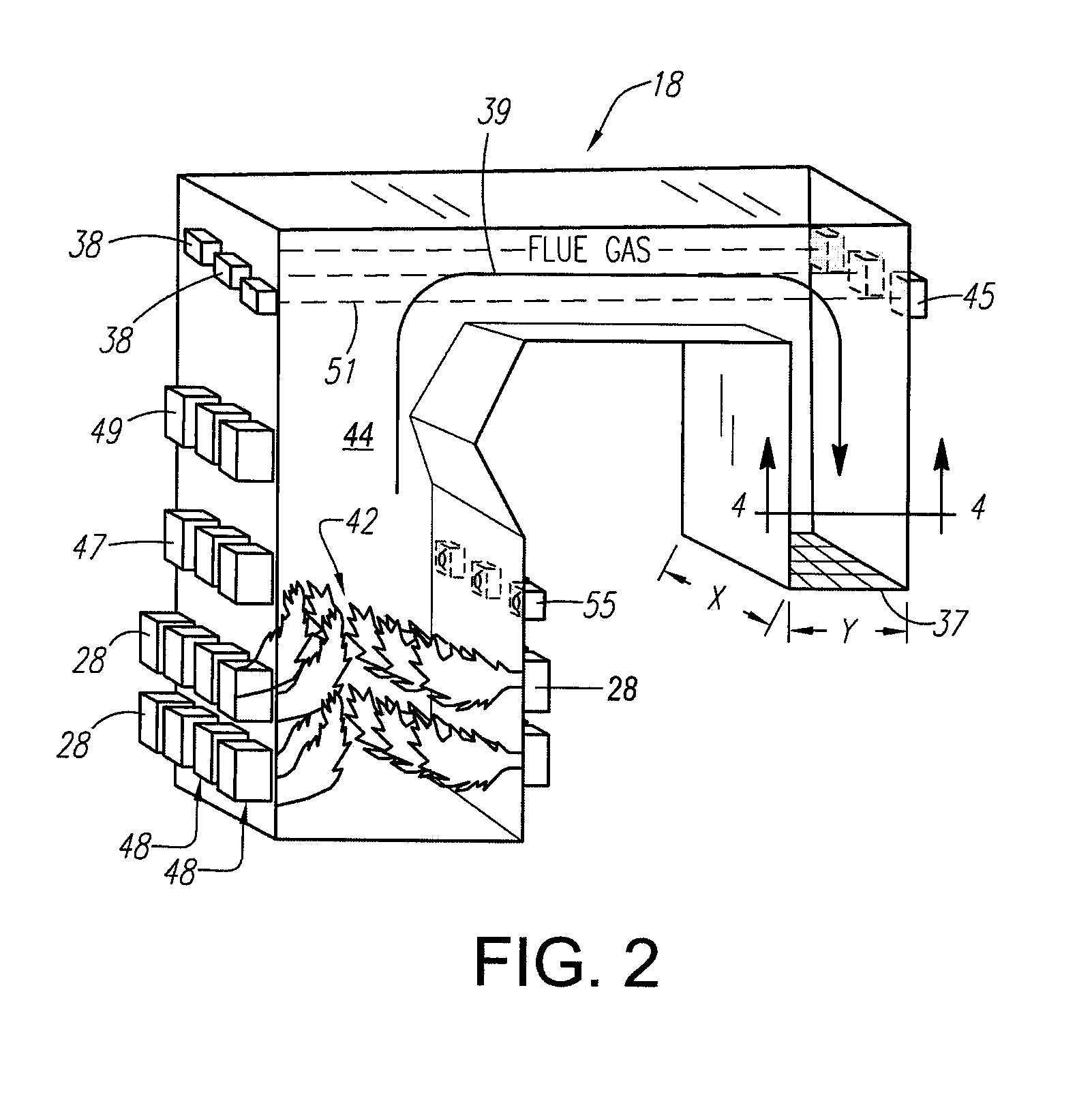

System for combustion optimization using quantum cascade lasers

InactiveUS20110056416A1Affect operationFuel supply regulationBoiler indication operationsCombustorEngineering

A system with a boiler and a turbine, and an associated control method. The method includes sensing a plurality of operating conditions at a first common boiler location. At least one of the plurality of operating conditions sensed at the first common location is indicative of a combustion anomaly occurring during operation. The combustion anomaly indicated by the plurality of operating conditions at the first common location is traced back to an offending burner that is at least partially responsible for the combustion anomaly based on a model that takes into consideration at least two of the plurality of operating conditions sensed at the first common location. At least one of a process input and a boiler configuration is adjusted to establish a desired value of the operating conditions at the first common location.

Owner:GENERAL ELECTRIC CO

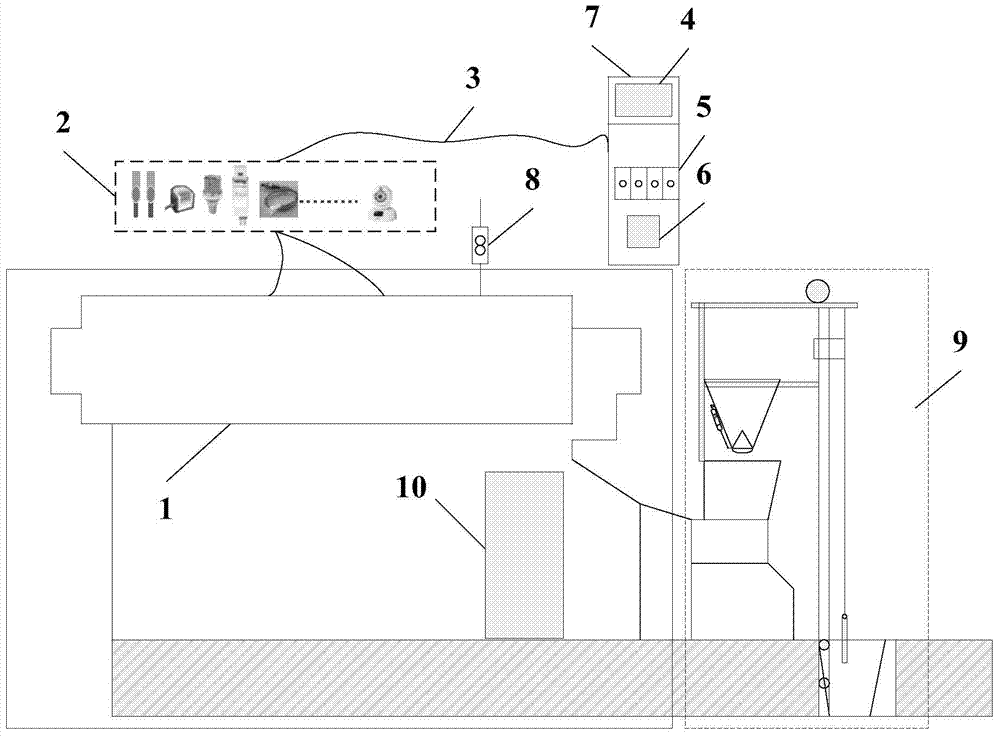

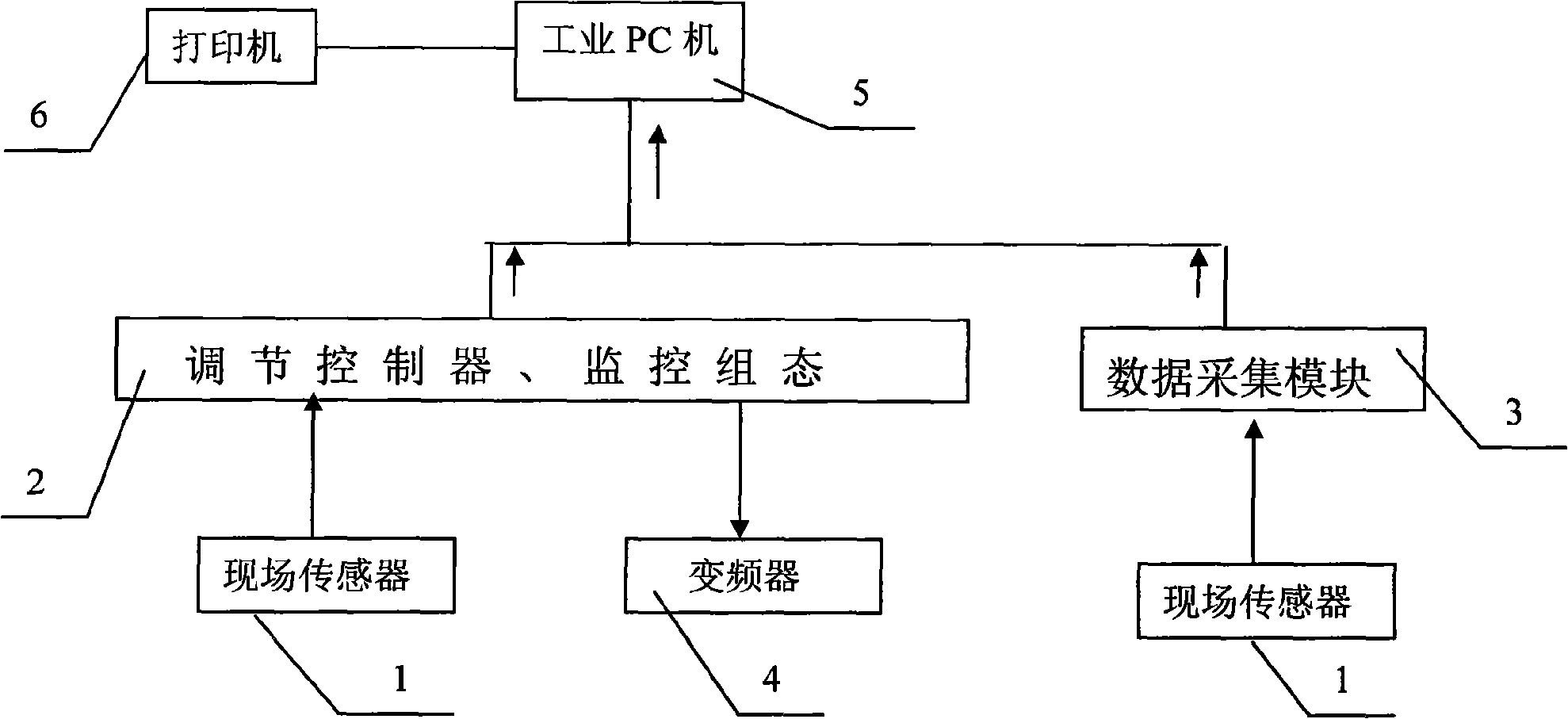

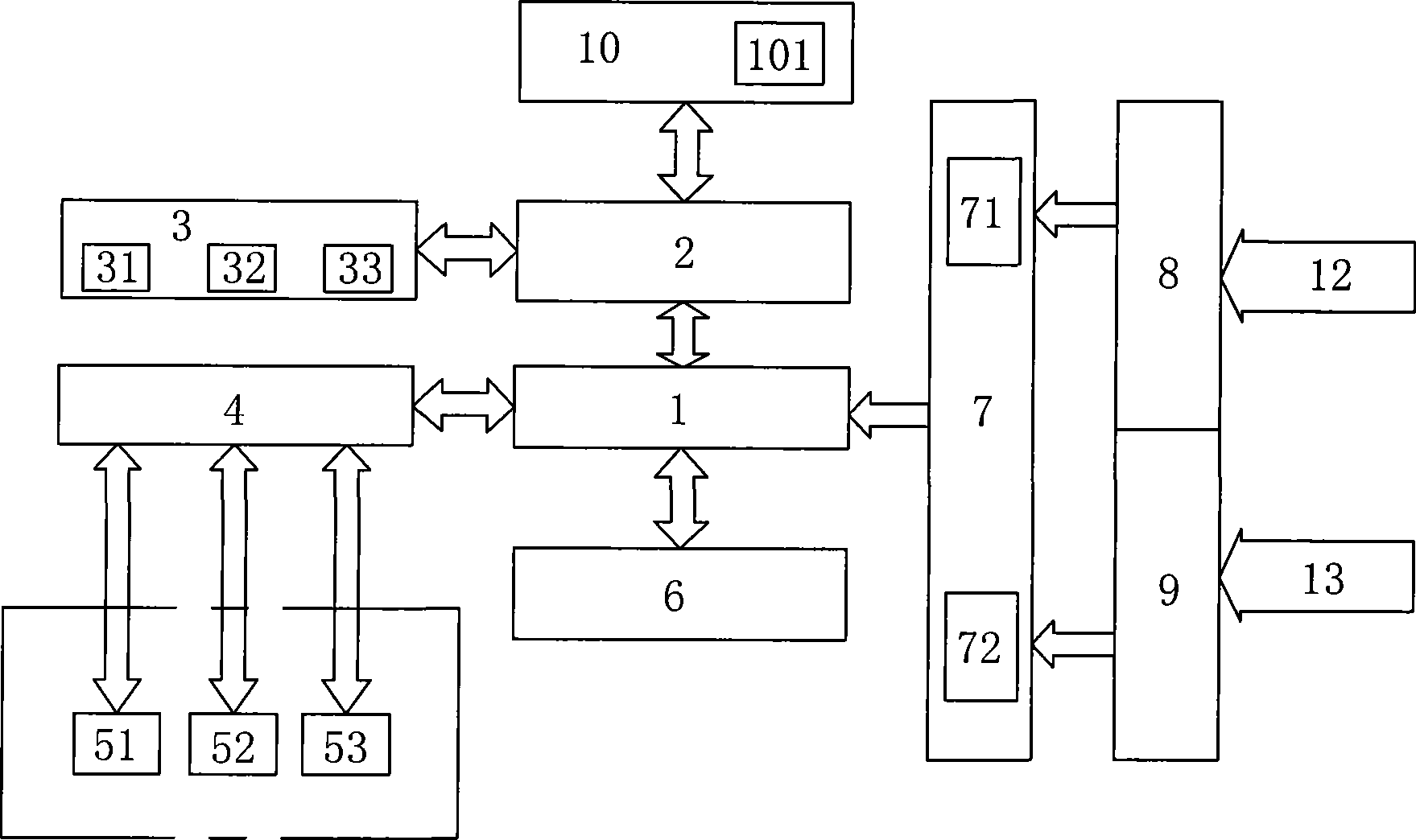

Combustion energy-saving automatic control device of coal-burning chain boiler

InactiveCN101270872ARich computing and processing functionsEasy to operateBoiler indication operationsBoiler controlFrequency changerAutomatic control

The invention discloses an automatic control device for the energy saving combustion of a coal burning chain boiler. The invention is characterized in that the device comprises an in-situ sensor (1) which is connected with a regulation controller, the monitoring configuration (2) and a data collection module (3) through the lines respectively; the regulation controller and the monitoring configuration (2) are connected with a transducer (4) through the lines; the regulation controller, the monitoring configuration (2) and the data collection module (3) are respectively connected with an industrial PC machine (5) through the lines; the industrial PC machine (5) is connected with a printer (6) through the line. The automatic control device for the energy saving combustion of a coal burning chain boiler has the advantages of the advanced controlling performance, high reliability, stable operation and high energy saving rate.

Owner:刘德胜

Electronic vaporiser system

An electronic cigarette vaporiser system operable in a ‘power’ mode to increase the amount of vapour produced by a vaporiser that forms part of the system, compared to normal, whilst monitoring the temperature of a heating element in the vaporiser to ensure that excessively high temperatures, associated with undesirable compounds in the vapour produced by the heating element, are not reached. The system includes a button or sensor that alters the operation of the heating element in such a way as to increase the vapour produced, compared to normal.

Owner:AYR LTD

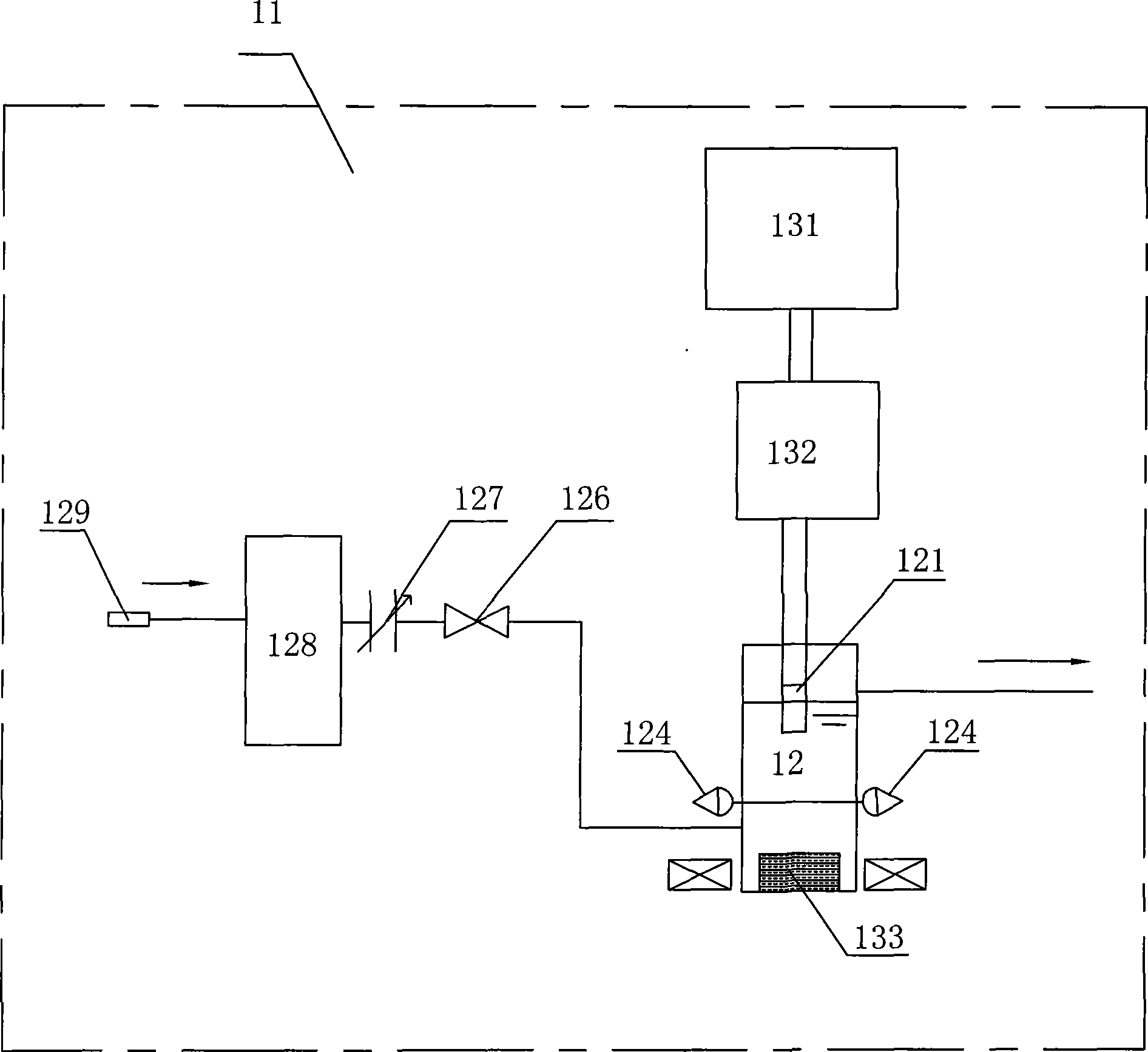

Industrial boiler efficiency remote online monitoring system

InactiveCN103968361ARealize online monitoringReal-time monitoringBoiler indication operationsBoiler controlDisplay deviceThe Internet

The invention discloses an industrial boiler efficiency remote online monitoring system. The remote online monitoring system comprises a data collecting and recording system, a data processing system and a client service terminal, wherein the data collecting and recording system comprises a plurality of data acquisition sensors and a remote monitoring control cabinet connected with the sensors; the data processing system comprises a data server and a display device; the data server is connected with the remote monitoring control cabinet through the internet; the client service terminal is connected with the remote monitoring control cabinet through the internet. According to the remote online monitoring system, safe, energy-saving and environment-friendly running parameters of a boiler are subjected to real-time online monitoring and data collection and storage through the sensors mounted on the boiler and a PLC (Programmable Logic Controller), transmitted to the data server through a network and processed by special software, so that the running boiler can be monitored by a remote platform and the purpose of safely and economically running the boiler is achieved.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

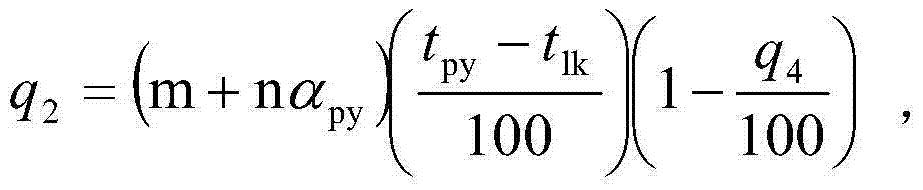

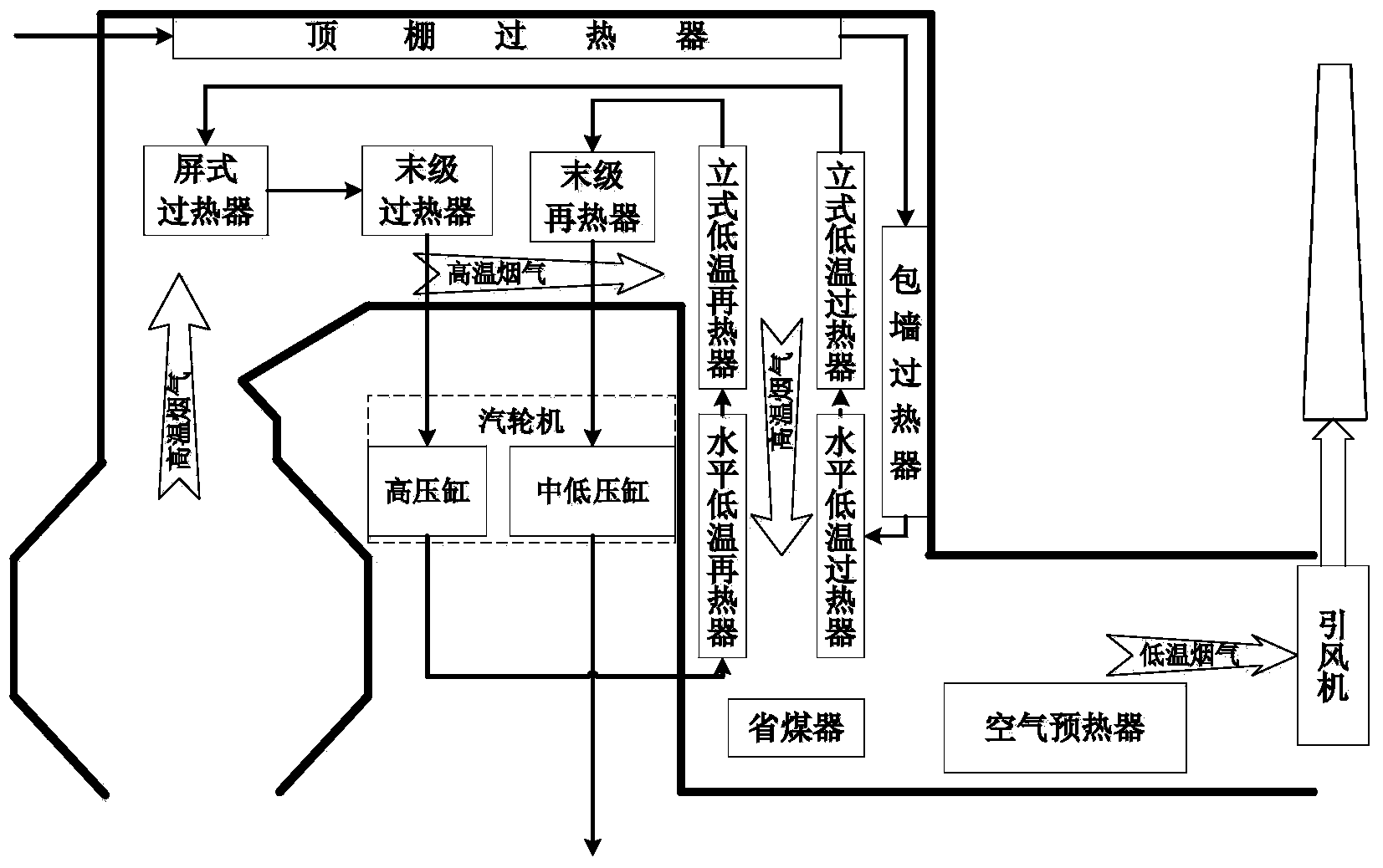

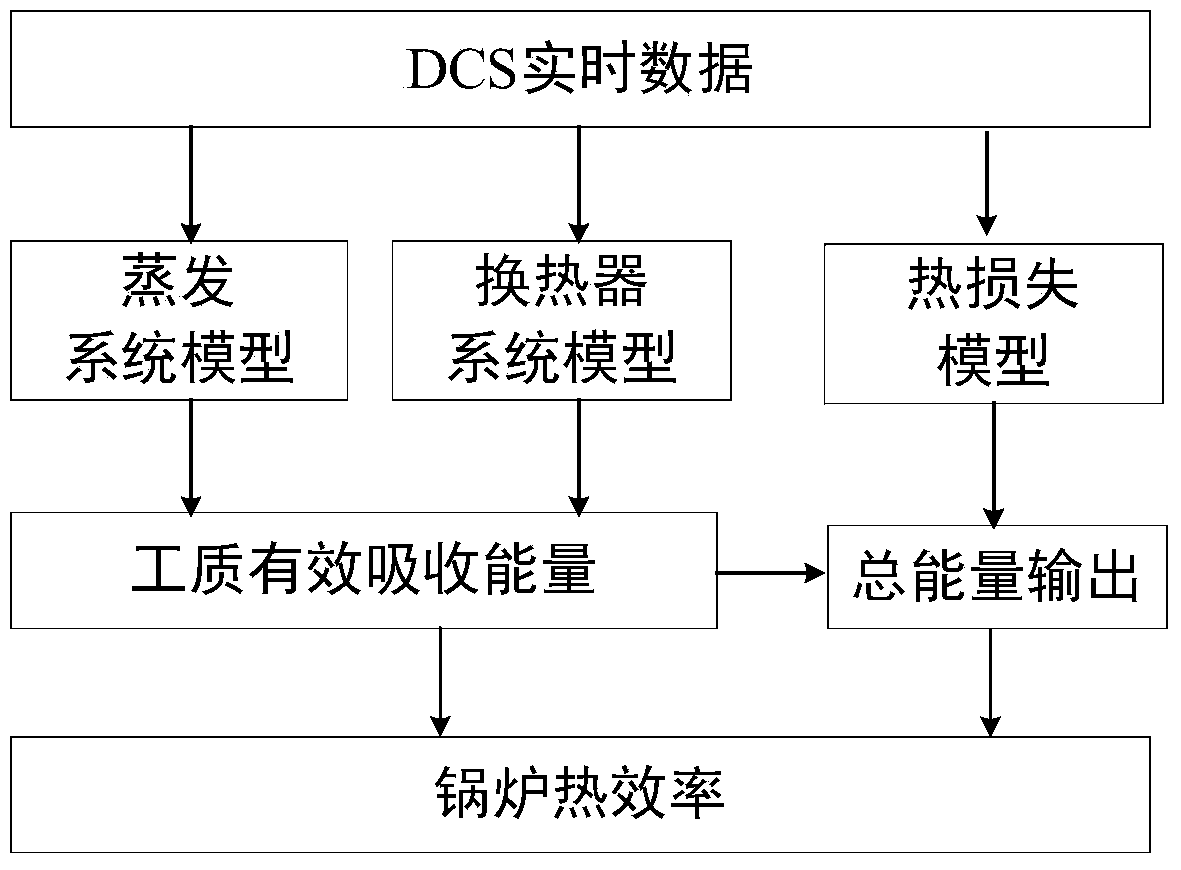

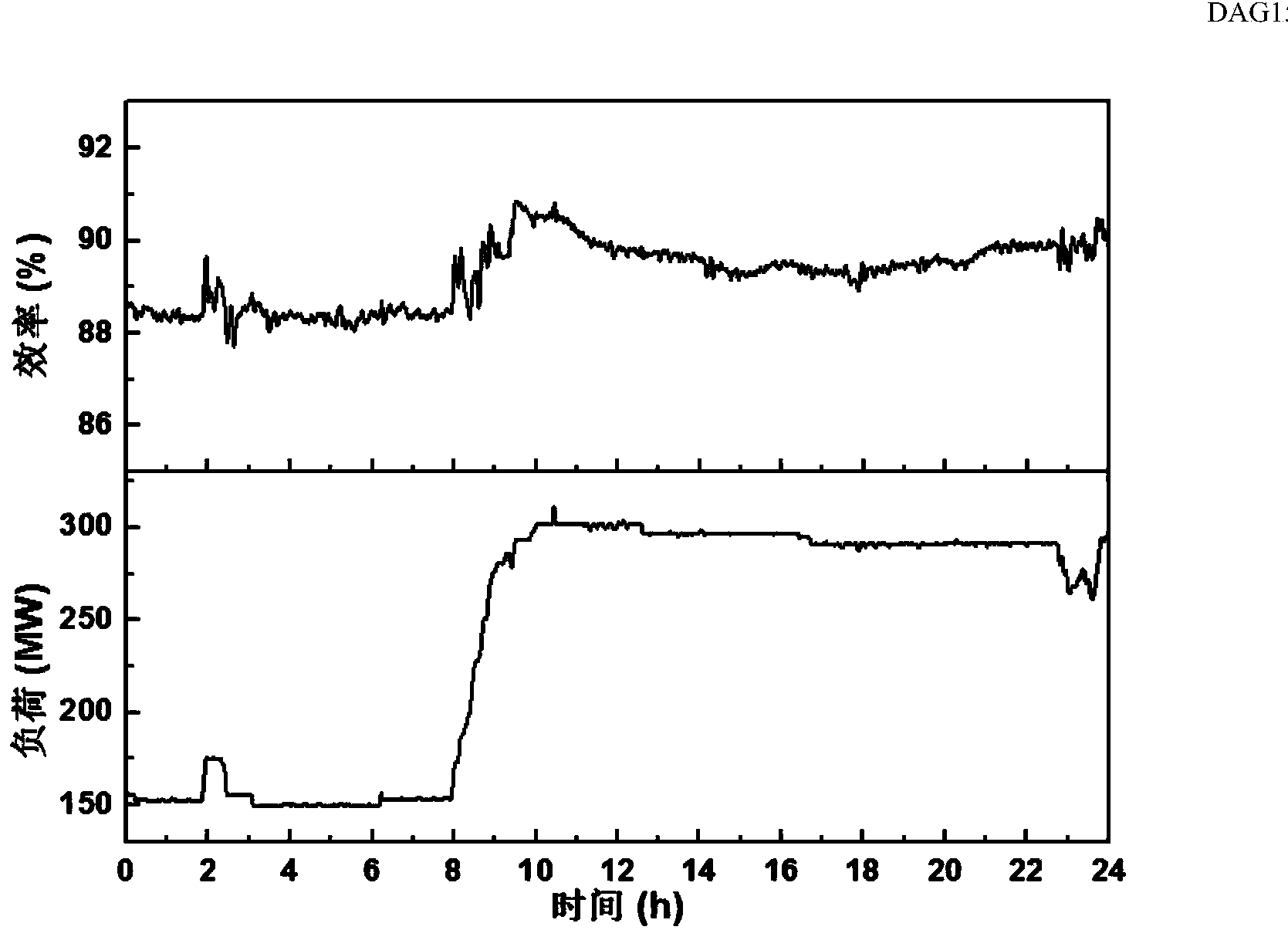

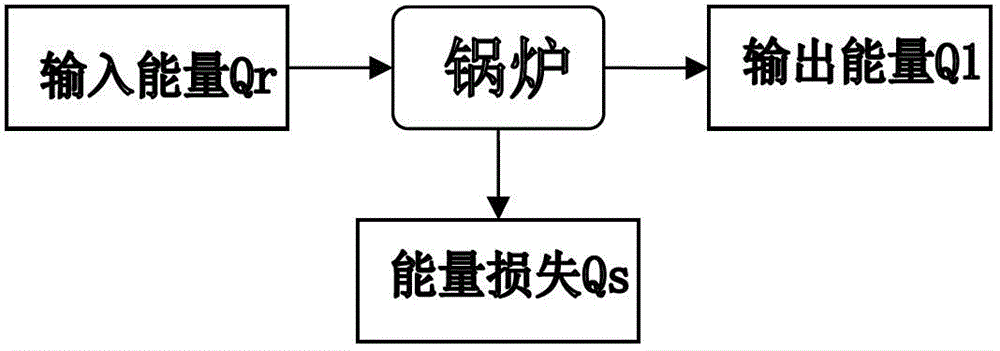

Method for measuring boiler thermal efficiency of coal fired power plant in real time

InactiveCN103778334AStable productionRealize online measurementBoiler indication operationsSpecial data processing applicationsVolumetric Mass DensityEngineering

The invention provides a method for measuring boiler thermal efficiency of a coal fired power plant in real time. The method comprises the following steps: step 1, obtaining boiler structure parameters according to the boiler operation design discipline, and reading a real-time value of an operation working condition measuring point at a set moment from the real-time database of a DCS (Distributed Control System); step 2, calculating the specific enthalpy and density of a working medium and the specific heat and density of fume according to a working medium physical property parameter library and a fume physical property parameter library; step 3, respectively determining the energy output of each part on the boiler side and the total energy output at the set moment according to an vaporization system model, a heat exchanger system (including a superheater system and a reheater system) model and a heat loss model on the boiler side; Step 4, determining the boiler thermal efficiency. The method can be used for measuring the boiler thermal efficiency in an online manner and further providing a technical support for plant-level load scheduling.

Owner:SHANGHAI JIAO TONG UNIV +1

Inspection system and inspection process utilizing magnetic inspection vehicle

An inspection vehicle configured to inspect steam generators includes a front chassis having two independently driven magnetic wheels, a rear chassis having two independently driven magnetic wheels, and a connecting member flexibly connecting the front chassis to the rear chassis to permit relative motion between the front chassis and the rear chassis along at least one axis. The connecting member, front chassis, and rear chassis collectively define a receiving area. The inspection vehicle also includes a navigation camera disposed on the front chassis and a pan and tilt inspection camera assembly including a first rotatable arm driven by a first motor, a second rotatable arm disposed on a distal portion of the first rotatable arm, the second rotatable arm being driven by a second motor, and an inspection camera rotatably disposed on a distal portion of the second arm, the inspection camera being driven by a third motor, the camera assembly being dimensioned to be received within the receiving area in a stowed position.

Owner:ROLLS ROYCE CONTROL SYST HLDG CO

Boiler operating parameter recorder

InactiveCN101520171AAvoid running sickKeep the economy runningAnalysis using chemical indicatorsBoiler indication operationsThe InternetNetwork communication

The invention discloses a boiler operating parameter recorder, wherein a microprocessor is connected with a clock circuit, a communication control circuit, and a data filtering and acquisition circuit. The communication control circuit is connected with a data communication interface, a network communication interface, a GPRS and a short message wireless communication interface. The data filtering and acquisition circuit is provided with a plurality of paths of analog signal filtering acquisition circuits and switch signal filtering acquisition circuits. The inside of a storage is provided with a module for recording boiler attribute parameters, a real-time recording module for recording operating parameters, a monitoring alarm module for setting operating monitoring and alarm control parameters of a boiler, and a real-time monitoring, alarm and communication program control module. Through the Internet or the GPRS and mobile phone short messages, the recorder can establish real-time communication and monitoring relation with safety monitoring and management departments as well as boiler installation and maintenance enterprises, record, monitor and send safe operation information of the boiler, ensure that related departments can promptly adopt preventive measures, exclude and avoid the faulty operation of the boiler, and prevent accidents.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

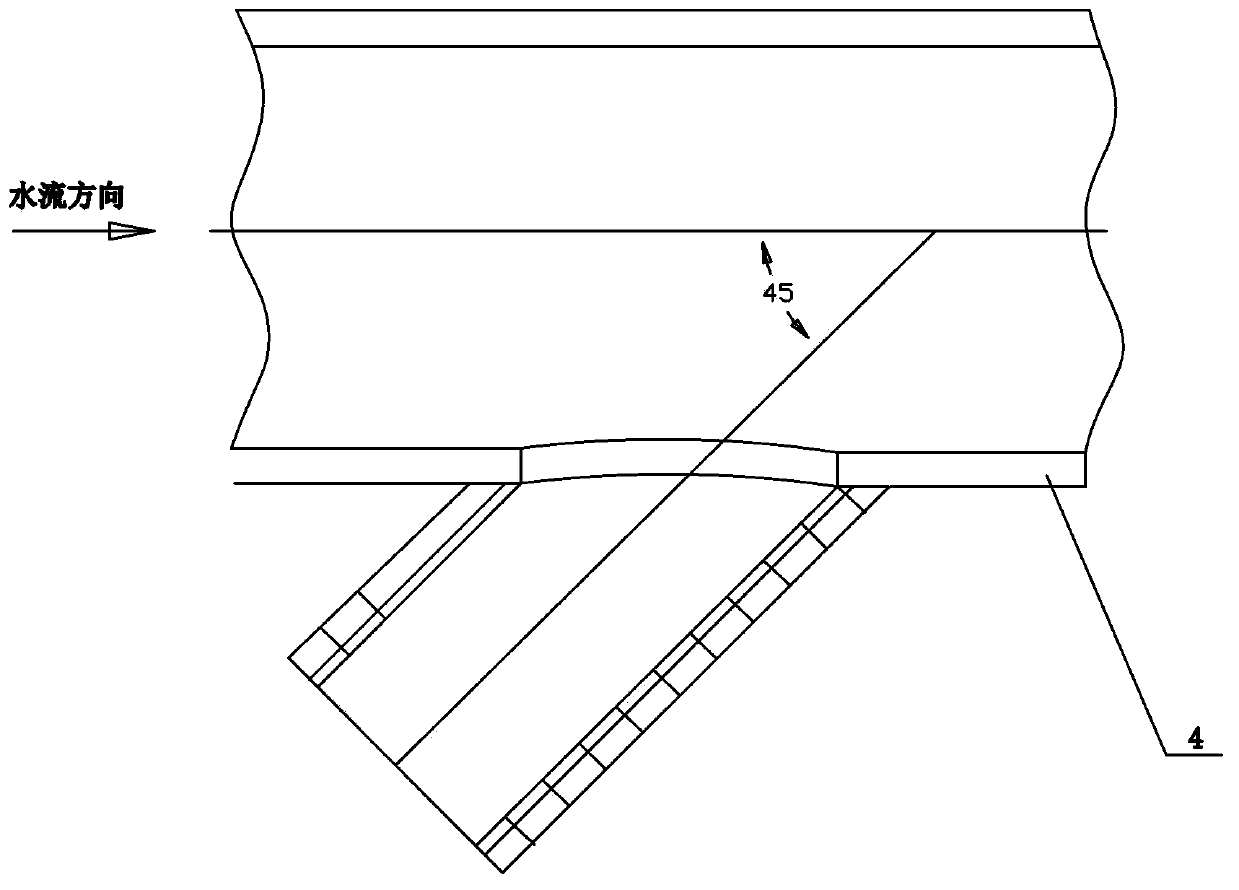

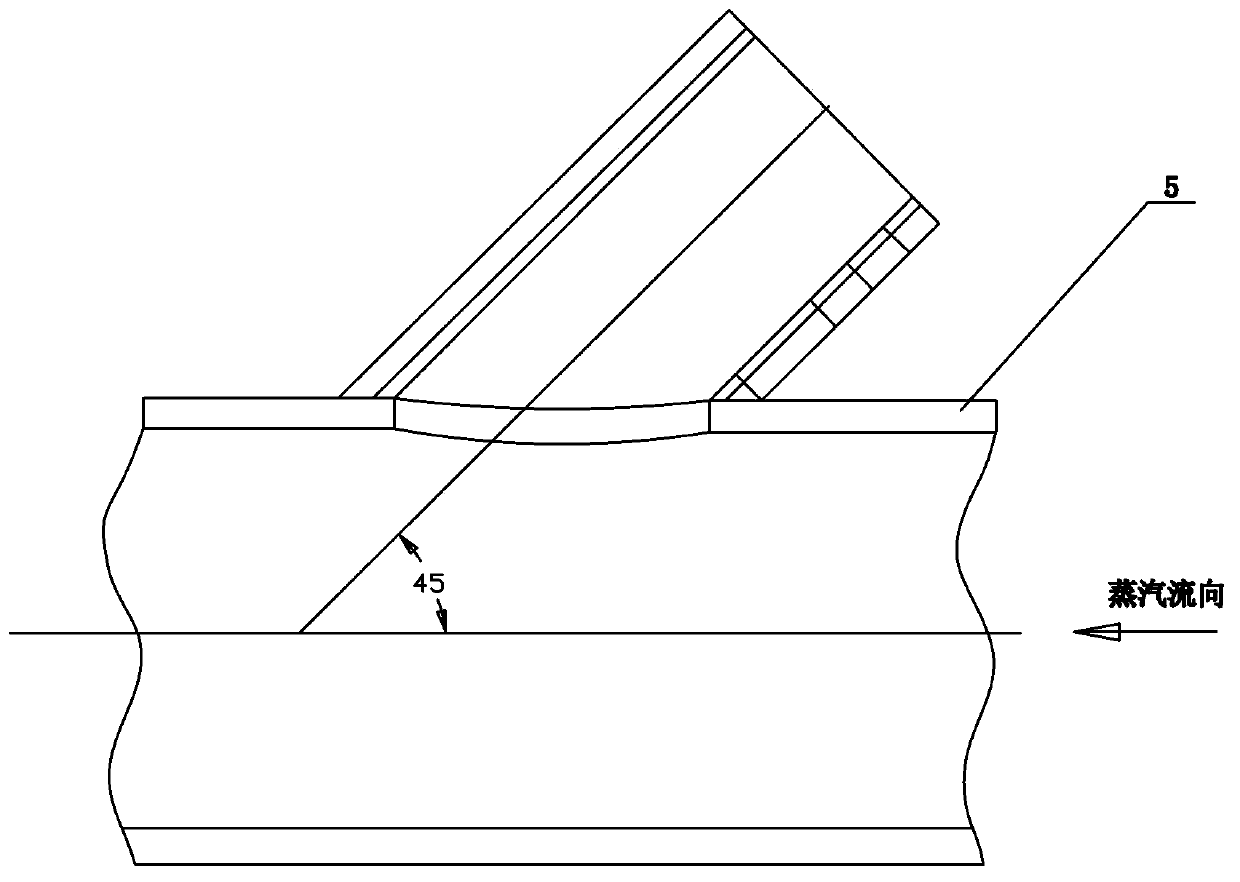

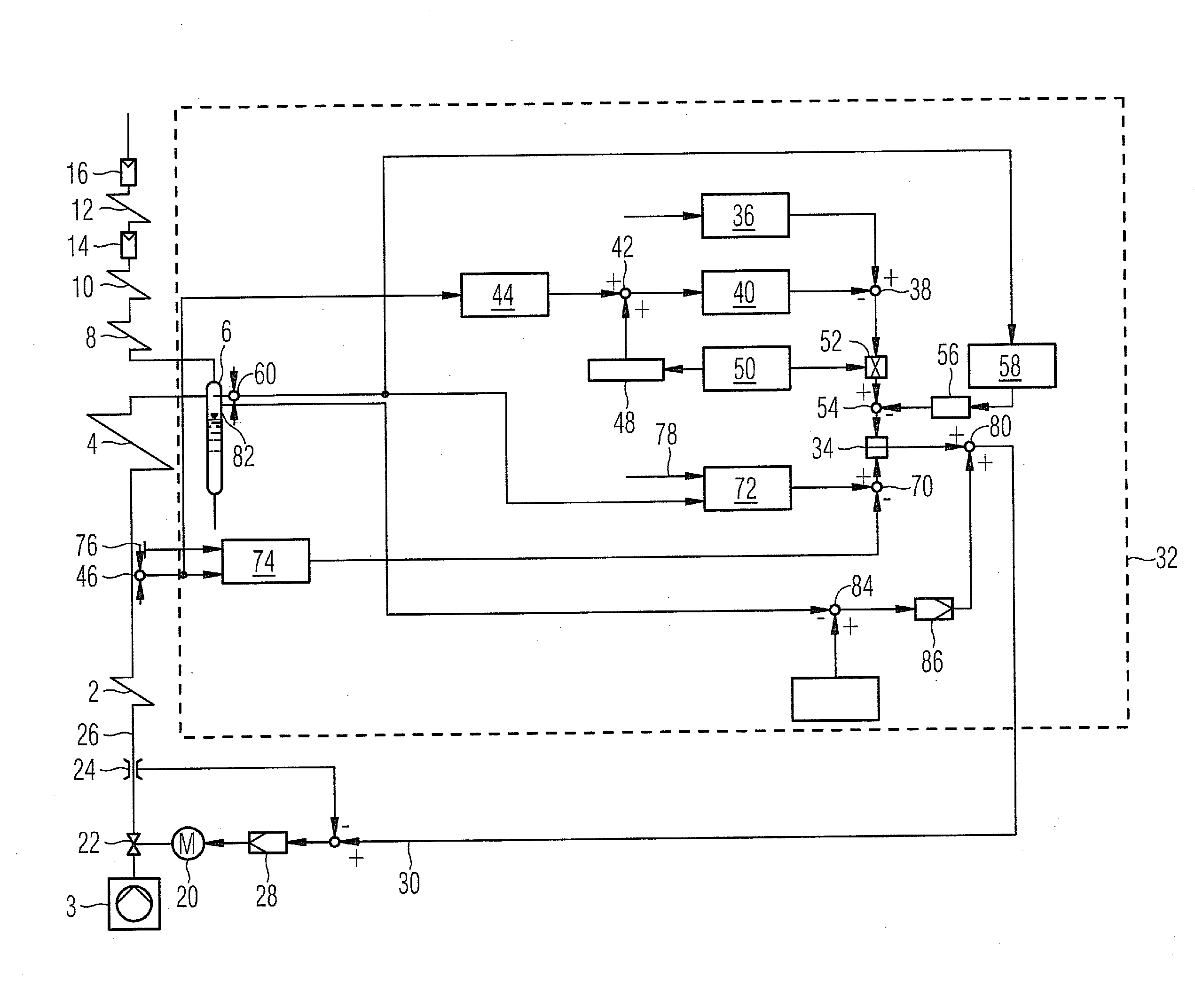

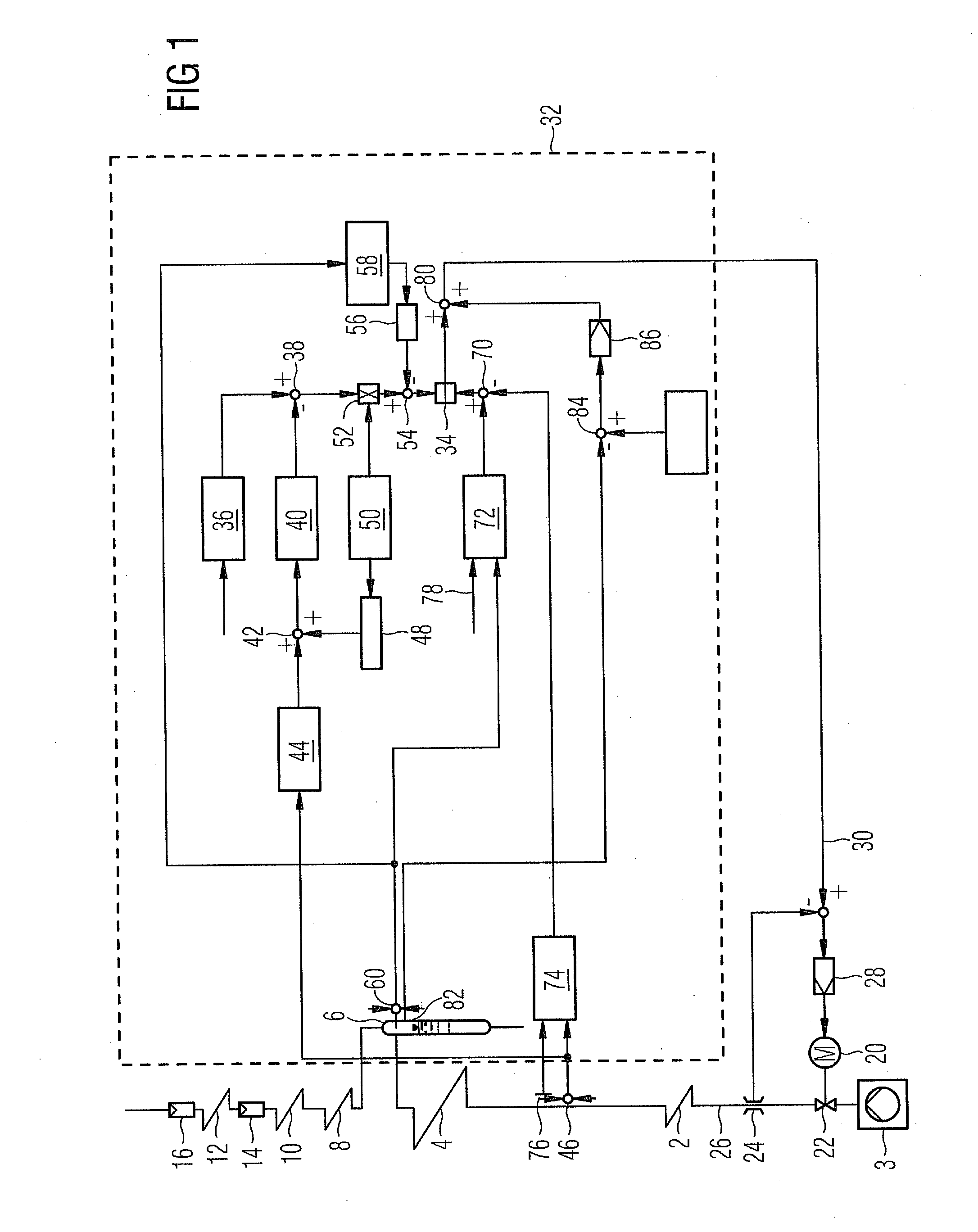

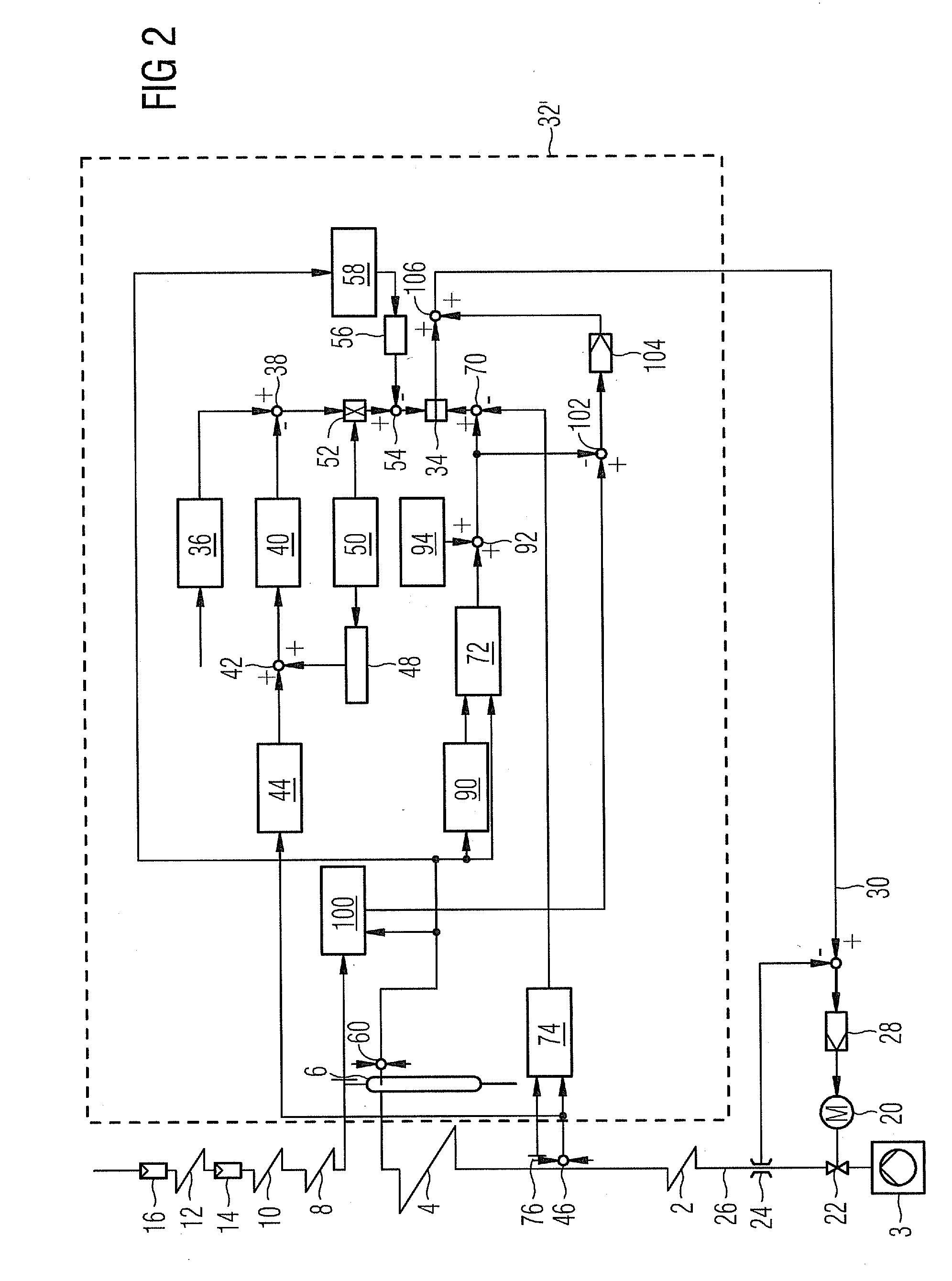

Method for operating a once-through steam generator and forced-flow steam generator

ActiveUS20100288210A1Regulation stabilityAdaptable and DurableBoiler indication operationsWater feed controlHeat flowEngineering

A method for operating a once-through steam generator including an evaporator heating surface is provided. A target value for the supply water mass flow is fed to a device for setting the supply water mass flow, which is predefined using the ratio of the heat flow currently being transferred in the evaporator heating surface from the hot gas to the flow medium to a target enthalpy increase predefined with respect to the desired live steam condition of the flow medium in the evaporator heating surface. A forced-flow steam generator used for carrying out the method is also provided. The heat flow transferred from the hot gas to the flow medium is ascertained for this purpose allowing for a specific temperature value characteristic of the current temperature of the hot gas at the evaporator inlet and a specific mass flow value characteristic for the current mass flow of the hot gas.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

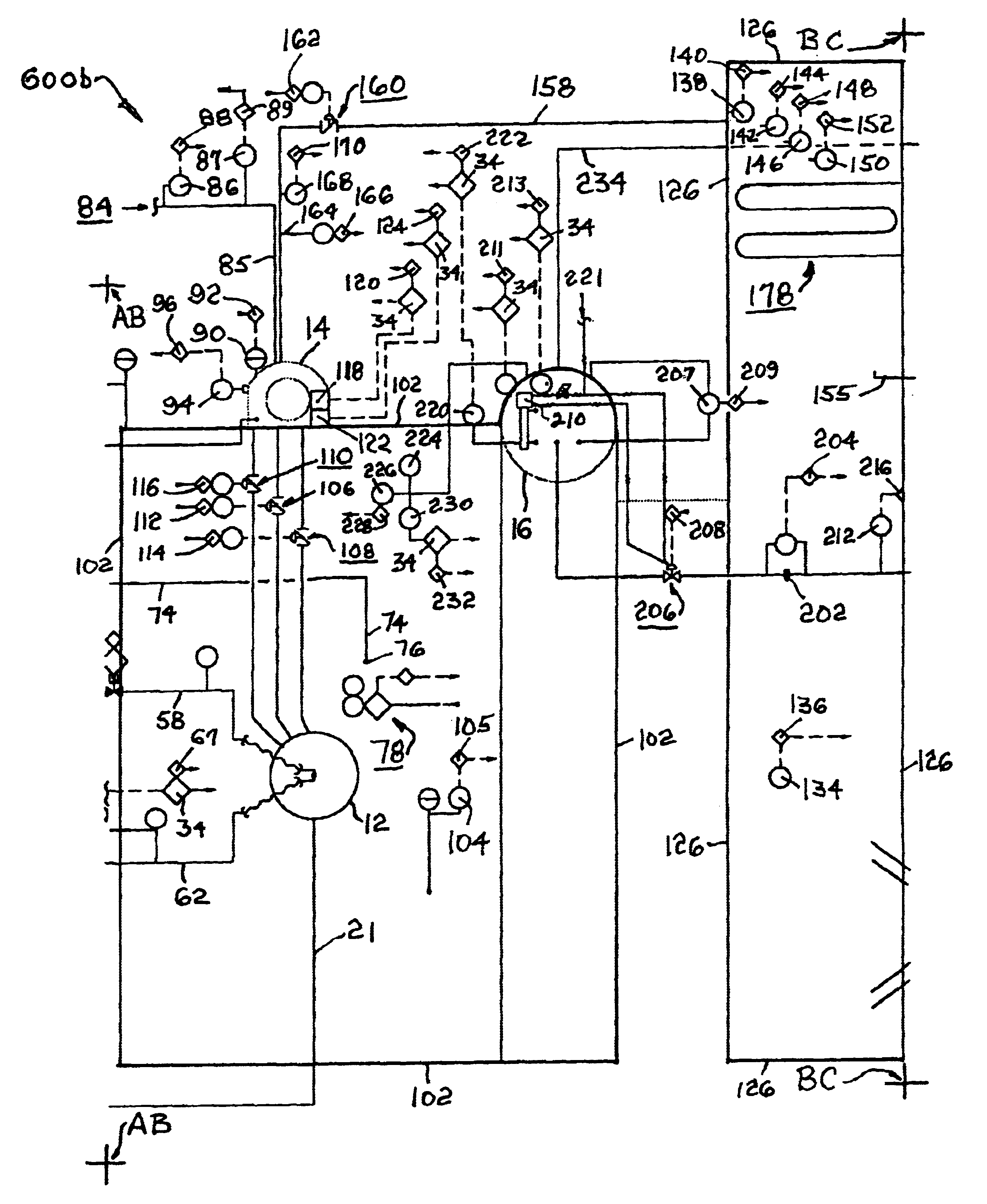

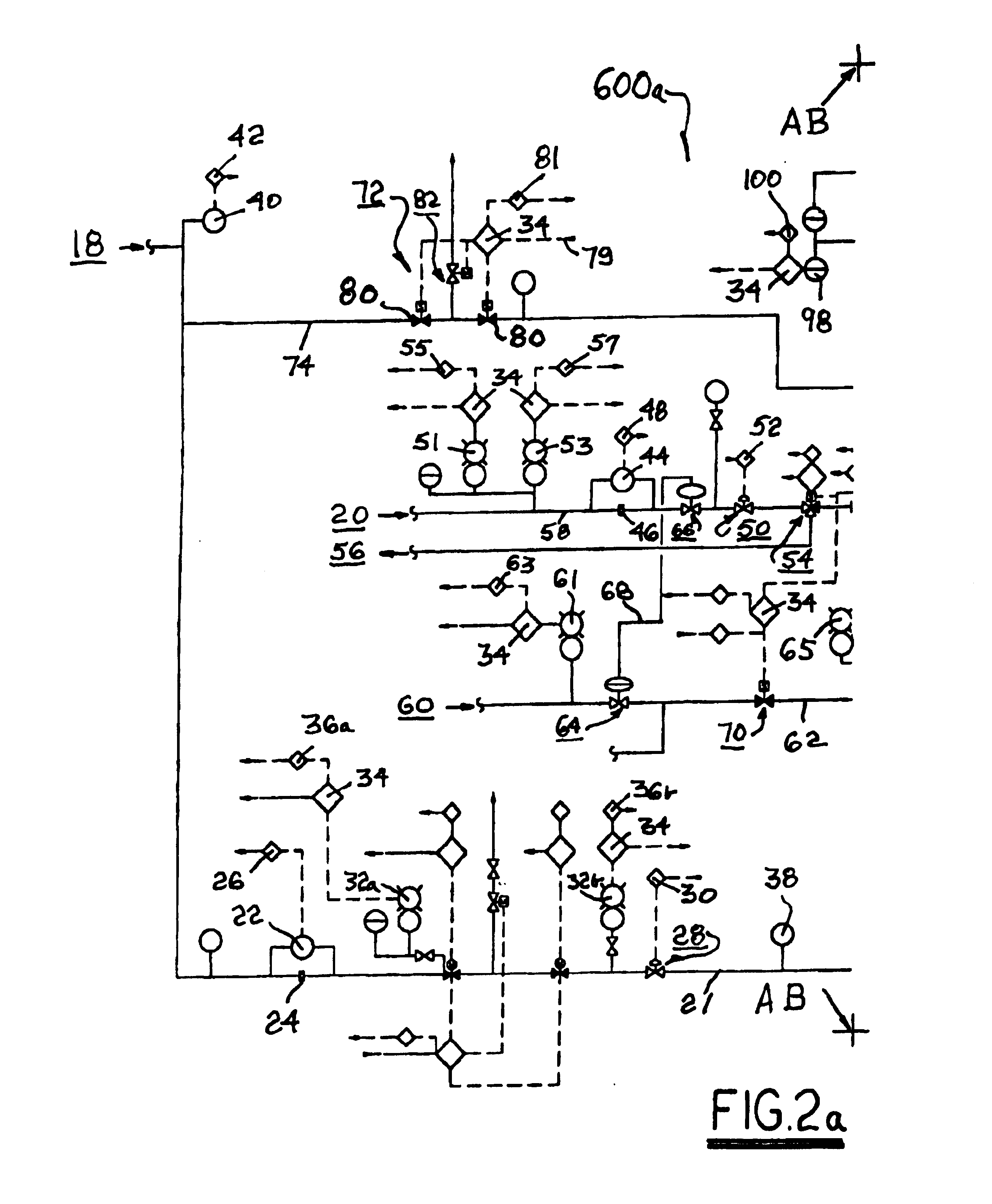

Method and apparatus for optimizing a steam boiler system

InactiveUS6918356B2Rapid and controlled adjustment to steady-state conditionsMinimal controlFuel supply regulationWater circulationSteam pressureInput control

A method for controlling a steam boiler or oil heater for maximum fuel efficiency by systematically finding the most fuel-efficient combination of input control values. A characteristic multi-dimensional look-up table is created by temporarily operating the process at all the possible functional combined settings of a plurality of input operators and recording for each combination of settings the resulting output values of a plurality of process parameters, for example, steam flow, steam pressure, and exhaust composition. Input combinations resulting in either non-functional process or unacceptable output values are eliminated. Steam flow rate is the primary output control parameter. A selected value of steam flow rate is the primary control setpoint for the process. If several combinations of input values can cause the process to meet the primary control setpoint, the combination using the minimum fuel flow is selected as optimal. If the desired setpoint does not correspond exactly to discrete input values in the table, the correct input settings may be inferred by interpolation. Valves and dampers are dynamically controlled by output drive signals in an improved closed-loop control, using a function of the process output value and time to recalculate and adjust the drive signals.

Owner:INTEL & BURN ENERGY SYST INC +2

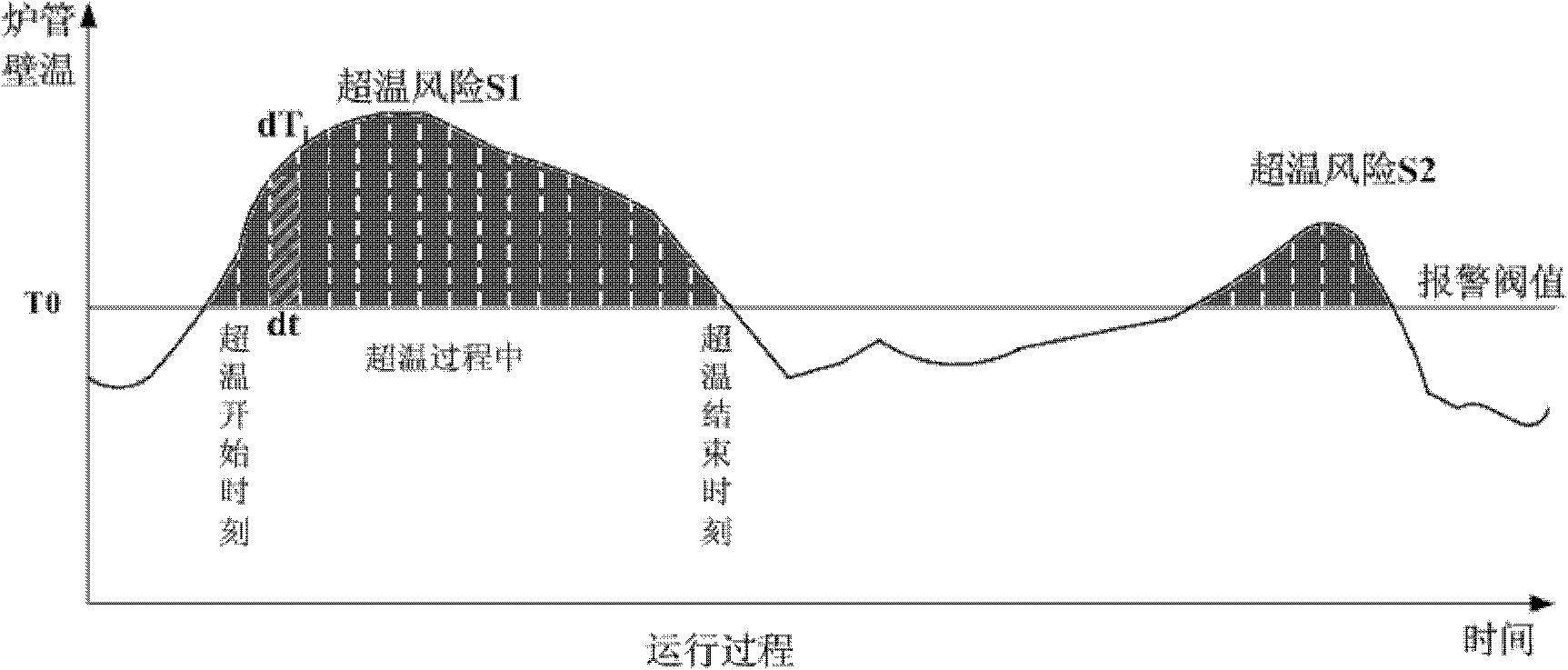

Over-temperature risk indicator-based boiler heating surface monitoring method

InactiveCN102032548AAccurate captureCapture automatic calculationBoiler indication operationsTemperature measurementEngineering

The invention discloses an over-temperature risk indicator-based boiler heating surface monitoring method. The method comprises the following steps of: 1) constructing a boiler heating surface parameter and a wall temperature measurement point information table; 2) setting a wall temperature alarm threshold of each section of furnace tube according to the type of a furnace tube material of a heating surface; 3) reading wall temperature data of the heating surface in real time; 4) judging a data state, namely switching to a step 5) when an over-temperature process is started, switching to a step 6) in the over-temperature process, switching to a step 7) after the over-temperature process is finished, and switching to the step 3) if the data is normal; 5) forming a new out-of-limit record and recording related information; 6) calculating an over-temperature risk value of the current over-temperature process, accumulating the over-temperature risk values of the part, and switching to the step 3); and 7) finishing the current out-of-limit process, forming a complete out-of-limit record and switching to the step 3). By the method, an indicator in an over-temperature degree, namely an over-temperature risk, is accurately evaluated; and a calculation method has a strict theoretical basis, so the over-temperature risk evaluation of the heating surface is fast, accurate and evidence-based.

Owner:XIAN THERMAL POWER RES INST CO LTD

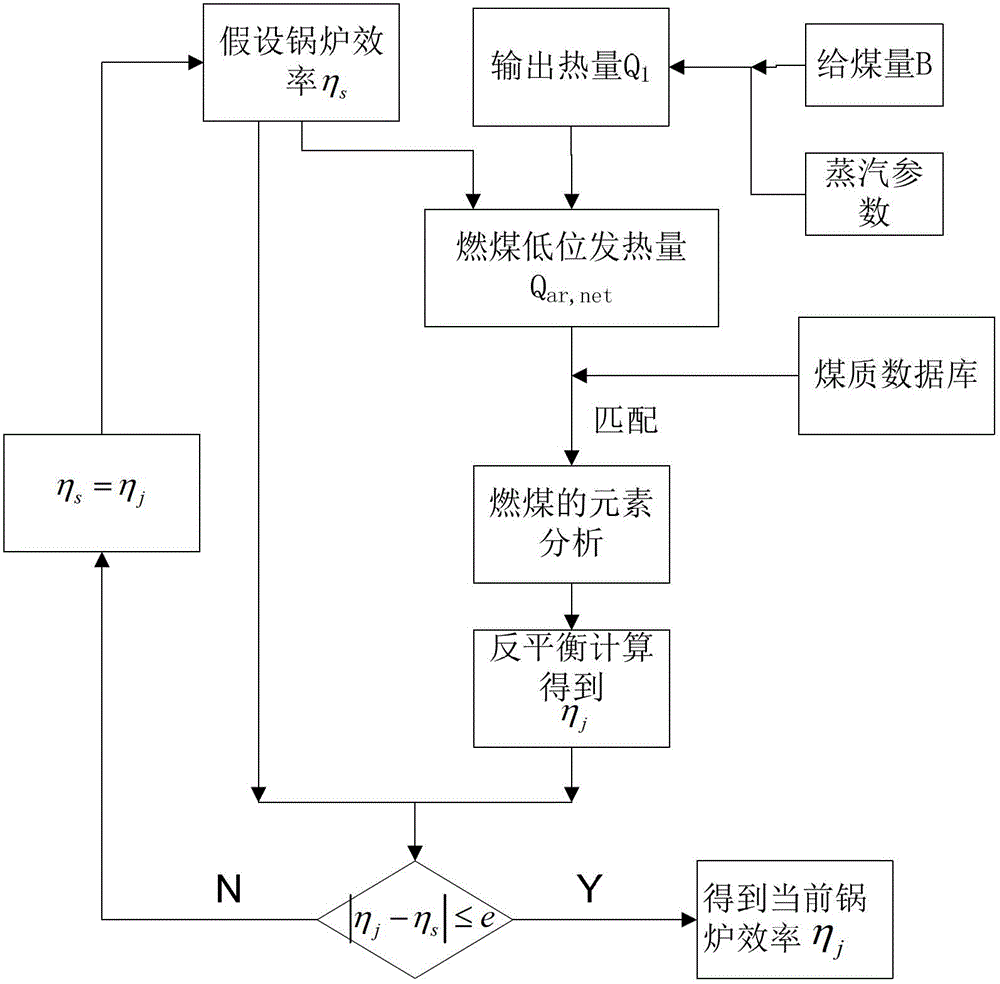

On-line monitoring method for heat efficiency of boiler based on coal quality database

InactiveCN102722657AAvoid divergenceReduce mistakesBoiler indication operationsSpecial data processing applicationsElemental analysisProcess engineering

The invention provided an on-line monitoring method for heat efficiency of a boiler based on a coal quality database. The method includes seeking the internal mapping relationship between coal heating value and coal composition by establishing the coal quality database, acquiring the coal composition by the database according to calculated coal heating value, and calculating the heat efficiency. Specifically, the method includes according to real-time output heat of the boiler during operation and coal supplying amount of the boiler, heat efficiency of the boiler is assumed, and lower heating value of fuels is acquired; lower heating values of various coals collected in the database are compared with the lower heating value of the fuels to locate the coal having consistent lower heating value with that of the fuels, real-time calculating of efficiency of the boiler is performed according to elemental analysis of the coal, the calculated efficiency of the boiler is compared with the assumed value, and if the calculated efficiency and the assumed value are within a certain error range, the calculated efficiency of the boiler is determined; and if the error is large, the assumed value is replaced by the calculated value, and iteration is performed until the error reaches an allowed range.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

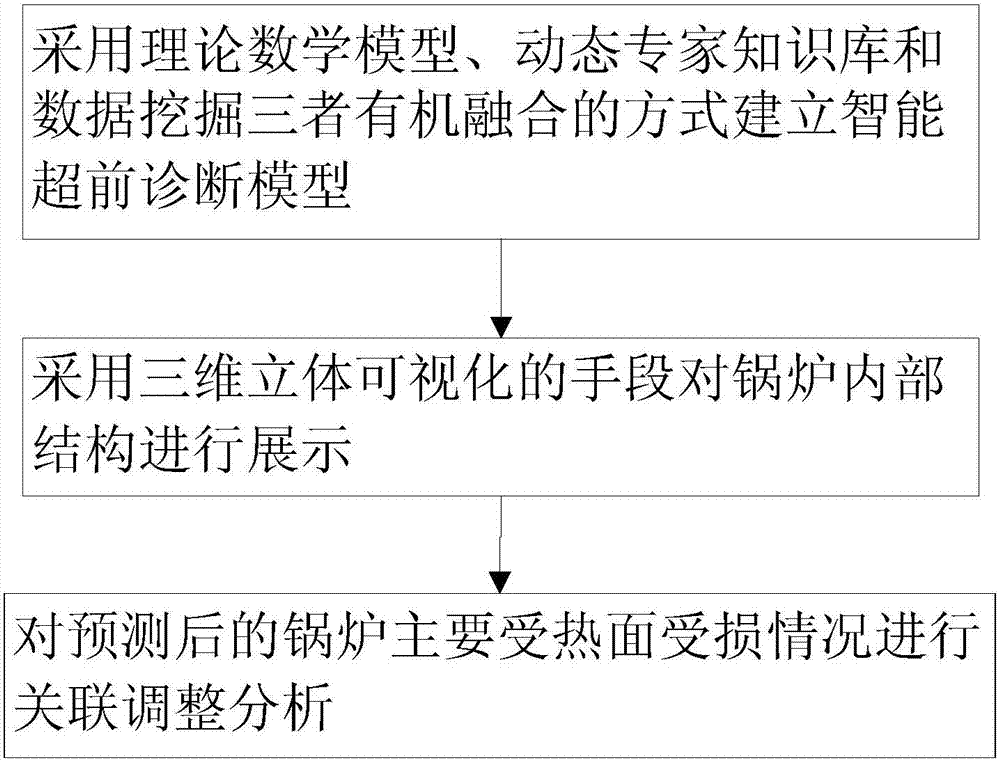

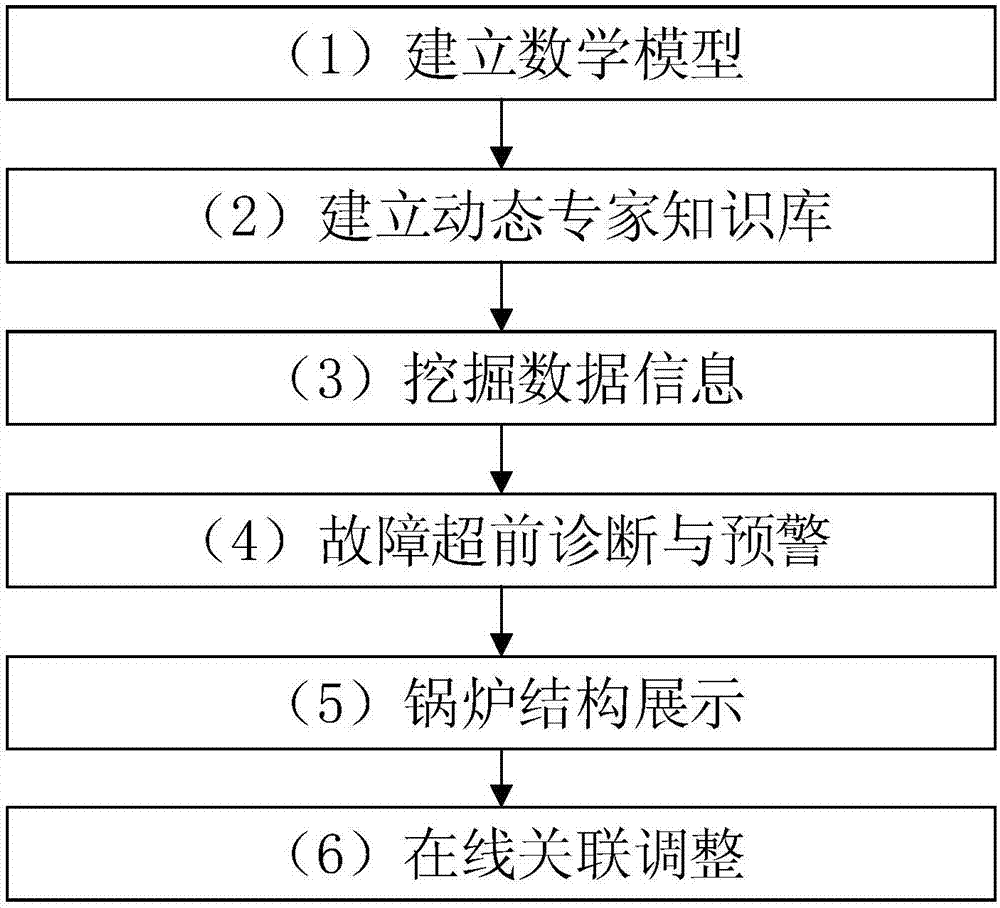

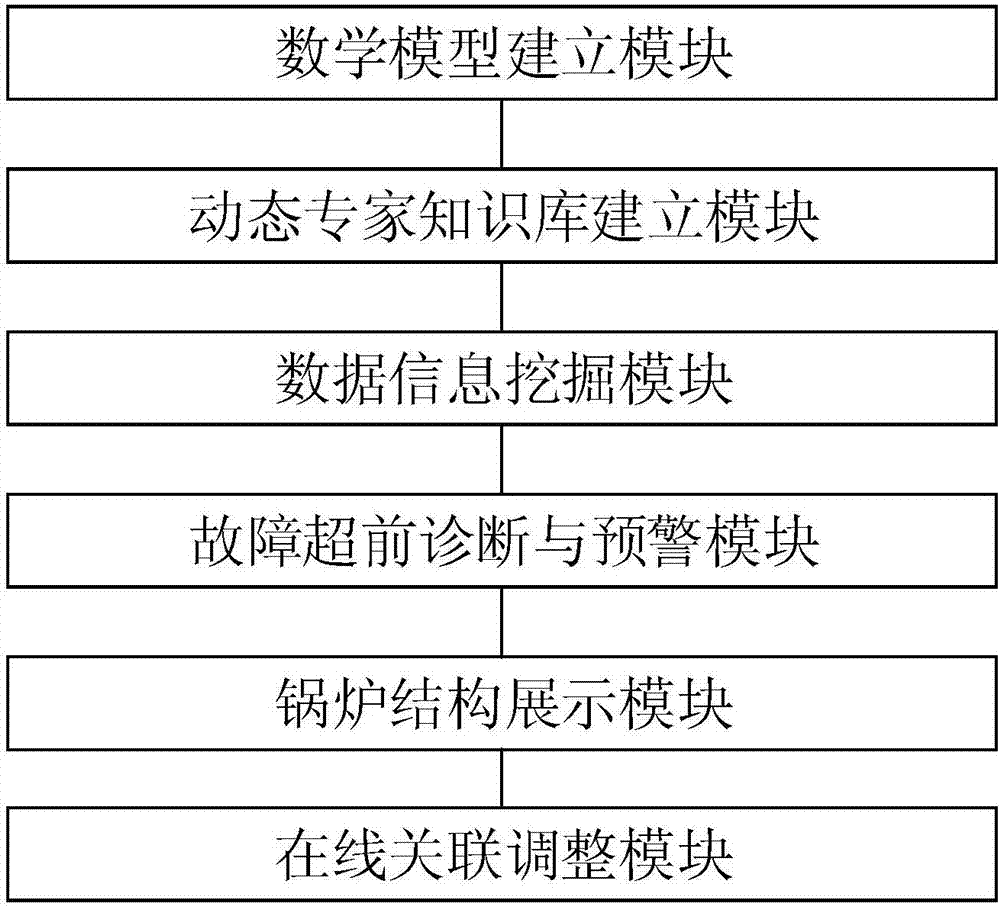

Method and system for advanced diagnosis and analysis of main heating surface of boiler

PendingCN107291944AEasy to adjust directionEasy to control the rate of deteriorationBoiler indication operationsData miningData informationMathematical model

The invention discloses a method and system for the advanced diagnosis and analysis of the main heating surface of a boiler. The method includes the steps of firstly, using the mode of the organic integration of the three of a pure mathematics model, a dynamic expert knowledge base and data mining to build an intelligent advanced diagnosis model; secondly, displaying the internal structure of the boiler by the means of three-dimensional visualization; finally, conducting correlation adjustment and analysis on the damage condition of the main heating surface of the boiler after prediction, conducting intervening adjustment on the main heating surface of the boiler after the advanced diagnosis, and forming closed loop management so as to avoid the occurrence of boiler failures. The system includes a mathematical model building module, a dynamic expert knowledge base building module, a data information mining module and an advanced fault diagnosis and early-warning module. The method and system can predict the future damage conditions of the four pipes of the boiler, and therefore taking measures in advance is convenient so as to reduce or avoid the occurrence of pipe explosion accidents.

Owner:济南作为科技有限公司

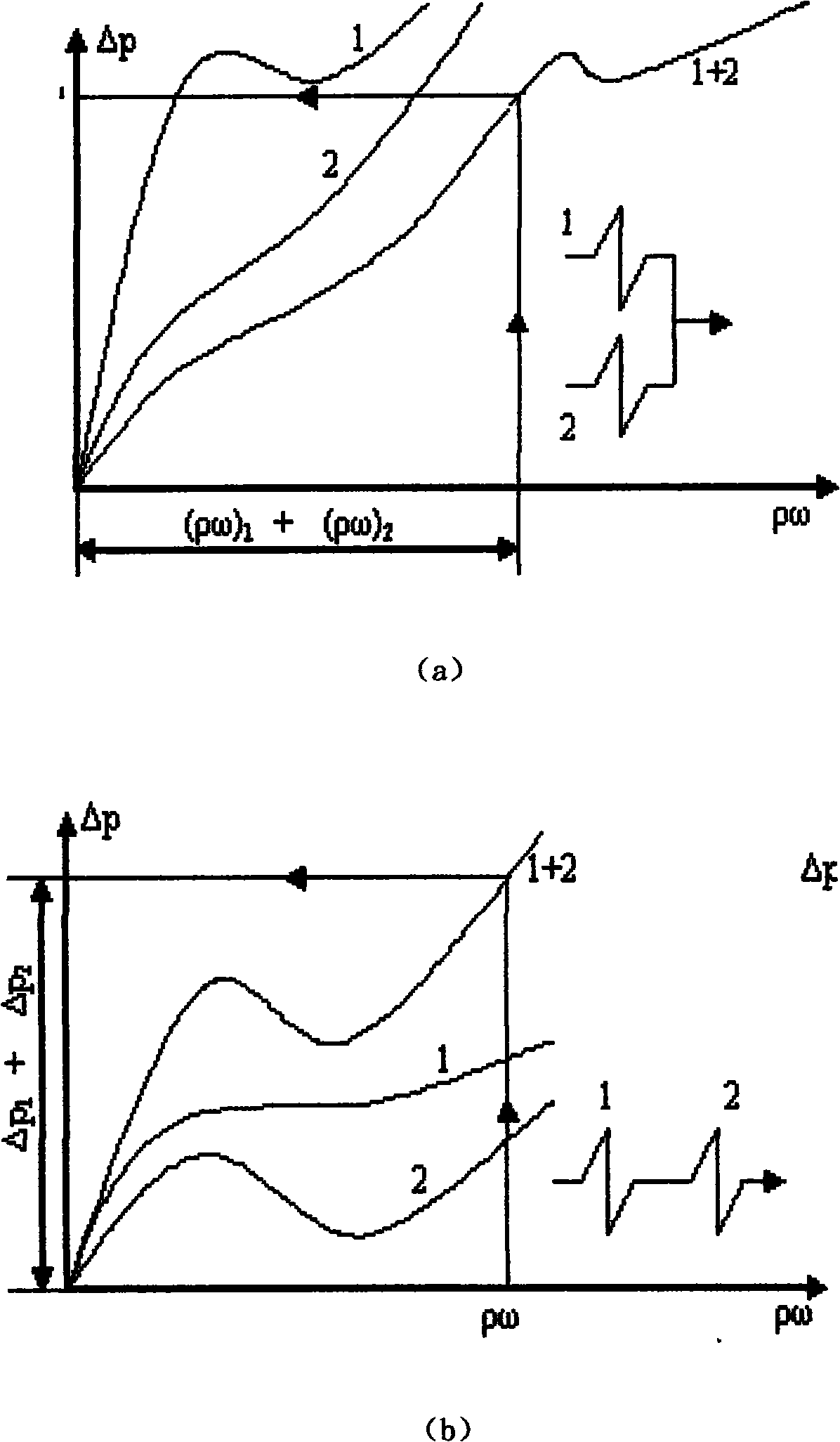

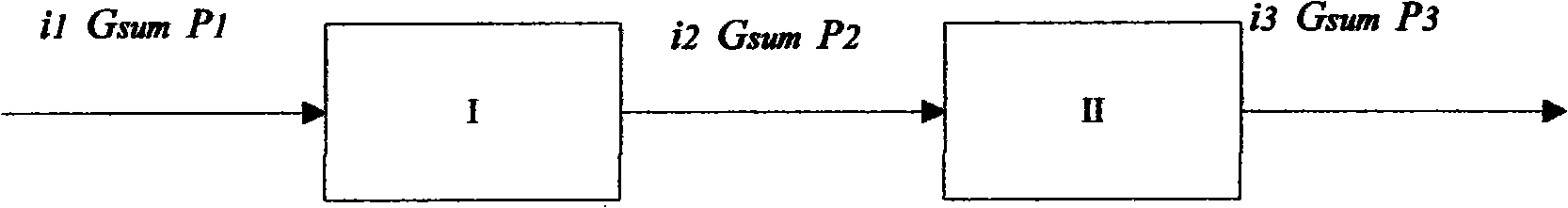

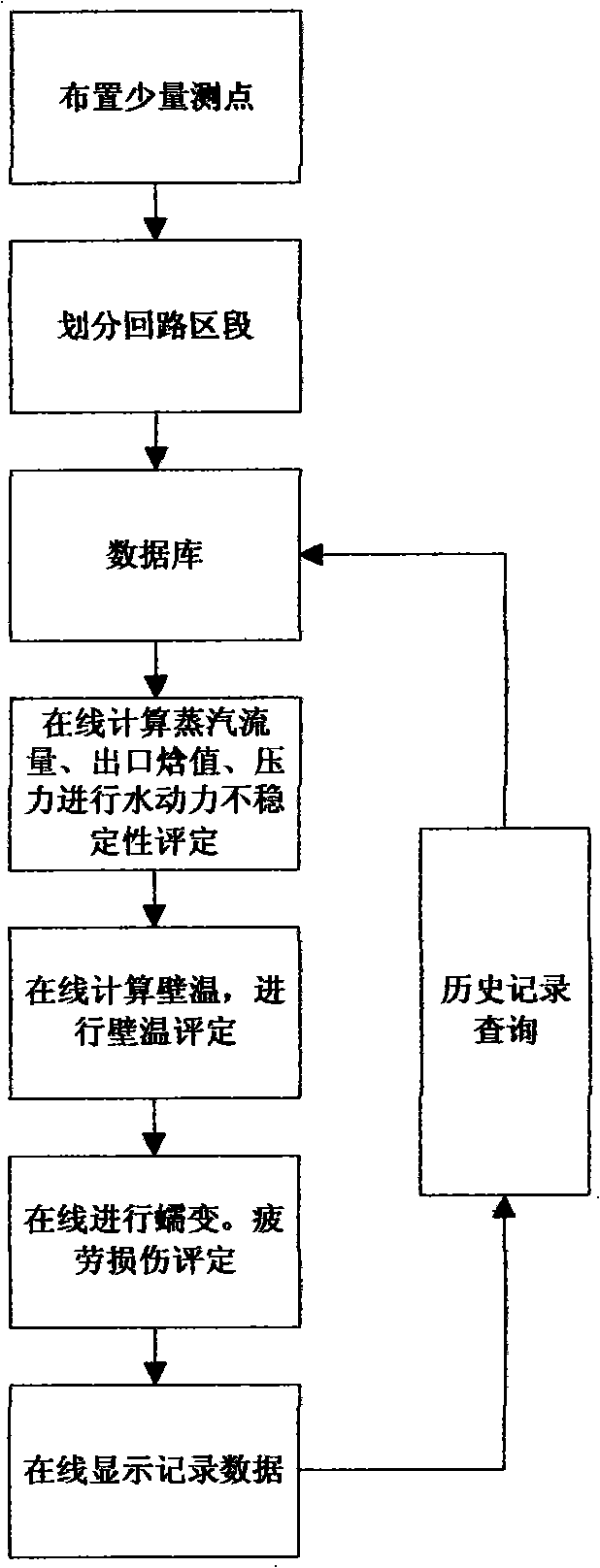

An on-line safety assessment method of water wall

InactiveCN101551650AHigh precisionReduce occupancyProgramme controlComputer controlInstabilityEngineering

The invention relates to an on-line safety assessment method of a water wall, comprising the following steps: firstly arranging a few test points at the pipe section with flow heat transfer representativeness in each radiated area for being combined with the existing inlet and outlet test points outside the furnace, monitoring characteristic parameters in the water wall pipes of the station boiler as calculation and checking point, inputting the characteristic parameters into a computer for processing, and computing the parameters such as the flow rate, the pressure of the inlet and outlet, the enthalpy value, the temperature value of furnace inner wall of each section of pipe along the length, the amplitude value of the variation of stresses and the like of all pipes in the group on line and in real time through a flow heat transfer law so as to judge whether unsafe factors including the instable hydrodynamic force, excess temperature, creep fatigue damage and the like occurs. The computed result is displayed in real time, and the related data is recorded as the basis for judging whether the water wall is in safe operation, thereby realizing optimized running of the equipment, arranging examination and maintenance management according to the state and fully implementing the examination and reparation based on the condition of the equipment.

Owner:SHANXI SHENGSHI HUIHUANG INTELLIGENT TECH

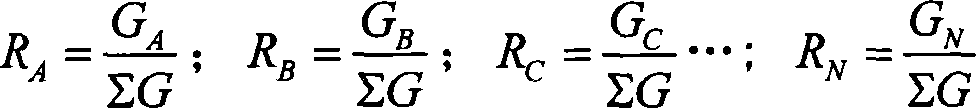

Method for carrying out real-time furnace monitoring for pulverized-coal boiler-superheater reheater

The invention relates to a method for carrying out real-time furnace monitoring for a pulverized-coal boiler-superheater reheater, which is the method for accurately extrapolating furnace smoke-gas heat-discharging nonuniformly-quantified indexes through an external inlet-outlet steam-temperature measured value outside the superheater reheater. The method comprises the following steps of: firstly obtaining the steam-flow deviation coefficients of pipe screens along the width of a furnace through the structure and the parameter of the superheater reheater; then computing the steam enthalpy-increasing deviation coefficients among all the screens along the width of the furnace through temperature-measuring points installed outside the furnace; multiplying the two coefficients of the same pipe screen to obtain the smoke-gas heat-discharging deviation coefficient of the screen along the direction of the width of the furnace, wherein the smoke-gas heat-discharging deviation coefficient represents the nonuniform degree of the smoke-gas heat-discharging strength along the width of the furnace; and displaying the heat-discharging strength situations of smoke gas along with the difference of working conditions in the furnace to provide important references for the burning adjustment of a boiler.

Owner:SHANGHAI WANGTE ENERGY RESOURCE SICENCE & TECH

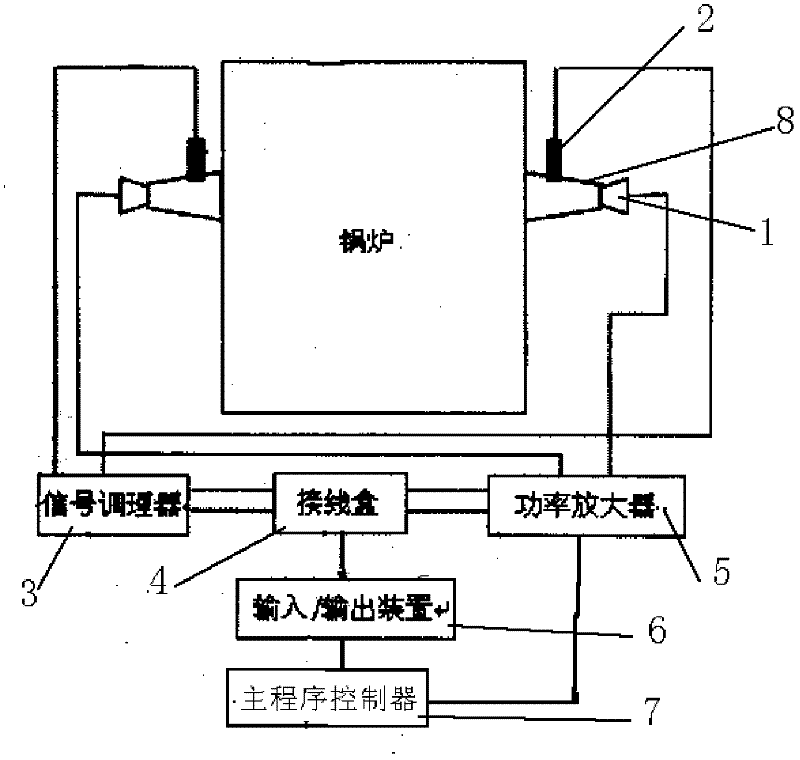

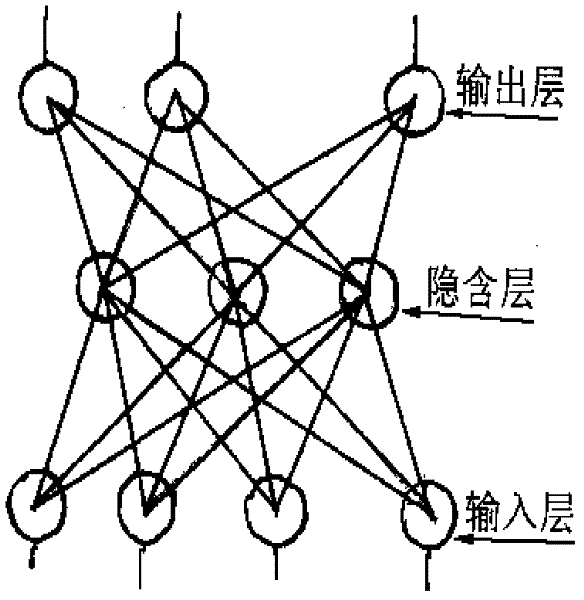

Monitoring system and monitoring method for soot on boiler convection heating surface

InactiveCN102588943AGuaranteed uptimeAvoid unplanned shutdownsBoiler indication operationsSlagData acquisition

The invention discloses a monitoring system and a monitoring method for soot on a boiler convection heating surface, which belong to the technical field of fuel burning on-line monitoring. A plurality of pairs of sound wave generators and sound wave receivers are installed on corresponding conduits on the peripheral plane of a boiler water-cooled wall, signal output of the sound wave receivers is connected with a signal regulator, the signal regulator is connected with a junction box through a data line, and the junction box is connected to a main machine programming controller through an input / output device. The monitoring system for the soot on the boiler convection heating surface is based on acoustical temperature measurement and a neural network. The monitoring system and the monitoring method for the soot on the boiler convection heating surface are respectively applied to the neural network and a data base, potential heat absorption capacity during cleaning of the boiler convection heating surface is predicted through the neural network, a data base system reads data in a data acquisition station (DAS) of a power station in fixed time, and finally a soot structure is conveyed to a main machine interface. The state of soot formation or slag build-up on the boiler heating surface can be timely learned, measures are taken in real time, normal running of a thermal generator set boiler is guaranteed, the running is safe, and accidental boiler shutdown accidents are avoided.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com