Patents

Literature

361results about "Boiler supporting/setting arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

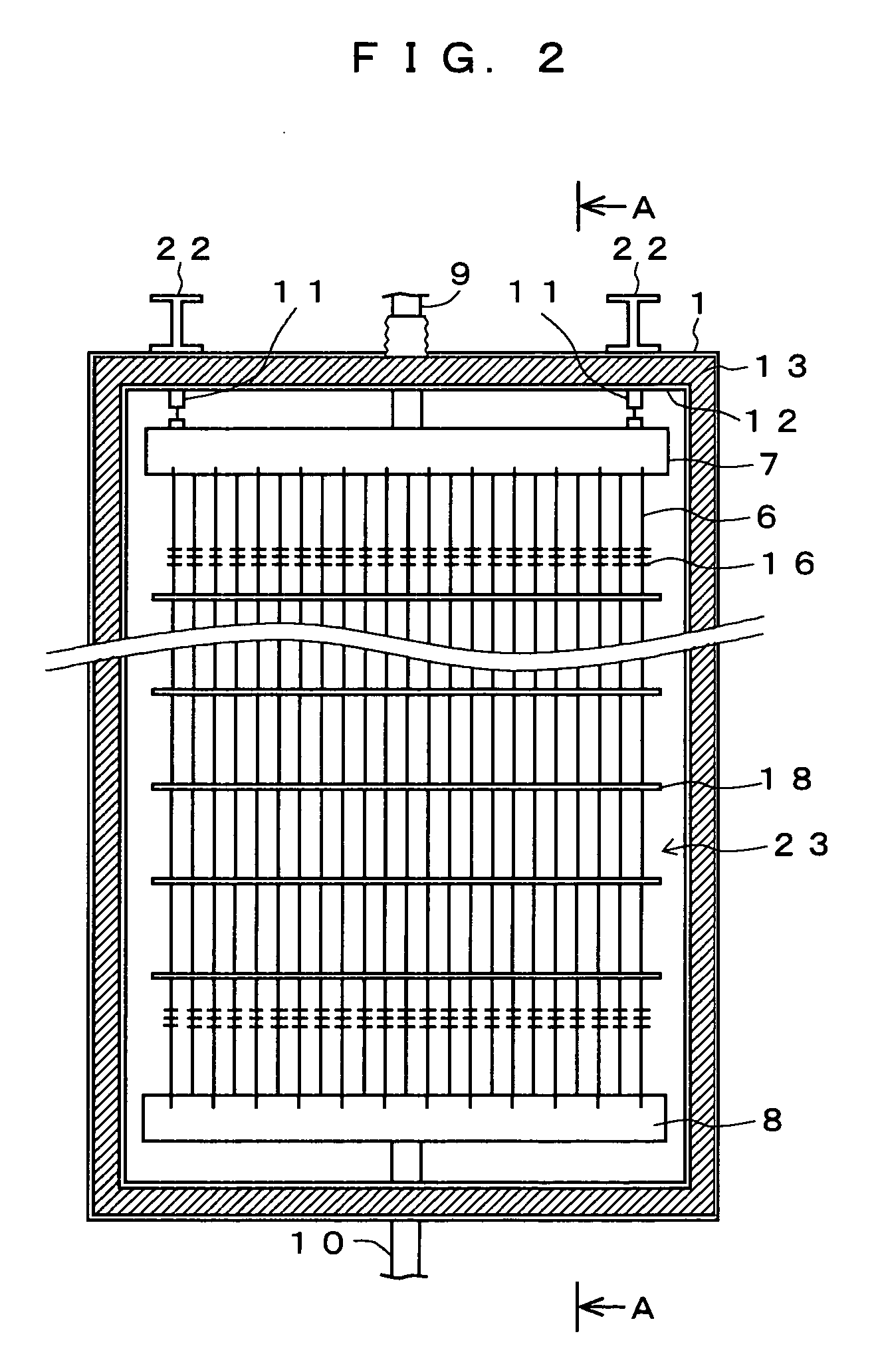

Heat exchanger tube panel module, and method of constructing exhaust heat recovery boiler using the same

InactiveUS20070119388A1Easy to installShort timeBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringRecovery boiler

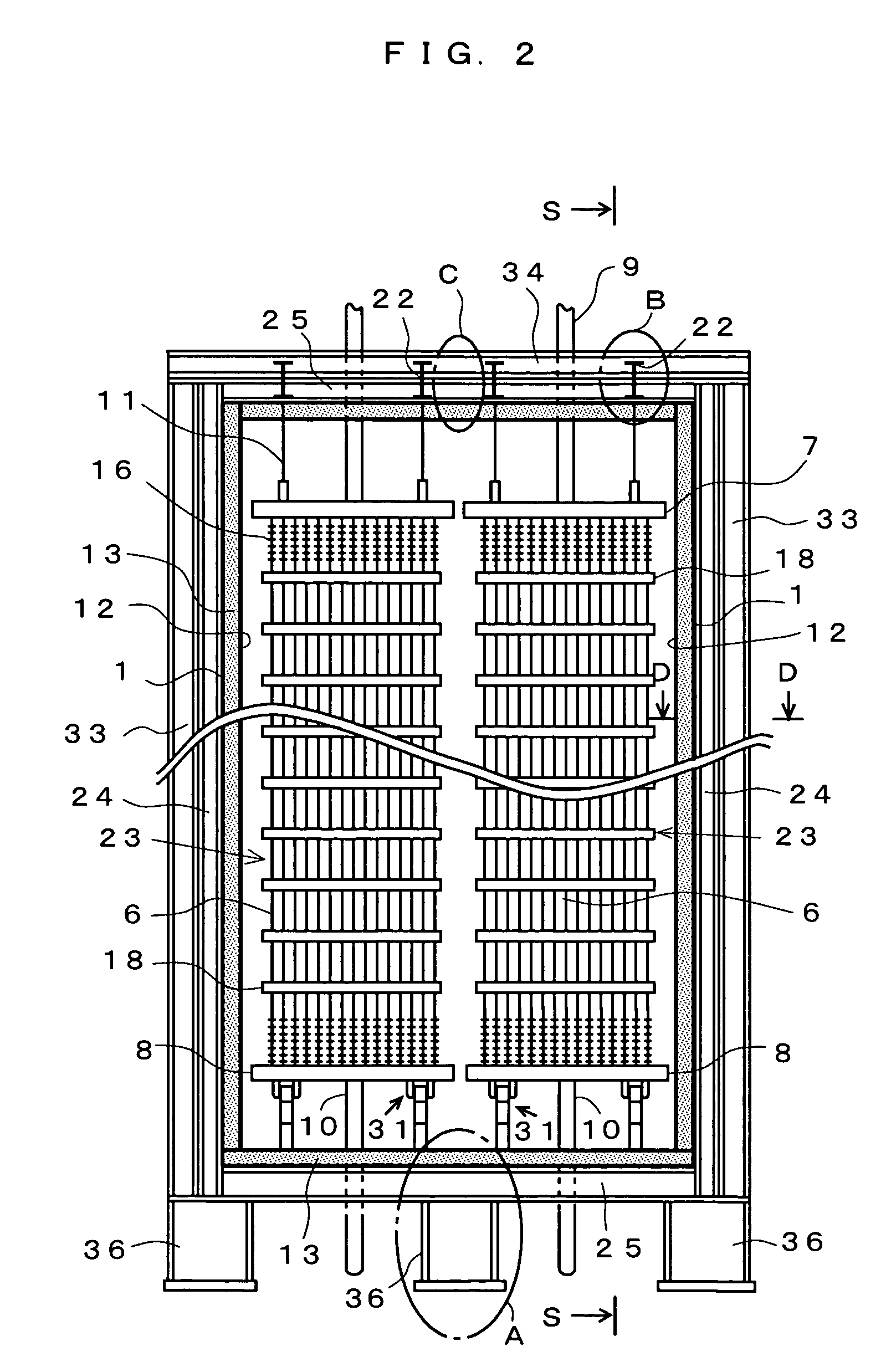

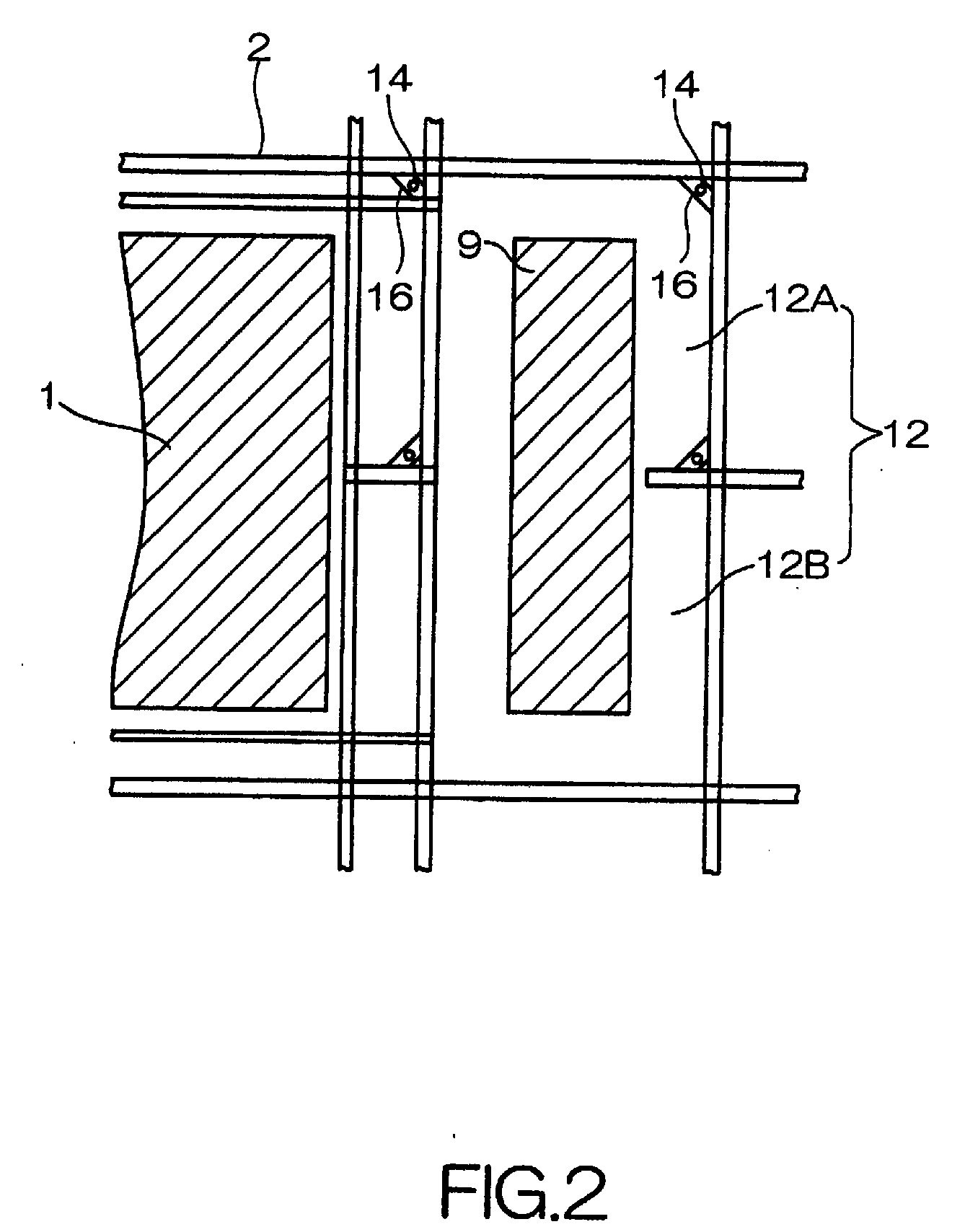

A necessary size and number of modules each obtained by housing a member including heat exchanger tube panels each comprising a heat exchanger tube bundle and headers for the heat exchanger tube bundle, an upper casing of an exhaust heat recovery boiler (HRSG), provided above the heat exchanger tube panels, heat insulators, and heat exchanger tube panel support beams provided on the upper surface of the upper casing into a transportation frame, are prepared according to design specifications of the HRSG, and side casings and a bottom casing except for the ceiling part casing are constructed in advance at a construction site of the HRSG, and the modules are suspended from above between adjacent support beams of the ceiling part to dispose the heat exchanger tube panel support beams of the modules at the set heights of the ceiling part support beams, and the support beams and the ceiling part support beams are connected and fixed via connecting steel plates, whereby the respective modules are transported to the HRSG construction site and can be easily constructed.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

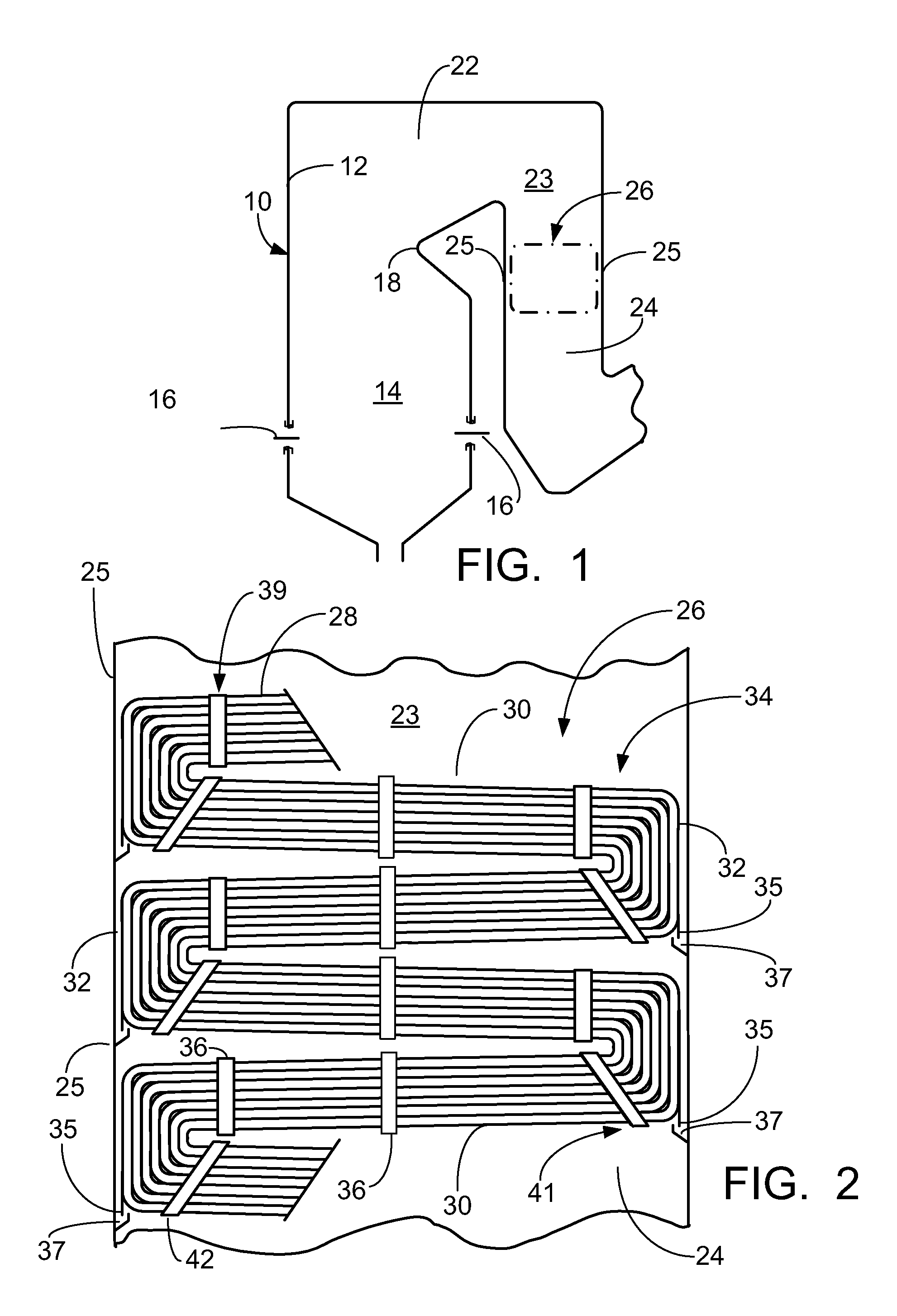

Anti-vibration tube support

InactiveUS20050279487A1Reduce the possibilityEasy to makeBoiler supporting/setting arrangementsSafety devices for heat exchange apparatusEngineeringMechanical engineering

Owner:EXXON RES & ENG CO

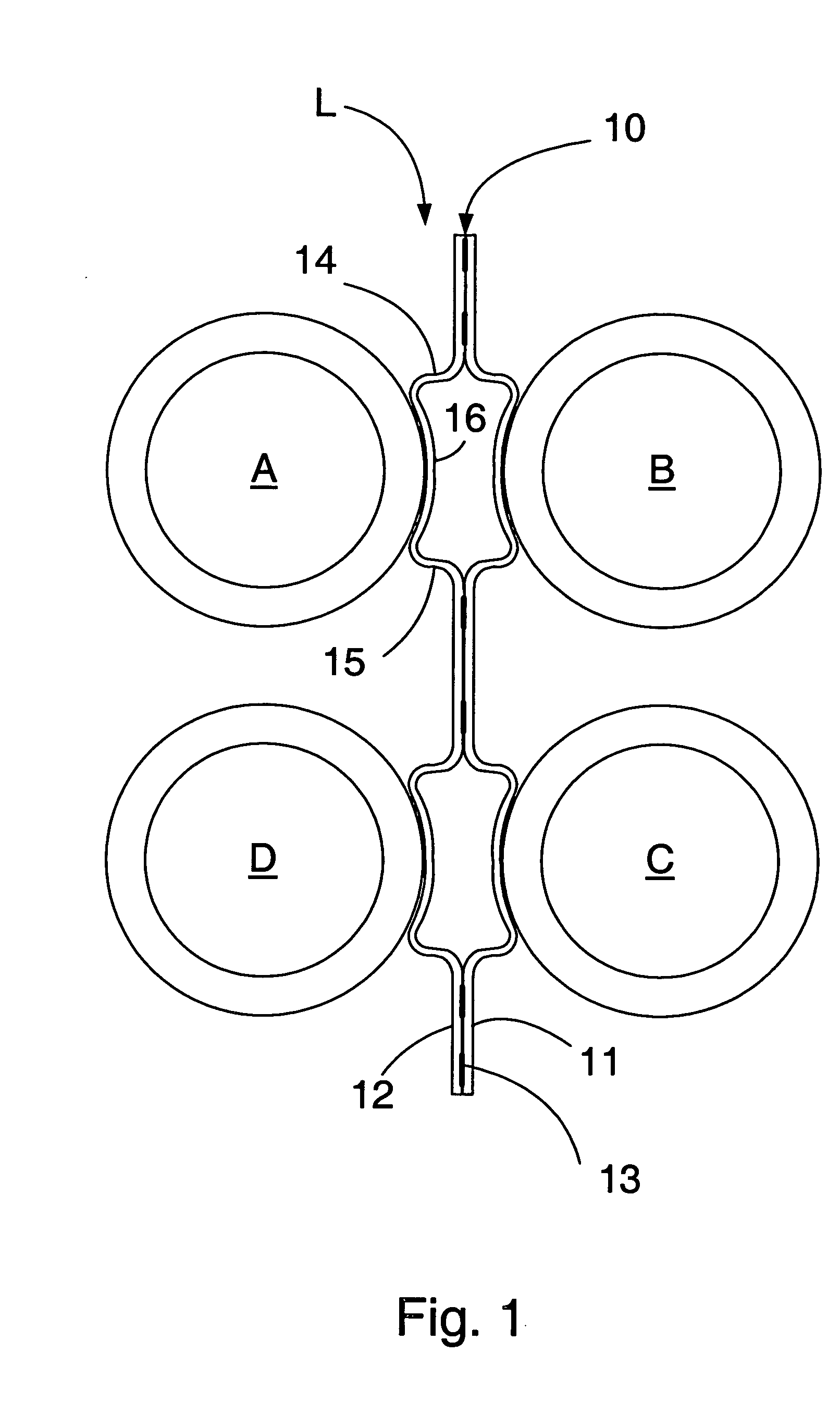

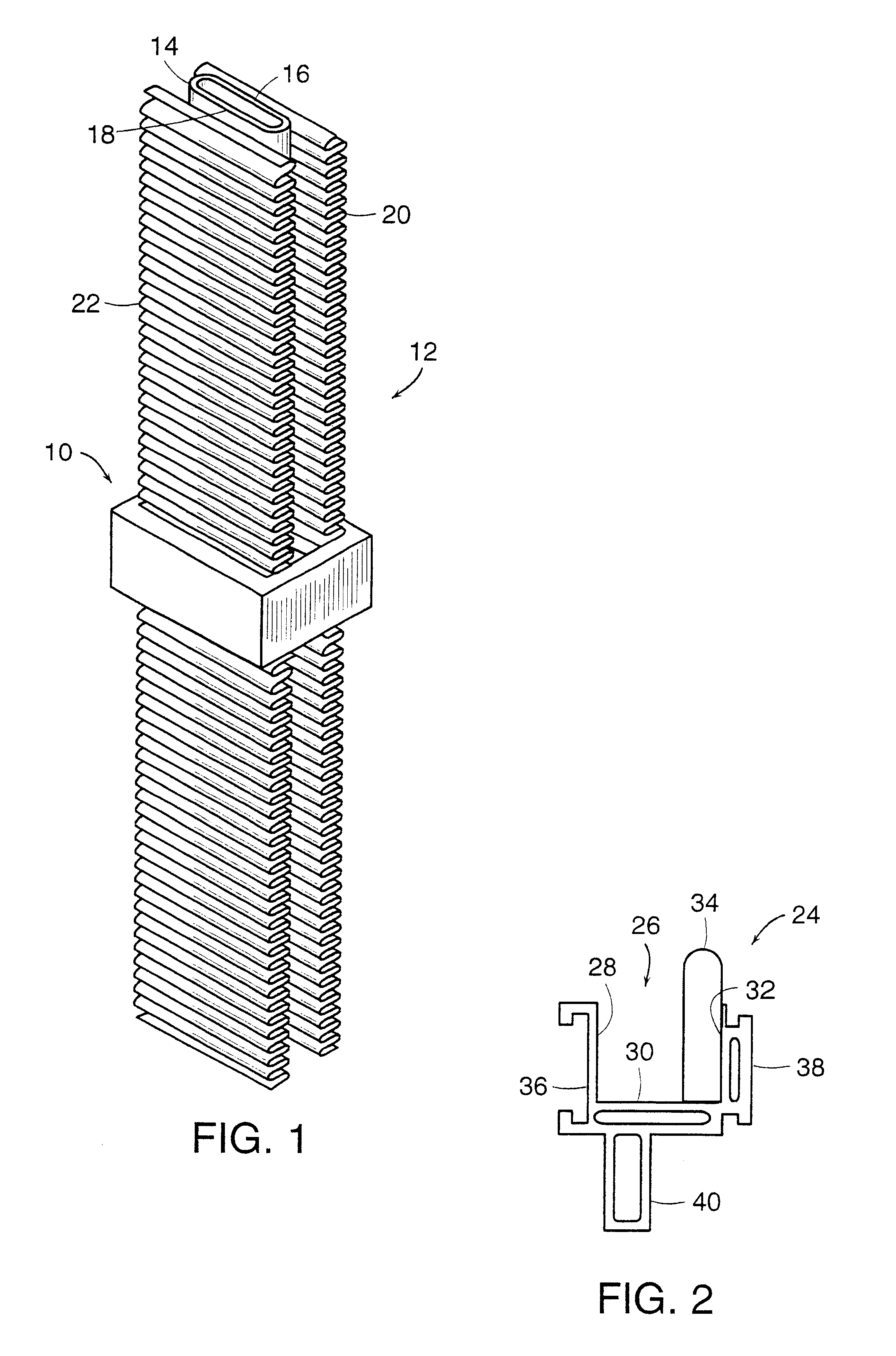

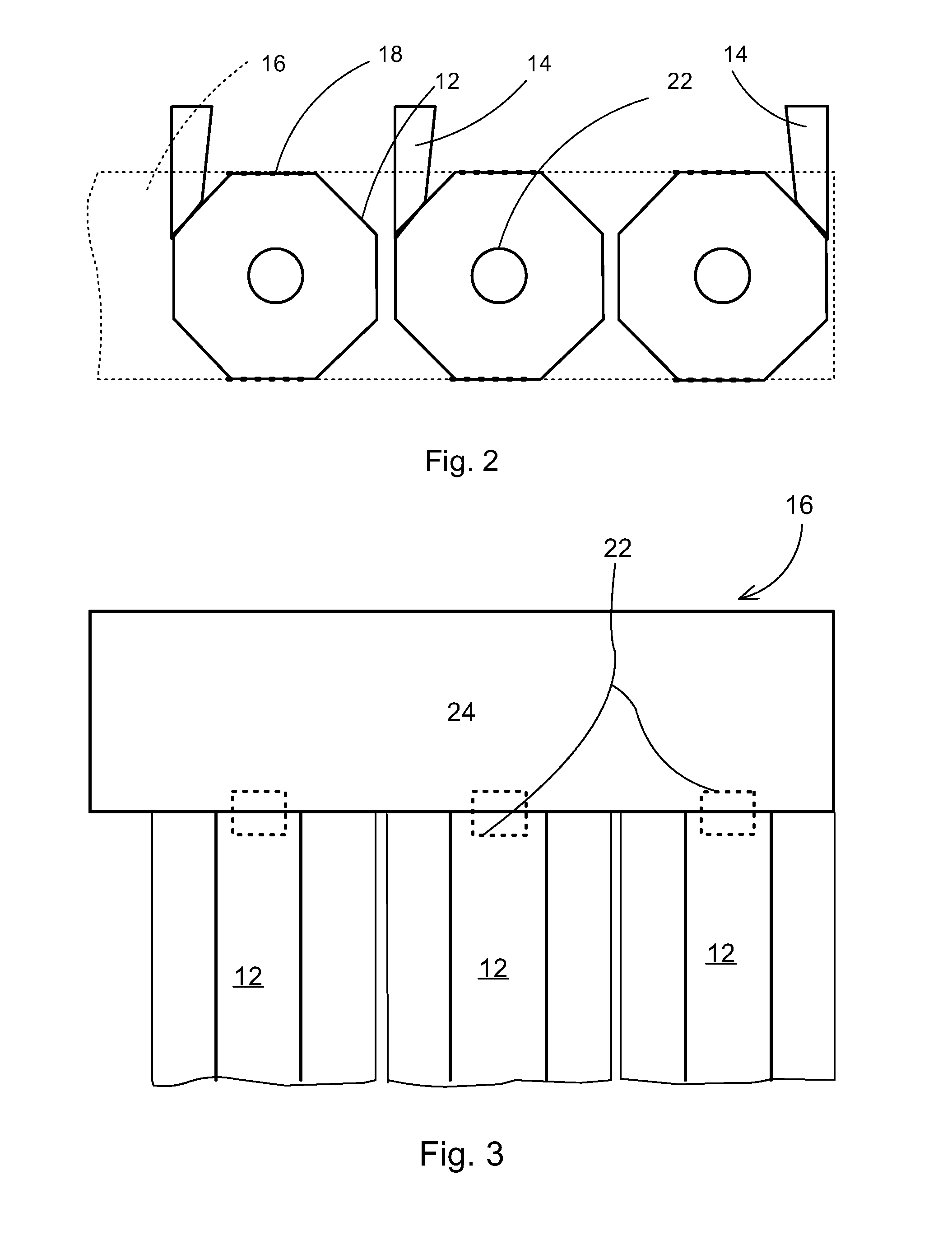

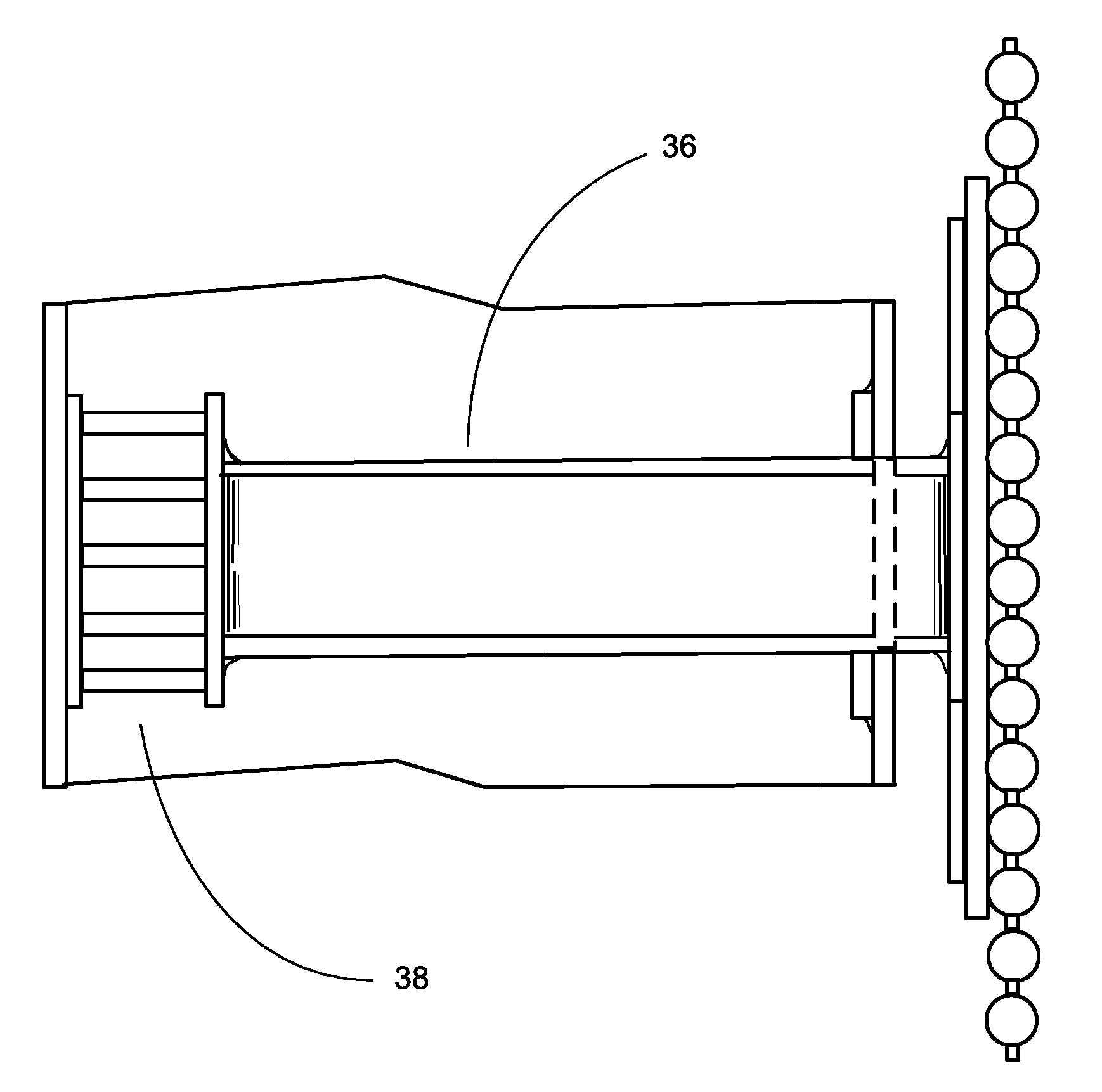

Support for heat exchanger tubes

InactiveUS6357513B1Boiler supporting/setting arrangementsHeat exchanger casingsEngineeringHeat exchanger

A novel individual support for a heat exchanger is disclosed which frictionally engages the outer surface of a tube-and-fin assembly and provides for interlocking of the supports. The novel support includes an alignment probe to facilitate installation and to prevent axial movement of the support.

Owner:L & M RADIATOR

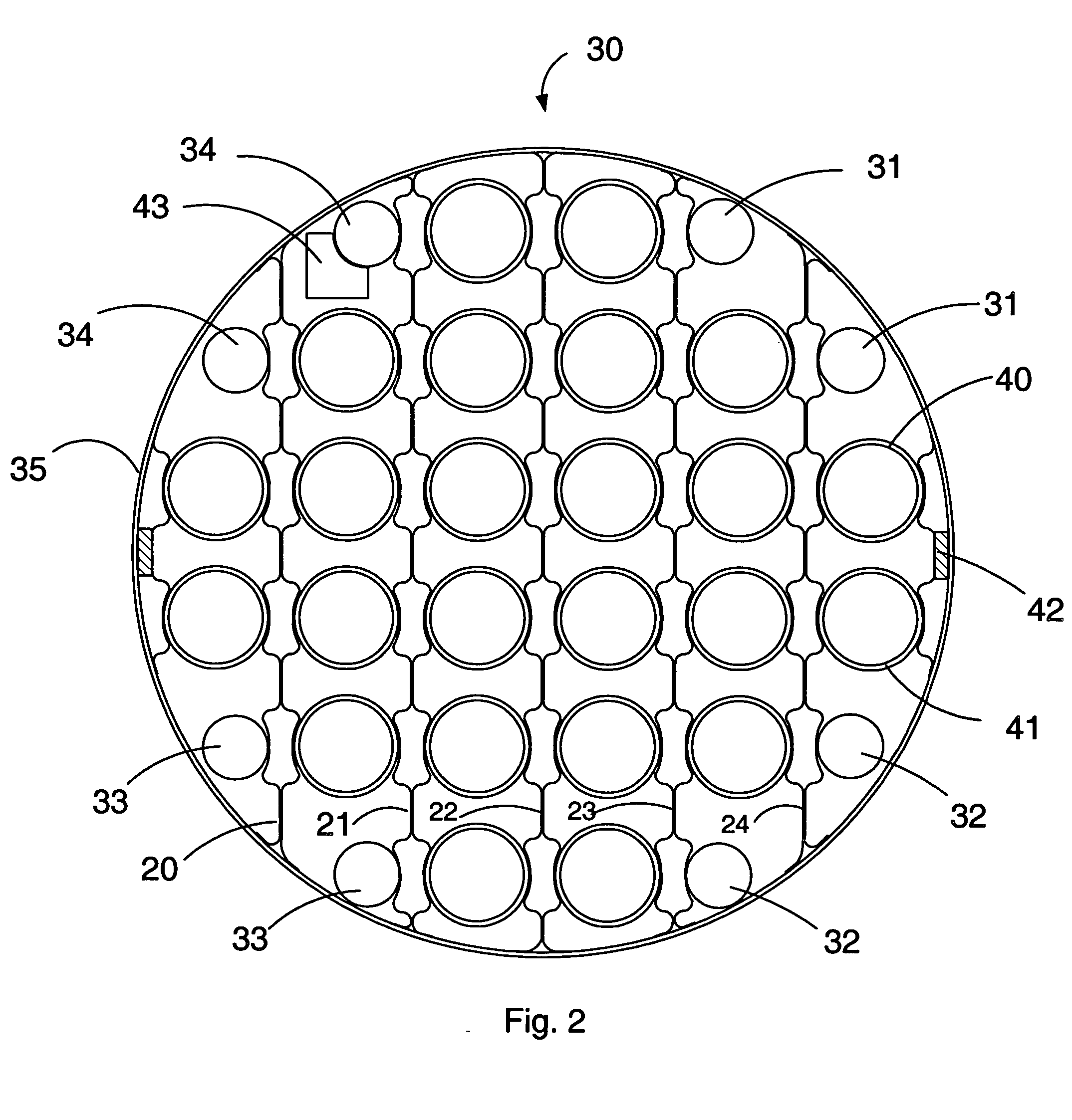

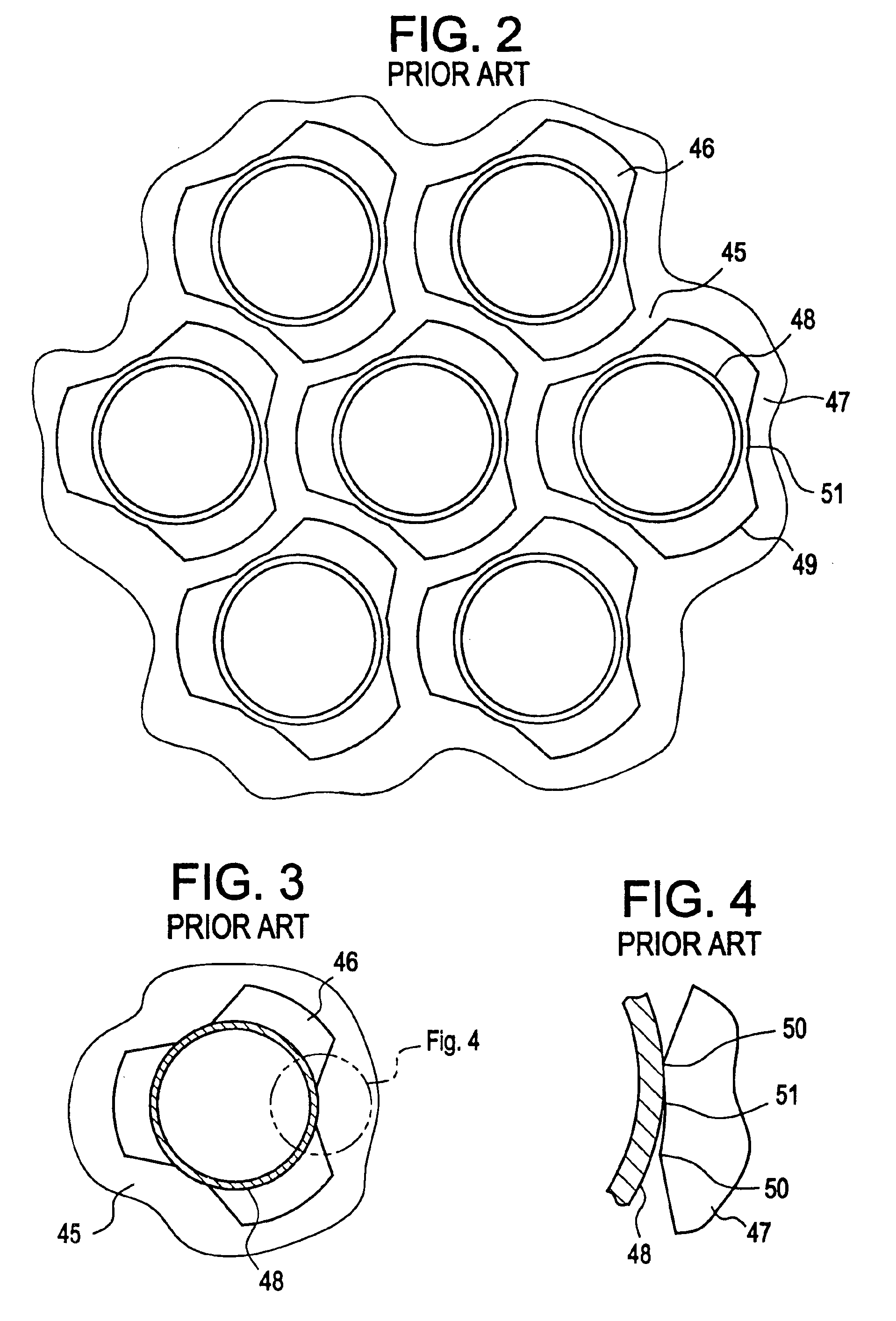

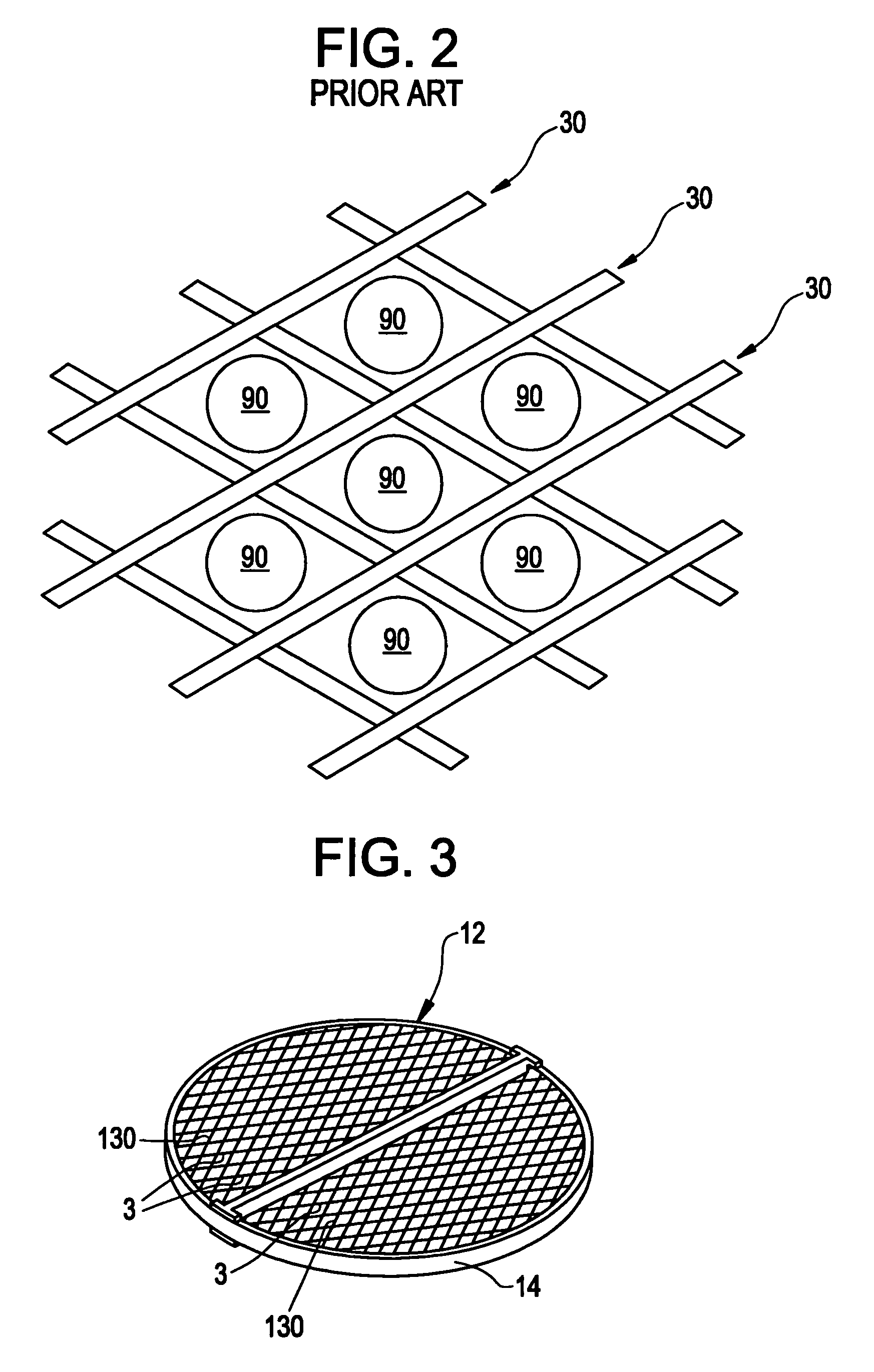

Heat exchanger tube support structure

InactiveUS6914955B2Minimized pressure dropReducing local turbulenceBoiler supporting/setting arrangementsFuel element assembliesParticulatesEngineering

A support plate for retaining tube array spacing within a heat exchanger tube and shell structure. The support plate having a plurality of individual tube receiving apertures formed therein. Each aperture has at least three inwardly protruding members and bights are formed therebetween when the tube associated therewith is lodged in place to establish secondary fluid flow through the support plate. The inwardly protruding members terminate in flat lands that restrain but do not all contact the outer surface of the respective tube. These flat lands minimize fretting wear and eliminate potential gouging of the outer wall of the tube. The plate wall forming each aperture has an hourglass configuration which, inter alia, reduces pressure drop, turbulence and local deposition of magnetite and other particulates on the support plates.

Owner:BWXT CANADA

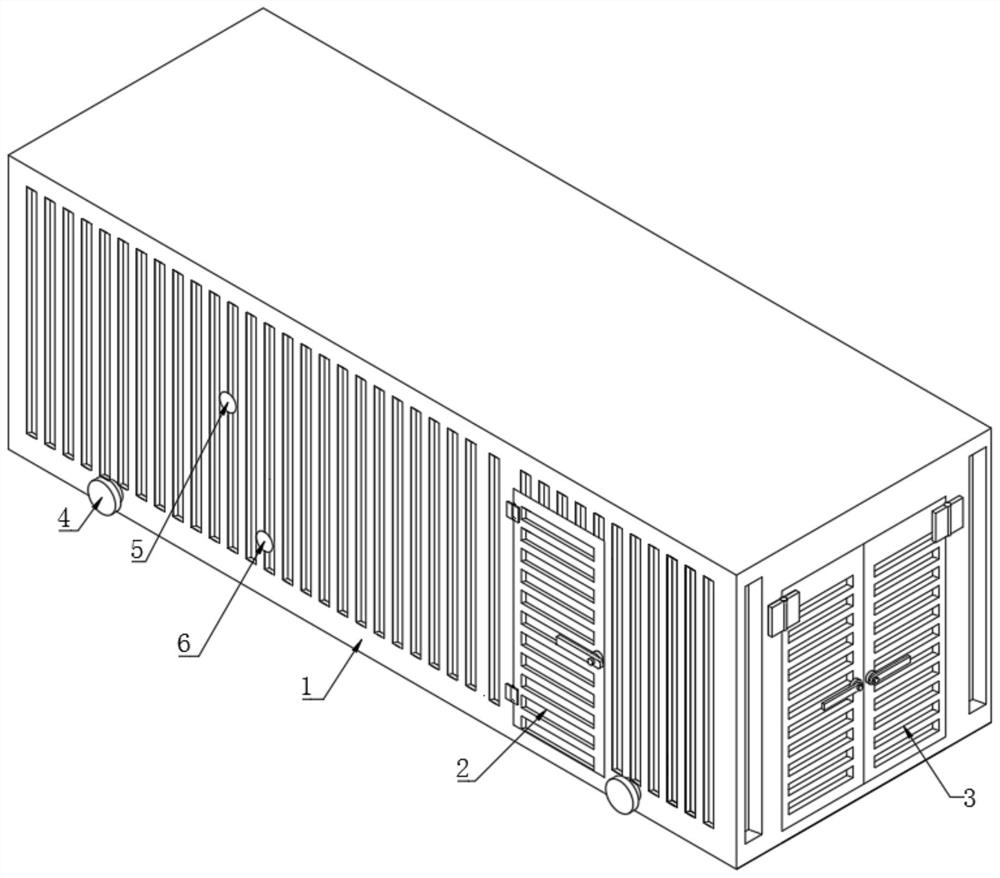

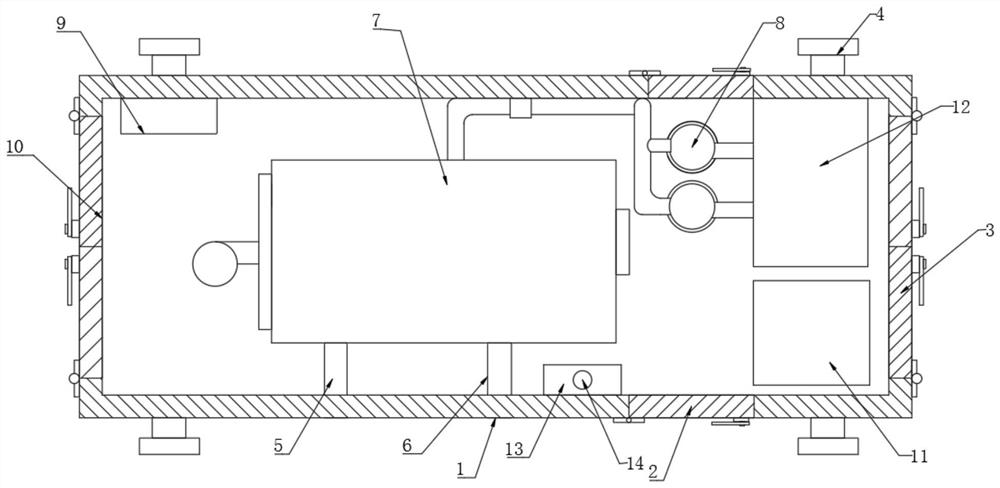

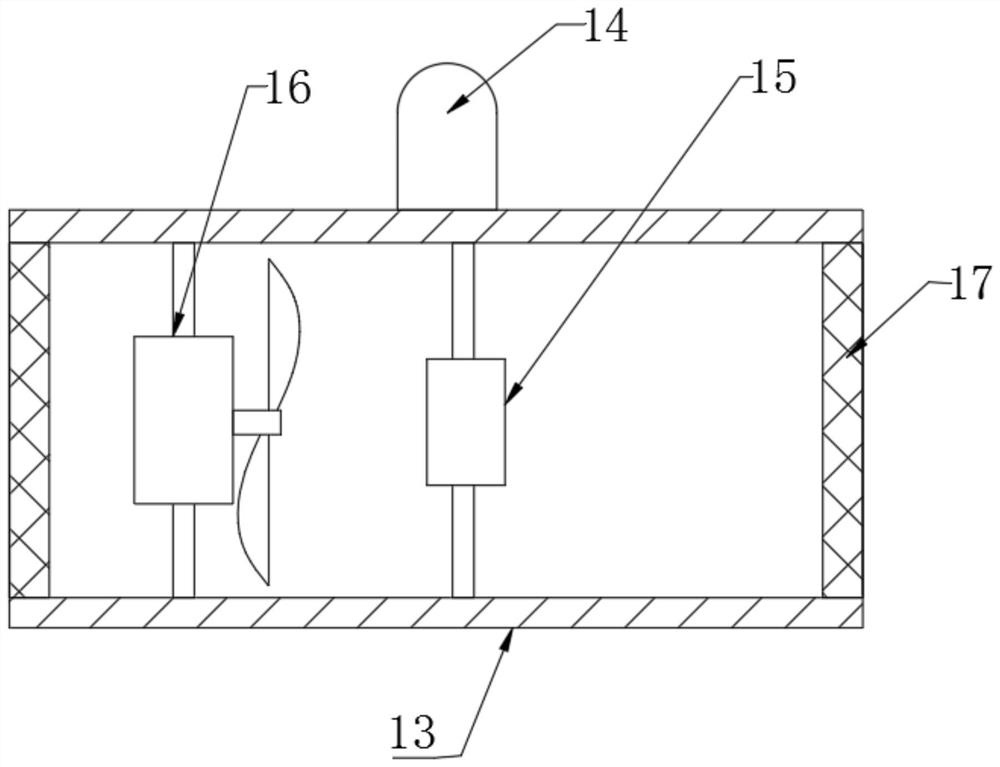

Skid-mounted movable boiler room

InactiveCN113266815ASpeed up the flowEasy to moveFluid heatersBoiler supporting/setting arrangementsToxic gasWater storage

A skid-mounted movable boiler room comprises a container, wherein production doors are hinged to two ends of the left side of the container, a distribution box is fixedly connected to the inner wall of the left side of the container, a boiler is fixedly connected to the lower end of the middle in the container, a water storage tank is fixedly connected to the front end of the right side in the container, and a daily oil tank is fixedly connected to the rear end of the right side in the container. The device is simple in structure, an exhaust fan rotates to introduce air in the container into the container, and when a toxic gas sensor detects harmful gas, an alarm box gives an alarm to timely remind a worker to open a rear access door and a side access door to accelerate air flow, so that the boiler can work stably in the container. When the boiler needs to be moved, a rope is sleeved with a reinforcing lifting lug, a crane is used for pulling the rope, the container is driven to move to a truck, the truck moves to a proper place to work, and therefore, the boiler can be conveniently moved.

Owner:宋占友

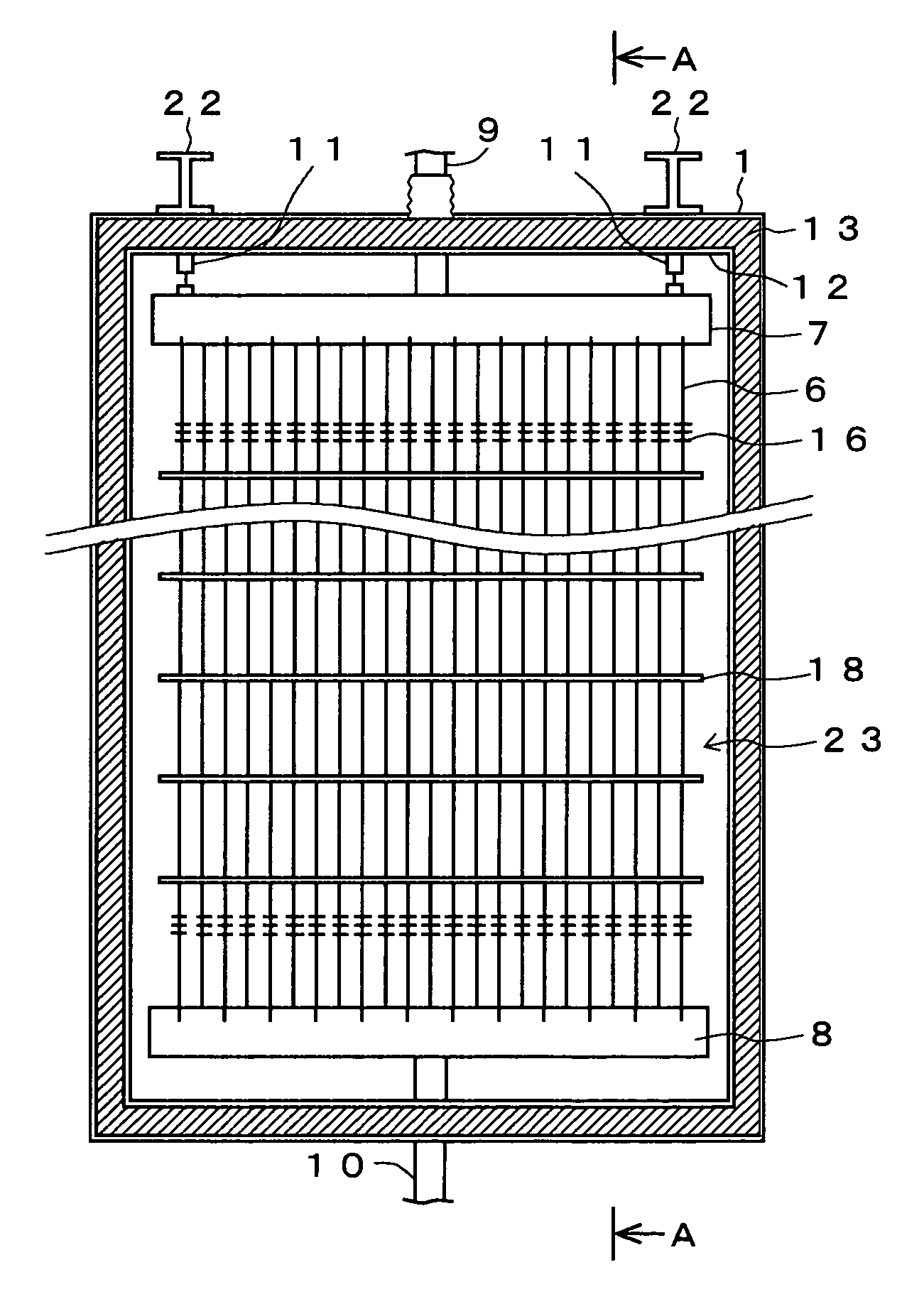

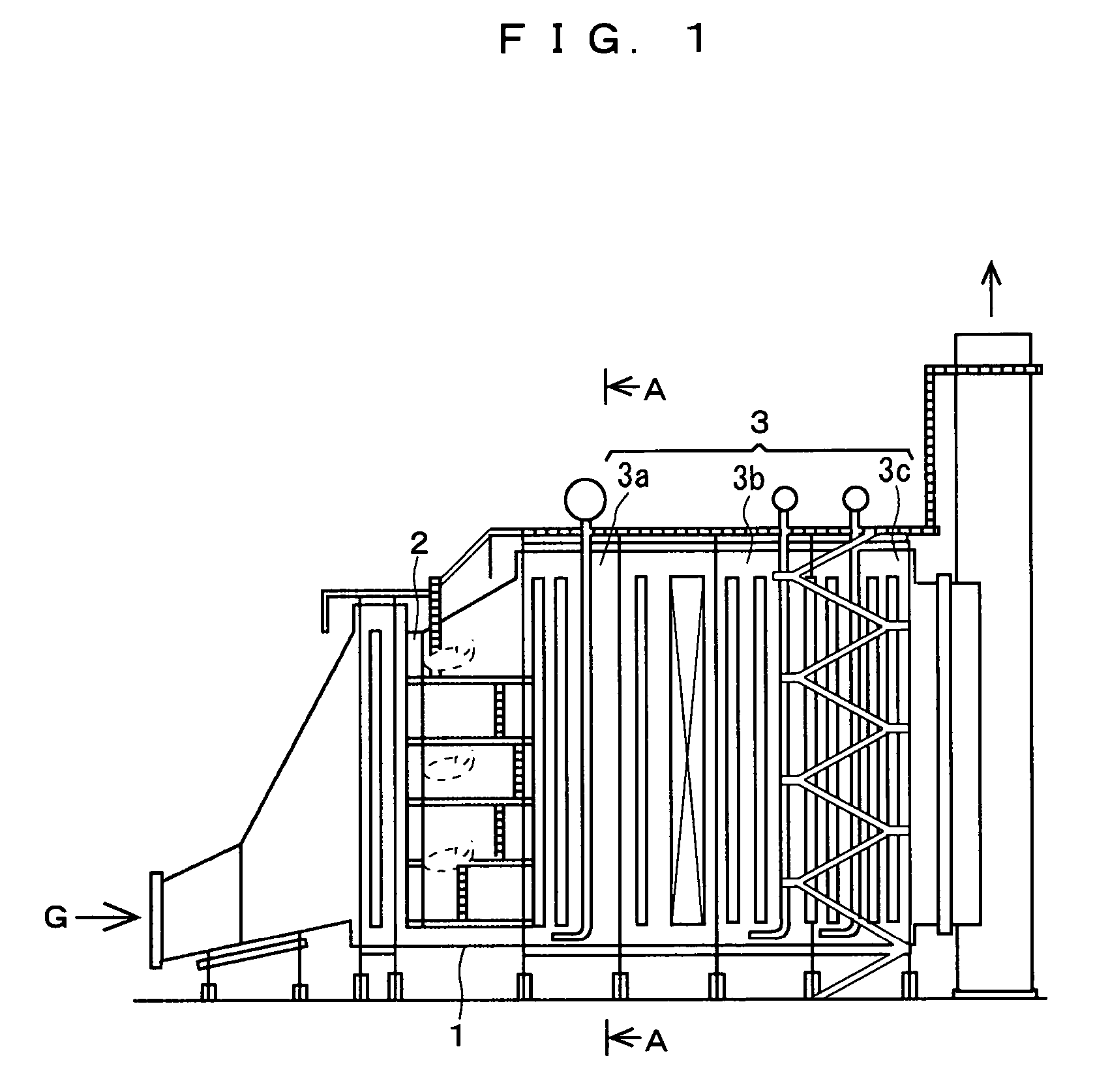

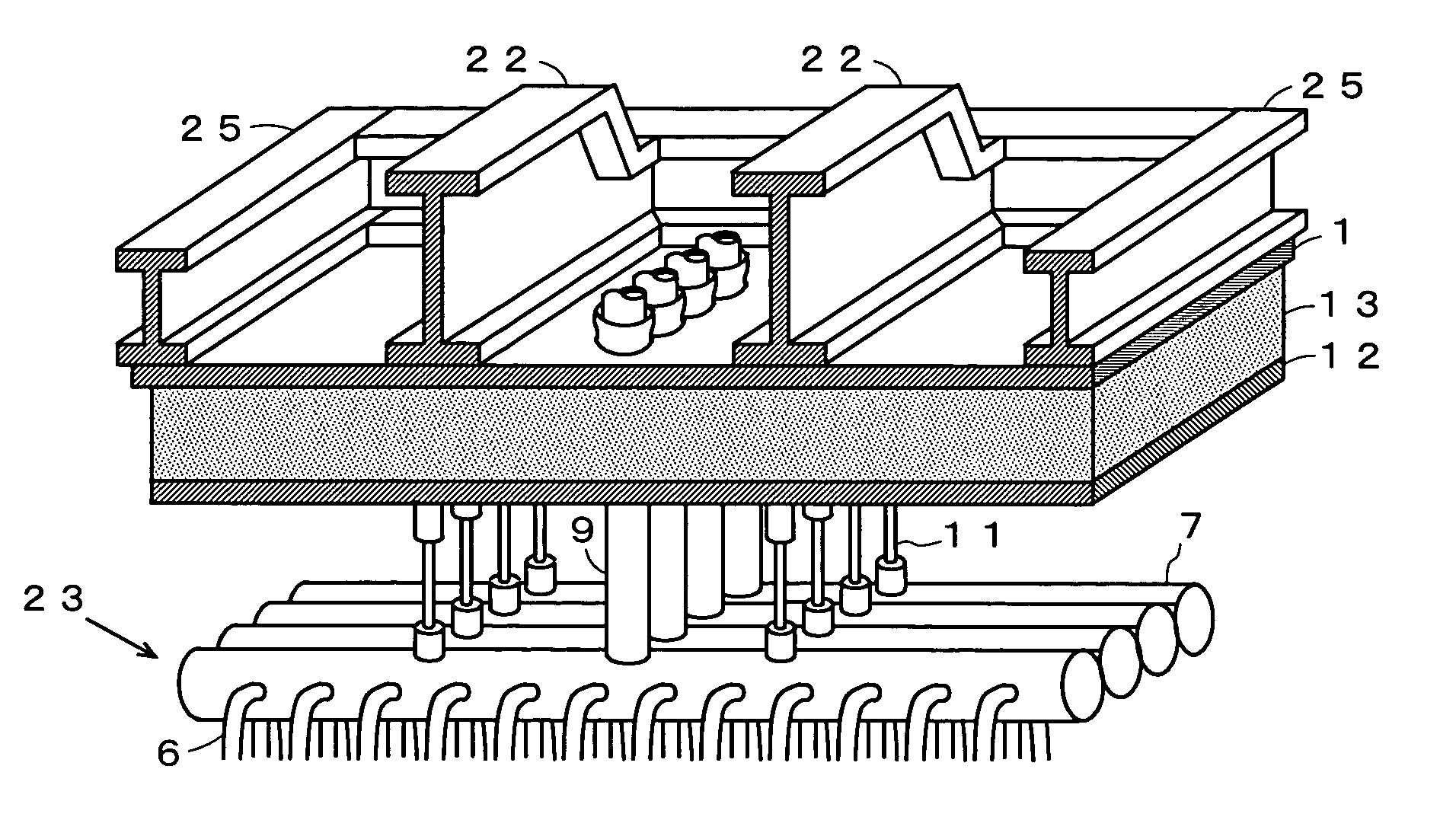

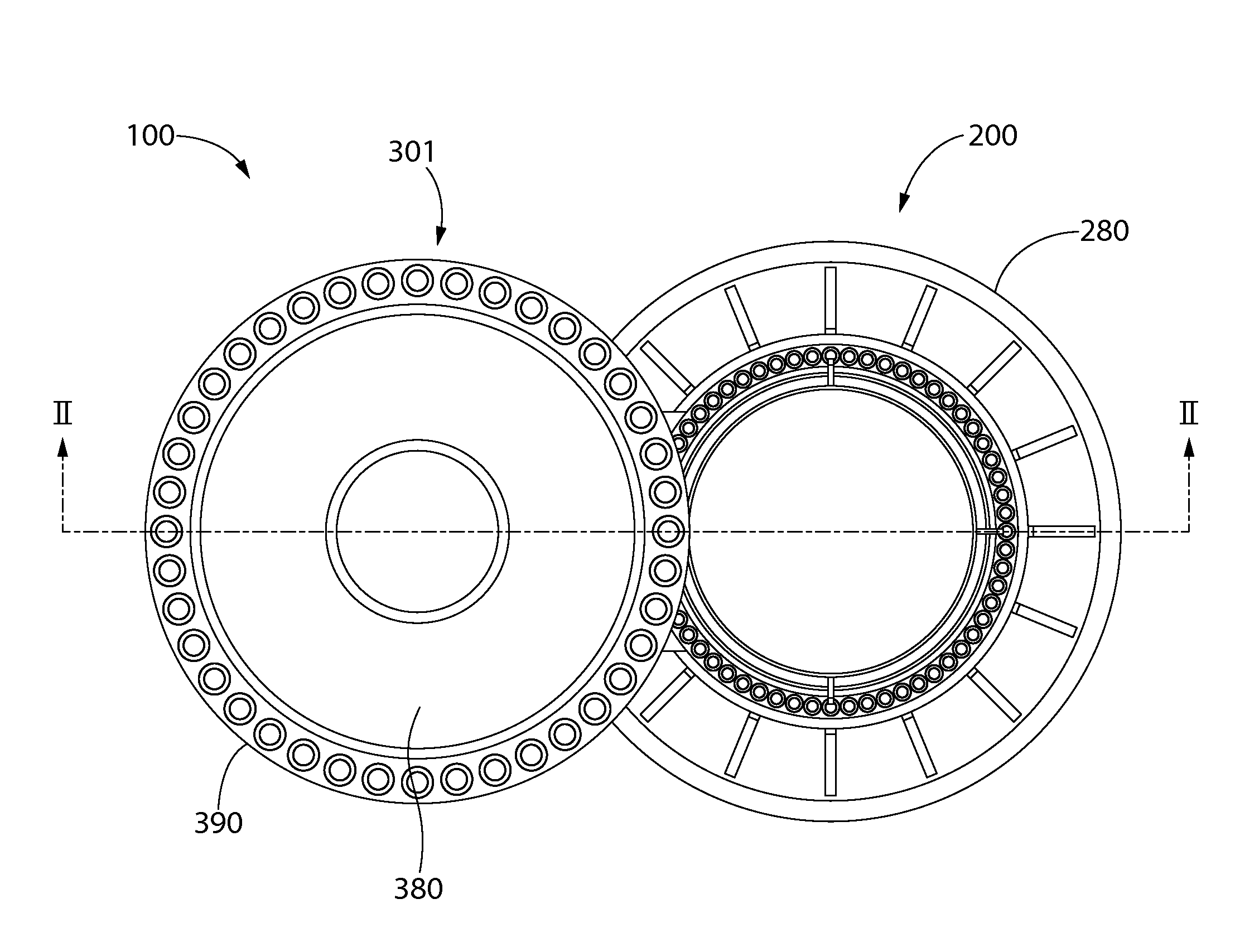

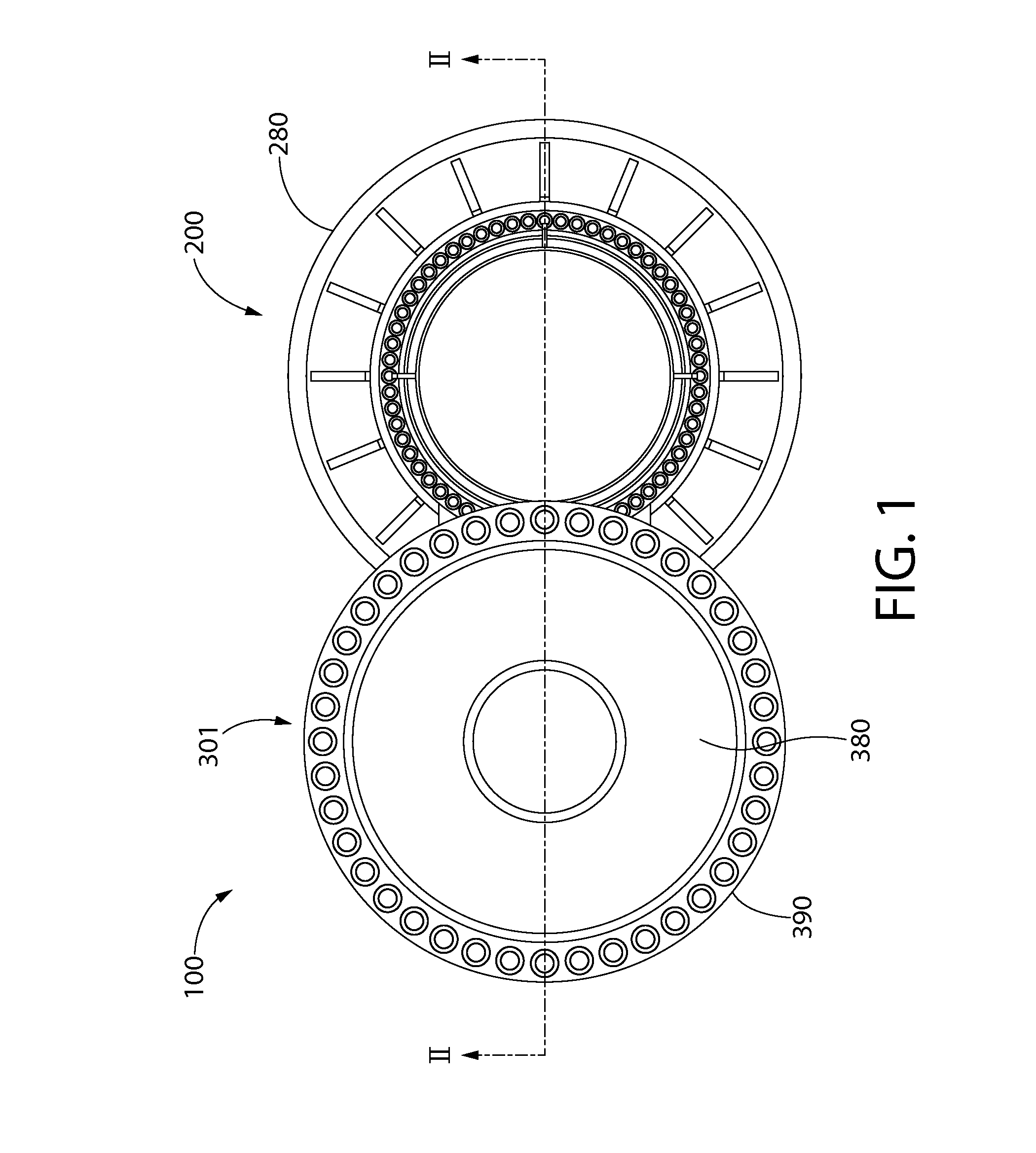

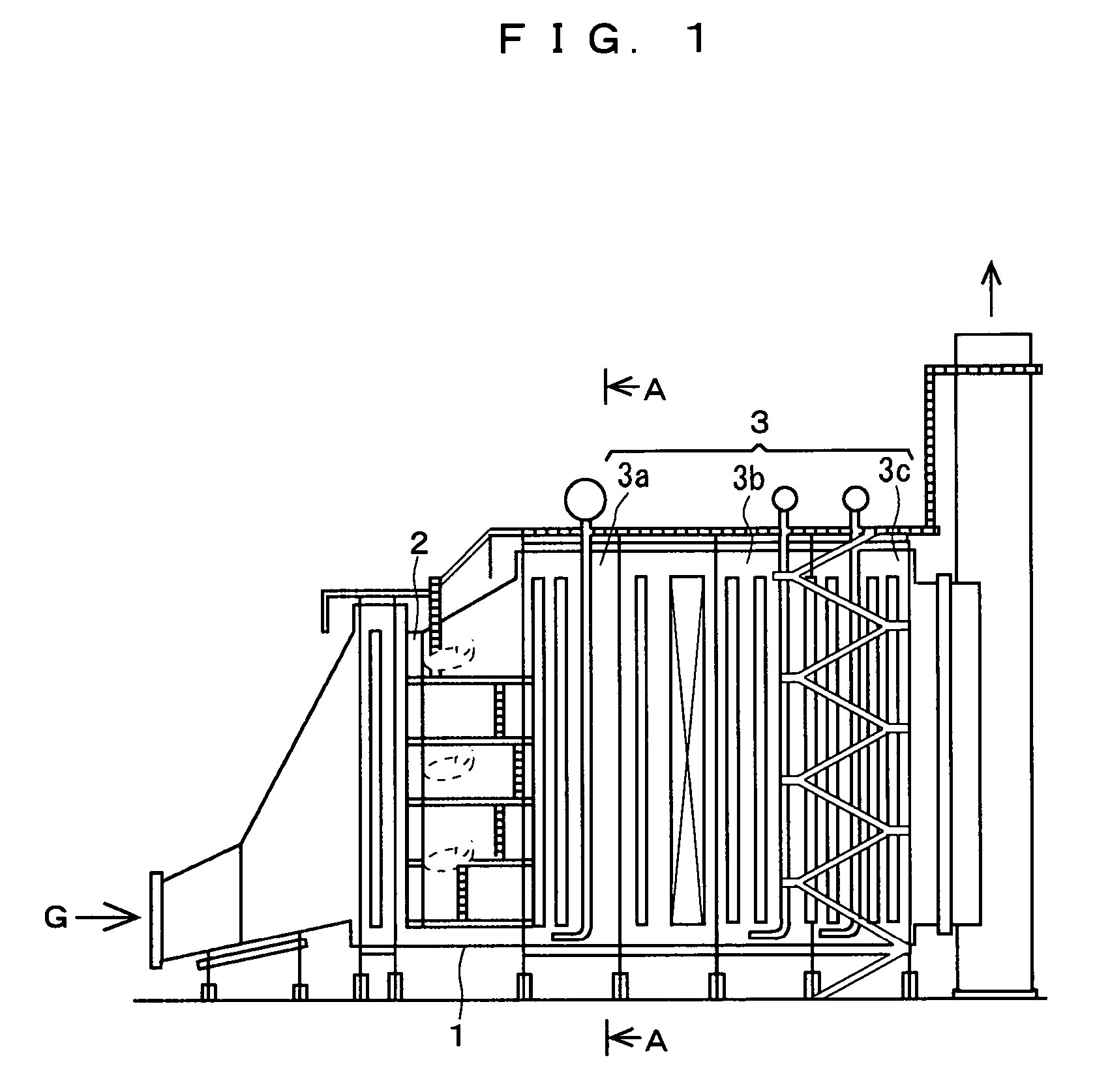

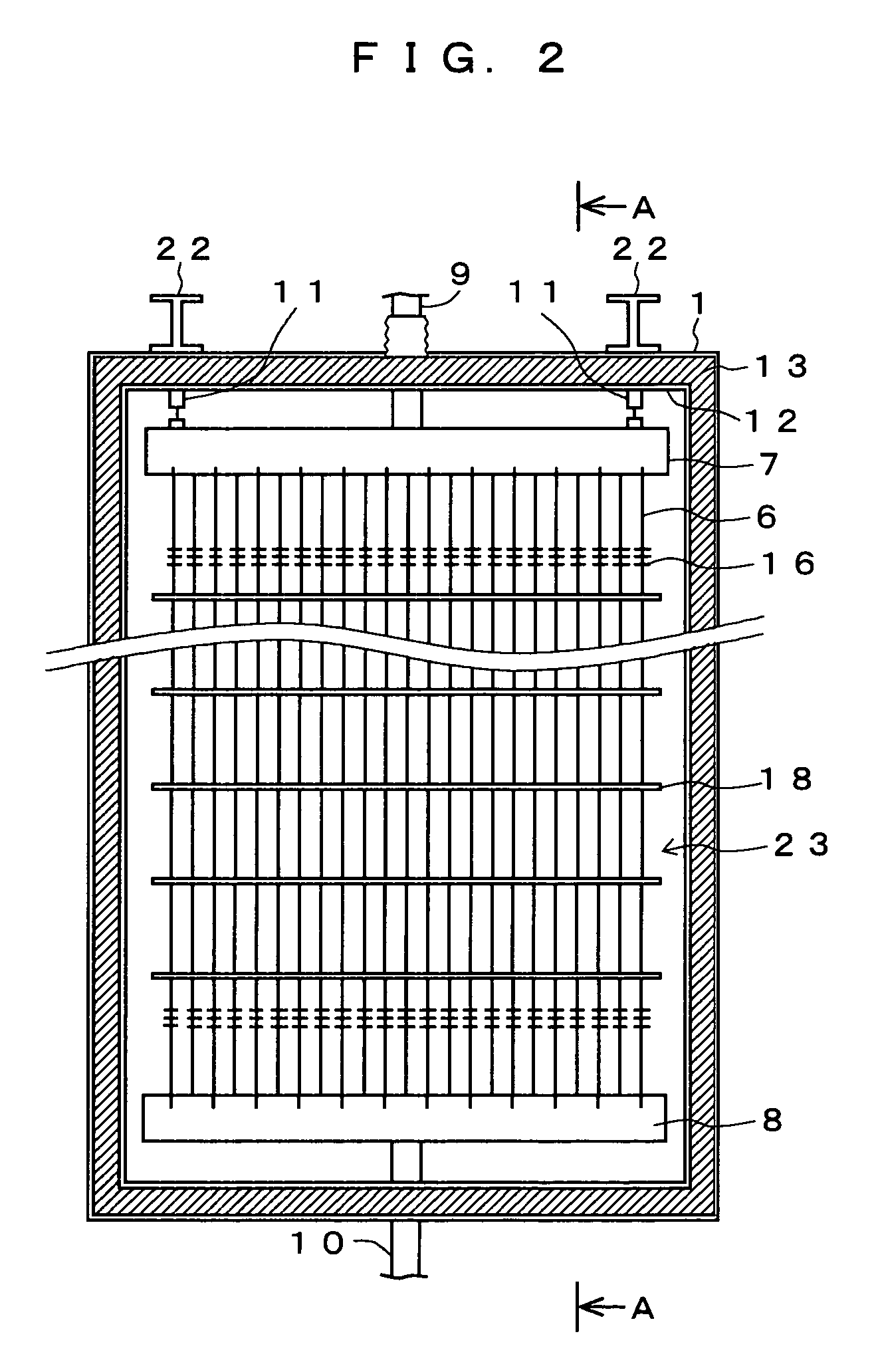

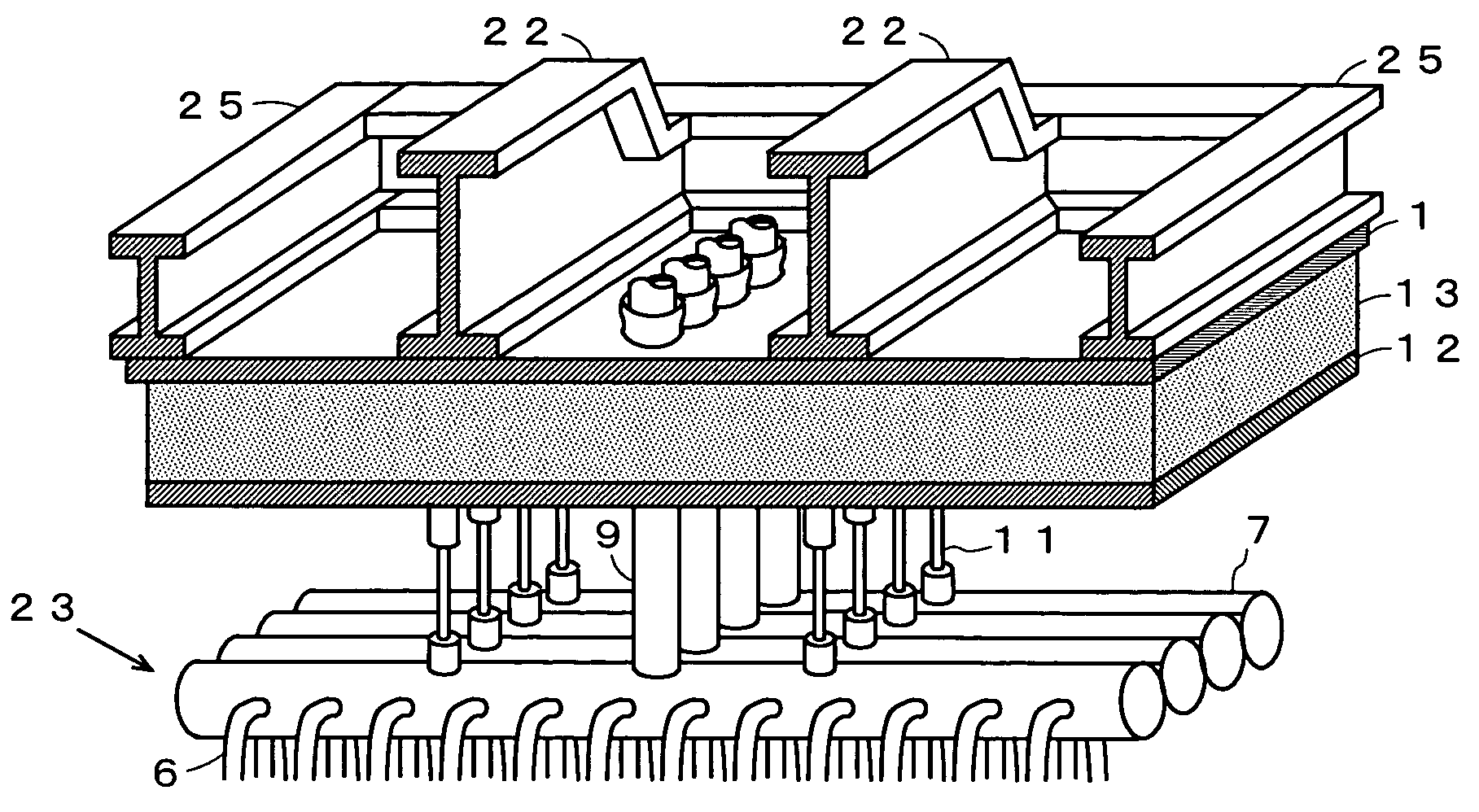

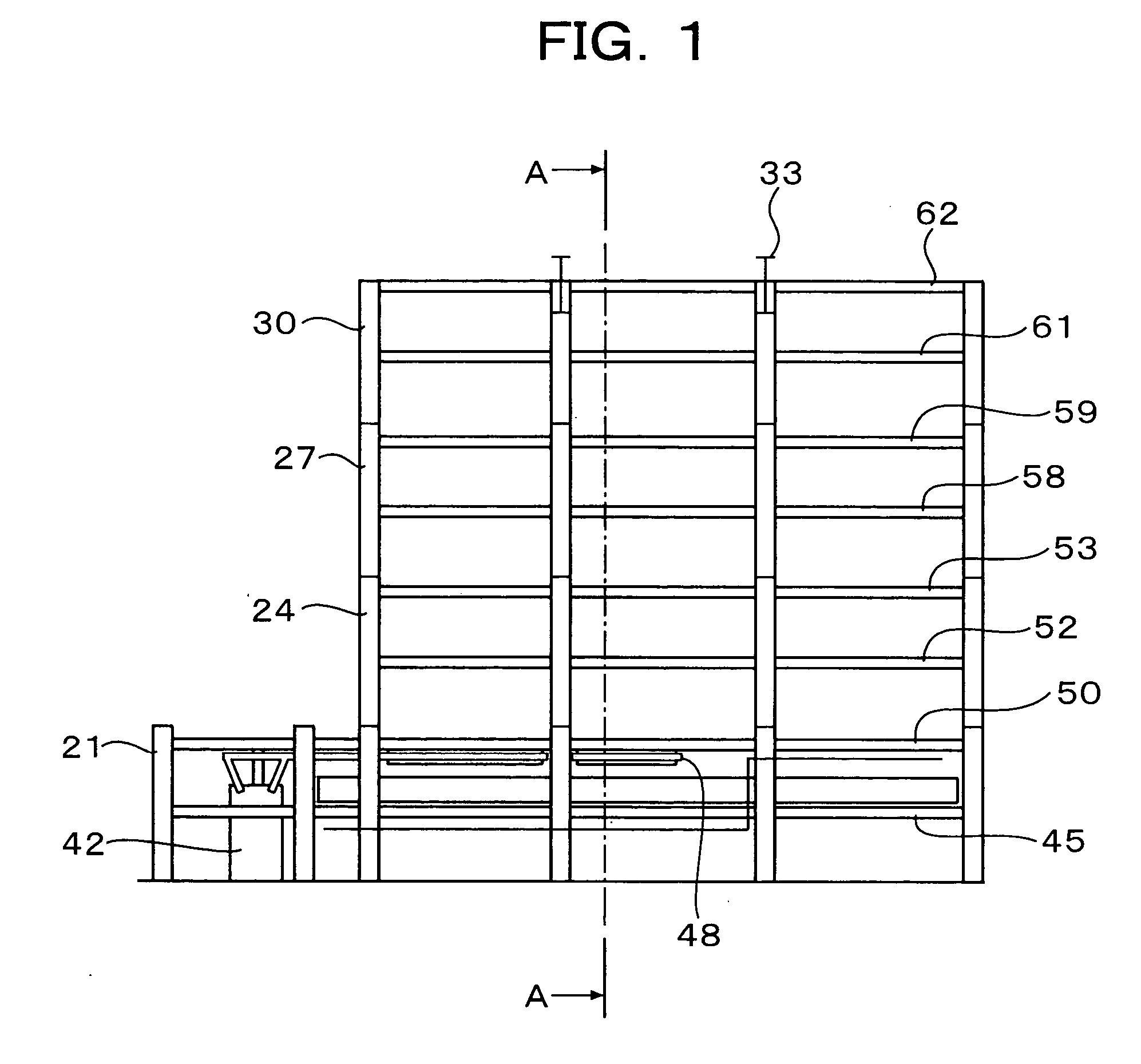

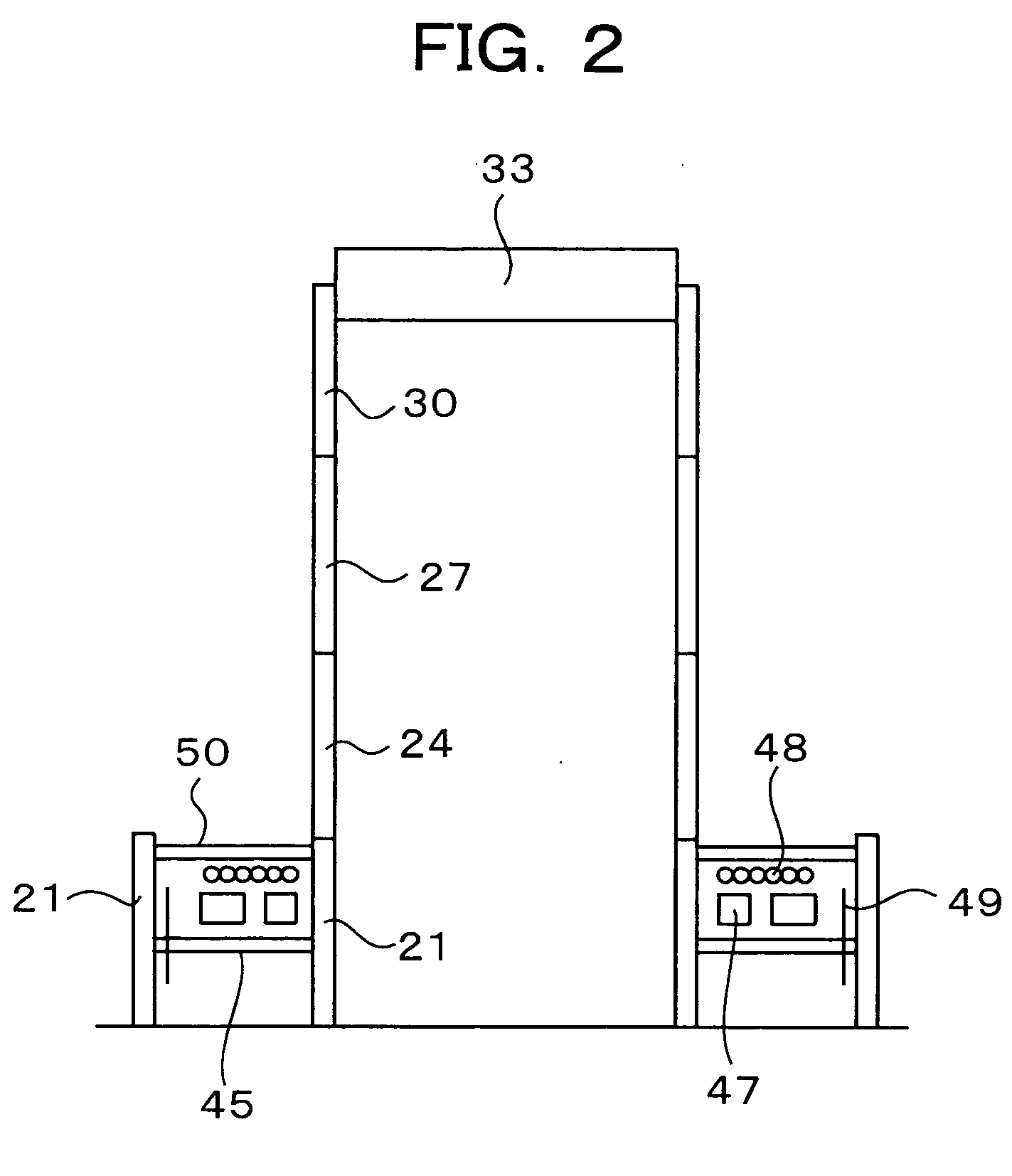

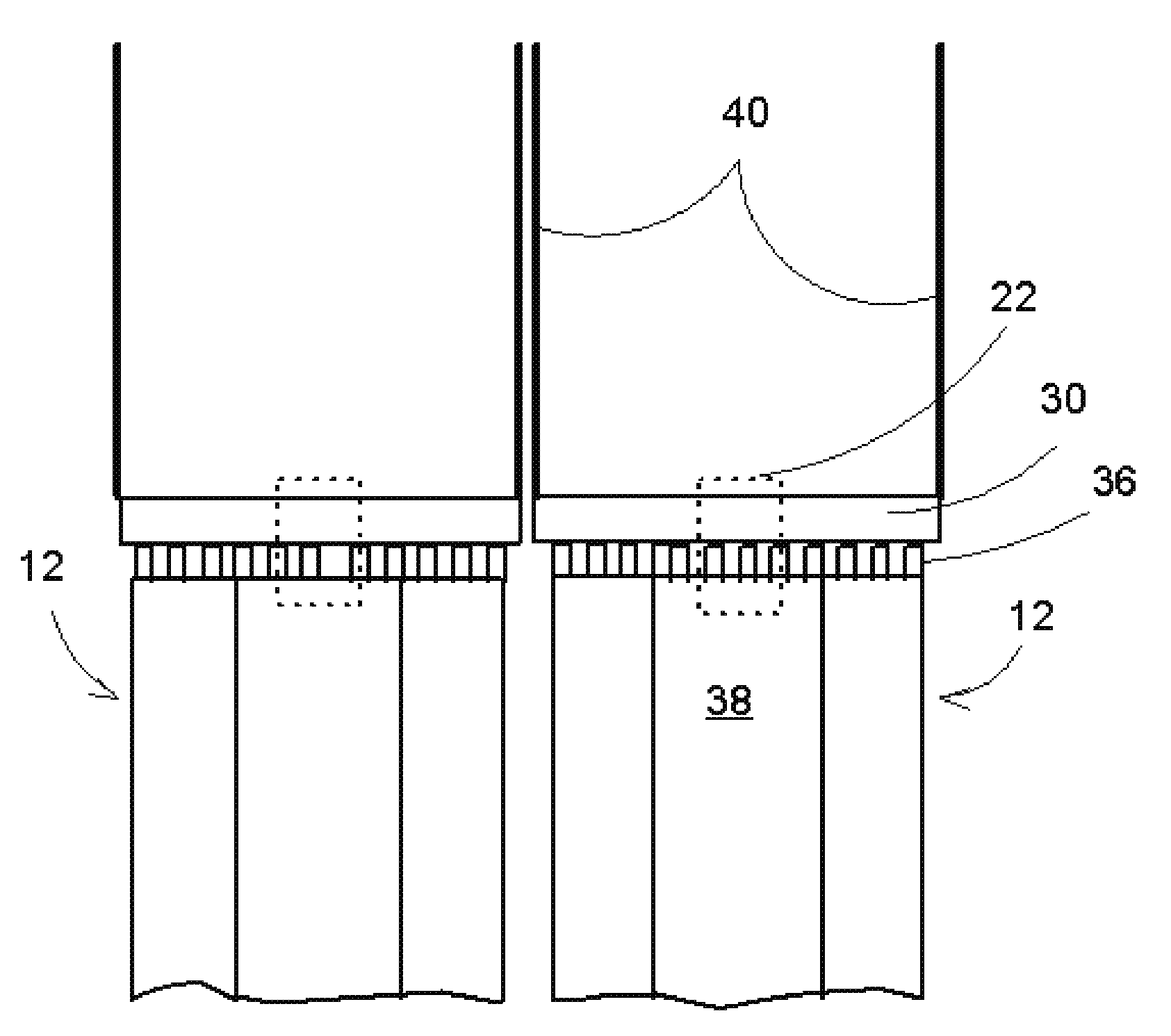

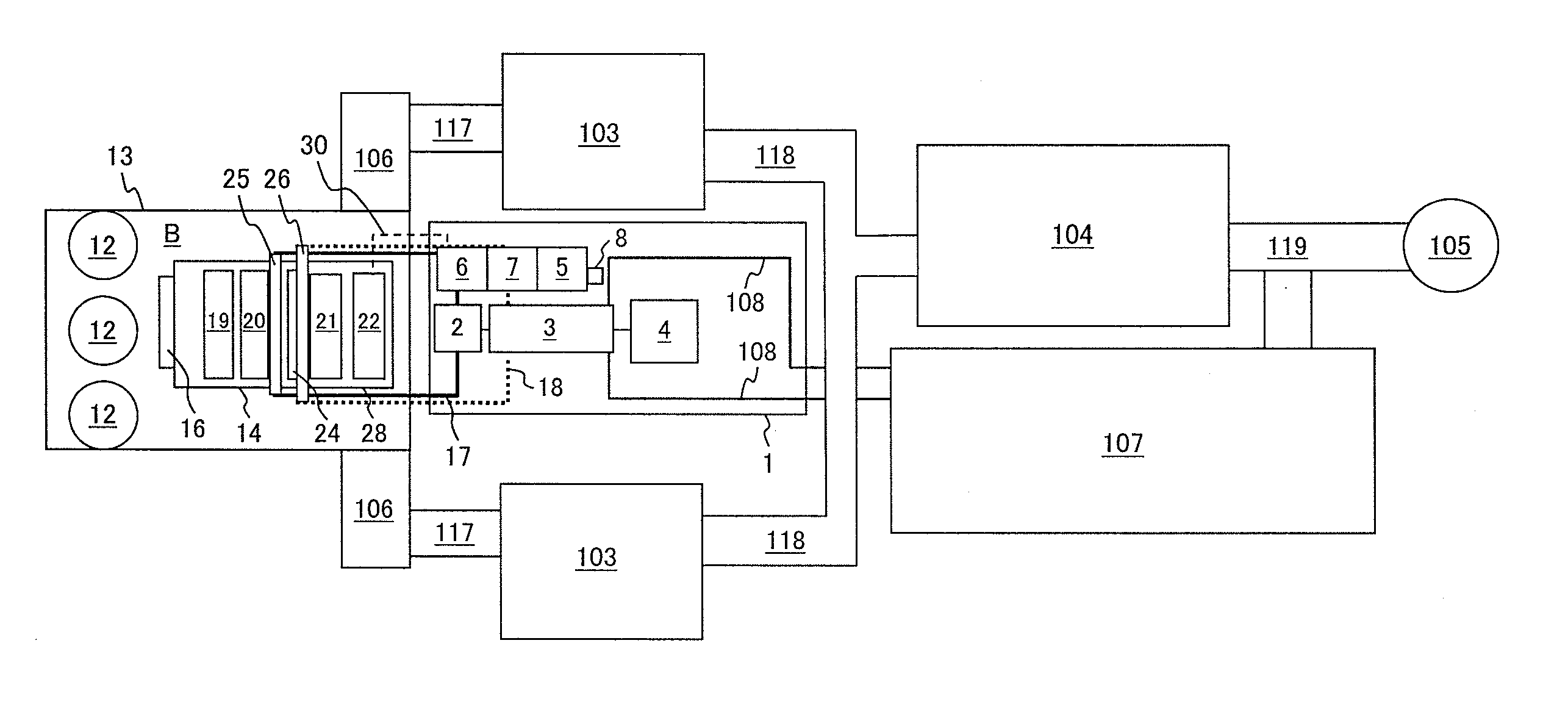

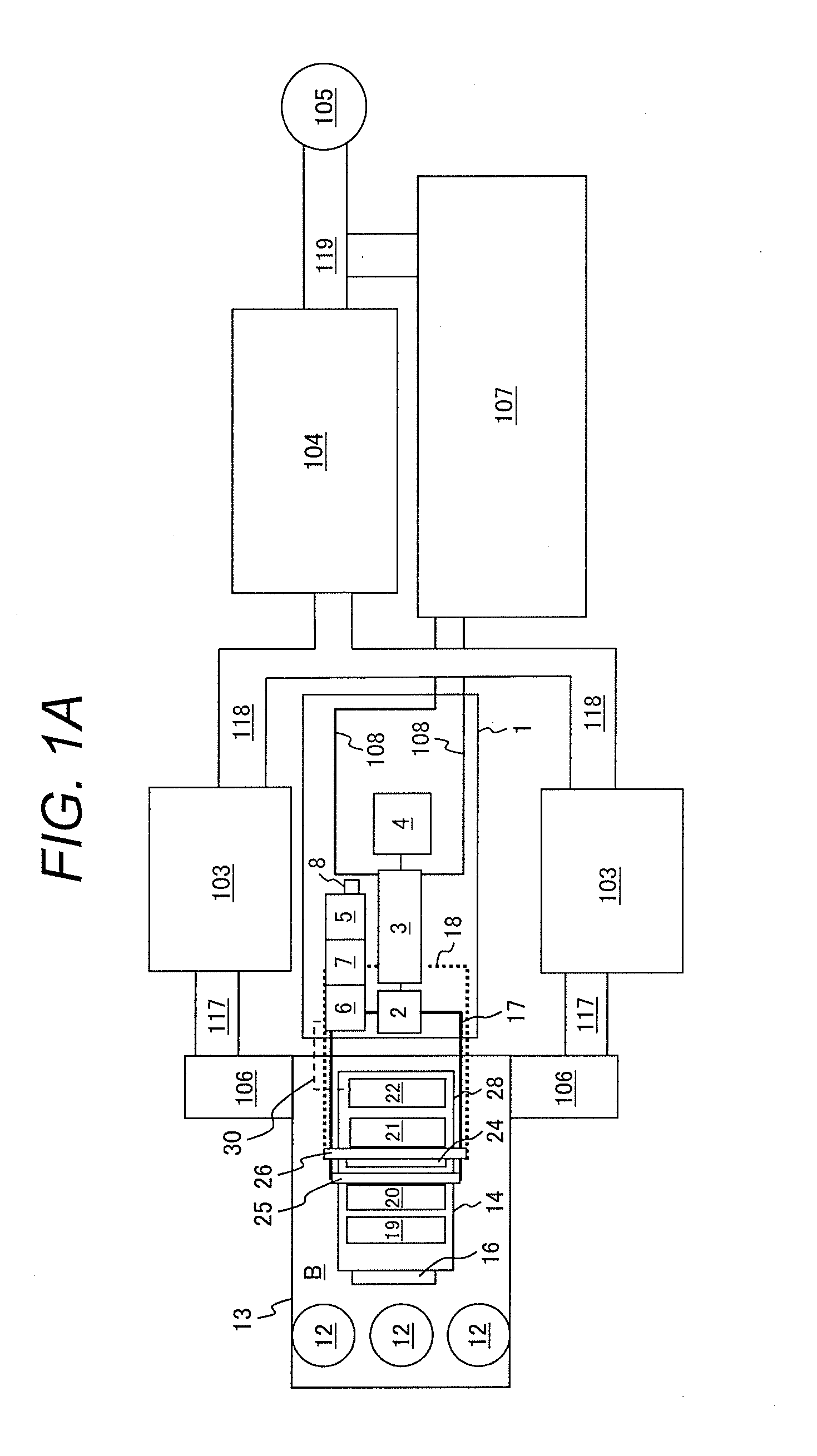

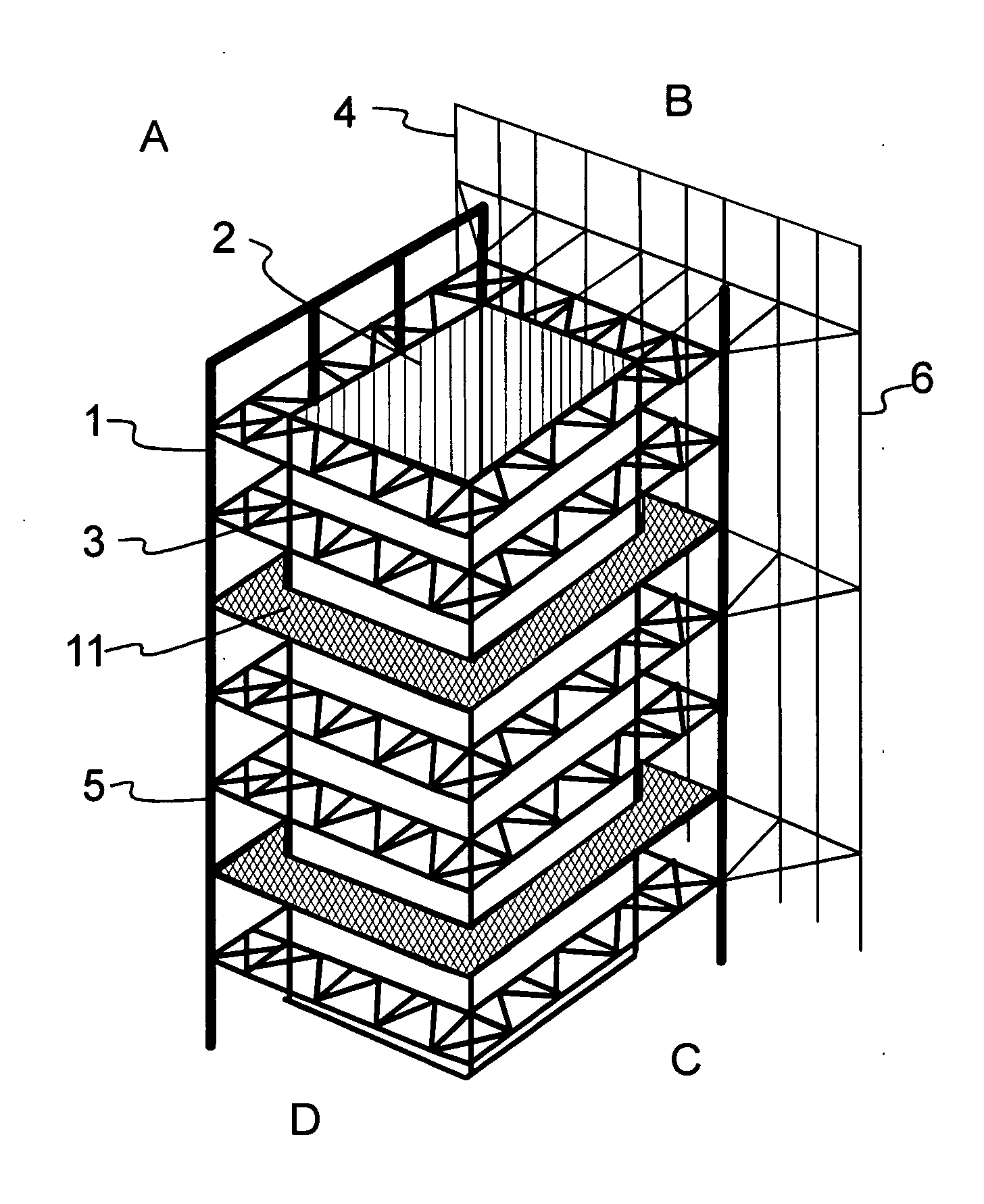

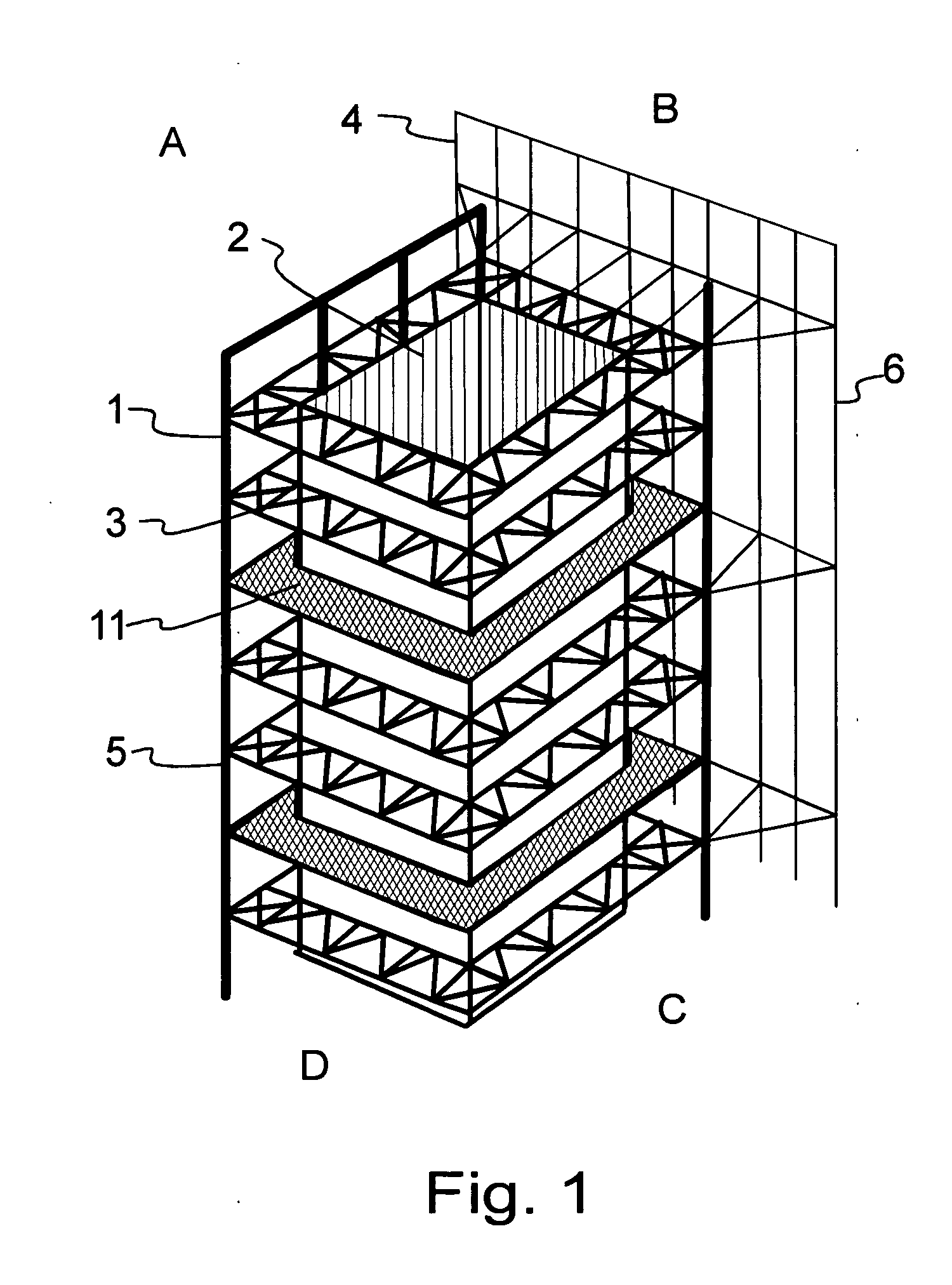

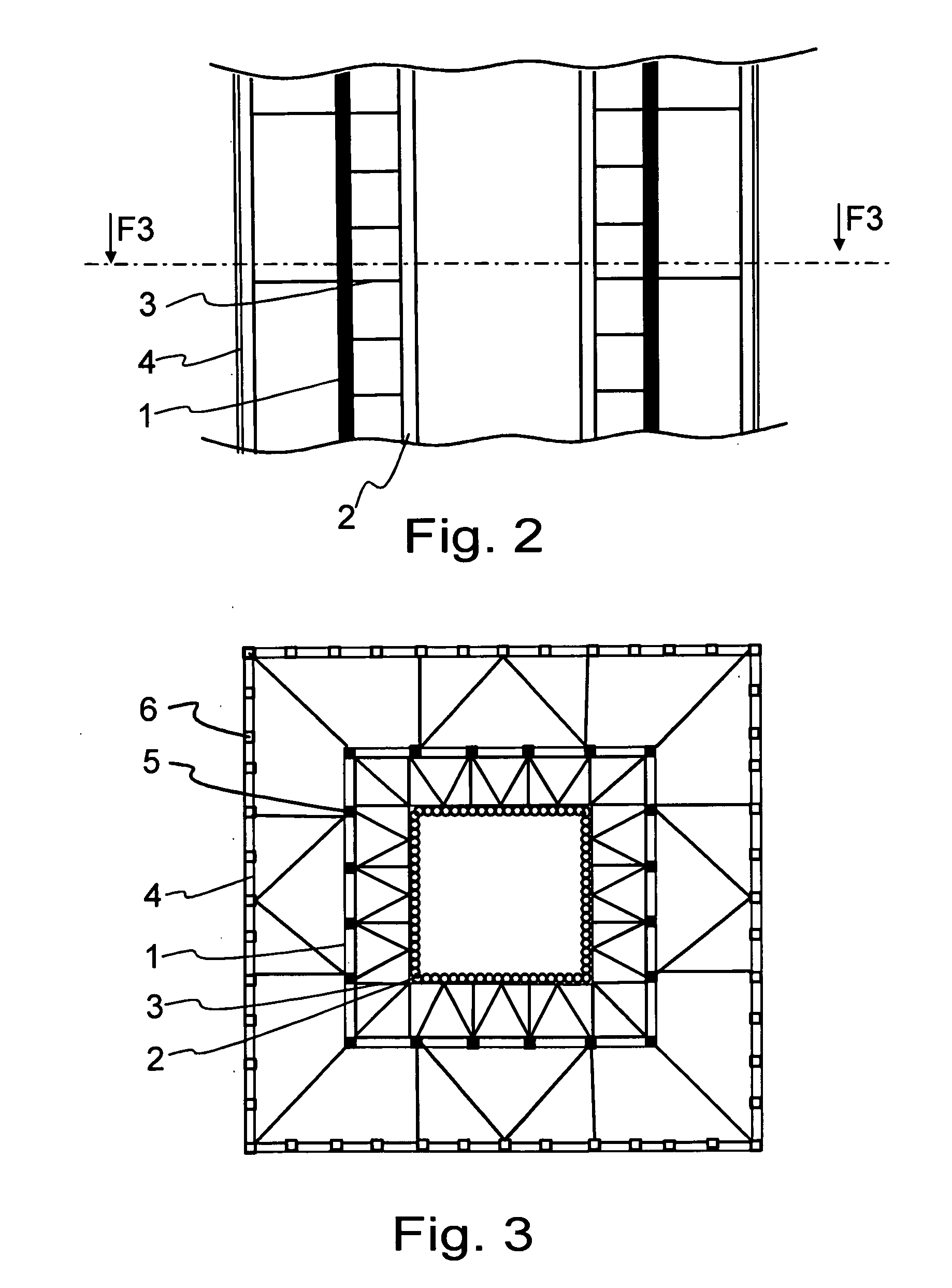

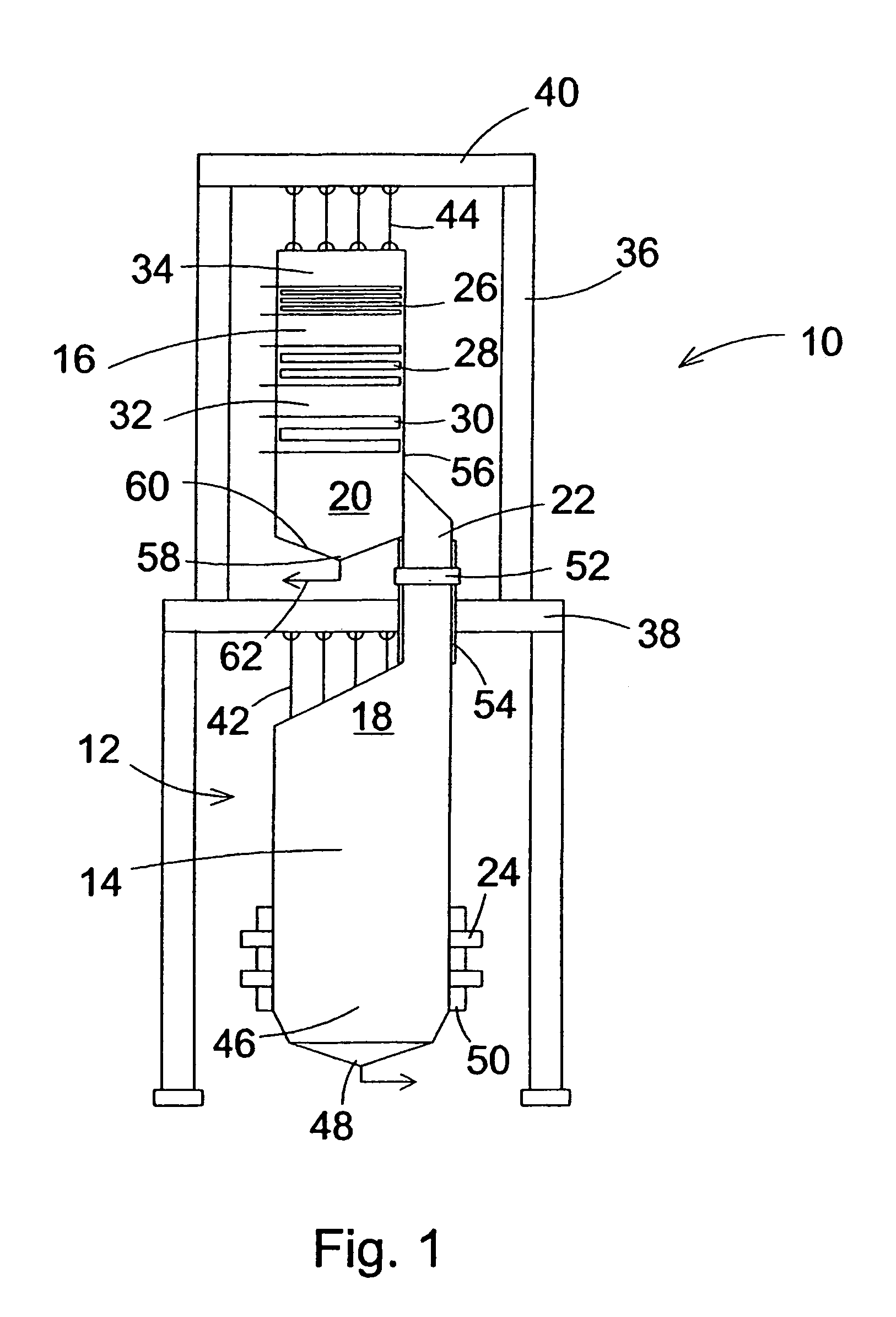

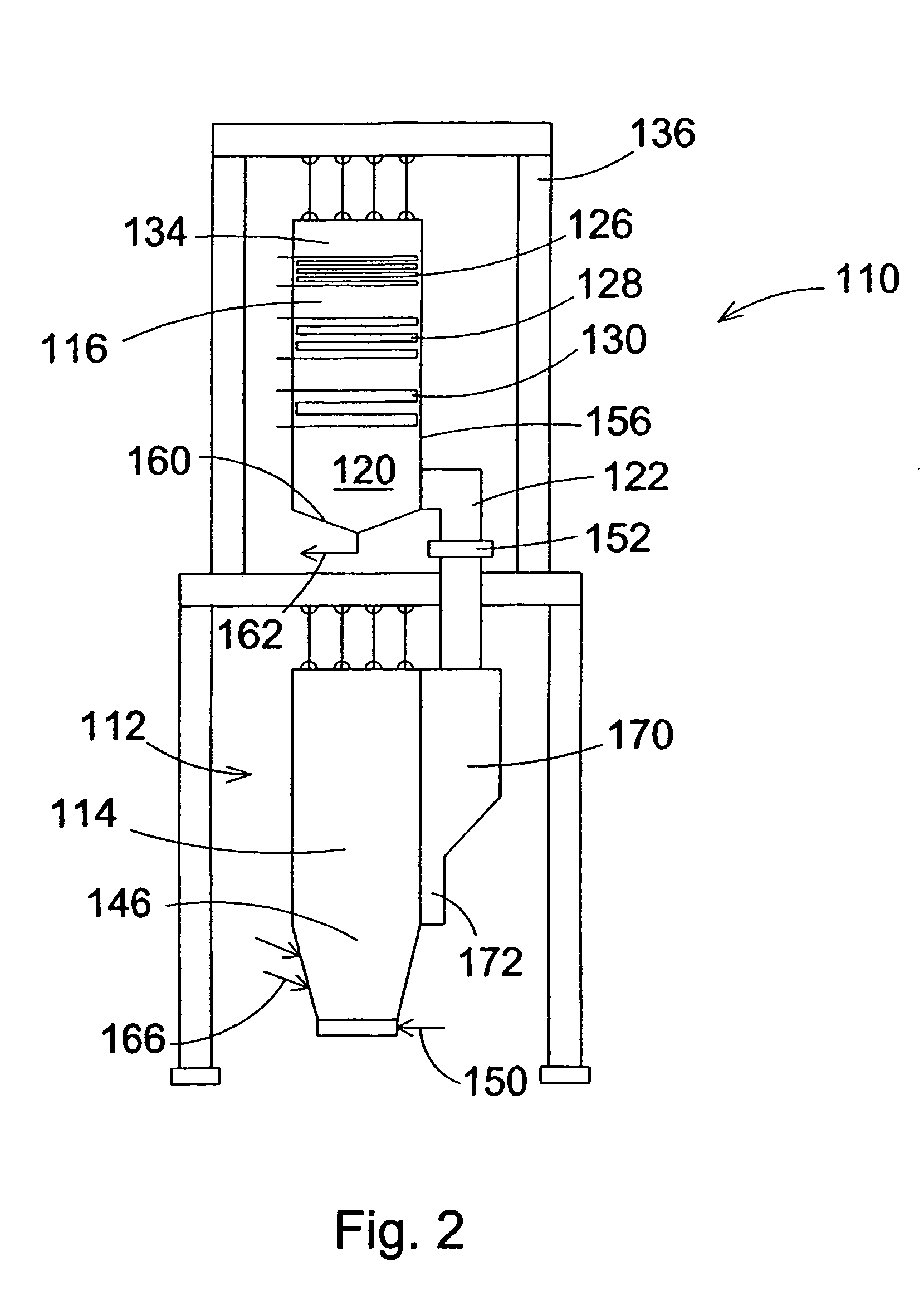

Heat transfer tube panel module and method of constructing exhaust heat recovery boiler using the module

ActiveUS20060175040A1Small sizeIncrease costBoiler supporting/setting arrangementsRecuperative heat exchangersEngineeringRecovery boiler

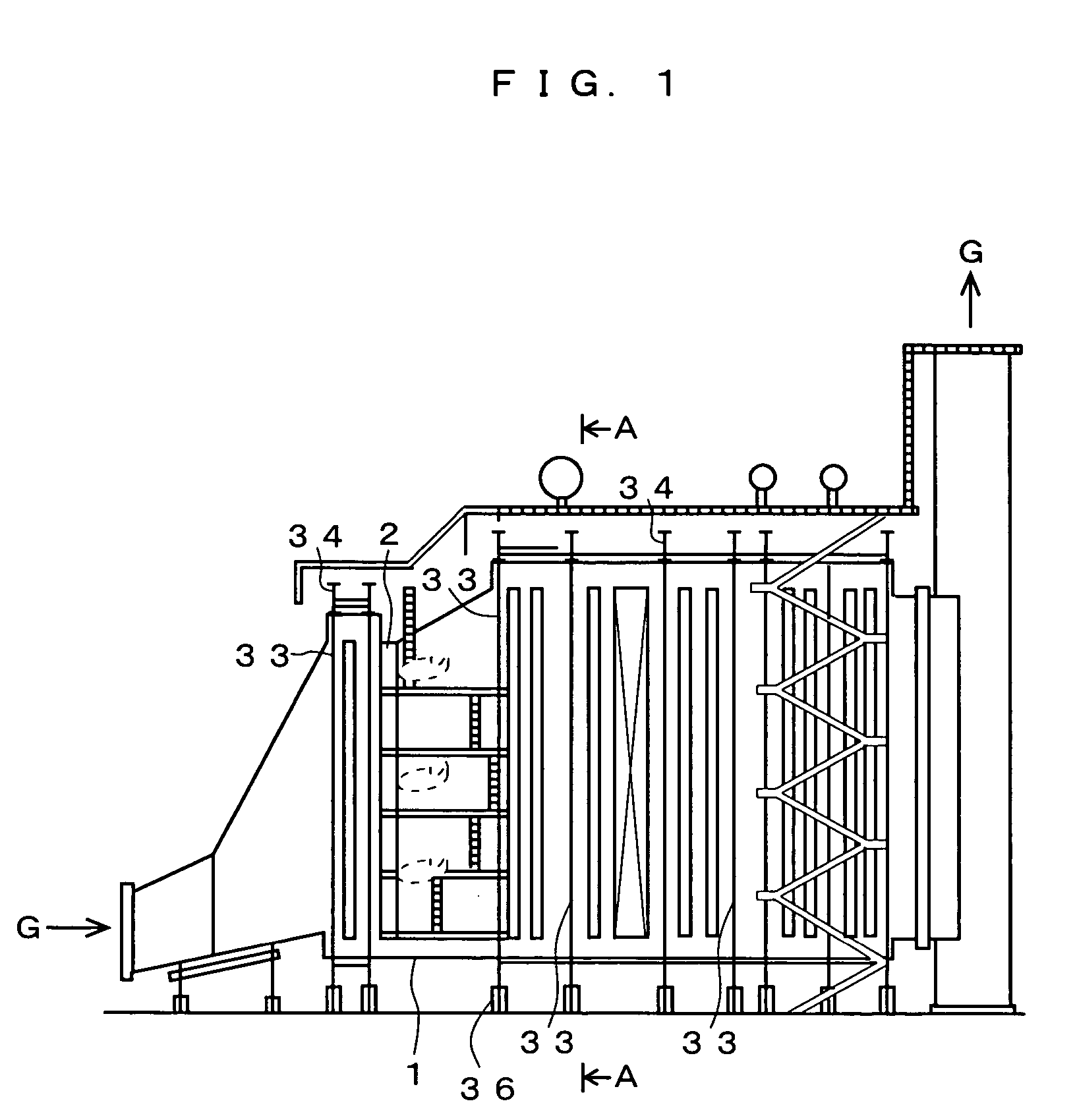

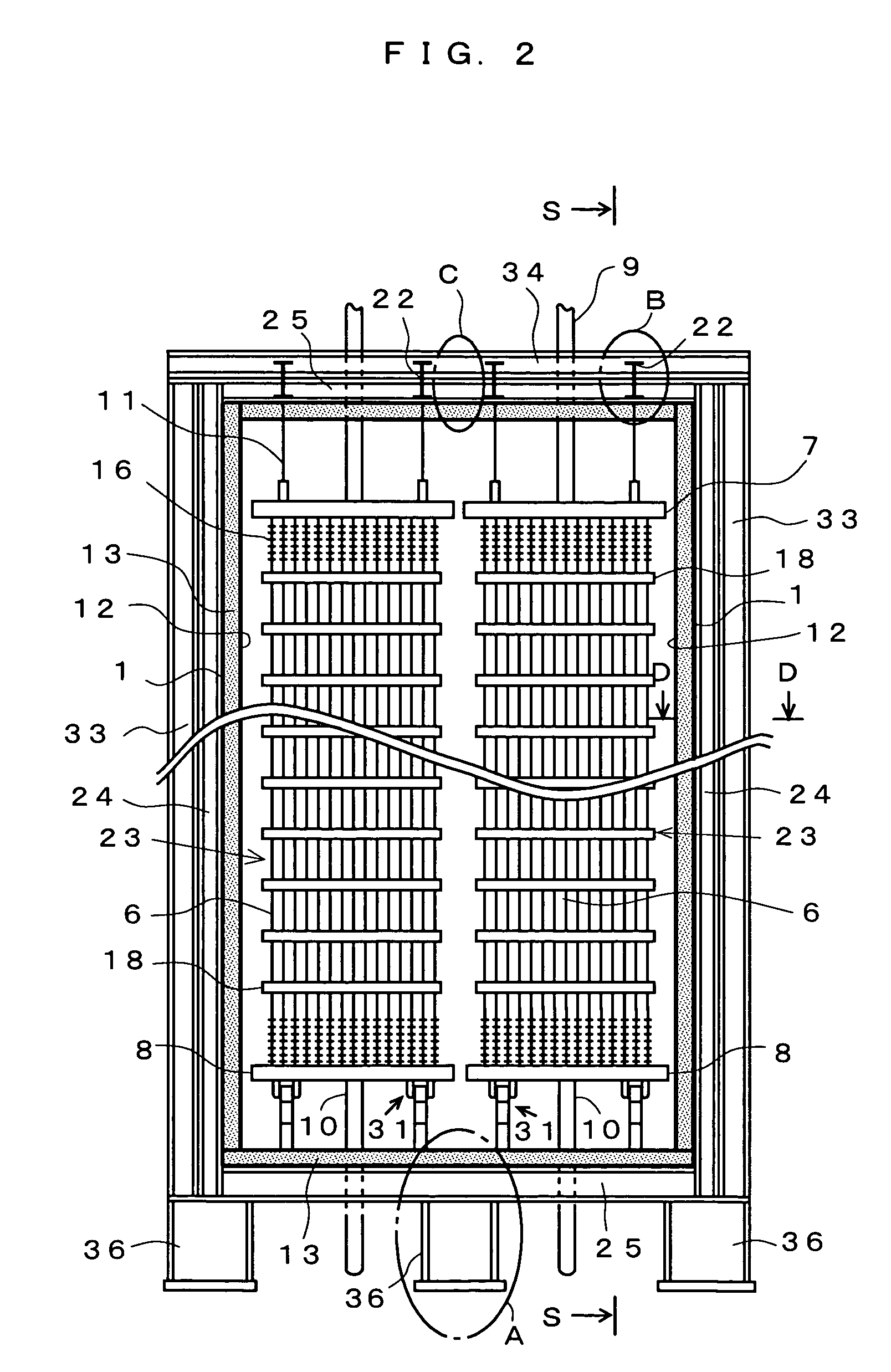

The invention provides an exhaust heat recovery boiler construction method in which a necessary number of heat exchanger tube bundle panel modules each having heat exchanger tube bundle panels including a number of heat exchanger tubes and upper and lower headers of the heat exchanger tubes, a casing of the heat exchanger tube bundle panels, heat exchanger tube bundle panel support beams located outside the ceiling wall of the casing, and vertical and horizontal module frames located outside the casing, are prepared so as to have a proper size according to the design specifications of the heat recovery boiler, main frames including main columns, main beams, and bottom wall columns for supporting the modules are constructed in advance at a construction site of the exhaust heat recovery boiler (heat recovery boiler), and the modules are transported and hung down by a crane between the main columns adjacent to each other at the construction site to set the support beams of the modules at the installation height of the main beams, and the horizontal module frames, the main beams, and the bottom wall columns are connected and fixed to each other and the vertical module frames and the main columns are connected and fixed to each other.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Heat-resistant assembly for protecting boiler tubes and method of assembling same

InactiveUS20020077767A1Thermometer detailsBoiler supporting/setting arrangementsEngineeringMechanical engineering

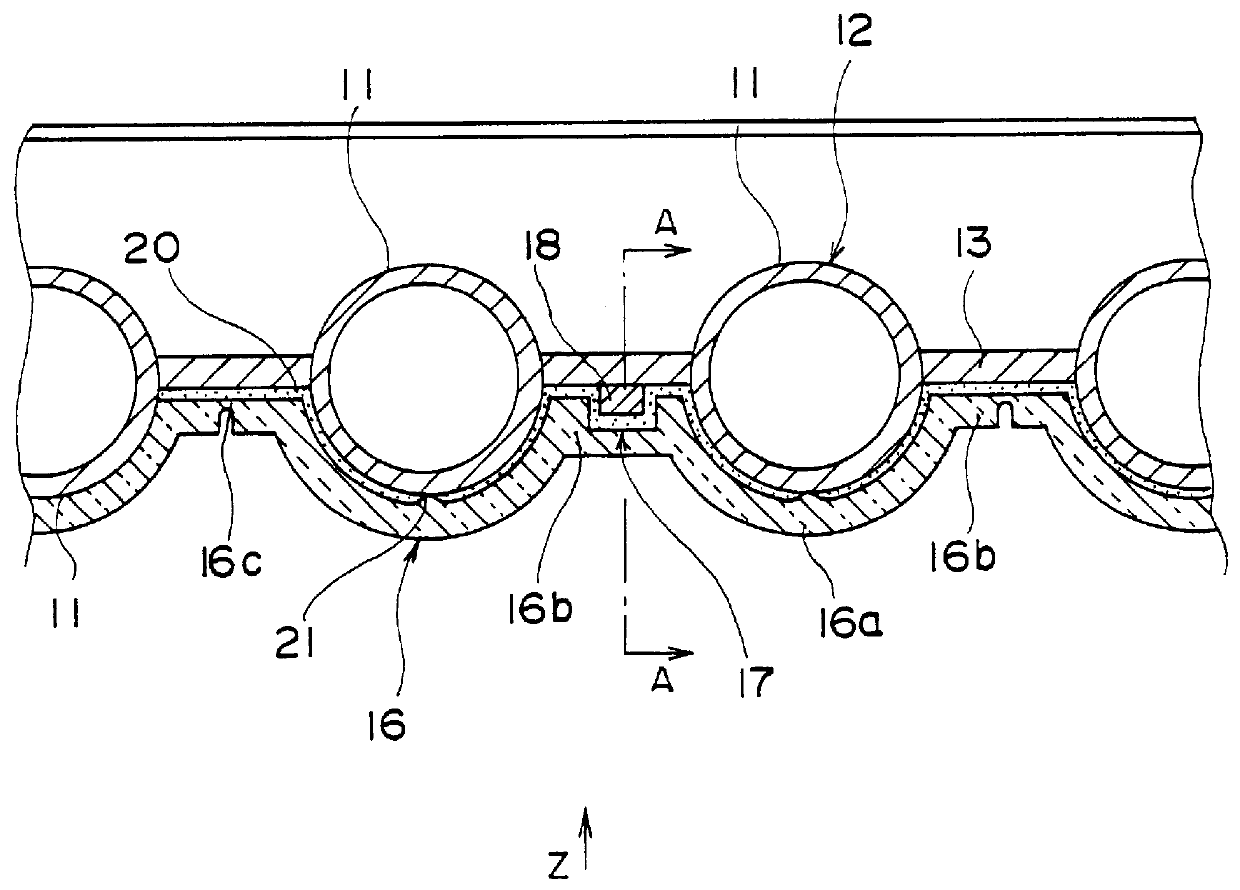

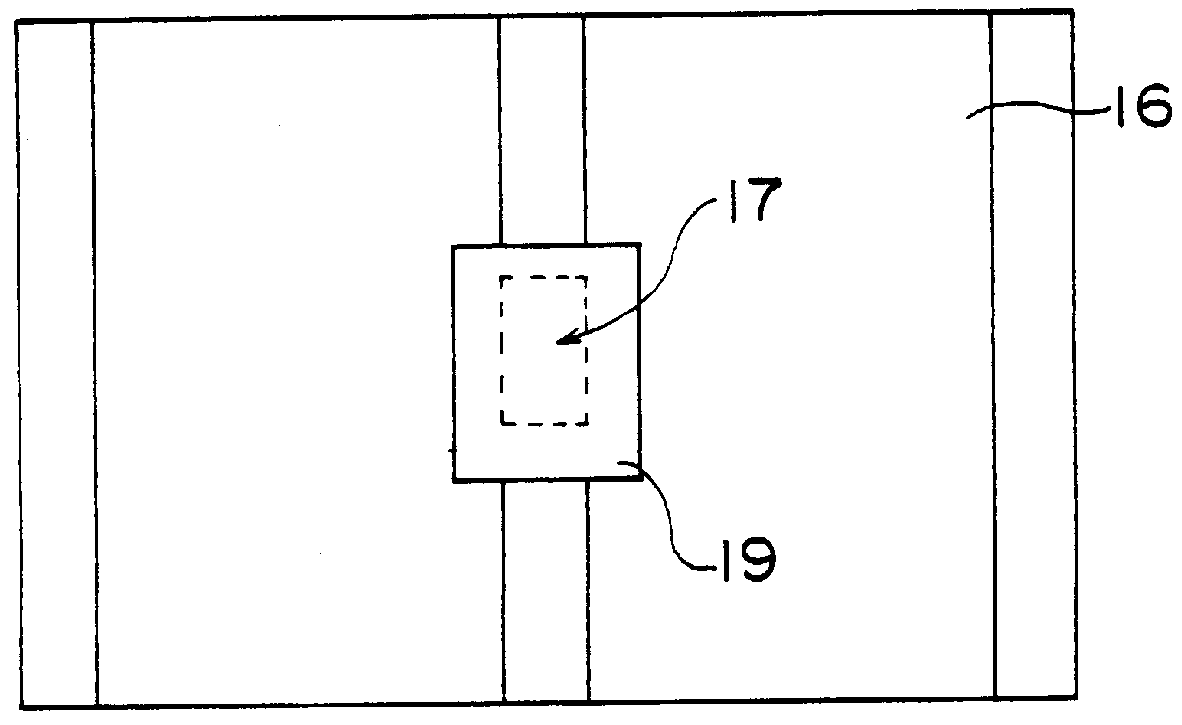

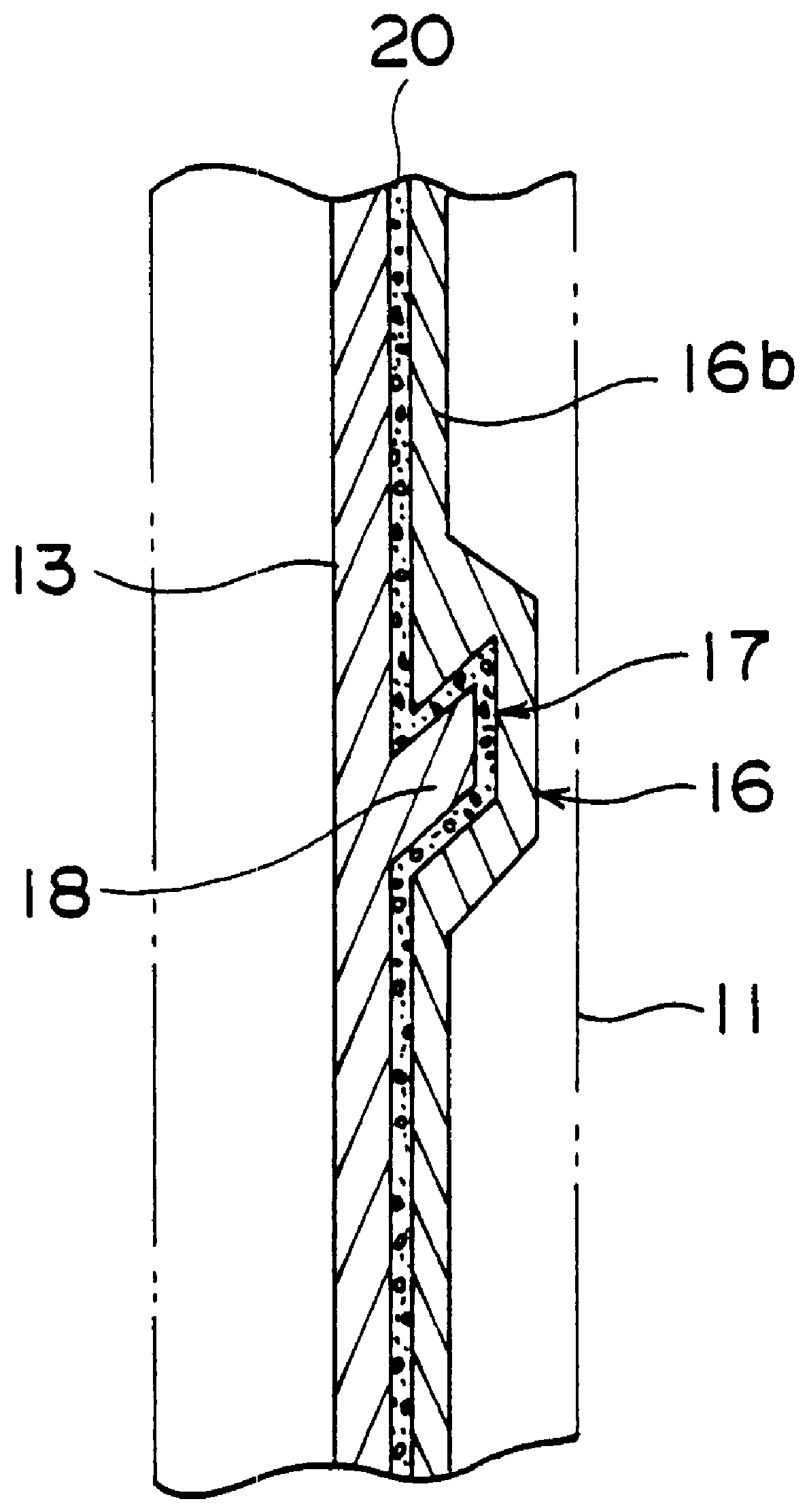

This invention concerns a heat-resistant assembly having a heat-resistant block conformed to the contours of boiler tubes and the surface of their connecting rib. The heat-resistant assembly has an arm which protrudes from the surface of the rib toward the heat-resistant block and which has a catch on the end. The block has an indentation in which the catch on the arm engages. The block can be hung on or removed from the tube assembly by means of the arms and indentations. The heat-resistant assembly is further distinguished by the fact that a space is created between the end of the arm and the indentation of the block. A fusible substance, which will melt when the temperature of the arm exceeds a given value, is placed in the space. The heat-resistant assembly is further distinguished by the fact that an indentation is formed in the block in which a heat-resistant sleeve is adhered to engage the arm. This arrangement makes it possible to manufacture the heat-resistant block using press molding.

Owner:MITSUBISHI HEAVY IND LTD

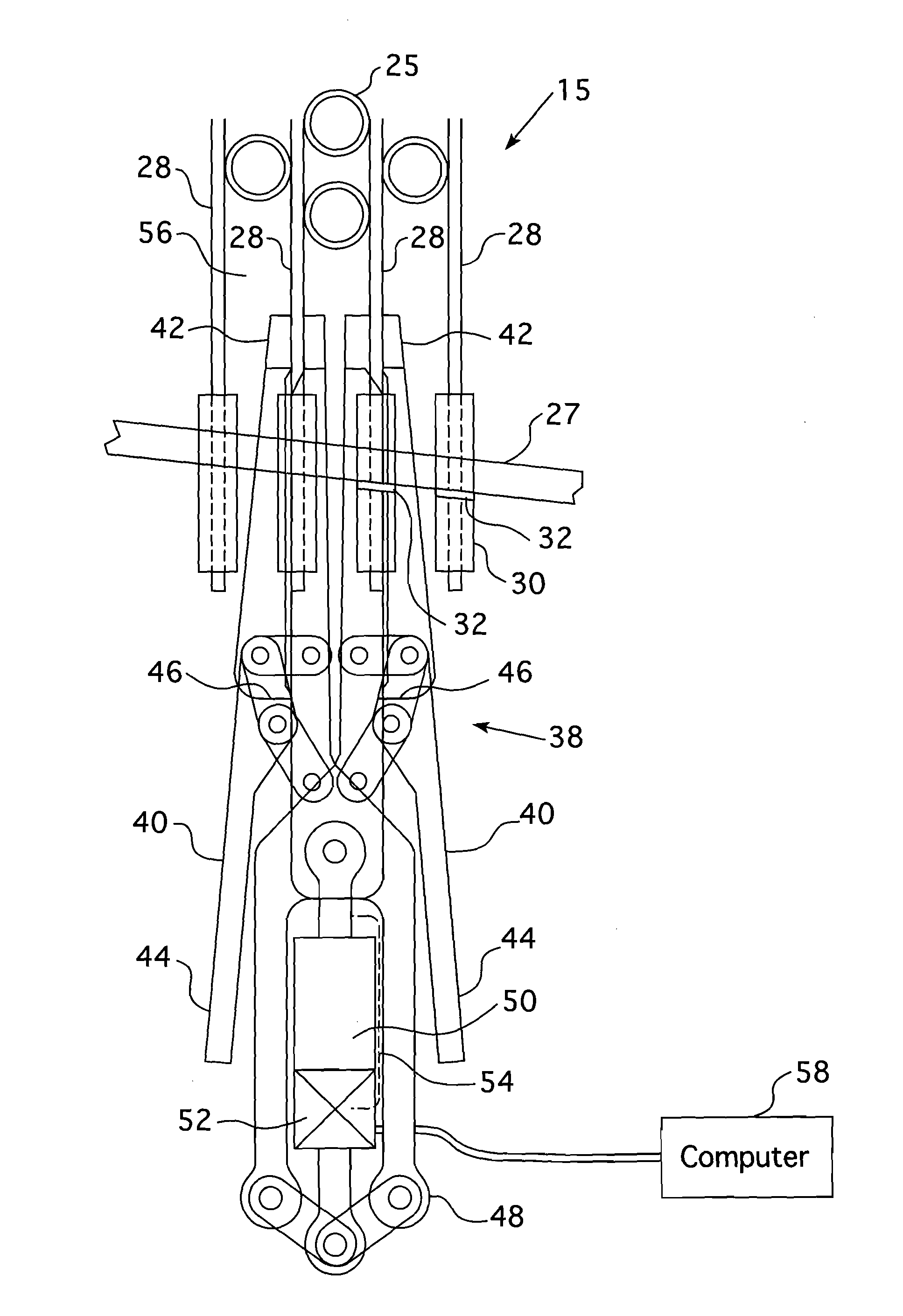

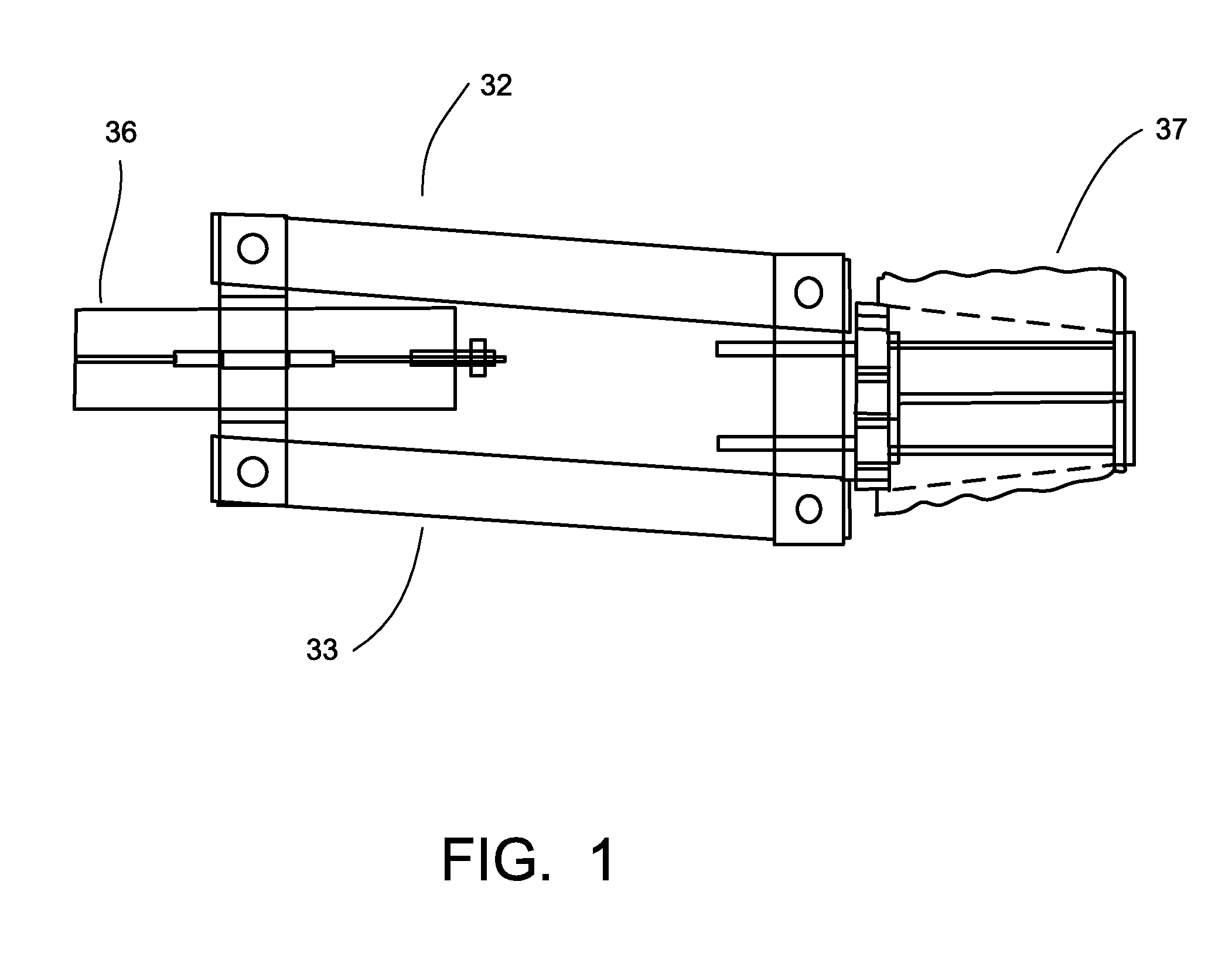

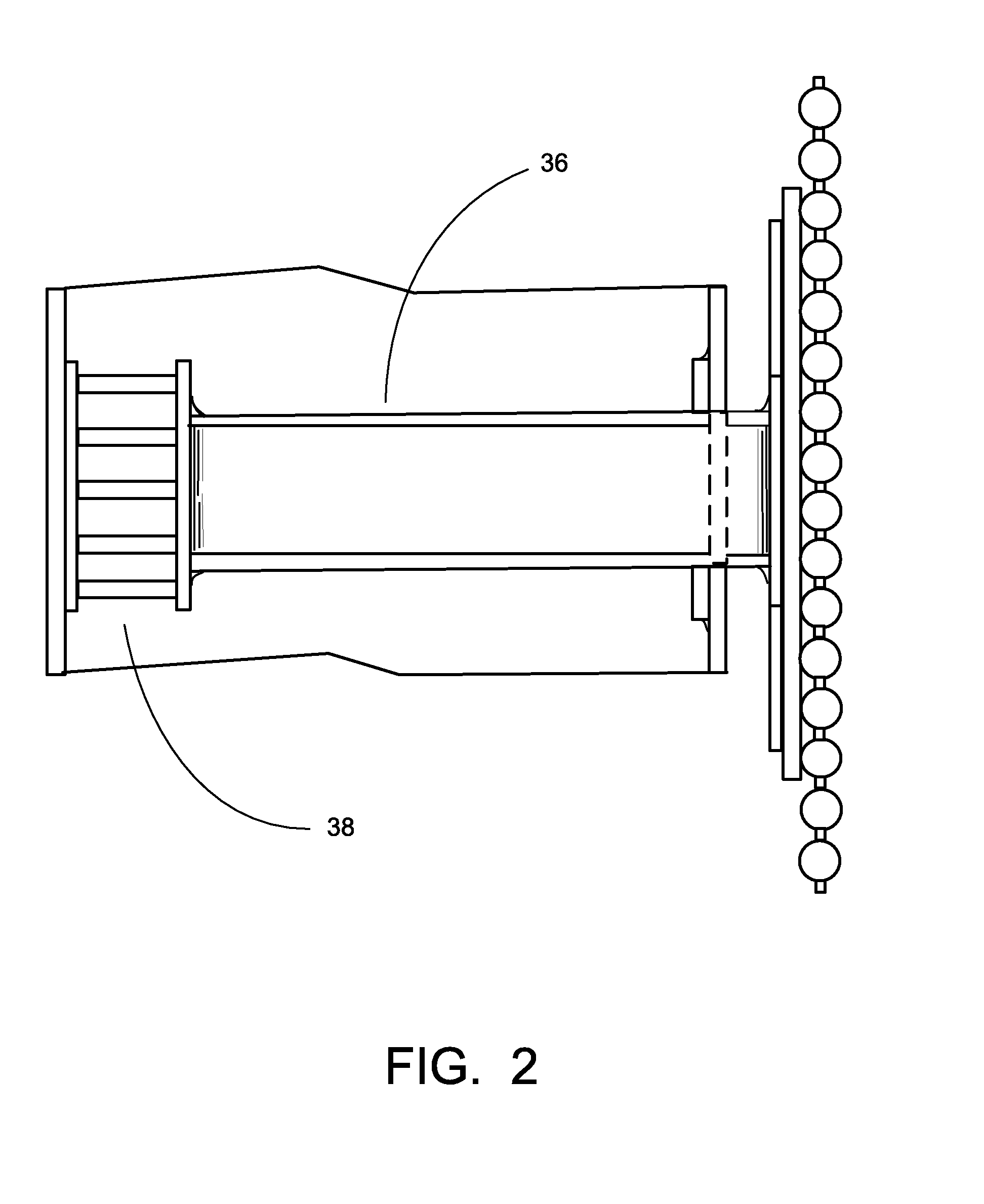

Anti-vibration bar clamping tool

An automated tool and method for spacing a gap between the anti-vibration bars and the flow tubing in the bend region of a tube bundle of a U-tube steam generator, prior to welding, during manufacture. The tool comprises two toggle clamp elements attached to a scissors assembly, which are actuated by a linear drive motor in line with a force gauge, and coupled to a distance measuring device. The tool is operated by first attaching the toggle clamps respectively to two adjacent anti-vibration bars. A linear drive motor on the tool is then cycled and readouts of force and distance are plotted on a curve to determine the point of contact between the anti-vibration bar and the tube. The computer then automatically cycles the drive motor to adjust the gap to a desired range of position coordinates adjacent the point at which the curve markedly changes slope.

Owner:WESTINGHOUSE ELECTRIC CORP

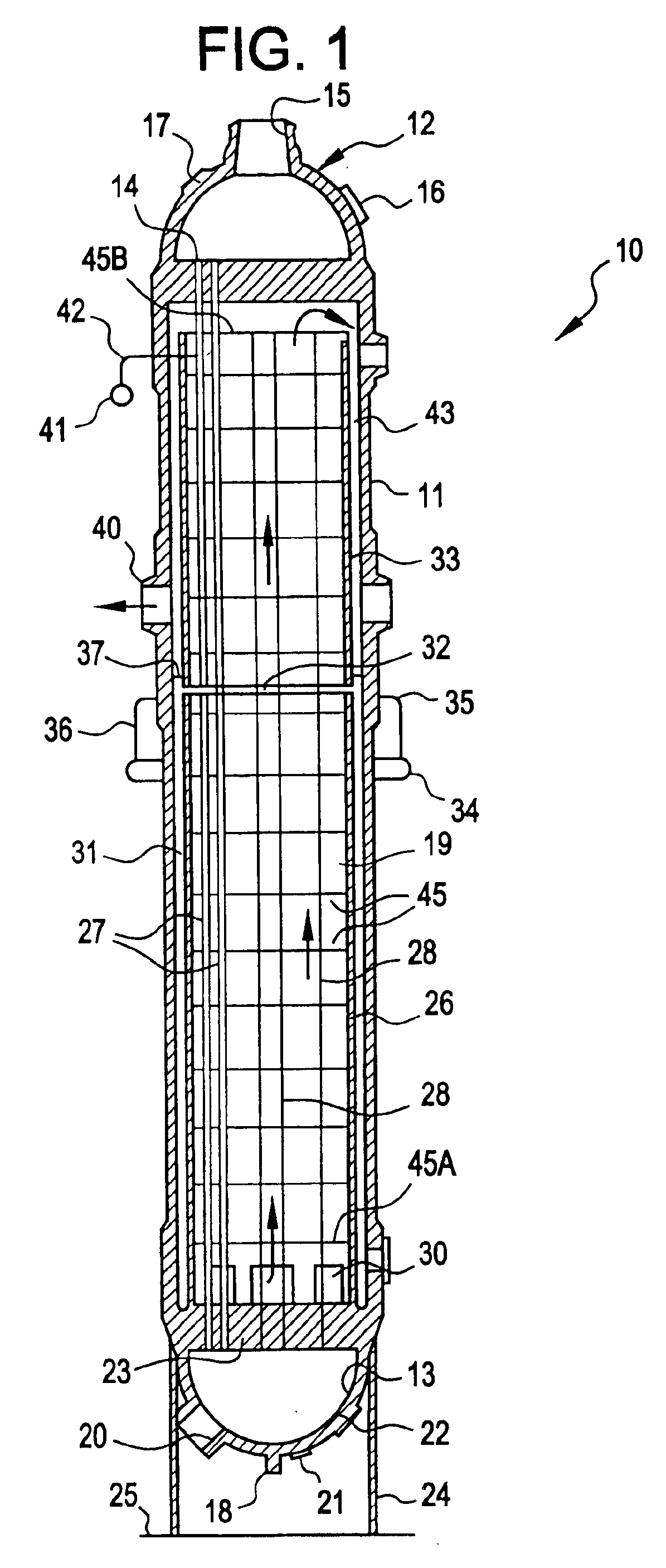

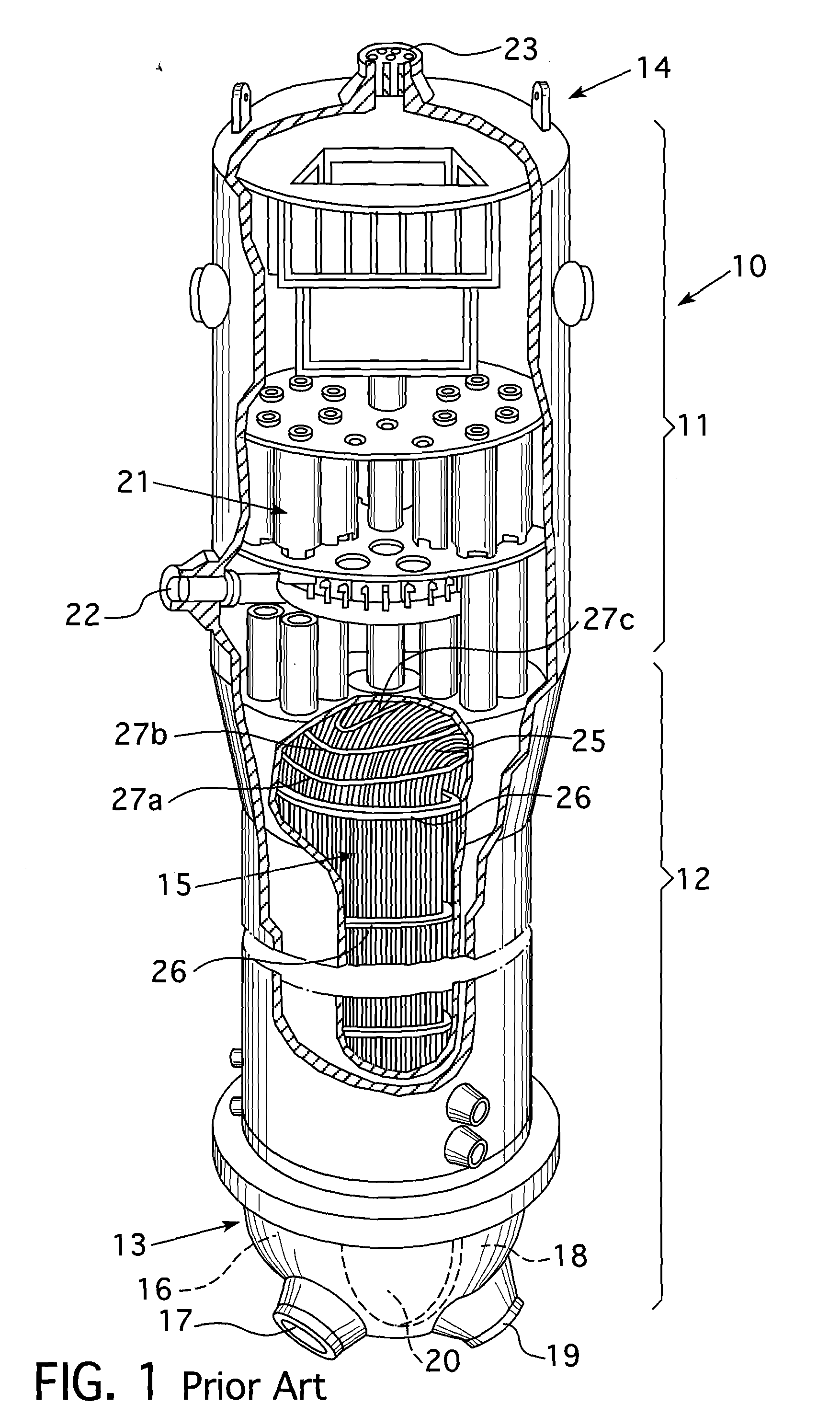

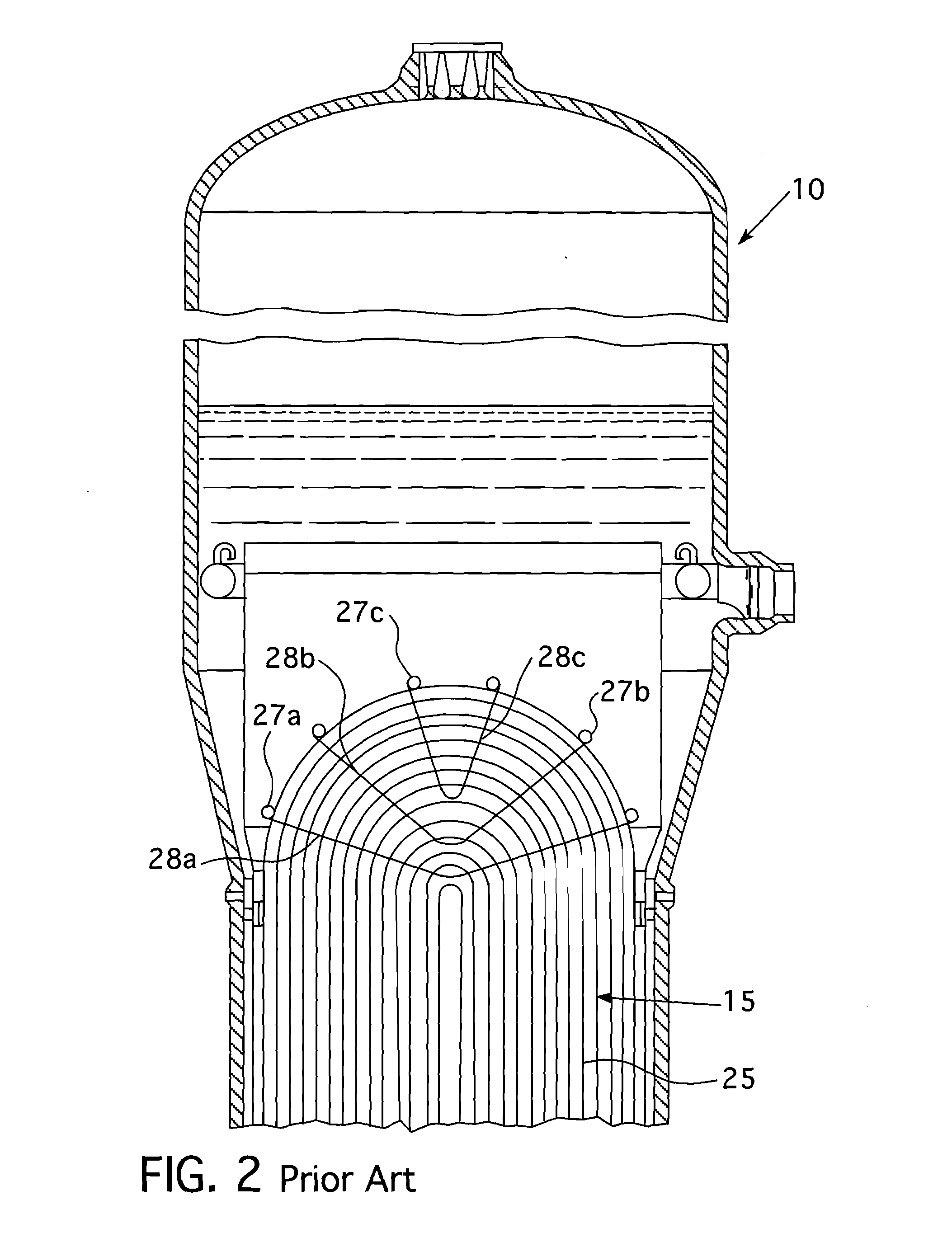

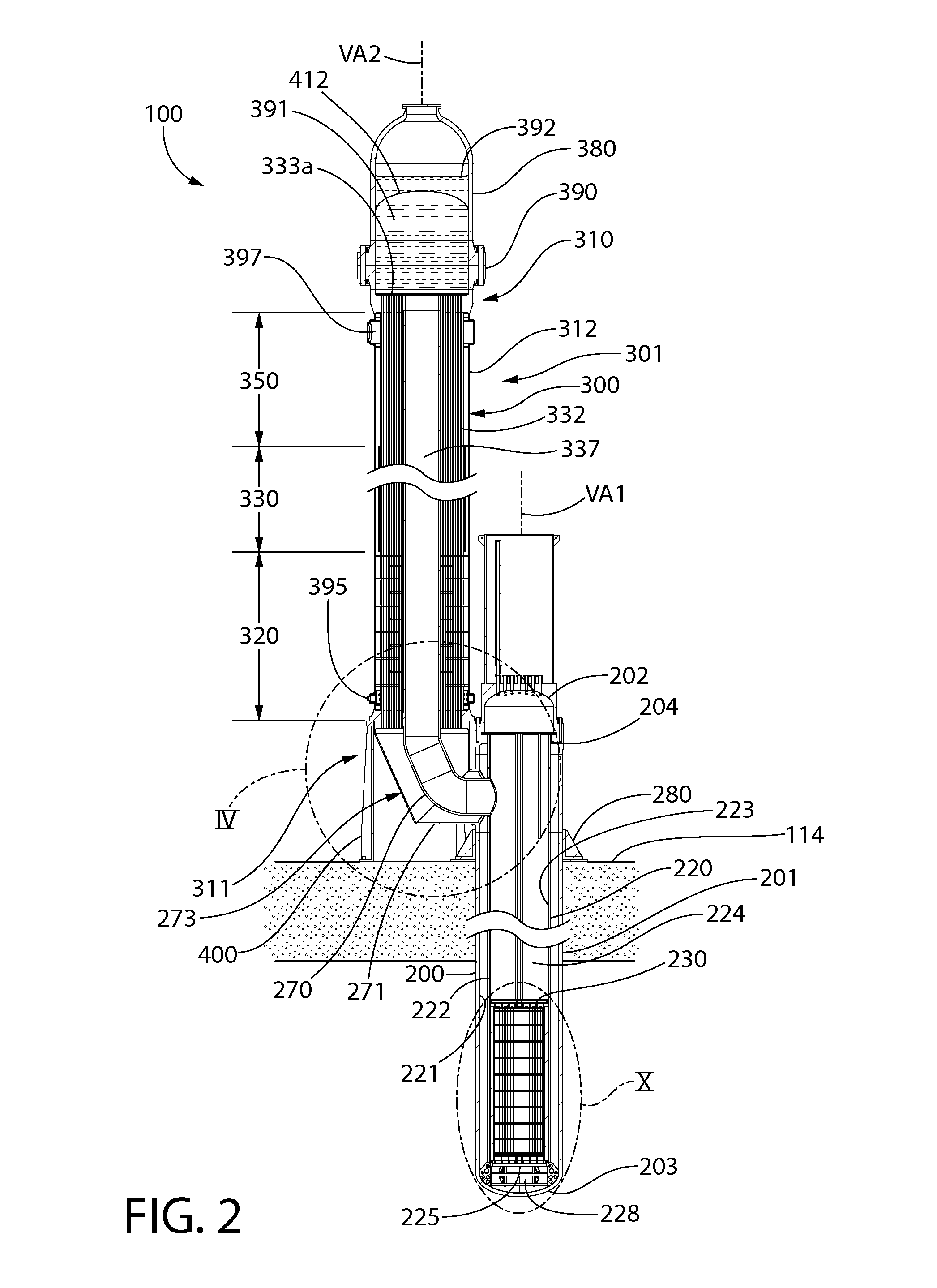

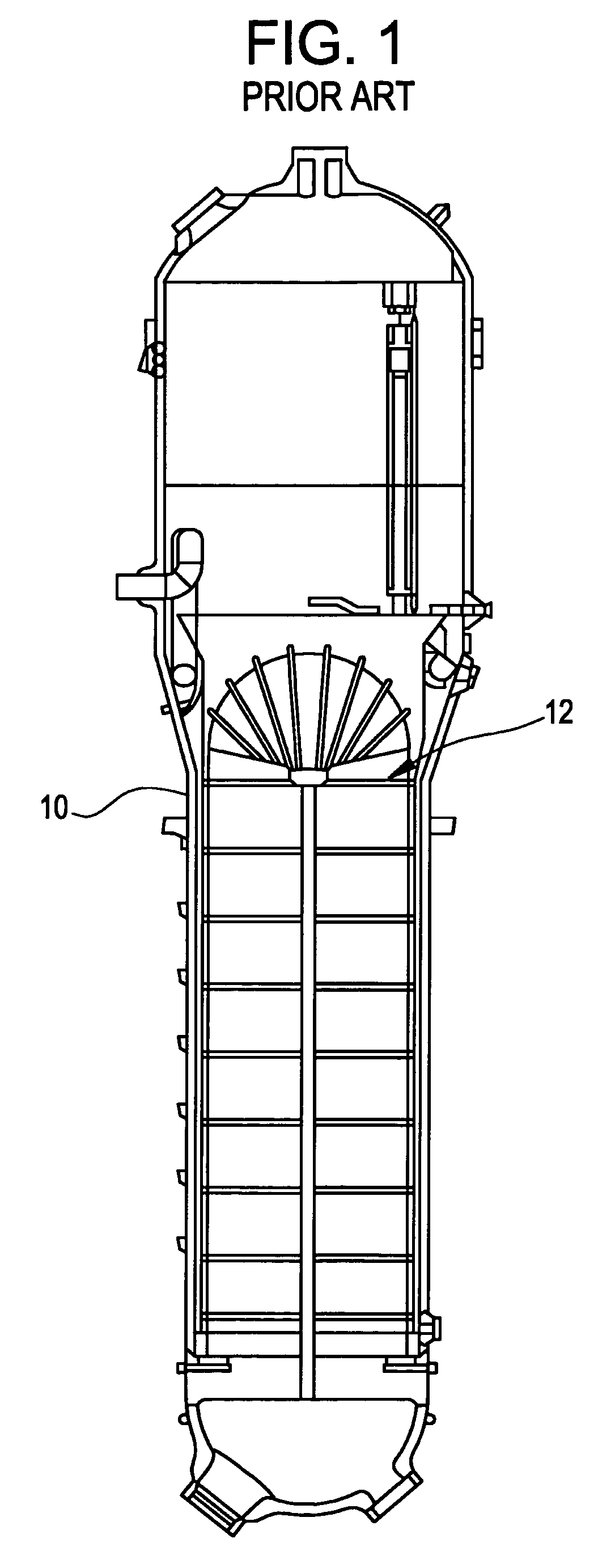

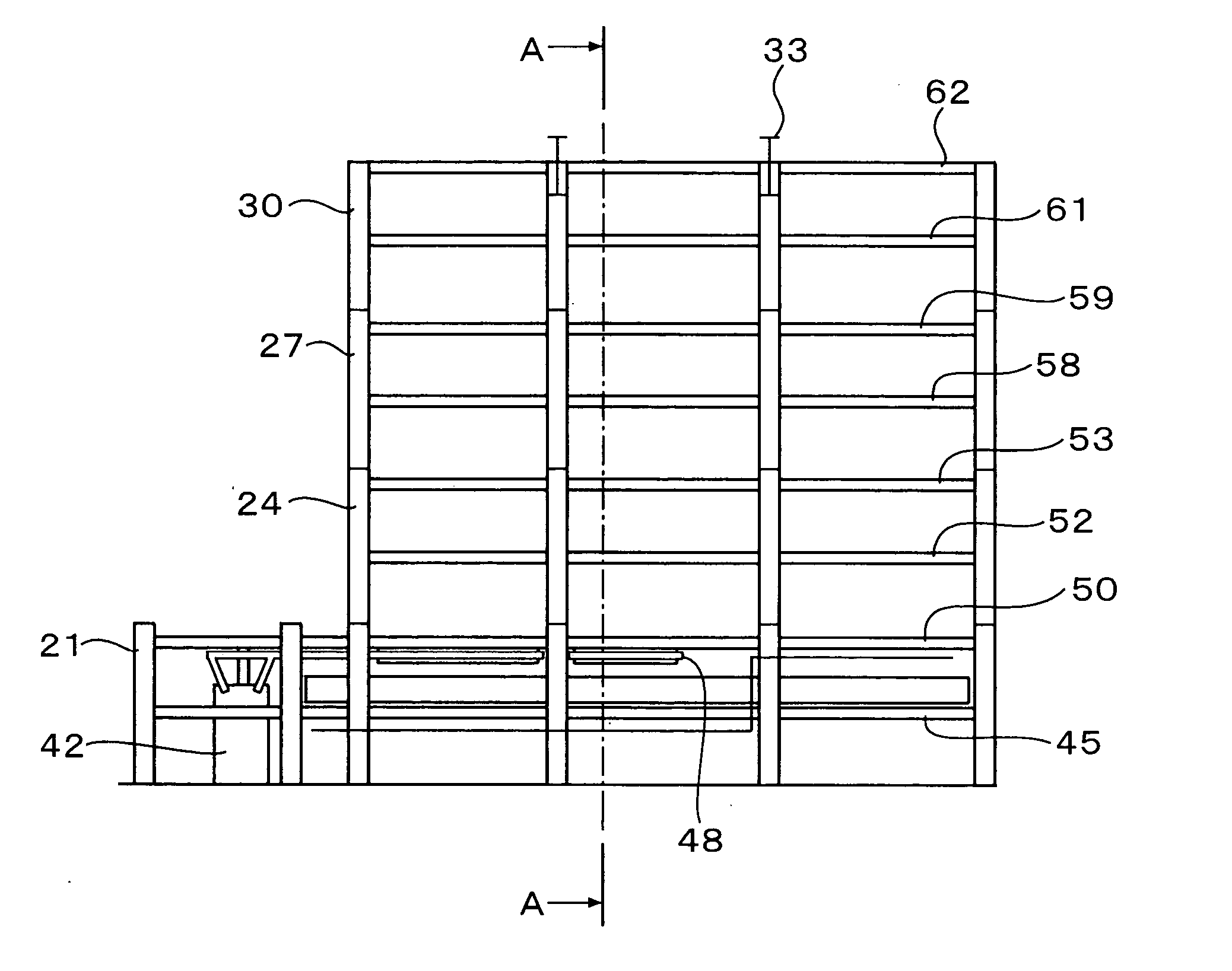

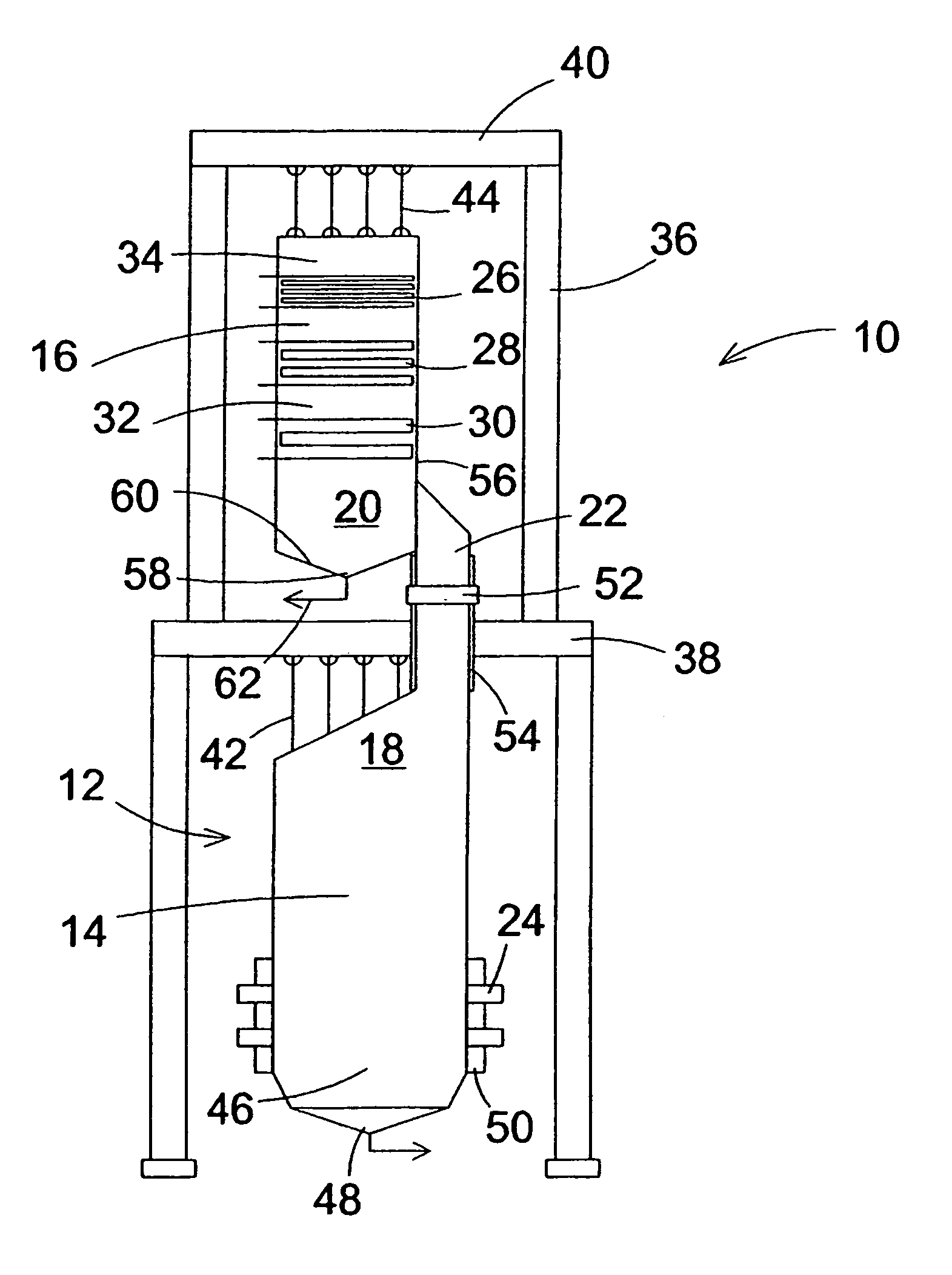

Steam generator for nuclear steam supply system

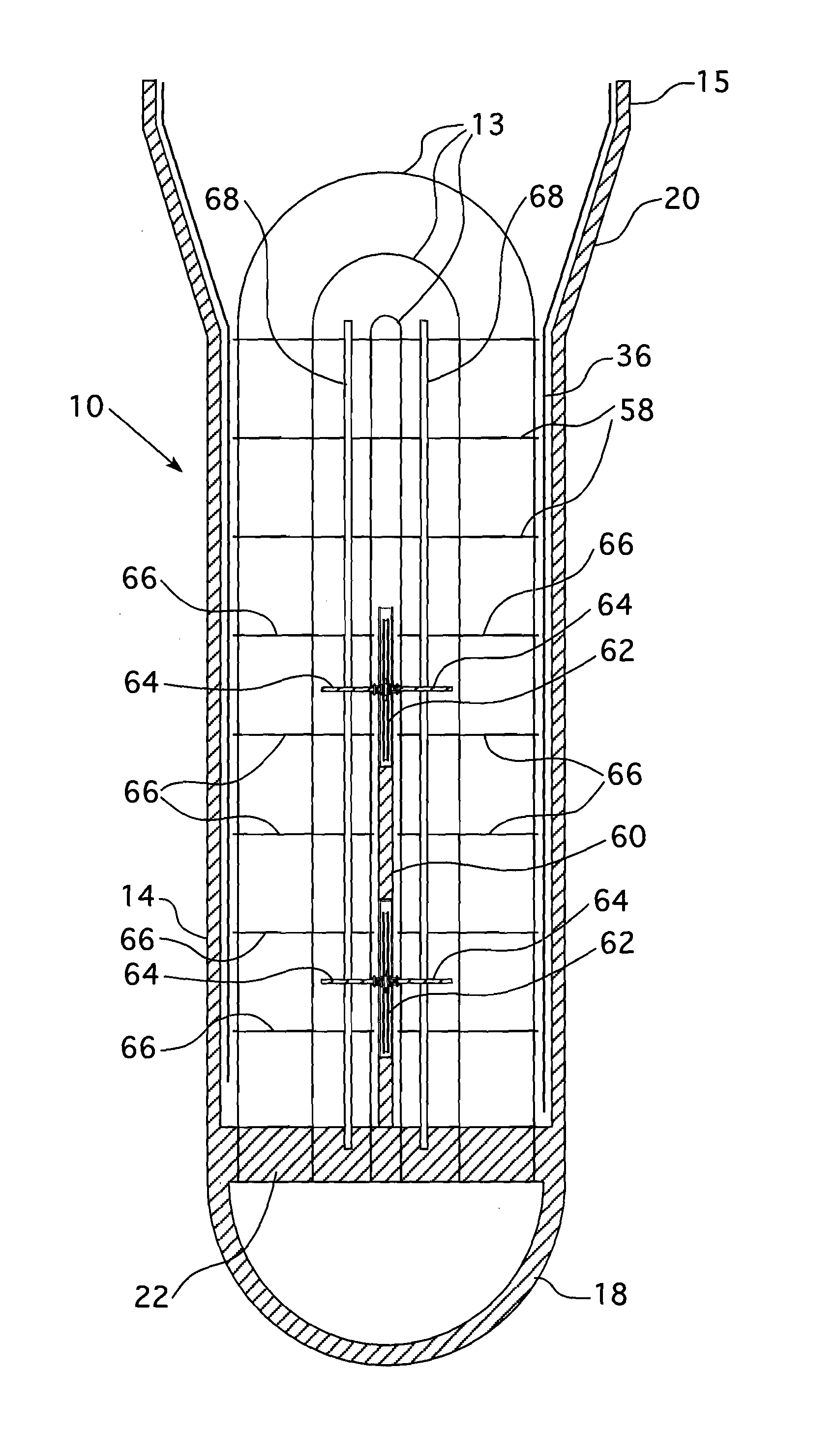

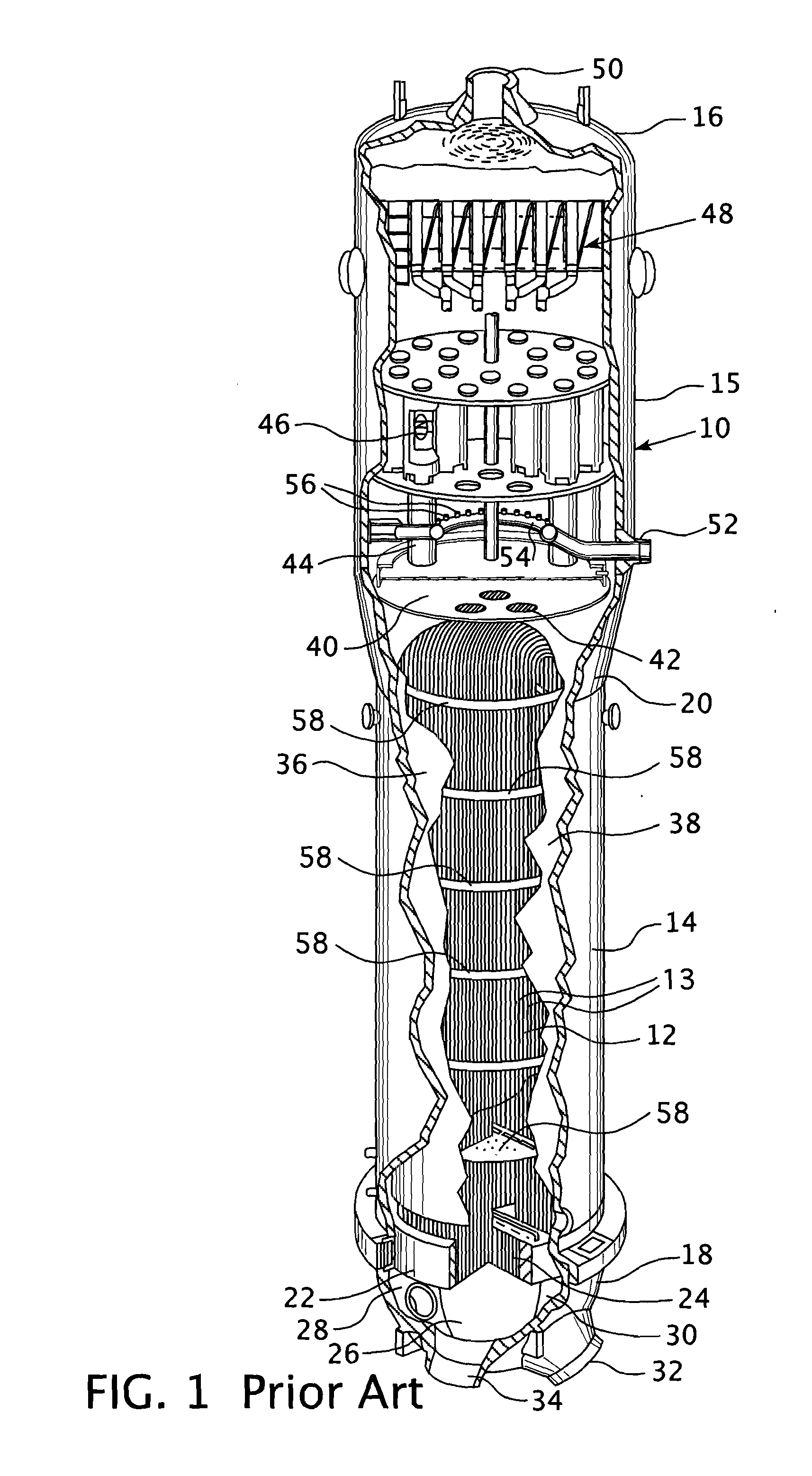

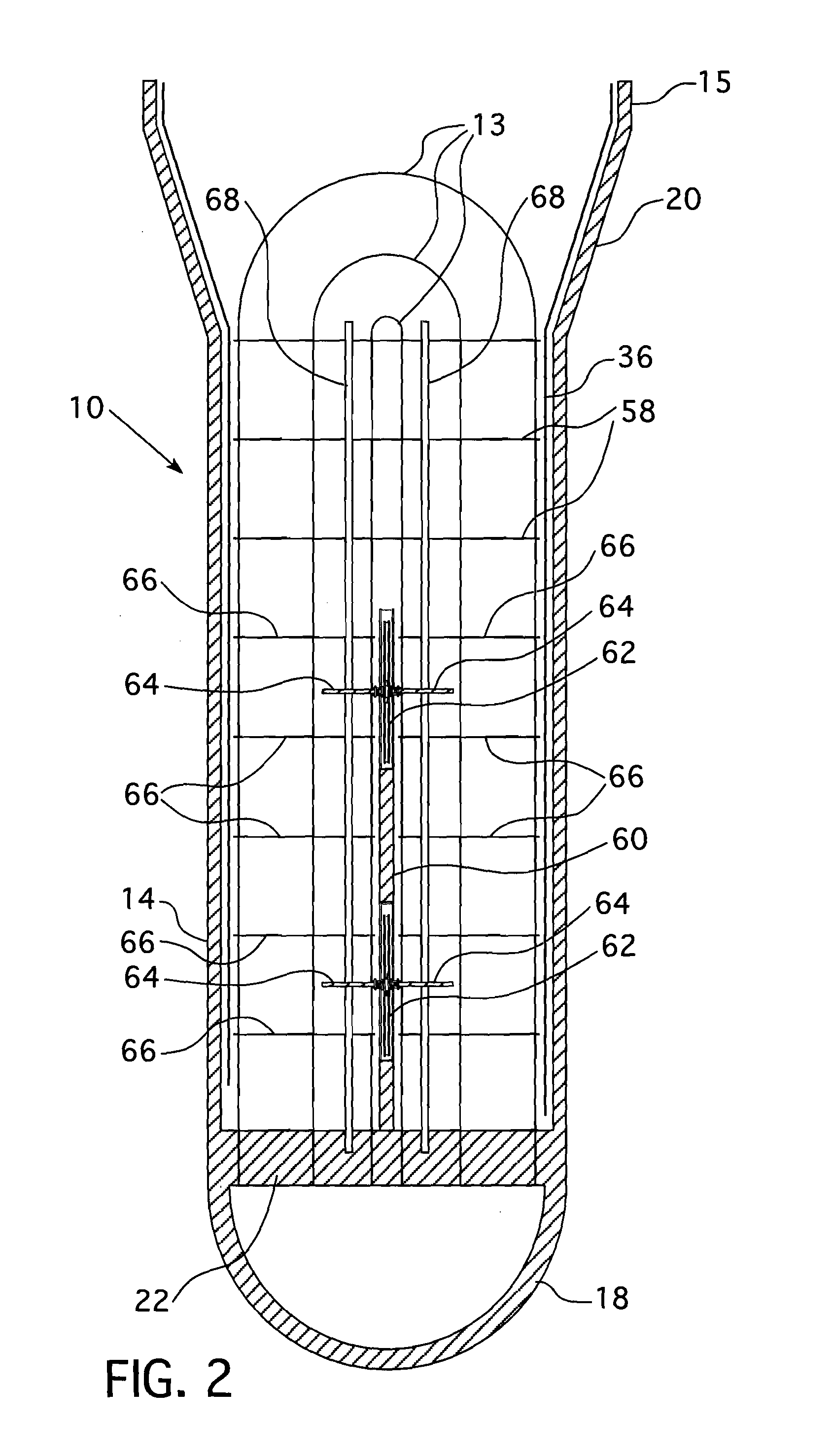

ActiveUS20160196885A1Reduced fretting damage rateAvoid failureBoiler supporting/setting arrangementsSteam generation heating methodsWorking fluidCoolant flow

A nuclear steam supply system utilizing gravity-driven natural circulation for primary coolant flow through a fluidly interconnected reactor vessel and a steam generating vessel. In one embodiment, the steam generating vessel includes a plurality of vertically stacked heat exchangers operable to convert a secondary coolant from a saturated liquid to superheated steam by utilizing heat gained by the primary coolant from a nuclear fuel core in the reactor vessel. The secondary coolant, may be working fluid associated with a Rankine power cycle turbine-generator set in some embodiments. The steam generating vessel and reactor vessel may each be comprised of vertically elongated shells, which in one embodiment are arranged in lateral adjacent relationship. In one embodiment, the reactor vessel and steam generating vessel are physically discrete self-supporting structures which may be physically located in the same containment vessel.

Owner:SMR INVENTEC

Heat exchanger tube panel module, and method of constructing exhaust heat recovery boiler using the same

InactiveUS7357100B2Avoid damageEffect of preventing damage due to shaking during transportation is increasedBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringRecovery boiler

A necessary size and number of modules each obtained by housing a member including heat exchanger tube panels each comprising a heat exchanger tube bundle and headers for the heat exchanger tube bundle, an upper casing of an exhaust heat recovery boiler (HRSG), provided above the heat exchanger tube panels, heat insulators, and heat exchanger tube panel support beams provided on the upper surface of the upper casing into a transportation frame, are prepared according to design specifications of the HRSG, and side casings and a bottom casing except for the ceiling part casing are constructed in advance at a construction site of the HRSG, and the modules are suspended from above between adjacent support beams of the ceiling part to dispose the heat exchanger tube panel support beams of the modules at the set heights of the ceiling part support beams, and the support beams and the ceiling part support beams are connected and fixed via connecting steel plates, whereby the respective modules are transported to the HRSG construction site and can be easily constructed.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Heat transfer tube panel module and method of constructing exhaust heat recovery boiler using the module

ActiveUS7275503B2Small sizeReduce shipping costsBoiler supporting/setting arrangementsRecuperative heat exchangersComputer moduleEngineering

Owner:MITSUBISHI HITACHIPOWER SYST LTD

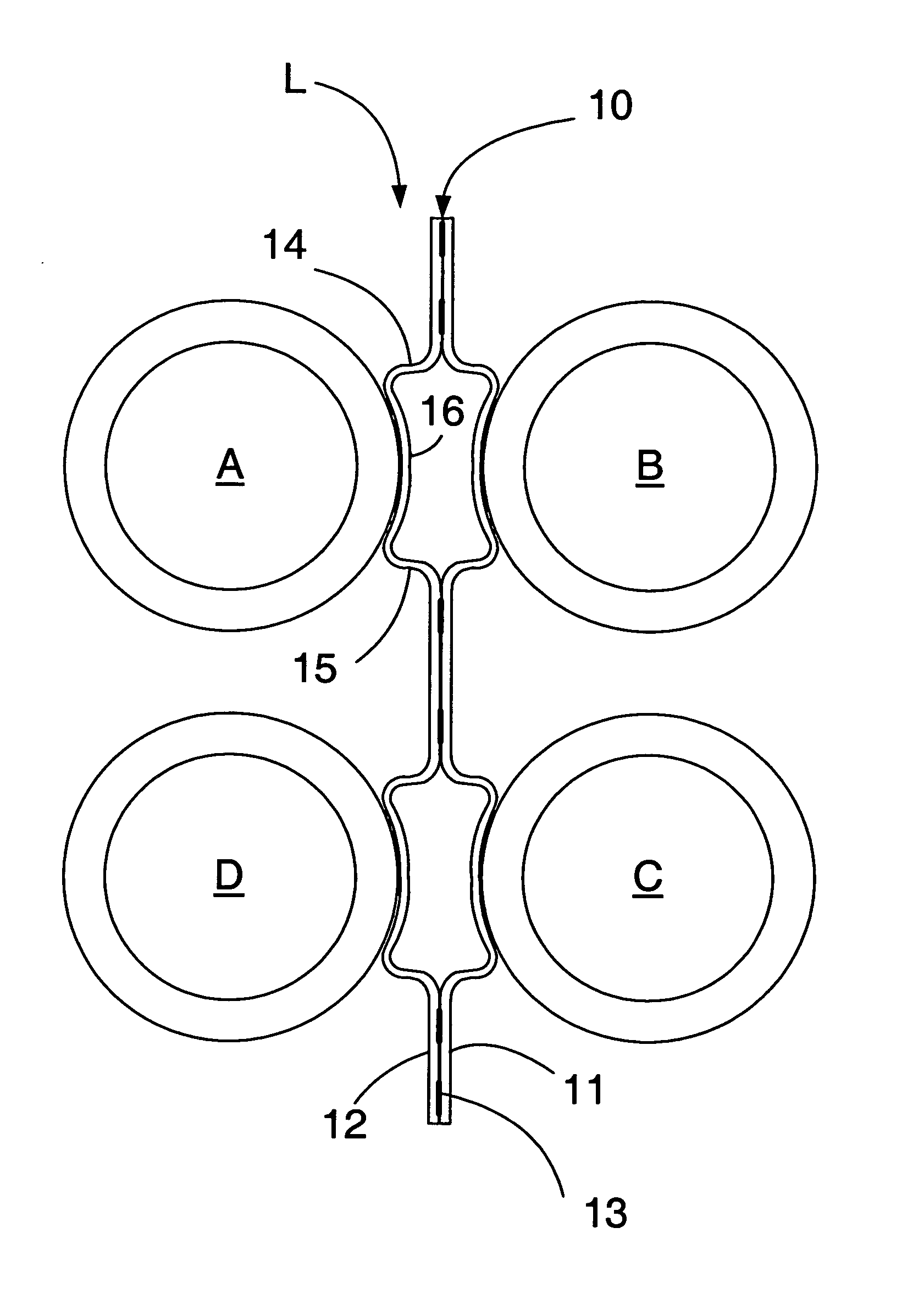

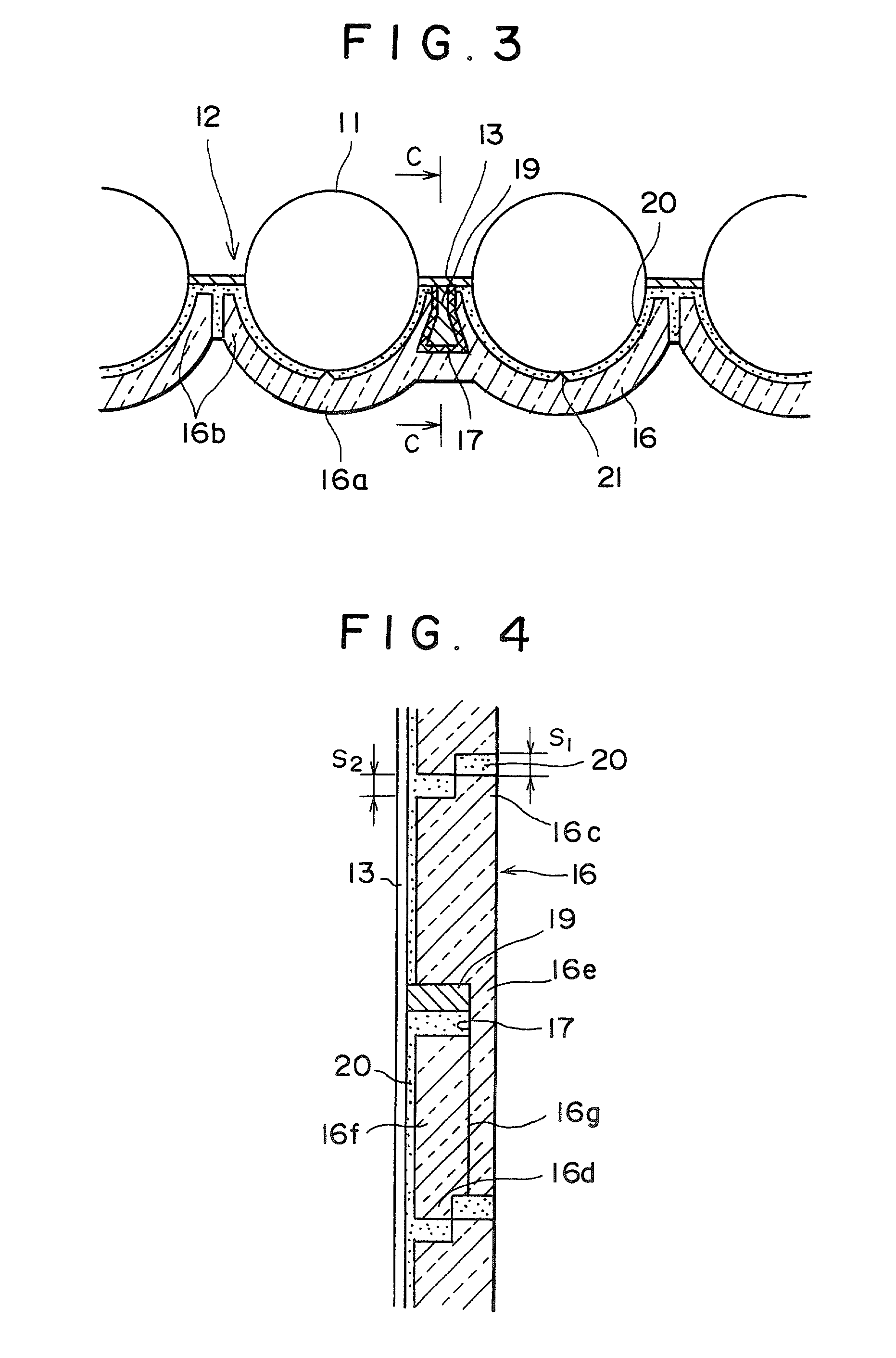

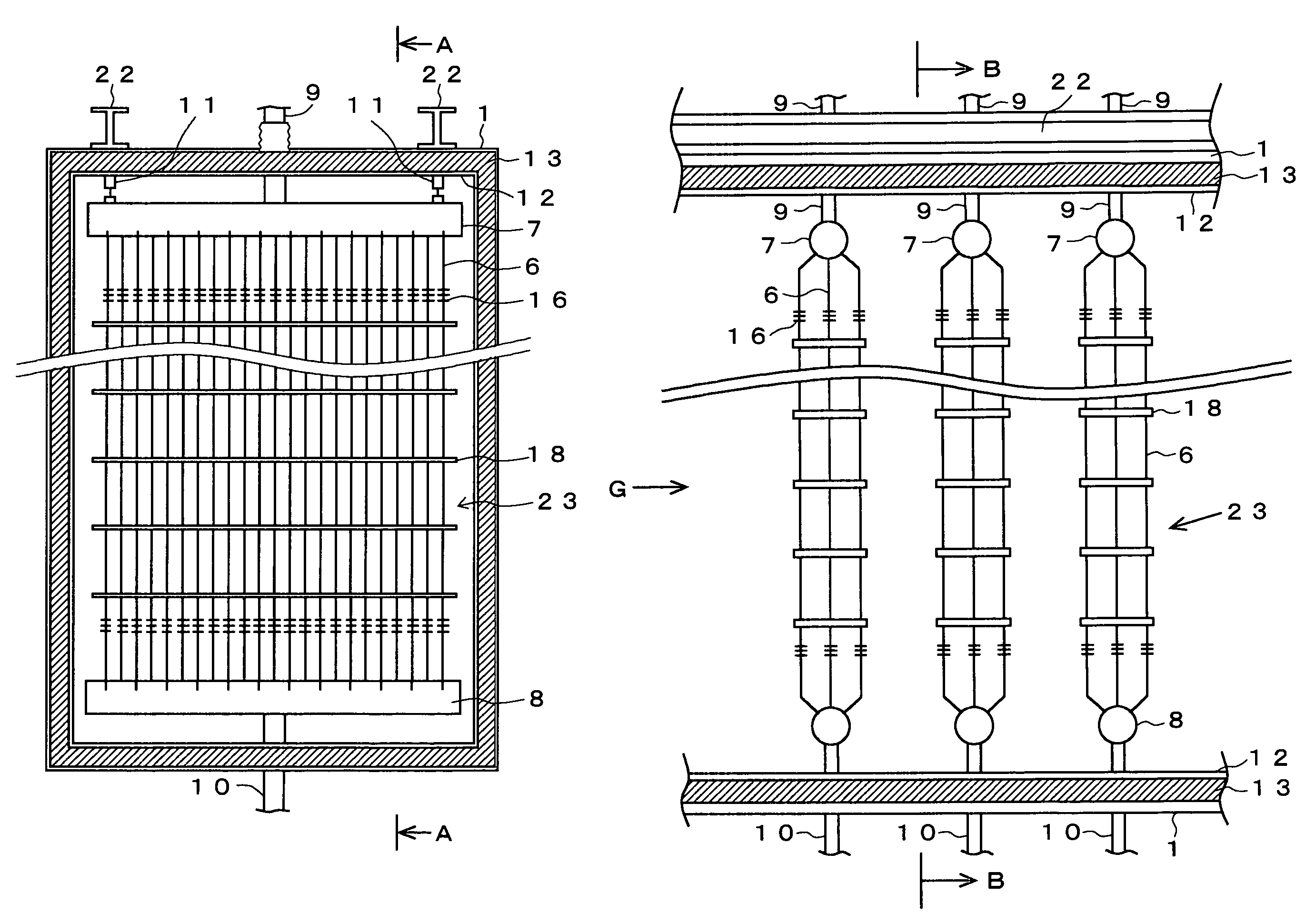

Water pipe protecting refractory structure

InactiveUS6012401AUniform thicknessImprove thermal conductivityFluid heatersBoiler supporting/setting arrangementsCombustionRefractory

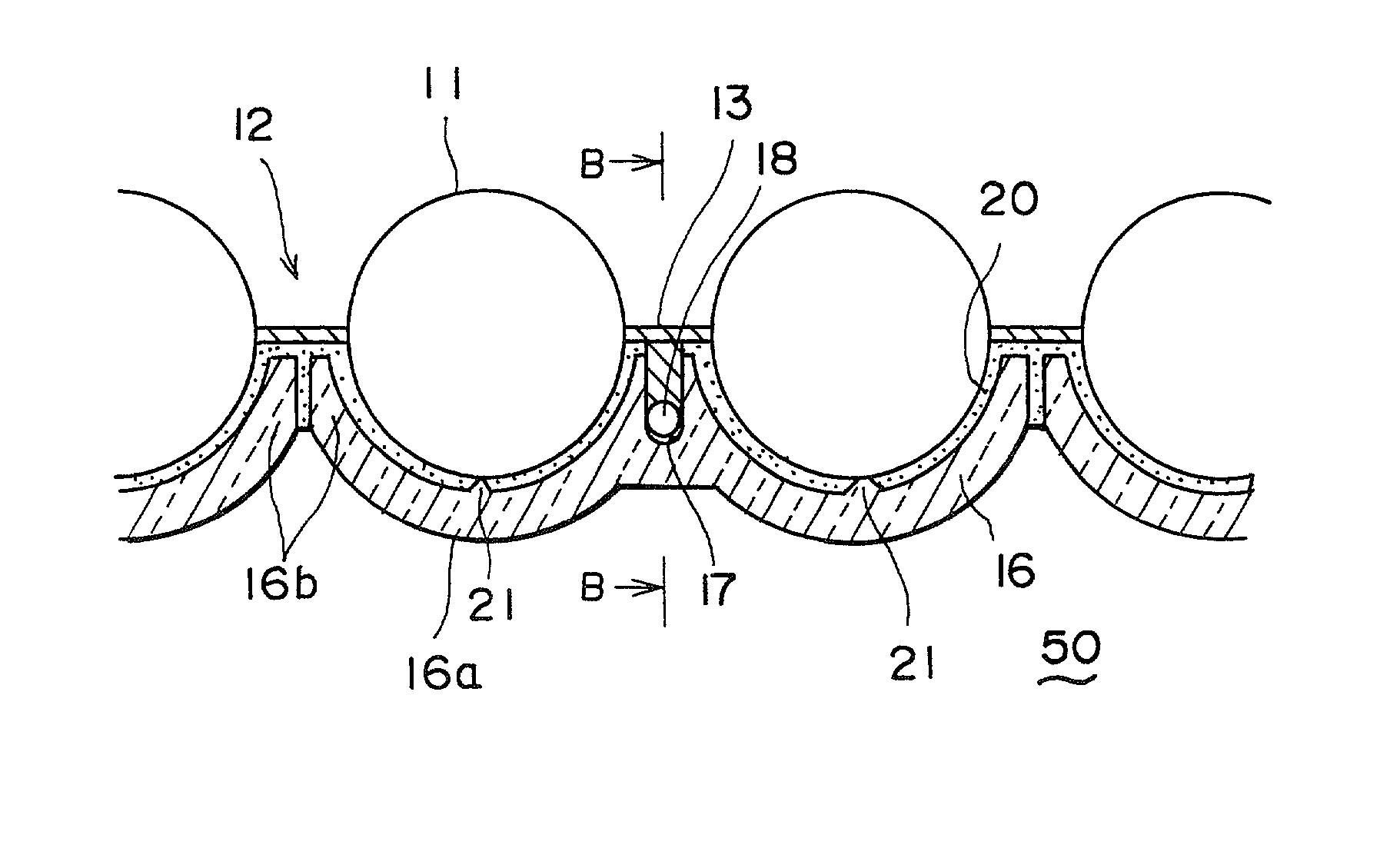

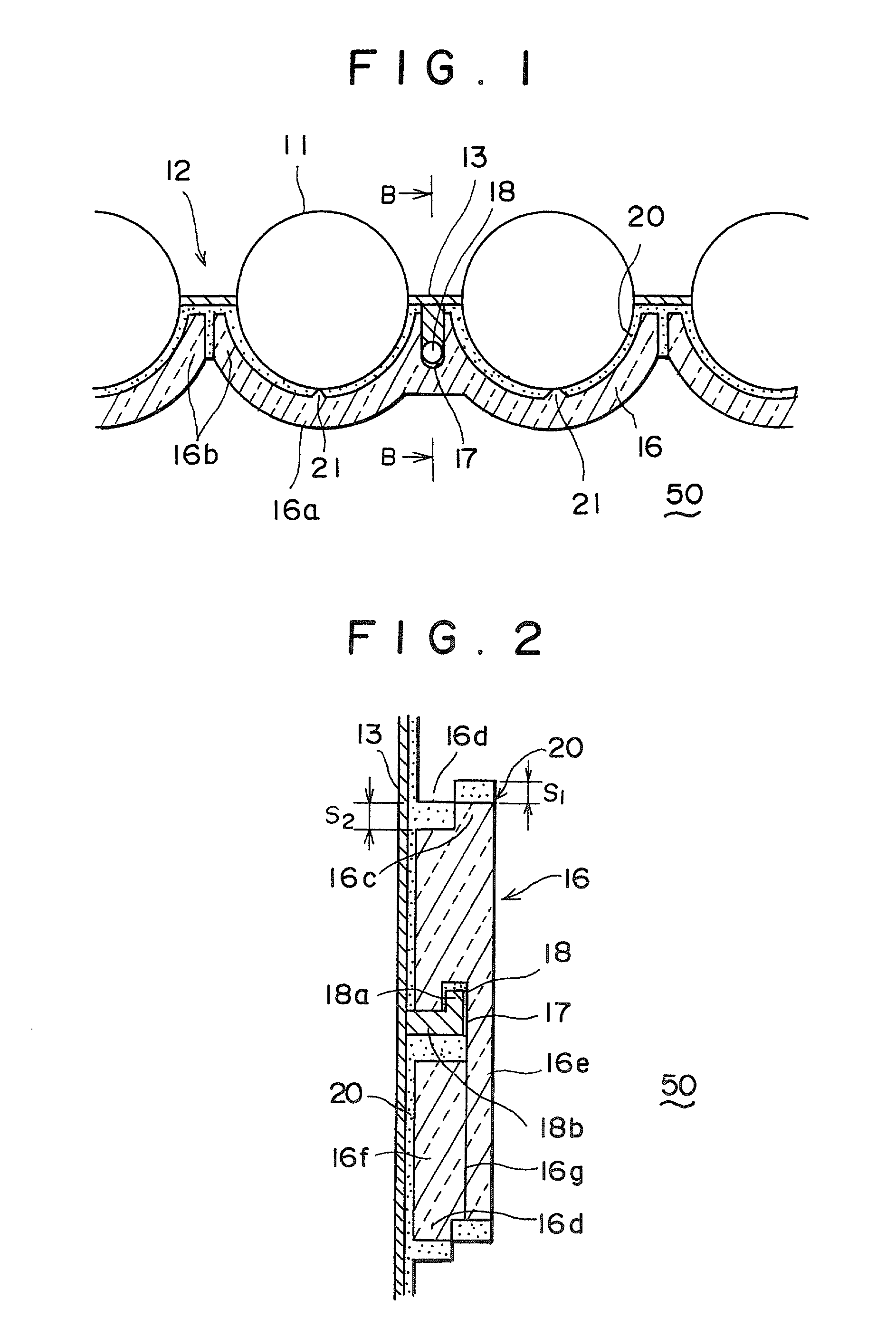

PCT No. PCT / JP97 / 02626 Sec. 371 Date Sep. 28, 1998 Sec. 102(e) Date Sep. 28, 1998 PCT Filed Jul. 29, 1997 PCT Pub. No. WO98 / 05901 PCT Pub. Date Dec. 2, 1998A heat-resistant assembly to shield boiler tubes which does not entail a thick heat-resistant block. This structure would be interposed between the boiler tubes and the combustion gases. Such a structure would be distinguished by the fact that it comprises heat-resistant block 16, itself composed of curved portion 16a, whose inner surface at one point comes in contact with the aforesaid boiler tube 11, and connecting portions 16b, and the aforesaid boiler tube assembly 12. The interlocking attachment structure which interlockingly secures these two components together in such a way that the block can be mounted or removed comprises recess 17, 58 or 68 and tongue 18, 59 or 69.

Owner:MITSUBISHI HEAVY IND LTD

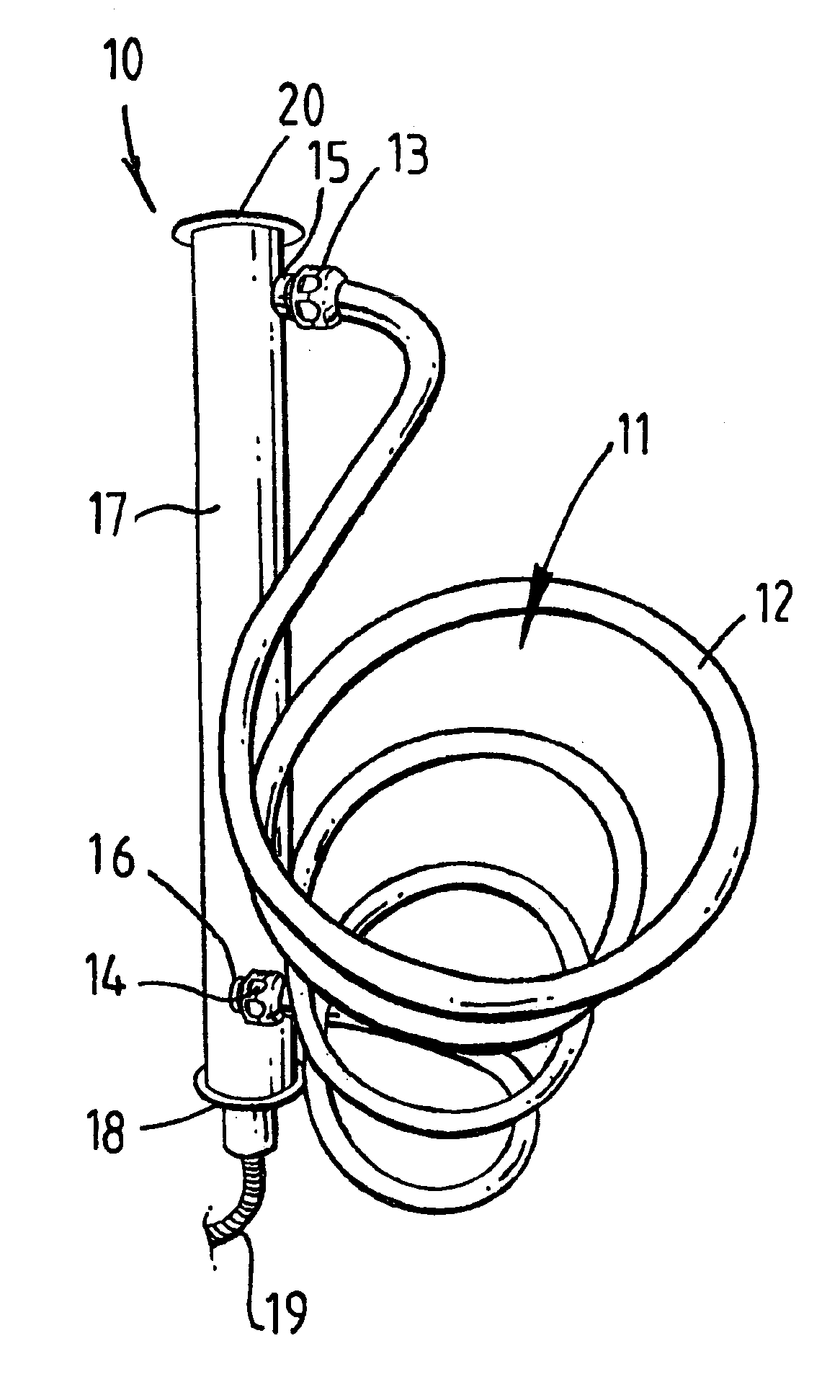

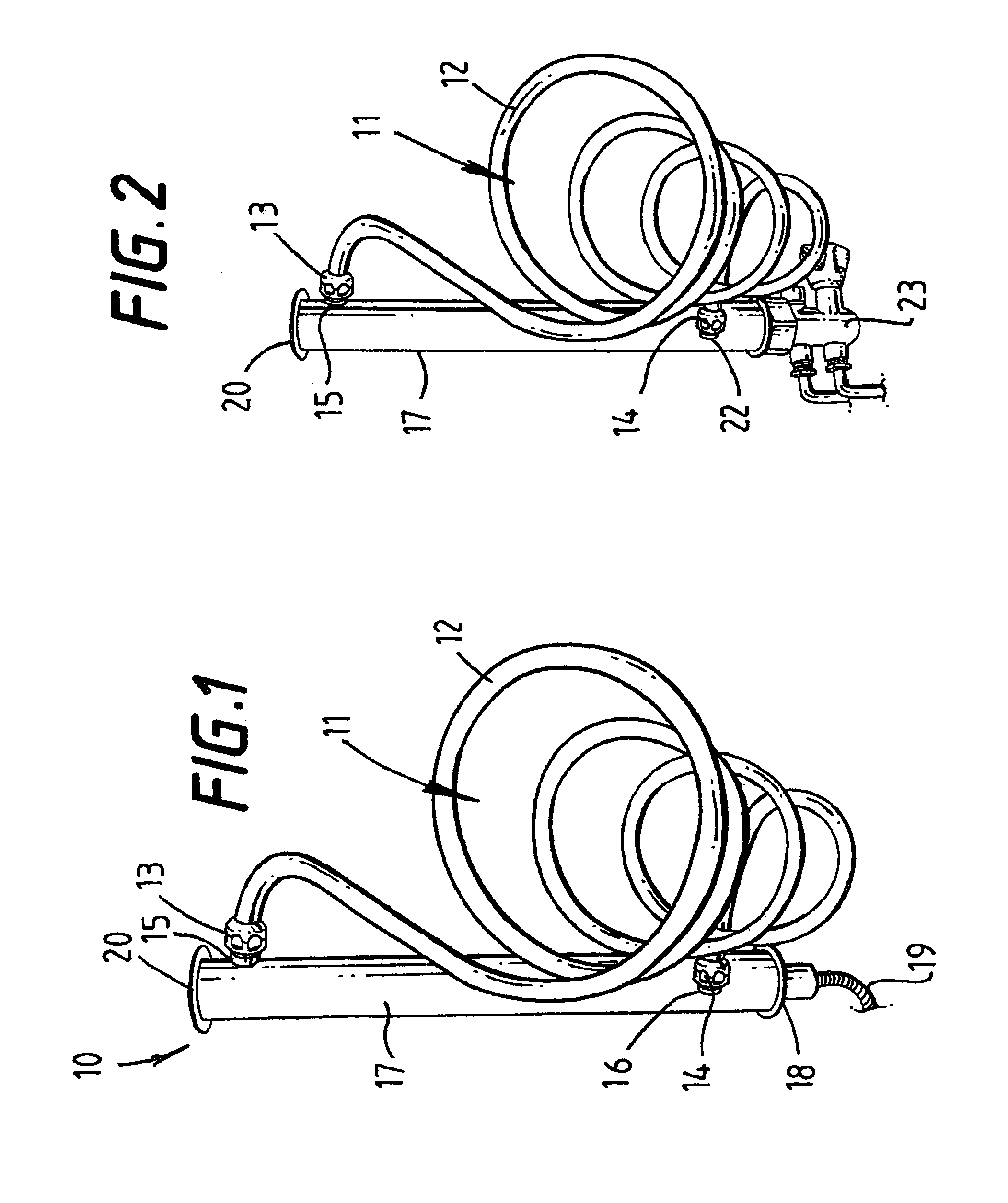

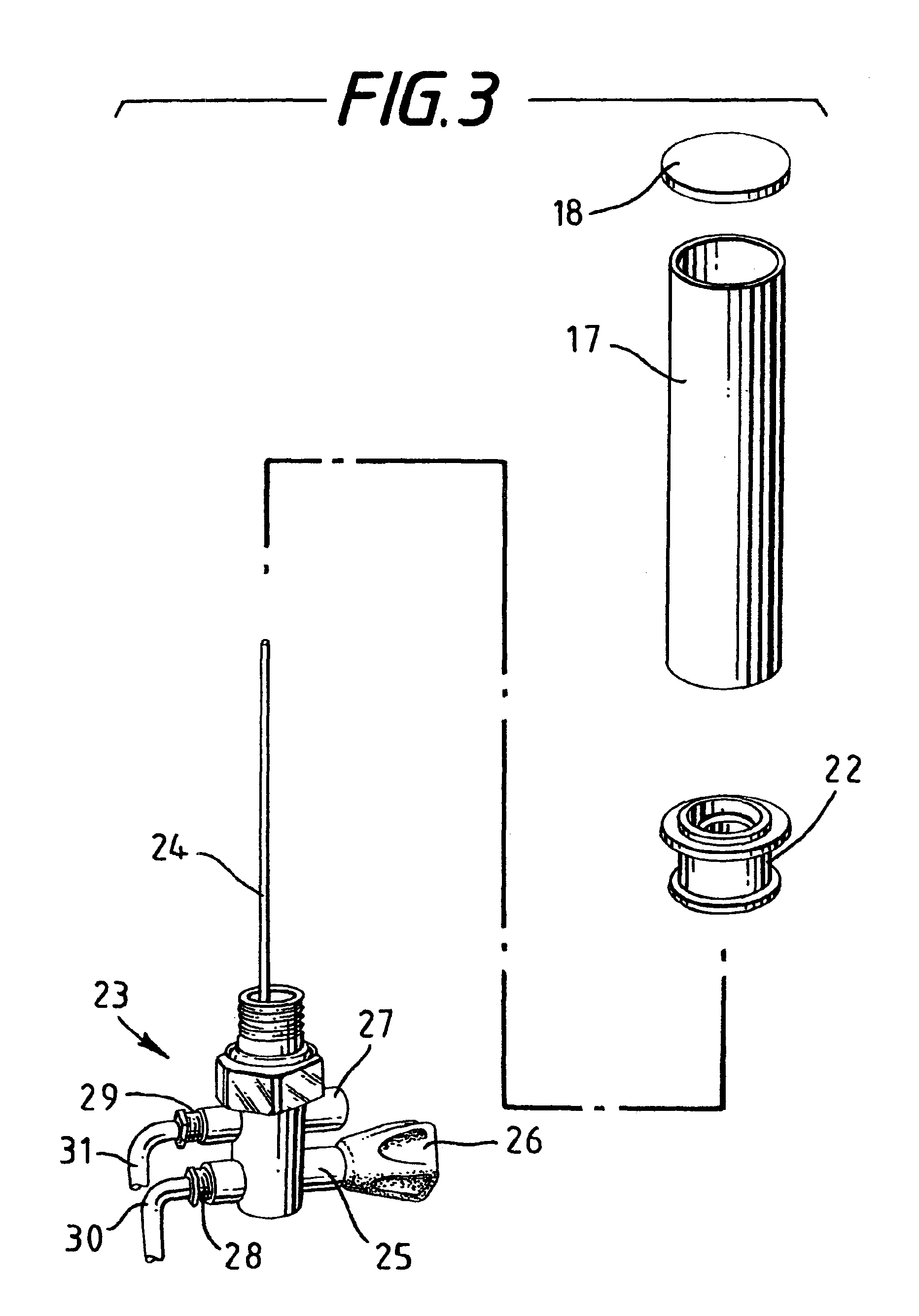

Towel rail or towel holder

InactiveUS6935279B2Easy to useEfficient dryingBoiler supporting/setting arrangementsSteam generation heating methodsEngineeringCooling fluid

A heated towel holder comprises an elongate tube formed into the general shape of a conical helix, supported by a mounting arrangement such that the smaller end of the conical helix shape is lowermost and the axis of that shape extends upwardly at a shallow angle to the vertical. The mounting arrangement feeds heated fluid into one end of the formed tube and allows cooled fluid to drain from the other end of the formed tube. At least the greater part of a towel may simply be dropped into the conical volume bound by the helix so as to remain therein and be heated by fluid flowing through the formed tube.

Owner:GRANDEE BOILERS

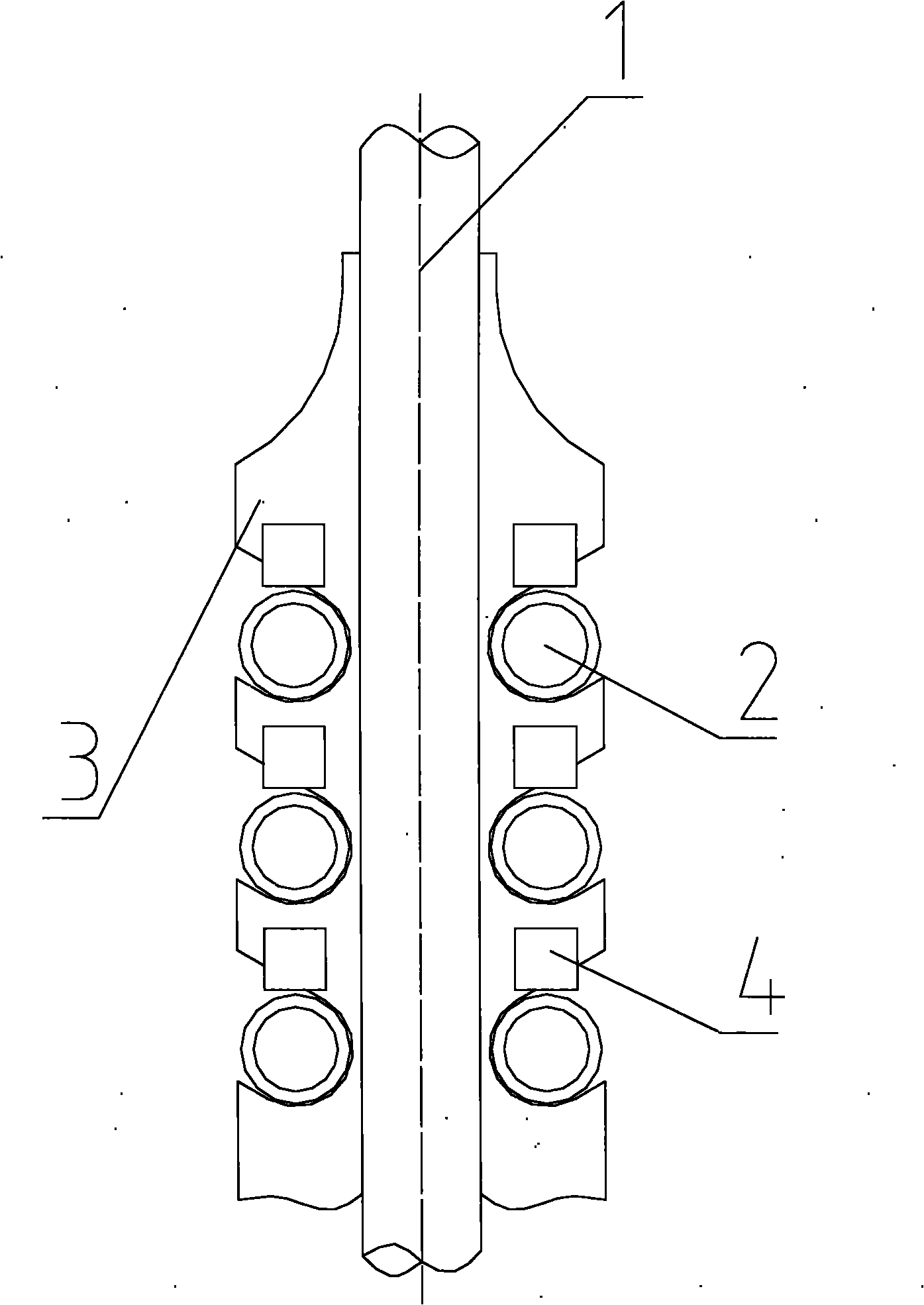

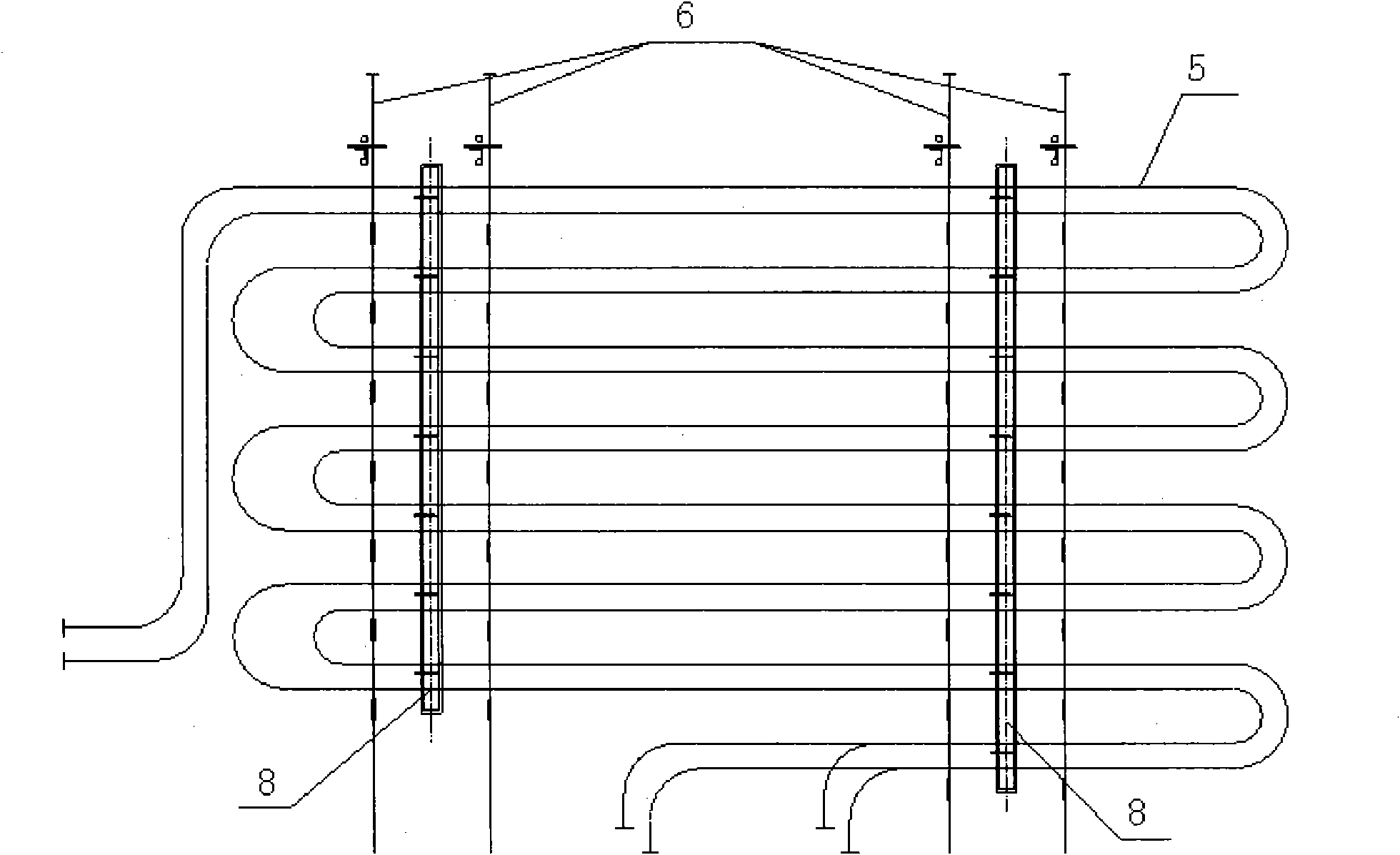

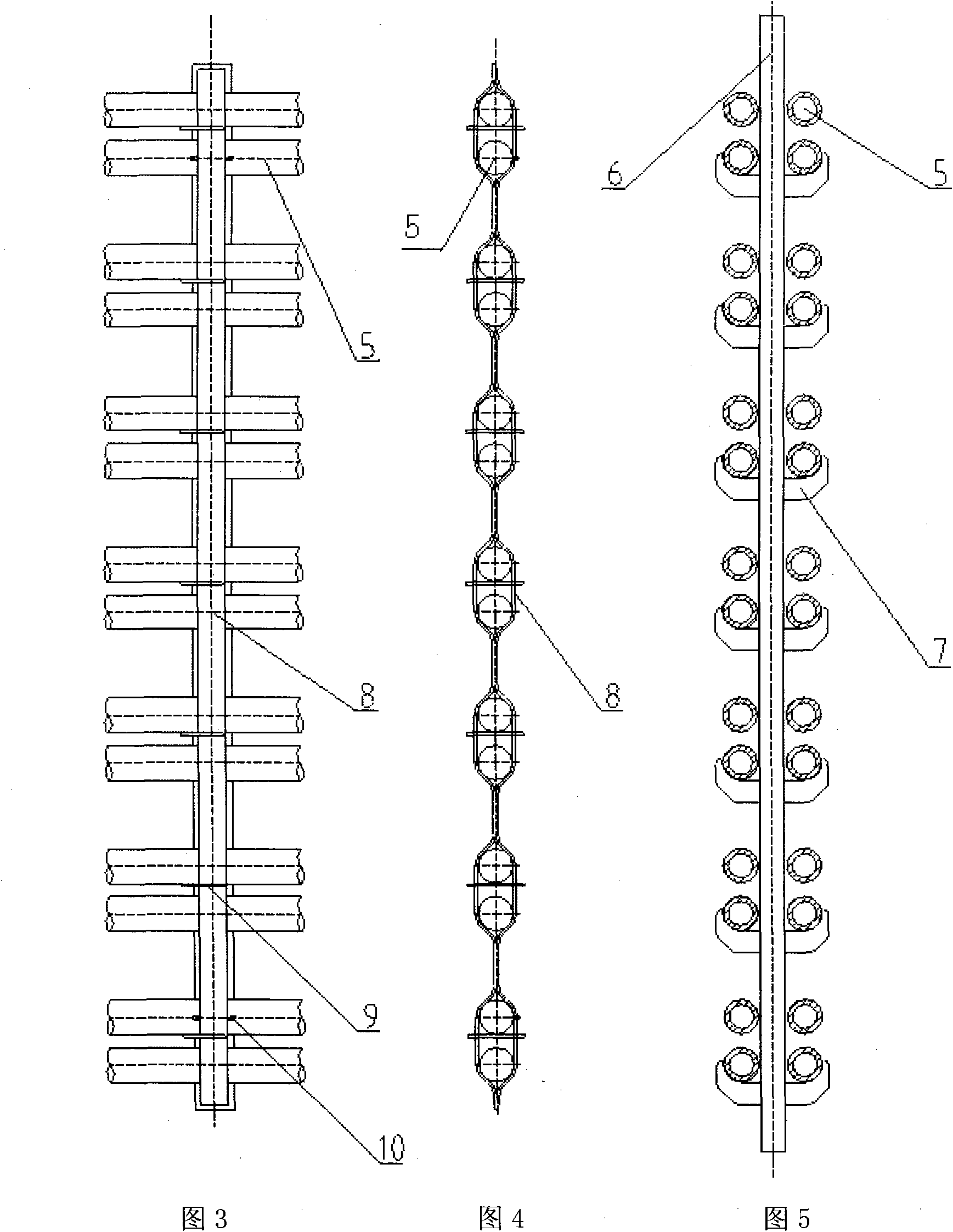

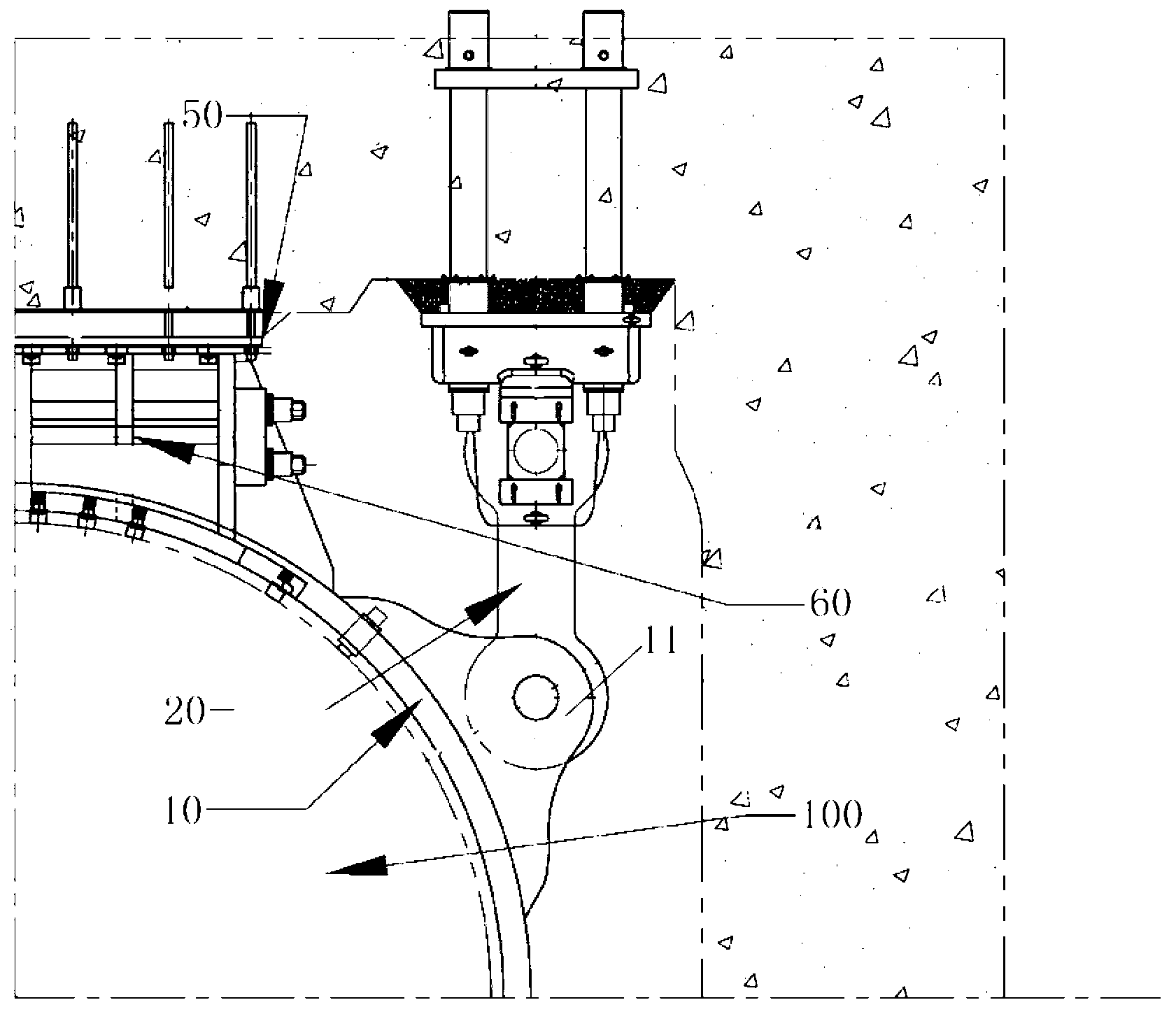

Suspension structure of pendent tube used for S-shaped tube panel

ActiveCN101788140APrevent dequeuingSimple suspension structureBoiler supporting/setting arrangementsStress pointEngineering

Owner:SHANGHAI BOILER WORKS

Support structure for steam generator in nuclear station and steam generator

ActiveCN102798115AEliminate gapsImprove seismic performanceSteam generation heating methodsBoiler supporting/setting arrangementsNuclear engineeringShock absorber

Owner:中广核工程有限公司 +1

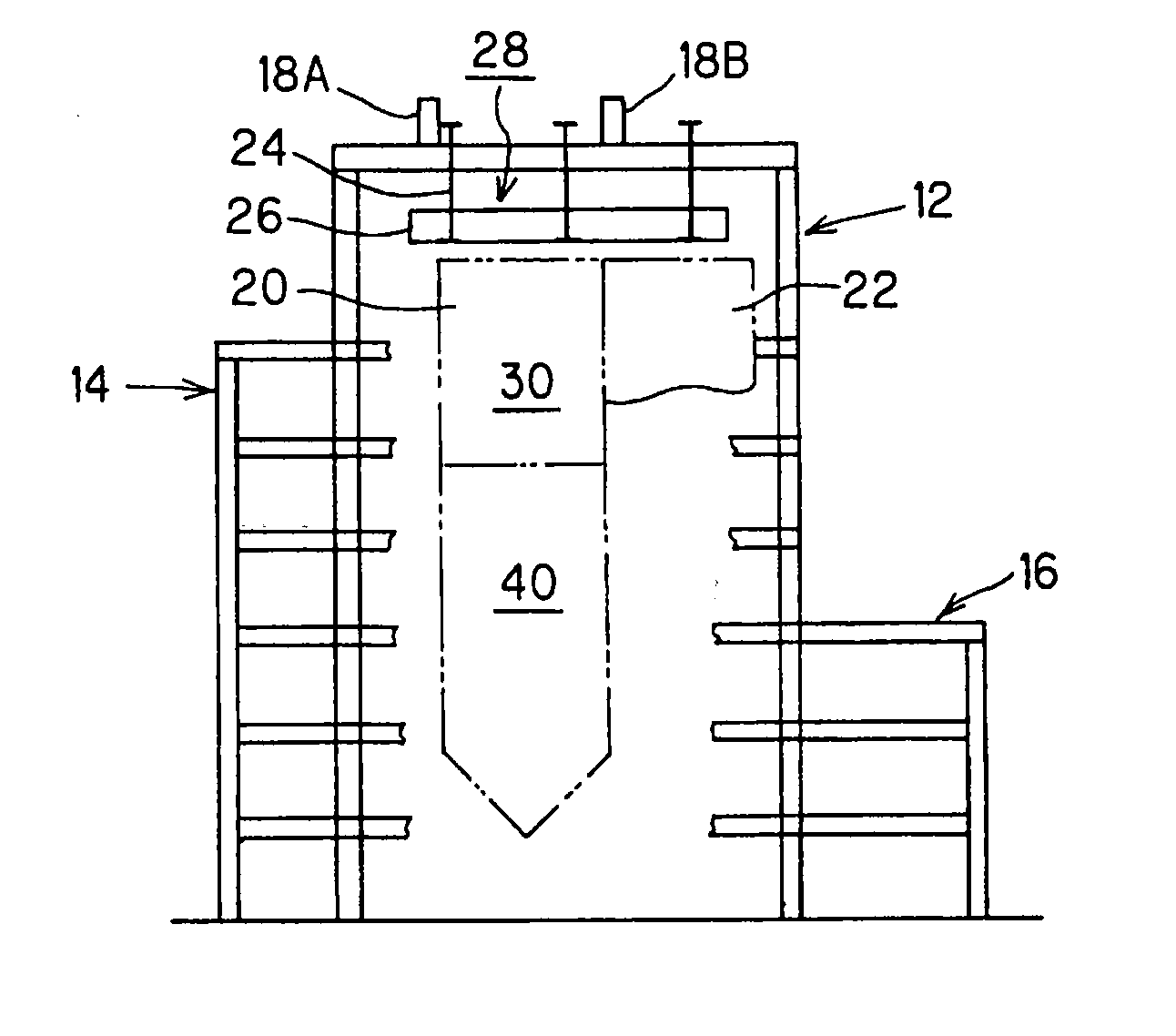

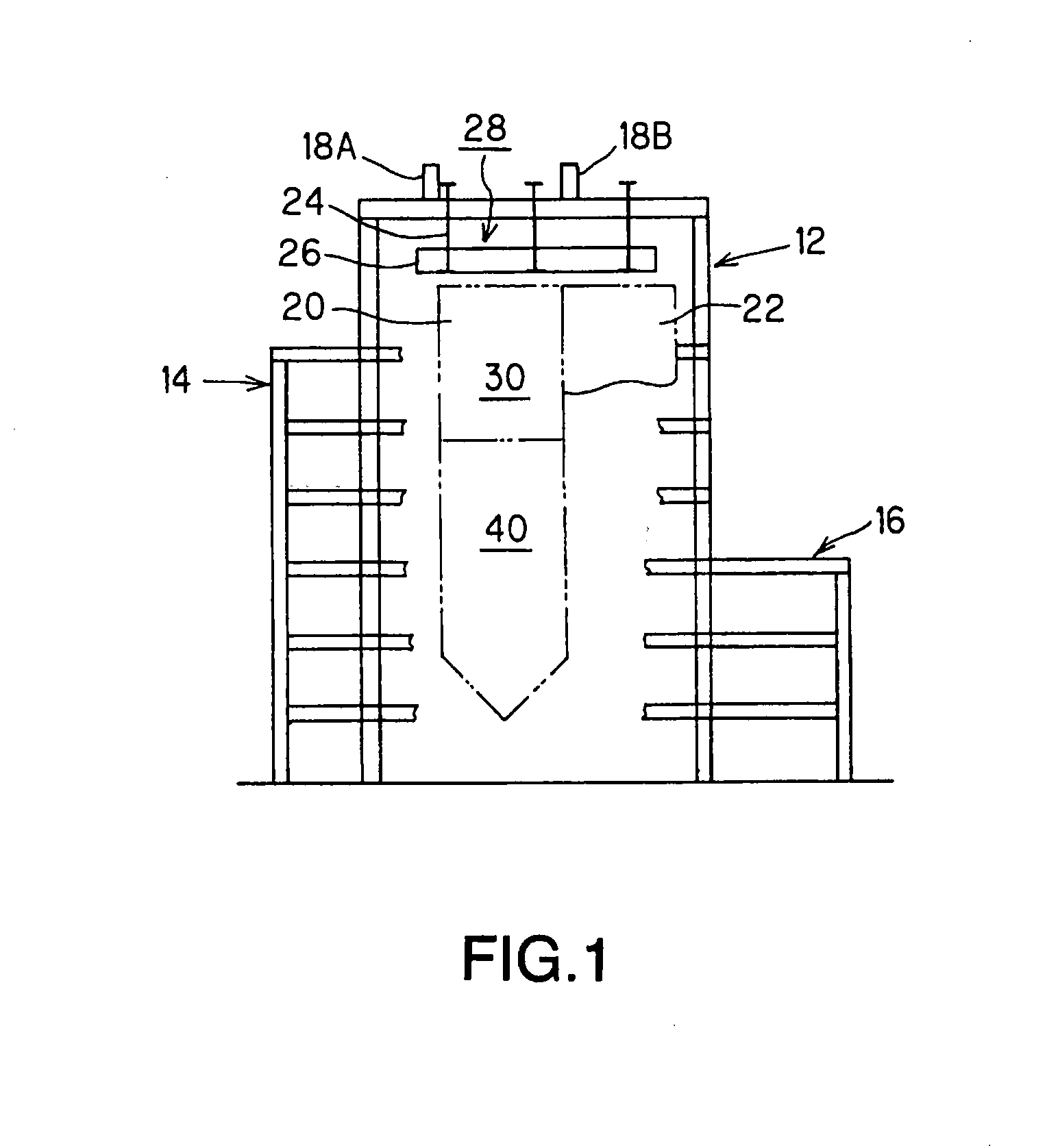

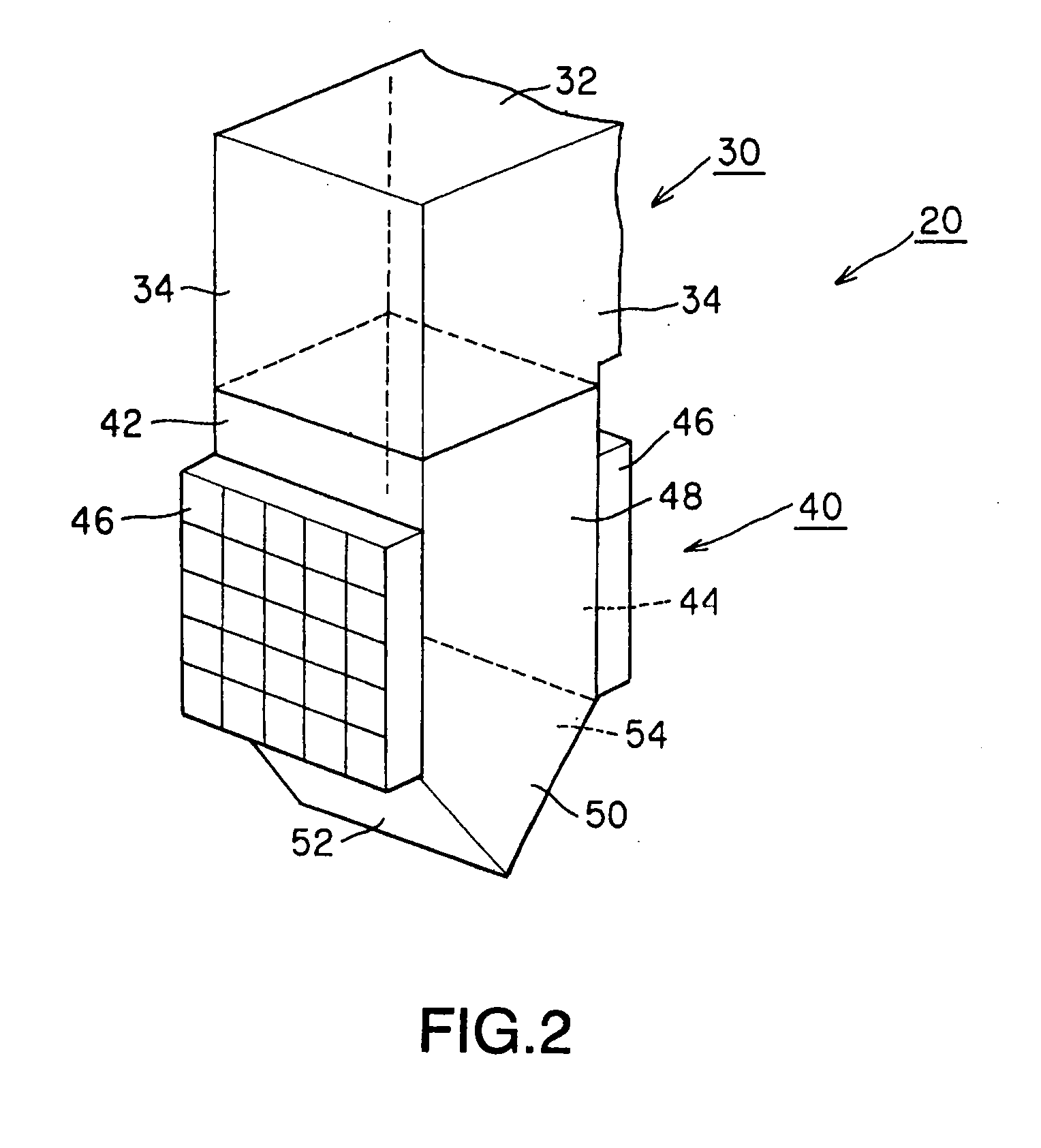

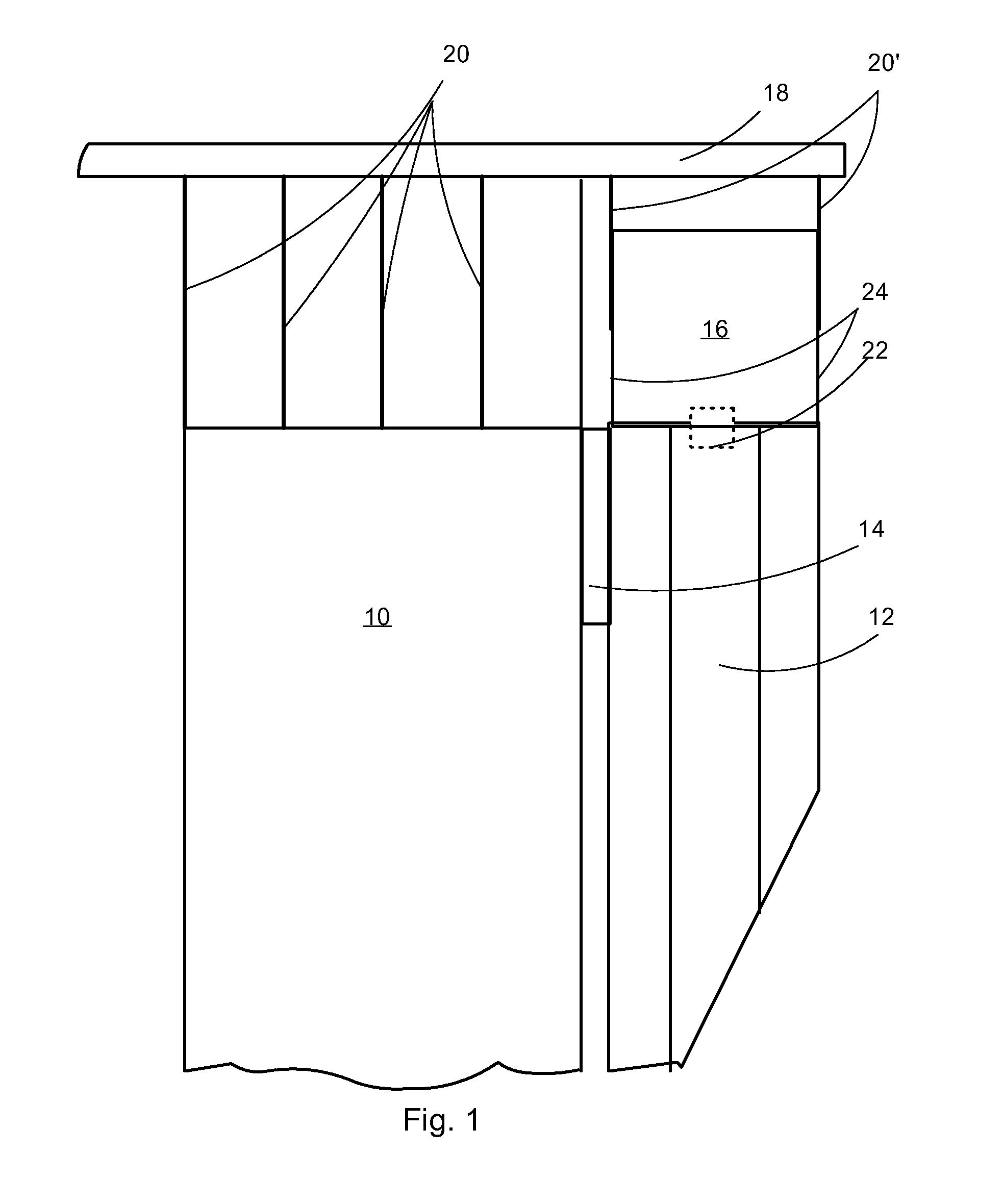

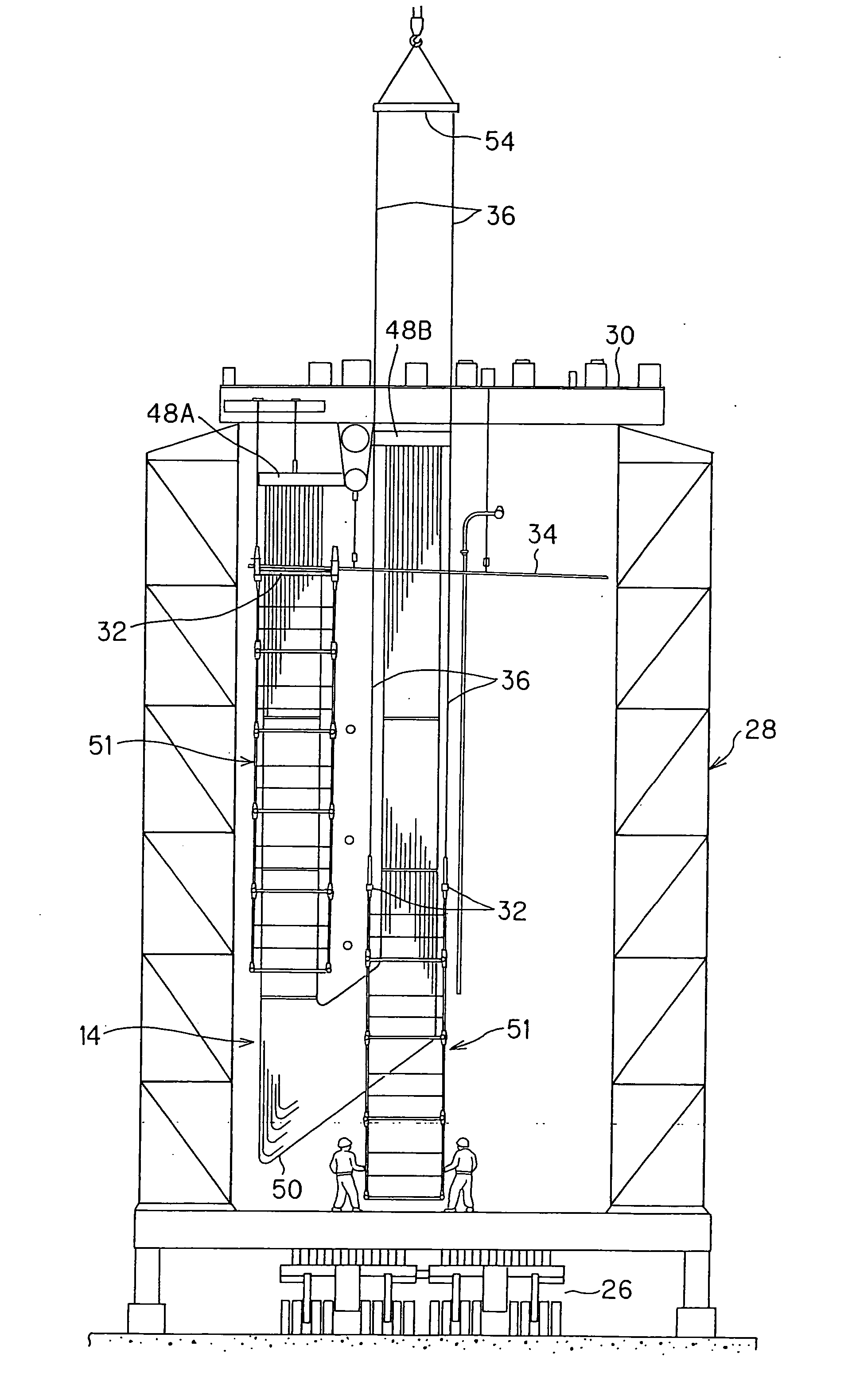

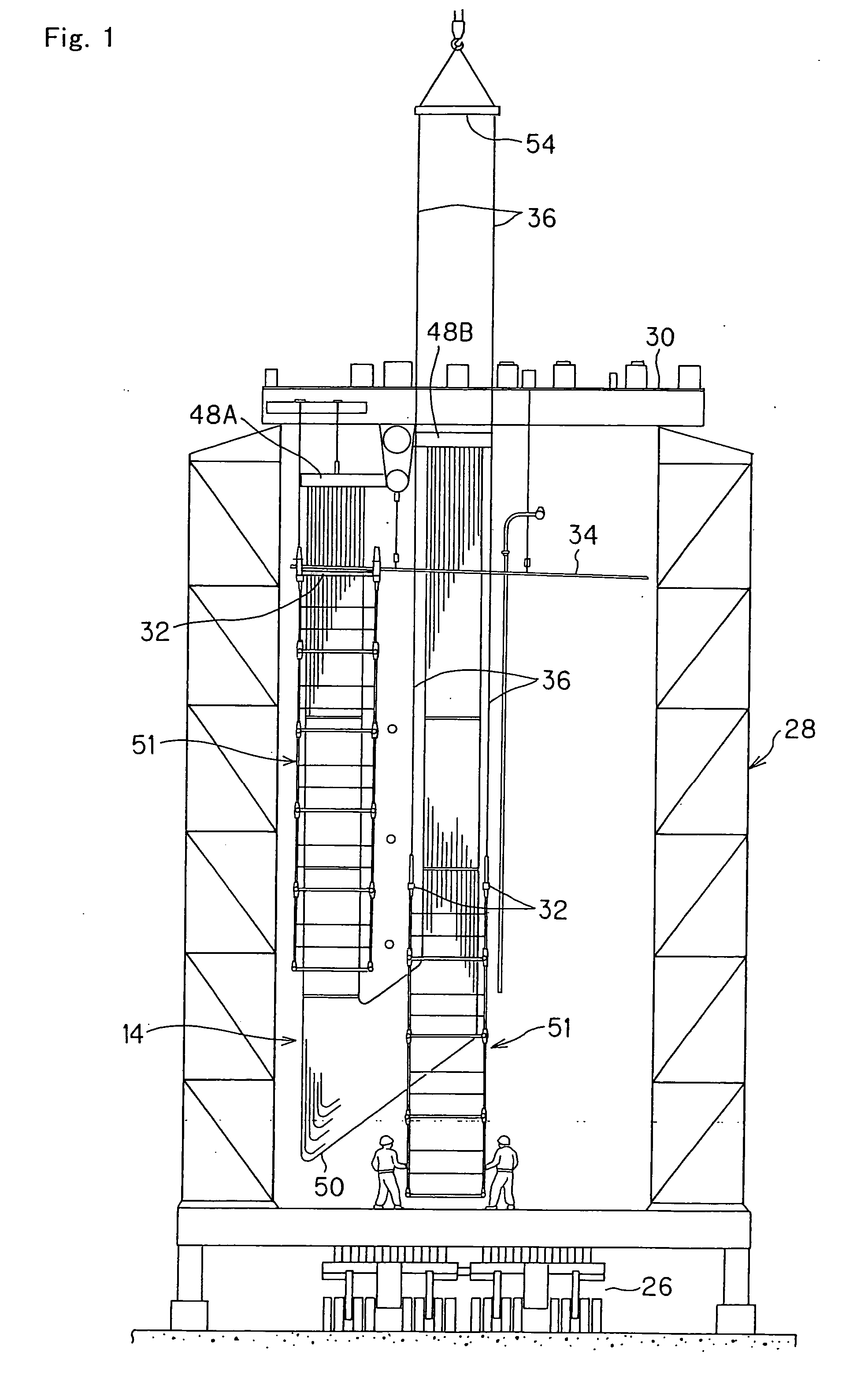

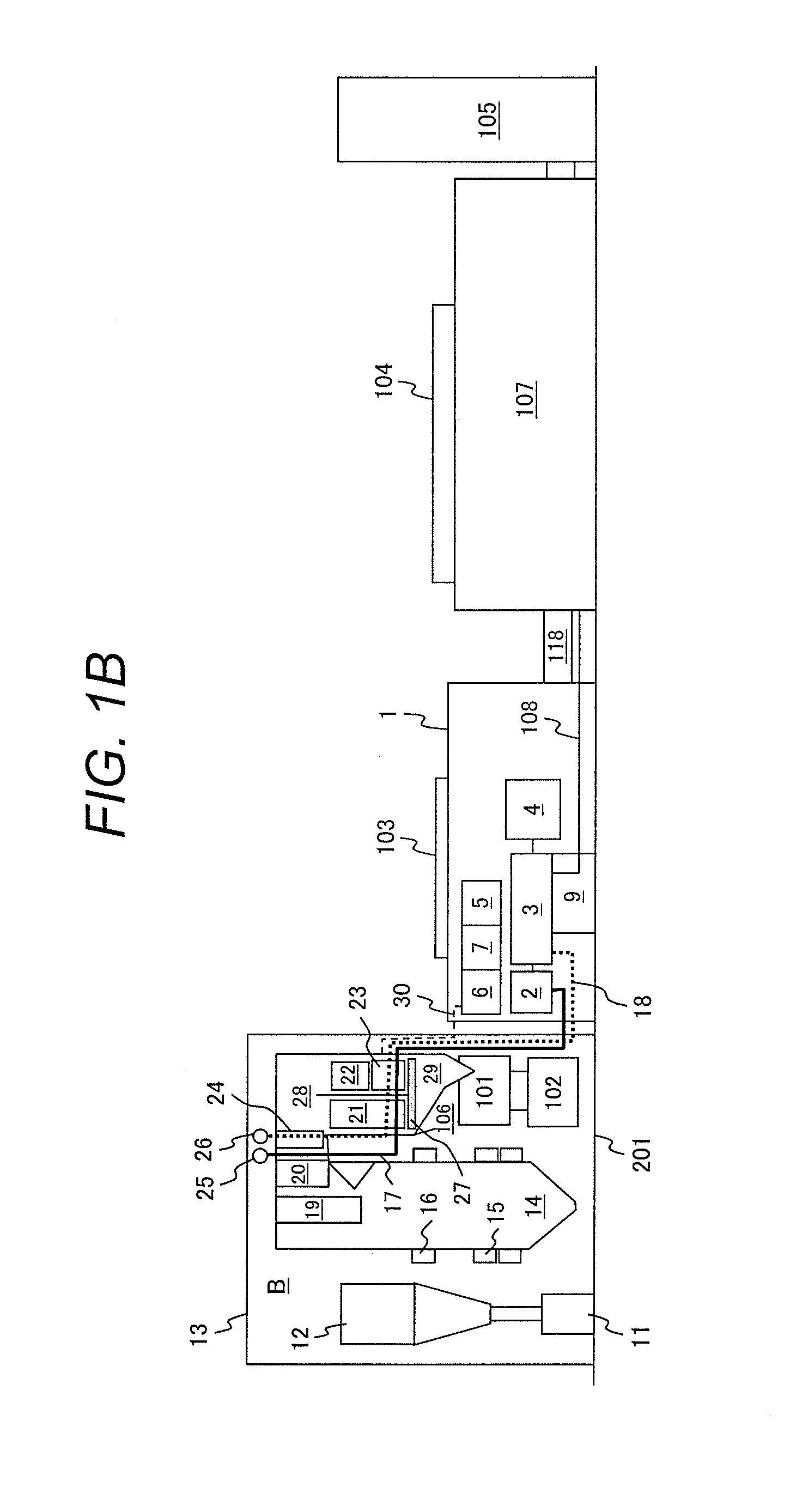

Method of installing furnace walls of a boiler

InactiveUS20070272172A1Guaranteed safe operationOptimize locationBoiler supporting/setting arrangementsFuel injection apparatusWork periodEngineering

New and useful method of installing furnace walls for a boiler that does not require dedicated temporary lifting mechanism and reduces the installation work period significantly is disclosed. The method of installing furnace walls for a boiler configured with an upper portion of boiler proper 30 and a lower portion of boiler proper 40, temporally suspending two left and right face furnace water wall panels 48 among four furnace water wall panels, the upper portion of boiler proper is assembled while it is hanged from a top girder module 28 positioned on the top portion of a center portion in a boiler frame, a furnace rear wall 44 and a furnace front wall 42 among the furnace water wall panels are hanged sequentially, the temporally suspended two left and right face furnace water wall panels 48 are moved to designated positions, and the upper ends of the furnace water wall panels 48, 44 and 42 are connected with the lower end of the upper portion of boiler proper 30.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

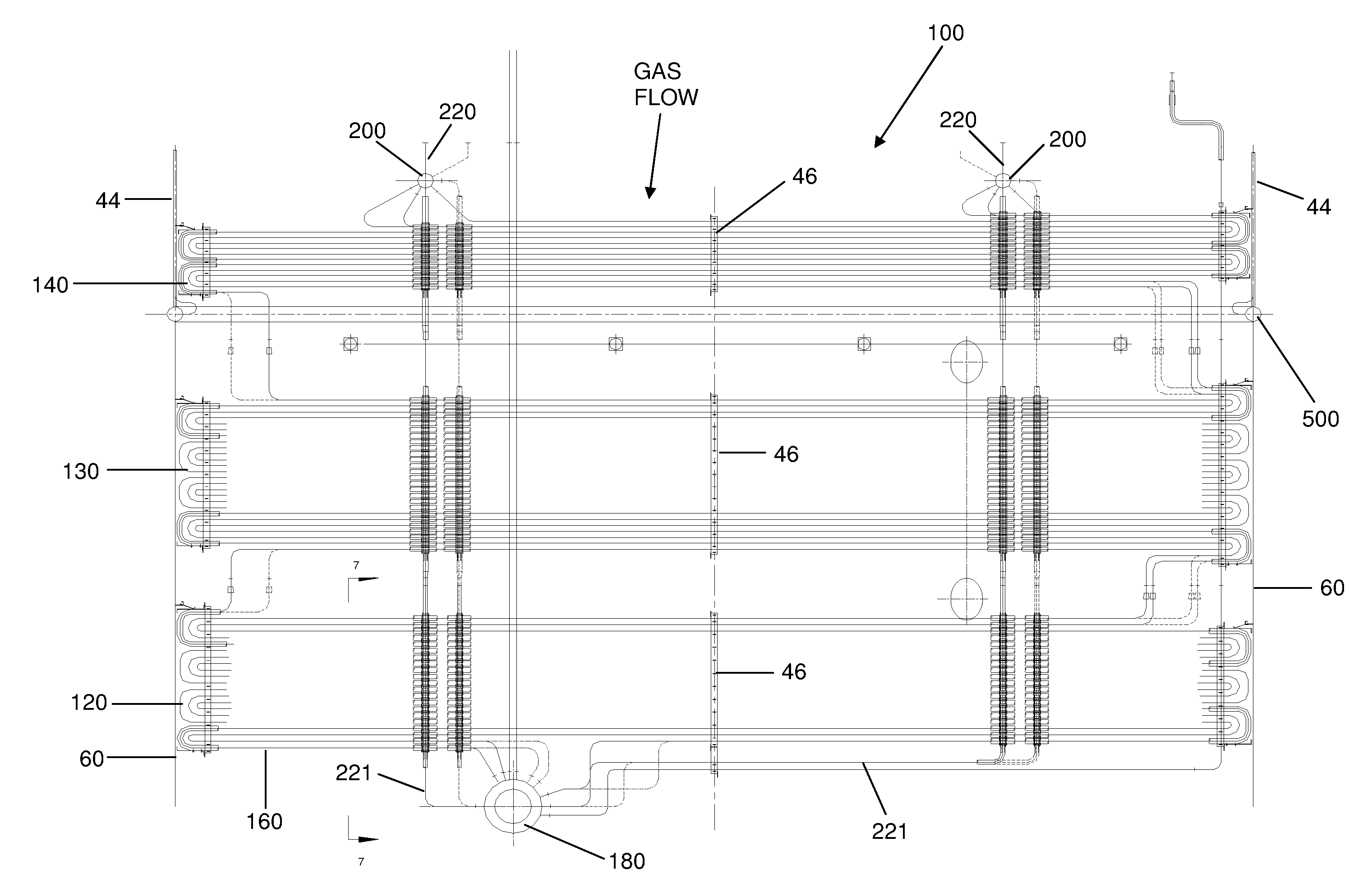

Economizer arrangement for steam generator

InactiveUS20080282997A1Simple designDifferent rate of erosionBoiler supporting/setting arrangementsSteam boilersSupercritical steam generatorFlue gas

An economizer arrangement particularly suitable for new or retrofit application to existing steam generators provides a water cooled stringer support tube system which can accommodate firing a wide range of fuels with varying characteristics in the steam generator. The economizer arrangement according to the present invention is particularly suited for retrofit applications to large supercritical steam generators. The use of water cooled stringer tube supports allows for higher flue gas temperatures in comparison to conventional non-cooled mechanical economizer supports. These features are provided in a design which fits within the existing economizer envelope of the steam generator.

Owner:THE BABCOCK & WILCOX CO

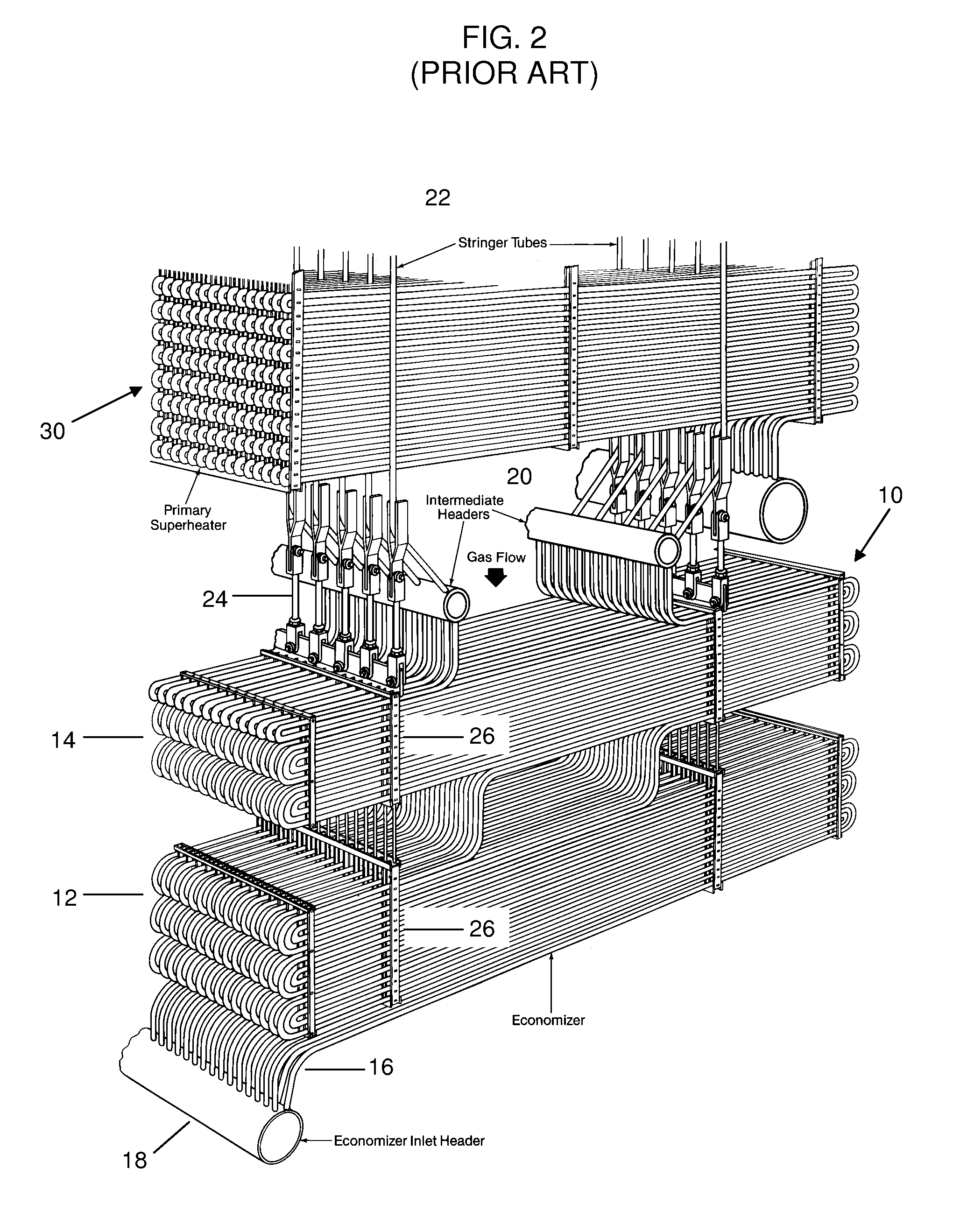

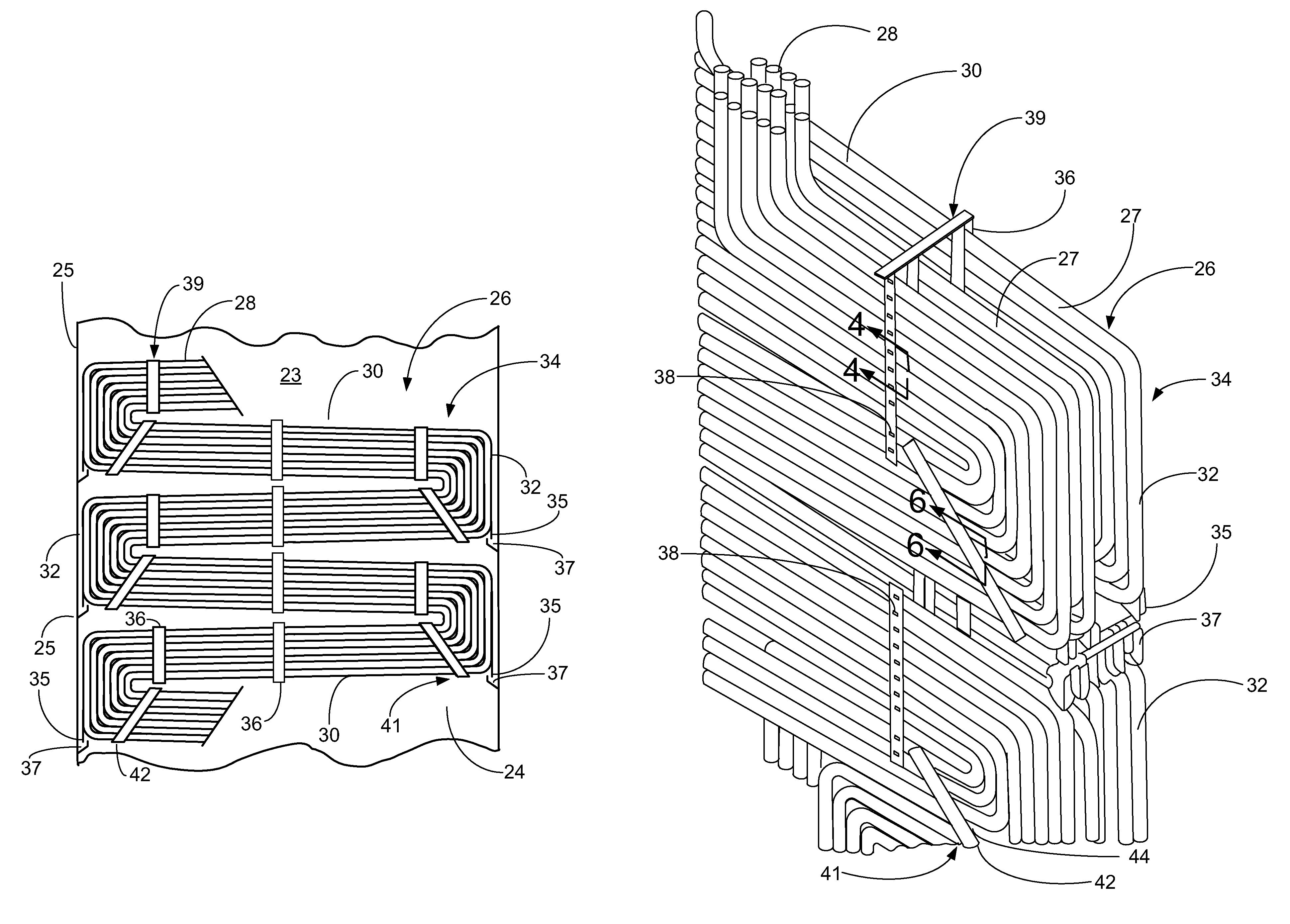

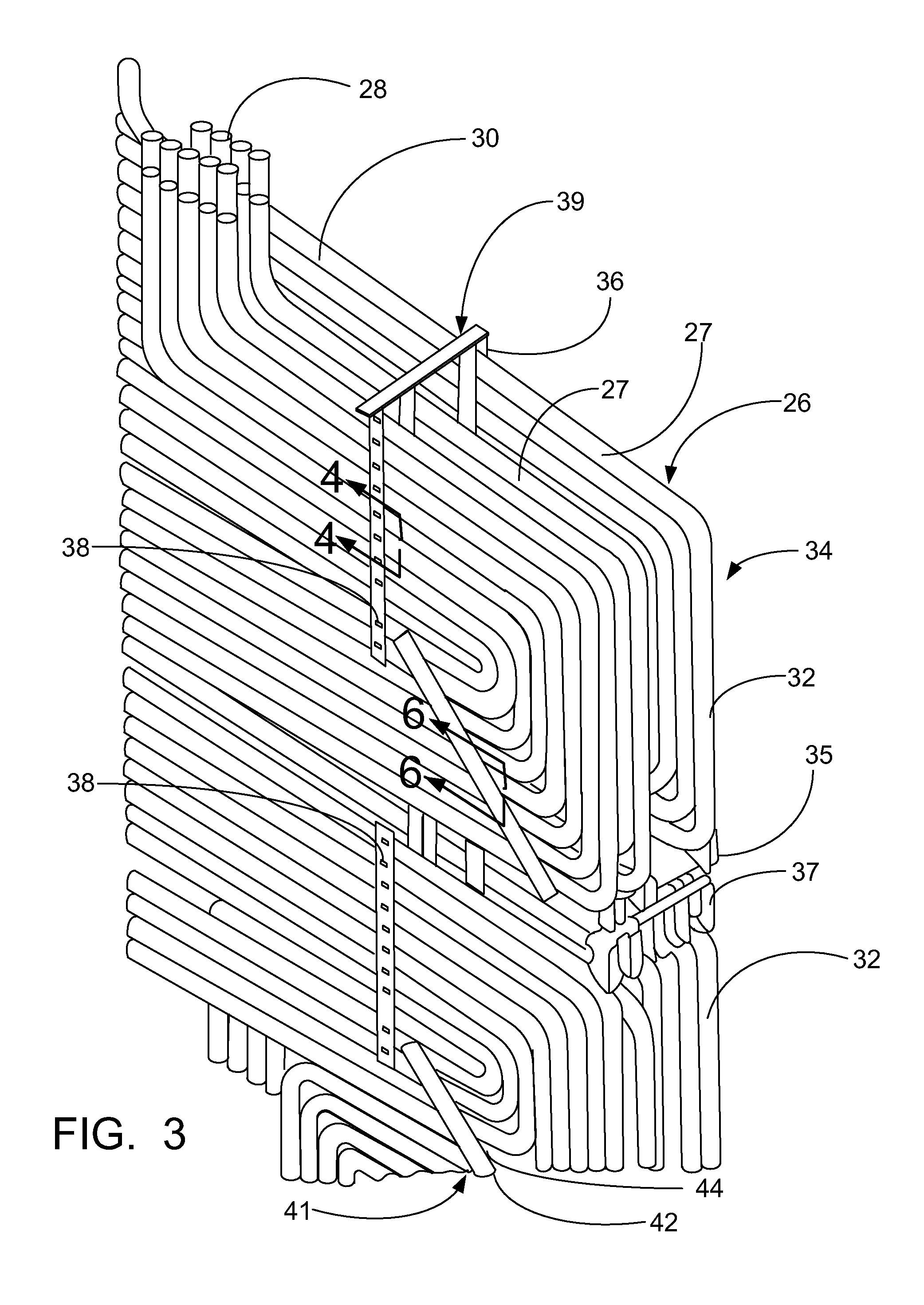

Heat exchanger framework

InactiveUS7464671B2Easy to drainAvoid distortionBoiler supporting/setting arrangementsBoiler flue tubes/fire tubesEngineeringStructural framework

A structural framework for supporting the heat exchanger of a steam generator, the former being comprised of serpentine tubes having sloped segments to facilitate the drainage of water from the heat exchanger when the steam generator is shutdown. The structural framework includes paired groups of vertically and diagonally extending first support members contiguously straddling the sloped-tube segments. The paired first support members are rigidly connected by second support members which extend between adjacent sloped-tube segments. The structural framework preserves the spacing between the sloped-tube segments and prevents direct contact between adjoining tube surfaces, but is not attached to the straddled tube segments and, thus, provides a tube supporting fit that is loose enough to permit the tubes to move freely due to expansion and contraction at different rates from that of the structural framework.

Owner:THE BABCOCK & WILCOX CO

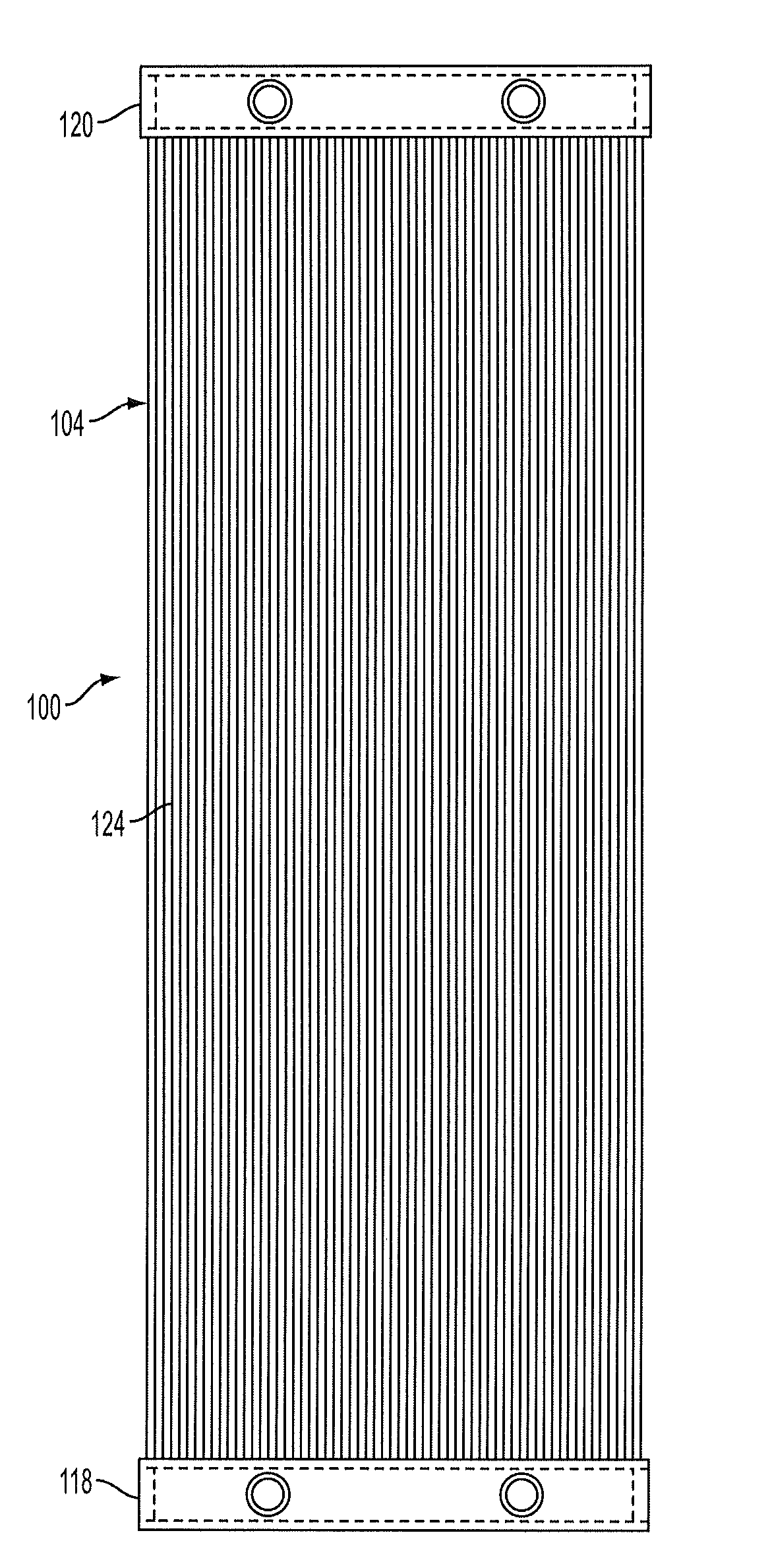

Solar boiler tube panel supports

InactiveUS20120312296A1Prevent movementPrevent rotationSolar heating energyBoiler supporting/setting arrangementsAerospace engineeringBoiler tube

Owner:BABCOCK POWER SERVICES

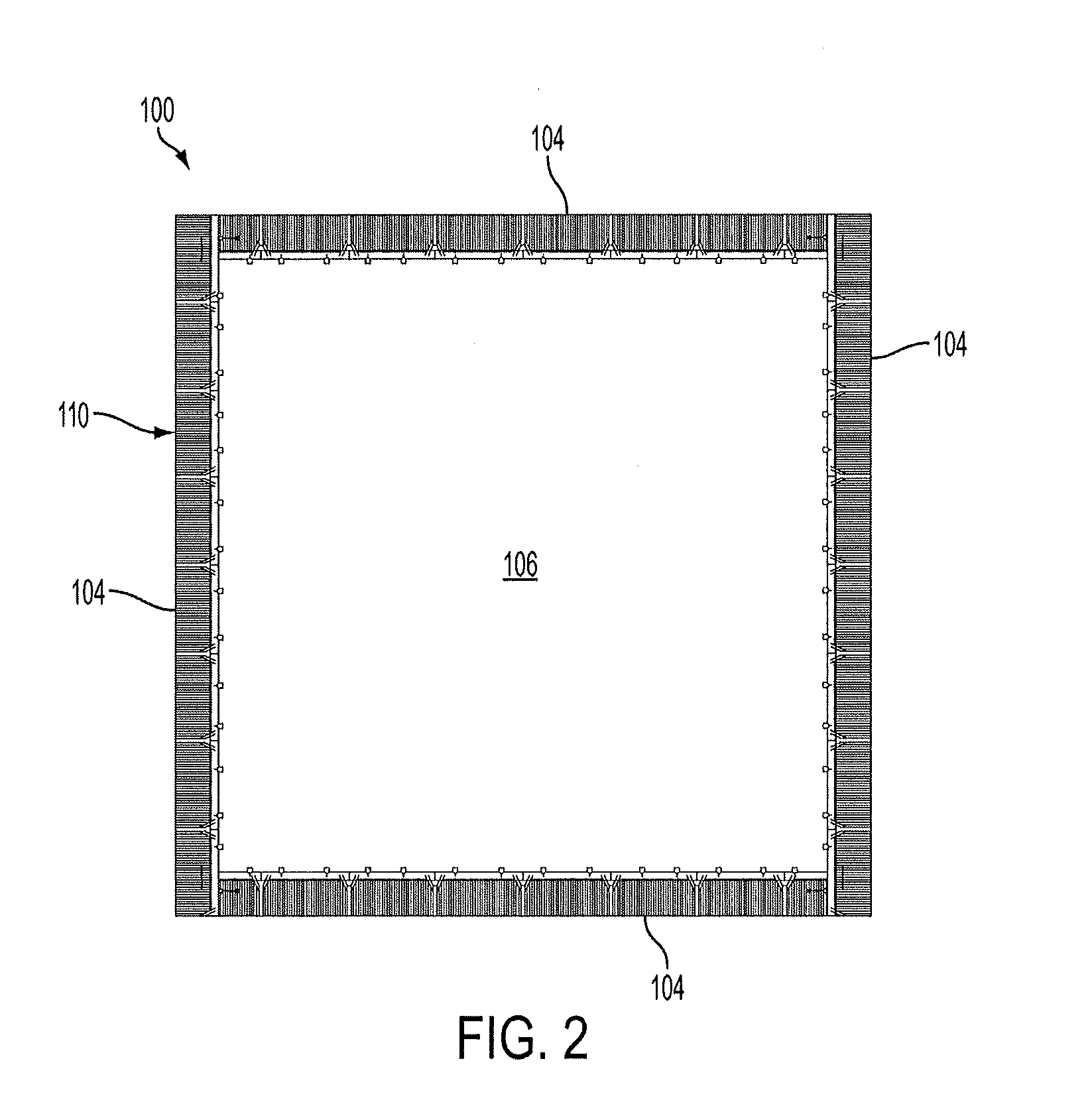

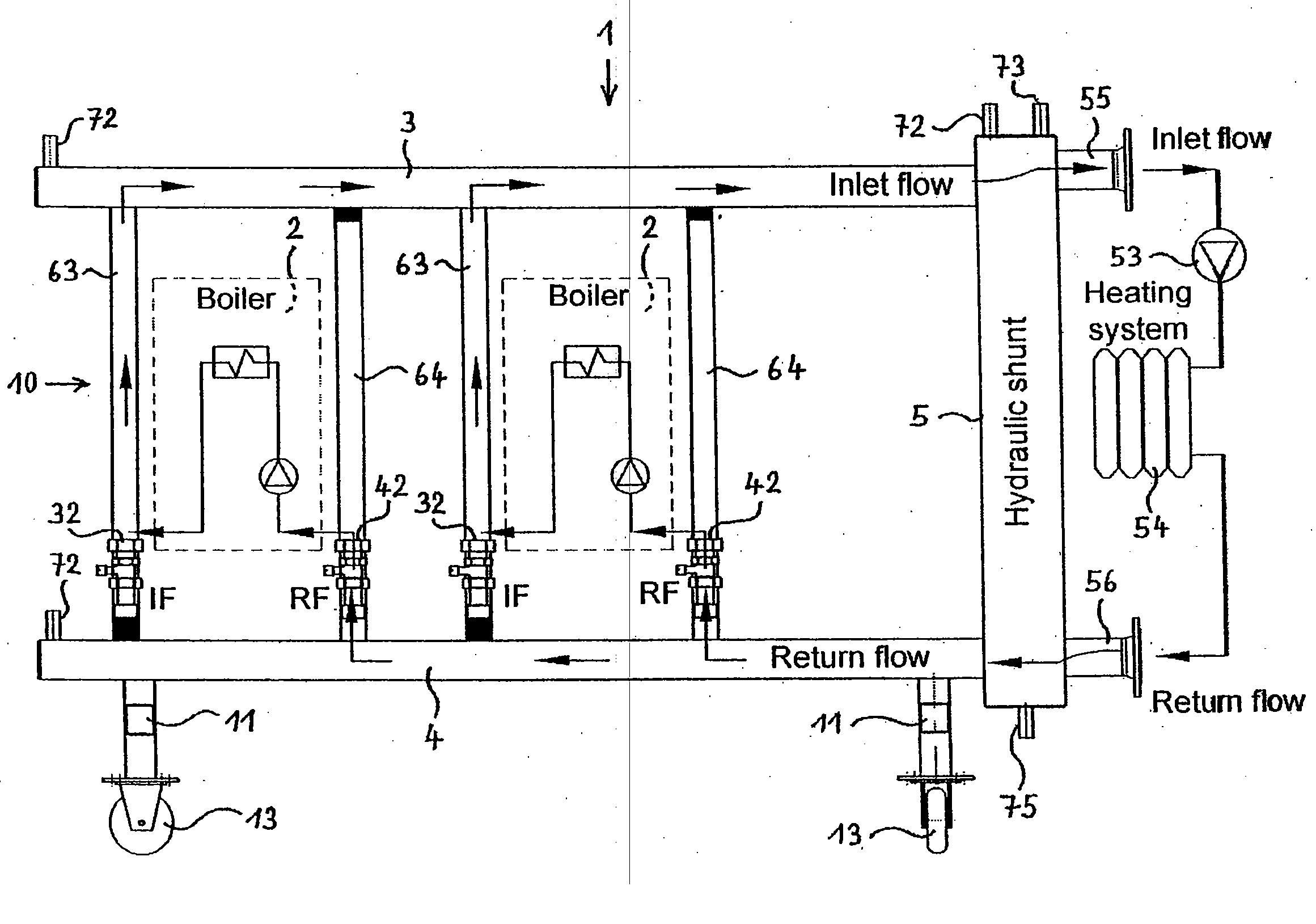

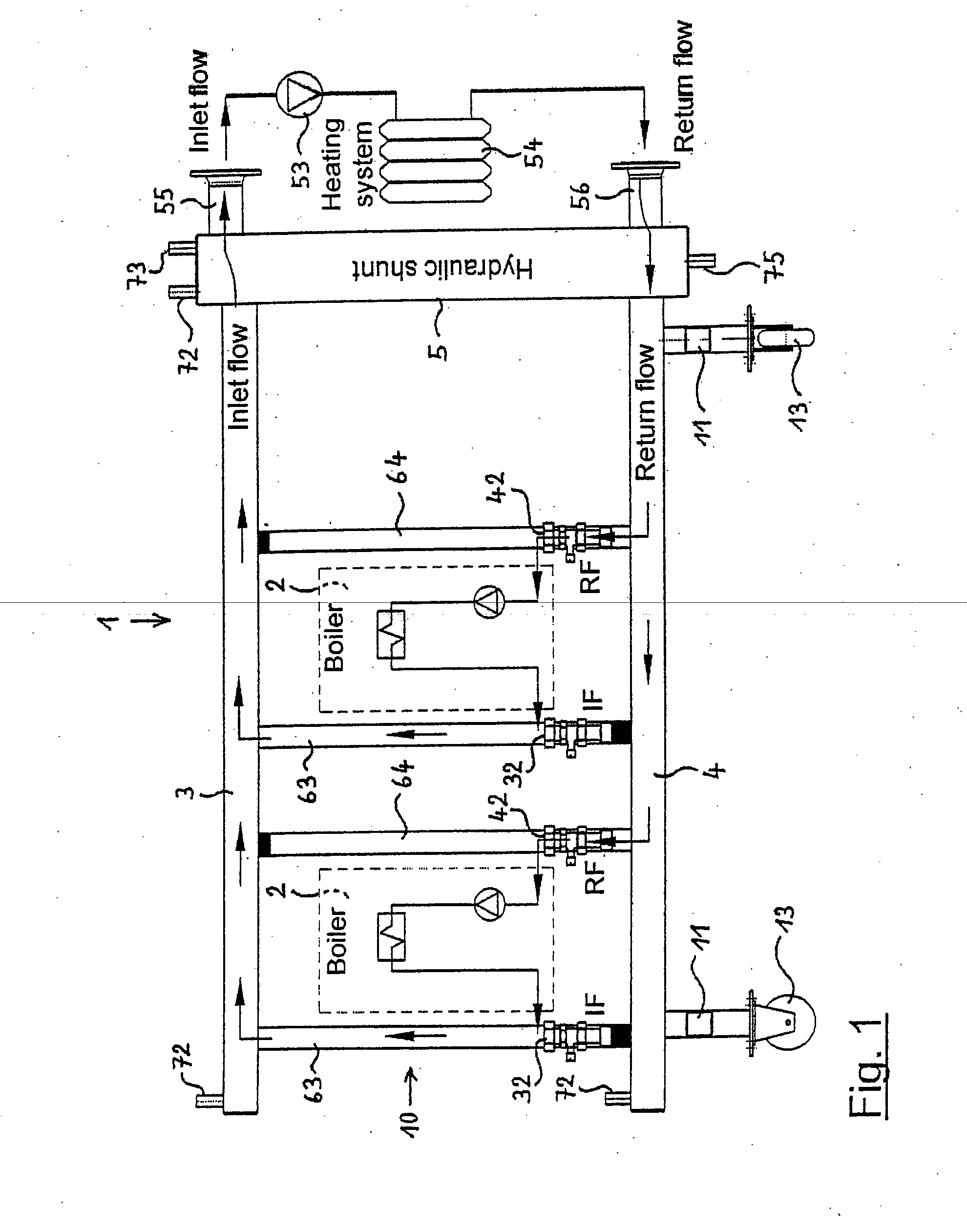

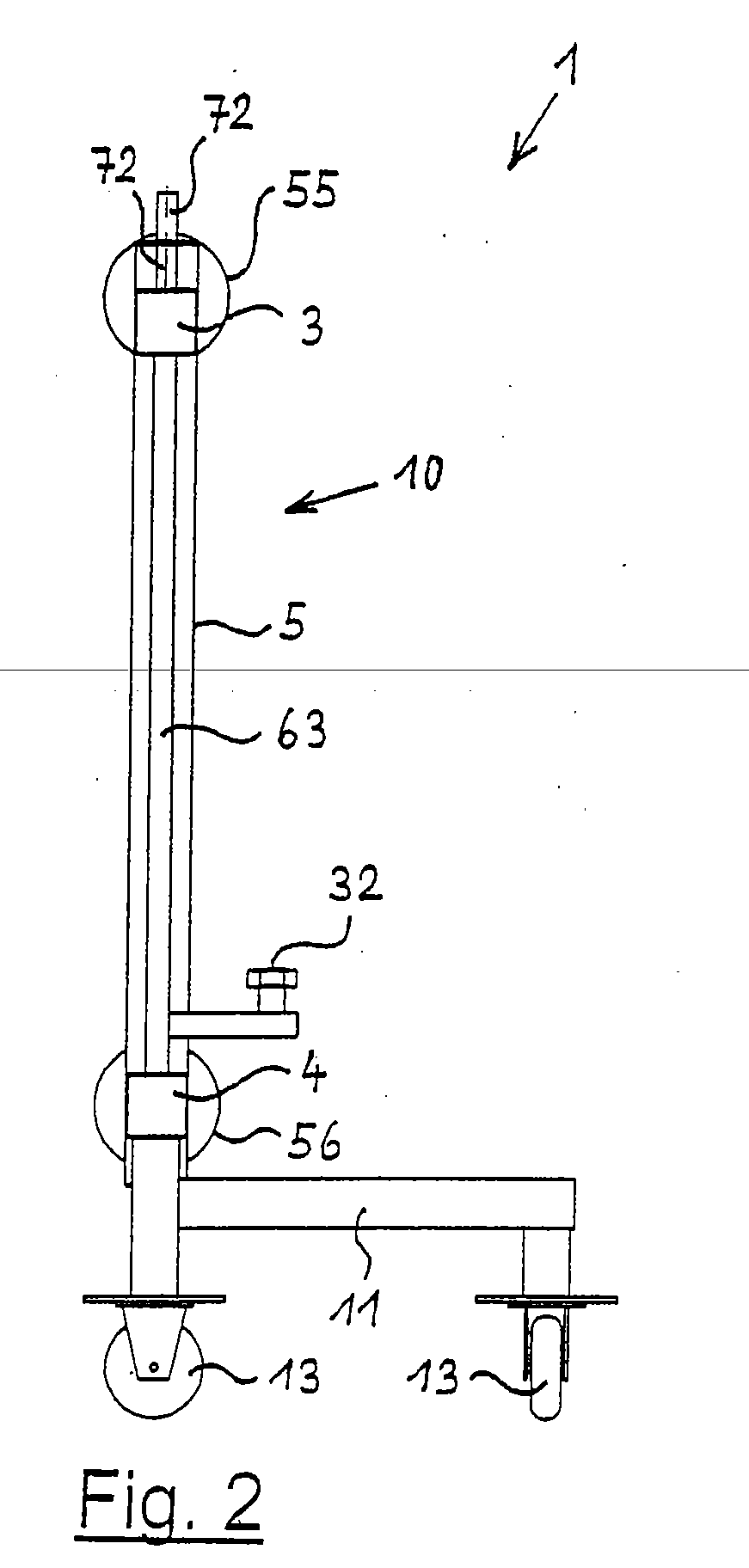

Cascade unit for a heating system with two or more heating boilers

ActiveUS20070144458A1Lower assembly costsExtensive and thus cost-saving prefabricationFluid heatersHeating fuelEngineeringInlet flow

The invention relates to a cascade unit for a heating system with two or more heating boilers, in particular condensing boilers, with a hydraulic shunt which is connected on the one hand with the inlet flows and return flows of all heating boilers and on the other hand with at least one heating circuit inlet flow and heating circuit return flow each, with the cascade unit furthermore comprising one each of the essentially horizontally extending boiler inlet flow header and boiler return flow manifold, the header and the manifold being connected with the hydraulic shunt, and the header and the manifold each being designed with prepared connecting nozzles fittingly placed for a group of two or more heating boilers the connection of the heating boiler inlet flows and the heating boiler return flows. The cascade unit forms at least one self-supporting support frame on which at least one of the heating boilers is mountable.

Owner:COMFORT SINUSVERTEILER

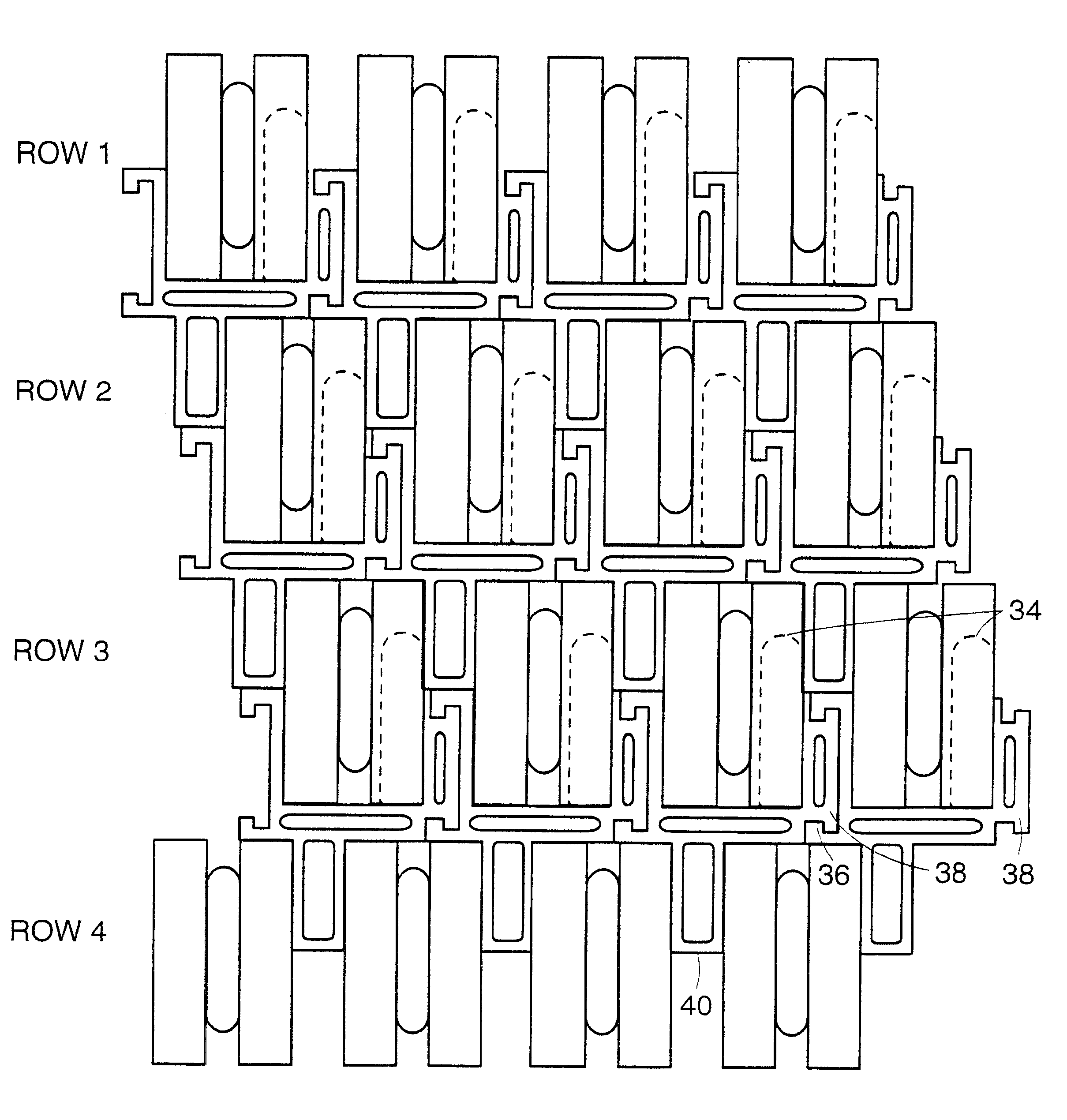

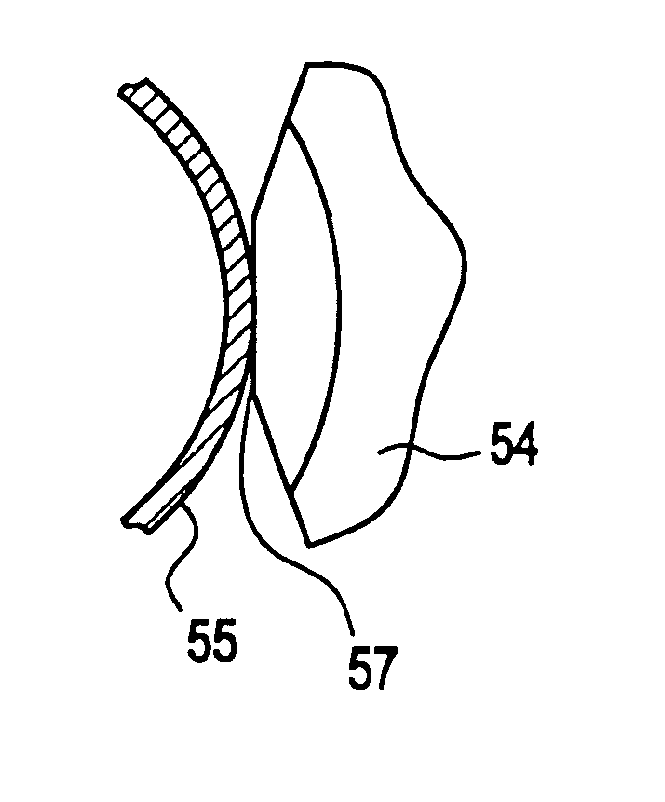

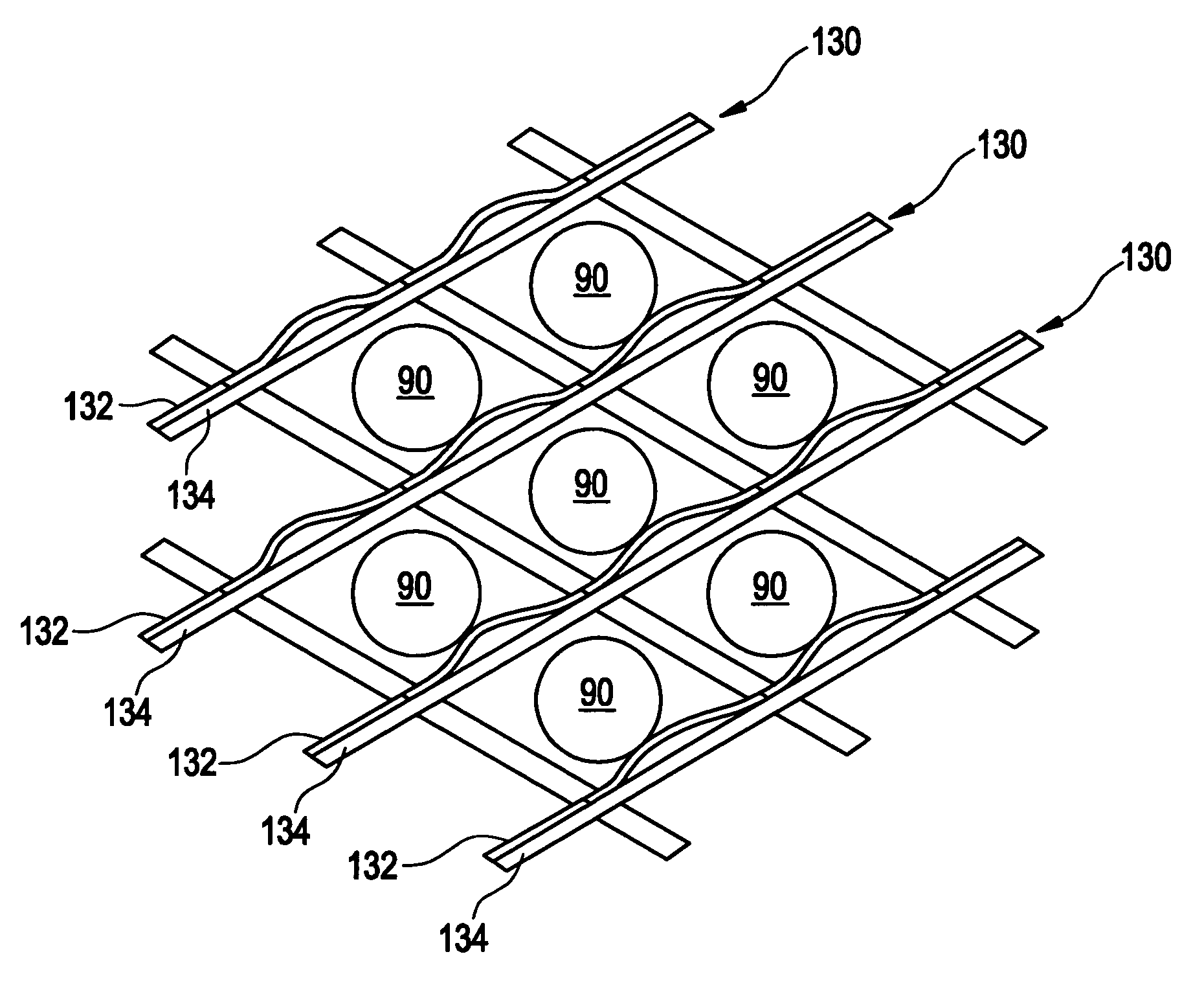

Anti-vibration support for steam generator heat transfer tubes and method for making same

InactiveUS6997141B2Easy to installEliminate damageBoiler supporting/setting arrangementsFuel element assembliesRoom temperatureThermal expansion

A tube support structure for heat transfer tubes in a steam generator has a plurality of tube support bars which are installed between the heat transfer tubes. At least one of the support bars has a first metal layer and a second metal layer. The first metal layer is preferably spot welded to the second metal layer at intervals. The first metal layer and second metal layer have different thermal expansion coefficients so that at room temperature the support bar is flat, and at the operating temperature of the steam generator the first layer forms a convex shape between the intervals to support the adjacent tube.

Owner:BABCOCK & WILCOX CANADA LIMITED

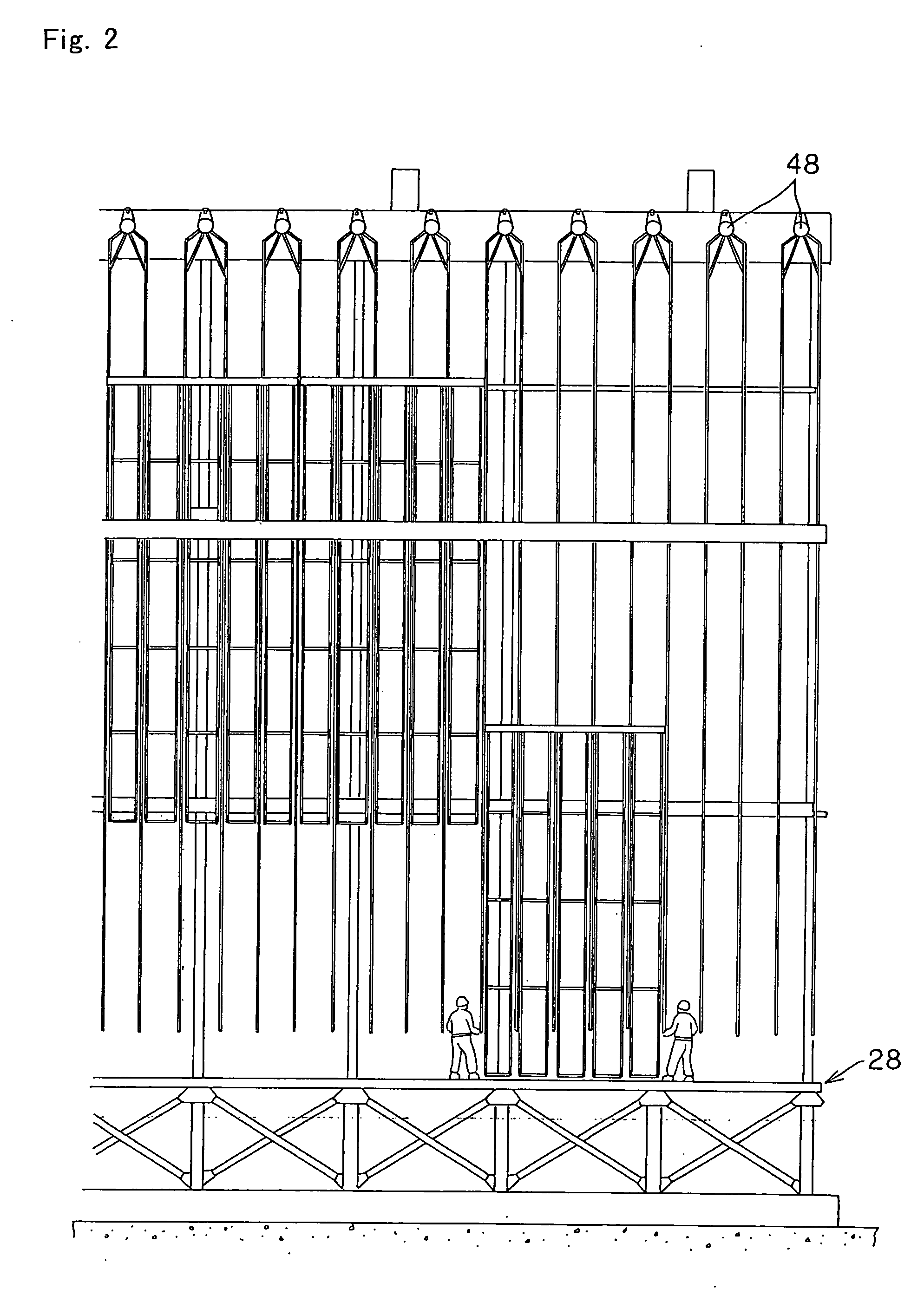

Installation construction method for boiler facilities

ActiveUS20070089296A1Shorten the construction periodBoiler supporting/setting arrangementsAssembly machinesEngineeringBuilding construction

Owner:MITSUBISHI POWER LTD

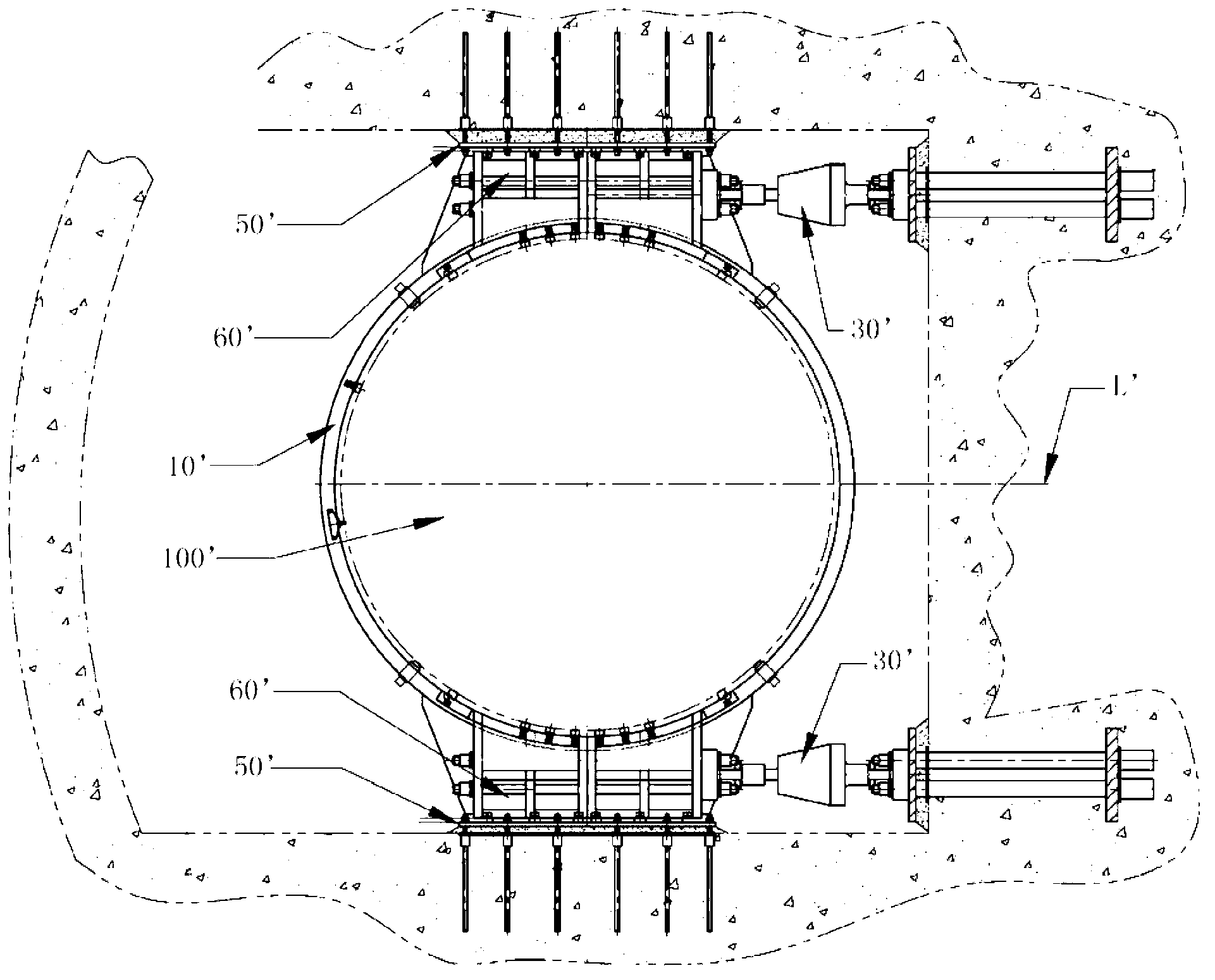

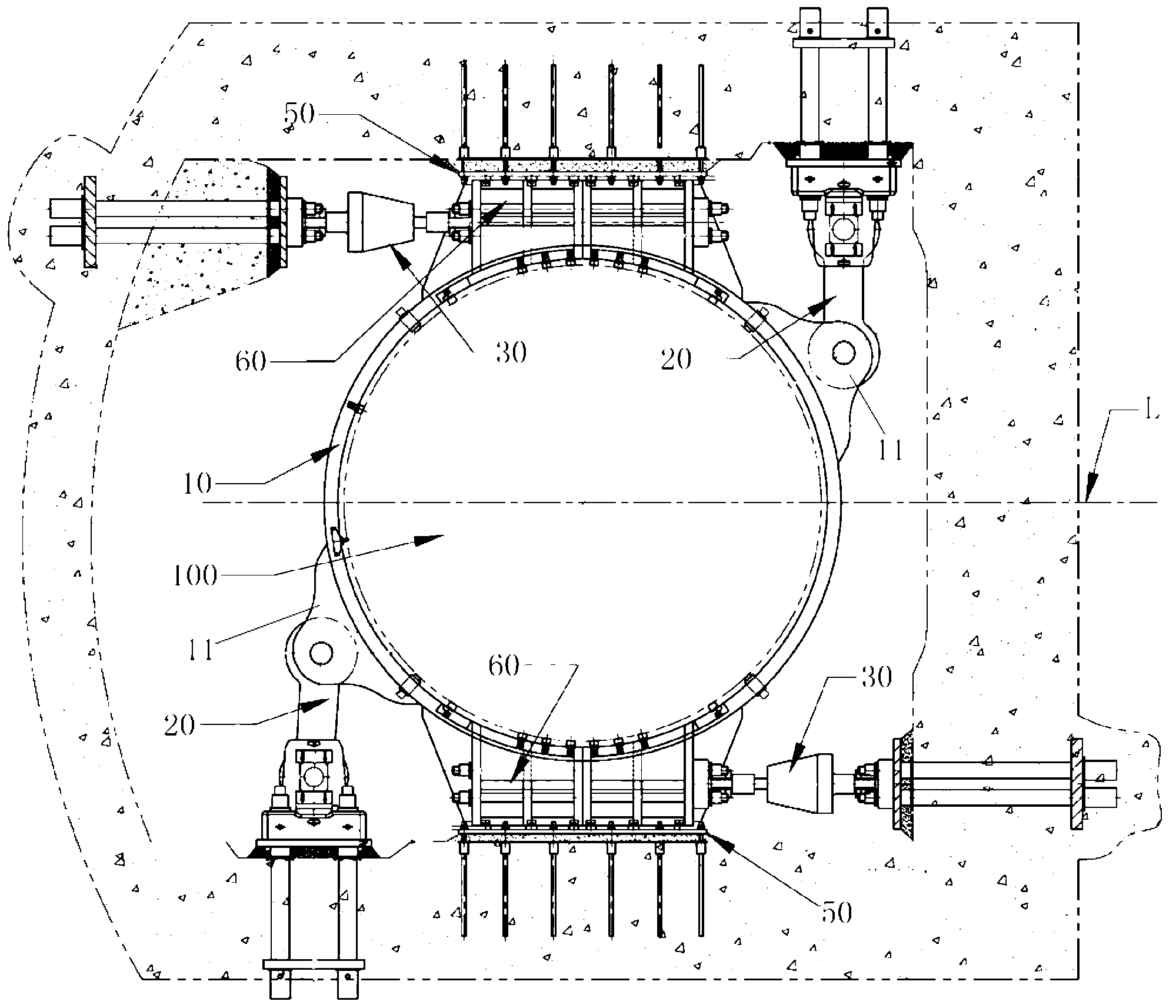

Separator Construction of a Fluidized Bed Boiler

ActiveUS20100024694A1Lose weightIncreased construction costFluidized bed combustionBoiler supporting/setting arrangementsFlue gasOperating energy

A separator construction, connectable to a fluidized bed boiler having a furnace, for circulating bed material and returning the material to the furnace. The separator construction includes walls, a ceiling, an inlet conduit, an outlet conduit in flow communication with a flue gas channel located above the separator, and a suspending device connecting the separator to a supporting structure in a building housing the boiler. The suspending device is formed of a frame arranged between the flue gas channel and the separator in connection with an upper circumference of the wall of the separator, and hanger rods or wires connecting the frame directly to the supporting structure.

Owner:FOSTER WHEELER ENERGIA OY

Inspection scaffold of large component for boiler and building method thereof

InactiveUS20070074934A1Short working hoursAssembly safetyBoiler supporting/setting arrangementsSteam boilersEngineeringSteel frame

A scaffold assembling of a large component for a boiler requiring inspection is not performed by a high-place work but assembled safely and in a short time. The scaffold is assembled to the large component for the boiler supported by a component supporting beam at the ground side before it is attached to a steel frame main-beam 16. Scaffold lifting / supporting beams interposing coil spaces of a superheater 14 are suspended on wires 36 lifted down from spaces of a ceiling tube wall 34 being a horizontal member of the superheater 14. The scaffold lifting / supporting beams 32 are lifted to raise little by lithe within the superheater, and scaffold components are assembled sequentially toward downward. After a required number of steps of scaffolds are assembled, the scaffold lifting / supporting beams 32 are coupled to the ceiling tube wall 34 to be supported. Finally, the superheater 14 is raised by a lifting means to install to the main-beam.

Owner:HITACHI LTD

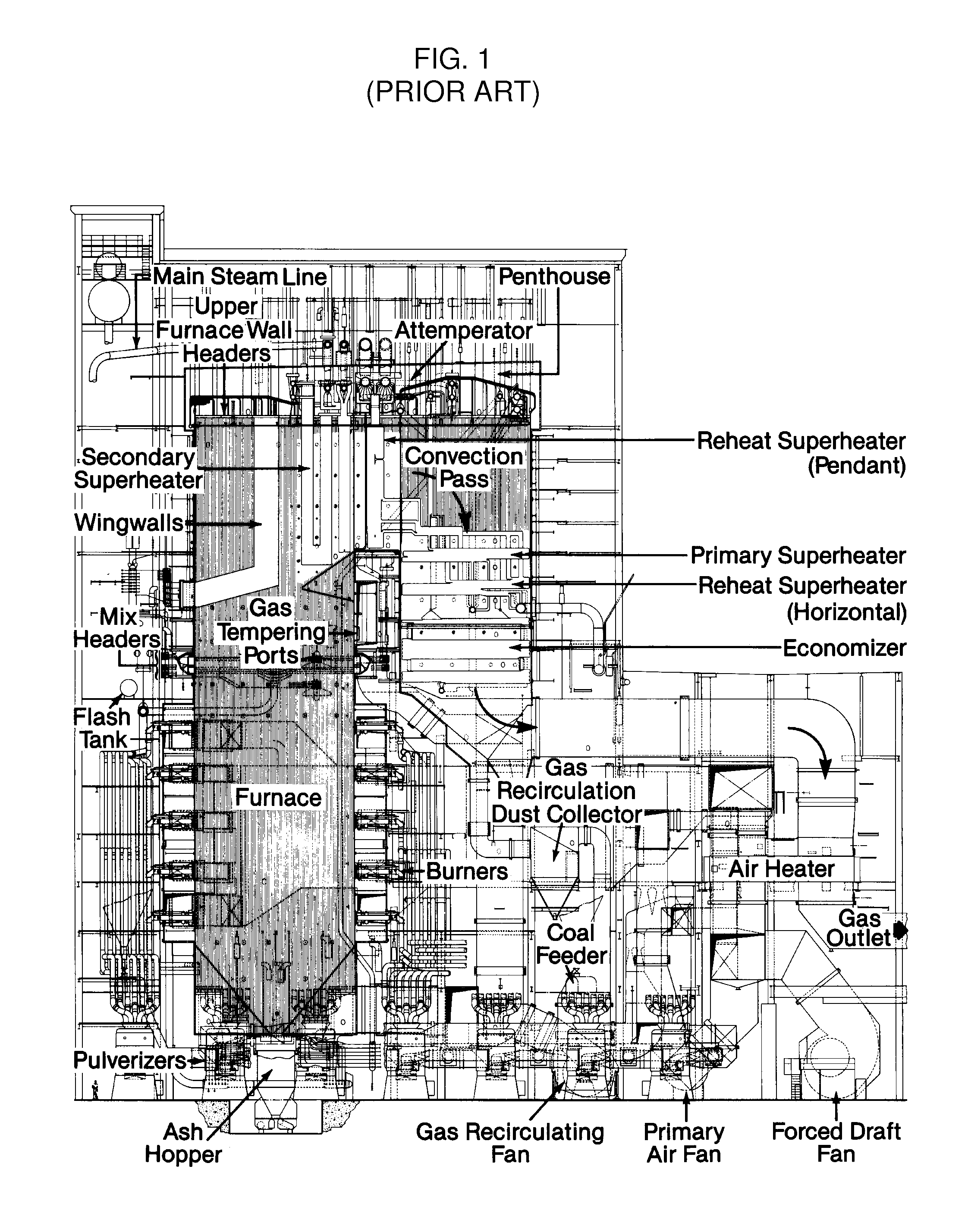

Thermal Power Plant

InactiveUS20120102955A1Reduce construction costsReduce material costsBoiler supporting/setting arrangementsDirect carbon-dioxide mitigationProcess engineeringSteam turbine

A thermal power plant is proposed for achieving high reliability, low material cost, and low construction cost by devising the arrangement and structures of a boiler, steam turbines, and a flue gas treatment apparatus to reduce a usage amount of high-temperature resistance material and further to reduce a thermal elongation of piping. In a thermal power plant including a 2 pass-type boiler having a furnace for burning fuel, a rear heat recovery area for recovering heat from combustion gas exhausted from the furnace, steam turbines are arranged near the rear heat recovery area.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Link Type Seismic Tie For Boilers

InactiveUS20080271686A1Avoid displacementMore dampingPipe supportsBoiler supporting/setting arrangementsGusset plateMechanical engineering

A link-type seismic tie is provided between a steel structural support and a buckstay, and includes two horizontally arranged, parallel, and spaced apart link members, which are connected at their ends to large vertical pins. Each of the link members includes two horizontally arranged and parallel longitudinal outboard stringers and a horizontally arranged and parallel longitudinal center stringer centered between the two outboard stringers. Each link member further includes finger plates standing upright and spaced apart from each other relatively perpendicular to the longitudinal stringers. The finger plates are held between each of the outboard stringers and the longitudinal center stringer. A gusset plate connects the outboard stringers to a pin plate, which is connected to a large pin at the buckstay. The other end of the link members is connected to a large pin at the steel structural support via the ends of the outboard stringers.

Owner:THE BABCOCK & WILCOX CO

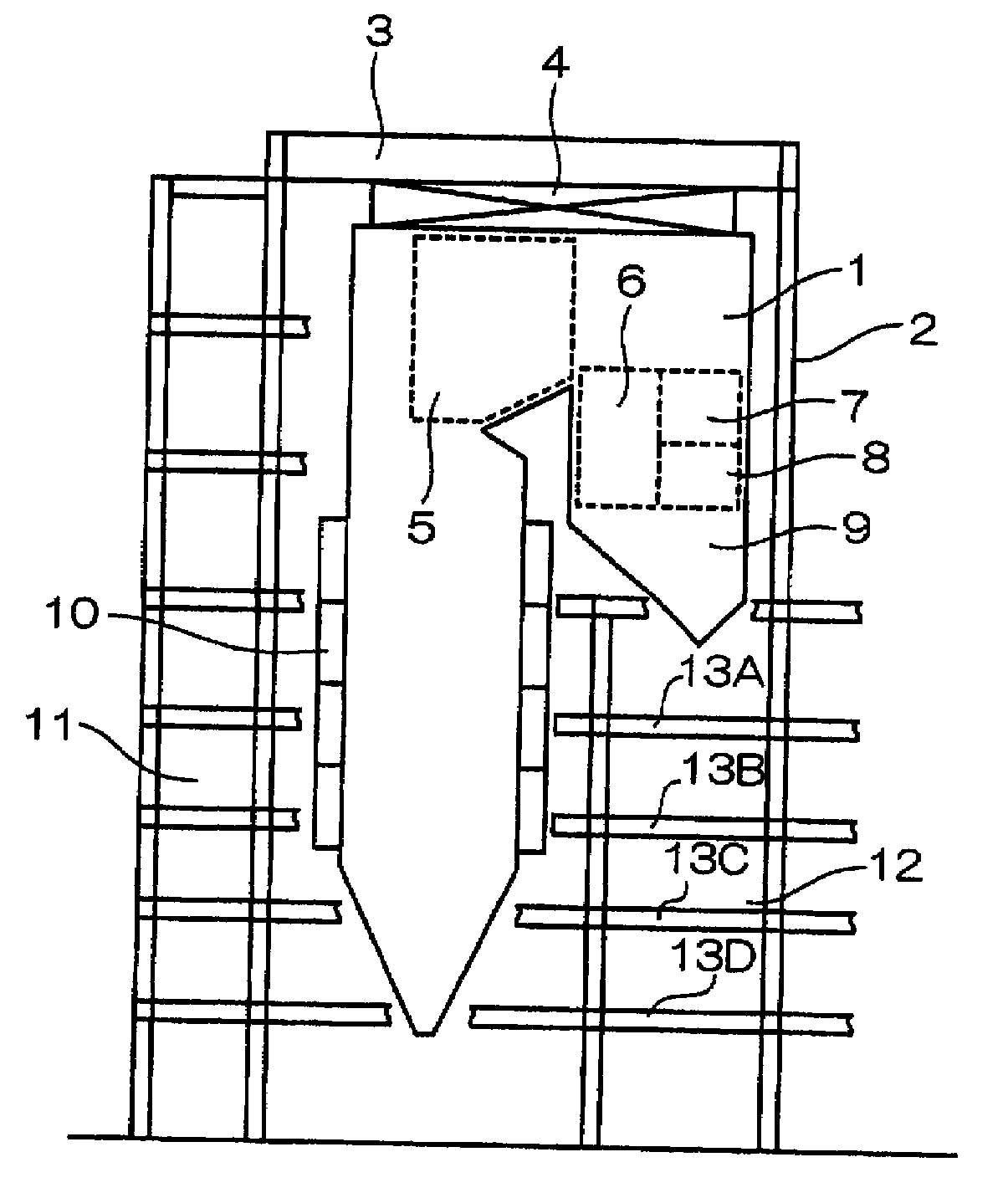

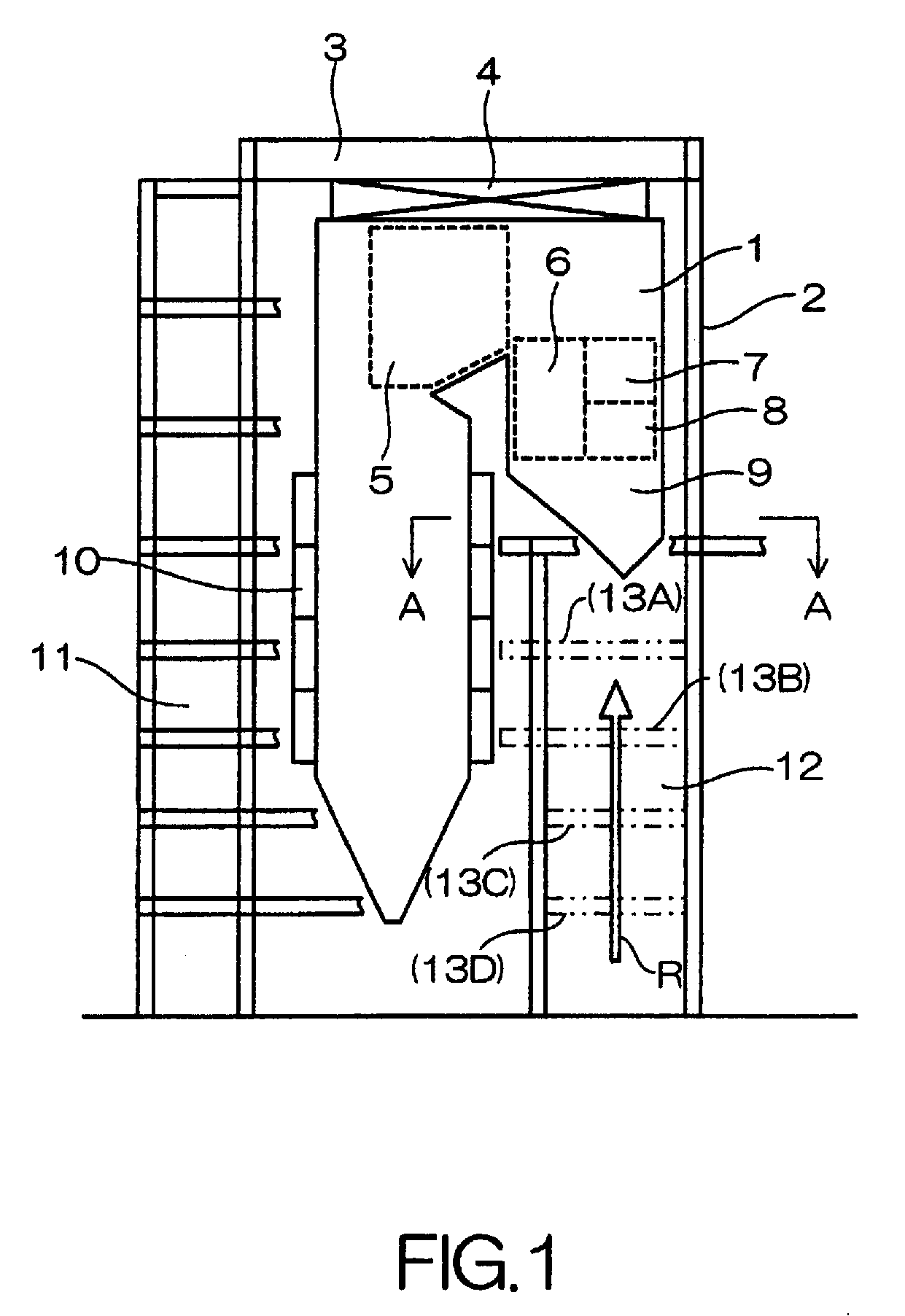

Method of building a floor for a boiler cage

InactiveUS20080028723A1Reduce construction costsShorten the construction periodCeilingsBoiler supporting/setting arrangementsUpper floorBuilding construction

The floor, which became a block, can easily be attached to the designated floor position, so that the reduction of both the construction cost and the construction period are achieved. It is a method of building the plural floors on the part of the boiler cage part, and one floor 13A is built on a lifting frame 18 put on the ground, and the floor 13A and the lifting frame 18 are both jacked up by jacks 14. Subsequently the lifting frame 18 which separated the floor 13A is jacking down and returned to the ground. Plural floors are built for lower floor from upper floor one after another by repeating such a series of steps.

Owner:MITSUBISHI POWER LTD

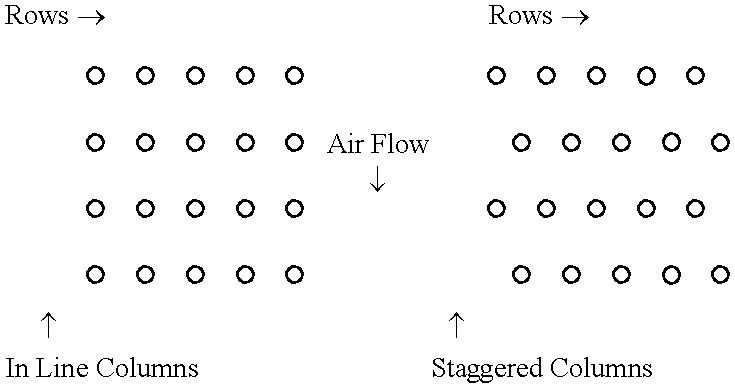

Anti-vibration tube support plate arrangement for steam generators

ActiveUS20120167839A1Avoid vibrationBoiler supporting/setting arrangementsSteam generation heating methodsEngineeringEconomizer

Owner:WESTINGHOUSE ELECTRIC CORP

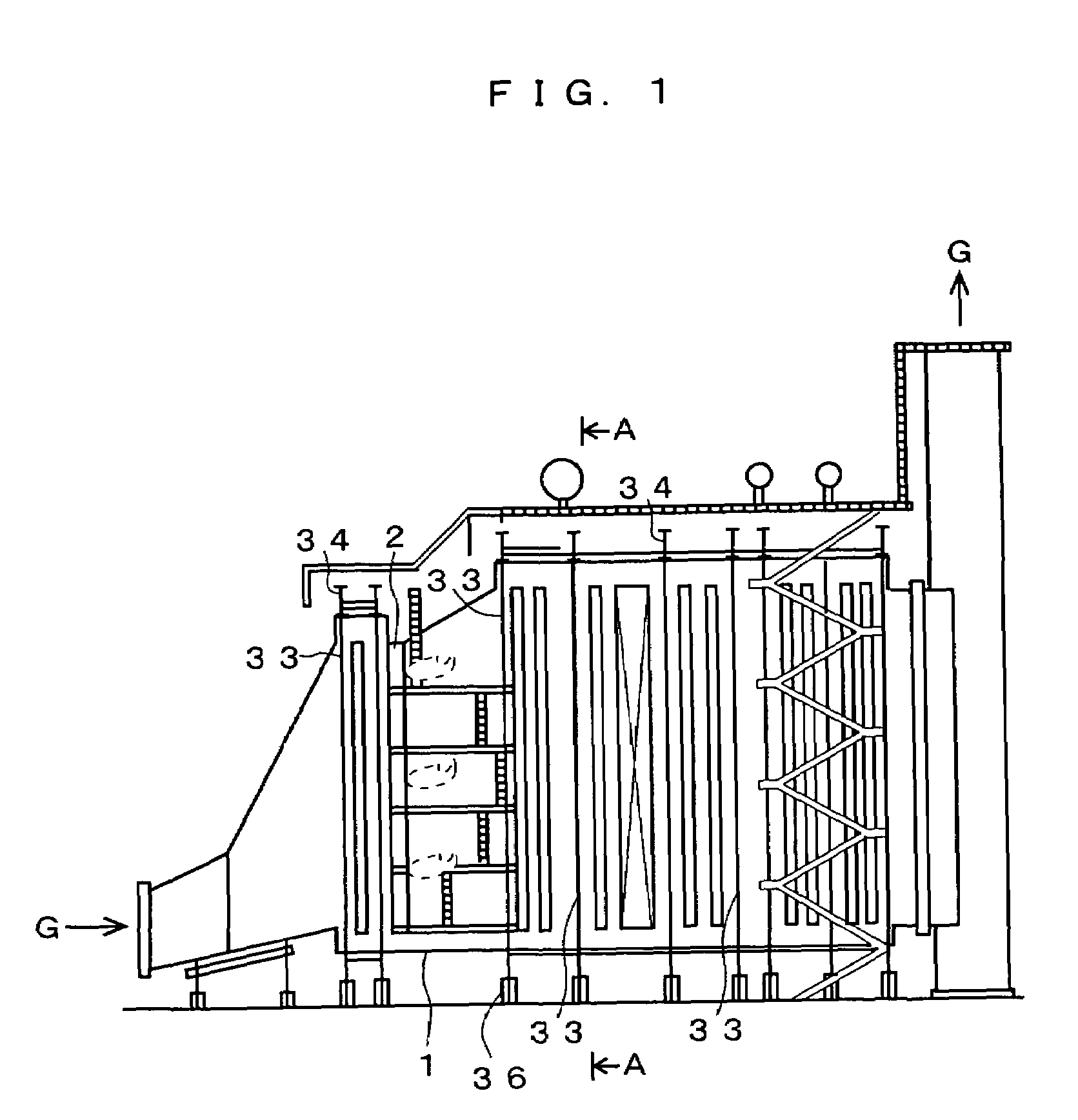

Boiler plant, a support structure and a method for supporting the walls of a steam boiler of a boiler plant

A boiler plant, which comprises a boiler (2) and a frame (1) of a boiler house surrounding the boiler. In addition, the boiler plant comprises support structures (3), by which the walls of the boiler (2) are supported laterally to the frame (1) of the boiler house. In addition, the invention relates to a support structure (3) and a method for supporting the walls of a boiler (2) of a boiler plant.

Owner:METSO POWER OY

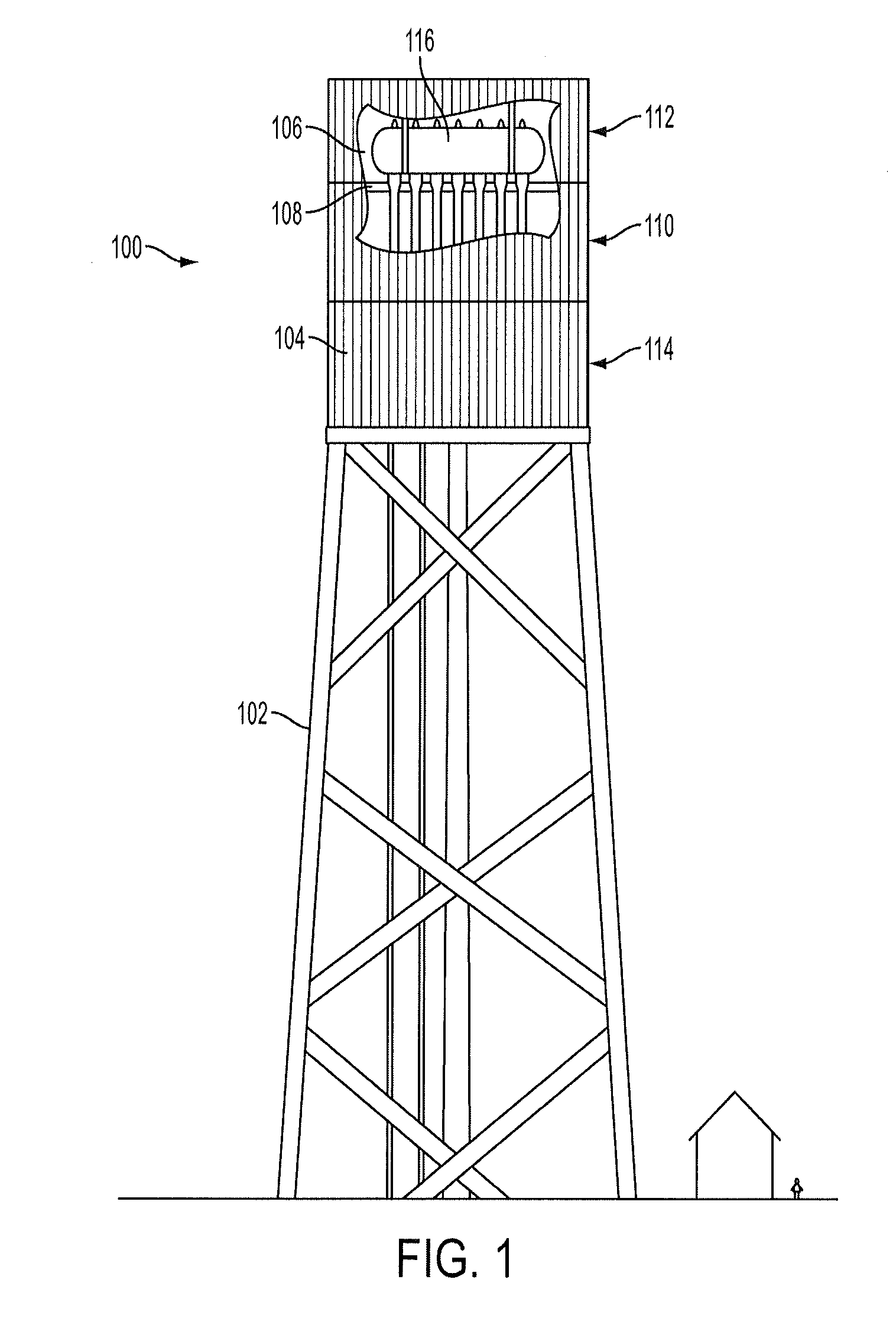

Tower boiler including a stationary supporting structure

InactiveUS7240640B2Reduce time consumptionShort timeBoiler supporting/setting arrangementsFuel injection apparatusCombustionBoiler plant

A boiler plant, including a combustion section, a heat exchange section including heat exchange surfaces, arranged above the combustion section and having a flow direction from the bottom upwards, and a stationary supporting structure. The combustion section and the heat exchange section are separate chambers, flexibly joined with each other, and the chambers are each separately hung from their upper part to the stationary supporting structure.

Owner:FOSTER WHEELER ENERGIA OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com