Patents

Literature

769results about "Fuel element assemblies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

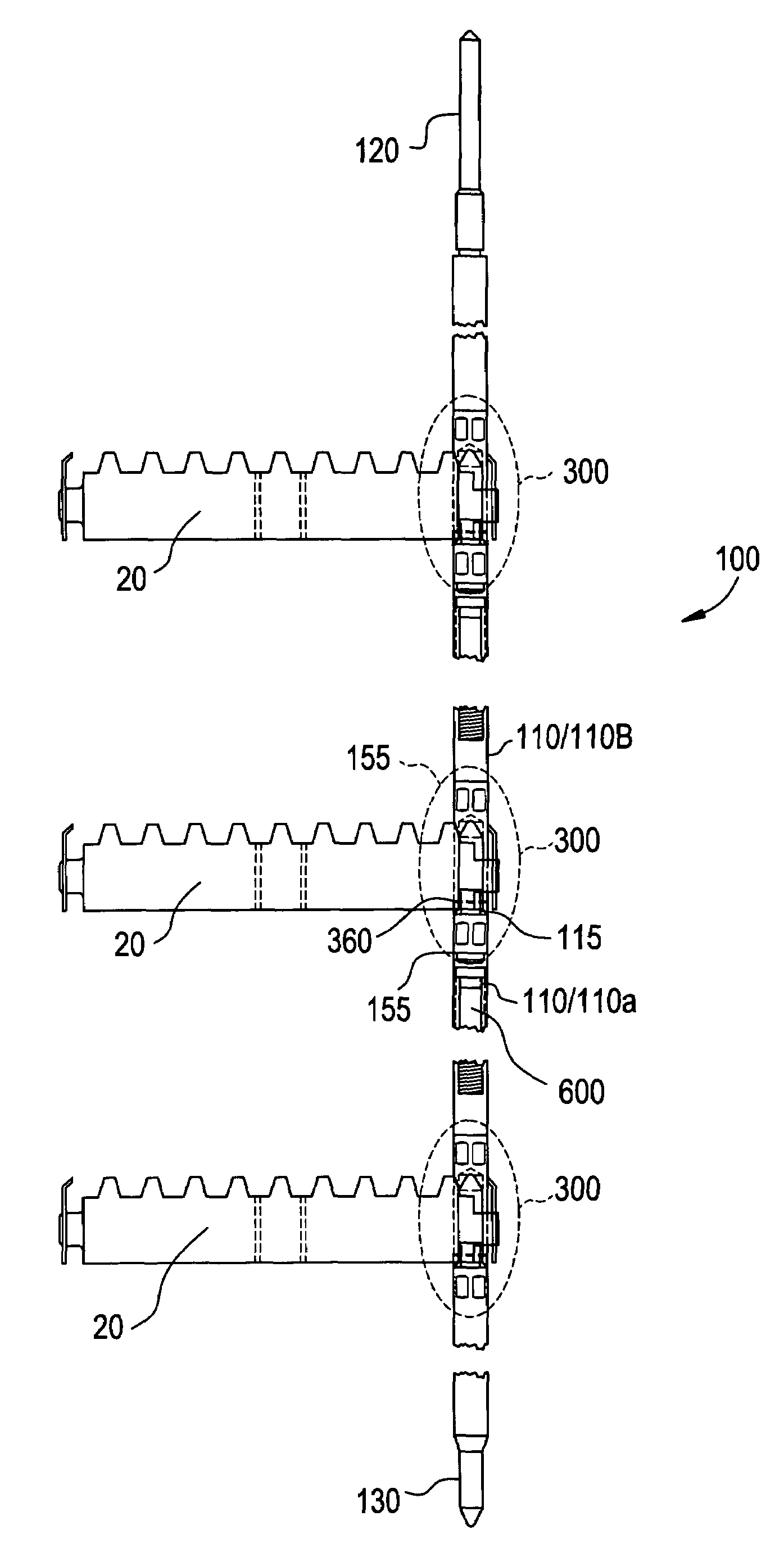

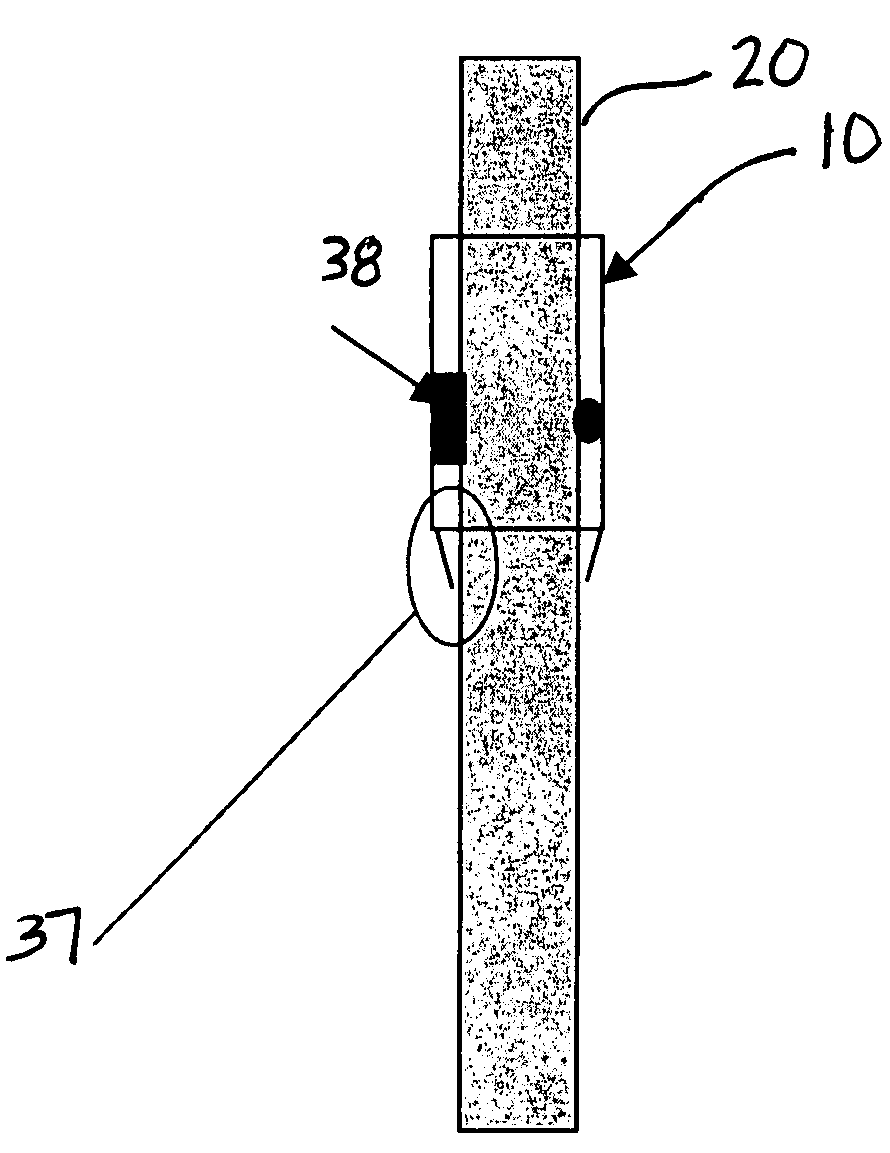

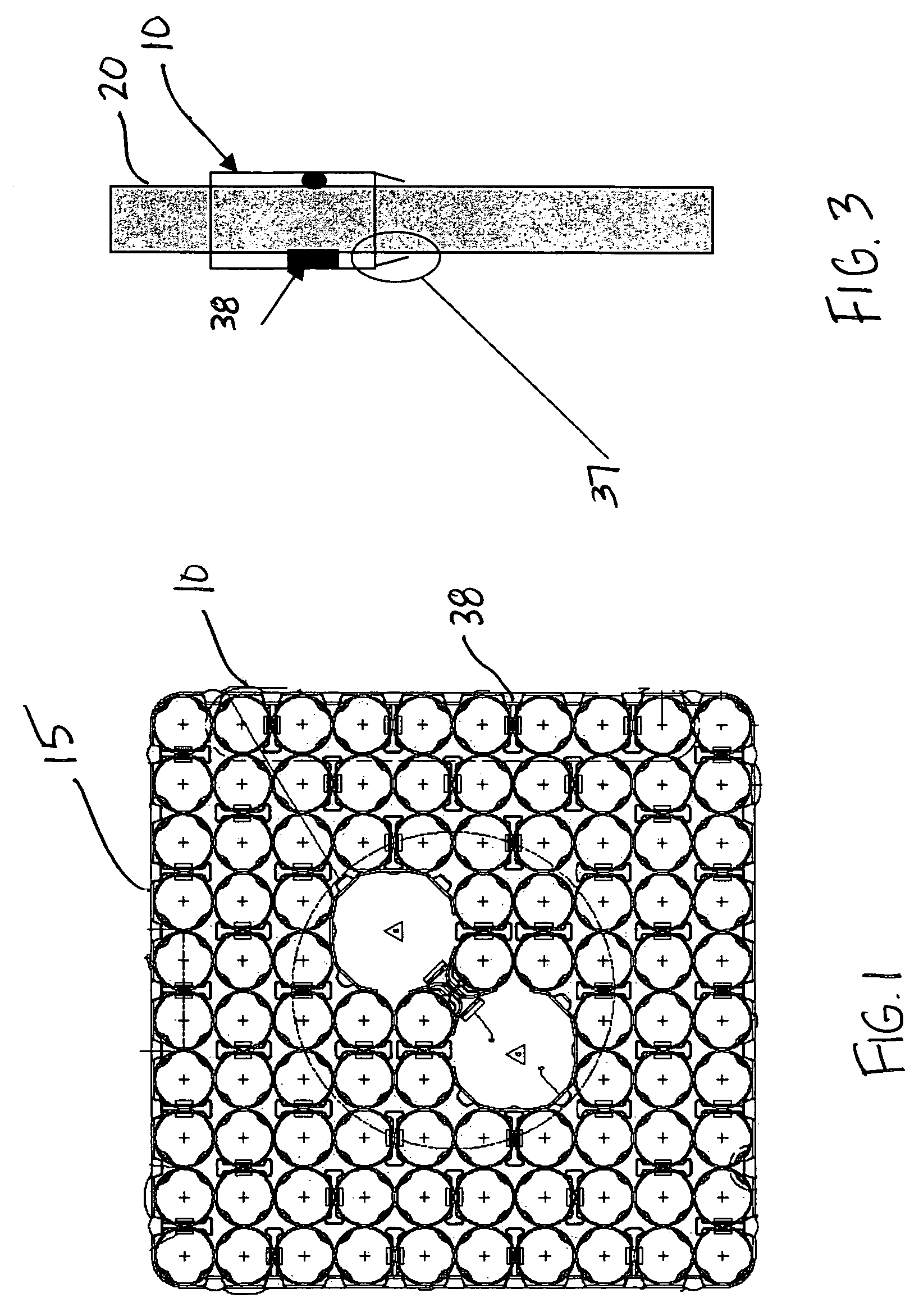

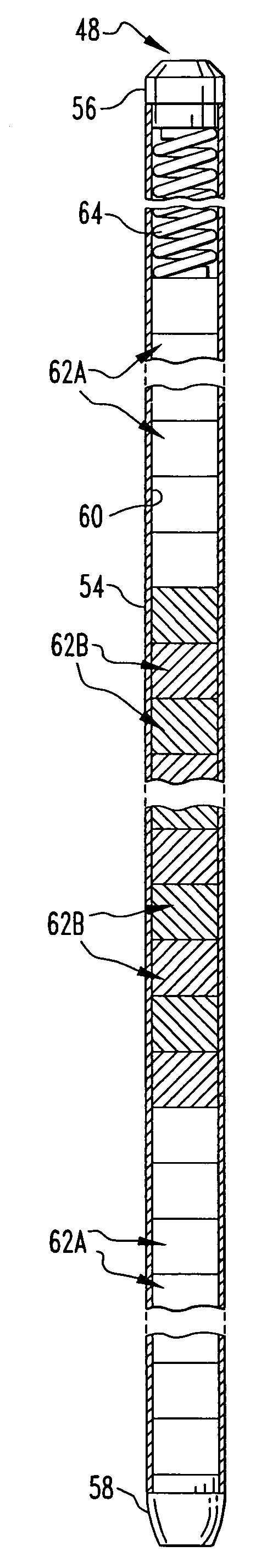

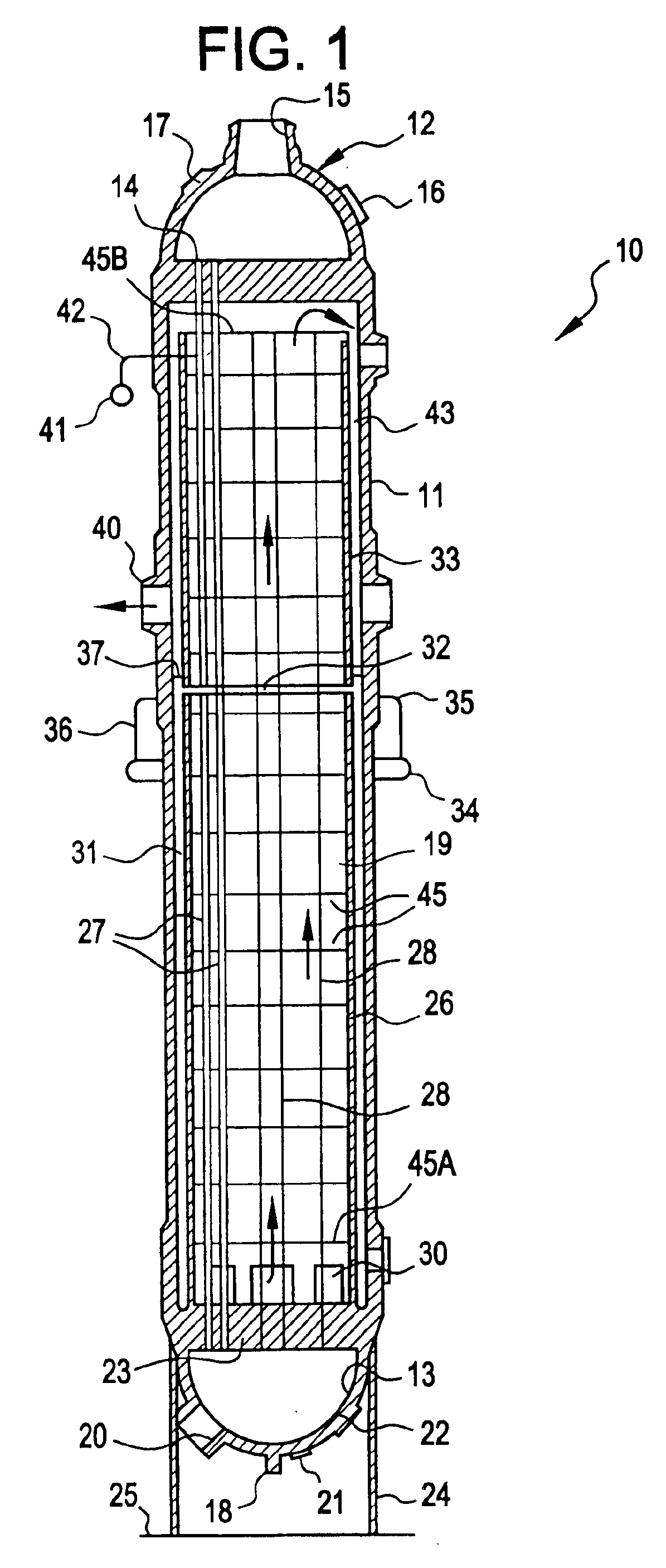

Rod assembly for nuclear reactors

A rod assembly for a fuel bundle of a nuclear reactor may include an upper end piece, lower end piece and a plurality of rod segments attached between the upper and lower end pieces and to each other so as to form an axial length of the rod assembly. The rod assembly may include an adaptor subassembly provided at given connection points for connecting adjacent rod segments or a given rod segment with one of the upper and lower end pieces. The connection points along the axial length of the rod assembly may be located where the rod assembly contacts a spacer in the fuel bundle. One (or more) of the rod segments may include an irradiation target therein for producing a desired isotope when a fuel bundle containing one (or more) rod assemblies is irradiated in a core of the reactor.

Owner:NORDION (CANADA) INC

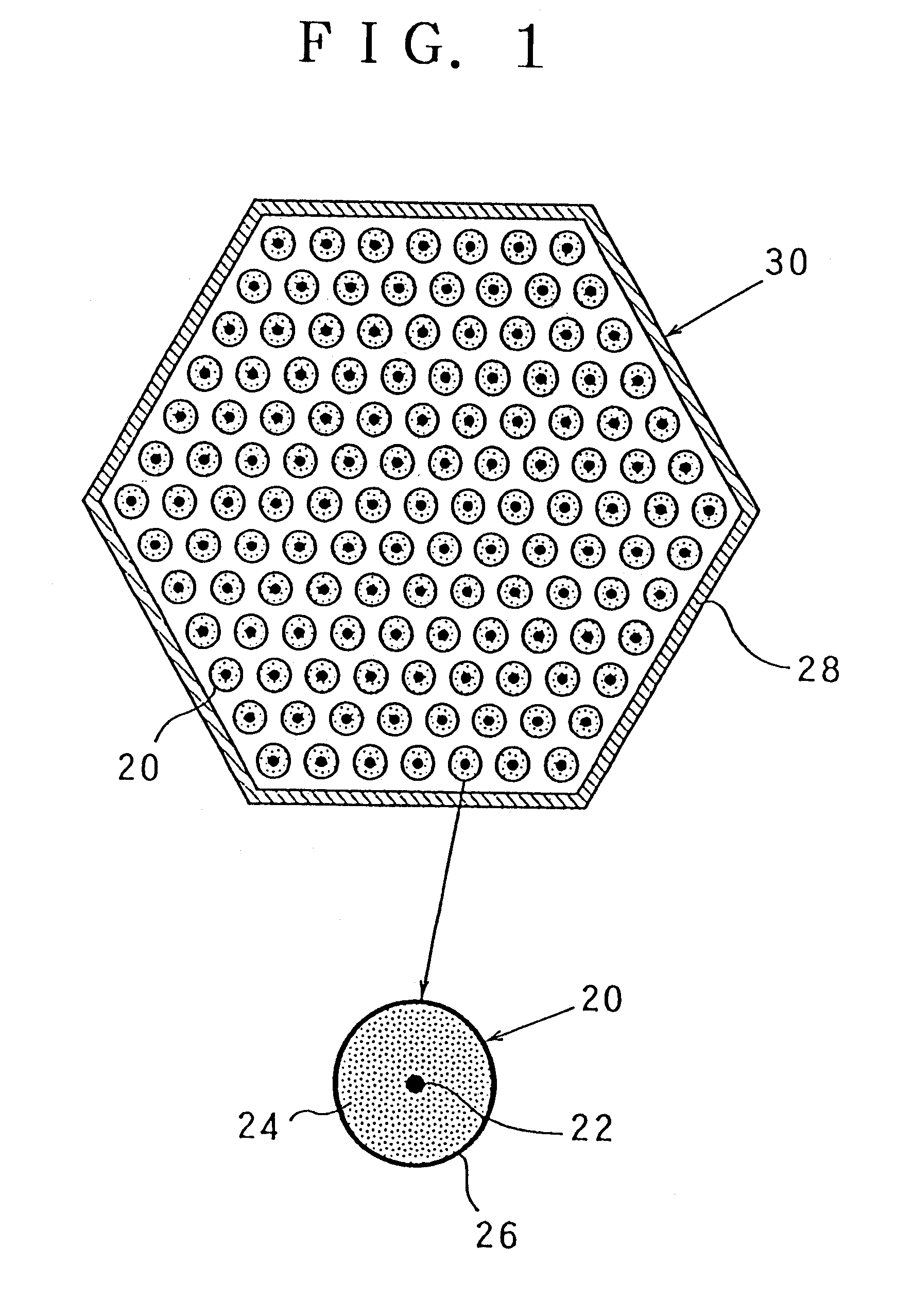

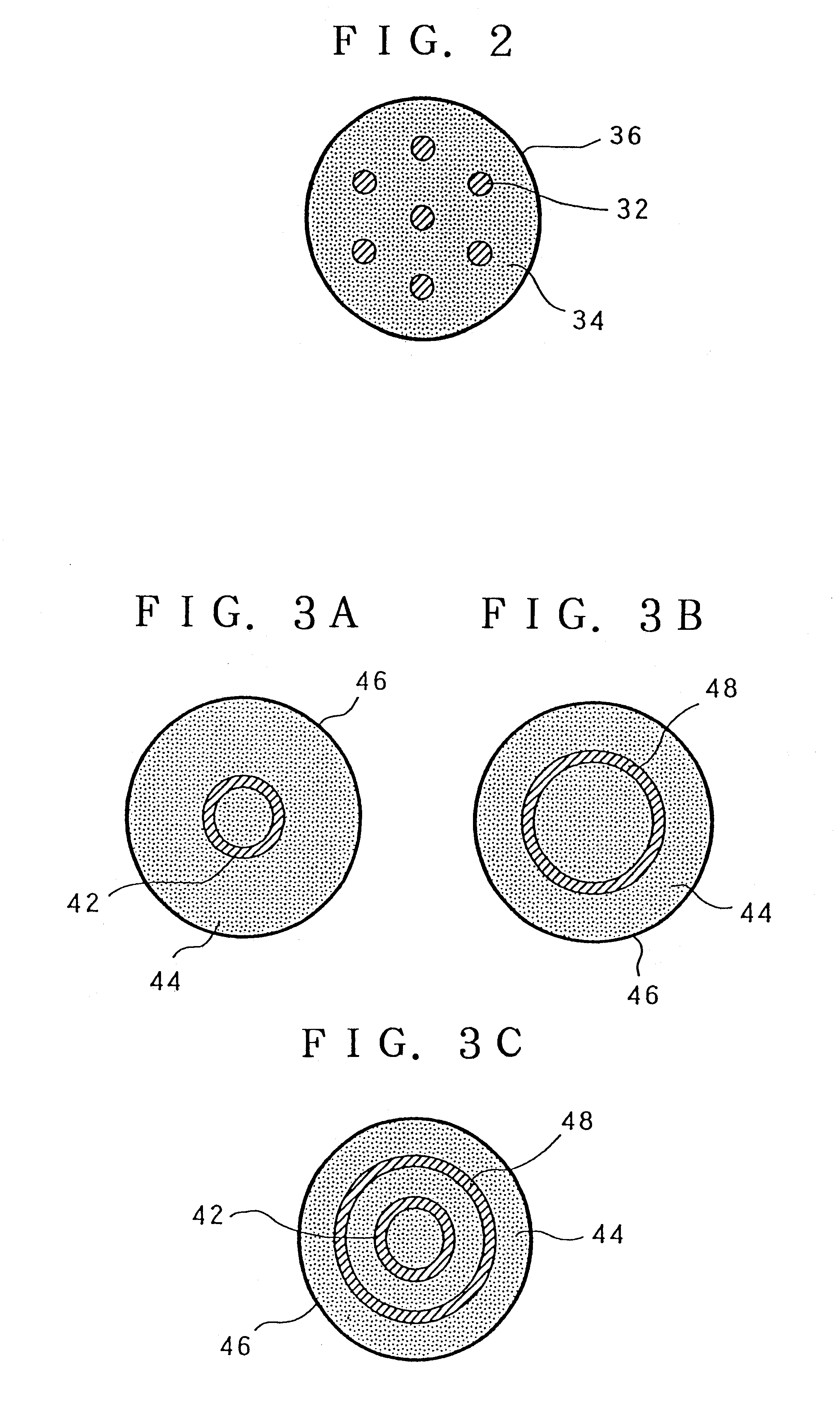

Assembly for transmutation of a long-lived radioactive material

InactiveUS6233299B1Conversion outside reactor/acceleratorsNuclear energy generationRadioactive agentTechnetium-99

A new transmutation assembly permits an efficient transmutation of a long-lived radioactive material (long-lived FP nuclides such as technetium-99 or iodine-129) which was produced in the nuclear reactor. Wire-type members of a long-lived radioactive material comprised of metals, alloys or compounds including long-lived FP nuclides are surrounded by a moderator material and installed in cladding tubes to form FP pins. The FP pins, and nothing else, are housed in a wrapper tube to form a transmutation assembly. The wire-type members can be replaced by thin ring-type members. The transmutation assemblies can be selectively and at least partly loaded into a core region, a blanket region or a shield region of a reactor core in a fast reactor. From a viewpoint of reducing the influence on the reactor core characteristics, it is optimal to load the transmutation assemblies into the blanket region.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

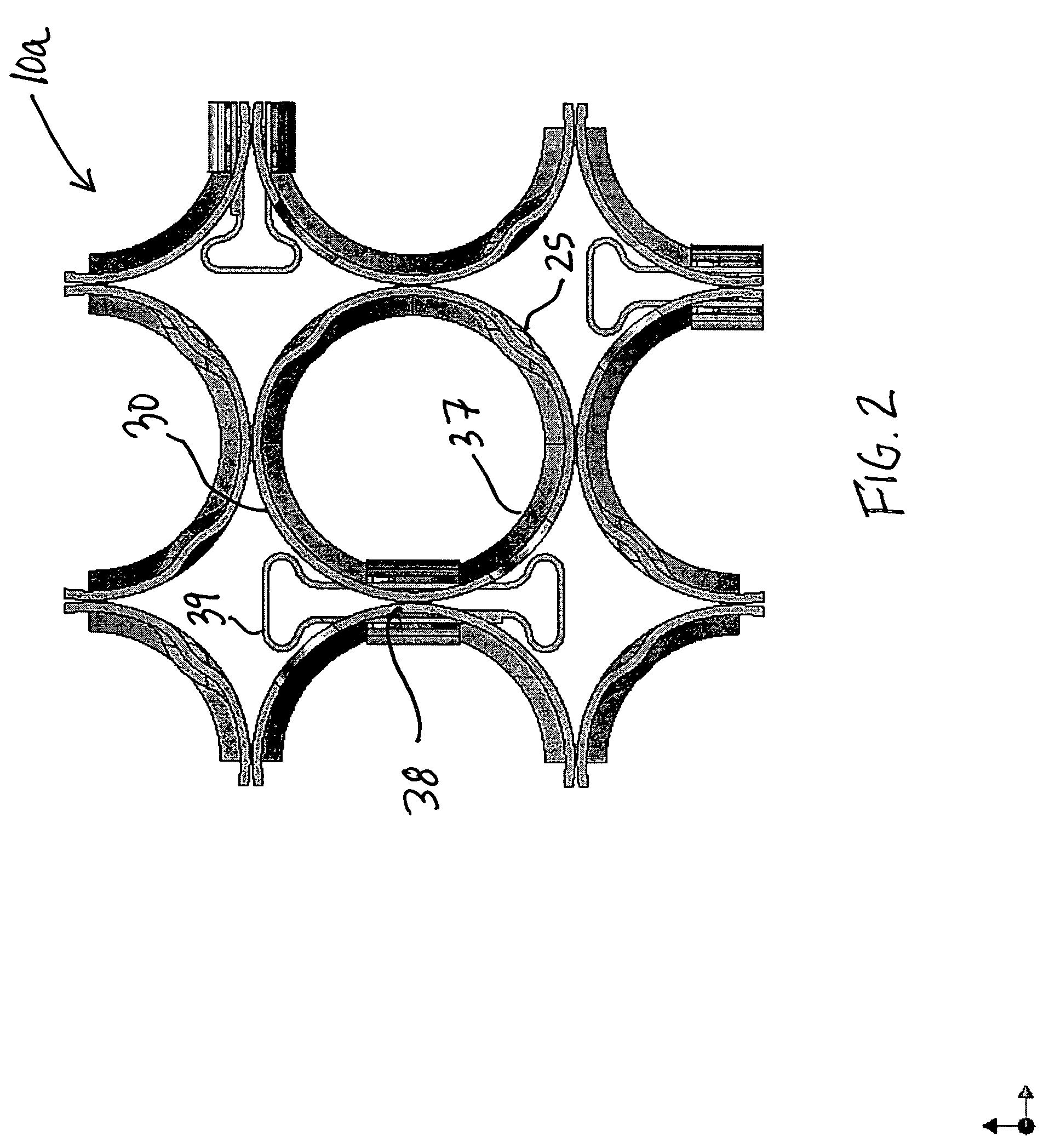

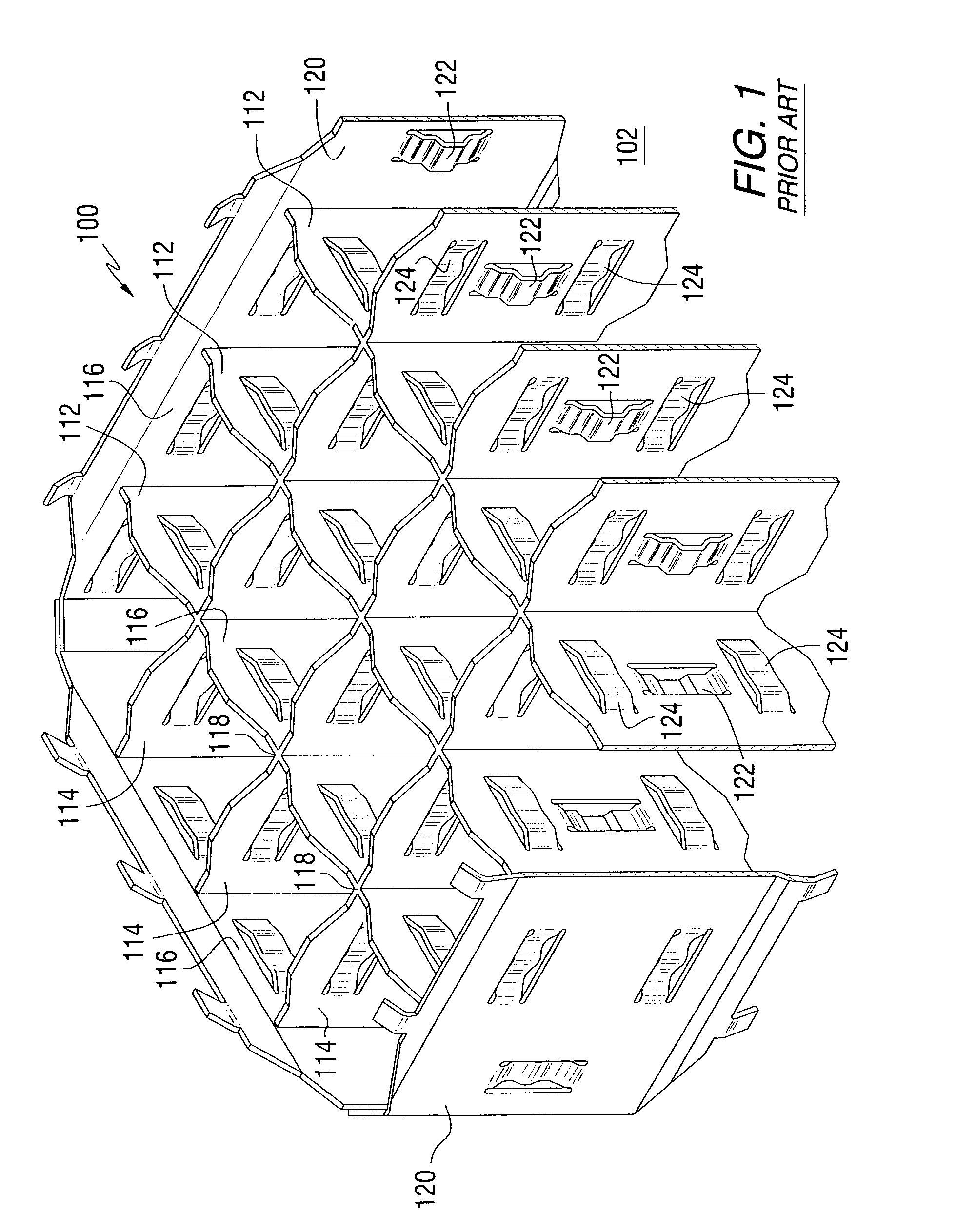

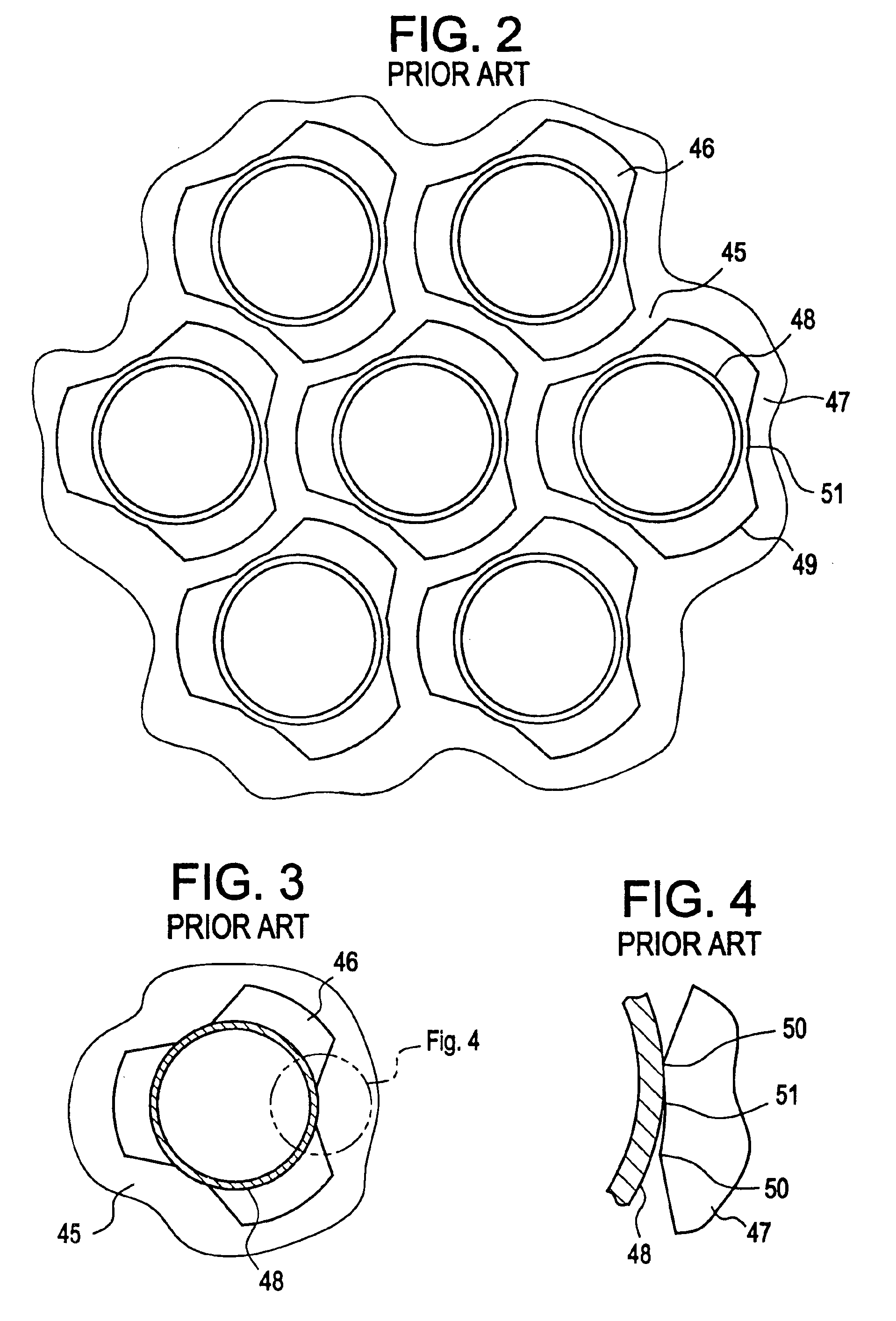

Helically fluted tubular fuel rod support

ActiveUS20060153327A1Minimal pressure dropUniform thicknessNuclear energy generationFuel element assembliesEngineeringCell contact

A support grid for a nuclear fuel assembly, the fuel rod assembly having a generally cylindrical fuel rod with a diameter, wherein the support grid includes a frame assembly having a plurality of generally uniform cells, each the cell having at least one wall and a width and at least one generally cylindrical tubular member having a cell contact portion with a greater diameter and at least one helical fuel rod contact portion with a lesser diameter, the cell contact portion and the fuel rod contact portion joined by a transition portion, the greater diameter being generally equivalent to the cell width, and the lesser diameter being generally equivalent to the fuel rod diameter such that a fuel rod disposed in the tubular member would engage the inner diameter. Wherein the least one tubular member disposed in one cell of the plurality of generally square cells so that the cell contact portion engages the at least one cell sidewall.

Owner:WESTINGHOUSE ELECTRIC CORP

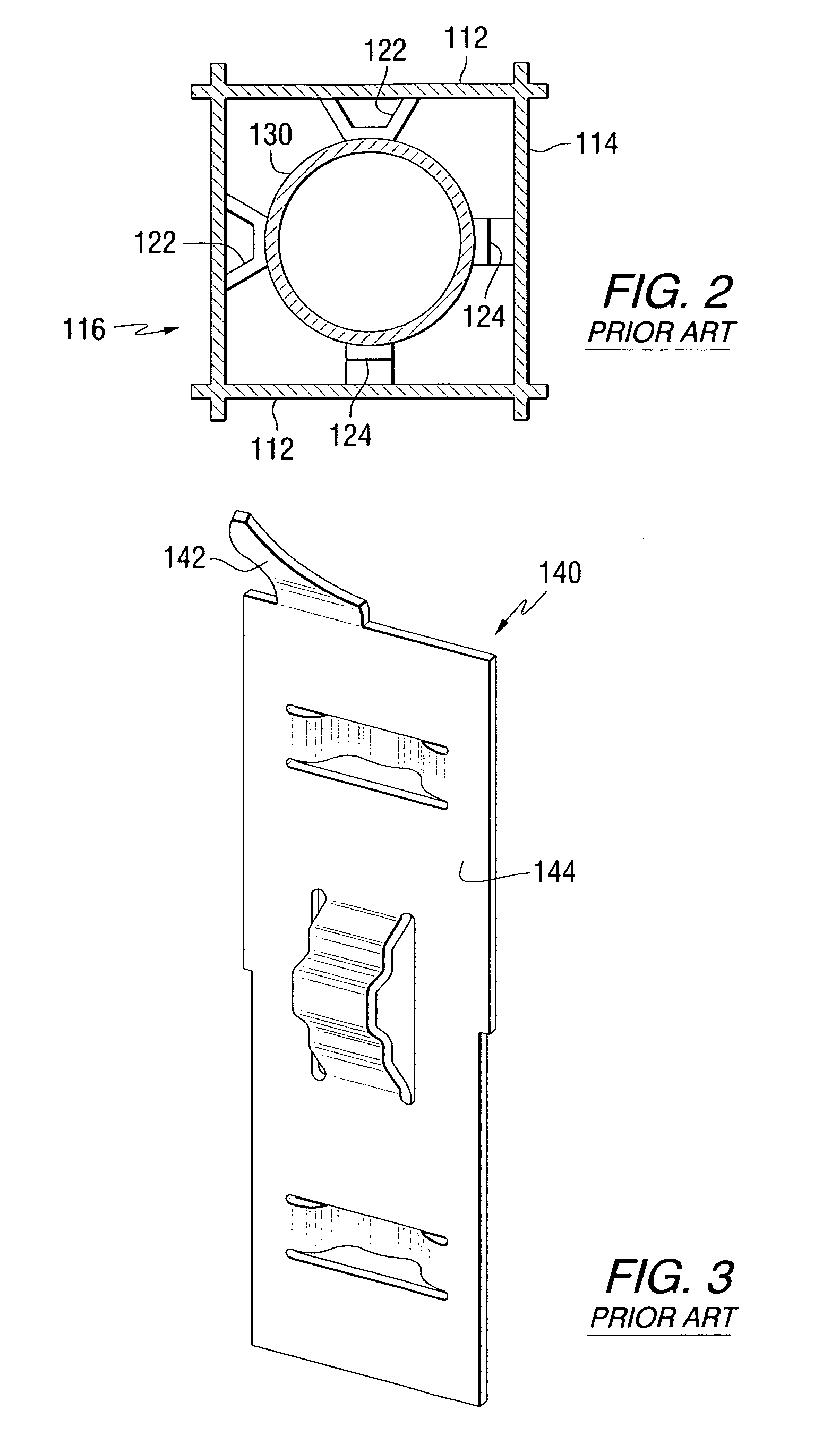

Fuel assembly spacer grid with swirl deflectors and hydraulic pressure springs

InactiveUS6236702B1Minimized pressure lossDecrease in initial mechanical spring forceNuclear energy generationFuel element assembliesSpring forceInterconnection

A fuel assembly spacer grid including swirl deflectors respectively arranged at interconnections between interconnecting longitudinally and laterally-extending straps on upper ends of the interconnecting straps adapted to support fuel elements of a nuclear fuel assembly. Each of the swirl deflectors has four vanes bent to have an air vane shape. By virtue of this configuration, an improvement in the efficiency of the spacer grid cooling the fuel elements. The spacer grid also includes springs each configured to generate not only a main spring force caused by a displacement of the spring occurring when the spring comes into contact with a fuel element placed in a reactor core, but also an additional spring force caused by hydraulic pressure applied to the spring. Each spring, which is in a fixed state at one end thereof, has a free bent portion at the other end. By virtue of such a spring configuration, it is possible to compensate for a reduction in the initial spring force of the spring resulting from a change in the property of the spring material. The spring has a curved contact portion configured in such a manner that it is in conformal surface contact with a circumferential surface of the fuel element, thereby enhancing vibration suppressing and abrasion resistance forces.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

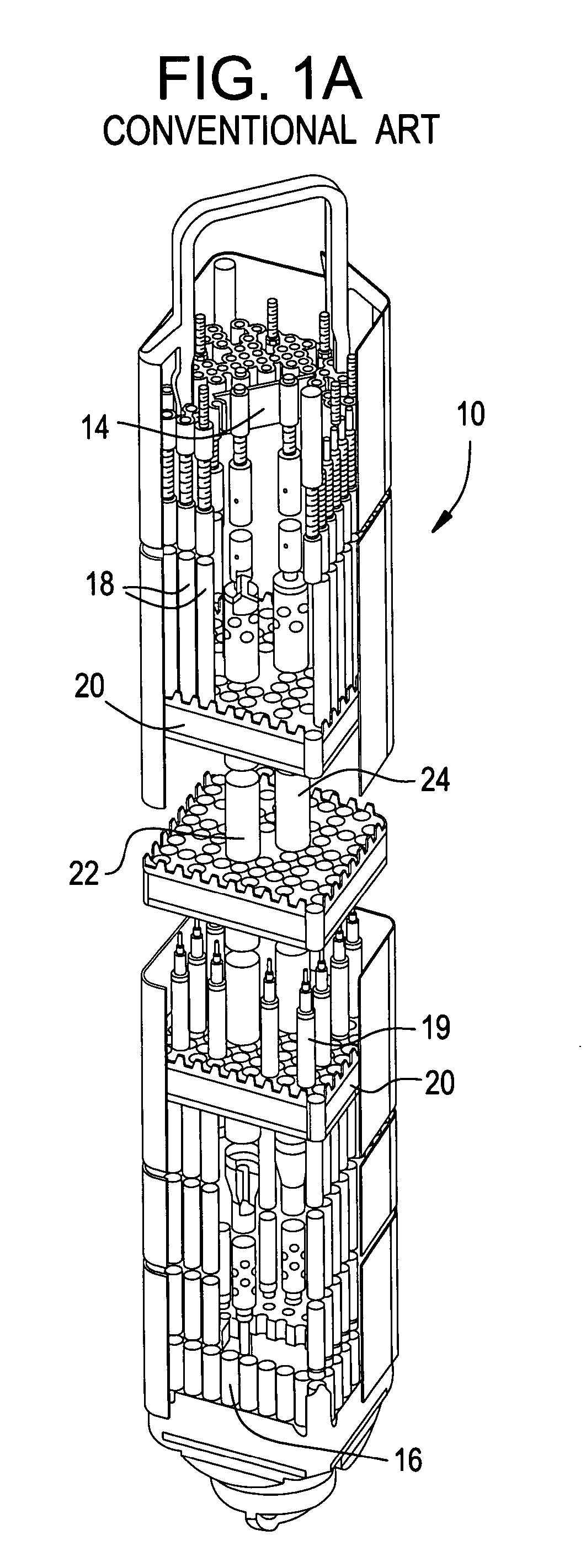

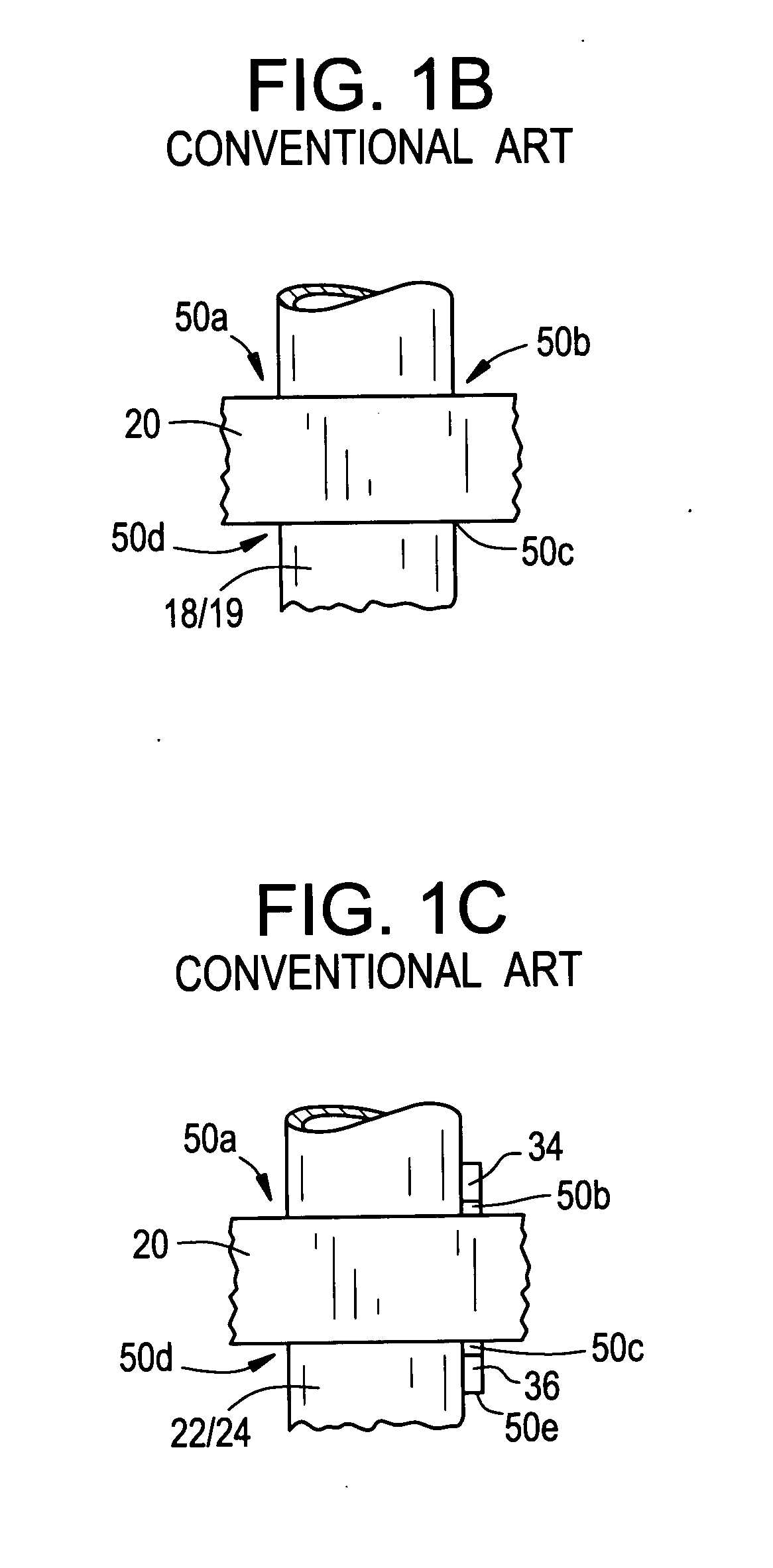

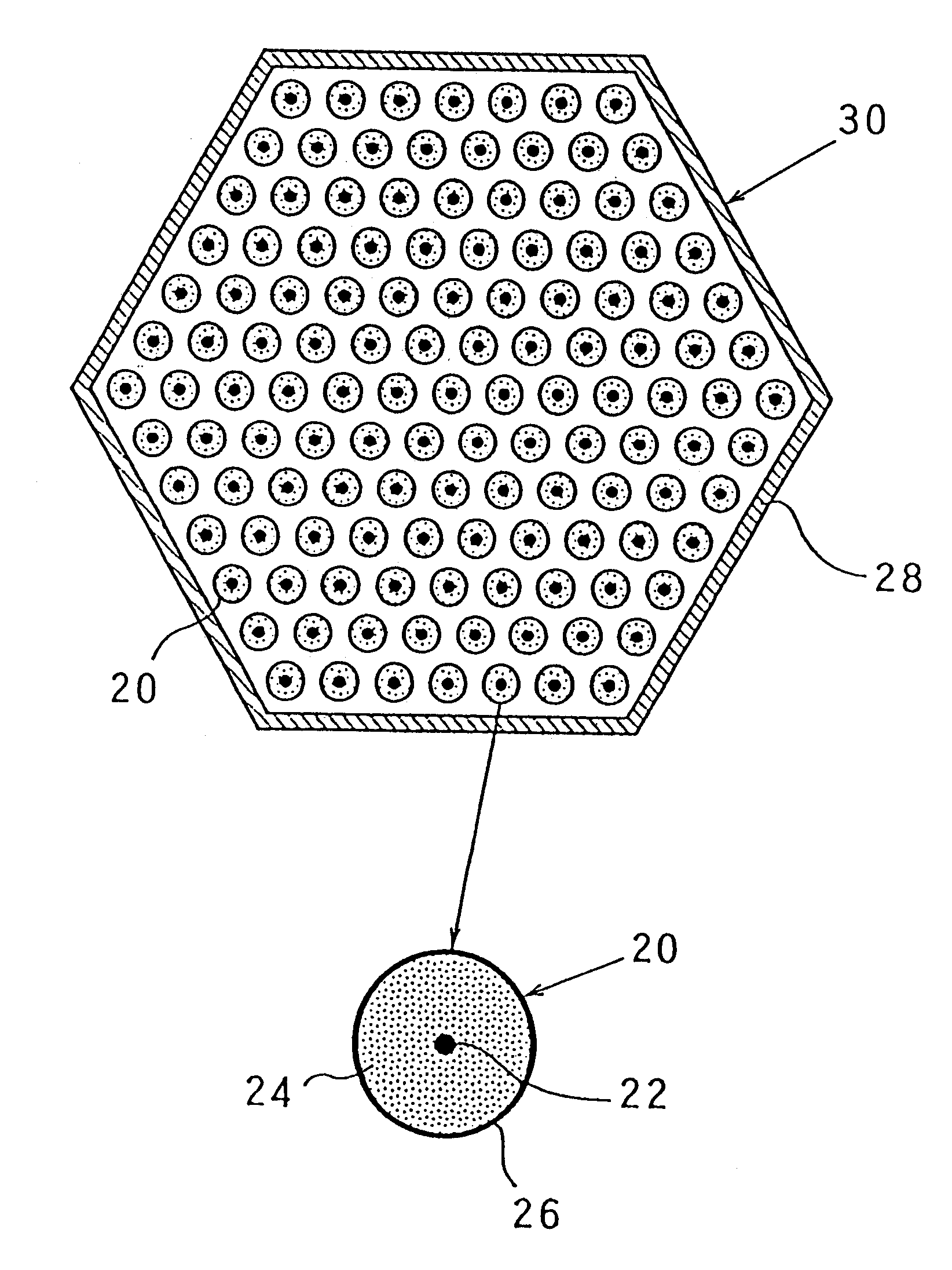

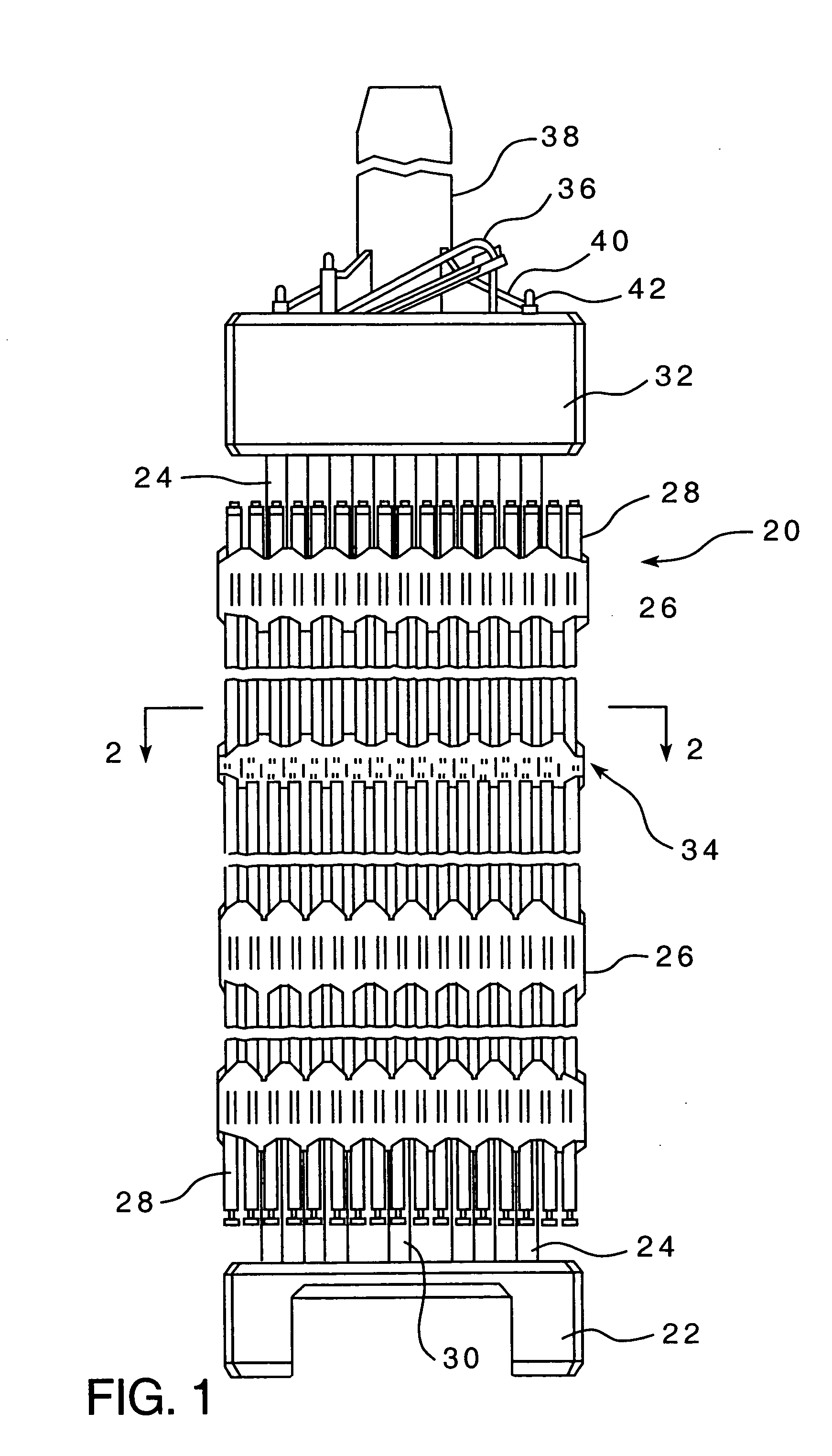

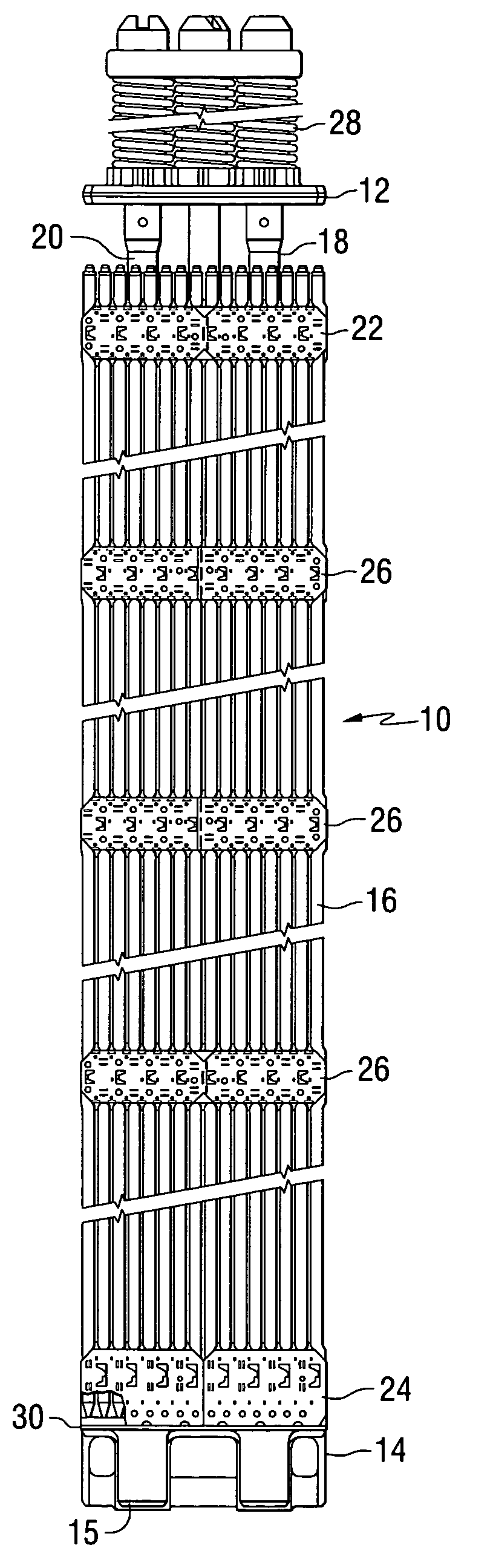

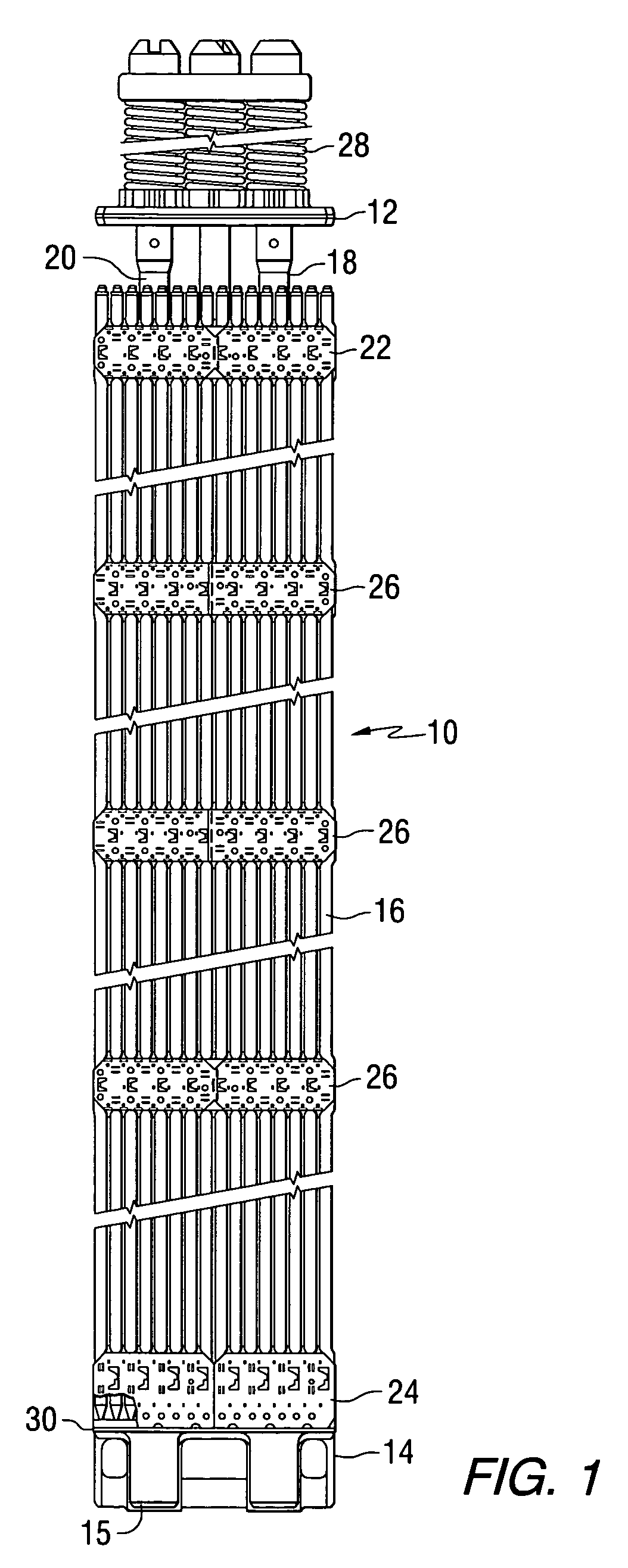

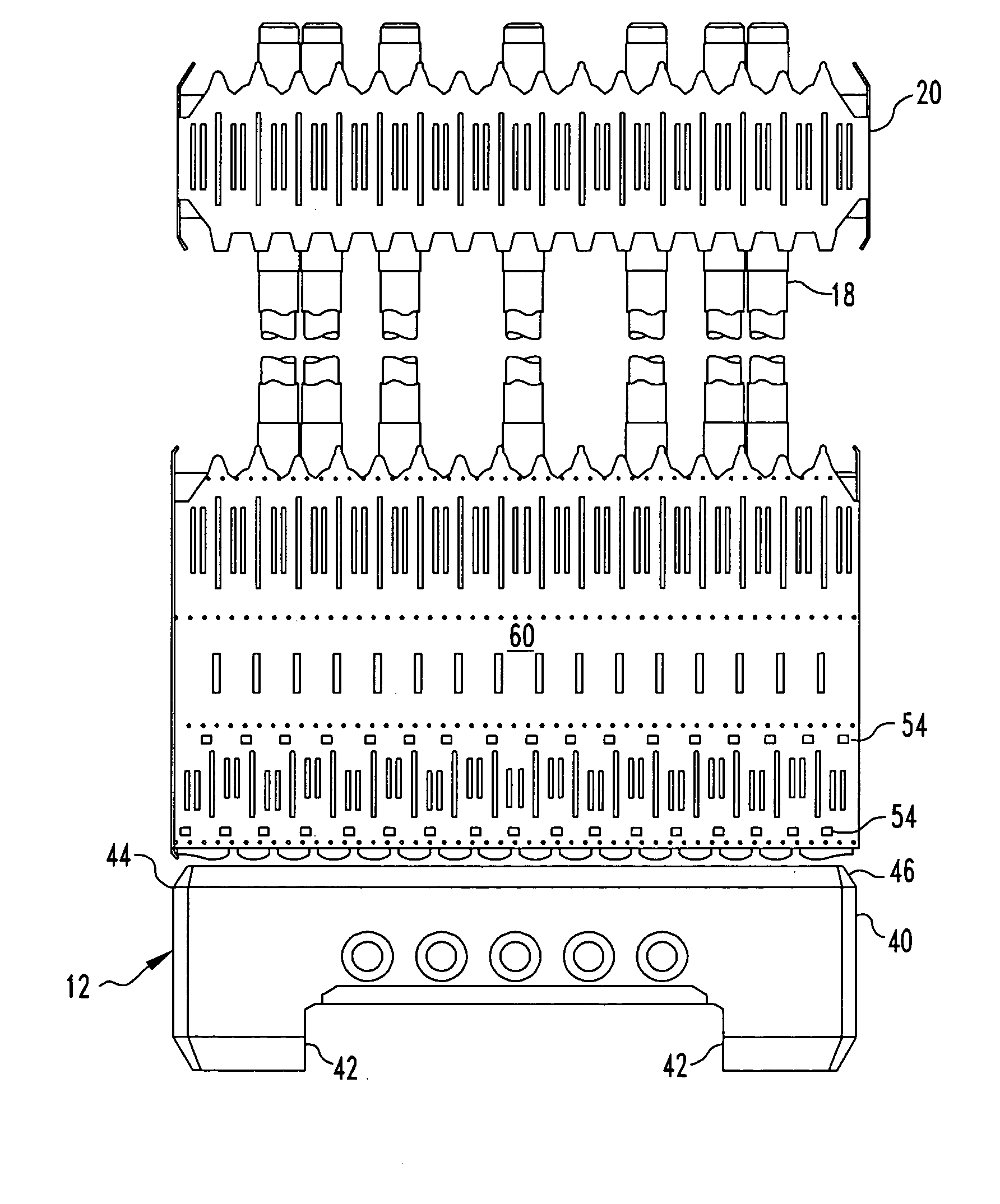

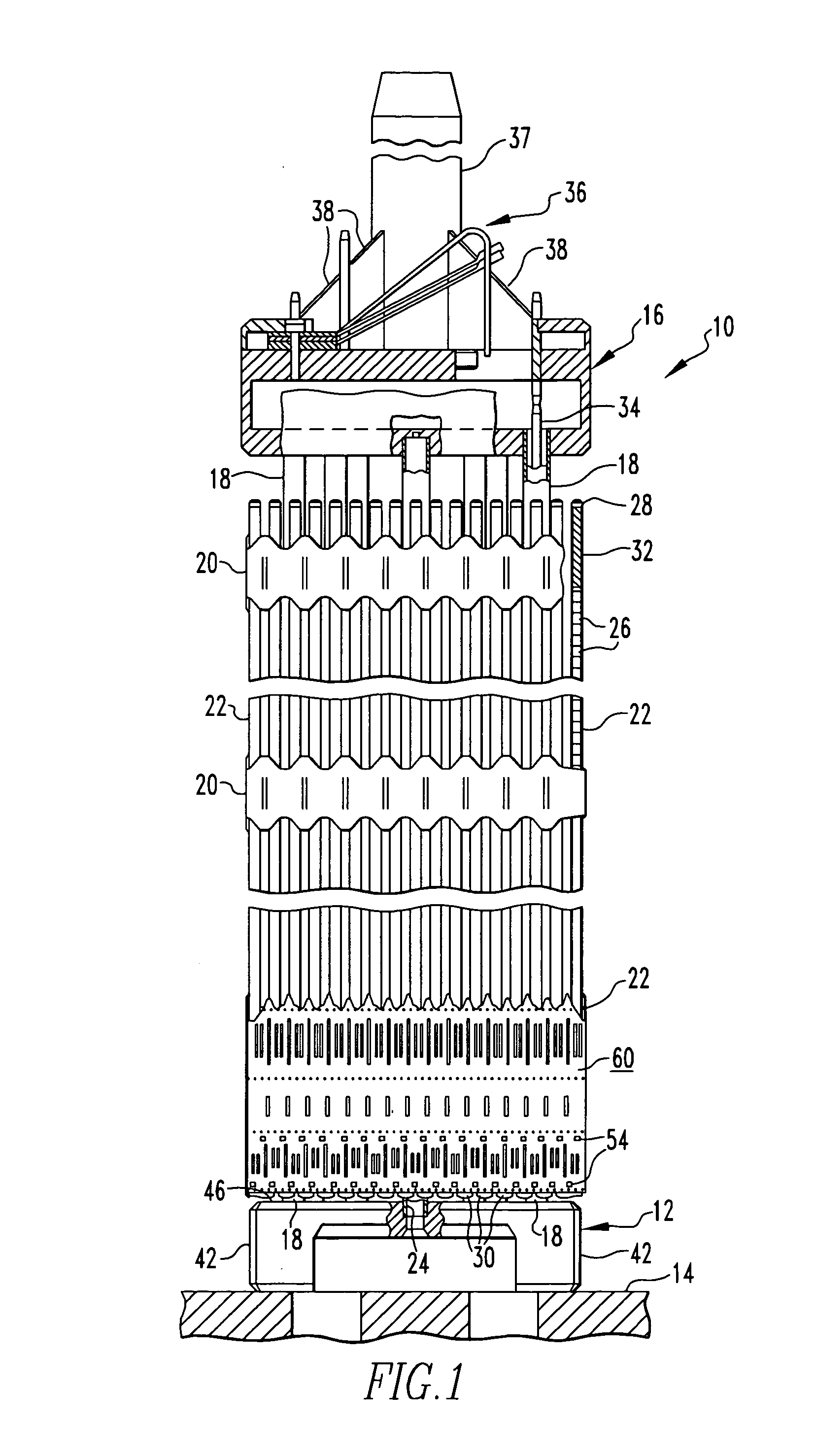

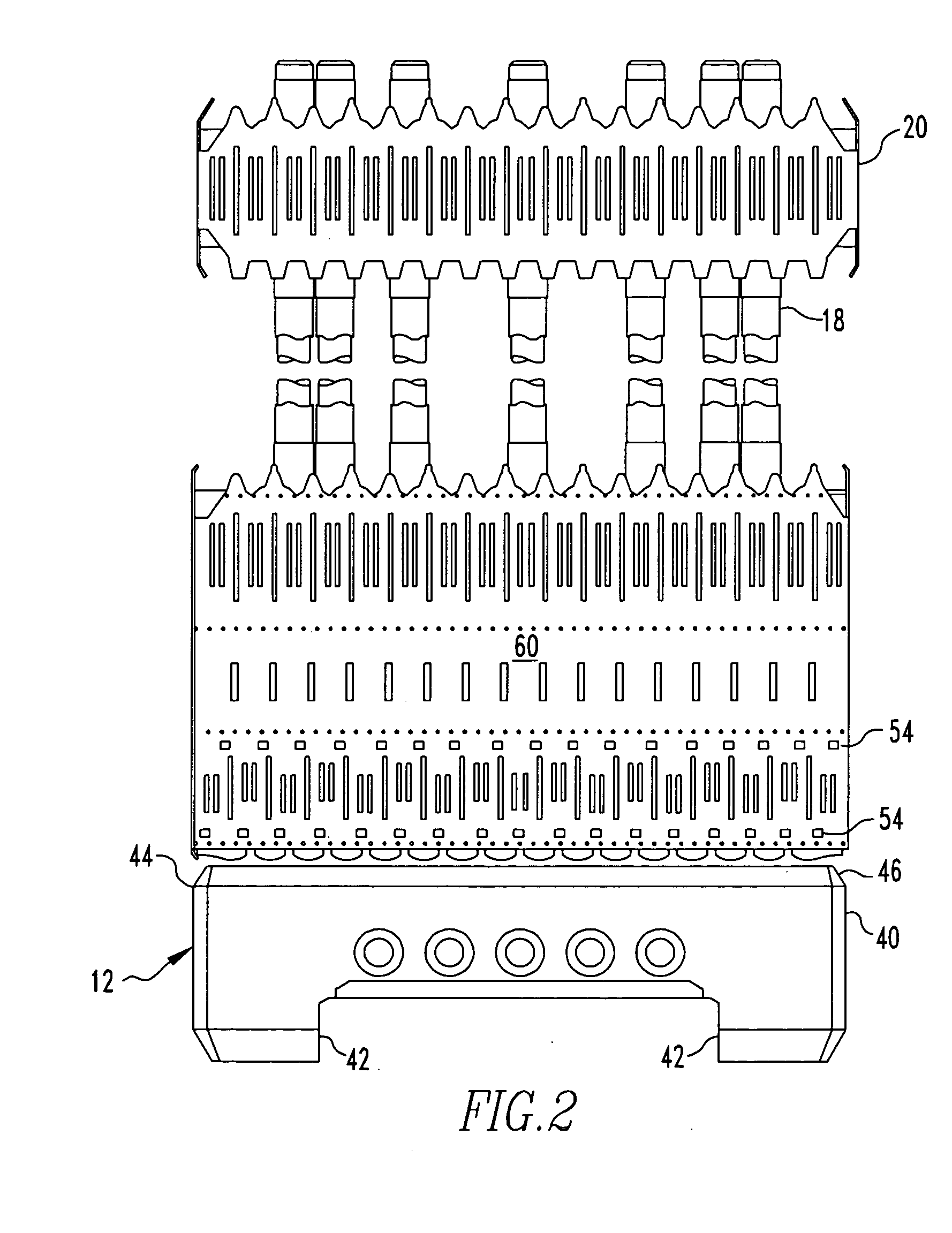

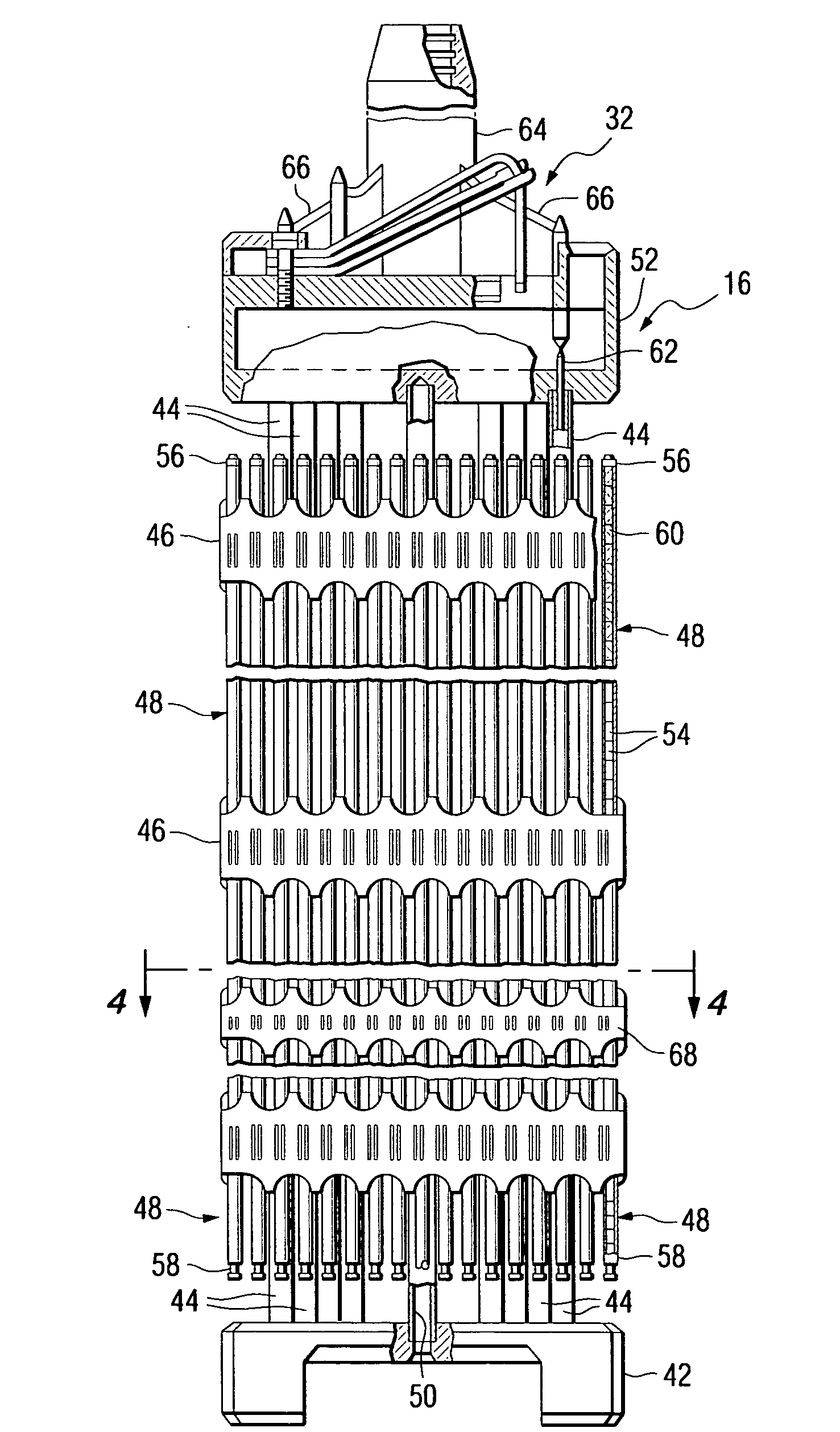

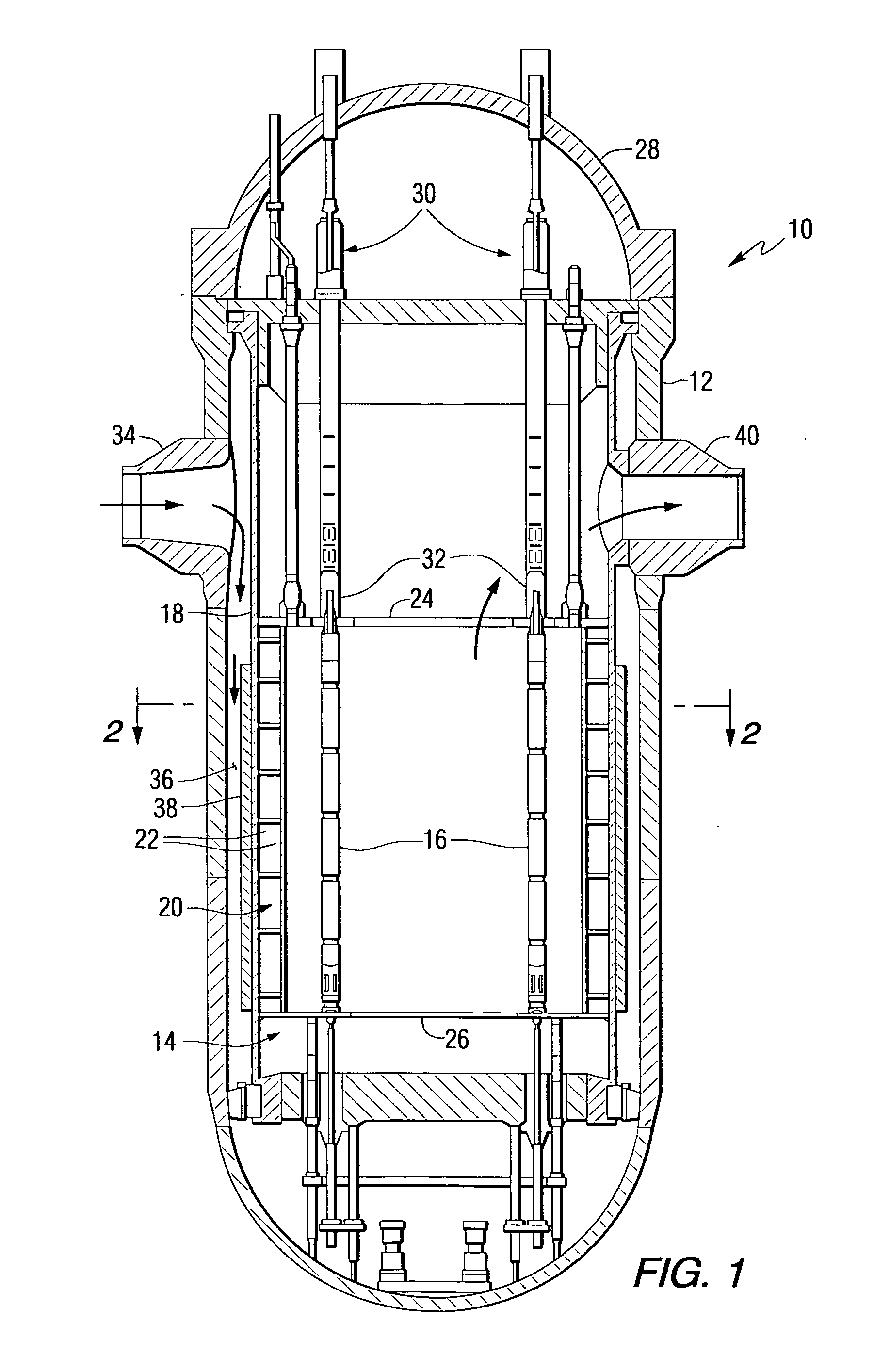

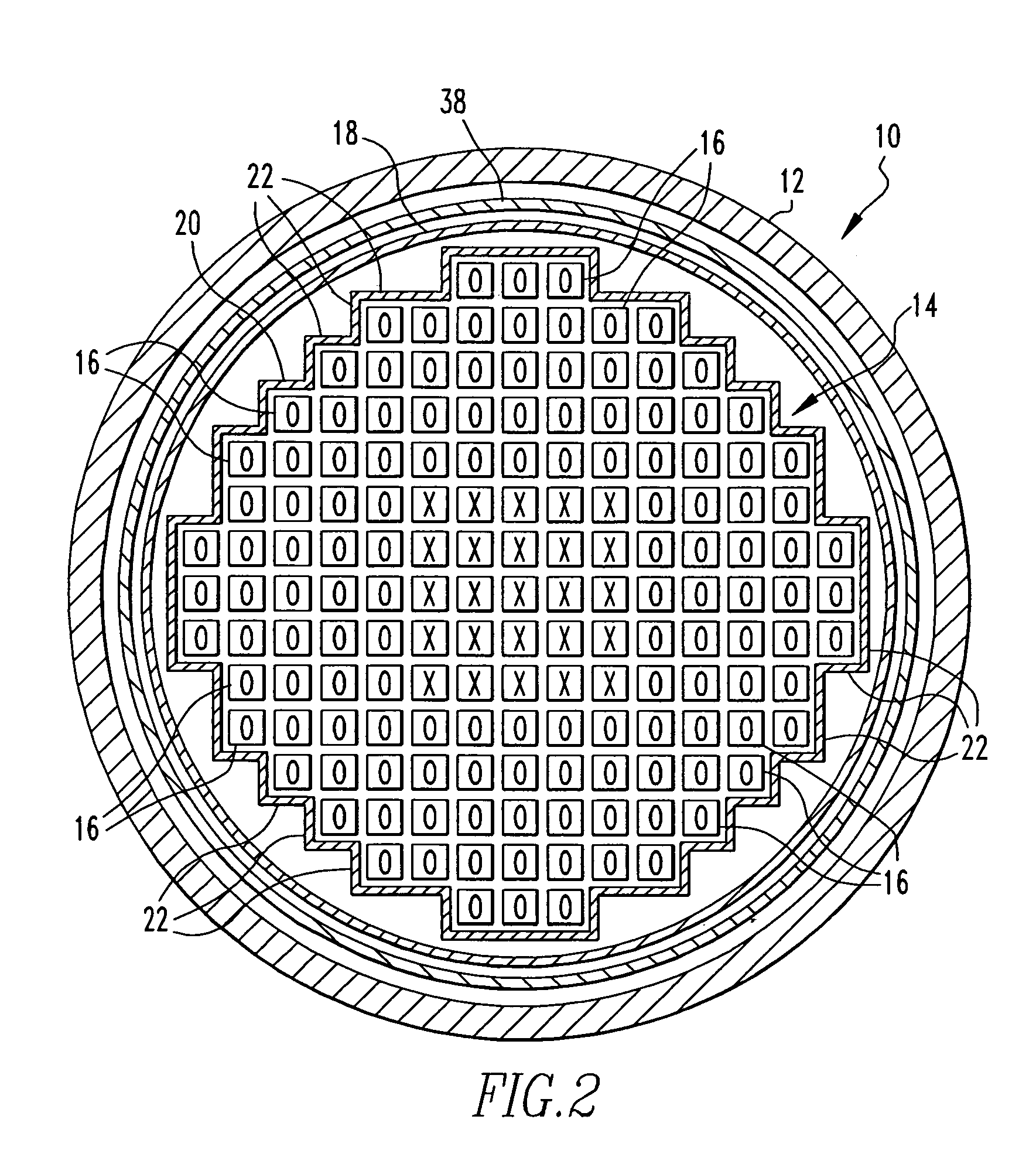

Nuclear reactor fuel assemblies

InactiveUS7085340B2Eliminate wearPrevent “hang-upsNuclear energy generationFuel element assembliesNuclear reactorParallel array

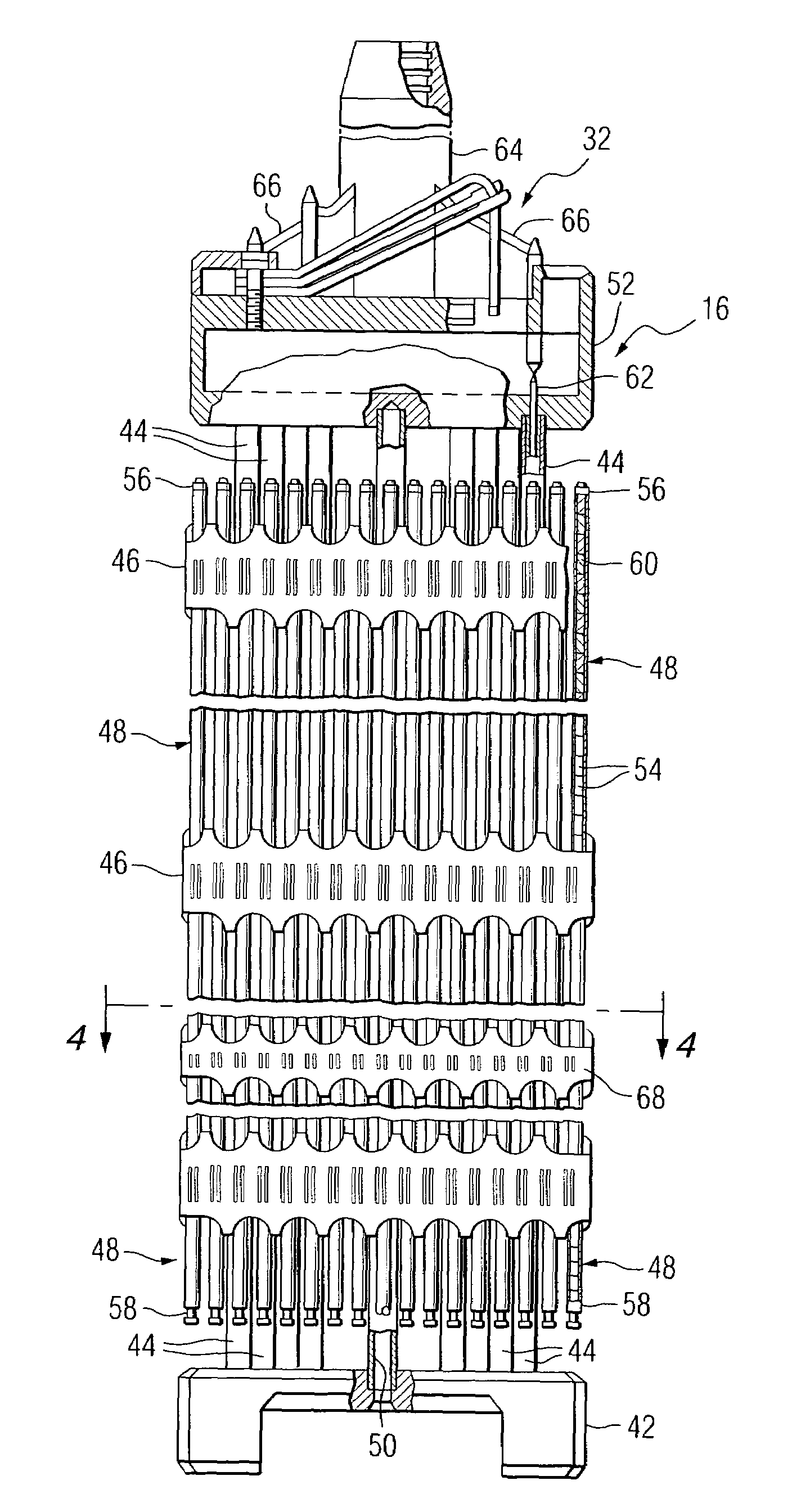

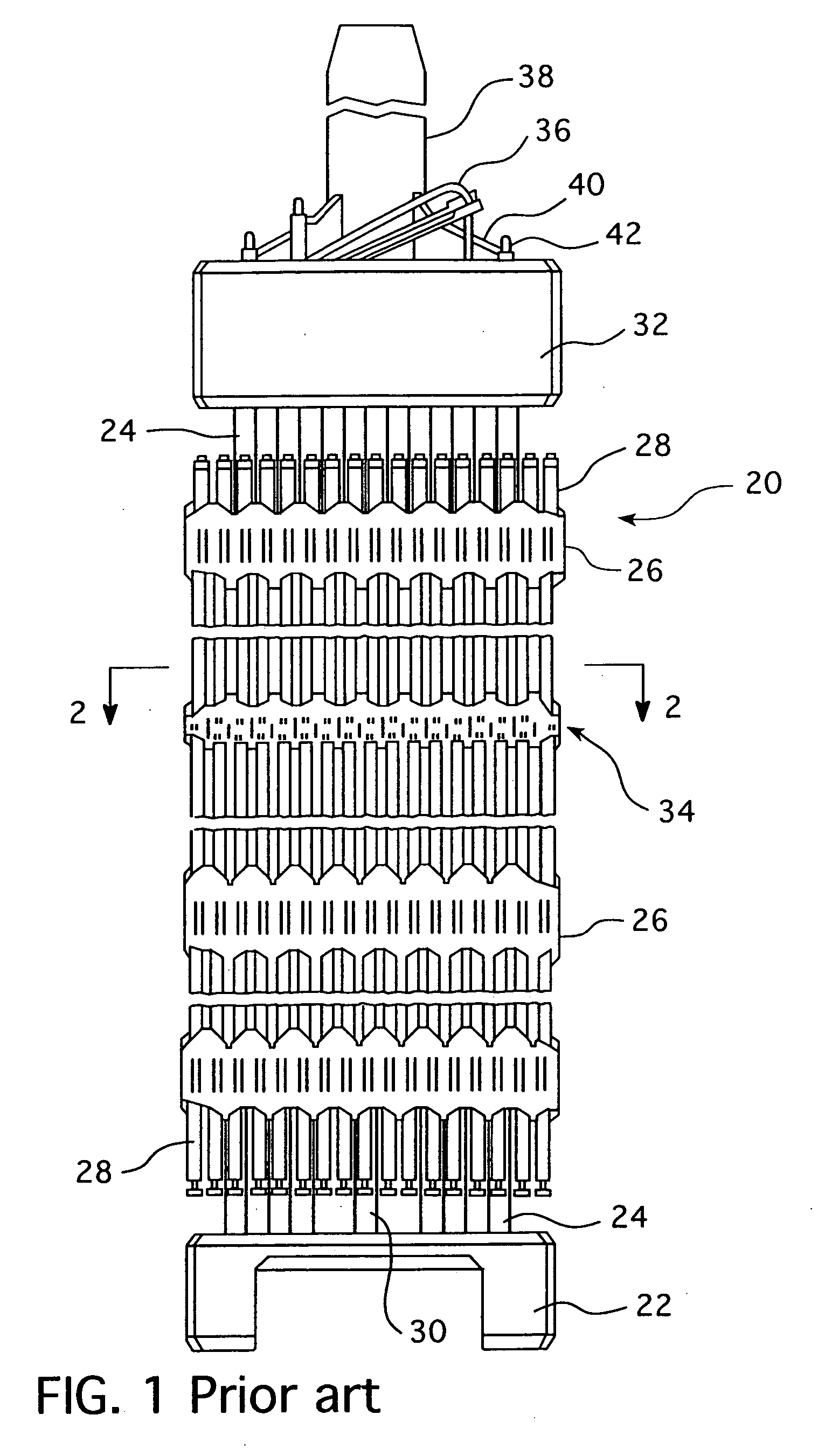

A nuclear fuel assembly having a parallel array of elongated fuel elements supported between an upper and lower nozzle. Main support grids are substantially evenly spaced along the elongated dimension of the assembly to maintain the spacing between fuel elements. A plurality of auxiliary vibration-resistant grids respectively positioned between the main support grids in the middle third elongated dimension of the fuel elements, that are smaller in height and provide a larger fuel element contact area than the main support grids.

Owner:WESTINGHOUSE ELECTRIC CORP

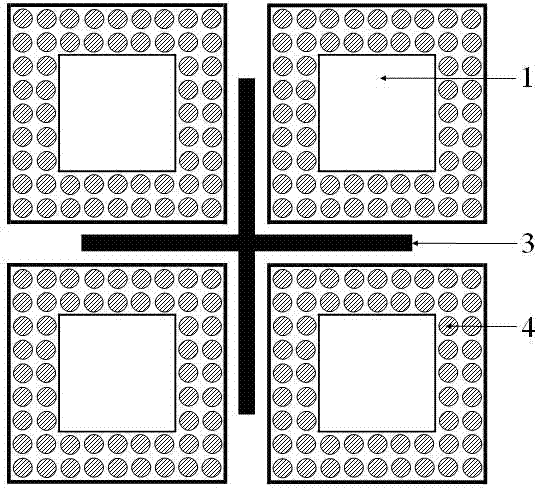

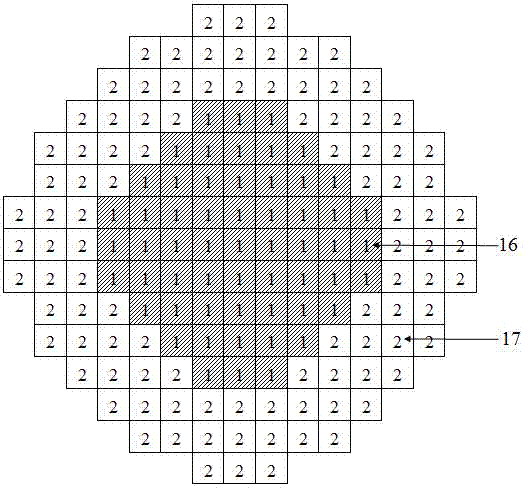

Combined square fuel assembly, reactor core and two-pass flowing method of super-critical water reactor

ActiveCN102737735AGuaranteed Moderation UniformitySlow down fully and evenlyNuclear energy generationFuel element assembliesNuclear engineeringCoolant flow

The invention provides a combined square fuel assembly, a reactor core and a two-pass flowing method of a moderator and a coolant, which are suitable for a super-critical water reactor. The fuel assembly consists of 4 same child components arranged in a 2*2 square form, wherein each child component consists of multiple fuel rods arranged in a square grid form, a water rod is arranged in a central area, and a guide tube of a crossed control rod and a conduit of the water rod are placed above the component and a conduit of the water rod and a moderator duct are placed below the component; the reactor core is divided into first and second pass areas; the moderator flows into the space between the water rod and the child component from top to bottom in both passes; the coolant flows into a first pass fuel area from top to bottom; and the moderator and the coolant flow into a second pass fuel area from bottom to top after being stirred and mixed below the reactor core and flow out of the reactor core. According to the combined square fuel assembly, the reactor core and the two-pass flowing method of the super-critical water reactor, the moderator and the coolant as well as the different pass coolants in the components and the reactor core can be effectively shunted when the fuel rod is fully and uniformly moderated, the structural materials are reduced and the feasibility and safety are high.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

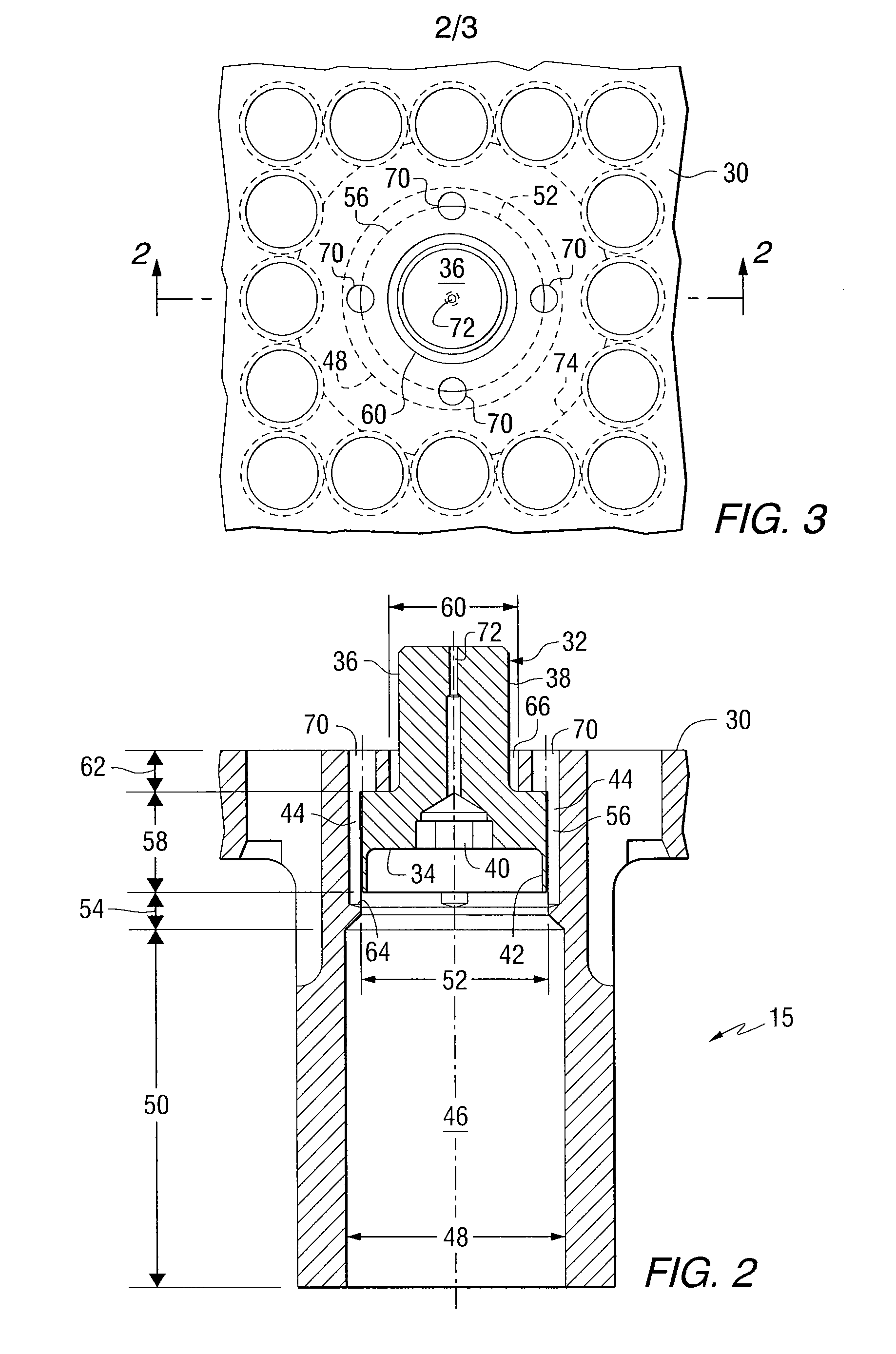

Nuclear fuel assembly control rod drive thimble to bottom nozzle connector

ActiveUS7453972B2Easy to implement and re-work and inspectLess componentsNuclear energy generationFuel element assembliesEngineeringPneumatic tool

A secure connection between the bottom nozzle of a nuclear fuel assembly and the control rod guide thimbles having two or four crimped pockets in the side wall of a bottom nozzle leg counterbore which are formed by drilling two or four blind holes through the top surface of the bottom nozzle. After attaching the bottom nozzle to the fuel assembly with a crimp bolt a pneumatic tool is then inserted into a flanged cup feature on the crimp bolt head and the flanged portion of the cup feature of the crimp bolt is deformed into the crimp pockets. The crimp pockets are contained within the leg counterbore and prevent the screw from rotating or falling out of the assembly in the event of preload loss or screw fracture.

Owner:WESTINGHOUSE ELECTRIC CORP

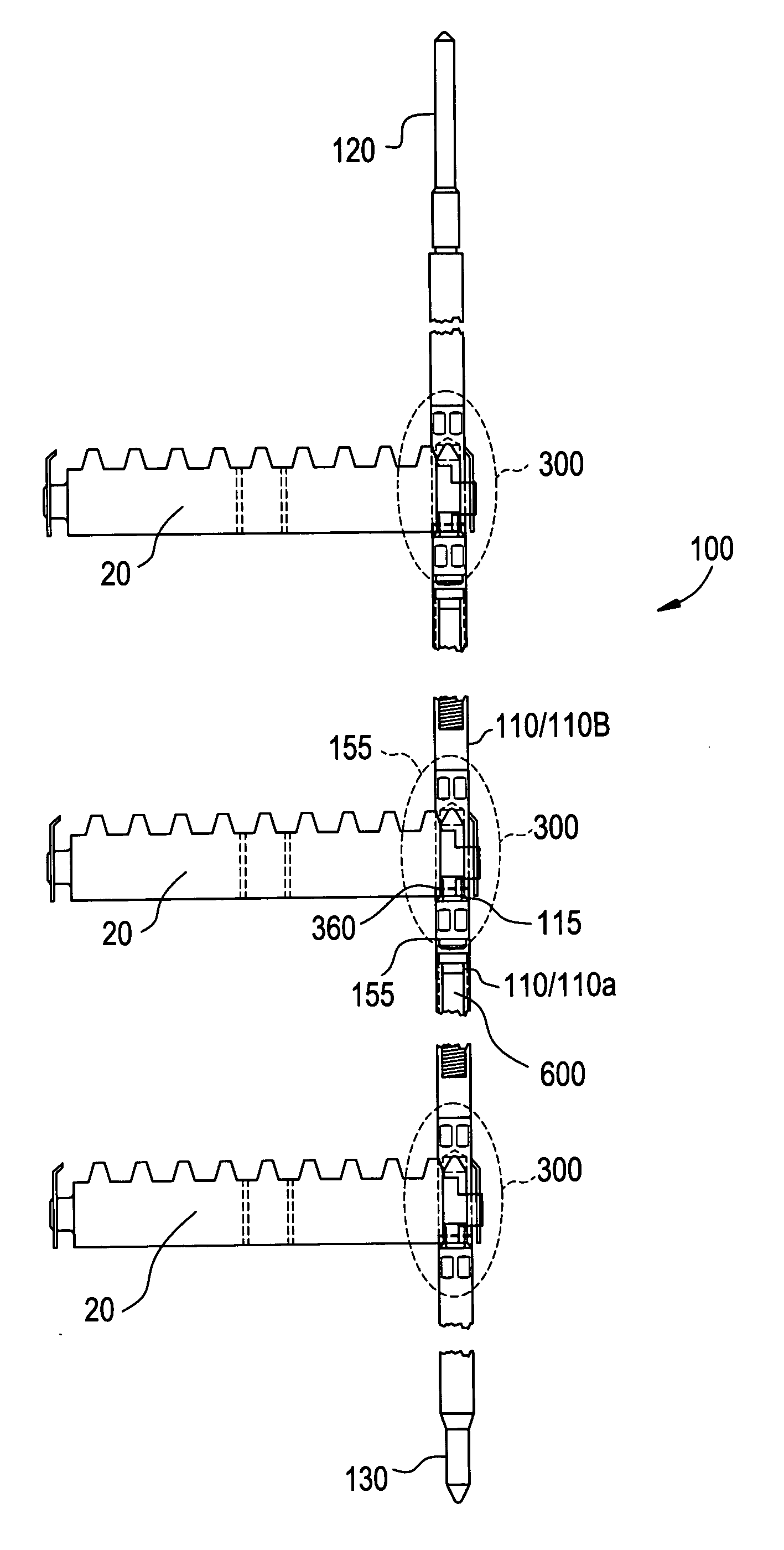

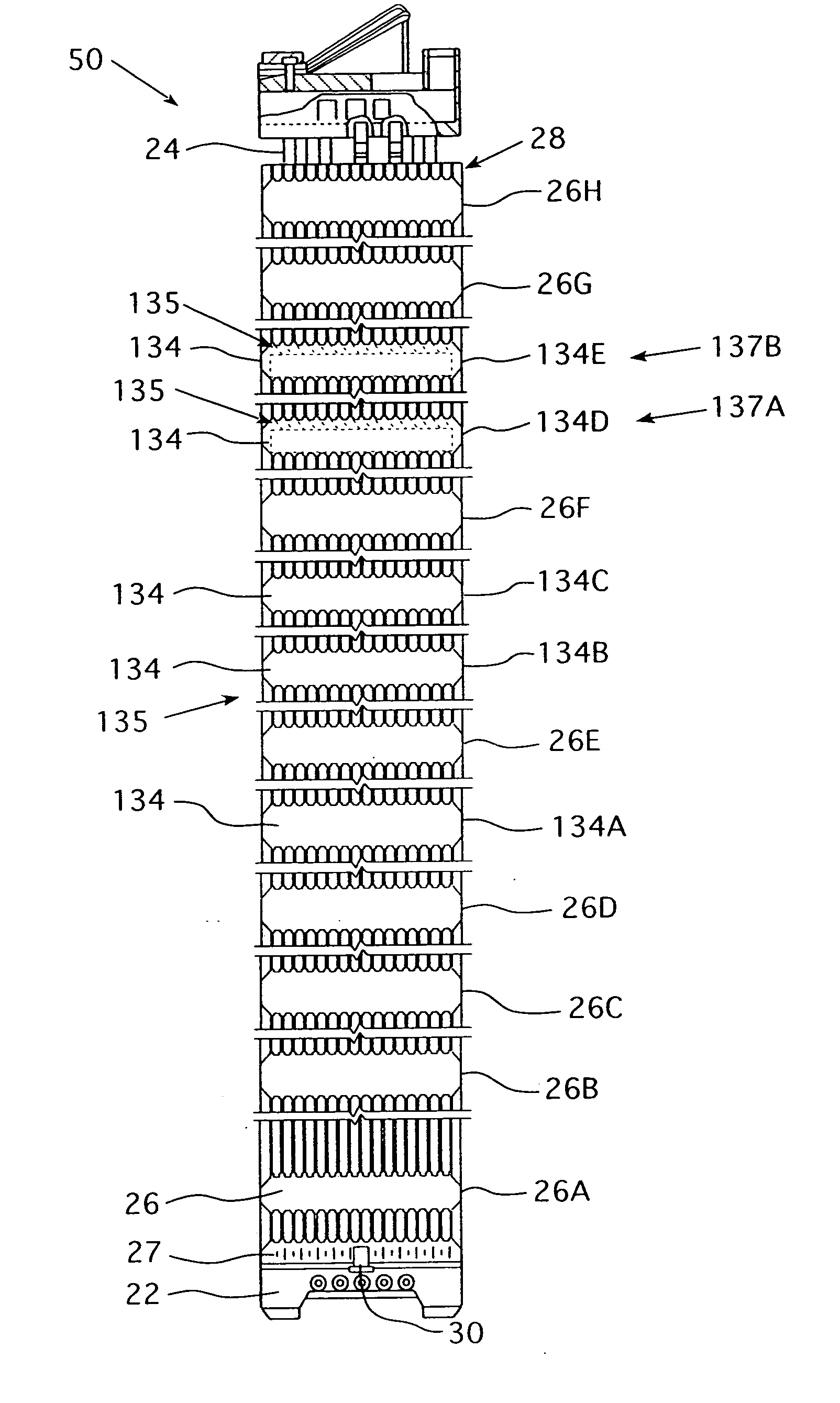

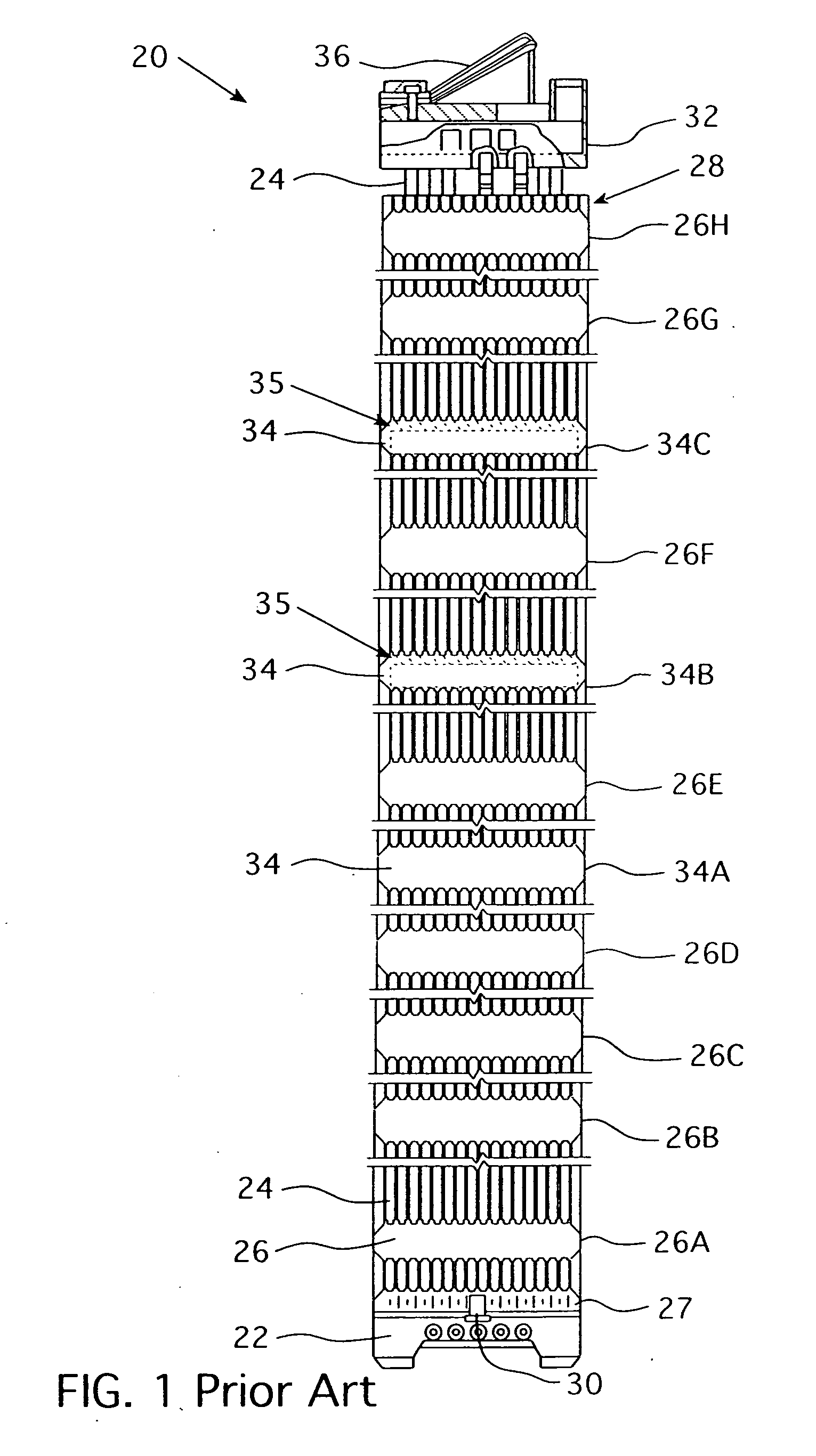

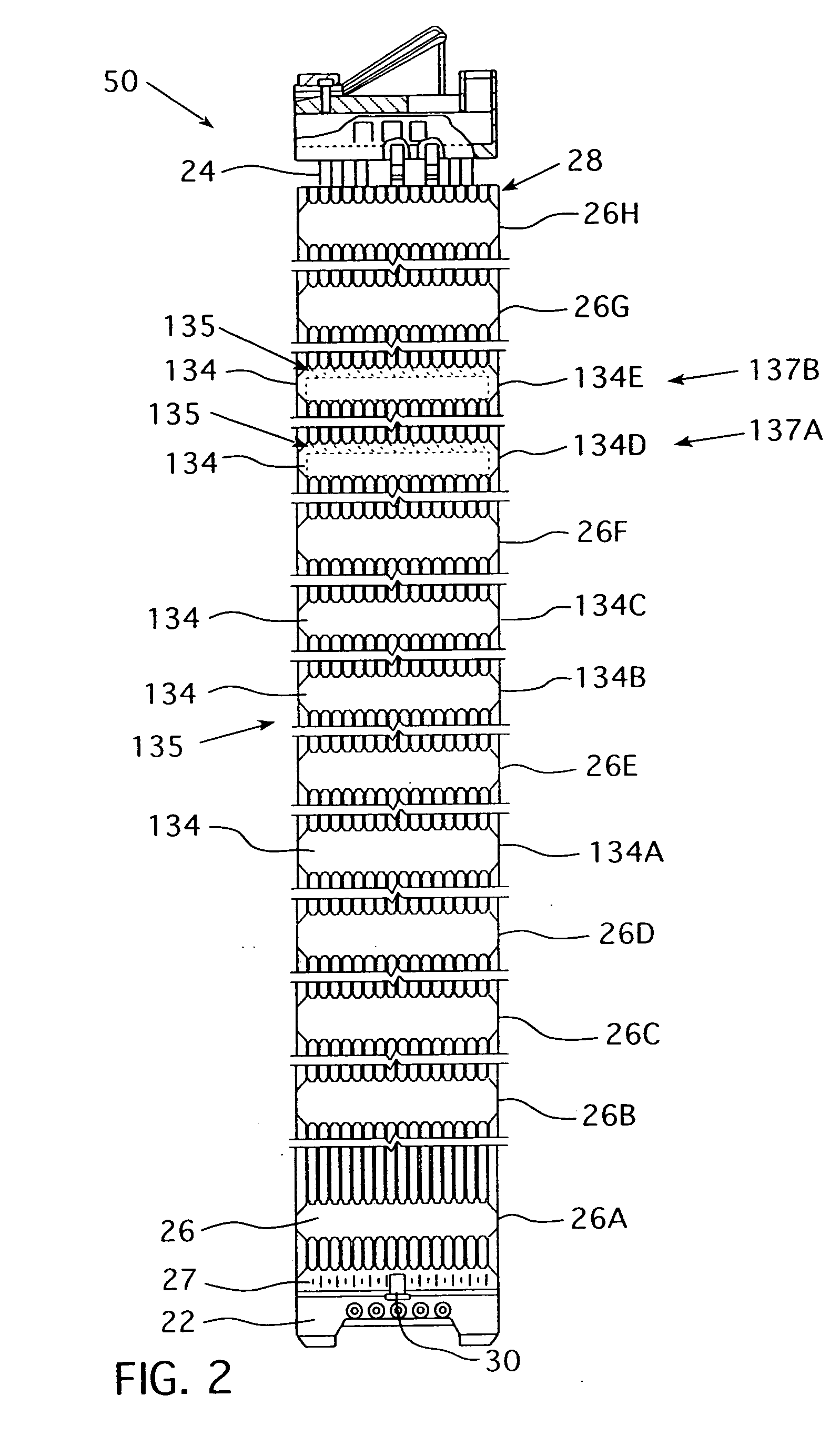

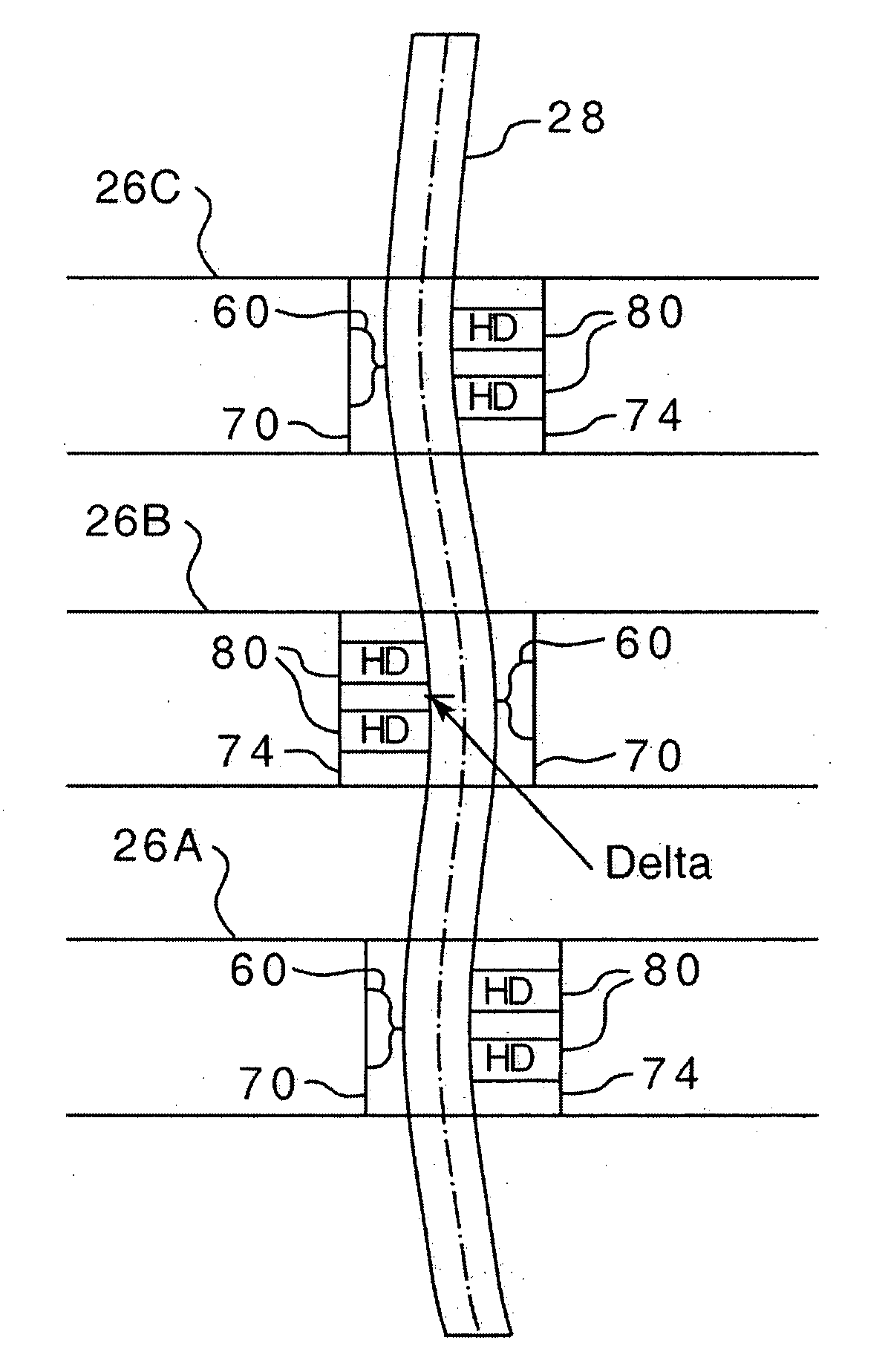

Rod assembly for nuclear reactors

A rod assembly for a fuel bundle of a nuclear reactor may include an upper end piece, lower end piece and a plurality of rod segments attached between the upper and lower end pieces and to each other so as to form an axial length of the rod assembly. The rod assembly may include an adaptor subassembly provided at given connection points for connecting adjacent rod segments or a given rod segment with one of the upper and lower end pieces. The connection points along the axial length of the rod assembly may be located where the rod assembly contacts a spacer in the fuel bundle. One (or more) of the rod segments may include an irradiation target therein for producing a desired isotope when a fuel bundle containing one (or more) rod assemblies is irradiated in a core of the reactor.

Owner:NORDION (CANADA) INC

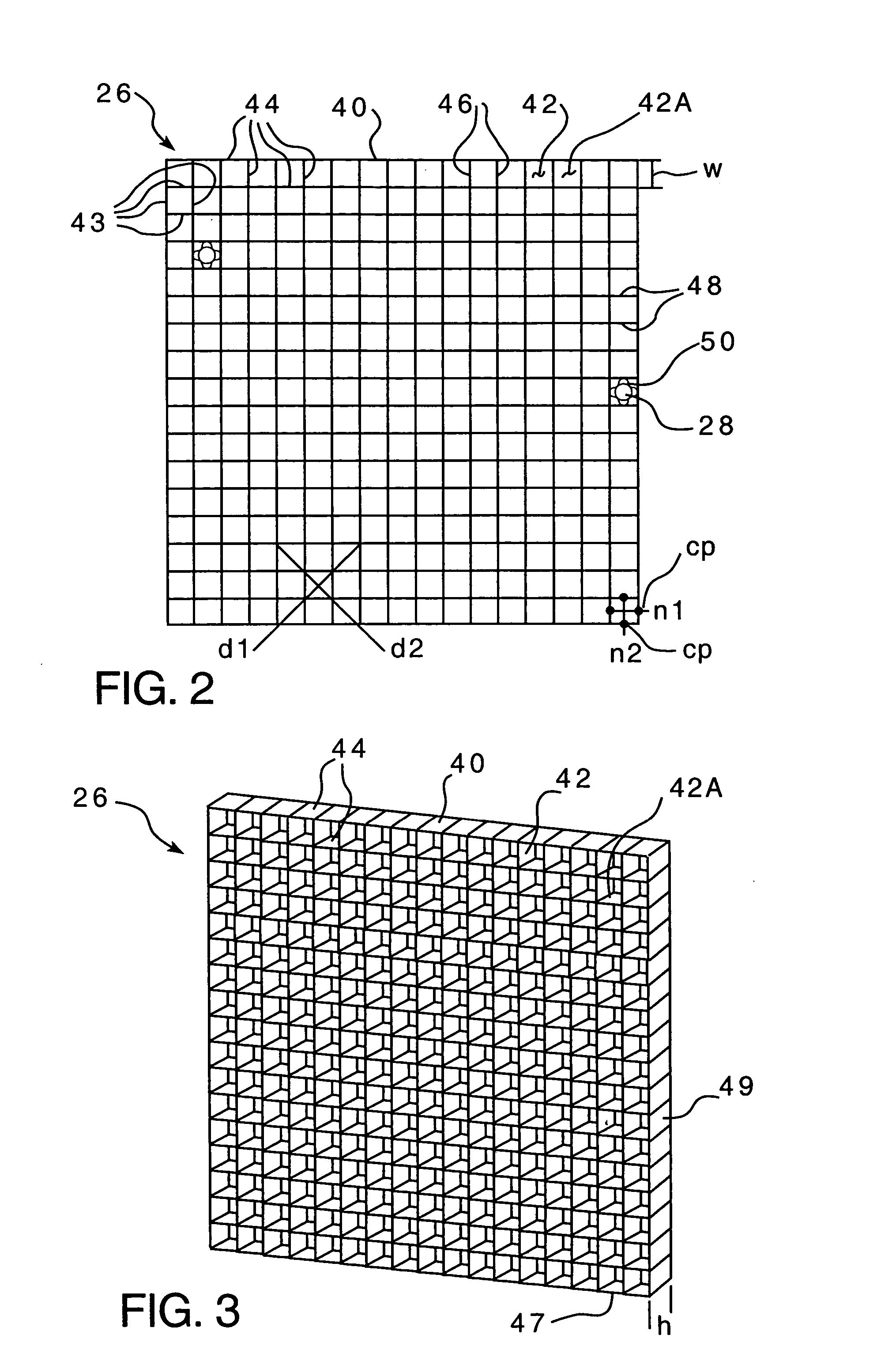

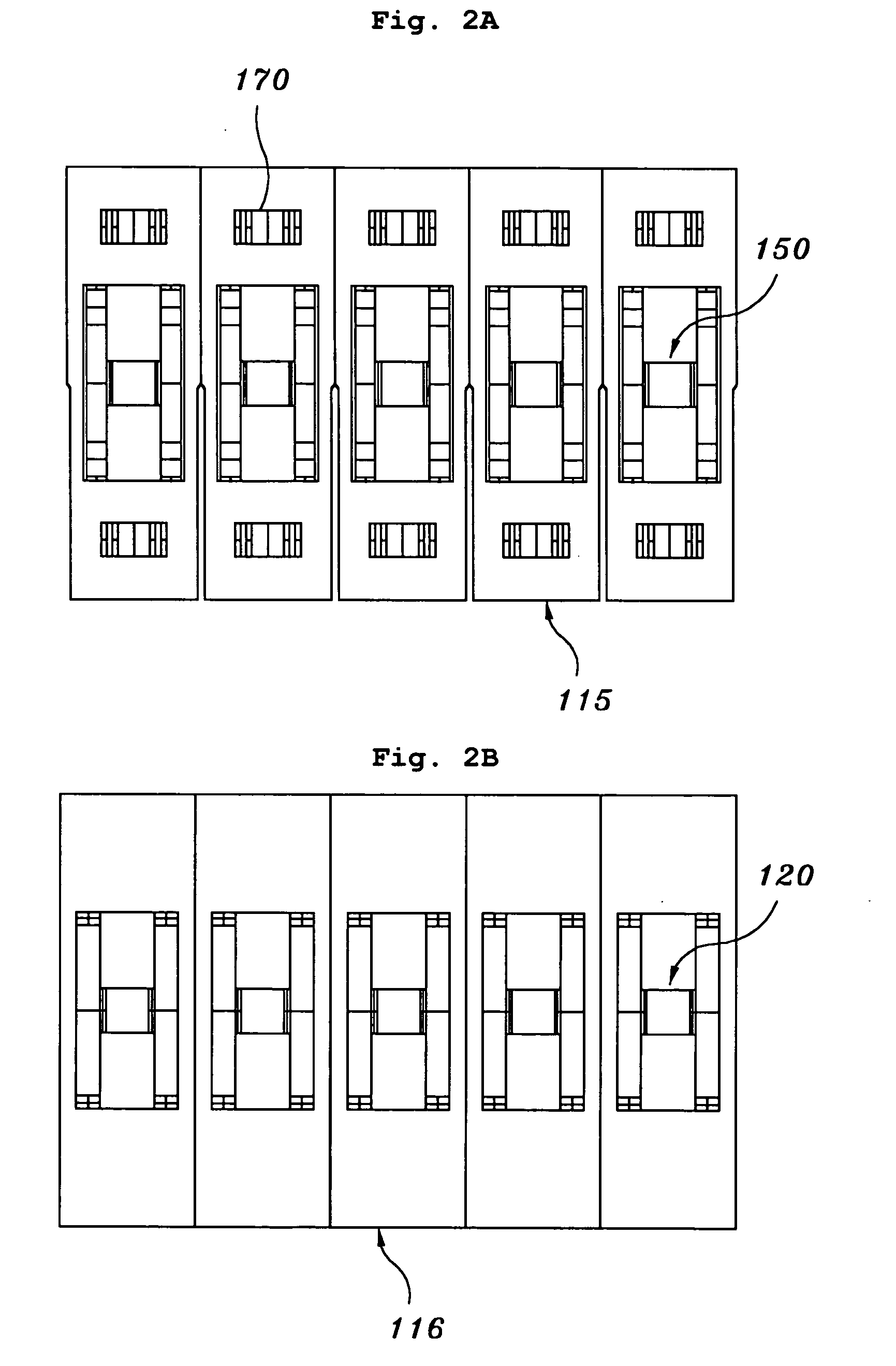

Multiple and variably-spaced intermediate flow mixing vane grids for fuel assembly

InactiveUS20070206717A1Improve heat transfer performanceReduce riskNuclear energy generationFuel element assembliesPressurized water reactorMesh grid

A fuel assembly for a pressurized water reactor that includes a bottom nozzle, a plurality of elongated guide thimbles projecting upwardly from the bottom nozzle, an array of fuel rods, a plurality of support grids axially spaced along the guide thimbles, and at least two Intermediate Flow Mixing grids, which may have different configurations of mixing device formations, disposed between pairs of non-uniformly spaced, adjacent support grids at selected locations.

Owner:WESTINGHOUSE ELECTRIC CORP

Eccentric support grid for nuclear fuel assembly

InactiveUS20060222140A1Reduce stressReduce stepsNuclear energy generationFuel element assembliesNuclear reactorEngineering

In a nuclear reactor fuel assembly structured to support at least one non-linear fuel rod, the nuclear reactor fuel assembly includes at least two support grids, a first support grid and a second support grid structured to support at least one fuel rod in a non-linear shape. Each support grid has a plurality of generally square cells and wherein the cells on the first support grid and the second support grid are generally vertically aligned. Each cell has a first side, a second side, a third side, and a fourth side. Each cell further has protrusions extending from each the cell sides, wherein the protrusions are selected from the group including a spring, a dimple or an extended dimple. A spring is always disposed opposite of a dimple or an extended dimple. The first support grid includes at least one cell having an extended dimple extending from at least one cell side. The second support grid includes at least one cell aligned with the first support grid at least one cell having an extended dimple, wherein the second support grid cell has an extended dimple extending from a cell side other than cell side having an extended dimple on the first support grid. Thus, the extended dimples cause the fuel rod to be deformed.

Owner:WESTINGHOUSE ELECTRIC CORP

Debris filter

ActiveUS20060283790A1Improve efficiencyEasy to assembleFuel element assembliesLiquid displacementCoolant flowEngineering

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

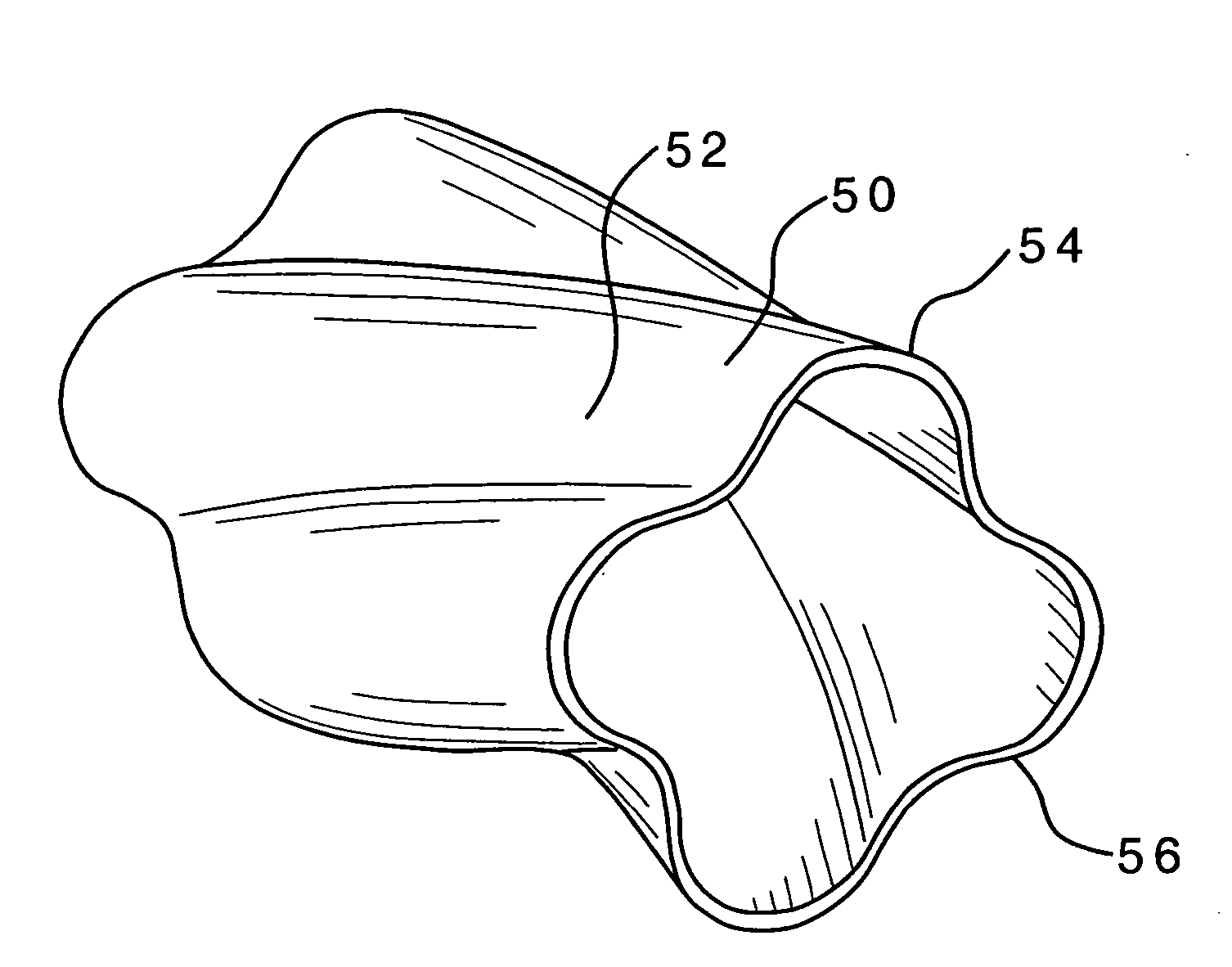

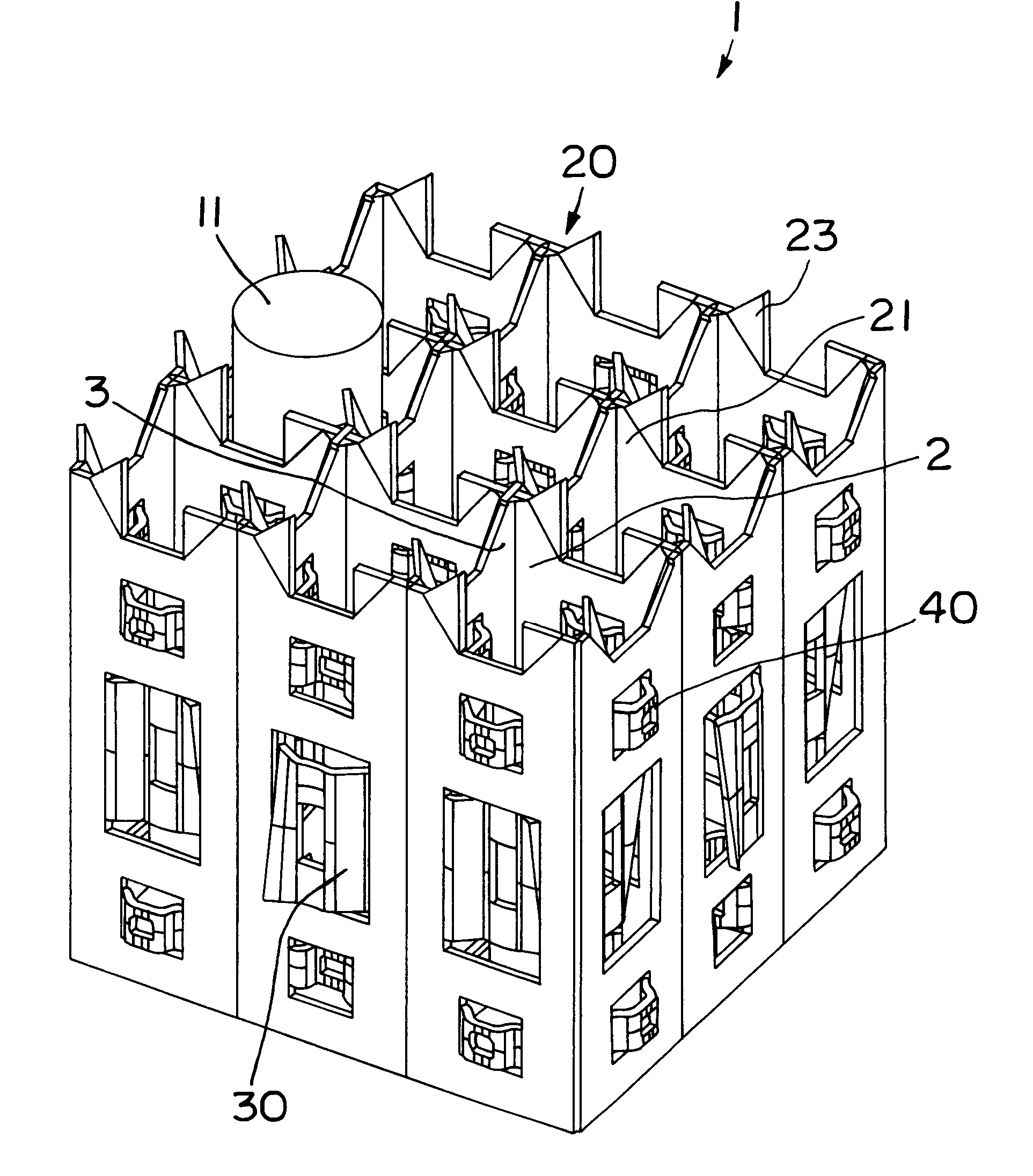

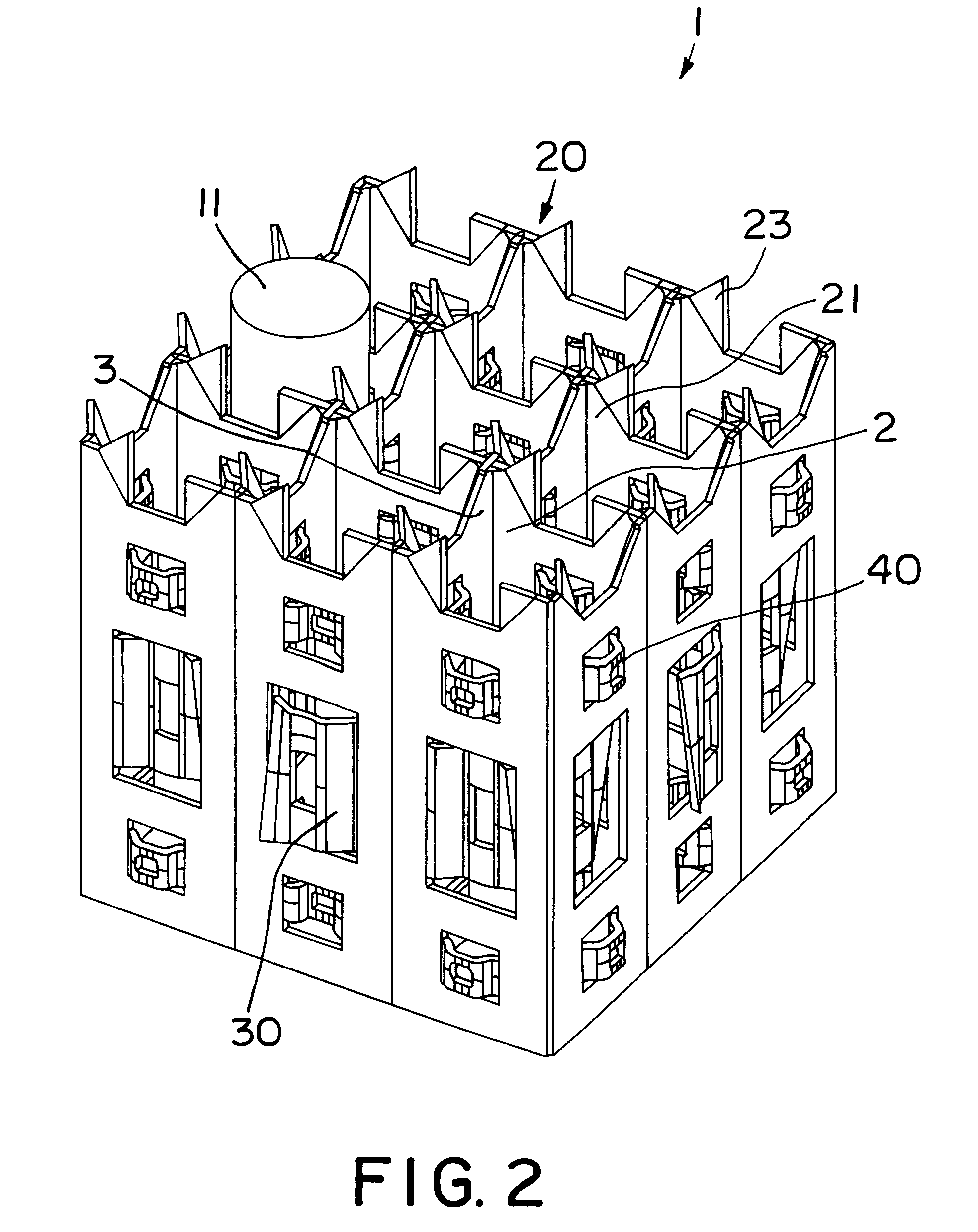

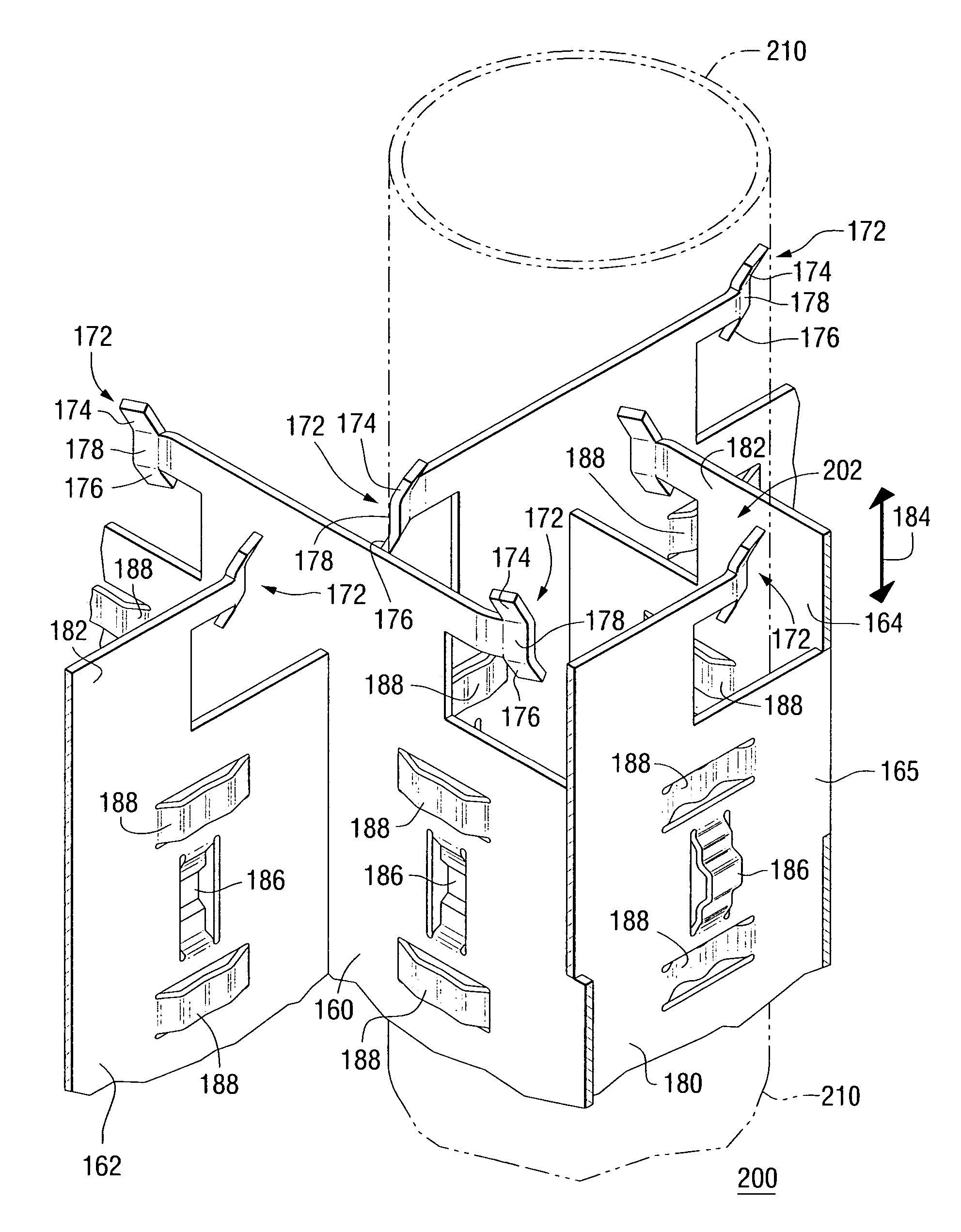

Nuclear fuel assembly protective grid

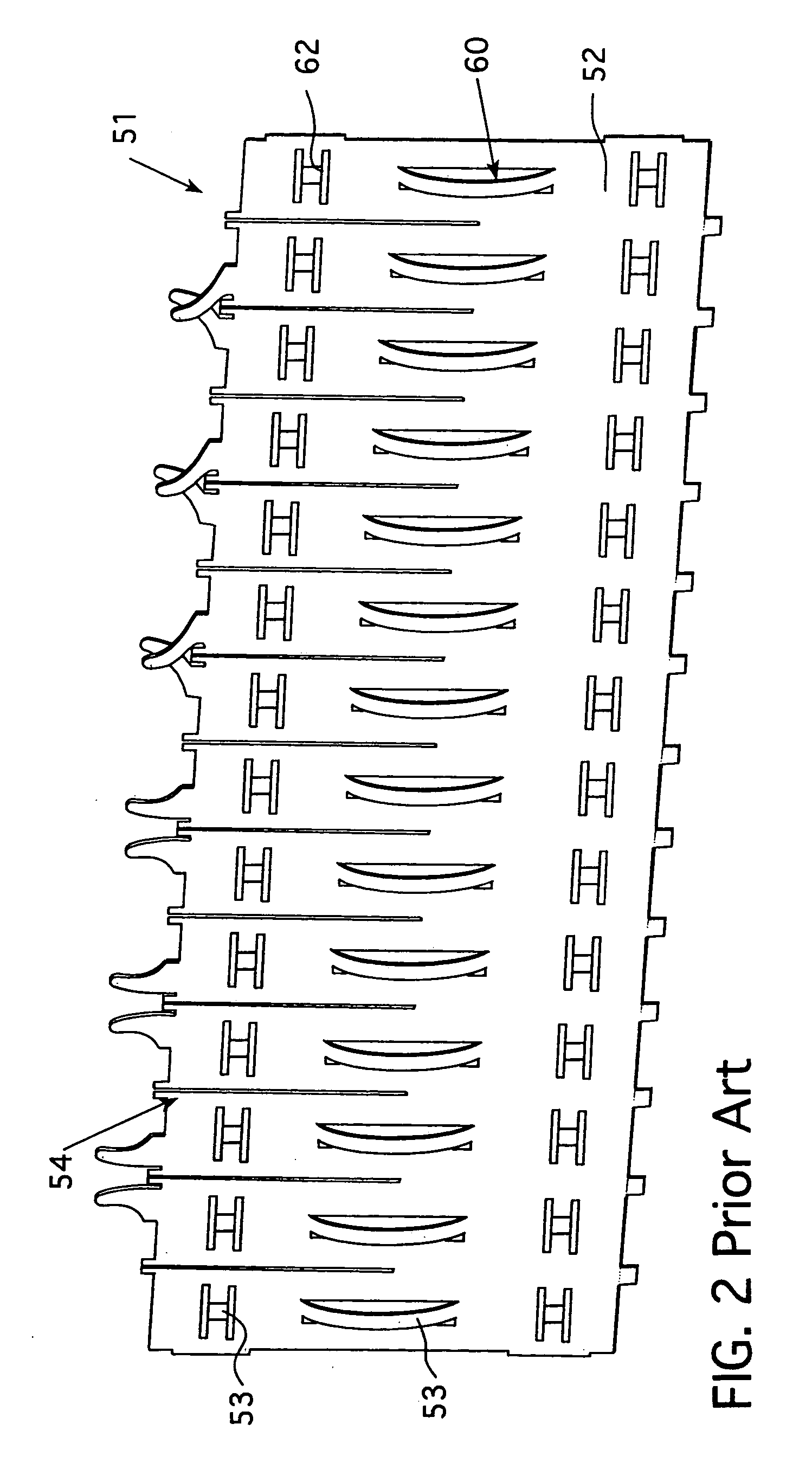

An integral multilevel debris-catching system for a nuclear reactor fuel assembly having a lower protective grid incorporating laterally offset debris-catching arches at several elevations, extended solid fuel rod bottom end plugs and a bottom debris-filtering nozzle. Dimples and opposing opposite springs and the debris-trapping arches, which are spaced from the end plugs, are all located at elevations below the fuel cladding.

Owner:WESTINGHOUSE ELECTRIC CORP

Lower and upper end plugs of an annular fuel rod

Owner:KOREA ATOMIC ENERGY RES INST +1

Spacer grid spring for increasing the conformal contact area with fuel rod

ActiveUS20070242793A1Increase elasticityEnlarge regionNuclear energy generationFuel element assembliesSupport conditionPlastic property

A grid strap includes a spacer grid spring that increases the conformal contact area with a fuel rod of a nuclear fuel rod assembly. The shape of the spacer grid spring of the grid strap which is in contact with the fuel rod is optimized, thereby the elasticity of the spacer grid spring contacting the fuel rod is increased, the conformal contact area with a contact portion of the spacer grid spring contacting the fuel rod when the fuel rod is inserted into each cell of a spacer grid is expanded to obtain uniform stress distribution, and excessive plastic deformation of the spacer grid spring can be reduced. Further, magnitude and distribution of contact pressure between the fuel rod and the spacer grid spring are improved, thereby reducing the possibility of fretting wear caused by contact between the fuel rod and the spacer grid spring. The elastic behavior region of the spacer grid spring is expanded, so that the fuel rod can be reliably supported until the lifetime of the fuel rod expires despite changes in the supporting conditions of the fuel rod.

Owner:KOREA ATOMIC ENERGY RES INST +1

Nuclear reactor fuel assemblies

InactiveUS20080084957A1Enhancing fuel assembly dimensional stabilityIncrease burn-upConversion outside reactor/acceleratorsNuclear energy generationNuclear reactorLateral stiffness

A nuclear fuel assembly having improved dimensional stability to support aggressive fuel management wherein the fuel skeleton lateral stiffness is enhanced by the addition of a second joint attachment between the control rod guide thimble and spacer grid support sleeve.

Owner:WESTINGHOUSE ELECTRIC CORP

Nuclear fuel spacer assembly with debris guide

ActiveUS7561654B2Increase probabilityReduce probabilityNuclear energy generationFuel element assembliesLeading edgeNuclear reactor

In a fuel assembly for a nuclear reactor, a plurality of nuclear fuel rods and at least one fuel rod spacer assembly supporting the fuel rods in an organized array. The fuel rod spacer assembly includes a guide at a leading edge of the fuel rod spacer assembly. The guide is angled towards the fuel rod for directing debris to open passages in the fuel rod spacer assembly.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

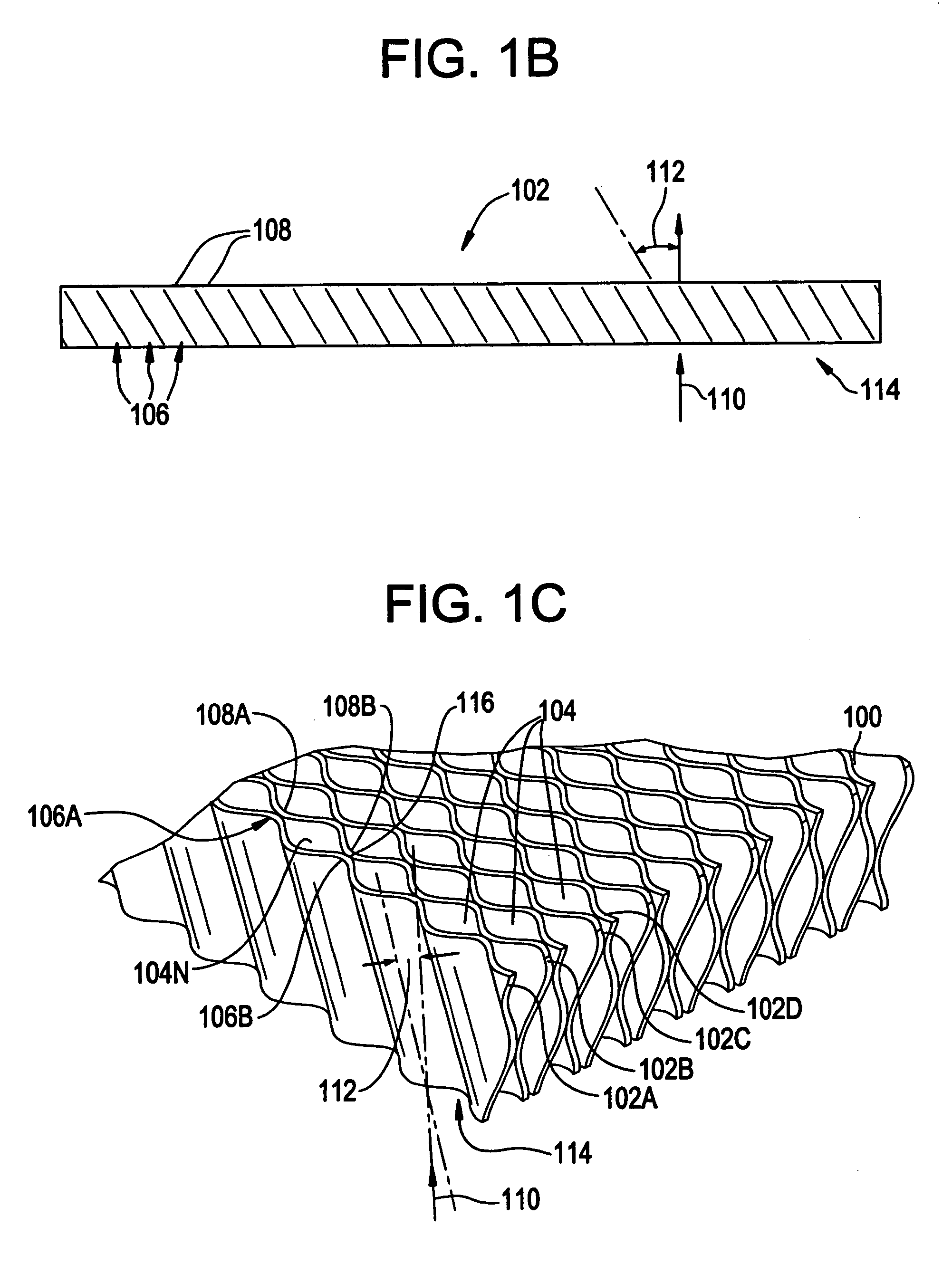

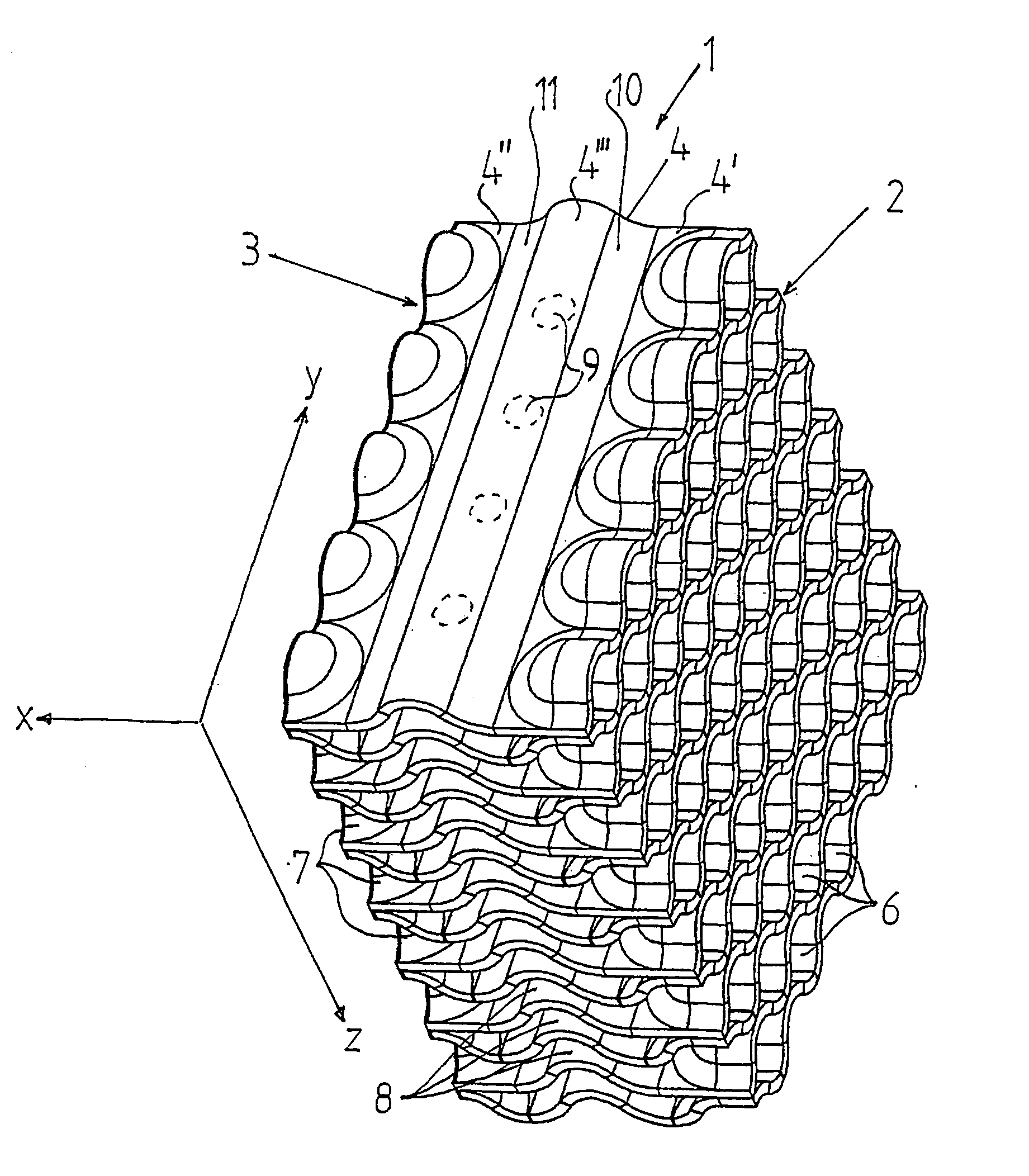

Filter for cooling water in a light water cooled nuclear reactor

InactiveUS7149272B2Lower overall flow resistanceLow costNuclear energy generationFuel element assembliesNuclear reactor coreNuclear plant

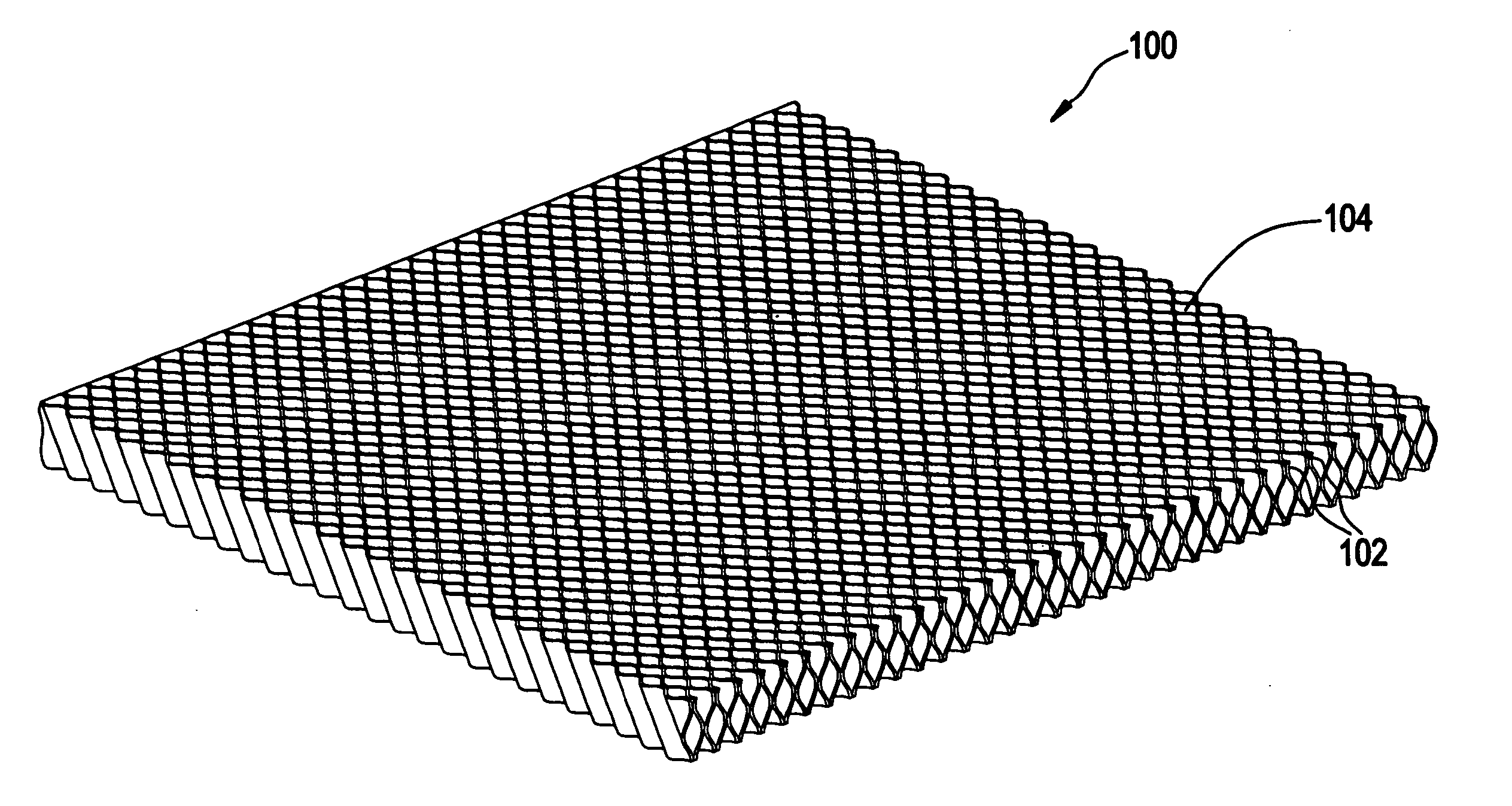

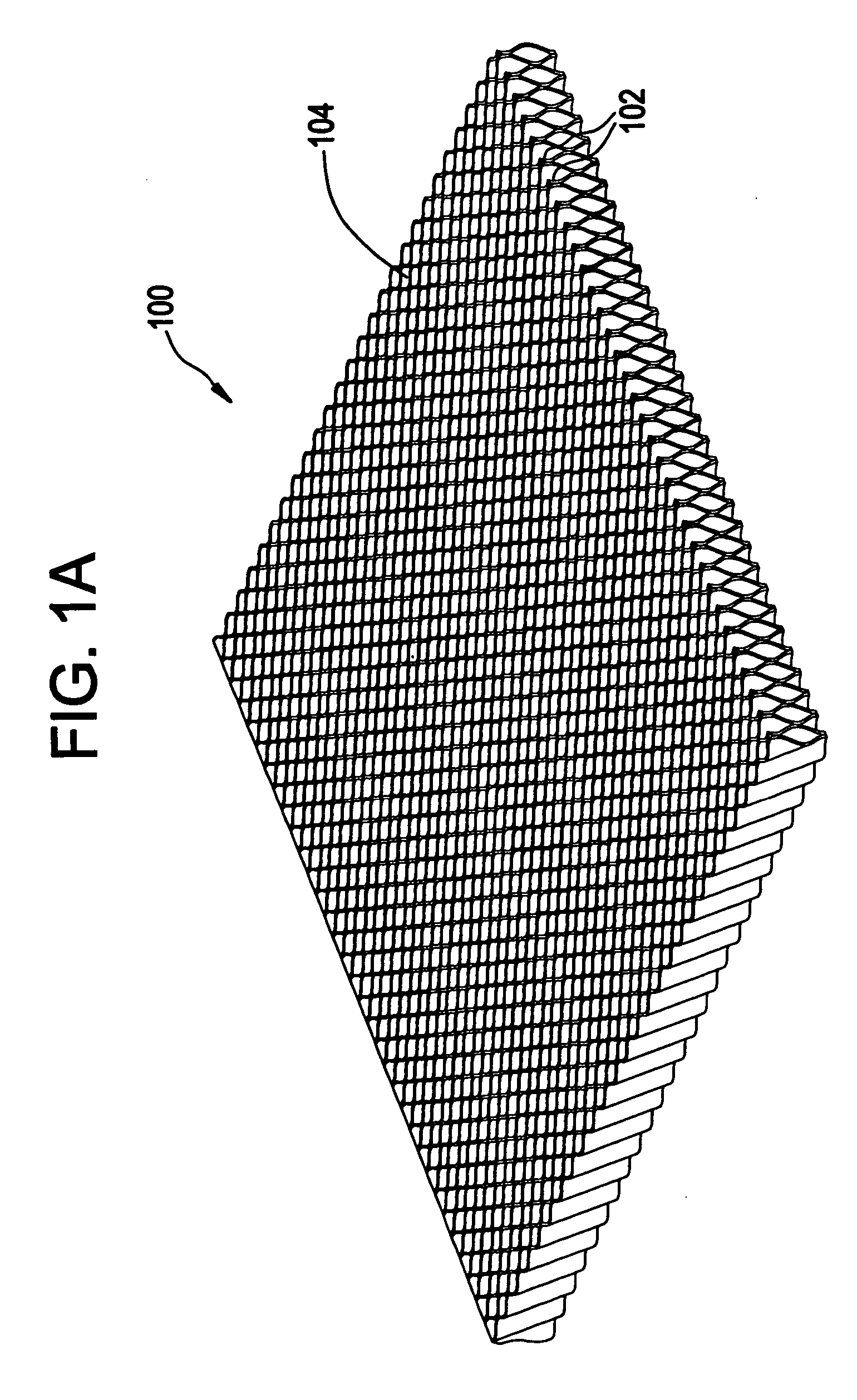

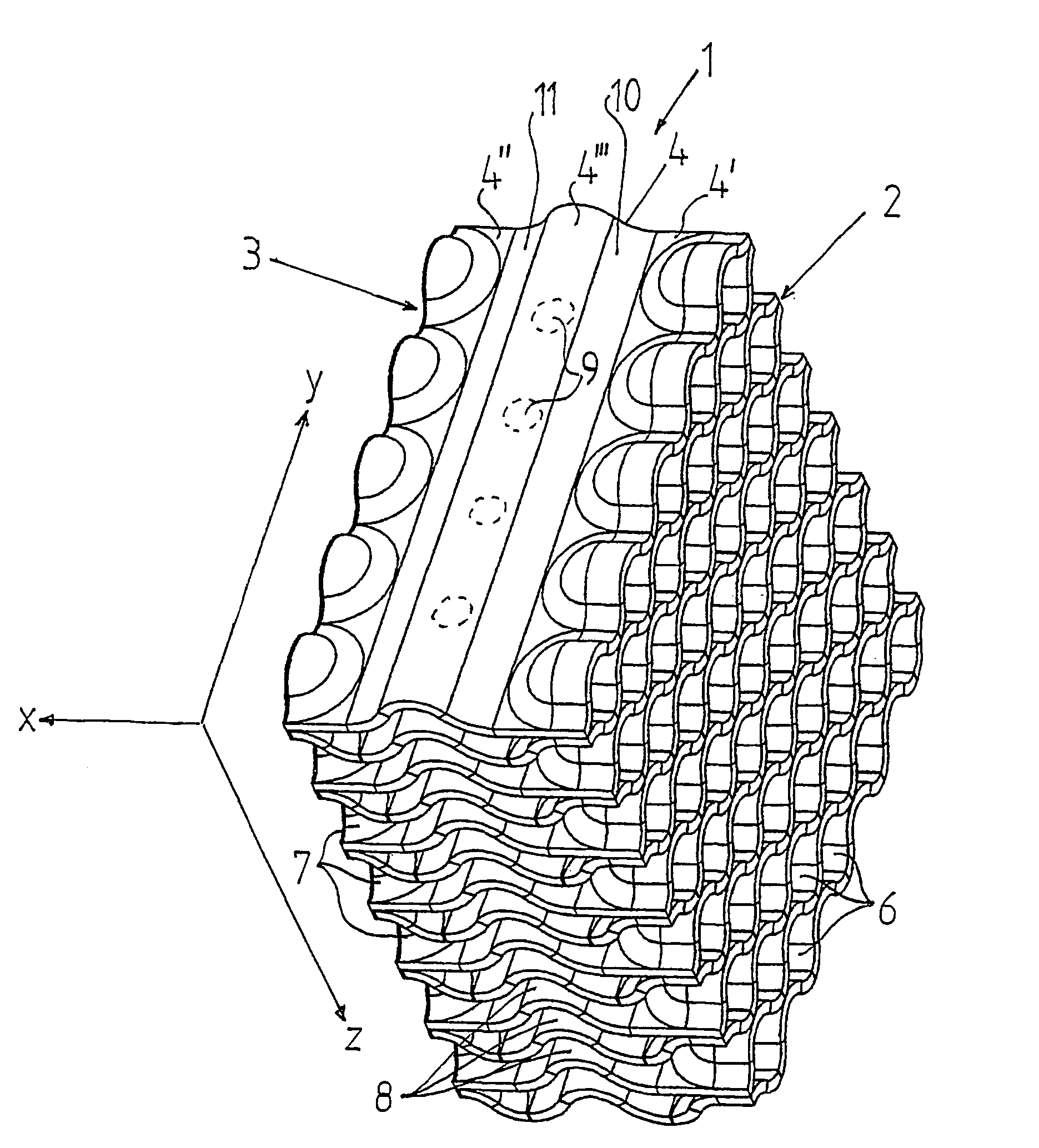

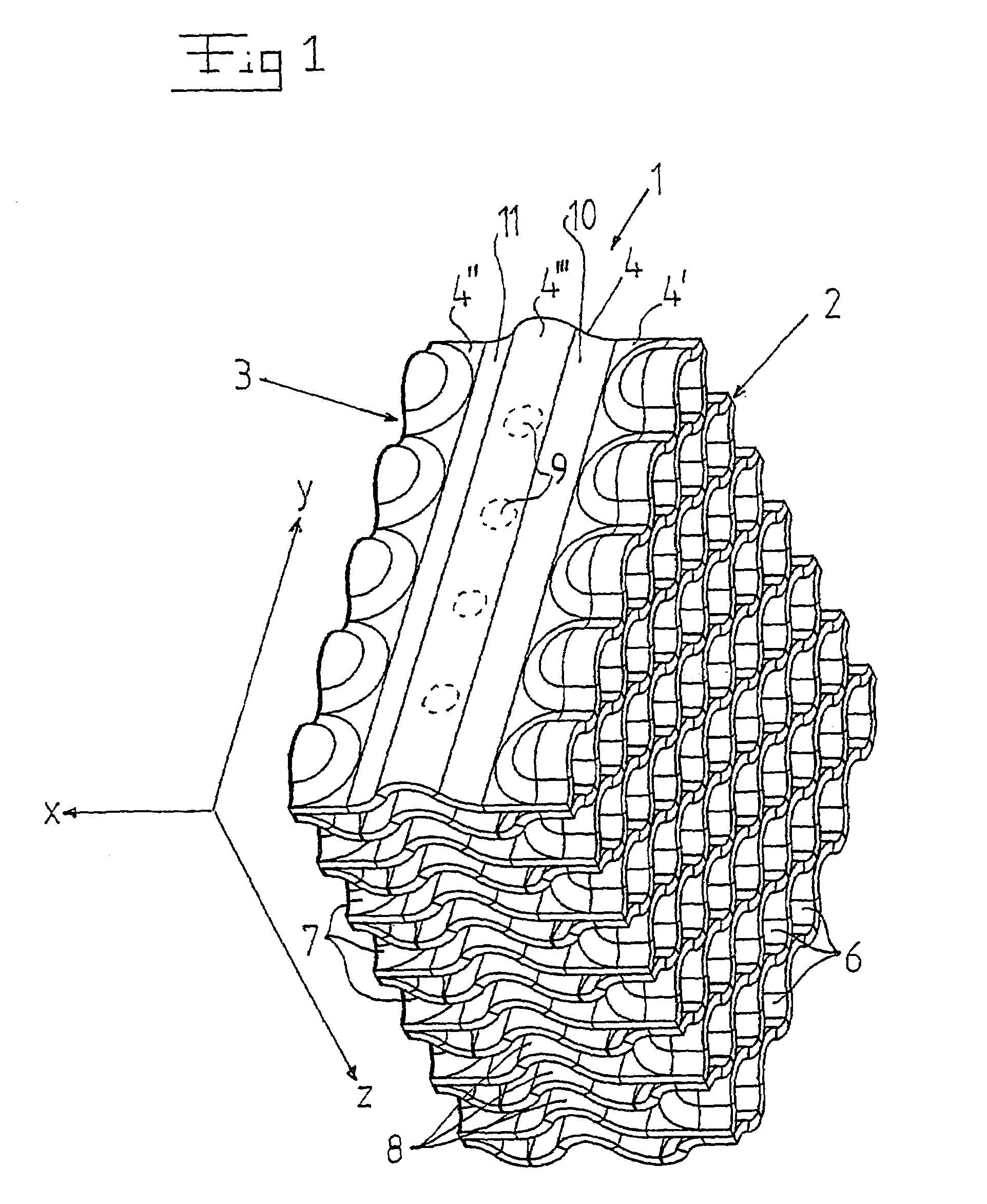

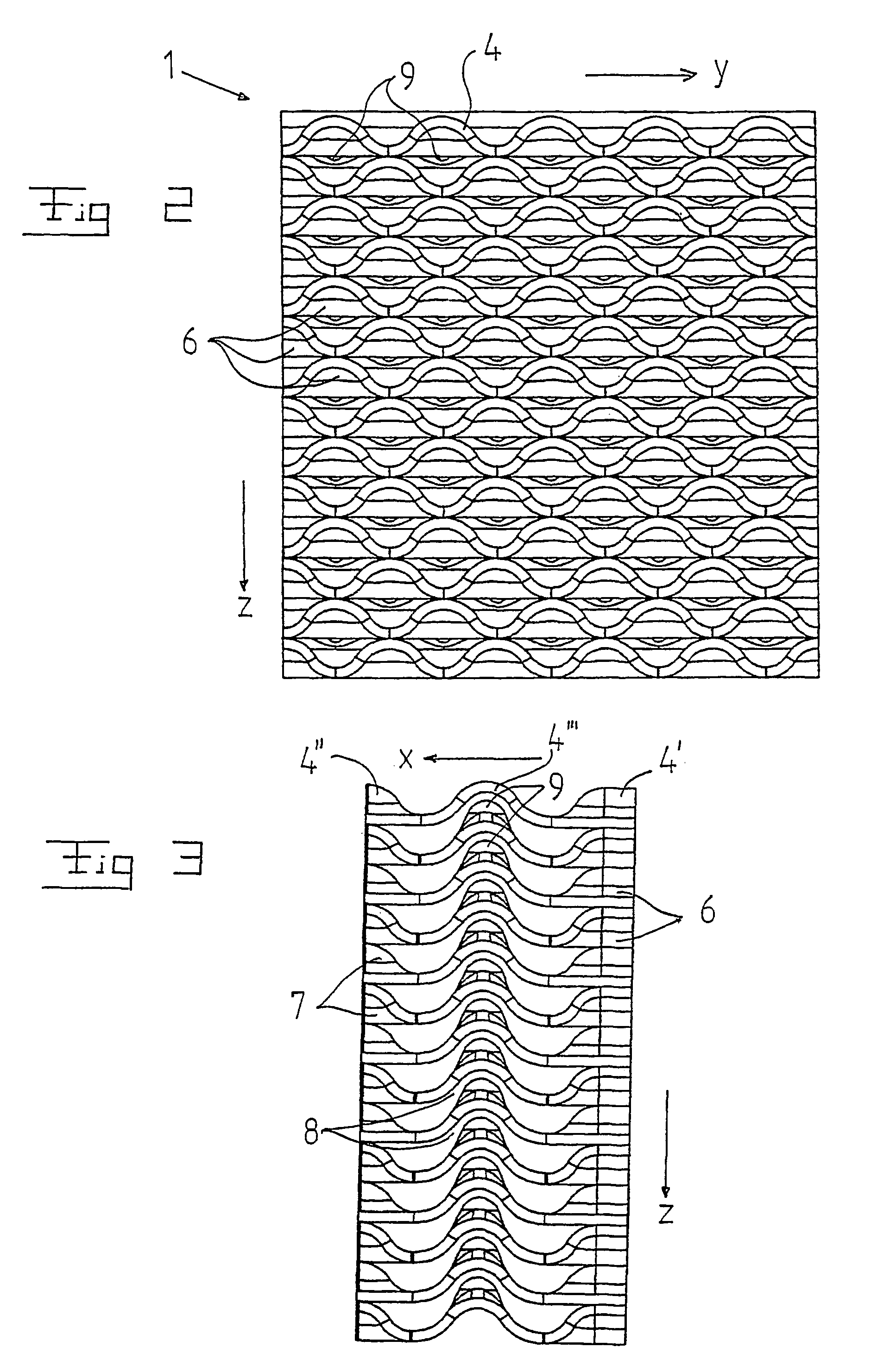

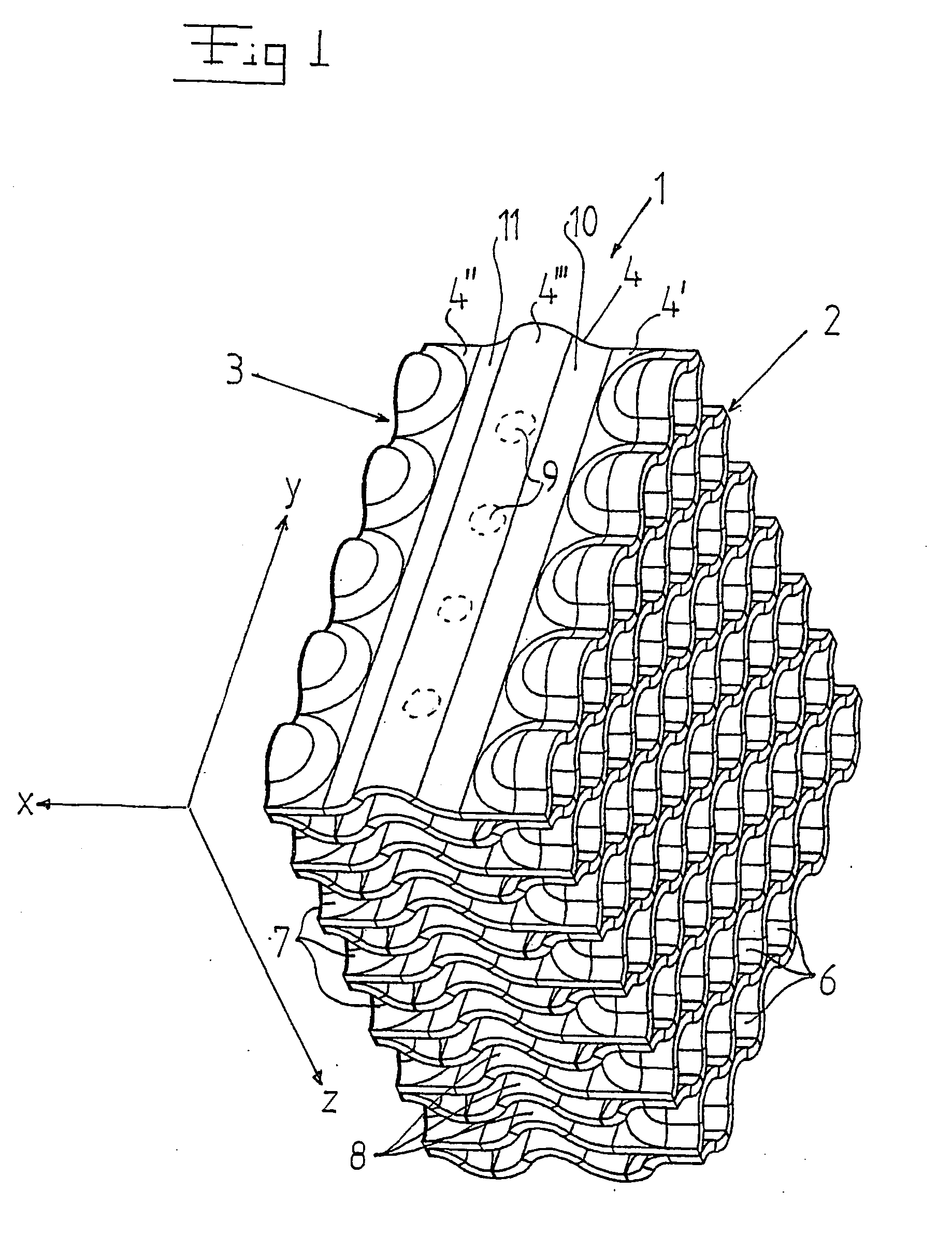

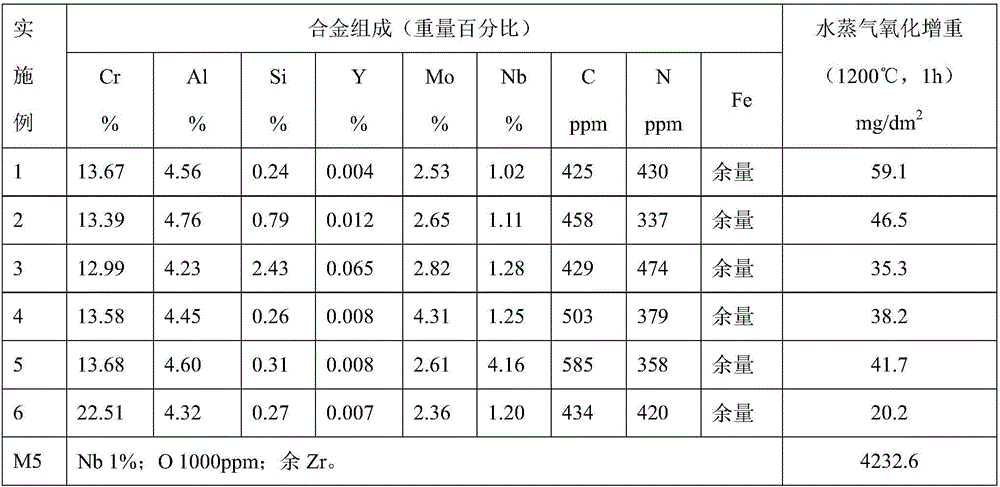

The invention refers to a filter (1) for separating particle from cooling water in a nuclear plant, and a fuel assembly with such a filter. The filter has an inlet end (2) and an outlet end (3) and permits through-flow of the cooling water in a main flow direction (x). The filter includes a number of sheets (4) extending in the flow direction from the inlet end to the outlet end. The sheets are arranged beside each other and form passages for the cooling water. The sheets include a first portion (4′) extending from the inlet end (2), a second portion (4″) extending from the outlet end (3), and a third portion (4′″) extending between the first portion (4′) and the second portion (4″). The sheets (4) have along the first portion continuous wave-shape extending in a direction (y) transversally to the flow direction (x) and along the third portion a continuous wave-shape extending in the flow direction (x).

Owner:WESTINGHOUSE ELECTRIC SWEDEN

Spacer grid with mixing vanes and nuclear fuel assembly employing the same

InactiveUS7548602B2Improve flowPromotes optimized even and sustainedNuclear energy generationFuel element assembliesCoolant flowNuclear engineering

A spacer grid having tunable mixing vanes for optimizing coolant flow is provided for a nuclear fuel assembly. The mixing vanes include an upper piece and a lower piece, which are coupled to a middle ligament that is coupled to the top or downstream portion of one or more of the grid straps forming the spacer grid. The upper piece, lower piece, and middle ligament are bent, rotated, and / or twisted into various positions to more effectively mix the coolant and affect the coolant's flow as it moves upwards through the fuel assembly. For example, in one embodiment, the mixing vane has an “S” shape wherein the middle ligament is positioned parallel to the longitudinal axes of the fuel rods of the fuel assembly, the upper piece bends towards one of the fuel rods, and the lower piece bends away from the fuel rod. In this manner, optimized even and sustained mixing of the coolant is provided.

Owner:WESTINGHOUSE ELECTRIC CORP

Use of boron or enriched boron 10 in UO2

InactiveUS7139360B2Low parasitic cross-sectionAvoid problemsNuclear energy generationFuel element assembliesBoron containingCarbide

The present invention provides a nuclear fuel assembly, where a boron-containing compound is used as a burnable poison and is distributed in a majority of the rods in the assembly. The assembly comprises a plurality of fuel rods, each fuel rod containing a plurality of nuclear fuel pellets, wherein at least one fuel pellet in more than 50% of the fuel rods in the fuel assembly comprises a sintered admixture of a metal oxide, metal carbide or metal nitride and a boron-containing compound.

Owner:WESTINGHOUSE ELECTRIC CORP

Spacer grid for nuclear reactor fuel assemblies

InactiveUS20050105677A1Prevent fretting corrosionImprove fuel rod cooling efficiency of fuelNuclear energy generationFuel element assembliesNuclear reactorContact pressure

A spacer grid used for placing and supporting fuel rods in nuclear reactor fuel assemblies is disclosed. The spacer grid of this invention has a plurality of inner strips intersecting each other to form a plurality of guide tube cells and a plurality of fuel rod cells, with a plurality of mixing blades projecting upward from the inner strips at intersections of the inner strips. The spacer grid further includes a plurality of perimeter strips to encircle the intersecting inner strips. Each of the perimeter strips is fabricated with a plurality of unit intermediate strips and a plurality of unit corner strips, with a grid spring provided on each of the unit strips. The grid spring includes a vertical opening formed at a central area of each of the unit strips, a vertical support part extending vertically between the central portions of top and bottom edges of the vertical opening, and a fuel rod support part provided at a central portion of the vertical support part while being bent to have an outward rounded cross-section. The vertical support part is bent at two steps, and the fuel rod support part is bent to be in equiangular contact with each of the fuel rods, thus accomplishing a uniform contact pressure distribution when the fuel rod support part is in contact with each of the fuel rods.

Owner:KOREA ATOMIC ENERGY RES INST

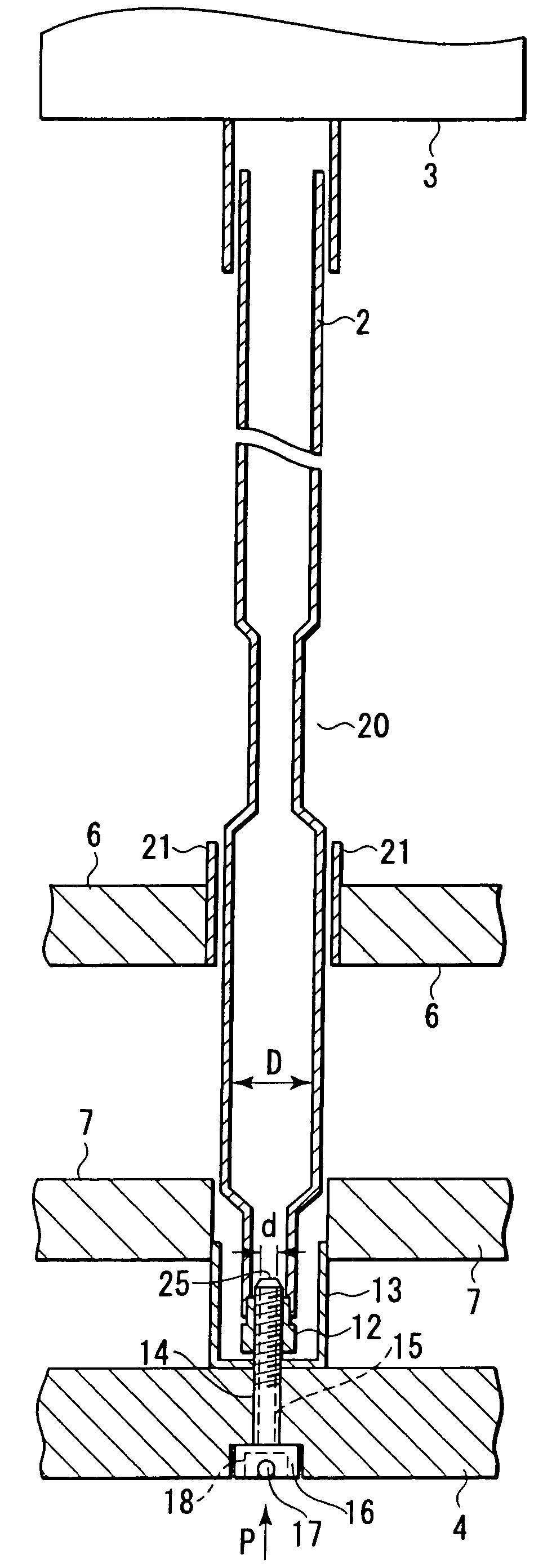

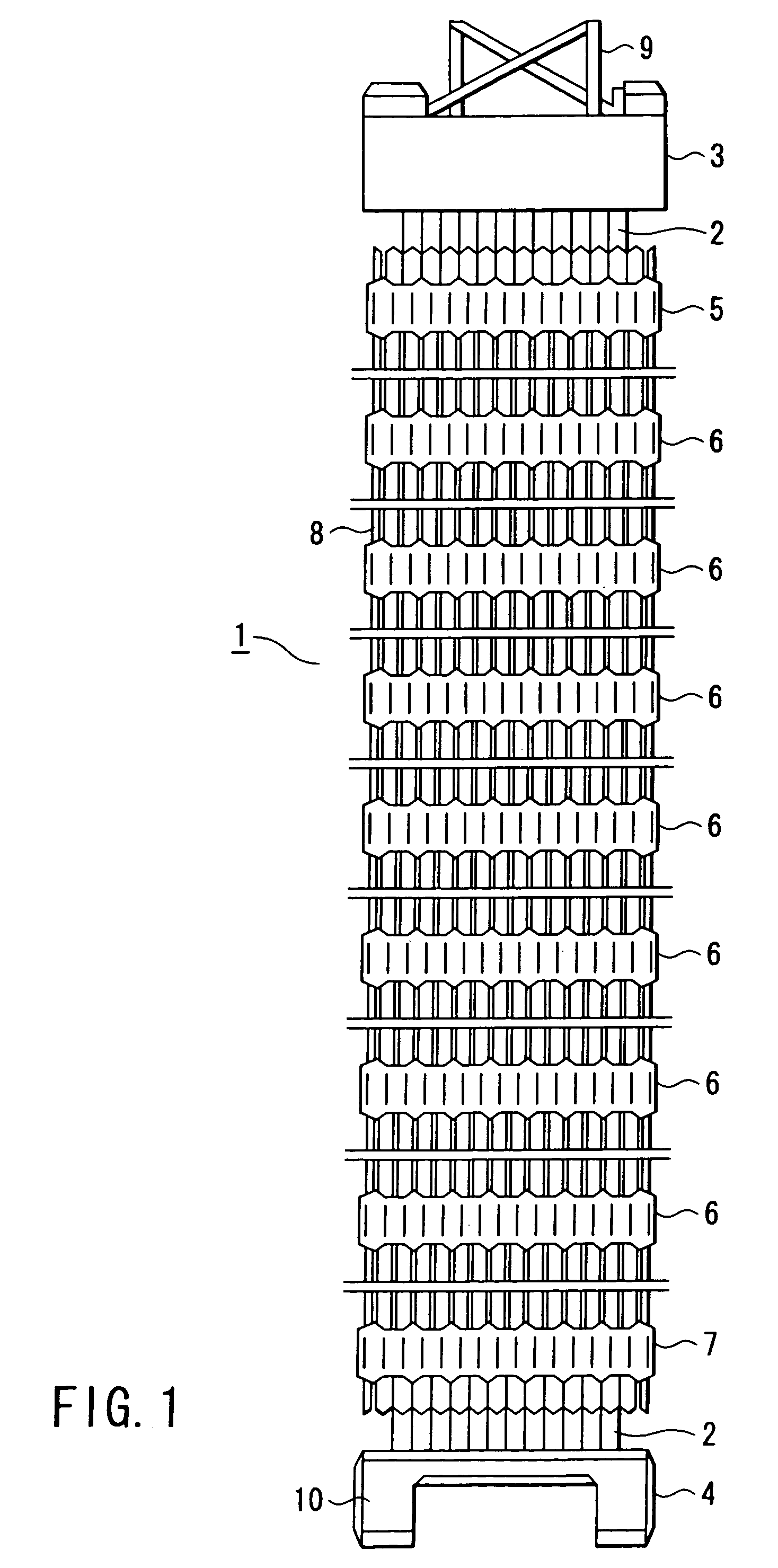

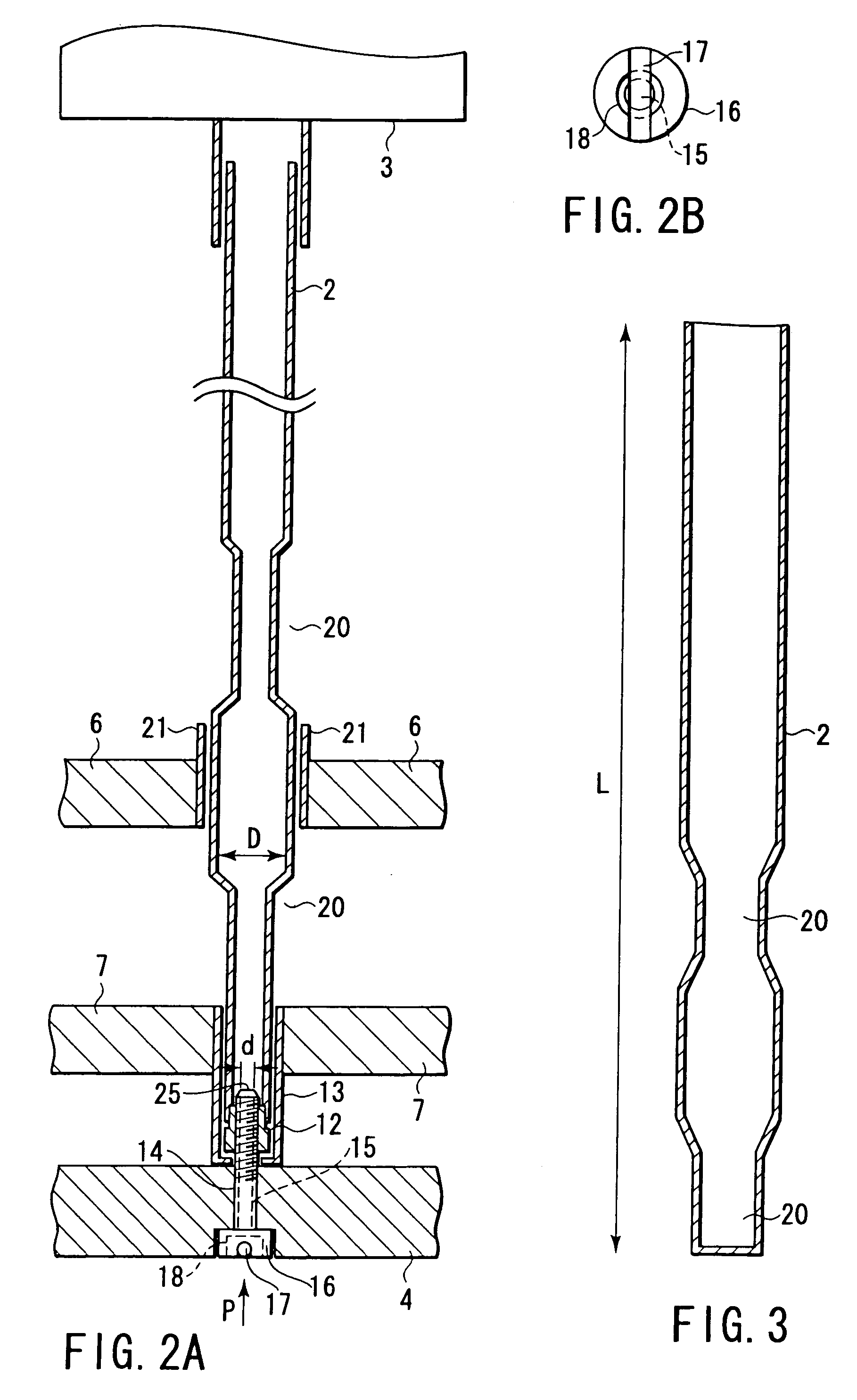

Fuel assembly and thimble screw of the same

InactiveUS7257185B1Avoid bending deformationAvoid deformationNuclear energy generationFuel element assembliesNuclear reactorDashpot

A fuel assembly includes a bottom nozzle set on a lower core plate of a nuclear reactor, a top nozzle with a hold down spring to urge the bottom nozzle against the lower core plate, guide thimbles which guide control rods, having passed through the top nozzle, toward the lower core plate, a dashpot formed on each of the guide thimbles to reduce the fall velocity of a corresponding one of the control rods, a thimble screw which connects each of the guide thimbles to the bottom nozzle, and a drain hole formed to extend through each of the thimble screw. The dashpot has a large-diameter portion with substantially the same diameter as that of each of the guide thimbles. The diameter d of the drain hole falls within a range of 0.04 D<d<0.08 D where D is an inner diameter of the large-diameter portion.

Owner:MITSUBISHI HEAVY IND LTD

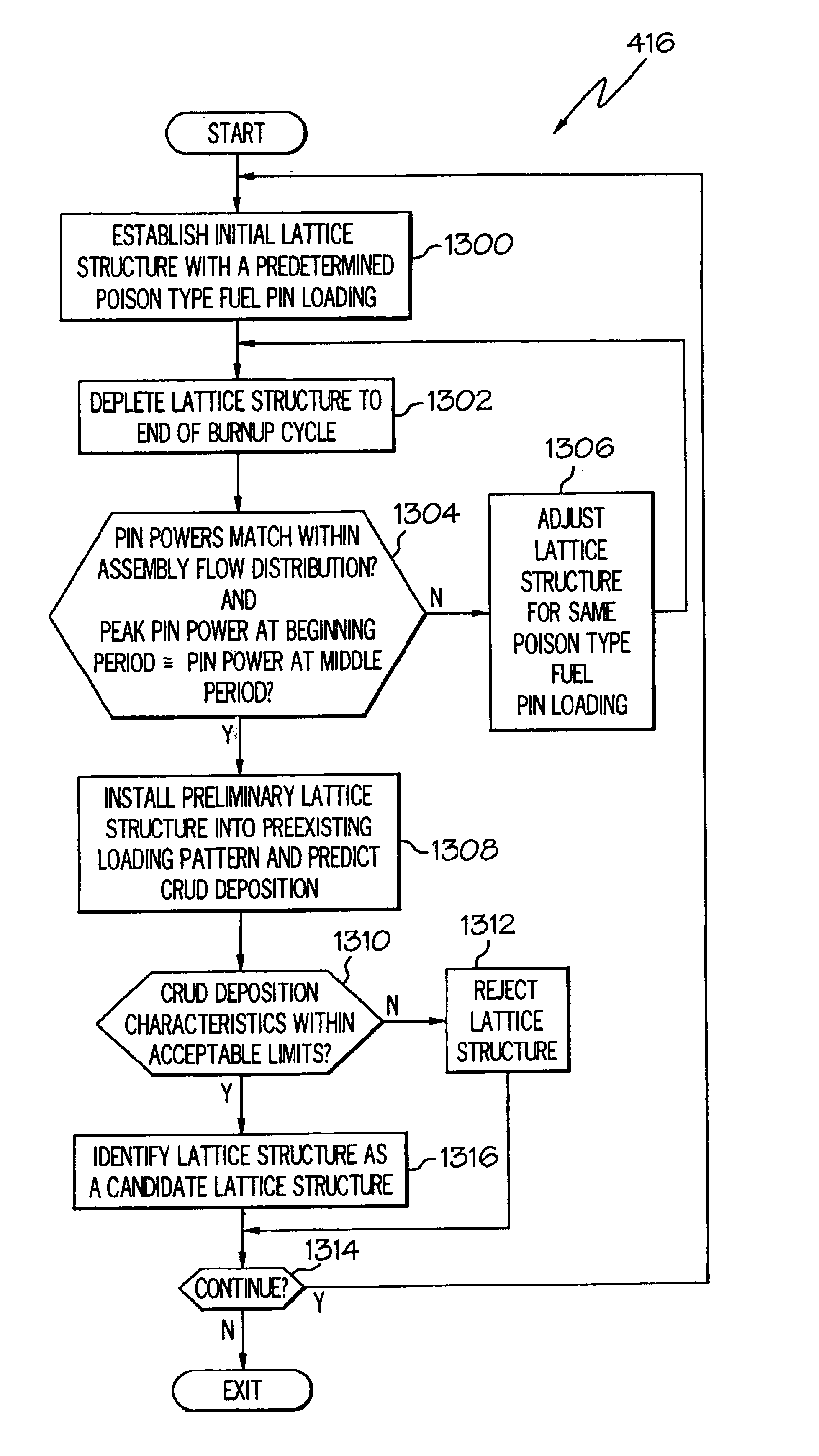

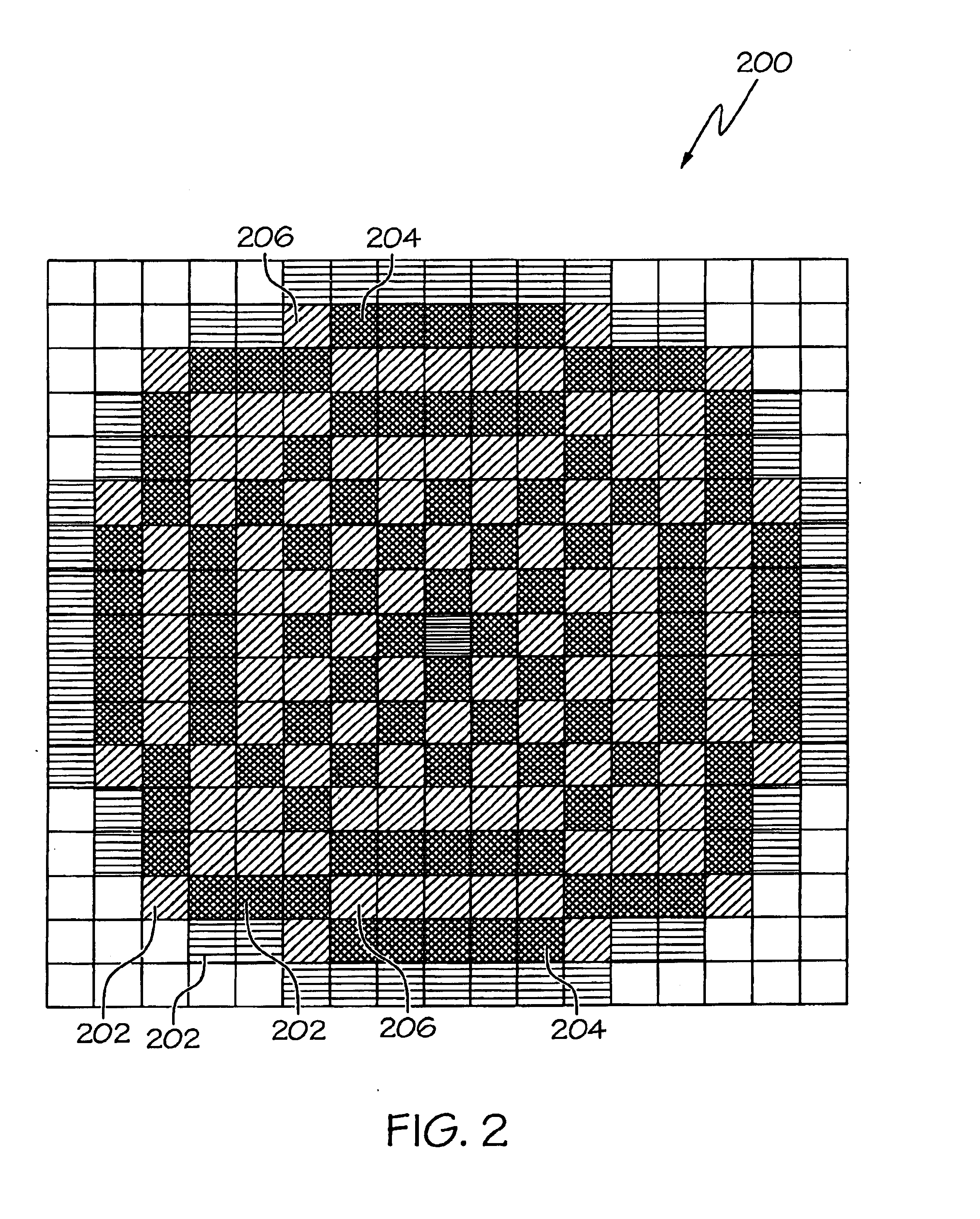

Fuel assemblies in a reactor core and method of designing and arranging same

InactiveUS6891912B1Reduce adverse effectsCost efficientNuclear energy generationFuel element assembliesNuclear engineeringPower level

Owner:ARIZONA PUBLIC SERVICE

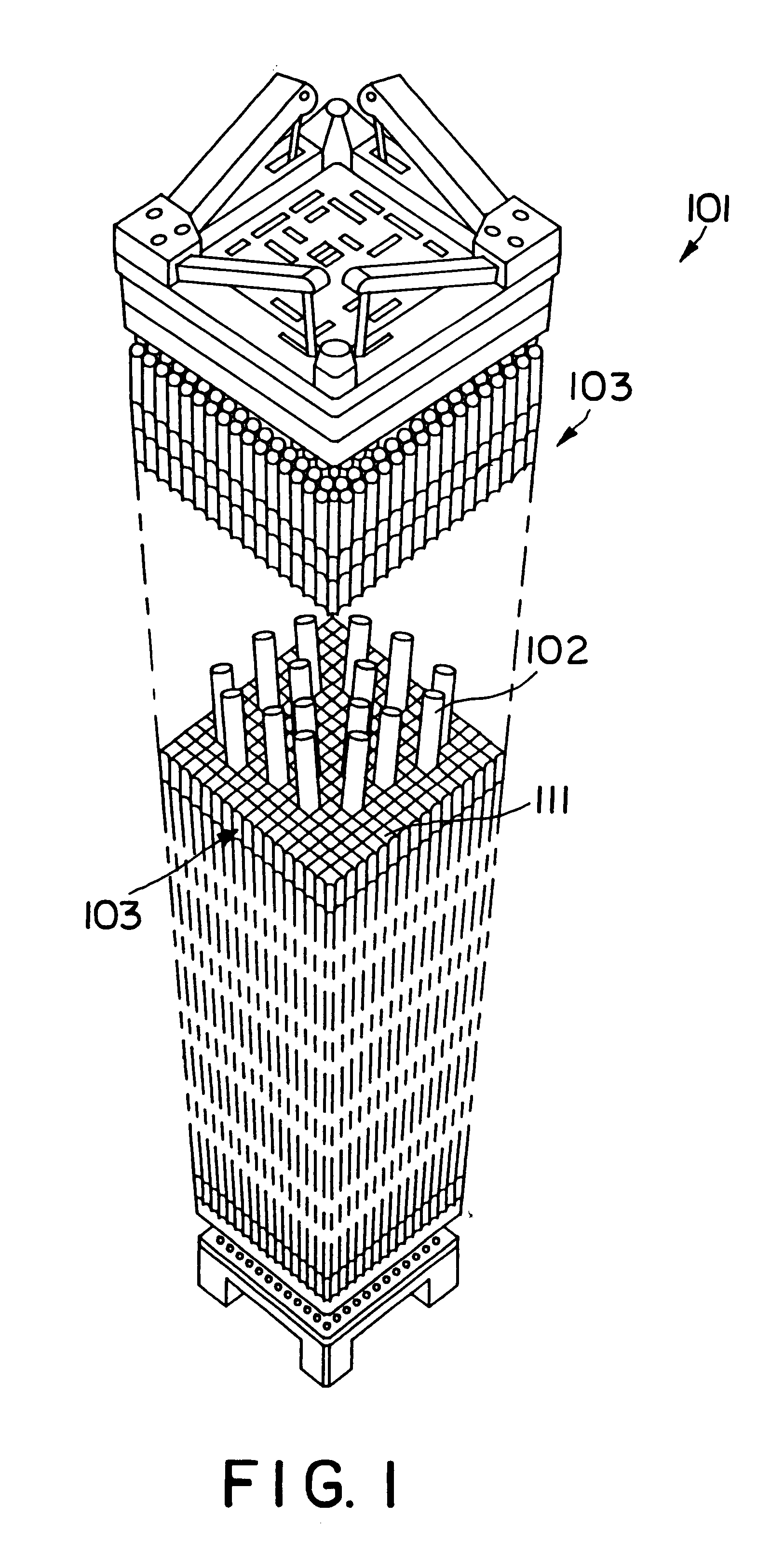

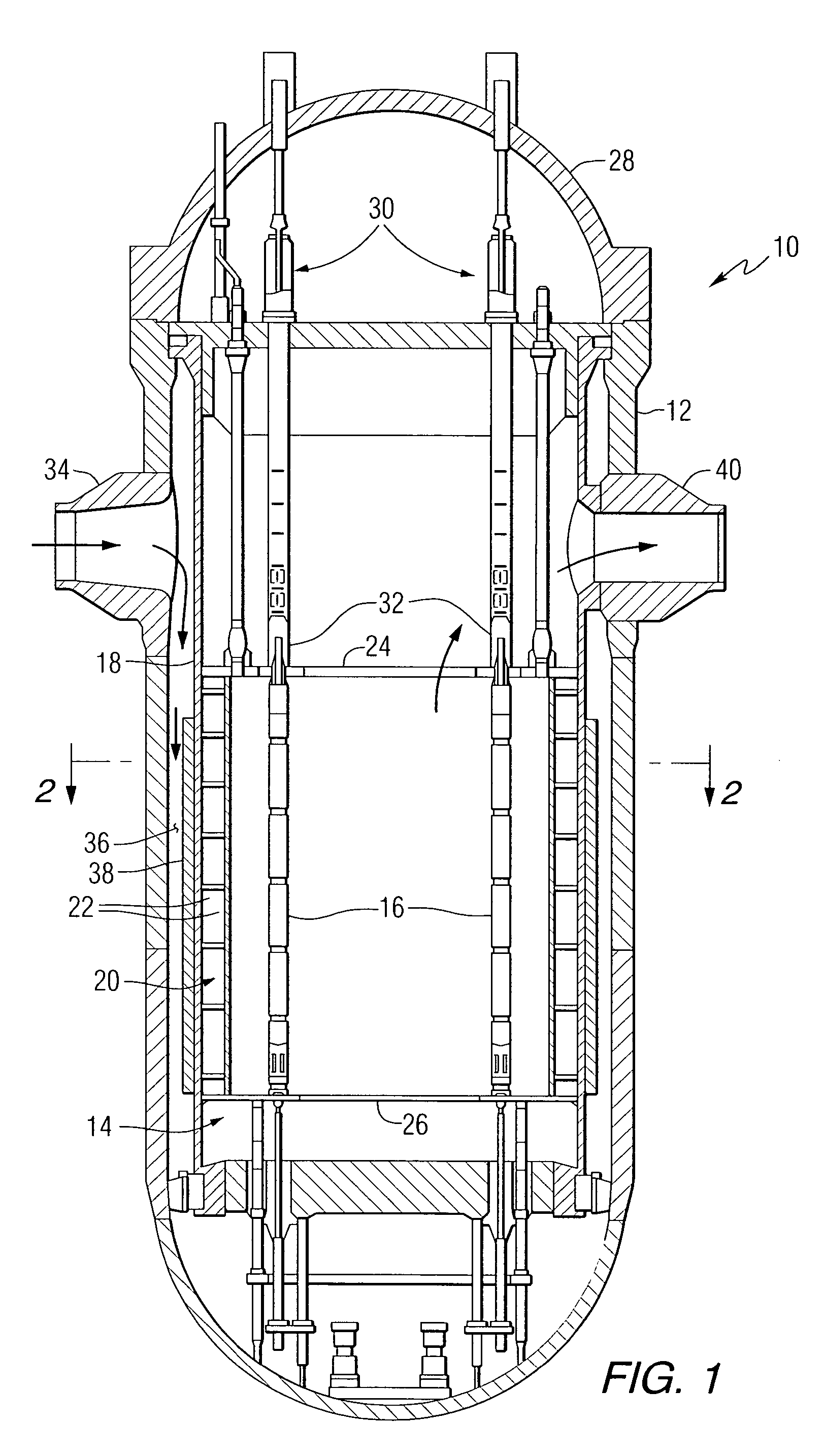

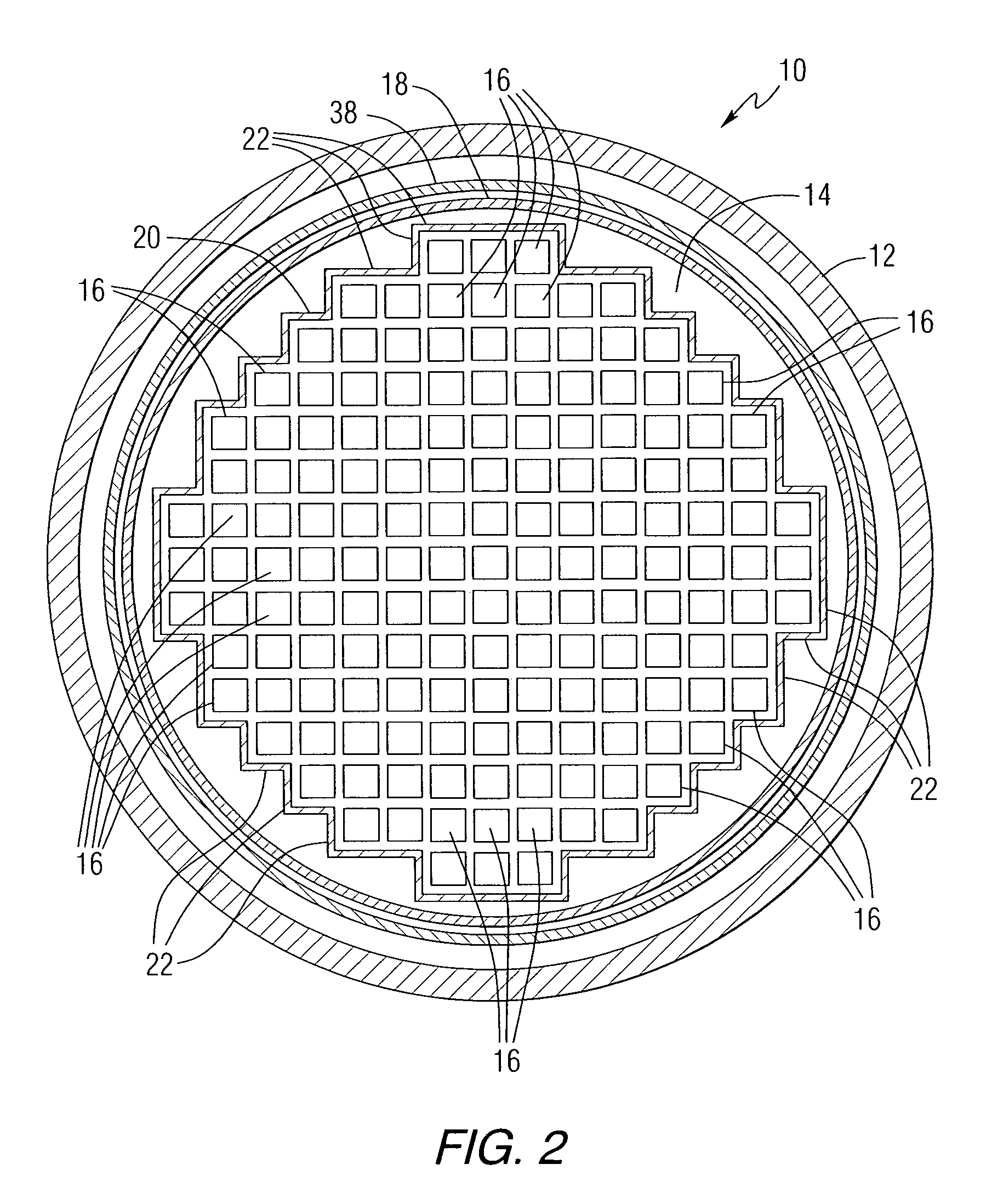

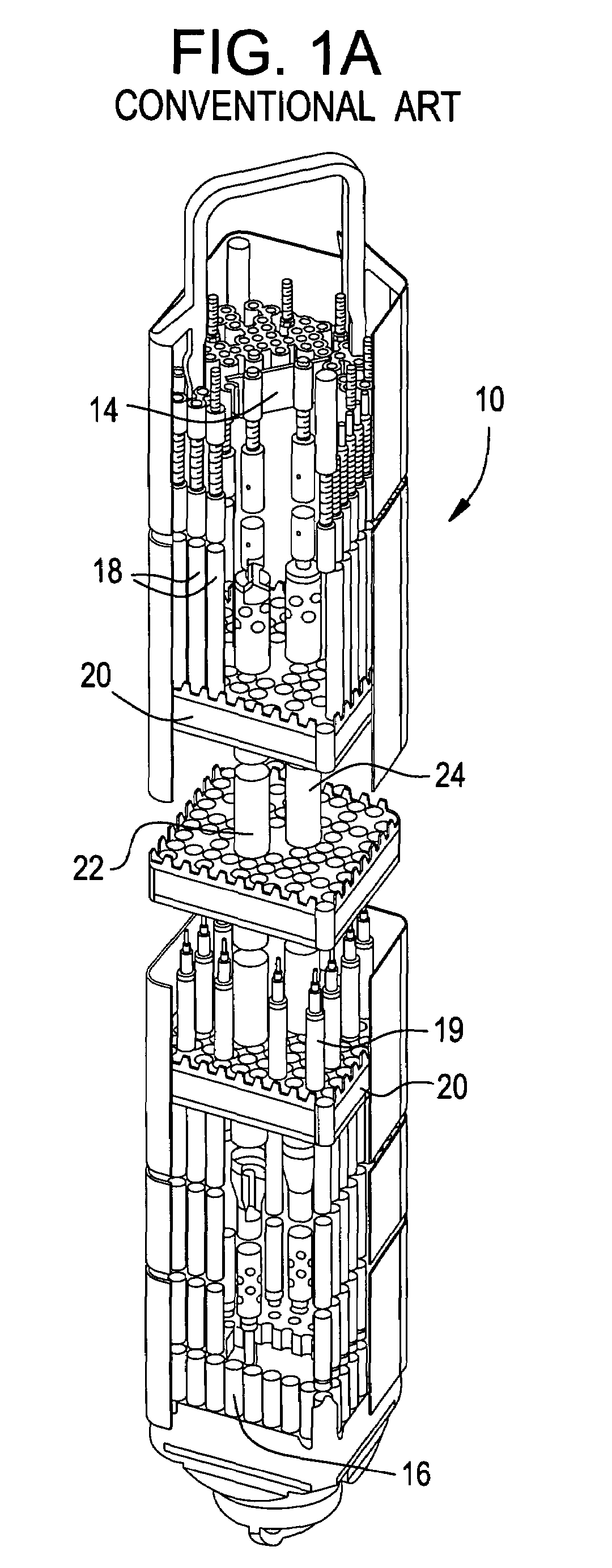

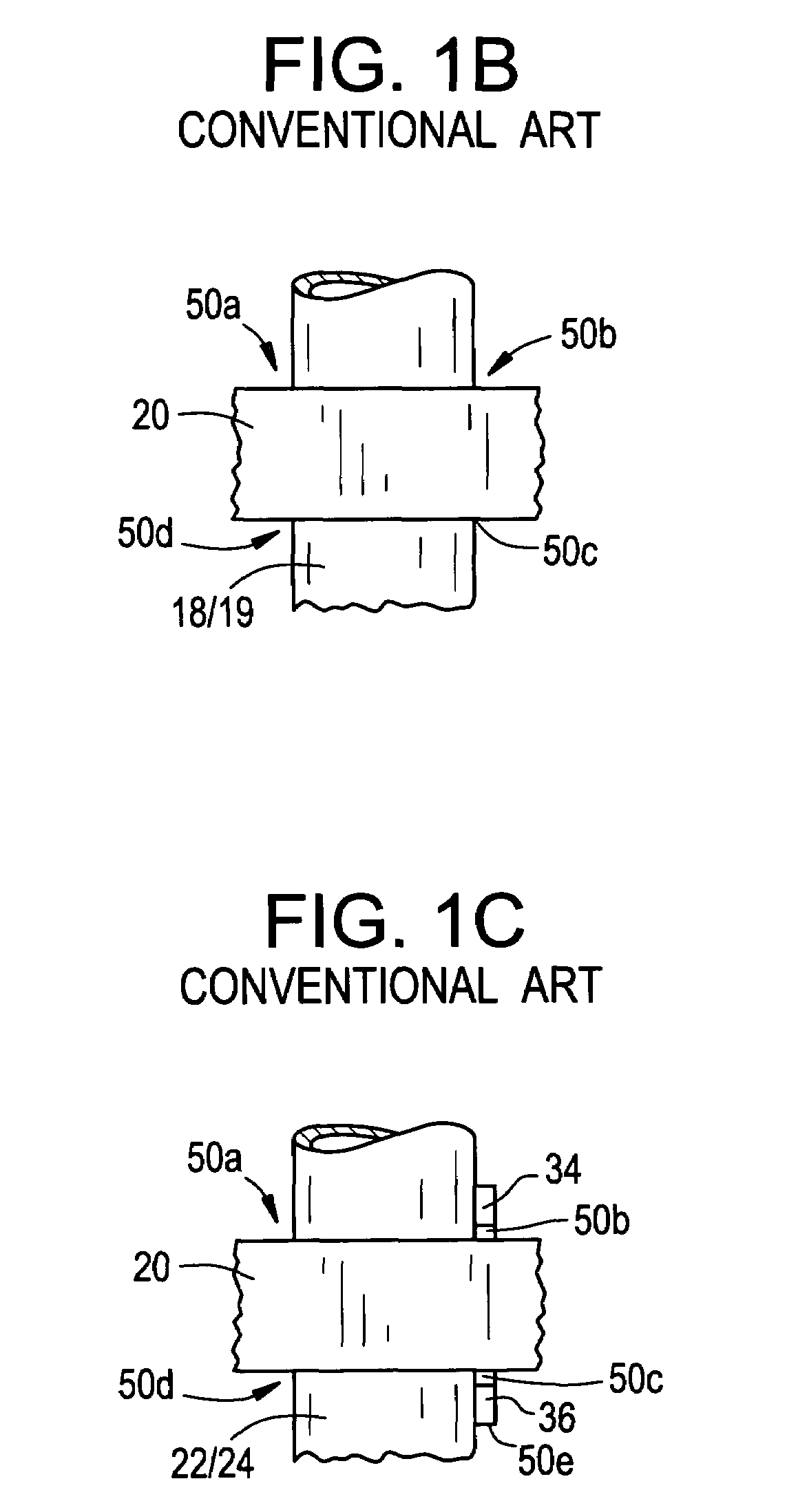

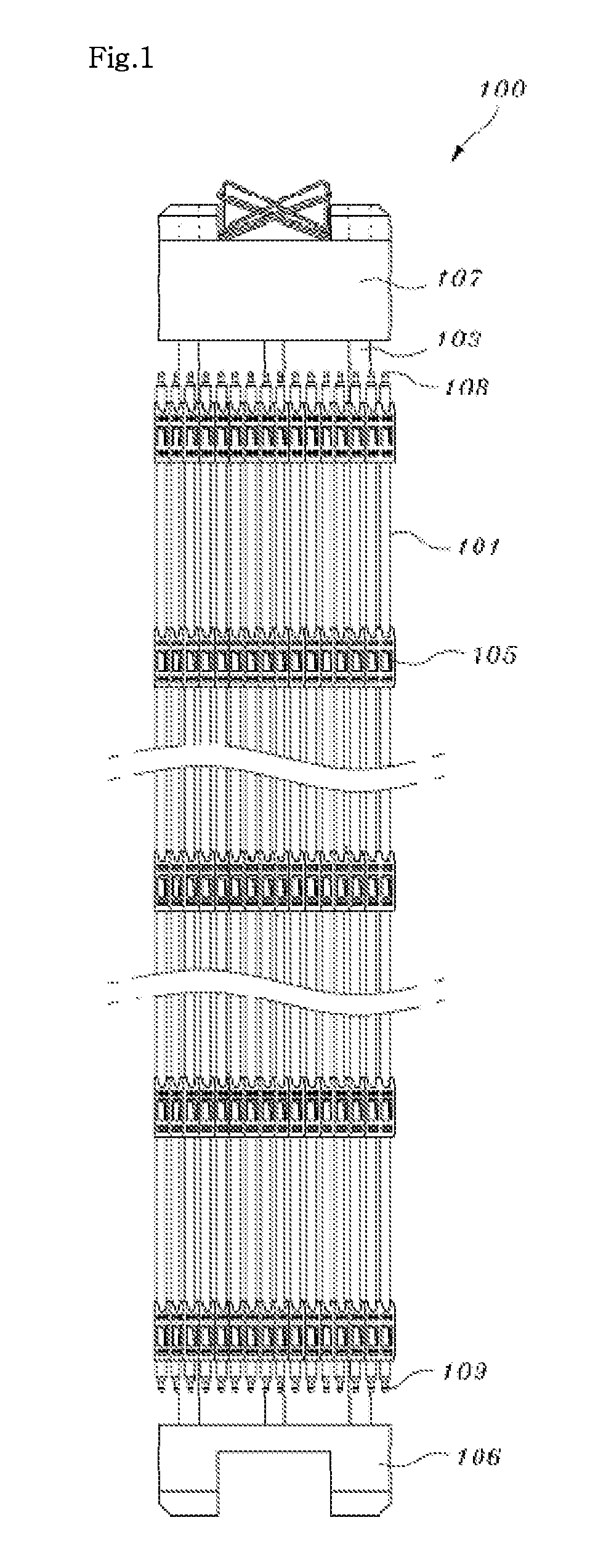

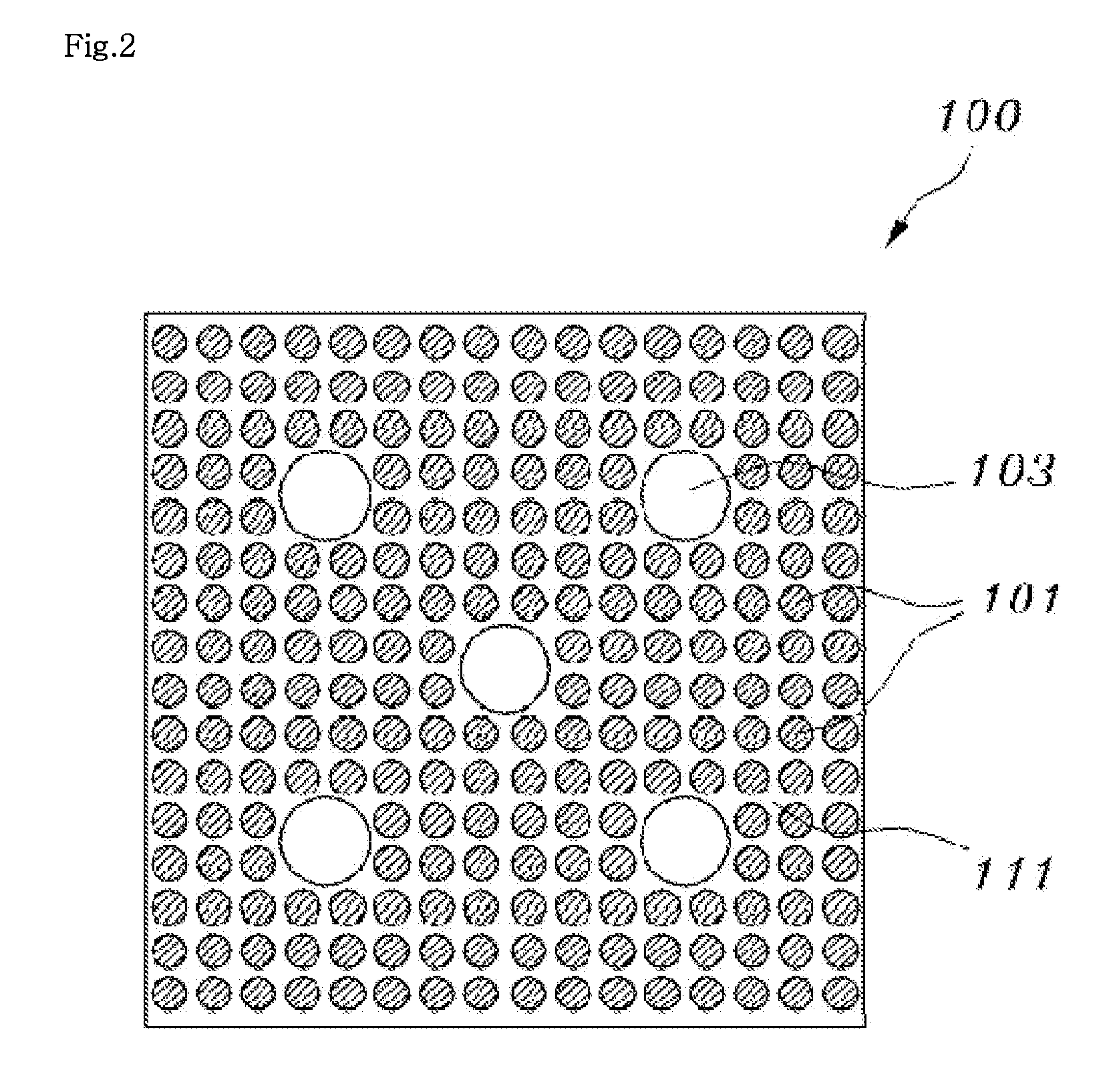

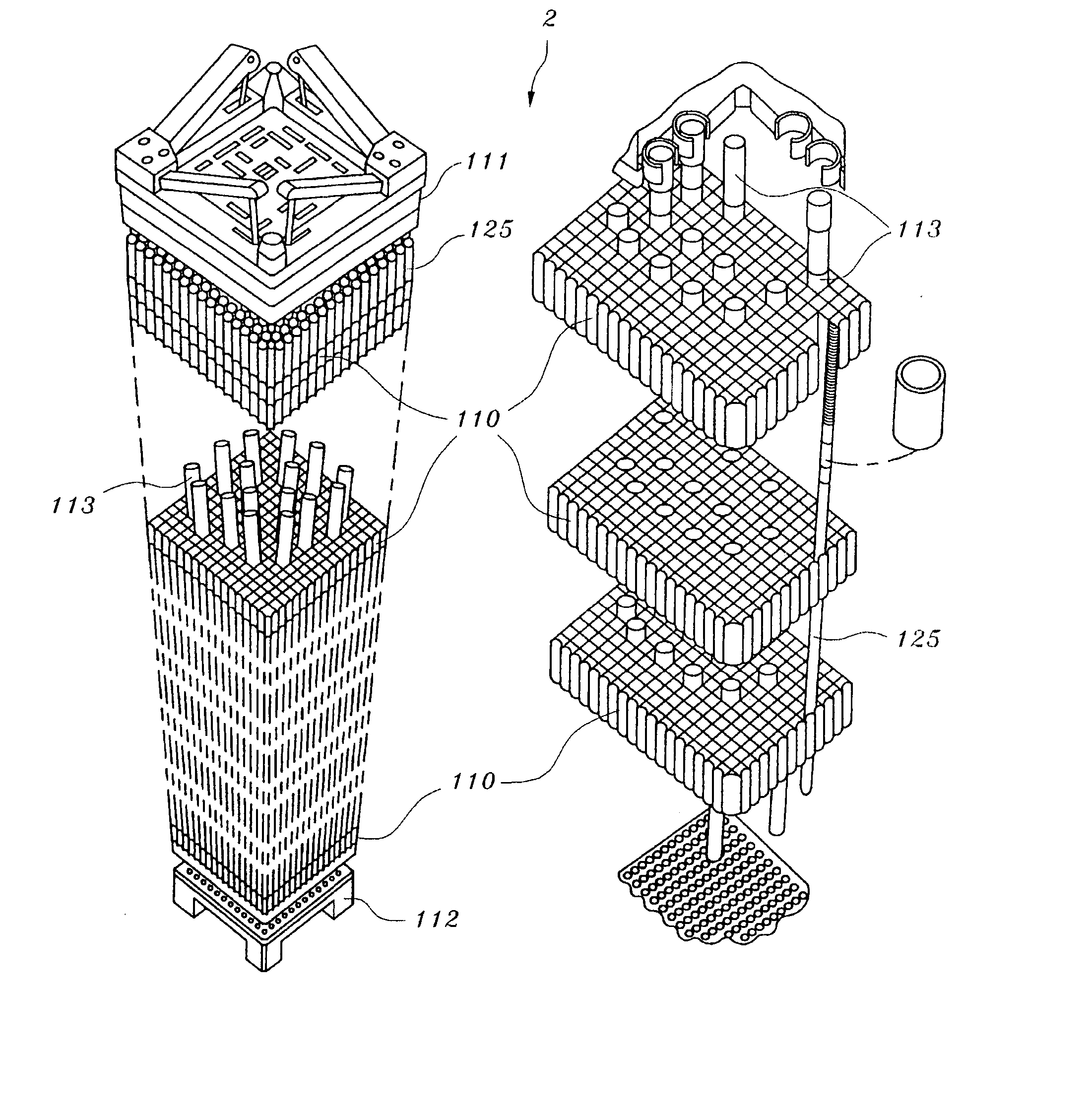

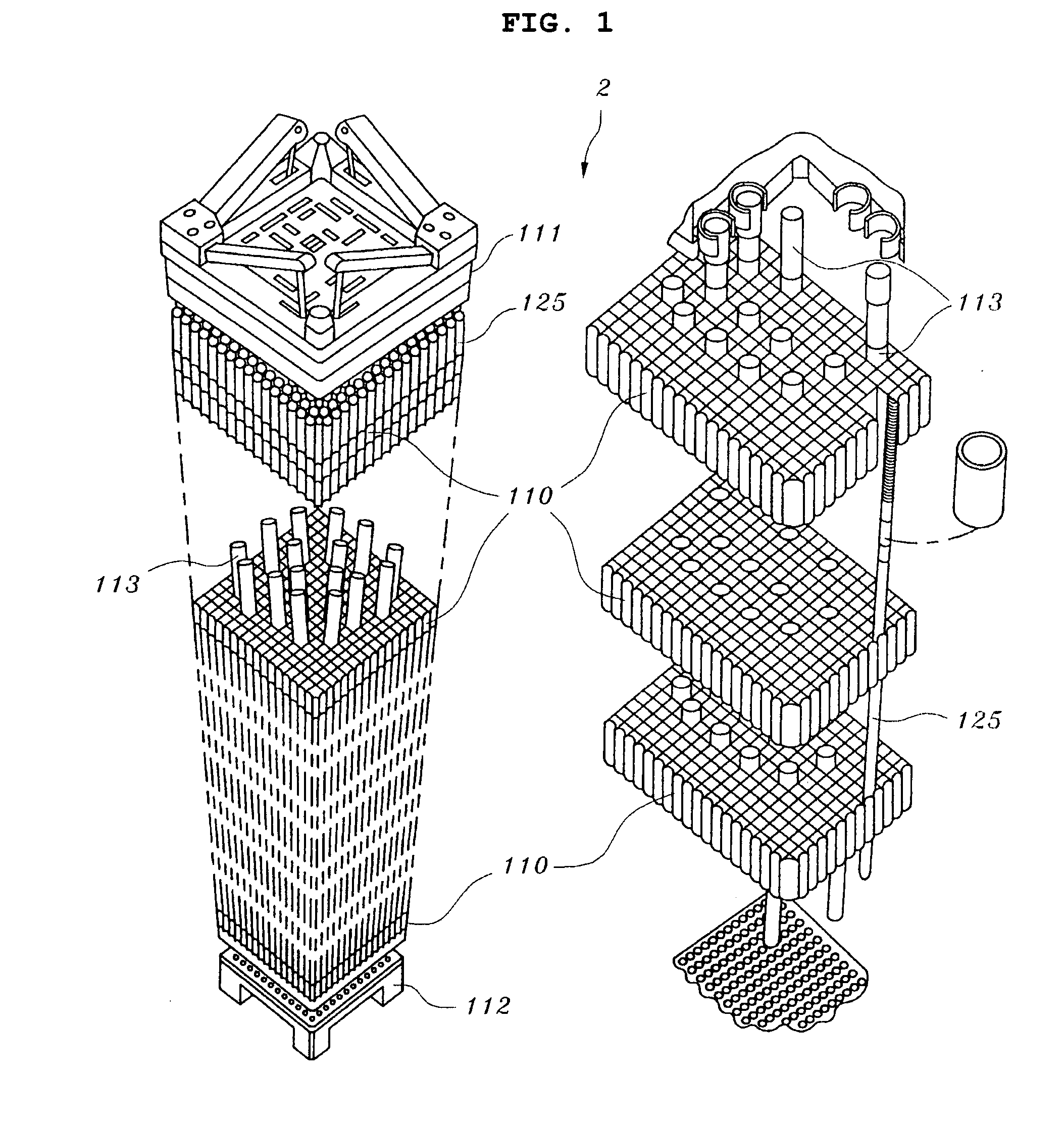

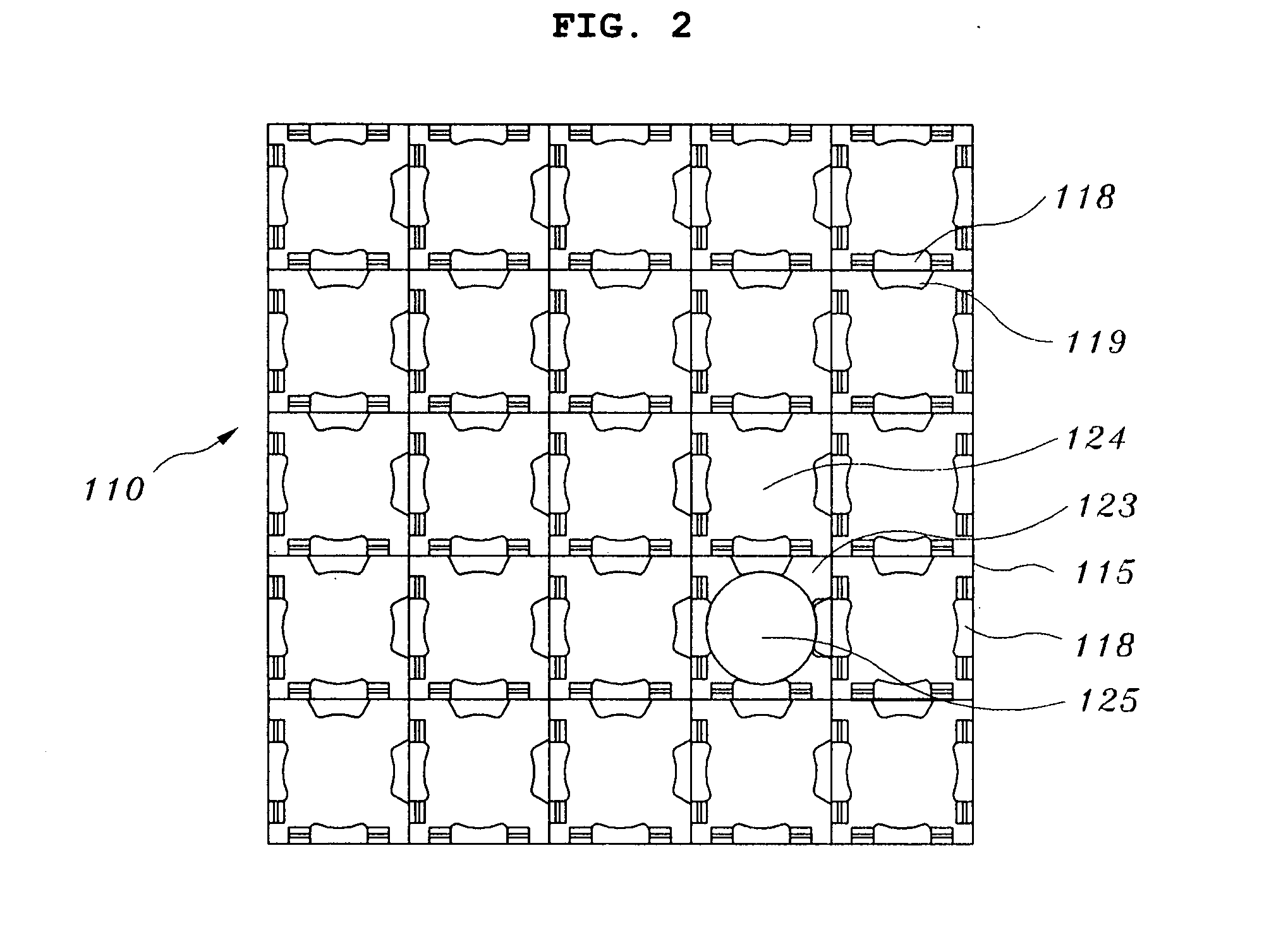

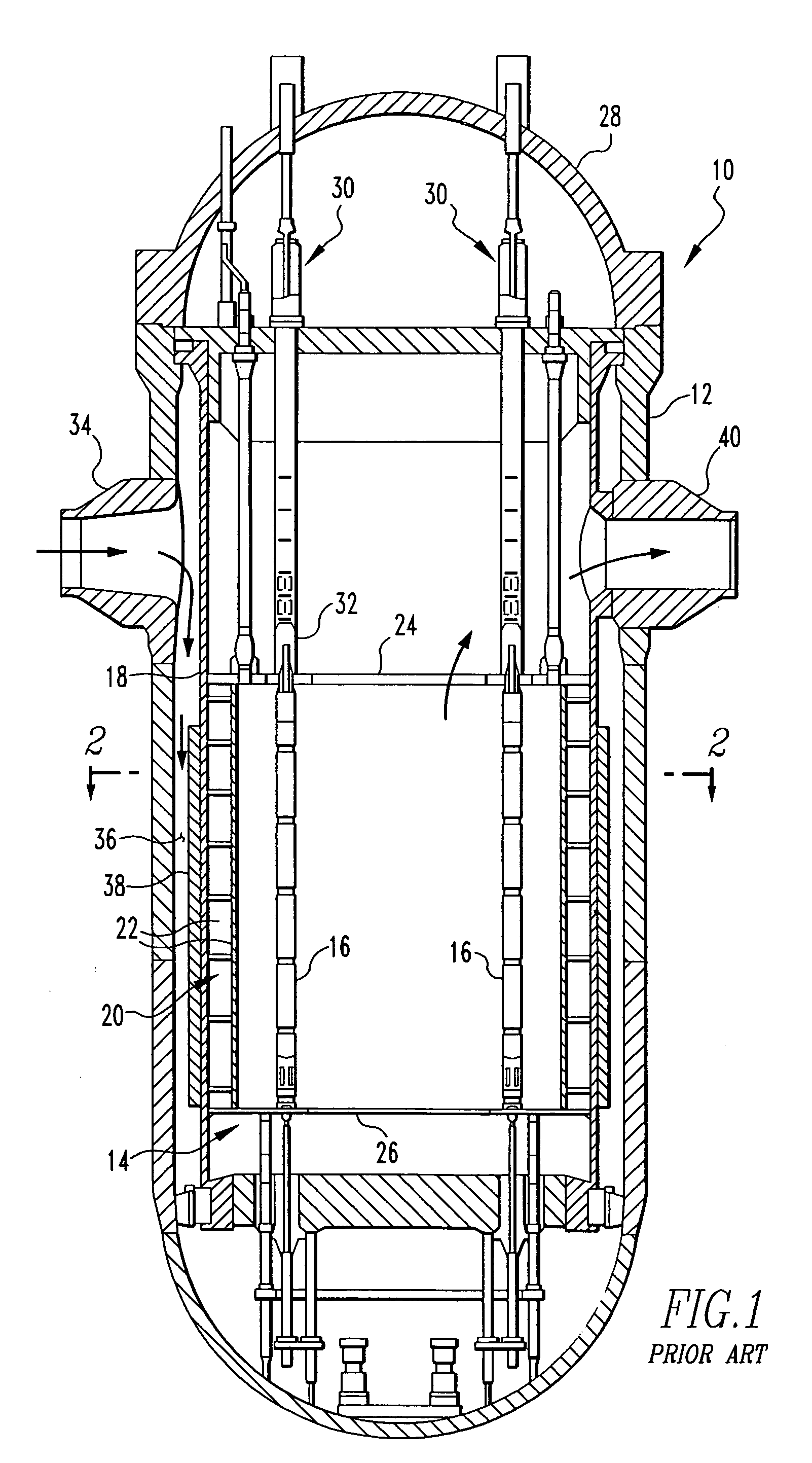

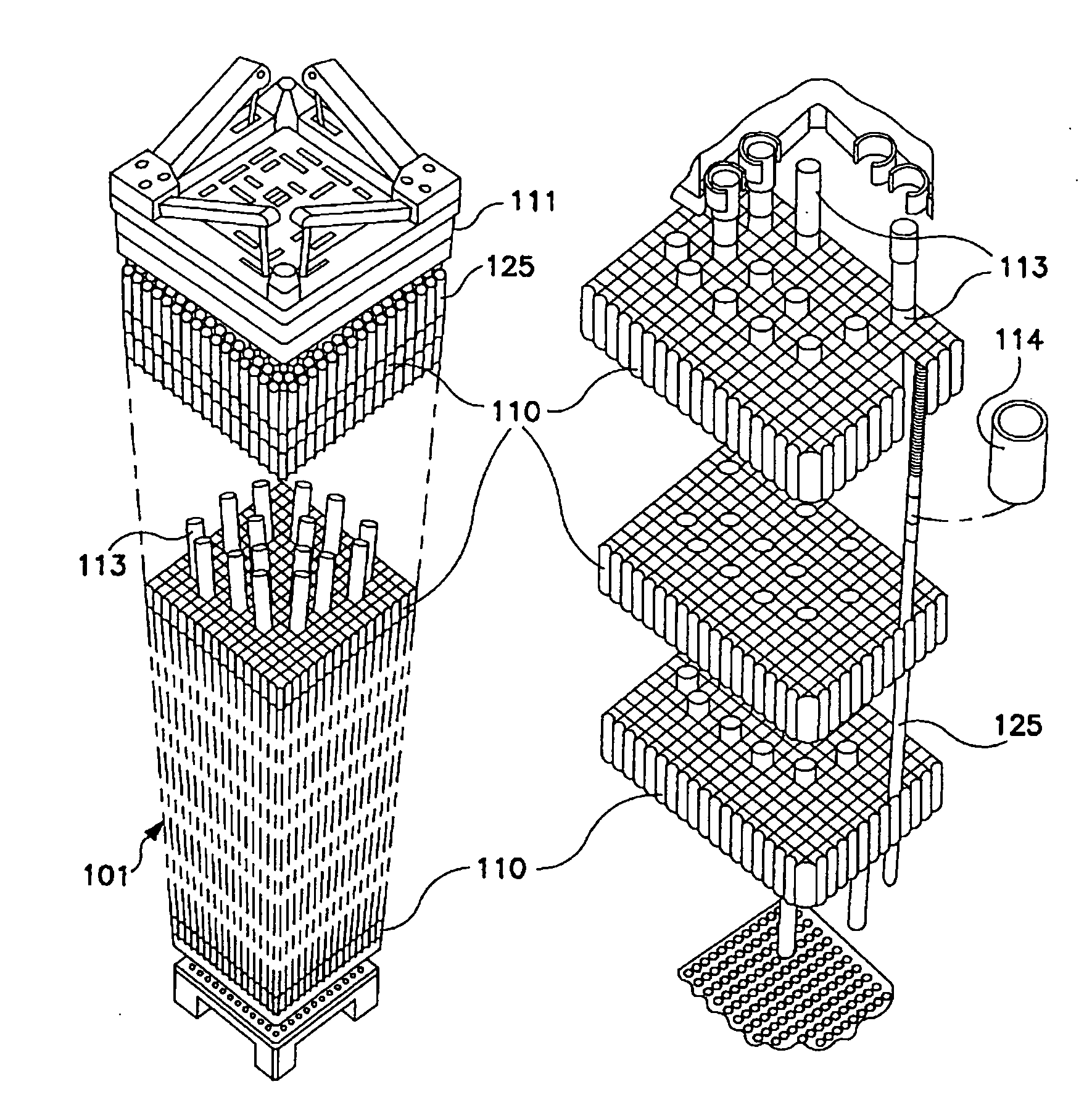

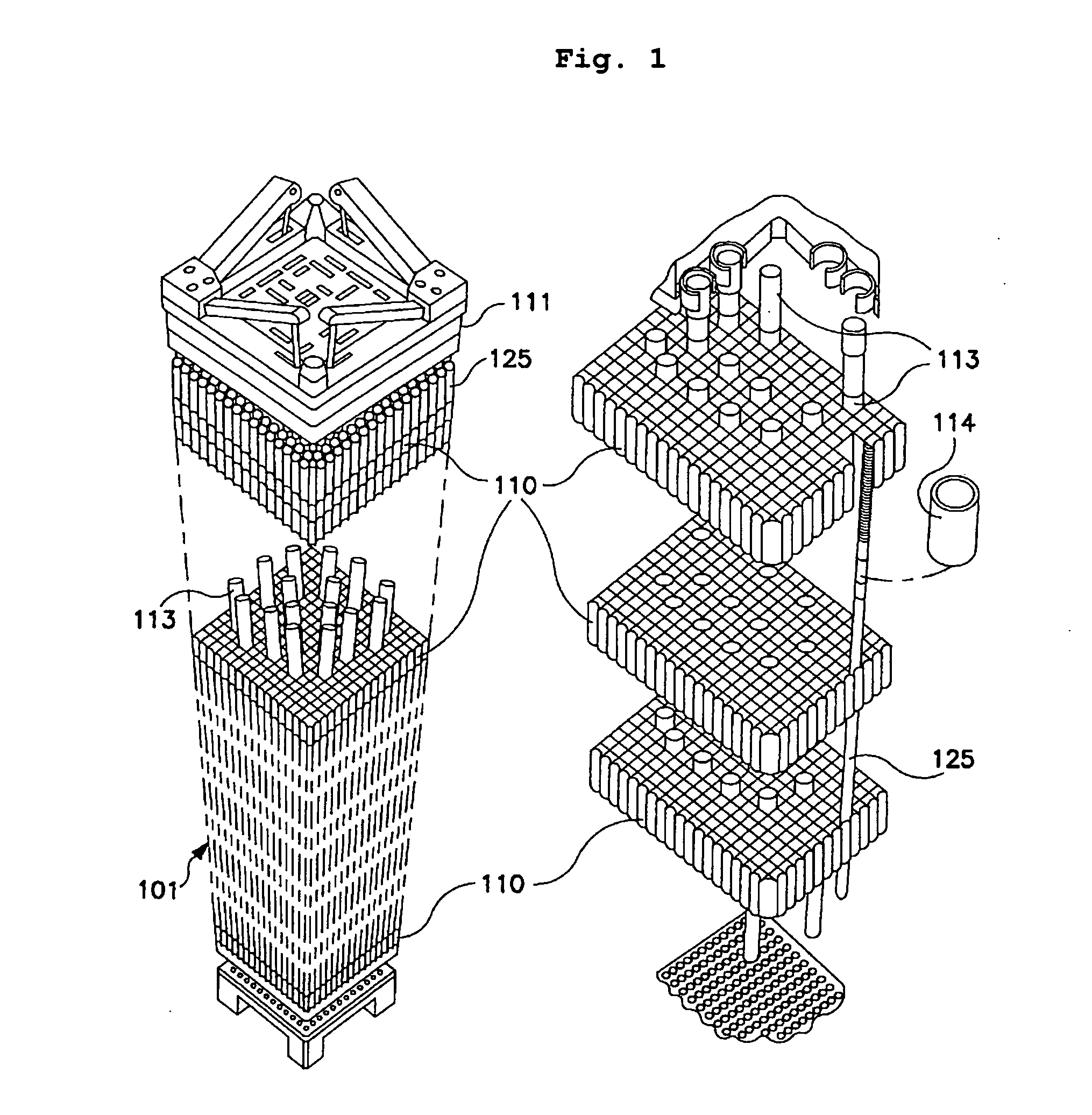

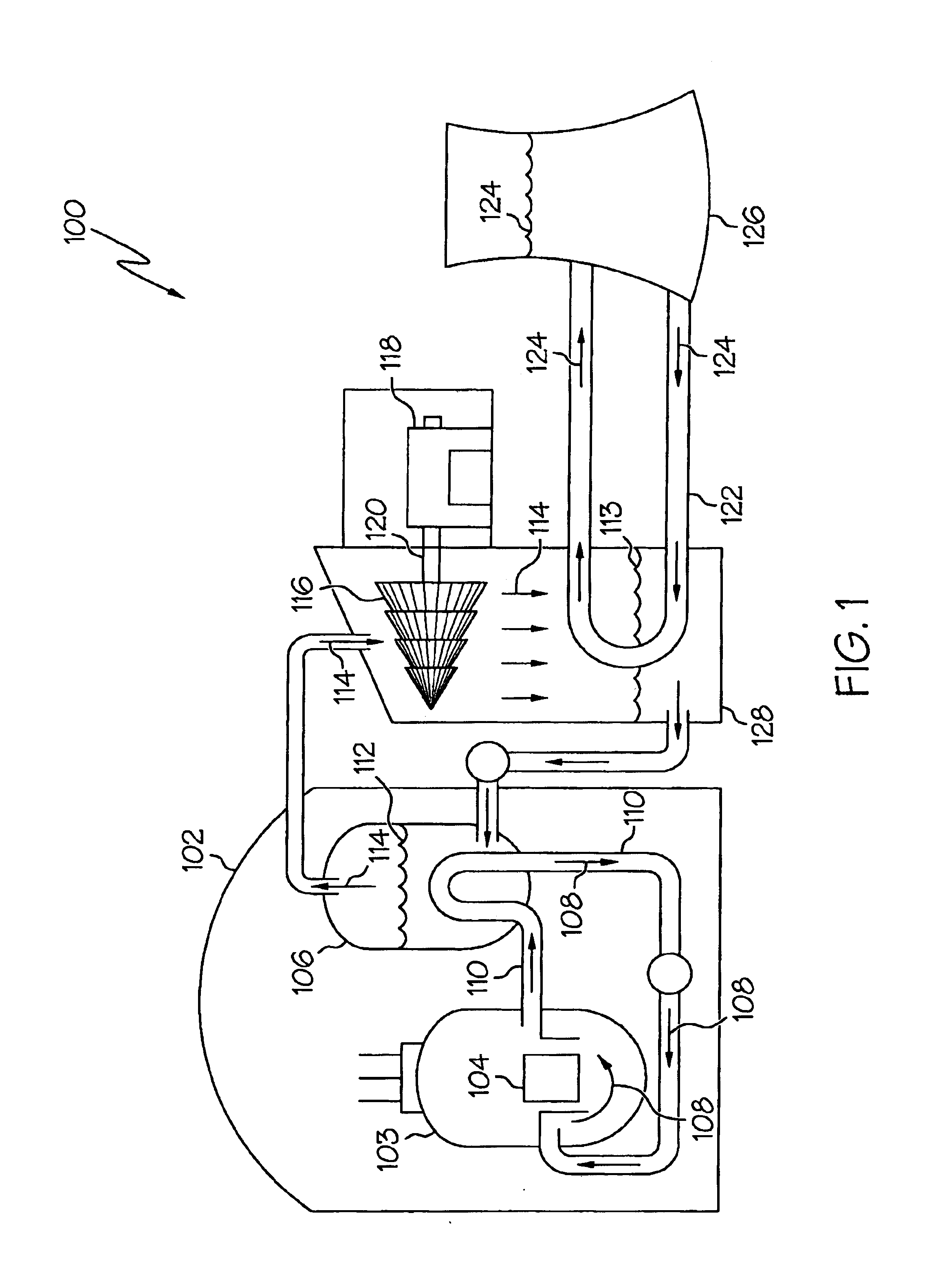

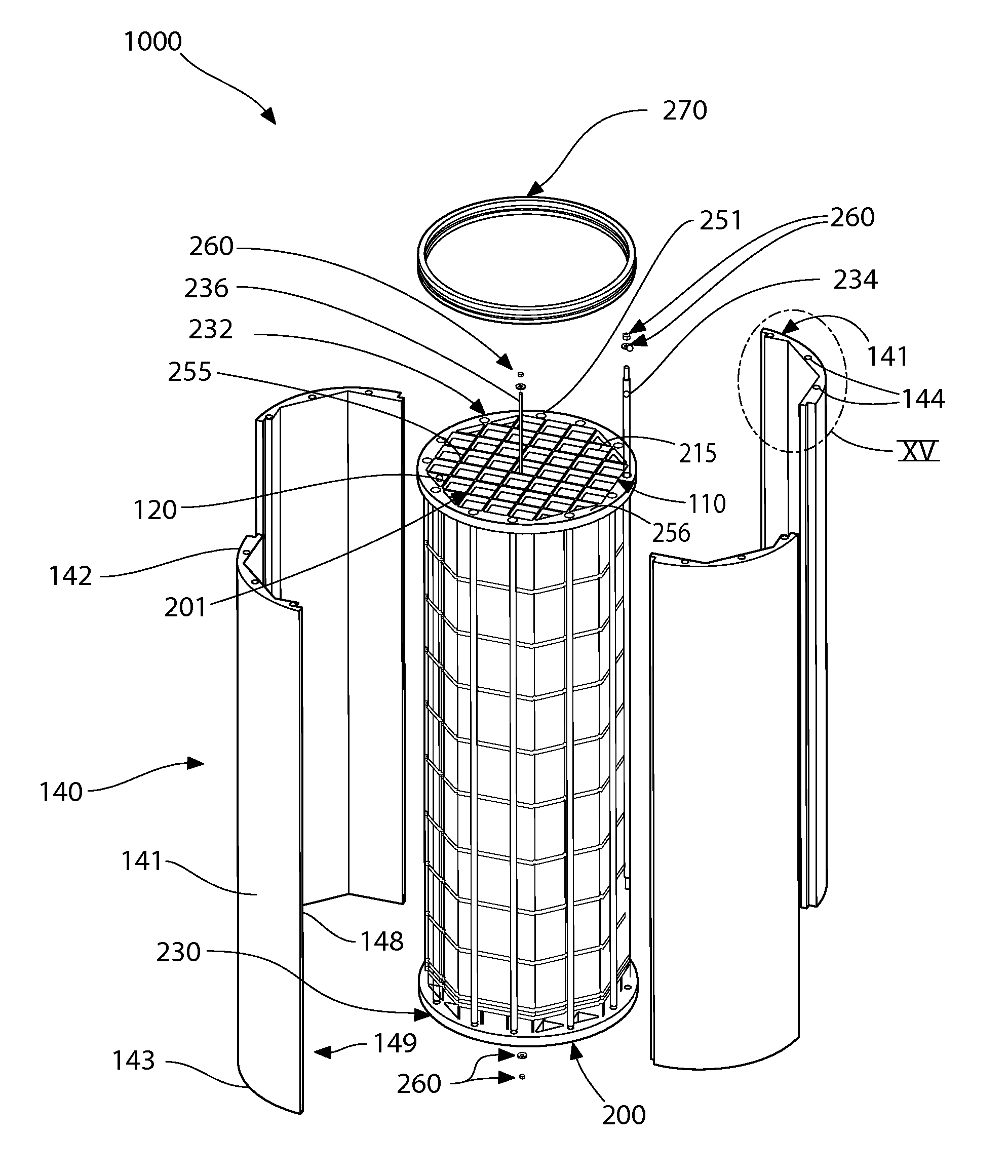

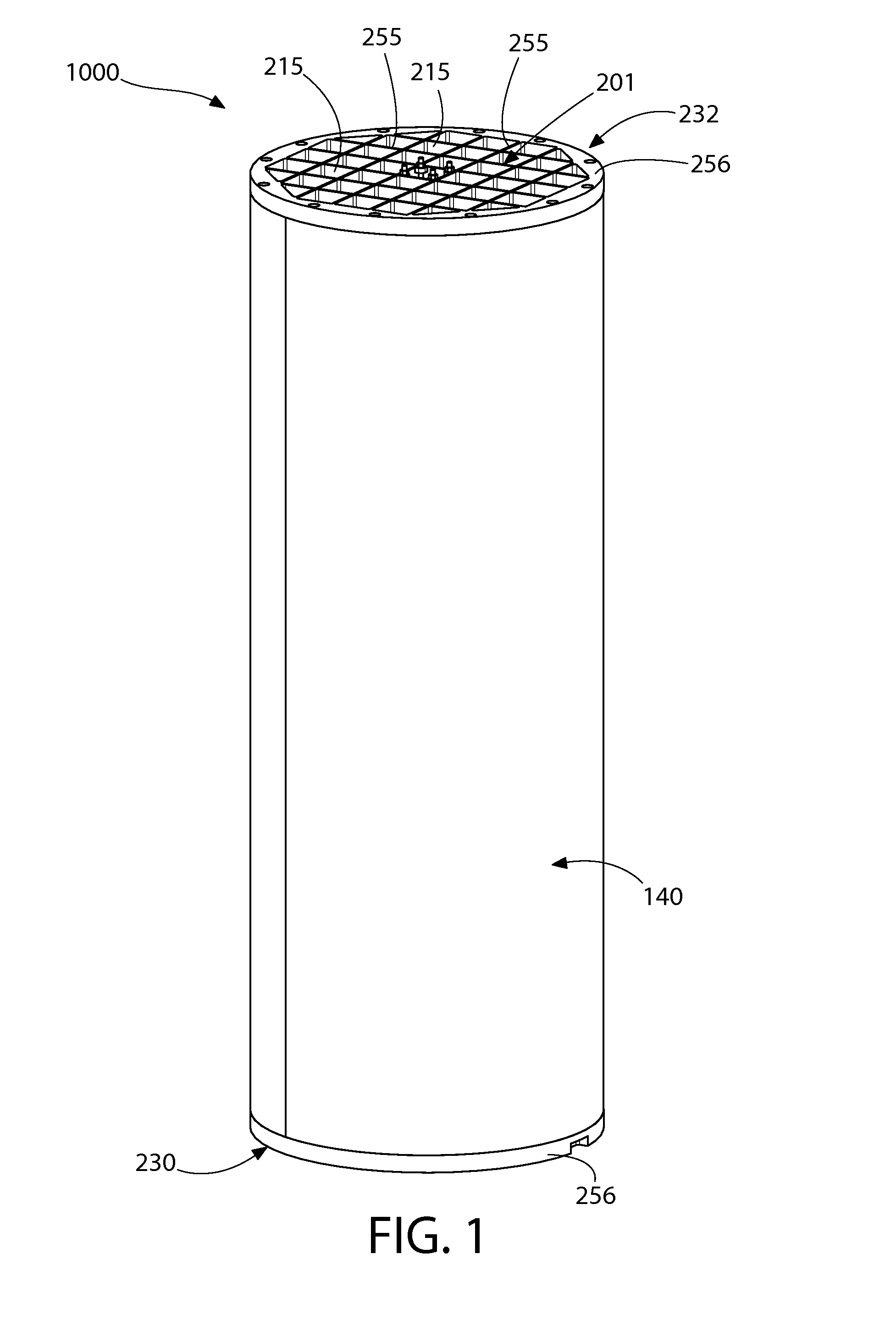

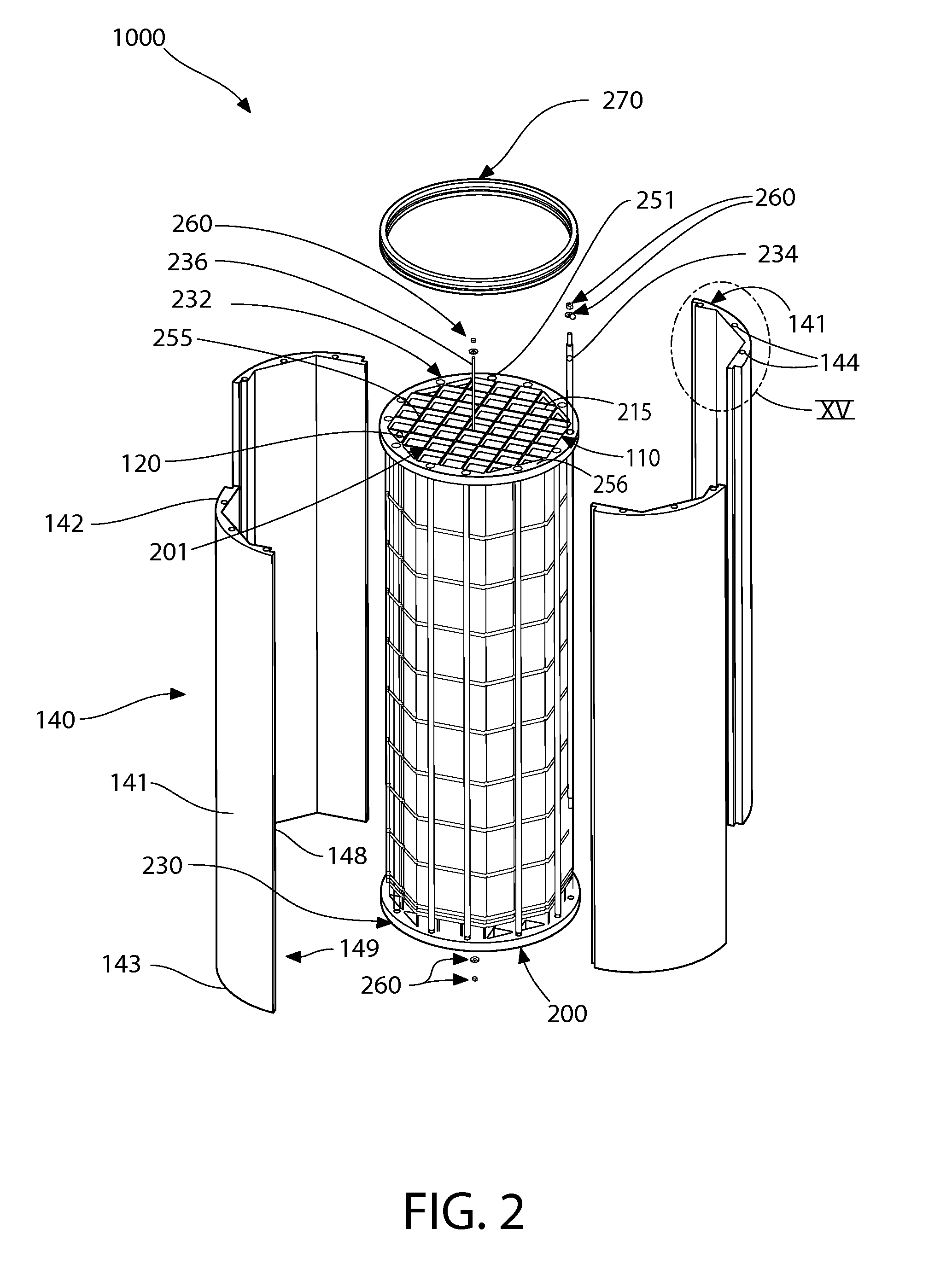

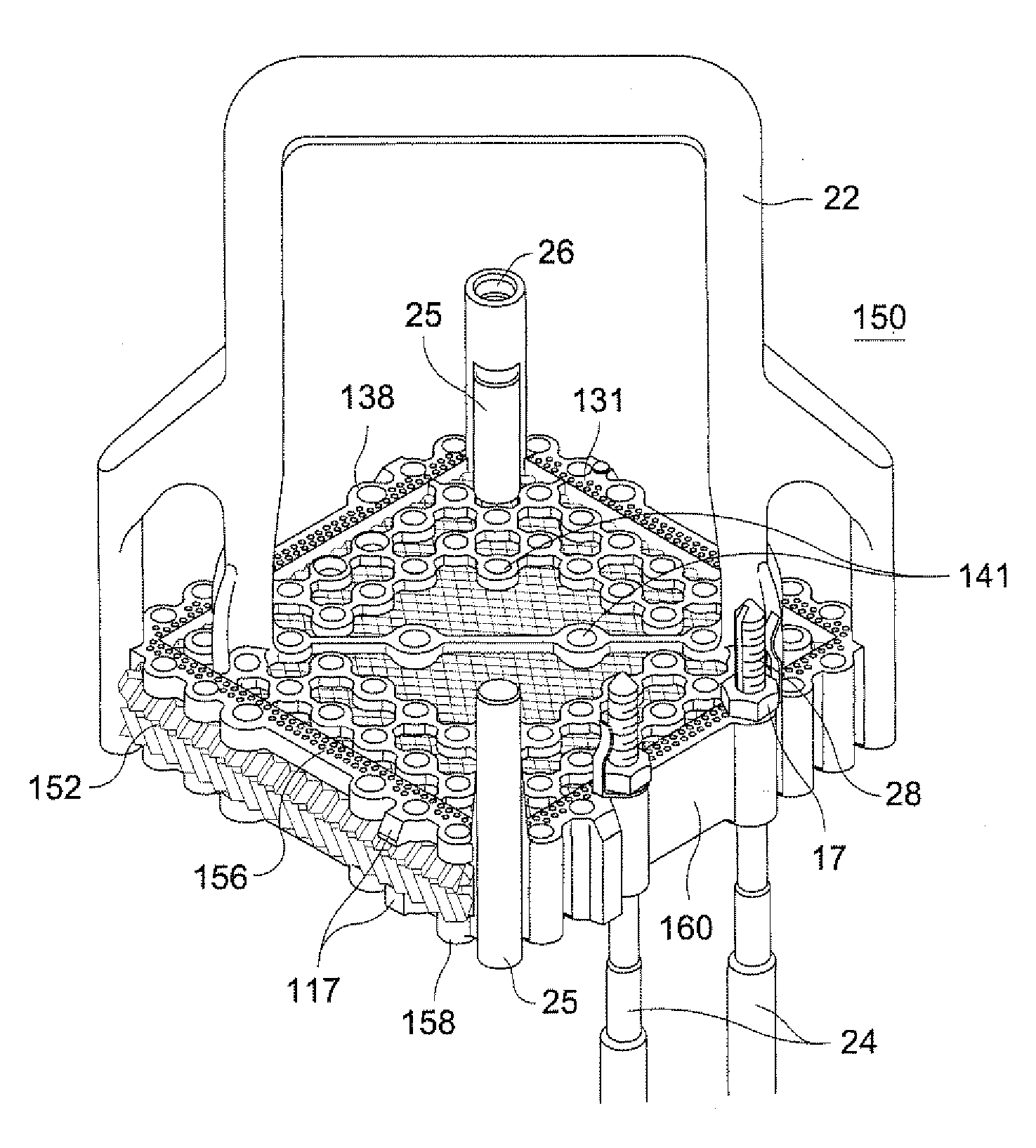

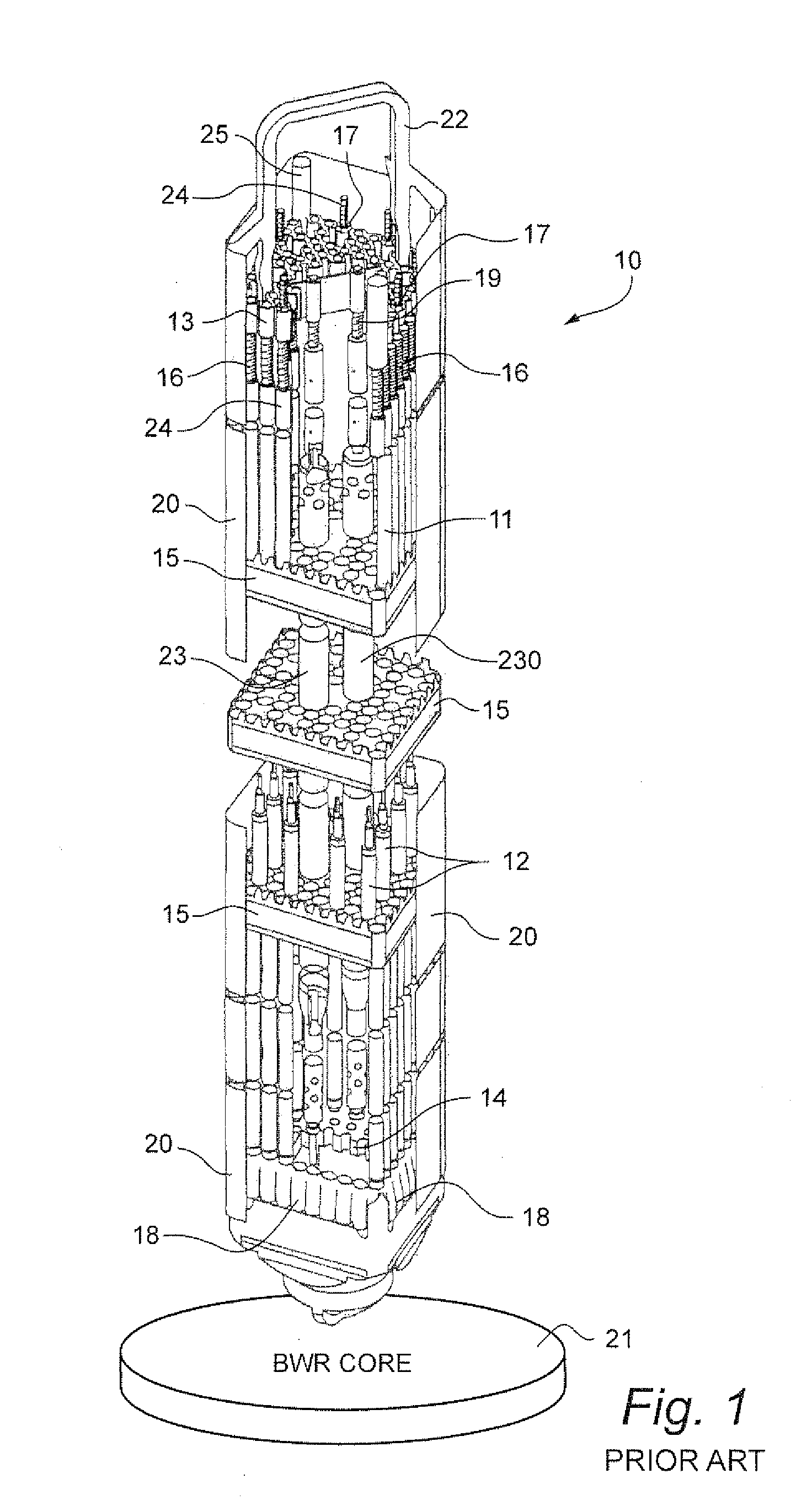

Nuclear fuel core, nuclear fuel cartridge, and methods of fueling and/or defueling a nuclear reactor

ActiveUS20150170766A1Improve cycle lifeExtended service lifeNuclear energy generationFuel element assembliesNuclear reactor coreNuclear reactor

A portable nuclear fuel cartridge comprising a unitary support structure and a plurality of nuclear fuel assemblies that collectively form a nuclear fuel core. The nuclear fuel core is integrated into the unitary support structure to collectively form a self-supporting assemblage than can be lifted as a single unit. In another aspect, the invention is a method of fueling and / or defueling a nuclear reactor utilizing a nuclear fuel cartridge that is loaded and / or unloaded from the nuclear reactor as a single unit. In another aspect, a nuclear reactor core is provided that comprises a nuclear fuel core comprising; a plurality of first nuclear fuel assemblies, each of the plurality of first nuclear fuel assemblies having a first transverse cross-sectional configuration; and a plurality of second nuclear fuel assemblies, each of the plurality of second nuclear fuel assemblies having a second transverse cross-sectional configuration that is different than the first transverse cross-sectional configuration.

Owner:SMR INVENTEC

Method, arrangement and computer program for determining standardized rod types for nuclear reactors

ActiveUS20040243370A1Fuel element assembliesAnalogue computers for electric apparatusNuclear reactor coreNuclear reactor

A method, arrangement and computer program is described for determining a set of standardized rod types for use in a nuclear reactor core. The method may include defining a set of rod type-related limits, and determining, based on the limits, an initial population of rod types to be evaluated for use in cores of a selected number of nuclear reactor plants. Based on the initial population of rod types a database of selectable fresh fuel bundle designs applicable to the one or more cores may be generated. Bundle data related to at least a subset of the selectable fresh fuel bundle designs may be retrieved from the database, and a target number of rod types may be selected from the initial population based on the retrieved bundle data as the set of standardized rod types.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

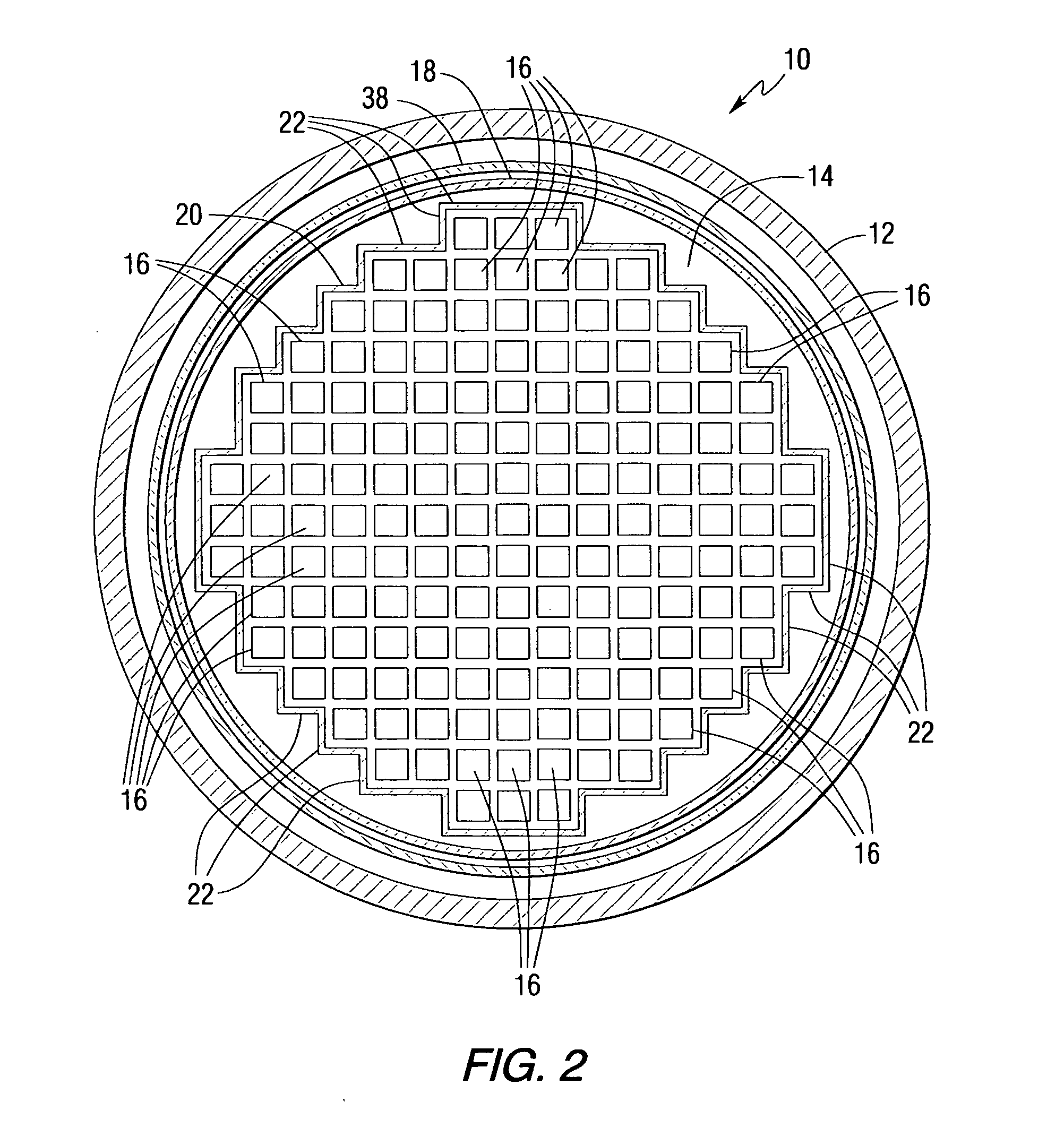

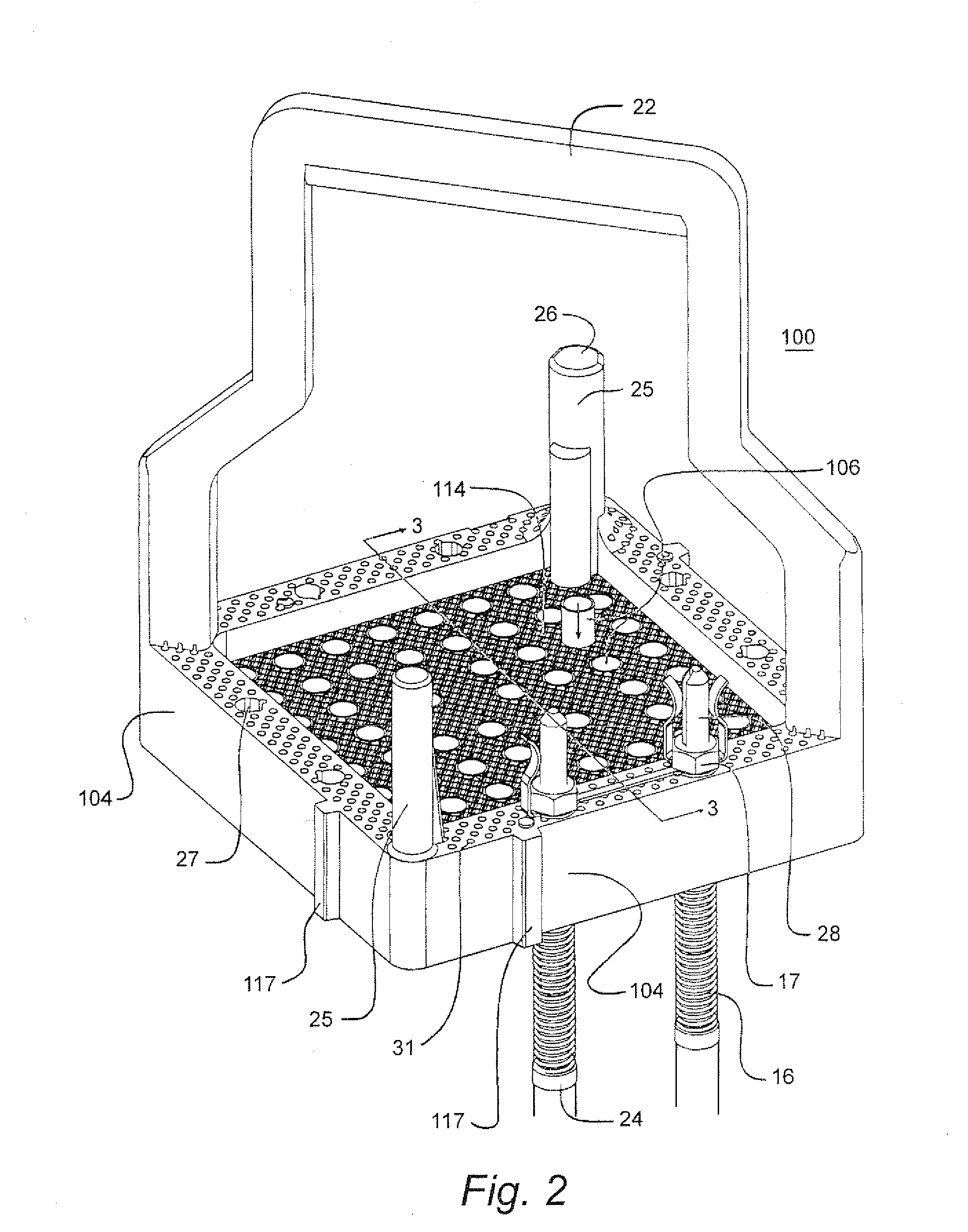

Debris shield for upper tie plate in a nuclear fuel bundle and method for filtering debris

A nuclear reactor fuel assembly including: an upper tie plate having apertures to receive and support fuel rods of a fuel bundle; the fuel bundle includes an array of the fuel rods mounted and housed in the walls of a channel, and a load bearing or non-load bearing debris shield may be mounted in the upper tie plate, wherein the debris shield is porous to prevent the passage of debris. The debris shield is mounted in the frame of the upper tie plate. The debris shield can be either a removable unit, or it can be attached as a permanent integrated structure within the upper tie plate. The upper tie plate frame is also porous, e.g., has small vertical openings to allow fluid to pass through the frame and block passage of debris. The openings in the frame increase the effective flow area of passages through the upper tie plate and thereby compensate or offset any flow restrictions due to the debris shield. Preventing debris falling into the fuel bundle is expected to assure the operational life of the fuel assembly by reducing the risk of fuel rod failure and premature discharge from the reactor core.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

Filter for cooling water in a light water cooled nuclear reactor

InactiveUS20040076253A1Lower overall flow resistanceEfficient captureNuclear energy generationFuel element assembliesNuclear plantNuclear reactor core

The invention refers to a filter (1) for separating particle from cooling water in a nuclear plant, and a fuel assembly with such a filter. The filter has an inlet end (2) and an outlet end (3) and permits through-flow of the cooling water in a main flow direction (x). The filter includes a number of sheets (4) extending in the flow direction from the inlet end to the outlet end. The sheets are arranged beside each other and form passages for the cooling water. The sheets include a first portion (4') extending from the inlet end (2), a second portion (4'') extending from the outlet end (3), and a third portion (4''') extending between the first portion (4') and the second portion (4''). The sheets (4) have along the first portion continuous wave-shape extending in a direction (y) transversally to the flow direction (x) and along the third portion a continuous wave-shape extending in the flow direction (x).

Owner:WESTINGHOUSE ELECTRIC SWEDEN

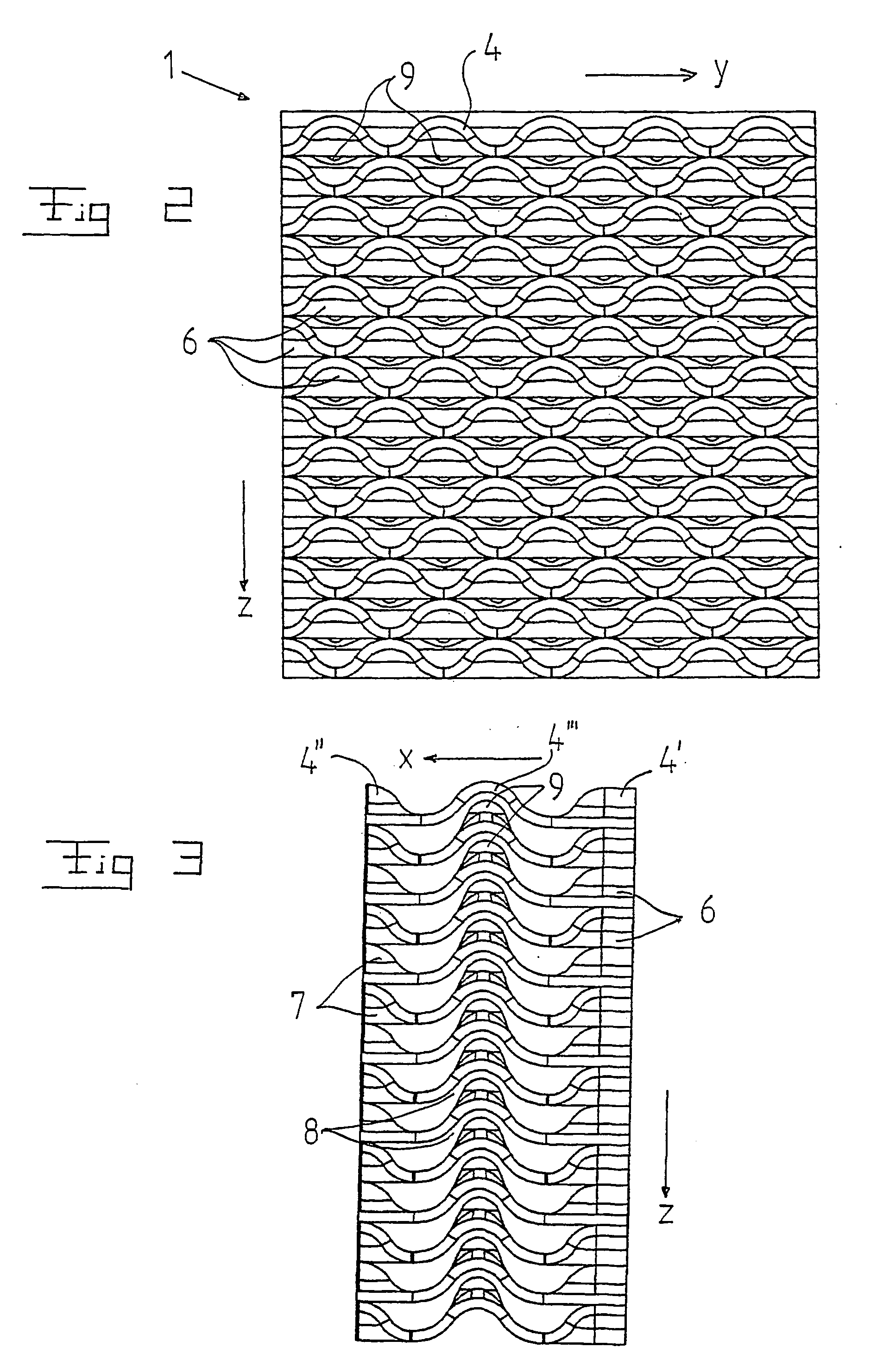

FeCrAl alloy material for preparing Nuclear reactor fuel cladding material

InactiveCN106399846AImprove performanceImprove resistance to water vapor oxidationOptical rangefindersNuclear energy generationNuclear reactor coreWater vapor

The invention relates to a FeCrAl alloy material for preparing a Nuclear reactor fuel cladding material. By taking the total weight of the FeCrAl alloy material as a benchmark, the FeCrAl alloy material is composed of the following components: 5%-25% of Cr, 3%-15% of Al, 0.01%-3.3% of Si, 0.001%-1% of Y, 5% or less of Mo, 5% or less of Nb, 1000 ppm or less of C, 1000 ppm or less of N and the balance of Fe and inevitable trace elements. The nuclear fuel cladding FeCrAl alloy has excellent oxidation resistance at the 1200 DGE C water vapor environment, which is obviously better than commercial M5 zirconium alloys, and the requirement for accident fault tolerance of the nuclear power plant is met. The alloy can be used for the preparation of oxide dispersion strengthened iron-base alloy base materials for fuel element cladding pipes, composite cladding pipes, zirconium alloy coatings and nuclear fuel cladding pipes, and core structural materials of positioning grid stripes and the like.

Owner:SUZHOU NUCLEAR POWER RES INST +3

Heat exchanger tube support structure

InactiveUS6914955B2Minimized pressure dropReducing local turbulenceBoiler supporting/setting arrangementsFuel element assembliesParticulatesEngineering

A support plate for retaining tube array spacing within a heat exchanger tube and shell structure. The support plate having a plurality of individual tube receiving apertures formed therein. Each aperture has at least three inwardly protruding members and bights are formed therebetween when the tube associated therewith is lodged in place to establish secondary fluid flow through the support plate. The inwardly protruding members terminate in flat lands that restrain but do not all contact the outer surface of the respective tube. These flat lands minimize fretting wear and eliminate potential gouging of the outer wall of the tube. The plate wall forming each aperture has an hourglass configuration which, inter alia, reduces pressure drop, turbulence and local deposition of magnetite and other particulates on the support plates.

Owner:BWXT CANADA

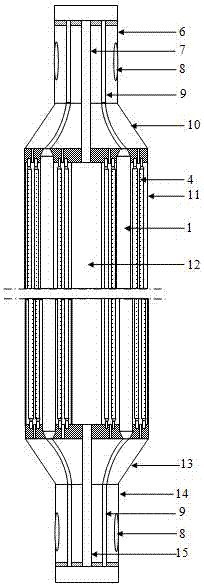

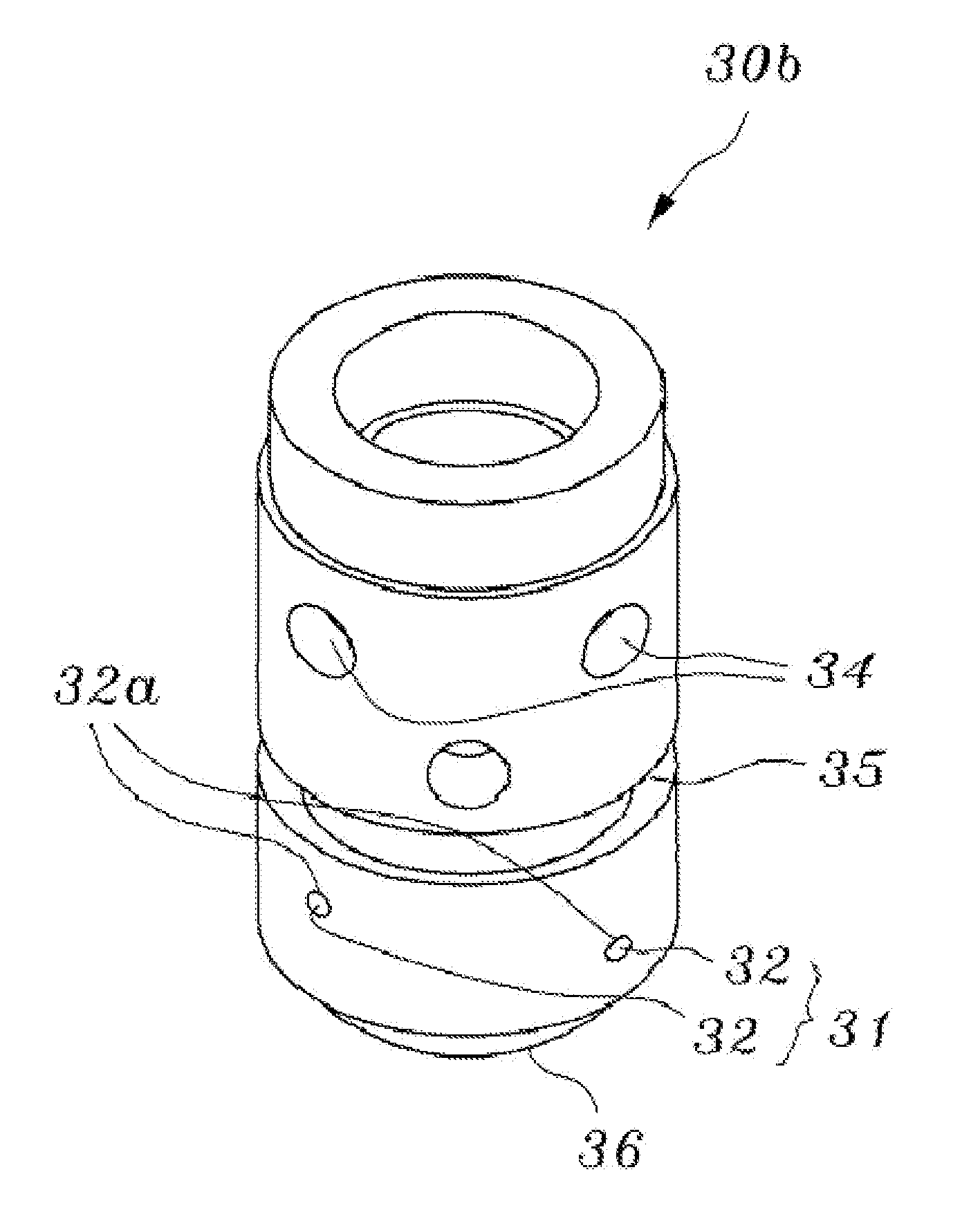

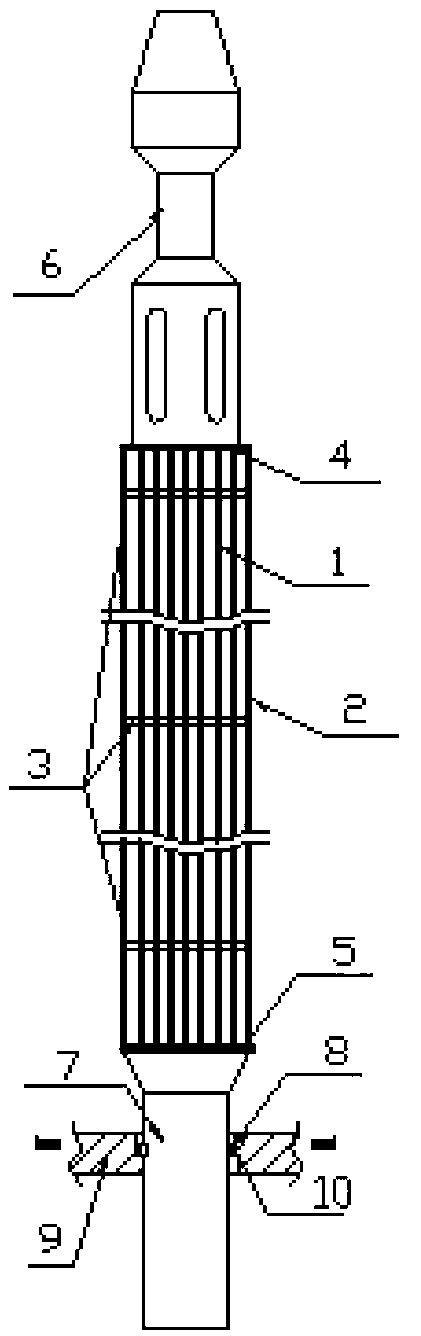

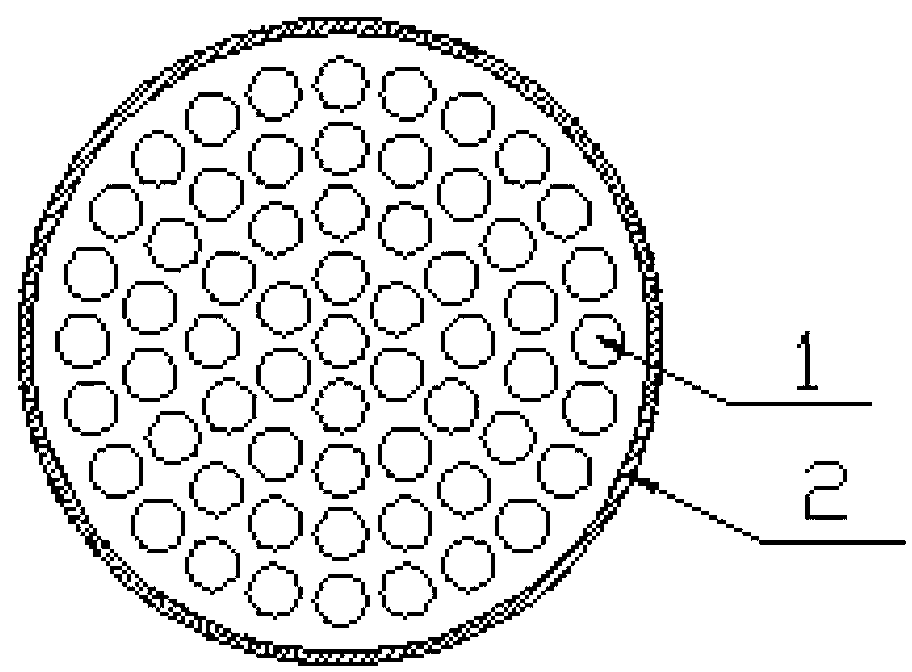

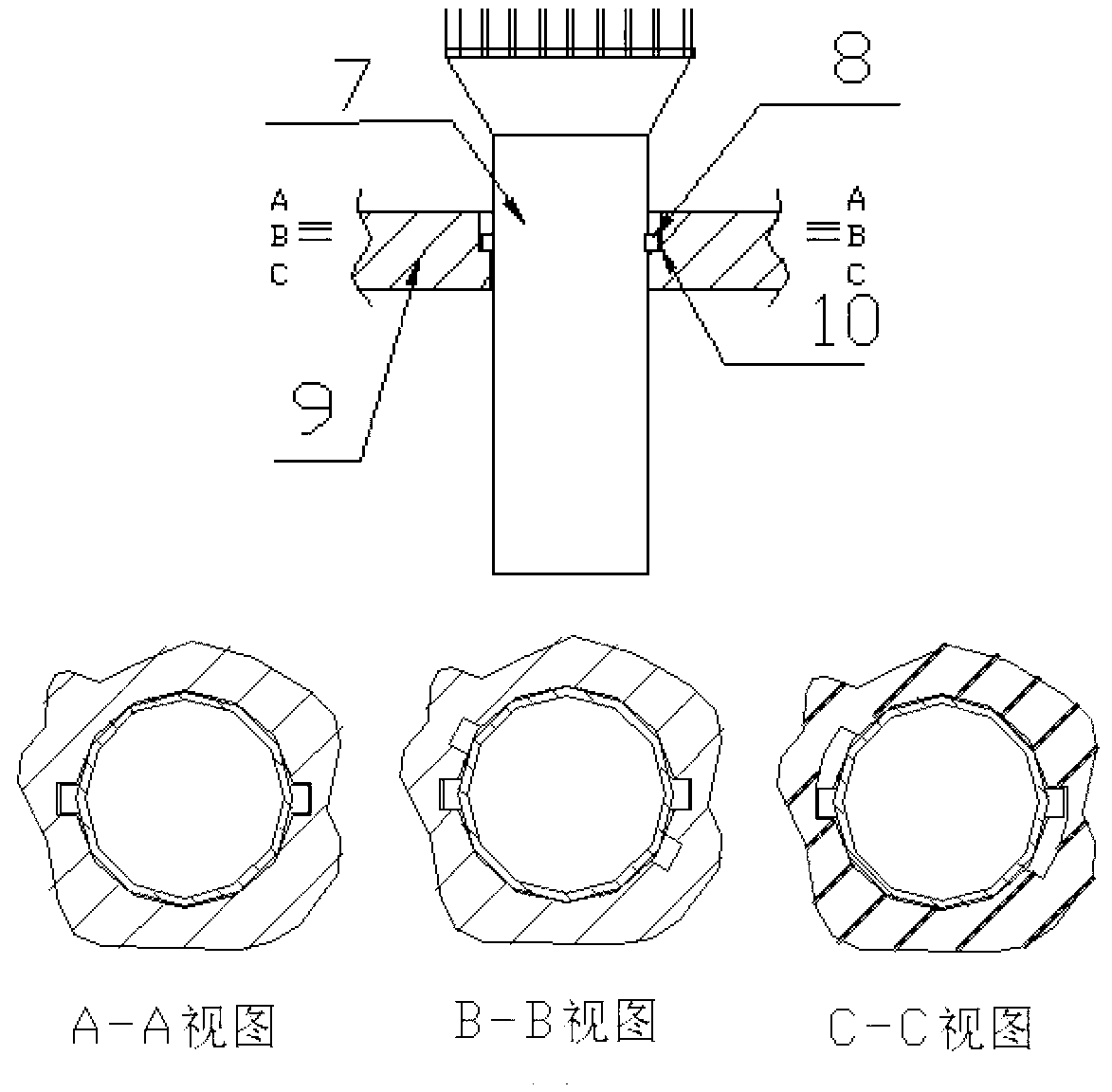

Fuel component and fixing method for liquid heavy metal cooling reactor

InactiveCN103077752ASimple structureImprove reliabilityFuel elementsNuclear energy generationNuclear engineeringLiquid state

The invention relates to a fuel component and a fixing method for a liquid heavy metal cooling reactor. The fuel component comprises fuel rods, component sleeves, a positioning grid rack, an upper grid, a lower grid, an operation head and a pin, wherein the component sleeves are circular sleeves; the fuel rods are arranged in a circular ring-shaped manner; and a positioning rack is arranged at the periphery of the pin. Through the adoption of the circular sleeves and the pin positioning rack, the fuel component has the advantages that the buoyancy of liquid heavy metal coolant is overcome, so that the fuel component can be fixed in the liquid heavy metal reactor; no movable part is required; the structure is simple; the reliability and the safety of the reactor are improved effectively.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

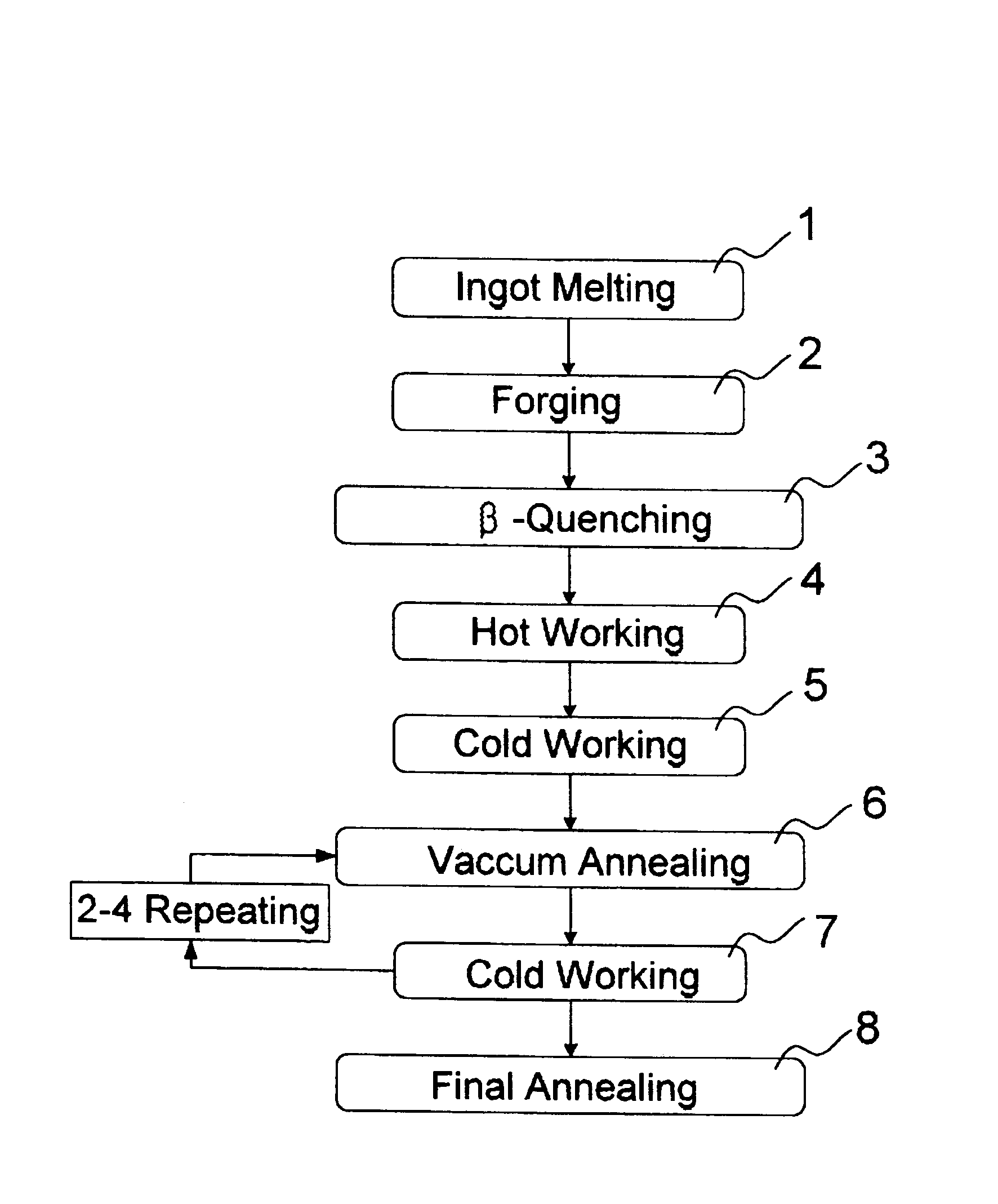

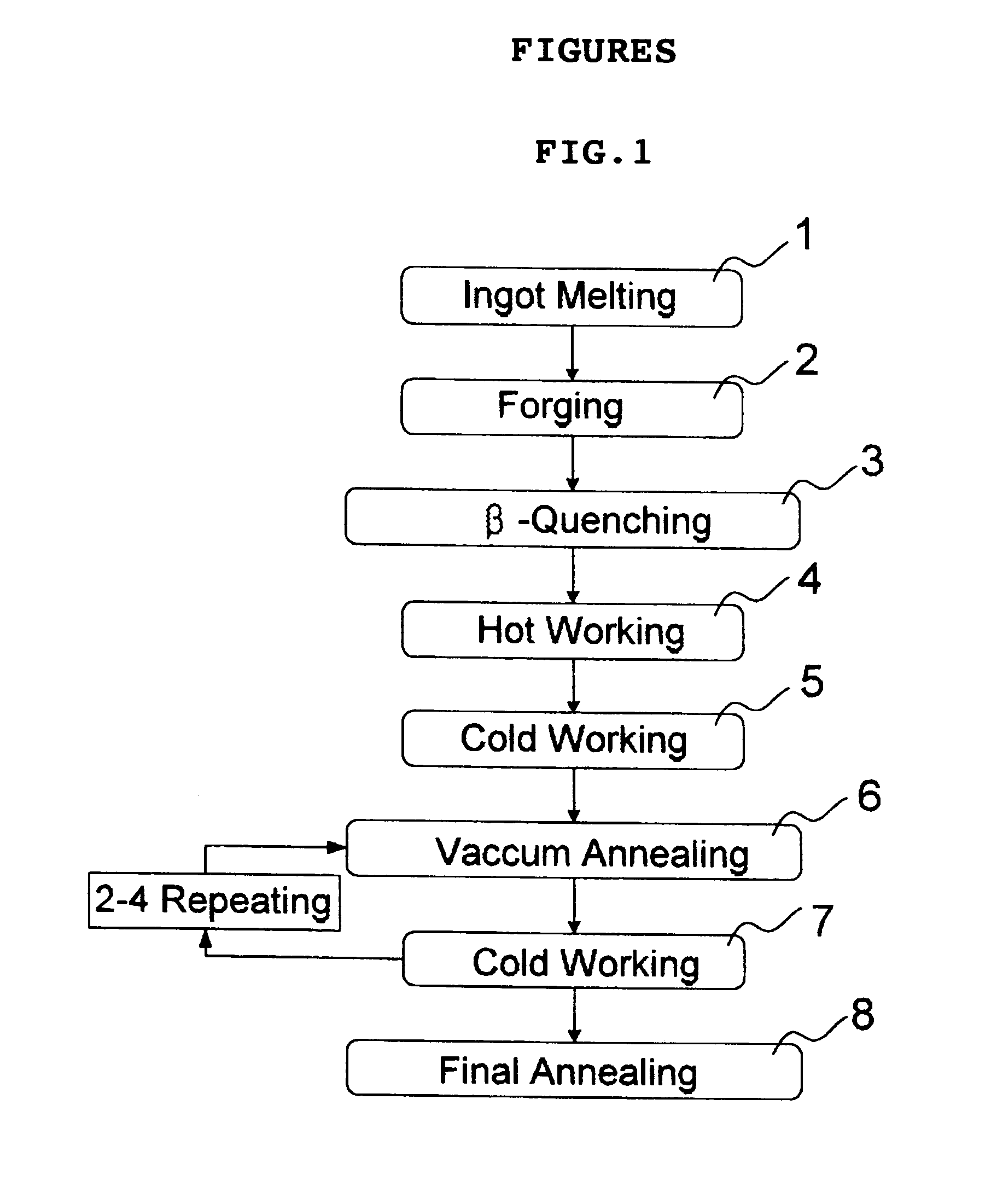

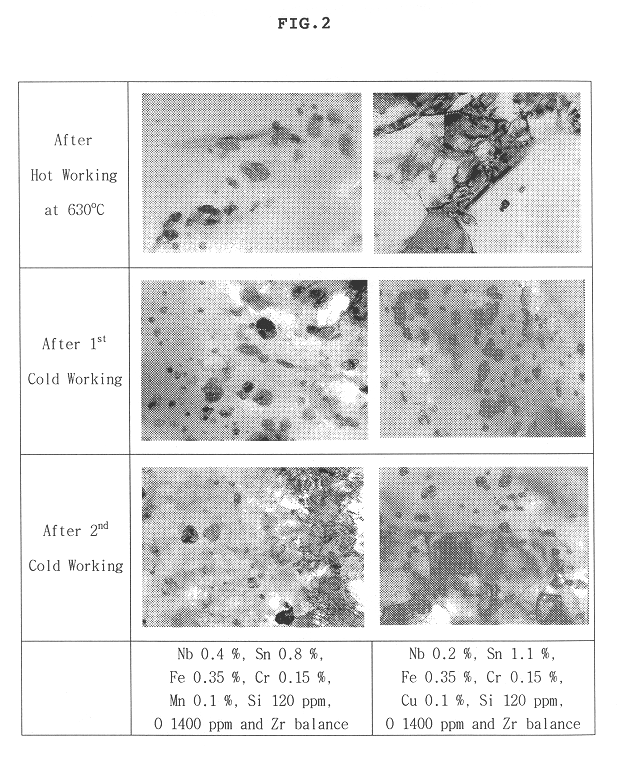

Method for manufacturing a tube and a sheet of niobium-containing zirconium alloy for a high burn-up nuclear fuel

Disclosed is a method for manufacturing a tube and a sheet of niobium-containing zirconium alloys for the high burn-up nuclear fuel. The method comprises melting Nb-added zirconium alloy to ingot; forging the ingot at beta phase range; beta-quenching the forged ingot after solution heat-treatment at 1015-1075° C.; hot-working the quenched ingot at 600-650° C.; cold-working the hot-worked ingot in three to five passes, with intermediate vacuum annealing; and final vacuum annealing the cold-worked ingot at 440-600° C., wherein temperatures of intermediate vacuum annealing and final vacuum annealing after beta-quenching are changed so as to attain the condition under which precipitates in the alloy matrix are limited to an average diameter of 80 nm or smaller and the accumulated annealing parameter (SIGMA A) is limited to 1.0x10-18 hr or lower.

Owner:KEPCO NUCLEAR FUEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com