Patents

Literature

1309results about How to "Avoid bending deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

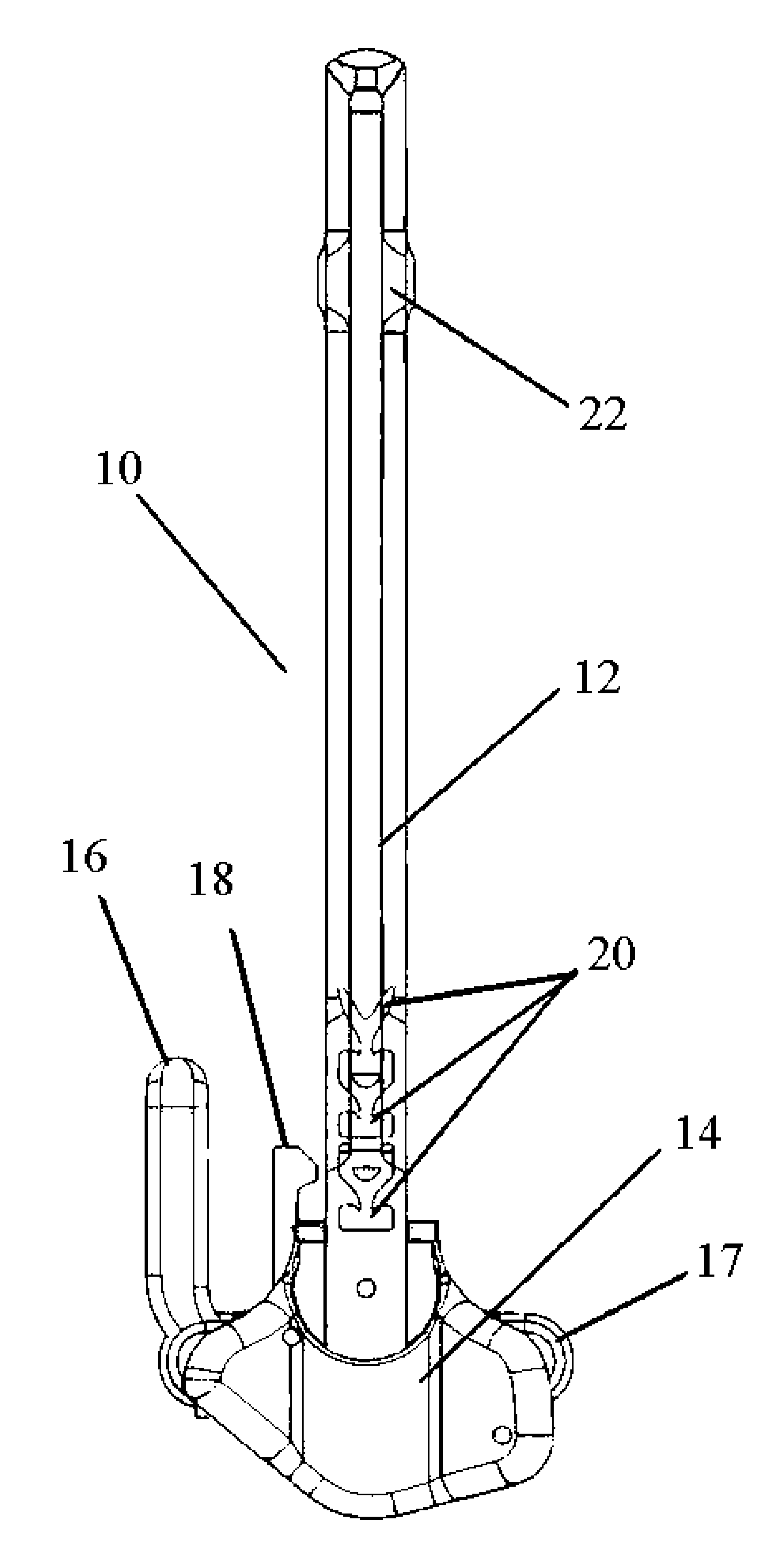

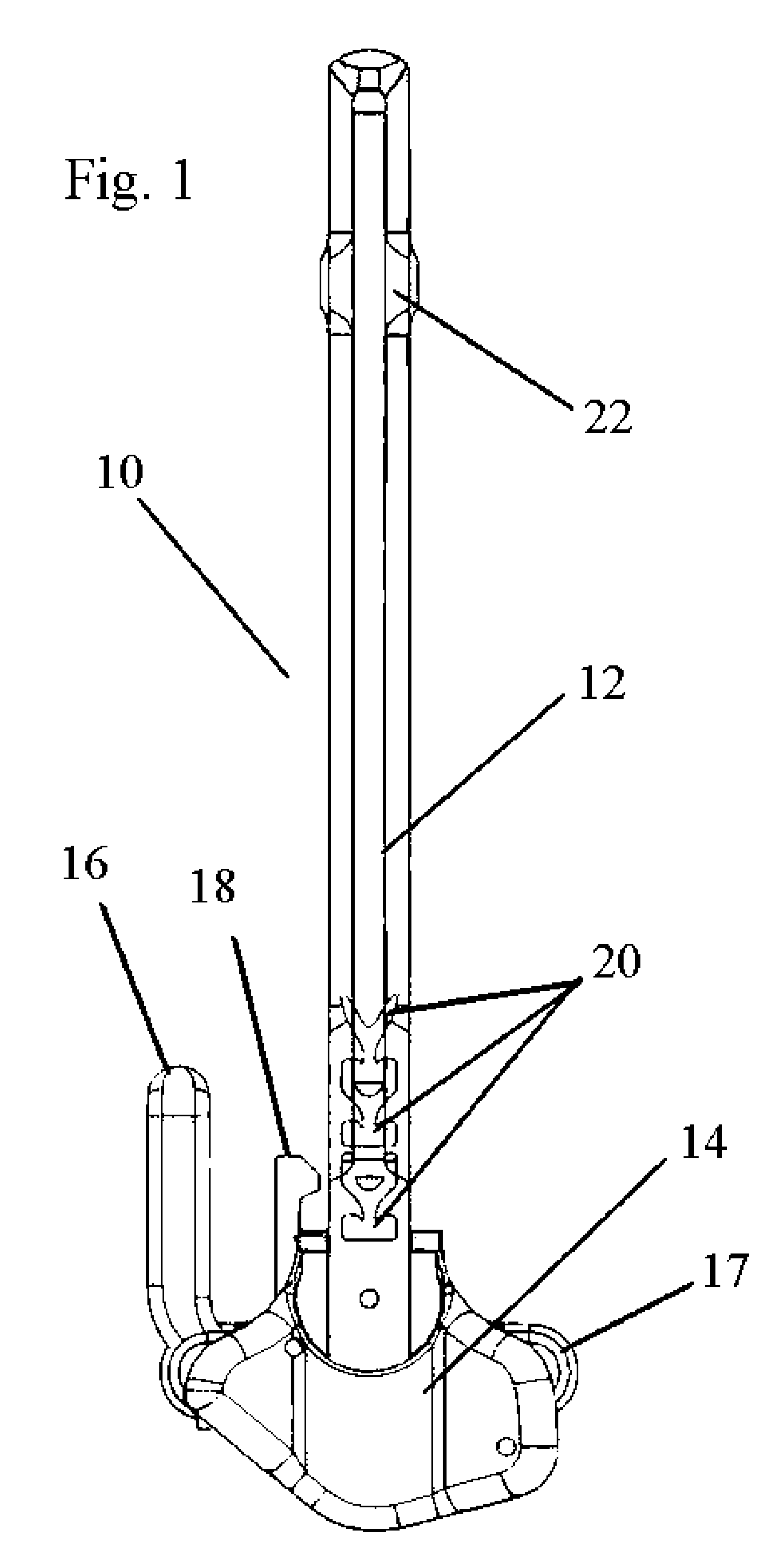

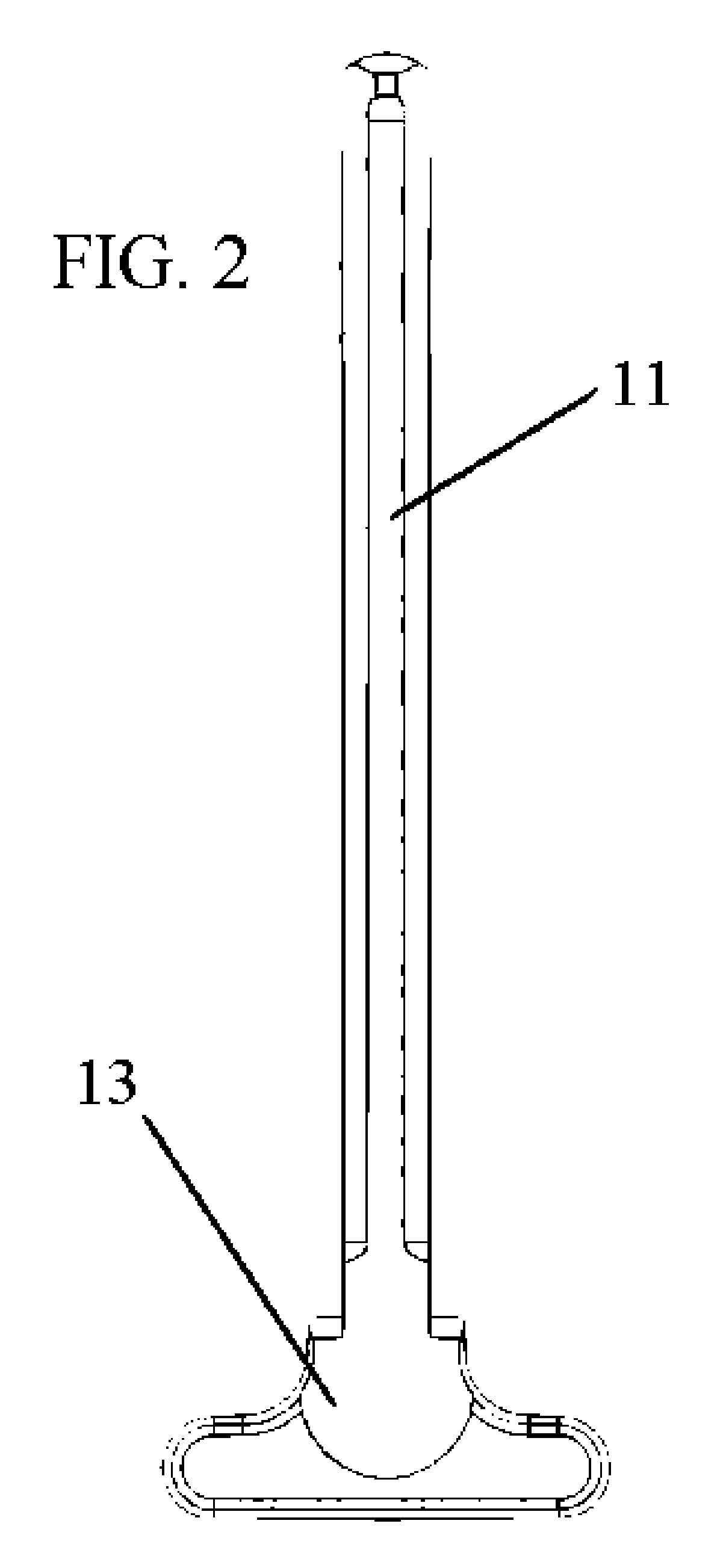

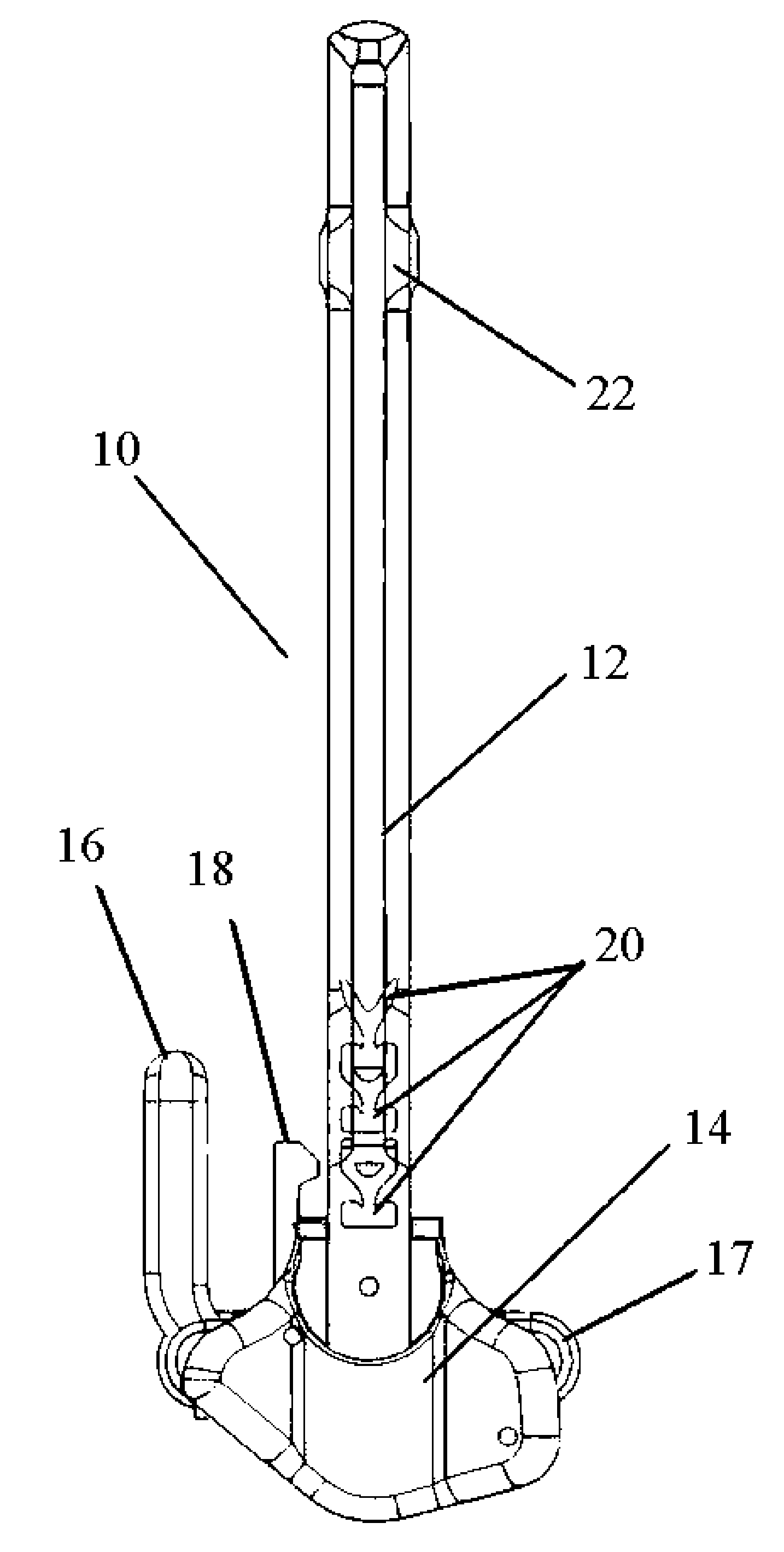

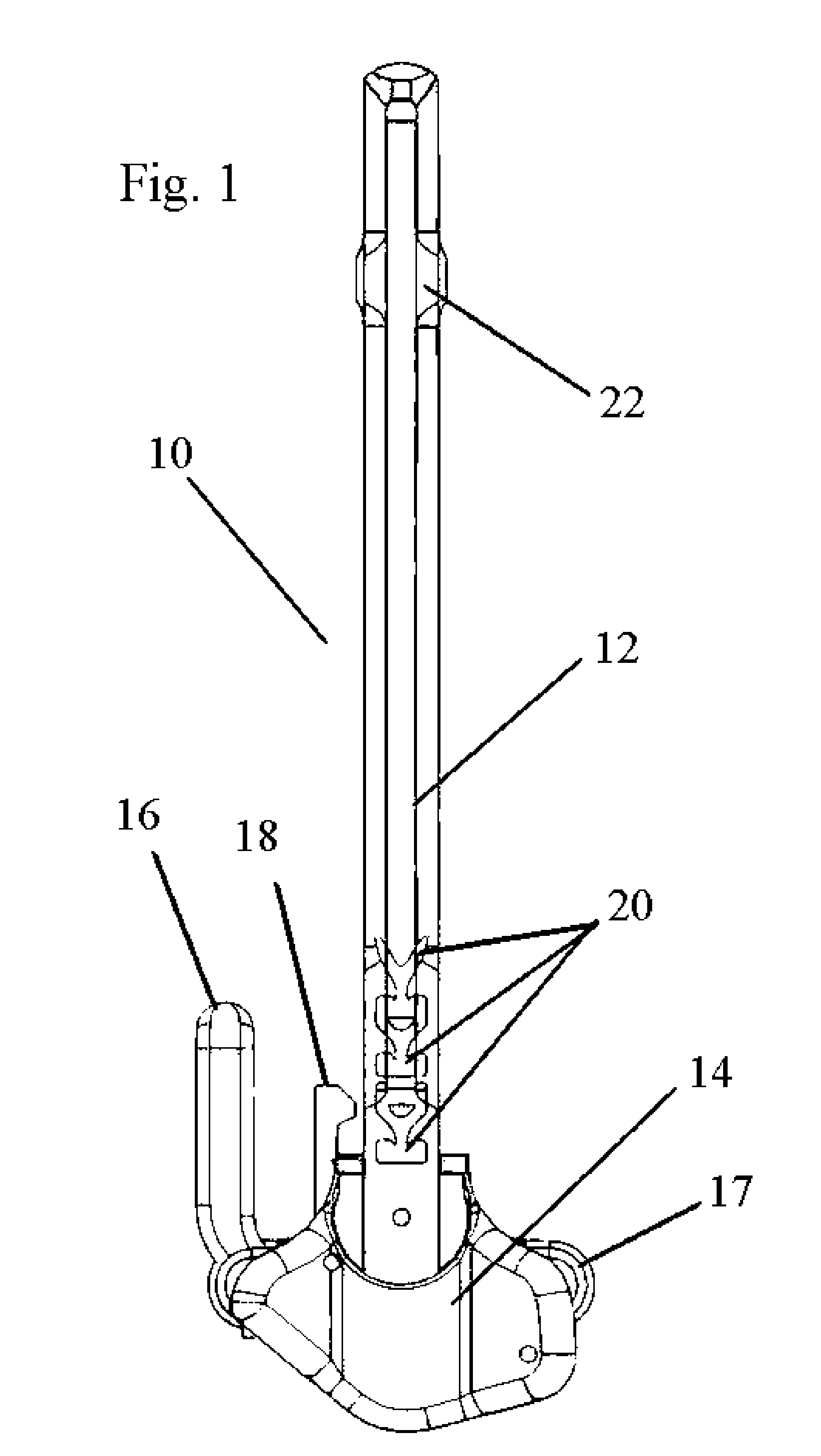

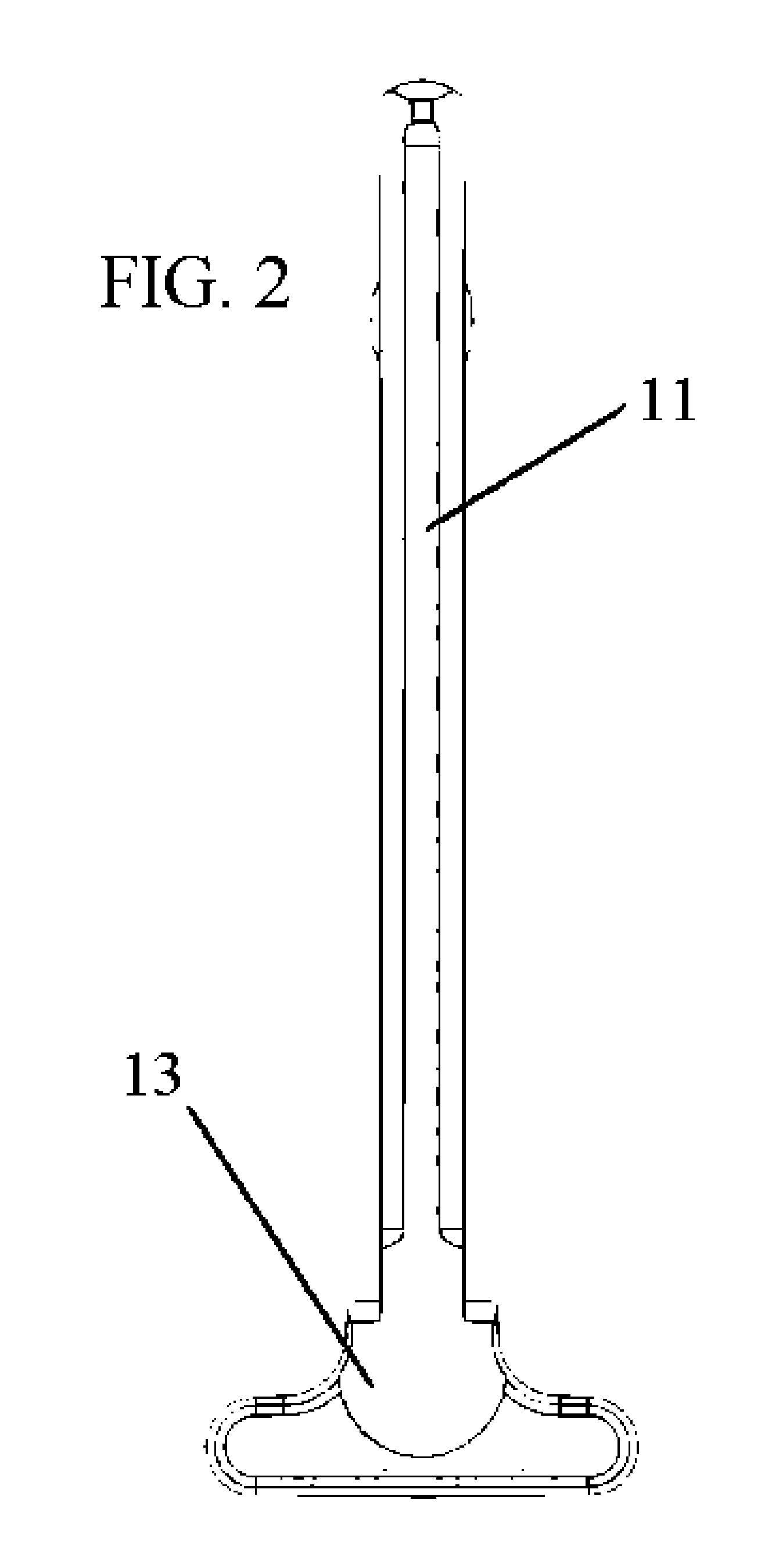

Charging handle for automatic rife

ActiveUS8261649B2Easy to startPowerfulFiring/trigger mechanismsRifleElectrical and Electronics engineering

Owner:MAGPUL INDUSTRIES

Charging Handle for Automatic Rife

ActiveUS20110226120A1Easy to startGreat leverageFiring/trigger mechanismsRifleElectrical and Electronics engineering

Owner:MAGPUL INDUSTRIES

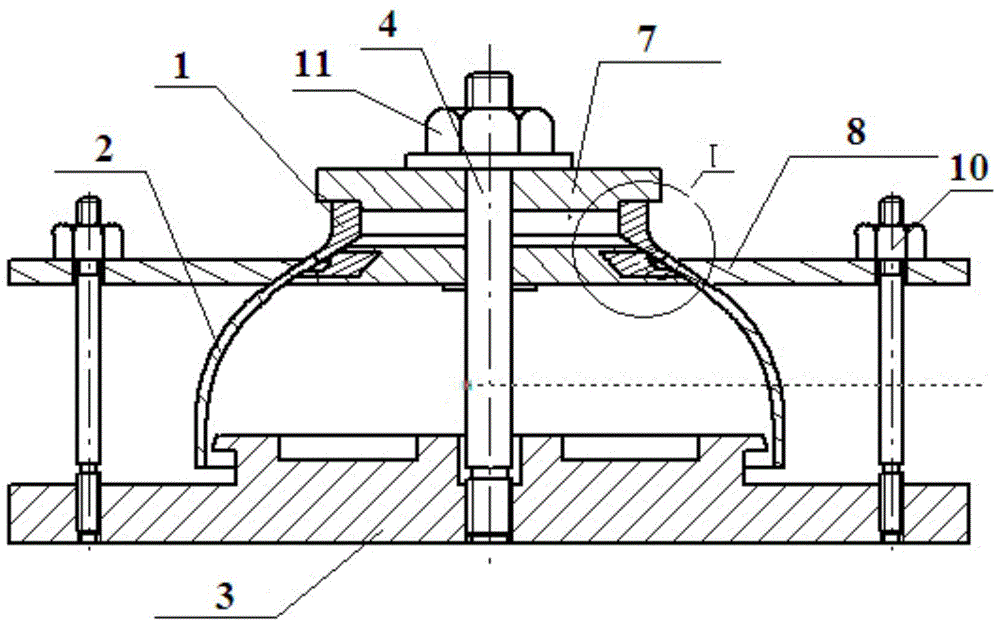

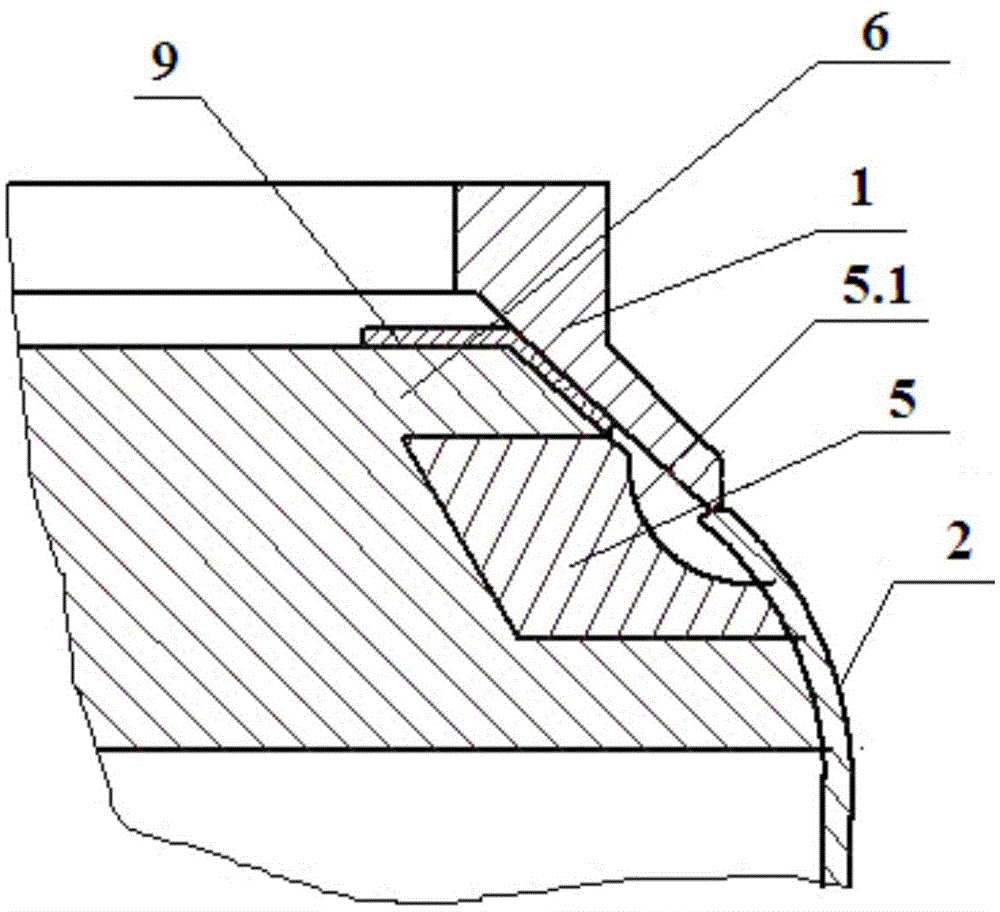

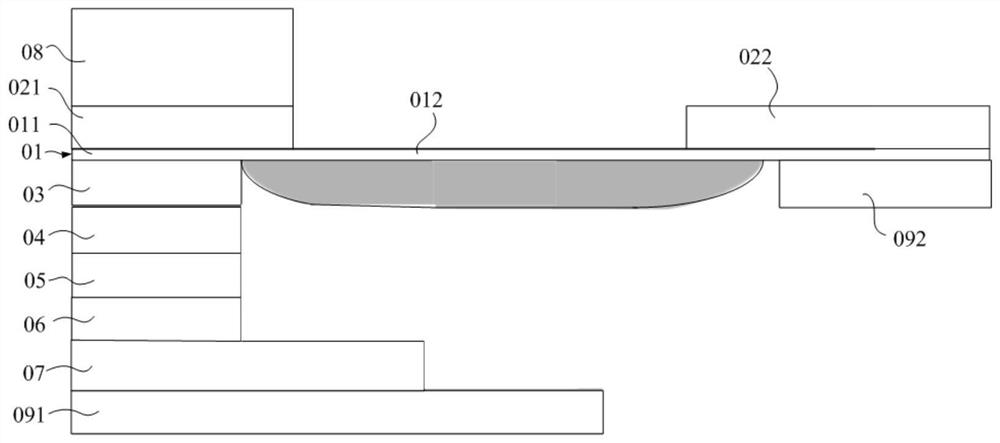

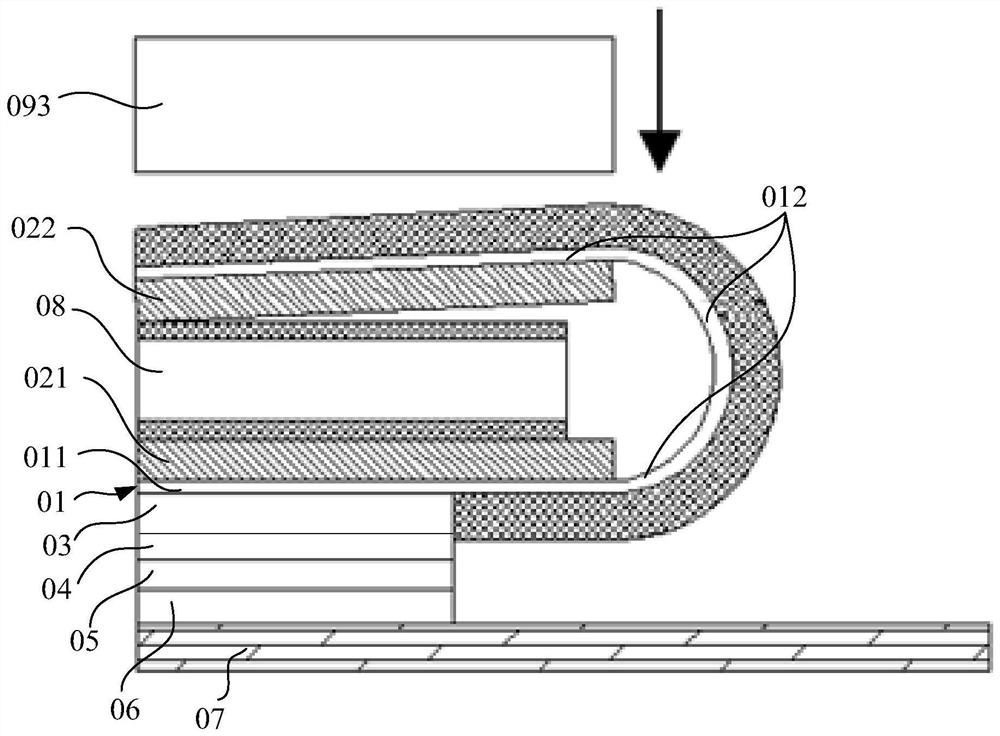

Welding process for ensuring smooth transition and molding of ellipsoidal circular seam and auxiliary welding clamp thereof

InactiveCN104475934AGuaranteed surface shapingControl welding deformation directionWelding/cutting auxillary devicesArc welding apparatusCombustion chamberCopper

The invention discloses a welding process for ensuring smooth transmission and molding of an ellipsoidal circular seam. The welding process comprises the following steps: 1) pre-setting a welding groove structure; 2) assembling a joint and an ellipsoid to an auxiliary welding clamp as follows: butting the ellipsoid with a to-be-welded end surface of the joint, adhering the ellipsoid with the lower part of a positioning block fixed on a core rod by virtue of an ellipsoidal pressure plate, adhering the joint with the upper part of the positioning block by virtue of a joint pressure plate, and ensuring a circular seam to-be-welded part of the ellipsoid and the joint to be corresponding to an arc-shaped groove on a ring-shaped copper pad in the middle of the positioning block; 3) respectively performing positioned welding, non-wired backing welding, wired cosmetic welding, non-wired re-melting welding; and 4) slowly cooling and performing annealing thermal treatment. The invention further discloses an auxiliary welding clamp designed for realizing the method. By pre-setting the welding groove structure and the auxiliary welding clamp, dislocation caused by welding shrinkage of the ellipsoidal surface can be balanced out reversely, and the inner surface of the welding seam can be ensured to be molded very well.

Owner:湖北三江航天江北机械工程有限公司

Method for optimization of pipe integrated numerical control machining process

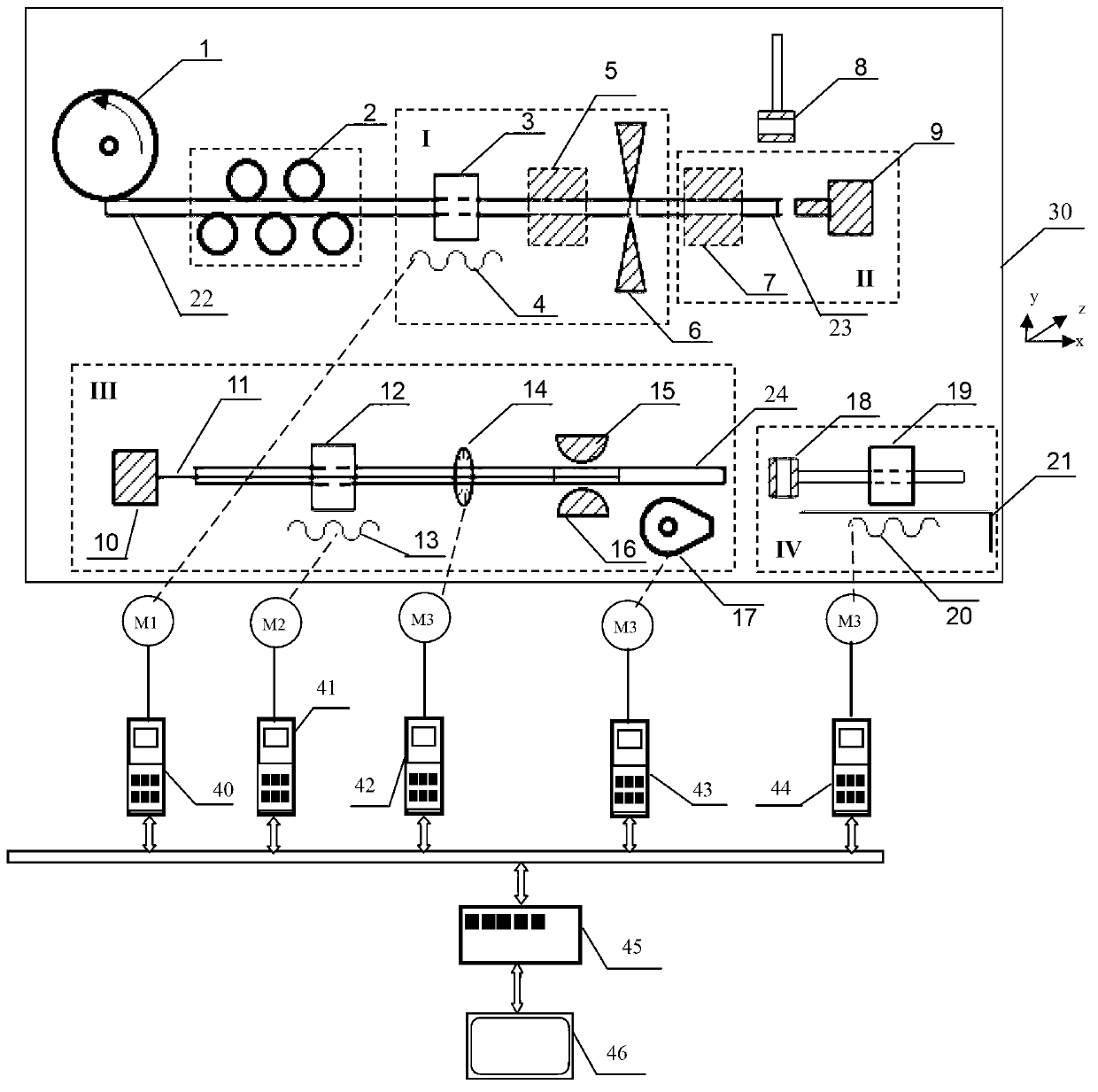

InactiveCN103341521AImprove production efficiencyImprove processing qualityMetal-working feeding devicesStripping-off devicesNumerical controlMotor drive

The invention provides a method for optimization of a pipe integrated numerical control machining process. The method comprises the following steps of rough shape cutting, pipe end molding, bend pipe molding, and split charging and discharging. A controller transmits control signals to servo drivers ((40)-(44)). The servo drivers drive motors (M1-M5) on processing devices and the motors drive the corresponding processing devices to work so that high-precision processing is finished. The method can automatically realize integrated numerical control machining or any combined machining such as pipe rough shape cutting and feeding, chipless rough shape cutting, spinning pipe end molding, bend pipe and manipulator automatic-feeding, three-dimensional bend pipe and manipulator automatic-discharging according to drawing information only by manual introduction of a pipe to a material picking opening of a machine tool, can avoid complex processing adopting multiple machine tools and multiple processing steps, can realize continuous automatic production, can improve production benefits and processing quality of pipe production, and can be used for bending molding processing of pipes used in the industries of air conditioners, water heaters, refrigerators or automobiles.

Owner:WUHAN UNIV OF TECH

Fuel assembly and thimble screw of the same

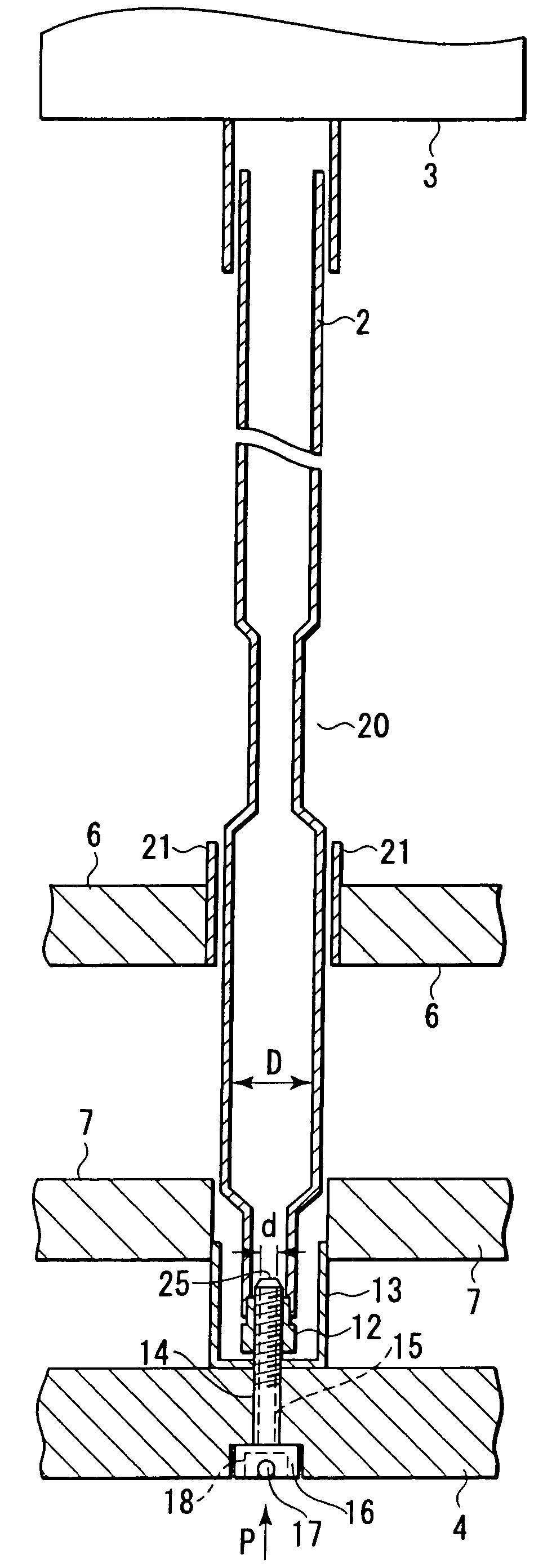

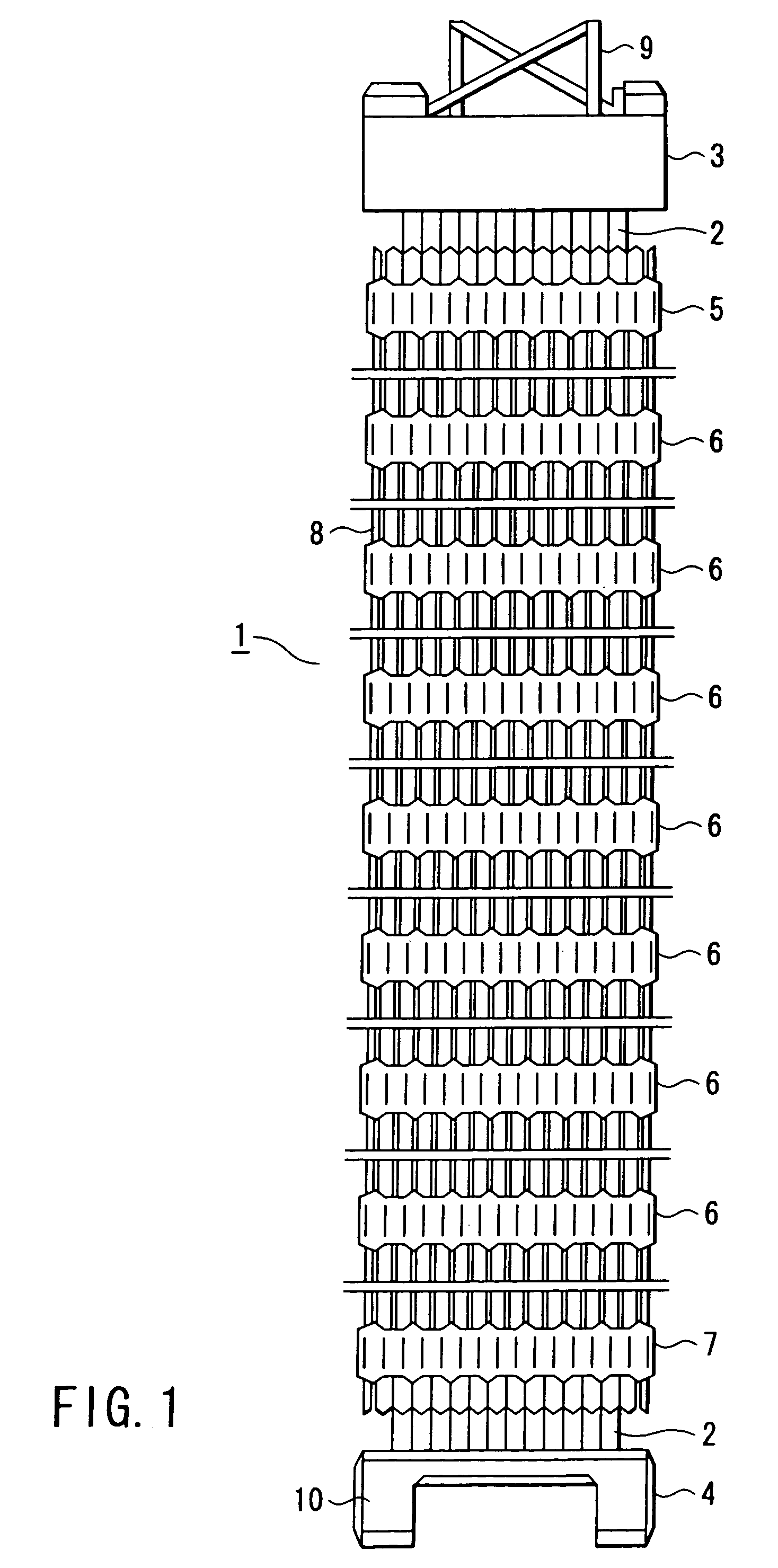

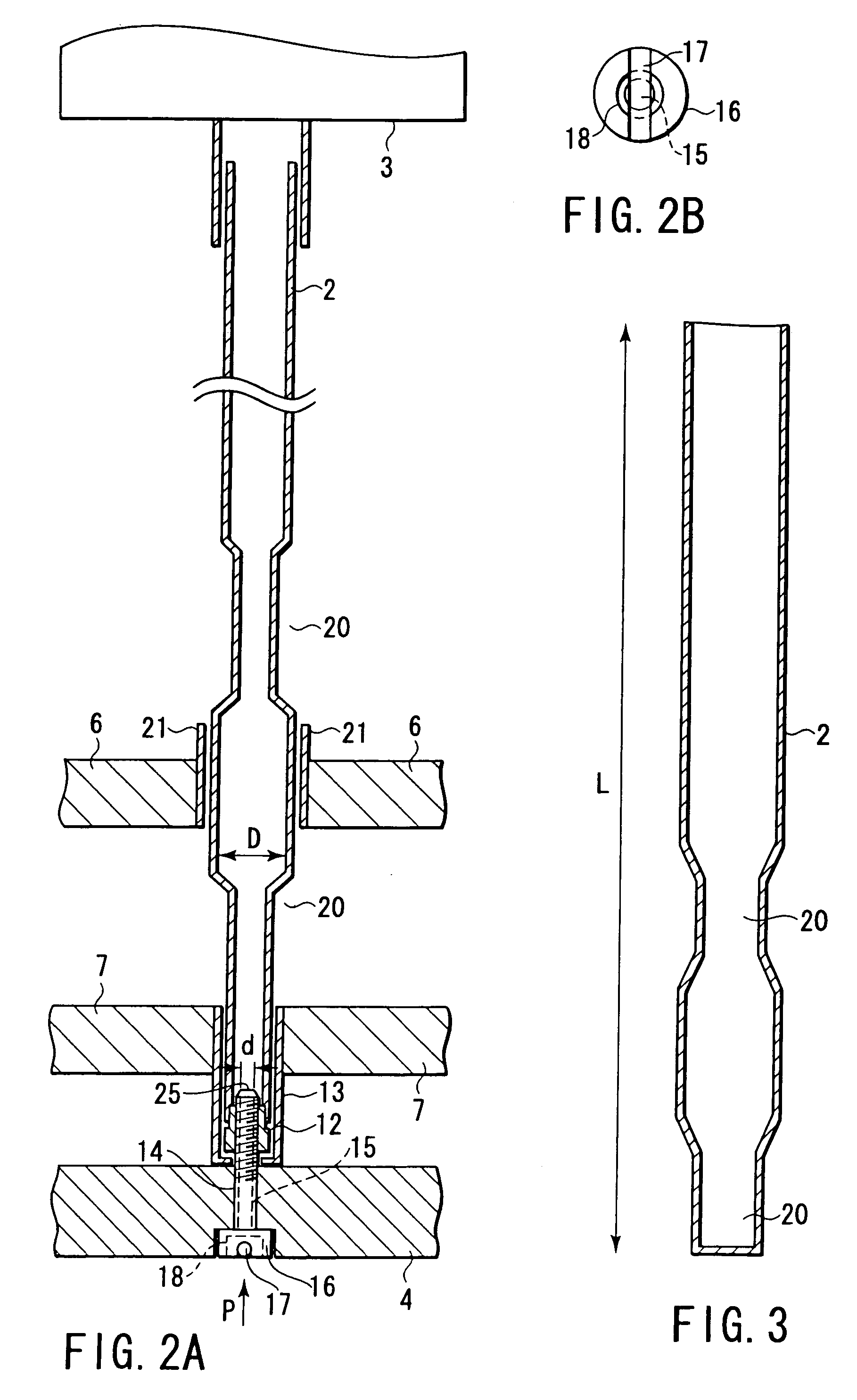

InactiveUS7257185B1Avoid bending deformationAvoid deformationNuclear energy generationFuel element assembliesNuclear reactorDashpot

A fuel assembly includes a bottom nozzle set on a lower core plate of a nuclear reactor, a top nozzle with a hold down spring to urge the bottom nozzle against the lower core plate, guide thimbles which guide control rods, having passed through the top nozzle, toward the lower core plate, a dashpot formed on each of the guide thimbles to reduce the fall velocity of a corresponding one of the control rods, a thimble screw which connects each of the guide thimbles to the bottom nozzle, and a drain hole formed to extend through each of the thimble screw. The dashpot has a large-diameter portion with substantially the same diameter as that of each of the guide thimbles. The diameter d of the drain hole falls within a range of 0.04 D<d<0.08 D where D is an inner diameter of the large-diameter portion.

Owner:MITSUBISHI HEAVY IND LTD

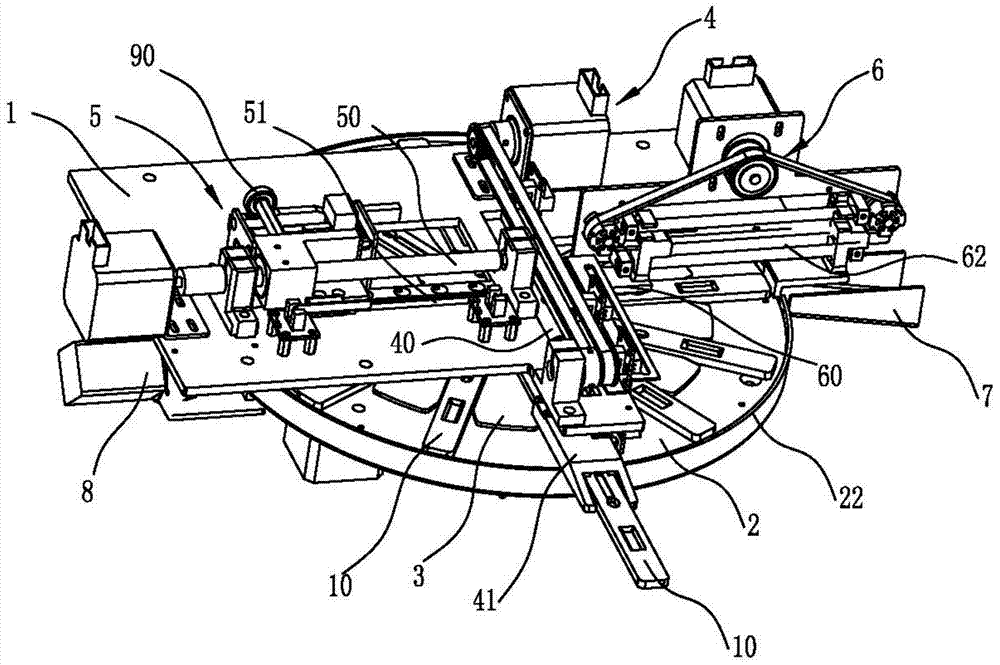

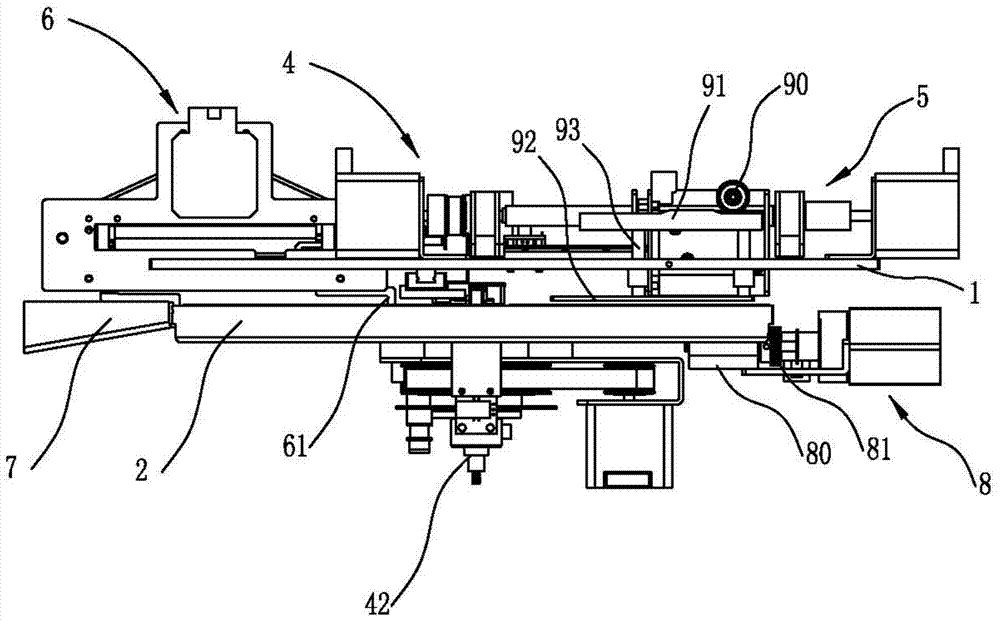

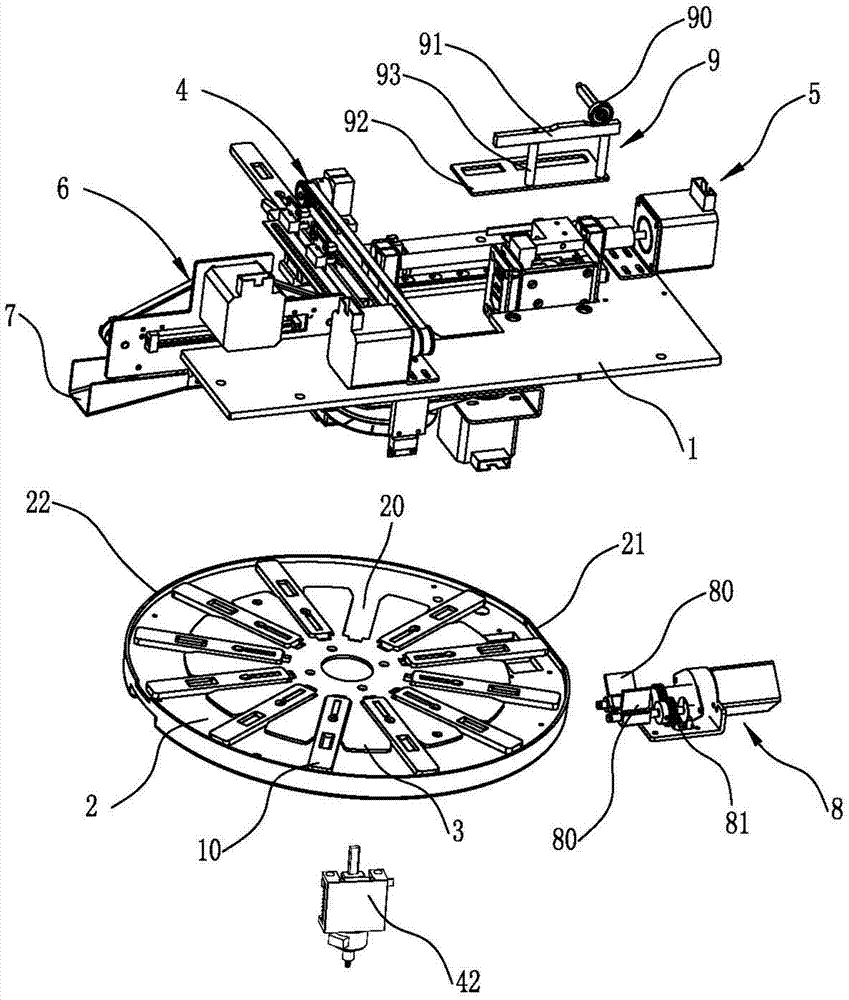

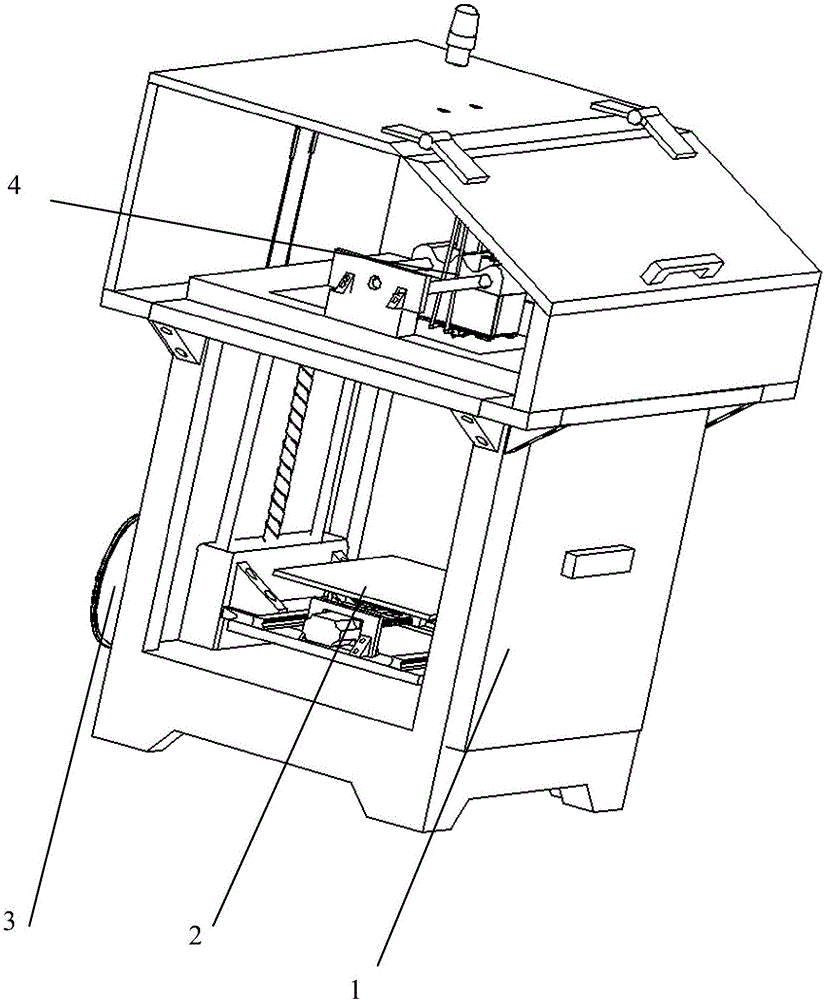

Stereotaxic localization rotating disc type multi-project dry-type fluorescence detector

ActiveCN104849445AImprove reliabilityImprove stabilityBiological testingFluorescence/phosphorescenceFluorescenceEngineering

The invention discloses a stereotaxic localization rotating disc type multi-project dry-type fluorescence detector. The stereotaxic localization rotating disc type multi-project dry-type fluorescence detector comprises a mounting plate, a testing card bearing plate, a card pulling device, a card entry device, a card reading detection device, a card exit device, a card pressing device and a card clamping device, wherein the mounting plate is fixedly arranged, the testing card bearing plate is fixedly arranged under the mounting plate, the card pulling device is rotationally overlapped on the testing card bearing plate, a card groove for preventing a testing card from sliding is formed in the testing card bearing plate, the testing card is radially conveyed to the clamping groove by the card entry device, the card reading detection device moves radially to detect the testing card, a baffle plate for preventing the testing card from sliding out of the card groove is arranged on the testing card bearing plate, the card pressing device can press the testing card when the card reading detection device performs detection, the card clamping device clamps the testing card from two sides and rights the testing card before the card reading detection device performs detection, and the testing card can be conveyed out of the card groove by the card exit device. According to the stereotaxic localization rotating disc type multi-project dry-type fluorescence detector, the detection error can be avoided, and the reliability and the stability of the detector are improved.

Owner:GUANGZHOU LABSIM BIOTECH CO LTD

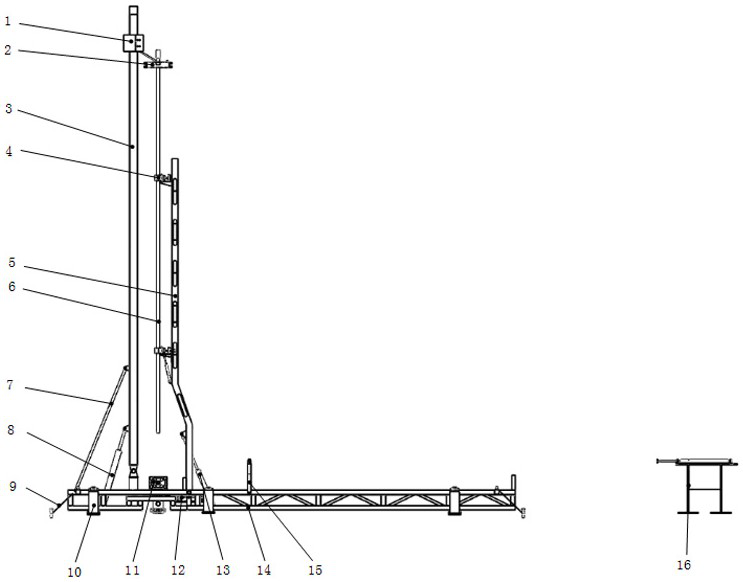

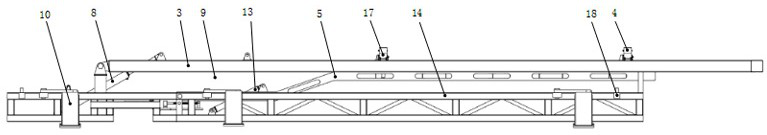

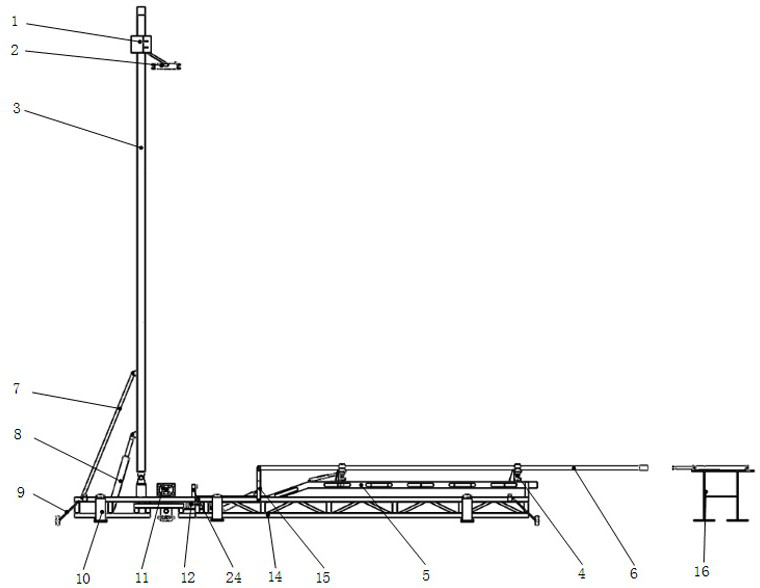

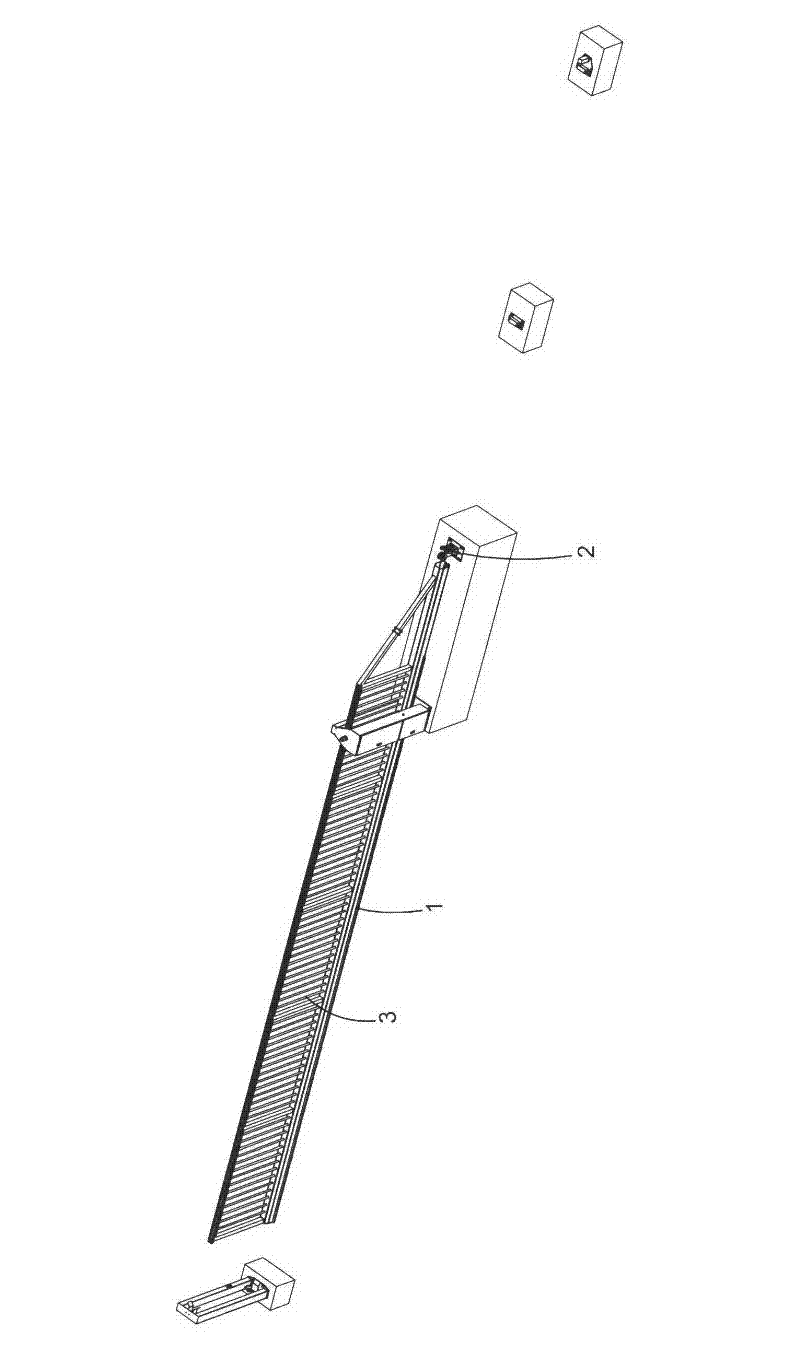

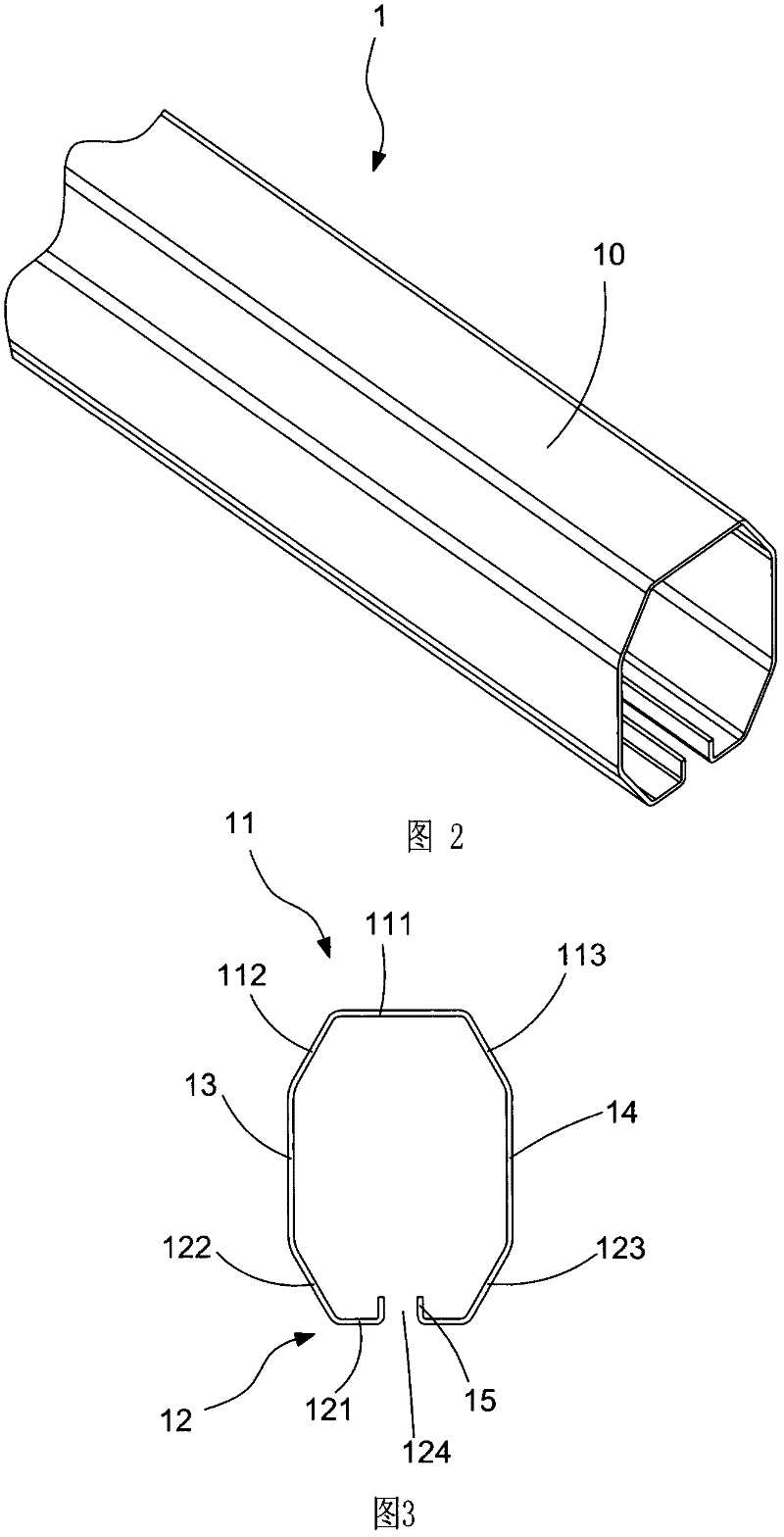

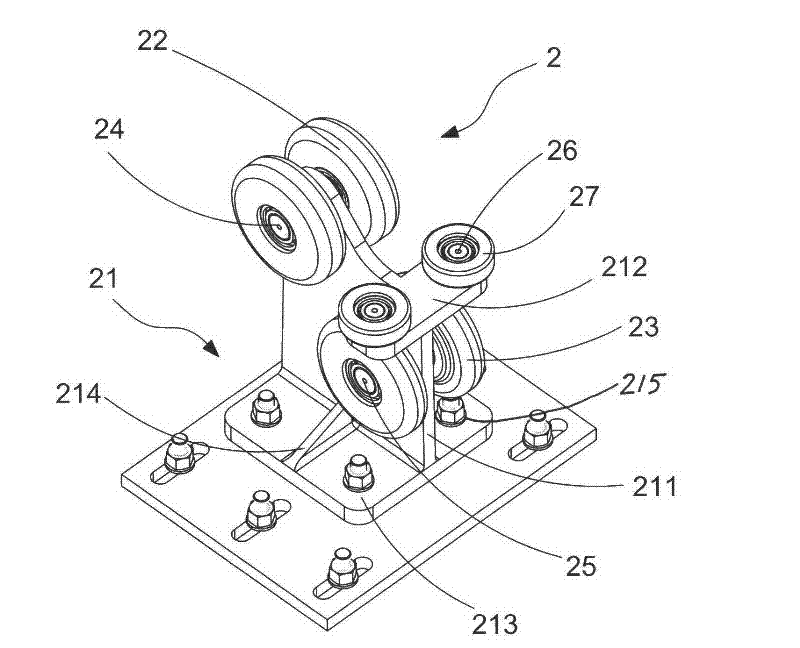

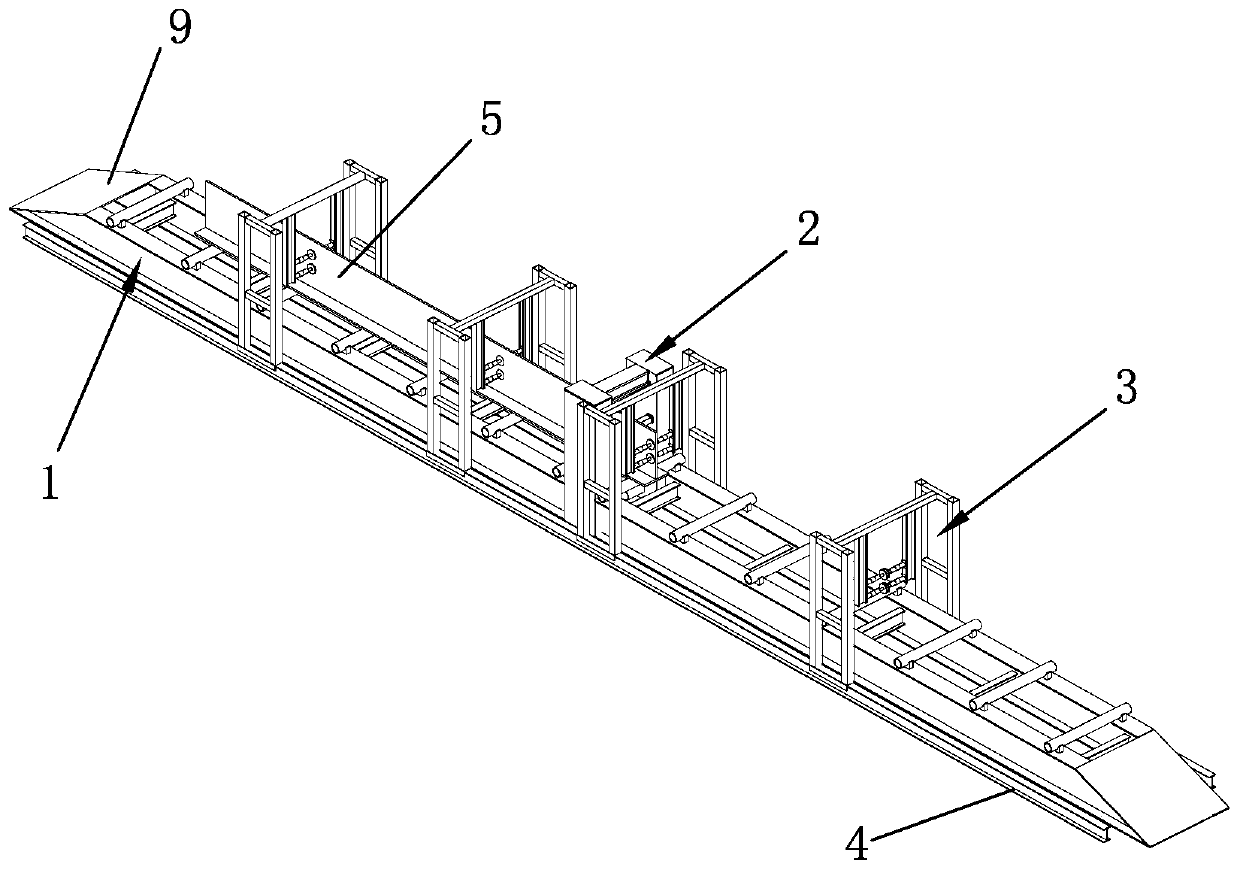

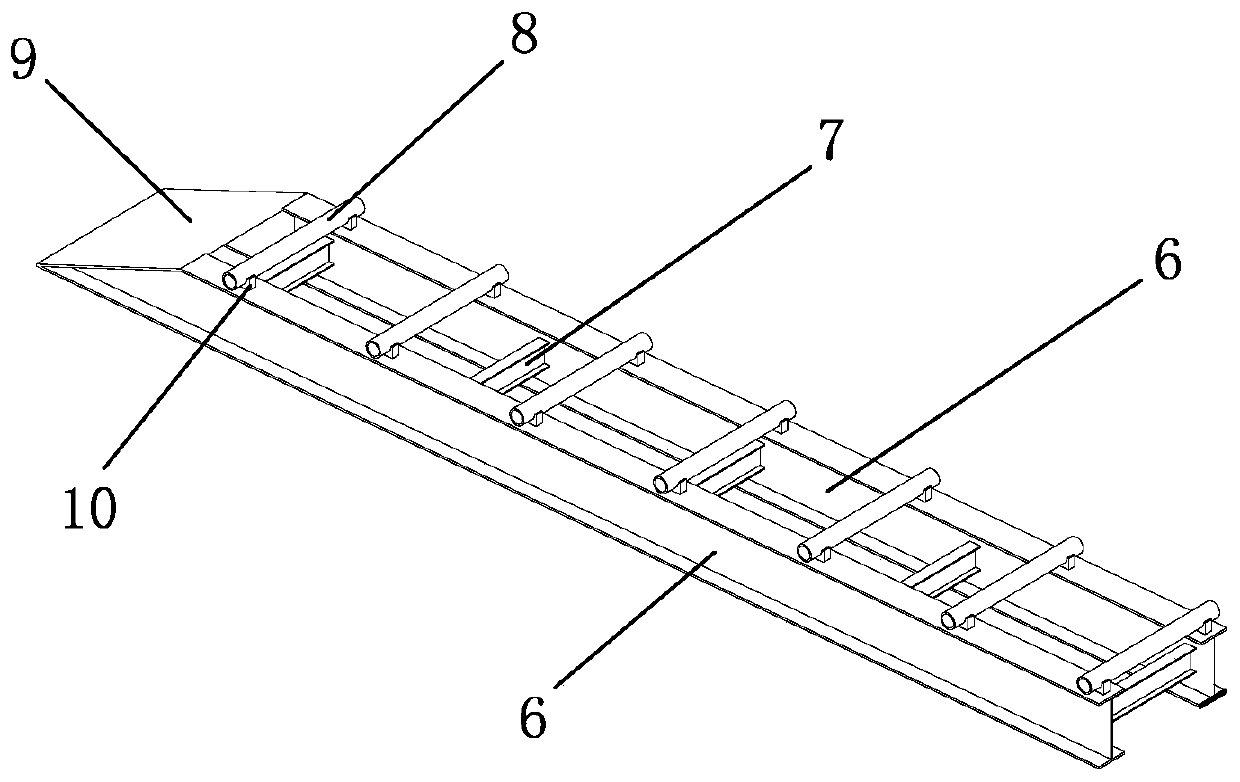

Wellhead positioned integrated guide vertical well repair catwalk and application method

ActiveCN111927347ARealize direct deliveryImprove work efficiencyDrilling rodsDrilling casingsMechanical engineeringSucker rod

The invention relates to a wellhead positioned integrated guide vertical well repair catwalk and an application method. According to the technical scheme of the wellhead positioned integrated guide vertical well repair catwalk, the two sides of a base are connected with a plurality of hydraulic supporting legs and a plurality of ground anchors and used for supporting the vertical catwalk; a lifting arm cylinder is hinged to a lifting arm; a guide rod is hinged to a guide rod cylinder; a guide rod diagonal brace is hinged to the guide rod; the lifting arm cylinder can drive the lifting arm to be turned over from the horizontal state to the vertical state; the guide rod cylinder can drive the guide rod to be turned over from the horizontal state to the vertical state; the guide rod diagonalbrace can make the guide rod maintain the vertical state; and the guide rod diagonal brace can be taken down in a transportation state for independent storage. The wellhead positioned integrated guidevertical well repair catwalk has the beneficial effects that an oil pipe or a sucker rod is turned over by 90 degrees and conveyed to above a wellhead instead of an original lifting mode; the intermediate link that the oil pipe or the sucker rod in an original lifting catwalk is conveyed to the wellhead and is in an inclined state is omitted; and the oil pipe or the sucker rod is directly conveyed from the horizontal state to the vertical state, and the working efficiency in the catwalk is improved.

Owner:SLOF KANGBEI IND & TRADING

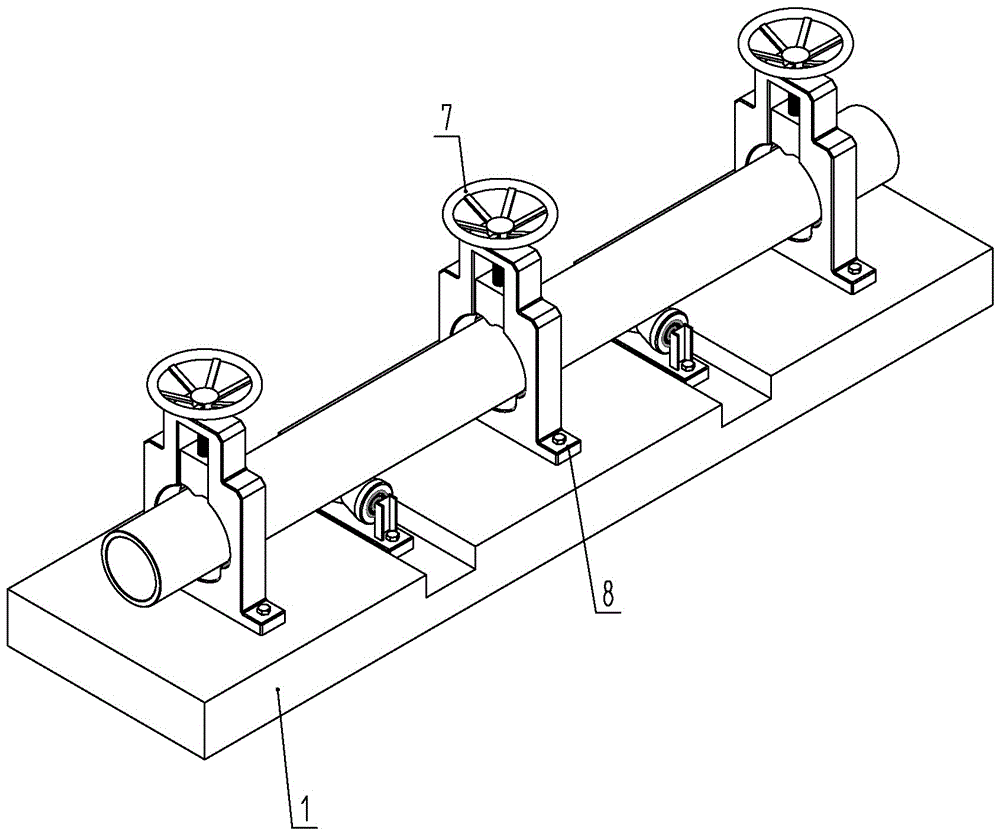

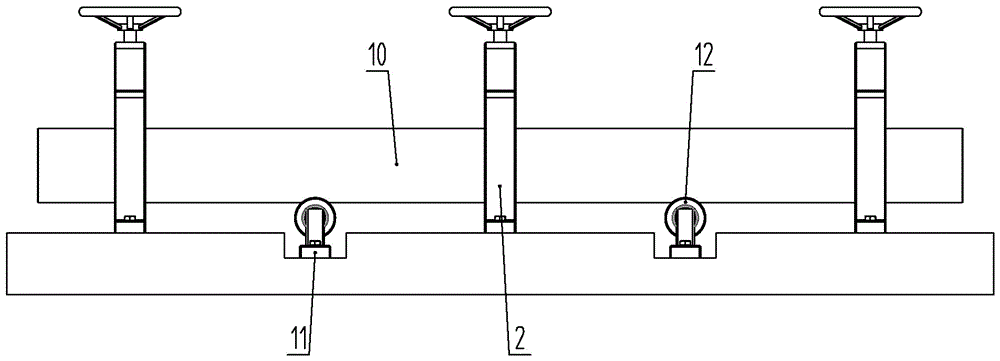

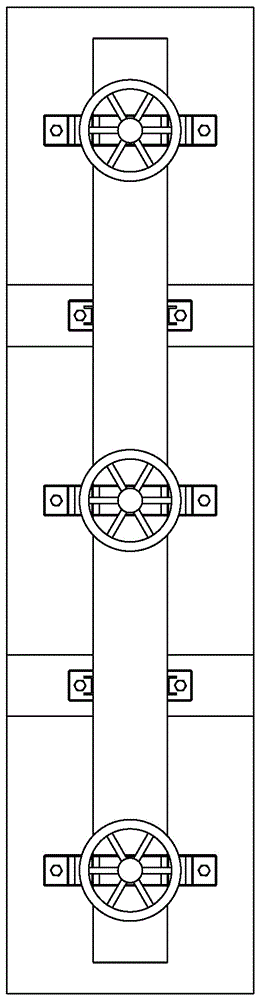

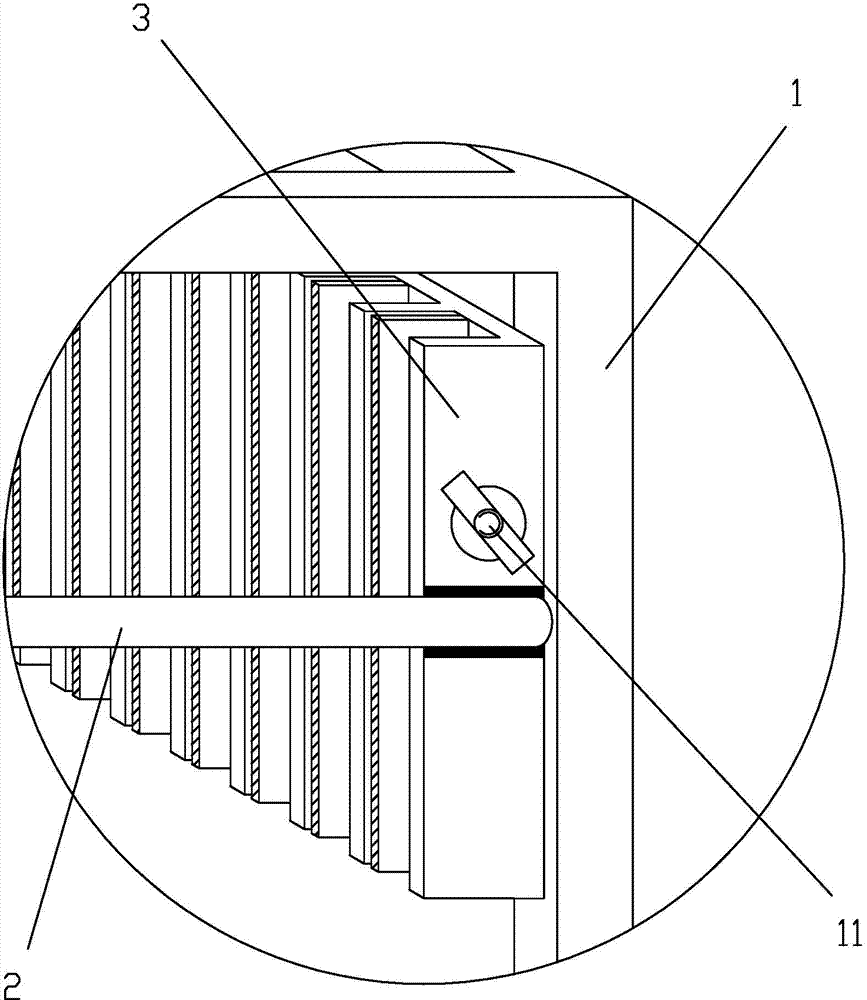

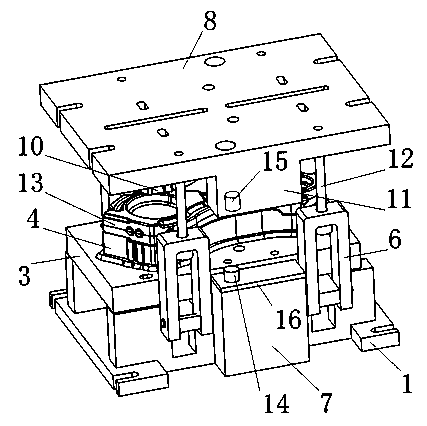

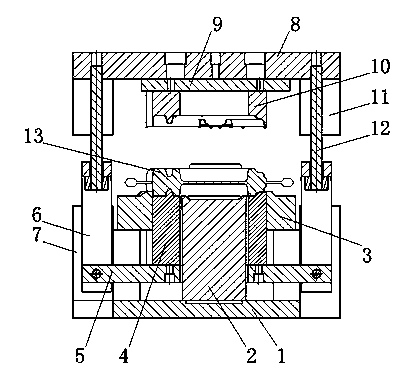

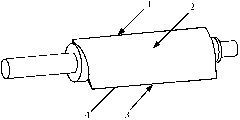

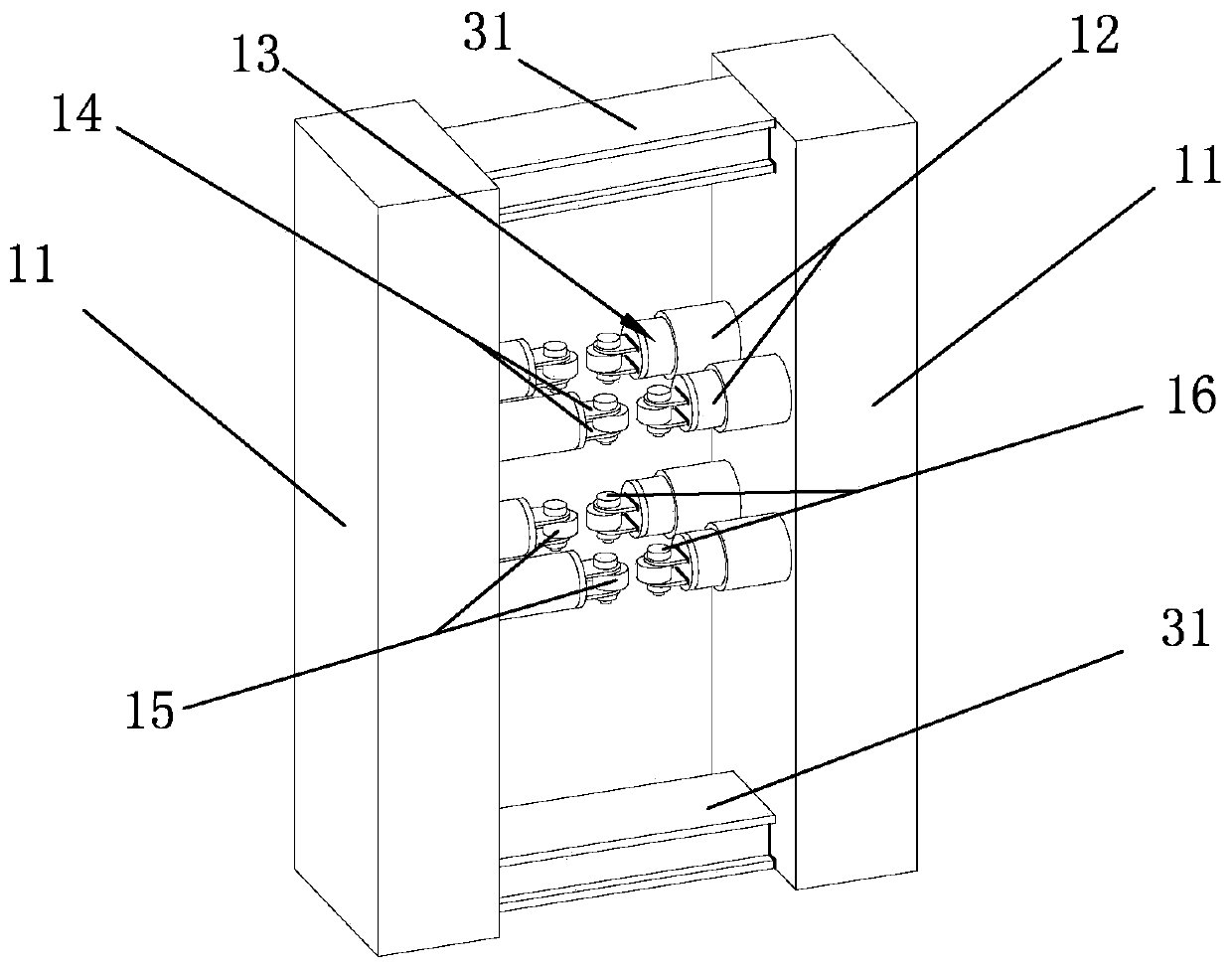

Auxiliary clamping mechanism for tubular and rod workpieces

InactiveCN105710677AAvoid bending deformationAvoid vibrationPositioning apparatusMetal-working holdersLocking mechanismEngineering

The invention discloses an auxiliary clamping mechanism for tubular and rod workpieces. The auxiliary clamping mechanism comprises a base, at least two positioning mechanisms which are coaxially arranged and assembled on the base in a sliding manner, and a locking mechanism capable of fixing the positioning mechanisms and a conveying mechanism to the base. The auxiliary clamping mechanism has the beneficial effects that through a tool, auxiliary positioning clamping of tubular and rod workpieces can be achieved, the workpieces are prevented from bending and deforming due to gravity, and coaxiality is improved; and the machining precision is improved, and vibration generated by high-speed rotation can be prevented. In addition, the beneficial effects of being simple in structure, high in practicability and the like are achieved.

Owner:句容五星机械制造有限公司

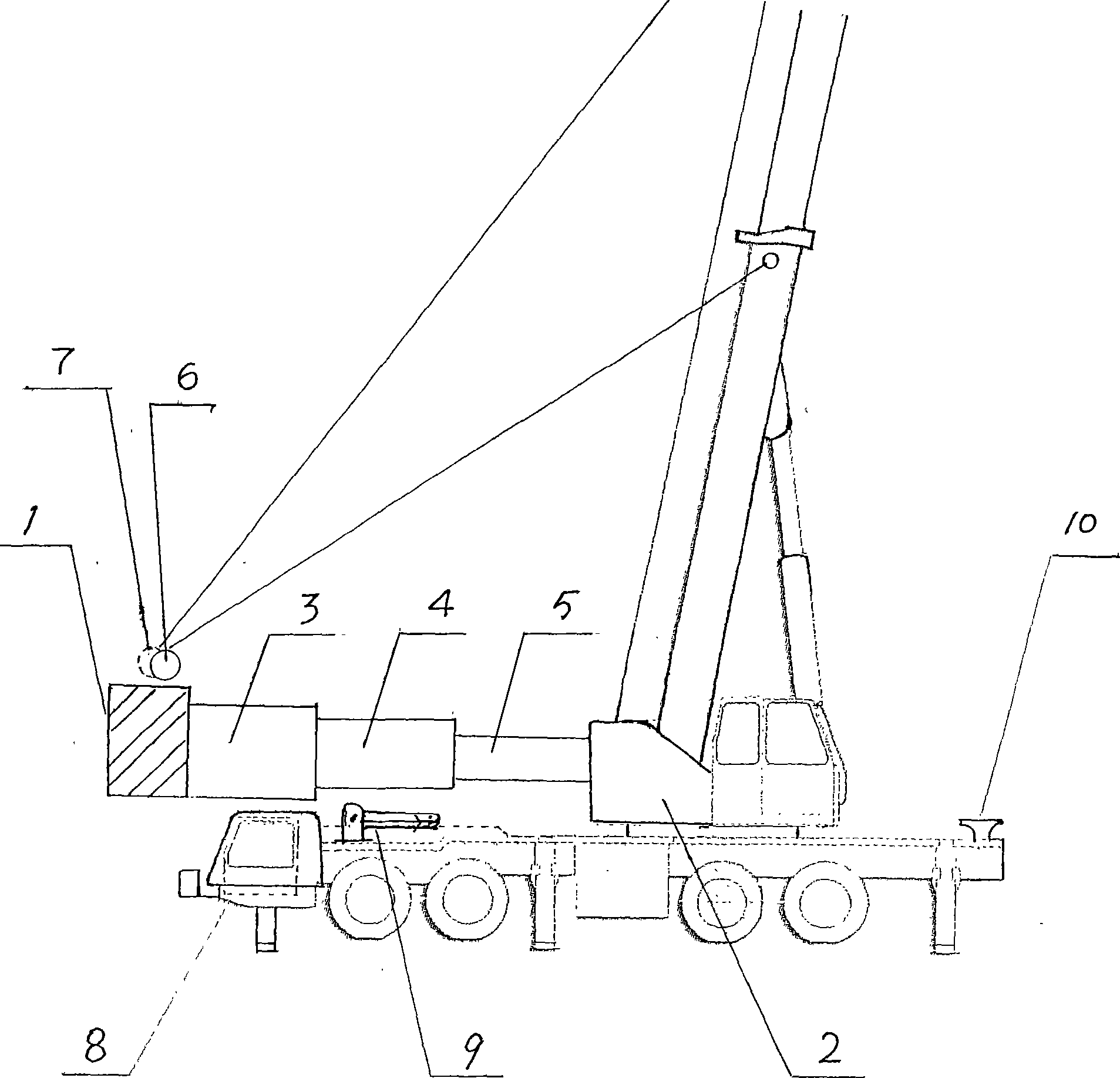

Wheel crane mobile counterweight

Wheel crane mobile counterweight relates to a wheel crane. In order to improve the structure form of the wheel crane counterweight, reduce the self-weight of a suspension arm, increase lift height, increase amplitude and hoisting, in the invention, the counterweight moves backwards following a counterweight framework along with a retractable counterweight framework and a fixed counterweight framework; the horizontal distance from the gravity force of the counterweight to a turret is increased; the stresses of the front and back supporting points of the turret reaches a relative balance by increasing the external load of the turret; and the steel wire ropes of a main suspension arm hoisting machine and a movable suspension arm hoisting machine are respectively connected with the ends of the suspension arm; due to the switch and the steel wire rope static locking device of the hoisting machine that linked with the counterweight and the suspension arm, the counterweight, the suspension arm and the turret keep a triangular structure, thus preventing the counterweight framework and the suspension arm from being bent and improving the overall stability of the crane; by applying a retractable cab, a foldable suspension arm support and a counterweight fixed device, the safety and flexibility of the crane is not effected by the movable counterweight.

Owner:艾凯

Sealed multi-material special engineering plastic additive manufacturing method and apparatus

ActiveCN106553337AImprove support strengthIncreased resistance to deformationManufacturing heating elementsManufacturing material handlingSelective laser sinteringManufacturing technology

The invention relates to sealed multi-material special engineering plastic additive manufacturing method and apparatus and belongs to the technical field of additive manufacturing of special engineering plastic. A three-axis movement platform assembly is installed inside a thermal insulation chamber assembly. A special engineering plastic filament delivery roll assembly is installed in a back surface plate of the thermal insulation chamber assembly. A spray nozzle assembly is disposed on the top of interior of the thermal insulation chamber assembly. The method and the apparatus achieve low temperature difference and low deformation in 3D printing of special engineering plastic, so that parts in complex structures, which have high crystalline degree, high mechanical strength and low surface roughness, can be formed from a high-melt-point special engineering plastic. Defects of large deformation, poor mechanical strength of a moulded part, and low size precision in a conventional high-temperature special engineering material printing process are overcome, and a defect of warping deformation during a powder moulding process in a selective laser sintering 3D printing technology is avoid. The method and the apparatus solve the problems such as high surface roughness in artificial bone 3D printing in the medical field, and have excellent medical and industrial application prospect.

Owner:JILIN UNIV

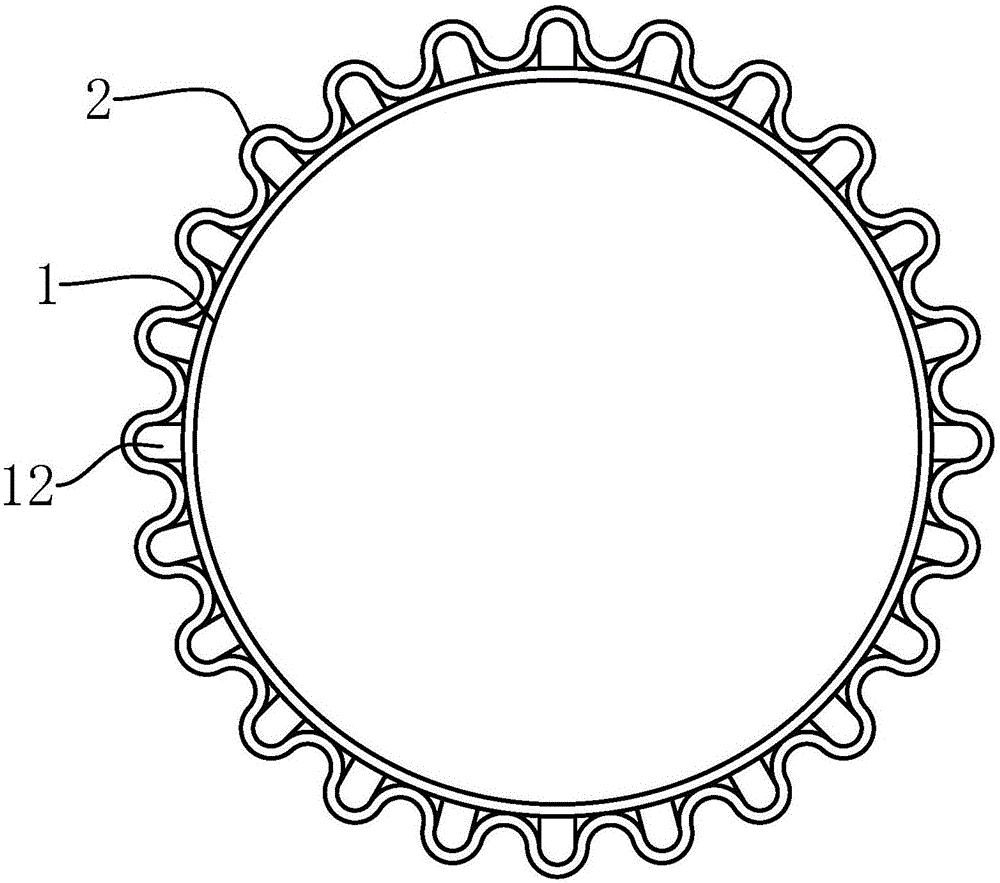

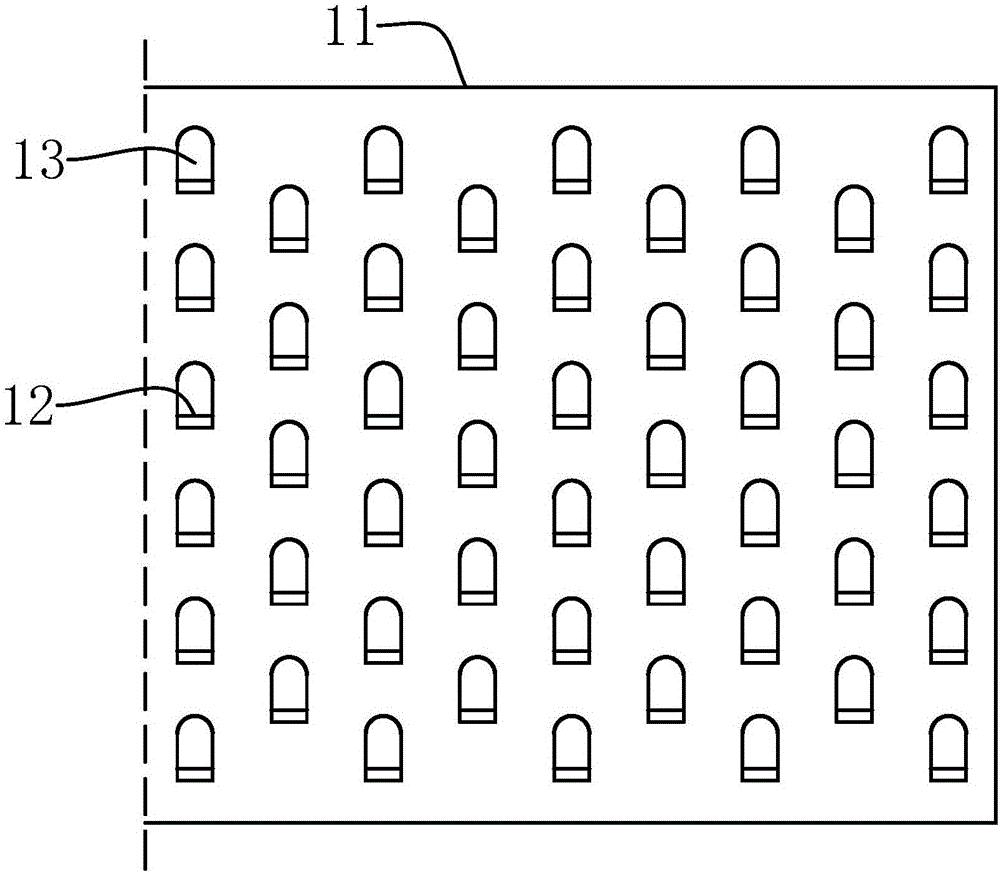

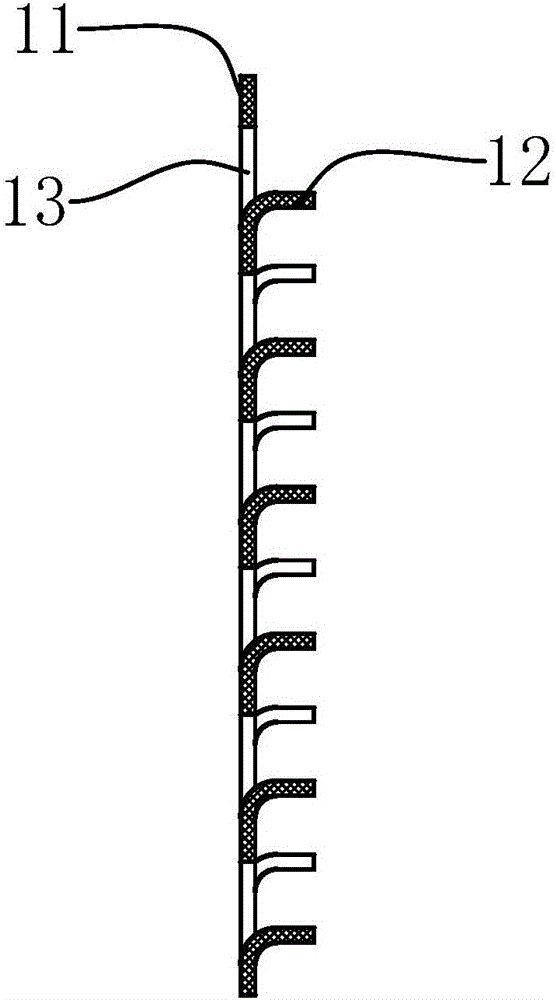

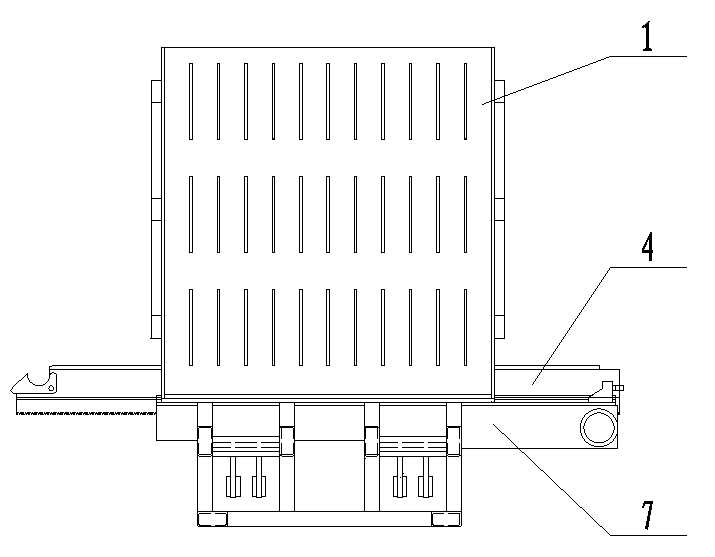

Air purifier filtration apparatus and production method thereof

ActiveCN106823601AAvoid bending deformationEasy to produceDispersed particle filtrationMembrane filtersFiltrationAir purifiers

The present invention provides an air purifier filtration apparatus and a production method thereof, and belongs to the field of air purifiers. A purpose of the present invention is to solve problems of instable structure and inconvenient production of the existing air purifier filtration apparatus. The air purifier filtration apparatus of the present invention comprises a cylindrical supporting cylinder, wherein the outer wall of the supporting cylinder is provided with a plurality of scale-like supporting sheets, the supporting cylinder is provided with supporting holes corresponding to the positions of the supporting sheets, the hole wall below the supporting hole is connected to the inner end of the supporting sheet, the air purifier filtration apparatus further comprises cylindrical filtration paper, the cross section of the filtration paper circumferentially forms a wave-like structure, the supporting sheets are supported at the corresponding wave peak positions of the cross section of the inner wall of the filtration paper, and the corresponding wave valley positions of the cross section of the inner wall of the filtration paper bear against the outer wall of the supporting cylinder. According to the present invention, wave form of the filtration paper can be well supported by the supporting sheets, such that the bending deformation of the filtration paper can be avoided; and the supporting holes can form the air inlet structure on the supporting cylinder, the supporting sheets can be naturally formed after the supporting holes are punched on the supporting cylinder, and the production is convenient through the production method of the present invention.

Owner:安徽奥雅纳科技有限公司

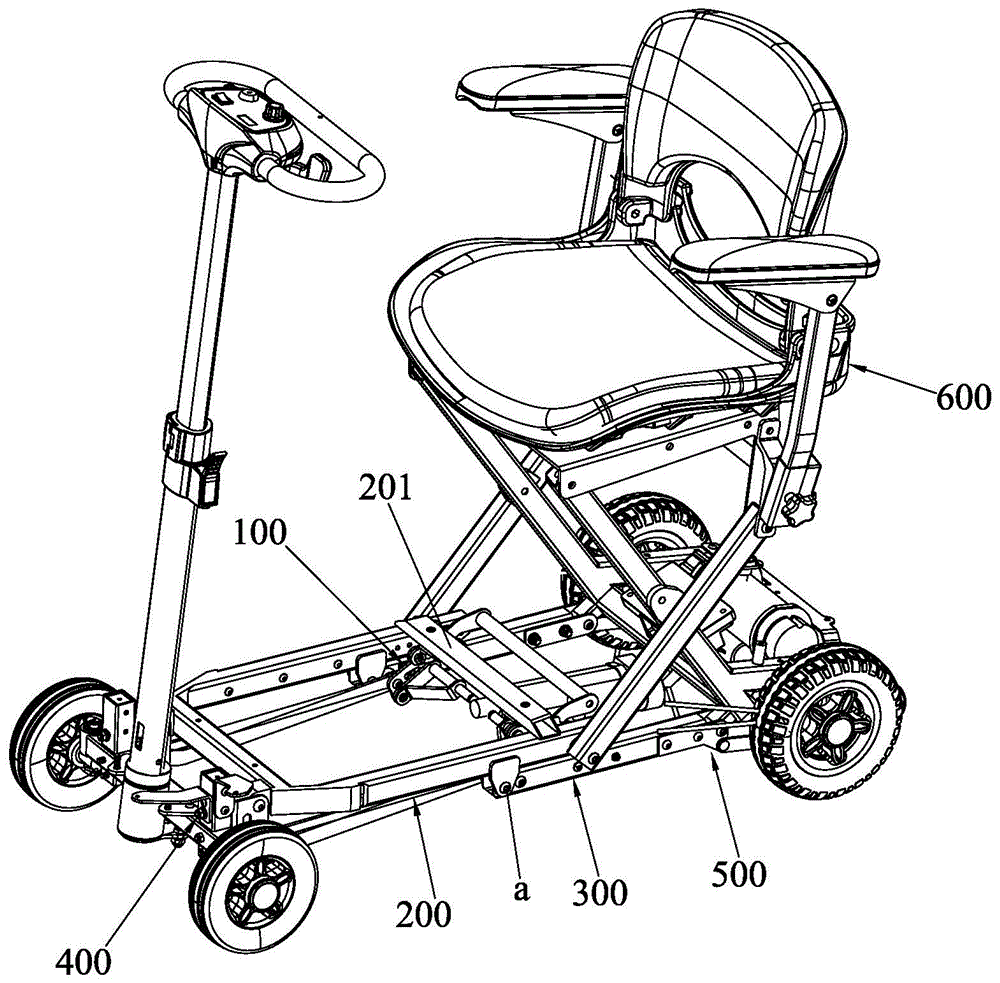

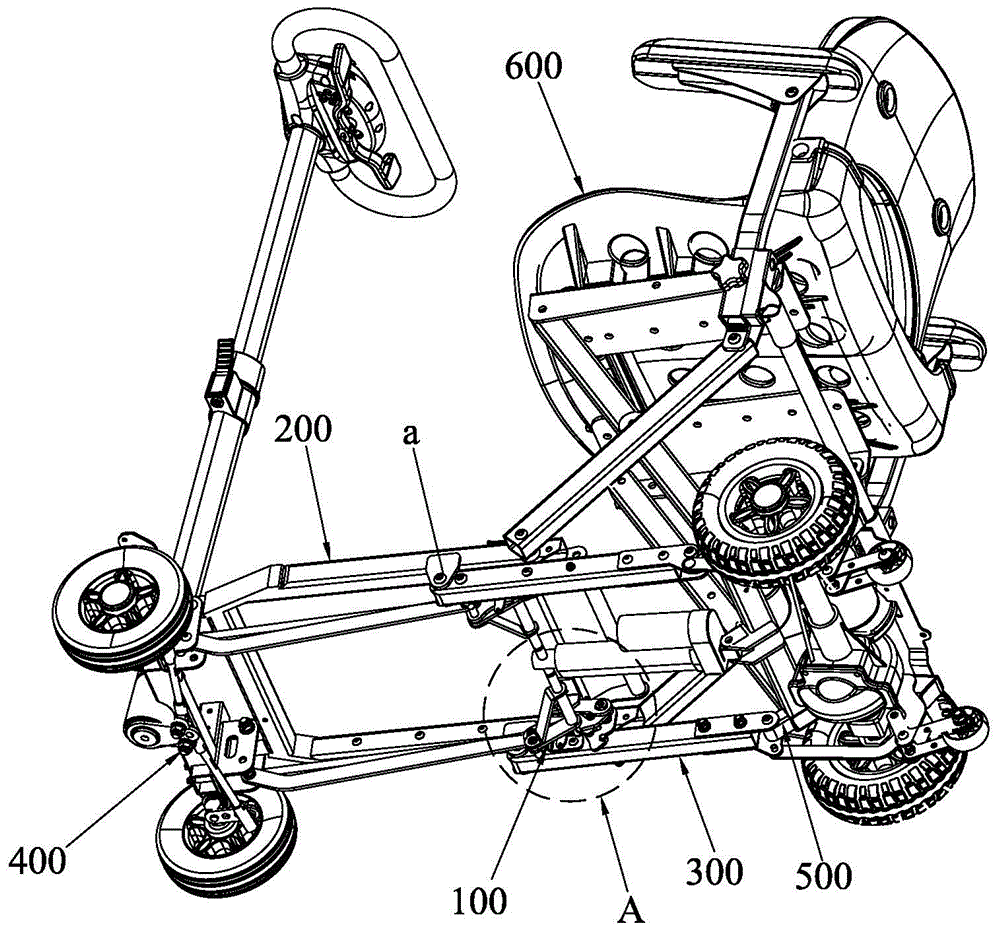

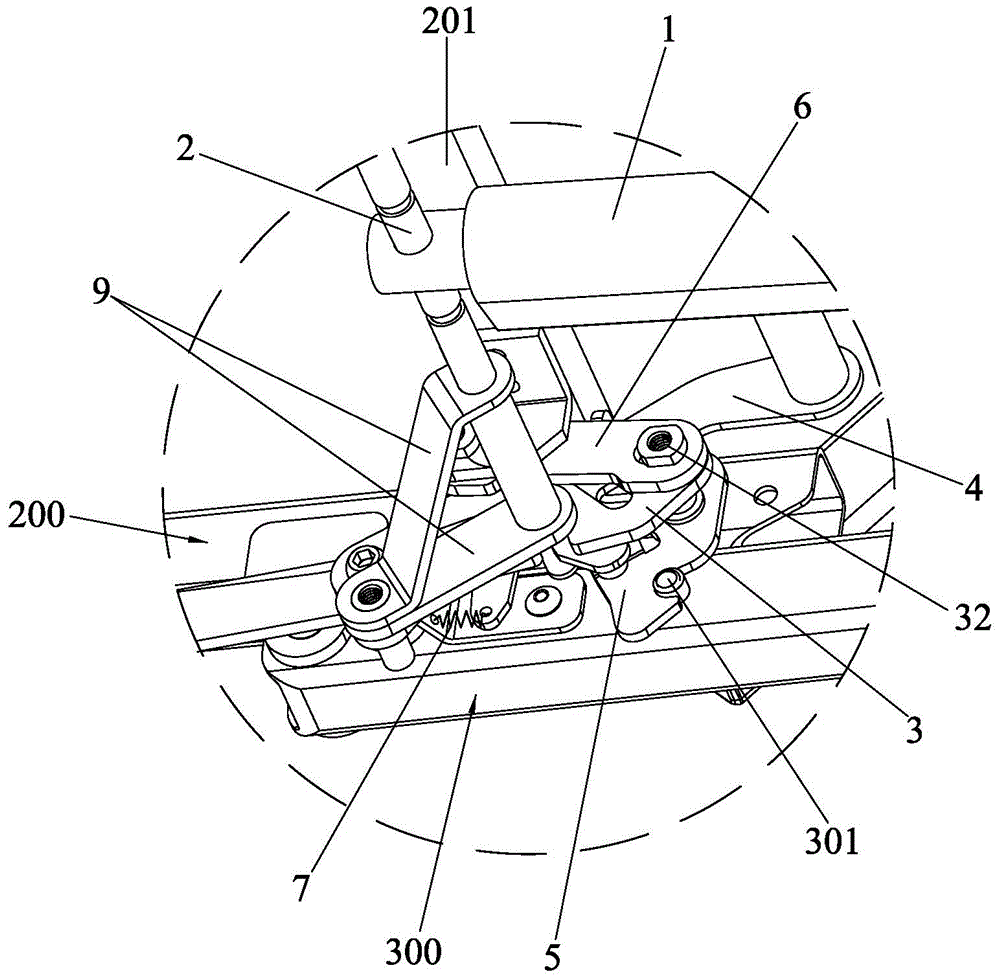

Folding drive structure of folding bicycle

ActiveCN104691683AHigh strengthAvoid bending deformationFoldable cyclesVehicle frameAgricultural engineering

Owner:DONGGUAN PRESTIGE SPORTING PROD CO LTD

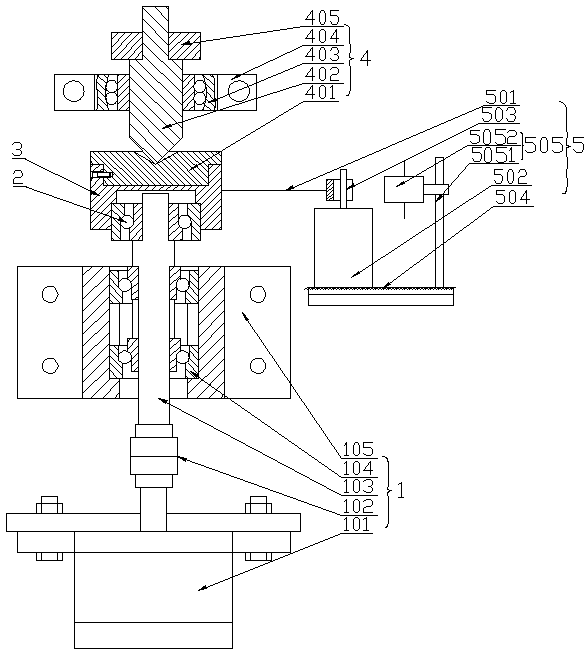

Miniature bearing friction torque measuring device

InactiveCN108918000AWith self-aligning functionNo overturning momentMachine bearings testingForce sensorsFriction torqueEngineering

The invention relates to the technical field of measuring equipment, in particular to a miniature bearing measuring device, comprising a power mechanism, wherein the output shaft of the power mechanism is connected with the inner ring of a bearing to be tested, the outer ring of the bearing to be tested is connected with a loading ring, the loading ring is provide with a loading mechanism, a forcemeasuring mechanism is arranged on the side of the loading ring, the force measuring mechanism comprises a force applying rod connected to the side of the loading ring at the left end, and the rightend of the force applying rod is connected with a sensor. In the invention, the loading part has a self-aligning function to well ensure pure axial loading without generating an overturning moment with respect to the axis; the position of the sensor increases a homing device of the electromagnet, so that the force sensor can automatically zero, and the problem that it is impossible for self-zeroing or it is too difficult for manual zeroing caused by too sensitive sensor and small range of the sensor; the installation and replacement are convenient and fast, and the loading block can be disassembled and replaced without affecting the test of the test bearing.

Owner:HENAN UNIV OF SCI & TECH

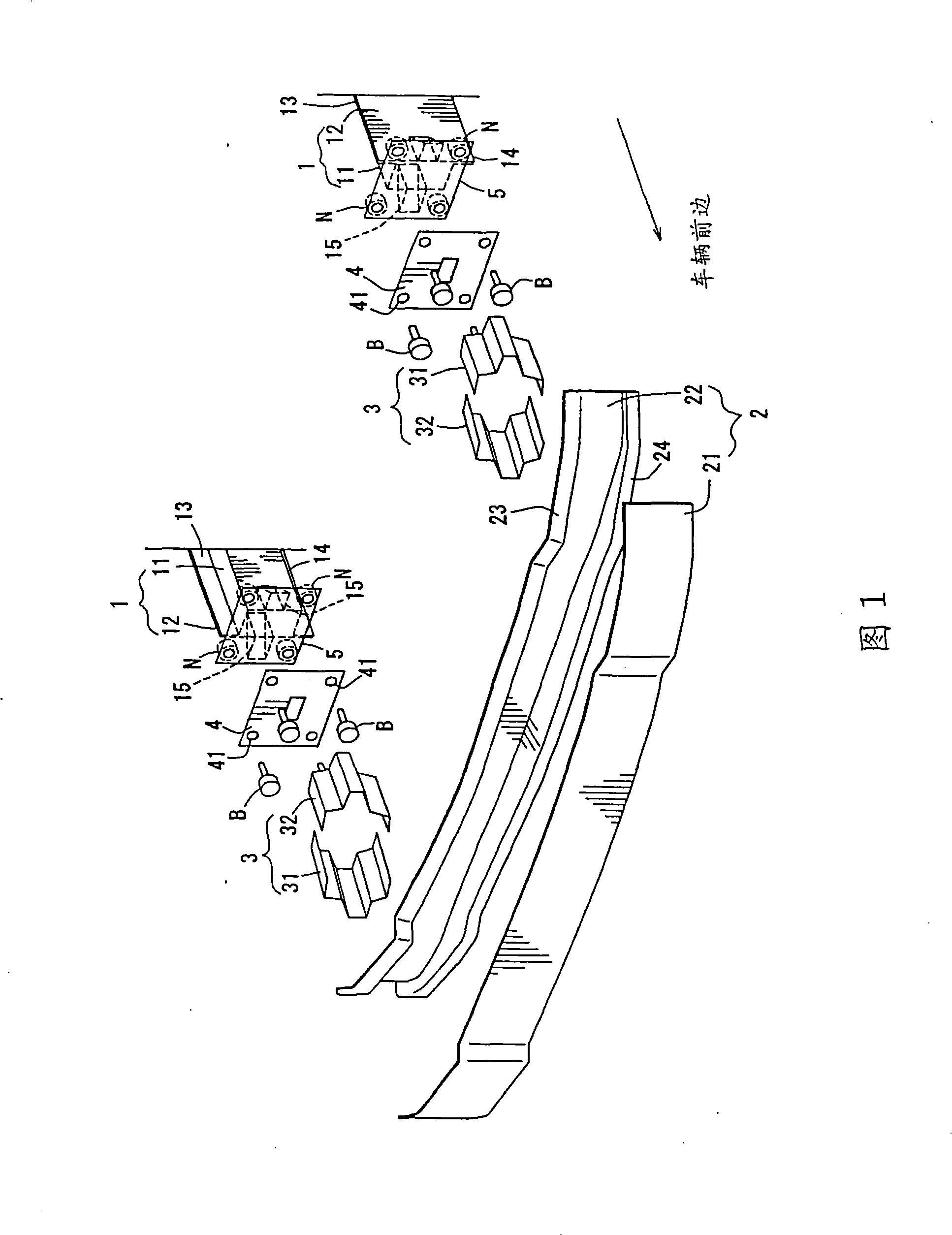

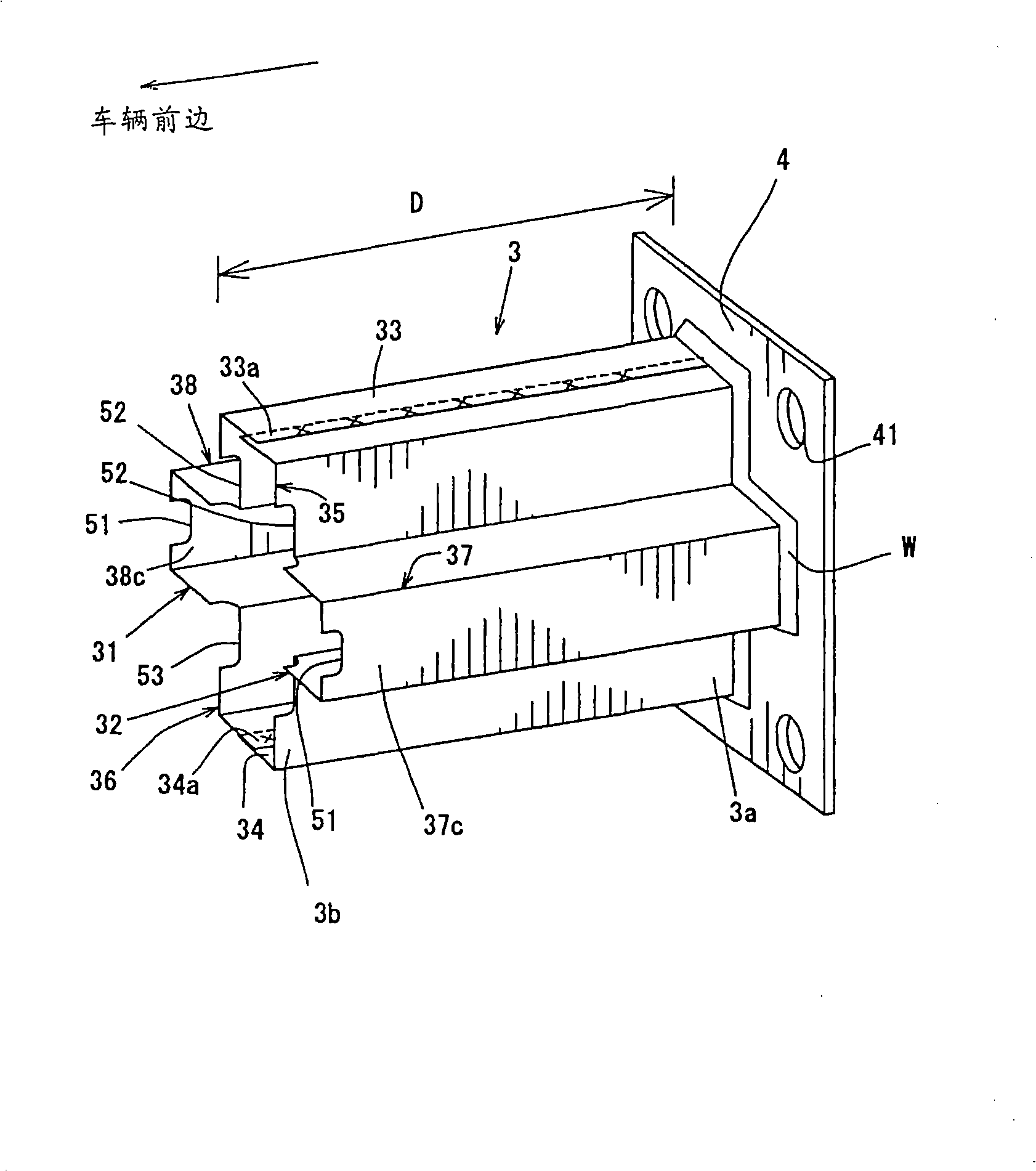

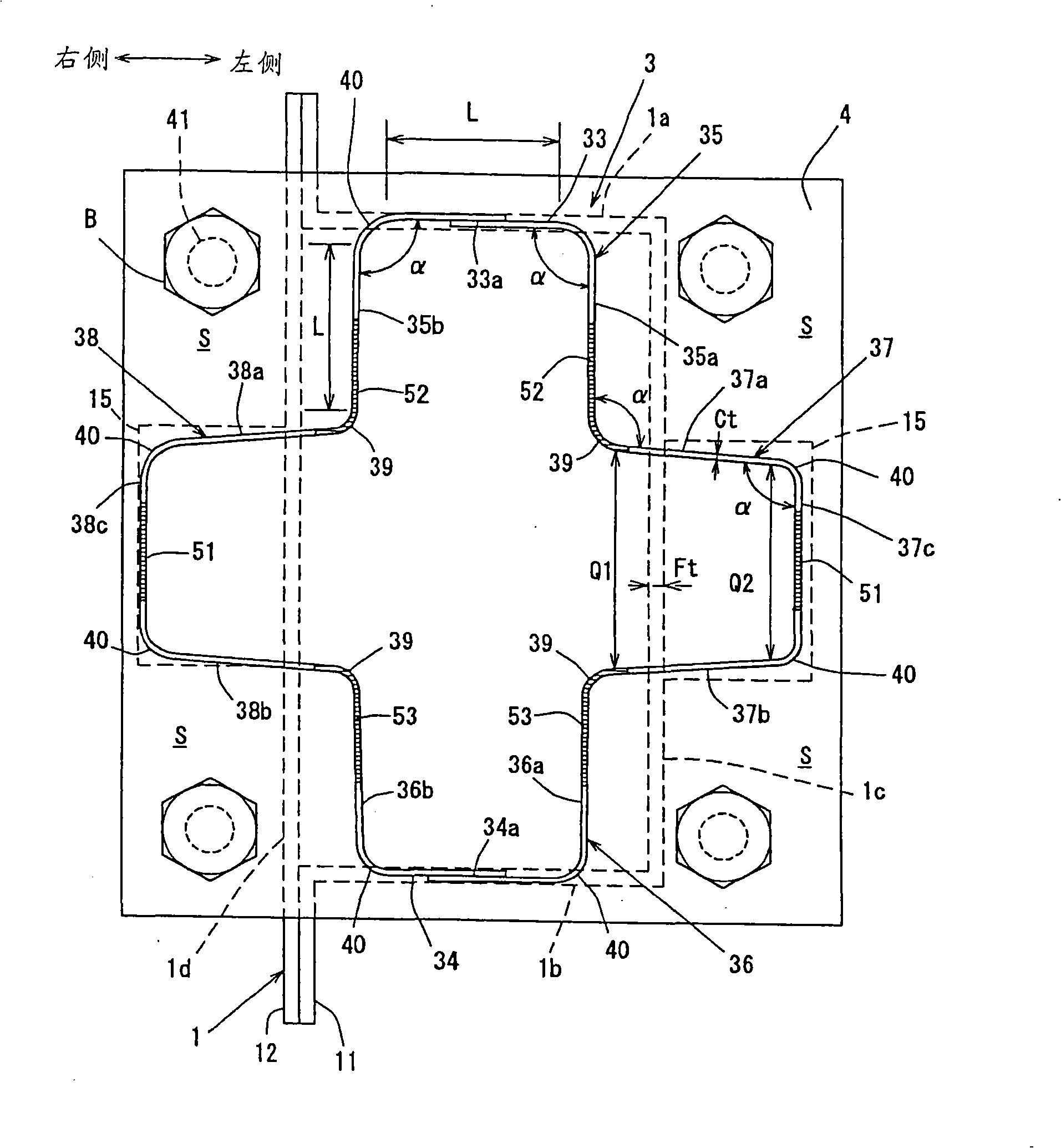

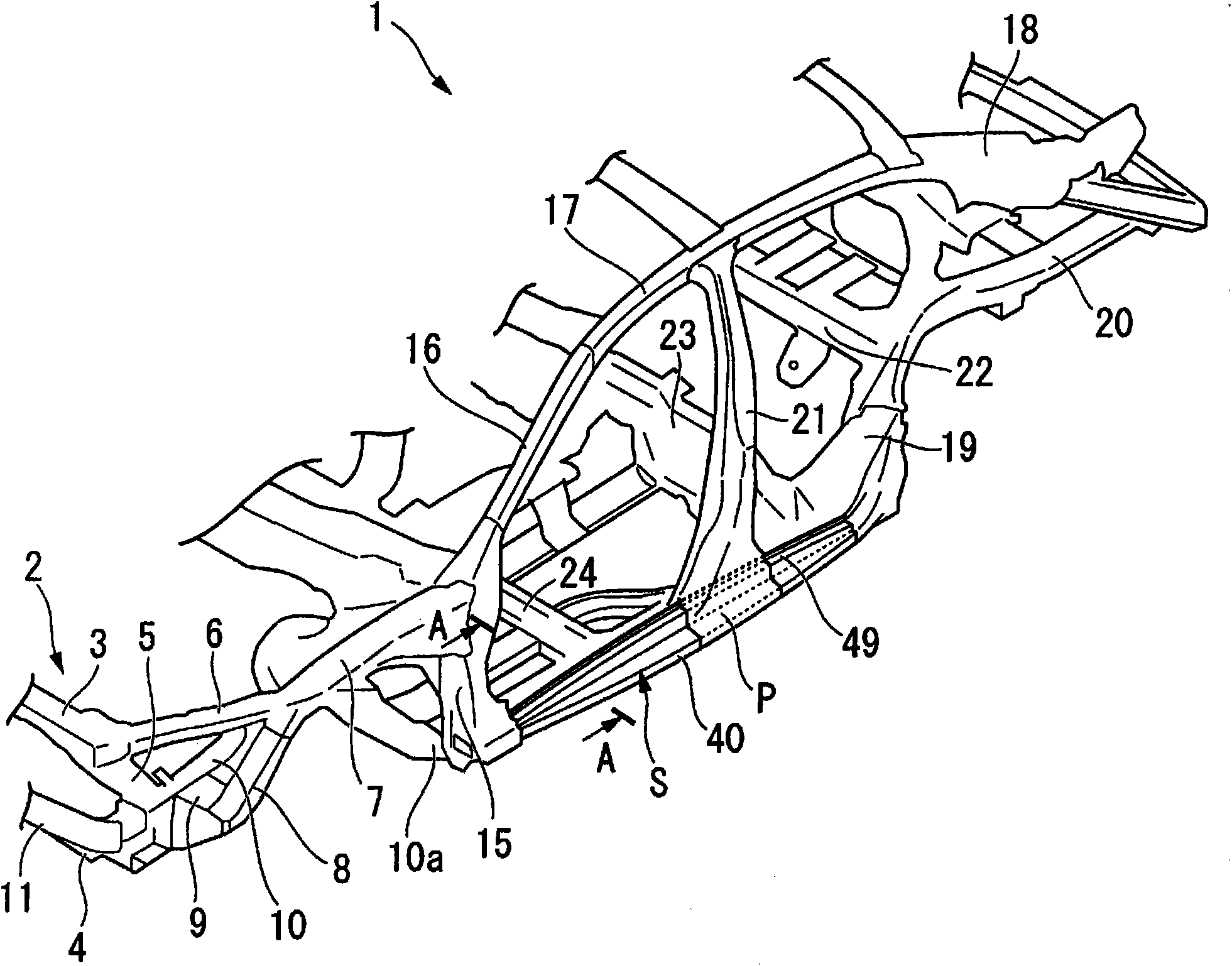

Vehicle structure for automobile

ActiveCN101402340AAvoid bending deformationImprove rigidityBumpersEnergy absorbingAutomotive engineering

Owner:MAZDA MOTOR

Railless sliding door

ActiveCN102418463AGuaranteed uptimeAvoid bending deformationWing arrangementsRolling resistanceEngineering

Owner:ZHANGJIAGANG GOLDNET FENCING SYST

Semiconductor chip assembly with post/base heat spreader and cavity over post

InactiveCN102456637AImprove cooling effectNot easy to delaminateSemiconductor/solid-state device detailsSolid-state devicesSignal routingElectrical conductor

The invention relates to a semiconductor chip assembly with a post / base heat spreader and a cavity over post. The semiconductor chip assembly at least includes a semiconductor device, the heat spreader, the substrate and an adhesive. The semiconductor device is electrically connected to the substrate and thermally connected to the heat spreader. The heat spreader at least includes a post and a base. The post extends upwardly from the base into an opening in the adhesive and an aperture in the substrate, and the base extends laterally from the post. The adhesive extends between the post and the substrate and between the base and the substrate. The assembly provides signal routing between a pad and a terminal.

Owner:BRIDGE SEMICON

Method for producing circuit board thin plates

The invention discloses a method for producing circuit board thin plates. The technical scheme is characterized in that the method comprises the following steps that: conducting plating though holes; conducting outer layer circuit pattern transfer; conducting graph electric plating and etching; penetrating a string through locating holes of the circuit board thin plates, utilizing string beads to separate the circuit board thin plates, and plating the circuit board thin plates though the holes, after plating the circuit board thin plates through the holes, washing liquid medicine on the surfaces of the circuit board thin plates away by horizontally drawing the circuit board thin plates through a thick plate; conducting electric test; conducting routing; utilizing a plastic package tray to package a finished-product unit plate subjected to routing. From the procedure of layer circuit pattern transferring to the procedure of routing, the circuit board thin plates are compressed through pressing grooves by the adoption of a pig cage frame device to be transferred between the procedures. The method for producing the circuit board thin plate solves the problems that the circuit board thin plates are prone to plate adhesion, plate curving, plate clamping and plate fracture due to the fact that the circuit board thin plates are small in size. The method for producing circuit board thin plates is simple in process and stable in product quality.

Owner:广东依顿电子科技股份有限公司

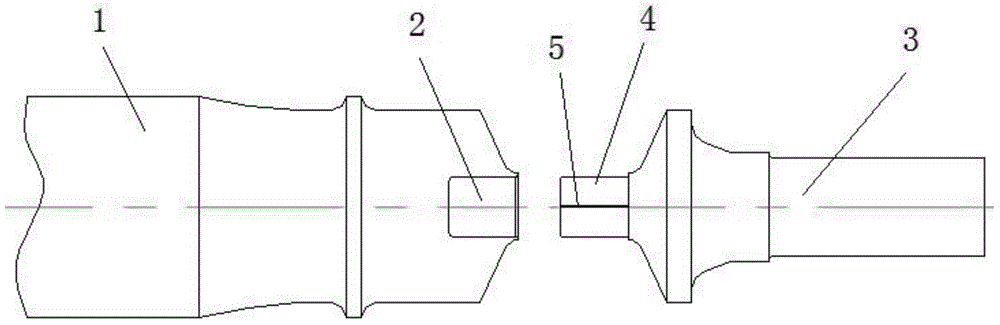

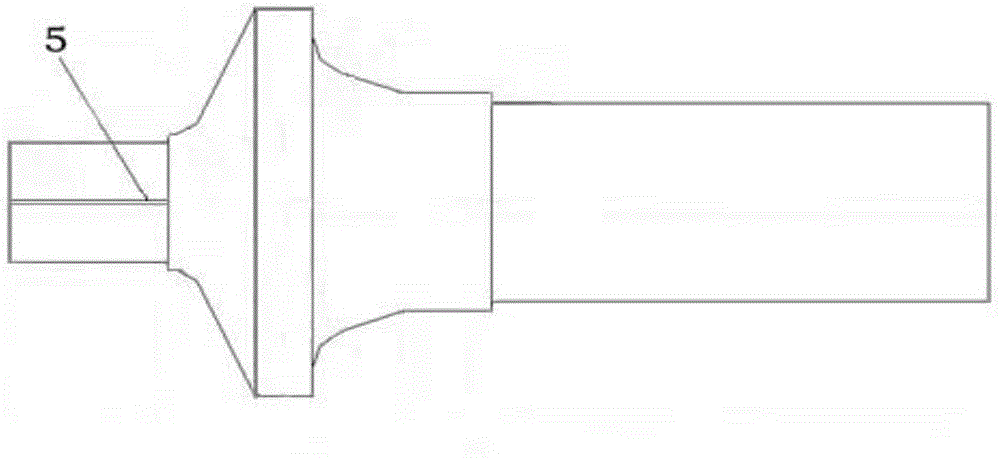

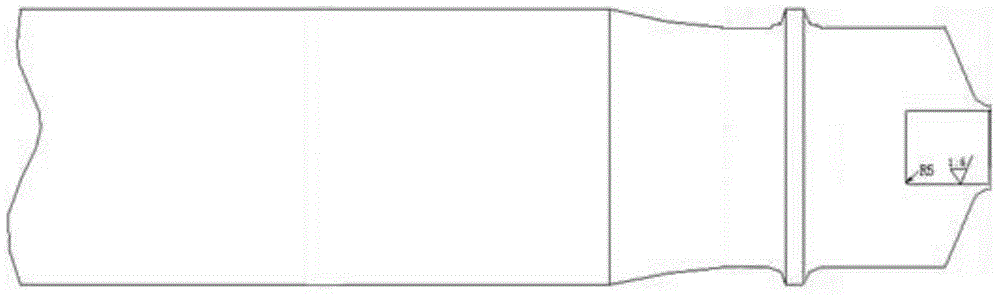

Method for repairing fractured roller way spindle nose

InactiveCN104801922AAvoid bending deformation after weldingAvoid bending deformationWorkpiece edge portionsWelding apparatusEngineeringRepair method

The invention discloses a method for repairing a fractured roller way spindle nose. The method comprises the following steps: step1, manufacturing a connecting spindle body, assembling and performing abutting joint, drilling inner holes (2) at one end of a spindle nose roller body (1), processing the matching end of the connecting spindle body (3), matching the connecting spindle body and the inner holes (2) of a mandrel (4) and the spindle nose roller body, and axially forming V-shaped grooves (5) on the mandrel (4) on the matching end of the connecting spindle body (3) to discharge air in the inner holes (2) during installation. Step2, welding, (2.1) placing the connecting spindle body (3) and the spindle nose roller body (1) on a lathe to process grooves after assembling, the grooves are V-shaped or U-shaped, and the opening angle is in the range of 45-55 degrees. The assembled work pieces are placed on a roller wheel carrier and heated along rotation, two sides of each groove include 250-300mm of a heating region, and the preheating temperature is in the range of 200-250 degrees centigrade; welding the root of the groove. Step3, performing heat treatment after welding and mechanically processing into the demanded size. According to the repairing method, the fractured spindle nose is welded on the spindle roller body to prevent from bending deformation after being welded.

Owner:BAOSHAN IRON & STEEL CO LTD

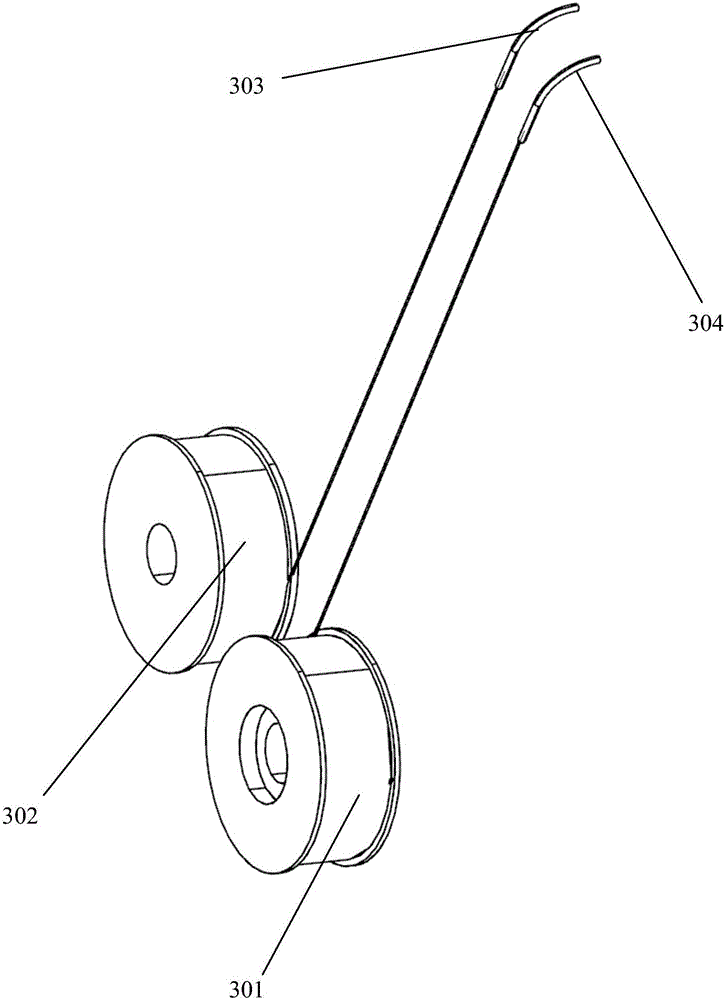

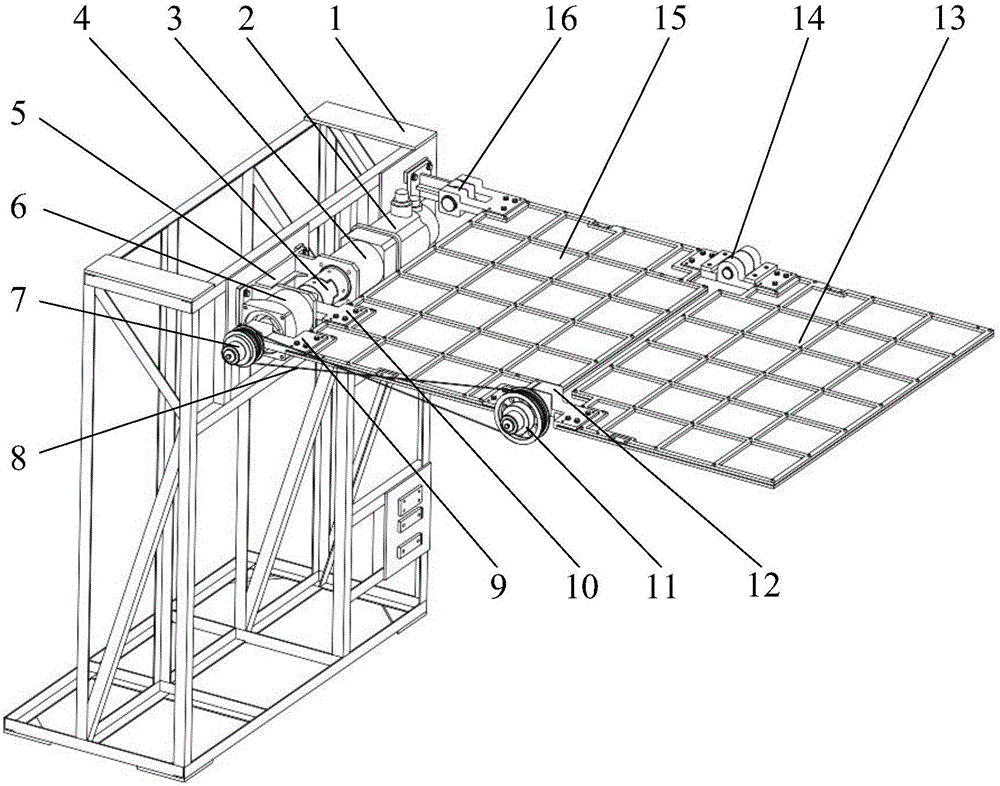

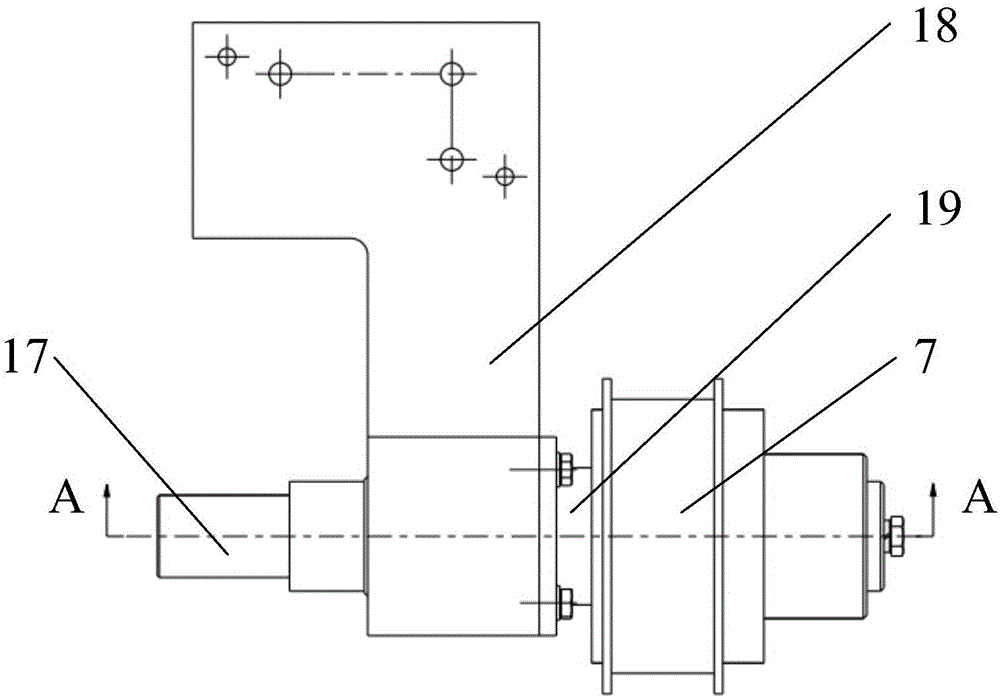

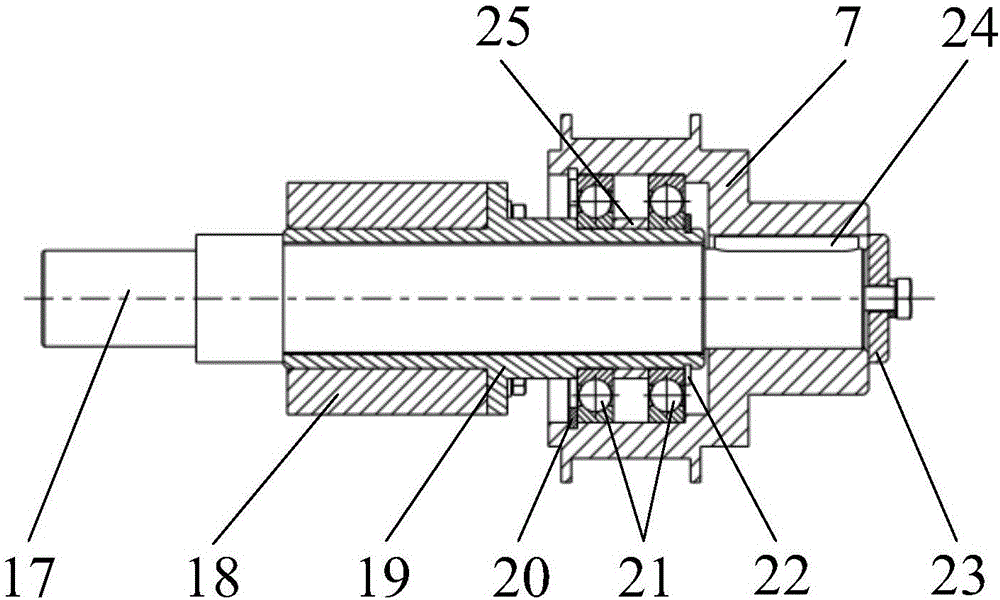

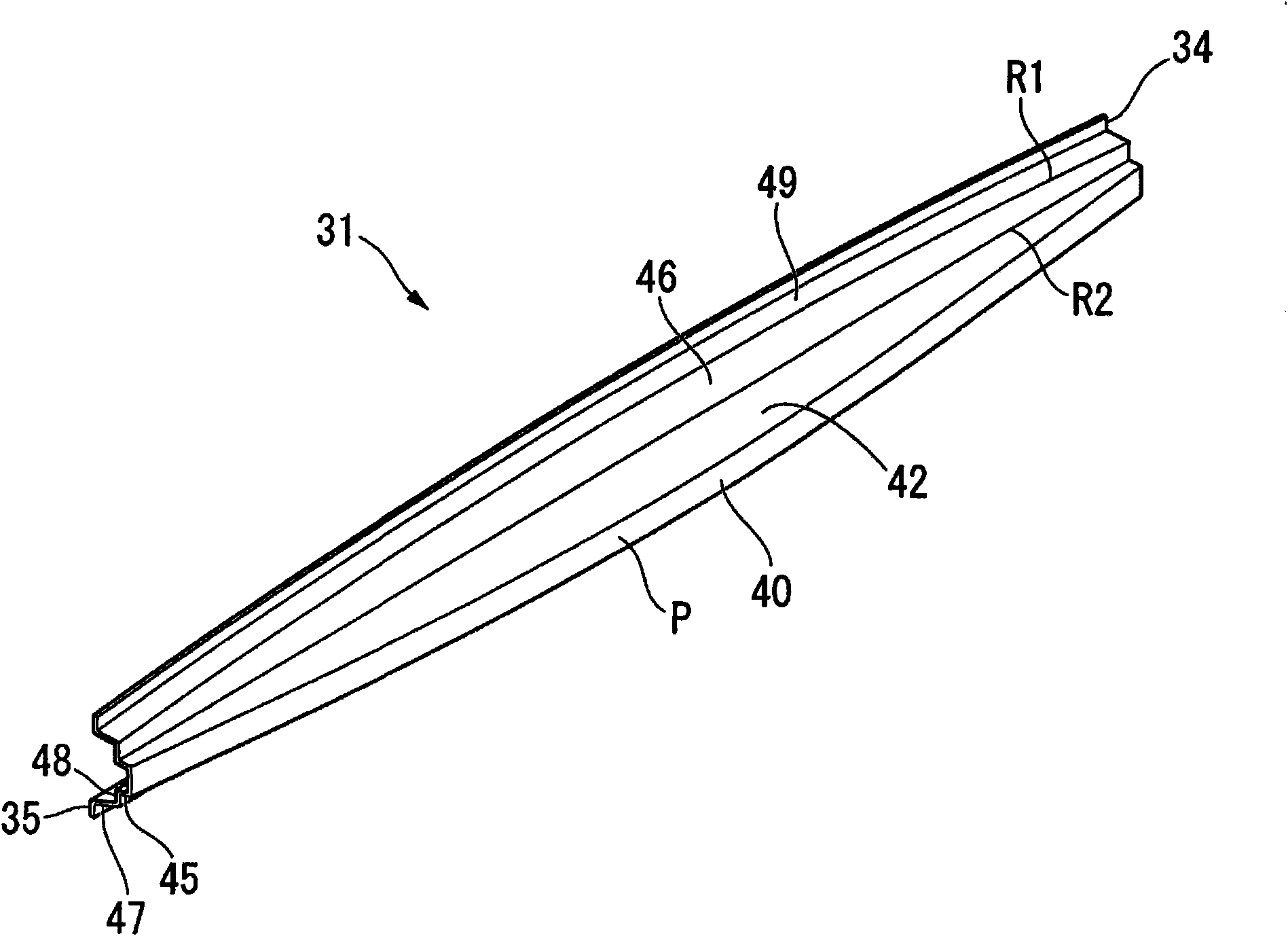

Single driving multi-stage synchronous stretch-retract repeatable solar panel unfolding mechanism

ActiveCN106428638ASimple structureLow costCosmonautic power supply systemsPhotovoltaicsFailure rateDrive shaft

Disclosed is a single driving multi-stage synchronous stretch-retract repeatable solar panel unfolding mechanism. The solar panel unfolding mechanism comprises a machine frame, a motor, a speed reducer, a speed accelerator, large and small steel wire rope wheel set components, steel wire ropes and two-stage solar panels, wherein the machine frame is fixed on the ground, the motor, the speed reducer, a coupling and the speed accelerator are in series connection, the speed reducer and the speed accelerator are fixed on the machine frame, the small steel wire rope wheel set component is fixed on one end of one side of a first stage solar panel, and the other end of the same side of the first stage solar panel is connected with the machine frame through a first hinge; two ends of the other side of the first solar panel are connected with the second solar panel through a second hinge and a third hinge respectively; the large steel wire rope wheel set component is arranged between the two-stage solar panels and the steel wire ropes are connected with the large steel wire wheel set component and the small steel wire rope wheel set component. The single driving multi-stage synchronous stretch-retract repeatable solar panel unfolding mechanism has the advantages of being simple in structure, low in cost, strong in reliability, low in failure rate and long in service life; meanwhile, the mechanism is capable of effectively unloading a radial tensile force exerted on a driving shaft during a driving process, can prevent the driving shaft from bending or deforming, thus increasing transmission precision.

Owner:YANSHAN UNIV

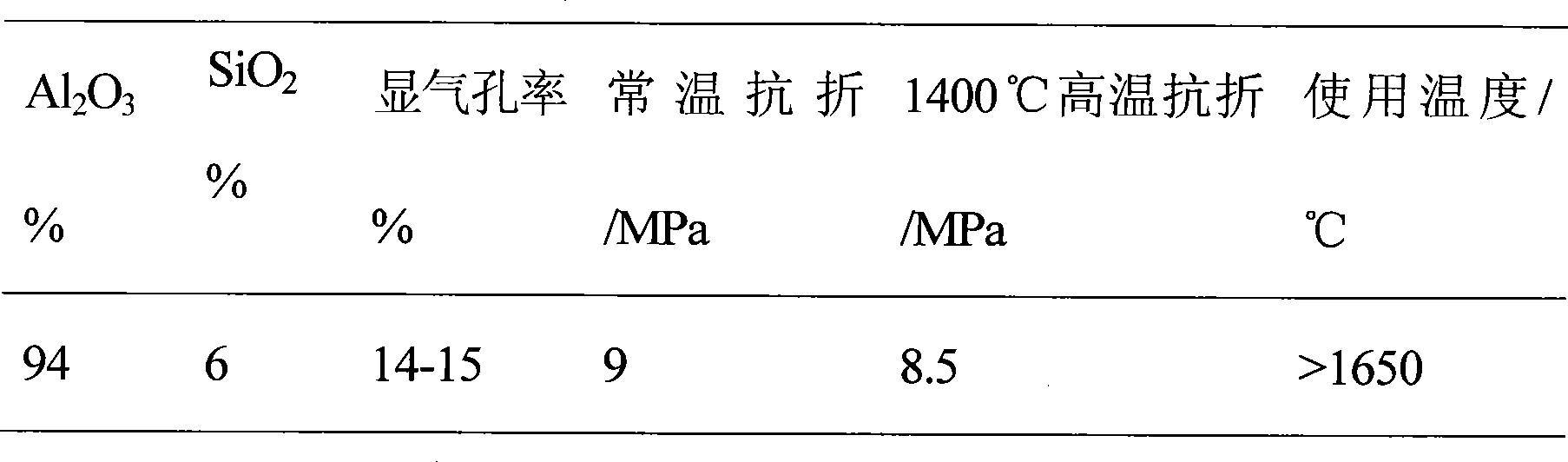

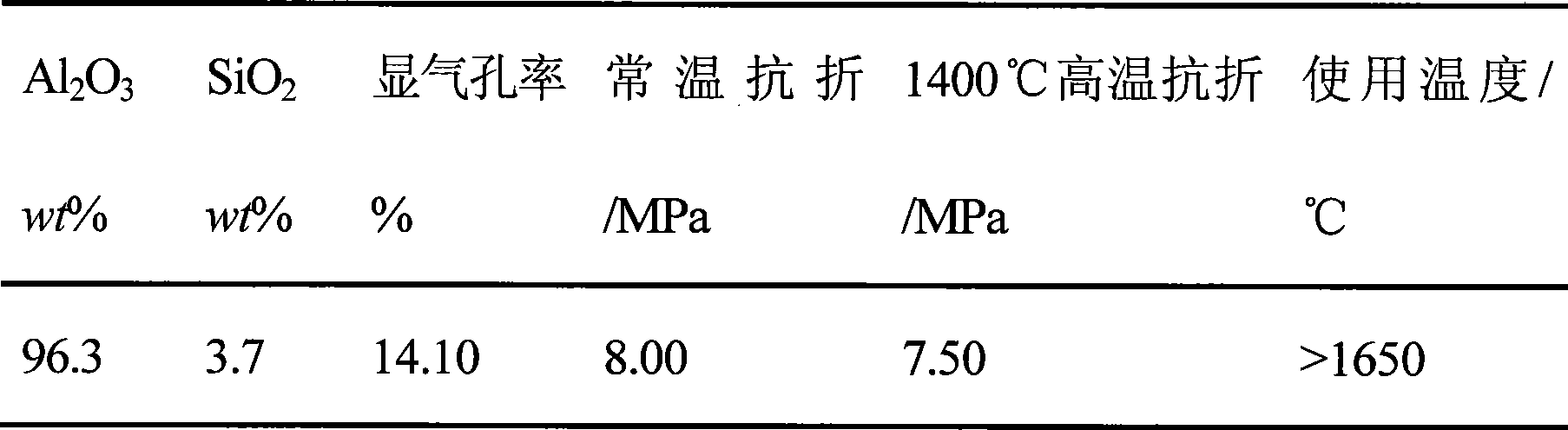

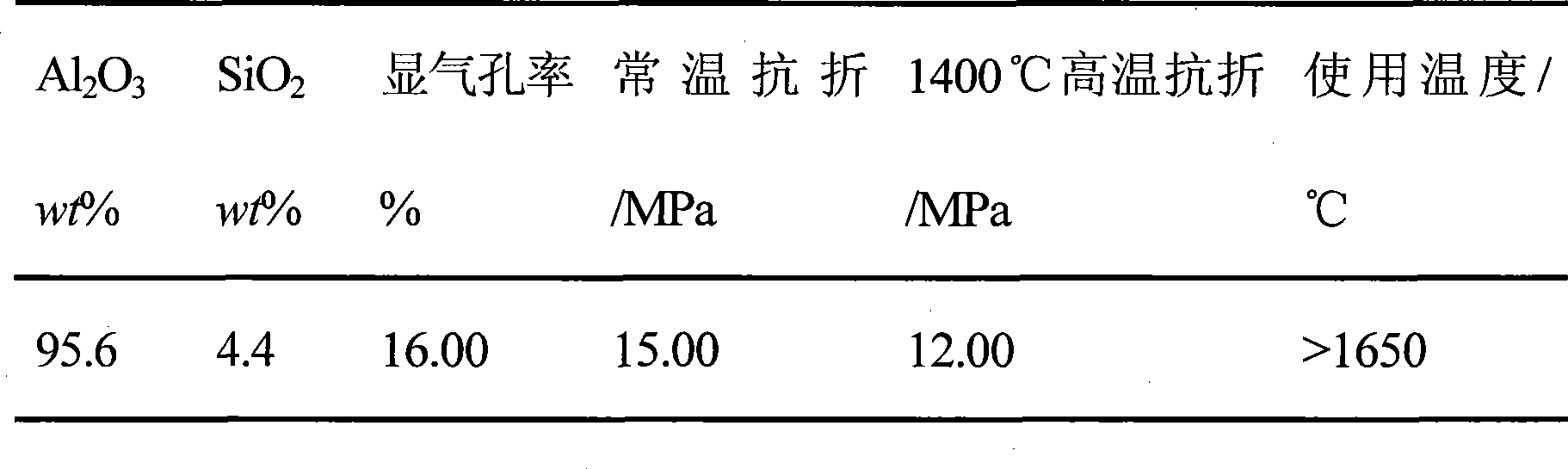

High temperature and creep resistance corundum-mullite load bearing board and preparation method thereof

ActiveCN101423414AIncrease temperatureImprove thermal shock resistanceMulliteHigh-temperature corrosion

The invention belongs to the technical field of ceramic kiln furniture and provides a corundum-mullite load bearing board and a preparation method. The corundum-mullite load bearing board comprises raw material compositions in the following mass percentage: 70 to 85 percent of alpha-Al2O3 particle material with the grain diameter of between 5 and 0.088 mm, 5 to 15 percent of alumina-silica sol fine powder with the grain diameter less than 0.08 mm, 5 to 15 percent of fused mullite fine powder with the grain diameter less than 0.088 mm, and 3 to 5 percent of bonding agent which is externally added. The characteristics of high purity and small particle size of alumina-silica sol are utilized to prepare the high-temperature creep-resistant load bearing board which has high purity and is formed by large-grained mullite bonded with corundum through high-temperature calcination, and the load bearing board does not deform and has good thermal shock resistance when the load bearing board is used at high temperature, and can be taken as the load bearing board used at a temperature higher than 1,650 DEG C in the fields of electronic ceramics and high temperature ceramics.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

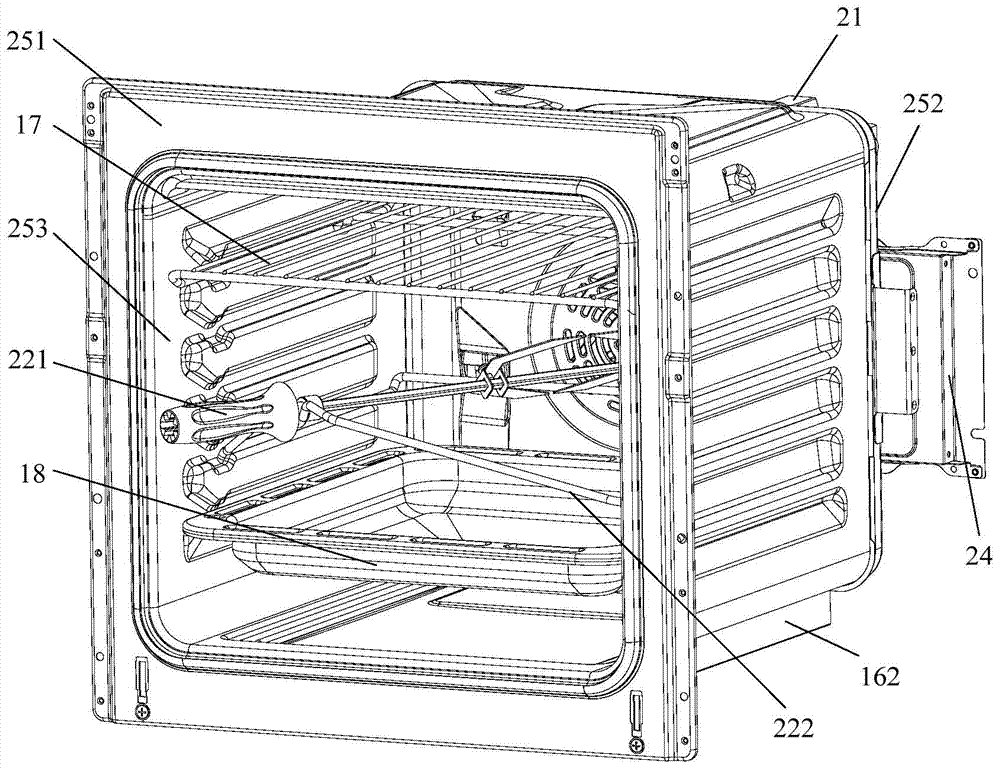

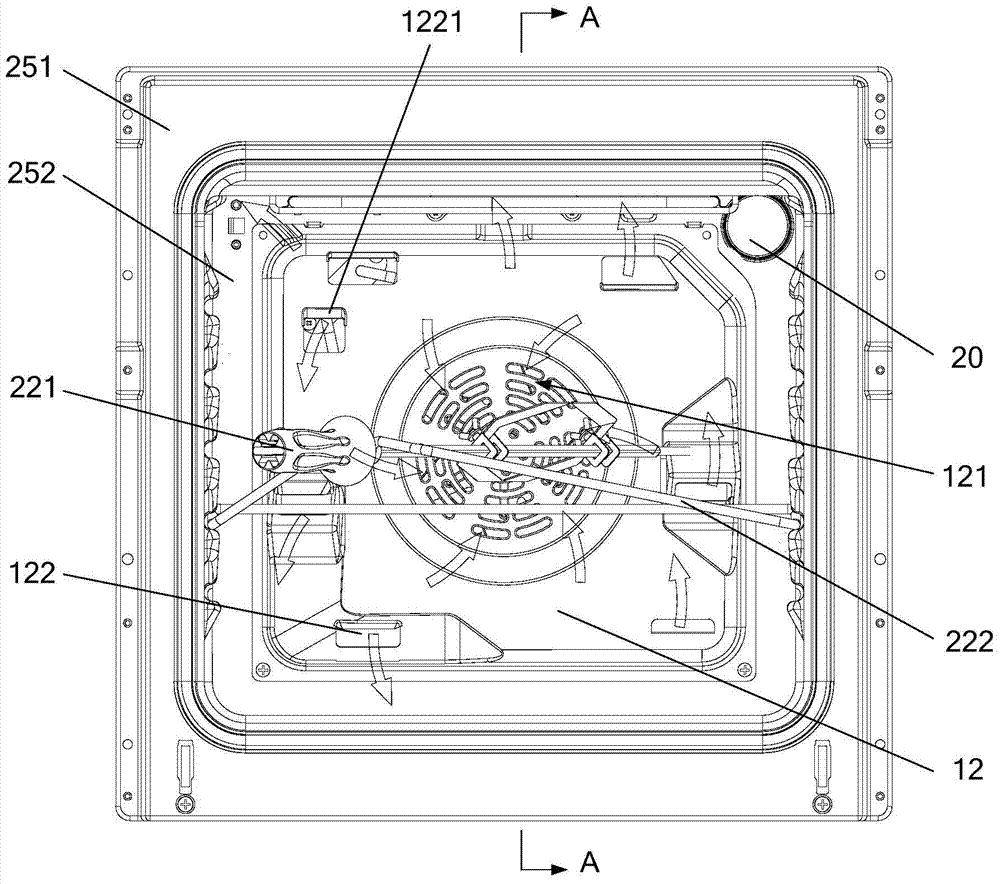

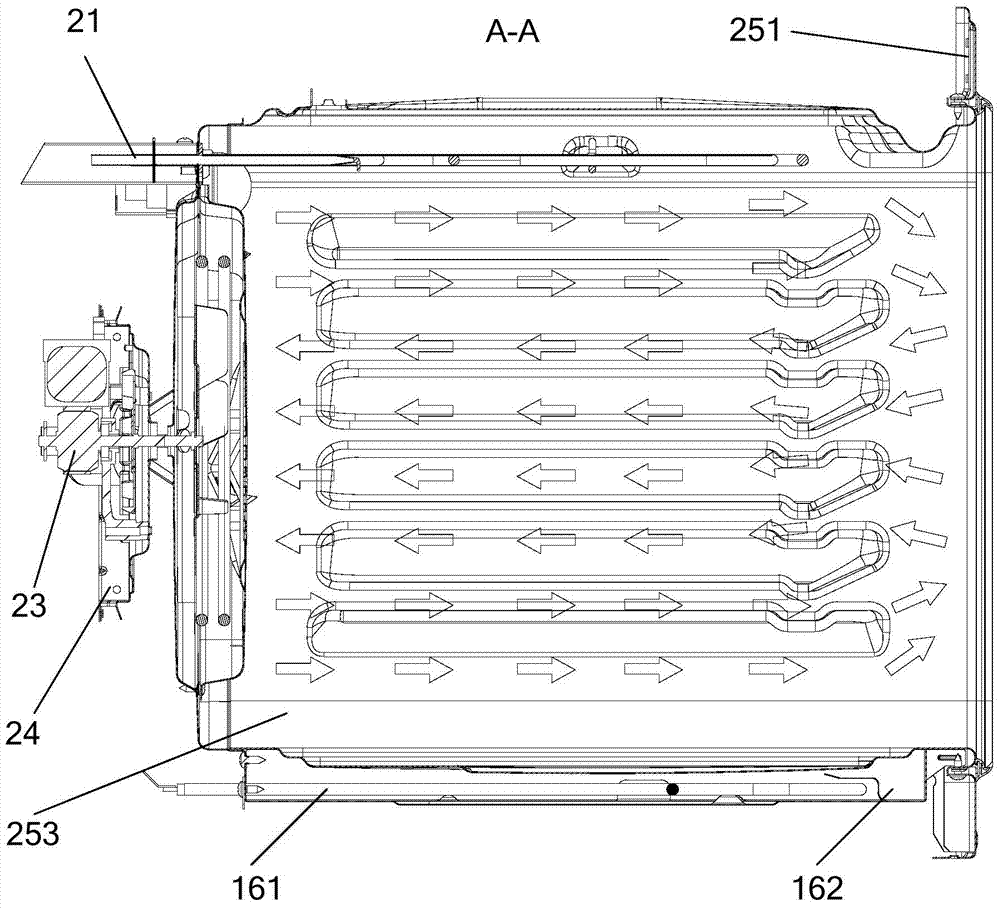

Electric oven

The invention provides an electric oven which comprises a cavity, a rear heating pipe, a wind wheel, wind wheel drive elements and a wind wheel cover. The cavity is hollow and provided with an opening at one end. The rear heating pipe is installed on the rear wall surface in the cavity. The wind wheel is installed on the rear wall surface in the cavity and located within an area enclosed by the rear heating pipe. The wind wheel drive elements are installed on the cavity and connected with the wind wheel and can drive the wind wheel to rotate. The wind wheel cover is installed on the rear wall surface in the cavity and covers the wind wheel and the rear heating pipe to enable the wind wheel and the rear heating pipe to be located between the wind wheel cover and the rear wall surface of the cavity. An air inlet is formed in the middle of the wind wheel cover, and a plurality of air outlets are formed in the edge of the wind wheel cover in the circumferential direction. The electric oven is simple in structure, and the internal temperature of the cavity is even; when the wind wheel works, an even and stable hot air circulation environment is formed in the cavity and provides a good heat source for the electric oven so that the taste of baked food can be better.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

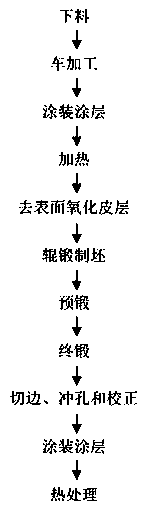

Large-scale locomotive connecting rod forging technology

ActiveCN104057263AReduce depthGuarantee the quality of raw materialsShaping toolsRailway componentsPunchingSurface oxidation

The invention discloses a large-scale locomotive connecting rod forging technology which comprises the steps of blanking, lathing, anti-decarburization coating application, blank heating, surface oxidation layer removal, roll forging of blanks, pre-forging, finish forging, trimming, punching and calibration, anti-decarburization coating application and heat treatment. According to the large-scale locomotive connecting rod forging technology, forming can be achieved through one time of heating only. Compared with the traditional technology that heating needs to be conducted twice or more, the technology has the advantages that surface oxidation and decarburization of a connecting rod are effectively reduced, the mechanical performance of the connecting rod is guaranteed, and time and energy resources are saved. Due to the adoption of roll forging of blanks, speed is high, labor is saved, the consistency of manufactured blanks is high, and time and labor are saved during forging in later periods. Due to the fact that high-temperature-resistant and oxidation-resistant anti-decarburization coating application is conducted twice during the whole technology, the decarburized layer on the surface of a final forged piece is thinner than 0.3 mm, and product quality is improved effectively. Due to the fact that the connecting rod forged piece is vertically hoisted for heat treatment, bending deformation of the forged piece is effectively prevented during heat treatment.

Owner:SICHUAN HAOTE JINGGONG EQUIP CO LTD

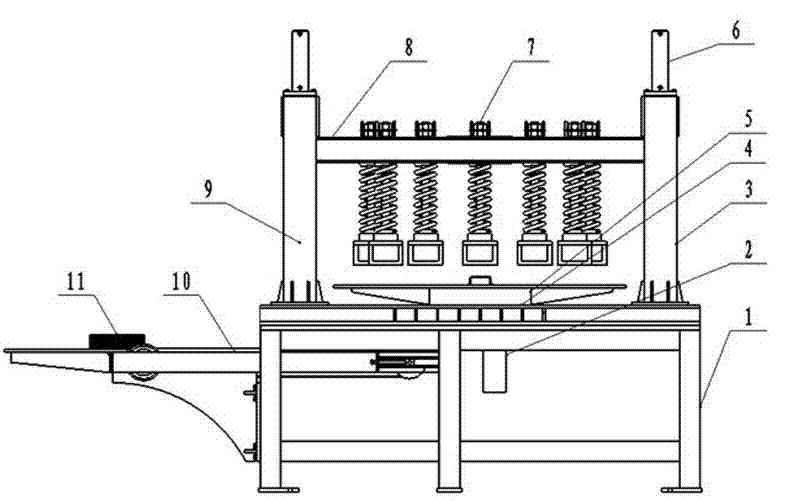

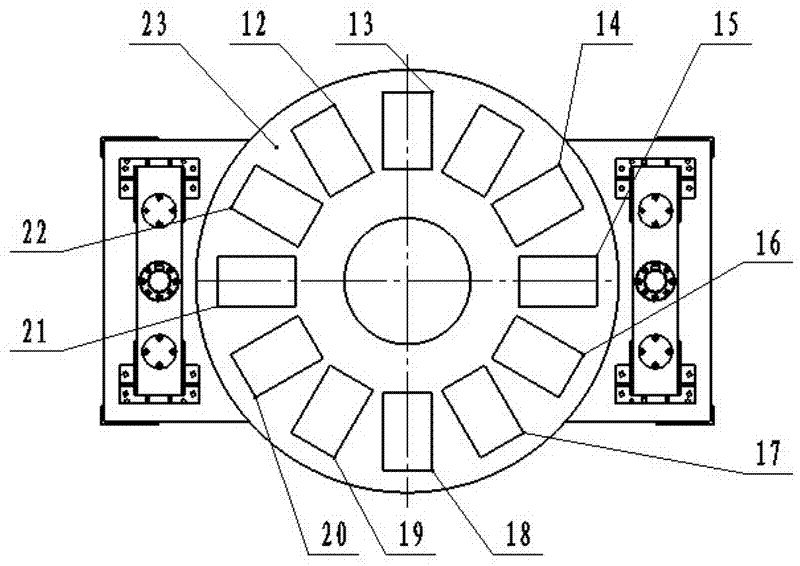

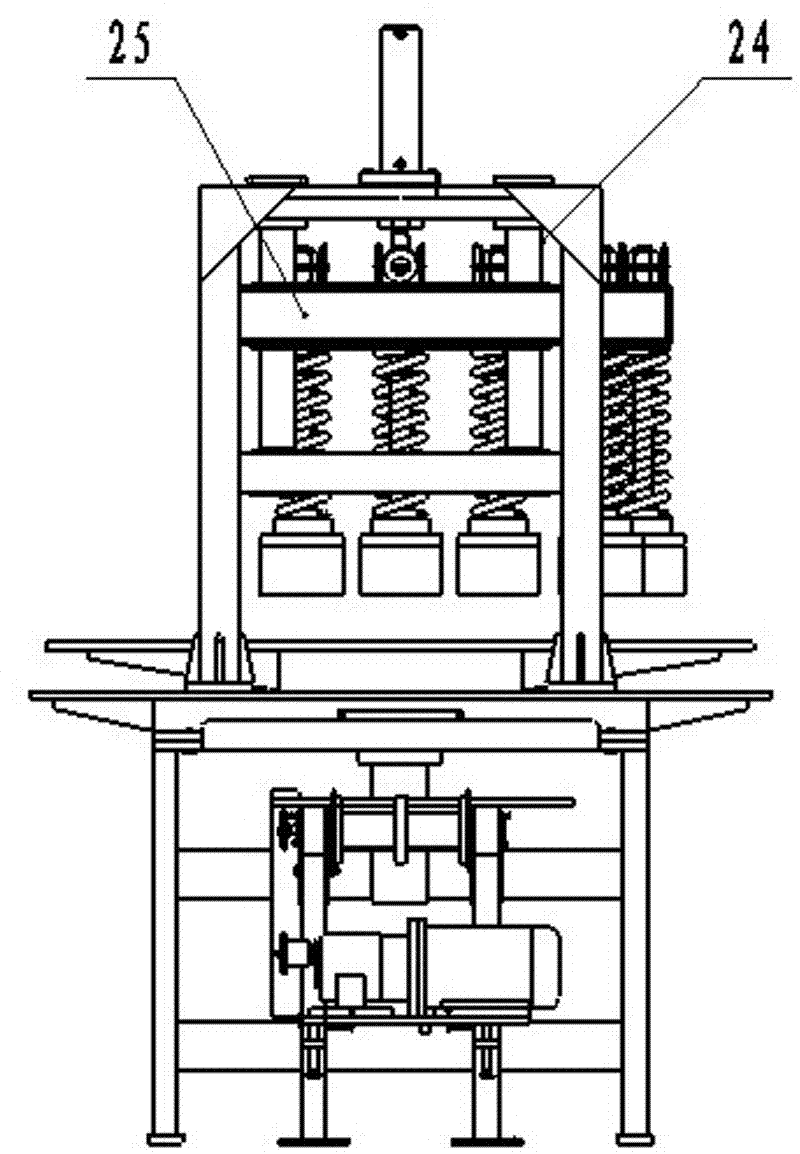

Hydraulic rotary koji pressing machine and pressing method thereof

InactiveCN102206564AUniform qualityQuality improvementAlcoholic beverage preparationEngineeringMechanical engineering

The invention relates to a hydraulic rotary koji pressing machine and a pressing method thereof. The hydraulic rotary koji pressing machine comprises a hydraulic motor, a frame, a rotary assembly, a pressure assembly and a runout table for starter materials. The hydraulic motor drives the rotary assembly into rotation, a hydrocylinder provides impetus for a pressuring hammer assembly to perform vertical reciprocating motion. The pressuring hammer crushes the koji material in a koji mould box located on a turntable, and the koji material is then output by the runout table for koji material. After prepressing and multiple crushing of the koji material, water and powder within the koji material have been mixed uniformly. The generated koji piece has appropriate tightness, so that the phenomena of tight koji piece surface, loose center and poor slurry extraction are completely avoided. The hydraulic rotary the koji pressing machine provided in the invention is characterized by simple structure, convenient operation, low energy consumption and high efficiency, thus being suitable for brewing and koji making.

Owner:TAIYUAN UNIV OF TECH

Speaker module

ActiveCN104796817AImprove acoustic performanceSmall lumen spaceLoudspeaker screensLoudspeaker transducer fixingEngineeringLoudspeaker

The invention discloses a speaker module and relates to the technical field of electroacoustic products. The speaker module comprises a housing; a single speaker is held within the housing; the single speaker comprises a single shell and a single front cover combined together; the single shell and the single front cover form a space in which a vibrating system and a magnetic circuit system are held; the end face of at least one sidewall of the single shell is provided with an ultrasonic face to be ultrasonically welded to the housing; the housing is provided with an ultrasonic line in ultrasonic joint with the ultrasonic face and corresponding to the ultrasonic face. The technical problems such that the prior speaker module is complex to assemble, poor in tightness and poor in appearance are solved; the speaker module is simple to assemble, good in tightness, high in appearance quality, good in acoustic performance, high in production efficiency and low in production cost.

Owner:GOERTEK INC

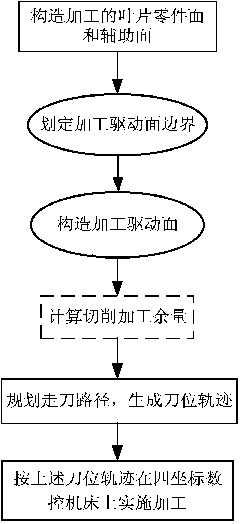

Two-way allowance-variable milling method for blade

ActiveCN103990840AHigh precisionImprove positionMilling equipment detailsEngineeringDimensional modeling

The invention discloses a two-way allowance-variable milling method for a blade. The method is used for solving the technical problem that an existing allowance-variable milling method for the blade is low in accuracy. According to the technical scheme, firstly, a three-dimensional blade model is established in three-dimensional modeling software UG; both the two end faces of the blade are made deflect towards a blade body in the three-dimensional blade model, so that two deflection faces, namely, the blade root edge interface and the blade tip edge interface, are obtained; a driving face is determined by means of a section line lofting method; then, machining routes on the driving face are determined; allowance of each machining route is determined by means of a lever allowance fine tuning method; finally, circulation machining is conducted on the blade according to the set allowance, so that machining accuracy is improved for the blade. According to the method, when the blade with the length which is about 70 mm is machined, the surface tolerance of the blade can be controlled within the range of 0.06 mm to 0.1 mm.

Owner:西安三航动力科技有限公司

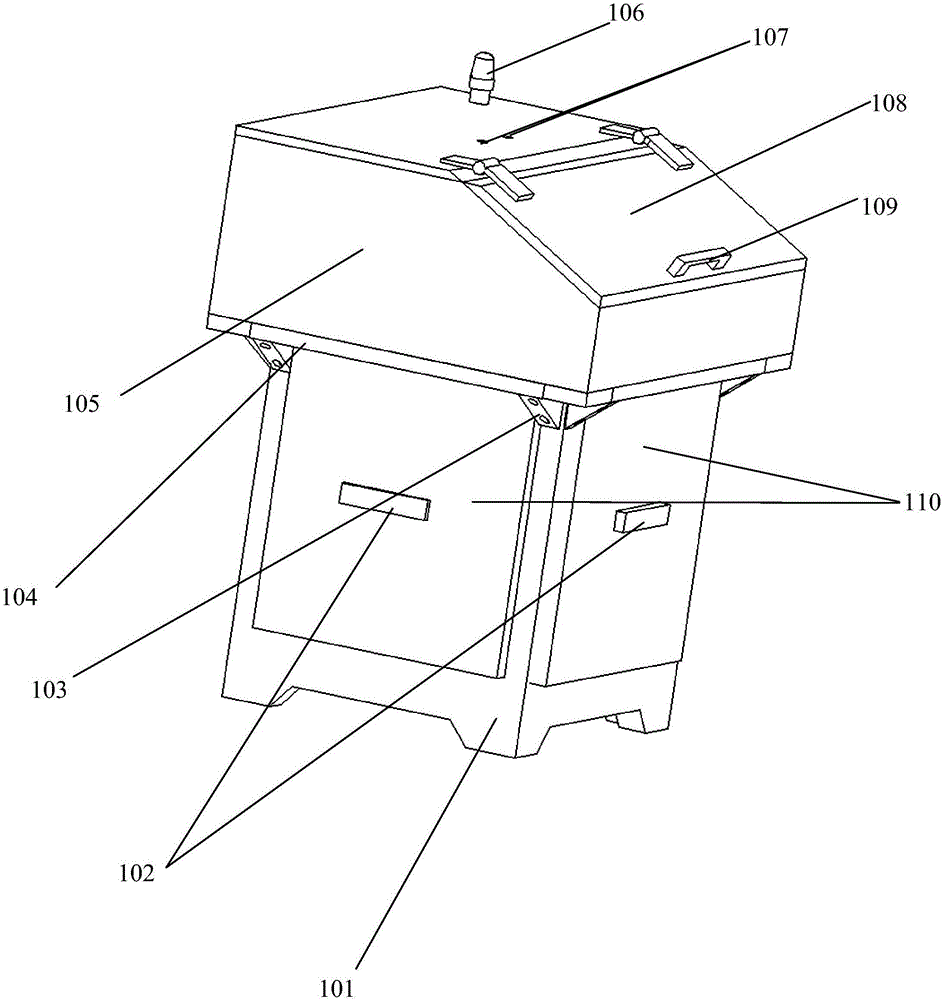

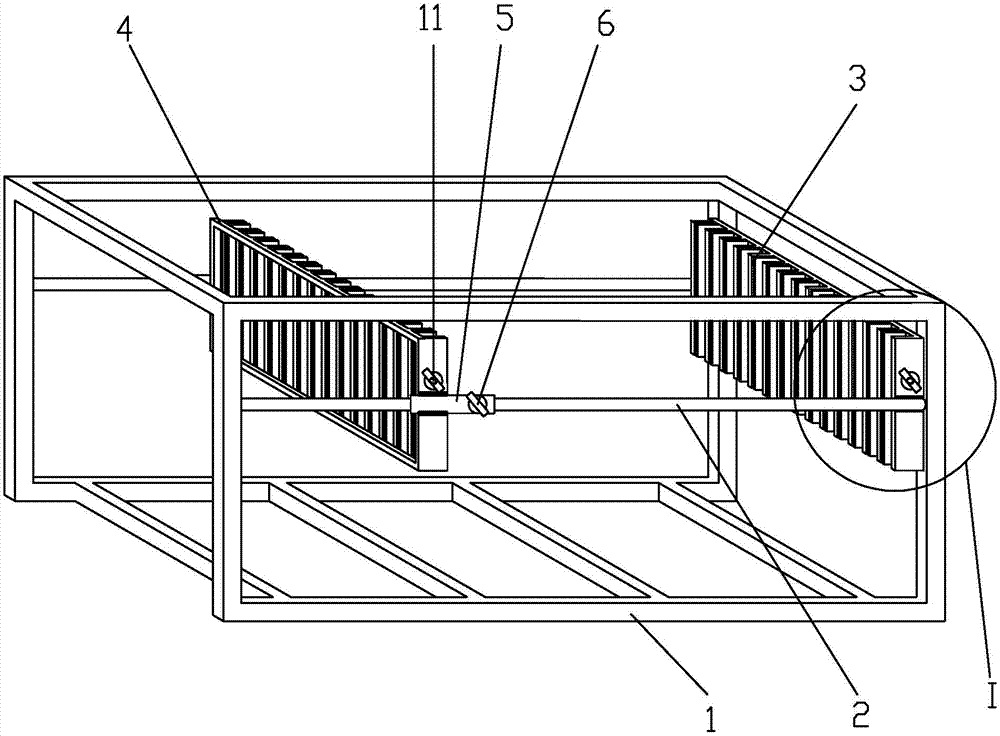

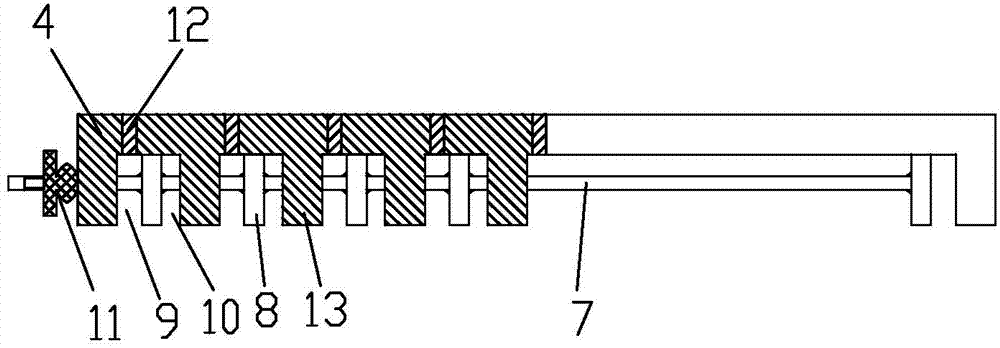

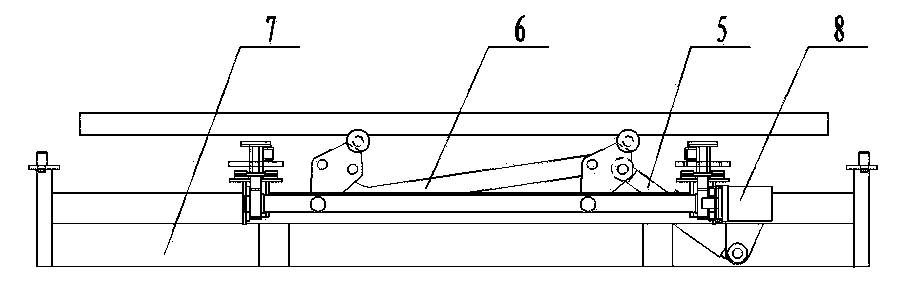

Drill pipe transit box of drilling machine

ActiveCN104278958ASolve the clutterAvoid bending deformationDrilling rodsDrilling casingsEngineeringDrilling machines

The invention provides a drill pipe transit box of a drilling machine. The drill pipe transit box comprises a box body, wherein multiple equidistantly arranged vertical partition boards are symmetrically arranged on the left and right side plates of the box body, a drill pipe storage chamber for holding a column of drill pipes is formed between two adjacent vertical partition boards, a base is installed at the bottom of the box body, drill pipe conveying mechanisms are arranged on the base, each drill pipe conveying mechanism comprises a supporting seat, a slideway is arranged on the supporting seat, and a sliding seat is installed in the slideway; a drill pipe lifting device is arranged between two drill pipe conveying mechanisms. The drill pipe conveying mechanism used for synchronously conveying drill pipes and arranged on the base is used for conveying the drill pipes to the underface of different drill pipe storage chambers in the box body, the drill pipe lifting device arranged between the two drill pipe conveying mechanisms is used for jacking the drill pipes into the drill pipe storage chamber, and the actions are performed in sequence to fill up the drill pipes in the box body, and thus the problem that the drill pipes are placed disorderly on a construction site is solved, the bending deformation of the drill pipes in a placement process is avoided, and the service life of the drill pipes is prolonged.

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

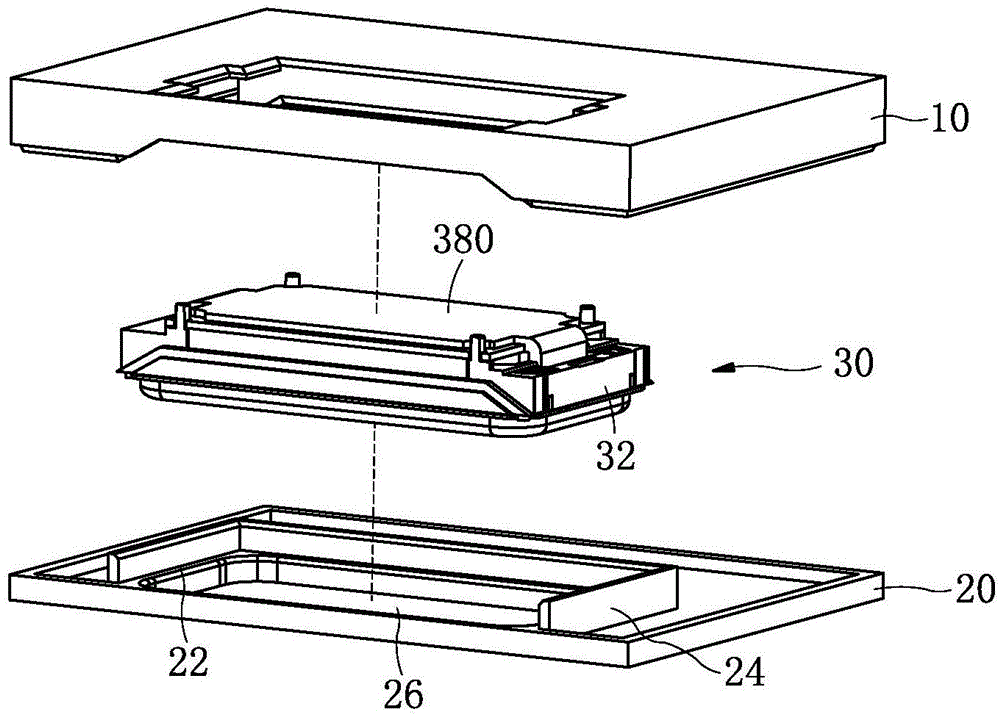

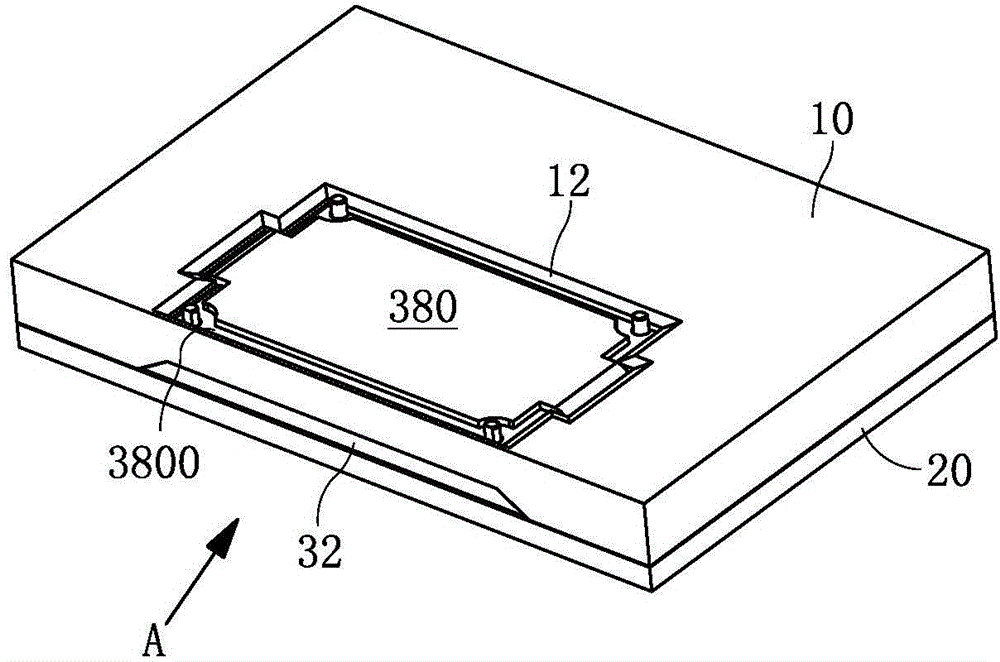

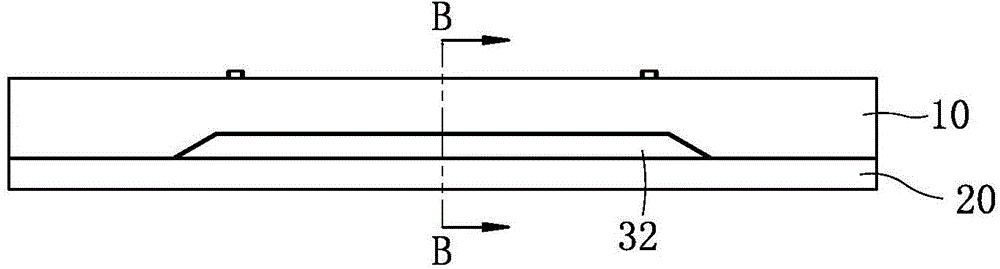

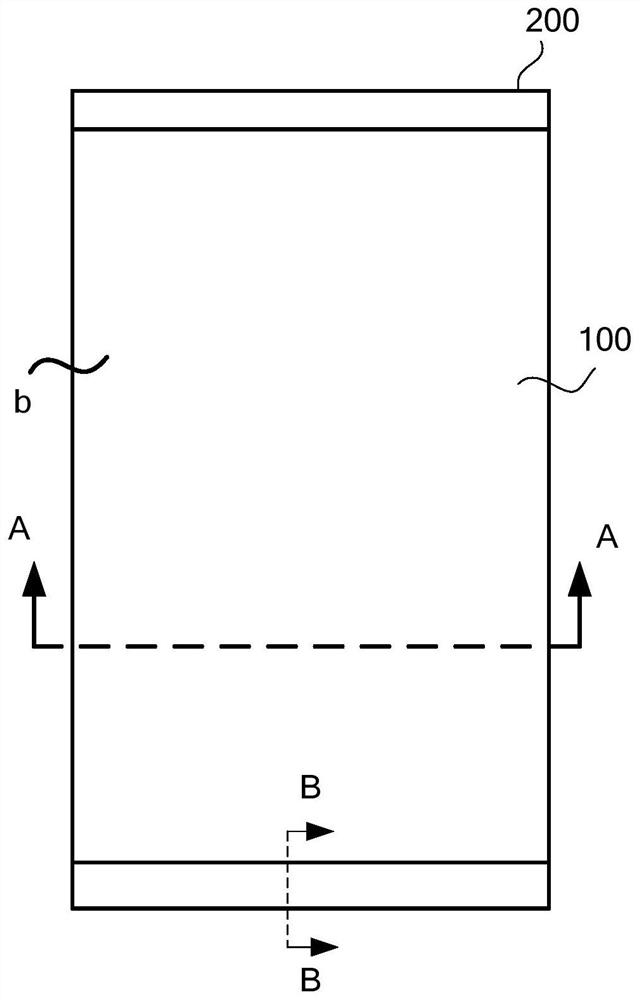

Display assembly and assembling method thereof, and display device

PendingCN111816082AAvoid bending deformationPrevent peelingInput/output processes for data processingIdentification meansDisplay deviceStructural engineering

The invention discloses a display assembly and an assembling method thereof, and a display device, relates to the technical field of display, and aims to solve the problem that a flexible display panel is easy to peel off from other film layers after being bent. The display assembly comprises a flexible display panel, a circuit board, a diaphragm assembly, a cover plate, a first supporting layer and a second supporting layer, wherein the flexible display panel comprises a panel body and a bent part, the first end, in the extending direction of the bent part, of the bent part is connected withthe edge of one side of the panel body, the circuit board is arranged on the back side of the panel body and is connected with the second end of the bent part, the diaphragm assembly is arranged on the display side of the panel body in a stacked mode, the cover plate is arranged on the side, away from the panel body, of the diaphragm assembly in a stacked mode, the first supporting layer is arranged on the back side of the panel body in a stacked mode and located between the panel body and the bent part, and the second supporting layer is arranged at the first end of the bent part and locatedbetween the cover plate and the bent part. The display assembly can be used in display devices such as mobile phones and the like.

Owner:BOE TECH GRP CO LTD

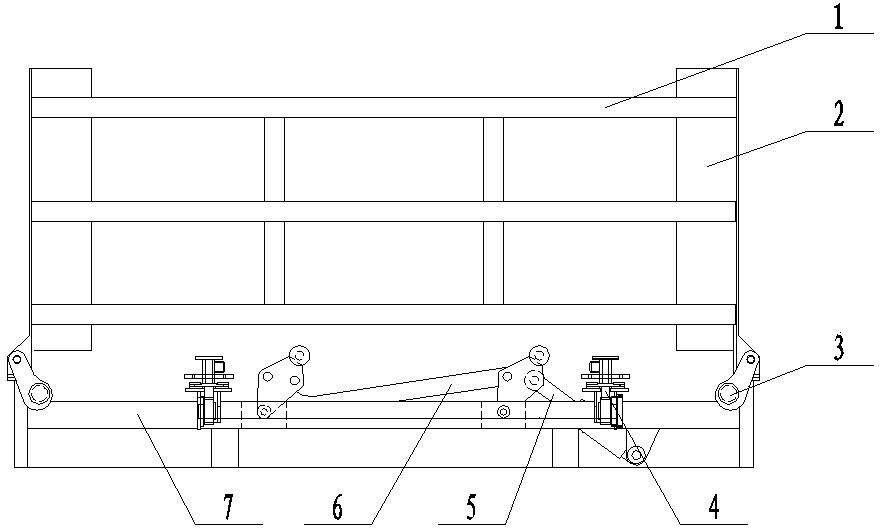

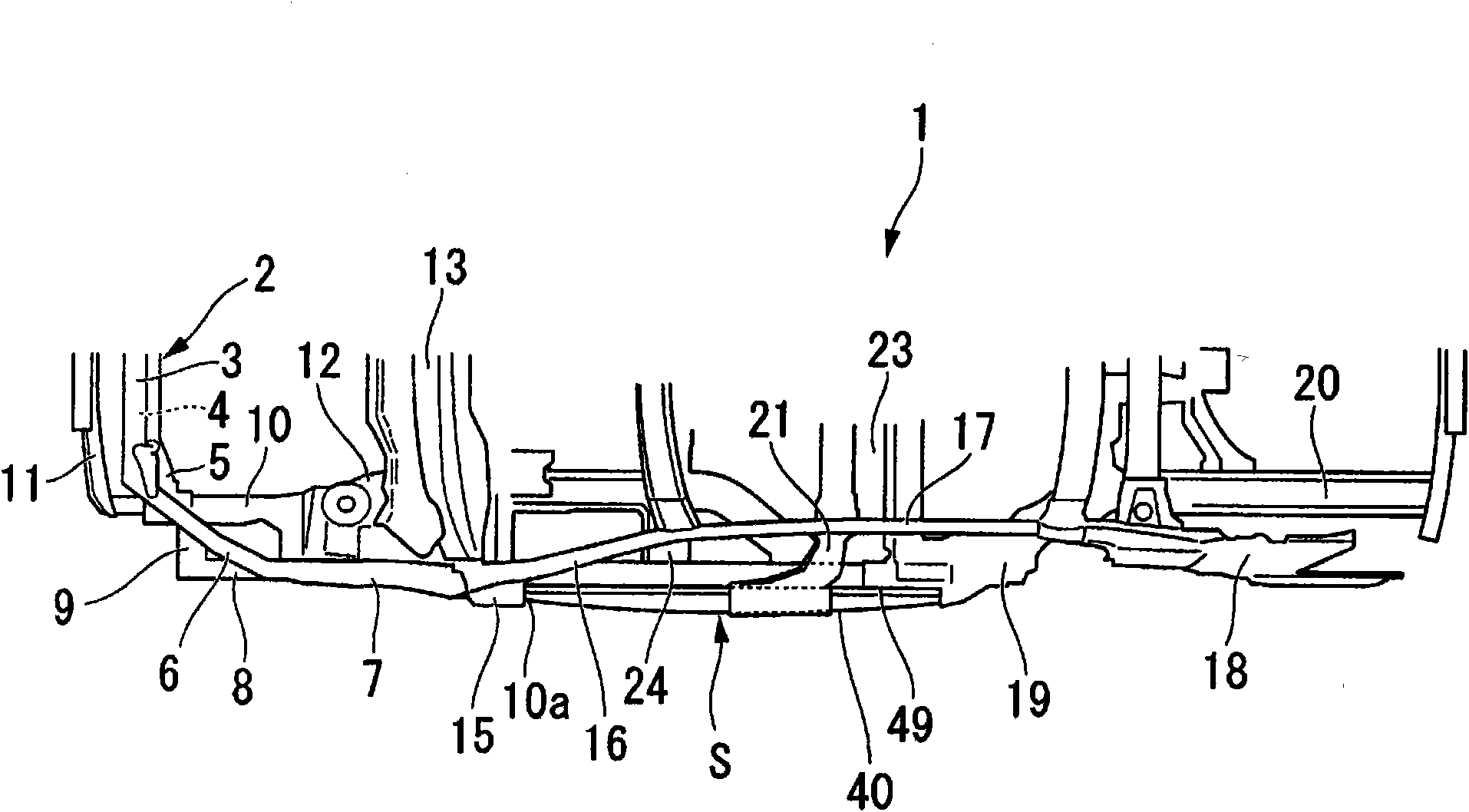

Anti-sidewise-bending deformation control device of H-shaped steel component and welding method

ActiveCN110102862AGuaranteed structural strengthEnsure structural stabilityWelding/cutting auxillary devicesAuxillary welding devicesCompression deviceEngineering

The invention discloses an anti-sidewise-bending deformation control device of an H-shaped steel component. The anti-sidewise-bending deformation control device comprises an assembly jig, an anti-sidewise-bending device, compression devices, a sliding rail and the to-be-welded component; the anti-sidewise-bending device is located in the middle of the assembly jig; the compression devices with thesame number are arranged on the left side and the right side of the anti-sidewise-bending device; and the compression devices are distributed in the direction of the assembly jig. A welding method comprises the steps: (1) the compression devices are adjusted; (2) a lower flange plate and a web are welded; and (3) an upper flange plate and the web are welded. During welding, the web at a welding point is compressed through the anti-sidewise-bending device, thus deformation and bending of the web in the welding process are avoided, two welding heads are symmetrically arranged on the welding positions of the flange plates and the web, the compression devices work to drive the to-be-welded component to move, the two sides of contact points of the web and the flange plates are synchronously welded through the two welding heads, in the process, the to-be-welded component can be semi-automatically welded, the machining efficiency of the H-shaped component can be improved, and the welding quality of the H-shaped component is guaranteed.

Owner:浙江中南绿建科技集团有限公司

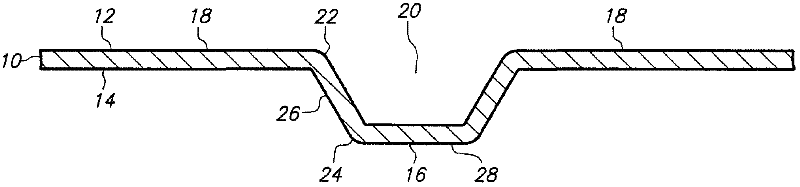

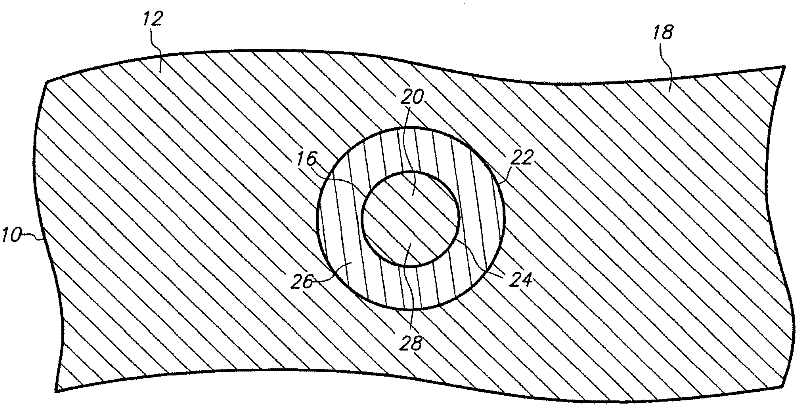

Structure for side portion of vehicle

InactiveCN101868399AEfficient deliveryWon't add weightSuperstructure subunitsVehicle frameEngineering

A structure for a side portion of a vehicle has a closed cross-section structure formed by joining together an inner panel on the vehicle interior side and an outer panel on the vehicle exterior side, and also has a side sill as a vehicle body frame member placed at the side portion of the vehicle so as to extend in the front-rear direction of the vehicle. At a portion of an outer wall of the outer panel, there is formed an arch surface projecting outwardly of the vehicle interior with a position near the joined position of a vehicle body center pillar defined as the top of the arch. The outer panel has a flat surface section adjacent to the arch surface and including a rectilinear section extending in the front-rear direction of the vehicle body. The front end of the side sill is connected to a front side frame of the vehicle body. The rear end of the side sill is connected to a rear frame of the vehicle body.

Owner:HONDA MOTOR CO LTD

Whole breast tumor small-interval subserial pathological slice preparation method

ActiveCN109000956AAchieve preliminary cuttingAvoid bending deformationWithdrawing sample devicesPreparing sample for investigationAbnormal tissue growthParaffin wax

The invention discloses a whole breast subserial large slice preparation method. The method comprises the following steps of collecting a tumor sample; performing continuous parallel splitting to obtain sample blocks which are split in parallel; performing soaking and fixing in a neutral formaldehyde solution with the concentration of 4% for 24 hours; removing redundant fat tissues by clipping; performing continuous parallel cutting in parallel to an original slice again to form a slice shape; performing continuous fixing for 48 hours by using the neutral formaldehyde solution with the concentration of 4%; performing sequential dehydration by adopting gradient ethanol; performing transparency treatment by using xylene; performing wax dipping in an electric heating constant temperature incubator at 62-65 DEG C to obtain a paraffin pathological sample; and slicing the paraffin pathological sample by adopting a rotary paraffin slicing machine, wherein each sample block can be subjected toconventional pathological staining including HE through continuous slicing. The thickness of a large slice prepared with the method can reach the conventional slice thickness of 4-5 microns; the slice is complete in tissue structure, smooth, clean and free of folds and pollution; no slice stripping phenomenon occurs; the cell nucleoplasm proportion is clear; and a staining result is consistent with a conventional clinical staining result.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com