Method for producing circuit board thin plates

A production method and circuit board technology, applied in printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems that tools cannot meet production requirements, thin plates are easy to be bent, and board surfaces are scratched, so as to improve the efficiency of electrical testing, Prevent stuck and broken boards, and avoid the effect of inserting wrong slots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

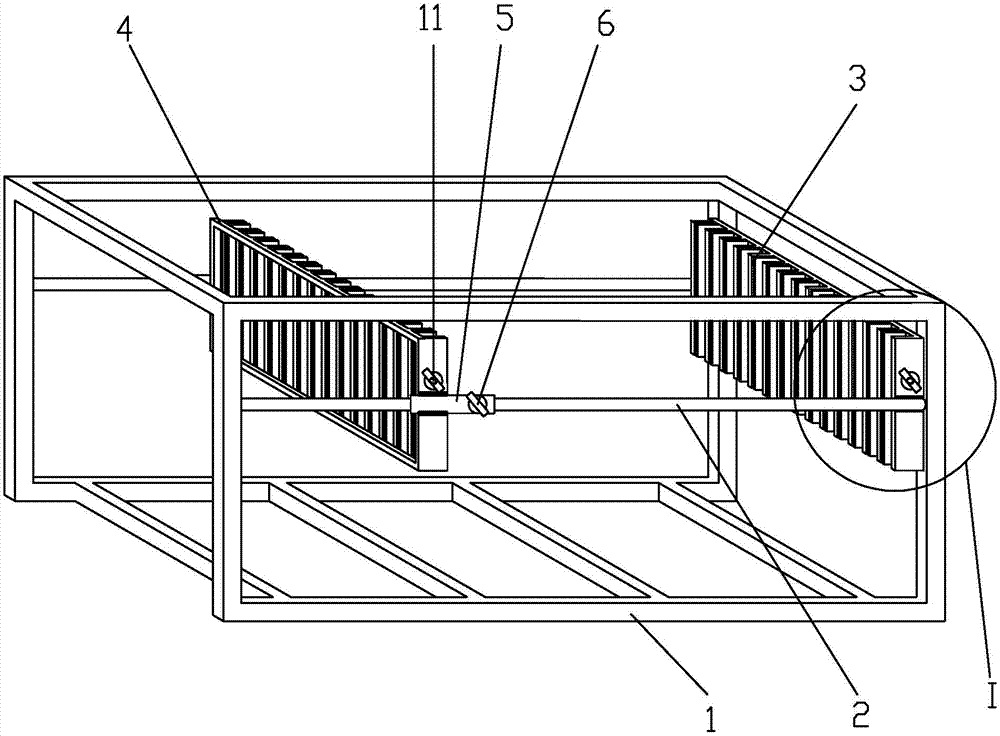

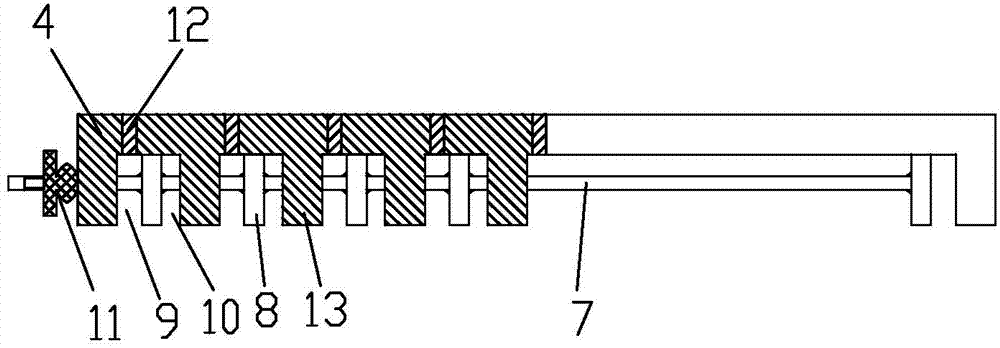

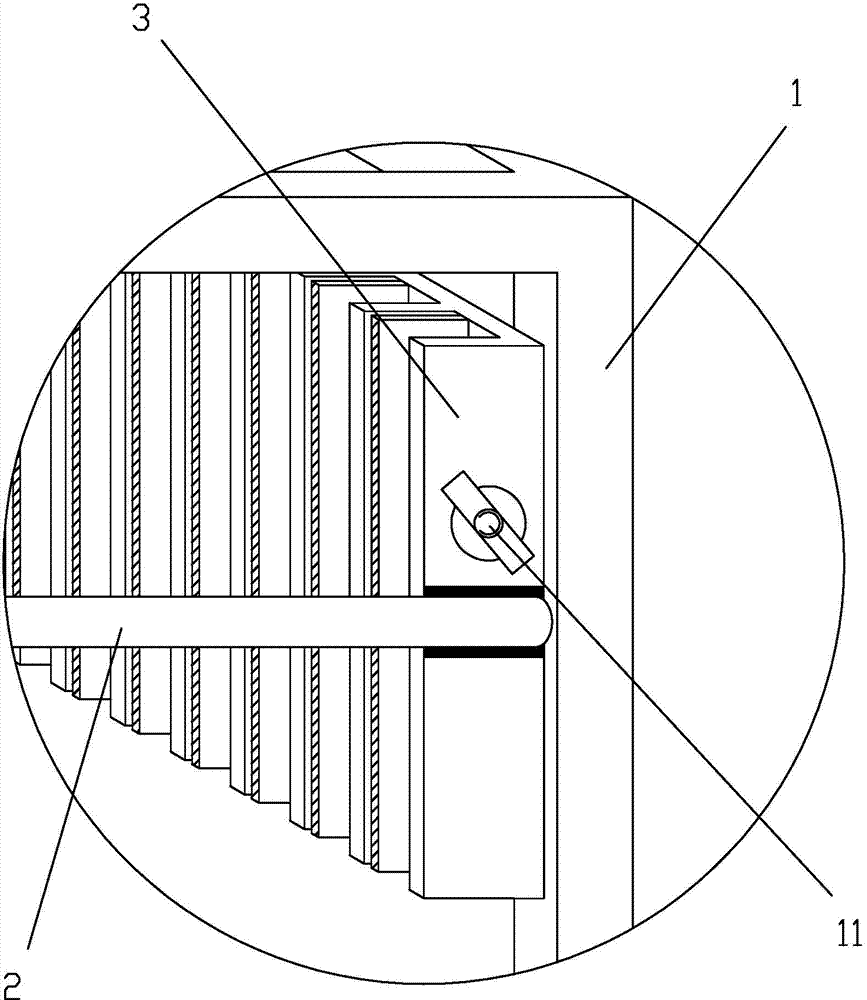

[0047] Below in conjunction with accompanying drawing, the present invention will be further described, and the operation of making circuit board sheet is as follows:

[0048] A) Cutting: Cutting the qualified raw material board is composed of copper clad laminate and resin film, cleaning and drying the surface;

[0049] B) Transfer of inner layer circuit pattern and circuit inspection: paste a layer of photosensitive material on the copper foil on the surface of the above circuit board, then carry out counter-position exposure through black film, form a circuit pattern after development, drill pipe position holes on the edge of the board, and Automatic optical detection equipment is used to detect whether there is a broken line or a short circuit on the circuit board surface;

[0050] C) Browning and pressing board: roughen the copper surface and wire surface as the inner layer; arrange the above-mentioned raw material boards according to the design requirements, and press th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com