Adjustable lead wire press-connection machine bracket

A wire crimping and crimping machine technology, which is applied to the connection, connection, line/collector parts and other directions where permanent deformation plays a role, can solve the problems that affect the quality of crimping and cannot guarantee the straightness of crimping joints, etc., to achieve Easy to transport, tightly pressed, and ensure the effect of crimping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present application, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] The orientation terms such as up, down, left, right, front and rear in this application document are established based on the positional relationship shown in the drawings. If the drawings are different, the corresponding positional relationship may also change accordingly, so this should not be understood as limiting the scope of protection.

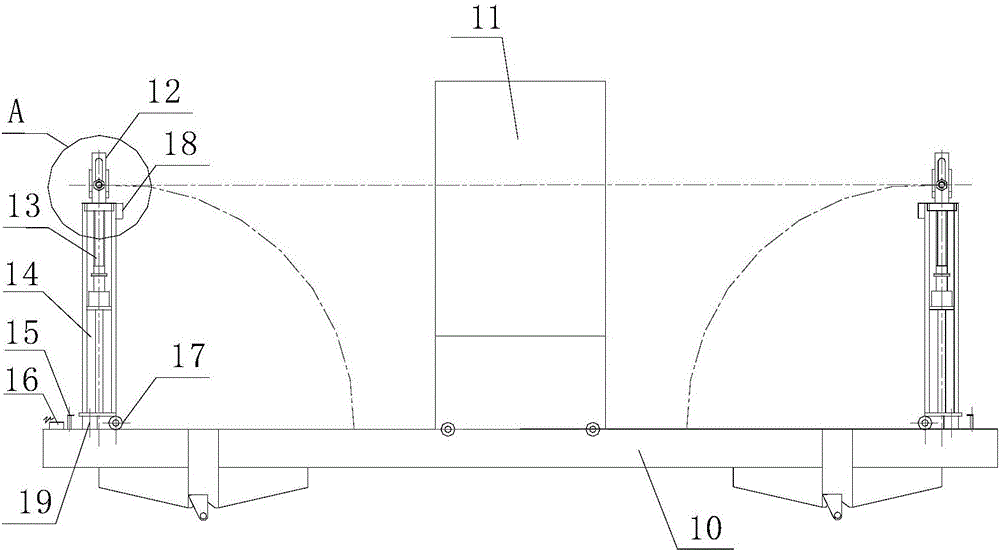

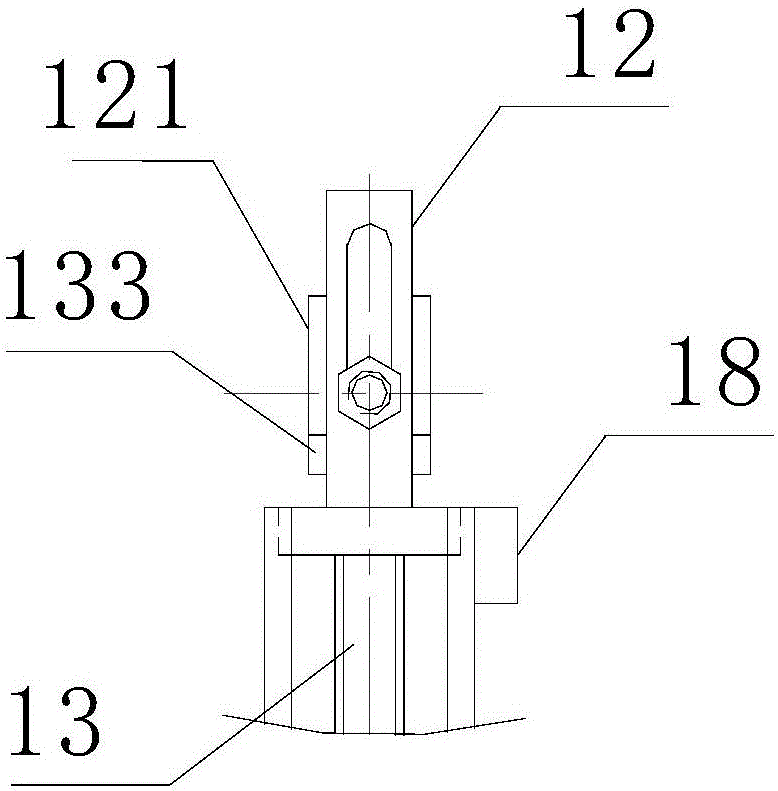

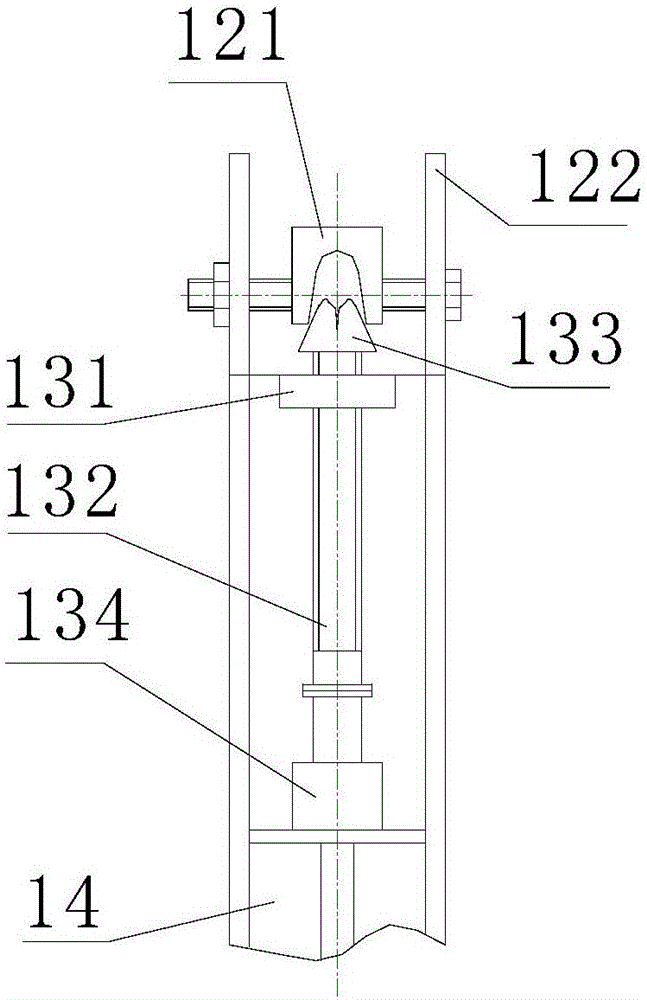

[0038] The invention provides an adjustable wire crimping machine bracket, the structure of which is as follows: Figure 1 to Figure 4 shown, which includes:

[0039] Crimping locomotive 10, crimping machine 11, upper adjustment unit 12, lower adjustment unit 13, column 14, displacement sensor 15, controller 16, hinge 17, first buffer pad 18, second buffer pad 19.

[0040] The crimping locomotive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com