Patents

Literature

242results about How to "Press tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

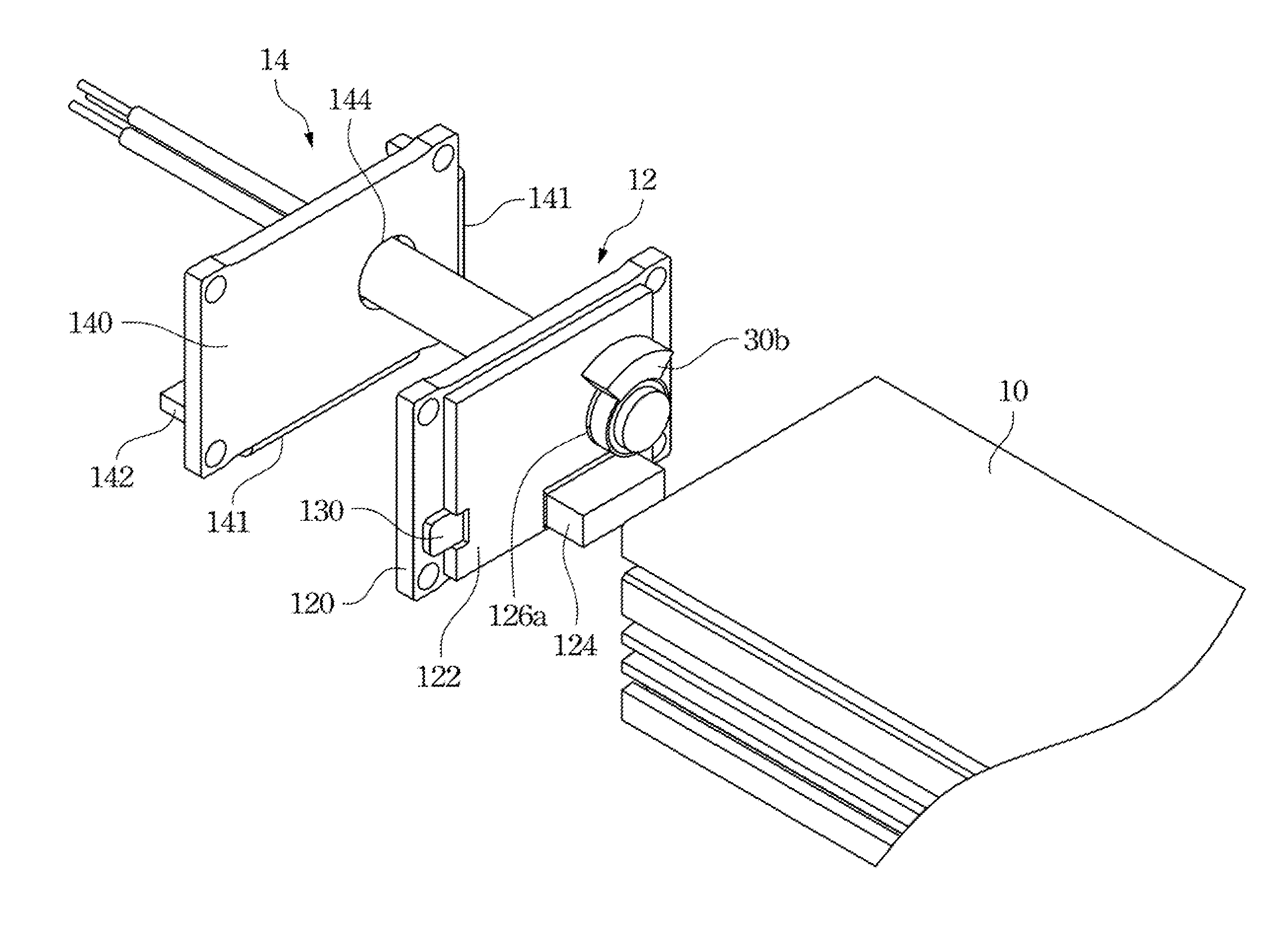

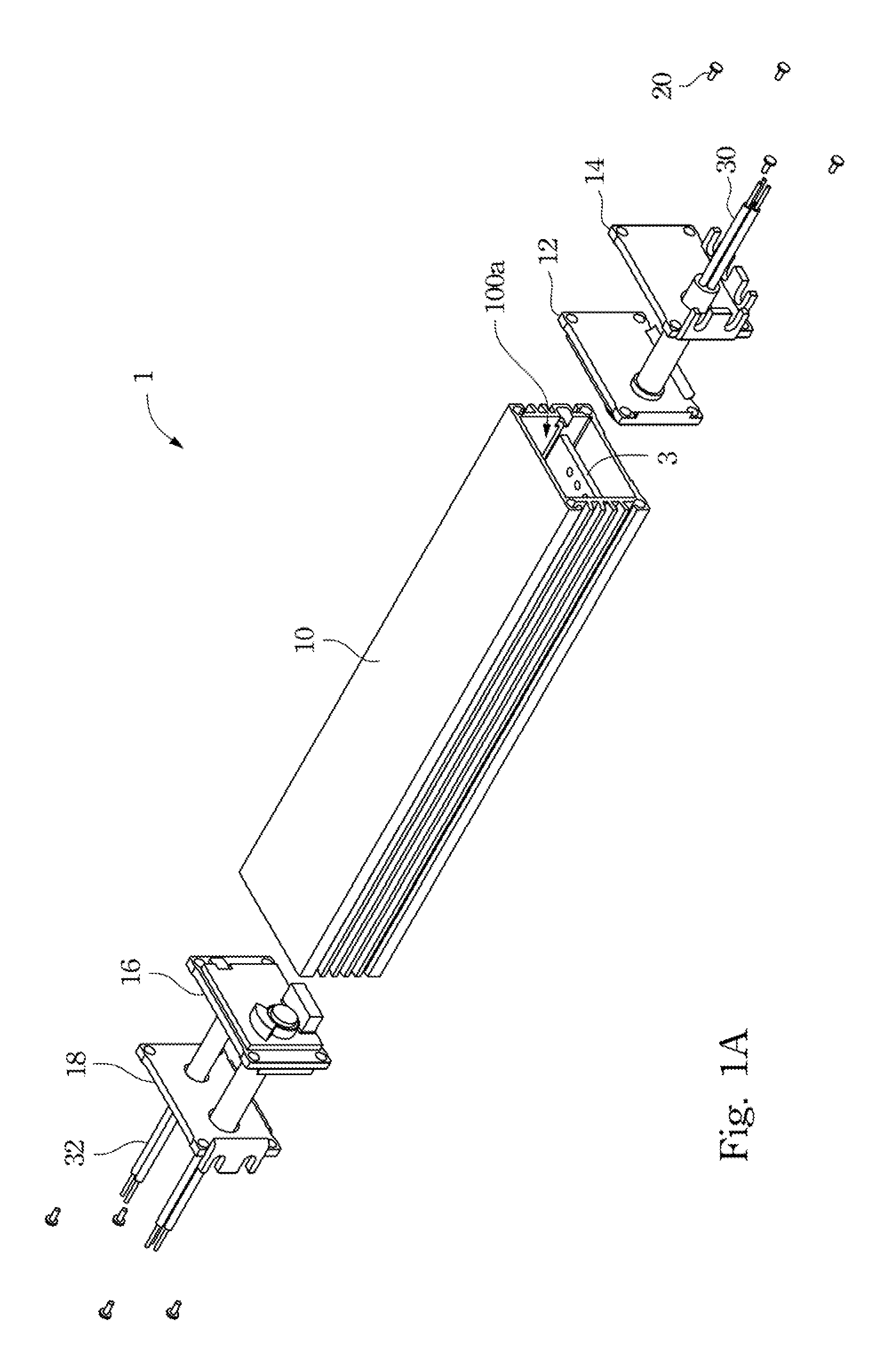

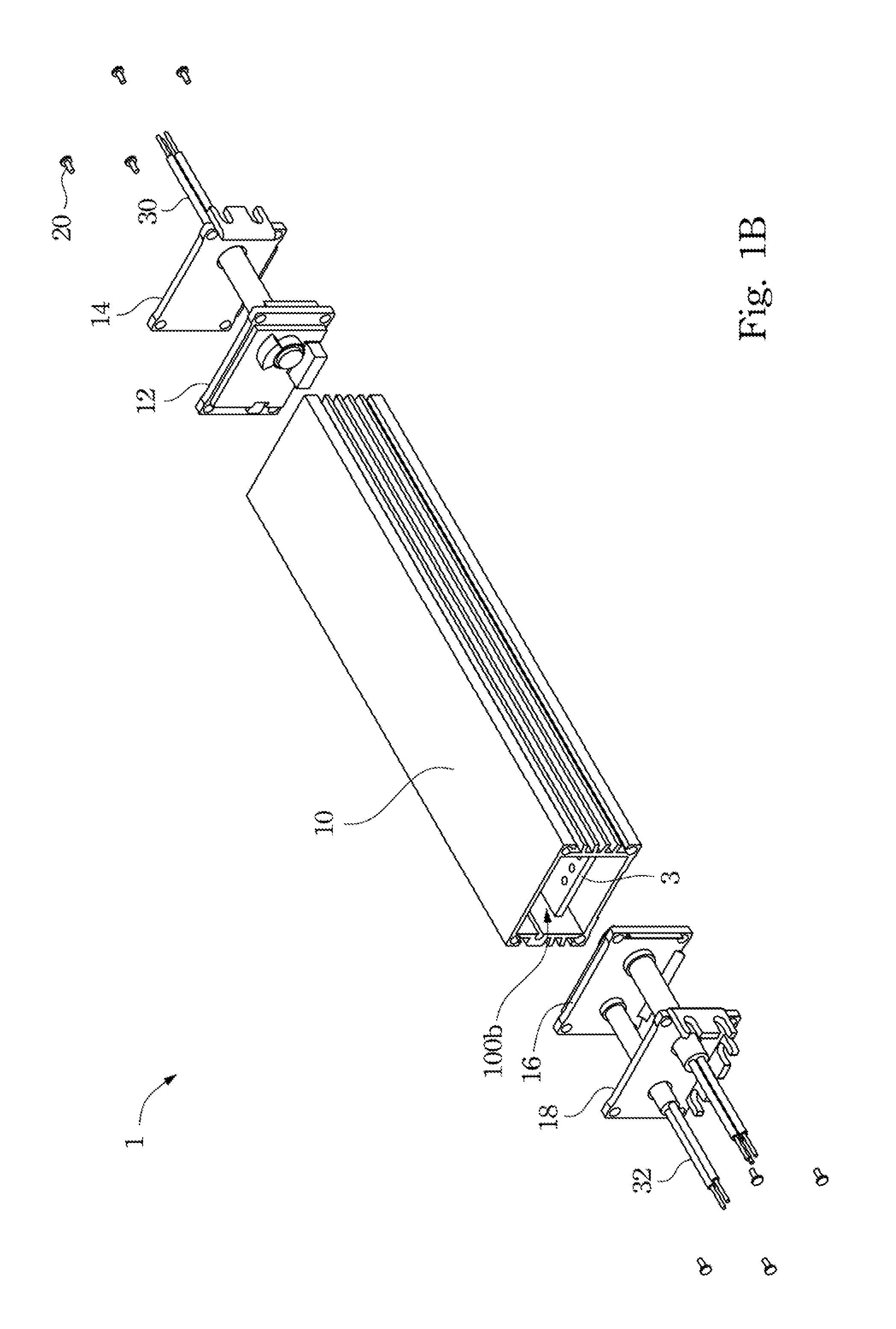

Auxiliary fastening apparatus

Owner:FAN EAGLE

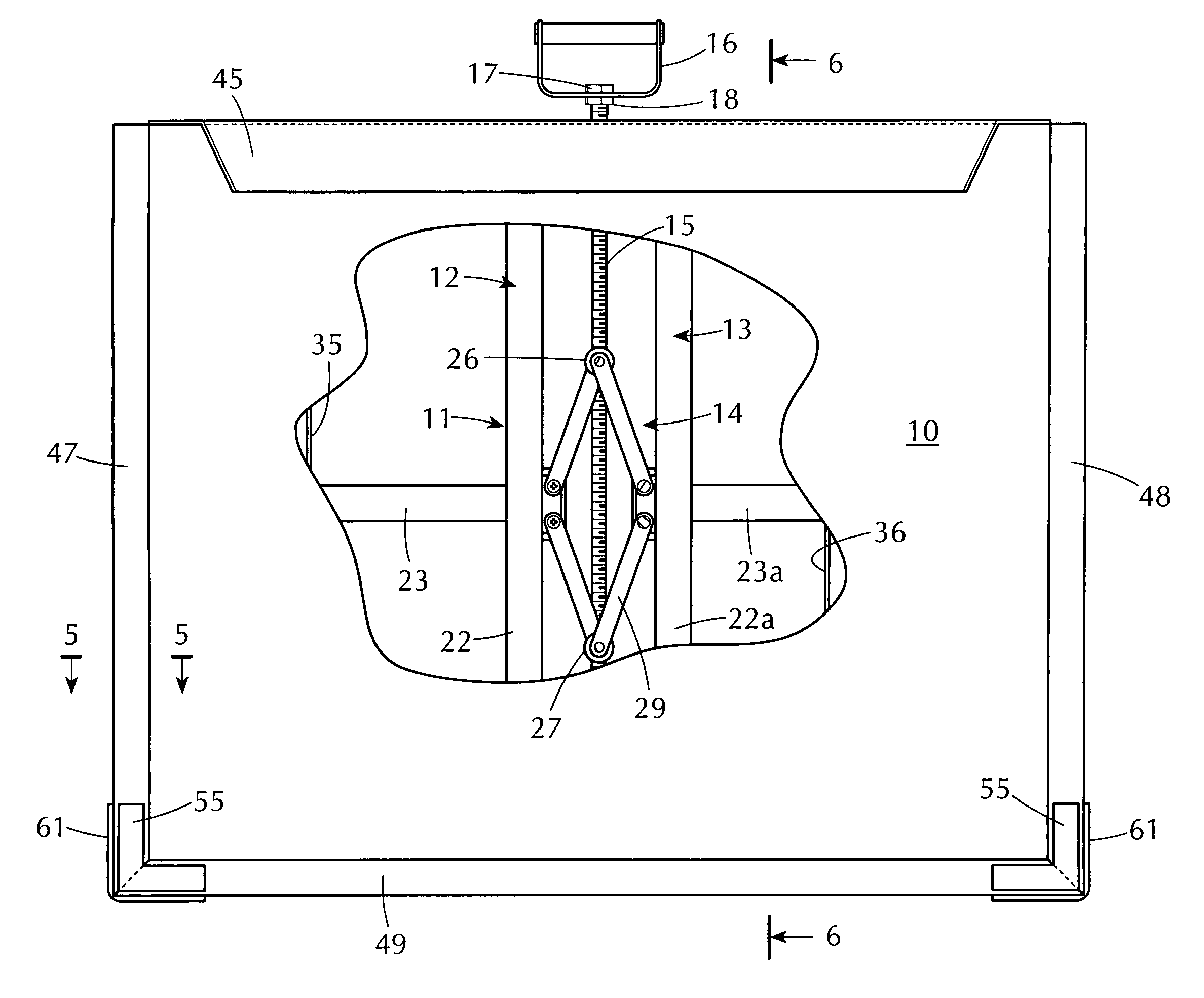

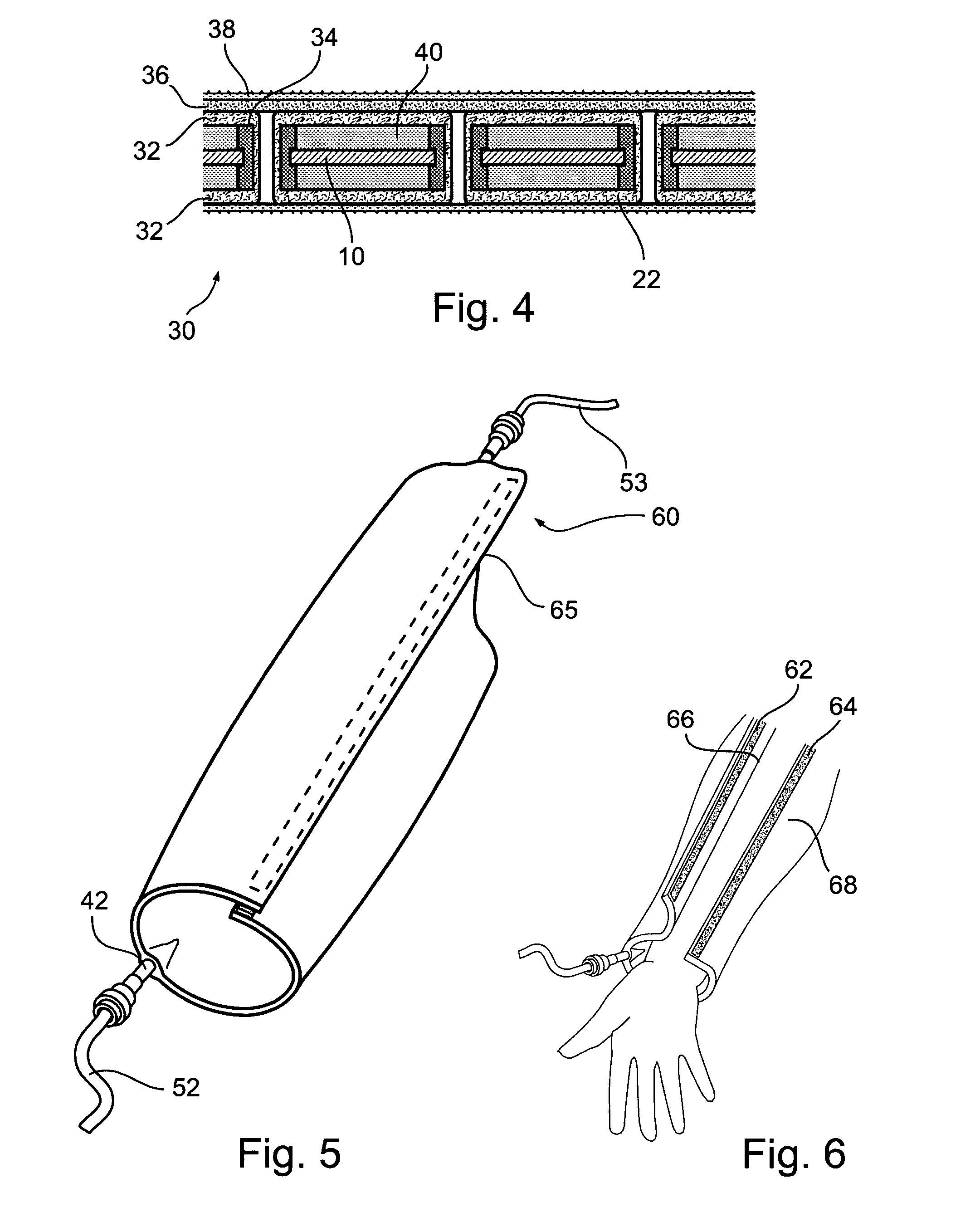

Portable flood barrier panel

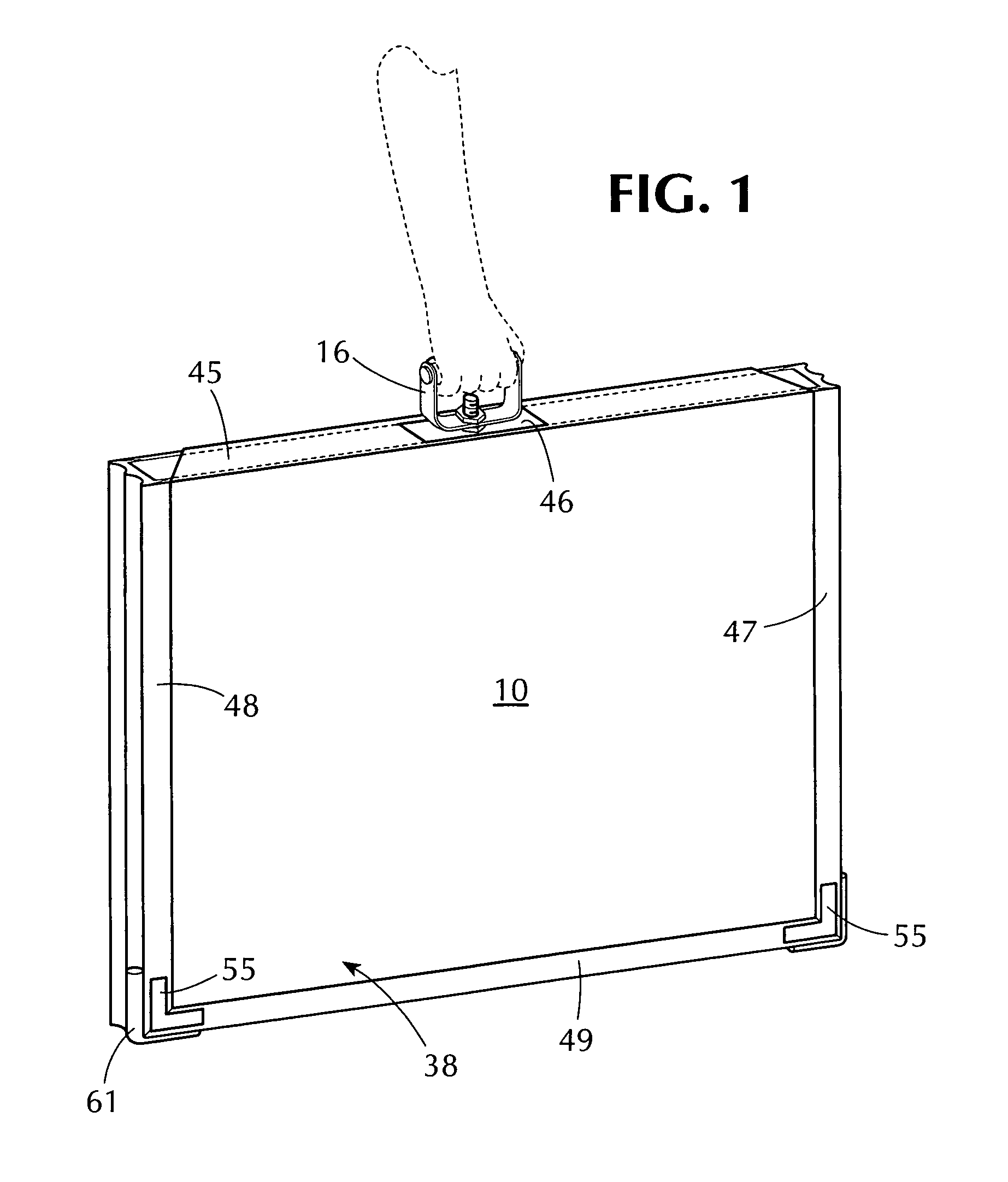

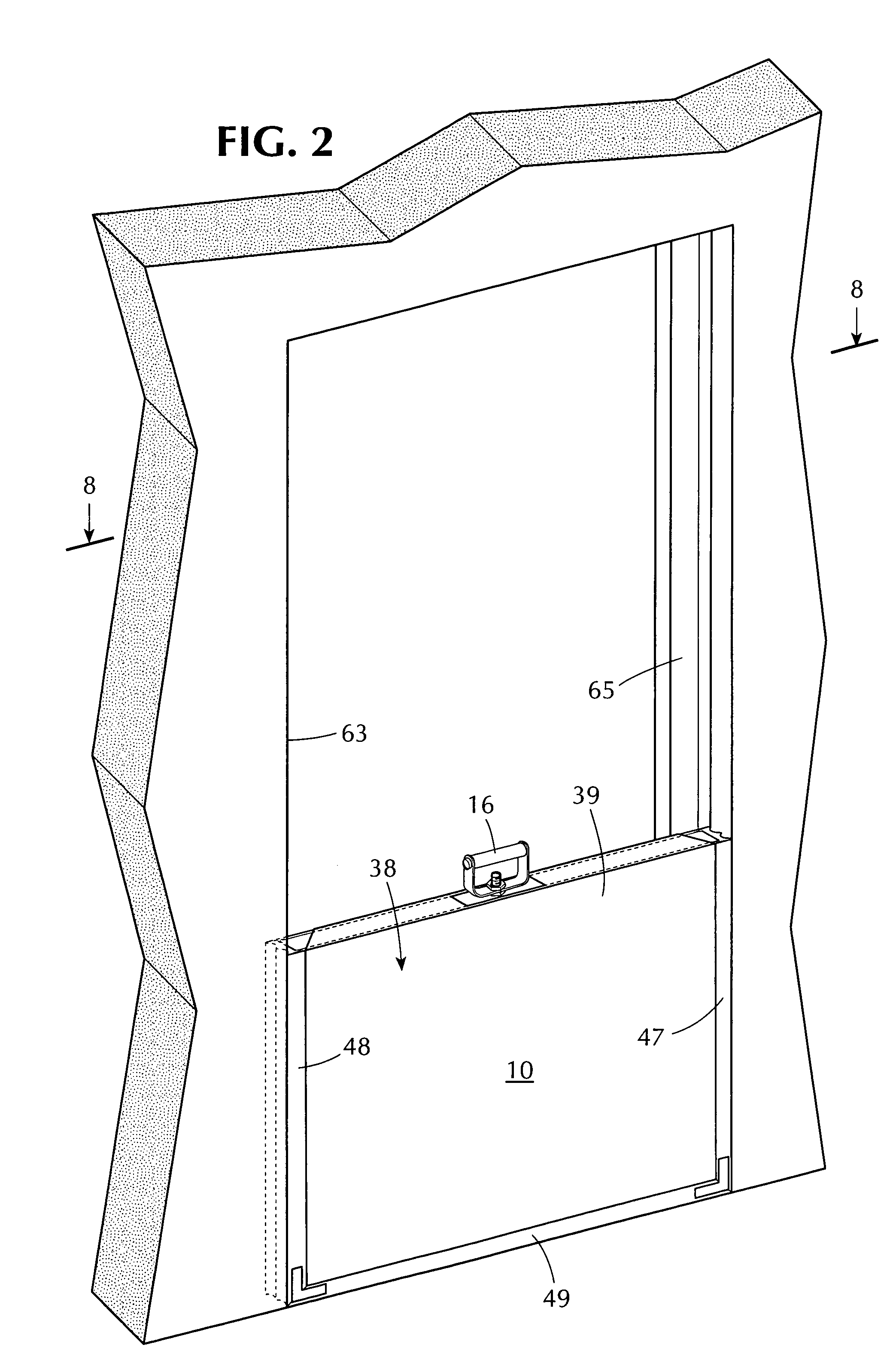

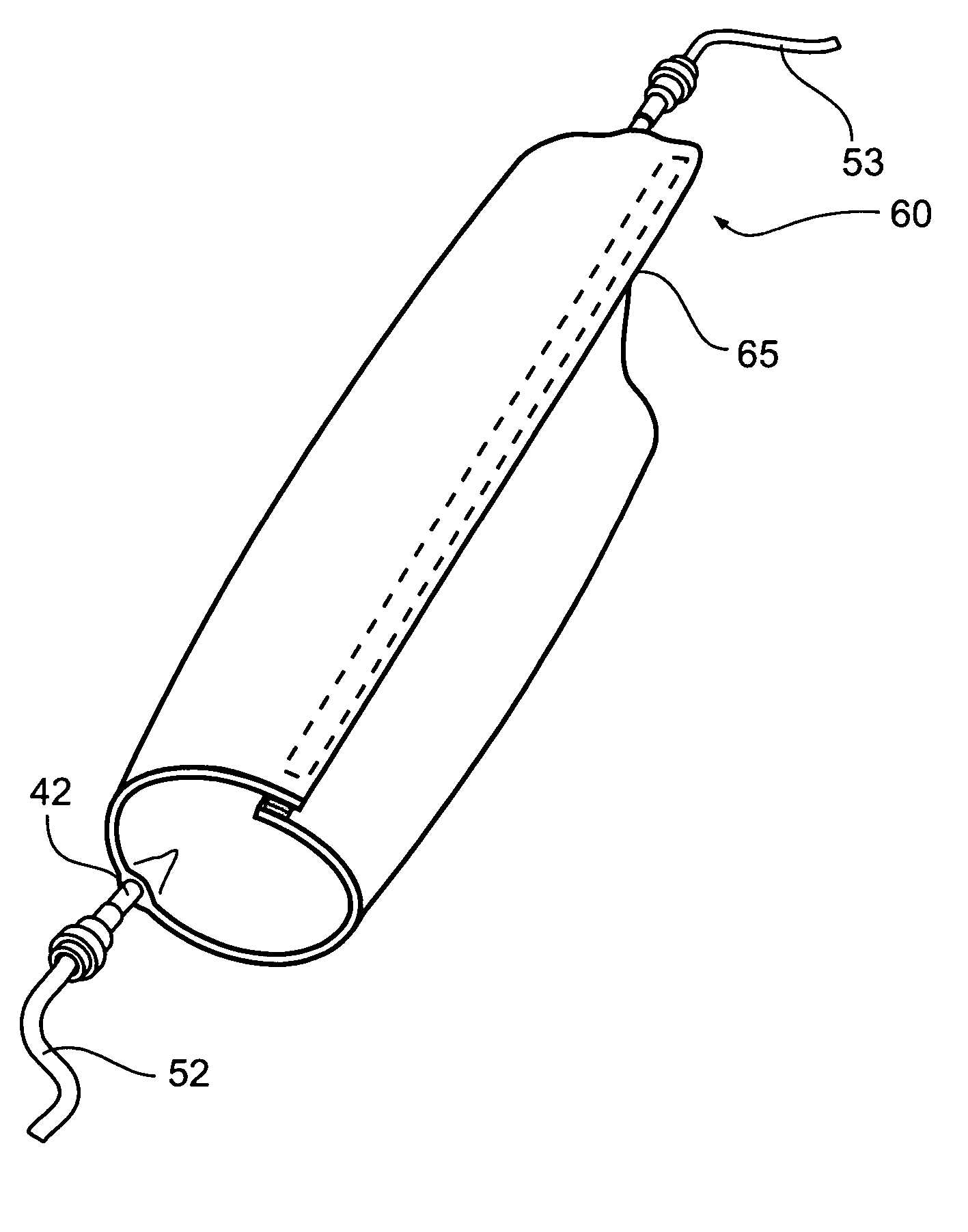

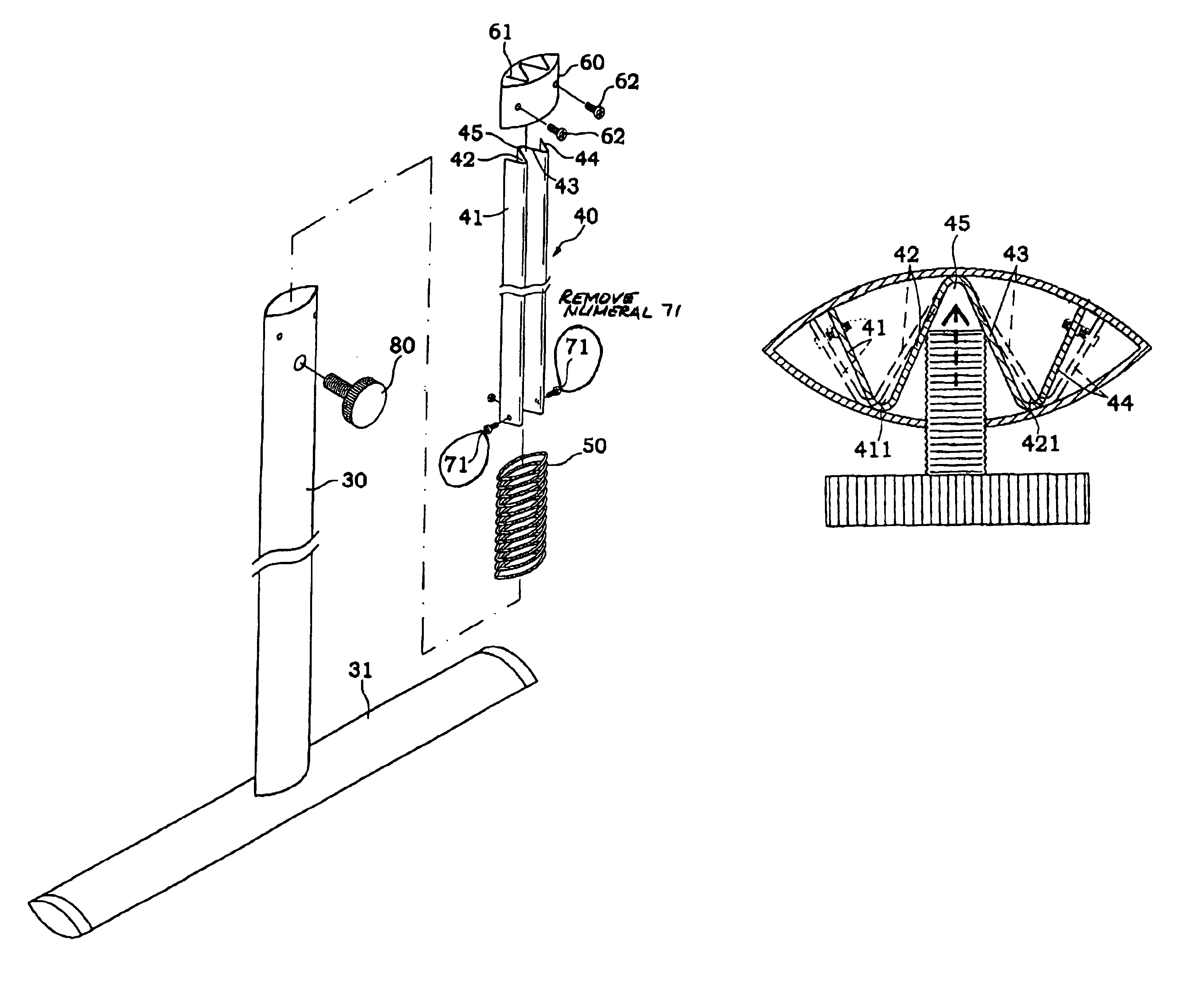

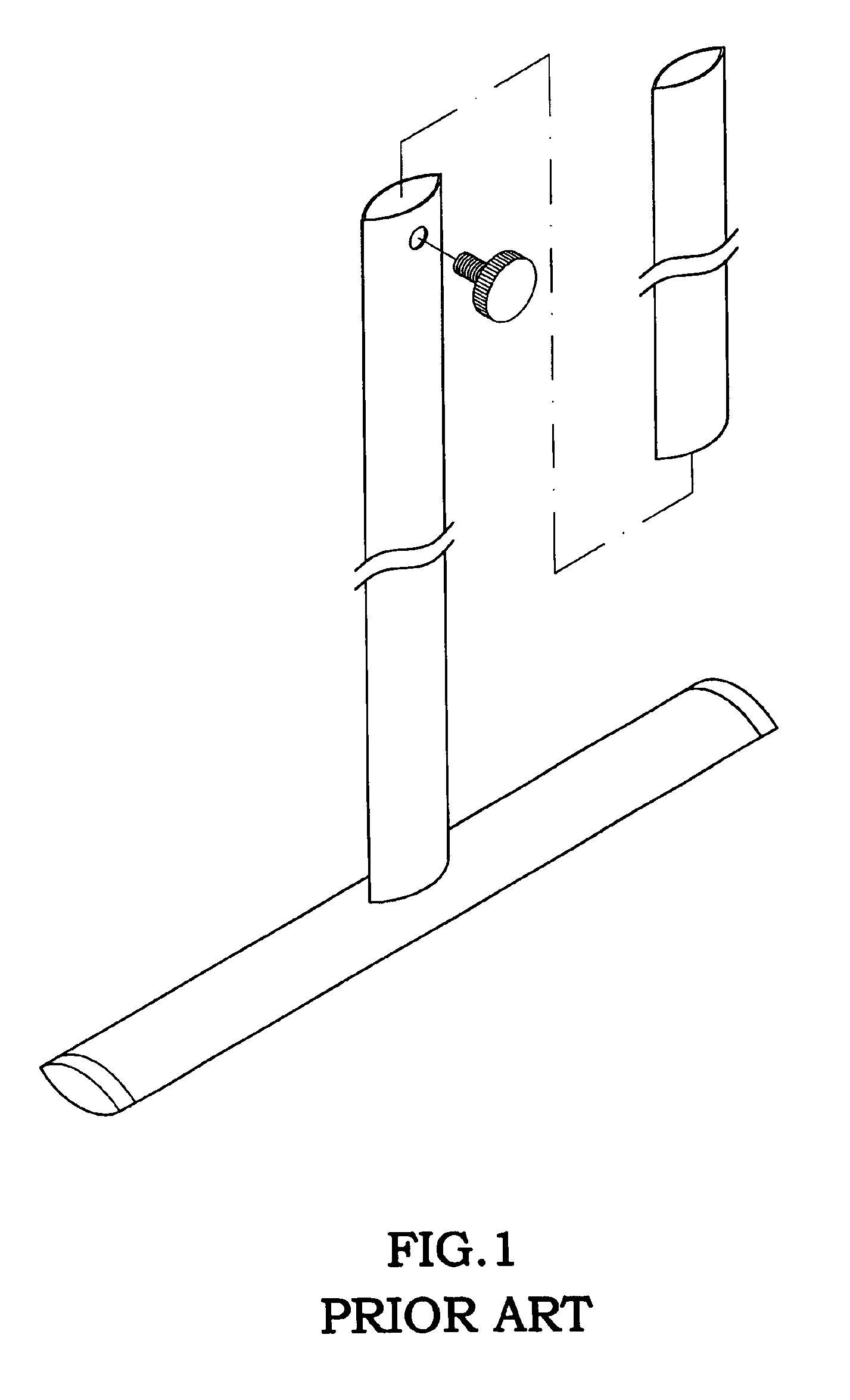

ActiveUS7523589B1Easy to installEasy to removeFlood panelsShutters/ movable grillesEngineeringMullion

An Adjustable flood-resistant barrier for removable installation in a window or door opening or the like. A laterally adjustable frame is received within an elastic envelope and can be laterally expanded to engage the sides and bottom of the opening. An adjusting mechanism includes a shaft, which projects upward above the top of the frame, approximately in the center thereof, and mounts a handle for both carrying the panel and rotating the shaft to effect width adjustments of the panel. An improved peripheral seal minimizes the likelihood of leakage at the corners. For wide openings, mullions are provided to support central areas and to increase downward sealing pressures in the center of the panel. Mullions can also be positioned between an opposed pair of barrier panels for closing off unusually wide openings.

Owner:PRESRAY

Temperature regulating suit

InactiveUS20070162096A1Cooling effectTemperature controlTherapeutic coolingTherapeutic heatingBiomedical engineeringHeat transfer

A device for the controlled heating or cooling of a portion of the body is disclosed. The device includes a contact surface; a plastically deformable, substantially sheet element configured to define the shape of the contact surface; and a heat transfer component, associated with the plastically deformable element, for adjusting the temperature of the contact surface.

Owner:MEDISUIT

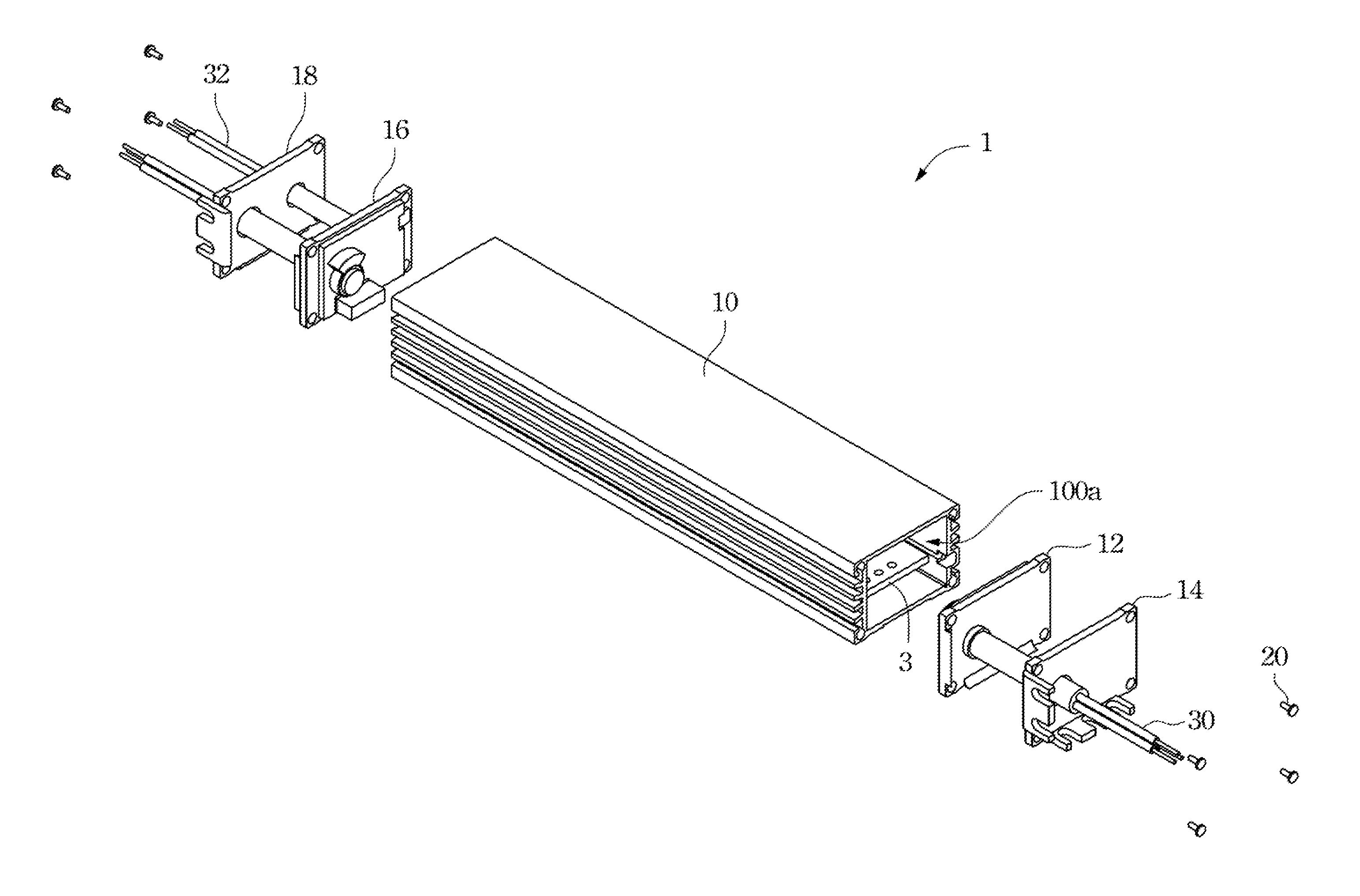

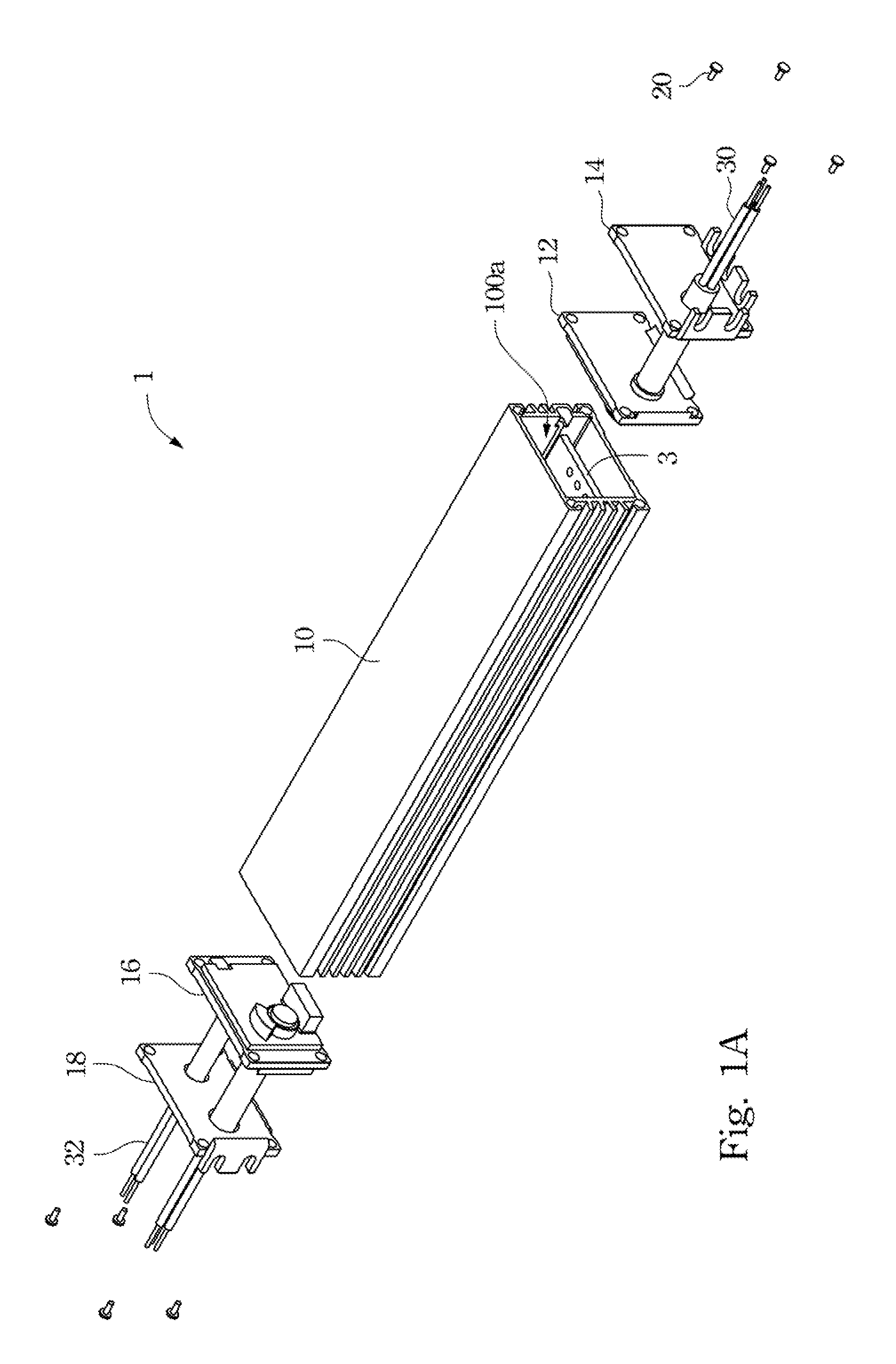

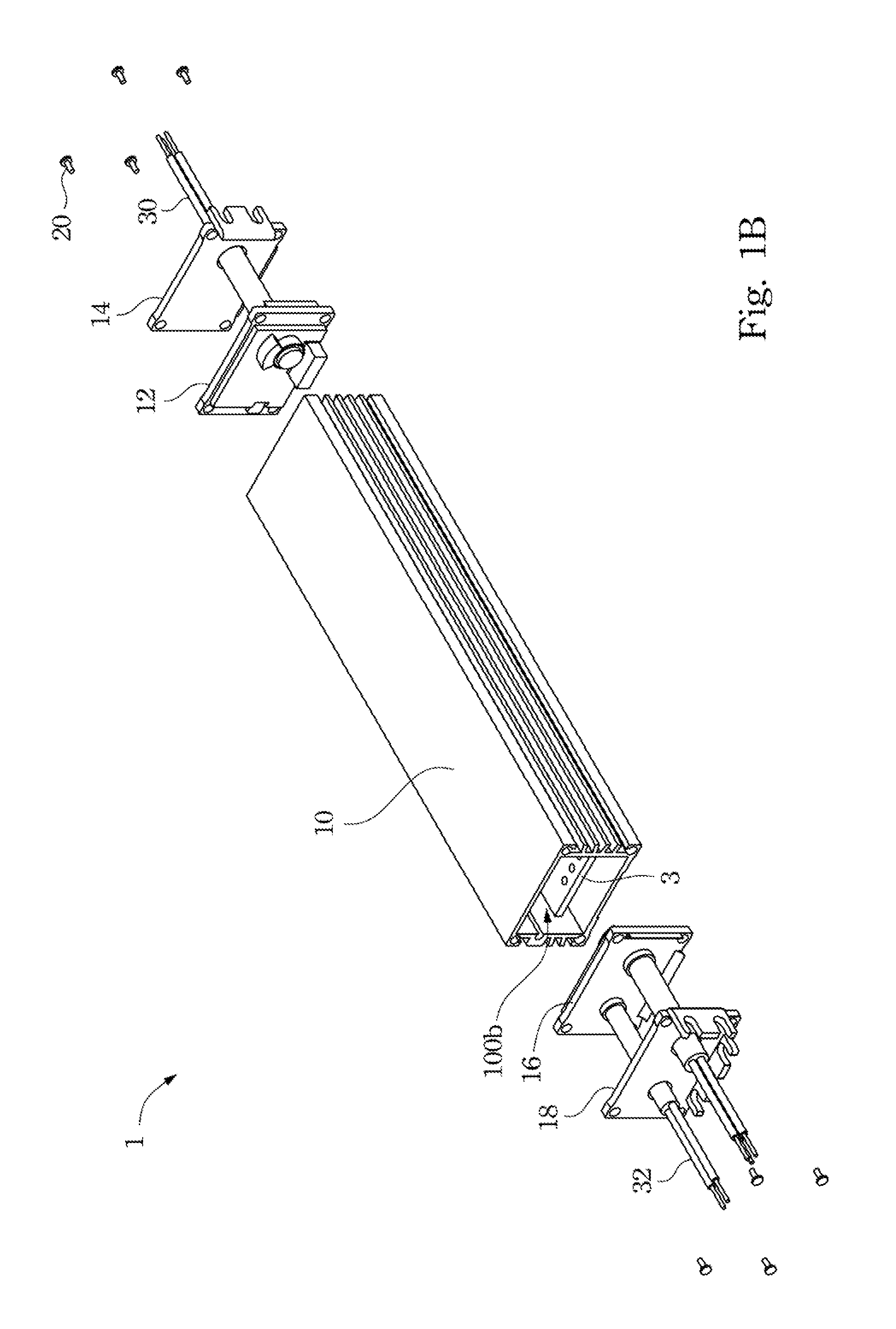

External structure of outdoor electronic apparatus

An external structure of an outdoor electronic apparatus for packaging a circuit board having a power line is provided. The external structure includes a housing having an opening and a waterproof gasket. The waterproof gasket includes a main body, a platform portion, a first protrusion, and a bushing portion. The main body covers the opening. The platform portion, located at the inner side of the main body, extends into the housing from the opening. The platform portion seals the opening and tightly fits with the housing. The first protrusion is located on the platform portion for abutting against the circuit board. The bushing portion, located at the outer side of the main body, has a channel. The channel passes through the main body and the platform portion and can be passed through by the power line. The bushing portion and the power line tightly fit to each other.

Owner:DELTA ELECTRONICS INC

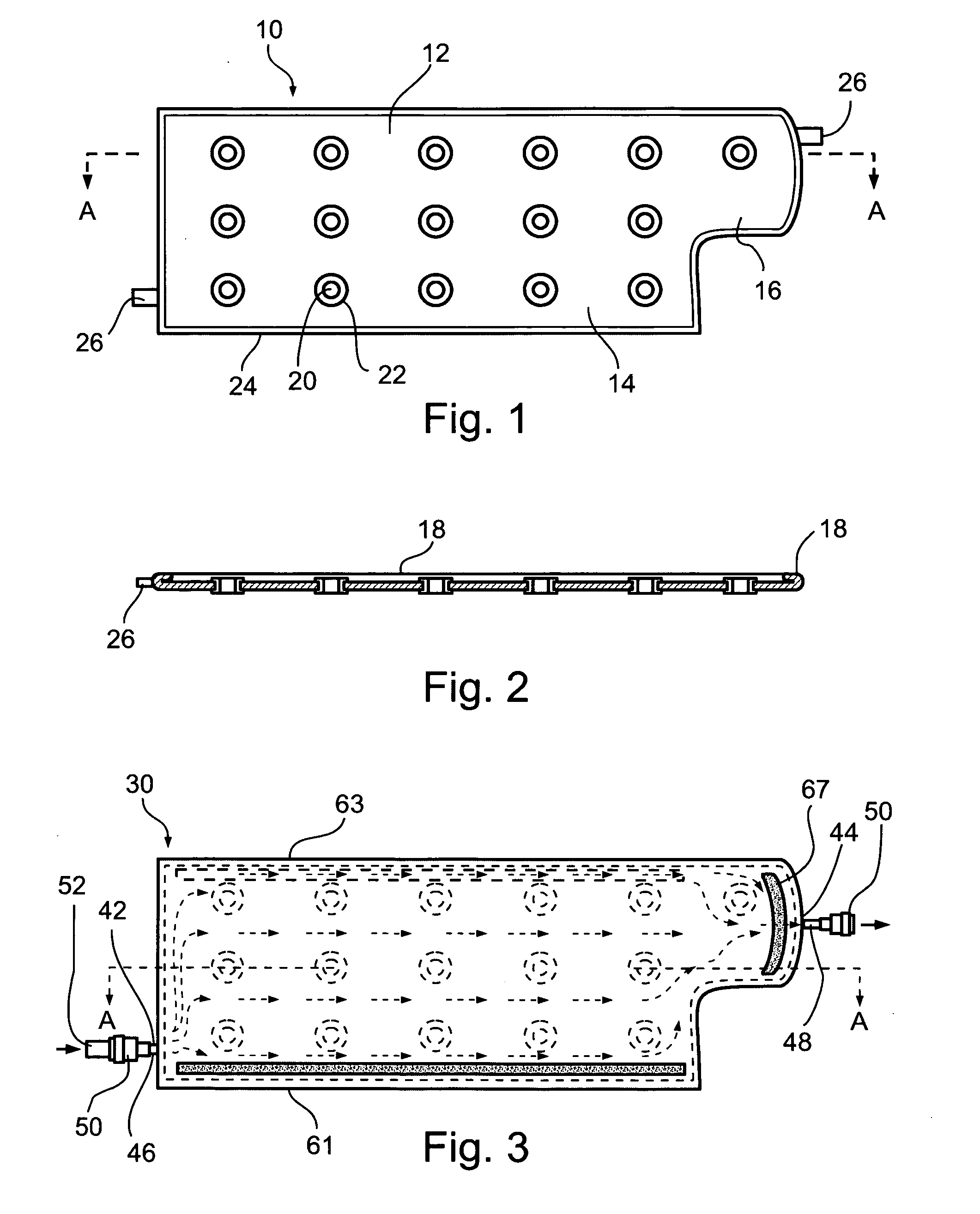

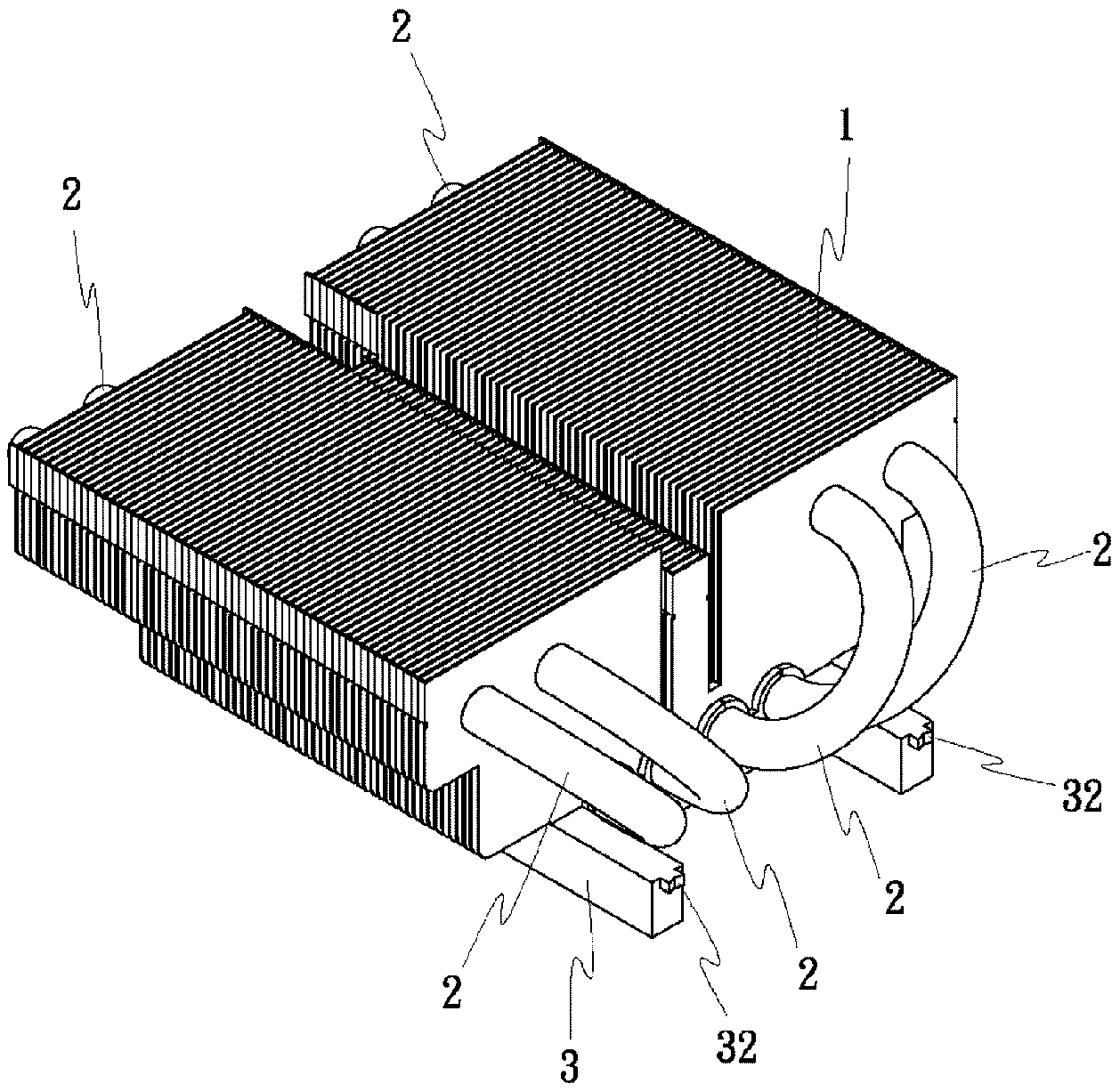

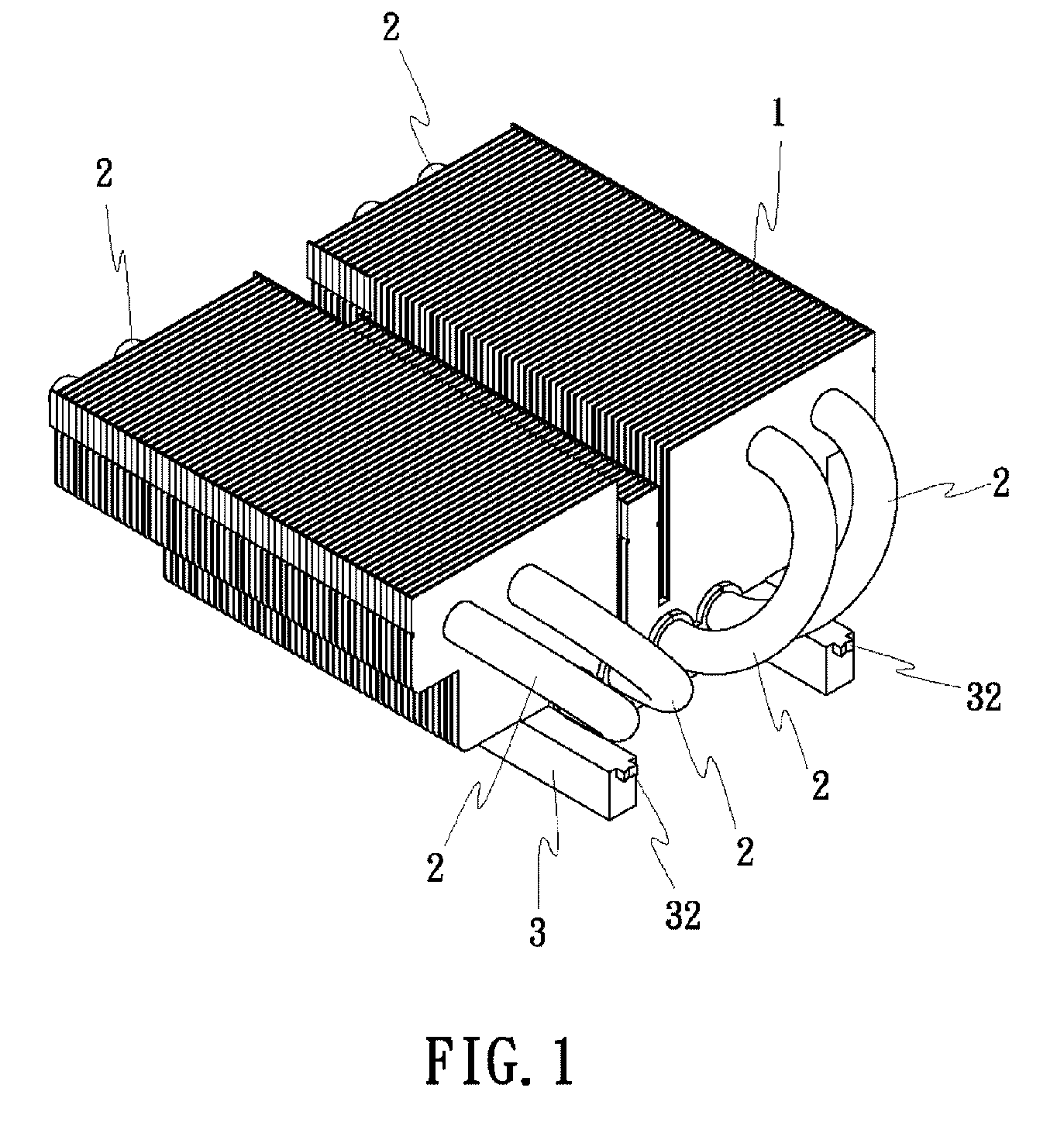

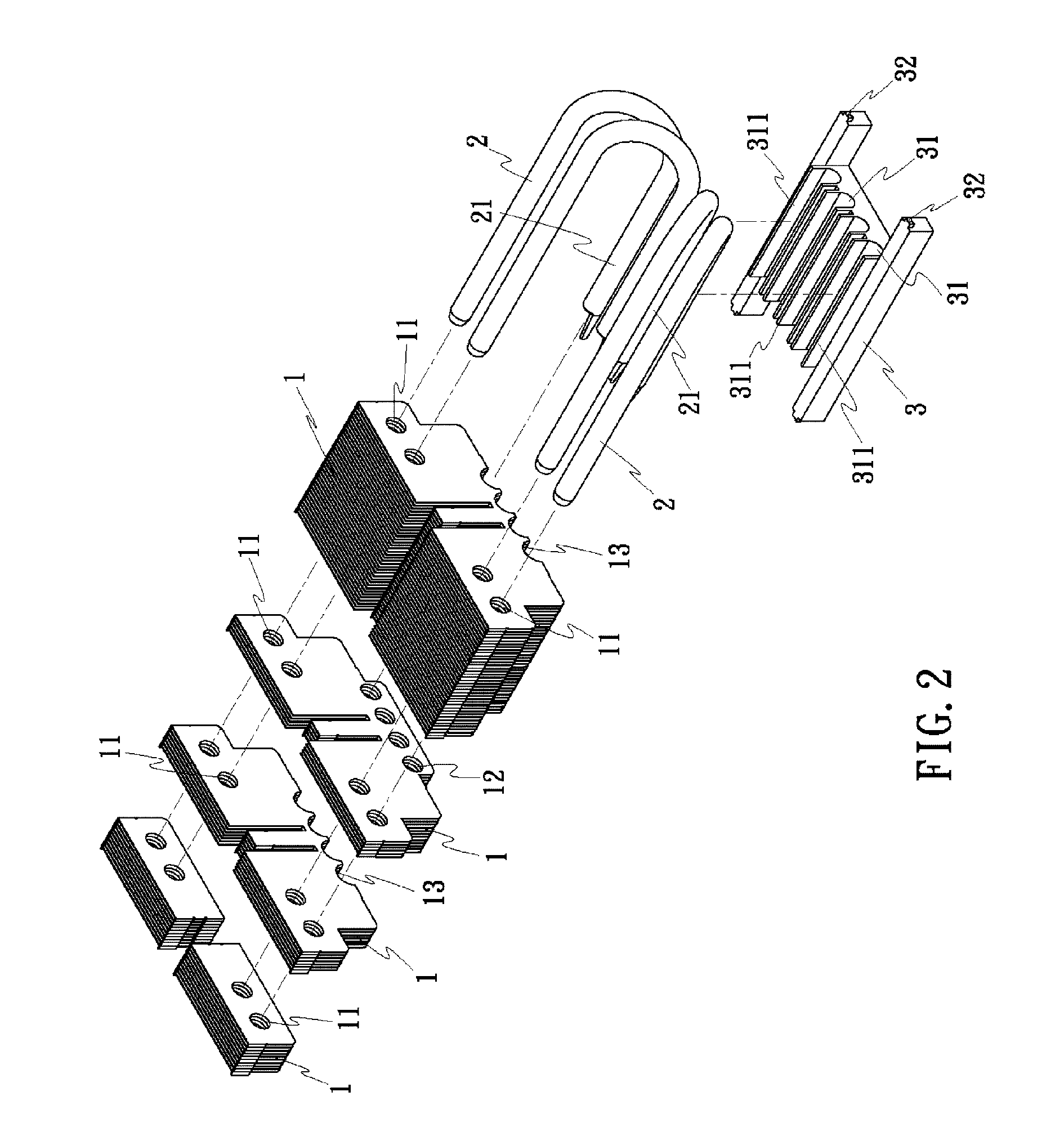

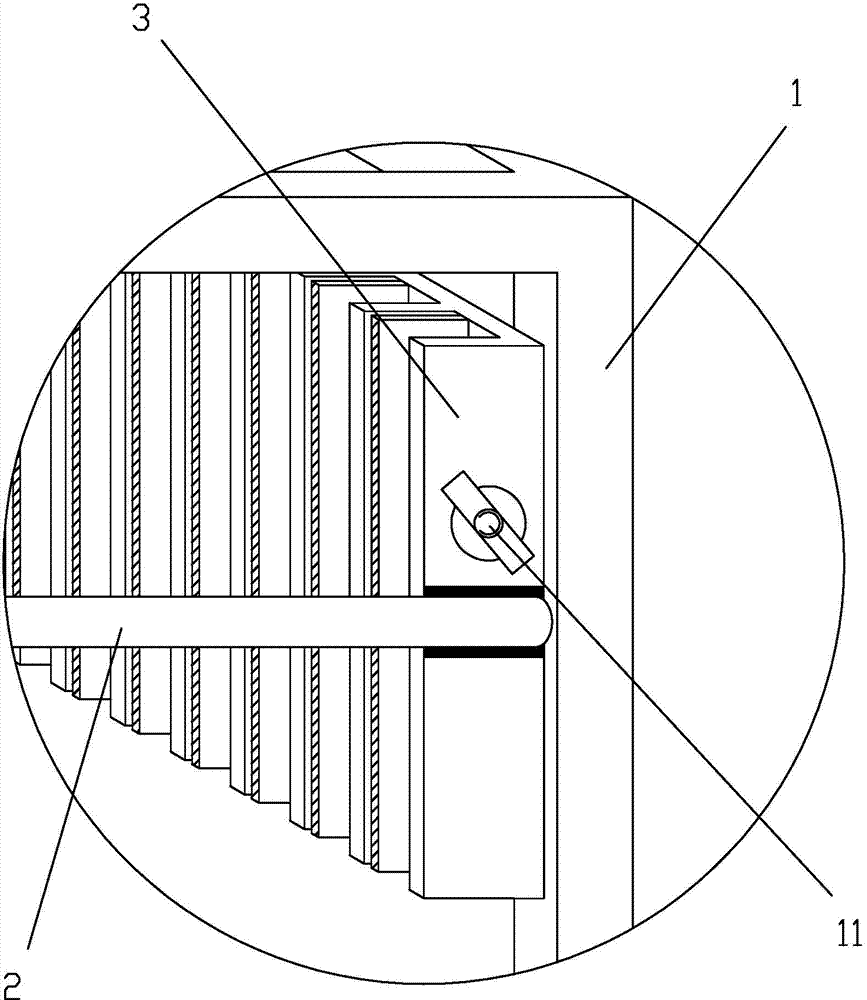

Heat dissipating module

ActiveUS7036566B1Easy to assembleHigh yieldSemiconductor/solid-state device detailsSolid-state devicesHeat sinkSolid metal

A heat dissipating module is disclosed, which comprises a plurality of fins having same or different shapes, a plurality of heat dissipating tubes, and a seat. The fins are stacked one next to another, each fin having a plurality of upper penetrating holes and a plurality of lower grooves or holes. The seat is formed of solid metal with a plurality of slots, each slot corresponding to the lower groove of the fin and having two upper sides extended with two shaping sheets. When the two shaping sheets are pressed and bent, they form a round hole with the slot for receiving a heat dissipating tube. This invention will result in improved heat dissipation.

Owner:HUANG TSUNG HSIEN

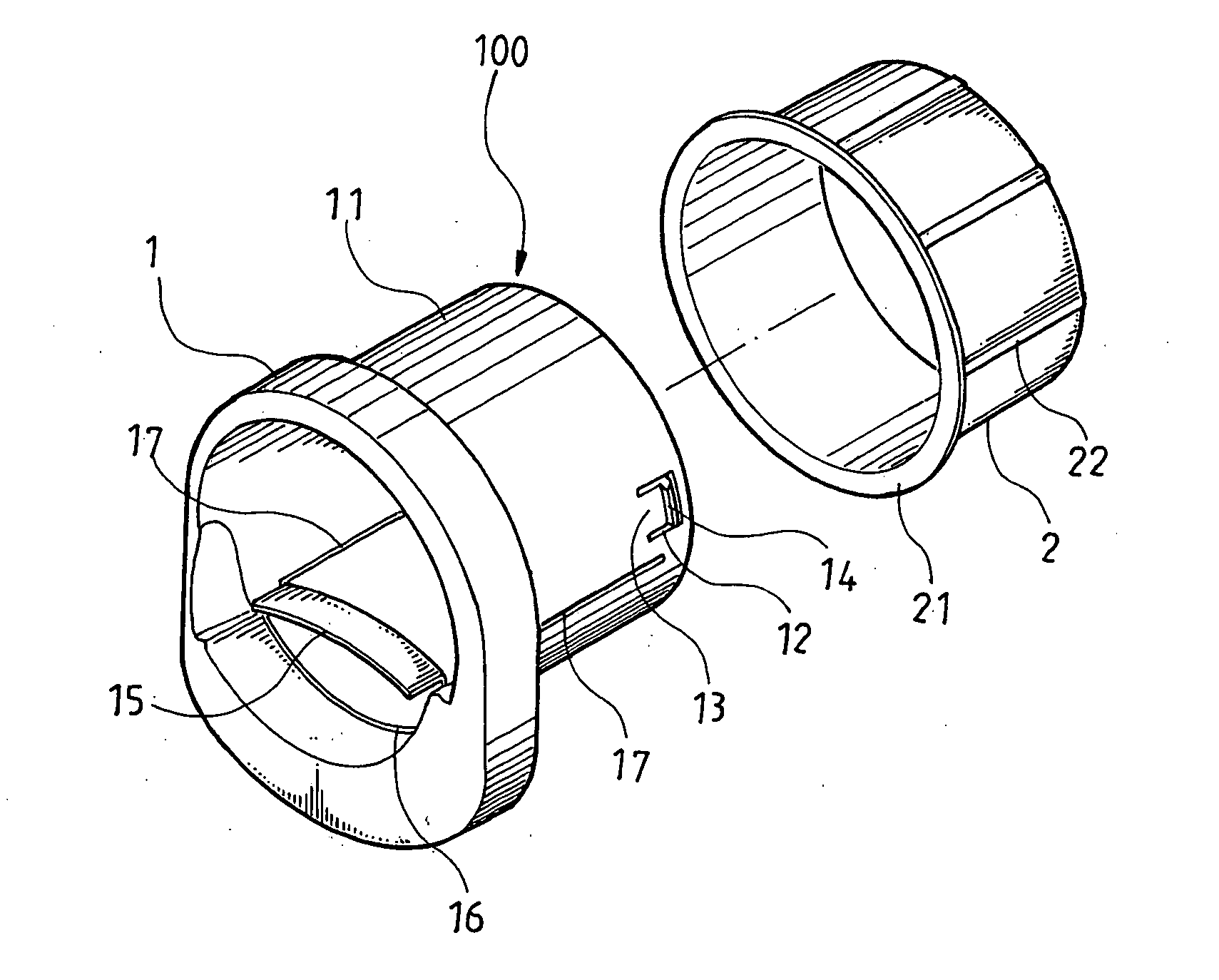

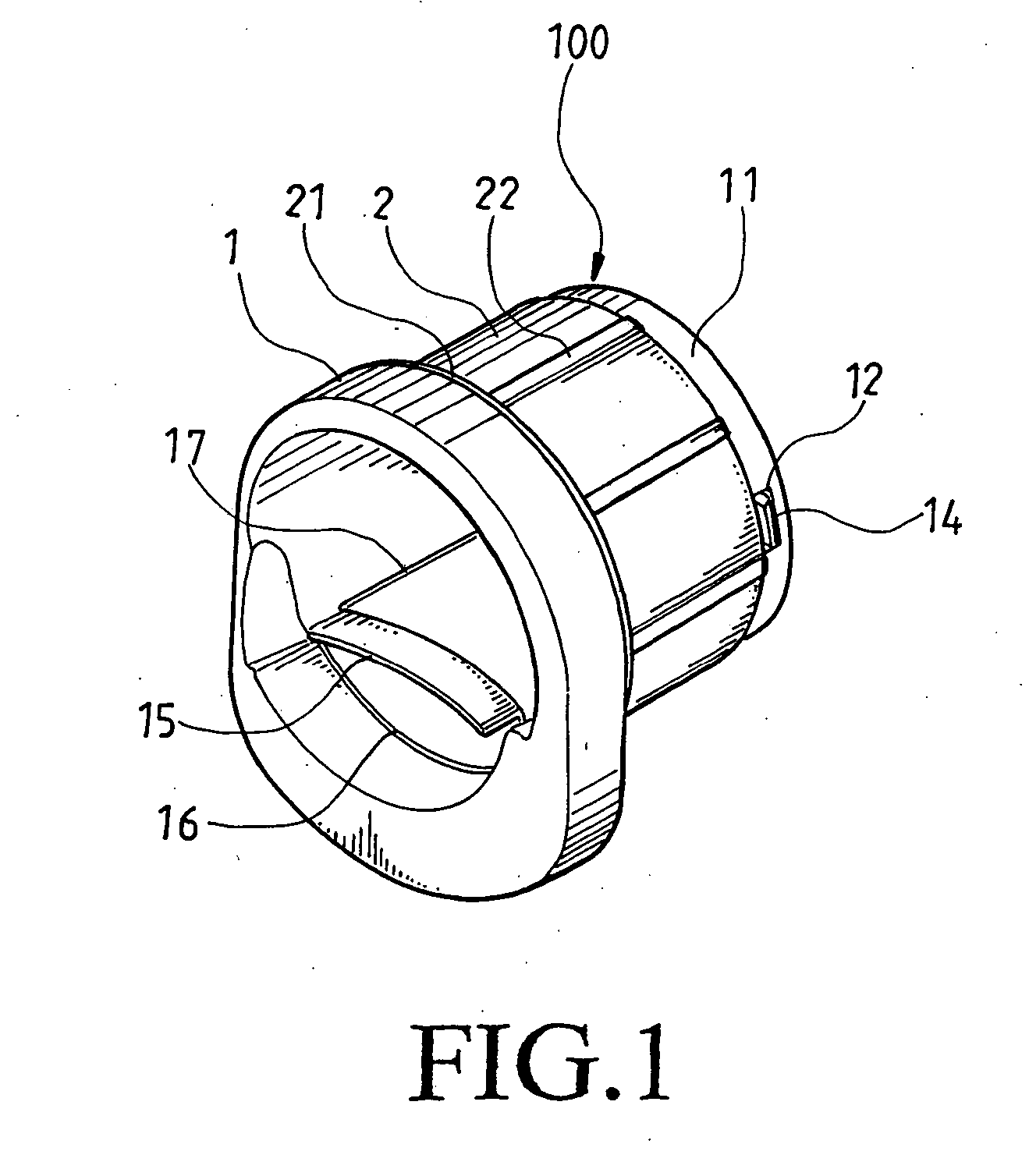

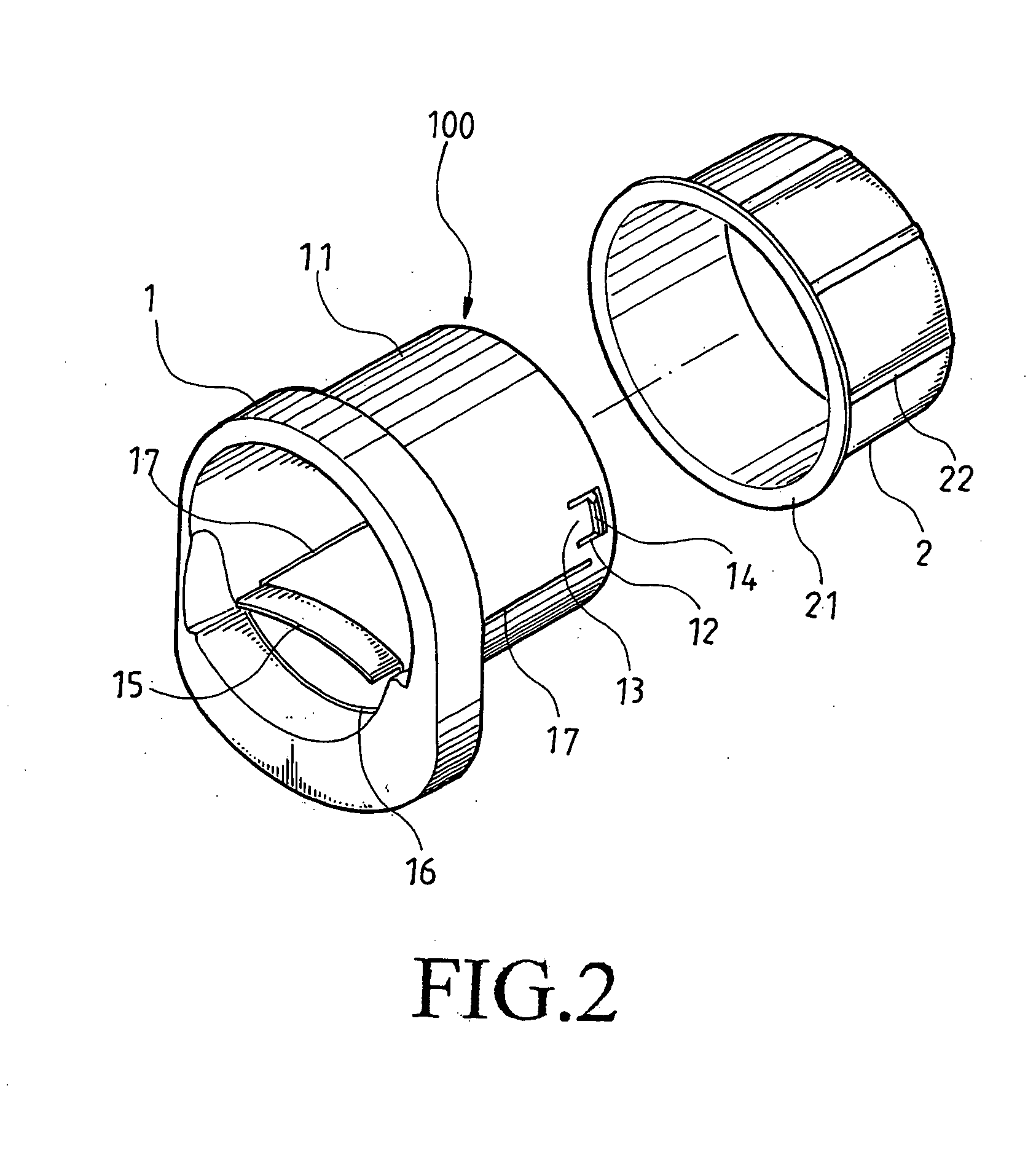

Hub for rolled wrap

InactiveUS20060175460A1Easy to operateCertain degree of elasticityWebs handlingEngineeringMechanical engineering

Owner:HUA WEI HSIU

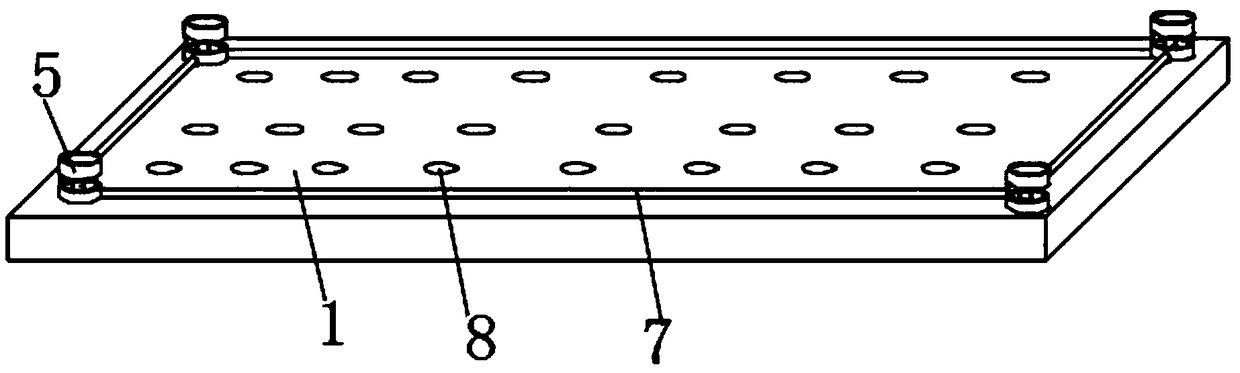

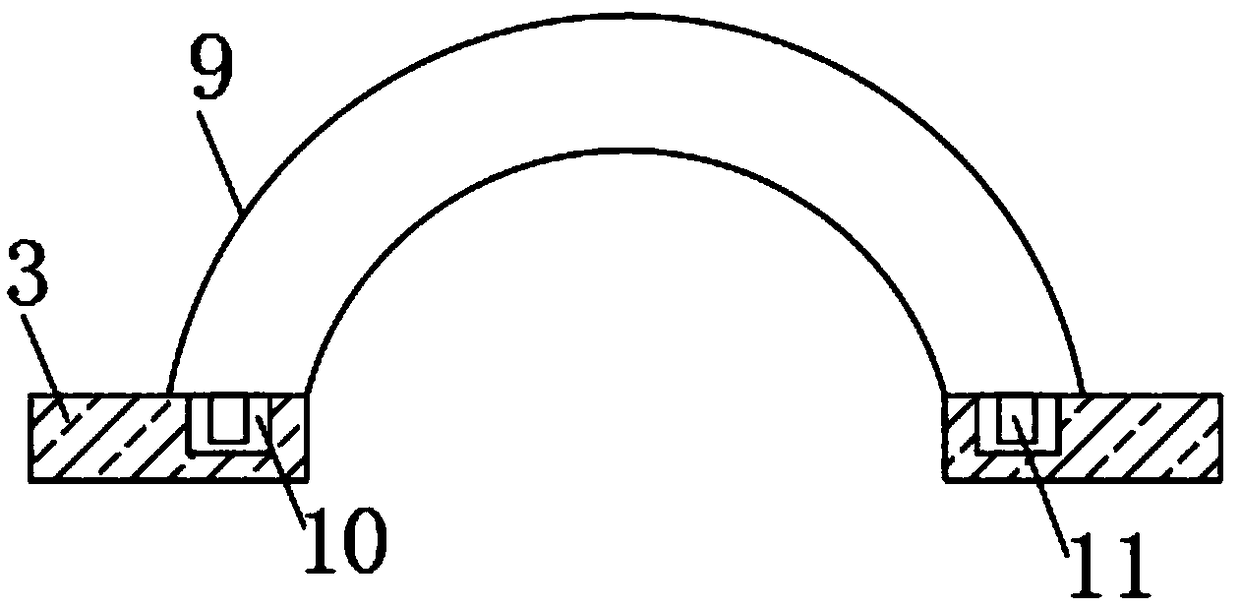

Method for producing circuit board thin plates

The invention discloses a method for producing circuit board thin plates. The technical scheme is characterized in that the method comprises the following steps that: conducting plating though holes; conducting outer layer circuit pattern transfer; conducting graph electric plating and etching; penetrating a string through locating holes of the circuit board thin plates, utilizing string beads to separate the circuit board thin plates, and plating the circuit board thin plates though the holes, after plating the circuit board thin plates through the holes, washing liquid medicine on the surfaces of the circuit board thin plates away by horizontally drawing the circuit board thin plates through a thick plate; conducting electric test; conducting routing; utilizing a plastic package tray to package a finished-product unit plate subjected to routing. From the procedure of layer circuit pattern transferring to the procedure of routing, the circuit board thin plates are compressed through pressing grooves by the adoption of a pig cage frame device to be transferred between the procedures. The method for producing the circuit board thin plate solves the problems that the circuit board thin plates are prone to plate adhesion, plate curving, plate clamping and plate fracture due to the fact that the circuit board thin plates are small in size. The method for producing circuit board thin plates is simple in process and stable in product quality.

Owner:广东依顿电子科技股份有限公司

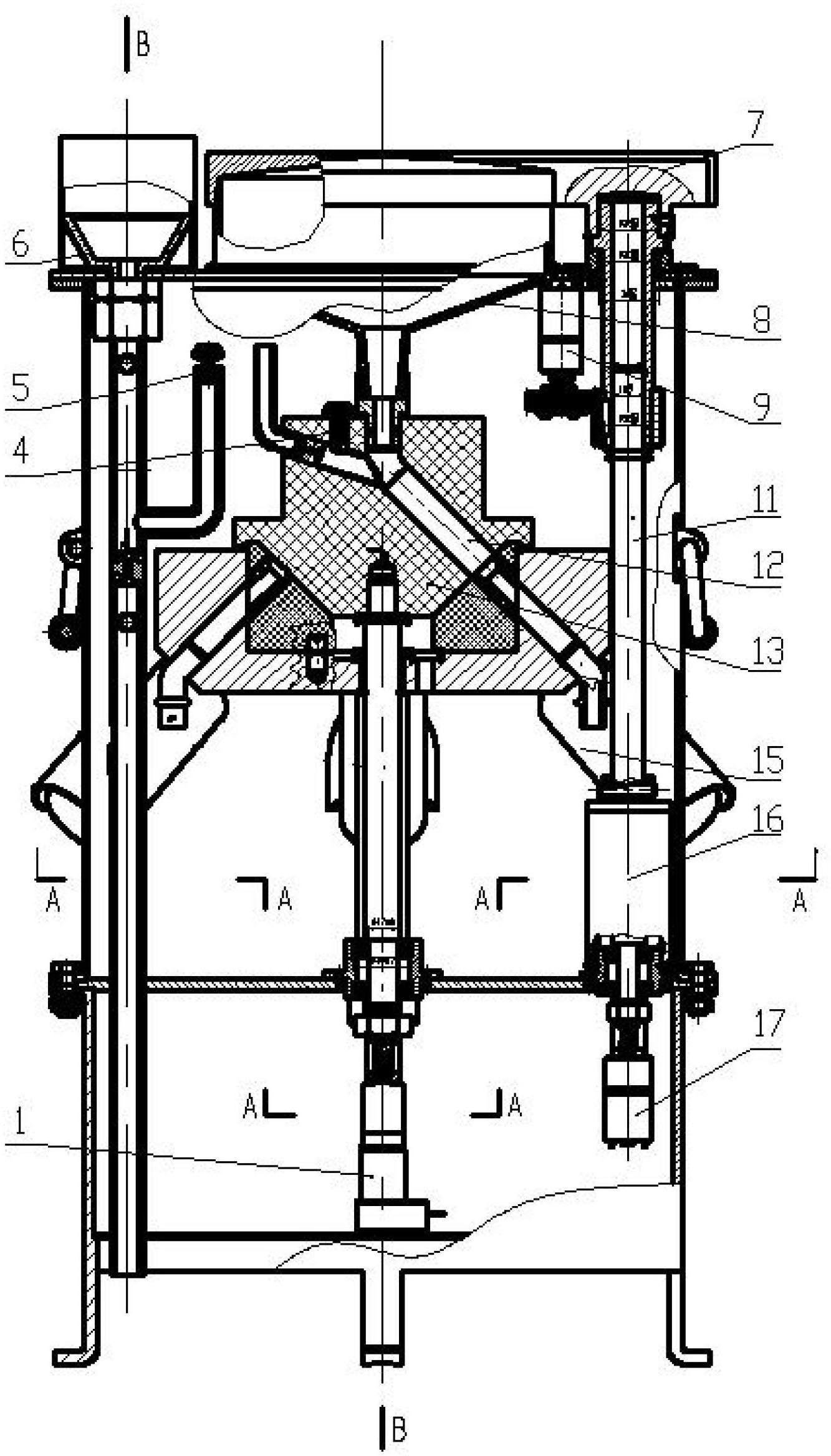

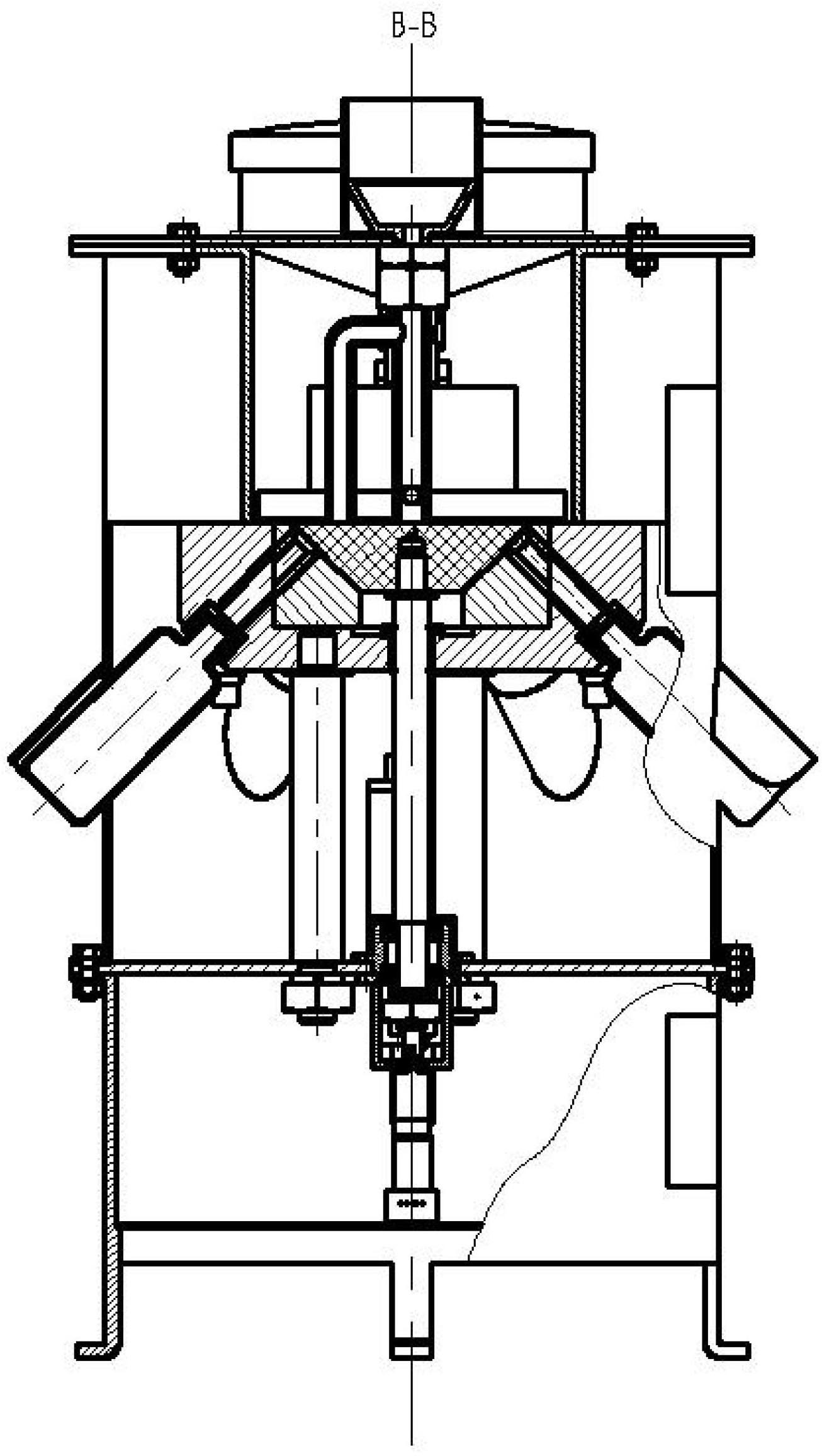

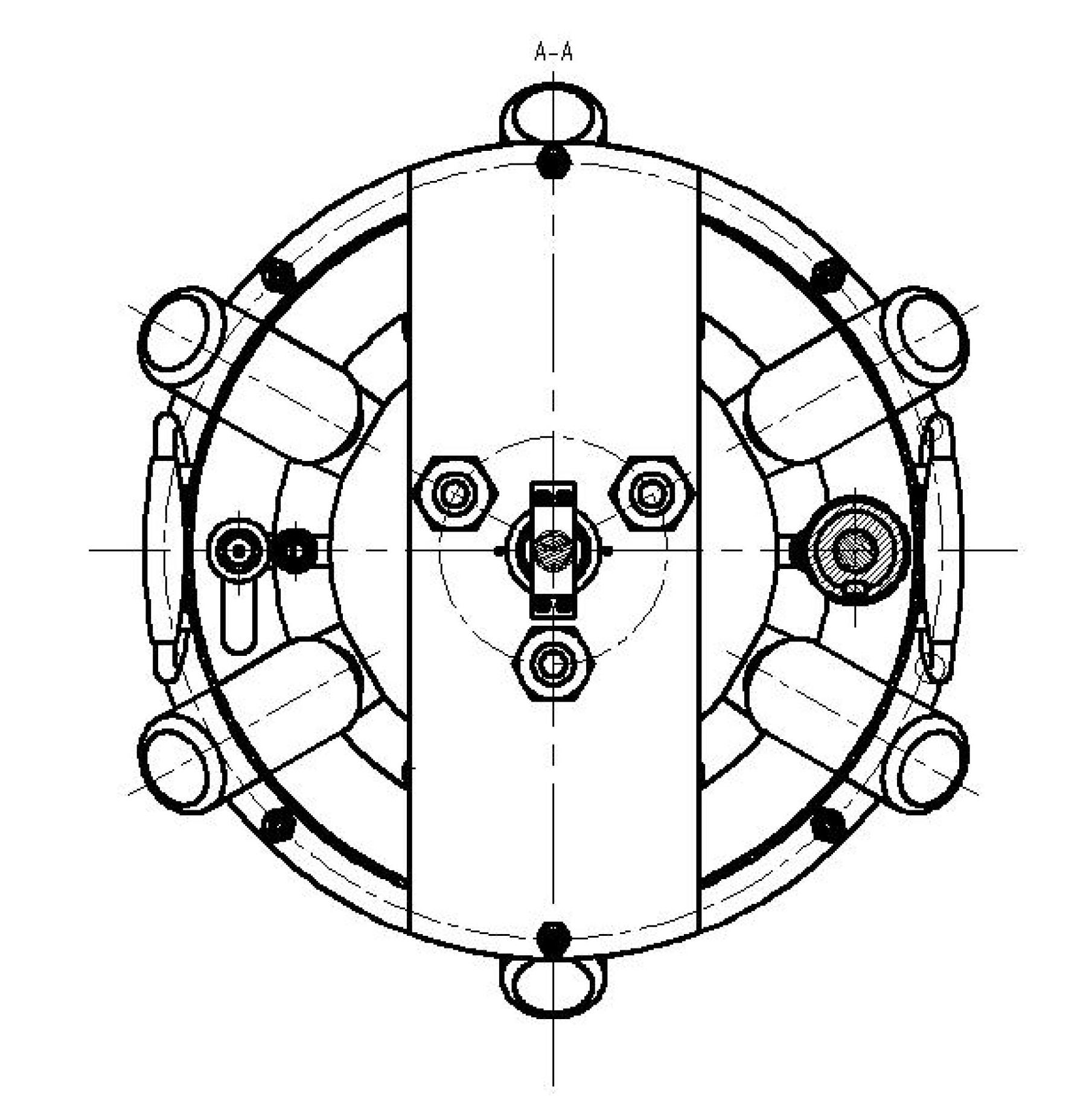

Automatic precipitation sampler

The invention aims to provide an automatic precipitation sampler which comprises a sampling bottle, a sampling bottle sensor, a pressure sensor, a detection funnel, a rain collection funnel, a cover, a rotary motor, a lifting rod, a lifting rod motor and a water injection mechanism, wherein the lifting rod is mounted below the cover; the lifting rod motor drives the lifting rod so that the cover moves up and down; the rotary motor is connected with the cover and drives the cover to rotate; the cover covers the rain collection funnel; the rain collection funnel is communicated with the water injection mechanism; the sampling bottle is arranged by corresponding to the water injection mechanism; the sampling bottle sensor is mounted on the water injection mechanism to detect whether the sampling bottle is full of water or not; the detection funnel is arranged beside the rain collection funnel; a pipeline blocking rainwater is connected below the detection funnel; a bypass pipe is mounted on the pipeline; and the pressure sensor is mounted on the bypass pipe. The automatic precipitation sampler provided by the invention can automatically collect rainwater in precipitation and automatically stop sampling after the rain stops; and after the collection, the precipitation automatic sampler can store the sample perfectly and record the precipitation-related data.

Owner:HARBIN ENG UNIV

Contractible table leg structure

Owner:CHANG CHIEN KUO

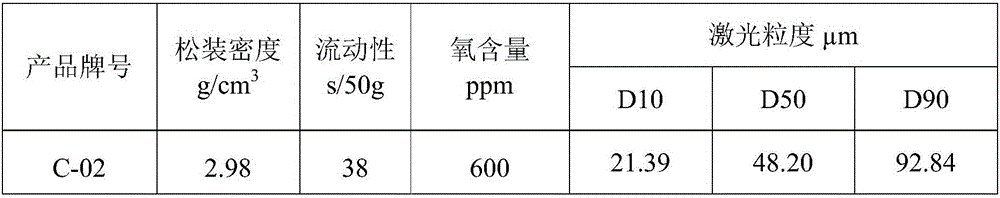

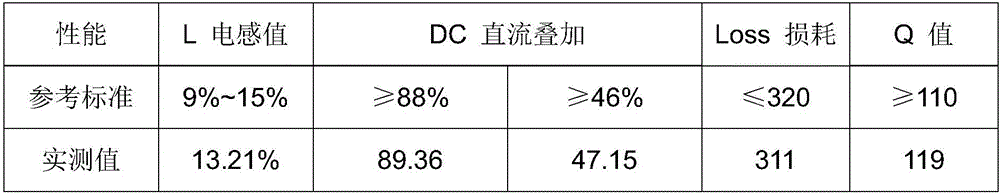

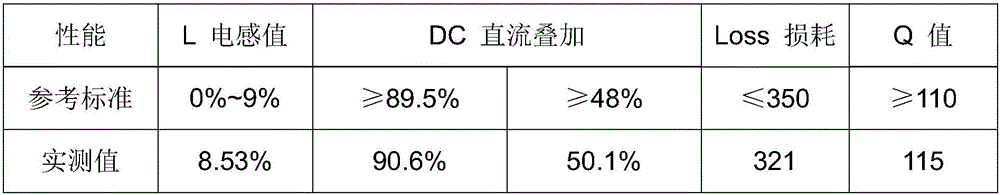

Manufacturing process for iron-silicon-aluminum alloy powder

InactiveCN105970083AVolatile fastNo safety accidentsTransportation and packagingMetal-working apparatusCooking & bakingShielding gas

The invention discloses a manufacturing process for iron-silicon-aluminum alloy powder and belongs to the technical field of metal soft magnetic materials. The manufacturing process for the iron-silicon-aluminum alloy powder includes the manufacturing steps that A, raw materials are weighed and mixed; B, a crucible is preheated; C, iron and silicon are added, aluminum is added after the iron and the silicon are completely molten, silicon-calcium alloy is added after the aluminum is molten, and the mixture is cooled into an iron-silicon-aluminum alloy block after boiling; D, the alloy block is crushed into alloy materials of 0.1-0.8 cm<2>; E, the alloy materials are subjected to ring milling, so that powder smaller than 60 meshes is obtained; F, ethyl alcohol is added, wet milling is conducted for 1-30 h, and then solid powder is obtained; G, open-area baking is conducted for 1-2 h at the temperature of 30-80 DEG C, and then screening is conducted; and H, the screened powder is placed in an annealing furnace with protective gas to be subjected to annealing heat treatment for 1-2.5 h at the temperature of 850-890 DEG C. By manufacturing the iron-silicon-aluminum alloy powder according to the above steps, burning loss of the aluminum can be reduced, the production cost is reduced, and an oven is prevented from catching a fire and exploding.

Owner:古前春

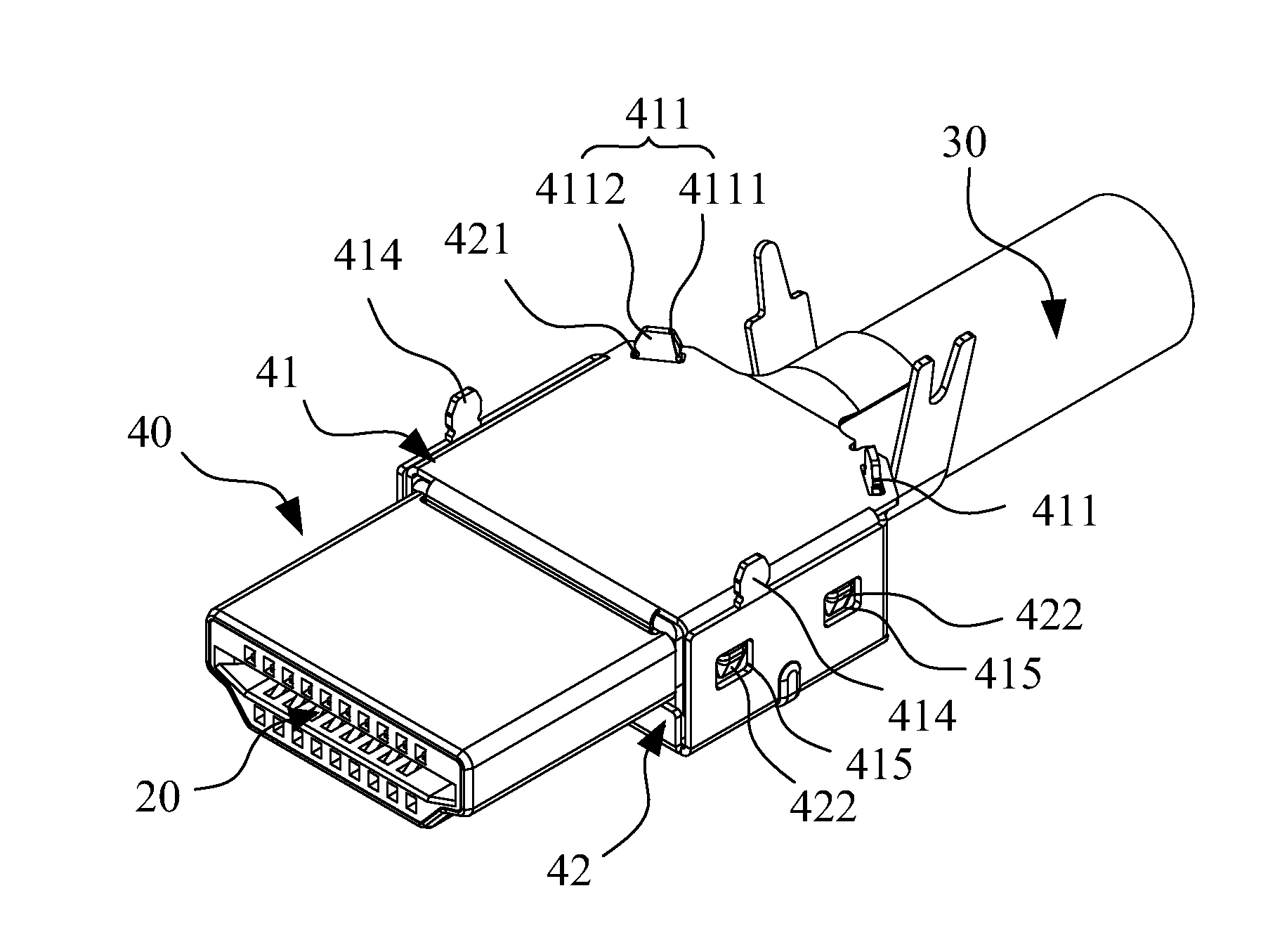

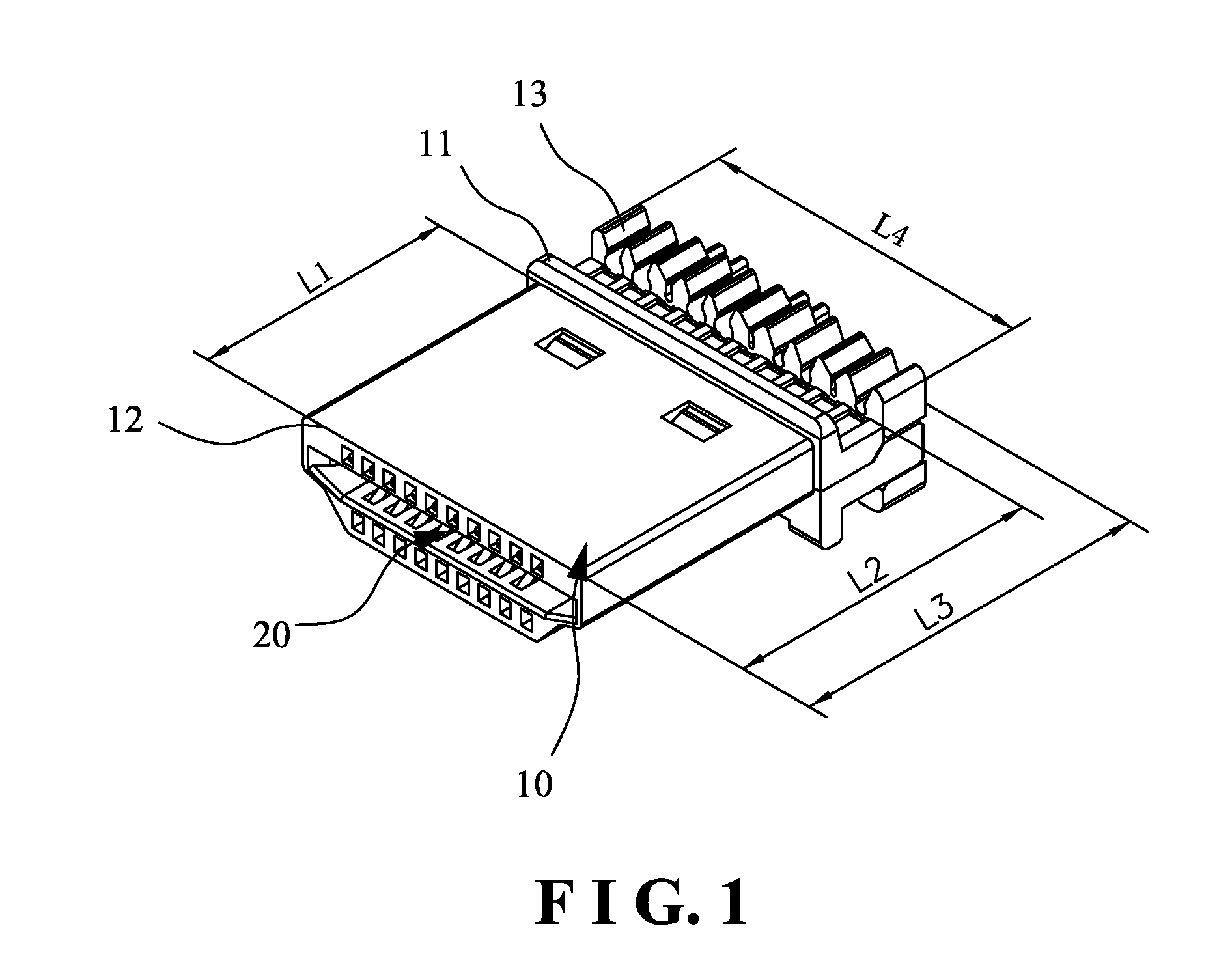

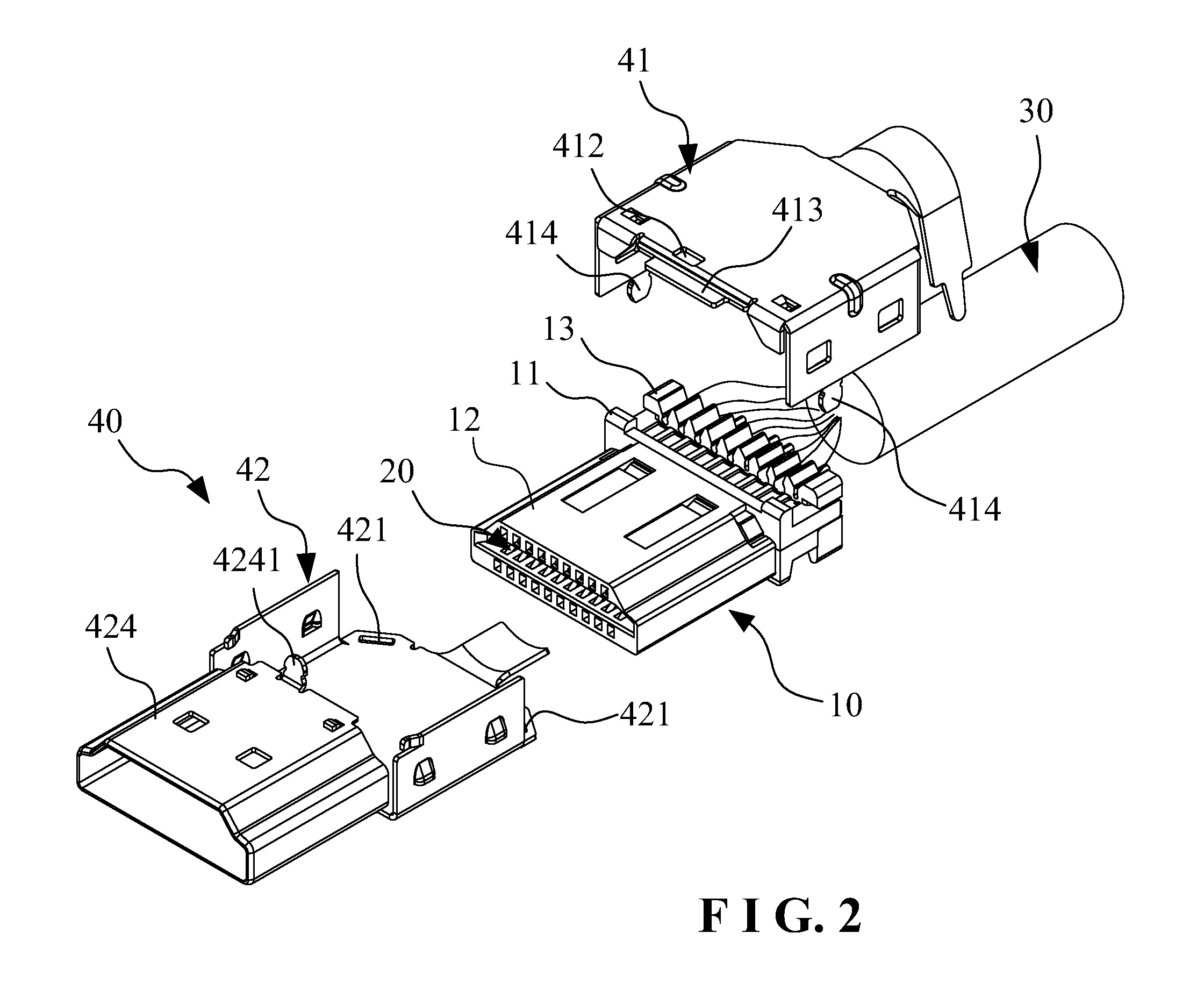

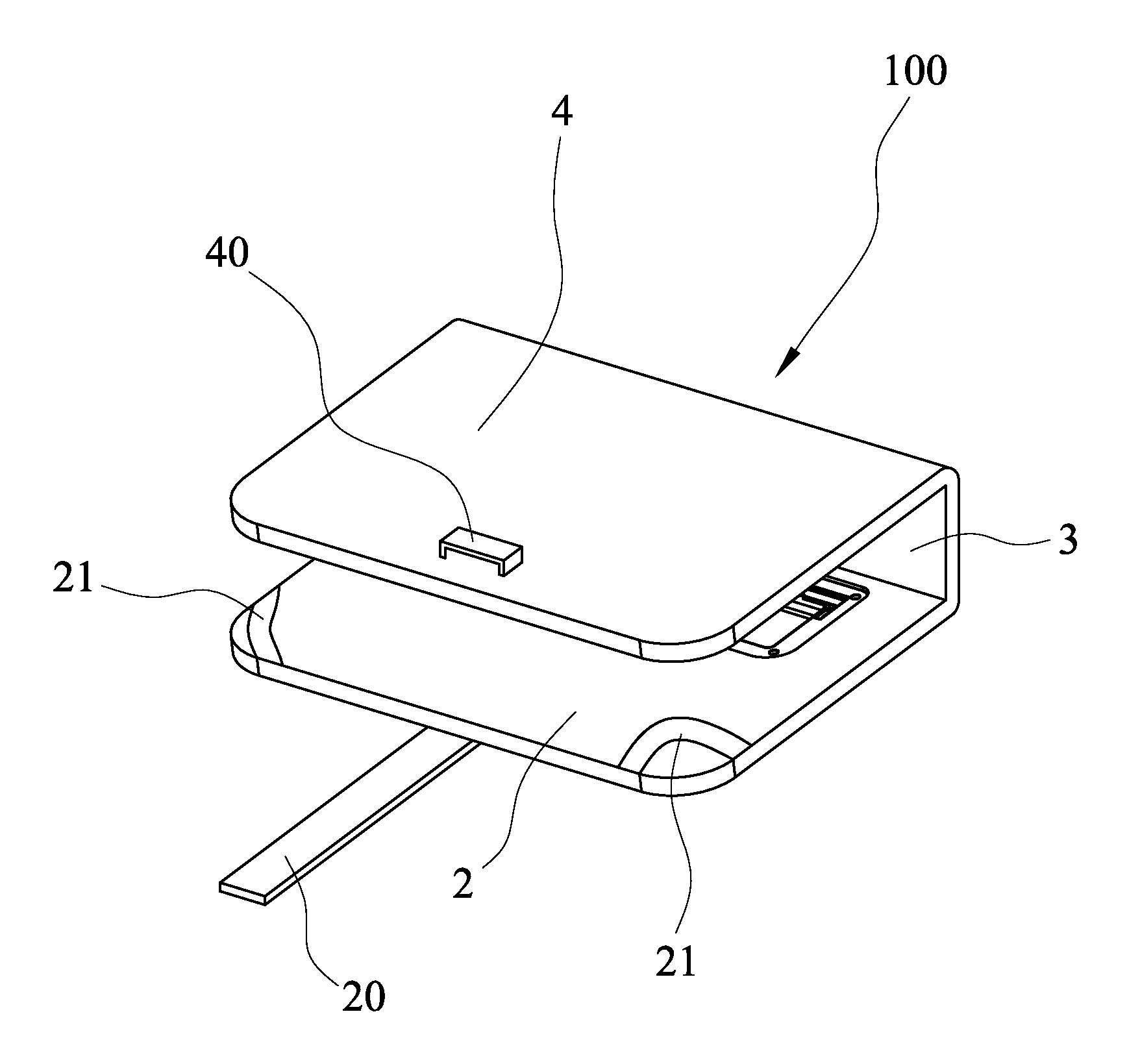

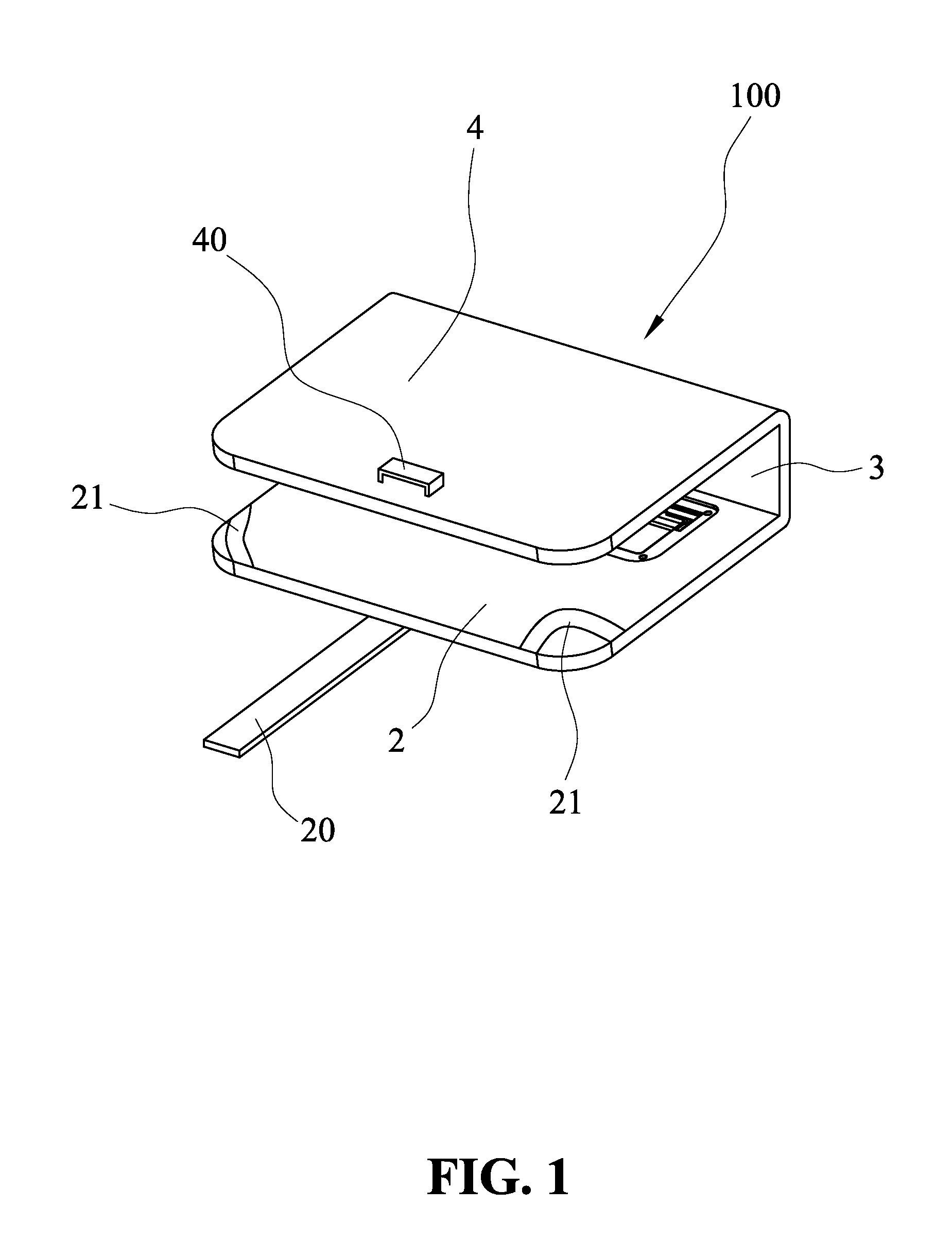

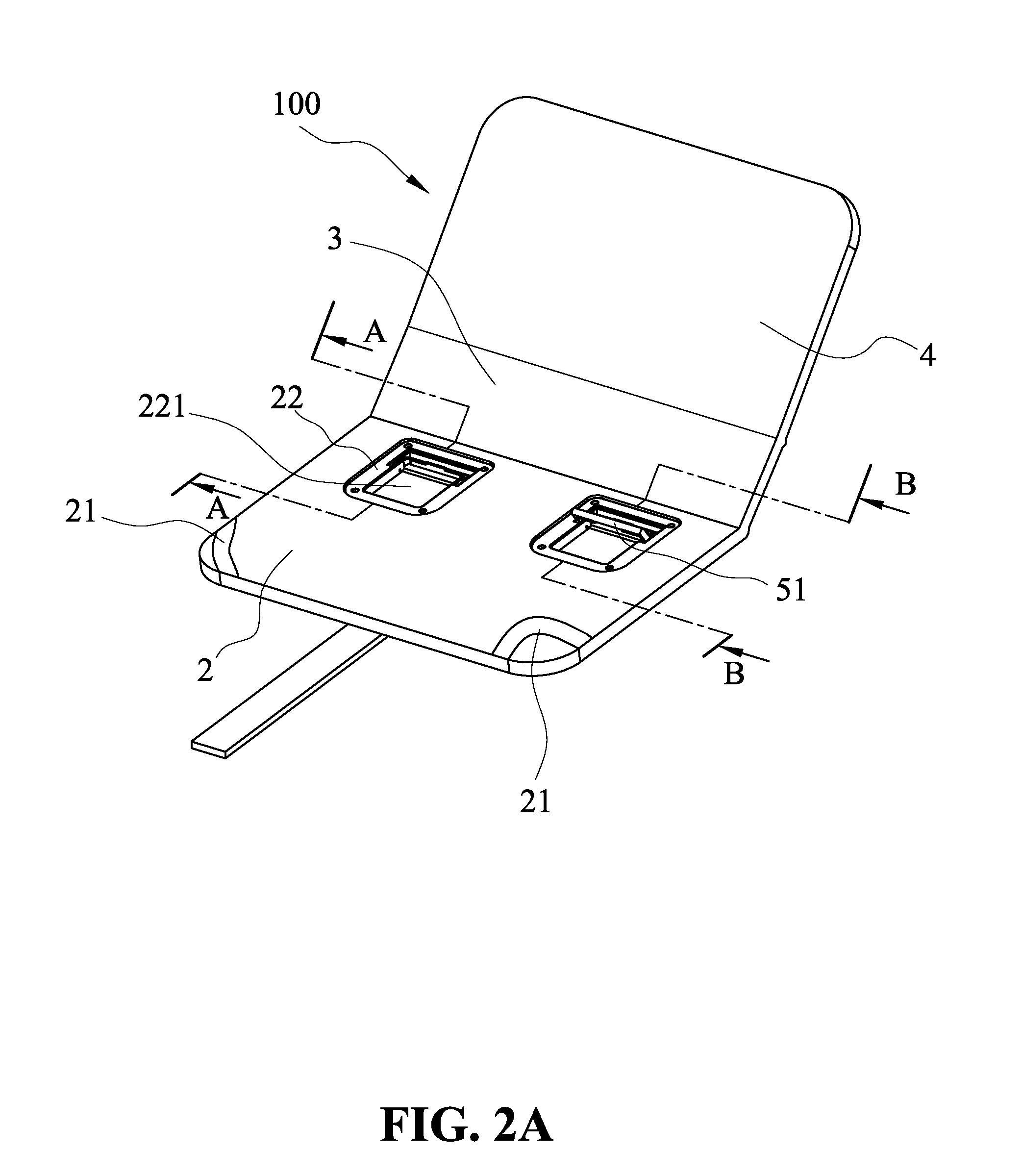

Electrical connector

ActiveUS20150303622A1Increase intensityReliability can be promotedElectrically conductive connectionsSecuring/insulating coupling contact membersEngineeringElectrical connector

An electrical connector includes an insulating body, a terminal set, a wire, and a shielding housing having an upper shell body and a lower shell body. A support part of the first buckling sheet which is penetrated through a first buckle hole of the lower shell body is rivetedly pressed on an outer peripheral edge of the first buckle hole of the lower shell body. An upper side and a lower side of the wire are pressed by a top plate of the upper shell body and the bottom plate of the lower shell body so that the upper and lower shell bodies of the shielding housing can be integrally formed, thereby promoting the bulk intensity of the produced electrical connector, preventing the internal mechanism of the electrical connector from damage due to the oscillation of the wire, and promoting the reliability of the produced electrical connector.

Owner:FREEPORT GUANGDONG PRECISION IND CO LTD

Micro-nano satellite

PendingCN110871910ALow costOperating attitude influenceCosmonautic power supply systemsArtificial satellitesStructural engineeringNano satellite

The invention relates to the technical field of aerospace equipment, in particular to a micro-nano satellite. The micro-nano satellite comprises a satellite main body, a folding sun wing, a pressing rod and a locking mechanism; the locking mechanism is arranged on the satellite main body; one end of the pressing rod is connected with an outermost substrate of the foldable sun wing, and the other end of the pressing rod penetrates through other substrates of the foldable sun wing and is matched with the locking mechanism; and the locking mechanism is used for releasably locking the pressing rodto lock the foldable sun wing in the folded state. Compared with a destructive release mode of releasing a foldable sun wing by cutting, fusing or blasting a pressing mechanism in the prior art, thesun wing, the pressing rod and the locking mechanism of the micro-nano satellite provided by the invention can be repeatedly used, so that the cost of the micro-nano satellite is reduced.

Owner:陕西国宇星空科技有限公司

Anti-crack ceramic tile

InactiveCN105000864AImprove crack resistanceStrong water resistanceClaywaresPublic placeCrack resistance

The invention discloses anti-crack ceramic tile, and belongs to the field of building ceramic materials. The ceramic tile is prepared by the following raw materials of 40-65 parts of SiO2, 20-25 parts of Al2O3, 8-12 parts of MgO, 1-3 parts of Na2O, 4-10 parts of TiO2 and 2-10 parts of Fe2O3. The prepared anti-crack ceramic tile has the advantages of being high in strength, good in anti-crack performance, good in water resistance, high in anti-erosion capacity and long in service life, can be used under the low temperature condition below negative 15 degrees for a long time and widely applied to the outer walls and indoor spaces of buildings such as residential buildings and public places, and is worthy of use and popularization.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

External structure of outdoor electronic apparatus

ActiveUS8902599B2Reduce assemblyLow costCouplings bases/casesSubstation/switching arrangement casingsEngineeringGasket

An external structure of an outdoor electronic apparatus for packaging a circuit board having a power line is provided. The external structure includes a housing having an opening and a waterproof gasket. The waterproof gasket includes a main body, a platform portion, a first protrusion, and a bushing portion. The main body covers the opening. The platform portion, located at the inner side of the main body, extends into the housing from the opening. The platform portion seals the opening and tightly fits with the housing. The first protrusion is located on the platform portion for abutting against the circuit board. The bushing portion, located at the outer side of the main body, has a channel. The channel passes through the main body and the platform portion and can be passed through by the power line. The bushing portion and the power line tightly fit to each other.

Owner:DELTA ELECTRONICS INC

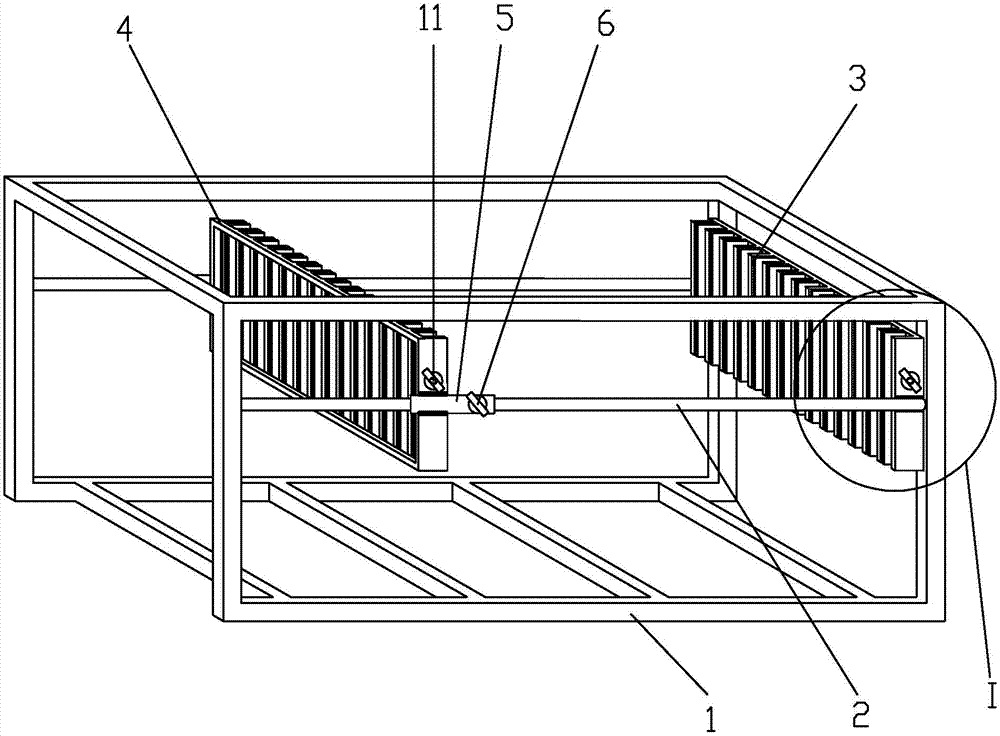

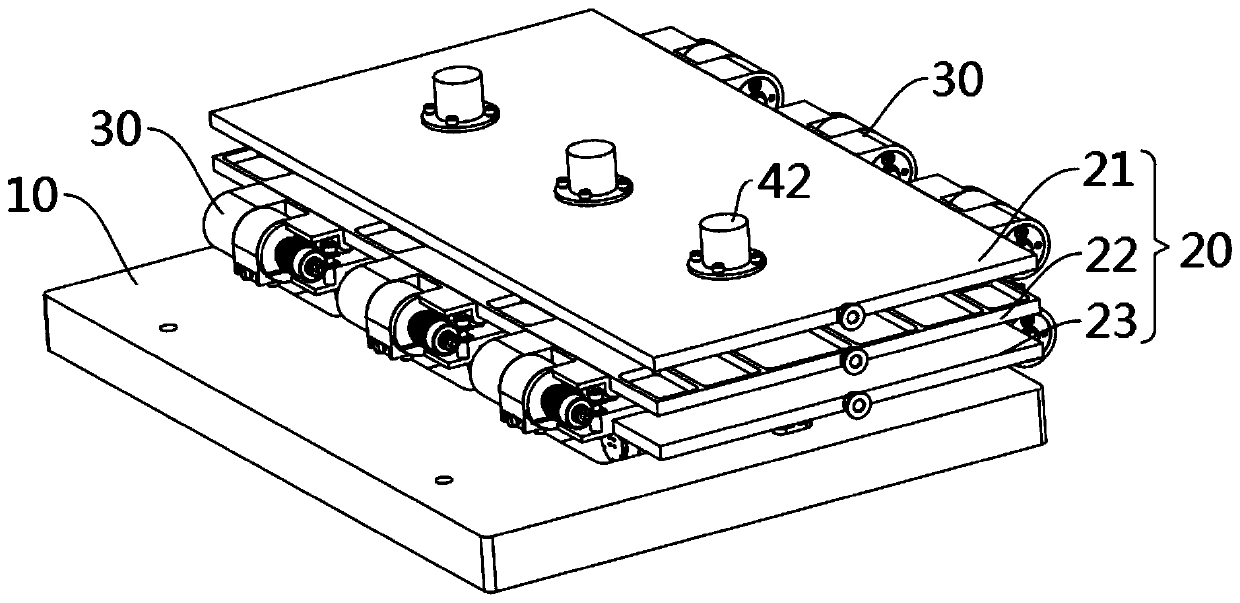

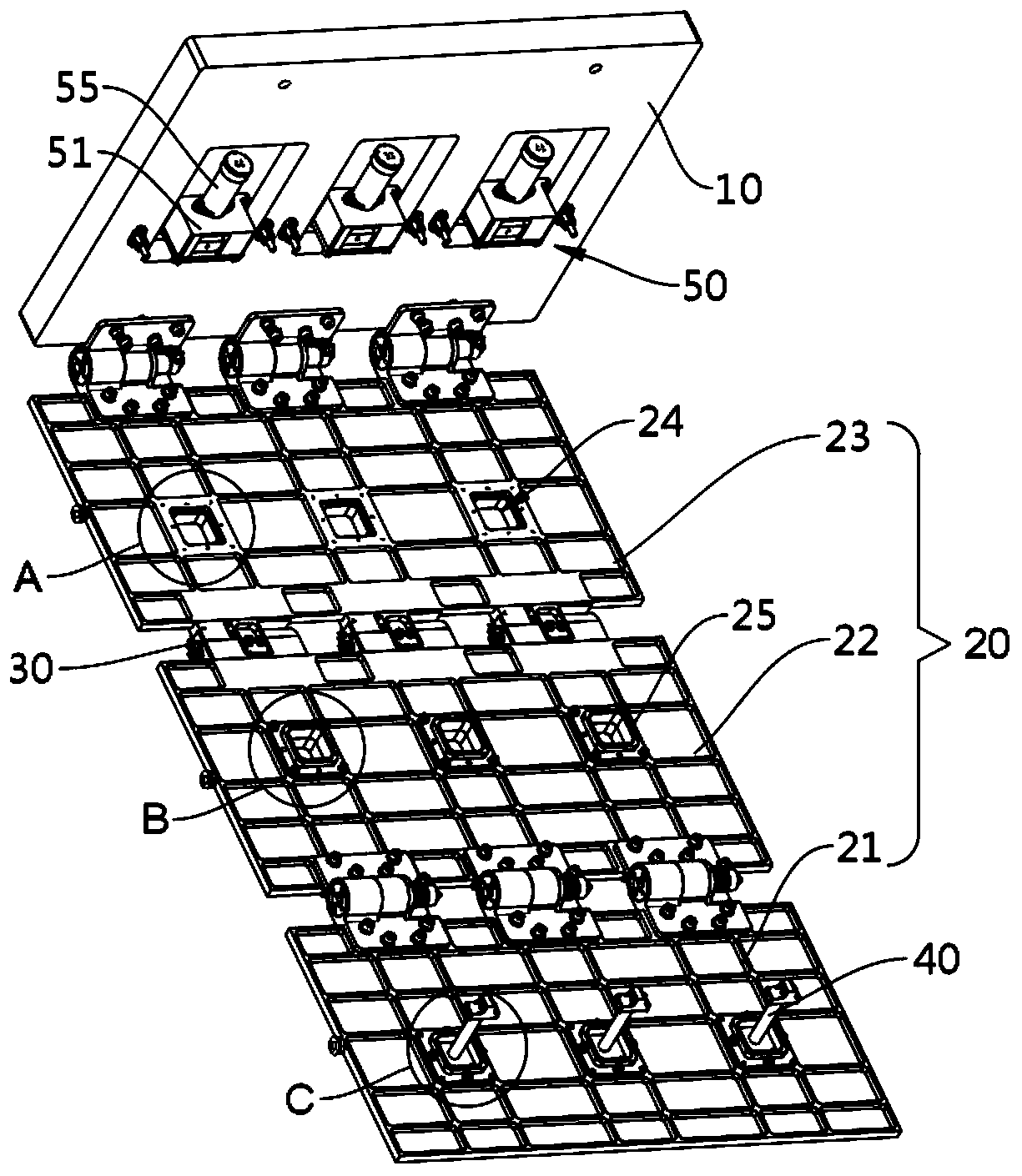

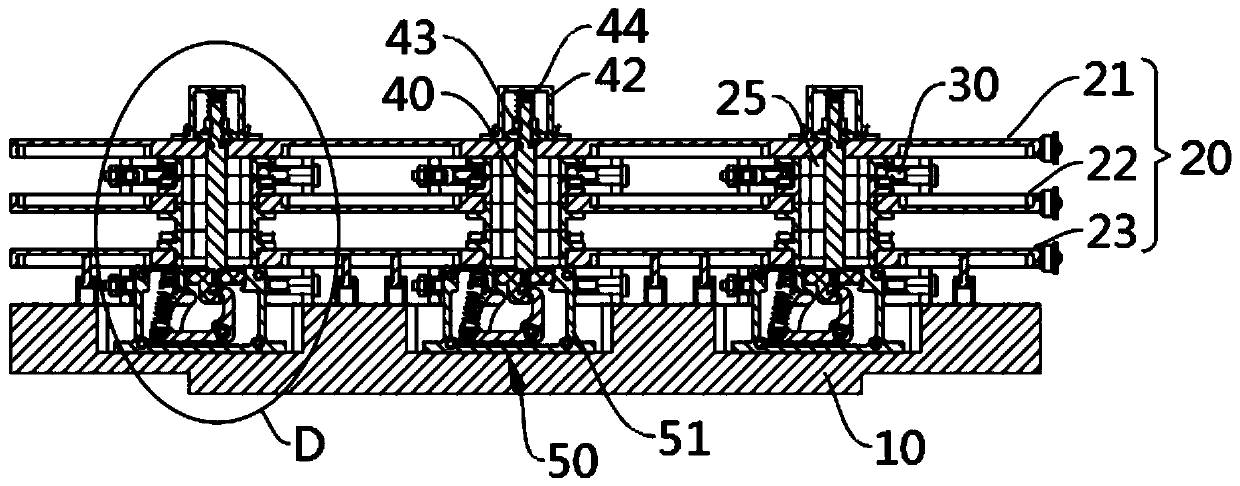

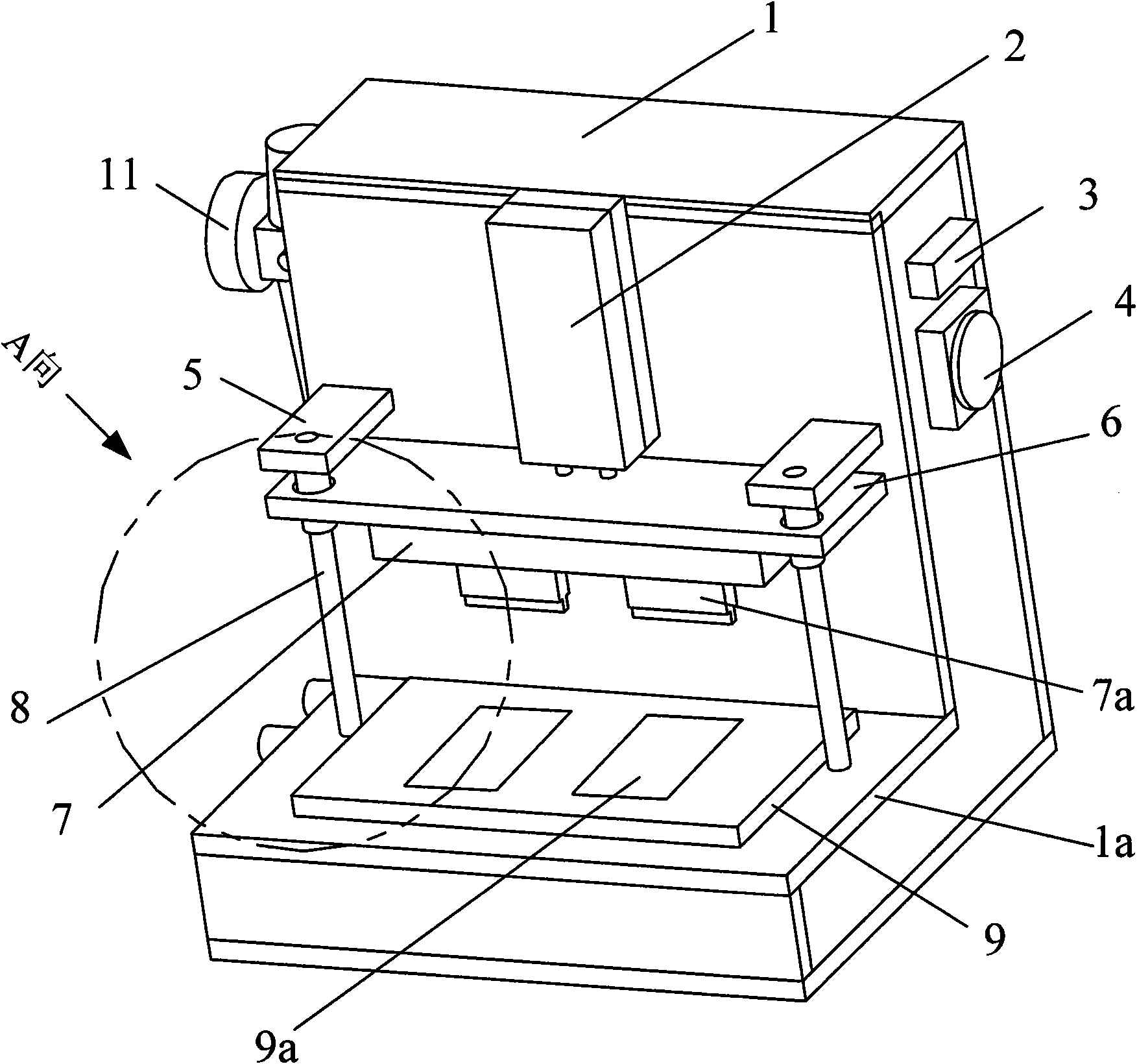

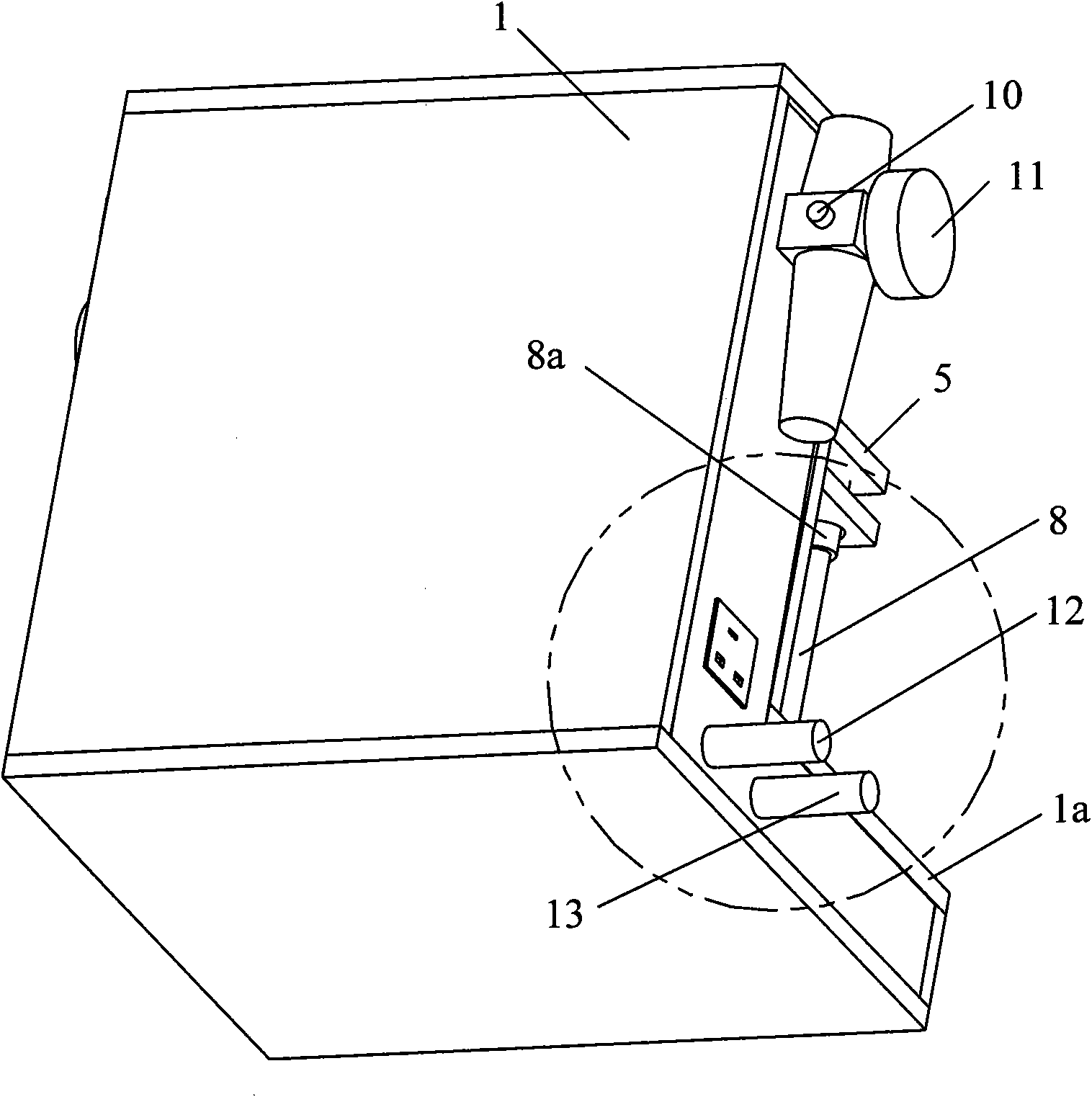

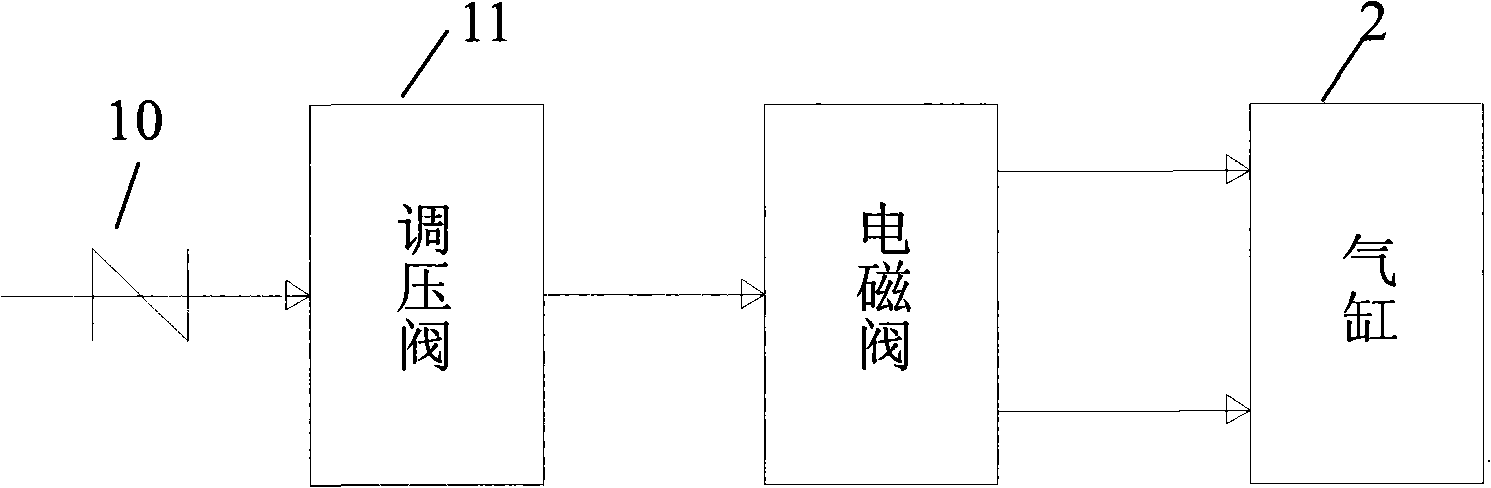

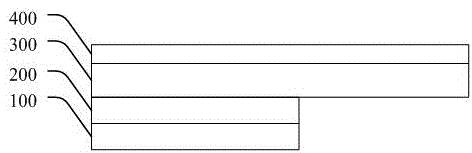

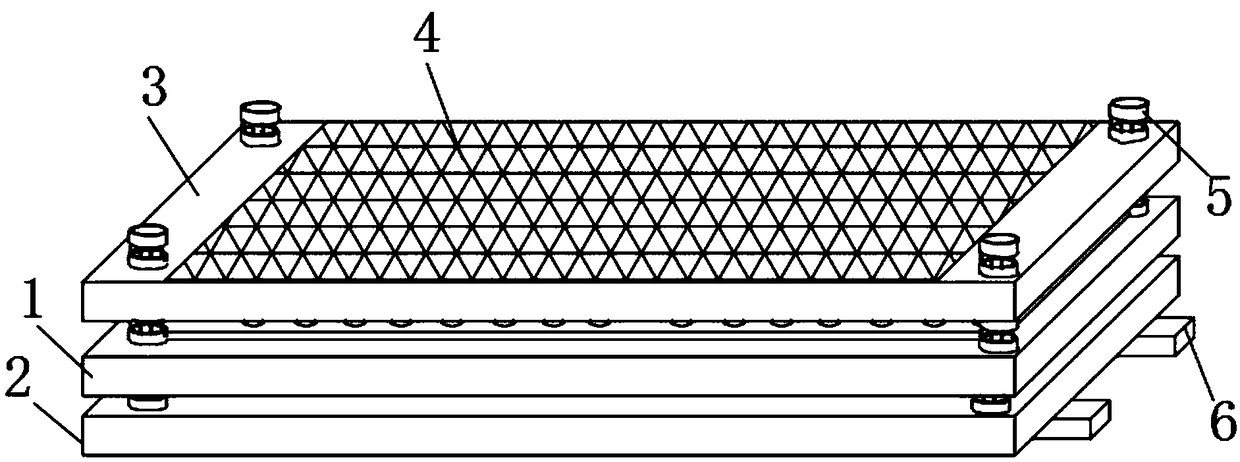

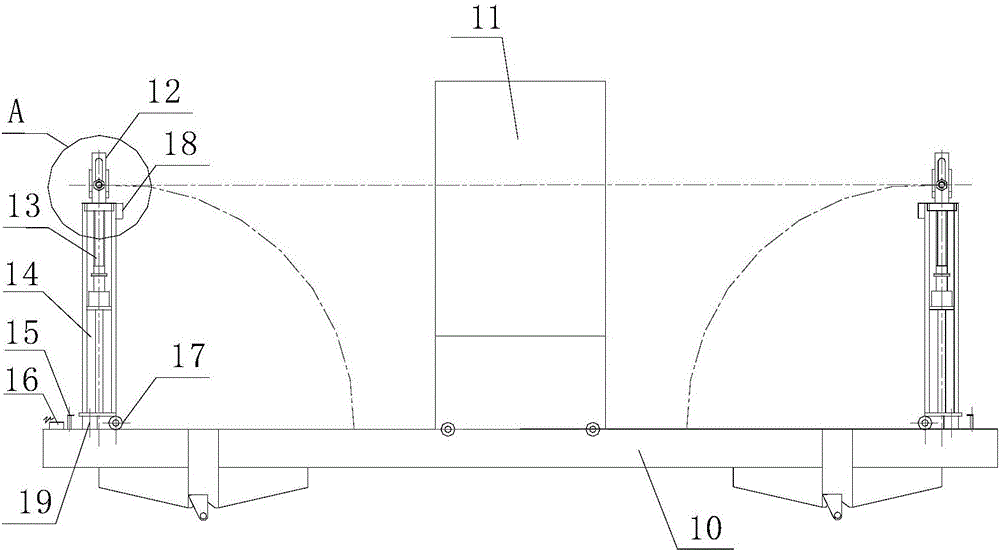

Backlight module press equipment and use method thereof

The invention discloses backlight module press equipment and a use method thereof. The equipment comprises a box body, an air cylinder, an upper press plate, a lower press plate, two guide rails, an air control unit and an electric control unit, wherein the box body is provided with a working platform; the air cylinder is fixed at the upper side of the box body; the upper press plate is connected with the air cylinder and can run up and down; the lower press plate is fixed on the working platform; one end of each guide rail is fixed with the working platform after penetrating through the lower press plate, and the other end of each guide rail is fixed on the box body after penetrating through the upper press plate; the air control unit controls the air cylinder to run up and down along the guide rails; and the electric control unit controls an air loop switch of the air control unit. The equipment can more tightly press a backlight module on the premise of manpower cost reduction and no any adverse impact generation, thereby effectively inhibiting the generation of light in the backlight module.

Owner:SHANGHAI CHENXING ELECTRONICS SCI & TECH CO LTD

Rigid-flex printed circuit board milling method

InactiveCN105050325APress tightlySolve the rough edge of the boardPrinted circuit manufactureEngineeringPrinted circuit board

The invention discloses a rigid-flex printed circuit board milling method. the method comprises steps: A, a layer of adhesive tape with the thickness between 0.025mm to 0.5mm is attached to the flexible face of the rigid-flex printed circuit board; B, a roller pressing mode is used for enabling the adhesive tape and the flexible face to be tightly attached, wherein the pressing roller has a pressure of 0.5 to 4kg / cm2; and C, board milling and gong appearance shaping are carried out on the rigid-flex printed circuit board, and after milling and shaping, the adhesive tape is removed. As the adhesive tape is attached to the flexible face, the roller pressing mode is used for pressing to enable the adhesive tape and the flexible face to be tightly attached, board milling and gong appearance shaping are carried out in a conventional board milling mode, and finally the adhesive tape is removed, the problems of rough board edges and flexible board burr remaining can be effectively solved.

Owner:SHENZHEN KINWONG ELECTRONICS

Circuit board

ActiveCN109168247AWon't shakeNot easy to shakePrinted circuits stress/warp reductionPrinted circuits structural associationsEngineeringElectrical equipment

A circuit board is disclosed and includes a circuit board body, A first cushion block and a mounting hole, A top frame is horizontally connected to the top of the circuit board body, and the bottom ofthe circuit board body is horizontally connected with a bottom plate, A longitudinally arrange first cushion block is connected with that top four corner of the circuit board body, the top frame andthe bottom plate, a second cushion block is connected with the bottom of the first cushion block, two sides of the bottom plate are clam with sliding rails along the length direction, and the bottom plate is fixedly connected with the sliding block through four groups of positioning holes and bolts. A limit position plate is horizontally connected between that two second pad blocks at the two endsof the top of the circuit board body and between the two second pads at the two side of the top, and a pressing plate connected with the horizontal arrangement is connected at the bottom of the limiting plate. The position of the circuit board body inside the electrical equipment is easy to adjust and change, and the circuit board body installation is more convenient and quick, and can meet different installation needs. When the whole circuit board needs to be disassembled, replaced or repaired, it can be disassembled freely.

Owner:惠州市连盟压合电子有限公司

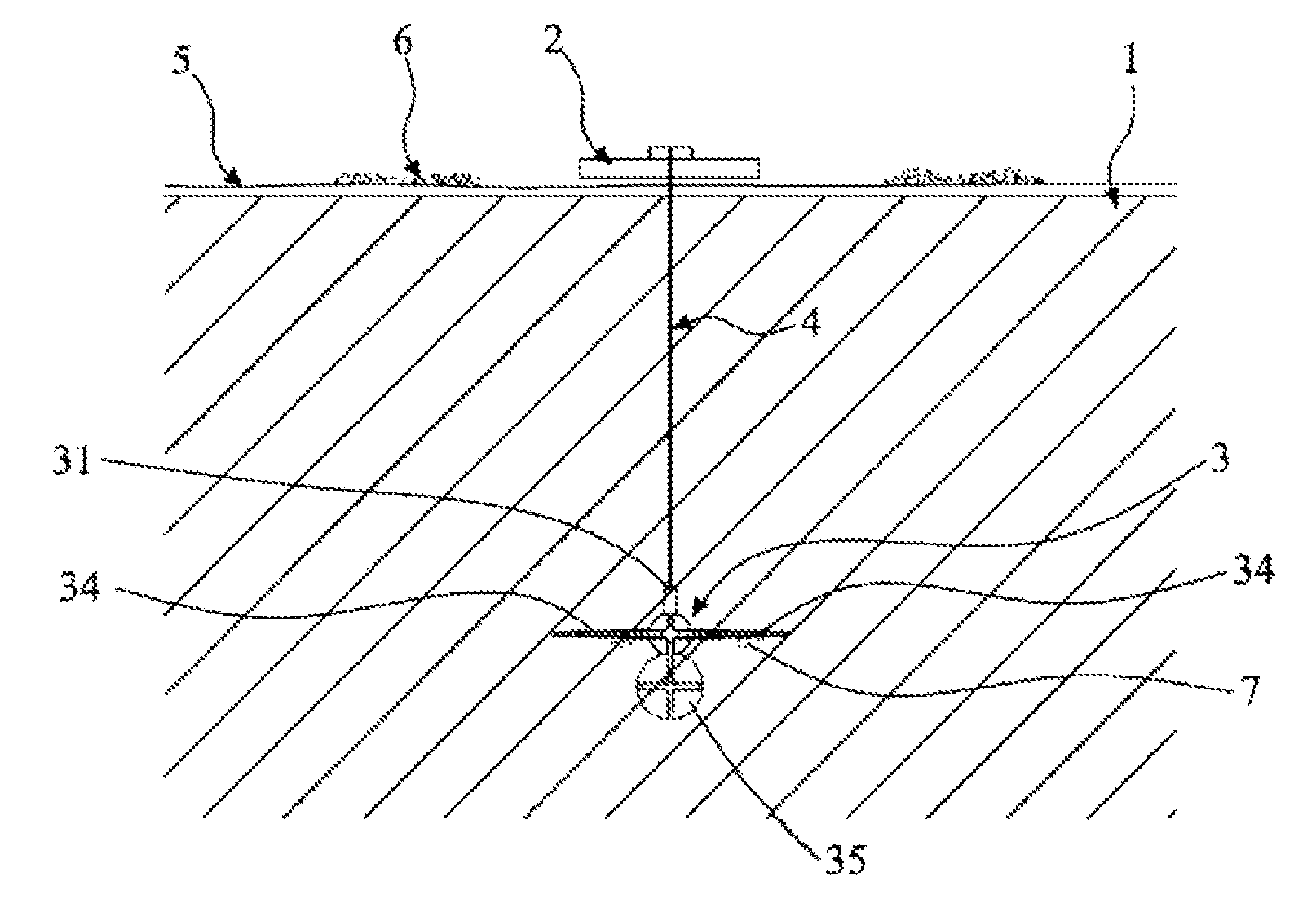

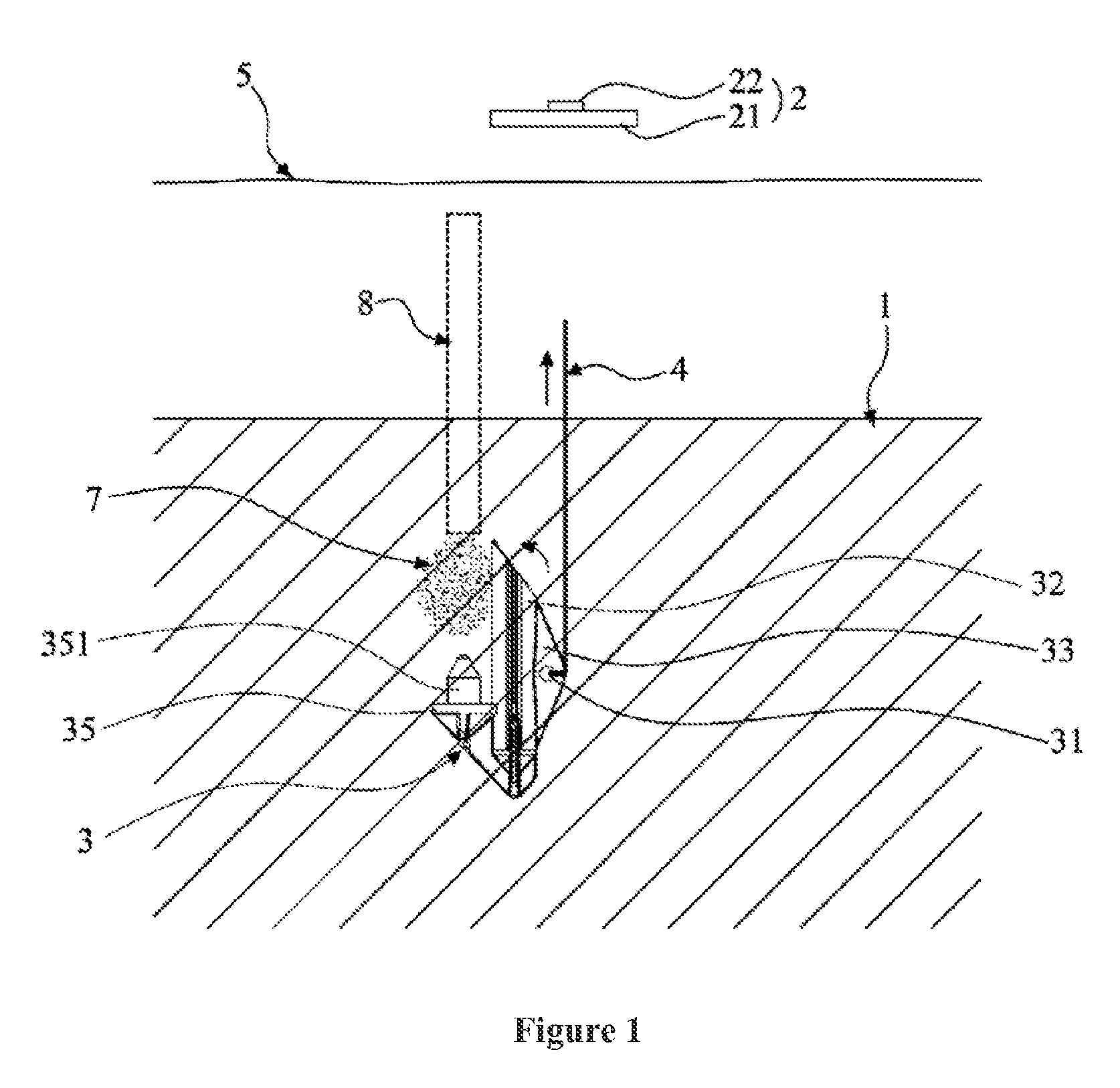

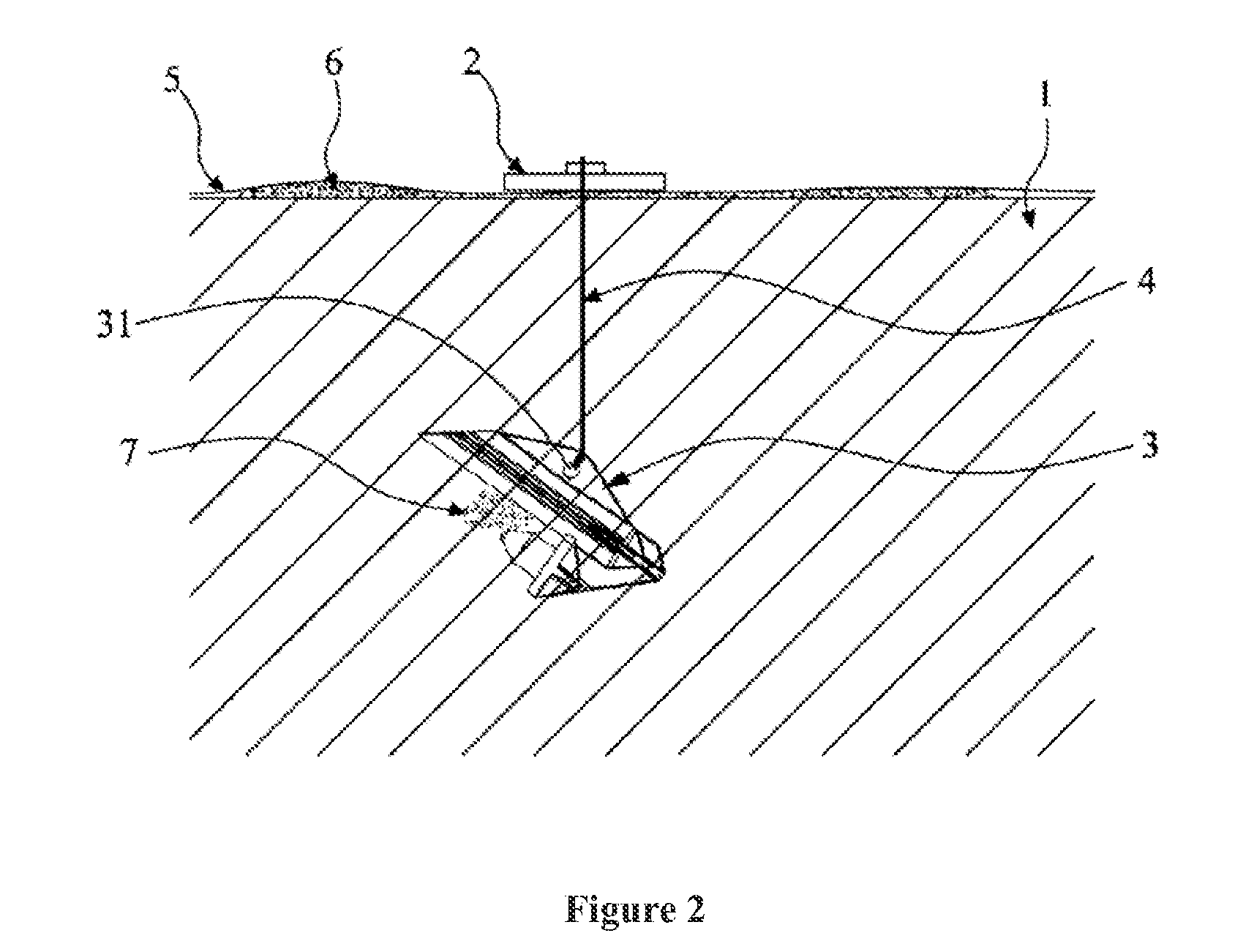

Structure for reinforcing greening member and construction method thereof

InactiveUS9049819B2Improve fastnessGood effectSeed and root treatmentExcavationsStructural engineering

A structure for reinforcing a greening member and a construction method thereof are provided. The structure for reinforcing a greening member comprises a greening member adapted for being placed on a surface of an area to be greened, a positioning cover (2), a positioning member (3) and a rope (4). The positioning member is adapted to be inserted into the ground of the area to be greened. A positioning member is provided with a pivot portion (31). One end of the rope is fixedly connected to the pivot portion, and the other end is exposed out of the ground of the area to be greened and passes through the greening member to reach the positioning cover. The other end of the rope is fixed by the positioning cover.

Owner:CHANG YUSHUN

Compression garbage truck with top-mounted pushing mechanisms

InactiveCN109625716AGuaranteed tightnessGuaranteed filling efficiencyRefuse receptaclesRefuse vehiclesTruckEngineering

The invention relates to a compression garbage truck with top-mounted pushing mechanisms. The compression garbage truck comprises a dustbin located on a truck chassis and a garbage compression mechanism connected to the dustbin. A garbage guide-in opening is formed in the top of the dustbin, and a garbage guide-in face is arranged on the wall face of the bottom of the dustbin. The garbage compression mechanism comprises a garbage compression plate. A sealing portion is arranged at the other end of the garbage compression plate. The rotating position between the garbage compression plate and the outer wall of the top of the dustbin serves as a rotating site A, and the rotating site A is located at the garbage guide-in opening in the horizontal direction. The pushing mechanisms used for driving the garbage compression plate to rotate relative to the rotating site A are further arranged on the dustbin on the opening on the outer wall of the top of the dustbin. The garbage compression plate moves into the dustbin through the garbage guide-in opening, and when the garbage compression plate rotates, the arc formed by the rotating path of the sealing portion is tangent to the surface of the garbage guide-in face. The garbage compression plate is of an inward concaved structure in the longitudinal direction, and the inward concaved face of the garbage compression plate backs on to thelinear pushing mechanism.

Owner:NANJING HUANLV NEW ENERGY VEHICLE CO LTD

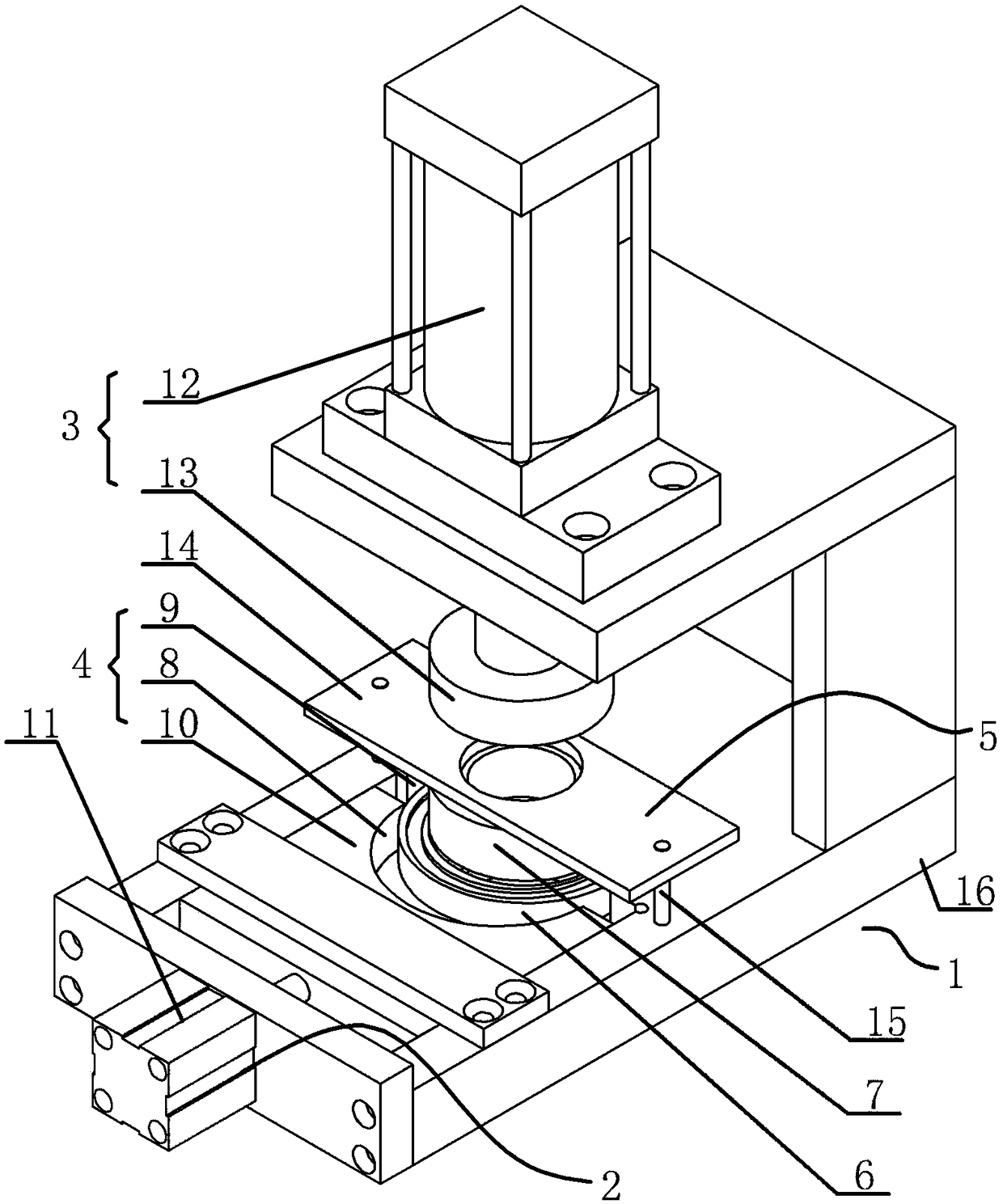

Assembling method of flexible bearing and cam

The invention provides an assembling method of a flexible bearing and a cam. According to the assembling method, the cam can be ensured to conveniently, rapidly and accurately pressed into an inner hole of the flexible bearing, the flexible bearing is not damaged, and the hidden danger of shortening the service life of a harmonic reducer is eliminated. The assembling method comprises the followingsteps that (1) according to the design, the cam is machined, and the machined cam is frozen; (2) according to the specification of the wave generator needing to be assembled, a corresponding assembling tool is machined, and the positioned cam is pressed into the flexible bearing which is subjected to deformation through a press-fitting part of the assembling tool; (3) the flexible bearing in thewave generator needing to be assembled is placed into a flexible bearing positioning cavity of a positioning part for positioning; (4) the frozen cam is taken out, and the cam is fixed through a cam positioning part; (5) a profiling part is used for carrying out pressure deformation on the flexible bearing to form an oval shape, and fixing is carried out; and (6) it is ensured that after the elliptical axis of the cam coincides with the corresponding elliptical axis of the flexible bearing, the positioned cam is pressed into the flexible bearing by the aid of a press machine.

Owner:ZHEJIANG UNIV KUNSHAN INNOVATION INST

Method for preparing graphite/resin compound bipolar plate for fuel cell

The invention provides a method for preparing a bipolar plate, which comprises the following steps of: dissolving binder into organic solvent, adding carbon black serving as additive, ultrasonically dispersing the mixture in an ultrasonic machine, adding required graphite conductive filler and water into the mixture, and then ultrasonically dispersing the mixture in the ultrasonic machine, stirring the mixture at the same time, and drying the mixture, wherein the ultrasonic frequency is between 20 and 80kHz; and crushing the mixture, and obtaining the bipolar plate by a molding-curing process. The method improves wetting property between inorganic conductive objects and organic polymer, and can also use a coupling agent. The method makes all the materials uniformly mixed and improves conductivity of the bipolar plate prepared by the method by near 70 percent.

Owner:HUNAN UNIV

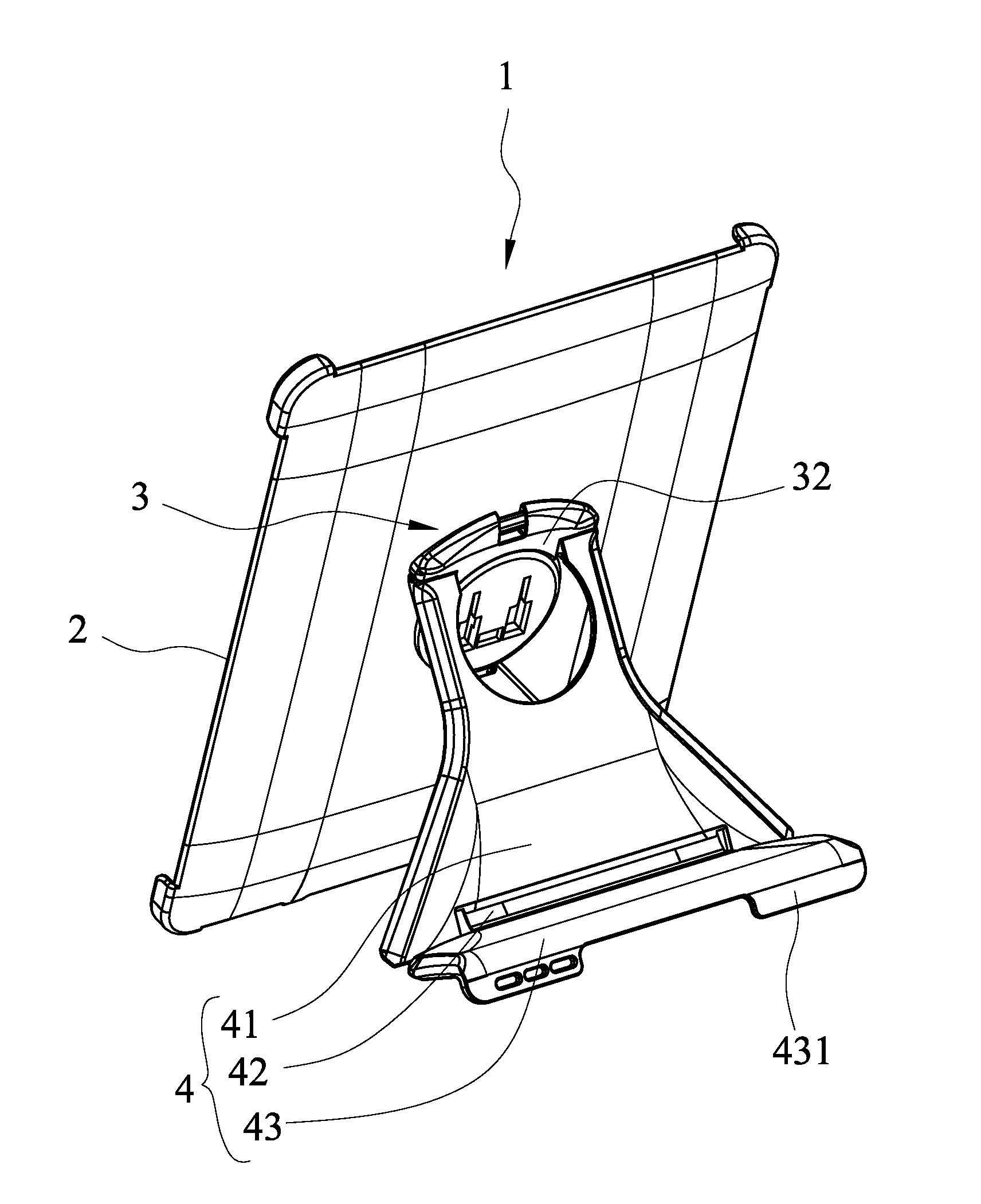

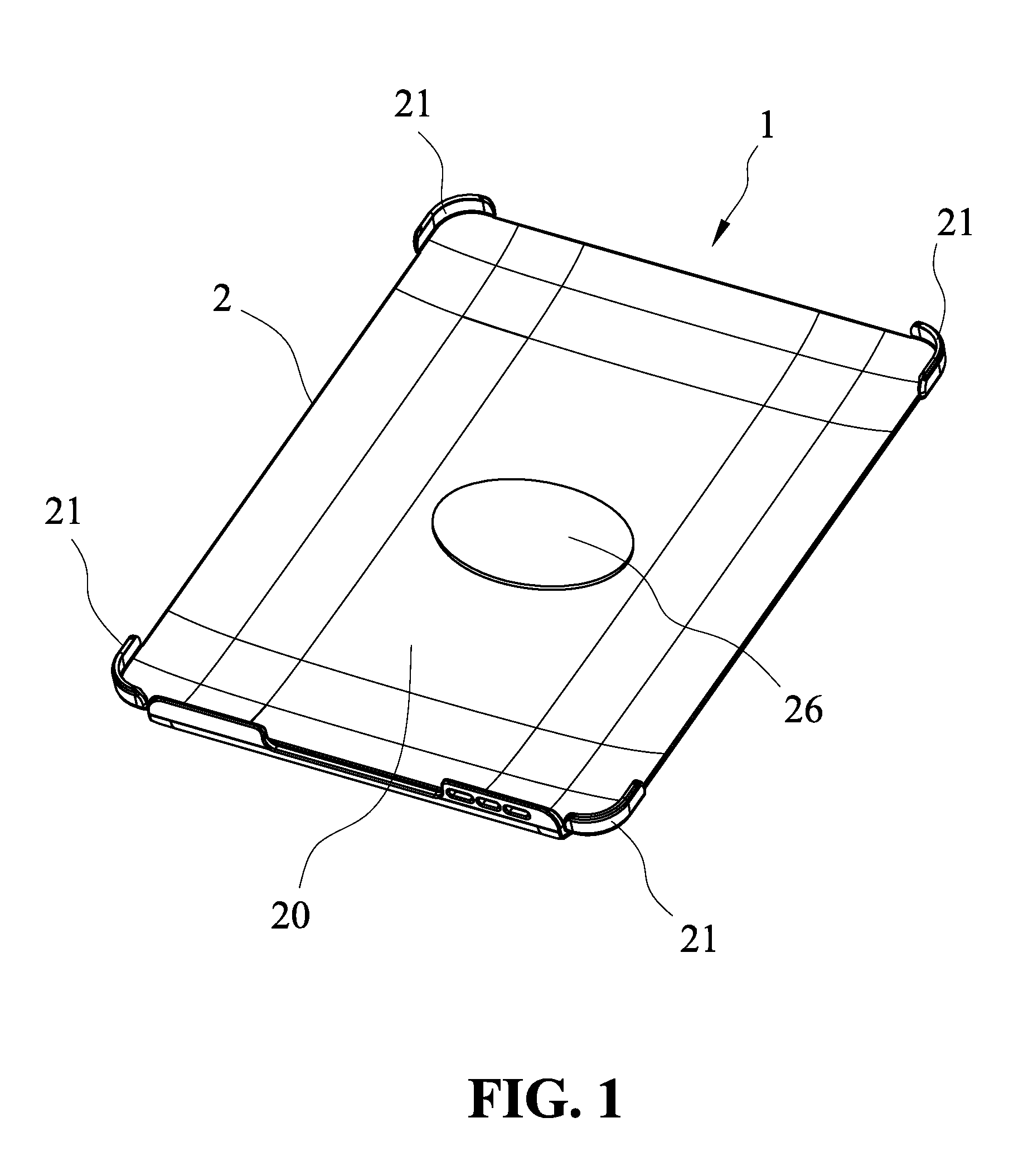

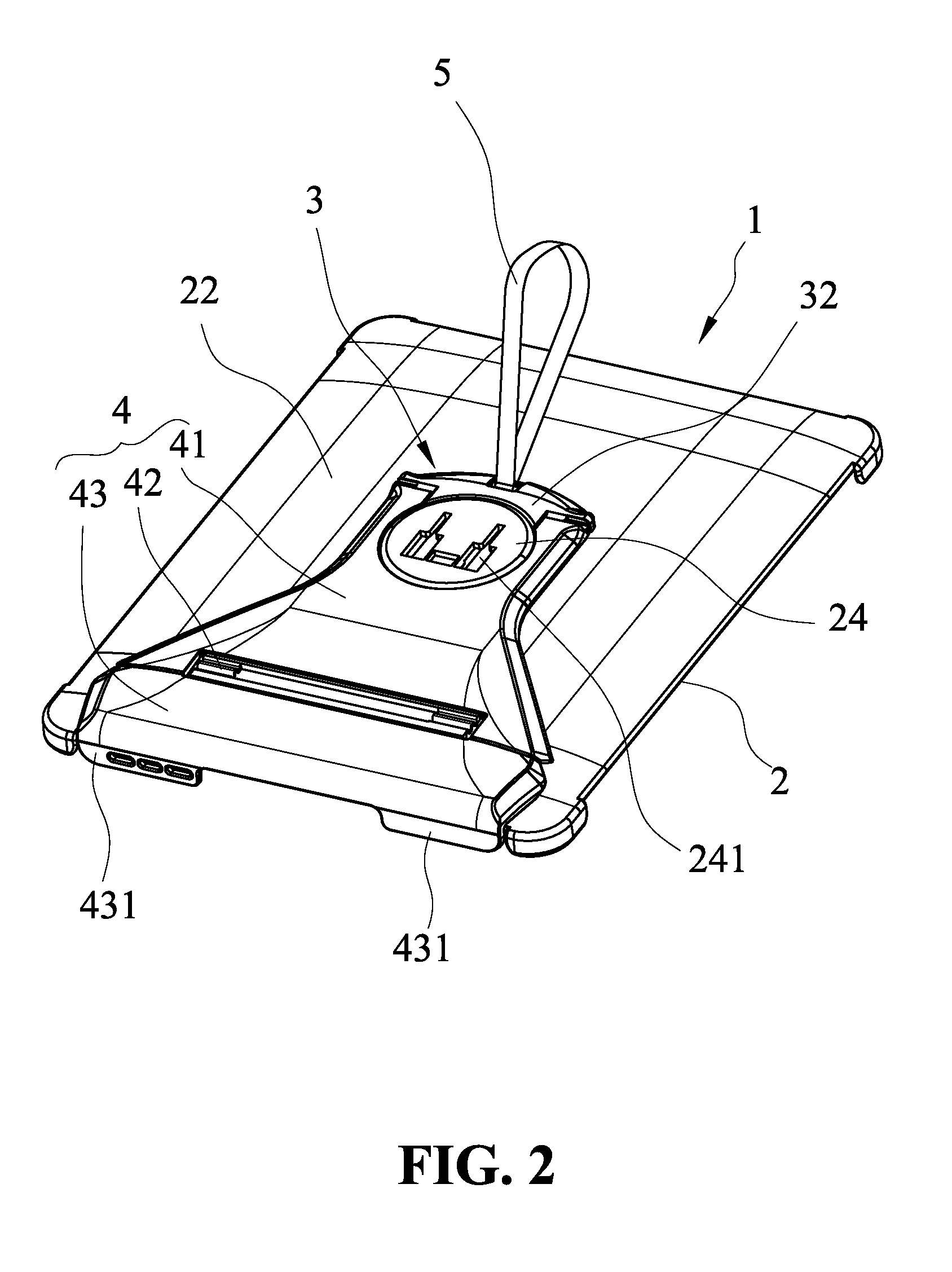

Protective cover for notebook personal computer

InactiveUS20110128701A1Small angle tiltHeat dissipating effect of heat dissipatingDigital data processing detailsCasings/cabinets/drawers detailsCouplingPersonal computer

A protective cover for notebook PC is provided, including a set of bendable plates, and can be folded into a sideway U-shape. The protective cover is pressed tightly against the surface of a notebook PC, and can be opened in synch with the notebook PC screen. The bottom plate of the protective cover is for the placement of notebook PC. The bottom plate includes at least a support unit. The support unit is coupled to the bottom plate, located near the coupling side of the bottom plate. The support unit is divided at the coupling point on the bottom plate into at least an upper support element and a lower support element. When the support unit is opened up, the upper support element and the lower support element will protrude beyond the upper surface and the bottom surface of the bottom plate, so that when the notebook PC is placed on the bottom plate, a angle exists between the notebook PC and the bottom plate, and an angle exists between the bottom plate and the surface on which the protective cover is placed on. In this manner, the heat dissipation effect is improved when the notebook PC is in use.

Owner:FAN EAGLE

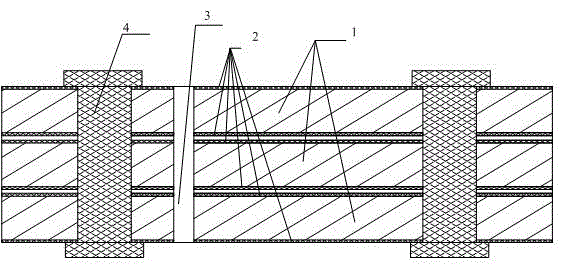

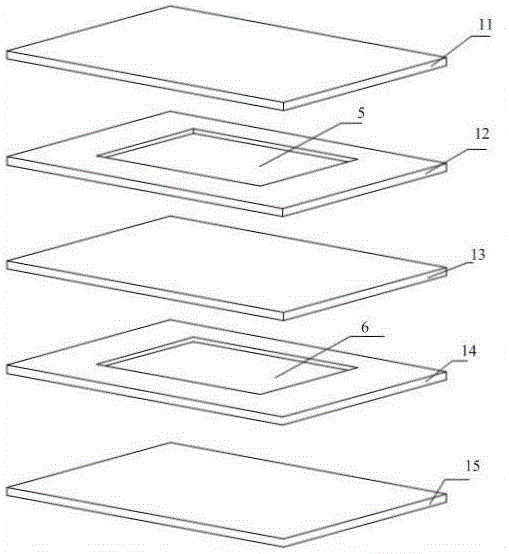

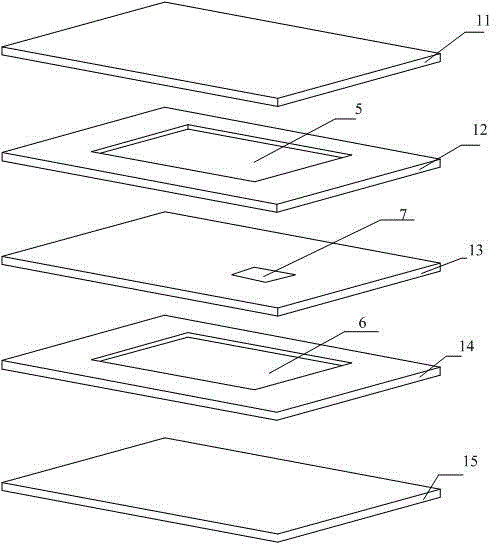

Multi-layer circuit board riveting structure, and suspended line circuit constituted by same, and realization method for suspended line circuit

ActiveCN105142329AOvercoming processabilityOvercome volumeMultilayer circuit manufactureConductive pattern layout detailsDielectric substrateHemt circuits

The invention discloses a multi-layer circuit board riveting structure, and a suspended line circuit constituted by the same, and a realization method for the suspended line circuit. The multi-layer circuit board riveting structure comprises at least two layers of circuit boards arranged in a laminated manner; each circuit board comprises a dielectric substrate and metal layers arranged on the front and back faces of the dielectric substrate; a multi-layer circuit board body is formed by the laminated circuit boards; rivet holes are formed in the multi-layer circuit board body; rivets are inserted in the rivet holes; the upper end parts of the rivets are press-fitted and riveted with the upper surface of the multi-layer circuit board body; and the lower end parts of the rivets are press-fitted and riveted with the lower surface of the multi-layer circuit board body.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

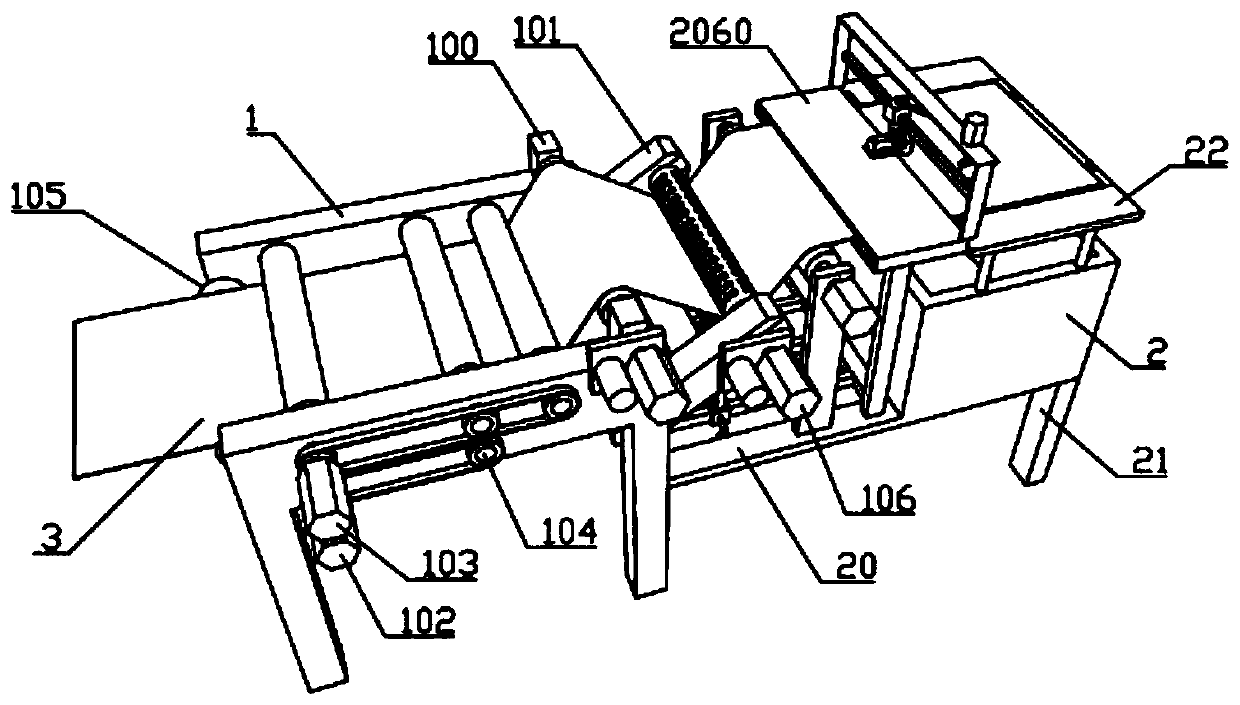

Method for gluing and drying copper-clad plate and device used by method

ActiveCN110370781AFast productionPrecision requirements are not highLamination ancillary operationsLayered product treatmentEngineeringCopper

The invention belongs to the technical field of copper-clad plate preparation, and particularly relates to a method for gluing and drying a copper-clad plate. The method comprises the steps of adhesive solution preparation, fiberglass cloth gluing, surface dry treatment, tailoring, and stacking and drying. The invention further relates to a device used by the method. The device comprises two traction supports and a drying box. The two traction supports face each other oppositely front and back, the traction supports are in reversed-U shapes, convex blocks are integrally formed at the right ends of the top surfaces of the traction supports, inclined support blocks low on the left and high on the right are integrally formed at the top ends of the right surfaces of the traction supports, gluing assemblies are mounted between the two front-back oppositely-faced convex blocks, gluing assemblies are also mounted between the two front-back oppositely-faced inclined support blocks, each gluingassembly comprises a gluing motor, a gluing rolling barrel, a fixing plate and a glue storing box, the fixing plates are fixedly mounted on power output shafts of the gluing motors, the glue storingboxes are mounted on the fixing plates, sleeve shafts are mounted at the rear end tips of the power output shafts of the gluing motors, the gluing rolling barrels sleeve the sleeve shafts and are fixed to the sleeve shafts, and first bearings are fixedly mounted at the two ends of each sleeve shaft.

Owner:黄瑞有

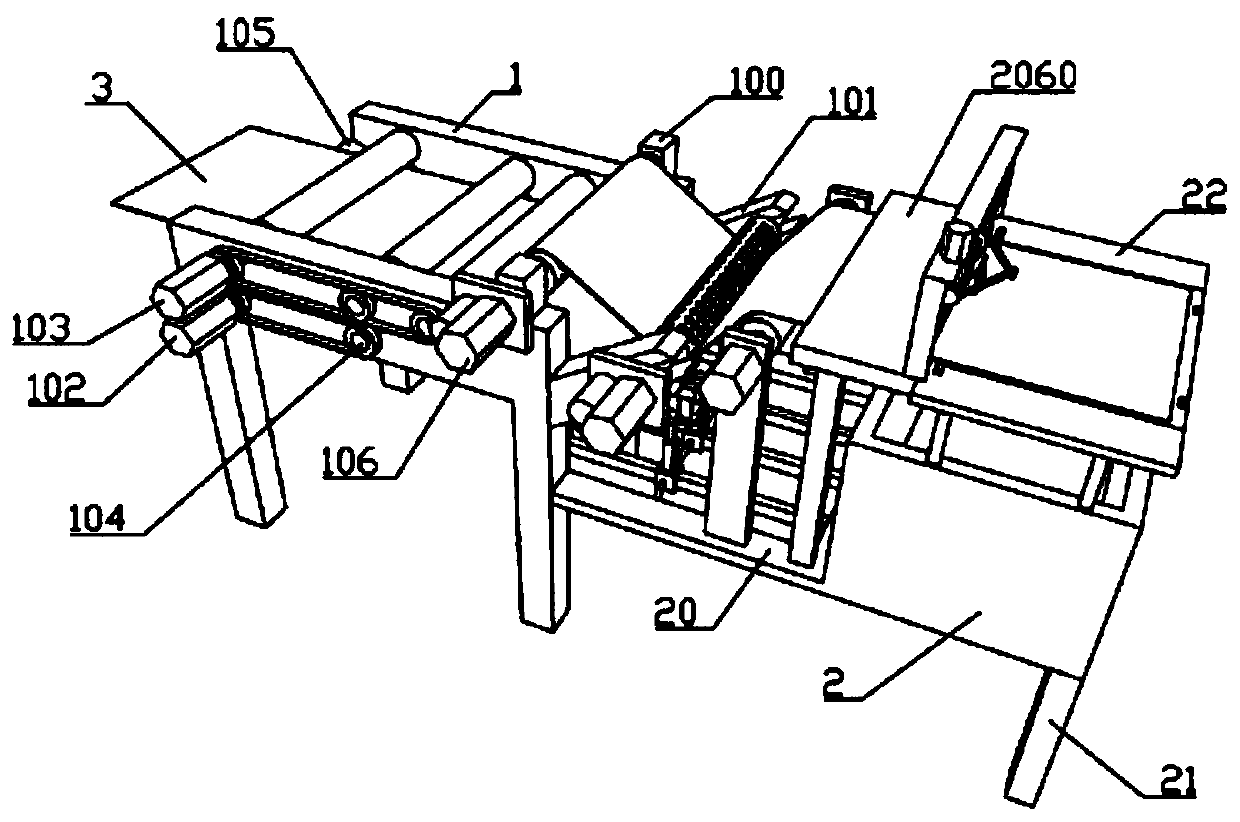

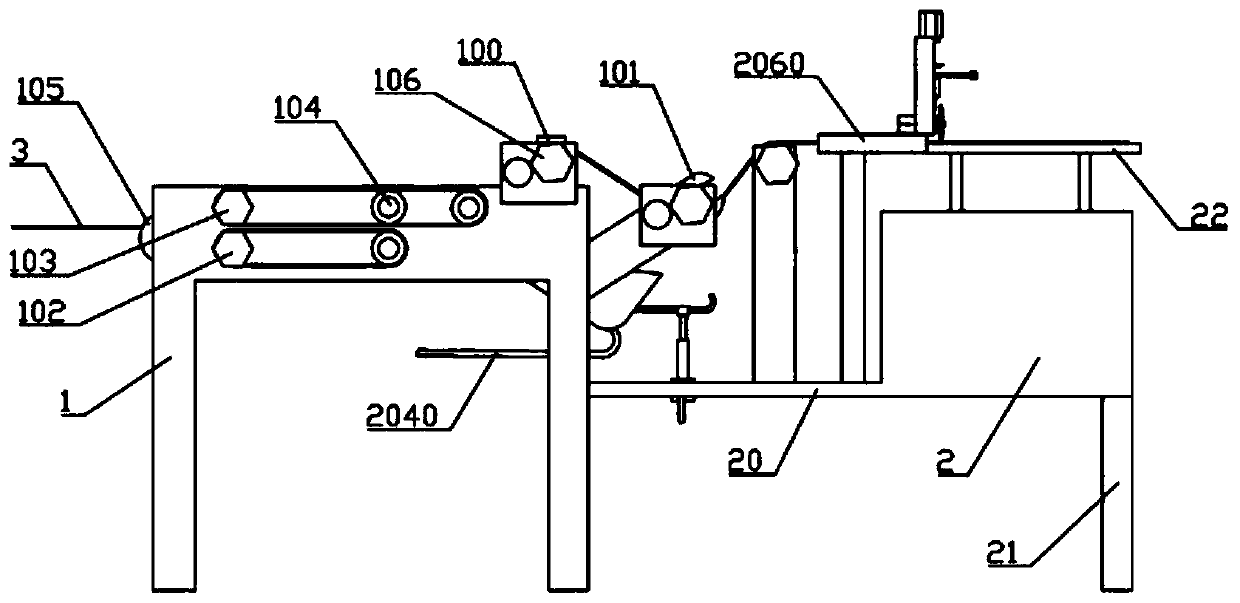

Ultrasonic capping machine

InactiveCN109623126APress tightlyReduce manual laborNon-electric welding apparatusEngineeringMechanical engineering

The invention provides an ultrasonic capping machine. The ultrasonic capping machine comprises a worktable; the worktable is concave; a bracket is arranged at the right end of the worktable; the leftside of the top end of the bracket is connected with a cross beam; a lower pushing cylinder is arranged at the lower end of the cross beam; a mounting plate is arranged at the lower end of the lower pushing cylinder; an ultrasonic generator is arranged on the lower side of the mounting plate; a capping head is connected to the lower end of the ultrasonic generator; the bottom surface of the capping head is boss-shaped; L-shaped slide rails are symmetrically arranged on two opposite sides of the worktable; slide blocks are arranged on the L-shaped slide rails; L-shaped baffle plates are oppositely and symmetrically arranged on the slide blocks on two sides; fixed plates are arranged at the back ends of the L-shaped slide rails; a loading conveying belt is arranged at the front end of the worktable; the back end of the loading conveying belt is embedded in a groove at the front end of the worktable; an unloading conveying belt is arranged on the right side of the worktable; a pushing cylinder is arranged on the left side of the worktable; and a pushing plate is arranged at the front end of the pushing cylinder. As the lower end of the capping head is boss-shaped, the capping is fitter; and the loading conveying belt and the unloading conveying belt are arranged for automatic loading and unloading, so that the working efficiency is improved.

Owner:TIANNENG BATTERY WUHU

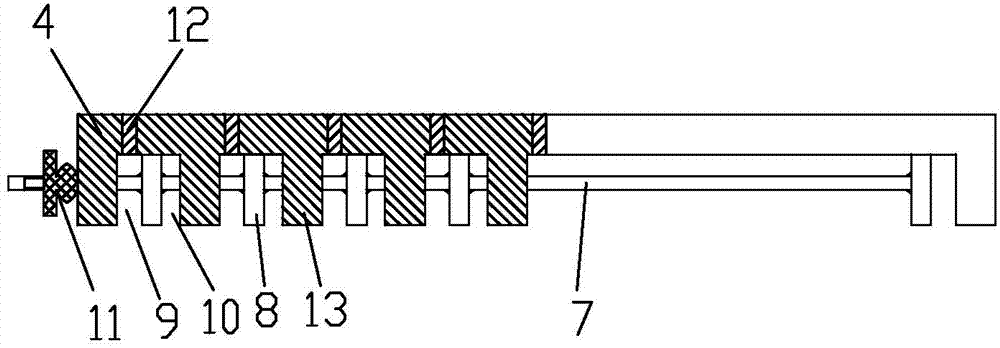

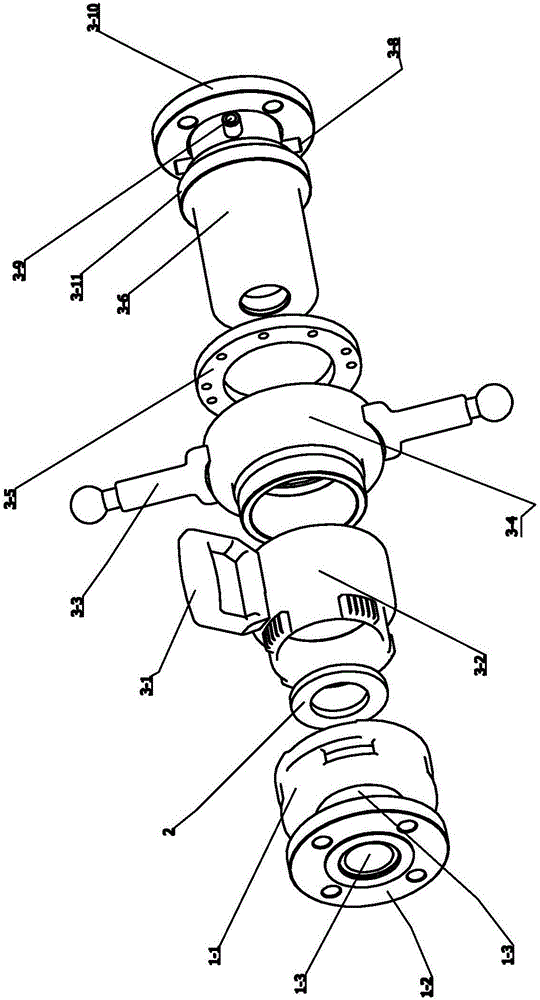

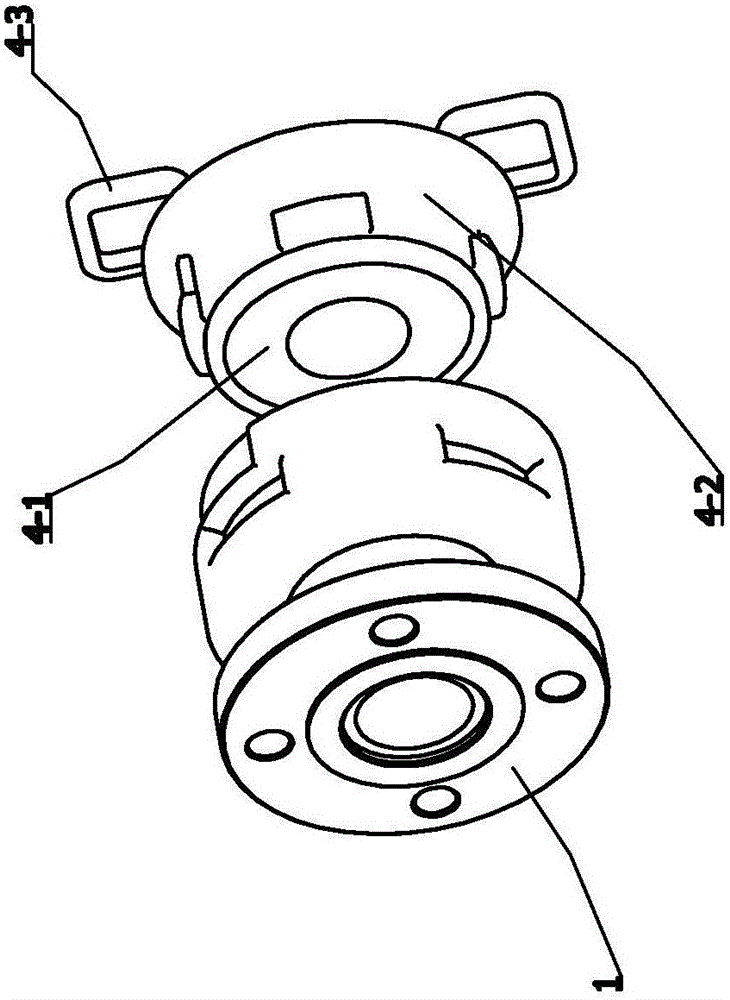

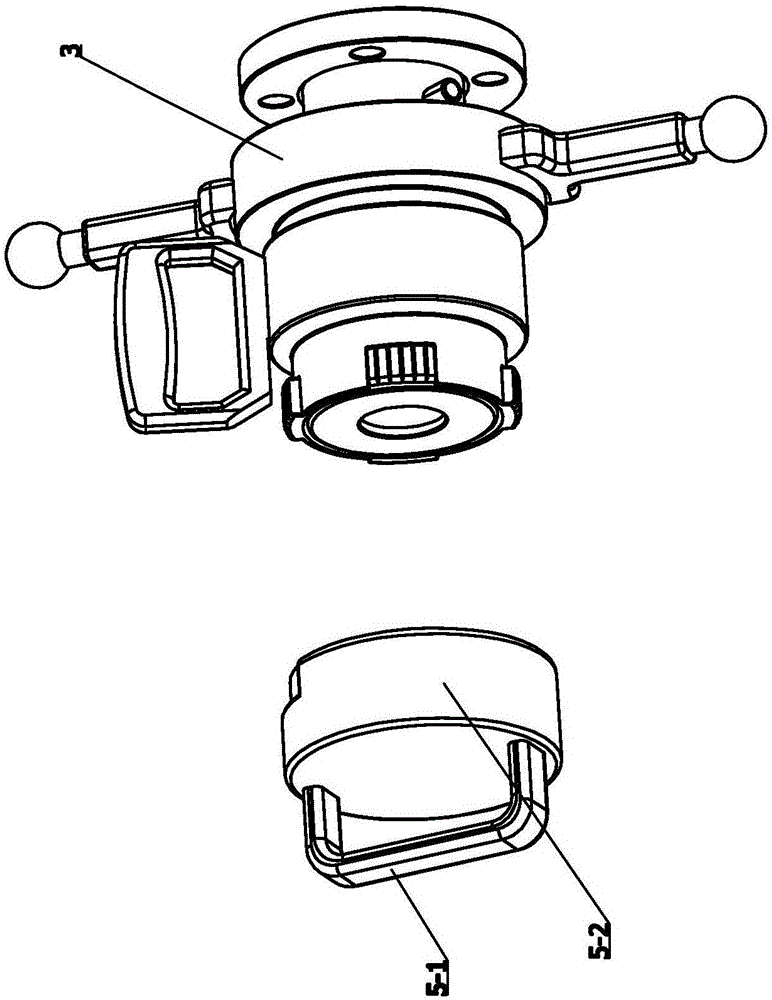

LNG special quick connector

ActiveCN105972360ASolve the freezing phenomenonPress tightlyThermal insulationJoints with sealing surfacesEngineeringElectrical and Electronics engineering

The invention discloses an LNG special quick connector. The LNG special quick connector comprises a female connector, a sealing ring and a male connector; the female connector comprises a female connector connecting clamping head, a female connector connecting part used for dismountably connected with an external pipeline, and a female vacuum connecting pipe used for connecting the female connector connecting clamping head and the female connector connecting part; the male connector comprises a male connector connecting clamping head, a threaded pushing ring and a male connector vacuum connecting pipe; the sealing ring is embedded in the interior of the female connector connecting clamping head; the male connector connecting clamping head can be axially docked with the female connector connecting clamping head in an embedded and limited manner; the threaded pushing ring is dismountably and axially fixed to the male connector vacuum connecting pipe in a limited manner and matched with the rear end of the male connector connecting clamping head. According to the technical scheme, the connecting can be realized in the way of axially positioning the male connector connecting clamping head and the female connector connecting clamping head and then screwing in the threaded pushing ring and finally pushing the male connector vacuum connecting pipe tightly onto the pre-installed sealing ring.

Owner:大连沃森达智能仪器有限公司

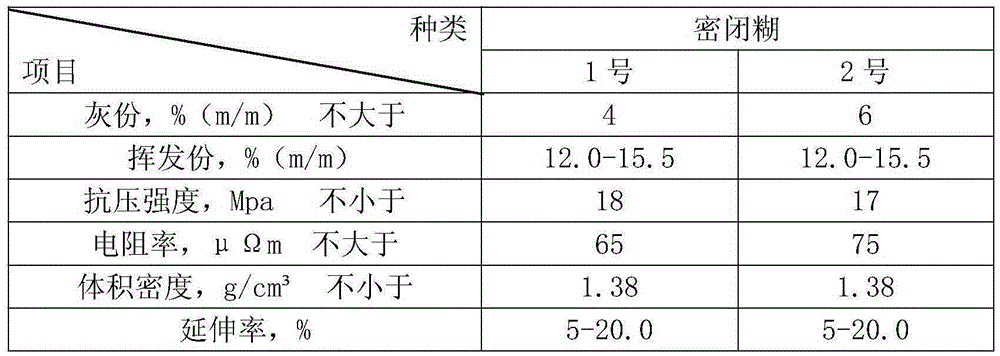

Production technology of high-strength electrode paste

ActiveCN105390211AGuaranteed Physical PropertiesImprove conductivityCable/conductor manufactureOperational costsFerrosilicon

The invention provides a production technology of high-strength electrode enclosing paste. The high-strength electrode enclosing paste is made of the following raw materials, by weight ratio: 35-40 parts of anthracite, 25-30 parts of anode remnants, 25-20 parts of metallurgical coke, 5-10 parts of synthetic graphite, and 18-23 parts of coal tar pitch; and the high-strength electrode enclosing paste is prepared by the following steps of careful choosing according to the weight ratios, milling and screening, mixing and stirring, and molding and cooling. The production technology of the high-strength electrode enclosing paste solves the problems in the production technology of conventional electrode enclosing paste that the selection of raw materials is not rigorous, environment pollution is caused, the mechanical strength of the product is poor, and the resistivity is high; in addition, the technology process is simplified, the production and operation cost is lowered, the practicality is high, and the production technology can be applied to conductive materials of self-baking electrodes such as a calcium carbide furnace, ferroalloy furnace and a ferrosilicon furnace.

Owner:HUNAN ZHENSHENG CARBON IND CO LTD

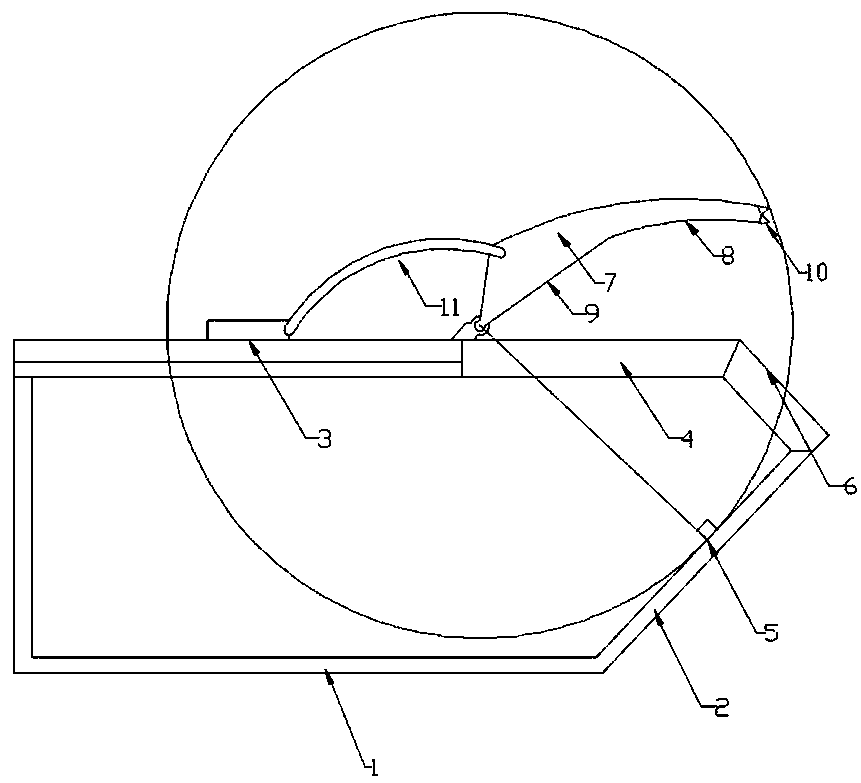

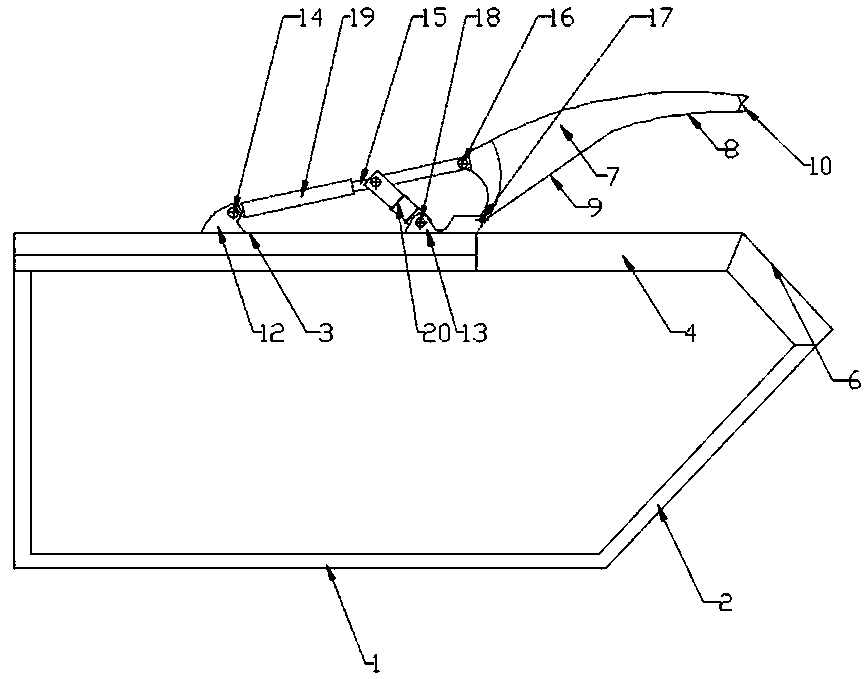

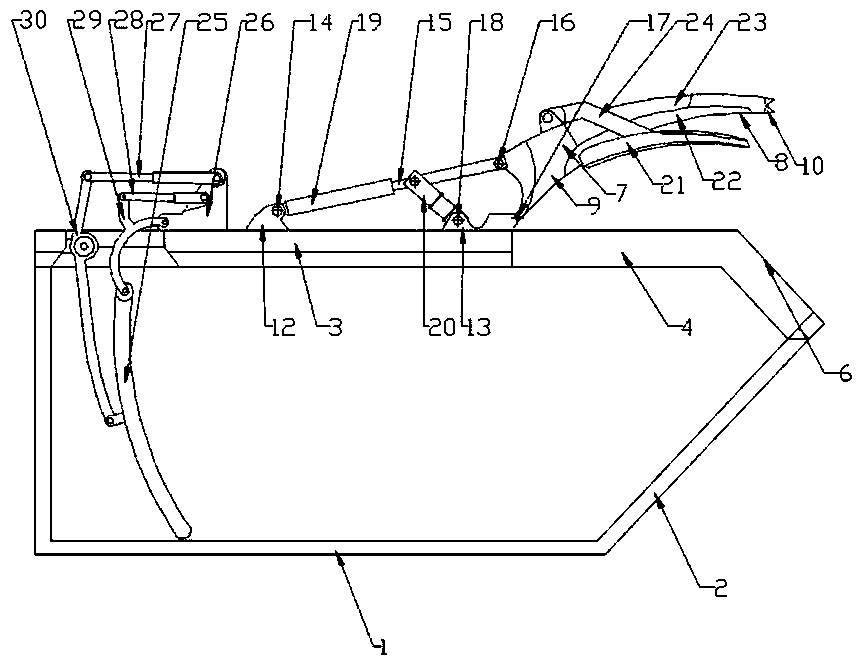

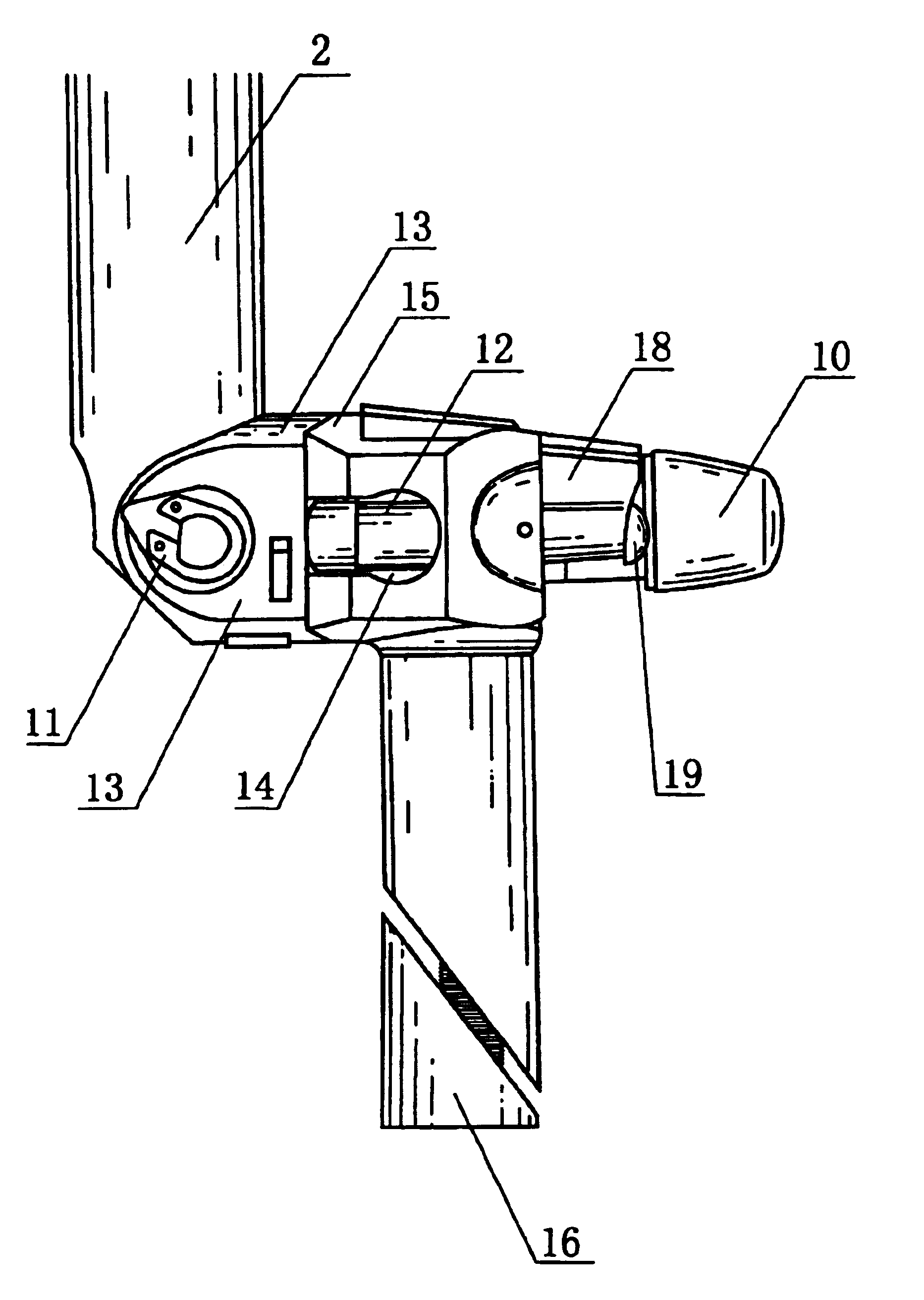

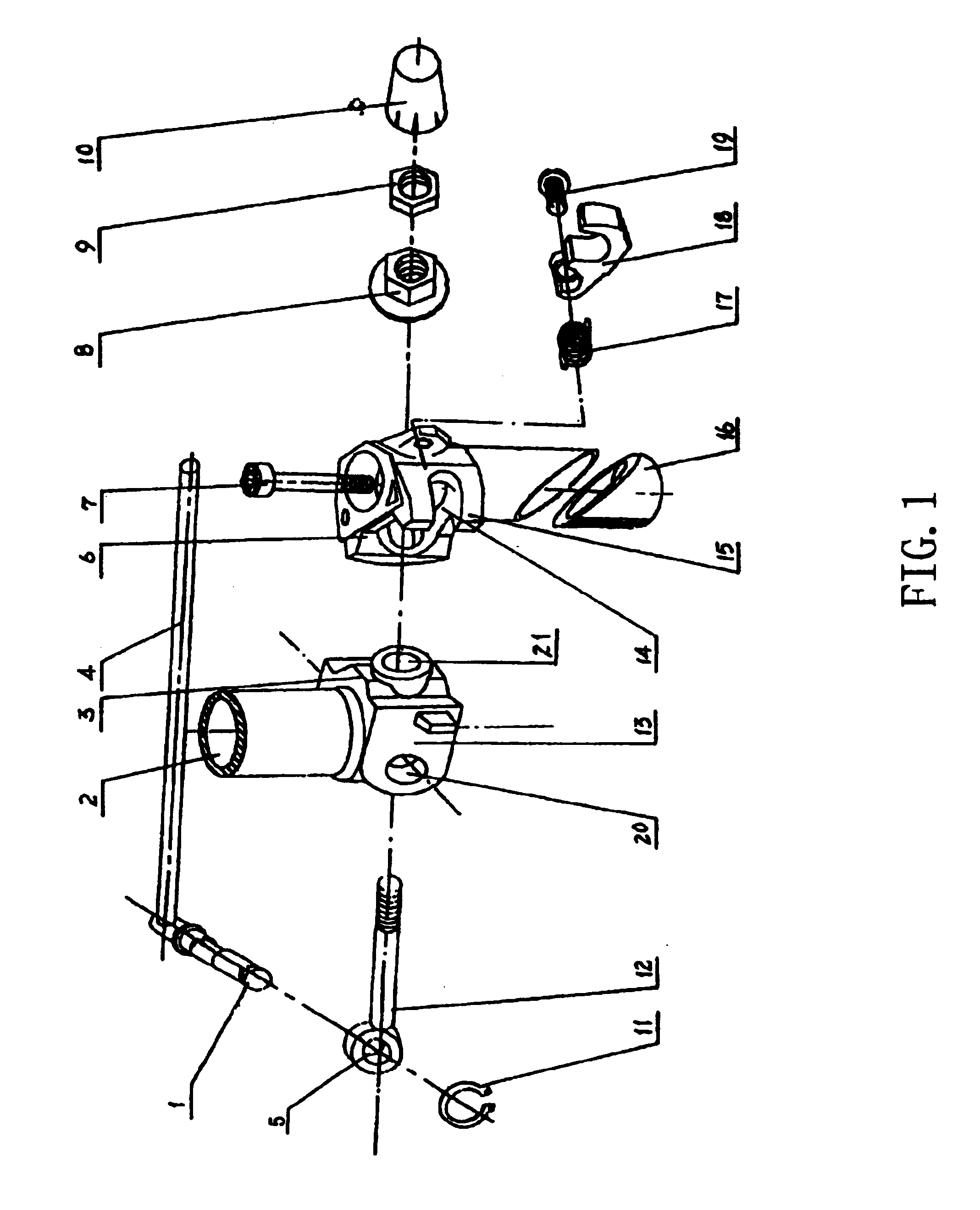

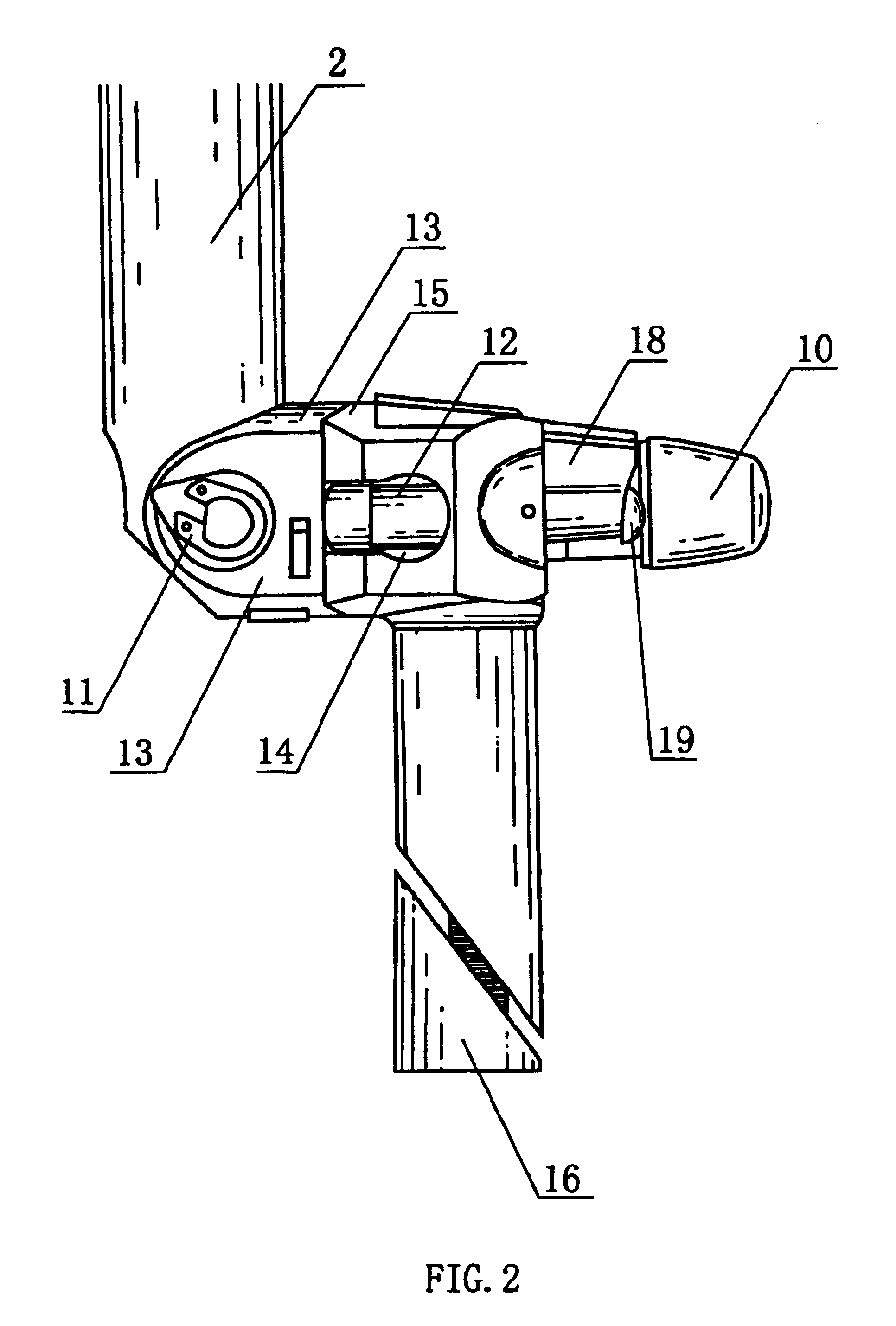

Overturning and folding device for handlebar

InactiveUS6941835B2Safe drive be guaranteeReasonable constructionMechanical apparatusSteering deviceFastenerEngineering

An overturning and folding device for a handlebar includes a tube (2) extending vertically from the handlebar base (13), a connecting member (15) next to the base (13), an eccentric axle (1) and a lug bolt (12). A first hole (21) in the axial direction and a second hole (20) in the perpendicular direction relative to the first hole are formed at the handlebar base (13) of said tube (2), which communicate with each other. The connecting member (15) is engaged to the fork of the bicycle, which defines a space (14) through which the lug bolt (12) can rotate from an axial position to a perpendicular position. The lug bolt (12) is fixed within the first hole (21) and space (14) by a fastener (8). The eccentric axle (1) is fitted rotatable in the second hole (20) and a third hole (5) on the head of the lug bolt (12).

Owner:YING XIONGXIN

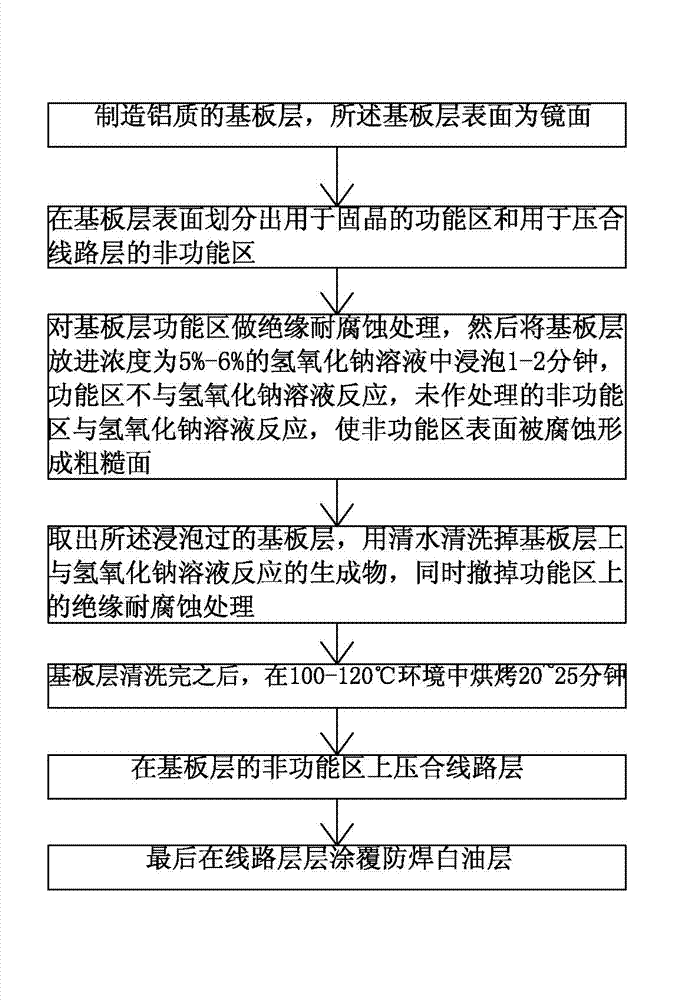

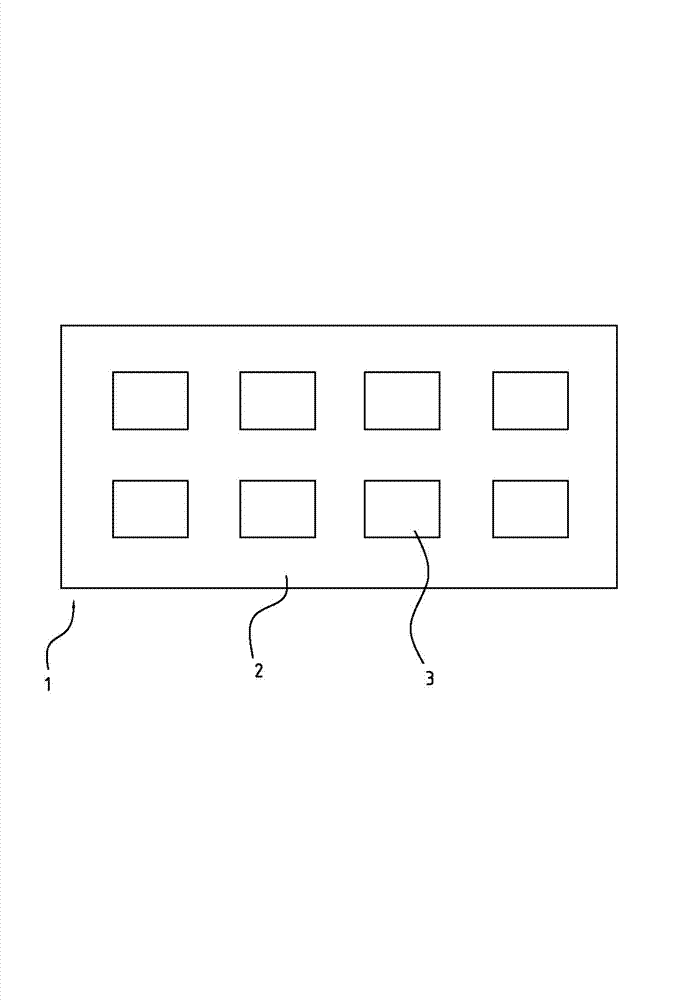

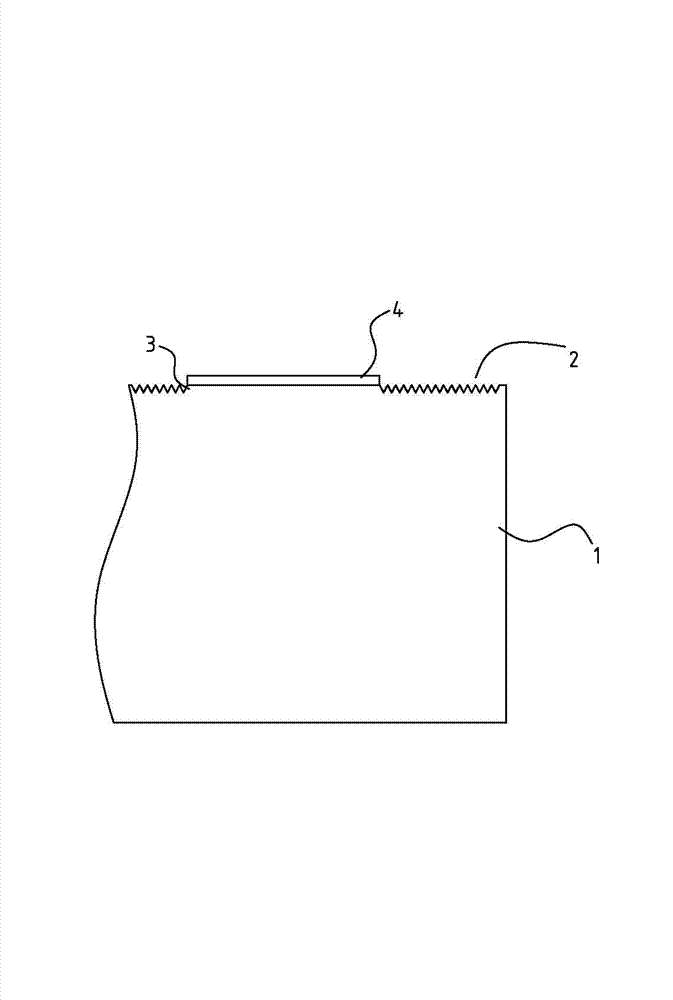

Light emitting diode (LED) aluminum substrate and manufacturing method thereof

ActiveCN103035830AReduce absorptionIncrease reflectionSemiconductor devicesRough surfaceAluminum substrate

The invention provides a light emitting diode (LED) aluminum substrate. A manufacturing method for the LED aluminum substrate includes the following steps of manufacturing the substrate layer, dividing functional zone and a non-functional zone on the surface of the substrate layer, doing isolation and corrosion resisting treatment to the functional zone of the substrate layer, then putting the substrate layer into 5%-6% sodium hydroxide solution to soak the substrate layer for 1-2 minutes, wherein the functional zone does not act with the sodium hydroxide solution, the non-functional zone acts with the sodium hydroxide solution, and surface of the non-functional zone is corroded to form a rough surface, taking out the soaked substrate layer, washing off sundries on the substrate layer through clear water, simultaneously removing the isolation and corrosion resisting treatment on the functional zone, baking the substrate layer for 20-25 minutes at the temperature of 100-120 DEG C after finishing cleaning the substrate layer, doing press fit of a wire level on the non-functional zone of the substrate layer, and coating the wire layer with an anti-welding white oil layer. The wire layer can be pressed tightly under the condition that good reflection efficiency of the substrate layer is guaranteed.

Owner:HONGLI ZHIHUI GRP CO LTD

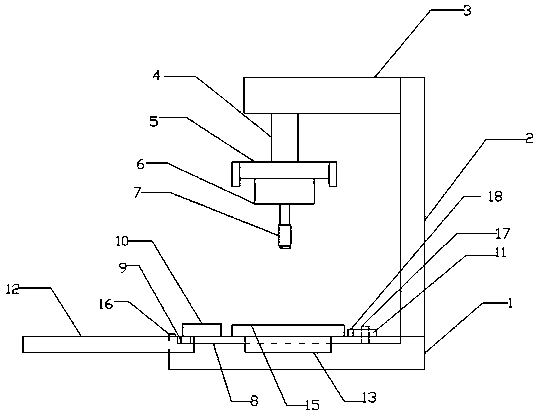

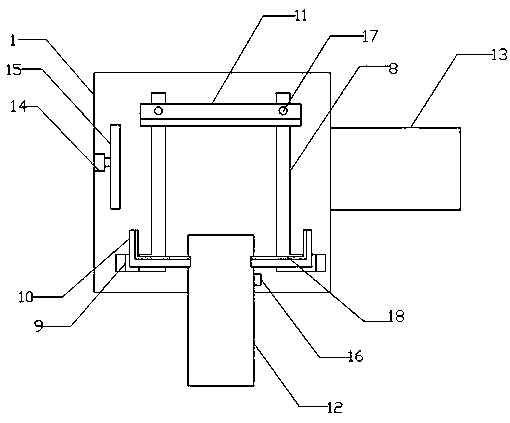

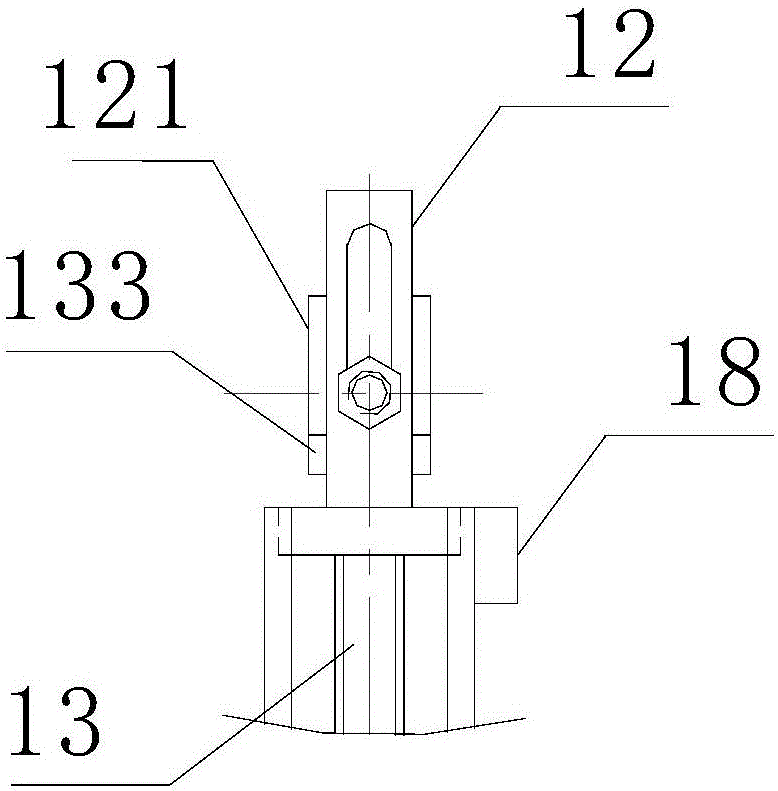

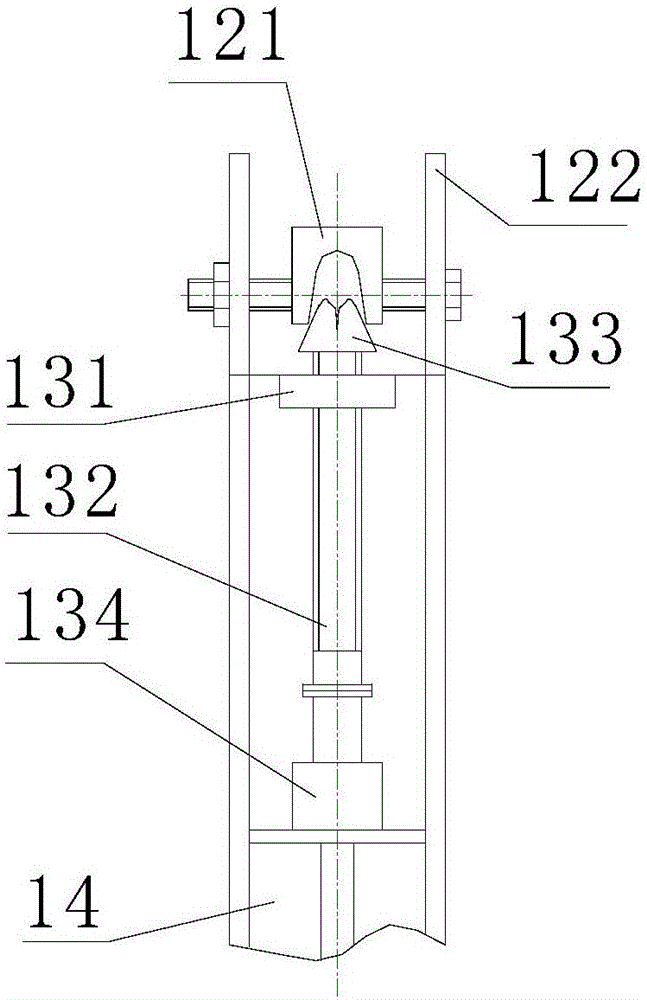

Adjustable lead wire press-connection machine bracket

ActiveCN106451007AGuaranteed crimp qualityEasy to transportLine/current collector detailsConnections effected by permanent deformationEngineeringMechanical engineering

The invention relates to an adjustable lead wire press-connection machine bracket. A press-connection machine (11) is arranged on a press-connection engine (10); stand columns (14) are located on two sides of the press-connection machine (11) respectively and each stand column is of a hollow structure provided with a slide way; a lower adjusting unit (13) is located in the hollow structure of each stand column (14), wherein a screw rod (132) is driven by a driving device (134) to rotate so as to drive a slide block (131) to move along the slide way of each stand column (14); lower adjusting blocks (133) are fixed with the slide blocks (131); each lower adjusting block (133) is of a tapered structure and a groove for containing a lead wire is formed in the upper end of each lower adjusting block (133); an upper adjusting unit (12) is arranged on each stand column (14); an upper bracket (122) acts above each stand column (14); upper adjusting blocks (121) are fixed on the upper brackets (122) through fastening bolts; and a reversed U-shaped groove is formed in each upper adjusting block (121) and and an opening end is inclined outward. By adopting the adjustable lead wire press-connection machine bracket, the straightness of a press-connection finished product can be guaranteed, and the adjustable lead wire press-connection machine bracket is simple in structure and convenient to transport.

Owner:DATONG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com