Light emitting diode (LED) aluminum substrate and manufacturing method thereof

A technology of LED aluminum substrate and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as tight lamination and shedding of circuit layers, and achieve the effects of improving light extraction efficiency, good reflection, and increasing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings of the description.

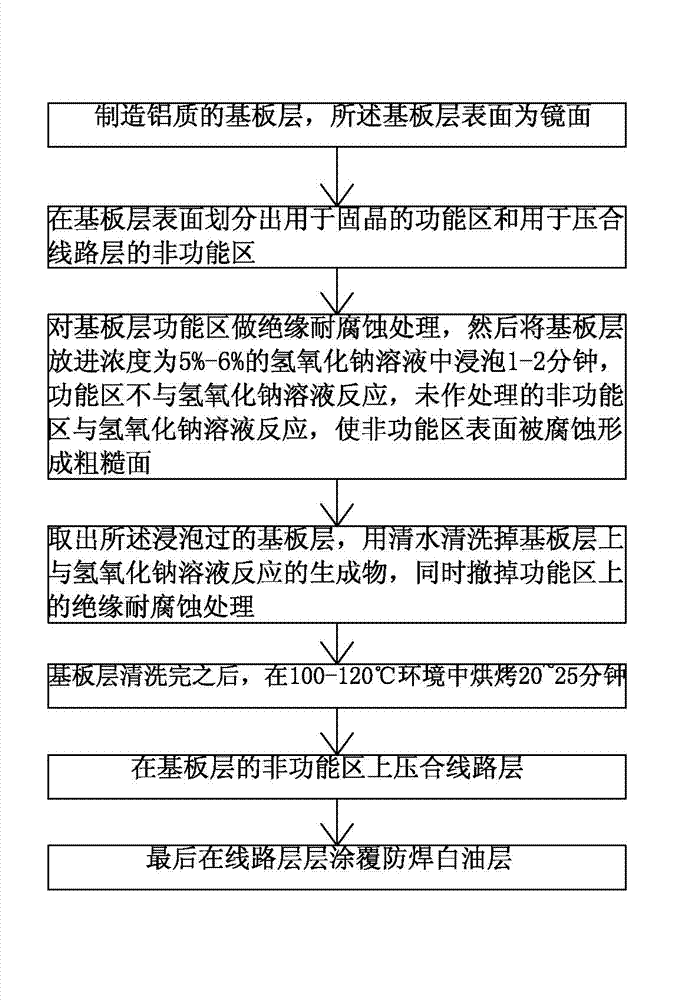

[0026] Such as Figures 1 to 3 Shown, a kind of LED aluminum substrate, its manufacturing method comprises the following steps:

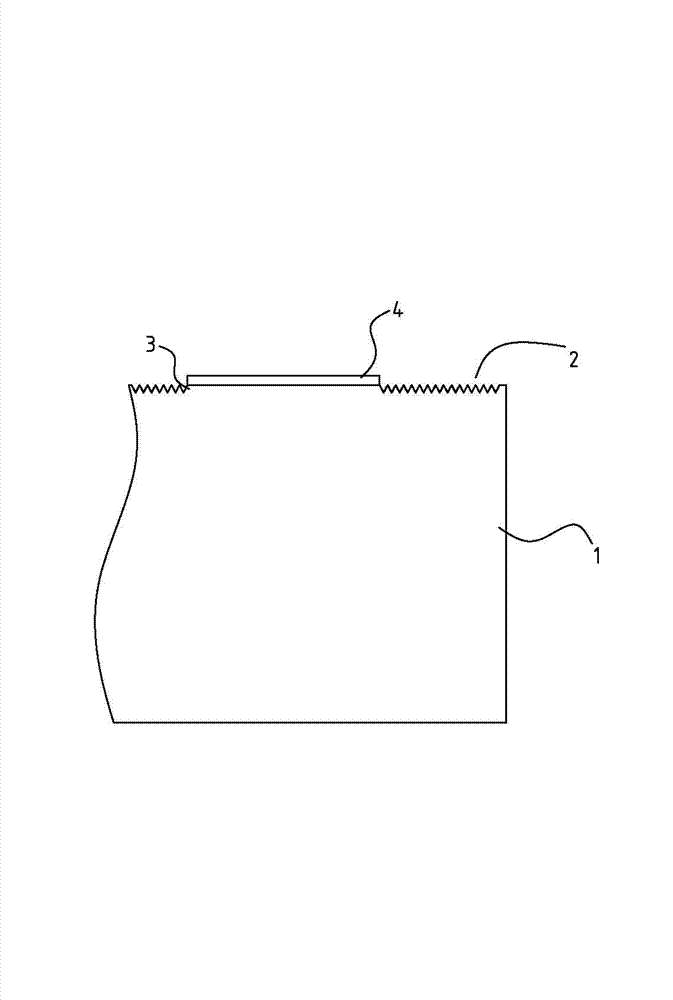

[0027] (1) Manufacturing an aluminum substrate layer 1, the substrate layer 1 is a mirror aluminum substrate, so that the surface of the substrate layer 1 is a smooth mirror surface;

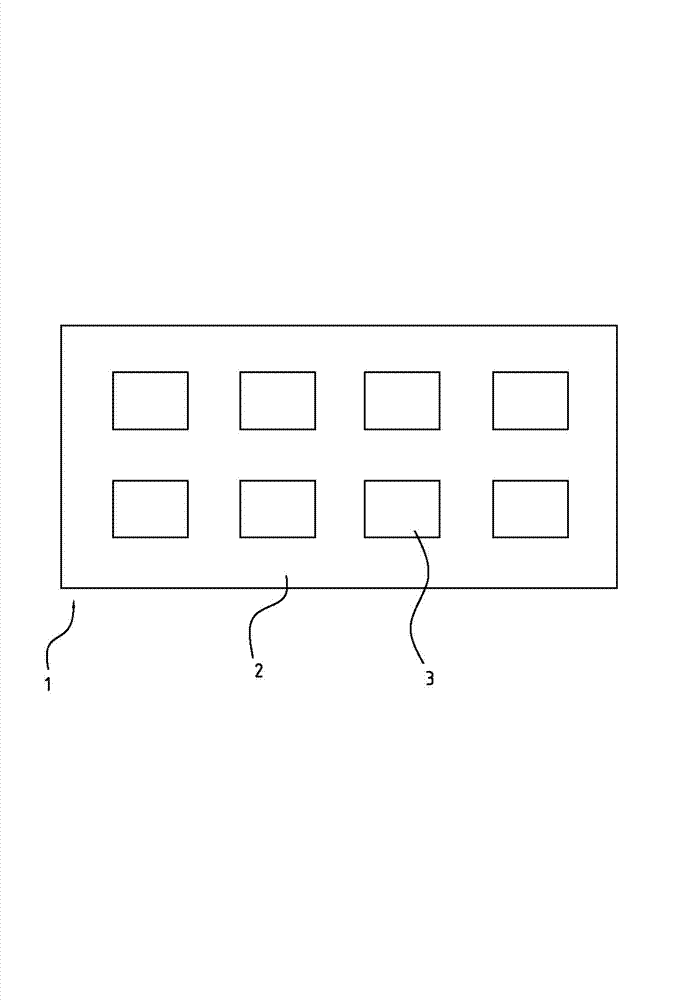

[0028] (2) Use film on the surface of the substrate layer 1 to divide the functional area 3 for die bonding and the non-functional area 2 for laminating the circuit layer;

[0029] (3) Perform insulation and corrosion resistance treatment on the functional area 3 of the substrate layer 1, first brush the blue oil on the functional area 3, and paste the blue film 4 on the area covered with the blue oil; the main components of the blue oil and the blue film 4 It is saturated hydrocarbon polyester, polyethylene or polypropylene, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com