Patents

Literature

1714 results about "White oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

White oil is a homemade insecticide spray used for controlling a wide range of insect pests in the garden. The spray works by blocking the breathing pores of insects, causing suffocation and death. It is effective in the control of aphids, scale, mealybug, mites, citrus leaf miner and smooth skinned caterpillars.

Process to make white oil from waxy feed using highly selective and active wax hydroisomerization catalyst

A process for producing one or more white oils, by: a) hydroisomerization dewaxing a waxy feed with a defined composition over a highly selective and active wax hydroisomerization catalyst with a defined composition under conditions sufficient to produce a white oil; and b) collecting one or more white oils, wherein the yield of white oils is high, and they have a low pour point and a good Saybolt color. Also, a process for producing medicinal grade white oils, by a)hydroisomerization dewaxing a waxy feed with a defined composition over a highly selective and active wax hydroisomerization catalyst with a defined composition under conditions sufficient to produce a white oil, b) collecting technical grade white oils having a low pour point and good Saybolt color in high yield, and c) hydrofinishing the technical grade white oils at conditions sufficient to produce medicinal grade white oils that pass the RCS test.

Owner:CHEVROU USA INC

Thermoplastic elastomer and its production method

The invention provides a high elasticity thermal plasticity elastic body and the method to make. The weight proportion of the elastic body includes: plasticity ingredient styrene-butadiene-styrene block copolymer 100, filling naphthenic oil or white oil 40-60, modification agent 0-110, stabilizing agent 2-10, lubricant 2-65, and other bulk agent 10-300. The invention has advantages of low compression deformation, strong flexing resistance and good resilience.

Owner:闫俊龙

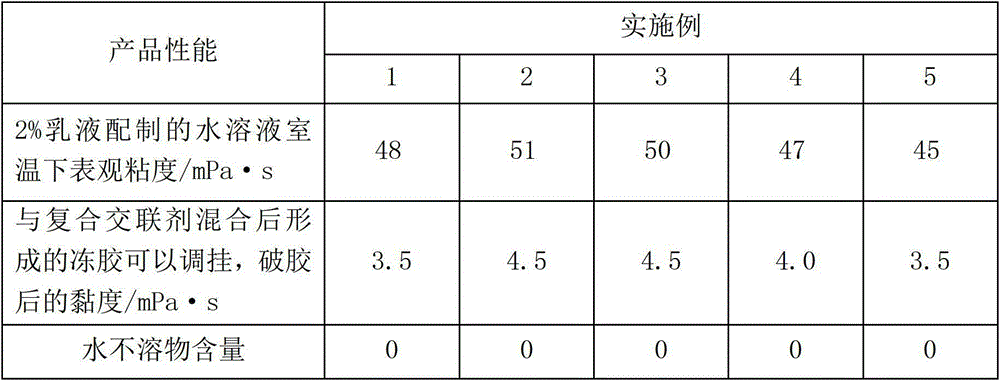

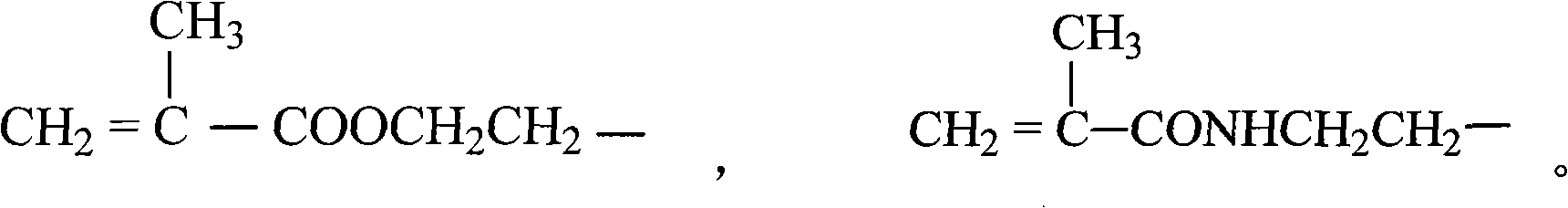

Inverse emulsion polymer thickener for fracturing fluid and preparation method thereof

ActiveCN103146372AAvoid harmMeet the fracturing constructionDrilling compositionPolymer sciencePersulfate

The invention relates to an inverse emulsion polymer thickener for a fracturing fluid and a preparation method thereof. The thickener is polymerized by water, 2-acrylamidyl-2-methyl sodium proparesulfonic acid liquid with mass fraction of 50%, alkyl acrylamide, acrylamide, a cationic monomer, N, N-methylene bisacrylamide, a tween-80 emulsifier, ethylene diamine tetraacetic acid disodium salt, 30% sodium hydroxide, white oil, acrylic ester, a span-80 emulsifier, sulfite, a peroxysulphate initiator, a water-soluble azo initiator and OP-15. According to the invention, raw materials are industrial products, and purification is not needed before reaction; polymerization is initiated by initiators by adding a complexing agent, and the preparation process is simple; the thickener provided by the invention is fast in dispersing, easy to prepare, free from pollution and harm, small in use level and good in stability, in particular resists high temperature of 220 DEG C, and is suitable for fracturing a high-temperature stratum; and the thickener is higher in shear resistance, can meet the fracturing construction of high flow, has high sand carrying performance, and is free from residue and is not harmful to the reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

Highly-efficient lubricant for drilling fluid

InactiveCN101735778AImprove the lubrication effectIncrease the extreme pressure valueDrilling compositionPolyesterPhosphate

The invention discloses a highly-efficient lubricant for a drilling fluid. The highly-efficient lubricant comprises the following components in percentage by weight: 10 to 40 percent of white oil, 30 to 70 percent of fatty acid methyl ester or methyl oleate, 5 to 20 percent of polyester, 2 to 8 percent of organic phosphate, 1 to 6 percent of oilness extreme-pressure additive, 0.5 to 2 percent of emulsifier OP-10 and 0.5 to 2 percent of span-80. The invention also discloses a method and steps for preparing the highly-efficient lubricant for the drilling fluid. The highly-efficient lubricant can enhance the lubricating property of the drilling fluid and increase an extreme pressure value of the drilling fluid, and is suitable for the demand of ordinary drilling and use in a high-difficulty highly deviated directional well and a horizontal well.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Wood-plastic composite material and preparation method thereof

The invention relates to the technical field of polymer processing, in particular to a wood plastic composite material and a preparation method thereof. The invention discloses the wood plastic composite material which is prepared from the following raw materials in weight percentage: 30 to 60 percent of wood fibre, 30 to 60 percent of waste plastics, 1 to 4 percent of stearic acid, 1 to 4 percent of industrial white oil, 1 to 3 percent of a coupling agent and 4 to 6 percent of a lubricant. The invention also discloses the method for preparing the wood plastic composite material and wood plastic products which are prepared from the wood plastic composite material. The wood plastic products produced by using the wood plastic composite material as a raw material are superior to similar products in the appearance quality and the physiochemical performance.

Owner:SHANGHAI BESTON PLASTICS

High-intensity wood plastic composite board and fabrication method thereof

InactiveCN101708614AEasy to produceHigh strengthWood veneer joiningFlat articlesMechanical propertyWhite oil

The invention relates to a wood plastic composite, in particular to a high-intensity wood plastic composite board and a fabrication method thereof. The method for fabricating the high-intensity wood plastic composite board comprises the following steps: treating nano titanium dioxide with silane coupling agent to obtain modified nano titanium dioxide; mechanically stirring the modified nano titanium dioxide, plastic particles, maleic anhydride grafted plastic particles, calcium stearate and the like, and extruding and pelleting all the materials to obtain modified plastic particles; mechanically stirring the modified plastic particles, wood flour, terpene resin, chopped glass fiber, white oil, antioxidant and the like, and extruding, melt-blending and pelleting all the materials to obtain high-intensity wood plastic composite particles; and finally extruding the high-intensity wood plastic composite particles with a machine to mold the high-intensity wood plastic composite board. The high-intensity wood plastic composite board has extremely wide application range, and is applied to the fields such as transportation, construction, decoration, ornament, municipal works, garden and park, packaging and the like. The high-intensity wood plastic composite board has the advantages of reproducibility, low cost and higher mechanical properties such as static bending strength and the like, thereby being an ideal material for replacing wood. Compared with traditional wood plastic composites, the high-intensity wood plastic composite board has longer service life, and is a novel upgrade product of the present wood plastic composites.

Owner:江苏森诺塑胶科技有限公司

Laundry sheet

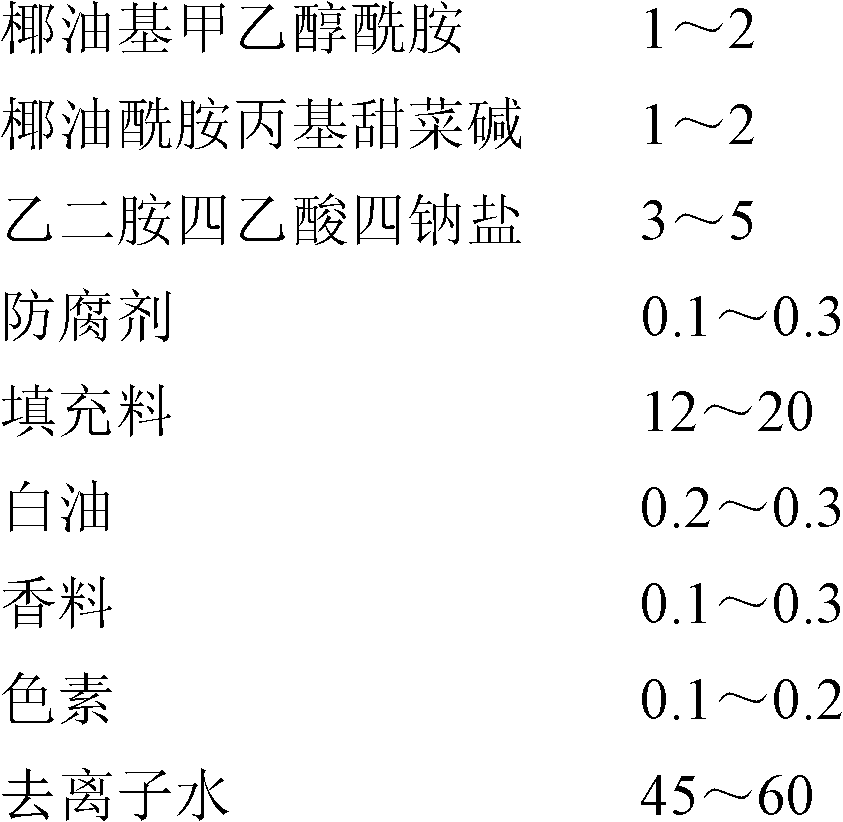

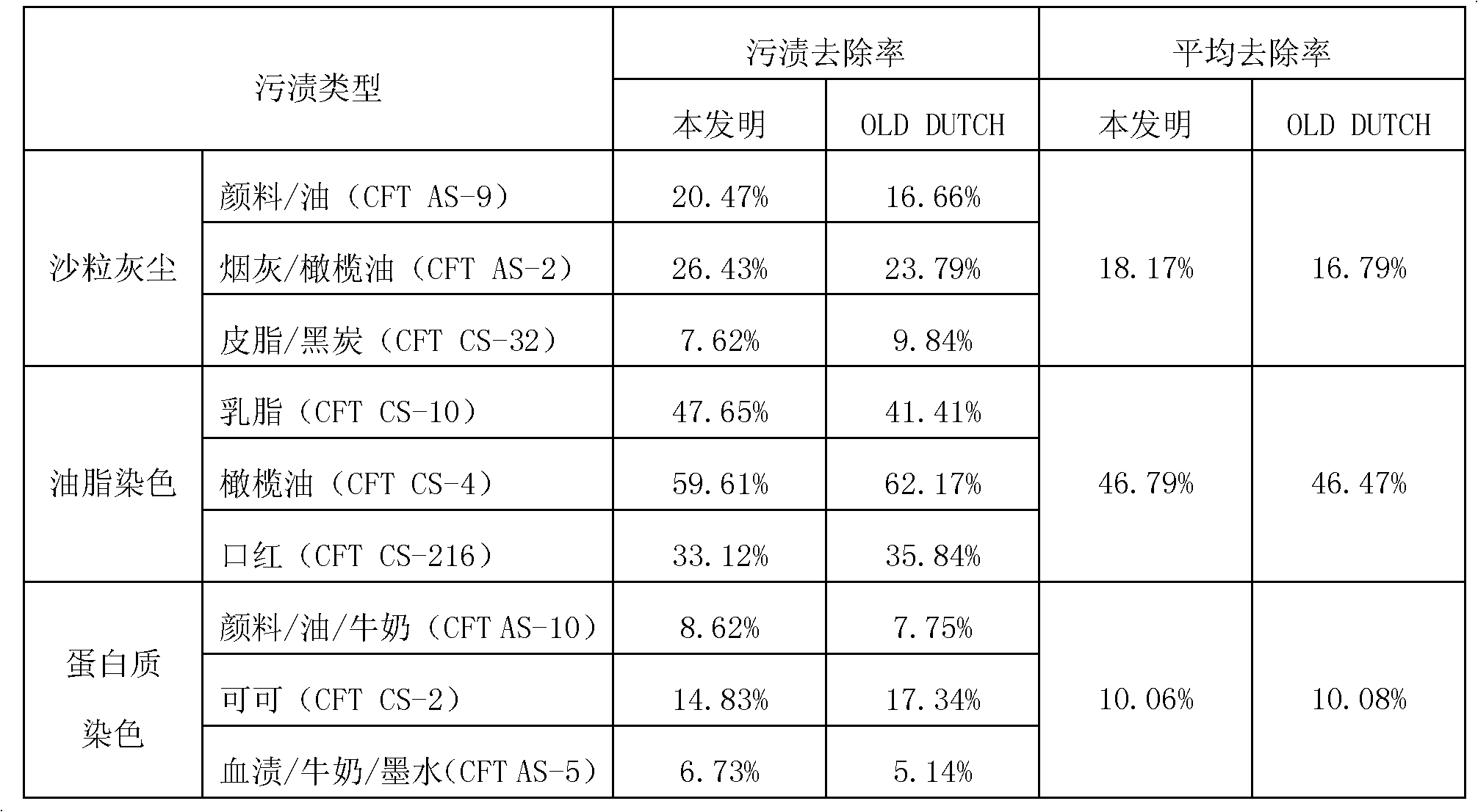

ActiveCN102492573APrevent overflowAvoid messOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsPhysical shapeCocamidopropyl betaine

The invention relates to a laundry sheet which comprises film former, sodium olefinsulfonate, coconut oil base methyl glycollic amide, coconut oil amide propyl lycine, ethylene diamine tetraacetic acid tetrasodium salt, preservative, filling material, white oil, essence, pigment and deionized water. The laundry sheet is prepared by the following steps: evenly mixing the raw materials according tomass parts, carrying out film formation by drying to a obtain paper type laundry sheet, cutting, punching, packaging and the like. The invention implements paper type laundry detergent in the aspect of physical shape, maintains the washing effect of the traditional laundry detergent, has the characteristics of less foam and high efficiency, and can be completely dissolved in water; the laundry sheet is convenient to store and use, and avoids the overflow problem in the common laundry detergent, thereby avoiding mess and difficulty in cleaning due to overflow of the laundry detergent; and the laundry sheet is convenient to, overcomes the defect that the traditional laundry detergent has heavy volume and can not be conveniently carried and stored after being opened, thereby providing convenience for clothes cleaning for people on a journey. The laundry sheet is free of any environment-polluting component, and can be completely degraded naturally, thereby making a contribution to environmental protection.

Owner:广州市黄埔南方供水环保工程有限公司

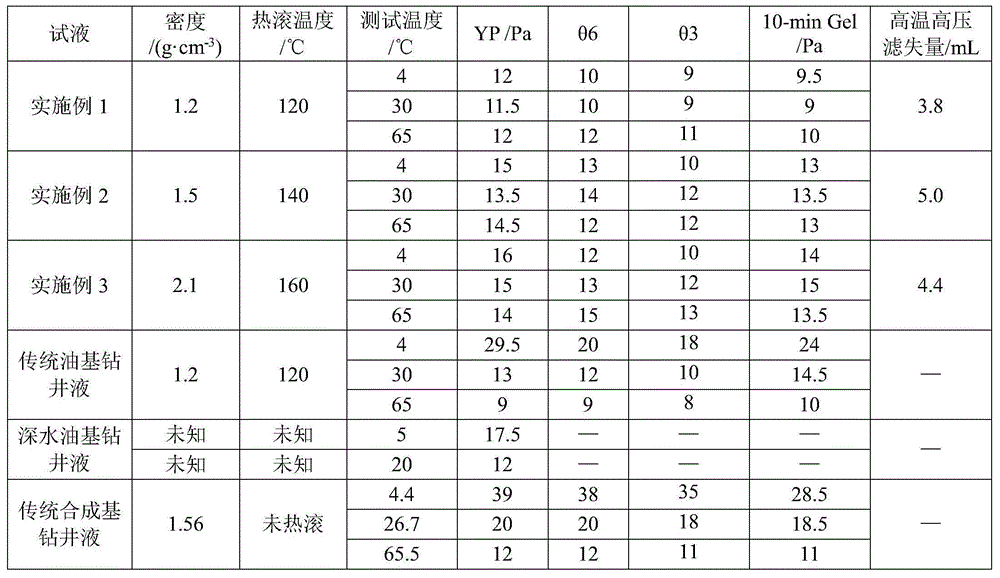

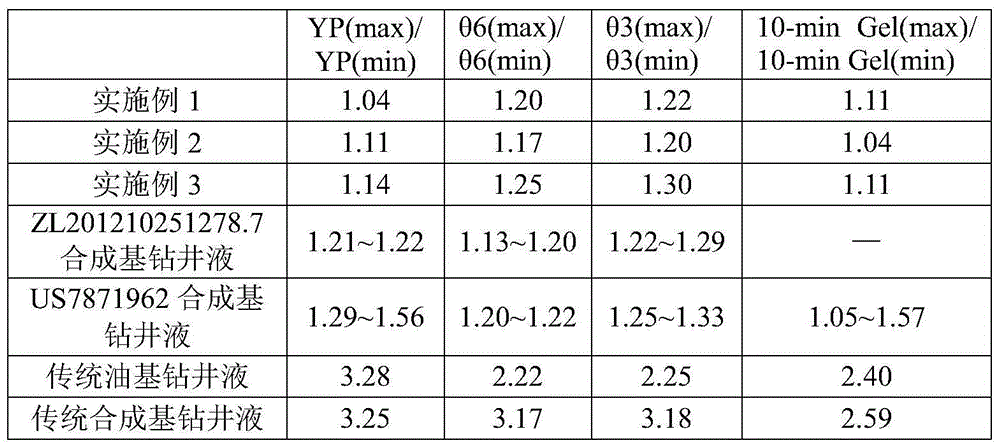

Deepwater constant-rheology oil base drilling fluid

ActiveCN104861944ARaw material requirements are relaxedLow costDrilling compositionDimer acidWhite oil

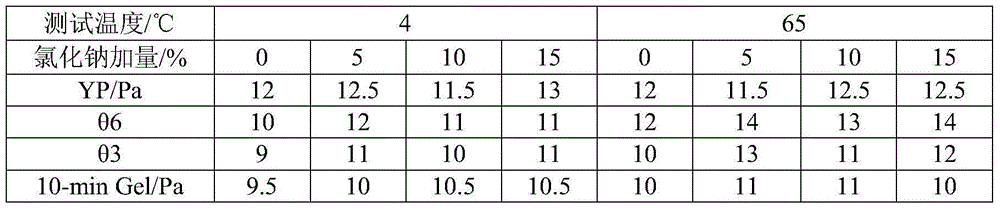

The invention discloses a deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling. The deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling comprises the following components in parts by weight: 70-100 parts of white oil, 0-30 parts of a calcium chloride aqueous solution, 1.5-5 parts of a fluid type conditioning agent, 1-4 parts of an emulsifying agent, 0.5-2.5 parts of a wetting agent, 1-3.5 parts of organic soil used for drilling fluid, 1.5-5 parts of a filtrate reducer, 0.2-0.6 parts of calcium oxide and 0-260 parts of a weighting agent. The fluid type conditioning agent is at least one of ethylene-propylene copolymer, polymethacrylate, trimeric acid, phenolic resin, copolymer generated from reaction of dimer acid, cholamine and polyethylene polyamine and copolymer generated from reaction of acrylamide, styrene and methacrylic acid. The movable shearing force and six-speed viscometer of the oil base drilling fluid is respectively less than 6 r / min and 3 r / min, and the 10-min static shearing force can be kept steady within 4-65 DEG C; constant eheology is realized in the temperature range of the barrel of the deepwater drilling, technical demands on sea deepwater drilling can be satisfied, requirements on base oil raw material are loose, and the cost is low.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method for artificially synthesized transparent soil material

InactiveCN103969099AHigh purityWide range of gradingPreparing sample for investigationAlkaneVisual observation

The invention discloses a preparation method for an artificially synthesized transparent soil material. The transparent soil material comprises baked silica sand particles and colorless pore fluids which have the same refractive index, wherein the pore fluids are mixed fluids of 12, alkane and 15# white oil; during preparation, a glass bar is used to stir constantly so as to ensure intensive mixing; a vacuum chamber is adopted for vacuumizing so as to remove residual air in a mixture until the mixture is transparent; finally, a consolidometer is adopted for consolidation. According to the invention, the preparation method is simple and convenient to operate and easy to implement; compared with other preparation methods, the preparation method is wide in material sources, low in cost, pollution-free and non-hazardous and can achieve a better transparent effect; the prepared transparent soil can be effectively used for model tests, and metabolic un-embedding visual observation in soil bodies can be realized.

Owner:HOHAI UNIV

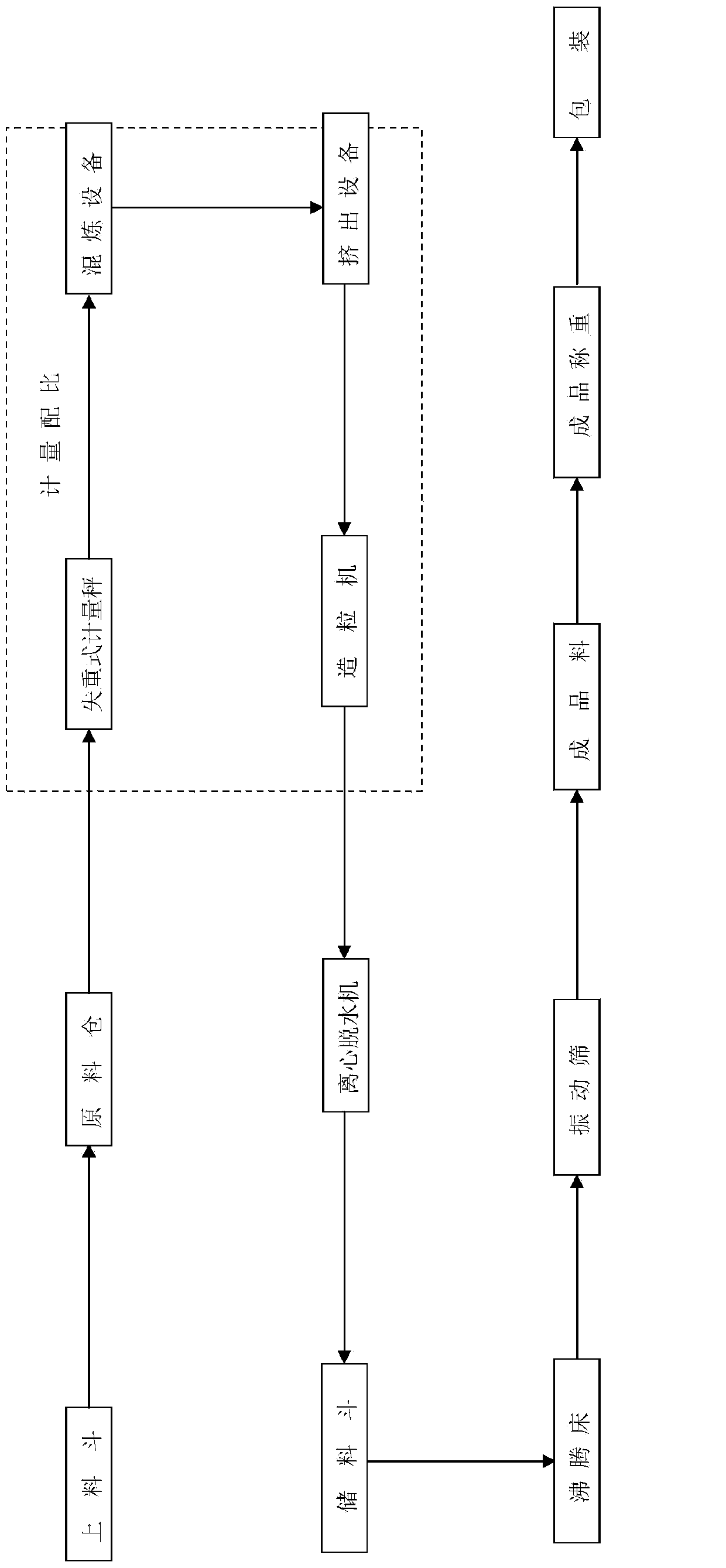

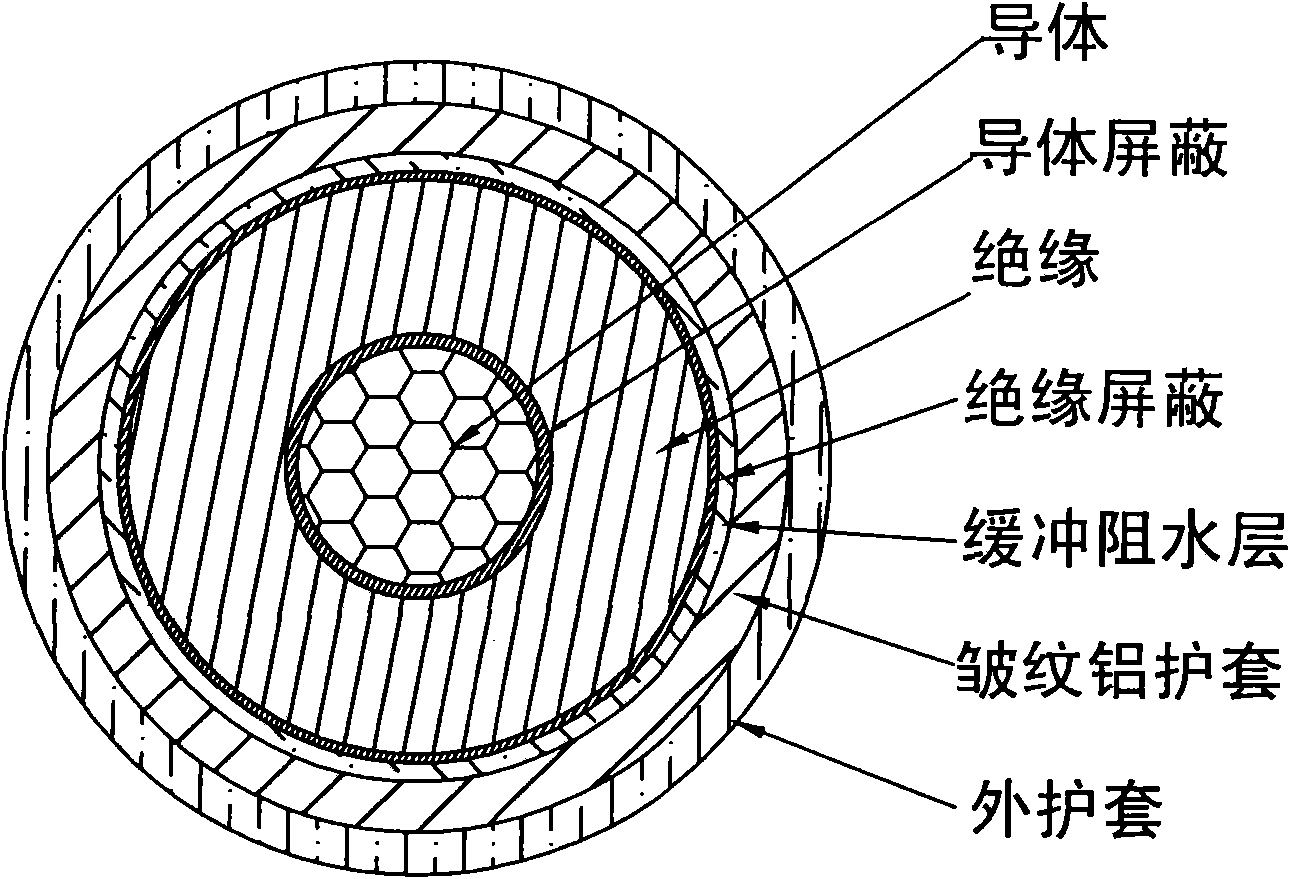

Graphene-containing polyolefin high semi-conductive shielding material for cable and preparation method thereof

ActiveCN103739929ALower volume resistivityImprove the effect of shielding and homogenizing electric fieldInsulation layerElectrical conductor

The invention discloses a graphene-containing polyolefin high semi-conductive shielding material for a cable and a preparation method thereof and aims at reducing the volume resistivity of the semi-conductive shielding material. The shielding material disclosed by the invention comprises the following components in percentage by weight: 83%-90% of ethylene-vinyl acetate copolymer, 3%-10% of graphene powder, 3%-6% of white oil, 0.5%-1% of antioxidant and 0.3%-0.6% of zinc stearate. The preparation method disclosed by the invention comprises the steps of mixing, plasticizing, granulating, dehydrating and drying. Compared with the prior art, graphene is uniformly dispersed into the ethylene-vinyl acetate copolymer, so that the volume resistivity is reduced to below 30 omega. cm, a homogeneous electric field is greatly improved, smooth and gapless contact of a conductor, an insulation layer and a metal shielding layer is realized, the effect of shielding the homogeneous electric field of the cable is improved, the electrical performance and the long-term operation reliability of the cable are improved, and the shielding material is suitable for non-metal shielding layers of the cables of above 6kV.

Owner:JIANGSU ZHONGCHAO HOLDING CO LTD

Composite flame-retardant expandable polystyrene particles and preparation technology thereof

Disclosed are composite flame-retardant expandable polystyrene particles and a preparation technology thereof. The particles are prepared from the following components of: by weight, 100 parts of styrene monomer, 100-150 parts of water, 1-10 parts of expandable graphite, 1-12 parts of a phosphorus compound, 0.1-0.5 part of white oil, 0.1-0.5 part of polyethylene wax, 0.05-0.2 part of dicumyl peroxide, 0.2-0.8 part of benzoyl peroxide, 0.1-0.4 part of polyvinyl alcohol, 1.1-2.1 parts of tricalcium phosphate and 8-12 parts of pentane. By the addition of a composite fire retardant of expandable graphite and the phosphorus compound before polymerization of styrene, adverse influence of the fire retardant on performance of the product is reduced; expandable graphite and the phosphorus compound are halogen-free fire retardants, the particles have good environmental protection performance; by the addition of white oil, the particles have plasticising and internal lubricant functions as well as good stability and low volatility, and fluidity during the forming of polystyrene particles can be greatly improved; polyvinyl alcohol and tricalcium phosphate are dispersion stabilizers and by timely adding a proper amount of the dispersion stabilizers, the product appearance can be improved, the production efficiency can be raised, and cost can be reduced; and the addition of all the components guarantees the performance of the product.

Owner:BEIJING HUACHEN DECHUANG CHEM TECH

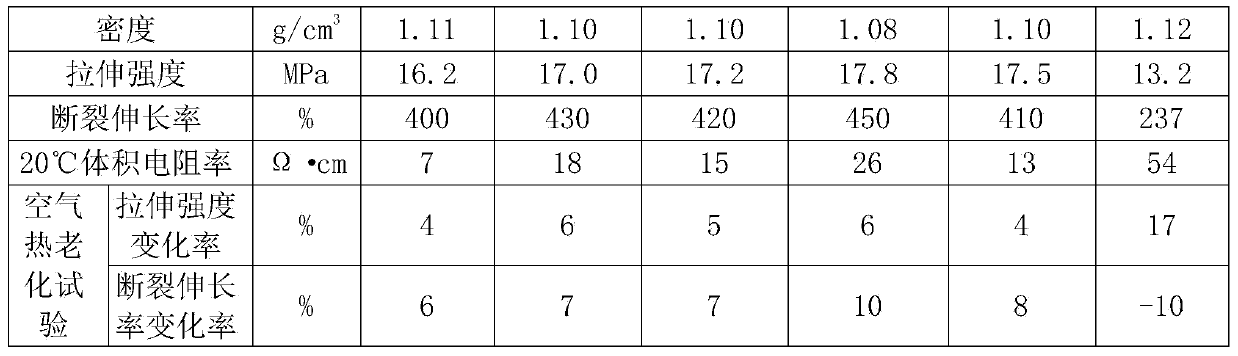

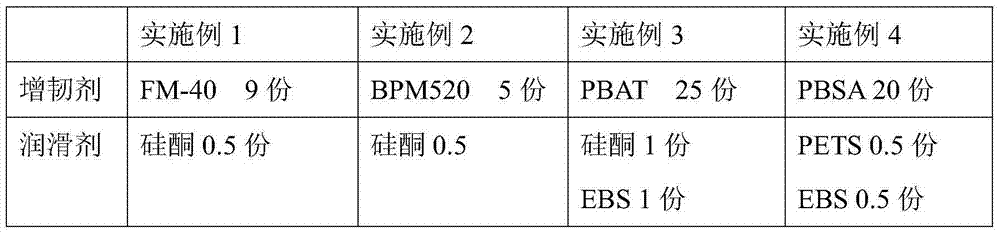

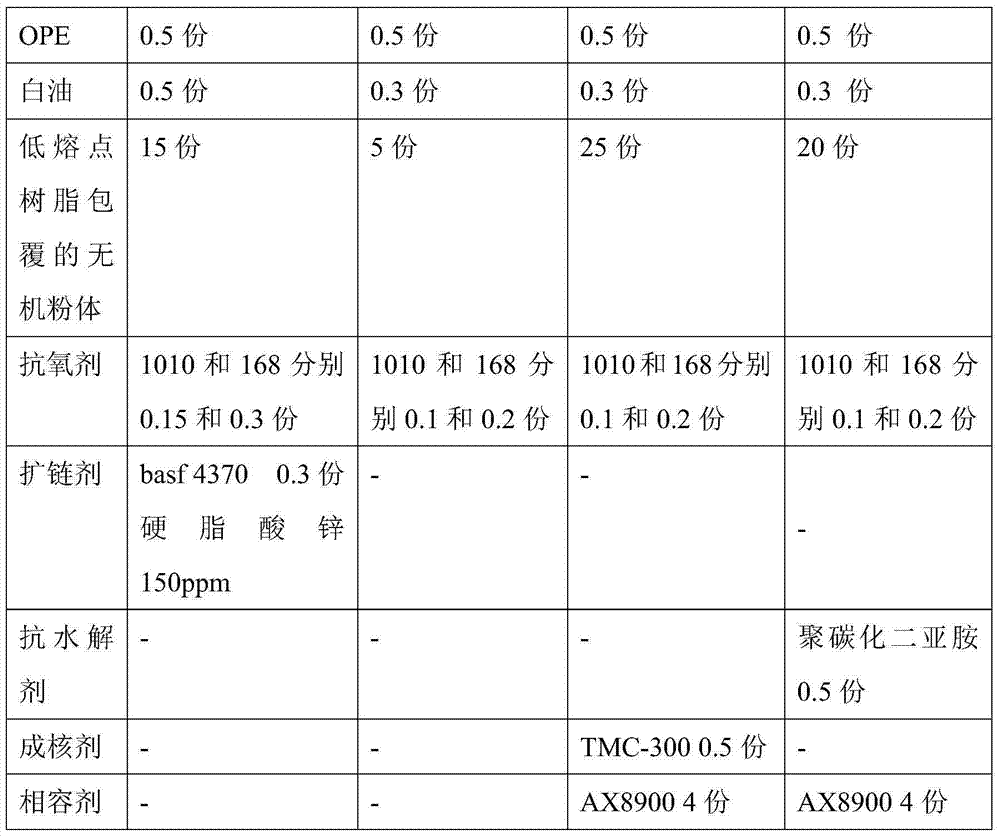

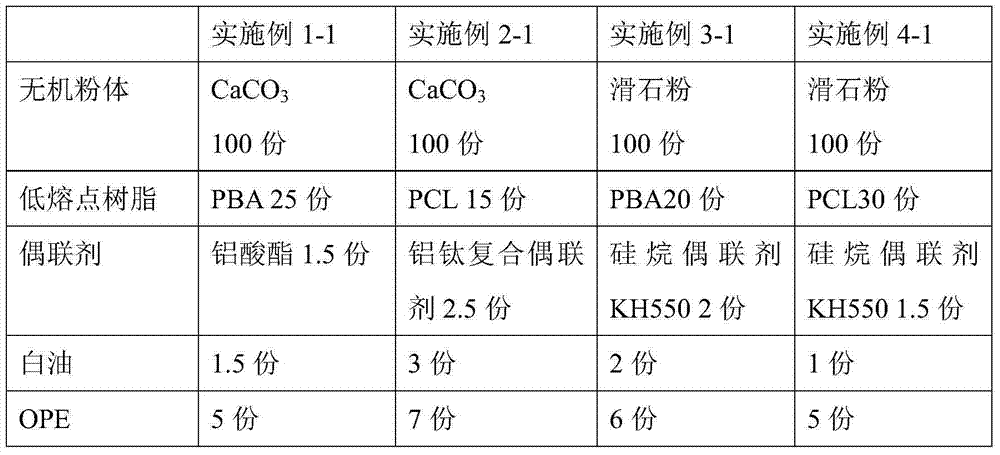

Polylactic acid toughened material for 3D printing and preparation method thereof

ActiveCN104725806AImprove toughnessImprove shrinkageAdditive manufacturing apparatusPolymer scienceAntioxidant

The invention discloses a polylactic acid toughened material for 3D printing, which comprises polylactic acid and the following components in percentage by mass (on the basis of polylactic acid): 5-25% of toughener, 0.5-2.0% of lubricant, 0.5-2.0% of oxidized polyethylene wax, 0.3-1.0% of white oil, 5-25% of low-melting-point resin-coated inorganic powder and 0.3-0.9% of antioxidant. The material prepared by the technical scheme has the advantages of favorable toughness, high extrusion forming regularity and favorable line roundness. The printing proves that the product has the advantages of low shrinkage, no edge lifting, no cracking, high cooling speed and favorable appearance and has wide printing application range.

Owner:SHENZHEN ESUN IND

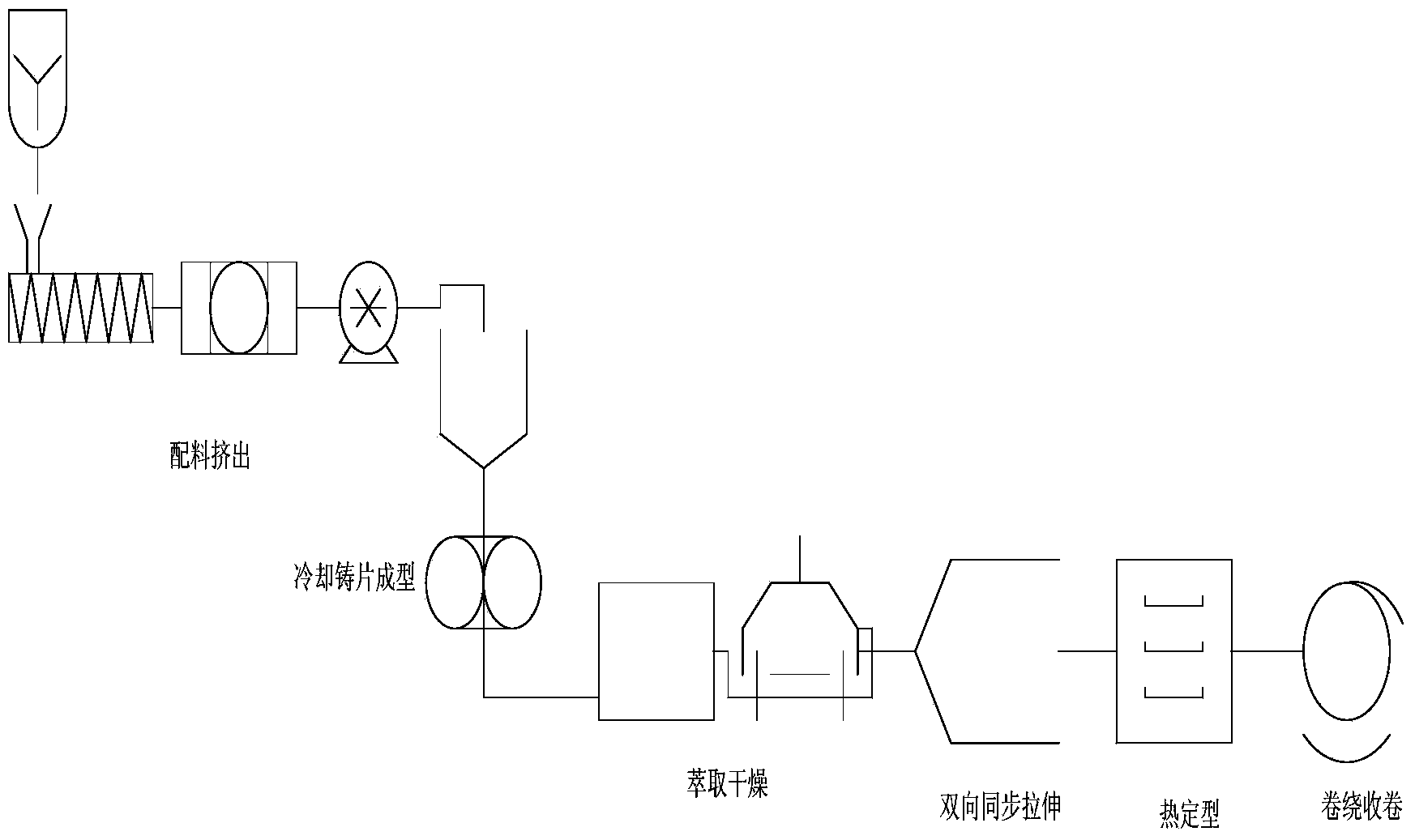

Novel high-temperature-resisting diaphragm of lithium battery and preparation process of diaphragm

ActiveCN103618054AHigh melting temperatureSynthetic resin layered productsLi-accumulatorsBiochemical engineeringLithium-ion battery

The invention discloses a novel high-temperature-resisting diaphragm of a lithium battery and a preparation process of the diaphragm, which belong to the field of a battery diaphragm, and solve the problem in the prior art that the lithium battery diaphragm which is prepared by adopting a wet-method process is low in fuse temperature. The high-temperature-resisting diaphragm of the lithium battery is prepared by adopting a wet-method process. The diaphragm comprises an inner layer, an intermediate layer and an outer layer, wherein both the inner layer and the outer layer are prepared by adopting polyethylene and white oil as raw materials; the intermediate layer is prepared by adopting polyethylene, white oil and nanometer inorganic oxide as raw materials. The preparation process comprises the following steps of mixing, extrusion, compounding through a die head, casting, cooling and molding, bidirectional synchronous stretching, extraction, drying, transversely stretching and expanding and thermal setting. The fuse temperature of the diaphragm prepared through the process is detected to be 50 to 70 DEG C higher than that of the diaphragm with a single PE (polyethylene) component.

Owner:QINGDAO LANKETU MEMBRANE MATERIALS CO LTD

Polyacrylamide microgel as well as preparation method and application thereof

ActiveCN102127189AImprove stabilityPrevent implosionDrilling compositionN,N-MethylenebisacrylamideMethylene bisacrylamide

The invention discloses a polyacrylamide microgel as well as a preparation method and application thereof. The particle size of the polyacrylamide microgel is 30-150 micrometers, acrylamide, sodium acrylate, N,N'-bisacrylamide, 2-acrylamide-2-methylpropanesulfonic acid sodium, styrenesulfonate and the like serve as polymerized monomers, white oil and the like serve as disperse phases, and the polymerized monomers and the disperse phases are subjected to thermal initiation suspension polymerization to obtain the polyacrylamide microgel. The polyacrylamide microgel synthetized by the method can be directly injected into an oil layer without being processed and has a good plugging effect.

Owner:北京石大万嘉新材料科技有限公司

Production of cationic microsphere with crosslinked swelling function

InactiveCN101029109AEasy speed controlControllable swelling ratioDrilling compositionCross-linkPersulfate

Production of cationic micro-sphere with cross-linking swelling function is carried out by taking persulfate and sulfite or persulfate and azo-diisobutyl nitrile binary composite or persulfate, sulfite and 2,2'-azo-(2-(2-imidazoline-2-radical)propane)dihydrochloride(VA-044)ternary composite as initiating agent, adding into dispersant and cross-linking agent, initiating DMC monomer and AM monomer in mixed medium of cyclohexane-water or industrial white oil-water or 120#solvent oil-water and reverse suspension polymerizing to obtain the final product. The grain size is 1-50 mu m, it has controllable swelling speed ratio and can be used for third oil-extraction plugging materials.

Owner:JIANGNAN UNIV

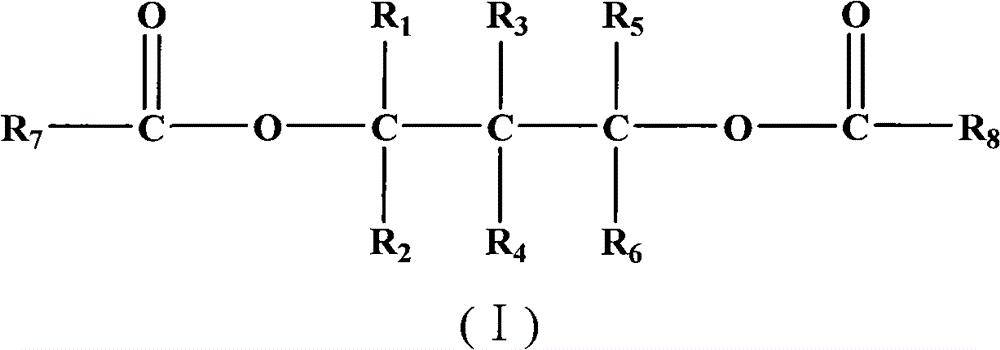

Catalyst component for olefin polymerization and catalyst thereof

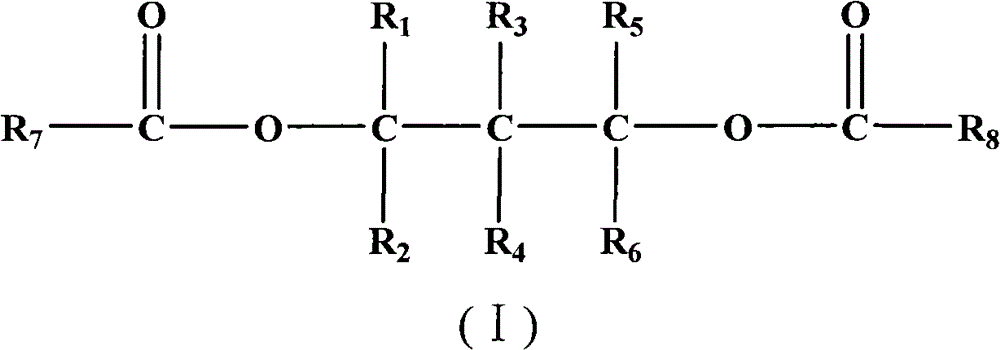

The invention provides a catalyst component for olefin polymerization. The catalyst component is prepared by: dispersing an alcohol adduct melt of magnesium halide in a dispersing agent system of white oil and silicone oil to form an emulsion, discharging the emulsion into a cooling liquid to perform cooling shaping, thus forming a magnesium halide alcohol adduct microsphere, washing and drying the magnesium halide alcohol adduct microsphere to form a spherical carrier; and then treating the spherical carrier through a titanium compound, raising the temperature gradually, adding an internal electron donor during treatment, and after treatment, carrying out washing with an inert solvent, and performing drying, thus obtaining the spherical catalyst component. Specifically, a phosphorus-containing compound is added during the steps, and the phosphorus content in the catalyst component is 0.2-3.0wt%. The internal electron donor compound contains at least one diol ester compound selected from the following general formula (I). When the catalyst is used for olefin polymerization, especially propylene polymerization, a polymer with a high isotactic index and a high melt flow rate can be obtained. Particularly under a high hydrogen concentration, a polymer with a high melt flow rate and a high isotactic index can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

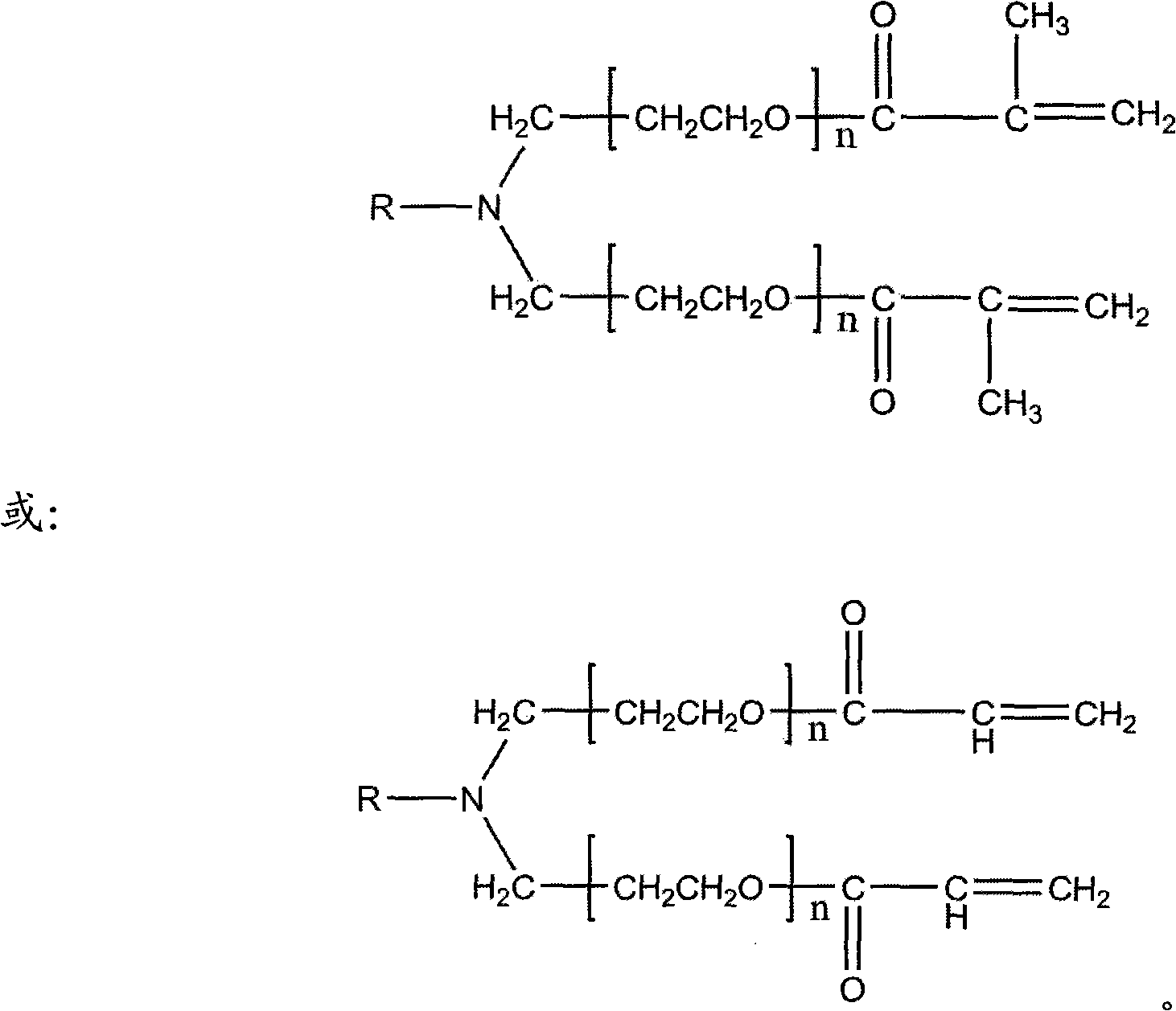

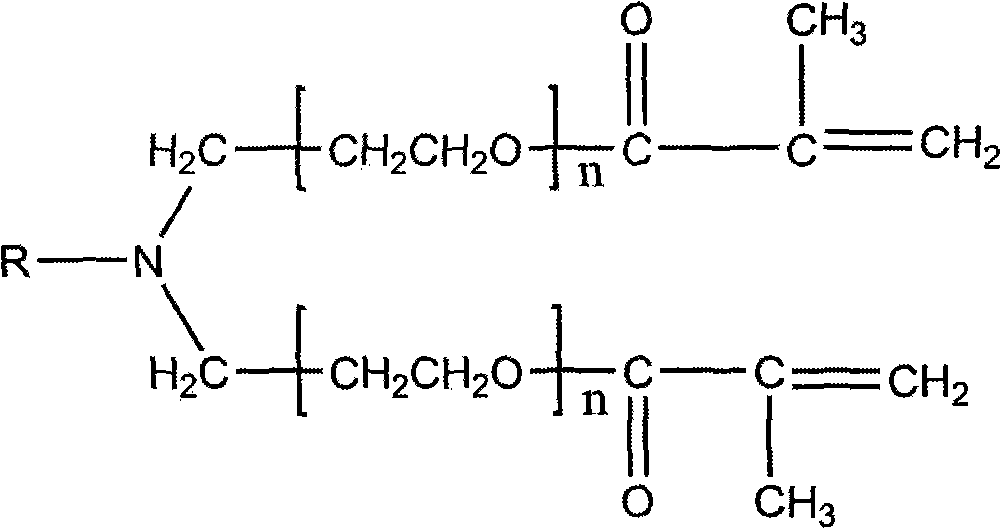

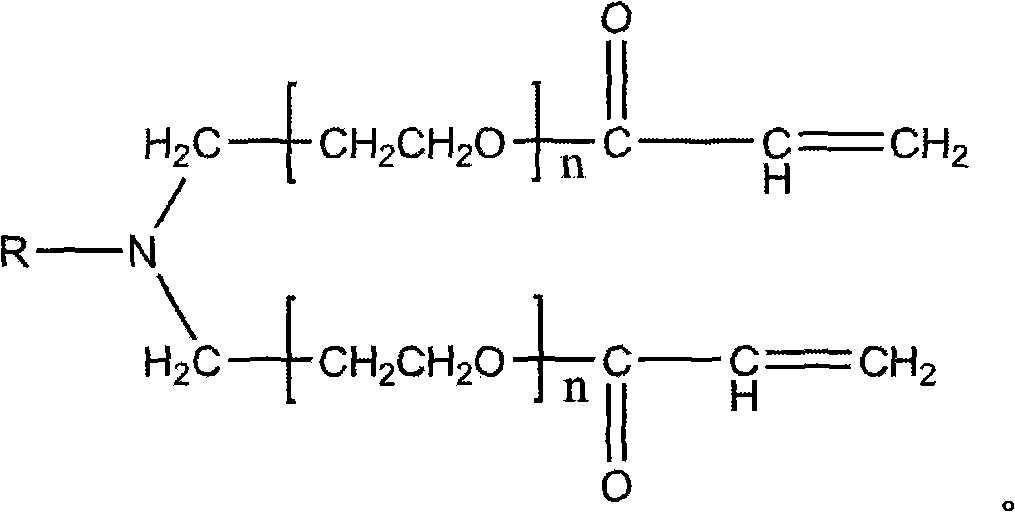

Thickening agent synthesized by acrylic ester and preparation method thereof

InactiveCN101619543AGood thickening effectStrong electrolyte resistanceOrganic compound preparationDyeing processTextile printerSodium methoxide

The invention discloses a preparation method for synthesizing a thickening agent by acrylic ester. The thickening agent synthesized by acrylic ester comprises crylic acid, acrylamide, 25 percent of ammonia water, a functional monomer, EDTA, deionized water, tasteless kerosene, 3<#> white oil, diallyl phthalate, ammonium persulphate, Span 80 and isomeric hexadecanol polyethenoxy ether, wherein the functional monomer is prepared from alicyclic amine polyethenoxy ether, methyl methacrylate, nitroxide free radical pipradrol and sodium methoxide. The preparation method synthesizes a special weak cation type (methyl) acrylic ester functional monomer by adopting an ester exchange method, and the functional monomer and vinyl monomers of the acrylic acid, the acrylamide, and the like are adopted to synthesize a textile printing thickening agent by adopting inverse emulsion polymerization. The thickening agent has the characteristics of high thickening capacity, strong electrolyte resistant capacity and good water-retaining property.

Owner:成都德美精英化工有限公司

Organic clay with high jellification rate in white oil and preparation method thereof

InactiveCN101624515AImprove gelationGood compatibilityDrilling compositionSodium BentoniteSurface-active agents

The invention provides organic clay with high jellification rate in the white oil and a preparation method thereof, wherein, the organic clay is composed of 60 to 70 parts of drier sodium base bentonite, 20 to 25 parts of quaternary cationics, 10 to 15 parts of nonionic surface active agent and 750 to 1200 parts of water. The preparation method comprises the following steps: (1) the drier odium base bentonite is dispersed in water, and impurity is removed through flotation process, therefore stable suspending liquid a is formed; (2) the quaternary cationics is added into water and evenly stirred, therefore liquid b is obtained; (3) the nonionic surface active agent is added into water and evenly stirred, therefore liquid c is obtained; (4) the liquid b is dipped into the suspending liquida to react for 1.5 to 2.5 hours at 75 to 95 DEG C, and then the liquid c is sequentially dipped into the suspending liquid a to react for 1.5 to 2.5 hours at 75 to 95 DEG C; and (5) the product obtained in step (4) is washed for 3 to 5 times, then dried at 100 to 110 DEG C, crushed and sifted with 100 meshes, and then the organic clay product with high jellification rate in the white oil is obtained.

Owner:HUBEI HANC NEW TECH

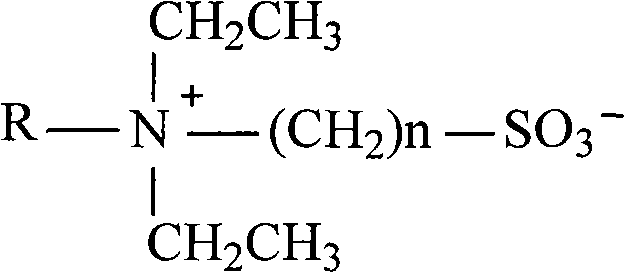

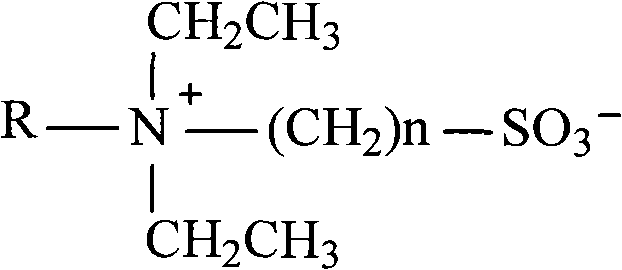

Amine lactone type amphoteric high polymer emulsion as well as preparation method and application thereof

ActiveCN102432747AEasy to controlEasy to operateFatty/oily/floating substances removal devicesPharmaceutical non-active ingredientsPolymer scienceWhite oil

The invention discloses an amine lactone type amphoteric high polymer emulsion as well as a preparation method and application thereof. The amine lactone type amphoteric high polymer emulsion is characterized in that a sulfobetaine type amphoteric ionic monomer and more than one acrylamide nonionic monomer are copolymerized by adopting an inverse emulsion polymerizing method to obtain a high polymer with nonionic copolymer characteristic and salt tackifying effect. Preferably, white oil is used as a dispersion phase, and the HLB (Hydrophile-Lipophile Balance) value of an emulsifying agent is 4.5-5.5. The amine lactone type amphoteric high polymer emulsion prepared by adopting an emulsion polymerization mode has the advantages of high solid content, high dissolvability and relative uniformity in relative molecular mass distribution. The polymer emulsion is easy to disperse and dissolve in fresh water and high-salinity saline water and is very convenient to apply.

Owner:CHINA PETROLEUM & CHEM CORP +1

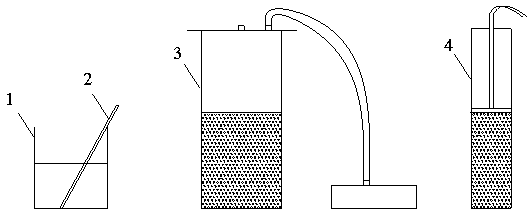

Production technology for novel high-porosity lithium ion battery membrane

The invention provides a production technology for a novel high-porosity lithium ion battery membrane, which belongs to the field of battery membranes, and solves the problem that the porosity of the conventional membrane in the market is low. Due to the adoption of the high-porosity membrane obtained by the production technology disclosed by the invention, the performance of a lithium ion battery can be obviously improved. The production technology comprises the steps of feeding polyethylene and white oil mixture into a double-screw extruder to obtain an oil-containing cast sheet through a metering, filtering and extruding die head and a cooling device; then putting the oil-containing cast sheet into an extraction tank, and extracting white oil in the cast sheet; volatilizing to remove a dichloromethane extracting agent on the surface and in the extracted cast sheet to obtain a dry cast sheet; performing bidirectional stretching on the dry cast sheet to obtain the membrane; finally coiling the membrane subjected to the bidirectional stretching after the membrane is subjected to thermal sizing treatment to obtain a finished membrane product. According to the membrane preparation technology, the cast sheet is extracted, then is subjected bidirectional stretching and is subjected to thermal sizing to obtain the lithium battery membrane with the porosity being over 60 percent.

Owner:QINGDAO ZHONGKEHUALIAN ADVANCED MATERIAL CO LTD

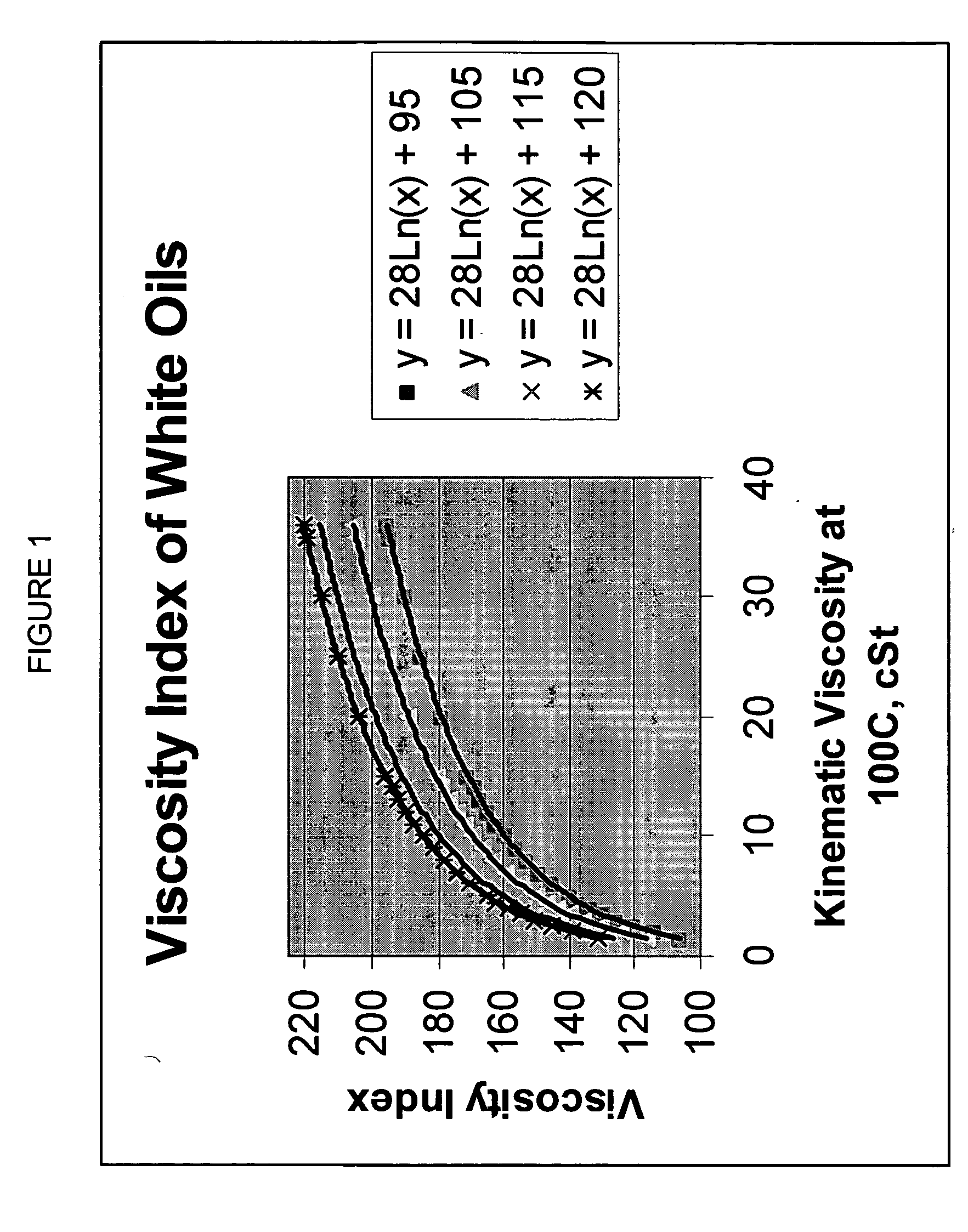

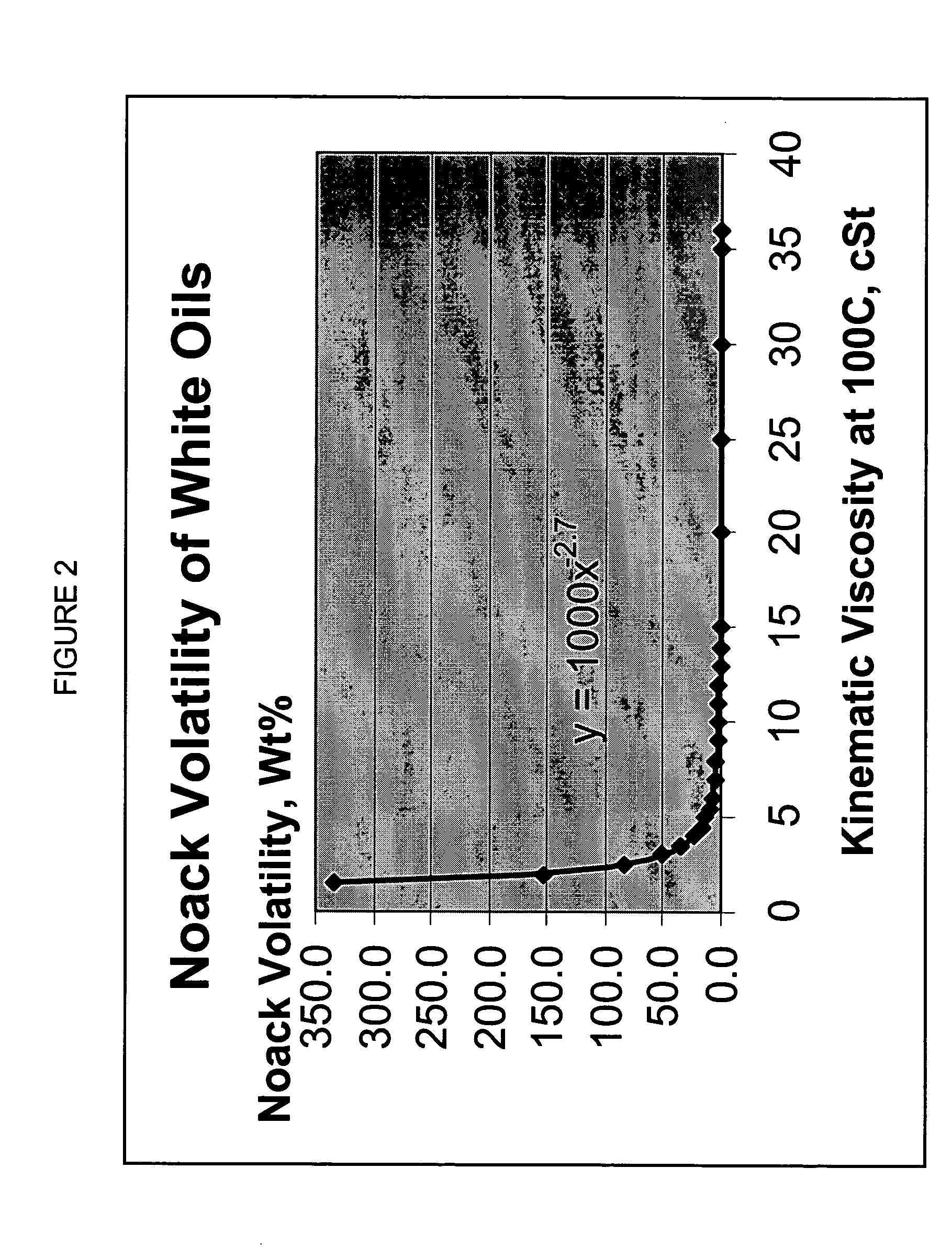

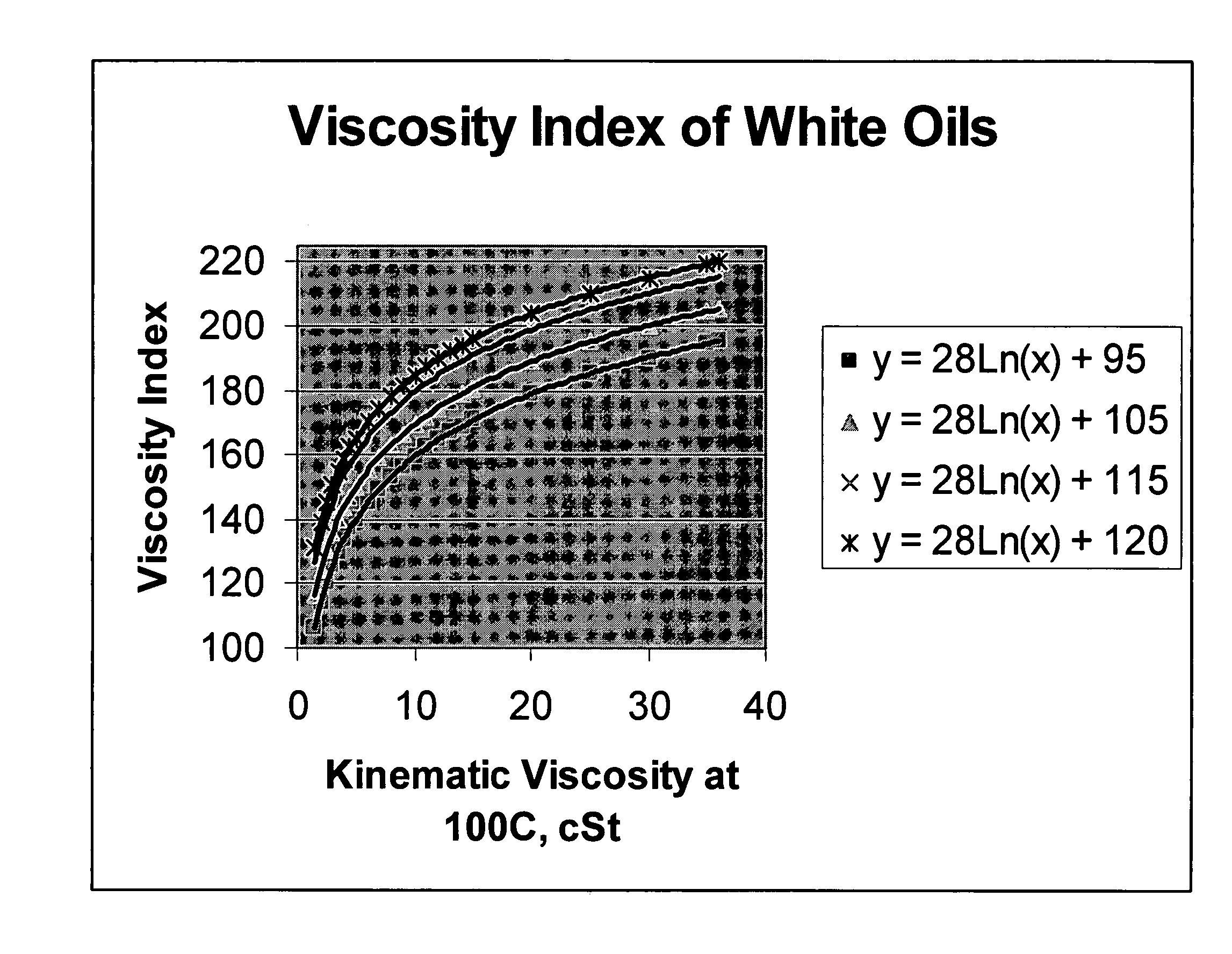

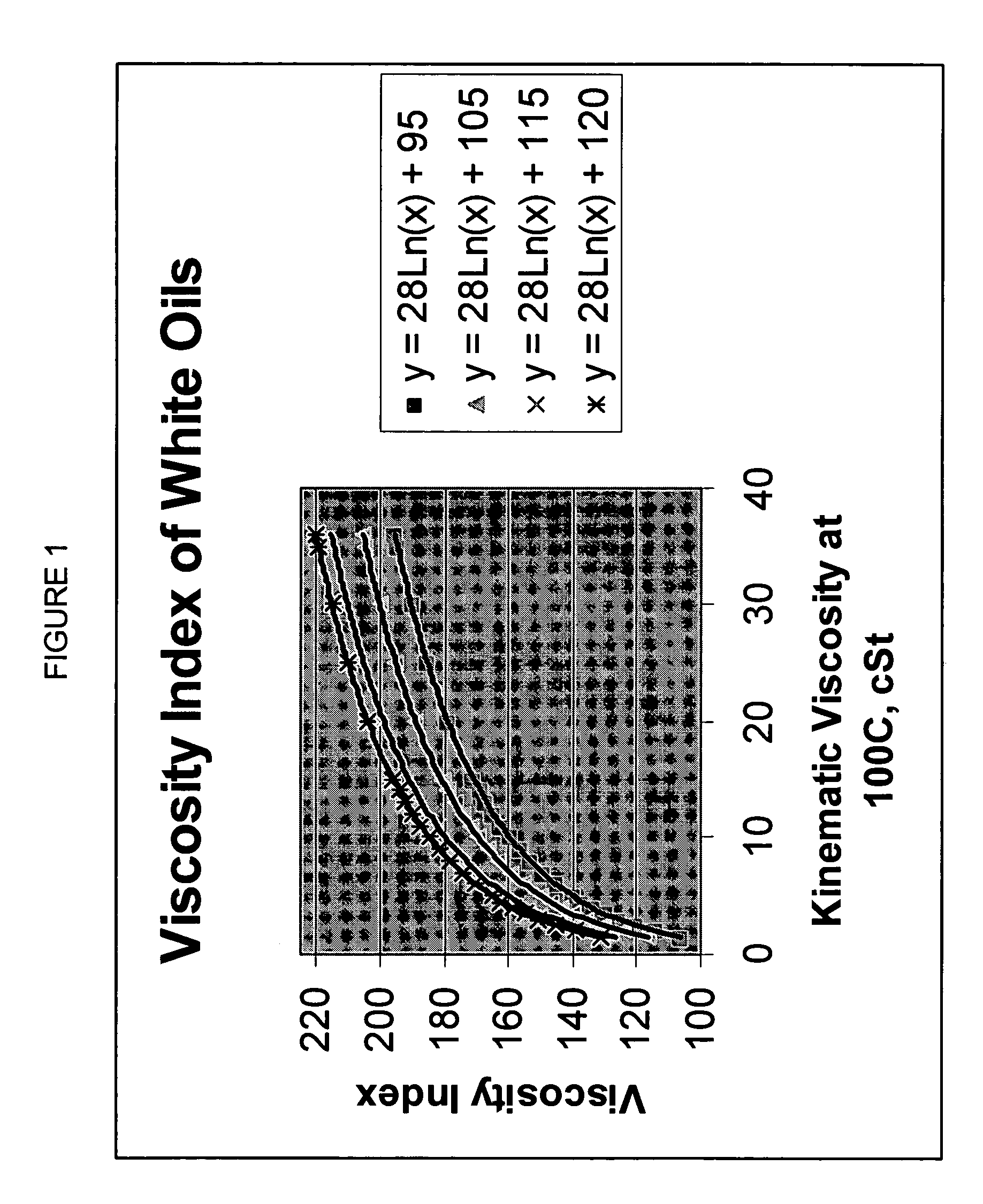

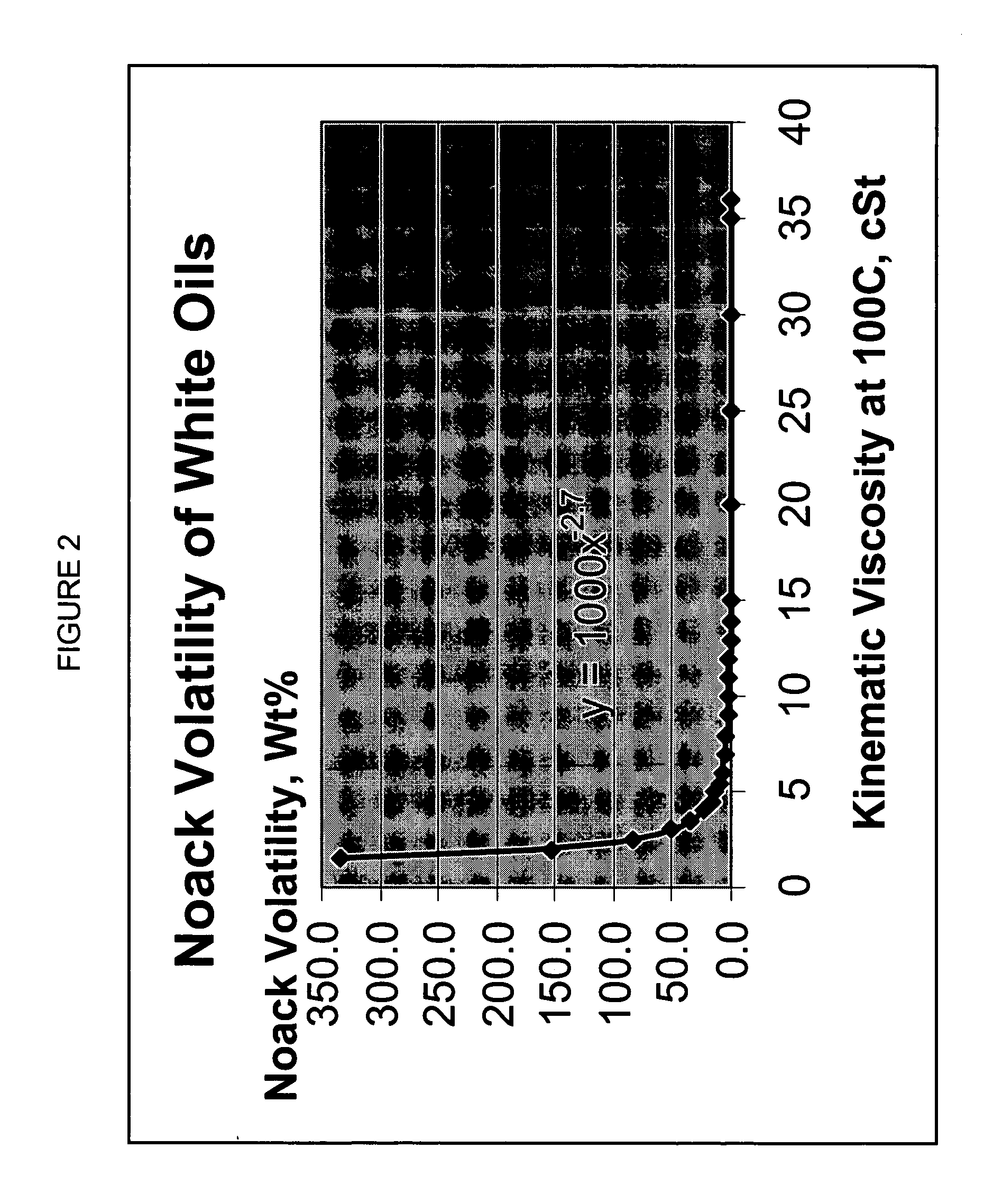

White oil from waxy feed using highly selective and active wax hydroisomerization catalyst

A composition of white oil having a kinematic viscosity at 100° C. between about 1.5 cSt and 36 cSt, a viscosity index greater than an amount calculated by the equation: Viscosity Index=28×Ln(the Kinematic Viscosity at 100° C.)+105, less than 18 weight percent of molecules with cycloparaffin functionality, a pour point less than zero degrees C., and a Saybolt color of +20 or greater. Also, a composition of white oil having a kinematic viscosity at 100° C. between about 1.5 cSt and 36 cSt, a viscosity index greater than an amount calculated by the equation: Viscosity Index=28×Ln(the Kinematic Viscosity at 100° C.)+95, between 5 and less than 18 weight percent of molecules with cycloparaffin functionality, less than 1.2 weight percent molecules with multicycloparaffin functionality, a pour point less than zero degrees C., and a Saybolt color of +20 or greater.

Owner:CHEVROU USA INC

Antibacterial engineering plastic and its preparing method

InactiveCN101070424AHas antibacterial propertiesHas antibacterial functionTemperature controlAntioxidant

The invention discloses an antibacterial engineering plastics and preparation methods, its composition by weight ratio (%):Engineering Plastics 83-92% ; antimicrobial agent 0.3-1%; toughener 6-10%; dispersant 0.5-1% white oil 0.5- 2% ;antioxidant 0.2-0.6% and other additives 0.1-3 %.The invention using engineering plastics PC, PC / ABS alloy as the mainstay and high temperature processing can be added containing silver ion antimicrobial agent, plasticizer, antioxidants and other chemicals, by melt blending, extrusion and granulation. The function of these engineering plastics is to maintain lasting antibacterial, keep a good performance of the materials' physical and mechanical and have a simply process. The process of manufacturing the antibacterial engineering plastics have some steps as following.First of all, raw materials will be mixed according to the above ratio, and then enter the plastic extrusion machine, the temperature controlled at 220 -250 degree C and then granuled to get the antibacterial engineering plastics.

Owner:SHENZHEN KEJU NEW MATERIAL

Thermoplastic elastomer composition for bonding ABS and preparation method thereof

The present invention relates to a thermoplastic elastomer composition for bonding ABS and a preparation method thereof. The composition is prepared by raw materials with the following weight proportion: 40 to 70 percents of polyurethane (TPU), 5 to 20 percents of SEBS, 10 to 30 percents of extending oil, 2 to 5 percents of SEBS-g-MAH, 0 to 30 percents of active calcium carbonate and 0.1 to 0.5 percent of antioxidant. The preparation method comprises the following steps of: weighting the raw materials according to weight proportion, mixing SEBS and white oil evenly in high mixing machine, then adding other raw materials and mixing for 2 to 5 minutes, discharging; putting the raw materials mixed evenly into an extruser for prilling. The invention has the characters that the prepared thermoplastic elastomer not only has good bonding property with ABS and PC, but also has adjustable hardness according to the client requirements, and can be used for producing handle sheath, cushion pad, and the like.

Owner:SHANGHAI SUNNY

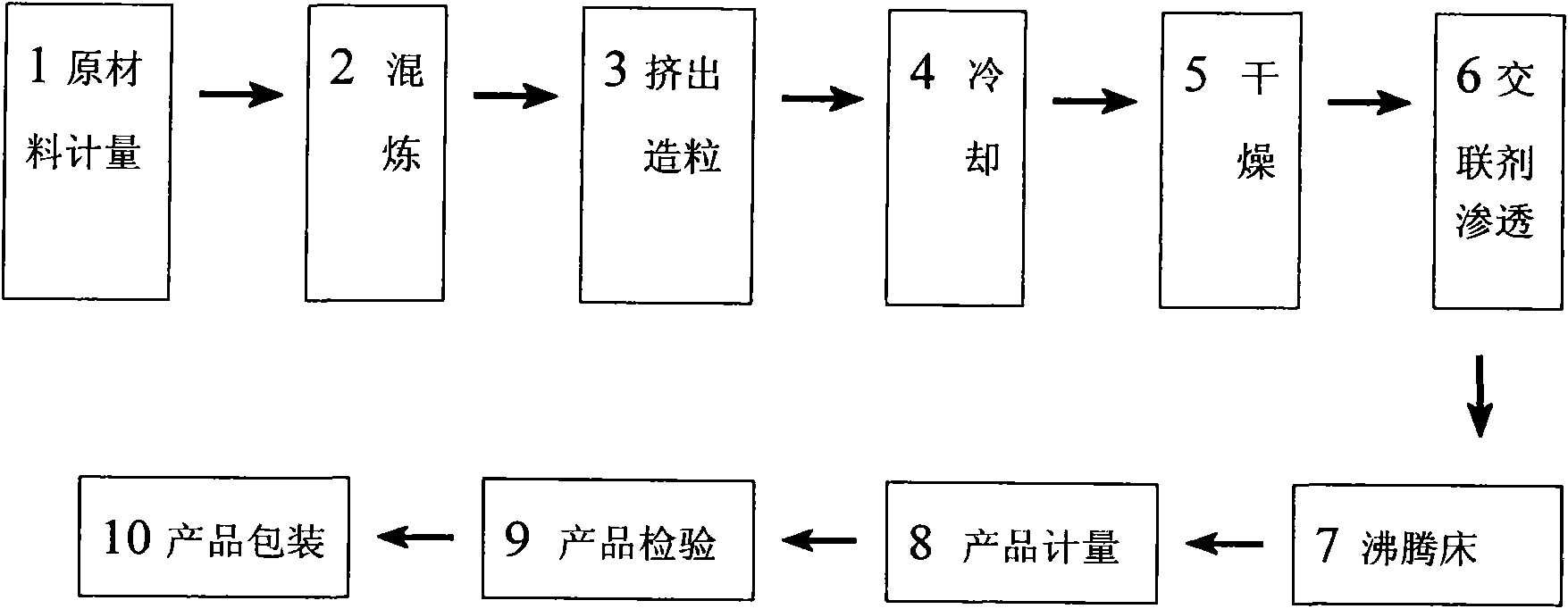

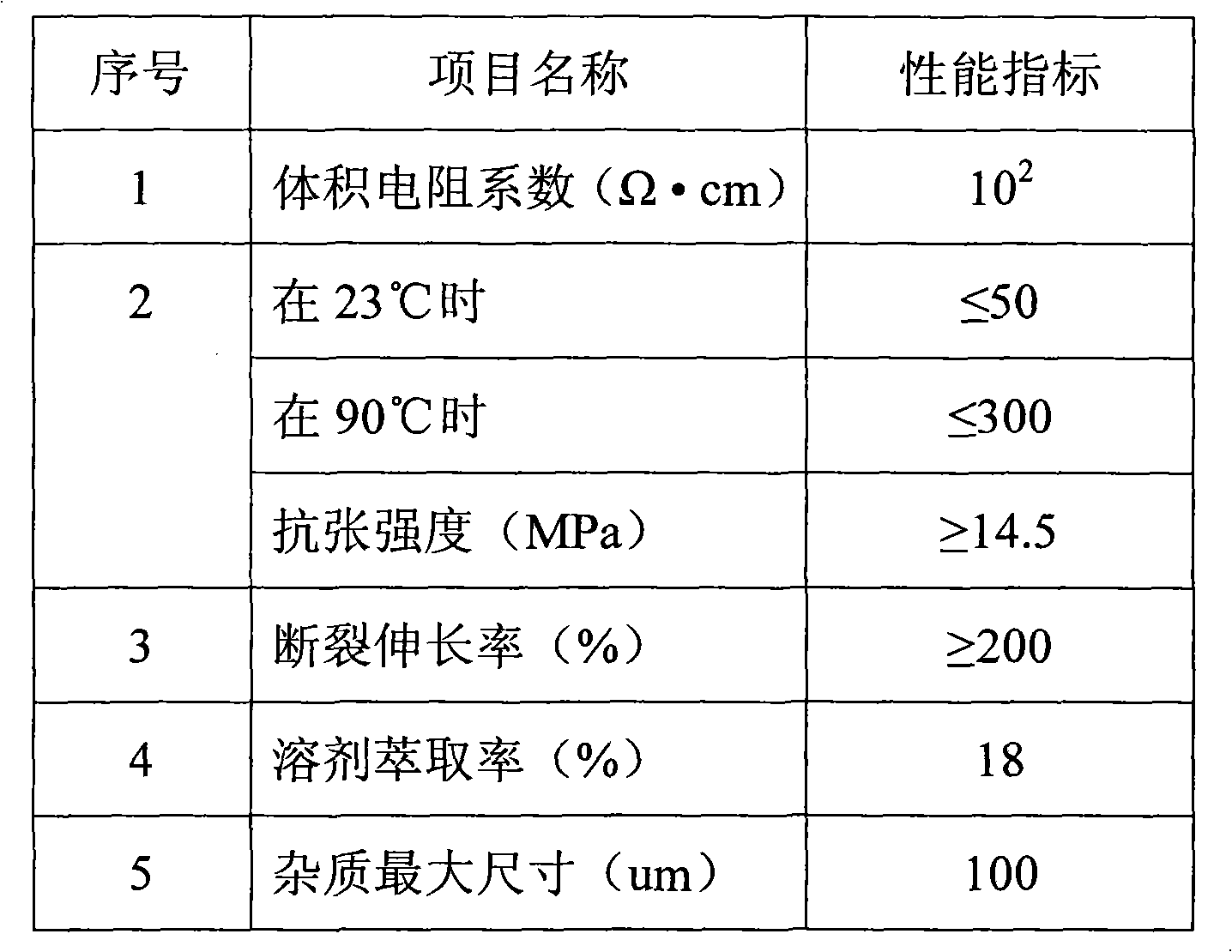

Preparation method of semiconductive shielding material for 110kV and above voltage class cables

ActiveCN101942142ANot easy to blockAchieve an ultra-smooth finishPower cables with screens/conductive layersCross-linkCross-linked polyethylene

The invention relates to a preparation method of a semiconductive shielding material for 110kV and abovevoltage class cables, comprising the following steps of: with an ethylene-ethyl acrylate resin as a basic resin and conductive carbon block as a carrier, adding an oxidation Inhibitor, polyethylene wax, white oil, glycol and zinc stearate; then adding a cross-linking agent for mutual absorption and permeation after mixing, extrusion and granulation, cooling and drying; and finally carrying out pneumatic conveying and drying by using a fluidized bed to finally prepare the granular semiconductive shielding material for cross-linked polyethylene insulated cables. The shielding material prepared in the method has the advantages of better conductivity and aging resistance, favorable process extrusion and strong stripping caking property and has the micro-powder ultrafine characteristic on material fineness.

Owner:江阴市海江高分子材料有限公司

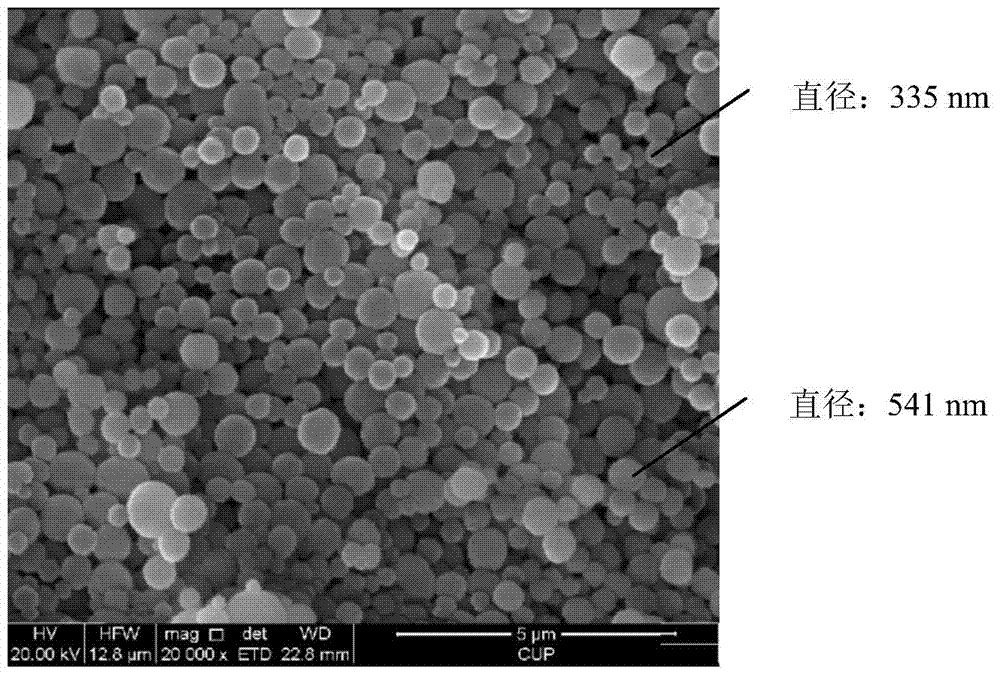

Monodisperse ternary copolymer microspheres and preparation method thereof

InactiveCN103613706AFast polymerization rateEasy to industrializeDrilling compositionFunctional monomerMicrosphere

The invention provides monodisperse ternary copolymer microspheres and a preparation method thereof. The monodisperse ternary copolymer microspheres consist of the following raw materials in percentage by weight: 5-15% of acrylamide, 4-6% of functional monomer, 0.05-1% of crosslinking agent, 0.1-0.3% of initiator, 40-60% of white oil, 3-5% of emulsifier and the balance of water. The preparation method of the monodisperse ternary copolymer microspheres comprises the following steps of adding the mixed aqueous solution of the acrylamide, functional monomer and crosslinking agent into a mixed oil solution of the emulsifier and white oil, and performing shear stirring to obtain mixed-phase liquid; dropwise adding the aqueous solution of the initiator into the mixed-phase liquid, and reacting to obtain a crude product of monodisperse ternary copolymer microspheres; performing centrifugal washing on the crude product to obtain the monodisperse ternary copolymer microspheres. The monodisperse ternary copolymer microspheres provided by the invention have excellent monodispersity and temperature resistance and can be applied to high-temperature oil reservoirs.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Ethane-vinyl acetate copolymer hole-opening foaming profile and method for manufacturing same

The invention discloses an ethene-vinyl acetate copolymer open foaming sheet and preparation method thereof. The ethene-vinyl acetate copolymer open foaming sheet comprises( by weight parts): mixture of ethene-vinyl acetate copolymer and low density polyethylene 100 parts; filler 0-40 parts; blowing agent 10-28 parts; crosslinking agent 0.5-1.0 parts; blowing promoter0.05-0.3 parts; flame retardant 0-65 parts; silicone oil or white oil 0-1.0 parts. The preparation method comprises mixing, banburing, roll mixing, preforming, once foaming, twice foaming. The invention can produce retardant and non-retardant ethene-vinyl acetate copolymer open foaming sheet with expansion ratio of 15-30.

Owner:常州美利晟高分子科技有限公司

High-dispersivity modified calcium carbonate for color masterbatches and preparation method thereof

ActiveCN103408800AUniform particle sizeLarge specific surface areaPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDispersityStearic acid

The invention provides a high-dispersivity modified calcium carbonate for color masterbatches, which is prepared from the following raw materials in parts by weight: 95-100 parts of ground calcium carbonate, 0.1-0.3 part of diffusant NNO, 0.1-0.3 part of ferrocene, 0.2-0.4 part of bisphenol A polycarbonate, 1-2 parts of rutile titanium dioxide, 0.4-0.6 part of talcum powder, 0.1-0.2 part of white oil, 0.5-1 part of methyl phenyl silicone oil ethylene bis-oleamide, 1-2 parts of high-density linear polyethylene, 0.3-0.4 part of stearic acid, 1-2 parts of paraffin and 2-3 parts of isopropyl tri(dioctylpyrophosphate)titanate. The preparation method comprises the following steps: mixing part of materials, drying calcium carbonate, mixing, proportionally and sequentially adding the other raw materials in batches, thoroughly mixing in a high-speed stirrer, drying and grinding. The modified calcium carbonate provided by the invention has the advantage of favorable dispersity, and can lower the cost and enhance the dispersity and shading property of the color masterbatches when being used in various color masterbatches.

Owner:青阳县恒源化工原料有限责任公司

Zinc base liquid composite heat stabilizer and preparation method of zinc base liquid composite heat stabilizer

The invention discloses a zinc base liquid composite heat stabilizer and a preparation method of the zinc base liquid composite heat stabilizer. The heat stabilizer is formed by the following raw materials according to mass ratio: 40-60 parts of barium fatty acid, 10-18 parts of zinc fatty acid, 10-35 parts of phosphite ester, 2-7 parts of beta-diketone, 1-10 parts of anti oxidizers and 10-20 parts of solvent, wherein barium in the barium fatty acid accounts for 10-15 percent in mass fraction, zinc in the zinc fatty acid accounts for 8-12 percent in mass fraction, and one of diethylene glycolmonobutylether, butyl cellosolve, dipropylene glycol methyl ether, tripropylene glycol methyl ether, white oil or coal oil is used as the solvent; the zinc base liquid composite heat stabilizer can effectively delay zinc burning phenomenon in a system, the PVC (polyvinyl chloride) thermal stabilization is improved, auxiliaries and PVC resin selected in the system have more approximate refractive indexes, a prepared PVC product has good transparent performance and good anti-precipitation property.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

High molecular emulsion polymer and preparation method thereof

ActiveCN101880354ASimple and fast operationGood coating inhibitionDrilling compositionPolymer scienceEmulsion

The invention relates to a high molecular emulsion polymer for drilling fluid and a preparation method thereof. The high molecular emulsion polymer is characterized by comprising the following raw materials in parts by weight: 2500-3500 parts of water, 1000-2500 parts of white oil, 500-1500 parts of acrylamide, 150-500 parts of acrylic acid, 150-250 parts of pH adjuster, 50-100 parts of 2-acrylamide-2-methyl propanesulfonic acid, 150-200 parts of composition formed by SA and Span 80, 0.2-0.5 part of oxidizer, 0.5-3.0 parts of reducer, and 0.2-0.5 part of azo initiator, wherein the ratio of Span 80 to SA in parts by weight is 1:0.05-1:0.3. The high molecular emulsion polymer prepared by the method with simple and convenient operation has the average molecular weight reaching 6-10 millions and good coating inhibition property.

Owner:濮阳市诚信钻采助剂有限公司

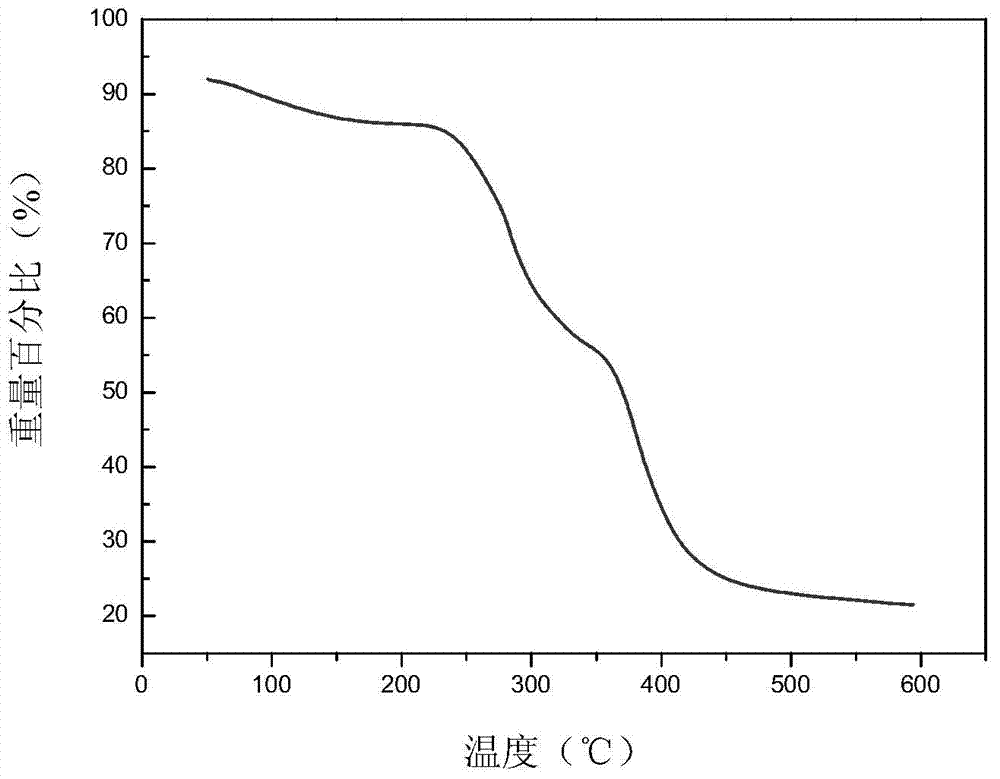

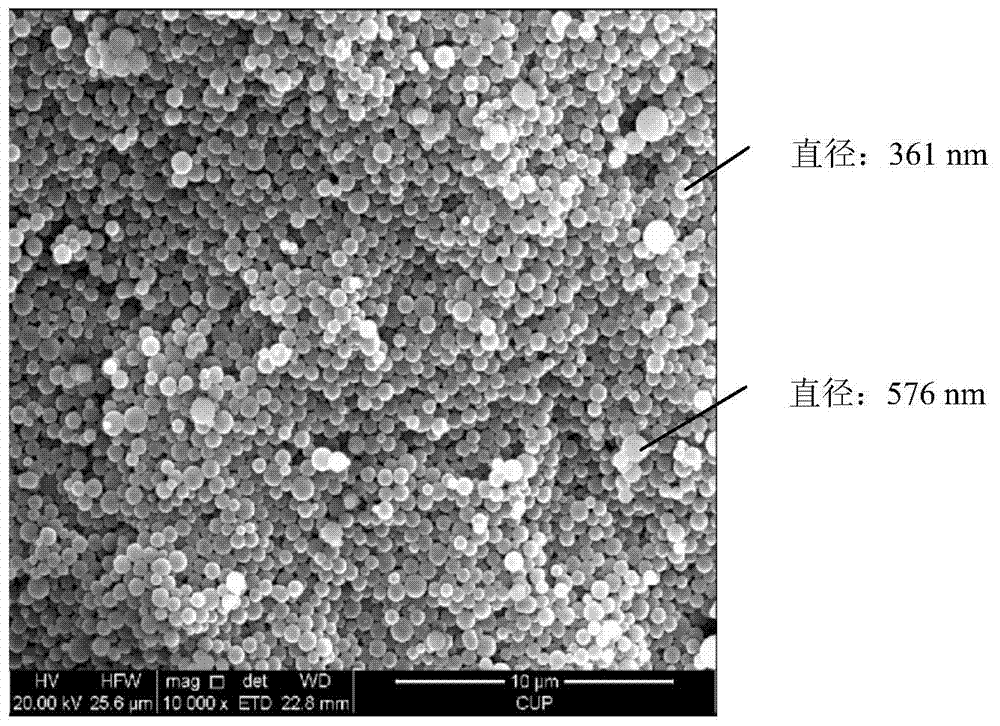

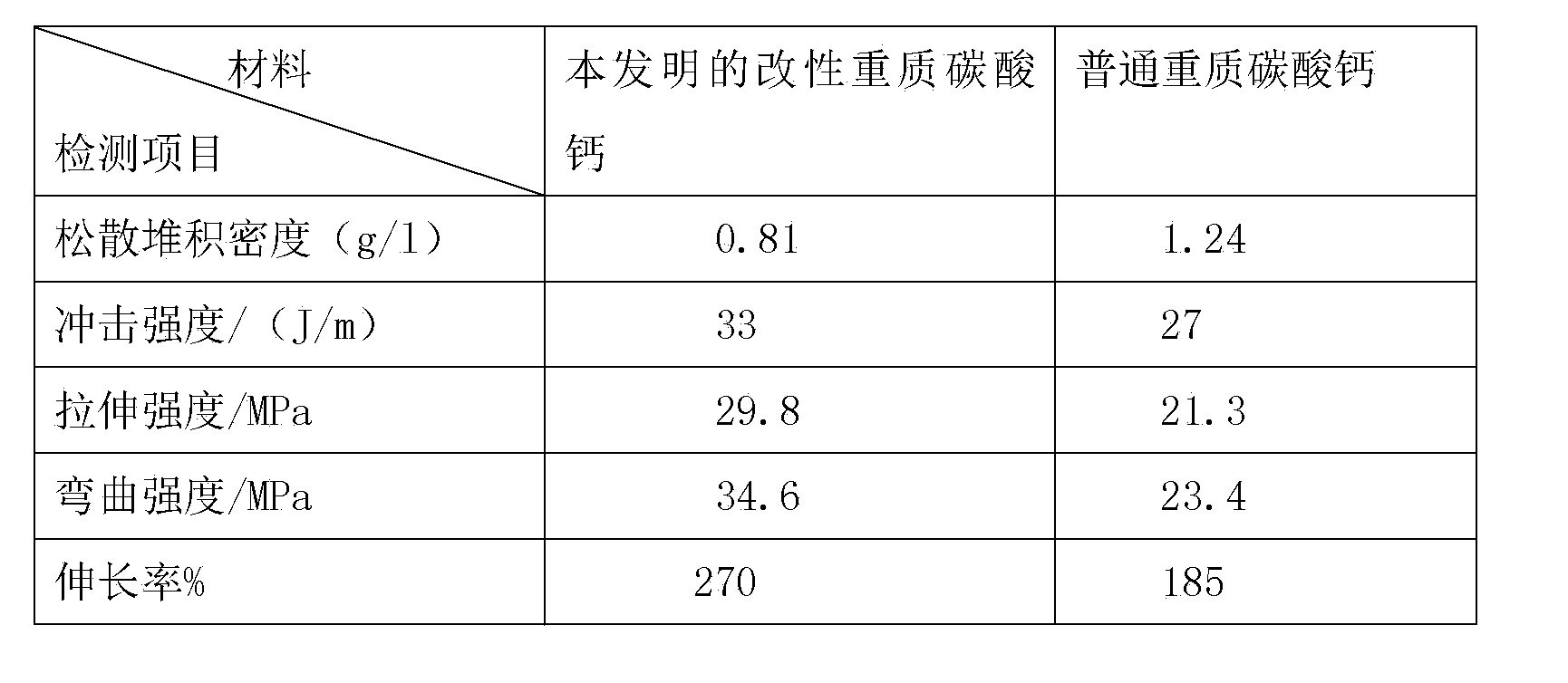

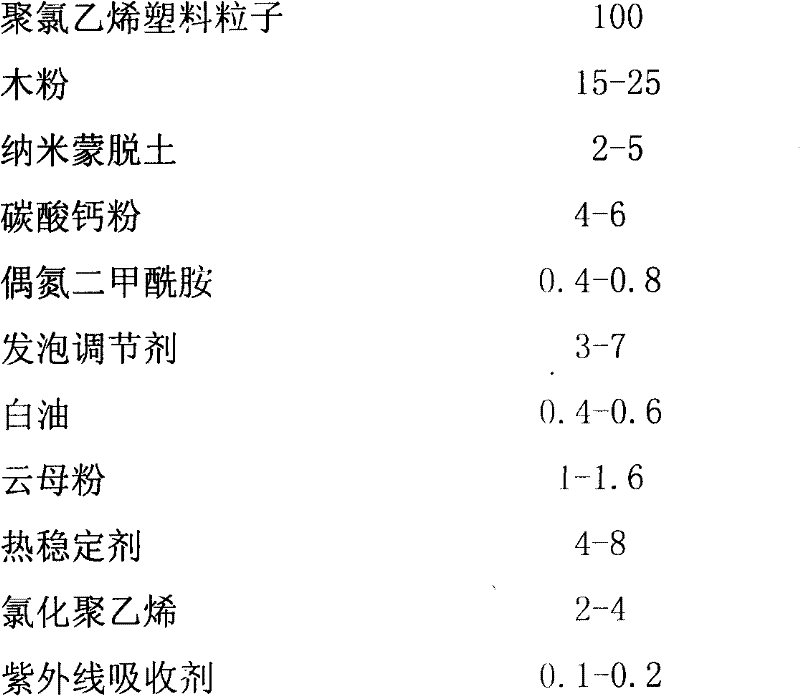

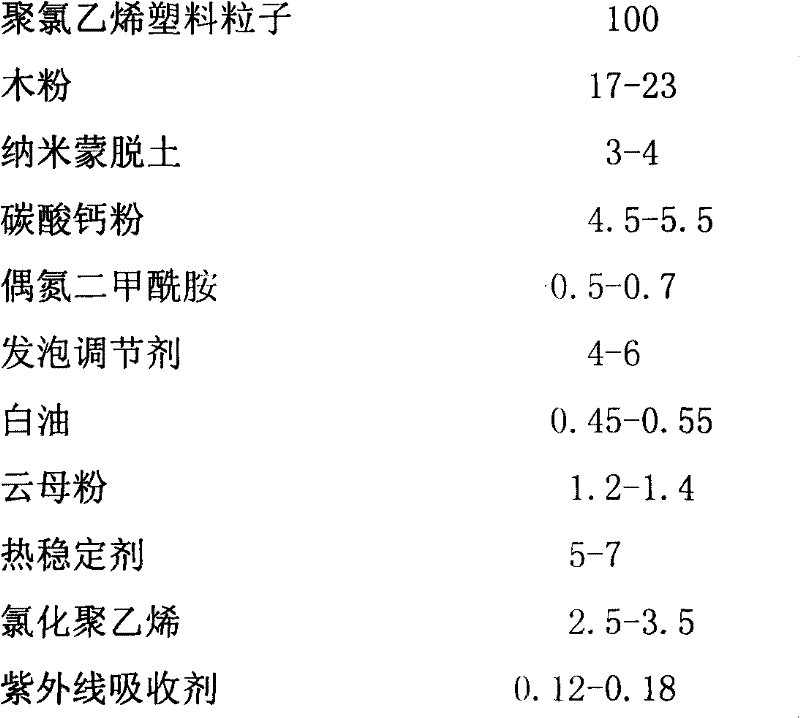

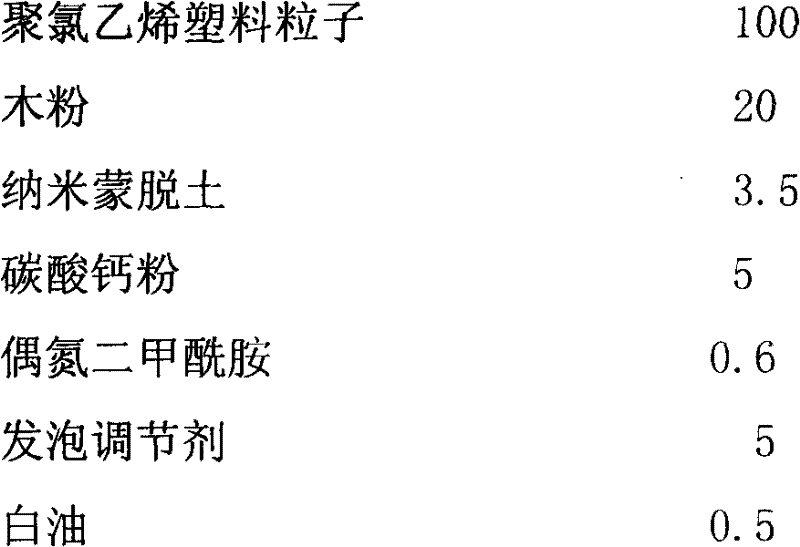

Micro-foaming wood plastic composite sheet and preparation method thereof

The invention relates to a wood plastic material and particularly relates to a micro-foaming wood plastic composite sheet and a preparation method thereof. The method provided by the invention comprises the following steps: evenly mixing polyvinyl chloride, nano-montmorillonite, calcium carbonate powder, white oil, a heat stabilizer and mica powder are uniformly stirred; and then carrying out extruding pelletization to obtain modified plastic particles; and then uniformly stirring the modified plastic particles with wood meal, azobisformamide, a foaming regulator, chlorinated polyethylene andan ultraviolent absorbent, and performing extrusion and foaming formation to obtain the micro-foaming wood plastic sheet. The micro-foaming wood plastic sheet has high degree of mechanization and lowcost, is lower in density, less in plastic amount and more environmentally-friendly compared with plastic sheets, is lower in density and higher in impact strength compared with other wood plastic materials, is lower in weight and cost and more convenient in installation and maintenance compared with gypsum boards, aluminum pinch plates and the like, and also has an air purification function. Themicro-foaming wood plastic sheet can be manufactured into products, such as photo frames, picture frames, skirtings, hangers and pinch plates and the like, and is widely applied to plenty of occasions, such as halls, guest houses, small offices and the like.

Owner:扬州润友复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com