Preparation method for artificially synthesized transparent soil material

A technology of synthetic and transparent soil, which is applied in the preparation of test samples, etc., can solve the problems of high compressibility of synthetic transparent soil, low purity of fused silica sand, difficulty in vacuum saturation, etc., and achieve visualization and good optical properties , stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited only to the description of this embodiment.

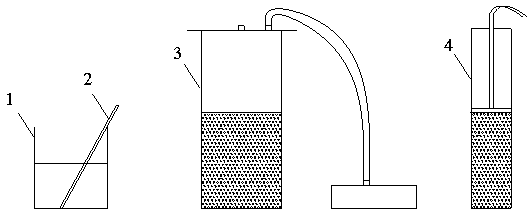

[0020] First, select a certain grade of pure baked quartz sand, wash it with water, then pickle it, and dry it in an oven to remove the impurities and moisture contained in it. The grade of baked quartz sand selected in this example is 0.1 mm-1 mm; select n-12 alkane and No. 15 white oil, and pour them into glass vessel 1 according to the mass ratio of 1:4. During the process, use glass rod 2 to continuously stir for about 20 minutes to ensure full mixing and uniform solution. The environment is 24 ° constant temperature; use the Abbe refractometer to measure the refractive index of the mixed solution at room temperature, during which the ratio of n-12 alkane and No. 15 can be fine-tuned until the refractive index of the mixed solution is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com