Organic clay with high jellification rate in white oil and preparation method thereof

A technology of gel formation and white oil, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., to achieve good gel formation effect and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Disperse 65 grams of sodium bentonite dry material into 600 grams of water, and after high-speed stirring, remove impurities by flotation to obtain a stable suspension for subsequent use; dissolve 20 grams of cetyltrimethylammonium bromide in 200 grams of In water, stir evenly to make it a clear and transparent solution; dissolve 12.5 grams of OP-10 in 150 grams of water, stir evenly, and set aside. Under the condition of high-speed stirring, slowly add cetyltrimethylammonium bromide solution to the suspension, react at 80°C for 1.5 hours, continue to drop OP-10 aqueous solution, and react at 80°C for 1.5 hours hours, finally wash the product three times, filter to obtain a solid product, dry the solid product at a temperature of 100-110°C, and then pulverize it, and pass through a 100-mesh sieve to obtain an organic soil product with a high gelation rate in white oil.

example 2

[0029] Disperse 70 grams of sodium-based bentonite dry material into 600 grams of water, and after high-speed stirring, remove impurities by flotation to obtain a stable suspension for subsequent use; dissolve 22 grams of octadecyltrimethylammonium chloride in 200 grams of In water, stir evenly to make it a clear and transparent solution for later use; dissolve 14 g of perfluorooctylsulfonyl 3-aminopropyltriethoxysilane in 150 g of water, stir evenly, and set aside for later use. Under the condition of high-speed stirring, the octadecyltrimethylammonium chloride solution was slowly added dropwise to the suspension, reacted at 90°C for 2 hours, and continued to dropwise add perfluorooctylsulfonyl 3-aminopropyltri Ethoxysilane aqueous solution, react at 90°C for another 2 hours, finally wash the product 4 times, filter to obtain a solid product, dry the solid product at a temperature of 100-110°C, crush it, and pass through a 100-mesh sieve to obtain white Organic soil product w...

example 3

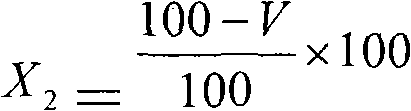

[0031] Disperse 62 grams of sodium-based bentonite dry material into 600 grams of water, and after high-speed stirring, remove impurities by flotation to obtain a stable suspension for subsequent use; dissolve 24 grams of cetyltrimethylammonium chloride in 200 grams of In water, stir evenly to make it a clear and transparent solution; dissolve 15 grams of OP-15 in 150 grams of water, stir evenly, and set aside. Under the condition of high-speed stirring, slowly add cetyltrimethylammonium chloride solution to the suspension, react at 95°C for 2 hours, continue to drop OP-15 aqueous solution, and react at 95°C for 2 hours , and finally wash the product 5 times, filter to obtain a solid product, dry the solid product at a temperature of 100-110° C., pulverize it, and pass through a 100-mesh sieve to obtain an organic soil product with a high gelation rate in white oil. The organic soil in the example is evaluated by gelation rate:

[0032] Prepare to measure 300 milliliters of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com