Patents

Literature

51results about How to "No variegation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

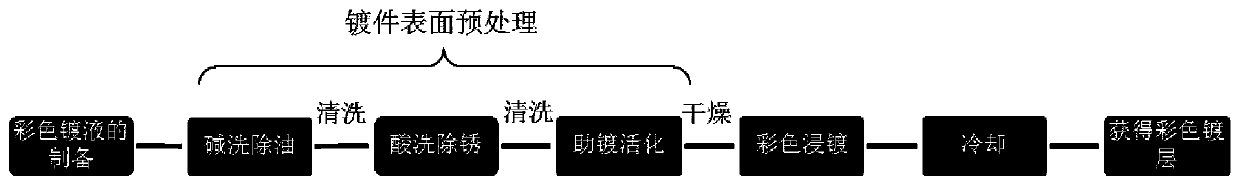

Method for anodizing and coloring surface of fluorine-free and environment-friendly titanium alloy

InactiveCN101717982AEasy maintenanceBright colorSurface reaction electrolytic coatingAnodizingHardness

The invention discloses a method for anodizing and coloring the surface of a fluorine-free and environment-friendly titanium alloy, relates to the anodizing and coloring for the surface of the titanium alloy, and provides a method for anodizing and coloring the surface of the fluorine-free and environment-friendly titanium alloy. The method comprises the steps of: washing a titanium alloy work piece with alkaline to remove oil, and carrying out electrolytic polishing; anodizing and coloring the titanium alloy work piece after electrolytic polishing to obtain an oxide film of the titanium alloy with different colors; closing the anodized and colored titanium alloy work piece; and drying the closed titanium alloy work piece to obtain the titanium alloy work piece with the anodized and colored surface. The invention has less technical steps, simple operation in each step and is easy to maintain. The oxide films of the titanium alloy with different colors are obtained through setting different voltage values; the oxide film is dazzlingly brilliant, has bright and uniform colors without allochromatic colors, strong smudge resistance, favorable decorative effect, higher surface hardness, favorable binding force and corrosion resistance and prevents fingerprints. The solution in each step is easy to maintain, and the invention can realize mass production and has favorable actual application prospect.

Owner:XIAMEN UNIV

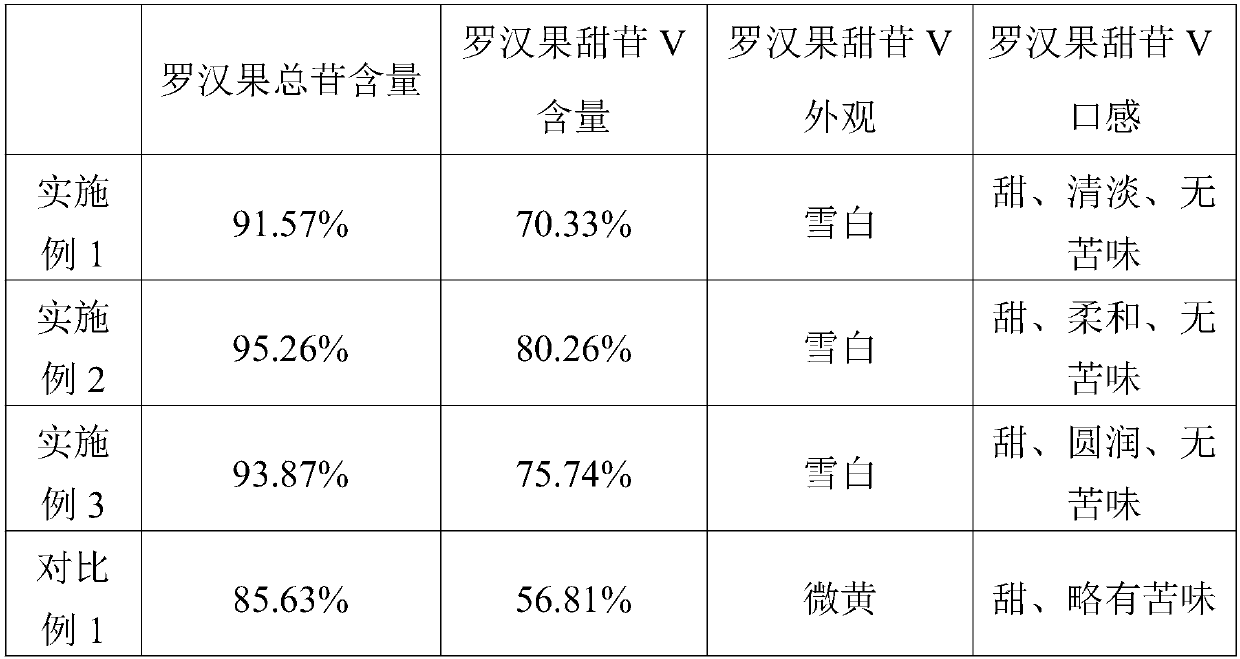

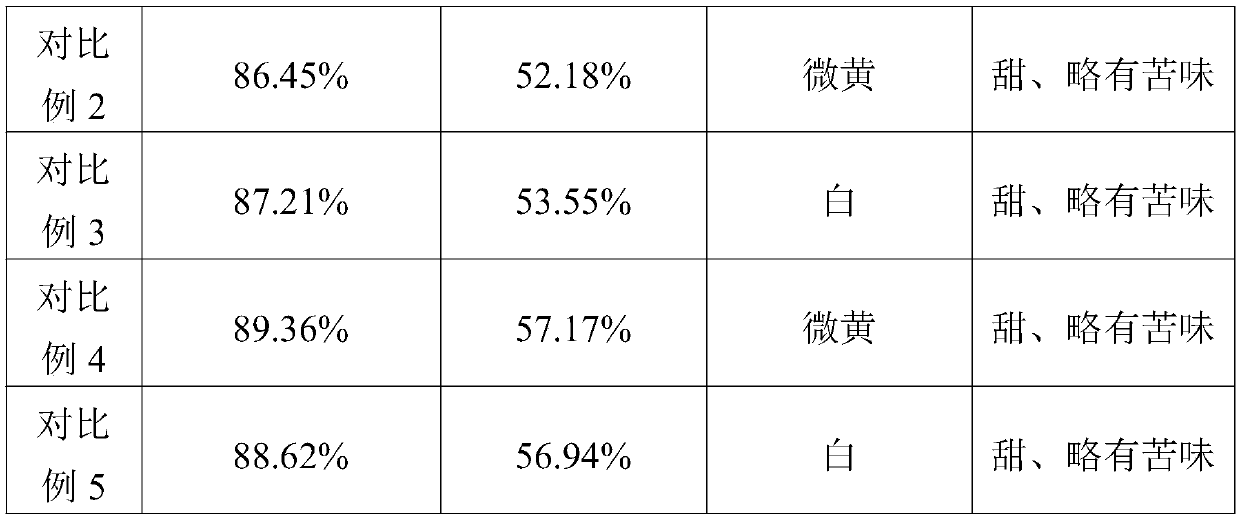

Method for separating mogroside V

The invention relates to the field of extraction and purification of plant effective components, and especially provides a method for separating mogroside V from grosvenor momordica fruits. The methodfor separating mogroside V comprises the following steps: addition of water to grosvenor momordica fruits, pulping, phytoenzyme enzymatic hydrolysis, biological enzyme hydrolysis, collection of the obtained enzymatic hydrolysate, enzyme deactivation, yeast fermentation, composite anion-cation exchange resin purification, and concentration drying for preparing the mogroside V. The product preparedthrough the production method has the advantages of snowy white color, no bitterness, small solvent residual, no pesticide residue and stable quality; and the content of the mogroside V in the product is greater than 60%, and total glycoside content of the product is greater than 90%.

Owner:GUILIN NATURAL INGREDIENTS CORP

Method for coloring titanium and titanium alloy surface through anodization

InactiveCN102242387AImprove corrosion resistanceImprove bindingSurface reaction electrolytic coatingToxic materialTitanium alloy

The invention relates to a method for coloring the titanium and titanium alloy surface through anodization. The invention aims to provide a novel fluoride-free and environmental-friendly technology to improve the present titanium and titanium alloy anodization technology generally employing the highly toxic substance hydrofluoric acid, so that the requirements for green and safe production and sustainable development can be met. The method comprises the following processes: acceptance inspection before anodization, hanging, oil removing, flowing hot water washing, flowing cold water washing, electrolytic polishing, flowing cold water washing, deionized water washing, anodization, flowing cold water washing, flowing hot deionized water washing, dismounting, drying and inspection. The anodization coloring technology of the invention has low cost, simple operation, and can generate colorful and bright-colored high quality oxide-film layers, characterized by fingerprint pollution prevention on the surface, strong stain resistance and excellent decorative effect.

Owner:XIAMEN CASAMOY TECH

Processing method of recombined braised tofu with seafood

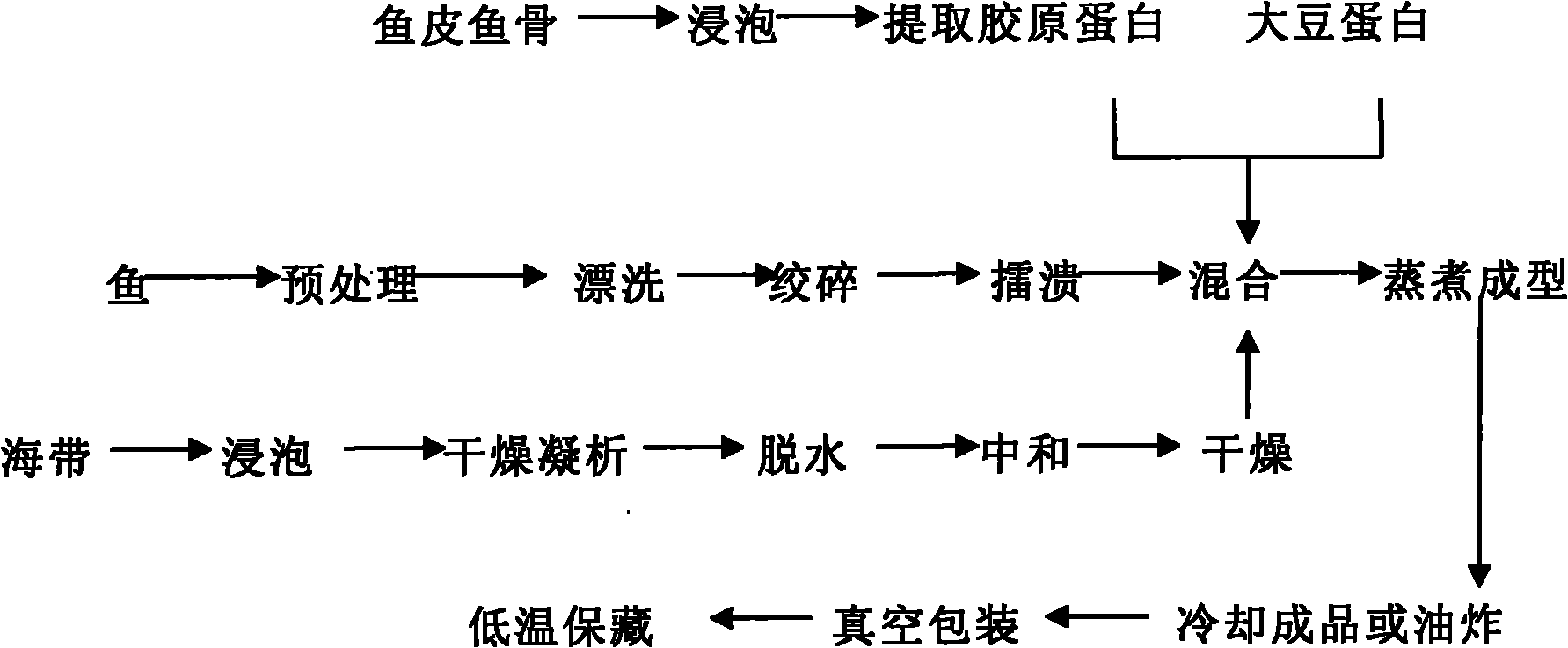

The invention relates to a recombined braised tofu with seafood and a processing method thereof, belonging to the food science and technology field. The method comprises the following steps of: adding accessories, such as soy protein, collagen of fish skin and fish bone, kelp extractives, and the like by using fresh-water minced fillet as a main raw material; and recombining, mixing (chopping in vacuum for 30 min), stewing and forming at a high temperature (for 30 min), frying with oil in vacuum, quickly cooling and packaging in vacuum to make a polymer of protein and amylase and form a tofu-shaped, fresh, tender and smooth product with seafood taste, i.e. the recombined braised tofu with seafood, and storing the finished product in the environment at 0-4 DEG C. The recombined braised tofu with seafood, which is produced by applying the technology, is rich in nutrition, has excellent consistency, white color and luster, great and strong seafood taste and long product shell life, and is widely suitable for Chinese and western foods.

Owner:TIANJIN UNIV OF SCI & TECH

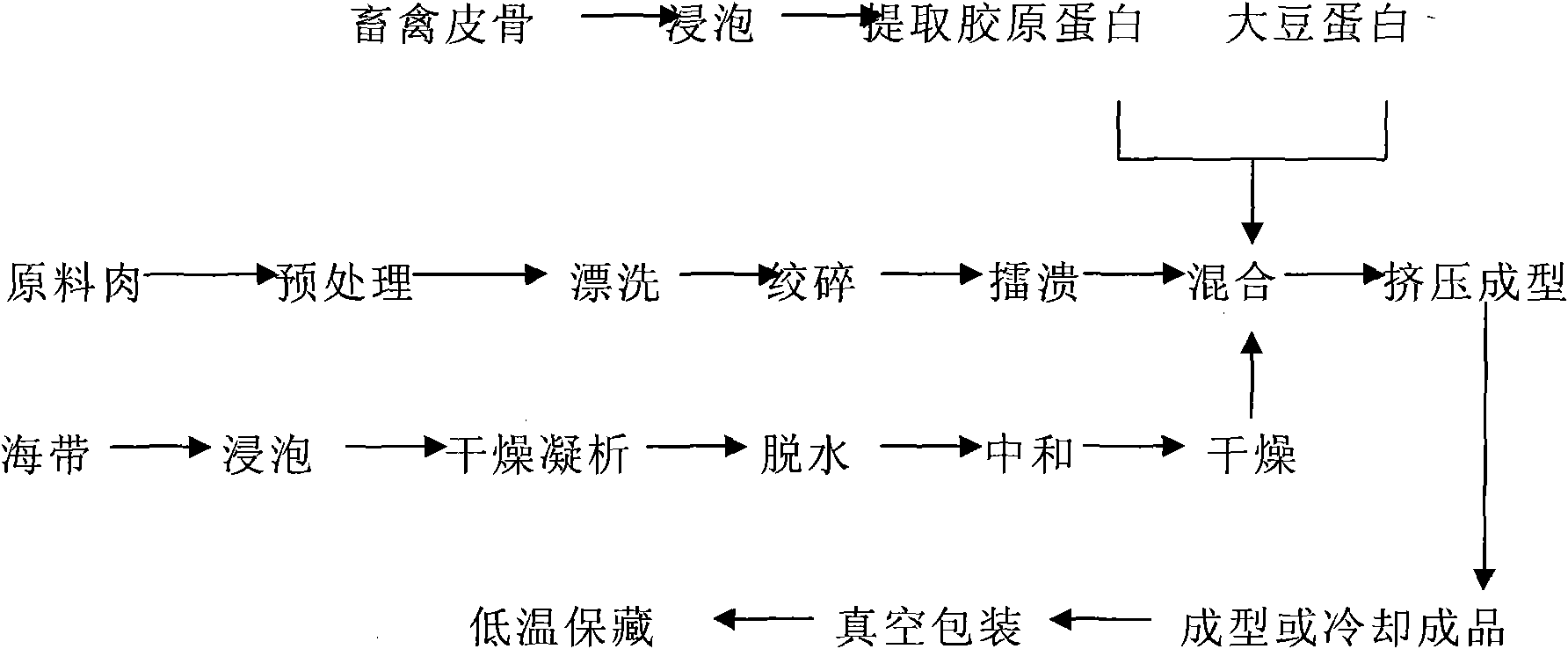

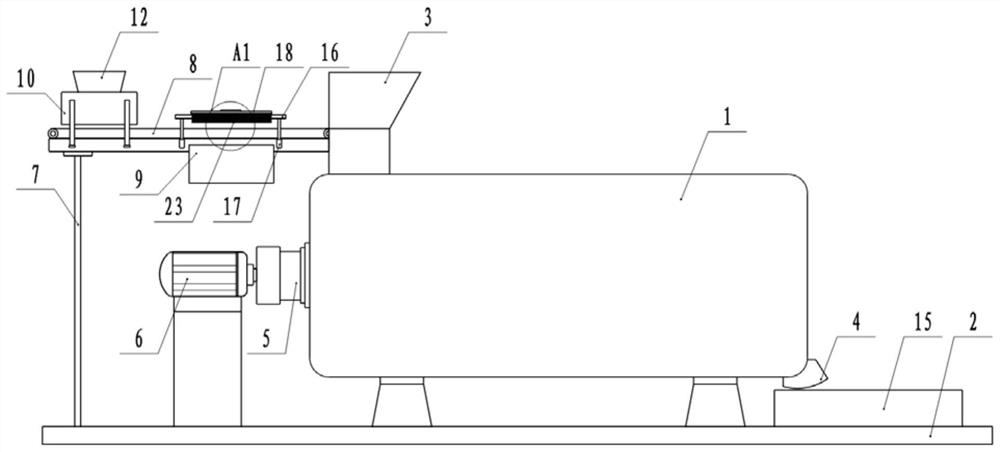

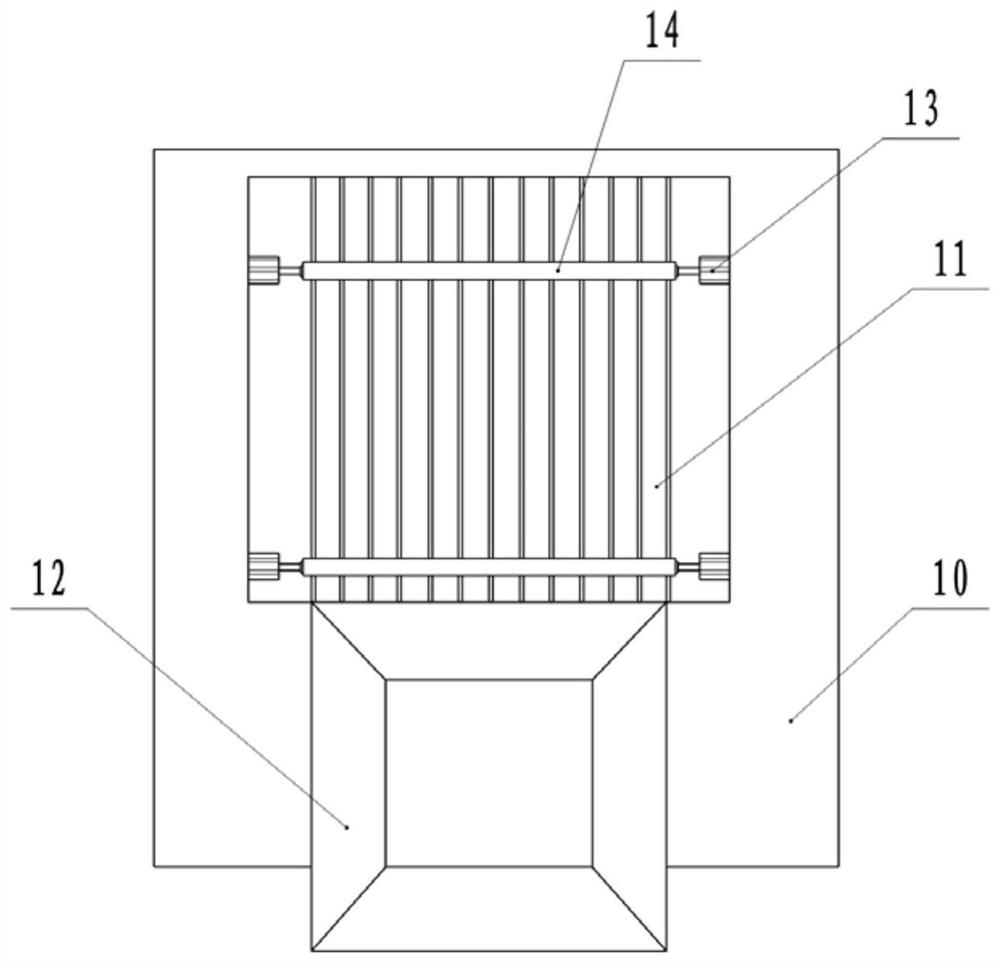

Extrusion production technique for meat simulated fibers

The invention relates to an extrusion production technique for meat simulated fibers, and belongs to the technical field of food science. A low-value meat raw material is used as a main raw material. The technique comprises the following steps of: adding auxiliary materials such as soy protein, animal dermal bone collagen, transglutaminase serving as meat protein coagulation additive, kelp glue serving as kelp extract and the like, performing recombination and cross-linking on multiple proteins and macromolecular polysaccharides by adopting double-screw extrusion technology (the rotational speed of screws is 280 to 450 revolutions per minute, the pressure of a micropore template is 1.7 to 6.0MPa at the temperature of between 150 and 200 DEG C, and the temperature of a cylinder is 170 DEG C), forming meat silk simulated fibers by extrusion, forming cross-linking reaction among meat protein molecules and in molecules, and reshaping micropore formed fibers to obtain recombinant meat food with good color, fragrance, taste and shape. The meat product produced by using the silk muscle simulated fibers produced by the technique is pure natural green food, does not contain chemical substances or preservatives, has the mouthfeel of real meat silks and the specific flavor of meat, has special fragrance and color at the same time, and can be absorbed more easily. Moreover, the added auxiliary materials such as collagen, kelp glue and the like form protein and polysaccharide polymers, so the nutritional components of the product are increased, the quality and structure properties of the product are greatly improved, the water holding property is improved, the problems such as gel cracking and the like are effectively avoided, the quality guarantee period of the product is prolonged, and the social benefit and the economic benefit of the product are increased.

Owner:TIANJIN UNIV OF SCI & TECH

Antique appearance 3D printing repair method using natural and safe materials

InactiveCN107891595ANumbers are accurateStrong expandabilityAdditive manufacturing apparatus3D object support structuresEngineering3d scanning

The invention discloses an antique appearance 3D printing repair method using natural and safe materials. The method includes the following manufacturing steps that first, 3D scanning is conducted; second, model processing is performed; third, model 3D printing is carried out and fourth, a fragment and a model are spliced. Through the invisible antique repair technology, a traditional repair method is broken through, the whole porcelain repair efficiency is improved by combining the 3D technology, and the repair cost is greatly reduced. The transparent environmental protection materials at themedical oral cavity using grade are used completely in the repairing process, and the effect that repaired utensils can be used in the daily life of people is guaranteed.

Owner:侯毅 +1

Method for dry method rice meal preparation, rice meal for fresh rice noodles, rice meal for baked foods and rice meal for cooked foods

InactiveCN106036409AMaximum damaged starch valueAvoid lostFood mechanical treatmentCooked foodMoisture

The invention relates to the technical field of food processing and particularly discloses a method for dry method rice meal preparation, rice meal for fresh rice noodles, rice meal for baked foods and rice meal for cooked foods. The preparation method sequentially comprises the steps of tempering, rice blending and grinding, wherein the tempering means that the moisture content of rice is adjusted to 16-25% and the rice moistening is performed for 12-18 h; reasonable rice blending is performed according to product usage and quality requirements; the grinding means that a roller mill is adopted to perform grinding, and a material is sieved through a sieve with 100-160 meshes, and the material placed above the sieve is placed in a Raymond mill to undergo secondary grinding. The rice meal prepared through the preparation method is low in damage starch ratio, multi-purpose rice meal such as the rice meal for fresh rice noodles, the rice meal for baked foods and the rice meal for cooked foods can be produced, and the method is favorable for industrial production and has the advantages of being high in production efficiency, low in energy consumption, high in raw material utilization rate and free of pollution.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Preparation method of lycium ruthenicum murr tea

The invention relates to a preparation method of boxthorn leaf tea, and particularly relates to a preparation method of lycium ruthenicum murr tea. The preparation method is characterized by comprising the following steps: as fresh lycium ruthenicum murr is taken as a raw material, cleaning the picked fresh tender leaves at the middle mature period; withering, de-enzyming, rolling, molding, drying and packaging. The lycium ruthenicum murr tea is unique in raw material, and good in taste, and has the health-care effects of resisting oxidation, reducing blood sugar, reducing blood fat and the like.

Owner:NINGXIA DINGLI AGRI DEV

Spread ceramic surface sintered silver paste and preparation method thereof

The invention discloses spread ceramic surface sintered silver paste, which comprises the following components in parts by weight: 45 to 55 parts of silver powder, 2 to 3 parts of sodium alginate, 2 to 3 parts of glass powder, 15 to 20 parts of polyethylene glycol, 5 to 8 parts of sucrose isobutyrate, 1 to 2 parts of an abietic acid, 3 to 5 parts of terpenic oil and 20 to 25 parts of water. A preparation method comprises the following steps: adding the silver powder into the water, adding the sodium alginate and the polyethylene glycol with stirring at 200 to 300rpm, and continuing stirring for 15 to 20min to obtain a solution A; dissolving the abietic acid into the terpenic oil, adding the sucrose isobutyrate, and performing uniform stirring to obtain a solution B; adding the solution B into the solution A, and performing stirring for 1 to 2h at 500 to 600rpm. According to the silver paste, the raw materials are readily available, a preparation process is simple, the silver paste is relatively low in cost, free of heavy metals, safe in use, green and environment-friendly, and no harmful gas is generated during sintering.

Owner:河北银瓷天成文化传播有限公司

Acidic cleaning agent special for stainless steel and preparation method and application thereof

The invention relates to an acidic cleaning agent special for stainless steel and a preparation method and application thereof. The cleaning agent is formed by mixing the following raw materials, by mass, of 15%-20% of organic acid, 4.5%-5.5% of etidronic acid, 0.5%-1.5% of thiocarbamide, 2.5%-3.5% of polyoxyethylene octylphenol ether-10, 1.5%-2.5% of sodium diethylhexyl sulfosuccinate, 1.5%-2.5% of secondary alcohol ethoxylate and the balance pure water. The organic acid is composed of citric acid, succinic acid and oxalic acid. Through collaborative compound of the three citric acid, the succinic acid and the oxalic acid, the acidic cleaning agent has good oil removing and wax removing effects. Uniform film forming of water is achieved on the surface of the stainless steel. The surface of the cleaned stainless steel is free from watermarks, the stainless steel cleaning working procedure is simplified, and the production efficiency is improved.

Owner:中山市浩科化工科技有限公司

Surface bright anodic oxidation coloring method for titanium and titanium alloy

ActiveCN105316744ANo variegationNo anti-fingerprintSurface reaction electrolytic coatingMegasonic cleaningTitanium

Owner:TRAUSON CHINA MEDICAL INSTR COMPANY

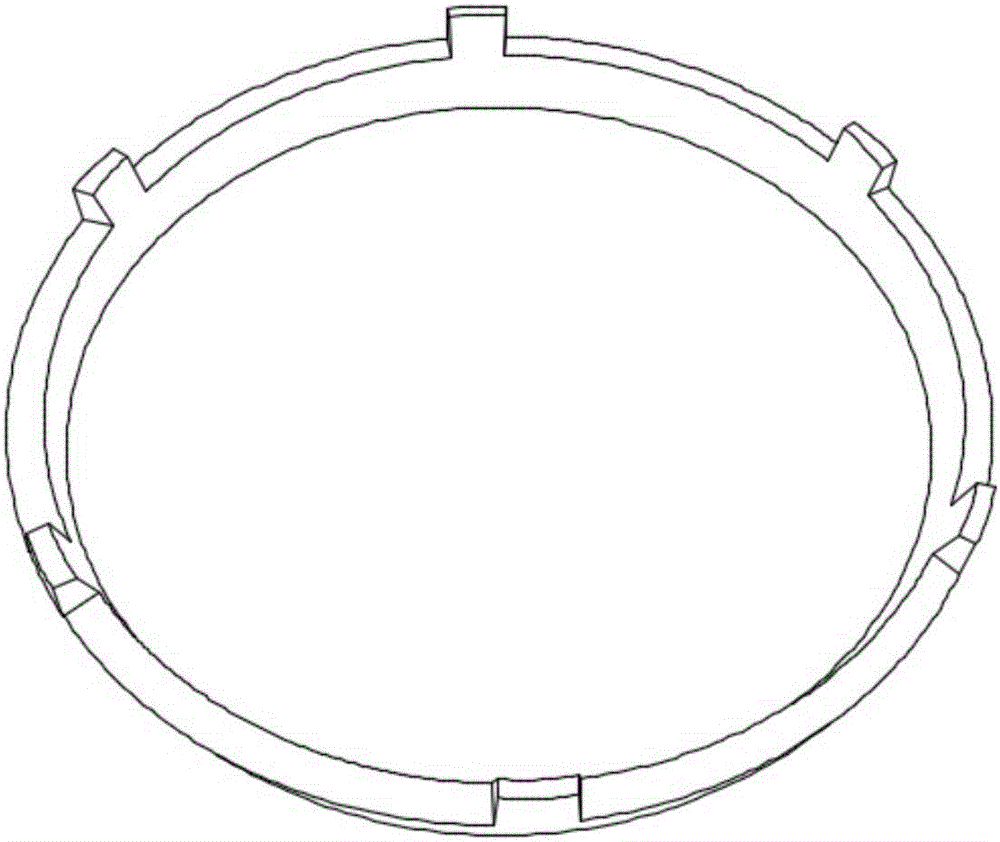

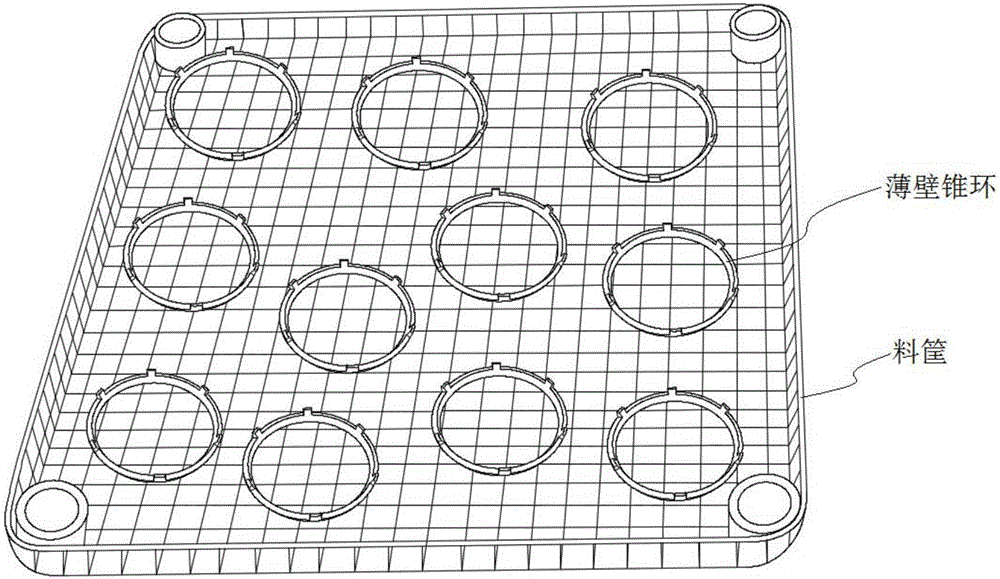

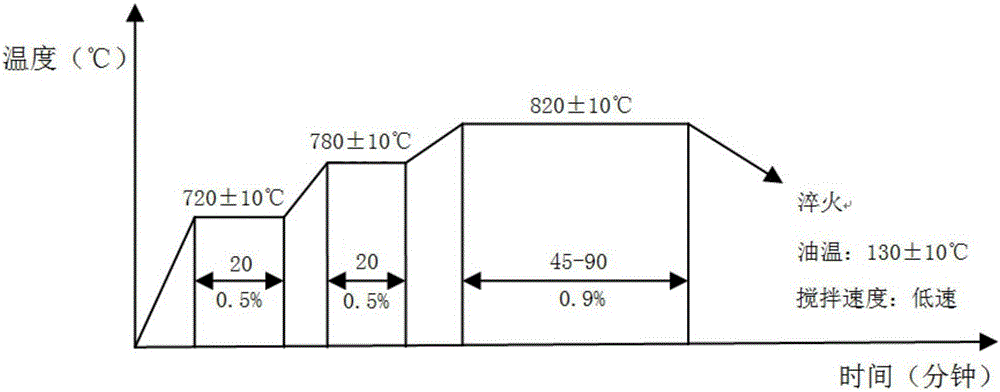

Heat treatment technology for reducing deformation of GCr15 thin-wall conical ring

ActiveCN106048195ASmall amount of deformationReduce grinding allowanceFurnace typesProcess efficiency improvementCarbon potentialThermal insulation

The invention discloses a heat treatment technology for reducing deformation of a GCr15 thin-wall conical ring and belongs to the field of heat treatment technology. The technology comprises the following steps: 1) machining of a spheroidized annealed blank into a thin-wall conical ring part; 2) crating; 3) front cleaning; 4) quenching: thermal insulation at 720 + / - 10 DEG C for 20 + / - 1 min, and carbon potential is 0.5 + / - 0.025%; thermal insulation at 780 + / - 10 DEG C for 20 + / - 1 min, and carbon potential is 0.5 + / - 0.025%; thermal insulation at 820 + / - 10 DEG C for 45-90 min, and carbon potential is 0.9 + / - 0.025%; and cooling in 130 + / - 10 DEG C of quenching oil; 5) post cleaning; and 6) tempering: tempering temperature is 185 + / - 5 DEG C, and time is 150 + / - 10 min. According to the invention, deformation of the thin-wall conical ring part after heat treatment is reduced, grinding allowance after heat treatment is decreased, grinding cost after heat treatment is lowered, and first pass yield for heat treatment reaches 100%.

Owner:常州新区河海热处理工程有限公司

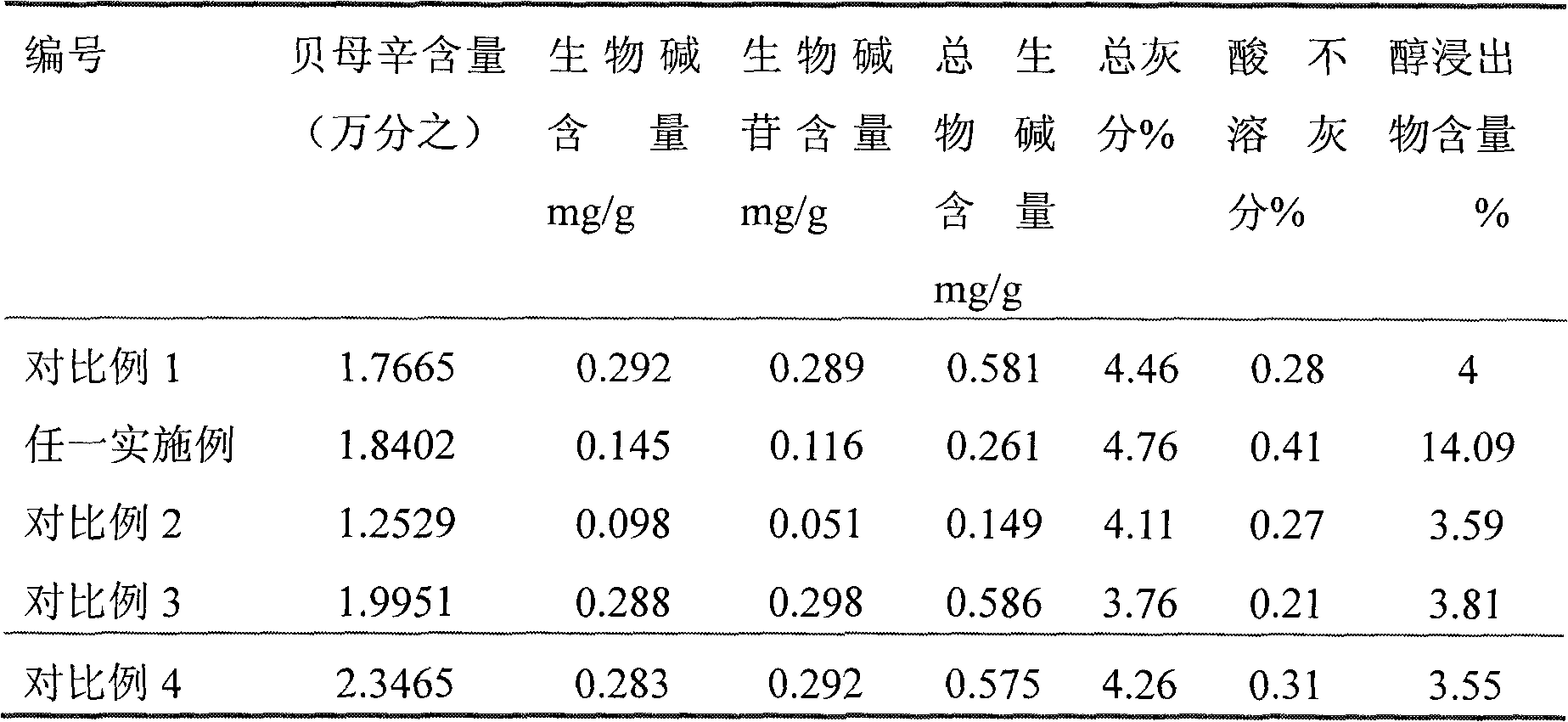

Method for processing bulbus fritillariae cirrhosae

InactiveCN101780210AThere is no problem of excessive sulfur contentUniform colorPlant ingredientsFritillaria cirrhosaAqueous solution

The invention relates to a method for processing bulbus fritillariae cirrhosae. The method comprises three steps, namely drying, cleansing, and redrying. The steps are characterized by the cleansing method: (1) preparation of cleansing liquid: preparing hypochlorite aqueous solution with 3 to 10 percent of mass concentration. (2) cleansing the dried bulbus fritillariae cirrhosae in the cleansing liquid for 3 to 5 minutes and taking dried bulbus fritillariae cirrhosae out. The bulbus fritillariae cirrhosae medicinal product obtained from the method is milk white and does not have any parti-colours. The colour is even so that the overall appearance is improved. The bulbus fritillariae cirrhosae processed by this method is free from excessive sulphur content, and the quality of the product is also improved.

Owner:CHONGQING HUAAO PHARMA IND CO LTD

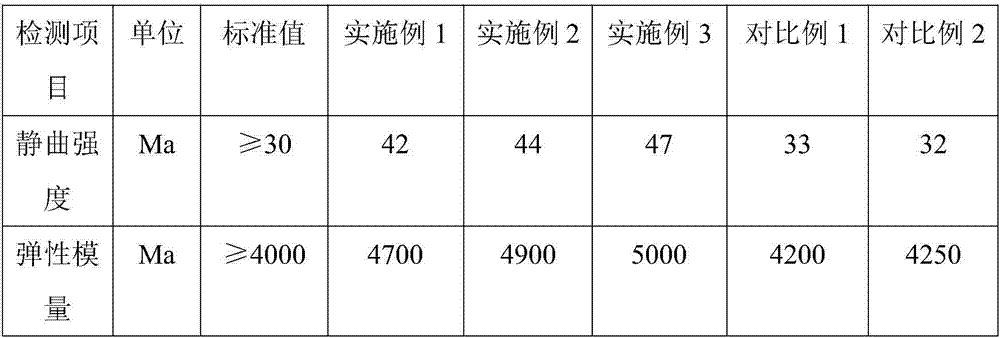

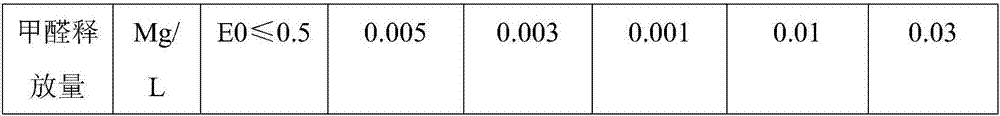

Composite board containing moxa residue as well as preparation method and application thereof

ActiveCN107283965AImprove mildew resistanceAvoid crackingDecorative surface effectsWood layered productsAdhesiveUltimate tensile strength

The invention belongs to the technical field of materials and in particular relates to a composite board containing moxa residues as well as a preparation method and application thereof. The provided composite board containing the moxa residues comprises a panel, a core board, a backing plate and adhesive layers, wherein the panel, the core board and the backing plate are glued by virtue of the adhesive layers, and the panel and the backing plate are a poplar plate, an eucalyptus plate, a birch plate or a basswood plate; the core board is prepared from the following raw materials in weight proportion: 11-15 parts of moxa residues, 63-68 parts of wood powder, 3-6 parts of bamboo charcoal powder, 15-20 parts of bamboo powder and 6-12 parts of soybean meal adhesive; each adhesive layer contains composite additives and an adhesive in a weight ratio of (1-3):(14-16). The provided composite board containing the moxa residues is flat, fine and smooth in surface, is not blistered when being scalded and ironed, does not discolor or deform and hardly cracks, is good in strength and has excellent insect-proof, anticorrosion and mildewproof properties. The provided composite board containing the moxa residues can be applied to pyrograph.

Owner:GUANGZHOU JINAN BIOMEDICINE RES & DEV CENT

Method for anodizing and coloring surface of fluorine-free and environment-friendly titanium alloy

InactiveCN101717982BEasy maintenanceBright colorSurface reaction electrolytic coatingAnodizingHardness

The invention discloses a method for anodizing and coloring the surface of a fluorine-free and environment-friendly titanium alloy, relates to the anodizing and coloring for the surface of the titanium alloy, and provides a method for anodizing and coloring the surface of the fluorine-free and environment-friendly titanium alloy. The method comprises the steps of: washing a titanium alloy work piece with alkaline to remove oil, and carrying out electrolytic polishing; anodizing and coloring the titanium alloy work piece after electrolytic polishing to obtain an oxide film of the titanium alloy with different colors; closing the anodized and colored titanium alloy work piece; and drying the closed titanium alloy work piece to obtain the titanium alloy work piece with the anodized and colored surface. The invention has less technical steps, simple operation in each step and is easy to maintain. The oxide films of the titanium alloy with different colors are obtained through setting different voltage values; the oxide film is dazzlingly brilliant, has bright and uniform colors without allochromatic colors, strong smudge resistance, favorable decorative effect, higher surface hardness, favorable binding force and corrosion resistance and prevents fingerprints. The solution in each step is easy to maintain, and the invention can realize mass production and has favorable actual application prospect.

Owner:XIAMEN UNIV

Processing method of fresh and spicy composite sauce

ActiveCN112971092ASolve precipitationBright red colorFood ingredient as thickening agentFood ingredient as colourBiotechnologyPreservative

The invention relates to the field of sauce processing, and discloses a processing method of a fresh and spicy composite sauce, which comprises the following steps: S1, pretreatment: cleaning, disinfecting and drying the equipment, selecting and crushing chili raw materials, and removing pedicles and seeds of the chili raw materials mechanically in the crushing process; S2, materials preparation: mixing and stirring seasoning, crushed chili, a freshener, a thickening agent, a preservative and food coloring in proportion to prepare a mixture for later use; S3, homogenization: performing homogenizing treatment on the mixed materials; and S4, emulsification: pumping the homogenized mixture into an emulsifying tank for emulsifying treatment, and cooling while stirring after emulsifying. The invention solves the problem that the sensory quality of the product is influenced by the existence of chili pedicles and chili seeds in the process of preparing the fresh and spicy sauce in the prior art.

Owner:重庆飞亚实业有限公司

Spraying type ceramic surface-sintered silver paste and preparation method thereof

The invention discloses a spraying type ceramic surface-sintered silver paste which contains the following components: 50-60 parts of nanometer silver powder, 1-3 parts of glass powder, 5-10 parts of twain, 5-10 parts of polyvinylpyrrolidone, 5-10 parts of dimeticone, 3-5 parts of sweet almond oil and 15-20 parts of water. A preparation method comprises the following steps: adding water into a container; adding polyvinylpyrrolidone and stirring till dissolving; adding twain, dimeticone and sweet almond oil and stirring for 0.5-1 hour at 500-600rpm; lastly, adding the nanometer silver powder and the glass powder and stirring for 20-30min at 500-600rpm. According to the invention, the preparation process of the silver paste is simple, the silver layer is firm after the sintering and is difficult to fall off; the silver paste is nontoxic and harmless and contains no other heavy metal; when the silver paste is applied to the food container, the silver paste has disinfecting and bactericidal effects; the silver paste is wide in application prospect.

Owner:河北银瓷天成文化传播有限公司

Functional coix seed beverage and preparation method of functional coix seed beverage

InactiveCN107691943AGreat tasteThe taste is sweet and sour, suitable for coordinationNatural extract food ingredientsFood ingredient functionsFermentationAcesulfame potassium

The invention relates to the technical field of beverage processing, in particular to a functional coix seed beverage. The beverage is prepared from raw materials as follows: coix seeds, herba dandrobii, apples, acesulfame potassium, tartaric acid and chitosan. The coix seeds are subjected to germination, hot pressing treatment, airing, red light treatment, decoction after fermentation and saccharifying during preparation, so that the prepared functional beverage has higher aroma content and has the ester content up to 41.92%, the beverage has fruit aroma and flower fragrance, and the taste ofthe functional coix seed beverage is improved.

Owner:贵州百科薏仁生物科技有限公司

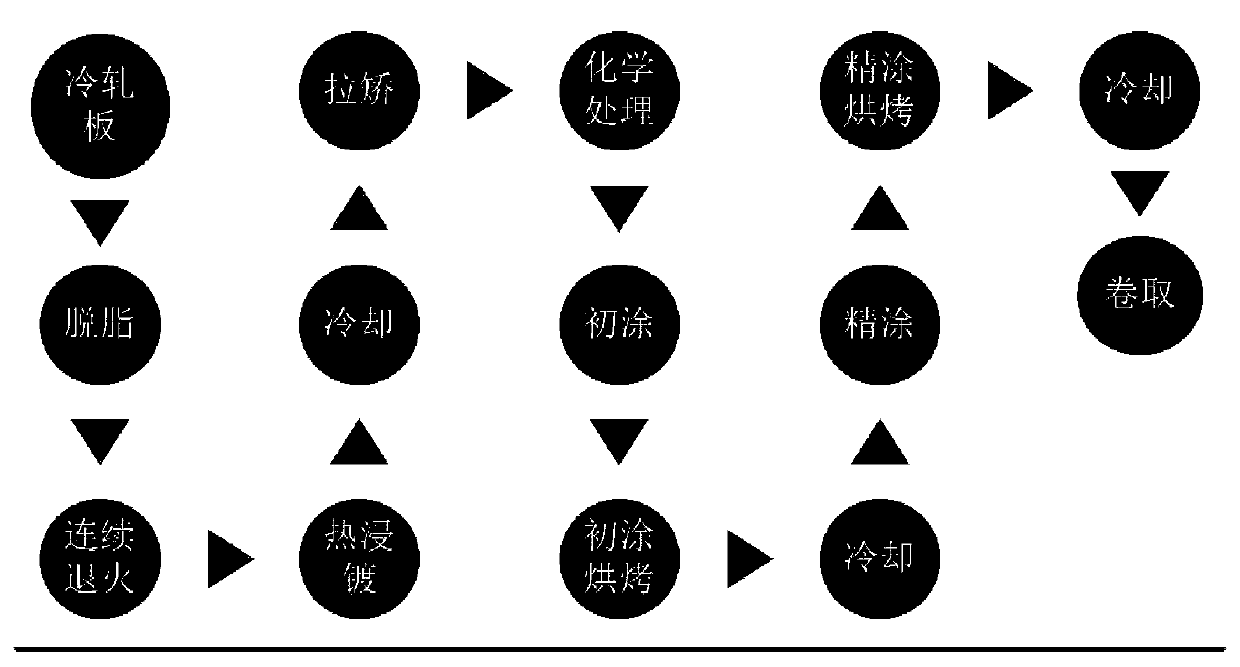

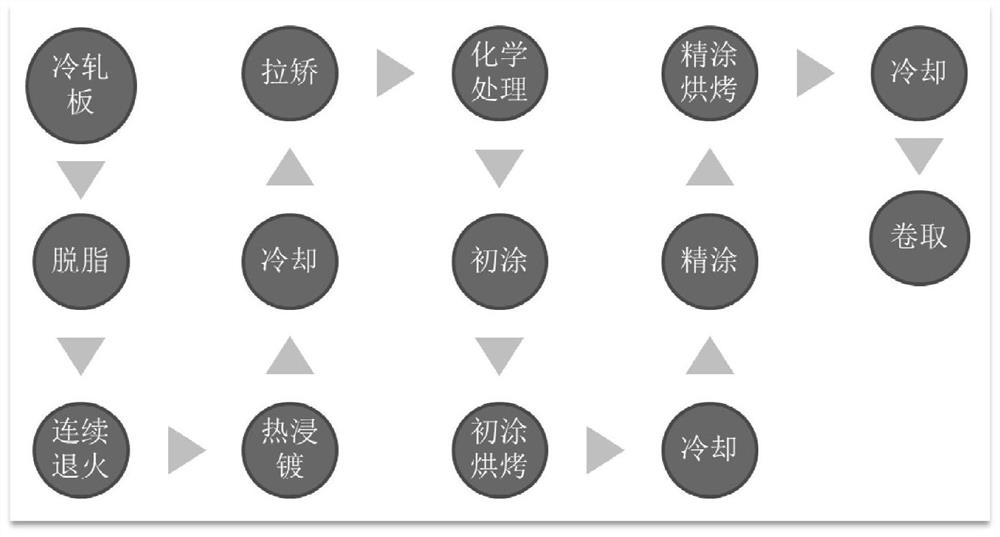

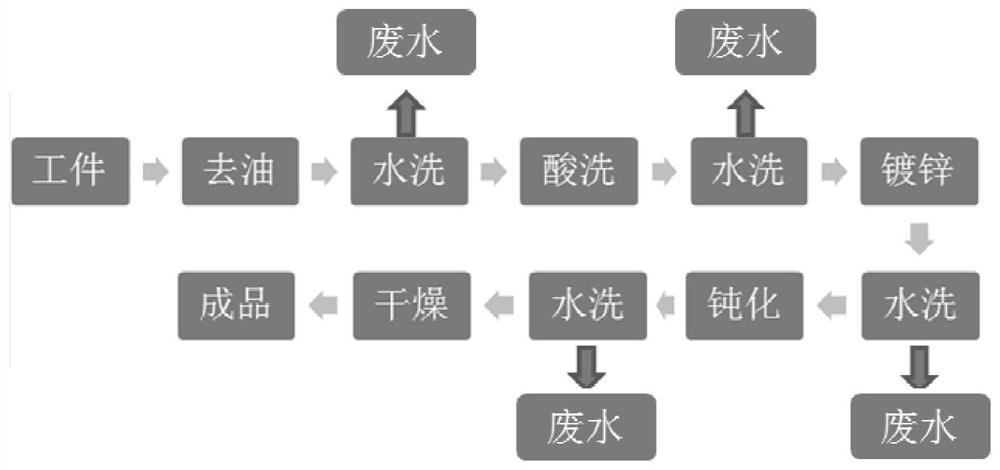

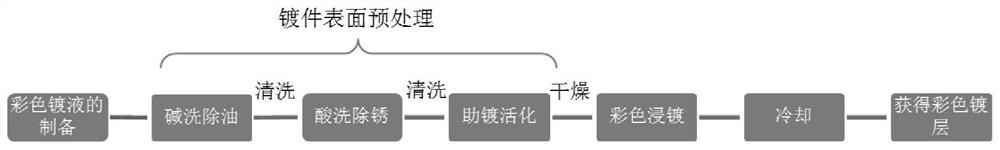

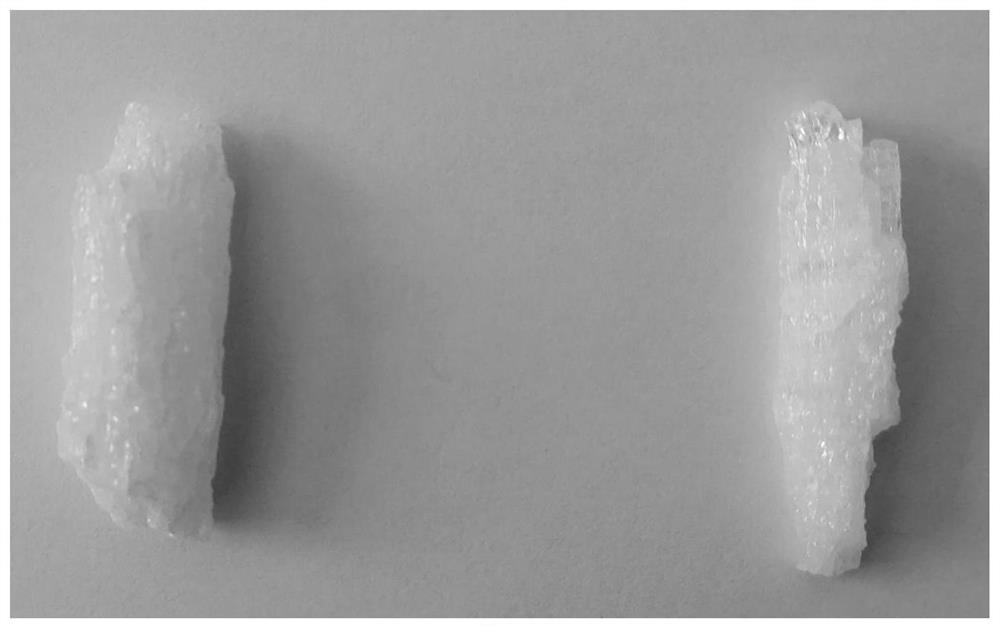

Hot-dip galvanizing method for obtaining colored plating on flat steel

The invention discloses a hot-dip galvanizing method for obtaining colored plating on flat steel. The method comprises the following steps of preparing alloy plating solution with special element proportion, placing the flat steel subjected to the surface pre-treatment in the hot plating solution at the rate of 0.01 m / s-0.03 m / s, carrying out immersion plating at the temperature of 430-560 DEG C for 0.5 min-10 min, taking out the flat steel from zinc liquid at the same rate, and carrying out air cooling and water cooling so as to obtain the colored coating which is uniform and single in color,good in surface smoothness and free of mixed color. According to the method, the steel can be divided into thin flat steel and thick flat steel according to the thickness of the steel, characteristics of a steel structure are fully analyzed, and technological parameters such as the immersion and leaching rate and the immersion plating temperature are regulated and controlled; the colored platingobtained through the colored hot-dip galvanizing carried out on the flat steep with different thickness and width is uniform in thickness, is stronger than that obtained through colored coating technology in terms of corrosion resistance and weather resistance, is stronger than that obtained through colored passivation technology in terms of adhesion and wear resistance, and is far higher than that obtained through original colored hot-dip galvanizing technology in terms of color uniformity; and the method is simple in process, easy to control, high in manufacturability, low in cost and wide in industrial popularization prospect.

Owner:NORTHEASTERN UNIV

L-ascorbyl palmitate and environment-friendly synthetic method thereof

The invention relates to L-ascorbyl palmitate and an environment-friendly synthetic method thereof. The environment-friendly synthetic method comprises the following steps: dissolving palmitic acid and dicyclohexylcarbodiimide in N,N-dimethylformamide, adding L-ascorbic acid to perform esterification reaction; adding N-hydroxysuccinimide, stirring and filtering to obtain a crude product; dissolving the prepared crude product in ethyl acetate and performing recrystalization to obtain L-ascorbyl palmitate. The synthetic method of L-ascorbyl palmitate is simple in technology, does not need concentrated sulfuric acid as a catalyst during production, helps to substantially reduce requirements on reaction containers, reaction conditions and the like, is mild in reaction conditions and low in production cost, does not generate strong acid and other waste liquids discharge, and has no pollution to environment. Produced L-ascorbyl palmitate has the impurity up to 98% or more, has no mixed color and is high in quality.

Owner:东莞市感恩食品科技有限公司

Preparation method of salicylamide

InactiveCN106518704AHigh purityReduce generationOrganic compound preparationCarboxylic acid amides preparationCentrifugationReaction temperature

The invention provides a preparation method of salicylamide and belongs to the field of fine chemicals. The preparation method is characterized by comprising the following steps that under normal pressure, methyl salicylate and a buffer solution are added into a reaction bottle according to the weight ratio being 1:2-4, the temperature is increased to 30-60 DEG C, ammonia gas is introduced continuously to conduct an amidation reaction, the reaction temperature is controlled to be 40-60 DEG C, the ammonia gas is stopped being introduced after the reaction is conducted for 1 hour, the temperature is decreased to 20-25 DEG C through cooling, centrifugation and drying are conducted, and the salicylamide is obtained. By the adoption of the preparation method, the hydrolysis side reaction of methyl salicylate is effectively reduced, the prepared salicylamide is high in yield, easy to separate, high in purity and free of mixed color in appearance, and the preparation method is low in cost and environmentally friendly.

Owner:禹城禹圳生物科技有限公司

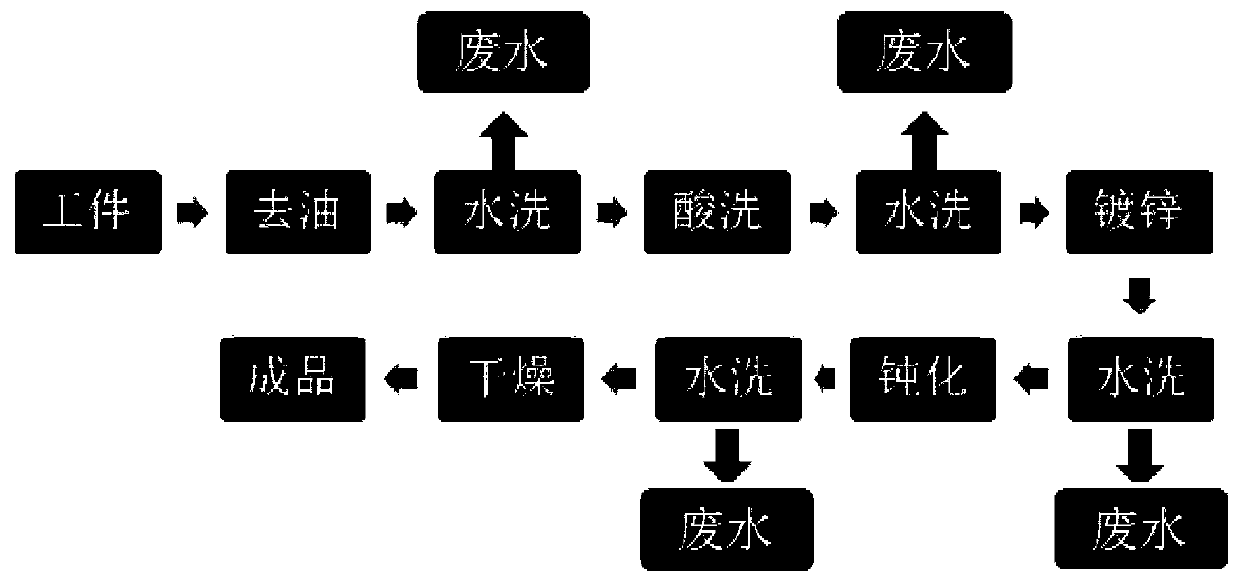

Titanium product anodic oxidation coloring method

ActiveCN111118575ABright colorUniform colorSurface reaction electrolytic coatingElectrolysisPhosphate

The invention relates to the field of anodic oxidation of metal surface treatment, in particular to a titanium product anodic oxidation coloring method which comprises the following steps: pretreatment: putting a titanium product in soda-wash solution under 75-85 DEG C ultrasonic condition for soda-wash oil removal; anodic oxidation: putting the titanium product treated in S1 in acid pickling solution for acid pickling treatment, then, adopting deionized water for flushing, putting in anodic oxidation solution for electrolytic treatment, wherein the anodic oxidation solution comprises dibasicsodium phosphate, sulfuric acid, potassium permanganate, ammonium fluoride and the balance of distilled water; and follow-up treatment: putting the titanium product after anodic oxidation coloring treatment in boiling water, carrying out ultrasonic vibration cleaning and sealing, taking the titanium product out, and drying the titanium product to obtain the colored titanium product. With adoptionof the titanium product anodic oxidation coloring method, the problems in the prior art that the surface of an oxidation film obtained through the traditional titanium alloy anodic oxidation technology is likely to be polluted, the color is likely to change after fingerprint pollution, and the polluted oxidation film is difficult to recover to seriously affect the decoration effect are solved.

Owner:西安庄信新材料科技有限公司

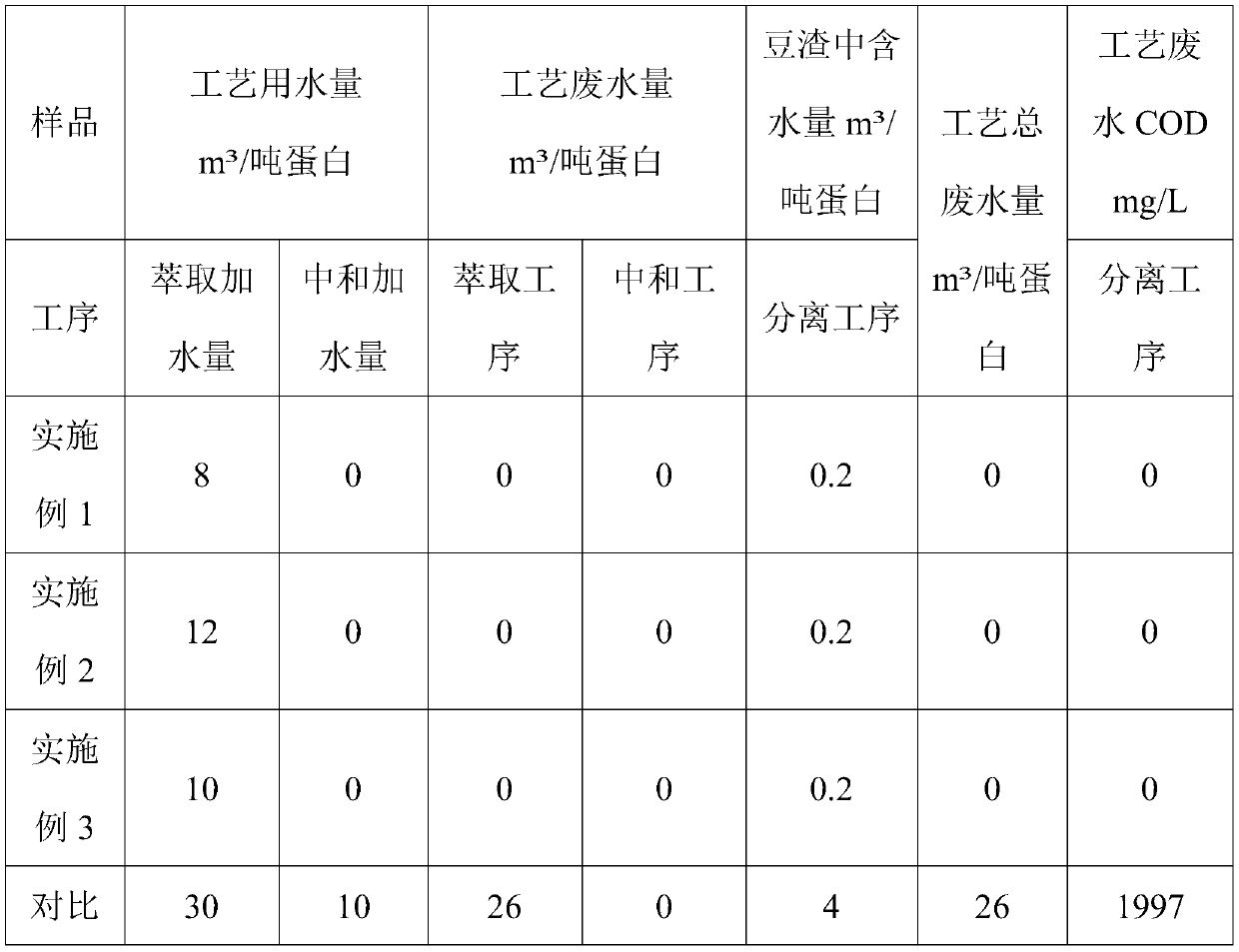

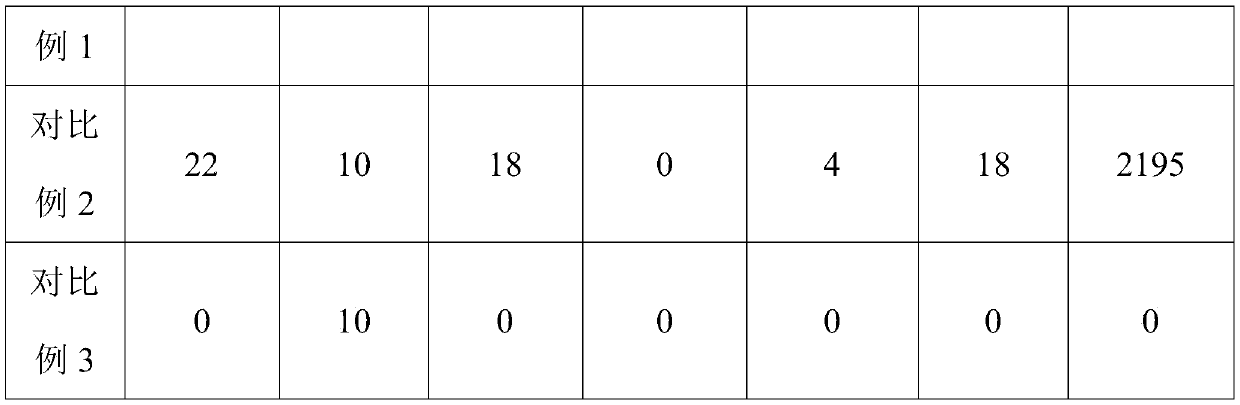

Extraction method of isolated vegetable protein

ActiveCN111233971AHigh in proteinEfficient killingFood processingPeptide preparation methodsBiotechnologyProtein solution

The invention discloses an extraction method of isolated vegetable protein. The method comprises steps as follows: (1), vegetable meal after being degreased at a low temperature is soaked with an alcoholic solution; (2), after a mixed solution obtained in step (1) is subjected to solid-liquid separation, solid matter is obtained, and water is added to the solid matter for extraction; and (3), extract liquor obtained in step (2) is centrifuged, a protein solution is obtained, and the isolated vegetable protein is obtained after the protein solution is sterilized and dried. According to the extraction method of the isolated vegetable protein, pigments and various lipids in the vegetable meal can be removed by adopting an ethanol and water combination mode, so that a final product is free ofmixed color and has no fishy smell, and the obtained isolated vegetable protein has high protein content. Besides, the whole process is lower in water consumption, water is required to be added only in an extraction process, the water can be removed from the product by evaporation in a product drying process, no waste water is produced, and the method is environmentally friendly.

Owner:北京杰英众汇科技有限公司

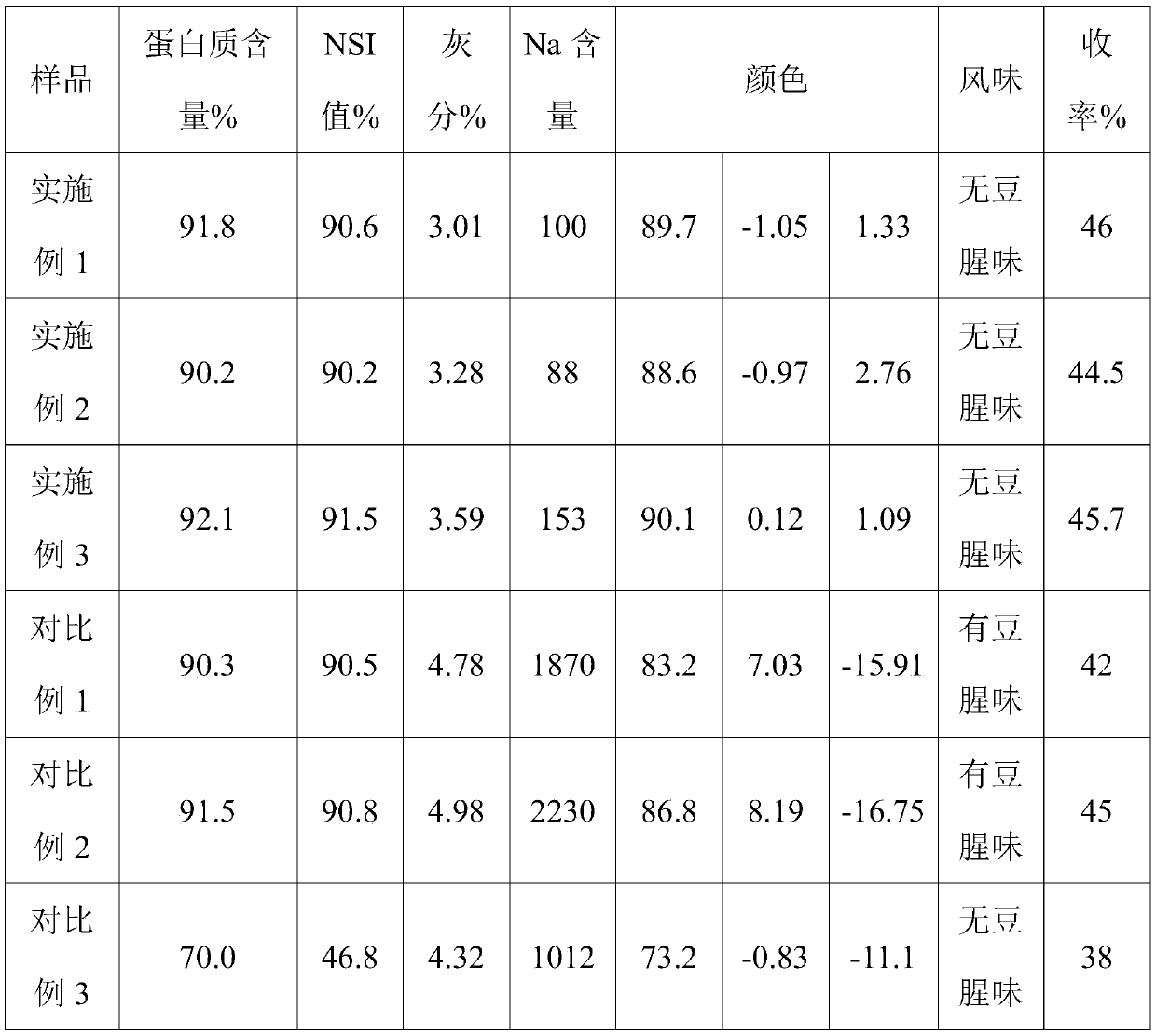

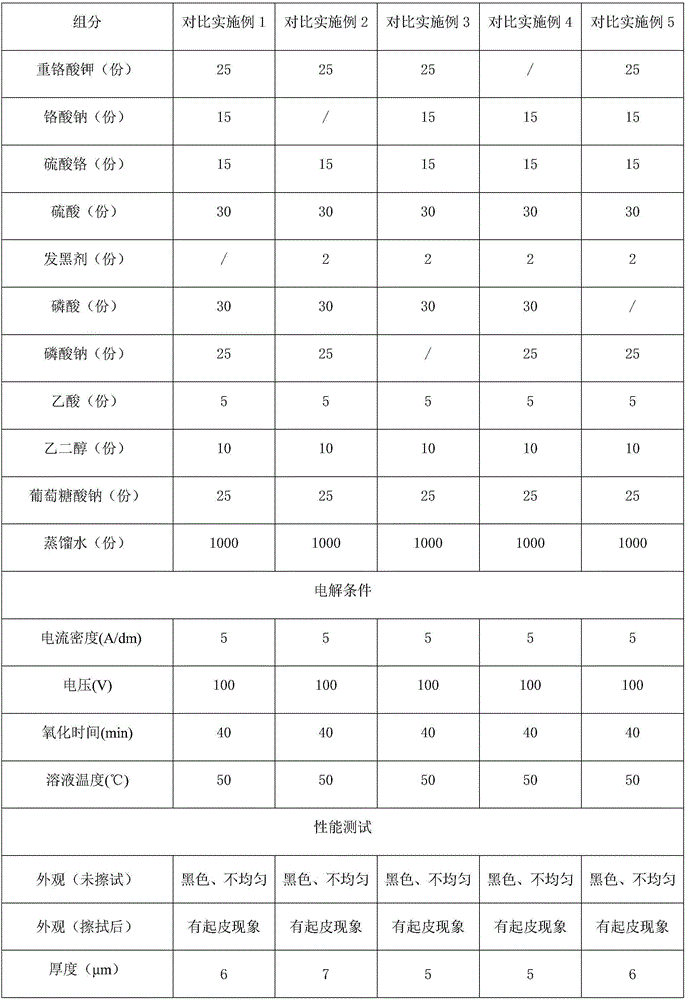

Anodizing coloring method for titanium-magnesium alloy

ActiveCN106835238AEasy maintenanceImprove bindingSurface reaction electrolytic coatingPhosphatePhosphoric acid

The invention discloses an anodizing coloring method for a titanium-magnesium alloy. The method comprises steps as follows: (1), pretreatment; (2), anodizing: an anodizing solution is prepared from 20-60 parts by weight of potassium dichromate, 10-30 parts by weight of chromate, 10-20 parts by weight of sulfate, 10-50 parts by weight of sulfuric acid, 2-4 parts by weight of a blackening solution, 25-40 parts by weight of phosphoric acid, 20-40 parts by weight of phosphate, 1-10 parts by weight of acetic acid, 10-20 parts by weight of ethylene glycol, 15-30 parts by weight of sodium gluconate and 700-1,000 parts by weight of distilled water through mixing, a sample is taken as a working electrode, graphite is taken as an auxiliary electrode, the working electrode and the auxiliary electrode are completely soaked in the anodizing solution for anodizing; (3), follow-up treatment. The method is simple and easy, oxidation films with different thicknesses and good compactness can be obtained by controlling different voltage values, pH values of the anodizing solution and power-on time, and the market requirement of anodizing for metal surface treatment is met.

Owner:FOSHAN KEITH TITANIUM TECH CO LTD

Cutting and seedling raising method for hydrangea macrophylla

InactiveCN109197486ANutrient Structure BalanceReasonable amount of fertilizationFlowers cultivationGrowth substratesFertilizerCarbendazim

The invention belongs to the technical field of planting, and discloses a cutting and seedling raising method for hydrangea macrophylla. The method comprises the steps of (1) planting a hydrangea macrophylla maternal plant in a cultivation matrix, spraying a nutrient solution, and timely watering; (2) picking cutting slips after the hydrangea macrophylla maternal plant grows for 10-20 days in thecultivation matrix, and cutting the cutting slips into cutting branches with the length being 3-5cm; (3) placing a cutting matrix in a 72-hole tray, soaking the cutting branches in a rooting solutionfor 1-3min, then cutting the cutting branches into the cutting matrix, profoundly watering immediately, profoundly spraying the cutting slips with carbendazim, placing the cutting slips in a greenhouse, setting a sunshade above the seedbed for shading, spraying water timely, spraying a foliar fertilizer 10 days after cutting, and then spraying the foliar fertilizer every 10-15 days after wateringuntil obtaining rooted hydrangea macrophylla seedlings. The cutting and seedling raising method is simple to operate and high in propagation speed, the survival rate of hydrangea macrophylla cutting propagation reaches up to 98% or above, and the cutting and seedling raising method can be applied to large-scale production.

Owner:云南鑫源花卉种植有限公司

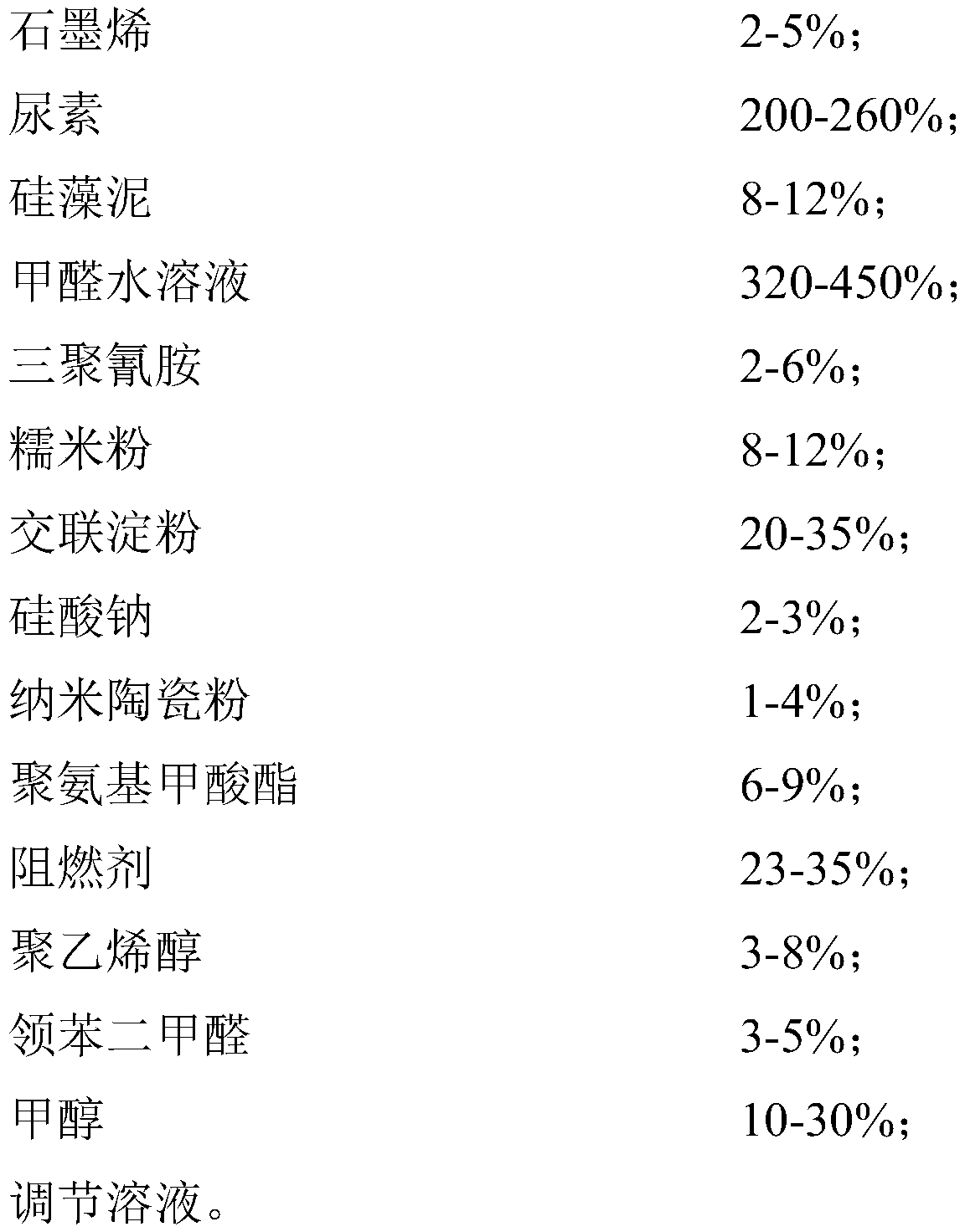

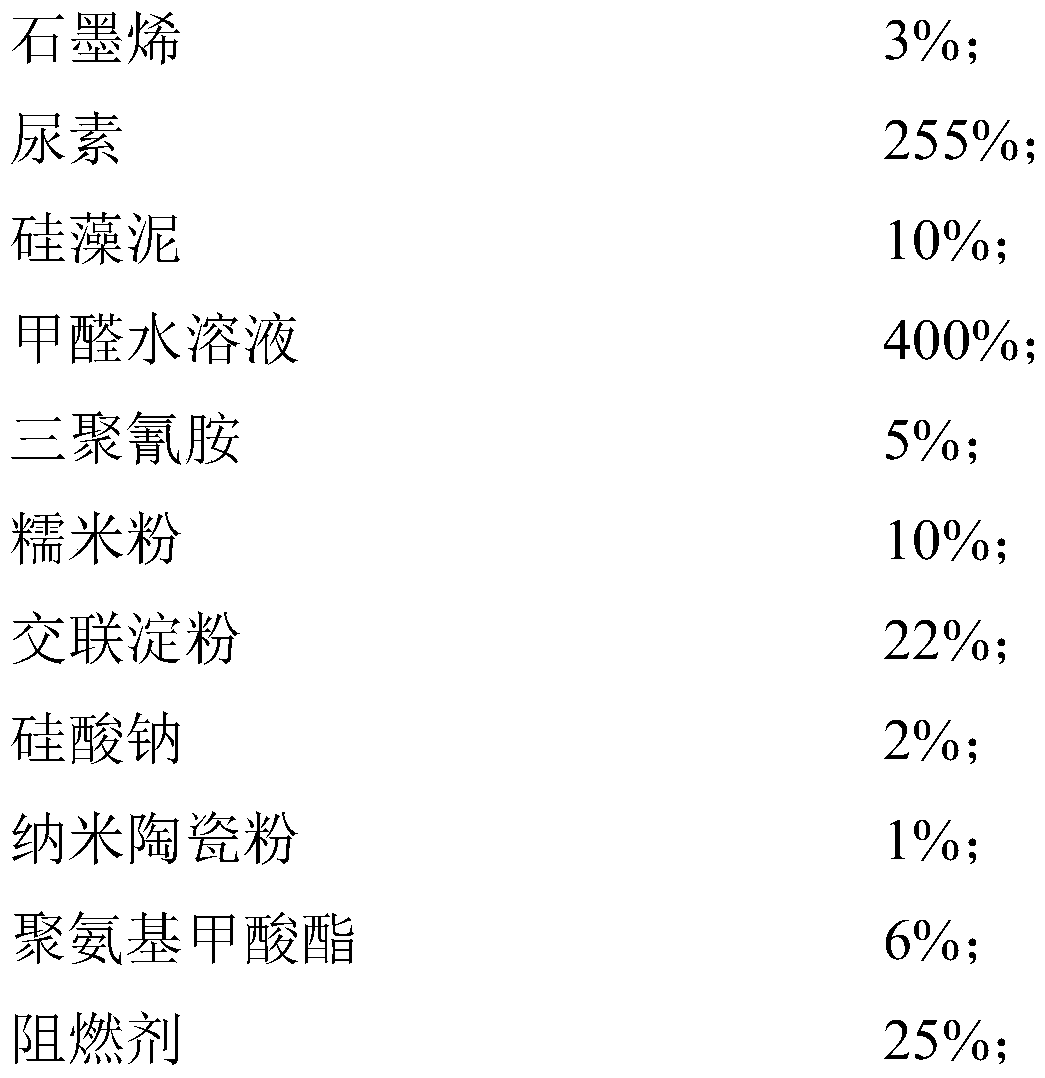

Modified flame-retardant urea-formaldehyde resin adhesive for producing artificial boards and preparation method of same

InactiveCN110128981AStir wellHigh transparencyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkPolyvinyl alcohol

The invention discloses a modified flame-retardant urea-formaldehyde resin adhesive for producing artificial boards and a preparation method of same. The resin glue comprises 2-5% of graphene, 200-260% of urea, 8-12% of diatom ooze, 320-450% of a formaldehyde aqueous solution, 2-6% of melamine, 8-12% of glutinous rice flour, 20-35% of cross-linked starch, 2-3% of sodium silicate, 1-4% of nano ceramic powder, 6-9% of polyurethane, 23-35% of a flame retardant, 3-8% of polyvinyl alcohol, 3-5% of o-phthalaldehyde, 10-30% of methanol and a regulation solution. The adhesive property of the resin adhesive is improved, the product is environmentally friendly, the comprehensive property is improved, free formaldehyde is reduced, the adhesive solution stability is high, the transparency of the adhesive solution is high, no mixed color exists, and the weather resistance is excellent.

Owner:河南森远科技有限公司

Production method of light yellow quartz glass tube

The invention discloses a production method of a light yellow quartz glass tube. The production method comprises the following steps: (S1) taking a quartzite raw material containing over 99% of SiO2 and lower than 20ppm of impurities, and breaking the quartzite raw material to obtain a quartzite material of 50-70 meshes; and (S2) transferring the quartzite in the step (S1) into a flushing tank for primary cleaning, flushing off the sediment, and airing the flushed quartzite material; and adding sodium nitrate and potassium nitrate in a ratio of 1:2 into the quartzite material and stirring to obtain a quartzite mixed material. According to the invention, a solution A is prepared by adding hydrochloric acid into europium oxide, vanadium pentoxide, yttrium oxide, praseodymium oxide and lanthanum oxide in (S5); a solution B is prepared by adding water into sodium nitrate and ammonium metavanadate; and the solution A and solution B are mixed and roasted with the quartzite material, the quartzite material is fully colored, mixed color is avoided, and a quartz glass tube with high-purity color can be obtained.

Owner:连云港市盛昌照明电器有限公司

A smearing type ceramic surface sintered silver paste and preparation method thereof

The invention discloses spread ceramic surface sintered silver paste, which comprises the following components in parts by weight: 45 to 55 parts of silver powder, 2 to 3 parts of sodium alginate, 2 to 3 parts of glass powder, 15 to 20 parts of polyethylene glycol, 5 to 8 parts of sucrose isobutyrate, 1 to 2 parts of an abietic acid, 3 to 5 parts of terpenic oil and 20 to 25 parts of water. A preparation method comprises the following steps: adding the silver powder into the water, adding the sodium alginate and the polyethylene glycol with stirring at 200 to 300rpm, and continuing stirring for 15 to 20min to obtain a solution A; dissolving the abietic acid into the terpenic oil, adding the sucrose isobutyrate, and performing uniform stirring to obtain a solution B; adding the solution B into the solution A, and performing stirring for 1 to 2h at 500 to 600rpm. According to the silver paste, the raw materials are readily available, a preparation process is simple, the silver paste is relatively low in cost, free of heavy metals, safe in use, green and environment-friendly, and no harmful gas is generated during sintering.

Owner:河北银瓷天成文化传播有限公司

A hot-dip galvanizing method for obtaining colored coating on flat steel

ActiveCN110318015BImprove uniformityImprove yieldHot-dipping/immersion processesSurface finishWeather resistance

The present invention is a hot-dip galvanizing method for obtaining colored coatings on flat steel materials. The steps are: preparing a special element ratio alloy plating bath, and placing the surface-pretreated flat steel materials into the hot-dip galvanizing bath at a rate of 0.01 to 0.03m / s. Medium, dip plating at 430~560°C for 0.5~10 minutes, take it out from the zinc liquid at the same rate, and stop air and water cooling to obtain a colored coating with uniform and single color, good surface finish, and no variegation. This method is divided into flat thin steel and thick steel according to the thickness of the steel. It fully analyzes the structural characteristics of the steel, controls the immersion and leaching rate, immersion plating temperature and other process parameters, and performs color hot plating on flat steel with different thicknesses and widths to obtain uniform coating thickness. The corrosion resistance and weather resistance of the coating are stronger than those of color coating technology, the adhesion and wear resistance of the coating are stronger than those of color passivation technology, and the color uniformity is much higher than that of the color coating of the original color hot-dip galvanizing technology. The process is simple, easy to control, strong in craftsmanship, low in cost, and has broad industrial promotion prospects.

Owner:NORTHEASTERN UNIV LIAONING

Preparation method of high-purity aluminum oxide for sapphire

PendingCN113292089AHigh purityReduce carbon residueAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxide/hydroxide preparationMineralogySapphire

The invention provides a preparation method of high-purity aluminum oxide for sapphire, and belongs to the technical field of preparation of inorganic functional materials. According to the method, residual organic carbon is oxidized into carbon dioxide at high temperature by using the carbon removal agent and utilizing the strong oxidation effect or auxiliary oxidation effect of the carbon removal agent, so that the residual carbon content in aluminum oxide prepared by the aluminum alcoholization method is reduced, and the problem that sapphire prepared from high-purity aluminum oxide prepared by the aluminum alcoholization method is faint yellow and even brown and cannot be used as a photoelectric device is solved. The result of the embodiment shows that the residual carbon content of the prepared aluminum oxide is less than 0.001 wt.%, the purity is higher than 99.99%, and when the high-purity aluminum oxide prepared by the method is used for producing sapphire, mixed colors are avoided, and the requirement for growing sapphire single crystals is met.

Owner:山东惠远科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com