Processing method of recombined braised tofu with seafood

A processing method and tofu technology, applied in the field of food science, can solve problems such as unsatisfactory, single variety, and lack of functionality, and achieve the effect of preventing oxidation and loss and extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

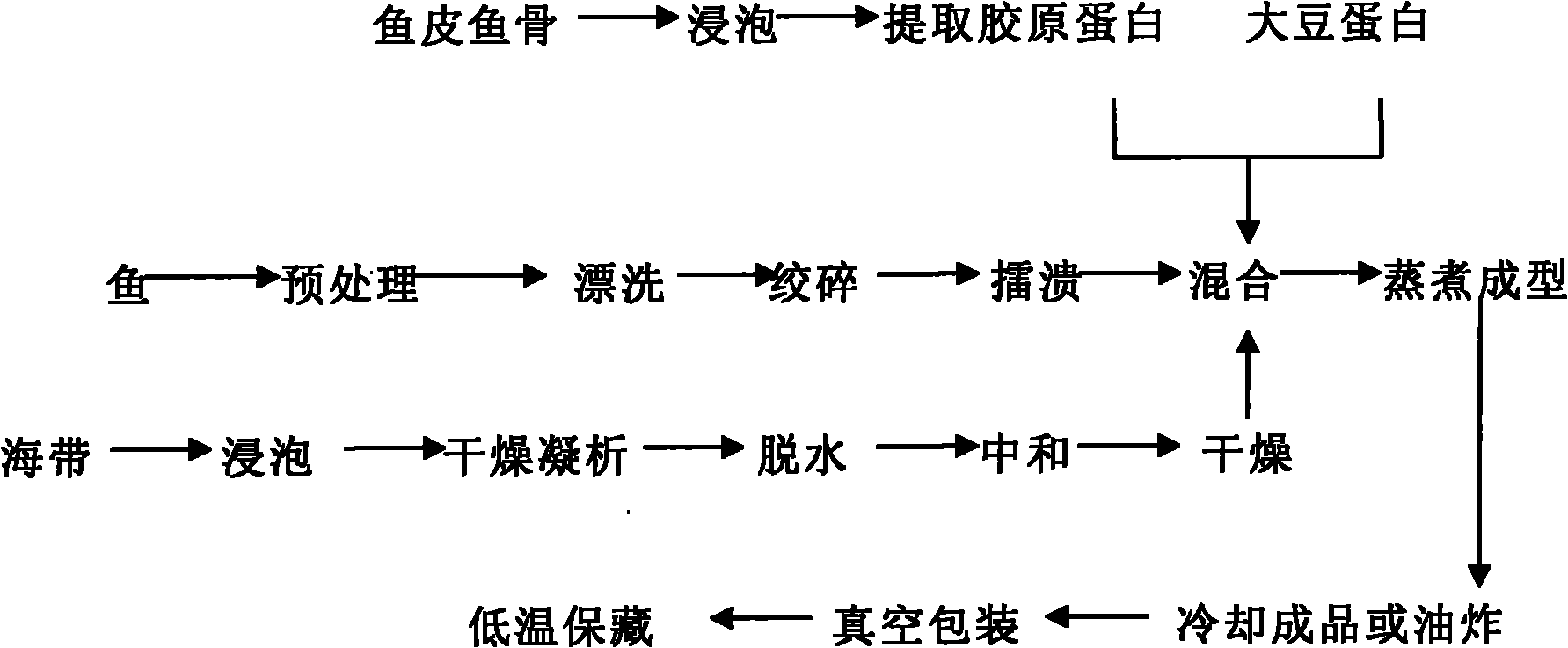

Method used

Image

Examples

example 1

[0030] 1. Remove the head, tail and viscera of fresh or thawed freshwater fish, and then separate the flesh from the skin, bones and bones.

[0031] 2. Under the condition of 10°C, mix and wash the fish meat with 5‰NaCl solution at a mass ratio of 1:5, and rinse twice, each time for 10-20 minutes.

[0032] 3. Crush the rinsed fish meat, put it into the crushing machine, enter one part to destroy the fish meat tissue, and the time is about 5 minutes; then add 2% to 2.5% salt to the minced fish and continue to crush until the minced fish becomes sticky Thicken, the time is about 15 minutes; finally seasoning and crushing, add 6% sugar, 10% potato starch and other auxiliary materials in proportion to the surimi, the time is about 15 minutes.

[0033] 4. Chop the cleaned kelp and then soak for 6-12h, NaCO 3 Transformation, alcohol precipitation and drying process to make kelp glue; fish skin fish bone collagen is washed with 1% to 5% salt water, and then the collagen is extracted...

example 2

[0037] 1. Remove the head, tail and viscera of the thawed freshwater fish, and then separate the fish meat from the skin, bones and bones.

[0038] 2. Under the condition of 10°C, mix and wash the fish meat with 5‰NaCl solution at a mass ratio of 1:5, and rinse twice, each time for 10-20 minutes.

[0039] 3. Crush the rinsed fish meat, put it into the crushing machine, enter one part to destroy the fish meat tissue, and the time is 5 minutes; then add appropriate amount of salt to the fish paste and continue to crush until the fish paste becomes sticky, the time is 15 minutes ;Finally, seasoning and grinding, adding sugar, starch, protein and other auxiliary materials to the surimi in proportion, for 15 minutes.

[0040] 4. Chop the cleaned kelp and then soak for 6-12h, NaCO 3Transformation, alcohol precipitation, and drying processes to make kelp glue; wash the fish skin and fish bone collagen with 1%-5% salt water, then remove fat, remove impurities, enzymatic hydrolysis, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com