Patents

Literature

2132 results about "Seasoning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seasoning is the process of treating the surface of a cooking vessel with heated fat in order to produce a corrosion-resistant and stick-resistant coating. Seasoning is required on cast-iron cookware and carbon steel, which rust rapidly when heated in the presence of available oxygen, notably from water, even small quantities such as drippings from dry meat. Food tends to stick to unseasoned iron and carbon steel cookware, both of which are seasoned for this reason as well. Some cast-iron cookware comes from the manufacturer pre-seasoned; most requires the user to season it.

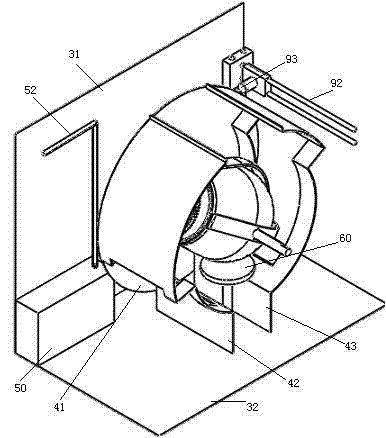

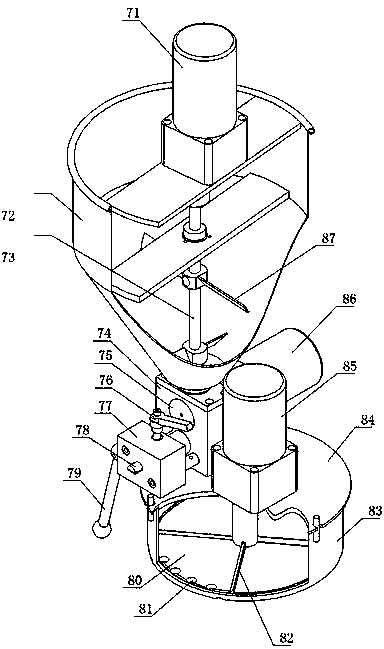

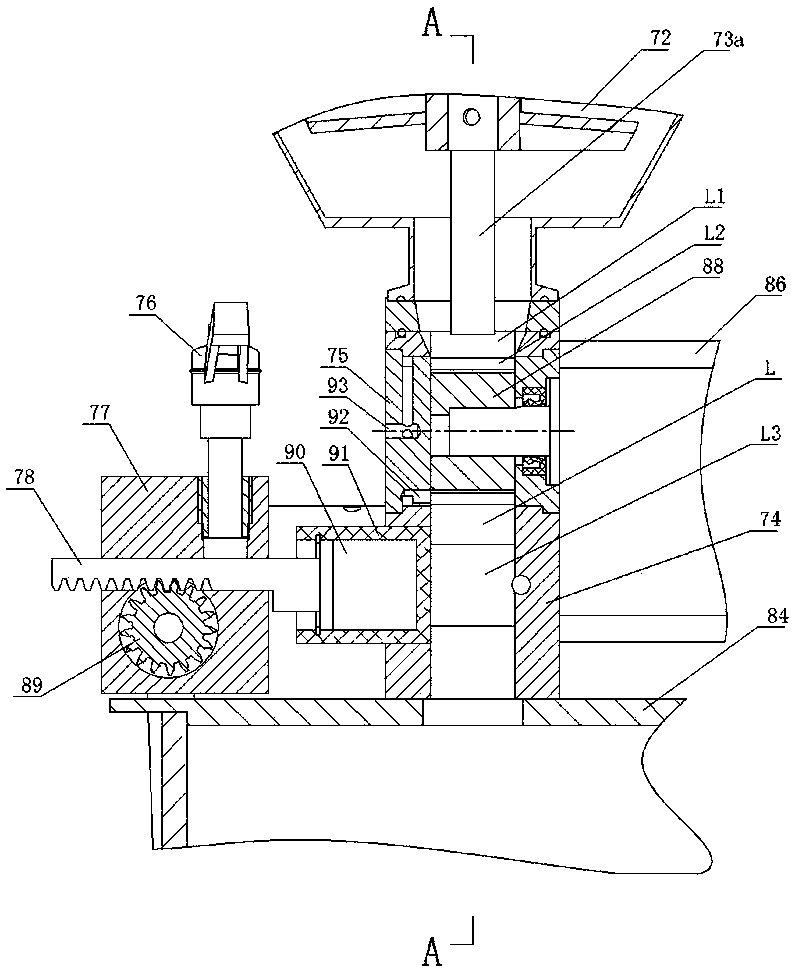

Automatic cooking machine

InactiveCN102813445AAutomatic quantitative addition solutionCooking vesselsControl systemEngineering

The invention relates to an intelligent kitchen device, in particular to an automatic cooking machine which is provided with a pot body with a spherical bottom and a cylindrical rotary body with a closing-up opening. The automatic cooking machine is provided with a mechanism capable of automatically feeding main materials, auxiliary materials and special seasonings, a rotary mechanism capable of simulating cooking, an automatic seasoning feeding device and a cleaning mechanism. The mechanisms are controlled by a control system through a power device in an unified mode, and each link of automatic cooking can be completed by means of ordination of the mechanisms.

Owner:宫超

Method for producing instant straw mushroom chips by adopting vacuum low-temperature dehydration technology

ActiveCN102406161AEfficient crushingIncrease penetration rateFood preparationUltrasonic assistedSulfur

The invention discloses a method for producing instant straw mushroom chips by adopting a vacuum low-temperature dehydration technology, and belongs to the technical field of deep processing of agricultural products. The method for producing the instant straw mushroom chips comprises the following main processes of: performing pretreatments such as conventional picking, cleaning, segmenting, blanching, non-sulfur color protecting, ultrasonic aid impregnating, sodium alginate film coating and the like on fresh straw mushrooms, and then, performing hot air and vacuum frying combined dehydrating, centrifugal oil removing, seasoning and packing. By adopting the new processes of non-sulfur color protecting, ultrasonic aid impregnating, sodium alginate film coating and hot air and vacuum fryingcombined dehydrating, the oil content of the product is remarkably reduced while the sensory quality of the product is improved and the impregnating efficiency is increased. In the method, necessary freezing treatment in the conventional fruit and vegetable chip frying process is not needed, so that the processing time is greatly reduced, and the production period of the product is effectively shortened. The product obtained by using the method has the characteristics of high puffing rate, low oil content, good sensory quality and the like; and a feasible new path is provided for deep processing utilization of the straw mushrooms.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

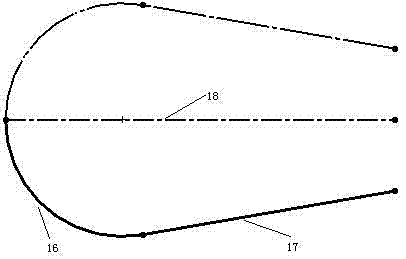

Vegetable protein meat analogues and methods of making the same

Meat analogue products and methods of making these products are provided. The products are made from compositions comprising a mixture of ingredients, including a vegetable protein, a dough conditioner, and less than about 25% by weight flour. These compositions can optionally further comprise: thermally-preformed, texturized, protein components; oils and / or fats; flavors; spices; seasoning; colors; acids; and preservatives. These products can be provided in a log or slab formation and cut into dices, slices, cubes or any other desired geometry, and packaged and / or further processed as necessary (e.g., added to pizza products). Novel methods for the continuous manufacture of these products using a forming heat exchanger are also provided. This continuous process provides casingless food products analogous to meat products such as pepperoni.

Owner:KERRY GRP SERVICES INT

Seasoned food, seasoning, and method for seasoning a food product

InactiveUS20080008790A1Reduce amountDesirable flavorMeat/fish preservationFruit and vegetables preservationFood productsChemistry

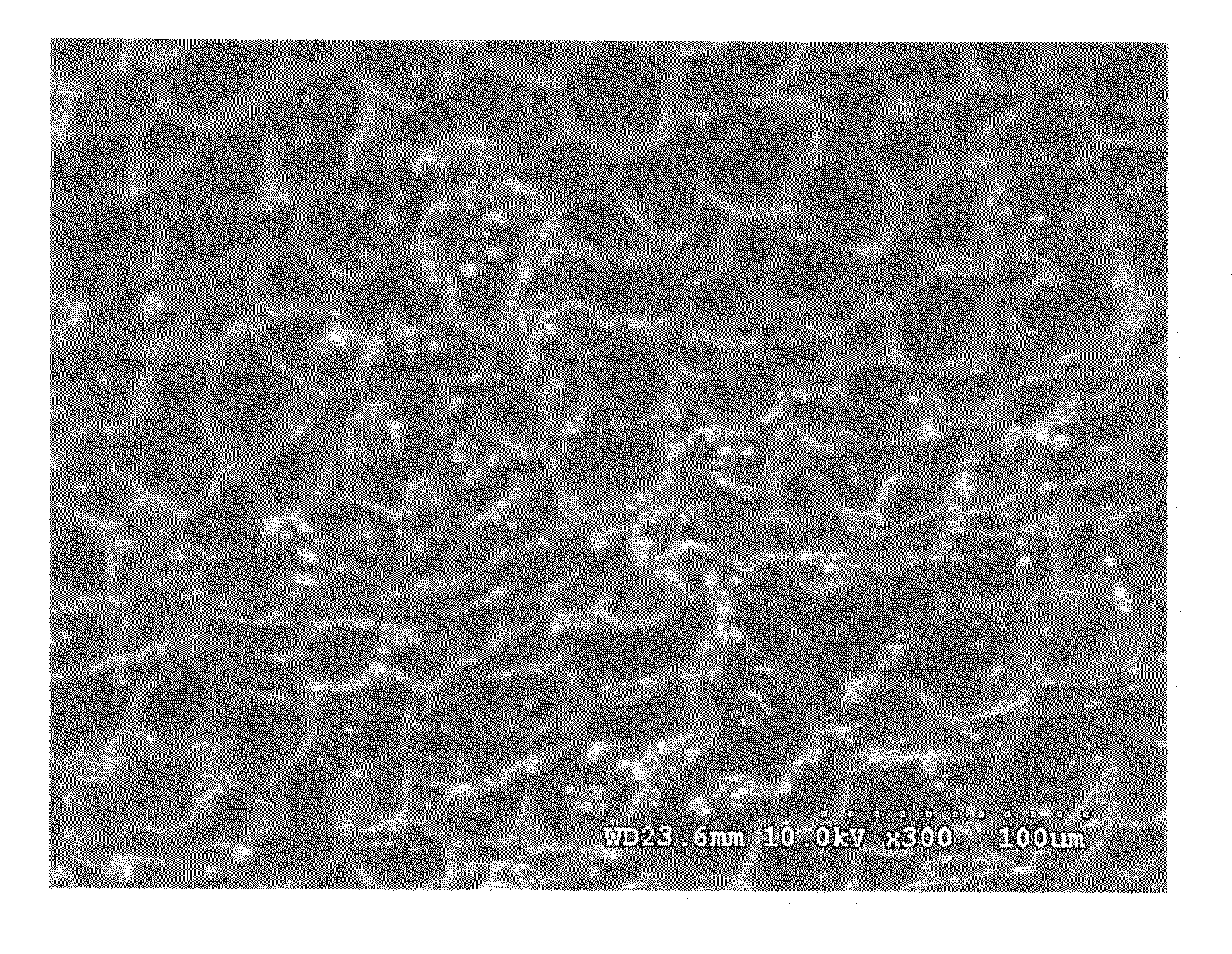

A seasoned food product, a seasoning, and a method for seasoning and / or preserving a food product is described in accordance with exemplary embodiments of the present invention. The charge of seasoning has a mean particle size of at least approximately less than 20 microns. In another embodiment, the present invention is a seasoning comprising a first seasoning component including a salt and a second seasoning component selected for at least one of complementing the first seasoning component and reducing the amount of the first seasoning component required for flavoring a food product. The first seasoning component and second seasoning component have a mean particle size of at least approximately less than 20 microns.

Owner:CONAGRA FOODS RDM INC

Seasoning sauce and preparation method thereof

The invention relates to a seasoning sauce and a preparation method thereof. The seasoning sauce comprises main materials, auxiliary materials, seasonings and blend oil. The preparation method comprises the following steps: cooking the blend oil to 80 DEG C, putting 1 to 3 parts of dry chili powder into a pot, and constantly stirring in moderate heat for 10 seconds; adding fermented blank beans into the pot, and stirring for 20 seconds in moderate heat; putting cooked beef dices with bean size into the pot, and frying for 15 seconds in moderate heat; mixing powdered broad bean paste, pickled chilies and chopped chilies for 3-4 times, and constantly stirring in the pot with a scoop; putting 0.5 to 1.0 part of edible salt, 0.7 to 1.2 parts of monosodium glutamate, 1.0 to 1.2 parts of chicken essence powder, 0.2 to 0.5 part of concentrated chicken broth and 2.5 to 4.5 parts of white sugar into the pot for seasoning when the temperature is 80 DEG C; and putting the rest main materials simultaneously into the pot, cooking for 40 minutes, and cooling and packaging. The seasoning sauce has the beneficial effects of transparent and bright color, pure and rich flavor and emphasized freshness, is suitable for cooked wheaten foods, rice, rice noodles, coarse cereals and the like, can be particularly used for cooking, household and business trip, can be presented for friends, and is convenient to carry.

Owner:李建峰

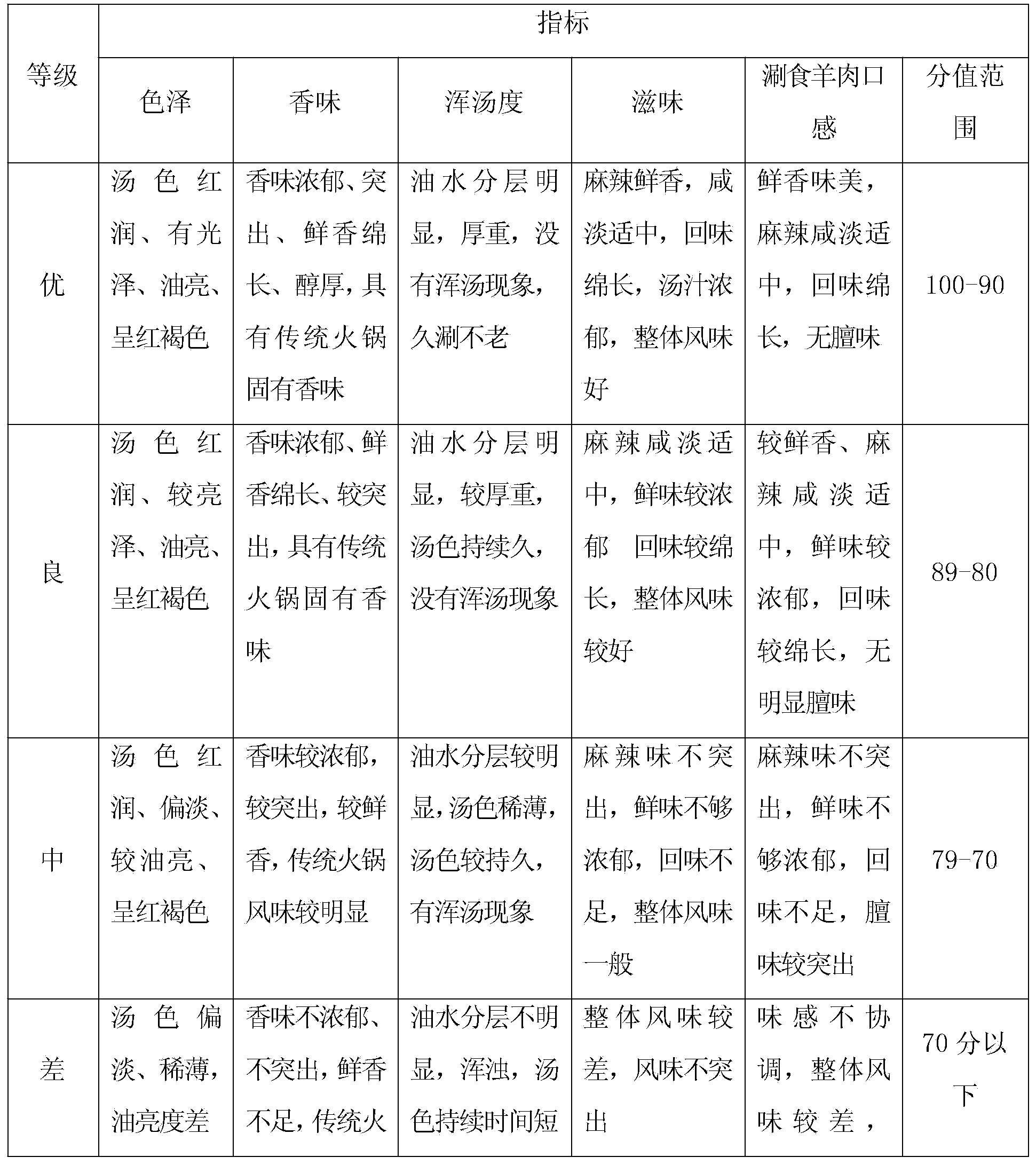

Slag-free hotpot condiment and preparation method thereof

ActiveCN103637154AIncrease fruit and vegetable nutritionPromote dissolutionFood preparationFood flavoringsSlag

The invention discloses a slag-free hotpot condiment and a preparation method thereof, and belongs to the field of food seasonings. The slag-free hotpot condiment is prepared from an oil bag, a seasoning bag and a composite chili oil bag in the mass ratio is (16-20):(1-6):(2-3), wherein the oil bag is prepared in the following steps: particularly adding 15 to 35 parts of fermented chili paste, 1 to 10 parts of pickle paste, 1 to 5 parts of pickle fermentation liquor, 1 to 10 parts of medlar juice, 1 to 20 parts of Chinese date juice, edible fungus enzymatic hydrolysate and the like on the basis of the commonly used raw materials of the hotpot condiment, and adopting a method of stir-frying matched with heat-insulating dipping; the composite chili oil bag is prepared in the steps of: particularly adding chili enzymatic hydrolysate, pickle liquor and the like and frying, and then stewing and dipping. The prepared hotpot condiment is fresh, spicy and delicious, mellow in taste, long and sufficient in taste, and is extremely delicious when food materials with strong muttony and fishy smells, such as beef, mutton and the like are cooked; the oil bag, the seasoning bag and the composite chili oil bag are separately packaged, so that the slag-free hotpot condiment can be conveniently blended by people with different demands on the taste according to respective taste at any time.

Owner:宁夏红山河食品股份有限公司

Instant spiced shredded beef food

The invention discloses an instant spiced shredded beef food, which is prepared from the following raw materials in parts by weight: 100,000 parts of beef, 2300 parts of edible salt, 1800 parts of white sugar, 1500 parts of aginomoto and 50 parts of vitamin C, and is prepared from the following spiced ingredients in parts by weight: 3,000 parts of red oil, 500 parts of five-spice oil, 40 parts of ethyl maltol, 1500 parts of beef cream, 1500 parts of chicken cream, 60 parts of ginger oil, 60 parts of scallion oil, 500 parts of five spice powder and 2,0000 parts of spice water. The preparation method comprises the following steps: preparing fresh meat, tumbling, pickling, charging, marinating, frying with hot oil, mixing raw materials and seasoning; carrying out vacuum packing and sterilization treatment; and cleaning, treating, airing, cooling, inspecting and warehousing. The invention aims at providing the instant spiced shredded beef food. The beef is uniformly seasoned and pickled, is good in flavor and taste, moderate in taste, neither too hard, nor too soft, and easy to chew and eat; most fresh taste of beef is reserved; the color of the beef is close to normal color; no toner needs to be externally added; and the food is relatively healthy.

Owner:XINHUANG XIAOFEINIU FOOD

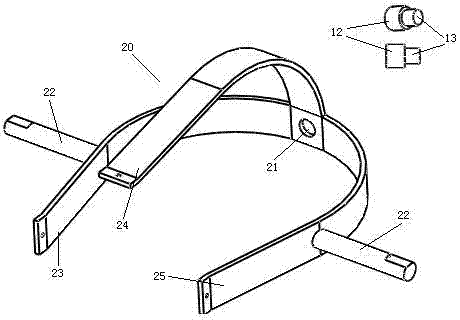

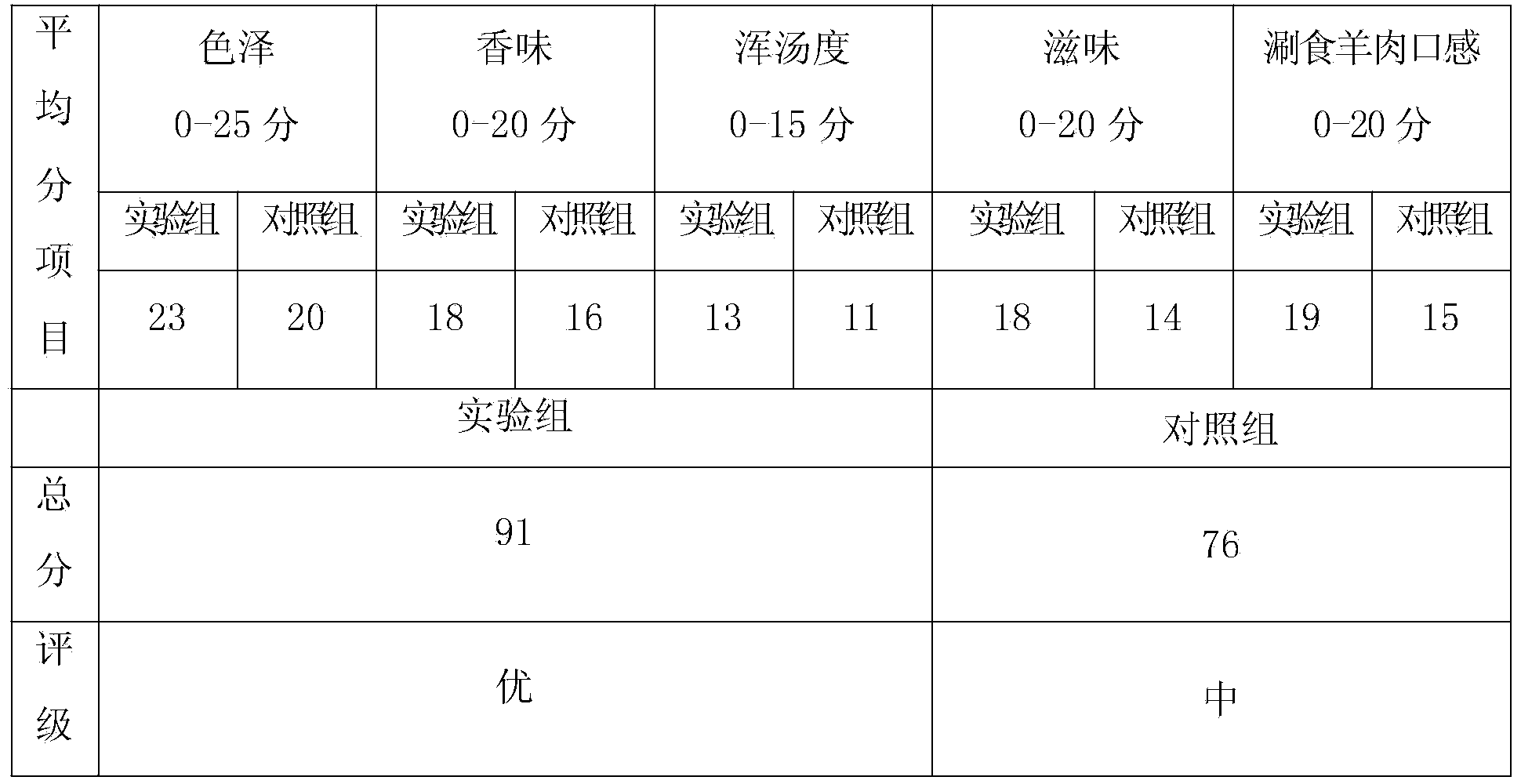

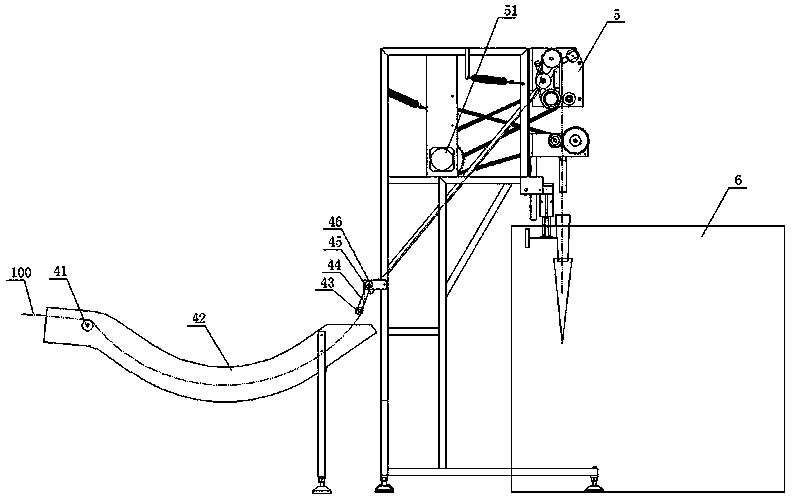

All-intelligent chef robot

ActiveCN105167567ASave human effortImprove cooking efficiencyCooking vesselsTableware washing/rinsing machinesProcess engineeringManipulator

The invention provides an all-intelligent chef robot and relates to a self-help cooking system. The purpose is to provide the all-intelligent chef robot which integrates functions of automatic food material taking, automatic washing and automatic cooking and the like. The all-intelligent chef robot comprises a food material storage area, a vegetable washing area, a seasoning storage area, a seasoning weighing area, a tableware storage area, a cooking area, a first mechanical hand, a second mechanical hand and a controller. A discharging port of the seasoning storage area is communicated with a feeding port of the seasoning weighing area. The operating range of the first mechanical hand covers the food material storage area, the vegetable washing area, the seasoning weighing area and the cooking area. The operating range of the second mechanical hand covers the tableware storage area and the cooking area. The controller is connected with the vegetable washing area, the seasoning weighing area and the cooking area, so as to control devices contained in each area to operate orderly. The controller is connected with the first mechanical hand and the second mechanical hand so as to control the two mechanical hands to operate orderly.

Owner:BEIJING ROC THEURGY TECH

Fish food and making method thereof

The invention discloses fish food and a making method thereof. The fish food is prepared by separately packaging fish meat as a main material, vegetables or fungi as auxiliary materials and seasonings and then putting all the materials into an outer package. The making method of the fish food comprises the following steps of: processing the main material, the auxiliary materials, the seasonings, and the like into semi-finished products in factories according to the cooking methods of dishes to ensure that the fish food is easier and more convenient to cook at home; and respectively packaging the main material, the auxiliary materials, the seasonings, and the like to achieve the purposes of long-term storage and market distribution to ensure that the fish food has the properties of food. The invention has the advantages that the names of products take the names of the dishes, and the products have the characteristics of the colors, the flavors, the tastes and the types of the dishes; complicated and difficult-to-master cooking technologies and various auxiliary materials and seasonings are subjected to factorial processing and production to ensure that the technologies and the materials are simpler, more standard and more convenient; and the dishes are scientifically and standardly matched and tightly packaged to ensure that the dishes are more nutrient and safer.

Owner:DALIAN POLYTECHNIC UNIVERSITY

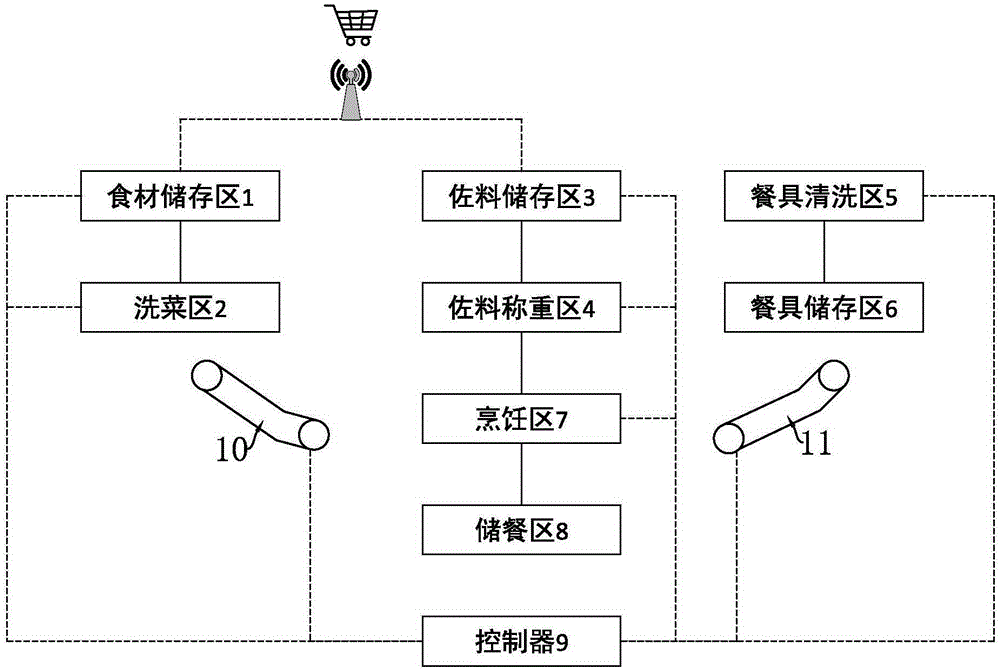

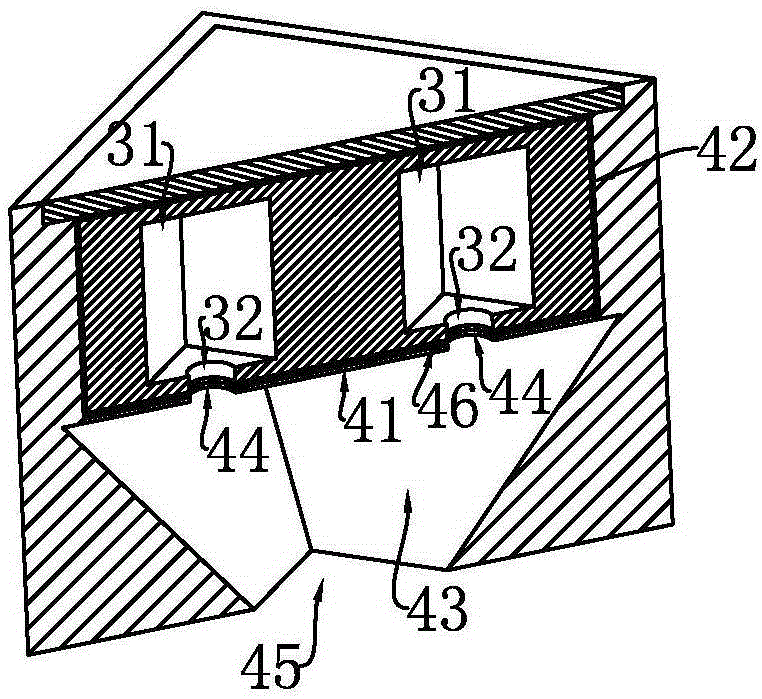

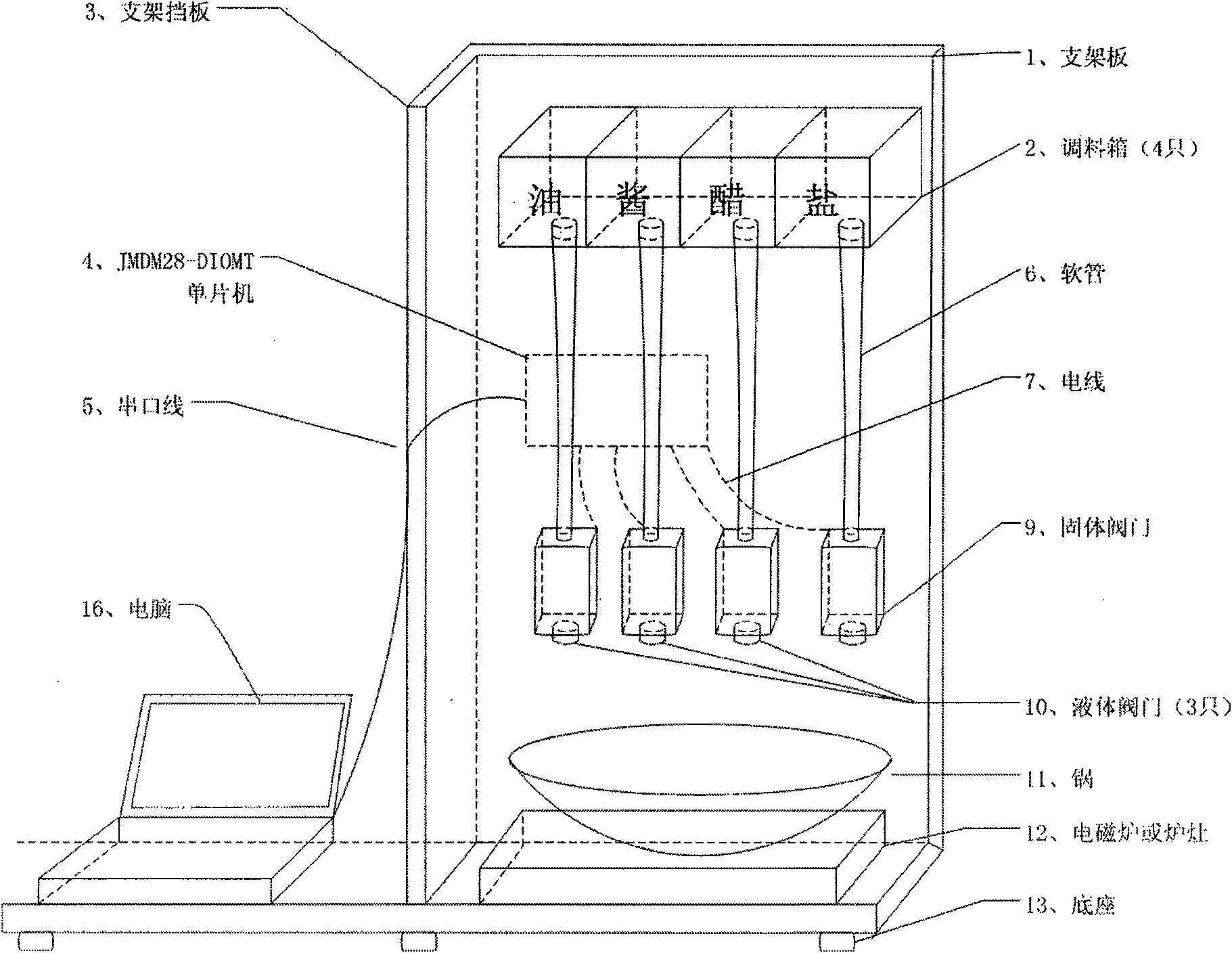

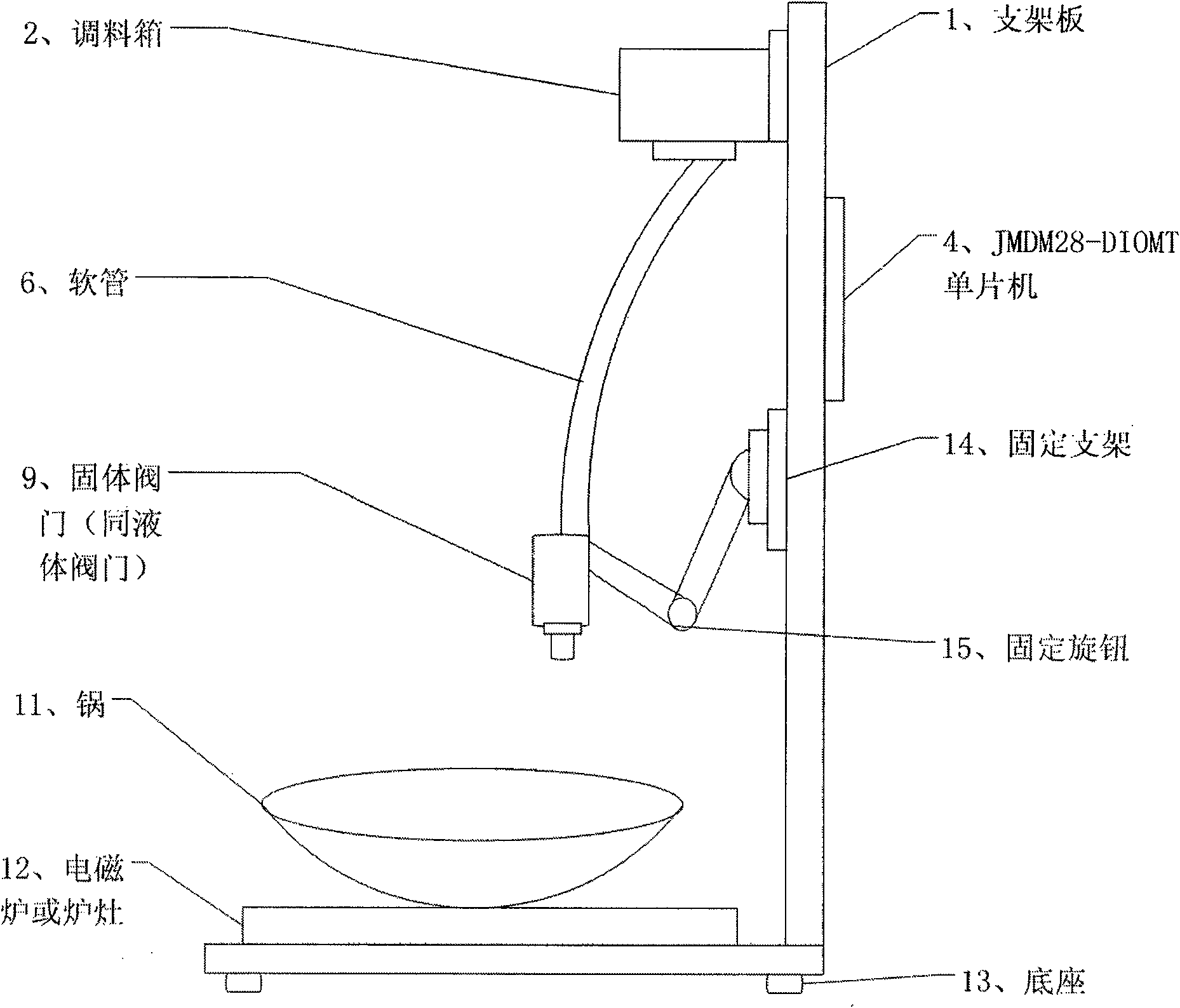

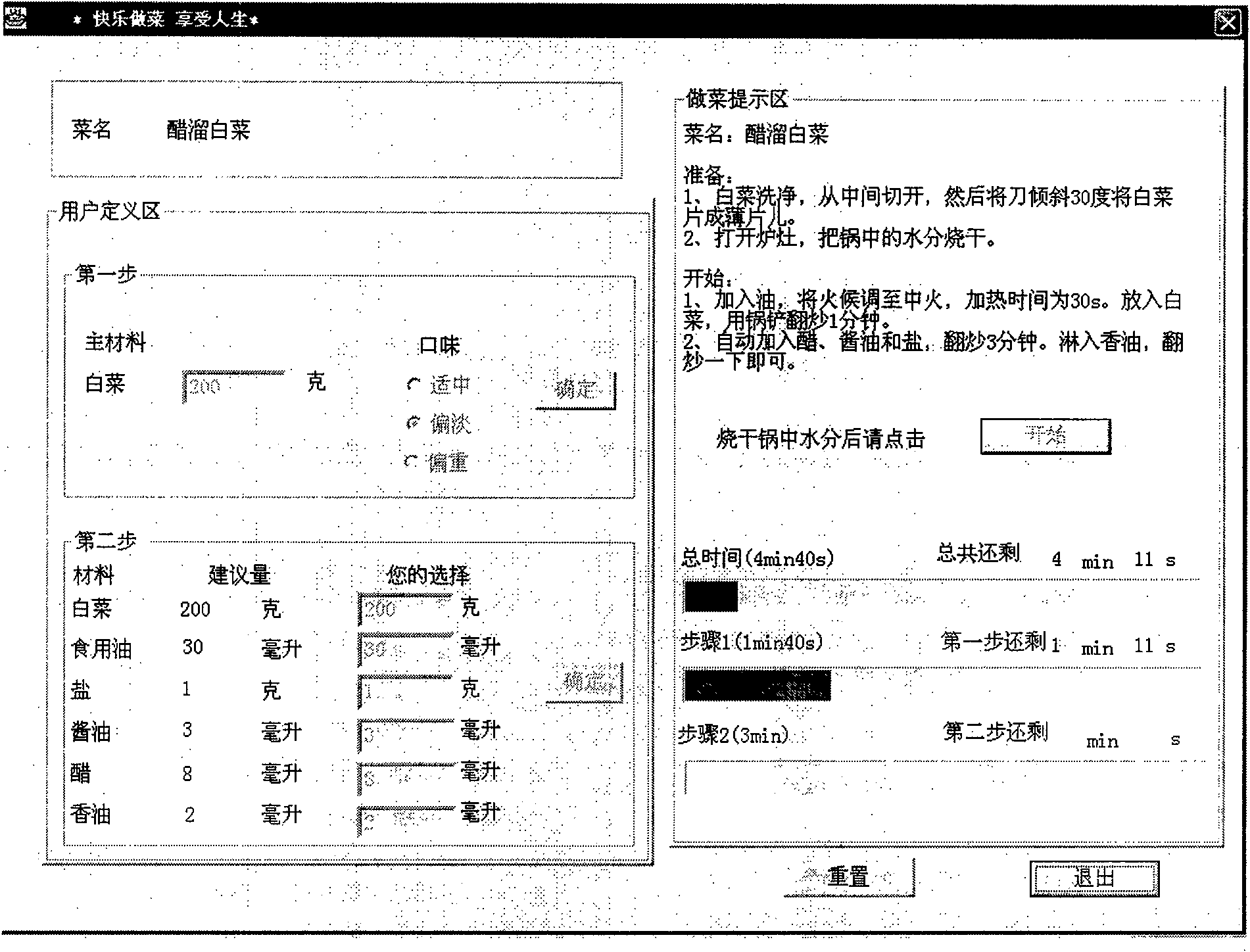

Intelligent seasoning box

InactiveCN103082898ANutrition scienceSimple and fast operationProgramme controlComputer controlProcess engineeringSingle chip

An intelligent seasoning box for household cooking comprises an intelligent control device, at least one solid seasoning box and at least one liquid seasoning box. The intelligent seasoning box is characterized in that the intelligent control device comprises a single chip microcomputer (4) and multiple solid valves (9) and liquid valves (10) composed of electromagnetic valves, the solid seasoning boxes and the liquid seasoning boxes are provided with discharging ports, each of the solid seasoning boxes is connected with one corresponding solid valve (9) through the discharging port, each of the liquid seasoning boxes is connected with one corresponding liquid valve (10) through the discharging box, the liquid valves (10) and the solid valves (9) are connected with the single chip microcomputer (4) respectively and controlled to be open or closed so as to control flowing out of liquid seasoning and outputting of solid seasoning, and the single chip microcomputer (4) uses civil 220V alternating current to 9V alternating current.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Convenient seasoner bag of powder and sauce in one bag and its preparation method

InactiveCN1754448ASolve the problem of flavor inconsistencyWell mixedEdible oils/fatsFood preparationEdible oilPharmaceutical preservatives

The invention discloses a convenient quelite bag which integrates a powder bag and a sauce bag, and comprises (by weight ratio) excipient 10-30, cooking oil 15-40, quelite 30045 and seasoning agent 5-30. The invention also discloses the process for preparing the convenient quelite.

Owner:GAEA GEM RICE

Mixed sauce seasoning packet suitable for non-fried miscellaneous-grain instant noodles, and production method thereof

The invention discloses a mixed sauce seasoning packet suitable for non-fried miscellaneous-grain instant noodles. The seasoning packet comprises a sauce packet, and a powder packet. The sauce packet comprises the raw materials of: fresh meat, palm oil, refined butter, sesame oil, soybean paste, soy sauce, old ginger, fresh garlic, shallot, chili pepper, white granulated sugar, pepper powder, and food additives. The powder packet comprises the raw materials of: edible salt, monosodium glutamate, white granulated sugar, chili pepper powder, ginger powder, garlic powder, yeast powder, ginger powder, onion powder, maltodextrin, and pure chicken powder. A dried vegetable packet comprises the raw materials of: Chinese cabbage, caraway, and celery. The seasoning packet has the advantages that: nutrients in pork and fresh vegetables are converted into amino acids which are easy to absorb by human bodies, such that the seasoning packet is beneficial for human health. The color, fragrance, and taste are good. The production method is simple and is easy to command; the technology is mature; and the method provided by the invention is suitable for popularization.

Owner:SICHUAN JIUJIUAI FOOD

Production method of air-dried yak meat

InactiveCN103238854AEasy accessGreat tasteClimate change adaptationFood preparationBiotechnologyFiber

The invention discloses a production method of air-dried yak meat. The production method comprises the following steps of: dividing yak meat into strips, removing fascias and oil, and cleaning and tenderizing; soaking with decontamination liquid; injecting brine; mixing the salted meat with seasoning powder at the temperature of 0-4 DEG C and tumbling a mixture in vacuum, setting the working time to be 45 minutes, the rest time to be 10 minutes and the interval tumbling time to be 16-24 hours; discharging the tumbled yak meat into a salting barrel, salting the yak meat for 24-36 hours at low temperature of 0-4 DEG C with a cover until the center of the yak meat becomes brilliant rosy and the surface of the yak meat is slightly sticky; and packaging after placing the treated yak meat in a cold air channel with a temperature which is less than or equal to -16 DEG C for freezing and drying. The structure of muscle fibers can be damaged through the tenderization treatment, so that the salting quality is improved. A part of water-soluble salting material can enter deep muscles rapidly through brine injection, so that the salting quality is improved. Moisture in the yak meat can be rapidly removed by drying with strong and cold air, so that the yak meat is porous and is melt in the mouth. The drying time of a traditional manner can be greatly reduced through freezing and drying.

Owner:西藏牦牛王生态食品开发有限公司

Chilli strip automatic production line

The invention discloses a chilli strip automatic production line. The chilli strip automatic production line is characterized by comprising a flour puffing mechanism, a vibration feeding mechanism, a seasoning charge mechanism, a material passing mechanism, a chilli strip feeding and cutting mechanism and a chilli strip packaging mechanism; long chilli strips produced by the flour puffing mechanism are vibrated and fed through the vibration feeding mechanism, pass through the material passing mechanism, are cut off at fixed length by the chilli strip feeding and cutting mechanism, and then are fed into the chilli strip packaging mechanism to be packaged; the vibration feeding mechanism is provided with a long-bar-shaped feeding groove; the seasoning charge mechanism is arranged above a feeding end of the feeding groove. The chilli strip automatic production line provided by the invention can achieve full-automatic production of chilli strips, the efficiency is improved, and hygiene is guaranteed.

Owner:RUIAN RUIZHI MACHINERY

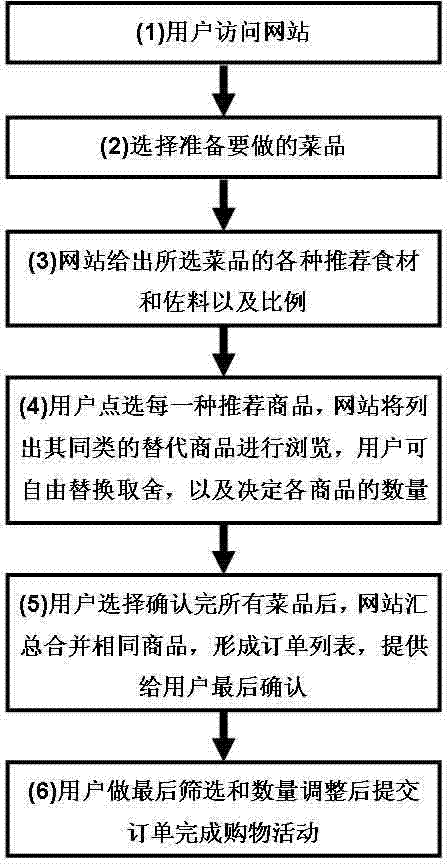

Mode and method for selecting and purchasing food materials online

InactiveCN104778191AShorten the timeImprove experienceSpecial data processing applicationsUser needsMedicine

The invention discloses a novel online food purchasing mode. Different kinds of food and seasonings can be classified and combined by using all kinds of commonly-used recipes, and thus a user just needs to care for dishes which are about to be eaten by the user in the day without thinking which kinds of food and seasonings can be used for making the dishes; the user needs not to find the food and the seasonings needed by one dish one by one any more, all kinds of food and seasonings needed for finishing the dish can be found out by a system, and the typical reference quantity of the food and the seasonings can be given out; the user just needs to correct, replace and accept or reject listed commodities; through the novel shopping mode, a person who cannot cook can also easily take part in the shopping activity of food purchasing, and the consumer group is enlarged; for the person who purchases the food frequently, the time for selecting and purchasing the food can be greatly reduced, and meanwhile, the situation of food missing during the food purchasing can be avoided.

Owner:刘莎

Low nitrite bacon and preparation method thereof

The invention relates to the processing field of meat, and in particular relates to a processing method of preserved pork. The method specifically comprises the following steps of: cutting fresh meat into cutlets, coating a seasoning matter until no water flows from the cutlets, wherein the seasoning matter comprises salt with the weight 0.4 to 0.8 times that of the fresh meat, honey with the weight 2-5 percent of that of the fresh meat and bitter allium with the weight 0.3-10 percent of that of the fresh meat; stewing and pickling the cutlets for 7 to 15 days under 0 to 6 DEG C, soaking the pickled meat for 8 to 14 hours by black tea water or Pu'er tea water, cleaning and draining, and baking under 40 to 60 DEG C so as to obtain the low nitrite preserved pork. The preserved pork is good in mouthfeel, and good in color. In the preparation process of the preserved pork, the black tea water or the Pu'er tea water in an appropriate mixture ratio is used as a seasoning toner; the preserved pork is suitable for patients with hyperlipoidemia. For the preserved pork, the bitter allium is used for replacing spice garlic; the preserved pork contains full garlic taste, and can obviously reduce the low nitrite.

Owner:周仕明

Novel string cheese and preparation method thereof

InactiveCN102090457AAdd hot water to scaldShorten acidification timeCheese manufactureFiber structureFlavor

The invention relates to novel string cheese and a preparation method thereof. The preparation method comprises the following steps of: making a cheese coagulum by using lactic acid bacteria and acidulant chymosin; performing steam jet or hot-water hot iron on the cheese coagulum; stretching at a high temperature to obtain a cheese block mass; adding emulsifying salt, table salt and seasoner into the cheese block mass; and extruding to obtain a product, wherein the product can be eaten without being cooked and has a hand-torn string texture and various flavors. On the basis of a Mozzarella cheese technology and the novel string cheese and the preparation method thereof, the acidulant is used, the hot-water hot iron is performed, a minor-diameter long-distance outlet molding method is used, and the positive effects of shortening acidification time, increasing the adaptability to production conditions and improving the uniformity and the stability of a cheese fiber structure are achieved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Health nutrition chafing dish, soup pot bottom seasoning and its preparing method

InactiveCN1748558ARich in nutritional valueLight tasteMilk preparationFood preparationFlavorNutritive values

The health nutritious chafing dish and soup pot bottom material consists of thin soup, seasoning, milk and soybean milk in certain proportion. The seasoning consists of edible oil, table salt, perfume, pepper, ginger, yellow wine, wine, wolfberry fruit and date in certain weight proportion. The making process of the health nutritious chafing dish and soup pot bottom material includes the steps of: making thin soup, decocting seasoning, adding milk and soybean milk, and boiling. The health nutritious chafing dish and soup pot bottom material has rich nutrients and health effects, is light and not greasy, causes no excessive internal heat, and is suitable for all people.

Owner:胡明

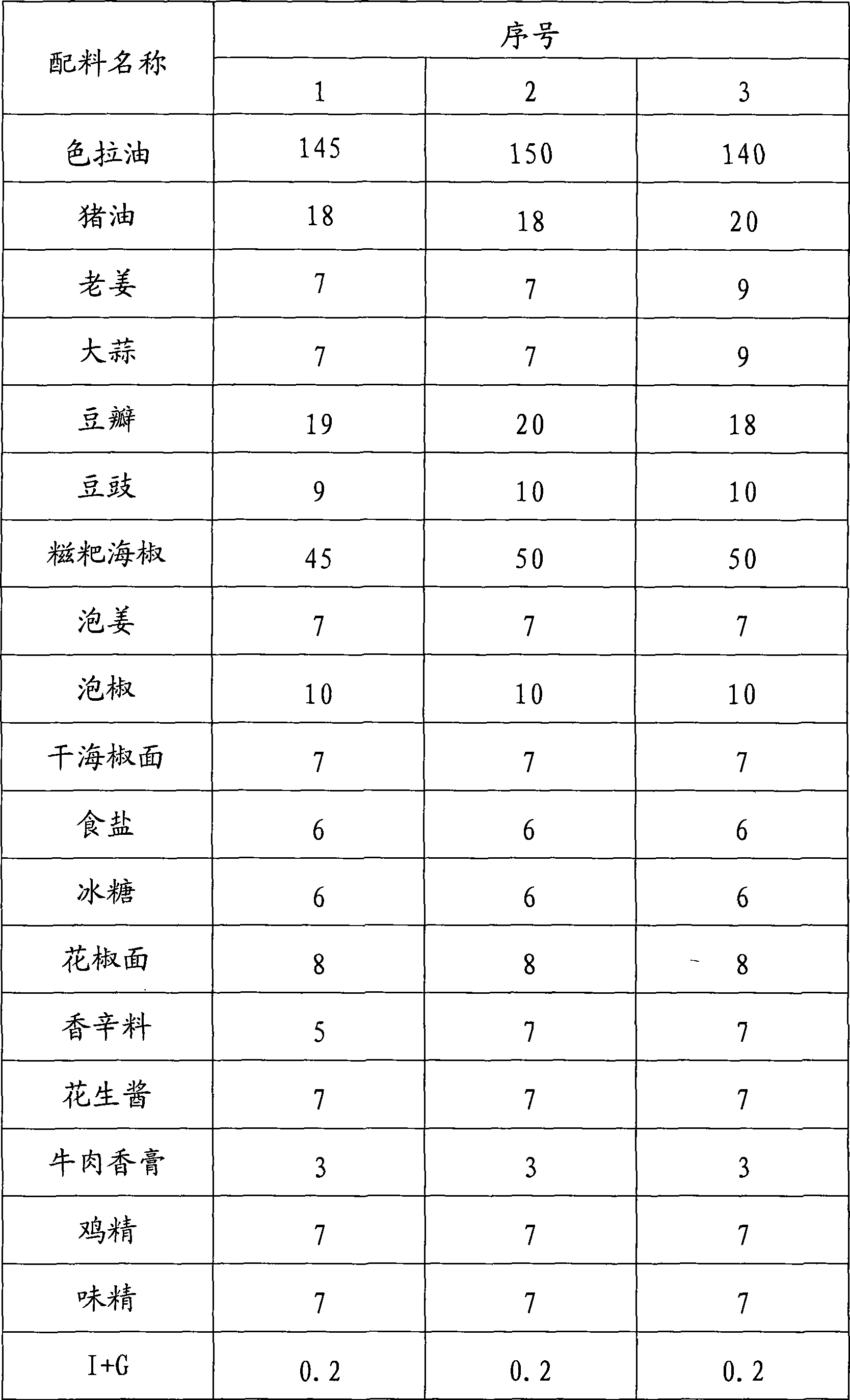

Bottom flavorings of dry pot and preparation method thereof

The invention relates to a dry pot basic flavoring and a preparation method thereof, wherein the formula of the basic material comprises edible oil, old ginger, garlic, hot pepper, bean sauce, lobster sauce, spice, edible salt, seasonings and so on. The dry pot basic material is convenient to use, and the mixed ratio of various seasonings is easy to control so as to meet requirement of catering chain.

Owner:重庆刘一手餐饮管理有限公司

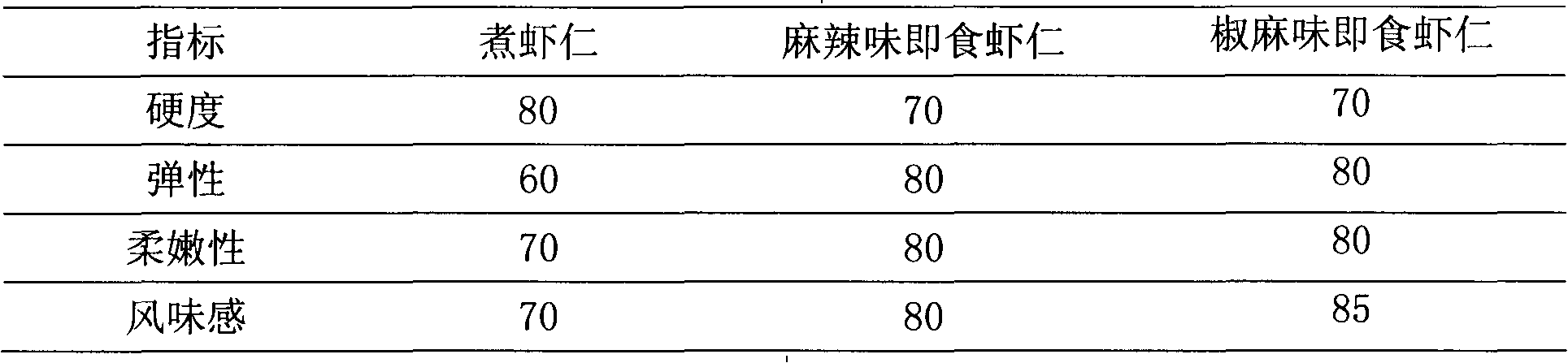

Production technology for seasoned prawns with soft package

The invention discloses production technology for seasoned prawns with soft package, which is characterized in that the production technology comprises the steps of treating raw materials, pickling, brine boiling, deep frying, seasoning, packaging and the like. The technology saves a pre-boiling process, reduces the content of moisture, and better saves the delicate flavor of prawns and the flavor after the seasoning; the shelf life of products is prolonged through pickling and sterilization working procedures; the fishy smell is better removed; and the production technology has simple operation and easily realizes industrialized production. The seasoned prawns prepared by the technology have good color and luster and unique flavor, and are prawn leisure food which can be directly eaten.

Owner:连云港中医药高等职业技术学校

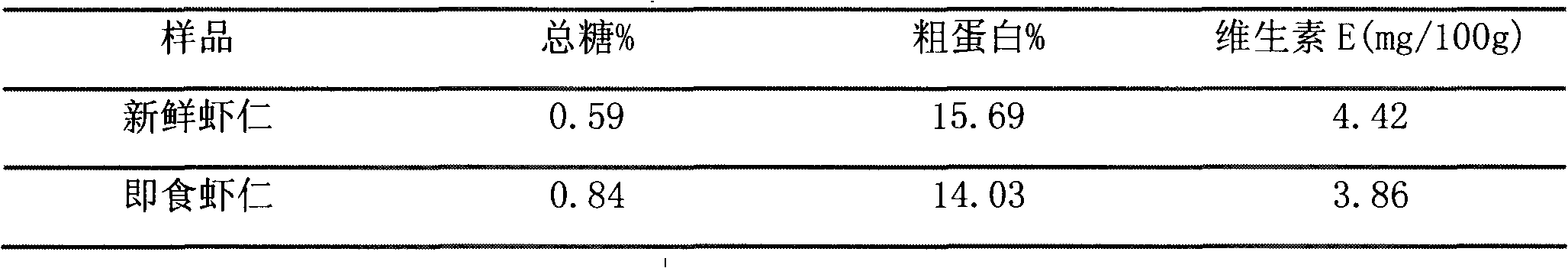

Method for producing instant leisure peeled prawn food

The invention belongs to the technical field of food production, and relates to a method for producing instant leisure peeled prawn food, which mainly comprises the technical units such as peeling, poaching, leaching, procuring, seasoning, prefreezing, sublimation drying, analysis drying, packaging, and the like. The instant peeled prawn food prepared by the method is full of nutrition, unique in flavor, long in shelf life, and convenient to carry and eat.

Owner:江苏戚伍水产发展股份有限公司 +1

Factory production process of instant seasoned lobster

InactiveCN102228272ARemarkable bowel cleansing effectImprove cleanlinessFood preparationShrimpRefrigerated temperature

The invention discloses a factory processing and sterilization preservation process of instant seasoned lobster, which comprises the following steps of selecting raw materials, cleaning, boiling, removing heads of the selected lobster, half drying the lobster, packaging the half-dried lobster in bags, sterilizing and preserving the packed lobster. The process is remarkably characterized by comprising the steps of: cleaning intestine, seasoning and boiling, half drying in microwave and sterilizing by irradiation, wherein the factory processing and sterilization preservation process specifically comprises the following steps of: selecting qualified, fresh and alive lobsters, flushing, brushing, soaking for removing dirt, rinsing, and then boiling the clean lobsters with an amount of water and seasoners, heating the boiled lobsters through microwave for steaming till the lobsters are half dried, packing the certain amount of the lobsters in a soft-package plastic bag, vacuuming and sealing, irradiating by gamma-rays generated by isotope cobalt 60 for sterilizing, and refrigerating in a refrigerator at a temperature under 5 DEG C. The instant seasoned lobster prepared by the factory production process disclosed by the invention has the advantages of delicious taste, abundant nutrition, environment protection, safety and convenience for carriage.

Owner:CHAOHU DAXIN FOODSTUFFS

Bottom flavorings of spicy chaffy dish and processing method thereof

InactiveCN101411447AOvercome the problem that the more rinse the taste, the weaker it isFood preparationBiotechnologyNutritive values

The invention provides a spicy hot pot basic flavoring and a processing method thereof. The basic flavoring is formed by adopting 20 raw materials such as green beef tallow, beef marrow fat and natural auxiliary materials, and a seasoning, and performing orderly cooking, frying and processing treatment. The product in the invention is a dreg-contained concentrated basic flavoring, and solves the problem that dreg free basic flavoring is lighter by continuous rinsing. The product has rich nutrition, proper spice, supple mothfeel, fresh aroma and special flavor, and has the characteristics of tonic function and long preservation period. The basic flavoring is formed by using nutritive values of the beef tallow and the beef marrow fat as well as drug effects of natural spices, and adopting scientific formulation for processing, and is a high-nutrition dreg-contained concentrated spicy hot pot basic flavoring.

Owner:GANSU ZHONGHUI AGRI DEV

Production method for shredded mackerel

ActiveCN103054079AOvercome the shortcomings of insufficient deep processingTake advantage ofFood preparationNutritionProcess engineering

The invention relates to the technical field of food science and aims at providing a production method for shredded mackerel. The production method comprises the following steps of pre-treating materials, deburring, removing peels, degreasing, removing fishy smell, carrying out antioxidant treatment, seasoning, cooking, squeezing, roasting and rubbing, and packaging. According to the production method disclosed by the invention, the operation is simple and the processing cost is low. The mackerel in the production process is not easy to deteriorate, and the prepared shredded mackerel is rich in various nutrient substances needed by a human body, full of nutriments, free from fishy smell, convenient to eat, delicious, good in mouthfeel, quick to digest and absorb, and capable of satisfying the requirements of different crowds. Moreover, the shredded mackerel is soft, not easy to harden and long in quality guarantee period.

Owner:ZHEJIANG MARINE DEV RES INST

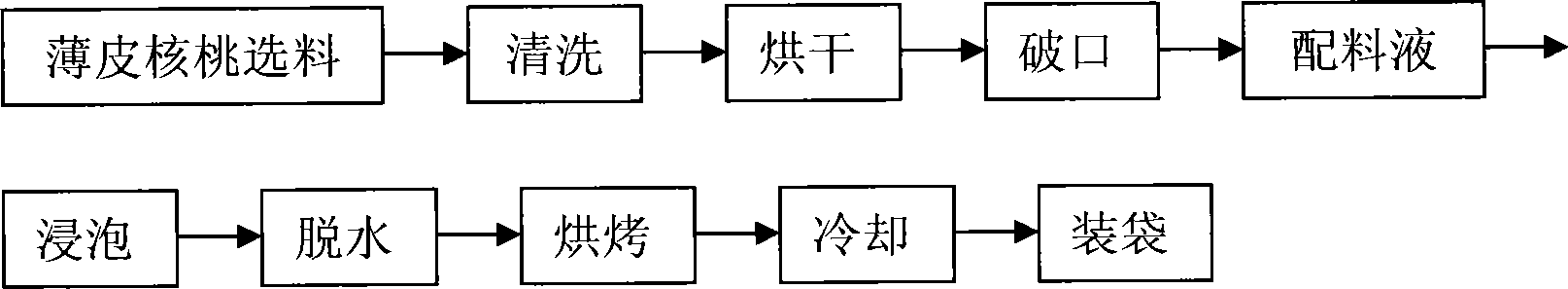

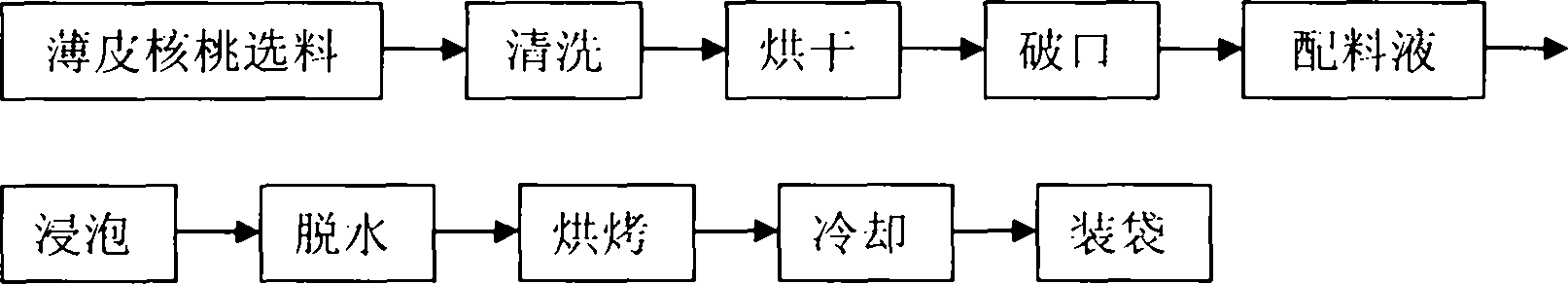

Processing method for multi-flavor thin-skin walnut and walnut prepared by same

The invention relates to the technical field of production and processing of walnut products, in particular to a processing method for a multi-flavor thin-skin walnut and the walnut processed by the processing method. The processing method comprises the following process steps of: selecting a thin-skin walnut; cleaning, drying and cracking; preparing a liquid; soaking the walnut in a seasoning liquid at high pressure for 24 hours; removing a residual liquid in the walnut by using a food dryer; placing the walnut into an electro-thermostatic blast oven for roasting; controlling the temperatureto be about 100DEG C for 2 hours; cooling the roasted walnut; and bagging, vacuumizing and sealing. According to the processing method disclosed by the invention, a traditional production process of easily-cracked nuts is improved from the selecting and processing method; and the thin-skin walnuts from Sinkiang are selected and a high-pressure soaking technology is adopted, so that the process time is shortened and the quality of products is improved. The invention provides the simple and high-efficiency processing method with easiness in operation; peels of walnut products processed by the processing method are easily stripped; and the walnut products are convenience to eat, can be processed to obtain spiced and cream flavors and have fragrant and crisp mouthfeeling.

Owner:BEIJING UNIV OF AGRI

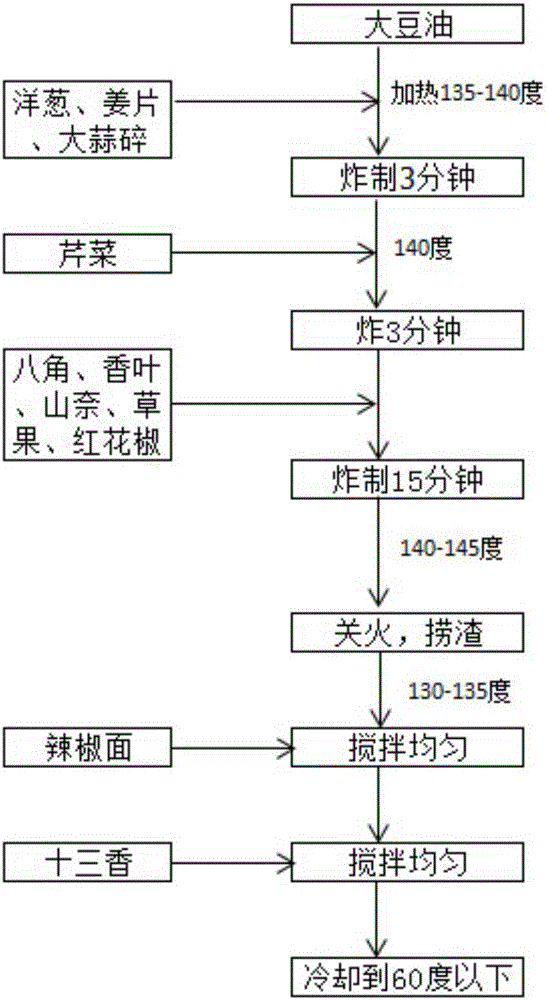

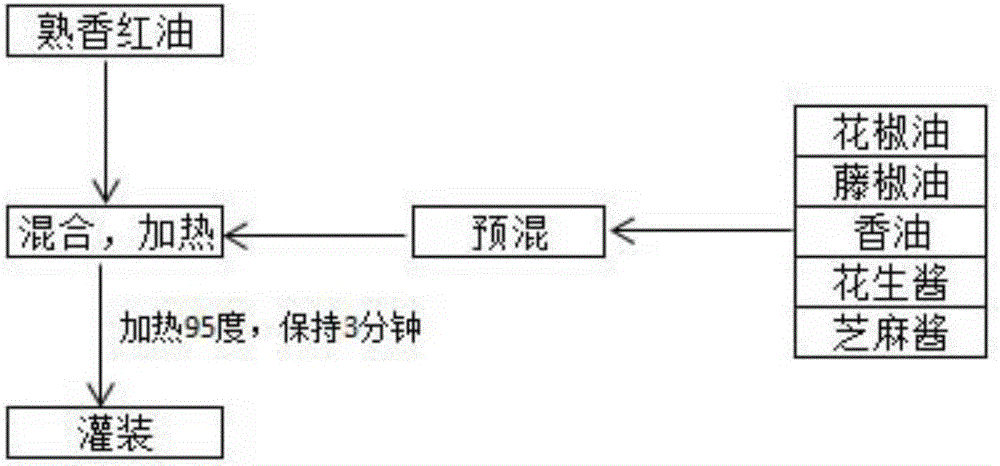

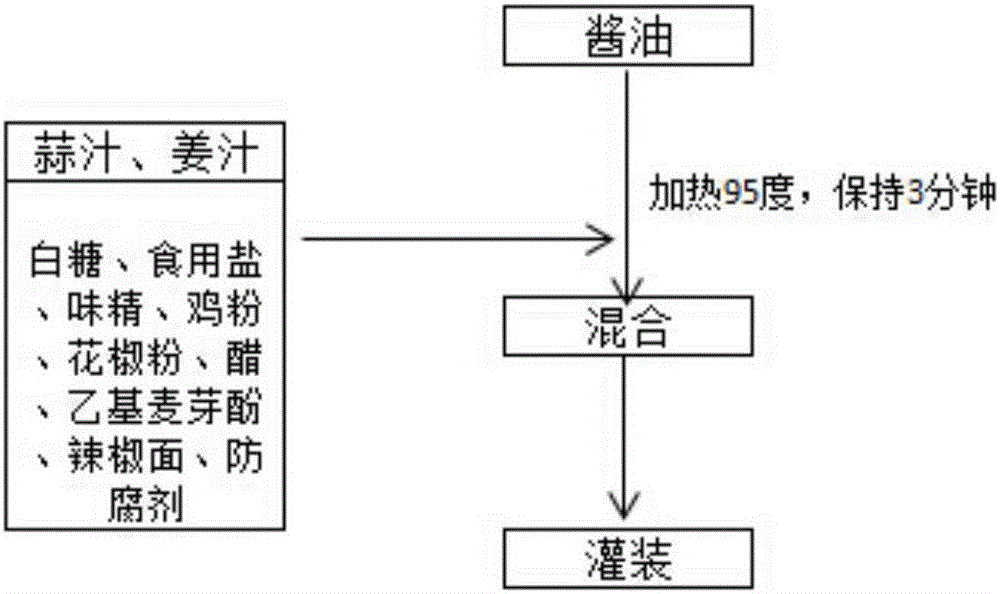

Seasoning for spicy mix and preparation method of seasoning

The invention relates to a seasoning for a spicy mix and a preparation method of the seasoning. The seasoning for the spicy mix is divided into forms of seasoning red oil packs and seasoning packs, wherein the seasoning red oil packs contain cooked fragrant red oil. The seasoning for the spicy mix disclosed by the invention is prepared through the following steps of separately filling the seasoning red oil packs and the seasoning packs, and performing combined packaging. According to the seasoning and the preparation method thereof disclosed by the invention, raw materials, components and the proportion thereof of the seasoning red packs are adjusted, and the refining technology of the cooked fragrant red oil is improved, so that the taste of products is guaranteed to the maximum extent, the quality guarantee period is prolonged, and the seasoning has the advantages of being convenient to eat and store, good in mouth feel, low in salt and the like.

Owner:YIHAI CHINA FOOD CO LTD

Quick-frozen unshelled instant abalone and preparation method thereof

The invention relates to a preparation method of quick-frozen unshelled instant abalones, which sequentially comprises the following steps: seasoning the abalones; shelling the abalones and removing internal organs; removing black membranes of the abalone meats in warm water and cleaning the abalone meats; sizing, seasoning and naturally cooling the abalone meat; providing shells for the abalone meats one by one and packaging the abalone meats under vacuum one by one, sterilizing and quickly freezing the packaged products. The invention also relates to the quick-frozen unshelled instant abalones prepared by the method. The preparation method of the quick-frozen unshelled instant abalones can retain the original flavor of the abalones, make the cooking of the abalones convenient and prepare the quick-frozen unshelled instant abalones which have an original flavor and can be cooled conveniently.

Owner:ZHANGZIDAO GRP

Processing method for crisp fritter prepared by using minced fillet as raw material

InactiveCN102726763AAvoid potential hazardsHigh nutritional valueFood preparationNutritive valuesManihot esculenta

The invention discloses a processing method for a crisp fritter prepared by using minced fillet as a raw material. The method comprises the following steps: thawing frozen minced fillet and blending the minced fillet for 3 to 10 min in the air; successively adding, in terms of the minced fillet, 2.5% by mass of salt and 10% by mass of cassava starch, adjusting the percentage of moisture to be 79 to 90%, continuing blending the minced fillet for 30 min and maintaining the temperature of the minced fillet to be lower than 10 DEG C in the process of blending; spreading the minced fillet to form a thin layer after blending, drying or steaming the thin layer and then frying or roasting a minced fillet slice so as to obtain a plain minced fillet crisp fritter; and sprinkling seasoning powder onto the plain minced fillet crisp fritter or spraying or dipping the plain minced fillet crisp fritter with non-powder seasoning so as to obtain the seasoned minced fillet crisp fritter. According to the invention, fish protein is used as a main raw material, potential hazards of starch products fried at a high temperature are prevented, and the obtained product has good nutritional values and commodity values; when the processing method is used for producing the minced fillet crisp fritter, the minced fillet crisp fritter does not foam or get expanded and has crisp taste.

Owner:ZHEJIANG UNIV

Marinated product seasoning, marinated soup, marinated product and preparation methods

InactiveCN106107878AMellow tasteRich tasteClimate change adaptationFood ingredient as taste affecting agentBiotechnologyChinese cinnamon

The invention relates to the technical field of foods, in particular to a marinated product seasoning, marinated soup, a marinated product and preparation methods. The marinated product seasoning is prepared from the following raw materials of pepper, Chinese prickly ash, star anise, Chinese cinnamon, dried orange peel, bay leaves, Chinese angelica, liquorice root, netmeg, amomum cardamomum, fructus amomi, kaempferia galangal, fennel, garlic and onion. The marinated soup is prepared from the following raw materials: the marinated product seasoning and soup stock. The preparation method of the marinated soup comprises the following steps of putting the marinated product seasoning and an auxiliary material into the soup stock; boiling; standing for 10-14h at normal temperature. The marinated product is prepared from the following raw materials: to-be-marinated food and the marinated soup. The preparation method of the marinated product comprises the following steps of pickling the to-be-marinated food for 10-14h, and marinating. The marinated product seasoning is suitable for various types of marinated products, and the convenience in use is realized. The marinated soup has the advantages that the mouth feel is more mellow and rich. The marinated product has the advantages that the mouth feel is more spicy and rich, and the flavor of the kaempferia galangal is heavy. The preparation methods of the marinated soup and the marinated product have the advantages that the simplicity and rapidity are realized, the operation is easy, and the operation methods are suitable for industrial production.

Owner:郑州市百年粥道餐饮管理有限公司

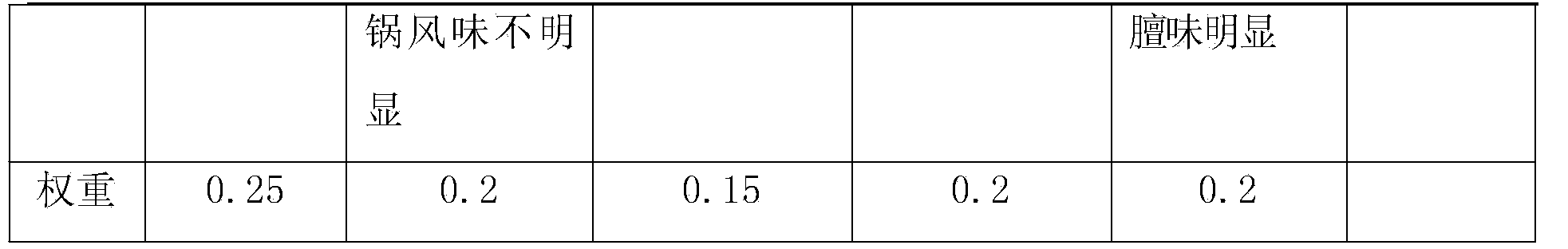

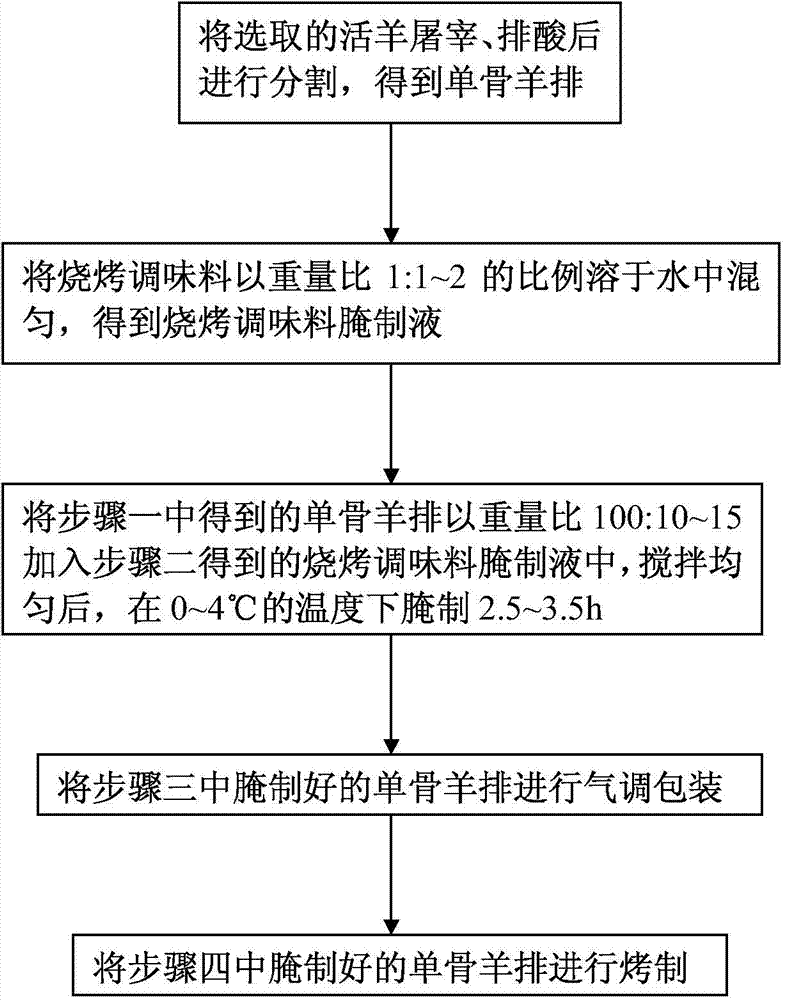

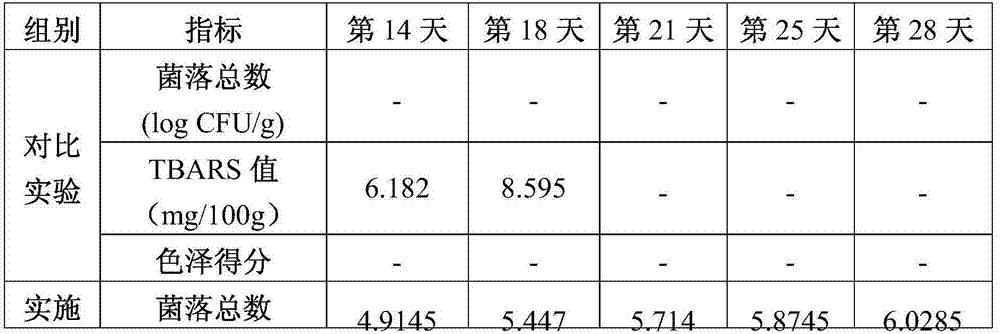

Method of seasoning grilling mutton chops

ActiveCN103478751AAttractive tasteRich varietyFood ingredient as antioxidantFood preparationProduct processingCHOP

The invention relates to the technical field of meat product processing, in particular to a method of seasoning grilling mutton chops. The method comprises the steps as follows: 1), a live goat is killed, acid is discharged, and the goat is divided, so that single-bone lamb chops are obtained; 2), grilling seasoning is dissolved in water in a weight ratio of 1: (1-2) and mixed uniformly, so that a grilling seasoning curing liquid is obtained; 3), the single-bone lamb chops obtained in the step 1) are added to the grilling seasoning curing liquid obtained in the step 2) in a weight ratio of 100: (10-15), the mixture is mixed uniformly, and the mixture is cured at a temperature of 0-4 DGE C for 2.5-3.5 h; 4), the cured single-bone lamb chops in the step 3) are subjected to modified atmosphere packaging; and 5), the cured single-bone lamb chops in the step 4) are grilled. According to the method, the shelf lives of the seasoning grilling mutton chops are prolonged, the product variety is enriched, and the product flavor is improved.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com