Patents

Literature

165 results about "Normal color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and devices useful for analyzing color medical images

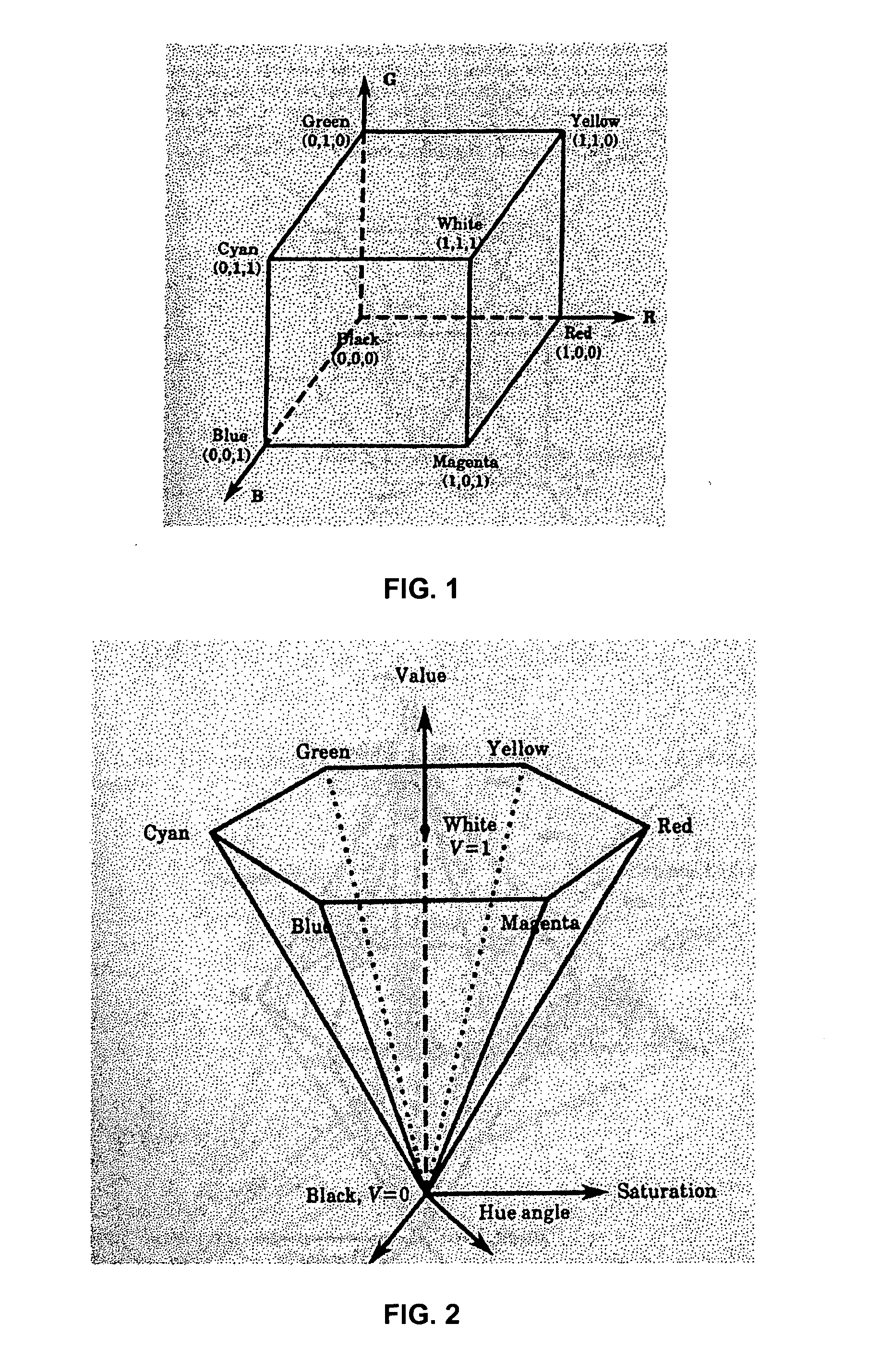

InactiveUS7613335B2Image enhancementImage analysisPattern recognitionApplication-specific integrated circuit

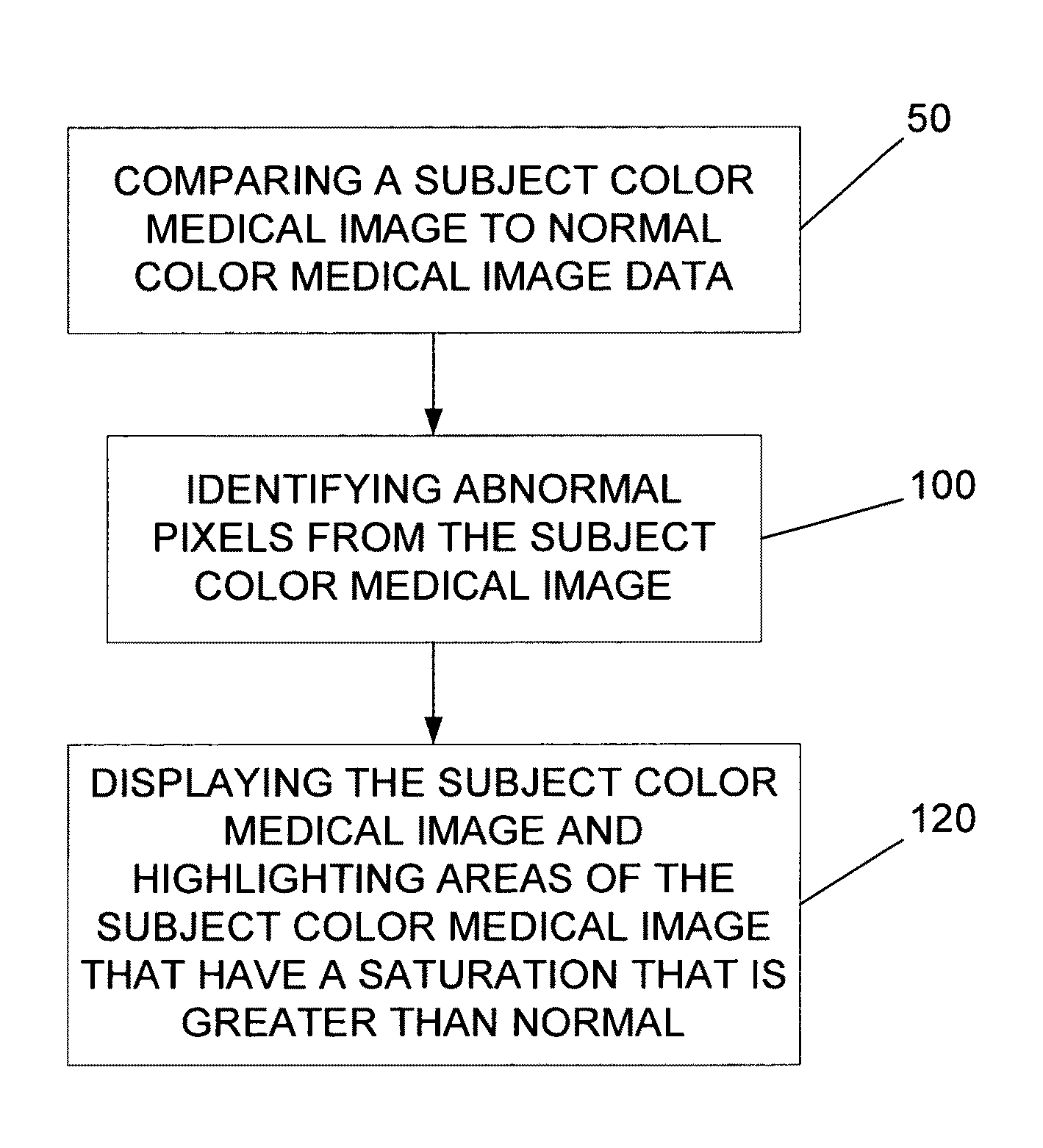

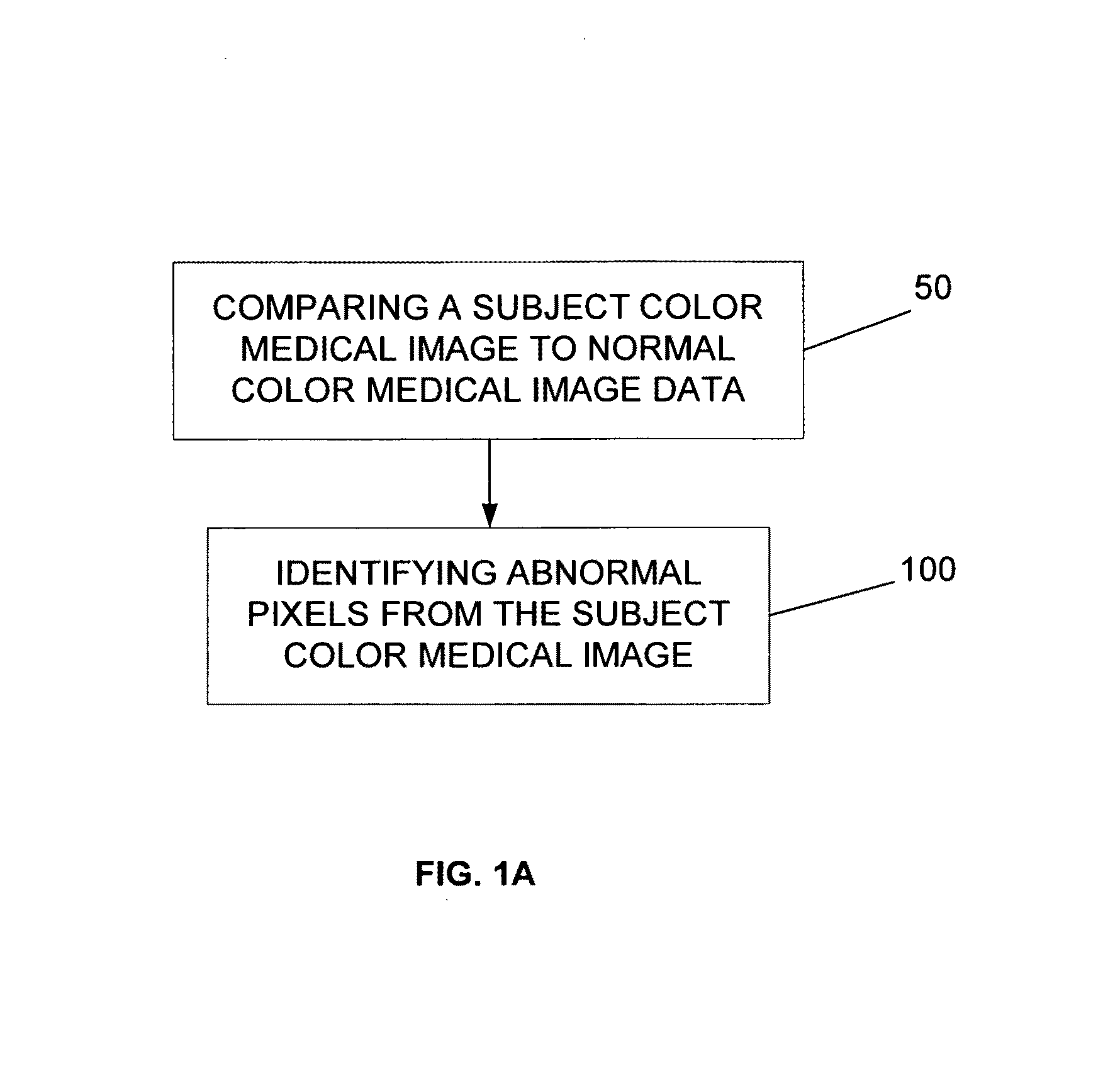

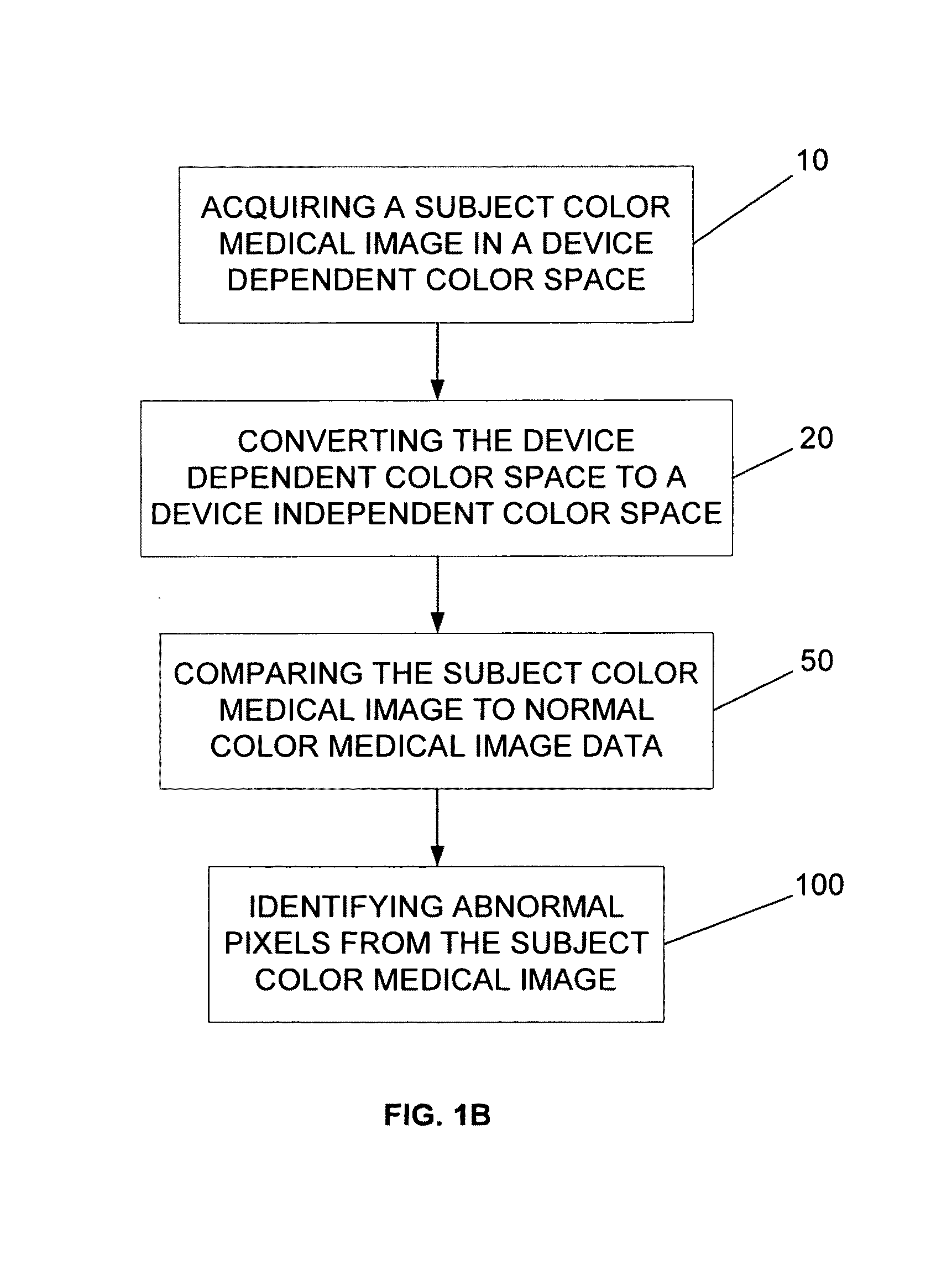

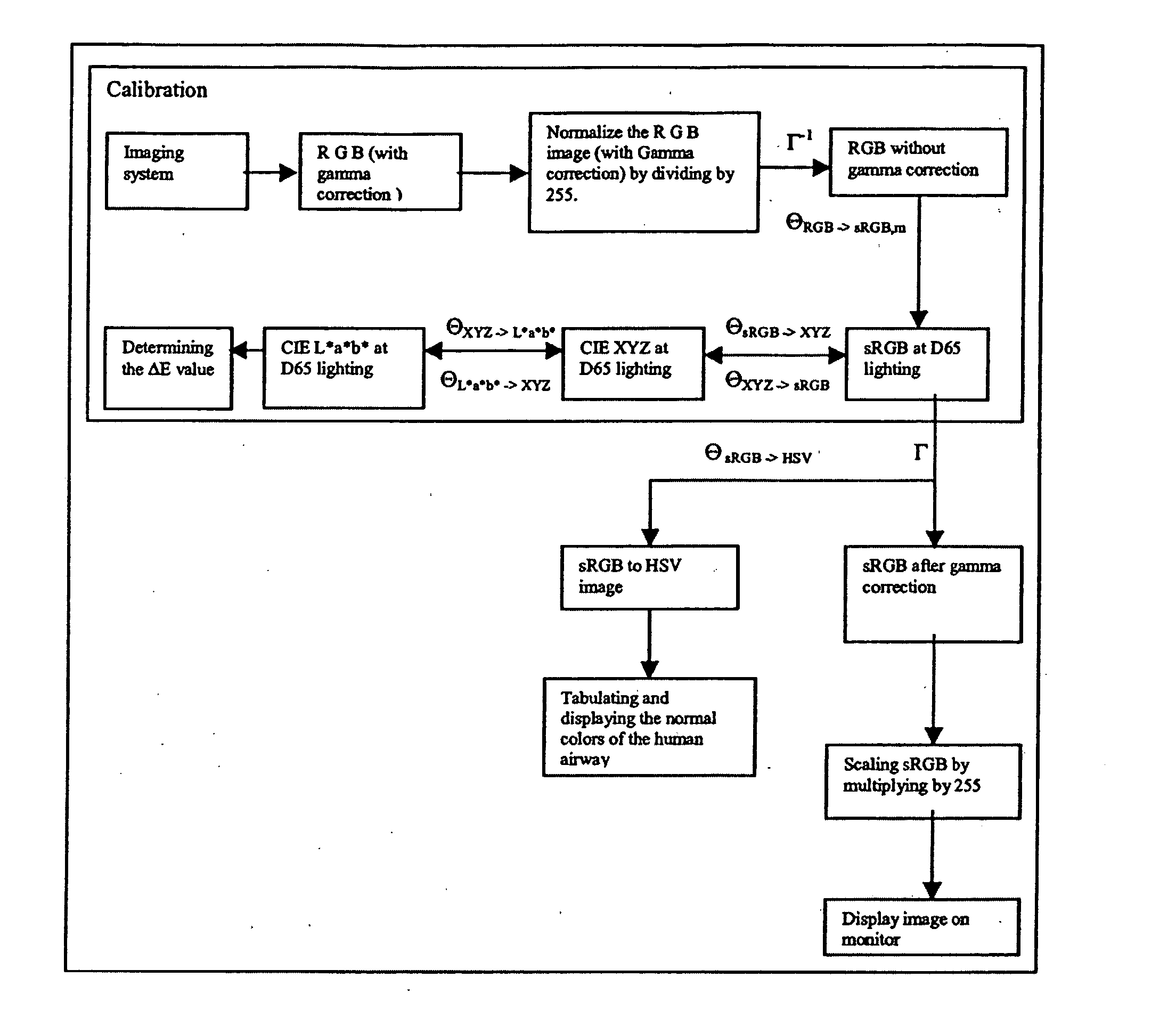

In one embodiment, a method that includes comparing a subject color medical image to normal color medical image data; and identifying abnormal pixels from the subject color medical image. Another embodiment includes a computer readable medium comprising machine readable instructions for implementing one or more steps of that method. Another embodiment includes a device that has a field programmable gate array configured to perform one or more of the steps of that method. Another embodiment includes a device that has an application specific integrated circuit configured to perform one or more of the steps of that method.

Owner:UNIV OF IOWA RES FOUND

Methods and devices useful for analyzing color medical images

InactiveUS20050036668A1Image enhancementImage analysisPattern recognitionApplication-specific integrated circuit

In one embodiment, a method that includes comparing a subject color medical image to normal color medical image data; and identifying abnormal pixels from the subject color medical image. Another embodiment includes a computer readable medium comprising machine readable instructions for implementing one or more steps of that method. Another embodiment includes a device that has a field programmable gate array configured to perform one or more of the steps of that method. Another embodiment includes a device that has an application specific integrated circuit configured to perform one or more of the steps of that method.

Owner:UNIV OF IOWA RES FOUND

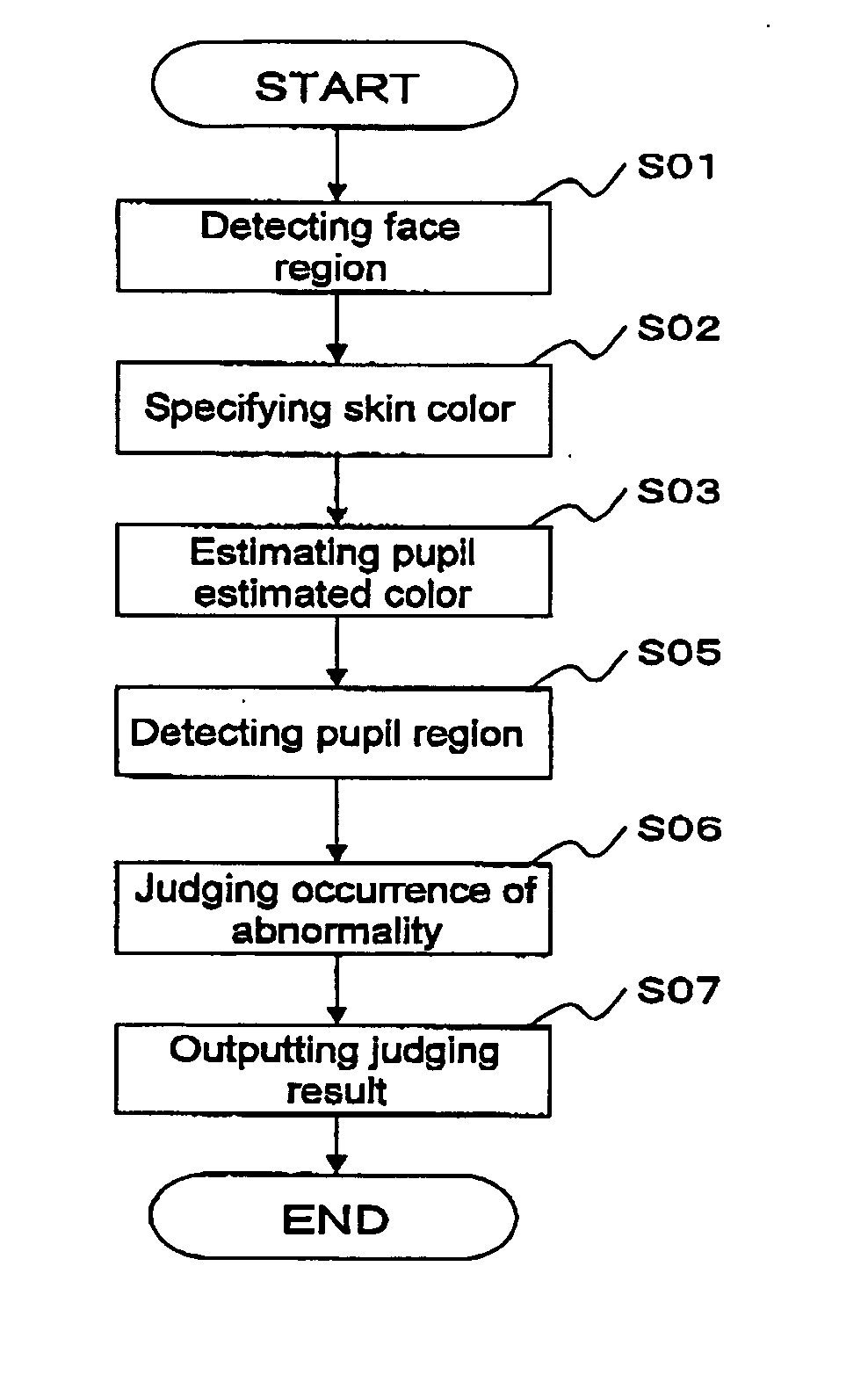

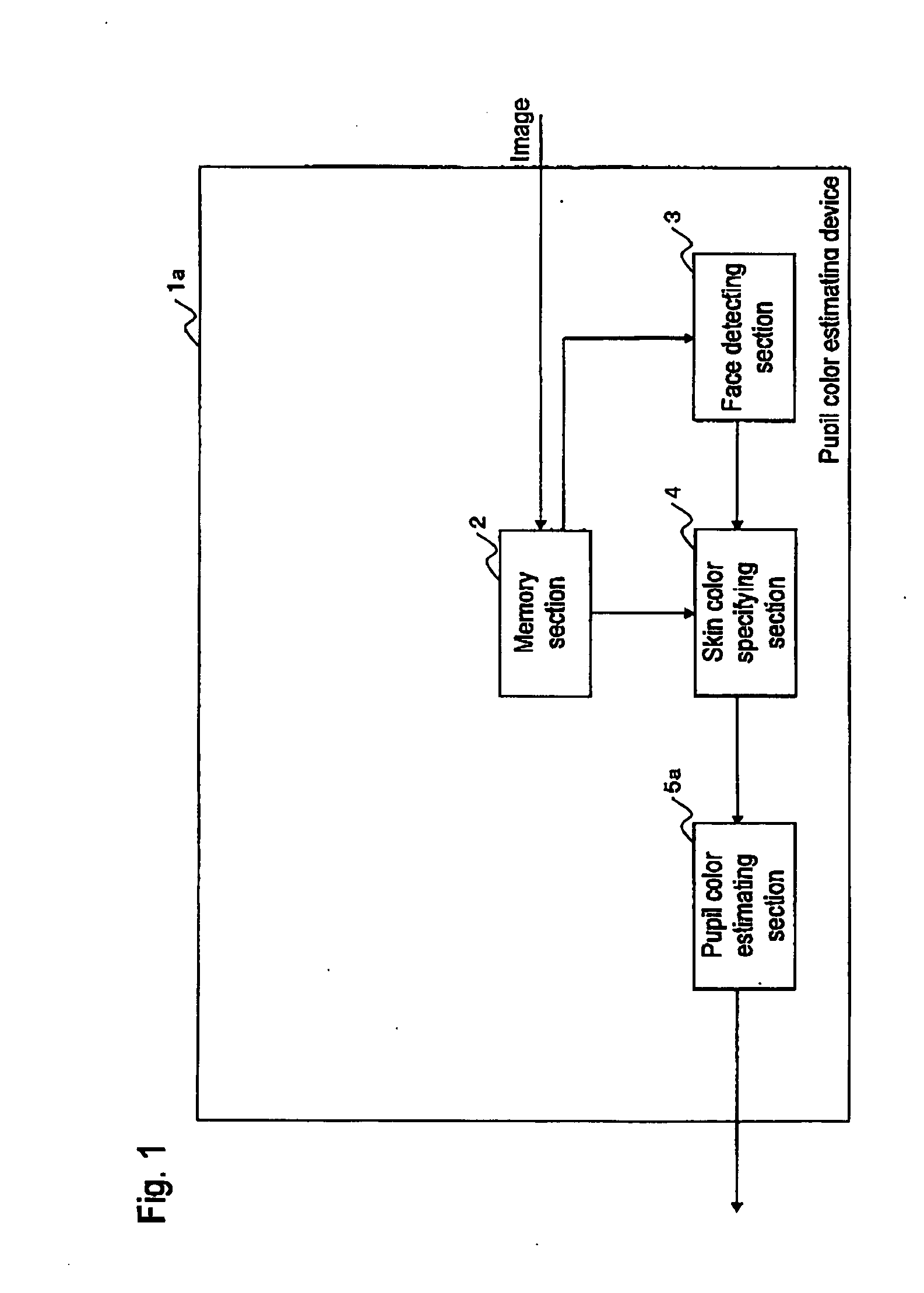

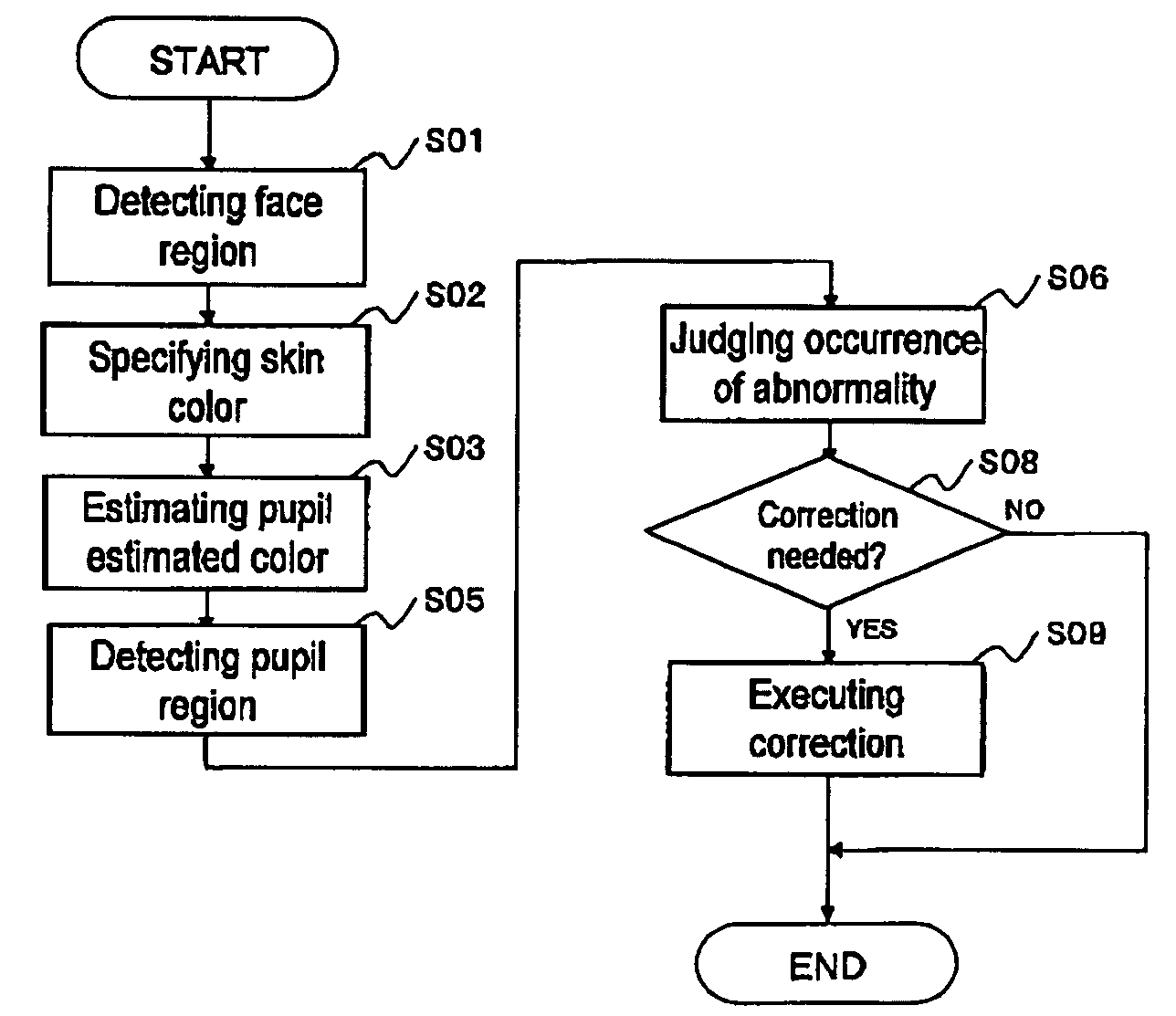

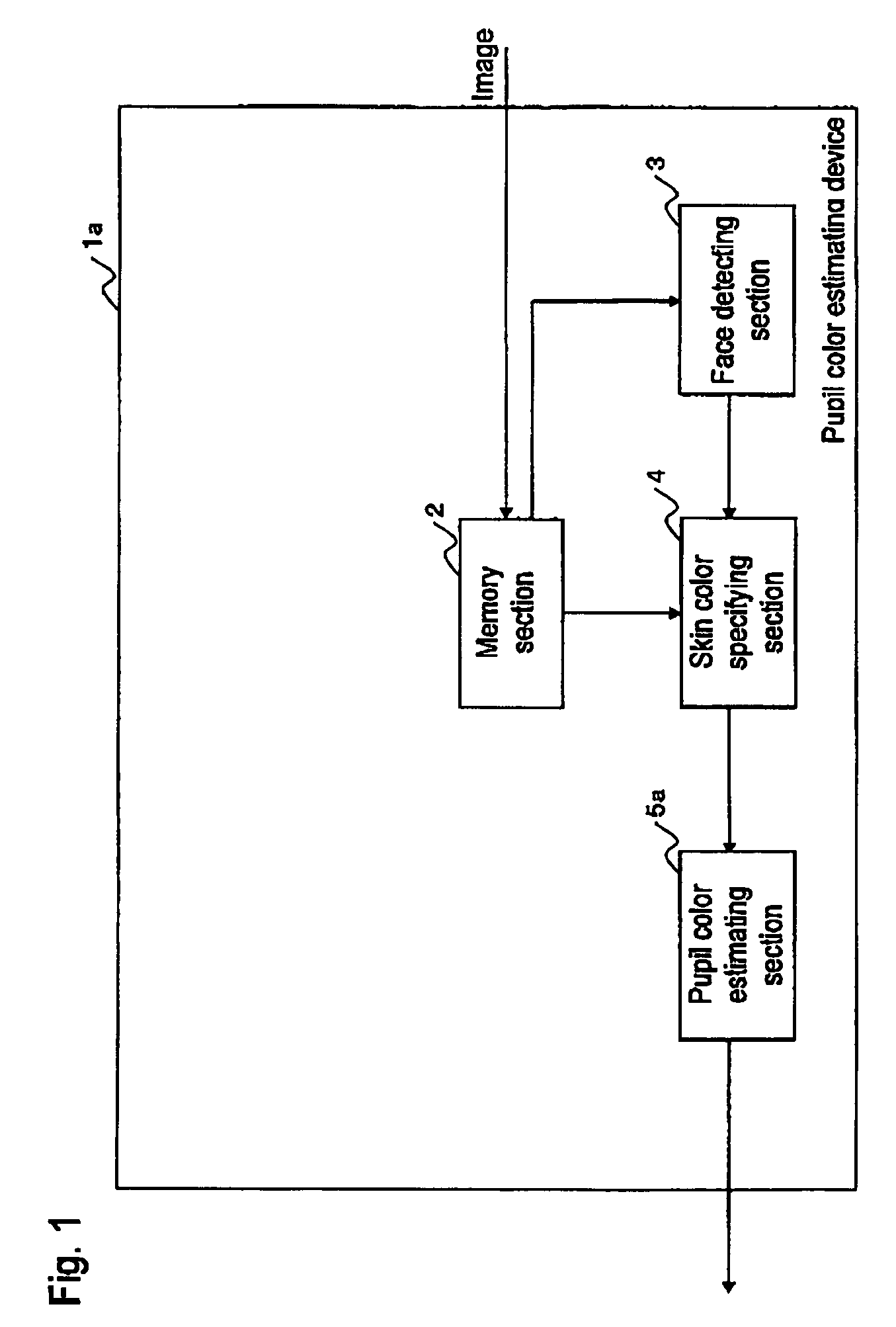

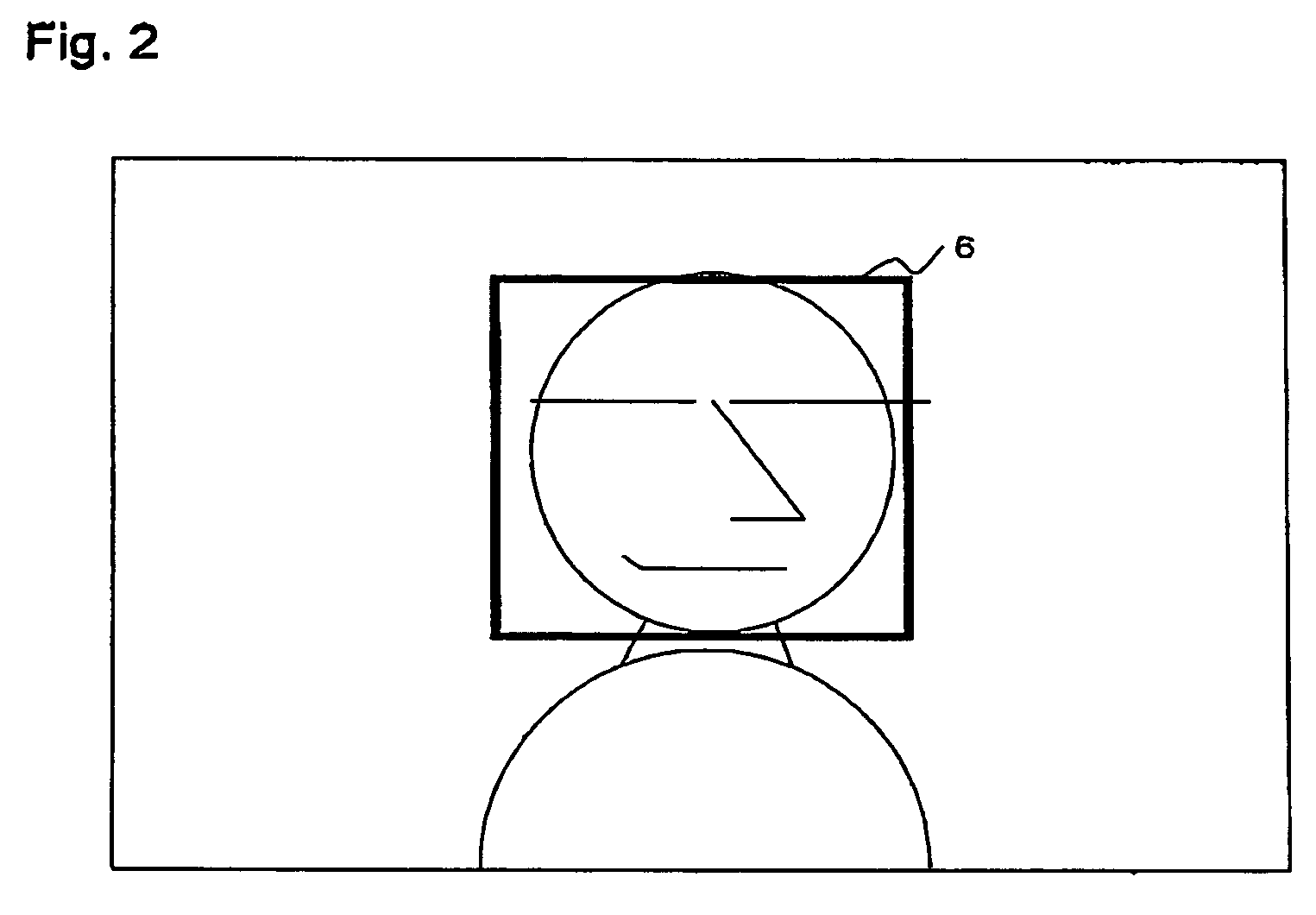

Pupil color estimating device

An original pupil color of a subject person in an image in which an abnormality such as a red-eye or gold-eye occurs is estimated. Further, whether an image correction is required or not and to produce an image having a natural pupil color in the image correction by estimating the original pupil color from the image is judged. A pupil color estimating device has a skin color of a subject person specified from an inputted image, regardless of whether an abnormality such as a red-eye or gold-eye occurs. This skin color is substituted in an approximate equation based upon a statistical result carried out in advance, and thereby a normal color component of a pupil is estimated from the skin color of the subject person.

Owner:ORMON CORP

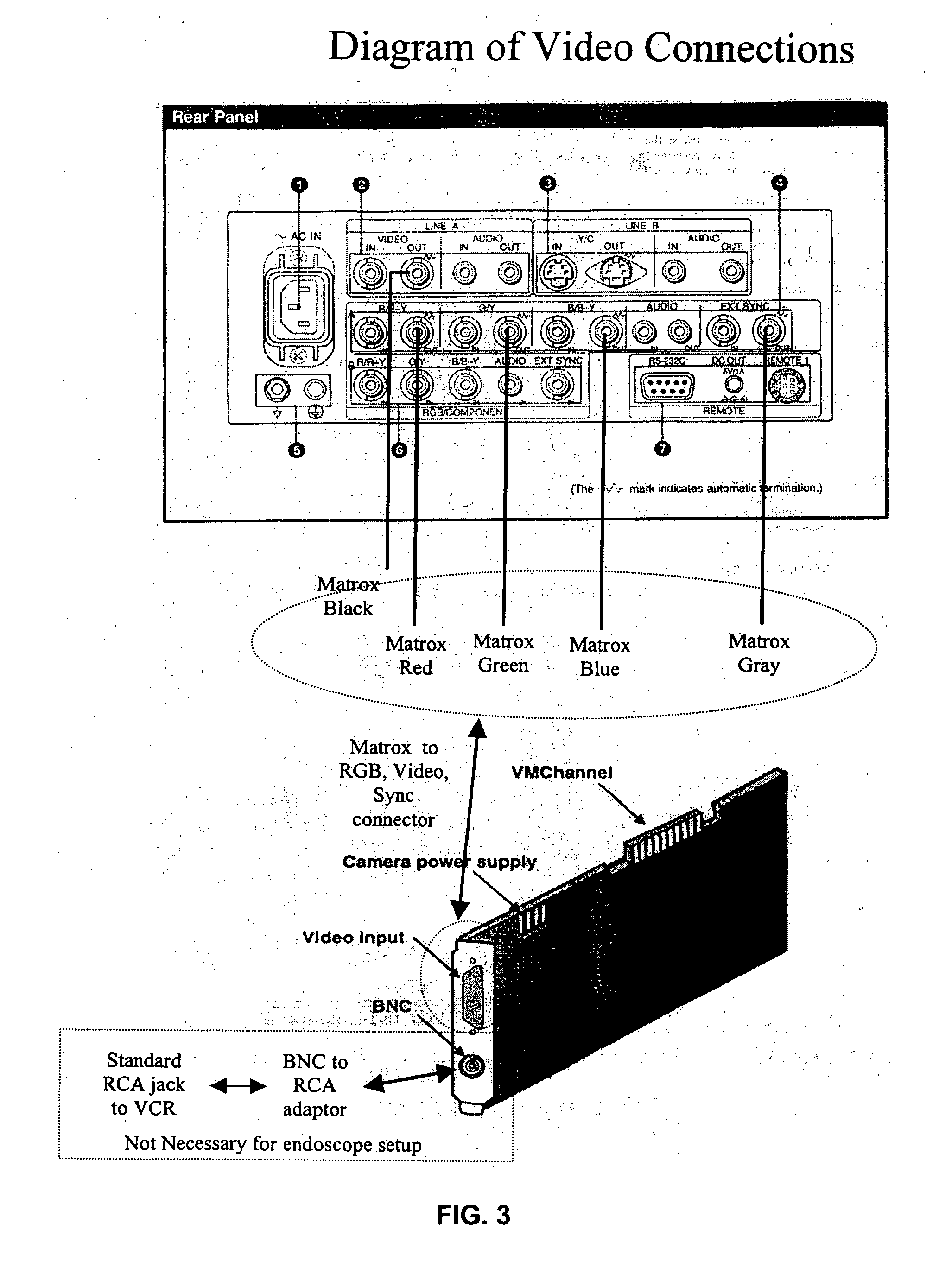

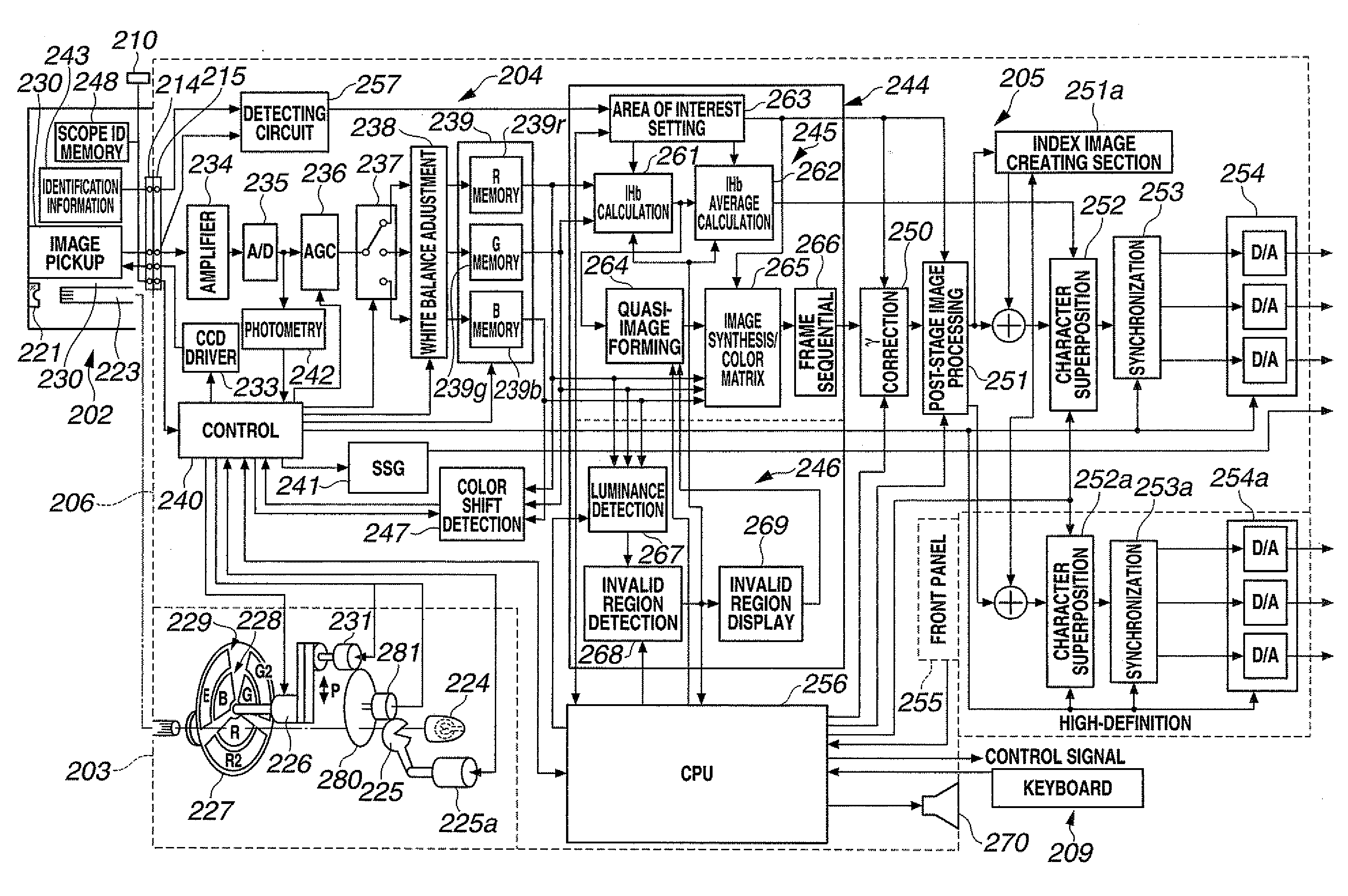

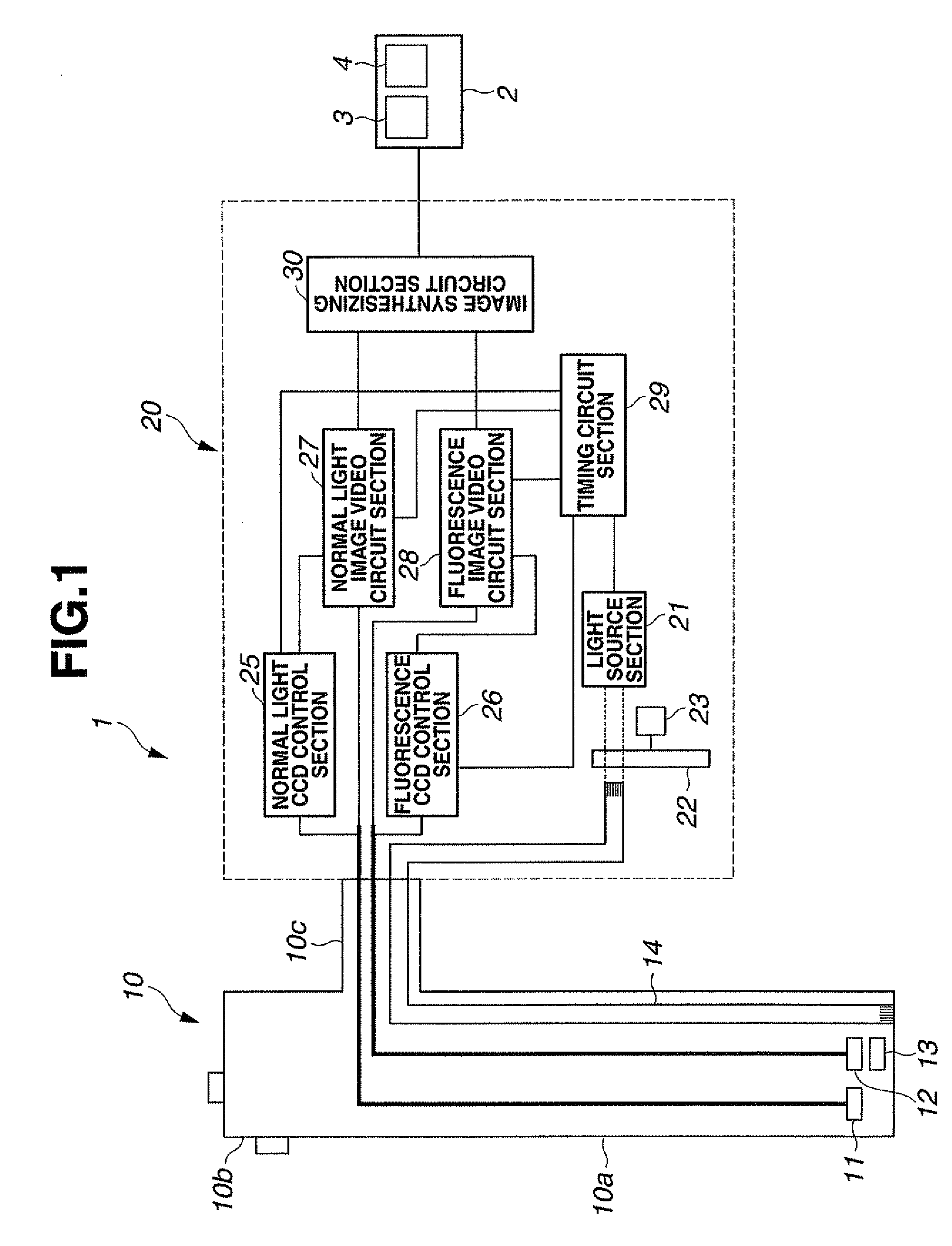

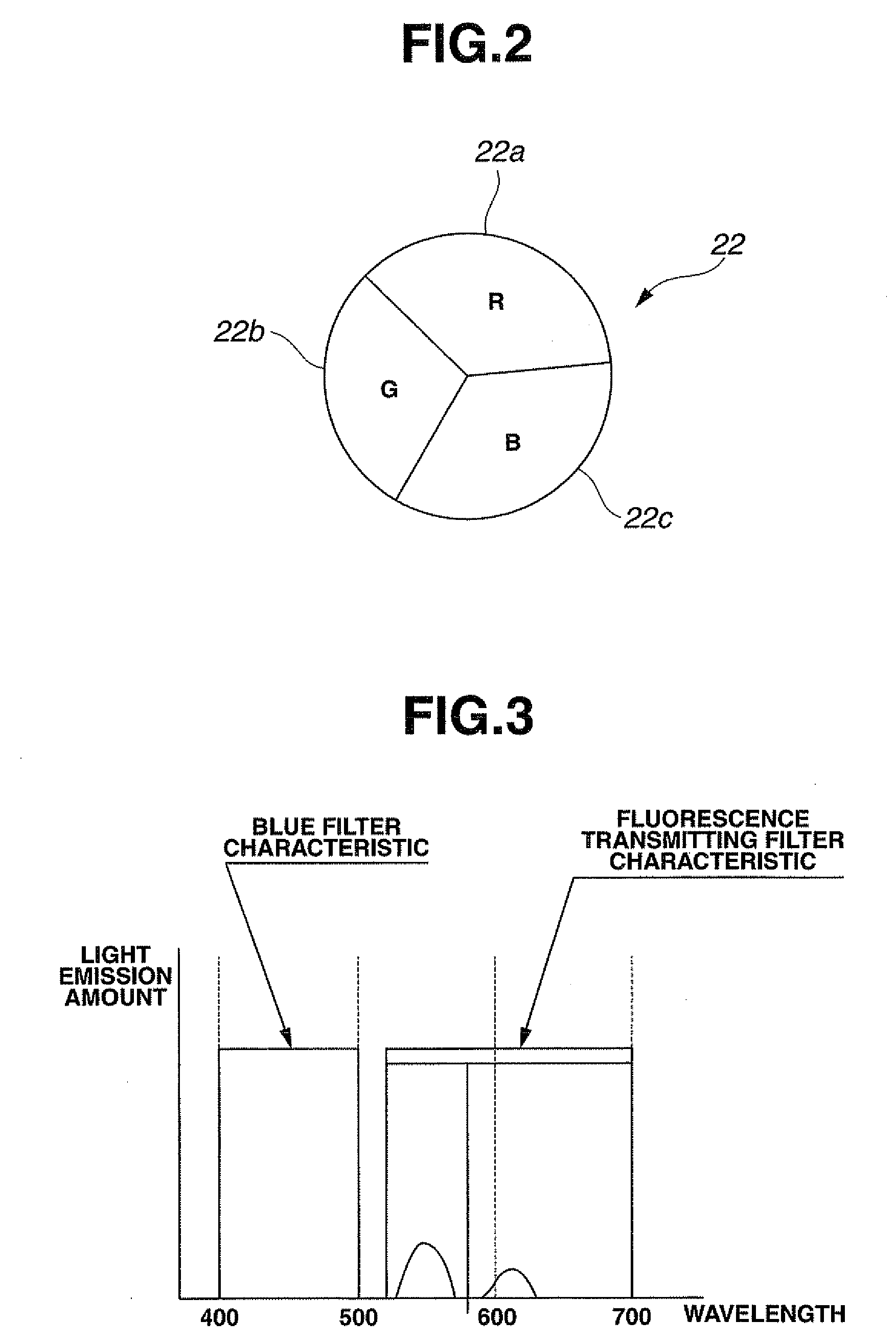

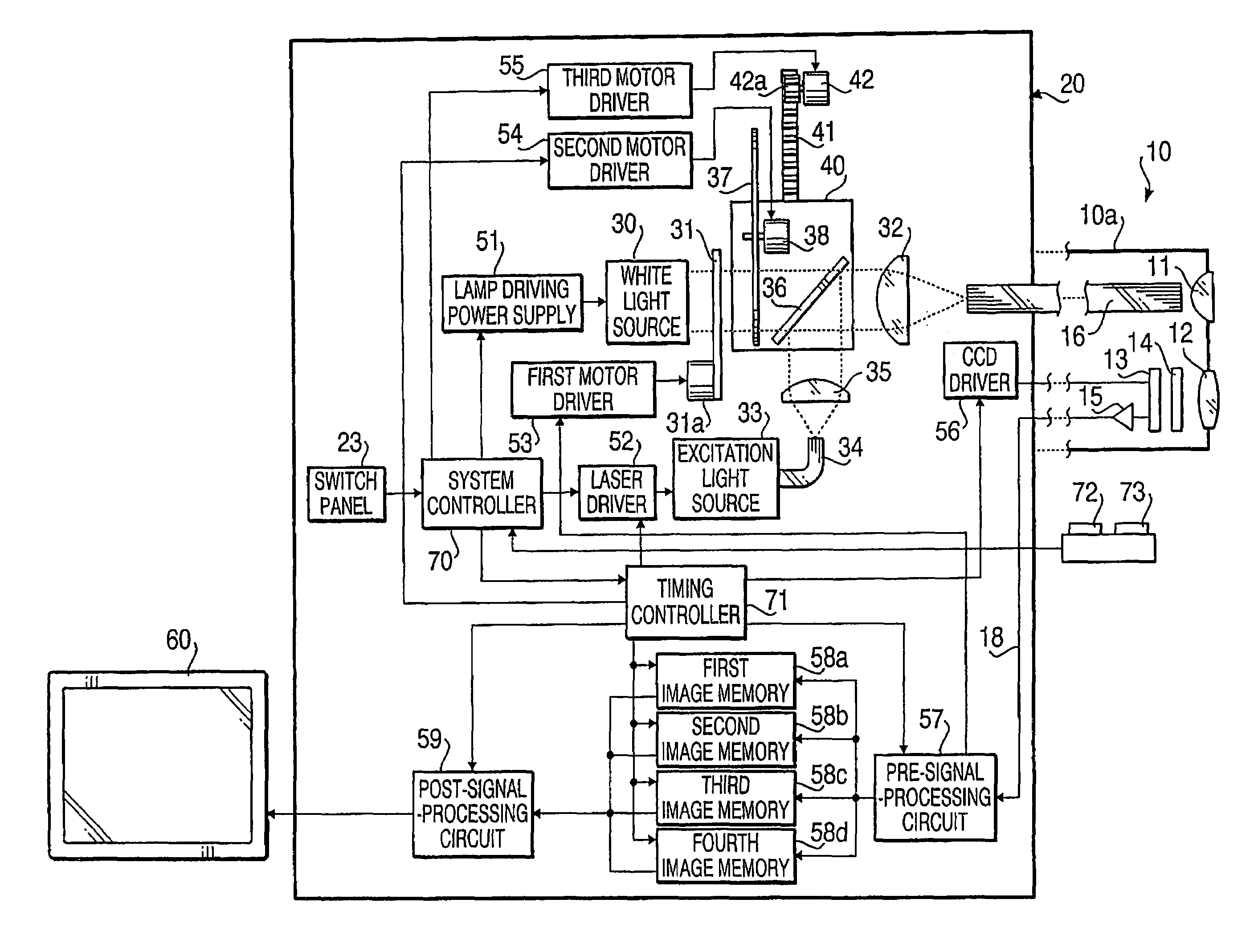

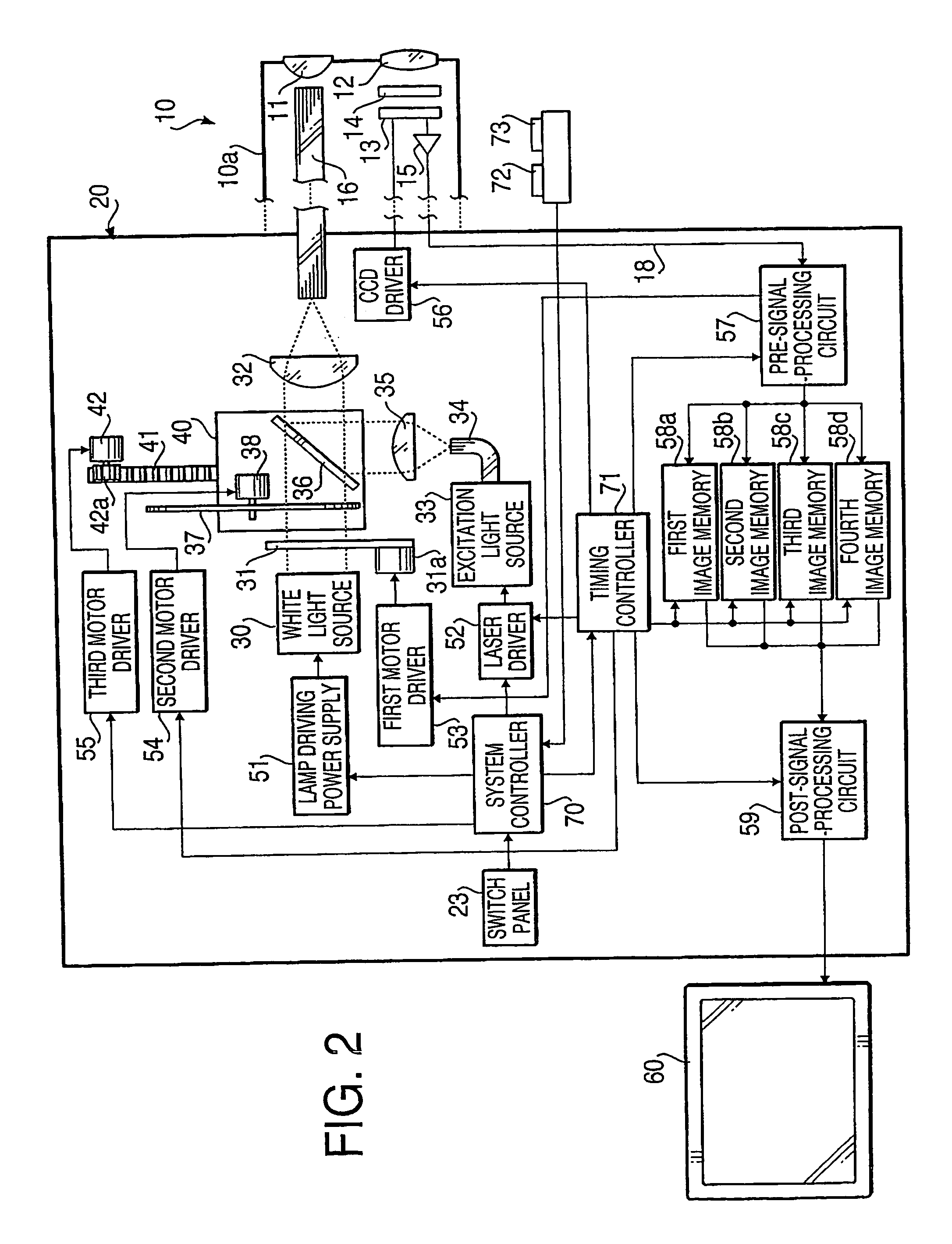

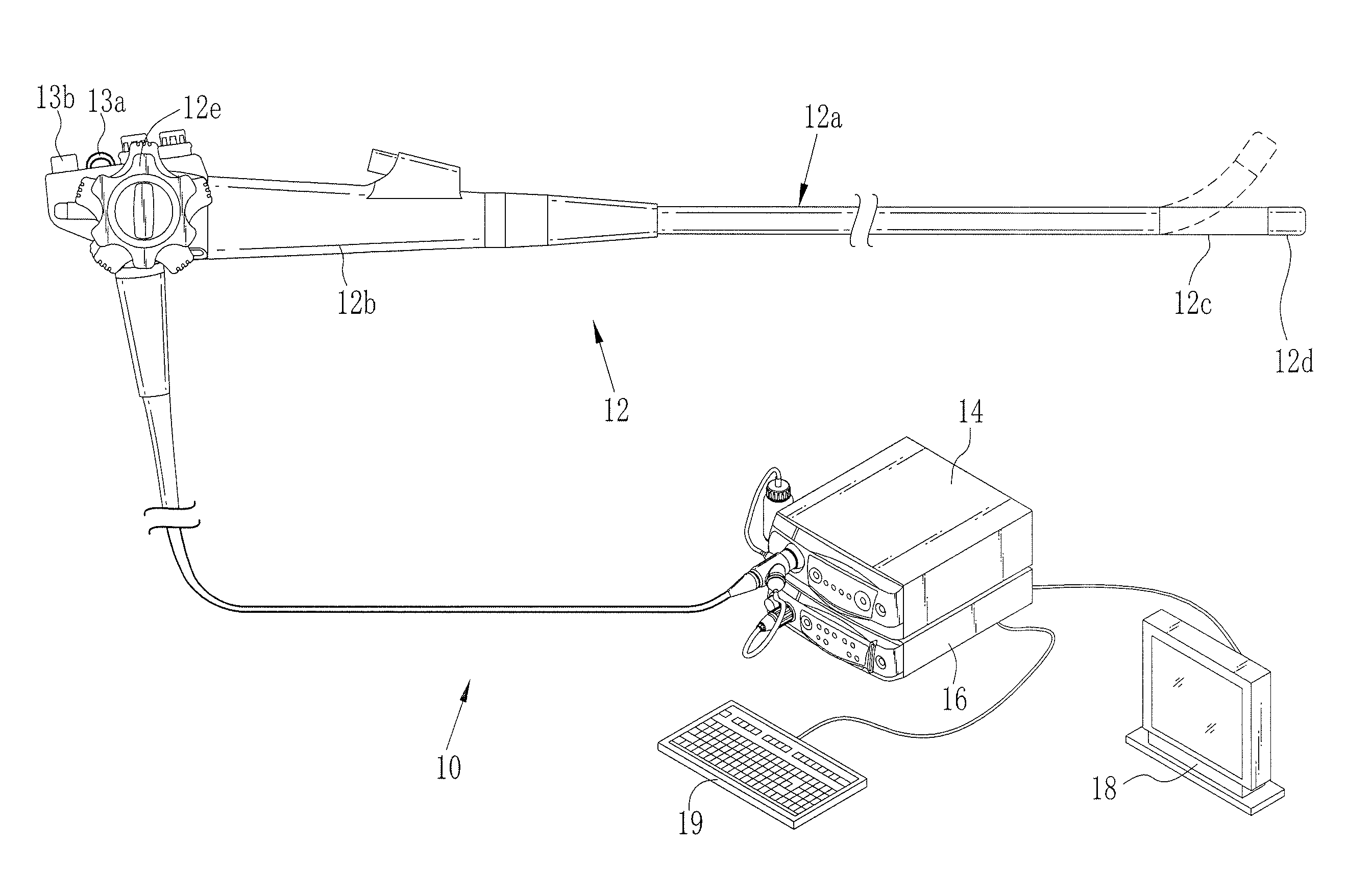

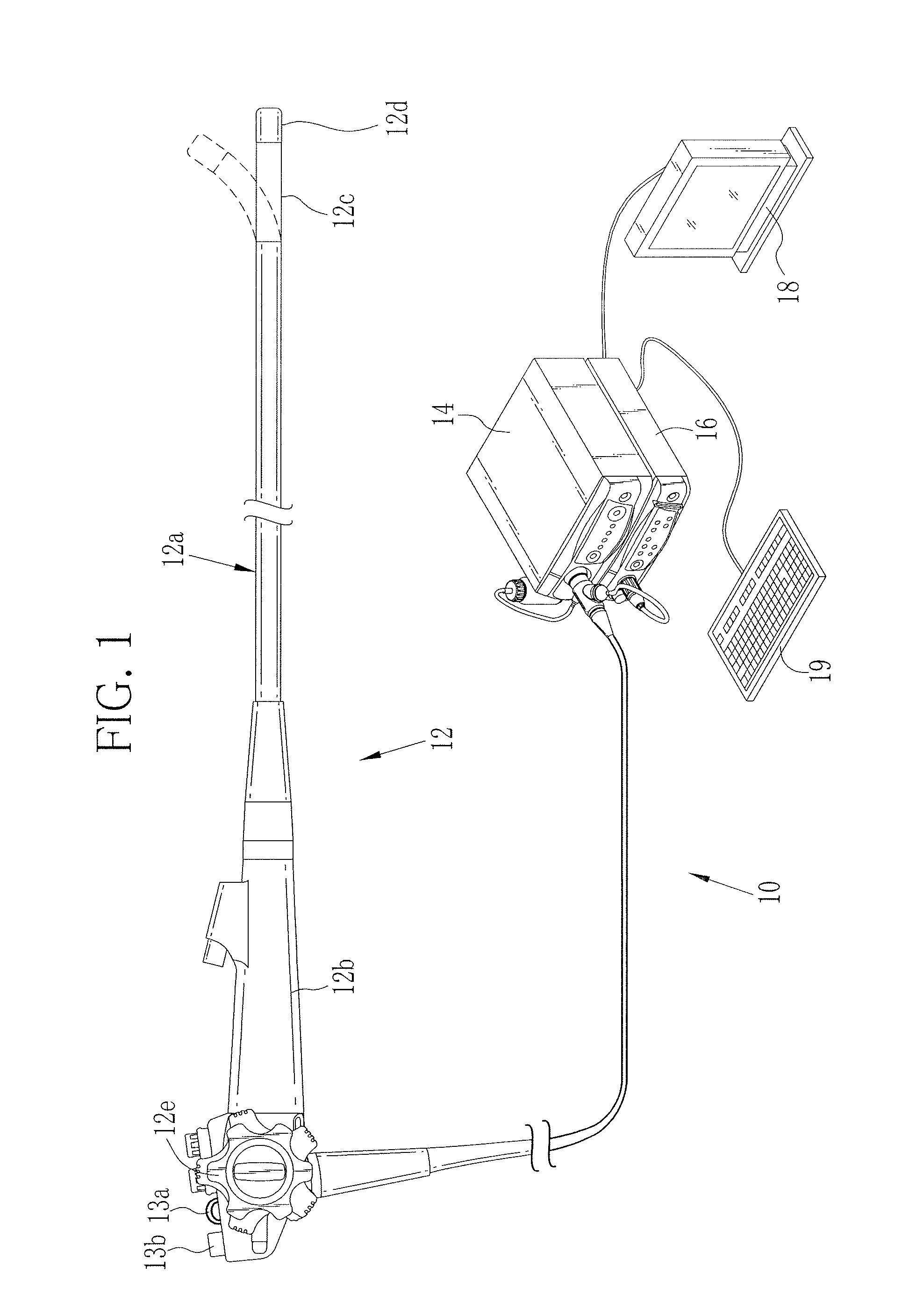

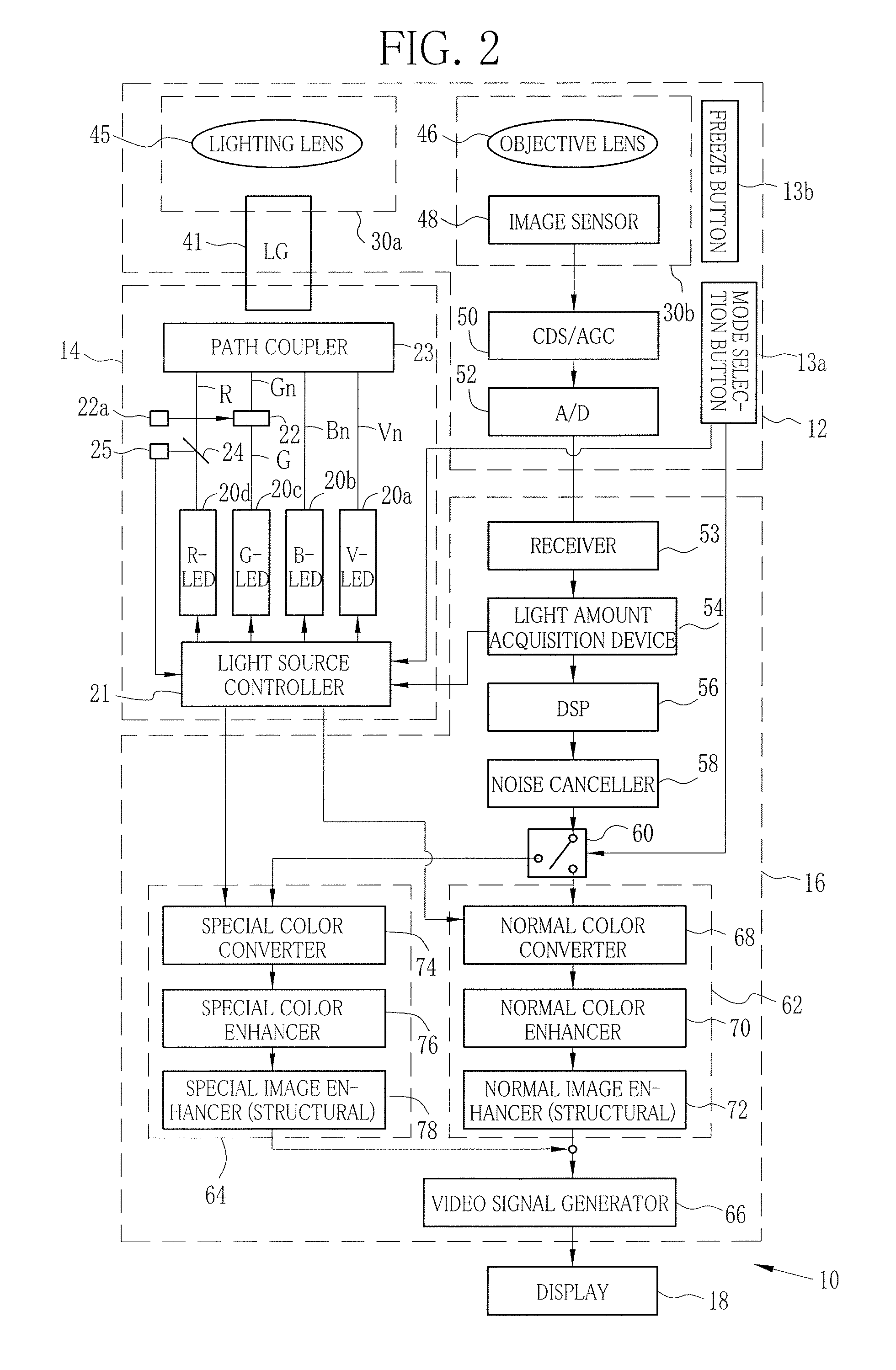

Endoscope apparatus and image processing apparatus

ActiveUS20090118578A1Easy to compareTelevision system detailsSurgeryImaging processingSequential method

A normal light CCD 11 is driven via a normal light CCD control section 25 by a timing signal from a timing circuit section 29 of a video processor 20. At the same time, a fluorescence CCD 12 is driven via a fluorescence CCD control section 26. Then, an image pickup signal according to an RGB frame sequential method from the normal light CCD 11 is processed by a normal light image video circuit section 27 and a normal color image is created while an image pickup signal from the fluorescence CCD 12 is processed by a fluorescence image video circuit section 28, and an image pickup signal of a subject excited by blue illumination light and transmitted through a fluorescence transmitting filter 13 is extracted to create a fluorescence image of the subject. The normal color image and the fluorescence image of the subject are synthesized by an image synthesizing circuit section 30 and outputted to a monitor 2, whereby the normal light image and the fluorescence image is displayed side by side or on top of each other.

Owner:OLYMPUS CORP

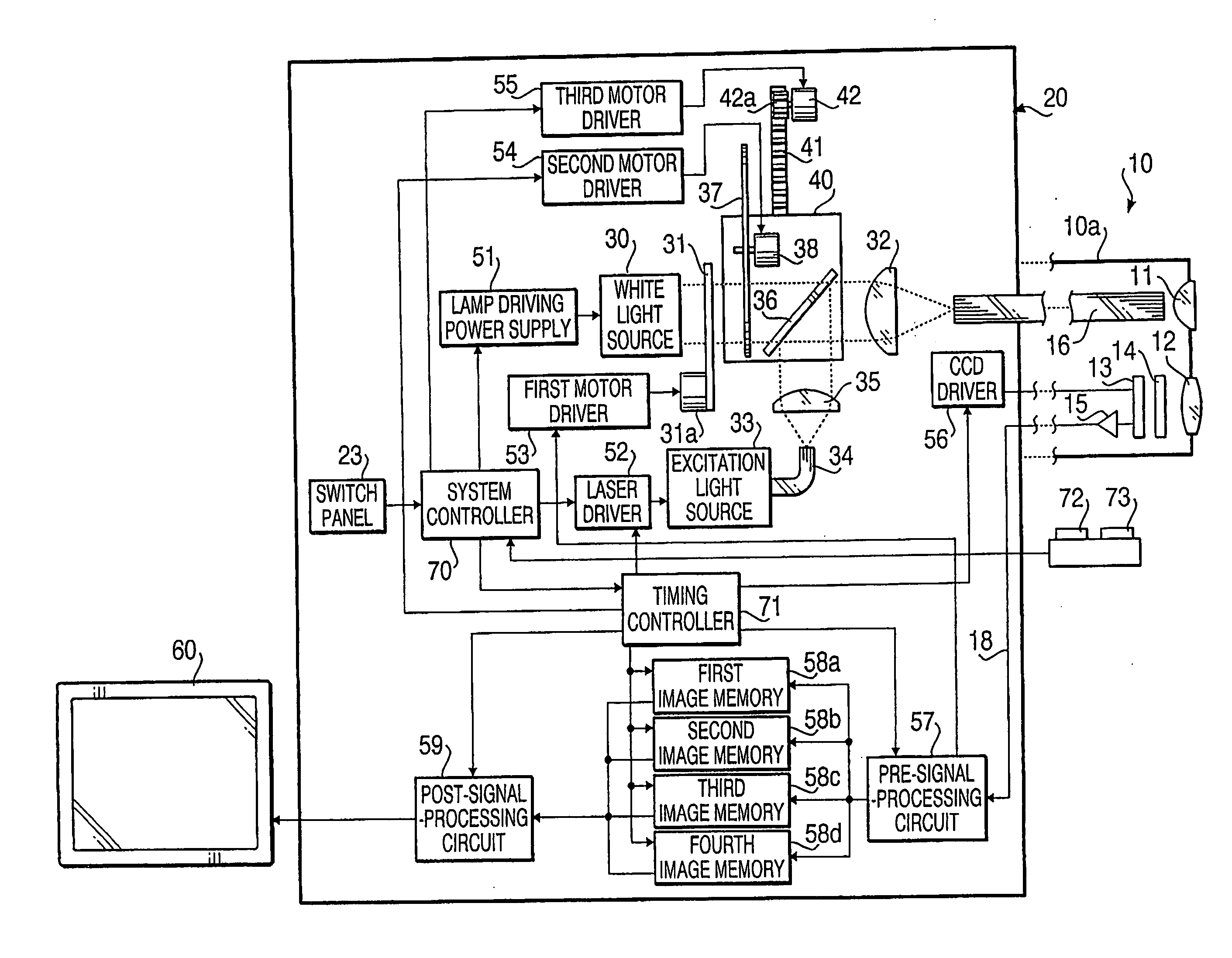

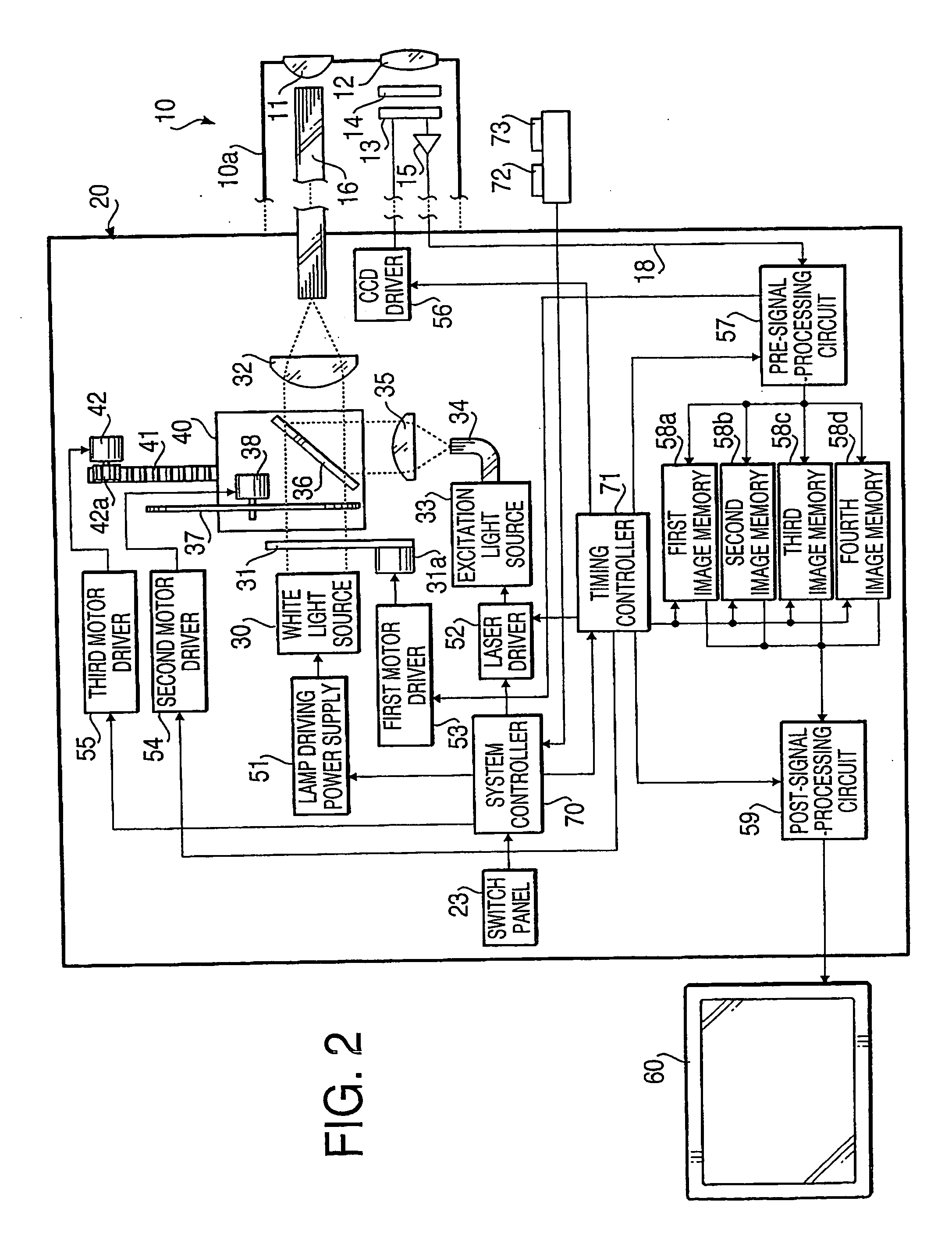

Electronic endoscope system for fluorescence observation

An electronic endoscope system, which is adapted to observe a fluorescence image of autofluorescence emitted from a body cavity wall irradiated with excitation light, includes a controller that controls a light source apparatus to alternately introduce either white light or excitation light into a light guide while taking a normal color image and the fluorescence image, and controls an image signal generating system to generate normal color image signals and fluorescence image signals. The controller further controls a display device to display a still fluorescence image in a first window defined on a displaying area thereof based on the fluorescence image signals which have been generated when a still image switch is turned ON during the time to take the fluorescence image, and simultaneously to display a moving normal color image in a second window defined on a displaying area thereof based on the normal color image signals generated every time the body cavity wall is intermittently illuminated with the white light, the first window being larger than the second window.

Owner:HOYA CORP

Water-based ink set for ink-jet recording

InactiveUS20060268084A1High chroma saturationGood colorMeasurement apparatus componentsDuplicating/marking methodsWater basedEngineering

Owner:BROTHER KOGYO KK

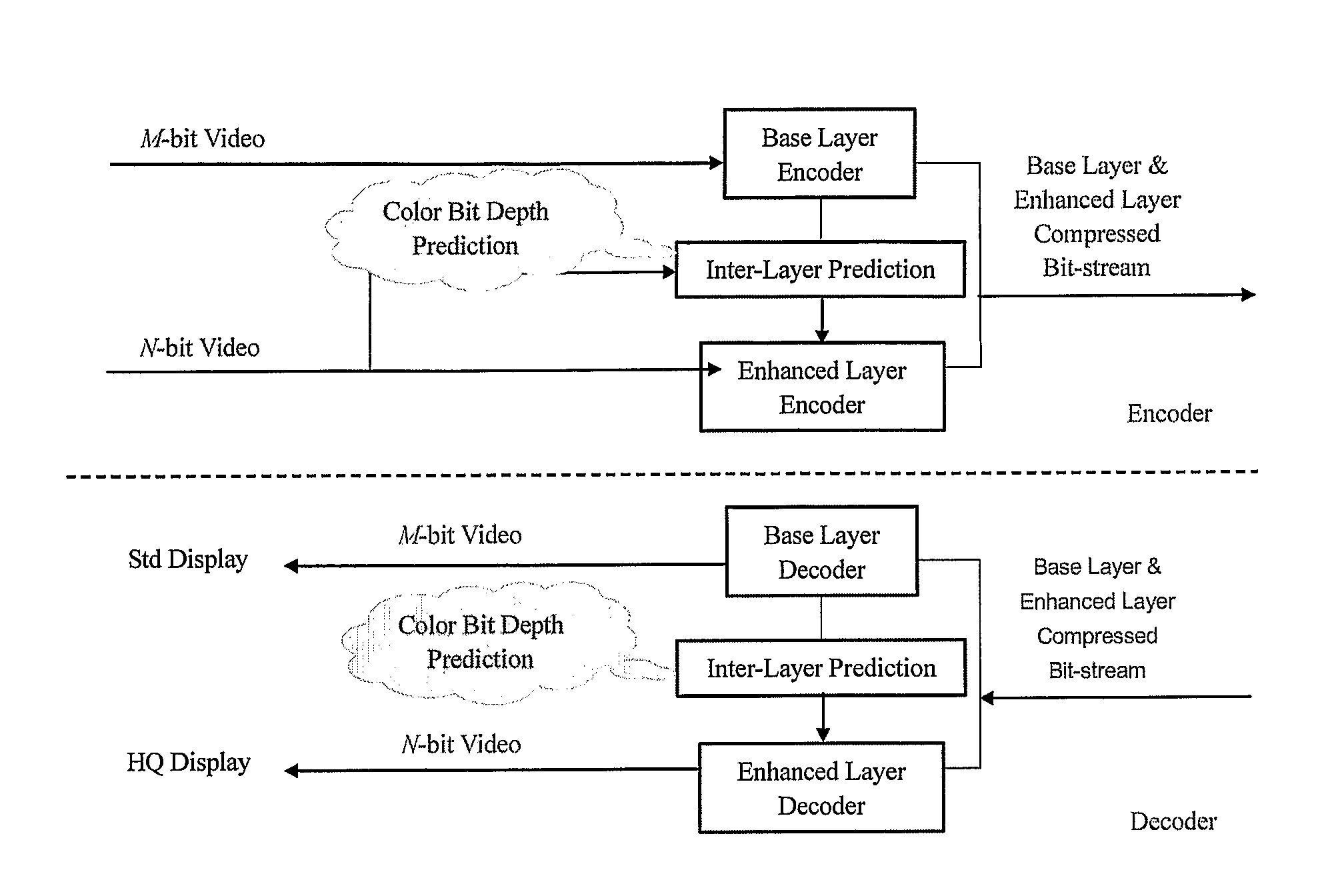

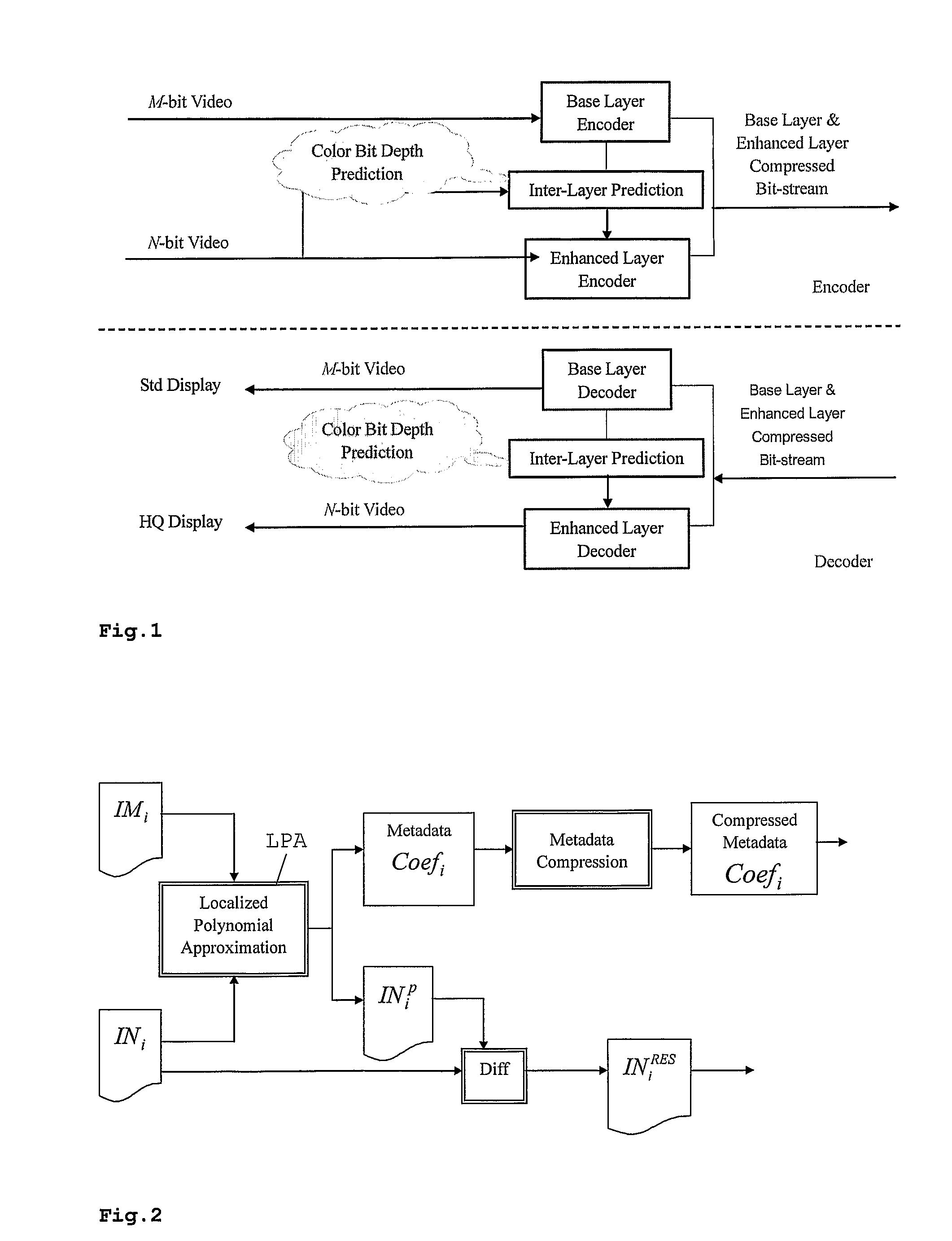

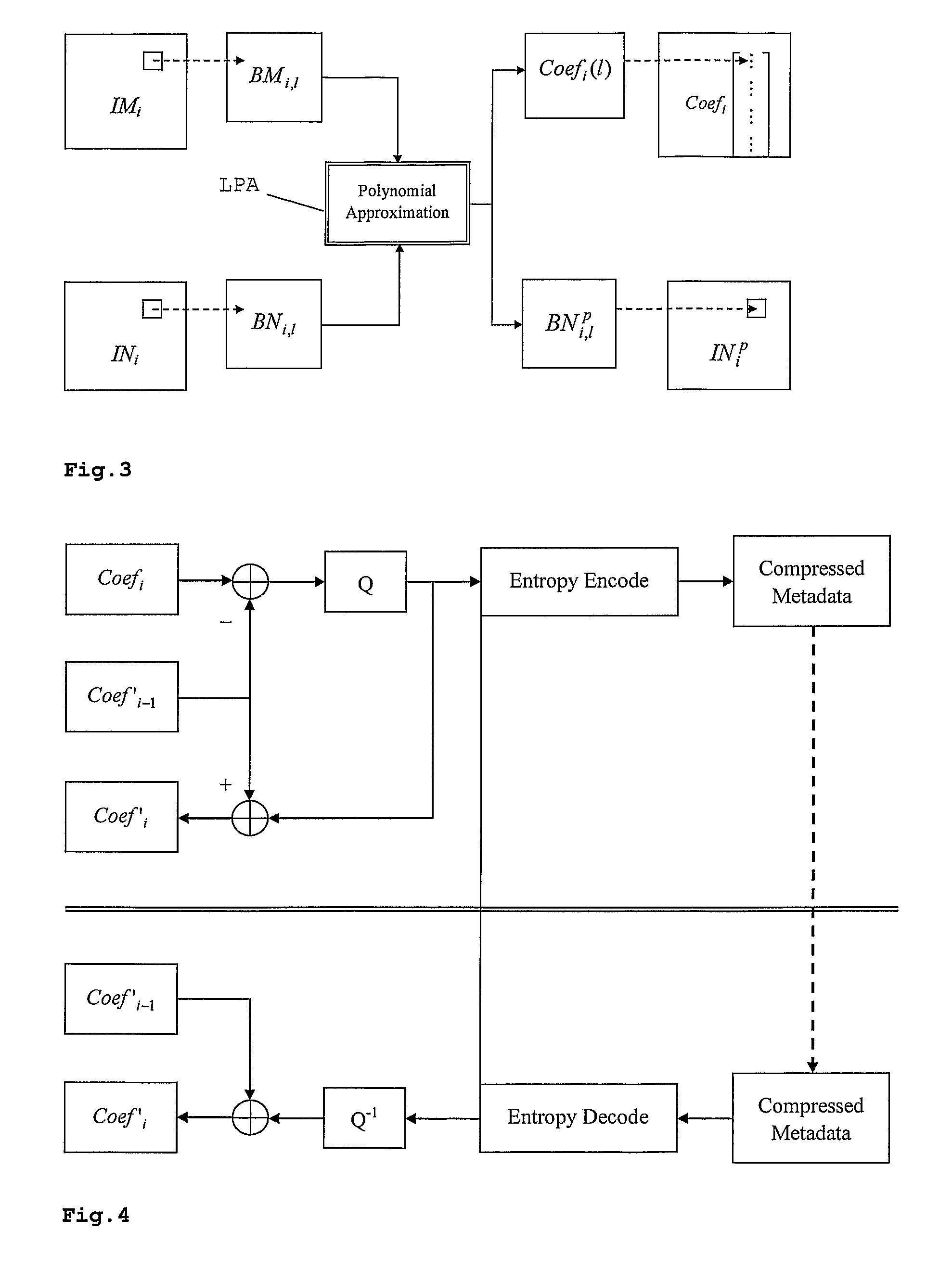

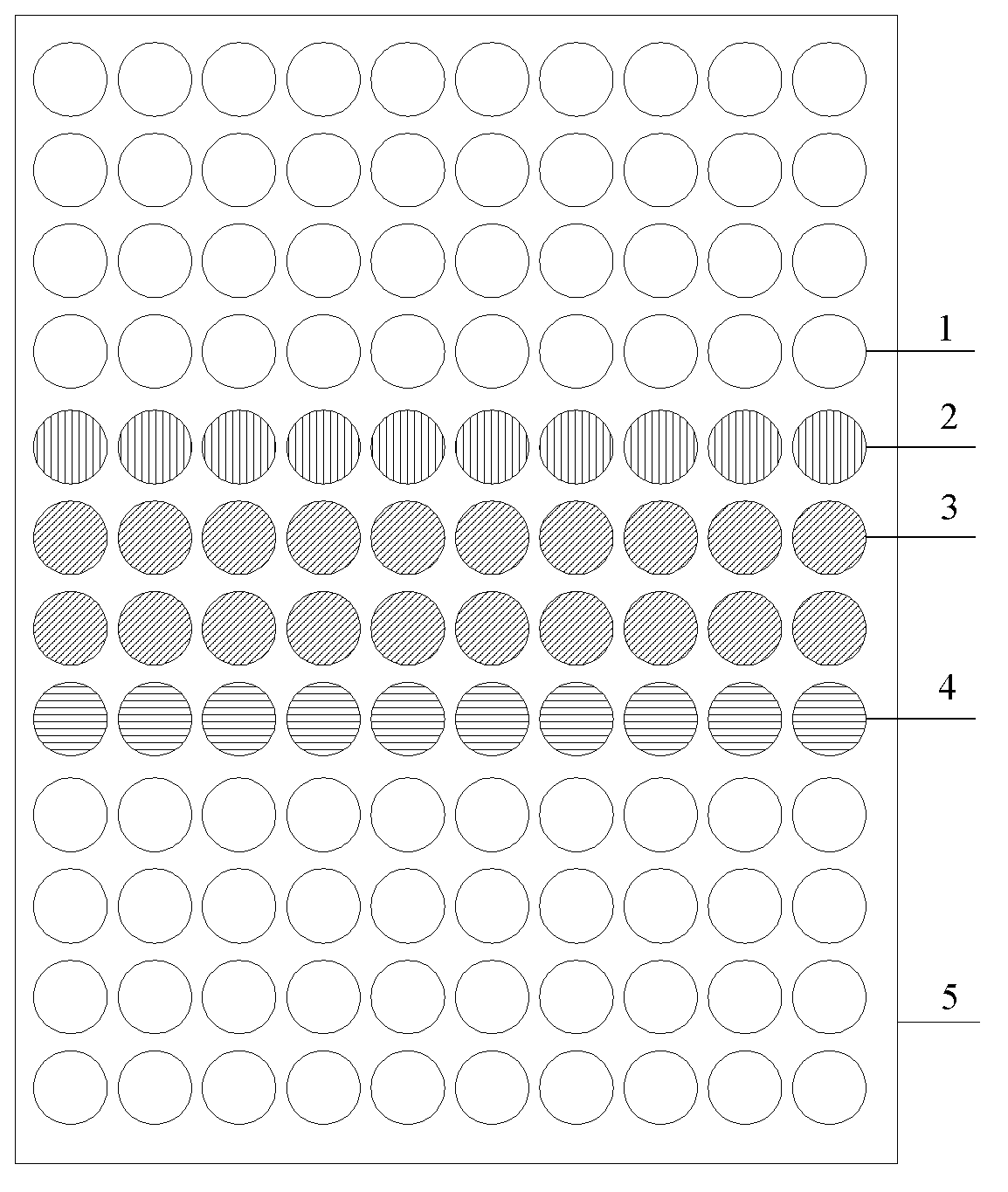

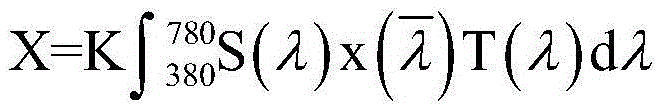

Method and device for encoding and decoding color enhancement layer for video

ActiveUS20100272185A1Easy to useColor television with pulse code modulationColor television with bandwidth reductionTemporal resolutionData stream

Enhanced dynamic range requires more than 8 bit representation for single color components of pixels. For this purpose, normal color resolution images and high color resolution images are available. Backward compatibility can be achieved by a layered approach using a color enhancement layer, and a conventional image as color base layer. Both have same spatial and temporal resolution. Encoding of the color enhancement layer uses prediction and residual. A methods for optimized color enhancement prediction is disclosed. Color bit depth prediction is done by constructing a polynomial that approximates for all pixels of one color component of a block the color enhancement layer from the color base layer. A predicted version of the high color resolution image and a residual are generated and updated by a residual. The coefficients are compressed and added as metadata to the data stream.

Owner:INTERDIGITAL VC HLDG INC

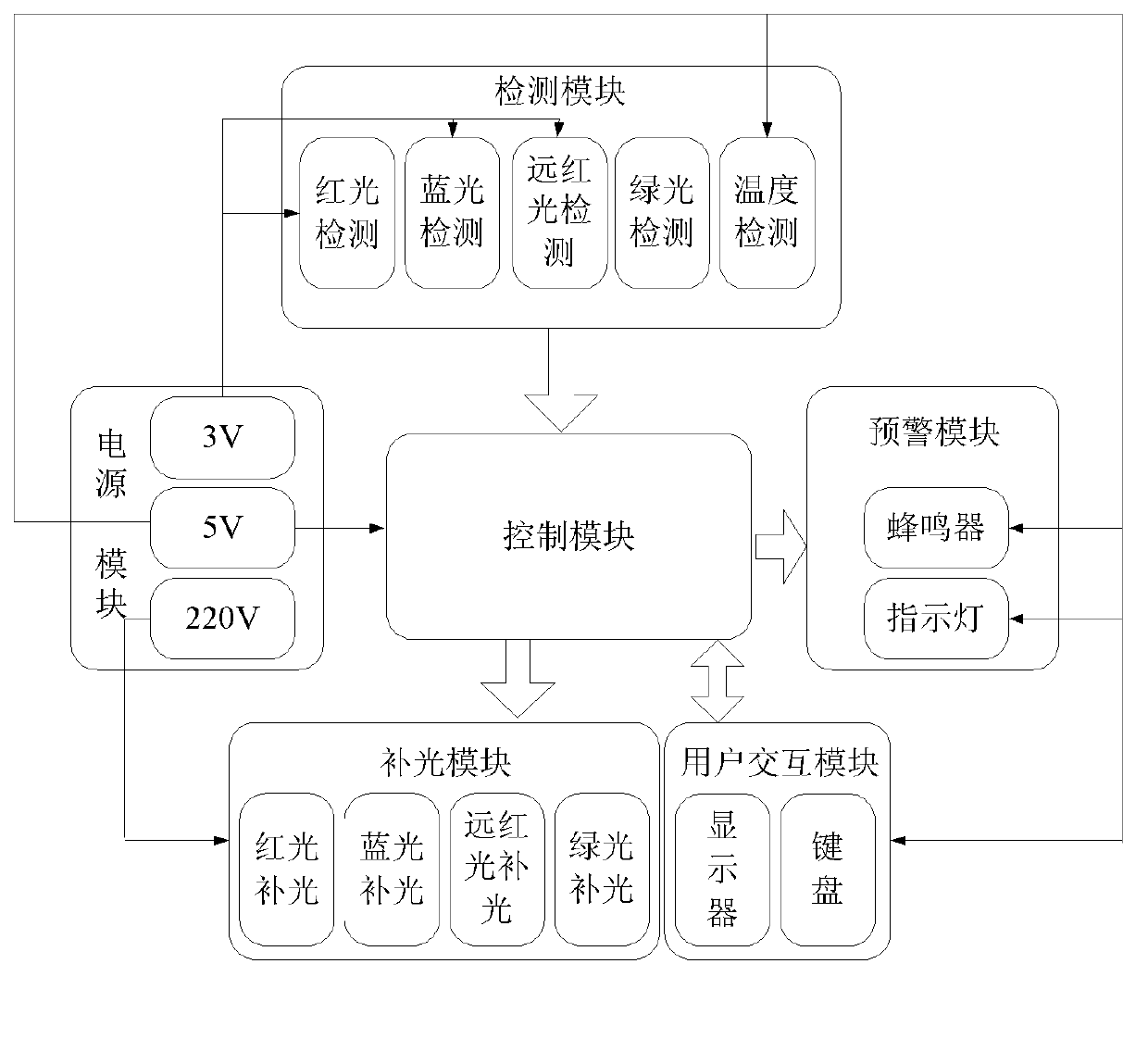

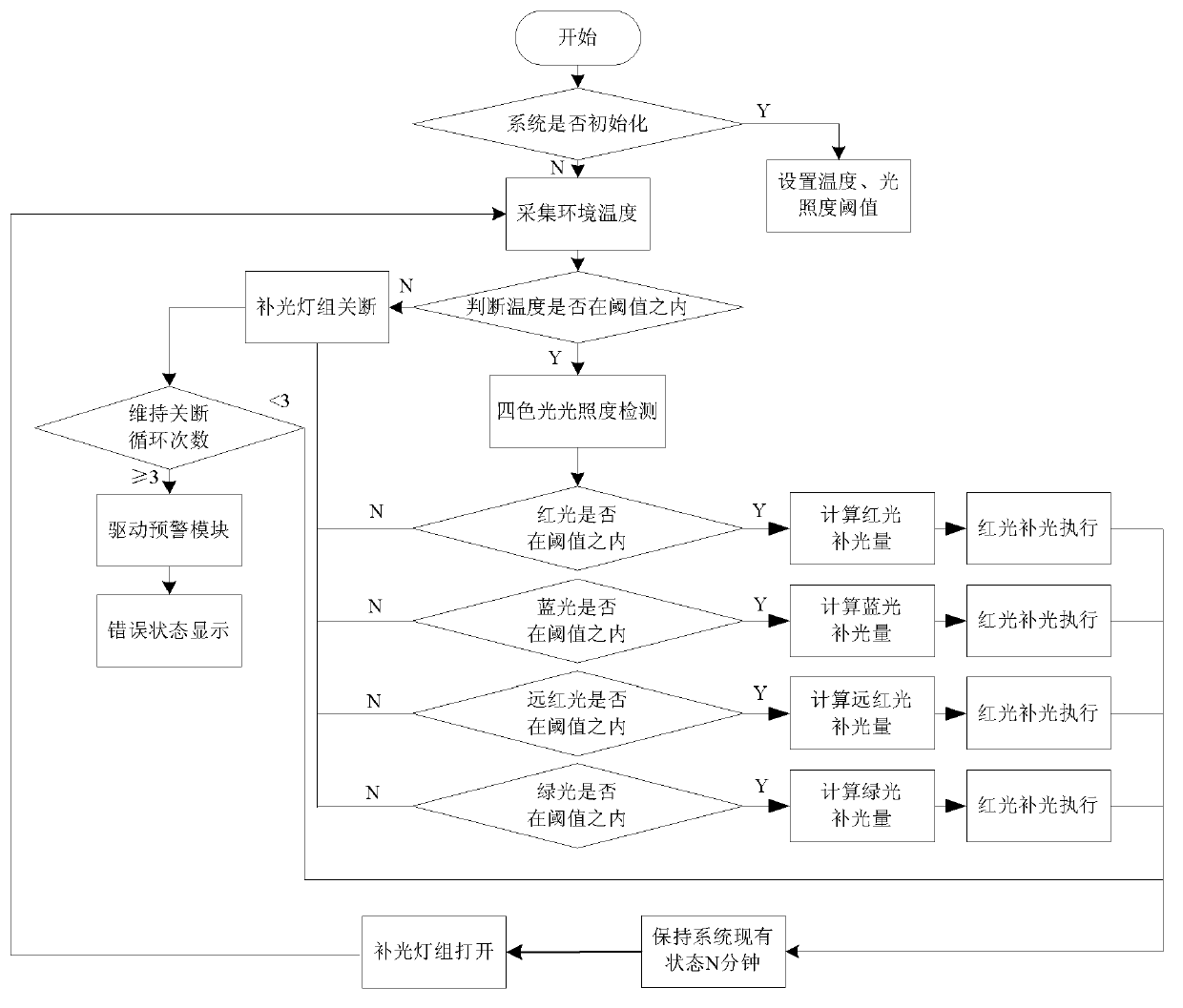

Light supplemental device of plant and light supplemental method thereof

ActiveCN103104839AMeet the needs of targeted trainingPoint-like light sourceElectric circuit arrangementsFar-redLed array

The invention discloses a light-emitting diode (LED) four-color light supplemental device of a plant. The light supplemental device of the plant comprises a red-light LED array, a blue-light LED array, a far-red-light LED array, a green-light LED array, a substrate 5 and a control circuit, wherein the red-light LED array, the blue-light LED array, the far-red-light LED array and the green-light LED array are sequentially and fixedly arranged on the substrate 5, and the control circuit is used for controlling the red-light LED, the blue-light LED, the far-red-light LED, and the green-light LED to supplement light. According to the light supplemental device of the plant and a light supplemental method of the plant, the four-color light LED with a specific specification is selected, not only are colored lights which have a plurality of wavelengths and specific effects on plants by means of centralization of a variety of photosynthesis considered, but also economy and practicability are further taken into account. Meanwhile, considering the comfort of the human eyes, the four-color light LED with normal colors such as red, blue, far-red and green are selected. When the color lights are selected, according to the power of the selected LED with various colors, a reasonable ratio of R / B, R / FR and R / G can be obtained through the control circuit, thus the photosynthesis of the plant and the comfort requirement of the eyes of human can be met, and the requirements of orientation of cultivation of the plant with the need of participation of human can be better met.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Electronic endoscope system for fluorescence observation

An electronic endoscope system, which is adapted to observe a fluorescence image of autofluorescence emitted from a body cavity wall irradiated with excitation light, includes a controller that controls a light source apparatus to alternately introduce either white light or excitation light into a light guide while taking a normal color image and the fluorescence image, and controls an image signal generating system to generate normal color image signals and fluorescence image signals. The controller further controls a display device to display a still fluorescence image in a first window defined on a displaying area thereof based on the fluorescence image signals which have been generated when a still image switch is turned ON during the time to take the fluorescence image, and simultaneously to display a moving normal color image in a second window defined on a displaying area thereof based on the normal color image signals generated every time the body cavity wall is intermittently illuminated with the white light, the first window being larger than the second window.

Owner:HOYA CORP

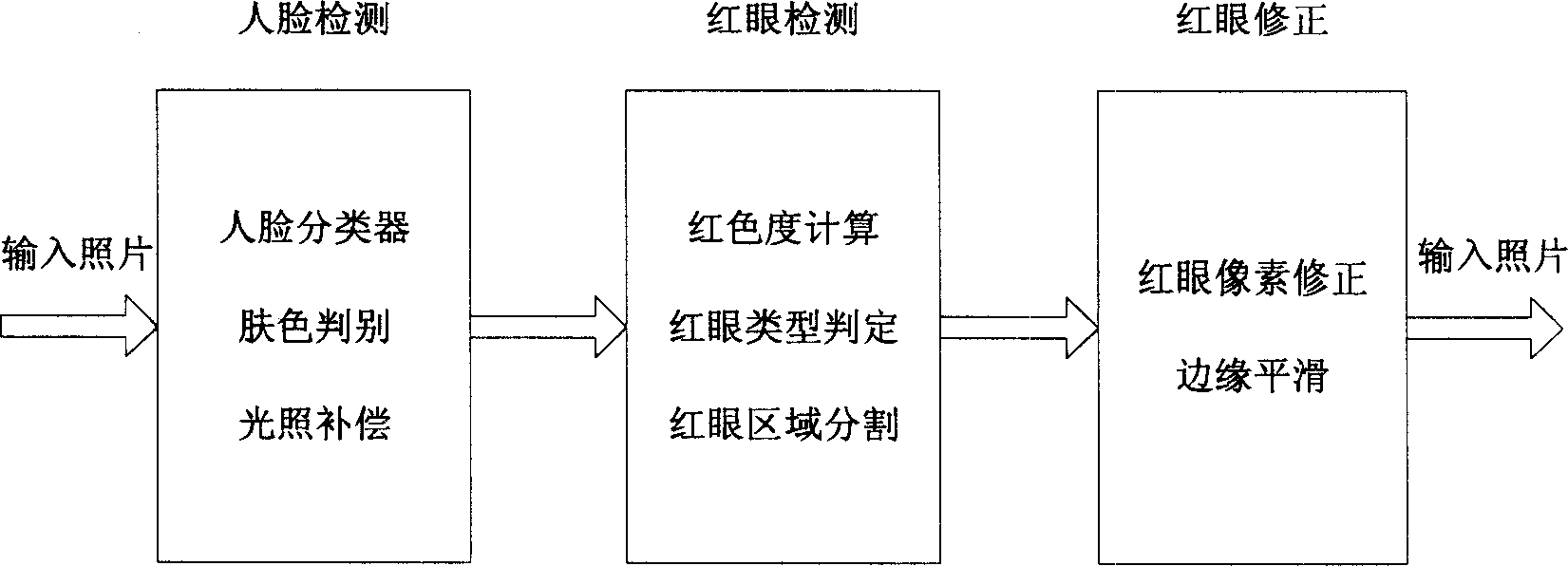

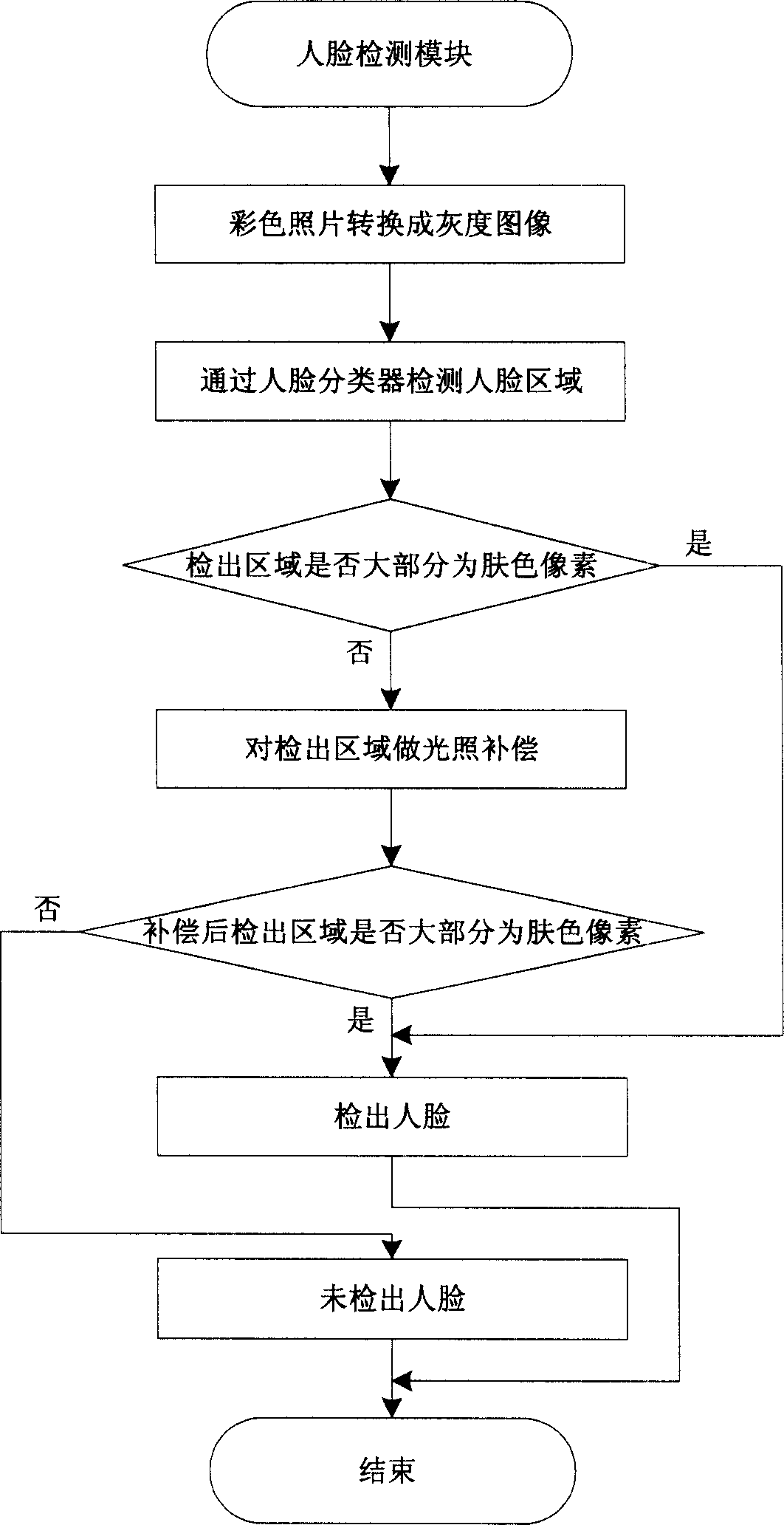

Red eye moving method based on human face detection

InactiveCN1750017ANarrow searchImprove accuracyImage enhancementCharacter and pattern recognitionFace detectionPattern recognition

The red eye eliminating method based on human face detection in image treating technology includes three steps of: 1. human face detection with human face classifier obtained through computer learning algorithm training combined with skin color information to obtain the human face area from the picture; 2. red eye detection via dividing the detected area into typical red eye and wear red eye based on the red color distribution in the human face area; and 3. red eye correction via searching red eye area, color correction and edge smoothening to restore normal color of picture. The present invention adopts fast human face detecting algorithm to reduce red eye searching range and correction based on the color of pupils, and can detect precisely and correct red eye in digital picture in reasonable image processing speed even in condition of no attendance.

Owner:SHANGHAI JIAO TONG UNIV +1

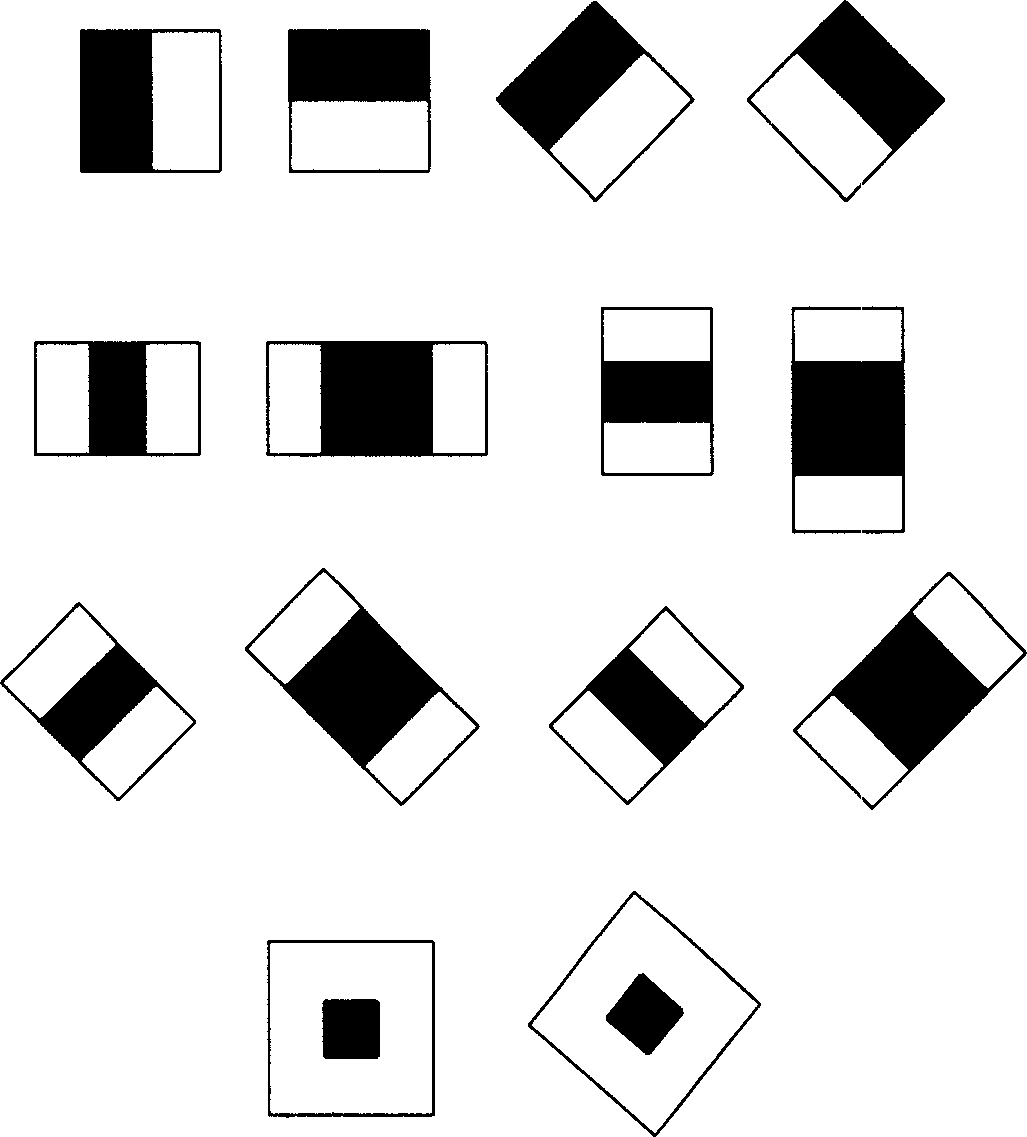

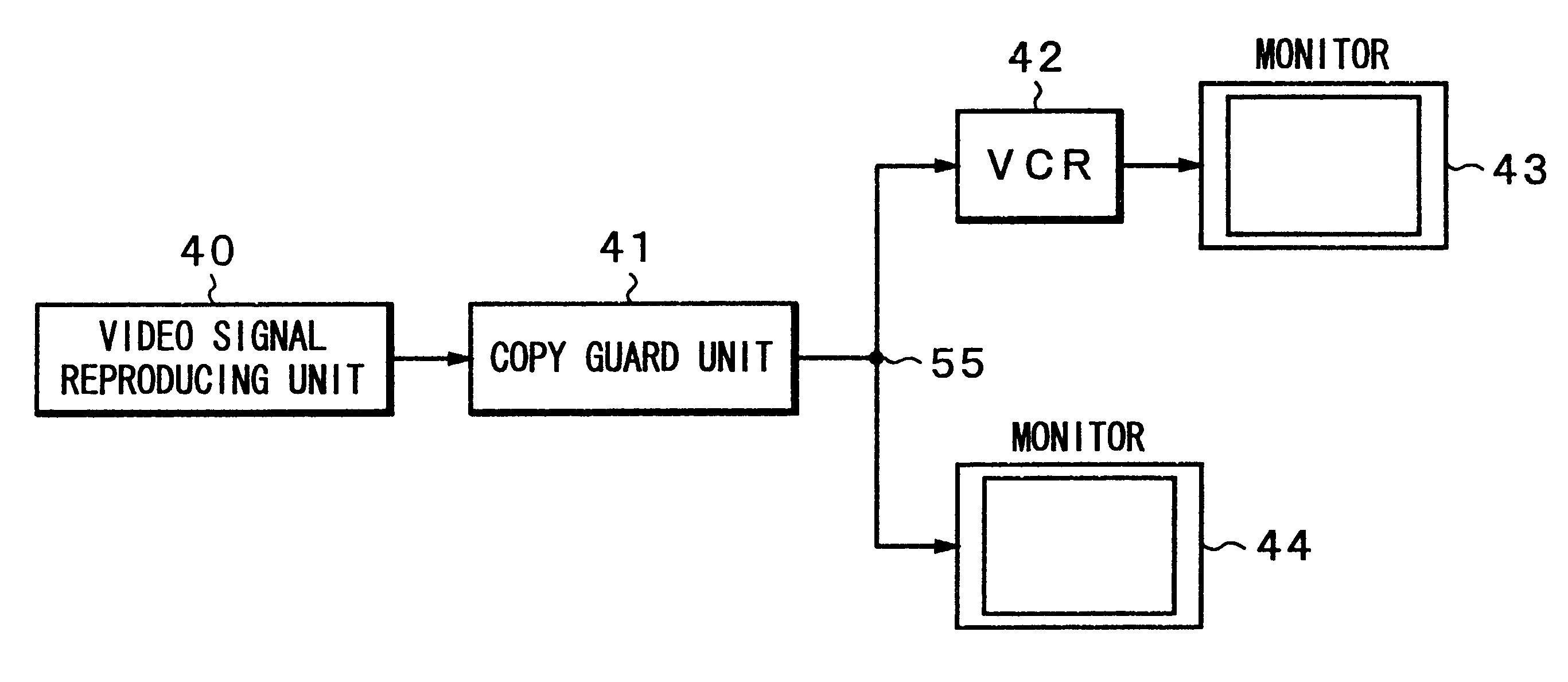

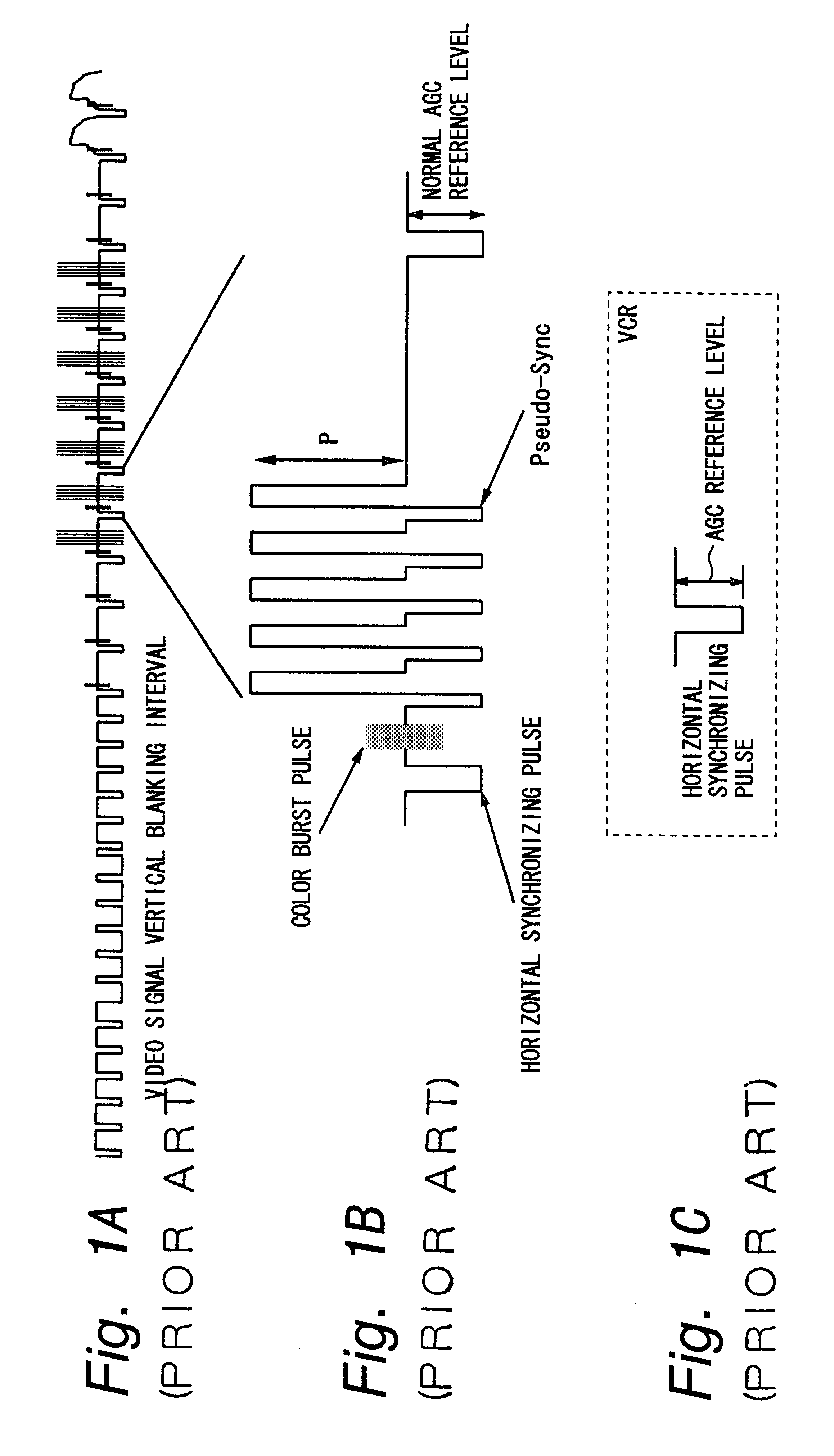

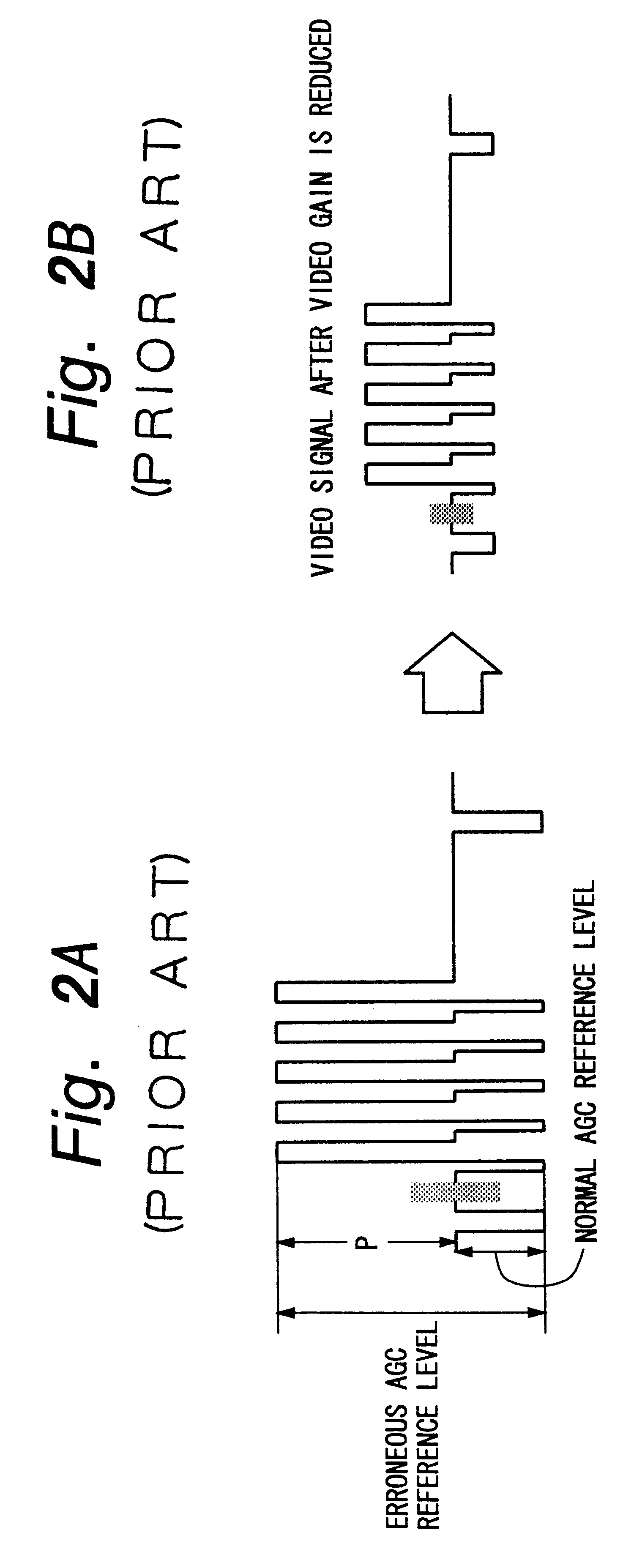

Video signal copy guard apparatus and method

InactiveUS6222978B1Television system detailsAnalogue recording/reproducingProtection systemComputer science

A video signal copy guard system in which a special color burst signal (or "copy prohibition signal") is inserted into the video signal to be copy protected so that the protected signal includes both a special color burst signal and a normal color burst signal. The special color burst signal is placed adjacent to the normal color burst signal, and its phase, frequency, and / or amplitude is varied with respect to the normal color burst signal. The special color burst signal interferes with the normal color burst signal when an analog VCR attempts to process the protected signal. Thereby, preventing unauthorized dubbing of the protected signal.

Owner:SONY CORP

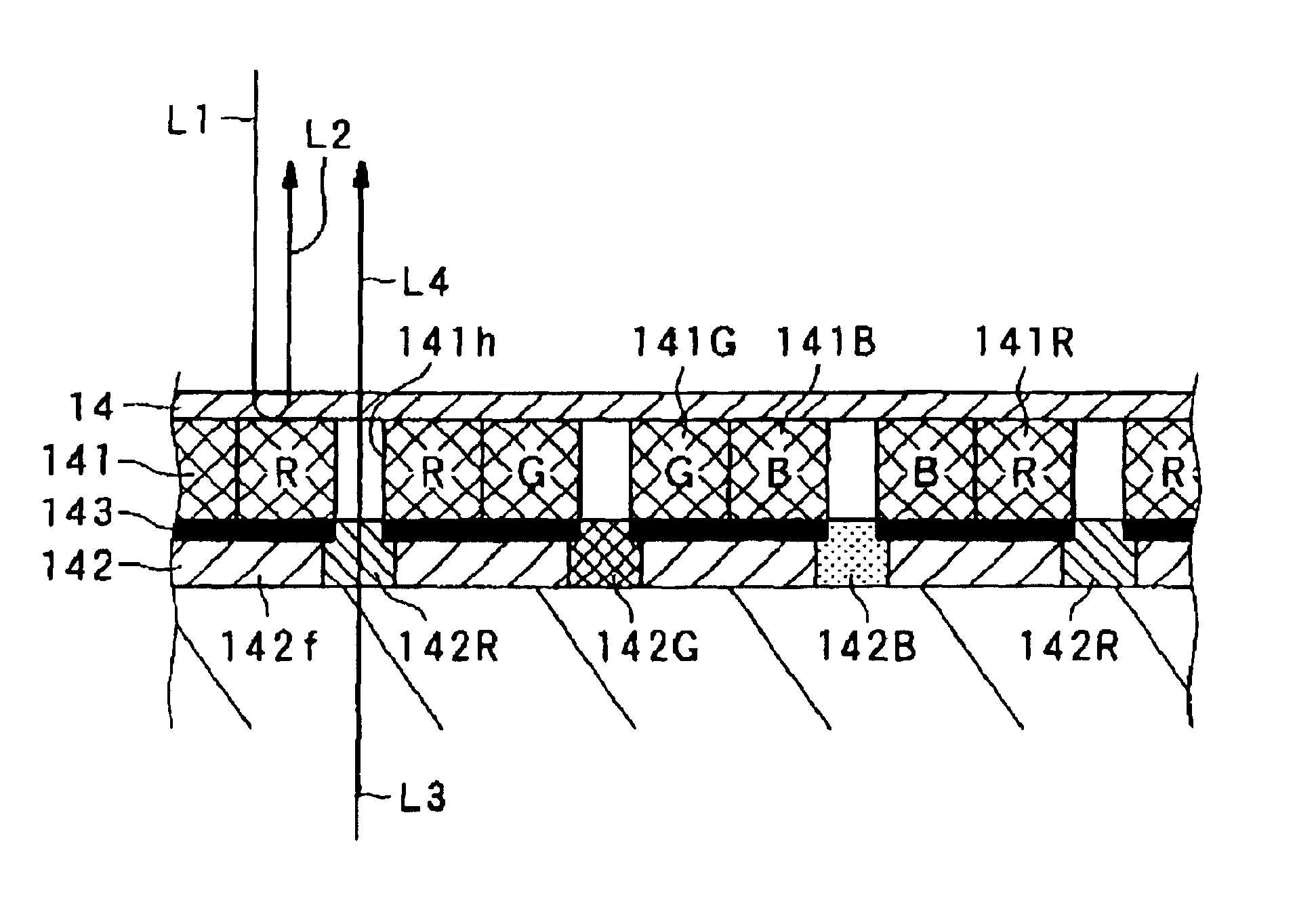

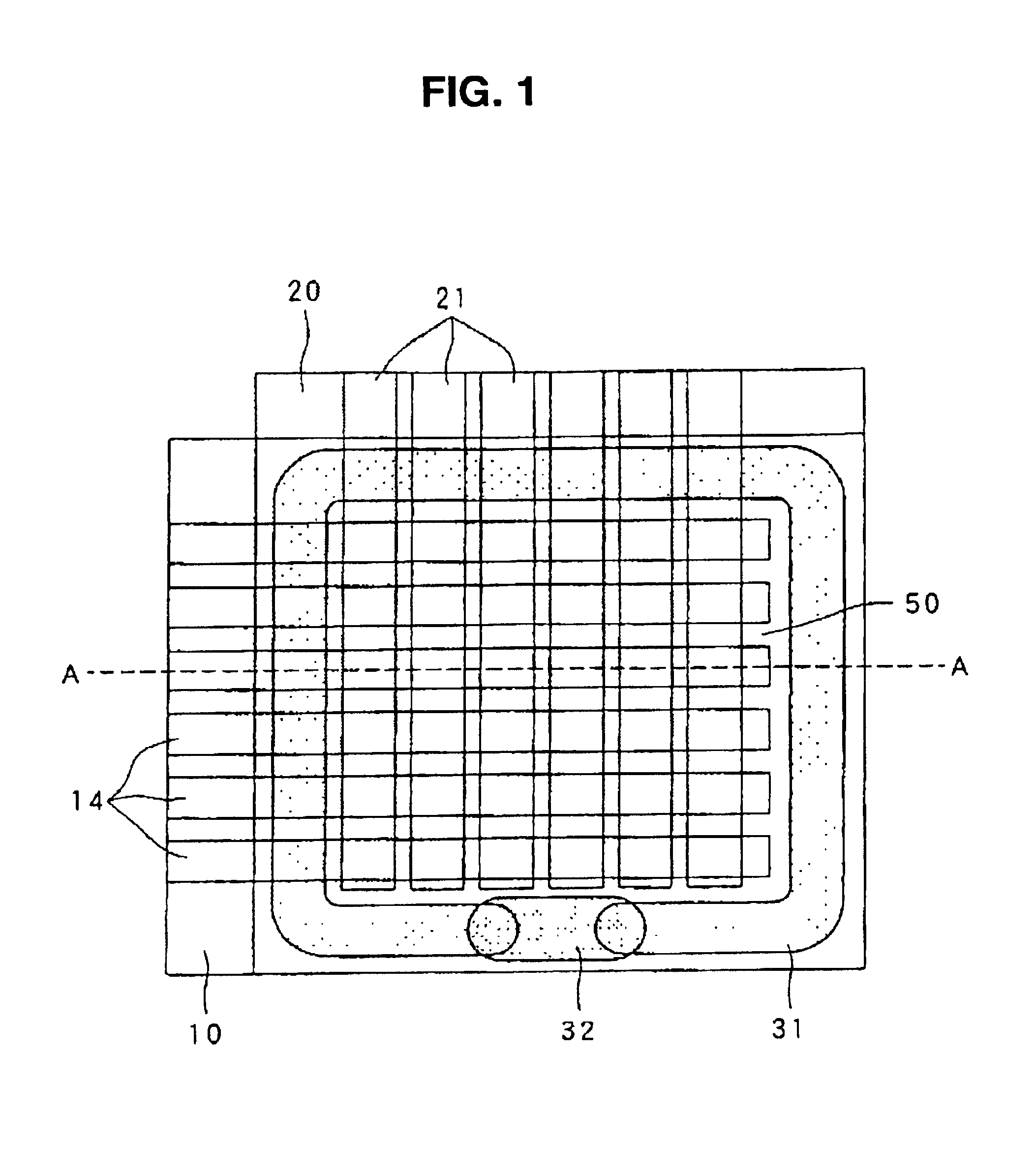

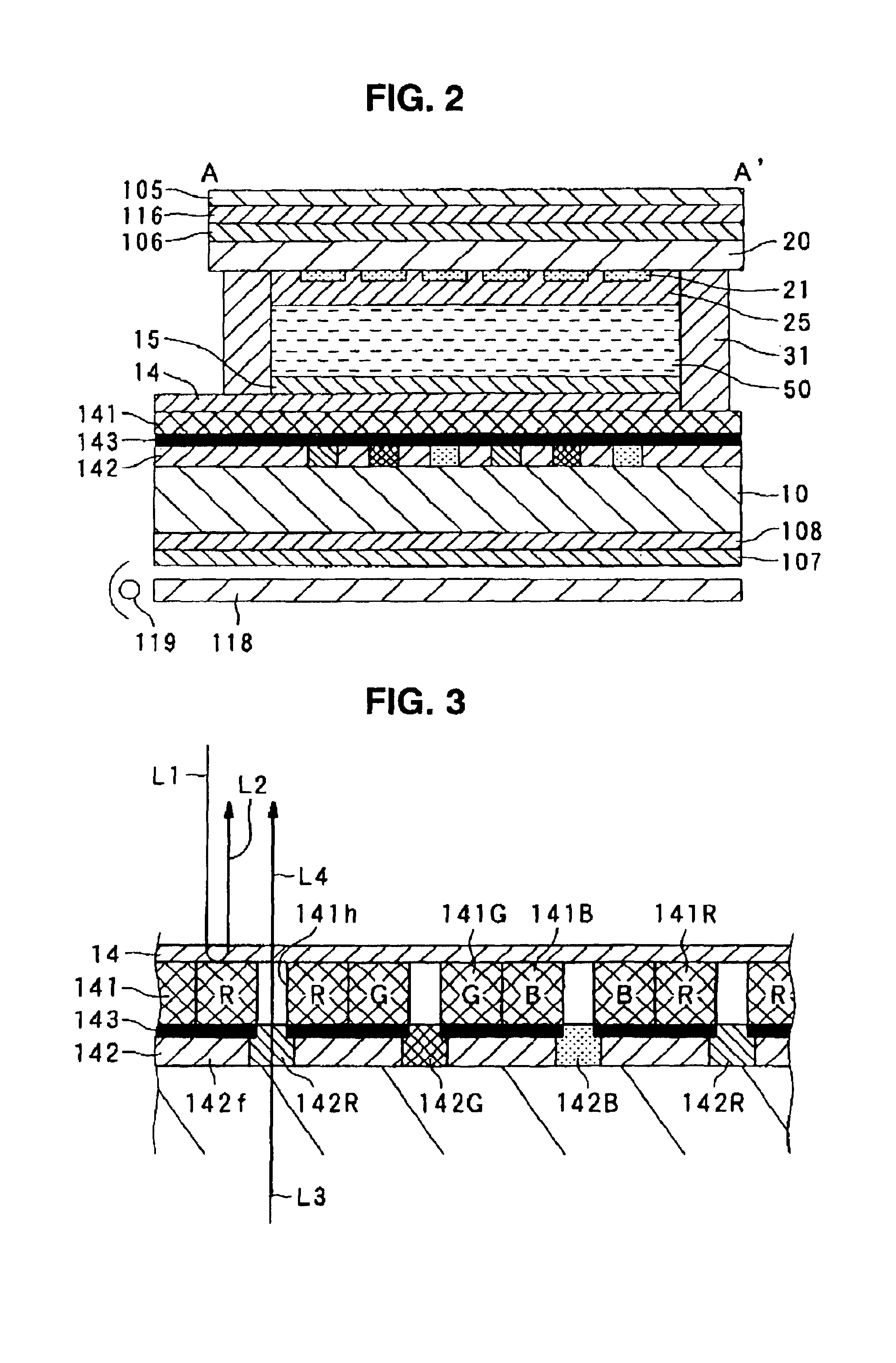

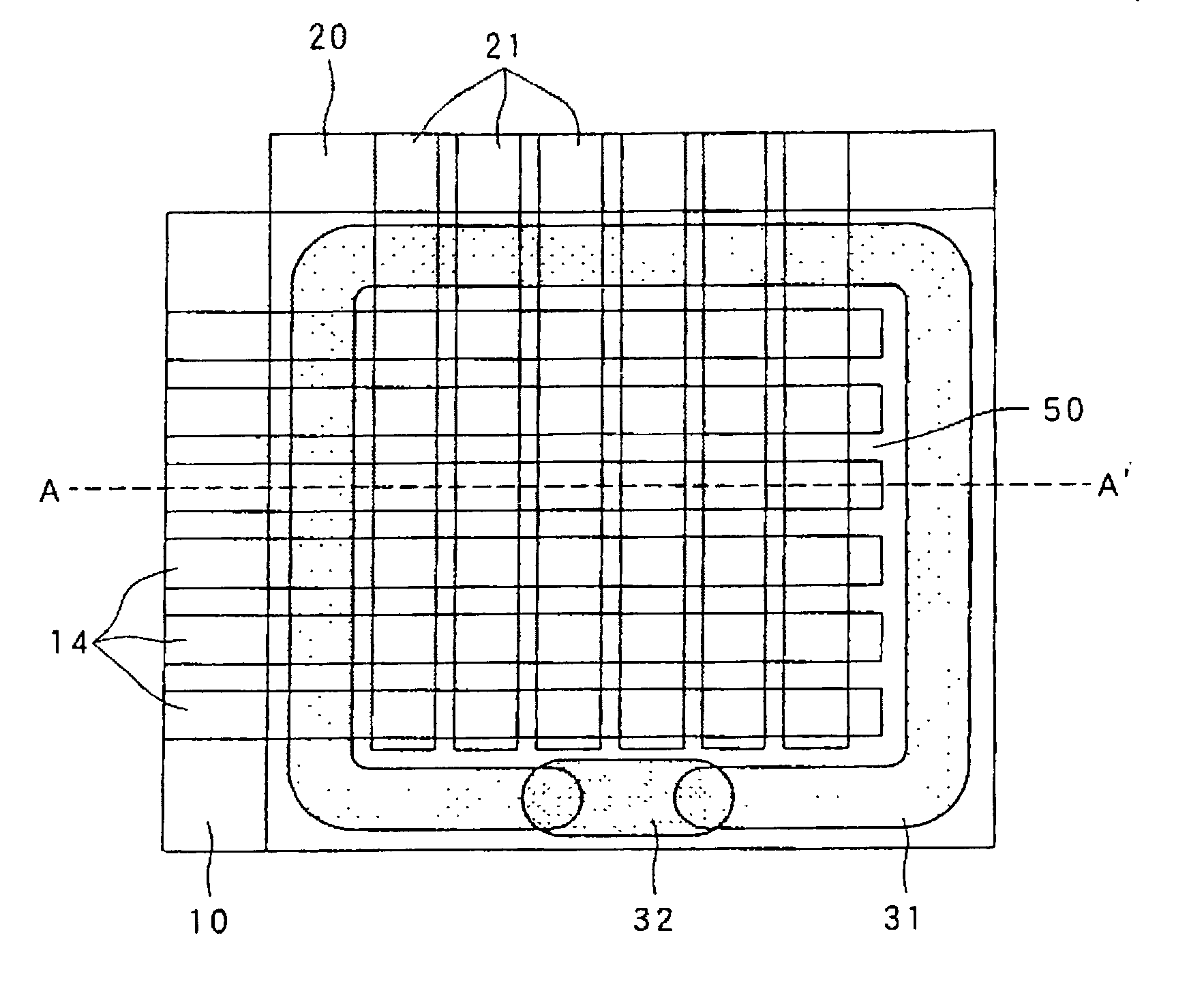

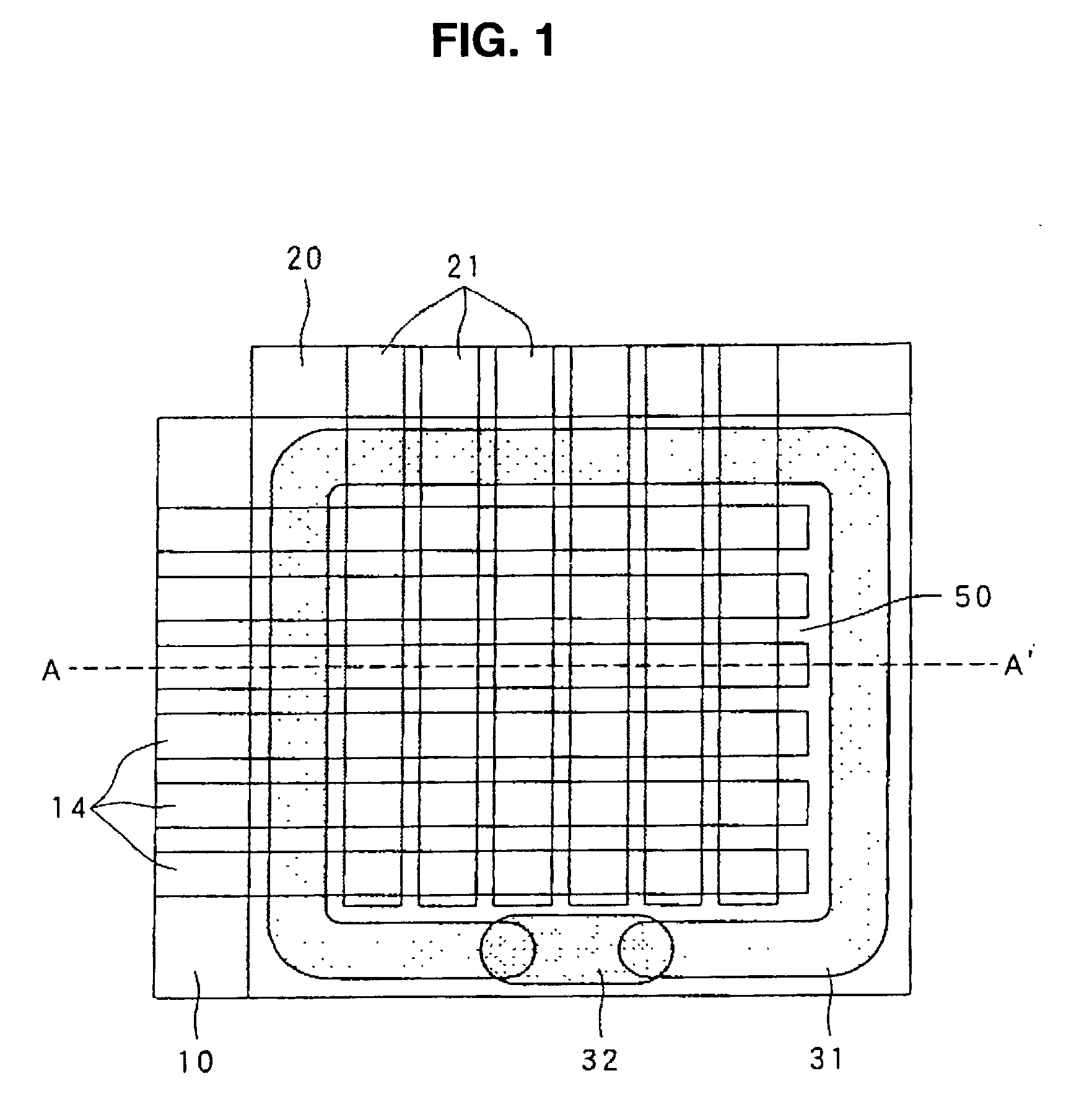

Transflective electro-optical device and electronic apparatus

InactiveUS6900864B2Create displayNon-linear opticsIdentification meansSelective reflectionDisplay device

In an electro-optical device, such as a transflective liquid crystal device, color transmissive display having normal color tones is performed, and in addition, bright, color reflection display is also performed. The electro-optical device in accordance with the invention includes an electro-optical material provided between a first substrate and a second substrate, and display electrodes provided above the first substrate so as to be opposed to the second substrate. The electro-optical device further includes a first color filter having a selective-reflection region in each pixel that selectively reflects light in a predetermined wavelength range, and a light transmission region in each pixel that transmits light outside of the predetermined wavelength range; a light-shielding film provided so as to be opposed to the selective-reflection regions; and a second color filter having a selective-transmission region in each pixel that selectively transmits light in the predetermined wavelength range.

Owner:SEIKO EPSON CORP

Aqueous flexible plate printing ink and preparation thereof

InactiveCN101328329AReduce pollutionFine inkInksOther printing apparatusSolubilityAtmospheric contamination

A water-basedsoft printing ink comprises the following compositions: 30 to 35 percent of pigment, 25 to 32 percent of acrylic resin, 0.2 to 0.5 percent of antifoaming agent, 2 to 5 percent of ethylene glycol monomethyl ether, 1.0 to 2.5 percent of wax slurry, 0.9 to 1.5 percent of leveling agent, and 23 to 30 percent of water. A preparation method comprises the three working procedures of colored slurry grinding, aquosity treatment and printing ink preparation in turn. The water-basedsoft printing ink has novel compositions, scientific blending, simple preparation, lower cost, fine ink quality, mellow brightness, high color saturation, brilliant color, high drying speed, grid point superimposition and overprinting, good water solubility, easy cleaning, corrosiveness free on printing rollers, low viscosity, high color content, good penetrability and printing adaptability, suitability for multicolor machine high-speed printing, high abrasion resistance, difficult decolorization, wide color range, closeness to a normal color sample, and consistency to the requirements on top-grade printing; and the printing ink also meets EU ROHS standards, and facilitates safe production and environmental protection with low air pollution and without any noxious solvent residual.

Owner:广东佳景科技股份有限公司

Mechanization seed making method of hybridized rice using three line method

InactiveCN1442038AImprove seed production efficiencyRealize the whole process of mechanized operationPlant genotype modificationMechanizationNormal color

A mechanized method for preparing the seeds of three-line hybridized paddy rice includes such steps as hybridizing the rice whose husk color is different from rormal color with the maintenance line whose husk color is normal to obtain the maintenance-line seeds whose husk color is different from normal color; transfer culturing of the sterile-line seeds whose husk color is different from normal color, mixing the maintenance-line seeds with the sterile-line seeds, mechanical sowing, harvesting; and further using color selecting machine for color separation to obtain the hybridized seeds and recovery-line seeds.

Owner:曹立勇

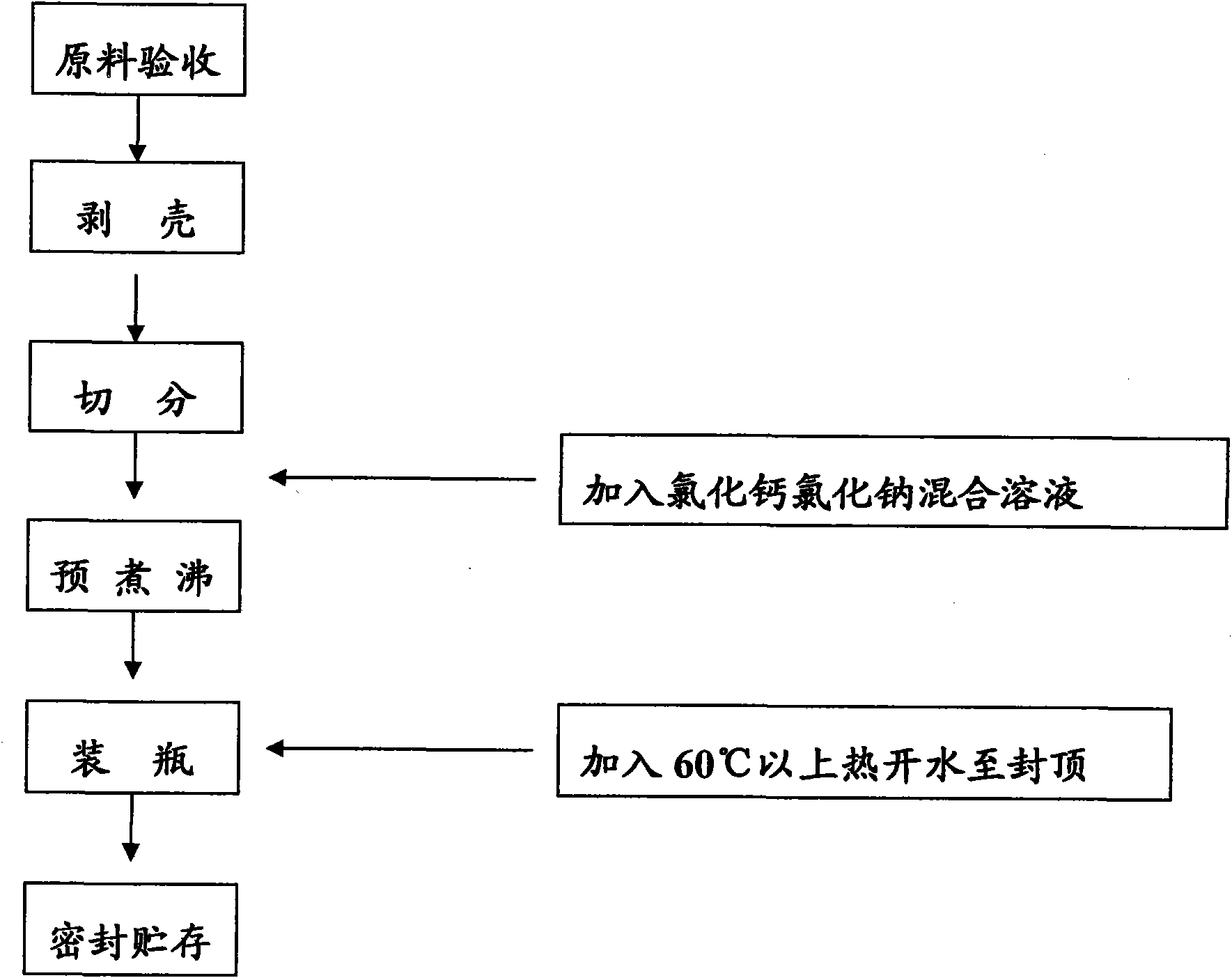

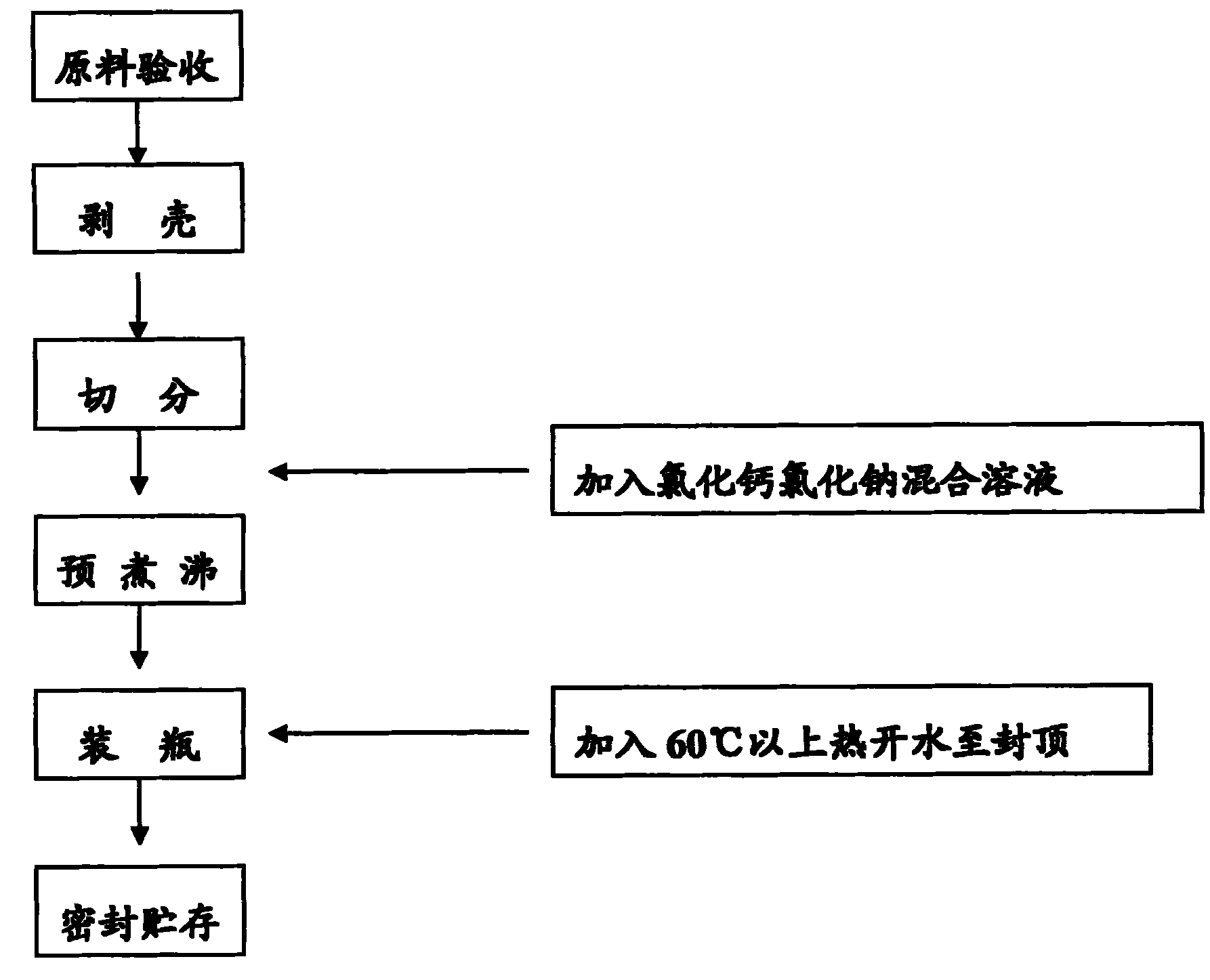

Method for keeping bamboo shoots fresh

The invention provides green technology for keeping bamboo shoots fresh, which comprise the following steps of: husking and slicing fresh bamboo shoots; adding the husked and sliced bamboo shoots into mixed solution which is prepared from calcium chloride and sodium chloride in a mass ratio of 1:1-1:1.5, wherein the calcium chloride accounts for 0.4 to 0.6 percent of the mass of the total solution; cooking the bamboo shoots for sterilizing; directly putting the cooked bamboo shoots into a container on which pasteurization is performed in advance; adding hot boiled water into a plastic bottle to exhaust air in the bottle until the bamboo shoots are submerged by the water and the water level of the bottle reaches the neck of the bottle; and sealing a bottle cap for storing. The bamboo shoots stored by a method are non-toxic, do not have sour or peculiar smell and have normal color and certain brittleness. The retention period of the bamboo shoots can reach over 12 months. The method of the invention has the advantages of small investment, simple device, convenient operation and the like.

Owner:ZHEJIANG UNIV

Endoscope system and operating method thereof

A V-LED, B-LED, G-LED and R-LED for an endoscope are all driven to apply normal light to an object of interest in a body. An image sensor images the illuminated object and outputs an RGB image signal. A measurement sensor measures a light amount of red light from the R-LED. A light source controller acquires a current value for the R-LED according to a light amount signal from the measurement sensor and a target light amount signal for the R-LED. A normal color converter and the R-LED receive a current of the current value. Each LUT_Mij in the normal color converter is referred to for outputting a matrix coefficient according to the current value of the R-LED. The RGB image signal is converted into a processed image signal by matrix operation according to the matrix coefficient.

Owner:FUJIFILM CORP

Pupil color estimating device

An original pupil color of a subject person in an image in which an abnormality such as a red-eye or gold-eye occurs is estimated. Further, whether an image correction is required or not and to produce an image having a natural pupil color in the image correction by estimating the original pupil color from the image is judged. A pupil color estimating device has a skin color of a subject person specified from an inputted image, regardless of whether an abnormality such as a red-eye or gold-eye occurs. This skin color is substituted in an approximate equation based upon a statistical result carried out in advance, and thereby a normal color component of a pupil is estimated from the skin color of the subject person.

Owner:ORMON CORP

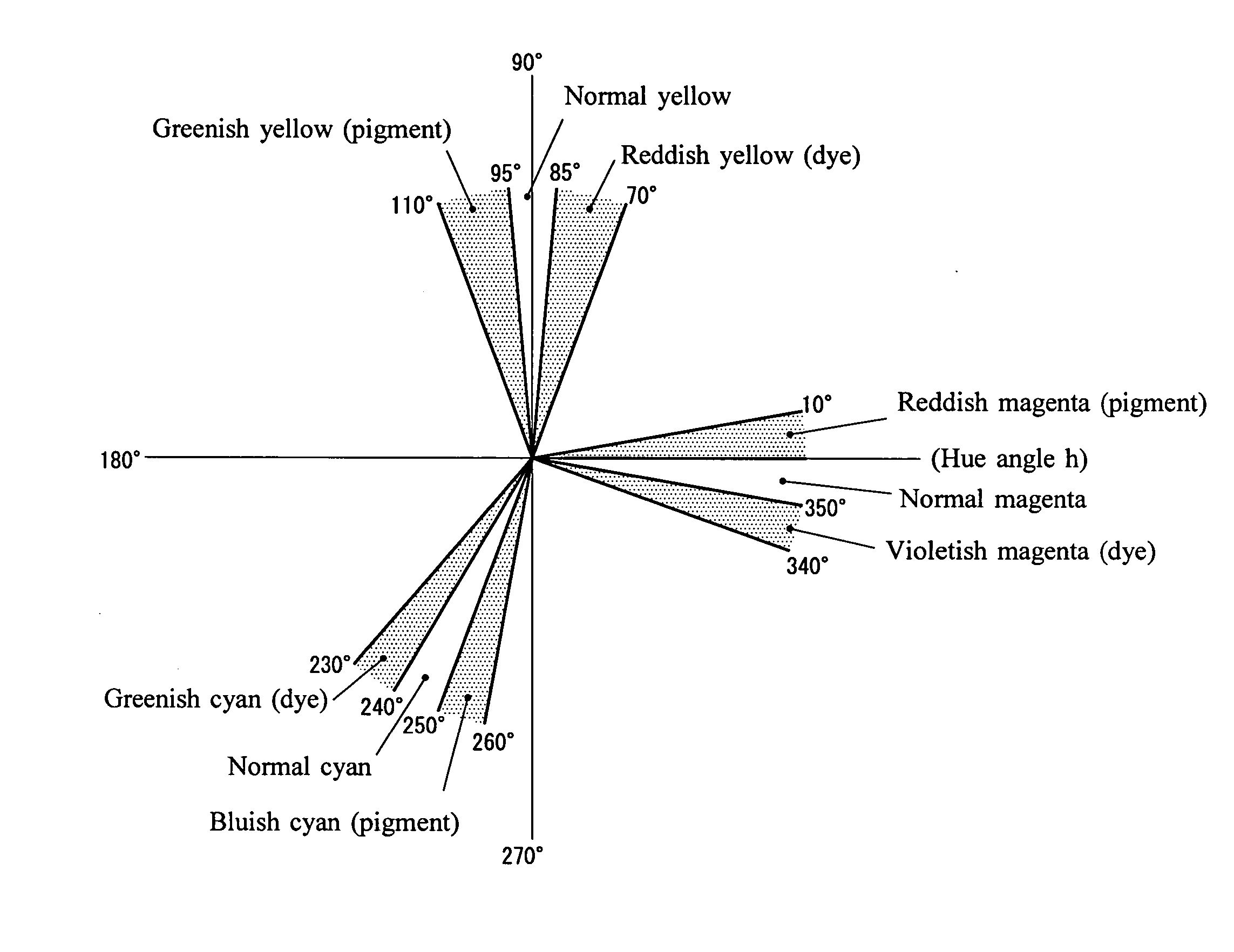

Water-based ink set for ink-jet recording

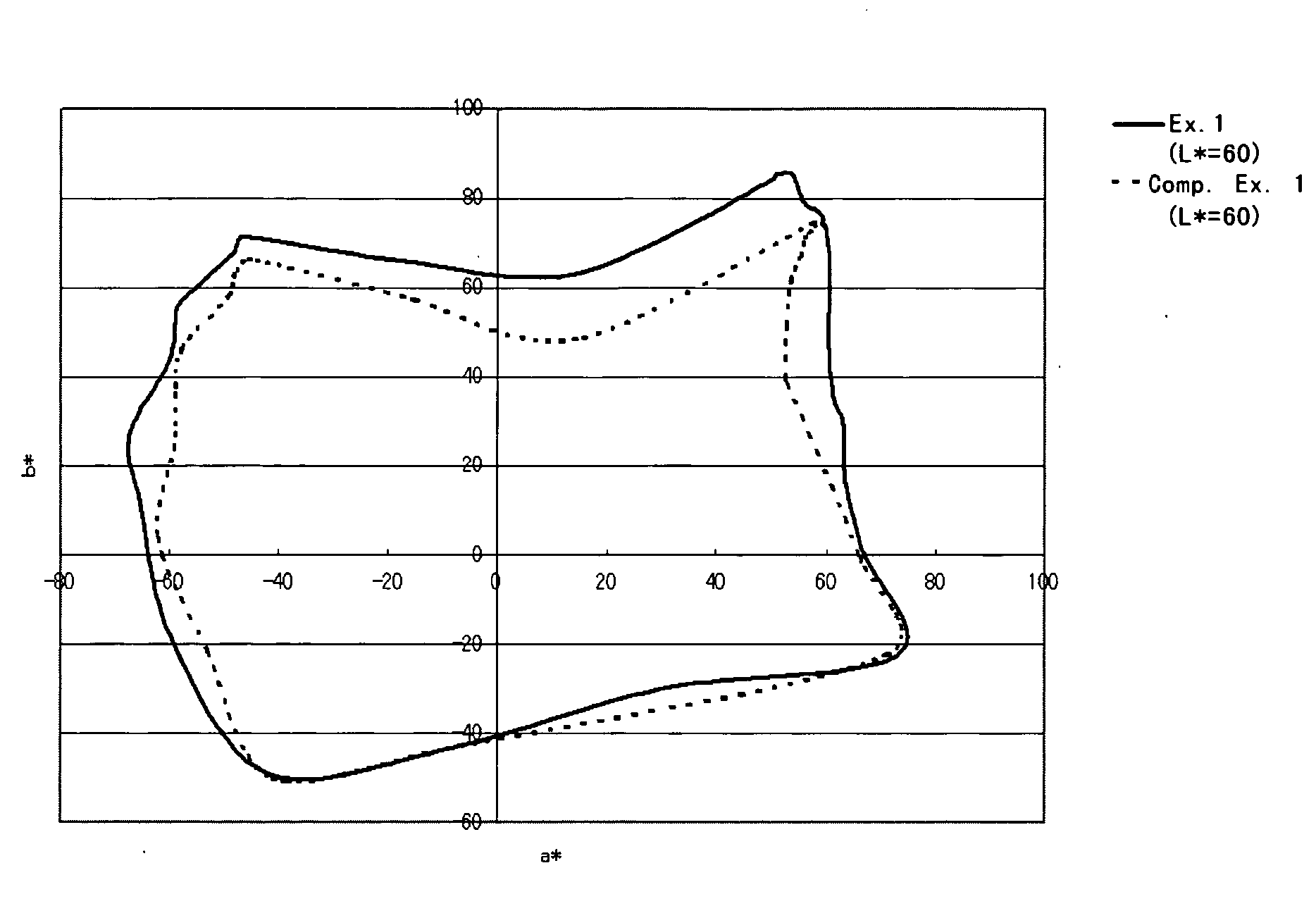

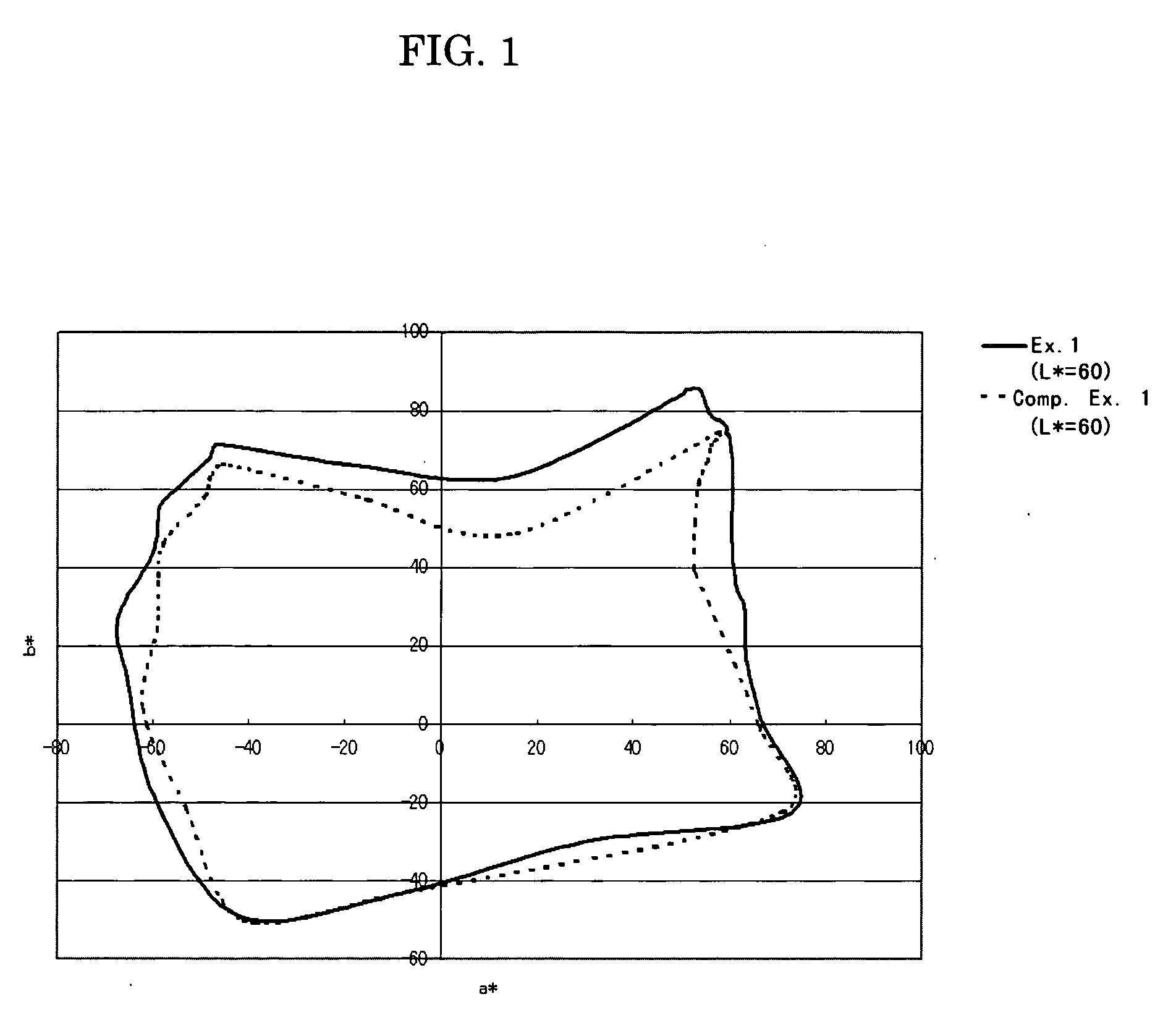

ActiveUS20060119681A1Good colorGood reproducibilityMeasurement apparatus componentsDuplicating/marking methodsWater basedHue

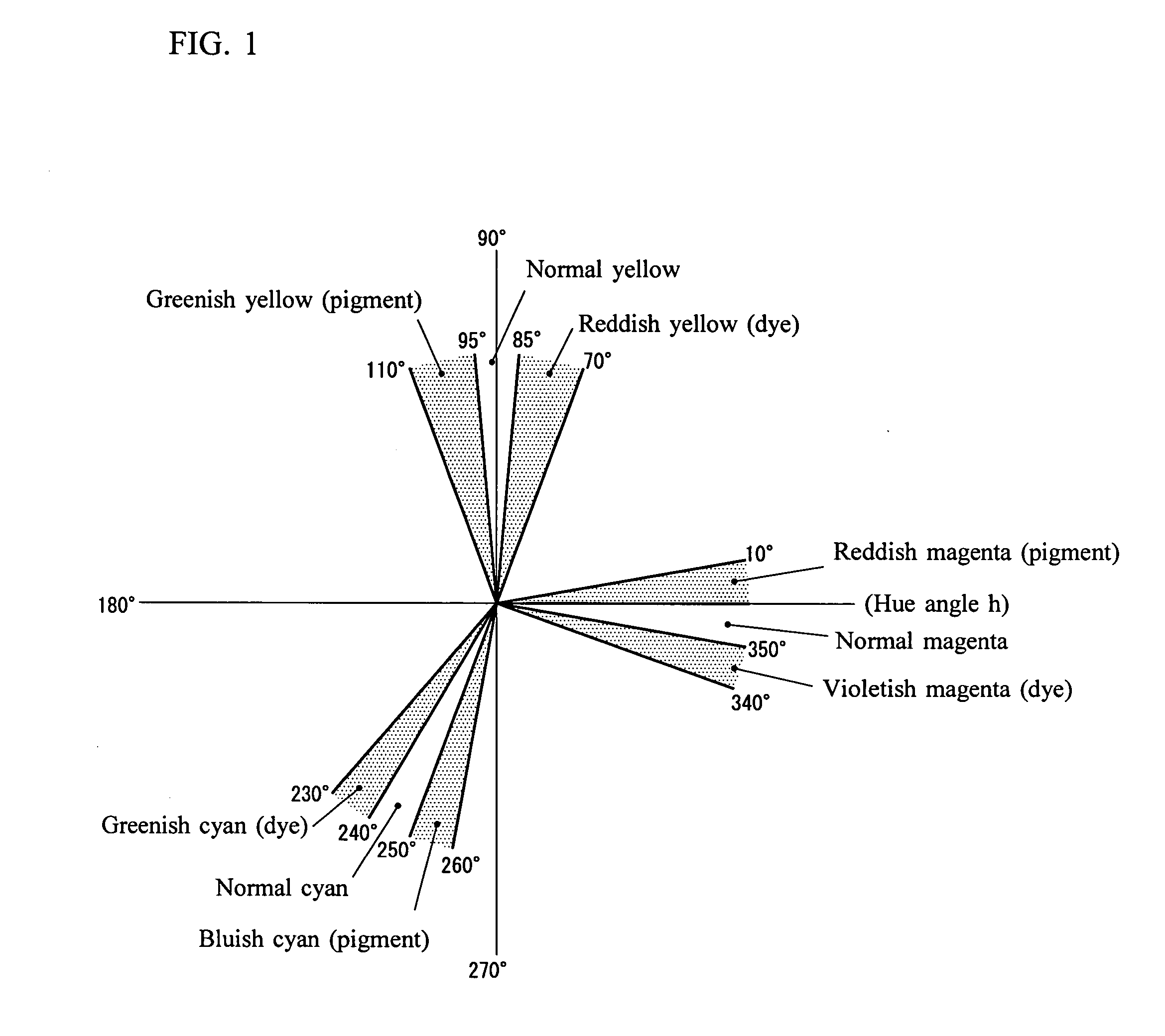

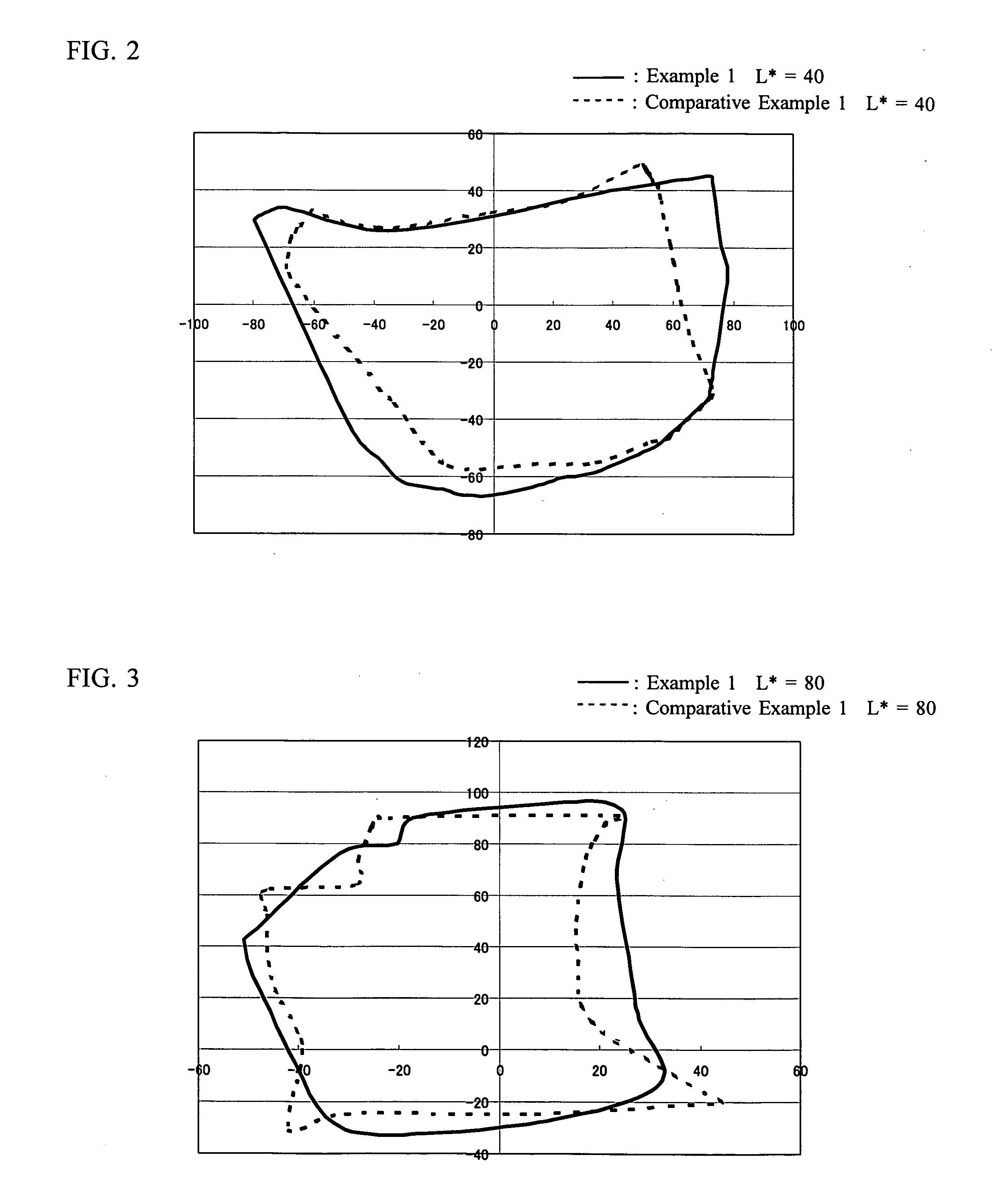

A water-based ink set for ink-jet recording includes at least a yellow ink, a magenta ink and a cyan ink. At least one color ink of the yellow, magenta and cyan inks includes a first ink and a second ink which have different hue angles h having therebetween the color range of the normal color of the color ink. Preferably, the yellow ink includes a greenish yellow ink having a hue angle h of about 95° to about 110° and a reddish yellow ink having a hue angle h of about 70° to about 85°; the magenta ink includes a reddish magenta ink having a hue angle h of about 0° to about 10° and a violetish magenta ink having a hue angle h of about 340° to about 350°; and the cyan ink includes a bluish cyan ink having a hue angle h of about 250° to about 260° and a greenish cyan ink having a hue angle h of about 230° to about 240°.

Owner:BROTHER KOGYO KK

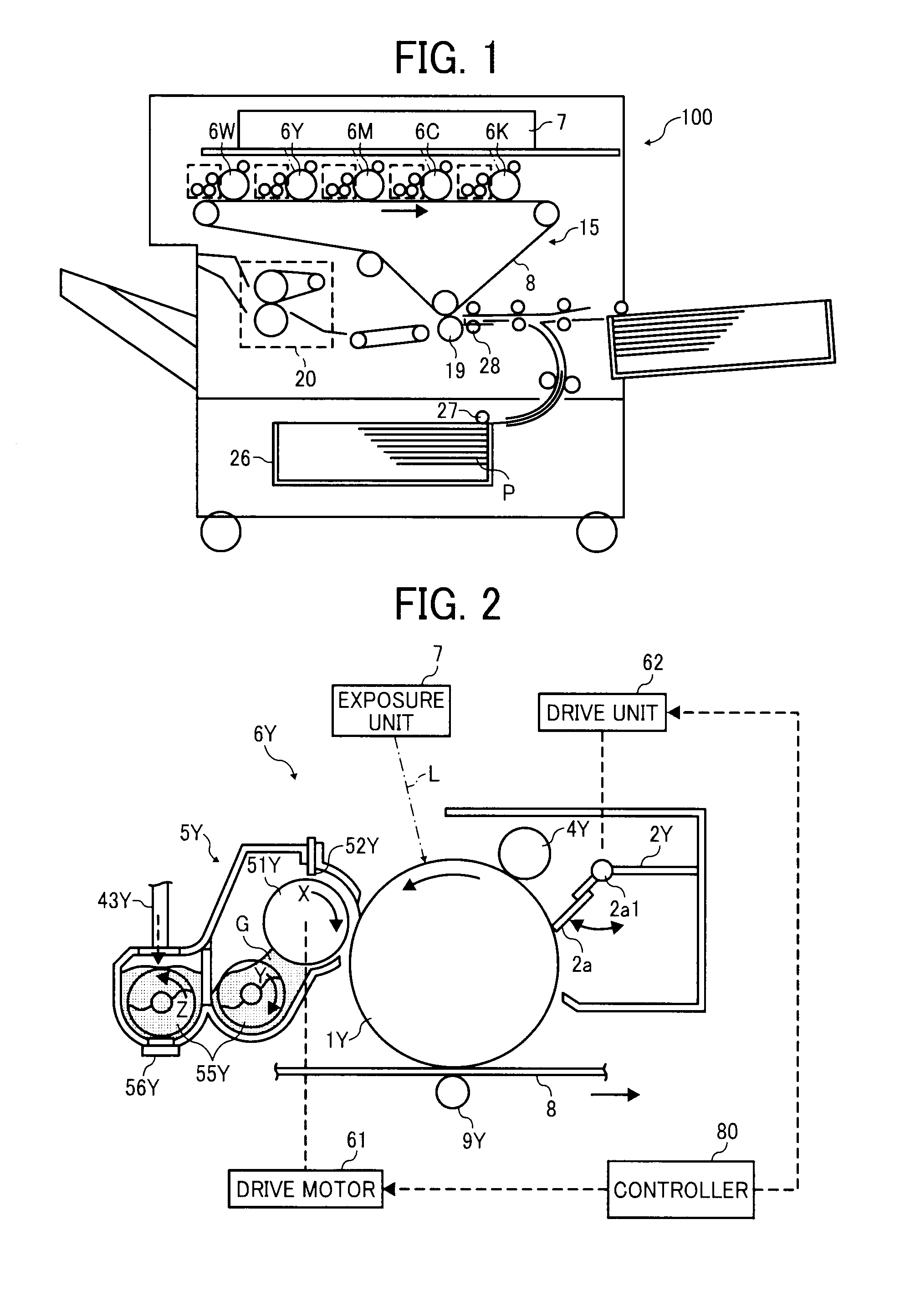

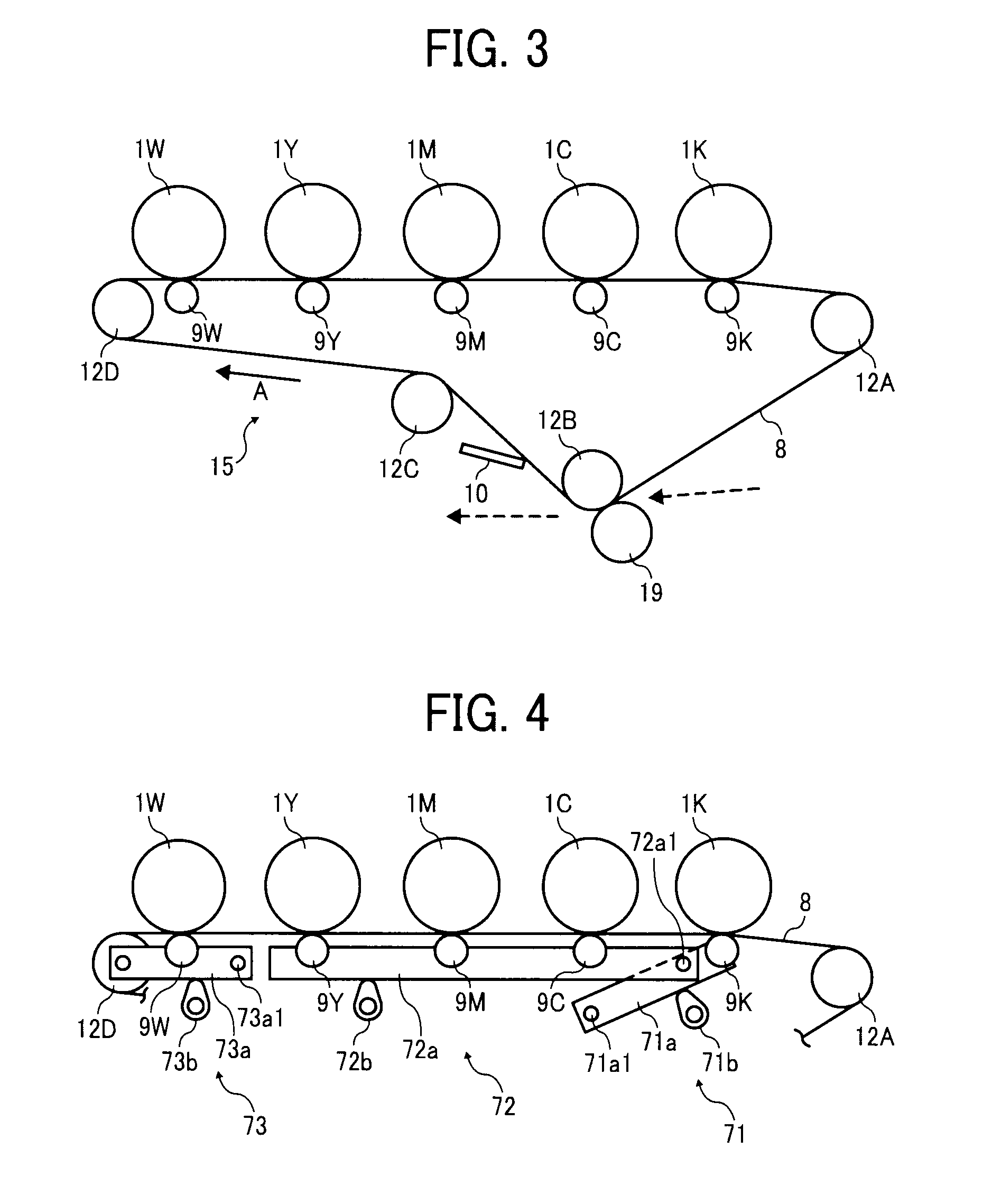

Image forming apparatus

ActiveUS20110249992A1Improve productivityLong life-timeElectrographic process apparatusImage formationEngineering

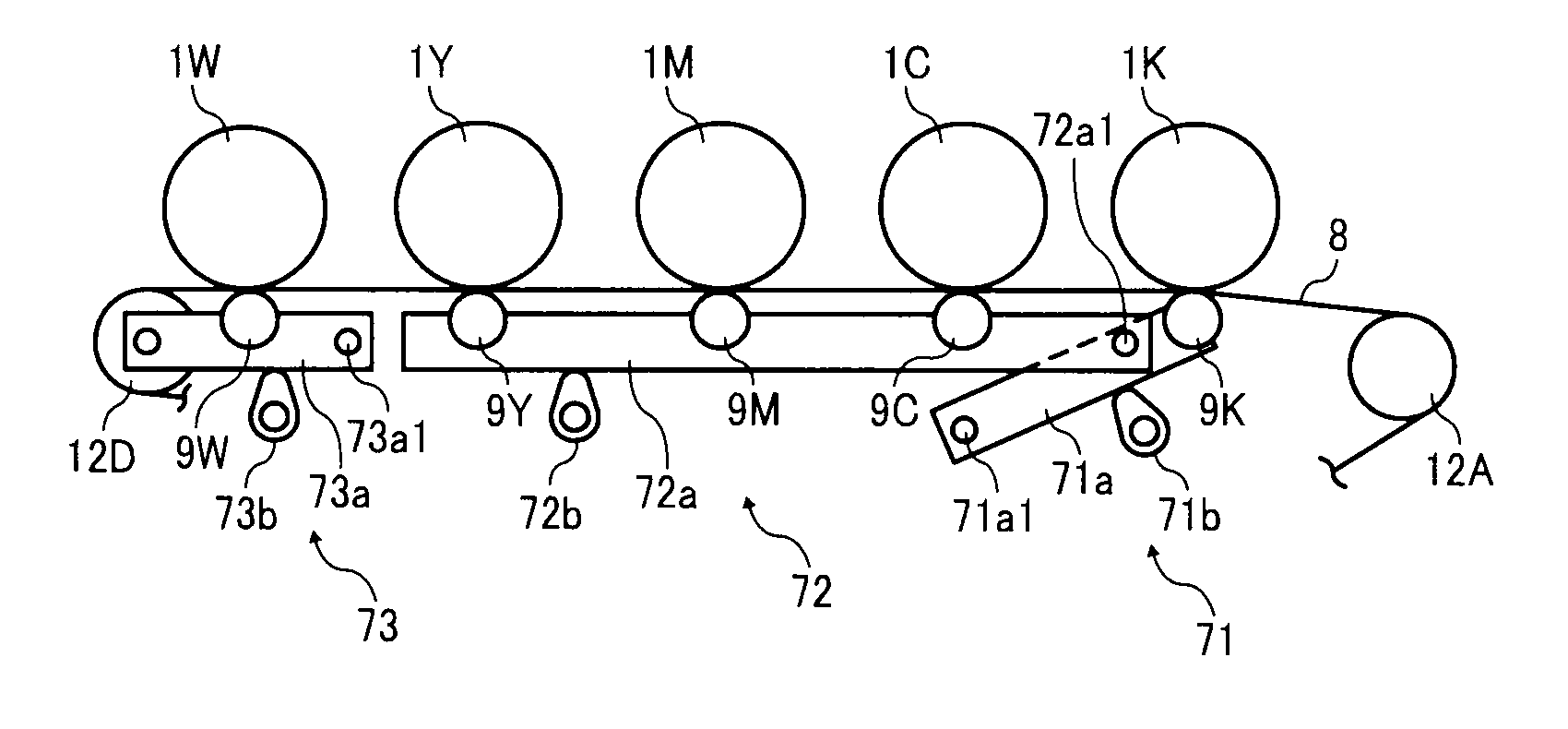

An image forming apparatus includes a first image carrier forming a black toner image, a plurality of second image carriers forming a yellow, magenta, or cyan toner image, a third image carrier forming a special color toner image, and a transfer target member or an intermediate transfer belt. The apparatus further includes first and second detachment units. The first detachment unit detaches only the third image carrier from the transfer target member, and the second detachment unit detaches the second image carriers and the third image carrier. When switching from a special color image mode to either a normal color image mode or a monochrome image mode is performed during continuous printing of the recording media, the first detachment unit or the second detachment unit controls the detachment operation based on the number of recording media continuously printed by the normal color image mode or the monochrome image mode.

Owner:RICOH KK

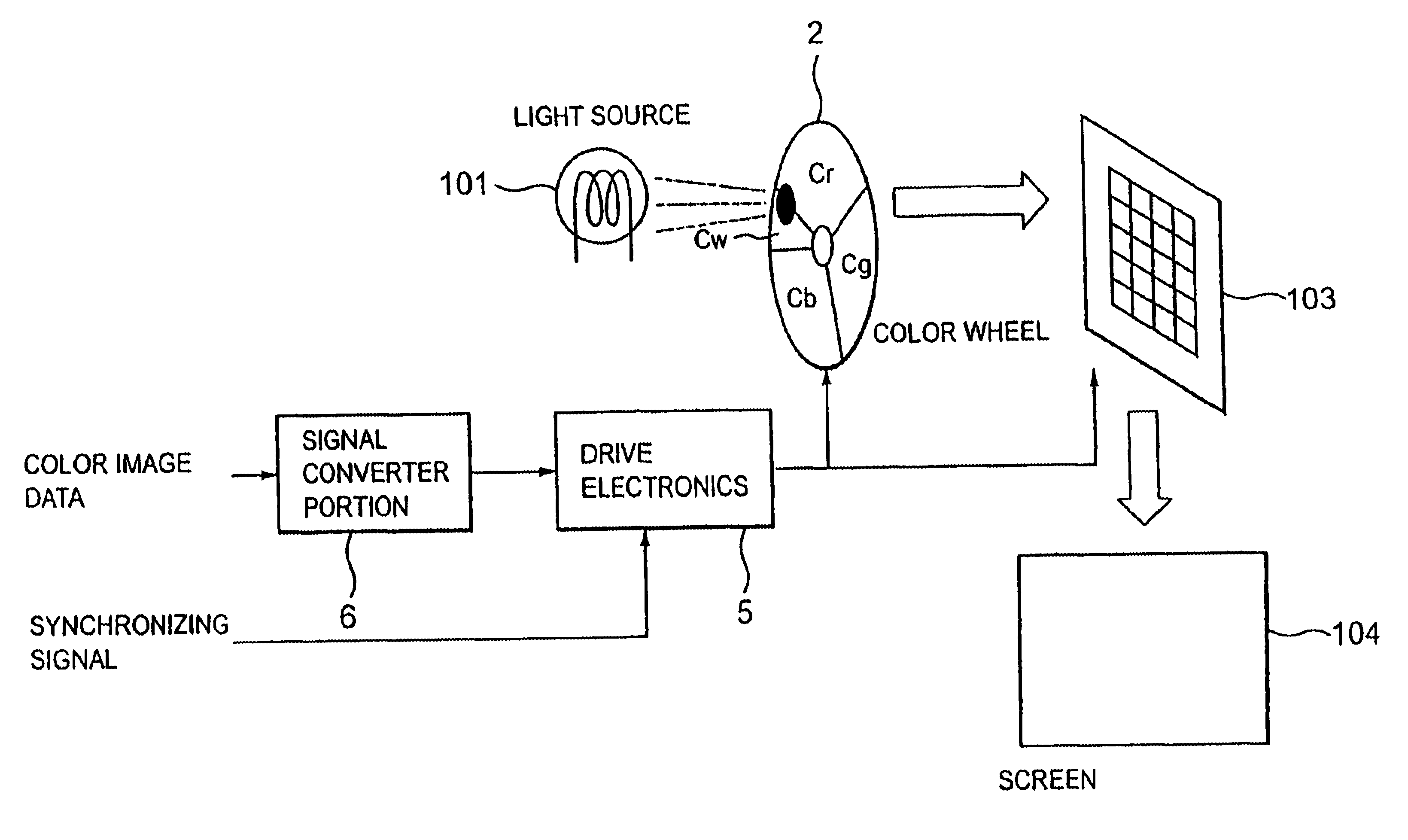

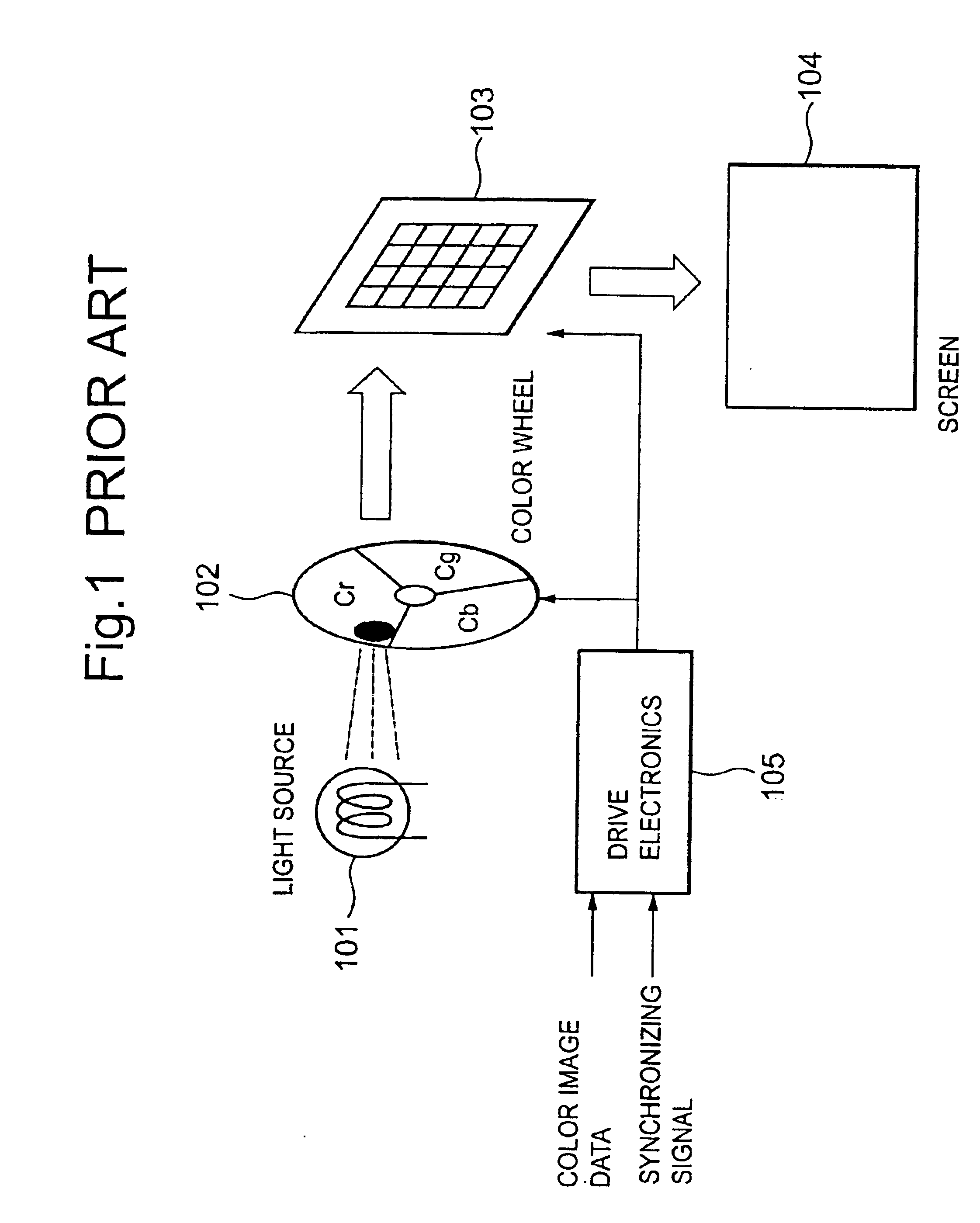

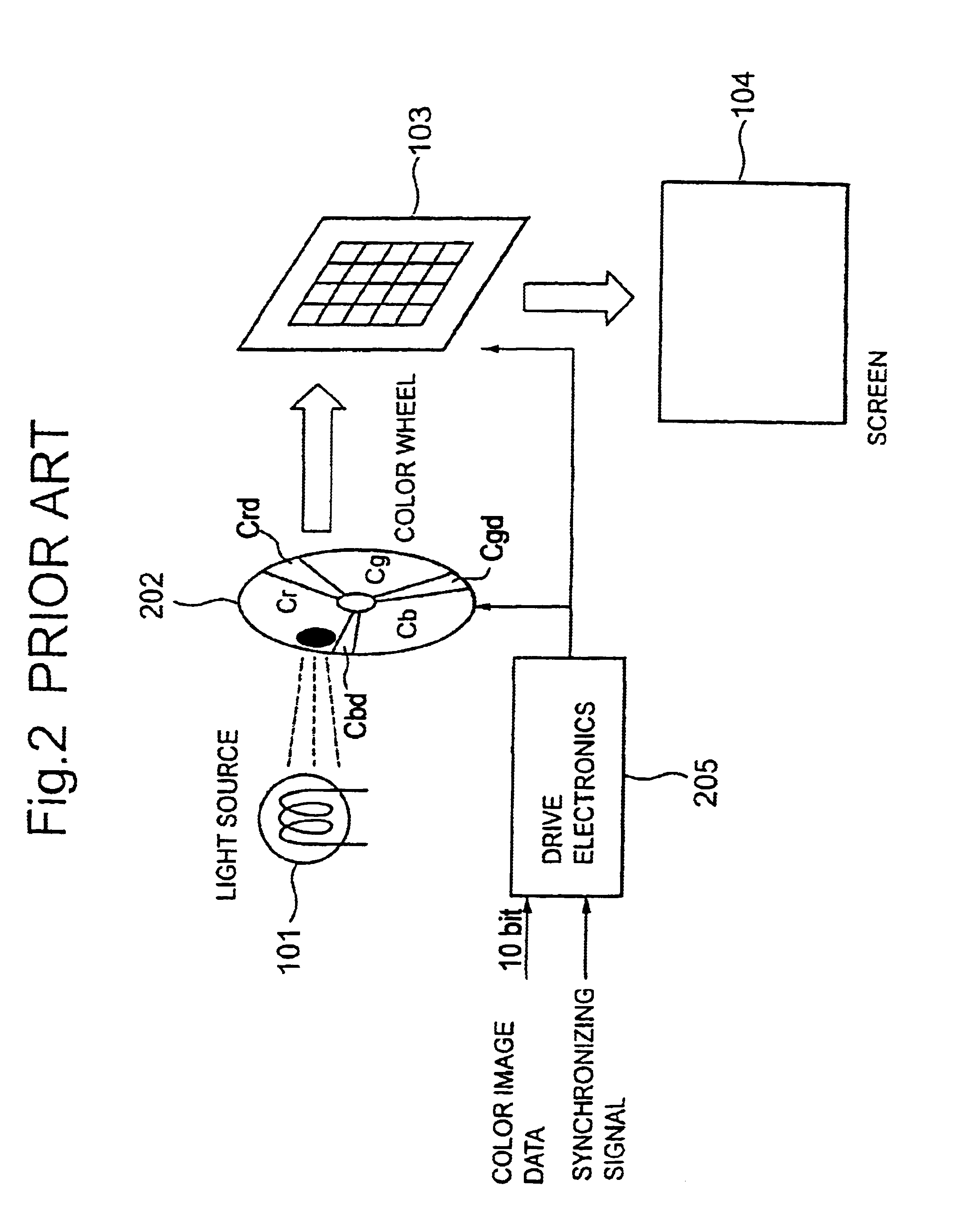

Display device for displaying digital input image data using different filter segments for the lower and higher order bits

InactiveUS6912017B1Smoother gray-scale representationNo brightness decreaseTelevision system detailsColor signal processing circuitsSpectral transmissionColor image

There is disclosed a display device using a color wheel having a color filter Cw, in addition to normal color filters corresponding to the three primary colors. The filter Cw has almost flat spectral transmission characteristics. Brightness information included in a color image signal is quantized with (n+m) bits. Information corresponding to the lower-order n bits is displayed by light transmitted through the filter Cw. Information corresponding to the upper-order n bits is displayed by light transmitted through the normal color filters. Only brightness information to which the human eye is visually sensitive is reproduced by the filter Cw having a lower transmissivity. This can eliminate a lack of the number of gray levels due to a constraint on the minimum switching speed of a light valve. Furthermore, the brightness little deteriorates.

Owner:RAKUTEN INC

Transflective electro-optical device and electronic apparatus

InactiveUS20030001994A1Improve optical efficiencyBright, color reflective displayNon-linear opticsIdentification meansSelective reflectionDisplay device

In an electro-optical device, such as a transflective liquid crystal device, color transmissive display having normal color tones is performed, and in addition, bright, color reflection display is also performed. The electro-optical device in accordance with the invention includes an electro-optical material provided between a first substrate and a second substrate, and display electrodes provided above the first substrate so as to be opposed to the second substrate. The electro-optical device further includes a first color filter having a selective-reflection region in each pixel that selectively reflects light in a predetermined wavelength range, and a light transmission region in each pixel that transmits light outside of the predetermined wavelength range; a light-shielding film provided so as to be opposed to the selective-reflection regions; and a second color filter having a selective-transmission region in each pixel that selectively transmits light in the predetermined wavelength range.

Owner:SEIKO EPSON CORP

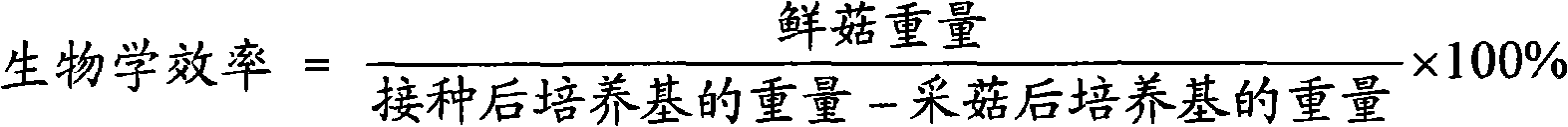

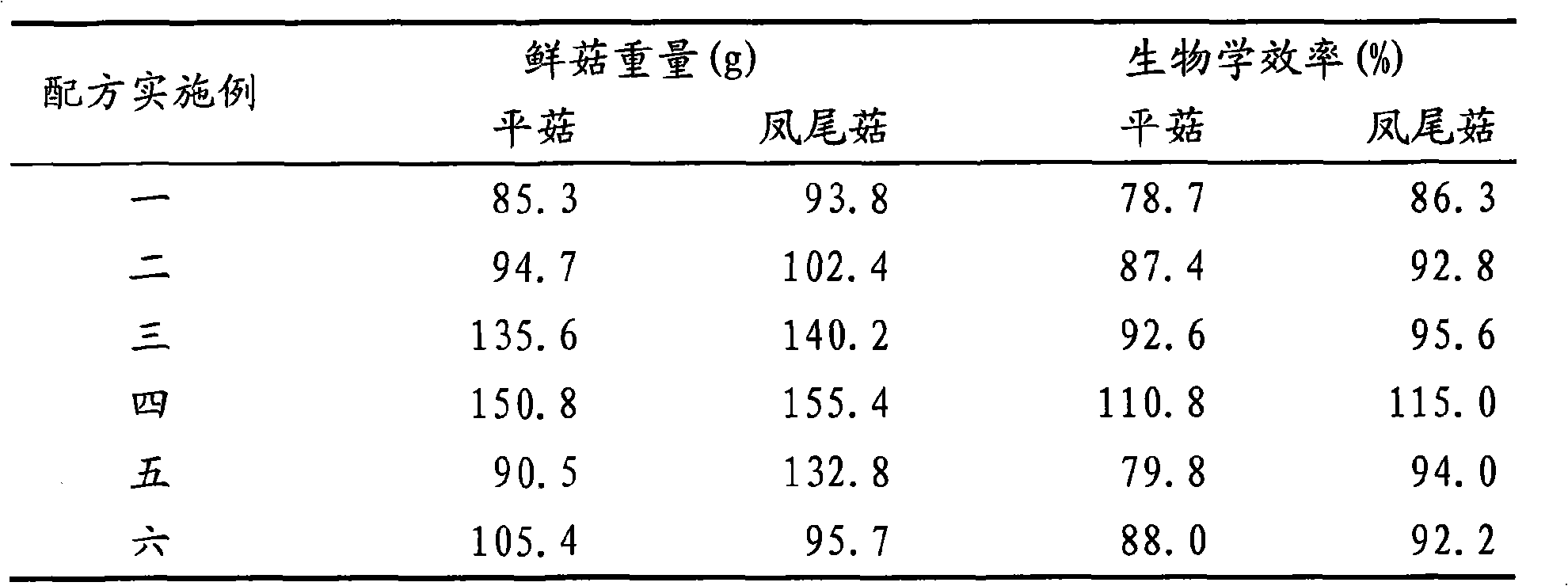

Rubber-woodflour edible fungus culture medium and preparation method thereof

InactiveCN101921147AExpand the range of raw materialsReduce manufacturing costHorticultureFertilizer mixturesBiotechnologyEconomic benefits

The invention discloses a rubber-woodflour edible fungus culture medium and a preparation method thereof. The culture medium comprise major materials and auxiliary materials, wherein rubber and woodflour are the major materials, accounting for 50-100% of the formula content. The invention also discloses the preparation method of the rubber-woodflour edible fungus culture medium, comprising four steps of crushing, mixing, drying as well as packaging and sterilizing. The rubber-woodflour edible fungus culture medium can be used for culturing edible fungi with high biological efficiency and low cost, and the obtained edible fungi have normal color, beautiful fungus appearance, excellent quality and fragrant flavor; a large number of waste rubber branches can be fully utilized, and favorable economic benefit and environmental benefit are obtained; and the preparation method of the rubber-woodflour edible fungus culture medium has simple technology and easy popularization.

Owner:叶礼奎

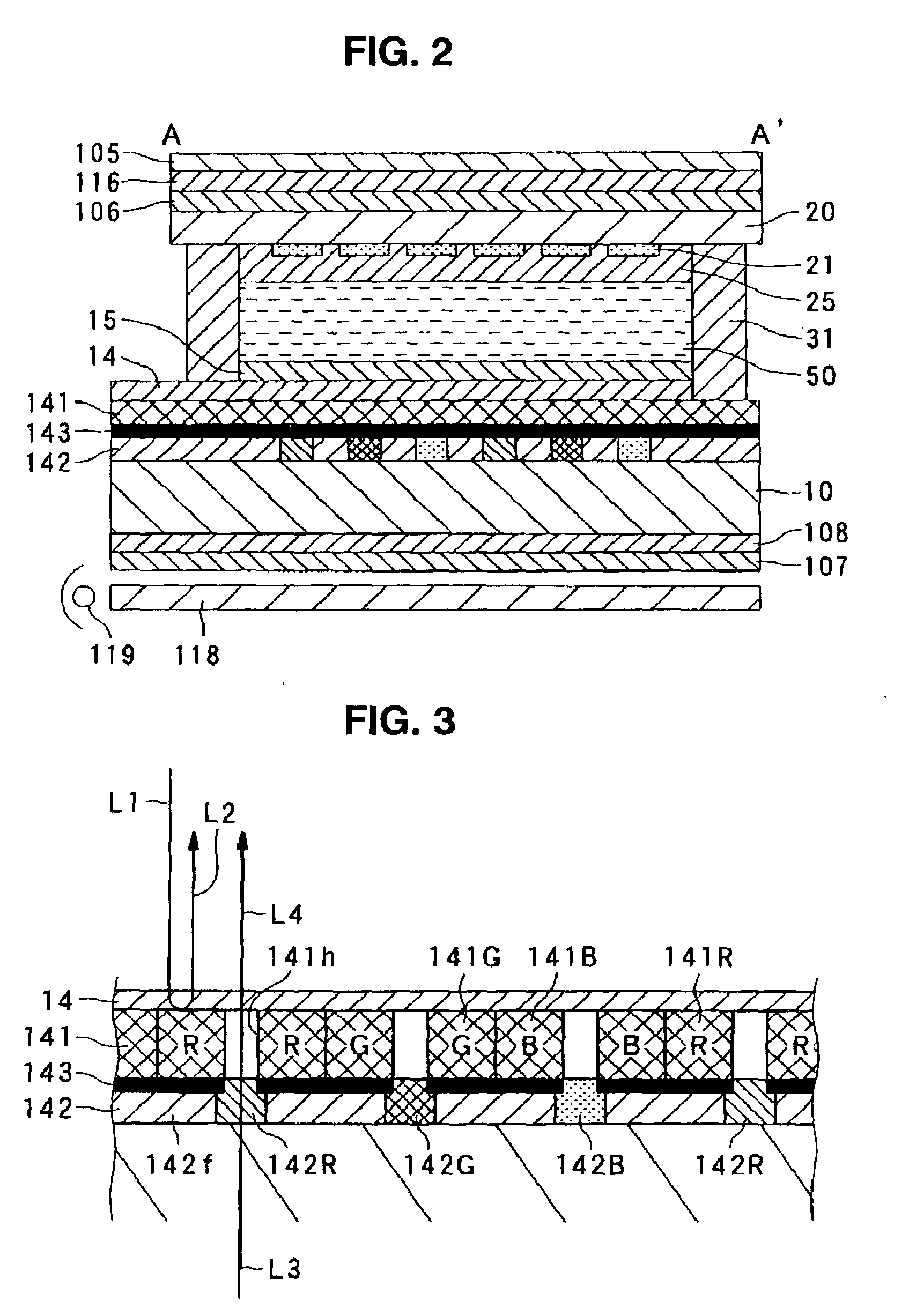

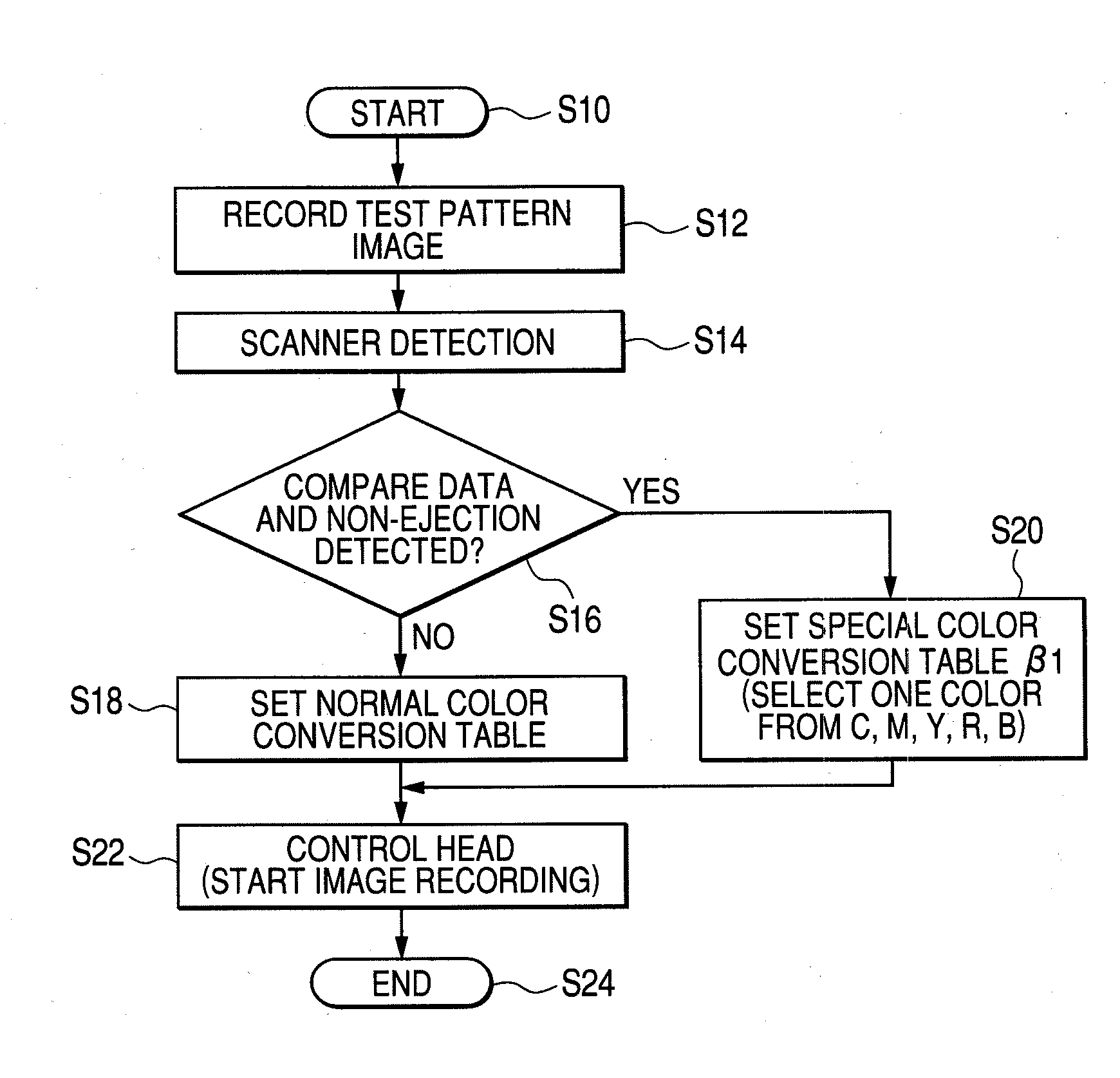

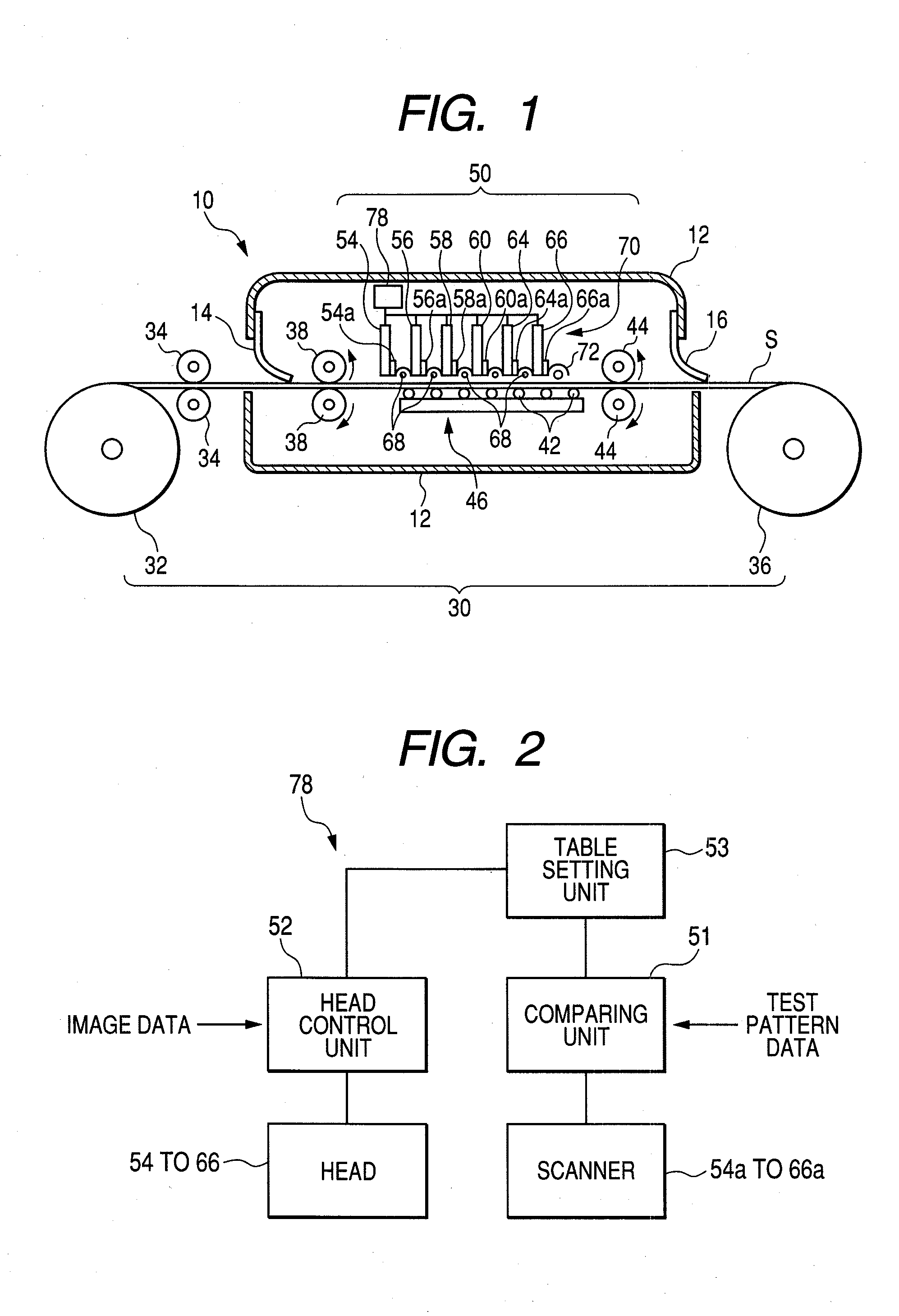

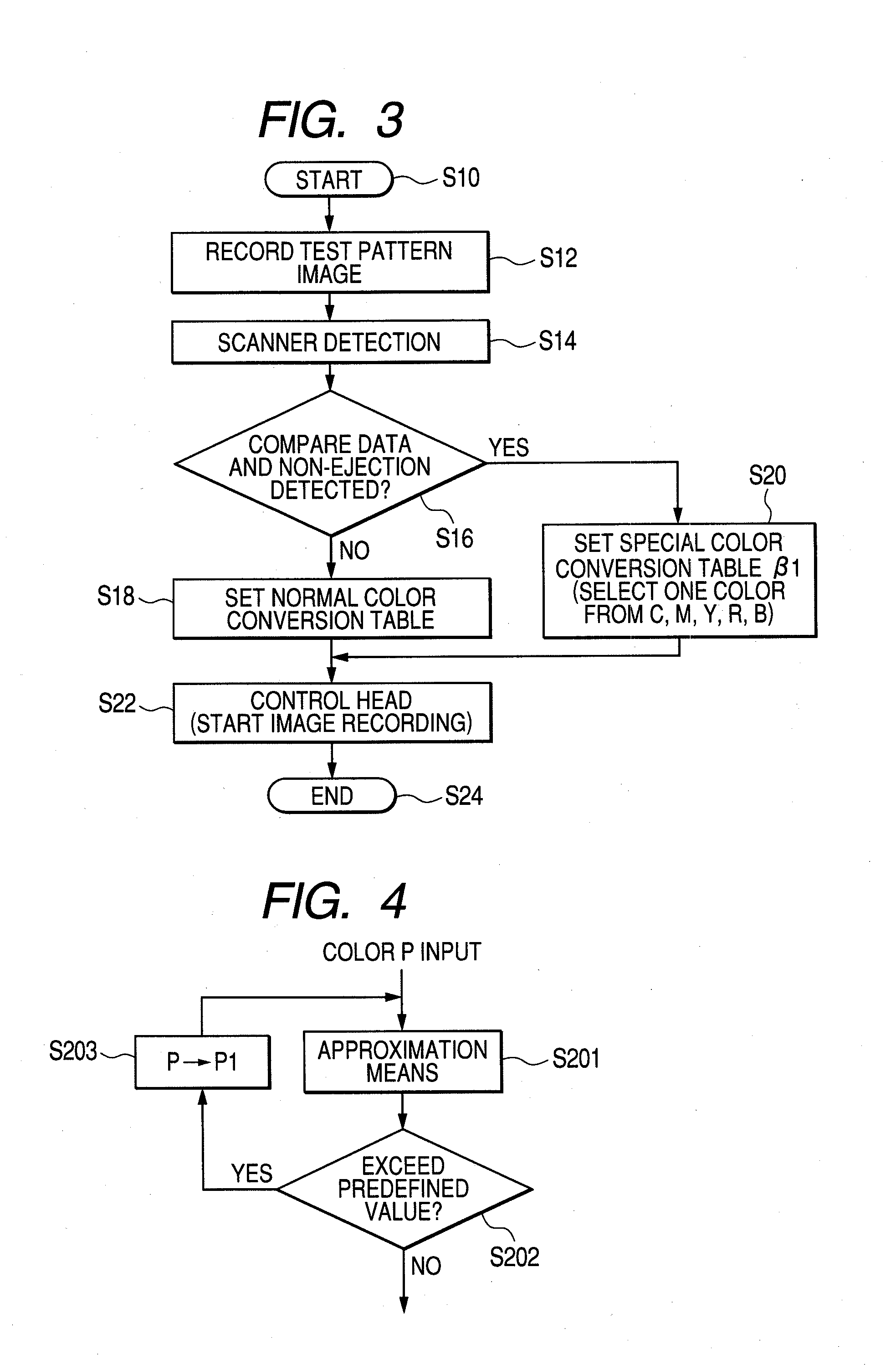

Image forming method and image forming apparatus

ActiveUS20080309704A1Cope wellOptimally copingDigitally marking record carriersDigital computer detailsColor transformationImage formation

An image forming method that forms an image by using inks of secondary chromatic colors based on an input image, the method including: forming a test pattern that uses a color chart with the entire secondary chromatic colors of the used inks by using a normal color conversion table for converting a first color space of the input image into a second color space of the formed image; comparing data obtained by scanning the formed test pattern with second color space data of the test pattern, and identifying a non-matching color portion as a non-ejection color and a line position containing a non-ejection nozzle thereof; preparing a special color conversion table, the special color conversion table being provided for each omission ink; and setting and using the special color conversion table for an omission ink corresponding to the non-ejection color at the line position containing the identified non-ejection nozzle.

Owner:FUJIFILM CORP

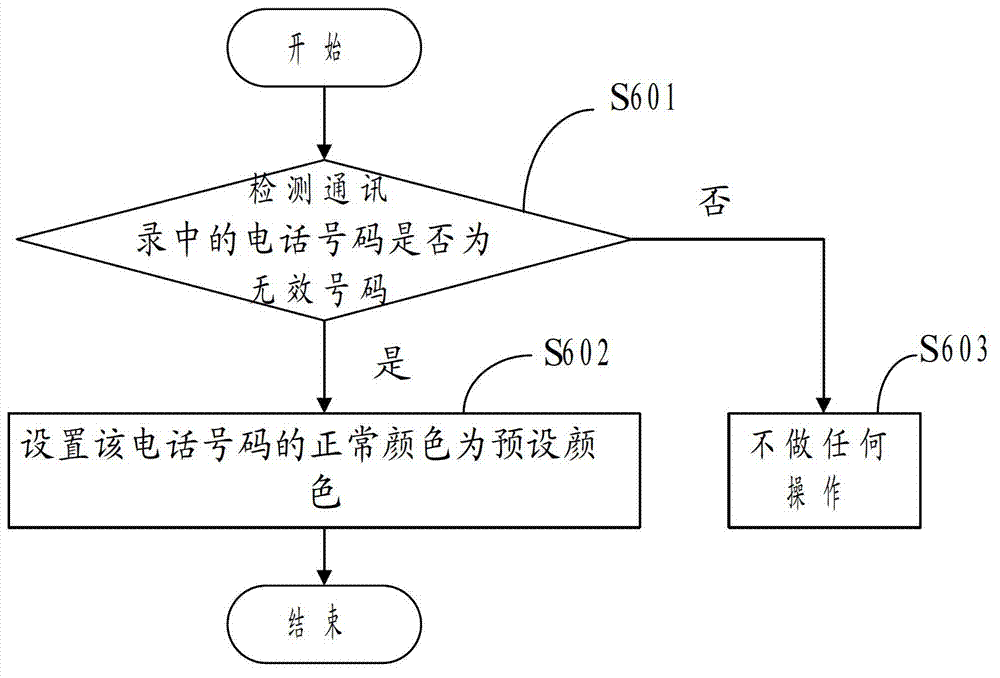

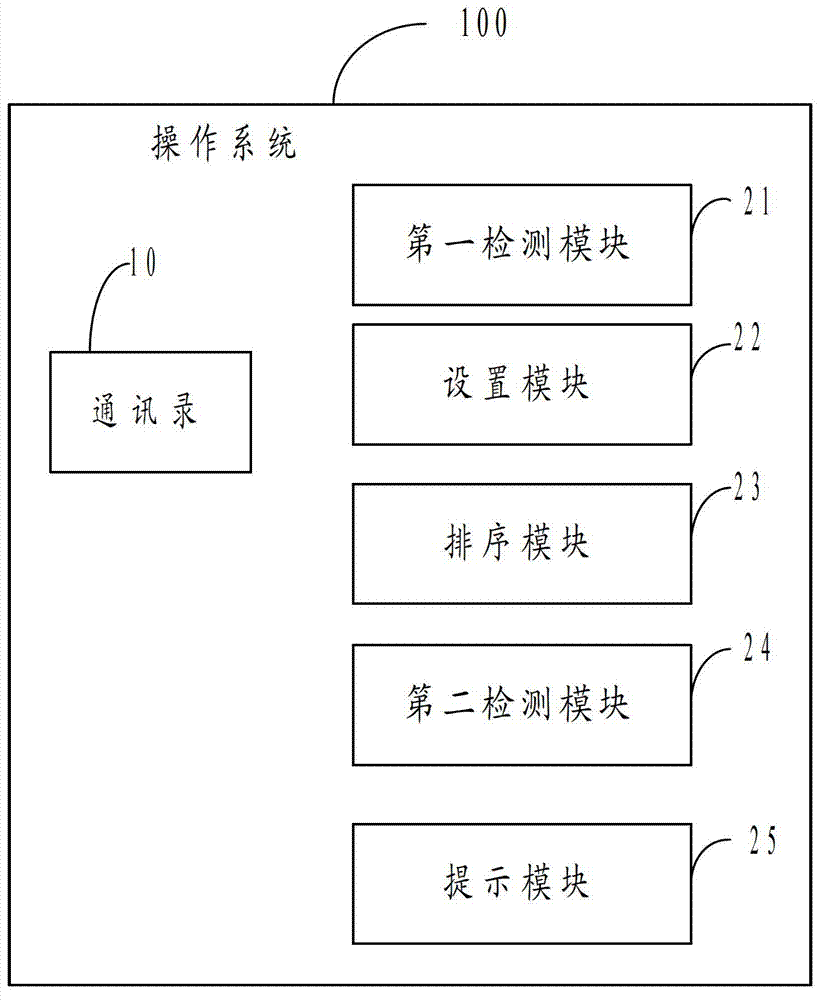

Operation method and operation system for address book at mobile terminal

ActiveCN102857636AEasy to operateEasy to distinguishSubstation equipmentAddress bookOperational system

The invention provides an operation method and an operation system for an address book at a mobile terminal. The method comprises the following steps of detecting that whether a phone number in the address book is an invalid number, and setting the normal color of the phone number to be the preset color when the phone number in the address book is the invalid number. According to the operation method and the operation system for the address book at the mobile terminal, the phone number is automatically detected to be the invalid number or not, the invalid number is set to be the preset color, so as to facilitate distinguishing, and therefore, the user can conduct the relevant operation for the invalid number fast and conveniently.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

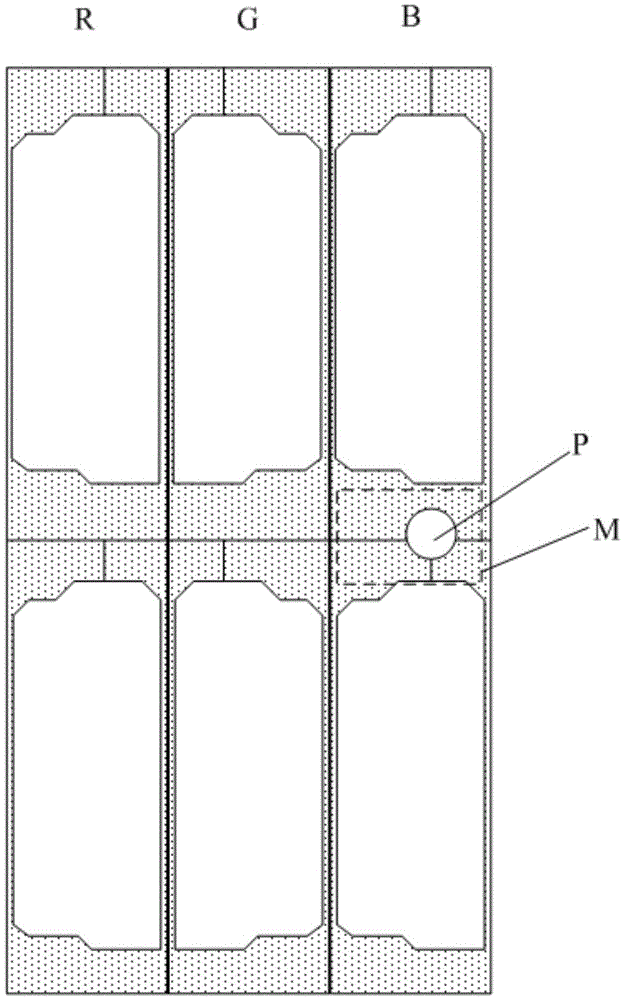

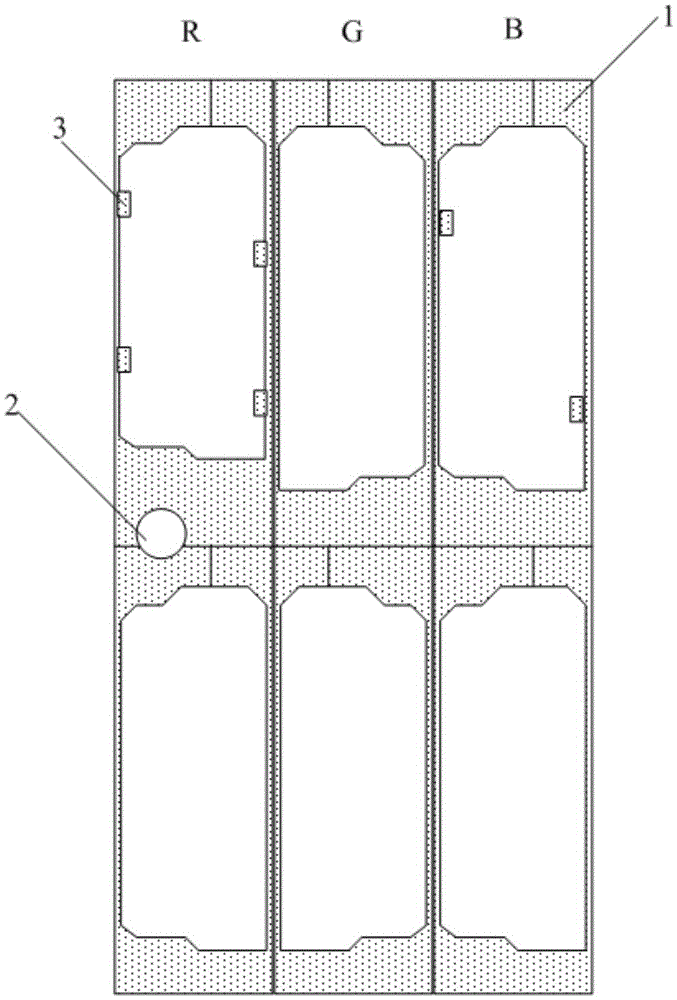

Display substrate and display device

InactiveCN105551390AIncrease widthReduce aperture ratioNon-linear opticsIdentification meansDisplay deviceComputer science

The invention discloses a display substrate and a display device. At least part of support columns of the display substrate are arranged in black matrix areas, each black matrix area is located between red pixels in every two adjacent rows of pixels and a same column of pixels, the width of black matrixes in the areas where the support columns are located is increased, and therefore compared with the prior art, the phenomenon that the blue points are bad due to the fact that the support columns are arranged in the black matrix areas corresponding to blue pixels can be effectively improved; through chromaticity simulation, it can be known that on the condition that the normal color temperature conditions are met, the influence of red pixel opening ratio decreasing on the color temperature is the least, therefore, the width of the black matrixes corresponding to red pixels can be increased, that is, the opening ratio of the red pixels can be decreased on the condition that the normal color temperature conditions are met. Accordingly, by arranging the support columns in the black matrix areas corresponding to the red pixels and correspondingly increasing the width of the black matrixes in the corresponding areas, the problem that the blue points of the display substrate are bad can be solved, and meanwhile the product with the better color displaying quality can be obtained.

Owner:BOE TECH GRP CO LTD +1

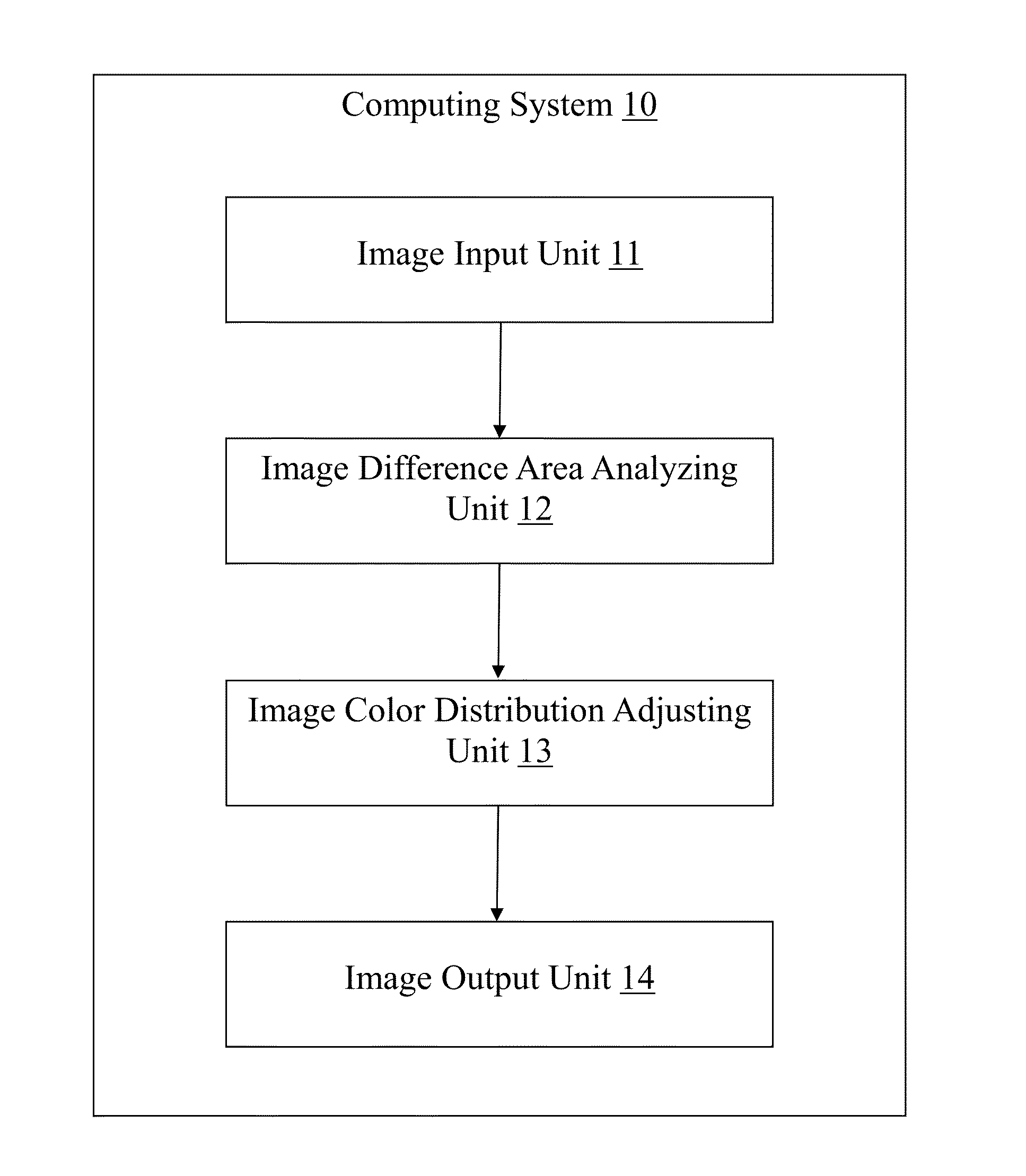

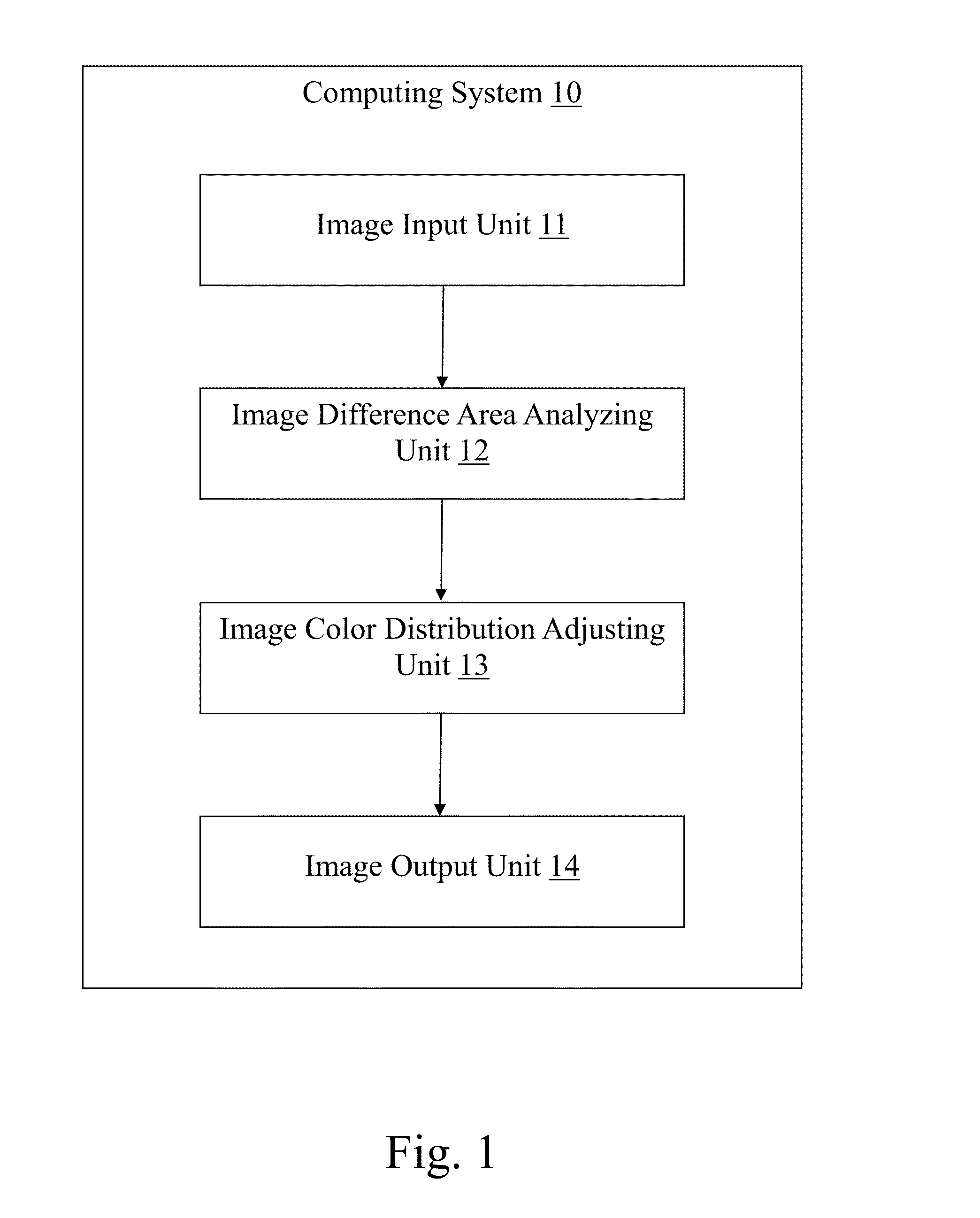

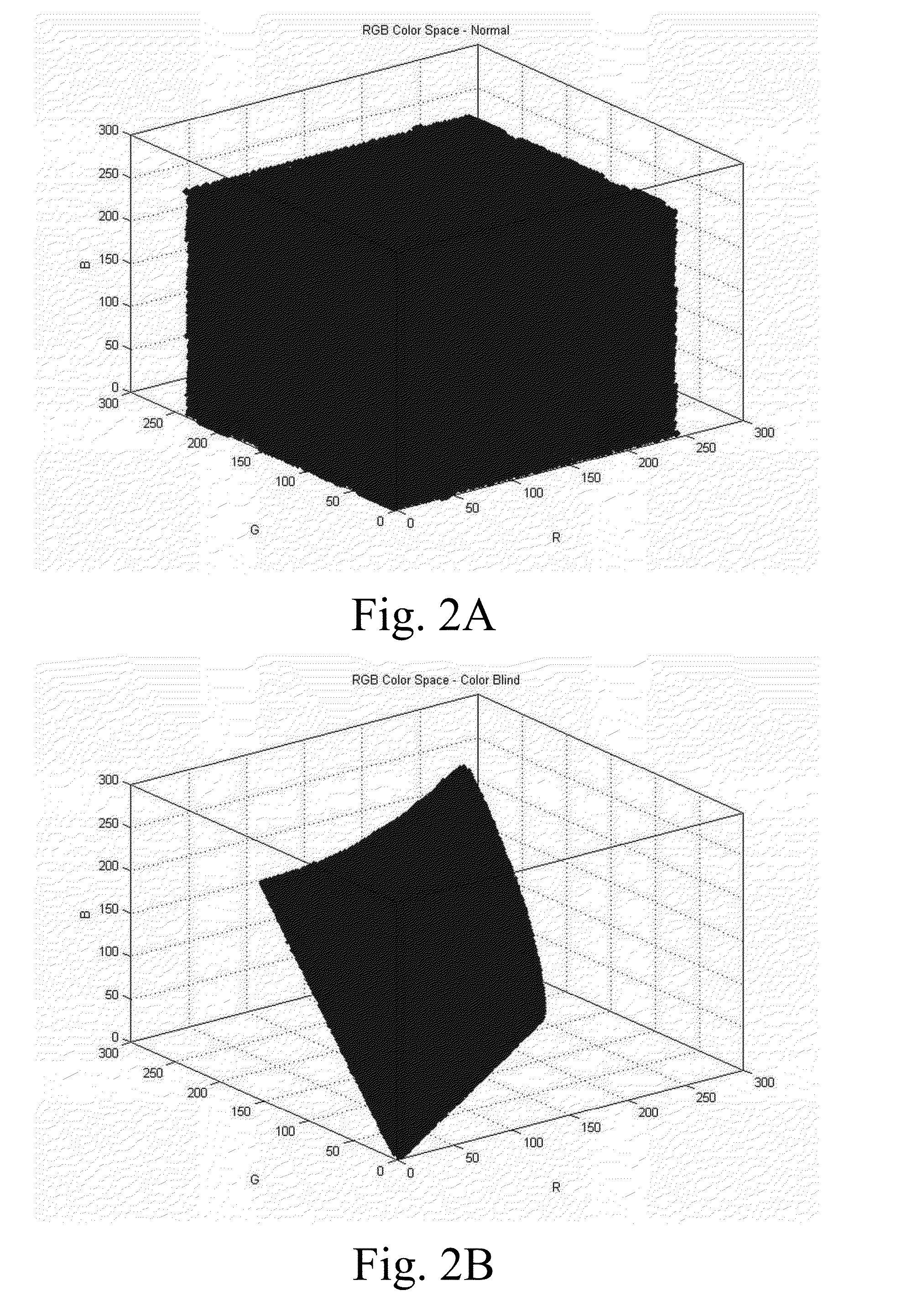

Image enhancement method for improving color perception of colorblind viewers

InactiveUS20140270516A1Improve color perceptionGood colorImage enhancementImage analysisPattern perceptionColor vision

An image enhancement method for improving color perception of colorblind viewers has an image input step, an image difference area analyzing step, an image color distribution adjusting step, and an image output step. In such method, a normal image and a colorblindness-simulative image are input and calculated to produce a colorblindness-optimized image. Color vision obtained by a colorblind person from the colorblindness-optimized image is substantially identical to that obtained by a person with normal color perception from the normal image.

Owner:SHOW CHWAN MEMORIAL HOSPITAL

Edible fungus culture medium of citrus skin slag and method for preparing same

InactiveCN101337839ABroaden the range of main ingredientsReduce manufacturing costOrganic fertilisersBiotechnologyFlavor

The invention discloses an edible fungi medium containing orange peel dregs, which comprises a main material and an adjuvant material. The main material comprises the orange peel dregs with a mass percentage not less than 80%. The invention also discloses the preparation method of the edible fungi medium containing orange peel dregs, which comprises the following four steps: pulverizing, mixing, drying, and packaging and sterilizing. The edible fungi medium containing orange peel dregs can be used for culturing edible fungi and has high biological efficiency and low cost. The obtained edible fungi have normal color, good shape, high quality, and good flavor. Meanwhile, the large amount of wasted orange peel dregs can be fully utilized to achieve good economic and environmental benefits. The preparation method of the edible fungi medium containing orange peel dregs has the advantages of simple technique and easy generalization.

Owner:重庆工学院

Three-dimensional (3D) printing method

The invention discloses a three-dimensional (3D) printing method. A 3D printer appeared in the middle of 90 years in 20th century. In practice, the 3D printer is a fast molding device by the adoption of technologies of photocuring, paper stacking and the like. An operating principle of the 3D printer is basically same as that of a normal printer. 'Materials for printing' are arranged in the printer. The 'materials for printing' are liquid or powder and the like. After the printer is connected with the computer, the 'materials for printing' are stacked layer by layer through a computer controlling, and at last a blueprint of the computer is changed into a material object. Fast molding technologies in the market are divided into a 3DP technique, an FDM melting lamination molding technique, an SLA three-dimensional planographic printing technique, an SLS precinct laser sintering, a DLP laser molding technique, an ultraviolet (UV) ray molding technique and the like. At present, the 3D printing method is used in a motor industry, a medical treatment die processing industry and the like. A printing coverage is coated on a polymer clay sheet, an image printing is carried out on the coverage by a normal color printer, the printed image is carried out on counterpoint superposition and stretching to form a 3D image.

Owner:陈绪国

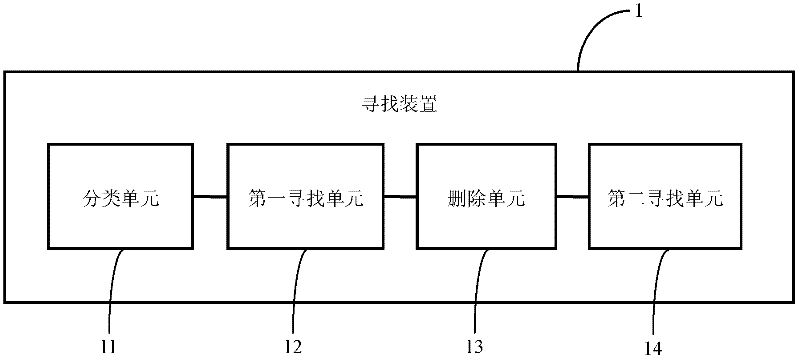

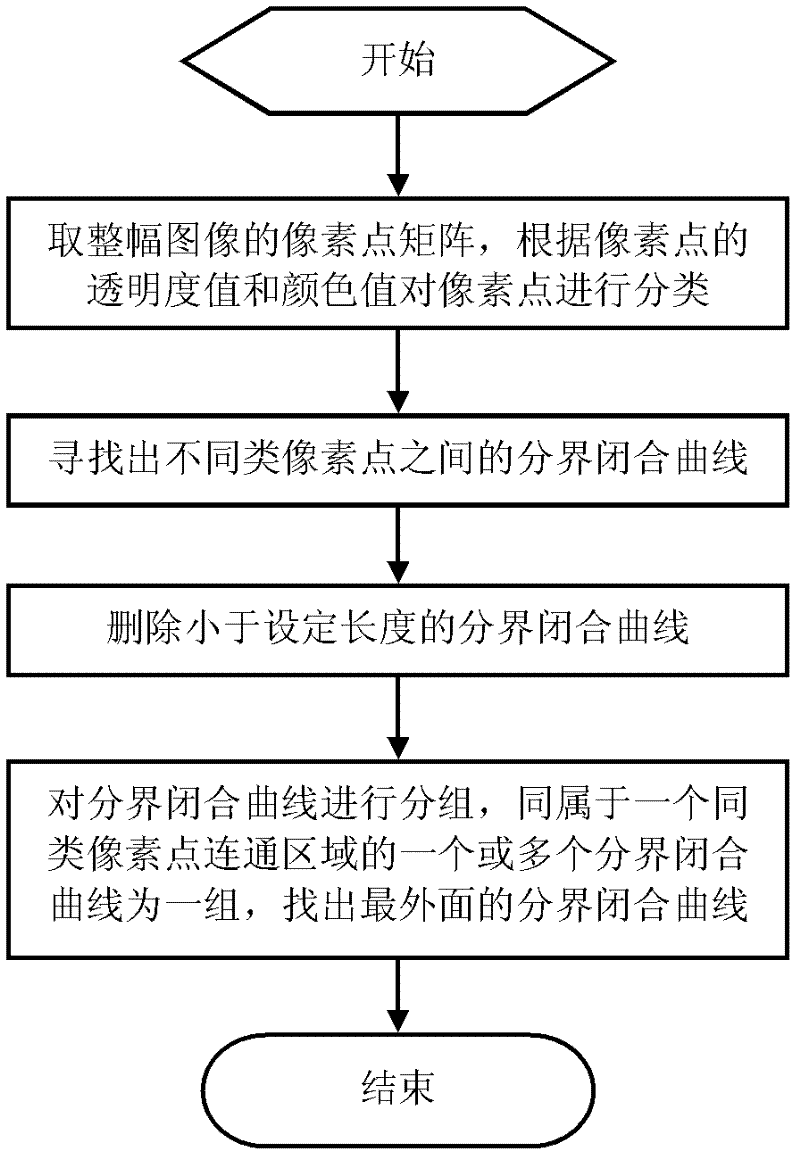

Image processing method, device and system

ActiveCN102572205AEliminate distractionsImprove trapping effectImage analysisPictoral communicationPattern recognitionImaging processing

The invention relates to a searching method for a regional boundary of a color block in an image. The method comprises the following steps of: taking a pixel point matrix of an entire image; classifying pixel points according to transparency values and color values of the pixels; searching boundary closed curves between different types of pixel points; finally grouping the boundary closed curves, wherein one or more boundary closed curves which belong to a communication region of the same type of pixel points to form a group to construct a polygon; and finding out the outermost boundary closed curve, wherein the polygon is the regional boundary of the color block. The invention also relates to a searching device for the regional boundary of a white block in the image and image bottoming and trapping method and system on the basis. The regional boundary of the white block in the image is additionally searched, so that the white region in the image is neglected during bottoming; color transfer trapping occurs when a normal color block meets white in the image; meanwhile, the interference of a small white region in the image is eliminated; and the trapping effect is better.

Owner:FOUNDER INTERNATIONAL CO LTD +1

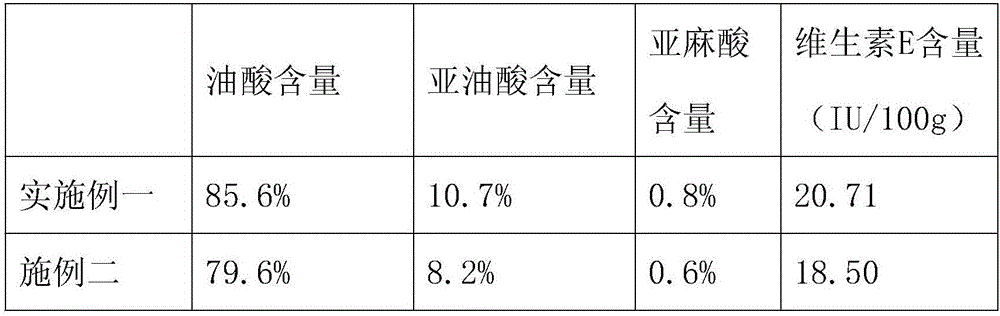

Method for producing camellia seed oil by virgin and refining-free process

InactiveCN106244319ARetain pure natural activityYellowish colorFatty-oils/fats refiningFatty-oils/fats productionActivated carbonWater vapor

The invention discloses a production process of virgin and refining-free camellia seed oil, which comprises the following steps: (1) selecting seeds: selecting camellia seeds which have normal color, no mildew and no impurities and are full, and drying the camellia seeds in the sun; (2) performing coarse crushing: crushing the camellia seeds obtained in the step (1) by a crushing machine; (3) drying: adding the camellia seeds obtained in the step (2) into a stir-frying pan, and stir-frying at the temperature of 60 to 65 DEG C until the water content of the camellia seeds is 9%; (4) performing fine crushing: crushing the camellia seeds obtained in the step (3) into camellia seed powder; (5) steaming and preparing cakes: placing the materials obtained in the step (4) into a steamer, steaming with water vapor for 0.5 to 1 hour, and then preparing cakes; (6) squeezing: placing the material cakes obtained in the step (5) into a hydraulic oil press and squeezing; and (7) filtering: adding 0.1 percent to 0.2 percent of active carbon according to the weight ratio of crude oil of the squeezed camellia seed oil, stirring uniformly, freezing at the temperature of -2 DEG C for 4 hours and filtering to obtain finished product oil.

Owner:ANHUI PROVINCE JINTIANZHU AGRI TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com