Patents

Literature

125 results about "Sequential method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sequential method. The sequential method is used to allocate the cost of service departments to other departments within an organization. Under this approach, the cost of each service department is allocated one department at a time.

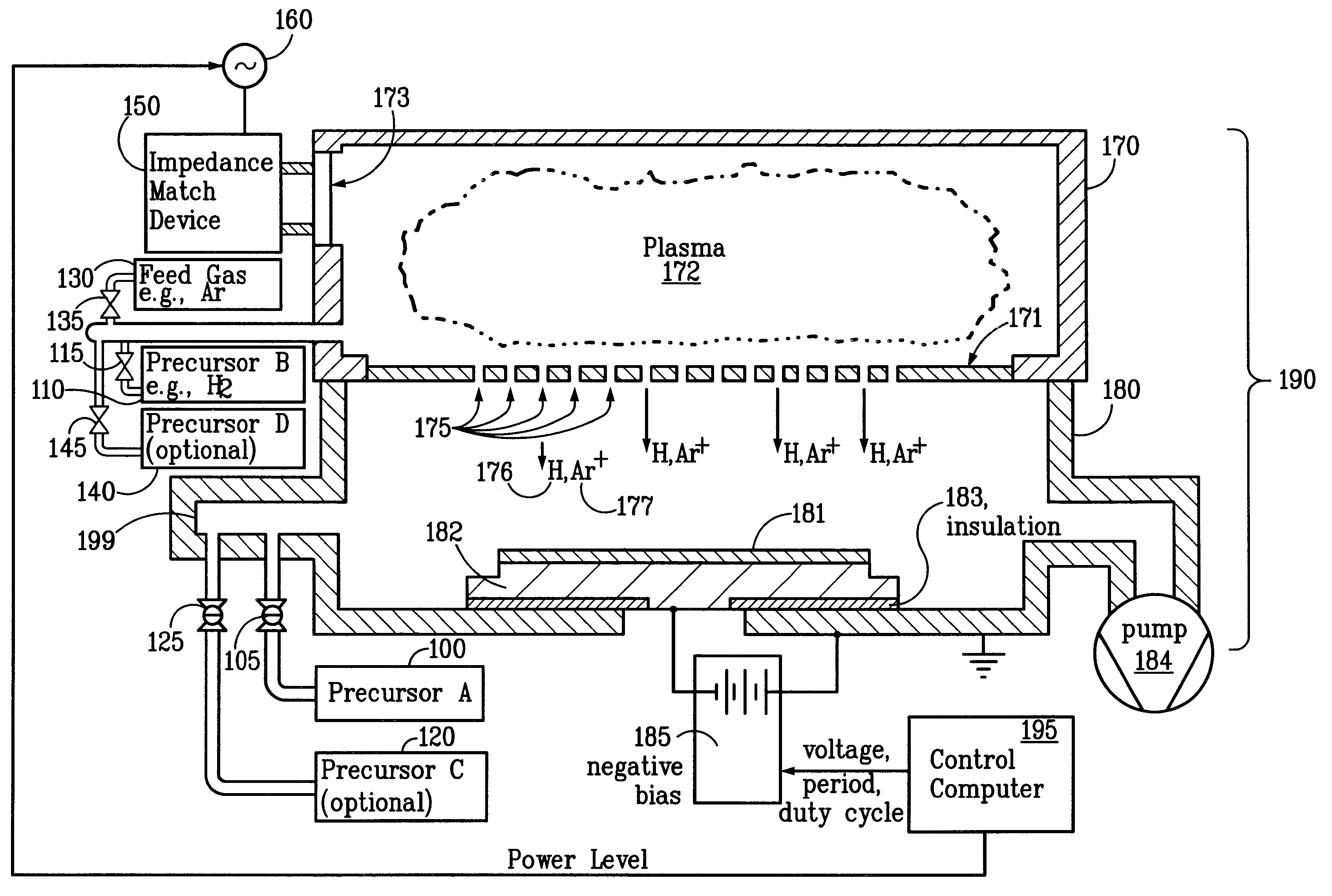

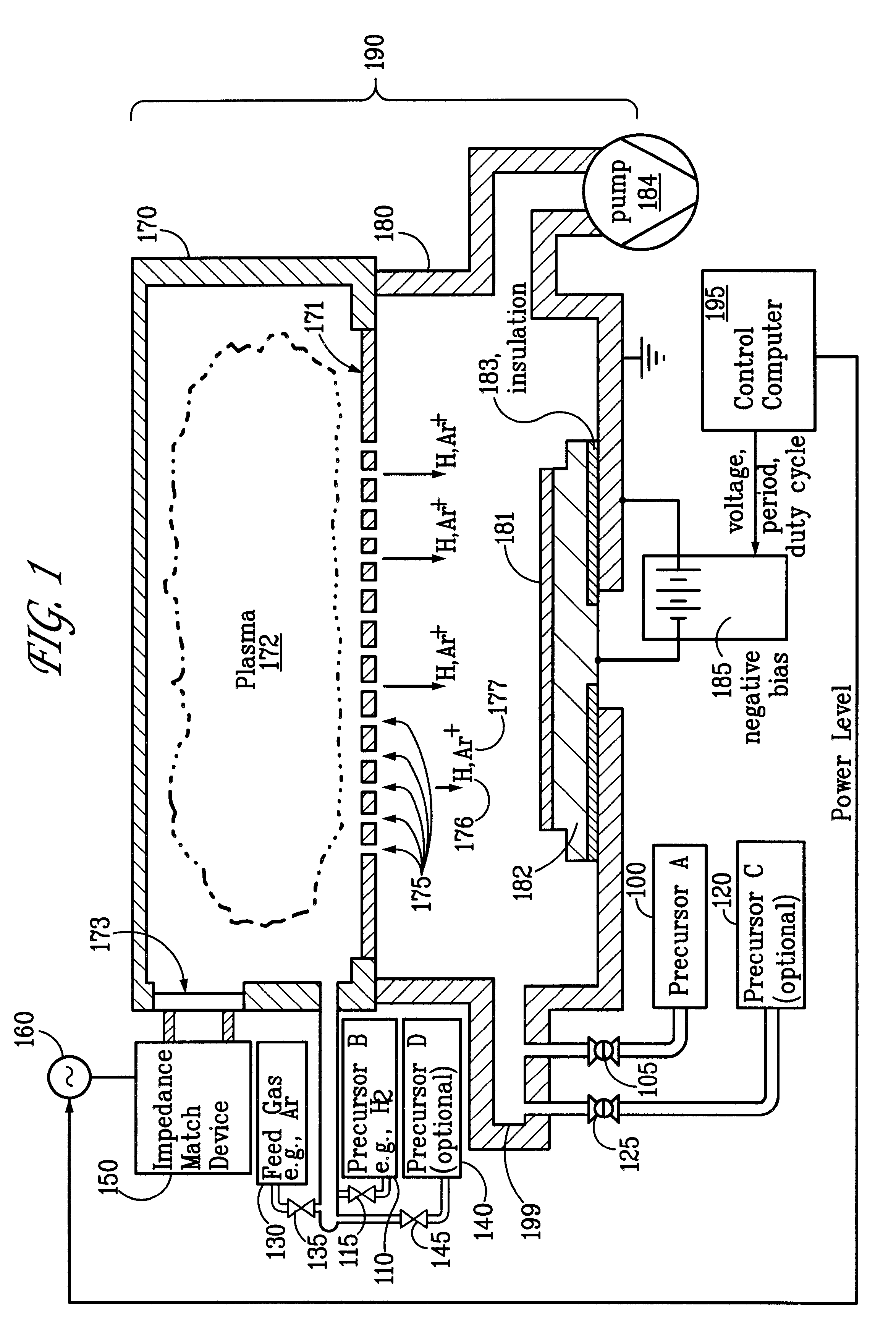

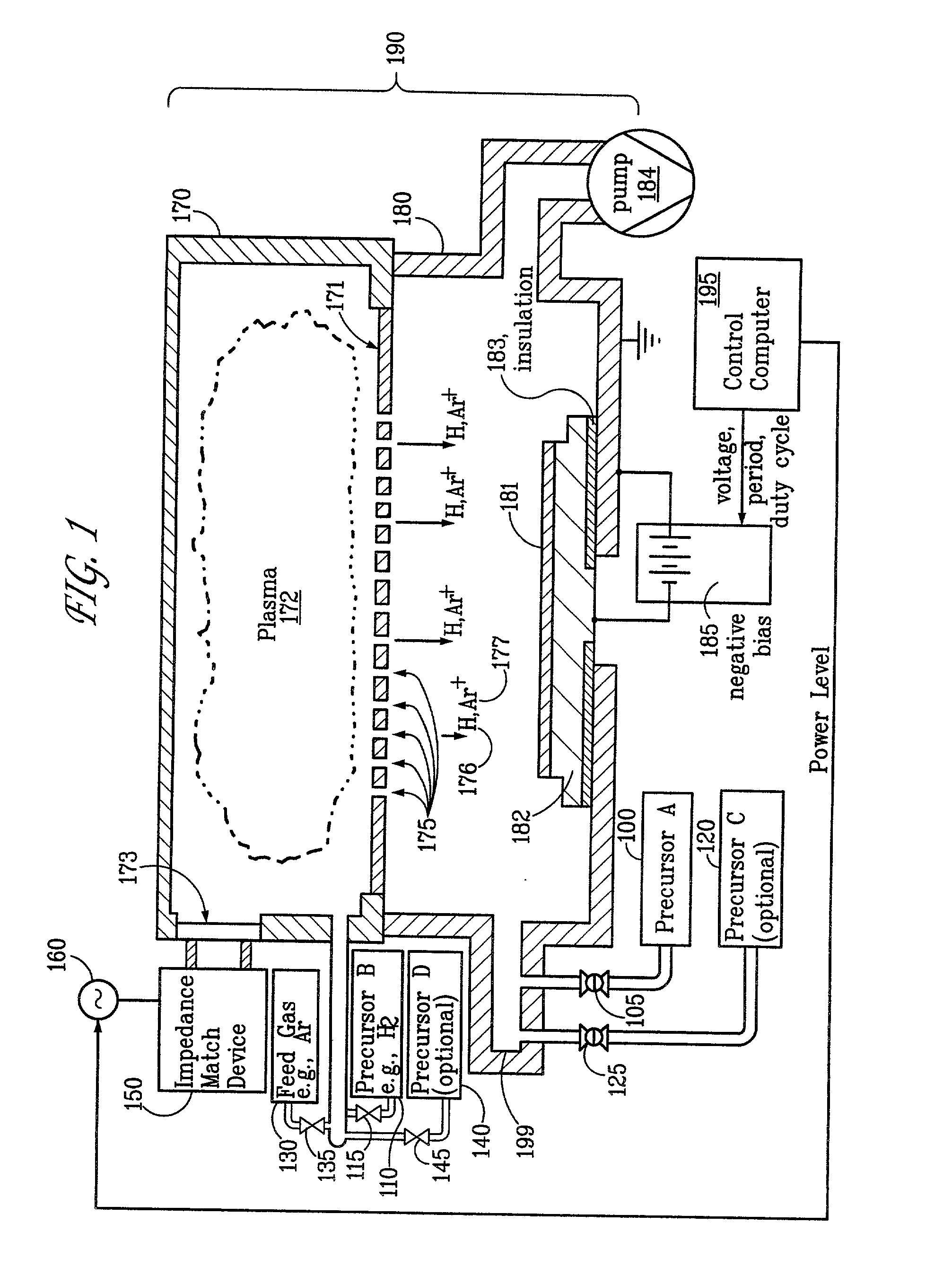

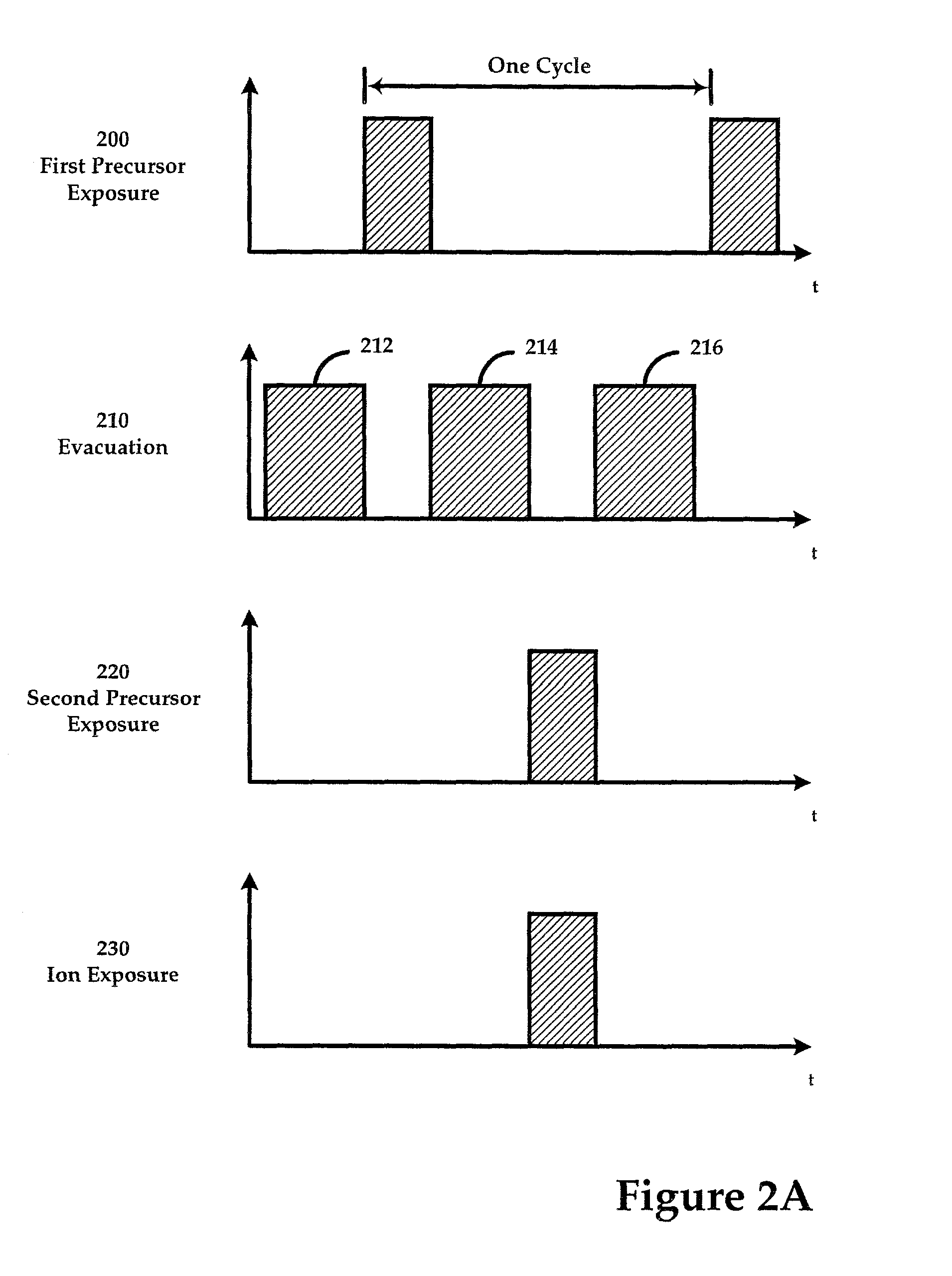

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS6428859B1Faster efficient meanSimple methodVacuum evaporation coatingSputtering coatingSequential methodHigh density

The present invention relates to an enhanced sequential atomic layer deposition (ALD) technique suitable for deposition of barrier layers, adhesion layers, seed layers, low dielectric constant (low-k) films, high dielectric constant (high-k) films, and other conductive, semi-conductive, and non-conductive films. This is accomplished by 1) providing a non-thermal or non-pyrolytic means of triggering the deposition reaction; 2) providing a means of depositing a purer film of higher density at lower temperatures; and, 3) providing a faster and more efficient means of modulating the deposition sequence and hence the overall process rate resulting in an improved deposition method. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:NOVELLUS SYSTEMS

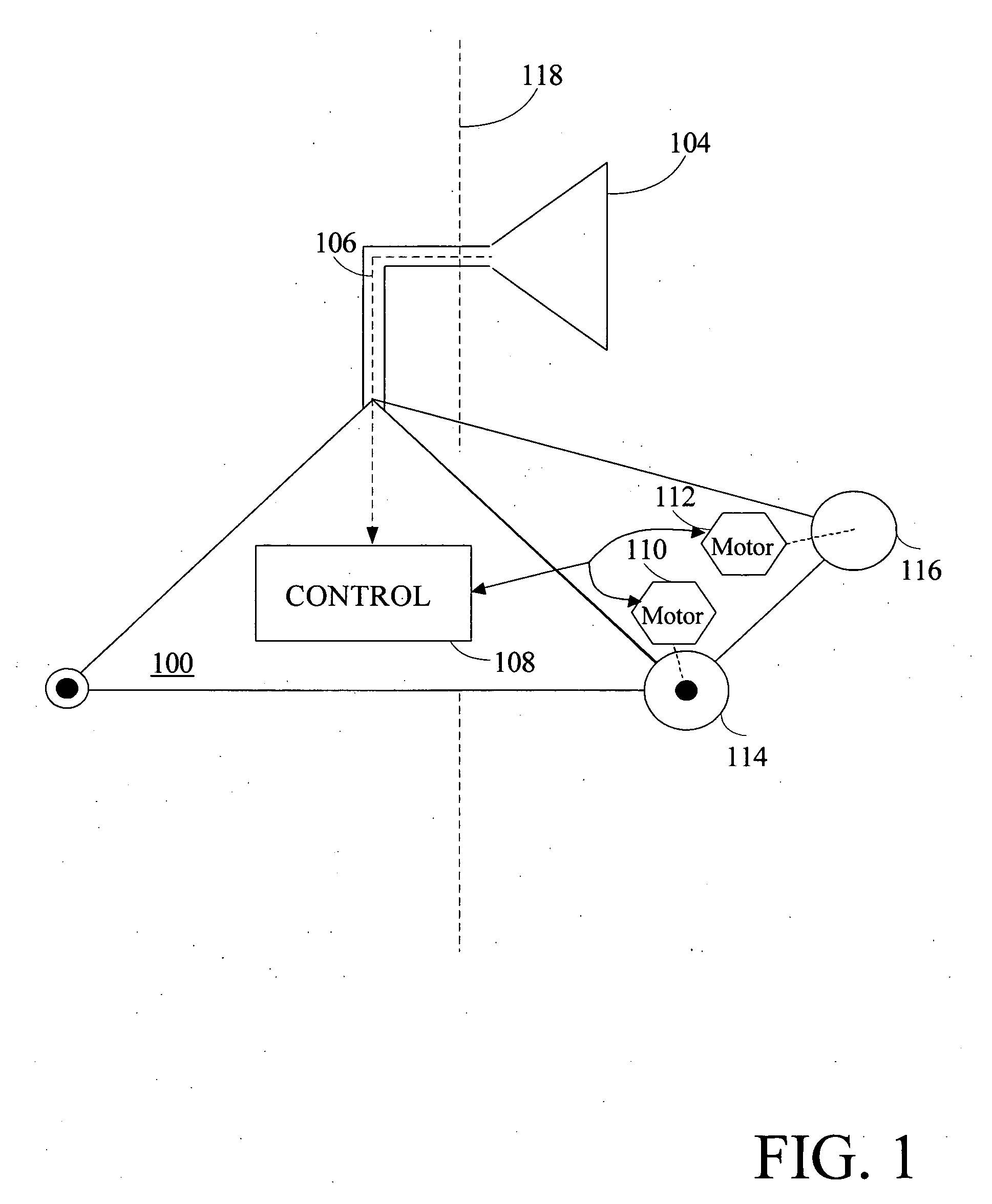

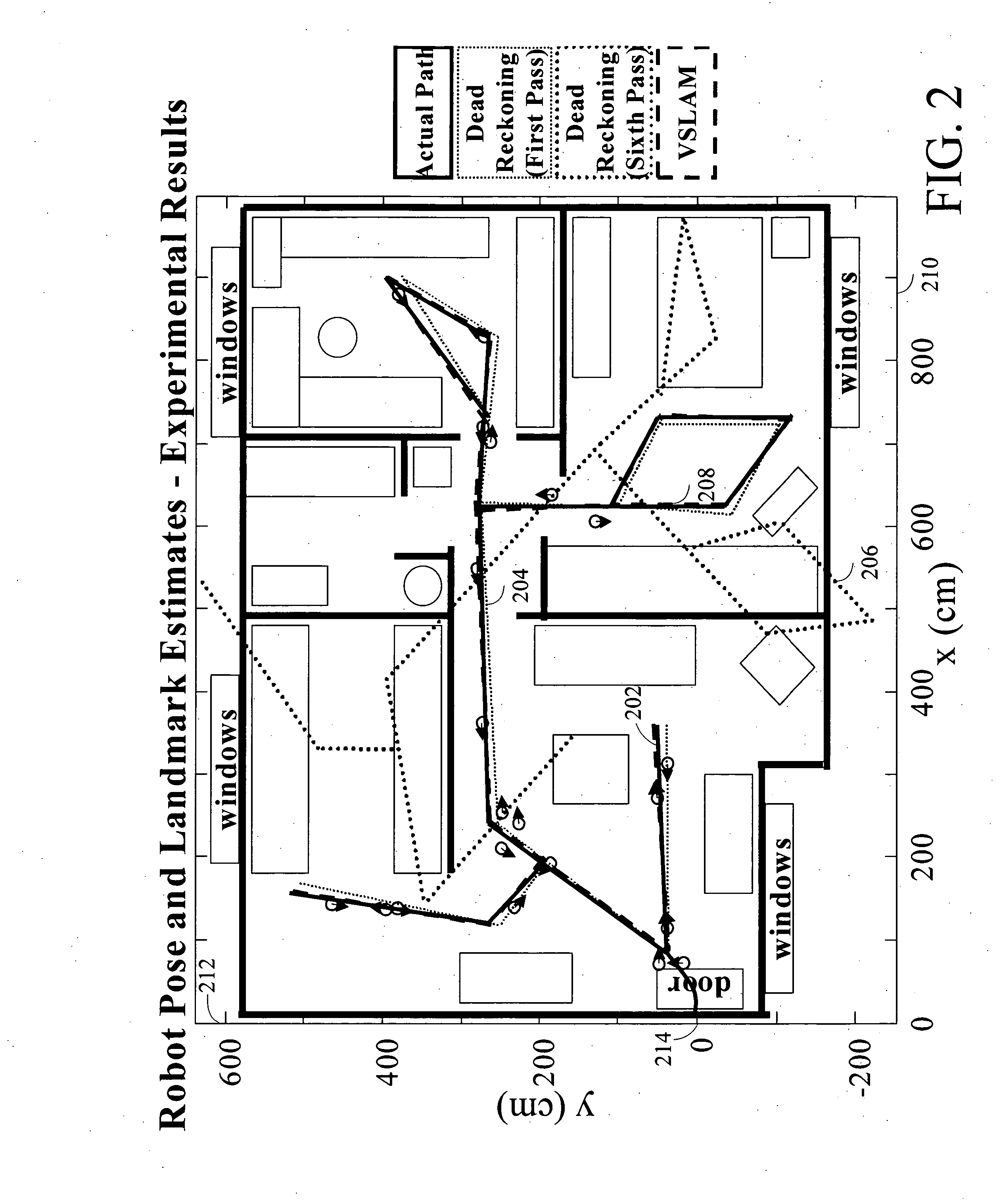

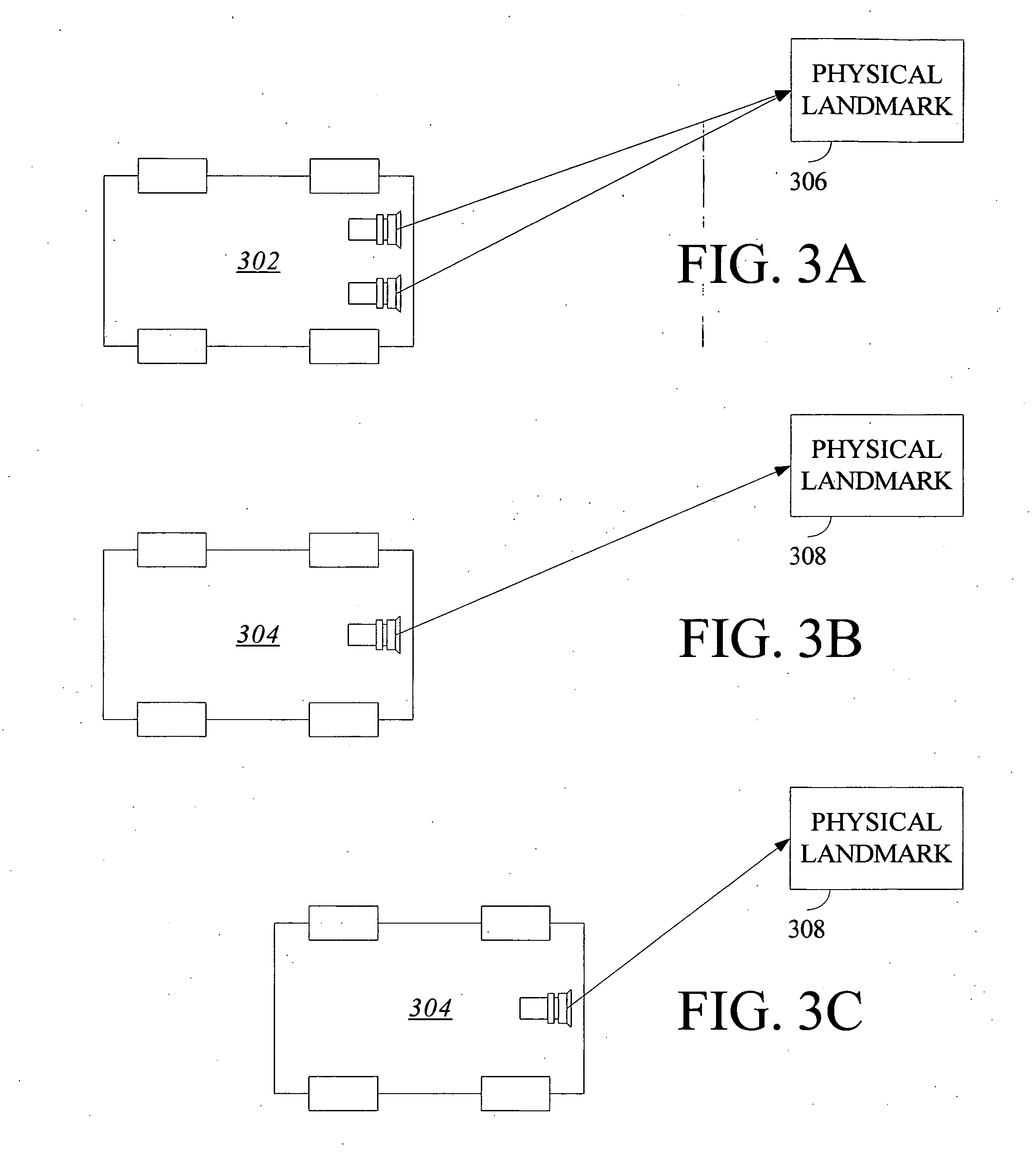

Sequential selective integration of sensor data

InactiveUS20050234679A1Broaden applicationDigital computer detailsComplex mathematical operationsSequential methodMobile device

This invention is generally related to sequential methods and apparatus that permit the measurements from a plurality of sensors to be combined or fused in a robust manner. For example, the sensors can correspond to sensors used by a mobile device, such as a robot, for localization and / or mapping. The measurements can be fused for estimation of a measurement, such as an estimation of a pose of a robot.

Owner:EVOLUTION ROBOTICS

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

InactiveUS20020164421A1Faster efficient meanSimple methodVacuum evaporation coatingSemiconductor/solid-state device manufacturingSequential methodHigh density

Owner:NOVELLUS SYSTEMS

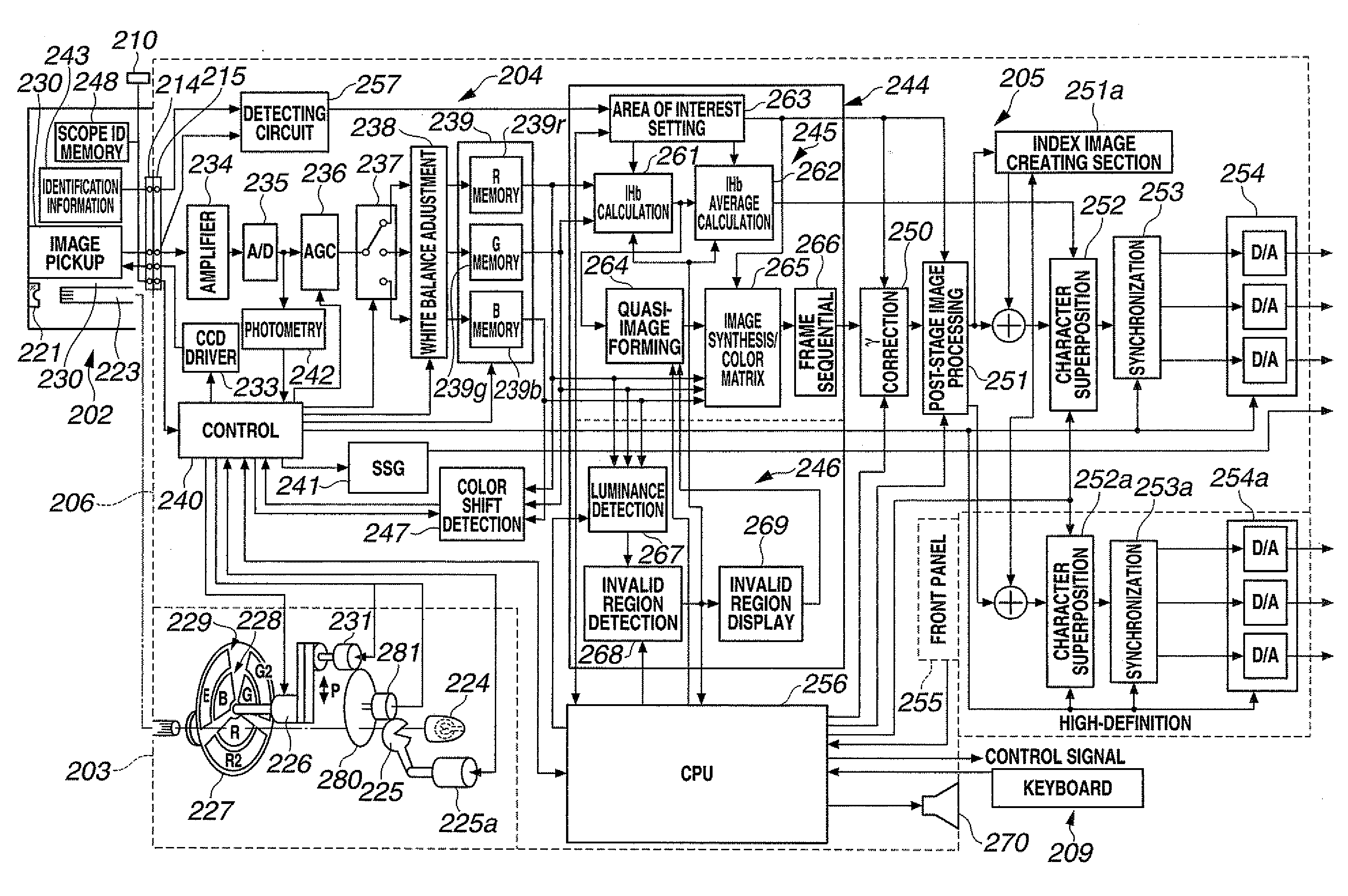

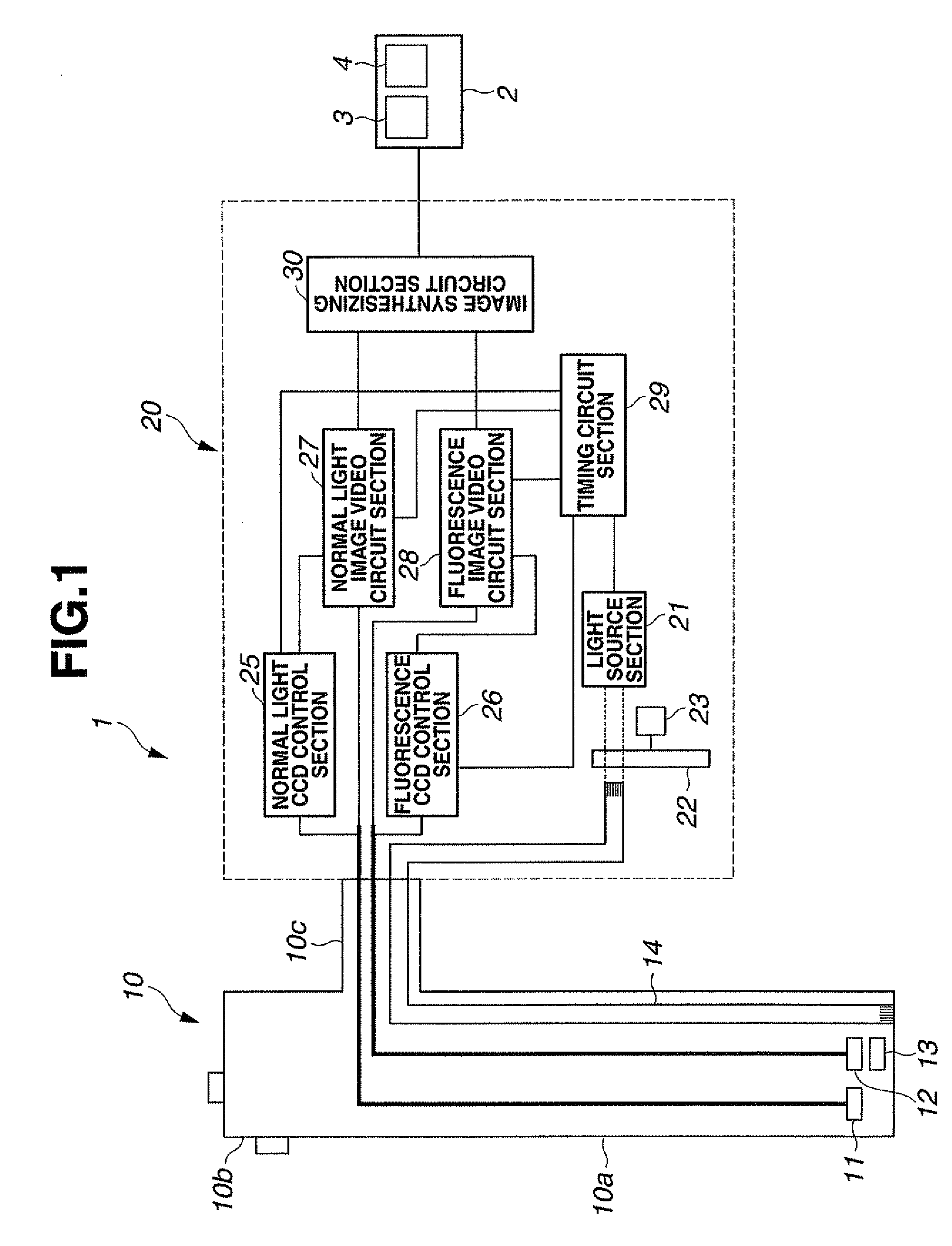

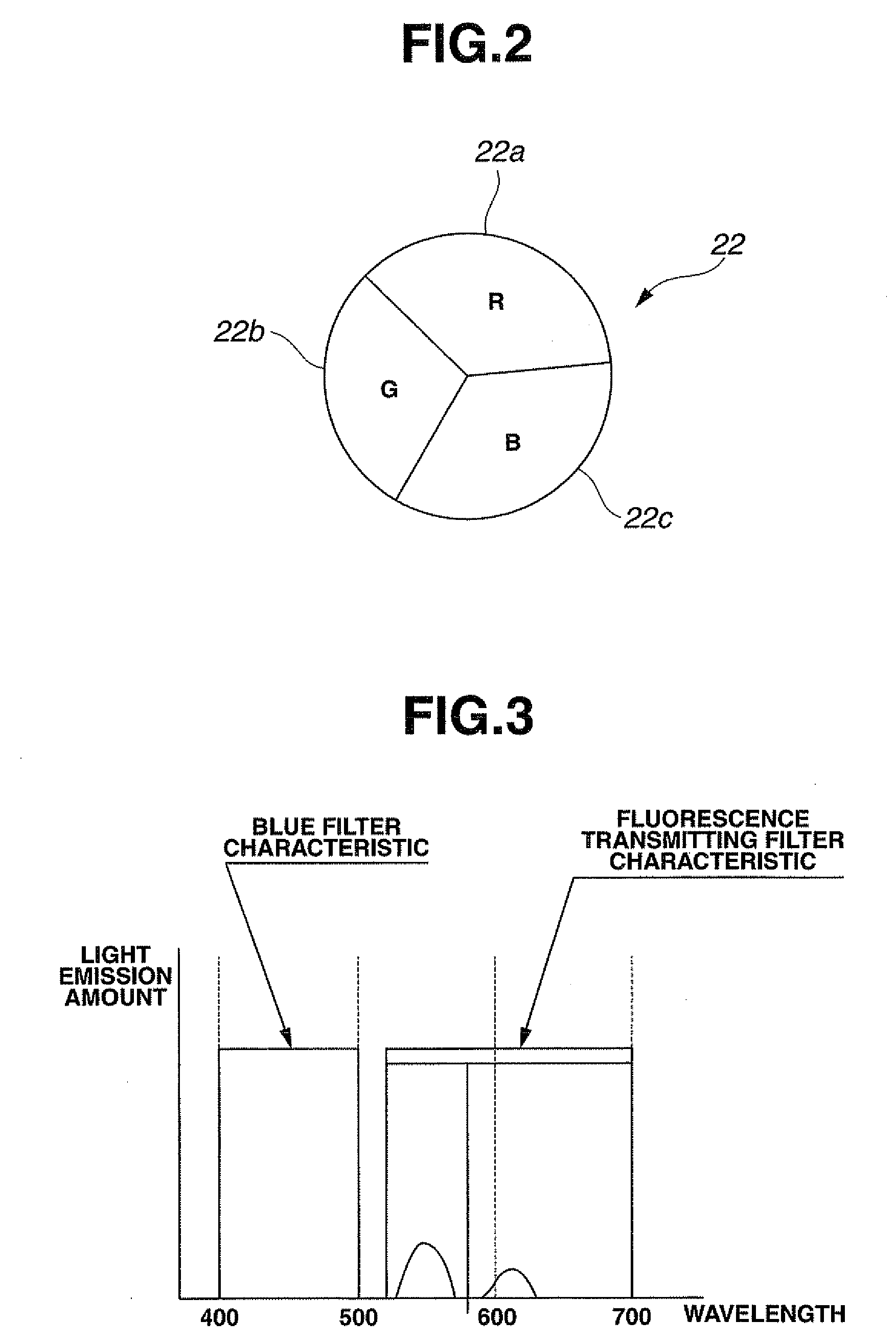

Endoscope apparatus and image processing apparatus

ActiveUS20090118578A1Easy to compareTelevision system detailsSurgeryImaging processingSequential method

A normal light CCD 11 is driven via a normal light CCD control section 25 by a timing signal from a timing circuit section 29 of a video processor 20. At the same time, a fluorescence CCD 12 is driven via a fluorescence CCD control section 26. Then, an image pickup signal according to an RGB frame sequential method from the normal light CCD 11 is processed by a normal light image video circuit section 27 and a normal color image is created while an image pickup signal from the fluorescence CCD 12 is processed by a fluorescence image video circuit section 28, and an image pickup signal of a subject excited by blue illumination light and transmitted through a fluorescence transmitting filter 13 is extracted to create a fluorescence image of the subject. The normal color image and the fluorescence image of the subject are synthesized by an image synthesizing circuit section 30 and outputted to a monitor 2, whereby the normal light image and the fluorescence image is displayed side by side or on top of each other.

Owner:OLYMPUS CORP

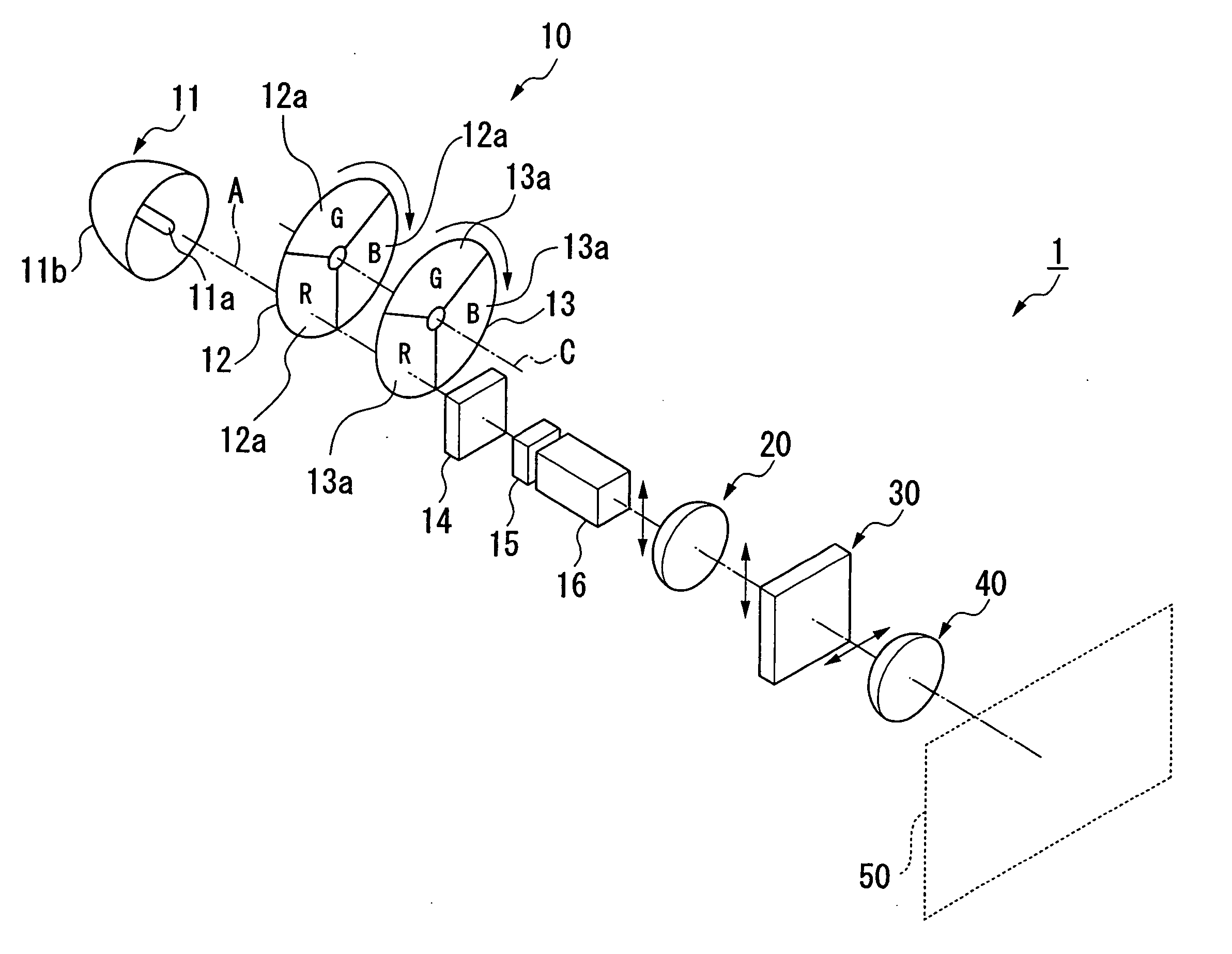

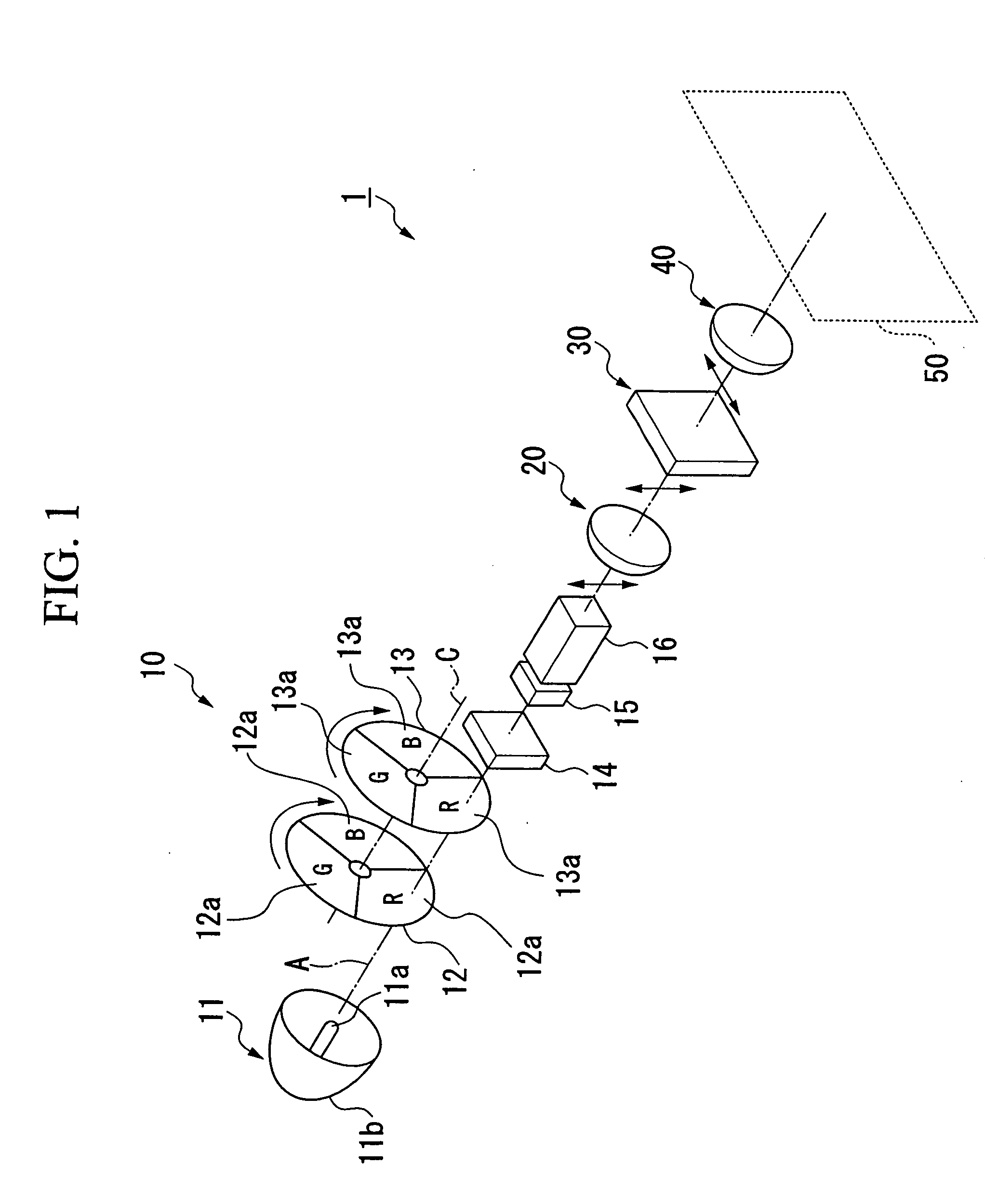

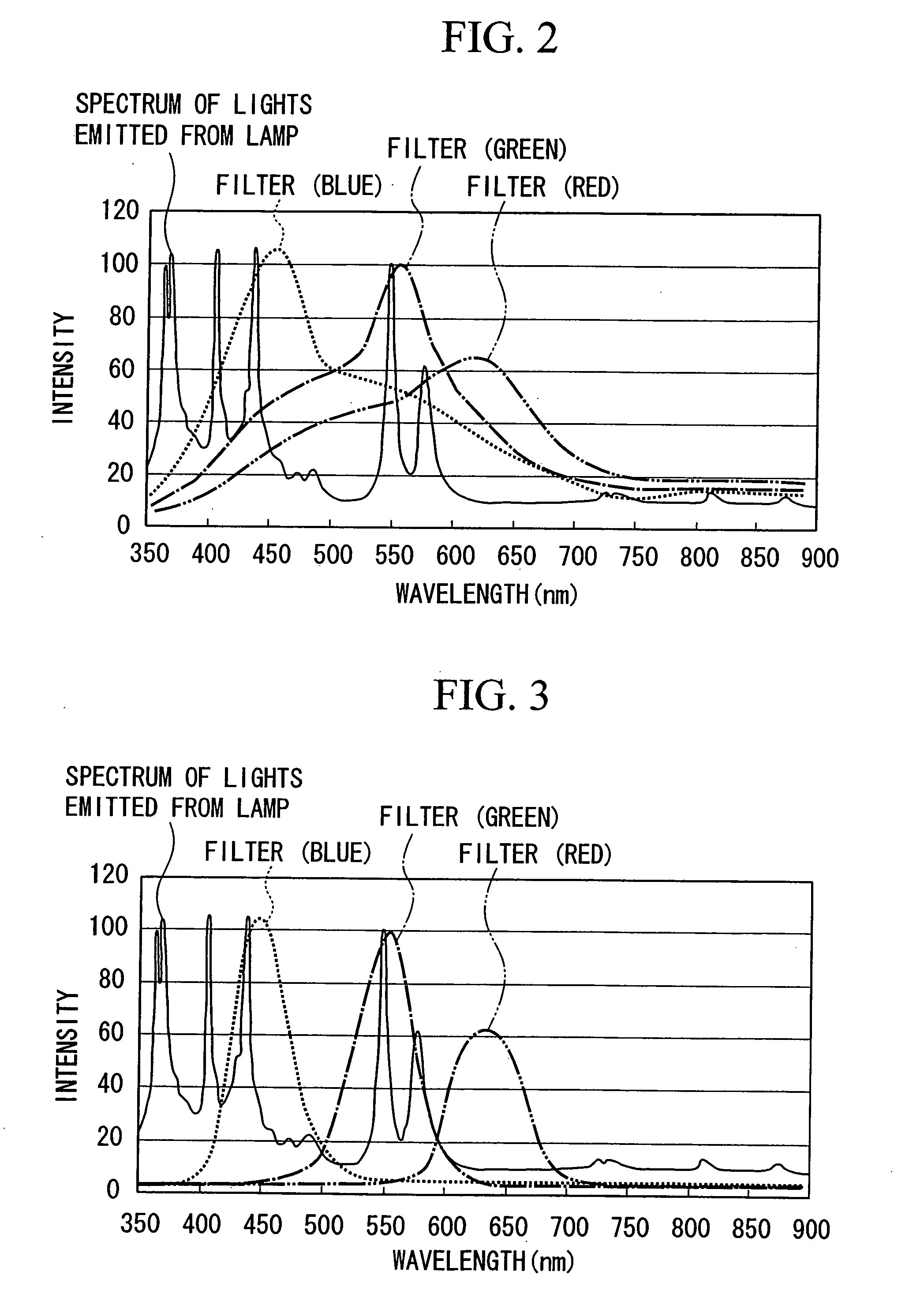

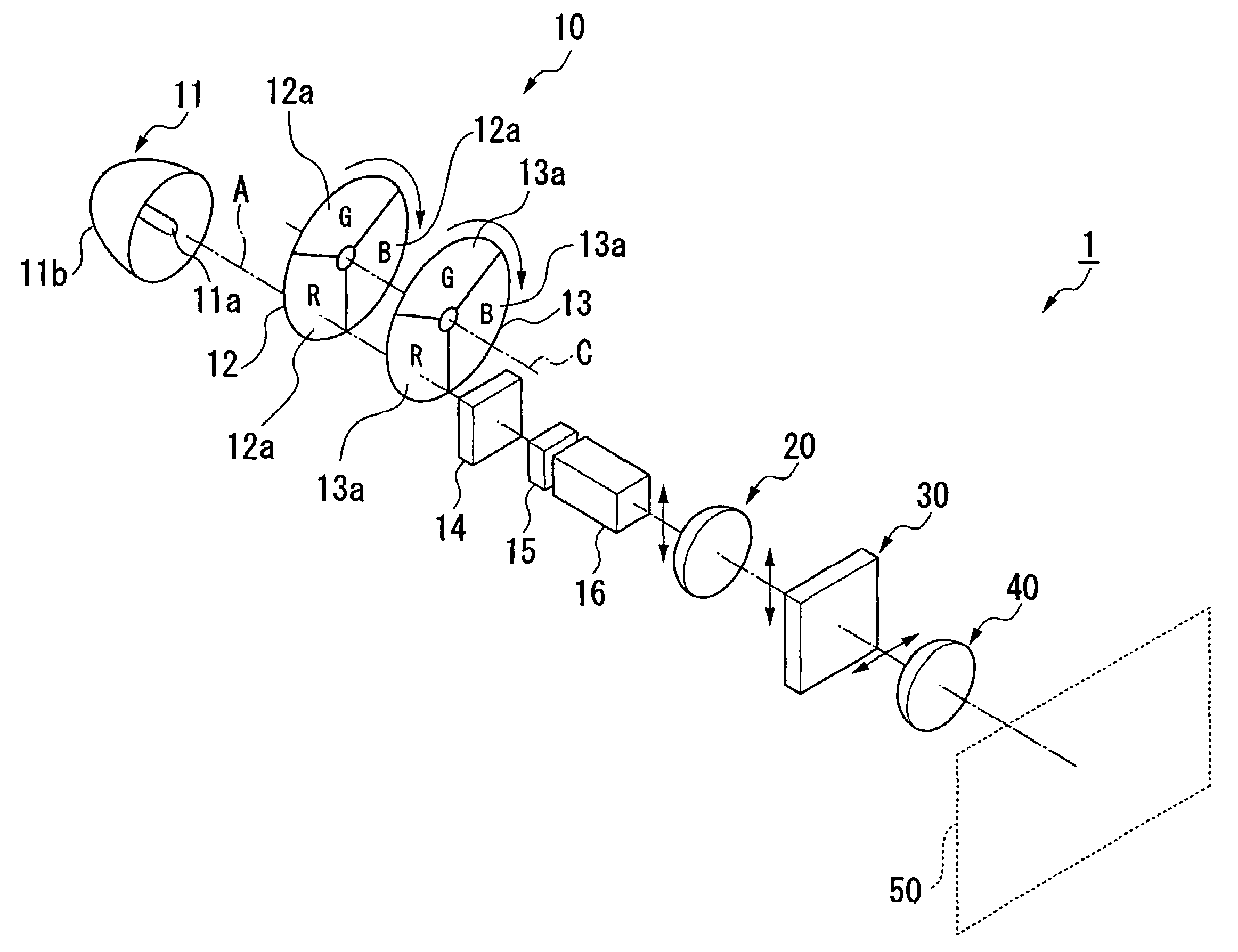

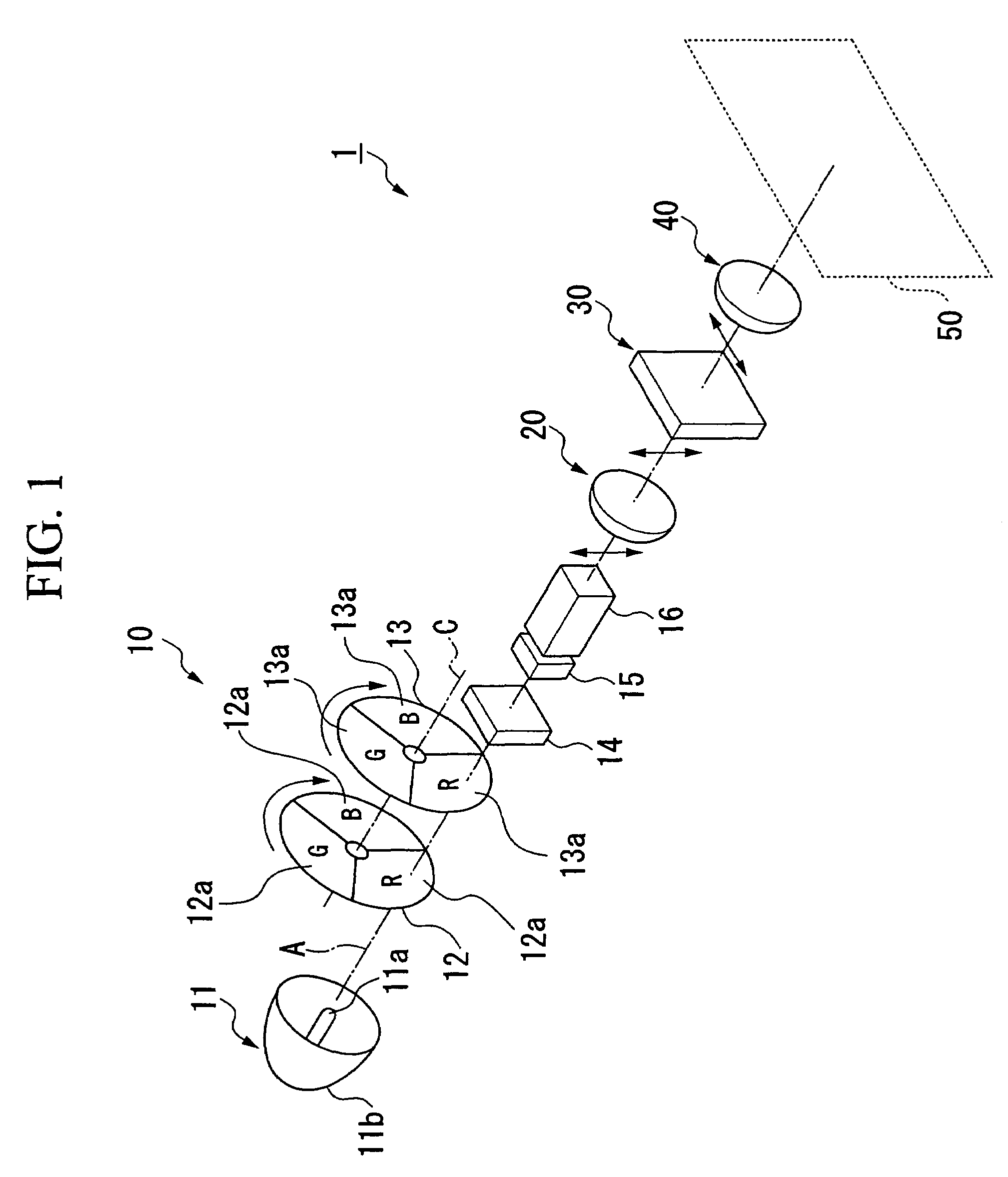

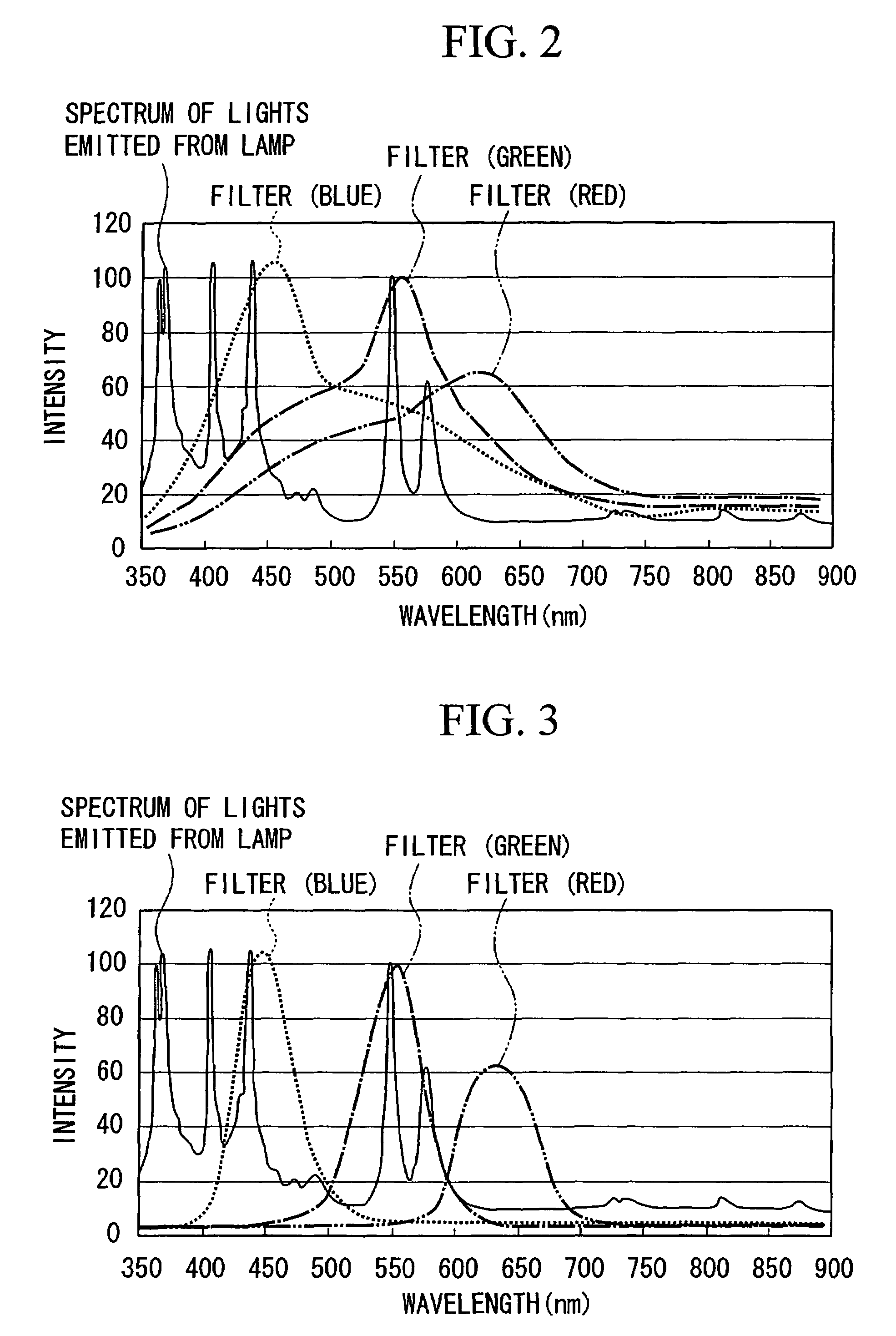

Field sequential lighting device and image projecting device

InactiveUS20060087847A1Desirable brightnessDesirable color reproducibilityPoint-like light sourceProjectorsSequential methodEffect light

A field sequential lighting device for emitting light corresponding to a plurality of colors using a field sequential method includes: a light source; and a light converting section for intensifying the emitted light by sequentially converting the light, emitted from the light source, corresponding to the plurality of colors. By doing this, it is possible to provide a field sequential lighting device using the light emitted from the light source efficiently and having desirable color reproducibility, and an image projecting device having it.

Owner:OLYMPUS CORP

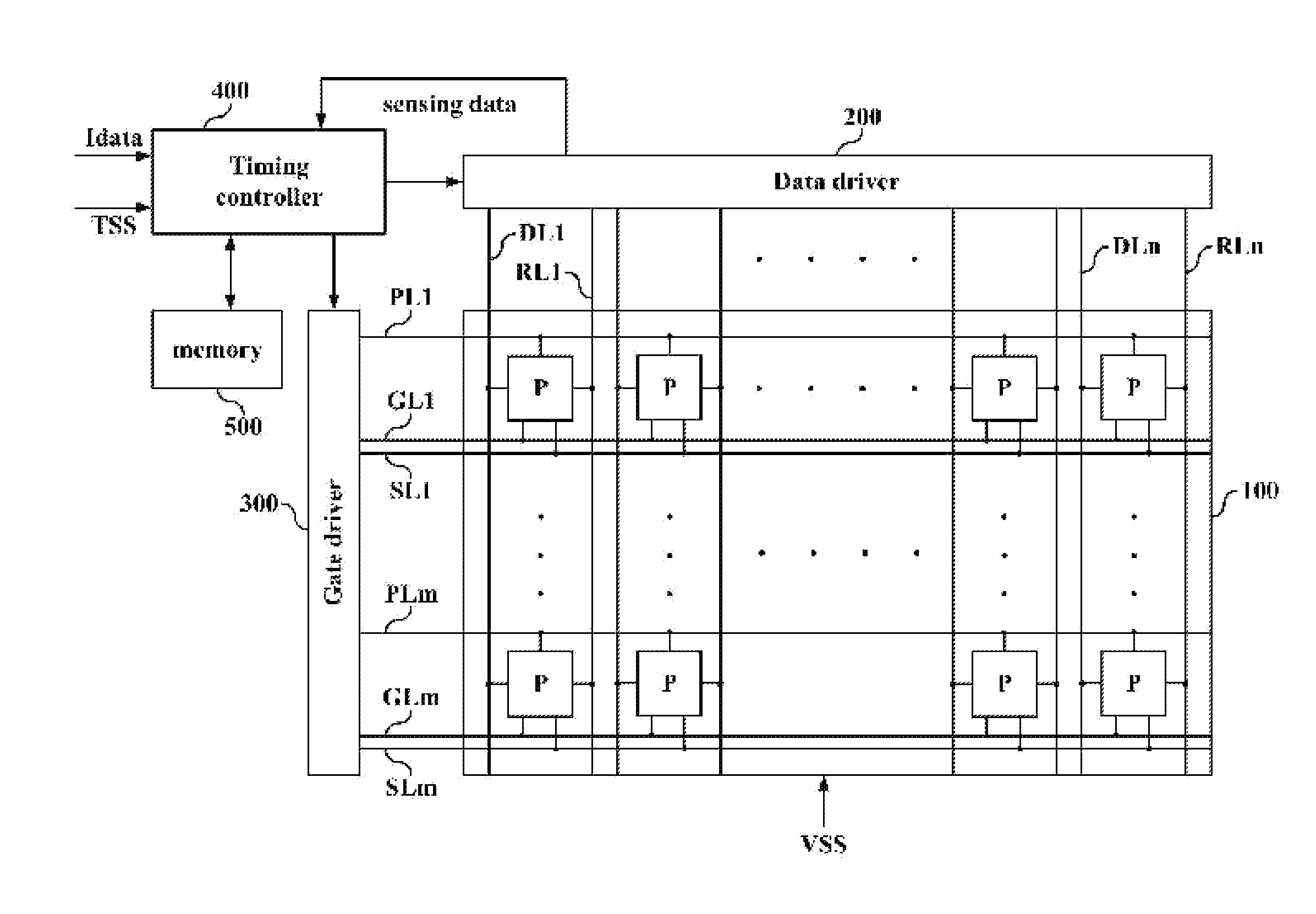

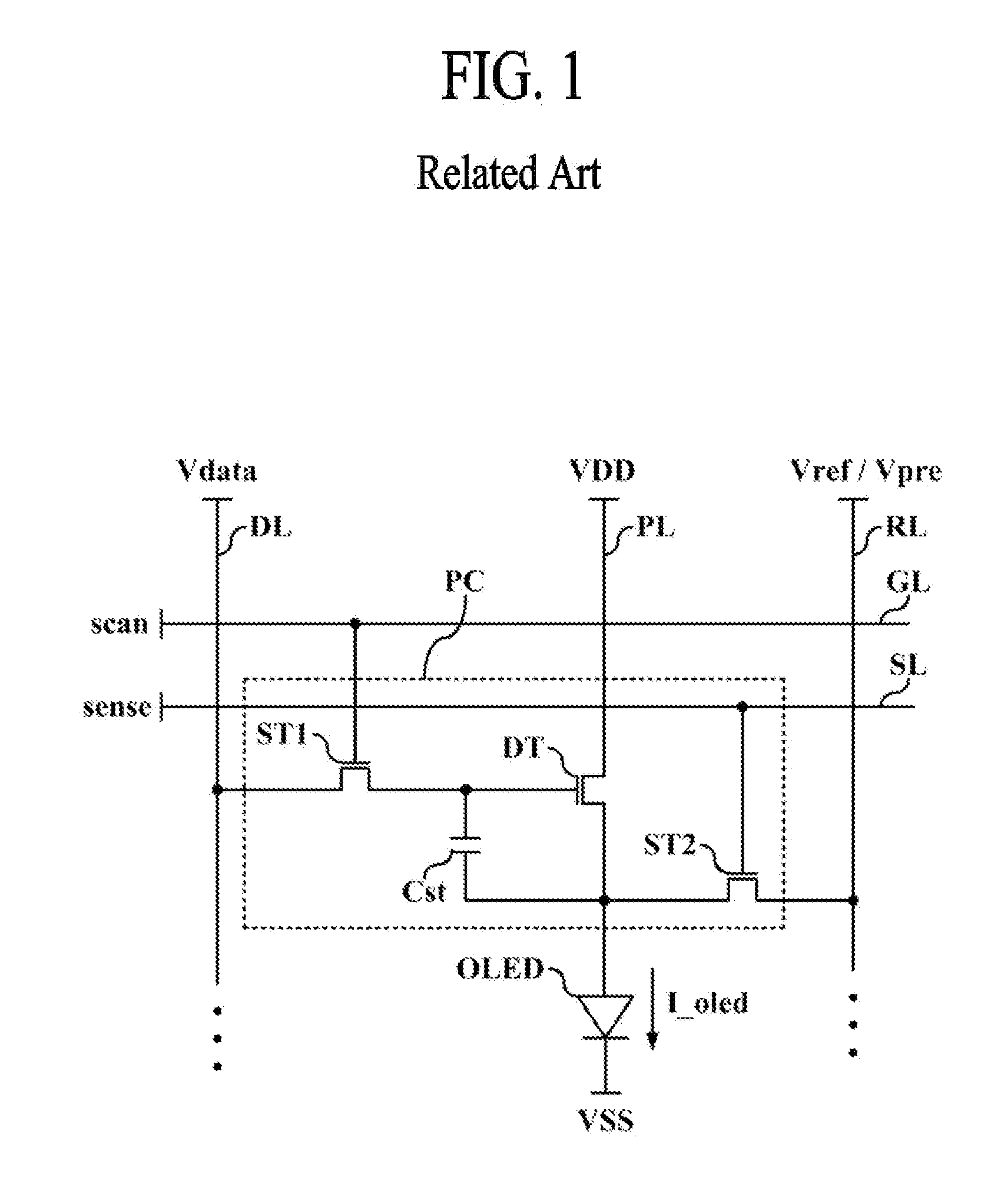

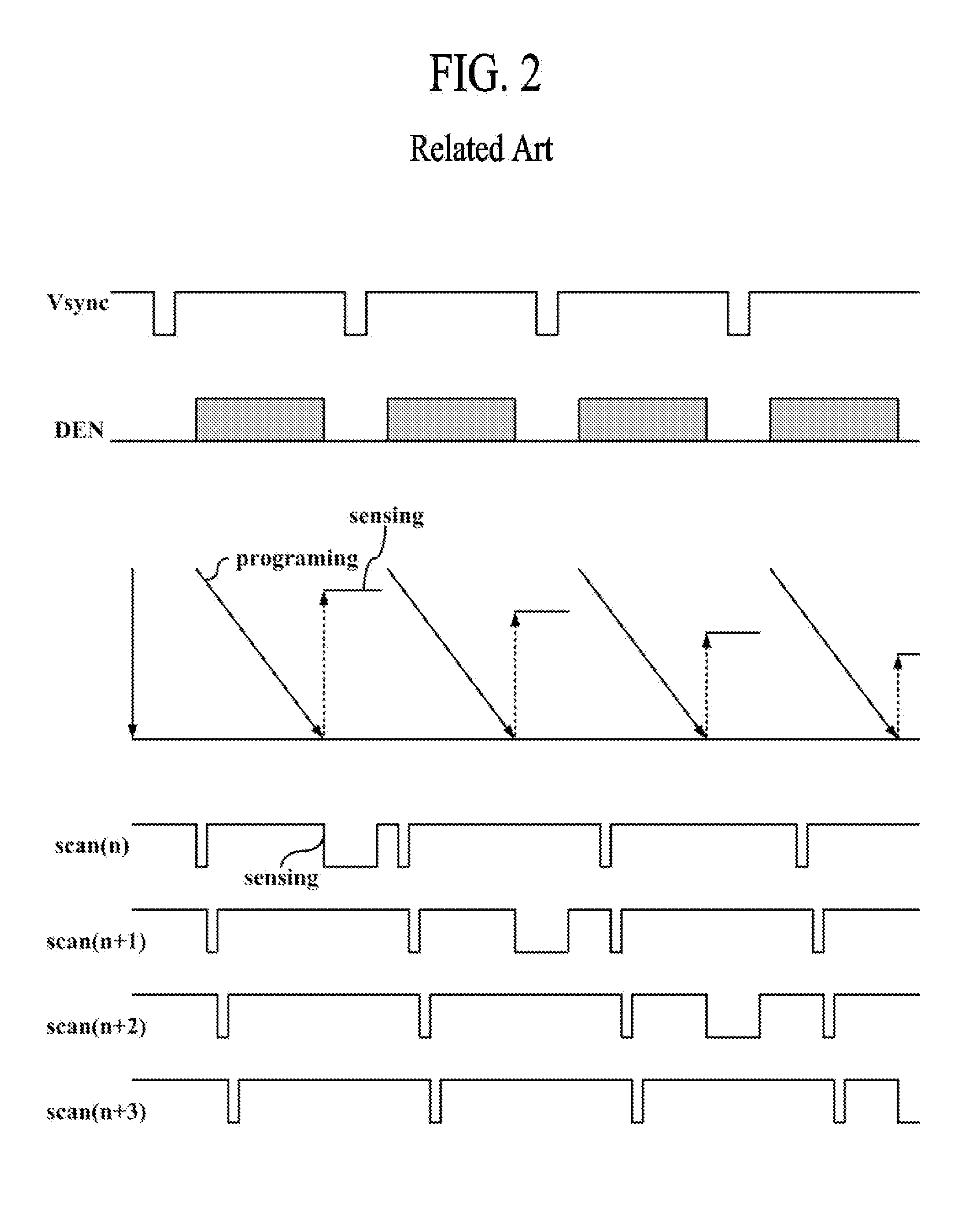

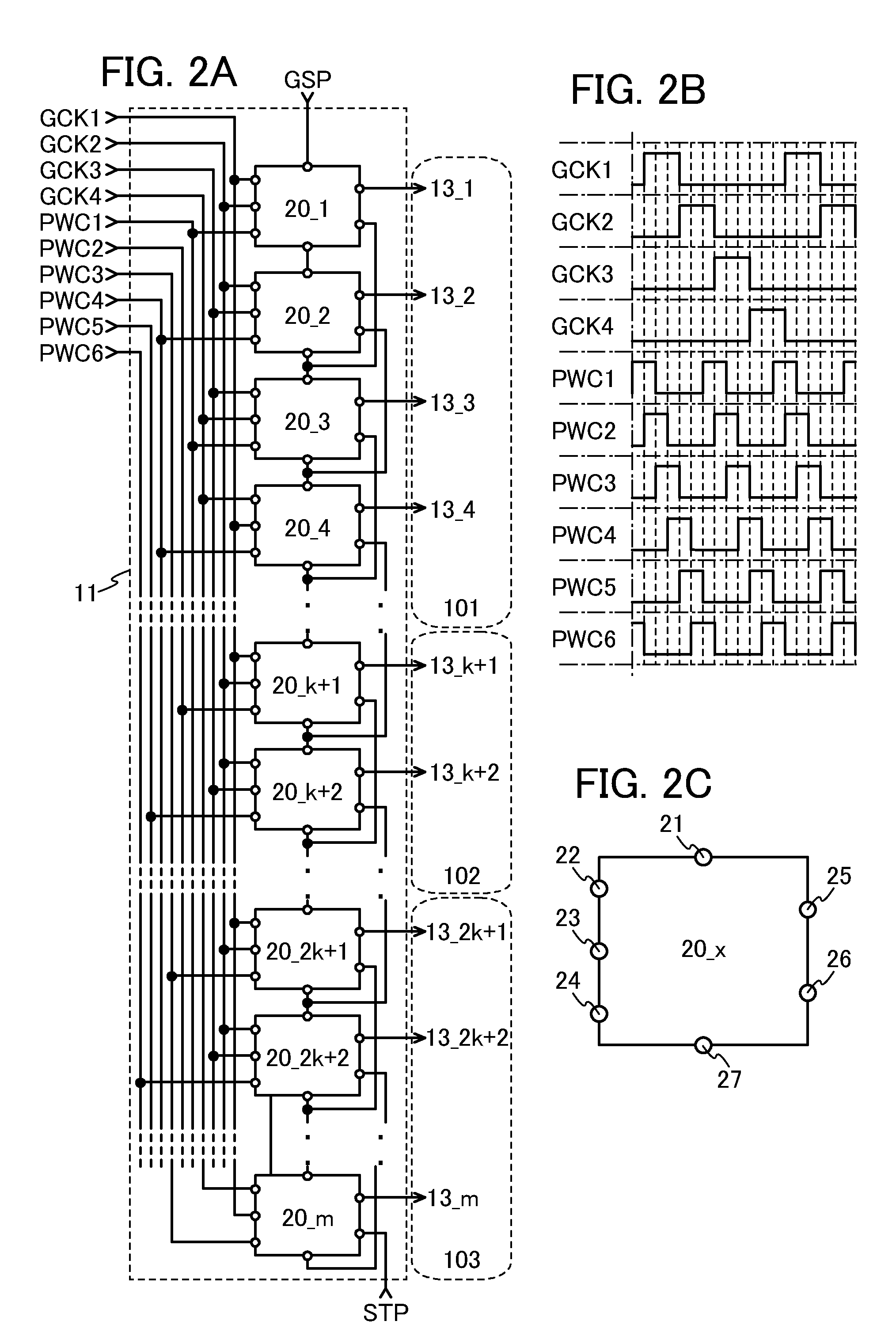

Method of driving organic light emitting display device

ActiveUS20140176401A1Picture quality is deterioratedQuality improvementStatic indicating devicesSequential methodDisplay device

An organic light emitting display device includes a display panel having a plurality of pixels provided with a pixel circuit to operate an organic light emitting diode, and a driving circuit to drive the display panel, wherein ‘n’ horizontal sensing lines are formed in the display panel, and a method for driving the display device includes: dividing the ‘n’ horizontal sensing lines formed in the display panel into a plurality of blocks; and sequentially or non-sequentially sensing the plurality of blocks via the sensing lines, wherein the plurality of blocks are sensed in order from the first to the last of the ‘n’ sensing lines by a sequential or non-sequential method.

Owner:LG DISPLAY CO LTD

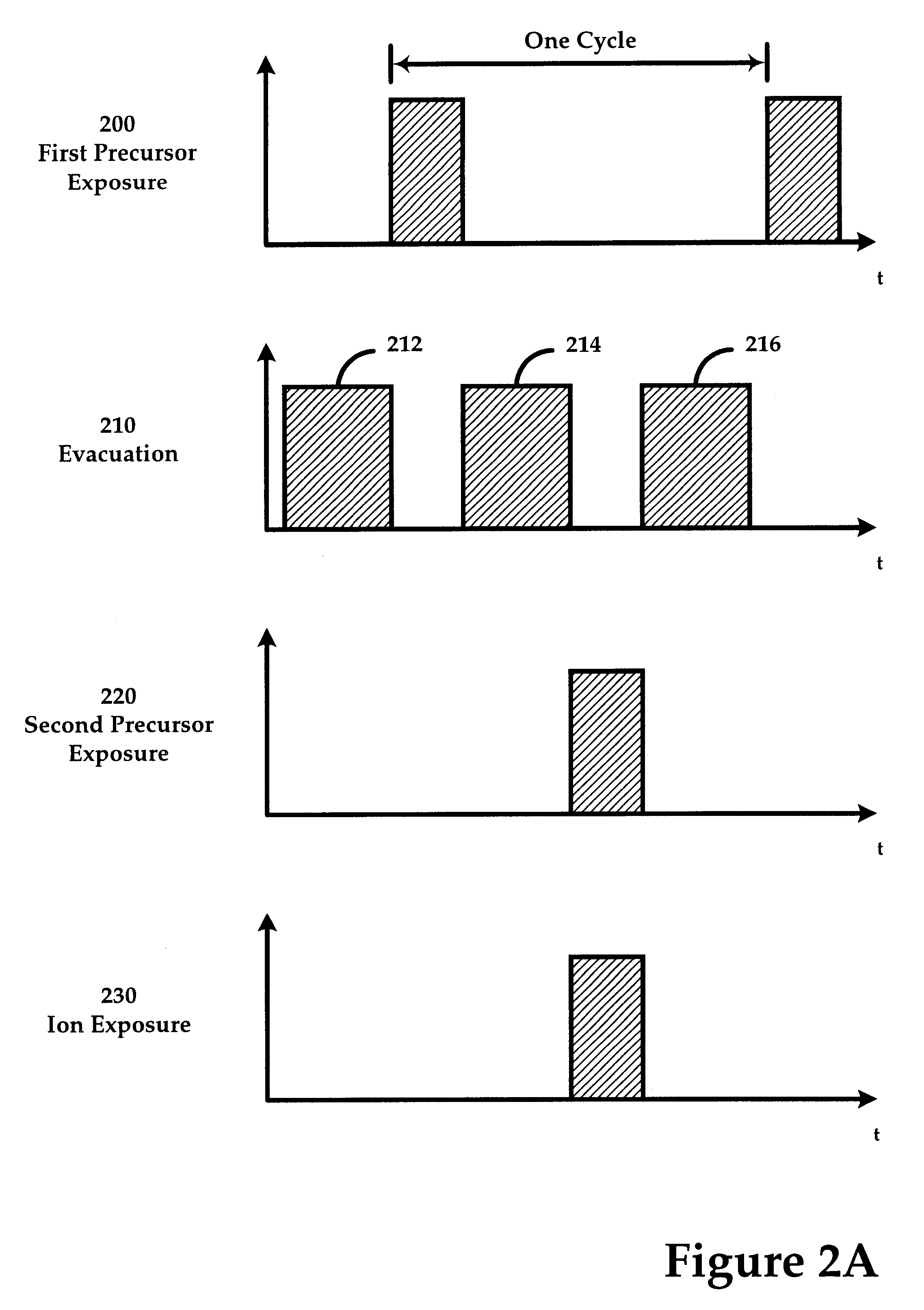

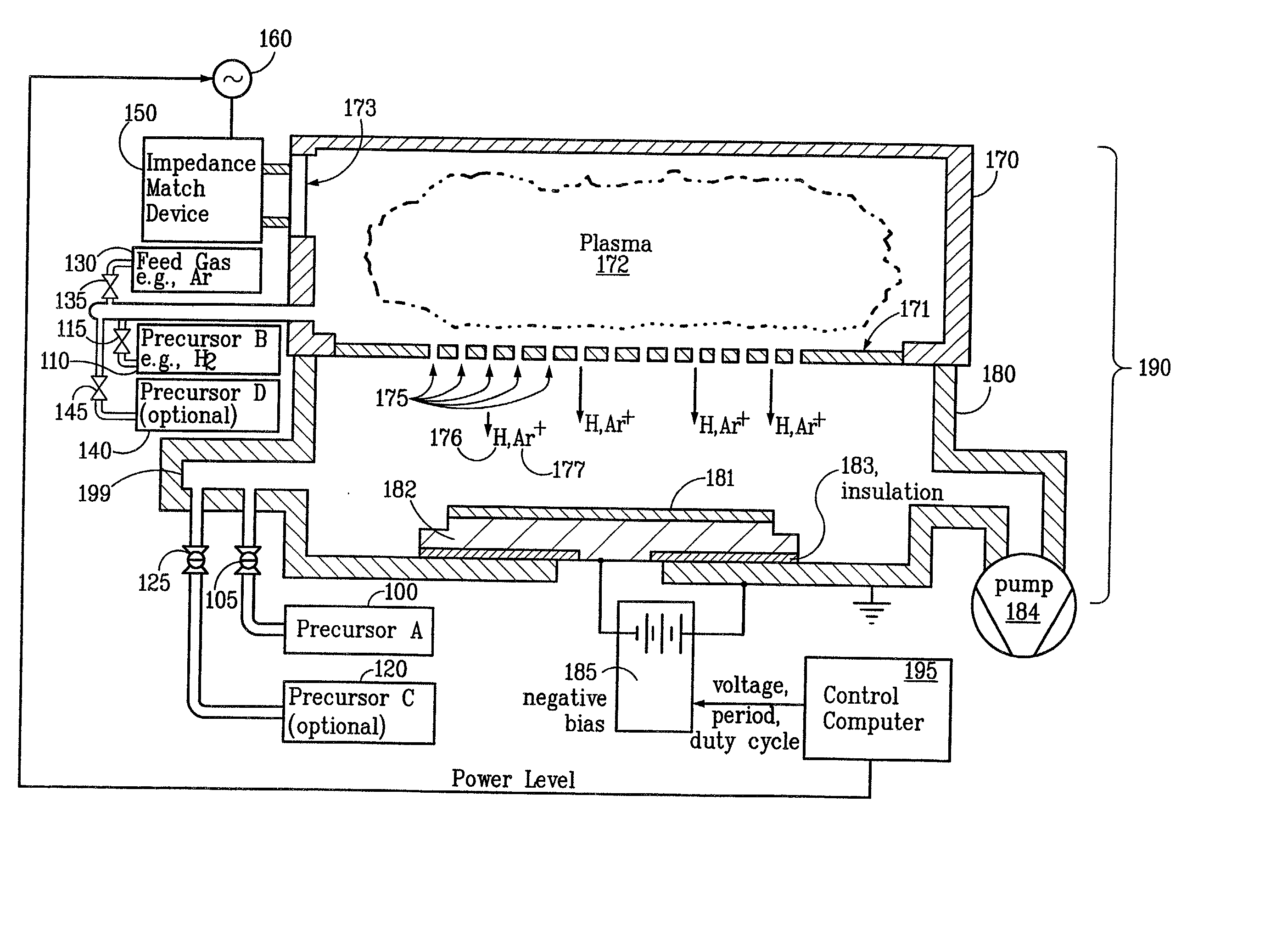

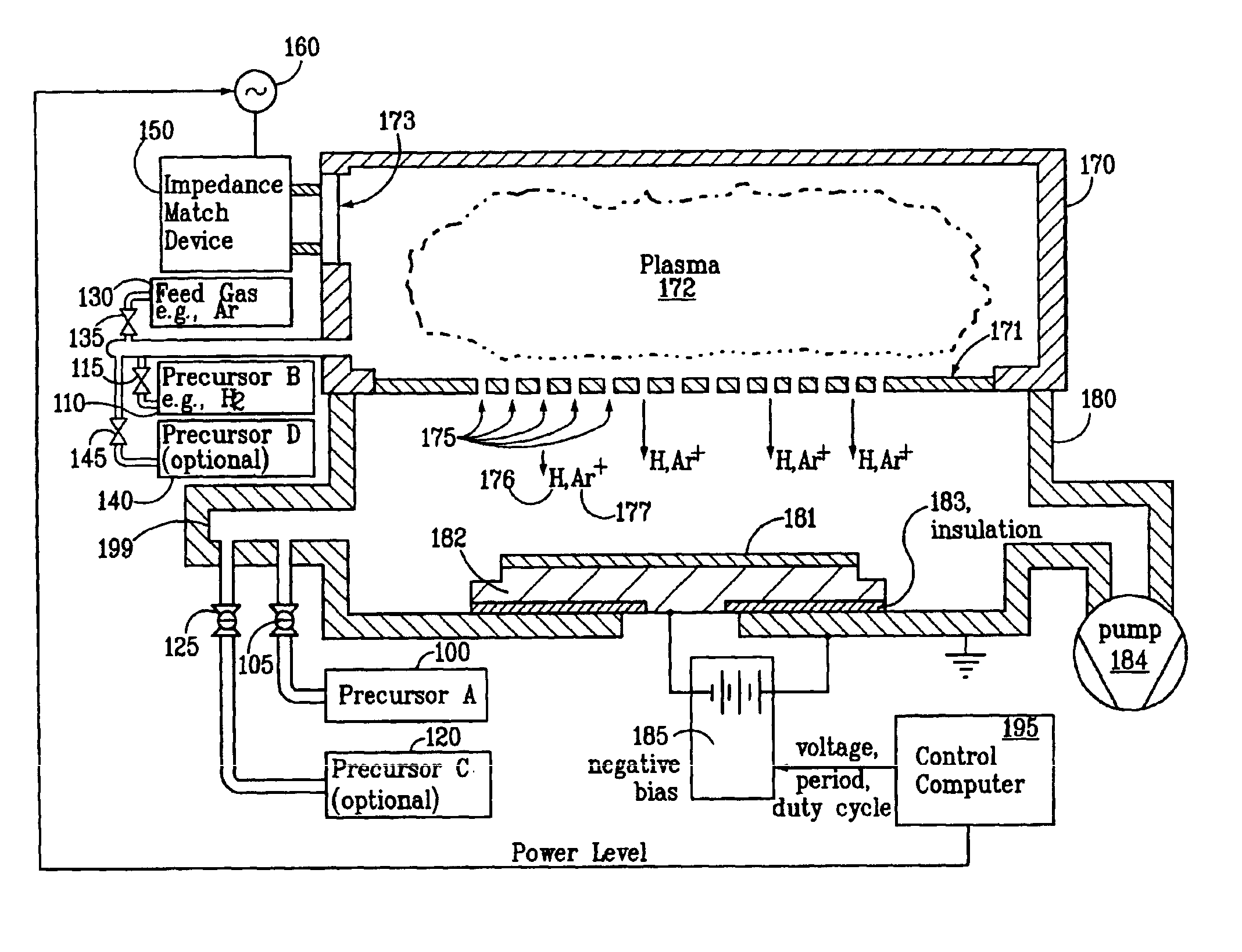

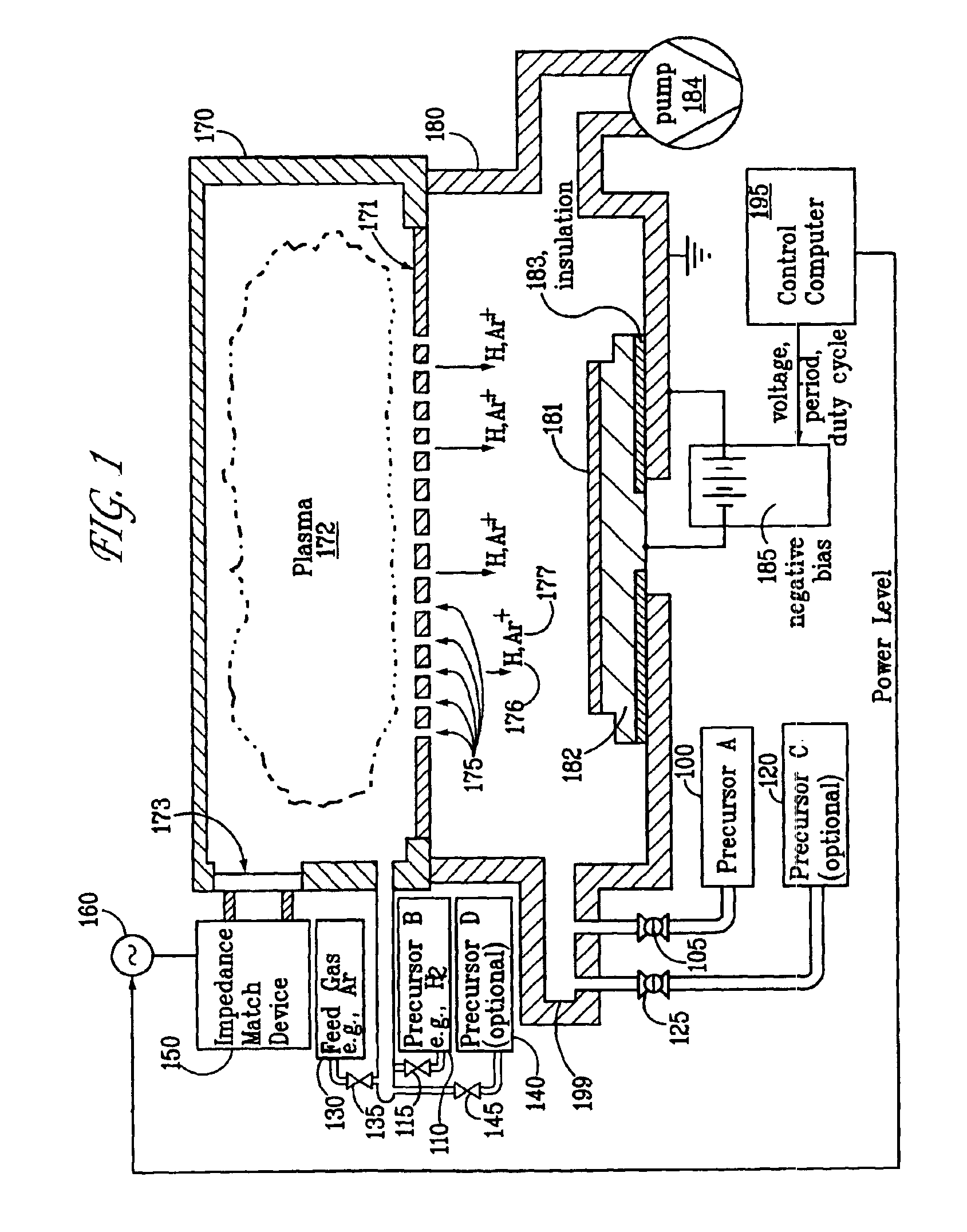

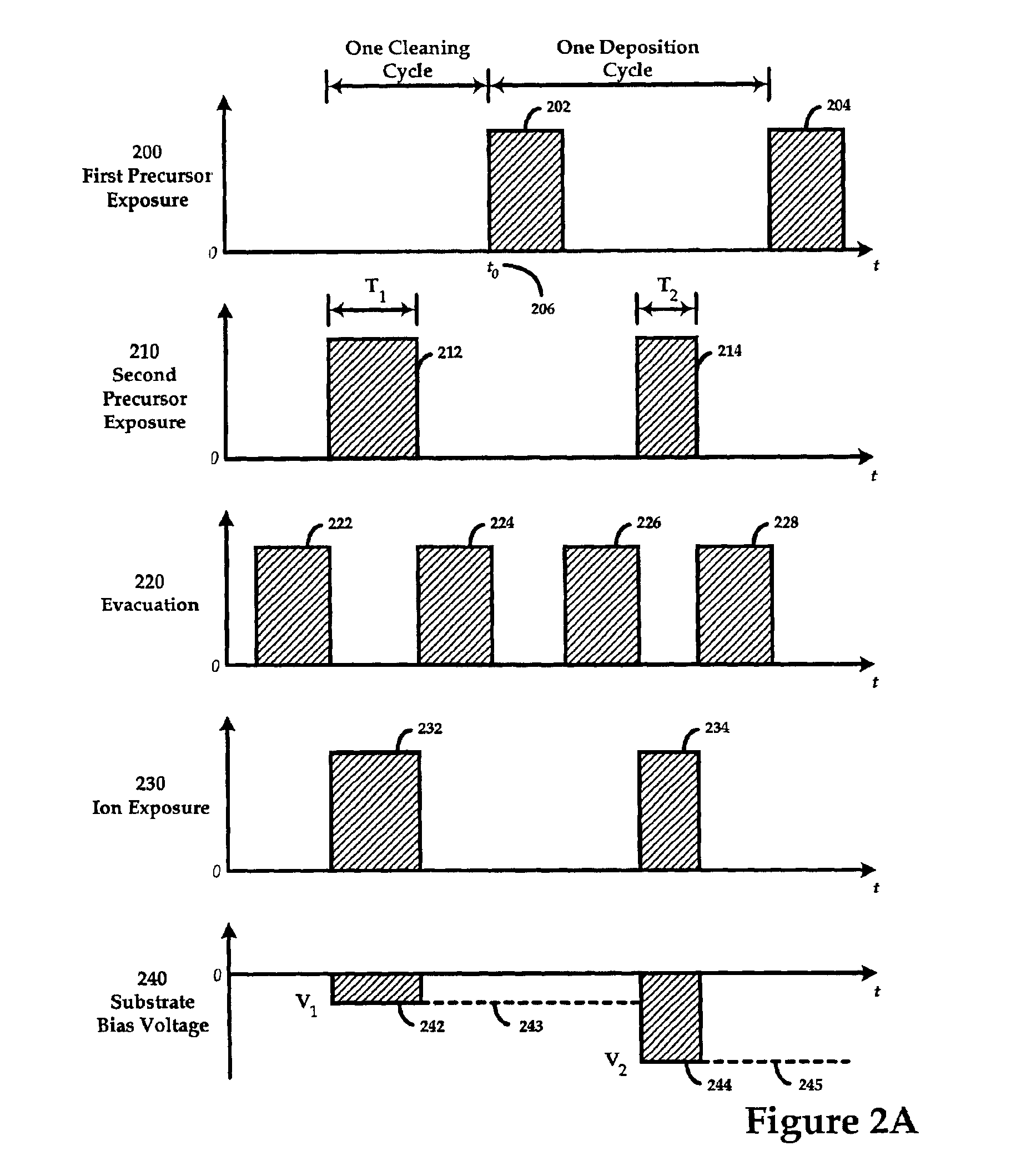

Method for integrated in-situ cleaning and subsequent atomic layer deposition within a single processing chamber

InactiveUS6949450B2Improve stack performanceElectric discharge tubesSemiconductor/solid-state device manufacturingSequential methodProduct gas

A system and sequential method for integrated, in-situ modification of a substrate and subsequent atomic layer deposition of a thin film onto the substrate in an evacuated chamber includes introducing at least one feed gas into the chamber; generating a plasma from the feed gas; exposing said substrate to ions and / or radicals formed by the plasma; modulating any ions; reacting the substrate with said modulated ions and / or radicals to remove any contaminants from the substrate and producing a modified substrate. These steps are followed, in-situ, by performing an atomic layer deposition of a thin film onto the modified substrate in the chamber including introducing a first reactant gas into said chamber; adsorbing at least one monolayer of the first reactant gas onto the modified substrate; evacuating any excess first reactant gas from the chamber; introducing at least one additional feed gas into the chamber, generating a second plasma from the additional feed gas; exposing the modified substrate to additional ions and / or radicals formed by the plasma; modulating any additional ions; and reacting the adsorbed monolayer of the first reactant gas with any modulated additional ions and / or radicals to deposit the thin film.

Owner:NOVELLUS SYSTEMS

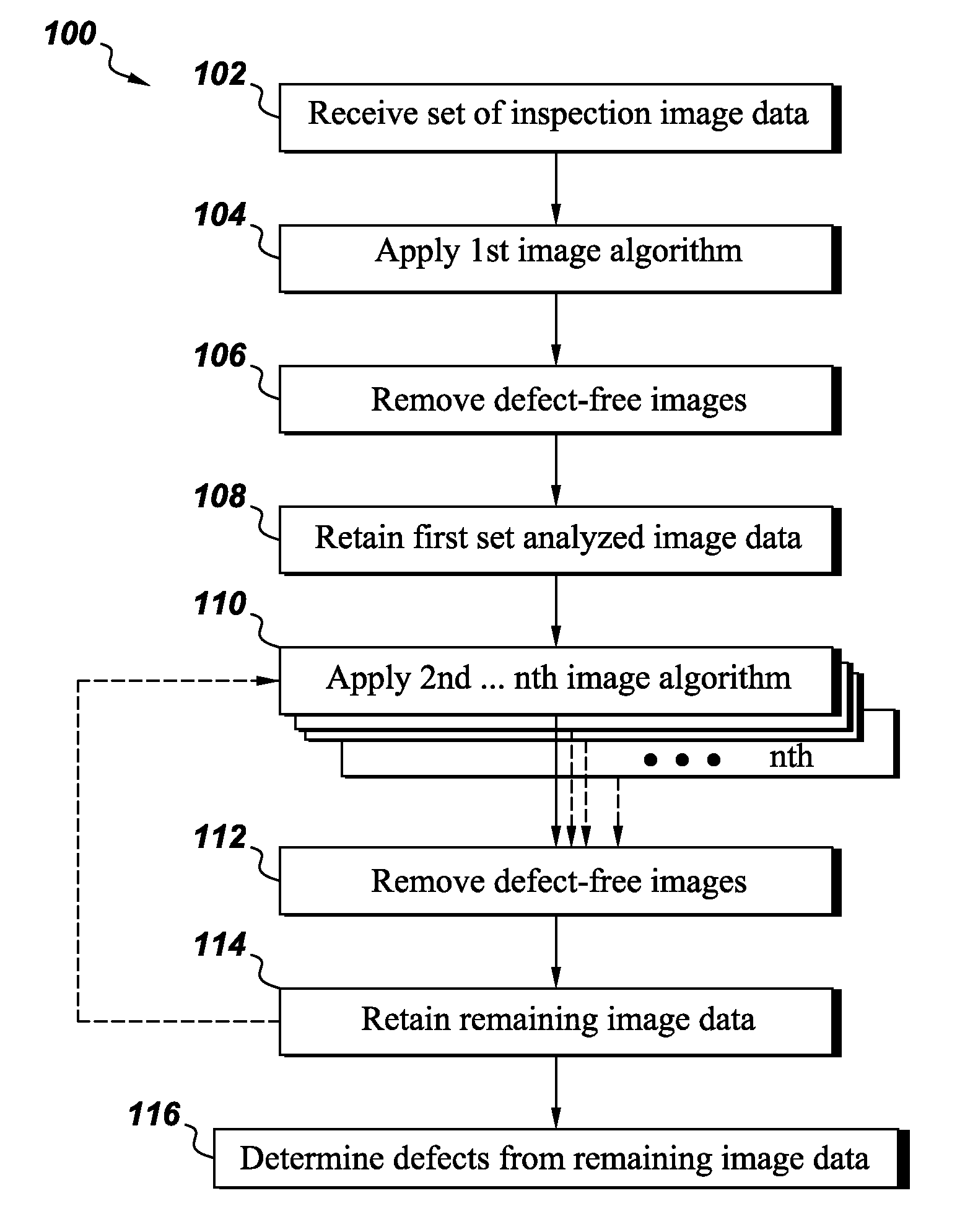

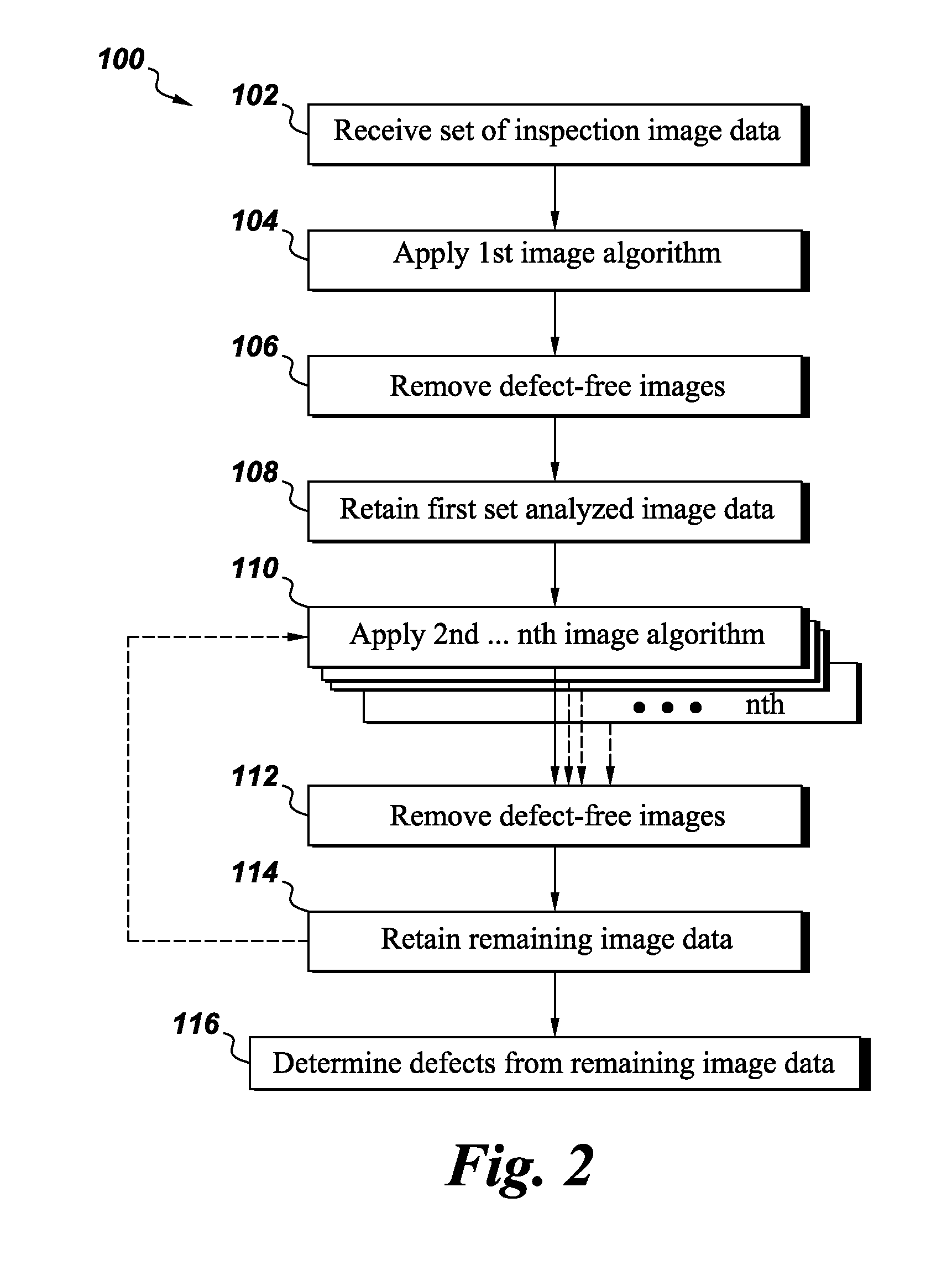

Sequential approach for automatic defect recognition

A method of automatic defect recognition includes receiving a initial set of inspection image data of a scanned object from a scanning machine; applying a first image analysis algorithm to this set of inspection image data; then removing from the set of inspection image data any defect-free image regions, so as to retain a set of analyzed inspection image data; applying an additional image analysis algorithm(s) to the set of analyzed inspection image data, wherein the additional algorithm(s) has a higher computational cost than the first image analysis algorithm; and based on the applying of the additional image analysis algorithm(s), removing from the first set of inspection image data a second set of defect-free image regions, thereby retaining a set of twice-analyzed inspection image data.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

Method of providing more vibrant, natural and long-lasting color to hair

InactiveUS20050000035A1Long lastingLong lasting colorCosmetic preparationsHair removalHair dyesSequential method

A sequential method for dyeing hair which comprises: contacting the hair with a substantially inactive dye precursor mixture containing at least one primary intermediate and an optional coupler having at least 50% of the molecules comprising these precursors are in their non-anionic form, for a period of time, followed by contacting the hair with a developer mixture capable of oxidizing the hair dye precursors to react and form hair color molecules.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

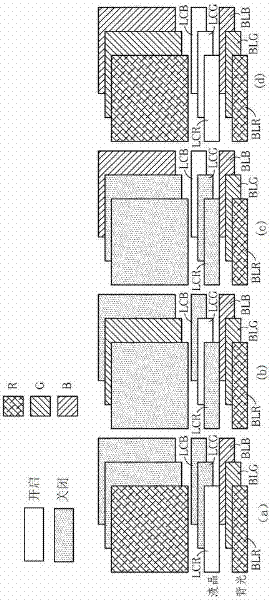

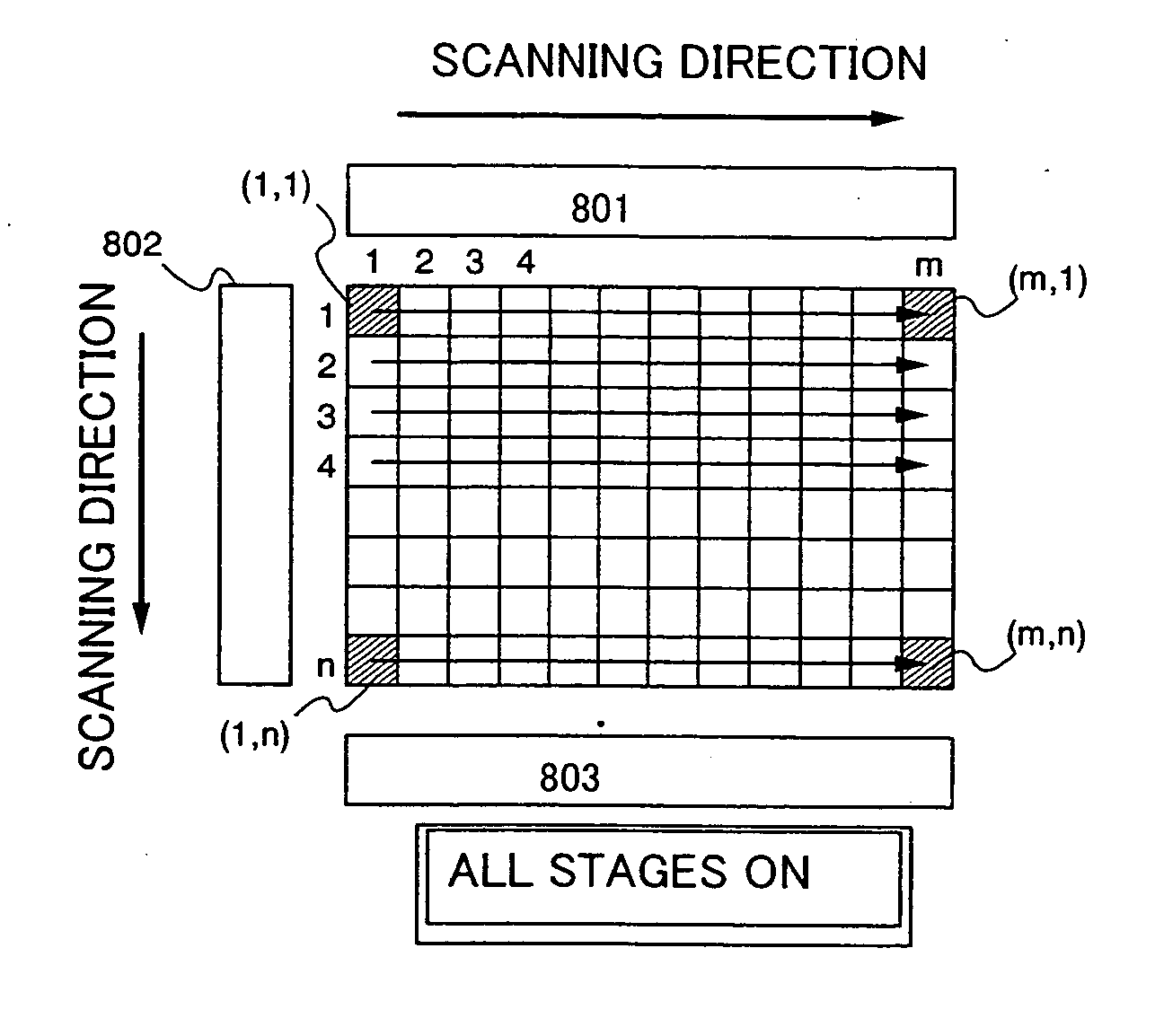

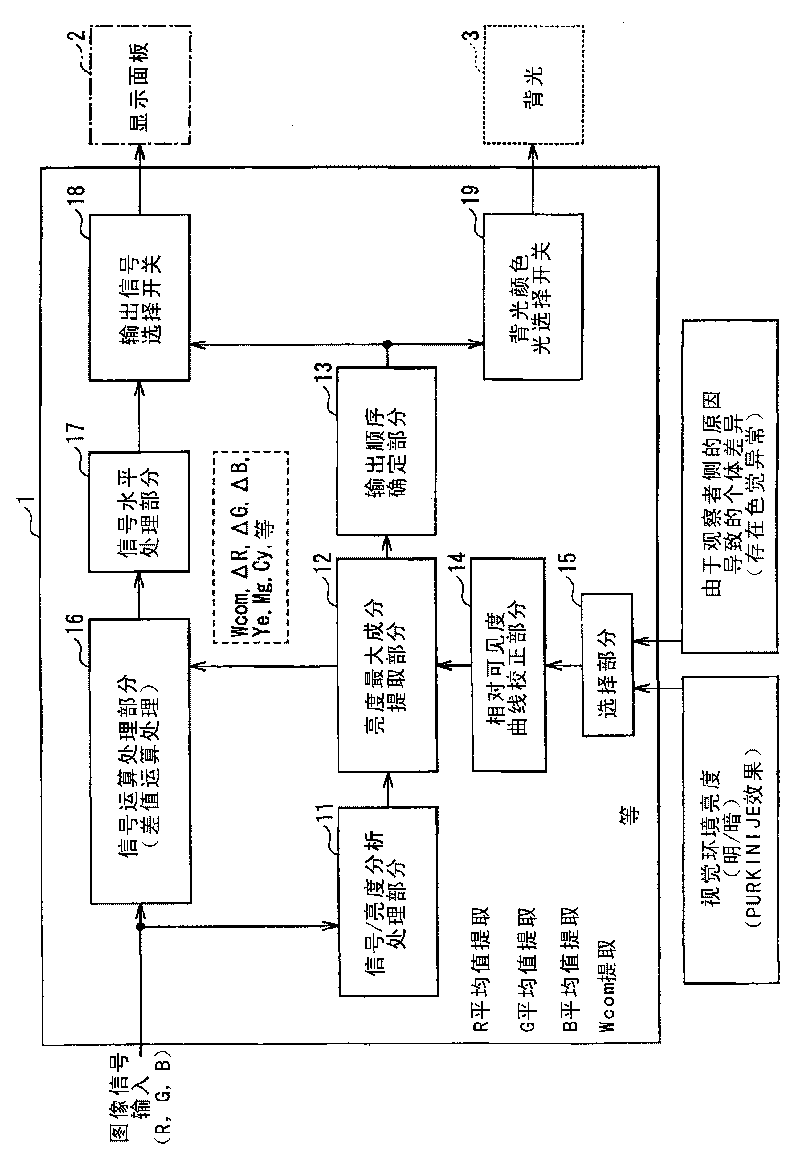

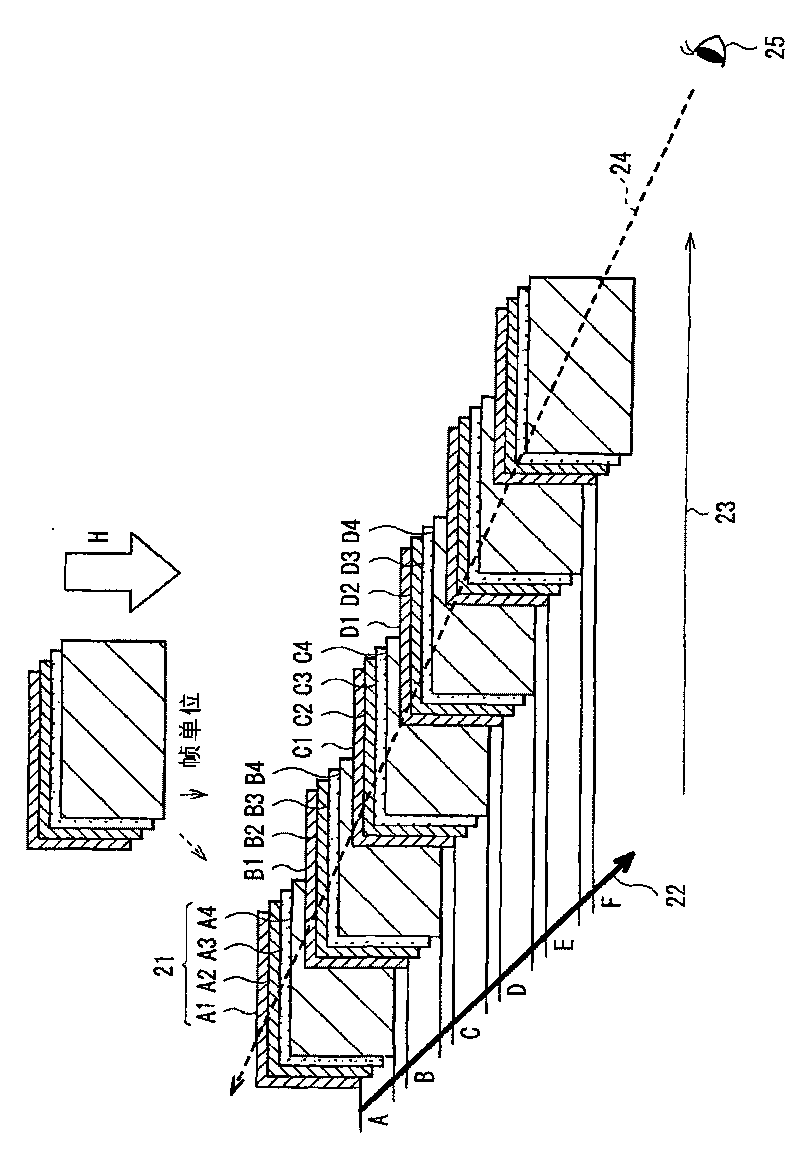

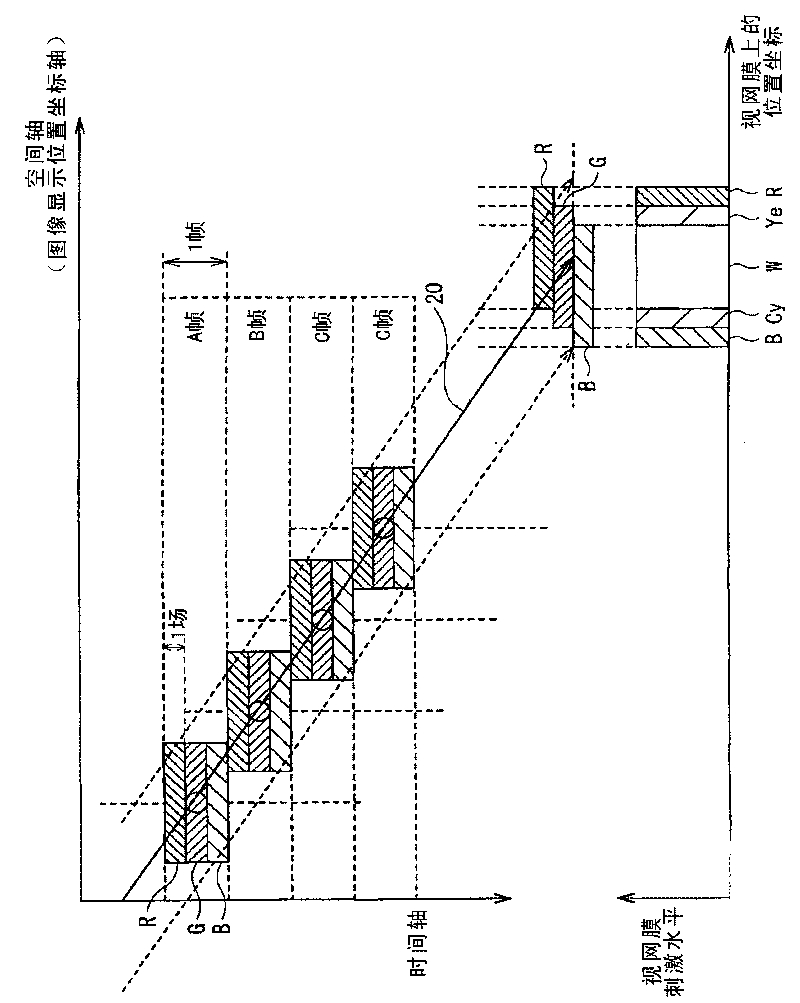

Liquid crystal display device and method for driving liquid crystal display device

ActiveUS20120002133A1Reduce eye fatigueHigh-speed drivingStatic indicating devicesNon-linear opticsImaging qualityEffect light

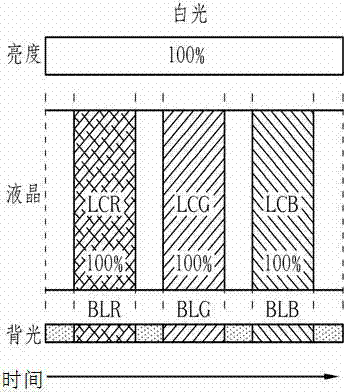

An object of the invention is to suppress degradation in image quality of a liquid crystal display device which performs display by field sequential method and to reduce power consumption of a backlight. The highest brightness of a first color light in a pixel region is detected. Gamma correction is performed so that transmittance of a pixel of the region displaying the highest brightness of the first color light is set to maximum and transmittance of other pixel of the region is decreased in accordance with lowering of the first color light intensity, and the region is irradiated with the highest brightness of the first color light. Similarly, a second color light is irradiated in another region concurrently with irradiation of the first color, whereby input of an image signal and lighting of the backlight are performed simultaneously in every region of the pixel portion.

Owner:SEMICON ENERGY LAB CO LTD

Circuit and method for compensating color shift of color sequence method

InactiveCN102262868ASolve the problem of uneven color scaleCathode-ray tube indicatorsBase NumberPhoton

The invention discloses a circuit for compensating the color deviation of a color sequential method, which comprises an image processing unit and a time sequence control circuit, wherein the image processing unit comprises a gray scale value generating unit, a preprocessing unit and a color gradation compensating unit. The gray scale value generating unit is used for generating a first gray scalevalue of sub-pixels of red, green and blue lights; the preprocessing unit is used for generating the uniformity degree of a pure color and a color gradation compensating base number of a display panel; the color gradation compensating unit is used for generating a color saturation level of a pixel, a compensating difference of the pixel and generating a gray scale value compensating the sub-pixels of red, green and blue lights of a compensating pixel. The time sequence control unit is used for compensating the gray scale value of the sub-pixels of red, green and blue lights according to the color sequential method and outputting the gray scale value to the display panel.

Owner:CPT DISPLAY TECH FUJIAN +1

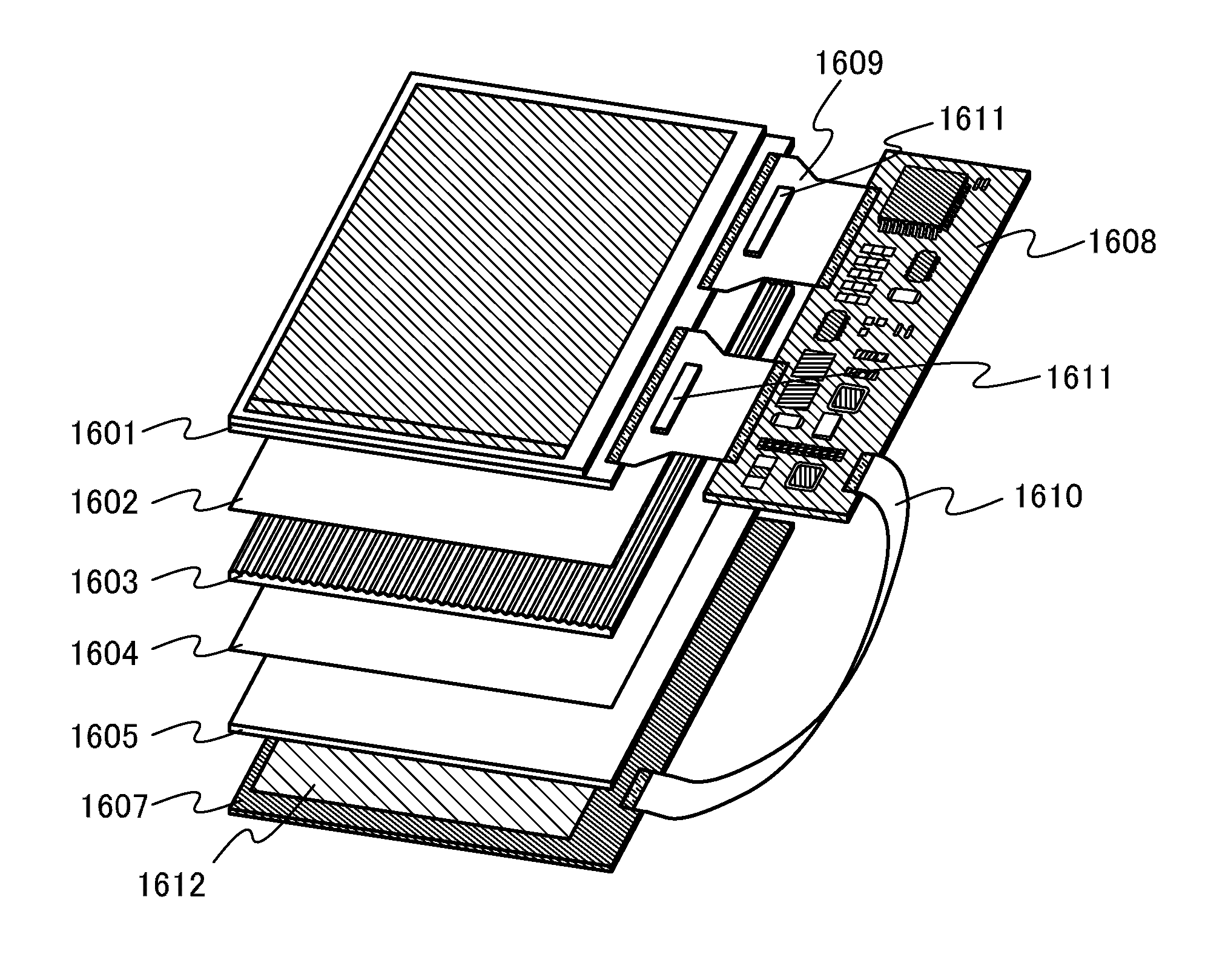

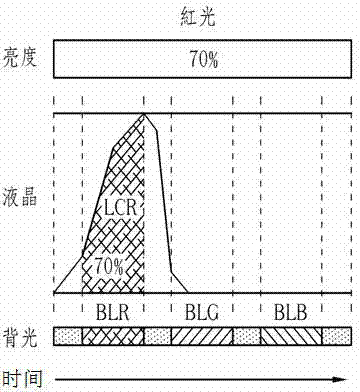

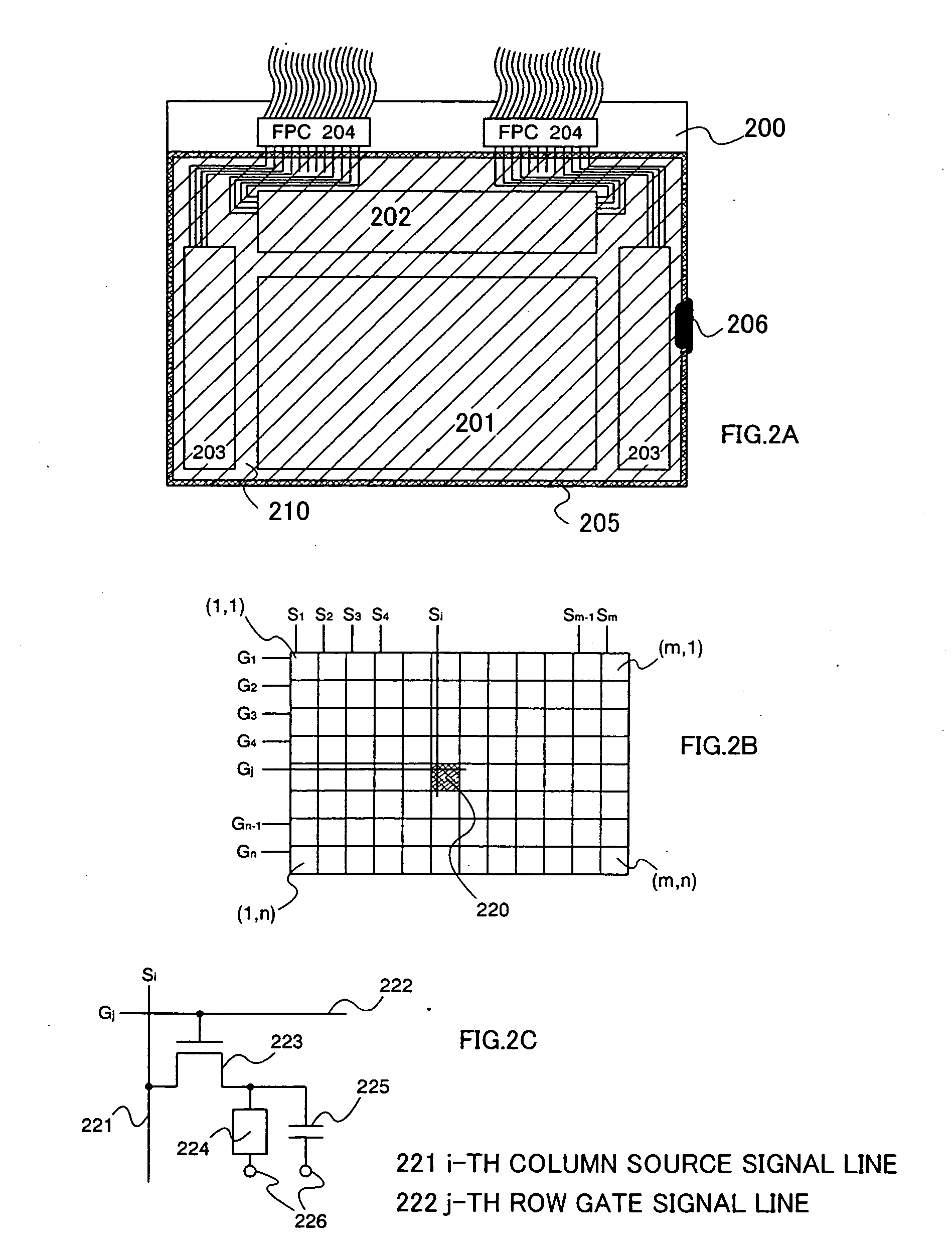

Display device and driving method

InactiveUS20060082536A1Easy to switchImprove image qualityStatic indicating devicesDriver circuitSequential method

A display device capable of switching a screen between a display in the vertical direction and a display in a horizontal direction. The scanning direction of a first gate signal line driver circuit is perpendicular to that of a source signal line driver circuit, and the scanning direction of a second gate signal line driver circuit is perpendicular to that of the first gate signal line driver circuit. In a normal display, the vertical scanning of a screen is performed by the first gate signal line driver circuit. Meanwhile, in the case of switching between the display in the vertical direction and the display in the horizontal direction, the vertical scanning of the screen is performed by the second gate signal line driver circuit. The screen is driven by a field sequential method and a pixel is not divided into RGB; therefore, switching of the display direction can be facilitated.

Owner:SEMICON ENERGY LAB CO LTD

Field sequential lighting device and image projecting device

A field sequential lighting device for emitting light corresponding to a plurality of colors using a field sequential method includes: a light source; and a light converting section for intensifying the emitted light by sequentially converting the light, emitted from the light source, corresponding to the plurality of colors. By doing this, it is possible to provide a field sequential lighting device using the light emitted from the light source efficiently and having desirable color reproducibility, and an image projecting device having it.

Owner:OLYMPUS CORP

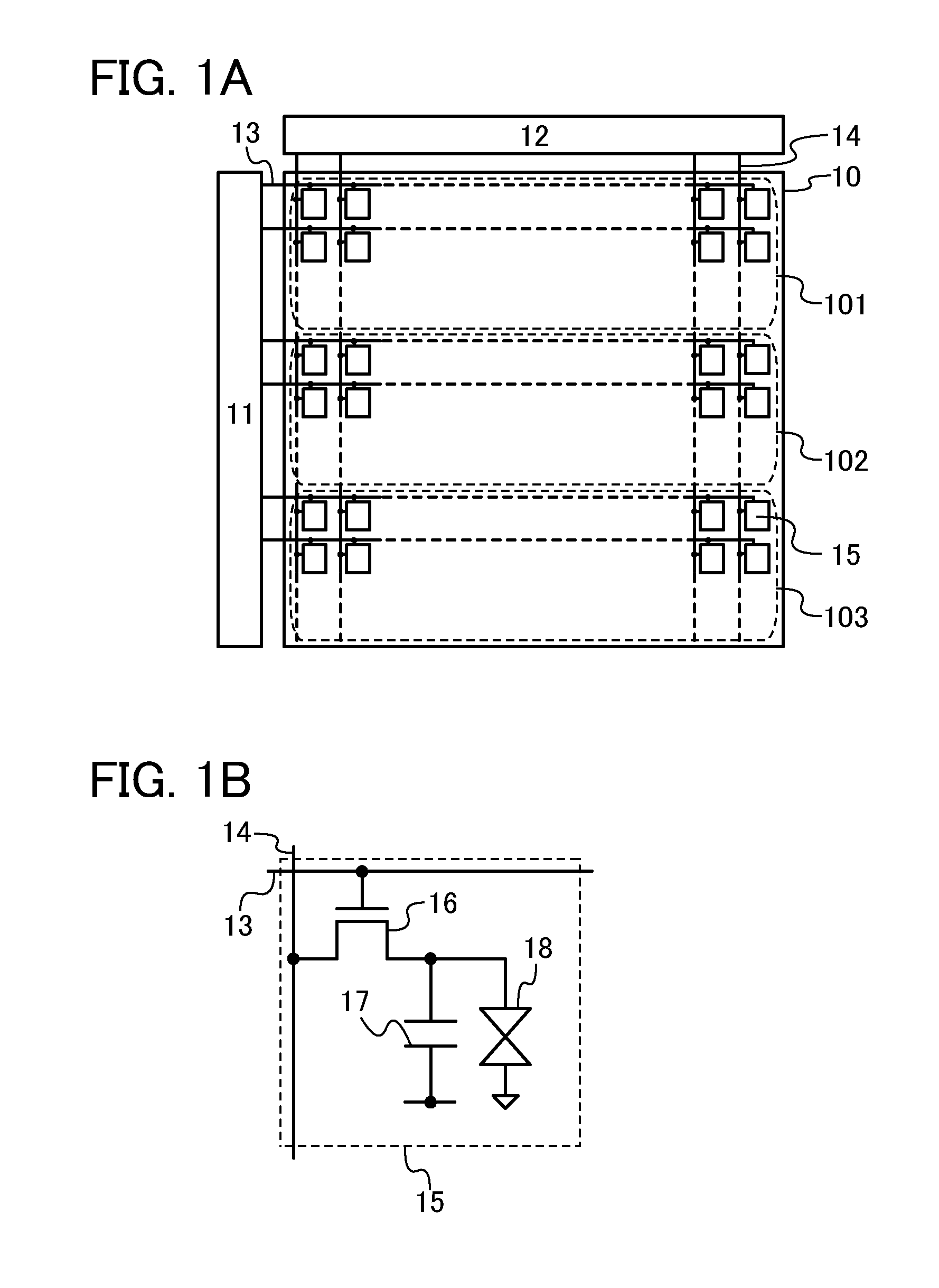

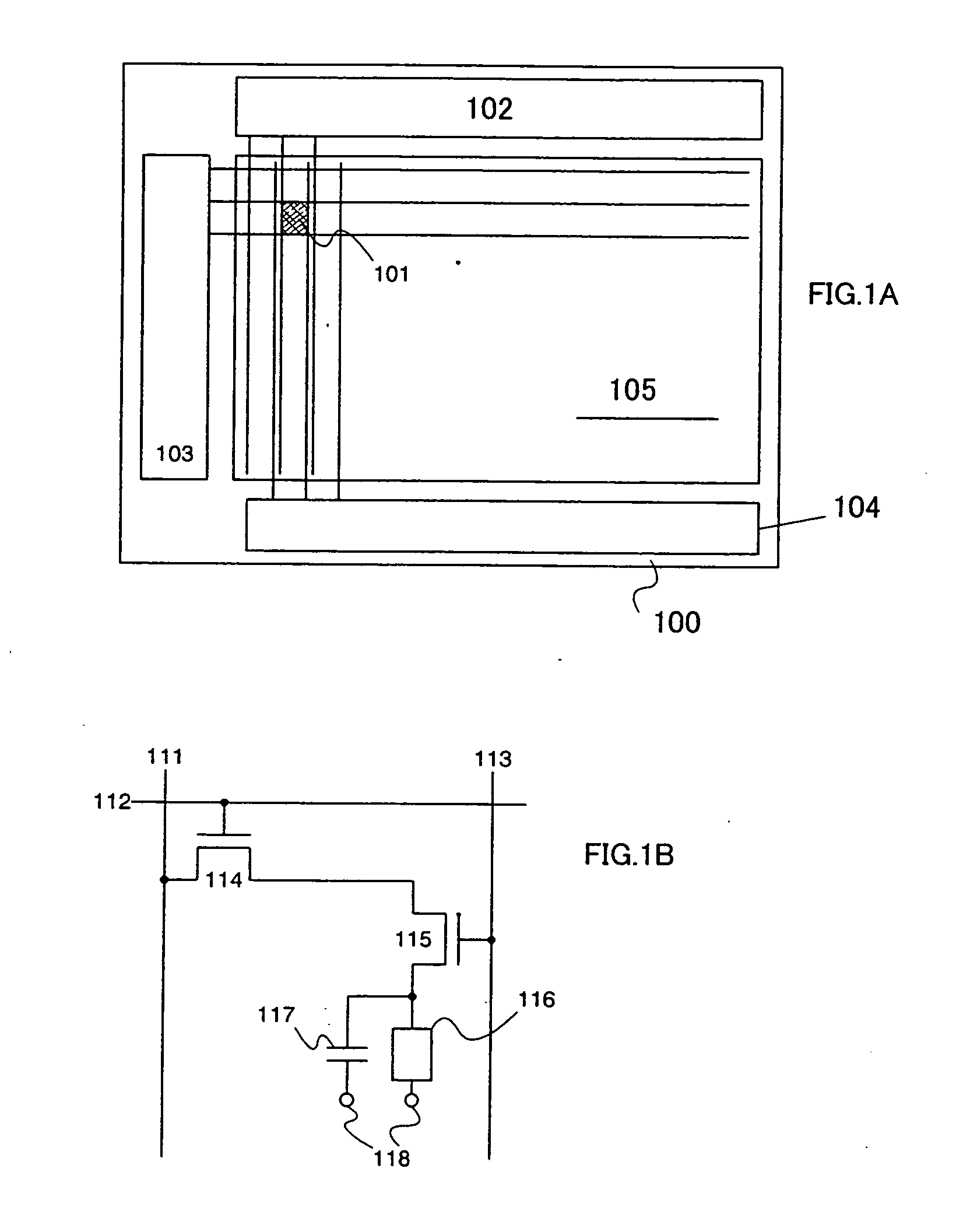

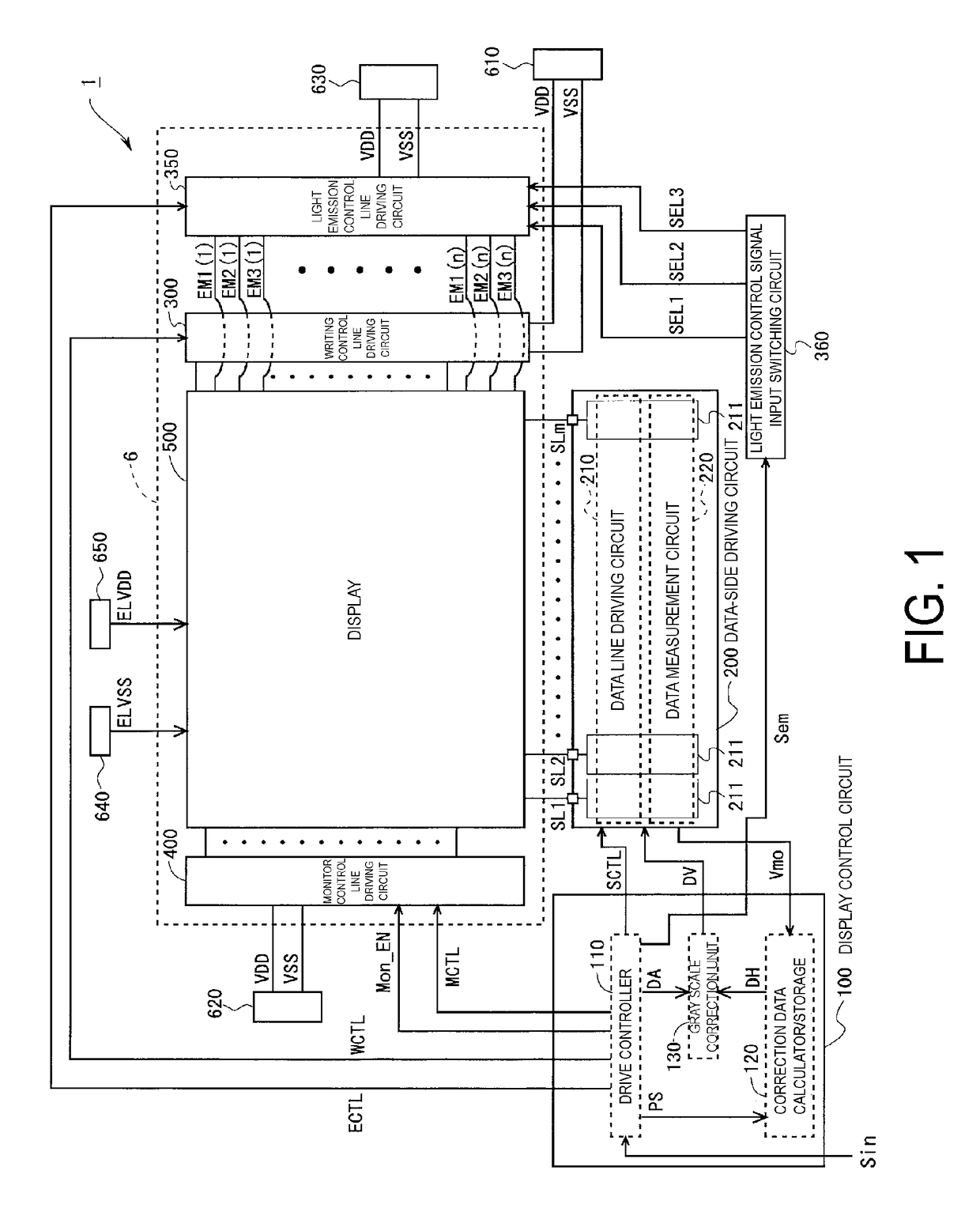

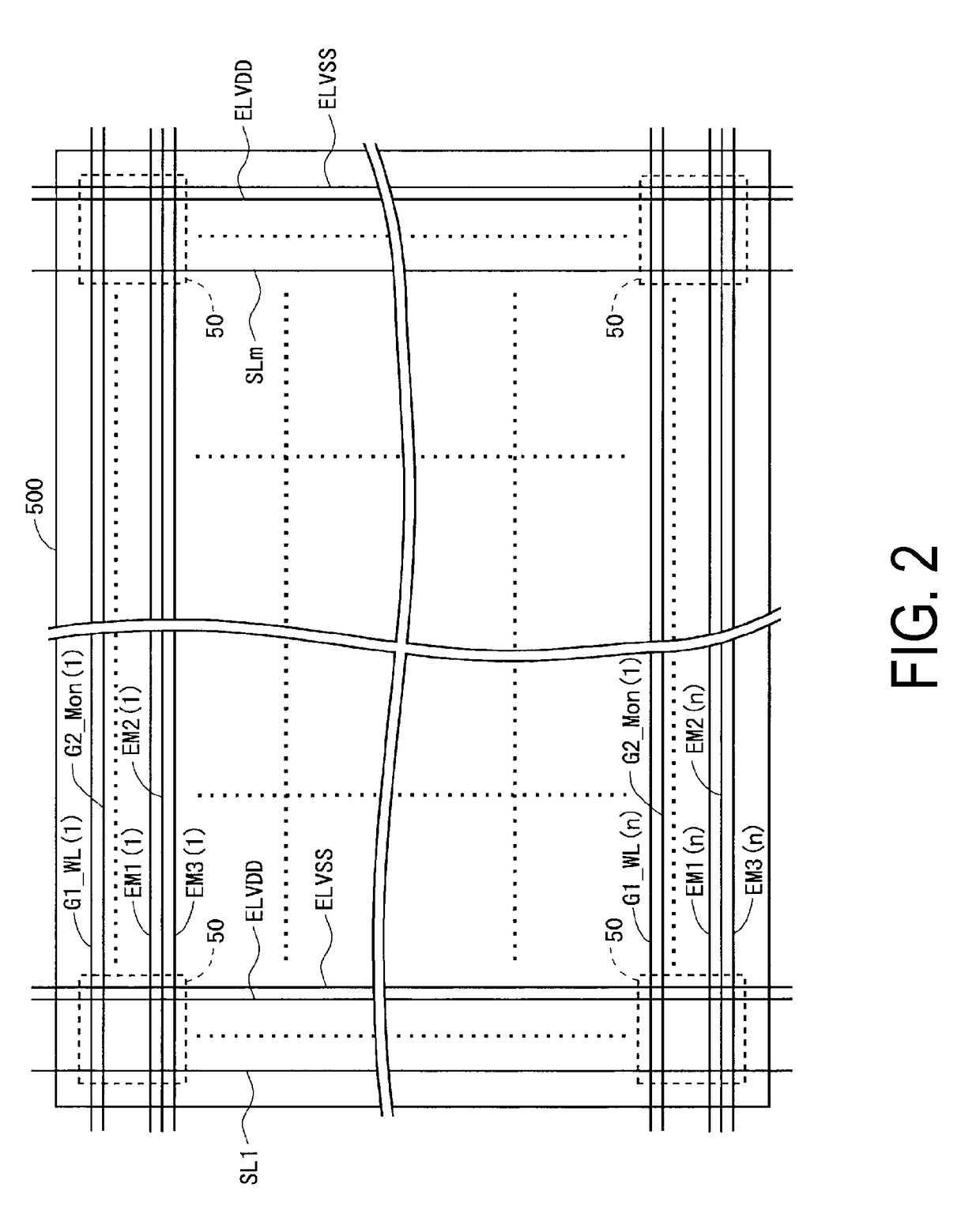

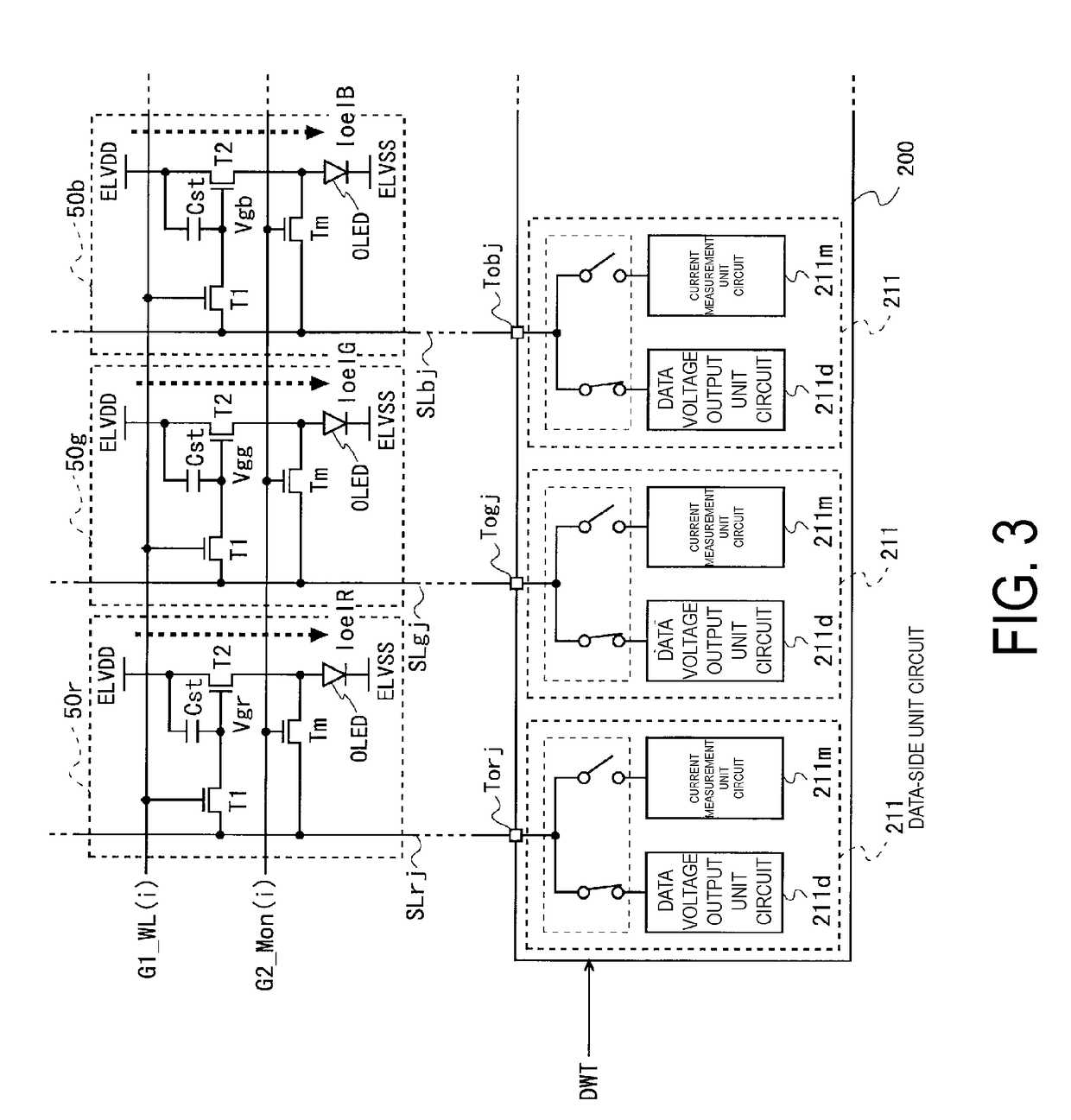

Pixel circuit, and display device and driving method therefor

InactiveUS20190012948A1Reduce in quantityIncrease the number ofStatic indicating devicesSolid-state devicesColor imagePower flow

In each of pixel circuits in an organic EL display device configured to display color images in a field sequential method, a drive transistor is connected to first to third organic EL elements configured to emit red light, green light, and blue light through first to third light emission control transistors. A connection point between the drive transistor and the light emission control transistors is connected to a data line through a monitor control transistors. A data-side driving circuit is provided with a data voltage output unit circuit and a current measurement unit circuit for each of data lines. The data-side driving circuit is configured to be able to switch between the unit circuits to connect either one of the unit circuits to the data line.

Owner:SHARP KK

Approach to molecular diagnosis of human papillomavirus-related diseases

ActiveUS7361460B2Accurate sensitive toolReduce in quantitySugar derivativesMicrobiological testing/measurementProtein markersSequential method

The present invention relates to an accurate, sensitive, and efficient sequential or concurrently sequential method for molecular diagnosis of human papillomavirus (HPV)-based disease, where the method improves the accuracy and reliability of diagnostic and prognostic assessments of HPV-based disease. The method of the invention comprises a primary screen of a sample for HPV nucleic acids, followed by a secondary screen for molecular markers, such as proliferation and cell cycle control group protein markers. The sequential or concurrently sequential method significantly reduces the number of false positive results.

Owner:DIGENE CORP

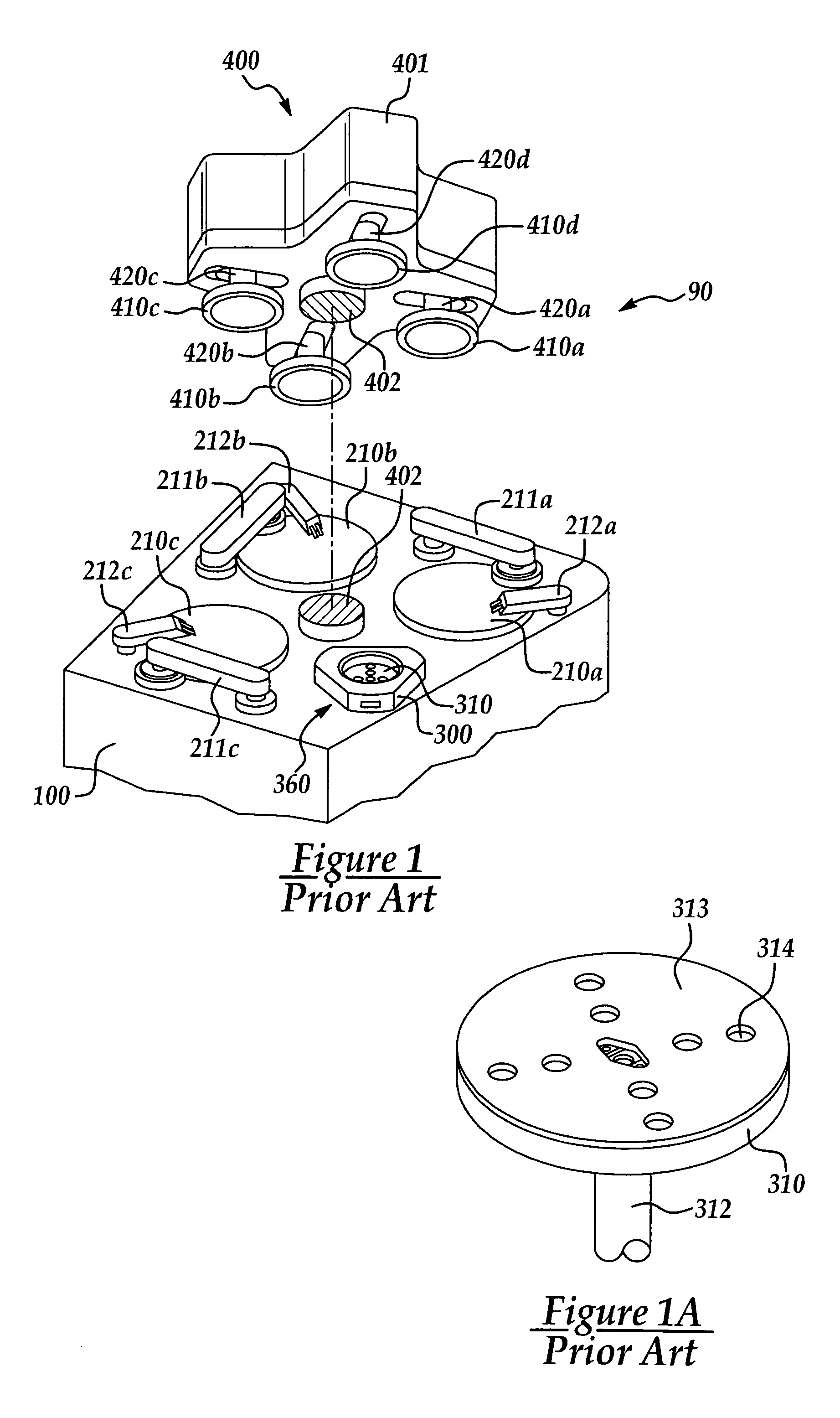

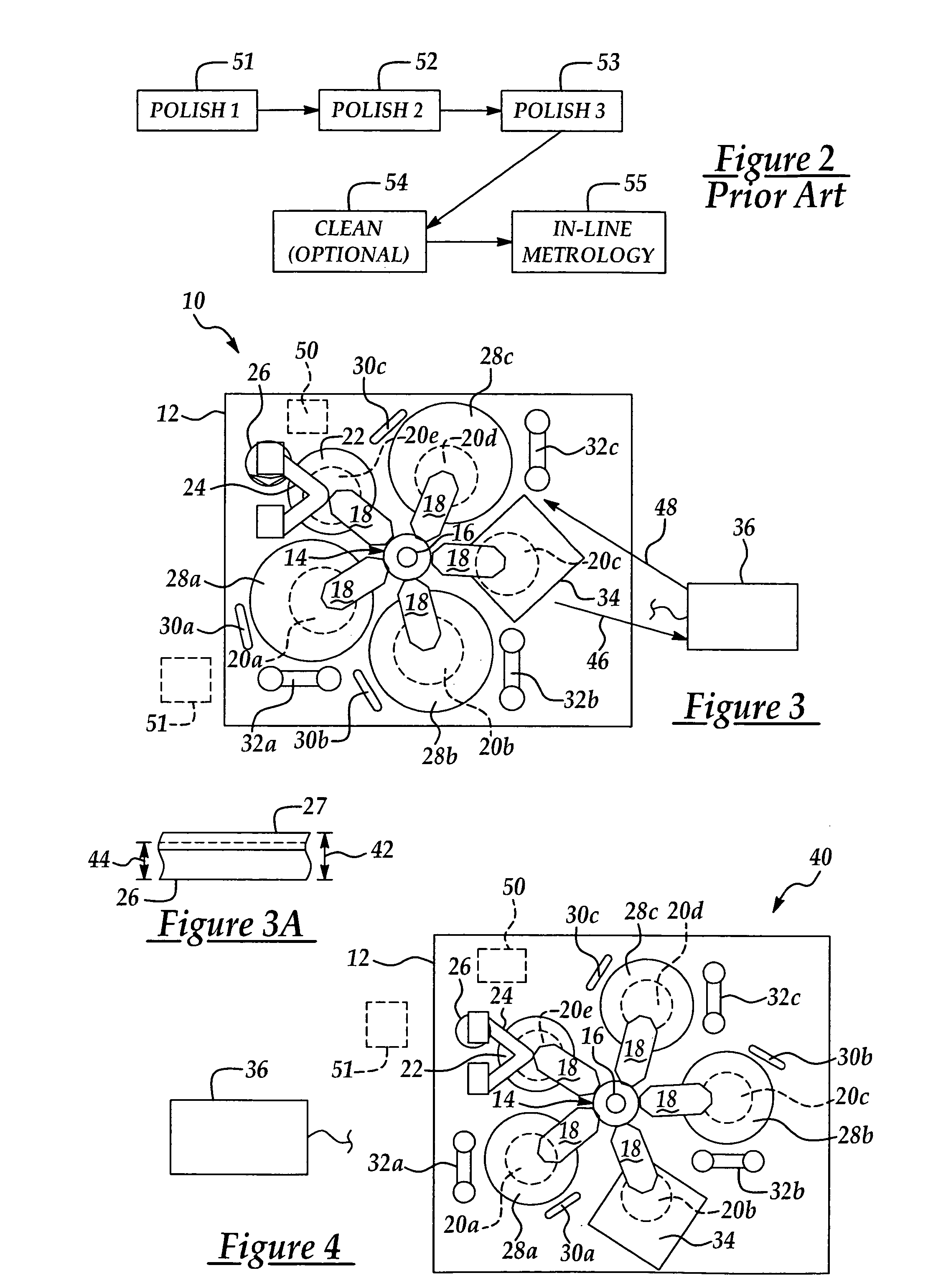

CMP apparatus and process sequence method

ActiveUS7118451B2Belt grinding machinesSemiconductor/solid-state device manufacturingSequential methodEngineering

A CMP apparatus and process sequence. The CMP apparatus includes multiple polishing pads or belts and an in-line metrology tool which is interposed between adjacent polishing pads or belts in the apparatus. A material layer on each of multiple wafers is successively polished on the polishing pads or belts. The metrology tool is used to measure the thickness of a material layer being polished on each of successive wafers in a lot prior to the final polishing step, in order to precisely polish the layer to a desired target thickness at the final polishing step. This renders unnecessary an additional process cycle to polish the layer on each wafer to the desired target thickness. The metrology tool may be modularized as a unit with the polishing pads or belts.

Owner:TAIWAN SEMICON MFG CO LTD

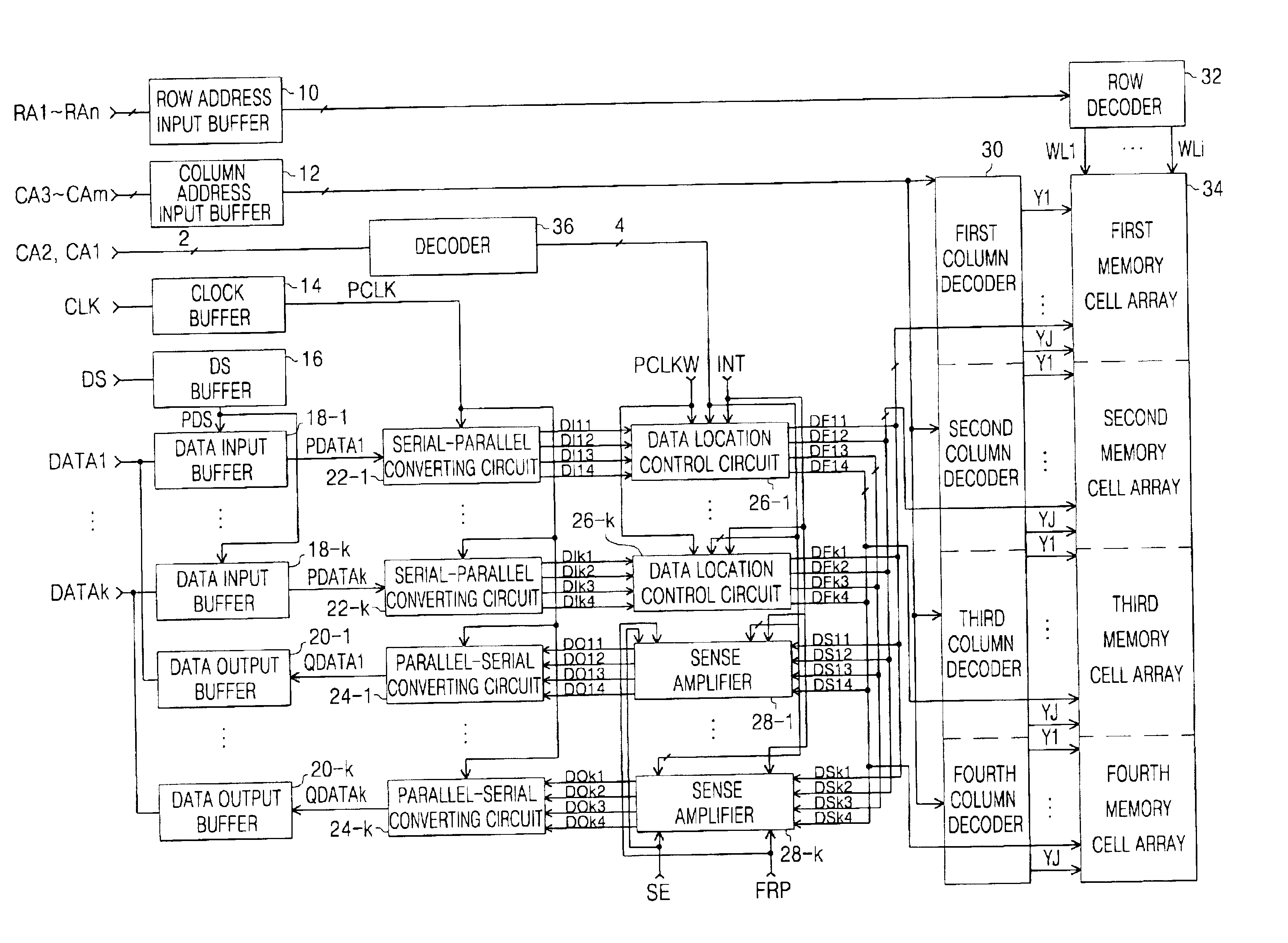

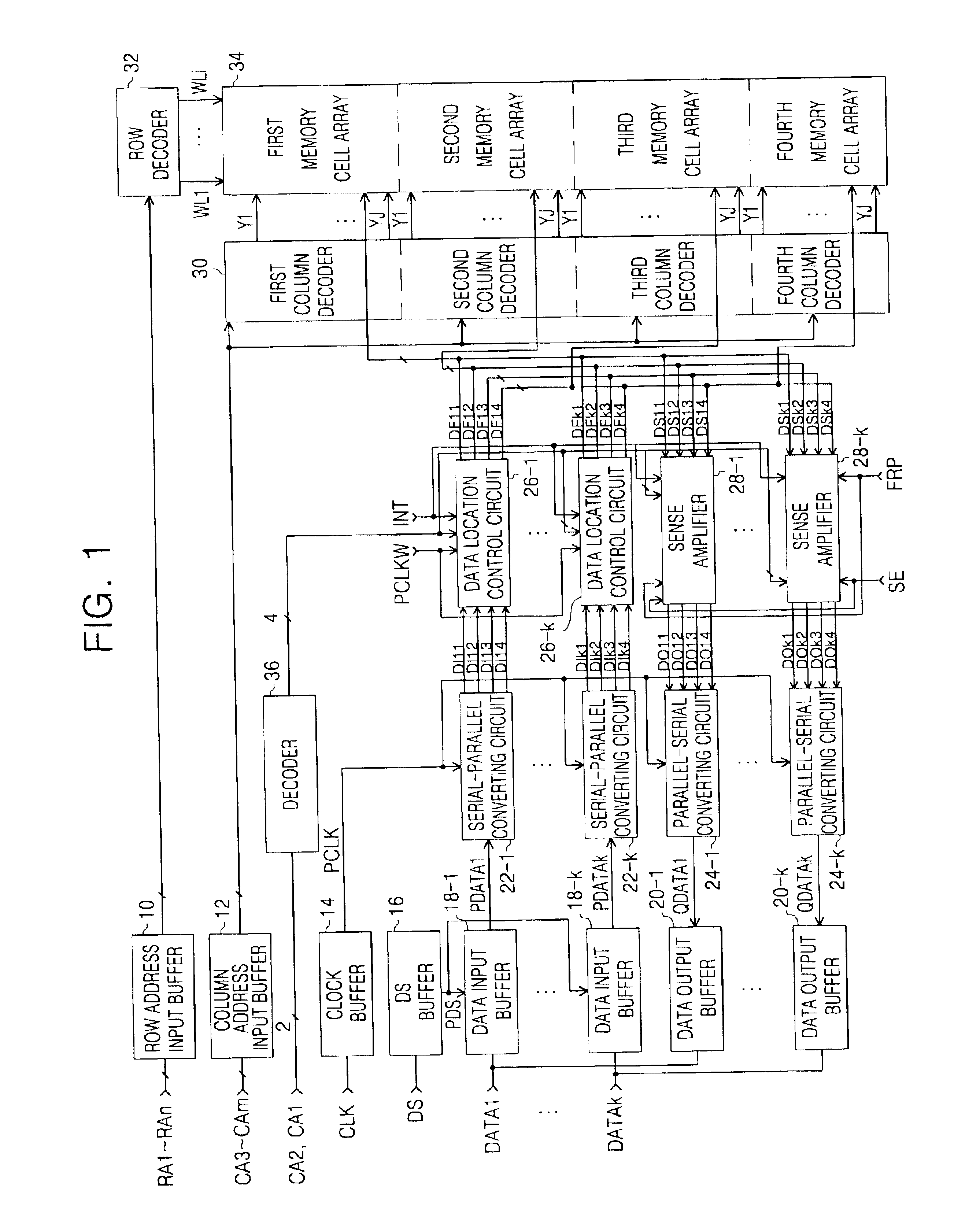

Synchronous semiconductor memory device and method of processing data thereof

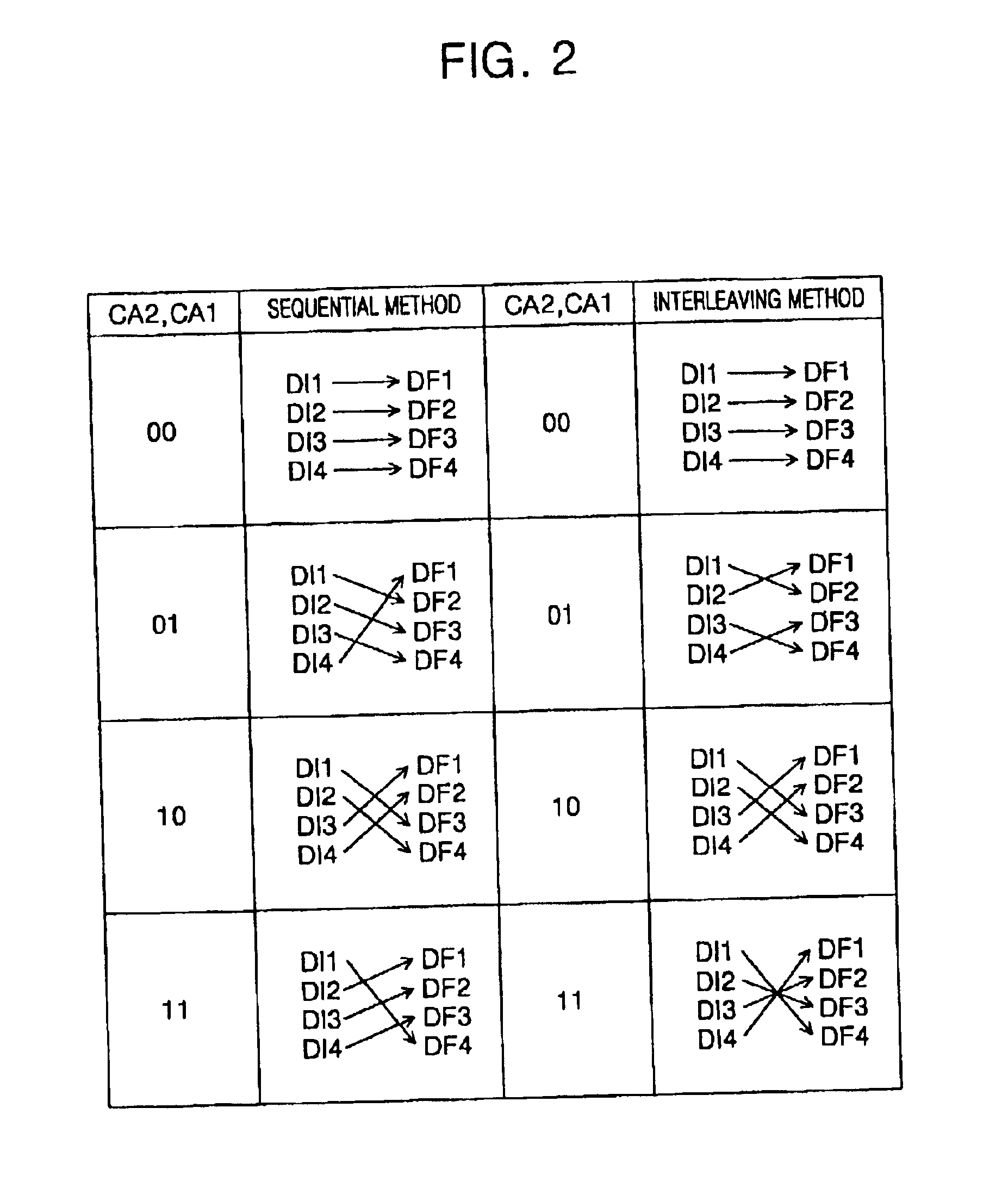

The present invention involves a synchronous semiconductor memory device having a 4-bit prefetch mode a method of processing a data thereof, comprising first to fourth memory cell arrays each having memory cells, a serial-parallel converting means converting a plurality of 4-bit data serially applied during a write operation into a plurality of 4-bit parallel data, a data loation control means location-controlling and outputting each of the plurality of the 4-bit parallel data output from the serial-parallel converting means in response first to fourth decoding signals generated by decoding the 2-bit column address to the first to fourth memory cell arrays, by a sequential method or by an interleaving method, during the write operation, a sense amplifier amplifying a plurality of 4-bit data output from each of the first to fourth memory cell arrays, and location-controlling and outputting them in response the first to fourth decoding signals, by a sequential method or by an interleaving method, during a read operation, and a parallel-serial converting means converting and outputting a plurality of 4-bit parallel data output from the sense amplifier during a read operation into a plurality of 4-bit serial data, whereby the circuit configuration is simple.

Owner:SAMSUNG ELECTRONICS CO LTD

Liquid crystal display device

InactiveUS20130076864A1Avoid crosstalkHigh quality imagingCathode-ray tube indicatorsSteroscopic systemsLiquid-crystal displaySequential method

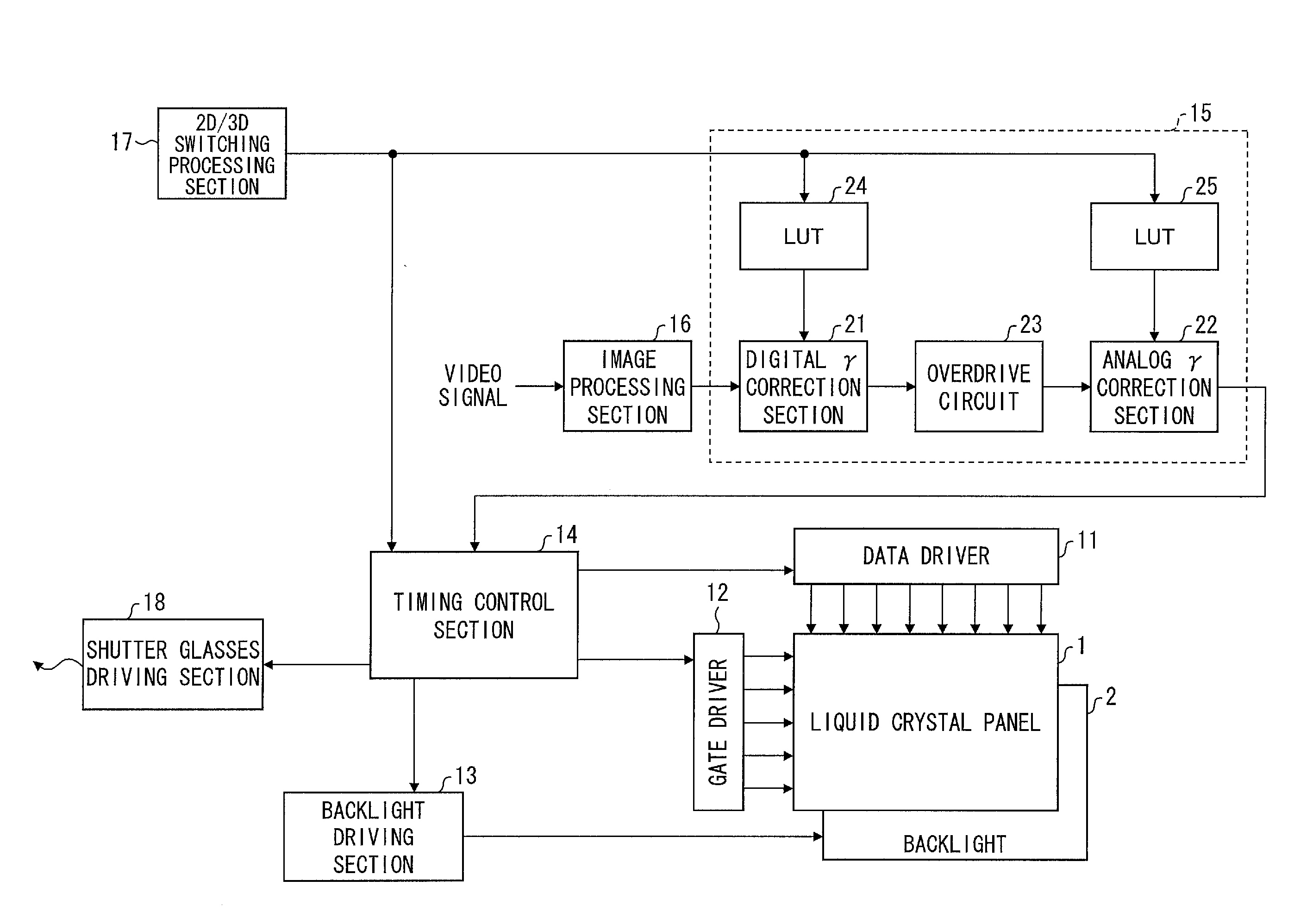

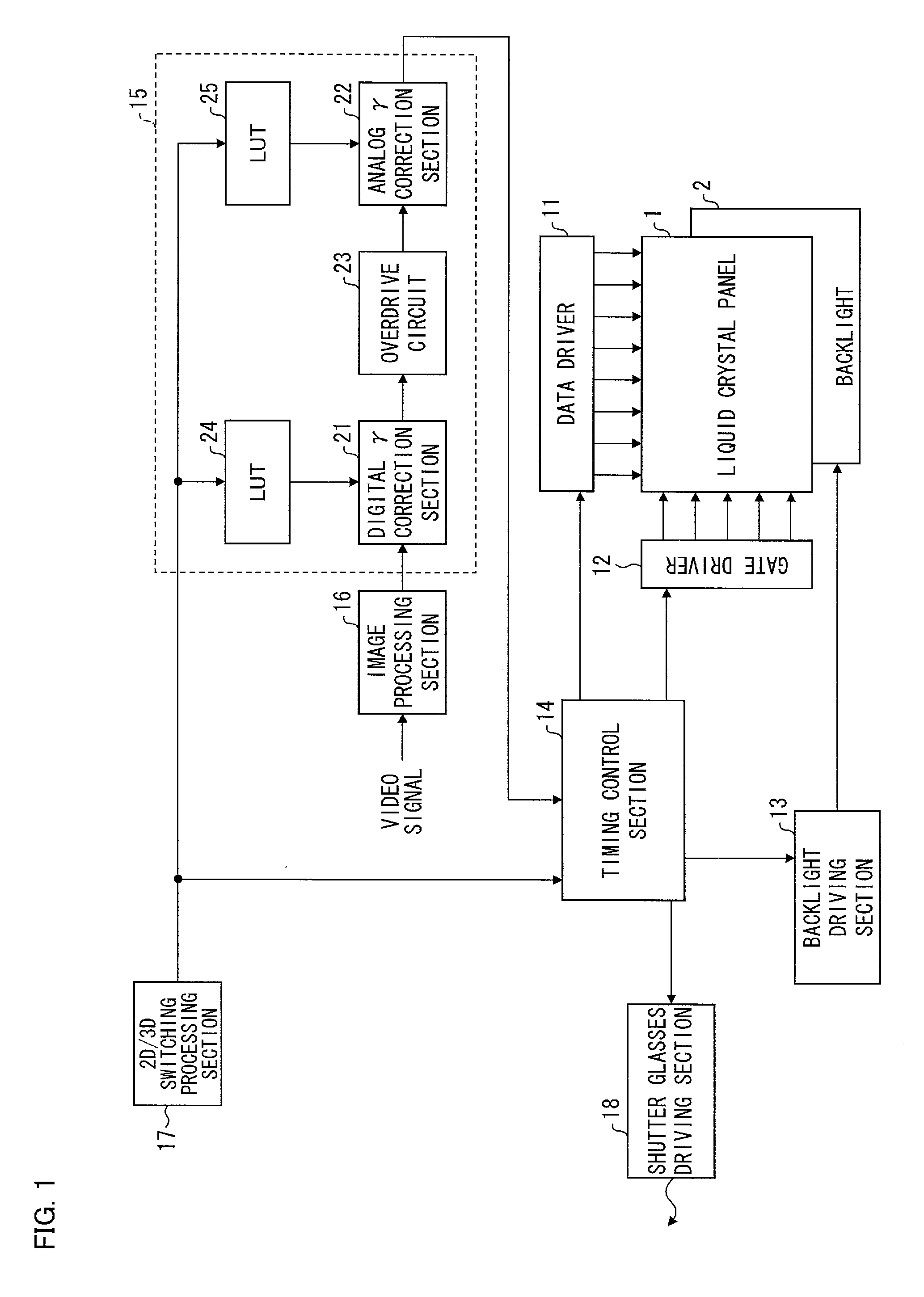

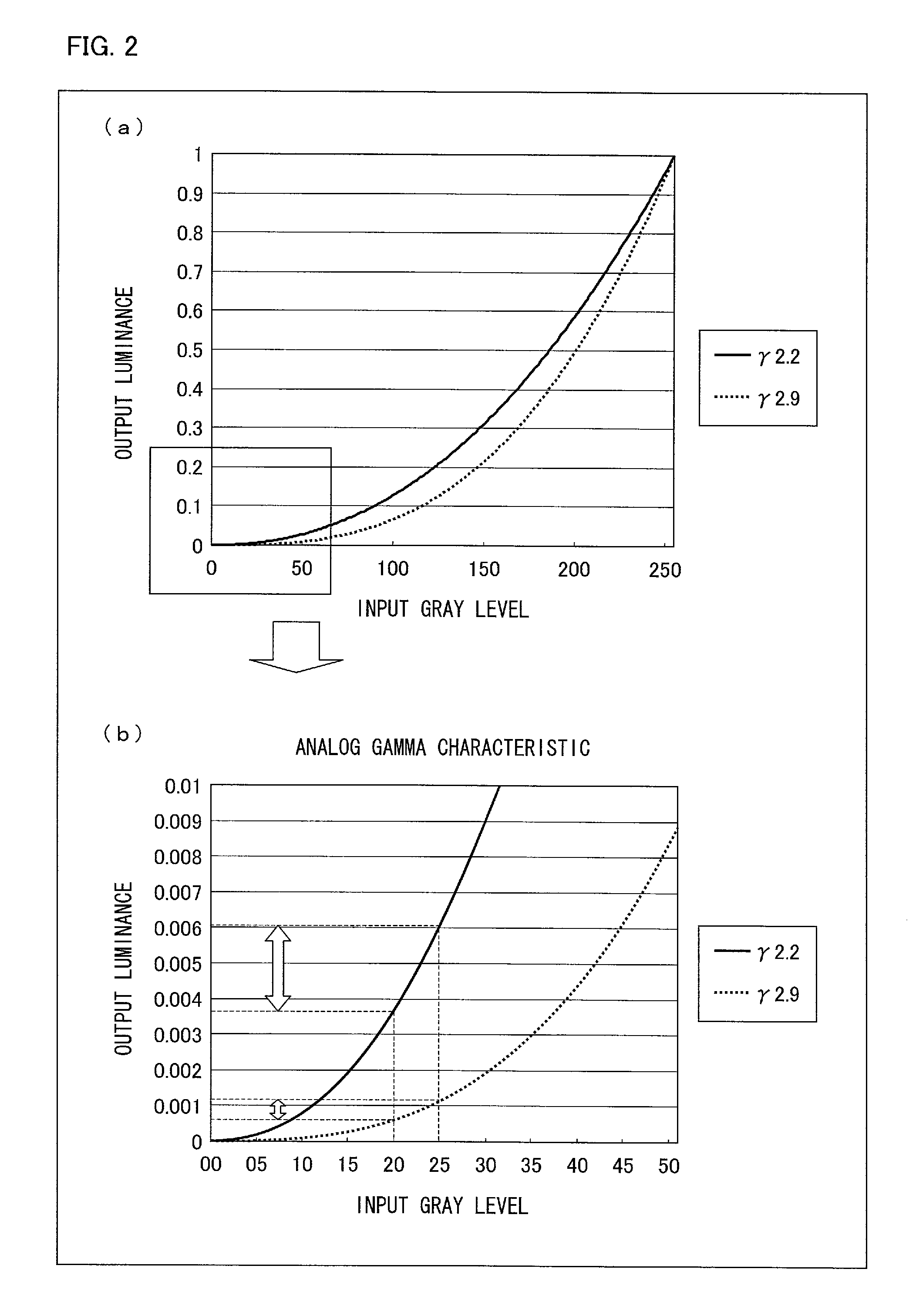

A liquid crystal display device for carrying out a 3D display by a frame sequential method as well as a 2D display includes: a digital γ correction section (21) for changing an input gray level to a gamma characteristic corresponding to either the 2D display or the 3D display in accordance with a preset analog gamma value; an overdrive circuit (23) for finding, in accordance with a parameter set according to the gamma characteristic thus corrected by the digital γ correction section (21), an overdrive value corresponding to the input gray level; and an analog γ correction section (22) for finding a voltage value to be applied to liquid crystal by correcting the overdrive value found by the overdrive circuit (23). In the digital γ correction section (21), an analog gamma value for the 3D display is set to be larger than an analog gamma value for the 2D display. This makes it possible to display a high-quality display with no crosstalk when carrying out a 3D display by a frame sequential method.

Owner:SHARP KK

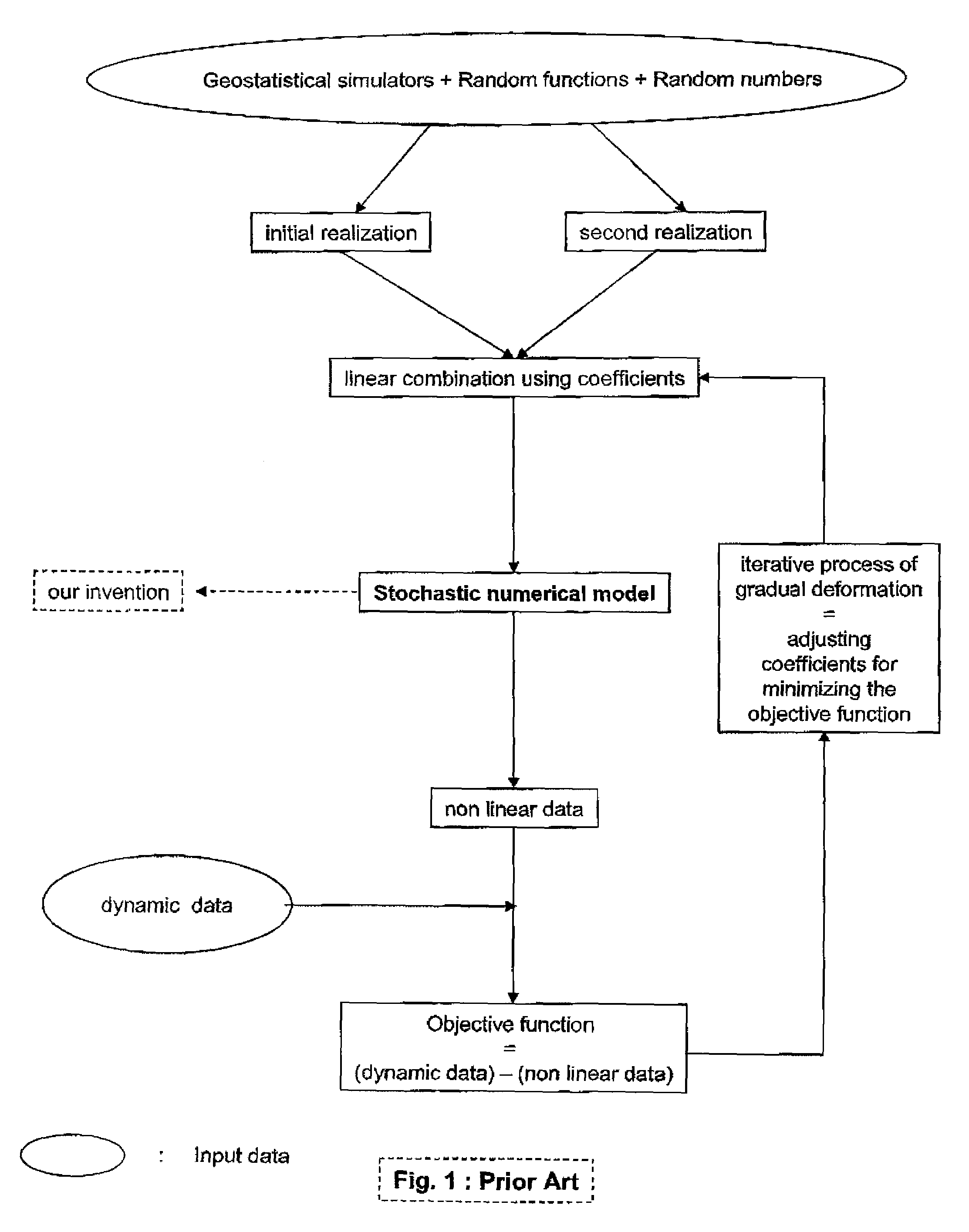

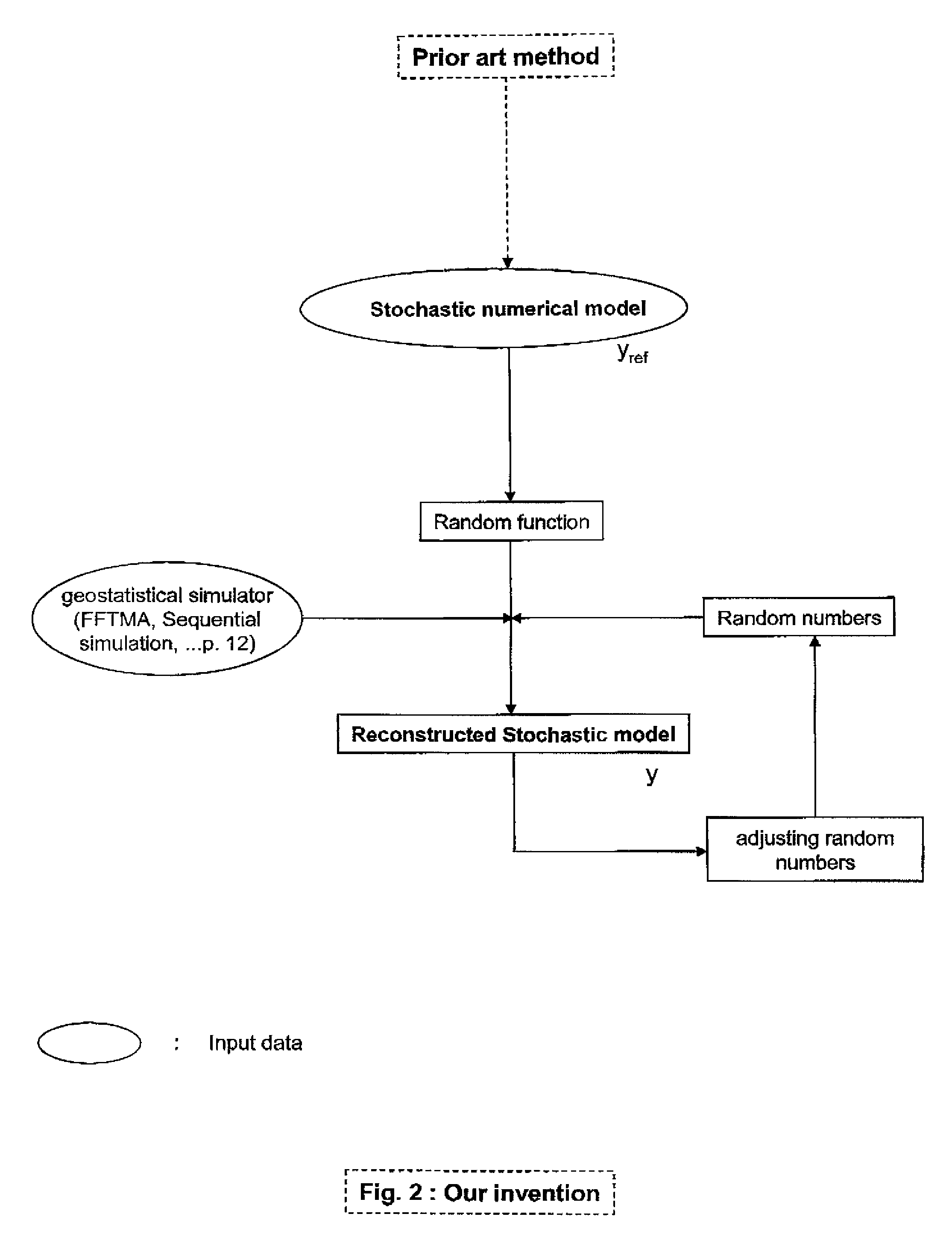

Method of reconstructing a stochastic model, representative of a porous heterogeneous medium, to improve its calibration by production data

InactiveUS20060241920A1Computation using non-denominational number representationSeismic signal processingSequential methodReconstruction method

Method of reconstructing a stochastic realization, continuous or discrete, resulting from a random function representing a numerical model, that can be representative of a porous heterogeneous medium such as an underground reservoir. It is based on identification, for a given realization, of a random function and of a set of random numbers allowing, from a given geostatistical simulator, to reconstruct the reference realization. The reconstruction techniques proposed are either general or specific to a type of geostatistical simulator. They concern the sphere of optimization, relaxation, filtering and sequential approaches. The reconstruction method allows to estimate a set of random numbers for regenerating the reference realization, this reference realization can then be locally or globally modified, by gradual deformation, so as to better reproduce newly acquired dynamic data (production data for example). Application: notably oil reservoir development for example.

Owner:INST FR DU PETROLE

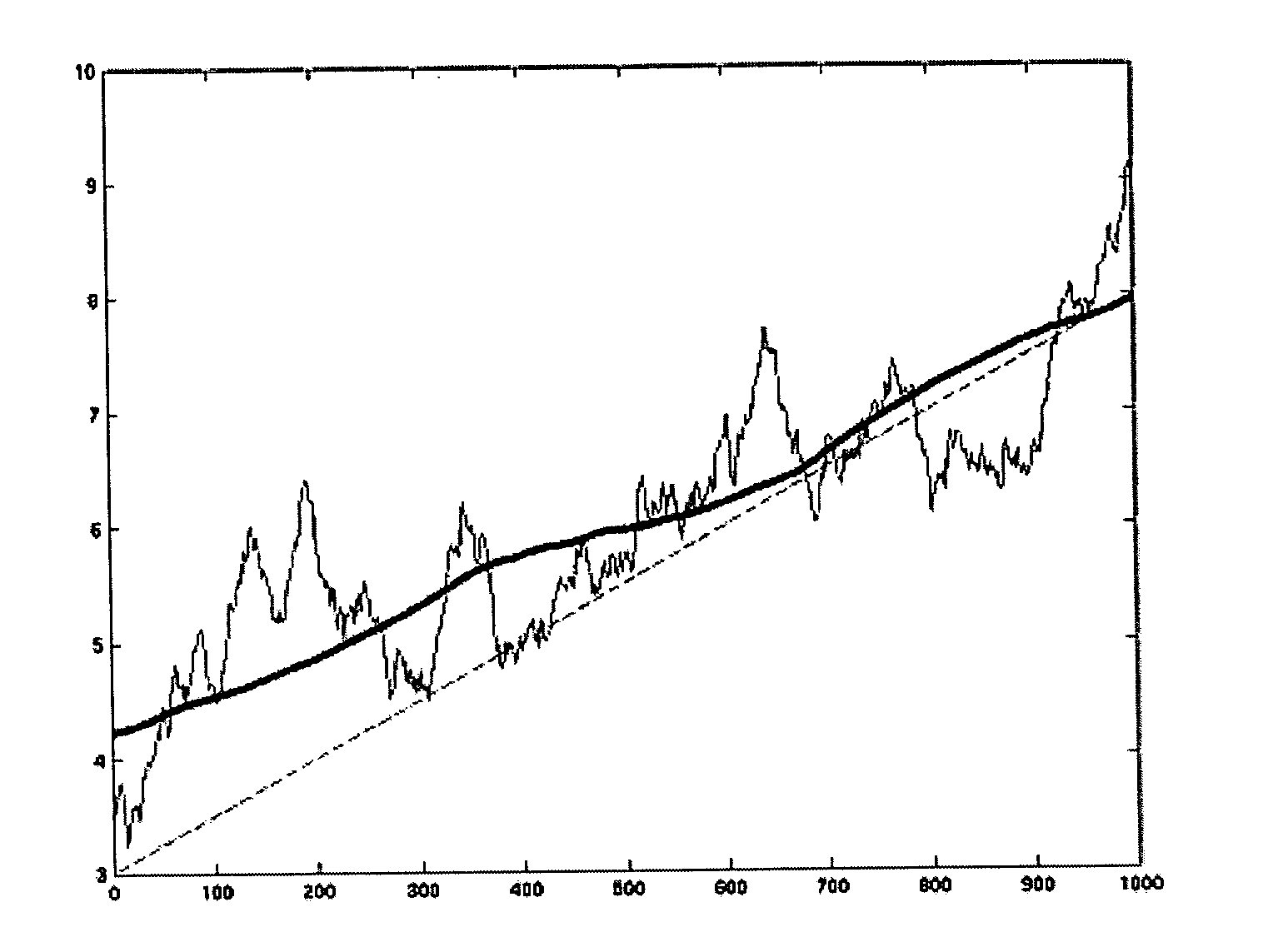

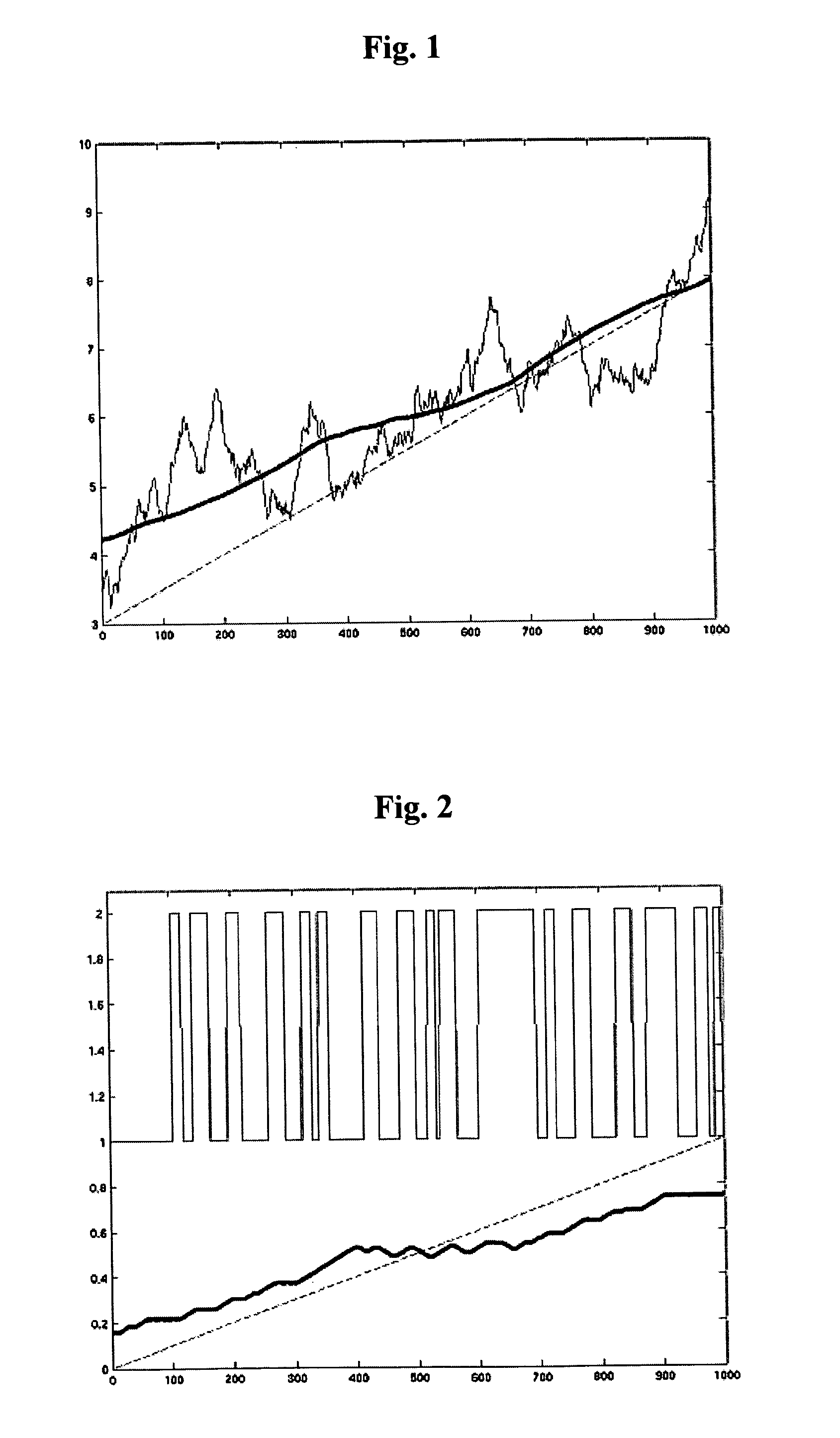

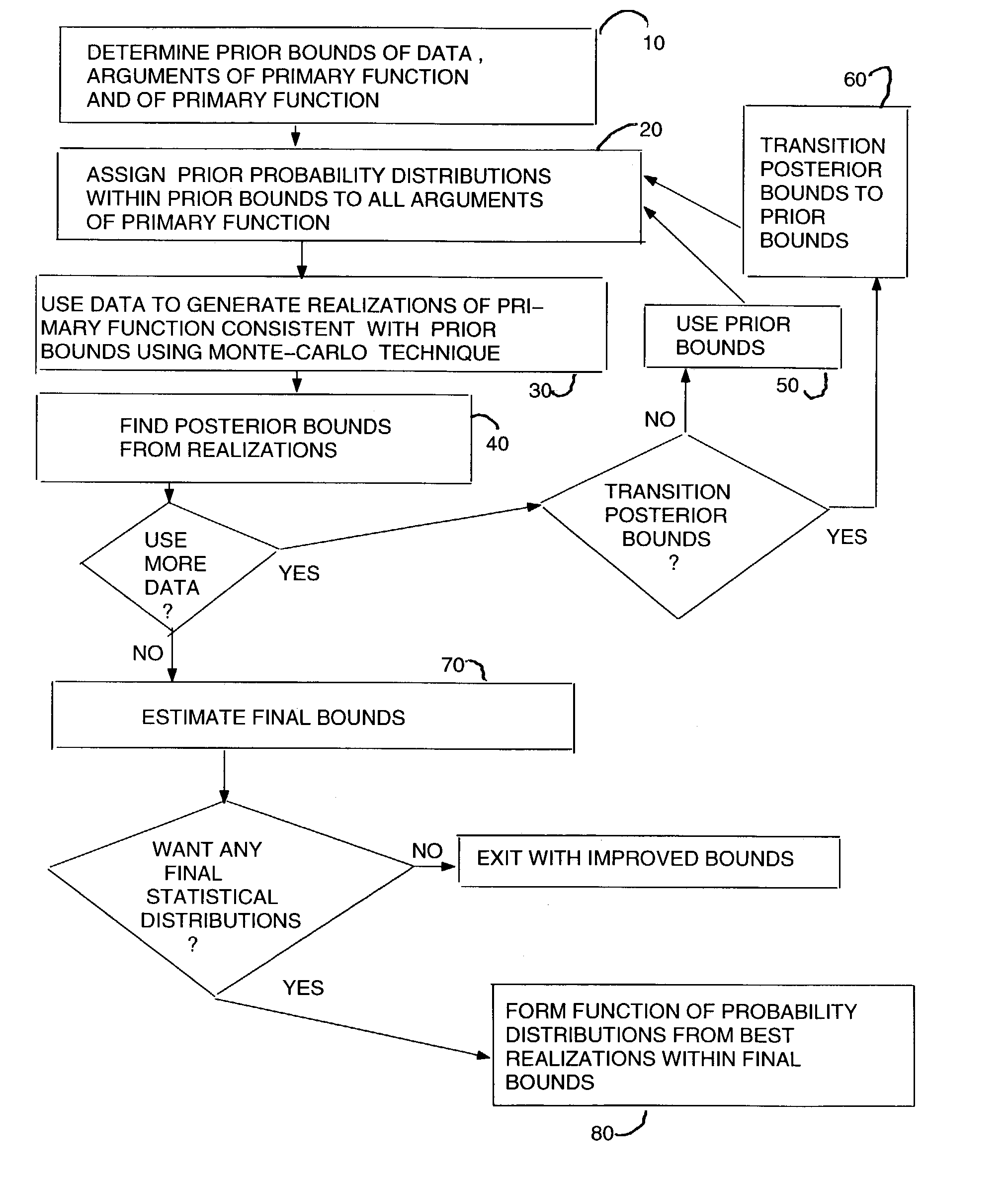

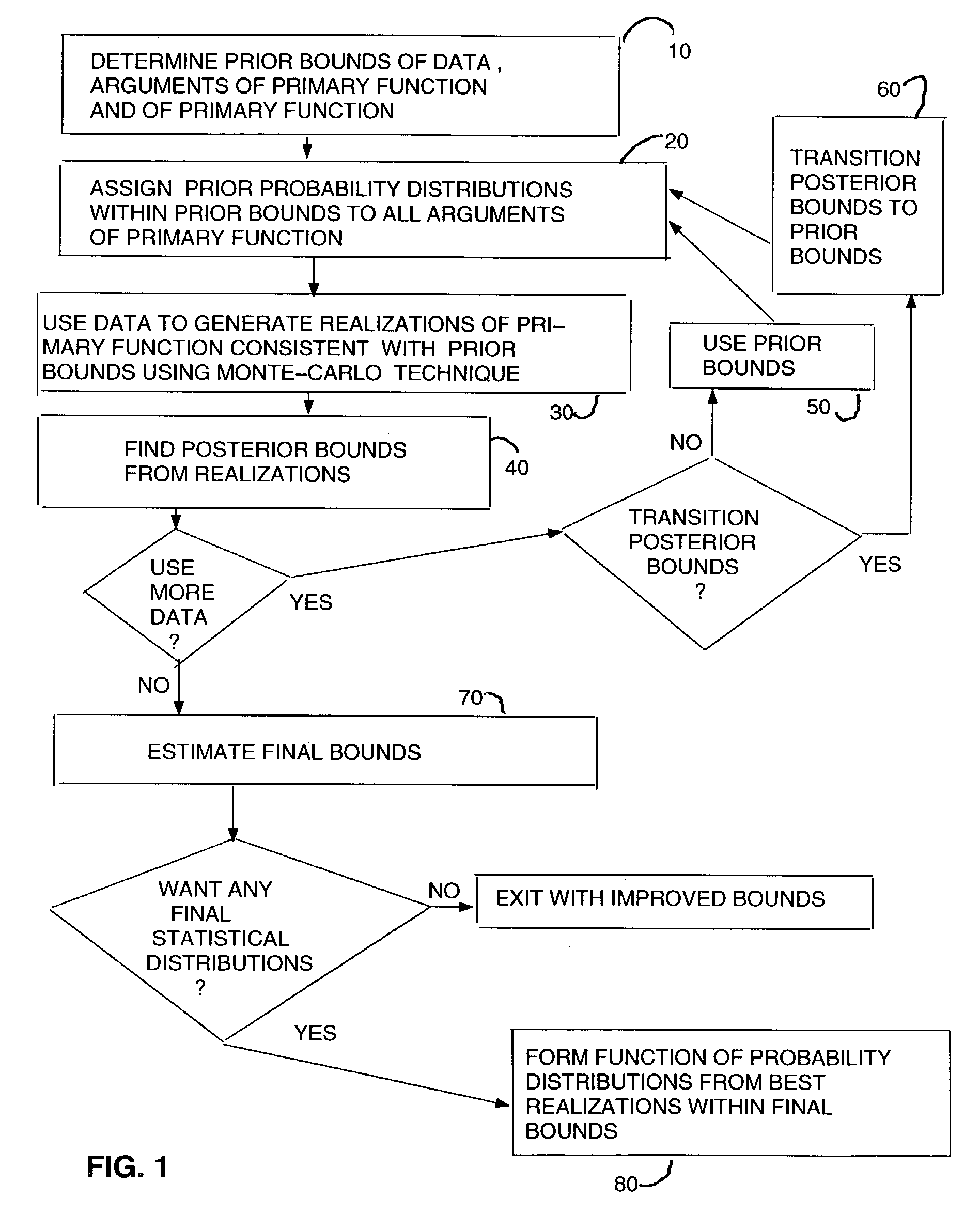

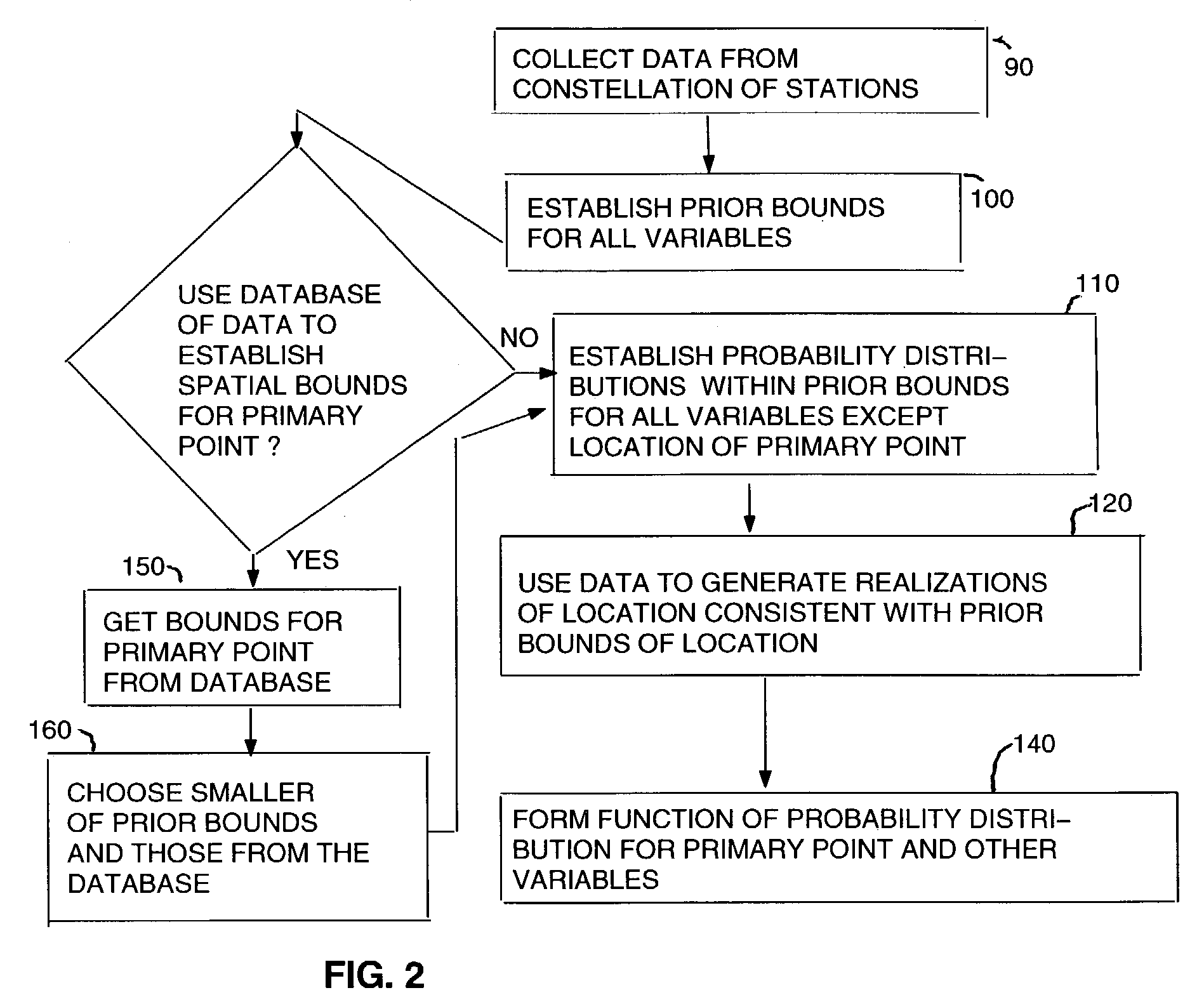

Estimation algorithms and location techniques

ActiveUS7219032B2Easy to understandAccelerated settlementDigital computer detailsPosition fixationObservational errorSequential method

Robust methods are developed to provide bounds and probability distributions for the locations of objects as well as for associated variables that affect the accuracy of the location such as the positions of stations, the measurements, and errors in the speed of signal propagation. Realistic prior probability distributions of pertinent variables are permitted for the locations of stations, the speed of signal propagation, and errors in measurements. Bounds and probability distributions can be obtained without making any assumption of linearity. The sequential methods used for location are applicable in other applications in which a function of the probability distribution is desired for variables that are related to measurements.

Owner:SCIENTIFIC INNOVATIONS INC

Novel approach to molecular diagnosis of human papillomavirus-related diseases

ActiveUS20070243552A1Accurate sensitive toolReduce in quantitySugar derivativesMicrobiological testing/measurementProtein markersHuman papillomavirus

The present invention relates to an accurate, sensitive, and efficient sequential or concurrently sequential method for molecular diagnosis of human papillomavirus (HPV)-based disease, where the method improves the accuracy and reliability of diagnostic and prognostic assessments of HPV-based disease. The method of the invention comprises a primary screen of a sample for HPV nucleic acids, followed by a secondary screen for molecular markers, such as proliferation and cell cycle control group protein markers. The sequential or concurrently sequential method significantly reduces the number of false positive results.

Owner:QIAGEN GAITHERSBURG

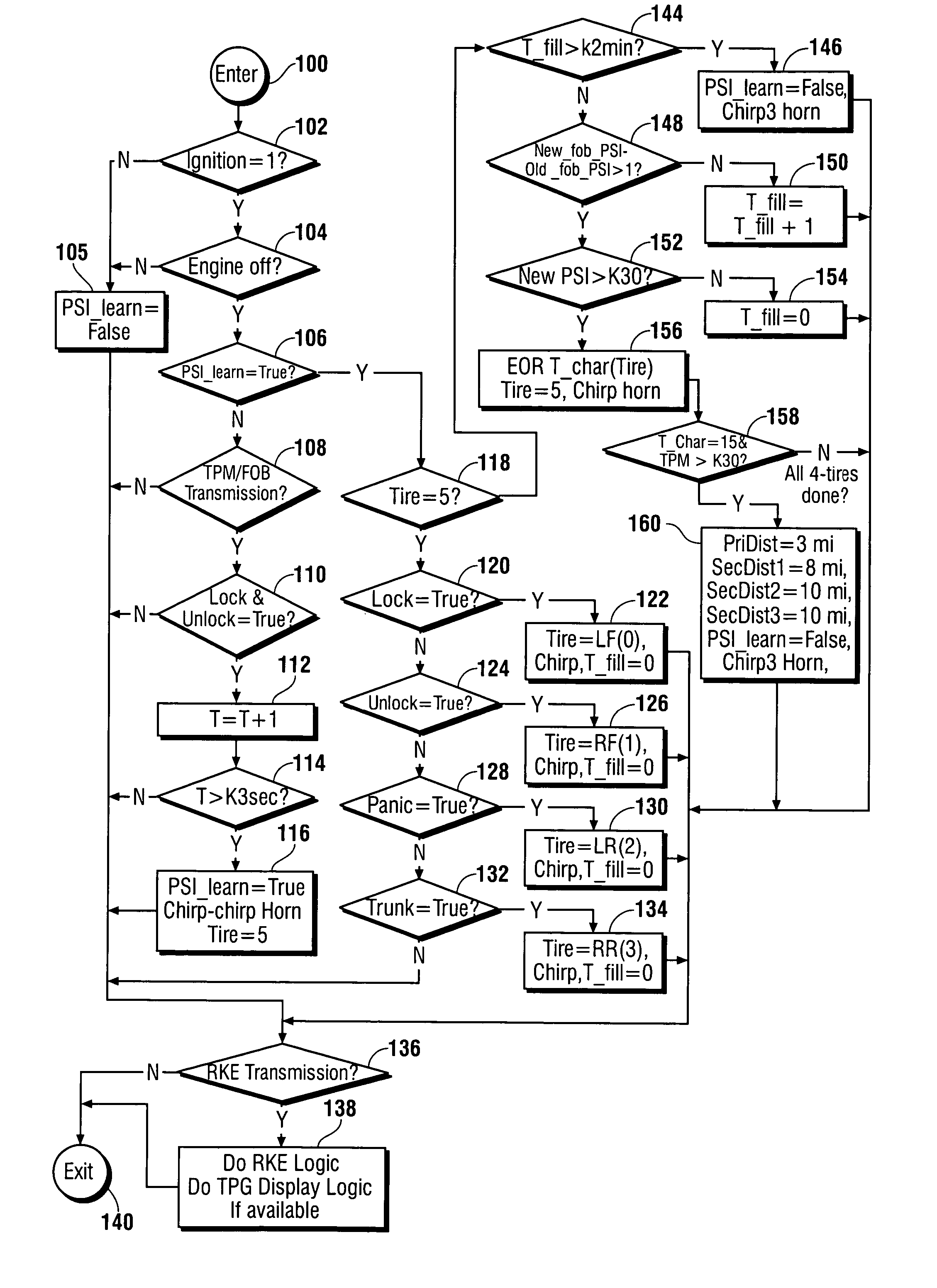

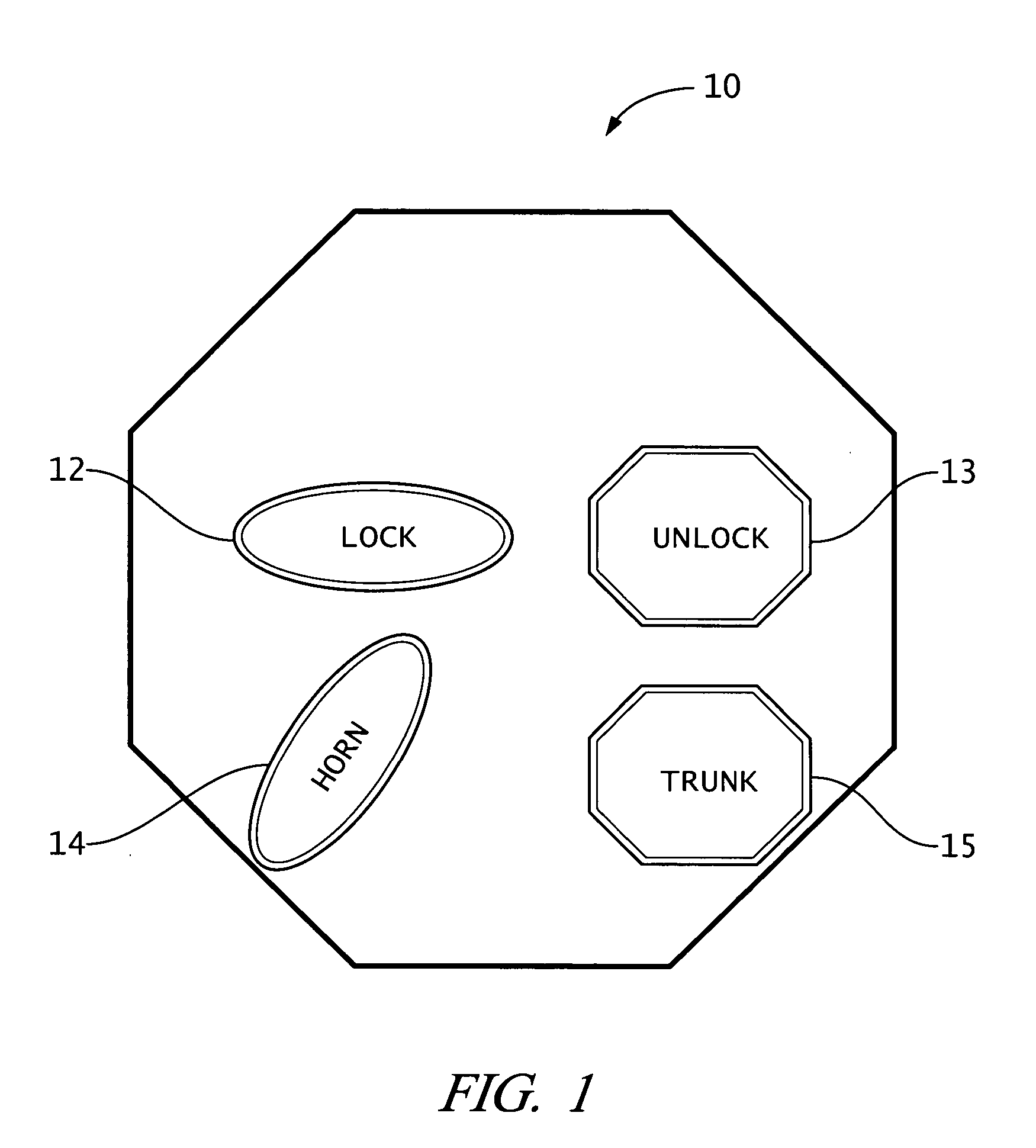

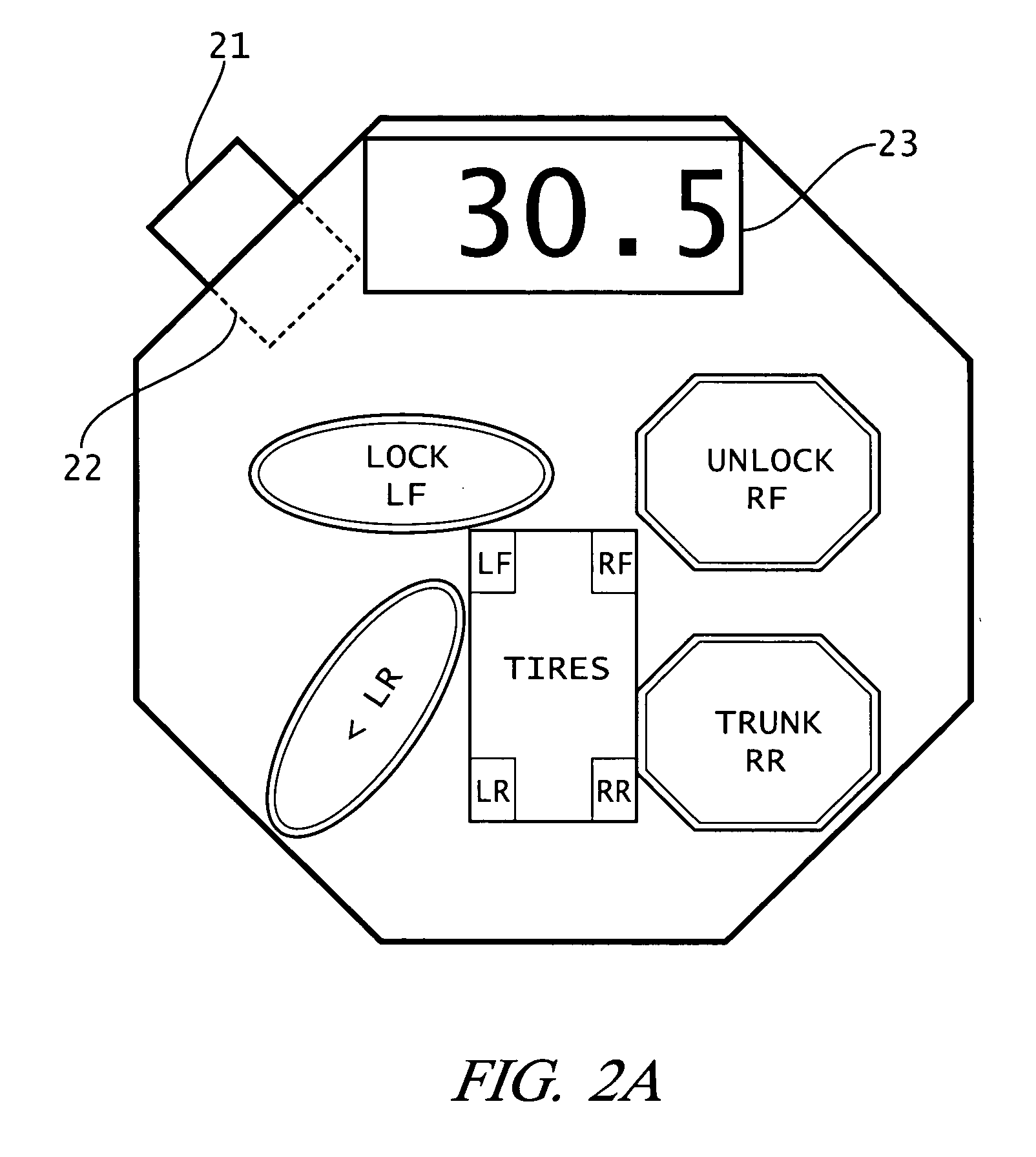

Tire pressure characterization method and key fob

InactiveUS20060055522A1Improve functionalityImprove accuracyCheck valvesIndividual entry/exit registersSequential methodTire-pressure gauge

The present invention provides an apparatus and method for characterizing tire pressure on the four tires of a conventional passenger automobile. The method uses an apparatus disposed on a key fob. The key fob includes a tire valve stem interface that is capable of taking manual measurements of tire pressure. The fob further includes a pressure transducer that translates tire pressure into electronic form where it can be displayed on an LCD screen and transmitted by RF to an automobile computer. The automobile computer further includes a program that provides for the measurement of tire pressure in a sequential method thereby assuring that the tires are at placarded pressure or more. The method includes steps of using the key fob to measure the tire pressure and transmitting the tire pressure to the computer for processing.

Owner:GM GLOBAL TECH OPERATIONS LLC

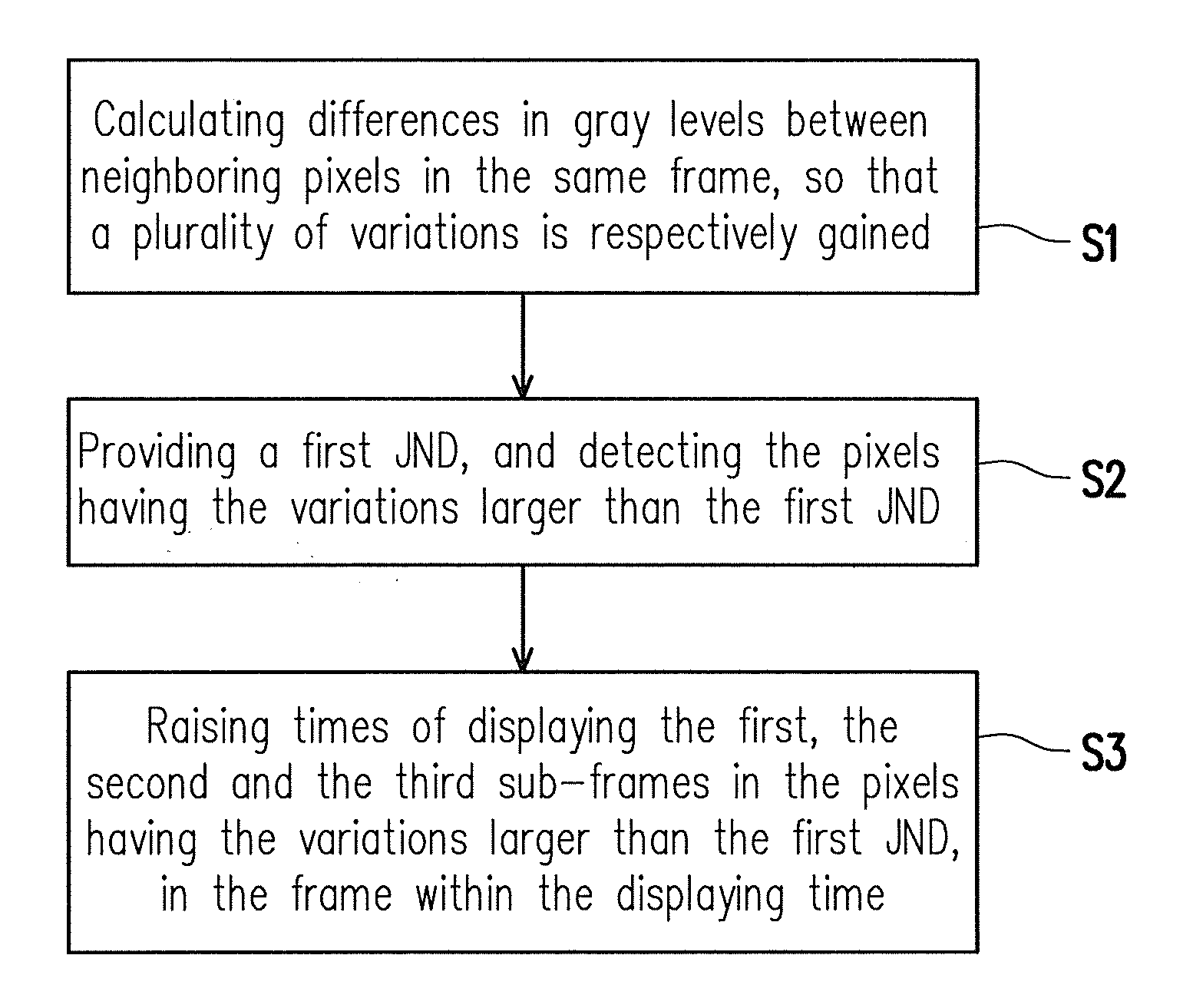

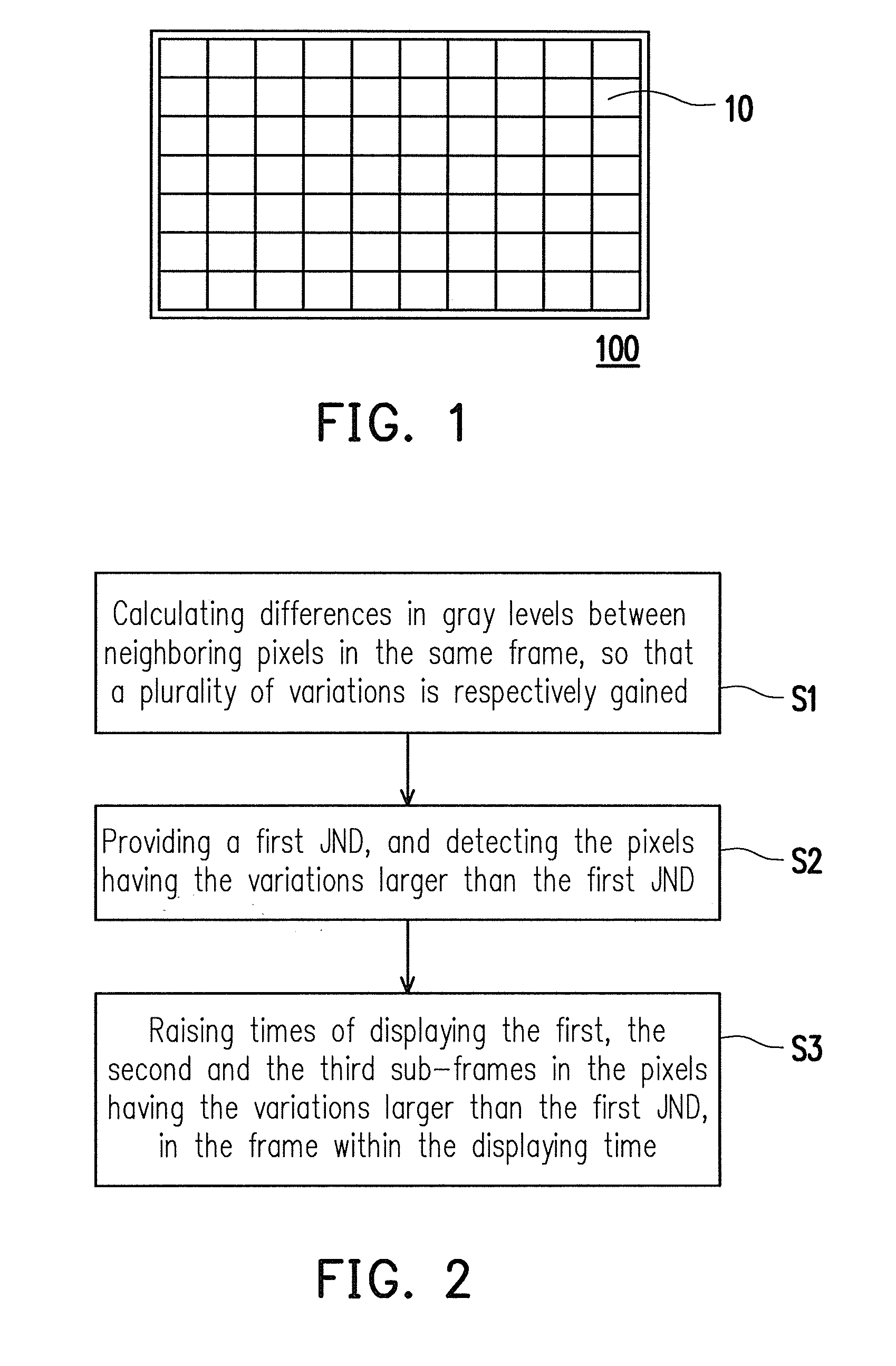

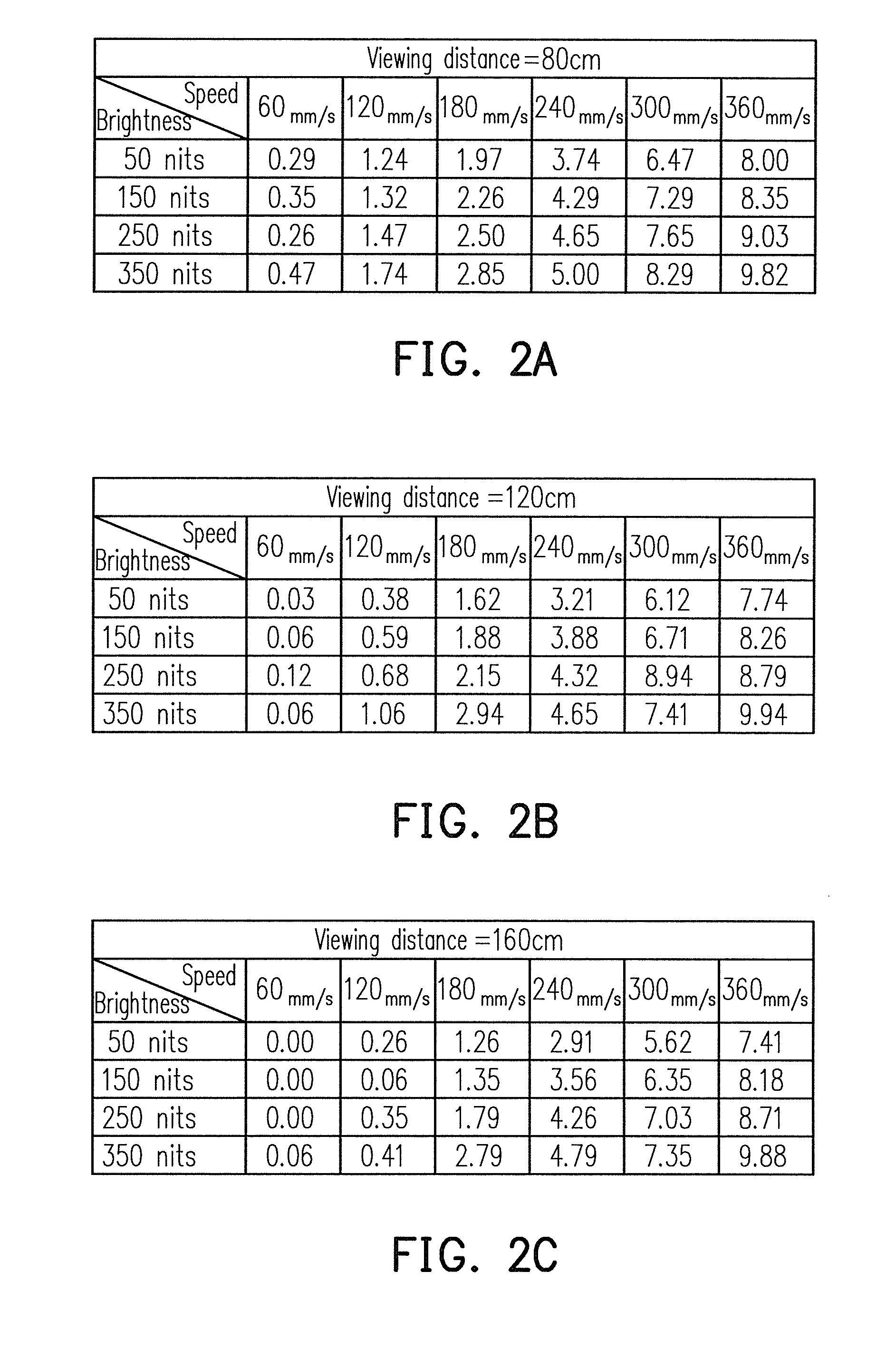

Color sequential method for displaying images

InactiveUS20100045707A1Increase display frequencyEfficiency problemCathode-ray tube indicatorsInput/output processes for data processingSequential methodComputer graphics (images)

A color sequential method for displaying images is suitable for applying in a display with pixels. Each of frames is formed by displaying a first sub-frame, a second sub-frame and a third sub-frame within a displaying time by the pixels. By calculating differences in gray levels between neighboring pixels, variations are gained. Then, a first just noticeable difference is provided, and the pixels having the variations larger than the first just noticeable difference are detected. Next, times of displaying the first, the second and the third sub-frames in the pixels are raised within the displaying time.

Owner:CHUNGHWA PICTURE TUBES LTD

Image display device and image display method

InactiveCN101763806ASuppressionWith a clear purposeStatic indicating devicesVisibilityImage extraction

An image display device is provided, with less color breaking in the field sequential method. A color component image with a relatively high luminance level is extracted as a fundamental image from an input image. A differential image is obtained by subtracting color component of the fundamental image from an input image, and is decomposed into a plurality of color components. The differential image for each color component is divided into two. The fundamental image is displayed at a middle timing of a frame period. The half-divided differential images are displayed at timings before and after the middle timing for the fundamental image so that the half-divided differential image with higher luminance level with consideration for visibility characteristic is displayed at a timing closer to the middle timing for the fundamental image.

Owner:SONY CORP

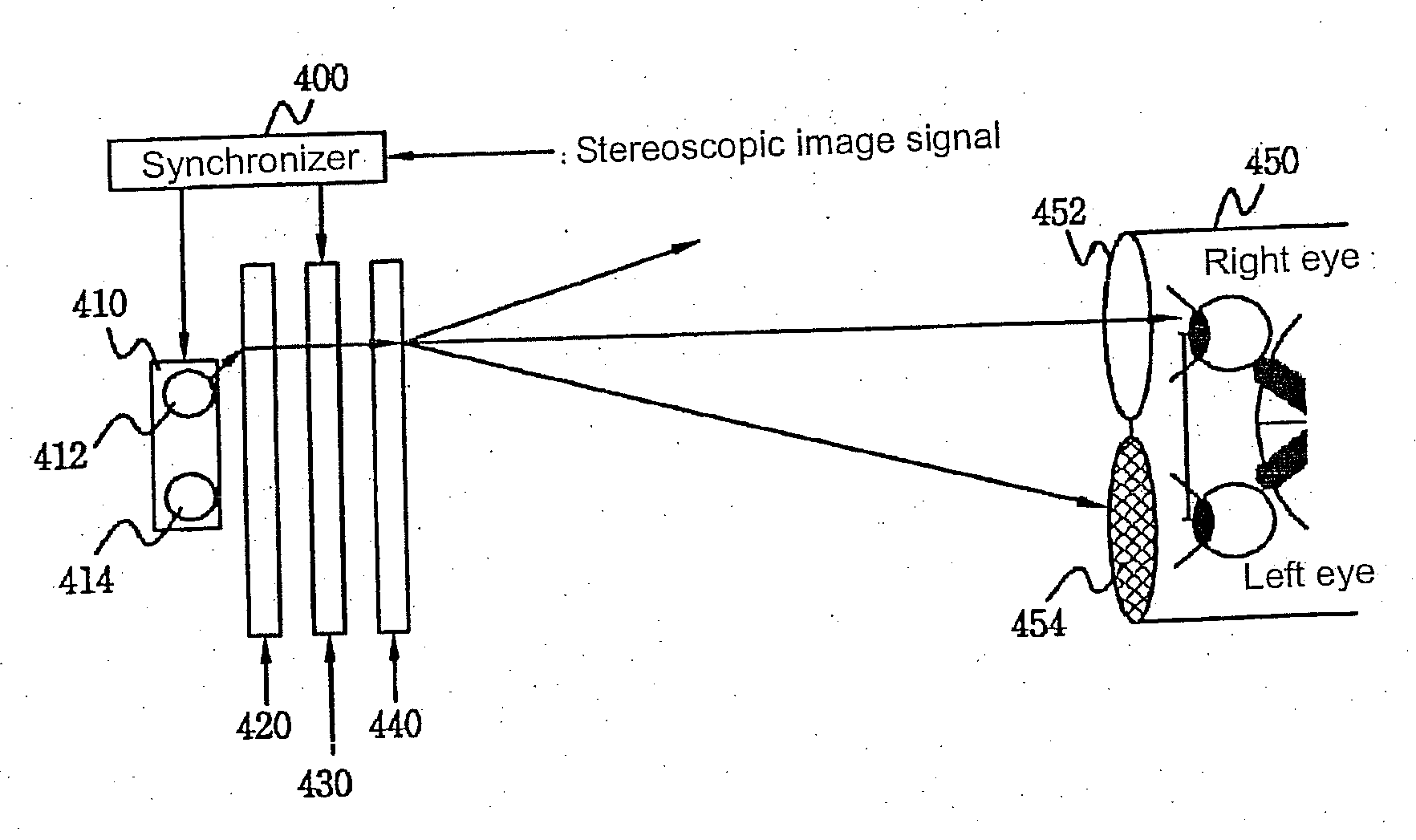

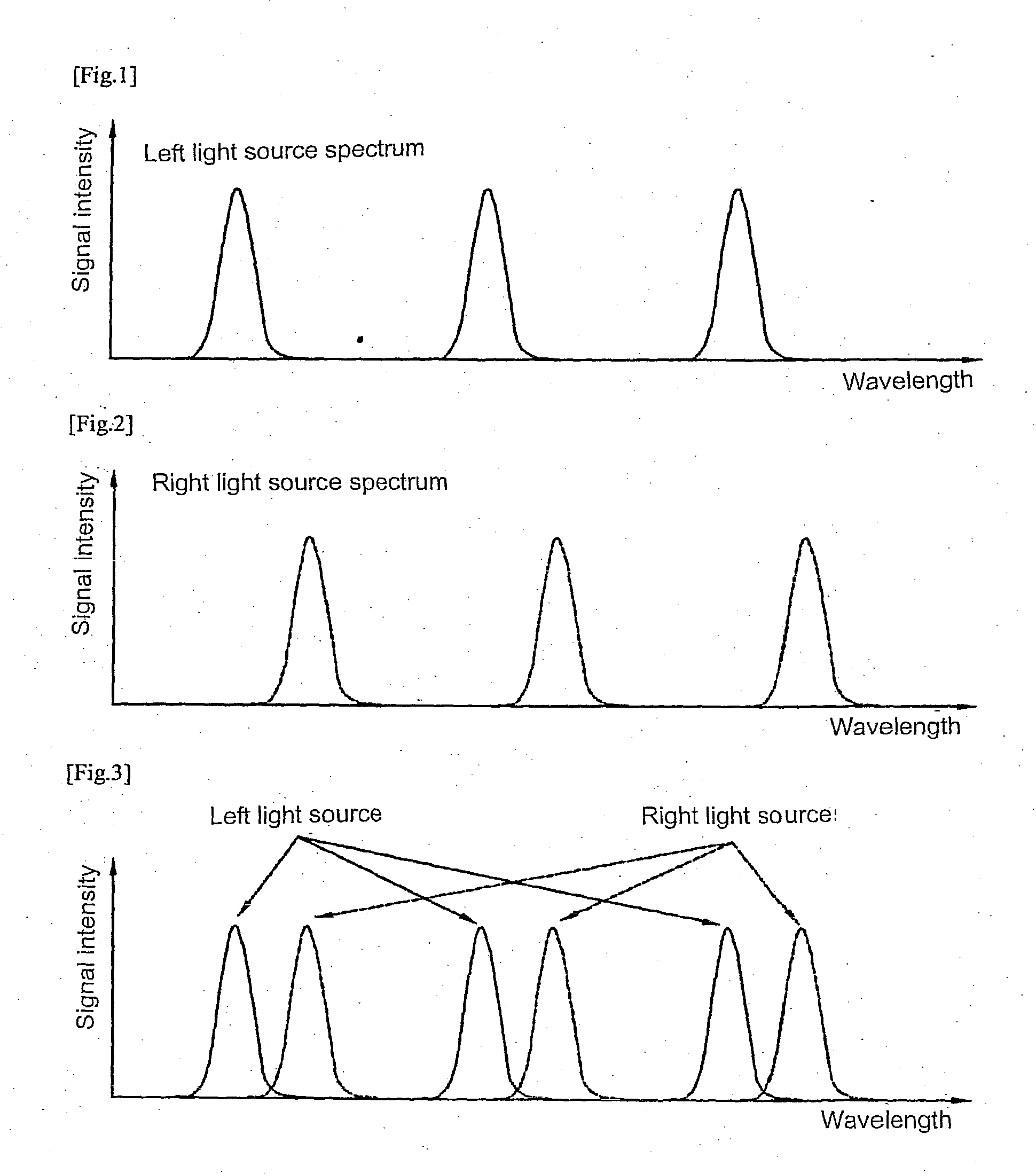

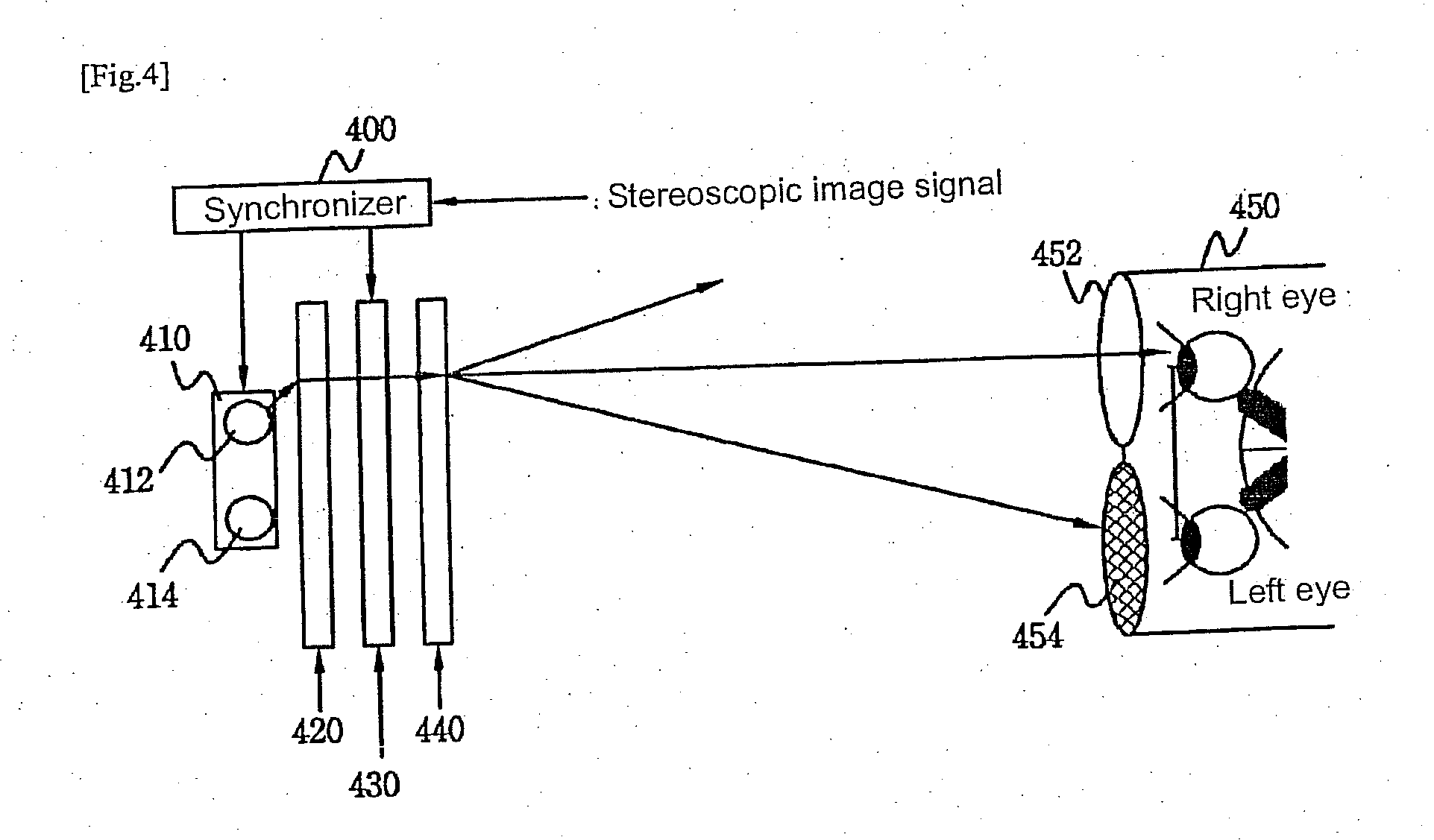

3D LCD using spectrum method and 3D image display apparatus using the same

InactiveUS20110267438A1Increase brightnessImprove resolutionTelevision system detailsSteroscopic systemsManufacturing cost reductionManufacturing technology

The present invention provides a 3D LCD using a spectrum method. The 3D LCD which forms and displays a 3D image using light sources comprises: a 1st light source that forms an image for a left eye; a 2nd light source that forms an image for a right eye; and a control unit that is connected to the 1st and 2nd light sources and drives the light sources in turn, wherein the RGB spectrum bands of each light source overlap to a degree that does not cause interference between the RGB spectrum bands. Preferably, the 1st and 2nd light sources include an LED. More preferably, the 1st and 2nd light sources are installed on a light source unit for a back light unit. Selectively, the 1st and 2nd light sources comprise at least one light source body respectively. Therefore, the invention can: produce a 3D image of which brightness and definition are more improved than a 3D LCD using a polarization method; display the 3D image at a cheaper cost than a 3D LCD using a time-sequential method; and improve user satisfaction by increasing user convenience. In addition, the invention is able to simplify the fabrication processes of the 3D LCD and reduce fabrication costs as the 3D image can be produced through the spectrum method by using little-changed conventional LCD production processes.

Owner:LG ELECTRONICS INC

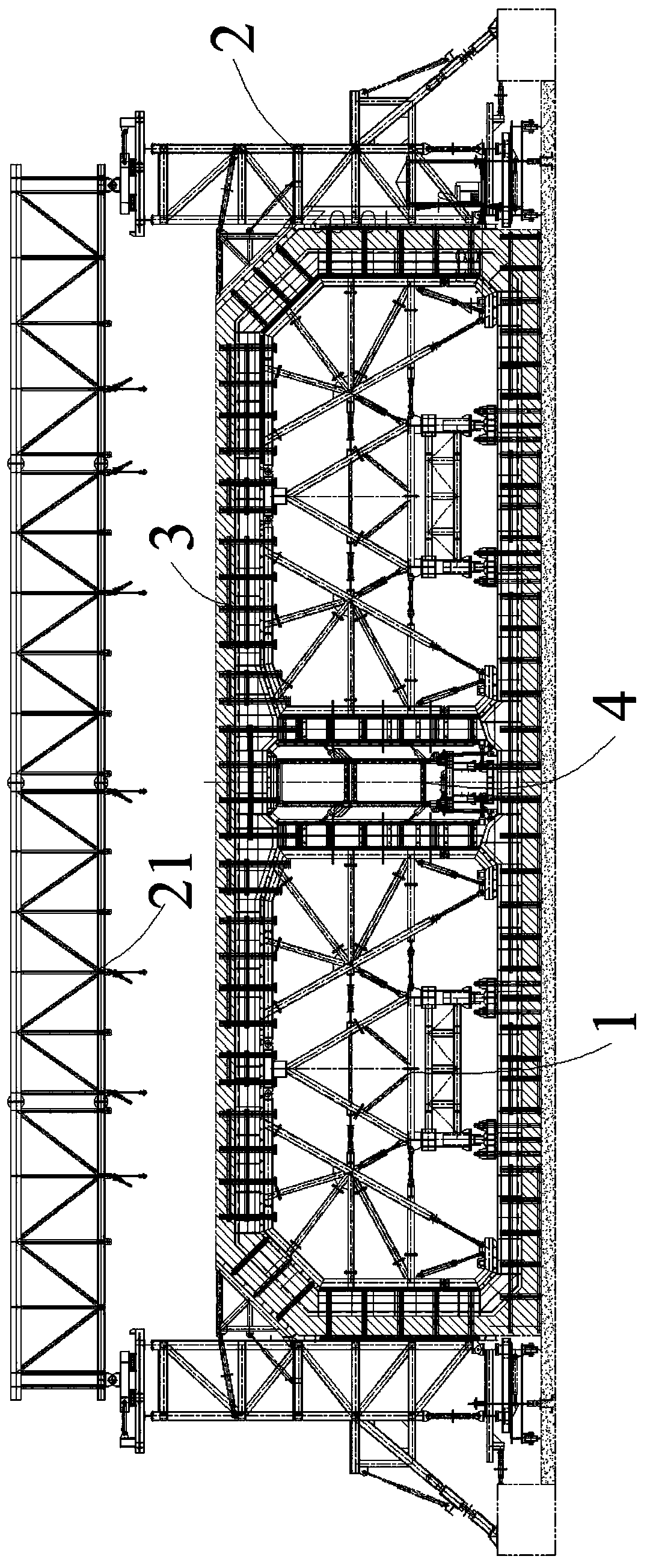

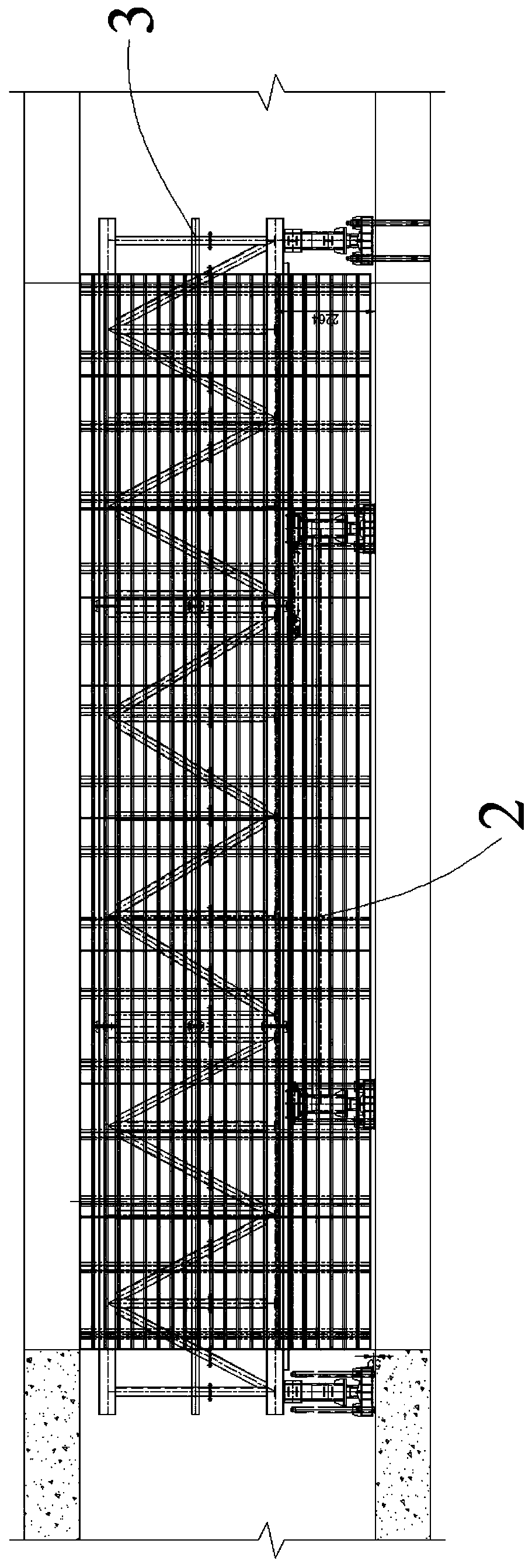

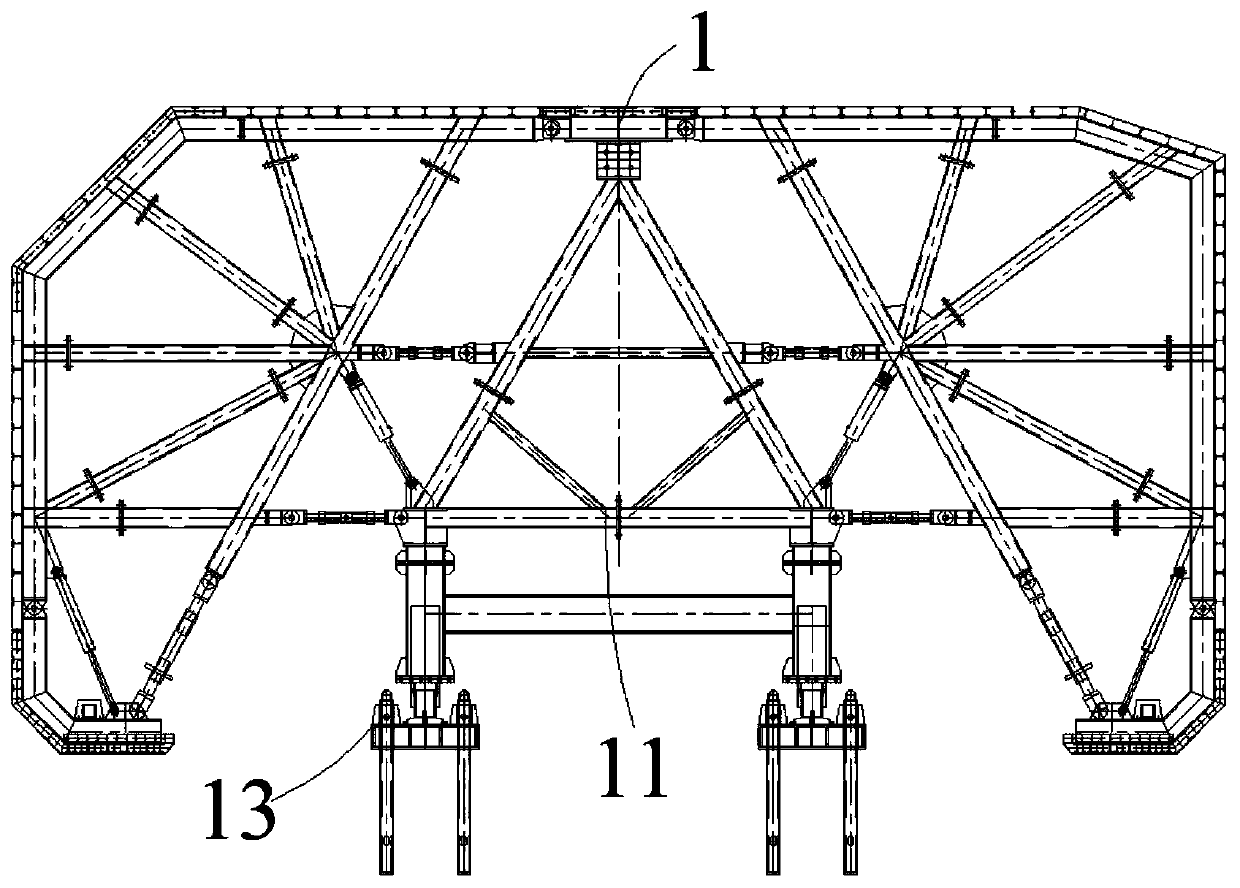

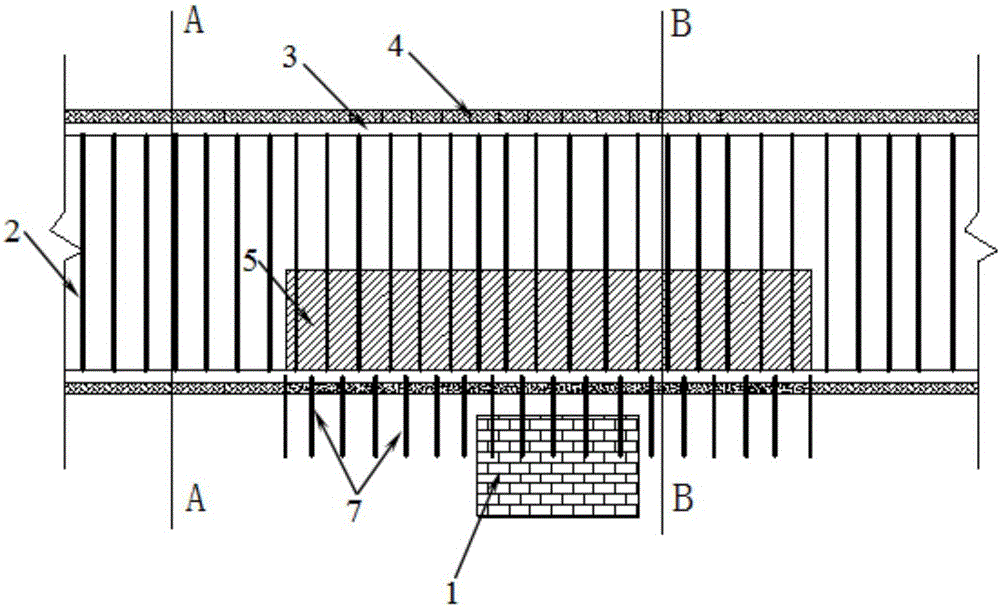

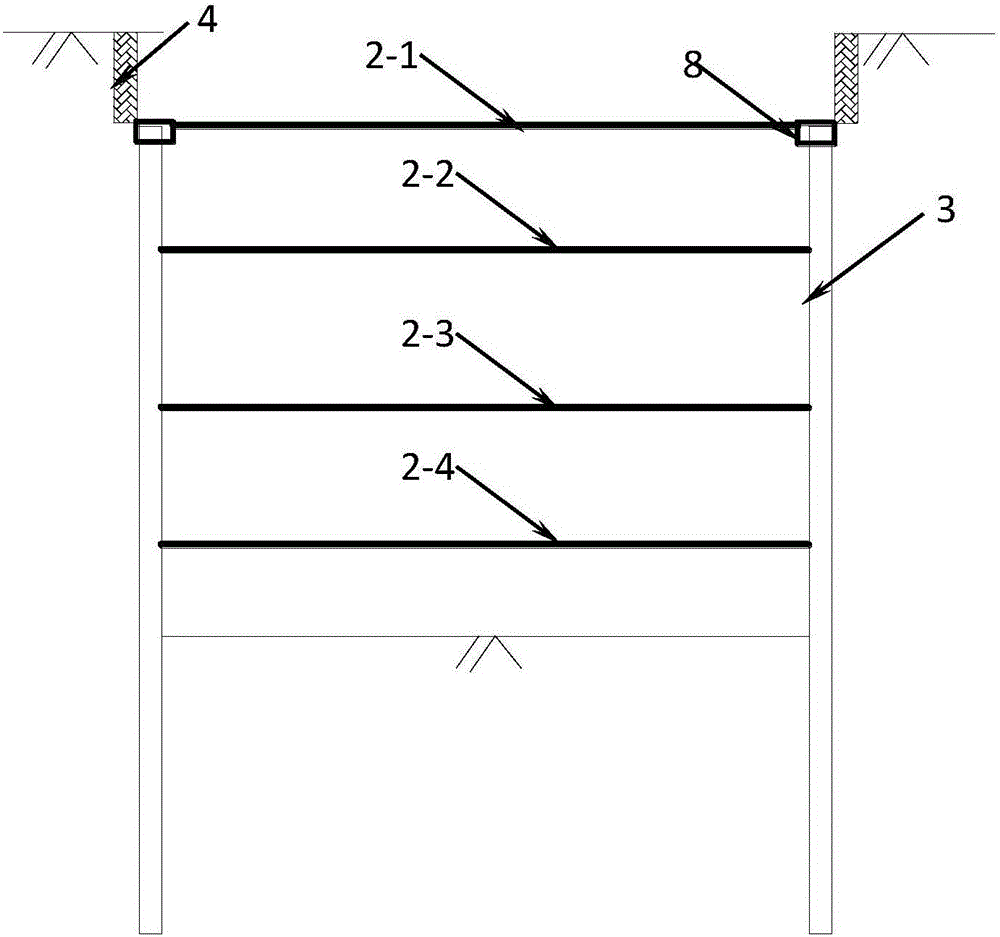

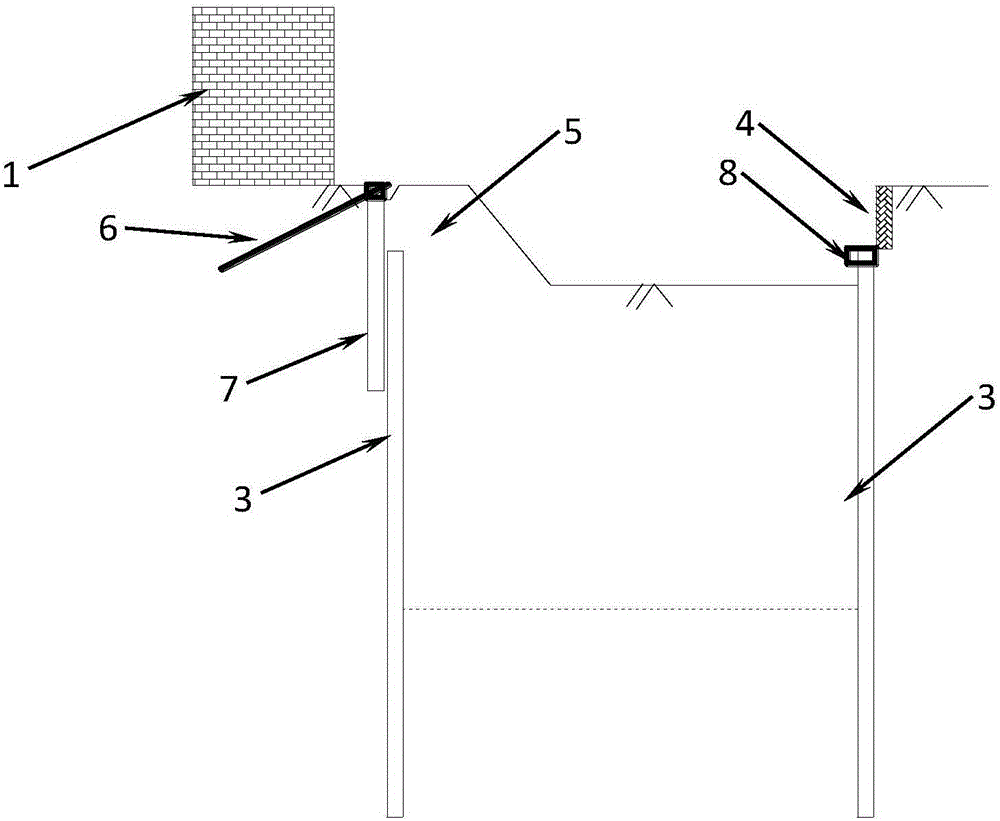

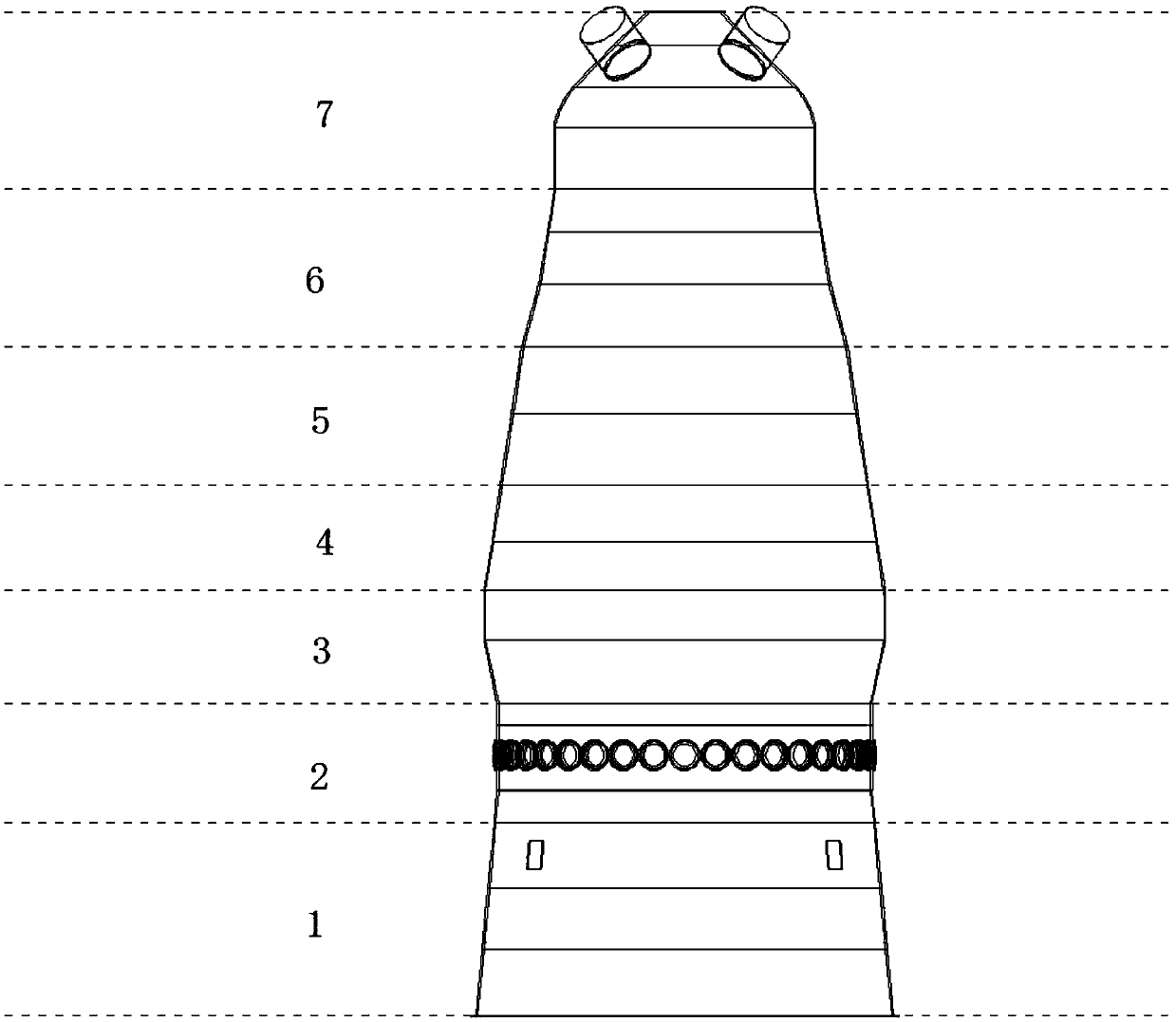

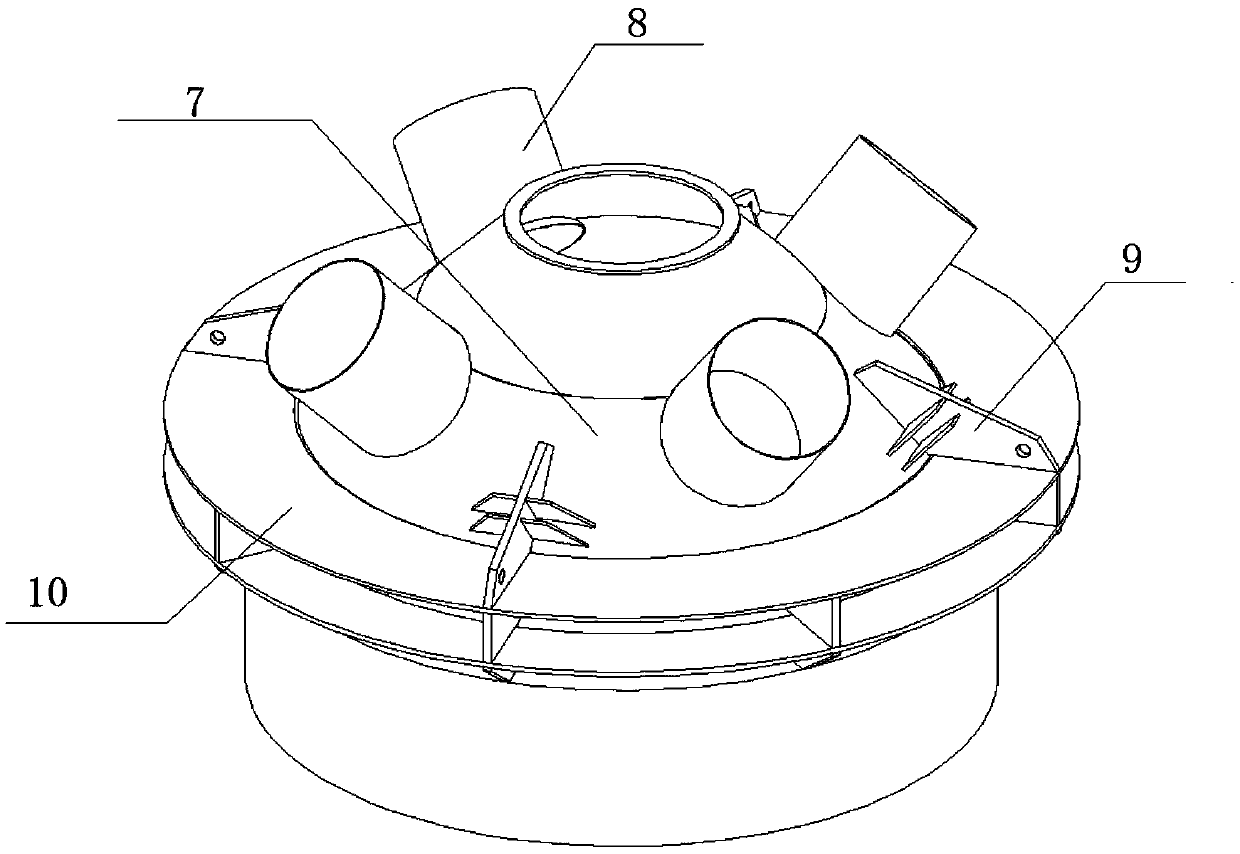

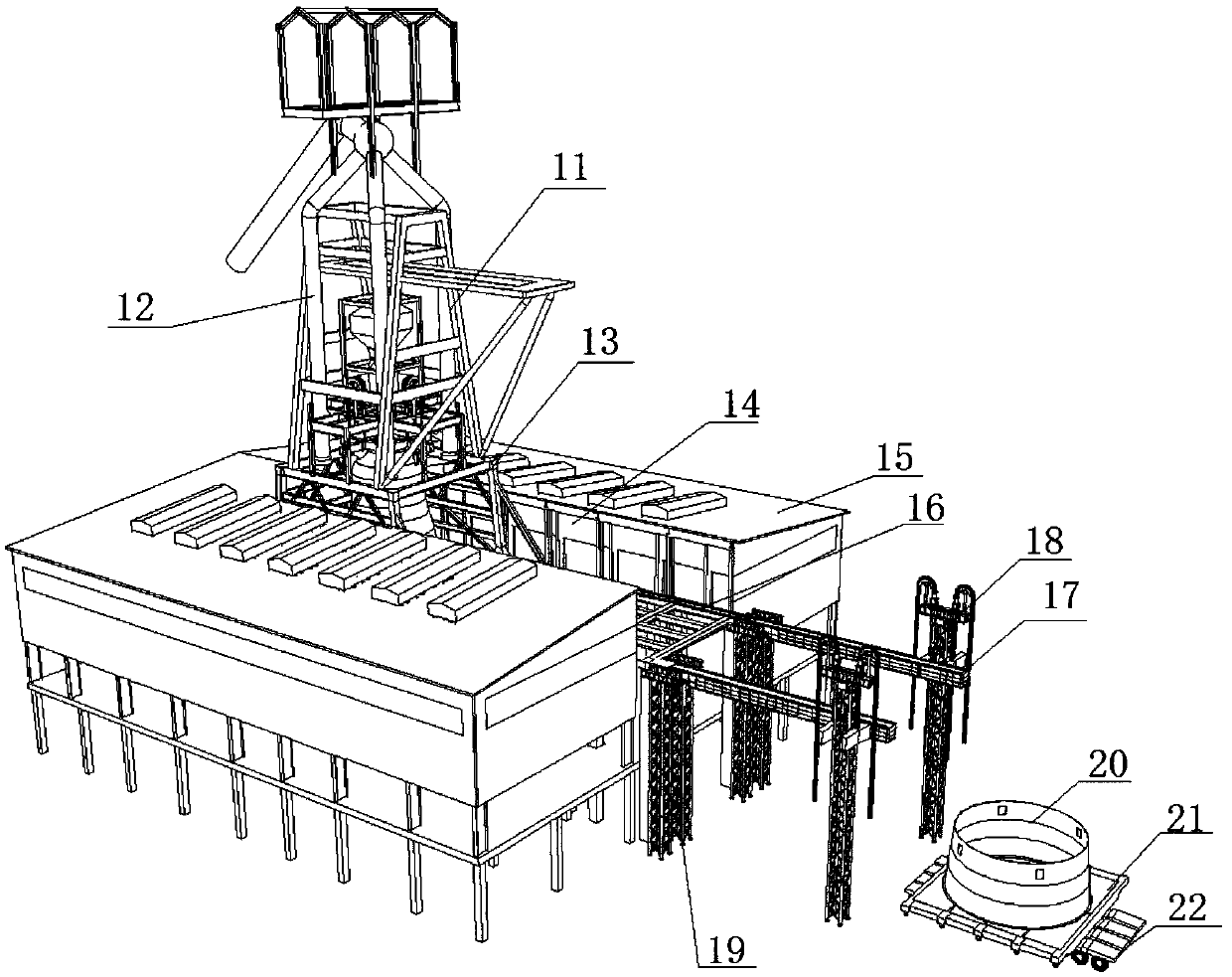

Dry dock sequential method full-section integral immersed tube prefabrication formwork system

PendingCN110076889AEasy to adjustSimple travel adjustmentDischarging arrangementMouldsSequential methodEngineering

The invention relates to the technical field of immersed tube prefabrication construction, in particular to a dry dock sequential method full-section integral immersed tube prefabrication formwork system. The system comprises an inner mold system, an outer mold system and an end mold system, wherein the inner mold system is located on the inner side of an immersed tube casting space and is connected with the outer mold system located outside the immersed tube casting space into a whole through the end mold system positioned at the longitudinal end part of the immersed tube casting space, the lower end of the inner mold system is provided with an inner mold travelling support device which is used for carrying out longitudinal, transverse and vertical position adjustment on the inner mold system, and the outer mold system is an outer side formwork structure capable of being adjusted in the longitudinal direction, the transverse direction and the vertical position. The immersed tube prefabrication method has the advantages of being accurate in position adjusting, less in main body structure damage and capable of operating all weather, so that the technical problems of sequential prefabrication, adjacent operation, compact space, longitudinal long-distance travel of an ultra-large super-heavy formwork is long, being prone to deviation and the like which occur to a sequential methodare solved.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

Method of reconstructing a stochastic model, representative of a porous heterogeneous medium, to improve its calibration by production data

InactiveUS7558708B2Computation using non-denominational number representationSeismic signal processingSequential methodReconstruction method

A method of reconstructing a stochastic realization, continuous or discrete, resulting from a random function representing a numerical model, can be representative of a porous heterogeneous medium such as an underground reservoir. It is based on identification, for a given realization, of a random function and of a set of random numbers allowing, from a given geostatistical simulator, to reconstruct the reference realization. The reconstruction techniques proposed are either general or specific to a type of geostatistical simulator. They concern the sphere of optimization, relaxation, filtering and sequential approaches. The reconstruction method allows to estimate a set of random numbers for regenerating the reference realization, this reference realization can then be locally or globally modified, by gradual deformation, so as to better reproduce newly acquired dynamic data (production data for example). The method is applicable notably to oil reservoir development for example.

Owner:INST FR DU PETROLE

Metro station foundation pit construction method for controlling deformation of neighboring buildings

InactiveCN105756091AControl the timeControl timeArtificial islandsExcavationsMetro stationSequential method

Owner:SHANDONG UNIV OF TECH

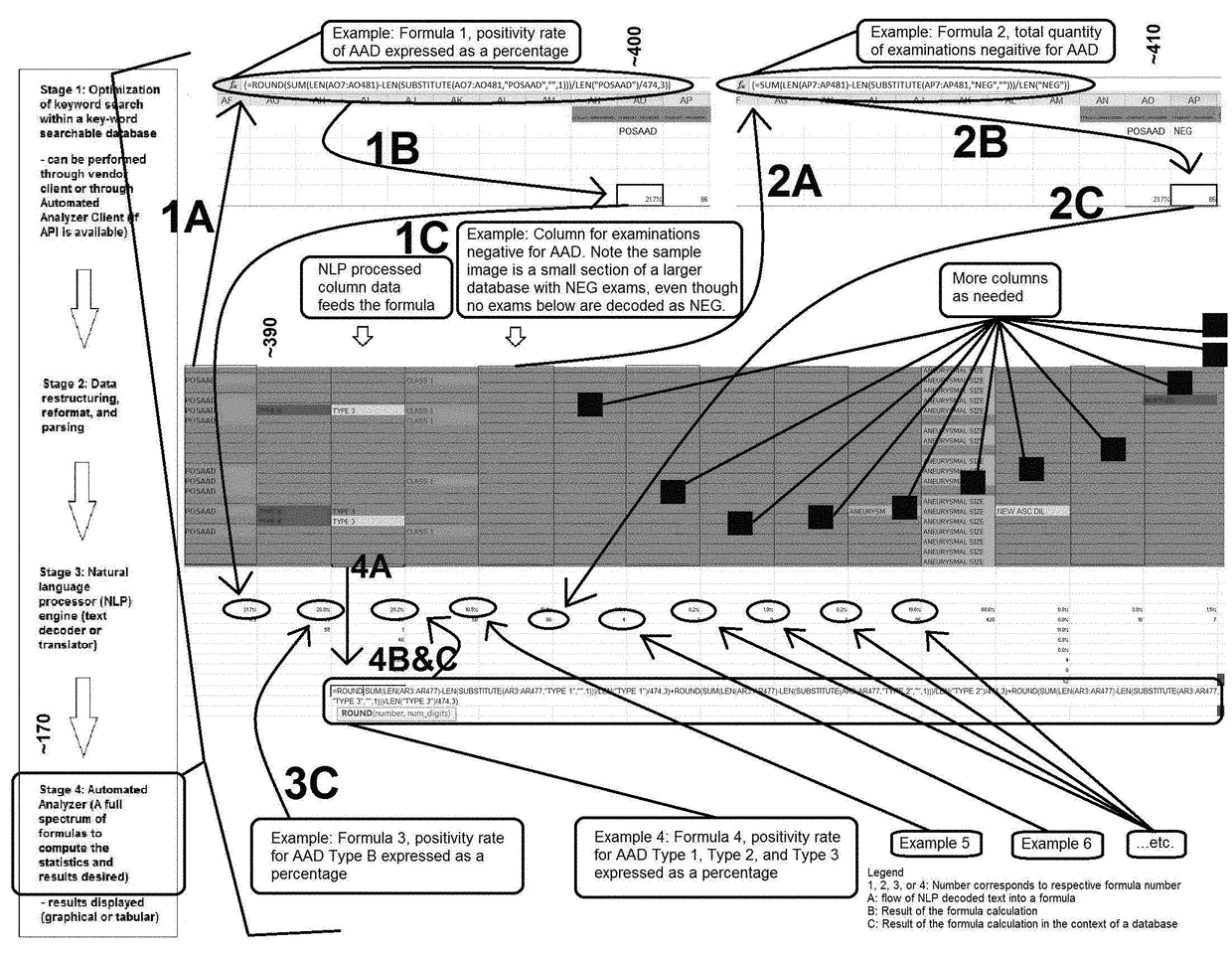

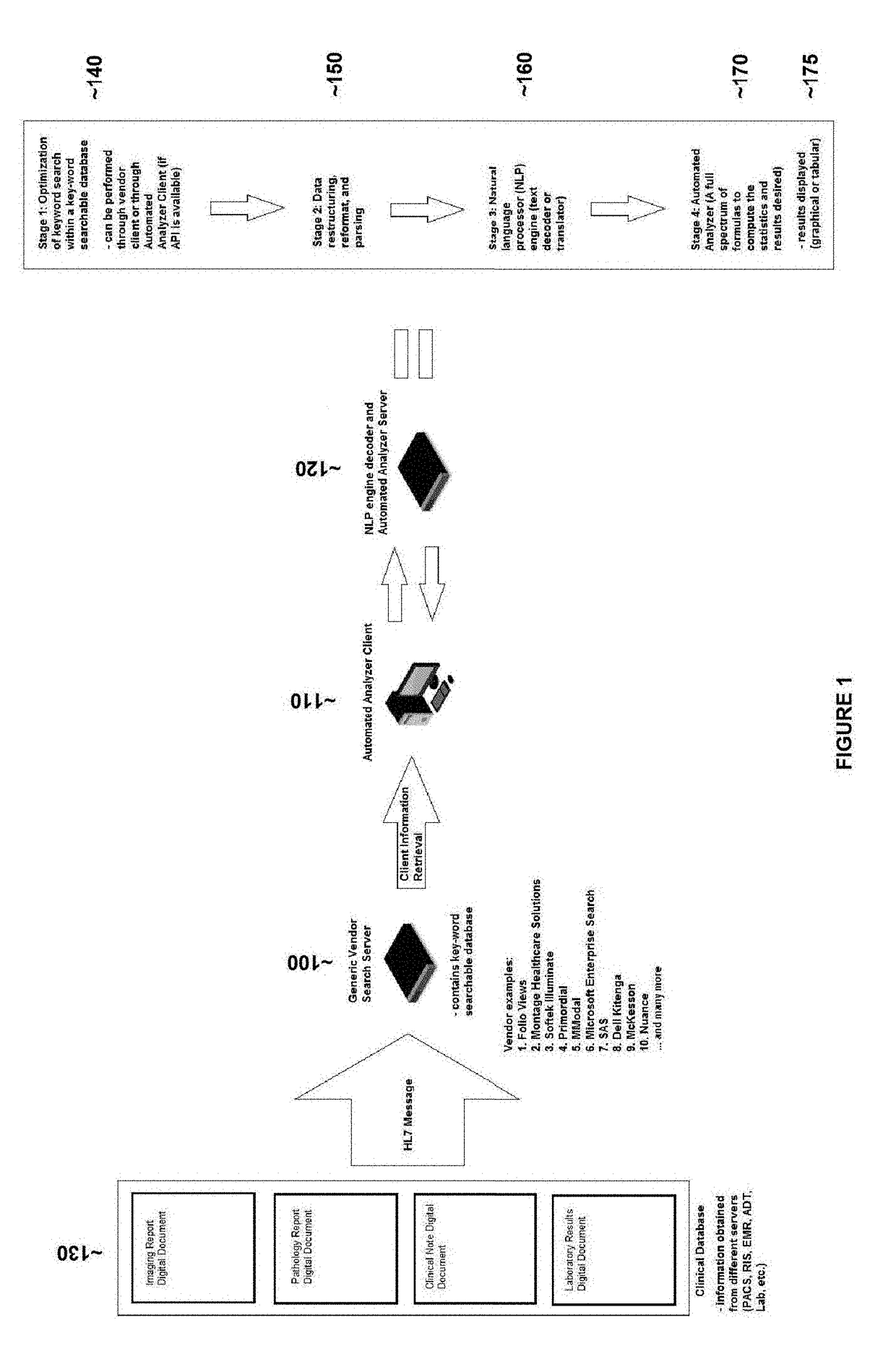

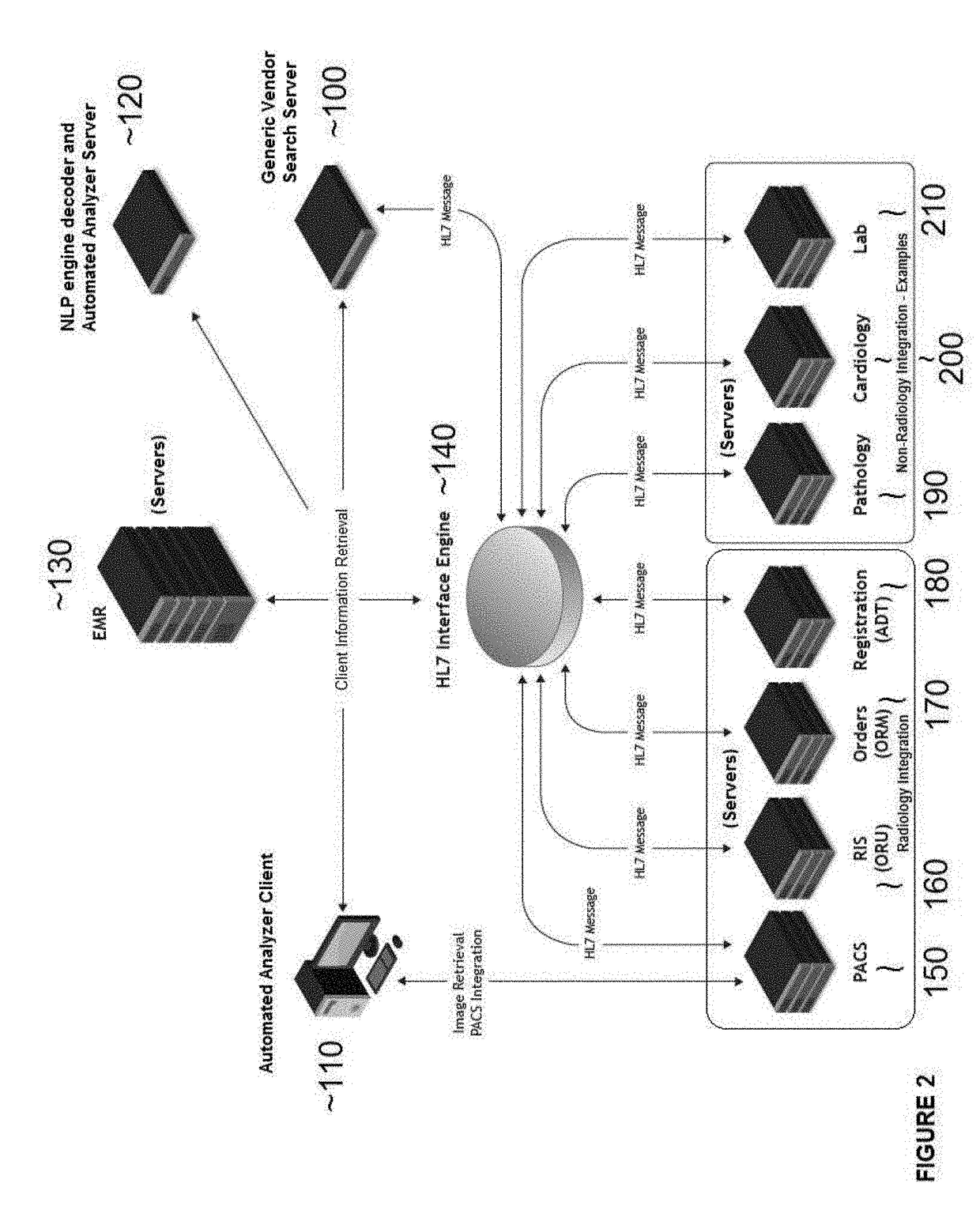

Method for searching a text (or alphanumeric string) database, restructuring and parsing text data (or alphanumeric string), creation/application of a natural language processing engine, and the creation/application of an automated analyzer for the creation of medical reports

A sequential series of methods for optimized searching within a text (or alphanumeric string) database to retrieve specific and relevant results, followed by optimized restructuring and parsing of text data (or alphanumeric string), followed by creation / application of a natural language processing engine, followed by the creation / application of an automated analyzer is presented.

Owner:HAYTER II ROBERT G

Construction method for replacement of blast furnace shell in blast furnace overhaul project

InactiveCN109097516ABlast furnace componentsBlast furnace detailsAccessory structureSequential method

The invention discloses a construction method for replacement of a blast furnace shell in a blast furnace overhaul project. The construction method comprises the following steps: a new blast furnace shell is divided into sectional combining structures, and a lifting support frame and a pushing trolley are erected on the pushing side of a new blast furnace outside a cast house; a lifting device iserected on a blast furnace top rigid frame, a plurality of furnace body frame platforms on the upper surface of the pushing side of an old furnace shell and the wall surface and roof of the cast houseon the pushing side are dismounted, a pushing channel for the new furnace shell is erected, and the old blast furnace shell and accessory structures to be replaced are dismounted; the lower half of the new blast furnace shell is hoisted with a sequential method; the upper half of the new blast furnace shell is hoisted with a reverse loading method, and the upper half and the lower half of the newblast furnace shell are connected. According to the construction method for replacement of the blast furnace shell in the blast furnace overhaul project, influence on overall stability and bearing capacity of the furnace body frame can be reduced, and the problem of incapability of large crawler cranes to enter for operation is solved.

Owner:CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com