Metro station foundation pit construction method for controlling deformation of neighboring buildings

A technology for subway stations and construction methods, applied in construction, infrastructure engineering, excavation, etc., can solve the problems of enclosure wall deformation, large surface settlement, and difficulty in protecting adjacent buildings, and reduce the offset of enclosure walls Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

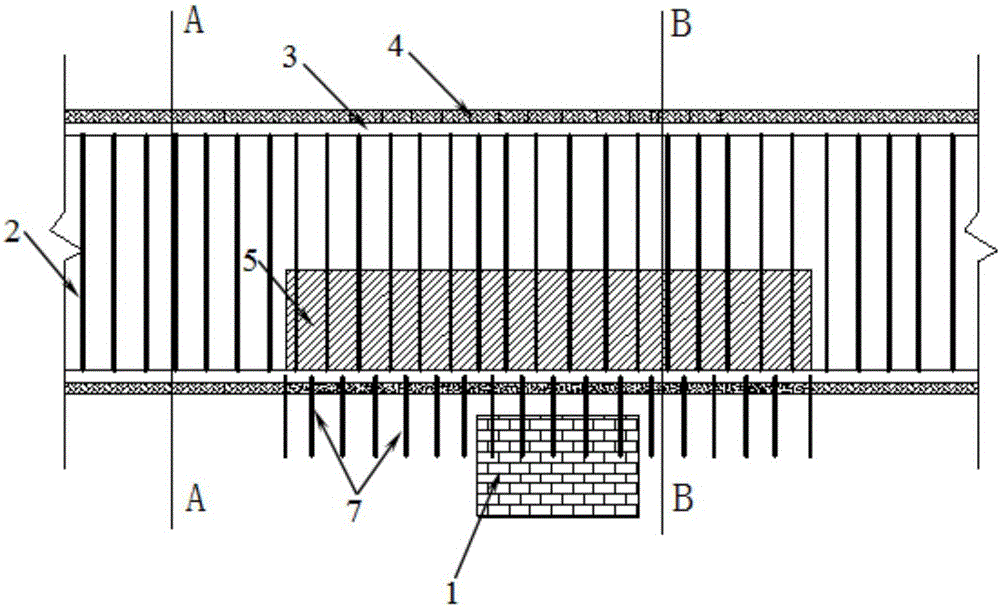

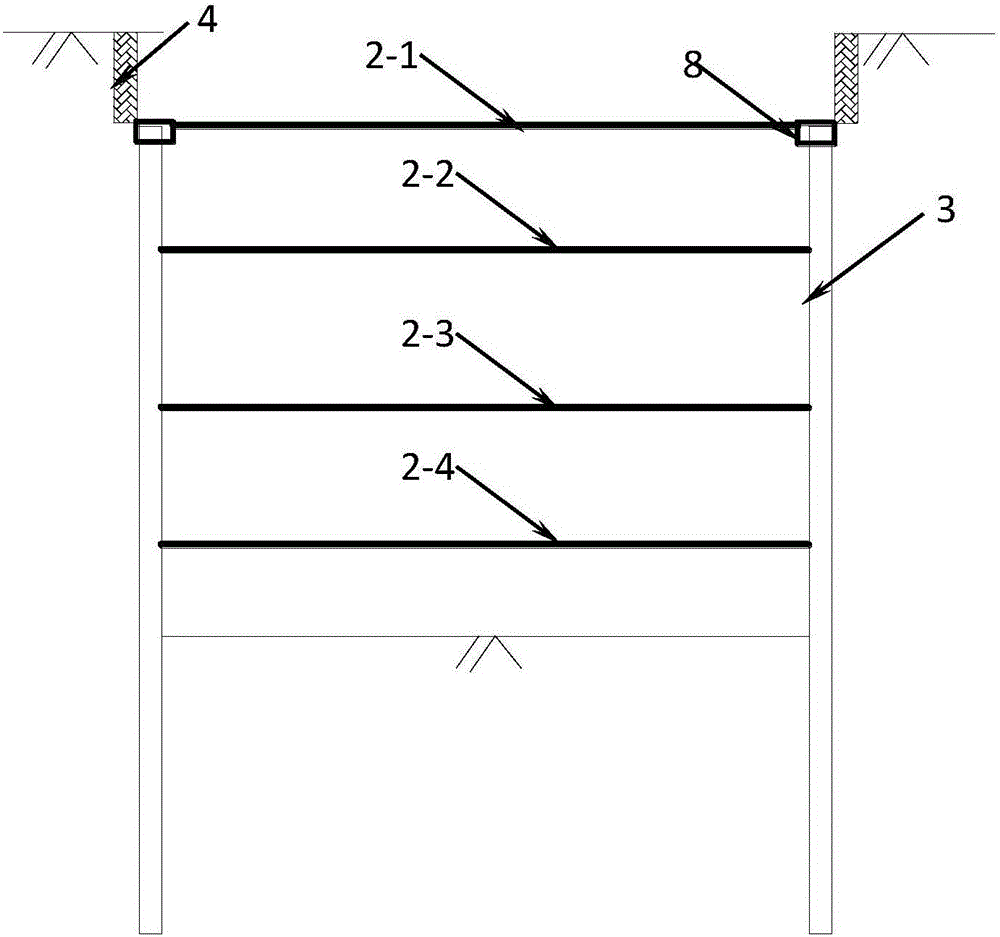

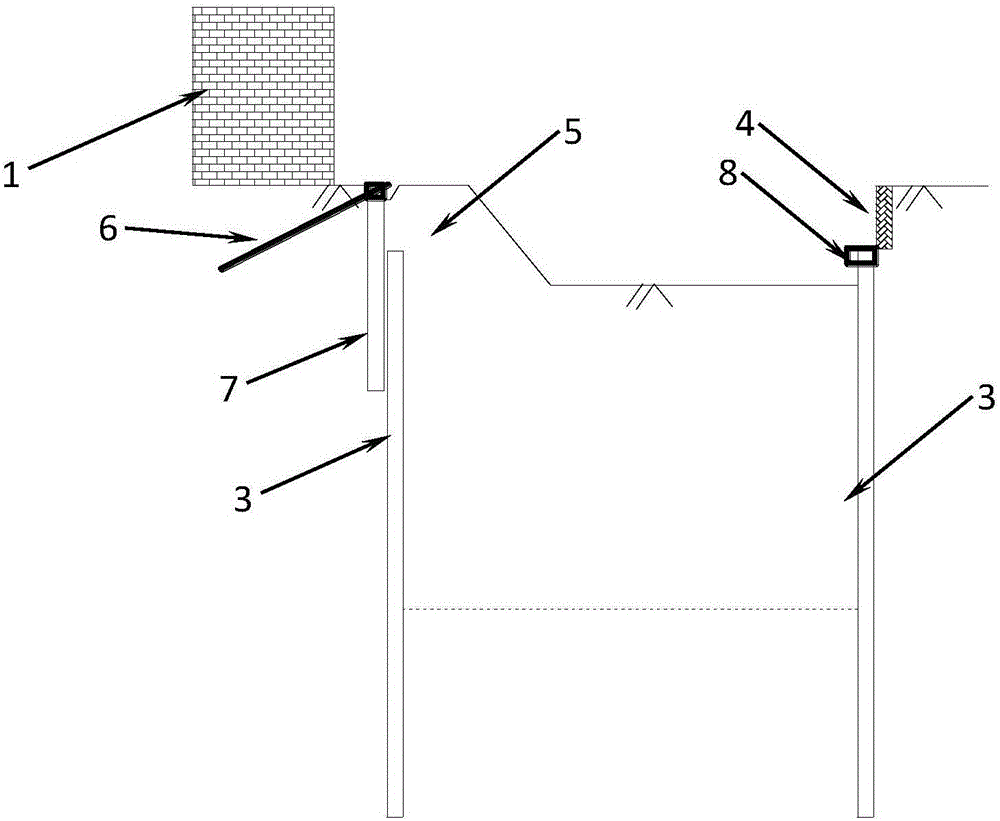

[0031] Such as figure 1 , figure 2 , image 3 As shown, the positional relationship between the foundation pit of the station and the adjacent building 1 is constructed according to the conventional method. Local construction isolation pile 6, the effect of isolation pile 6 is to protect building; On isolation pile 6, construct anchor rod 7 and apply prestress; Excavate foundation pit soil mass then, but keep the soil mass 5 closer to building 1 , construct the retaining wall 4 at the position where the top of the foundation pit enclosure wall 3 is exposed during the excavation, to support the deformation of the upper soil body; and pour the enclosure wall crown beam 8 on the top of the foundation pit enclosure wall 3 to increase the foundation pit The stiffness of the retaining wall 3; next, the supporting support 2 will be supported in the foundat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com