Magnetic separation enhanced type electromagnetic thermal desorption method and device for remediating soil

A repair method and thermal desorption technology, which is applied in the field of contaminated site repair, can solve the problems of exhaustion of waste heat of flue gas and low heat utilization rate, and achieve the effects of high heat transfer efficiency, good reaction effect and good mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

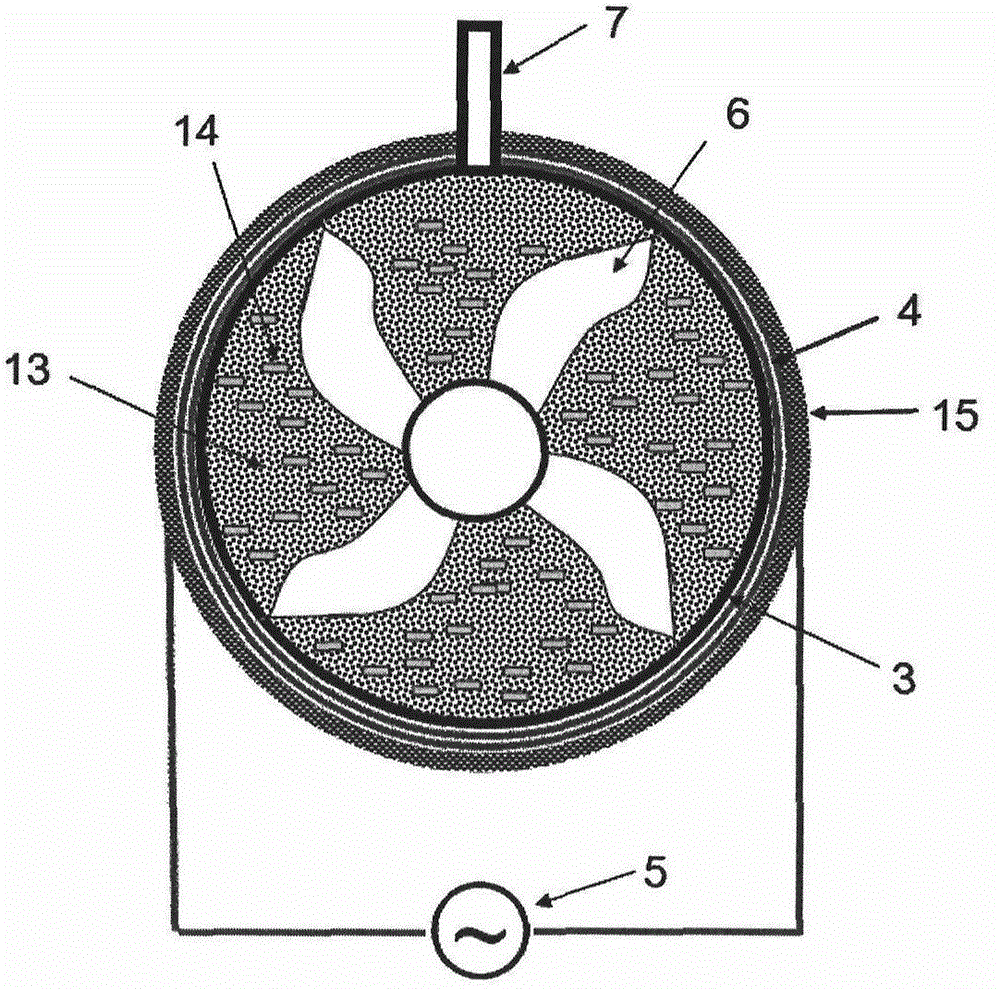

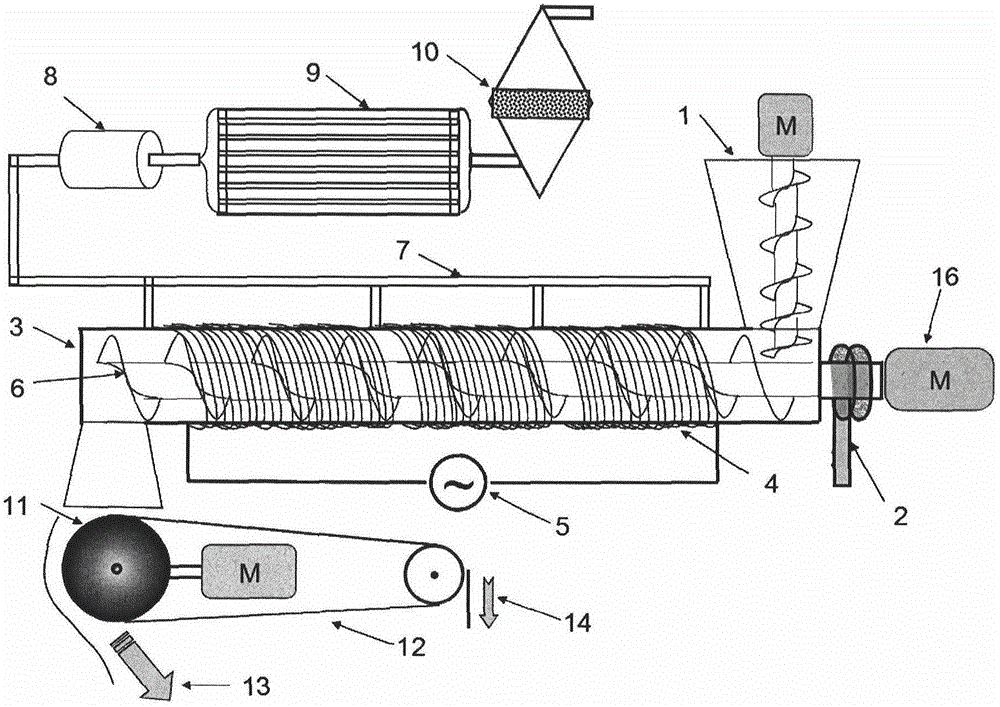

[0039] The structural representation of an embodiment of the present invention is shown in figure 2 . The magnetic separation enhanced spiral stirring electromagnetic thermal desorption system of the present invention is composed of a material feeding stirring device, an electromagnetic thermal desorption device, a magnetic separation device, a tail gas treatment device and a control system. The electromagnetic thermal desorption device is cylindrical, with an inner diameter of 200 mm and a length of 3000 mm. It is made of heat-resistant ceramics, with a built-in stainless steel stirring device, and aluminum silicate cotton insulation material is laid on the outside. A temperature sensor is connected to the electromagnetic controller 5 inside the device. Can automatically display and control the heating temperature.

[0040] Contaminated soil is fed into the thermal desorption device by the stirring screw, and the mass ratio of iron powder and polluted soil added is 1:50; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com