Power plant and coking plant coal processing equipment

A technology for processing equipment and coal, which is applied in chemical instruments and methods, solid separation, filtration and screening, etc. It can solve the problems of increasing oxygen supply, not being able to control the temperature of the combustion furnace in a timely manner, increasing the gap, etc., and achieving temperature control speed Fast, improve the utilization rate, reduce the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

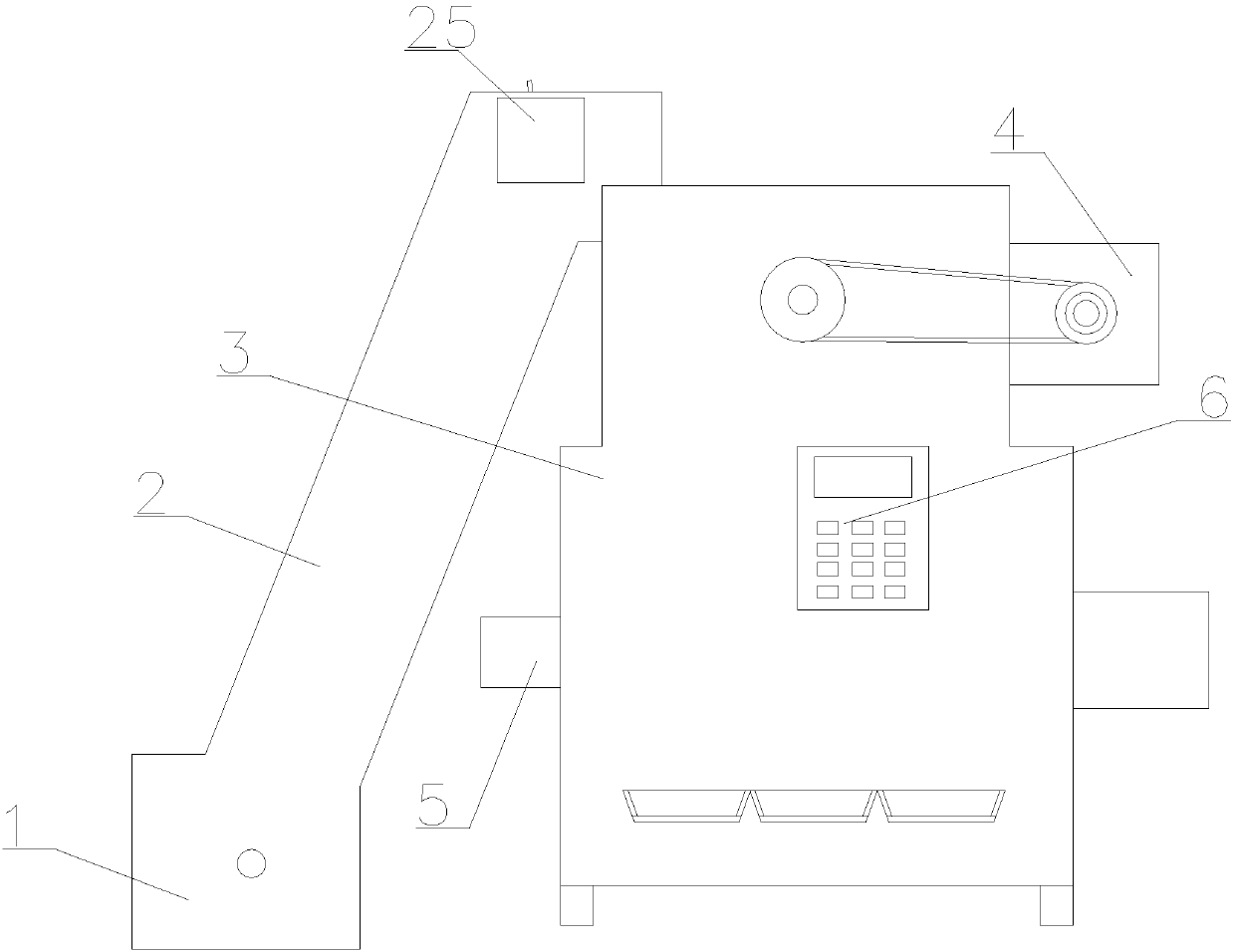

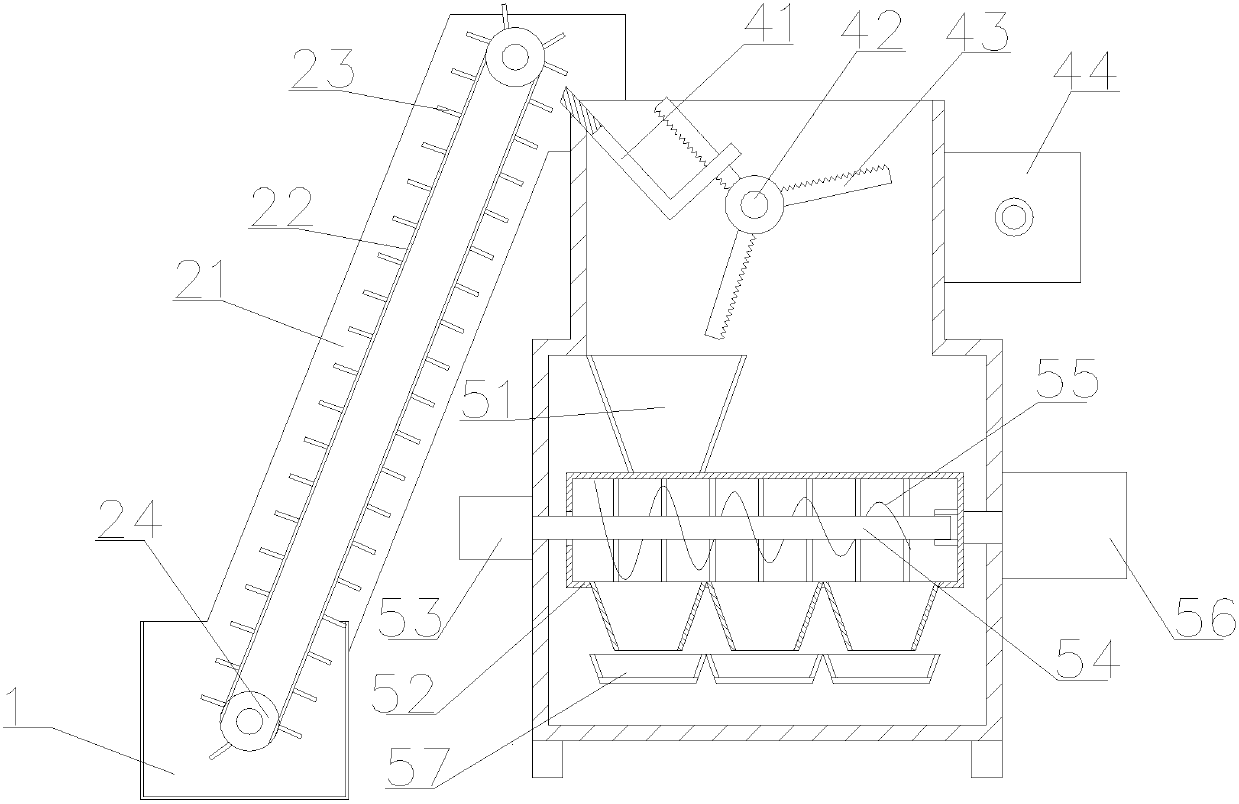

[0023] refer to Figure 1-Figure 6 , a kind of coal processing equipment for power plants and coking plants of the present invention, comprising a material storage box 1, a material feeding part 2, a working box body 3, a cutting and crushing part 4, a grading and screening part 5 and an electric control box 6, the material storage box 1 There is a feeding part 2 for conveying materials upwards, a working box 3 is arranged on the lower part of the upper end of the feeding part 2, and a cutting and crushing part 4 for crushing materials is arranged on the upper part of the working box 3. A grading and screening unit 5 is arranged inside the working box 3 at the lower part of the crushing unit 4 , and the electric control box 6 is electrically connected to the feeding unit 2 , the cutting and crushing unit 4 and the grading and screening unit 5 through wires. The feeding part 2 includes a feeding transmission guard plate 21, a feeding conveyor belt 22, a material lifting plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com