Patents

Literature

395 results about "Coking plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Description. The Coking Plant is the first way to create Coal in the game before mines become available. It converts Pinewood into Coal which is required for weapon smiths and ore smelting. Coking remains useful throughout and combined with mines really helps when you start mass producing Weapons . As with other production buildings its...

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

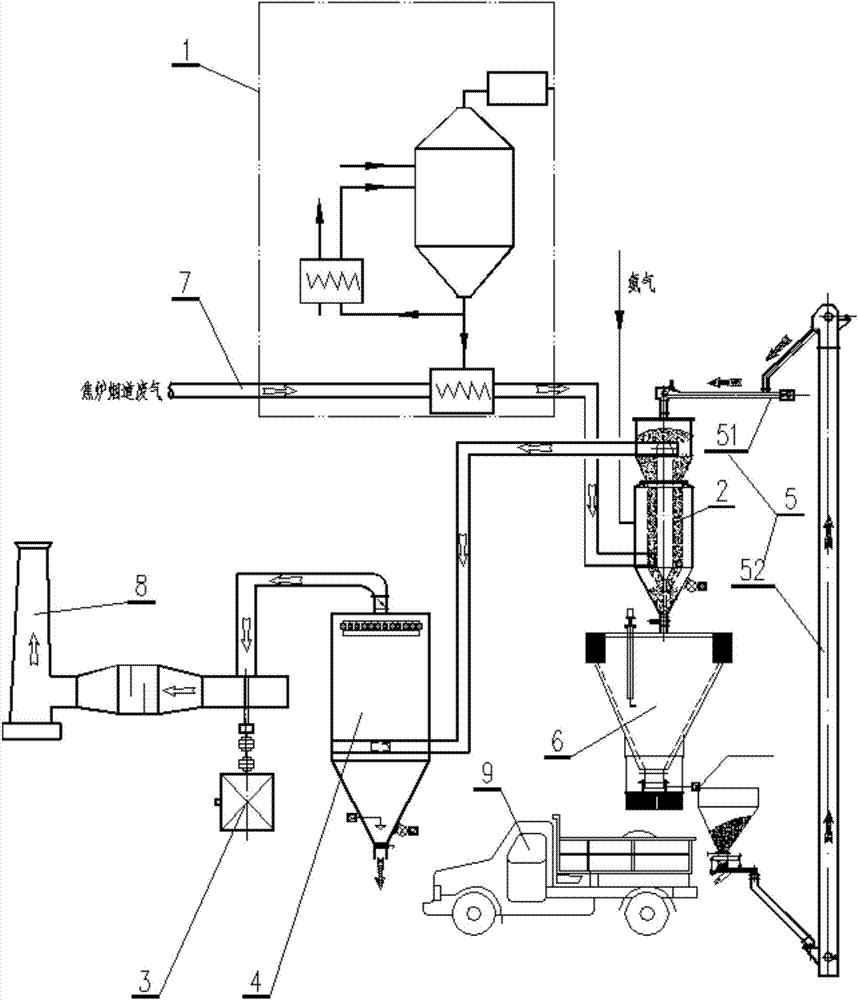

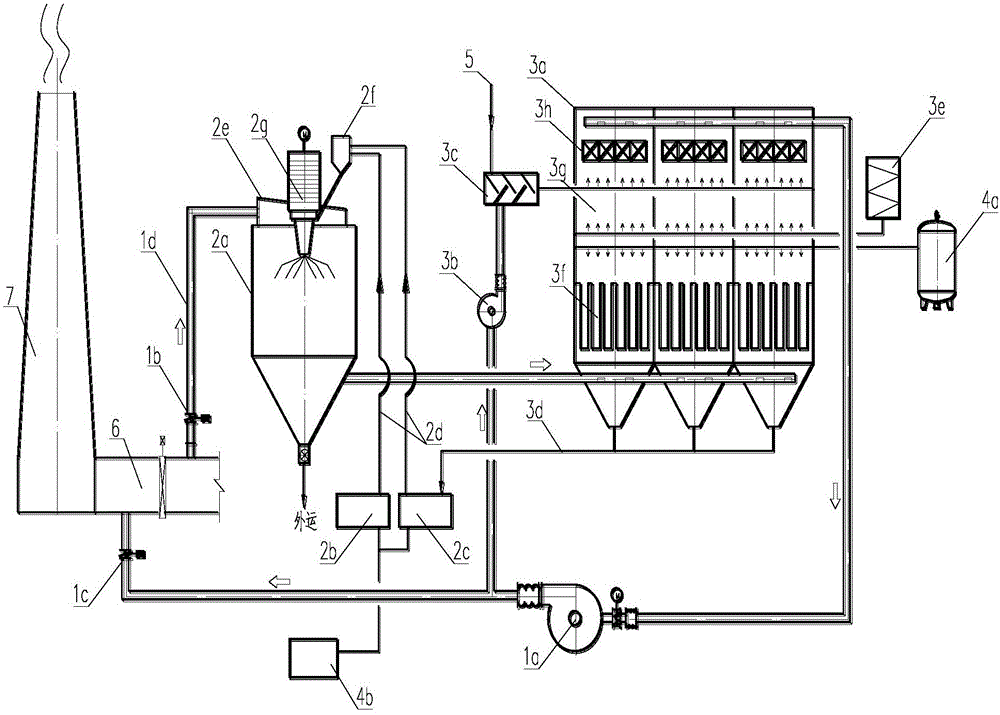

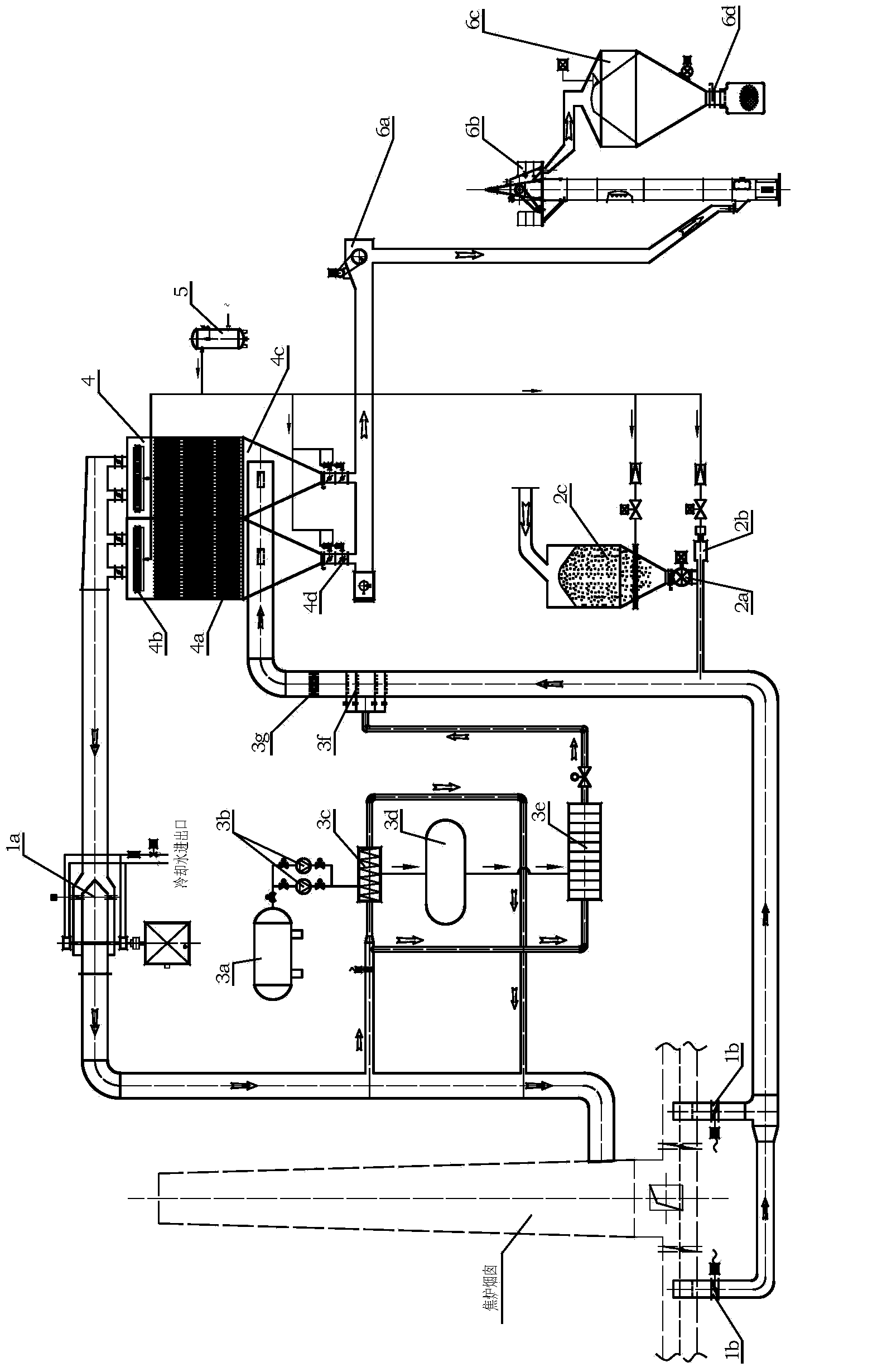

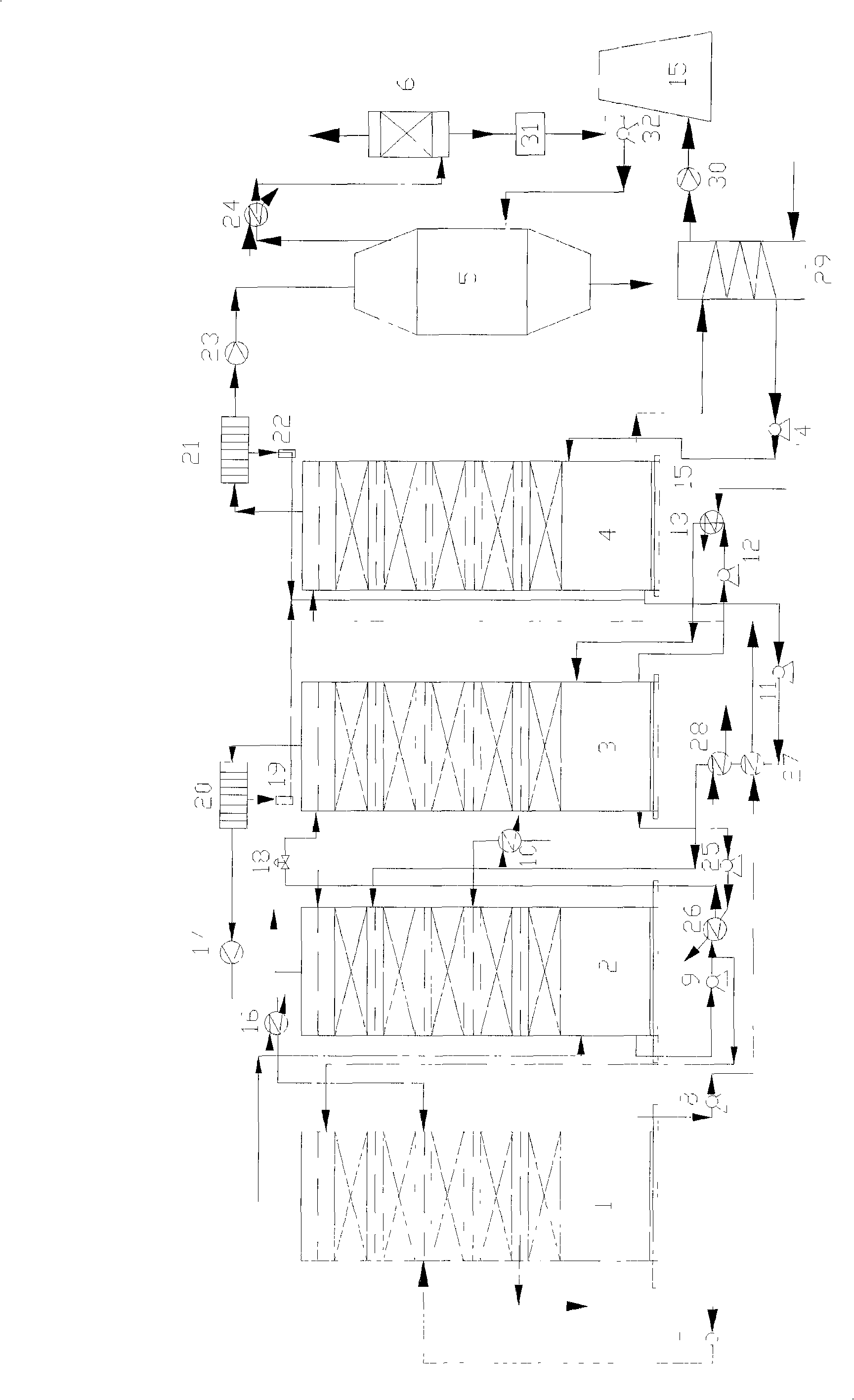

Coke oven flue gas waste heat utilization and purification method

ActiveCN103877856AReduce consumptionEfficient governanceDispersed particle separationPurification methodsCoking plant

The invention relates to the technical field of coke oven flue gas integrated utilization and pollution treatment and in particular relates to a coke oven flue gas waste heat utilization and purification method. The method is characterized in that flue gas waste heat is recovered by utilizing a flue gas waste heat recovery device, the temperature of the flue waste gas is reduced, and integrated desulfurization and denitration of the flue waste gas is realized by utilizing the activated adsorption capacity and low-temperature denitration catalytic capability of the coke. Compared with an existing process, the method has the beneficial effects that the flue waste gas desulfurization and denitration is performed under low-temperature working conditions, an additional heating system is not needed, and the energy consumption is reduced. In order to realize the desulfurization and denitration under low-temperature working conditions, the flue waste gas is cooled through the waste heat recovery device, so that the waste heat of the flue waste gas is fully utilized. The coke serves as a main catalyst for desulfurization and denitration and comes from a coking plant, the source is sufficient, and waste loss is avoided. The method disclosed by the invention can be widely applied to pollution treatment and integrated utilization of coke oven heated flue waste gas in coking production enterprises.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

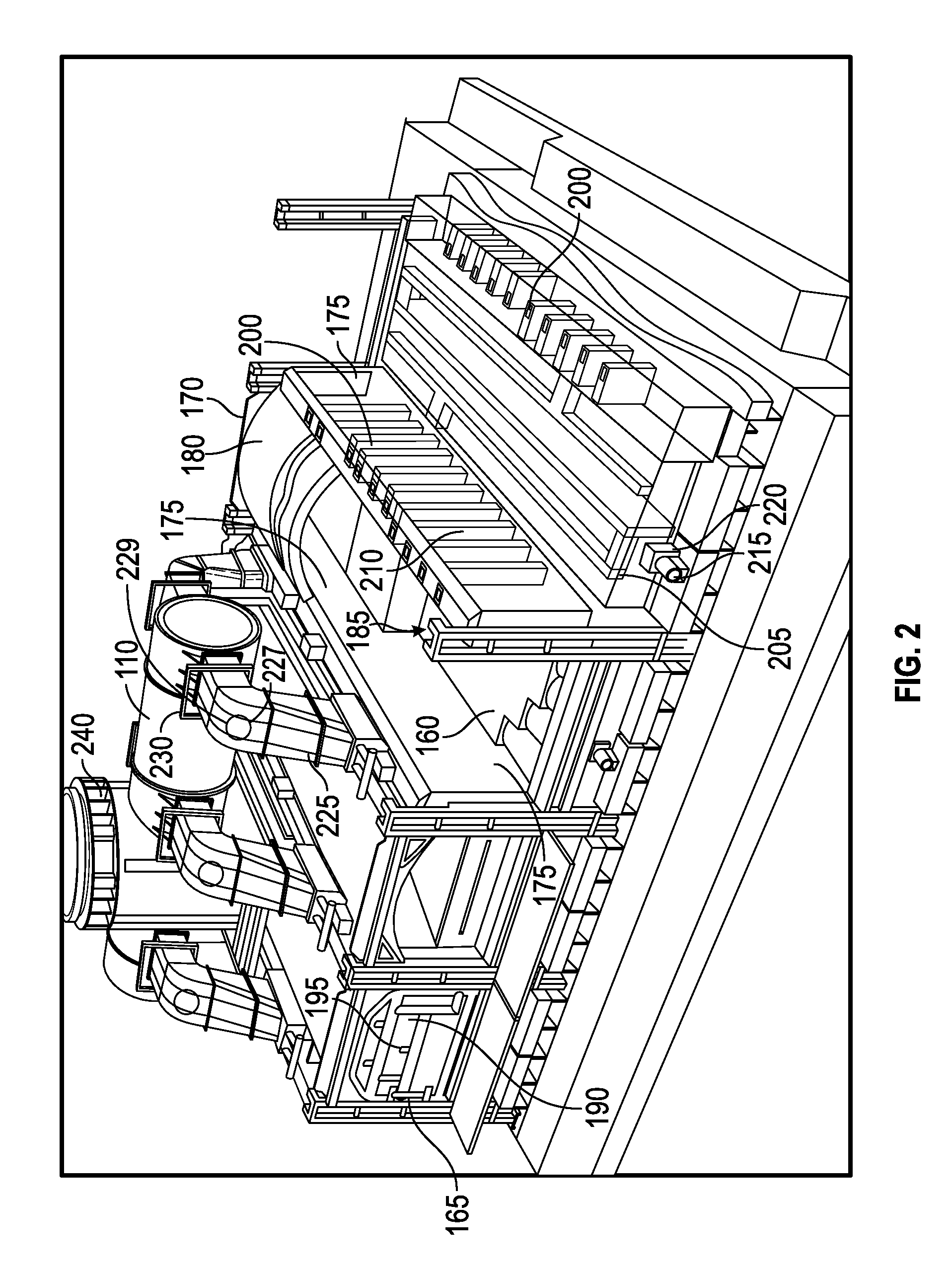

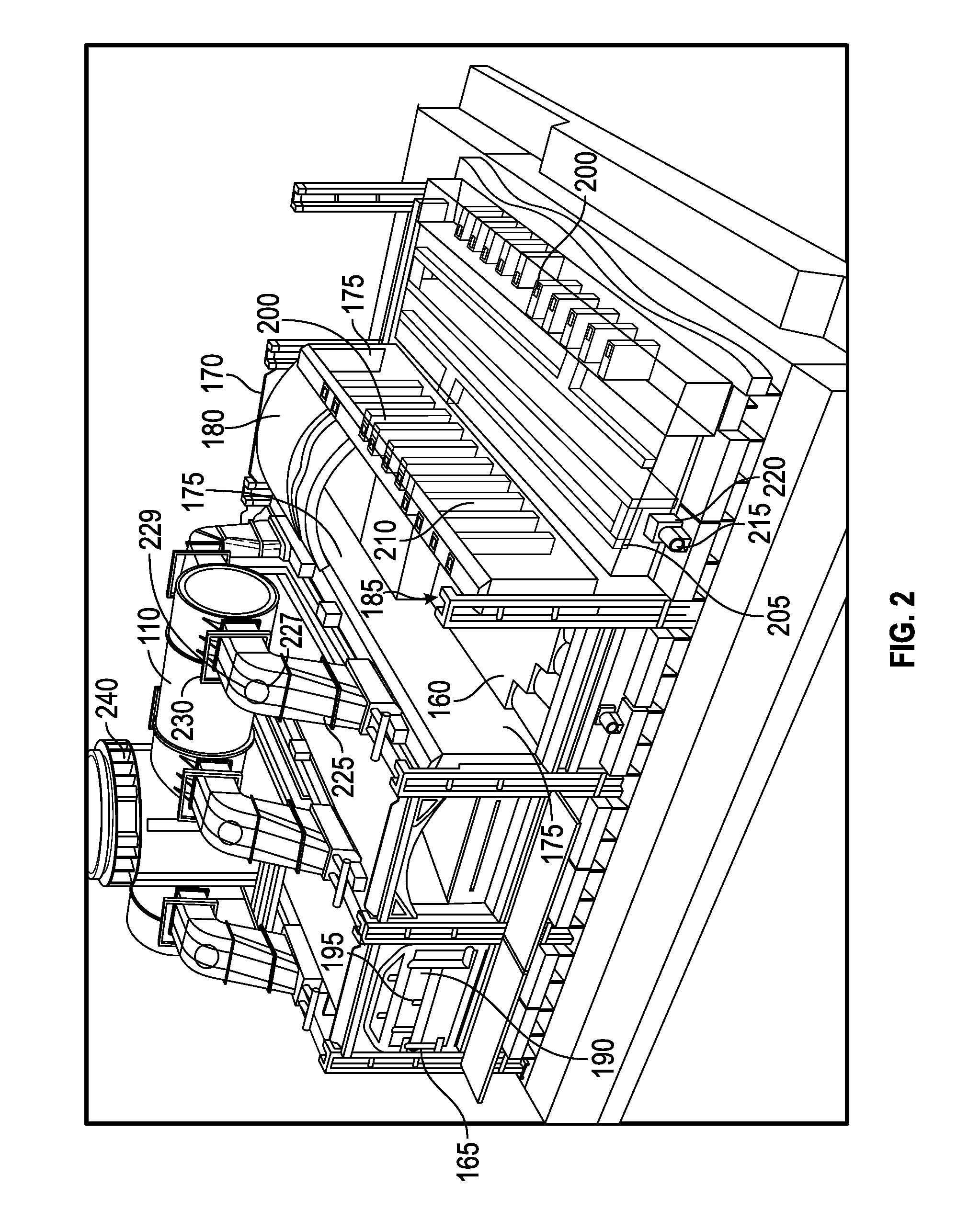

Automatic draft control system for coke plants

ActiveUS20140048402A1Change positionCombustible gas coke oven heatingHorizontal chamber coke ovensAutomatic controlAutomatic train control

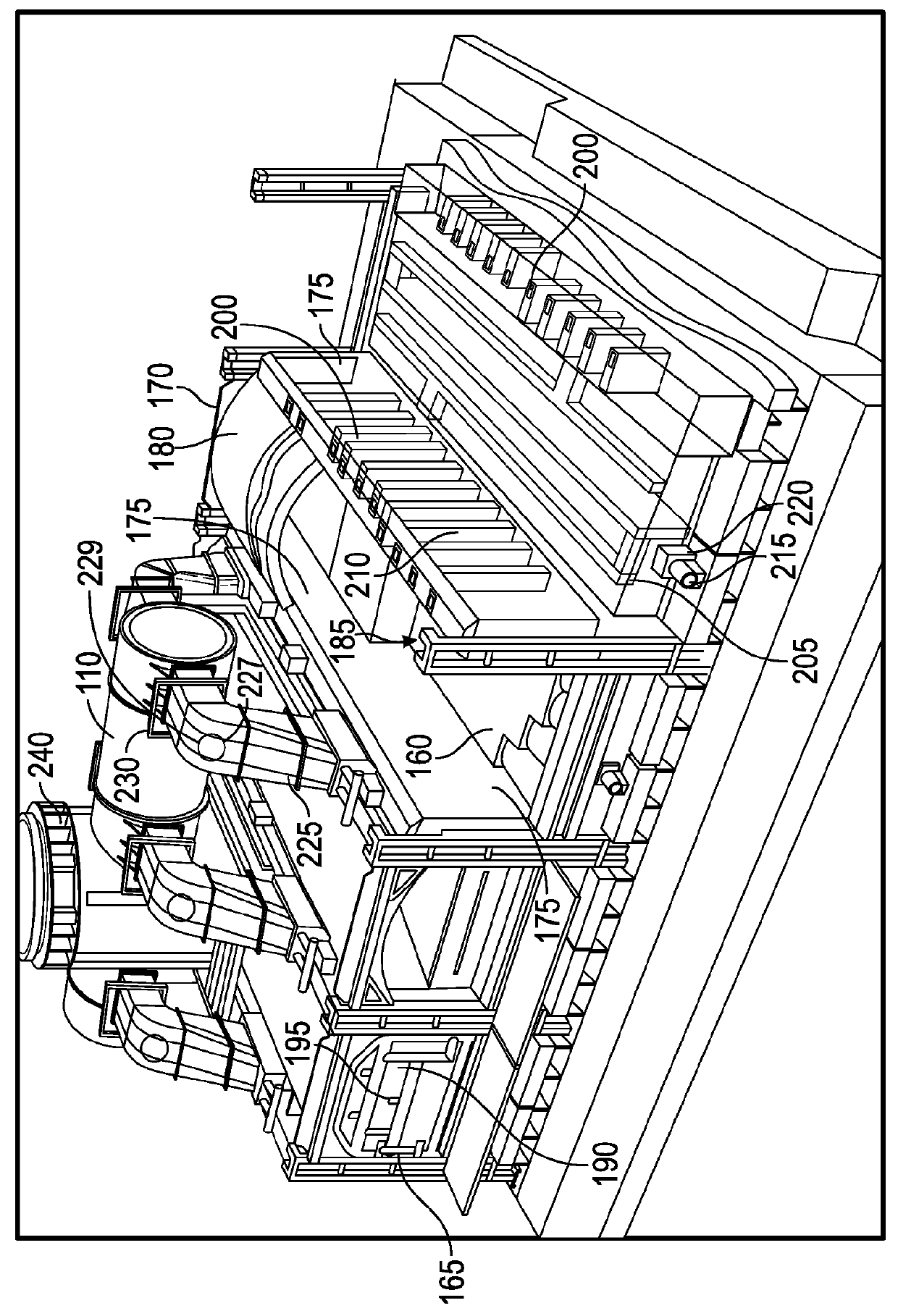

A coke oven includes an oven chamber, an uptake duct in fluid communication with the oven chamber, the uptake duct being configured to receive exhaust gases from the oven chamber, an uptake damper in fluid communication with the uptake duct, the uptake damper being positioned at any one of multiple positions, the uptake damper configured to control an oven draft, an actuator configured to alter the position of the uptake damper between the positions in response to a position instruction, a sensor configured to detect an operating condition of the coke oven, wherein the sensor includes one of a draft sensor, a temperature sensor configured to detect an uptake duct temperature or a sole flue temperature, and an oxygen sensor, and a controller being configured to provide the position instruction to the actuator in response to the operating condition detected by the sensor.

Owner:SUNCOKE TECH & DEV LLC

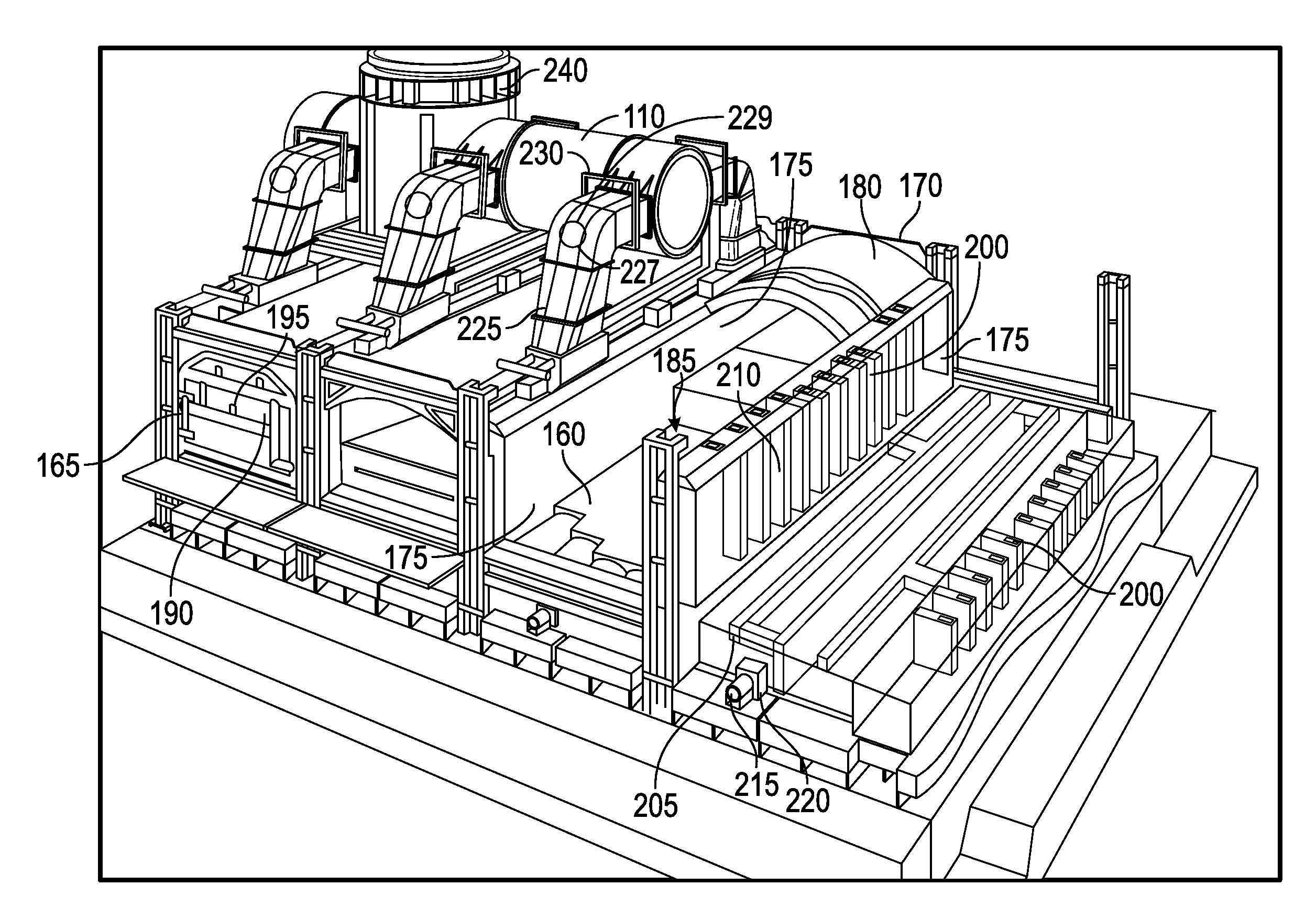

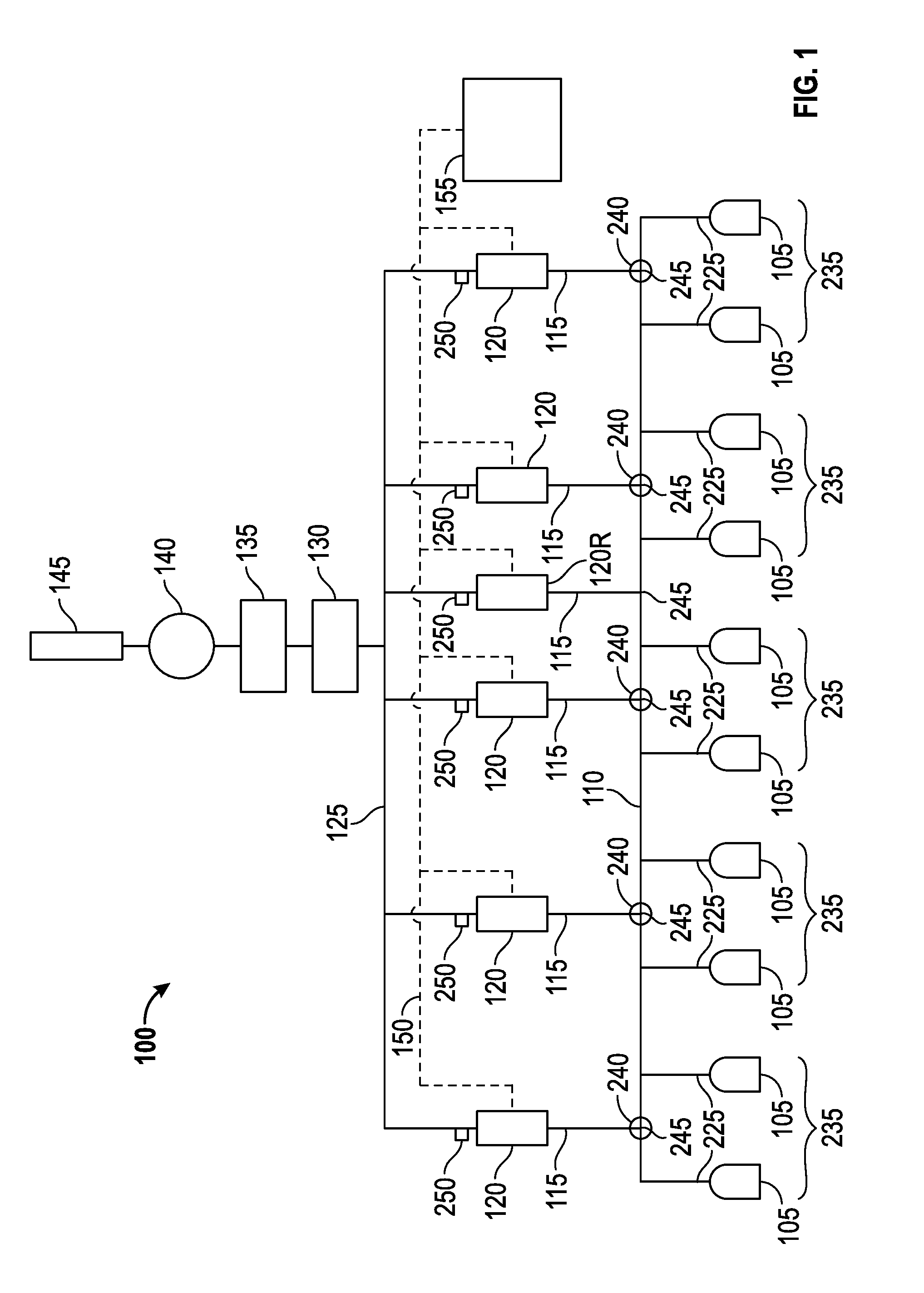

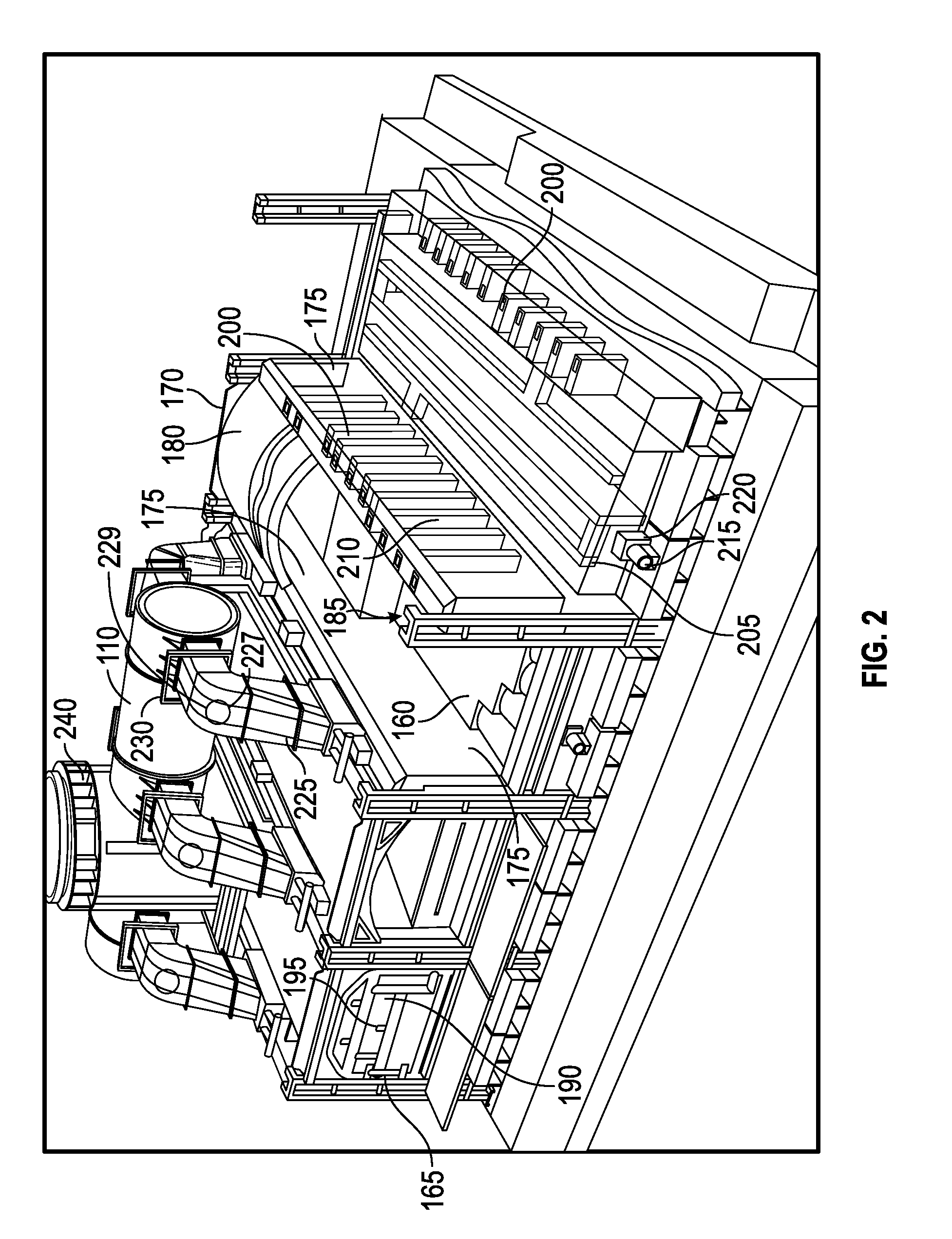

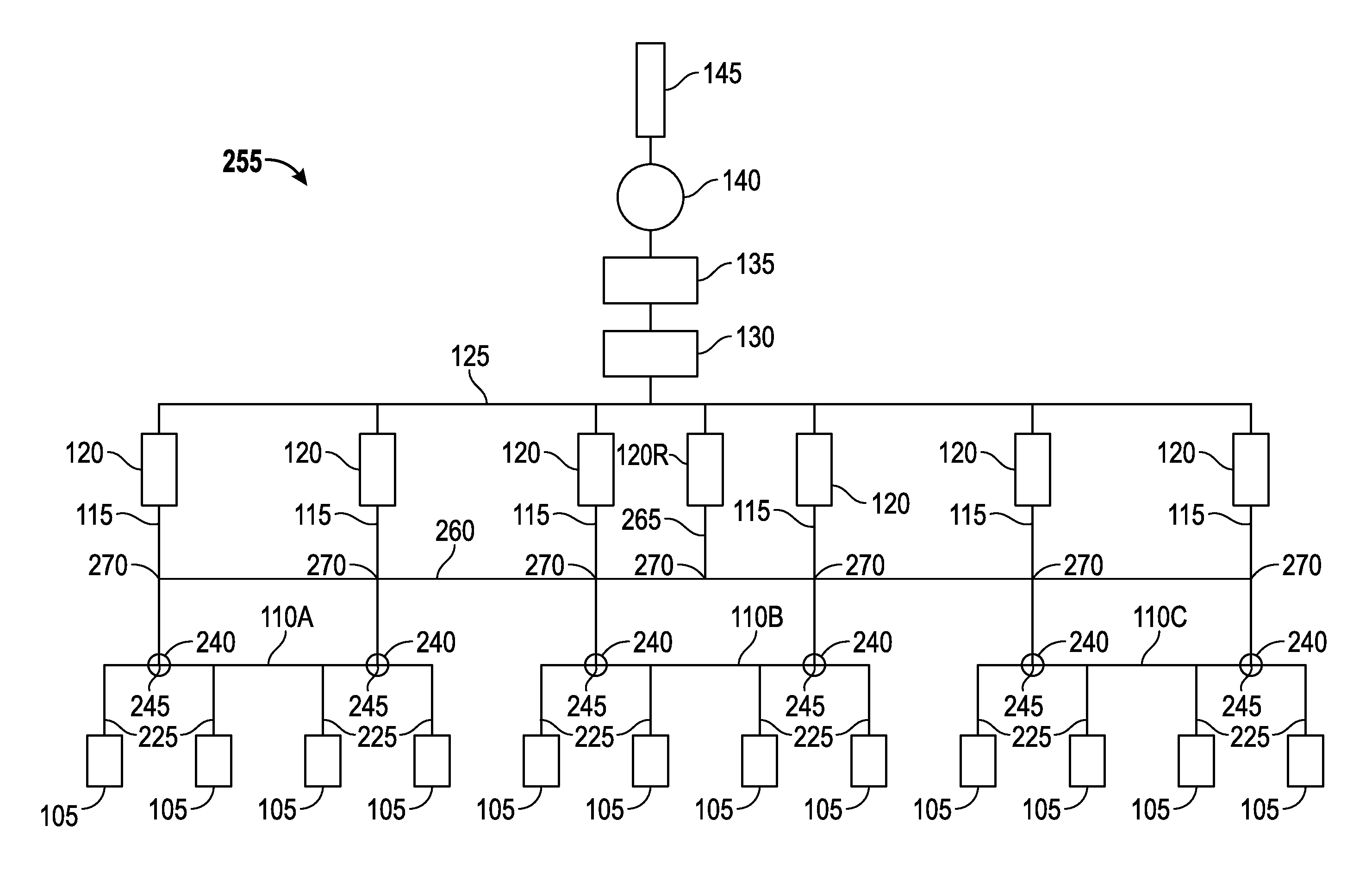

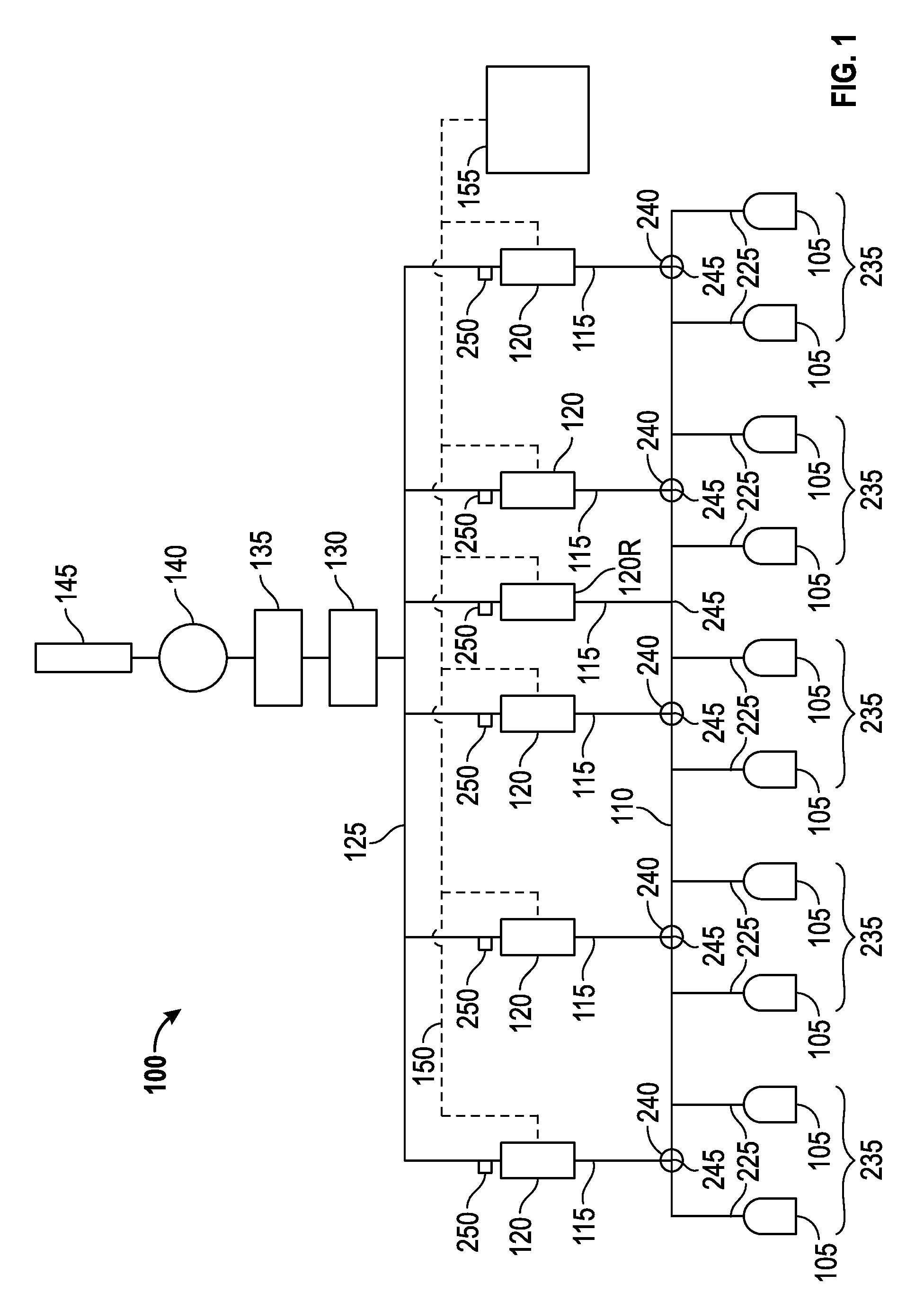

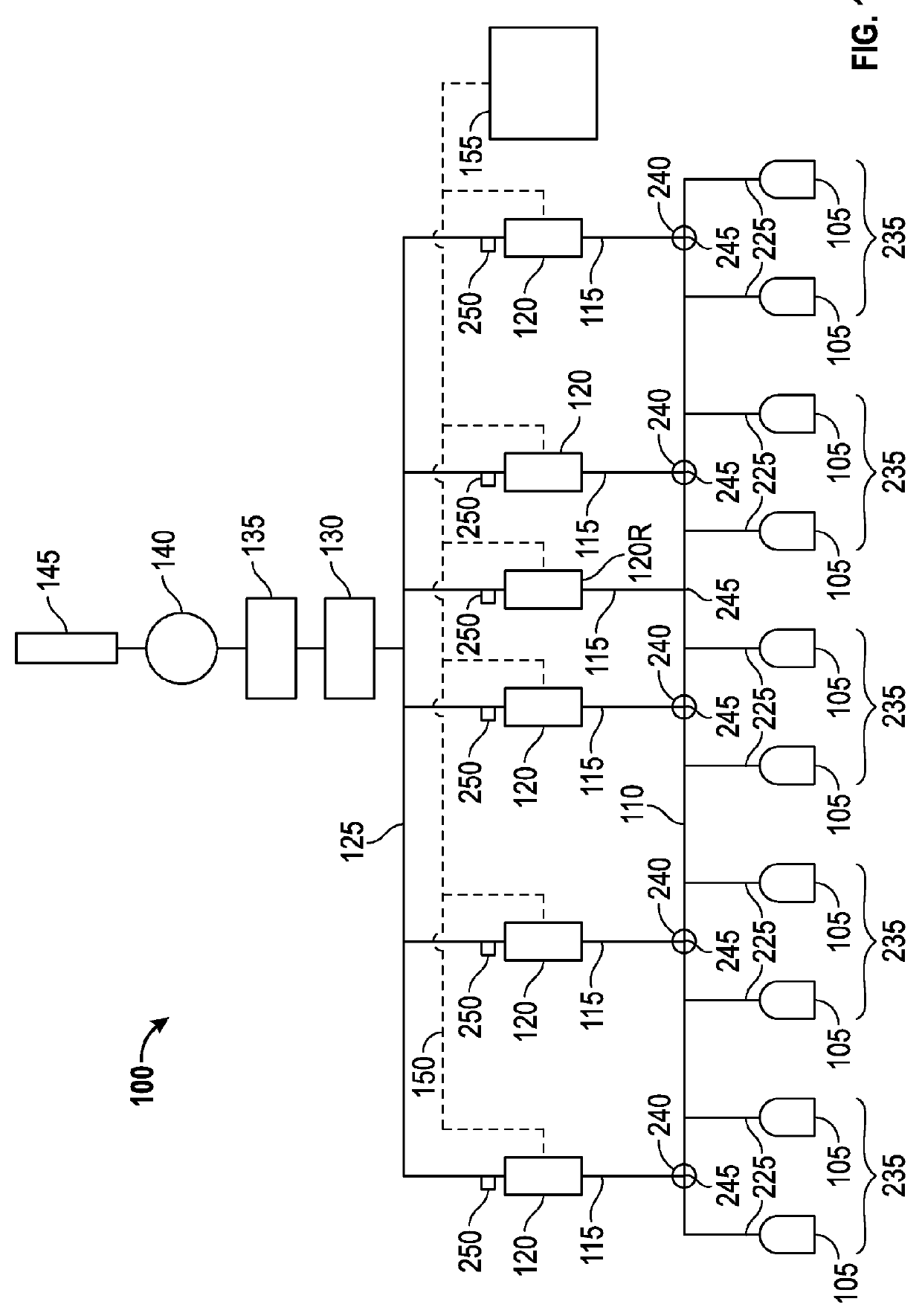

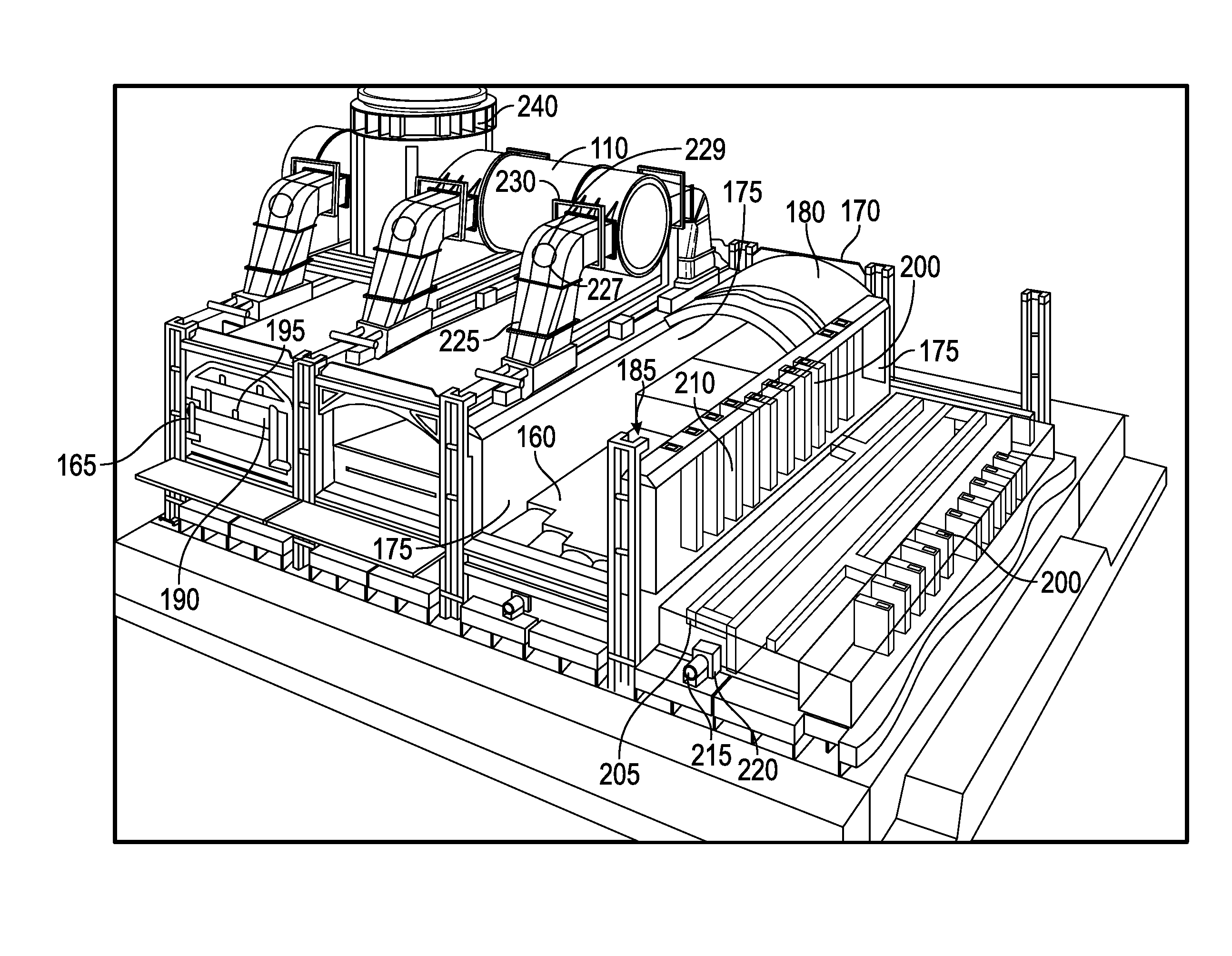

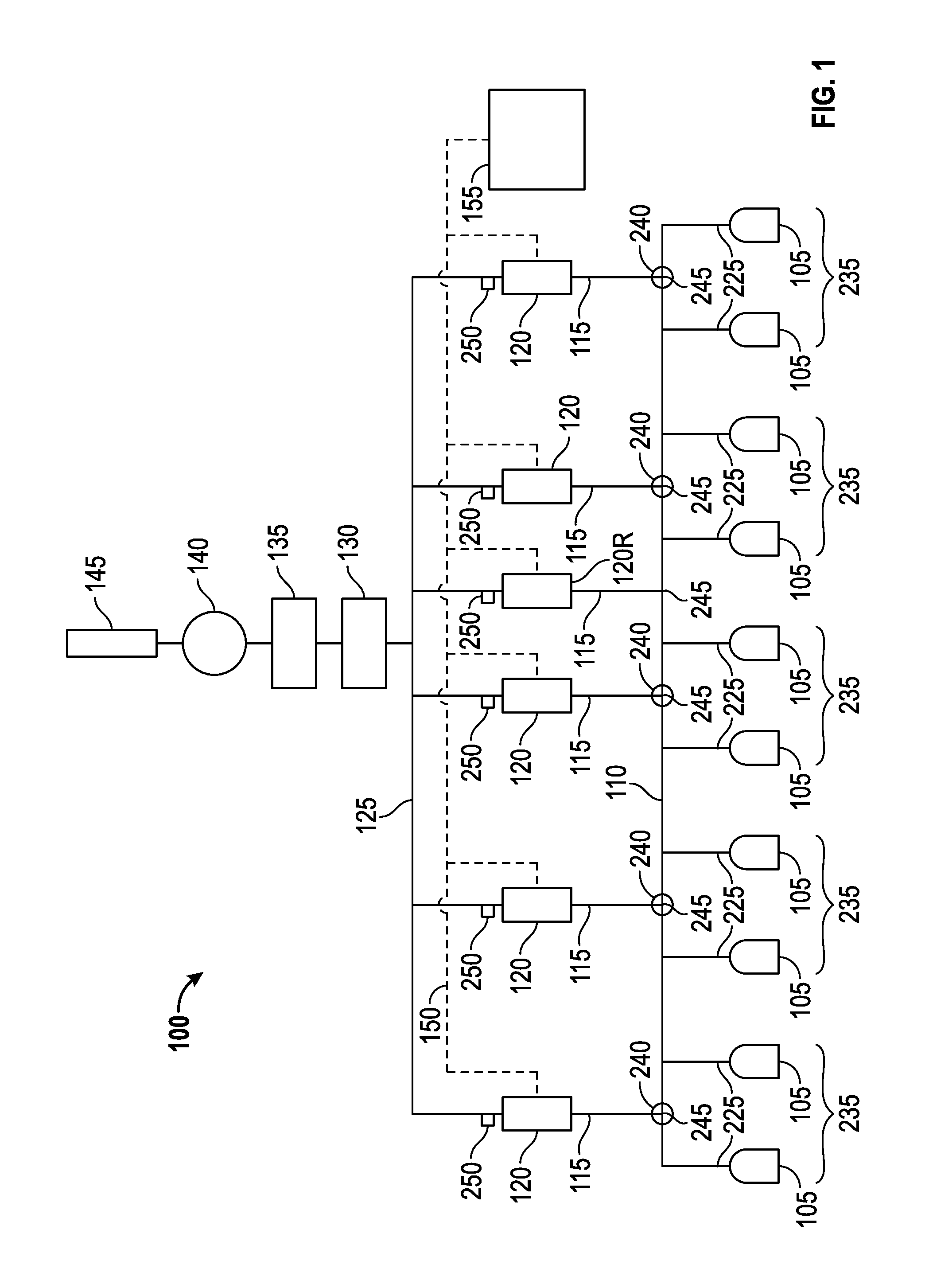

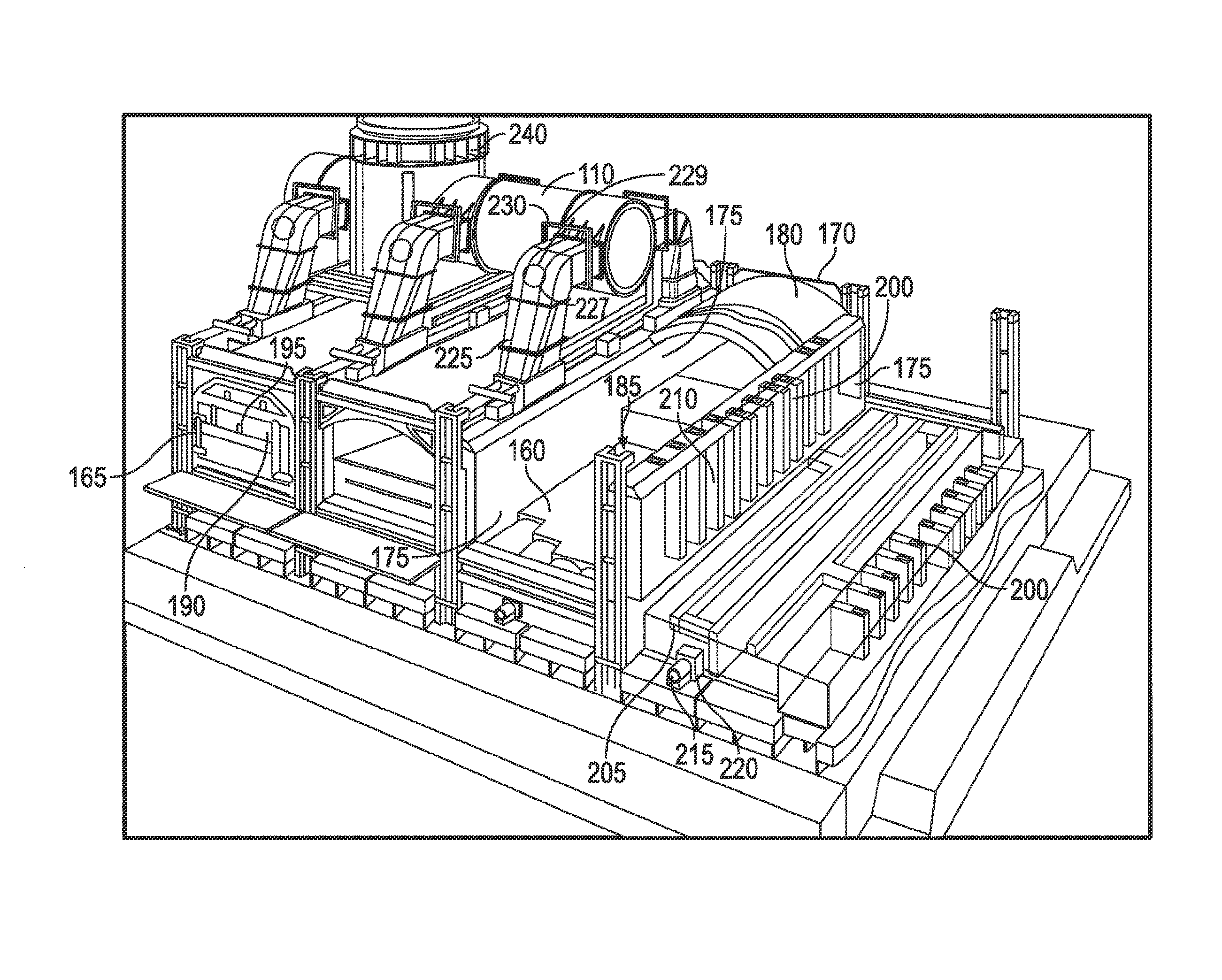

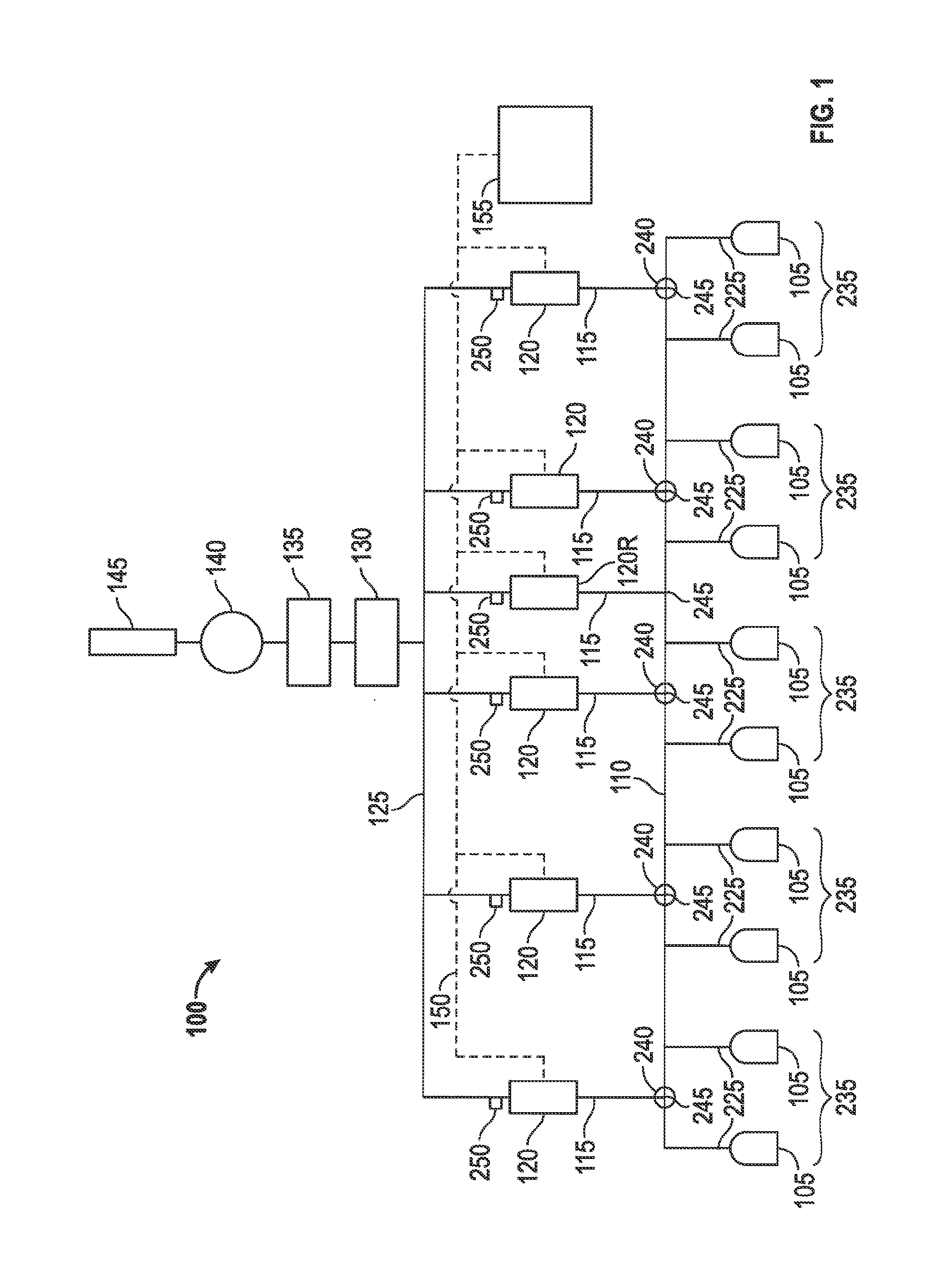

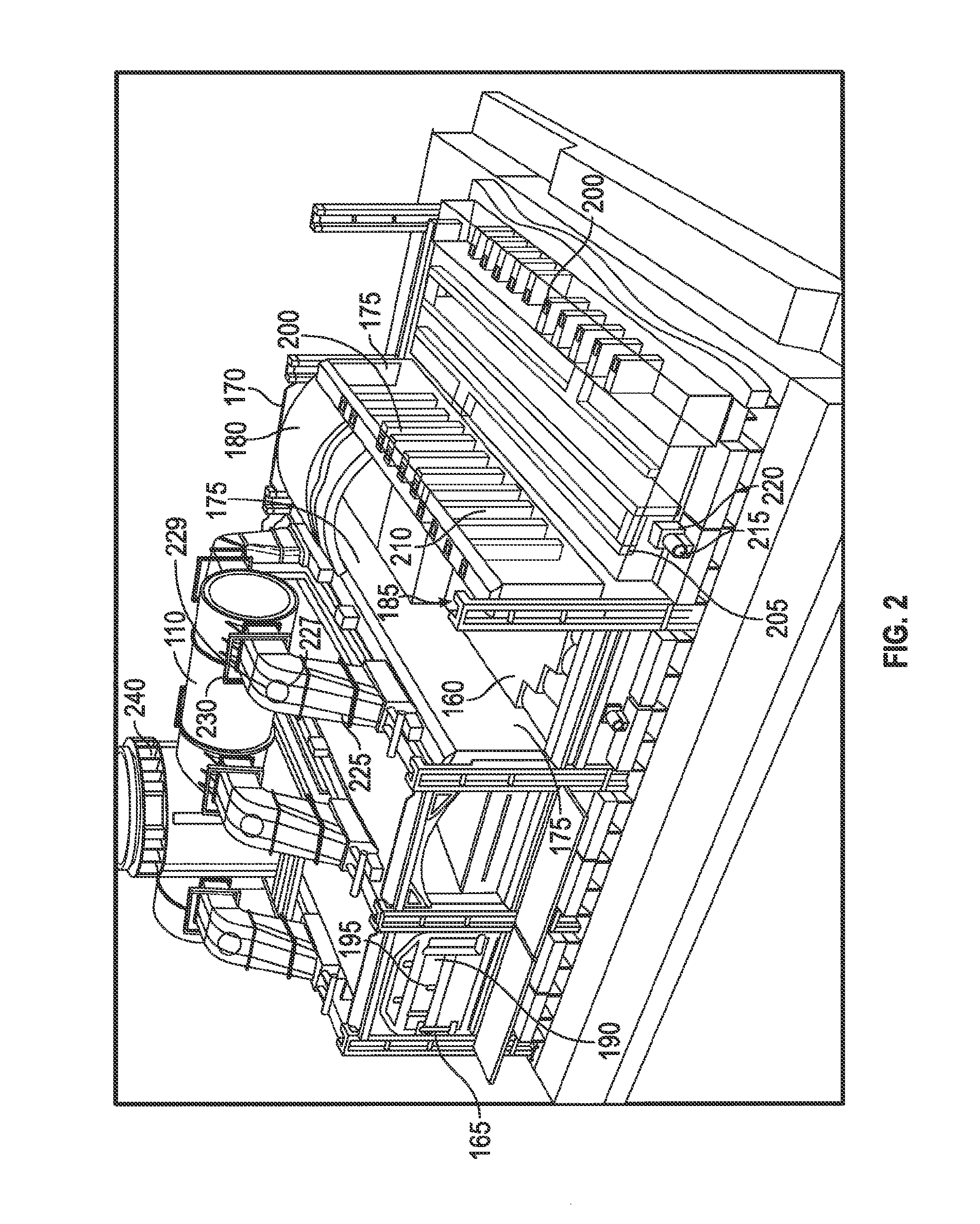

Coke plant including exhaust gas sharing

ActiveUS9243186B2Coke oven safety devicesHorizontal chamber coke ovensExhaust fumesProcess engineering

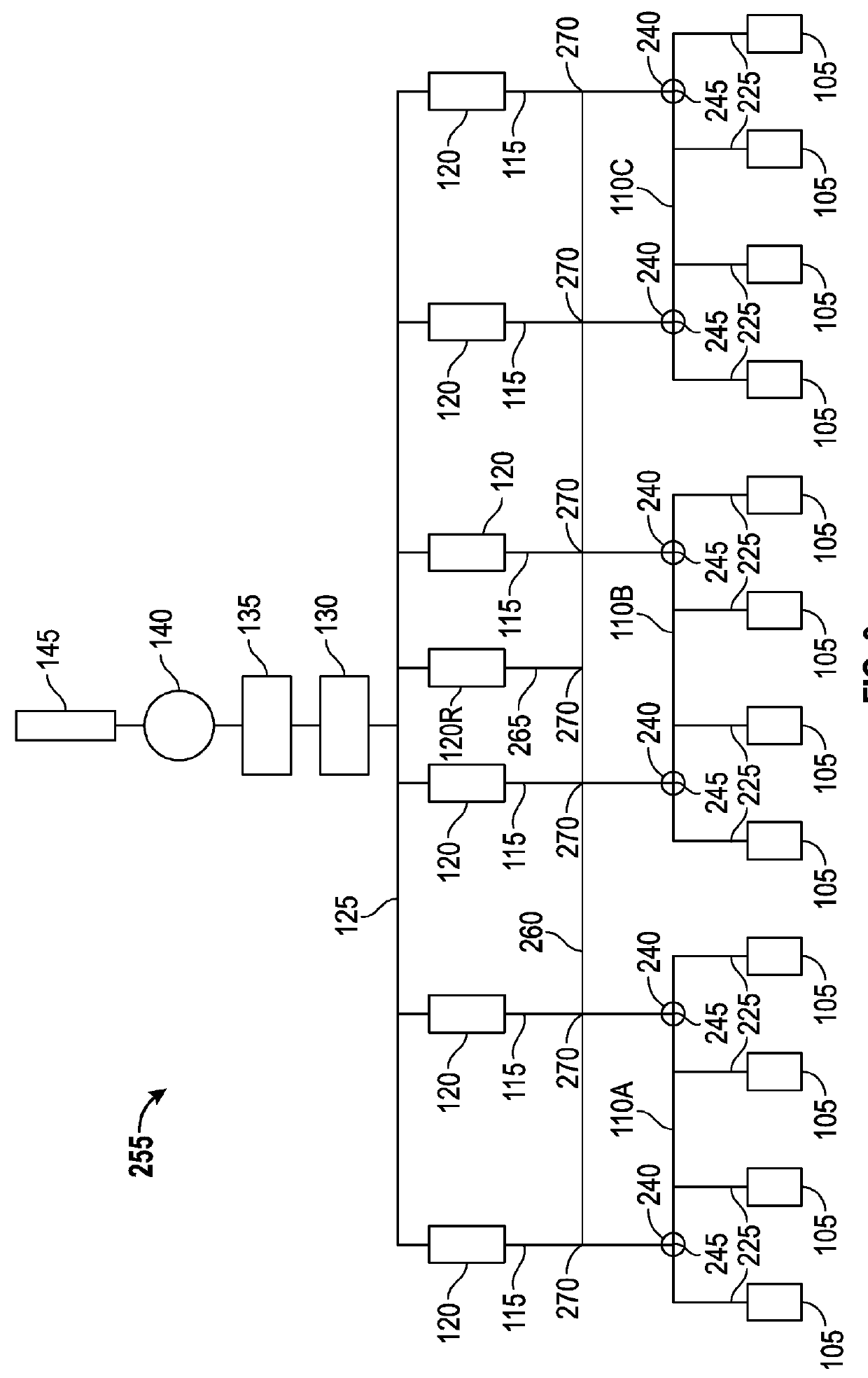

A coke plant includes multiple coke ovens where each coke oven is adapted to produce exhaust gases, a common tunnel fluidly connected to the plurality of coke ovens and configured to receive the exhaust gases from each of the coke ovens, multiple standard heat recovery steam generators fluidly connected to the common tunnel where the ratio of coke ovens to standard heat recovery steam generators is at least 20:1, and a redundant heat recovery steam generator fluidly connected to the common tunnel where any one of the plurality of standard heat recovery steam generators and the redundant heat recovery steam generator is adapted to receive the exhaust gases from the plurality of ovens and extract heat from the exhaust gases and where the standard heat recovery steam generators and the redundant heat recovery steam generator are all connected in parallel with each other.

Owner:SUNCOKE TECH & DEV LLC

Automatic draft control system for coke plants

ActiveUS9359554B2Combustible gas coke oven heatingHorizontal chamber coke ovensAutomatic train controlOxygen sensor

A coke oven includes an oven chamber, an uptake duct in fluid communication with the oven chamber, the uptake duct being configured to receive exhaust gases from the oven chamber, an uptake damper in fluid communication with the uptake duct, the uptake damper being positioned at any one of multiple positions, the uptake damper configured to control an oven draft, an actuator configured to alter the position of the uptake damper between the positions in response to a position instruction, a sensor configured to detect an operating condition of the coke oven, wherein the sensor includes one of a draft sensor, a temperature sensor configured to detect an uptake duct temperature or a sole flue temperature, and an oxygen sensor, and a controller being configured to provide the position instruction to the actuator in response to the operating condition detected by the sensor.

Owner:SUNCOKE TECH & DEV LLC

Method for treating coking wastewater

InactiveCN101602564AHigh activityNo reflow requiredTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationSludge

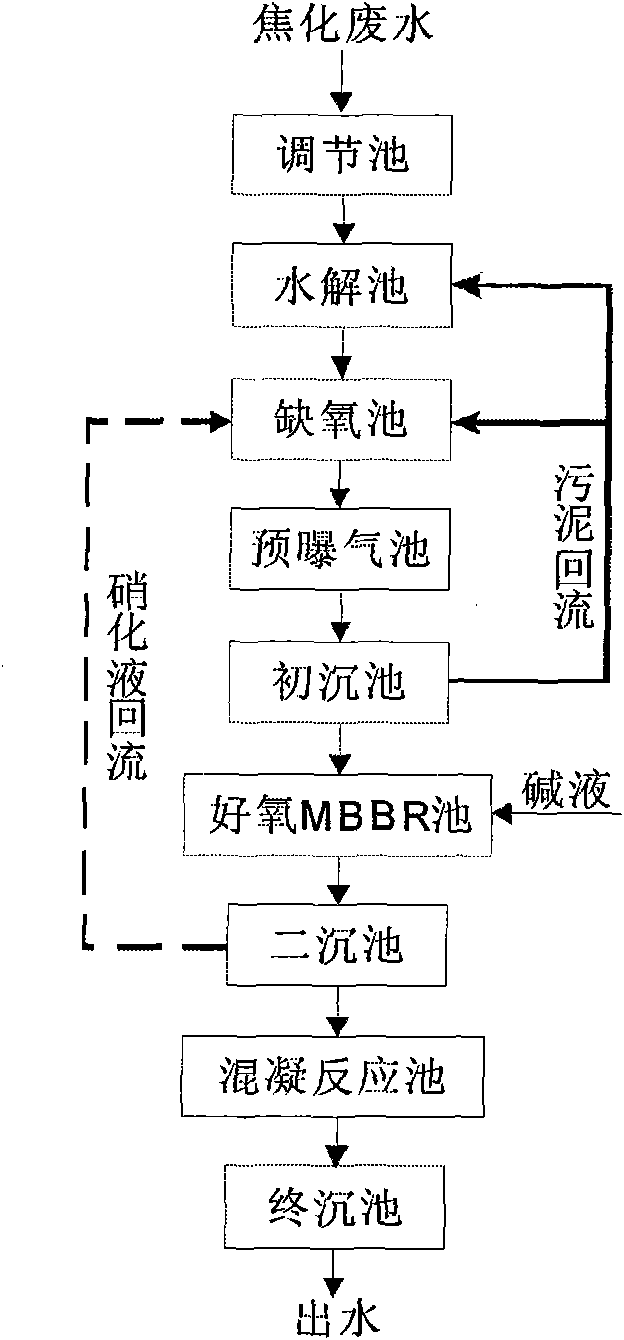

The invention discloses a method for treating coking wastewater, which belongs to the field of wastewater treatment. The method comprises the following steps that: wastewater of a coking plant enters a regulating reservoir for the adjustment of water quality and water amount, and orderly enters a hydrolytic tank, an anaerobic tank, a preaeration tank, a preliminary sedimentation tank, an aerobic tank, a secondary sedimentation tank and a coagulation reaction tank for treatment, wherein the hydrolytic tank and the preaeration tank are filled with a bio-cord filler; the sludge of the preliminary sedimentation tank refluxes into the hydrolytic tank and the anaerobic tank respectively; a clarifying solution of the secondary sedimentation tank refluxes into the anaerobic tank; and the aerobic tank adopts a moving bed bio-film reactor. The bio-cord filler adopted in the invention has short film formation time and high biomass, does not need repeated washing, and has strong shock resistance; and the moving bed bio-film reactor can fix a large amount of nitrobacteria with long generation time, and has no the problem of blocking. The method can remove high-concentration ammonia nitrogen and organic substances in the coking wastewater, and the COD and the ammonia nitrogen of treated effluent can synchronously achieve the primary standard of the national integrated wastewater discharge standard (GB9878-1996).

Owner:NANJING UNIV

Low-temperature coke oven flue waste gas desulphurization and denitration process

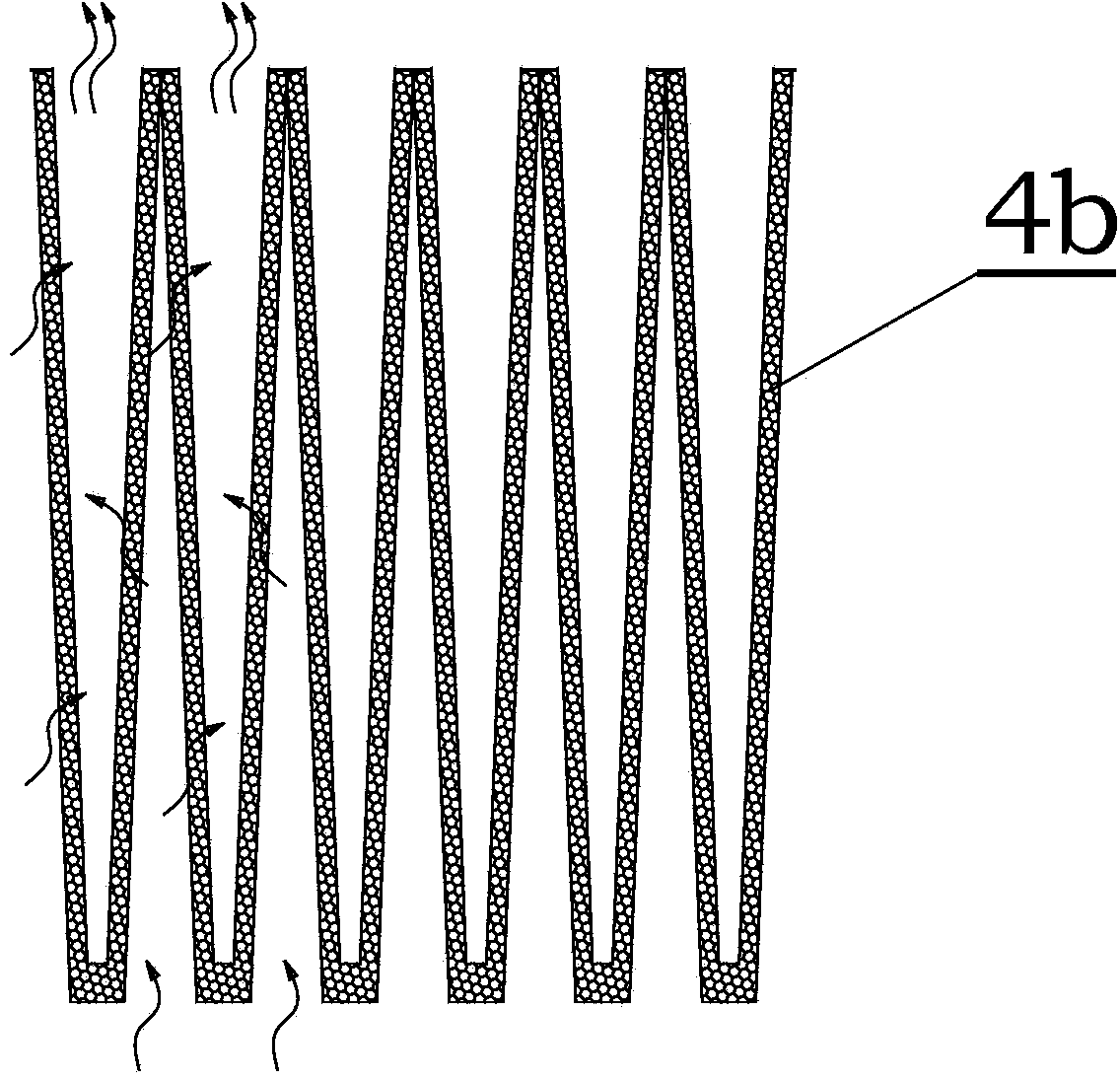

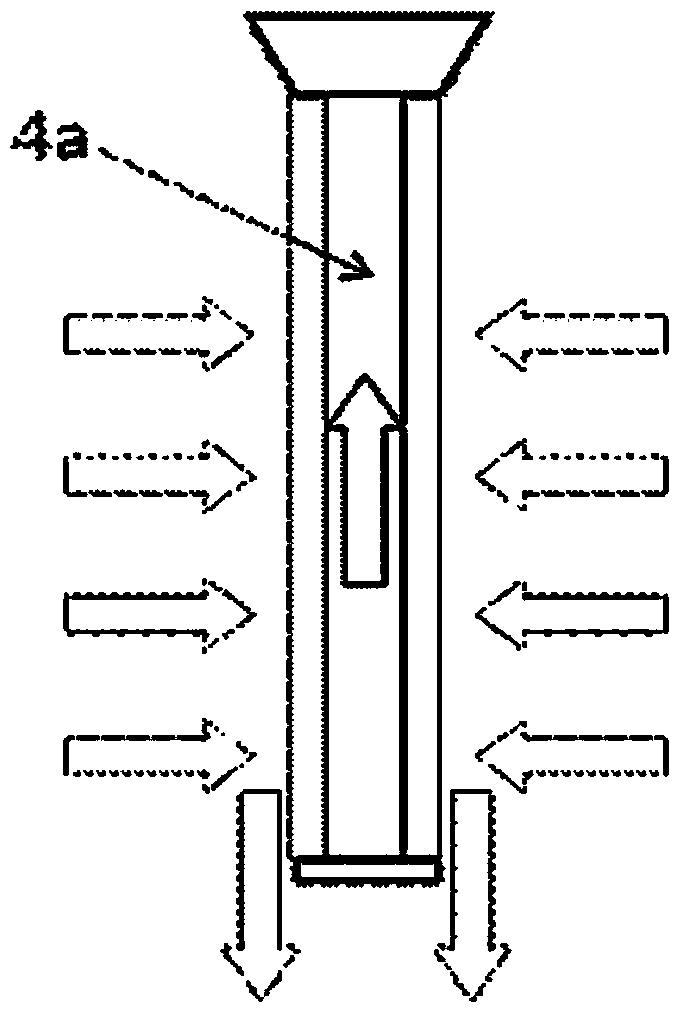

ActiveCN103816796AFully contactedReduce efflux concentrationDispersed particle separationFlue gasCoke oven

The invention relates to a low-temperature coke oven flue waste gas desulphurization and denitration process. According to the process, fluidized NaHCO3 fine powder is jetted into a flue gas conveying pipeline, so as to remove most of SO2 in the flue gas through the dry process; meanwhile, a denitration catalyst structure layer and an ammonia removal catalyst structure layer are combined for use, so that NOx in the coke oven flue gas is effectively removed; a denitration catalyst adopts a filtering-bag-shaped structure, and the ammonia removal catalyst adopts a V-shaped structure. The process utilizes a system consisting of an induced draft unit, a desulphurization unit, an ammonia preparation unit, a denitration and ammonia removal unit, a compressed air unit and a particle conveying unit to realize efficient denitration and desulphurization; compared with the prior art, the process has the benefits that residual ammonia water in a coking plant is fully utilized, a process combining a dry desulphurization method with an SCR (Selective Catalytic Reduction) denitration method is adopted, and the denitration catalyst and the ammonia removal catalyst are combined together, so that the efficient low-temperature coke oven flue gas desulphurization and denitration is realized.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

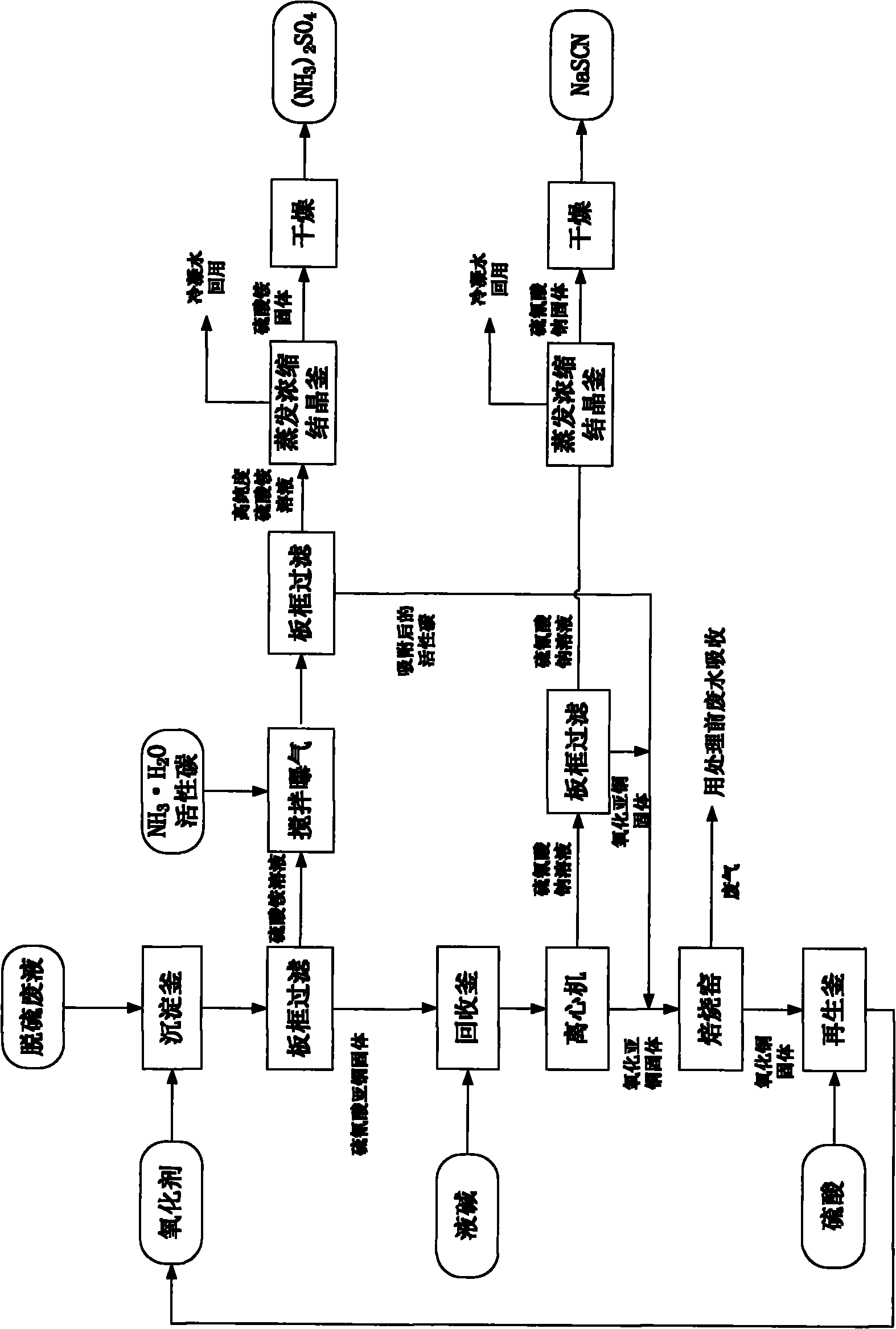

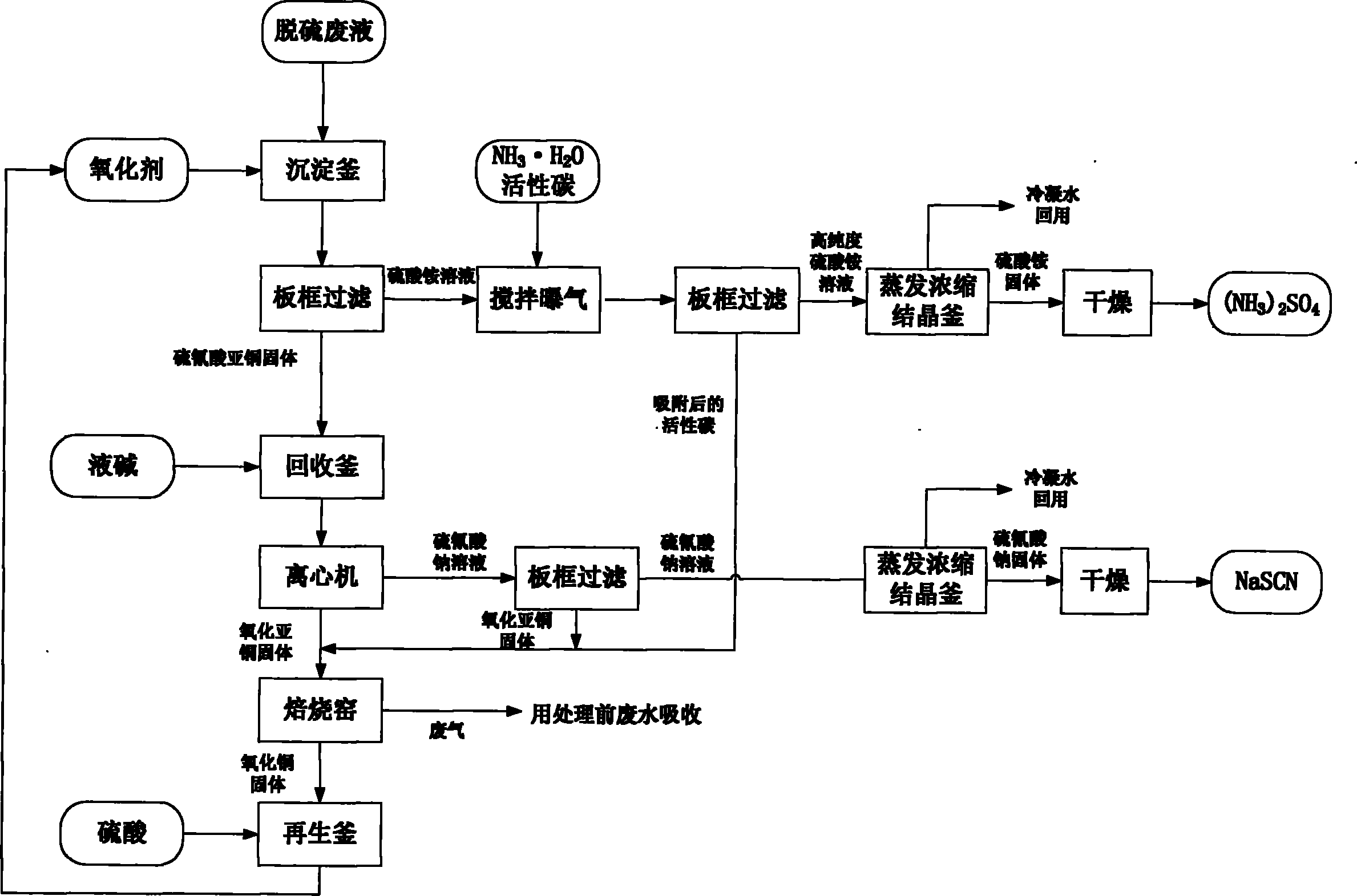

Method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in coking plant

ActiveCN101985359AReduce consumptionReduce lossesThiocyanic acidSulfate preparationActivated carbonSulfate

The invention relates to a method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in a coking plant, which comprises the following steps of: preparing saturated solution of copper sulfate, mixing the saturated solution with desulfuration waste liquor, and heating and stirring; performing solid-liquid separation to obtain a solid and sulfate liquid; adding aqueous alkali into the solid, heating at the temperature of between 50 and 98 DEG C, and stirring and reacting for 10 to 120 minutes; performing solid-liquid separation on slurry obtained by heating; concentrating the obtained liquid, and freezing for crystallizing and drying to obtain a high-purity thiocyanate product; calcining the obtained solid, adding solution of sulfuric acid, and stirring to produce the copper sulfate for circular use; adding activated carbon into the sulfate liquid, and aerating and oxidizing to purify sulfate; and concentrating the sulfate, and crystallizing and drying to obtain a high-purity sulfate product. The method solves the problem of pollution of the desulfuration waste liquor to the environment, and simultaneously, pollutants can become value products through the production of the high-purity thiocyanate product and the high-purity sulfate product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

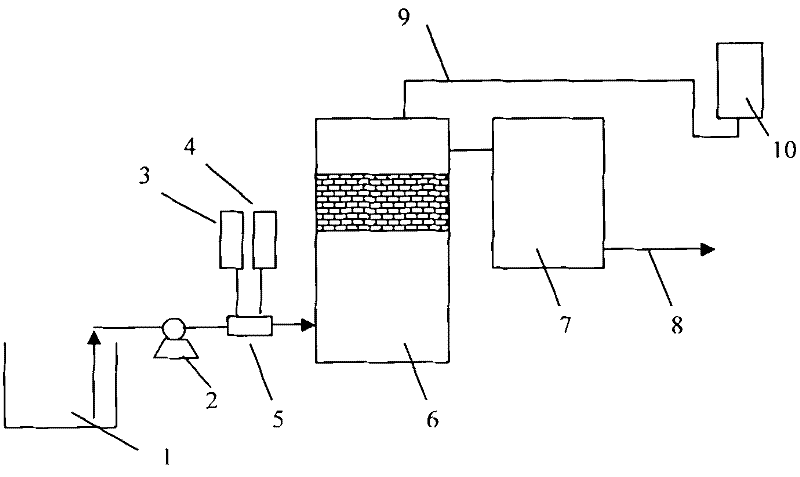

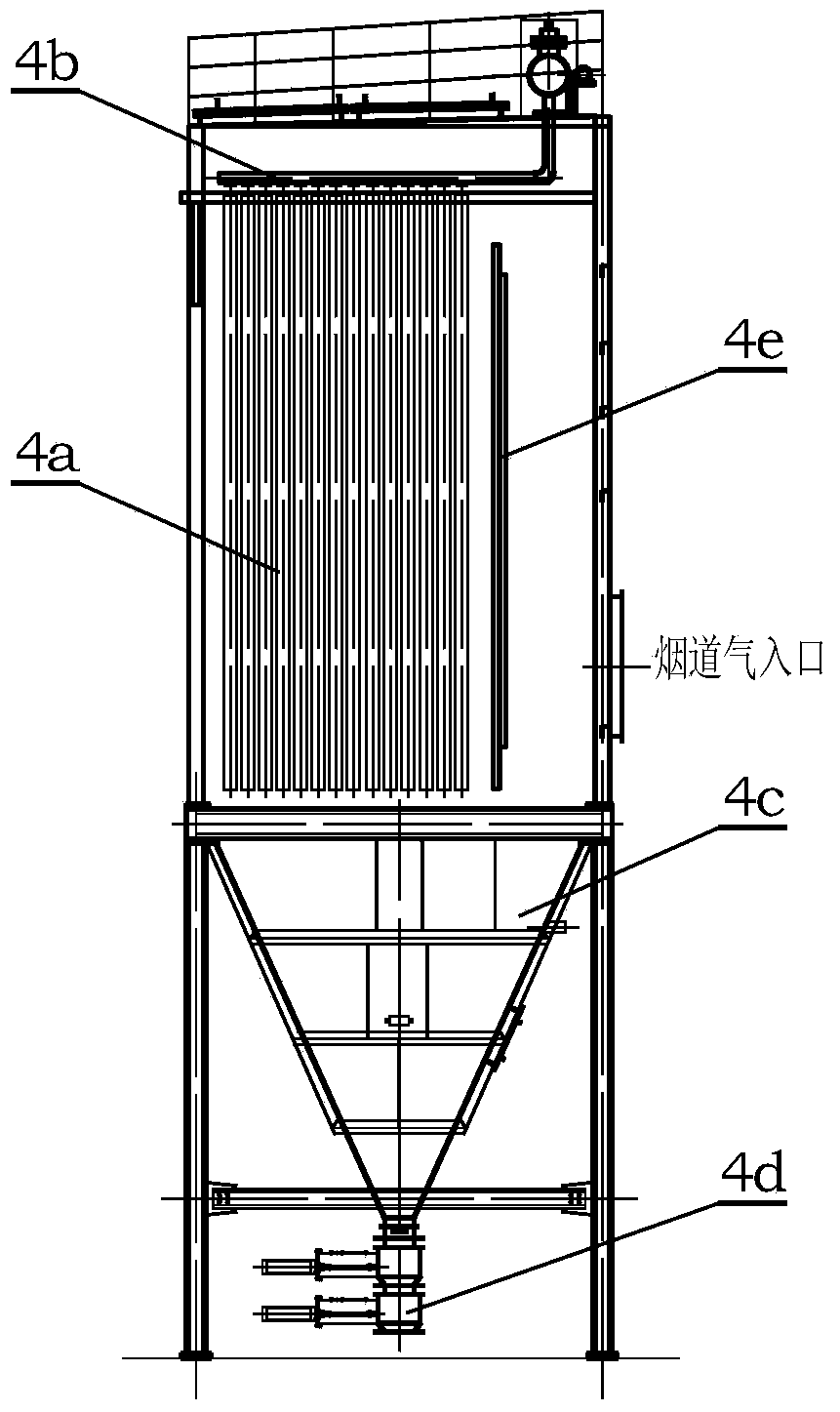

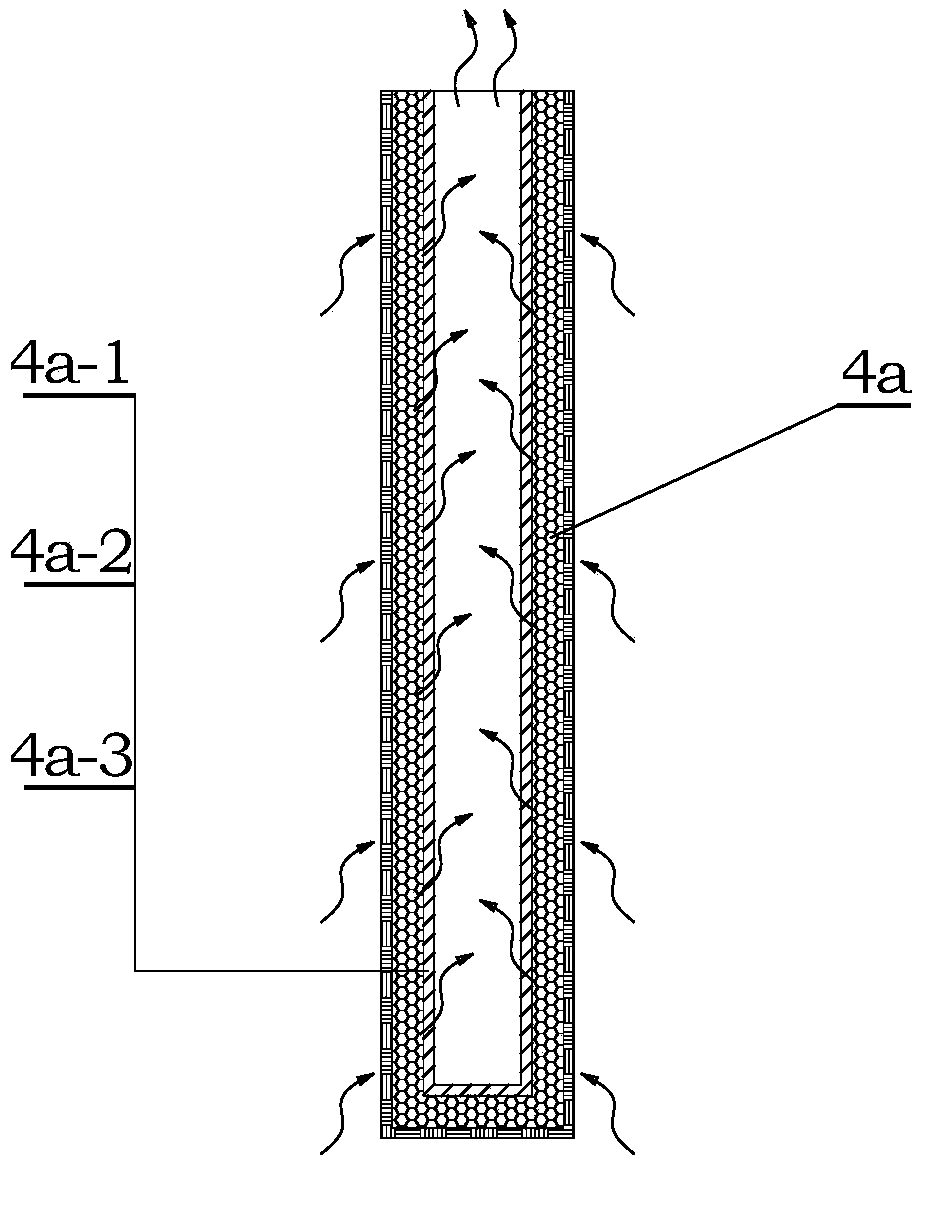

Coke oven flue gas desulfurization and denitrification purification process and device

InactiveCN105107349AGuaranteed negative pressureGuaranteed desulfurizationDispersed particle filtrationUsing liquid separation agentParticulatesFlue gas

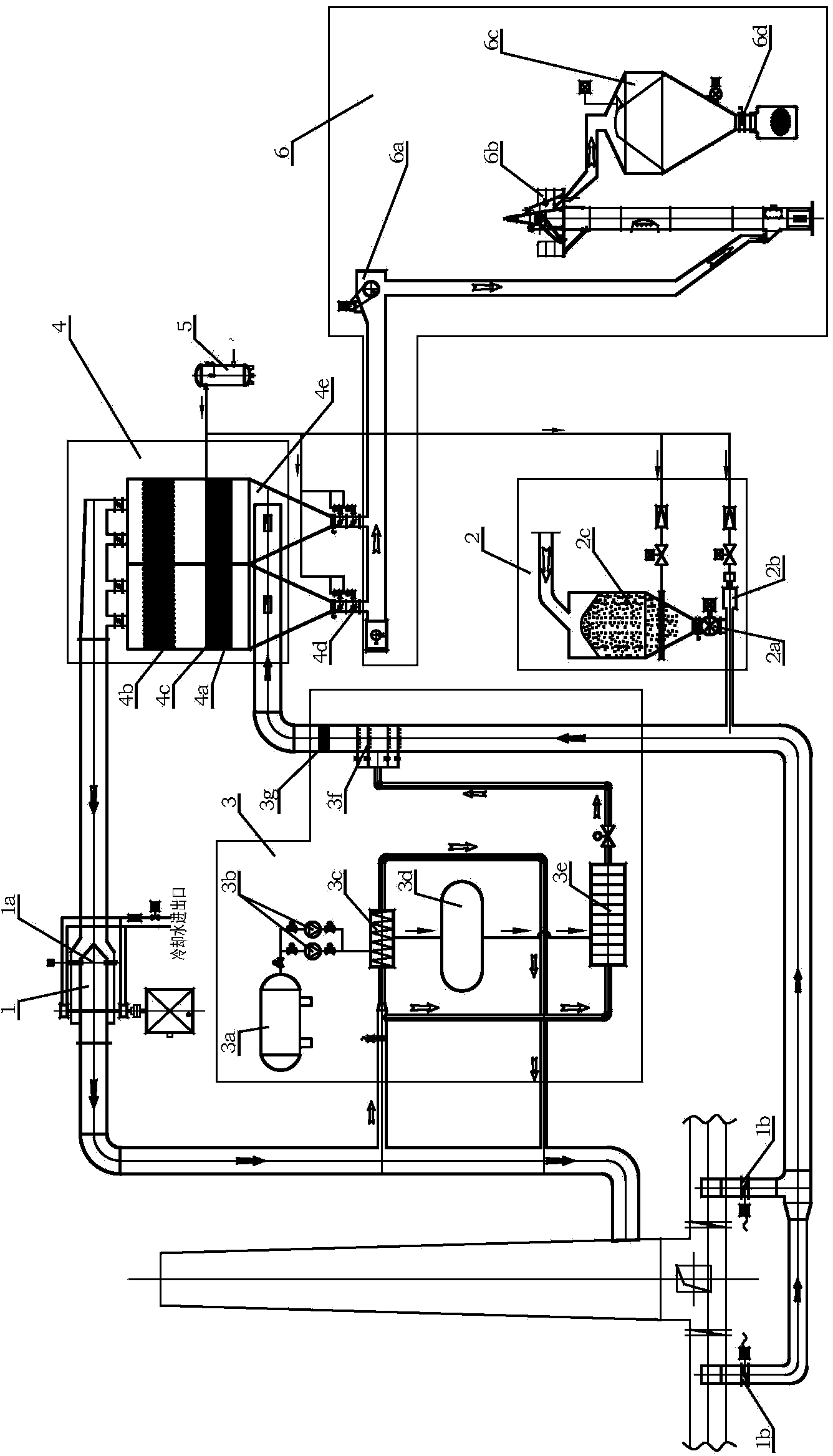

The invention relates to a coke oven flue gas desulfurization and denitrification purification process and a device, wherein flue gas is effectively desulfurated at low temperature through a rotating spray semi-dry method before denitrating, then is denitrated by utilizing a selective catalytic reduction method and utilizing an ammonia gas which is obtained by evaporating surplus ammonia water in a coking plant steamed ammonia section as a reducing agent, a denitration process is completed in a dust removal denitration integration device, dust in flue gas is removed and particulate matter is filtered out before denitrating, and the particulate matters in flue gas which is filtered and reactants which are generated through desulfurization are conveyed into a circulating ash solution preparation unit which is arranged in a desulfurization system through a desulfurization ash collecting transportation device, and are conveyed to the top portion of a desulfurization tower through a solution transportation unit to participate in the flue gas desulfurization process after being prepared to be a circulating ash solution, thereby enabling unreacted desulfurizer to be fully utilized. The coke oven flue gas desulfurization and denitrification purification process and the device combine rotating spray drying desulfurization method and a low temperature selective catalytic reduction (SCR) denitrification, achieve efficient desulfurization and denitrification of coke oven flue gas, and are simple in technological process, small in floor space and less in equipment investment.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

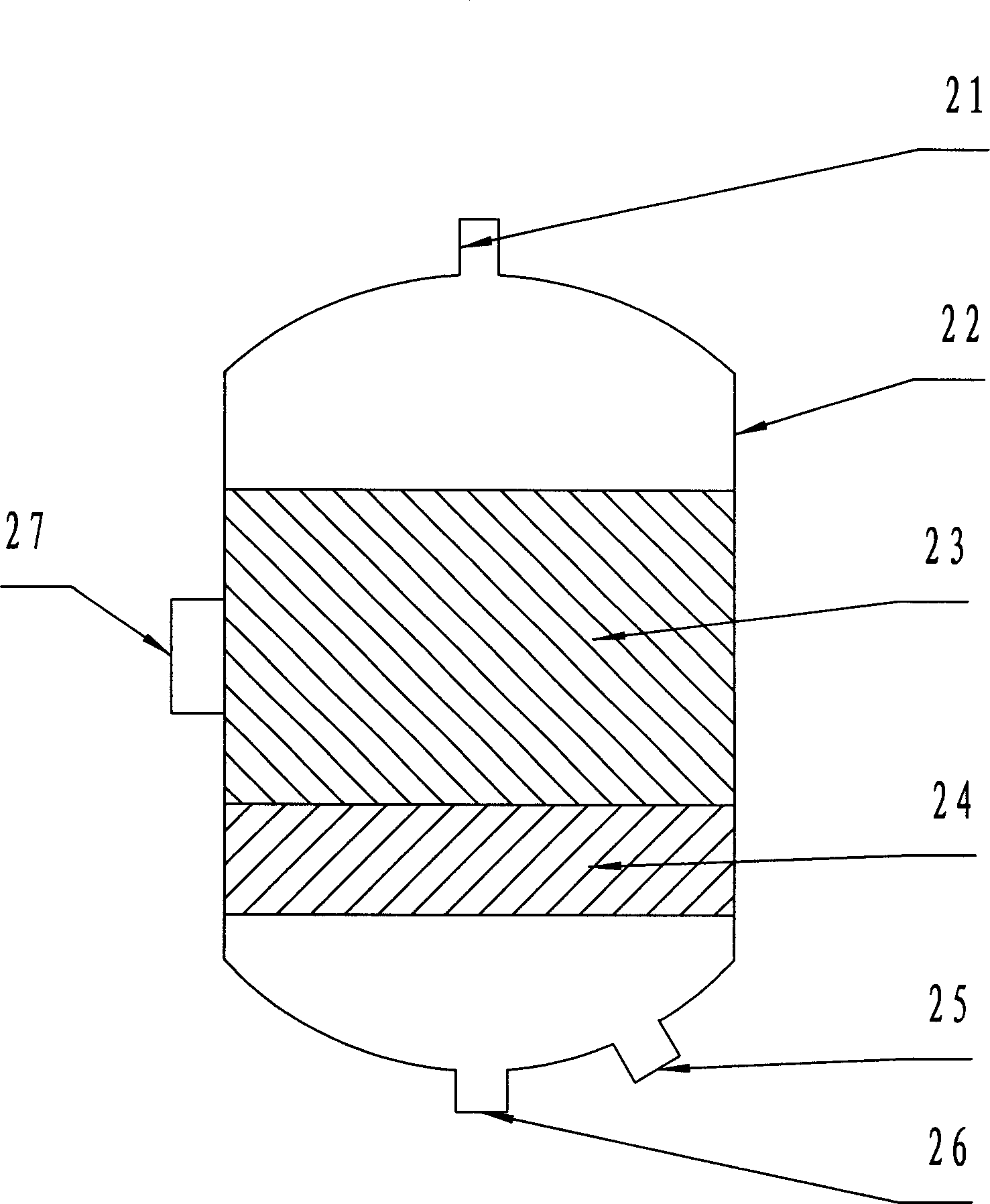

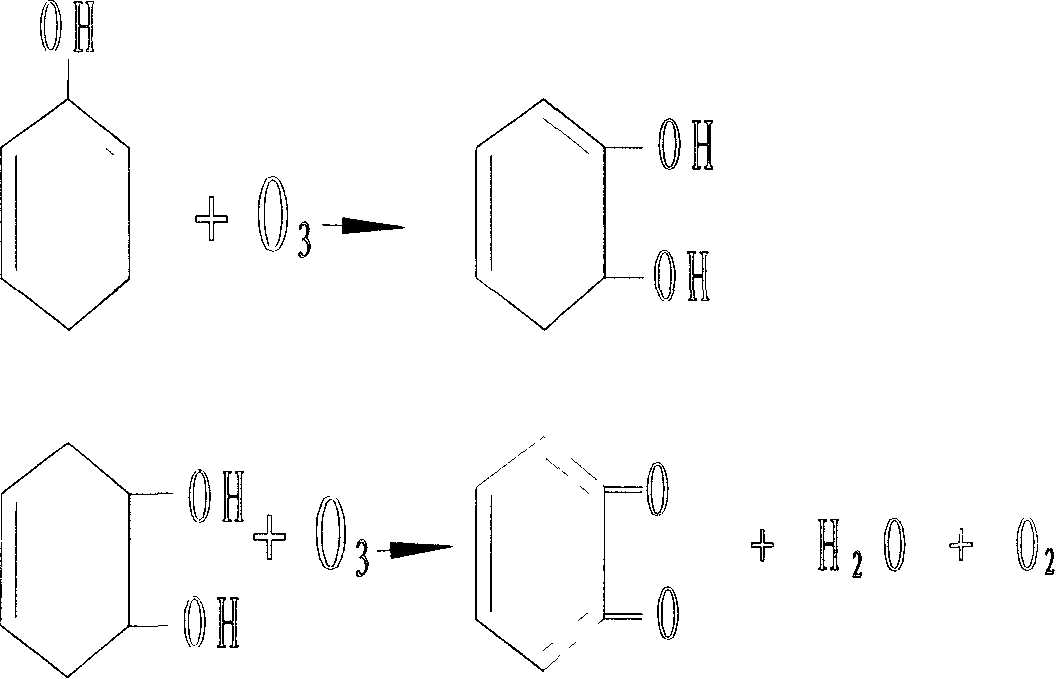

Deep purification method of coking wastewater based on advanced ozone oxidation

InactiveCN102161537ANo secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by oxidationPurification methodsChemical oxygen demand

The invention discloses a deep purification method of coking wastewater based on advanced ozone oxidation, belonging to the field of wastewater treatment, and particularly relating to a deep purification method for the effluent of the biochemical treatment facilities of coking plants. Aiming at the problem in the prior art, the invention provides a method for coupling homogeneous catalysis and non-homogeneous catalysis for ozone so as to realize deep purification of the effluent of the biochemical treatment facilities of coking wastewater. In the deep purification method, wastewater of which the pH value is 8-12 is subjected to homogeneous catalysis reaction in the presence of ozone and hydrogen peroxide; non-homogeneous catalysis is carried out in the presence of the non-homogeneous catalyst; thus, processed effluent COD (Chemical Oxygen Demand) is less than 100mg / L; and thus the processed effluent does not cause secondary pollution to environment.

Owner:王兵 +3

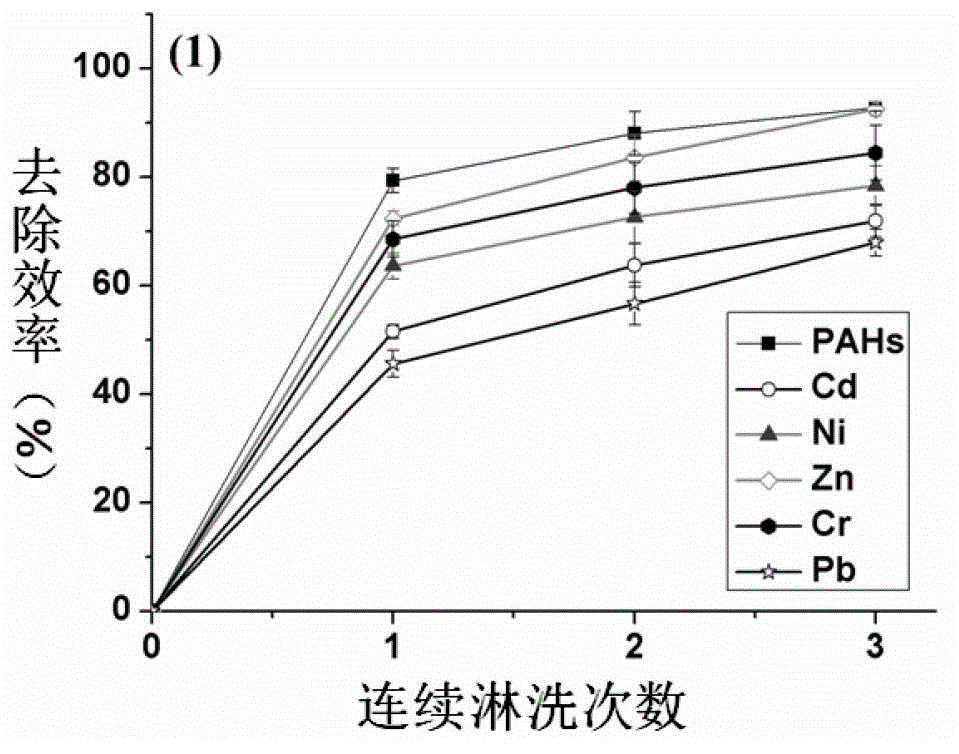

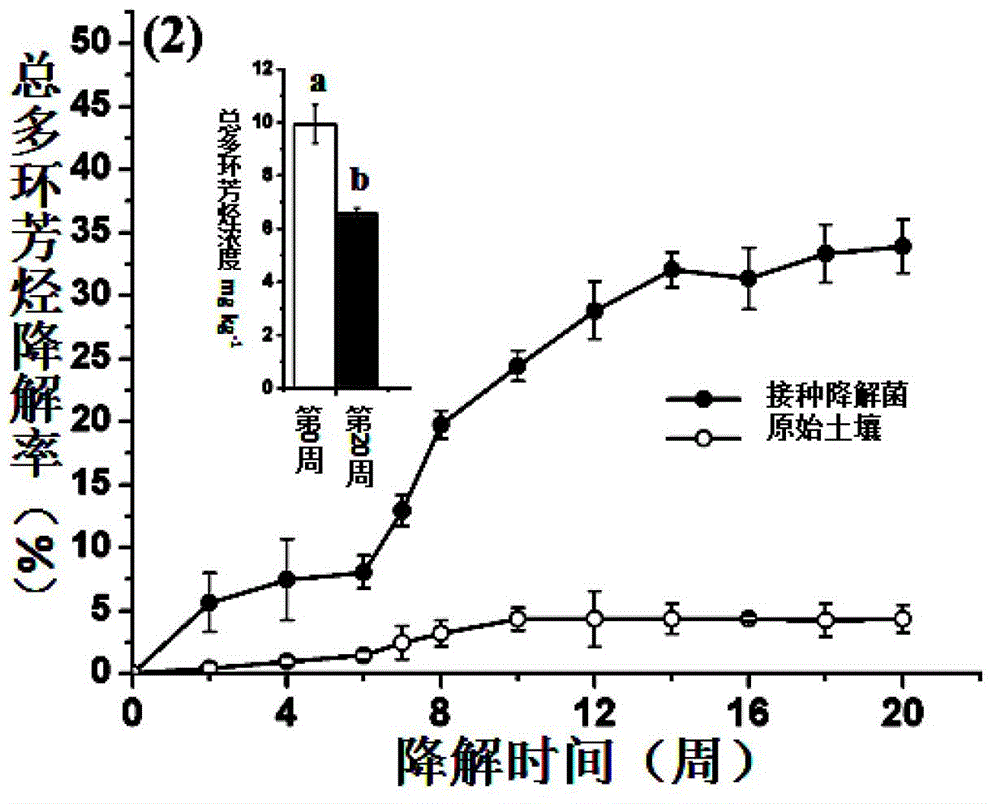

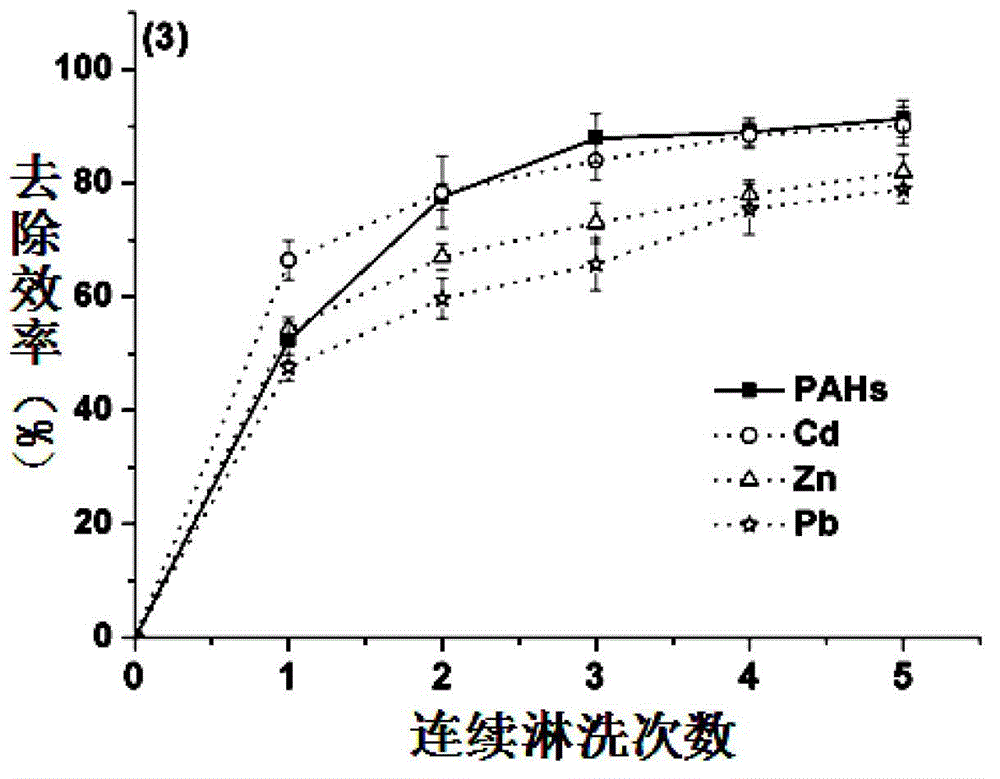

Chemistry-microorganism combination restoration method of polycyclic aromatic hydrocarbons and heavy metal composite contaminated site soil

InactiveCN102941225ANo secondary pollutionImprove environmental friendlinessContaminated soil reclamationCyclodextrinCoking plant

Disclosed is a chemistry-microorganism combination restoration method of polycyclic aromatic hydrocarbons and heavy metal composite contaminated site soil. The method comprises steps of (1), preparing soil particles and air drying and grinding contaminated site soil; (2), setting a restoration system, adding methyl beta cyclodextrin leacheate to a blender; (3), adjusting the reaction temperature to be 50+ / -2 DEG C; (4), adjusting an ultrasonic emission device to 35kHz for ultrasound of 30 minutes; (5) conducting continuous leaching, and repeating the continuous leaching for 3 times; and (6) conducting depth restoration of degrading bacteria, and inoculating polycyclic aromatic hydrocarbons degrading bacteria to soil which is subjected to continuous leaching restoration, adjusting the N / P to be 10:1 and conducting degradation for 90-140 days continuously. By the aid of the method, the restoration of the polycyclic aromatic hydrocarbons and heavy metal contaminated site soil generated by enterprises such as transferred coking plants, steel mills and power plants has wide application prospects.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Coke plant including exhaust gas sharing

ActiveUS20140048405A1Mechanical conveying coke ovensCoke oven safety devicesCoke ovenProcess engineering

A coke plant includes multiple coke ovens where each coke oven is adapted to produce exhaust gases, a common tunnel fluidly connected to the plurality of coke ovens and configured to receive the exhaust gases from each of the coke ovens, multiple standard heat recovery steam generators fluidly connected to the common tunnel where the ratio of coke ovens to standard heat recovery steam generators is at least 20:1, and a redundant heat recovery steam generator fluidly connected to the common tunnel where any one of the plurality of standard heat recovery steam generators and the redundant heat recovery steam generator is adapted to receive the exhaust gases from the plurality of ovens and extract heat from the exhaust gases and where the standard heat recovery steam generators and the redundant heat recovery steam generator are all connected in parallel with each other.

Owner:SUNCOKE TECH & DEV LLC

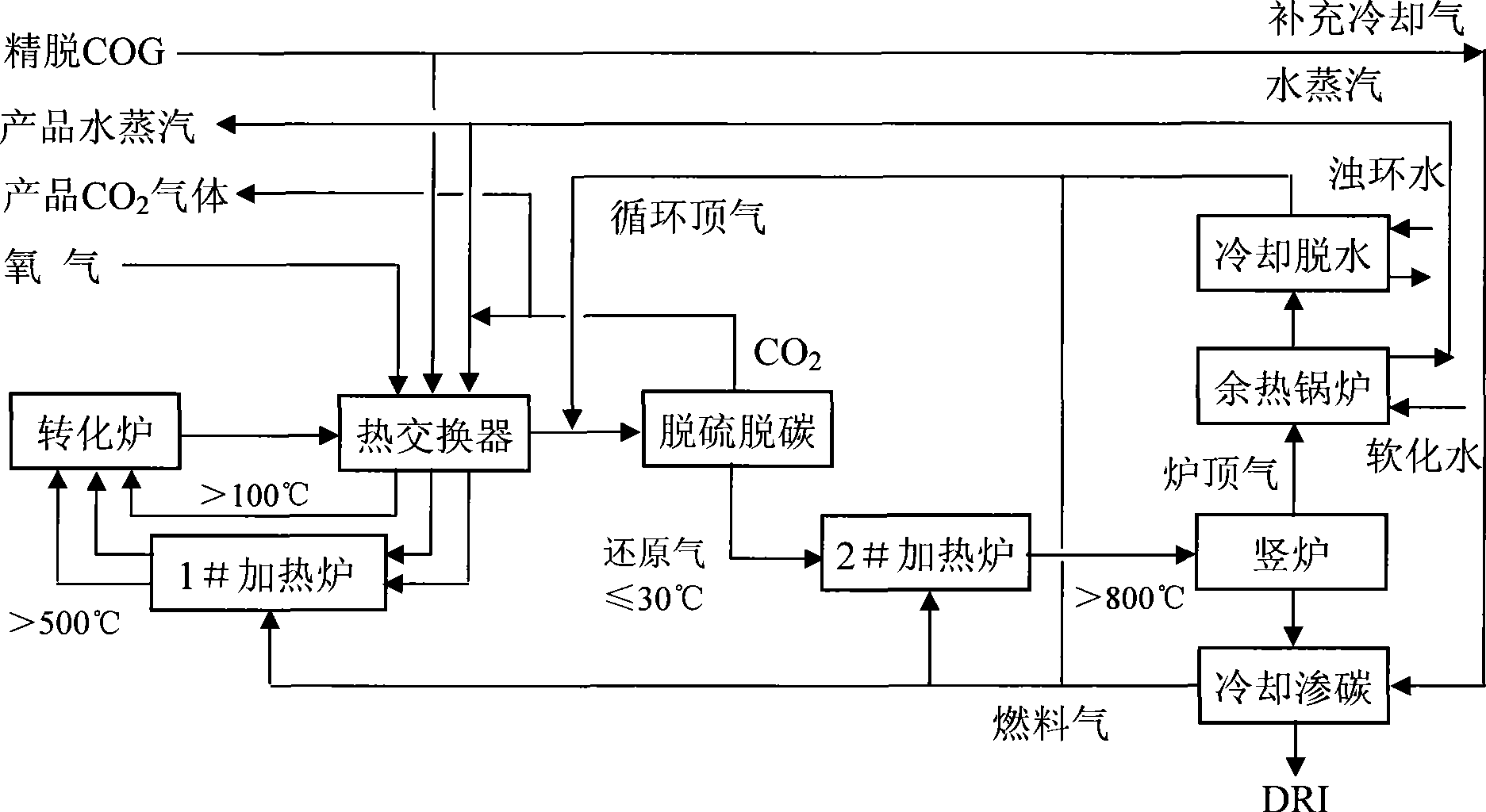

Conversion of coke oven gas carbon dioxide and gas-based shaft kiln directly reduced iron production method

ActiveCN101392192AMeeting Direct Reduction NeedsIncreased CO contentCombustible gas purificationComing outWater vapor

The invention discloses a method for conversing carbon oxide in coal oven gas and directly reducing Fe in a gas-based shaft furnace. The coal oven gas, to which initial purification treatment is carried out in a coking plant, is subjected to deep purification and desulfurization treatment and then is used as virgin gas, while oxygen, the carbon oxide and water vapour are used as a gas transforming agent and sent into a reformer for conversion, and reforming gas is used as reducing gas for directly reducing the Fe in the gas-based shaft furnace. Part of the gas that comes out from the top of the shaft furnace is used as fuel gas which is then used as fuel for a heating furnace; and part of the gas is used as process gas which returns to the shaft furnace as the reducing gas after being treated. The method solves a new gas source for the direction reduction in the gas-based shaft furnace and pertains to a new and highly efficient usage method of the coal oven gas. Compared with the current reforming gas from water vapour, the H2 / CO ratio of the reforming gas reduces from 4.6 of the reforming gas from the water vapour to 1.5 and is adjustable between 4.6 and 1.5.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

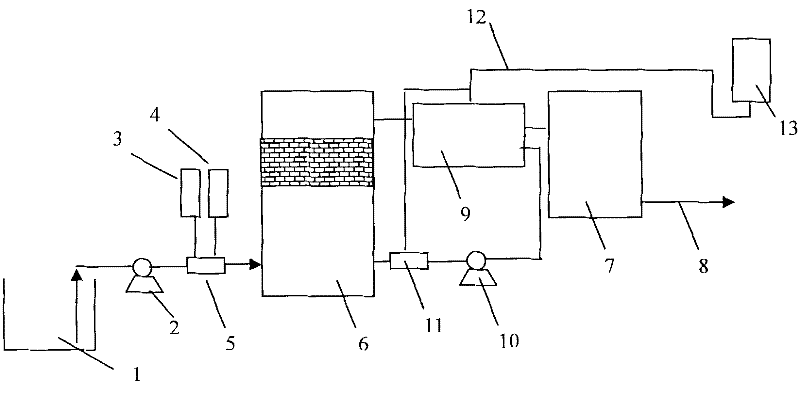

Integrated low-temperature flue gas desulfurization, denitration and ammonia removal process

ActiveCN103816780AImprove dust filtration efficiencyImprove efficiencyDispersed particle separationEvaporationEmission standard

The invention relates to an integrated low-temperature flue gas desulfurization, denitration and ammonia removal process suitable for the desulphurization and the denitration of coke oven flue waste gas of which flue gas temperature is greater than 180 DEG C and the content of SO2 is less than 150 mg / Nm3. According to the process, dry desulphurization is performed before denitration according to a fluidized principle, ammonia gas produced by evaporating residual ammonia water at an ammonia evaporation workshop section in a coking plant is used as a reducing agent, a cloth bag combining with an ammonia removal catalyst composite structure is used as a dust removing and denitration manner, and during efficient desulphurization and denitration, an escape amount of ammonia is controlled to be lower than a national emission standard value. Compared with the prior art, the process has the benefits that 1), the integrated desulphurization, denitration and ammonia removal efficiency is high; 2) the denitration manner is unique, and the structural form of equipment is advanced; 3) ash removal is simple; 4) the energy is saved, and the operating cost and the once investment are reduced; 5) residual ammonia water in a coal gas purification process is fully recycled; 6) the residual heat is fully recycled.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Method for preparing active semicoking H2S desulphurizer

InactiveCN1621498AWide variety of sourcesLow pricePhysical/chemical process catalystsOther chemical processesSorbentCoking plant

The present invention discloses the preparation process of active semi-coke H2S desulfurizer. The active semi-coke H2S desulfurizer is prepared with lignite semi-coke, anthracite or soft coal semi-coke and other carbon containing material and through first pressurized hydrothermal chemical modification, subsequent soaking with cuprammonia, CuSO4 solution or K2CO3 solution, drying and high temperature calcining. The present invention has the features of wide material source, low cost, repeated use of the adsorbent product, final use in waste water treatment and as fuel and no secondary pollution. The present invention may be used widely in purifying gas in various plants and environment protecting industry.

Owner:OCEAN UNIV OF CHINA

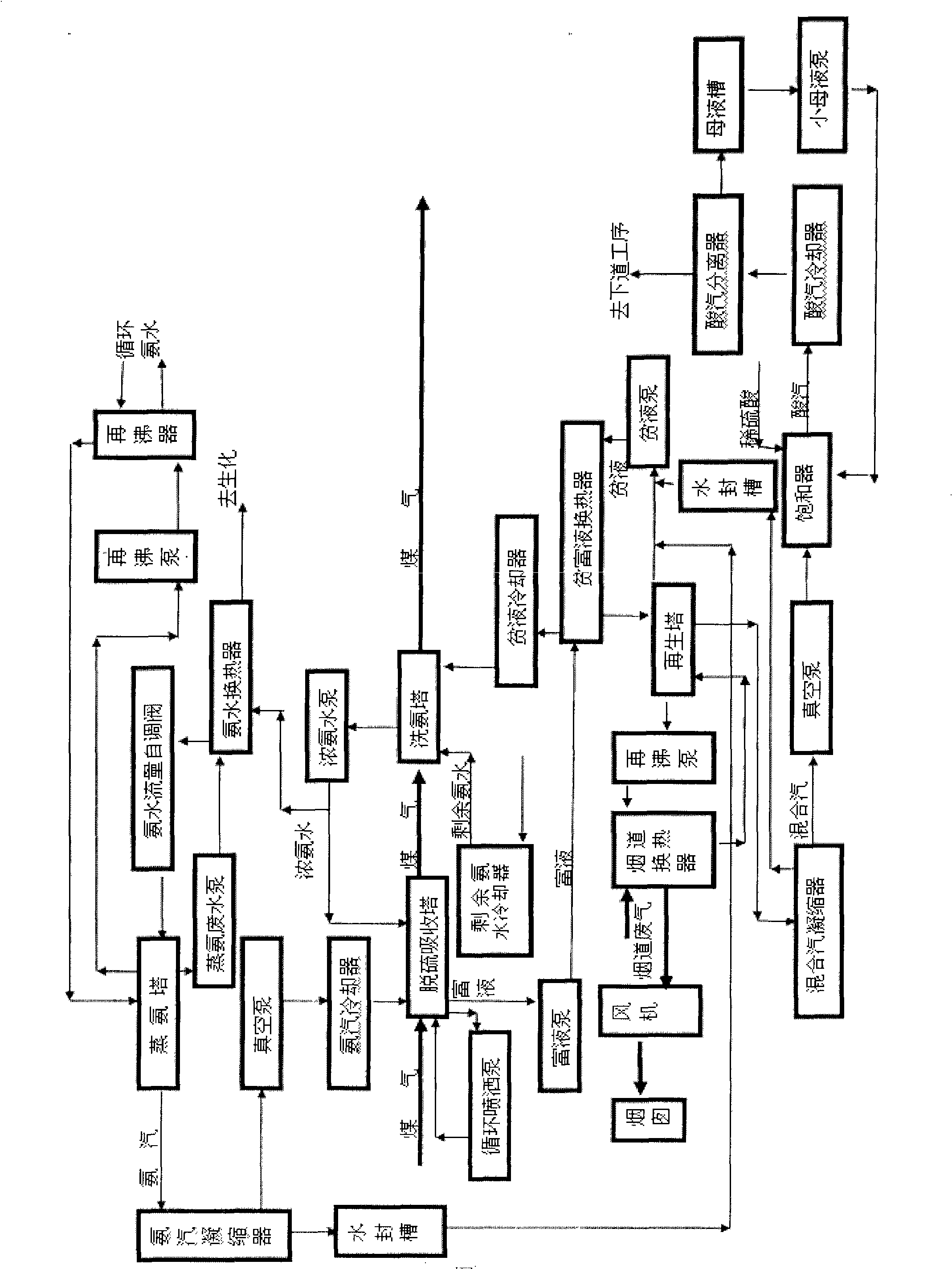

Desulphurization process by vacuum ammonia method

The invention provides a novel process for removing ammonia, H2S and HCN in coke-oven gas in the coking industry, comprising: taking ammonia in coke-oven gas and the residual ammonia water as an alkali source to have reaction with H2S and HCN in the coke-oven gas, then carrying out the resolution in a regeneration tower, removing ammonia in the obtained mixed gas by a saturex firstly, and producing elemental sulfur by the residual sour gas in a Claus furnace. The process is characterized in that: a rich liquid is obtained by utilizing the strong ammonia water obtained by ammonia in the coal gas to have reaction with H2S and HCN in the coal gas under the vacuum state, the tower bottom takes the sensible heat of flue waste gas as a heat source, the resolution is implemented in the regeneration tower under the negative pressure, and the obtained barren solution on the tower bottom is used for rewashing the ammonia. The process has advantages of simple technique, low running cost, investment saving, and high ammonia, H2S and HCN removal efficiency, and is an innovation of ammonia, H2S and HCN removing process in coal gas for coke plants.

Owner:马永伟 +1

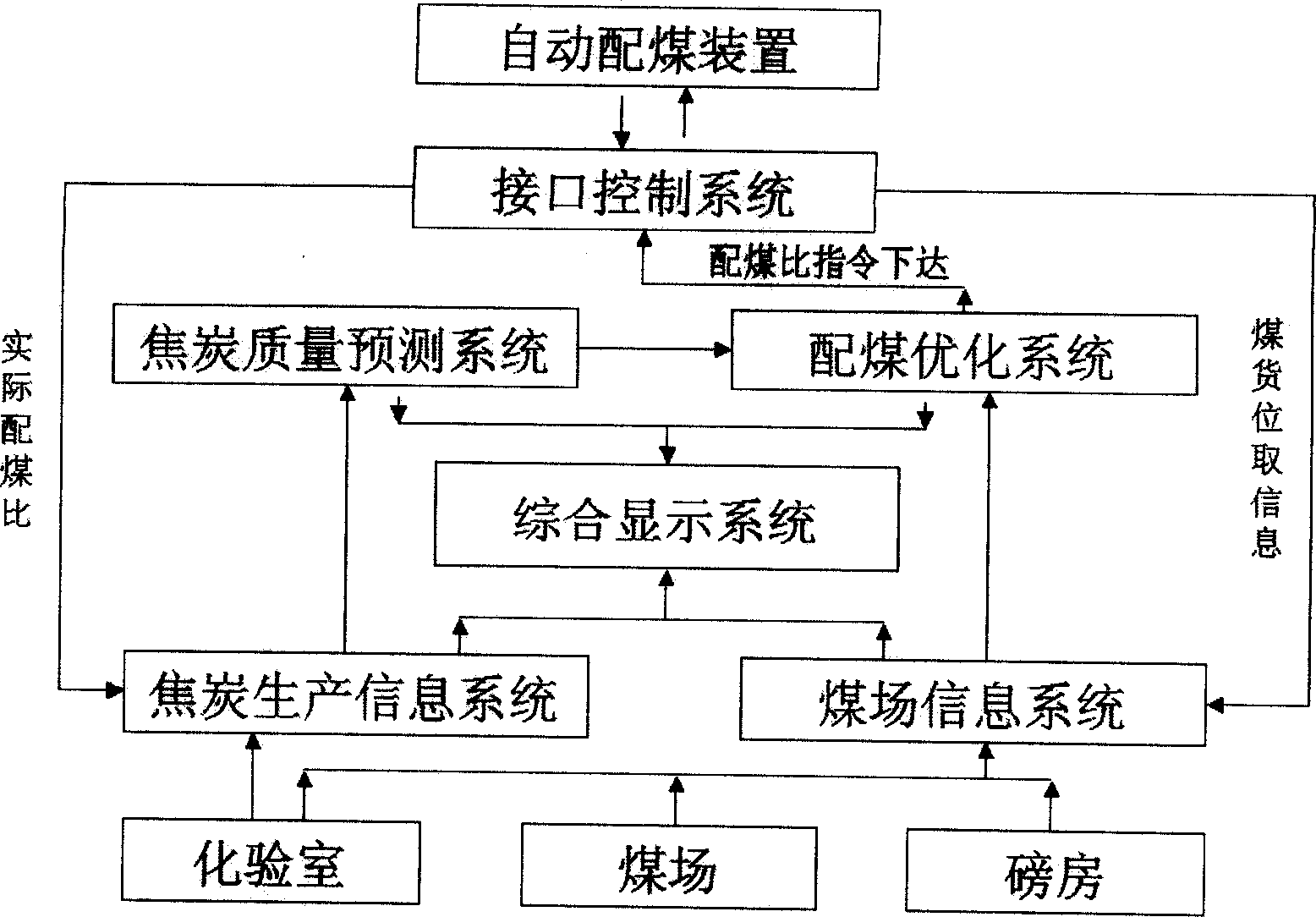

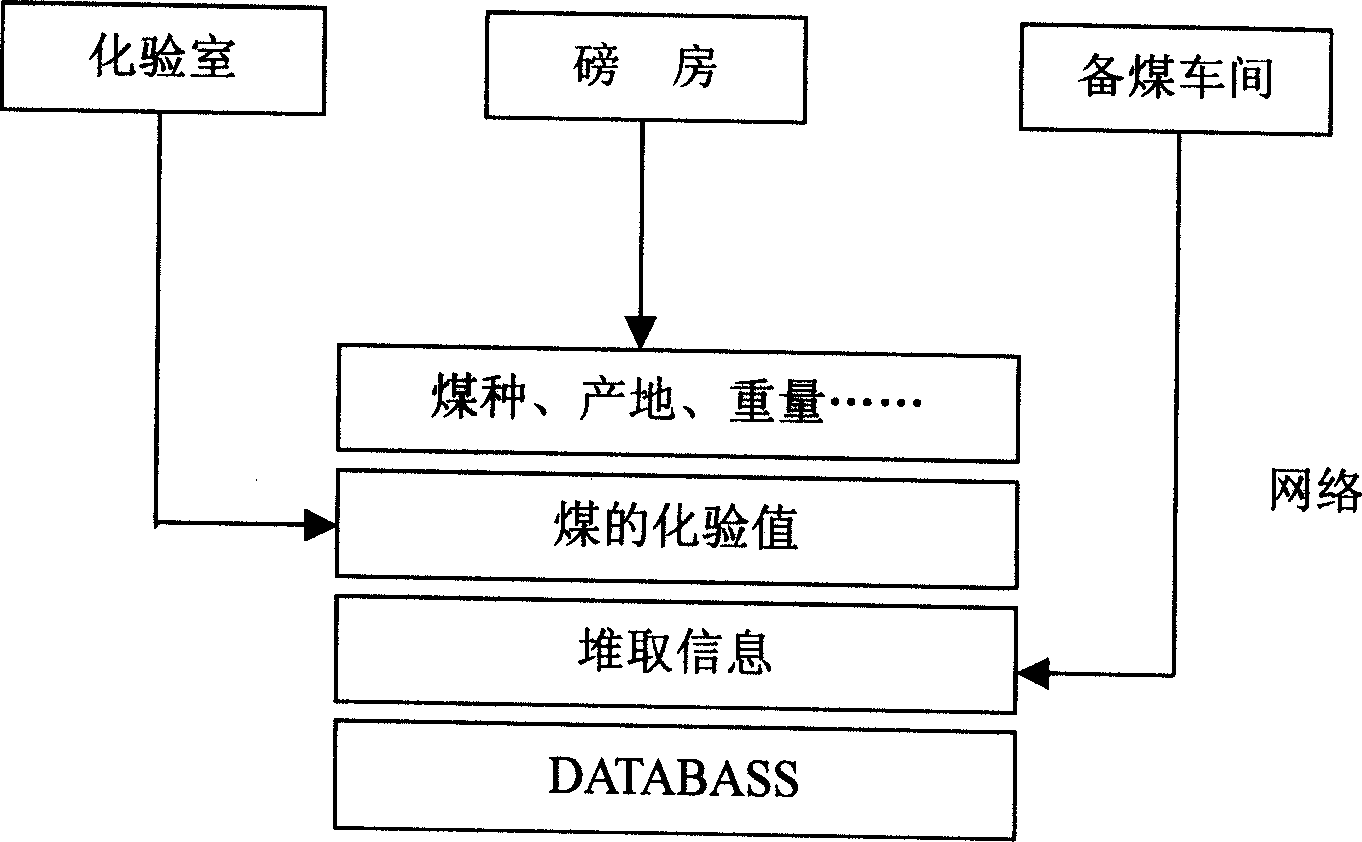

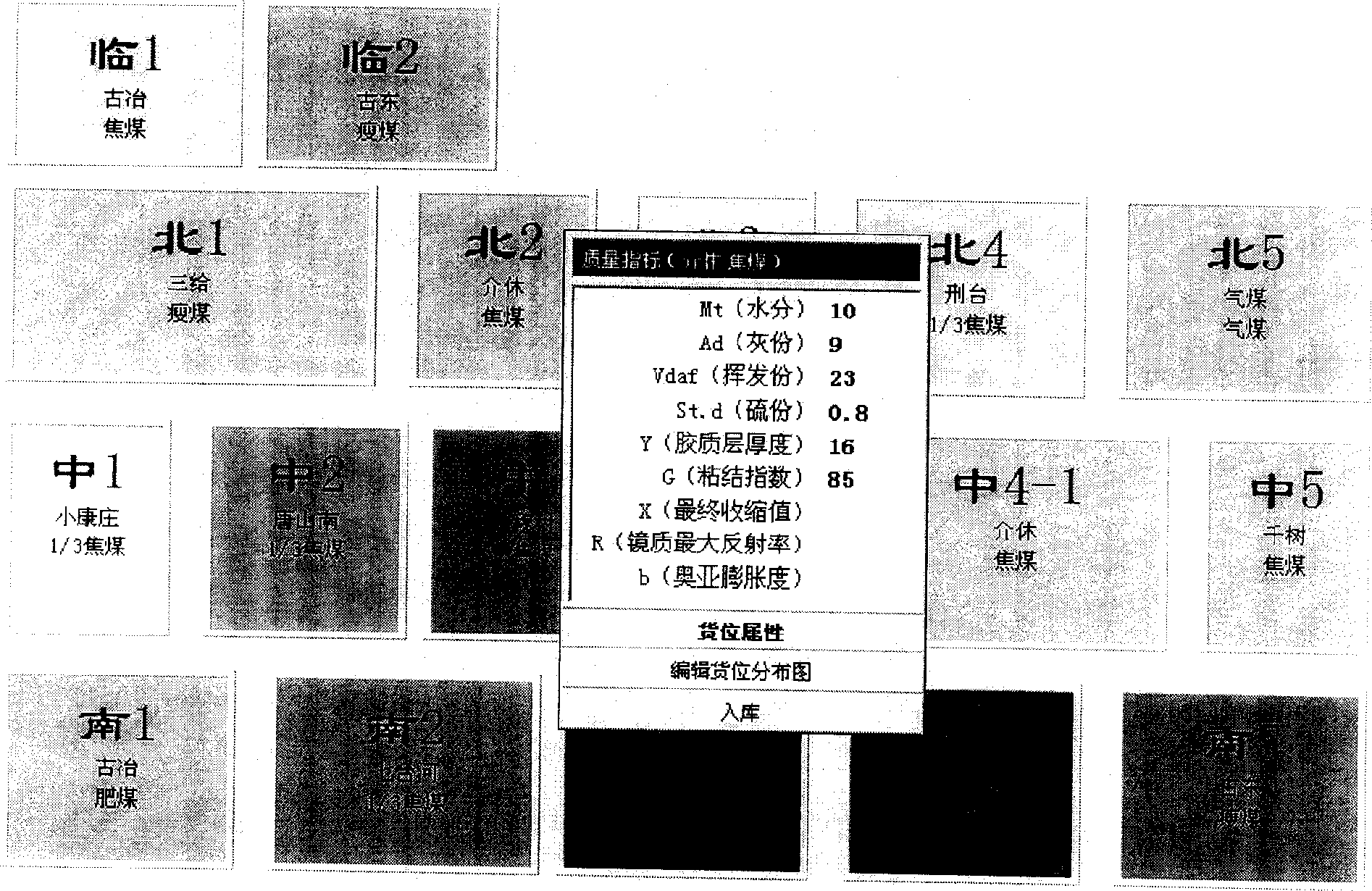

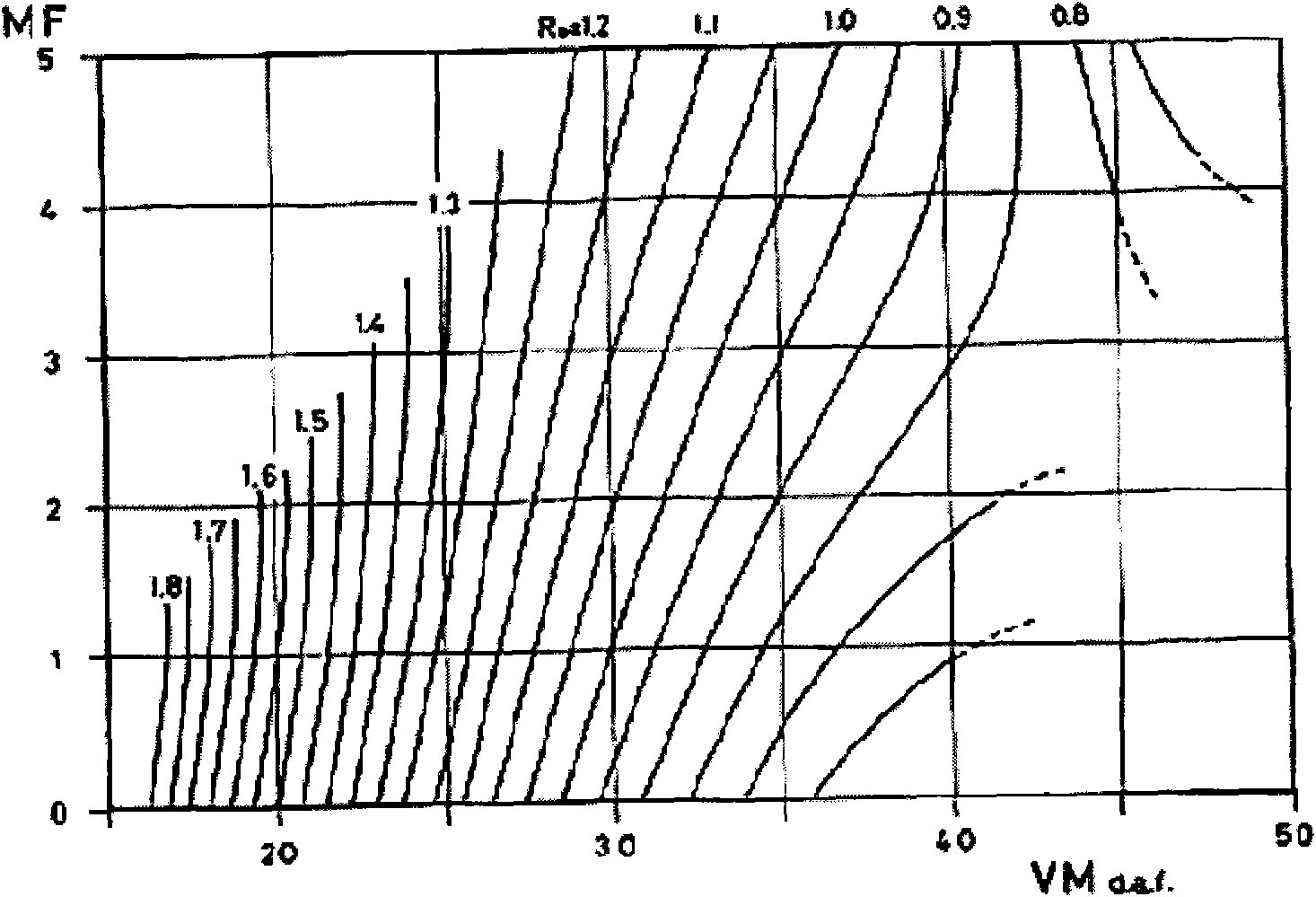

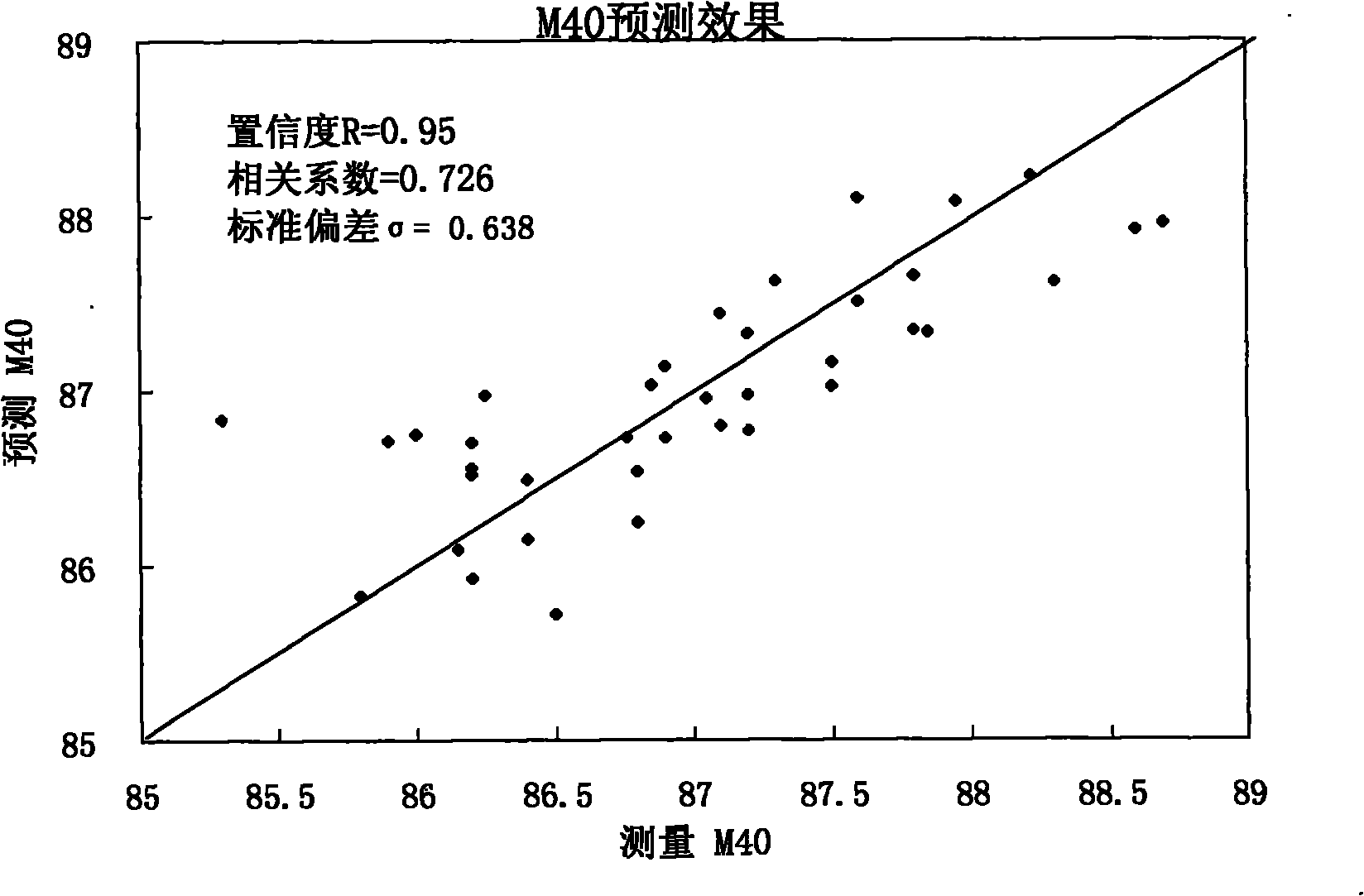

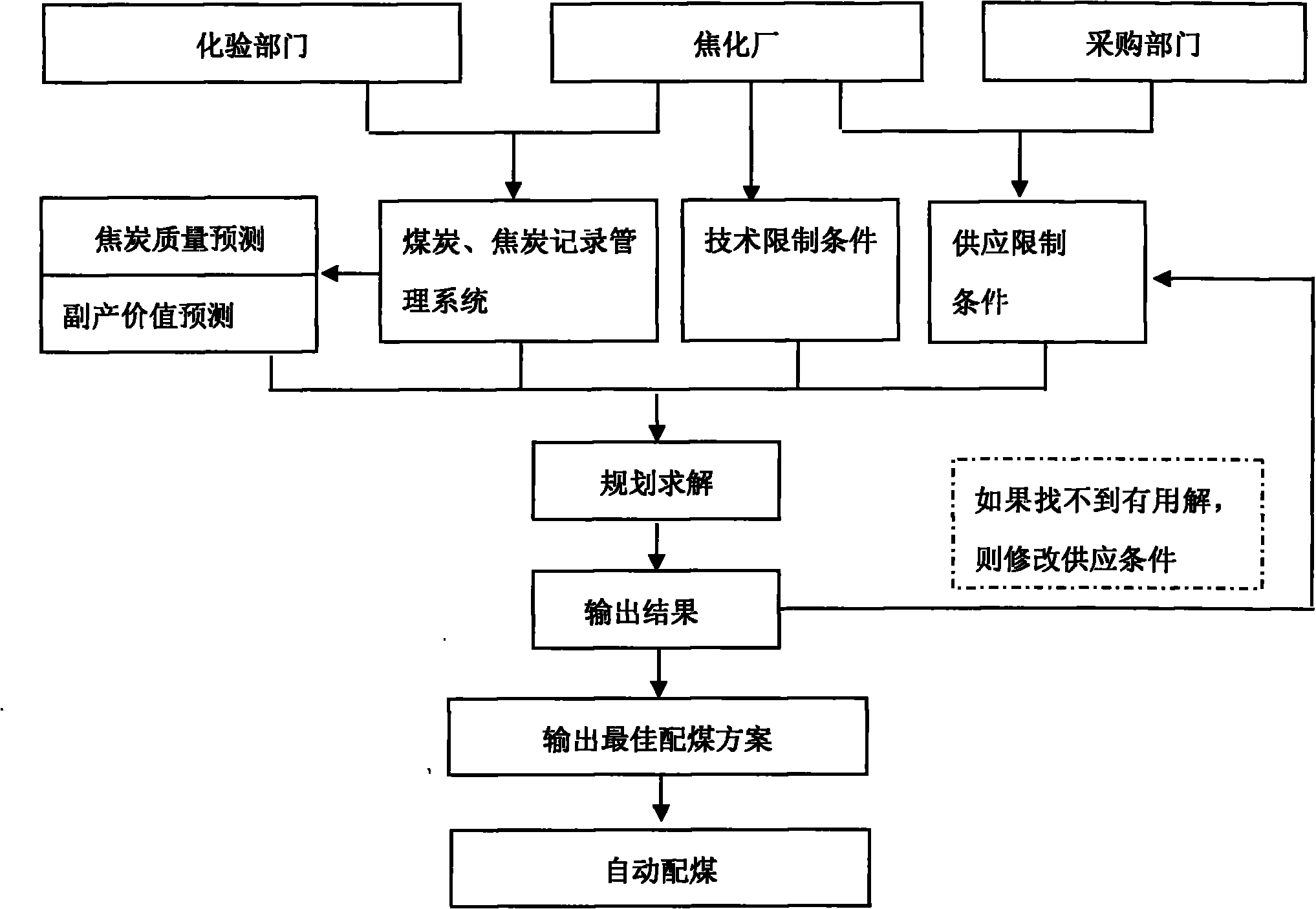

Optimum system for distributing coal of coking controlled by computer

ActiveCN1749358ALow costRealize scientificCoke oven safety devicesComputer controlInformation repositoryControl system

The computer controlled coking-coal distributing optimizing system has a coke producing information system integrating the coal compounding and coke information to form production information database; a coal yard information system integrating the coal information to form coal material database; a coal distribution optimizing system; a coke quality predicting system to ensure coke quality and an interface control system, integrated production control in coke plant. The computer controlled coking-coal distributing optimizing system can ensure the coke quality, and provide coal distributing scheme with minimized cost.

Owner:ACRE AUTOMATION CO LTD MCC

Method for thermally extracting coal

InactiveCN102512846AIncrease productionLow costCoke ovensSolid solvent extractionNitrogenNational standard

The invention relates to a method for thermally extracting coal, and the method comprises the following steps of: fully mixing crushed and dried coal granules with a solvent, and then adding the mixture into a high-pressure reaction kettle, raising the temperature to a specified temperature under a certain pressure after nitrogen metathesis; and thermally extracting, filtering, washing and drying to obtain black super-pure coal, wherein the solvent is industrial-grade national standard absorber oil or absorber oil produced by a coking plant. By utilizing the method, the coal thermal extraction rate can reach above 80%, the super-pure coal yield can reach above 70% and the super-pure coal ash content is less than 0.1%. The method has the advantages of high thermal extraction rate and good quality of the coal, and low production cost, as well as wide market application prospect because an extraction solvent can be recycled.

Owner:HEBEI IRON & STEEL GRP +1

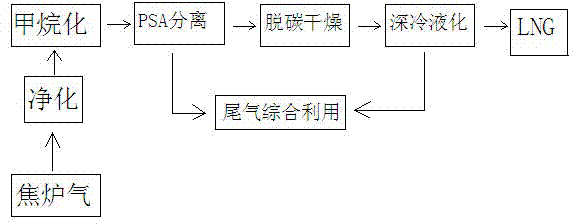

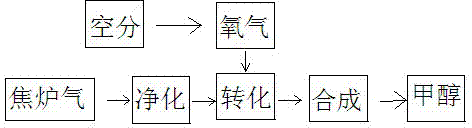

Method of combined production of methanol and liquefied natural gas in coking plant

InactiveCN104119975ASimple processEasy to operateHydrogen separationOrganic compound preparationSyngasThermodynamics

The invention belongs to the technical field of comprehensive coke-oven gas utilization, and particularly relates to a method of combined production of methanol and liquefied natural gas (LNG) in a coking plant. Coke-oven gas is subjected to temperature swing adsorption (TSA), desulphurization, vacuum pressure swing adsorption (VPSA), and other purifying treatment, and is subjected to cryogenic liquidation separation to obtain a liquefied natural gas (LNG) product. The main component of the non-liquefied part is (CO+H2), and is adopted as methanol synthesis gas used for producing methanol, wherein the insufficient carbon component based on the H2is supplied by continuous oxygen-rich gas production from chopped coke having a size of 7-24 mm by a normal-pressure gasifier. The method achieves direct utilization of CH4 that is one of the main components of the coke-oven gas, the (CO+H2) are directly used for methanol synthesis, and the insufficient carbon source is supplied by a normal-pressure gasifier adopting the chopped coke produced by the coking plant as a gas production raw material, and therefore intermolecular conversion and other main energy-consumption sections and high-investment devices are reduced, the whole process is simplified, the comprehensive energy consumption for producing the methanol and the liquefied natural gas (LNG) is low, the whole economic benefit of coking enterprises is increased, and the investment is saved.

Owner:COAL BRANCH YANZHOU MINING GRP

Coke plant including exhaust gas sharing

ActiveUS20160160123A1Coke oven safety devicesHorizontal chamber coke ovensCoke ovenProcess engineering

A coke plant includes multiple coke ovens where each coke oven is adapted to produce exhaust gases, a common tunnel fluidly connected to the plurality of coke ovens and configured to receive the exhaust gases from each of the coke ovens, multiple standard heat recovery steam generators fluidly connected to the common tunnel where the ratio of coke ovens to standard heat recovery steam generators is at least 20:1, and a redundant heat recovery steam generator fluidly connected to the common tunnel where any one of the plurality of standard heat recovery steam generators and the redundant heat recovery steam generator is adapted to receive the exhaust gases from the plurality of ovens and extract heat from the exhaust gases and where the standard heat recovery steam generators and the redundant heat recovery steam generator are all connected in parallel with each other.

Owner:SUNCOKE TECH & DEV LLC

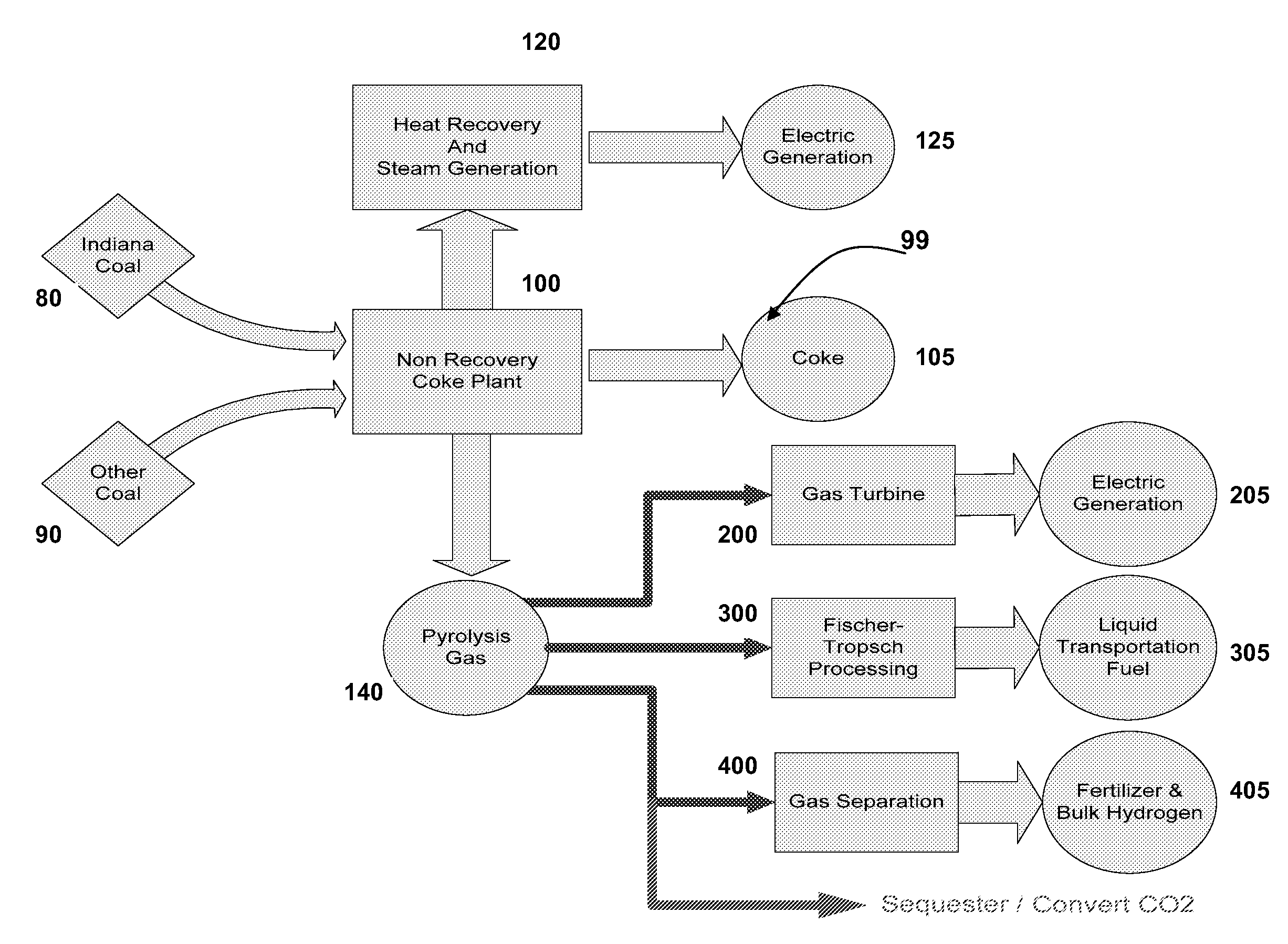

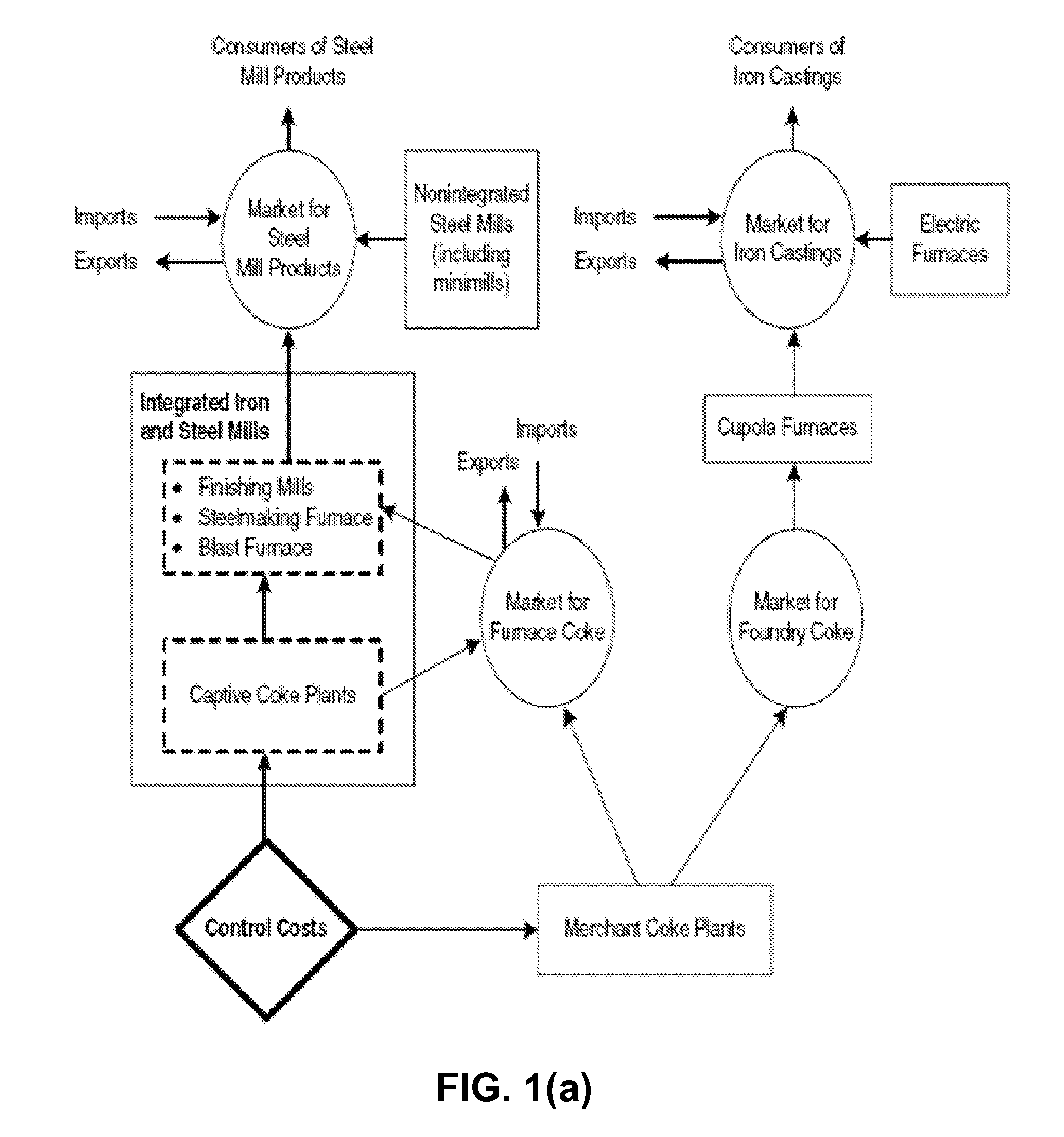

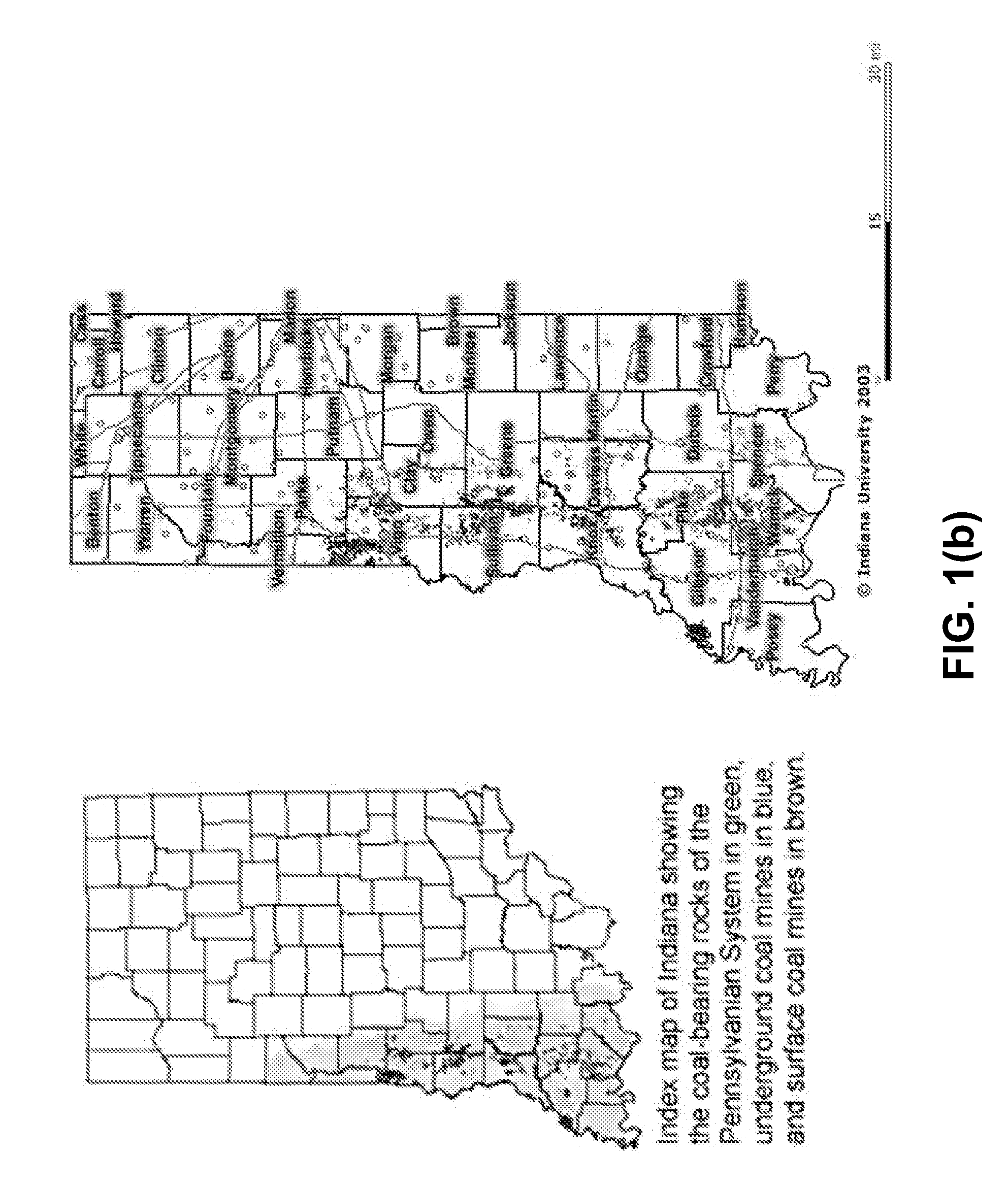

Multipurpose coke plant for synthetic fuel production

ActiveUS20100139287A1Combustible gas coke oven heatingDirect heating destructive distillationTechnological riskGas composition

A new approach to the production of coke. In this process multiple optimized value streams are produced from a coke facility located at mine mouth or locally at an existing plant. As part of the process, lower cost Indiana / Illinois Basin-type coals are blended with conventional metallurgical coals. The blending process is optimized to meet coke quality requirements and simultaneously to obtain a pyrolysis gas composition suitable for production of ancillary products including liquid transportation fuels, fertilizer, hydrogen, and electricity. By using lower cost Indiana / Illinois Basin coal it is possible to reduce net coal costs. This process provides a new direction and approach for the production of coke in the future that optimizes value over multiple product streams while reducing both business and technological risk.

Owner:PURDUE RES FOUND INC

Method for extracting sodium thiocyanate from coking desulfurization waste liquid

The invention relates to a method for extracting sodium thiocyanate from desulfurization waste liquid in a coking plant, which is characterized by comprising the following steps of: adding 2 to 6 weight percent of activated carbon into the desulfurization waste liquid, heating to the temperature of between 70 and 90 DEG C, and keeping stirring for 1 to 2 hours; filtering, adding sulfuric acid into filtrate in a closed container until pH is 3.5 to 4.5, heating to the temperature of between 60 and 80 DEG C, and keeping stirring for 1 to 2 hours; leading escaping sulfur dioxide gas out by using a guide pipe and absorbing by using dilute ammonia water; filtering after reaction is finished, adding sodium hydroxide with the same mol as ammonium thiocyanate in filtrate and calcium hydroxide with the same mol as ammonium sulfate in the filtrate into the filtrate in the closed container, heating to the temperature of between 50 and 70 DEG C, and keeping stirring for 1 to 2 hours; and leading escaping ammonia gas out by using the guide pipe and absorbing by using water to obtain the dilute ammonia water, filtering after reaction is finished, and performing evaporation crystallization on filtrate to obtain a sodium thiocyanate product.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

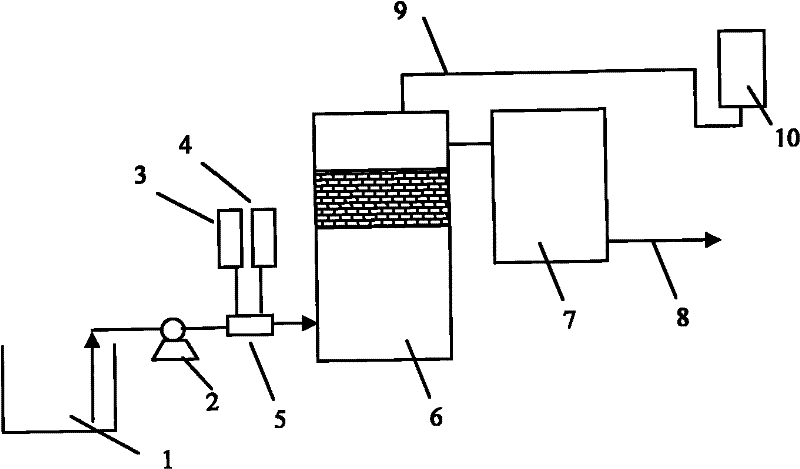

Low-temperature coke oven flue waste gas cleaning technology and equipment thereof

The invention relates to a low-temperature coke oven flue waste gas cleaning technology and equipment thereof. According to the technology, residual ammonia water of a coking plant is recycled, and a low-temperature SCR denitration technology and an ammonia desulfuration technology are combined; ammonia produced by evaporating the residual ammonia water produced by an ammonia evaporation working process of the coking plant is used as a denitration reducing agent; denitration is performed by adopting a low-temperature denitration catalyst by a selective catalysis reducing method; the denitration catalyst is of a honeycomb briquette type structure; SO2 in coke oven waste gas is removed by the ammonia desulfuration technology; the residual ammonia water of the coking plant and a byproduct (NH4)2SO4 are recycled, and secondary pollutants such as wastewater, waste gas and waste slag are avoided. The equipment consisting of all units is matched with the corresponding technology; high-efficiency desulfuration and denitration are realized, the ammonia escape rate is low, the byproduct (NH4)2SO4 can be produced, and considerable economical benefit is achieved; the relevant national environment-friendly policy requirement is met, and the running cost of desulfuration and denitration of a coking enterprise is lowered.

Owner:SEEWATER ENVIRONMENTAL ENG

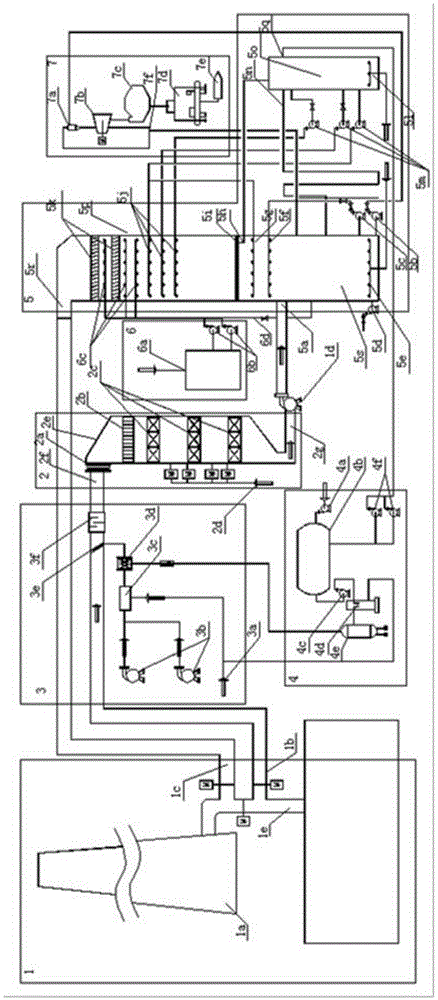

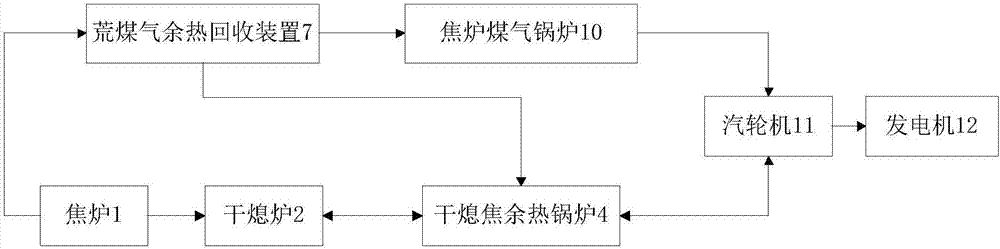

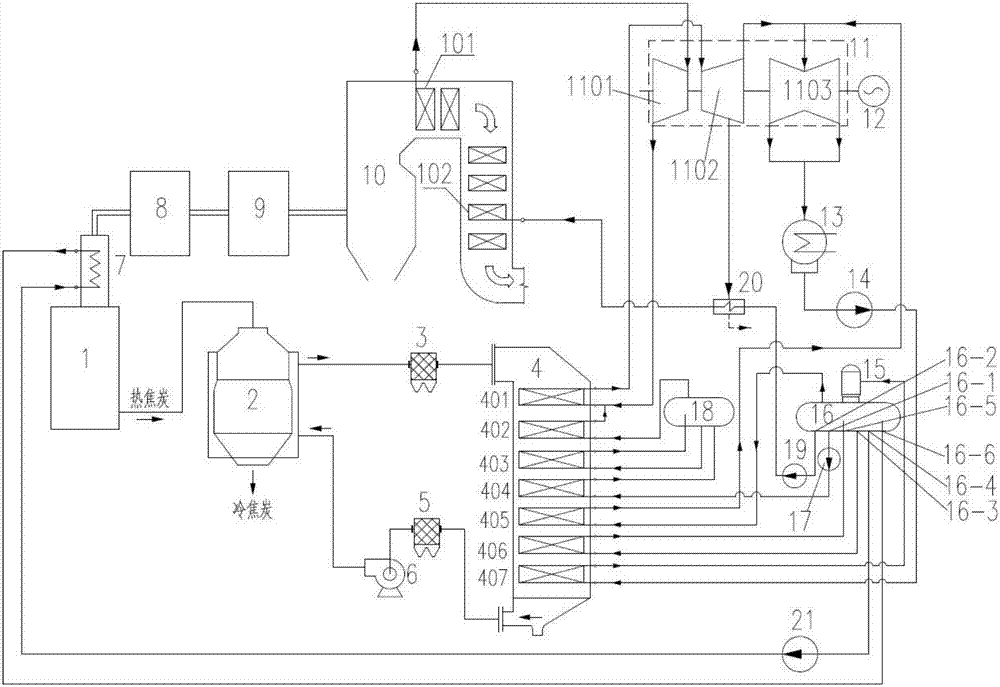

Thermal power generation system based on integrated utilization of afterheat and surplus energy of coking plant

PendingCN107014218AReduce areaLow costIncreasing energy efficiencySteam engine plantsCoking plantHigh pressure

The invention provides a thermal power generation system based on integrated utilization of afterheat and surplus energy of a coking plant. The system comprises a coke oven, a dry quenching furnace, a dry quenching afterheat boiler, a crude gas afterheat recovery device, a crude gas purification device, a coke oven gas boiler, a steam turbine and a generator; coke oven hot cokes are fed in the dry quenching furnace for cooling; the dry quenching afterheat boiler recovers sensible heat of circulating gas in an outlet of the dry quenching furnace; the crude gas afterheat recovery device recovers sensible heat of crude gas; the crude gas purification device purifies crude gas to feed in the coke oven gas boiler; steam generated by the coke oven gas boiler is acted by a high-pressure cylinder of the steam turbine to feed in the dry quenching afterheat boiler for reheating, and is fed in a medium-pressure cylinder of the steam turbine with superheated steam of a high-pressure section of the dry quenching afterheat boiler; exhausted steam of the medium-pressure cylinder of the steam turbine and superheated steam of a low-pressure section of the dry quenching afterheat boiler are fed in a low-pressure cylinder of the steam turbine; and the steam turbine drives the generator to generate electricity. The system efficiently integrates coke oven gas, coke oven sensible heat and crude gas sensible gas for use.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

Low-cost coking coal blending system

The invention relates to a low-cost coking coal blending system which can be applied to controlling the precise coal blending and the procurement plan making of a coking plant. In the system, a coal and coke record management module, a coke quality prediction module, a by-product value prediction module and an optimizing coal blending module are tightly combined by a server and a network, real-time update is carried out, and the lowest-net-cost coal blending scheme meeting the coke quality requirements and all technology, warehousing and procurement limiting conditions is automatically obtained by a programming solver method under the limiting conditions such as coal quality, coke quality prediction, coal net price, coal reserve and procurement, thereby precisely controlling the automaticcoal blending system and achieving the purposes of improving and stabilizing the coke quality and reducing the coking cost.

Owner:SHAGANG GROUP

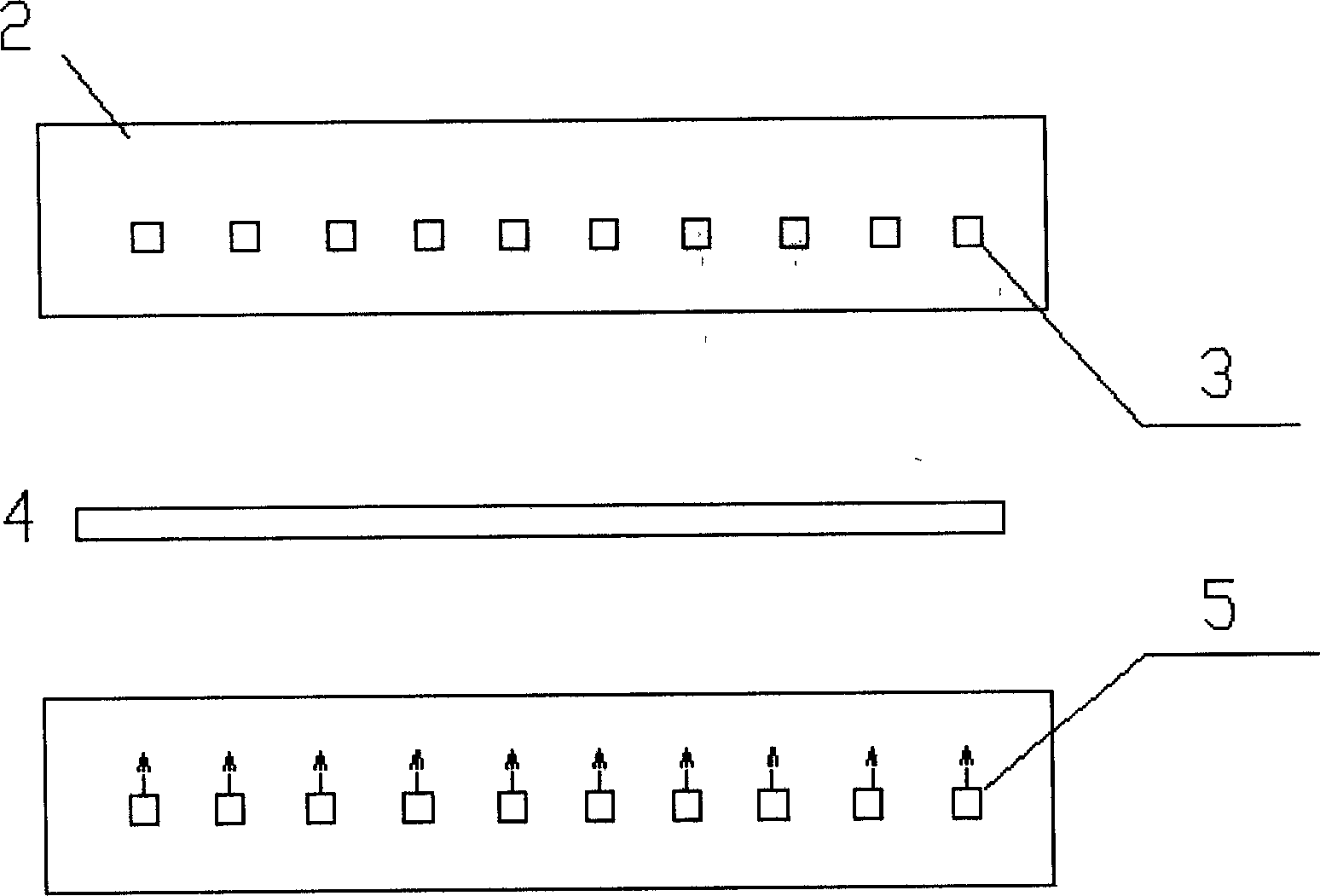

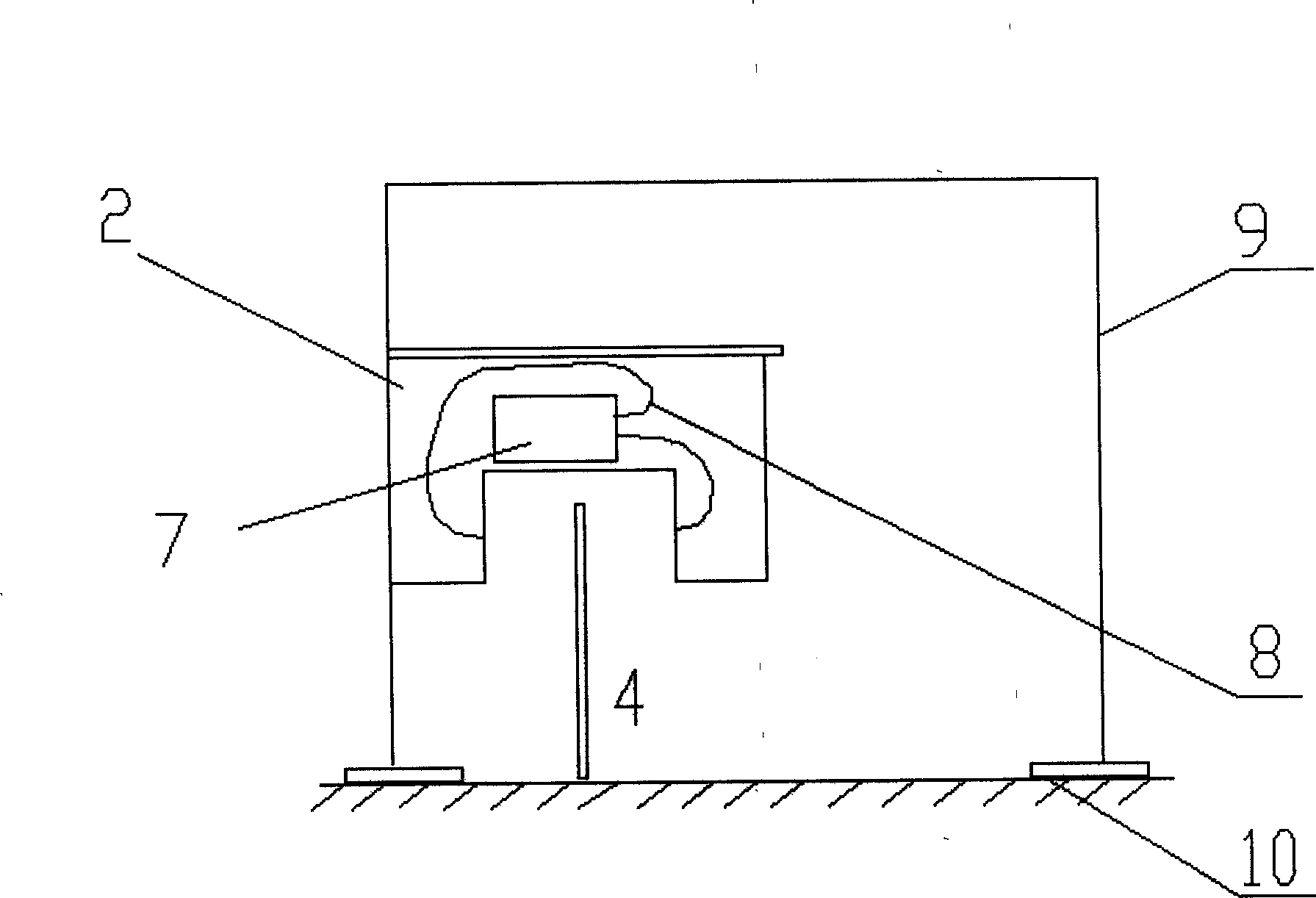

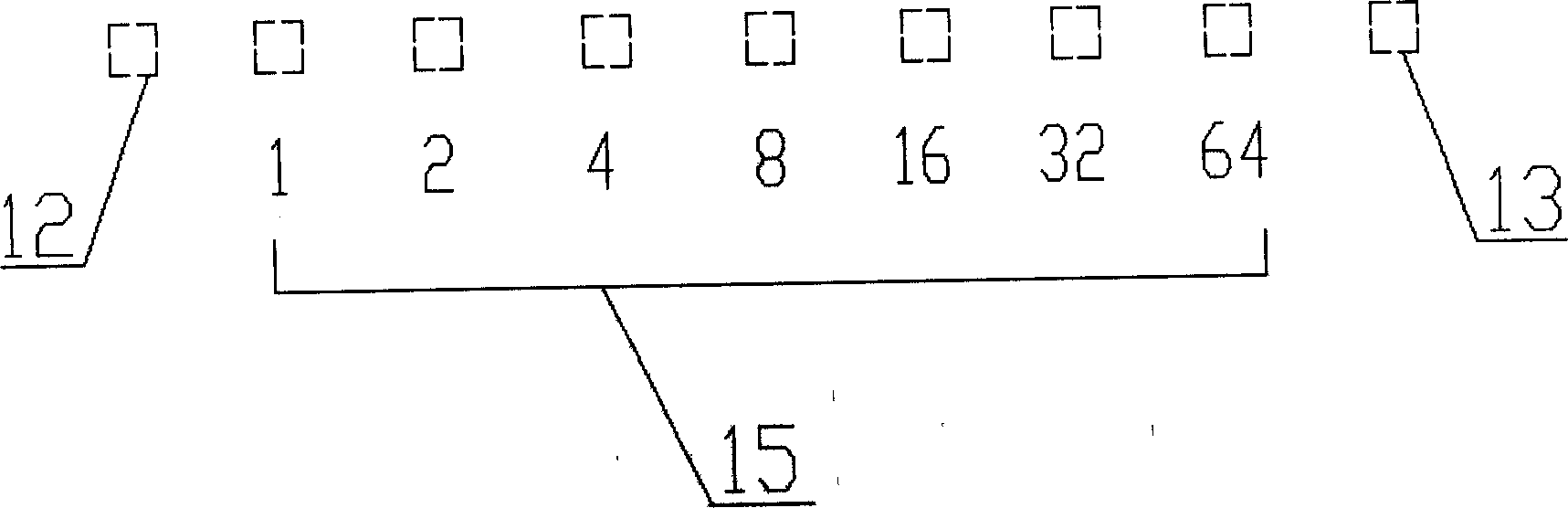

Identifying and automatic aligning system for coking furnace machinery furnace number

InactiveCN1749357AImprove the level of automatic operation controlImprove work efficiencyElectronic commutation motor controlCoke oven safety devicesLoop controlClosed loop

The coke oven machinery number identifying and automatically aligning system belongs to the field of industrial automatic technology. The present invention adopts binary coding technology, PLC interruption technology, frequency variator vector closed-loop control technology, Ethernet communication technology, bus communication technology, etc. to complete oven number identification, aligning and interlocking automatically. The present invention has raised automation level, reduced labor strength, raised production efficiency, and raised vehicle interlocking reliability, and is used mainly for coke oven machinery in coke plant.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

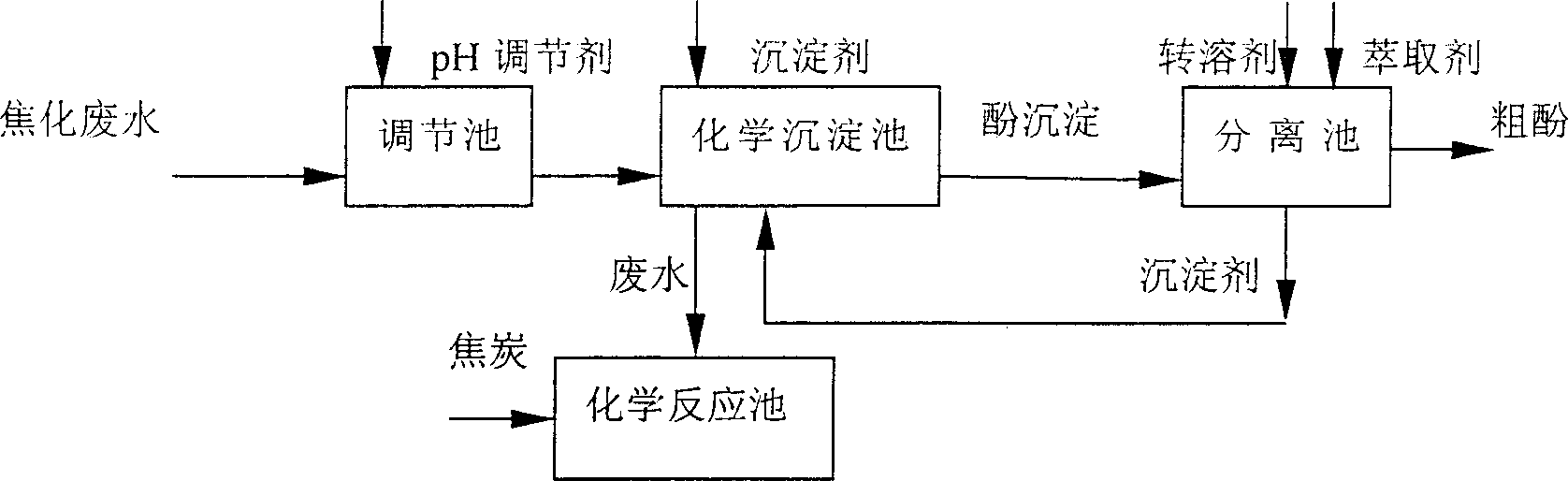

Technique for removing and reclaiming phenol from coke-plant waste water

InactiveCN1789164AOvercoming the defect of not being recycledShort processWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionSorbentWastewater

The invention relates to a method of removing phenol from charring wastewater and the recovery technology, that is to remove and recover phenol matter in the charring wastewater with ion-precipitation method firstly, then reduce the phenol content to a low concentration with coke adsorption method. The technology overcomes the shortcoming of no recovery of the large quantity of phenol with biological dephenolizing method, and is characterized by the short process, convenient operation and settling agents reusage, and develops a new way for phenol removing and recovery for the phenolic waste water. Furthermore, the further treatment of the charring water by employing coke as adsorbent can reduce the yielding water phenol content, and is characterized by simple process and low cost, and provides an economic feasible way for treating phenolic waste water.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

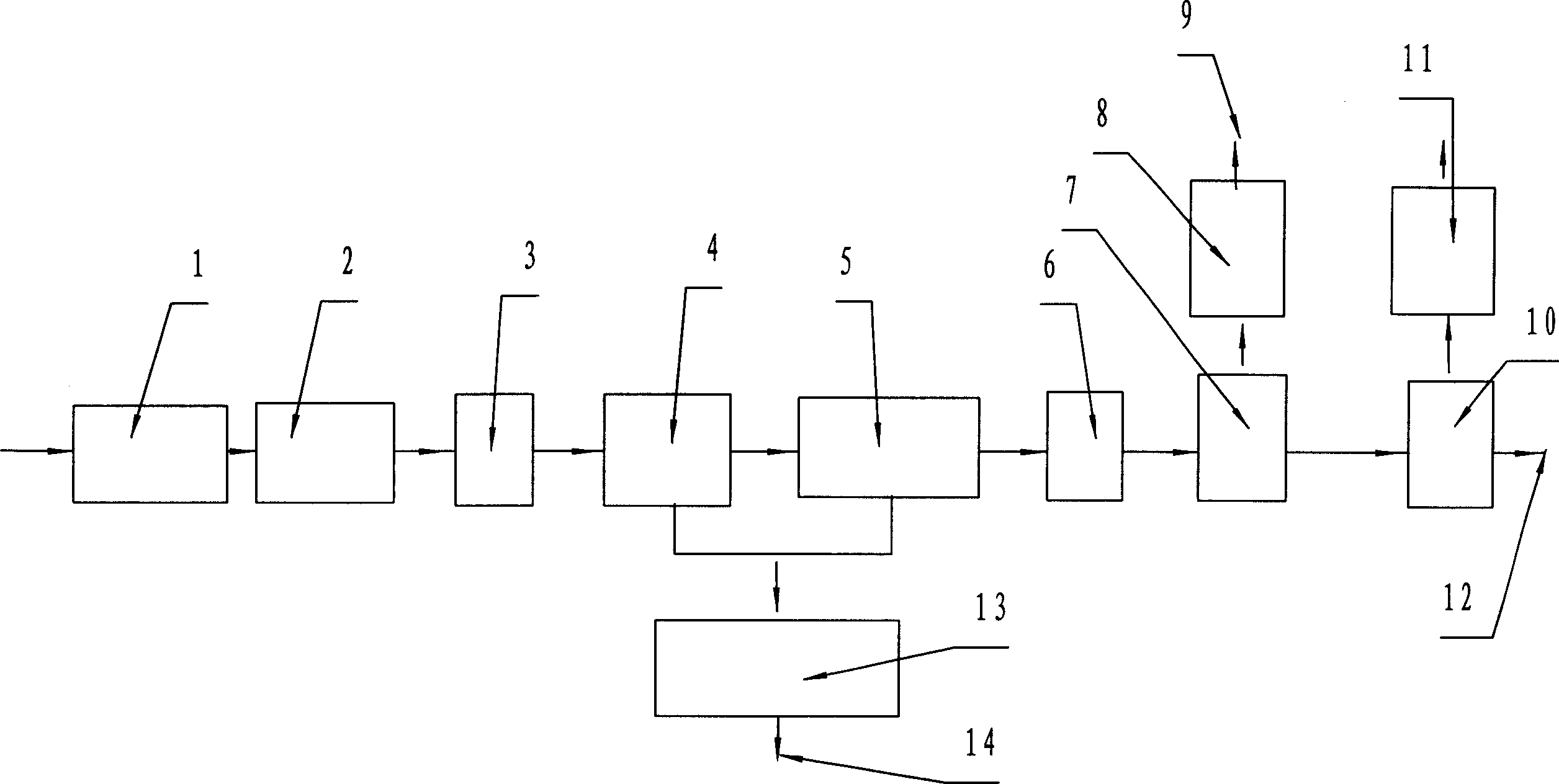

Process for treating coking waste water containing phenol and cyanogen by physical chemistry method and special device therefor

ActiveCN1837077ASimple structureEasy to handleFatty/oily/floating substances removal devicesAmmonium sulfatesWater useChemical treatment

The invention discloses a treatment technology and special equipment of carbonizing phenolic cyanogen waste water by physicochemical method, belonging to the processing technique of waste-water or sewage water, especially the waste-water multistep treatment technique which containing one chemical processing step at least. The technological process of this treatment technology is: air-float de-oiling-ferrum coagulate desulfuration and decyanation-coke adsorption filtration desorption floating precipitate-desorption and stripping NH3-N-ozone oxidation stripping hydroxybenzene and organic matter, the dealed waste-water used as make-up water of coke quenching and coal washing. The treatment technology and special equipment of carbonizing phenolic cyanogen waste water by physicochemical method of this invention has fewer invest and fine dealing effect than traditional treatment scheme, the available resources of waste-water such as tar, ammonia and so on can be reclaimed and utilized effectively, the dealed waste-water is used to coke quenching to reach the dealed waste-water and discharged, the coke quenching discharged gaseous effluent pollutant can reach criterion, not only is the same with waste water disposal of new coke-oven plant, but also is used to the technical betterment of quondam coke-oven factory's waste water disposal system.

Owner:王登富

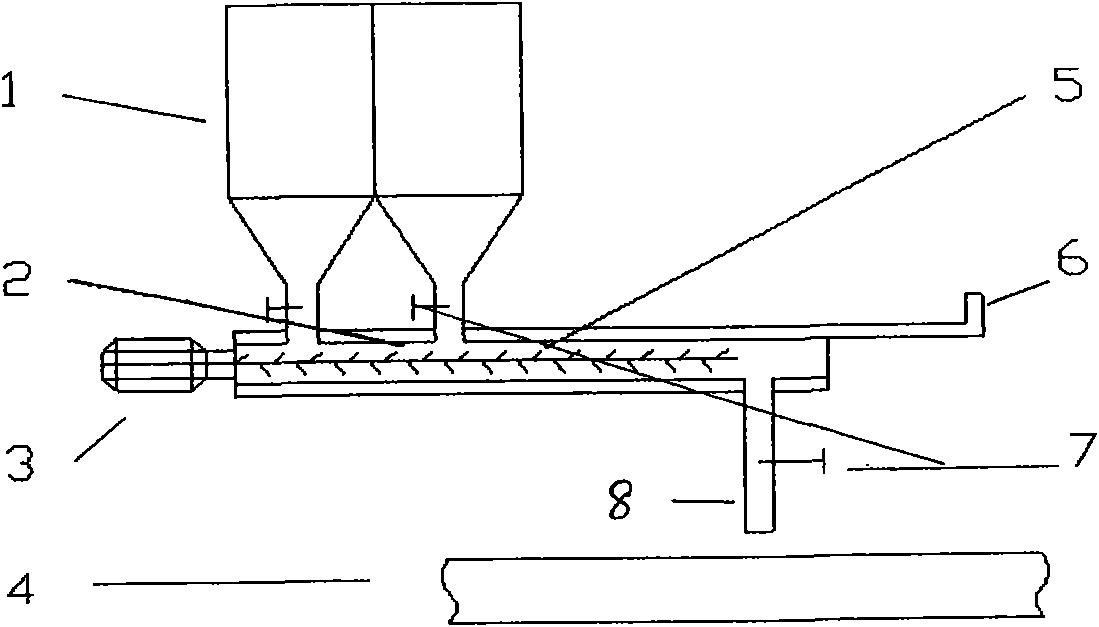

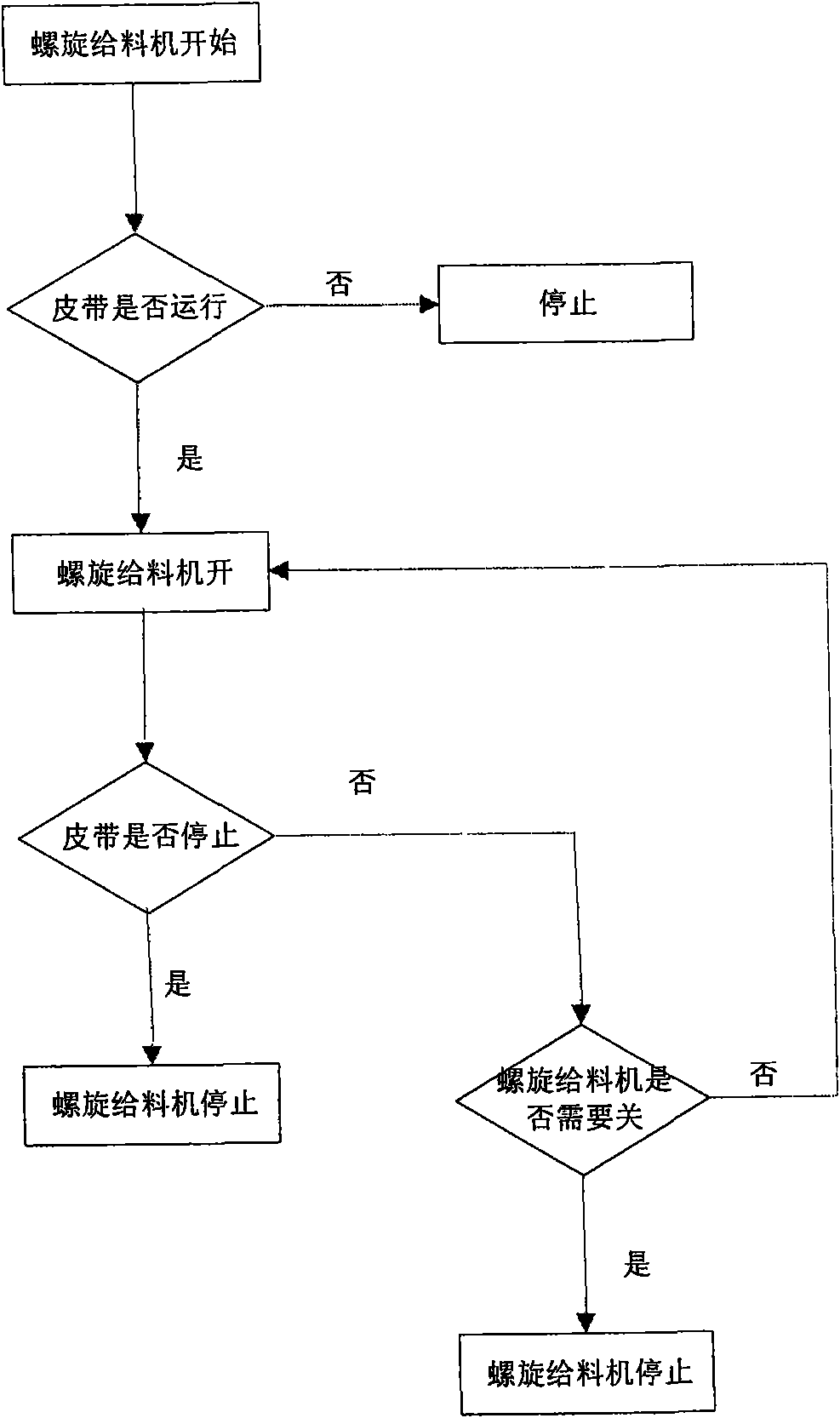

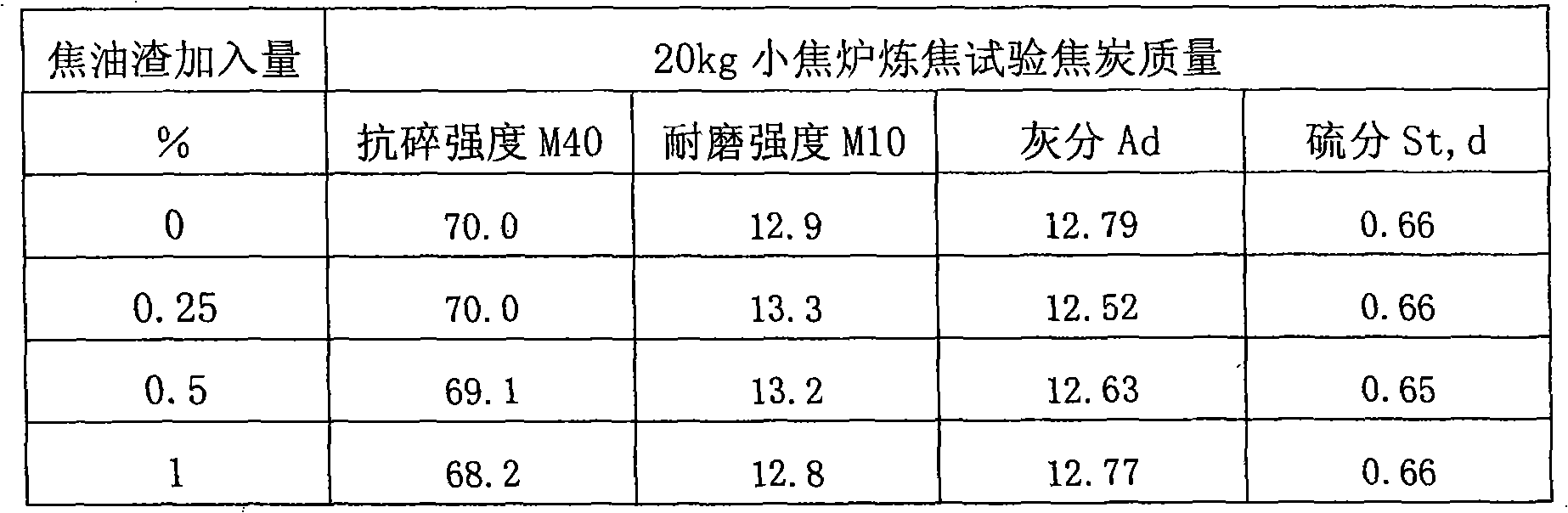

Method and device for coking by coke tar residue and blended coal

The invention relates to the technical field of waste oil residue treatment, in particular to a method and a device for coking by coke tar residue and blended coal, which mainly solve the technical problems that the coke oil treatment cost is high and the environment is polluted. The technical scheme is as follows: the method for coking by coke tar residue and blended coal is characterized by comprising the following steps: coke tar residue is conveyed to a sealed feeding tower by a coke tar residue tank in a steam heating and thermal insulation way; materials are conveyed by a spiral feeder; and the coke tar residue is accurately added into the blended coal through the interlocking control of spiral feeding electric valve and belt operation, wherein the ratio of the coke tar residue is controlled between 0.3% and 0.5% of the weight of the blended coal. The invention is mainly used for treating coke tar residue of coke plants.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

High-temperature coal tar hydrogenation, post-delayed coking and methanol preparation by utilizing coke oven gas combined technology

InactiveCN102634369ACombined CrossoverReduce pollutionOrganic compound preparationHydroxy compound preparationDelayed cokerCoking plant

The invention relates to a high-temperature coal tar hydrogenation, post-delayed coking and methanol preparation by utilizing coke oven gas combined technology. The combined technology comprises the following technologies: (1) a methanol preparation technology by utilizing coke oven gas, (2) a high temperature coal tar hydrogenation technology and (3) a needle coke preparation technology by utilizing a post-delayed coking technology. With the adoption of the combined technology provided by the invention, when a coking plant produces cokes, by-products coke oven gas and high-temperature coal-tar oil are produced, the coke oven gas is used as a raw material for manufacturing methanol, the by-product spread air escape of the methanol is used for preparing hydrogen through a pressure swing adsorption device and then the hydrogen is taken as the raw material for the high-temperature coal tar hydrogenation; the by-product maltha generated by the high-temperature coal tar hydrogenation enters a post-delayed coker, is used as the raw material for manufacturing the needle coke; each productive unit is connected with each step, and a circulation economic model with energy conservation and emission reduction is realized; and therefore, the composite cost is low, the air pollution of the coking plant to surrounding environment is reduced.

Owner:焦云

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com