Patents

Literature

36 results about "Methyl-beta-cyclodextrin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl-β-cyclodextrin is a reagent used to increase the solubility of non-polar substances such as fatty acids, lipids, vitamins and cholesterol for use in cell culture applications.

Chemistry-microorganism combination restoration method of polycyclic aromatic hydrocarbons and heavy metal composite contaminated site soil

InactiveCN102941225ANo secondary pollutionImprove environmental friendlinessContaminated soil reclamationCyclodextrinCoking plant

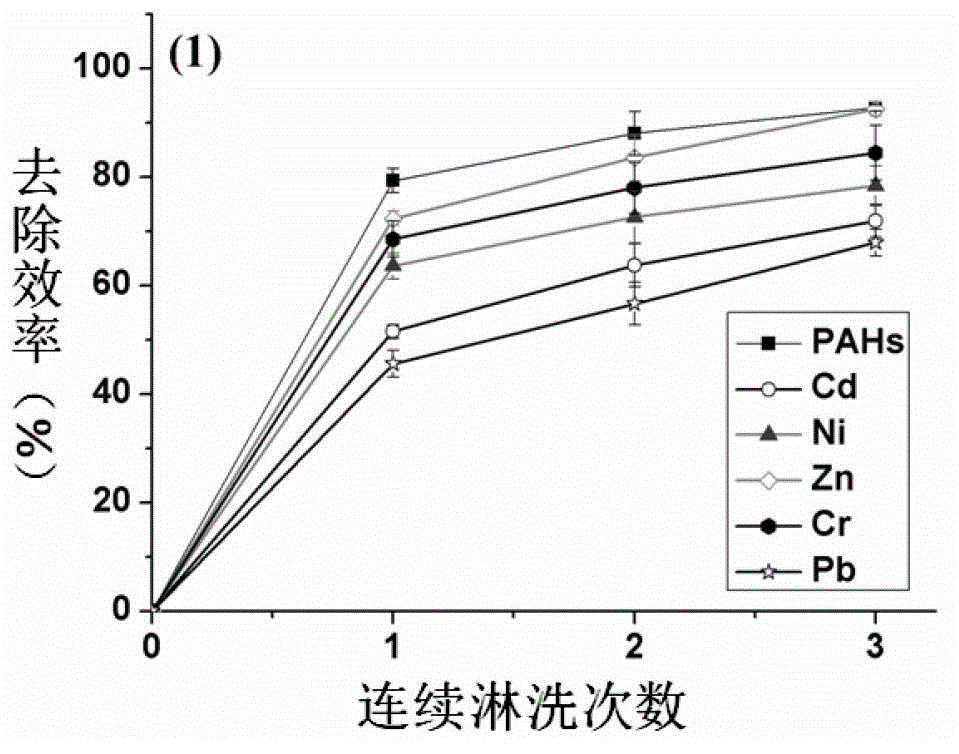

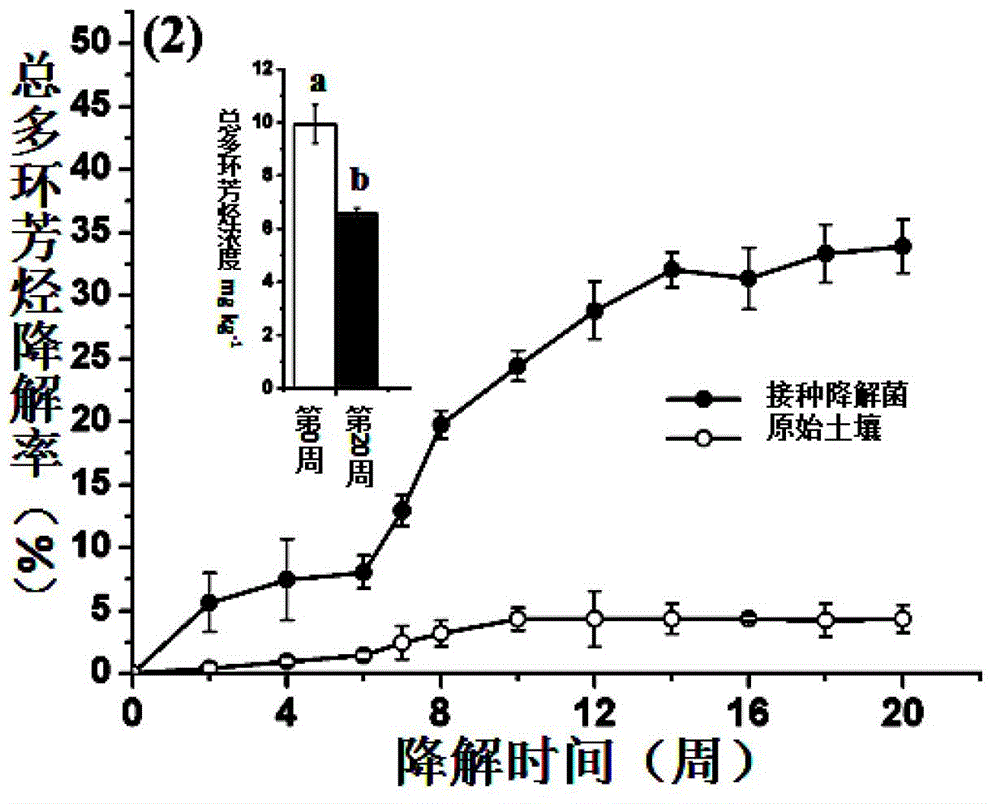

Disclosed is a chemistry-microorganism combination restoration method of polycyclic aromatic hydrocarbons and heavy metal composite contaminated site soil. The method comprises steps of (1), preparing soil particles and air drying and grinding contaminated site soil; (2), setting a restoration system, adding methyl beta cyclodextrin leacheate to a blender; (3), adjusting the reaction temperature to be 50+ / -2 DEG C; (4), adjusting an ultrasonic emission device to 35kHz for ultrasound of 30 minutes; (5) conducting continuous leaching, and repeating the continuous leaching for 3 times; and (6) conducting depth restoration of degrading bacteria, and inoculating polycyclic aromatic hydrocarbons degrading bacteria to soil which is subjected to continuous leaching restoration, adjusting the N / P to be 10:1 and conducting degradation for 90-140 days continuously. By the aid of the method, the restoration of the polycyclic aromatic hydrocarbons and heavy metal contaminated site soil generated by enterprises such as transferred coking plants, steel mills and power plants has wide application prospects.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

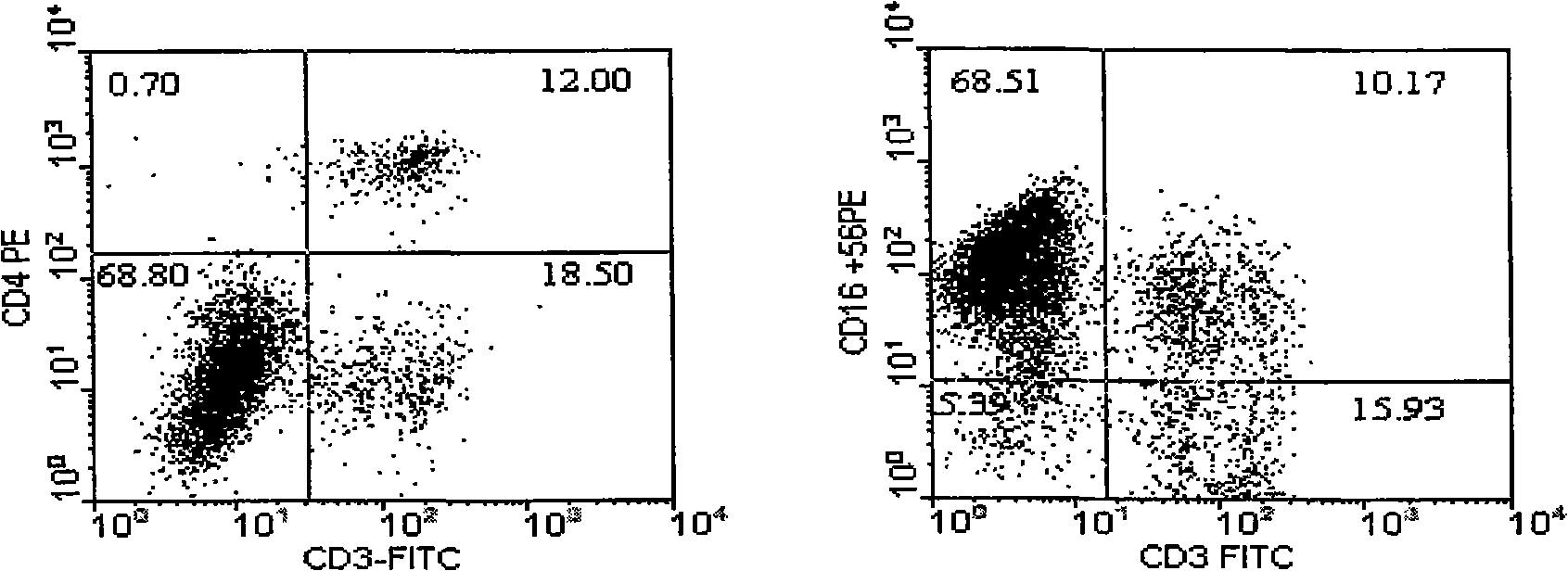

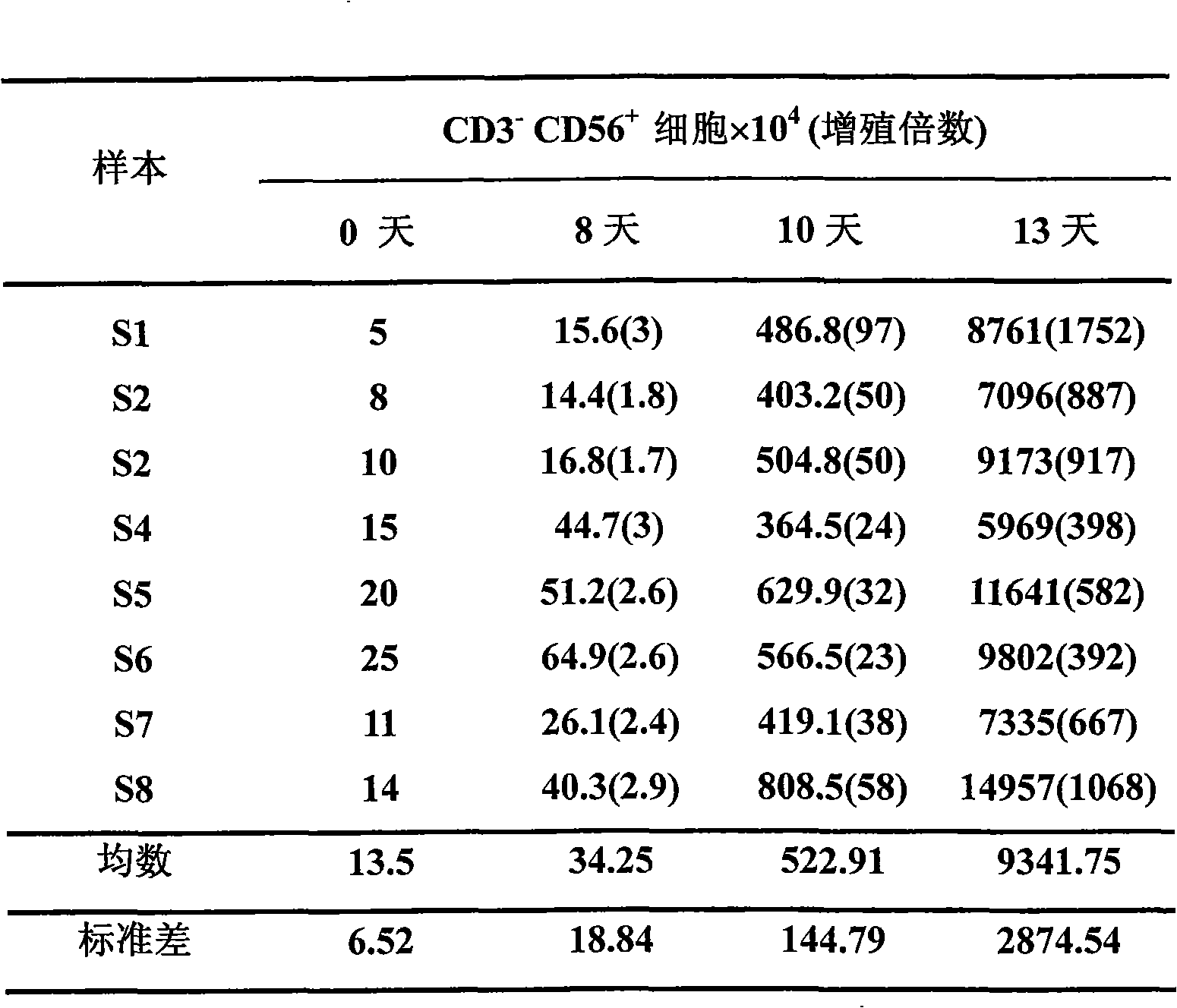

Method for external amplification natural killer cell

InactiveCN101314764AAmplification realizedLow costBlood/immune system cellsMethyl-beta-cyclodextrinInterleukin II

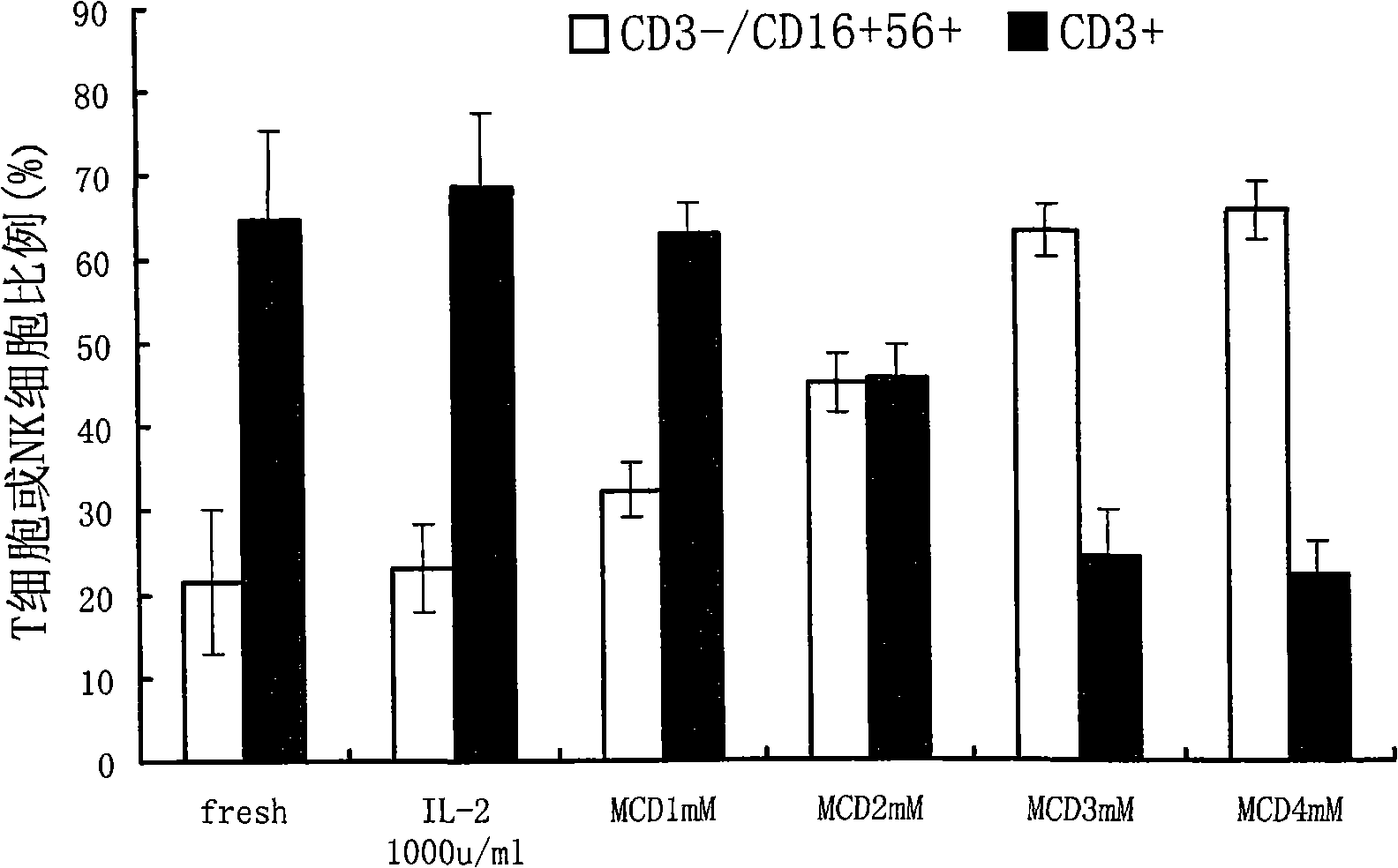

The invention belongs to the technology field of the cellular immunology, and particularly relates to a method for the dominant amplification of in vitro peripheral blood nature killer cells with a large amount. The method comprises the steps as follows: (1) separating single nucleus cell from human or animal peripheral blood; (2) suspending the single nucleus cell in an RPMI 1640 culture solution containing 5%-15% autologous serum and pretreating with methyl-Beta-cyclodextrin with an effective concentration of 1-4mmol / L for 36-60 hours; and (3) adding recombined interleukin 2, and amplification-culturing in an RPMI 1640 culture solution containing 5% of new-born calf serum and 5% of autologous serum for above 10 days. The method has the advantages that the blood sample amount is small; the cost is low; the operation is convenient; and the amplification multiple is high, and the nature killer cells can be amplified by 392-1752 times in a short term.

Owner:BENGBU MEDICAL COLLEGE

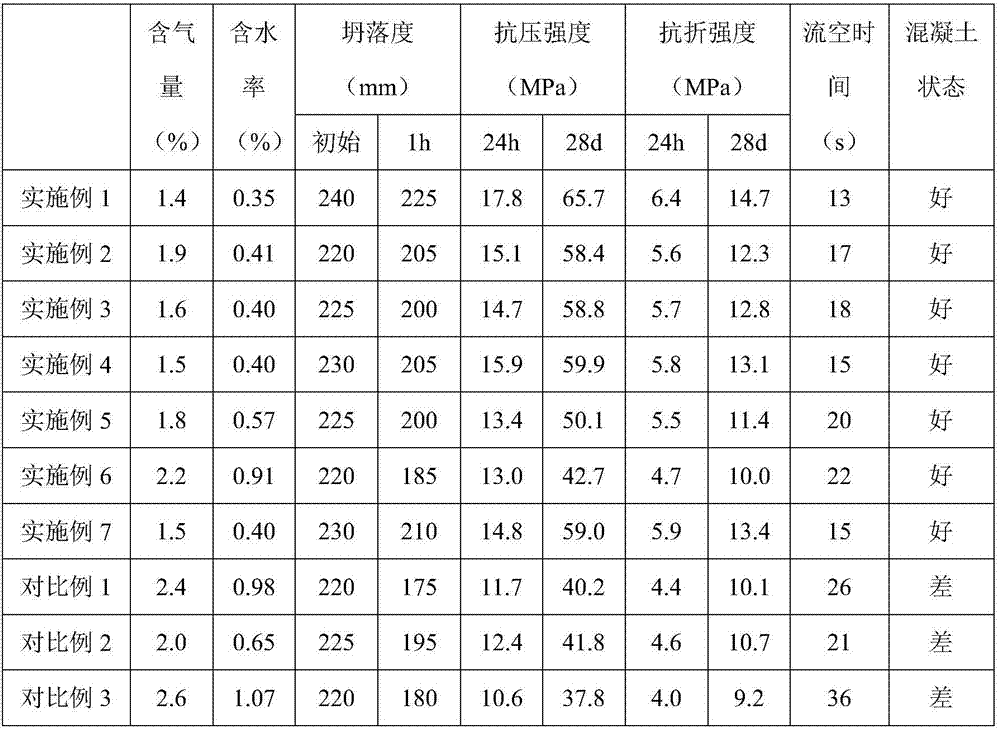

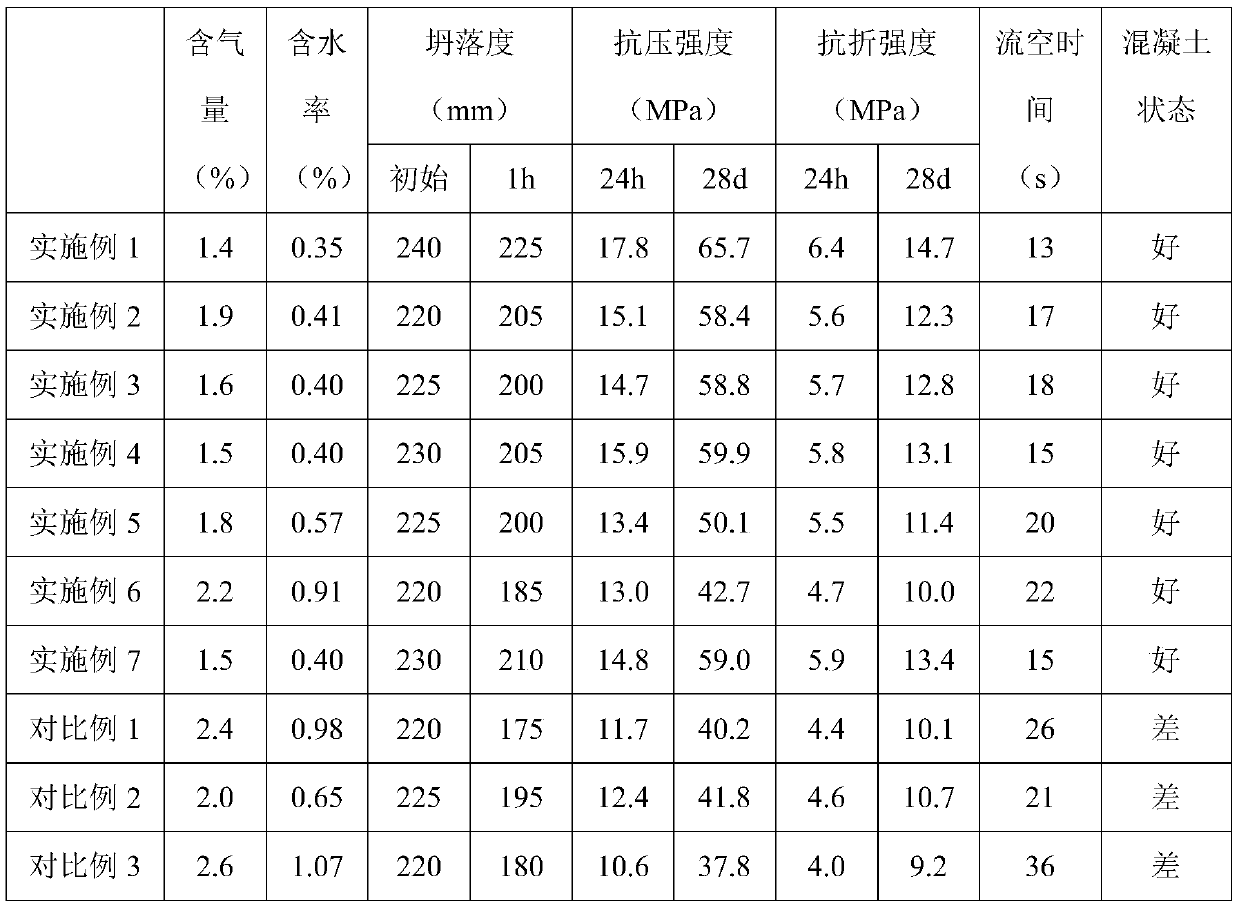

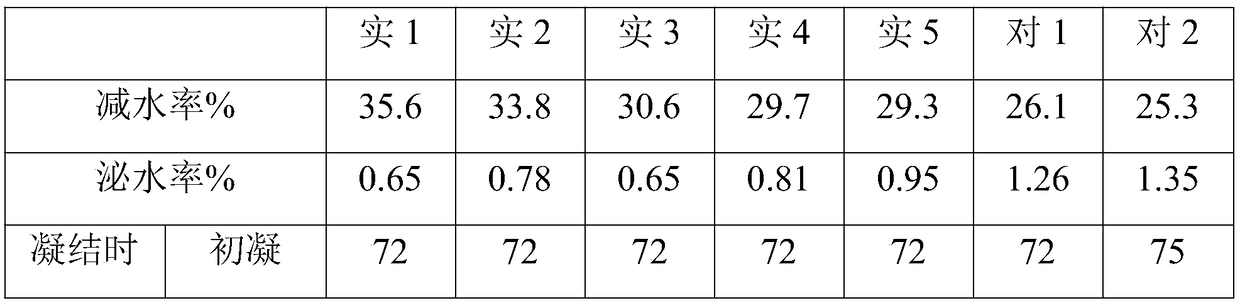

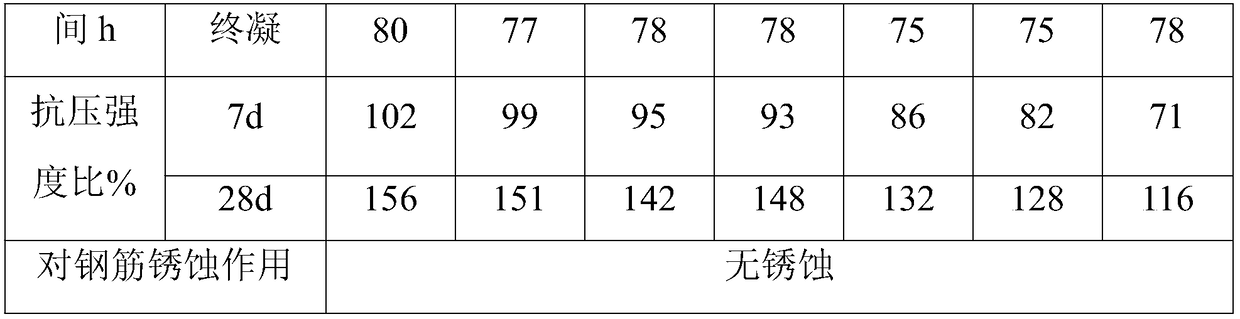

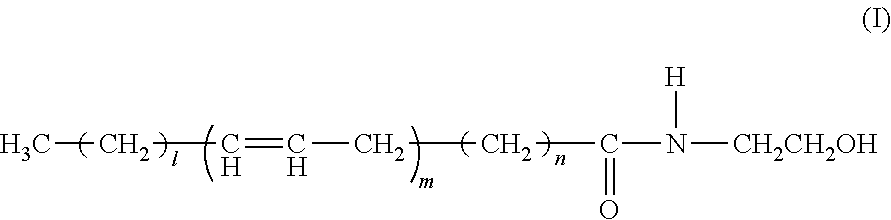

Viscosity reduction type composite polycarboxylic acid water reducing agent and preparation method thereof

The invention provides a viscosity reduction type composite polycarboxylic acid water reducing agent. The viscosity reduction type composite polycarboxylic acid water reducing agent is prepared from a polycarboxylic acid water reducing agent A, a polycarboxylic acid water reducing agent B, a polycarboxylic acid water reducing agent C, a beta-cyclodextrin derivative, methyl-beta-cyclodextrin and de-ionized water, wherein the polycarboxylic acid water reducing agent A is prepared from the following preparation raw materials: isopentenyl polyoxyethylene ether, acrylic acid, an initiator 1, a chain transferring agent 1 and de-ionized water; the polycarboxylic acid water reducing agent B is prepared from the following preparation raw materials: methylallyl polyethylene glycol ether, acrylic acid, sodium methallyl sulfonate, an initiator 2, a chain transferring agent 2 and de-ionized water; the polycarboxylic acid water reducing agent C is prepared from the following preparation raw materials: diallyl capped polyether, acrylic acid, methylallyl polyethylene glycol ether, an initiator 3, a chain transferring agent 3 and de-ionized water; the diallyl capped polyether is prepared by carrying out allylation capping on the methoxy polyethylene glycol through allyl bromide; the beta-cyclodextrin derivative is beta-cyclodextrin modified by sodium dodecyl sulfonate and carbon nanotubes.

Owner:南通瑞特建筑材料有限公司

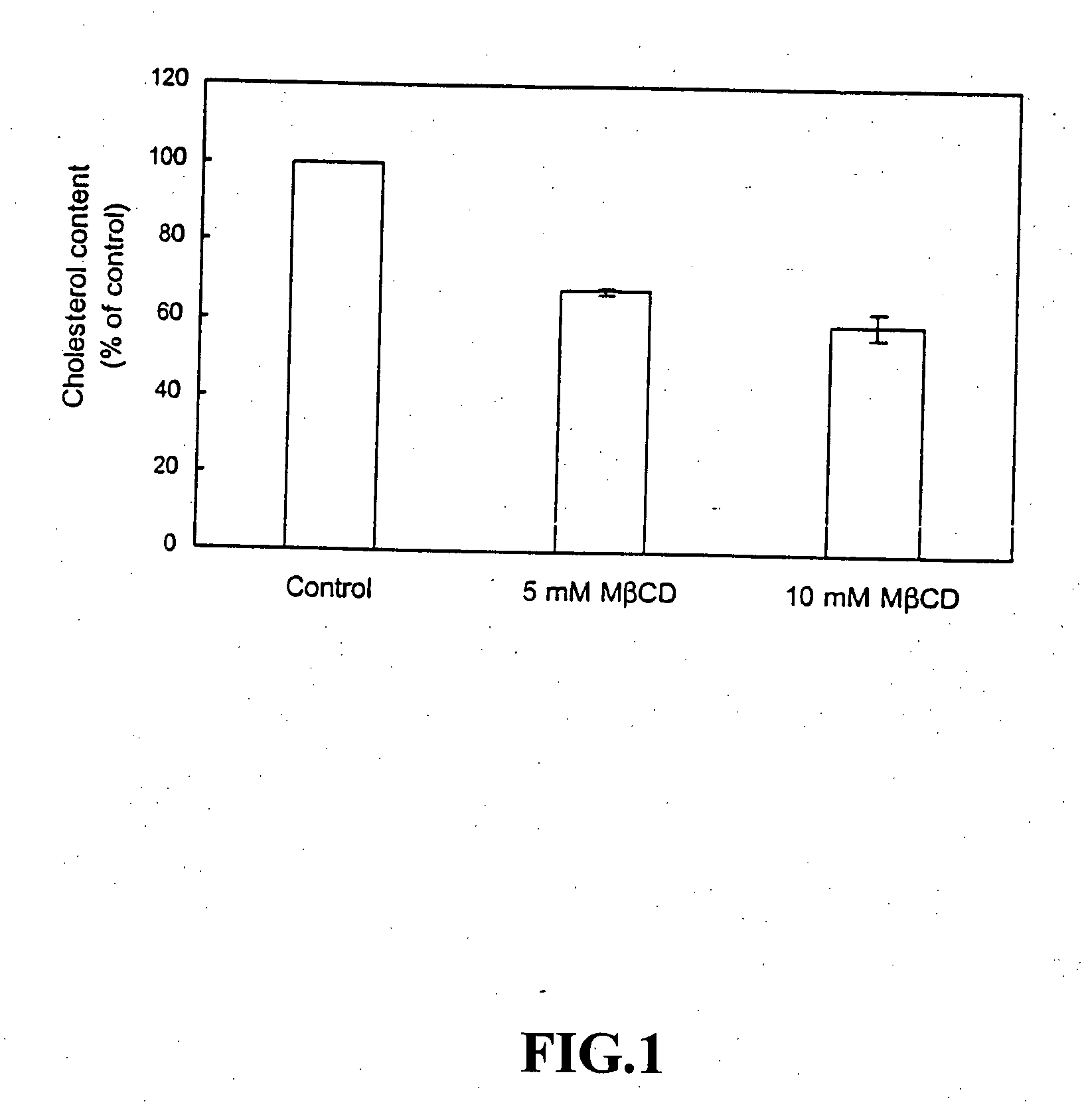

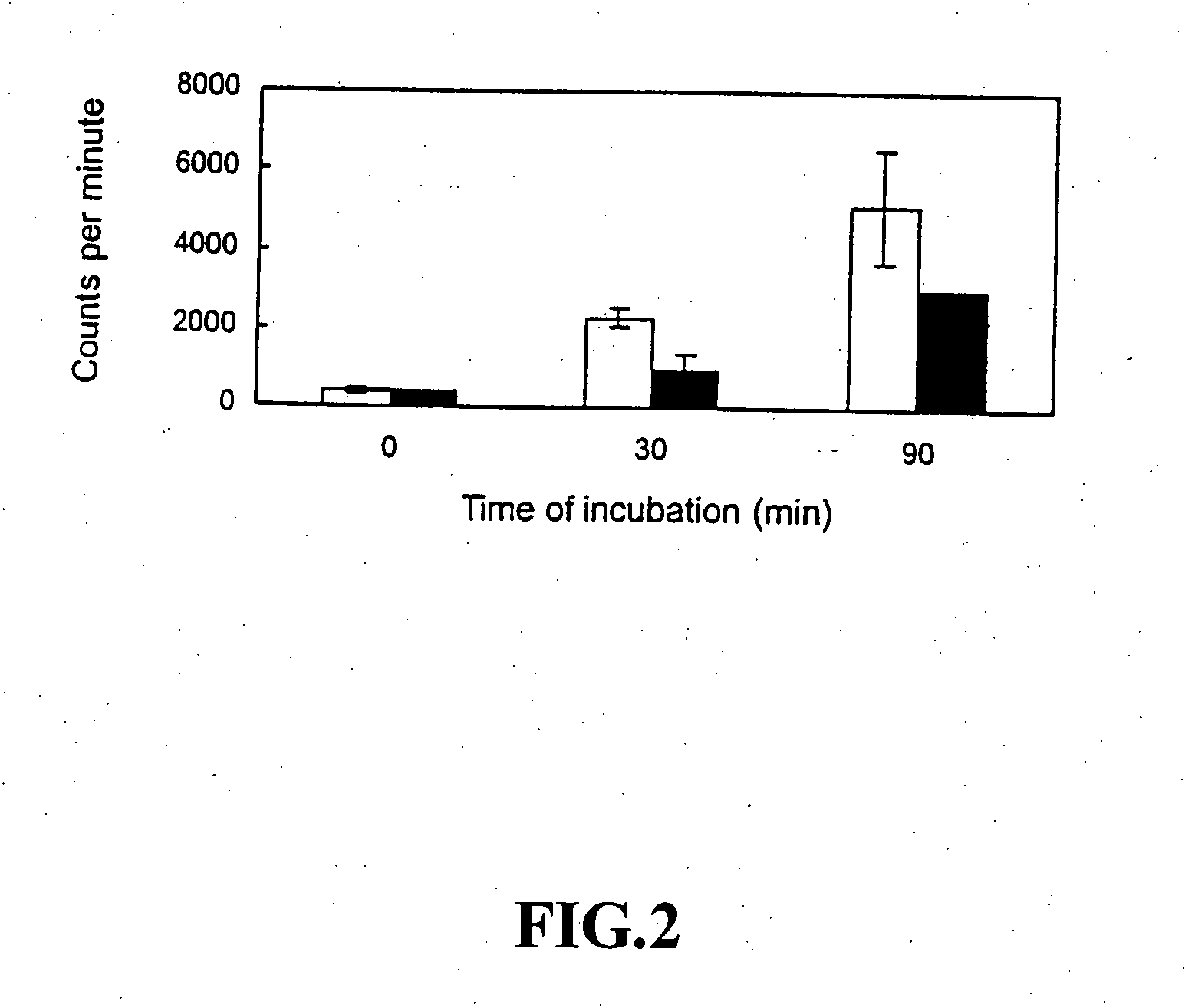

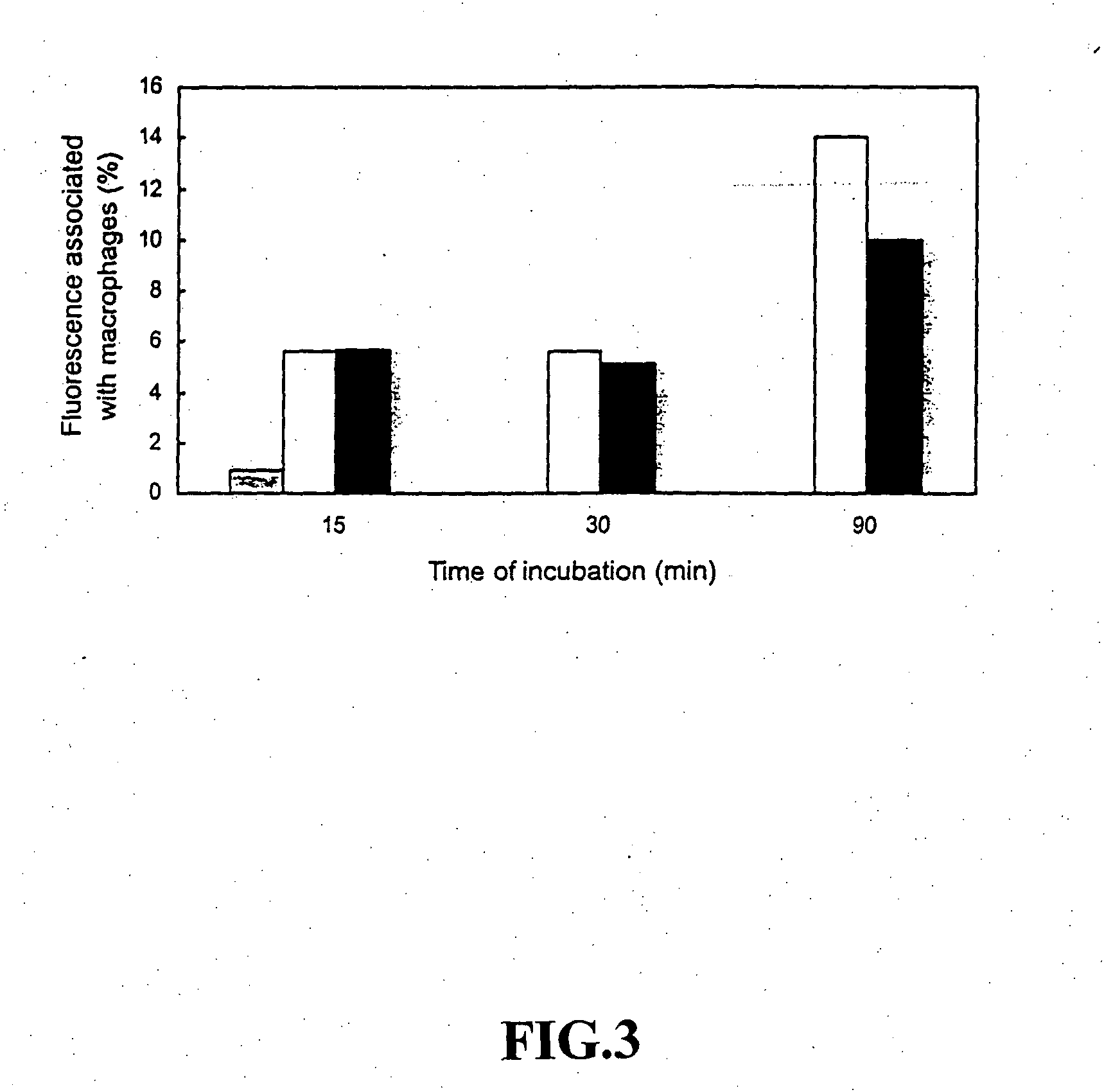

Method for treating leishmaniasis using methyl-beta-cyclodextrin

InactiveUS20040121983A1Safe and efficientSafe and efficient compositionOrganic active ingredientsBiocideMethyl-beta-cyclodextrinCyclodextrin

The present invention relates to a composition useful for the treatment of leishmaniasis said composition comprising pharmaceutically effective amount of methyl-beta-cyclodextrin, optionally along with other anti-leishmanial agent(s) and / or pharmaceutically acceptable additives, and a method thereof, wherein the said method reduces the cholesterol levels of the plasma membrane of the infected host cells by about 50%.

Owner:COUNCIL OF SCI & IND RES

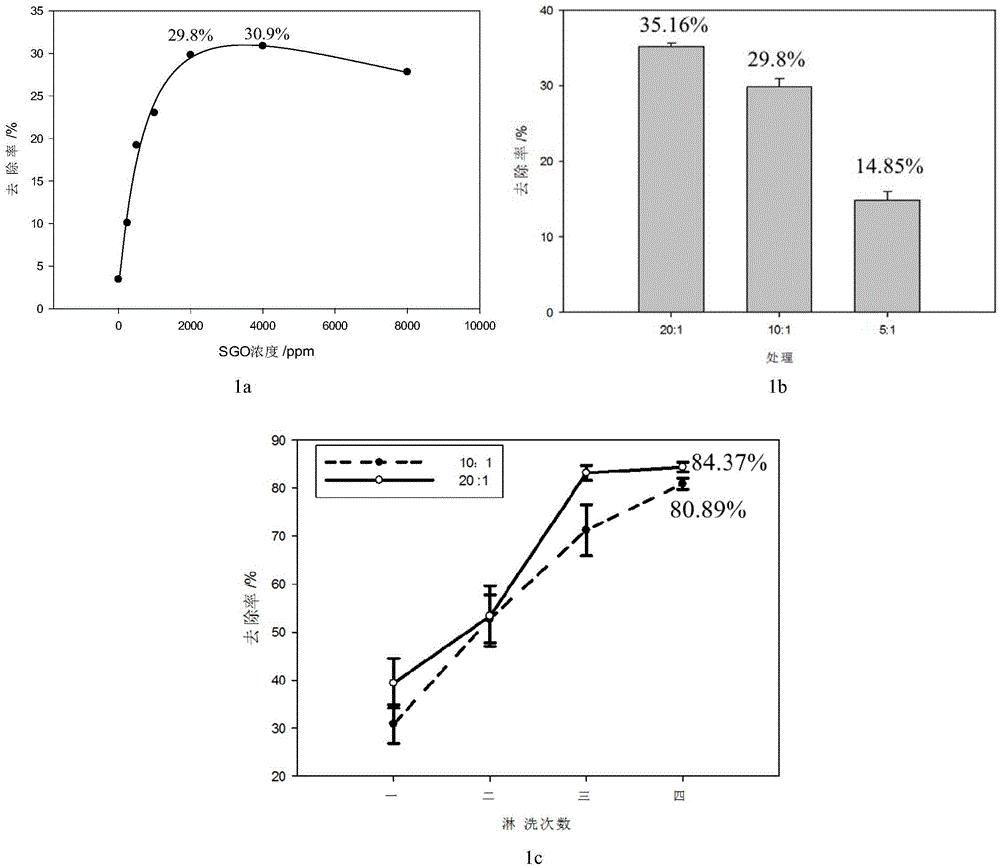

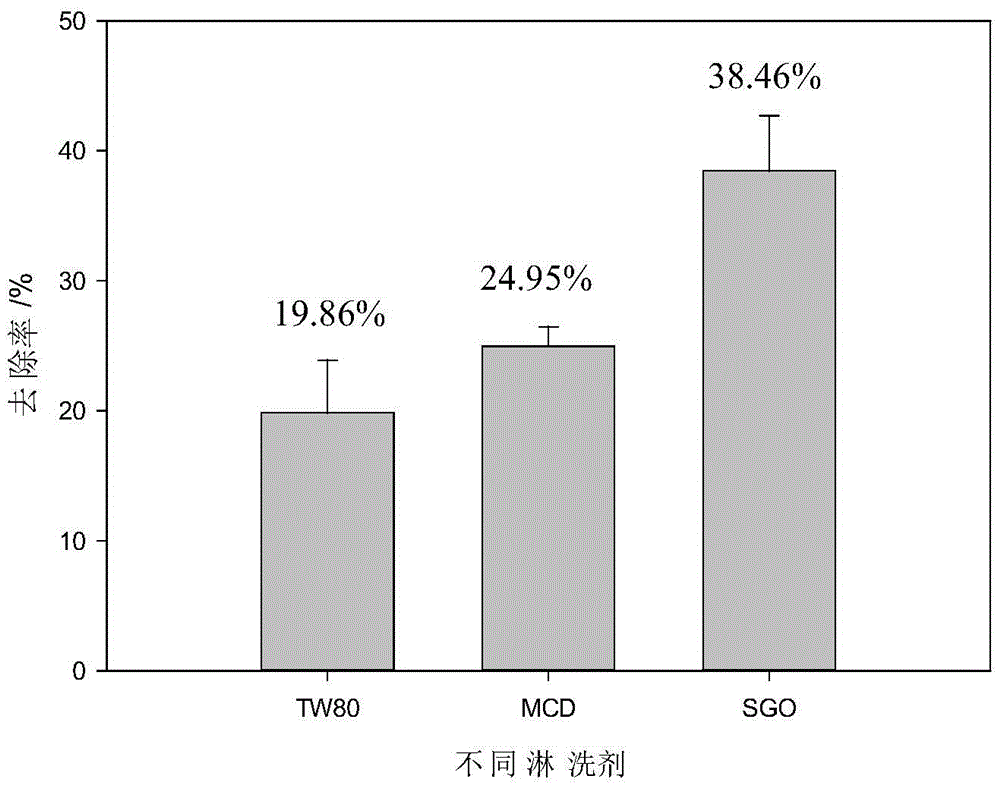

Application of sulfonated graphene oxide in remediation of soil contaminated by polycyclic aromatic hydrocarbons

InactiveCN105537255AEfficient removalHigh removal rateContaminated soil reclamationPolycyclic aromatic hydrocarbonMethyl-beta-cyclodextrin

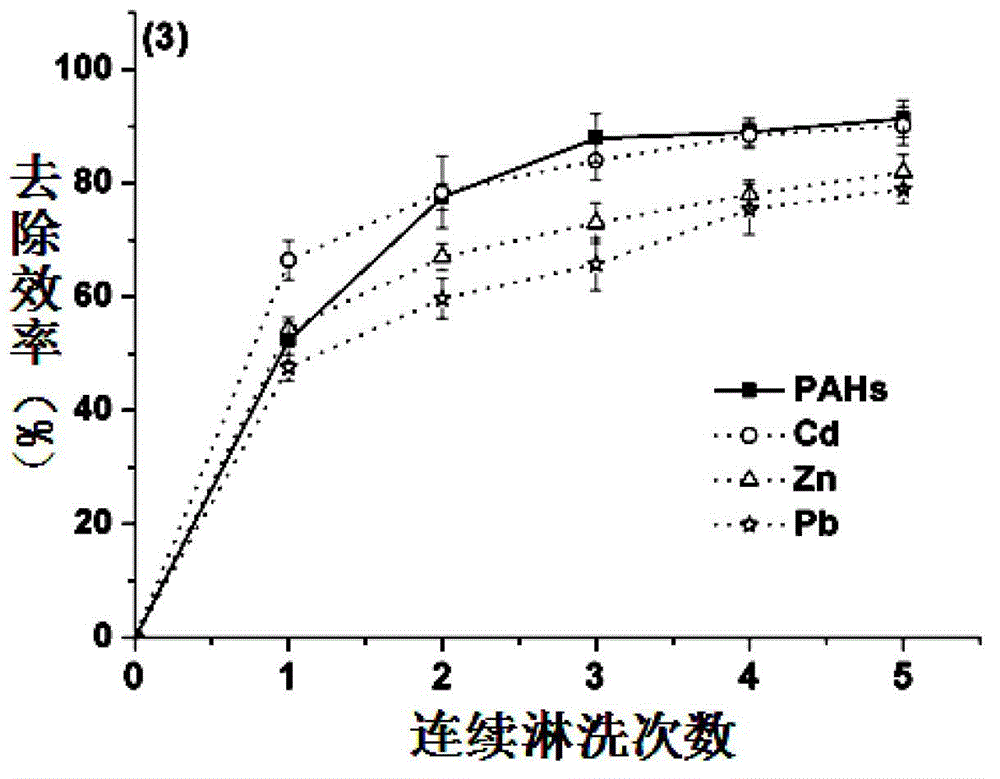

The invention relates to application of a sulfonated graphene oxide in remediation of soil contaminated by polycyclic aromatic hydrocarbons. A sulfonated graphene oxide eluting solution is added to soil according to a soil-solution ratio of 2g: (10-40)mL, and the mixture is put into a centrifugal tube; ultrasonic enhancement is carried out for 30 minutes, and then the centrifugal tube is placed on a shaker for shaking eluting at a room temperature and a speed of150rpm for 24h; and after shaking is completed, the supernatant liquor is abandoned after centrifuging, and then remediation is finished. According to the application of the sulfonated graphene oxide in the remediation of the soil contaminated by the polycyclic aromatic hydrocarbons, the PAHs in the contaminated soil can be effectively removed by using the sulfonated graphene oxide, and the removal rate of the PAHs is above 84%. Under the same eluting conditions (e.g., the eluting solution concentration, the soil-solution ratio, eluting times and the like), the removal rate of the PAHs by eluting the contaminated solution with the SGO is more than 150% and 200% of an eluting removal ratio achieved by using methyl-beta-cyclodextrin (methyl-beta-MCD) and an eluting removal ratio achieved by using polysorbate (TW80), respectively.

Owner:SUZHOU GRAPHENE NEW MATERIAL TECH +1

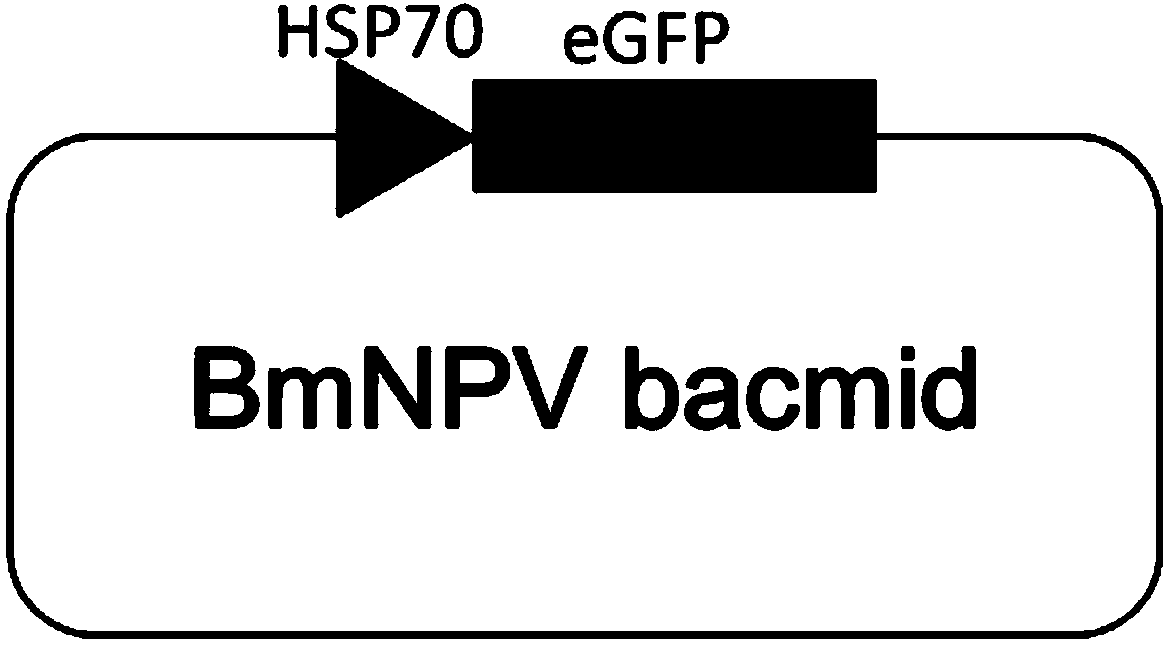

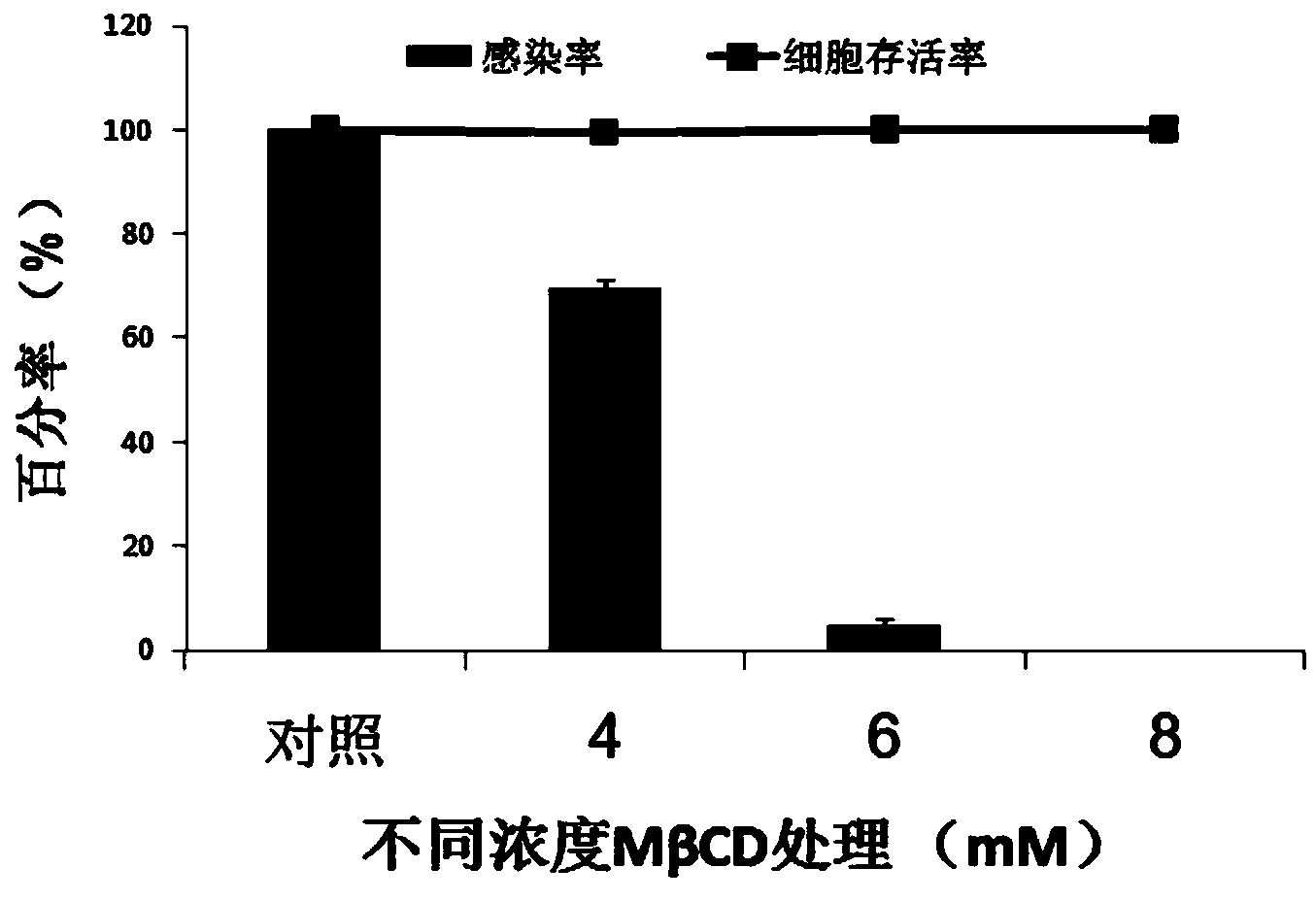

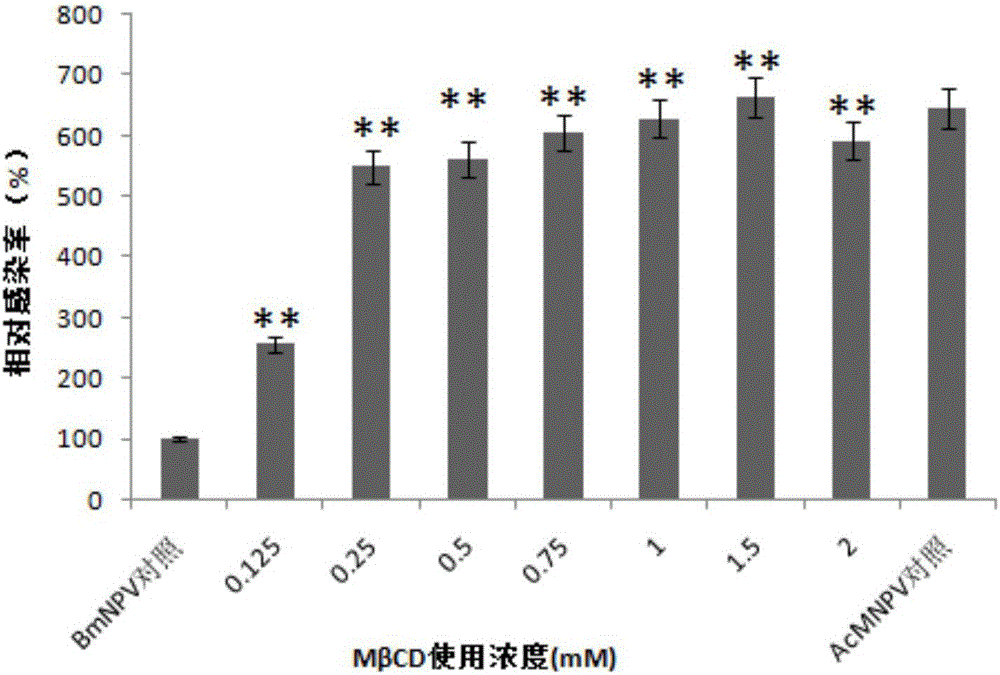

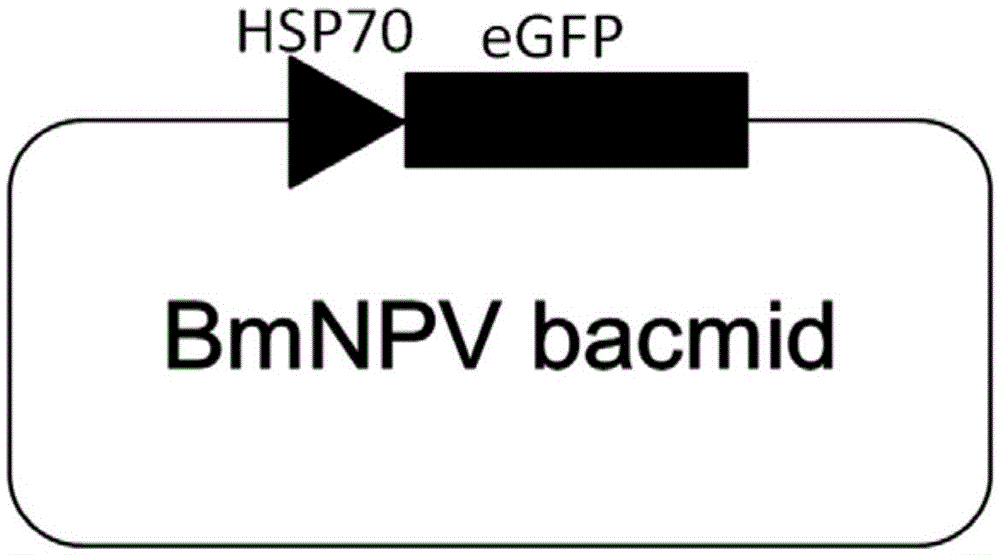

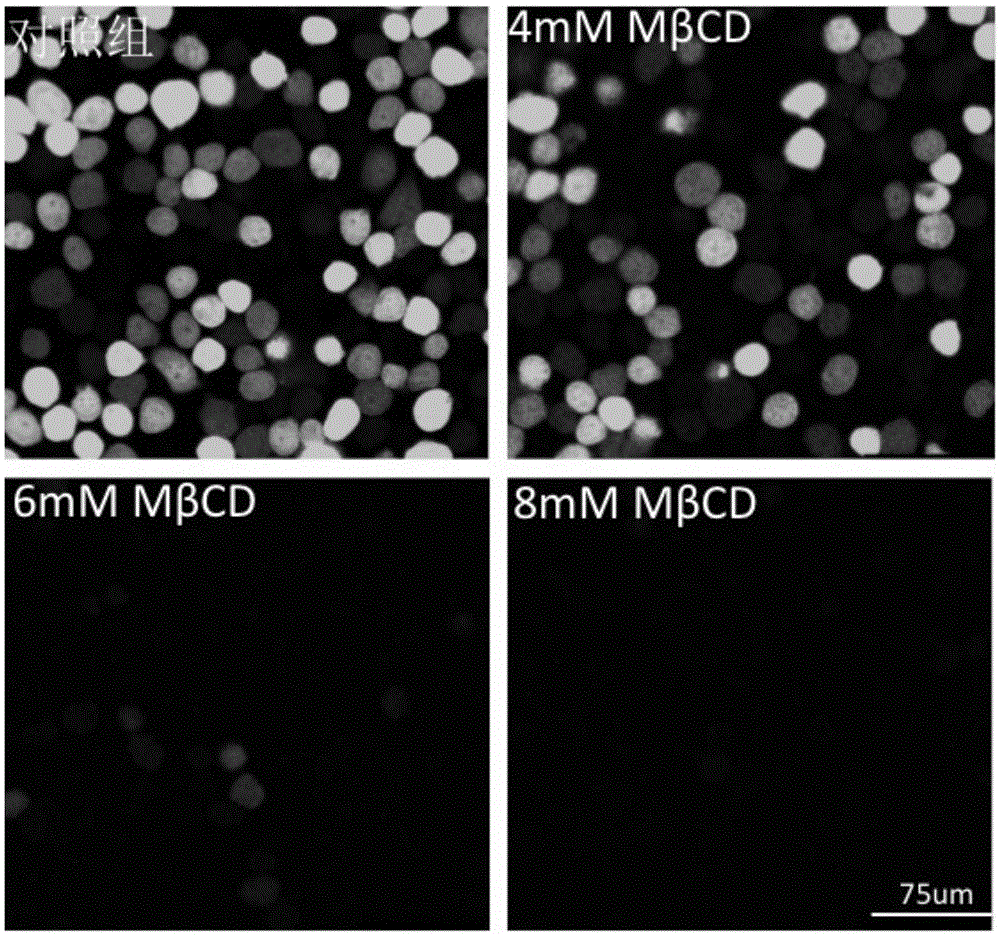

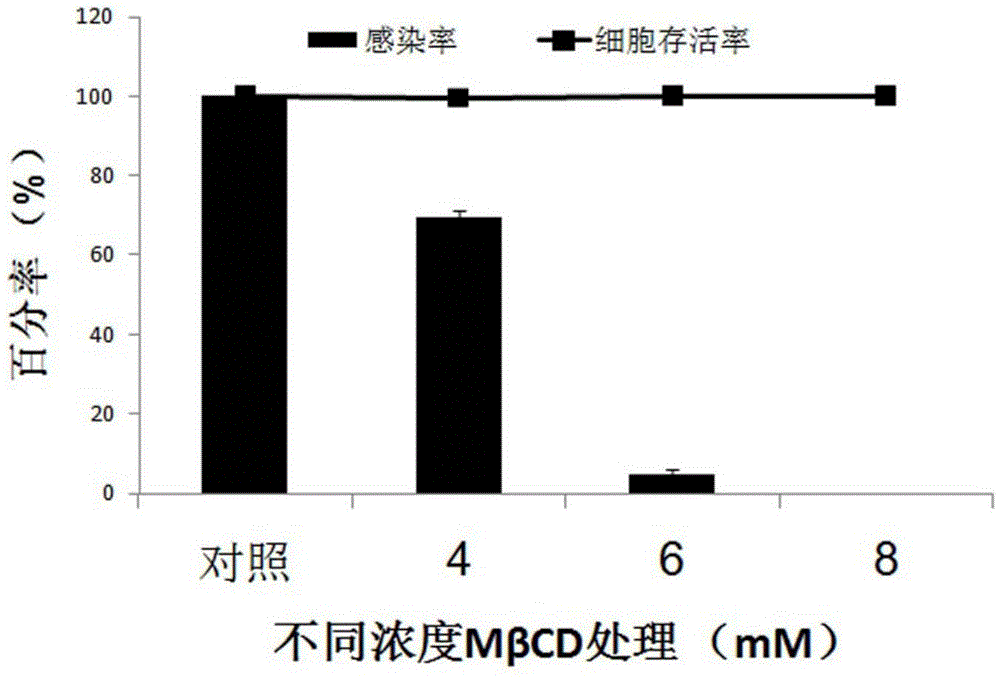

Application of methyl-beta-cyclodextrin in preparation of medicines for preventing and controlling BmNPV from infecting silkworm cells

InactiveCN104027347AAvoid infectionOrganic active ingredientsAntiviralsMethyl-beta-cyclodextrinBombyx mori

The invention discloses application of methyl-beta-cyclodextrin in preparation of medicines for preventing and controlling BmNPV from infecting silkworm cells and provides a medicine which takes MbetaCD as an active ingredient and is used for preventing and controlling BmNPV from infecting cells. The medicine has significance in intensive research on virus invasion mechanisms and the research aspect of receptors of hosts infected by baculovirus. When the MbetaCD concentration is over 8mM, the virus infection can be completely inhibited. The medicine has important application and popularization values in research and development and production of silkworm medicines for controlling grasserie.

Owner:JIANGSU UNIV OF SCI & TECH

Easy-to-wash active printing thickener

InactiveCN105113297AEasy to prepareEasy to operateDyeing processSodium bicarbonateMethyl-beta-cyclodextrin

The invention discloses an easy-to-wash active printing thickener. The easy-to-wash active printing thickener comprises the following raw material components in parts by weight (100 parts in total): 44-80 parts of a thickening component, 4-20 parts of a washing component, 1-5 parts of a stabilizer component, 2-30 parts of a filling component and 0.1-1 part of a wetting component, wherein the washing component is selected one or more of polyvinylpyrrolidone, sodium dodecyl sulfate, beta-cyclodextrin, methyl-beta-cyclodextrin, 2,6-dimethyl-beta-cyclodextrin, sodium metasilicate pentahydrate, sodium bicarbonate and trisodium phosphate. The active printing thickener has the advantages that the raw material components is wide in source, can dispense with sodium alginate and is relatively low in cost, and on the premise of meeting the printing demand, washing and paste removal are easy, the hand feeling is soft, the stability is good, the comprehensive performance is quite the same as sodium alginate, the cost is relatively low, and a wide application value is achieved.

Owner:SHANGHAI ANOKY GRP +5

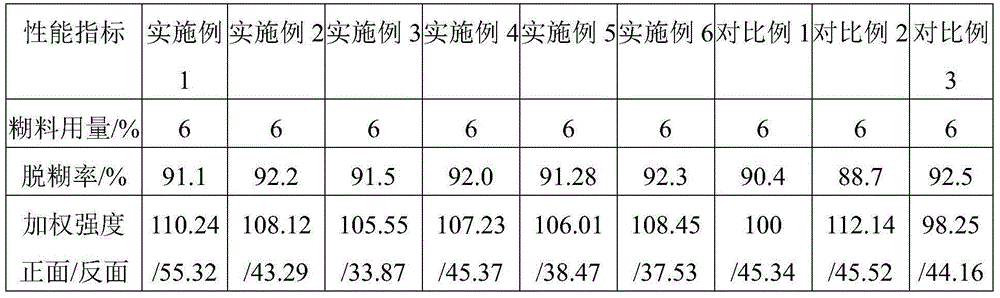

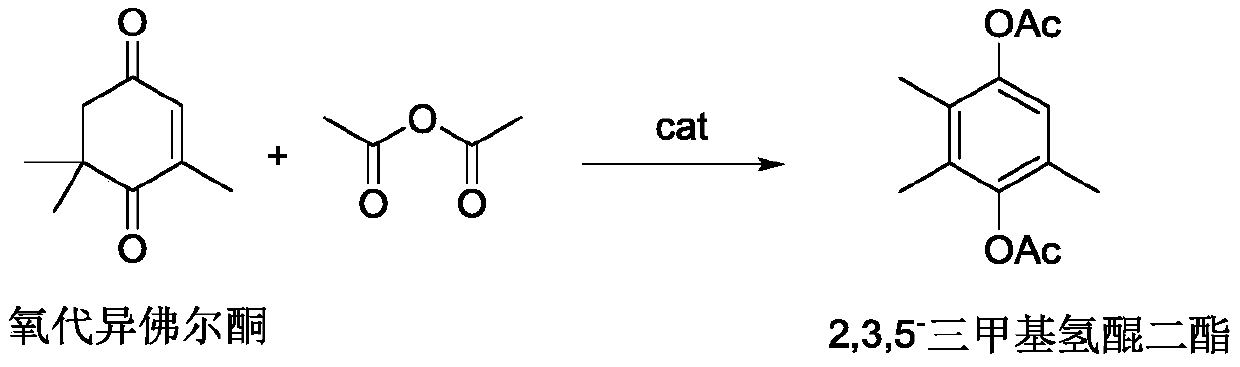

Preparation method of 2,3,5-trimethyl hydroquinone diester

ActiveCN109970553AImprove bindingStrong binding forceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMethyl-beta-cyclodextrinAcetic anhydride

The invention discloses a preparation method of 2,3,5-trimethyl hydroquinone diester. According to the preparation method, oxo-isophorone and acetic anhydride carry out rearrangement and acylation under the catalytic action of a modified cyclodextrin supported solid acid to prepare 2,3,5-trimethyl hydroquinone diester. The solid acid is loaded on poly(allyl amine) modified methyl-beta-cyclodextrin; the reaction conditions are mild, the oxo-isophorone conversion rate and the product selectivity are high, the catalyst can be repeatedly used, and the shortages of a conventional preparation technology such as bad selectivity, severe equipment corrosion, complicated operation, and the like, are overcome.

Owner:WANHUA CHEM GRP CO LTD

Green synthesis method of 2-O-methyl-6-O-(2-hydroxypropyl)-beta-cyclodextrin

InactiveCN104558253AImprove conversion rateGreat application potentialSynthesis methodsMethyl carbonate

The invention discloses a green synthesis method of a new compound 2-O-methyl-6-O-(2-hydroxypropyl)-beta-cyclodextrin. The method comprises the following steps: in the presence of anhydrous K2CO3 or anhydrous Na2CO3, reacting beta-cyclodextrin and dimethyl carbonate in a dimethylformamide organic solvent, after the reaction is complete, filtering to remove the anhydrous K2CO3 or anhydrous Na2CO3 and other insoluble substances, distilling under reduced pressure to remove the solvent, and concentrating the solution; precipitating out the product with acetone, and filtering to obtain 2-O-methyl-beta-cyclodextrin; dissolving the obtained 2-O-methyl-beta-cyclodextrin in a 30% sodium hydroxide solution, dropwisely adding quantitative epoxypropane at certain temperature, after the reaction is complete, adding hydrochloric acid to neutralize to neutrality, and distilling to obtain a white solid; and dissolving in dimethylformamide, filtering to remove the salt, pouring the filtrate into acetone to obtain a white precipitate, repeatedly washing with acetone, and finally, immersing in aether to obtain the white powder solid product 2-O-methyl-6-O-(2-hydroxypropyl)-beta-cyclodextrin. The method has the advantages of simple technological conditions, high conversion rate of beta-cyclodextrin and environment friendliness.

Owner:FUJIAN UNIV OF TECH

Reinforced reactive injectable bone cement and preparation method thereof

InactiveCN106267365AGood injectabilityGood bone conductionPharmaceutical delivery mechanismTissue regenerationSelf-healingBone cement

The invention discloses a reinforced reactive injectable bone cement and a preparation method thereof. The bone cement comprises the following components: tricalcium phosphate, polylactic acid, calcium sulphate, coral powder, ferulic acid, silk fibroin, talcum powder, barium sulfate, cervus and cucumis polypeptide, gastrodin, vitamin C, zinc oxide, tantalum oxalate, PEEK(polyether-ether-ketone), polyvinylpyrrolidone, methyl-beta-cyclodextrin, maleyl chitosan and normal saline. The injectable bone cement provided by the invention is excellent in syringeability, the compressive strength and the bending strength are high, and the mechanical property requirements of a bone repair material are met. In addition, the bone cement provided by the invention is good in cell compatibility, is relatively good in osteoconduction, is convenient for promoting the self-healing repair of bone tissue, and improves the firmness in the combination of the bone cement and bone, thereby well meeting clinic application requirements.

Owner:林春梅

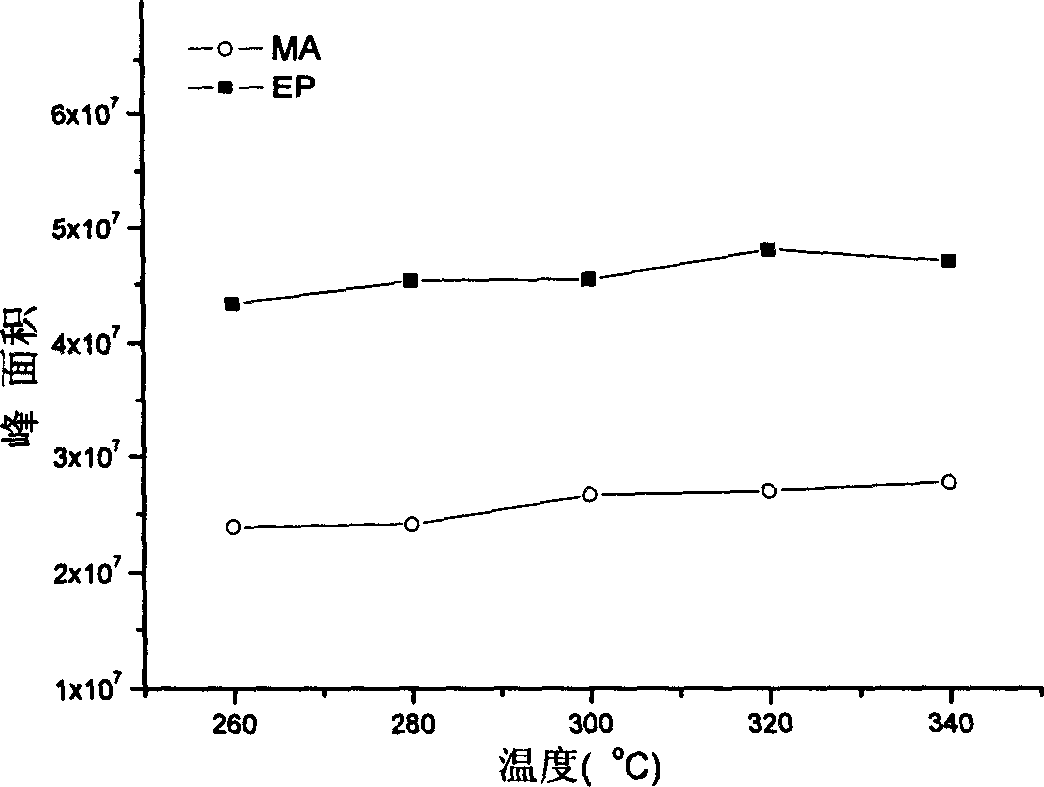

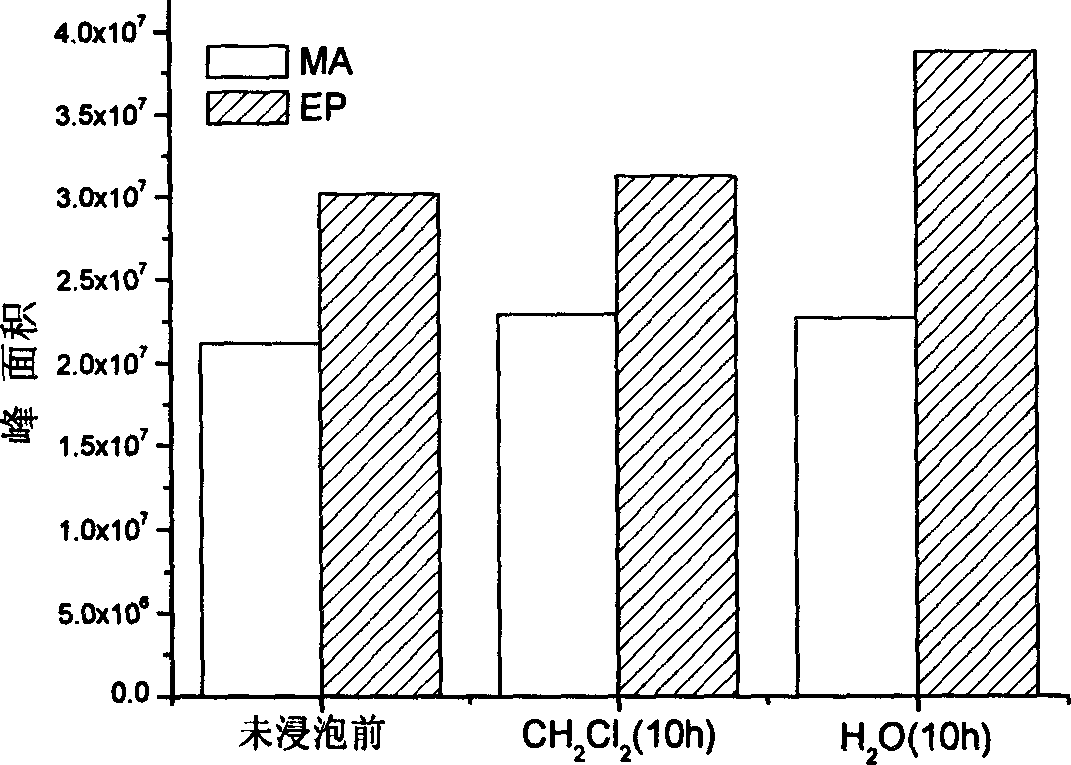

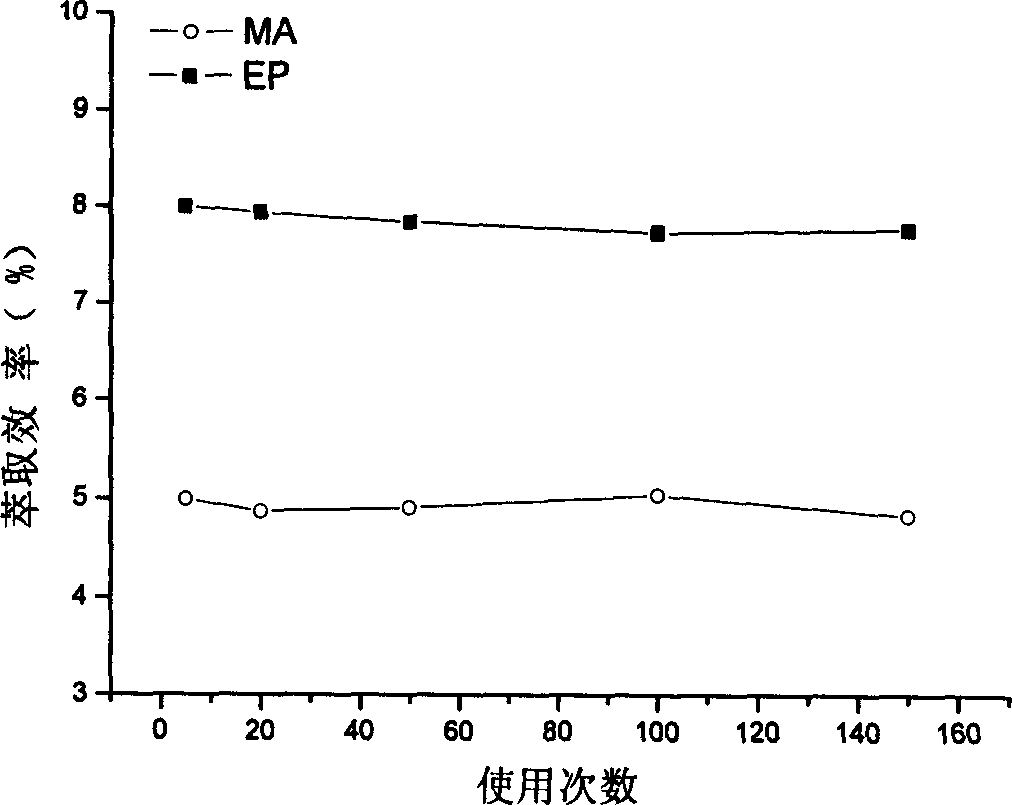

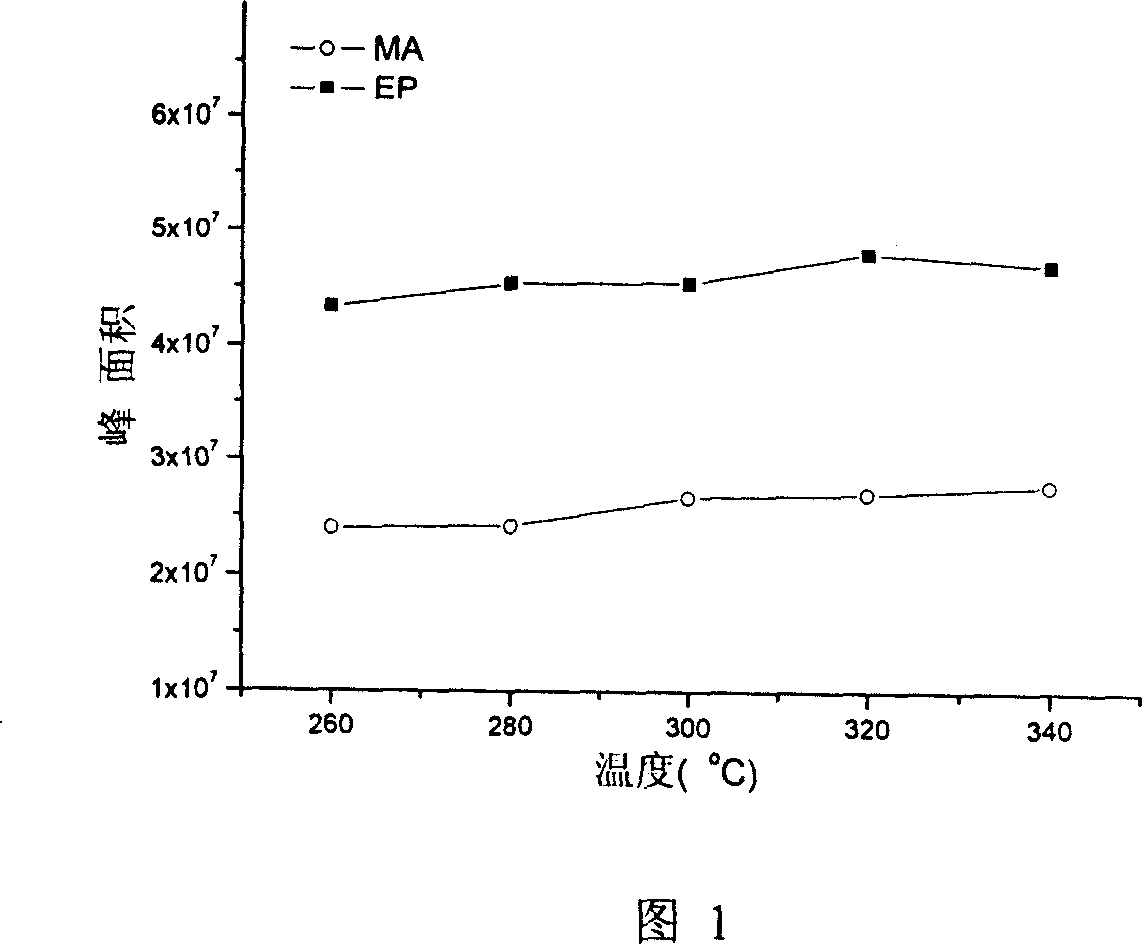

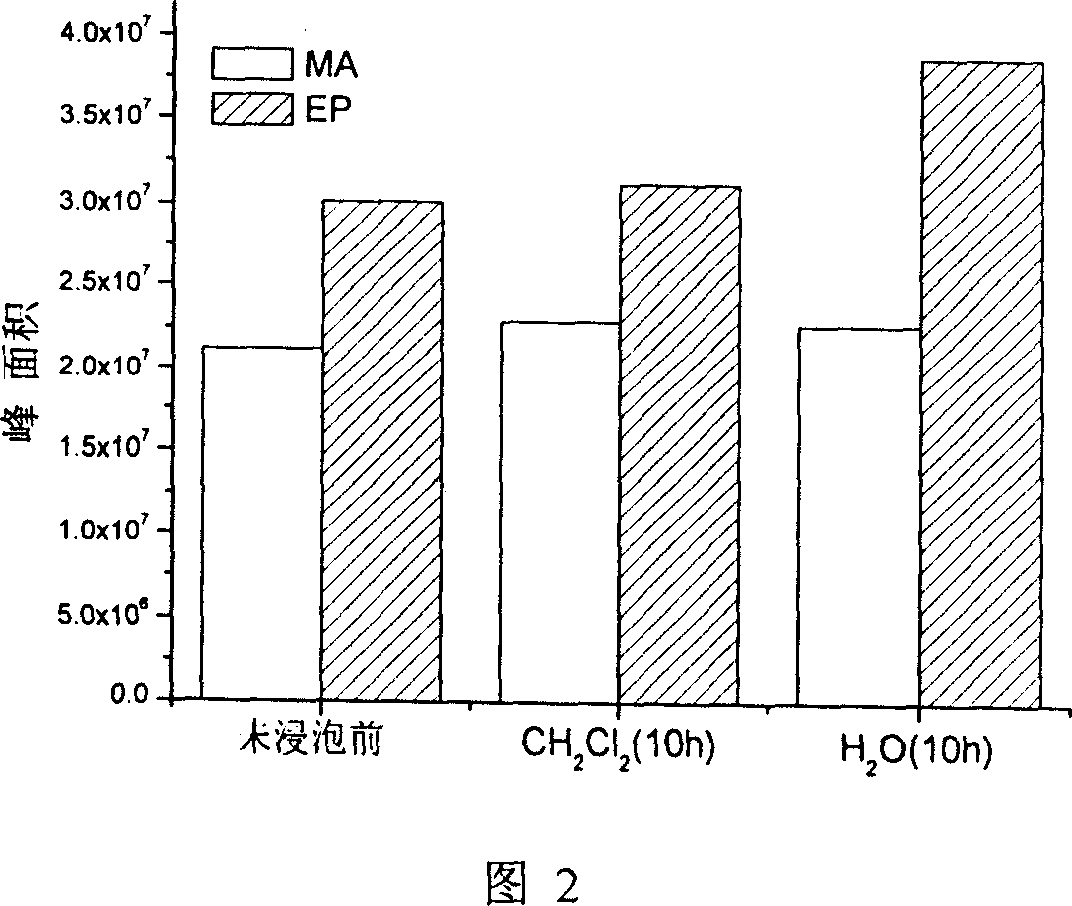

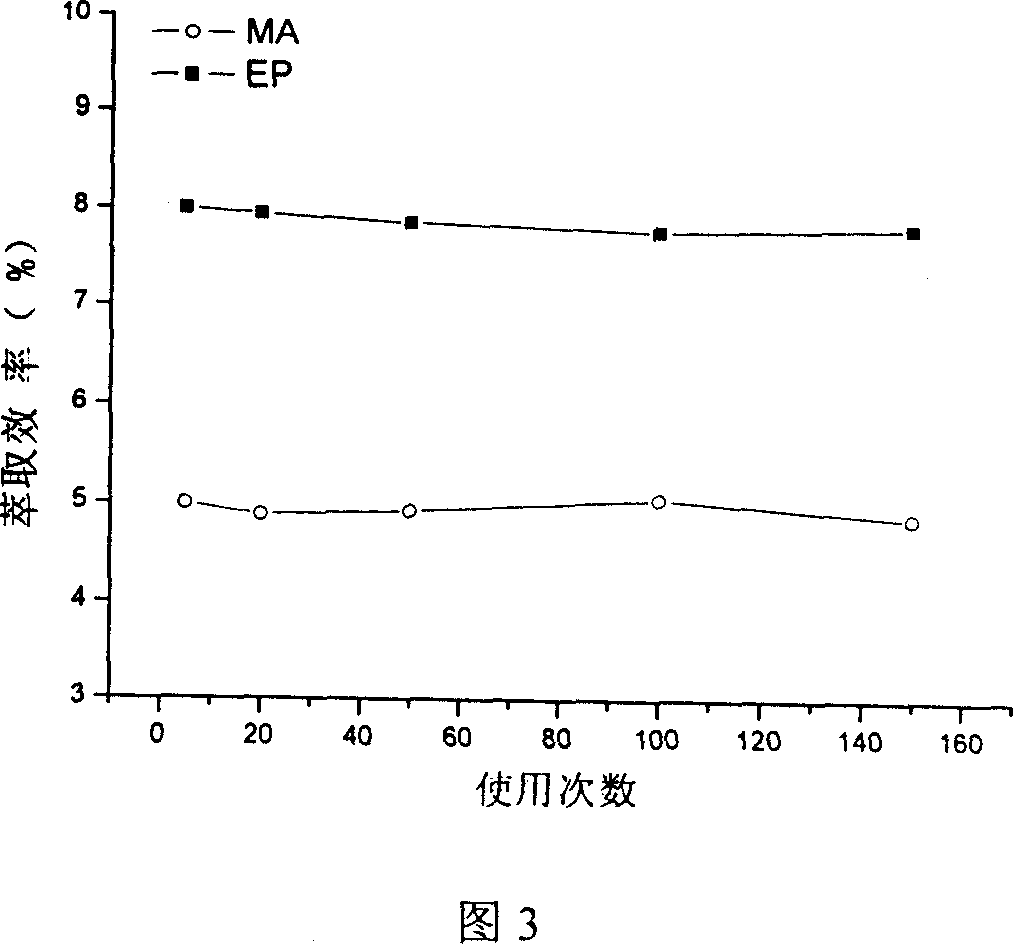

Extracting head for solid phase micro extraction of dextrin derivative and its making process

The extracting head for solid phase micro extraction of cyclodextrin derivative includes quartz fiber and its coating and the coating is composite coating of 2, 6-di-oxy-methyl-beta-cyclodextrin and hydroxyl silicon oil bonded to the surface of the quartz fiber. The preparation process of the extracting head includes the following steps: diluting 2, 6-di-oxy-methyl-beta-cyclodextrin with dichloromethane, adding hydroxyl silicon oil, tetraethoxy silane, 3-(2, 3-epoxy propane) propyl trimethoxy silane and water containing trifluoro acetic acid, adding hydrogen-containing silicon oil, ultrasonic vibration and centrifuging, and taking supernatant; inserting one end of the quartz fiber after eliminating protecting layer and drying into the sol liquid, taking out, drying and ageing under the protection of nitrogen to obtain the extracting head. The present invention has high heat stability, high solvent flush resistance, long service life, high in Benzedrine medicine capacity and excellent application foreground in medicine analysis, including stimulant detection.

Owner:WUHAN UNIV

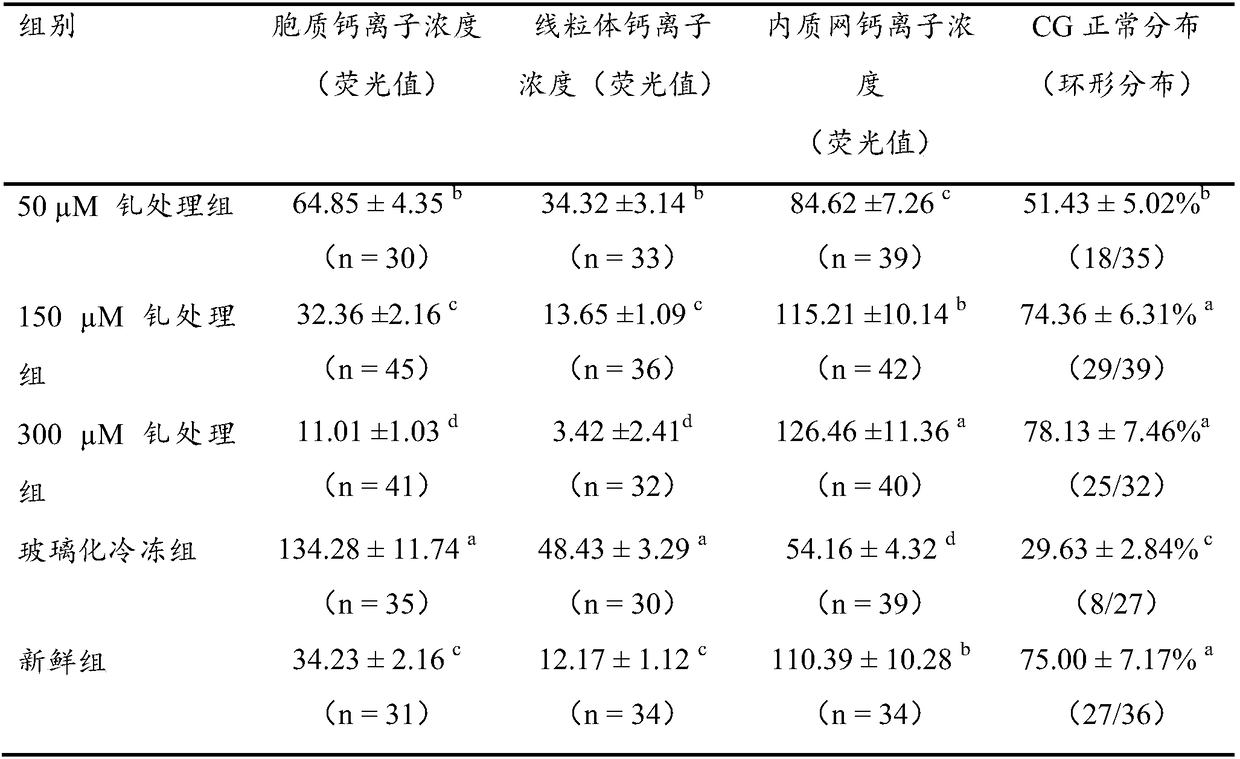

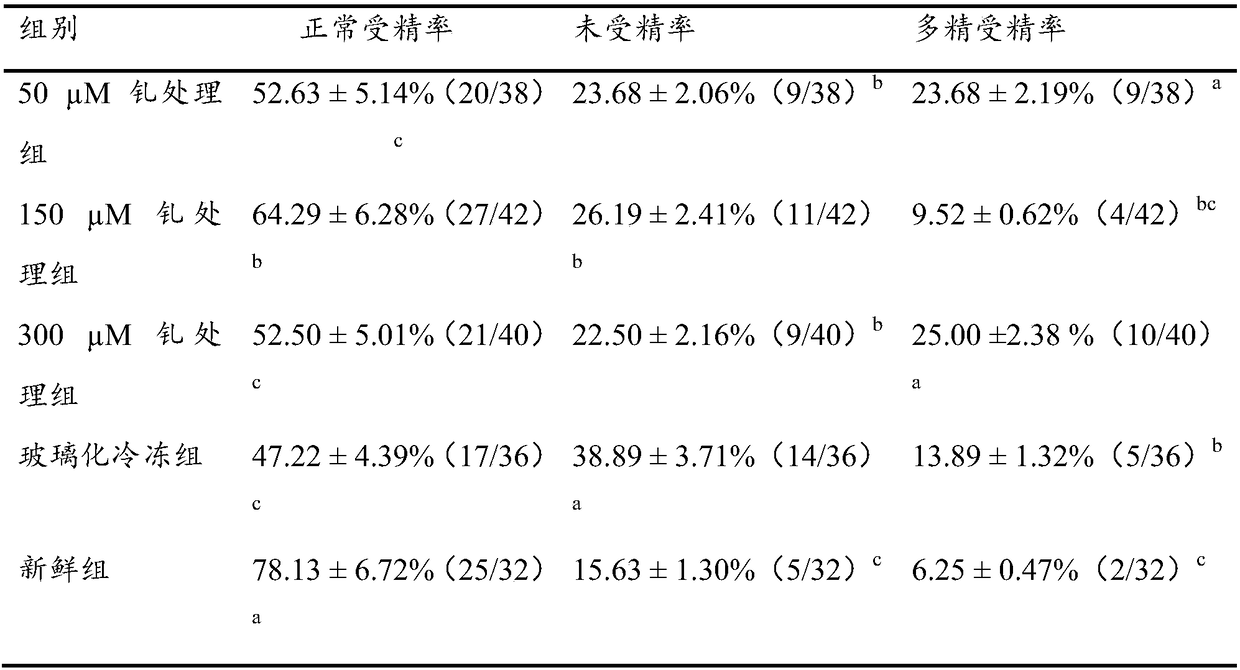

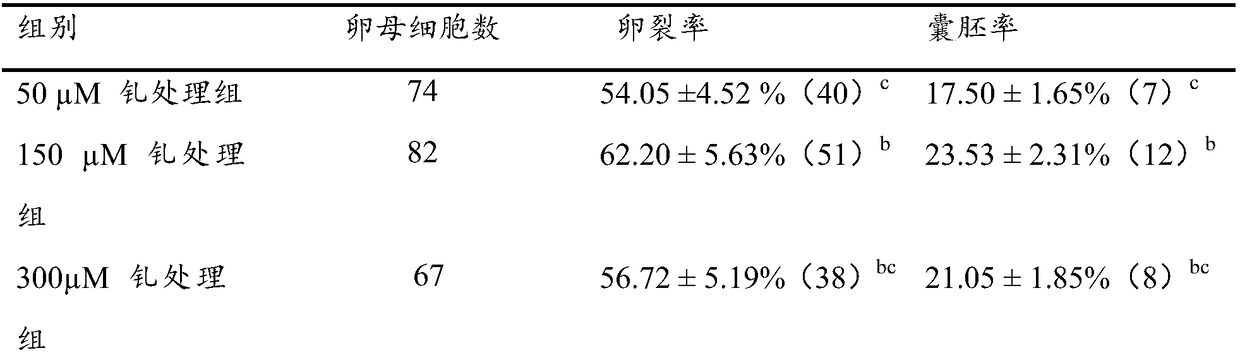

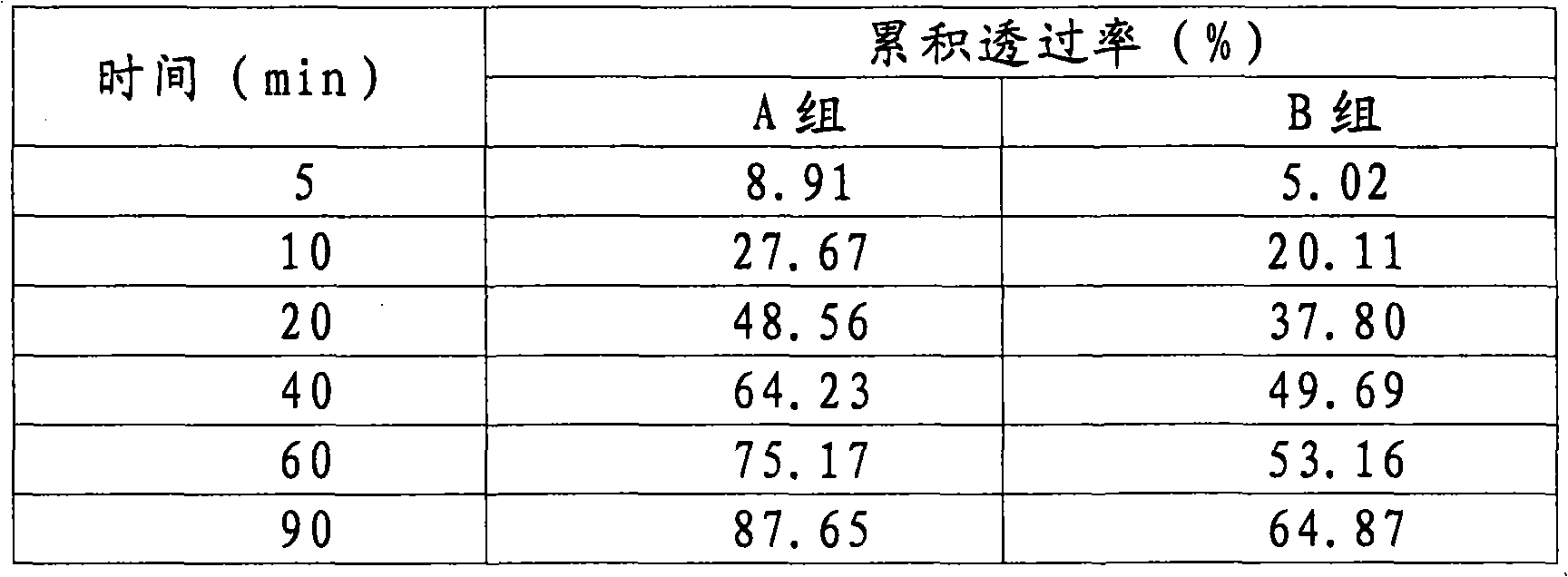

Method for improving in vitro fertilizable competence of vitrification freezing oocyte

ActiveCN108588011ASolve the problem of decreased fertilization abilityHigh in vitro fertilization efficiencyCulture processDead animal preservationVitrificationMethyl-beta-cyclodextrin

The invention provides a method for improving in vitro fertilizable competence of vitrification freezing oocyte. The method disclosed by the invention comprises the following steps: performing combined treatment on bovine oocyte with a solution containing gadolinium and CLC before vitrification freezing treatment, and performing vitrification freezing; treating with methyl-beta-cyclodextrin afterunfreezing, and performing in vitro fertilization. Results prove that the method is capable of obviously improving the cleavage rate and blastocyst rate of vitrification freezing bovine oocyte and achieving in vitro fertilization efficiency higher than that of fresh bovine oocyte, has a wide application prospect and is worthy of popularization.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

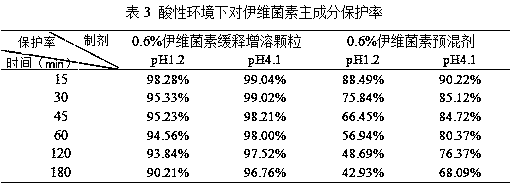

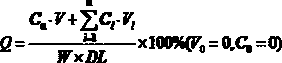

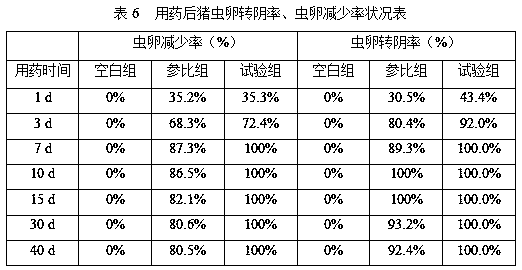

Ivermectin controlled-release capsule and preparation method and application thereof

InactiveCN107773554ARelease fullyHigh protection rateOrganic active ingredientsAntiparasitic agentsTherapeutic effectPhospholipid

The invention discloses an ivermectin controlled-release capsule and a preparation method and application thereof. The ivermectin controlled-release capsule comprises, by mass, 0.1-1% of ivermectin raw material, 20-60% of water-soluble carrier and 30-70% of enteric-soluble wrapping material, the water-soluble carrier is one or multiple of hydroxypropyl-beta-cyclodextrin, methyl-beta-cyclodextrin,HPMC, PVP, PEG, poloxamer 188, mannitol, D-alpha-tocopherol PEG 1000 succinate, cholate / phospholipid mixed micelle, polyethylenediamine dendritic polymer, phospholipid or cholesterol, and the enteric-soluble wrapping material is one or multiple of hydroxypropyl methyl cellulose phthalic acid, acrylic resin II, acrylic III, cellulose acetate phthalate, polyethylene diacetate phthalate or hydroxypropyl methyl cellulose acetate succinate. The ivermectin controlled-release capsule has the advantage of outstanding acid resistance, enables drug to reach intestinal tracts to be disintegrated and released, remarkably improves bioavailability and has remarkable treatment effect.

Owner:SOUTH CHINA AGRI UNIV

Midazolam combination as well as preparation method and application thereof

ActiveCN102462685AImprove physical stabilityGood chemical stabilityOrganic active ingredientsNervous disorderConvulsionMethyl-beta-cyclodextrin

The invention belongs to the field of medicines and pharmaceutics, and relates to a midazolam combination, a preparation method of the midazolam combination, and the application of the midazolam combination. Specifically, the midazolam combination comprises 2.5 to 8.0 percent (g / ml) of midazolam, 5 to 30 percent (g / ml) of cyclodextrin and 30 to 80 percent (ml / ml) of polyols through being calculated according to the total volume of the midazolam combination, wherein the cyclodextrin is carefully selected from one or more of beta cyclodextrin, hydroxypropyl-beta cyclodextrin, gamma cyclodextrin, dimethyl beta cyclodextrin, trimethyl beta cyclodextrin, hydroxypropyl beta cyclodextrin and HE-beta cyclodextrin; and the polyols are selected from one or more of propylene glycol, glycerol, polyoxyethylene castor oil and polyethylene glycol. The concentration of the midazolam in the combination can reach above 25mg / ml and the pH (potential of hydrogen) value of the midazolam is between 4.5 and 10.0. The invention additionally relates to the preparation method of the combination and the application of the combination during the preparation of medicines for curing epilepsy and achieving the effects of anti-anxiety, sedation, peaceful sleeping, muscular relaxation or anti-convulsion.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

A kind of viscosity-reducing composite polycarboxylate water reducer and preparation method thereof

The invention provides a viscosity reduction type composite polycarboxylic acid water reducing agent. The viscosity reduction type composite polycarboxylic acid water reducing agent is prepared from a polycarboxylic acid water reducing agent A, a polycarboxylic acid water reducing agent B, a polycarboxylic acid water reducing agent C, a beta-cyclodextrin derivative, methyl-beta-cyclodextrin and de-ionized water, wherein the polycarboxylic acid water reducing agent A is prepared from the following preparation raw materials: isopentenyl polyoxyethylene ether, acrylic acid, an initiator 1, a chain transferring agent 1 and de-ionized water; the polycarboxylic acid water reducing agent B is prepared from the following preparation raw materials: methylallyl polyethylene glycol ether, acrylic acid, sodium methallyl sulfonate, an initiator 2, a chain transferring agent 2 and de-ionized water; the polycarboxylic acid water reducing agent C is prepared from the following preparation raw materials: diallyl capped polyether, acrylic acid, methylallyl polyethylene glycol ether, an initiator 3, a chain transferring agent 3 and de-ionized water; the diallyl capped polyether is prepared by carrying out allylation capping on the methoxy polyethylene glycol through allyl bromide; the beta-cyclodextrin derivative is beta-cyclodextrin modified by sodium dodecyl sulfonate and carbon nanotubes.

Owner:南通瑞特建筑材料有限公司

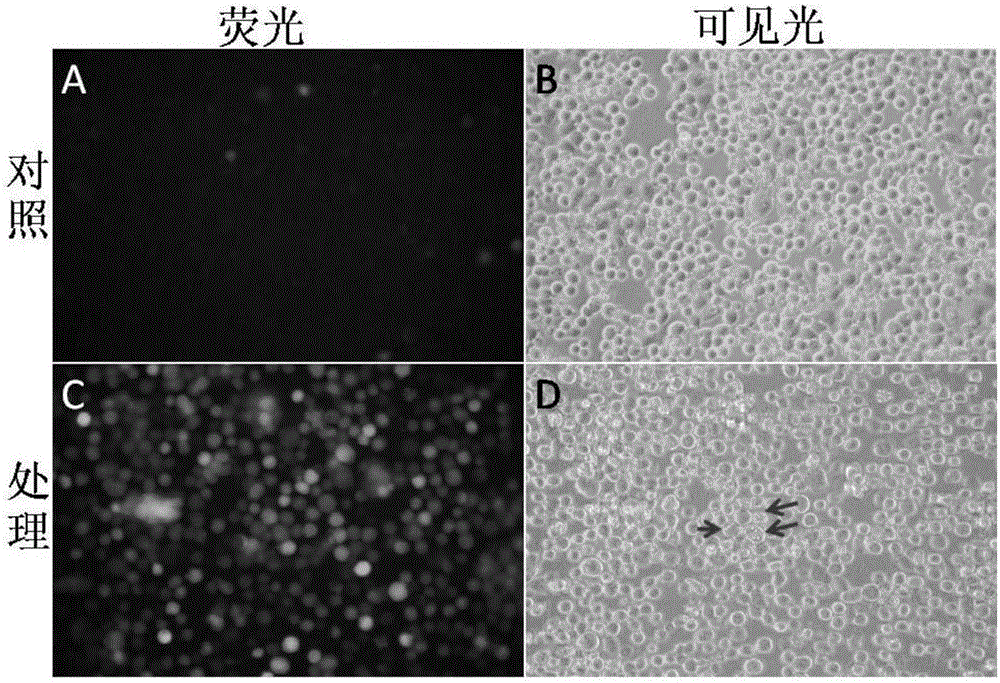

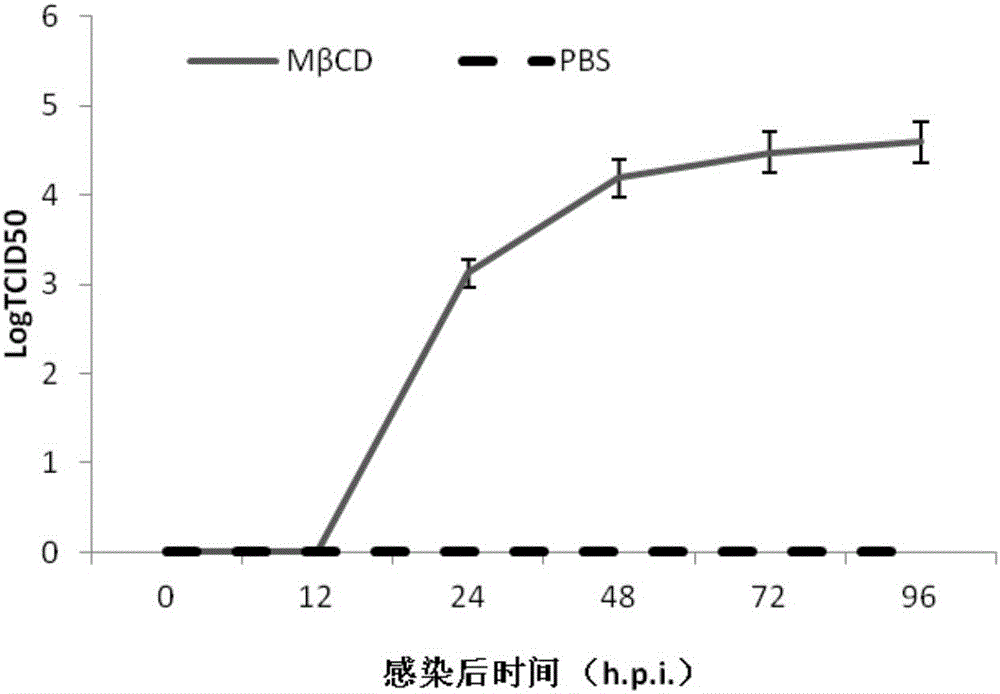

Application of methyl-beta-cyclodextrins to expansion of silkworm bombyx mori nuclear polyhedrosis virus host range

ActiveCN106047822AEfficient infectionImprove efficiencyDsDNA virusesMethyl-beta-cyclodextrinBombyx mori nuclear polyhedrosis virus

The invention discloses application of methyl-beta-cyclodextrins (MbetaCD) to expansion of a silkworm bombyx mori nuclear polyhedrosis virus (BmNPV) host range. After MbetaCD with a certain concentration is used for processing BmNPV non-host cells, the efficiency at which BmNPV infects non-host insect cells can be remarkably improved, BmNPV can be duplicated and amplified in the non-host cells, infectious virus particles and polyhedral bodies are produced, contrast cells BmNPV can not be duplicated at all, and no polyhedral bodies can be observed. The problem that the BmNPV host range is narrow is solved, and BmNPV can be duplicated in the non-host cells and efficiently infects the non-host cells to produce polyhedral bodies. Meanwhile, the defects that baculovirus is narrow in host range, low in insect killing speed and the like when serving as a biological insecticide can be overcome, and the development of research on the interaction of insect baculovirus and host cells, the mechanism of baculovirus receptors and baculovirus invading a host and the like can also be promoted.

Owner:JIANGSU UNIV OF SCI & TECH

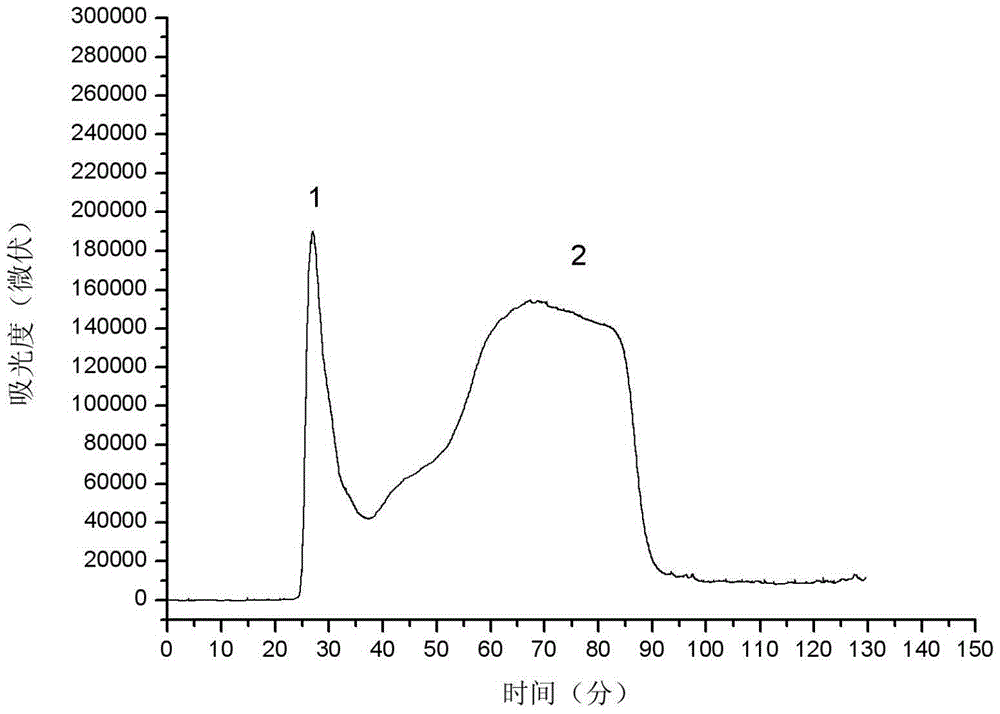

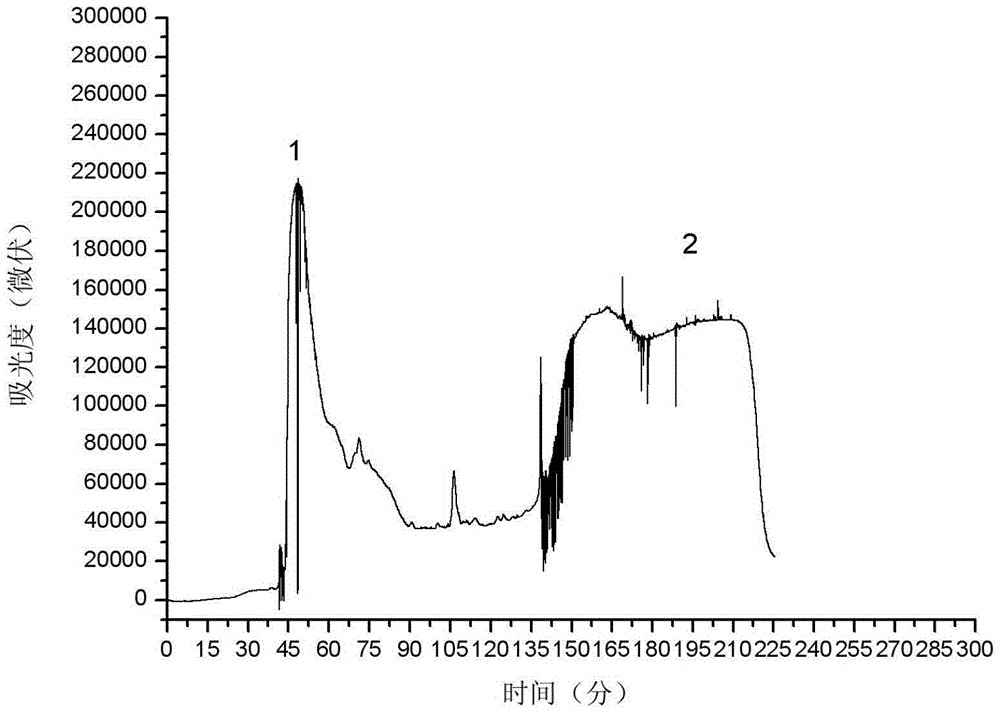

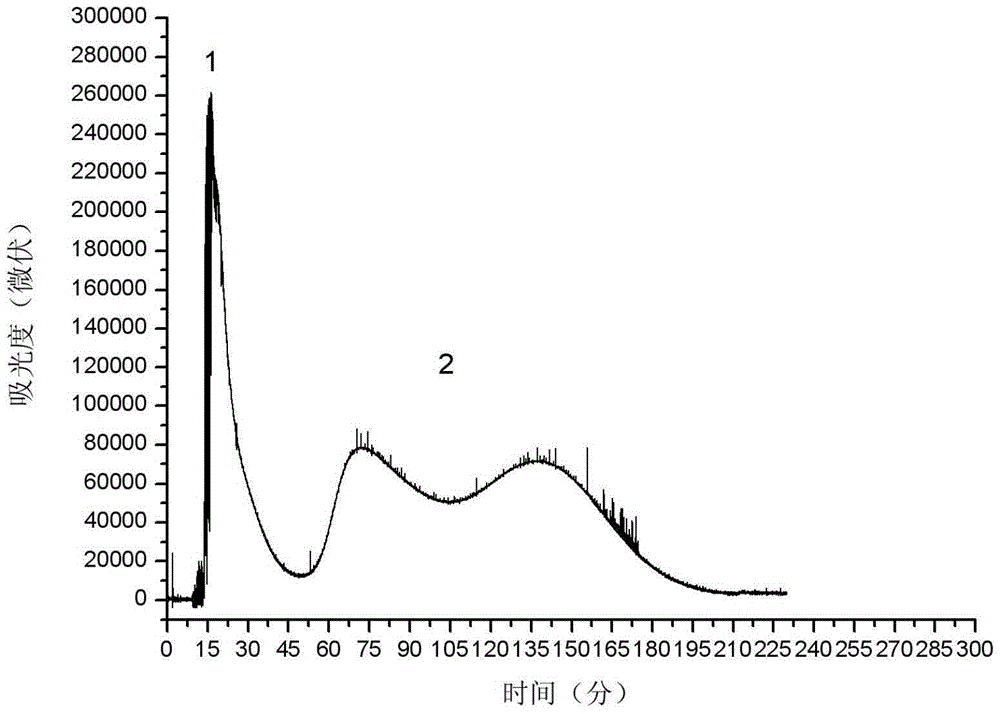

Method for separating germacrone from Curcuma wenyujin volatile oil

ActiveCN105237378AReduce consumptionSimple and fast operationCarbonyl compound separation/purificationMethyl-beta-cyclodextrinChromatographic separation

The invention discloses a method for separating germacrone from Curcuma wenyujin volatile oil. The method comprises the following steps: fully mixing an aqueous solution of methyl-beta-cyclodextrin with n-hexane according to a volume ratio of 1:0.5-2, standing, carrying out liquid separation to respectively obtain an upper phase which is a mobile phase and a lower phase which is the stationary phase of a high-speed countercurrent chromatograph; and weighing the Curcuma wenyujin volatile oil, dissolving the Curcuma wenyujin volatile oil in a mixture containing the upper phase and the lower phase according to a volume ratio of 1:1, introducing the above obtained sample, carrying out high-speed countercurrent chromatographic separation, detecting through an ultraviolet detector, collecting corresponding effluents corresponding to peaks in the spectrogram of the ultraviolet detector, concentrating germacrone-containing effluents, and drying to prepare pure germacrone. The method has the advantages of simple operation, less solvent consumption, high efficiency, fastness, strong purposefulness and good separation effect.

Owner:ZHEJIANG UNIV OF TECH

Mucosal Delivery of Stabilized Formulations of Exendin

InactiveUS20080318861A1Peptide/protein ingredientsMetabolism disorderMethyl-beta-cyclodextrinCyclodextrin

What is described is a pharmaceutical formulation for intranasal administration of exendin to a mammal, wherein the formulation comprises a therapeutically effective amount of an exendin, a viscosity enhancer, methyl-β-cyclodextrin, a surfactant, tartrate buffer to control pH and a chelating agent for cations, and wherein such exendin dosage form exhibits at least 95% exenatide recovery after storage for at least 365 days at 5° C.

Owner:AMYLIN PHARMA INC

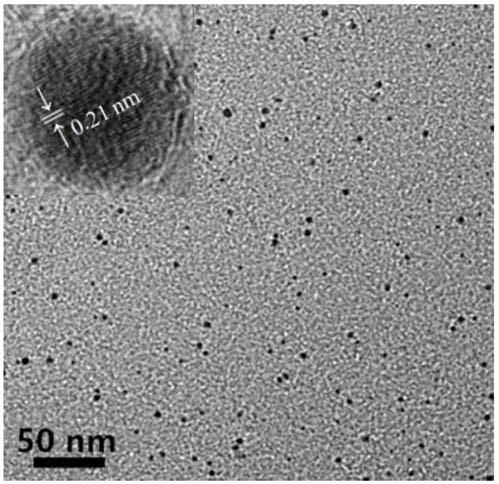

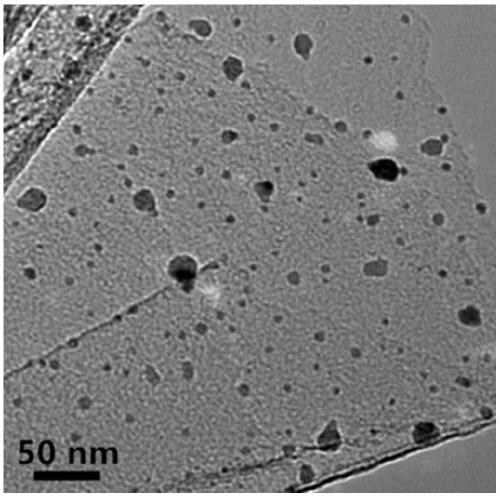

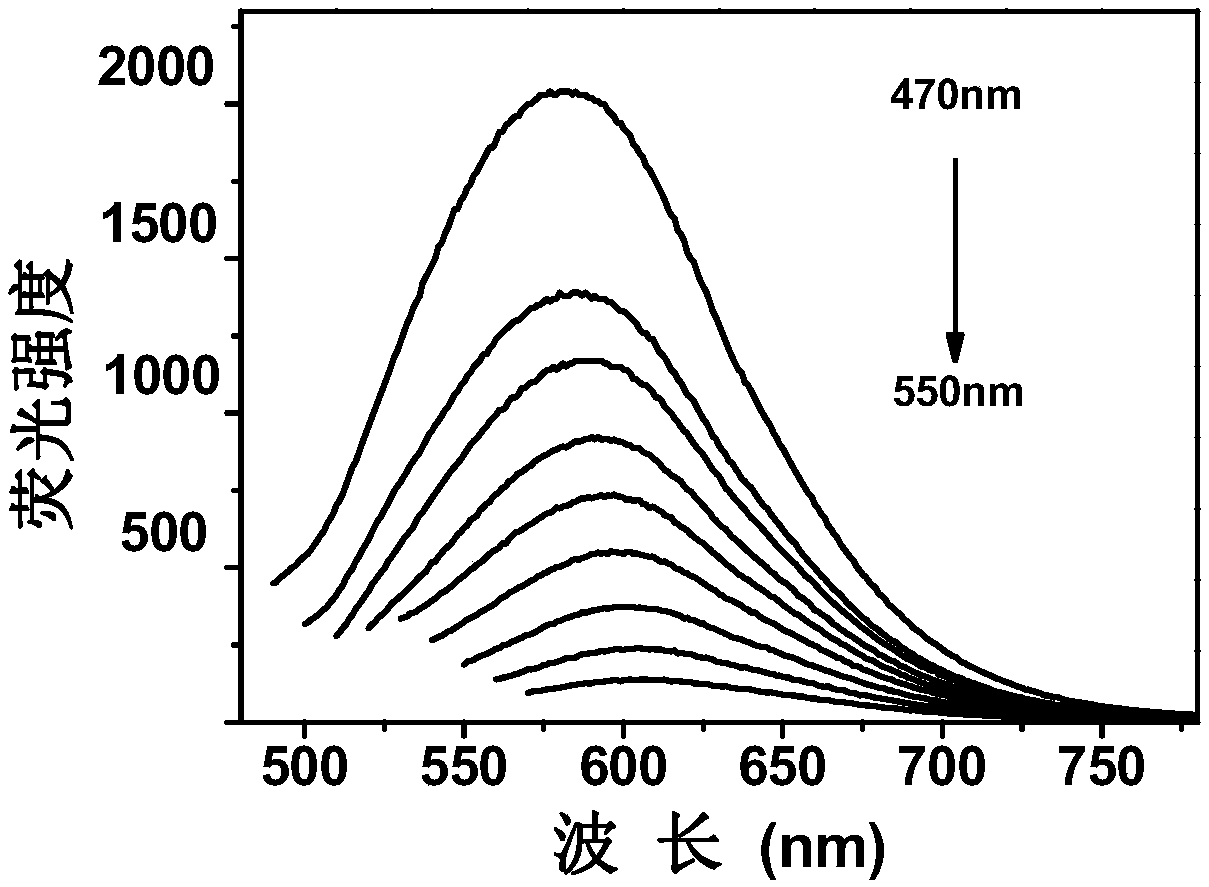

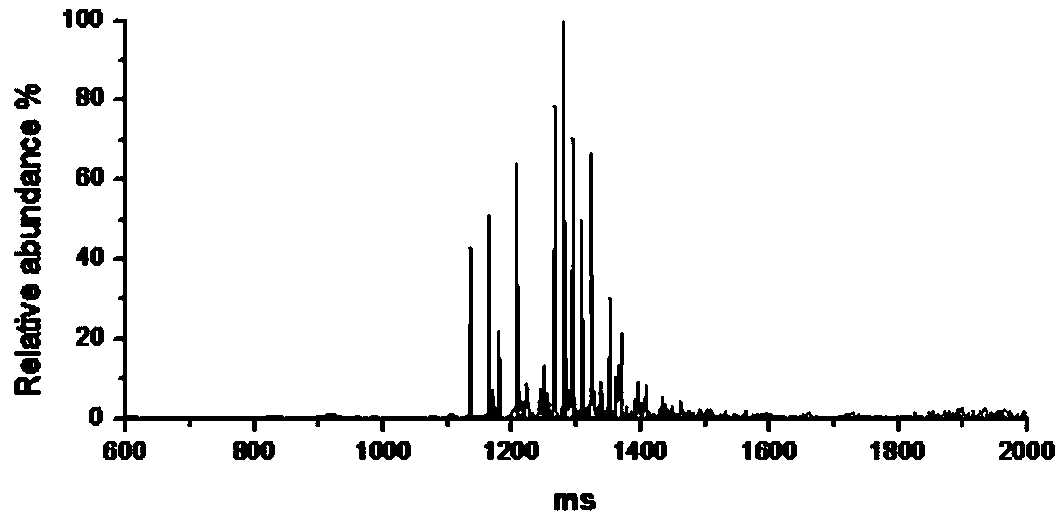

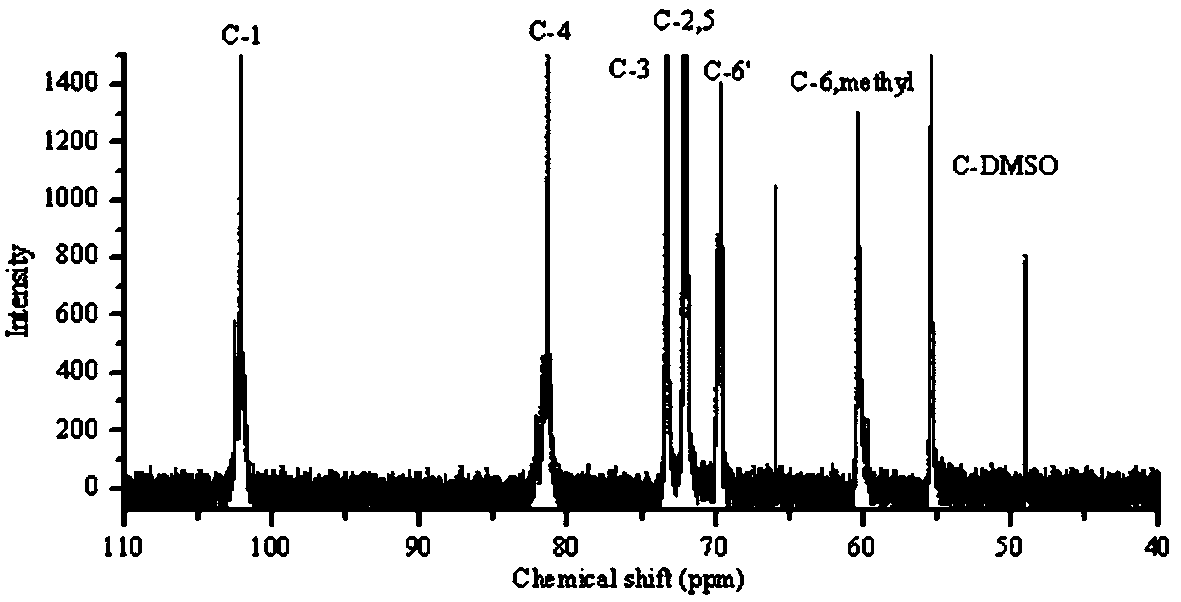

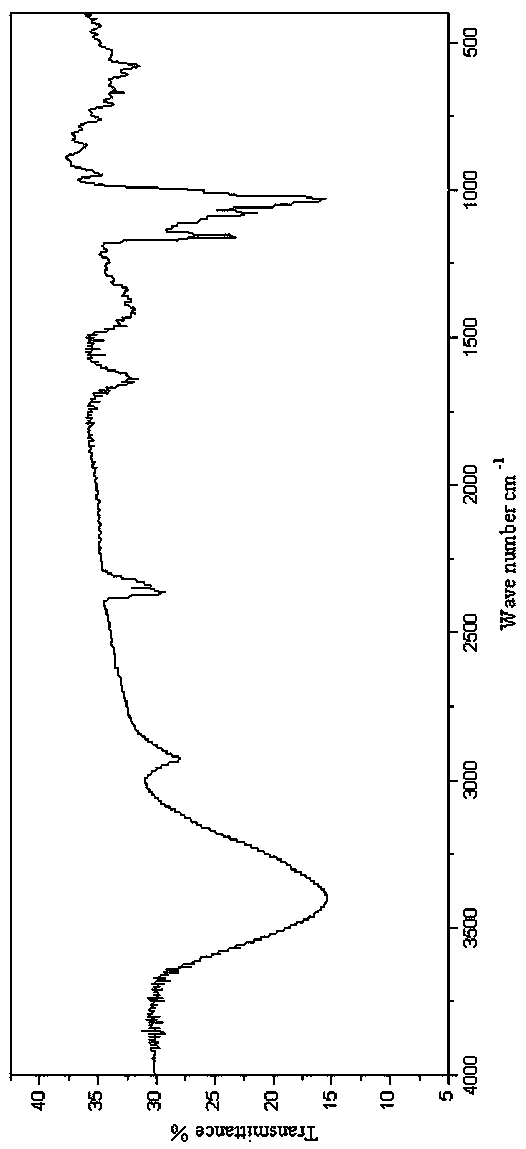

Nitrogen and sulfur double-doped yellow fluorescence carbon dot and application thereof in anticancer medicine

InactiveCN109207149ADoes not affect the anticancer effectHas sustained-release drug propertiesOrganic active ingredientsNanoopticsSolubilityBiocompatibility Testing

The invention provides a nitrogen and sulfur double-doped yellow fluorescence carbon dot and application thereof in anticancer medicine. Methyl-beta-cyclodextrin and methylene blue are used as raw materials; water is used as a solvent; the nitrogen and sulfur double-doped yellow fluorescence carbon dot is prepared by a hydro-thermal method. The prepared nitrogen and sulfur double-doped yellow fluorescence carbon dot can physically adsorb anti-tumor medicine mitoxantrone, so that a fluorescence nanometer medicine system combining tracking with treatment is obtained. Through the nanometer medicine system, the fluorescence is given to the mitoxantrone without the influence on the anti-cancer effect of the mitoxantrone. The prepared yellow fluorescence carbon dot has the advantages of good water solubility, stable fluorescence performance, good biocompatibility and low toxicity, and has wide application prospects in the fields of biological imaging, medicine delivery and the like.

Owner:SHANXI UNIV

Synthesizing process of beta-cyclodextrin derivative

The invention relates to a synthesizing process of a beta-cyclodextrin derivative. The synthesizing process includes: in the presence of barium carbonate, using tetrahydrofuran as the solvent to allowbeta-cyclodextrin to have reaction with dimethyl carbonate at the temperature of 10-60 DEG C and normal pressure for 0.5-48 hours, wherein the mole ratio of the beta-cyclodextrin to dimethyl carbonate is 1:0.1-1:9, the mass ratio of the tetrahydrofuran to the beta-cyclodextrin is 2:1-1500:1, and the weight ratio of barium carbonate to the beta-cyclodextrin is (0.25-2):1; filtering to remove the barium carbonate and insoluble matter, and performing reduced pressure distillation to remove the solvent to obtain intermediate product 2-O-methyl-beta-cyclodextrin; dissolving the intermediate product into a strong alkaline solution, and dropwise adding epoxy propane and anhydrous ethanol to perform reaction at the temperature of 0-70 DEG C and normal pressure for 0.5-56 hours; using a sulfuric acid solution to neutralize the strong alkaline solution until the strong alkaline solution is neutral, and distilling to obtain white solid; dissolving the white solid with tetrahydrofuran, filteringto remove sulfate, and distilling to remove the tetrahydrofuran to obtain 2-O-methyl-6-O-(2-hydroxypropyl)-beta-cyclodextrin. The 2-O-methyl-6-O-(2-hydroxypropyl)-beta-cyclodextrin has large application potential in fields such as medicine auxiliaries, food additives and chemistry and chemical engineering, and the synthesizing process is green and simple in synthesizing route and mild in reactioncondition.

Owner:JINGCHU UNIV OF TECH

Extracting head for solid phase micro extraction of dextrin derivative and its making process

The extracting head for solid phase micro extraction of cyclodextrin derivative includes quartz fiber and its coating and the coating is composite coating of 2, 6-di-oxy-methyl-beta-cyclodextrin and hydroxyl silicon oil bonded to the surface of the quartz fiber. The preparation process of the extracting head includes the following steps: diluting 2, 6-di-oxy-methyl-beta-cyclodextrin with dichloromethane, adding hydroxyl silicon oil, tetraethoxy silane, 3-(2, 3-epoxy propane) propyl trimethoxy silane and water containing trifluoro acetic acid, adding hydrogen-containing silicon oil, ultrasonic vibration and centrifuging, and taking supernatant; inserting one end of the quartz fiber after eliminating protecting layer and drying into the sol liquid, taking out, drying and ageing under the protection of nitrogen to obtain the extracting head. The present invention has high heat stability, high solvent flush resistance, long service life, high in Benzedrine medicine capacity and excellent application foreground in medicine analysis, including stimulant detection.

Owner:WUHAN UNIV

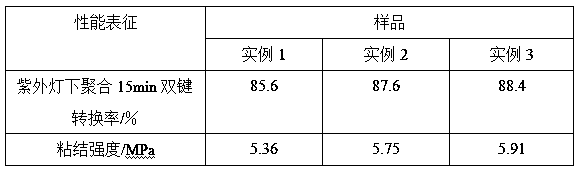

Preparation method of low-temperature photopolymerization catalyst for biological bonding agent

InactiveCN108853568AIncrease temperatureImprove performanceSurgical adhesivesParaffin waxBioadhesive

The invention relates to a preparation method of a low-temperature photopolymerization catalyst for a biological bonding agent, and belongs to the technical field of a biological material. According to the technical scheme, benzophenone and methyl-beta-cyclodextrin materials are compounded to form a grafting substrate; the cyclodextrin is a kind of tubular compound formed by connecting seven glucose molecules through glucosidic bonds, and realize the characteristics of hydrophobic inner cavities and hydrophilic outsides, so that the cyclodextrin can form clathrate compounds with various organic and inorganic molecules through Van der Waals' force, hydrophobic mutual action force, subject-object molecule matching action and the like; a photocatalyst is filled to from a wall material for preparing a photocatalyst wall material; the temperature performance of the material is effectively improved; in addition, the photocatalyst material is filled into the material; the formed wall materialis used for preparing the photocatalyst wall material with excellent performance; paraffin is clathrated; a phase change microcapsule structure material is prepared; the polymerization temperature inthe polymerization reaction process of the material is reduced; the temperature requirement and the use efficiency of biological materials in the polymerization process can be improved.

Owner:FOSHAN WANYANG BIOLOGICAL TECH CO LTD

afm1 fluorescent sensitizer

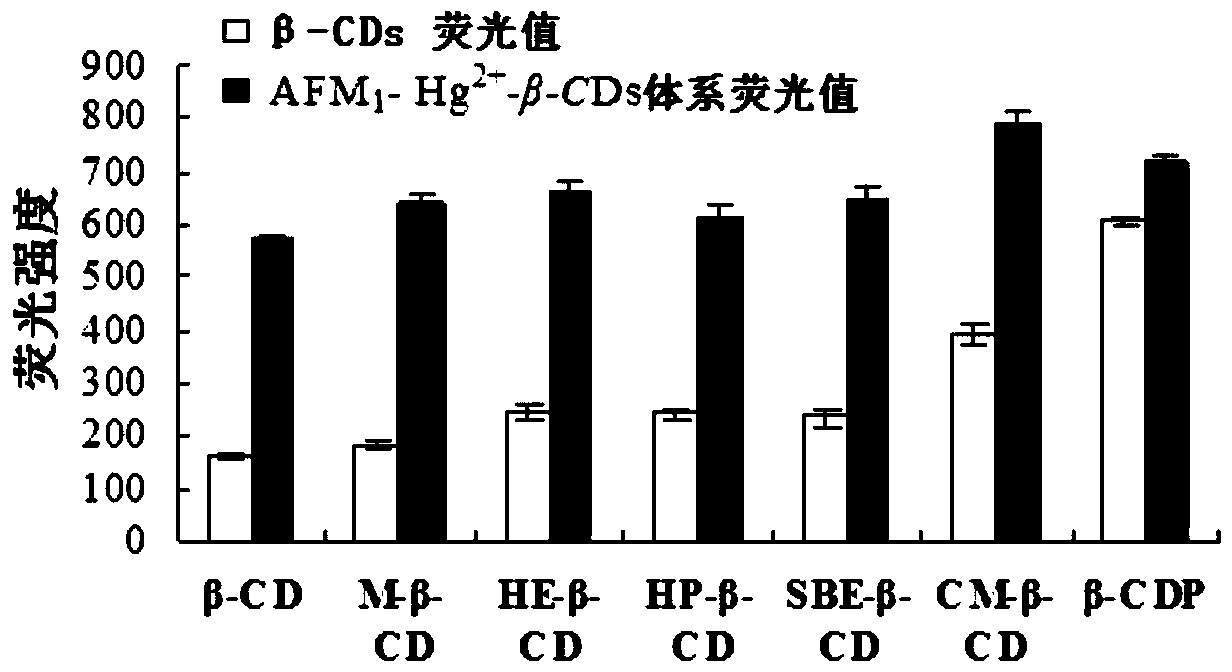

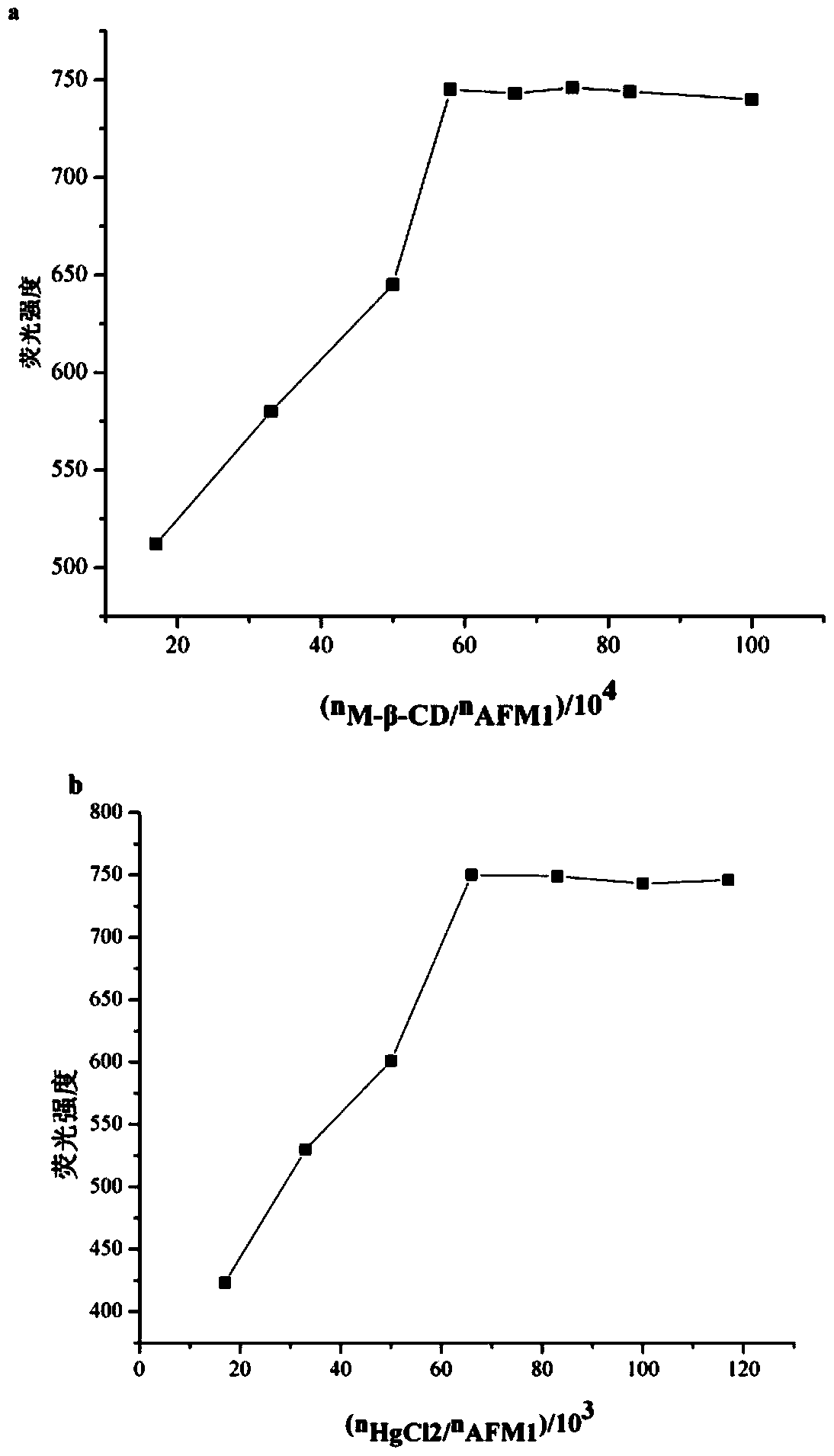

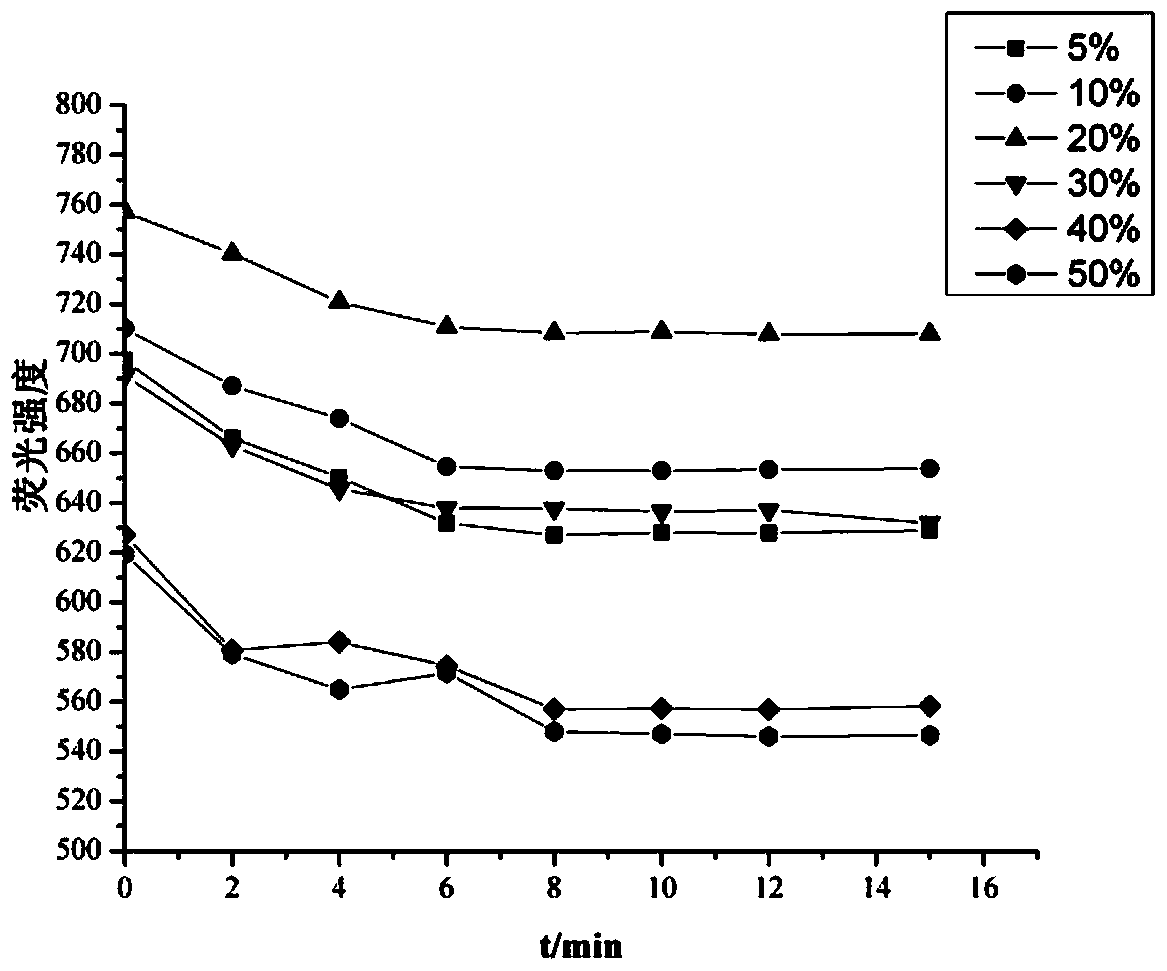

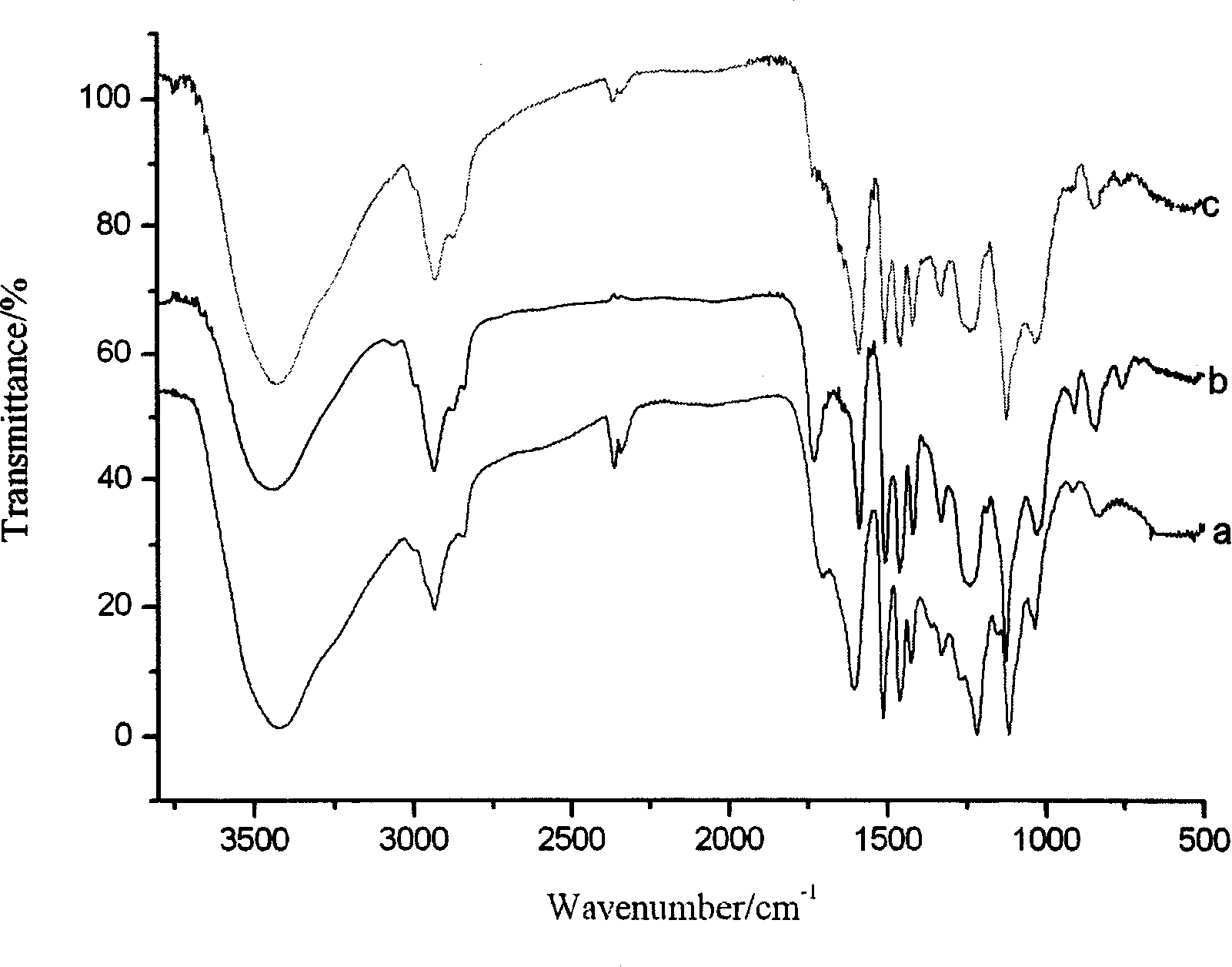

ActiveCN105486672BHigh fluorescence intensitySignificant effect of fluorescence enhancementFluorescence/phosphorescenceMethyl-beta-cyclodextrinAflatoxin M

Owner:SOUTHWEST UNIV

Lignin-Based cyclodextrin ester multi-purpose sorbent preparation method

InactiveCN100393735CFast adsorption rateImprove bindingOther chemical processesLignin derivativesSorbentButanediol

The invention discloses a preparing method of multi-effect lignin cyclodextrin ether to adsorb heavy metal, phenol, phenylamine and uric acid, which comprises the following steps: adopting lignin as material; dissolving through alkaline; purifying through acid settling; dissolving disposed lignin in certain density of sodium hydroxide; adding certain quantity of crosslinking agent in the alkaline solution with weight rate at 1:5-1:15; polymerizing under 50-90 deg.c for 1-5h; adding polymer into cyclodextrin with weight rate at 1-5:1; filtering; washing; drying; grinding; obtaining the lignin cyclodextrin ether adsorbent. The lignin is alkali lignin and lignin sulfonate. The crosslinking agent is epichlorohydrin, 1, 2-glycol bisglycidyl ether or 1, 2-butanediol bisglycidyl ether. The cyclodextrin is beta-cyclodextrin, methyl beta-cyclodextrin or hydroxypropyl beta-cyclodextrin.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

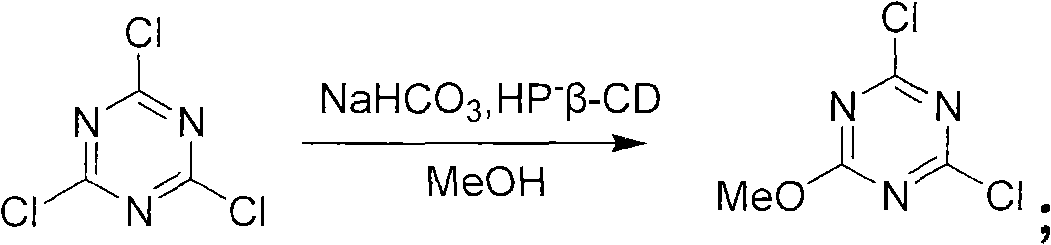

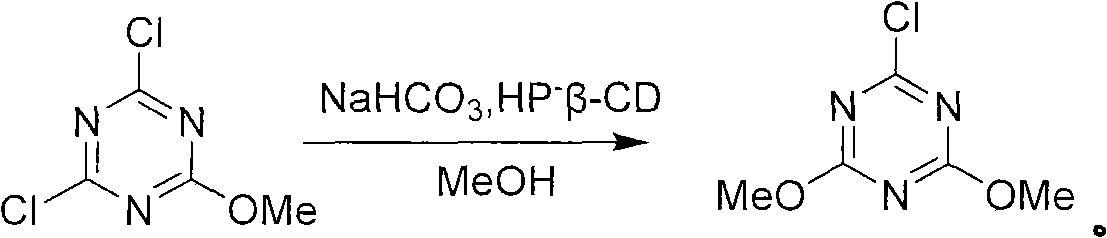

Method for preparing 2-chlorine-4, 6-dimethoxy-1, 3, 5-triazine

InactiveCN101624379BHigh yieldPlay a solubilizing roleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMethyl-beta-cyclodextrinSodium bicarbonate

The invention discloses a method for preparing 2-chlorine-4, 6-dimethoxy-1, 3, 5-triazine, mainly comprising the following steps: firstly, mixing sodium bicarbonate, water and catalytic amounts of catalyst hydroxypropyl methyl-beta-cyclodextrin uniformly to obtain a reactive solution, wherein the mass ratio of the water and the sodium bicarbonate is 1:3-1:10;secondly, at the temperature of 0-30 DEG C, slowly dripping a methyl alcohol solution in which cyanuric chloride is dissolved in the obtained solution in the first step to generate mono-substituted triazine, wherein the mass ratio of the cyanuric chloride and the methyl alcohol is 0.3-0.6:1, the mass ratio of the cyanuric chloride and the sodium bicarbonate is 0.7-0.9:1; and thirdly, rising the temperature to 35-70 DEG C to enable themono-substituted triazine generatd in the third step to continuously react to generate disubstituted triazine so as to obtain a mixture containing the disubstituted triazine. The raw materials used by the invention has low price, the cost of production materials is reduced. Compared with the prior art, the invention has simple process, higher yield of target products and is more suitable for industrialized production.

Owner:苏州永拓医药科技有限公司

Application of methyl-β-cyclodextrin in preparation of medicine for preventing and treating silkworm cells infected by bmnpv

InactiveCN104027347BAvoid infectionOrganic active ingredientsAntiviralsMethyl-beta-cyclodextrinMedicine

Owner:JIANGSU UNIV OF SCI & TECH

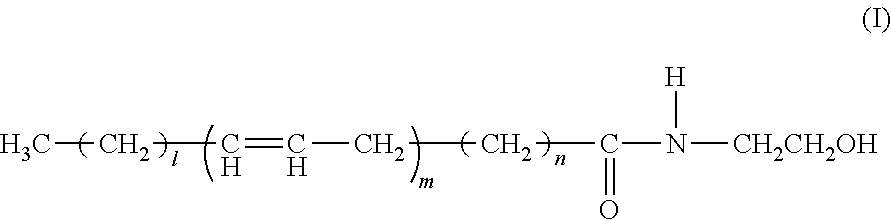

Ophthalmic, intra-articular or intravesical preparations containing n-acyl-ethanolamines

It is the object of the present invention a composition containing an N-acyl-ethanolamine in a solubilized form, particularly a solution for ophthalmic, intra-articular or intravesical use.Particularly, the present invention relates to a water-soluble composition comprising one or more N-acylethanolamines (NAE) in the form of an inclusion complex in methyl-beta-cyclodextrin (MβCD).

Owner:EPITECH GRP SRL

Preparation method of set-retarding water-reducing agent used in high-temperature construction environment

The invention relates to the technical field of set-retarding water-reducing agents, and particularly relates to a preparation method of a set-retarding water-reducing agent used in a high-temperatureconstruction environment. The preparation method of the set-retarding water-reducing agent used in the high-temperature construction environment comprises the following steps: (1) adding sodium polyaspartate, sulfanilic acid and iso-tridecanol polyoxyethylene ether into polyaluminium chloride, carrying out heating to 115-125 DEG C, carrying out mixing under heat preservation for 0.5-1 hour, thencarrying out sealing and standing in an environment of 0-5 DEG C for 1-2 hours, and preparing a micro-powder from the obtained material by using an ultrafine grinder to obtain modified polyaluminium chloride; and (2) adding kaolin, asbestos wool and the modified polyaluminium chloride into a mixed solution of water and acetone, fully carrying out mixing, then adding a polycarboxylic acid mother liquor, sodium gluconate, a methyl-beta-cyclodextrin polyacrylamide graft copolymer, ammonium citrate, anhydrous sodium sulfate and calcium chloride, and uniformly carrying out mixing to obtain the set-retarding water-reducing agent. The addition amount of the set-retarding water-reducing agent provided by the invention in the concrete is low, and a good economic benefit is achieved.

Owner:芜湖恒固混凝土材料有限公司

Ophthalmic, intra-articular or intravesical preparations containing N-acyl-ethanolamines

ActiveUS9668986B2Senses disorderPharmaceutical delivery mechanismMethyl-beta-cyclodextrinN-acylethanolamines

It is the object of the present invention a composition containing an N-acyl-ethanolamine in a solubilized form, particularly a solution for ophthalmic, intra-articular or intravesical use.Particularly, the present invention relates to a water-soluble composition comprising one or more N-acylethanolamines (NAE) in the form of an inclusion complex in methyl-beta-cyclodextrin (MβCD).

Owner:EPITECH GRP SRL

Preparation method of polyester filler material containing isosorbide and methyl-beta-cyclodextrin

The invention discloses a preparation method of a polyester filler material containing isosorbide and methyl beta cyclodextrin. According to the method, a diacid part, methyl beta cyclodextrin and anisosorbide part are taken as monomers, stannous pyrophosphate is taken as a catalyst for reaction, and polyester is prepared by utilizing existing polymerization equipment at enough temperature and pressure. The stannous pyrophosphate is a non-toxic organic metal catalyst, and when the polymer is applied to medicines, human bodies, agriculture and the like, the property is very important. According to the method, the temperature required by reaction can be reduced, the loss of raw materials in the system is reduced, the occurrence probability of side reaction is reduced, and the molecular weight is not reduced. Meanwhile, when stannous pyrophosphate is left in the polymer, the settling velocity of the coating filler can be reduced, and the filler performance is improved. Meanwhile, the methyl beta ring paste is used as an embedded part to be inserted into a polyester polymer structure, the material mobile phase selection range is wide, high pressure resistance is achieved, and the method can be applied to microsphere filler or coating filler.

Owner:南京江北新区生物医药公共服务平台有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com