Patents

Literature

638results about How to "Improve environmental friendliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

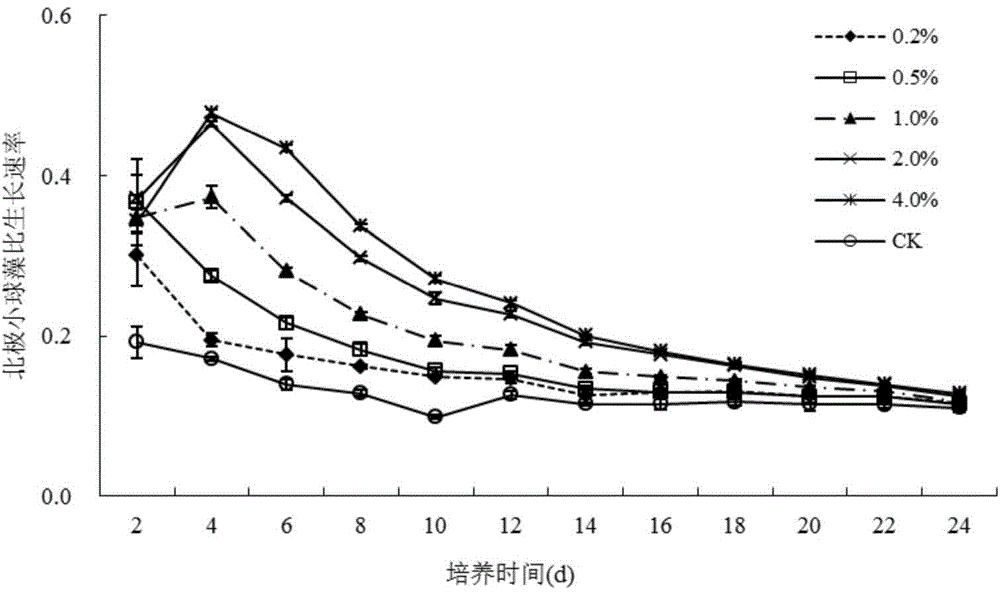

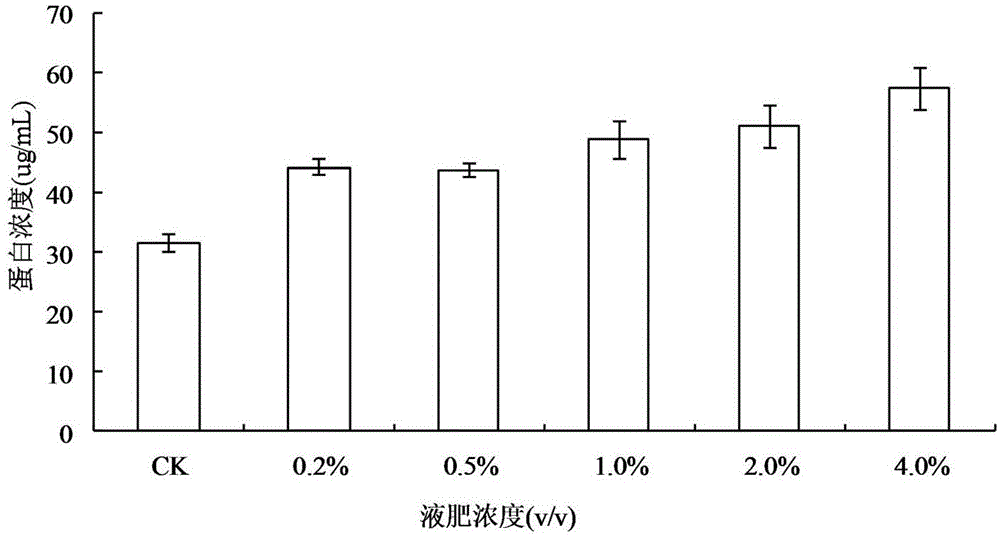

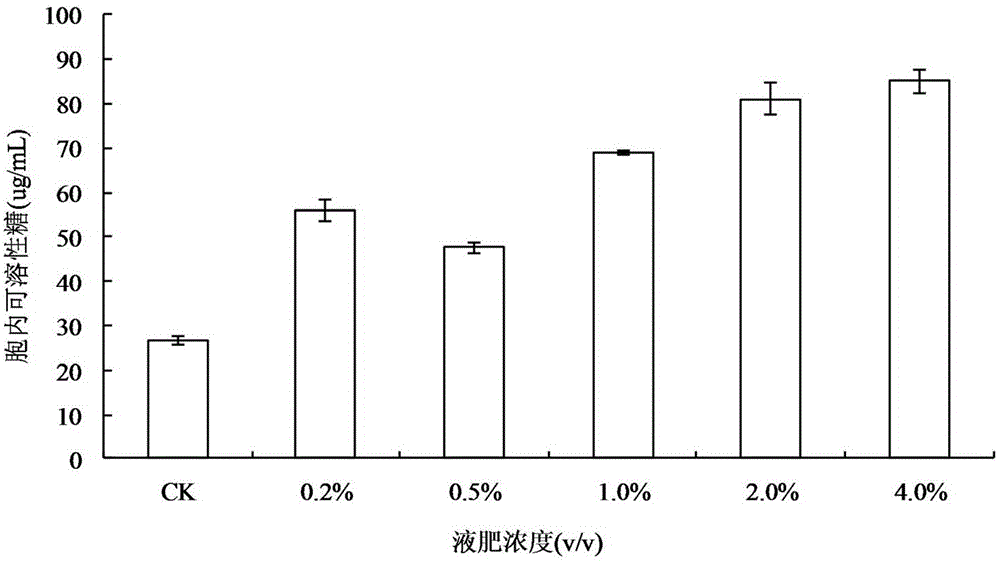

Method for producing organic seaweed fertilizer employing algae processing waste and prepared fertilizer

ActiveCN104387171ASimple and fast operationShort preparation cycleOrganic fertilisersAmmonium salt fertilisersHydrolysateAgricultural residue

The invention belongs to the fields of forestry and agricultural residue recycling and organic fertilizer production, and provides a method for producing an organic seaweed fertilizer employing an algae processing waste, and an organic seaweed fertilizer and an organic seaweed compound fertilizer prepared by the method. The method mainly comprises the following steps: crushing and evenly mixing the algae waste; decomposing an algae cell wall, polysaccharide and protein in an enzymolysis manner; carrying out solid-liquid separation on enzymatic hydrolysate, leaching enzymolysis algal residues to prepare extractum by adopting ethanol; mixing the enzymatic hydrolysate with the extractum to form an organic seaweed liquid fertilizer; mixing with a certain ratio of algae residue to form an organic seaweed granular fertilizer; and preparing the organic seaweed compound fertilizer after a proper amount of chemical fertilizer is added. The organic seaweed fertilizer is prepared by the wastes generated in macro-algae processing and micro-algae processing processes as the raw material, so that the operation is simple and convenient; the preparation cycle is short; a new idea for processing the wastes is provided for macro-algae or micro-algae processing enterprises; the environmental friendliness of enterprise production and processing is improved; and economic benefits of the enterprises are improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

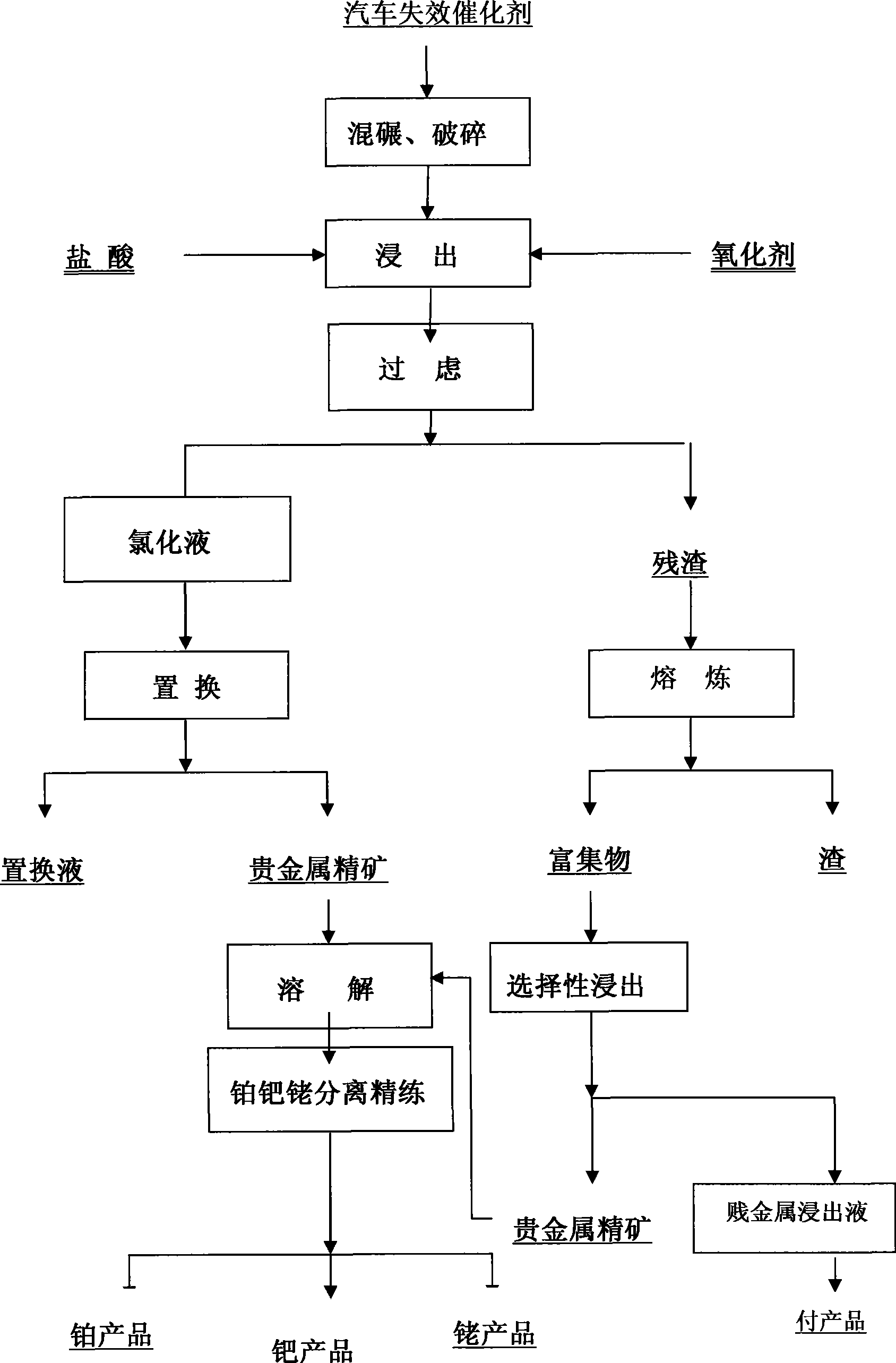

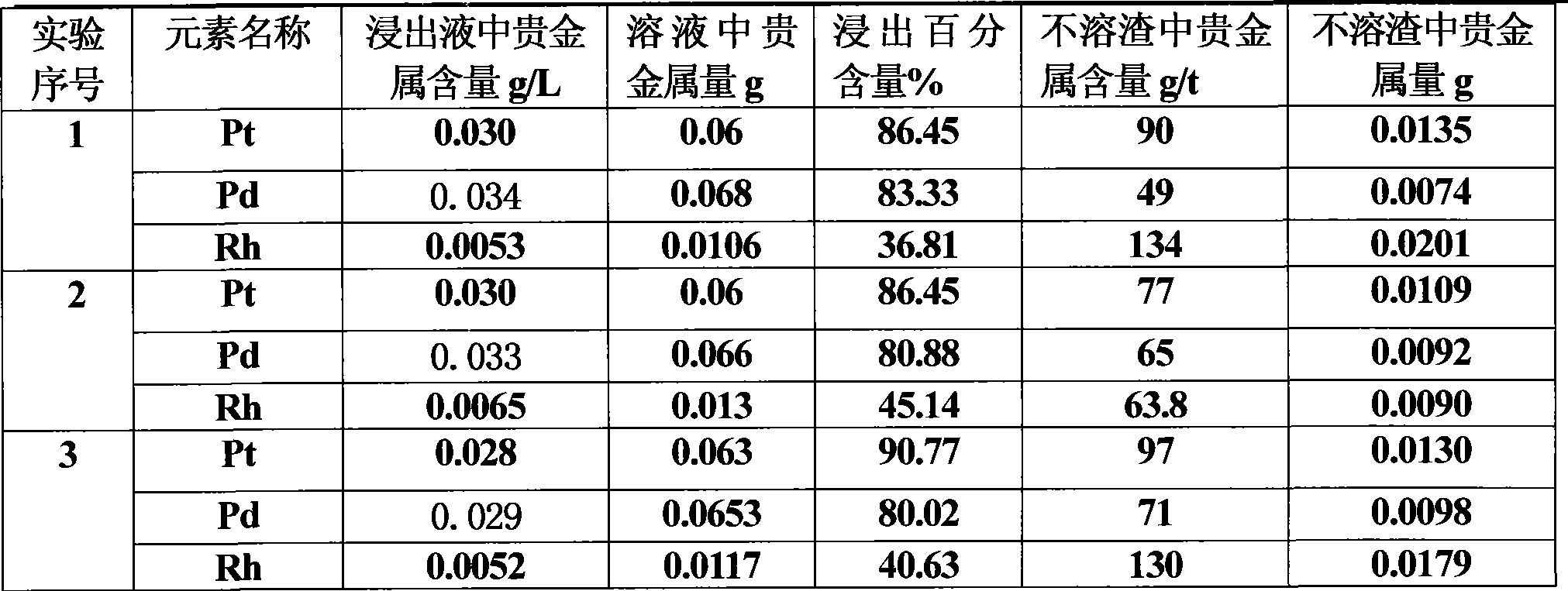

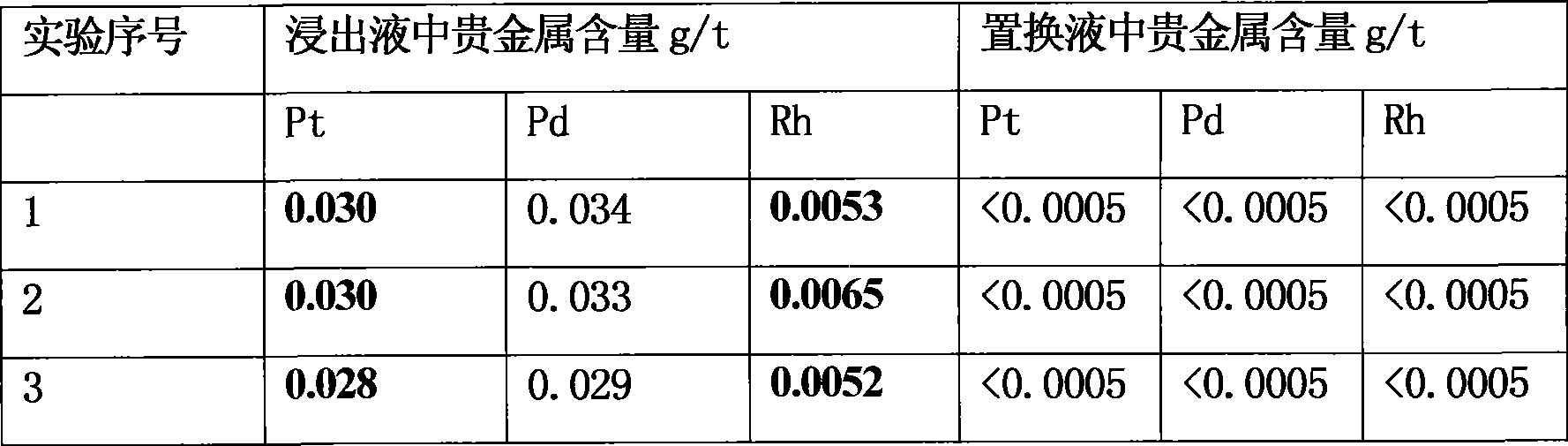

Method for extracting precious metal from auto-exhaust catalyst by hydrometallurgy and pyrometallurgy complex process

InactiveCN101519725ALoose process conditionsImprove leaching rateProcess efficiency improvementPregnant leach solutionPlatinum

The invention relates to a method for extracting precious metal from a disabled auto-exhaust catalyst, which comprises the following steps: 1. lixiviating precious metal from the disabled auto-exhaust catalyst by a hydrometallurgy process and obtaining precious metal concentrates after permuting lixivium; 2. lixiviating slag, collecting precious metal of the slag by a pyrometallurgy process to obtain a precious metal phase and selectively lixiviating base metal in the precious metal phase to obtain precious metal concentrates; and 3 combining the precious metal concentrates obtained in the first two steps and refining the precious metal concentrates to produce platinum, palladium and rhodium products. The invention compensates the deficiency that the percent recovery of the precious metal is low by simply treating the disabled auto-exhaust catalyst with the hydrometallurgy process and has the advantages that the contents of platinum, palladium and rhodium in the waste slag are smaller than 1g / t and the product purity reaches 99.95 percent.

Owner:KUNMING INST OF PRECIOUS METALS

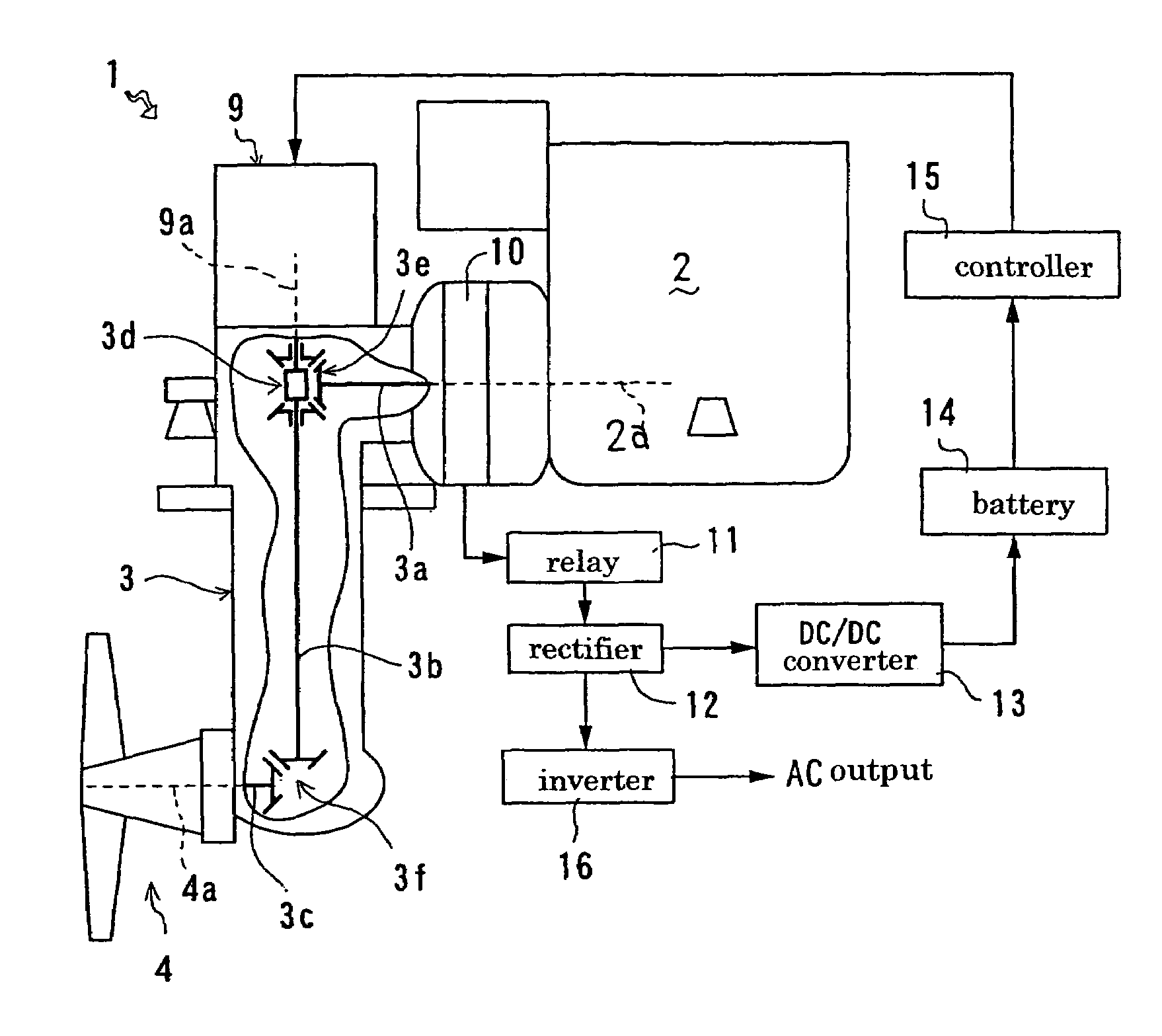

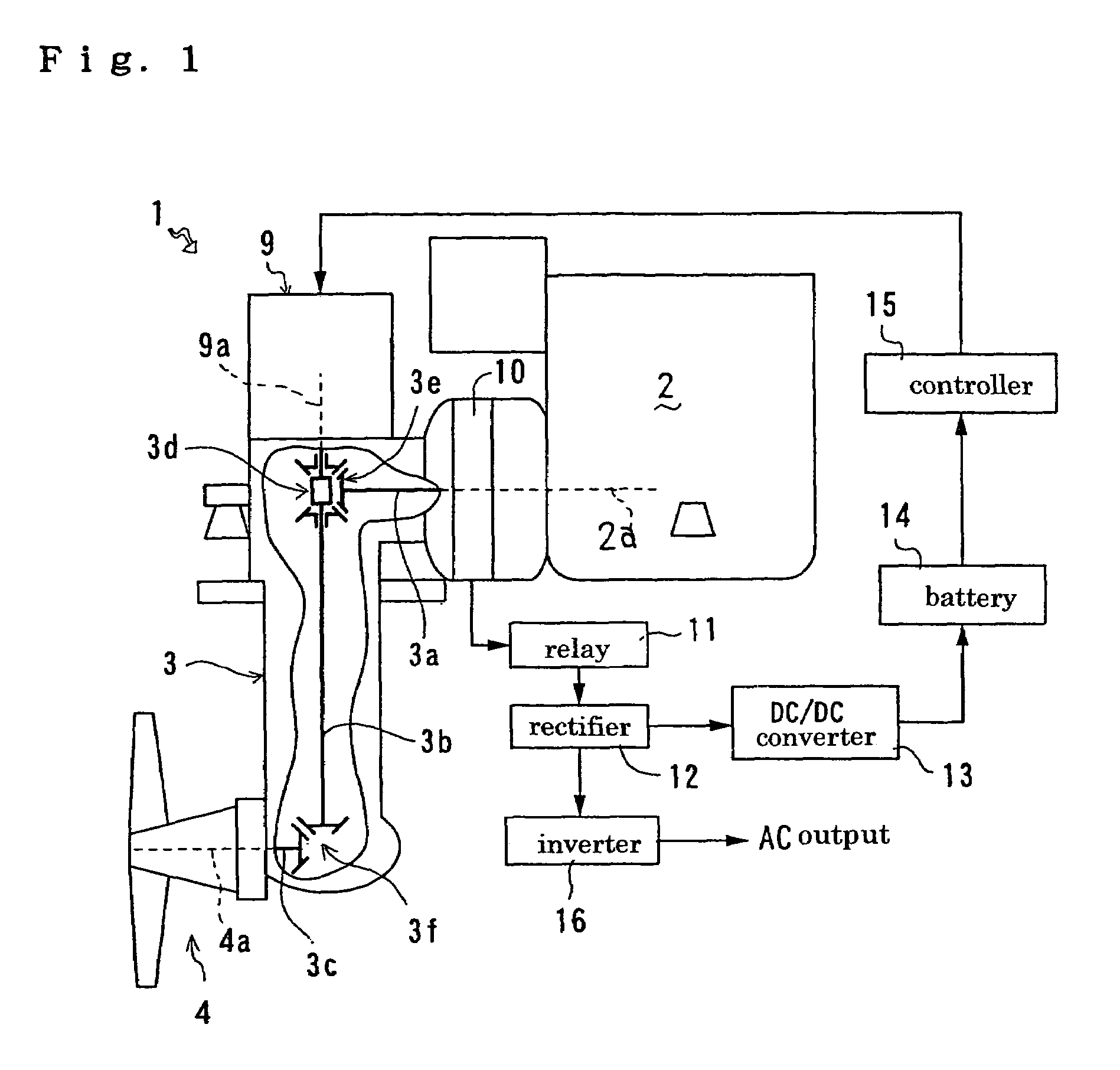

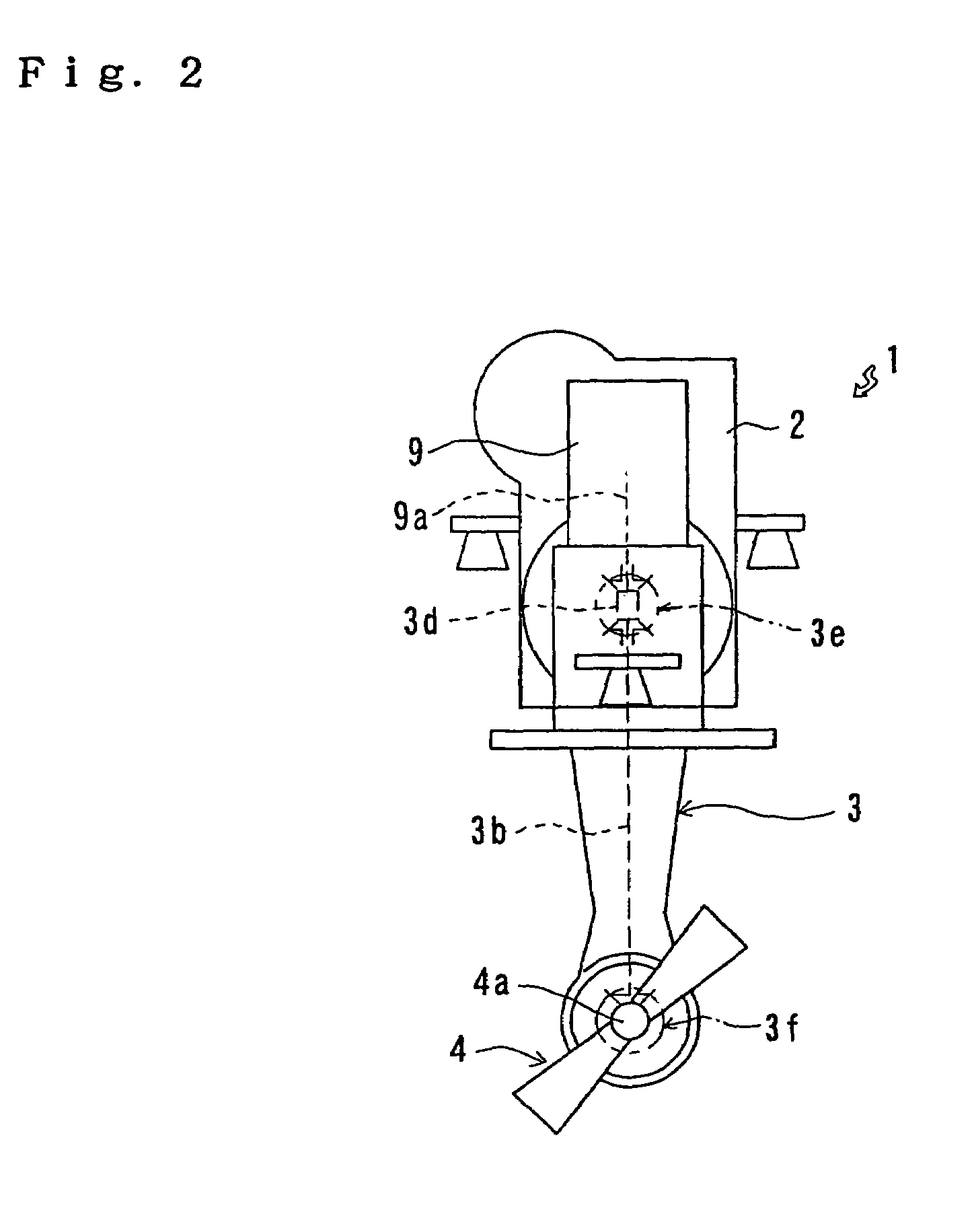

Power generating and propelling system of vessel

InactiveUS7147523B2Reduce usageEasy to usePropulsion based emission reductionAuxillariesInternal combustion engineElectric power

An electric power generating equipment (10) is provided between an internal combustion engine (2) and a power transmission device (3), and an electric motor (9) is disposed at an area of the power transmission device. An output shaft (9a) of the electric motor (9) is disposed coaxially to any of rotary shafts of the power transmission device (3).

Owner:YANMAR CO LTD

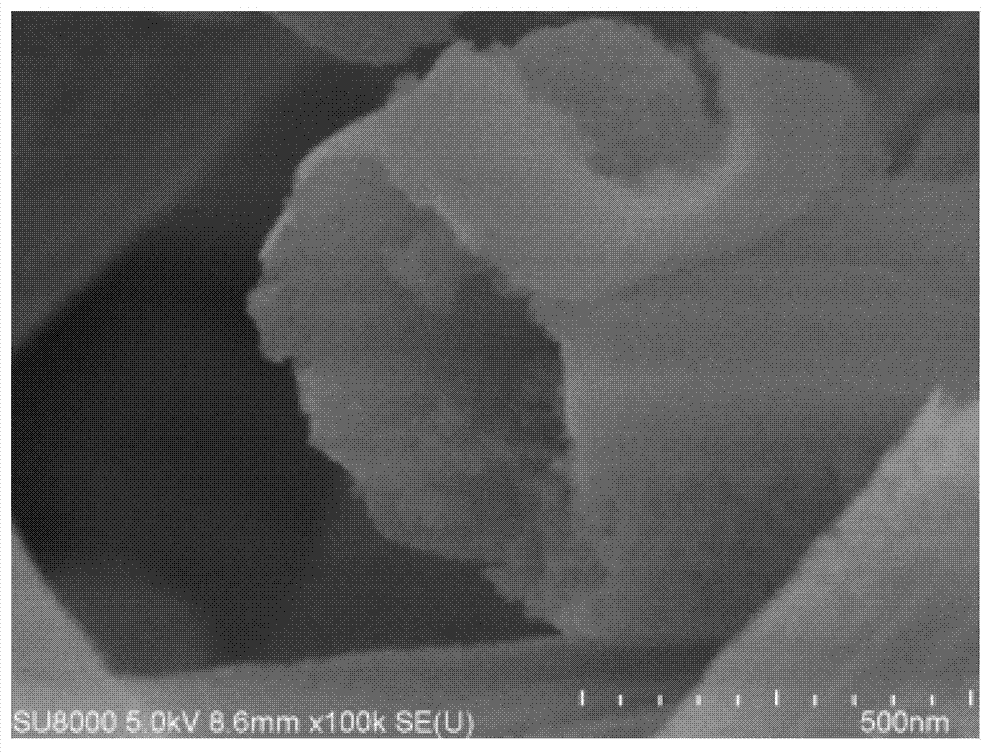

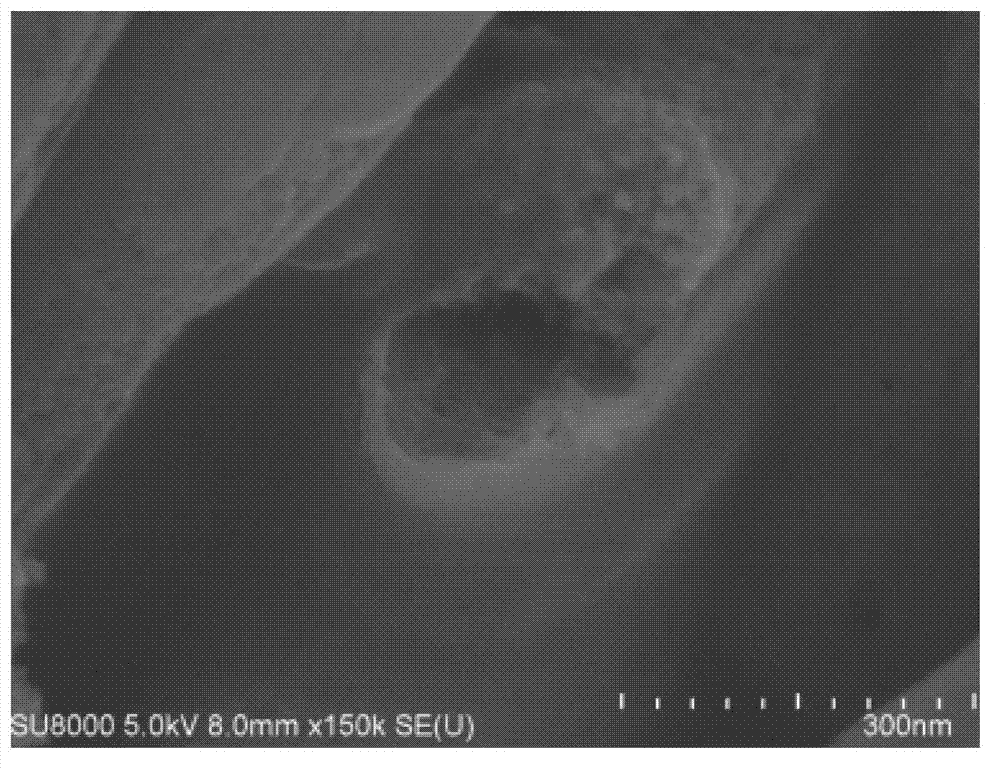

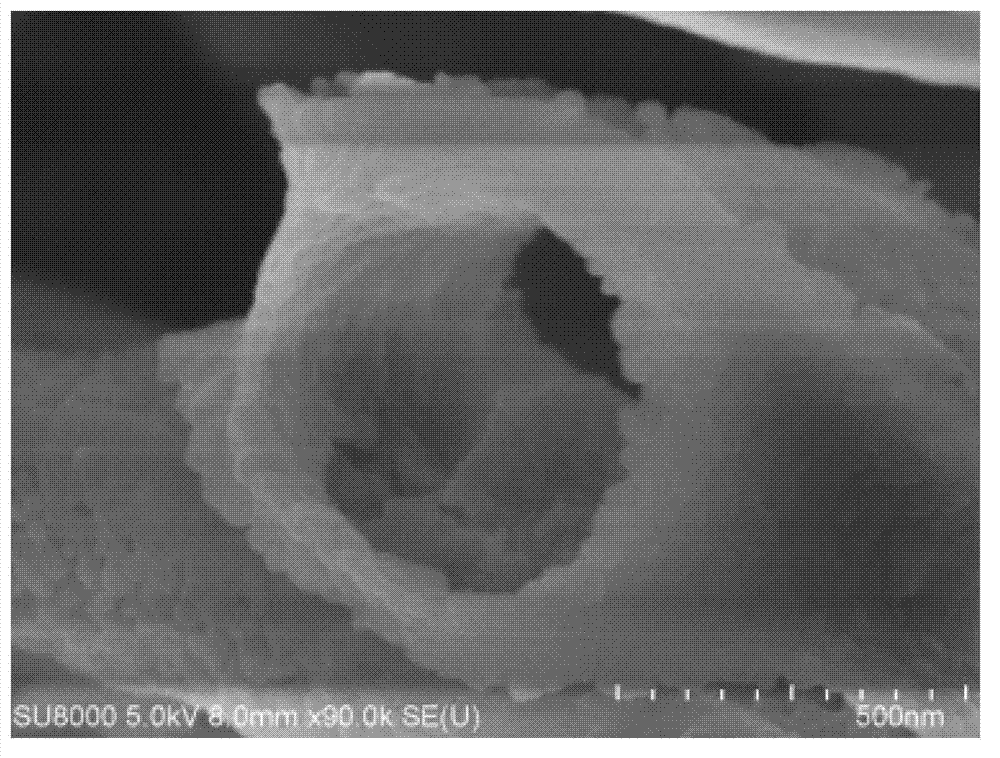

Method for preparing porous hollow nano-alumina fiber by static spinning

InactiveCN102776603ALow equipment requirementsImprove environmental friendlinessFilament/thread formingArtificial filament chemical after-treatmentPolymer dissolutionFiber

The invention relates to a method for preparing porous hollow nano-alumina fiber by static spinning. The method comprises the steps of: (1) dissolving metal salt and polymer into a cosolvent to obtain uniform or stably diffused spinning liquid, wherein the decomposing temperature of the metal salt is lower than that of the polymer, the vitrification transformation temperature of the polymer is lower than the decomposing temperature of the metal salt, and the diffusing rate of the oxide produced by decomposing the metal salt is less than the diffusing rate of the metal salt; (2) carrying out static spinning on the spinning liquid to obtain hybridized nanometer fiber; and (3) drying the hybridized nanometer fiber, and thermally processing to obtain the porous hollow nano-alumina fiber. According to the static spinning preparation method, the preparation technology is simple, and a special spinning needle head with an internal inserting pipe is not needed, and the requirement on equipment is low; and the obtained alumina fiber has the characteristics of high specific surface area, porous performance, and hollow performance and the like.

Owner:DONGHUA UNIV

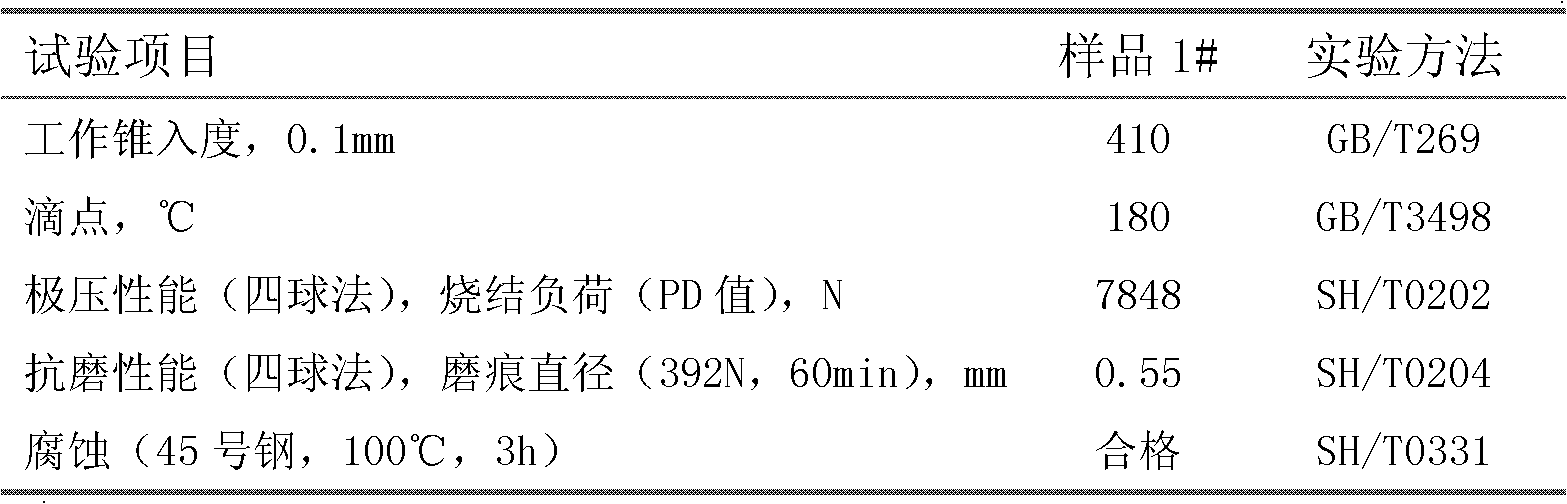

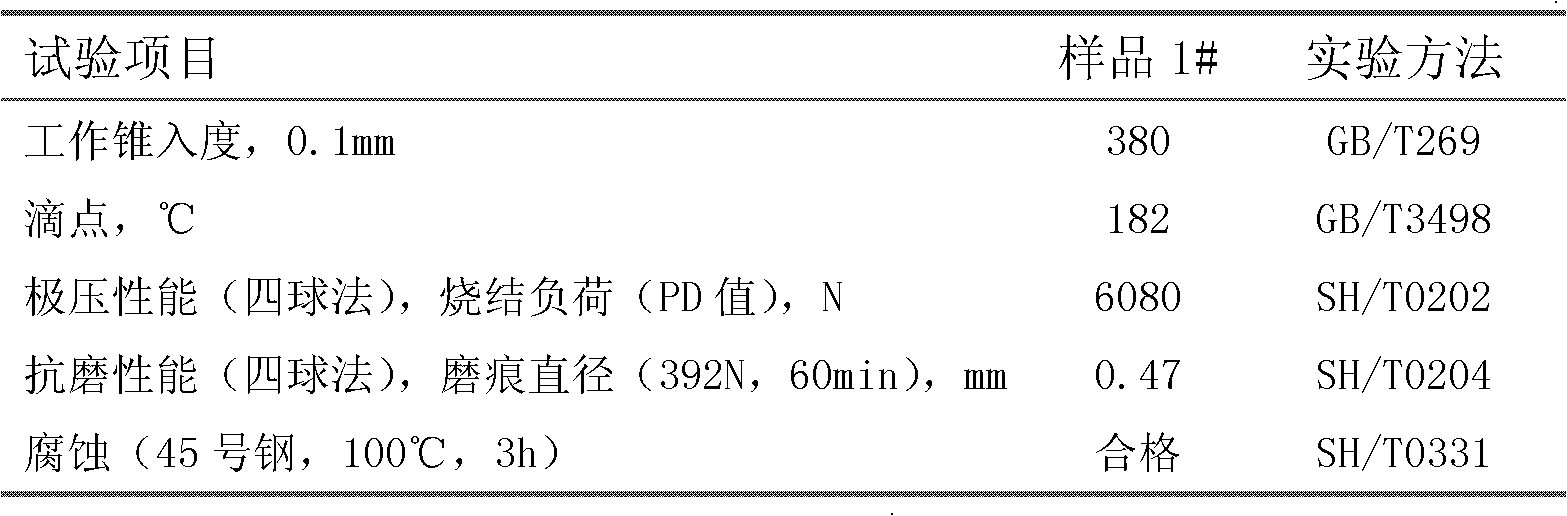

Open gear lubricating grease composition

ActiveCN102433195AGood extreme pressure and anti-wear propertiesImprove the protective effectLubricant compositionVegetable oilPreservative

The invention relates to an open gear lubricating grease composition, which comprises the following components in percentage by weight: 15 to 25 percent of metallic soap, 40 to 50 percent of vegetable oil, 15 to 25 percent of ester-based oil and 10 to 20 percent of polyisobutene. Based on the 100-percent total weight of the base oil and a thickening agent, 2 to 5 percent of dialkyl dithiocarbamate, 0 to 4 percent of boric acid ester, 3 to 8 percent of borate, 1 to 3 percent of dialkyl dithiophosphate, 3 to 10 percent of sulfurized fat, 3 to 10 parts of graphite, 2 to 8 parts of molybdenum disulfide, 0.5 to 1 percent of antioxygen and 0 to 2 percent of preservative are added. The lubricating grease has the advantages that: a proper raw material mixing ratio is selected, so the extreme pressure wear-resistance performance, protective performance and adhesive performance are high; and as biodegradable raw materials are selected, environment friendliness is high.

Owner:CHINA PETROLEUM & CHEM CORP

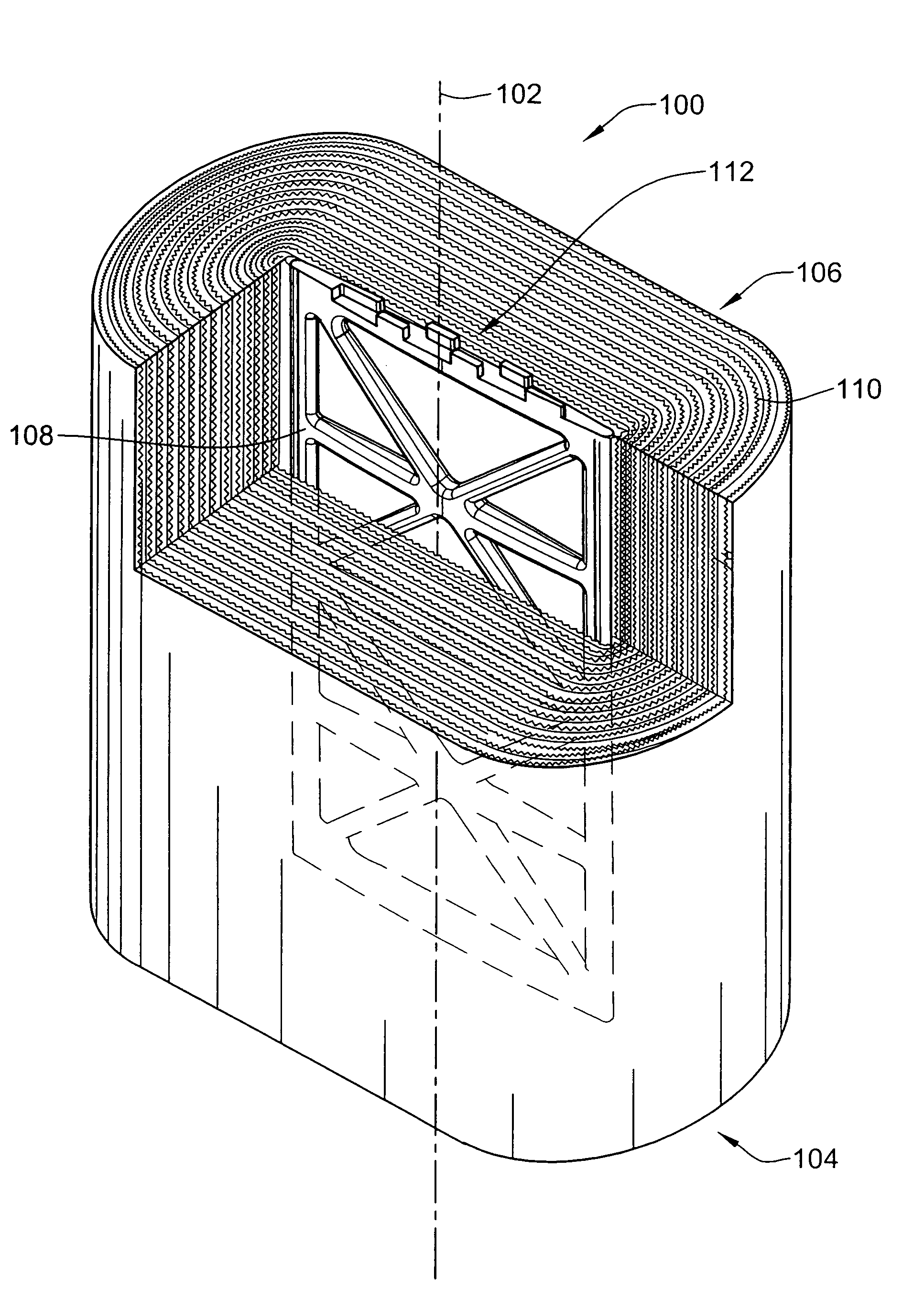

Method and apparatus for winding a filter element

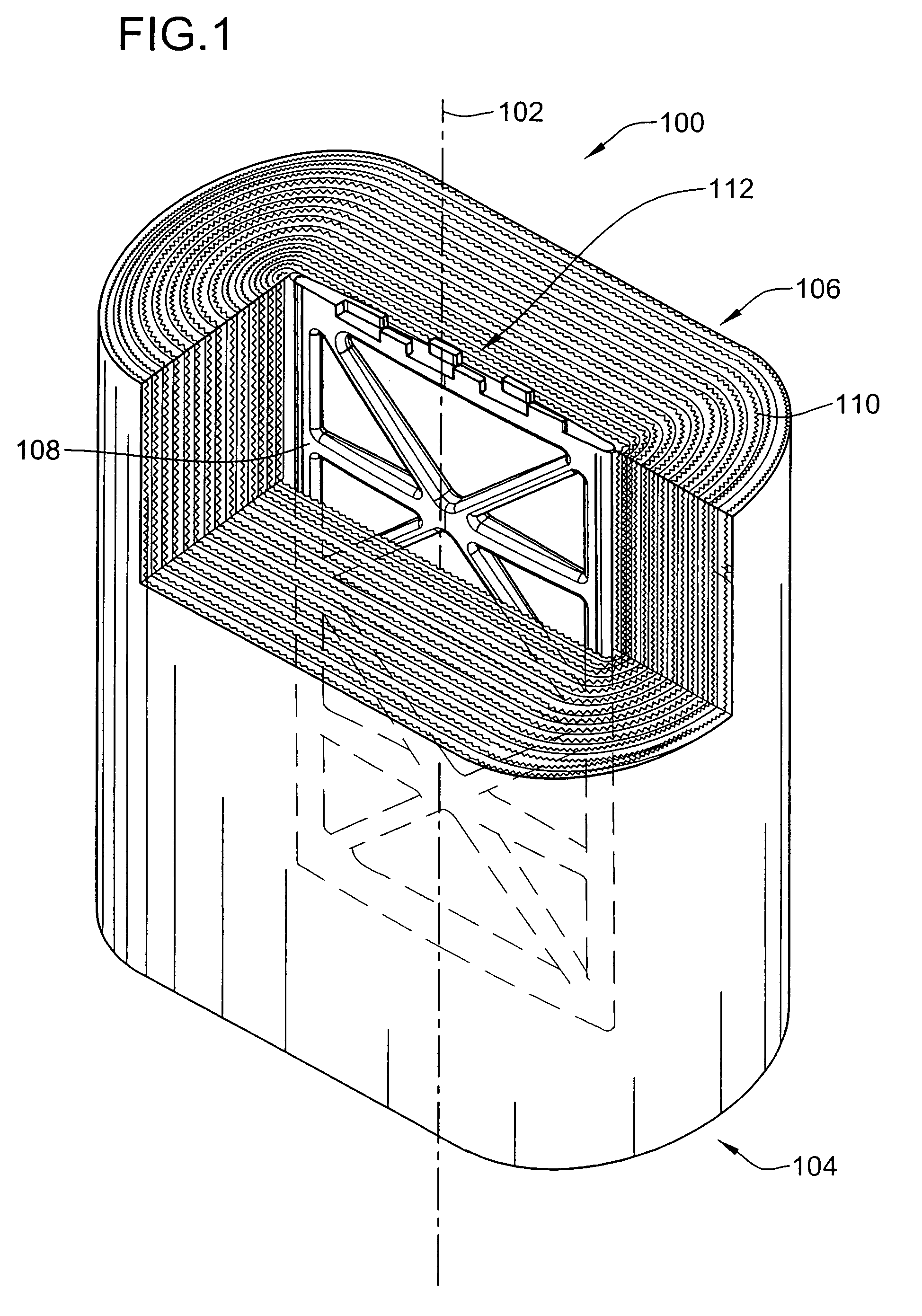

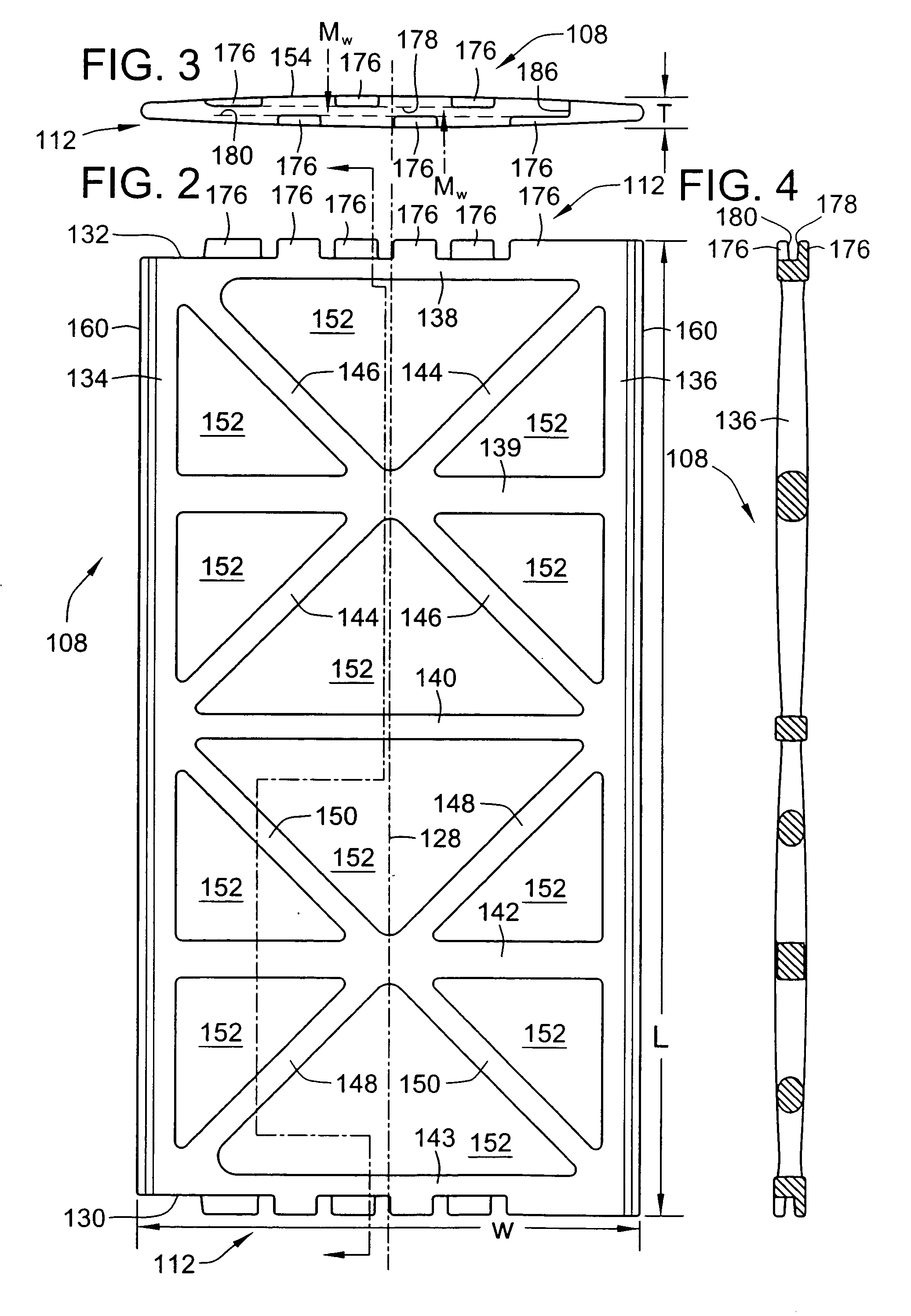

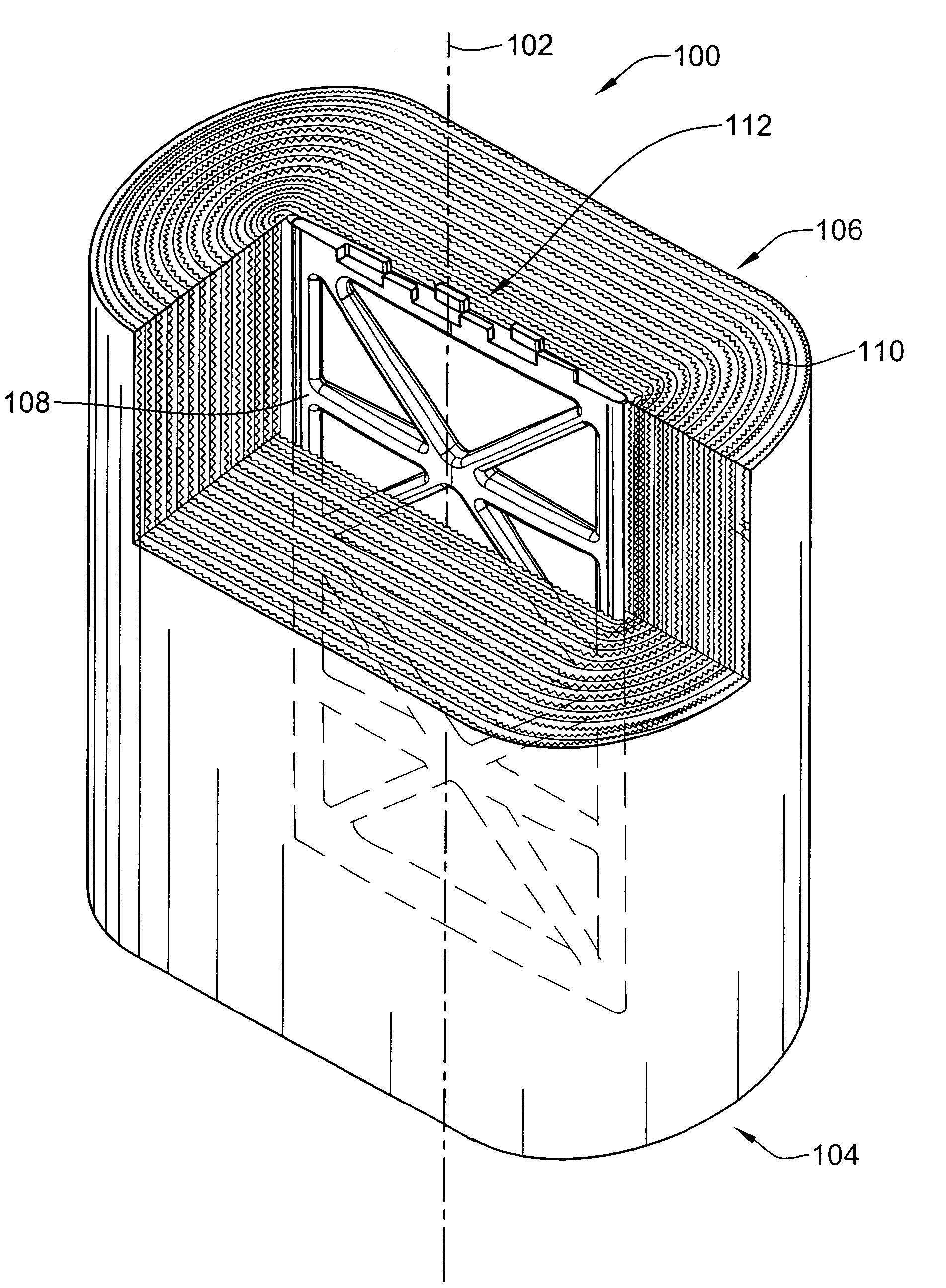

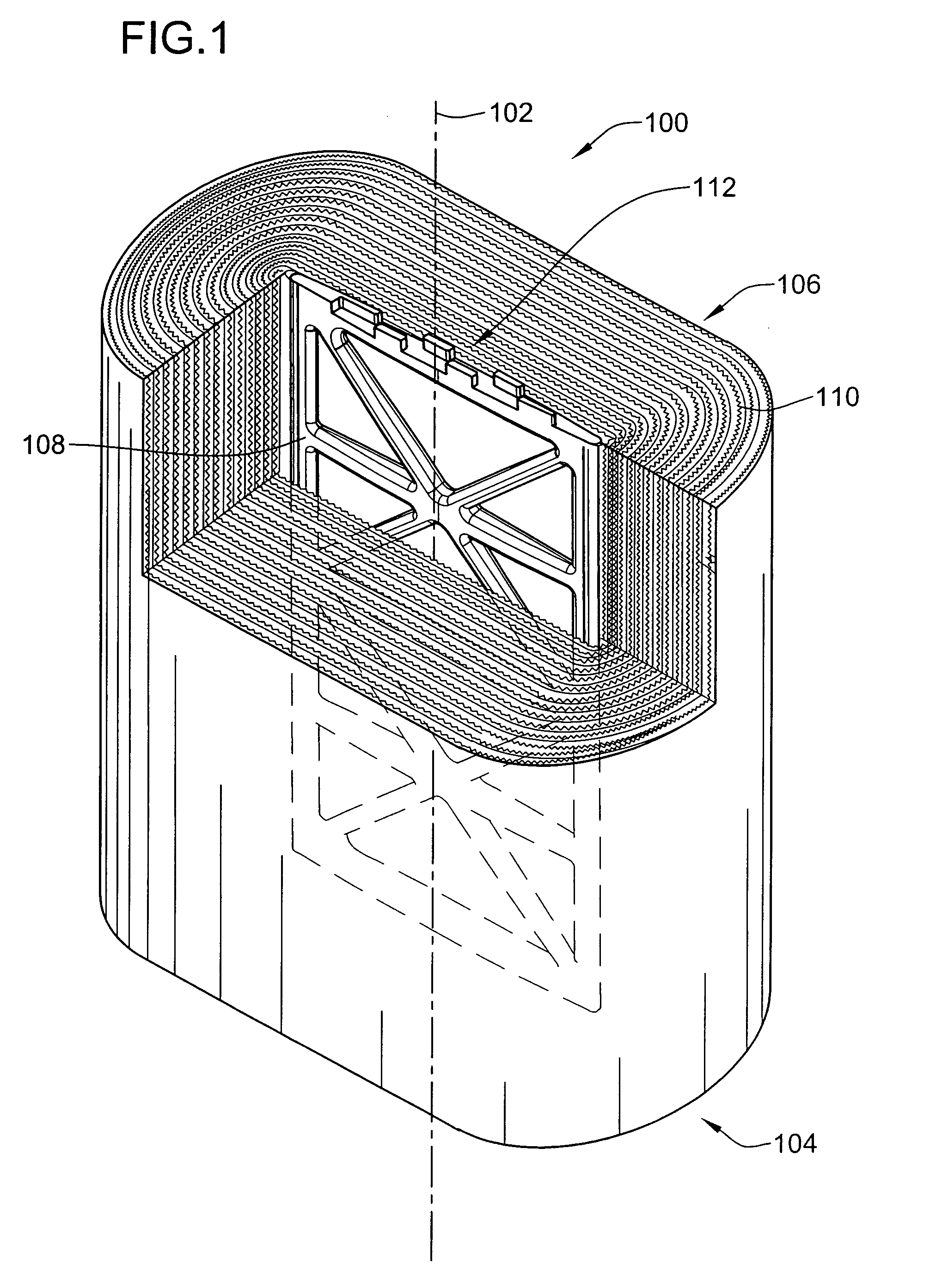

ActiveUS20080135471A1Increase activity areaImprove environmental friendlinessDispersed particle filtrationMembrane filtersFilter mediaEngineering

A filter apparatus and method utilize a filter element, defining a longitudinal axis and an axial end thereof, and having a central winding structure and a length of fluted filter material wound about the winding structure with the flutes of the media oriented to provide for filtration of fluid passing axially through the filter element. An edge of filter media defines the axial end of the filter element when the media is wound about the winding structure. An axial end of the winding structure is disposed adjacent the axial end of the filter element. A winding feature extends substantially axially outward from the axial end of the winding structure to a distal end of the winding feature. The filter media is wrapped about the winding structure such that the axial end of the filter element is disposed substantially flush with the distal end of the winding feature.

Owner:BALDWIN FILTERS

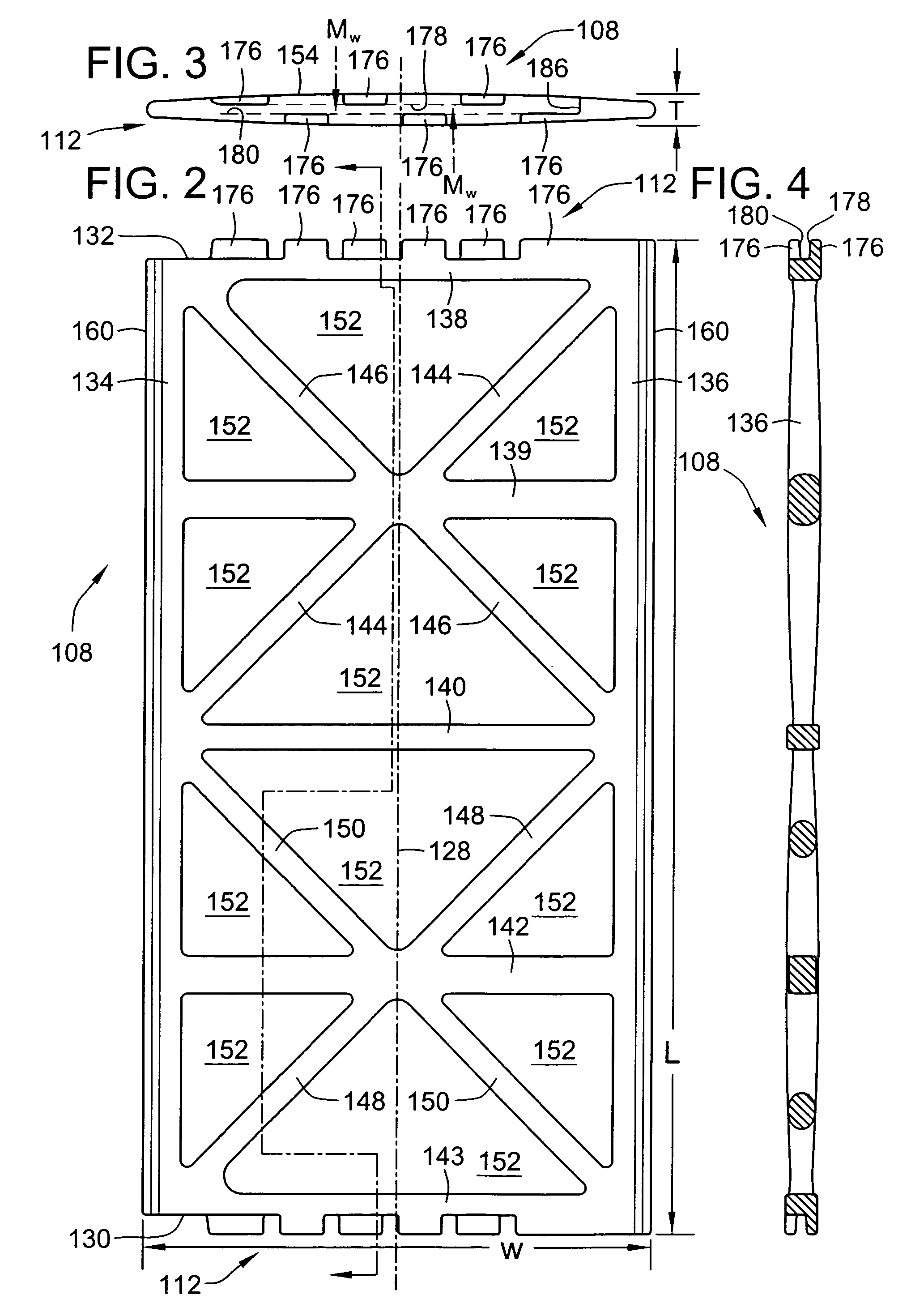

Fluid filter apparatus having filter media wound about a winding frame

ActiveUS20080135470A1Improve manufacturabilityImprove operational capabilitiesDispersed particle filtrationCartridge filtersLeading edgeFilter media

A filter apparatus and method utilize a filter element having a central winding frame and a length of fluted filter material wound about the frame with the flutes of the media oriented substantially longitudinally, to thereby provide for filtration of a flow of fluid passing axially through the filter element. The winding frame is a substantially open, truss-like structure, having a smooth outer periphery and an axially extending winding feature to facilitate pulling the media into intimate contact with the smooth outer periphery during fabrication of the filter element. A leading edge of the filter media is anchored to a leading edge of the frame by a length of tape.

Owner:BALDWIN FILTERS

High-efficiency formaldehyde scavenging agent

InactiveCN101181677AThorough responseTo achieve the purpose of removing formaldehydeDispersed particle separationWastewaterSURFACTANT BLEND

The invention discloses a high effect formaldehyde dispelling agent. The formaldehyde dispelling agent of the invention comprises formaldehyde dispelling factors, a stabilizing agent, a synergistic agent, surfactants and water, etc. The product is nonpoisonous and tasteless, safe and environmental friendly, which can quickly and thoroughly dispel free formaldehyde in air, waste water and various boards and furniture, and a dense protecting film is formed on the surface of solid, working for a long time. The method of the invention is characterized by simple production technique and devices, no three wastes pollution and low production cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

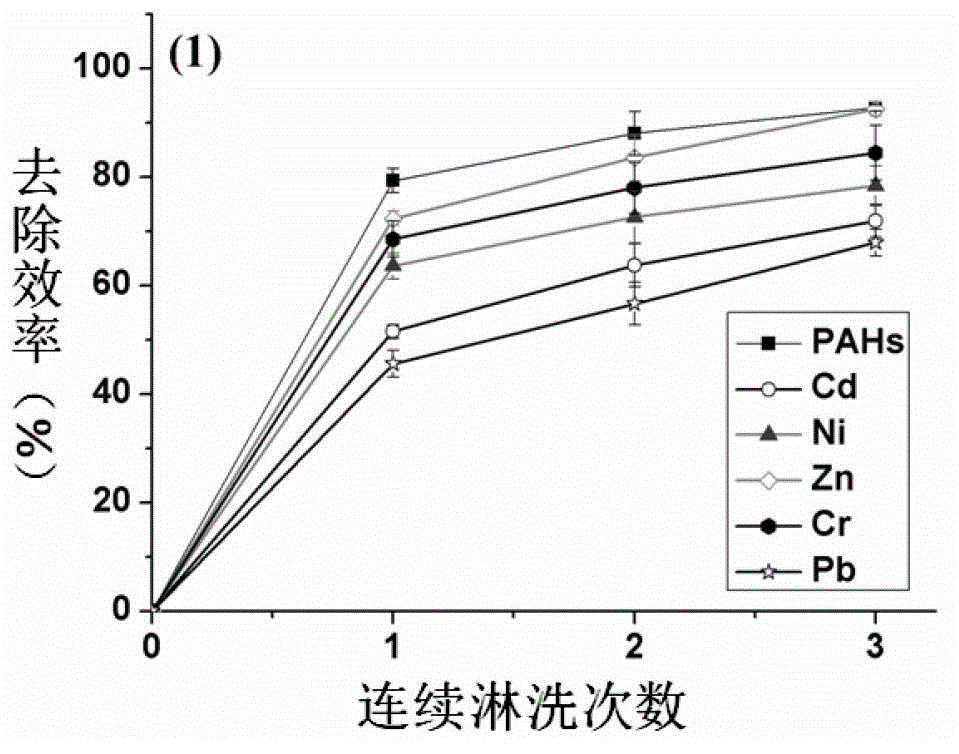

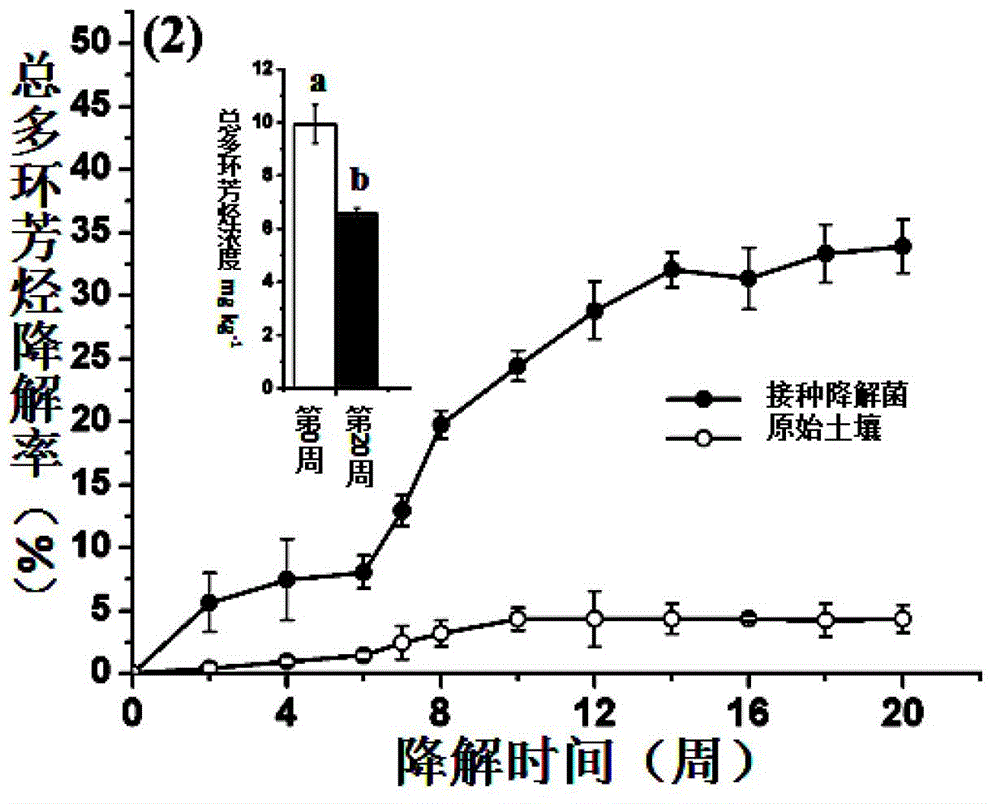

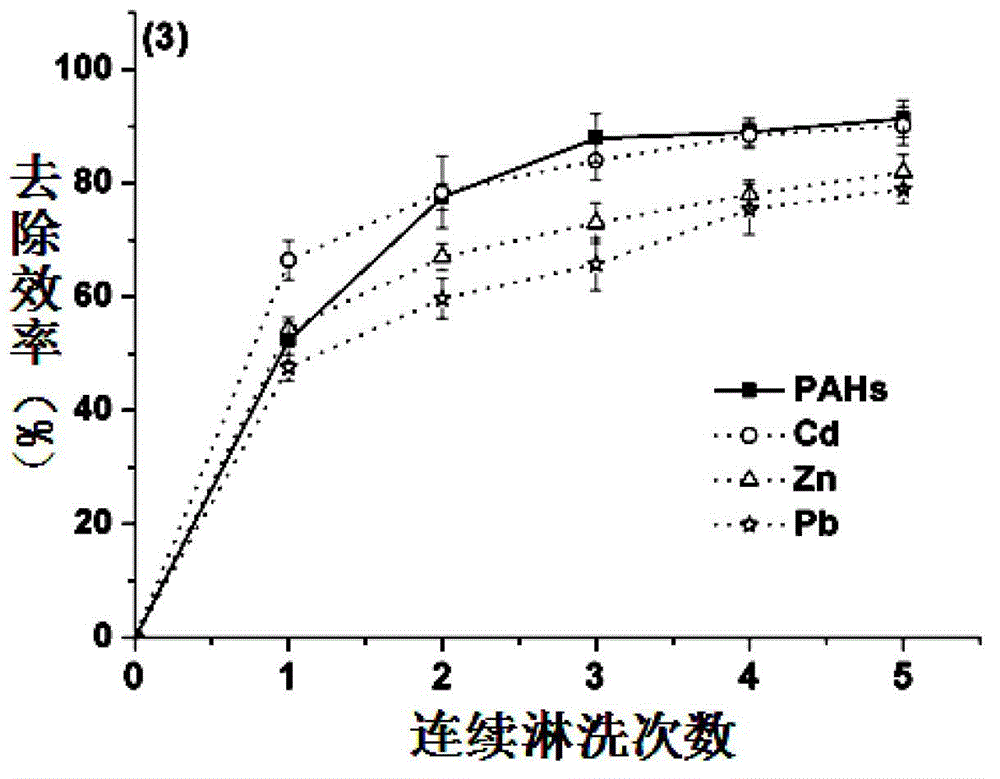

Chemistry-microorganism combination restoration method of polycyclic aromatic hydrocarbons and heavy metal composite contaminated site soil

InactiveCN102941225ANo secondary pollutionImprove environmental friendlinessContaminated soil reclamationCyclodextrinCoking plant

Disclosed is a chemistry-microorganism combination restoration method of polycyclic aromatic hydrocarbons and heavy metal composite contaminated site soil. The method comprises steps of (1), preparing soil particles and air drying and grinding contaminated site soil; (2), setting a restoration system, adding methyl beta cyclodextrin leacheate to a blender; (3), adjusting the reaction temperature to be 50+ / -2 DEG C; (4), adjusting an ultrasonic emission device to 35kHz for ultrasound of 30 minutes; (5) conducting continuous leaching, and repeating the continuous leaching for 3 times; and (6) conducting depth restoration of degrading bacteria, and inoculating polycyclic aromatic hydrocarbons degrading bacteria to soil which is subjected to continuous leaching restoration, adjusting the N / P to be 10:1 and conducting degradation for 90-140 days continuously. By the aid of the method, the restoration of the polycyclic aromatic hydrocarbons and heavy metal contaminated site soil generated by enterprises such as transferred coking plants, steel mills and power plants has wide application prospects.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

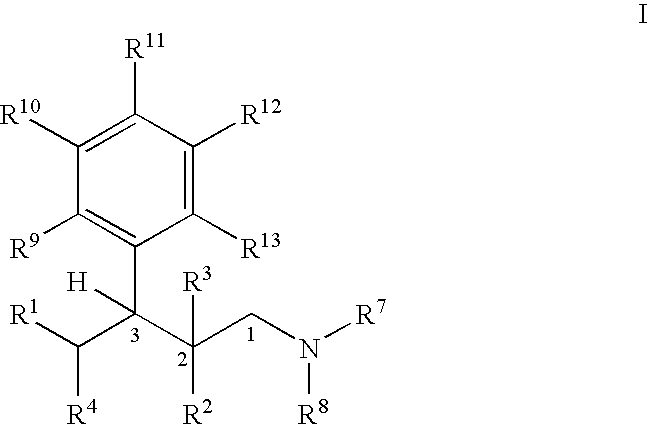

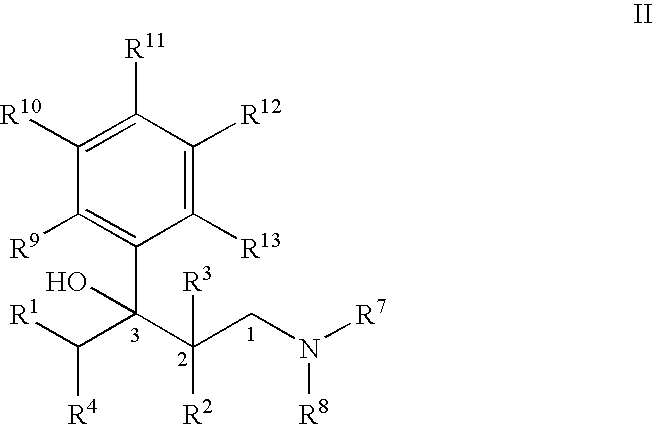

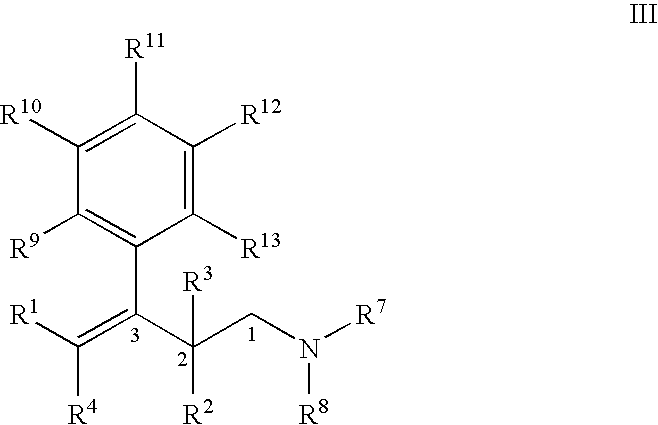

Process for the preparation of substituted 3-aryl-butylamine compounds

ActiveUS7417170B2High yieldImprove environmental friendlinessOrganic compound preparationAmino compound preparationArylAlcohol

Methods for the dehydration of substituted 1-amino-3-aryl-butan-3-ol compounds for the preparation of substituted 3-aryl-butyl-amine compounds.

Owner:GRUNENTHAL GMBH

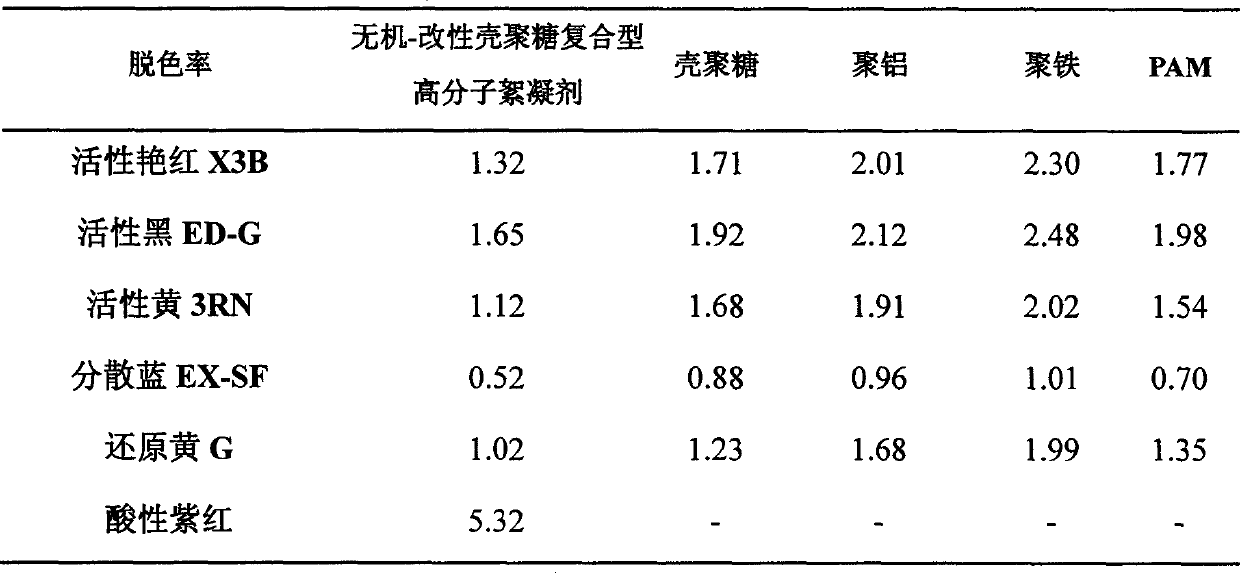

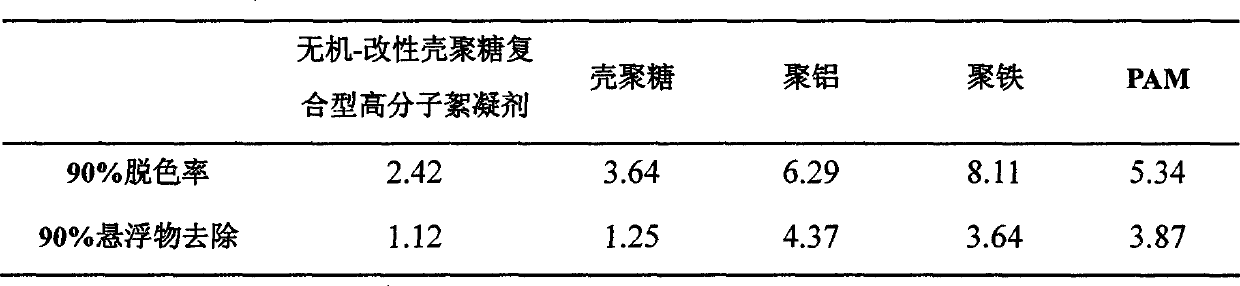

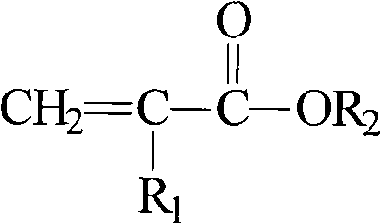

Inorganic-modified chitosan composite type polymeric flocculant

InactiveCN103121742ASimple structureRich sourcesWater/sewage treatment by flocculation/precipitationAluminium chlorideMeth-

The invention relates to an inorganic-modified chitosan composite type polymeric flocculant. The inorganic-modified chitosan composite type polymeric flocculant is characterized in that a method for preparing the composite type polymeric flocculant comprises the following steps of: taking polyacrylamide-modified chitosan as a raw material and methacryloyloxyethyl trimethyl ammonium chloride, maleic acid and ceric ammonium nitrate as initiators, synthesizing a modified chitosan copolymer under a faintly acidic condition and blending the modified chitosan copolymer with polymerized ferric chloride and polymerized aluminium chloride to obtain the inorganic-modified chitosan composite type polymeric flocculant. According to the steps, the mass ratio of modified starch to the chitosan is (1-2): 1, the reaction temperature is 50-60 DEG C, the reaction time is 2-3 hours, and the use amount of the initiators accounts for 0.02 part of the total mass of the system. The inorganic-modified chitosan composite type polymeric flocculant prepared by using the method has the characteristics of high efficiency, low cost and low secondary pollution to environment; and aiming at different sludges, compared with a conventional flocculant, the inorganic-modified chitosan composite type polymeric flocculant disclosed by the invention has the advantages that the wastewater decoloring rate and the wastewater deturbidity rate can reach more than 99 percent under the condition of low use amount.

Owner:WUHAN SLOAN ELECTRIC

Straw powder-based anti-blocking agent of compound fertilizer

InactiveCN102050679APromote decompositionEasy to decompose naturallyFertilizer mixturesOil and greaseParaffin wax

The invention provides a straw powder-based anti-blocking agent of a compound fertilizer, which is prepared by mixing the following raw materials in parts by weight: 7.5-9 parts of straw powder, 0.5-5 parts of stearic acid, 0.1-1 part of stearin, 0.1-0.5 part of hydramine, 0.5-5 parts of white oil or paraffin wax and 2-15 parts of natural oil, the six components are uniformly stirred at 60-120 DEG C and then cooled to the room temperature after reaction for 5-60 minutes so that the finished-product anti-blocking agent is obtained. The main component of the straw powder-based anti-blocking agent is straw which belongs to natural biological raw material so that the straw powder-based anti-blocking agent has biodegradability and favorable environment friendliness and can be repeatedly used for a long term without resulting in adverse influences on soil, crops and farm environments. The straw powder-based anti-blocking agent has the advantages of high-efficiency and full utilization of straw resources, environmental protection, convenience for processing and high cost performance without using engine oil.

Owner:FUJIAN UNIV OF TECH

Preparation method of bacterial cellulose/graphene oxide nano-composite sphere adsorption material

InactiveCN104209099AGood environmental friendlinessConducive to ecological balance and environmental protectionOther chemical processesWater contaminantsAcetobacter xylinumHeavy metals

The invention discloses a preparation method of a bacterial cellulose / graphene oxide nano-composite sphere adsorption material. The preparation method comprises the following steps: preparing a liquid culture medium; adding a graphene oxide aqueous solution, uniformly mixing, then inoculating with strain, namely acetobacter xylinum, carrying out rotating and shaking culture at the temperature of 4-35 DEG C, secreting cellulose by acetobacter xylinum to attach graphene oxide dispersed in the liquid culture medium to the surface, winding and wrapping the cellulose to form a spherical three-dimensional network bacterial cellulose / graphene oxide nano-composite sphere nanocomposite material; and boiling the formed nano-composite material by using a potassium hydroxide aqueous solution, filtering, washing by using deionized water, then freeze-drying to prepare the bacterial cellulose / graphene oxide nano-composite sphere adsorption material. The adsorption material prepared by the method is large in specific surface area, environmentally friendly and low in cost and has the good function of adsorbing radionuclides such as uranyl ions and strontium ions, as well as heavy metal ions in industrial wastewater.

Owner:SOUTHWEAT UNIV OF SCI & TECH

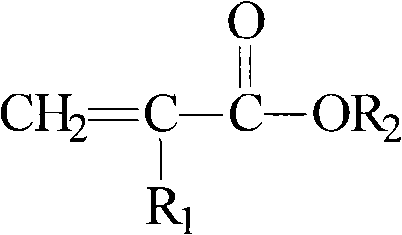

Method for preparing multi-color long afterglow water borne luminescent coatings

InactiveCN101555376ALong glow timeNo emissionsLuminescent paintsLuminescent compositionsEmulsionLuminous paint

The invention discloses a method for preparing multi-color long afterglow water borne luminescent coatings. The coating is prepared by taking a high molecular polymer formed by mutual polyreaction of three monomers through initiating agents as acrylic emulsion, taking the synthetic acrylic emulsion as a base resin of the coating and adding luminescent powder, auxiliary agents and fillers; the prepared multi-color long afterglow water borne luminescent coatings have good luminescent property, wear-resisting property, adhesion property and the like. The coatings feature simple preparation process and convenient construction, and compared with the traditional oil soluble luminescent coatings, the coatings discharge no noxious solvents and enjoy environment-friendly production process.

Owner:GUANGDONG UNIV OF TECH

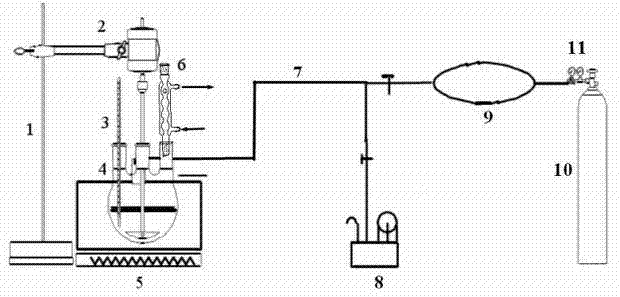

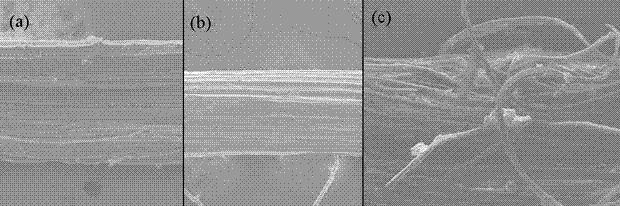

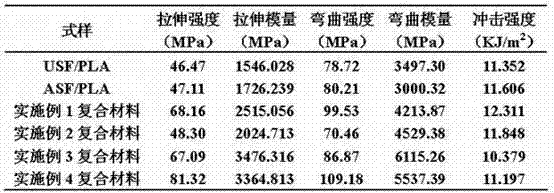

Preparation method for lactide grafted plant fiber reinforced poly lactic acid composite material

The invention discloses a preparation method for a lactide grafted plant fiber reinforced poly lactic acid composite material. The preparation method comprises: carrying out an alkali liquid soaking treatment on plant fibers, and drying; mixing the resulting plant fibers and a lactide monomer; carrying out a graft reaction under an anhydrous and anaerobic condition under a catalysis effect of stannous octanoate to obtain lactide grafted plant fibers; drying; mixing the dried lactide grafted plant fibers and ungrafted plant fibers; and carrying out blending, hot pressing molding and cooling shaping on the mixed fibers and completely-molten poly lactic acid to obtain the composite material. According to the present invention, lactide ring opening polymerization is adopted to carry out a graft treatment on plant fibers to change surface polarity of the fibers so as to improve interface compatibility between the plant fibers and the poly lactic acid matrix, and improve the whole performance of the composite material; compared with pure poly lactic acid and untreated plant fiber reinforced poly lactic acid composite materials, the composite material prepared by the preparation method of the present invention has the following characteristics that: interface properties between the plant fibers and the poly lactic acid matrix, and mechanical properties are significantly improved.

Owner:SOUTH CHINA UNIV OF TECH

Method for extracting and purifying anthocyanins from blueberry pomaces

InactiveCN103289430AIncrease added valueRealize large-scale productionOrganic chemistryNatural dyesFreeze-dryingSolvent

The invention relates to a method for extracting and purifying anthocyanins from blueberry pomaces. The method comprises the following steps of: mashing blueberries, separating pulps from pomaces, sequentially carrying out enzymolysis, separation, ultra-filtrated impurity removal, nanofiltration concentration and macroporous resin purification on the obtained object, recovering ethanol and an intercepting liquid through nanofiltration, and carrying out freeze drying on the intercepting liquid so as to obtain claret-colored blueberry anthocyanin powder, wherein the anthocyanins content of the blueberry anthocyanin powder is 50-90%. According to the invention, the added value of blueberry resources is improved; the process is not only simple, but also low in operating cost, therefore, the process is suitable for the large-scale production of anthocyanins; the whole process adopts a physical method, no poisonous and harmful solvents are adopted, and the energy consumption is low, therefore, the method effectively protects the environment; and medium-temperature (25-55 DEG C) enzymolysis is adopted, thereby maximumly keeping that anthocyanins not destroyed.

Owner:LIM KUM KEE FOODSTUFF CO LTD ANHUI

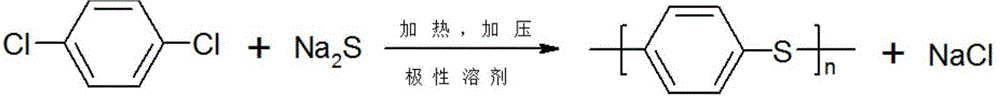

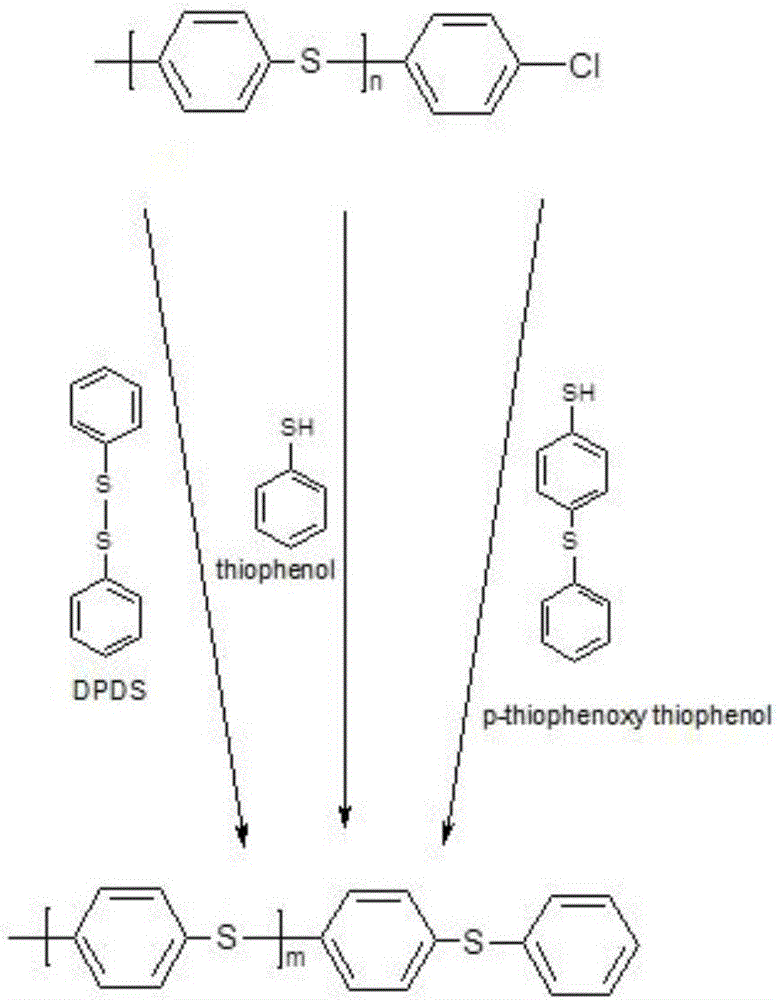

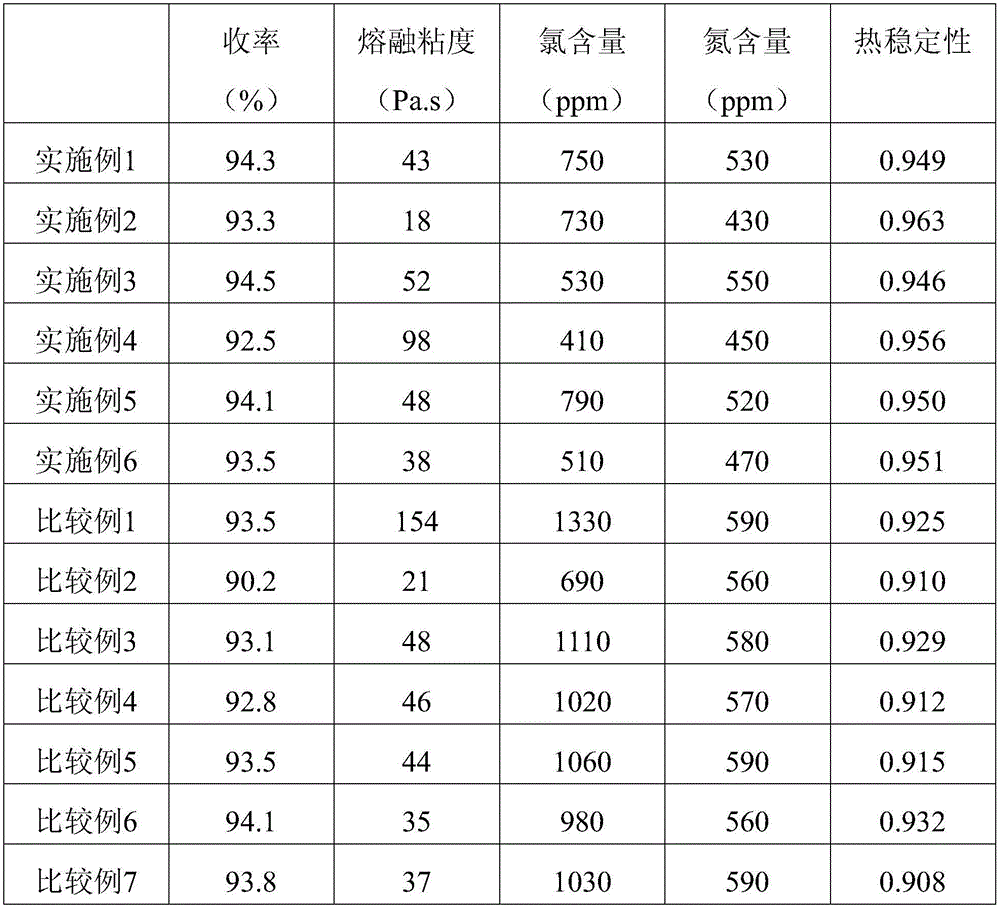

Polyphenylene sulfide with low chlorine content, preparation method of polyphenylene sulfide, resin composition and formed body

ActiveCN106633062AGood environmental friendlinessExcellent fluidity and thermal stabilitySulfur containingEthyl Chloride

The invention discloses polyphenylene sulfide with low chlorine content, a preparation method of the polyphenylene sulfide, a resin composition and a formed body. The polyphenylene sulfide with low chlorine content is prepared by performing end-capping 4-thiophenyl-benzenethiol. The method for preparing the polyphenylene sulfide disclosed by the invention comprises the following steps: taking a sulfur-containing compound, an alkaline matter and paradichlorobenzene as raw materials, taking fatty acids as polycondensation additives, taking 4-thiophenyl-benzenethiol (PTT) as an end group regulator, and carrying out a condensation polymerization reaction. The method disclosed by the invention is high in product yield and low in cost, the obtained polyphenylene sulfide product is low in chlorine content and has excellent fluidity and heat resistance. Therefore, the operating requirements of low chlorine and high fluidity in electronic enterprises can be met.

Owner:ZHEJIANG NHU SPECIAL MATERIALS +2

Lignin and waste rigid foam powder fluorine-free polyurethane heat insulation material and preparing method

InactiveCN101012332AHigh strengthImprove environmental friendlinessOther chemical processesPolyolFoaming agent

The invention discloses non-fluorine polyurethane insulating material and making method, which comprises the following steps: allocating raw material with 10-16% isocyanate, 6-10% polyether polyol, 0.05-0.25% water, 2-.35% foamer, 0.05-0.2% foam-even agent, 0.04-0.08% initiator, 0.1-3% lignin and 0.1-2% waste hard foaming powder; blending each component together under normal temperature and normal pressure; stirring evenly; casting into mould or plastic filling space immediately; foaming; obtaining the product.

Owner:HEILONGJIANG INST OF TECH

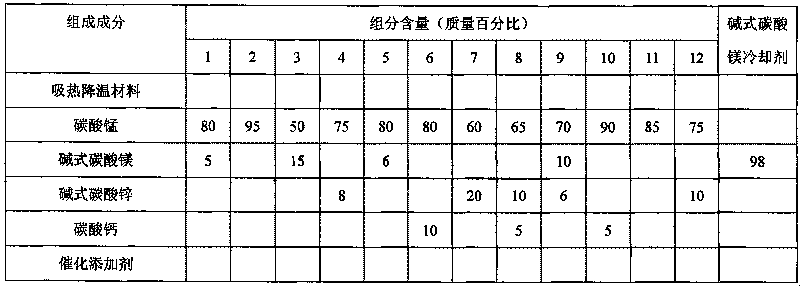

Catalytic chemical coolant for hot aerosol and preparation method thereof

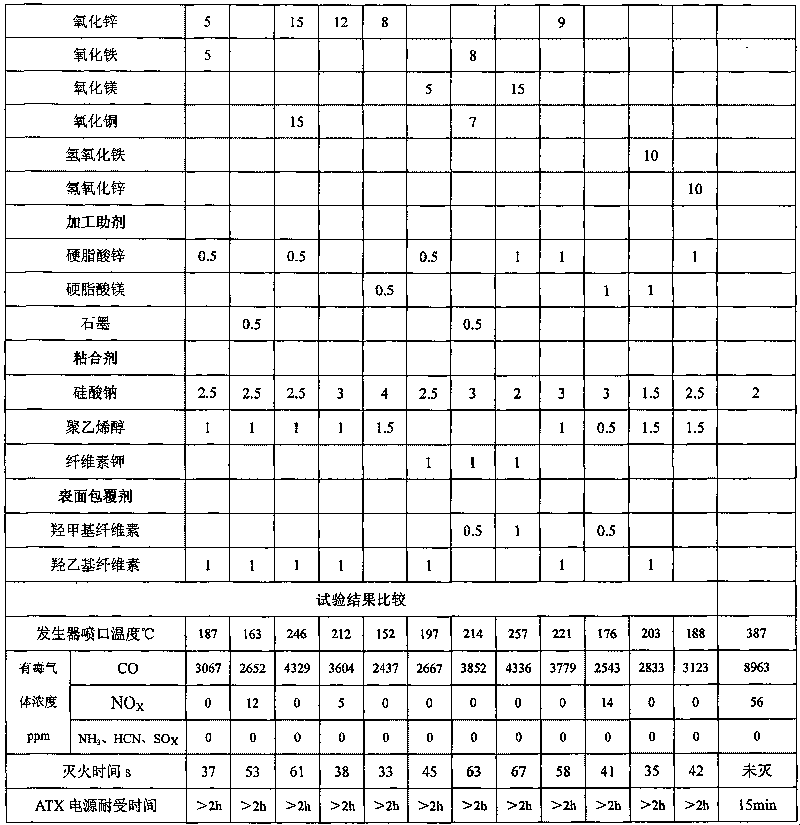

InactiveCN101757760AImprove cooling efficiencyLow toxicityFire extinguisherHydroxyethyl celluloseFilm material

The invention relates to a catalytic coolant used in a hot aerosol fire extinguishing device and a processing technique of the catalytic coolant. As to the coolant, heat absorption cooling components mainly include manganese carbonate or manganese oxalate, manganese phosphate, potassium manganate, metal carbonate of a family I, a family II and a transition family, basic carbonate, oxalate and the like; a metal oxide or a hydroxide are adopted as a catalyst, an oxidant and a reinforcing filling; stearate, graphite and the like are adopted as a processing aid; composite solution of alkalis silicate and a water soluble polymer is adopted as an adhesive; and film materials such as hydroxymethyl or hydroxyethyl cellulose are adopted as a surface coating agent. The processing technique includes the steps of mould pressing, squeezing, pelletizing, coating and forming. Compared with the prior art, the catalytic coolant not only has high intensity and good cooling effect, but also can reduce secondary damage of an extinguishing agent and eliminate the content of poisonous gases in an extinguishing agent product so as to improve the environmental safety of the extinguishing agent.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

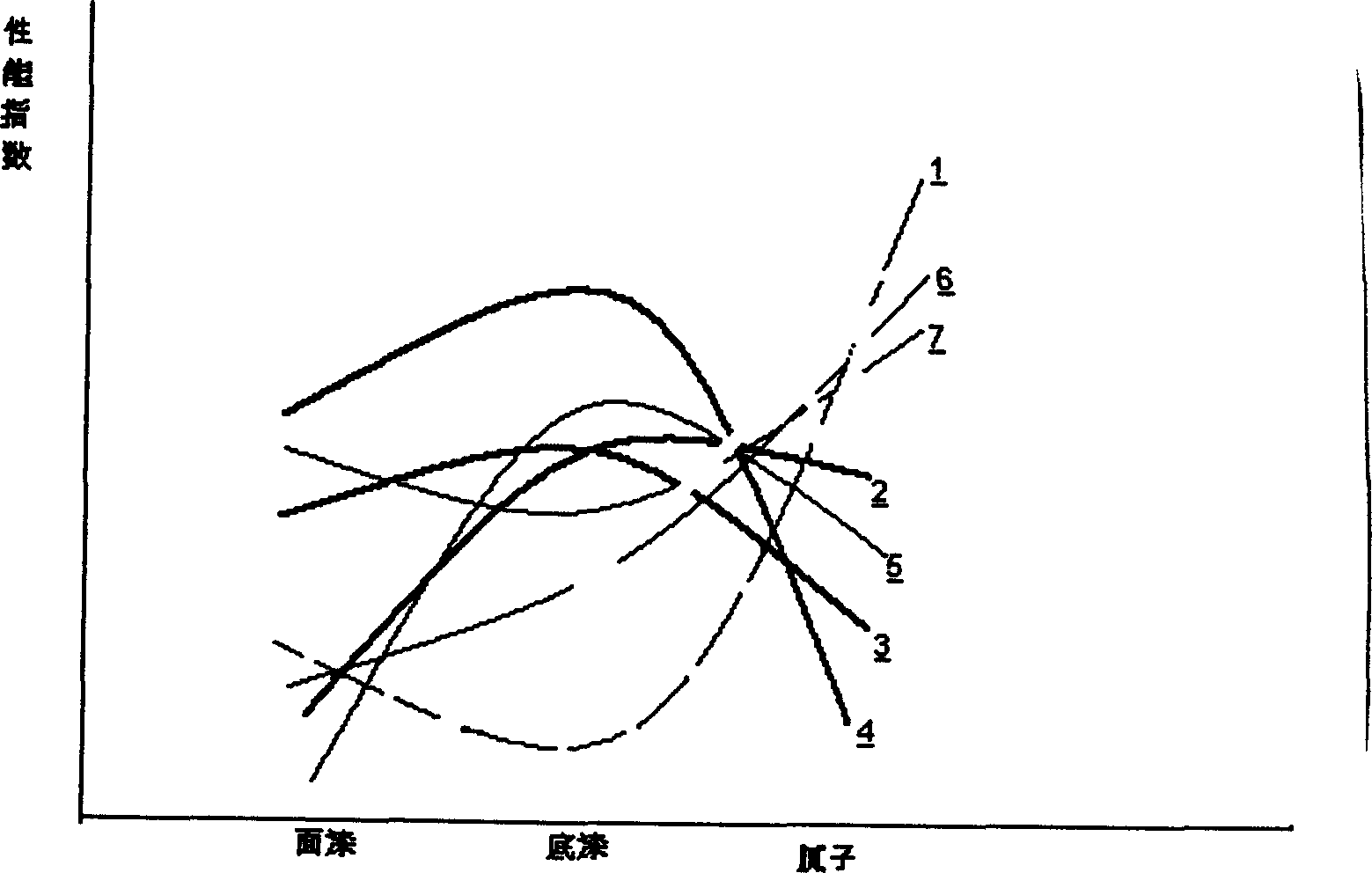

Anti-radon paint

InactiveCN1554719AHigh radon level capabilityGood construction performancePolyurea/polyurethane coatingsFiberMildew

The anti-radon paint has the function of shielding and absorbing ray to lower the indoor radon density and avoid the harm of radon on human body. The present invention includes putty, primer and face paint, and features that the putty, the primer and the face paint include composite polymer latex, composite fiber, stuffing, anti-mildew agent, preservative, dispersant, rheologic agent, ARP5, ARG6 and ARB7 material.

Owner:东莞东成发化工有限公司 +1

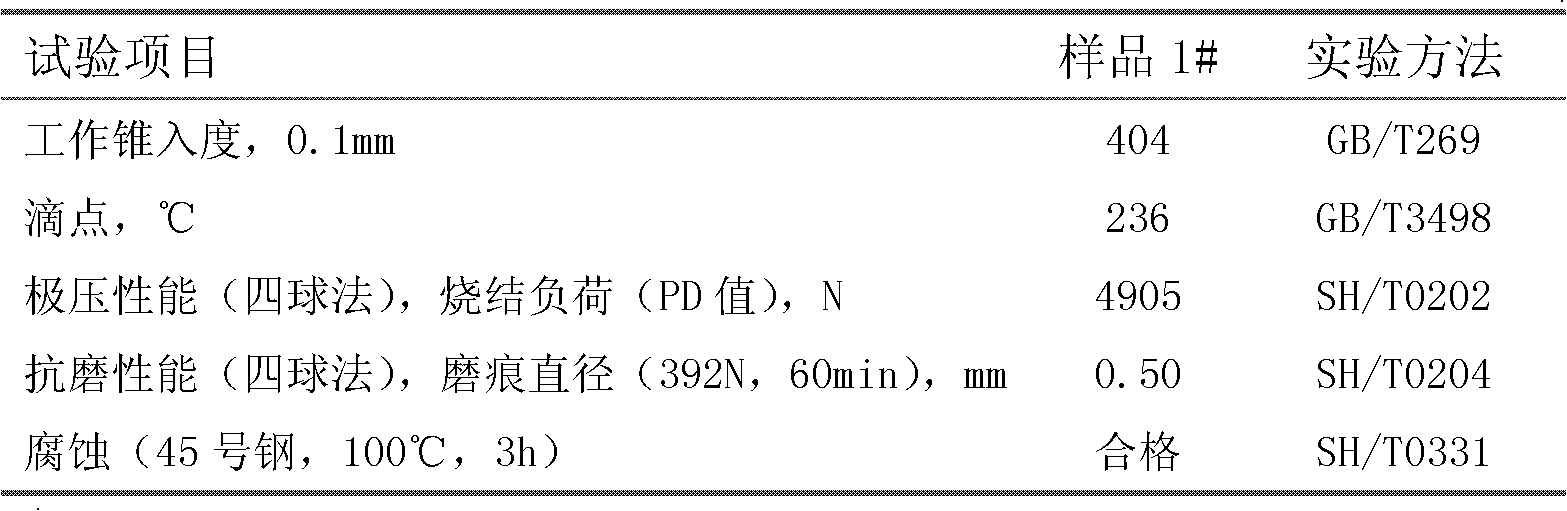

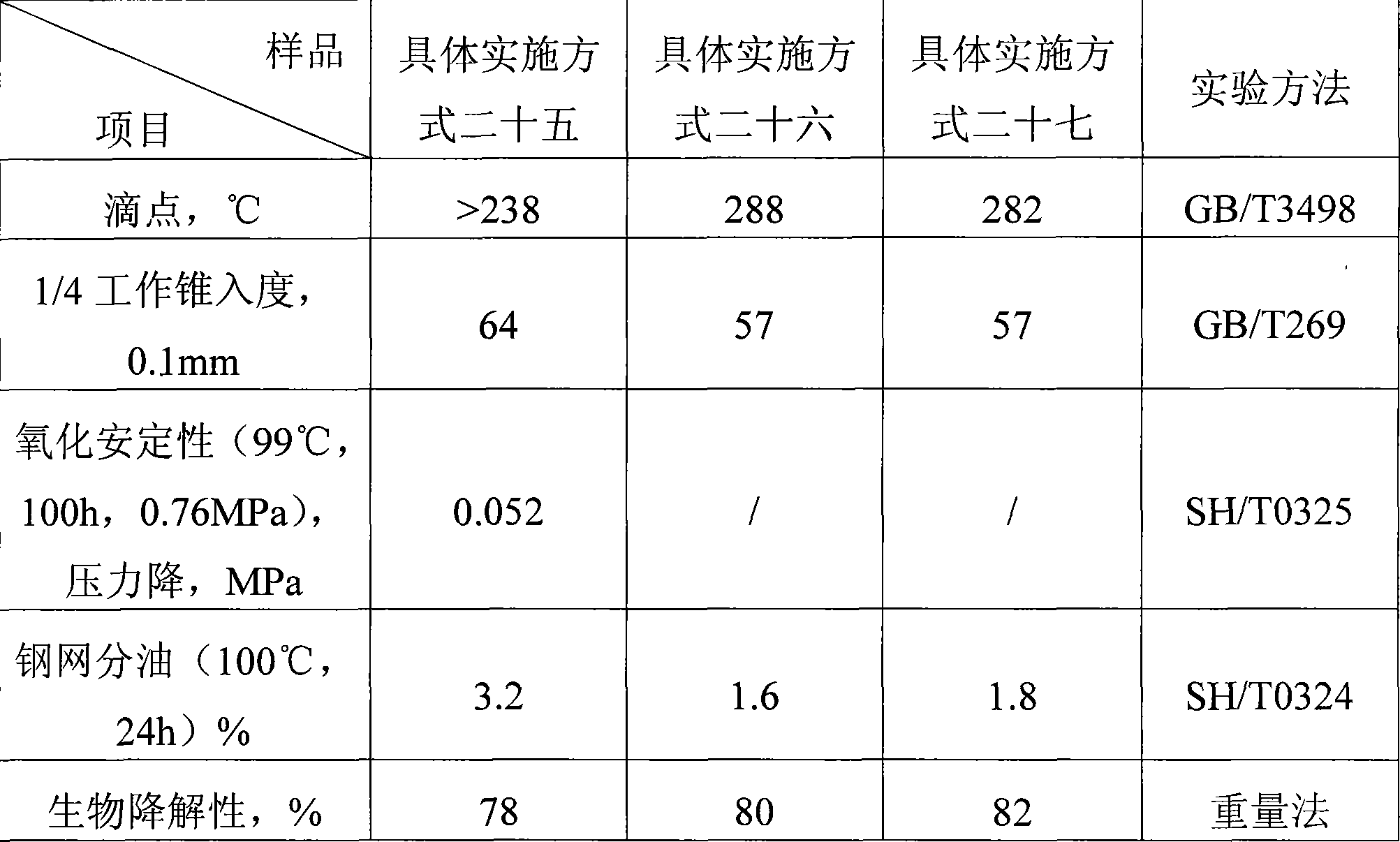

Environment-friendly lubricating grease and preparation method thereof

InactiveCN101058762AImprove performanceIncreased working penetrationThickenersAdditivesBase oilOrganic chemistry

The invention discloses an environment-friend lubricating grease and making method, which comprises the following parts: 15-95% basic oil, 5-85% thickener, 0. 01-5% additive. The making method comprises the following steps: 1. blending the basic oil and thickener; stirring; heating until the thickener is dissolved in the basic oil; insulating 0-8h; 2. heating the composition; stirring; insulating 0-5min; 3. cooling the composition; adding the additive; grinding or cutting. The invention improves the awl-in degree, dripping point, oxidizing stability and environment friendness, which simplifies the technique.

Owner:HARBIN INST OF TECH

Modified double-component epoxy resin paint

InactiveCN1704454AReduce volatilityLow viscosityEpoxy resin coatingsAntimony trioxideSilicon dioxide

The invention relates to a modified double-component epoxy resin paint, wherein the raw materials of the main ingredients includes bisphenol A epoxy resin, multiple functional group glycide amine epoxy resin and filler selected from silicon dioxide, titanium oxide, antimony trioxide, zinc oxide and calcium carbonate, the raw material of the curing agent includes modified aliphatic polyamines, organic diatomaceous soil and methyl ethylene glycol.

Owner:BEIJING HANTECH BUILDING MATERIALS TECH

Sand fixation method of green degradable inorganic sand fixation material

InactiveCN106753384AReduce the impactHold onOther chemical processesOrganic fertilisersCalcium silicateEcological environment

The invention relates to a sand fixation method of a green degradable inorganic sand fixation material, belonging to the field of environmental protection. The inorganic sand fixation material is prepared by mixing calcium silicate slag, fly ash, industrial mineral slag powder, gypsum, cement and solid aggregate used as main raw materials. The sand fixation material and water are mixed to prepare a sand fixation slurry; and the sand fixation slurry is sprayed or spread on sand soil to form a solidifying layer on the sand soil surface. The solidifying layer can satisfy the mechanical property requirements for fixing traveling dunes. After the sand fixation layer is laid, the sand fixation region is subjected to soil improvement and plant growth, so that the sand fixation layer can be degraded into substances which are nontoxic and harmless to the environment within 1-5 years, thereby obtaining the soil components and lowering the influence of artificial buildings on the desert ecological environment. After the sand fixation material reacts with water, no toxic component resides, and thus, the sand fixation material has the advantages of high safety and no secondary pollution. Besides, abundant industrial solid wastes are doped to lower the influence of solid waste piling on the environment; and the method has the advantages of low cost, simple construction technique and high practicality, and is applicable to related fields of desertification control and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

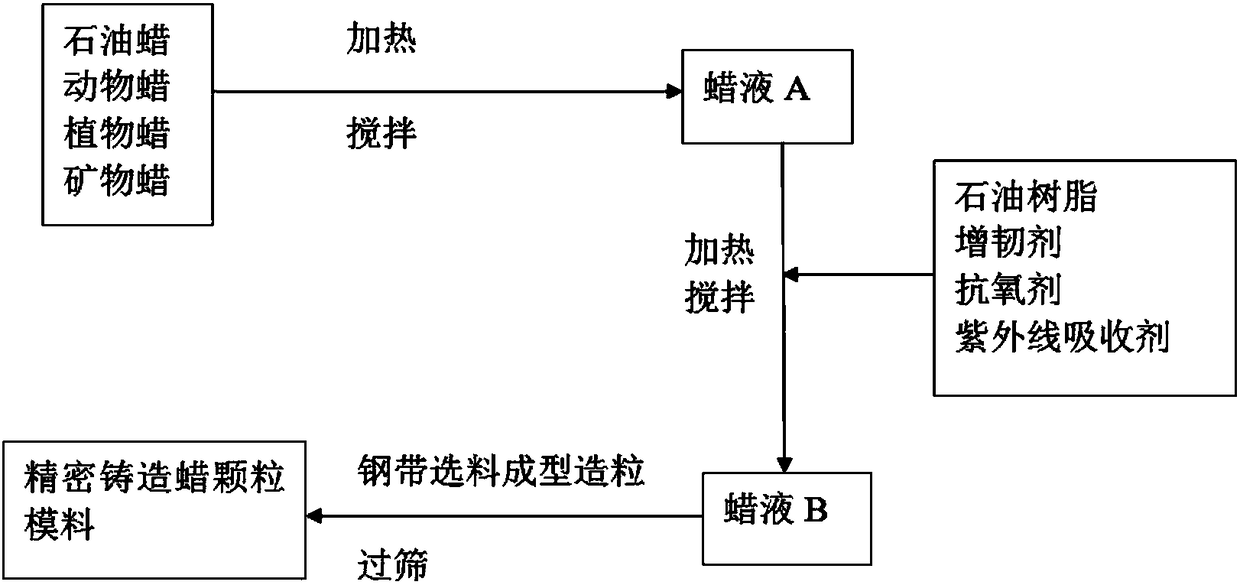

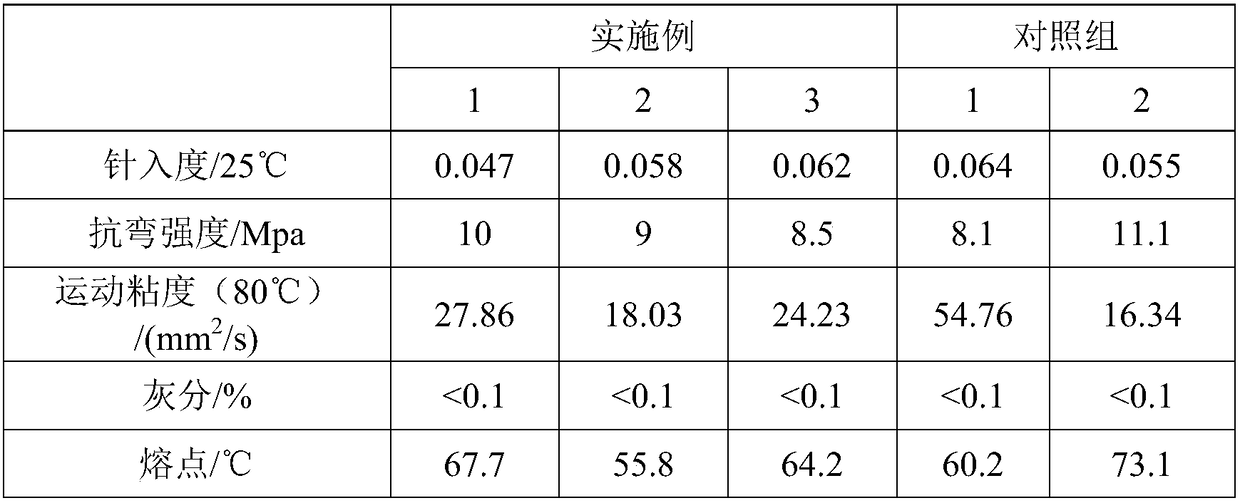

Precision casting wax granular molding material and preparation method and application of precision casting wax granular molding material

The invention belongs to the technical field of precision casting and discloses a precision casting wax granular molding material and a preparation method and application of the precision casting waxgranular molding material. The precision casting wax granular molding material comprises components including, by mass percent, 50%-70% of petroleum wax, 0%-10% of animal wax, 10%-15% of mineral wax,0%-15% of vegetable wax, 0%-15% of petroleum resin, 0%-10% of flexibilizer, 0.0%-0.5% of an ultraviolet light absorbent and 0.0%-1% of an antioxygen. The raw material of petroleum wax is stable and easy to obtain, the petroleum wax serves as a raw material, the cost of the printing wax powder material is greatly reduced, meanwhile, the animal wax, the mineral wax, the vegetable wax, the petroleumresin, the flexibilizer and the like are added to improve the tenacity, the strength and the hardness, the molding material is low in viscosity and melting point and good in flowability, and the granular material is convenient to transport and process. By means of a formula without rosin, it is guaranteed that the casting wax can be repeatedly used several times and is good in environment affinity, meanwhile, the process is simple, the working efficiency is improved, the cost is reduced, and wide market prospects and market competitiveness are achieved.

Owner:广州市德隆化工贸易有限公司

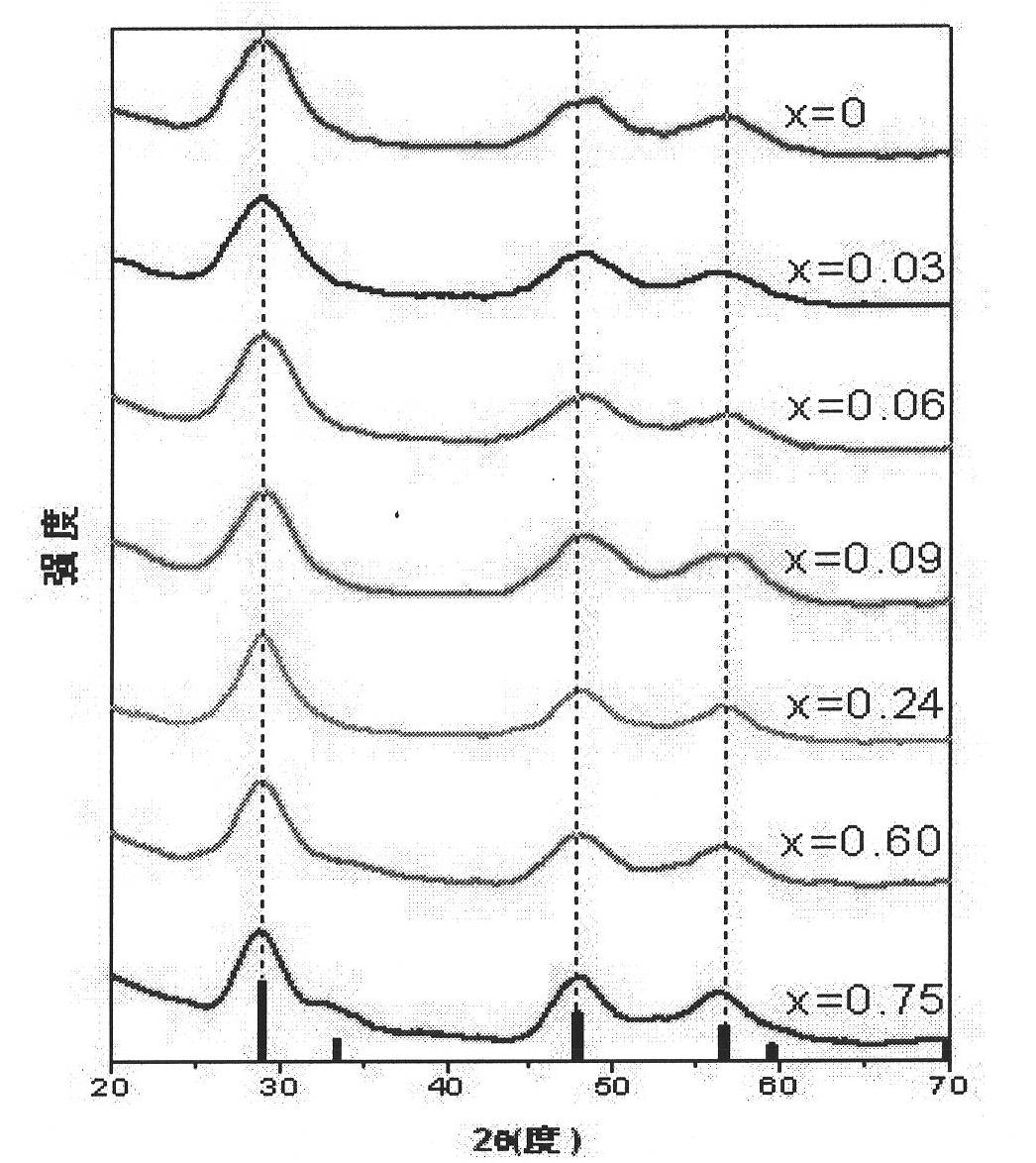

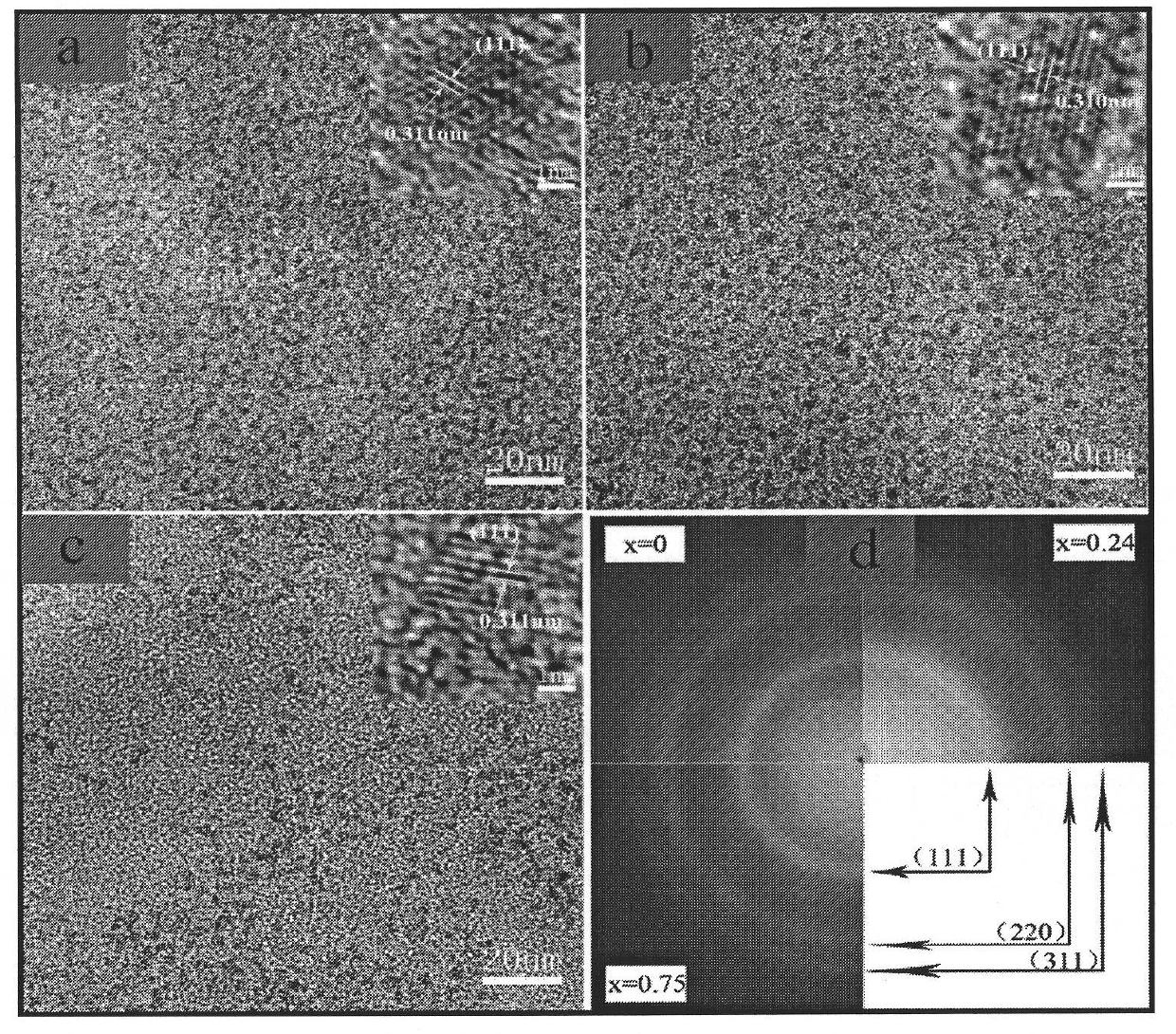

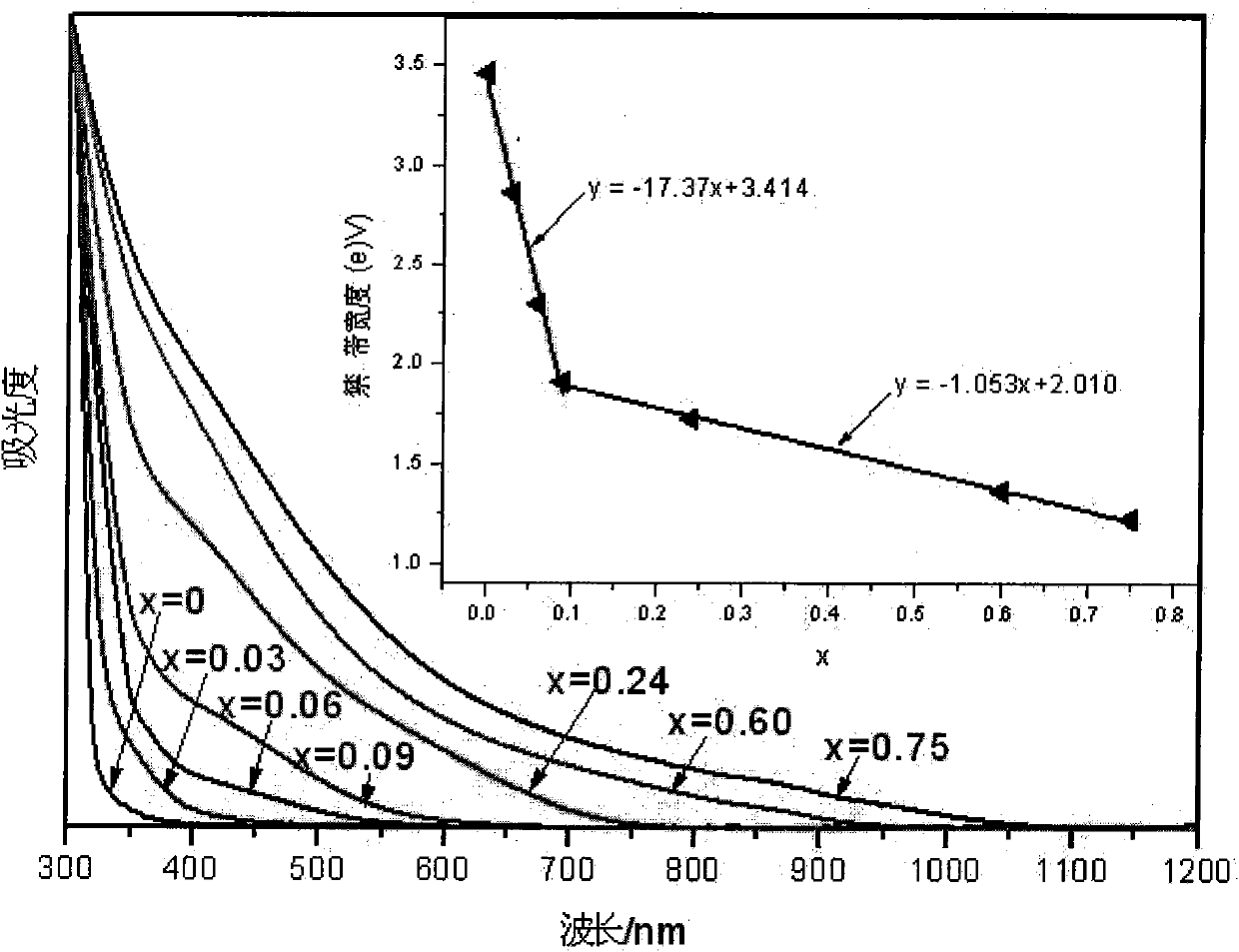

Cu-Sn-Zn-S semiconductor material with adjustable forbidden band width and preparation method thereof

InactiveCN101792175AStable in natureImprove environmental friendlinessTin compoundsSemiconductor materialsSolvent

The invention relates to a Cu-Sn-Zn-S semiconductor material with an adjustable forbidden band width and a preparation method thereof, which belong to the technical field of preparing inorganic materials. The semiconductor material has a general formula of (Cu2Sn)x / 3Zn1-xS, wherein x is the mol percent content of Cu and Sn in metallic elements. The preparation method comprises the following steps of: dissolving a divalent cupric salt, a divalent tin salt and a divalent zinc salt in a polar solvent or a nonpolar solvent; adding a sulfur source into the mixture, and mixing the sulfur source with the mixture uniformly; and heating the mixture at the temperature of between 180 and 280 DEG C, and taking a deposit to obtain the semiconductor material. The semiconductor material contains no toxic elements, has very high environmental friendliness, can be prepared from a raw material with an abundant storage and a low price by a green method, and has a low cost and good repeatability; and the material has stable performance, and the forbidden band width can be adjusted between 3.5 and 0.9 electron volt. The form of the material can be nano particles, films and bulk phase material, and the material can be applied in the fields of solar batteries, microelectronic devices, environmental monitoring, pollutant disposal, biological detections and the like.

Owner:SHANDONG UNIV

Preparation method and application of hydroxypropyl guar gum/nanocellulose cross-linked adsorption film

ActiveCN106345424AGood adsorption/desorption performanceImprove mechanical propertiesSemi-permeable membranesOther chemical processesCross-linkMethyl violet

The invention discloses s preparation method of a hydroxypropyl guar gum / nanocellulose cross-linked adsorption film. The method takes hydroxypropyl guar gum and microcrystalline cellulose as main raw materials, and comprises the steps: thinning the microcrystalline cellulose in a nano grinder and a high-strength ultrasonic wave generator successively to prepare nanocellulose, then respectively dispersing and dissolving the nanocellulose and hydroxypropyl guar gum in maleic acid, then adding maleic anhydride and sodium hypophosphite, stepwise heating to carry out esterification and cross-linking reaction, centrifuging and defoaming the reactant, shaping the reactant in a mold, forming a film by drying, and cleaning and freeze-drying the film to obtain the adsorption film. The film prepared by the method is light yellow and transparent, has good adsorptive capacity on copper ions, zinc ions, led ions, methylene blue and methyl violet, and simultaneously has higher mechanical properties.

Owner:KUNMING UNIV OF SCI & TECH

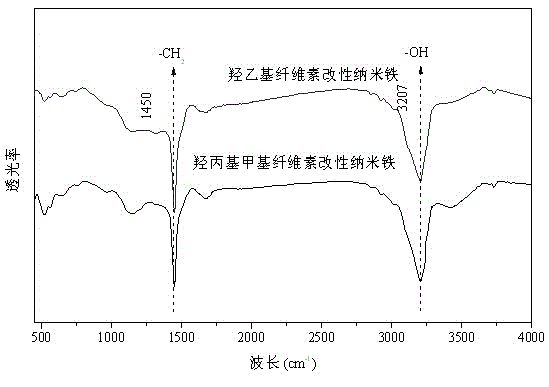

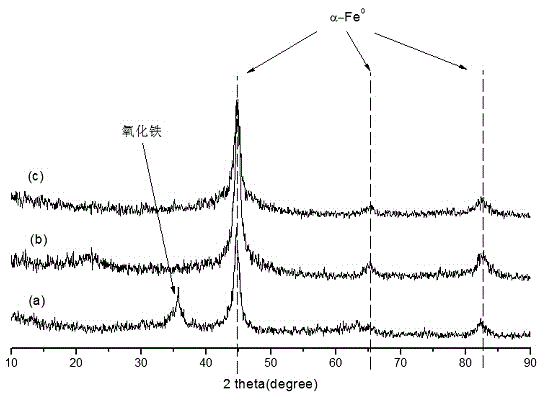

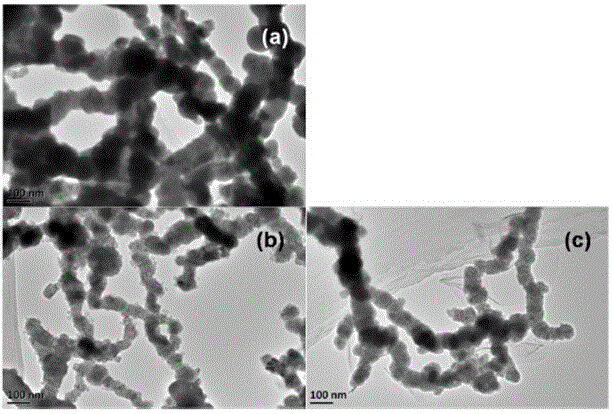

Preparation method for cellulose modification nano iron particles

ActiveCN104785793AFacilitate adaptation to in situ and heterotopic repairSimple processWater/sewage treatmentCelluloseNitrate salts

The invention discloses a preparation method for cellulose modification nano iron particles. According to the preparation method, two kinds of environment-friendly non-poisonous and innocuous cellulose are taken as dispersing agents to conduct surface modification on particles in the preparation process of the nano iron particles, and the cellulose dispersing agent modified nano iron particles are obtained. According to the preparation method for the cellulose modification nano iron particles, the process is simple and convenient, the operation is easy, the cost is low, the dispersity of the nano iron particles is good, the agglomeration of the particles in water can be reduced, and the removal efficiency of the particles to organic pollutants, dyestuff, pesticides, nitrate and heavy metal is improved.

Owner:KUNMING UNIV OF SCI & TECH

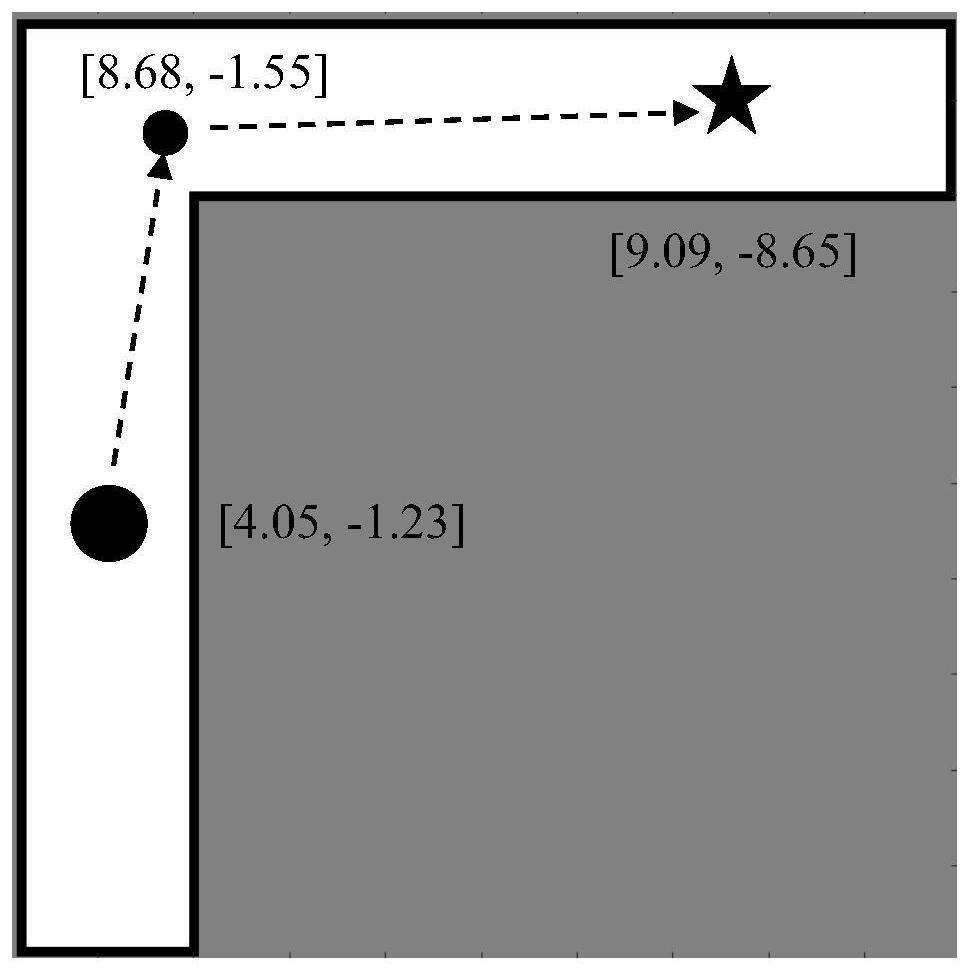

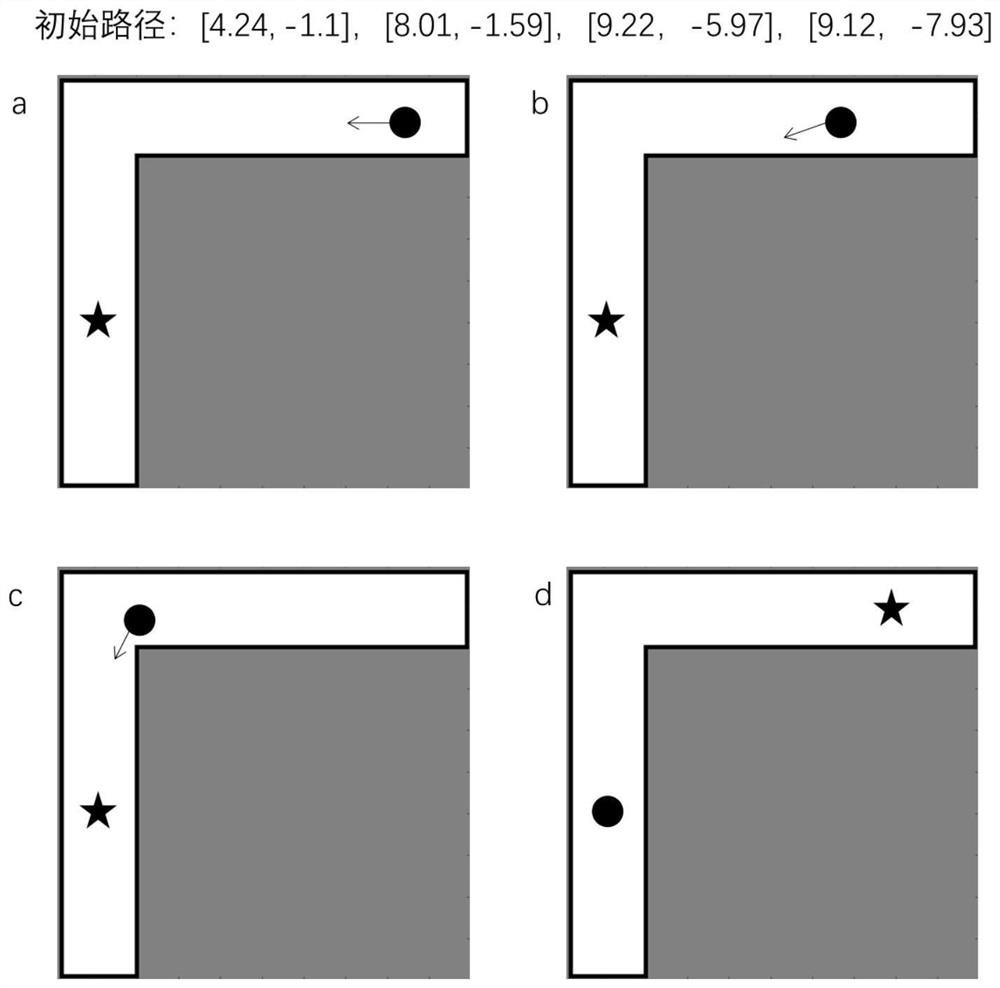

Deep reinforcement learning obstacle avoidance navigation method fusing global training

ActiveCN112882469AReduced precision requirementsFast convergencePosition/course control in two dimensionsVehiclesSimulationEngineering

The invention discloses a deep reinforcement learning obstacle avoidance navigation method fusing global training. The method comprises the steps that: an initial path is planned according to known information; a robot moves from an initial point to a target point along the initial path; a temporary target is selected, and the robot moves towards the temporary target; an accumulated expected reward and punishment value is set, navigation is conducted continuously for multiple times, and a reward and punishment value is given to each frame in the robot navigation process; an interaction tuple is obtained from a sensor; the interaction tuple is input into a deep learning network for training; and a to-be-navigated interaction tuple is input into the trained deep learning network, an optimal path and an accumulated expected reward and punishment value are output, and the robot moves according to the optimal path. According to the method, the convergence speed of deep reinforcement learning can be effectively improved, the navigation efficiency of the robot is improved in the navigation process, meanwhile, the motion of the robot is environment-friendly, and the influence on the surrounding environment is reduced to the minimum.

Owner:ZHEJIANG UNIV

Light sand without burning and preparation method thereof

The invention discloses light sand without burning and a preparation method thereof. The light sand without burning is prepared by the following steps: crushing aerated concrete leftover material or waste aerated concrete into particles, stirring cement, finely ground silicon-contained material and water storage material uniformly so as to prepare powder body material with canned surface; and spraying a surface modifier solution on the surfaces of aerated concrete particles, then canning the aerated concrete particles and the powder body into a ball, standing for one hour so as to conduct secondary canning to a ball, standing the formed spherical particle for 2-10h, and then pressurizing and evaporating the particle under the conditions of 80-190 DEG C and 1atm-15atm, thereby obtaining light particles with particle size being not more than 5mm, stacking density being not more than 1200kg / m3, cylinder pressure being more than 3.5MPa and water absorbing rate being not more than 5%. On the basis of saving production raw materials, the strength of the light aggregate can be improved effectively, and the water absorbing rate is reduced.

Owner:HOHAI UNIV +1

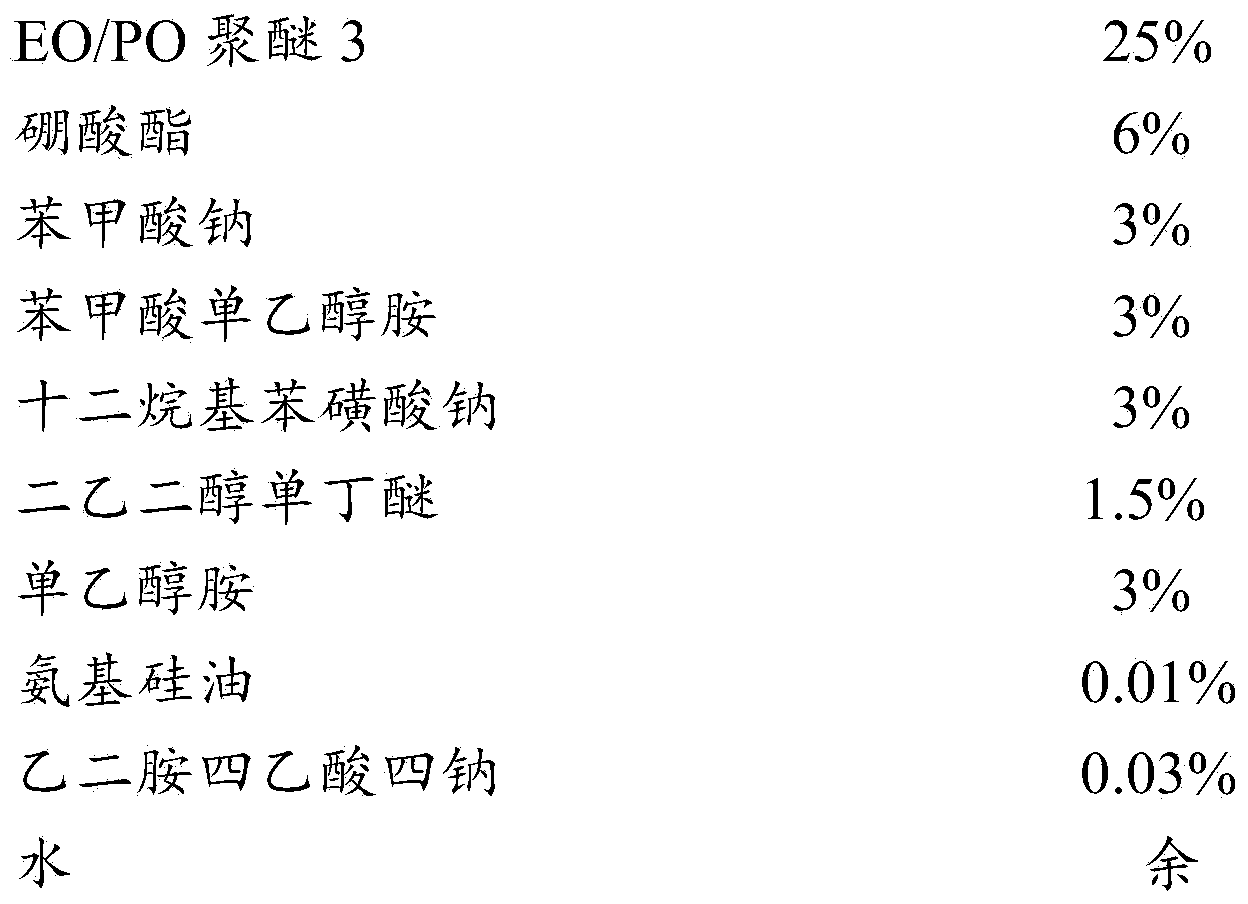

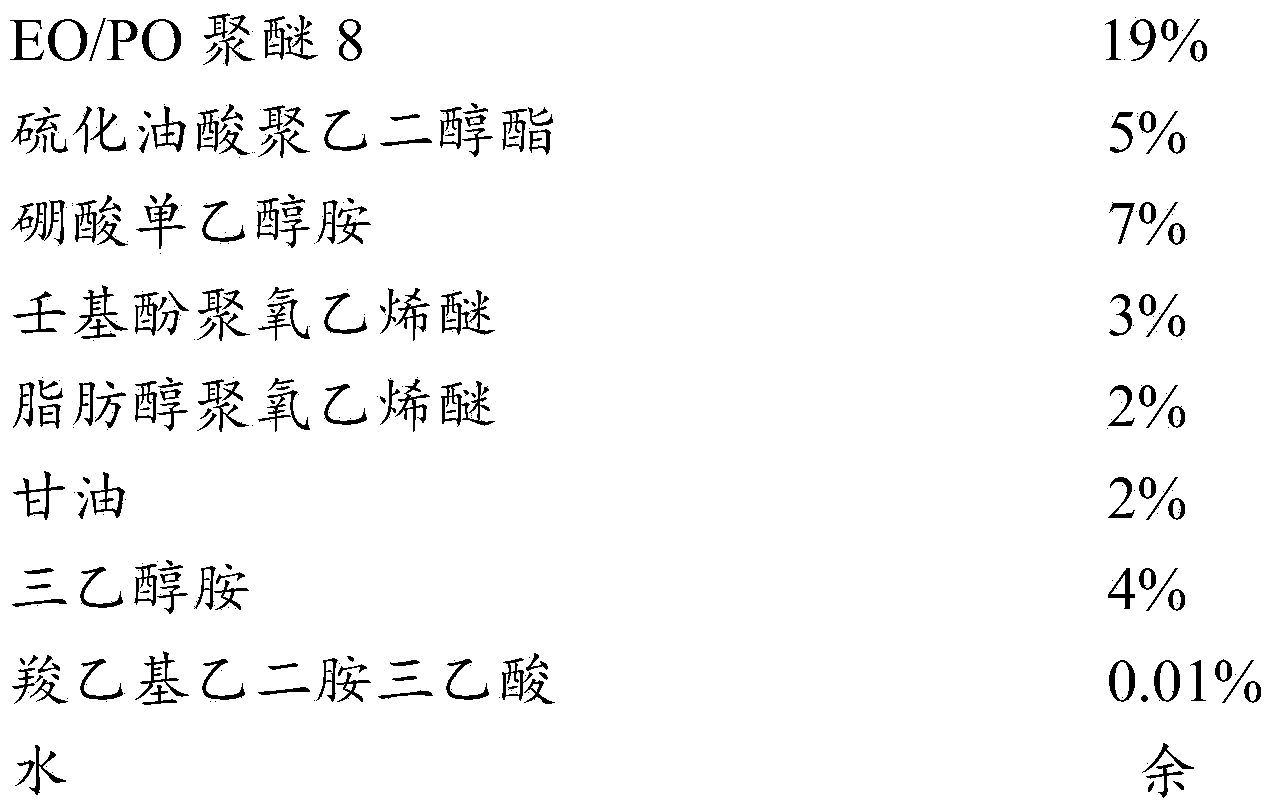

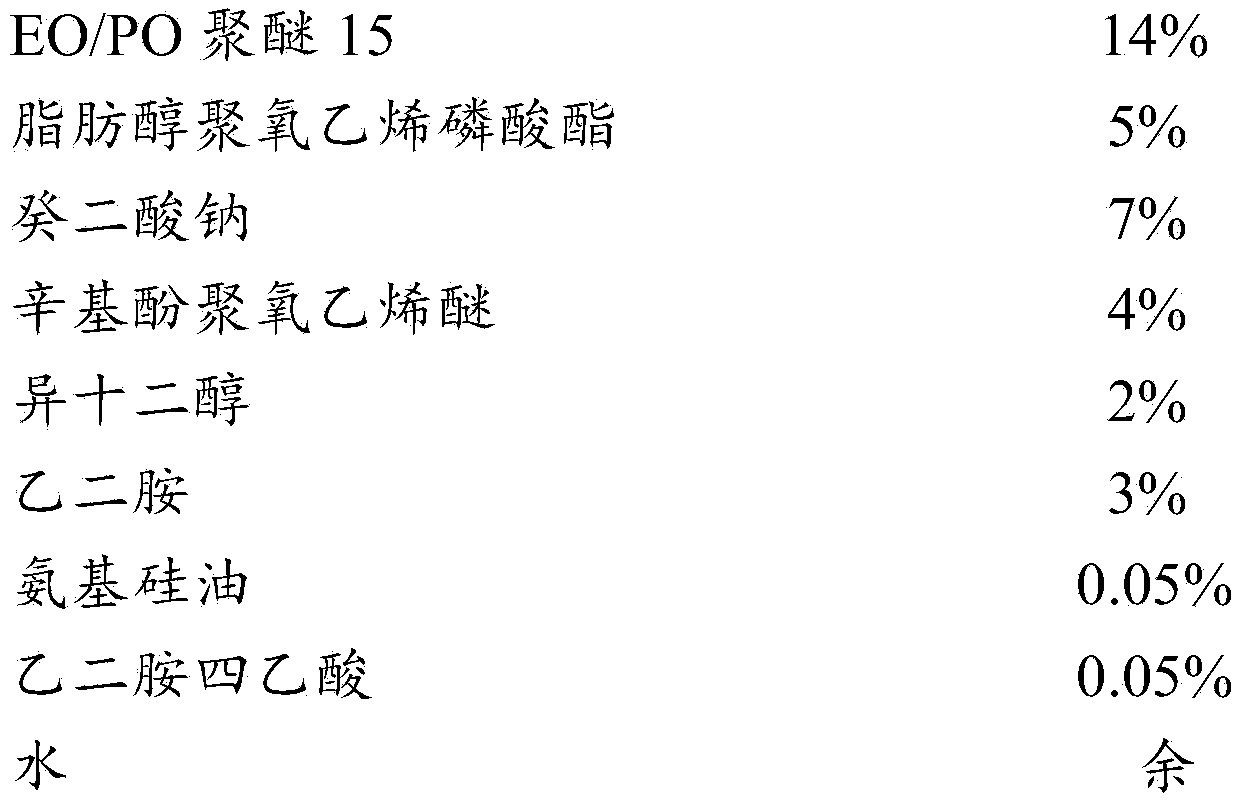

Fully synthetic stainless steel cold rolling mill compound and application thereof

InactiveCN104342274AExtended service lifeGood lubricating and cooling effectLubricant compositionWater solubleCleansing Agents

The invention relates to a fully synthetic stainless steel cold rolling mill compound and application thereof and mainly aims to solve the problems of poor lubricating extreme pressure property and short service life. The fully synthetic stainless steel cold rolling mill compound comprises the following components in parts by weight: a) 5-30 parts of water-soluble polyether; b) 1-10 parts of a water-soluble extreme pressure agent; c) 3-10 parts of a water-soluble antirust agent; d) 1-10 parts of a cleaning agent; e) 1-5 parts of a coupling agent; f) 0.01-0.5 part of a chelating agent; and g) 35-65 parts of water. With application of the technical scheme, the problems in the prior art are solved very well; and the fully synthetic stainless steel cold rolling mill compound can be applied to the stainless steel cold rolling process.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com