Preparation method for lactide grafted plant fiber reinforced poly lactic acid composite material

A plant fiber and composite material technology, applied in the field of preparation of lactide-grafted plant fiber reinforced polylactic acid composite materials, to achieve the effects of improved mechanical properties, large-scale production, and excellent environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

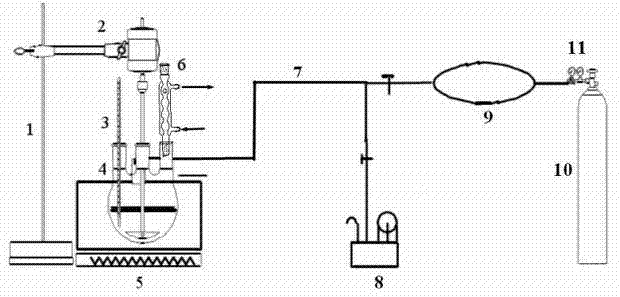

Method used

Image

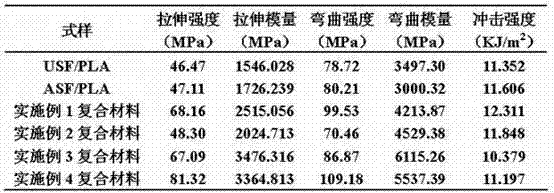

Examples

Embodiment 1

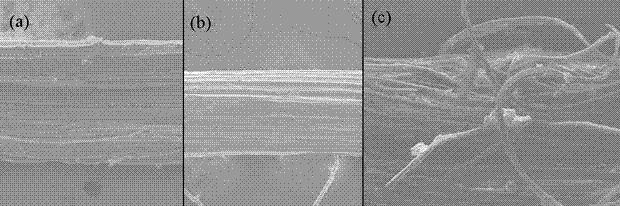

[0024] (1) Surface pretreatment of plant fibers: Cut sisal fibers into 10mm long chopped fibers with a fiber cutter; then dry the chopped fibers in a vacuum drying oven at -0.1Pa, 80°C for 5 hours, take 150g Add 18%wt sodium hydroxide solution to the above-mentioned chopped fibers, soak them at 50°C for 3 hours, then wash the sisal fibers with distilled water until neutral, spread them out and air-dry them, and dry them in a vacuum drying oven at -0.1Pa, 80°C 5 hours to obtain alkali-treated sisal fiber (abbreviation: ASF);

[0025] (2) Carry out lactide grafting modification to plant fibers: add 500mL toluene into a four-necked flask, heat up to 111°C, boil the toluene for 30 minutes to remove water, cool down to 50°C, add 8g ASF and 4g For L-lactide monomer, vacuumize the reaction system for 20 minutes, then fill it with nitrogen, and raise the temperature to 130°C, add 0.032g of stannous octoate catalyst dropwise, react for 30 minutes under strong stirring, and end the reac...

Embodiment 2

[0030] (1) Surface pretreatment of plant fibers: Cut sisal fibers into 10mm long chopped fibers with a fiber cutter; then dry the chopped fibers in a vacuum drying oven at -0.1Pa, 80°C for 5 hours, take 150g Add 20%wt sodium hydroxide solution to the above chopped fibers, soak them at 25°C for 4 hours, then wash the sisal fibers with distilled water until neutral, spread them out and dry them in a vacuum oven at -0.1Pa, 60°C 10 hours, get ASF;

[0031] (2) Carry out lactide grafting modification to plant fibers: Add 500mL toluene into a four-necked flask, heat up to 111°C, boil the toluene for 30 minutes to remove water, cool down to 50°C, add 6g ASF and 4g For L-lactide monomer, vacuumize the reaction system for 20 minutes, then fill it with nitrogen, and raise the temperature to 150°C, add 0.016g of stannous octoate catalyst dropwise, and react for 20 minutes under strong stirring, and finish the reaction in a cold water bath to obtain SF- g-LA;

[0032] (3) 2g of SF-g-LA ...

Embodiment 3

[0034](1) Surface pretreatment of plant fibers: Cut sisal fibers into 10mm long chopped fibers with a fiber cutter; then dry the chopped fibers in a vacuum drying oven at -0.1Pa, 80°C for 5 hours, take 150g Add 18%wt sodium hydroxide solution to the above-mentioned chopped fibers, soak them at 50°C for 1 hour, then wash the sisal fibers with distilled water until neutral, disperse and air-dry them, and dry them in a vacuum drying oven at -0.1Pa, 80°C 8 hours, get ASF;

[0035] (2) Carry out lactide grafting modification to plant fibers: add 500mL toluene into a four-necked flask, heat up to 111°C, boil the toluene for 30 minutes to remove water, cool down to 50°C, add 8g ASF and 4g For L-lactide monomer, vacuumize the reaction system for 20 minutes, then fill it with nitrogen, and raise the temperature to 130°C, add 0.032g of stannous octoate catalyst dropwise, and react for 30 minutes under strong stirring, and finish the reaction in a cold water bath to obtain SF- g-LA;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com