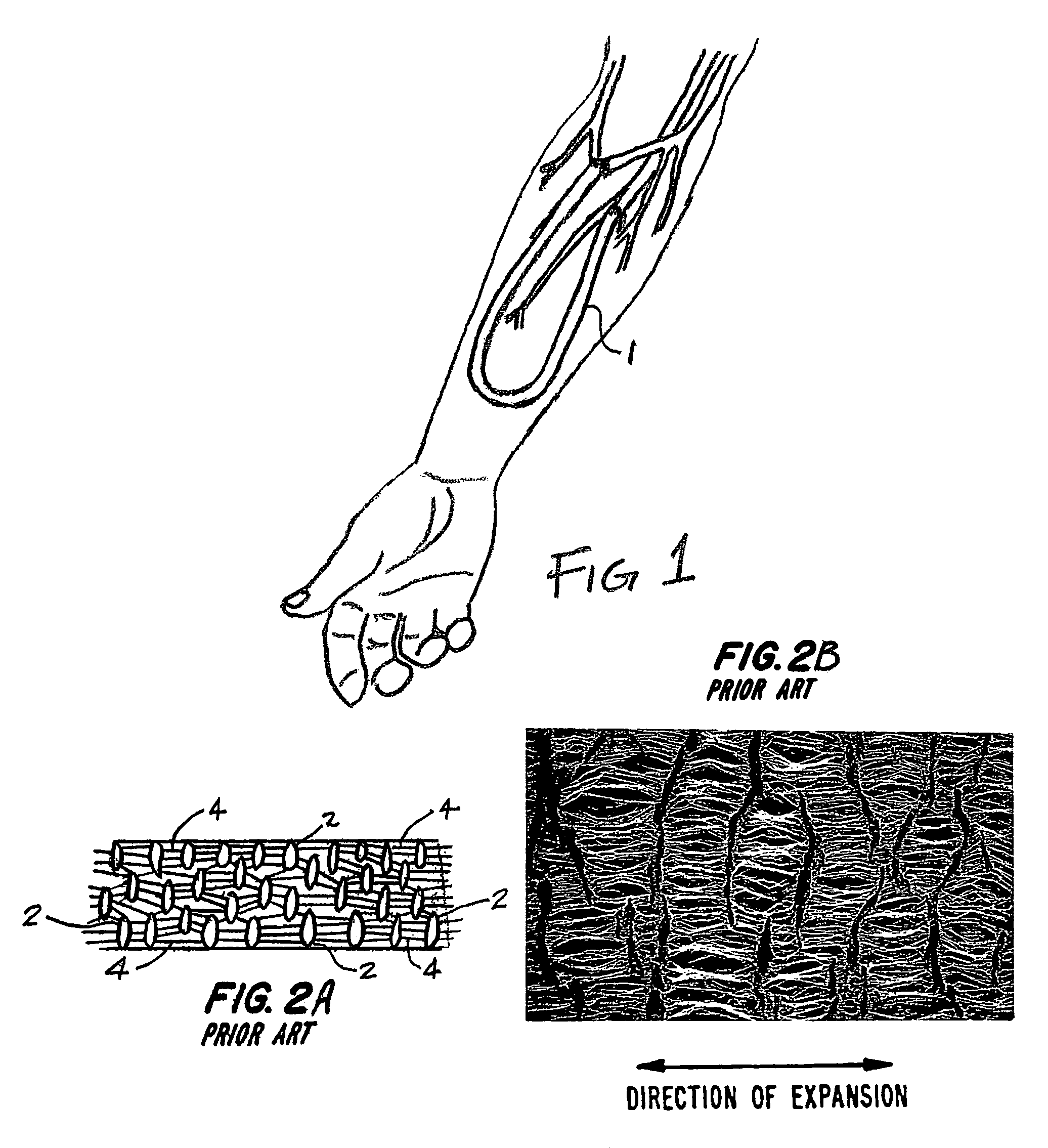

Patents

Literature

1964results about How to "Improve bending performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical fiber cable

InactiveUS7171087B2Improve the level ofImprove bending performanceCladded optical fibreFibre mechanical structuresGlass fiberTension member

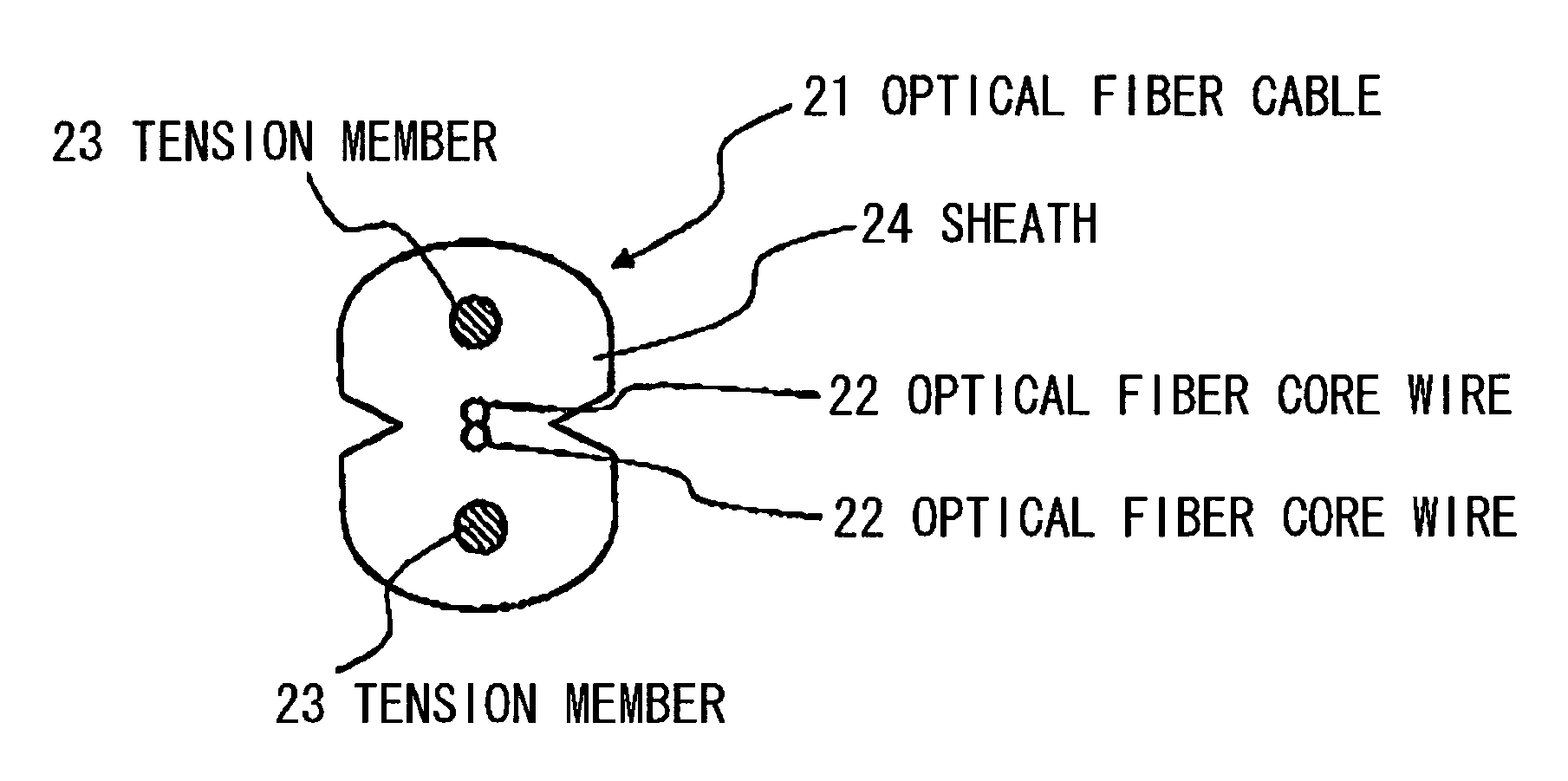

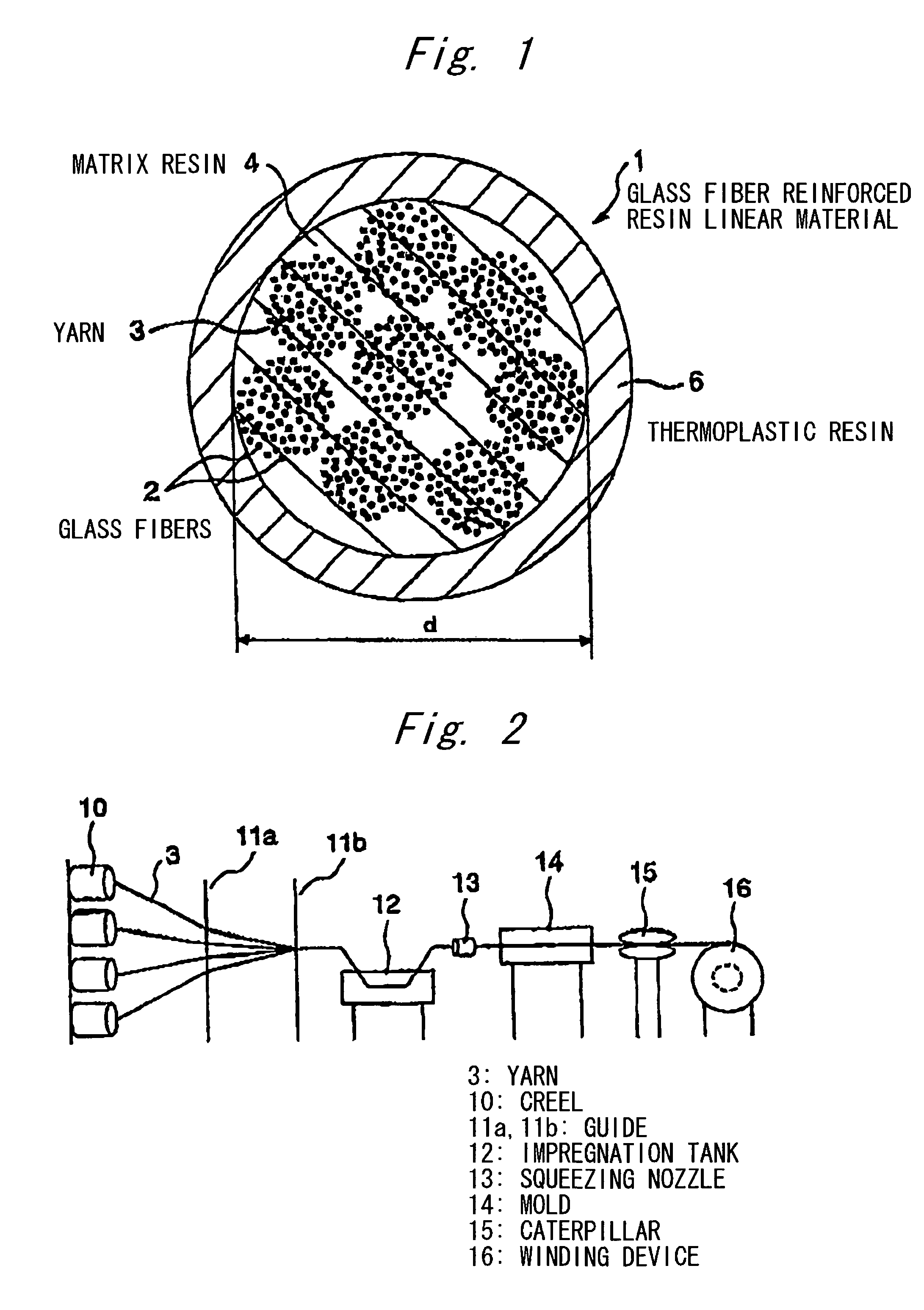

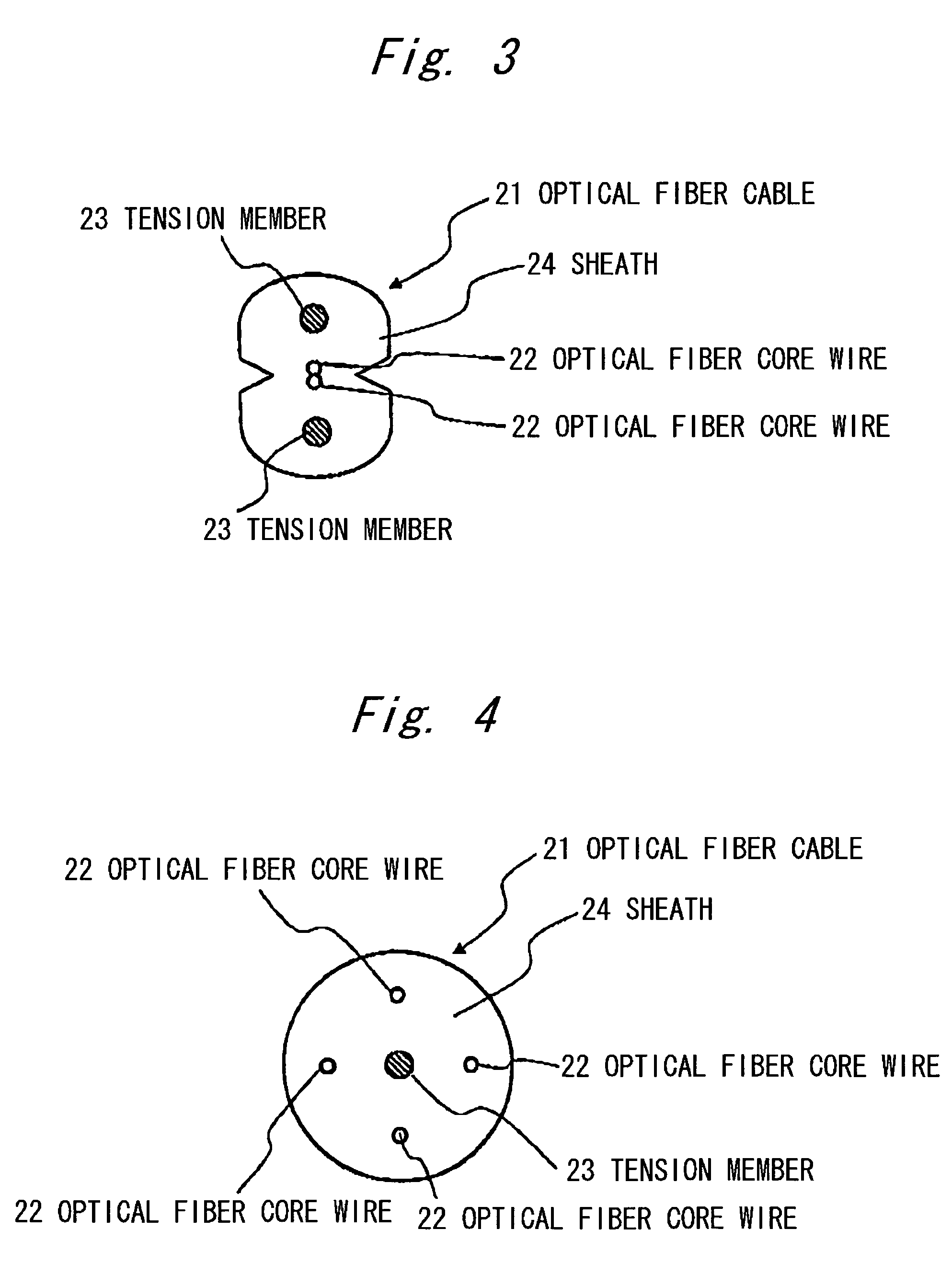

An optical fiber cable has an optical fiber core wire and a tension member. The tension member is formed of a glass fiber reinforced resin linear material with glass fibers and a matrix resin, and satisfies the following requirements: (1) (EfVf+EmVm)d2≧8.3 / n wherein Ef represents the modulus of elasticity of glass fibers, GPa; Vf represents the content of glass fibers, % / 100; Em represents the modulus of elasticity of matrix resin, GPa; Vm represents the content of matrix resin, % / 100; d represents the diameter of tension member, mm; and n represents the number of tension members used in optical fiber cable; (2) (Ef / Em)≧22; (3) Vf=0.6 to 0.88; and (4) an elongation at break of glass fibers of not less than 5% and an elongation at break of matrix resin of not less than 5%.

Owner:HITACHI CABLE

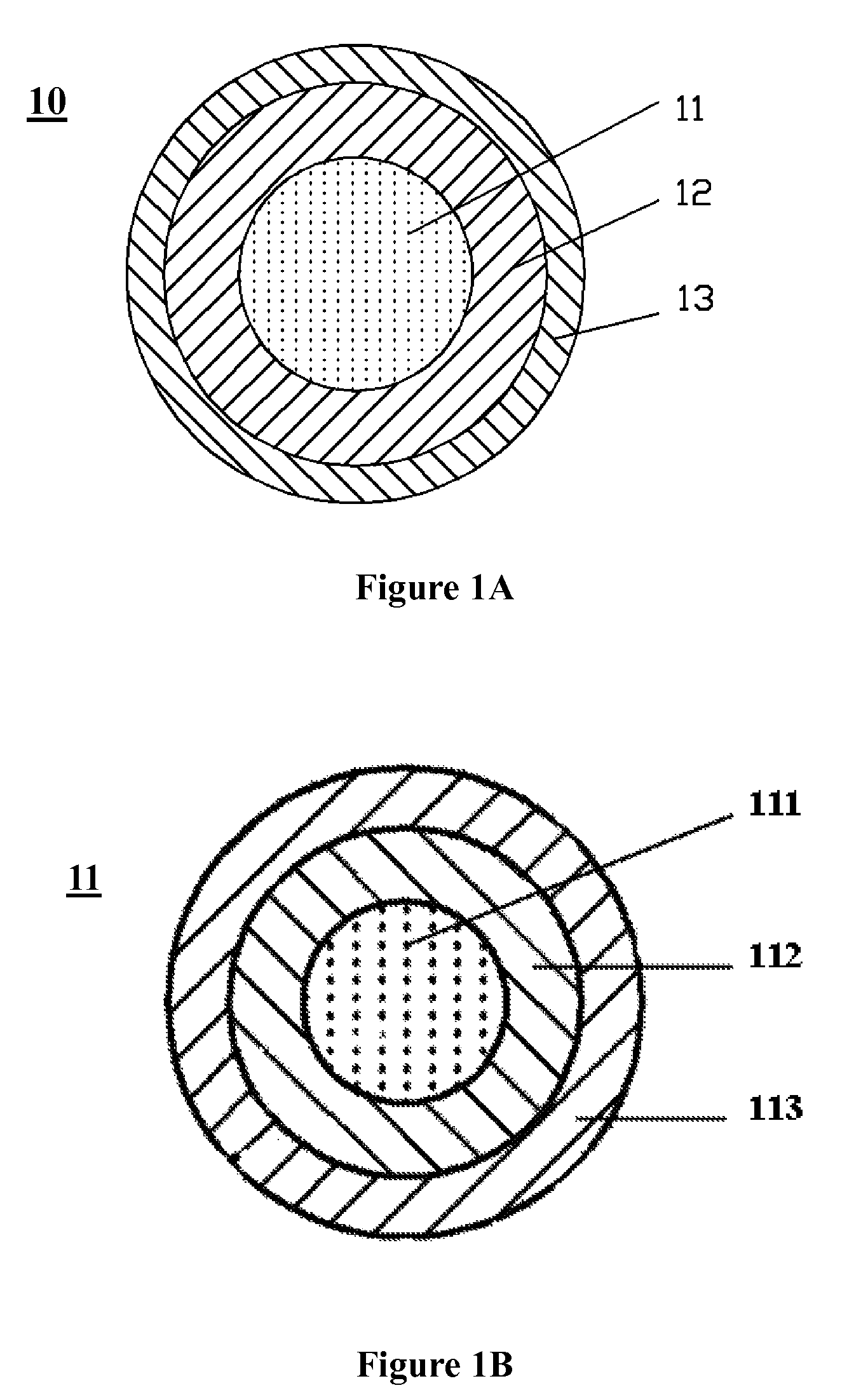

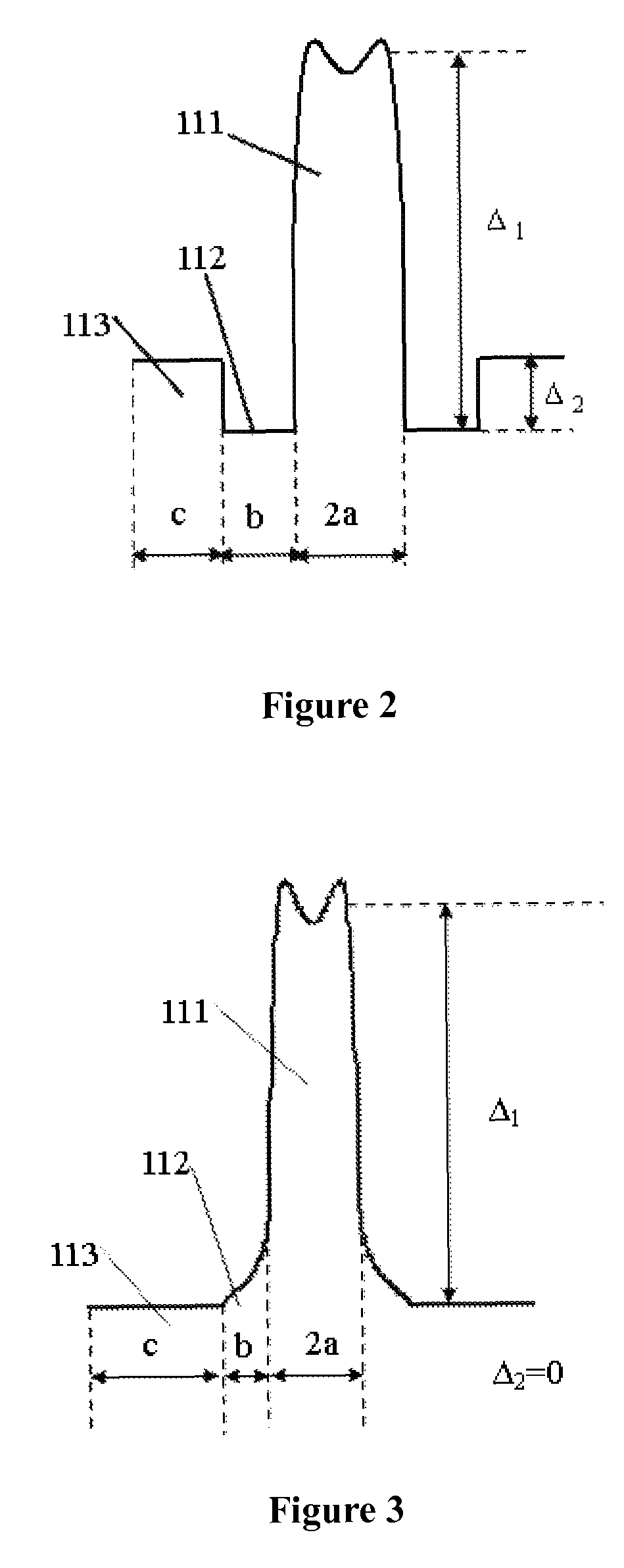

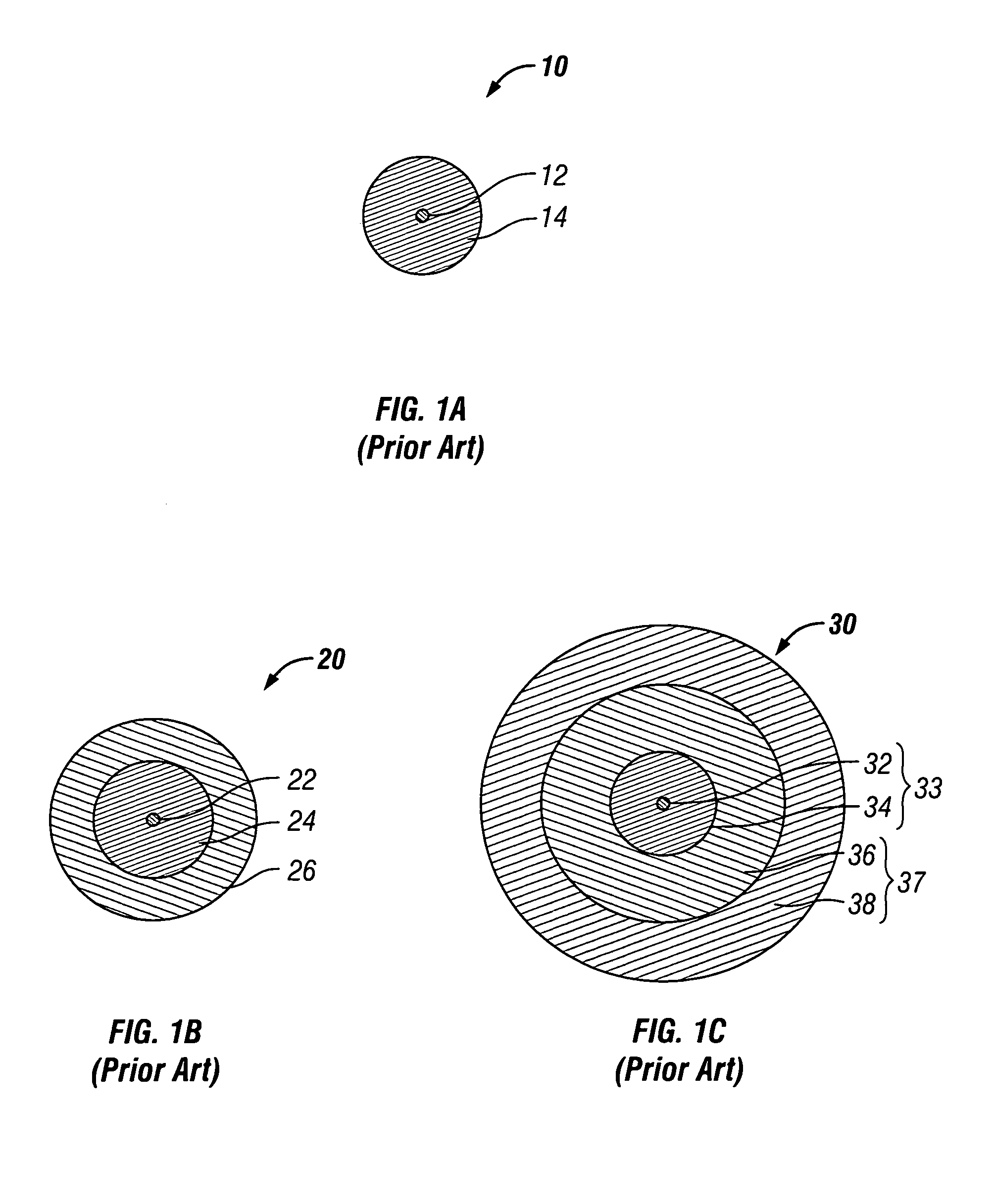

Bend insensitive single mode fiber

ActiveUS8750664B2Manufacturing toleranceReduce manufacturing costGlass optical fibreOptical fibre with multilayer core/claddingGlass fiberAccess network

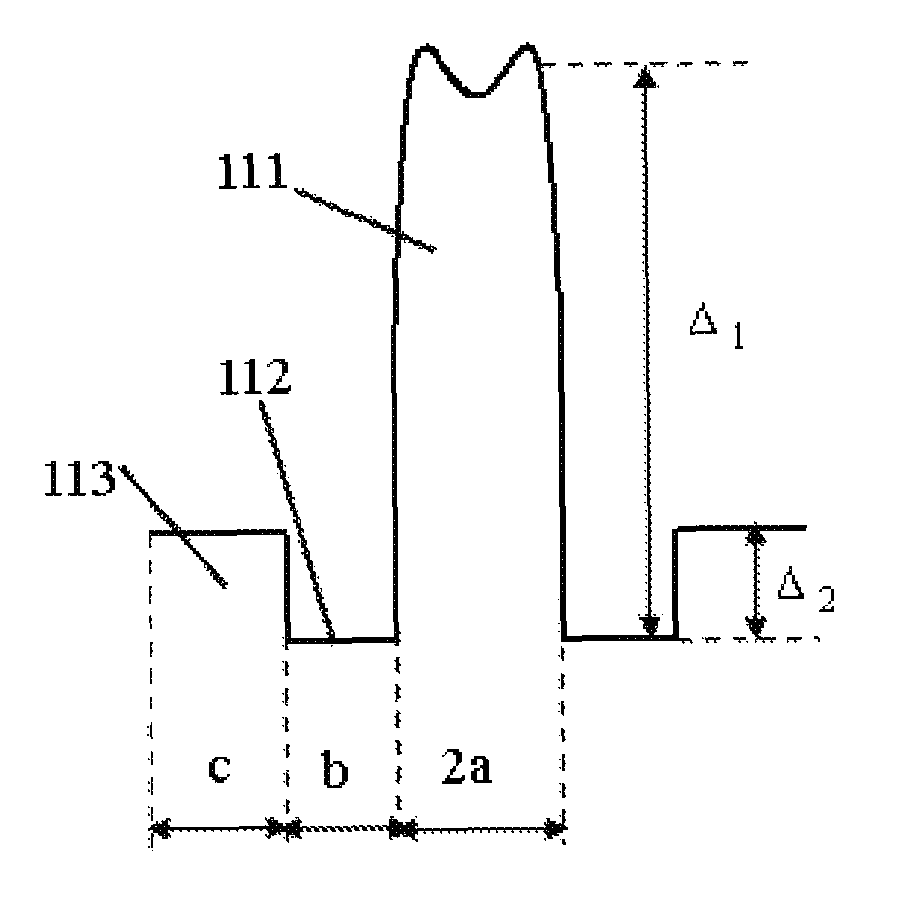

This invention discloses a bend insensitive single mode fiber, which is composed by a bare glass fiber with a round cross section and two resin protective layers with circular cross sections surrounding the outer of the bare glass fiber. It is characterized in that the bare glass fiber is composed by a core layer with a round cross section and two claddings with circular cross sections. The refractive index of the core layer is higher than the index of the two claddings and the refractive index difference between the core layer and the first cladding is larger than the difference between the first and second claddings. The second cladding is made of pure SiO2. The refractive index profile of the core layer follows a power function, and the refractive index profile of the two claddings follow a ladder-type distribution. The loss of the invented fiber is insensitive to the bending of the fiber, which meets the requirements of ITU.T G.657.A and G.657.B standards, respectively. It is applicable to the Fiber To The Home (FTTH) and other local area network and the access network systems.

Owner:FUTONG GROUP CO LTD

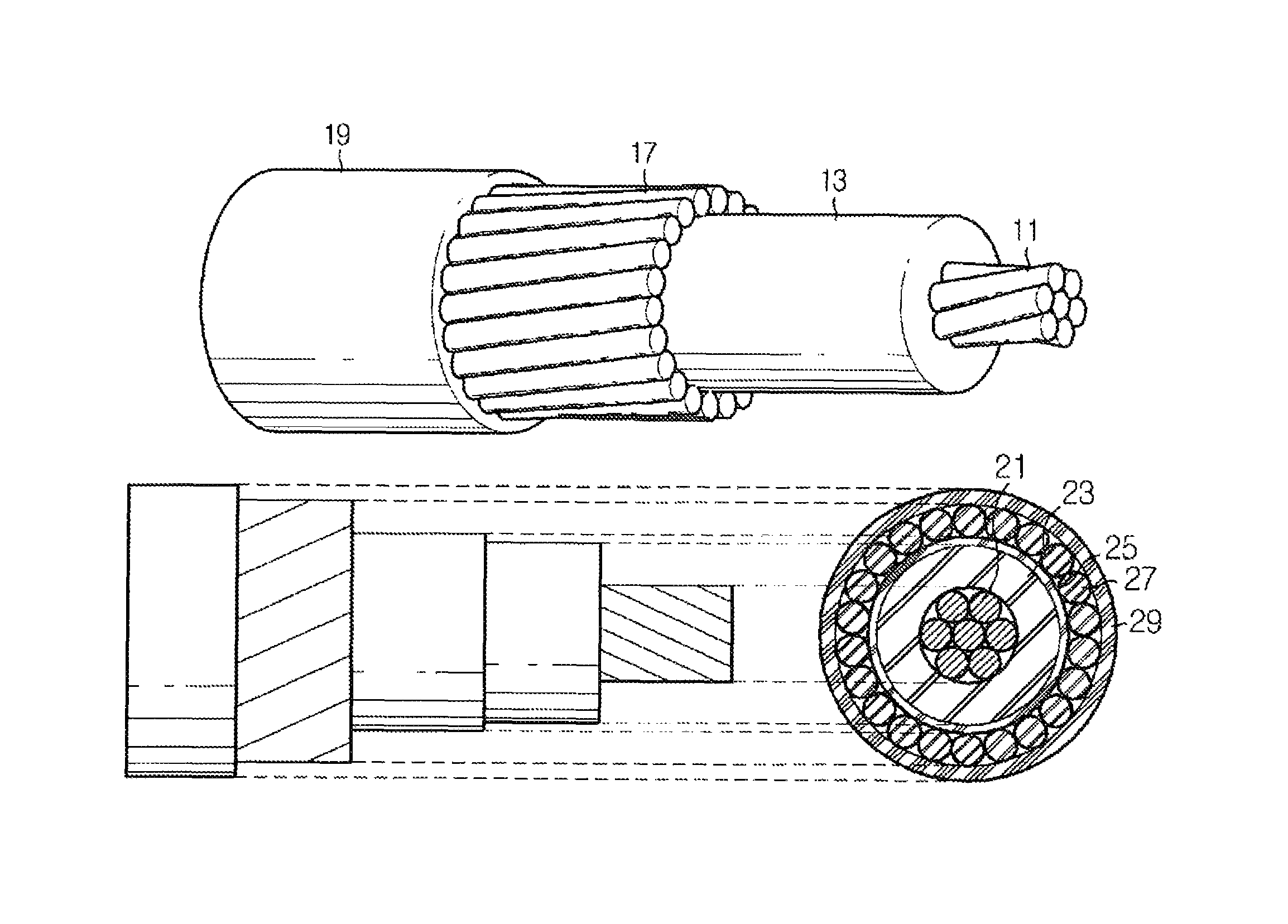

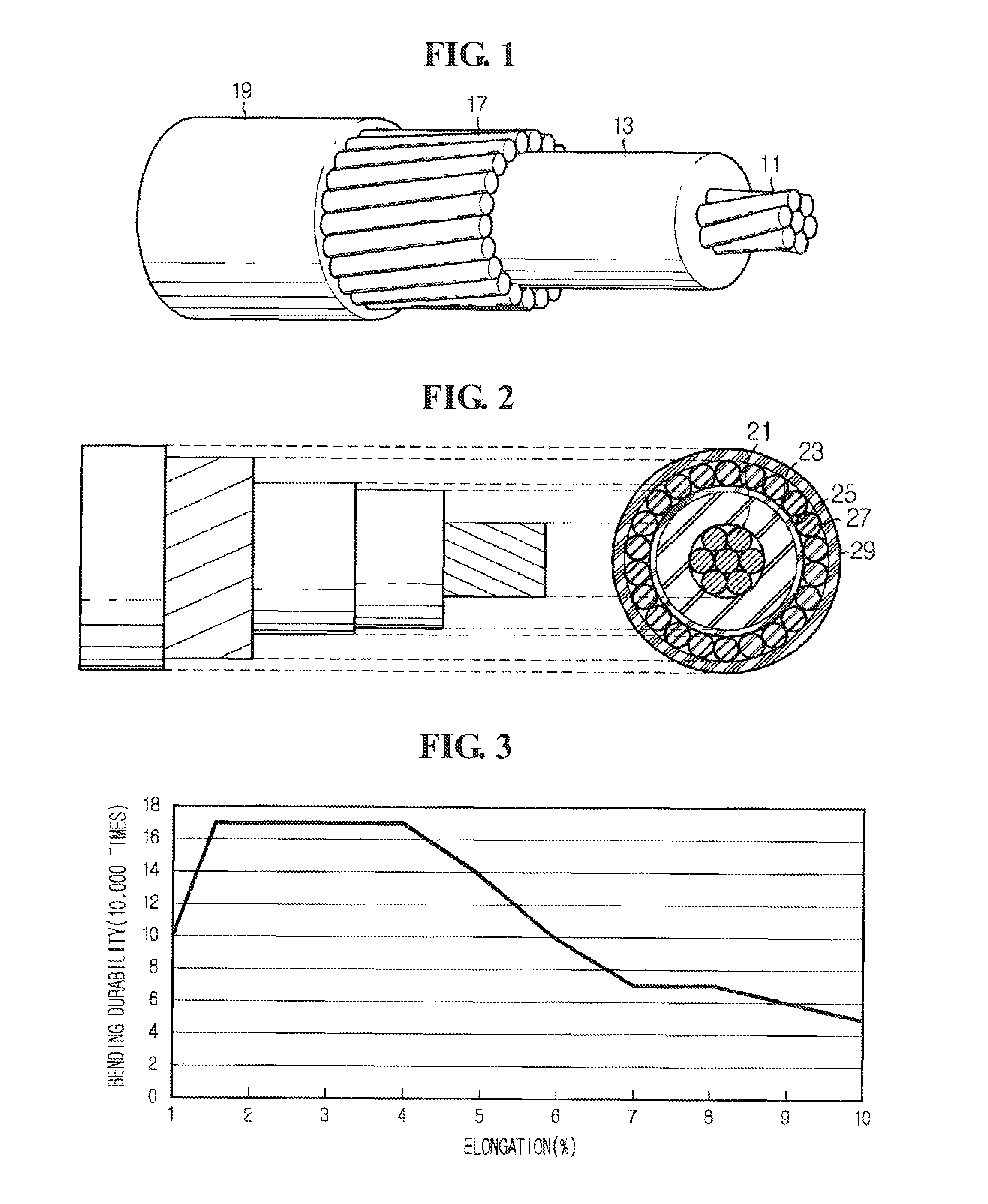

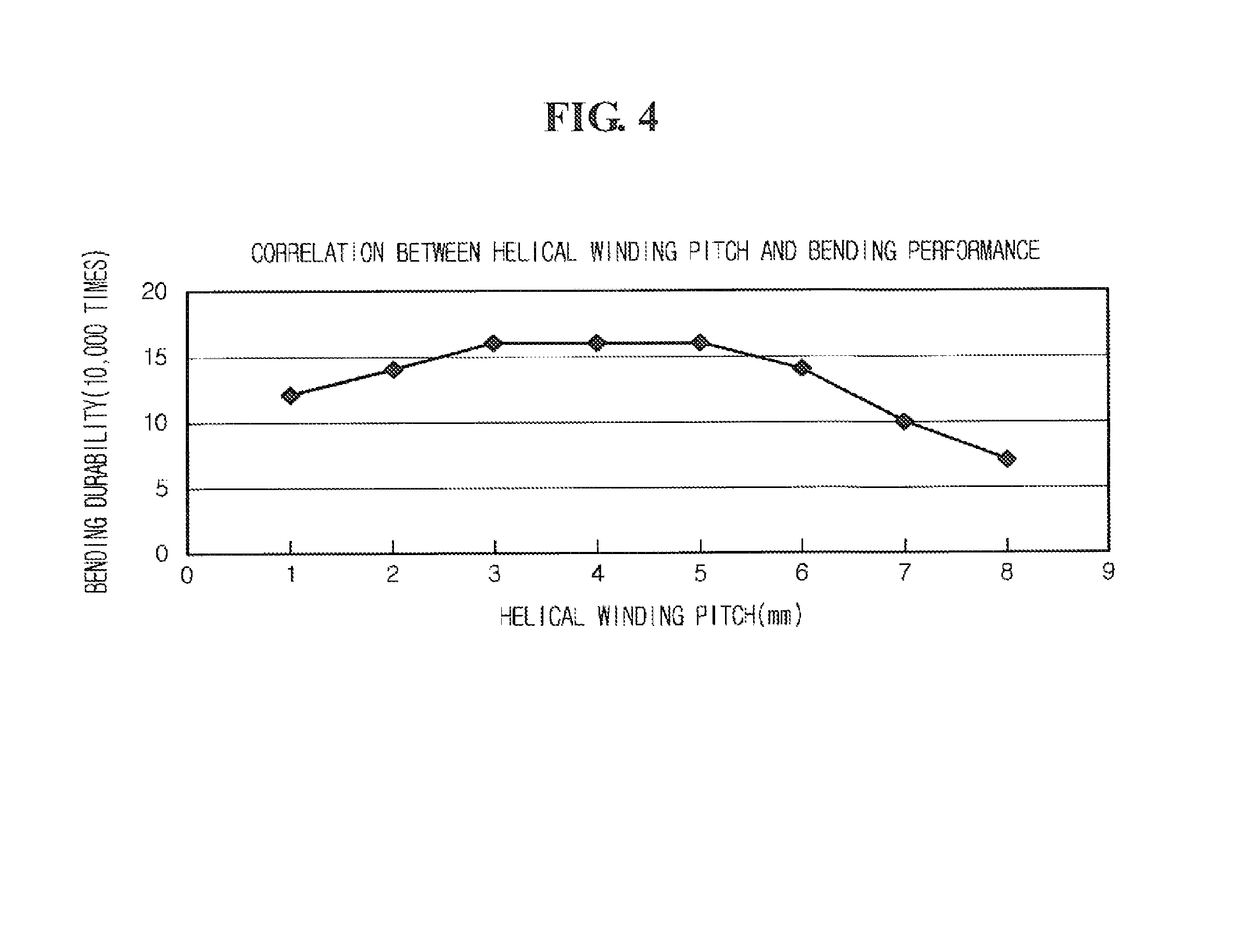

Micro coaxial cable for high bending performance

ActiveUS8242358B2Improve bending performanceLong-term reliabilityCable conductor constructionPower cables with screens/conductive layersElectrical conductorCoaxial cable

A micro coaxial cable with a high bending performance, having an inner conductor; an insulating layer configured to surround the inner conductor, and a helical winding conductor configured to surround the insulating layer and having an elongation of 1.5 to 4% and a pitch of 3.0 to 5.0 mm.

Owner:HITACHI METALS LTD

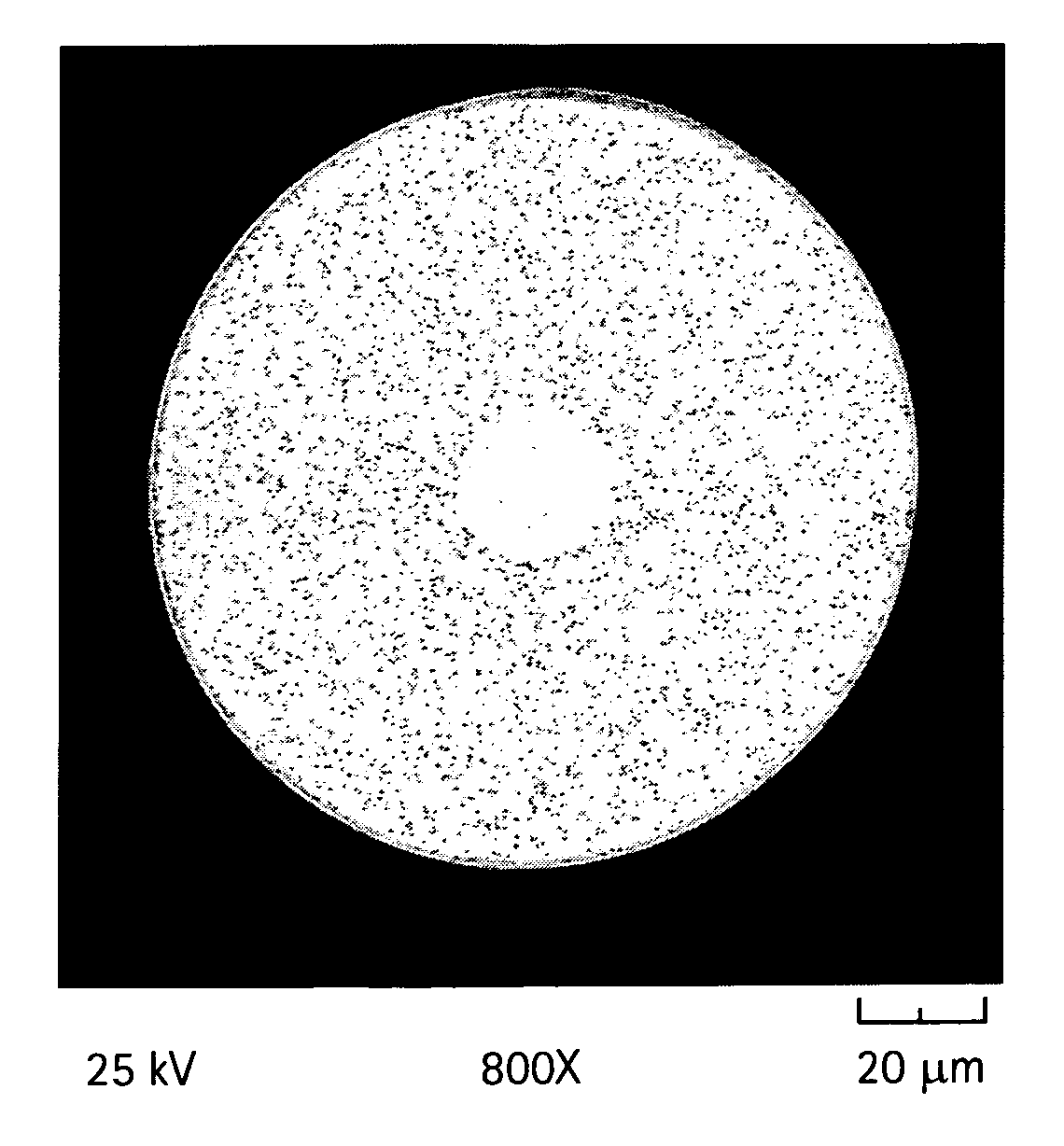

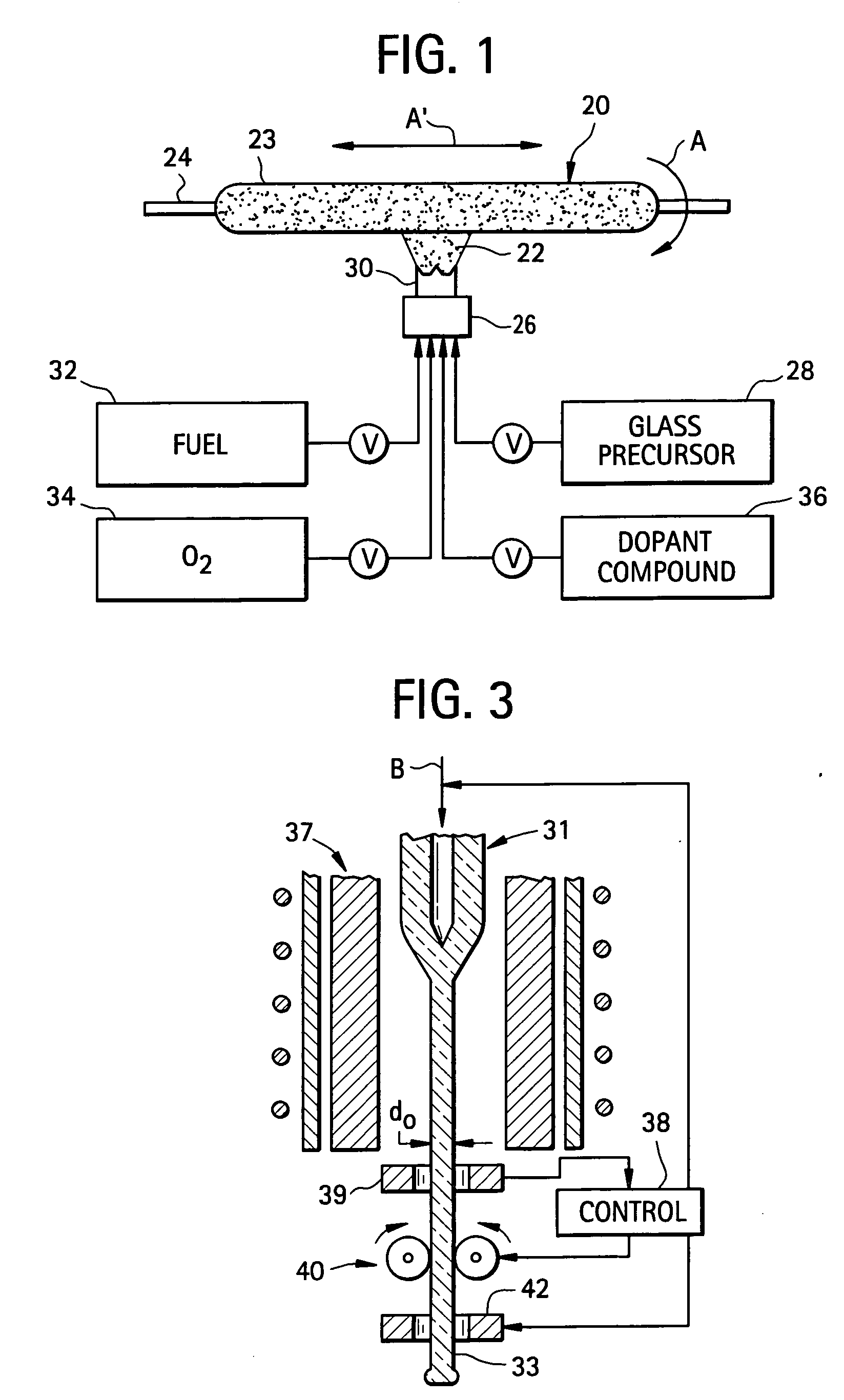

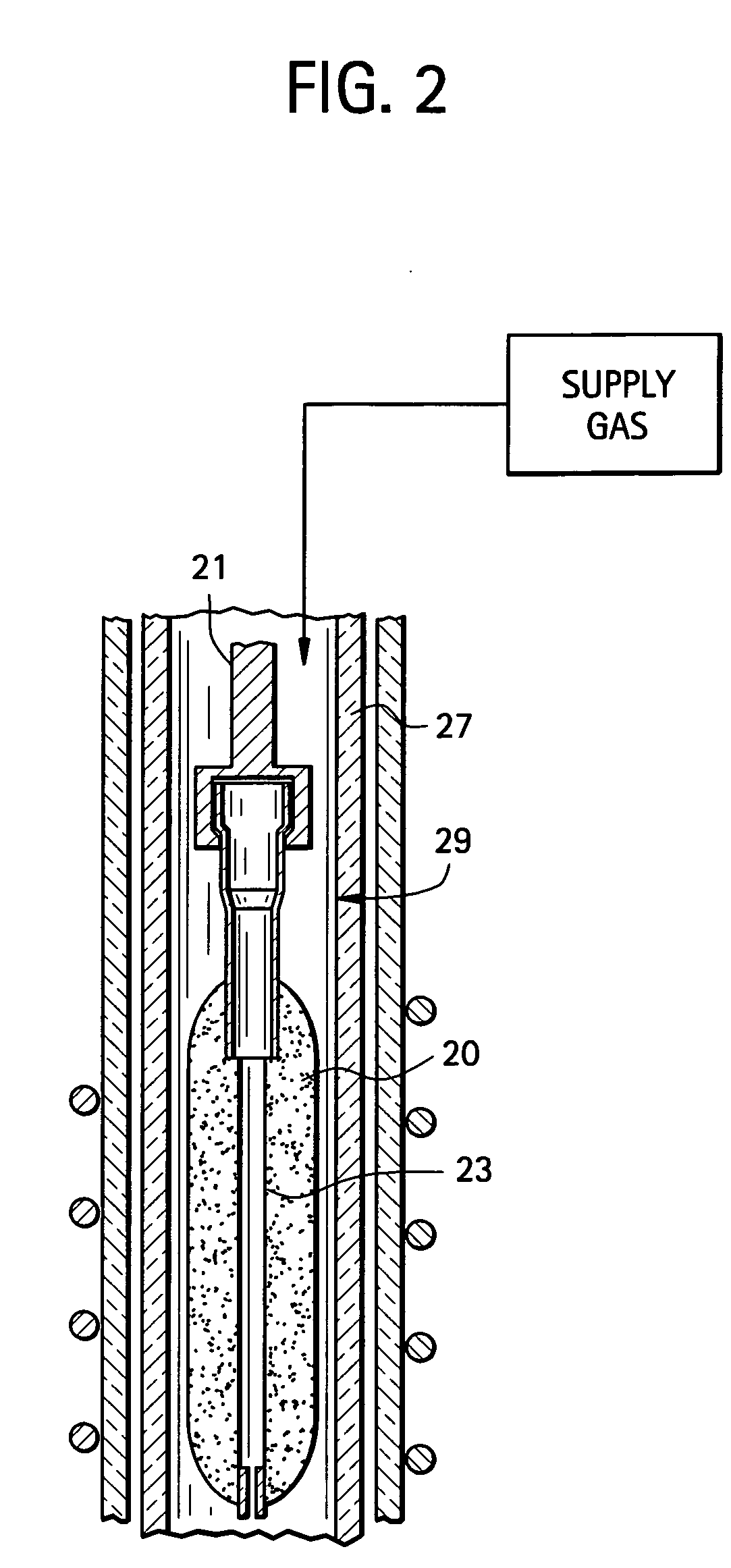

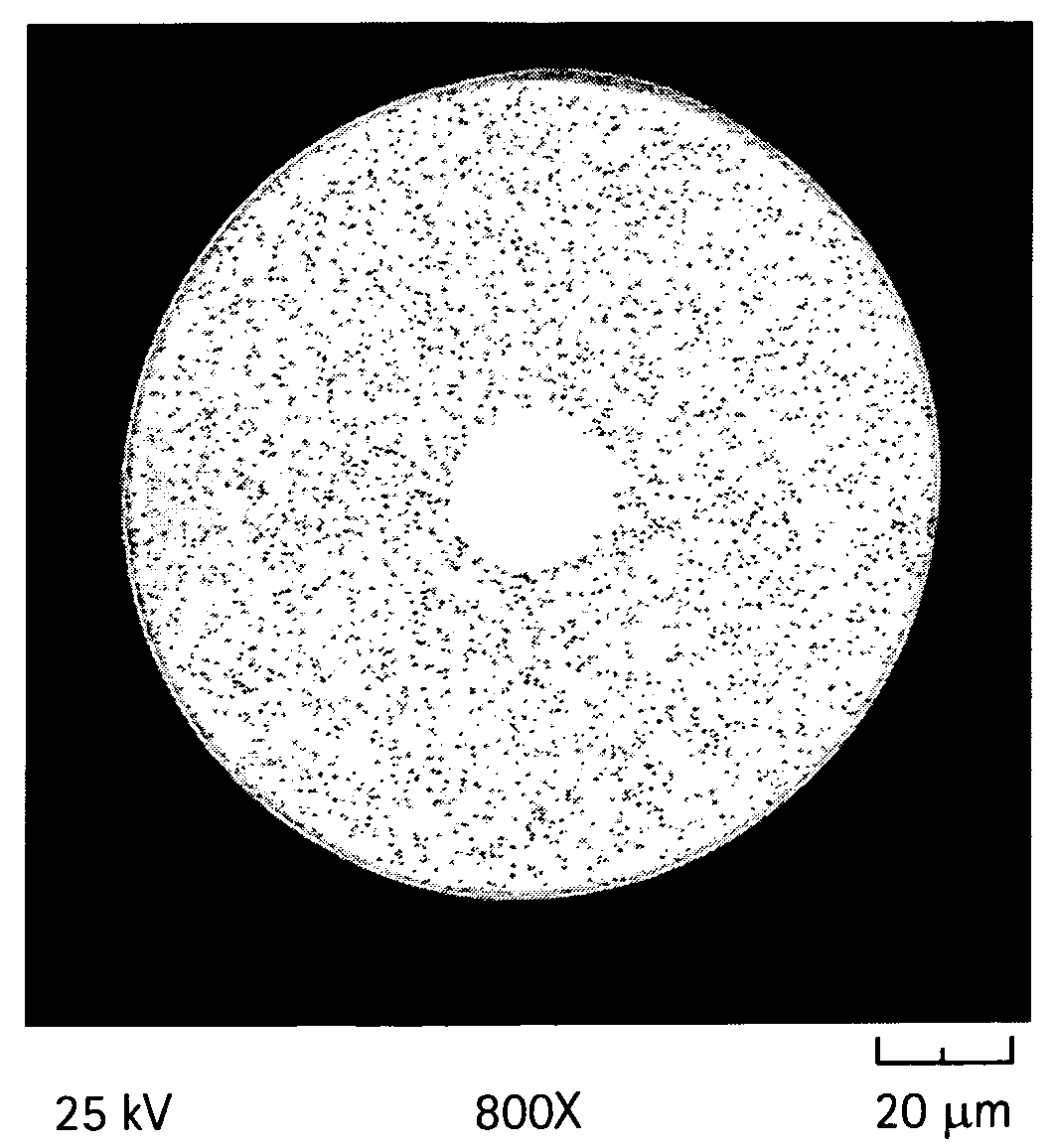

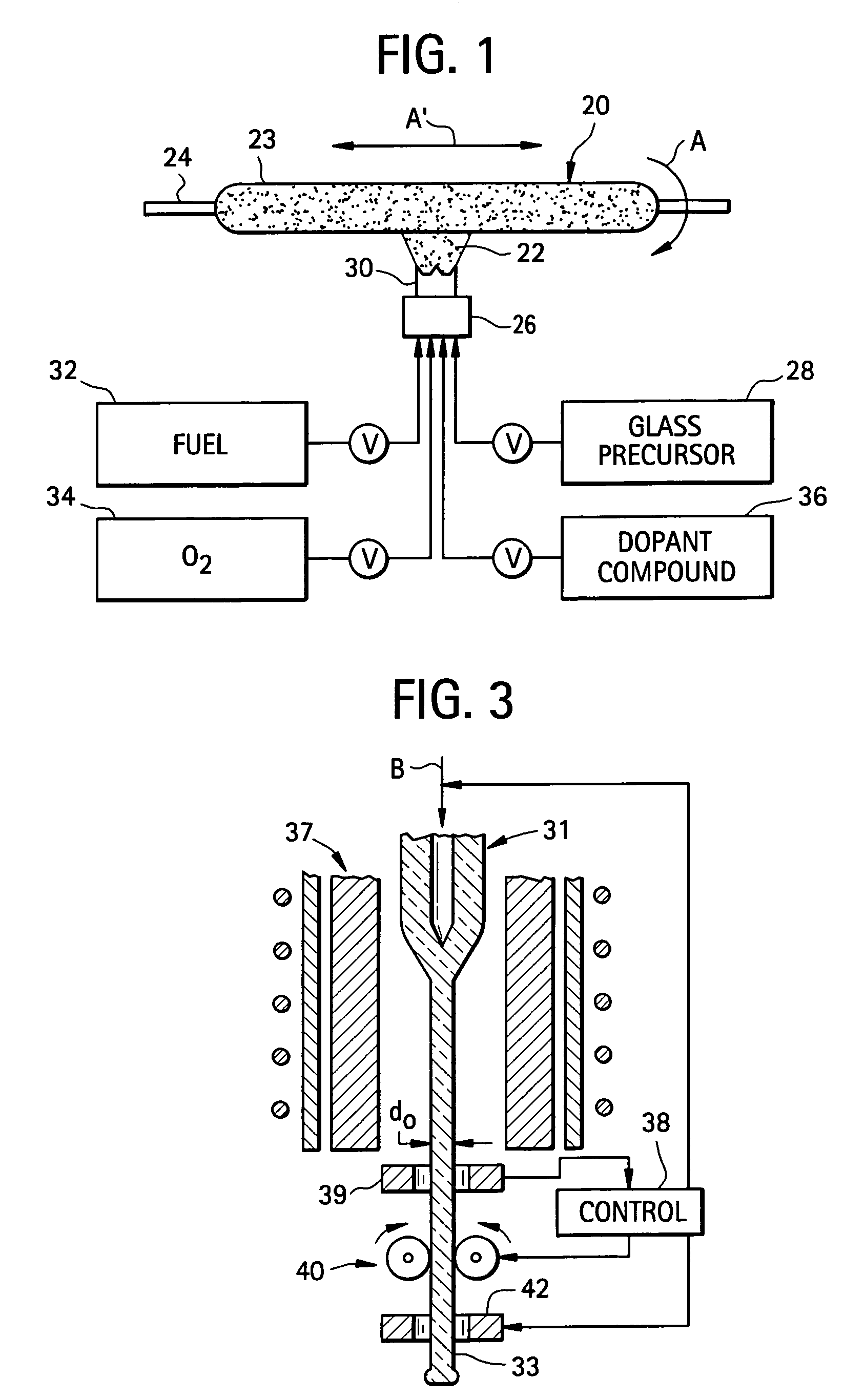

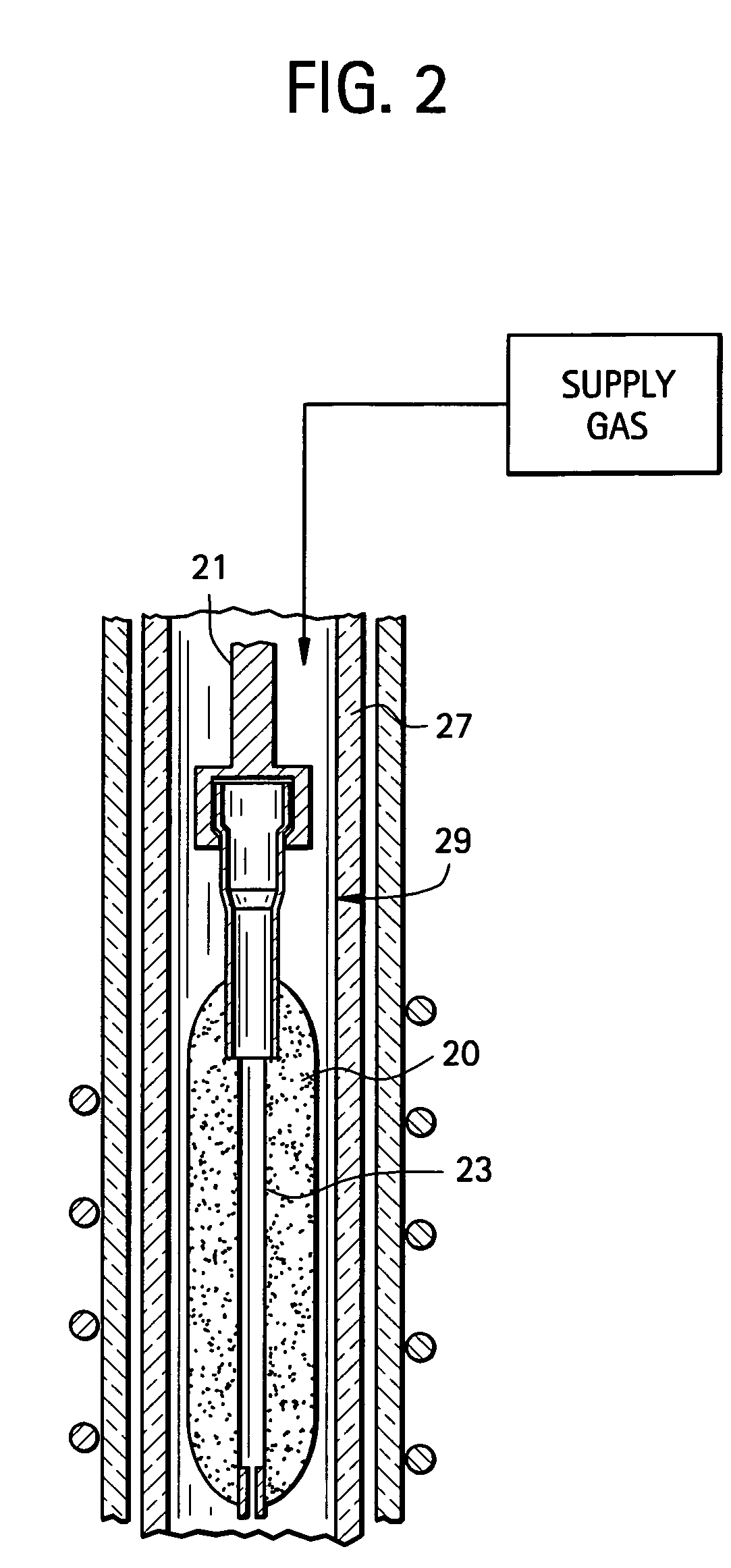

Microstructured optical fibers and methods

InactiveUS20070104437A1Improve bending performancePromote lowerGlass making apparatusOptical fibre with graded refractive index core/claddingNitrogen gasNitrogen

Microstructured optical fiber and method of making. Glass soot is deposited and then consolidated under conditions which are effective to trap a portion of the consolidation gases in the glass to thereby produce a non-periodic array of voids which may then be used to form a void containing cladding region in an optical fiber. Preferred void producing consolidation gases include nitrogen, argon, CO2, oxygen, chlorine, CF4, CO, SO2 and mixtures thereof.

Owner:CORNING INC

Microstructured optical fibers and methods

InactiveUS7450806B2Improve bending performanceLower refractive indexGlass making apparatusOptical fibre with graded refractive index core/claddingNitrogenNitrogen gas

Microstructured optical fiber and method of making. Glass soot is deposited and then consolidated under conditions which are effective to trap a portion of the consolidation gases in the glass to thereby produce a non-periodic array of voids which may then be used to form a void containing cladding region in an optical fiber. Preferred void producing consolidation gases include nitrogen, argon, CO2, oxygen, chlorine, CF4, CO, SO2 and mixtures thereof.

Owner:CORNING INC

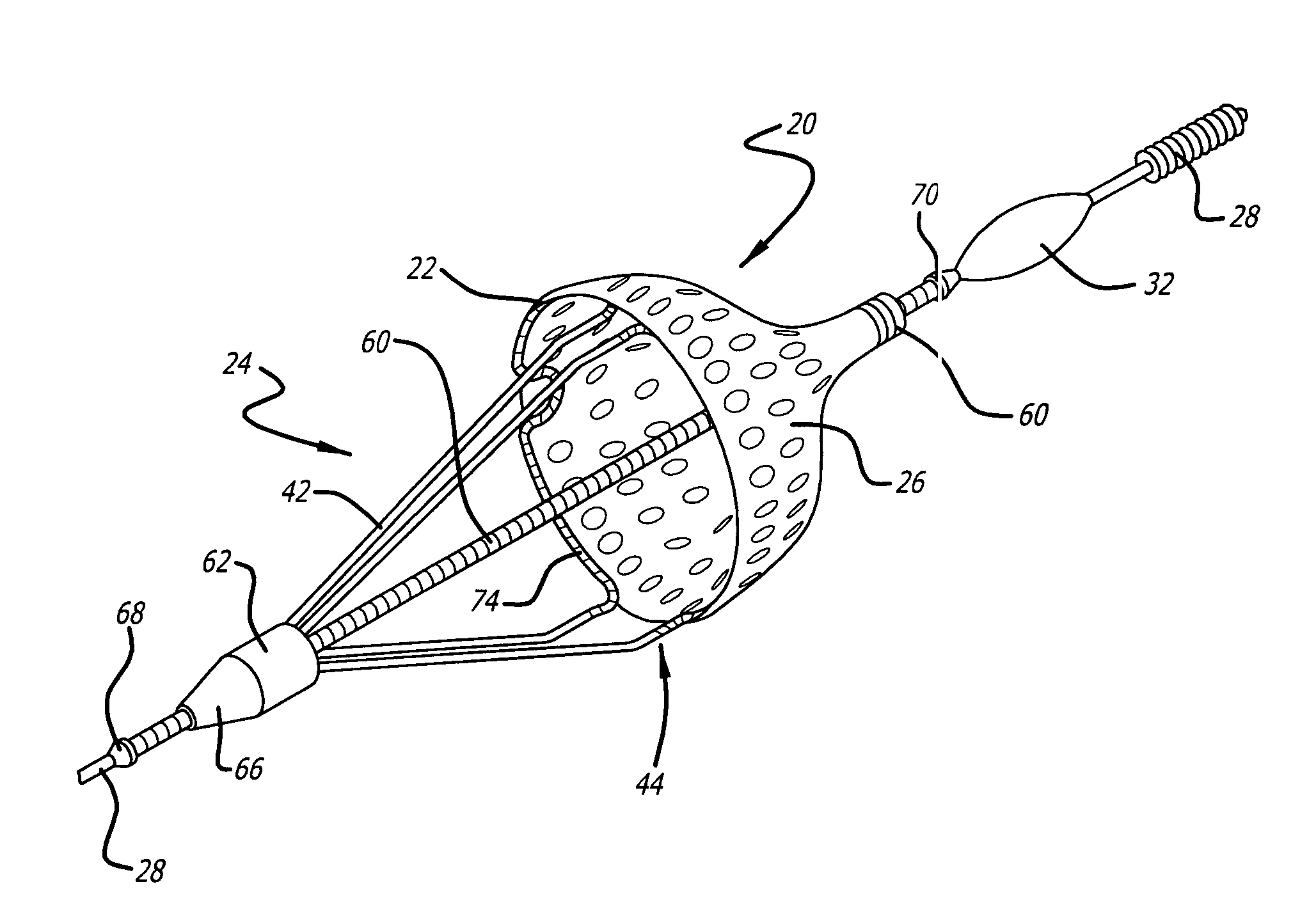

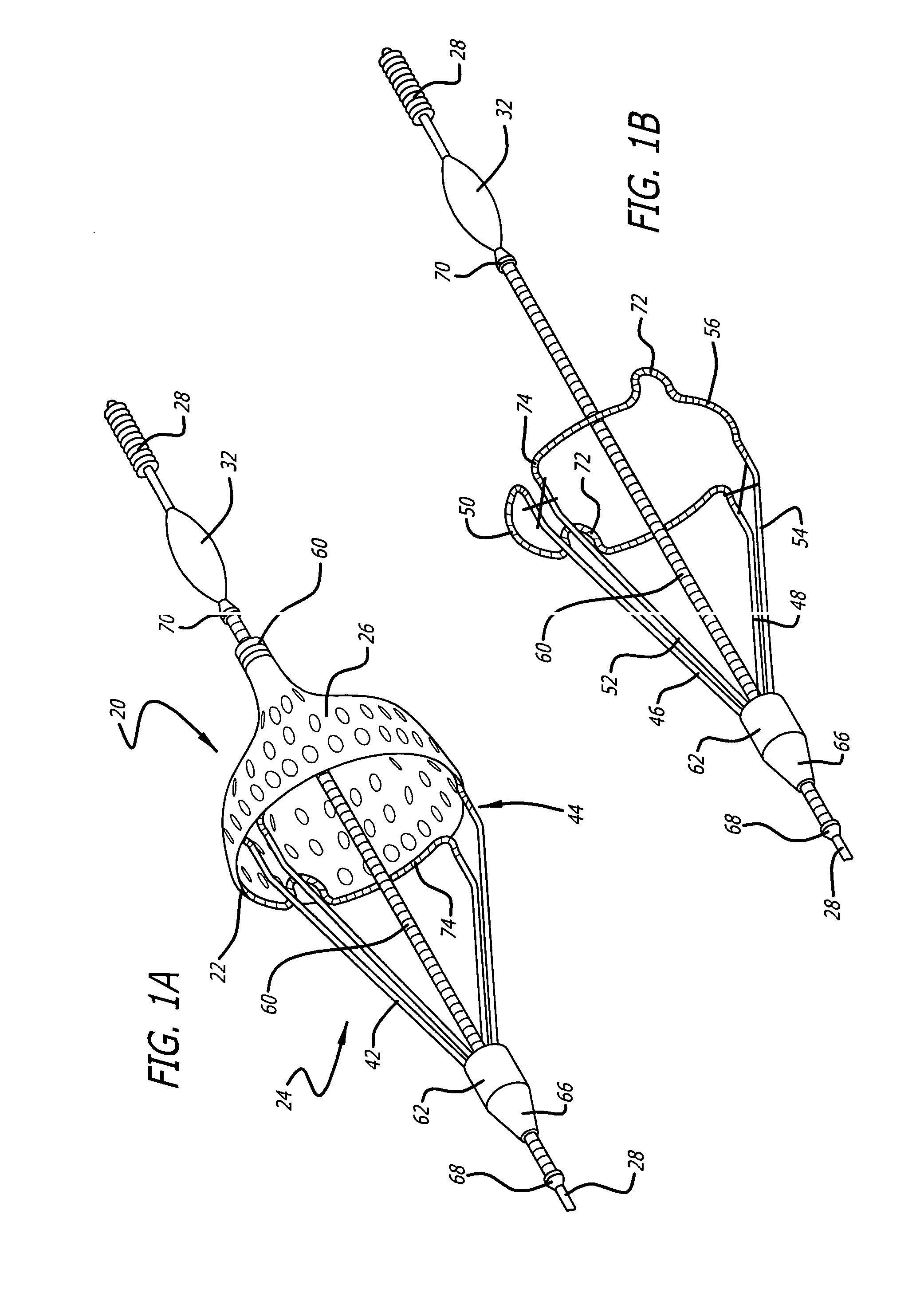

Embolic filtering devices

Owner:ABBOTT CARDIOVASCULAR

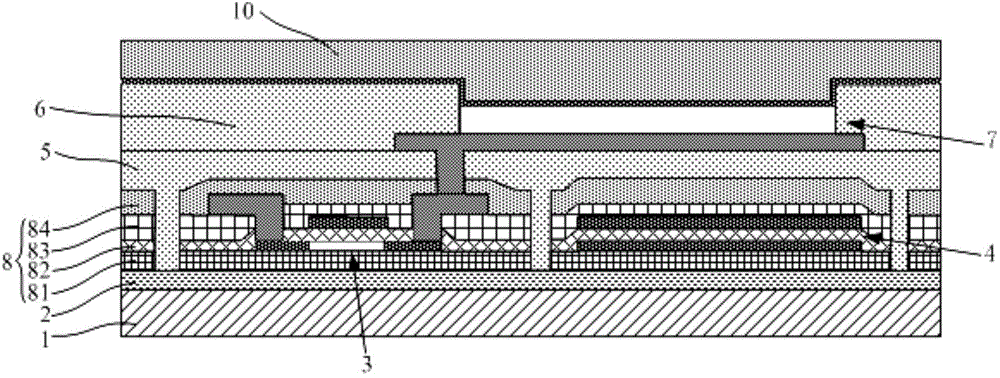

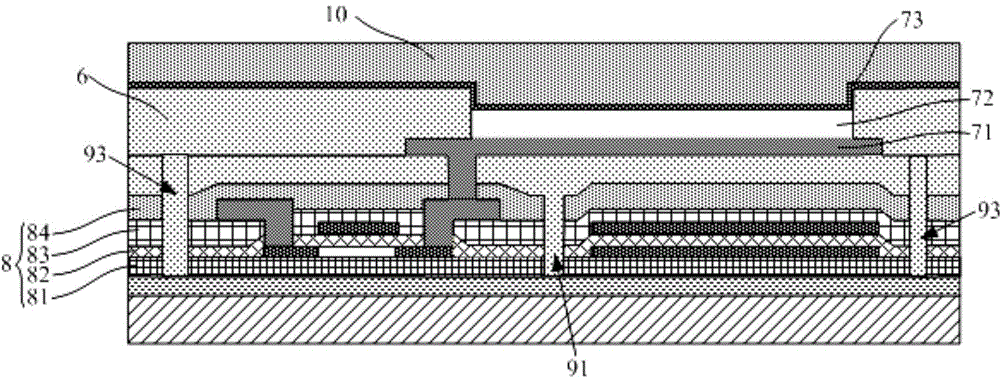

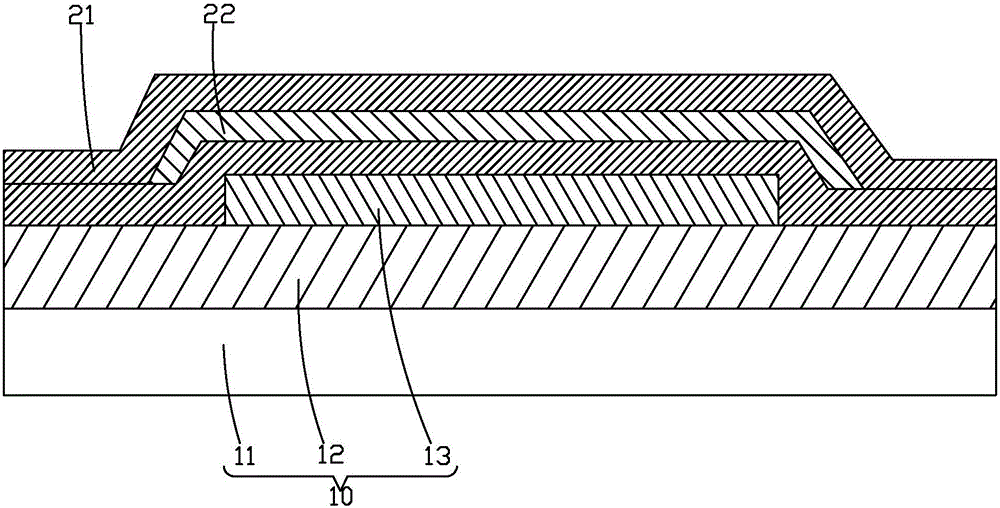

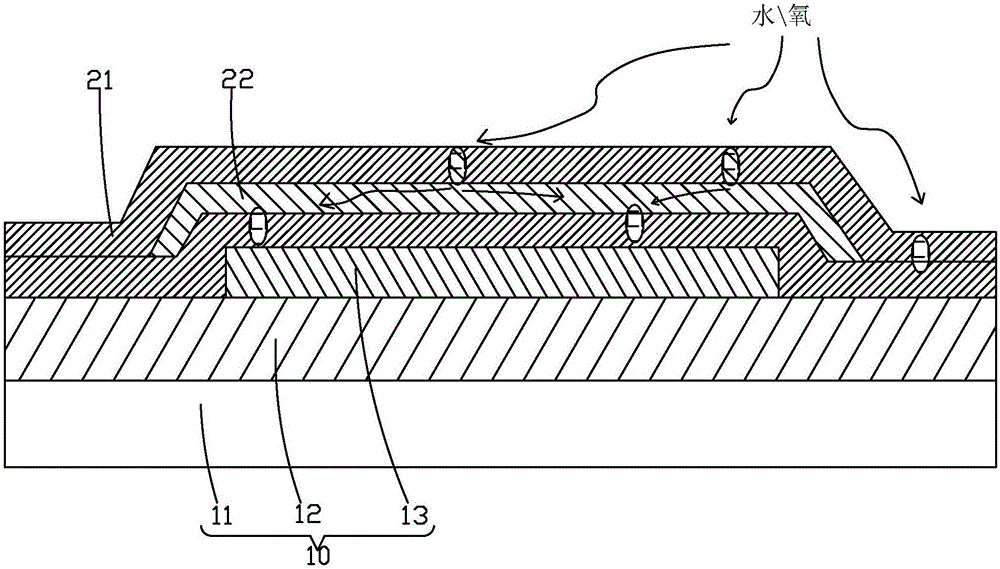

Flexible substrate, manufacturing method thereof and display device

ActiveCN104795403AImprove reliabilityImprove bending performanceFinal product manufactureSolid-state devicesDisplay deviceEngineering

The invention relates to the technical field of display and discloses a flexible substrate, a manufacturing method thereof and a display device comprising the flexible substrate. The flexible substrate comprises a flexible substrate body and a plurality of insulating layers formed on the flexible substrate body, and via holes are formed in at least one insulating layer and filled with organic materials. In the flexible substrate, the organic materials in the via holes of the insulating layers can absorb stress, the stress of the flexible substrate generated during bending can be reduced, the insulating layers are prevented from fracturing due to overlarge stress, and accordingly, the flexible substrate is high in reliability and good in bendability.

Owner:BOE TECH GRP CO LTD

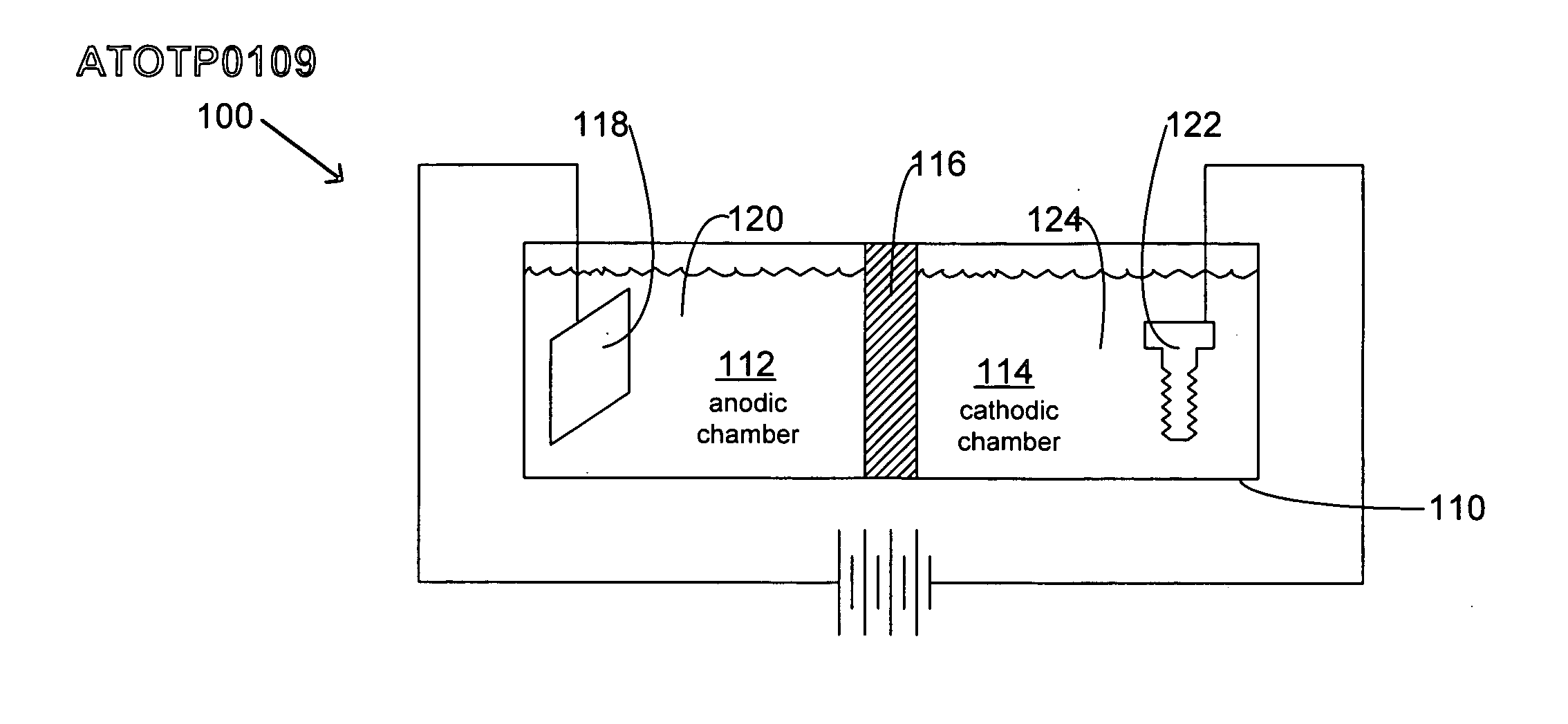

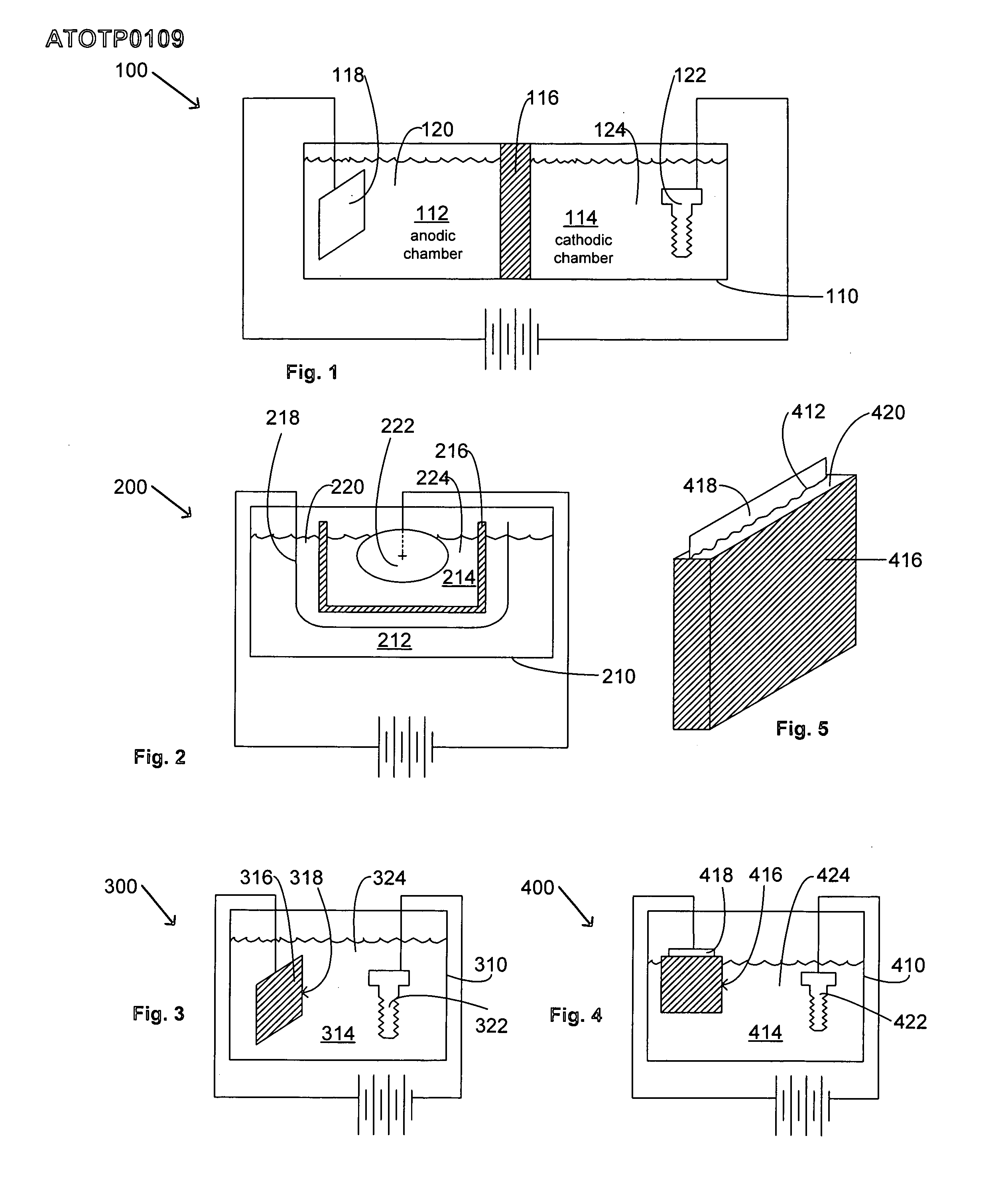

Articles with electroplated zinc-nickel ternary and higher alloys, electroplating baths, processes and systems for electroplating such alloys

An electroplating bath, a system, a process for, and the article obtained from, depositing a zinc-nickel ternary or higher alloy, a) zinc ions; b) nickel ions; and c) one or more ionic species selected from ions of Te+4, Bi+3 and Sb+3, and in some embodiments, further including one or more additional ionic species selected from ions of Bi+3, Sb+3, Ag+1, Cd+2, Co+2, Cr+3, Cu+2, Fe+2, In+3, Mn+2, Mo+6, P+3, Sn+2 and W+6. In some embodiments, the system includes a divider forming a cathodic chamber and an anodic chamber, with the electroplating bath in the cathodic chamber only. In various embodiments, the zinc-nickel ternary and higher alloys may provide improved properties to the conductive substrates upon which the alloys are deposited.

Owner:ATOTECH DEUT GMBH

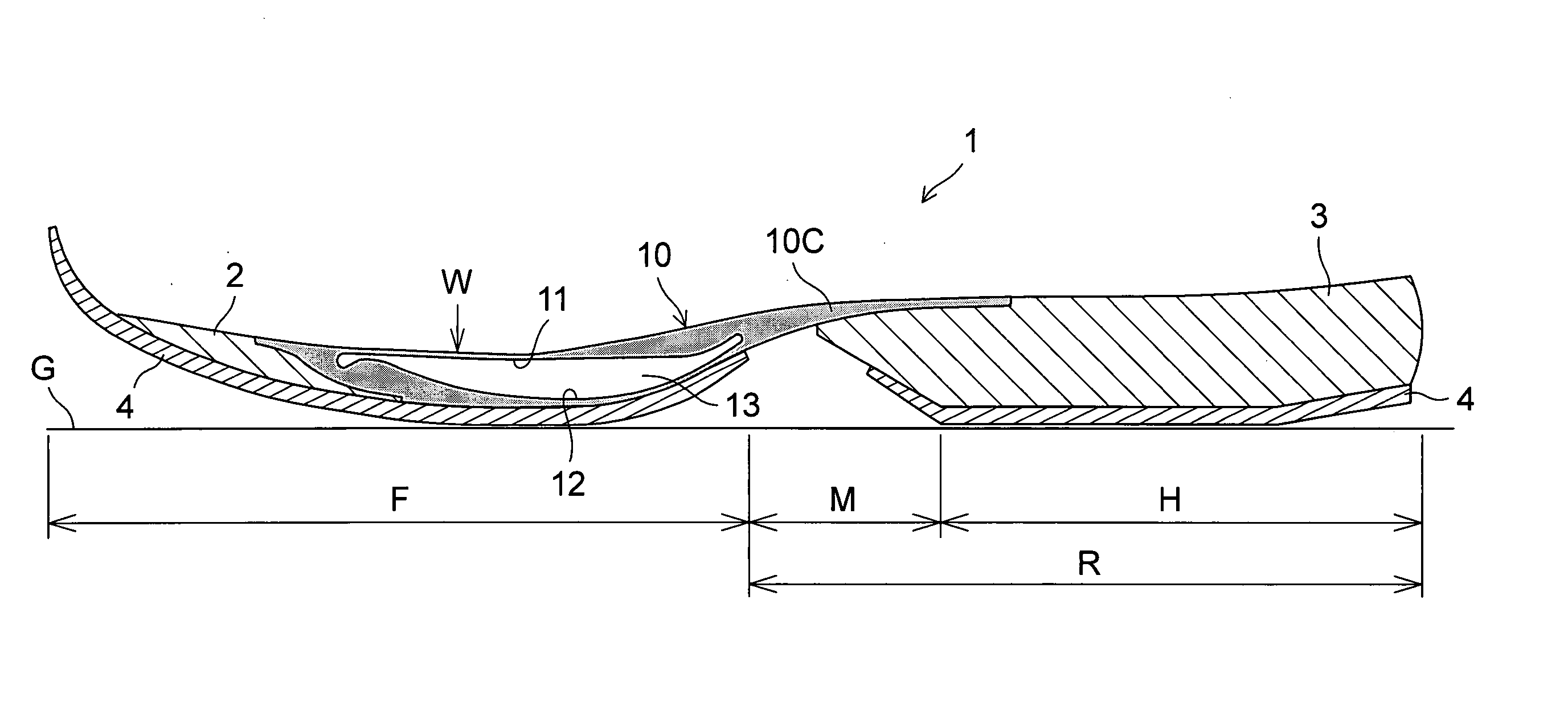

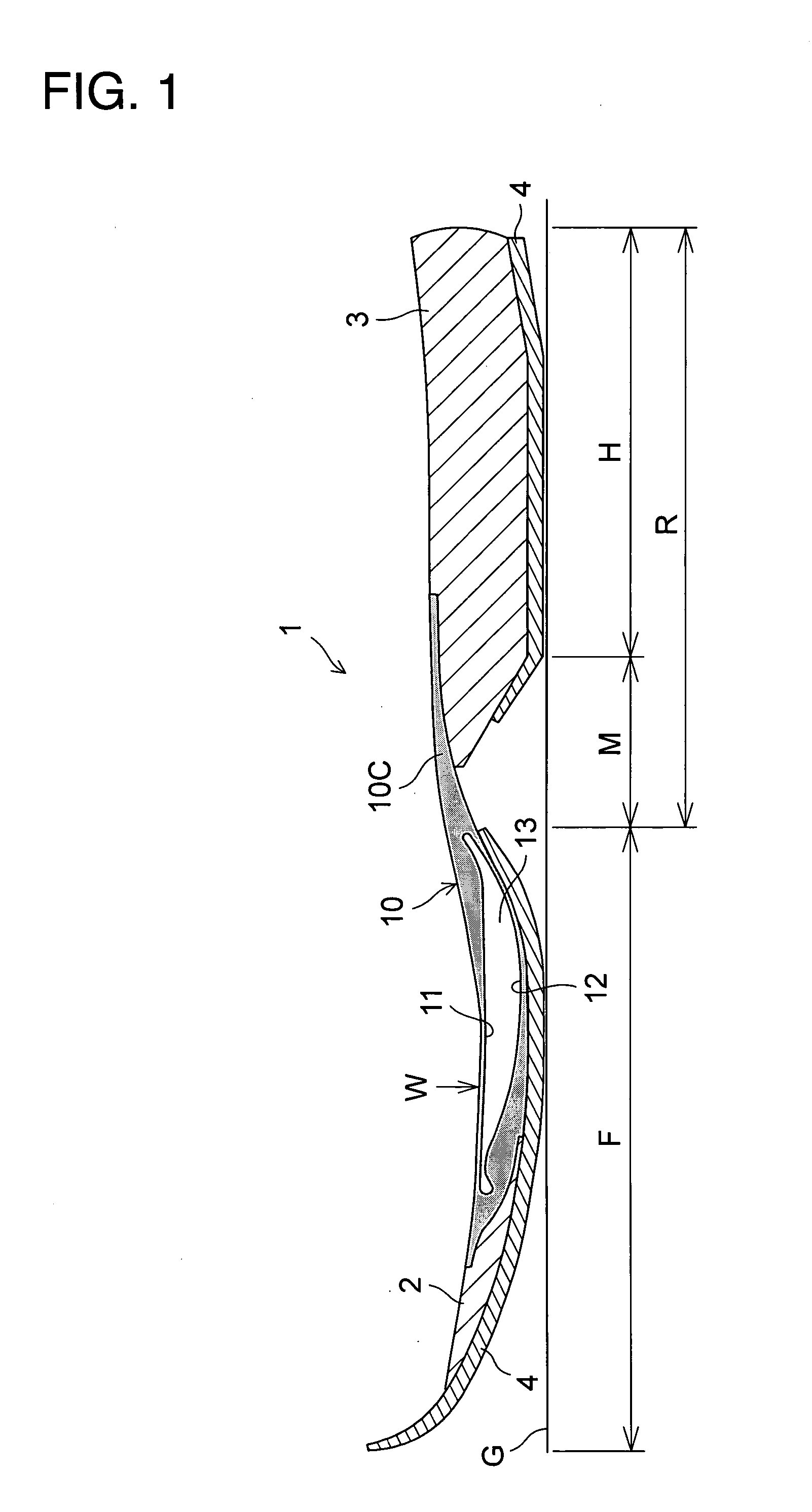

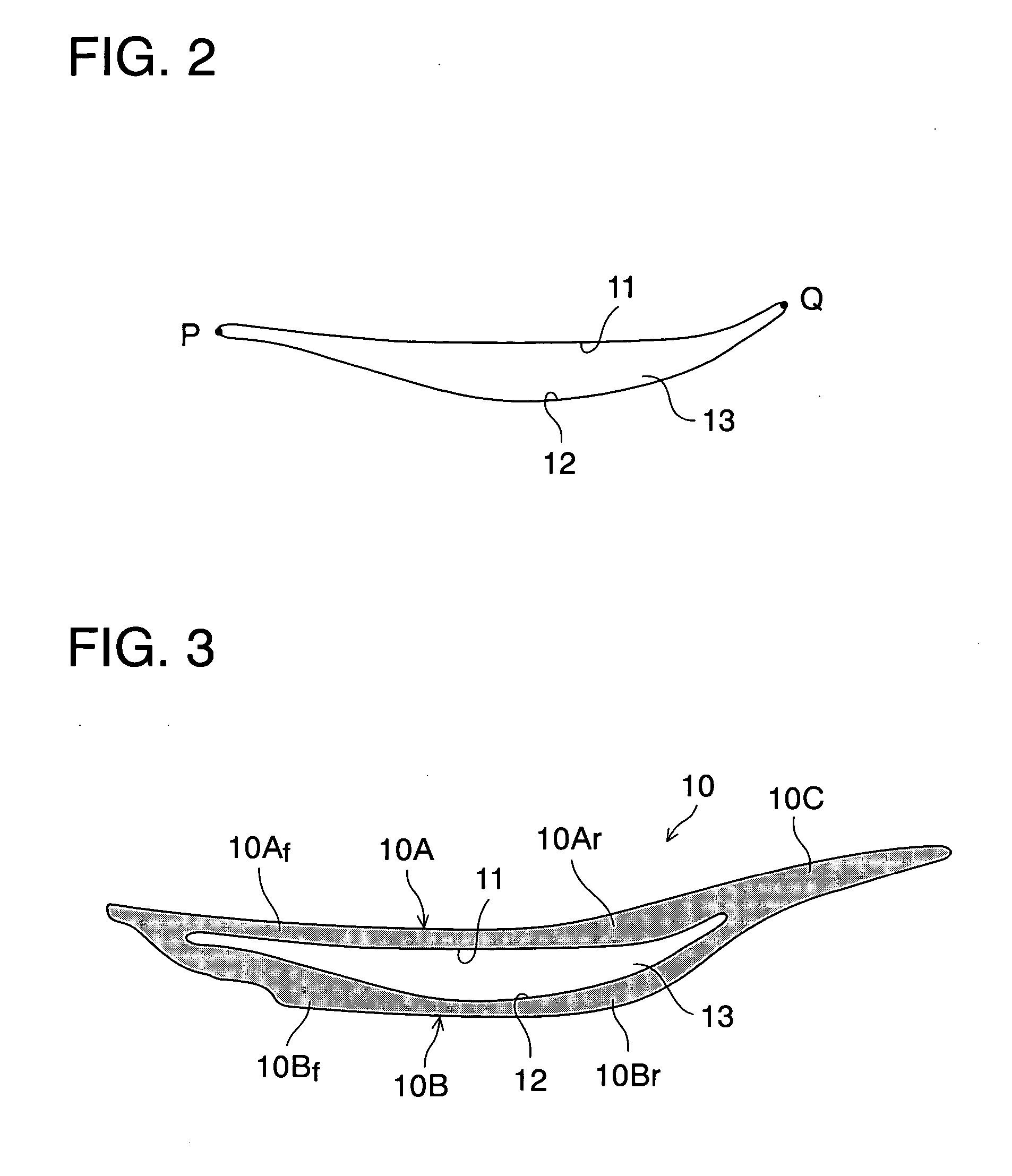

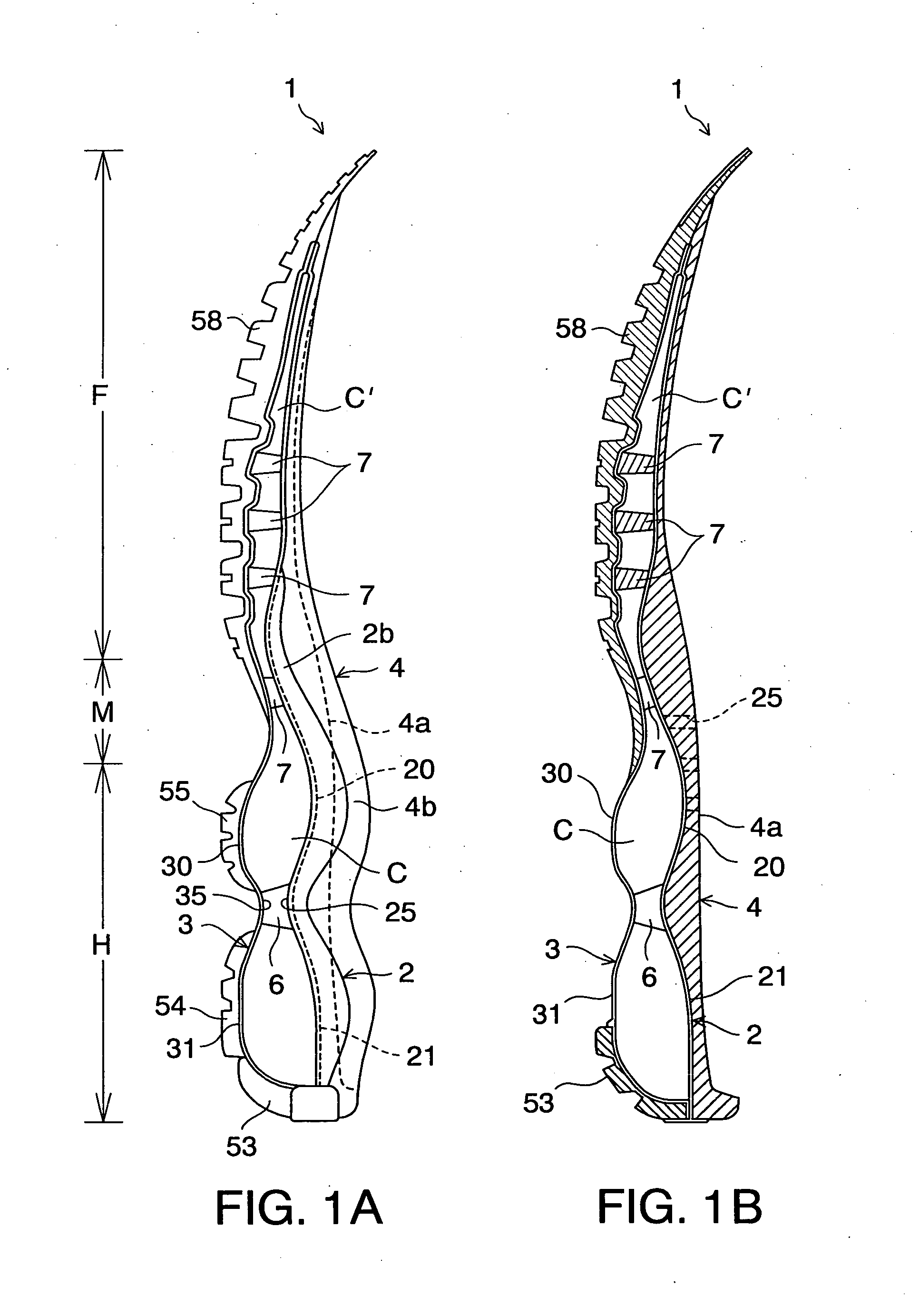

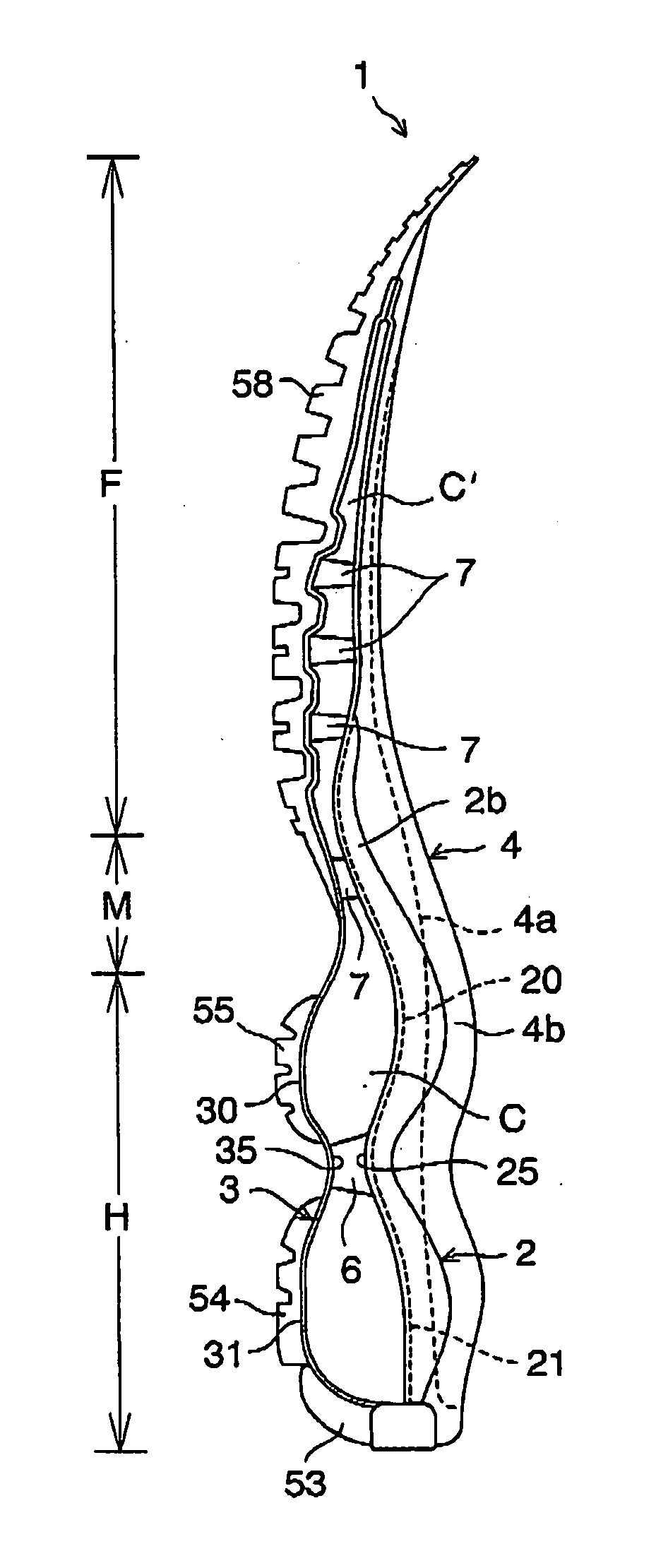

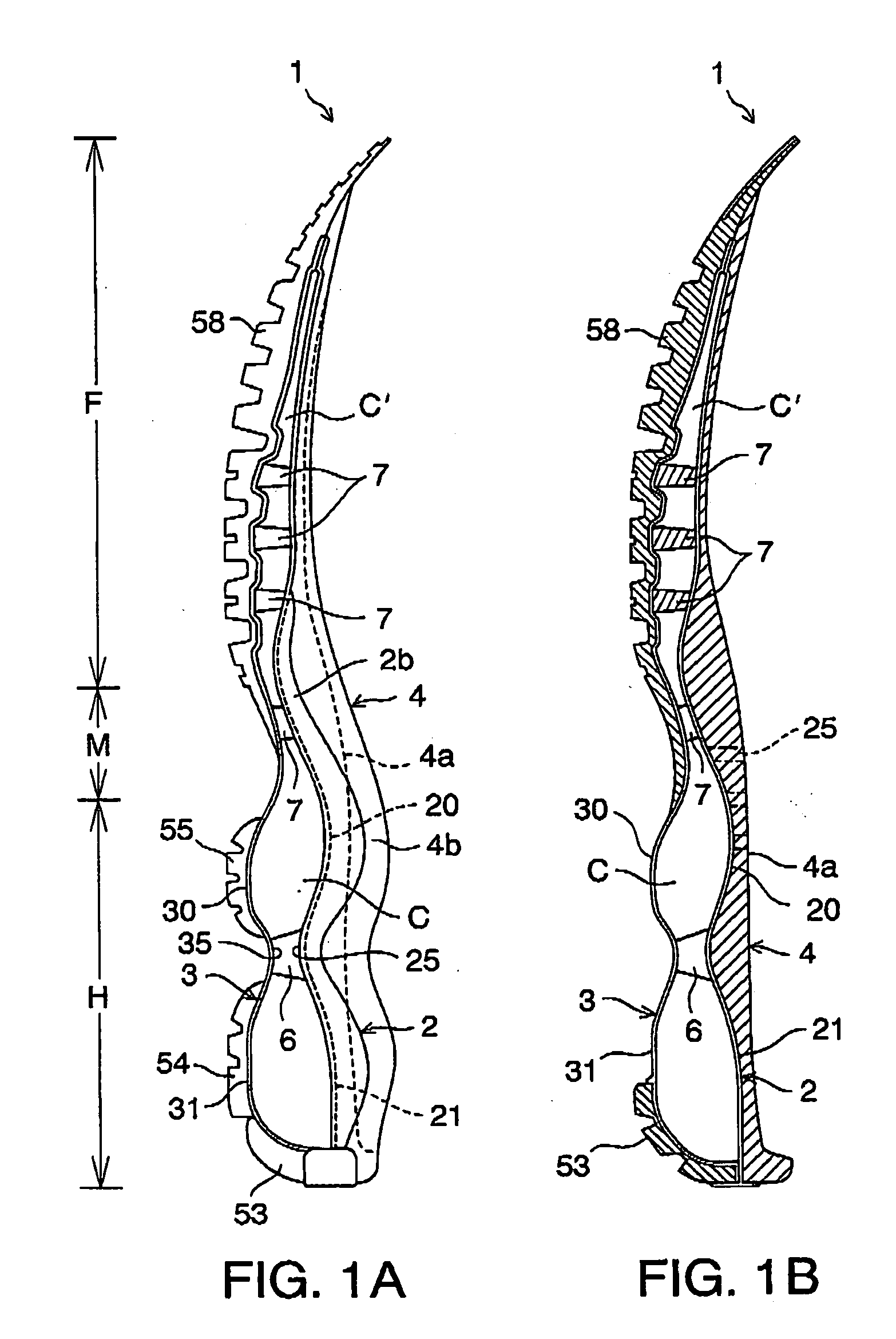

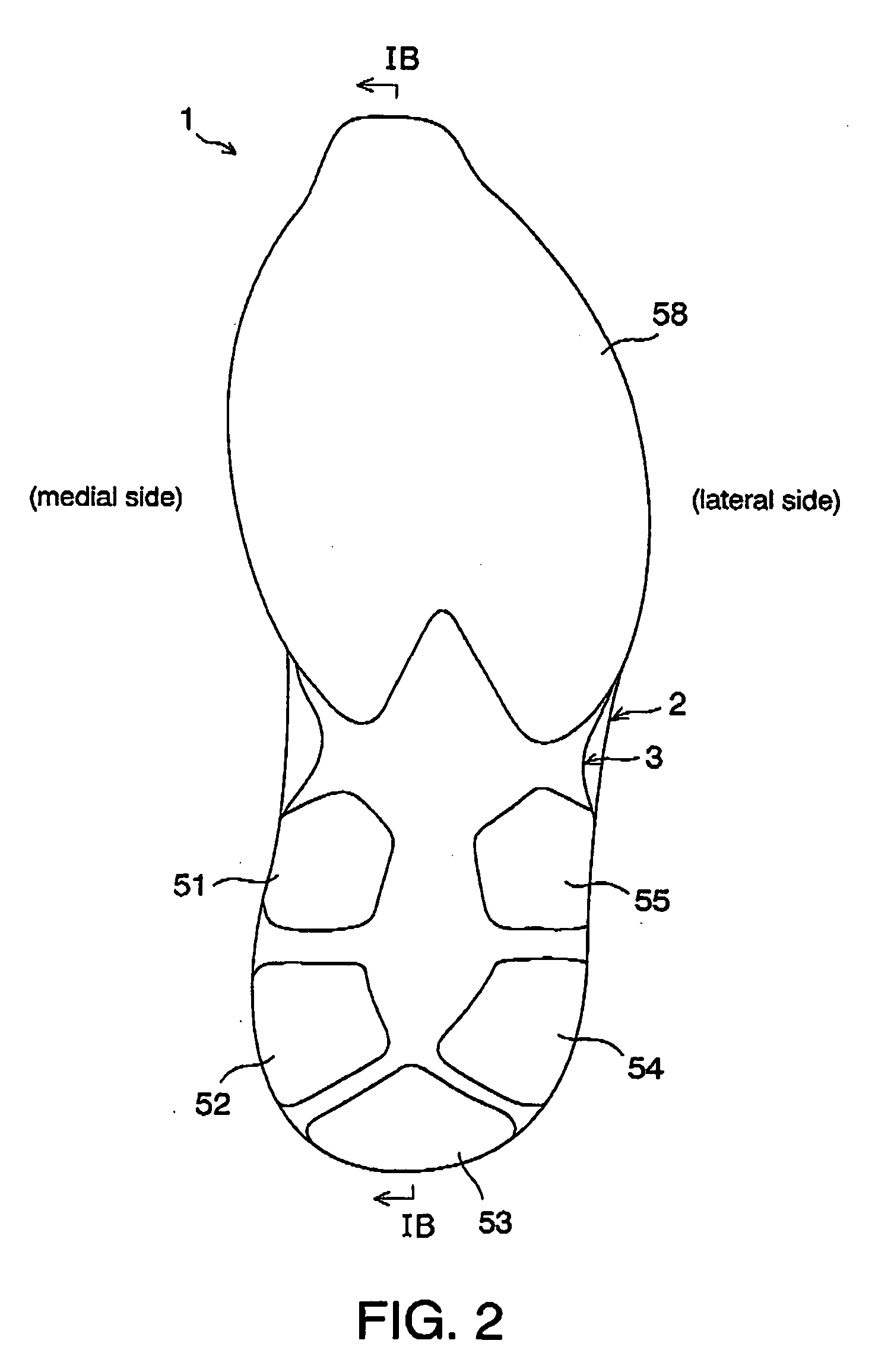

Sole structure for a shoe

A hard elastic body (10) having a longitudinally extending cavity (13) formed therein is provided mainly at a forefoot region (F) of a sole body. The cavity (13) is formed of a first curved surface (11) extending curvedly in a longitudinal direction and a second curved surface (12) disposed under the first curved surface (11) and extending curvedly in a longitudinal direction as well. A front and rear end of the second curved surface (12) is connected to a front and rear end of the first curved surface (11) respectively and an intermediate portion of the second curved surface (12) is spaced apart downwardly from an intermediate portion of the first curved surface (11). A path (PQ1) between the front and rear end of the first curved surface (11) is substantially equal to a path (PQ2) between the front and rear end of the second curved surface (12). When the first curved surface (11) is pressed downwardly, the sole body is deformed in such a way that a rear foot region (R) of the sole body is lifted upwardly.

Owner:MIZUNO CORPORATION

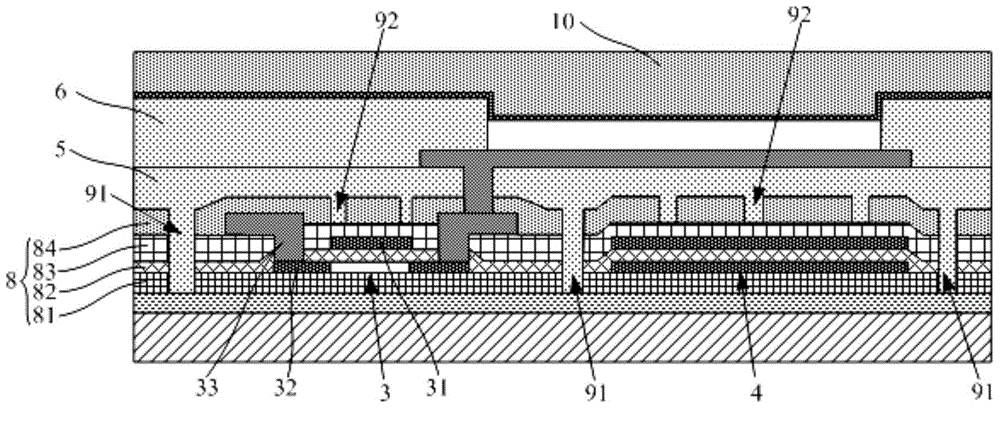

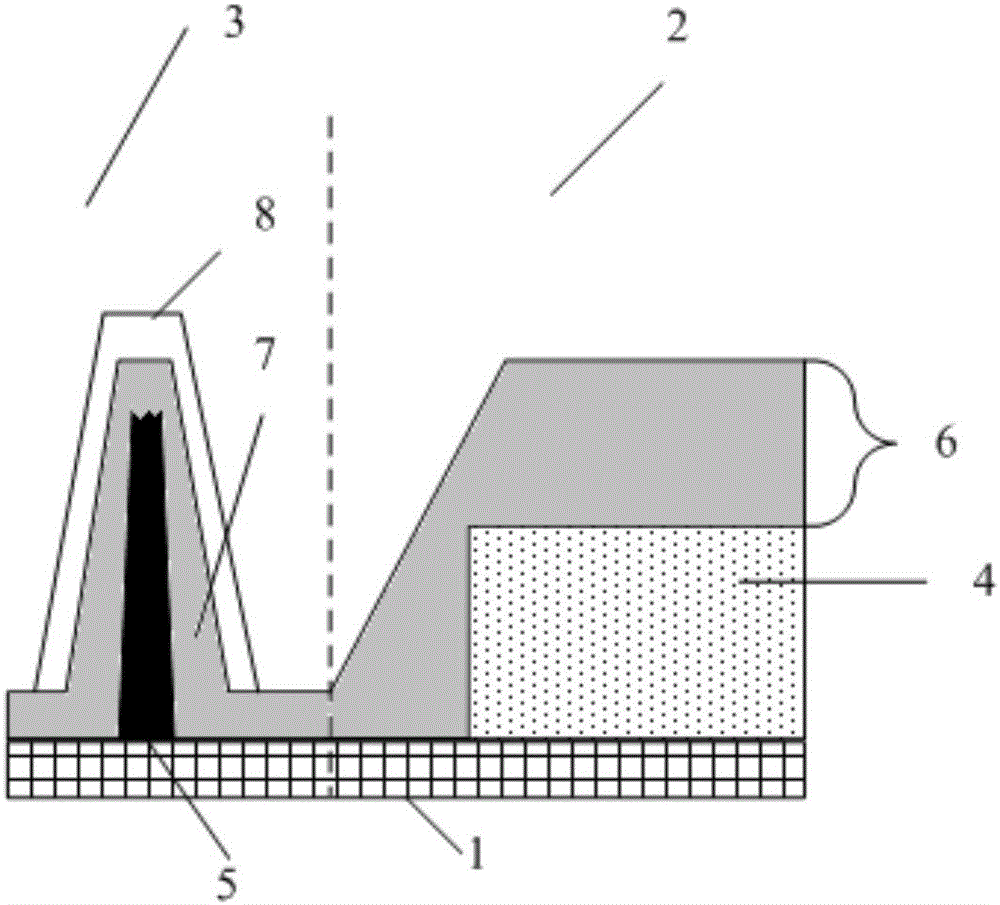

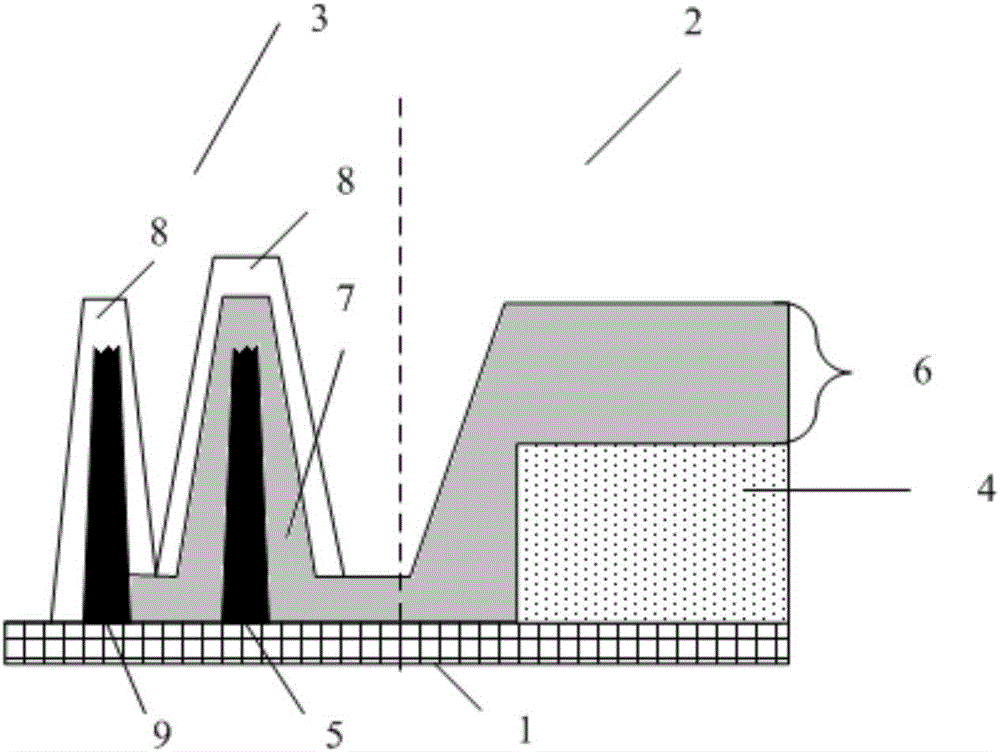

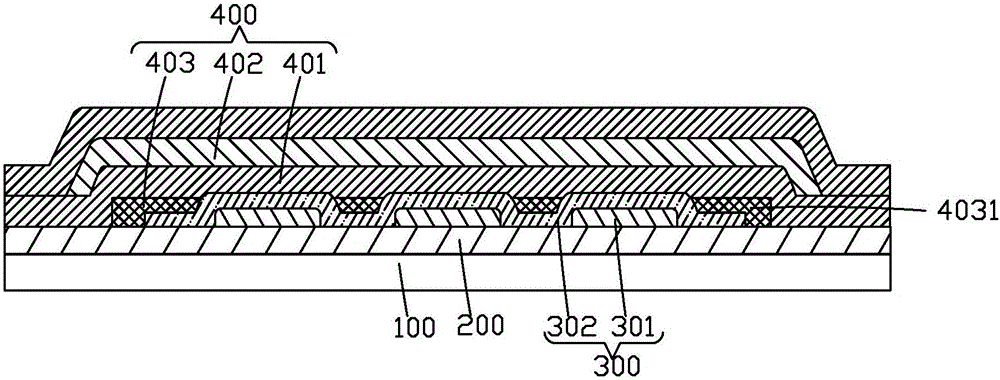

Organic light-emitting diode display panel and display

ActiveCN106816456AInhibit growthImprove sealingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides an organic light-emitting diode display panel and a display. A protection layer additionally disposed on an inorganic layer on a retaining wall is used to prevent an inorganic layer crack from continuously growing, and therefore product sealing performance is improved, and product bending performance is improved. The organic light-emitting diode comprises a display area and an adjacent peripheral area. The display panel comprises a substrate, a display function layer, and a packaging layer. The display area comprises a display function layer, and the peripheral area comprises a first retaining wall, which is disposed around the display area. The packaging layer comprises at least one inorganic layer, which is vertical to the direction of the substrate, and is used to cover the first retaining wall. The display panel comprises the protection layer, which is vertical to the direction of the substrate, and is used to cover the at least one inorganic layer on the upper part of the first retaining wall.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

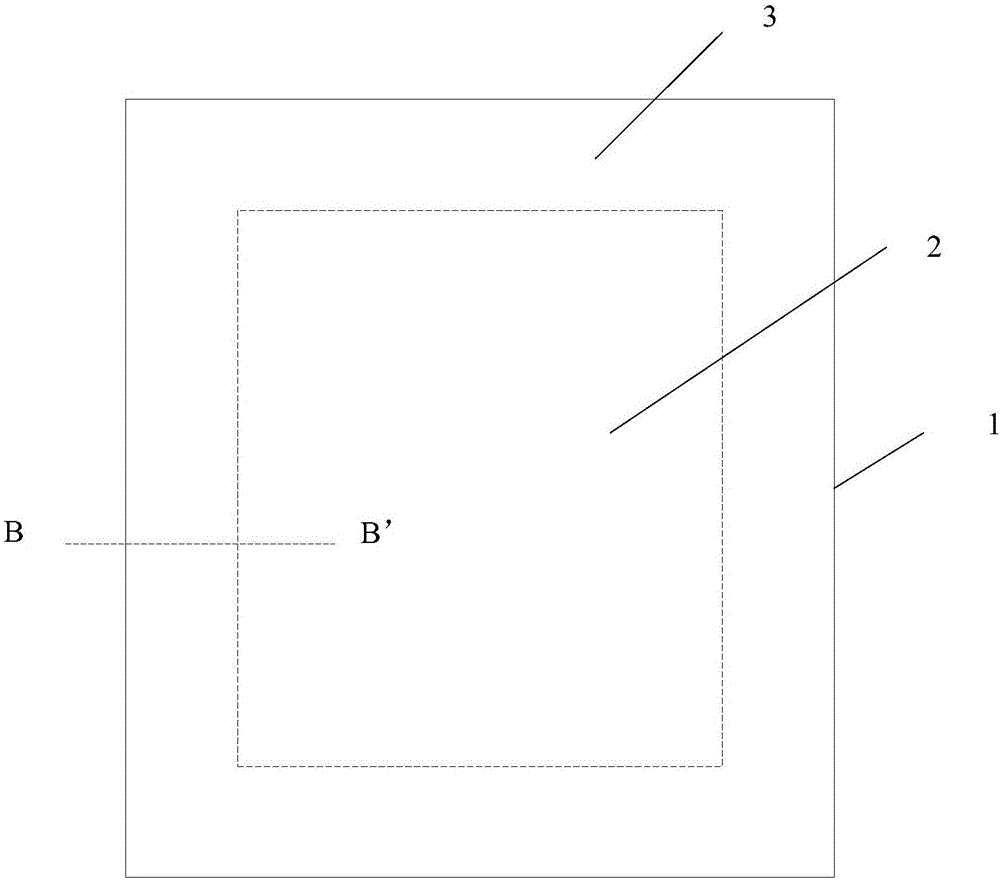

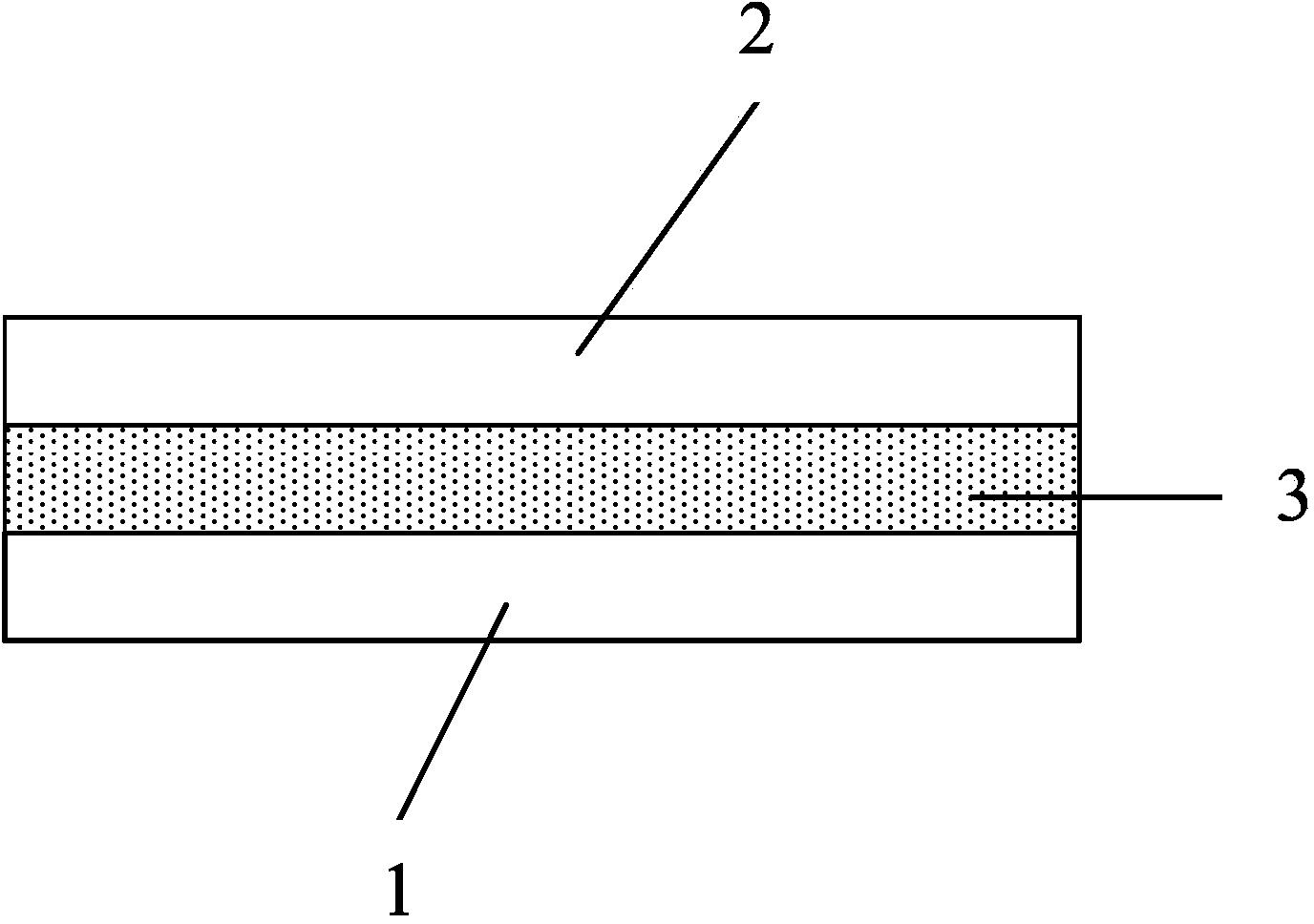

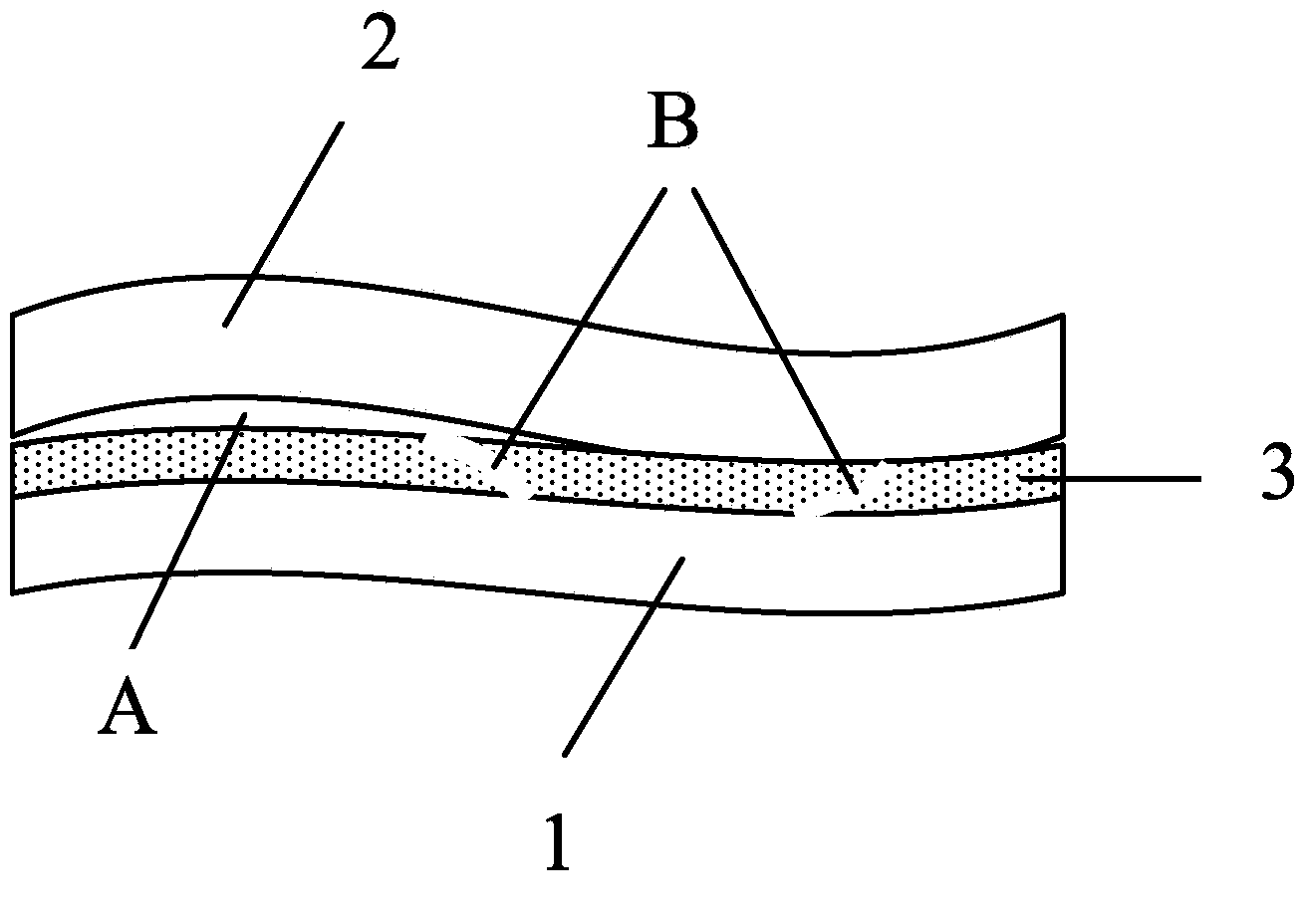

Flexible display panel, production method for same, and flexible display device

ActiveCN103985321AImprove bendabilityAvoid breakingSolid-state devicesIdentification meansElastic componentEngineering

The invention discloses a flexible display panel, a production method for the same, and a flexible display device. The flexible display panel comprises a flexible substrate and a transparent flexible cover plate which are oppositely arranged; the flexible display panel is provided with a display area and a border area surrounding the display area; a rubber layer is arranged in the border area, and used for bonding and fixing the flexible substrate and the transparent flexible cover plate; a plurality of elastic components are arranged in the rubber layer. The flexible display panel is good in bendability. The production method can be used for producing the flexible display panel with good bendability, and the flexible display device is produced by the flexible display panel and good in bendability.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

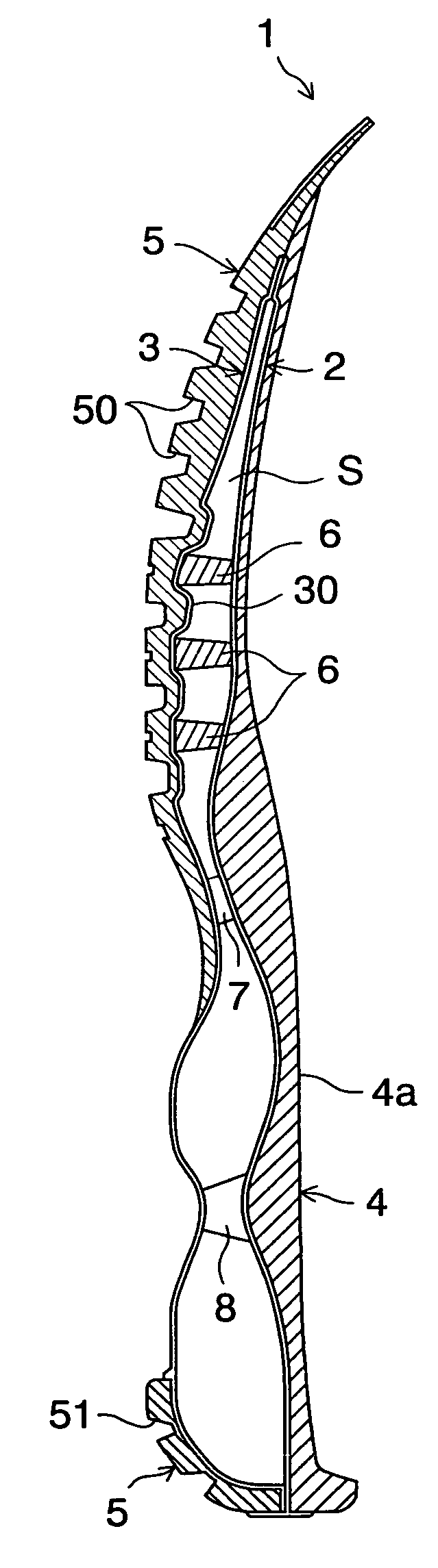

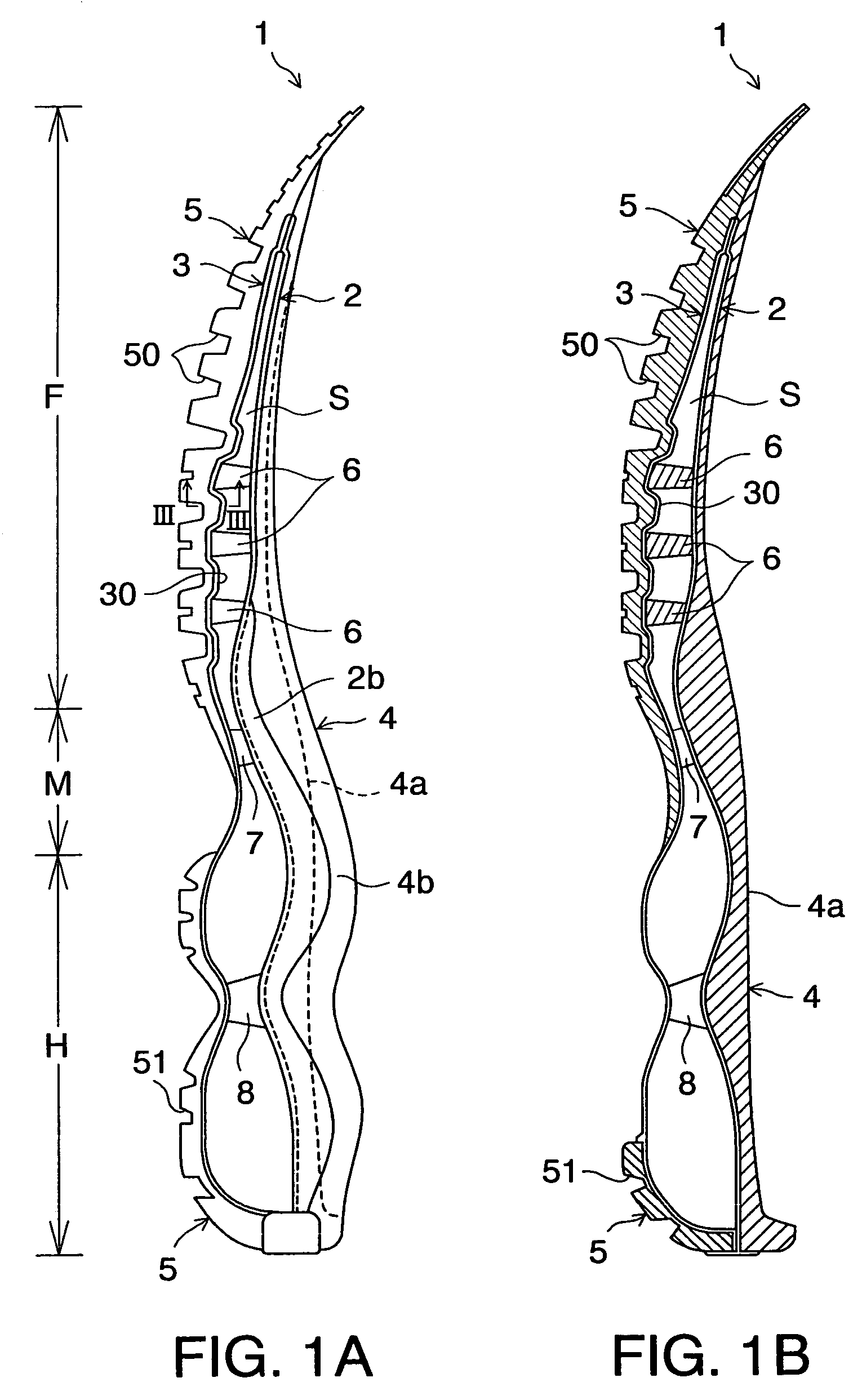

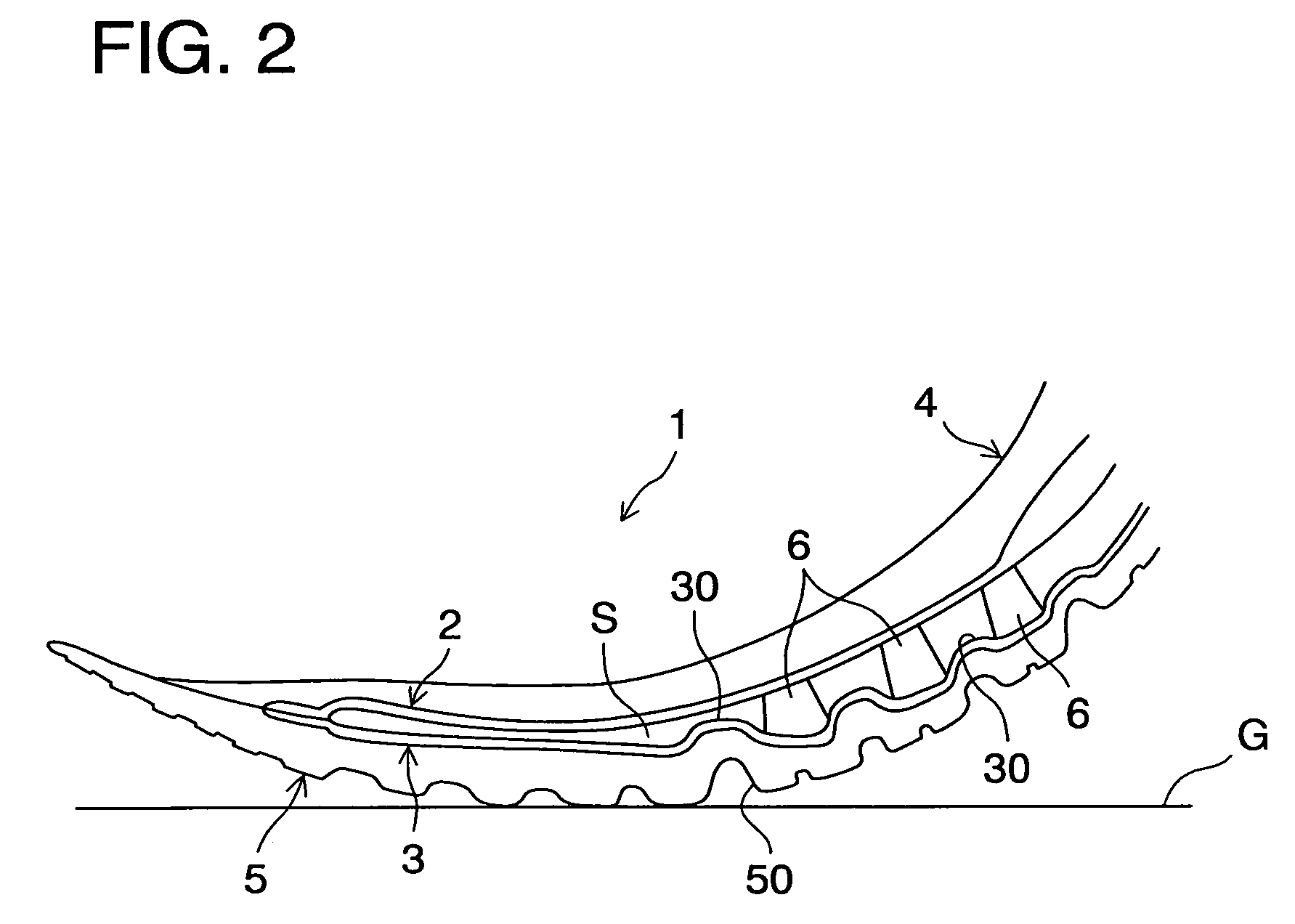

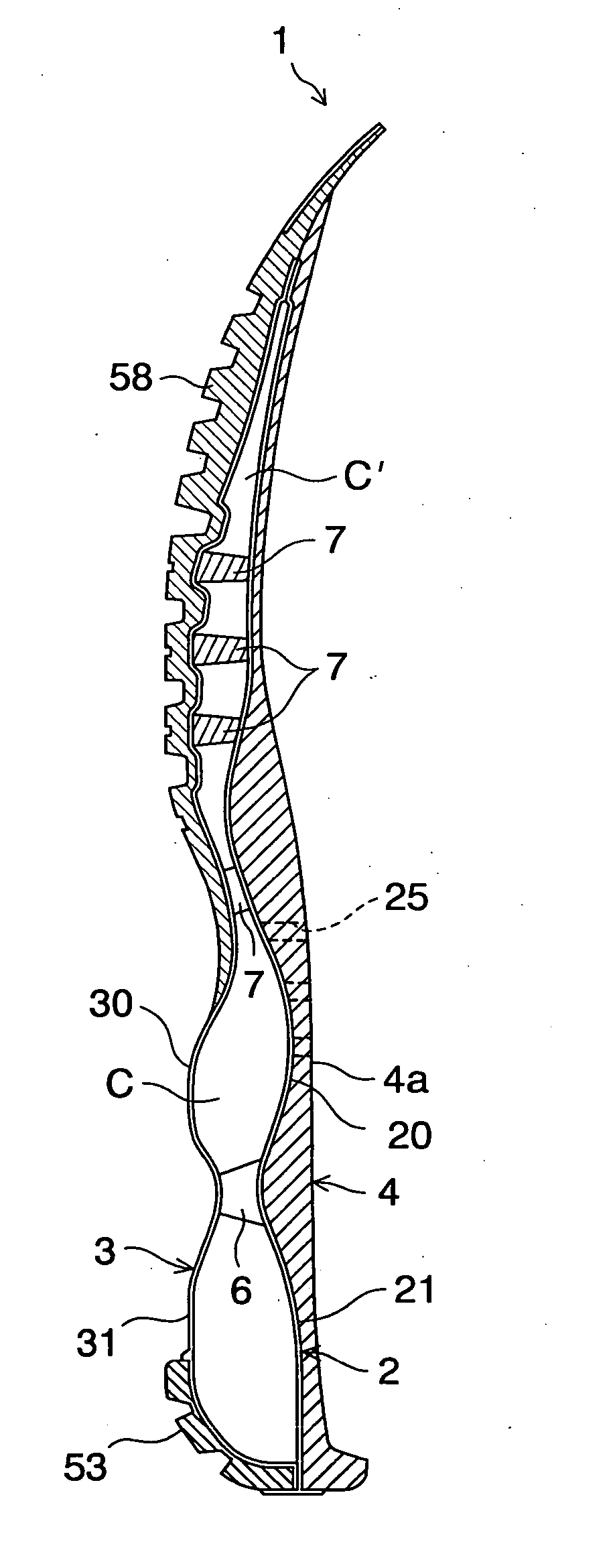

Sole structure for a shoe

A sole structure is provided that can improve bendability and cushioning ability of the sole forefoot portion. The sole assembly 1 is formed of an upper plate 2, and a lower plate 3 provided below the upper plate 2 and spaced apart from the upper plate 2 via a void S. The lower plate 3 has a plurality of protrusions 30 that protrude toward the upper plate 2. The longitudinal path length L1 of the lower plate 3 is longer than the longitudinal path length L2 of the upper plate 2. More specifically, the path length L1 of the lower plate 3 is 40-60% longer than the path length L2 of the upper plate 2.

Owner:MIZUNO CORPORATION

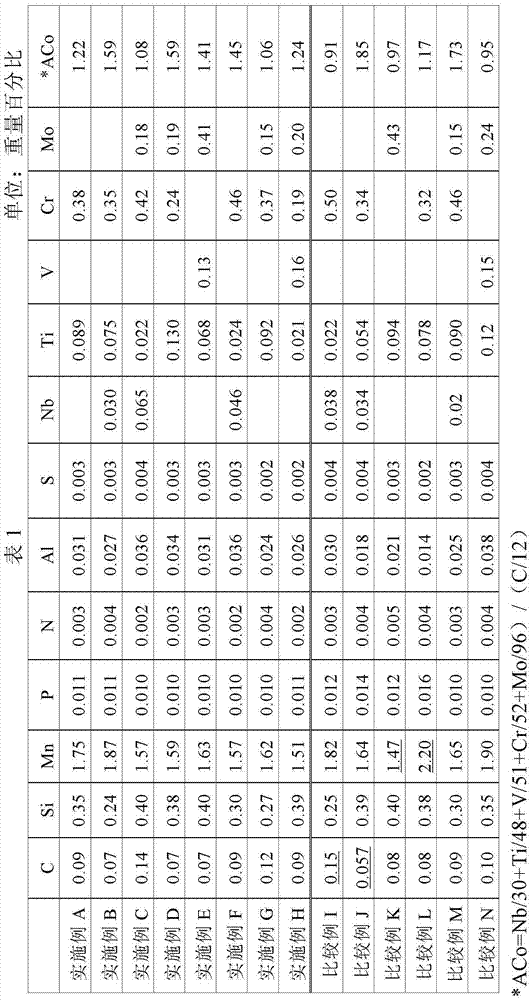

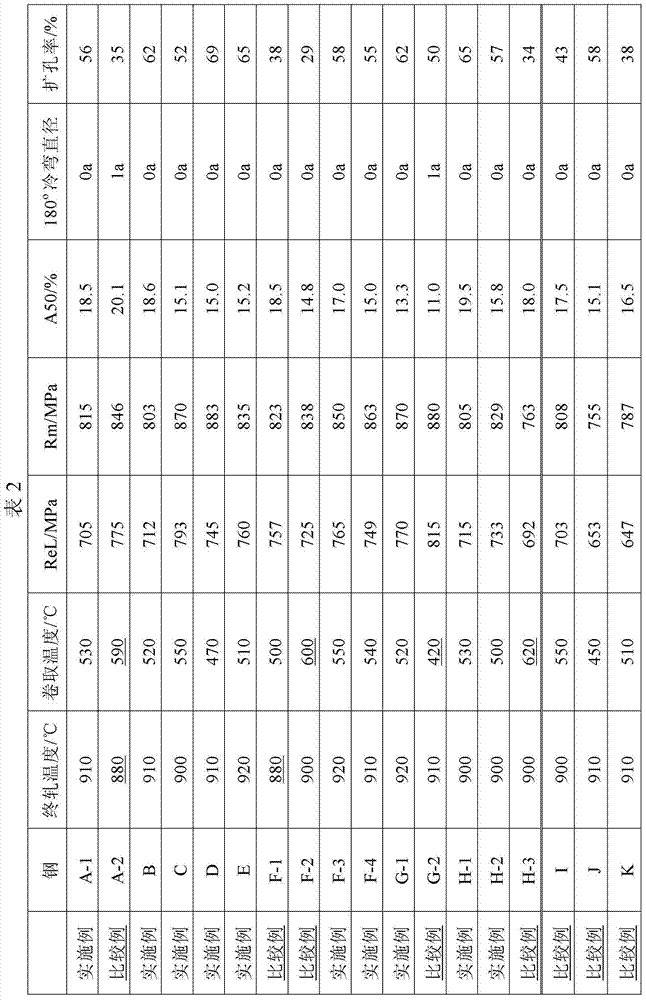

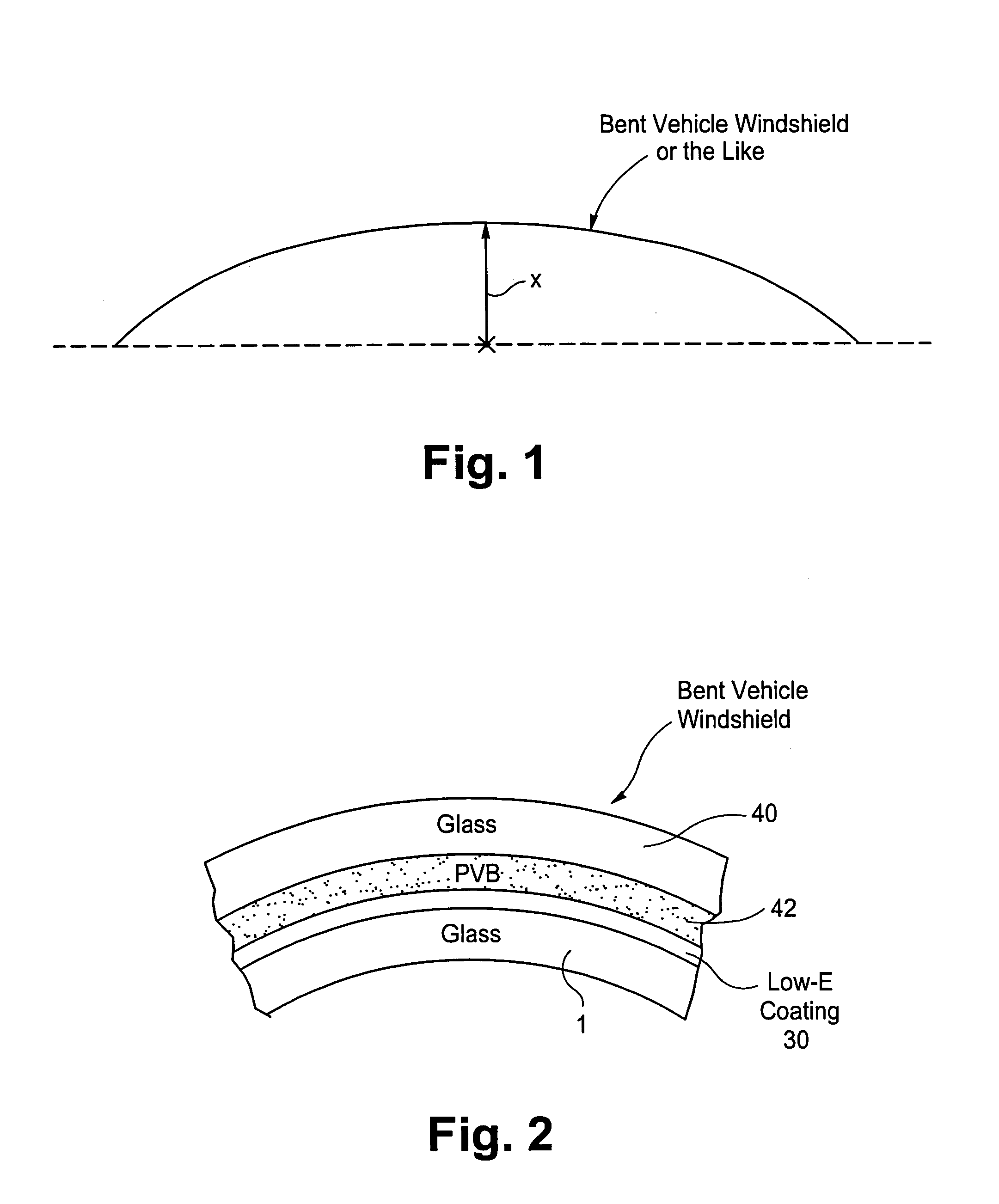

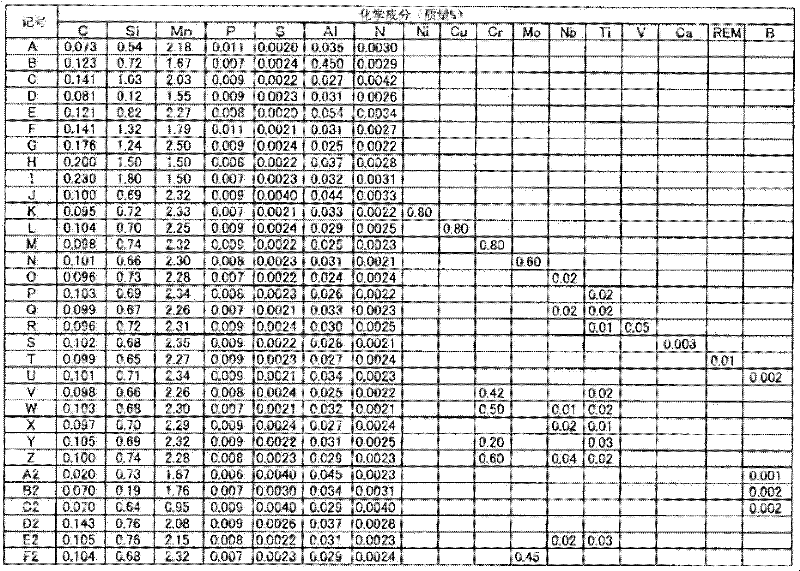

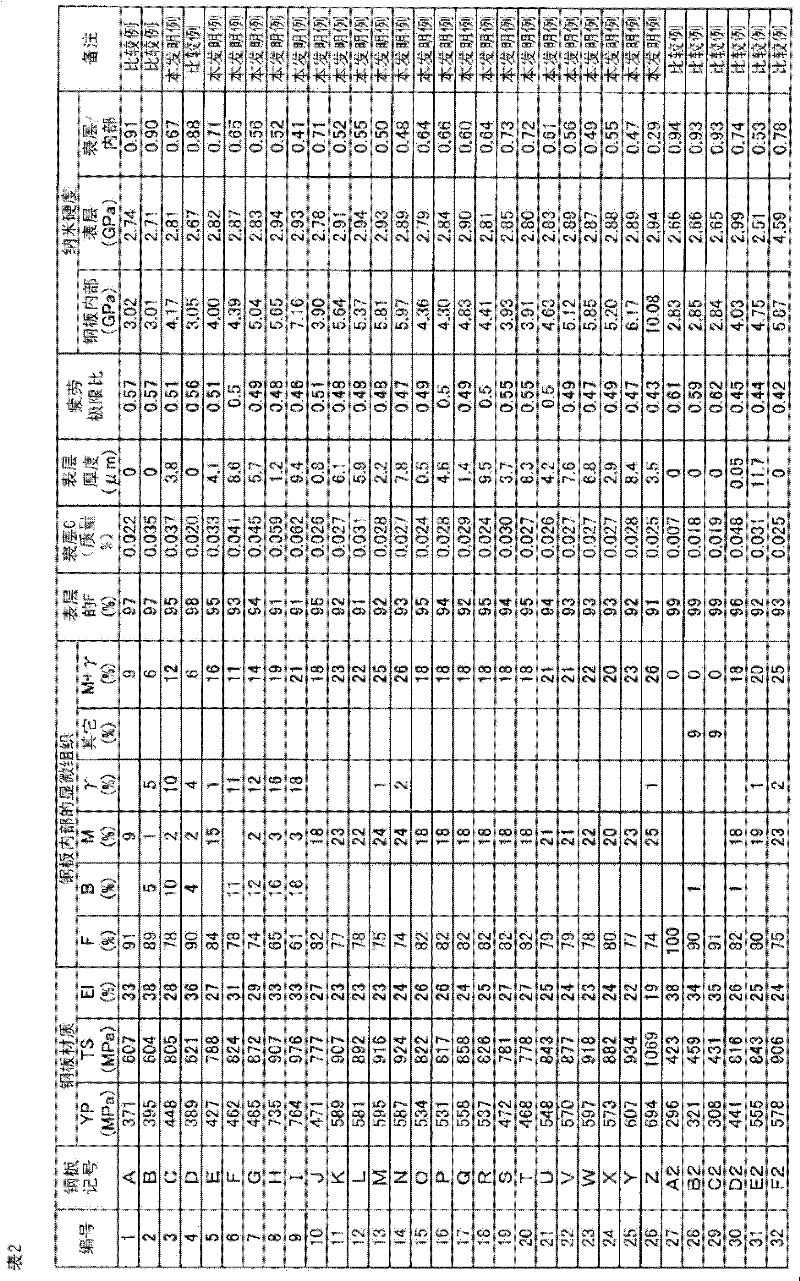

Ultrahigh-strength hot-rolled complex phase steel plate and steel strip with good bending and broaching performance and manufacturing method thereof

The invention discloses an ultrahigh-strength hot-rolled complex phase steel plate and steel strip with good bending and broaching performance and a manufacturing method thereof. The ultrahigh-strength hot-rolled complex phase steel plate and steel strip comprise the following components in percentage by weight: 0.07-0.14% of C, 0.1-0.4% of Si, 1.55-2.00% of Mn, less than or equal to 0.015% of P, less than or equal to 0.004% of S, 0.01-0.05% of Al and less than or equal to 0.005% of N, and further comprises at least one of alloy elements of less than or equal to 0.07% of Nb, 0.02-0.15% of Ti and 0.10-0.20% of V, at least one of alloy elements of 0.15-0.50% of Cr and 0.15-0.50% of Mo, and the balance of Fe and inevitable impurities. The ultrahigh-strength hot-rolled complex phase steel has the tensile strength of above 800 MPa, the yield strength of above 700 MPa, the cold bending performance of 0a at 180 DEG C, the broaching rate of above 50%, and the microstructure of bainite (at least 80%) and a small amount of ferrite, martensite and retained austenite, wherein the bainite is mainly lower bainite. The ultrahigh-strength hot-rolled complex phase steel can be applied to manufacture of an automobile chassis, a hanging component, a bumper and other products.

Owner:BAOSHAN IRON & STEEL CO LTD

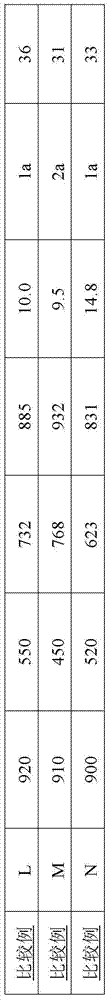

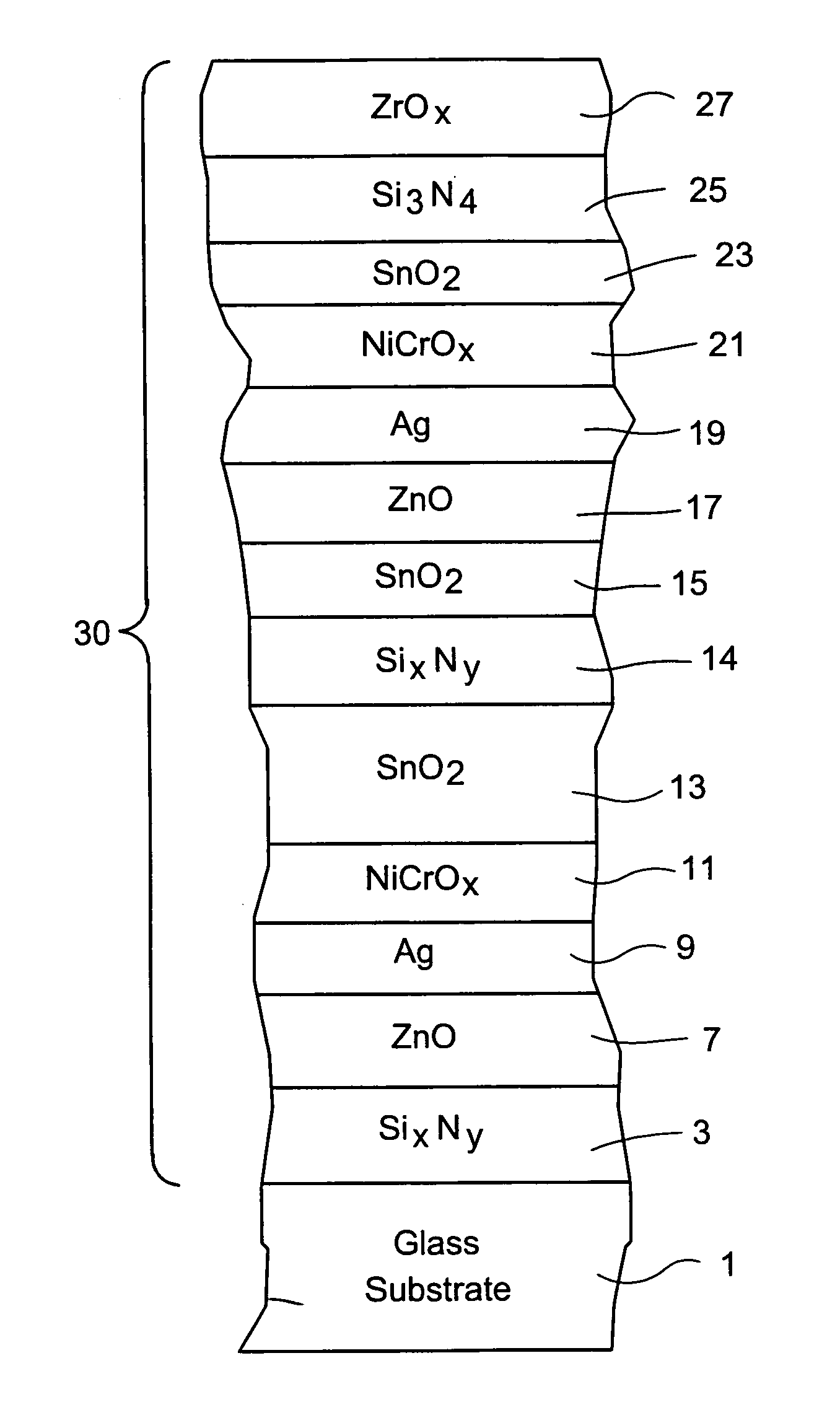

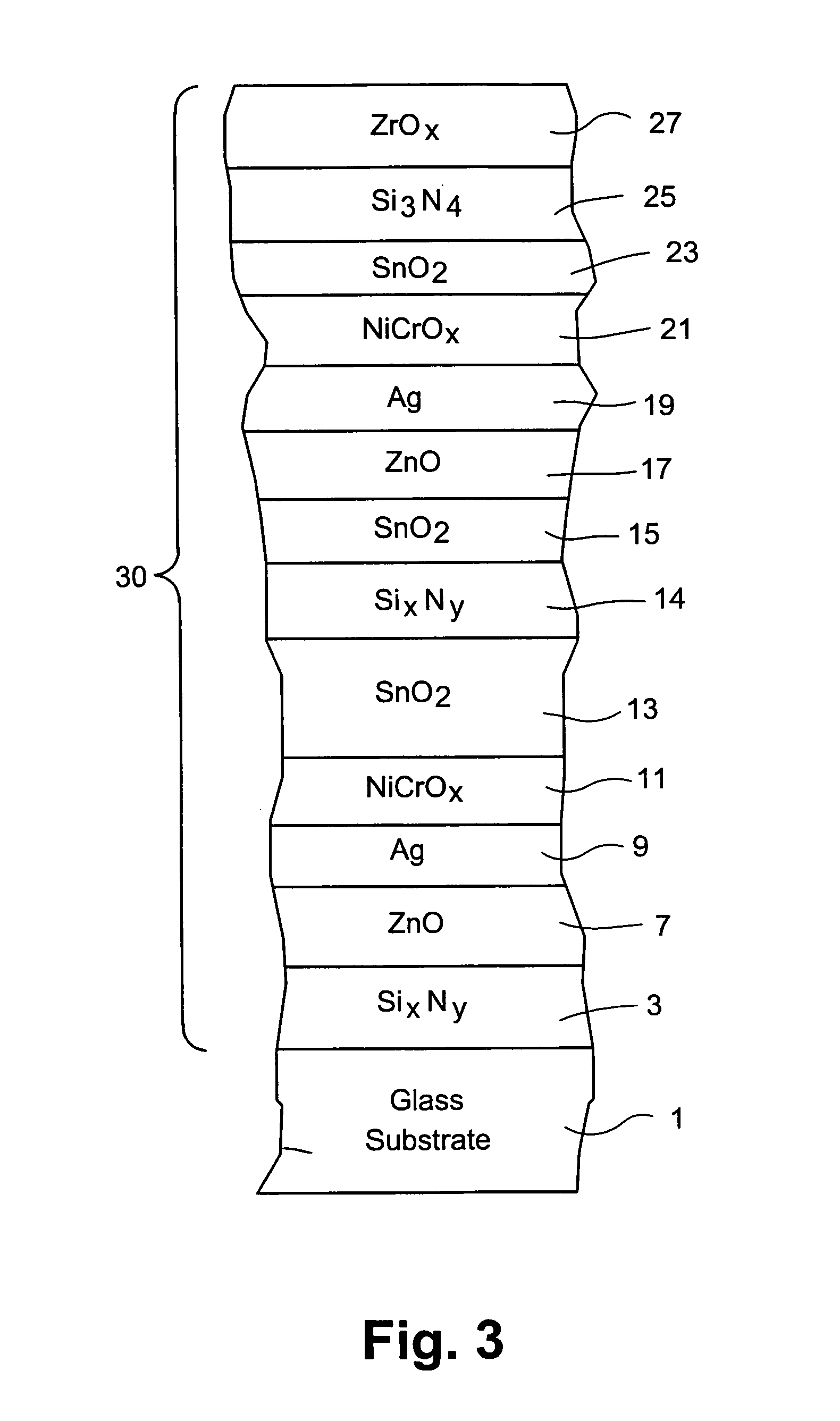

Coated article with low-E coating including tin oxide interlayer for high bend applications

InactiveUS7150916B2Improve bending performanceImprove mechanical durabilityGlass/slag layered productsCoatingsZincMetal

A coated article is provided which may be heat treated (e.g., thermally tempered) and / or heat bent in certain example instances. In certain example embodiments, an interlayer of or including a metal oxide such as tin oxide is provided under an infrared (IR) reflecting layer so as to be located between respective layers of or including silicon nitride and zinc oxide. It has been found that the use of such a tin oxide inclusive interlayer results in significantly improved bendability of the coated article in applications such as vehicle windshields with deep bends. In certain example instances, an overcoat of a material such as zirconium oxide may also be provided.

Owner:GUARDIAN EURO S A R L +1

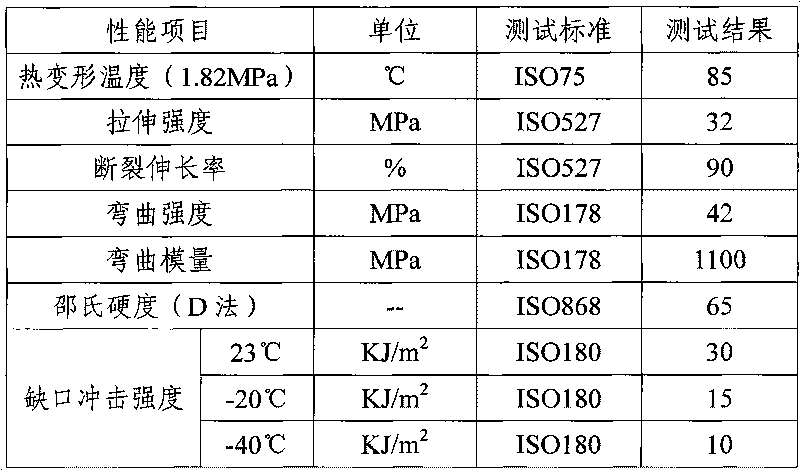

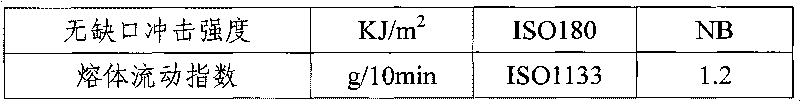

PP/PA composite material used for corrugated pipe and preparation method thereof

InactiveCN101724197ASolve heat resistanceSettle the priceFlexible pipesProcedure AgentsHeat resistance

The invention discloses a PP / PA composite material used for a corrugated pipe, which is prepared by processing polypropylene, nylon, compatilizer, toughening agent, filling master batch, light stabilizer, heat stabilizer and processing aid. The PP / PA composite material is prepared by feeding the components into mixing equipment according to a proportion, and melting, mixing, scattering, extruding and granulating the components at the temperature of between 210 and 280 DEG C. The PP / PA composite material not only has higher toughness, excellent high impact resistance and bending property and extremely good high temperature resistance, but also are excellent in the aspects of surface gloss, abrasion resistance, chemical corrosion resistance, electric insulation and the like, and solves the defect problems of insufficient heat resistance of the conventional PP corrugated pipe, over-high price of the PA corrugated pipe; and in addition, a preparation method for the PP / PA composite material is simple and meets the requirement of industrialized production.

Owner:SHANGHAI KINGFA SCI & TECH +1

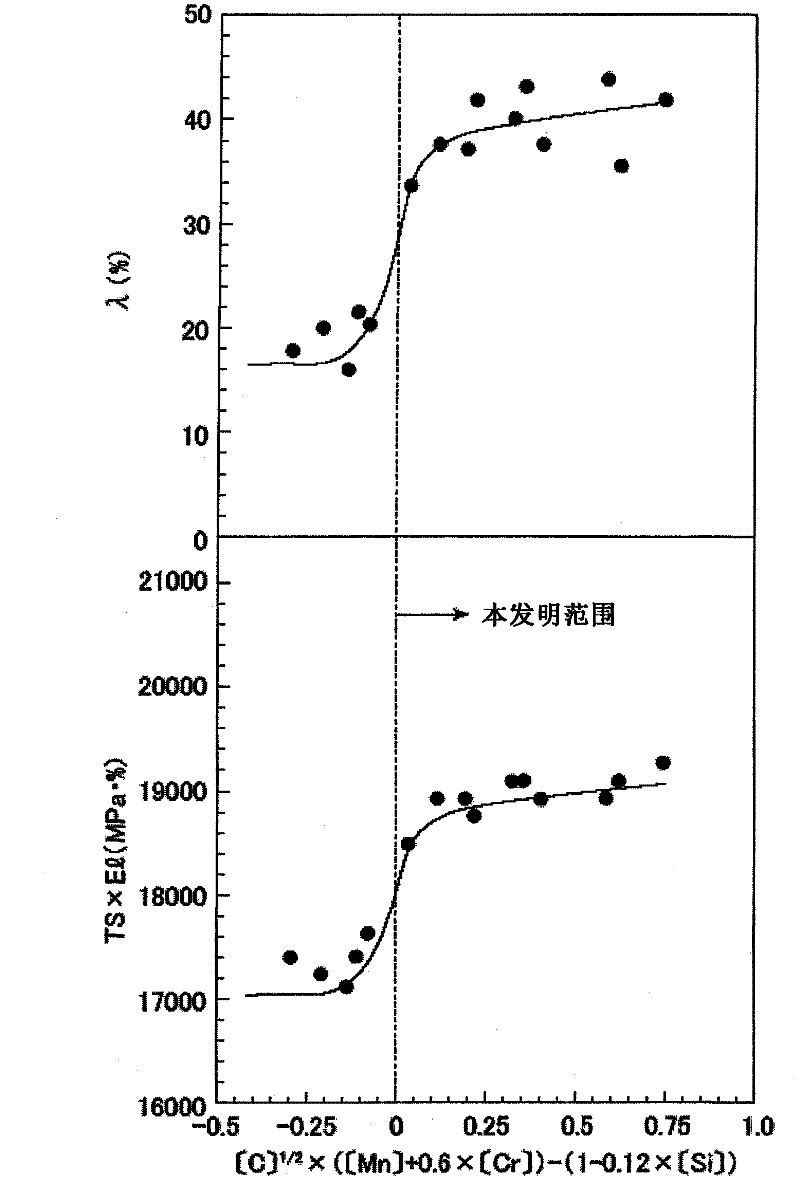

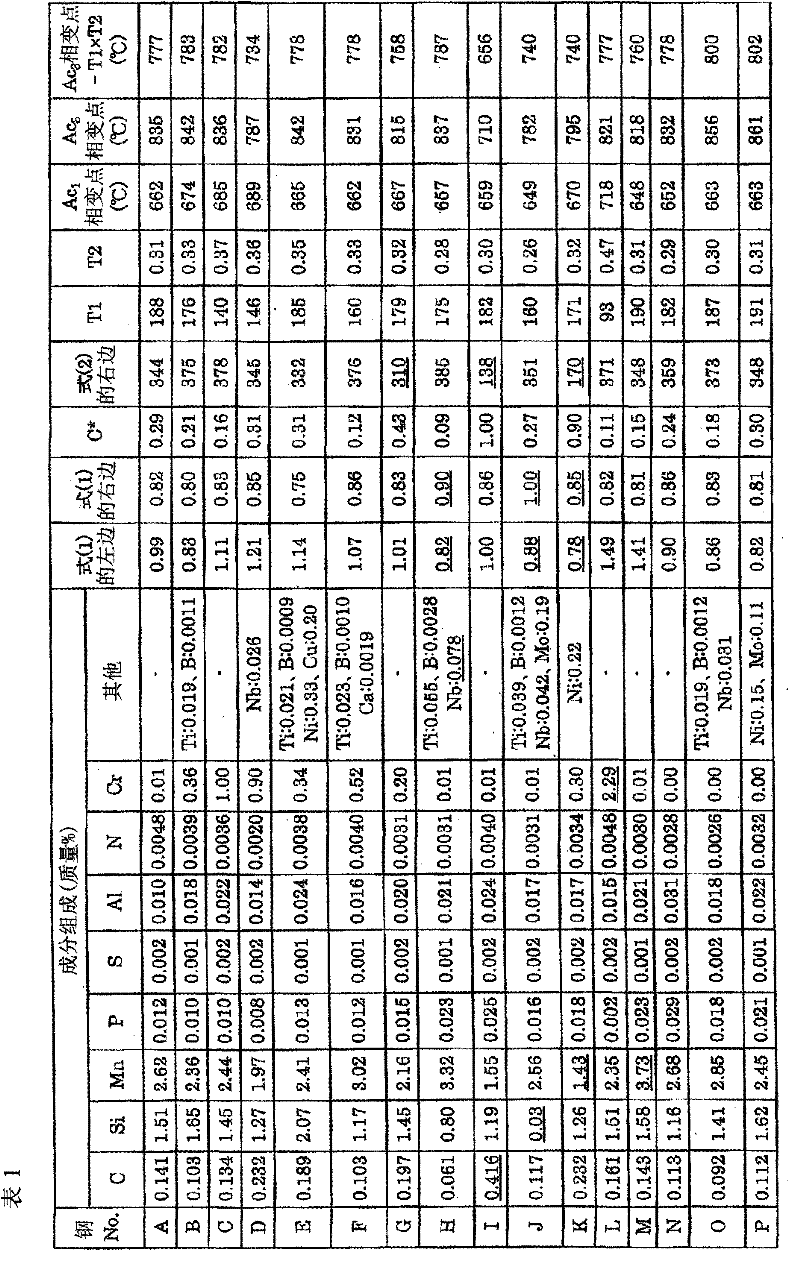

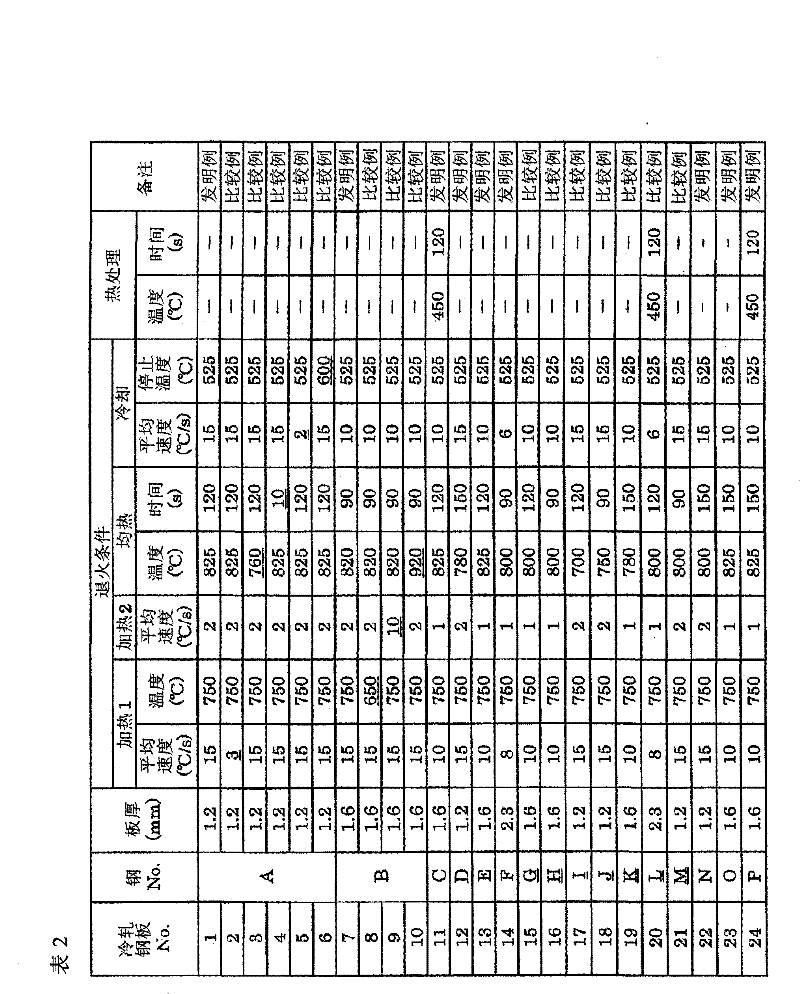

High-strength cold-rolled steel sheet having excellent workability, molten galvanized high-strength steel sheet, and method for producing same

ActiveCN102227511AExcellent hole expandabilityImprove bending performanceHot-dipping/immersion processesFurnace typesUltimate tensile strengthMartensite

The invention provides a high-strength cold-rolled steel sheet having a TS of 1,180 MPa or greater and excellent workability, such as stretch flange workability and bendability. Also provided are a molten galvanized high-strength steel sheet, and a method for producing the same. The high-strength cold-rolled steel sheet having excellent workability has a composition that comprises, by mass%, C: 0.05 to 0.3, Si: 0.5 to 2.5, Mn: 1.5 to 3.5, P: 0.001 to 0.05, S: 0.0001 to 0.01, Al: 0.001 to 0.1, N: 0.0005 to 0.01, and Cr: 1.5 or less (including 0) and satisfies formulas (1) and (2), with the balance being Fe and inevitable impurities. The steel sheet has a microtexture wherein there is a ferrite phase and a martensite phase, the percentage of the texture total surface area occupied by martensite phase is 30% or greater, (the surface area occupied by martensite phase) / (surface area occupied by ferrite phase) exceeds 0.45 but is less than 1.5, and the average particle diameter of the martensite phase is 2 microns or larger. [C]1 / 2*([Mn]+0.6*[Cr])> / =1-0.12*[Si] (1), and 550-350*C*-40*[Mn]-20*[Cr]+30*[Al]> / =340 (2), wherein C*=[C] / (1.3*[C]+0.4*[Mn]+0.45*[Cr]-0.75).

Owner:JFE STEEL CORP

Sole structure for a shoe

ActiveUS20060283045A1Improve buffering effectImprove bending performanceCarriage/perambulator accessoriesSolesEngineeringHeel

Owner:MIZUNO CORPORATION

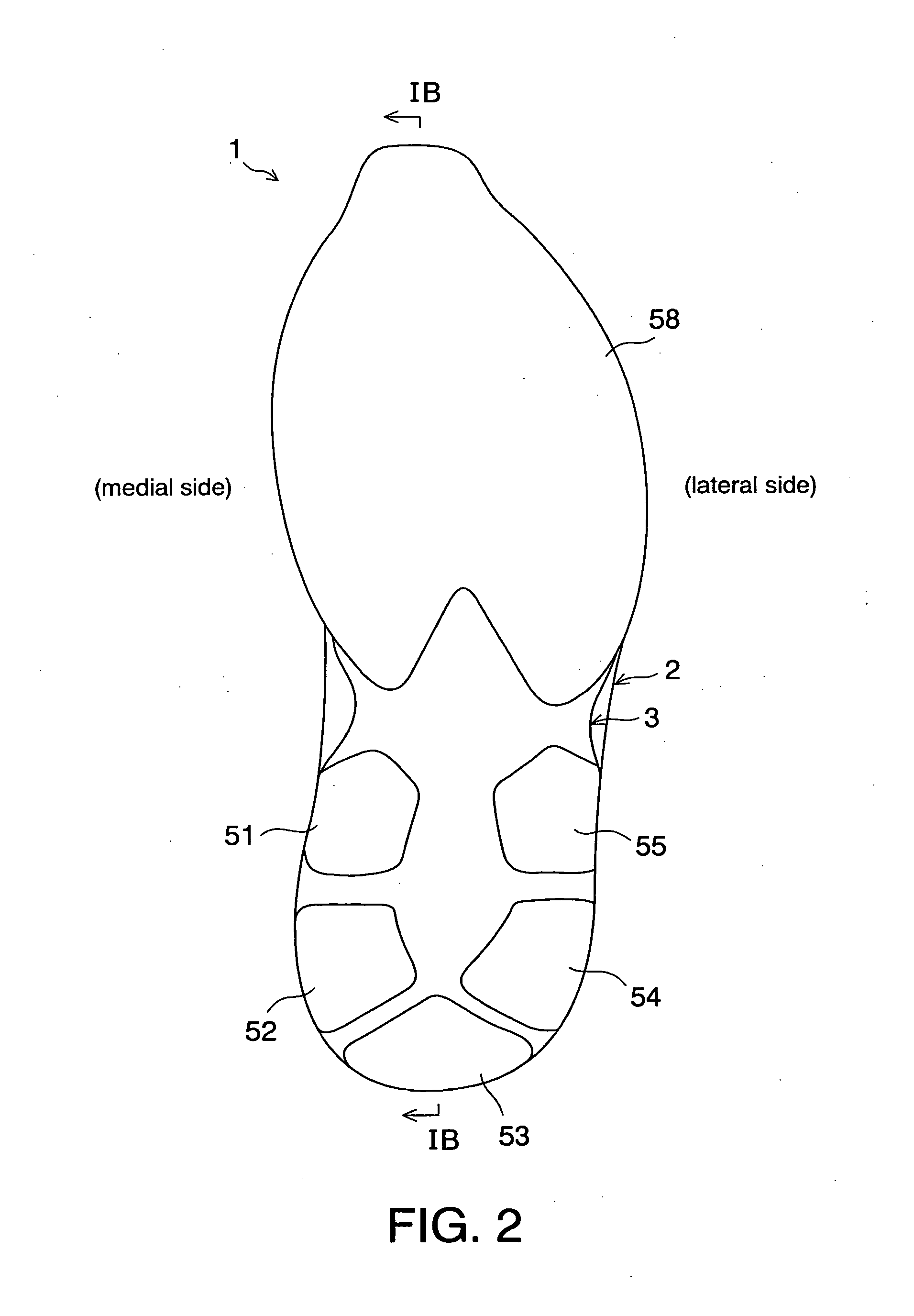

Implantable devices with reduced needle puncture site leakage

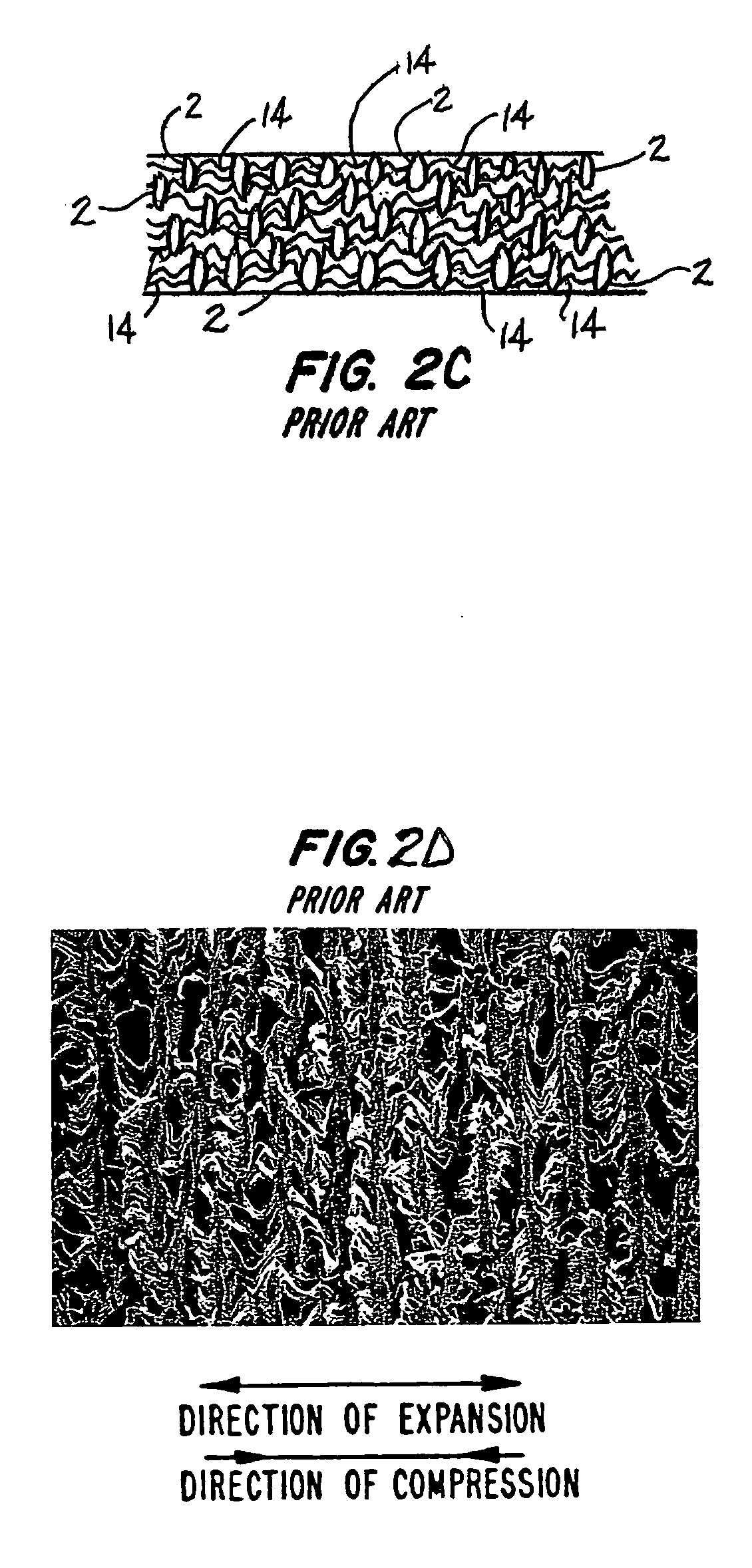

ActiveUS8029563B2Easy to handleIncrease resistanceSynthetic resin layered productsLaminationFiberSuturing needle

Owner:WL GORE & ASSOC INC

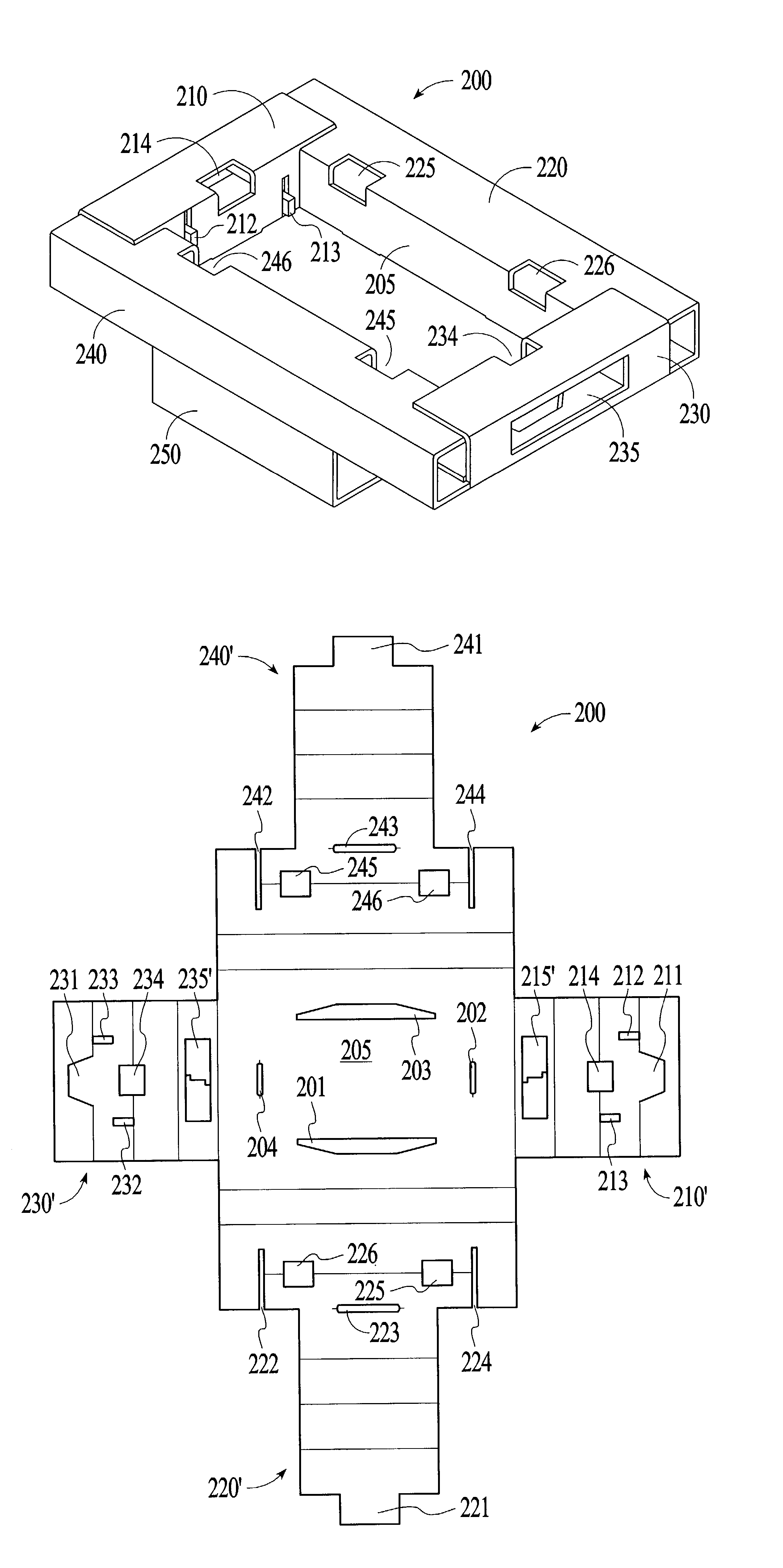

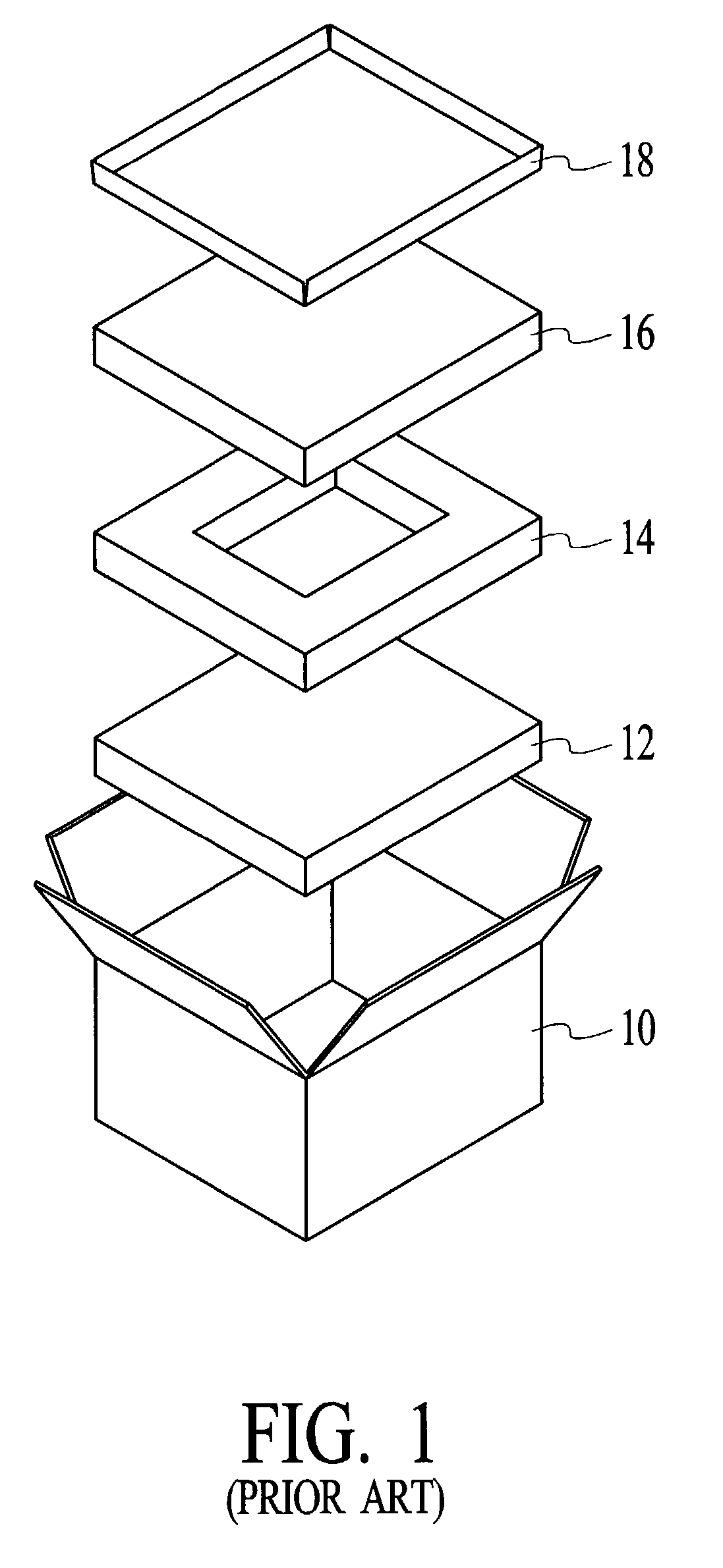

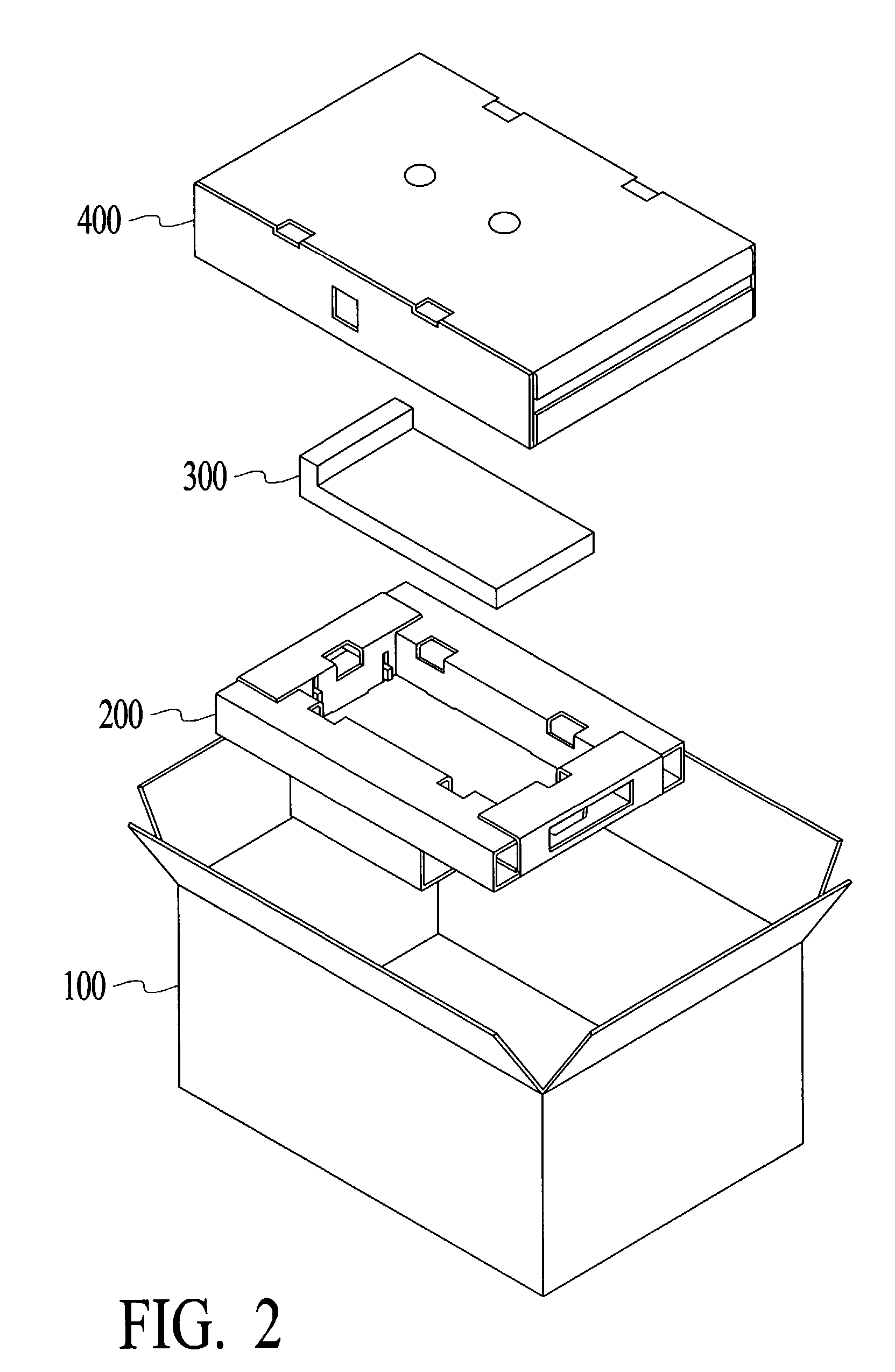

Packaging system for a component including a compressive and shock-absorbent packing insert

InactiveUS6997323B2Enhance flexing capabilityLow costPackaging vehiclesContainers for machinesEngineeringSurface plate

A packaging system for a component is disclosed. The packaging system comprises a box and a compressible and shock-absorbent packing insert. The packing insert is placed in the box after nesting a component within the insert. The insert comprises a main panel, a first end tube hingedly coupled to the main panel, a second end tube hingedly coupled to the main panel opposite the first end tube, a first side tube hingedly coupled to the main panel, the first side tube being adjacent to the first end tube and a second side tube hingedly coupled to the main panel, the second side tube being adjacent to the second end tube and opposite the first side tube wherein the first and second side tube panels and the first and second side tube panels may include at one or more cutouts to enhance the flexing capability of the packing insert. Accordingly, the packing insert in accordance with the present invention employs low cost, environment friendly material to protect fragile components from any potential damage that can be caused during the shipping process.

Owner:IBM CORP

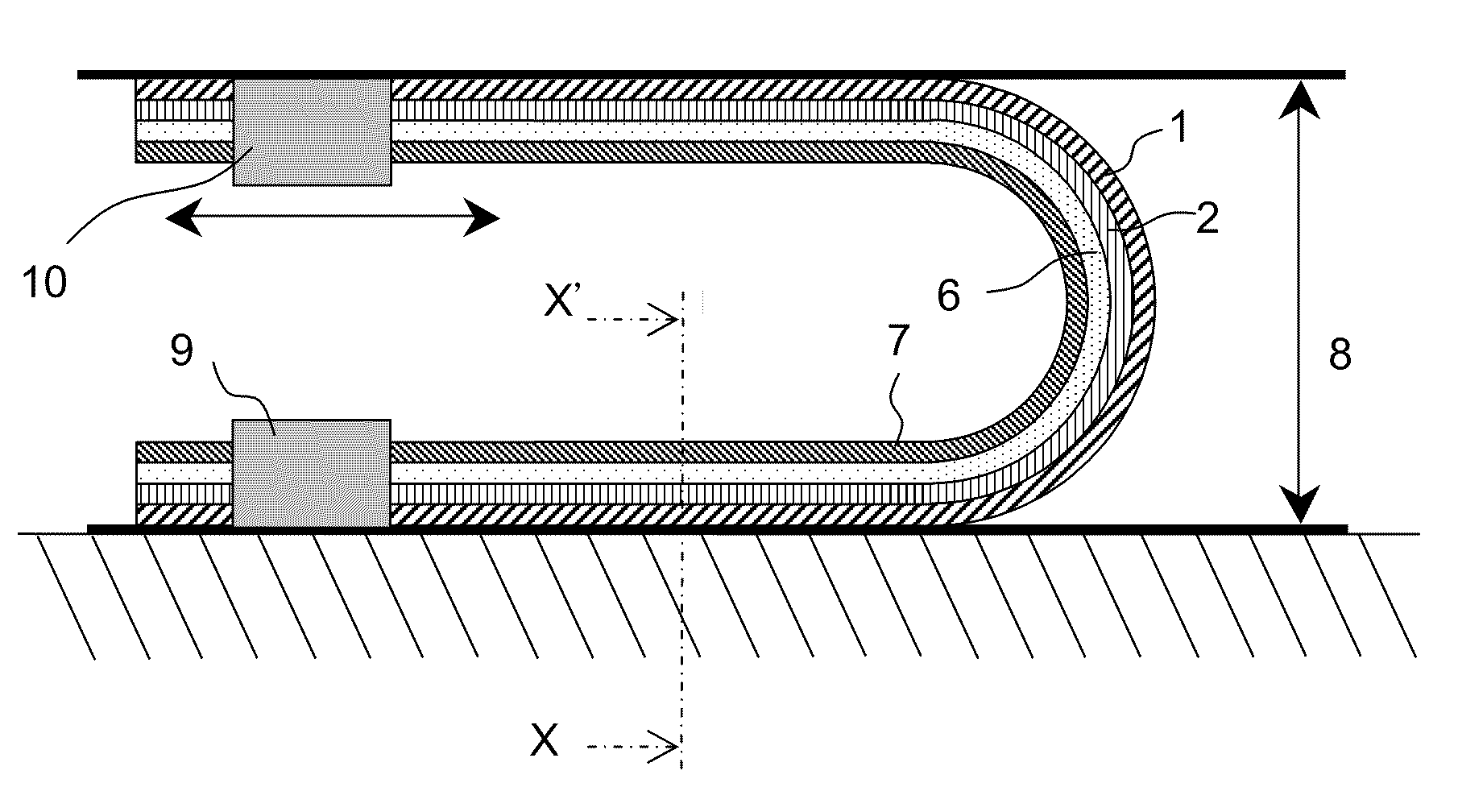

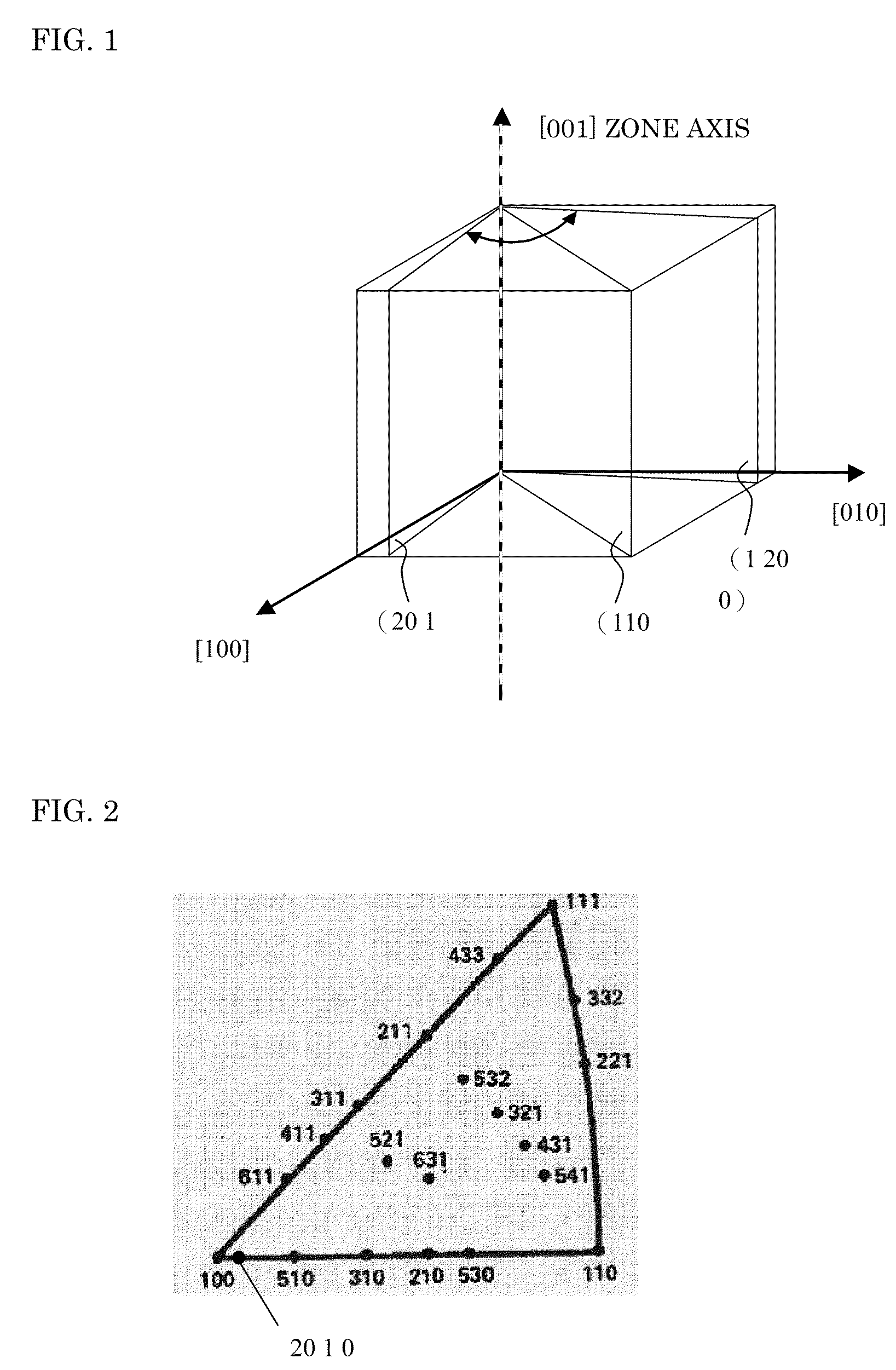

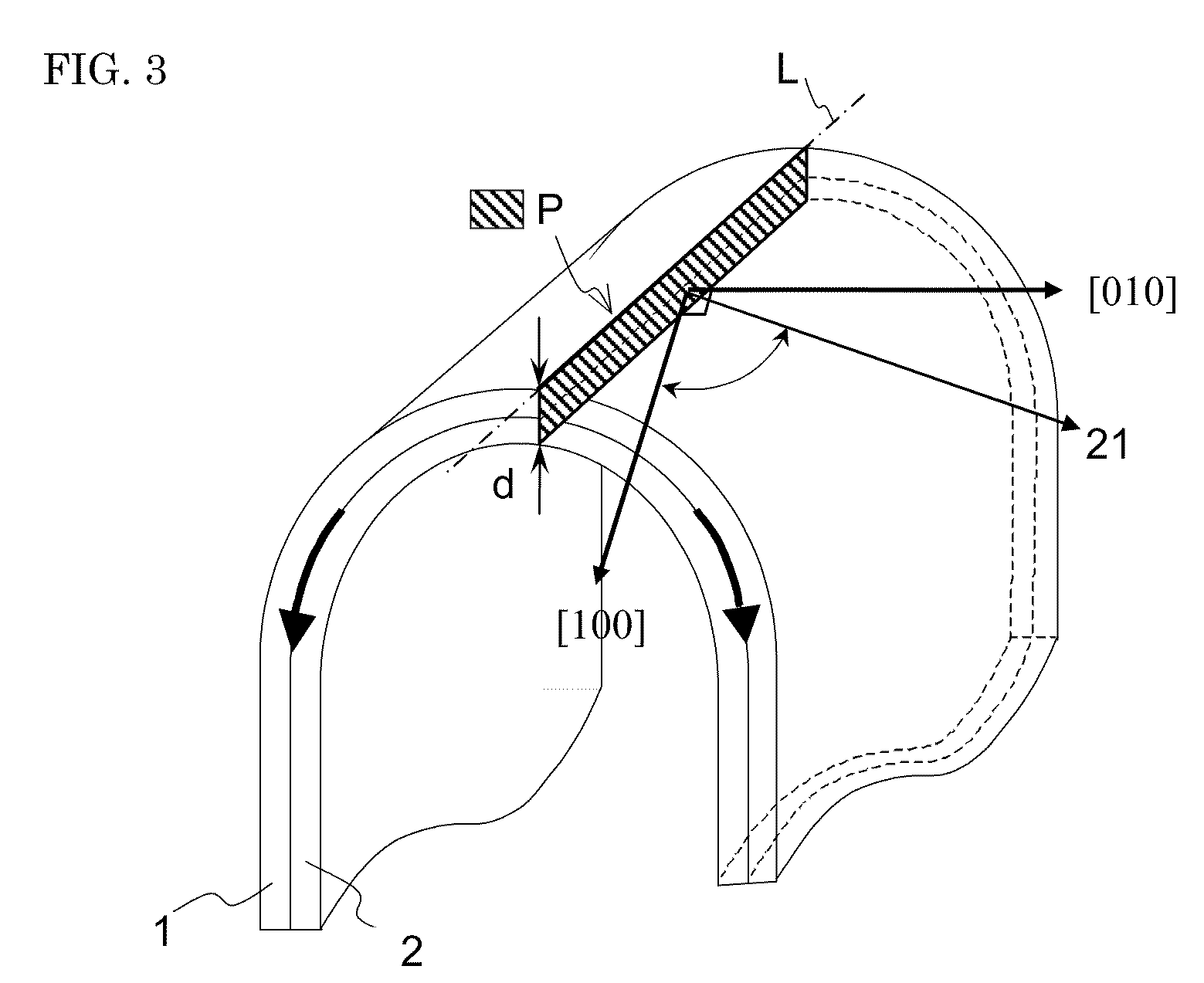

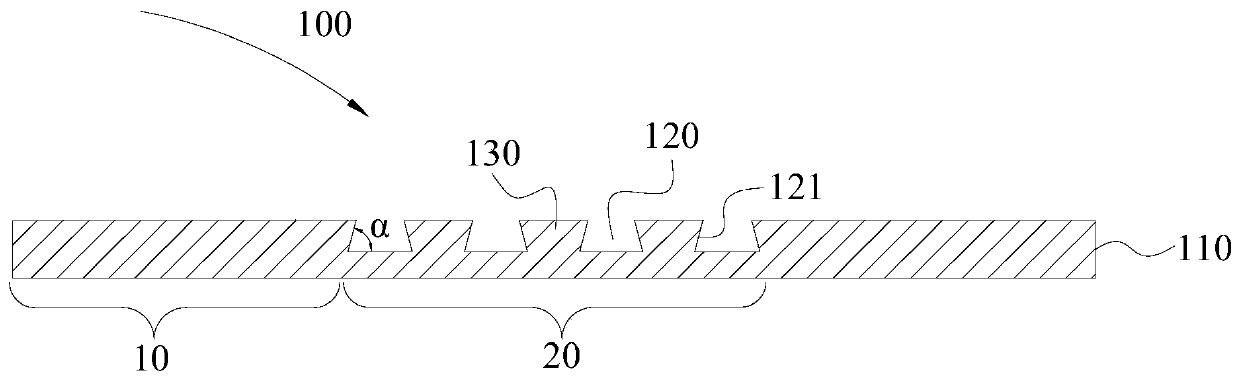

Flexible circuit board and method for producing same and bend structure of flexible circuit board

InactiveUS20110132643A1Improve bending performanceIncreased durabilityPrinted circuit aspectsConductive pattern formationFlexible circuitsMetal foil

Provided are a flexible circuit board with excellent bendability and durability against hard conditions particularly in a repeated bend portion having a small curvature radius, and a method of producing the same. The flexible circuit board includes a resin layer and a wiring formed of a metal foil and is used with a bend portion provided at least one position of the wiring. The metal foil is made of a metal having a cubic crystal structure, and a cross section of the wiring cut in a thickness direction from a ridge line in the bend portion forms a principal orientation on any one of planes within a range of (20 1 0) to (1 20 0) in a rotation direction from (100) to (110) with [001] set as a zone axis. The wiring is formed so that the metal foil is made of a metal having a cubic crystal structure, and that the ridge line in the bend portion has an angle in a range of 2.9° to 87.1° relative to one of fundamental crystal axes <100> in a surface of the metal foil.

Owner:NIPPON STEEL CHEMICAL CO LTD

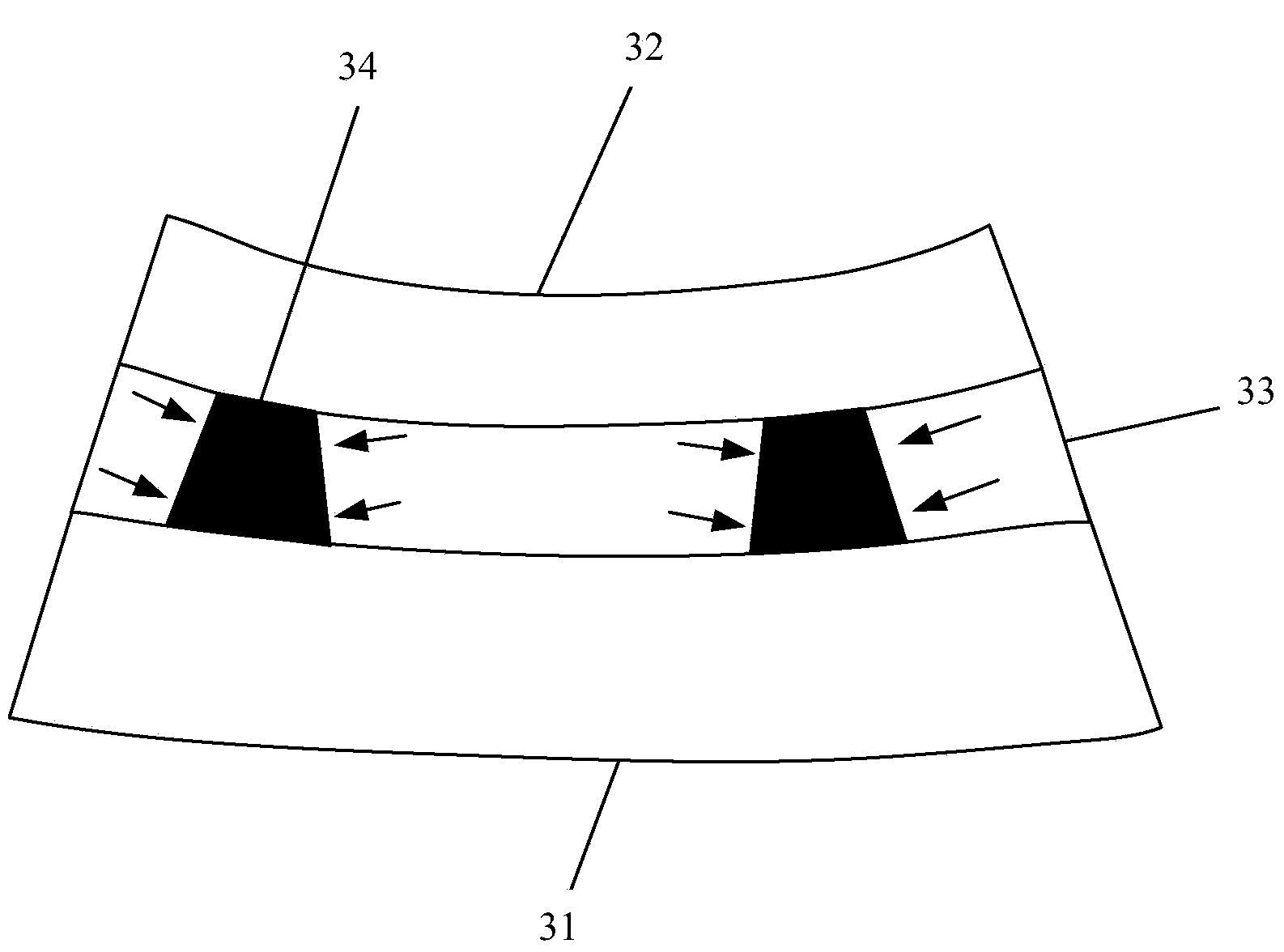

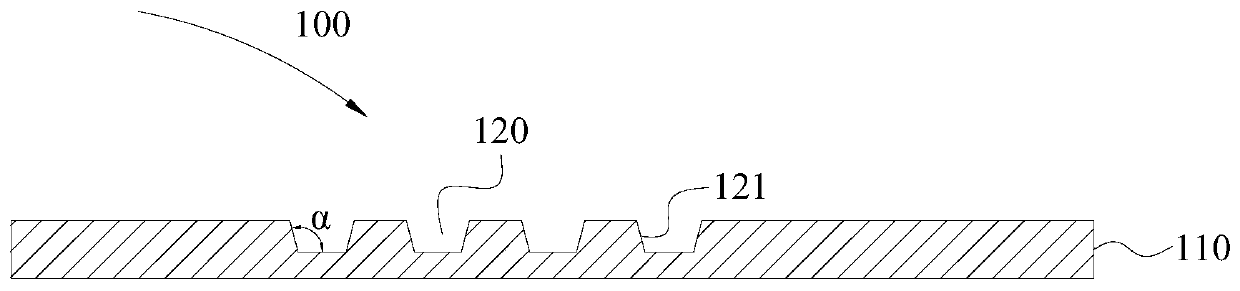

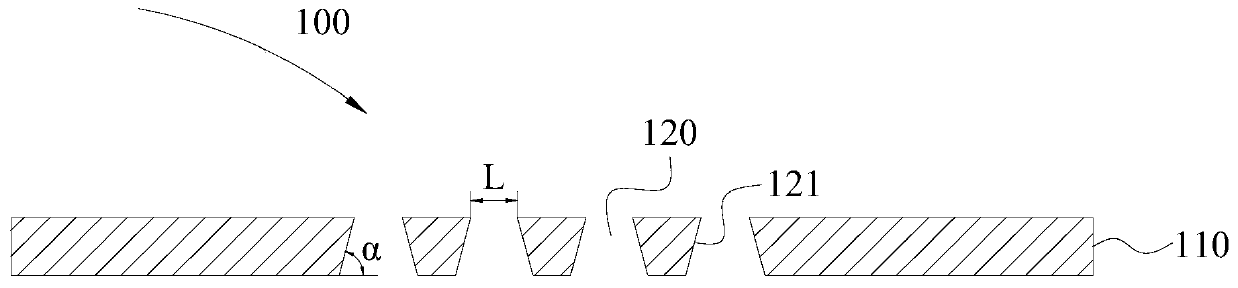

Foldable supporting piece and preparation method and display device

PendingCN110767098AImprove stress concentrationImprove bending performanceDetails for portable computersIdentification meansEngineeringMechanical engineering

The invention discloses a foldable supporting piece and a preparation method and a display device. The foldable supporting piece comprises a metal layer, wherein the metal layer comprises a non-bending region and at least one bending region; the part, located in the bending region, of the metal layer has a plurality of concave parts; and at least one sidewall of the concave parts are not perpendicular to the plane where the metal layer is located. Therefore, the foldable supporting piece can provide a high plane support function for a flexible display panel, in particular to provide high support for the bending region of the flexible display panel, and the overall anti-extrusion capability of the flexible display panel is improved; and meanwhile, the bending performance of the foldable supporting part and the performance of flatness recovery after bending are effectively improved, the problem of peeling of the flexible display panel and the foldable supporting piece can be effectivelyimproved, and the problem of creasing of the foldable supporting piece can be solved.

Owner:BOE TECH GRP CO LTD

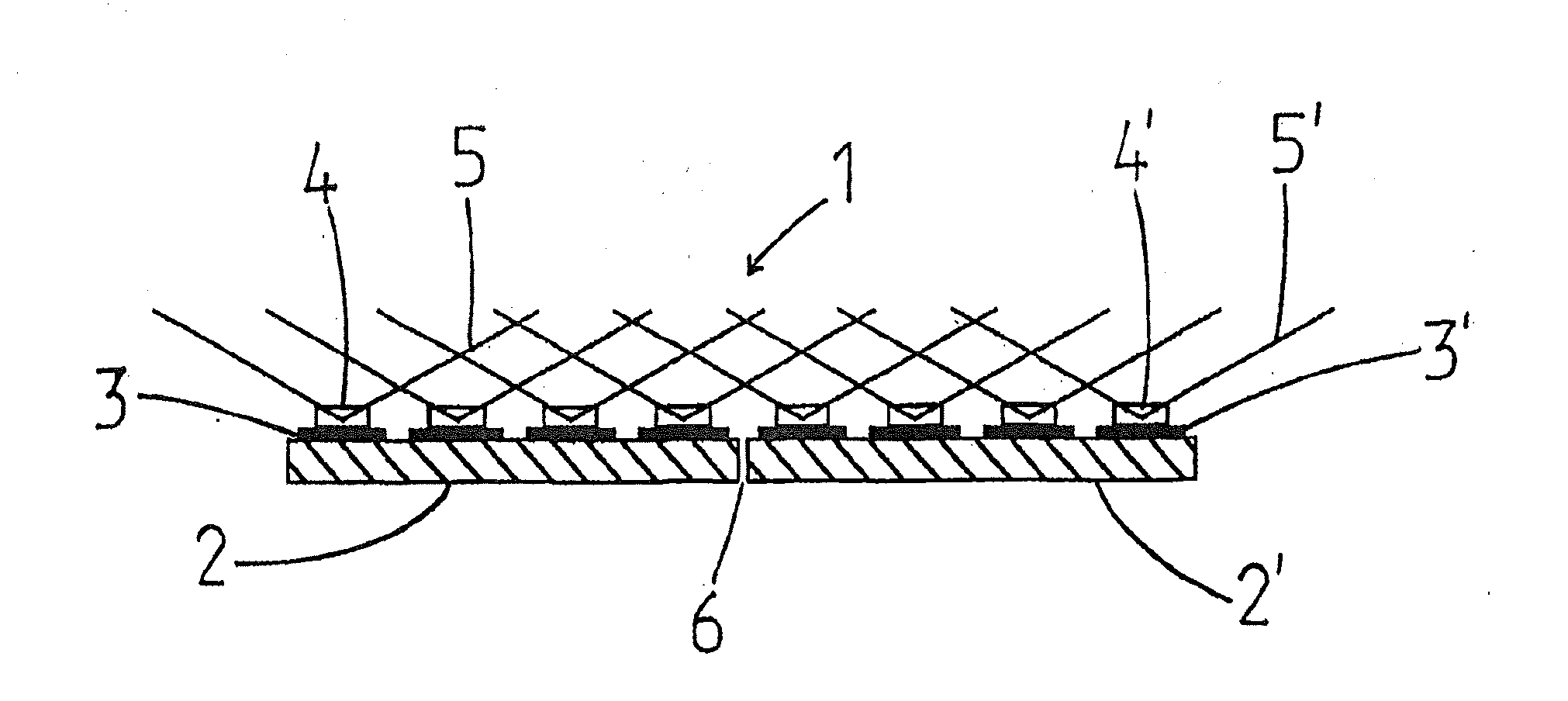

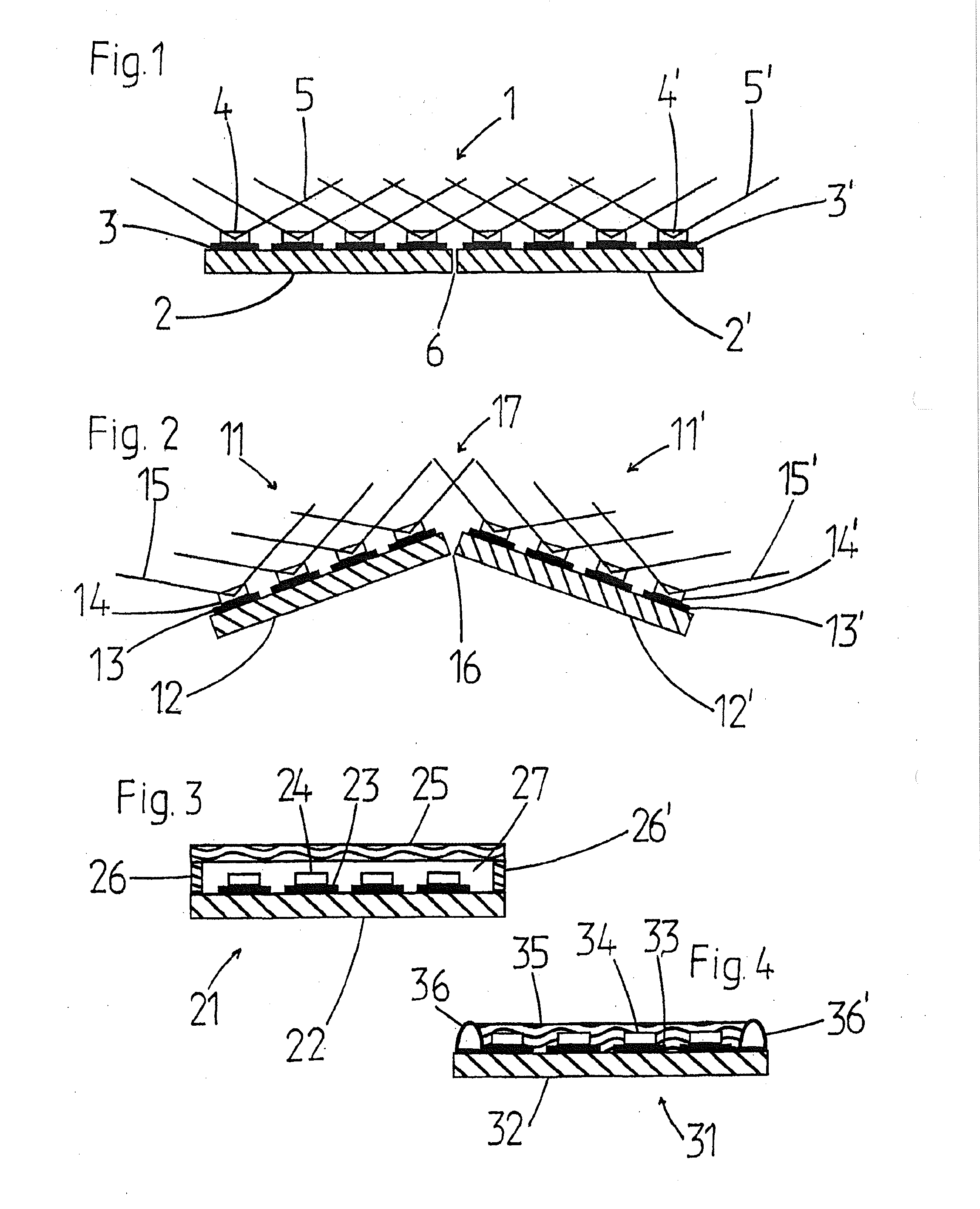

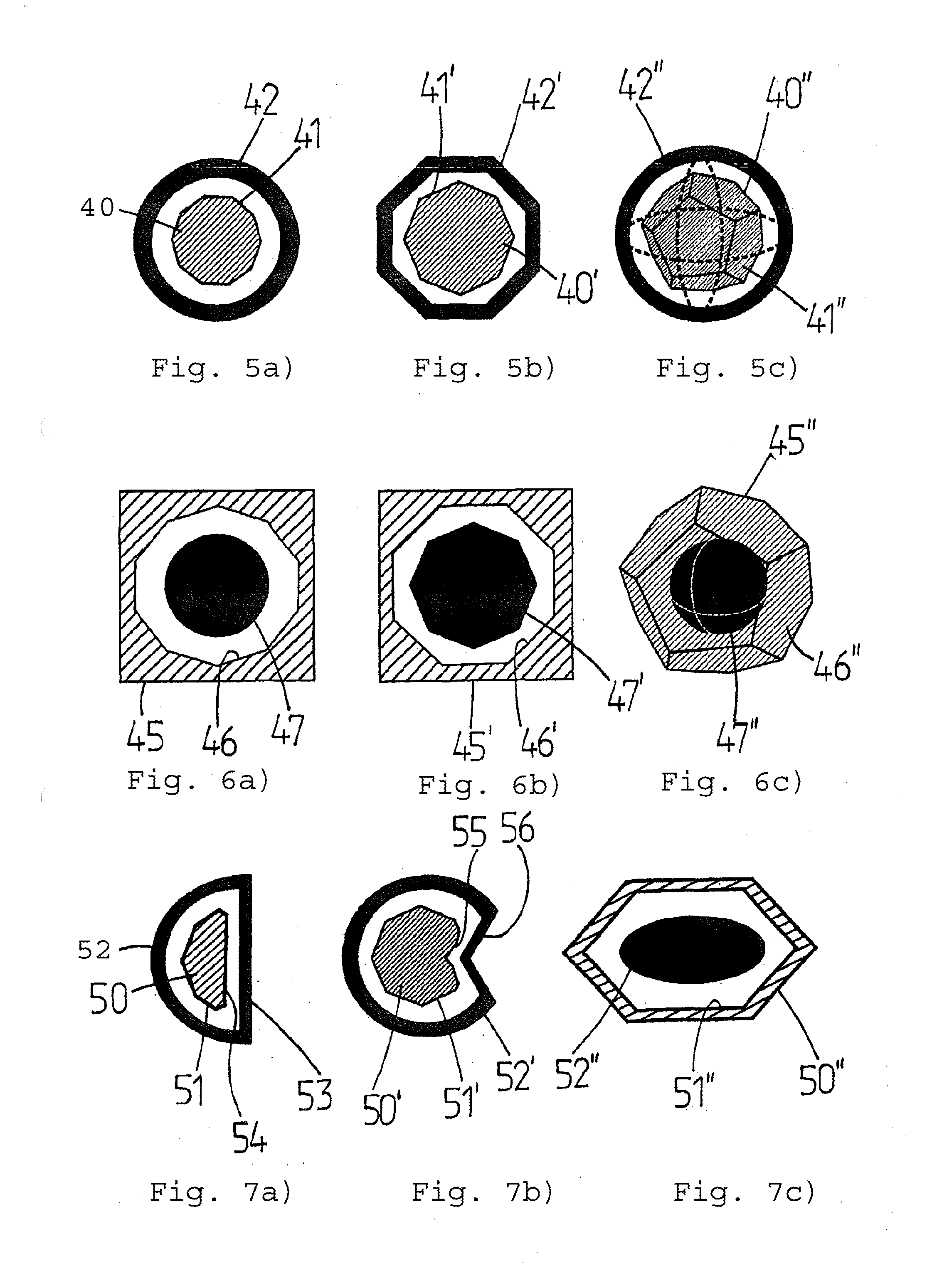

LED lamp for homogeneously illuminating hollow bodies

ActiveUS20130010460A1Small intensityReduce overlapNon-electric lightingPoint-like light sourceEngineeringOn board

A lighting device (40-40″, 45-45″, 50-50″, 60, 80, 93-93″) is provided for the uniform illumination of curved, uneven, or polyhedral surfaces. The lighting device has a plurality of flat chip-on-board LED modules (1, 11, 11′, 21, 31, 41-41″, 46-46″, 51-51″, 61-61″, 71-71′″, 811-818), which are arranged adjacent to each other at least in pairs. Each chip-on-board LED module (1, 11, 11′, 21, 31, 41-41″, 46-46″, 51-51″, 61-61″, 71-811-818) has a plurality of light-emitting LEDs (4, 4′, 14, 14′, 24, 34, 64, 72). The lighting device (40-40″, 45-45″, 50-50″, 60, 80, 93-93″) is characterized by at least one pair of the adjacent chip-on-board LED modules (1, 11, 11′, 21, 31, 41-41″, 46-46″, 51-51″, 61-61″, 71-71′″, 811-818) being arranged at an angle greater than 0° with respect to the surface normals of the modules.

Owner:HERAEUS NOBLELIGHT GMBH

OLED (organic light emitting diode) display

ActiveCN106328825AImprove bending performanceReduce the number of layersSolid-state devicesSemiconductor/solid-state device manufacturingChemical reactionOxygen

The invention provides an OLED (organic light emitting diode) display. A thin film packaging layer of the OLED display comprises inorganic passivation layers, organic buffer layers and moisture / oxygen quenching layers. Stacking structures are jointly formed by the inorganic passivation layers and the organic buffer layers, and each moisture / oxygen quenching layer is a first moisture / oxygen quenching layer positioned between the corresponding stacking structure and an OLED layer or a second moisture / oxygen quenching layer positioned between the two corresponding inorganic passivation layers in the corresponding stacking structure or a combination of the first moisture / oxygen quenching layer and the second moisture / oxygen quenching layer. The OLED display has the advantages that damage of OLED devices due to moisture / oxygen can be effectively prevented by means of physical adsorption or chemical reaction under synergistic effects of the moisture / oxygen quenching layers, the inorganic passivation layers and the organic buffer layers in the thin film packaging layer on the premise that the light emitting performance of the OLED devices is unaffected, accordingly, the service lives of the OLED devices can be prolonged, and effects of releasing stress of the inorganic passivation layers further can be realized; the numbers of layers of the thin film packaging layer and the thickness of the thin film packaging layer are reduced, accordingly, the thickness of the OLED display can be integrally reduced, and the bending performance of the flexible OLED display can be enhanced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Sole structure for a shoe

A sole structure is provided that can improve cushioning and bending properties of the sole heel portion. The sole assembly 1 is formed of an upper plate 2 disposed on the upper side of the heel portion H, a wavy lower plate 3 provided below the upper plate 2 in the heel portion H and having at least two convex portions 30, 31 that protrude downwardly and that are adapted to form voids C relative to the upper plate 2, and a plurality of outsole portions 51-55 that are divided in the longitudinal direction and that are attached to the lower surfaces of the convex portions 30, 31 of the lower plate 3.

Owner:MIZUNO CORPORATION

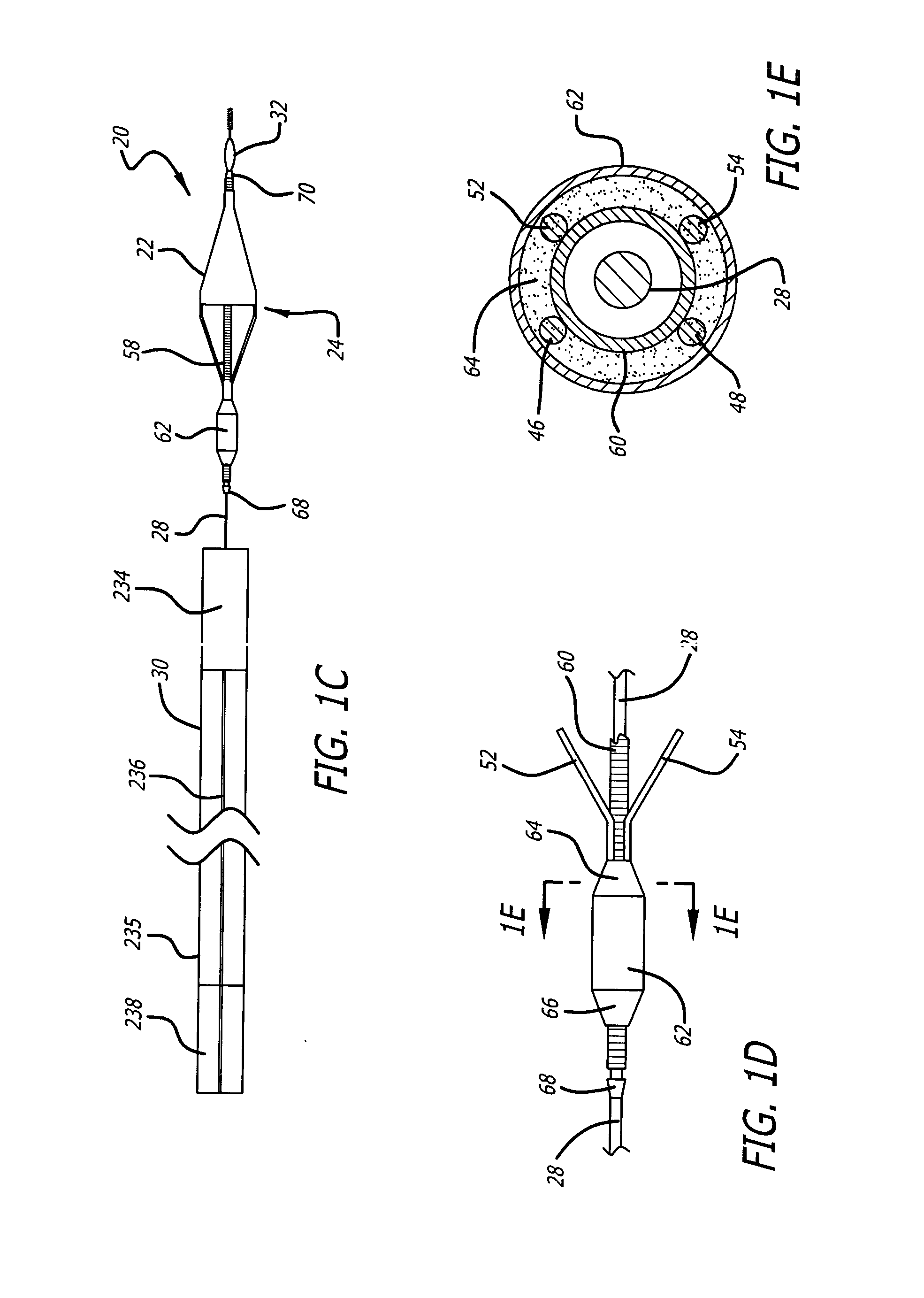

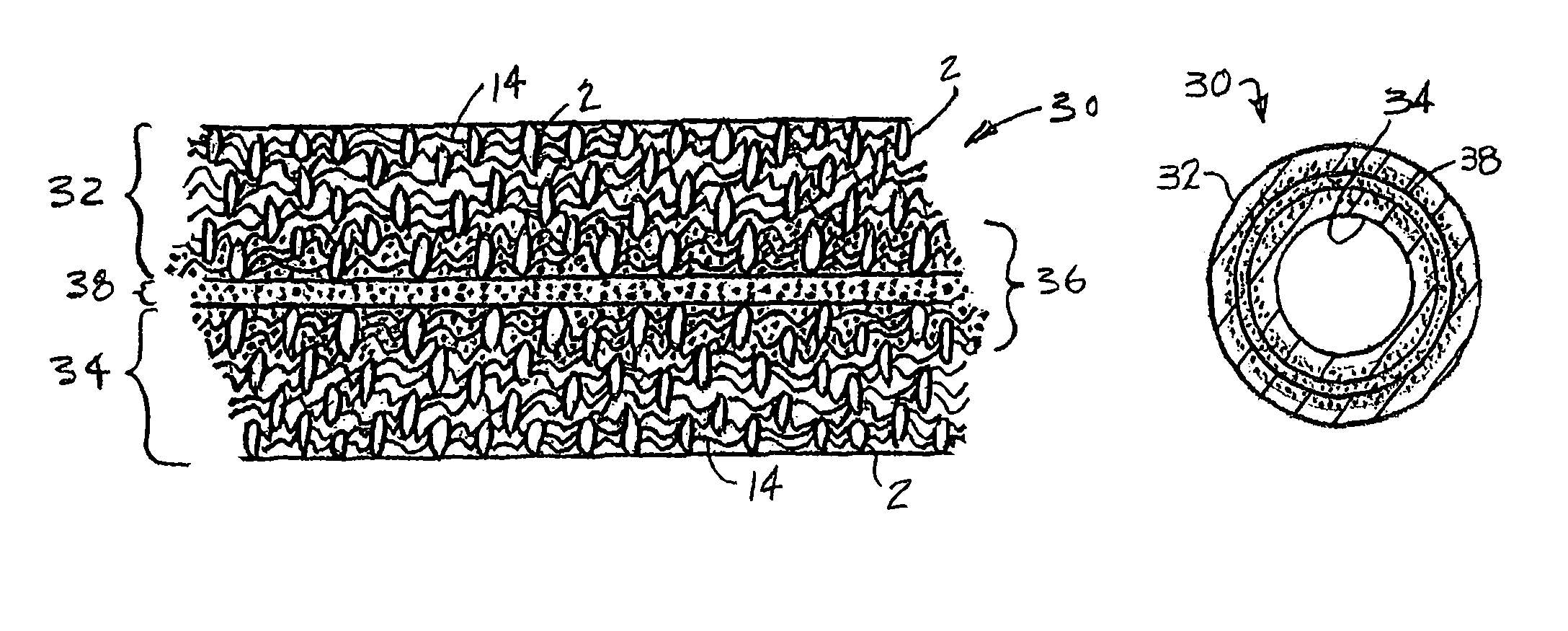

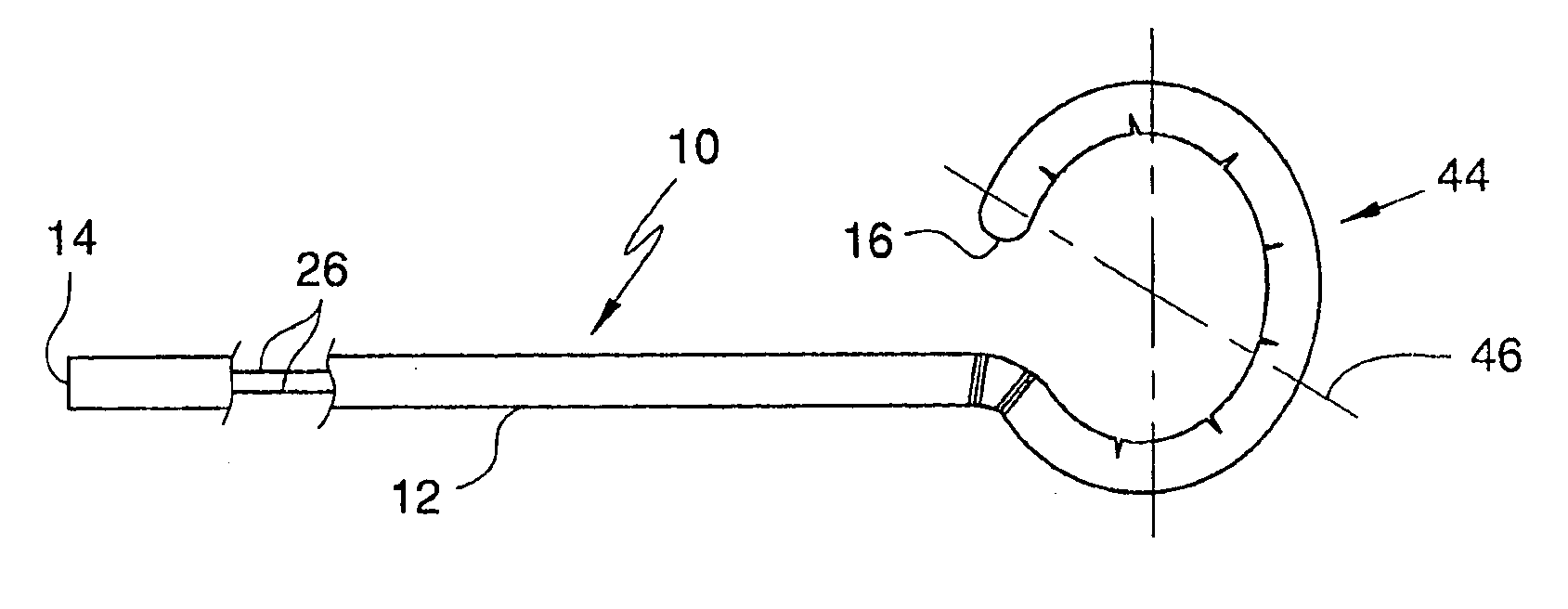

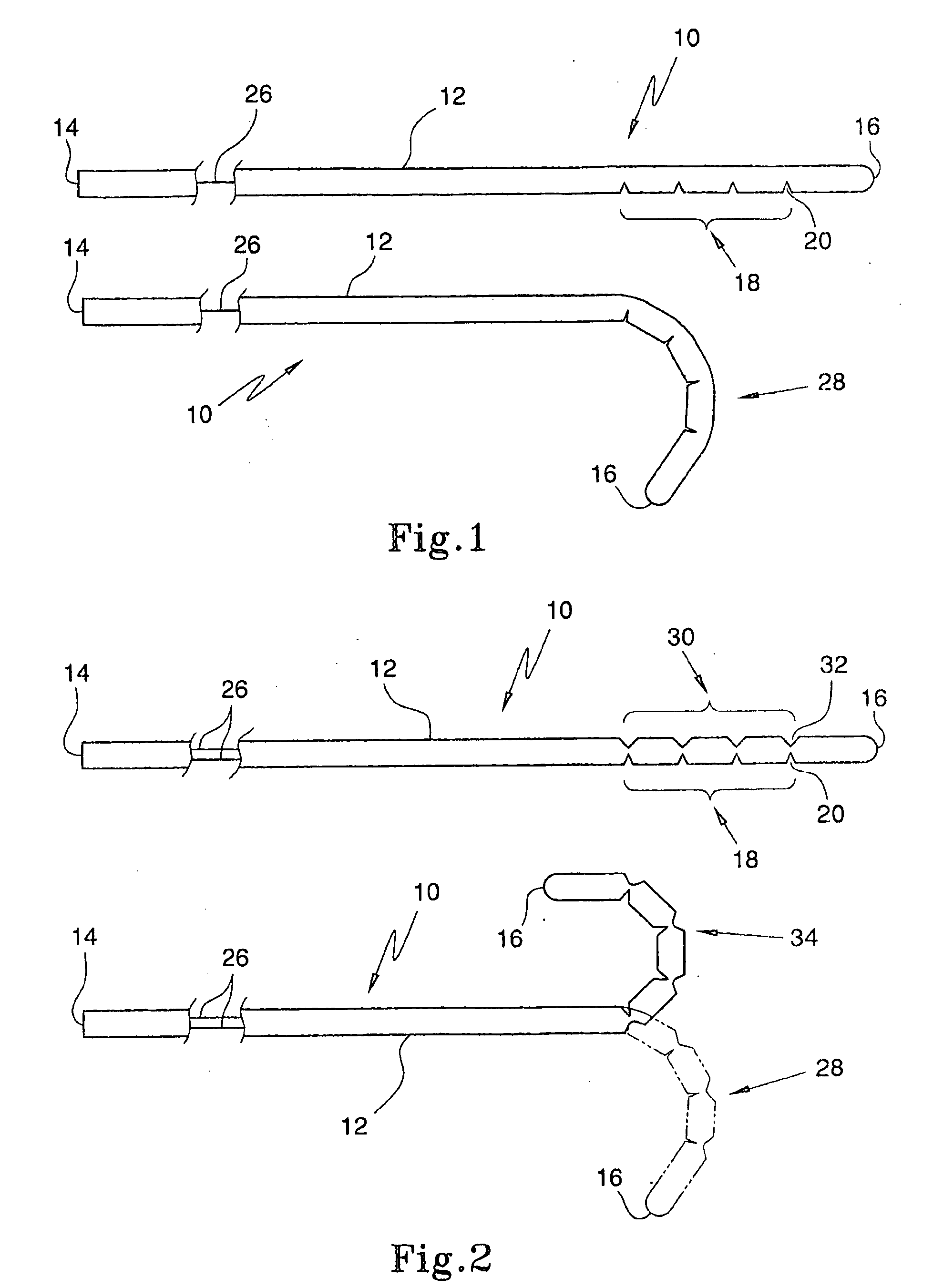

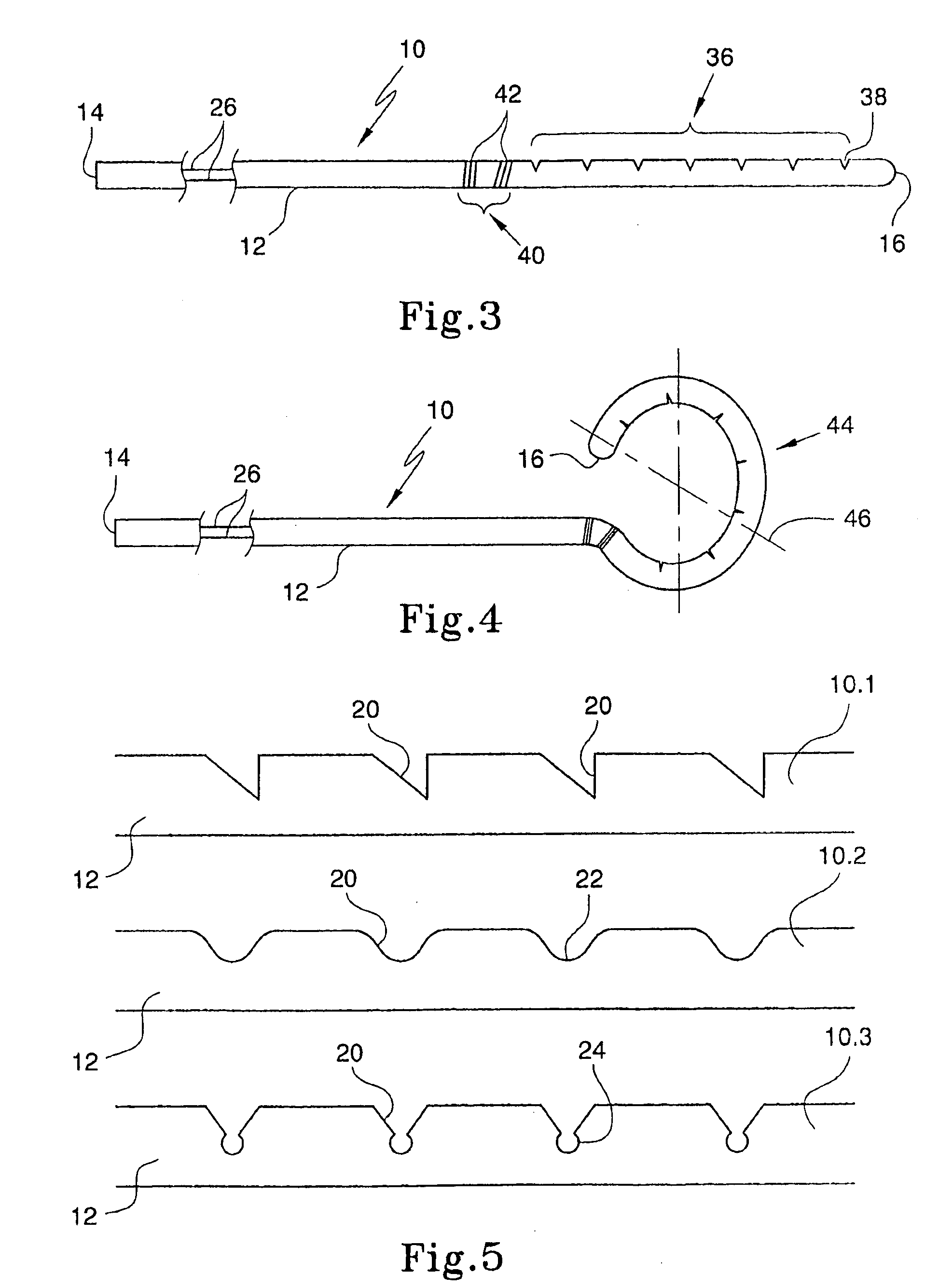

Catheter Steering Device

InactiveUS20080319418A1Help shapeImprove bending performanceElectrocardiographyTransvascular endocardial electrodesBiomedical engineeringCatheter device

A catheter steering and shape forming device (10) comprises an clongate element (12) having a proximal end (14) and a distal end (16) and defining a longitudinal axis. A plurality of longitudinally spaced, transversely extending notches (20) is formed in the clongate element (12, the notches (20) having non-parallel sides and the notches (20) being arranged in at least one group (18) proximate the distal end (16) of the clongate element (12).

Owner:CATHRX LTD

Copper alloy plate for electric and electronic parts having bending workability

ActiveUS20090010797A1Improvement and stabilization of bendabilityUniform deformationSemiconductor/solid-state device detailsPrinted circuit aspectsMicrostructureHigh intensity

A Cu—Fe—P copper alloy sheet which has the high strength and the high electrical conductivity compatible with excellent bendability is provided. The Cu—Fe—P copper alloy sheet contains 0.01% to 3.0% of Fe and 0.01% to 0.3% of P on a percent by mass basis wherein the orientation density of the Brass orientation is 20 or less and the sum of the orientation densities of the Brass orientation, the S orientation, and the Copper orientation is 10 or more and 50 or less in the microstructure of the copper alloy sheet.

Owner:KOBE STEEL LTD

Copper Alloy Having High Strength, High Electric Conductivity and Excellent Bending Workability

InactiveUS20090101243A1High strengthImprove bending performanceConductive materialContactsMagnificationHigh intensity

The present invention relates to a copper alloy having high strength, high electrical conductivity, and excellent bendability, the copper alloy containing, in terms of mass %, 0.4 to 4.0% of Ni; 0.05 to 1.0% of Si; and, as an element M, one member selected from 0.005 to 0.5% of P, 0.005 to 1.0% of Cr, and 0.005 to 1.0% of Ti, with the remainder being copper and inevitable impurities, in which an atom number ratio M / Si of elements M and Si contained in a precipitate having a size of 50 to 200 nm in a microstructure of the copper alloy is from 0.01 to 10 on average, the atom number ratio being measured by a field emission transmission electron microscope with a magnification of 30,000 and an energy dispersive analyzer. According to the invention, it is possible to provide a copper alloy having high strength, high electrical conductivity, and excellent bendability.

Owner:KOBE STEEL LTD

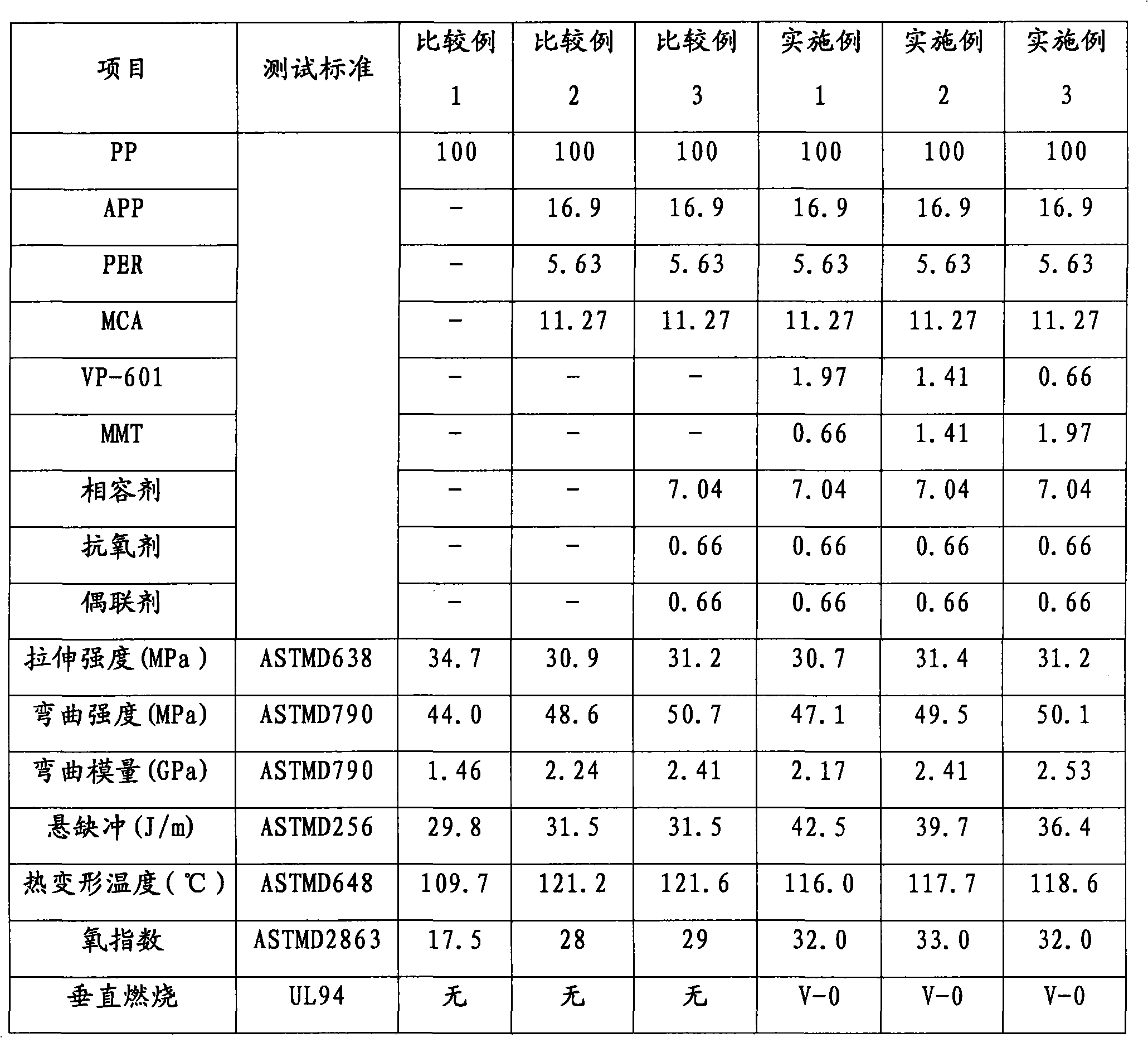

Expansion flame-proof polypropelene composition and preparation method thereof

The invention relates to an expansive flame-retardant polypropylene composition and a production method thereof. The composition comprises the following components: 100 weight parts of polypropylene, 10-30 weight parts of ammonium polyphosphate, 3.3-10 weight parts of pentaerythritol, 6.6-20 weight parts of melamine cyanurate, 0.5-5 weight parts of silicone rubber and 0.5-5 weight parts of montmorillonite. The total additional amount of ammonium polyphosphate, pentaerythritol and melamine cyanurate is at least 31 weight parts. The production method comprises the following steps: proportioning the components according to the weight parts, melting, mixing, extruding, and granulating. The composition has better flame retardation, good processability and mechanical property. The production method is simple and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

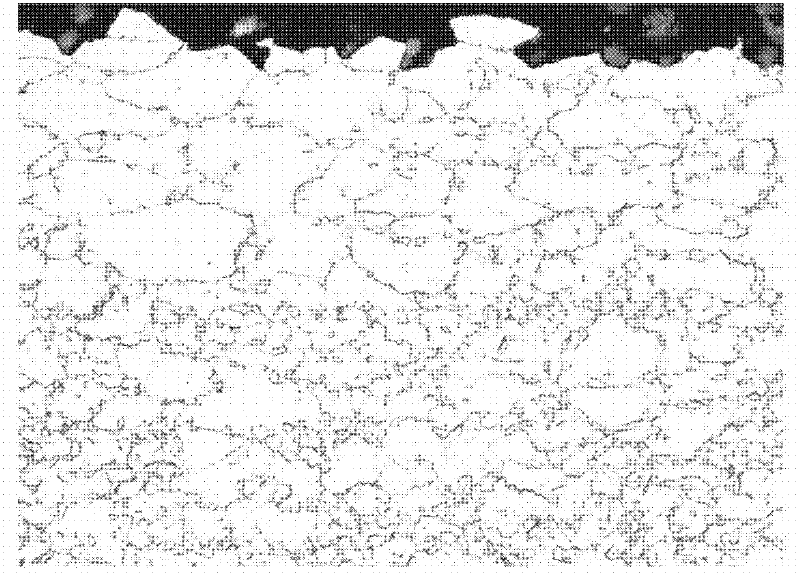

High-strength hot-dip galvanized steel sheet and process for producing same

ActiveCN102482753AImprove fatigue durabilityExcellent resistance to hydrogen embrittlementHot-dipping/immersion processesFurnace typesSoft layerHigh intensity

Disclosed is a hot-dip galvanized steel sheet which comprises a steel sheet part and a deposit formed on the surface of the steel sheet part and has a tensile strength of 770 MPa or higher, wherein the deposit is a zinc layer formed by hot-dip plating or an alloyed zinc layer formed by hot-dip plating, the steel sheet part comprises a soft layer, which is in direct contact with the deposit, and an inner layer, which is the part other than the soft layer, and the thickness (D) of the soft layer is 0.001 to 5% of the thickness (t) of the steel sheet part. In a cross-section along the thickness direction of the steel sheet part, when the hardness of the soft layer measured by a nanoindentation method is expressed by H1 and the representative hardness of the steel sheet part measured by the nanoindentation method is expressed by Ha, then H1 is 5-75% of Ha.

Owner:NIPPON STEEL CORP

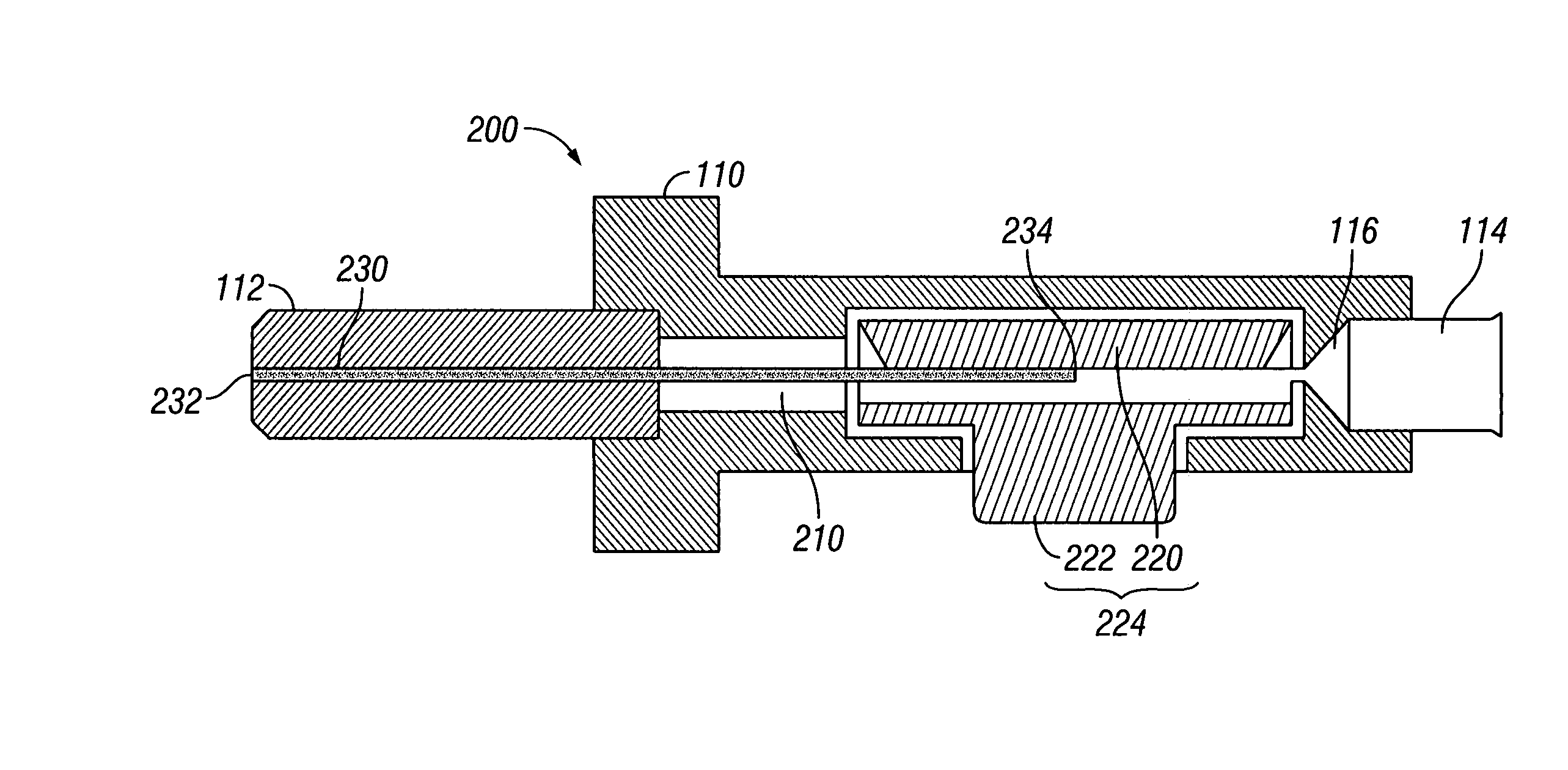

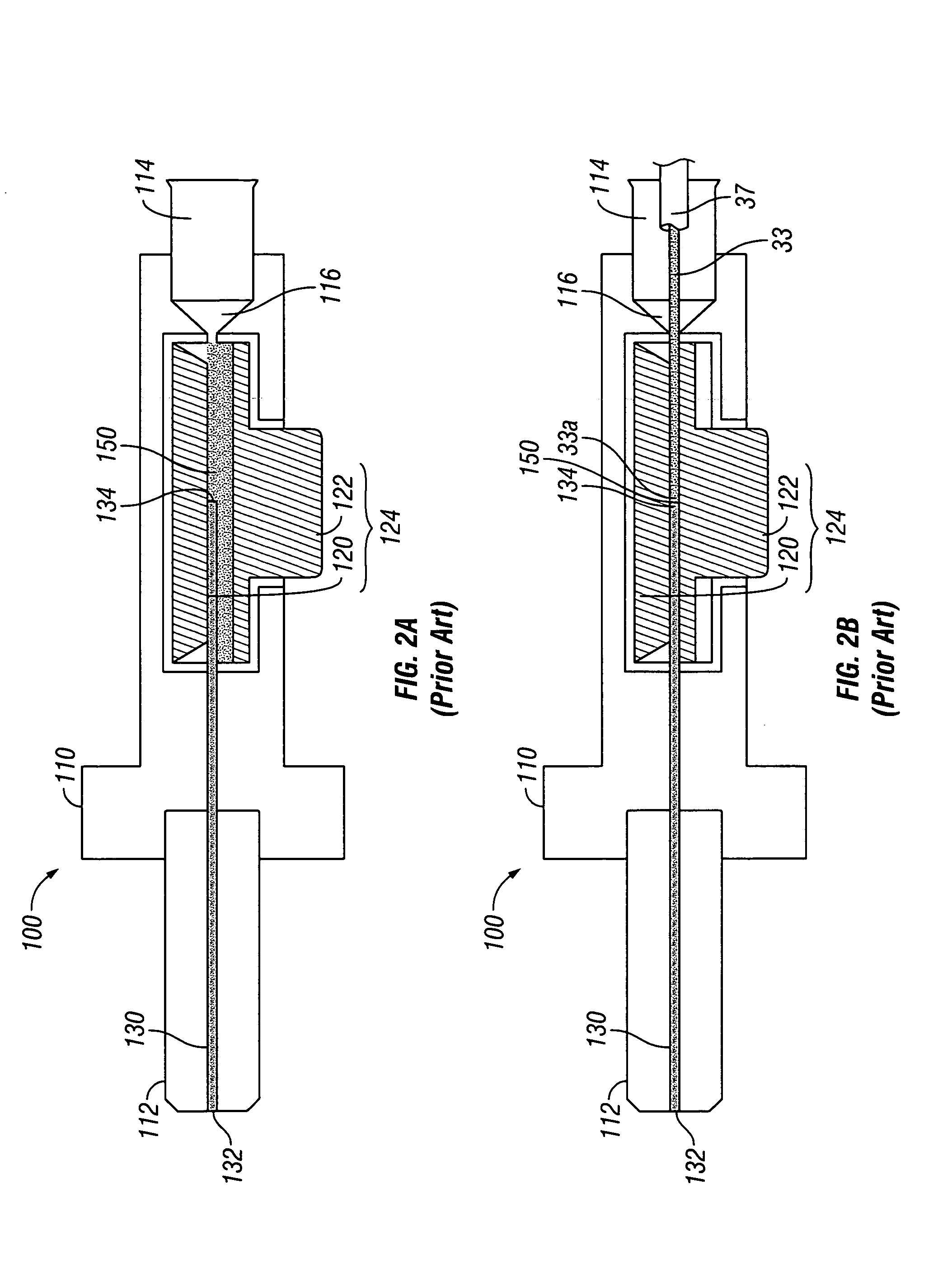

Optical fiber mechanical splice connector

ActiveUS20080019646A1Robust and reliable connectorPrecise alignmentCoupling light guidesFiberMechanical splice

An optical fiber mechanical splice connector including a connector body having a fiber alignment mechanism and a cavity, and a ferrule including a stub fiber, wherein an end of the stub fiber extends from the ferrule through the cavity of the connector body and into the fiber alignment mechanism, and wherein the stub fiber buckles within the cavity when a field fiber is introduced into the connector body and contacts the distal end of the stub fiber. A mechanical splicing method including inserting a field fiber into a splice connector such that an end of the field fiber contacts an end of the stub fiber within an alignment mechanism of the splice connector, and applying axial force to the field fiber so as to cause the stub fiber to buckle within a cavity defined by the splice connector.

Owner:CORNING OPTICAL COMM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com