Flexible display panel, production method for same, and flexible display device

A flexible display and manufacturing method technology, which is applied in the direction of identification devices, instruments, semiconductor devices, etc., can solve the problems of poor bendability, fracture, and poor bendability of flexible display panels, so as to avoid glue layer breakage, good bendability, and good bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

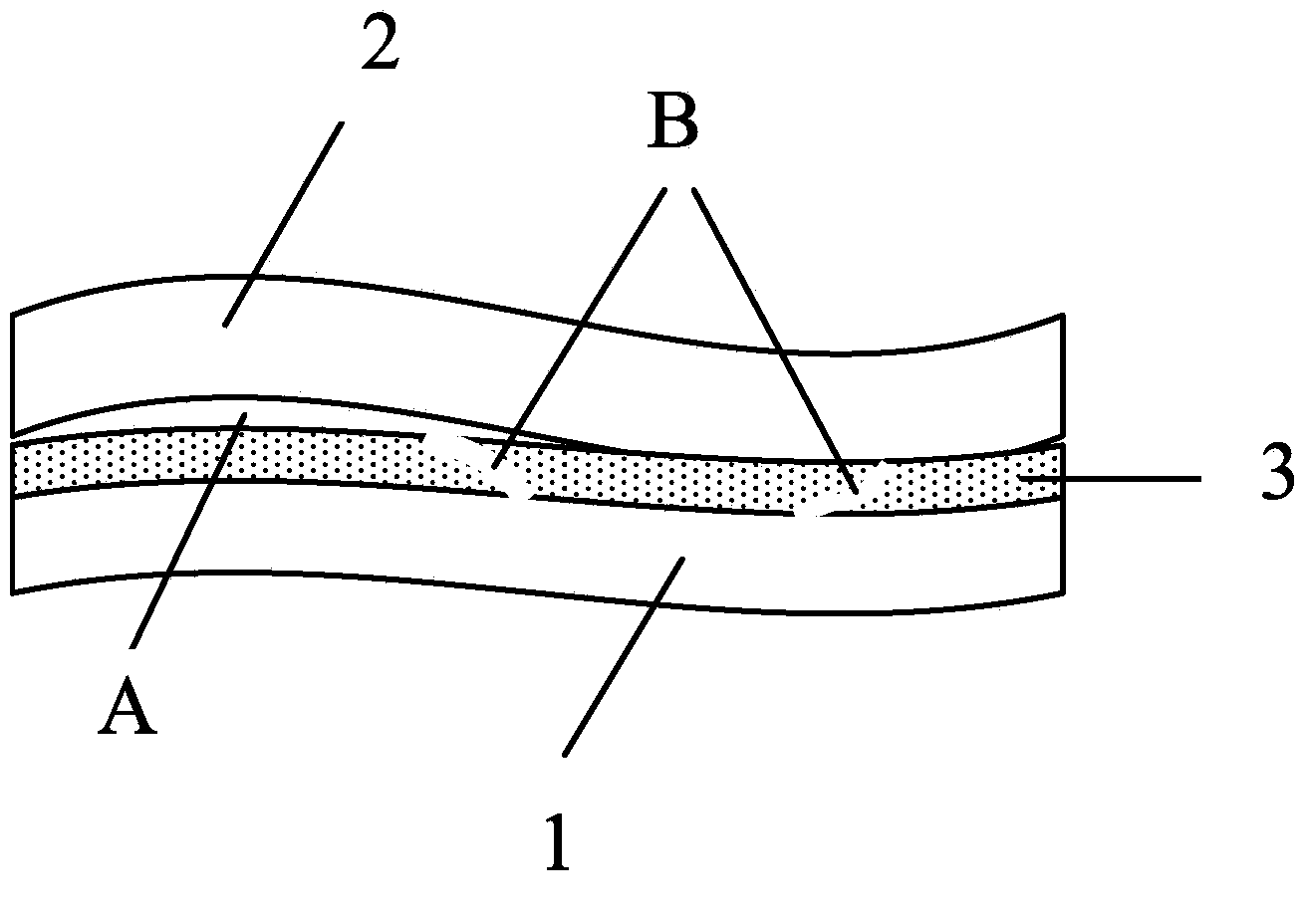

[0042] As mentioned in the background art, the existing flexible display panel will cause the adhesive layer to peel off or break when it is bent, which makes the flexible display panel poor in bendability, and the flexible display panel is prone to damage when it is bent, which affects its use. life.

[0043] The inventors of the present invention have found that elastic components are installed in the adhesive layer of the flexible display panel to disperse and buffer the stress generated when the flexible display panel is bent, which can effectively improve the bendability of the flexible display panel and prevent it from being damaged when it is bent. The problem of peeling or breaking of the adhesive layer makes it not easy to be damaged when it is bent, ensuring its service life.

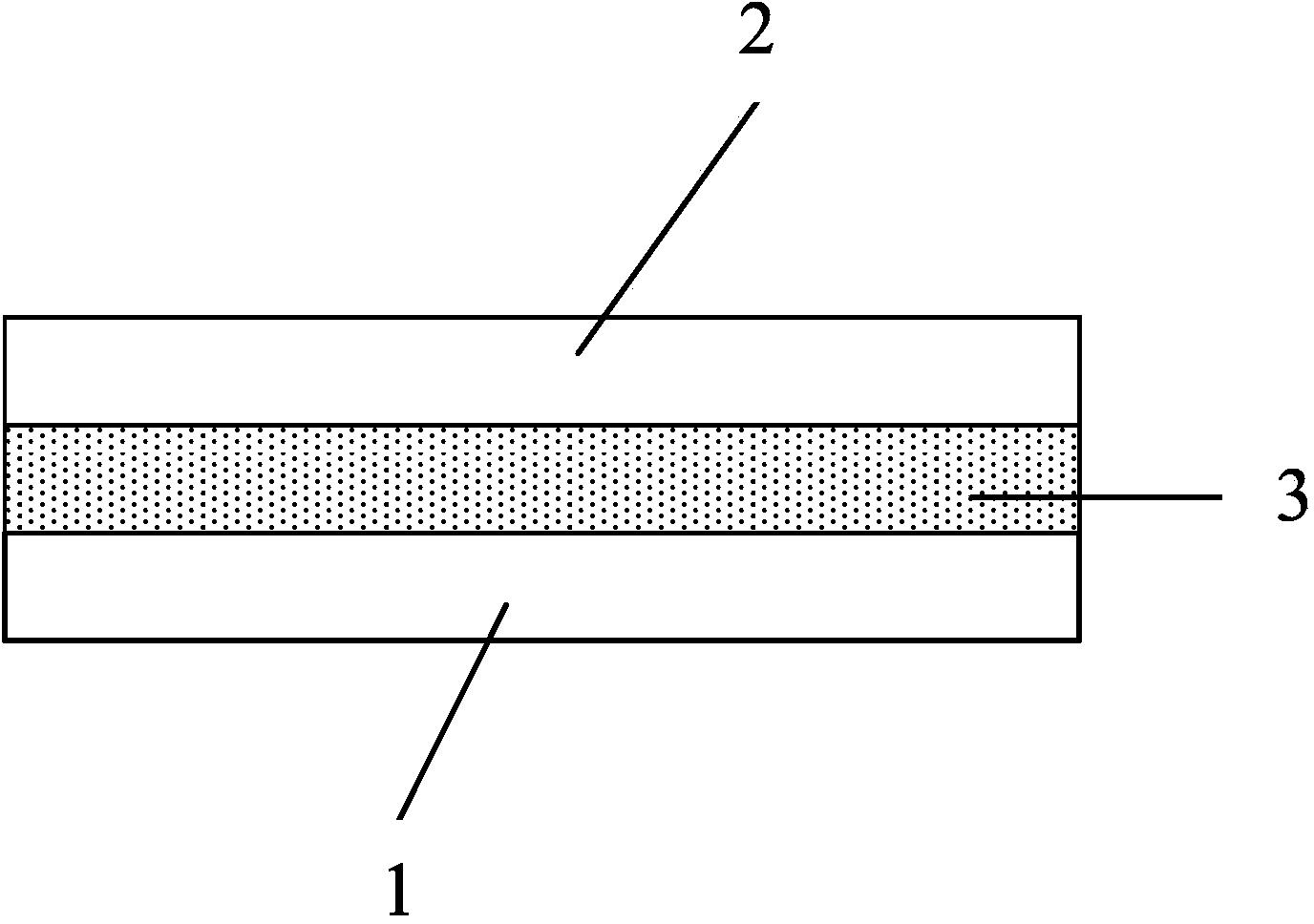

[0044] Based on the above research, this embodiment provides a flexible display panel, referring to image 3 , image 3 It is a schematic structural diagram of a flexible display panel when ...

Embodiment 2

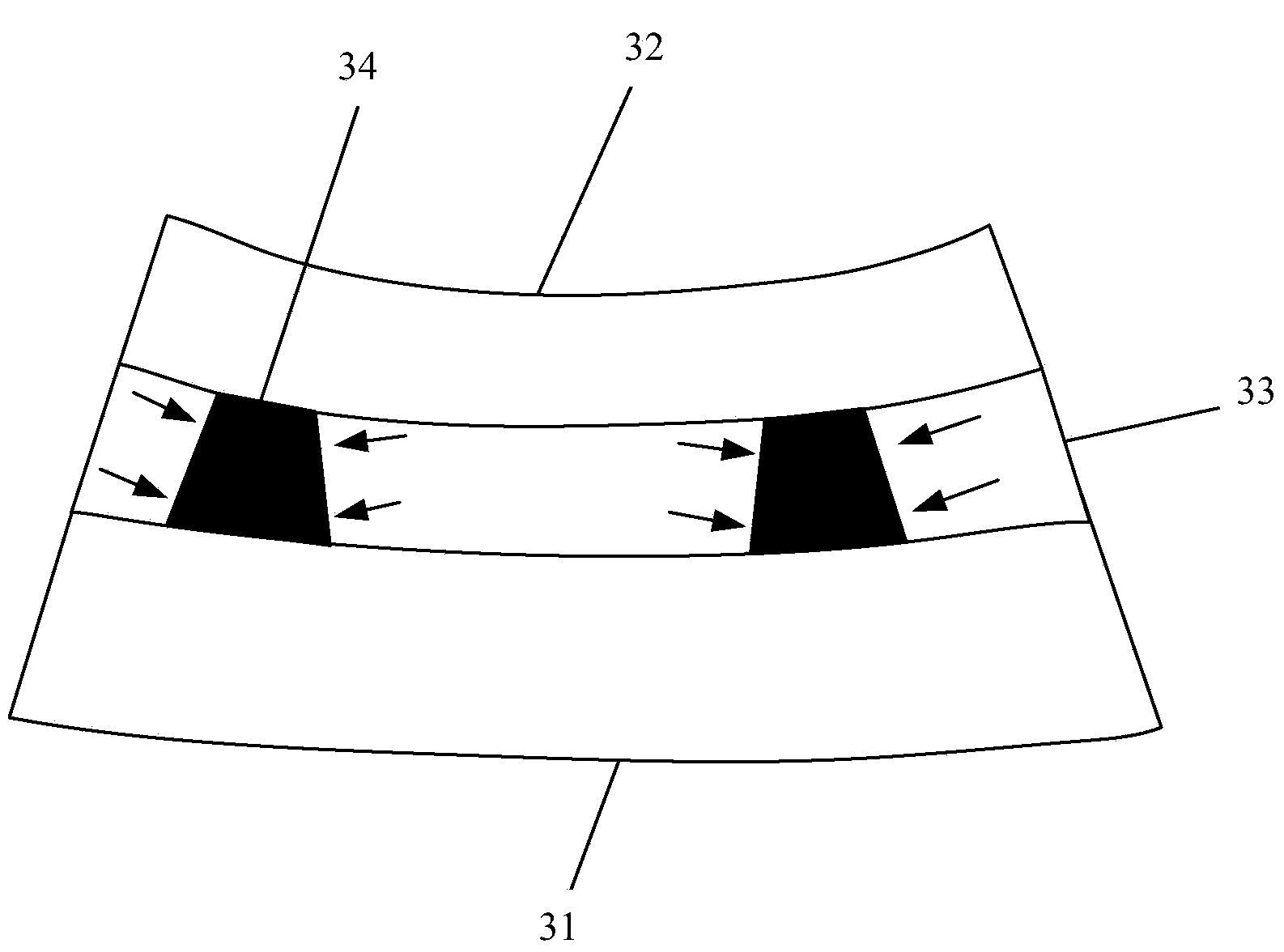

[0051] For the implementation of the flexible display panel described in Embodiment 1, please refer to Figure 4 and Figure 5 , Figure 4 It is a schematic structural diagram of the frame area of the flexible display panel provided by Embodiment 2 of the present invention, Figure 5 It is a top view of the frame area, and a plurality of elastic components 34 are arranged at equal intervals in the adhesive layer 33. Since the elastic components 34 are arranged at equal intervals, the layout is simple, which can make the production of the flexible display panel simple.

[0052] The implementation of the flexible display panel described in the first embodiment can also refer to Figure 6 and Figure 7 , Figure 6 It is a schematic structural diagram of a frame area of another flexible display panel provided in Embodiment 2 of the present invention, Figure 7 for Figure 6 As shown in the top view of the frame area, in the adhesive layer 33 on each side of the frame area,...

Embodiment 3

[0055] Based on the above embodiments, this embodiment provides a flexible display panel, referring to Figure 8 , Figure 8 It is a structural schematic diagram of a flexible display panel provided by Embodiment 3 of the present invention. The elastic member 34 provided in the adhesive layer 33 of the flexible display panel is cylindrical, and the cylindrical elastic member 34 has a simple structure and a simple forming process.

[0056] In this embodiment, the diameter of the cylinder may be set to range from 200 μm to 400 μm, including endpoints. The cylinder density is 10%-30%, including the endpoint value, that is, the area of the frame area occupied by all cylinders is 10%-30%.

[0057] The flexible display panel in this embodiment can be bent in two directions, on the one hand, it can be bent towards the direction of the flexible substrate 31 , and on the other hand, it can also be bent towards the direction of the transparent flexible cover plate 32 .

[0058] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com