Patents

Literature

362results about How to "Increase bulk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

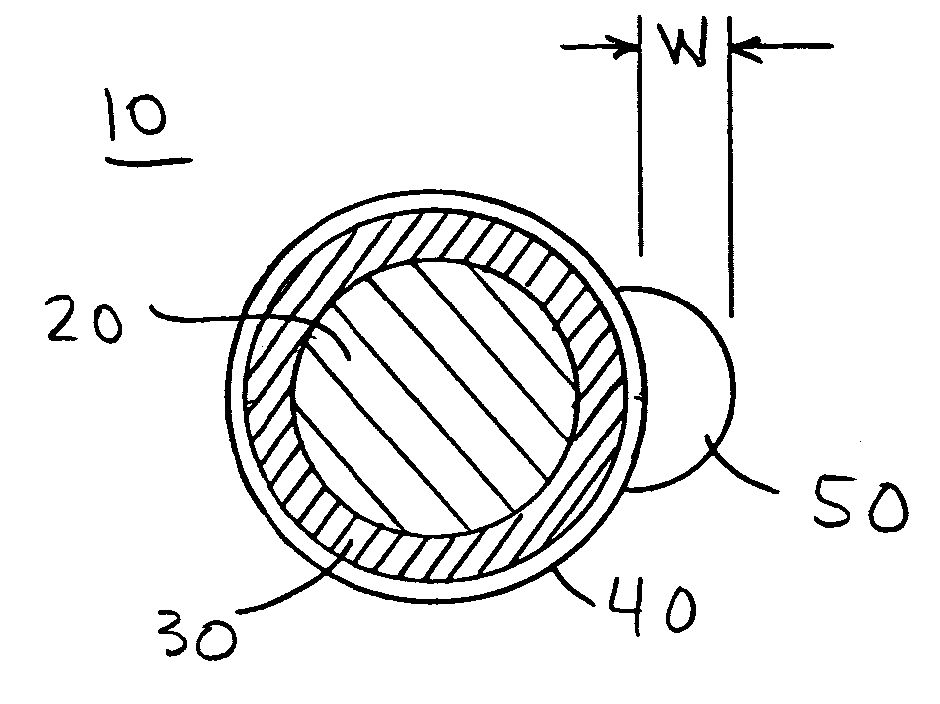

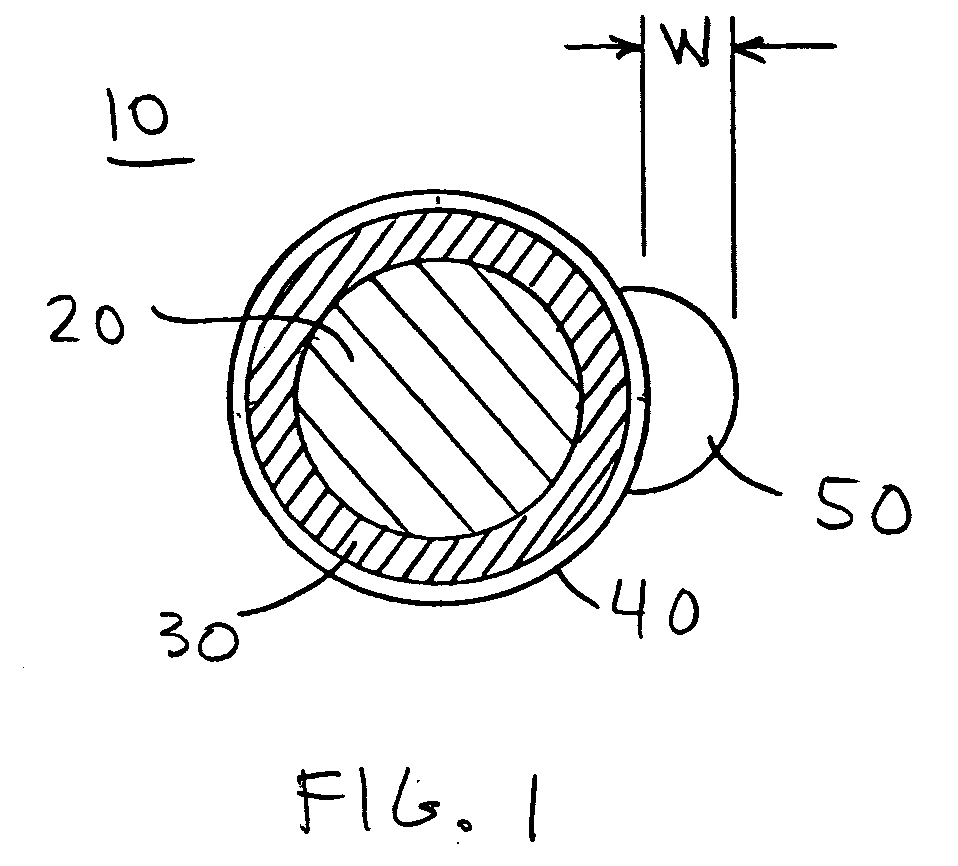

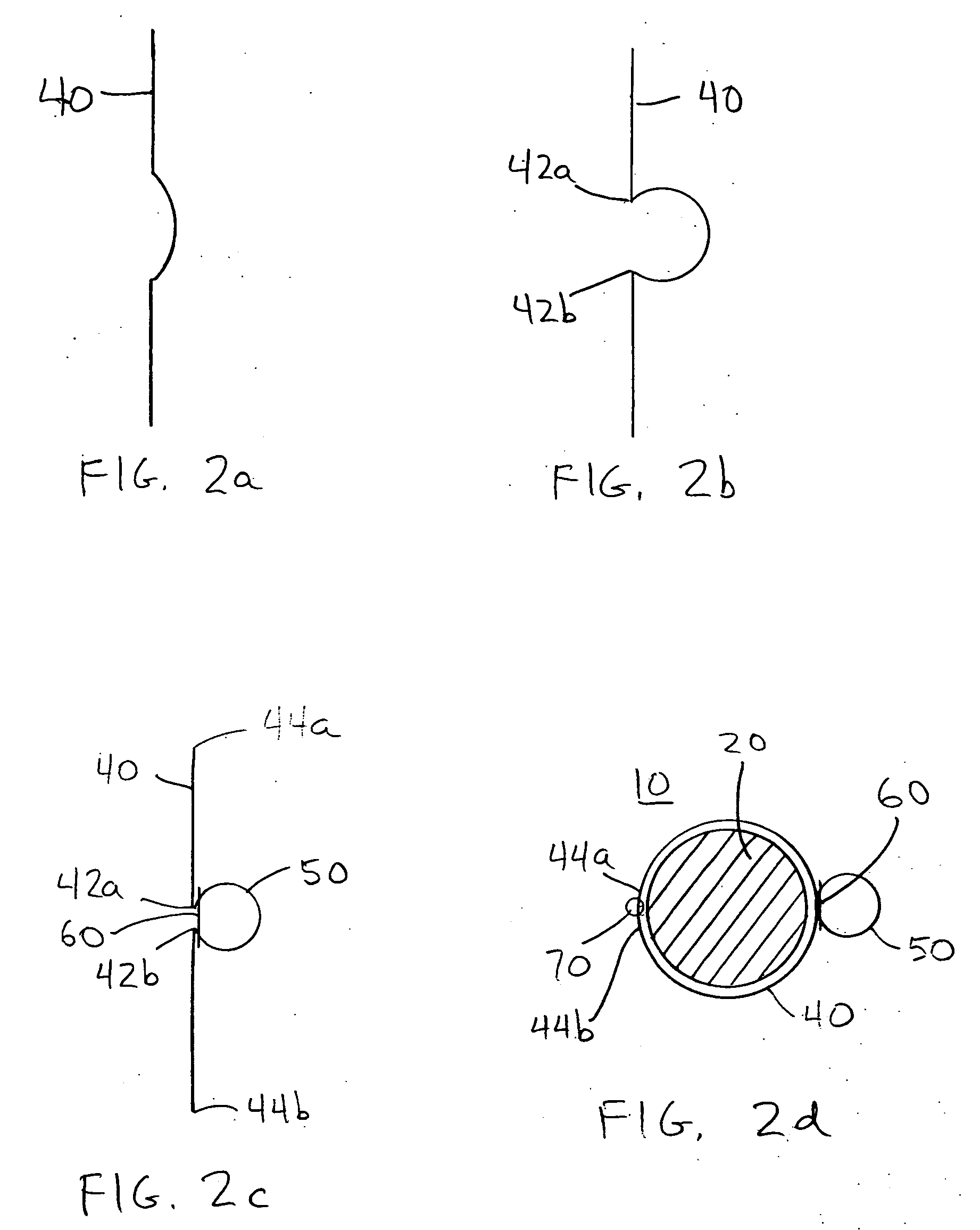

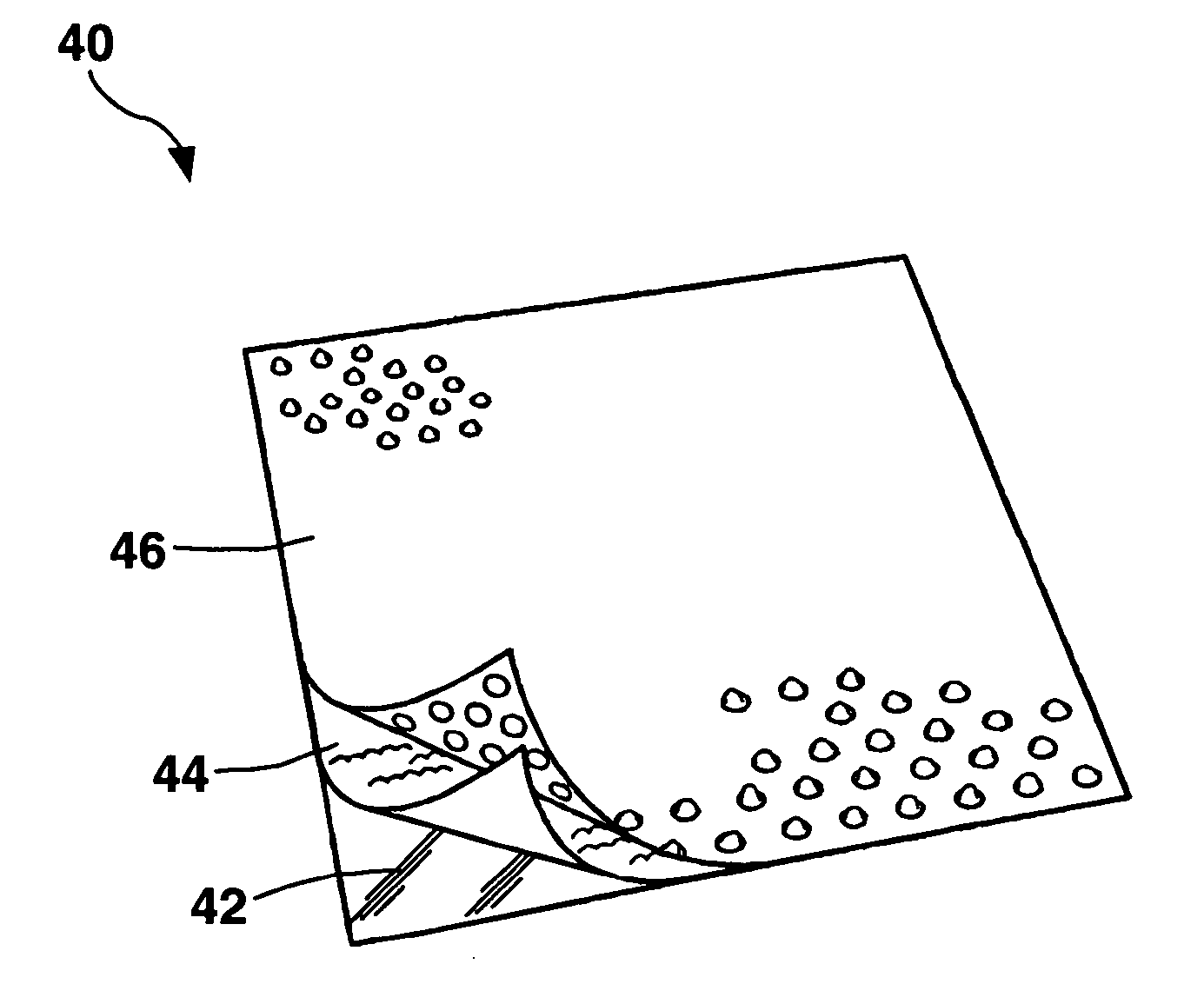

Heart valve annuloplasty prosthesis sewing cuffs and methods of making same

An annuloplasty prosthesis for a heart valve has a sewing cuff added to the conventional structure. The sewing cuff is preferably an extension of the fabric cover that is provided around the core of the prosthesis. The sewing cuff preferably extends radially outwardly from cross sections of the remainder of the prosthesis. Methods of making such a sewing cuff are also disclosed.

Owner:ST JUDE MEDICAL LLC

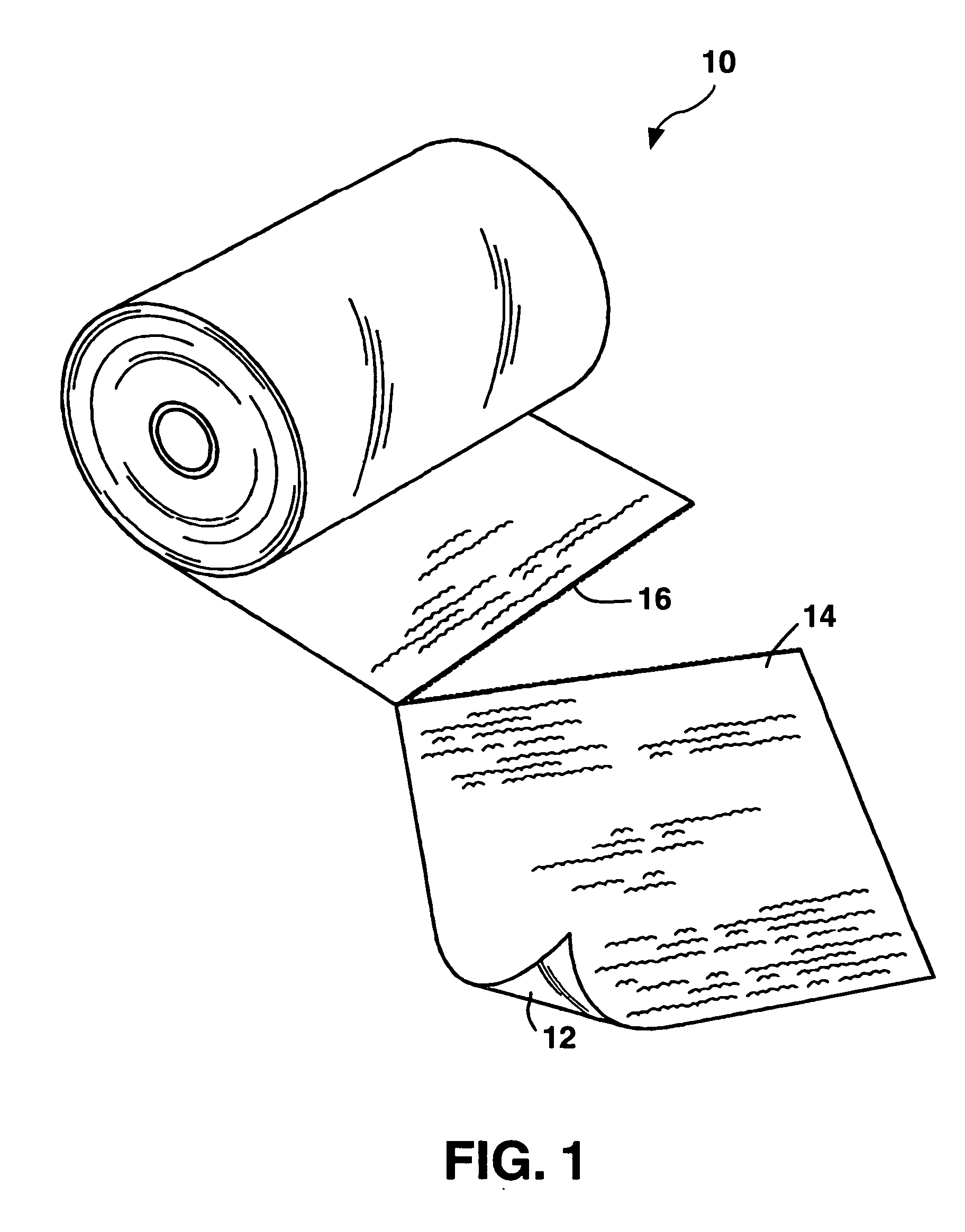

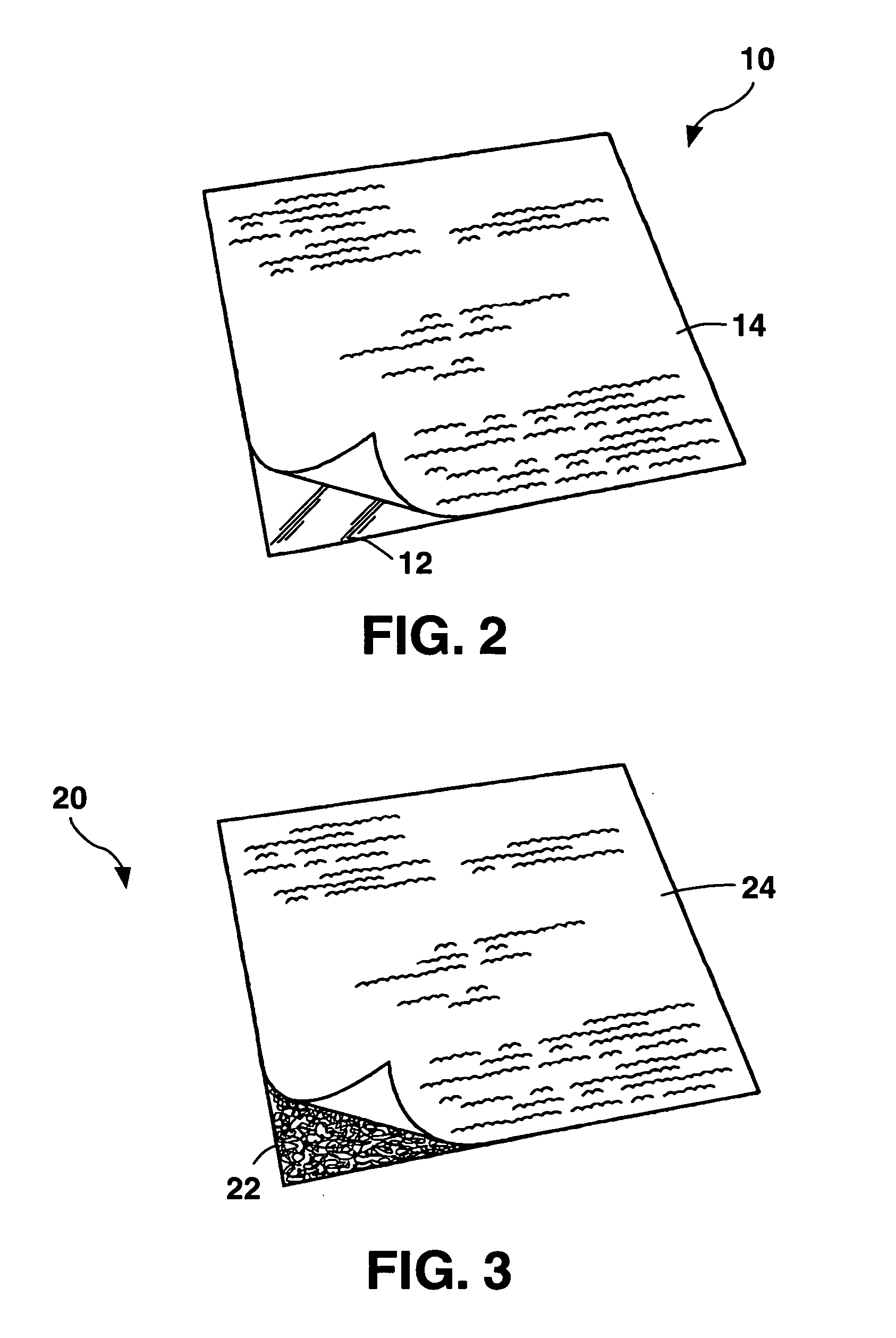

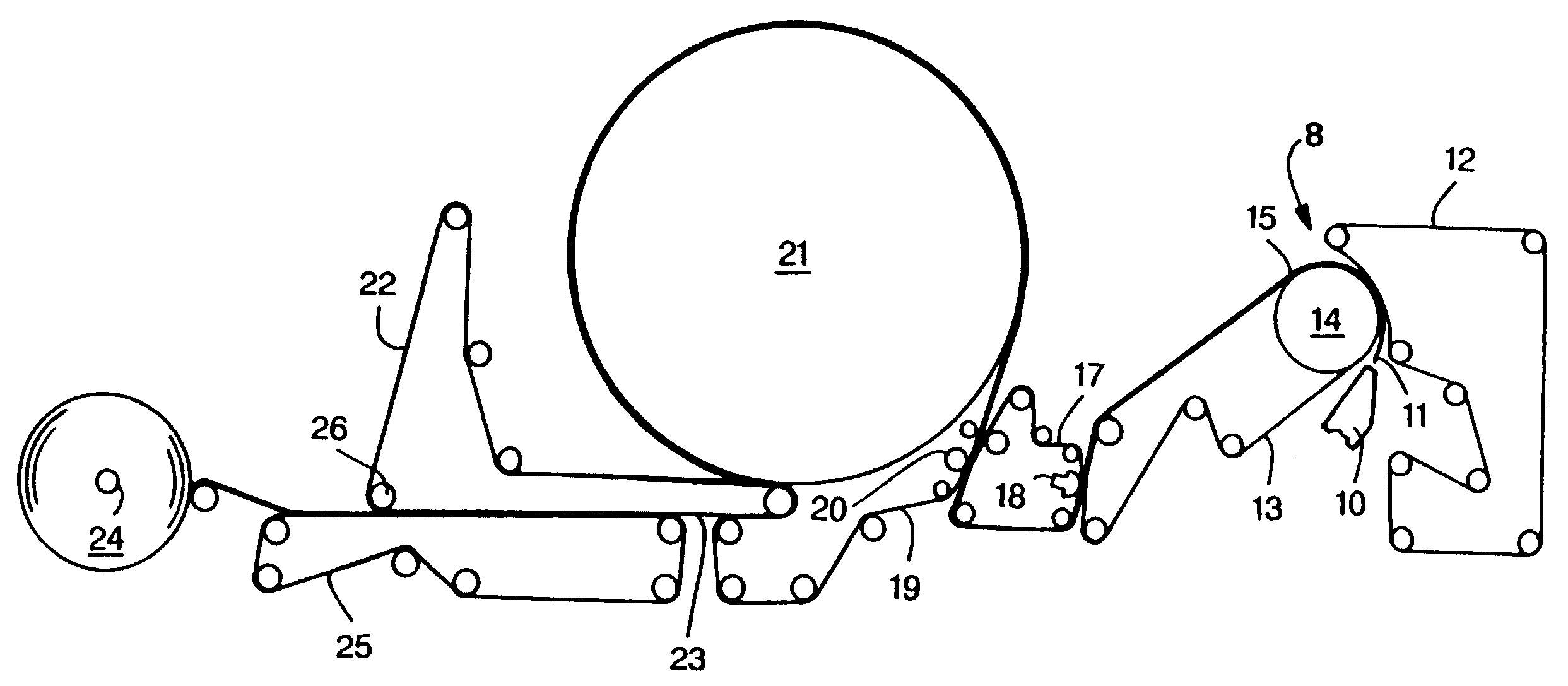

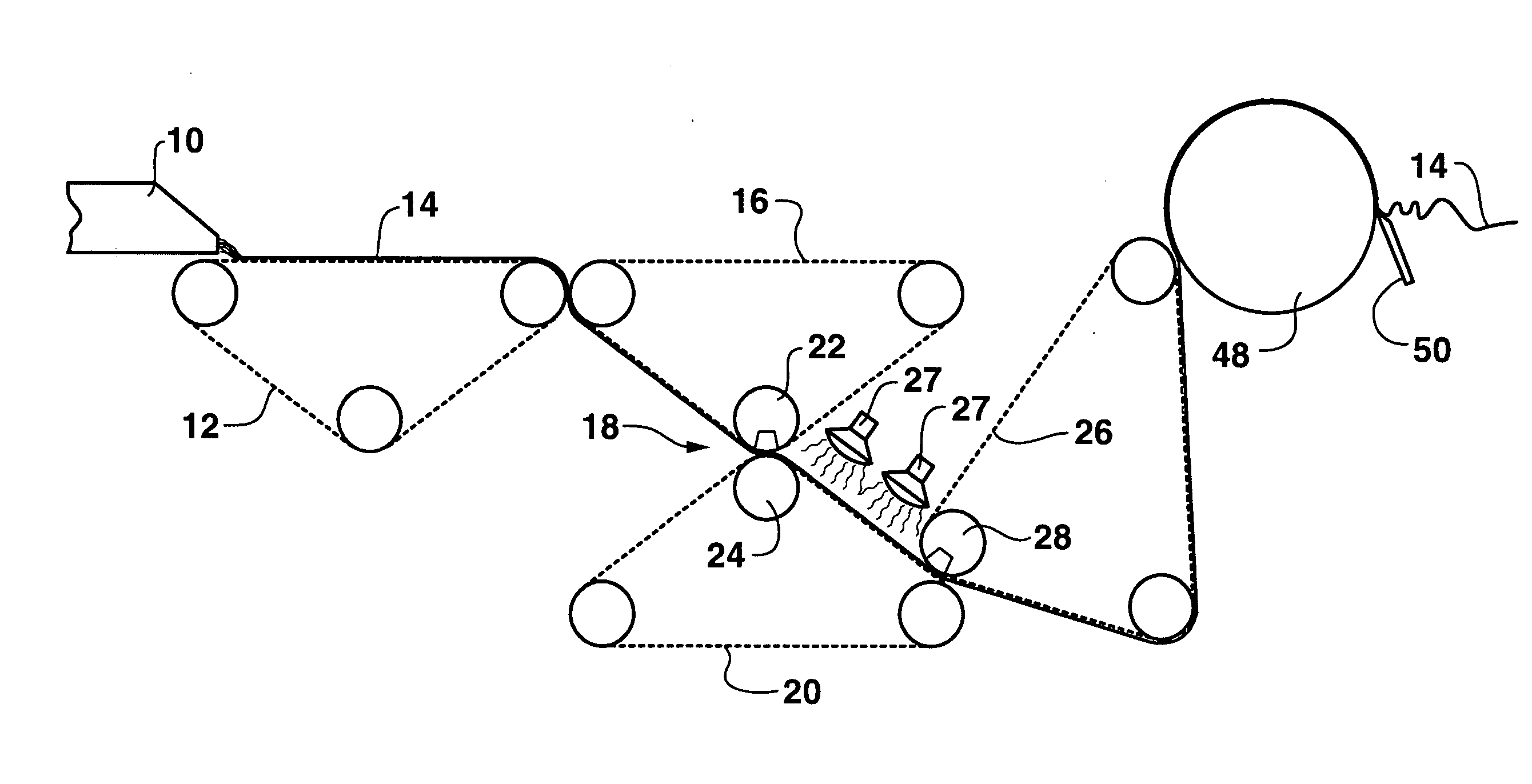

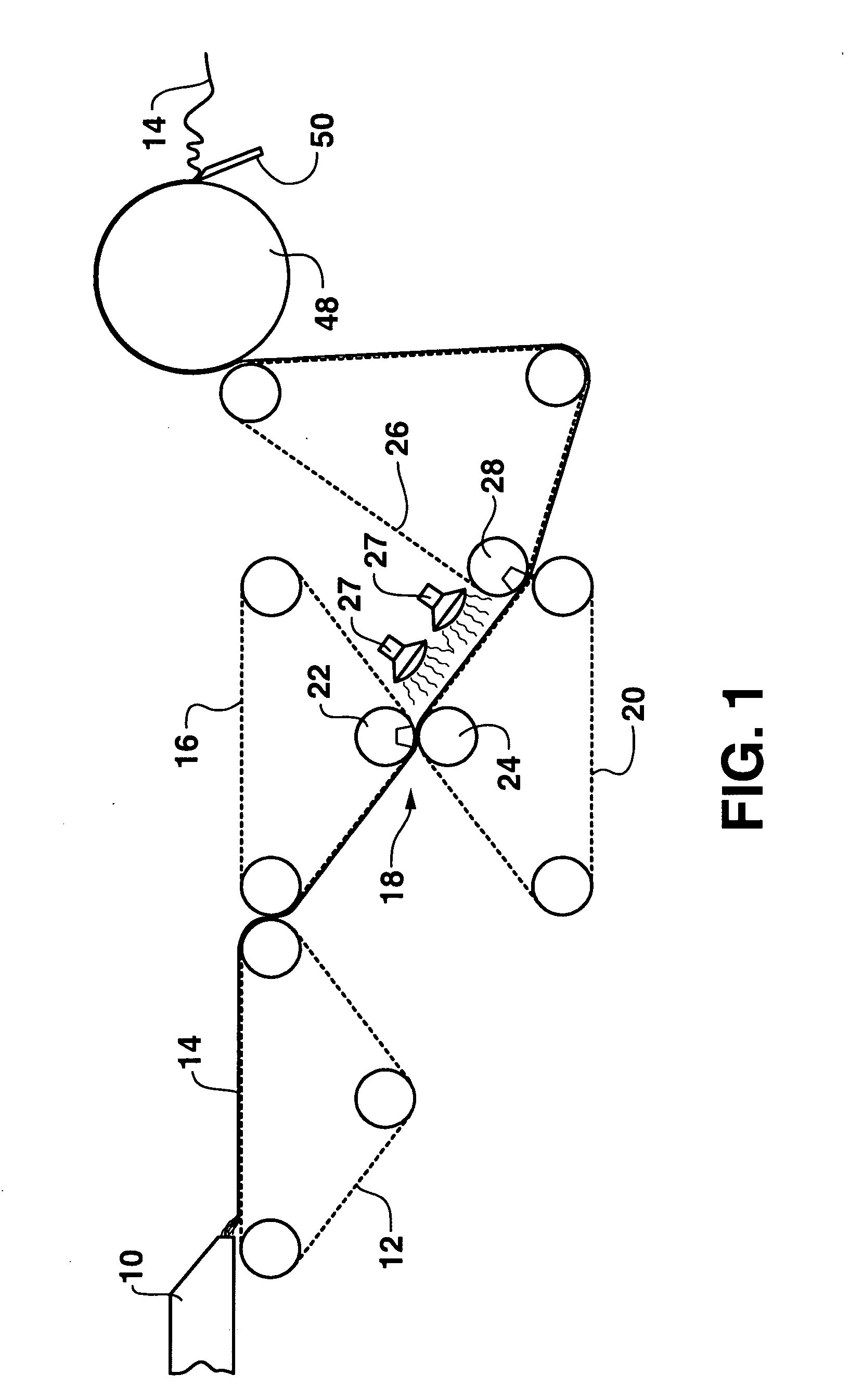

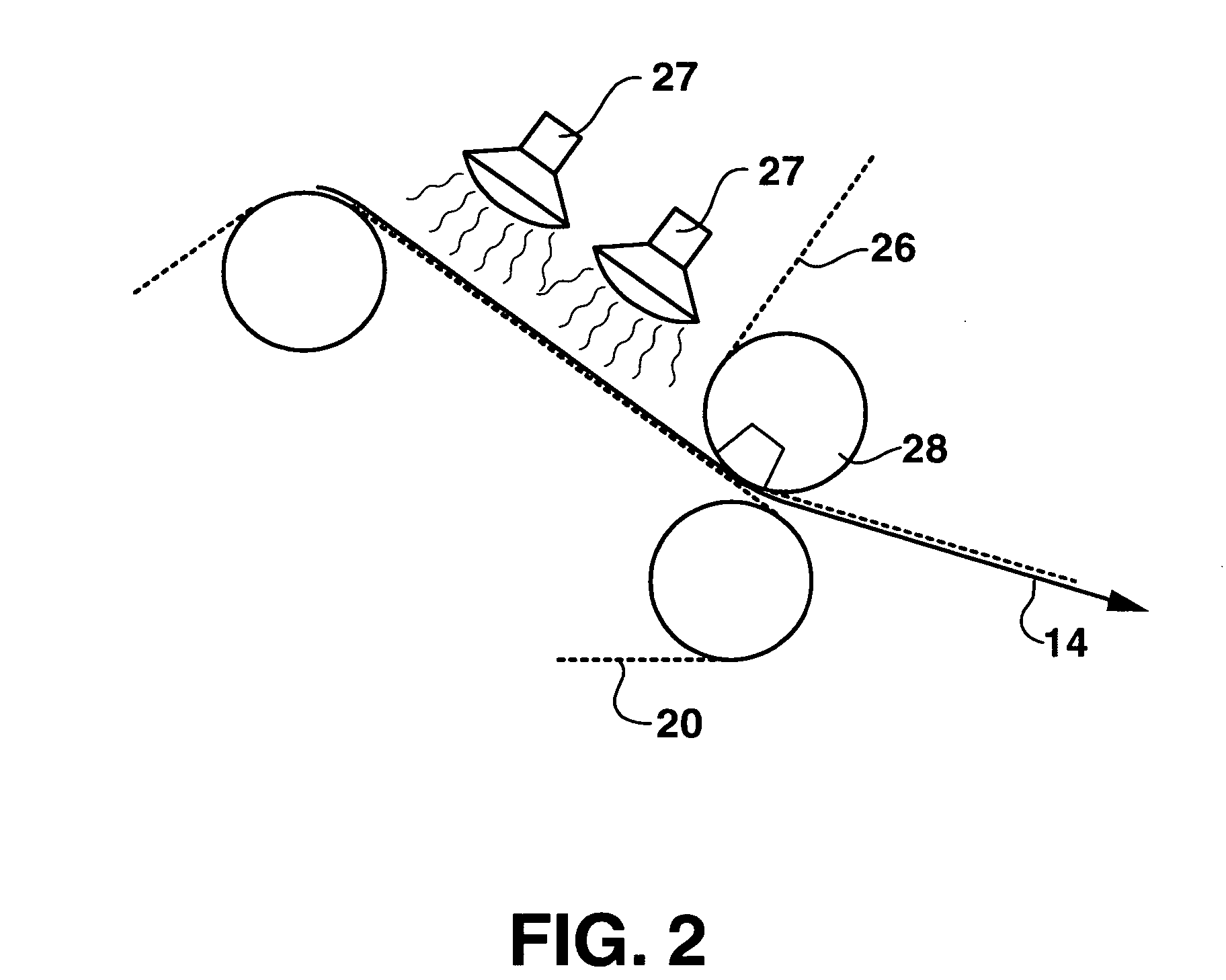

Disposable food preparation mats, cutting sheets, placemats, and the like

InactiveUS20060093788A1Decrease liquid permeable propertyGood bulkSynthetic resin layered productsCooking vesselsEngineeringFiber

Disposable liquid absorbent mats are described. The mats generally include at least a liquid absorbent layer and a liquid impervious layer. The liquid absorbent layer may be made from a tissue web, a hydroentangled web, an airlaid web, a coform web, and the like. The liquid impervious layer, on the other hand, may comprise a meltspun web, a film, a hydroentangled web, or even a tissue web that has been treated with a sizing agent that renders the web resistant to fluid flow. In one embodiment, the mats can be made so as to have a relatively low caliper so that the mats can be spirally wound into a roll. In other embodiments, however, the mats may be packaged in a stacked arrangement. The mats have various uses and applications. For instance, the mats are well suited for use during food preparation. The mats are well suited to absorbing fluids while preventing the fluids from striking through the product. In some embodiments, the mats are also well suited to serve as an absorbent and cut resistant surface. An added benefit is the addition of a layer of polymer to the bottom side of the film to achieve non-slip feature to an absorbent and cut resistant food prep mat.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Soft Single-Ply Tissue

ActiveUS20100051218A1Low breaking lengthIncreased durabilityCellulosic pulp after-treatmentNon-fibrous pulp additionBiomedical engineeringPaper sheet

A soft single-ply tissue sheet is produced by making a textured, high bulk, through dried tissue sheet and calendering the sheet with a high level of compression energy to substantially reduce the bulk and impart improved properties to the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Acoustic ceiling tiles made with paper processing waste

ActiveUS20090173464A1Promote absorptionReduce the amount of solutionFibreboardNatural cellulose pulp/paperCellulose fiberSlurry

A composition and process suitable for making acoustic tiles are disclosed. Certain embodiments of the composition comprise: perlite; inorganic material selected from the group consisting of calcium sulfate, calcium carbonate, clay and mixtures thereof; a binder selected from the group consisting of starch, a combination of starch and cellulosic fibers, latex, kraft paper gel and mixtures thereof; optionally mineral wool; optionally gypsum; and cellulosic fiber, wherein at least a portion of the cellulosic fiber and at least a portion of the inorganic material are pulp and paper processing waste comprising cellulosic fiber, clay and calcium carbonate. Certain embodiments of the process comprise: forming an aqueous slurry; continuously flowing slurry onto a moving foraminous wire to form a cake; dewatering the cake to form a base mat; and drying the base mat.

Owner:USG INTERIORS INC

Differential shrinkage polyester combined filament yarn

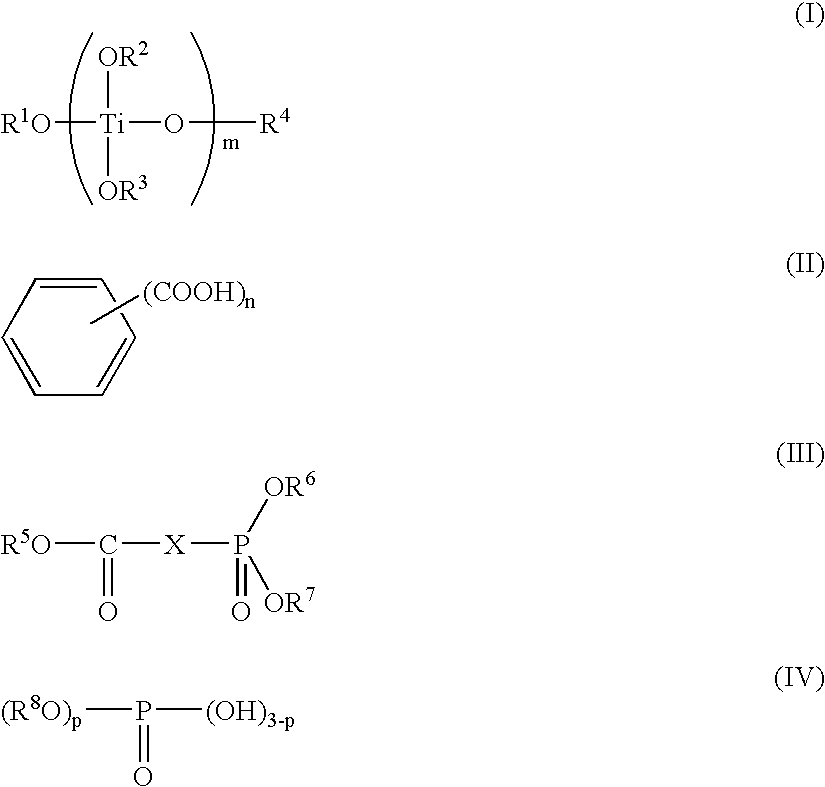

InactiveUS20060147709A1Satisfactory color toneQuality improvementYarnThin material handlingChemical compoundCarboxylic acid

High-quality differential-shrinkage polyester combined filament yarn having good color tone and being free from fluffing can be made from a polyester polymer produced by using a catalyst comprising (I) a mixture consisting of a Ti compound component composed of one or more members selected from among titanium alkoxides of the general formula (I) and products of reaction of these alkoxides with carboxylic acids of the general formula (II) or anhydrides thereof and a P compound component consisting of a compound of the general formula (III) and / or (2) a product obtained by reacting a Ti compound component composed of one or more members selected from among titanium alkoxides of the general formula (I) and products of reaction of these alkoxides with carboxylic acids of the general formula (II) or anhydrides thereof with a P compound component consisting of a compound of the general formula (IV).

Owner:TEJIN FIBERS LTD

Soft single-ply tissue

ActiveUS7935221B2Low breaking lengthIncreased durabilityCellulosic pulp after-treatmentNon-fibrous pulp additionBiomedical engineering

A soft single-ply tissue sheet is produced by making a textured, high bulk, through dried tissue sheet and calendering the sheet with a high level of compression energy to substantially reduce the bulk and impart improved properties to the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

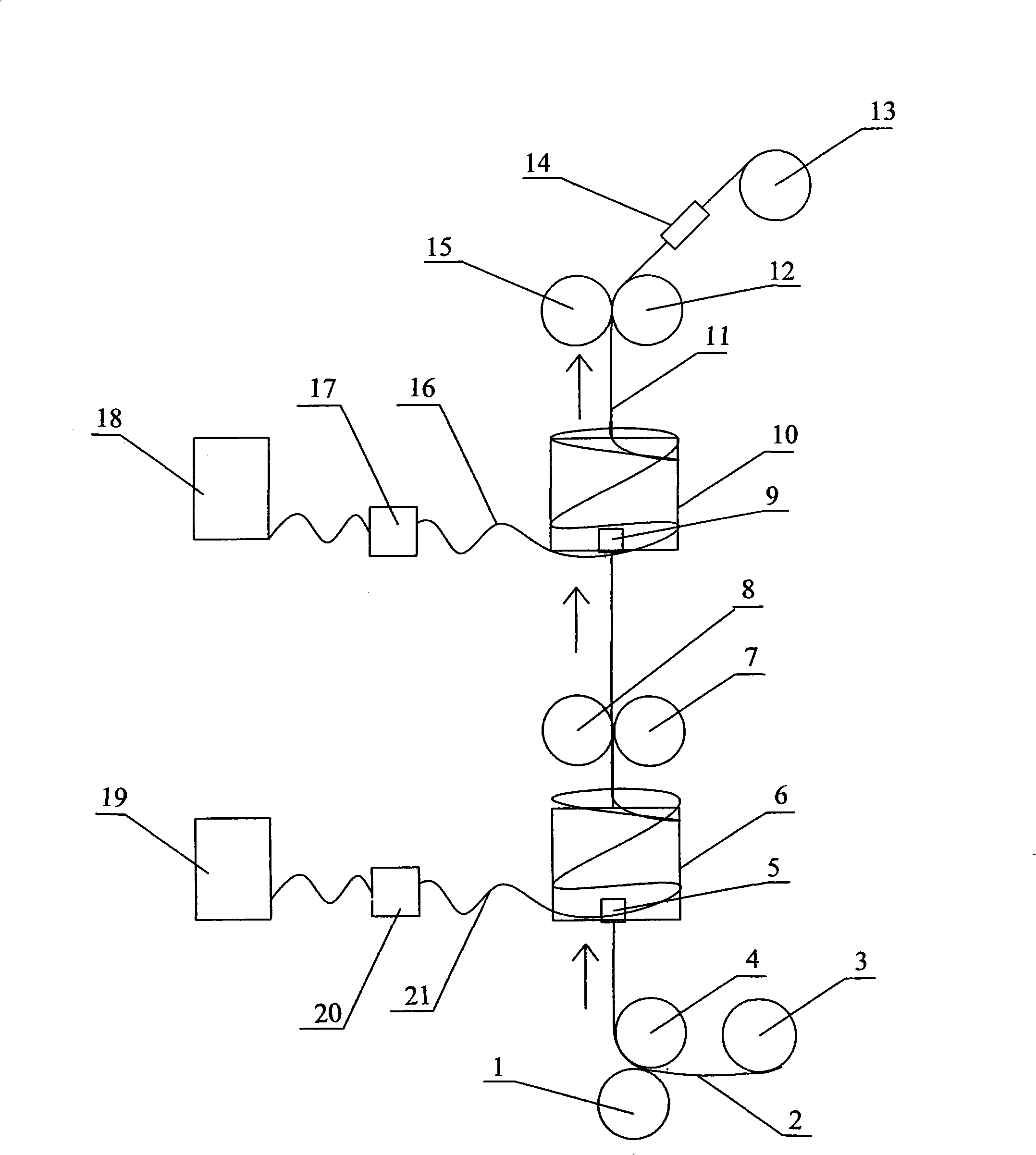

Dissimilar materials double-layer superpacket center thread and manufacturing method thereof

InactiveCN101328637AGuaranteed wrapping tensionFeel comfortableContinuous wound-up machinesYarnYarnFiber

The invention discloses an abnormal material dual-layer composite clad yarn, which comprises an upper fiber-wrapped clad material layer, a lower fiber-wrapped clad material layer and a clad yarn layer which is positioned in the middle, wherein, the clad yarn layer adopts chemical fiber filament clad yarns and fiber-wrapped clad materials with different materials to be compositely processed into a dual-layer composite clad yarn. The invention also discloses a method for manufacturing the dual-layer composite clad yarn. The dual-layer composite clad yarn has the characteristics of comfortable hand feeling, large strength and toughness of chemical fiber filaments of the sandwich layer, burliness and durability, and high performance and use value.

Owner:鲁建国

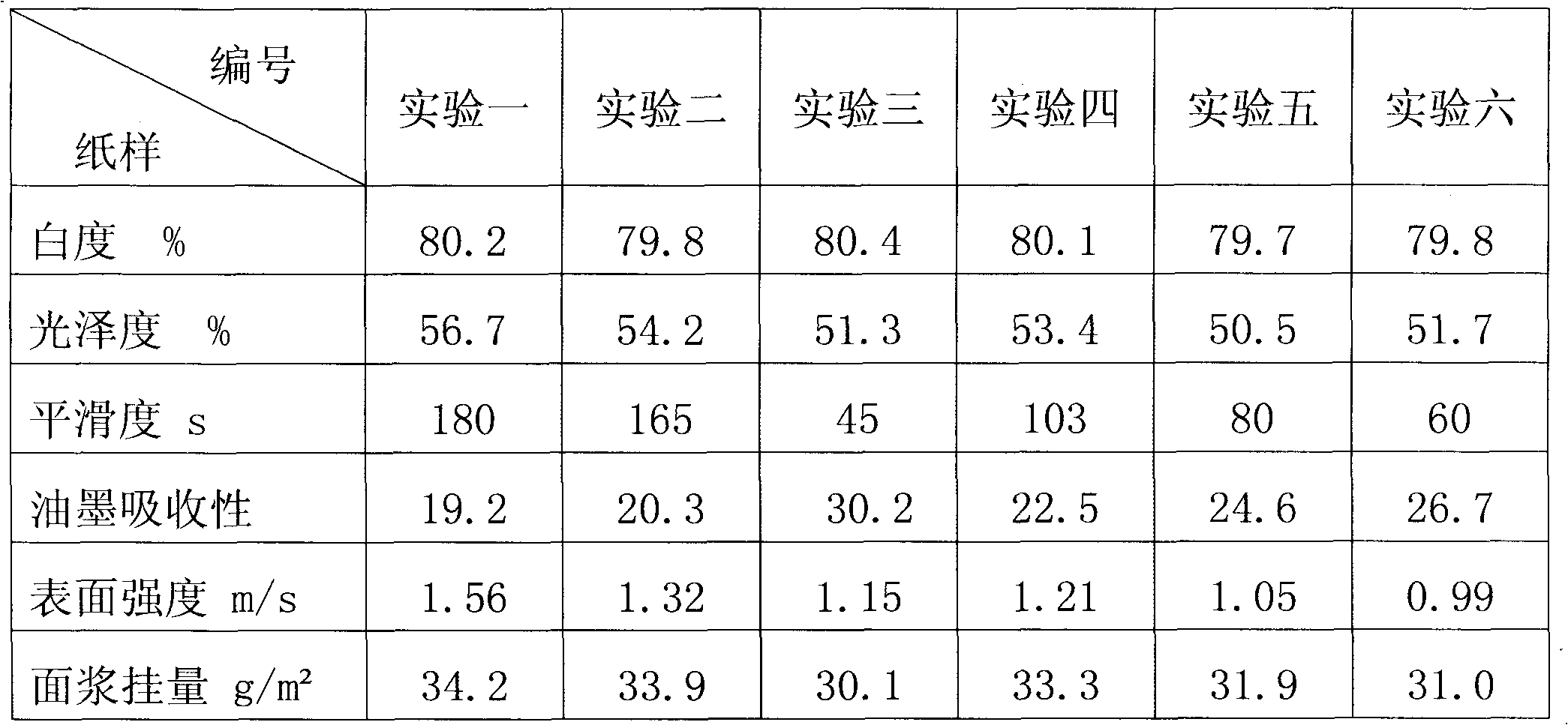

Light coated printing paper and manufacturing method thereof

InactiveCN1455047AEase the strain on resourcesAdjustable structurePaper/cardboardSulfatePulp and paper industry

The present invention discloses a light-weight coated printed paper and its making method. It includes the following steps: using bleached sulfate needle wood (pulp (BKP). Italia poplar alkaline hydrogen peroxide hot-ground mechanical wood pulp (APMP), bleached sulfate reed pulp (BKP) or commercial bleached hard wood pulp; respectively beating, proportioning and making them into mixed pulp; adding auxiliary material to obtain material for making paper and making paper. Said invention adopts the advanced making process of AKD neutral sizing, internal coating and calendering by using soft roll, so that said printing paper has good surface strength, bulkness and air permeability, and is suitable for implementing various colour printing.

Owner:YUEYANG FOREST & PAPER CO LTD

Special pigment finishing offset paper and producing method thereof

InactiveCN1584205AReduce particle contentIncrease bulkNon-fibrous pulp additionCoatings with pigmentsGreen environmentXerography

This invention discovers a special pigment groom hectograph paper and its preparation. It utilizes the advantages of high yields machine pulp (PRC-APMP) and deink pulp (DIP) which is well thickness and green environment. That is optimizing pigment spreading formulation, optimizing pulp to materials ratio and its wet end chemical and copy making technique to reach the white value of all bleaching chemical pulp proportioning copy paper. The advantages of the products are: better printing adaptability, better relaxation thickness, better printing effect features compared with all chemical pulp hectograph paper. It's capable of producing top grade office and printing culture special pigment groom hectograph paper which is made according to different clients' requirement and selecting different optimized features' technique for different application such as laser printing, xerography and hectograph etc. So, it's capable of decreasing all chemical pulp quantity, saving wood, protecting forest, protecting environment from pollution.

Owner:YUEYANG FOREST & PAPER CO LTD

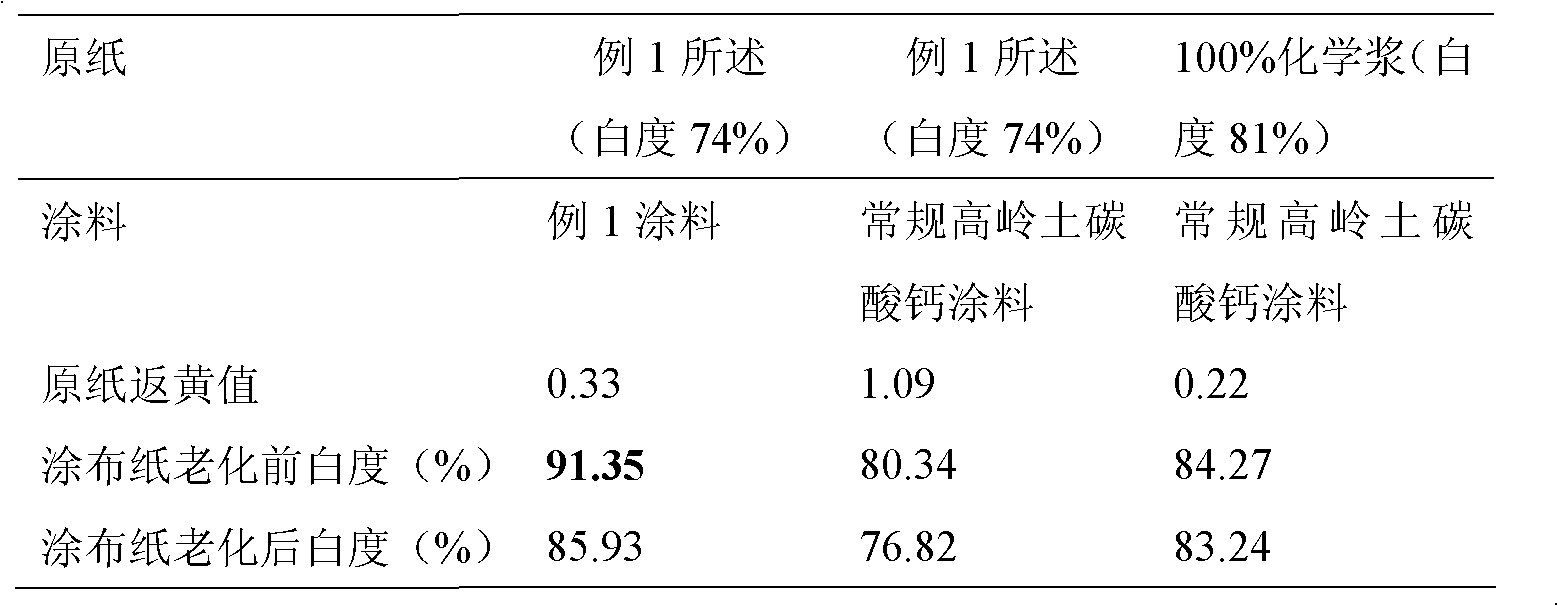

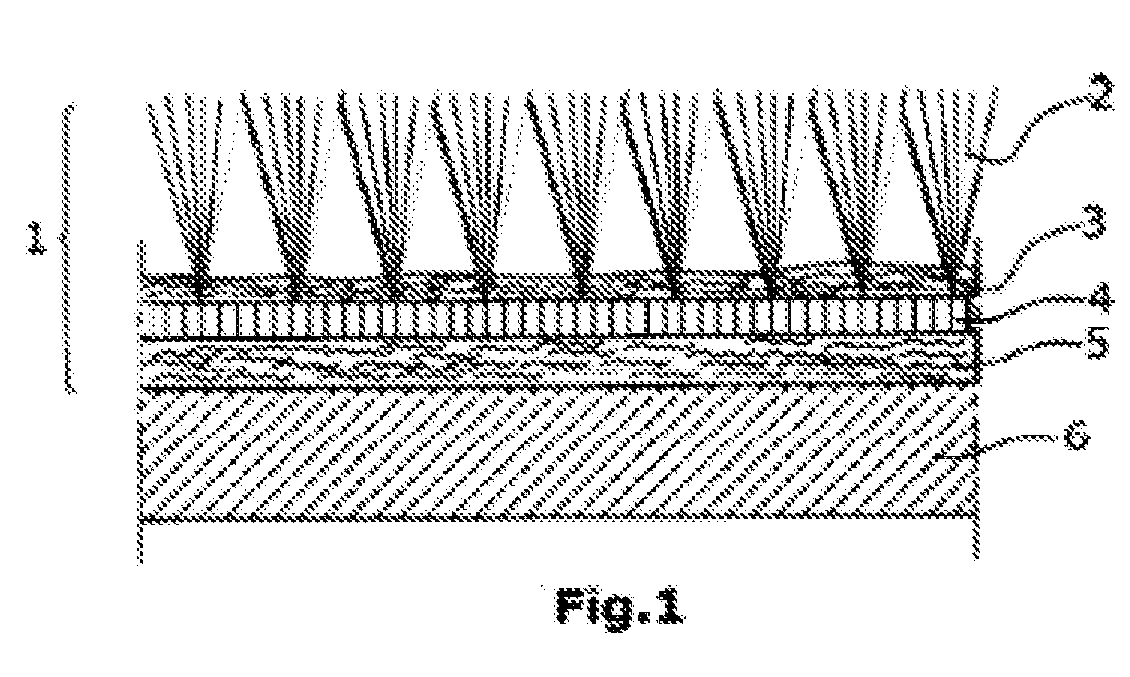

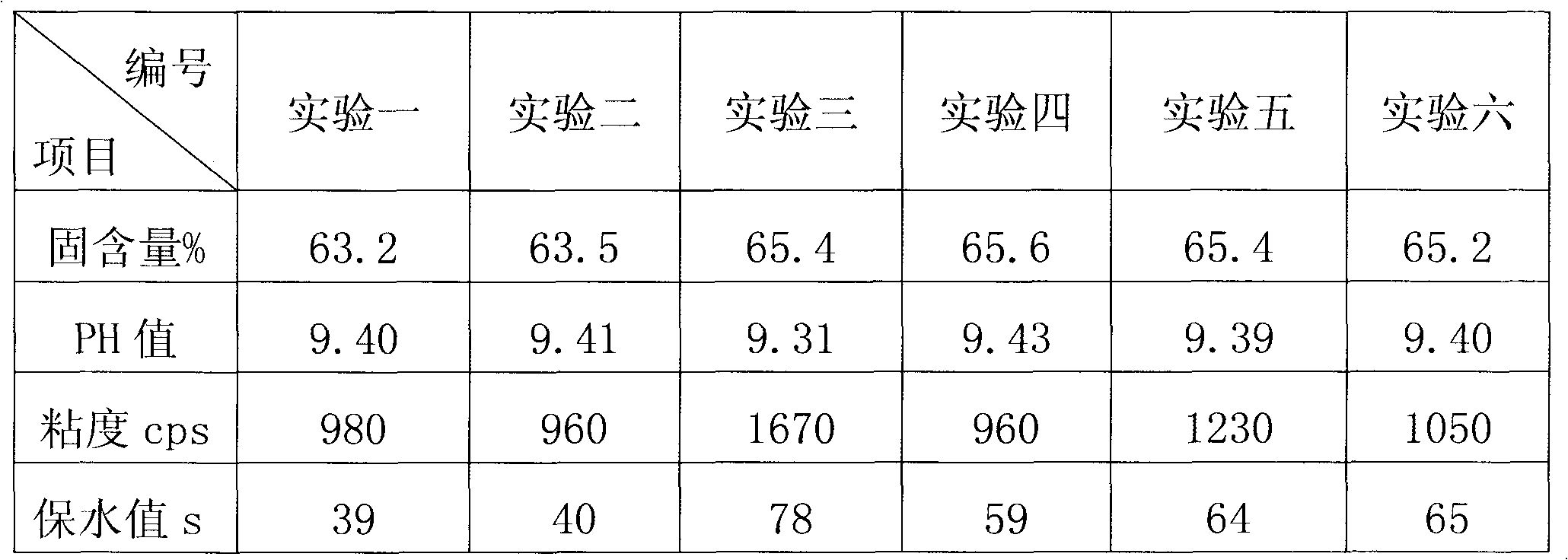

High-whiteness coated paper coated by using raw paper with medium whiteness, coating method and coating

InactiveCN102199897AReduce whitenessFulfil requirementsCoatings with pigmentsReinforcing agents additionCardboardManufacturing technology

The invention relates to high-whiteness coated paper coated by using raw paper with medium whiteness, a coating method and a coating. The coating method is mainly characterized by greatly reducing the whiteness of the raw paper for producing conventional high-grade coated paper such as copper plate paper and coated white cardboards. The coating mode is a common single-side or double-side two-layer (double-coating) or multi-layer coating mode in a papermaking plant. By using the mechanical property of the raw paper, the printing property of coatings and the synergetic whitening effect between the coatings, yellowing of the raw paper is inhibited, and the whiteness of the coated paper is improved to over 86 percent so as to meet the requirements of national standards on the high-grade copper plate paper. The raw paper of the high-grade coated paper can be made by using various kinds of environment-friendly and resource-saving pulp of medium whiteness more widely, and is favorable for promoting the development of the low-carbon manufacturing technology of the pulping papermaking industry. The newly invented coated paper can substitute the traditional high-grade paper such as the copper plate paper, the coated white cardboards and the like in the fields of printing and packing.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

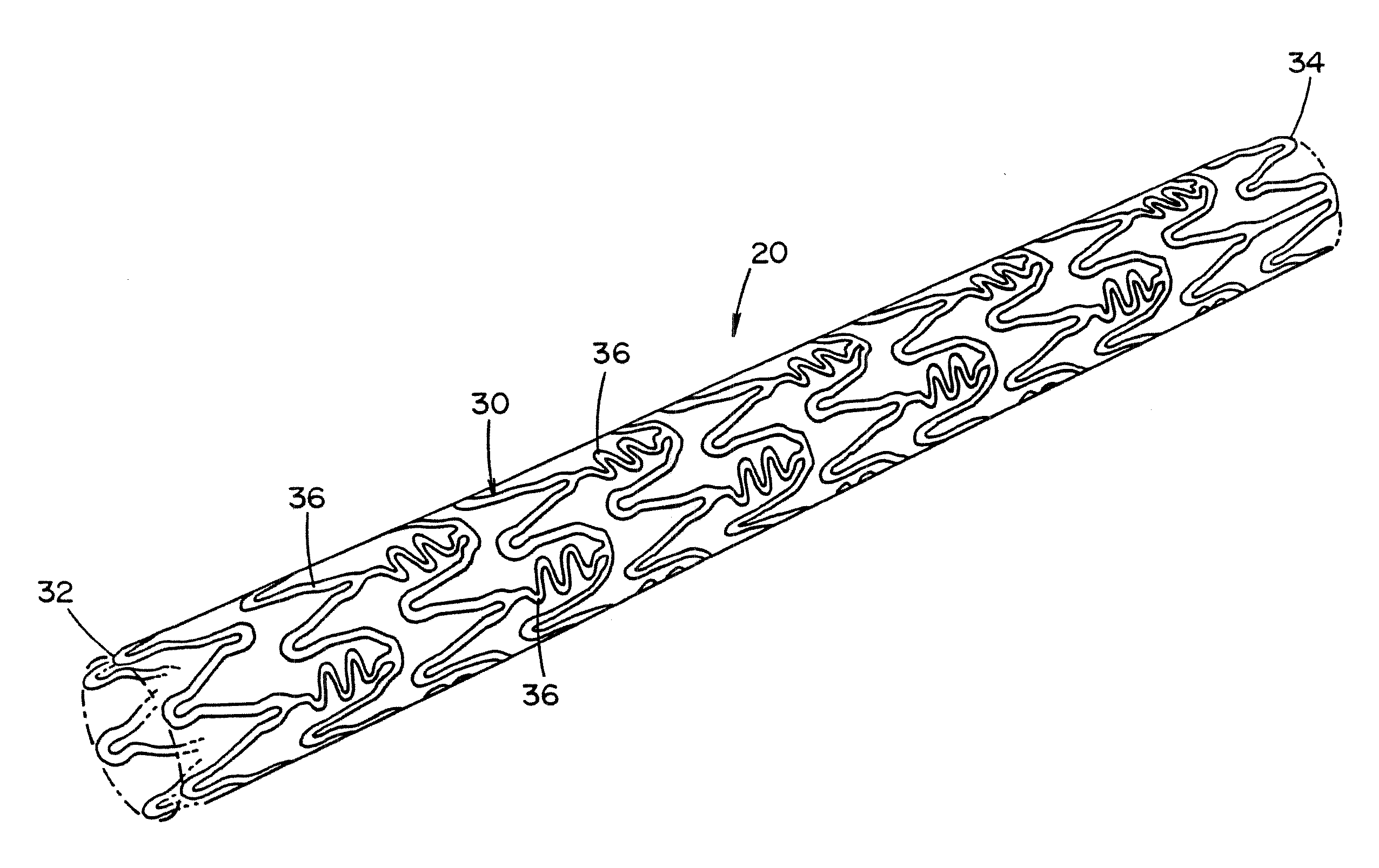

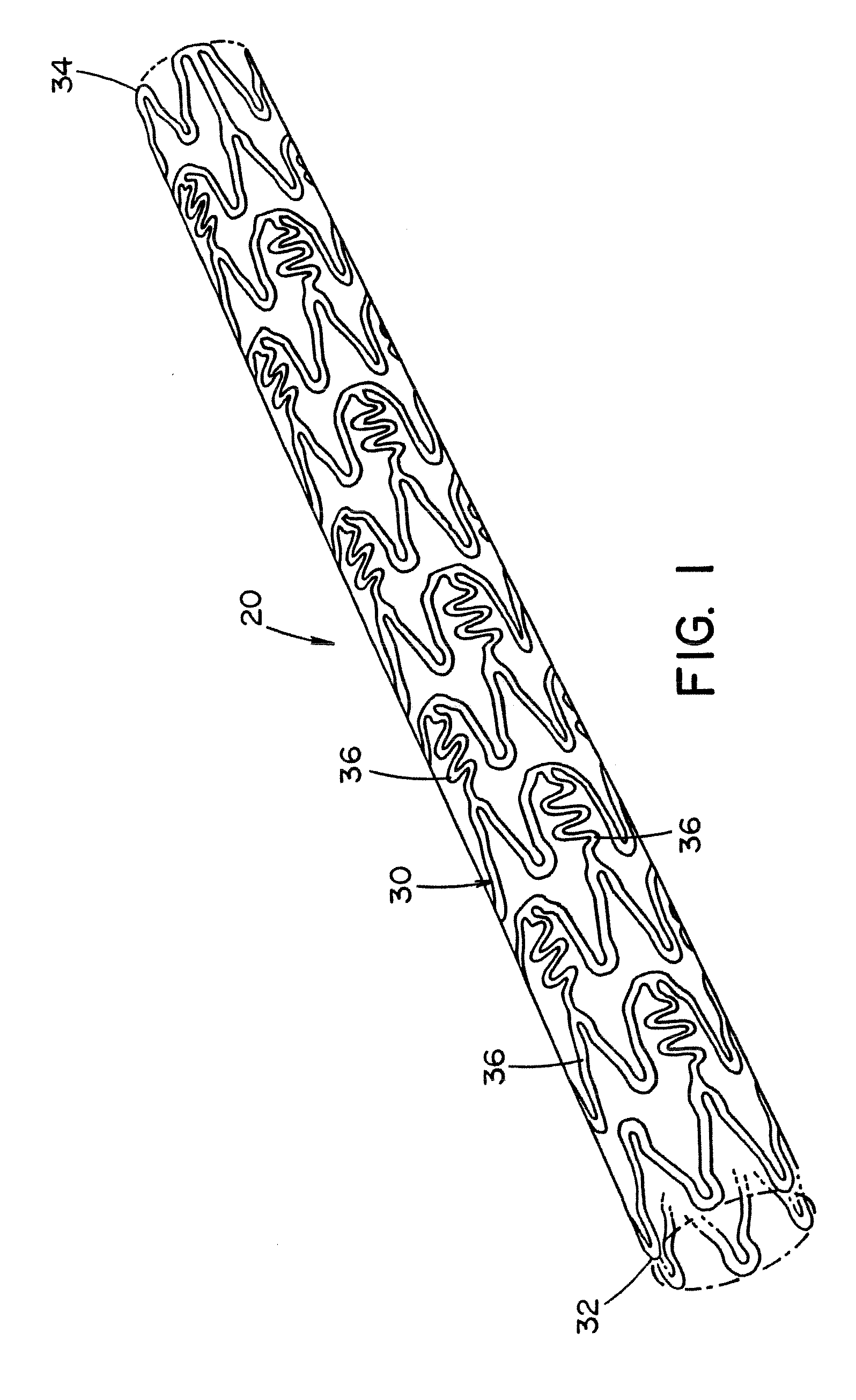

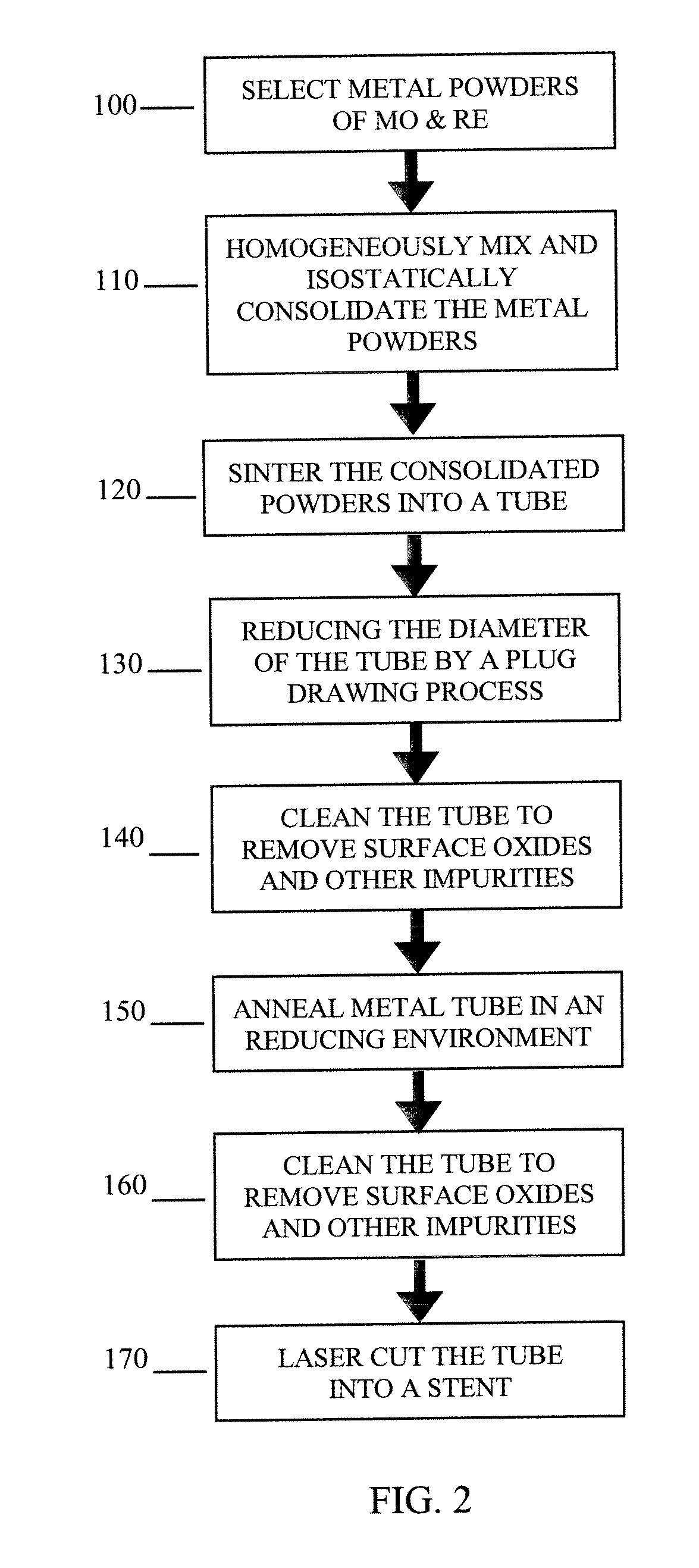

Method for forming a tubular medical device

A method and process for at least partially forming a medical device that is at least partially formed of a metal alloy which improves the physical properties of the medical device.

Owner:MIRUS LLC

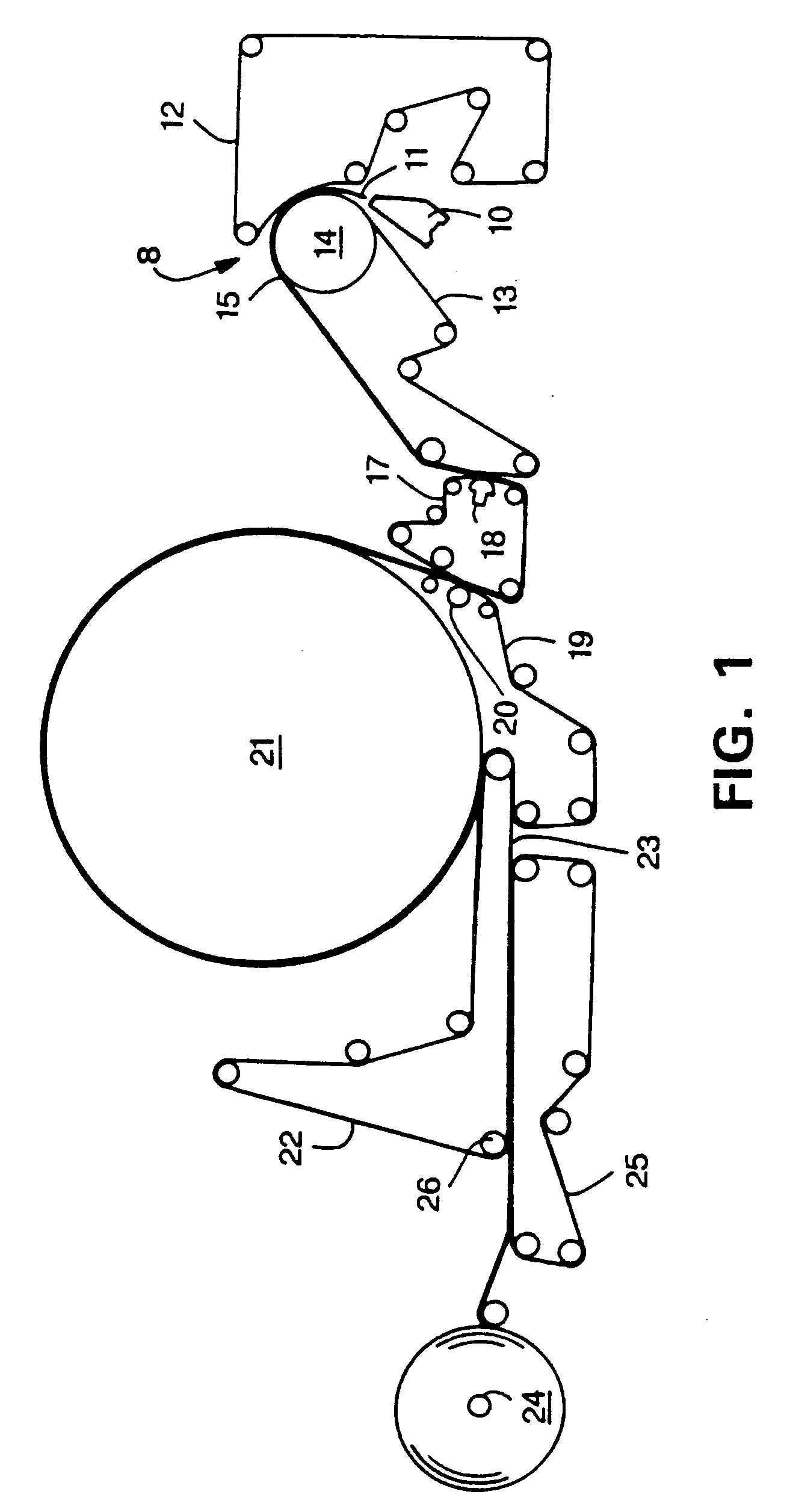

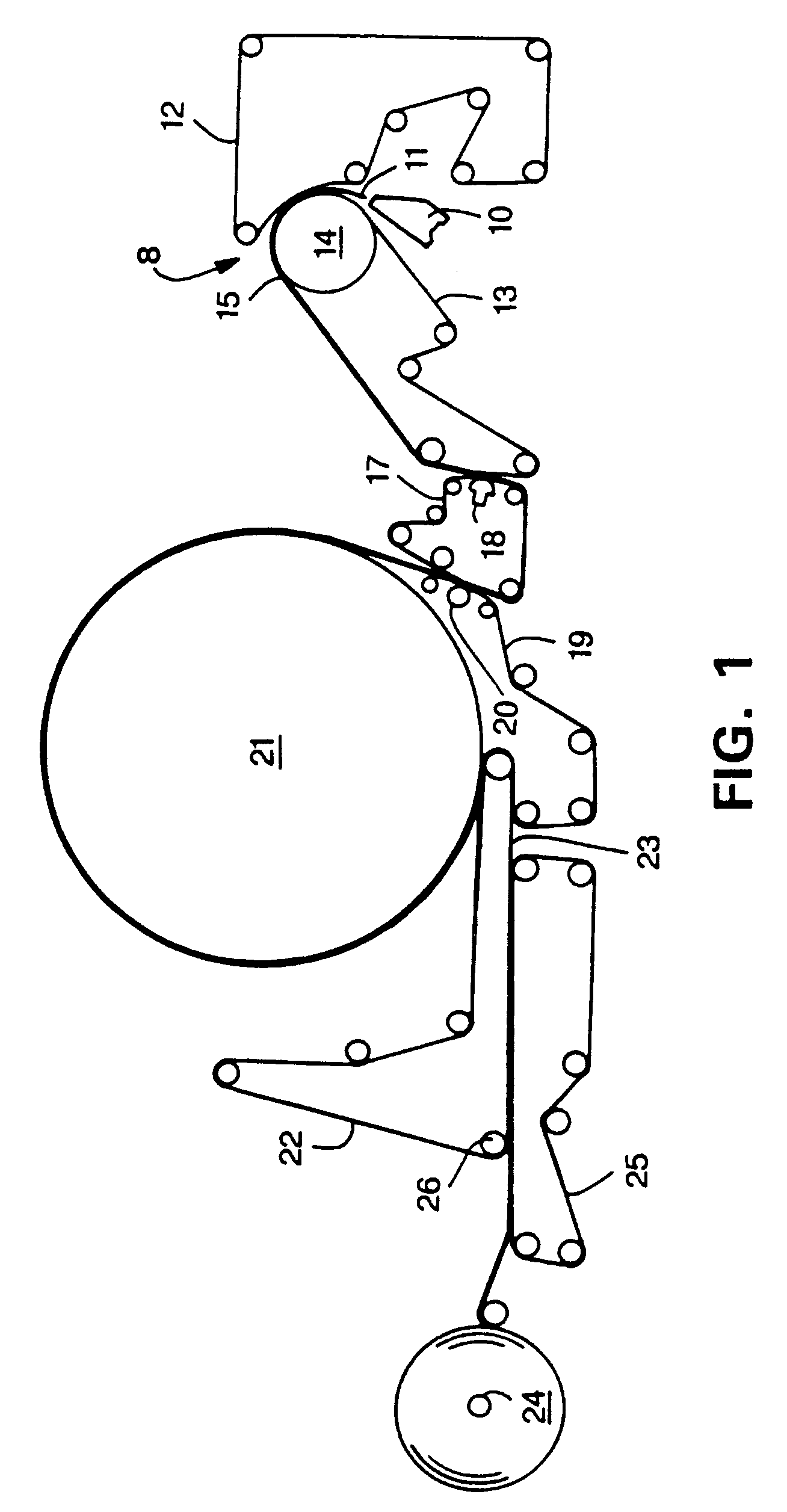

Method of transferring a wet tissue web to a three-dimensional fabric

InactiveUS20060243408A1Increase in sizeEasy to separateFibreboardDrying solid materials without heatSuction forceWater vapor

A process for producing tissue webs is disclosed. In particular, the process is directed to transferring a wet web from a transfer surface to a separate conveyor, such as a fabric. The process, in one embodiment, may include the steps of partially dewatering a tissue web, subjecting the web to at least one deflection against a fabric, such as a coarse fabric, and then creping the web. During the process, after being dewatered, the tissue web is transferred from a transfer surface to the fabric while subjecting the wet tissue web to temperatures and pressures sufficient to cause gases to evolve from liquids associated with the web. The gases form in between the tissue web and the transfer surface facilitating transfer of the web onto the fabric. In one particular embodiment, for example, gases are evolved by heating the wet web and then subjecting the web to a suction force. The gases that are evolved from the liquid include gases that were dissolved in the liquid and may include vapors that are also formed during the process, such as water vapor.

Owner:KIMBERLY-CLARK WORLDWIDE INC

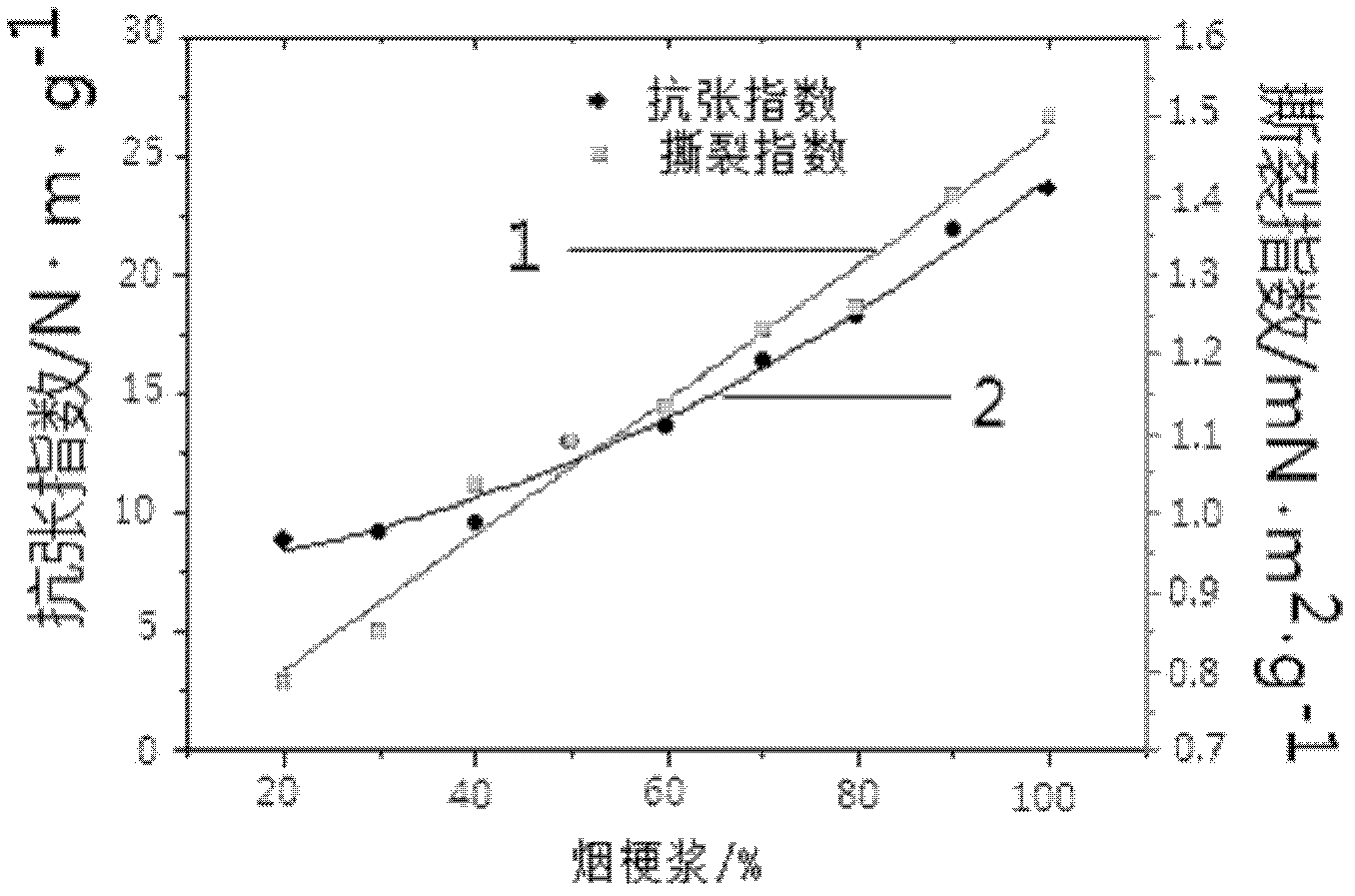

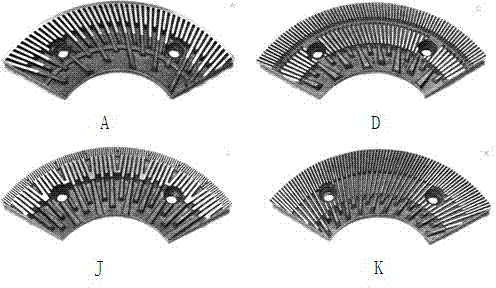

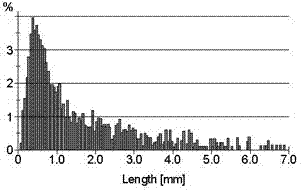

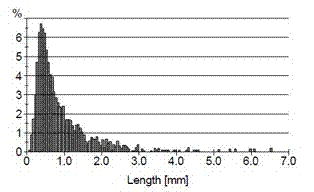

Method for preparing reconstituted tobacco paper base made from tobacco stems

The invention discloses a method for preparing reconstituted tobacco paper base made from tobacco stems, wherein the reconstituted tobacco paper base is prepared through taking the tobacco stems as a raw material and adopting a papermaking method and the preparing method comprises the steps of impregnation, defibrination, pulping, sheet making and drying of the tobacco stems. According to the invention, a technical scheme capable of optimizing the comprehensive property of the reconstituted tobacco paper base made from the tobacco stems is provided, which comprises treatment conditions of key processes of the impregnation, the defibrination, the pulping and the like; and a technical mean capable of improving the fiber morphology of the tobacco stems and the physical property of paper pulp is obtained. Showed by results, contents of water-soluble sugar, total plant alkaloid, chlorine and total nitrogen in the tobacco stems are decreased to varying degrees and the holocellulose content is relatively increased by 12.4% after the impregnation and extraction in the technical scheme provided by the invention are adopted; the fiber length of the obtained tobacco stem pulp is longest and the bulk of the finished paper is highest through selecting different types of refining plates and different defibrination gaps; and the tensile index, the tear index, the bulk, the air permeability and the burst index of a paper base product are appropriate and the good quality of reconstituted tobacco is guaranteed through combining the design of the beating degree of the tobacco stem pulp and the technical condition of the sheet making.

Owner:CHINA TOBACCO GUANGDONG IND +1

Paper pulp prepared from maize straw, preparation method thereof and paper product prepared from paper pulp

ActiveCN102154906AIncrease pulp yieldGood performance parametersPulp bleachingPulping with inorganic basesBlack liquorTear resistance

The invention relates to maize straw paper pulp, which is prepared from maize straw serving as a raw material. The whiteness of the maize straw paper pulp is 38-60 percent ISO (International Standardization Organization), the bulk is 1.8-2.5 cm<3> / g, the tensile index is 35-65 N.m / g, the folding resistance is 10-40 times, the fracture length is 4.0-6.5 km, the air permeability is 70-200 ml / min, the ash content is 5-10 percent, the tear resistance is 180-260 mN, and the tear resistance index is 3.0-4.2 mN.m<2> / g. The paper pulp has good performance parameters, can replace the conventional wood pulp and can be used for preparing cultural paper and paper for daily use. A preparation method of the maize straw paper pulp comprises stock preparation, cooking and black liquor extraction, wherein the heat preserving time in the cooking process is 0-50 minutes.

Owner:SHANDONG TRALIN PAPER

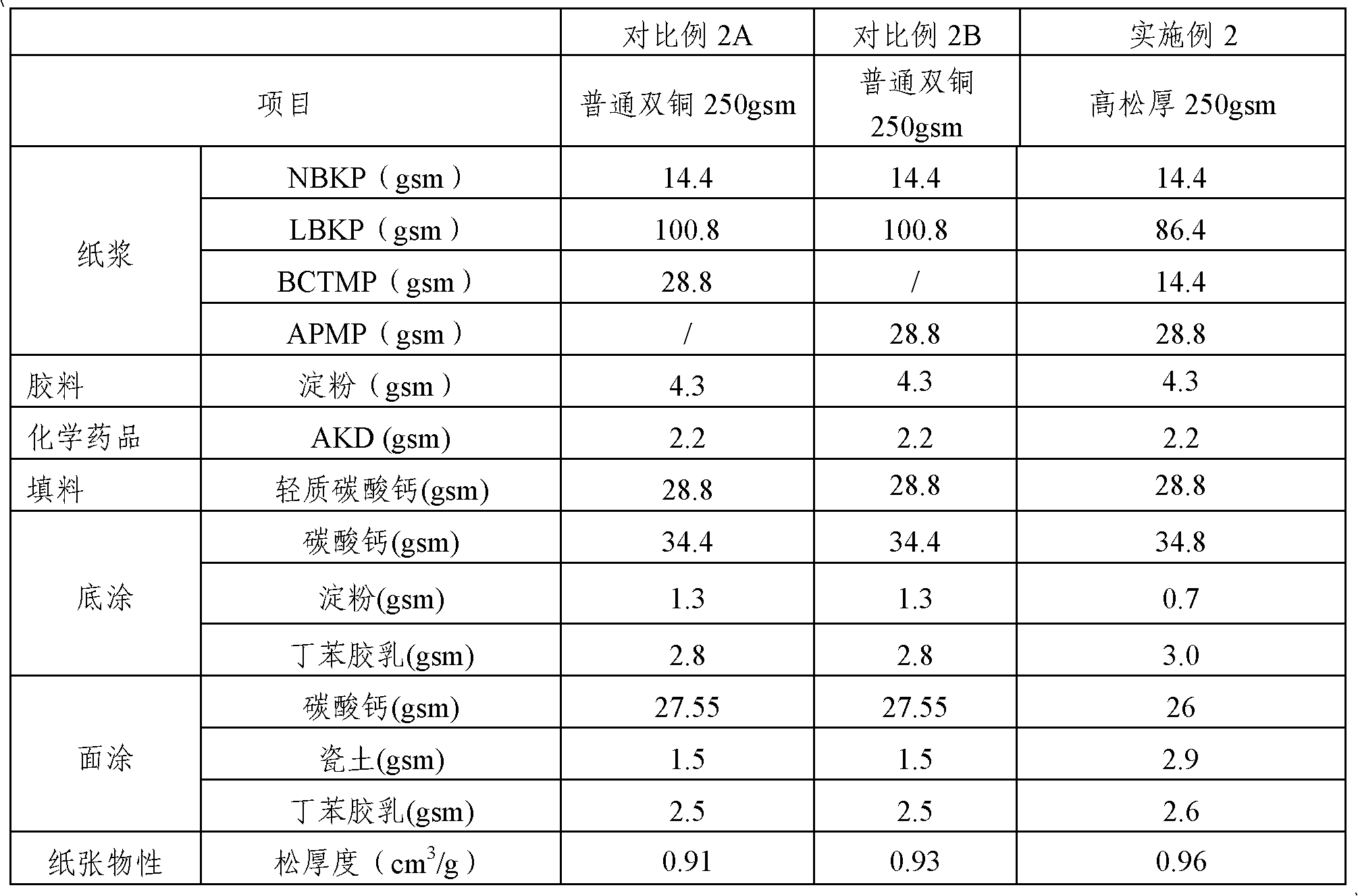

Manufacturing method of high-bulk coating printing paper

ActiveCN102877365AReduce smoothnessDegree of reductionDefoamers additionCoatings with pigmentsColor printingPulp and paper industry

The invention discloses a manufacturing method of high-bulk coating printing paper. In the method, high proportion chemical pulp is adopted for coating body paper, light calcium carbonate is used as filler, and high bulk is achieved. A door roller coating machine is used for coating the body paper, and the coating paint adopts plastic paint with a given proportion and a hollow structure, so that the bulk of the coat and the formed paper brightness can be effectively improved. Meanwhile, a soft calender is used for pre-calendering and polishing the coated body paper, so that the fineness of the paper surface is greatly improved while the thickness of the original paper is maintained. The bulk of the high-bulk coating printing paper manufactured through the method is 1.3 to 1.5 cm<3> / g and is far better than that of the ordinary copper paper and light coating paper; and meanwhile, the surface of the paper is smooth and fine, so that printed patterns are full and rich in color, image dots are clear and strong in three-dimensional impression, and the paper is applicable to top-grade color printing.

Owner:MCC PAPER YINHE

Method for preparing rose calcium carbonate from low-grade limestone

InactiveCN102502749AFull flowImprove mass transfer efficiencyCalcium/strontium/barium carbonatesChemical industryPorosityHigh surface

The invention discloses a method for preparing rose calcium carbonate from low-grade limestone, which comprises the following steps: 1) proportionally calcining low-grade limestone and blind coal to prepare calcium oxide; 2) screening under vibrations to remove coal ash and lime powder, thereby obtaining lumpy lime; 3) adding water to slake the lumpy lime, removing impurities by hydrocyclone and vibration screening to obtain fine emulsion slurry, adding a whitener, and aging to obtain the Ca(OH)2 prime slurry; 4) after regulating the temperature and concentration of the Ca(OH)2 prime slurry, adding a crystal form control agent, carrying out bubbling carbonation reaction, and adding a dispersant; when the pH value of the slurry is lower than or equal to 7, stopping carbonation to obtain a cured slurry; and 5) after the cured slurry is thickened, dehydrating to obtain the rose calcium carbonate. Compared with common light calcium carbonate, the rose calcium carbonate disclosed by the invention has the advantages of higher crystal completeness, high surface porosity, high light scattering coefficient and stronger covering power; and the invention is applicable to the industries of paper making, rubber, plastics and paint.

Owner:福建省万旗非金属材料有限公司

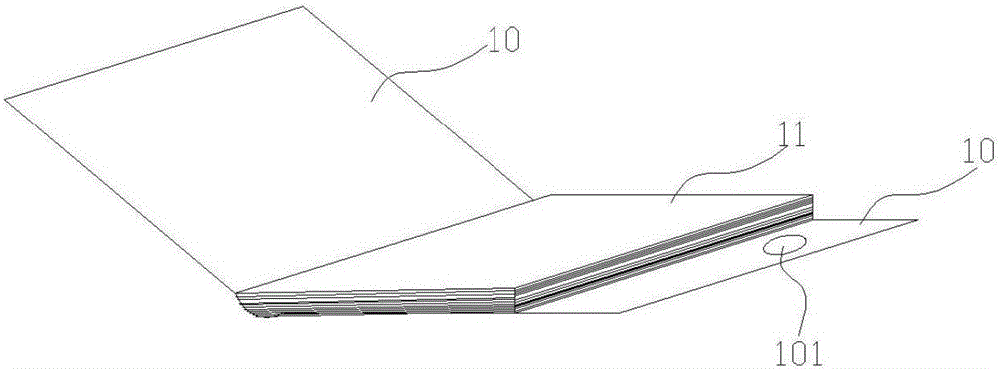

High-bulk papermaking method reconstruction tobacco leaf fiber composition and preparation method and application

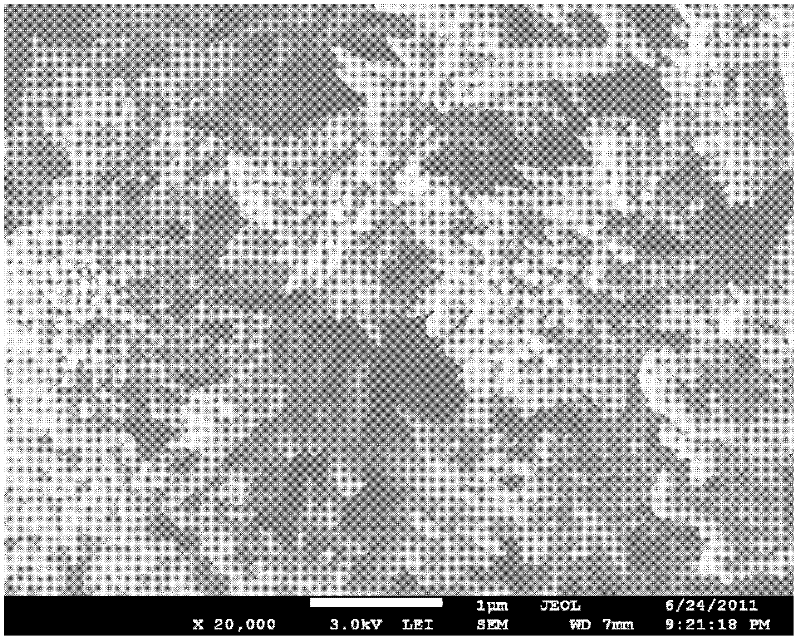

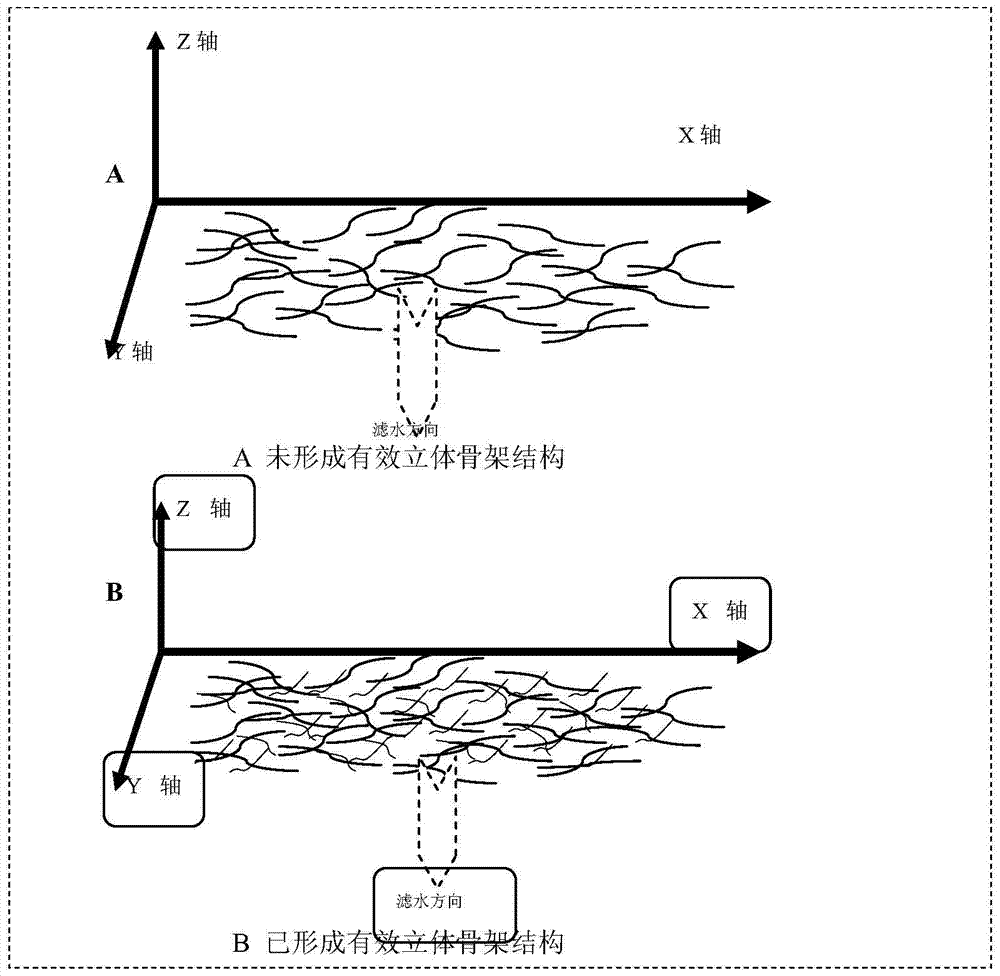

ActiveCN106993820AAchieve absorbency and bulkImprove filler retentionTobacco preparationCo releaseTobacco leaf

The invention belongs to the special papermaking production field, and specifically relates to a high-bulk papermaking method reconstruction tobacco leaf fiber composition and a preparation method and application; the reconstruction tobacco leaf comprises a tobacco raw material, wood long fibers and wood short fibers, and is prepared by mixing said compositions; the short fibers are arranged in a Z-type in a water filtering process, thus effectively improving the bulk property and spreading rate while fully ensuring the substrate tensile strength and paper machine operationability, improving filling material retention rate and product yield, reducing production cost, improving product fully combustion level, and reducing CO release amount.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Color ink-jet print paper and its producing method

InactiveCN1458337AImprove surface strengthPrint with rich and vivid colorsNon-fibrous pulp additionSulfatePulp and paper industry

The color ink-jetting print paper is produced with bleached sulfate needle leaved wood pulp, mechanical milled Italian poplar, bleached sulfate reel pulp or bleached broadleaf wood pulp and proper supplementary material and through making base paper, applying AKD glue, painting special paint, soft roller burnishing and finishing. The color ink-jetting print paper product has areal weight 70-100 g / sq m, black light density not lower than 1.2, drying time less than 20 s, color optical density not lower than 0.75, ink water dispersing time not less than 60 s, and whiteness higher than 88 %. Ithas high surface strength, and is level and smooth and results in images with bright color and clear netted points. It is suitable for color jetting printing.

Owner:YUEYANG FOREST & PAPER CO LTD

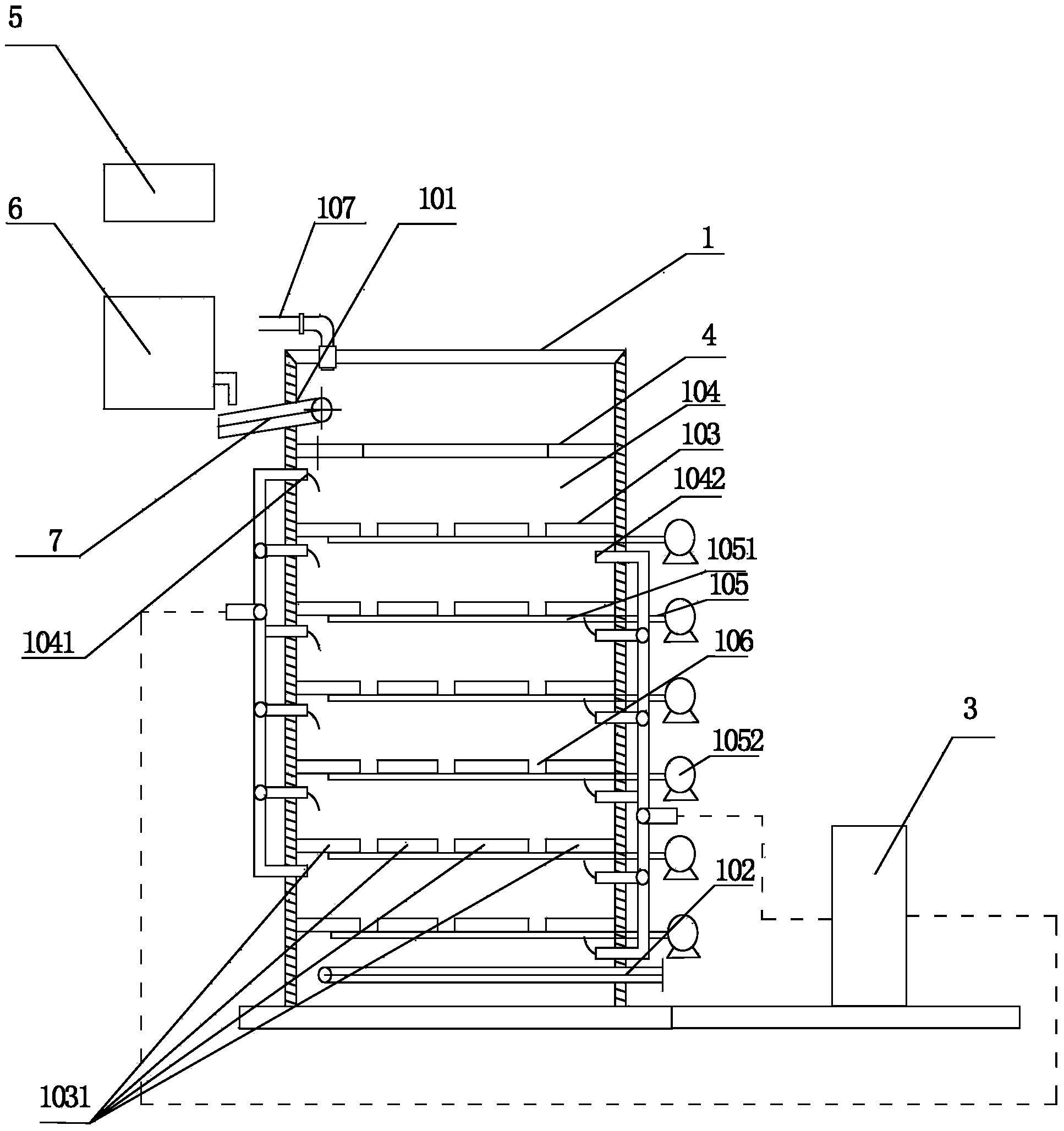

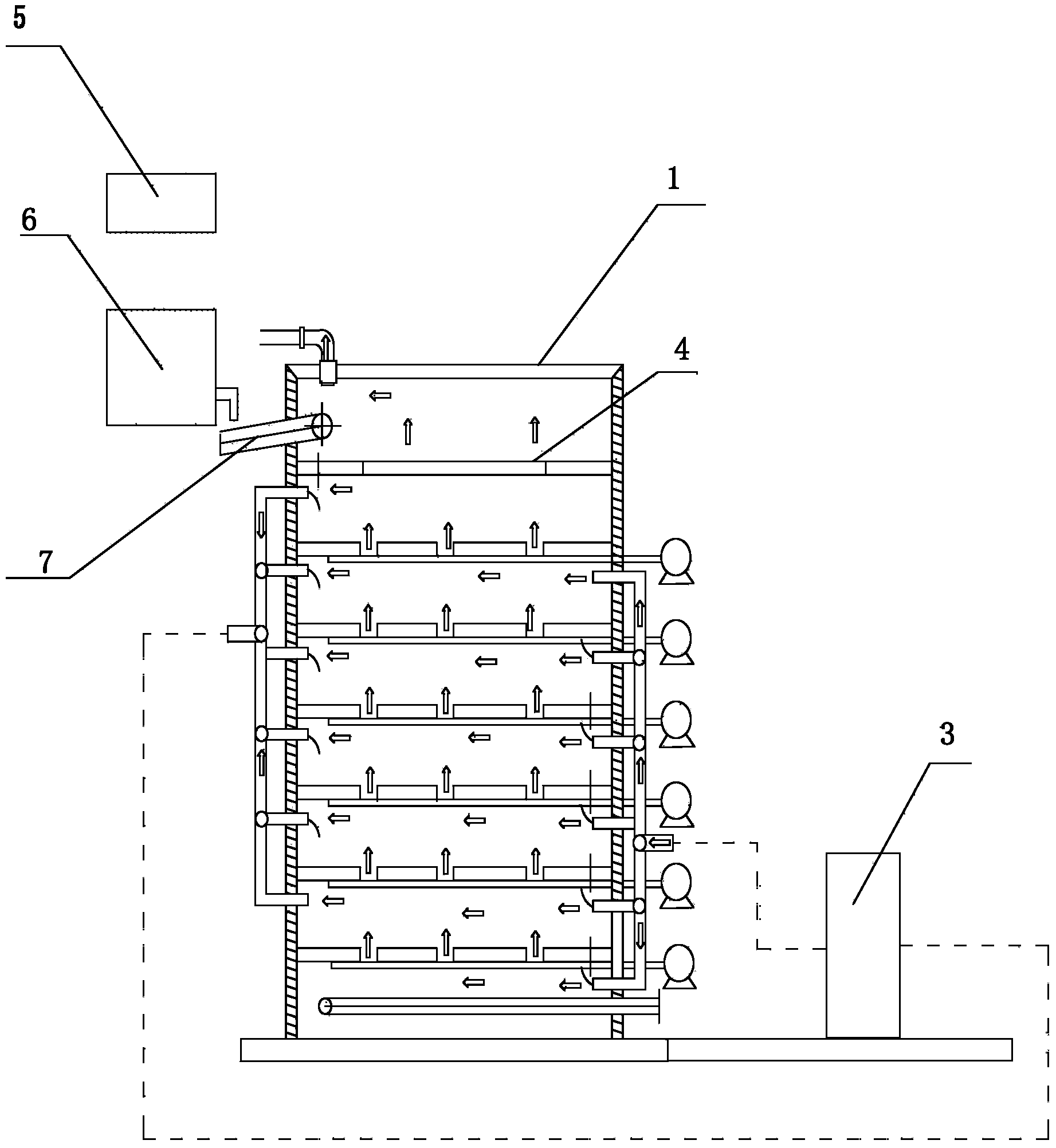

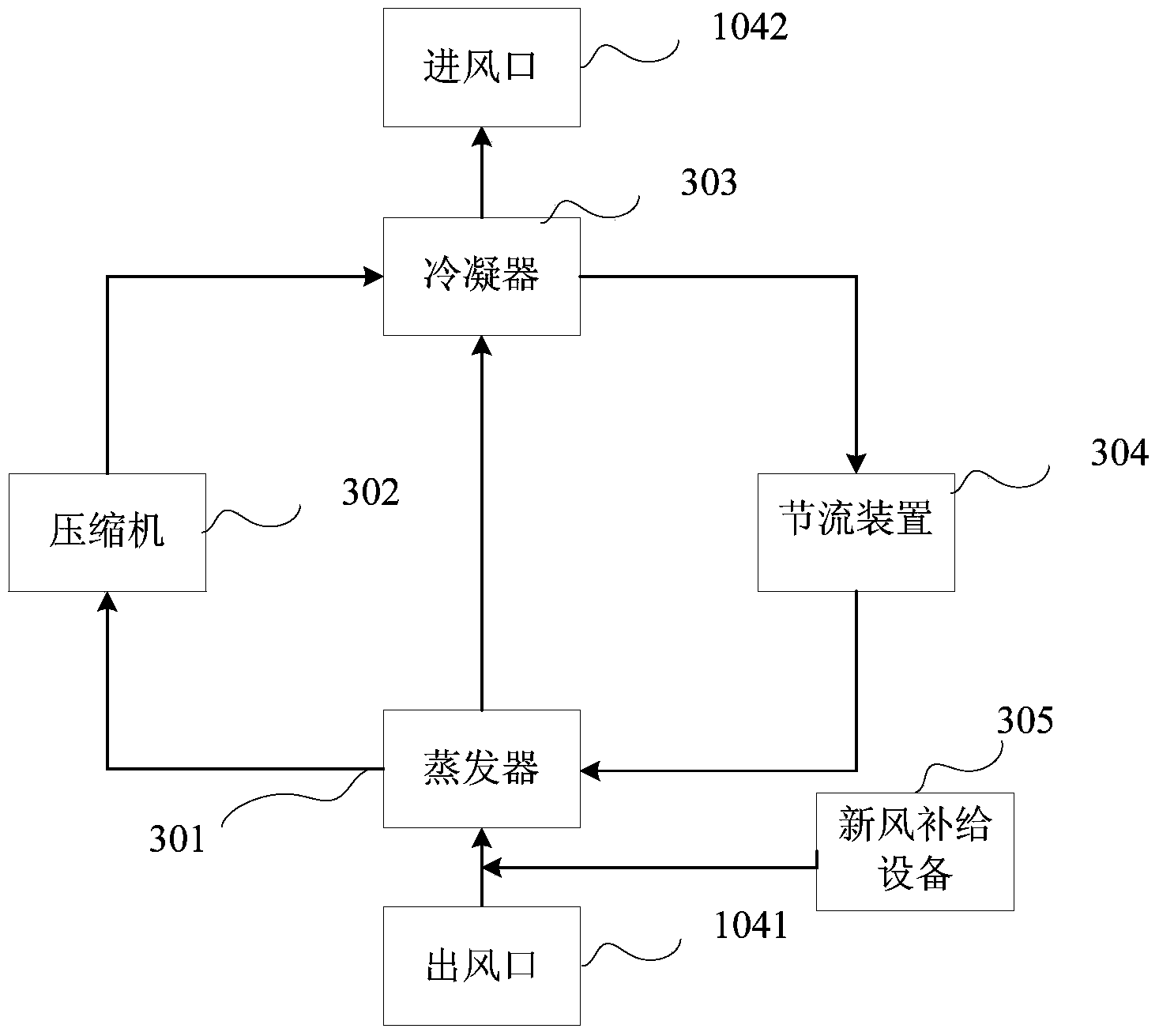

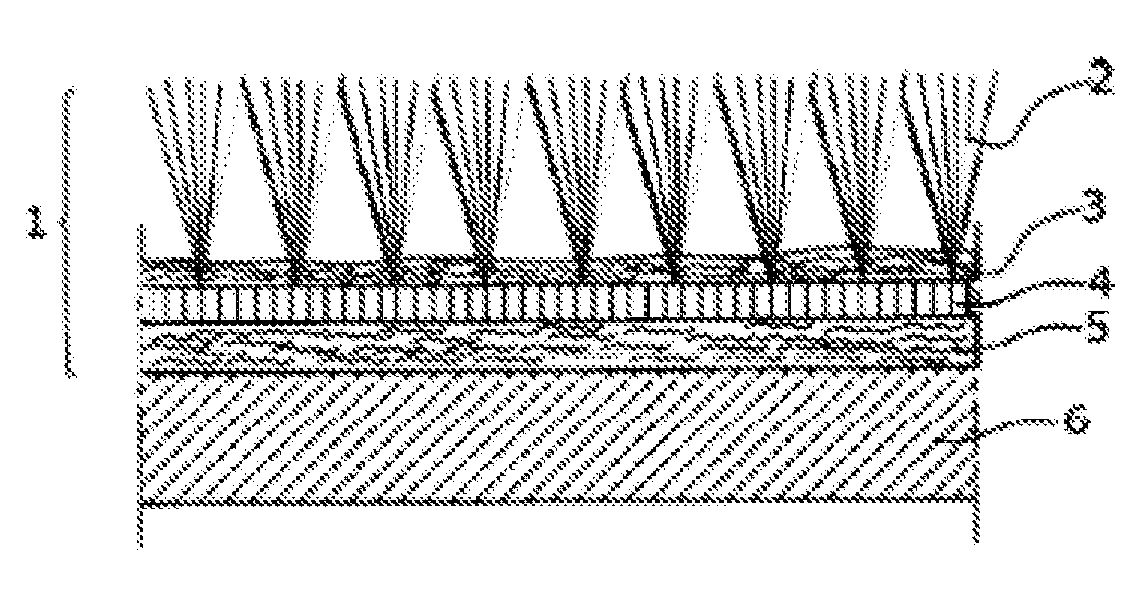

Bio-drying and dehumidifying coupled heat-pump flap tower type sludge drying process and system thereof

InactiveCN103864275AImprove utilization efficiencyAvoid cakingSludge treatment by de-watering/drying/thickeningSludge processingSludgeTower

The invention discloses a bio-drying and dehumidifying coupled heat-pump flap tower type sludge drying process and a system thereof. On one hand, the process comprises a sludge pretreatment step, so as to obtain sludge with the moisture content of 62-70%, wherein the sludge pretreatment step comprises the steps: (1) adding inoculation strains and a conditioner into the sludge with the moisture content of 62-70%, and feeding into a fermentation chamber; (2) carrying out biological aerobic fermentation treatment on the inoculation strain added sludge in the fermentation chamber for 3-10 days, and controlling the temperature of the fermentation chamber to 40-62 DEG C and the humidity of the fermentation chamber to 45-55%; (3) shipping out the sludge subjected to the biological aerobic fermentation treatment from the interior of a vertical fermentation tower, wherein the moisture content of the sludge subjected to the biological aerobic fermentation treatment is 30-50%. On the other hand, the invention further provides the system for realizing the process. The process and system disclosed by the invention have the advantages that the sludge drying effect is good, the energy consumption is low, the process and the system are suitable for continuous operation, and the like.

Owner:禹云环境科技(广州)有限责任公司

Motor vehicle parts

InactiveUS20150118437A1Reduce weightImprove relationshipSeat coveringsLayered productsUnderlayMotor vehicle part

The invention relates to a motor vehicle part material structure for sound insulation for the motor vehicle interior and motor vehicle trunk, namely floor mats floor coverings, and trunk linings, that makes it possible to industrially implement complete reprocessing of the entire composite, in particular the fiber material. The motor vehicle part has a PIT fiber layer, an optional substrate layer made of PET and / or COPET, an optional PET adhesive layer, a PET adhesive layer, a layer made of PET fiber nonwoven & brie or woven fabric, and an insulating layer made of PET / COPET.

Owner:HP PELZER HLDG GMBH

Production method of high stiffness heat transfer raw paper

ActiveCN103726396AHigh tensile strengthImprove transfer rateWater-repelling agents additionPaper coatingFiberSodium metasilicate

The invention discloses a production method of high stiffness heat transfer raw paper, which comprises the following steps: 1), disintegrating a mixed slurry; 2), preparing a glue solution applied in the slurry; 3) preparing the slurry; 4), preparing the glue solution applied on a surface; 5), forming on a net; 6), applying the glue solution onto the surface. A hardwood slurry with the fiber length of 1.25 to 1.65 mm is added into the mixed slurry, sodium metasilicate and CMC (Carboxyl Methyl Cellulose) are added in the disintegrating process of the mixed slurry, the positive surface and negative surface glue applying methods are adopted, and the prepared heat transfer raw paper is fine and smooth in surface, has a proper double-side hygroscopic property and excellent tensile strength, and has higher bulk and stiffness. Therefore, the advantages of no warpage, no wrinkle, high ink-transfer rate and bright-colored transfer can be ensured during the using process.

Owner:安徽华邦古楼新材料有限公司

Production method of art paper containing crude fibers

The invention relates to a production method of art paper containing crude fibers, which comprises the steps: preparing slurry, manufacturing by a paper machine, drying before sizing, sizing on a surface, drying after sizing, slitting, packaging and the like. Commercial bleached sulfate chemical wood pulp and sisal yarn are selected as raw materials; the raw materials comprises the following components in percentage by weight: 50-70% of softwood pulp boards, 10-30% of sisal yarns and 20-30% of hardwood pulp boards; beating processing is carried out by a beater; the beating degree of the slurry is 35-36 degrees SR; the wet weight is 4-5g; a polyvinyl alcohol aqueous solution is used as sizing liquid for surface sizing; and the concentration of polyvinyl alcohol is 5-6%, and the temperature of the surface sizing liquid is 55-60 DEG C. The production method provided by the invention is easy to implement and simple in formula of the surface sizing liquid; the surface of the obtained paper product is rough; the crude fibers protrude on the paper surface; and the processed paper is high in bulk, high in strength, high in stiffness and good in natural texture of coming back to earth.

Owner:SHANDONG KAILI SPECIAL PAPER

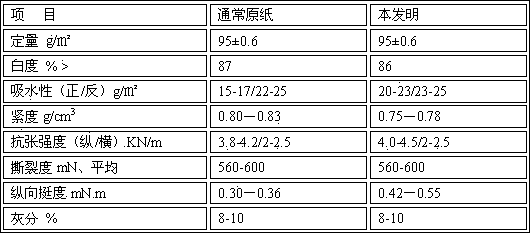

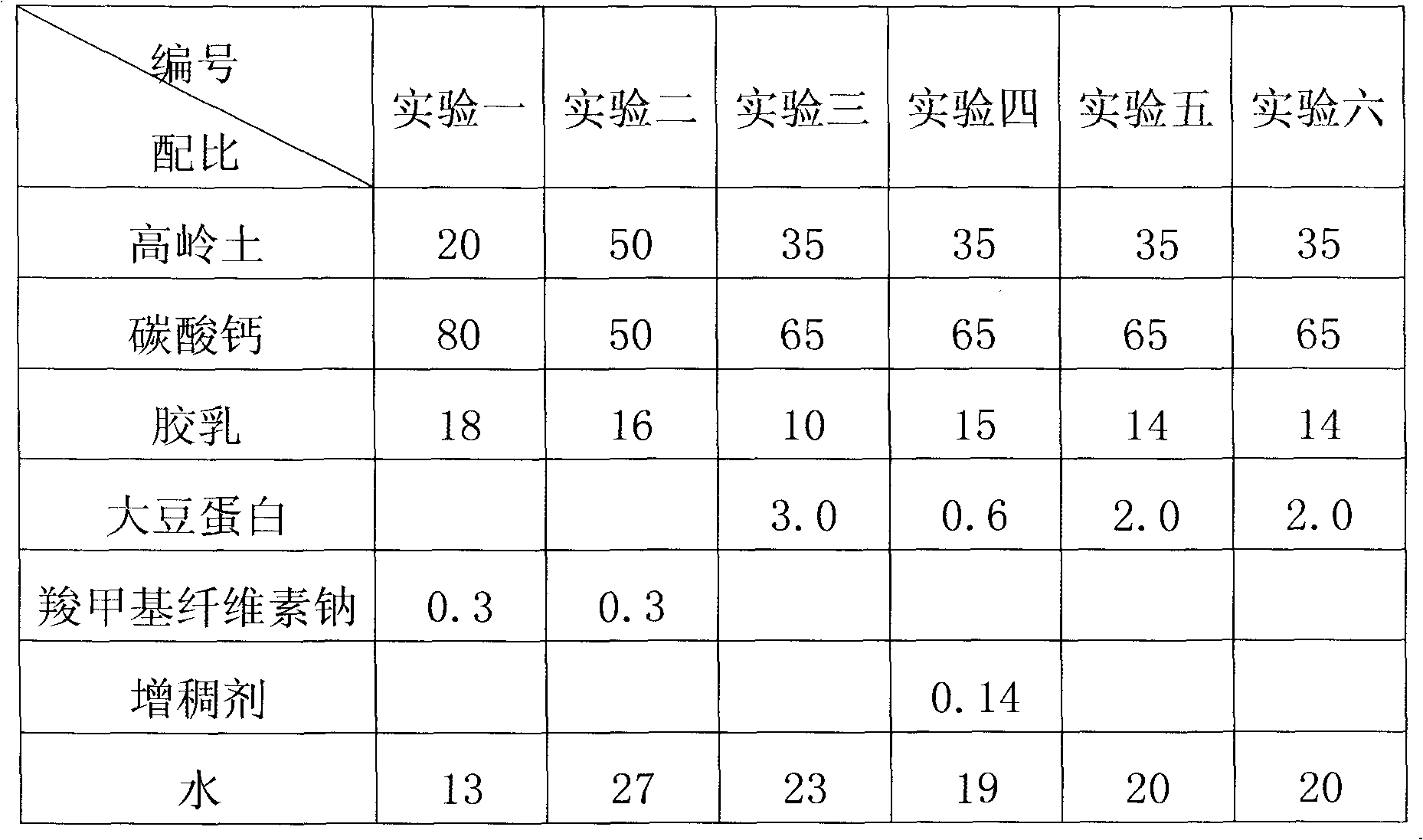

Top coating for coating layer of double-sided coating white board as well as preparation method and application thereof

The invention discloses a top coating for a coating layer of a double-sided coating white board as well as a preparation method and application thereof. As the top coating, the double-sided coating white board after being applied and coated by a coating machine not only is suitable for high-grade printing but also is suitable for vacuum forming. The top coating comprises the following components in parts by mass: 20 to 50 parts of kaolin, 50 to 80 parts of calcium carbonate, 10 to 18 parts of latex and 25 to 35 parts of water. The top coating also contains the components of a dispersant, a lubricant, a water repellent agent, a bactericide, a pH regulator and a functional assistant of 0.6 to 3.0 parts by mass of PC4200 soybean protein. By adding the functional assistant, the closure property of the coating layer can be opened, the covering property of the coating is enhanced, the use quantity of wood pulp is reduced, the smoothness of finished paper is lowered, and the infiltration of vacuum forming oil is benefited. The coating is applied and coated on a paperboard by the coating machine, can enable the paperboard to have favorable printing ink acceptance, improves the covering property of a paper face greatly and has lower smoothness and roughness and favorable printing adaptability.

Owner:YUANTONG PAPER SHANDONG

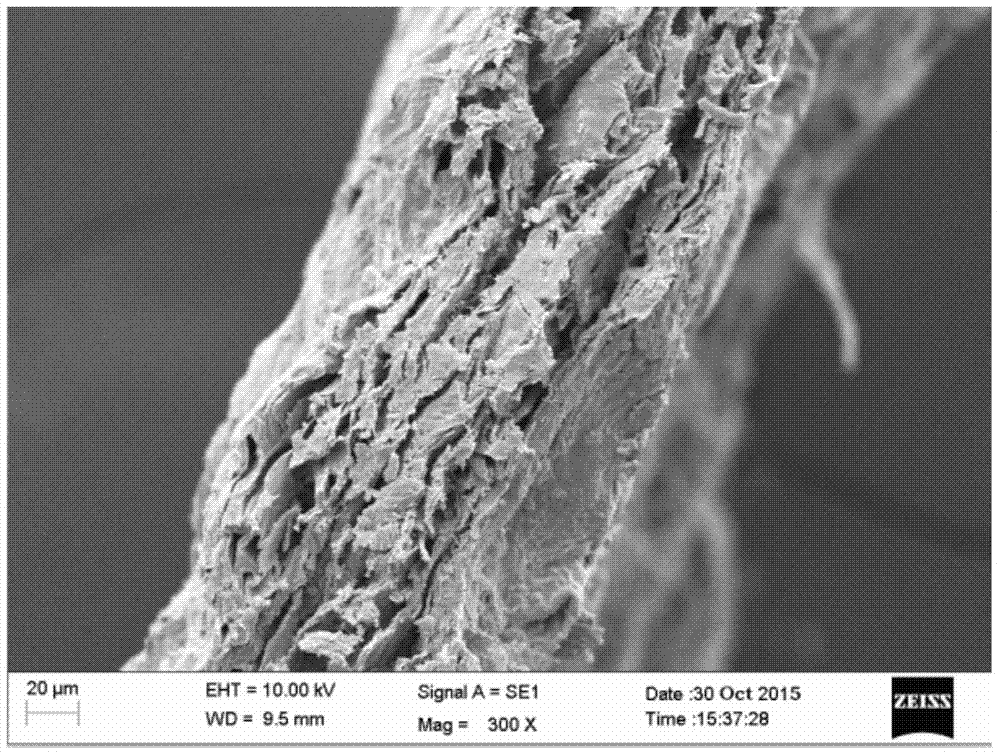

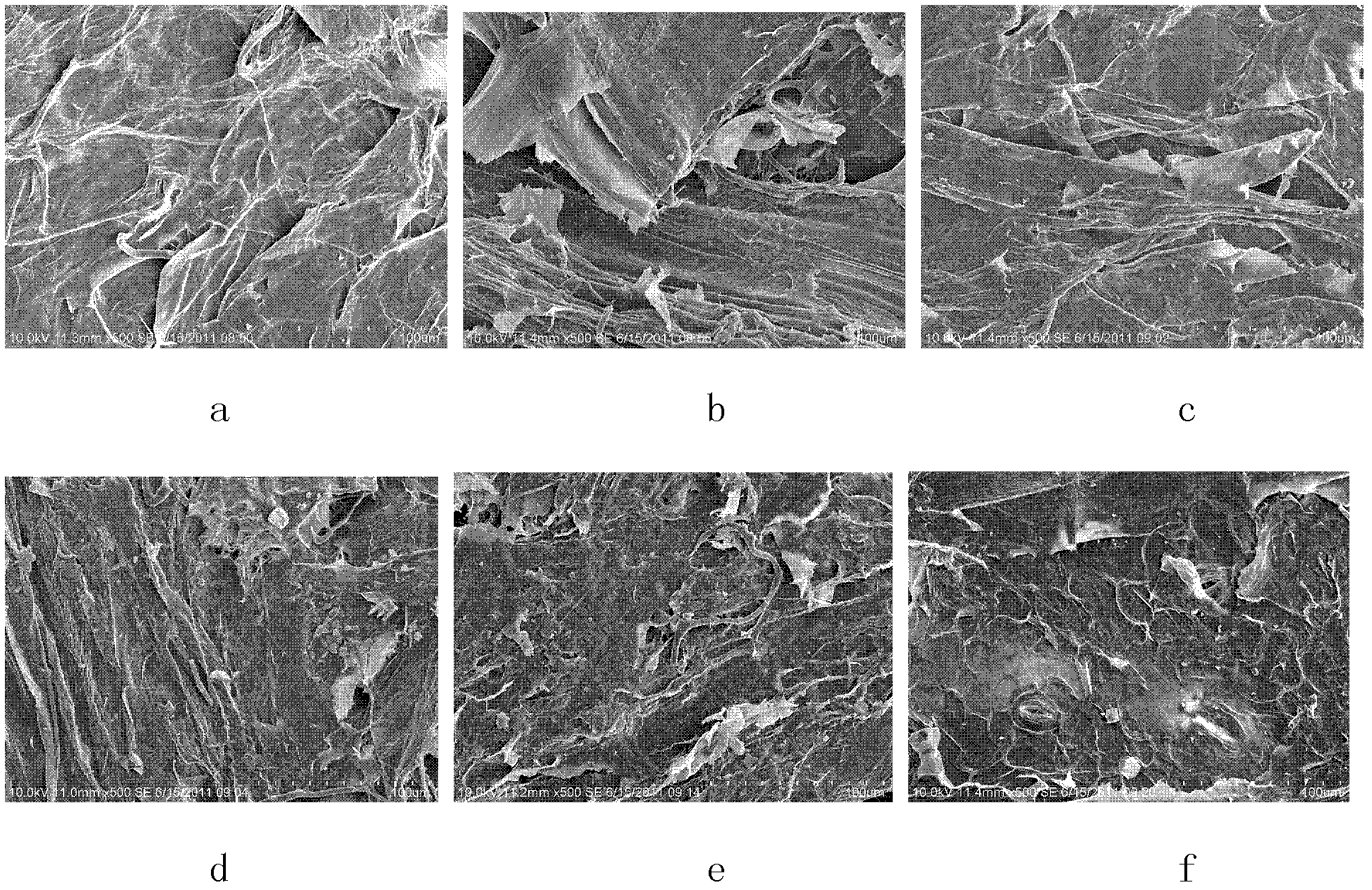

Preparation method of reconstituted tobacco from tobacco stem and tobacco powder

ActiveCN102599636AUnderstanding of physical propertiesOptimize chemical compositionTobacco preparationProduction lineChemical composition

The invention discloses a preparation method of reconstituted tobacco from tobacco stem and tobacco powder by papermaking method. The method comprises soaking to extract tobacco stem and tobacco powder, and filtering to obtain extractive solution and residue; subjecting the residue to pulping, sheet-making, squeezing and drying to obtain sheet base; and coating the extractive solution on the sheet base. The invention performs systematic research on squeezing process, provides suitable squeezing process conditions, effectively improves physical properties, chemical composition, tensile index, tearing index, bulkiness, density, air permeability, filling value, wettability and permeability of tobacco sheet base, comprehensively improves surface properties and interior structure of sheet base, and improves operation performance and effectiveness of tobacco sheet base production line.

Owner:CHINA TOBACCO GUANGDONG IND +1

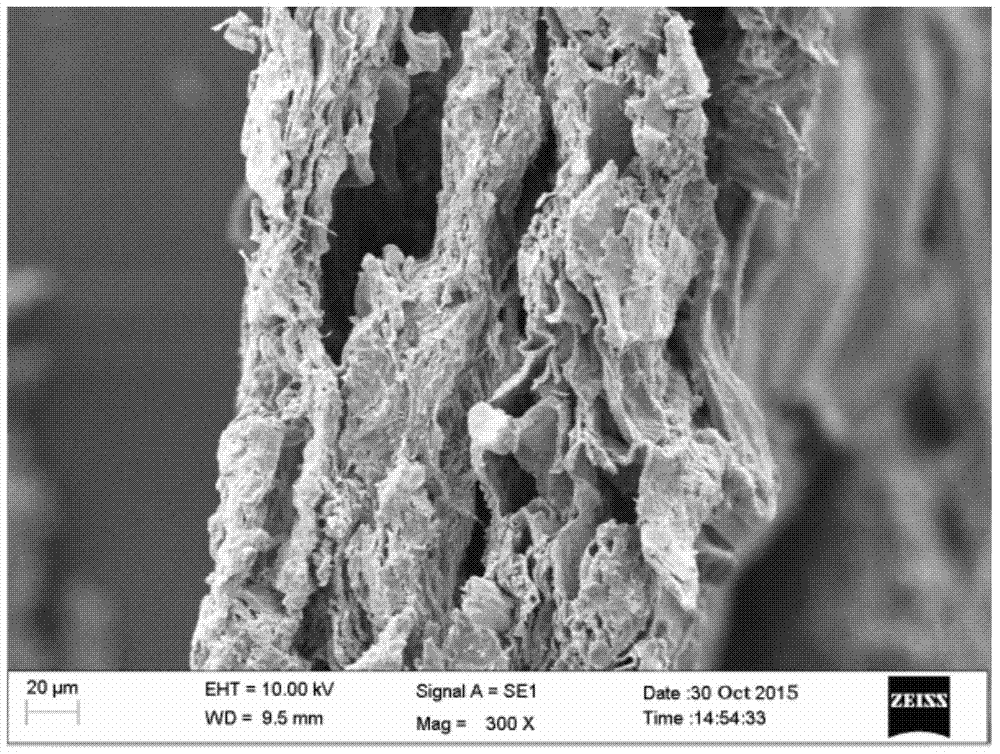

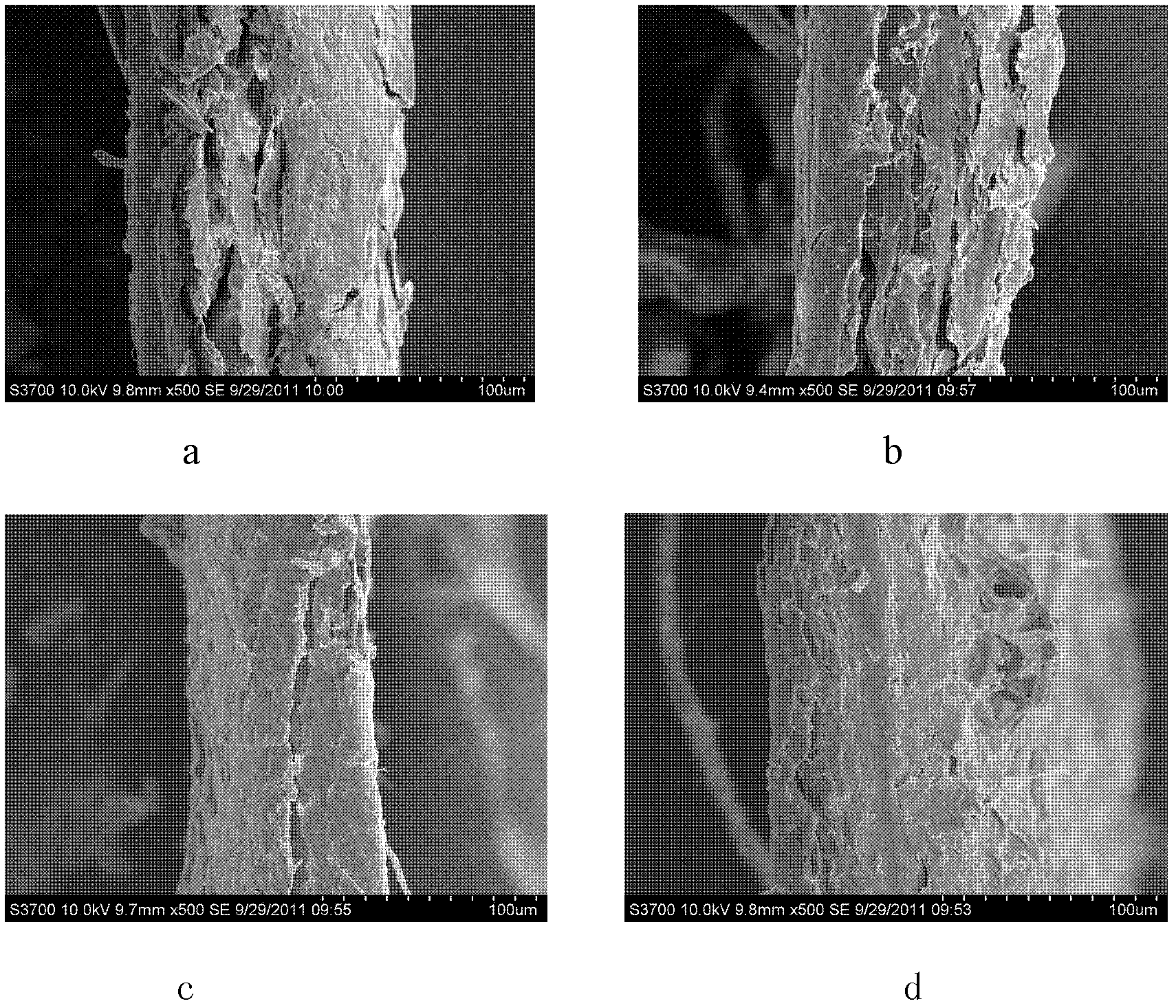

Method for preparing tobacco sheet paper base from tobacco stems

The invention discloses a method for preparing tobacco sheet paper base from tobacco stems as raw materials by adopting the paper making process. The method comprises the following steps: impregnating, pulping and making sheets. The invention changes the traditional technological prejudice and custom of controlling the pulping by controlling the current of a pulping machine and innovatively realizes the pulping by controlling the pulping disc, the pulping gaps, the pulping segments and the pulping concentration. The condition of the pulping process is optimized systematically, two or three segments of pulping are adopted, the pulping concentration is controlled at 20%, and the pulping gaps for the first and second segments of pulping are respectively 0.4mm and 0.20mm. Through studying and analyzing the relation between the pulping process and the performance of the tobacco stem fiber integrally, the controllable optimum pulping condition is summarized, the longest fiber of the tobacco stem pulp, the highest bulk of the formed paper and the good quality of the reconstituted tobacco are guaranteed, the performance of the tobacco sheet paper base is improved comprehensively, and finally the technological basis is provided for improving the quality of the tobacco sheets and the cigarettes.

Owner:CHINA TOBACCO GUANGDONG IND +1

Myopia preventing paper and production technology and application thereof

The invention discloses myopia preventing paper and a production technology and application thereof. The myopia preventing paper comprises a paper body, and the paper body reflects colored light with the wavelength of 480 nm-550 nm and presents yellow with the brightness of 56%-64%. The production technology comprises the steps that waste paper and straw are taken as raw materials, the straw is crushed into flakes, subjected to impurity removing, dewatered and then placed in a container, a swelling agent, a cooking agent and water are added into the container, and all the materials are mixed to be uniform; heating is conducted for cooking, and straw pulp is prepared; the waste paper is placed in the container; water is added into the container, and paper pulp is prepared; deinking treatment is conducted on the paper pulp; impurities are removed; the straw pulp and the paper pulp are mixed to be uniform; impurities are removed again; the mixed pulp is subjected to hot-grinding dissociation and delivered into a pulp pool, and packing and a water repellent agent are added; the mixture is fed into a paper making machine, and the paper is made. The myopia preventing paper can be applied to books of accounts, exercise books and reading materials. The finished paper made through the technology is high in fiber strength, is naturally yellow without bleaching treatment, does not need to be dyed with a dyeing agent, cannot cause environmental pollution and has the effect of preventing myopia.

Owner:重庆市林浩教学设备有限公司

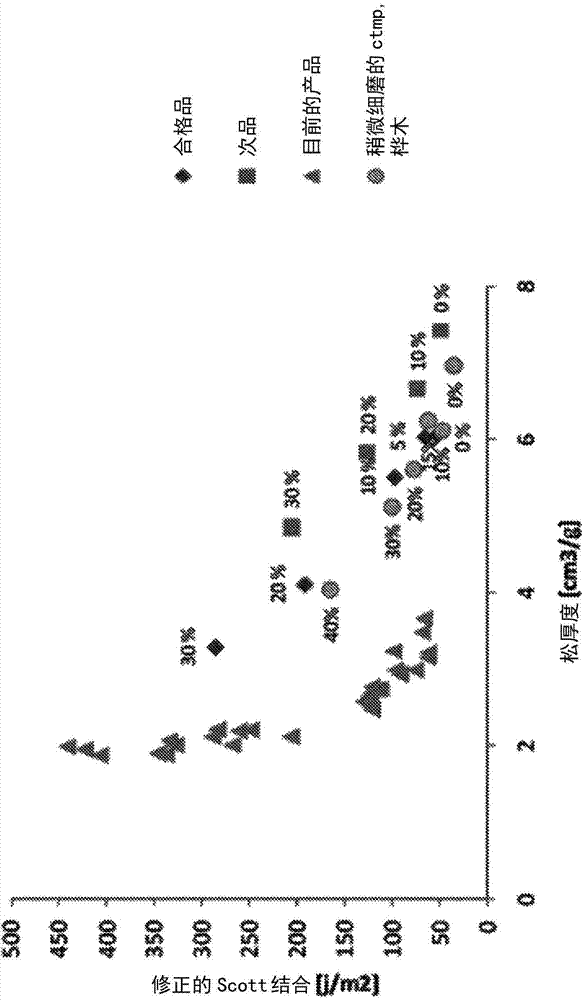

Fibrous web of paper or board and method of making the same

ActiveCN104302834AIncrease bulkImprove internal strength propertiesSpecial paperTransportation and packagingCardboardCellulose

The invention relates to a fibrous web product such as paper, and a method for the preparation of such fibrous web. According to the method microfibrillated cellulose (MFC) together with a pulp of a greater fibre length, such as chemithermomechanical pulp (CTMP), are mixed with a foam of water and a sur- factant, the foam is supplied to a forming fabric of a paper or board machine, dewatered by suction of air through the forming fabric, and dried to the final web product. The method brings a high bulk in combination with a high Scott bond value, to provide improved wet and dry tensile strength for the paper and board products.

Owner:STORA ENSO OYJ

Acoustic ceiling tiles made with paper processing waste

ActiveUS8133354B2Promote absorptionReduce the amount of solutionFibreboardCeilingsCellulose fiberSlurry

A composition and process suitable for making acoustic tiles are disclosed. Certain embodiments of the composition comprise: perlite; inorganic material selected from the group consisting of calcium sulfate, calcium carbonate, clay and mixtures thereof; a binder selected from the group consisting of starch, a combination of starch and cellulosic fibers, latex, kraft paper gel and mixtures thereof; optionally mineral wool; optionally gypsum; and cellulosic fiber, wherein at least a portion of the cellulosic fiber and at least a portion of the inorganic material are pulp and paper processing waste comprising cellulosic fiber, clay and calcium carbonate. Certain embodiments of the process comprise: forming an aqueous slurry; continuously flowing slurry onto a moving foraminous wire to form a cake; dewatering the cake to form a base mat; and drying the base mat.

Owner:USG INTERIORS INC

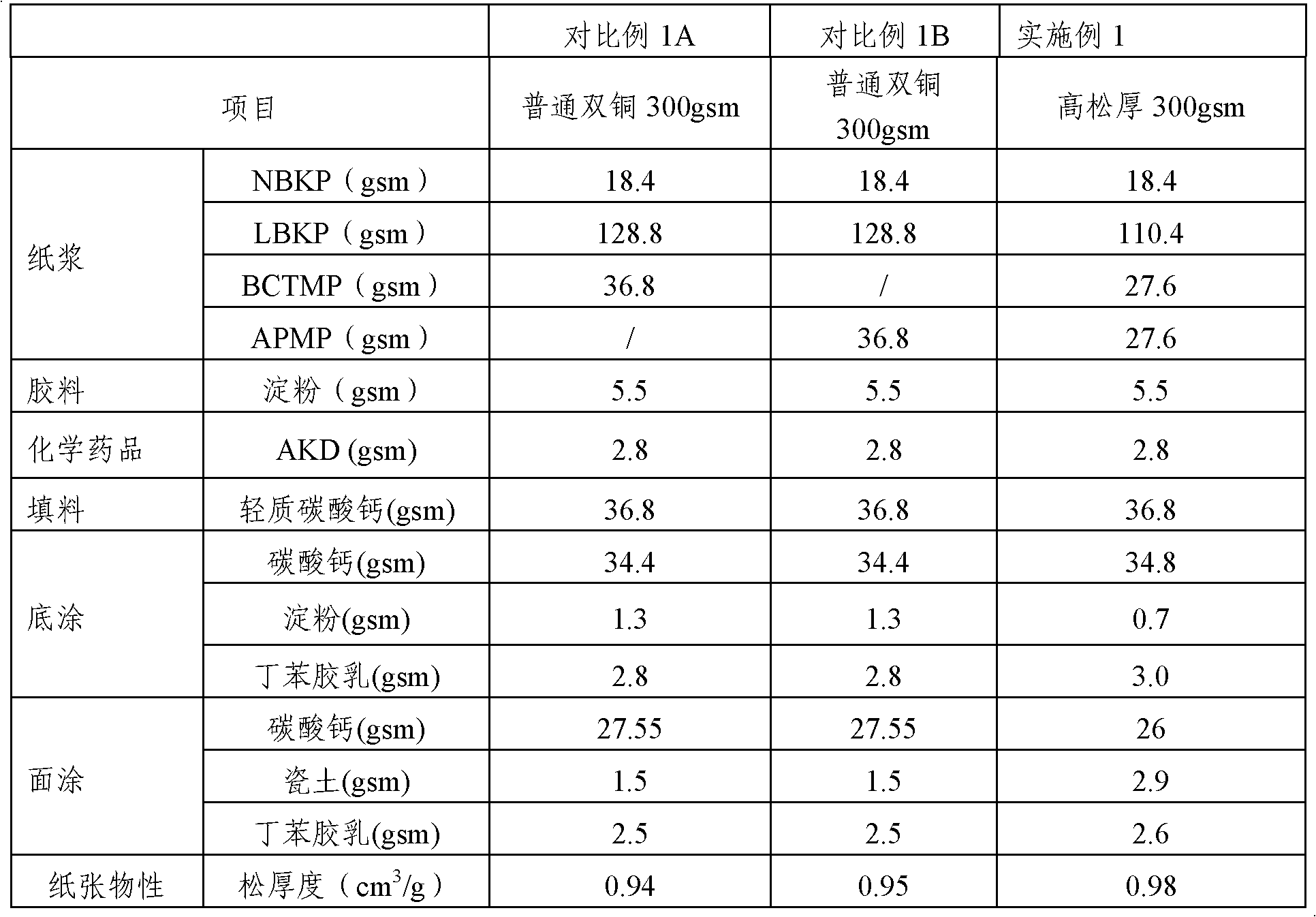

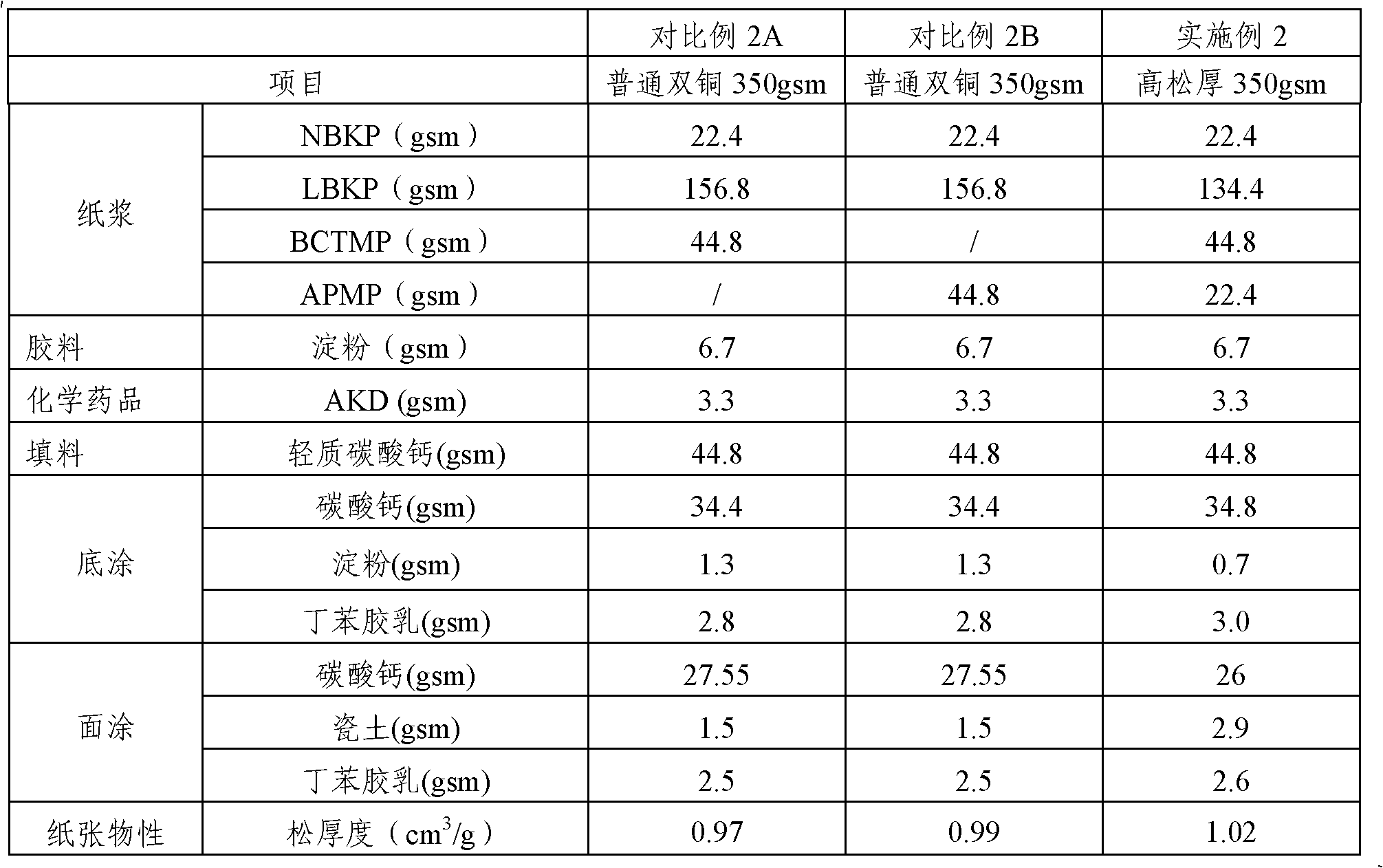

Paper pulp and high-bulk energy-saving environment-friendly card prepared from same

ActiveCN102535240AStable qualityAvoid overproductionCoatings with pigmentsSynthetic cellulose/non-cellulose material pulp/paperGramHardwood

The invention discloses paper pulp and a high-bulk energy-saving environment-friendly card prepared from the same. The paper pulp is prepared from the following components in percentage by weight: 1 to 10 percent of bleached sulfate softwood pulp, 30 to 70 percent of bleached sulfate hardwood pulp, 20 to 50 percent of chemithermomechanical pulp, and 10 to 30 percent of alkaline peroxide mechanical pulp. The invention also provides the copperplate card prepared from the paper pulp and other components. The paper made with the paper pulp is high in bulk, the gram weight of the paper is effectively controlled to be in a certain range, the paper pulp is prevented from being put into production excessively, and the defibrination energy consumption of a paper machine is reduced correspondingly, so that the effects of environment friendliness and energy saving are effectively achieved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Preparation method of bouquet type non-combustible reconstituted tobacco for heating non-combustible cigarettes

The preparation method of the bouquet type non-combustible reconstituted tobacco for the heating non-combustible cigarette comprises the following steps: respectively extracting a tobacco stem raw material and a leaf powder raw material, and carrying out solid-liquid separation after extraction to obtain tobacco stem residues and a tobacco stem extracting solution as well as leaf powder residues and a leaf powder extracting solution; mixing and grinding the tobacco stem residues and the leaf powder residues into pulp, and obtaining tobacco mixed pulp; respectively carrying out vacuum concentration on the tobacco stem extracting solution and the leaf powder extracting solution to obtain stem paste and leaf paste, and mixing the stem paste and the leaf paste to obtain a tobacco extract; mixing the tobacco mixed pulp, wood pulp fibers, a solid-phase wine aroma type substance and a filler to prepare pulp, adding an auxiliary agent, and making paper into a substrate by adopting a papermaking process; mixing and blending the tobacco extract, the atomizing agent and the essence to obtain coating liquid, coating the coating liquid on the sheet base, and drying to obtain the bouquet type non-combustible reconstituted tobacco. The reconstituted tobacco prepared by the method has unique wine fragrance and good bulk, and is particularly suitable for making low-temperature heating non-combustible cigarette products.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com