Production method of high stiffness heat transfer raw paper

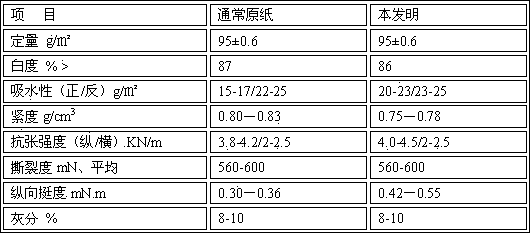

A production method and thermal transfer printing technology, which is applied in paper, papermaking, paper coating, etc., can solve the problems of inconvenient paper feeding, inconvenient finishing and transfer of printers, and wrinkling of paper surface, etc. Simple and practical, delicate surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for producing high-stiffness thermal transfer base paper, comprising the steps of:

[0042] 1) Disintegration of mixed pulp

[0043] The bleached kraft poplar pulp with a length of 1.1 mm, the bleached kraft softwood pulp with a length of 2.8 mm and the hard miscellaneous wood pulp with a length of 1.35 mm are (1.5:2:1) 1000 kg by weight. Disintegrate with a pulper (adding 3.0kg of natron, 40-45°Be in concentration, 35kg in CMC, 10% in concentration), dilute with water to 4.0% in concentration, and beat The degree of percussion is 26 0 SR slurry.

[0044] 2) Preparation of sizing solution in slurry

[0045] Add 500kg of clear water and 40kg of cationic starch into the glue pot, stir evenly, then slowly raise the temperature to 95°C, keep it warm for 20 minutes, add water to the mark, and stir evenly to prepare the slurry sizing solution for later use.

[0046] 3) Mixing slurry

[0047] Pump the mixed slurry prepared in step 1) into the batching tank, filte...

Embodiment 2

[0056] A method for producing high-stiffness thermal transfer base paper, comprising the steps of:

[0057] 1) Disintegration of mixed pulp

[0058] The bleached kraft poplar pulp with a length of 1.1mm, the bleached kraft softwood pulp with a length of 2.8mm and the hard miscellaneous wood pulp with a length of 1.35mm are (1.75:2:1) 1000 kg by weight, Disintegrate through a hydraulic pulper (adding 3.0kg of sodium hydroxide, a concentration of 40-45°Be, a weight of 50kg of CMC, and a concentration of 10%), and then dilute with water to a slurry with a weight concentration of 4.0% , and then labeled as a percussion degree of 28 0 SR slurry.

[0059] 2) Preparation of sizing solution in slurry

[0060] Add 500kg of clear water and 40kg of cationic starch into the glue pot, stir evenly, then slowly raise the temperature to 95°C, keep it warm for 20 minutes, add water to the mark, and stir evenly to prepare the slurry sizing solution for later use.

[0061] 3) Mixing slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| beating degree | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com