Patents

Literature

2073 results about "Sodium metasilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium metasilicate is a highly corrosive substance, particularly when water is added. For this reason, it is used in a variety of settings. The compound is found as an ingredient in fireproofing mixtures, household cleaning, insecticides, fungicides and as a bleaching aid.

Water-based cleaner

ActiveCN101538512ACause wasteAvoid cleaning costsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedSodium metasilicate

A water-based cleaner is prepared by surfactant primary washing part, alkaline auxiliary washing part, solvent part, preservative and water; wherein the surfactant primary washing part is compounded by anion and nonionic surfactant; the alkaline auxiliary agent part selects trolamine, sodium metasilicate pentahydrate which has dispersive action on dirt and EDTA disodium which has chelation on metallic ions, and excludes phosphate accessory aid which pollutes water quality. The solvent part selectes alcohol, glycol ether or natural orange oil extract D-limonene which have good safety performance, strong solvency and little environmental pollution. The preservative selects food grade preservative propylparaben which is safe and nontoxic. The invention adopts concentrate formula, the preparation method is simple, users can dilute the product according to object to be washed and the degree of dirt, and operate with reasonable using concentration, thus avoiding the waste of washing cost due to excessive concentration and the waste of energy. The inventive water-based cleaner reduces package cost and transportation cost, and has no adverse effect on the environment.

Owner:SHANGHAI JIUSHENG IND

Glass cleaning agent composite for electronic industry

InactiveCN1482223AEasy to cleanRaw materials are easy to getInorganic non-surface-active detergent compositionsSodium bicarbonateSodium metasilicate

The electronic industrial glass cleaning agent composition belongs to the field of electronic industrial cleaning technology. The cleaning agent consists of sodium metasilicate, sodium hydroxide, sodium carbonate, sodium bicarbonate, Pluronic polyol, CMC, fluoric surfactant, complexing agent, defoaming agent and deionized water. It is used to clean substrate glass and coated conducting glass. During the cleaning, the cleaning agent in 1-5 % is compounded with deionized water in 95-99 % to compound the cleaning liquid for showering or ultrasonic cleaning to eliminate pollutant on glass fastcompletely. It is used to replace strong acid and strong alkali cleaning agent and has no damage to glass surface and no corrosion to ITO film. The cleaning agent has no bad smell, no toxicity and no corrosion, and is safe, reliable, environment friendly and low in cost.

Owner:SHANDONG UNIV

System for Highlighting Hair

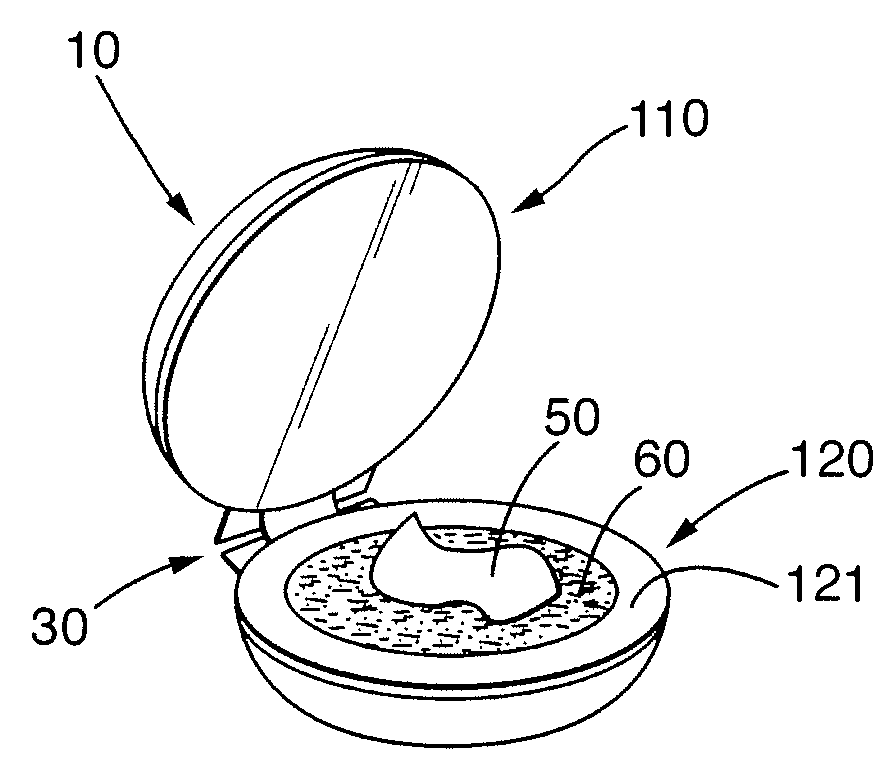

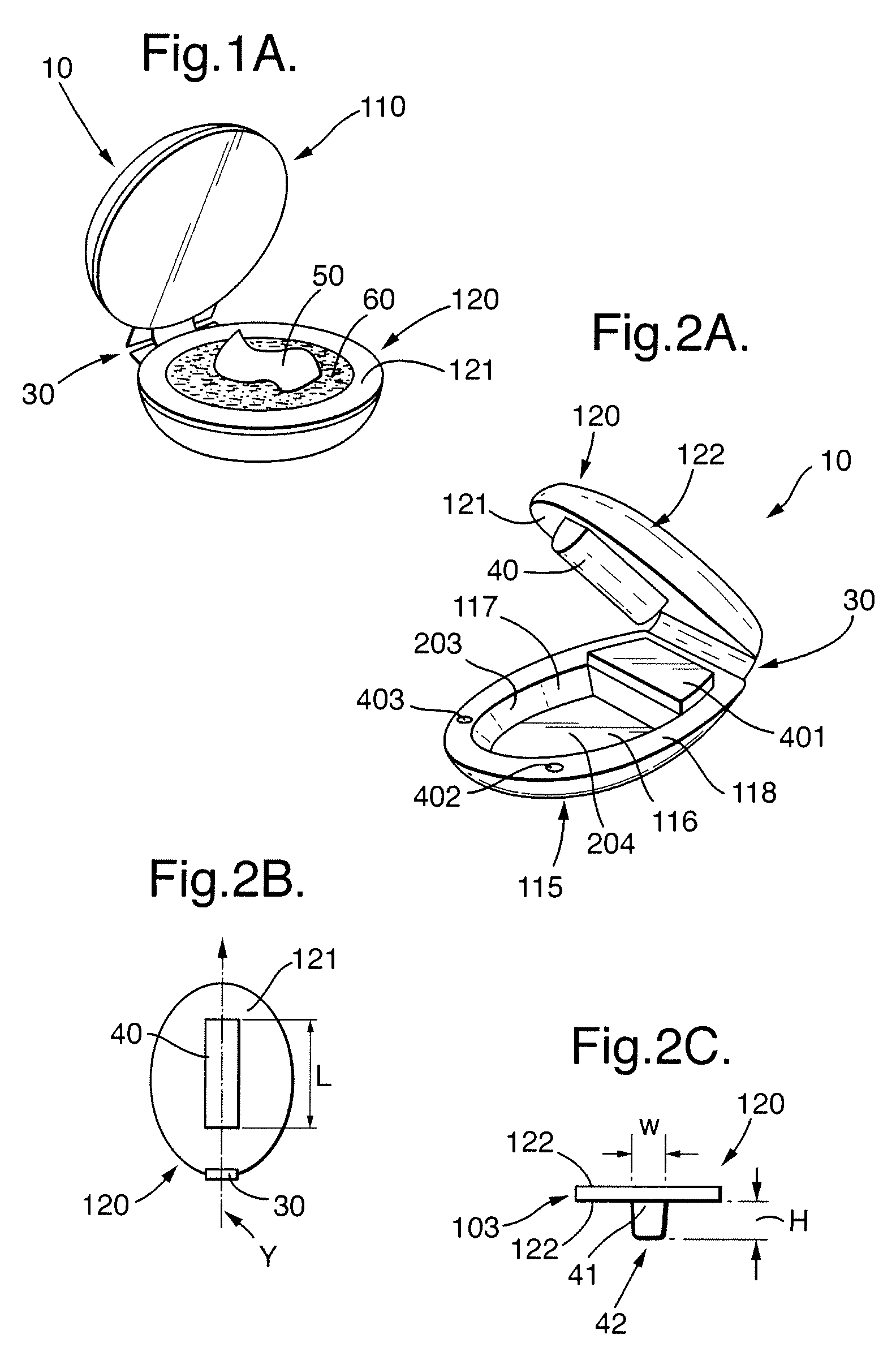

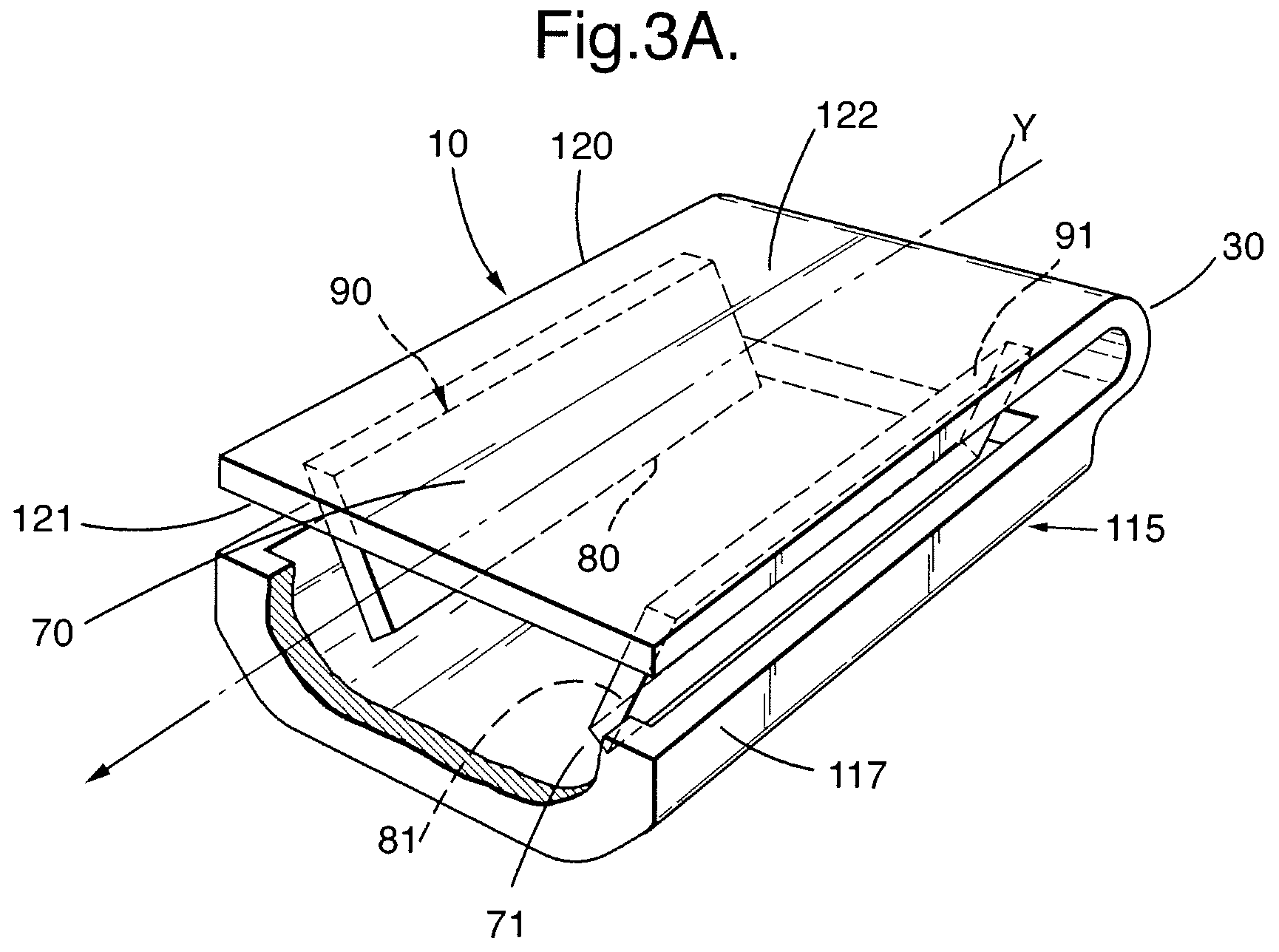

The present invention relates to a system to highlight the hair. The system comprises a device (10) and a composition (50). Device (10) comprises a first portion movably joined to a second portion. Composition (50) comprises a percentage of hydrogen peroxide and a percentage of an alkalizer by weight of said composition (50). The weight percentages of hydrogen peroxide and of an alkalizer are defined by equation (I): X+1.5Y≧15 (I) wherein X is the percentage by weight of hydrogen peroxide by weight of the composition (50) and wherein Y is the percentage by weight of an alkalizer by weight of the composition (50). Said composition (50) comprises at least 2% of hydrogen peroxide by weight of said composition (50) and said alkalizer is an inorganic salt selected from the group consisting of sodium silicate, sodium metasilicate, potassium hydrogen carbonate, ammonium carbonate, ammonium hydrogen carbonate and sodium hydrogen carbonate and mixtures thereof. Said composition (50) allows to perform highlighting when applied with the device (10) as described herein.

Owner:WELLA OPERATIONS US LLC

Modified physical refining of soybean oil

ActiveUS6924381B2Fatty oils/acids recovery from wasteOrganic compound preparationSodium metasilicatePhospholipid

A solvent extraction free, process for producing refined soybean oil that is high in calcium and / or magnesium is described in which mechanically extracted crude soybean oil is subjected to a two-stage process to separate hydratable and nonhydratable phospholipids. In the first stage, the crude oil is intimately mixed with water or with a weakly acidic aqueous solution, e.g., a aqueous solution of citric acid or a similar organic acid, to form gums of the hydratable phospholipids. After removing the gums from the oil, e.g., by centrifuging, the oil from the first degumming is intimately mixed with a weakly basic solution, e.g., an aqueous solution of sodium hydroxide or sodium metasilicate, to produce soapstock and reduce the magnesium and calcium in the oil to less than 100 ppm, followed by separation of the soapstock, e.g., by centrifuging. Free fatty acids are then removed through physical refining.

Owner:WHOLE HARVEST FOODS

High-temperature-resisting easy collapse molding sand and preparation method thereof

InactiveCN103495693AImprove breathabilityImprove liquidityFoundry mouldsFoundry coresWet bondingSodium metasilicate

High-temperature-resisting easy collapse molding sand is made from, by weight, 240-280 parts of quartz sand, 50-55 parts of lightweight calcium carbonate powder, 20-30 parts of hollow ceramic microspheres, 10-15 parts of hollow glass microspheres, 40-55 parts of aluminum silicate powder, 25-30 parts of titanium dioxide, 35-40 parts of fluorite nano-powder, 30-40 parts of gypsum whisker, 60-70 parts of expanded perlite, 10-15 parts of talcum powder, 2-4 parts of sodium metasilicate, 1-2 parts of glucose powder, 1-2 parts of urea, 1-2 parts of chlorinated paraffin, and a proper amount of water. The materials such as the hollow ceramic microspheres and the hollow glass microspheres are used, so that the molding sand is fine in breathability and fluidity; meanwhile, the lightweight calcium carbonate, the glucose, the urea and the like are used, so that the molding sand is fine in high temperature collapsibility, high dry strength of sand molds, high in wet bonding power, excellent in sticking resistance and applicable to various hardening manners; drying time after CO2 hardening is shortened, and reuse rate of used sand can be increased significantly.

Owner:HEFEI CITY TENVER PRECISION CASTING

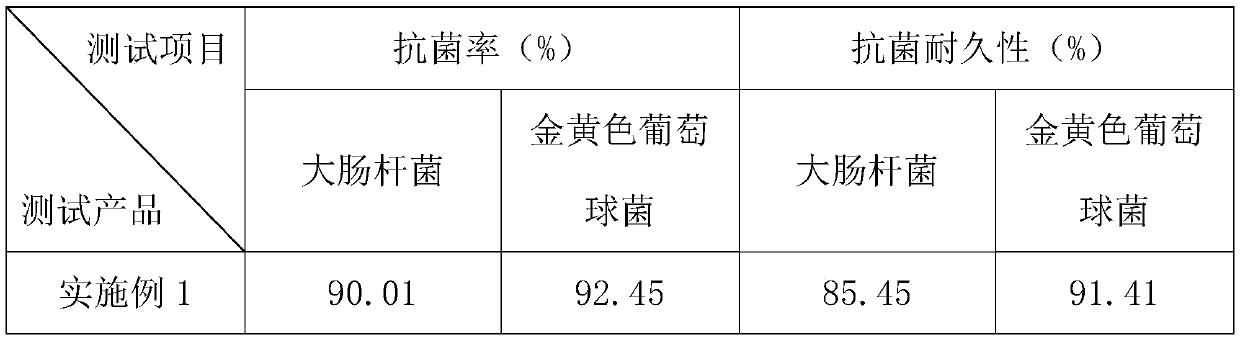

Antibacterial ceramic glaze, and preparation method and application thereof

The invention relates to the technical field of architectural ceramics, and in particular, relates to antibacterial ceramic glaze, and a preparation method and an application thereof. The antibacterial ceramic glaze is composed of the following raw material components: a ceramic glaze material, an antibacterial agent, a suspending agent and a peptizing agent, wherein the antibacterial agent is a mixture of nano zirconium silicate loaded silver and nano zinc oxide, and the addition amount of the nano zirconium silicate loaded silver is 2-6% and the addition amount of the nano zinc oxide is 0.05-2% according to the weight percentage of the dry weight of the ceramic glaze material; the suspending agent is a mixture of low-viscosity sodium carboxymethyl cellulose and medium-viscosity sodium carboxymethyl cellulose; the peptizing agent is one of sodium tripolyphosphate or sodium metasilicate. The invention aims to provide the antibacterial ceramic glaze, and the preparation method and the application thereof; the prepared ceramic glaze can realize uniform dispersion of an antibacterial agent in the ceramic tile surface glaze, and has efficient sterilization and bacteriostasis effects and stable sustainable sterilization effect.

Owner:FOSHAN DONGPENG CERAMIC +3

Organic/inorganic slow-release fertilizer for flowers and preparation method of slow-release fertilizer

InactiveCN104355802AHigh nutrient contentExtended nutrient release periodAlkali orthophosphate fertiliserExcrement fertilisersSodium metasilicateSlag

The invention discloses an organic / inorganic slow-release fertilizer for flowers and a preparation method of the slow-release fertilizer. The organic / inorganic slow-release fertilizer is prepared from the following raw materials in parts by weight: 45 to 55 parts of horse manure, 20 to 30 parts of wheat bran, 15 to 25 parts of brewer's grains, 12 to 18 parts of flour beetle frass sand, 10 to 15 parts of residual tea, 5 to 10 parts of edible fungi waste, 18 to 26 parts of sorgo straw, 10 to 15 parts of mung bean shells, 5 to 10 parts of sugar beet meal, 1 to 3 parts of spawn powder, 16 to 22 parts of yellow phosphorus furnace slag, 20 to 30 parts of obsidian, 17 to 24 parts of hectorite, 10 to 15 of parts zeolite 4A, 32 to 44 parts of ammonium nitrate, 22 to 28 parts of ammonium hydrogen phosphate ammonium dihydrogen phosphate, 8 to 14 parts of potassium carbonate, 2 to 3 parts of diaminoferric xanthohumate, 3 to 6 parts of sugar calcium, 4 to 8 parts of sodium metasilicate, 15 to 20 parts of polyvinyl alcohol, 5 to 10 parts of carboxymethyl cellulose, 9 to 16 parts of hydroxypropyl xanthan gum, 2 to 4 parts of algal polysaccharides, and 3 to 5 parts of polyglutamic acid. The fertilizer provided by the invention is high in nutrient amount and high and long in fertilizer efficiency, can improve soil, enables soil to form granular structures, and harmonizes water and gas in soil to enable flowers to grow up well and quickly, thereby improving the quality and the yield of flowers and lowering the fertilization cost; important economic benefits are brought.

Owner:CHONGQING UNIV OF ARTS & SCI

Development of radiation-sensitive elements

InactiveUS20060154187A1Easily rinse awayModerates aggressivenessPhotomechanical apparatusOriginals for photomechanical treatmentSodium metasilicatePolyvinyl alcohol

An aqueous alkaline developer for use with an imaged lithographic printing precursor comprises an aqueous alkaline medium, sodium metasilicate, a steric or electrosteric stabilizer, and a rinse aid or a phase stabilizer. It is suited for developing a lithographic printing precursor comprising, on a substrate, a coated and dried layer of a radiation-sensitive composition comprising one or more acetal resins. The developer may further contain a moderator, a dispersing agent capable of solvating a hydrophobic image colorant, and a wetting agent. The acetal resin of the precursor may be derived from polyvinyl alcohol by condensation with aldehydes. The imageable element is imageable by radiation, preferably infrared radiation, and provides good sensitivity for use in lithographic applications, such as conventional imaging systems, computer-to-plate systems or other direct imaging elements and applications when treated with the developer. The invention also provides a positive-working lithographic printing master comprising a precursor as aforesaid, imaged and developed with the developer. The invention further provides a method for cleaning the processor equipment in which the imaged lithographic printing precursor has been developed, comprising treating the deposit with an acid to yield liberated image colorant and treating the liberated image colorant with a cleaning composition.

Owner:KODAK GRAPHIC COMM CANADA CO

Processing and antistaling technology for vegetable

InactiveCN1413473AImprove preservation qualityExtended shelf lifeFruit and vegetables preservationSodium metasilicateMixed gas

An antistaling technology for cleaned vegetables includes such steps as reaping the raw vegetables in time, screening, adding sodium metasilicate to water, washing vegetables, flushing wich clean water, immersing the vegetables in the cold water containing ozone, surficial dewatering, loading in antistaling bags, aerating gas mixture, sealing and storing in antistaling warehouse. Its avvantages are longer antistaling period and retaining the nutrients to maximum, and high effect of cleaning and bacteride.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Composite porous activated carbon flue gas adsorbent and preparation method thereof

InactiveCN104437371AImprove toughnessHigh strengthOther chemical processesDispersed particle separationPorositySodium metasilicate

The invention discloses a composite porous activated carbon flue gas adsorbent which is characterized by comprising the following raw materials in parts by weight: 98-105 parts of shell activated carbon, 36-40 parts of diatomite, 2-3 parts of sodium metasilicate, 2-3 parts of rosin, 2-3 parts of VAE emulsion, 2-3 parts of polyvinyl alcohol, 1-2 parts of sodium alcohol ether sulphate, 1-2 parts of sodium citrate, 1-2 parts of gypsum residue, 2.5-3.5 parts of pulverized fuel ash, 4-5 parts of edible corn starch, 2-3 parts of lanthanum nitrate, 9-12 parts of glass fiber powder, 4-6 parts of adsorption aids and a proper amount of water. The composite porous activated carbon flue gas adsorbent disclosed by the invention is reasonable in formula, viscous matters such as polyvinyl alcohol and edible corn starch are added, the toughness and strength of the activated carbon are improved, and the service life is prolonged; and due to the addition of the adsorption aids, the adsorbent has special porosity, the contact time between gas and the adsorbent is prolonged, and the effects of inhibiting bacteria and purifying the air are achieved. Therefore, the adsorption efficiency is high, the production process is simple, and the adsorbent is suitable for industrial dry desulfurization, automobile exhaust desulfurization and daily air purification.

Owner:ANHUI TOPTECHSCR ENVIRONMENTAL SCI & TECH

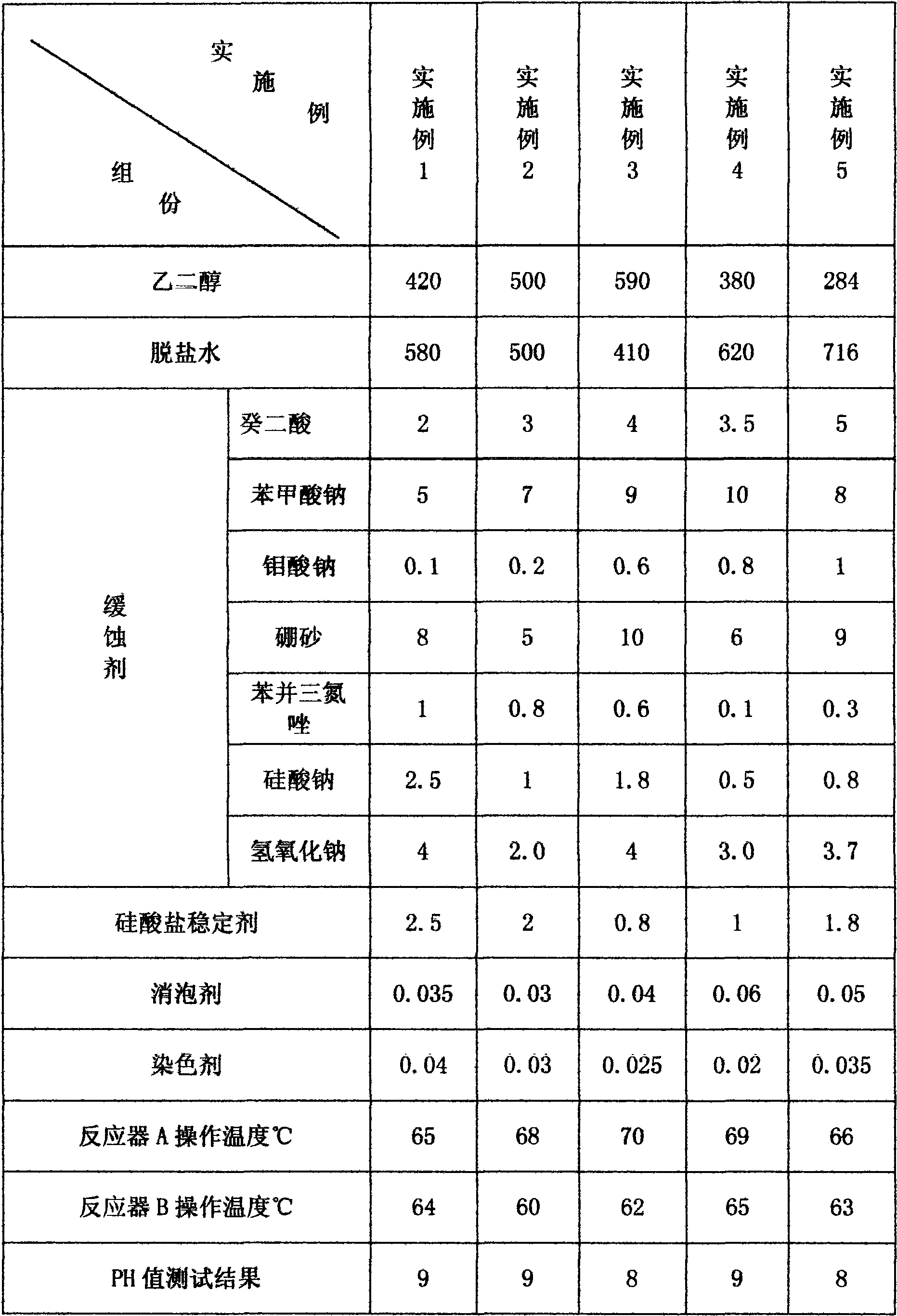

Environment-friendly type long-acting automobile cooling liquid formulation and producing technique thereof

InactiveCN101215460AImprove the protective effectExtend the life cycleHeat-exchange elementsSodium metasilicateHazardous substance

The invention discloses a formula of environmental friendly type long-term automobile coolant and a process for preparation, the formulation contains glycol, desalting water, decanedioic acid, sodium benzoate, sodium molybdate, borax, polybenzotriazole, sodium metasilicate, sodium hydroxide, metasilicate, stabilizing agent, defoaming agent and coloring agent, catalyst cases A, B and C are adopted to mix and react under normal temperature and normal pressure, the pH value of the coolant which is generated is controlled within 8-9, the automobile coolant of the invention has the efficiencies of anti-freeze, anti-boiling, anti-corrosion, anti-fouling and can diffuse heat fast, the cooling effect is good, the necessary raw materials can be easily bought on the market, the coolant has non hazardous substances such as sodium nitrite and the like, lowers the harm to environment and human bodies, generates non gelatin during storing periods, can not dilute any inhibitor, and has long-term performance, the manufacturing process of the product is simple, the using equipment is less, the operation is easy, the demanding energy consumption is low, the producing cost is low, the coolant is easy for industrial-scale production and has high promotion and application value and good market prospects.

Owner:吉化集团吉林市星云化工有限公司

Water based detergent for oil dirty

InactiveCN101003769AImprove rust resistanceImprove defoaming abilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedSodium metasilicate

This invention discloses a waterborne detergent for cleaning oil stains. The detergent is composed of: oleic acid 2-10%, ethanolamine 10-20%, surfactant 10-20%, sodium metasilicate 5-10%, sodium carbonate 5-10%, sodium fluosilicate 2-4%, defoamer 0.05-0.1%, and water. The detergent has good anti-rust performance on a variety of metals and alloys, and is suitable for cleaning oil stains on metals and alloys. The detergent has good effect on oil stains of machine tools, hardware, household range hoods, and especially dark red fused-ring aromatic hydrocarbon stains in oil-refinery apparatus.

Owner:JIANGSU UNIV OF SCI & TECH

Nourishing liquid fertilizer for plant and method for preparing the same

InactiveCN1482110AAvoid pollutionSolve the rejuvenation periodFertilizer mixturesSodium metasilicateSucrose

The liquid fertilizer is compounded with potassium dihydrogen phosphate, potassium nitrate, boric acid, urea, calcium nitrate, magnesium sulfate, zinc sulfate, copper sulfate, manganese sulfate, nickel sulfate, ammonium molybdate, iron trichloride or ferrous sulfate, sodium silicate or sodium metasilicate, cane sugar or glucose, nitric acid, phosphoric acid, alcohol, rosin and sulfuric acid. Applying the liquid fertilizer can avoid pollution to soil, environment and river, and its application is saving in labor. The liquid fertilizer is non-toxic, harmless and pollution-free.

Owner:昆明虹之华园艺有限公司

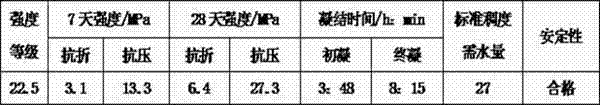

Ecotypic cementing material

ActiveCN102515588AIncreases hydration activityImprove grinding efficiencyCement productionSodium metasilicateBrick

The invention relates to an ecotypic cementing material, which comprises the components of: 40-60 parts of building waste brick powder, 15-30 parts of slag, 10-20 parts of steel plant semi-dry sintering flue gas desulfurization ash, and 10-15 parts of a composite grinding aid activator, which is prepared by raw materials in the following weight ratio: 70-85 parts of calcination modified desulfurization gypsum, 5-10 parts of sodium metasilicate pentahydrate, 5-10 parts of sodium aluminate, 1-5 parts of a naphthalene-based water reducer, 0.1-0.5 part of triethanolamine, 0.05-0.1 part of potassium humate, and 0.05-0.1 part of glycerol. The cementing material of the invention utilizes the synergetic and complementary effects of component materials, realizes resource utilization of building waste brick powder and semi-dry desulphurization ash as well as other solid wastes, thus making waste profitable.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Molding sand and preparation method thereof

InactiveCN103521681AGood collapsibilityImprove adhesionFoundry mouldsFoundry coresSodium metasilicateSodium Bentonite

The invention discloses molding sand. The molding sand is characterized by being prepared from the following materials in parts by weight: 200-240 parts of quartz sand, 30-35 parts of sericite, 60-70 parts of kaolin, 30-40 parts of calcium carbonate, 10-15 parts of coke powder, 10-15 parts of clays, 2-4 parts of titanium dioxide, 4-5 parts of aluminum oxide powder, 20-30 parts of argil, 3-4 parts of asphalt, 10-15 parts of bentonite, 3-4 parts of ammonium dihydrogen phosphate, 4-5 parts of sodium metasilicate, 2-3 parts of sodium dodecyl benzene sulfonate and an appropriate amount of water. According to the invention, the quartz sand, the sericite and the kaolin are used and roasted to achieve abundant pores and good gas permeability, moreover, mobility is good, and grinding of added calcium carbonate, clay, titanium dioxide, asphalt, and the like is combined, so that the molding sand has excellent cohesiveness, plasticity and heat stability, and also has high collapsibility. The molding sand material disclosed by the invention is fine and uniform; a casting piece produced by the molding sand has a smooth surface and a few flaws.

Owner:HEFEI CITY TENVER PRECISION CASTING

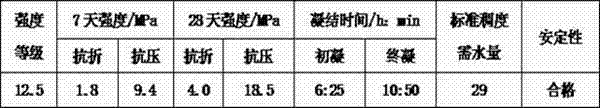

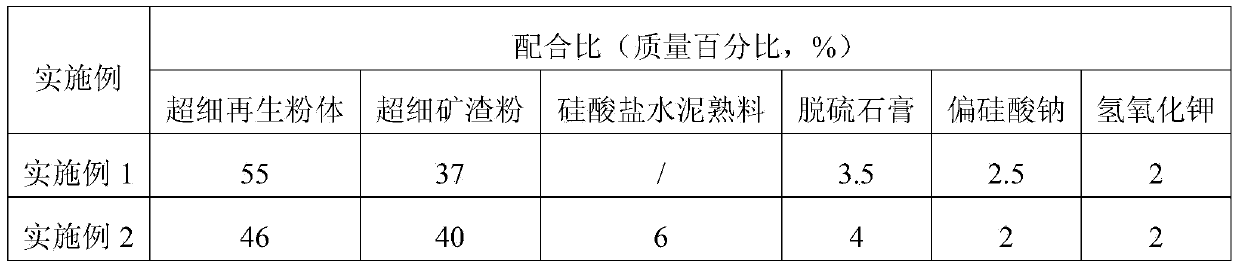

Superfine regeneration powder compound geopolymer cementing material

ActiveCN103787602AIncrease valueEasy to useSolid waste managementCement productionBrickSodium metasilicate

The invention provides a superfine regeneration powder compound geopolymer cementing material. The superfine regeneration powder compound geopolymer cementing material is prepared from raw materials comprising superfine waste brick regeneration powder, superfine slag powder, desulfurization gypsum, sodium metasilicate and potassium hydroxide according to a weight ratio of (40-70):(30-60):(2-8):(1-4):(1-4). The invention also provides a novel application of building rubbish regeneration powder. According to the novel application, the building rubbish regeneration powder is at least used together with an active excitation agent and prepared into a compound geopolymer cementing material. According to the superfine regeneration powder compound geopolymer cementing material, no portland cement clinker is used or few portland cement clinkers are used; and the superfine regeneration powder compound geopolymer cementing material is capable of making full use of solid waste and building rubbish and greatly improving use value of the building rubbish, is free of burning process, green and environment-friendly and is capable of providing a novel method for recycling the building rubbish.

Owner:北京联绿技术集团有限公司

Compound chloride-based environment-friendly snowmelt agent

InactiveCN101691481AAvoid Decomposition DefectsEasy to operateOther chemical processesSodium metasilicateDecomposition

The invention relates to a compound chloride-based environment-friendly snowmelt agent, which comprises a main component of a chloride mixture of calcium chloride dihydrate and magnesium chloride hexahydrate, contains various additives of sodium citrate, disodium hydrogen phosphate, sodium metasilicate, urea and the like and can contain abscisic acid or indoleacetic acid or a mixture thereof, sodium tartrate, humic acid or a salt thereof. The snowmelt agent in the invention can reduce the corrosivity to a metal object and a concrete structure effectively, improves the anti-salinization capabilities of a seed, a plant and soil, can be used when the temperature is as low as -25 DEG C, and solves the problems of bad snow melting effect caused by an autologous freezing point characteristic when a sodium chloride-based snowmelt agent is used and high cost caused by using an anhydrous calcium chloride-based snowmelt agent under the condition. The invention also provides a use method of the snowmelt agent, which places the main component and each additive separately without preparing a finished product of the snowmelt agent in advance and compounds the snowmelt agent on the spot before using. The method can avoid the problems of wetting, hardening and the like of the finished product of the snowmelt agent in the processes of storing and transporting, can avoid the defects of high-temperature energy consumption in the process of preparing compound granules (such as coating and granulating) and the capability of causing decomposition of the additives, has simple operations and a low cost, and is particularly suitable for on-site mechanical shed work.

Owner:CHINA ACAD OF TRANSPORTATION SCI +1

Micro-expansion and anti-cracking super-early strength double-component geopolymer grouting material

ActiveCN107601988AImprove early strengthImprove mechanical propertiesCement productionFiberSodium metasilicate

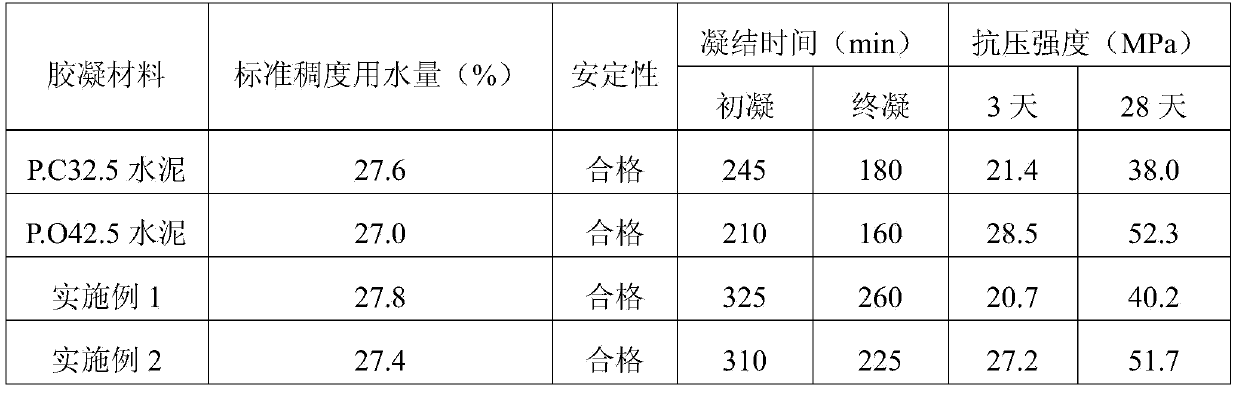

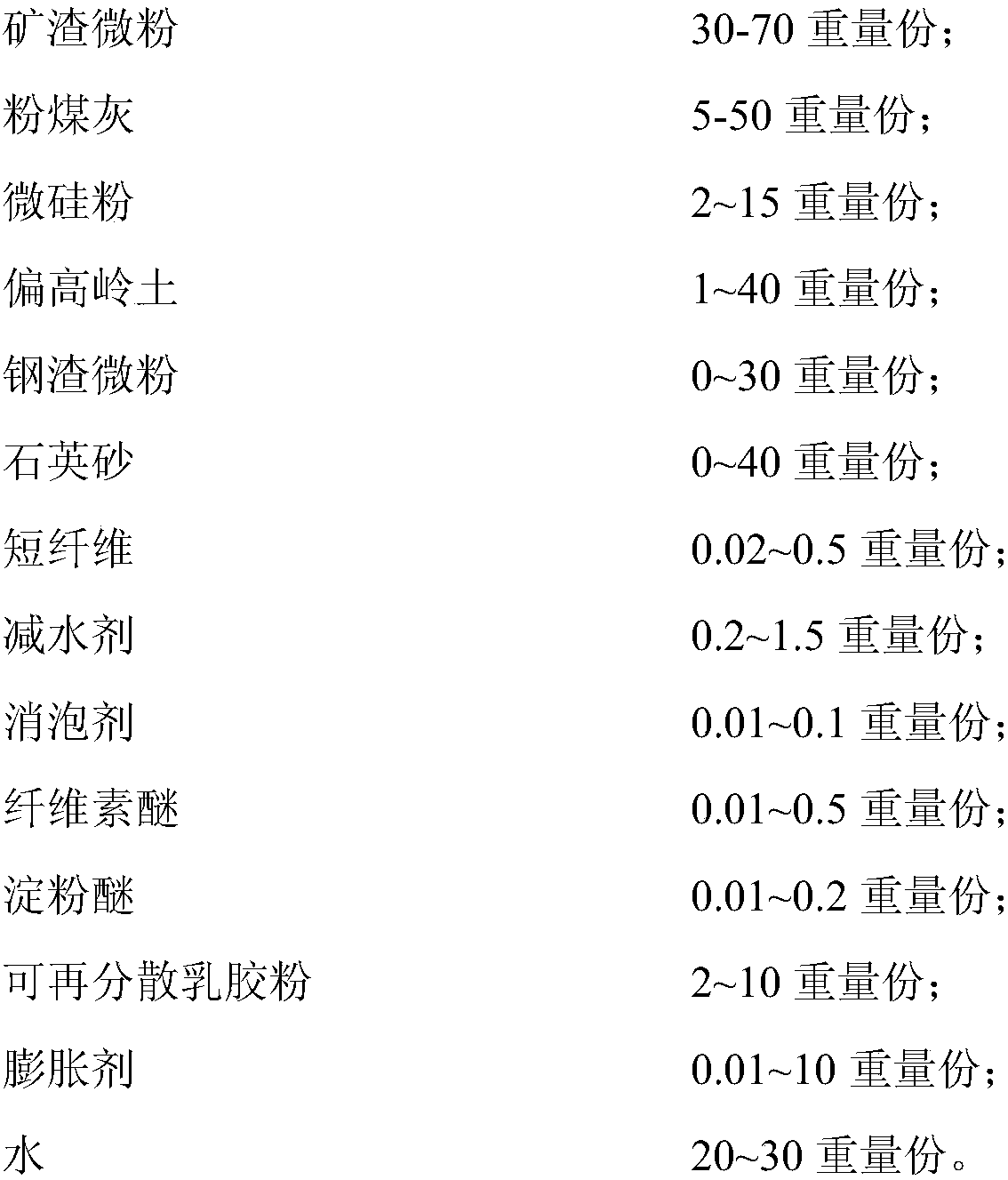

The invention discloses a micro-expansion and anti-cracking super-early strength double-component geopolymer grouting material. The micro-expansion and anti-cracking super-early strength double-component geopolymer grouting material is prepared from mineral mixture slurry and an active exciting agent solution, wherein the content of the mineral mixture slurry and the active exciting agent solutionis as follows in parts by weight: 70 to 80 parts of the mineral mixture slurry and 20 to 30 parts of the active exciting agent solution; the mineral mixture slurry is prepared from the following components: slag micro-powder, fly ash, silica fume, metakaolin, steel slag micro-powder, quartz sand, staple fibers, an additive and water; the active exciting agent solution is prepared from the following components: sodium silicate, sodium hydroxide, sodium metasilicate and sodium sulfite. The micro-expansion and anti-cracking super-early strength double-component geopolymer grouting material disclosed by the invention has higher early strength and better later-period mechanical property and toughness, has micro-expansion and no shrinkage cracks, and also has good corrosion resistance at the same time; the micro-expansion and anti-cracking super-early strength double-component geopolymer grouting material can have extremely strong durability under various bad climatic environments and is anideal grouting material.

Owner:SHANGHAI LIYANG ROAD REINFORCEMENT TECH

Highly fire-resistant foundry sand for steel casting and preparation method of highly fire-resistant foundry sand

The invention discloses highly fire-resistant foundry sand for steel casting and a preparation method of the highly fire-resistant foundry sand. The highly fire-resistant foundry sand is prepared from the following raw materials in parts by weight: 50-80 parts of fused ceramite, 10-15 parts of high-alumina cement, 17-23 parts of sludge dry powder, 20-30 parts of volcanic tuff, 15-25 parts of dickite, 16-22 parts of natural manganese sand, 8-12 parts of nacrite, 10-15 parts of asbestos powder, 5-10 parts of aluminum dihydrogen tripolyphosphate, 10-15 parts of modified bentonite, 4-8 parts of alumn powder, 3-6 parts of cellulose glycolate, 2.5-4.5 parts of corn syrup, 4.5-6.5 parts of beryllium oxide, 3-5 parts of China wood oil, 4-6 parts of sodium metasilicate, 2-4 parts of polyethylene glycol and an appropriate amount of water. Compared with conventional foundry sand, the highly fire-resistant foundry sand provided by the invention is not only excellent in fire-resistant performance, can maintain a higher strength and relatively low thermal expansion coefficient under high temperature, does not easily cause expansion and breakage, has excellent plasticity, air permeability and collapsibility, can remarkably improve the surface quality of castings and improve the finished product rate of castings.

Owner:江守仲

Tipping paper and production method thereof

InactiveCN103741551AGood yellowing resistanceImprove toughnessSpecial paperPaper/cardboardSodium metasilicateSilanes

Tipping paper is prepared from the following raw materials in parts by weight: 60-70 parts of softwood pulp, 100-120 parts of hardwood pulp, 2-3 parts of trimethoxy(methyl)silane, 3-4 parts of triethoxyvinylsilane, 1-2 parts of sodium metasilicate, 1-2 parts of ethanol, 2-3 parts of polyvinyl acetate emulsion, 1-2 parts of sodium carbonate, 1-2 parts of an anti-oxidation agent 168, 3-4 parts of meerschaum powder, 2-3 parts of vermiculite powder, 1-2 parts of sodium tripolyphosphate, 1-2 parts of sodium carboxymethylcellulose, 1-2 parts of sodium persulfate and 1-2 parts of grape seed oil. The technological effects comprise that by adding the anti-oxidation agent into the raw materials, the tipping paper is increased in yellowing resistance, and also is substantially prolonged in storage time; and also, by adding ester materials into the raw materials and through cross-linking polymerization, the toughness and the flexibility of the tipping paper are increased, also the tipping paper is improved in water resistance and wet resistance, and a paper sheet has good lip sticking resistance.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

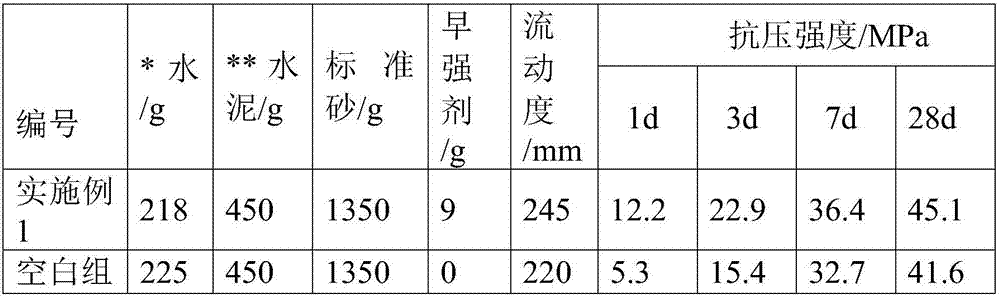

Crystal nucleus concrete early strength agent and preparation method thereof

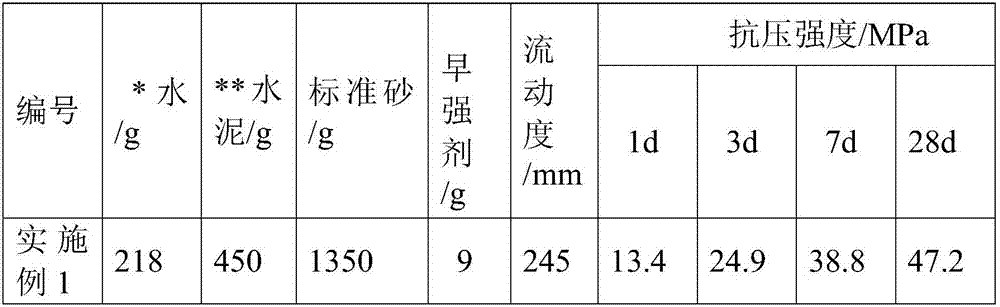

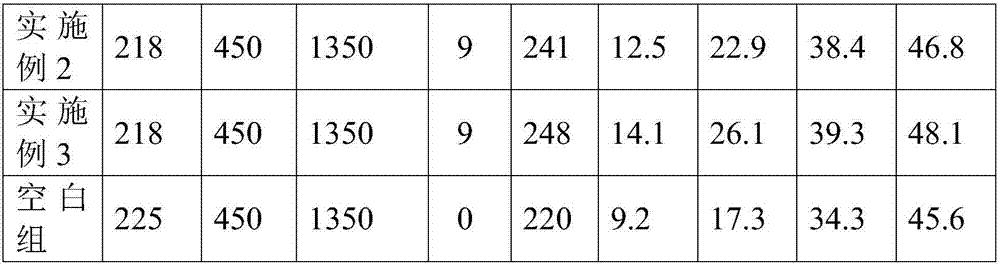

The invention discloses a crystal nucleus concrete early strength agent and a preparation method thereof. 1,000 parts of crystal nucleus concrete early strength agent are prepared from the following raw materials in parts by weight: 100-150 parts of a polymer, 20-50 parts of sodium metasilicate pentahydrate, 60-90 parts of calcium nitrate tetrahydrate and the balance of deionized water. The preparation method comprises the steps of firstly adding the polymer to a three-neck flask, adding the deionized water to form a base solution, putting the flask into a hot water bath, controlling the temperature and stirring; taking the sodium metasilicate pentahydrate, and adding the deionized water to prepare a solution A; taking the calcium nitrate tetrahydrate and adding the deionized water to prepare a solution B; dropwise adding the solution A and the solution B to the base solution at the same rate, carrying out heat preservation on the product, stirring and reacting; and finally quickly cooling a product to a room temperature to obtain the final product, namely the crystal nucleus concrete early strength agent. The crystal nucleus concrete early strength agent is good in performance, is capable of making concrete solidified quickly, is short in demolding time and not easy to collapse and has a certain water reducing effect, and the later strength loss of the concrete is small.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

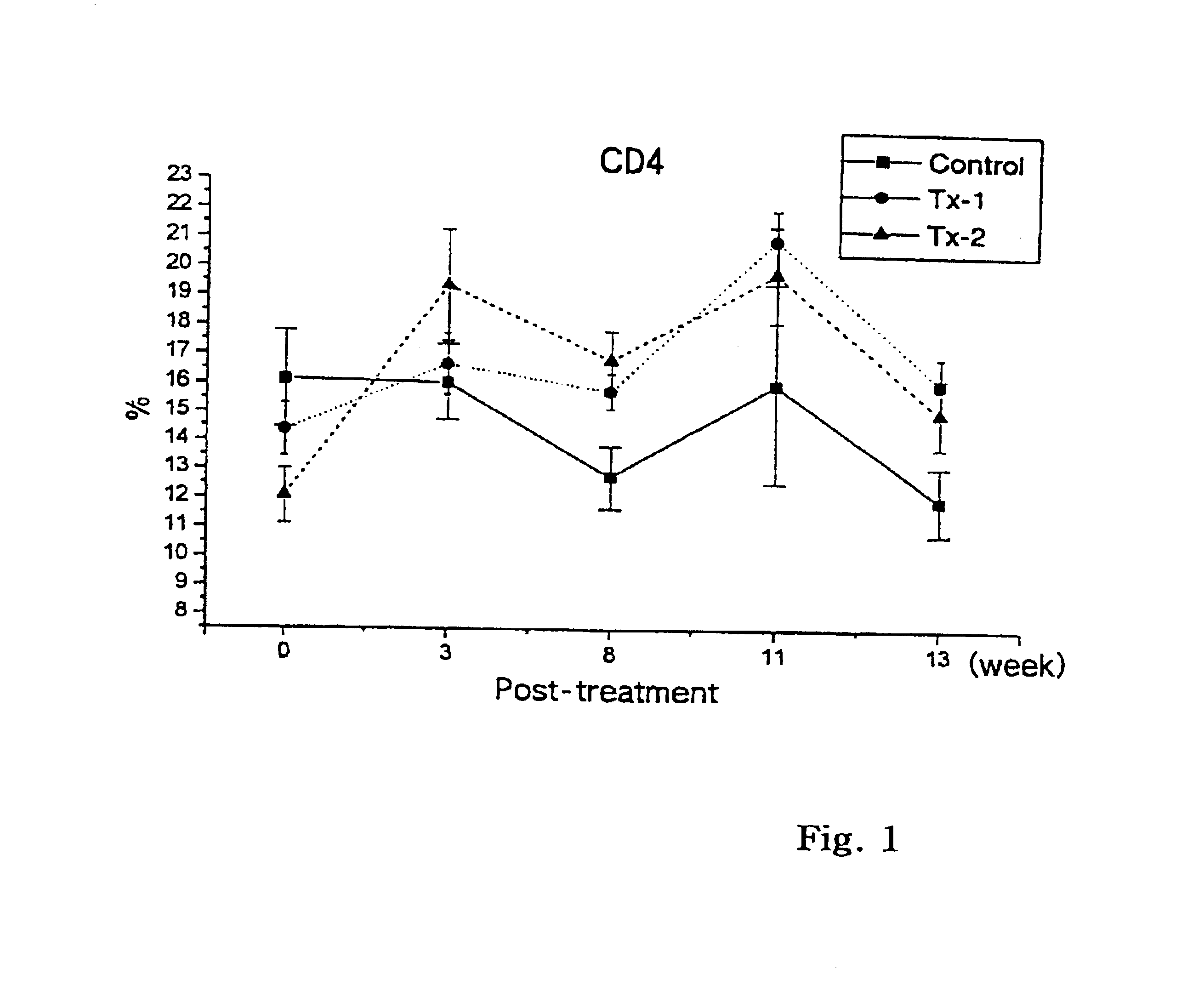

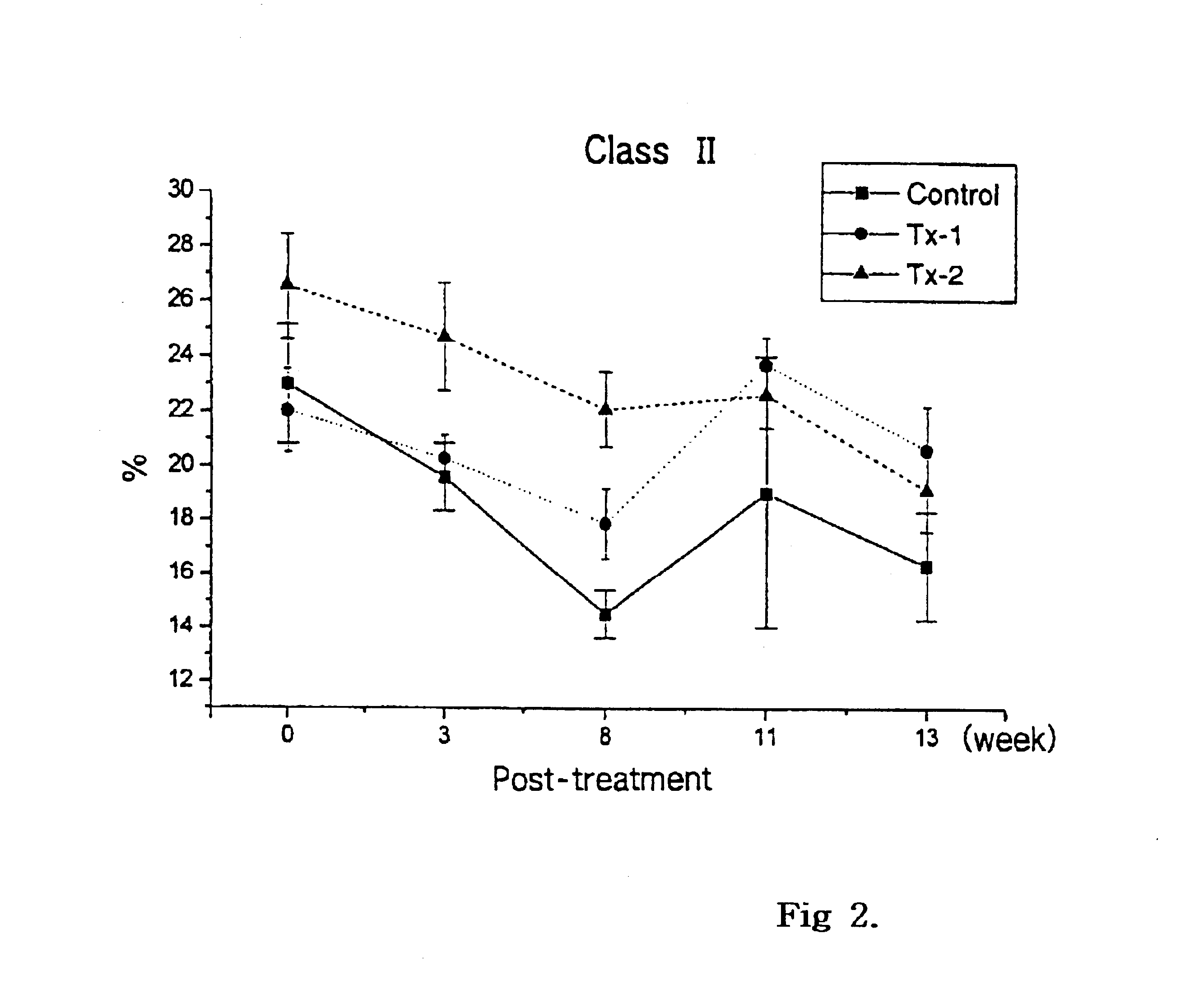

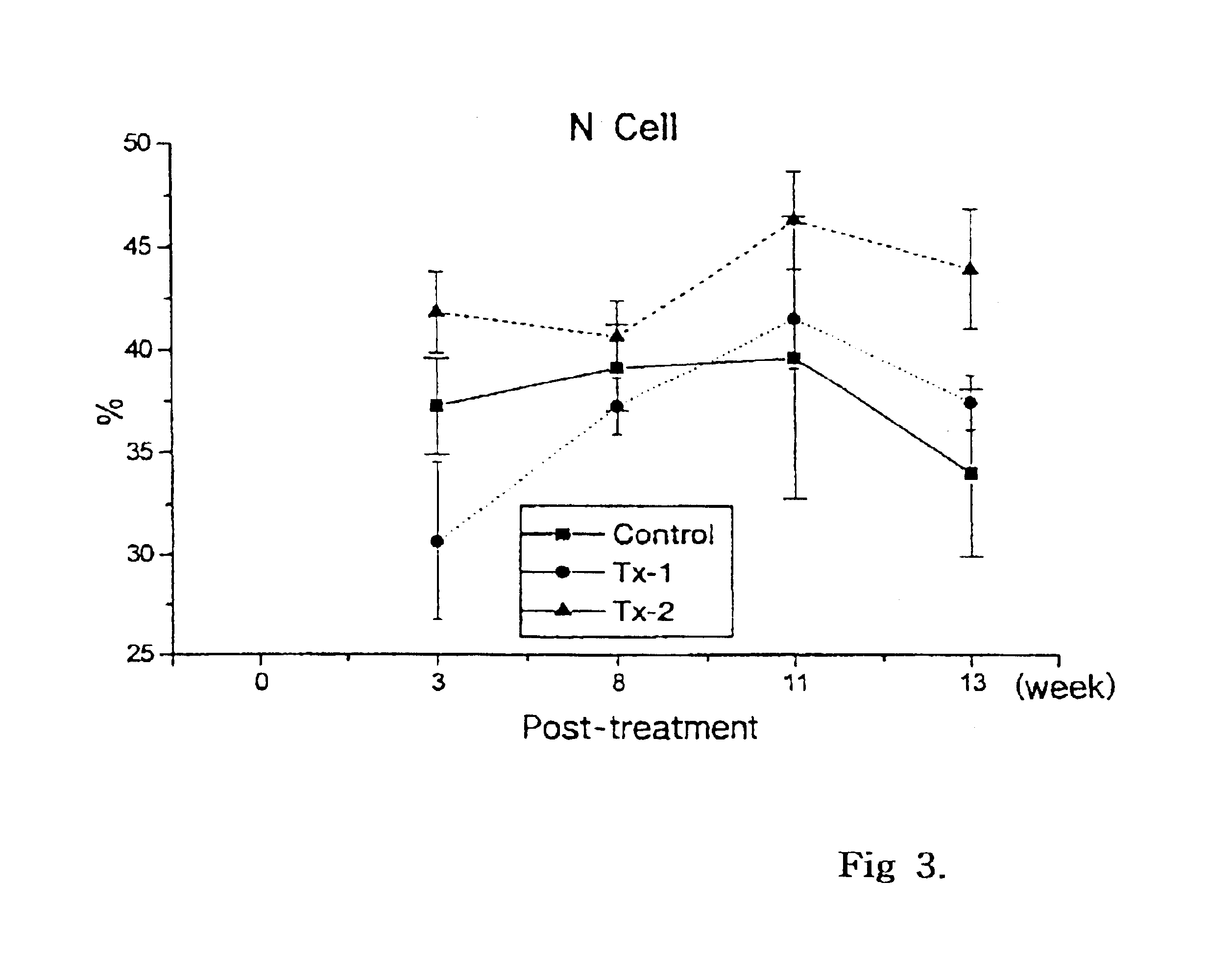

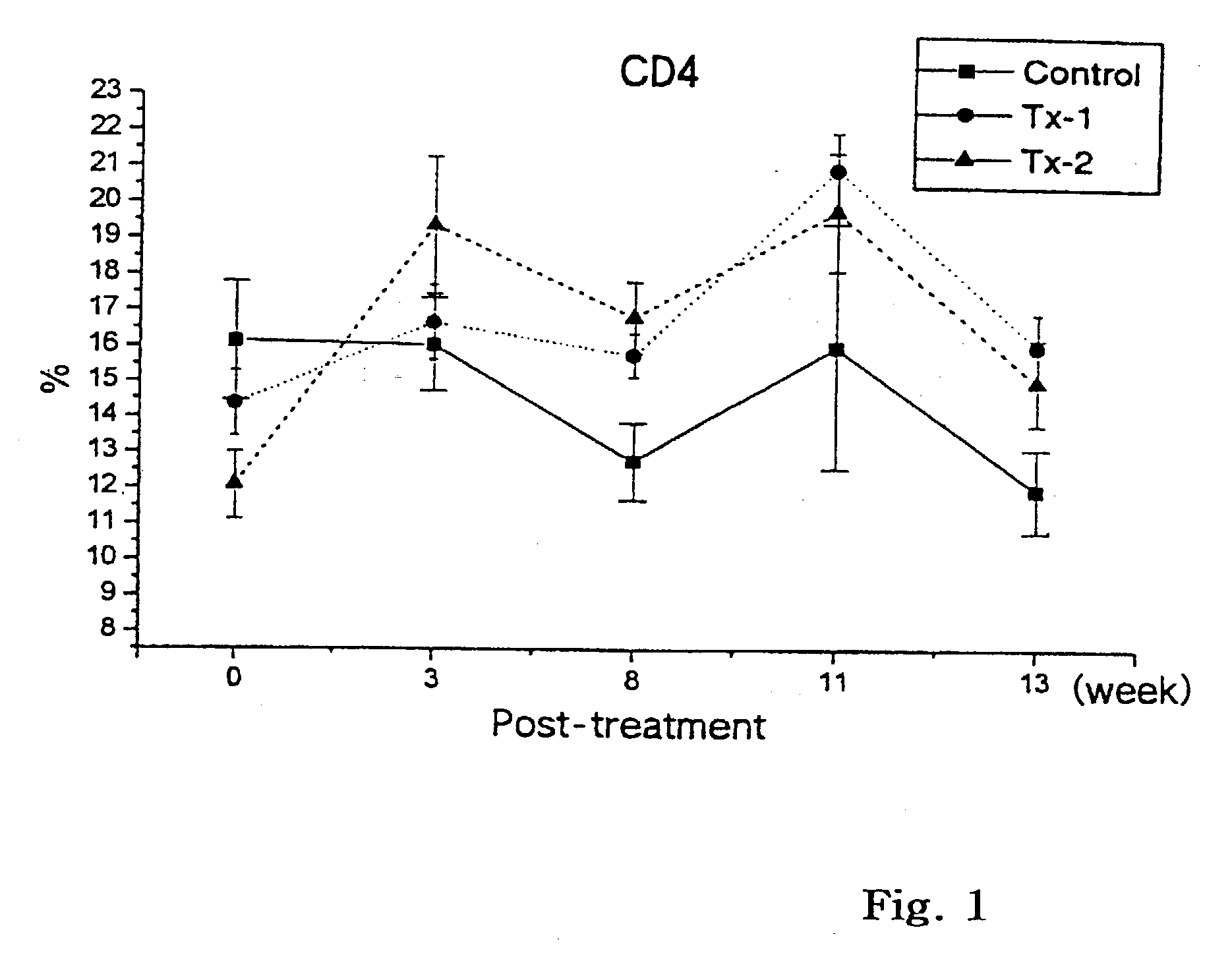

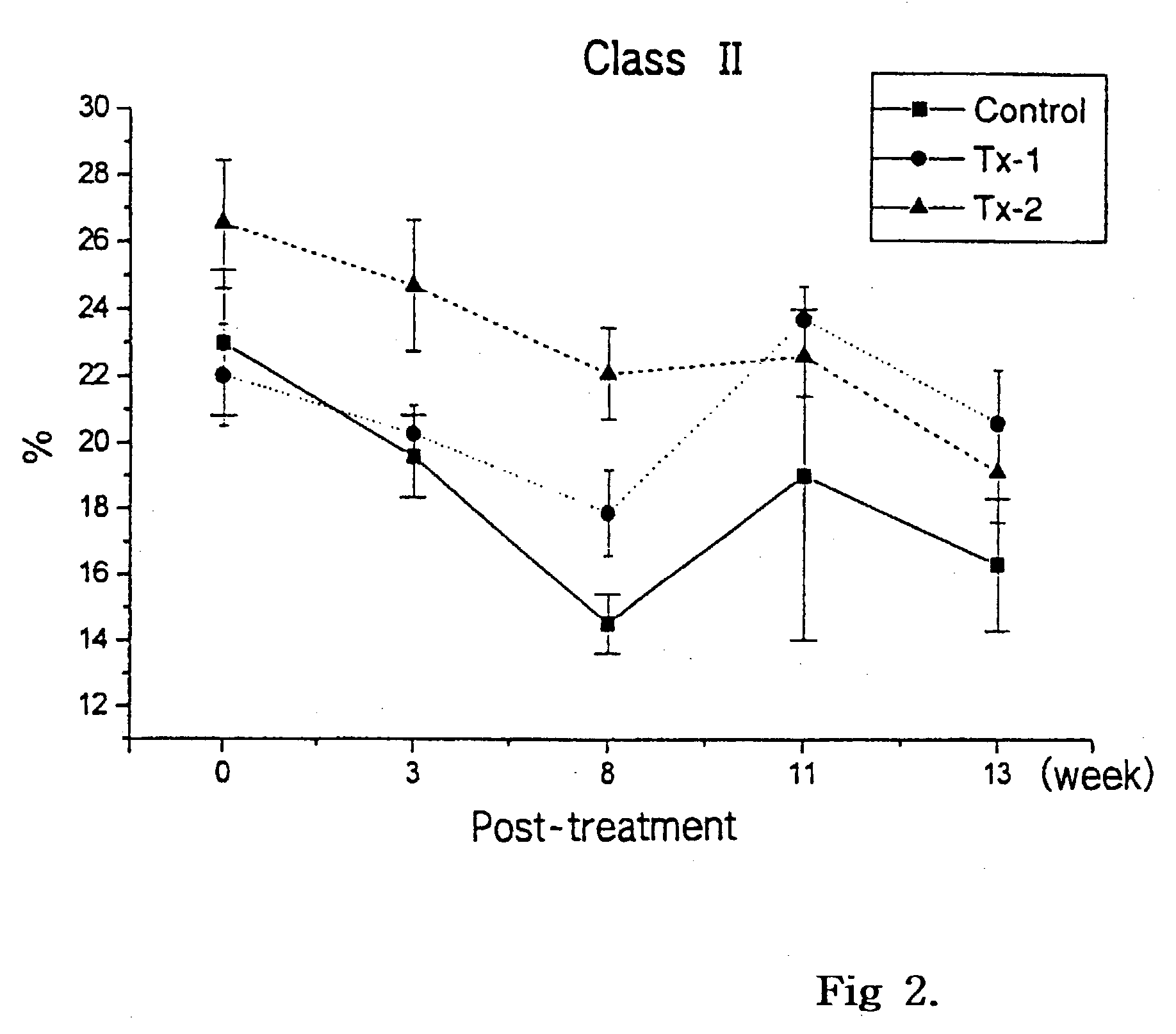

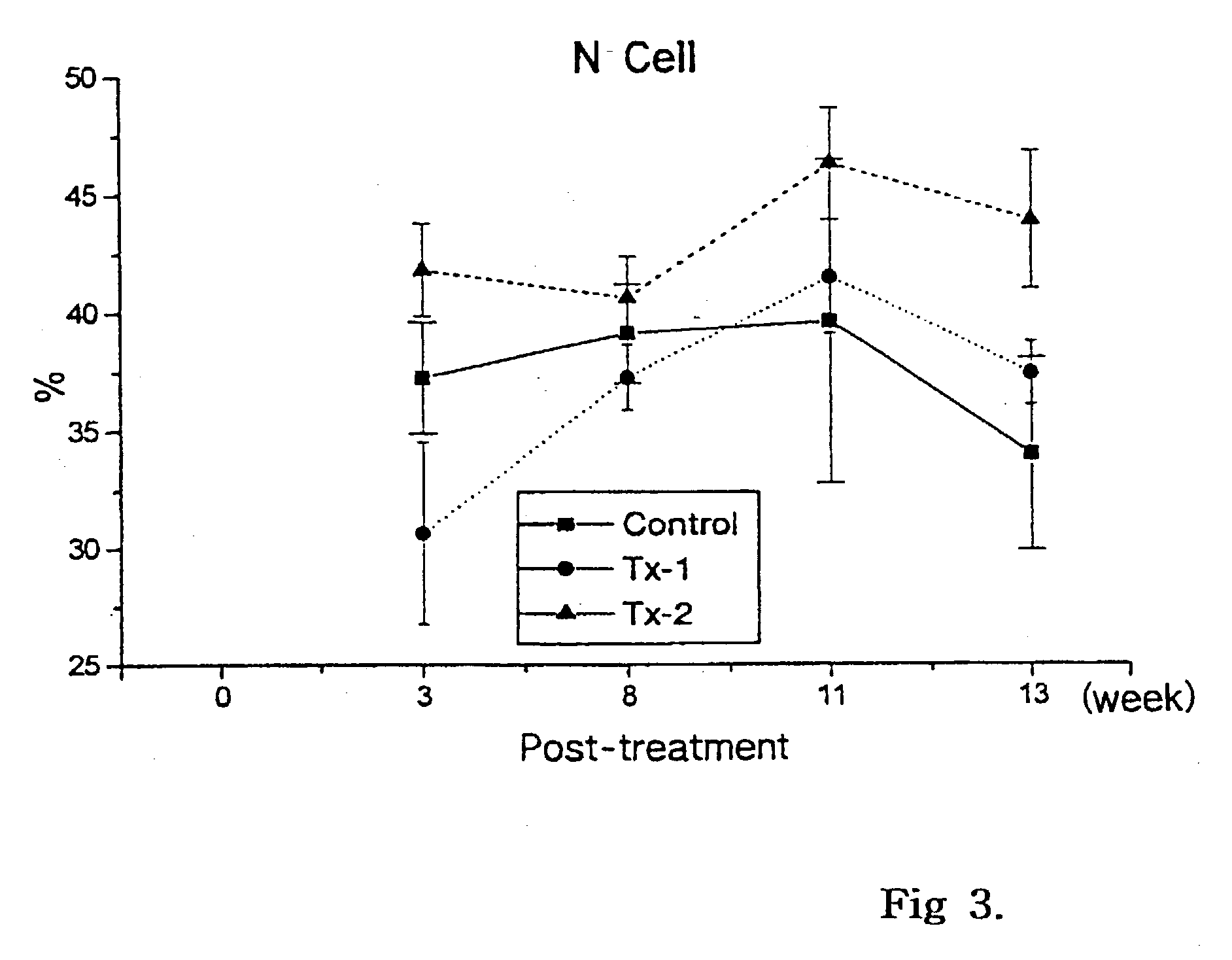

Composition of multipurpose high functional alkaline solution composition, preparation thereof, and for the use of nonspecific immunostimulator

Disclosed are a multipurpose, high-functional, alkaline solution composition, preparation therefor and use thereof as a nonspecific immunostimulator. The composition comprises 1-25 parts by weight of borax (Na2B4O7.10H2O), 10−5-10−4 parts by weight of sodium thiosulfate (Na2S2O3.5H2O), 30-150 parts by weight of potassium carbonate, 30-200 parts by weight of refined sugar (C12H22O11), and 100-200 parts by weight of water, based on 100 parts by weight of sodium metasilicate (Na2SiO3.5H2O). In addition to bringing about an improvement in disease resistance, weight gain rate, crop yield, crop quality, harvest time, the composition shows nonspecific immunostimulating activities, including antibody production and immune enhancement, by activating immune cells, thereby maximizing vaccination effects on malignant viral diseases.

Owner:BARODON S F CORP

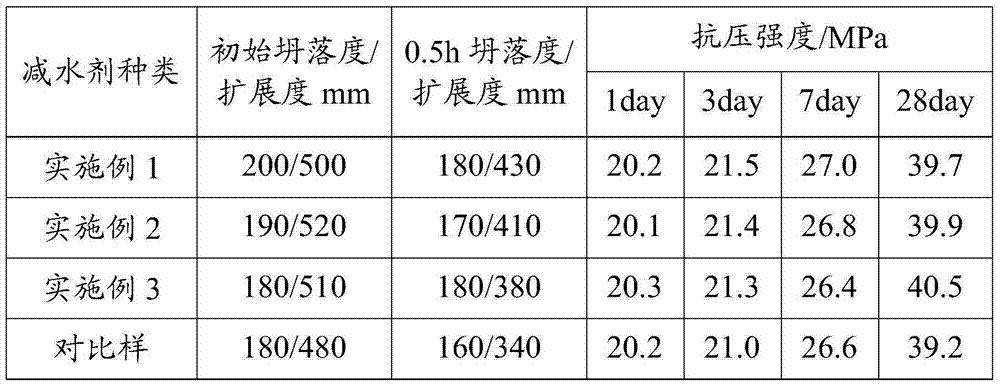

Preparation method of slump loss resistant naphthalene water reducer

ActiveCN103864332AEnhanced controllability of molecular structureSave resourcesSodium metasilicateOrganic solvent

The invention discloses a preparation method of a slump loss resistant naphthalene water reducer. The naphthalene water reducer is prepared by sulfonating, hydrolyzing, condensing and neutralizing raw materials including crude naphthalene, naphthalene derivatives such as methylnaphthalene, concentrated sulfuric acid, formaldehyde, caustic soda liquid, water and the like. According to the production process, monomer substituents, such as methylnaphthalene and acenaphthene are introduced, an organic solvent azeotropic method is adopted for synthesizing, and finally sodium metasilicate is adopted for neutralizing to adjust pH to 7-10 to obtain the final naphthalene water reducer. The slump loss resistant naphthalene water reducer is prepared by the implementation mode disclosed by the invention, the crude naphthalene is replaced by partial naphthalene derivatives, an effective path of reducing the cost is proposed, naphthalene steam and a solvent are condensed to form a naphthalene solution to be recycled, and thus the product yield is improved and the environmental pollution is reduced.

Owner:SHAANXI KZJ NEW MATERIALS

Flame-retardant viscose fiber and preparation method thereof

InactiveCN102505169AGood textile processing performanceReduce usageArtificial filaments from viscoseWet spinning methodsCellulosePolymer science

The invention discloses flame-retardant viscose fiber and a preparation method thereof. The flame-retardant viscose fiber mainly comprises the following components in percentage by weight: 20 to 55 percent of polysilicic acid (based on SiO2), 0.5 to 10 percent of pyrophosphoric acid ester and 40 to 70 percent of cellulose. The preparation method comprises the following steps of: (1) adding a solution of sodium metasilicate and a solution of pyrophosphoric acid ester into a yellowed cellulose viscose solution respectively, and uniformly mixing the sodium metasilicate, the pyrophosphoric acid ester and cellulose viscose to obtain a flame-retardant spinning viscose solution; (2) performing spinning molding on the flame-retardant spinning viscose solution in coagulating bath containing sulfuric acid, zinc sulfate and sodium sulfate to obtain as-spun fiber; and (3) after-treating the as-spun fiber, namely washing, desulfurizing, applying oil and drying to obtain the flame-retardant viscose fiber. The synergistic effect of silicon and phosphorus flame retardants greatly improves the flame-retardant effect and high temperature resistance of flame-retardant fiber and the textile processing performance of fabrics.

Owner:阜宁澳洋科技有限责任公司

Cement base inorganic waterproof grouting material

InactiveCN101811855AEfficient use ofHigh strengthSolid waste managementOther chemical processesSodium metasilicateWater leakage

The invention discloses a cement base inorganic waterproof grouting material, which is prepared by uniformly mixing the following raw materials in percentage by weight: 30.0 percent of ordinary Portland cement, 20.0 percent of high-alumina cement, 12.0 percent of fly ash, 6.0 percent of gypsum powder, 2.0 percent of lime powder, 30.0 percent of quartz sand and 2.31 percent of functional additive, wherein the functional additive is prepared by mixing the following raw materials in percentage by weight: 0.7 percent of naphthalin water reducing agent, 0.75 percent of sodium aluminate, 0.25 percent of anhydrous sodium sulfate, 0.3 percent of sodium metasilicate, 0.3 percent of hydrophobic powder and 0.01 percent of HPMC; and the weight error for taking all the raw materials is controlled to be + / -5 percent. The inorganic waterproof grouting material is suitable for leak stoppage and solidification of waterproof work and reinforcement projects such as dame seepage, piping water leakage, road slab breaking, mile collapse, equipment base anchoring, column stabilization and the like, and has the advantages of high water resistance, convenient construction, simple manufacturing and low cost.

Owner:河南省绿韵建材有限公司

Zero residual base normal-pressure or low-pressure boiling high-concentration pulp preparing method by using base process

InactiveCN101215794ARapid responseNo residual alkaliDigestersNon-macromolecular organic additionHigh concentrationSodium metasilicate

The invention relates to a method for boiling high concentration pulping in normal pressure or low pressure by an alkaline method with zero residual alkaline, and the method comprises adding accelerating agent in the boiling process and utilizing a double screw to rub and squeeze a pulper, leading pulp making and boiling process with an alkaline method to go on in normal pressure or low pressure, and leaving no residual alkaline in black liquor, leading pulp to always keep a higher density in the pulping process of boiling, washing and bleaching, and the pulp which is prepared can meets the requirement of paper making. Accelerating agent chooses one or a plurality of magnesium hydrate, potassium hydrate, sodium metasilicate, sodium sulfide, sodium sulfite, ammonium sulfite and carbamide. Special-purpose pulping boiling equipment and high-pressure boilers are not needed by pulping paper mills through utilizing the invention, in the process of pulping, pulp always keeps higher density, and black liquid has high density, little numbers and low energy consumption, alkaline recovery project with great investment is not needed to be built, and the invention enables black liquid to prepare fertilizer or other chemical products with high quality, and the invention is suitable for popularizing and applying.

Owner:晏永祥

Composition of multipurpose high functional alkaline solution composition, preparation thereof, and for the use of nonspecific immunostimulator

InactiveUS20030206967A1Less offensive odorAntibacterial agentsHeavy metal active ingredientsDiseaseWeight gaining

Disclosed are a multipurpose, high-functional, alkaline solution composition, preparation therefor and use thereof as a nonspecific immunostimulator. The composition comprises 1-25 parts by weight of borax (Na2B4O7.10H2O), 10<-5>-10<-4 >parts by weight of sodium thiosulfate (Na2S2O3.5H2O), 30-150 parts by weight of potassium carbonate, 30-200 parts by weight of refined sugar (C12H22O11), and 100-200 parts by weight of water, based on 100 parts by weight of sodium metasilicate (Na2SiO3.5H2O). In addition to bringing about an improvement in disease resistance, weight gain rate, crop yield, crop quality, harvest time, the composition shows nonspecific immunostimulating activities, including antibody production and immune enhancement, by activating immune cells, thereby maximizing vaccination effects on malignant viral diseases.

Owner:BARODON S F CORP

Antibacterial tipping paper and production method thereof

InactiveCN103741552AGood antibacterial effectImprove toughnessSpecial paperNon-macromolecular organic additionSodium metasilicateSodium sulfate

Disclosed antibacterial tipping paper is prepared from the following raw materials in parts by weight: 70-80 parts of softwood pulp, 80-90 parts of hardwood pulp, 2-3 parts of sodium carboxymethylcellulose, 1-2 parts of 3-(trimethoxysilyl)-1-propanamine, 1-2 parts of 3-aminopropyltriethoxysilane, 1-2 parts of sodium dodecyl sulfate, 1-2 parts of N,N'-ethylenebis(stearamide), 5-8 parts of attapulgite, 2-3 parts of sodium metasilicate, 2-3 parts of ascorbic acid, 1-2 parts of sodium persulfate and 1-2 parts of wintergreen oil. The technological effects comprise that by adding wintergreen oil into the raw materials, the tipping paper is increased in sterilization effect and antibacterial effect and also is prevented from mildewing; and also, by adding ester materials into the raw materials and through cross-linking polymerization, the toughness and the flexibility of the tipping paper are increased, also the tipping paper is improved in water resistance and wet resistance, and a paper sheet has good lip sticking resistance.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Water-based metal-degreasing cleaning agent

The invention discloses a water-based metal-degreasing cleaning agent. The water-based metal-degreasing cleaning agent comprises the components in percent by weight: 10-30% of composite surface active agent, 5-10% of cleaning additive, 2-5% of corrosion inhibiting agent, 0.4-0.8% of hard-water resistant agent, 0.05-0.2% of defoaming agent and the balance of deionized water. By mass, the composite surface active agent is a mixture compounded by LAS (sodium alkyl benzene sulfonate), AEO-9 (Fatty alcohol polyoxyethylene ether) and TX-10 (alkylphenol ethoxylates) according to the mass ratio of 1:2:1; the corrosion inhibiting agent is a mixture compounded by benzotriazole (BTA) and benzimidazole (BIA) according to the mass ratio of 1:1; the cleaning additive is a mixture compounded by 4A zeolite, sodium metasilicate and sodium carbonate according to the mass ratio of 1:1:1; the defoaming agent is a polyether-modified organic silicon defoaming agent. The water-based metal-degreasing cleaning agent disclosed by the invention has the characteristics of low surface tension, fast defoaming, long foam-inhibiting time, low cost and less use amount and the like.

Owner:SUZHOU LOTTE CHEM TECH

A kind of flame-retardant viscose fiber and preparation method thereof

ActiveCN102286799AIncreased residue on ignitionImprove high temperature resistanceArtificial filaments from viscosePolymer scienceSodium metasilicate

The invention discloses a fire-retardant viscose fiber and a preparation method thereof, wherein a silicon and aluminum composite fire retardant is contained in the fire-retardant viscose fiber and the preparation method of the fire-retardant fiber comprises the steps of: obtaining a spinning solution through taking cellulose pulps as a raw material and subjecting to the processing steps of yellowing, dissolving, defoaming and filtering, subjecting the spinning solution to spinning and forming in a coagulating bath, subjecting to post-processing steps of washing and desulfurization, adding right amount of sodium metasilicate and sodium metasilicate solution into a cellulose viscose solution which is dissolved to any process before the spinning and then uniformly mixing. According to the invention, the silicon and aluminum composite fire retardant is utilized to ensure that the fire-retardant effect of the prepared fire-retardant viscose fiber is greatly increased and the high temperature and alkaline resistances of the fire-retardant viscose are greatly increased; and therefore, the fire-retardant viscose fiber can be popularized and applied in high-temperature environments such as the fields of high-temperature filter media, filter materials and the like.

Owner:赛得利(盐城)纤维有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com