Micro-expansion and anti-cracking super-early strength double-component geopolymer grouting material

A technology of geopolymers and grouting materials, applied in cement production, etc., can solve problems such as shrinkage cracking, poor toughness, and low early strength, and achieve good toughness, good later mechanical properties and durability, and high early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

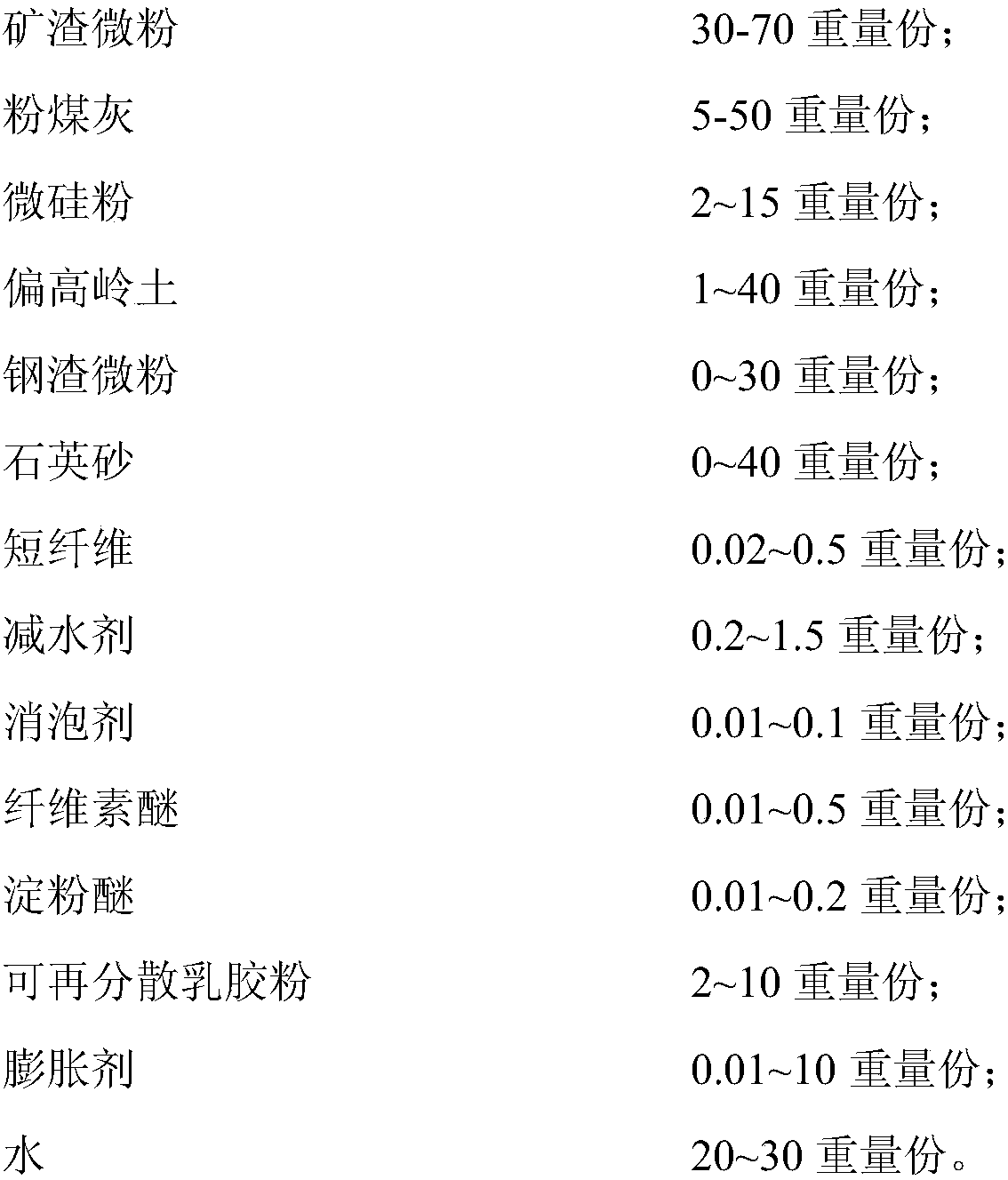

[0032] The weight ratio of each component of the two-component geopolymer grouting material is:

[0033] 70 parts by weight of mineral mixture slurry;

[0034] Active stimulator solution 30 parts by weight.

[0035] The mineral mixture slurry component includes:

[0036]

[0037] The weight ratio of described activity stimulating agent solution component is:

[0038]

Embodiment 2

[0040] The weight ratio of each component of the two-component geopolymer grouting material is:

[0041] 75 parts by weight of mineral mixture slurry;

[0042] Active stimulator solution 25 parts by weight.

[0043] The mineral mixture slurry component includes:

[0044]

[0045] The weight ratio of described activity stimulating agent solution component is:

[0046]

Embodiment 3

[0048] The weight ratio of each component of the two-component geopolymer grouting material is:

[0049] 80 parts by weight of mineral mixture slurry;

[0050] Active stimulator solution 20 parts by weight.

[0051] The mineral mixture slurry component includes:

[0052]

[0053]

[0054] The weight ratio of described activity stimulating agent solution component is:

[0055]

[0056] A kind of micro-expansion anti-crack ultra-early strength two-component polymer grouting material prepared by the above-mentioned embodiment of the present invention has a higher early Strength, better mechanical properties and toughness in the later stage, micro-expansion, no shrinkage cracking, good corrosion resistance, and strong durability in various harsh weather environments. Refer to the "Technical Regulations for Geopolymer Grouting Reinforcement of Highway Subgrade and Base Course" (SZ-G-B04-2007), Appendix B test method, micro-expansion anti-cracking super early strength tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com