Ultra-high performance hybrid fiber concrete shield segment and preparation method thereof

A hybrid fiber and ultra-high-performance technology, which is applied in earth cube drilling, mining equipment, shaft equipment, etc., can solve the problems of concrete protective layer bursting, uneven heat distribution, and water vapor cannot be discharged, etc., and achieves short steam curing time , reduce production time, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

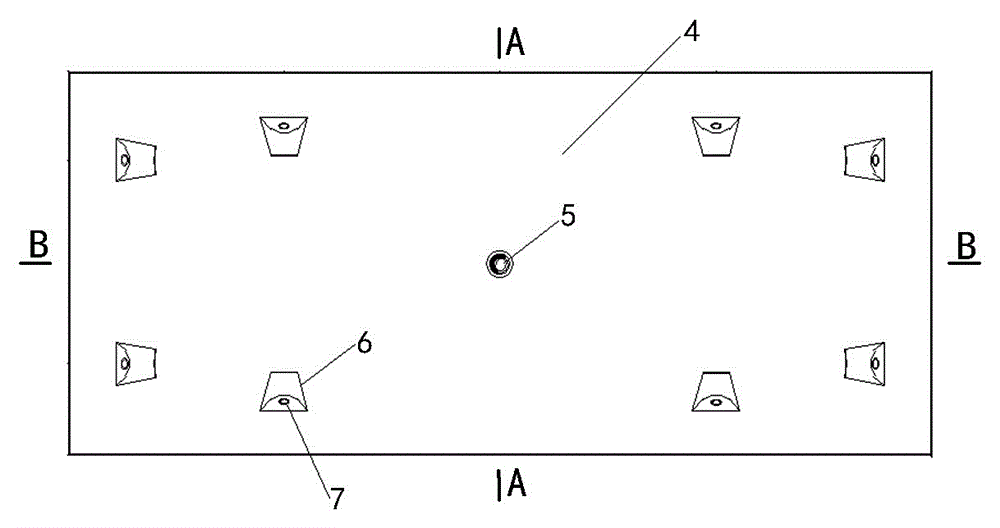

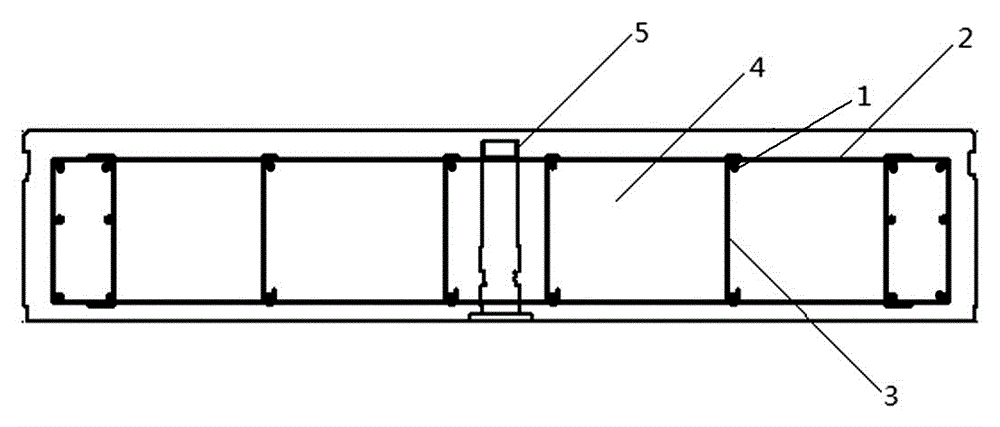

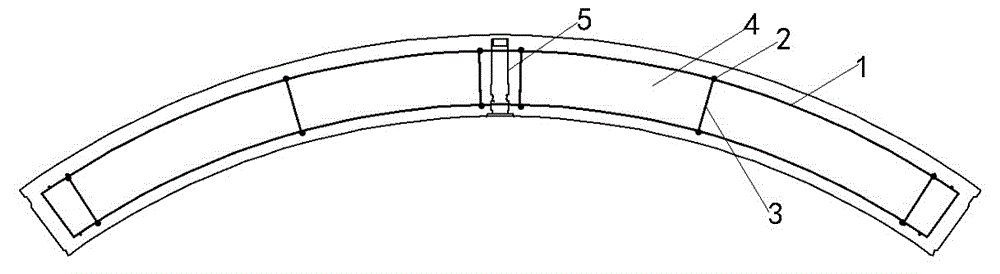

[0056] 1. Processing of steel skeleton:

[0057] The segment standard block has a width of 2000mm, a thickness of 315mm, and an inner arc length of 3492mm. Compared with the traditional reinforced concrete segment (width of 2000mm, thickness of 380mm, and inner arc length of 3492mm), the thickness is reduced by 17%, the volume is reduced by 18%, and the amount of main reinforcement 1 167kg, the reinforcement ratio is 0.83%, which is 21% less than the traditional one, and the amount of distributed reinforcement 2 is 39kg, which is 60% less than the traditional one.

[0058] 2. Mixing of ultra-high performance hybrid fiber concrete:

[0059] For cementitious materials, the total addition amount is 100 parts, of which the addition amount of ordinary Portland cement accounts for 75% of the total, secondary fly ash is 18.5%, and silica fume is 6.5%;

[0060] Manufactured sand, Zone II, fineness modulus 2.7, mud content less than 2%, and the addition amount is 135 parts;

[0061] ...

Embodiment 2

[0071] 1. Processing of steel skeleton:

[0072] The segment standard block has a width of 1000mm, a thickness of 225mm, and an inner arc length of 1746mm. Compared with the traditional reinforced concrete segment (width of 1000mm, thickness of 270mm, and inner arc length of 1746mm), the thickness is reduced by 17%, the volume is reduced by 18%, and the amount of main reinforcement 1 28kg, the reinforcement ratio is 0.85%, which is 17% less than the traditional one, and the distributed reinforcement 2 dosage is 9kg, which is 50% less than the traditional one.

[0073] 2. Mixing of ultra-high performance hybrid fiber concrete:

[0074] For cementitious materials, the total addition amount is 24%, of which ordinary portland cement is 75%, secondary fly ash is 18.5%, and silica fume is 6.5%;

[0075] Manufactured sand, Zone II, fineness modulus 3.0, mud content less than 2%, admixture of 140 parts;

[0076] Crushed stone, graded crushed stone with a diameter of less than 20mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com