Patents

Literature

8049 results about "Defoamer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A defoamer or an anti-foaming agent is a chemical additive that reduces and hinders the formation of foam in industrial process liquids. The terms anti-foam agent and defoamer are often used interchangeably. Commonly used agents are insoluble oils, polydimethylsiloxanes and other silicones, certain alcohols, stearates and glycols. The additive is used to prevent formation of foam or is added to break a foam already formed.

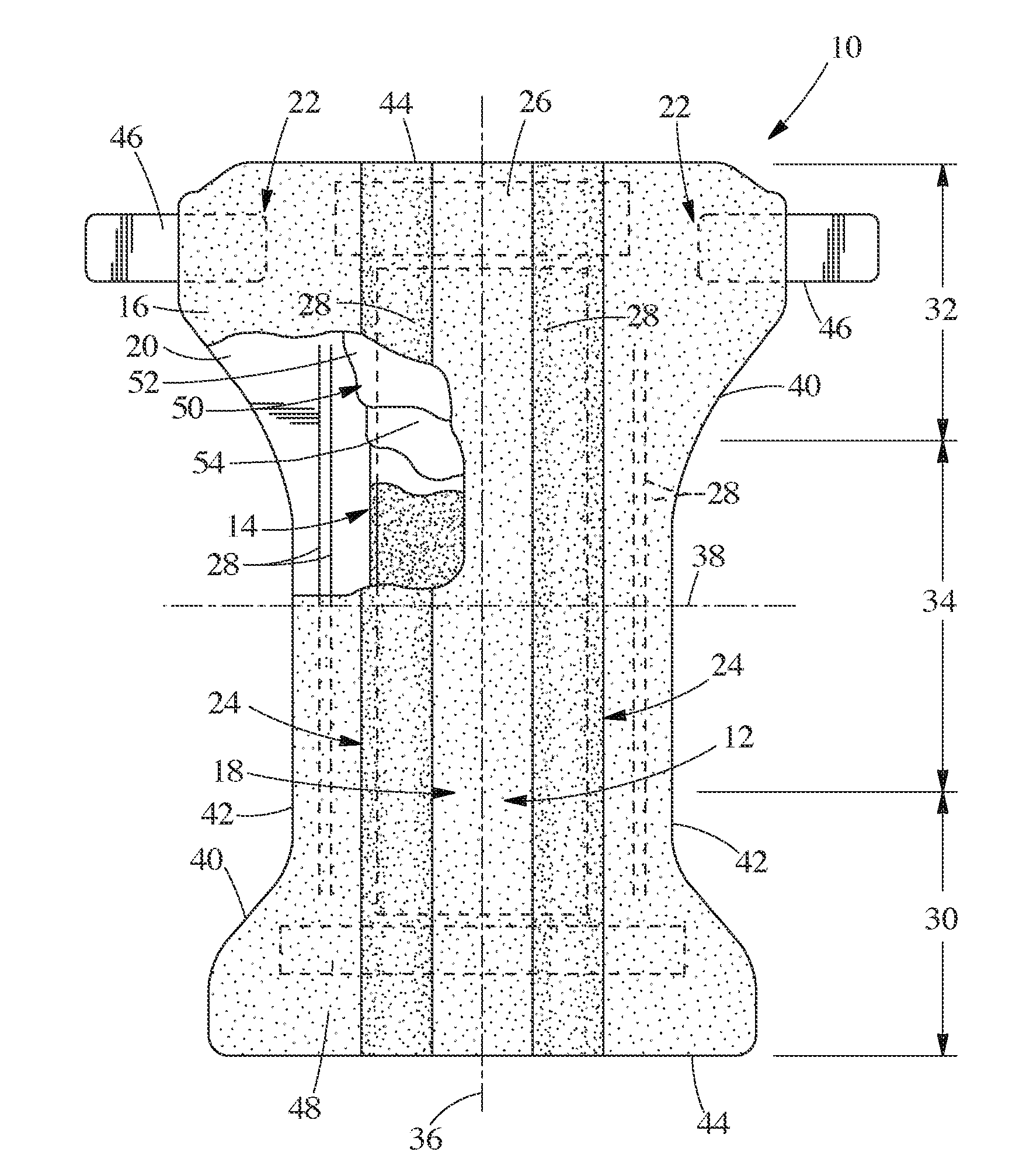

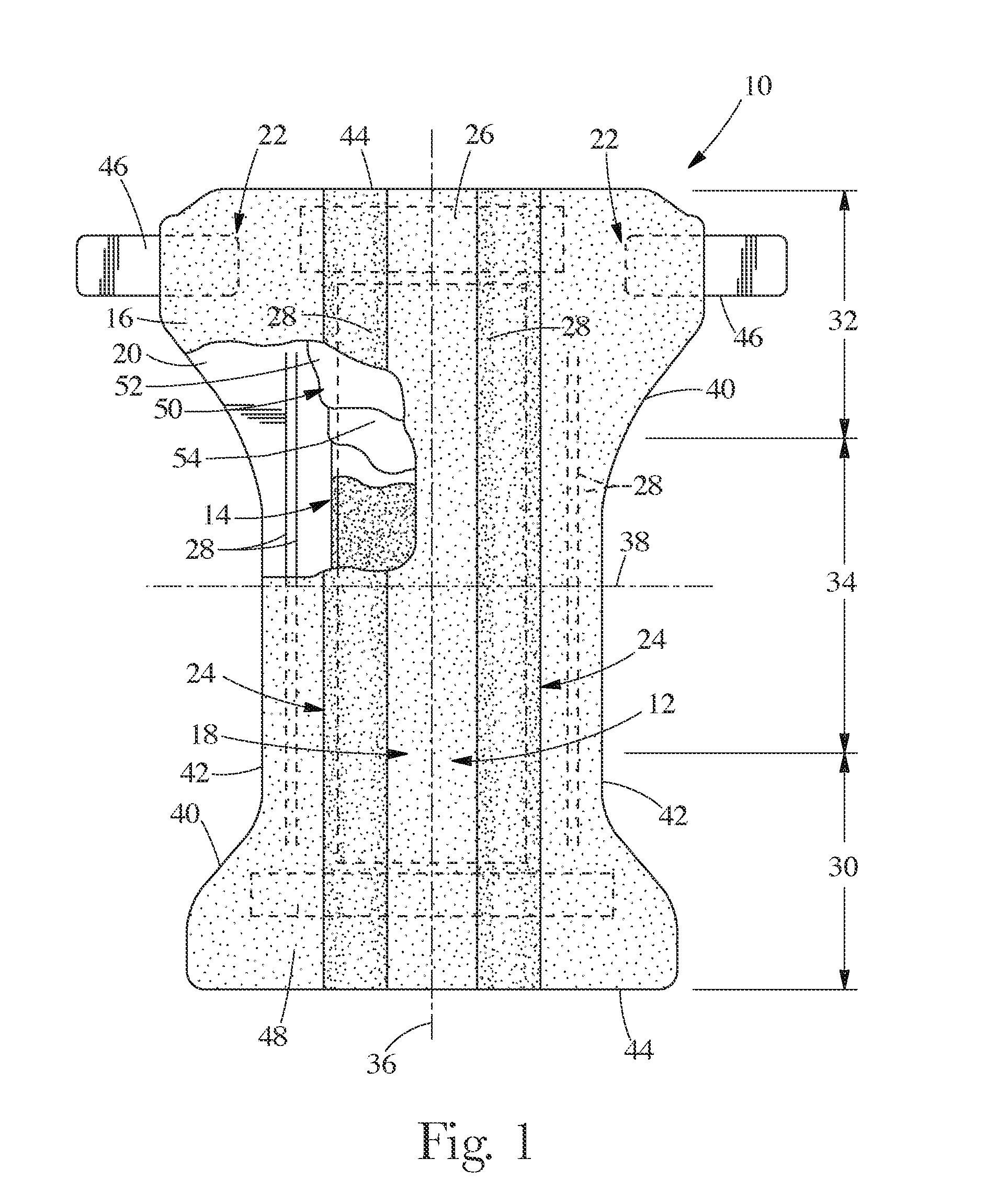

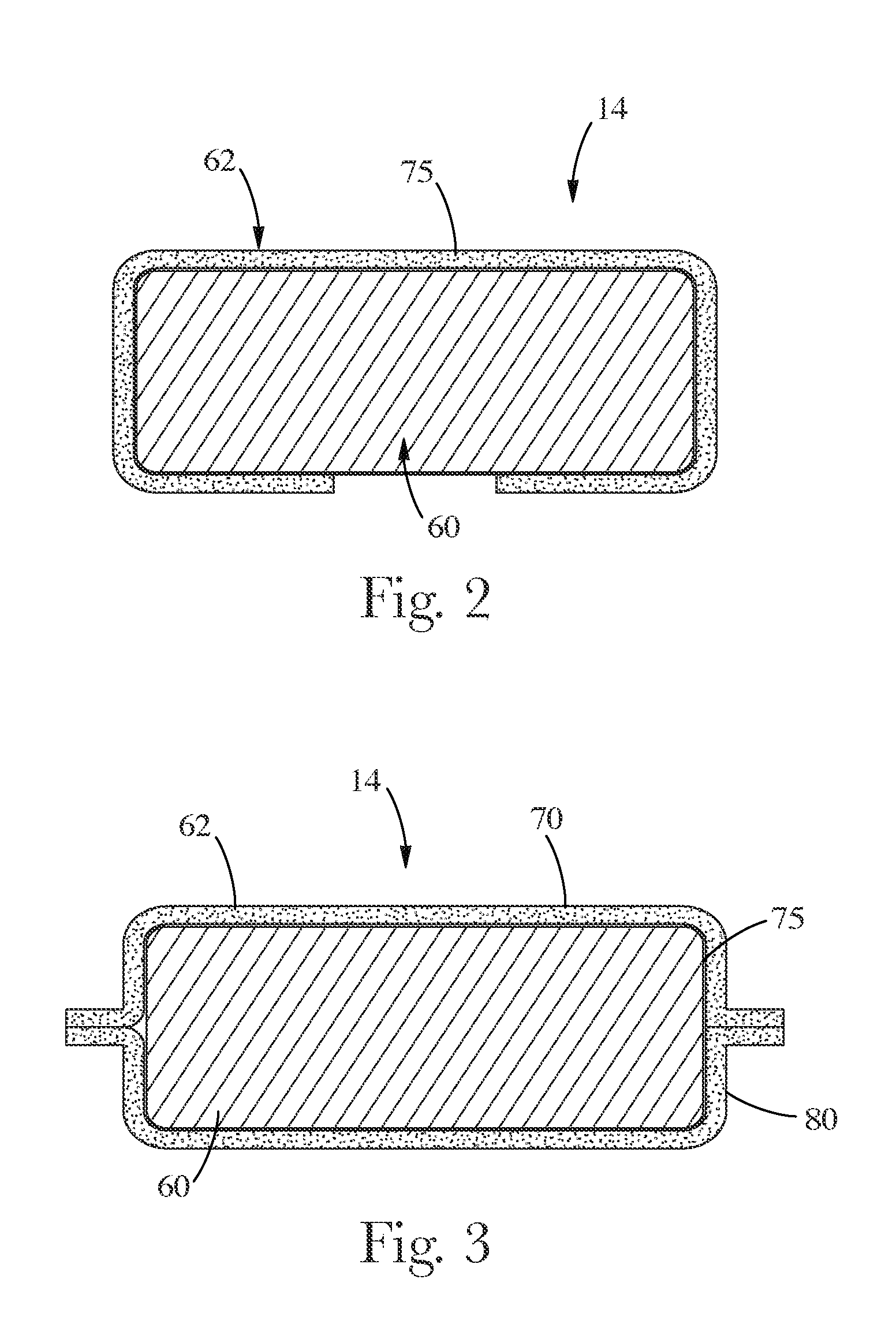

Nonwoven Having Durable Hydrophilic Coating

InactiveUS20110268932A1Promote migrationLamination ancillary operationsDecorative surface effectsHydrophilic coatingTrace Amounts

A nonwoven material coated with an amine-polyether silicone. The coating composition may include a wetting agent, an acid, and / or a defoamer. The nonwoven may be incorporated into a disposable absorbent article. The disposable absorbent article may include at least trace amounts of a mineral oil. The coating of the nonwoven may be durable even in the presence of mineral oil.

Owner:THE PROCTER & GAMBLE COMPANY

Water soluble full-alloy metal grinding fluid

ActiveCN104017636ALubricity achievedImprove stabilityLubricant compositionOrganic EsterNonferrous metal

The invention discloses a water soluble full-alloy metal grinding fluid which belongs to the technical field of metal grinding fluids. The metal grinding fluid is prepared from the following components in percentage by weight: 5-40wt% of an antirust agent, 1-20wt% of a cleaning agent, 0.1-10wt% of a lubricating corrosion inhibitor, 1-20wt% of a penetrant, 1-20wt% of a solubilizer, 10-40wt% of a PH adjustor, 0.5-5wt% of a defoamer and the balance of water. Based on the total weight of the water soluble full-alloy metal grinding fluid, the pH value of the water soluble full-alloy metal grinding fluid is 7-11. The lubricating corrosion inhibitor is long chain nitrogen heterocyclic ring organic ester. The water soluble full-alloy metal grinding fluid has excellent lubricating, rust-preventing, cleaning and cooling performances and can be widely applied to grinding of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

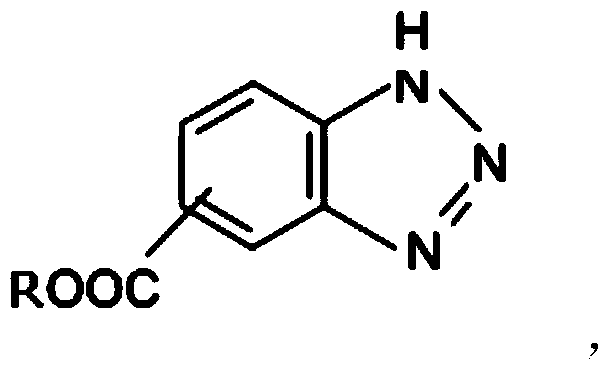

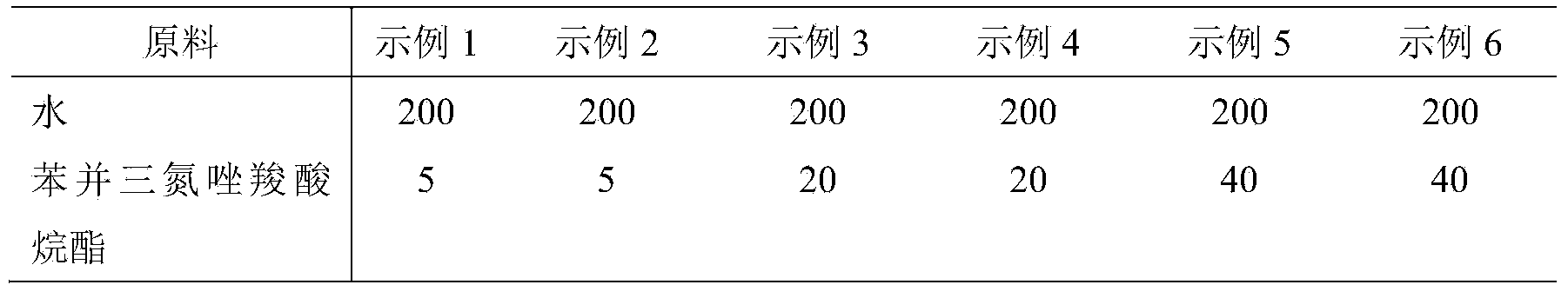

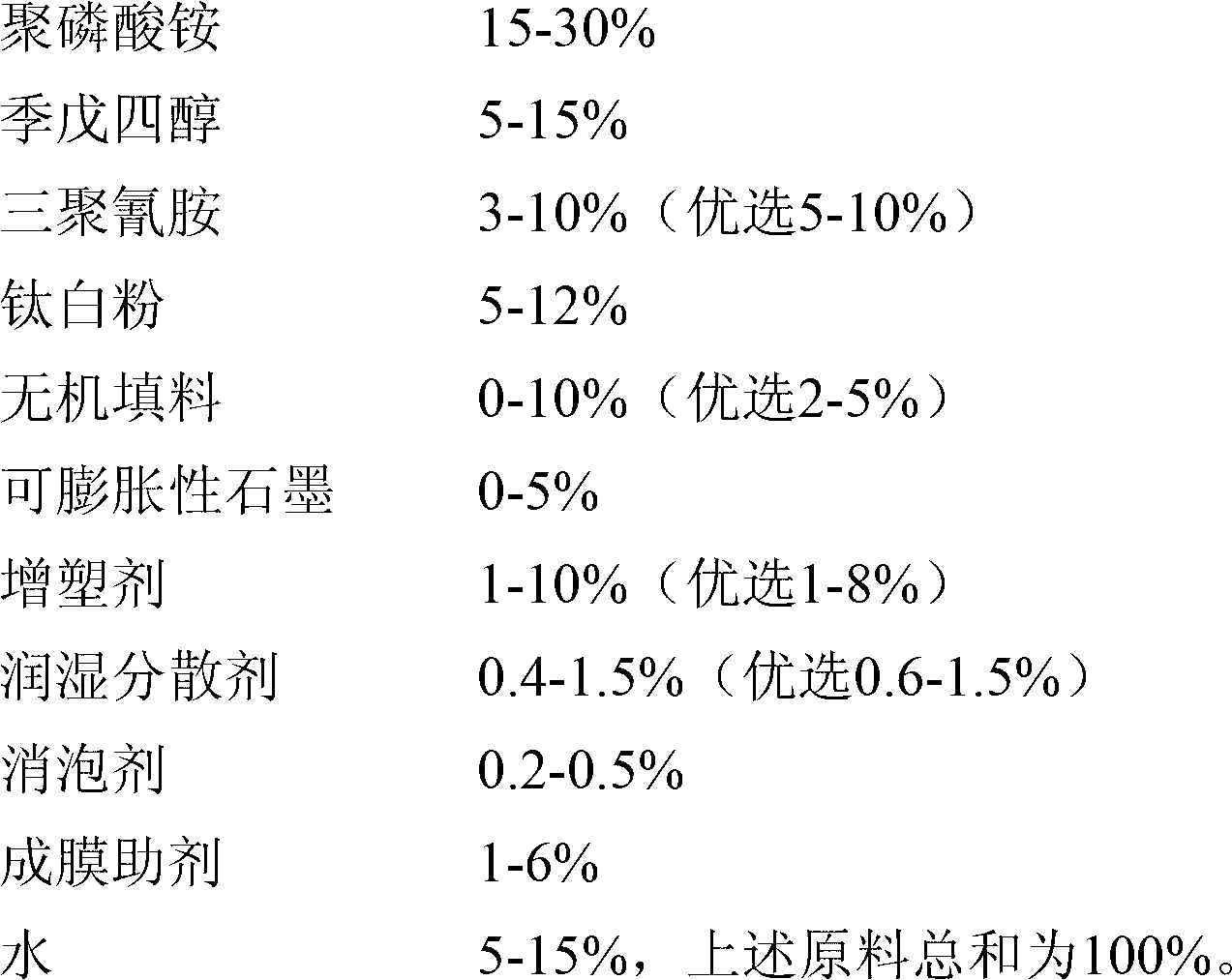

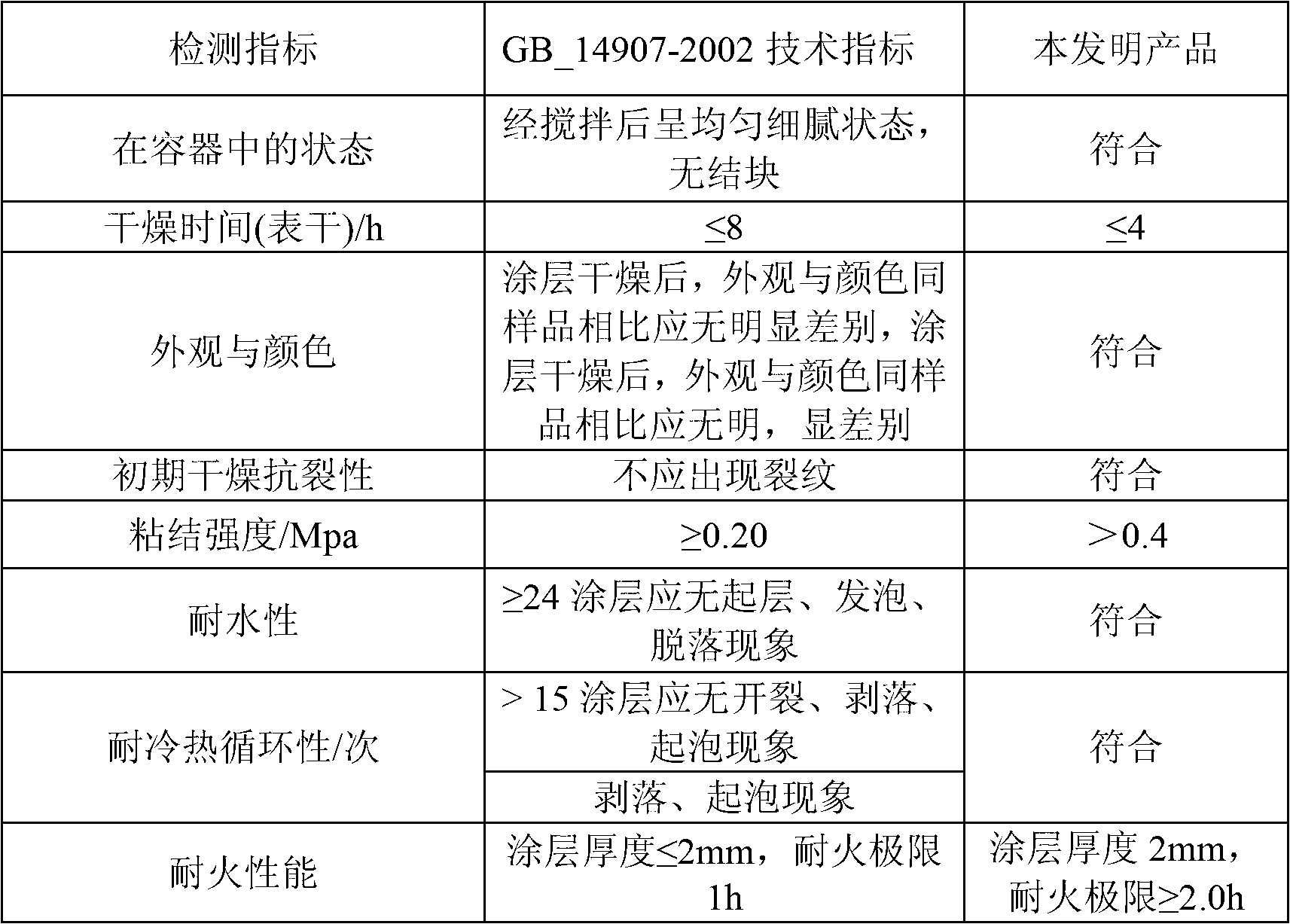

Waterborne ultra-thin steel structure fire retardant coating and preparation method thereof

ActiveCN102838907AGood foaming effectThe pores are small and uniformFireproof paintsCarbonizationMaterials science

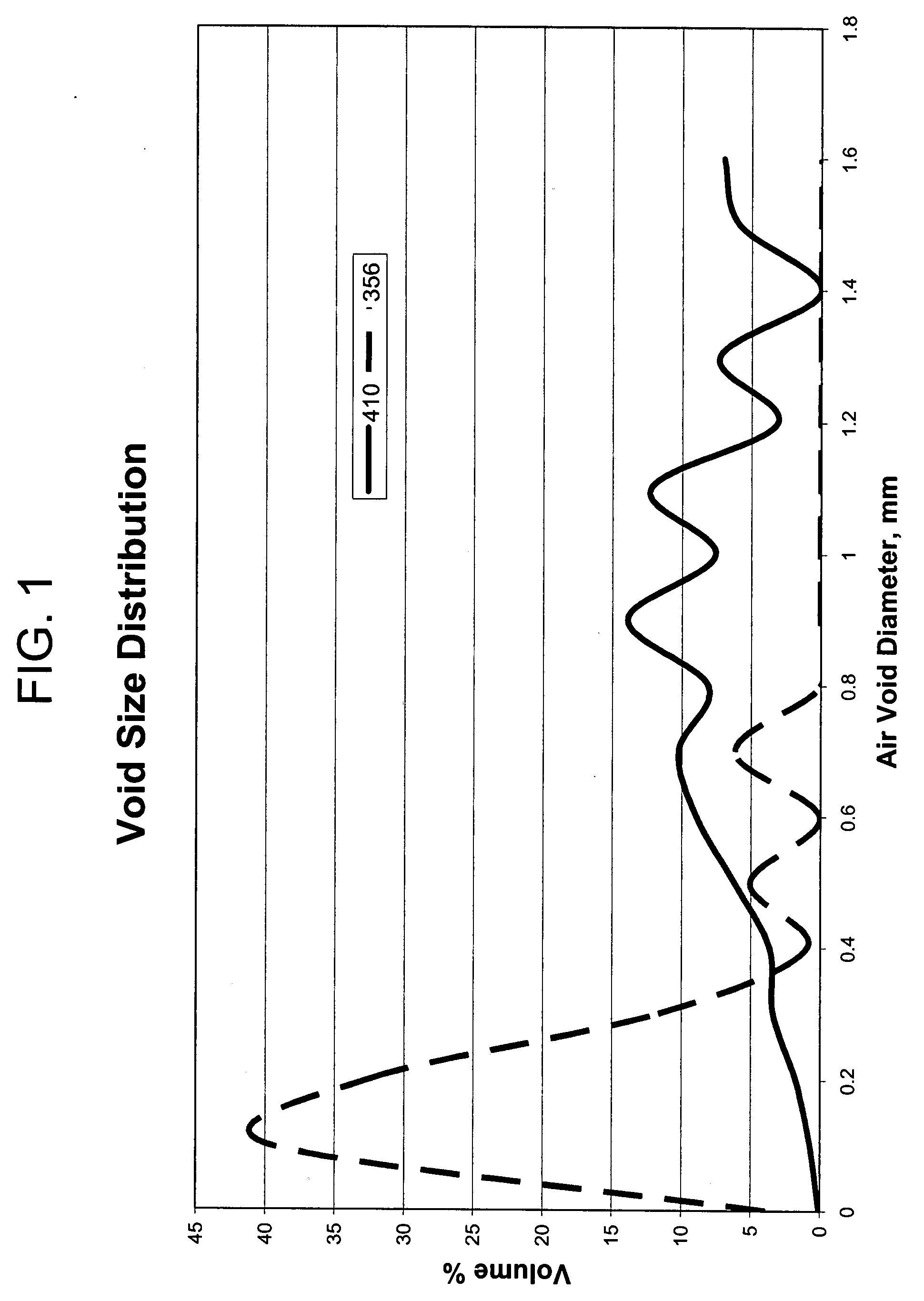

Provided is a waterborne ultra-thin steel structure fire retardant coating and a preparation method thereof. The raw material ratio of the coating includes 15-50% by weight of polymer latex, 15-30% by weight of ammonium polyphosphate, 5-15% by weight of pentaerythritol, 3-10% by weight of cyanurtriamide, 5-12% by weight of titanium dioxide, 2-13% inorganic filler, 0-5% by weight of expansiveness graphite, 1-10% by weight of plasticizer, 0.4-1.5% by weight of wetting dispersant, 0.2-0.5% by weight of defoamer, 1-6% by weight of coalescing agents and 5-15% by weight of water, and total raw material ratio is 100%. A high-speed dispersion method or a grinding dispersion method is adopted in preparation of the coating. A coating layer of the fire retardant coating can form a carbonization layer which is good in foaming effect, small and uniform in air holes and high in expansion times when in heating. The final fire retardant performance of the coating is far higher than technical requirements of a national standard. The waterborne ultra-thin steel structure fire retardant coating is a waterborne coating product, is non-poisonous and odorless and environment-friendly, and can be coated in a mode of brushing or spraying or roller coating.

Owner:SOUTH CHINA UNIV OF TECH +1

Pharmaceutically elegant, topical anhydrous aerosol foam

ActiveUS20050287081A1Excellent emollientExcellent rub-in characteristicCosmetic preparationsAerosol deliveryMedicineSilicone

A topical pharmaceutical aerosol foam containing liquid silicones to enhance cosmetic elegance. Although liquid silicones are inherent defoamers, a high quality, stable foam is produced.

Owner:DPT LAB LTD

Microemulsion metal cutting fluid

ActiveCN104164283AMeet cutting processing requirementsHigh thermodynamic stabilityLubricant compositionEmulsionNonferrous metal

The invention discloses a microemulsion metal cutting fluid which contains 1-20 wt% of fatty oil, 1-40 wt% of emulsifier, 5-40 wt% of co-emulsion, 5-30 wt% of wear and rust inhibitor, 1-20 wt% of penetrant, 5-30 wt% of pH regulator, 0.5-5 wt% of defoaming agent and 0.1-5 wt% anticorrosive bactericide. The microemulsion metal cutting fluid has excellent lubricating, antiwear, antirust, cleaning and cooling properties, and can be widely used in precise cutting work of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

Oil resistant (solvent), heatproof static conducting anti-corrosive paint and preparation thereof

InactiveCN101372601AHigh solid contentReduce the number of coatsAnti-corrosive paintsPolyurea/polyurethane coatingsPlasticizerSolvent

The invention belongs to the corrosion protective coating technique field and provides an oil resistance (solvent) and temperature resistance electrostatic conducting corrosion protective coating and a preparation method thereof. The coating is mainly made by raw components by weight percentage of 20-35 percent of resinI which is used as basic material, 0-15 percent of modified resin II, 15-30 percent of conductive fillers, 1-3 percent of coupling agent, 8-20 percent of fillers, 10-15 percent of solvent, 2-10 percent of plasticizer, 0.5-1 percent of defoamer, 0.5-1 percent of flatting agent and 6-15 percent of curing agent. The coating is prepared according to the following steps: the resin I, the modified resin II, the coupling agent, the plasticizer, the flatting agent and the defoamer are put in a distributing tank. And part of mixed solvent is added to be stirred and distributed uniformly. The fillers are added proportionally and are put in a sand mill for sand milling after being dispersed and stirred uniformly at high speed, so as to obtain upper grinding pigment paste. The conductive fillers and the rest mixed solvent are added at low stirring speed. The conductive fillers are totally blended into the upper grinding pigment paste and stirring is carried out at middle speed, the viscosity is adjusted to be qualified and the fillers are filtered to obtain a qualified component A product. The curing agent is carried out subpackage according to proportion.

Owner:洛阳双瑞防腐工程技术有限公司

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

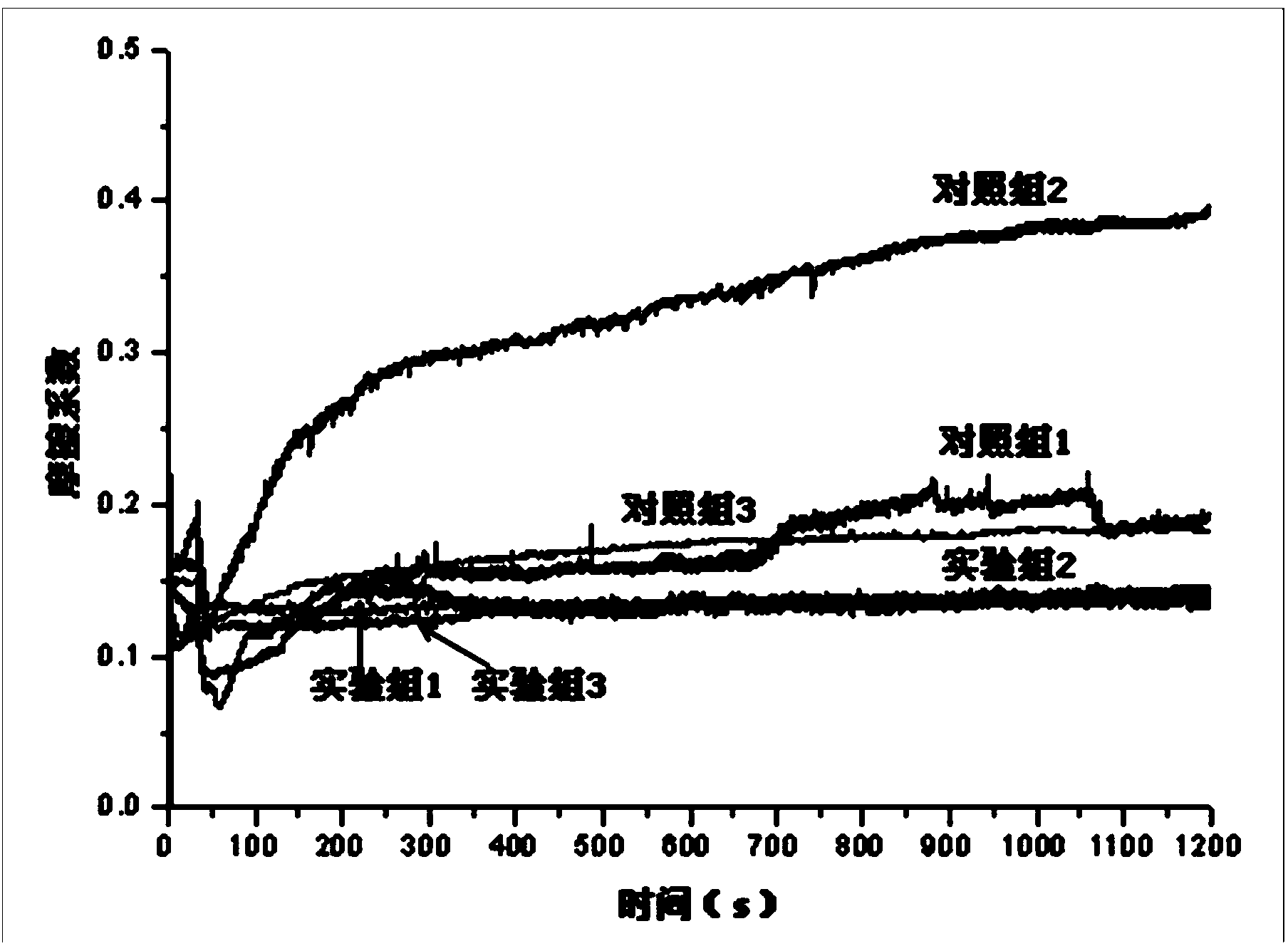

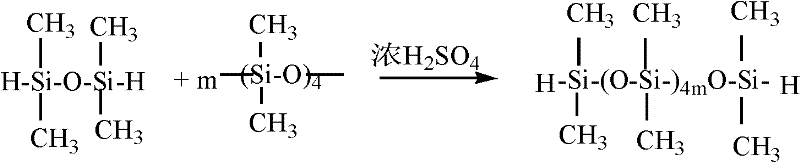

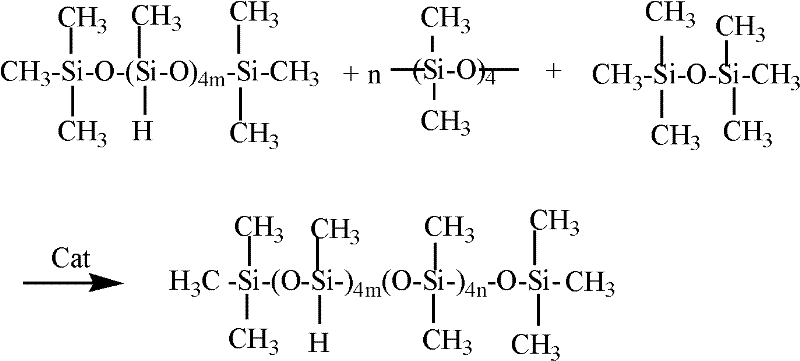

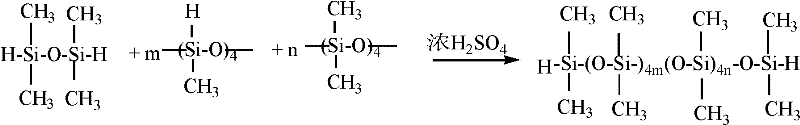

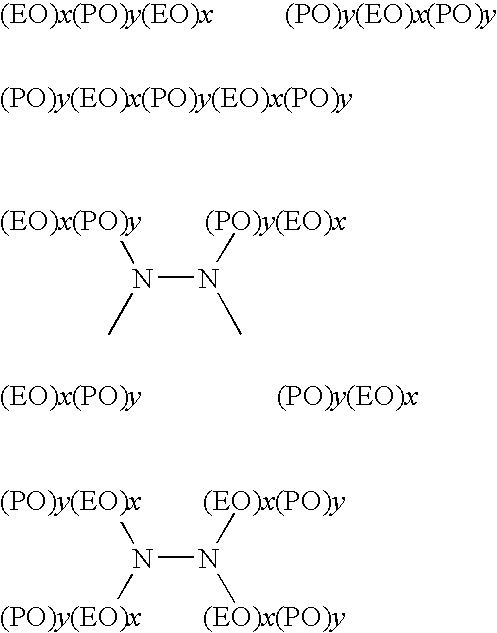

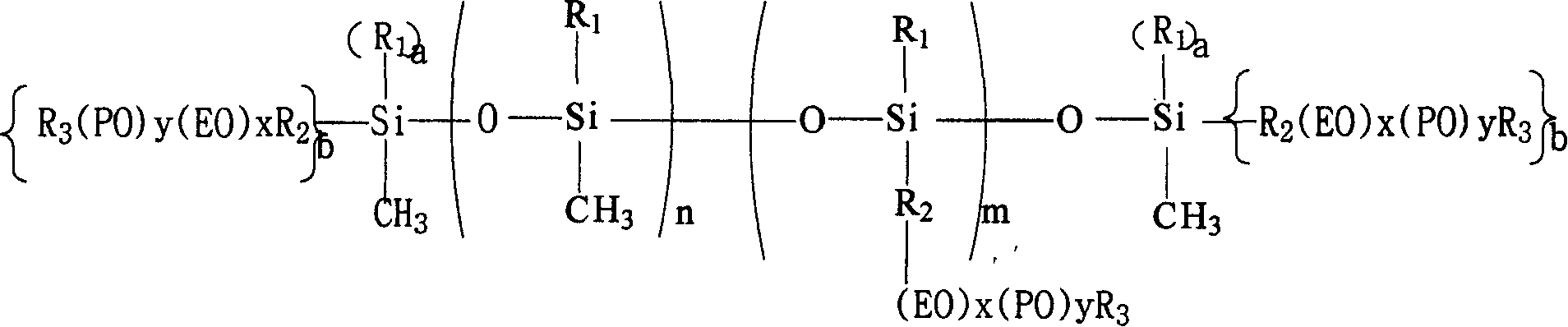

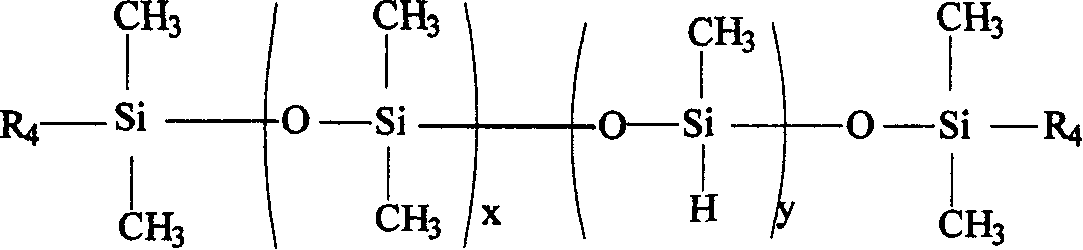

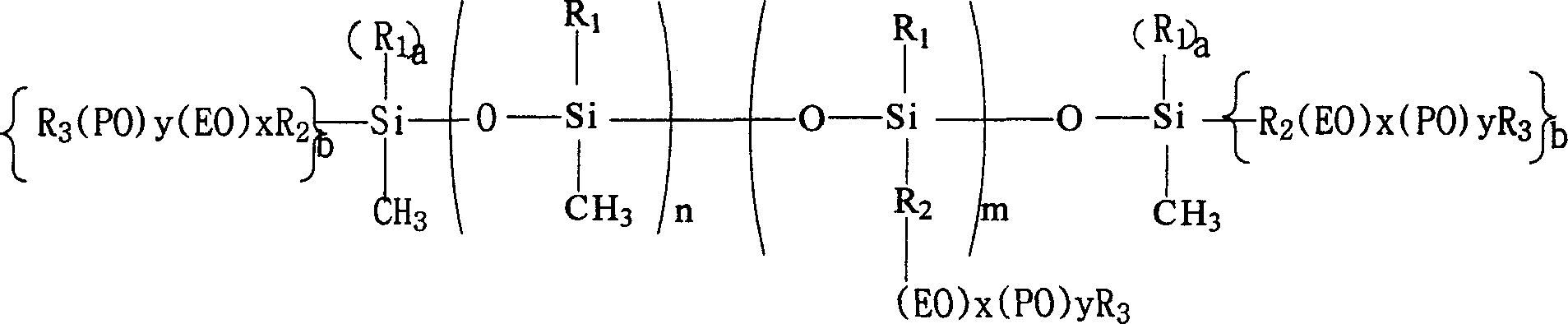

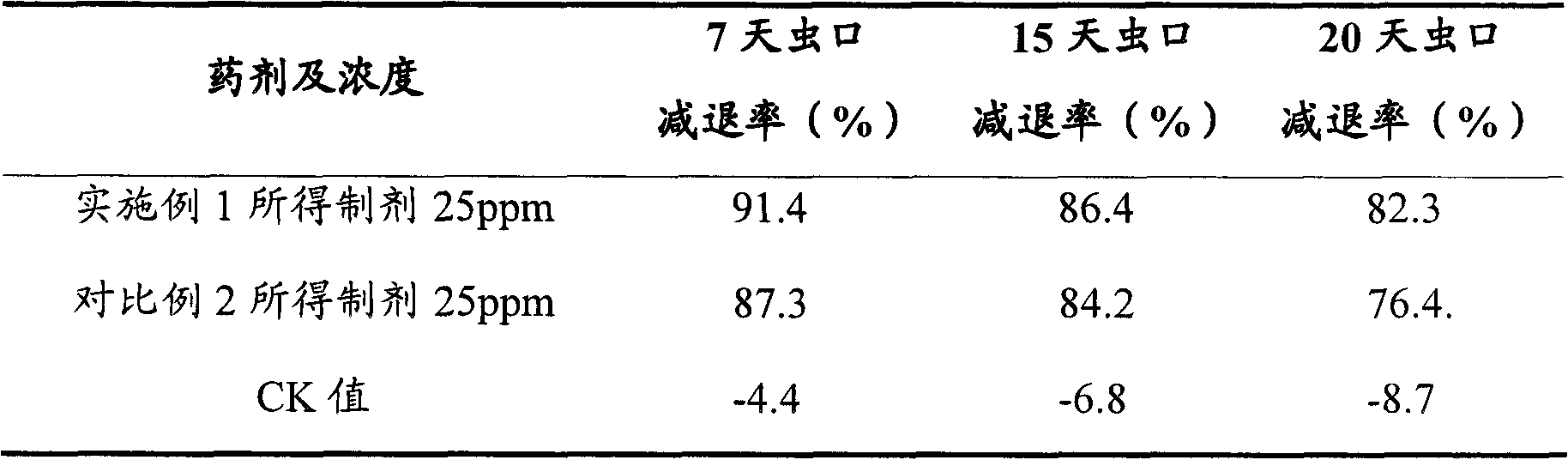

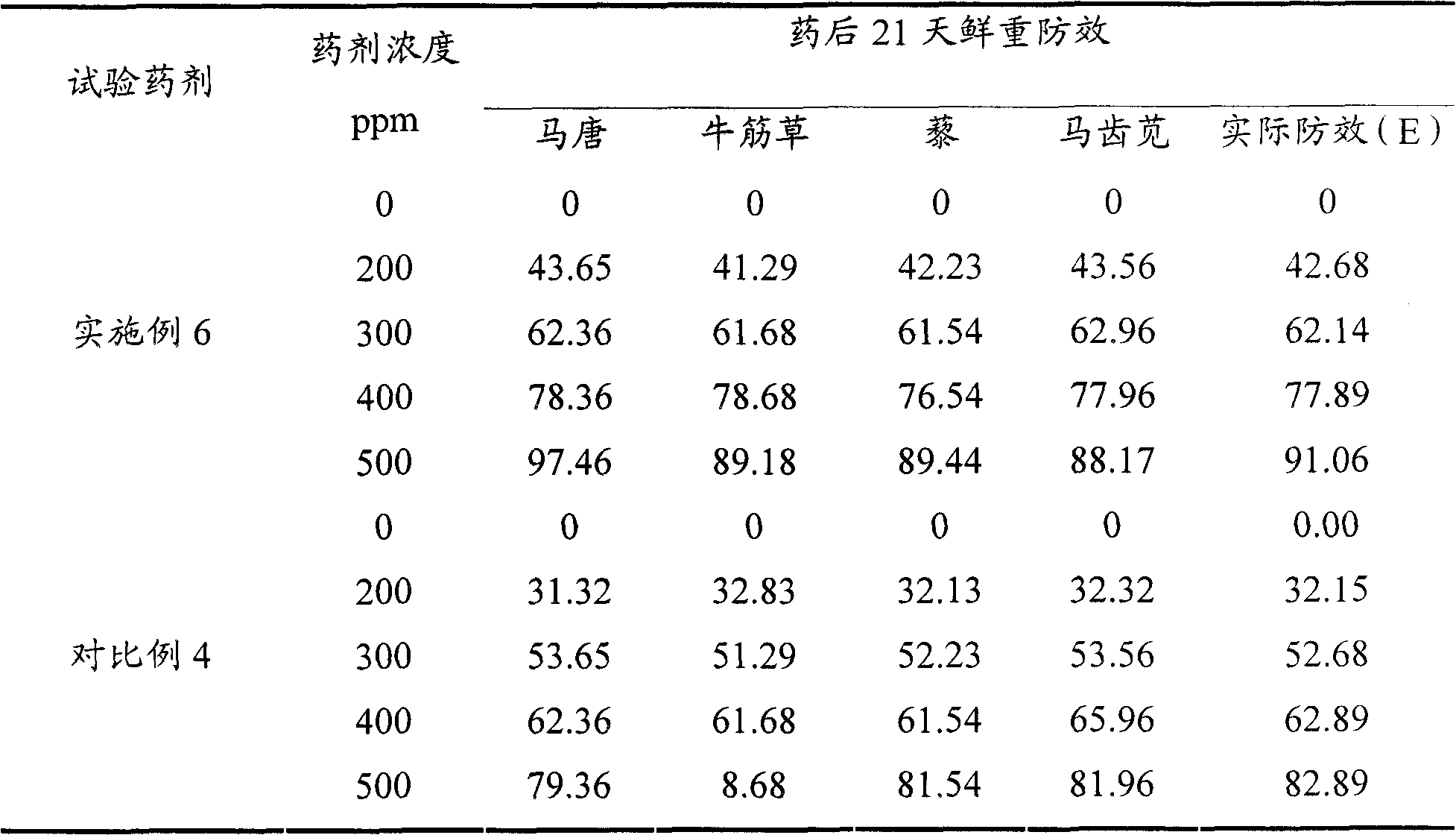

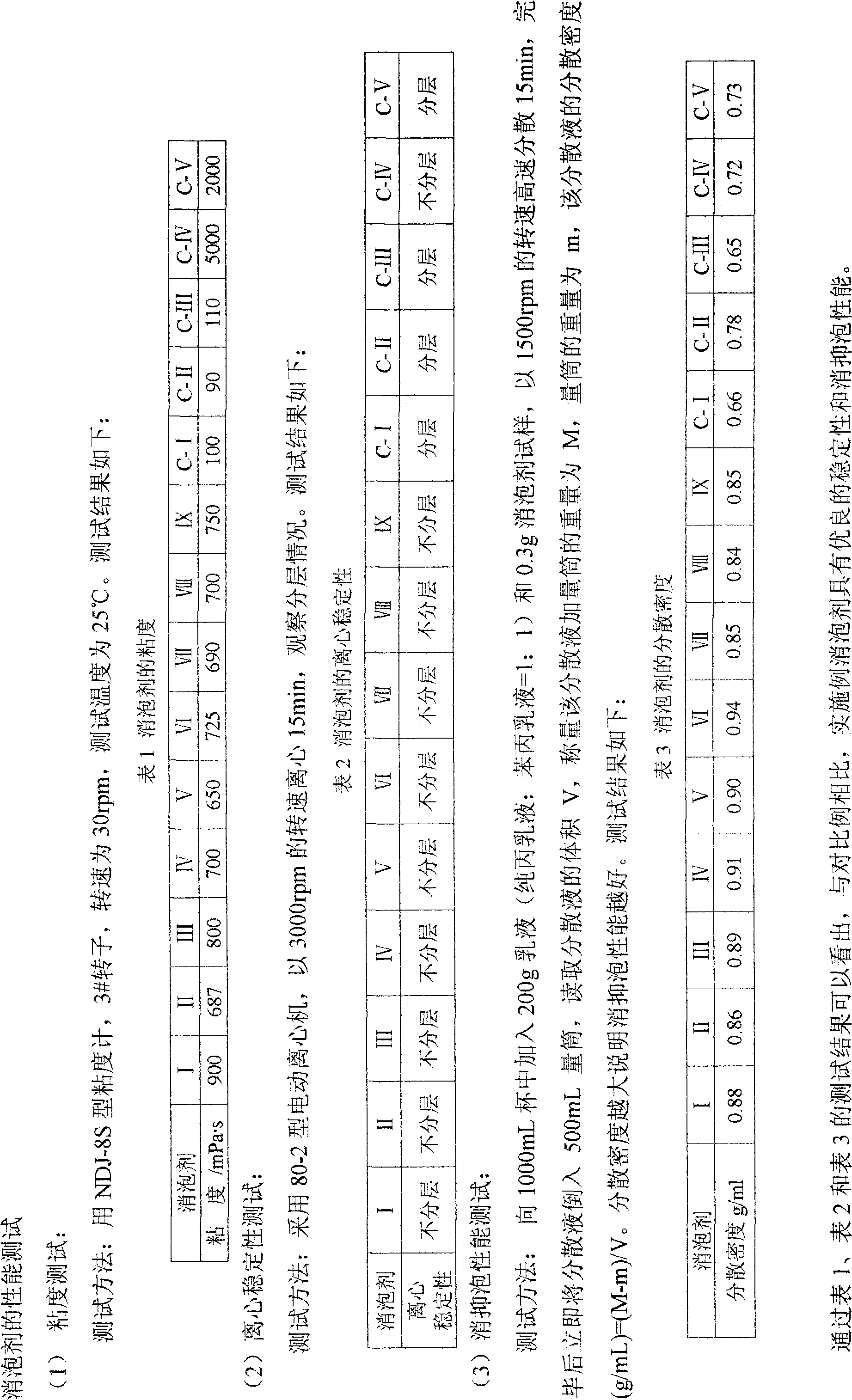

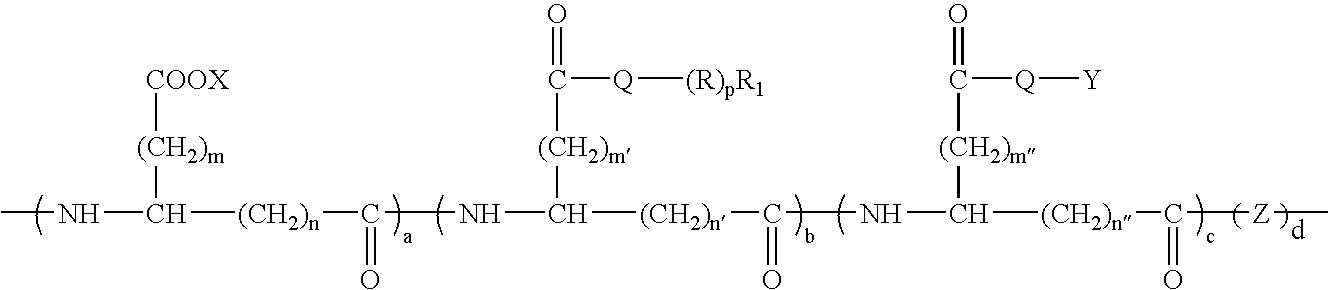

A kind of water-soluble polyether modified silicone defoamer and its preparation and compounding method

The invention relates to a water-soluble polyether modified silicone defoamer. The preparation method of the polyether-modified silicone defoamer comprises the following steps: firstly, adding terminal allyl polyoxyalkylene ether into a container for stirring, removing water; then adding solvent and low hydrogen-containing silicone oil into the above solution and stirring; then The catalyst is added to carry out stirring and heating reaction under N2 atmosphere and reflux condensation conditions; after the reaction is completed, the solvent and low boilers are removed to obtain the water-soluble polyether modified silicone. The invention also provides a compounding method of the water-soluble polyether modified silicone defoamer prepared by the above preparation method. The defoaming agent solves the problems that polysiloxanes are difficult to dissolve in water, have poor high temperature resistance and strong alkali resistance, and polyether defoaming agents have unsatisfactory defoaming speed and foam suppression time. The compounding method of water-soluble polyether-modified silicone defoamer solves the problems of incomplete emulsification of simethicone-type defoamer, demulsification when used, low temperature resistance and poor foam suppression ability.

Owner:黄山市强力化工有限公司

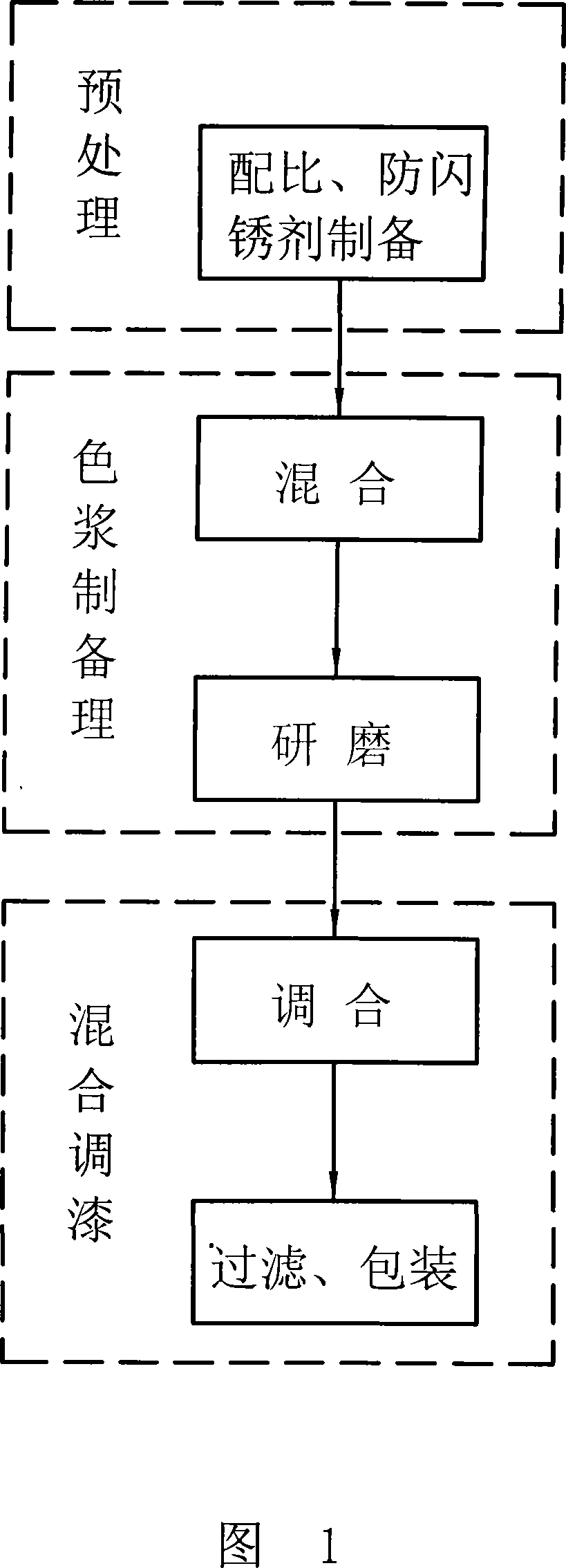

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

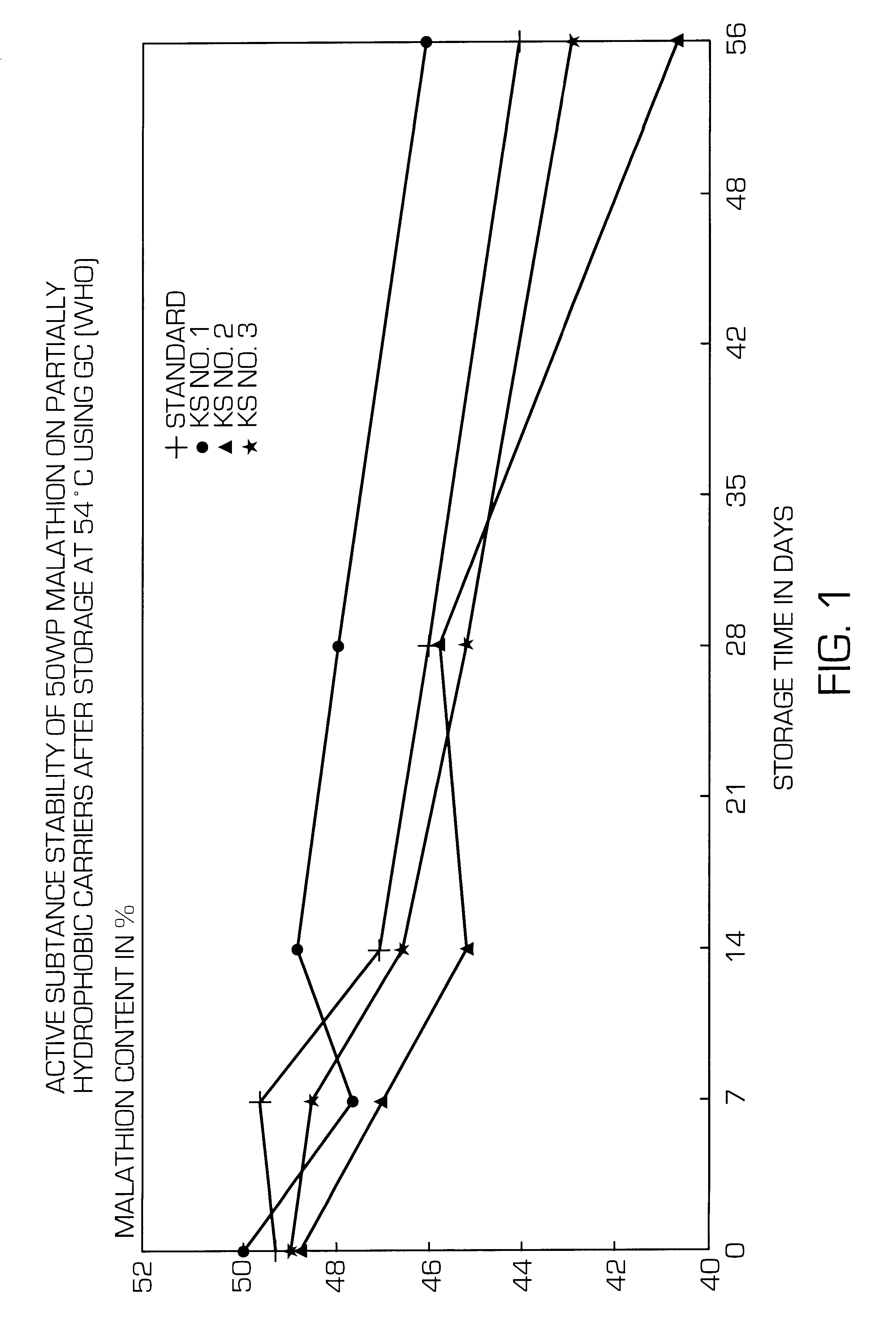

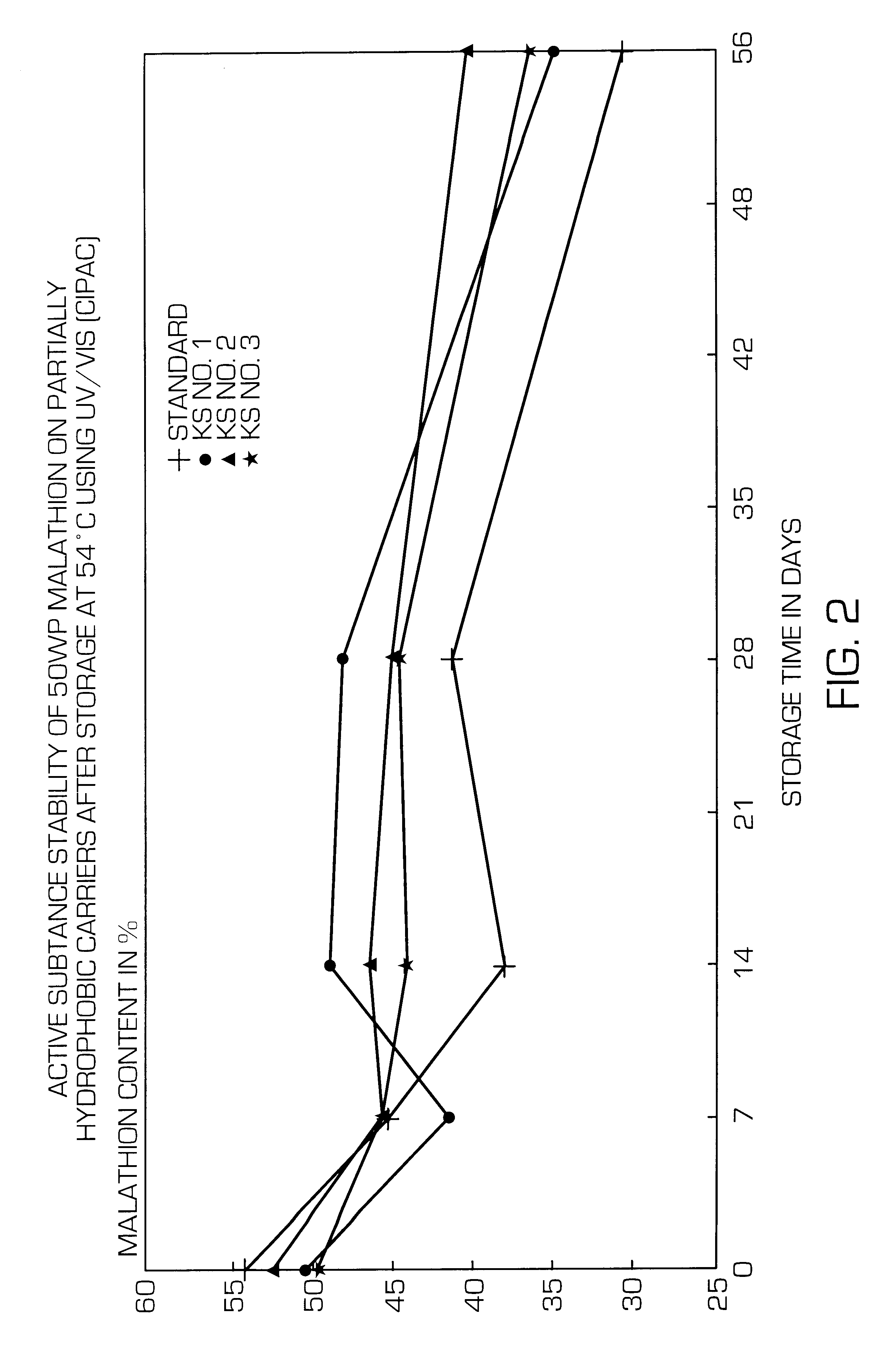

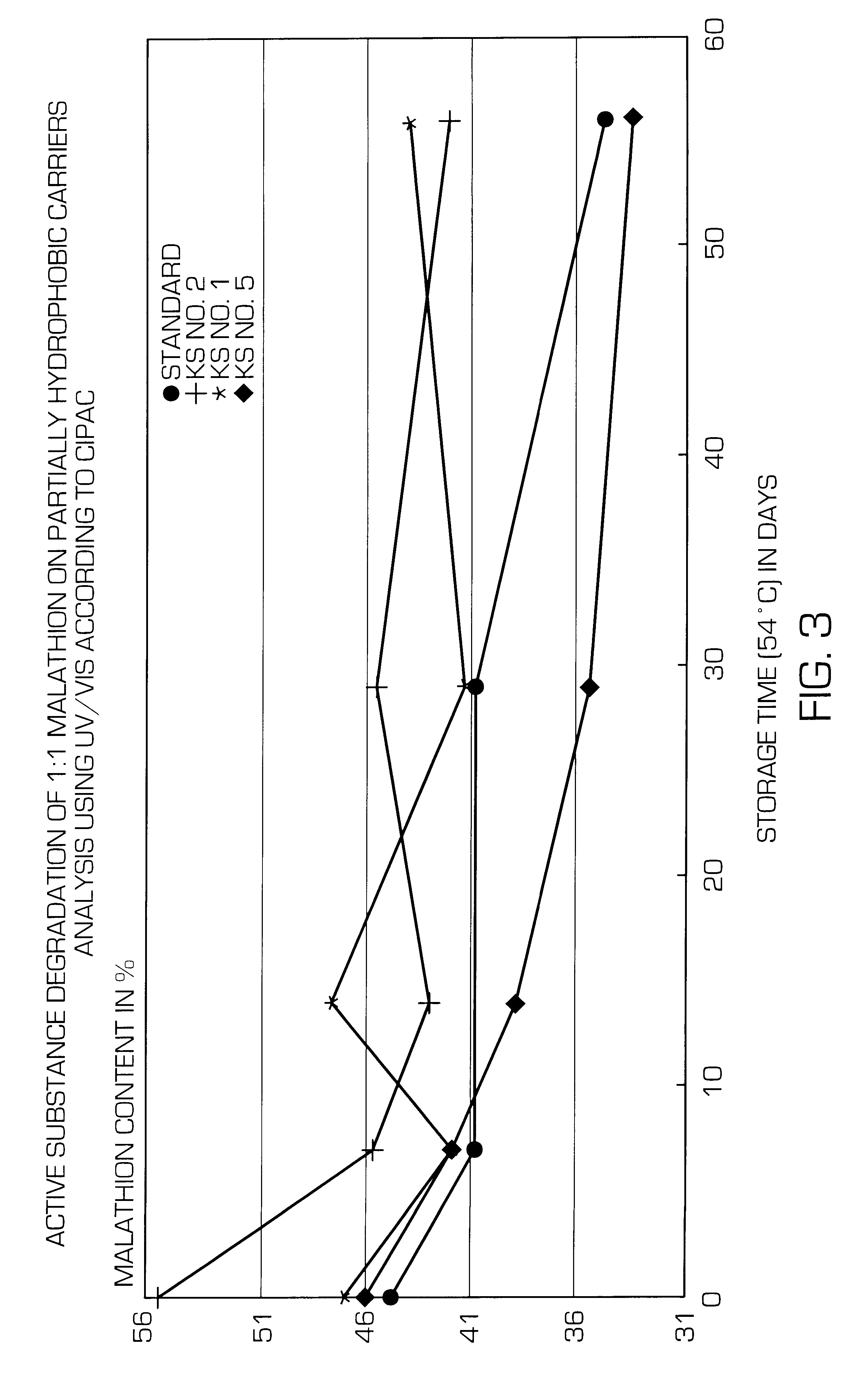

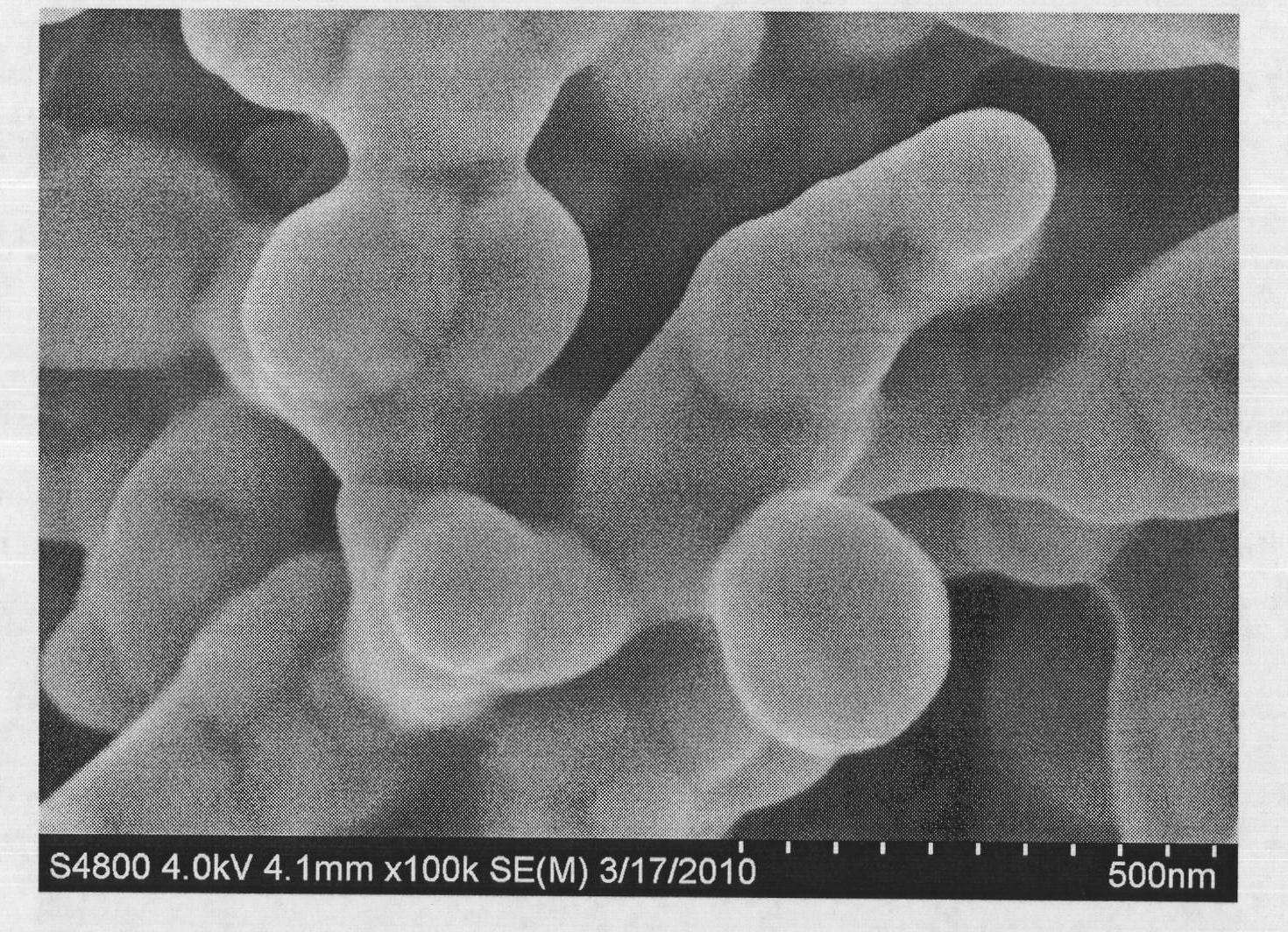

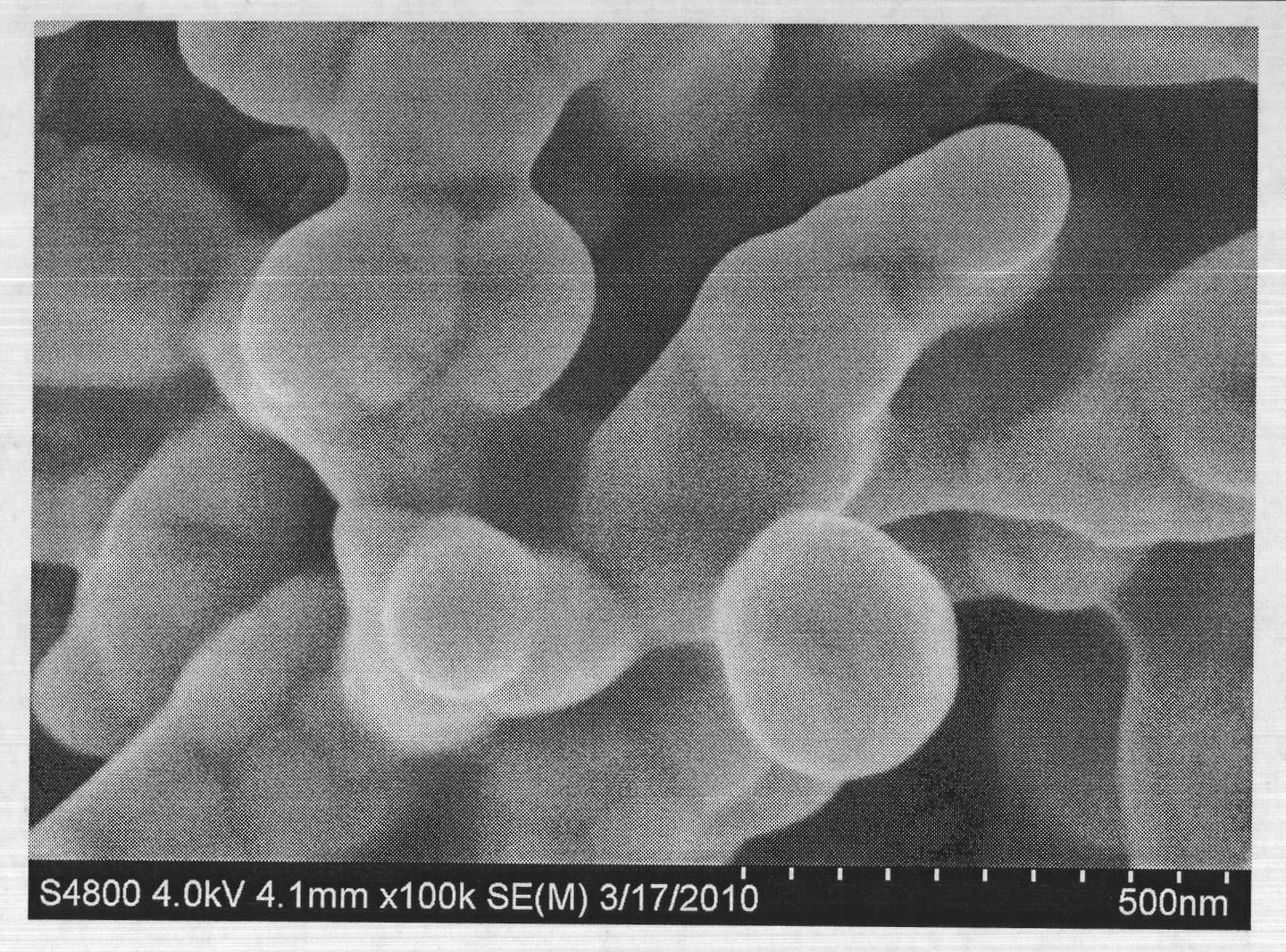

Partially hydrophobic precipitated silicas

A partially hydrophobic precipitated silica having a methanol wettability of 10 to 49%, in particular with a DBP uptake on a dry basis of greater than 250 g / 100 g and a mean particle size of 1 to 12 mum and / or a carbon content of 0.3 to 1.85% and / or a loss on drying of 2.6 to 10.0% and / or a pH value of 5.5 to 10.0, is prepared by mixing the amount of water-repellent agent with the precipitated silica suspension at very short residence time and low pH value, filtering off the solid substance, washing free of salt, drying, post-treating thermally and milling. The partially hydrophobic precipitated silica can be used in active substance formulations and active substance formulations of hydrolysis-sensitive substance and in defoaming agents.

Owner:EVONIK DEGUSSA GMBH

Water-based sound-proof damping coating and preparation method thereof

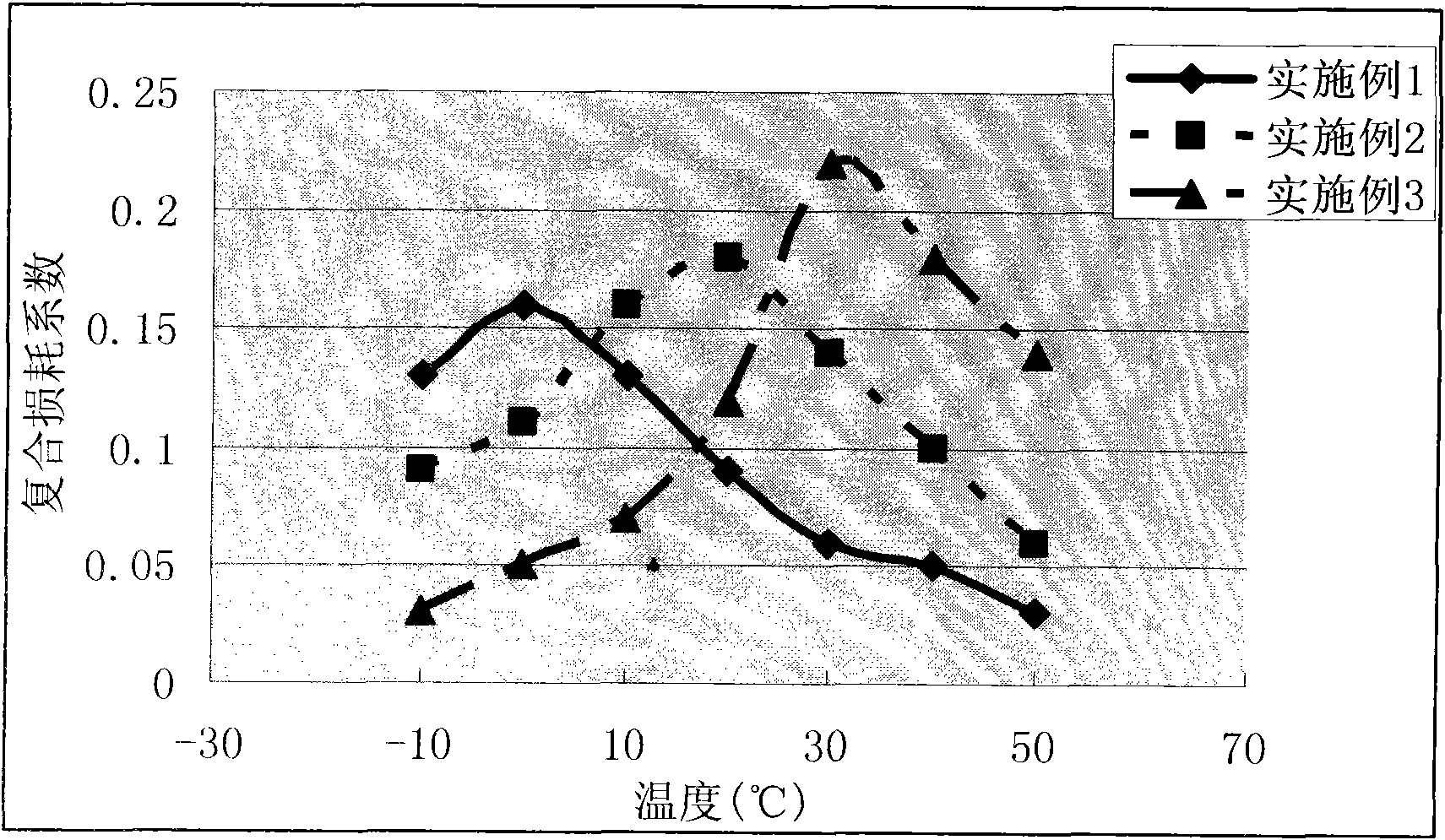

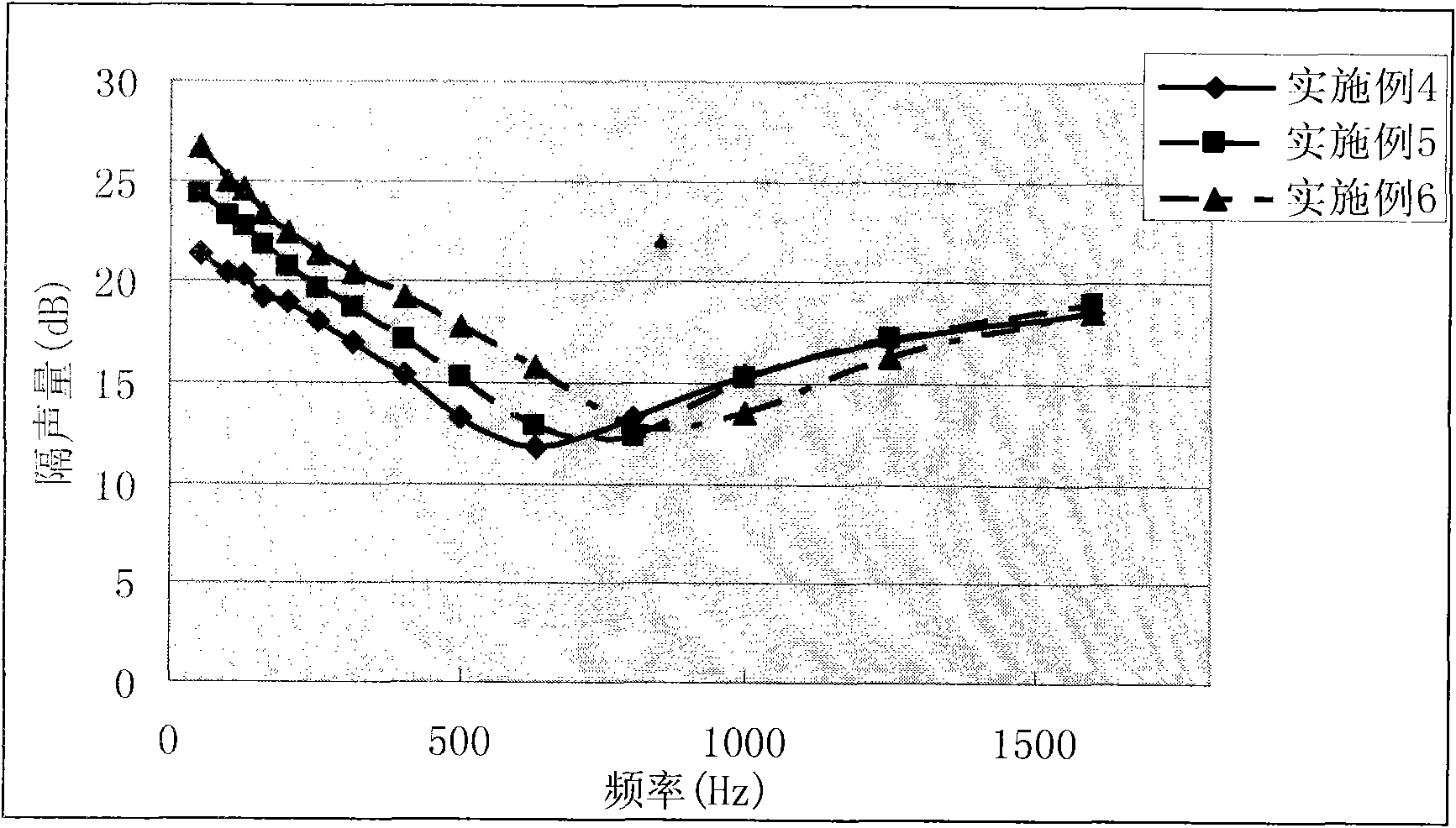

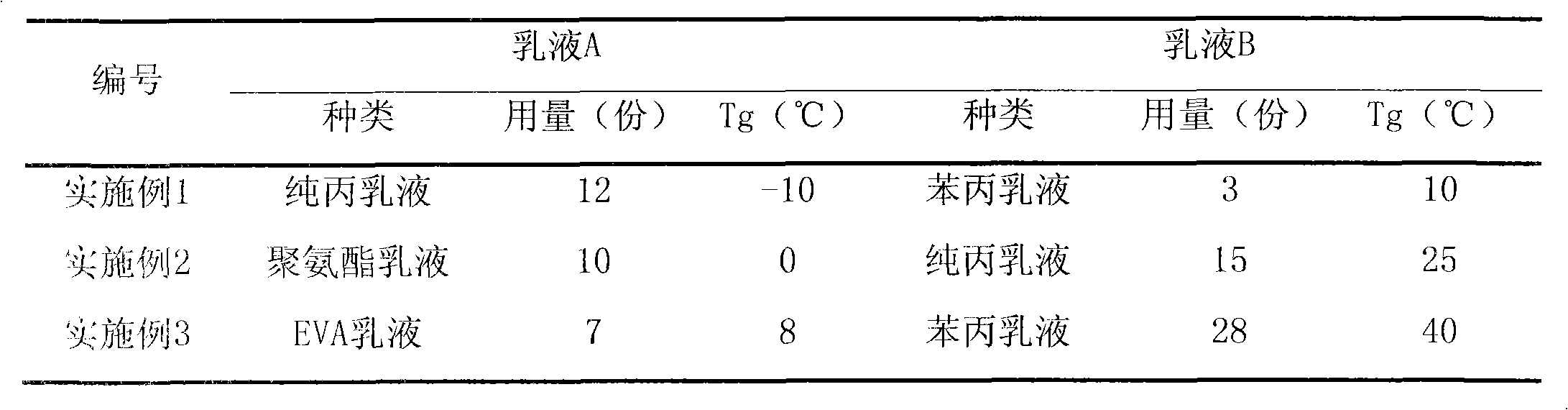

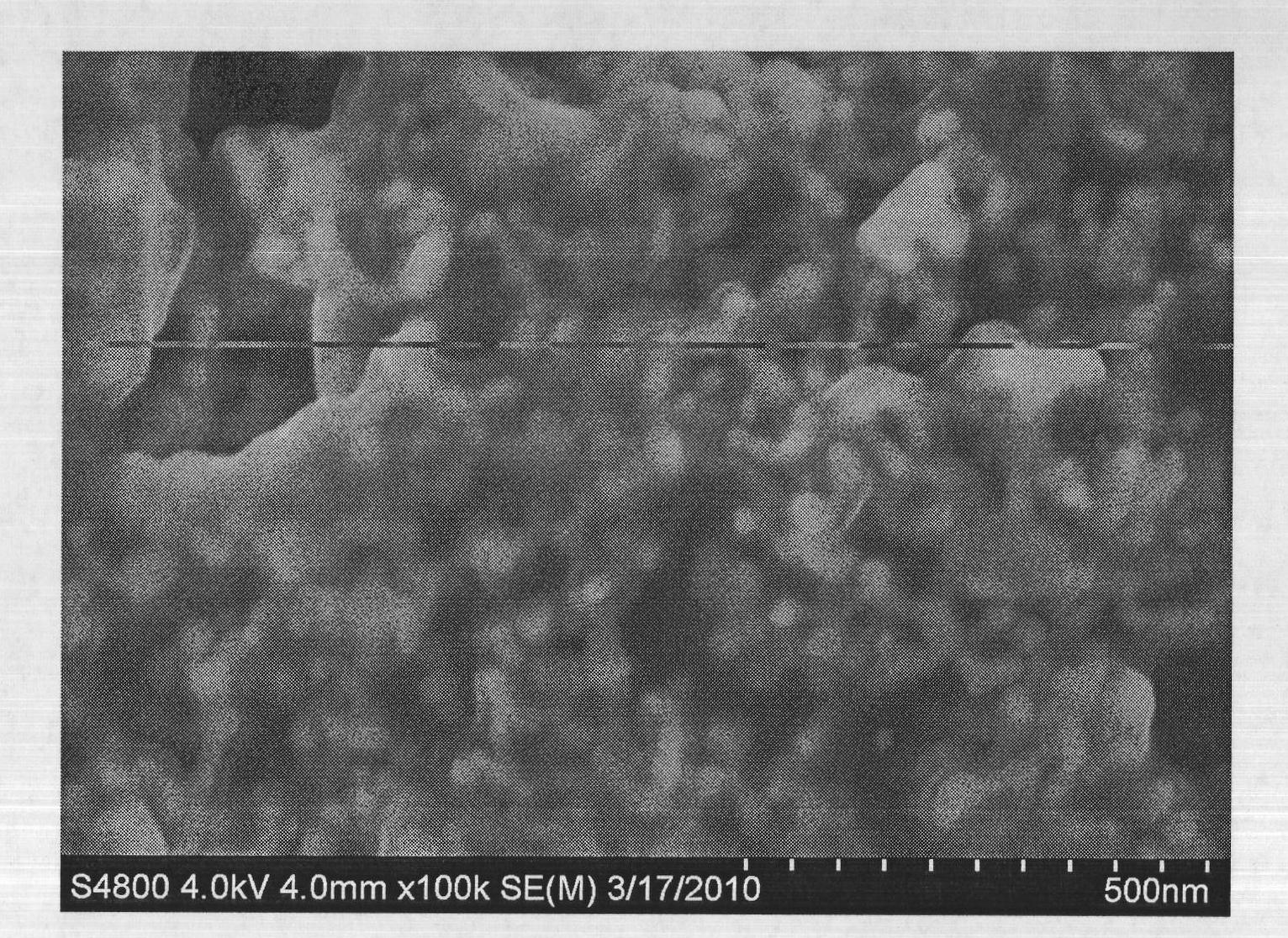

ActiveCN101891990AImprove performanceGood damping of vibrationPolyurea/polyurethane coatingsFiberWater based

The invention discloses a water-based sound-proof damping coating and a preparation method thereof. The water-based sound-proof damping coating comprises the following raw materials in part by weight: 15 to 35 parts of polymer emulsion, 35 to 55 parts of inorganic filler, 10 to 20 parts of powdery flame retardant, 2 to 5 parts of auxiliary agent, and 10 to 20 parts of deionized water. The preparation method comprises the following steps of: uniformly mixing the deionized water and a wetting and dispersing agent, and adding part of inorganic filler with stirring at a high speed to prepare inorganic filler water dispersible slurry; and adding the polymer emulsion into the inorganic filler water dispersible slurry with stirring at the high speed, sequentially adding the powdery flame retardant, the rest part of inorganic filler, reinforcing fibers, a mould inhibitor and an antifoaming agent, and finally adding a thickening agent to adjust consistency. The coating of the invention has excellent vibration and noise reduction effect, is mainly used for internal coating of carriage floors, side walls and roofs of vehicles, and can play a good role in inhibiting vibration and reducing noise.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

Lower-temperature sintered conductive ink

ActiveCN101805538AIncrease base rangeReduce consumptionInksMetallic pattern materialsAdhesivePreservative

The invention discloses a low-temperature quickly sintered conductive ink for use in ink jet printing, which comprises 1 to 70 weight percent of nano metal particles, 0.1 to 10 weight percent of dispersant, 25 to 98 weight percent of solvent and 0.01 to 36 weight percent of additive, wherein the additive is one or a mixture of two or more of a surfactant, a reducer, a defoamer, an adhesive, a preservative and a humectants. Compared with the prior art, the low-temperature sintered conductive ink can reduce sintering temperature and keep the high conductivity of a wire. For example, at a sintering temperature of 150 DEG C, the conductive ink can make the resistance of a silver wire reach 10 to 7ohm.m. Therefore, the conductive ink can enlarge the range of substrates to which the conductive ink is applied in ink jet printing and reduce energy consumption, and has a great significance for the cost control and environmental protection of manufacturers.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Dimensionally Stable Solid Rinse Aid

ActiveUS20080293615A1Reduced water solid filming in waterReduce spotting and water solids filmingOrganic detergent compounding agentsDrying soapAlcoholPreservative

The present invention is a solid rinse aid composition and methods of making and using the same. The solid rinse aid composition generally includes sodium sulfate and urea as solidification agents and an effective amount of an alcohol ethoxylate compound sheeting agent component and an effective amount of defoamer component. The solid rinse aid composition may also incorporate a preservative system including sodium bisulfate. The solid rinse aid composition may be phosphate-free, aminocarboxylate-free, and GRAS if desired.

Owner:ECOLAB USA INC

Epoxy resin embedding glue and method for producing the same

The invention relates to an epoxy resin potting adhesive which consists of component A and component B. By weight portion, the component A consists of 90-130 portions of bisphenol A type epoxy resin, 240-320 portions of filling, 15-25 portions of thinner, 10-25 portions of toughener, 1-2.5 portions of defoamer and 0.8-2 portions of black pigment, and the component B consists of 60-130 portions of estolide and 1-3 portions of imidazole accelerator. The mixing proportion of the component A and the component B is (3-5):1. The invention also provides a preparation method of the epoxy resin potting adhesive. The epoxy resin potting adhesive provided by the invention has low cost and long resting period; after being mixed, the component A and the component B have low viscidity, good wetting quality, good heat resistance, good defoaming performance, good fluidity and long operating time and are solidified between 70 DEG C and 160 DEG C; a product after solidifying has bright surface, good mechanical performance and insulating performance and high glass transition temperature; and the quality of a potting component is stable.

Owner:NICHE TECH KAISER SHANTOU

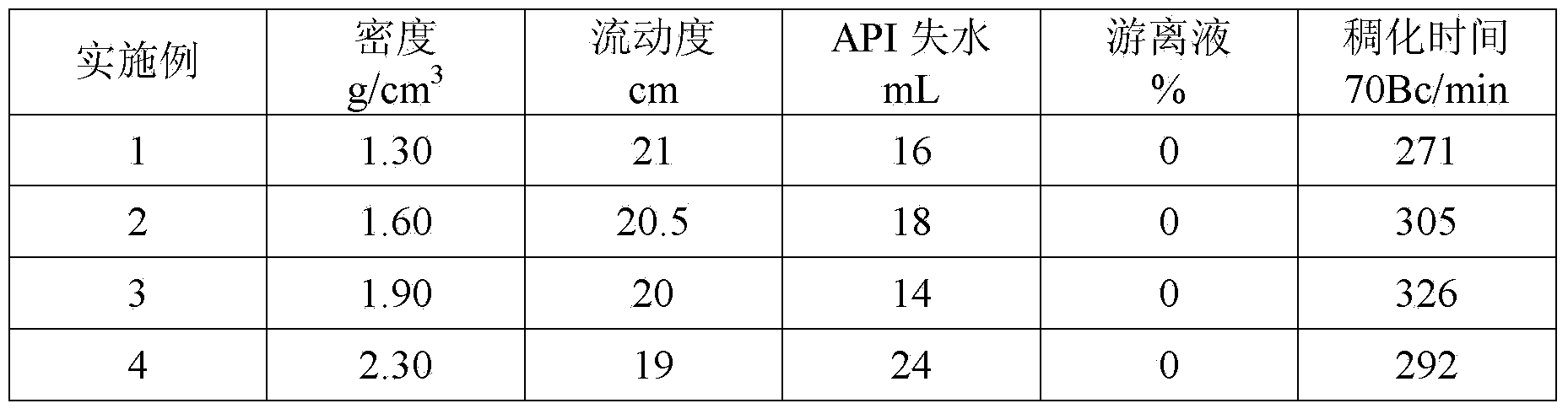

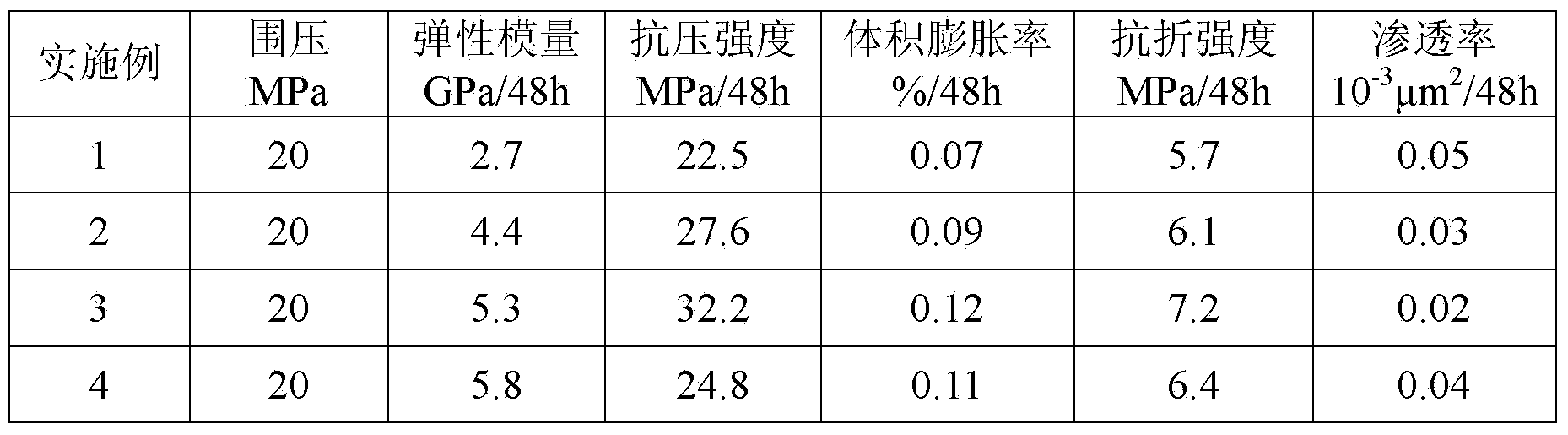

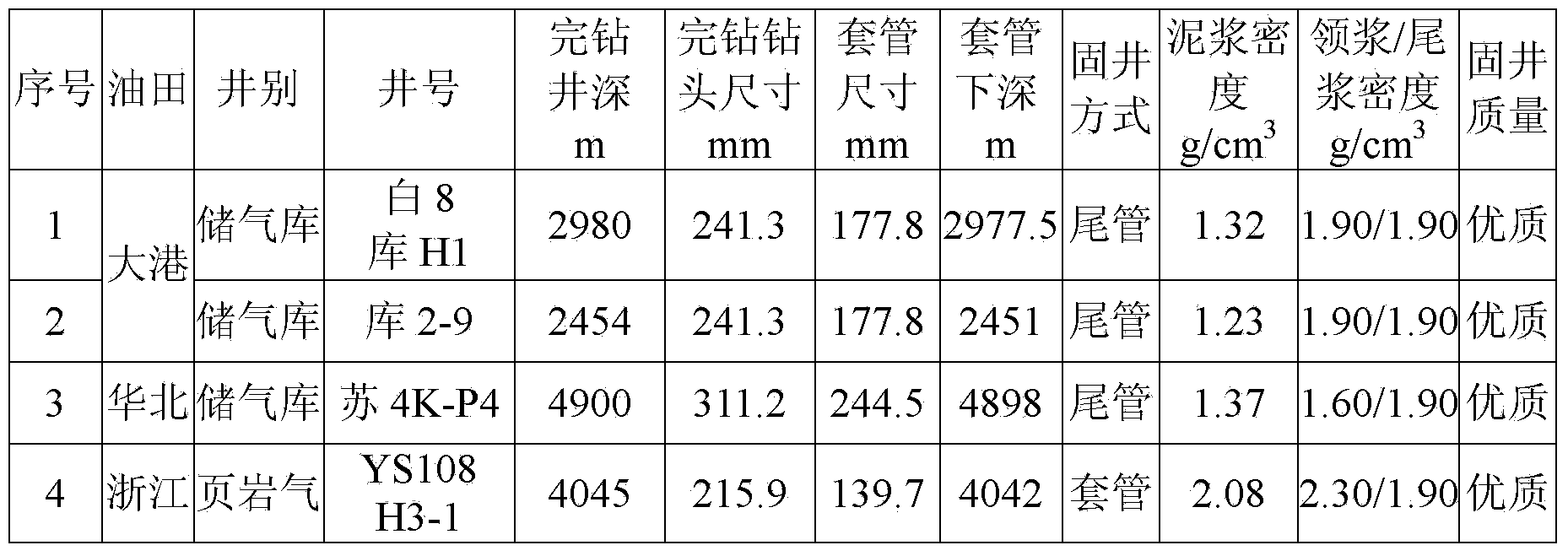

Expanded flexible well cementing grout and preparation method thereof

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Organosilicon defoaming agent for water-based system and preparation method thereof

The invention discloses an organic silicon defoamer and preparing method in the hydraulic flexible ink and paint, which comprises the following parts: silicon polyether, silicone grease, emulsifier and thickener, wherein the active content is 10-50% corresponding to emulsion; the silicon polyether and silicone grease is 70-90% in the active content; the disperse dielectric adopts deionized water.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Deep-water low-temperature low-density early-strength cementing slurry for well cementation

ActiveCN101747880ARapid development of strengthImprove early strengthDrilling compositionVolumetric Mass DensityCement slurry

The invention relates to deep-water low-temperature low-density early-strength cementing slurry for well cementation in petroleum drilling engineering, which contains 100 parts of low-temperature early-strength cement, 10 to 30 parts of low-temperature reinforcing material, 10 to 80 parts of low-density light-weight material, 0.5 to 4 parts of drag reducer, 2.5 to 8 parts of fluid loss additive, 0.1 to 5 parts of retarder, 0.15 to 1.2 parts of defoamer, 2.5 to 8 parts of early strength agent and 57 to 95 parts of water, and slurry with the density of 1.2g / cm3 to 1.7g / cm3 can be prepared. The slurry system at least has the following advantages that: the maximum early strength (24 hours) can reach 14.7MPa, the long-term strength stability is good, the static gelling transition time is short, and the system is stable. The invention provides technical support for the quality of deep-water well cementation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Pesticide oil suspension agent and preparation method thereof

ActiveCN101785455ASmall particle sizeGood spreadabilityBiocideFungicidesDispersion stabilityVegetable oil

The invention provides a pesticide oil suspension agent and a preparation method thereof; the pesticide oil suspension agent contains a pesticide active component, emulsifier, defoamer and a dispersion medium; and the dispersion medium is methyl oleate or the mixture of oil methyl ester and vegetable oil. The method for preparing the pesticide oil suspension agent comprises the following steps that: the dispersion medium and the emulsifier are mixed and emulsified; other components are added in to be mixed into pulp; and the pulp is ground by a grinder to prepare the oil suspension agent. Thepesticide oil suspension agent of the invention has small average grain size and high dispersion stability, has good extendibility and permeability on plant leaves, and improves the medicine effect of the product; and the preparation method of the pesticide oil suspension agent has simple process and low cost, facilitates industrial production, and has wide production application prospect.

Owner:SHENZHEN NOPOSION AGROCHEM

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

Mineral oil defoaming agent and preparation method thereof

ActiveCN101991975AImprove performanceGood defoaming performanceFoam dispersion/preventionBlack liquorSewage

The invention provides a mineral oil defoaming agent comprising mineral oil, a fatty acid metal soap, fatty acid amide, white carbon black, a defoaming auxiliary agent and an emulsifying agent. The invention has the technical scheme that the fatty acid metal soap, the fatty acid amide and the white carbon black are simultaneously selected as defoaming substances and a method mixing the defoaming substances into the mineral oil is changed, thus the stability and the foam removing and depressing properties of the mineral oil defoaming agent are improved. The mineral oil defoaming agent has better foam removing and depressing effects in the processes of papermaking black liquor, coating, sewage treatment, latex, cleaning, and the like.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Cement compositions comprising improved lost circulation materials and methods of use in subterranean formations

The present invention relates to subterranean cementing operations and, more particularly, to cement composition that include improved lost circulation materials, and methods of using such cement compositions in subterranean formations. In certain exemplary embodiments, the improved lost circulation materials include inelastic particles of polyethylene, polystyrene and / or polypropylene. Optionally, the cement compositions also may include additives such as fly ash, a surfactant, a dispersant, a fluid loss control additive, a conventional lost circulation material, an generator, a retarder, a salt, a mica, fiber, a formation-conditioning agent, fumed silica, bentonite, expanding additives, microspheres, weighting materials, or a defoamer.

Owner:HALLIBURTON ENERGY SERVICES INC

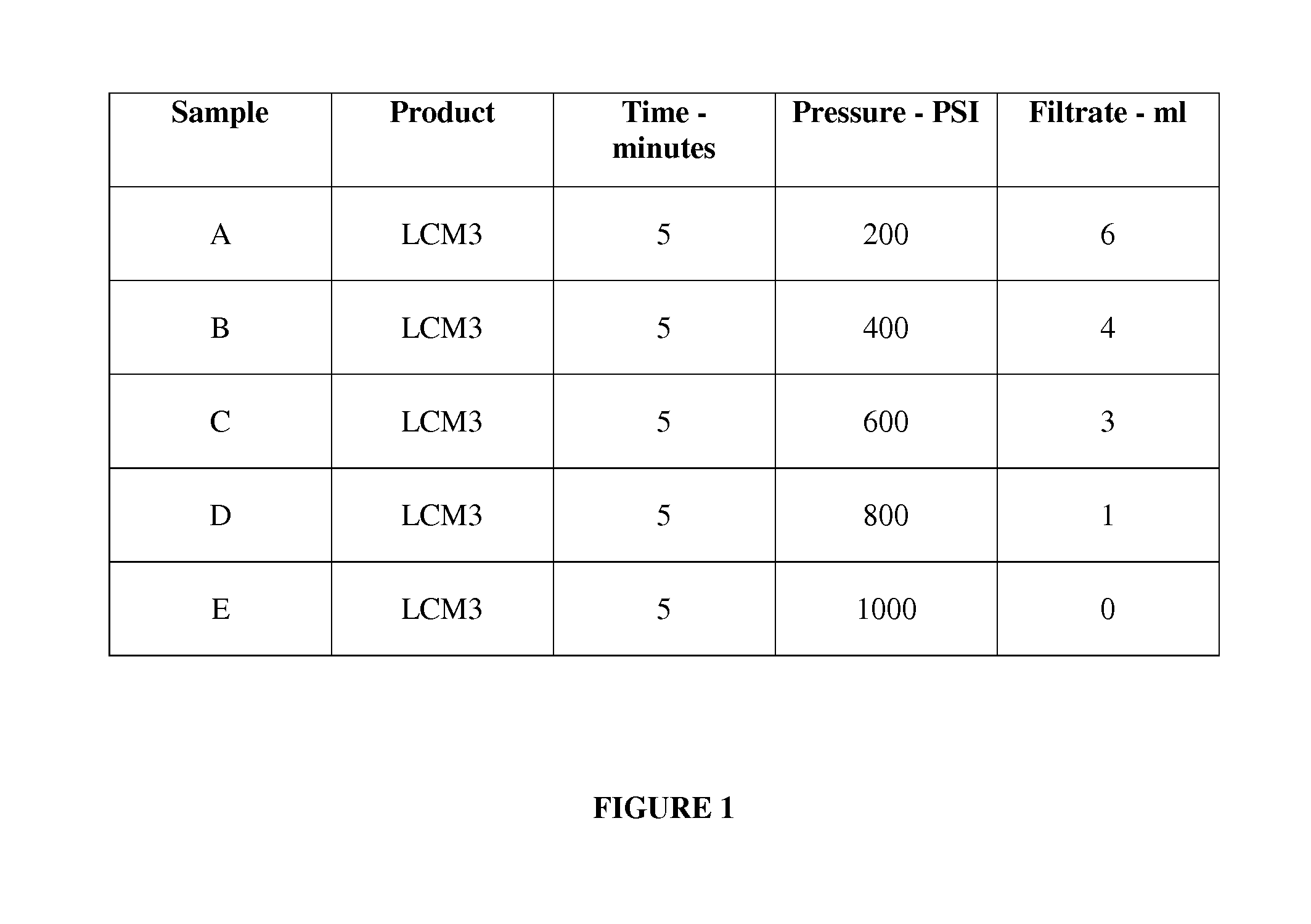

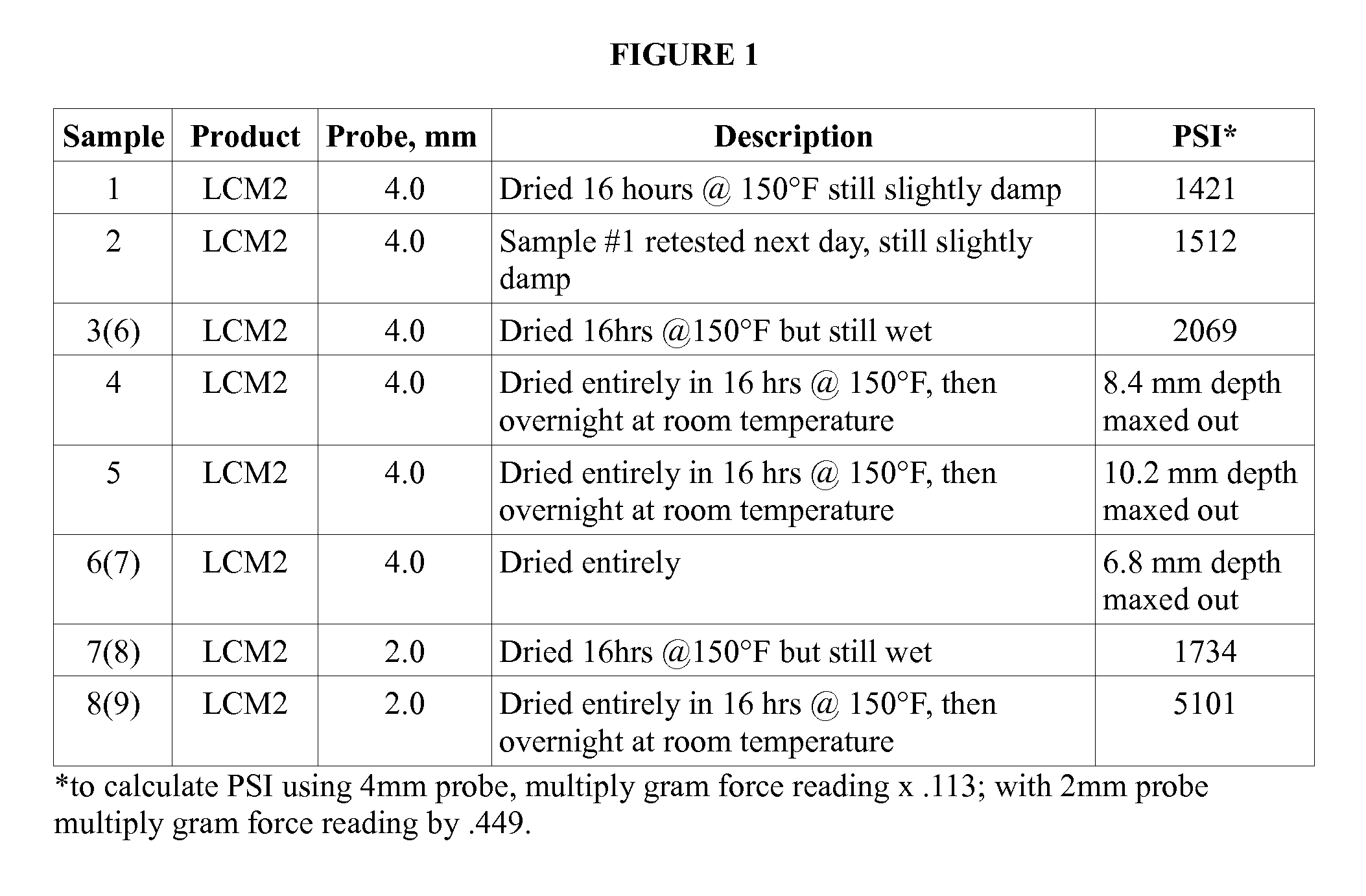

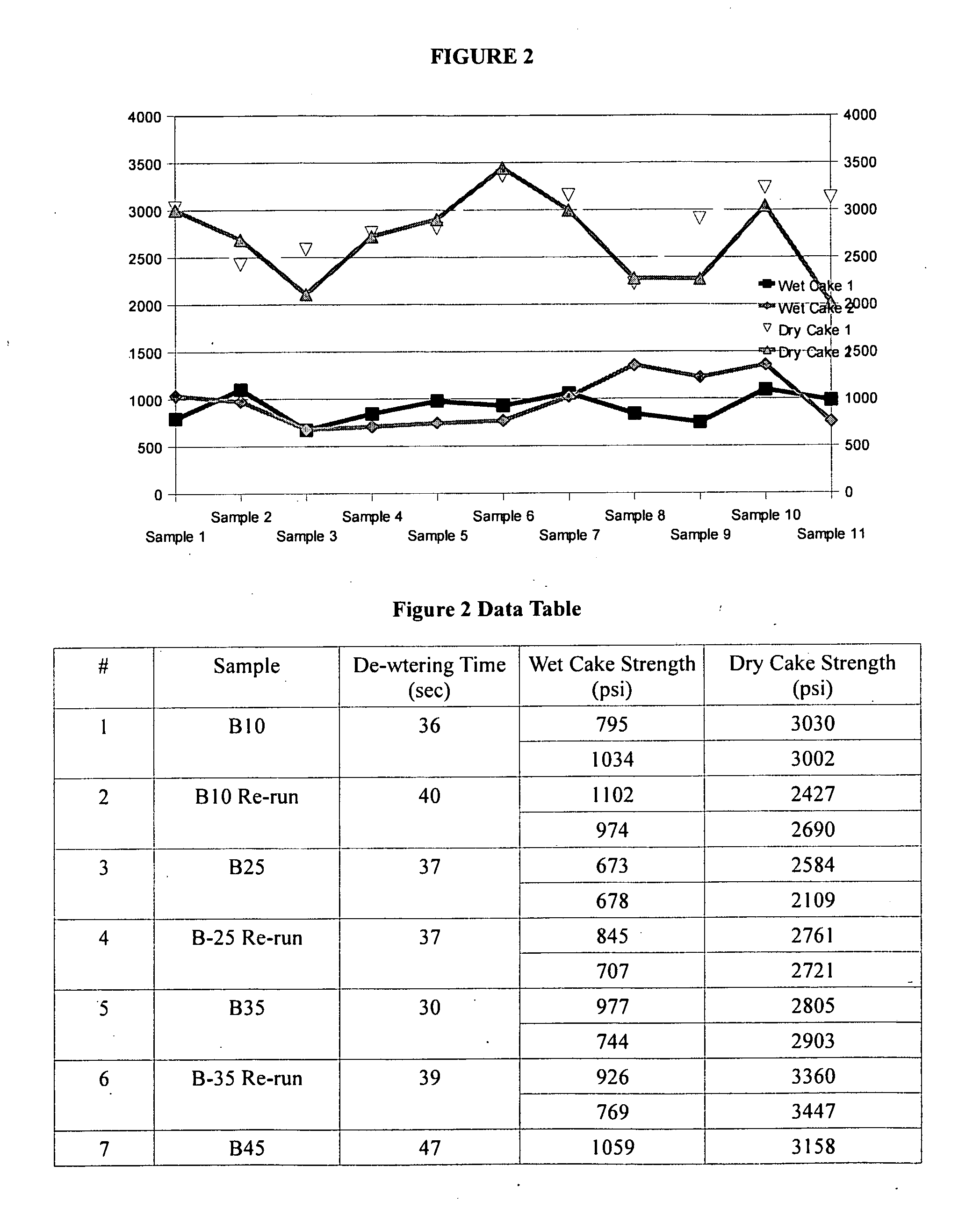

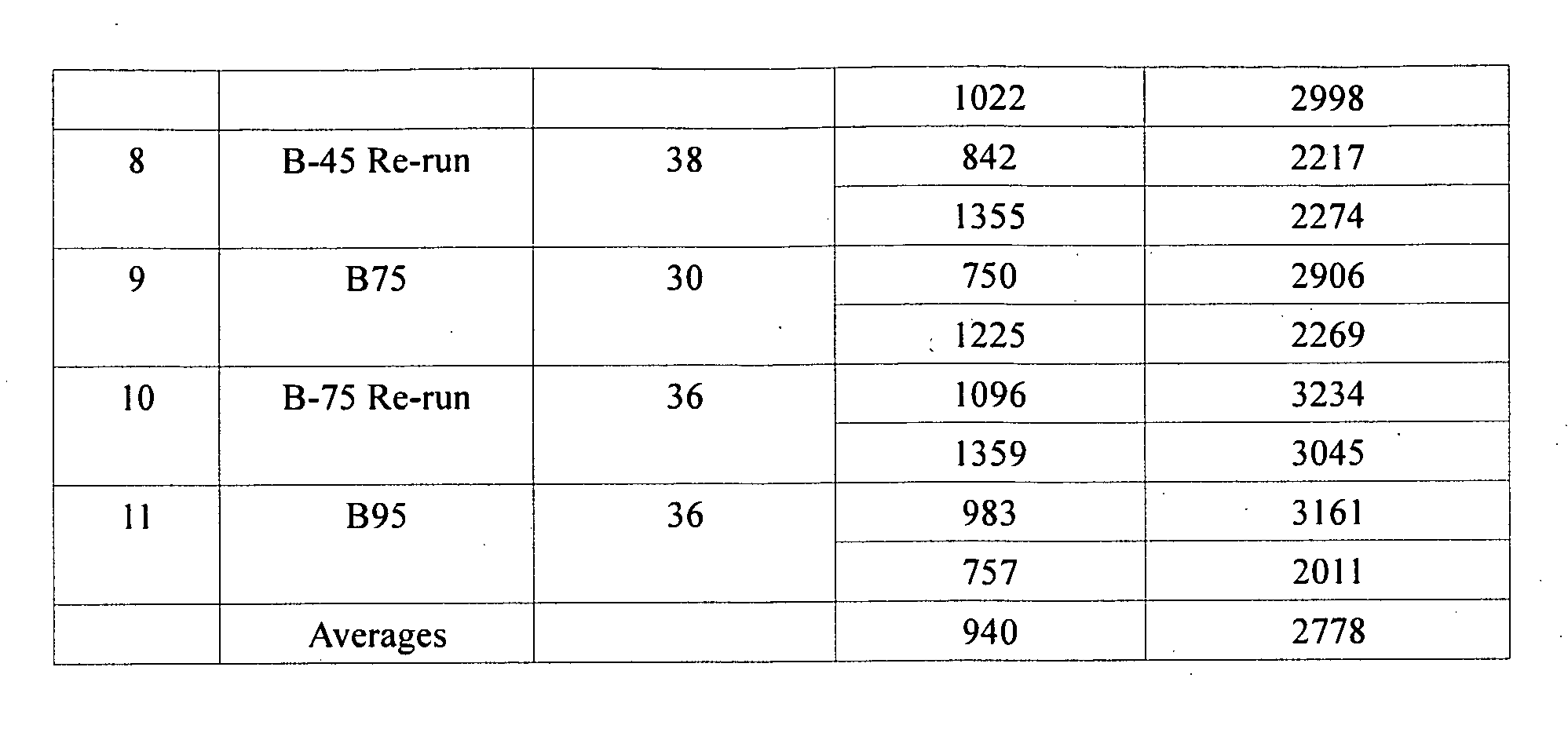

Lost circulation composition

InactiveUS20110214870A1Low costReduce formulation requirementFluid removalFlushingEngineeringLost circulation

A composition of matter and a method of sealing a permeable formation are provided incorporating the composition to reduce or eliminate lost circulation in permeable formations up to at least 6000 psi. The composition comprises one or more sealing components, a wetting component, a viscosifier component, an activator or flocculant component, and an extender. A dry mixture of the components may be added directly from the bag to the drilling mud up to the rate of 90 pounds per barrel. The mixture will seal the formation in an aqueous or organic environment. The mixture de-waters at a rapid rate without regard to the time and temperature required for curing agents or other additives. The mixture may be weighted and does not require additional agents such as defoamers, accelerators, retarders or spacers to de-water and set as a solid plug.

Owner:SHAARPOUR MANO

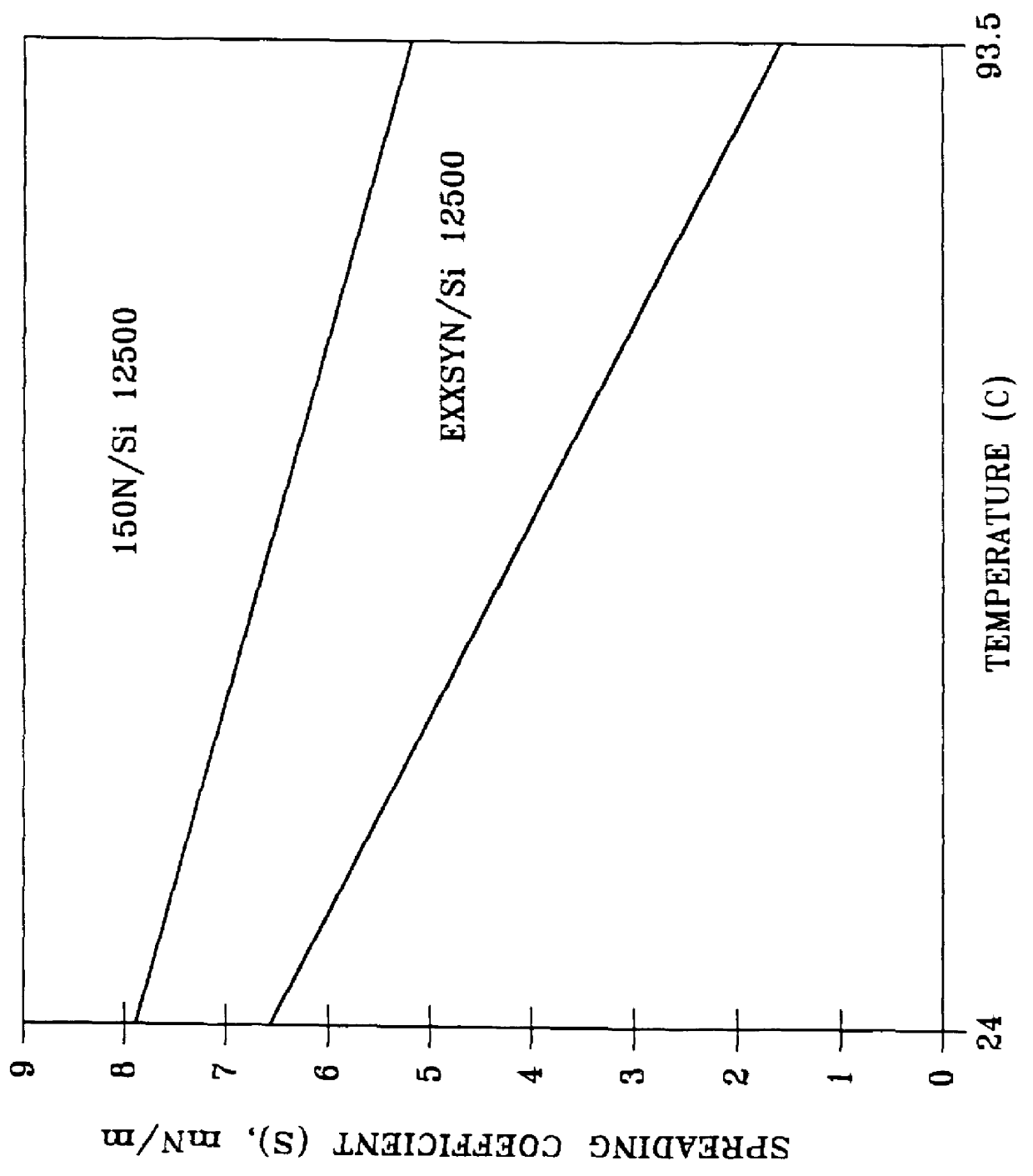

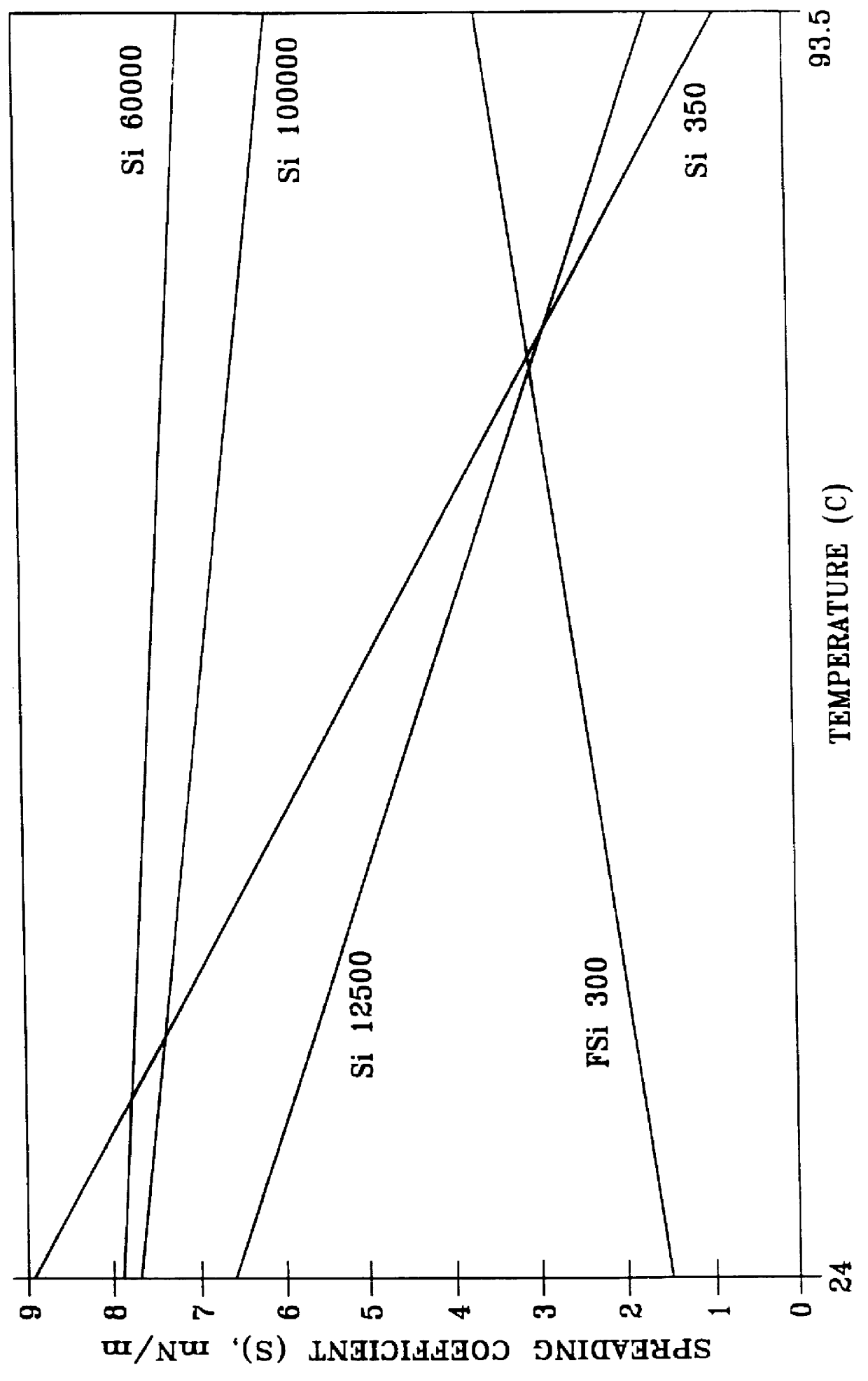

Method for reducing foaming of lubricating oils

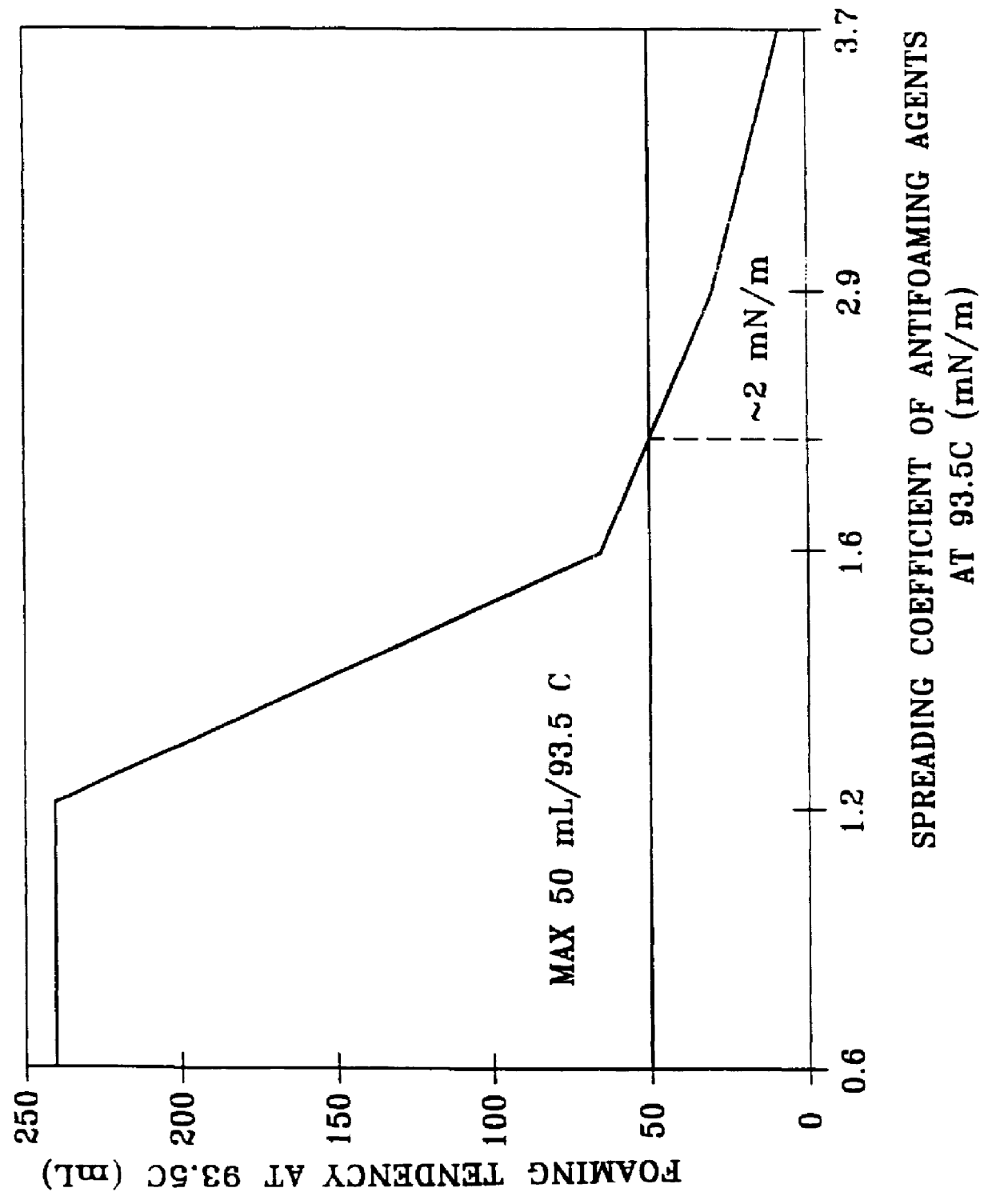

Foaming of a lube oil comprising a base stock derived from wax isomeration and an additive package is effectively reduced to within specification limits of 50 ml / ml over a temperature range of from at least 24 DEG C. to 93.5 DEG C. by adding to the oil an effective amount of an antifoamant exhibiting a spreading coefficient of at least about 2 mN / m. This has been found to be particularly effective in reducing foaming of lube oils containing a mixture of a wax isomerate oil and a petroleum oil fraction. Antifoamants typically used with conventional lube oils containing one or more petroleum fraction base stocks, but which do not exhibit a spreading coefficient of at least 2 mN / m with the wax isomerate containing oil, have been found not to be effective in reducing the foaming of the oil.

Owner:EXXON RES & ENG CO

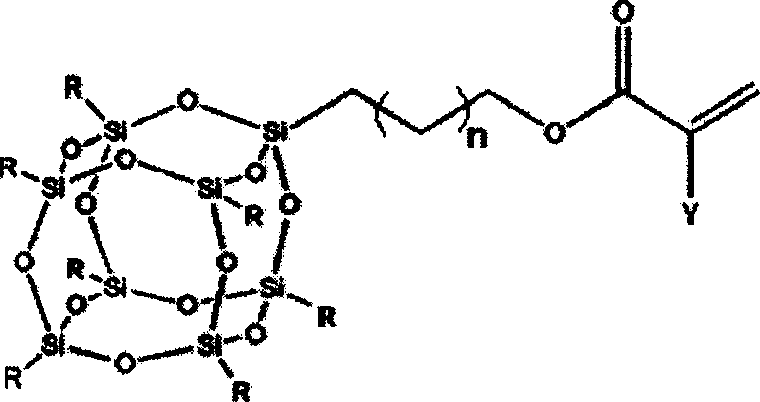

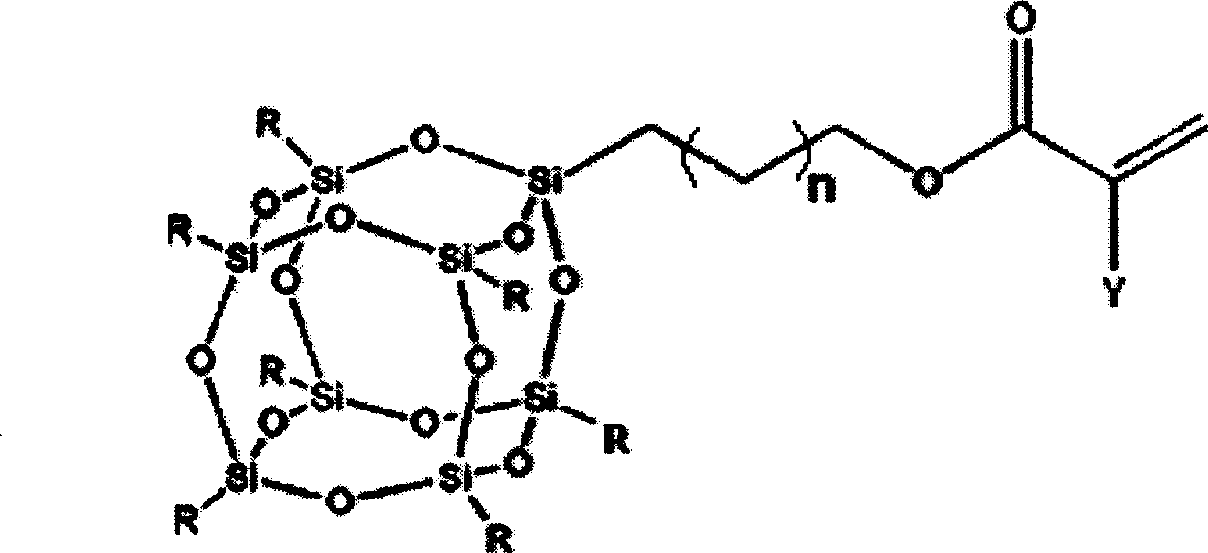

Coating material containing POSS acrylate copolymer and preparing method

The invention relates to a manufacturing method for coat material containing POSS acrylate copolymer. It takes free radical copolymerized to acr monomer and other acr monomer, and uses as modifier adding into the base compounding of UV coat, after taking UV solidification the coat material of high rigidity would be gained. The constituent includes 40-55% light-cured resin, 5-20% active modifier, 20-45% spike, 1-10% photoinitiator, 2-10% anti-foam additive. The rigidity of coat could reach to 6H, and the shrinkage ratio could reach 2%.

Owner:XIAMEN UNIV

Environment protection efficient water-based circuit board cleaning agent and preparation thereof

InactiveCN101440332ANo pollutionThe raw materials are scientific and reasonableNon-ionic surface-active compoundsOrganic detergent compounding agentsWater basedActive agent

The invention provides an environment-friendly high-efficiency water-based circuit board cleaning agent and a method for preparing the same. The raw material formulation of the cleaning agent comprises a surfactant, a corrosion-retarding active agent, a chelating agent, a defoamer, a cleaning solvent and water. The preparation method comprises the following steps: accurately weighing various raw materials according to the ratio of the formulation, adding the raw materials into a reactor to be stirred evenly, and keeping the mixture stand to obtain the cleaning agent of the invention. The cleaning agent has the advantages of scientific and reasonable raw materials, simple and practicable preparation method, nontoxic and non-corrosive product, no inflammable and explosive properties, non pollution to the environment, high cleaning cleanliness and low cost, is biodegradable, can be cleaned through both immersion and ultrasonic, and has significant economic benefits.

Owner:潘惠凯 +1

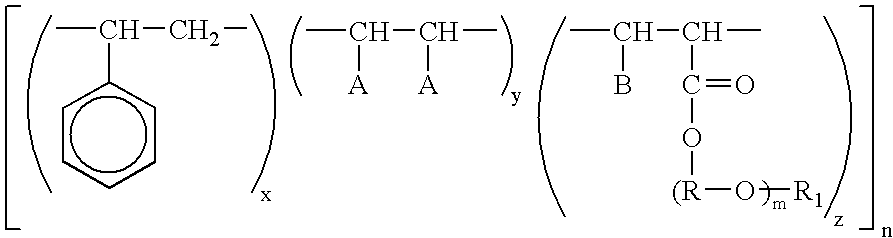

Foamed slurry and building panel made therefrom

A gypsum slurry is described that includes water, a hydraulic component comprising at least 50% calcined gypsum by weight based on the dry weight of the hydraulic component, foam, a defoamer and a polycarboxylate dispersant. In some embodiments of the invention, the defoamer is combined with the dispersant prior to being added to the gypsum slurry. The defoamer and dispersant can be added as a physical mixture, wherein the defoamer is attached onto the dispersant polymer, or a combination thereof. In some embodiments, a gypsum building panel is made from the gypsum slurry.

Owner:UNITED STATES GYPSUM CO

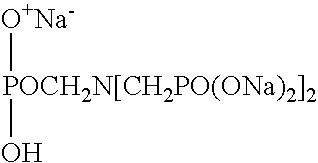

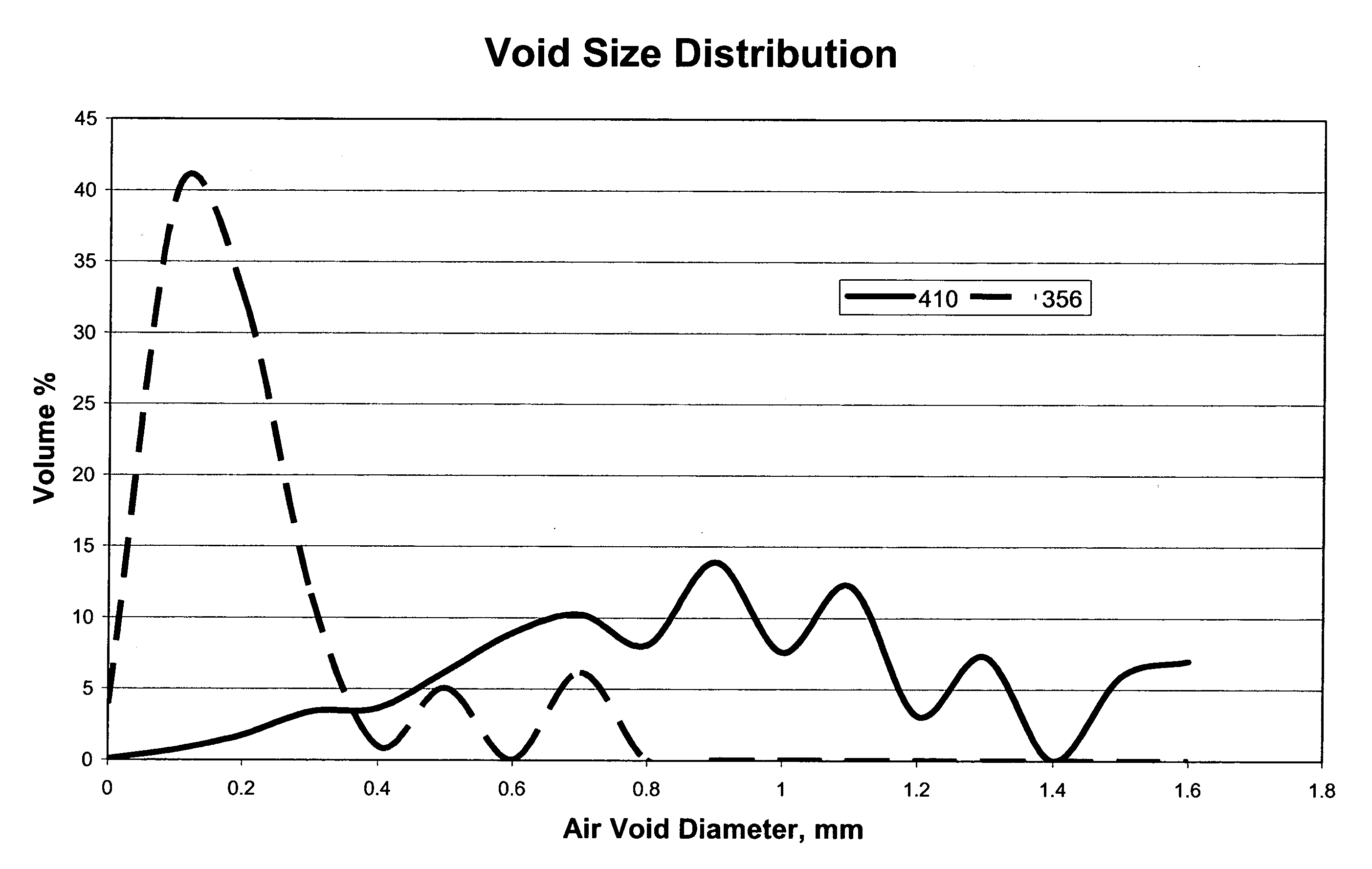

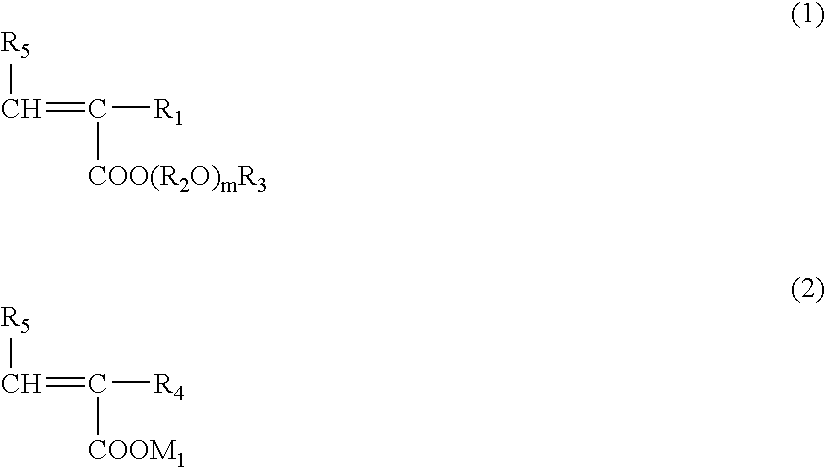

Solubilized defoamers for cementitious compositions

InactiveUS6875801B2Long-term storage stabilitySolid waste managementTransportation and packagingWater insolubleSolvent

Amine solubilizing agents are mixed with water insoluble defoamers and optionally a dispersant for cementitious compositions to provide an admixture for cementitious compositions that is stable over time. A cementitious composition is provided that includes cementitious material, water, a water insoluble defoamer, optionally a dispersant for cementitious compositions, and an amine solubilizing agent that solubilizes the water insoluble defoamer. A method is provided for making a cementitious composition that includes mixing cementitious material, water, a water insoluble defoamer, an amine solubilizing agent that solubilizes the water insoluble defoamer, and optionally a dispersant for cementitious compositions.

Owner:MBT HLDG +1

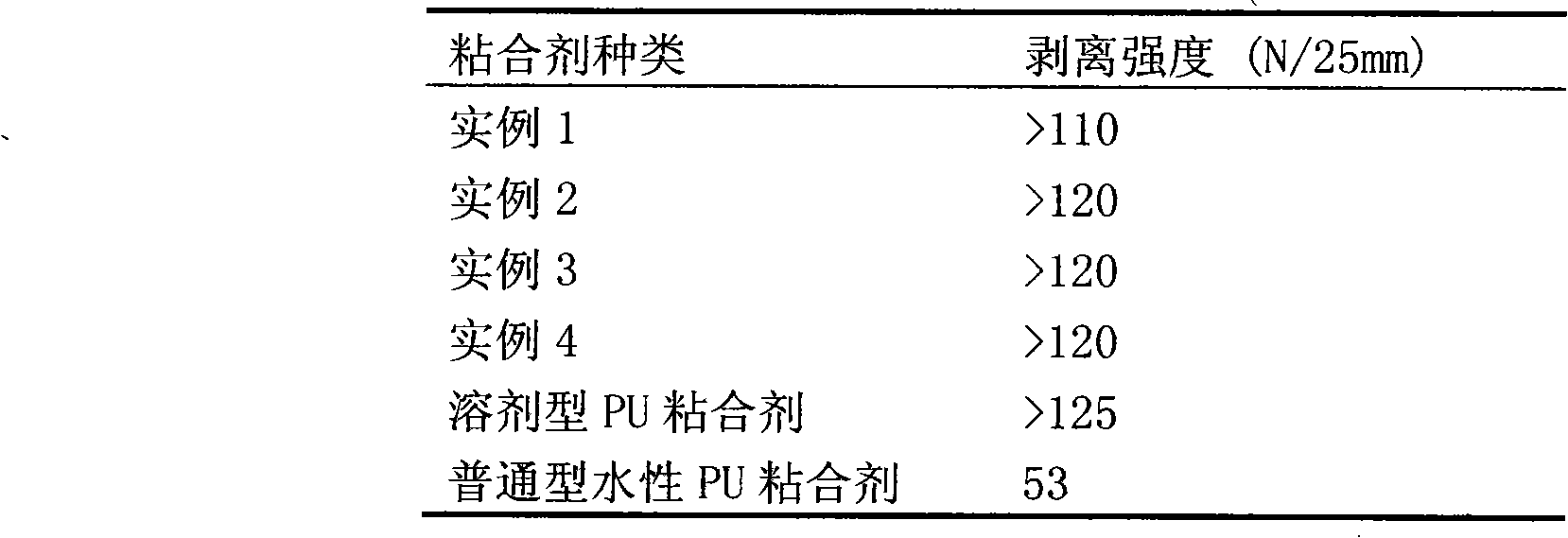

Method for preparing aqueous polyurethane adhesive and superfine fiber synthetic leather

ActiveCN101665675AHigh peel strengthIncrease elasticityPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterFolding endurance

The invention relates to a method for preparing an aqueous polyurethane adhesive and superfine fiber synthetic leather, which belongs to the technical field of chemical products and preparation methods thereof. The method is characterized by comprising the following steps: mixing polyester polyol, isocyanate, a hydrophilic chain extending agent, a micromolecule chain extending agent and an amine environment friendly catalyst to obtain a hydrophilic aqueous polyurethane prepolymer; adding a neutralizing agent to the aqueous polyurethane prepolymer to obtain an aqueous polyurethane latex; then adding an amine chain expanding agent, a thickening agent, a defoaming agent and a flatting agent to the aqueous polyurethane latex to obtain the aqueous polyurethane adhesive; coating the aqueous polyurethane latex on release paper; drying the release paper; then coating the aqueous polyurethane adhesive on the dried release paper; and pressing the release paper and base cloth together to obtain the superfine fiber synthetic leather. The high solid content aqueous polyurethane adhesive prepared by the method has better initial tack and rebound resilience and higher final strength, and the prepared superfine fiber synthetic leather has higher peel strength and low-temperature folding endurance. The preparing process of the method greatly reduces the use and the discharge of organic solvents, reduces the energy consumption and furthest reduce the environmental pollution.

Owner:HUADA CHEM GRP CO LTD

Lost circulation composition

InactiveUS20090286697A1Low costIncrease profitFlushingDrilling compositionEngineeringLost circulation

A composition of matter and a method of sealing a permeable formation are provided incorporating the composition to reduce or eliminate lost circulation in permeable formations up to at least 5100 psi. The composition comprises one or more sealing components, a wetting component, a viscosifier component, an activator or flocculant component, and an extender. A dry mixture of the components may be added directly from the bag to the drilling mud up to the rate of 90 pounds per barrel. The mixture will seal the formation in an aqueous or organic environment. The mixture de-waters at a rapid rate without regard to the time and temperature required for curing agents or other additives. The mixture may be weighted and does not require additional agents such as defoamers, accelerators, retarders or spacers to de-water and set as a solid plug.

Owner:SHAARPOUR MANO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com