Lower-temperature sintered conductive ink

A conductive ink, low-temperature sintering technology, applied in the direction of ink, printed circuit parts, metal pattern materials, etc., can solve the problem of not involving the sintering process and sintering temperature of conductive ink, limiting the speed of decomposition into metal elements, not inkjet printing, etc. problems, to achieve the effect of improving the substrate range, good electrical conductivity, and reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Disperse 10 parts of spherical silver powder with a particle diameter of 50 to 80 nanometers in 70 parts of isopropanol, then add 10 parts of polyethylene glycol with a molecular weight of 10,000, and disperse the resulting solution with ultrasound for 30 minutes, 3000rpm Centrifuge for 10 minutes, then filter; after filtering, add 5 parts of glycerol as a humectant, 1 part of polysiloxane as an antifoaming agent, 2 parts of epoxy resin as an adhesive, and 2 parts of potassium sorbate As a preservative, stir at 200 rpm for 30 minutes to obtain a conductive ink that can be sintered at a low temperature.

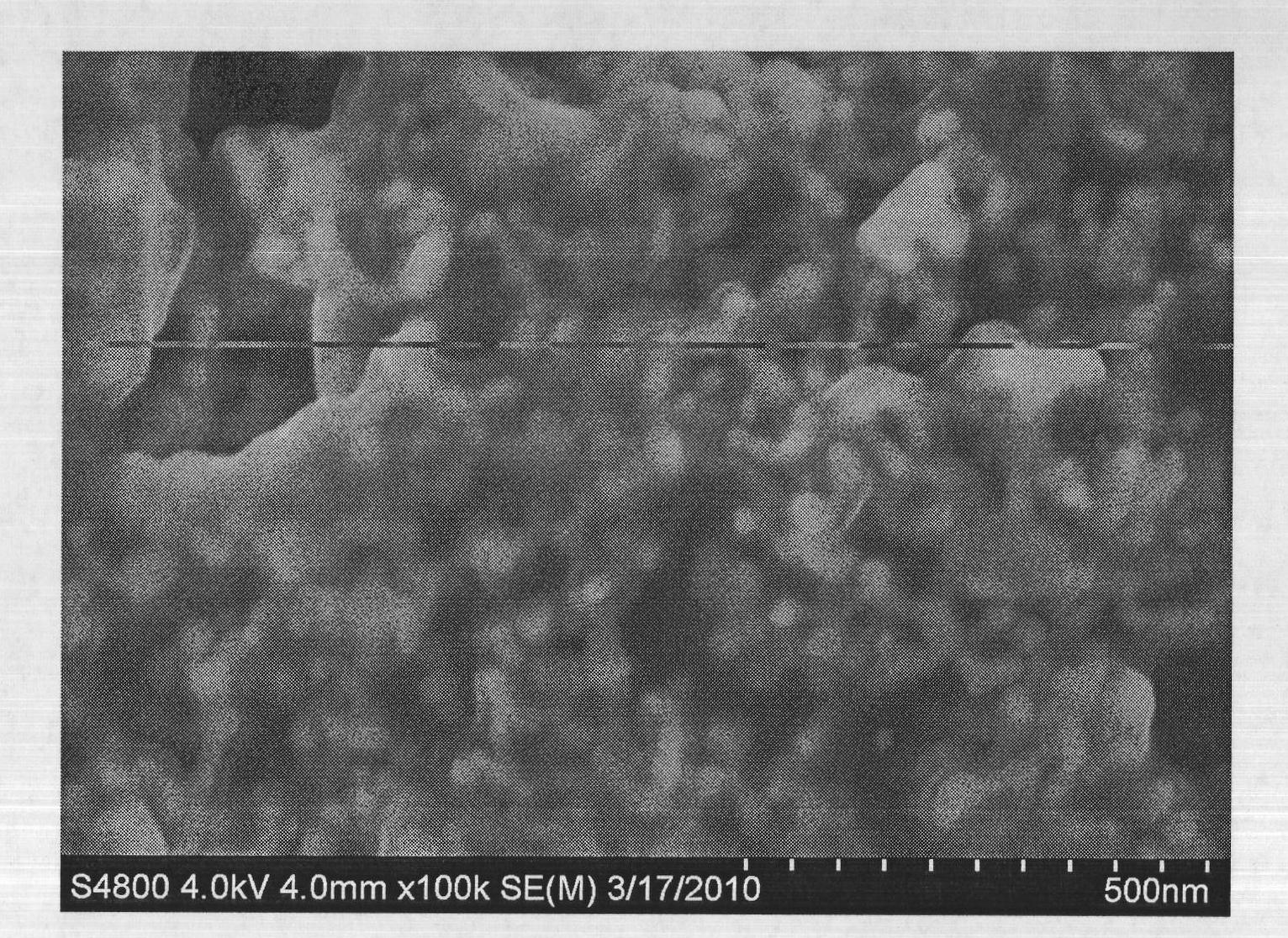

[0046] Take a small amount of the above-mentioned conductive ink and dry it at 100°C for 1 hour, then use a field emission scanning electron microscope (SEM) to observe, as shown in figure 1 As shown, it can be seen that the metal particles in the conductive ink are distributed discretely.

[0047] The conductive ink prepared above is printed into a prefabricated patte...

Embodiment 2

[0049] Dissolve 20 parts of silver nitrate in 50 parts of water, add 10 parts of polyethylene glycol with a molecular weight of 100,000, stir at 500 rpm for 60 minutes, then heat in a water bath to 50°C and continue stirring and add 10 parts of 50% sodium borohydride dropwise as a reducing agent. After adding, keep stirring for 30 minutes, then centrifuge at 3000rpm for 30 minutes and then filter; after filtering, conduct electrodialysis on the resulting solution for 20 minutes, then add 5 parts of glycerol as a humectant, and 1 part of polysiloxane as a defoamer agent, 1 part of stearic acid as a surfactant, 2 parts of epoxy resin as an adhesive, 1 part of potassium sorbate as a preservative, and then stirred at 200 rpm for 30 minutes to obtain a low-temperature sinterable conductive ink.

[0050] The above-mentioned low-temperature sinterable conductive ink was printed into a prefabricated pattern on paper by self-made inkjet equipment, and sintered at 150°C for 30 minutes to...

Embodiment 3

[0052] Dissolve 25 parts of silver nitrate in 50 parts of water, add 10 parts of polymethacrylic acid with molecular weight of 200000, stir at 500rpm for 60 minutes, add 2 parts of polysiloxane as defoamer, stir at 1000rpm, then add 10 parts of 50% hydrated Hydrazine was used as a reducing agent, continuously stirred for 10 minutes, and then filtered at 3000 rpm for 30 minutes; after filtration, 3 parts of glycerol were added as a humectant in the resulting solution, and 1 part of potassium sorbate was used as a preservative. After stirring at 200 rpm for 30 minutes, The conductive ink that can be sintered at low temperature is obtained.

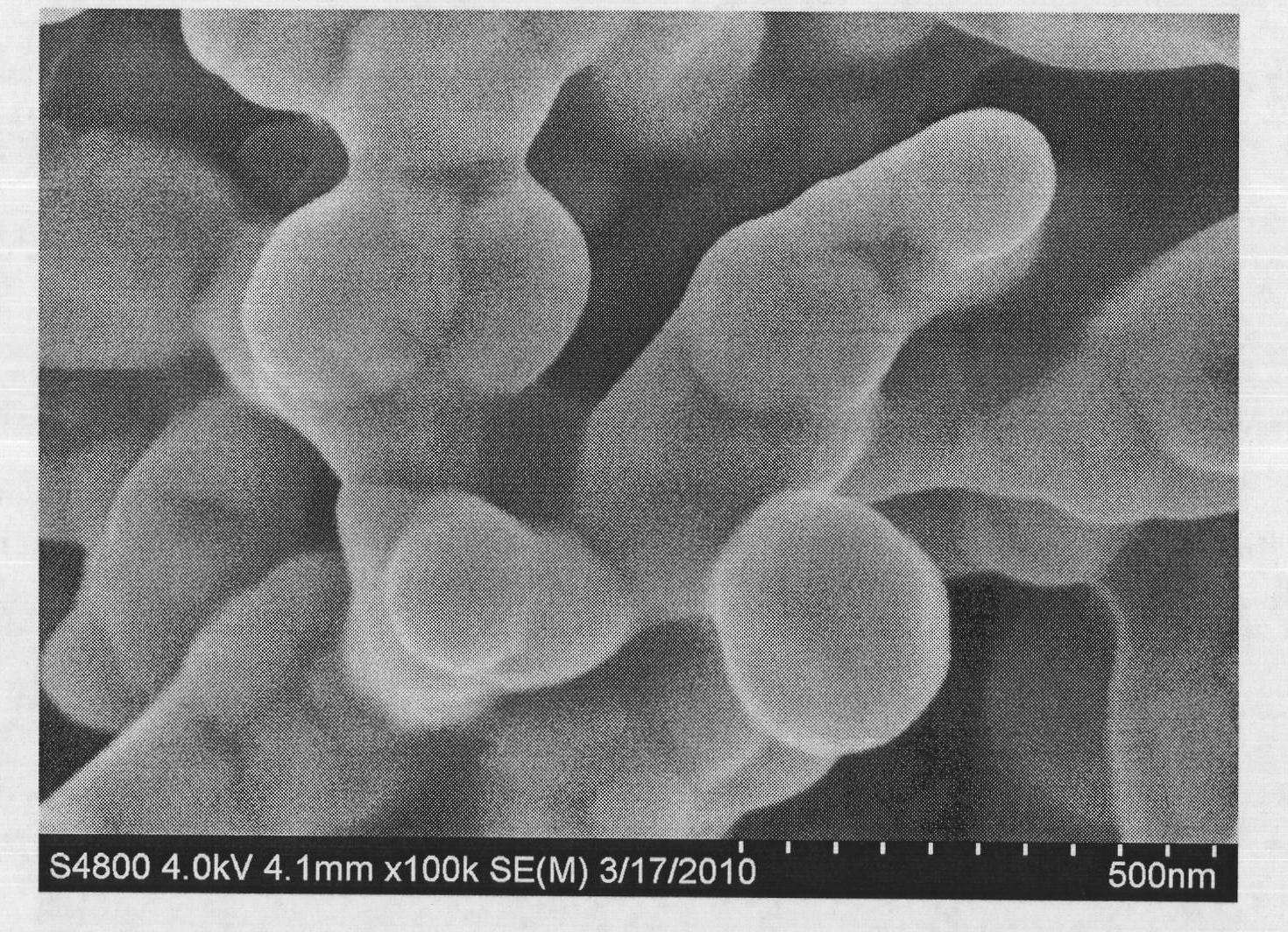

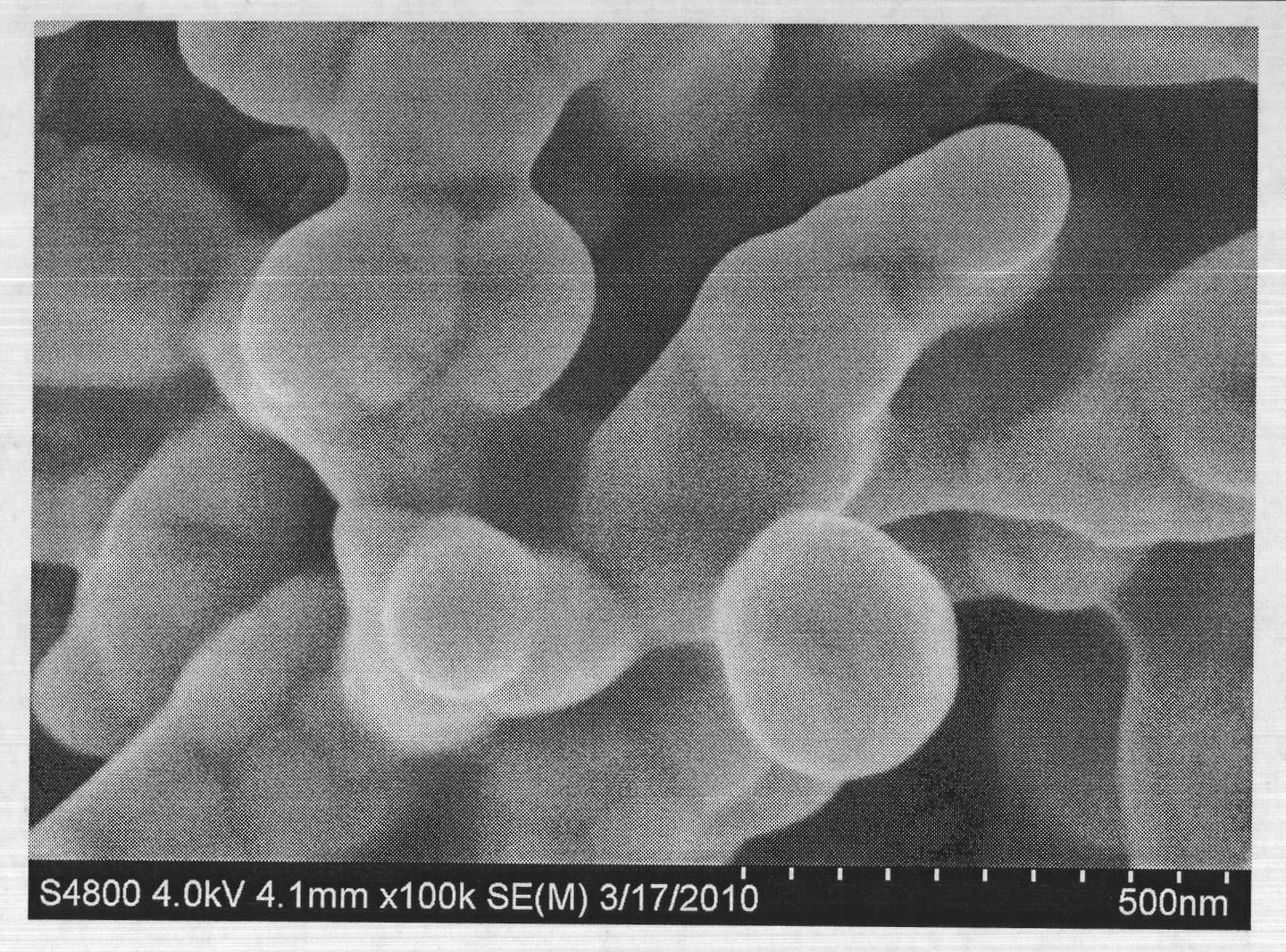

[0053] The above-mentioned conductive ink that can be sintered at low temperature is printed into a prefabricated pattern on paper by self-made equipment, and sintered at 130 ° C for 30 minutes to obtain a sintered product. Use SEM to observe the sintered product, and the result is similar to figure 2 As shown, it can be seen that the silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com